Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12418results about How to "Solve pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

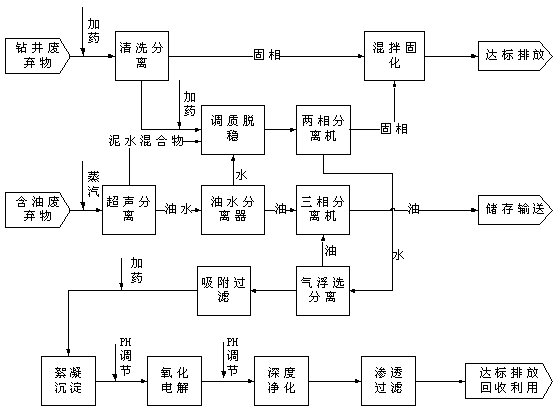

Method for comprehensive treatment of oilfield waste

ActiveCN102849880ALarge amount of processingReduce governance costsWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesSolid phasesChemistry

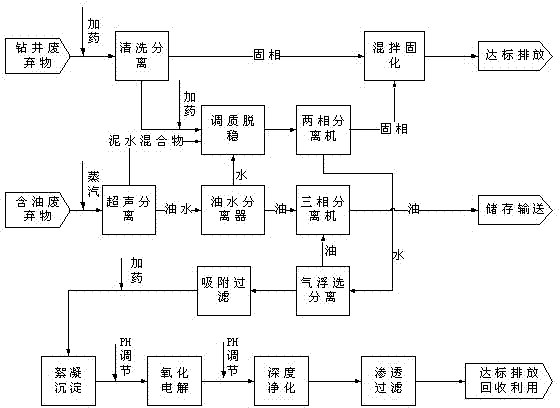

The invention discloses a method for comprehensive treatment of oilfield waste, which is characterized by comprising the process steps of cleaning and separation, ultrasonic separation, tempering and destabilization, oil-water separation, centrifugal separation, mixed curing, air floatation separation, adsorption filtration, flocculating settling, oxidization electrolysis, deep purification and permeable filtration. Thus, the oilfield waste is treated and utilized in a classified manner, so that sump oil is recovered, the solid phase achieves the discharge standard of oilfield sludge treatment design specifications (SY / T6851-2012) or is reutilized for construction material manufacturing, and the liquid phase achieves the sewage comprehensive discharge standard (GB8978-1996) after being subjected to water treatment.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

Road dust suppressant

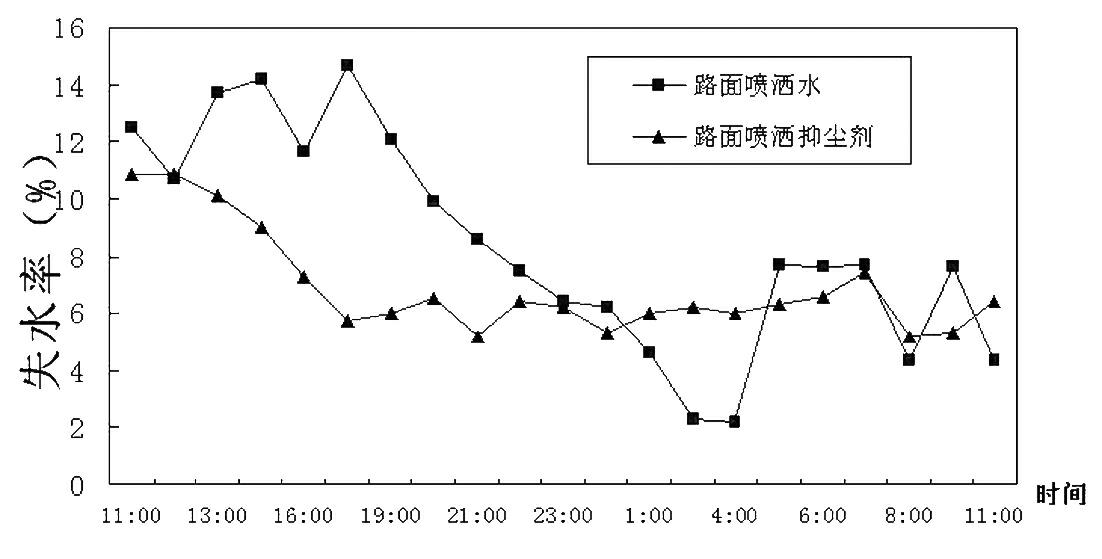

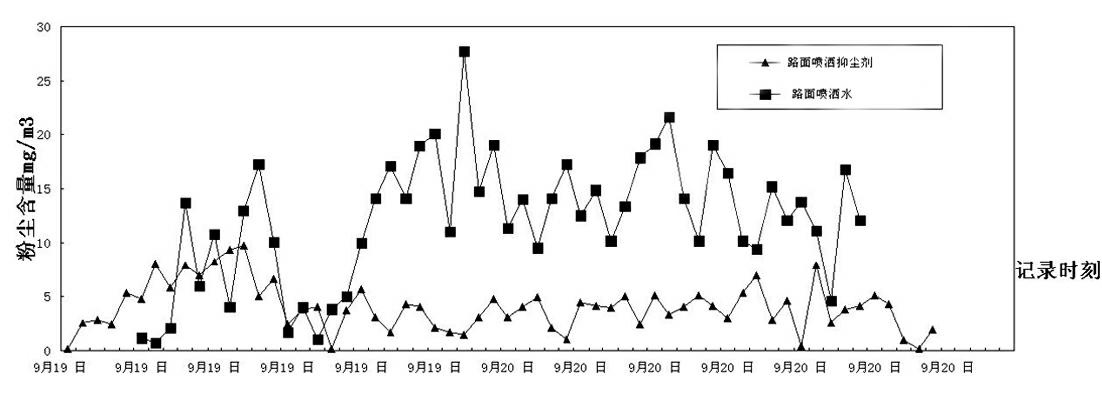

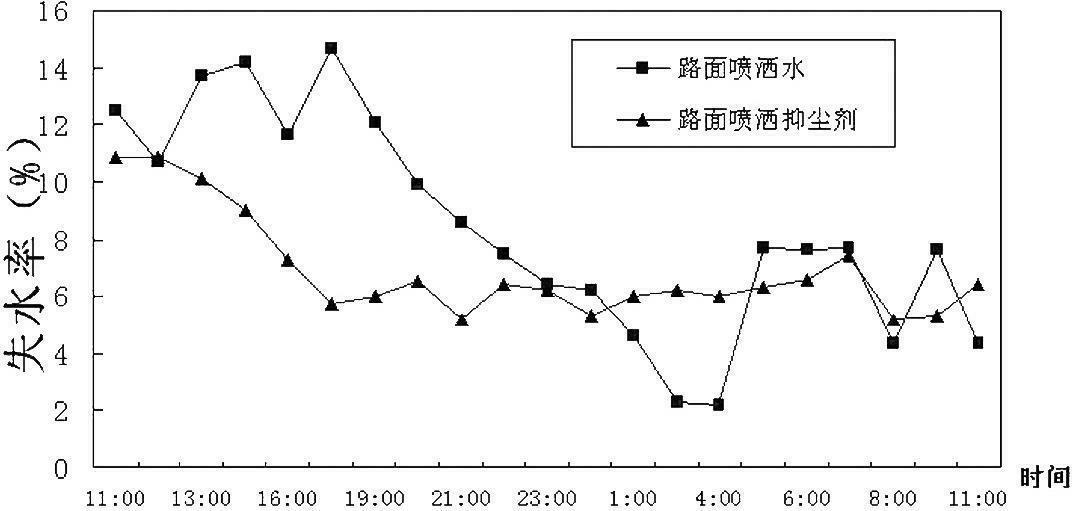

ActiveCN102660227AStrong anti-pressure functionLarge particle sizeOther chemical processesLiquid productEvaporation

The invention discloses a road dust suppressant, which is prepared by mixing and blending 0.1-2.0% of water-soluble high molecular polymer, 20-50% of moisture absorption humectant, 1.0-5.0% of preservative, 0.5-5.0% of penetrating agent and the balance water. The road dust suppressant is a dynamic dust-proof and dust-suppressing liquid product which combines functions of wetting, bonding, permeating, adsorbing moisture and the like into a whole and has extremely strong pressurization-resistant function. The road dust suppressant has the advantages of obvious anti-evaporation performance and good water retention hygroscopicity, and dust on the road surface can be coagulated and is unlikely to fly. The road dust suppressant disclosed by the invention not only can be applied to road dust suppressing but also can be simultaneously used for the aspects, such as the mine exploration and transportation environment, storage yards of coal ash, coal and other ores, and the treatments of municipal construction earthwork dust raise.

Owner:山西兴源盛科技有限公司

Method for comprehensive treatment of oilfield waste

ActiveCN102849880BSolve the use problemMeet the actual needs of protectionWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesElectrolysisSludge

The invention discloses a method for comprehensive treatment of oilfield waste, which is characterized by comprising the process steps of cleaning and separation, ultrasonic separation, tempering and destabilization, oil-water separation, centrifugal separation, mixed curing, air floatation separation, adsorption filtration, flocculating settling, oxidization electrolysis, deep purification and permeable filtration. Thus, the oilfield waste is treated and utilized in a classified manner, so that sump oil is recovered, the solid phase achieves the discharge standard of oilfield sludge treatment design specifications (SY / T6851-2012) or is reutilized for construction material manufacturing, and the liquid phase achieves the sewage comprehensive discharge standard (GB8978-1996) after being subjected to water treatment.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

Method for producing biological diesel oil by using high-acidity waste animal and vegetable oil

InactiveCN1412278ASolve pollutionReduce pollutionLiquid hydrocarbon mixture productionBio-feedstockVegetable oilPtru catalyst

The present invention relates to a method for producing biological diesel oil-fatty acid methyl ester by using waste animal and vegetable oil with high acid value. It is characterized by that it adopts acidic catalysis method, under the action of acidic catalyst is makes the waste animal and vegetable oil react with low carbon alcohol, and adopts the following four steps: (1) dewatering; (2) esterification and ester exchange; (3) phase separation; and (4) decolouring so as to produce the invented biological diesel fatty acid methyl ester.

Owner:宋庭礼 +1

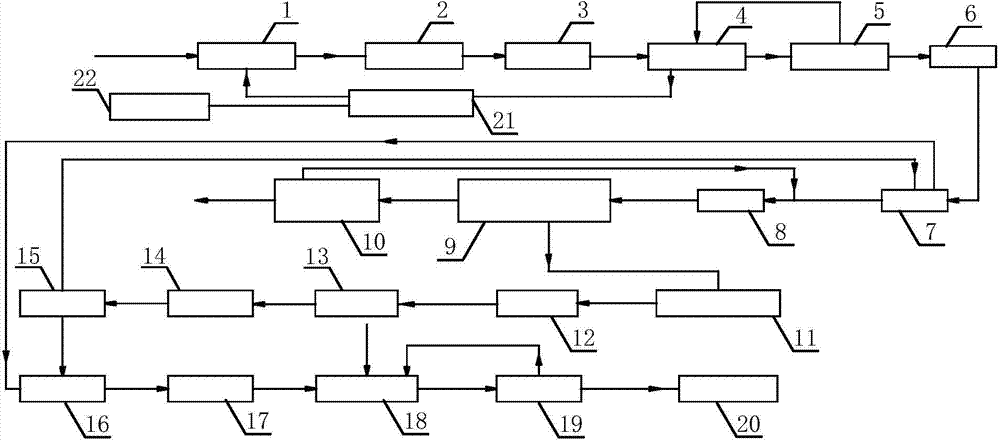

Desulfurization waste water zero discharging process and system

ActiveCN104843927ASolve pollutionWaste water treatment from gaseous effluentsMultistage water/sewage treatmentWater useHydration reaction

The invention discloses a desulfurization waste water zero discharging process. The process comprises a chemical dosing softening process and a microfiltration membrane treatment process; after incoming water is subjected to two-stage softening, nanofiltration and reverse osmosis separation are performed; sodium sulfate decahydrate with the purity of more than 99% is separated out by utilizing freezing crystallization; a reverse osmosis concentrated water regeneration sodium ion exchange device is utilized; sodium chloride with the purity of more than 98% is separated out by utilizing evaporative crystallization; solids are comprehensively utilized, and no liquid is discharged outside. The invention further provides a desulfurization waste water zero discharging system. According to the desulfurization waste water zero discharging process and the system, water in desulfurization waste water can be separated to be reutilized as domestic and industrial usable water, and other impurities in the desulfurization waste water are separated in solid form, so that pollutants harmful to the natural environment do not generate, and the problem that the desulfurization waste water pollutes the environment can be completely solved.

