Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7022results about "Ceramic materials production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic slurry preparation and 3D (three dimensional) printing light curing molding method

ActiveCN106810215ALow viscosityHigh solid contentAdditive manufacturing apparatusCeramic shaping apparatusFlexural strengthVolumetric Mass Density

The invention provides a ceramic slurry preparation and 3D (three dimensional) printing light curing molding method. 25-85vol% of ceramic powder and 15-75vol% of an optical resin premix solution are mainly involved, and the method includes: A), preparation of the optical resin premix : namely stirring a low polymer, a reactive diluent, a photoinitiator, a dispersing agent, a photosensitizer and a sensitizer according to a certain proportion under intermediate speed for 0.5-3 hours to enable the components to be mixed evenly; B), placing the premix solution and the ceramic powder in a ball mill according to certain volume for ball-milling for 5-15 hours to prepare the ceramic slurry high in solid content and low in viscosity; subjecting the ceramic slurry to curing molding layer by layer gradually on a 3D light curing molding machine to obtain a ceramic green body prior to aftertreatment of drying, degreasing, sintering and the like to obtain ceramic part. The method is high in preparation molding precision and free of molds to prepare complex structure parts, the ceramic product can reach more than 92% in density, 320-1750MPa in flexural strength and 1800-4500MPa in compression strength.

Owner:重庆摩方科技有限公司

Gravel attapulgite flower ceramsite

ActiveCN102503372BHigh strengthLower sintering temperatureCeramic materials productionCeramicwarePhysical chemistryMaterials science

The invention discloses gravel attapulgite flower ceramsite. The key point of the technical scheme is that the gravel attapulgite flower ceramsite consists of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, red bentonite powder, sludge, kieselguhr tailing powder and rice husk powder.t. The gravel attapulgite flower ceramsite is produced by the following steps of mixing the ingredients, pelleting, baking, cooling, smashing, sieving and packaging. The gravel attapulgite flower ceramsite is an irregularly-shaped granule, and has a rough and porous surface, light weight, high strength and high water absorption. The gravel attapulgite flower ceramsite can be soaked in water without being cracked and release nutrition required by flowers continuously and slowly. The gravel attapulgite flower ceramsite is produced by utilizing the sludge and tailings comprehensively, so that the utilization rate of resources is improved, waste materials are changed into wealth, and environment is protected. Besides, the gravel attapulgite flower ceramsite is suitable for planting the flowers and vegetables.

Owner:江苏世澳非金属应用科技有限公司

Spherical attapulgite flower ceramsite

ActiveCN102503539AReduce manufacturing costHigh strengthCeramic materials productionCeramicwareMetallurgyBentonite powder

The invention discloses spherical attapulgite flower ceramsite. The key points of the technical scheme are that the spherical attapulgite flower ceramsite consists of high-adhesion attapulgite clay powder, attapulgite clay tailing powder, red bentonite powder, sludge, diatomite tailing powder and rice husk powder. The spherical attapulgite flower ceramsite is produced by the following steps of mixing the ingredients, pelleting, roasting, cooling, screening and packaging. The spherical attapulgite flower ceramsite has a rough and porous surface, is light in weight, high in strength and water absorption rate, can be immersed in water throughout the year without cracking and can continuously and slowly release nutrition required by flowers. Moreover, the spherical attapulgite flower ceramsite is produced by comprehensively utilizing the sludge and tailings, so that the resource utilization rate is improved, waste is turned into wealth, and environment is protected. Besides, the cylindrical attapulgite flower ceramsite is applicable to cultivation of various flowers and vegetables.

Owner:江苏世澳非金属应用科技有限公司

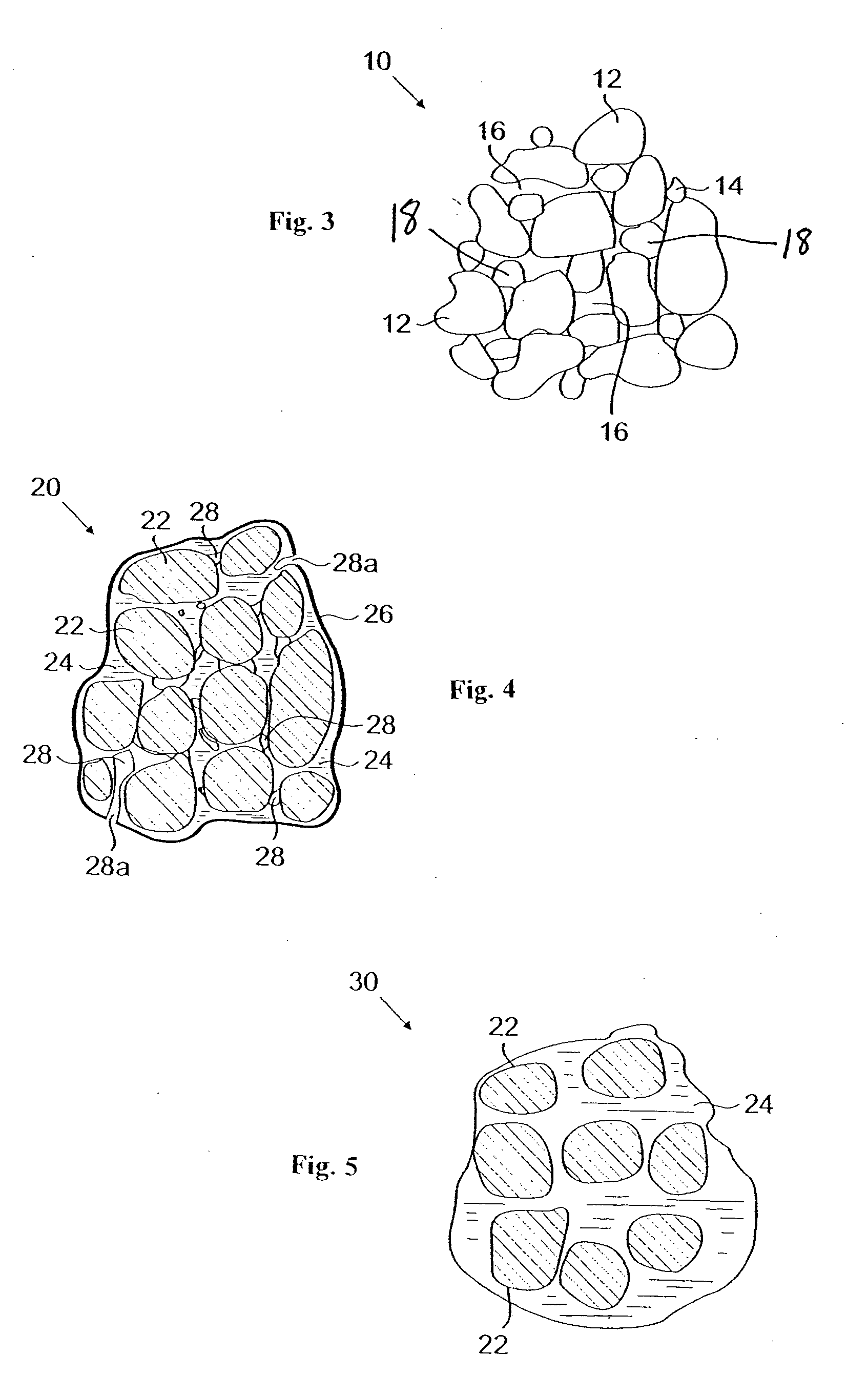

Lightweight proppant and method of making same

InactiveUS20060016598A1Manufactured usingSuitable viscosityFluid removalDrilling compositionPrillHigh intensity

A lightweight, high-strength proppant is disclosed, comprising the formation of finely dispersed ceramic precursors and sintering at low temperatures, causing the formation and retention of mesopores and micropores in pelletized ceramic. A method of manufacturing such a proppant is also disclosed, comprising the steps of manufacturing finely divided ceramic precursors and additives using grinding, milling, and preferably sol-gel processes, and dispersing the finely divided ceramic precursors and additives in a liquid, preferably water. The dispersion has a viscosity profile, which permits the shaping of spheres using conventional pelletizing techniques. Drying of the pellets and sintering at temperatures below 1,400.degrees. C. forms and retains mesopores and micropores in the ceramic. Preferred total pore volumes range from 0.05 to 0.7 cm.sup.3 / g. The pelletized and porous ceramic is useful as lightweight and high-strength proppants.

Owner:URBANEK THOMAS WILHELM

Coal gangue lightweight through-hole ceramsite

The invention discloses coal gangue lightweight through-hole ceramsite. The technical scheme has the essentials that the coal gangue lightweight through-hole ceramsite is composed of coal gangues, attapulgite clay, a powdery coal gangue foaming agent, active carclazyte waste dreg, hollow microspheres, lightweight magnesium oxide, expanded perlite, expanded vermiculite, ferrous sulfate and quick lime. The materials of the coal gangue lightweight through-hole ceramsite are stirred and mixed, extruded and granulated, dried, roasted, subjected to heat insulation, sieved, sealed and packaged to prepare the coal gangue lightweight through-hole ceramsite. The coal gangue lightweight through-hole ceramsite has the characteristics of large specific surface area, small bulk density, high water absorption rate, excellent ventilation performance, beautiful appearance and shape and no odors, no harmful bacteria, good lightweight strength, and consistent micro-pores and macro-pores. When the coal gangue lightweight through-hole ceramsite is used for culturing or planting various types of nursery stocks, flowers and vegetables, the roots of the plants can absorb nutrition constituents of water or a liquid fertilizer from the coal gangue lightweight through-hole ceramsite, so that good growth and development and the survival rate of the plants are ensured and the coal gangue lightweight through-hole ceramsite is suitable for preparing a soilless culture substrate and nutrient soil.