Owner:华电水务工程有限公司

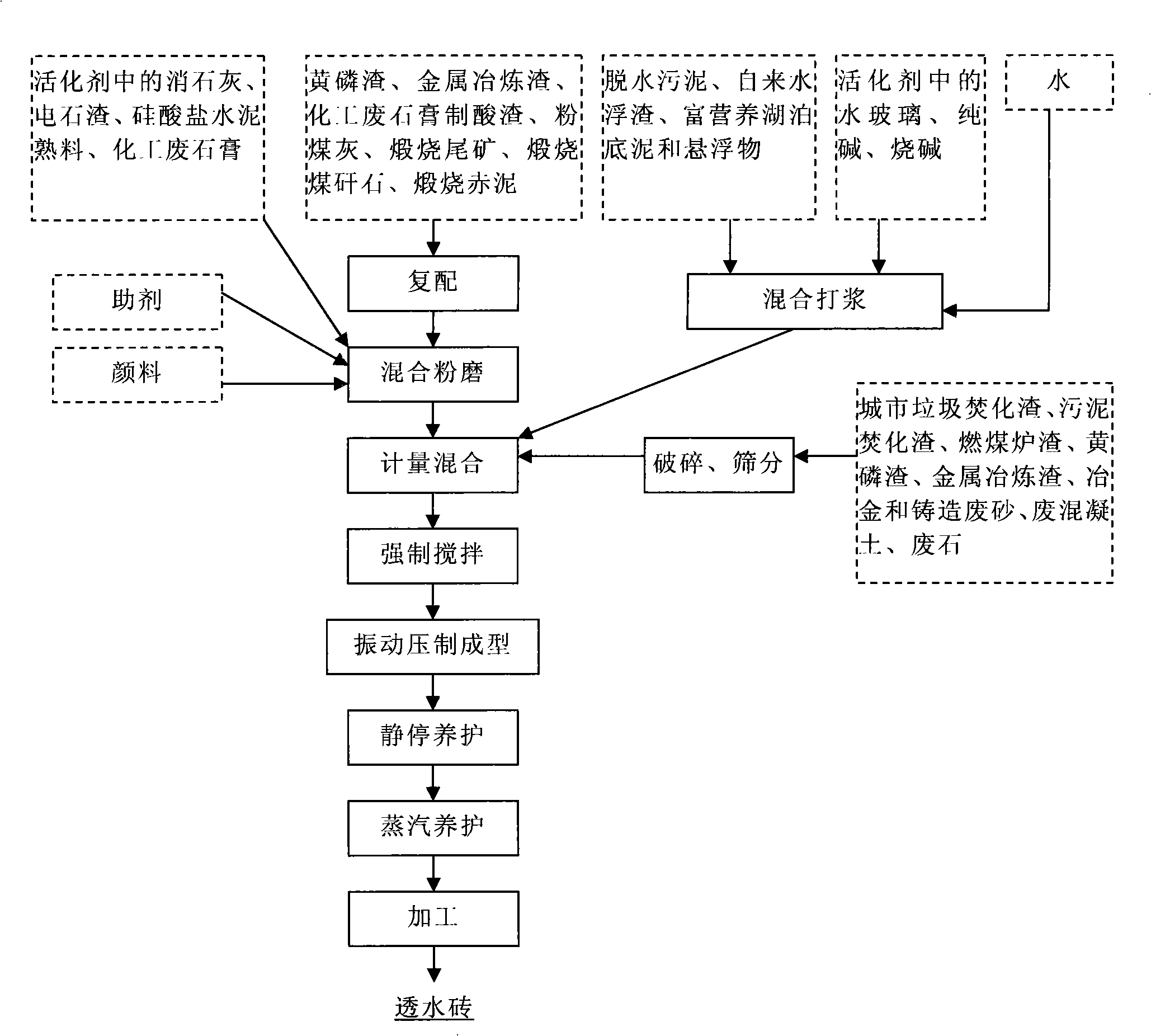

Low-temperature ceramic permeable bricks and production method thereof

InactiveCN101289310ASolve pollutionLow costCeramic materials productionClaywaresNatural resourceState of art

The invention relates to a low temperature ceramics non-watertight brick made of solid waste slag and a manufacture method thereof, belonging to the technical field of building materials. The mixture ratio by weight of the components of the low temperature ceramics non-watertight brick is that waste slag gelled material to waste slag skeletal material to porogenic agent to activating agent to addition agent to paint to water is equal to 100:200-800:0.1-40:13-50:0.2-3.0:0.1-7.0:1-20. After the process, mixture, vibrating forming and maintenance process for the raw materials, the raw materials are prepared into the low temperature ceramics non-watertight brick with a filled pore by taking the low temperature ceramics mineral as the matrix phase and taking the inorganic waste slag particle as the wild phase. Compared with the prior art, the low temperature ceramics non-watertight brick has the advantages of high strength, good permeability of water, high salvage value, simple process, low cost, environment protection and natural resources reservation, etc. which can be widely applied to the laying of urban highways.

Owner:KUNMING UNIV OF SCI & TECH

Sea shell micropowder filler and its use

InactiveCN1475520AImprove the level of comprehensive utilizationImprove mechanical propertiesPre treatmentMaterials science

A shell microparticle filler used for high-molecular materials to improve their thermal and mechanical performance is prepared from shell through pulverizing, classifying, high-temp stabilizing and decoloring, and chemical surface modifying. It features its surficial hydrophilic, lipophilic and active properties.

Owner:孙建宁 +1

Compact type substrate seedling nursery culture pan

InactiveCN1965638ASolve pollutionAddressing Bulk Substrate DeficienciesCultivating equipmentsAdditive ingredientPeat

The invention relates to a nutrition pot for grow seedling, wherein the constituents of the pot materials comprise the following ingredients (by weight ratio): peat coal 35-40, xylon nutrient 20-25, animal manure 15-20, Attapulgite 20-25, aggregate bacterium species 0.2-0.3. The pot material is produced through steps of mixing raw materials, stirring homogeneously, carrying out fermentation for 15-25 days at 50-70 Deg C, and press forming in pot-making machines.

Owner:方立成

Whole-nutrition biological flushing and spreading fertilizer and preparation method thereof

InactiveCN101037369ASolve the single nutrientSolve solubilityClimate change adaptationAlkali orthophosphate fertiliserMicroorganismNicotiana tabacum

A full nutrition fertilizer of biology type and its producing method belongs to organic complex fertilizer field in biology type. The components of the full nutrition fertilizer is 20-50% of organic waste liquid, 10-30% of urea, 8-15% of diammomium phosphate, 10-25% of potassium sulfate, 5-20% of medium trace element, 1-5% of microbial inoculum, 0-0.2% of root-promoting agent; 0-2% of solutizer, effective viable count content of the microbial inoculum of more than 1010 / g. The fertilizer is produced by adding the urea, diammomium phosphate, potassium sulfate, medium trace element, root-promoting agent, solutizer into organic waste liquid and blending uniformly, then adding microbial inoculum. The invention uses the wastes to produce fertilizer with a low cost a high availability and a good prospect in the fertilizer industry. The fertilizer can be widely applied to the vegetables, melon and fruits, food, tobacco, forests and different commercial crops.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

Method for preparing ethylene glycol from cellulose

ActiveCN101723802ALow costWide variety of sourcesOrganic compound preparationCatalyst activation/preparationHydrogen pressurePolyethylene glycol

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Compressed type plant culture stroma

InactiveCN101036442ASolve pollutionAddressing Bulk Substrate DeficienciesCultivating equipmentsSoilless cultivationGrowth plantPreservative

The invention relates to a cultivation medium dedicated for roof afforestation, container plant cultivation, especially relating to compression type plant cultivation medium suitable for ground cover plant, perennial plant, undershrub etc. The inventive medium is composed of fertilizer, binding agent, plant growth regulator. The fertilizer comprises wooden nutrient, organic fertilizer, composite bacteria strain, the said binding agent is attapulgite soil, while plant growth regulator is rare earth additive. The inventive medium is optimum for nutrient collocation, light-weighted, washout-resistant, water-preservative, drought-resistant, air-permeable which can be widely used in court afforestation, especially for roof afforestation.

Owner:方立成

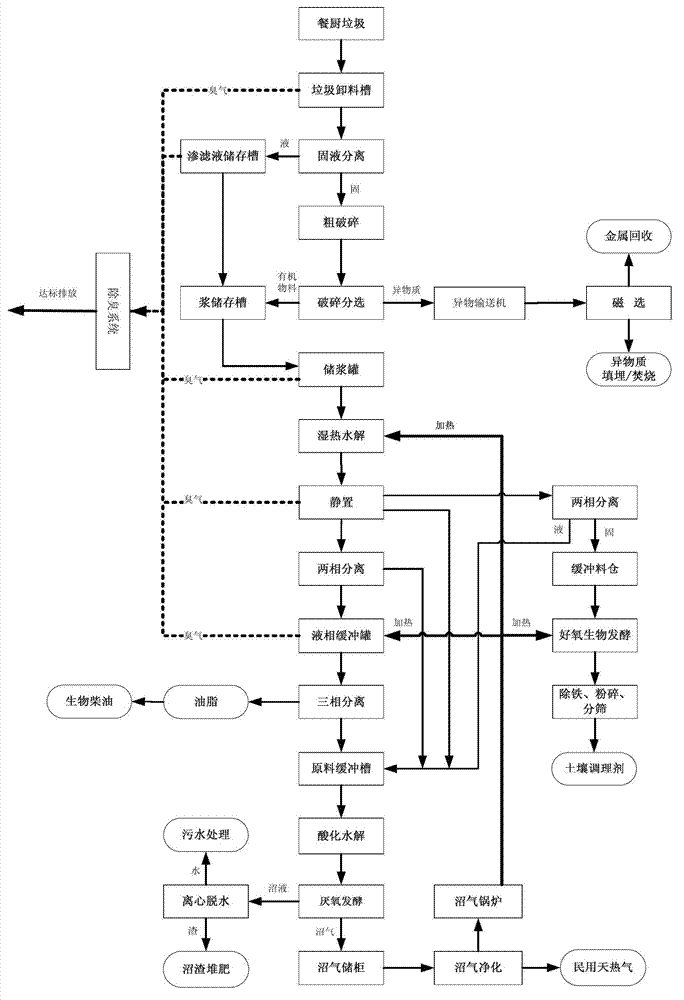

Harmless disposal method of kitchen garbage

InactiveCN102921704AShorten the processing chainPromote engineering applicationSolid waste disposalFurniture waste recoveryOil and greaseEconomic benefits

The invention relates to a harmless disposal method of kitchen garbage, which comprises the following steps of: (1) pretreatment: after unloading the kitchen garbage, performing solid-liquid separation, rough crushing, crushing and sorting and performing magnetic separation, and recycling metal substances mixed in the kitchen garbage; (2) hydrothermal hydrolysis: after the pretreatment, adopting the hydrothermal hydrolysis to fully inactivate viruses and bacteria in the kitchen garbage, separating out animal and vegetable fatty oil from the kitchen garbage, and hydrolyzing organic materials at the same time; (3) using the fatty oil obtained in the step (2) as an industrial fatty oil material or further performing deep processing to obtain fatty acid methyl ester or biodiesel; mixing and proportioning the pasty organic materials and then conveying into an anaerobic fermentation system; and conveying large granular organic materials into an aerobic biological fermentation device. The method provided by the invention realizes harmless disposal of the kitchen garbage mainly by the pretreatment and the hydrothermal hydrolysis process, increases the conversion rate of biological energy of the kitchen garbage and increases the economic benefit of kitchen garbage recycling products.

Owner:CHINA URBAN CONSTR DESIGN & RES INST CO LTD +2

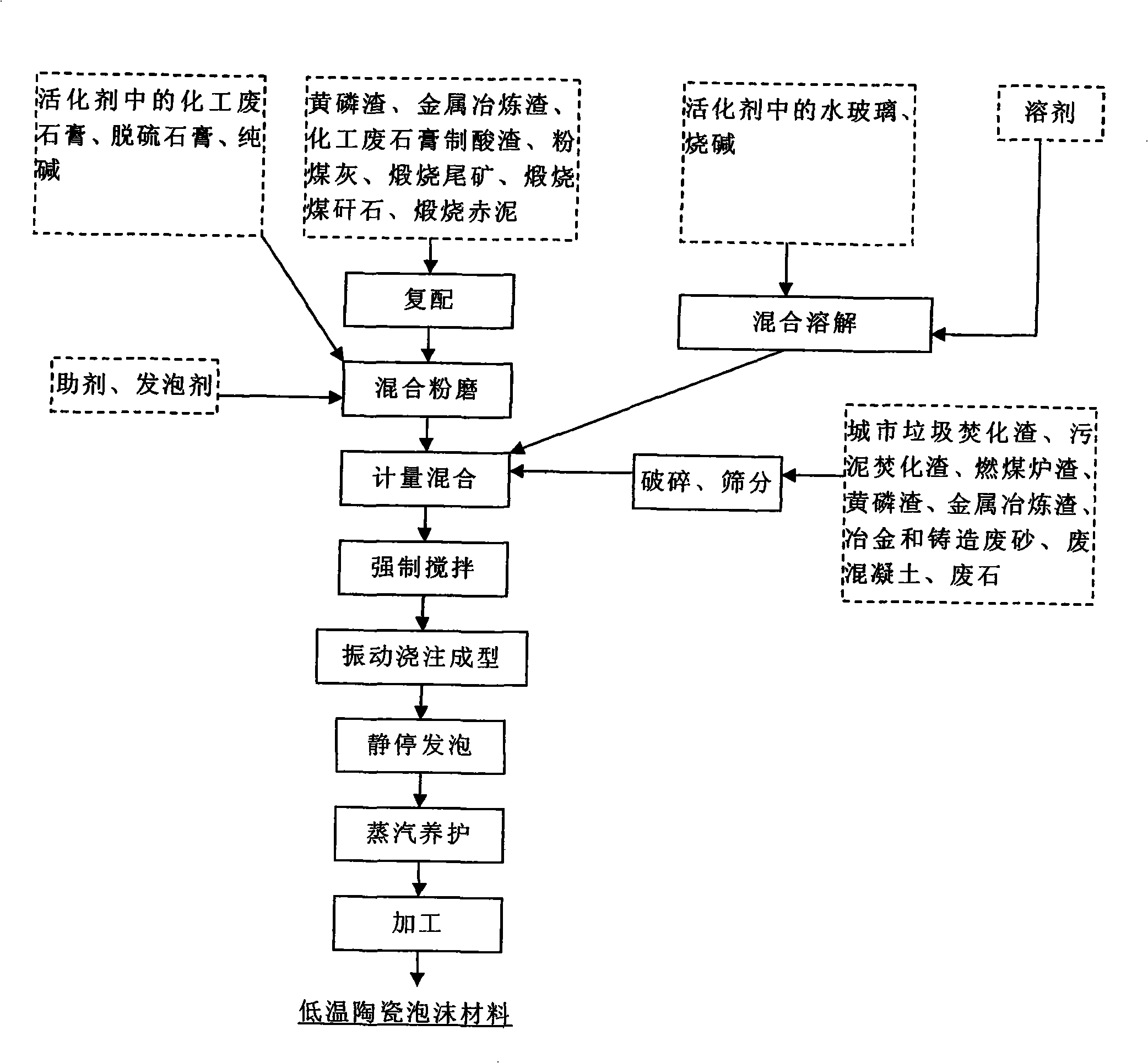

Low-temperature ceramic foam material and production method thereof

The invention relates to a production method producing low temperature ceramic foam material by using solid waste slag, which belongs to the technical field of building materials. Combined according to the mass ratio, the components of the low temperature ceramic foam materials consist of 100 portions of cementing materials, 100 to 400 portions of skeletal materials, 13 to 50 portions of activators, 0.2 to 3.0 portions of accessory ingredient, 0.04 to 1.0 portions of foaming agents and 15 to 50 portions of solvents. By the processes of raw material treatment, mixing, casting molding and maintenance, the raw materials with the formulas are made into the low temperature ceramic foam material which takes low temperature ceramic compound reinforced by inorganic waste slag particles as matrix phase and stomas as dispersed phase. Compared with the prior art, the material produced by the method has the advantages of high strength, good thermal and heat insulating property, high waste slag utilization ratio, low cost, environmental protection and saving natural resources, etc., which can be widely used as decoration material and thermal and heat insulating material.

Owner:KUNMING UNIV OF SCI & TECH

Graphene/carbon black thermoplastic resin master batch with high dispersibility and preparation method thereof

The invention discloses a graphene / carbon black thermoplastic resin master batch with high dispersibility and a preparation method thereof. The graphene / carbon black compound in the master batch is formed in an electrostatic self-assembly manner, and comprises 10-50% of graphene, 5-20% of carbon black, 0.5-10% of surfactant, 10-65% of carrier resin and 2-10% of assistant. The preparation method comprises the following steps: (1) compounding and dispersing graphene by adopting the surfactant to control the positive electricity of the graphene surface; (2) forming a stable graphene / carbon black compound from the modified graphene and carbon black with positive electricity through electrostatic incorporation in a self-assembly manner; (3) preparing the graphene / carbon black thermoplastic resin master batch with high dispersibility by matching with a solution blended process, a melt-blending method and an in-situ polymerization method; (4) adding the assistant to extrude and pelletize, so as to prepare the graphene / carbon black / thermoplastic resin master batch particles after processing the master batch. By adopting the obtained master batch, the problems of difficult charging of graphene powder, uneven dispersion, dust pollution, unstable product performance and the like are solved.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

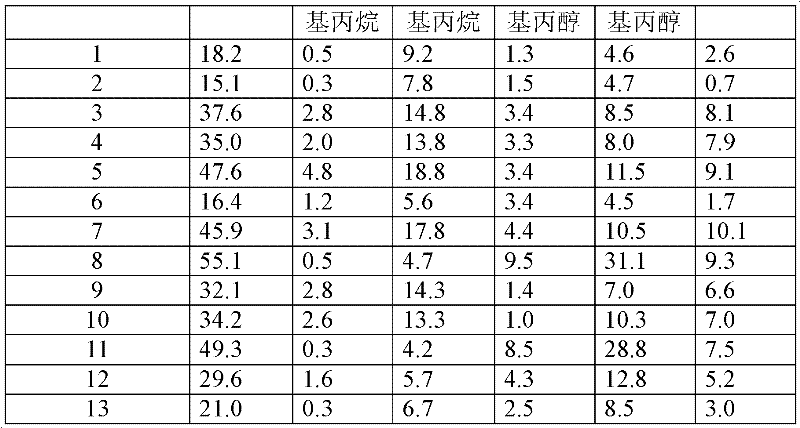

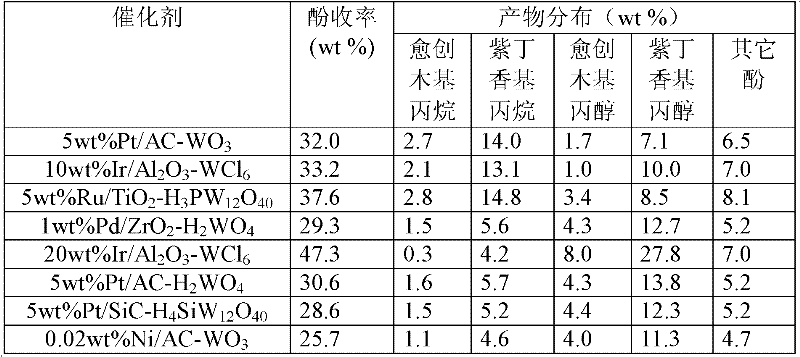

Application of tungsten-based catalyst in lignin catalytic hydrogenation for producing aromatic compound

ActiveCN102476980AWide variety of sourcesLow costCatalyst carriersOrganic compound preparationIridiumHydrogen pressure

The invention relates to hydrocracking of lignin, and specifically relates to a method for applying a tungsten-based catalyst to catalyze lignin hydrocracking for producing an aromatic compound. The catalyst comprises a main active component of non-zero-valent tungsten, and a second metal component of a small amount of one or more transition metals selected from zero-valent nickel, cobalt, ruthenium, iridium, palladium, platinum, iron, and copper. According to the method, raw materials such as lignin, biomass hydrolysis residue, lignosulfonate, and alkaline lignin are subject to catalytic hydrogenation under a hydrothermal condition with a temperature of 120 to 450 DEG C and a hydrogen pressure of 1 to 20MPa; the raw materials are cracked into C6-C9 phenolic compounds with high selectivity. A maximal phenol yield reaches 55.6%. Compared to existing technologies, according to the invention, renewable natural biomasses are adopted as raw materials, such that the raw materials are cheap, and have wide sources; inorganic acid and alkali are not required, such the production of a large amount of alkaline solution in traditional lignin catalysis is avoided; the tungsten-based catalyst is cheap; the reaction process is green, and has atom economical characteristics.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for recovering rare earth from ionic type rare earth crude ore

ActiveCN102190325AReduce or eliminate pollutionSolve pollutionRare earth metal compoundsAmmonium sulfateCarbonic acid

The invention discloses a method for recovering rare earth from ionic type rare earth crude ore, which comprises the following steps of: leaching the ionic type rare earth crude ore by taking at least one of magnesium sulfate, magnesium chloride and calcium chloride, instead of most or all ammonium sulfate, ammonium chloride or sodium chloride, as an ore leaching agent to obtain rare earth leachate, performing neutralization and impurity removal, and precipitating rare earth by adopting solution of magnesium hydrogen carbonate or / and calcium bicarbonate to obtain a rare earth carbonate product. In the method, an ammonium bicarbonate precipitator and most or all ammonium sulfate, ammonium chloride and sodium chloride serving as ore leaching agents are eliminated, pollution of ammonia nitrogen wastewater and high-salinity sodium salt wastewater on environment and underground water is greatly reduced or eliminated, and the method is an environment-friendly ionic type rare earth ore mining process.