Owner:平凉华晨非金属应用科技有限公司

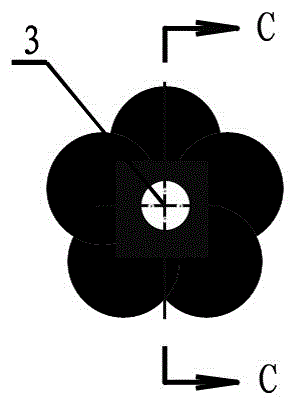

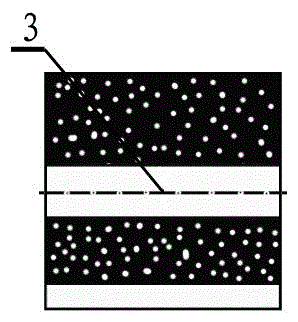

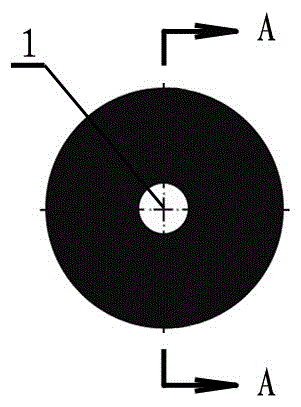

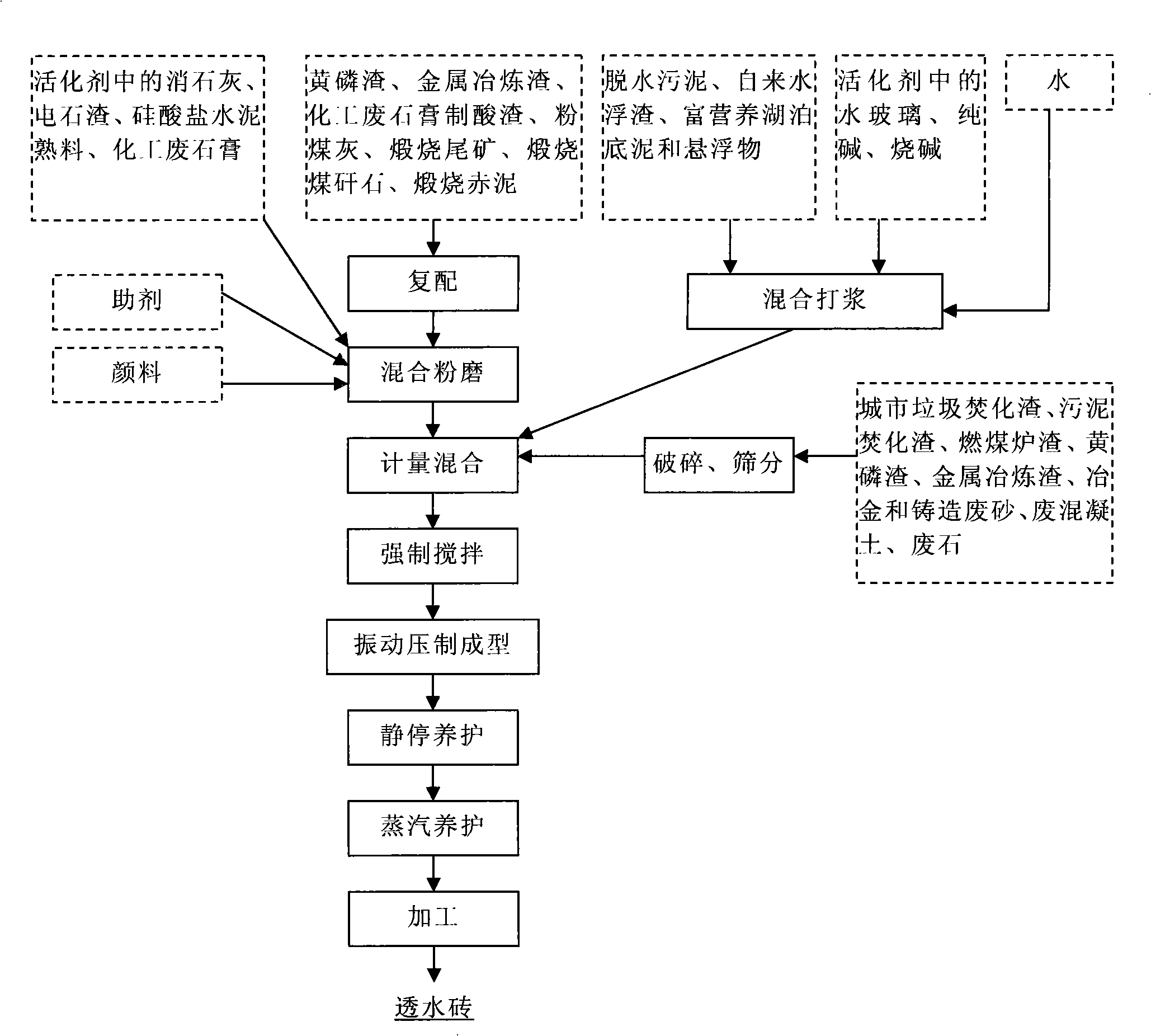

Low-temperature ceramic permeable bricks and production method thereof

InactiveCN101289310ASolve pollutionLow costCeramic materials productionClaywaresNatural resourceState of art

The invention relates to a low temperature ceramics non-watertight brick made of solid waste slag and a manufacture method thereof, belonging to the technical field of building materials. The mixture ratio by weight of the components of the low temperature ceramics non-watertight brick is that waste slag gelled material to waste slag skeletal material to porogenic agent to activating agent to addition agent to paint to water is equal to 100:200-800:0.1-40:13-50:0.2-3.0:0.1-7.0:1-20. After the process, mixture, vibrating forming and maintenance process for the raw materials, the raw materials are prepared into the low temperature ceramics non-watertight brick with a filled pore by taking the low temperature ceramics mineral as the matrix phase and taking the inorganic waste slag particle as the wild phase. Compared with the prior art, the low temperature ceramics non-watertight brick has the advantages of high strength, good permeability of water, high salvage value, simple process, low cost, environment protection and natural resources reservation, etc. which can be widely applied to the laying of urban highways.