Owner:GRIREM ADVANCED MATERIALS CO LTD

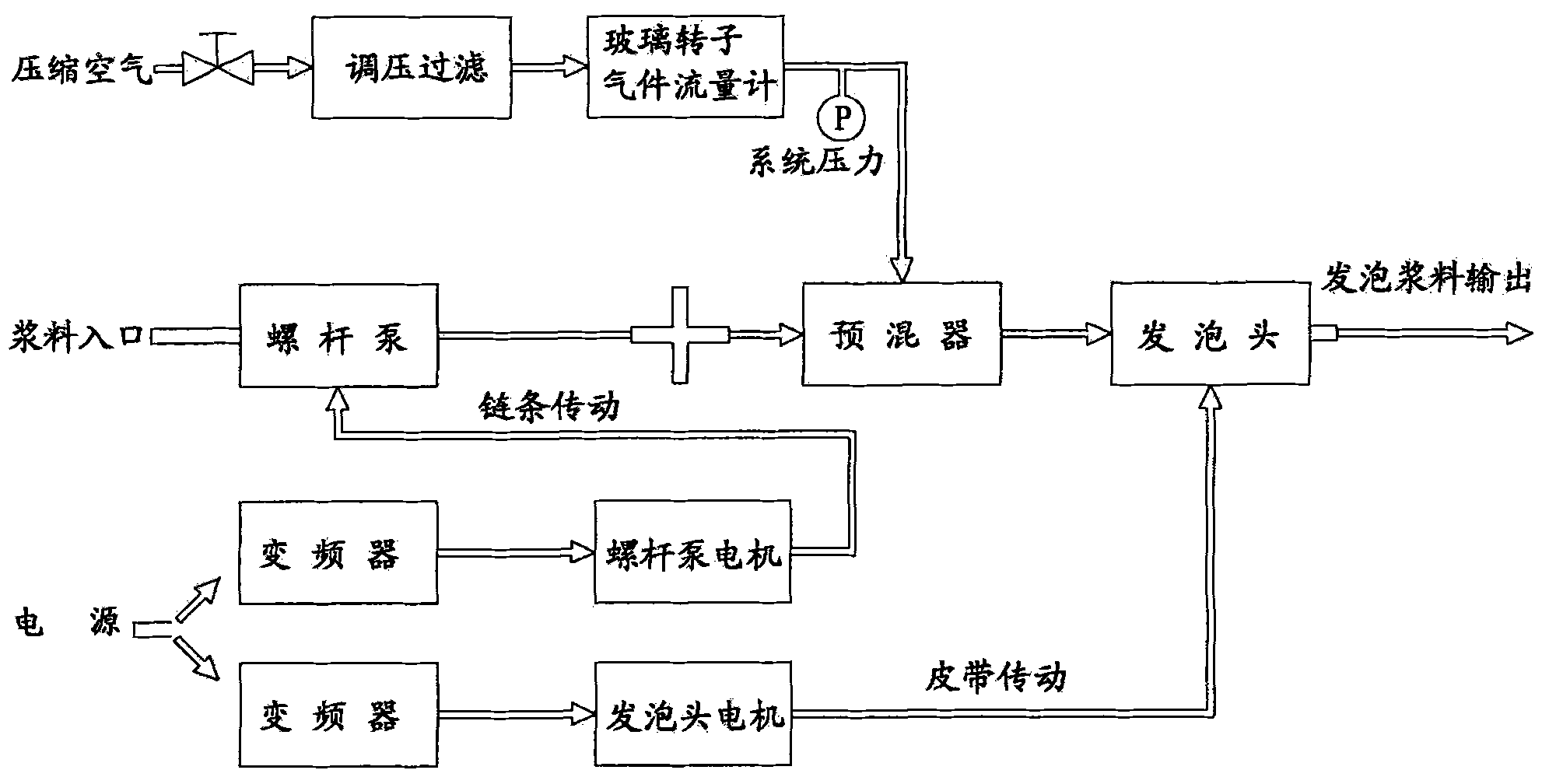

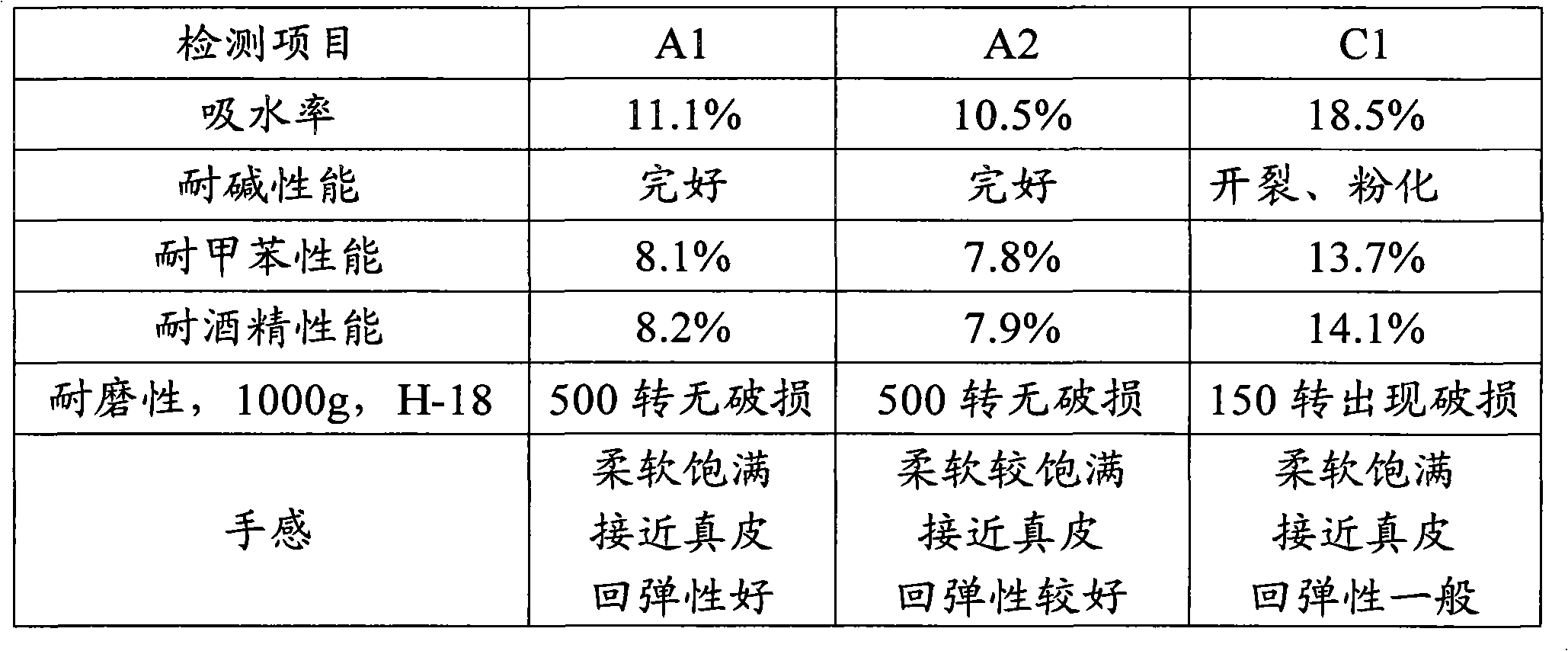

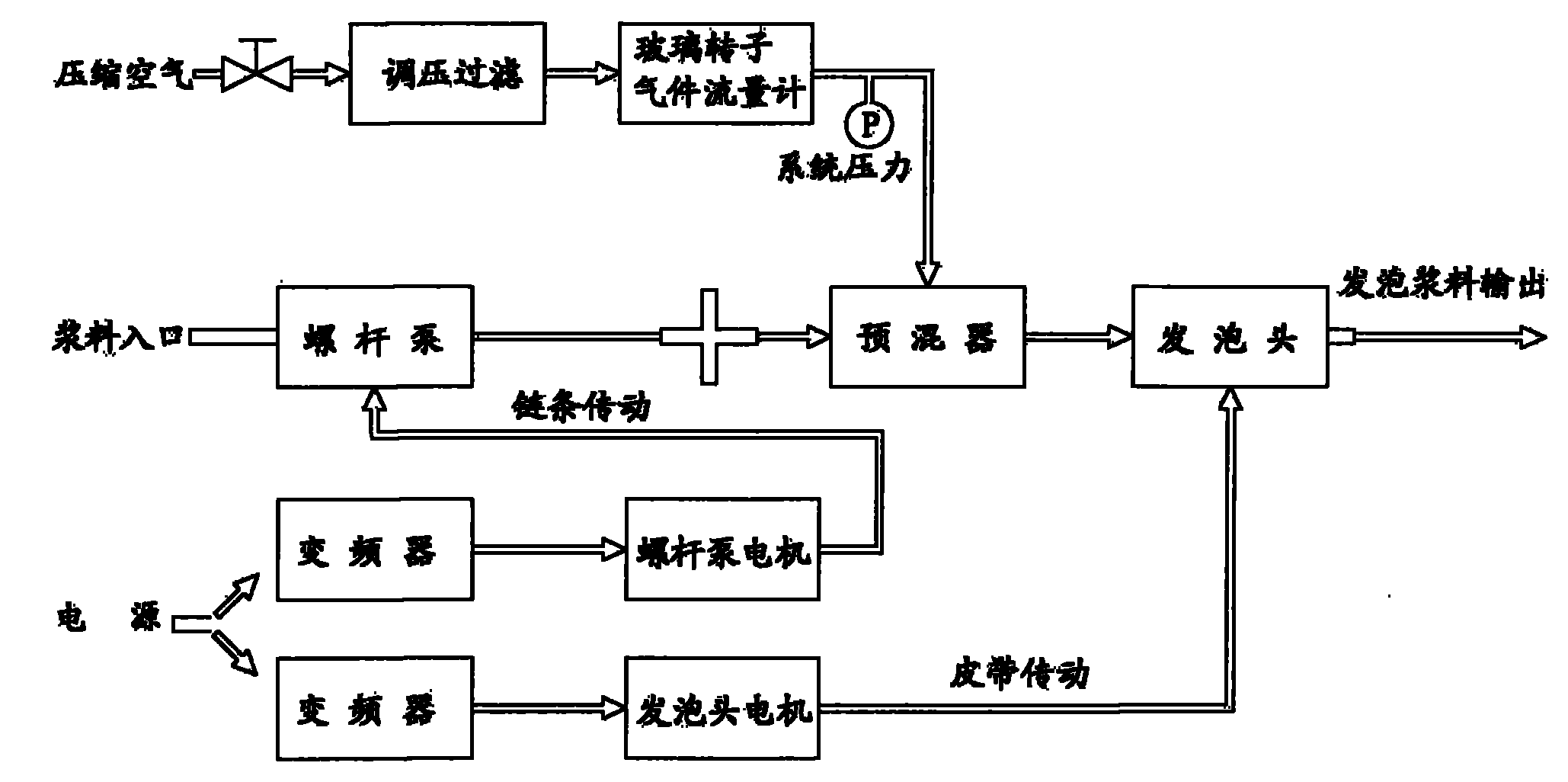

Method for manufacturing synthetic leather and synthetic leather

InactiveCN101941321AAchieving water-basedRealize cleaner productionSynthetic resin layered productsTextiles and paperLeather industryPolymer science

The invention provides a method for preparing synthetic leather and the synthetic leather prepared by the method. The method comprises the following steps: (1) coating slurry containing surface waterborne polyurethane resin on the surface of release paper, and drying to form a finishing coat; (2) mixing and foaming the slurry containing the foaming waterborne polyurethane resin with air by using a foaming machine, and coating the foamed slurry on the surface of the finishing layer, and drying to form a medium foaming layer; and (3) adhering the surface of the foaming layer and a basic fabric by using an adhesive containing waterborne polyurethane resin, and drying. The method uses the waterborne resin foaming layer to replace the Base leather manufacturing process, avoids using toxic and harmful organic solvents, such as dimetbyl formamide (DMF), toluene and the like, solves the pollution problem in the synthetic leather industry, and realizes clean manufacture of the synthetic leather.

Owner:丽水市优耐克水性树脂科技有限公司

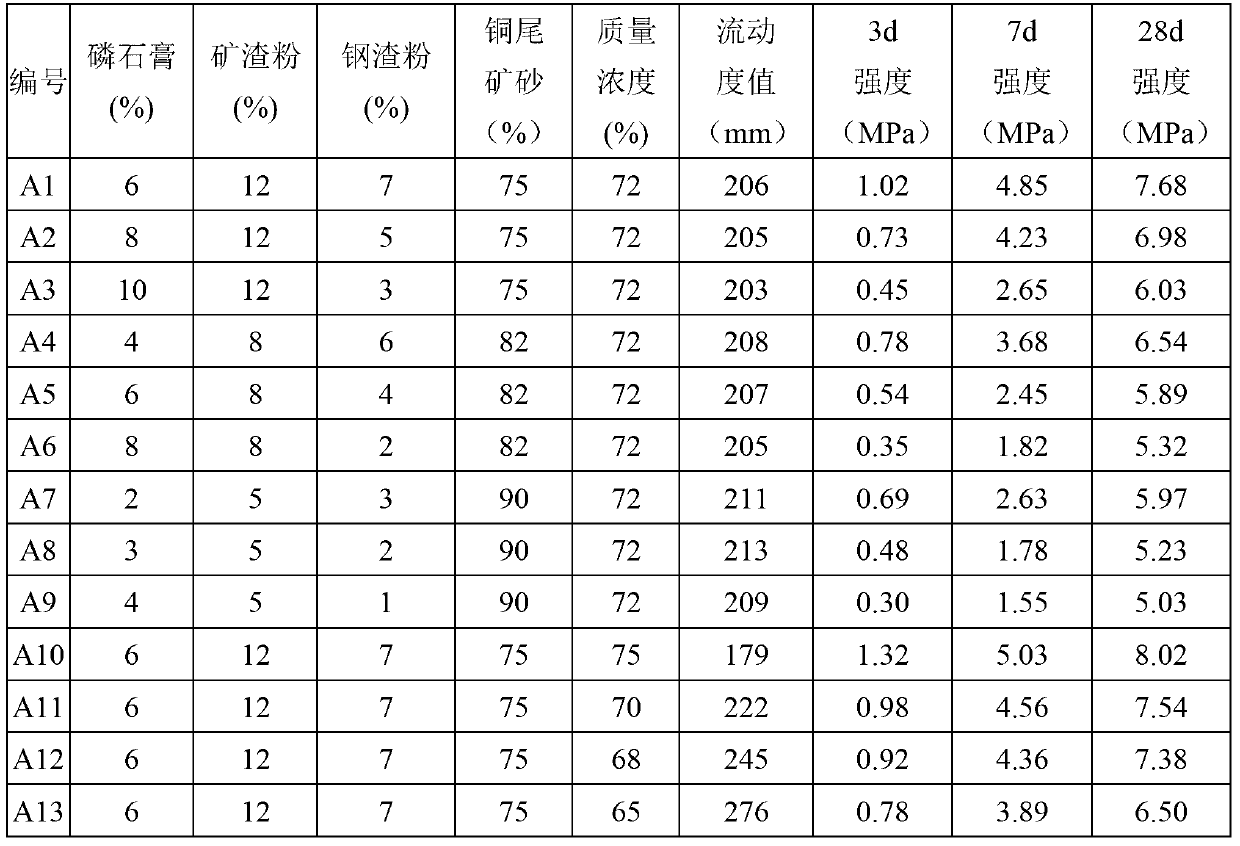

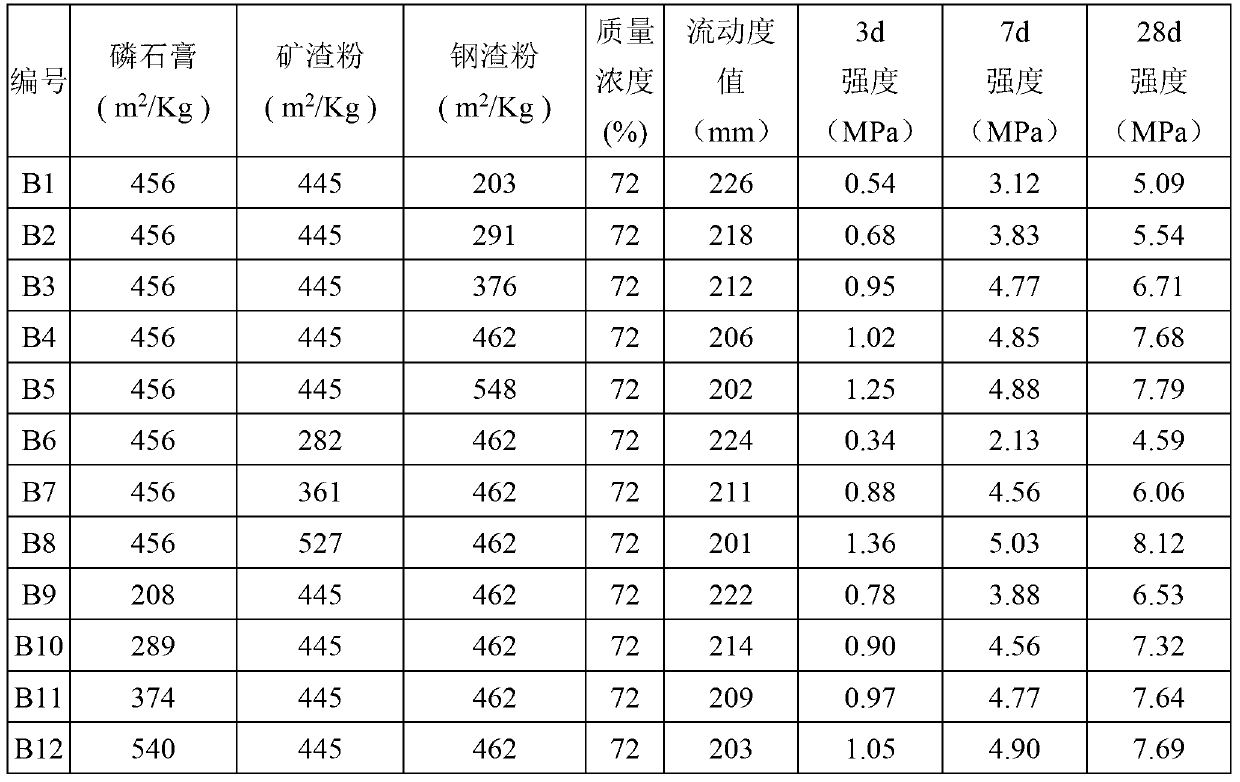

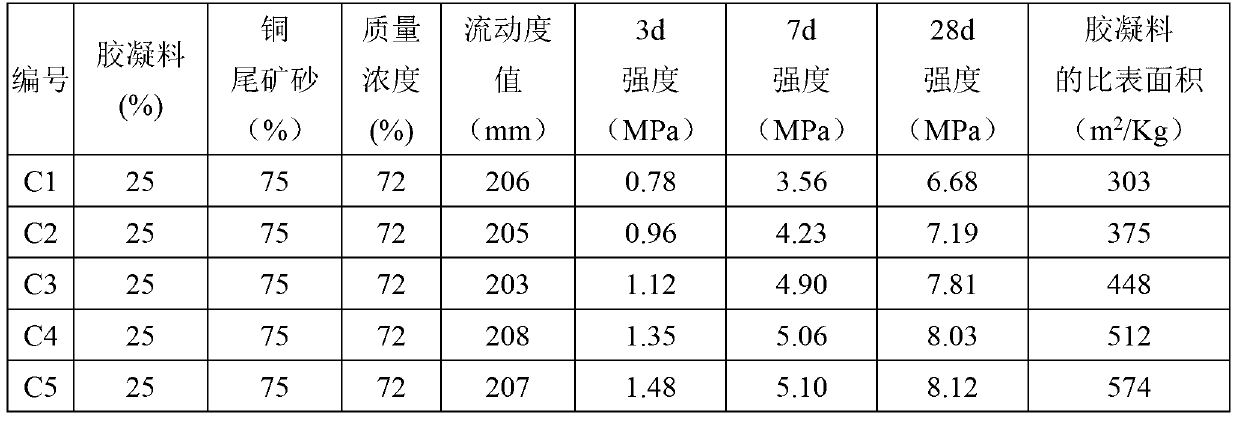

Mine filling cementing material slurry and preparation method thereof

The invention belongs to the technical field of mining engineering and building materials and particularly relates to a mine filling cementing material slurry and a preparation method thereof. The preparation method comprises the following steps of: with steel slag, mineral slag and industrial byproduct gypsum as cementing agents and tailing sand as a filling aggregate, adding water, mixing and stirring uniformly to prepare mine filling cementing material slurry, wherein a dry basis of raw materials comprises the following components in percentage by weight: 1-7% of steel slag, 5-12% of mineral slag, 2-10% of industrial byproduct gypsum and 75-90% of tailing sand, and the sum of the weight percentage of the dry basis of all the raw materials is 100%; adding water to regulate the mass concentration of the filling cementing material slurry to be between 65-75%. The mine filling cementing material slurry has the beneficial effects of higher strength, simple process, high flowability and suitablity for self-flowing filling; no cement or cement clinker or additives are added in the components of the filling cementing material slurry which is completely made of solid wastes, so that the utilization rate of the tailing sand is high, and the production cost is very low.

Owner:WUHAN UNIV OF TECH

Method for recovering valuable metals from waste printed circuit board

ActiveCN101787547ASolve pollutionReduce energy consumptionPhotography auxillary processesProcess efficiency improvementElectrolysisFiltration

The invention discloses a method for recovering valuable metals from a waste printed circuit board. The method comprises the following steps: sorting and crushing the printed circuit board, evenly mixing powder containing multiple metal parts with a fluxing agent, and smelting at low temperature for 1-3.5h; adding hot water into smelting products for leaching; evaporating and concentrating filtrate after filtration, and then returning evaporation mother liquor to the water leaching process step; using solution after leaching for swirl electrodeposition of metal silver, and adding 5-25% of HNO3 into filter residue for leaching; filtering the solution after electrodeposition, and adding 1-5 times of the weight of aqua regia into the filter residue for leaching; using the solution after leaching by the aqua regia for the swirl electrodeposition of gold, adding saturated NH4Cl into the solution after the electrodeposition for reaction, then filtering, using ammonium chloroplatinate for refining the filter residue, obtaining sponge platinum, adding methanoic acid into the solution after precipitation, and carrying out reaction for obtaining crude palladium powder. The method can extract copper, nickel, silver, gold, platinum, palladium and other main products and other by-products, realize the maximization of reutilization of value metal resources in the waste printed circuit board and solve the environmental pollution problem; and the adoption of the swirl electrolysis technology can realize low energy consumption, low reagent consumption, short process flow and simple operation.

Owner:HUNAN JIANG YE MECHANICAL & ELECTRICAL TECH CO LTD

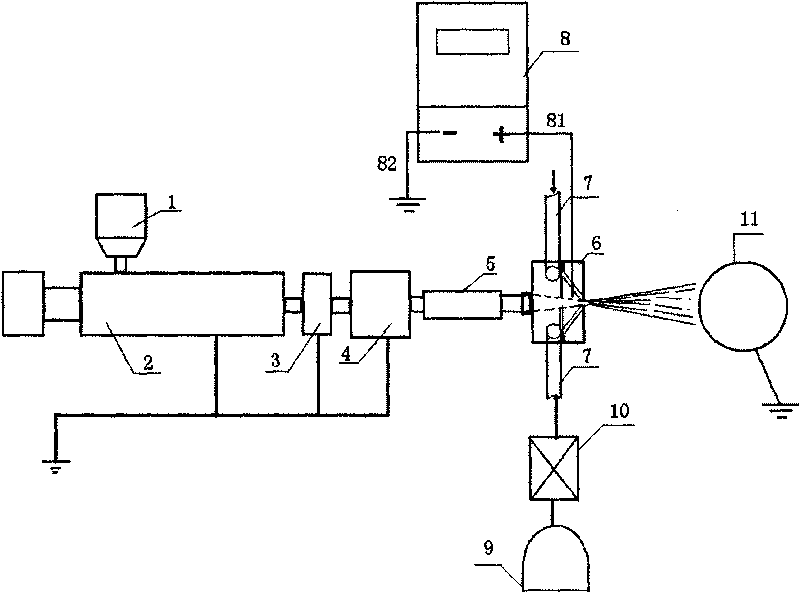

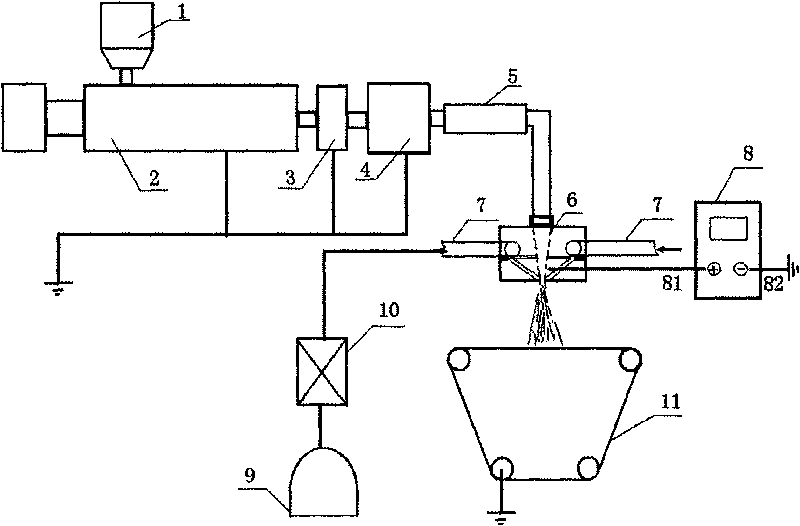

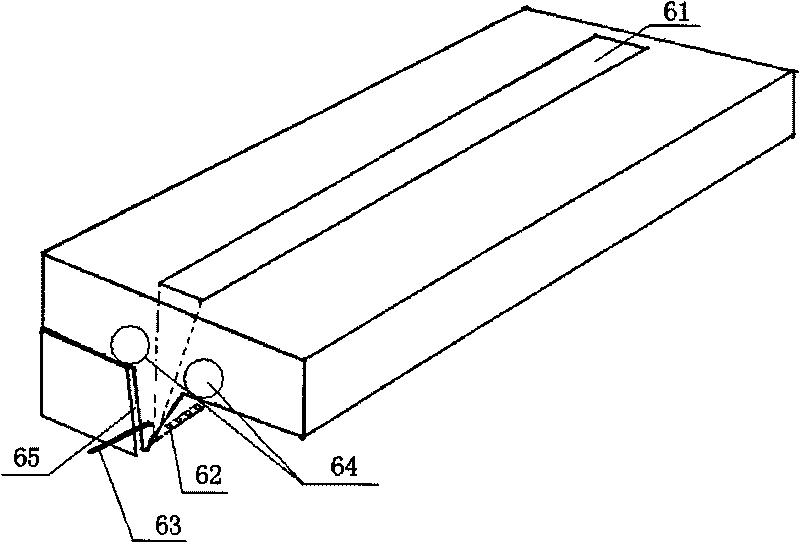

Device and method for manufacturing airflow melting electrostatic spinning nano-fiber non-woven fabric

InactiveCN101709534AThin diameterNarrow distributionSpinnerette packsSpinning head liquid feederFiberManufacturing technology

The invention relates to a device and a method for manufacturing an airflow melting electrostatic spinning nano-fiber non-woven fabric. The device for manufacturing the airflow melting electrostatic spinning nano-fiber non-woven fabric comprises a stock hoper, a screw extruder, a filter, a metering pump, a material path, a melt-blown die head, a hot-air pipeline, an air compressor, a heating device, a high voltage electrostatic generator and a receiving device. The material path is made of high thermal conductivity insulating ceramics. The method for manufacturing the nano-fiber non-woven fabric adopts the device disclosed by the invention and comprises the following processing steps: (1) preparing a polymer melt; (2) jetting nano-fibers by using airflow static electricity; and (3) moulding the non-woven fabric. The method for manufacturing the nano-fiber non-woven fabric of the invention adopts airflow-melting electrostatic spinning technology, avoids a problem of pollution of electrostatic spinning solvent, and is novel environment-friendly non-woven fabric manufacturing technology. In the manufacturing method, high voltage electrostatic is directly acted on the melt-blown die head; the melt has high and uniform charge; and simultaneously by utilizing drafting of the airflow, the prepared nano-fiber has the advantages of thin diameter and narrow distribution. The device can meet production requirements by improving the conventional melt-blown manufacturing device, and has low implementation cost and easy industrialization promotion.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method of water-based polyurethane/nano-silicon dioxide composite emulsion

InactiveCN101845217AEliminate pollutionAddress pollution and damagePolyurea/polyurethane coatingsPrepolymerSolvent

The invention relates to a preparation method of a water-based polyurethane / nano-silicon dioxide composite emulsion, which comprises the following steps: uniformly mixing and stirring ethyl orthosilicate, absolute ethyl alcohol and octadecyl trimethyl ammonium chloride for reacting to obtain nano-silicon dioxide sol; heating polyglycol, and then, adding diisocyanate and dibutyltin dilaurate for reacting to form polyurethane prepolymer; adding a hydrophilic chain extender and a cross-linking agent into the polyurethane prepolymer for carrying out chain extending reaction, adding organic base for regulating the pH value to be 7.0-8.0, and then, adding deionized water to obtain 30% of water-based polyurethane emulsion; and mixing the nano-silicon dioxide sol and the water-based polyurethane emulsion in a water bath, and carrying out ultrasonic treatment to obtain the water-based polyurethane / nano-silicon dioxide composite emulsion. Harmful solvents and emulsifying agents do not need to be added in the preparation process of the invention, thereby solving the problems of polluting environment and injuring operators.