Owner:KUNMING UNIV OF SCI & TECH

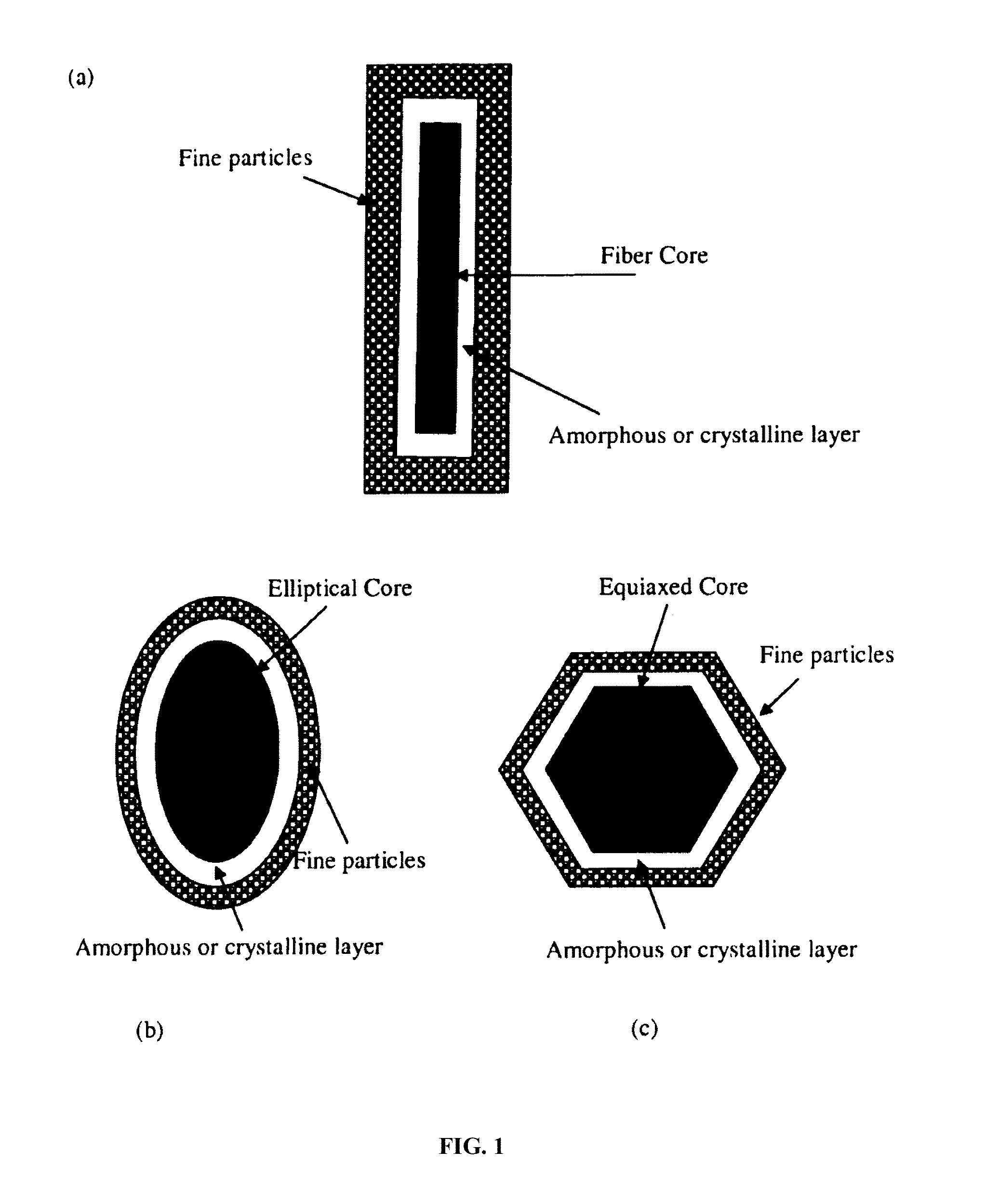

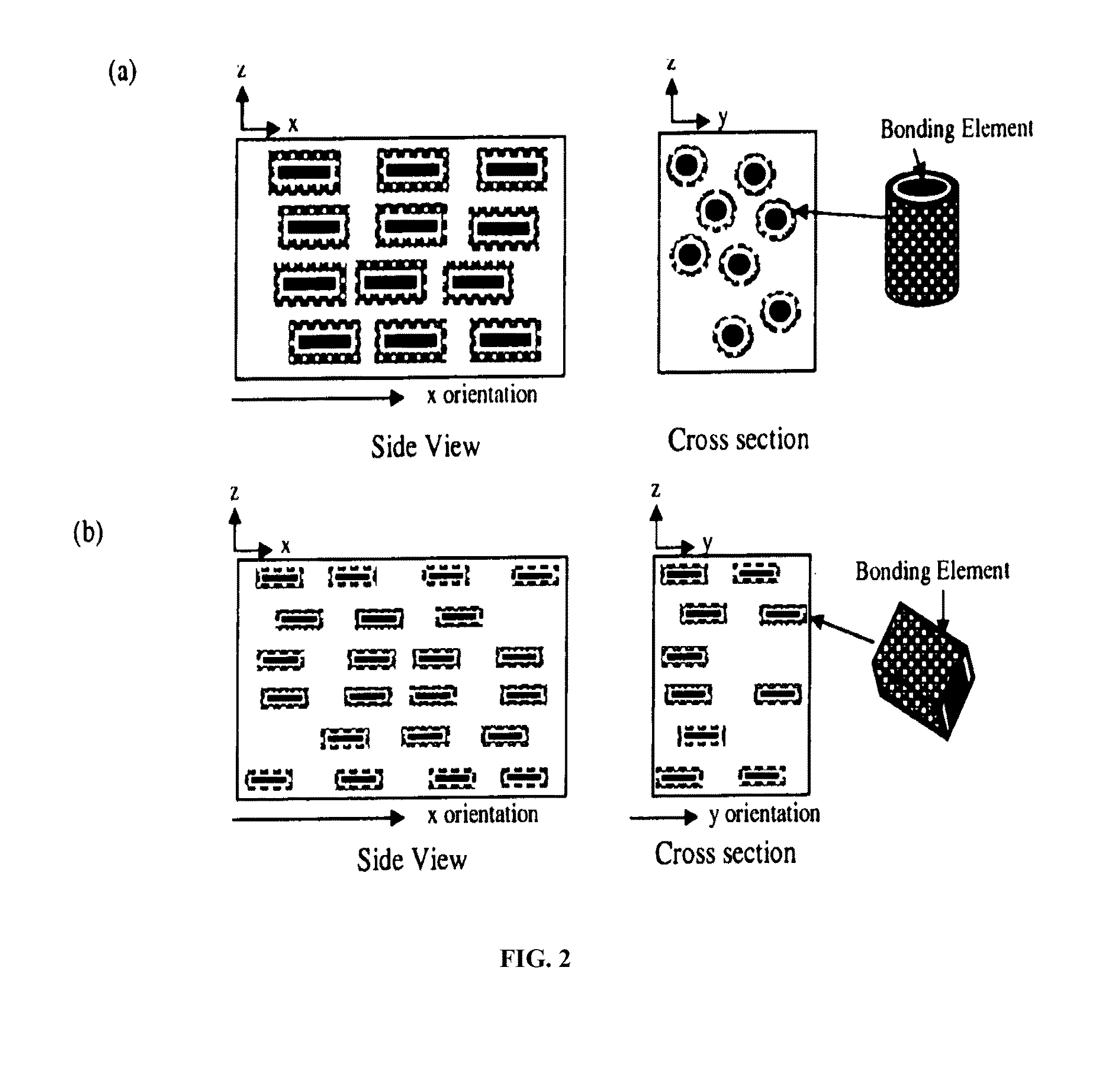

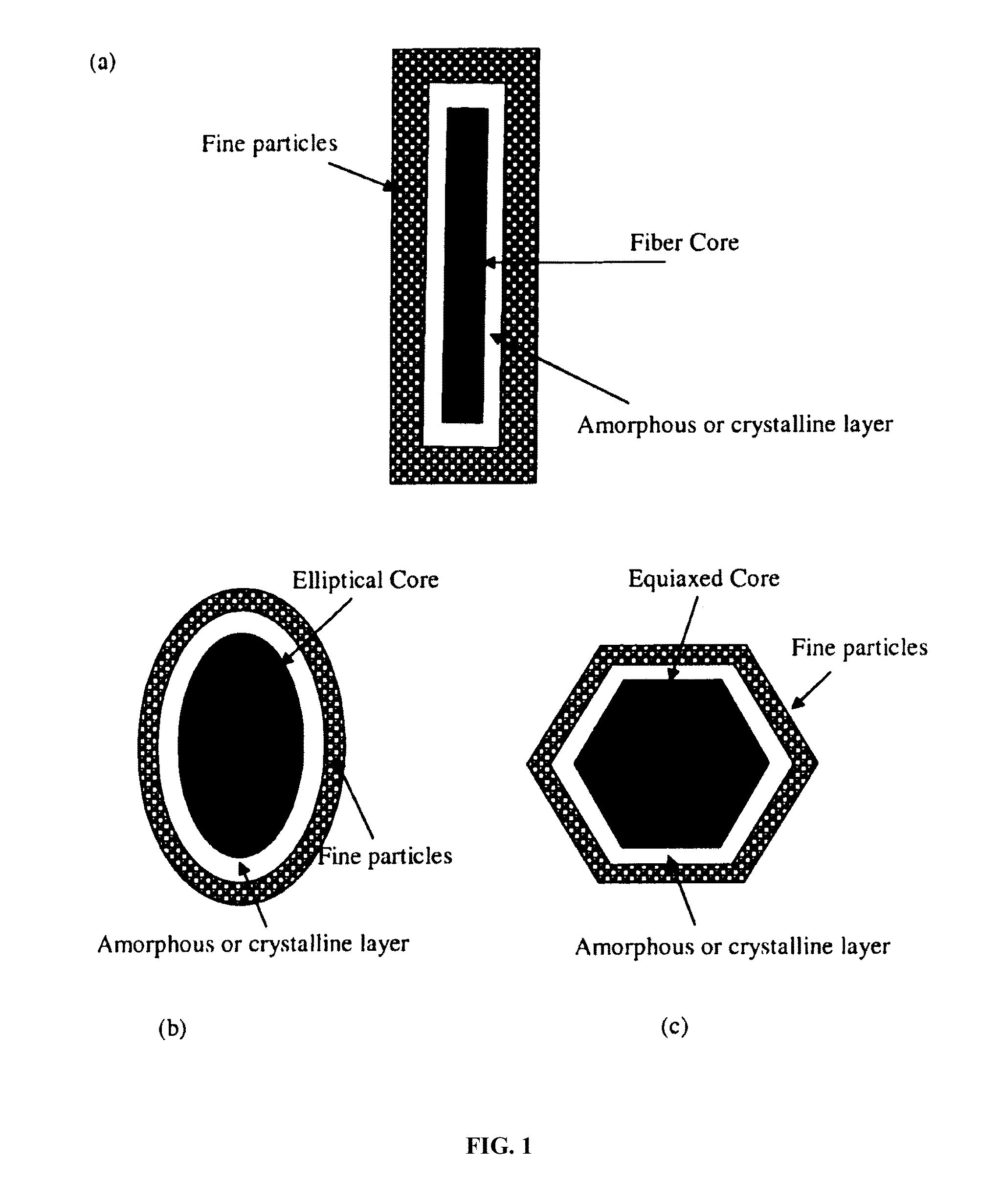

Proppants and their manufacture

Owner:1389414 ALBERTA

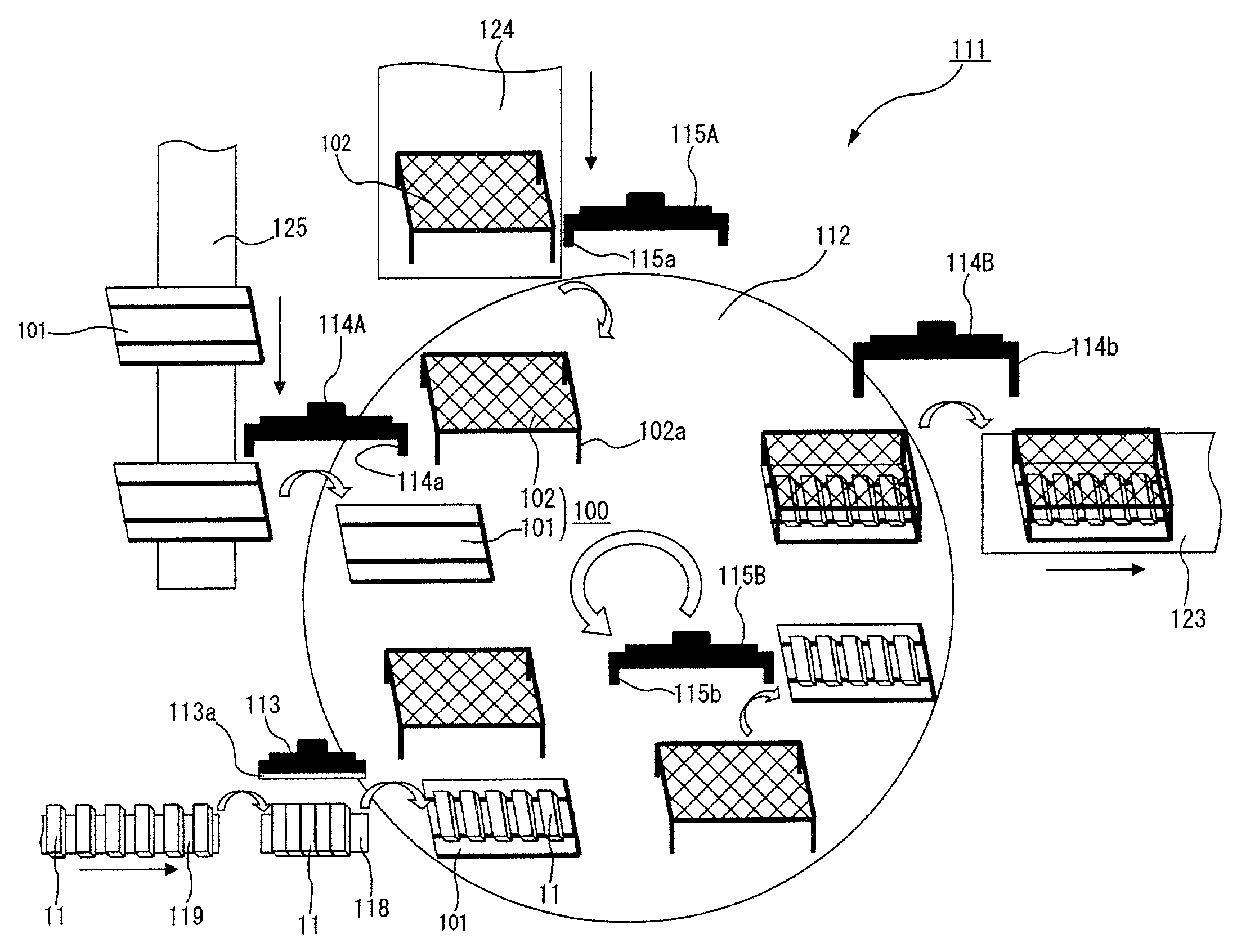

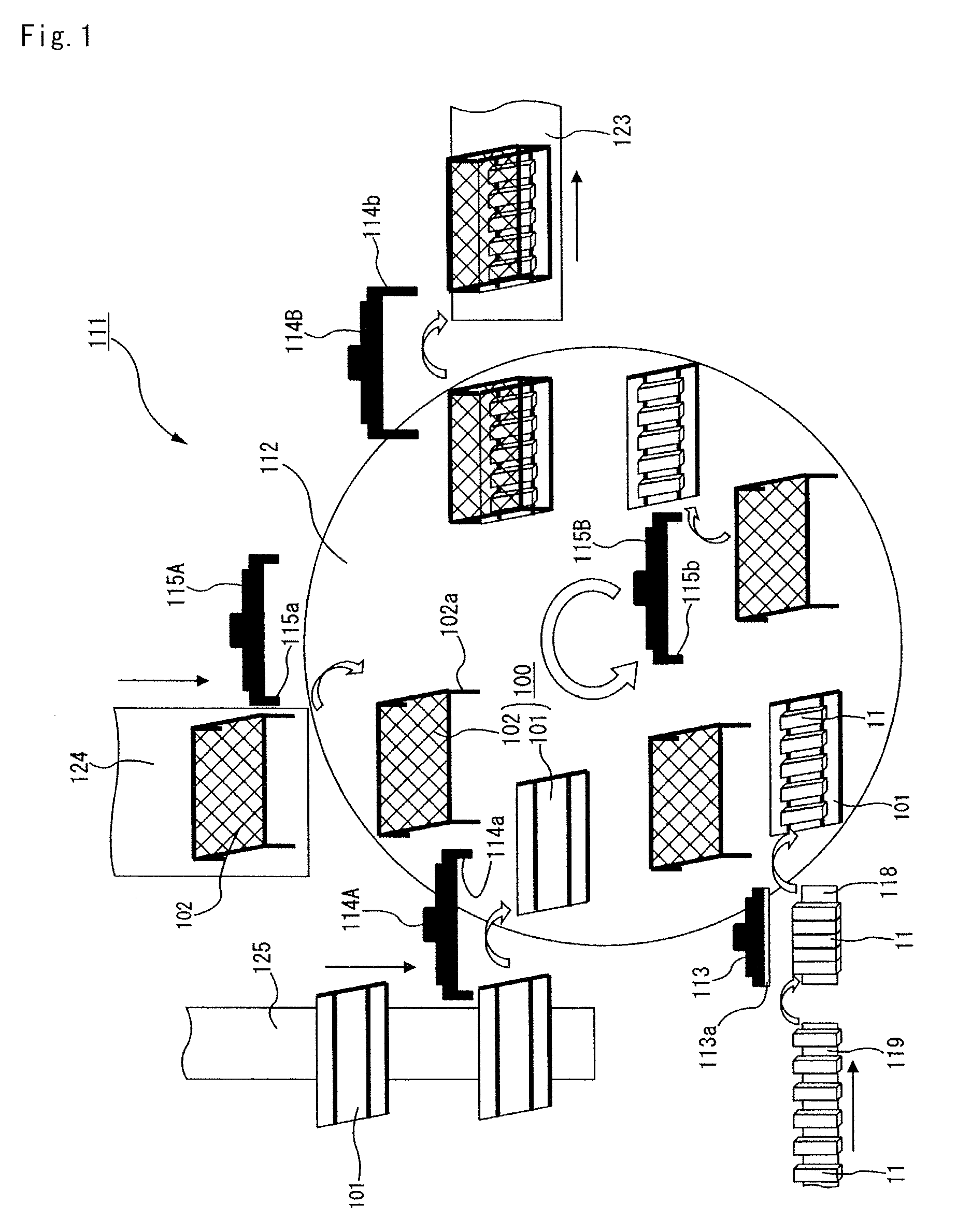

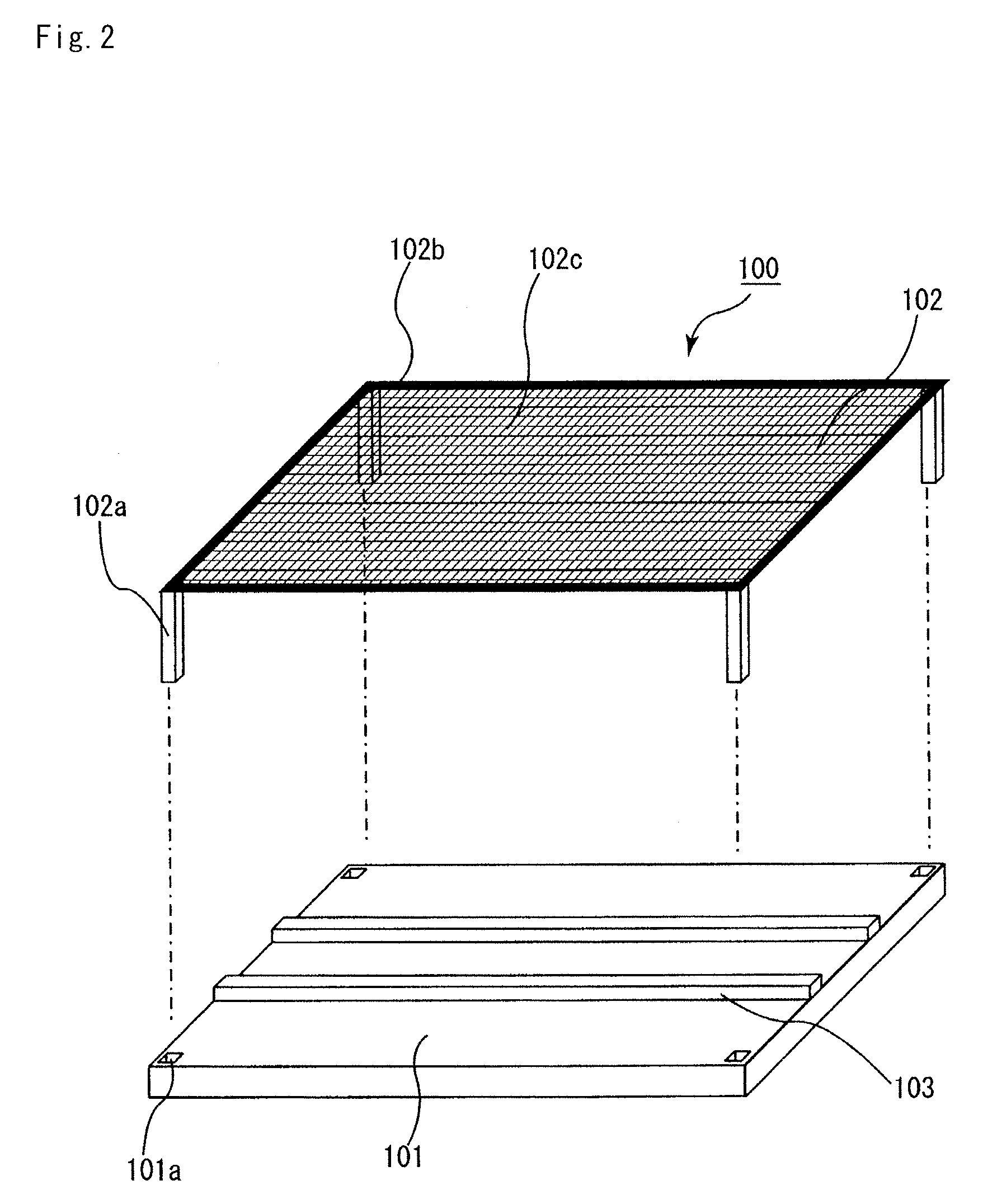

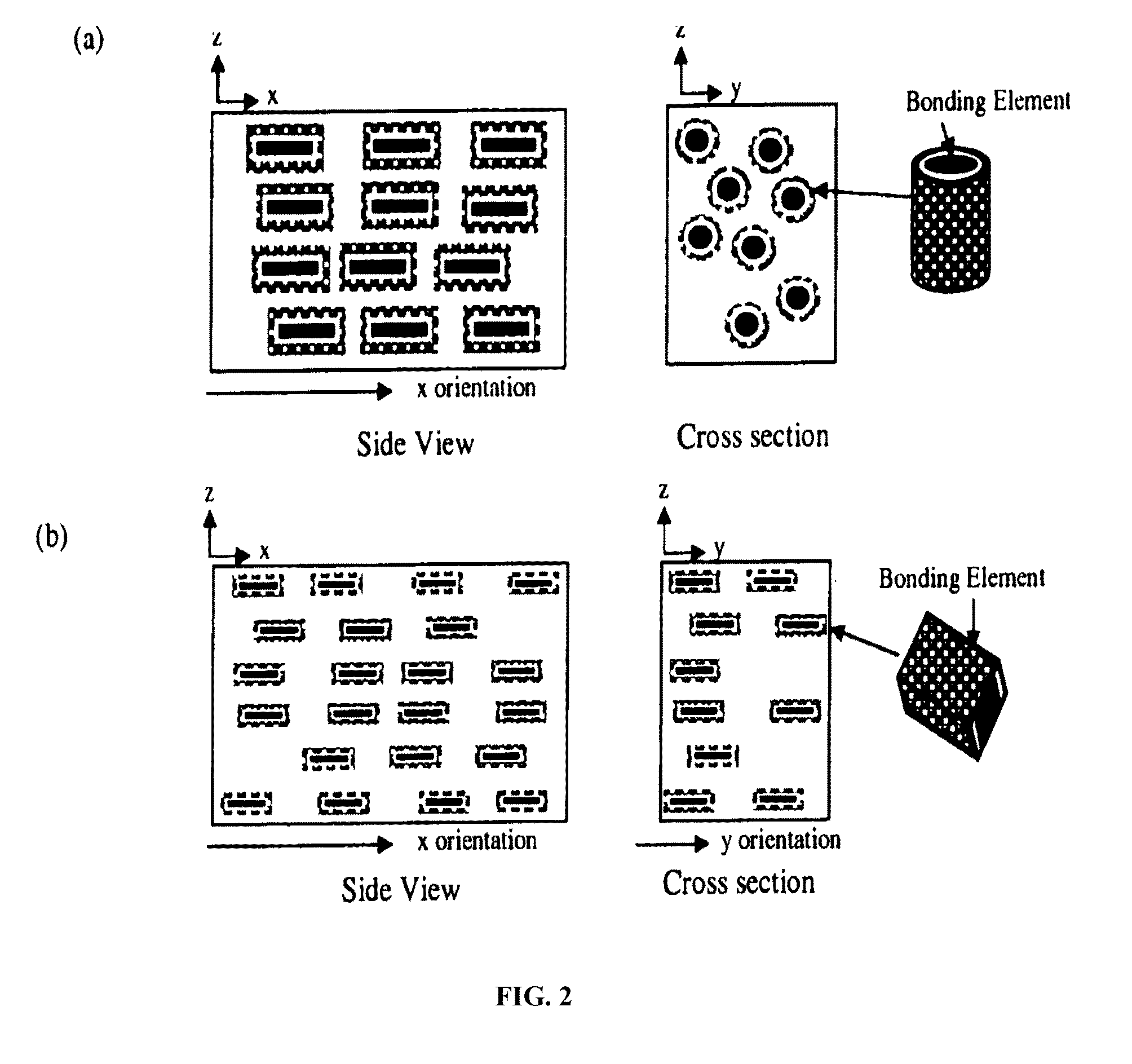

Degreasing jig assembling apparatus, degreasing jig disassembling apparatus, degreasing jig circulating apparatus, method for degreasing ceramic molded body, and method for manufacturing honeycomb structured body

A degreasing jig assembling apparatus includes a robot arm and a table or a conveyor on which a degreasing jig including a bottom plate and a cover member is placed. A ceramic molded body is mounted on the degreasing jig upon degreasing the ceramic molded body. The ceramic molded body is mounted on the degreasing jig on the table or the conveyor. The degreasing jig assembling apparatus further includes a molding body mounting mechanism and a cover member. The molding body mounting mechanism mounts the ceramic molded body at a predetermined position on the bottom plate placed on the table or the conveyor by using the robot arm. The cover member attaching mechanism attaches the cover member to the bottom plate in a manner so as to cover the ceramic molded body mounted on the bottom plate.

Owner:IBIDEN CO LTD

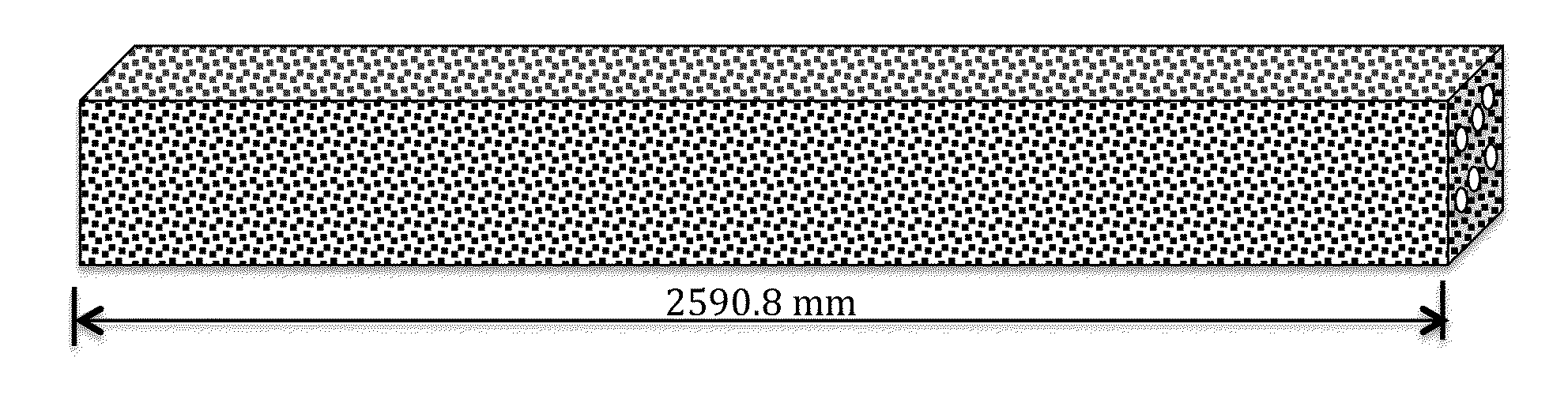

Composite railroad ties and methods of production and uses thereof

ActiveUS20140263683A1Excellent physical and performance characteristicExcellent weatherability and performance characteristicBallastwayCeramic shaping apparatusCarbon footprintMethods of production

The invention provides novel railroad ties manufactured from novel composite materials that possess excellent physical and performance characteristics matching or exceeding existing concrete RRTs. The RRTs of the invention can be readily produced from widely available, low cost raw materials by a process suitable for large-scale production with improved energy consumption and more desirable carbon footprint and minimal environmental impact.

Owner:SOLIDIA TECH

Aerated composite materials, methods of production and uses thereof

InactiveUS20140272216A1Excellent physicalExcellent performance characteristicSolid waste managementLayered productsCarbon footprintMethods of production

The invention provides novel aerated composite materials that possess excellent physical and performance characteristics of aerated concretes, and methods of production and uses thereof. These composite materials can be readily produced from widely available, low cost raw materials by a process suitable for large-scale production with improved energy consumption, desirable carbon footprint and minimal environmental impact.

Owner:DEO OMKAR +6

Foamed ceramics energy saving and heat preservation decorative wall brick and manufacture method thereof

InactiveCN101560111ALow thermal conductivityLow densityCeramic materials productionCeramicwareBrickSlurry

The invention discloses a foamed ceramics energy saving and heat preservation decorative wall brick and a manufacture method thereof, including the steps of conducting ball milling on 15-65 percent wt of industrial residues, 10-45 percent wt of plastic clay, 15-60 percent wt of solvent, 10-45 percent wt of pore-forming agent with the fineness being 1-100mum and proper amount of water to form slurry; spray drying or dehydration and clay preparation, and forming powder material or clay segment through staleness; and implementing pressure forming to make billet which is burned under heat preservation at temperature of 1140-1240 DEG C to finally form the foamed ceramics wall brick. The wall brick can be used not only for the heat preservation and decoration of external walls, but also for indoor heat preservation and decoration, and the external wall and the indoor space can realize the organic combination of uniform heat preservation and decoration, which agrees with the development direction of heat preservation material industry of external walls. The wall brick has the advantages of: I. high temperature resistance, acid and alkali-resistance, good chemical stability, no ageing, strong durability, long service life, no generation of heat channel and good adhesive fixity; and II. difficult water seepage and crack, strong anti-corrosion capacity, uneasy deformation and damage, simplification of mounting, laying and sticking procedures, convenience for construction, relief of labor intensity and decrease of material consumption quantity.