Owner:SHAANXI UNIV OF SCI & TECH

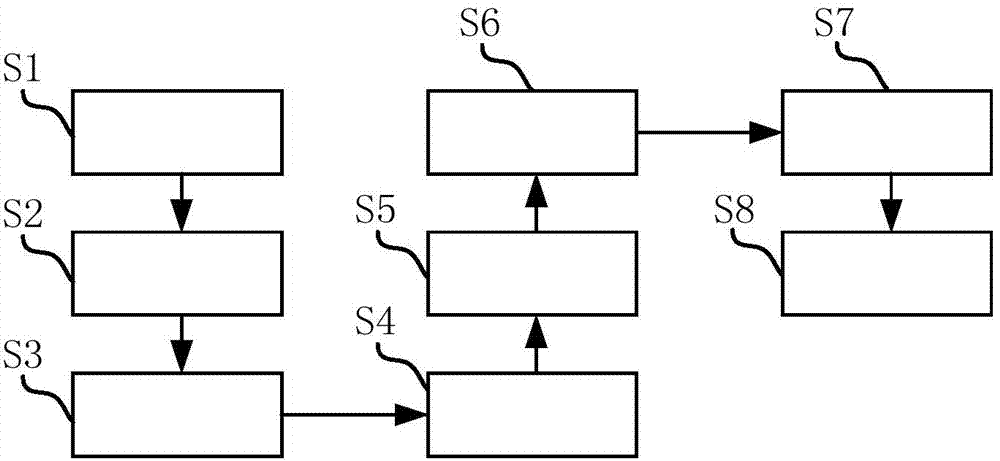

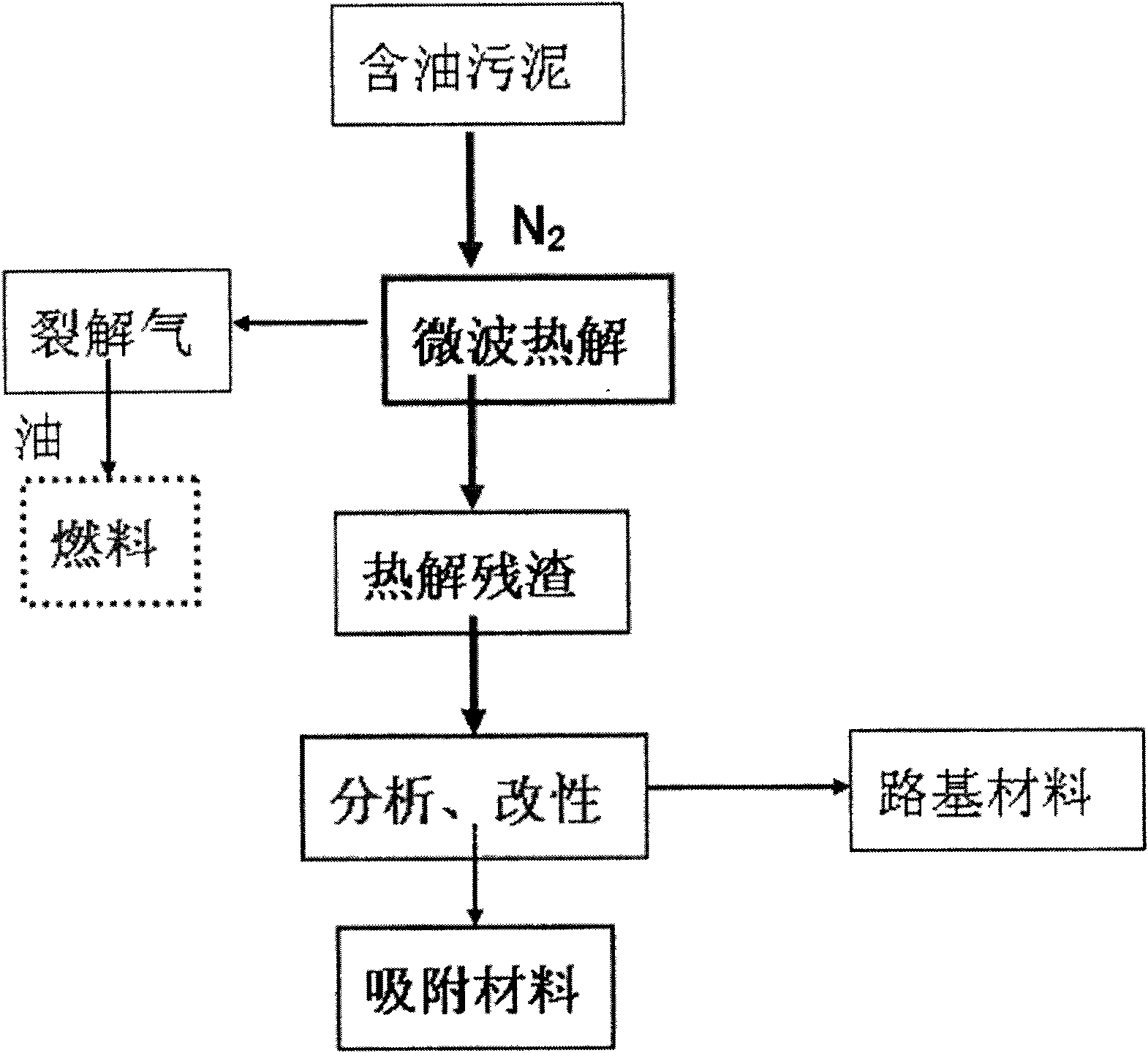

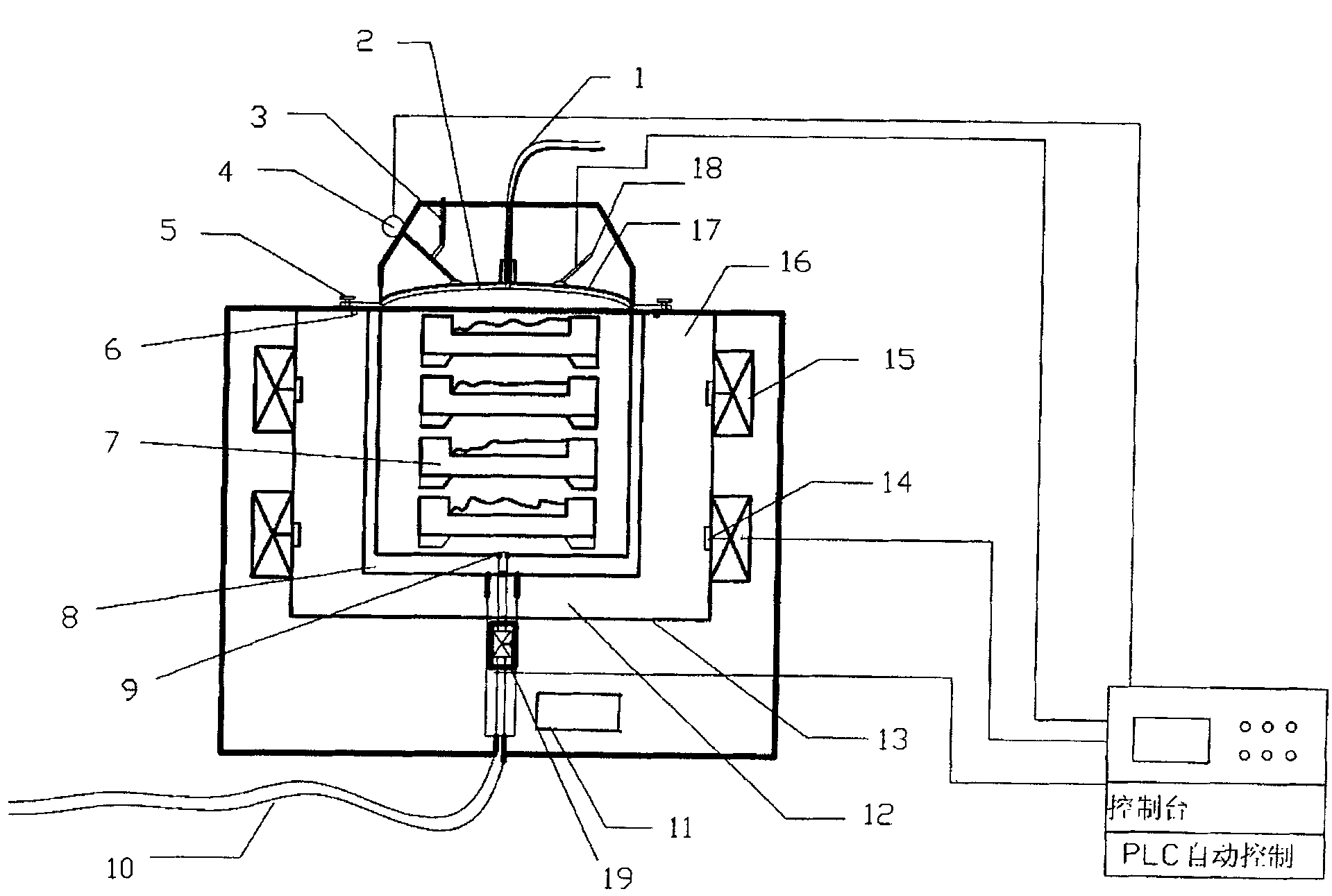

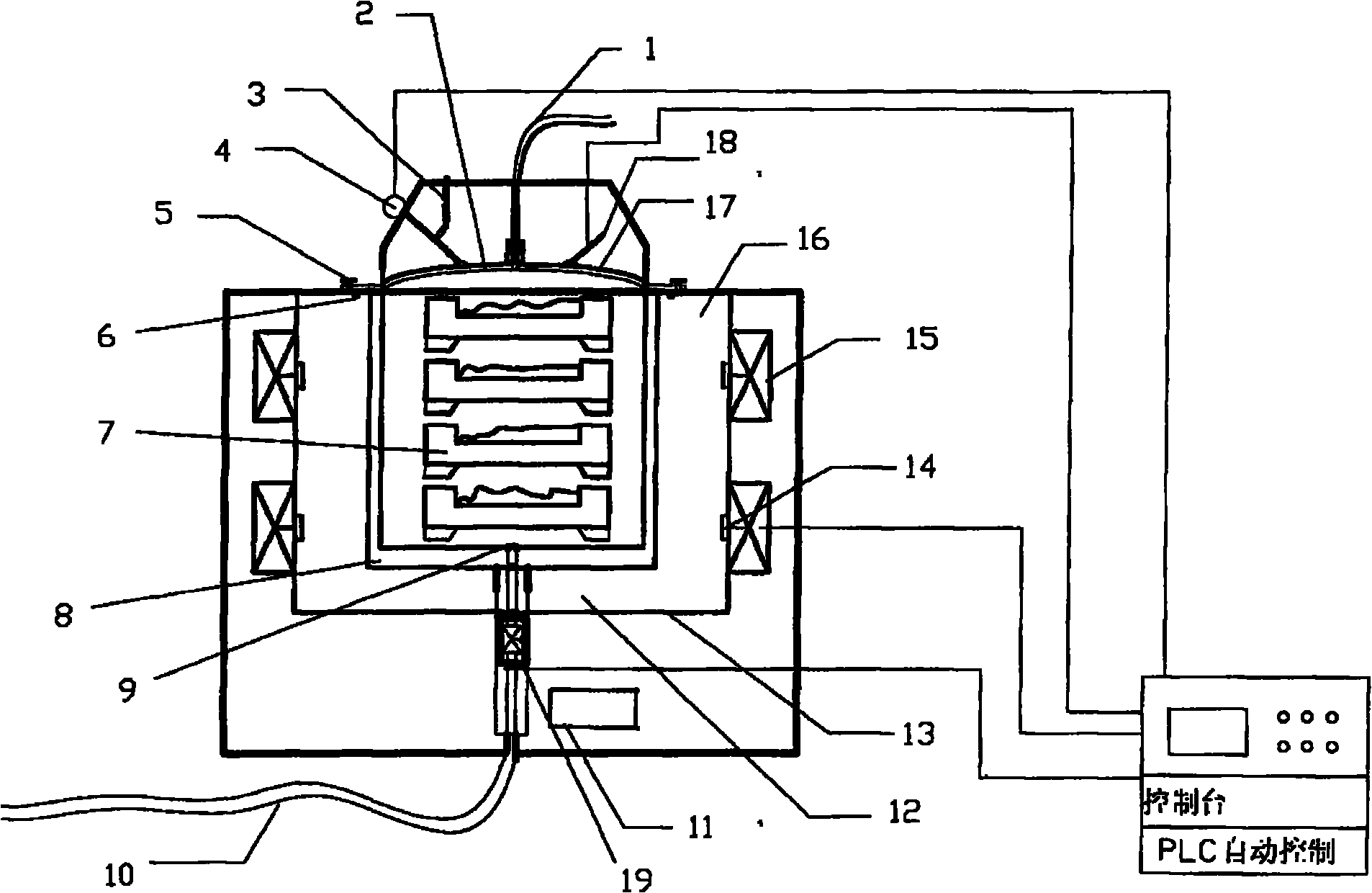

Resourceful treatment method and device for oil-containing sludge in oil fields by microwave pyrolysis

ActiveCN101838094ASolve pollutionAvoid Hazardous Waste Sewage FeesOther chemical processesSludge treatment by pyrolysisMicrowave pyrolysisSludge

The invention discloses a resourceful treatment method and a resourceful treatment device for oil-containing sludge in oil fields by microwave pyrolysis. The oil-containing sludge is conveyed into an enclosed reactor heated by microwaves, and is subjected to pyrolysis treatment at the temperature of between 200 and 900 DEG C; oil, gas and water generated by the pyrolysis treatment are recycled; the residue after the pyrolysis is used as a roadbed material or modified by nitric acid or NaOH alkali; and the modified residue is used as an adsorbing material. After the method and the device are implemented, over 75 percent of crude oil in the oil-containing sludge can be recycled, the pollution fee of 1,000 yuan / t can be saved, the social and economic benefits are obvious, and the method and the device have wide market application prospect.

Owner:CHINA PETROCHEMICAL CORP +2

Fruity ice cream and its production process

The present invention relates to fruity ice cream and its production process. The fruity ice cream has fruit shell in 0.5-2.5 thickness, top cover and inside soft ice cream comprising fruit juice and ice cream in the same weight ratio. It is produced through the following steps: making the shell with fruit, making the top cover, making fruit juice, making ice cream, storing and transporting, and making fruity ice cream. The present invention makes it possible to ingest the nutrients of fruit while eating ice cream, and the fruity ice cream has different components, unique flavors and excellent functions of quenching thirst and eliminating summer heat.

Owner:陈鹏

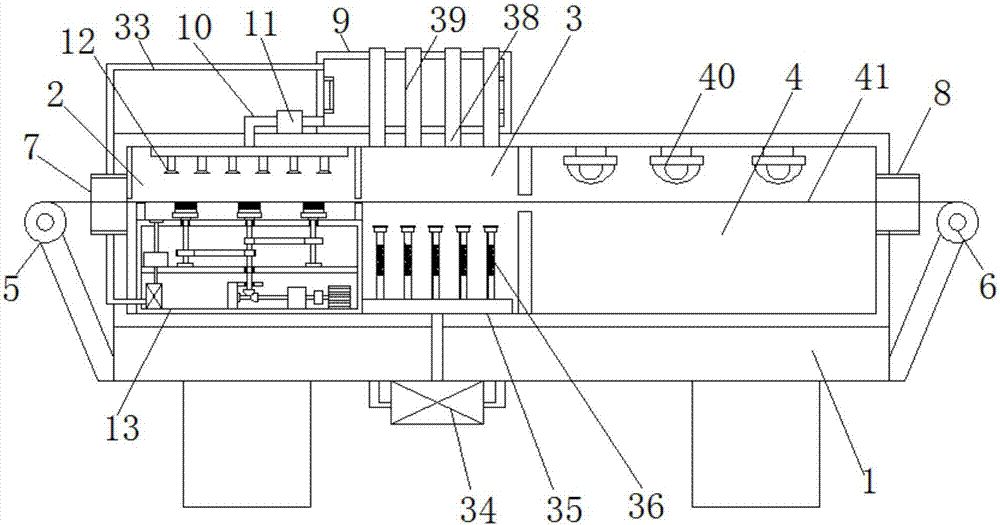

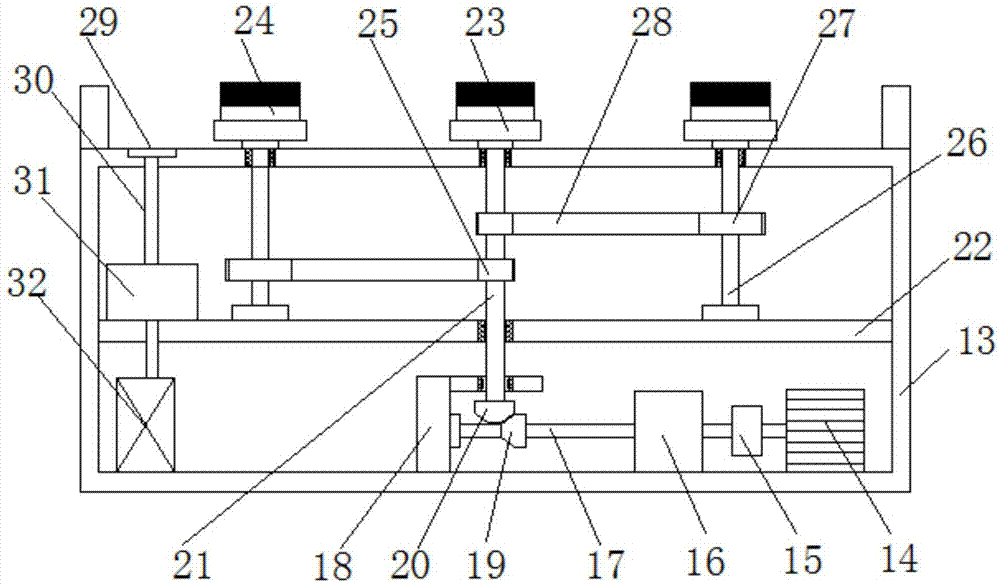

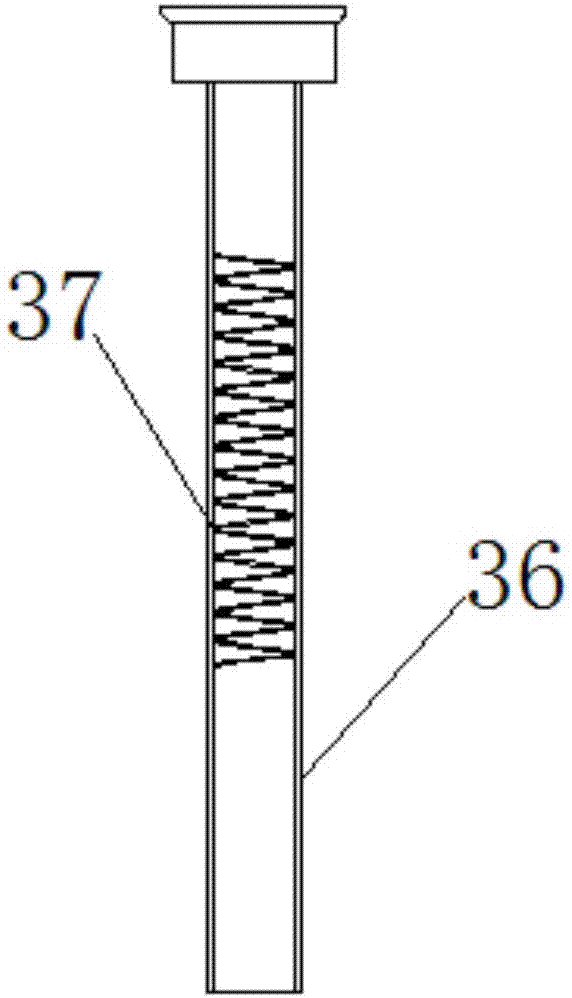

Energy-conserving textile fabric washing device

InactiveCN107326567AWash thoroughlySolve incomplete cleaningLiquid/gas/vapor removalTextile treatment machine arrangementsAgricultural engineeringWater pipe

The invention discloses an energy-conserving textile fabric washing device. The washing device comprises a case. A cleaning room, a drying room and a disinfection room are formed in an inner cavity of the case in sequence from left to right. A fixed support on the left side face of the case is fixedly connected with a feeding roller through a fixed shaft. A fixed support on the right side face of the case is fixedly connected with a discharge roller through a fixed shaft. A feeding opening is formed in the upper portion of the left side face of the case. A discharge opening is formed in the upper portion of the right side face of the case. The upper surface of the case is fixedly connected with a water storage tank, and the bottom of the left side face of the water storage tank is fixedly connected with a water pipe fixedly connected with a booster pump. The energy-conserving textile fabric washing device has the advantages of thoroughly cleaning and disinfecting cloth, effectively recycling cleaning fluid to avoid water body pollution and effectively utilizing heat in the drying room. The problems are solved that existing textile fabric wastes energy and cannot be cleaned thoroughly.

Owner:秦泽坤

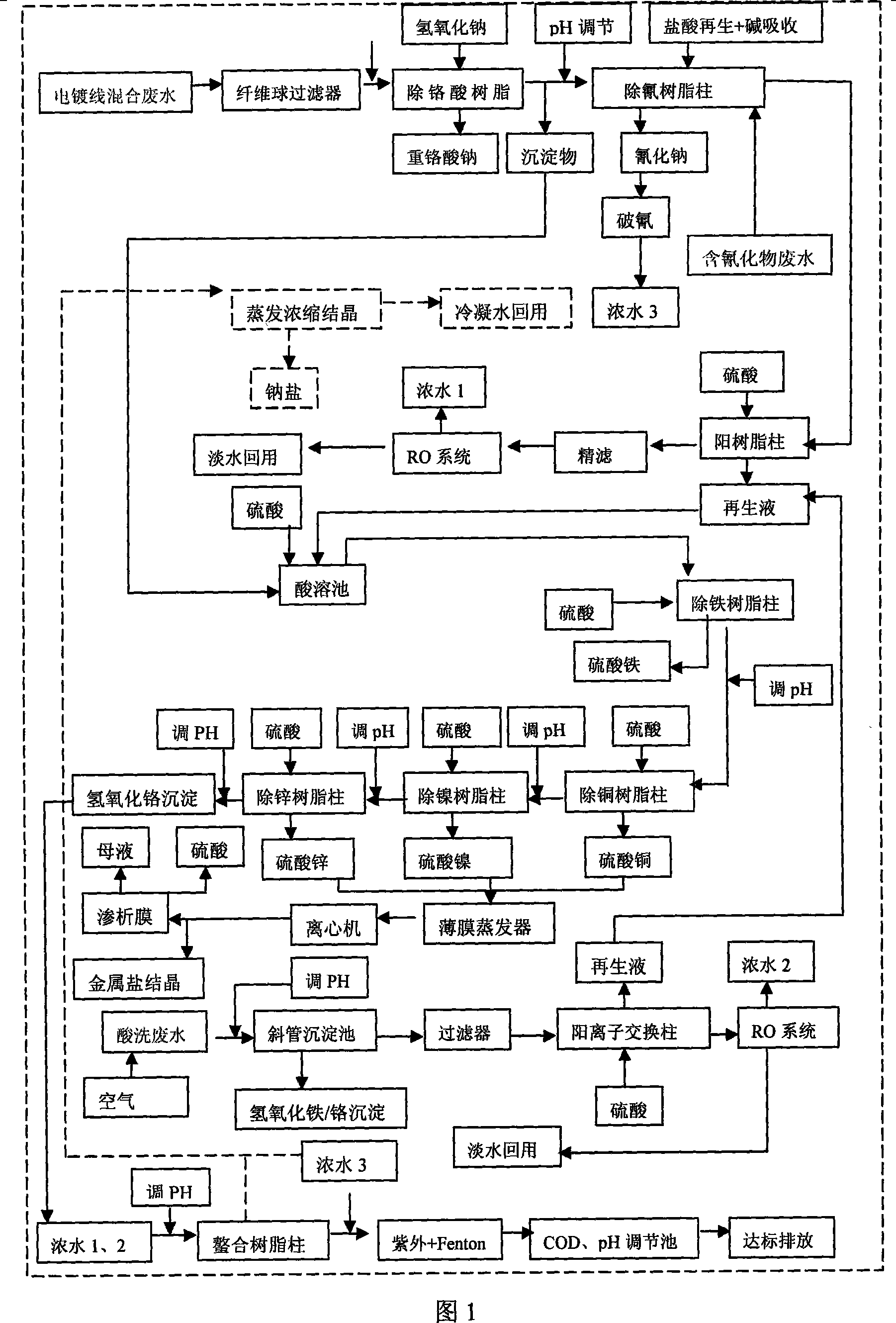

Electroplating wastewater zero-discharge or low-discharge handling method

InactiveCN101157509ASolve pollutionReduce processing costsFatty/oily/floating substances removal devicesWater/sewage treatment by irradiationIonAutomatic control

The invention provides a processing method for zero draining or low draining of electroplating wastewater. The method adopts an integrative technique, such as barrier concentration, barrier separation, ion exchange, and ultraviolet light catalytic oxidation, etc. The following steps are adopted: the pretreatment of the electroplating wastewater; the treatment for the three types of wastewater including pickling wastewater, wastewater containing cyanide and passivating and electroplating rinsing composite wastewater; and the treatment for the wastewater in an acid-soluble pool. Compared with the wastewater in an integrative electroplating plant with universal generic multi-plating species, only the prior water separation method with no need to control the troubled water strictly can realize : first, zero draining of the electroplating wastewater is performed; second, when operating in the low energy consumption way, 65 to 85 percent of water recovery is realized, the left wastewater which can not be recovered is discharged when reaching the primary discharge standard of National Standard; third, the processing cost is reduced; fourth, the metallic ion in the wastewater can be effectively recovered and utilized, at the same time, the benefit disinvestment cost is produced; fifth, the amount for causing solid waste is reduced; sixth, the invention is advantageous to realize the automatic control and the operation.

Owner:SURFACE & INTERFACE CHEM ENG TECH RES CENT NANJING UNIV +1

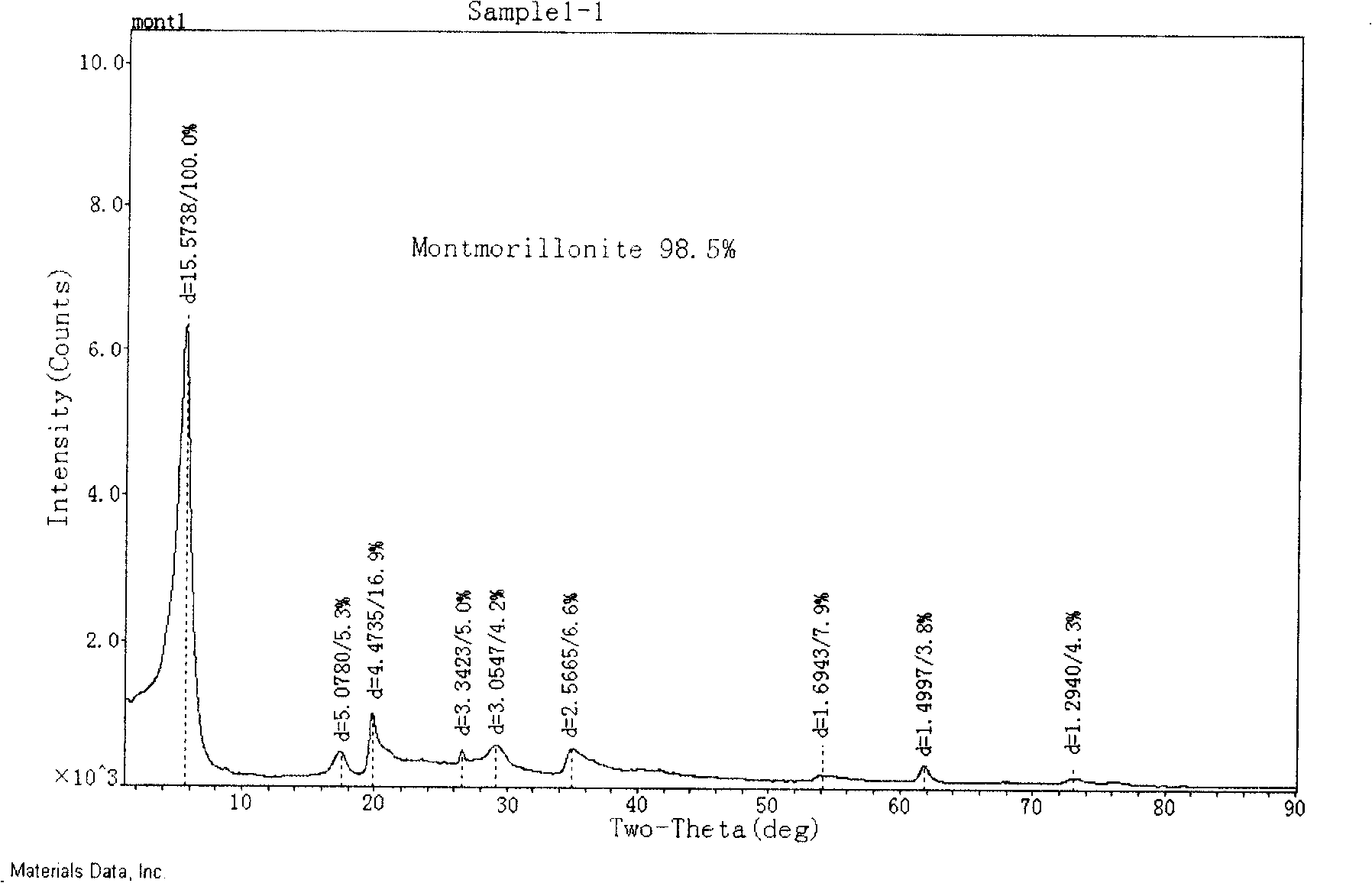

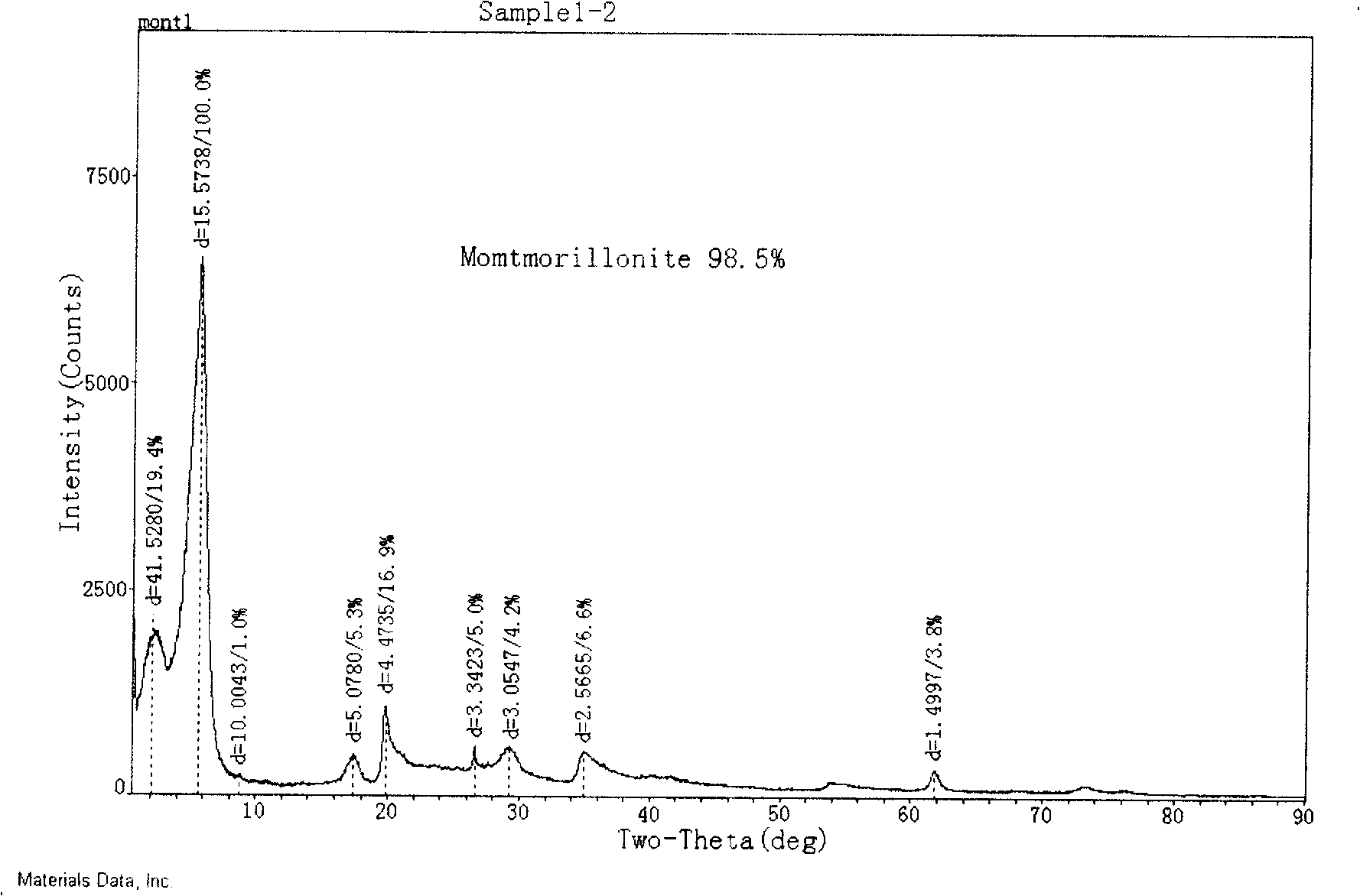

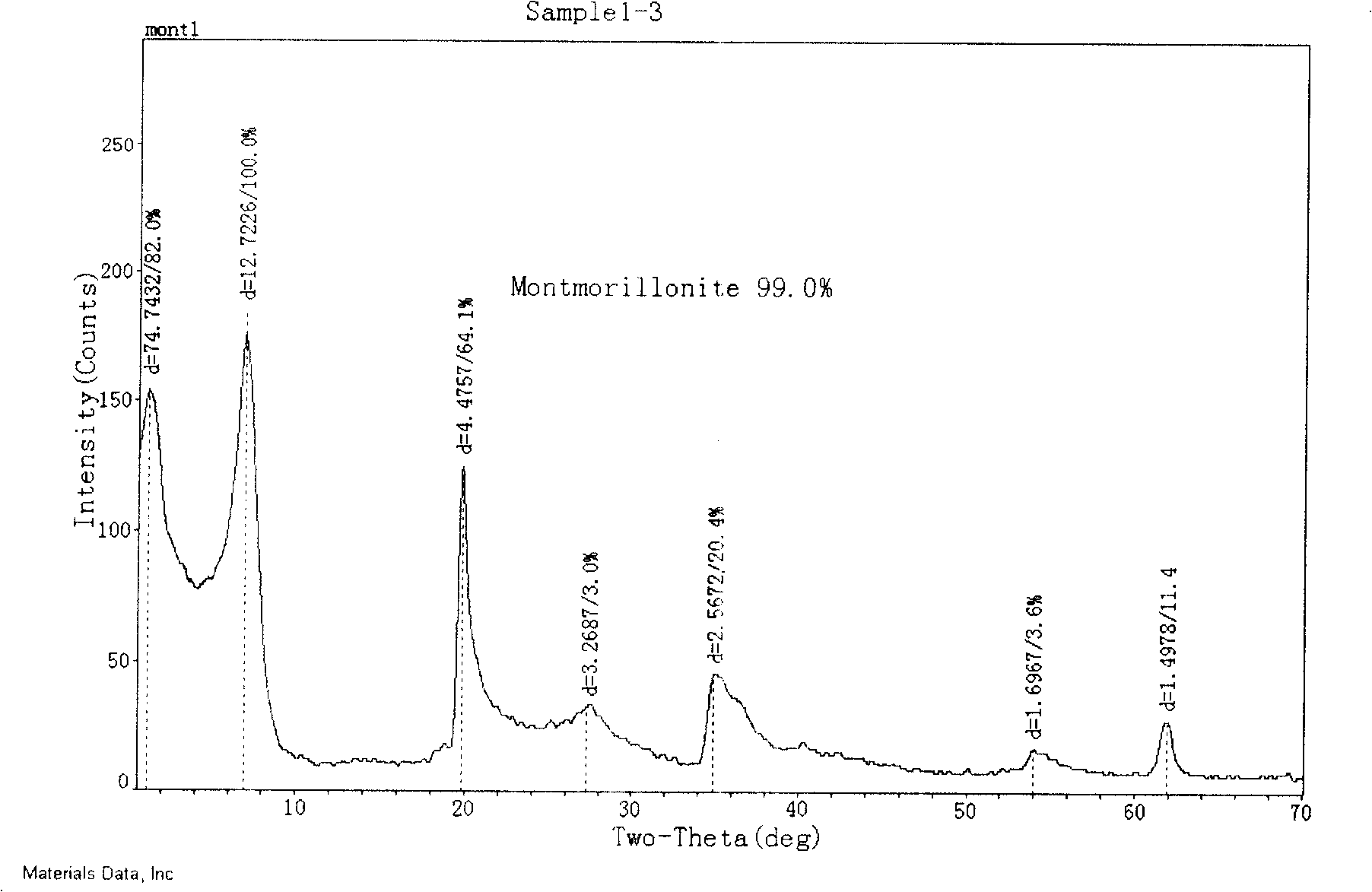

Modified smectite and method for producing the same and its application

ActiveCN101272986ANot easy to raise dustReduce moisture contentCosmetic preparationsOther chemical processesChemical compositionMontmorillonite

Disclosed is an inorganic medicine, particularly modified montmorillonite, method for preparing the same and use thereof. The said modified montmorillonite means that dioctahedron of natural montmorillonite is not destroyed and basic chemical composition for the same is not changed, and the microstructure stacked from dioctahedron layer is changed to decrease the thickness of stacking layer and to expose and increase the end face charge and the interlayer charge of montmorillonite, thereby resulting in its lower degree of C axis order. The present medical use of montmorillonite is thus significantly strengthened, particularly the reversal treatment effect on chronic atrophic gastritis. Also disclosed are a medicine composition containing modified montmorillonite and the reversal treatment effect of natural montmorillonite on chronic atrophic gastritis.