Owner:吴汉阳

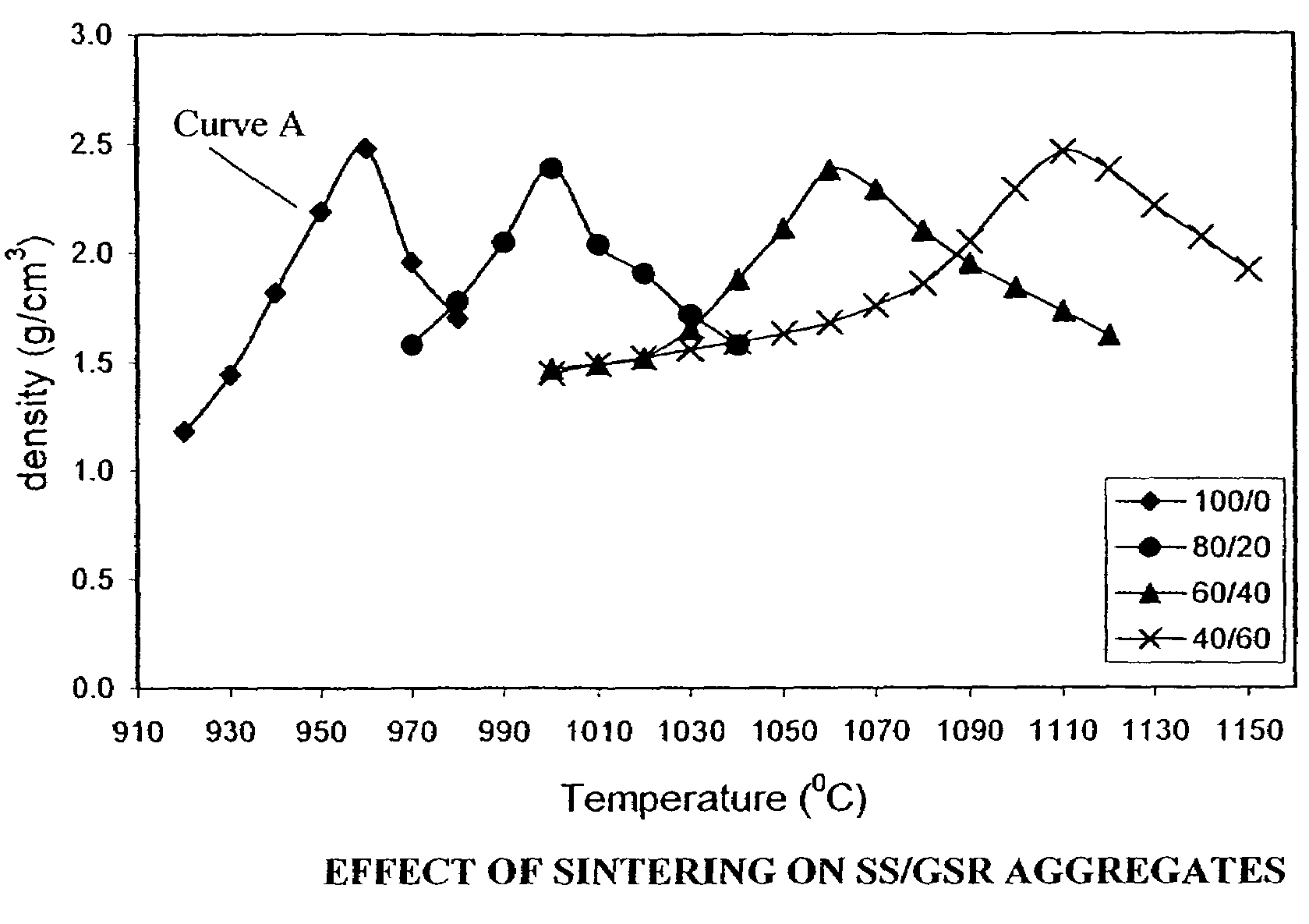

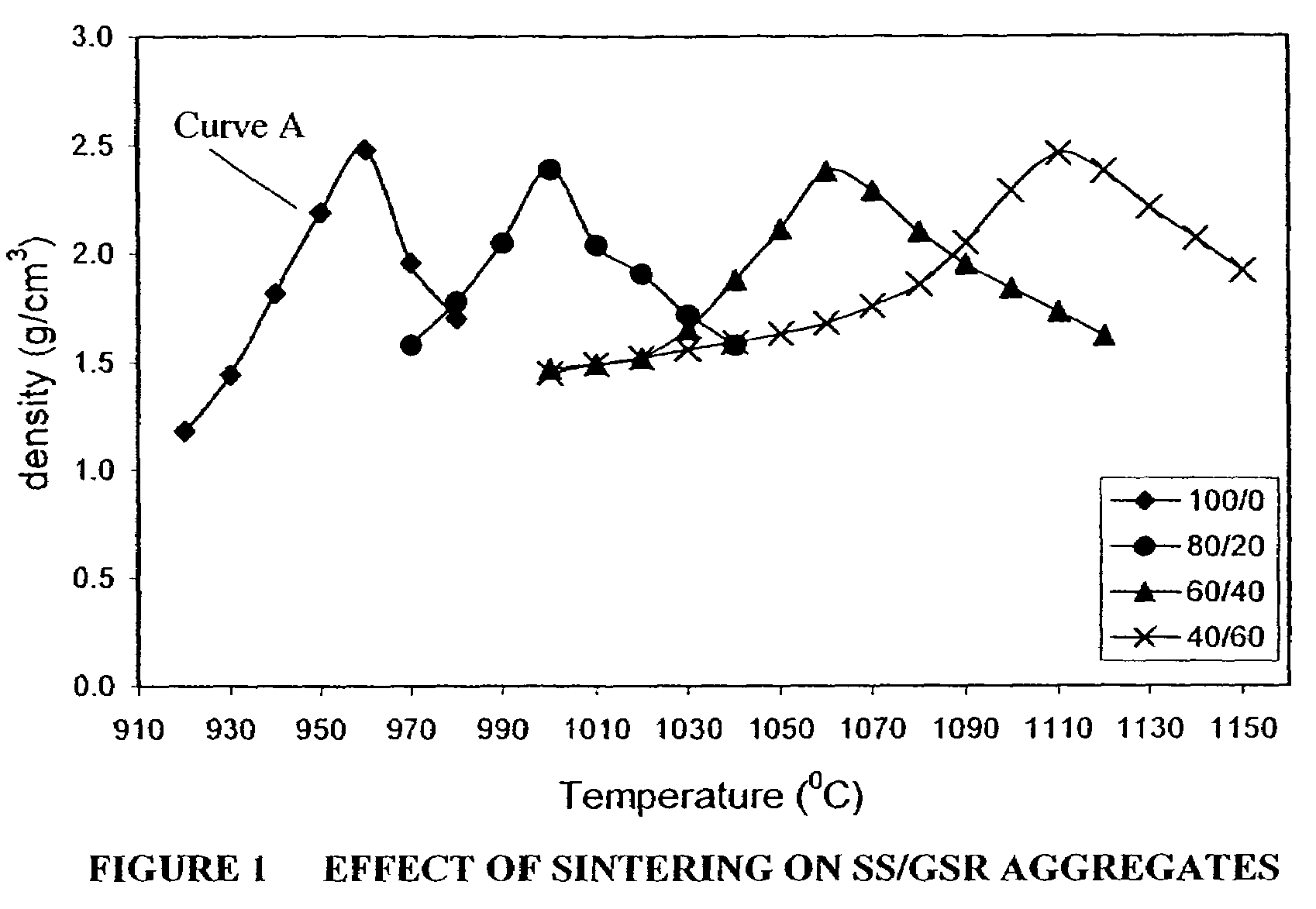

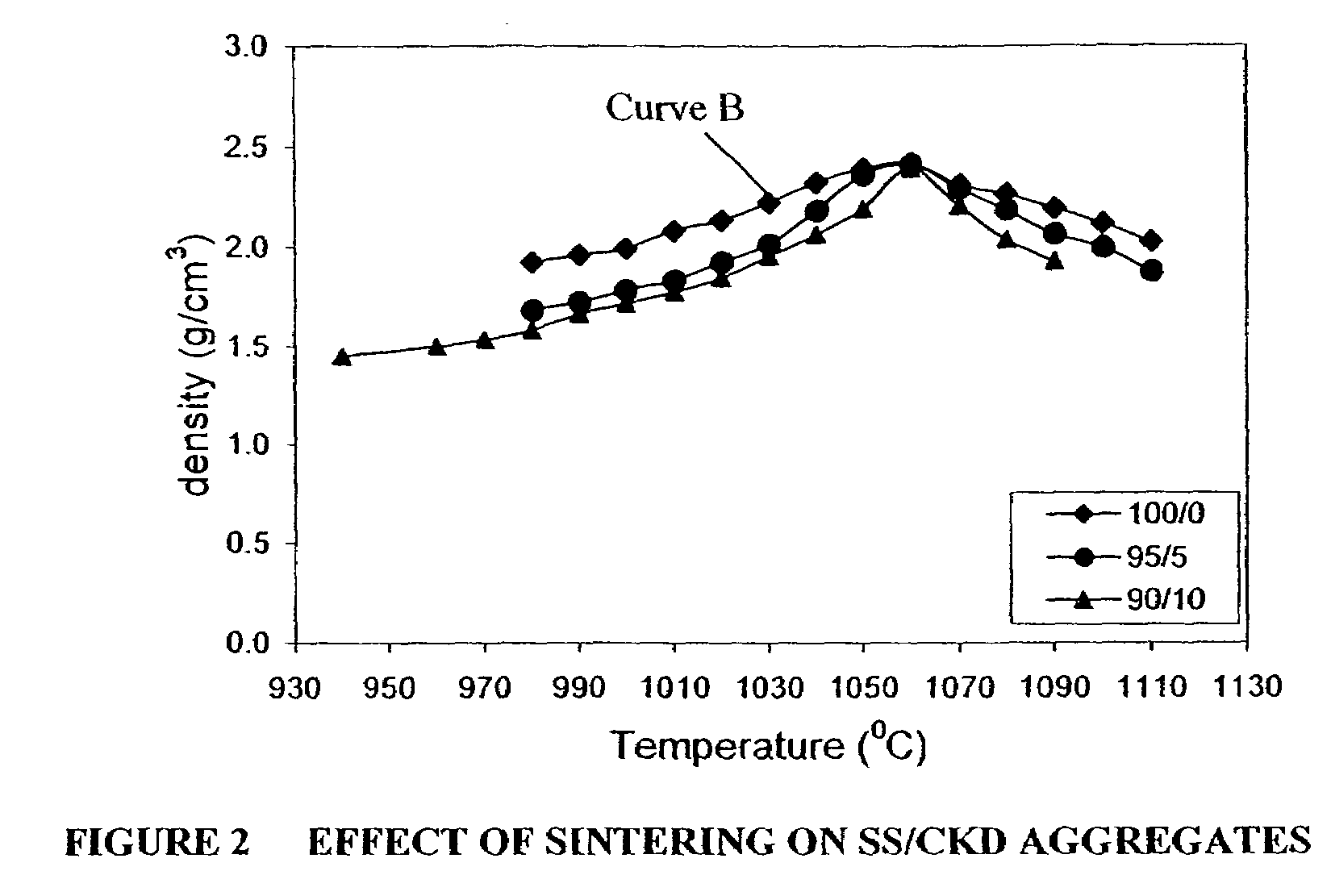

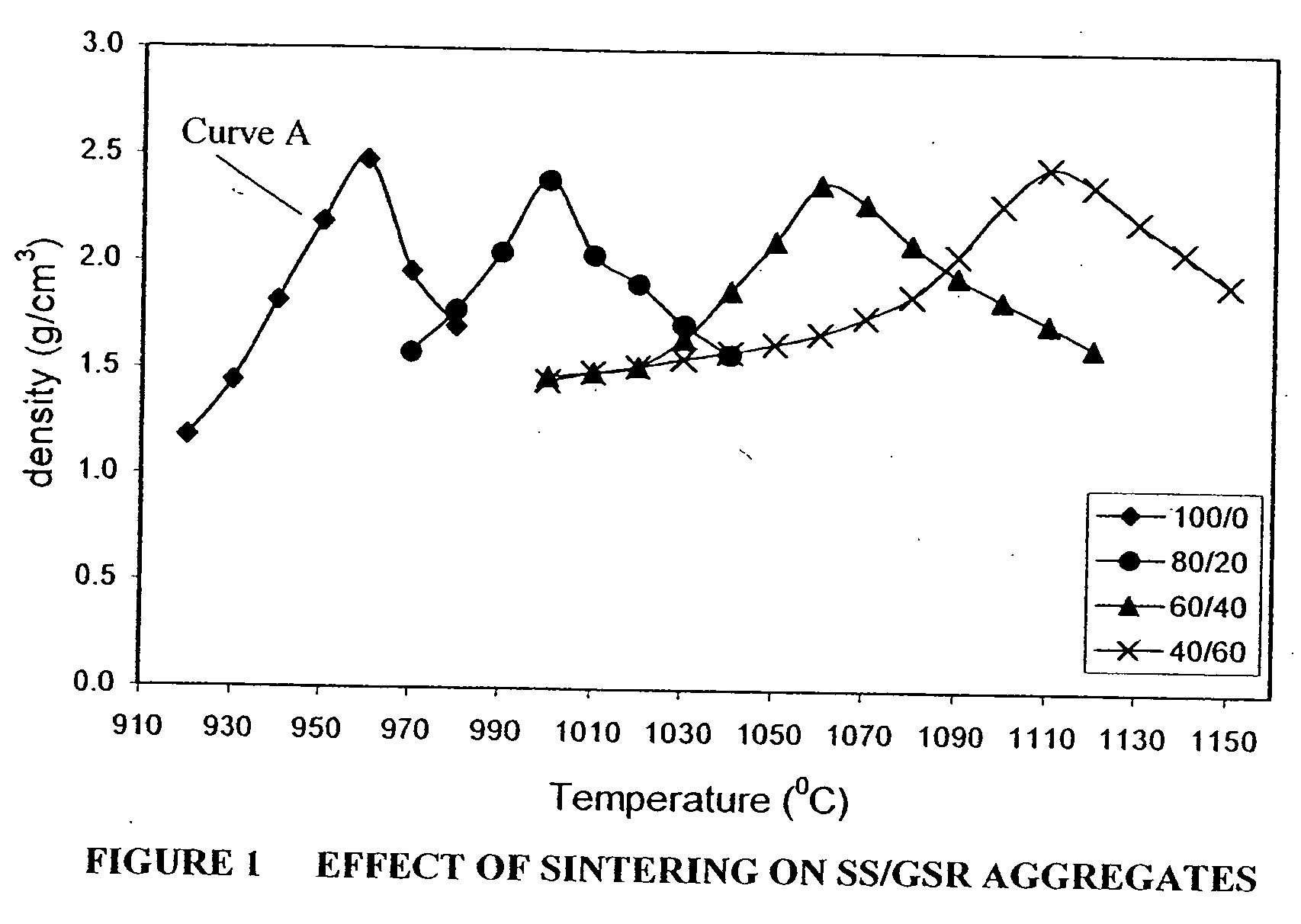

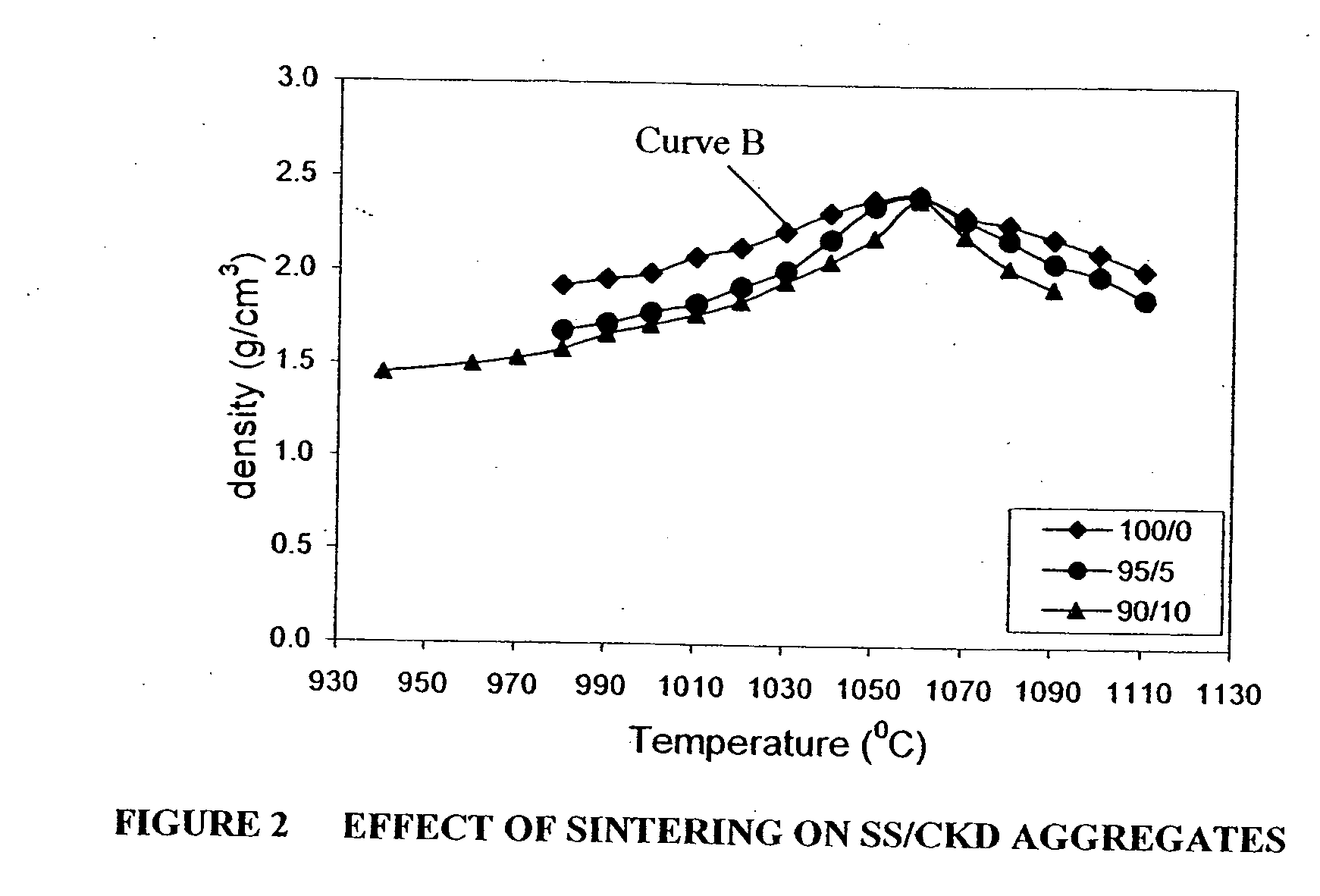

Synthetic aggregates comprising sewage sludge and other waste materials and methods for producing such aggregates

In one example of an embodiment of the invention, a method for producing an aggregate is disclosed comprising mixing sewage sludge from a waste water treatment facility with a non-coal combustion ash silicoaluminous waste material, agglomerating the mixture to form an agglomerate, and pyroprocessing the agglomerate to form an aggregate. The waste material may comprise municipal solid waste incinerator bottom ash, incinerator fly ash, incinerator filter dusts, cement kiln dusts, waste glass, blast furnace slag, kiln dusts, and / or granite sawing residues, for example. The method may further comprise milling the waste material prior to mixing. Preferably, the milling is wet milling. Pyroprocessing of the agglomerate may take place in a rotary kiln. The resulting aggregate may be a lightweight or a normal weight, sintered or vitrified aggregate. Aggregates and methods for making aggregates of high and low calcium silicoaluminous materials are also disclosed.

Owner:ALKEMY

Method for preparing porcelain granules by using fly ash

InactiveCN101585698AImprove protectionSave natural resourcesFluid removalCeramic materials productionExpanded clay aggregateSlurry

The invention discloses a method for preparing porcelain granules by using fly ash, which comprises the following steps: putting fly ash, potassium feldspar and quartz as raw materials into a ball mill respectively, dry-milling the raw materials, sieving the milled raw materials respectively, removing iron from the sieved fly ash, putting the fly ash after iron removal, the sieved potassium feldspar and quartz and kaolin into the ball mill, and wet-milling and evenly mixing the materials to form mixed slurry; and granulating the mixed slurry by adopting a pressure type spray granulator, putting the granules into an alumina crucible, placing the alumina crucible into a silicon-carbon rod resistance furnace, sintering and naturally cooling the granules, and taking out the granules to obtain the high-strength porcelain granules. The method for preparing the porcelain granules by using the fly ash is not only favorable for saving natural resources and reducing the production cost, but also favorable for environmental protection. The fly ash does not need to be crushed by a high-power crusher, and the fly ash is mixed evenly. The production process is easy to control, and has little energy consumption; the strength of the prepared fly ash porcelain granules can reach 60 to 120MPa; and the porcelain granules have good properties of light weight, high temperature resistance, corrosion resistance and the like, and can be used as a fracturing propping agent for middle and deep layer oil-gas fields.

Owner:SHAANXI UNIV OF SCI & TECH

Reproducible phosphorus-uptake ceramsite and preparation method thereof

InactiveCN102515830AStrong phosphorus removal capacityAdaptableOther chemical processesCeramic materials productionHydration reactionWastewater

The invention discloses a reproducible phosphorus-uptake ceramsite and a preparation method thereof. The technical scheme provided by the invention comprises the following steps of: respectively drying 70-85 wt% of fly ash, 10-16 wt% of pore-forming agent and 5-14 wt% of clay powder and uniformly mixing the raw materials; after balling the mixture, baking at a temperature in a range of 950-1100 DEG C for 30-50 min to obtain a baked porous ceramsite; sequentially immersing the baked porous ceramsite with HCl, washing with water and drying; and loading zirconium oxide hydrate to obtain the phosphorus-uptake ceramsite. The phosphorus-uptake ceramsite prepared by the invention can be directly added into or filled as a filtering column to remove phosphorus in the water and the adsorbed phosphorus-uptake ceramsite can be desorbed by a NaOH solution to be reproduced; the saturated adsorption capacity to the phosphorus is 10-11 mg / g and the adaptability to the change of the phosphorus concentration in the water is good; after the treatment, the solid-liquid separation is easy to realize and the water quality of the discharged water is better. The reproducible phosphorus-uptake ceramsite provided by the invention has the advantages of strong phosphorus-uptake capability, easiness of realizing the solid-liquid separation, good cyclic usability and higher cost performance, so that the reproducible phosphorus-uptake ceramsite is applicable to phosphorous removal of various types of wastewater and surface water.

Owner:WUHAN UNIV OF SCI & TECH

Ceramic proppant with low specific weight

InactiveUS20080070774A1Avoid product qualitySintering range is again narrowedFluid removalCeramic shaping apparatusMagnesium orthosilicateUltimate tensile strength

A precursor composition for the production of granulated ceramic material, particularly for ceramic proppants, comprises 20 to 55% by weight of magnesium orthosilicate, 20 to 35% by weight of MgO, and 2.5 to 11% by weight of Fe2O3. The resulting lightweight proppant material shows high mechanical strength. To further decrease the specific density of the proppant, the formation of small pores can be increased by adding 0.3 to 2.4% carbon as a gas-forming agent.