Owner:ZHEJIANG HAILISHENG PHARM CO LTD

Method for preparing soil for flowers by using edible fungus chaff

InactiveCN101544512ANutritional balanceImprove disease resistanceBio-organic fraction processingOrganic fertiliser preparationBiotechnologyDisease

The invention belongs to the technical field of the recycling of fungus chaff from edible fungus cultivation, and in particular relates to a method for preparing soil for flowers by using edible fungus chaff. In the method, dried and crushed edible fungus chaff is uniformly mixed with auxiliary raw materials, the mixed raw material is fermented, the fermented mixed raw material is subjected to pH value adjustment and sterilization, and thus the soil for flowers is obtained. In the method, processed edible fungus chaff are used as a raw material for the soil for flowers, the original various nutrients and trace elements of the fungus chaff are retained, and thick, hard and wide fibers in the fungus chaff become short, loose and soft after the fermentation; and thus, the method improves the aggregate structure, organic matter content and fertility level of the soil, makes the nutrition of the soil for flowers more balance, contributes to the growth of flowers and trees, as well as promotes the improvement in the resistance against diseases and the quality of flowers.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

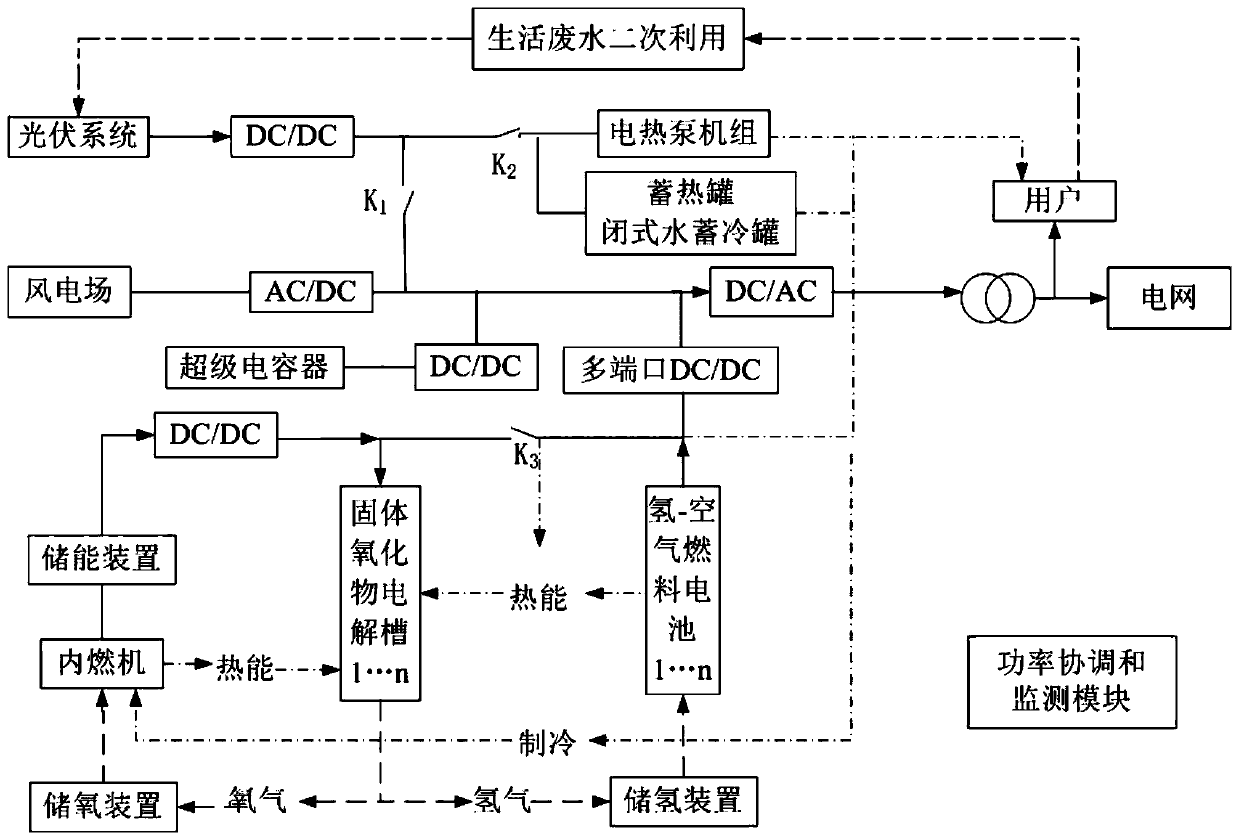

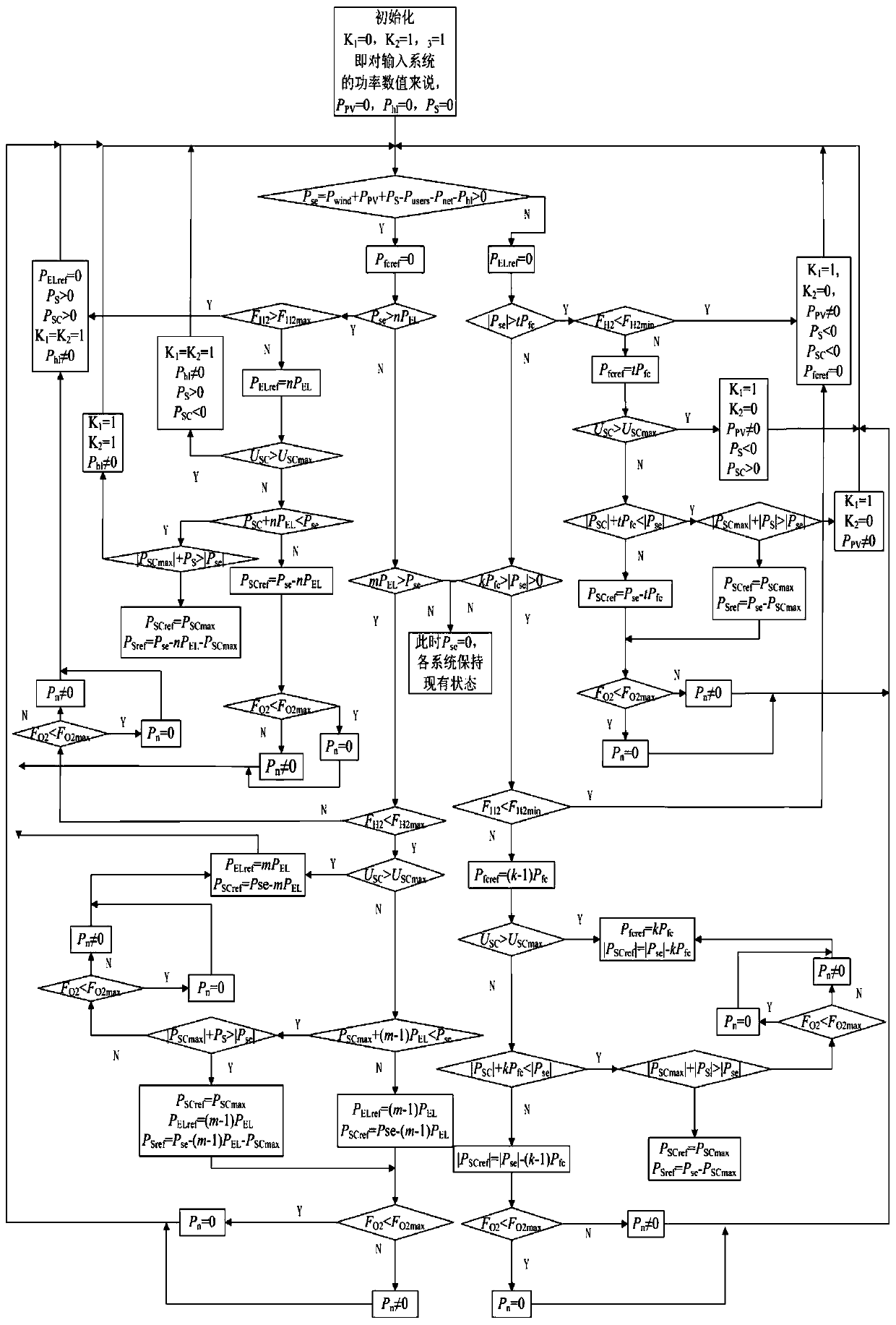

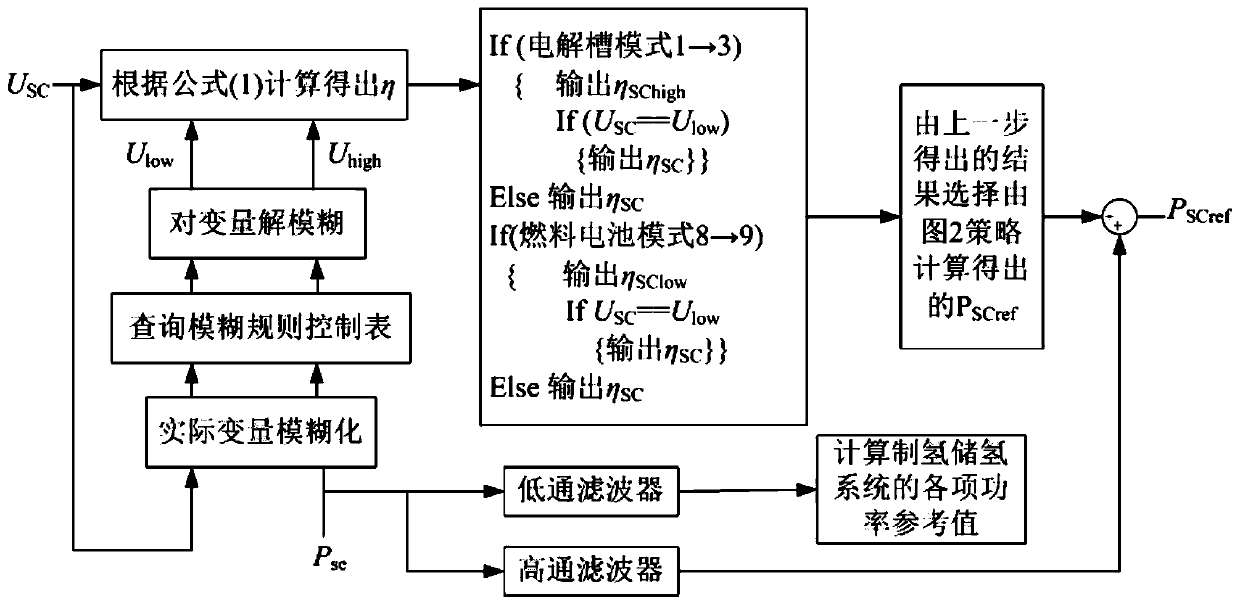

Wind-solar power generation and hydrogen-production hydrogen-storage system and operation control method thereof

ActiveCN109755965AIncrease profitSolve the requirements of evening peak loadBatteries circuit arrangementsSingle network parallel feeding arrangementsHydrogen productionGrid connection

The invention relates to a wind-solar power generation and hydrogen-production hydrogen-storage system and an operation control method thereof, and relates to the technical field of new energy wind-solar power generation and hydrogen production. According to the invention, a rectifier at a fan side of a wind power farm is connected with a grid side inverter; a DC (Direct Current) bus is connectedwith a supercapacitor of a DC / DC convertor; the rear surface of the supercapacitor is connected with a hydrogen production and hydrogen storage system; a photovoltaic system is connected with the DC bus in front of the supercapacitor by the DC / DC convertor and is used as a power compensation unit of the wind power farm; the wind-solar power generation and hydrogen-production hydrogen-storage system further comprises a power coordination control module and a monitoring module; and problems of poor peak regulation capacity, unsmooth hydrogen production, short service life of equipment and the like of a wind-solar power generation and hydrogen-production hydrogen-storage system are mainly solved. The wind-solar power generation and hydrogen-production hydrogen-storage system has the characteristics that the system is high in peak regulation capacity; the requirement of a load evening peak can be met; smooth hydrogen production can be ensured; the service life of the equipment is prolonged; flexible grid connection can be implemented in the premise of ensuring purity of produced hydrogen; and an energy utilization rate is high.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for producing baking-free bricks by using phosphorous gypsum based cementitious material to solidify yellow phosphorous slags

InactiveCN101637936ASolve pollutionLow costSolid waste managementMixing operation control apparatusBrickSlag

Owner:KUNMING UNIV OF SCI & TECH

Process of twice fermenting garbage-sludge mixture to produce microbial fertilizer

ActiveCN1974492ASolve pollutionPromote growthBio-organic fraction processingClimate change adaptationMicroorganismSludge

The present invention is process of twice fermenting garbage-sludge mixture to produce microbial fertilizer. The production process can eliminate environment pollution caused garbage and sludge while providing environment friendly efficient microbial fertilizer. The produced microbial fertilizer has high fertility, beneficial bacteria content up to 10<8>-10<10> / g and various bioactive matters. The produced microbial fertilizer can promote the growth of crop, strengthen the disease resistance of crop and raise yield of crop.

Owner:陕西文岭微生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com