Owner:OBSCHESTVO S OGRANICHENNOY OTVETSTVENNOSTYU FORES

Method for preparing haydite from urban sewage plant sludge

InactiveCN101148346AHas a lightweightLight weightCeramic materials productionClaywaresChemical industryExpanded clay aggregate

The present invention discloses one kind of haydite produced with dewatered sludge, fly ash and clay as material and its production process, and belongs to the field of environment technology. The haydite is produced dewatered sludge, fly ash and clay as material, and through mixing and sintering at gradually raised temperature. It is yellow or brown spherical solid in the bulk specific weight of 650-750 kg / cu m, granular specific weight of 1050-1150 kg / cu m, water absorption of 5.80-10.8 %, and specific surface area of 2.29-5.56 sq m / g. The production process is simple and low in cost, and the haydite has light weight, high strength, small water absorption, great specific surface area and other features. The haydite has wide use in building, environment protection, metallurgy, chemical industry, and other industry.

Owner:SHANDONG UNIV

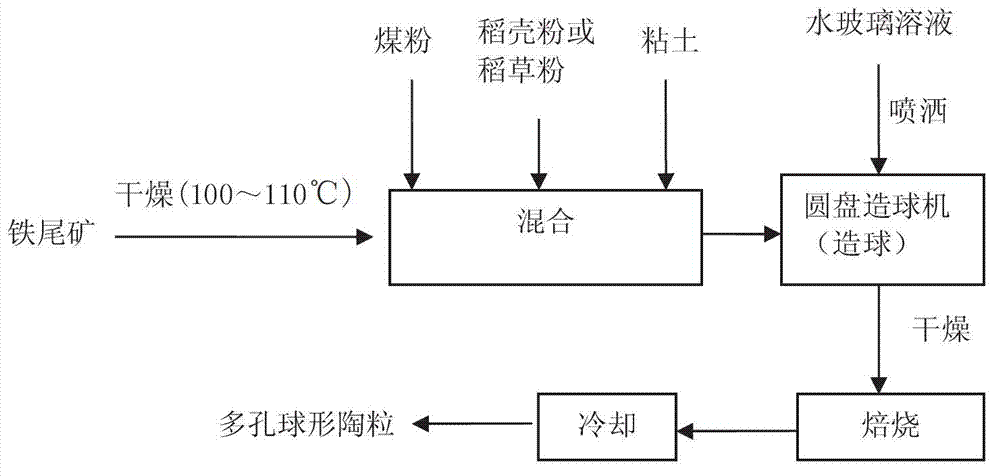

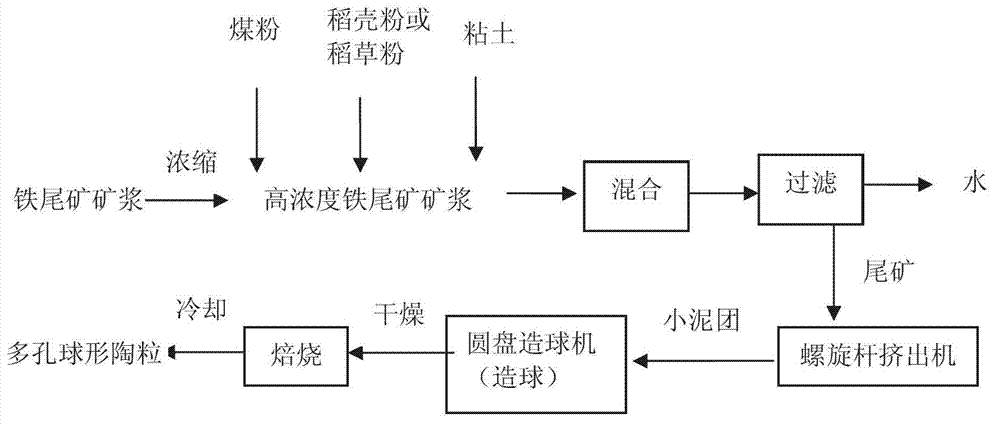

Porous ceramsite made of low-silicon iron tailings and preparation method of porous ceramsite

ActiveCN102815965AReduce usageLow costCeramic materials productionCeramicwarePorosityThermal insulation

The invention discloses porous ceramsite made of low-silicon iron tailings and a preparation method of the porous ceramsite. The porous ceramsite is prepared from, by weight, 75-90 parts of low-silicon iron tailing powder or low-silicon iron tailing pulp, 5-20 parts of pore-forming agents and 1-8 parts of clay, wherein the SiO2 content in the low-silicon iron tailing powder or low-silicon iron tailing pulp is lower than 40%. The method includes: weighing and mixing the iron tailings, the pore-forming agents and the clay, and granulating the mixture into green balls; and after the green balls are dried, calcinating the dried green balls for 40-60min at the temperature of 1100-1180 DEG C, so that the ceramsite made of the iron tailings is obtained. By the method, the porous ceramsite conforming to architecture application and water treatment application can be prepared respectively. The ceramsite prepared by the method has the advantages of high strength and apparent porosity, low density, good thermal insulation property, high cost performance and the like, and can be used for preparing various light, sound-insulation and thermal-insulation materials or used as light building aggregate, water treatment biological carriers and the like.

Owner:武钢资源集团有限公司 +1

Synthetic aggregates comprising sewage sludge and other waste materials and methods for producing such aggregates

In one example of an embodiment of the invention, a method for producing an aggregate is disclosed comprising mixing sewage sludge from a waste water treatment facility with a non-coal combustion ash silicoaluminous waste material, agglomerating the mixture to form an agglomerate, and pyroprocessing the agglomerate to form an aggregate. The waste material may comprise municipal solid waste incinerator bottom ash, incinerator fly ash, incinerator filter dusts, cement kiln dusts, waste glass, blast furnace slag, kiln dusts, and / or granite sawing residues, for example. The method may further comprise milling the waste material prior to mixing. Preferably, the milling is wet milling. Pyroprocessing of the agglomerate may take place in a rotary kiln. The resulting aggregate may be a lightweight or a normal weight, sintered or vitrified aggregate. Aggregates and methods for making aggregates of high and low calcium silicoaluminous materials are also disclosed.

Owner:ALKEMY

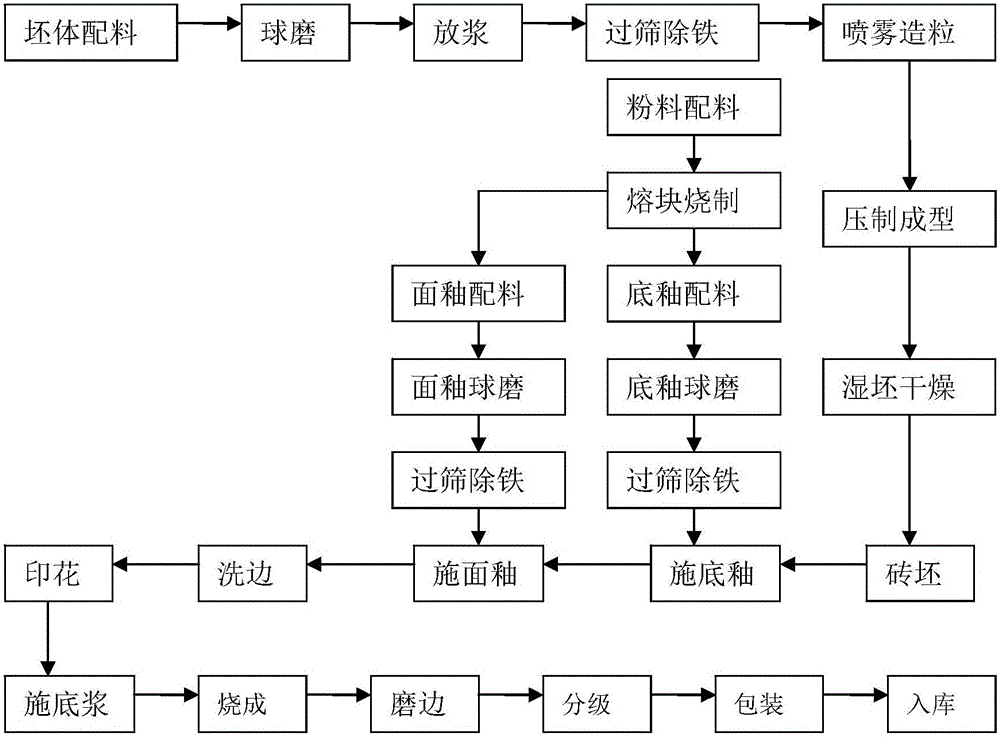

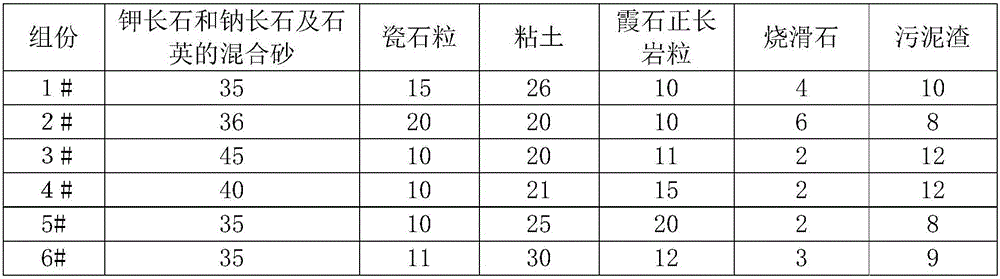

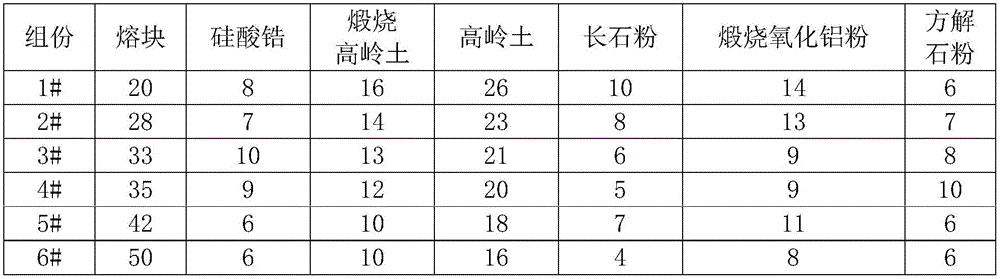

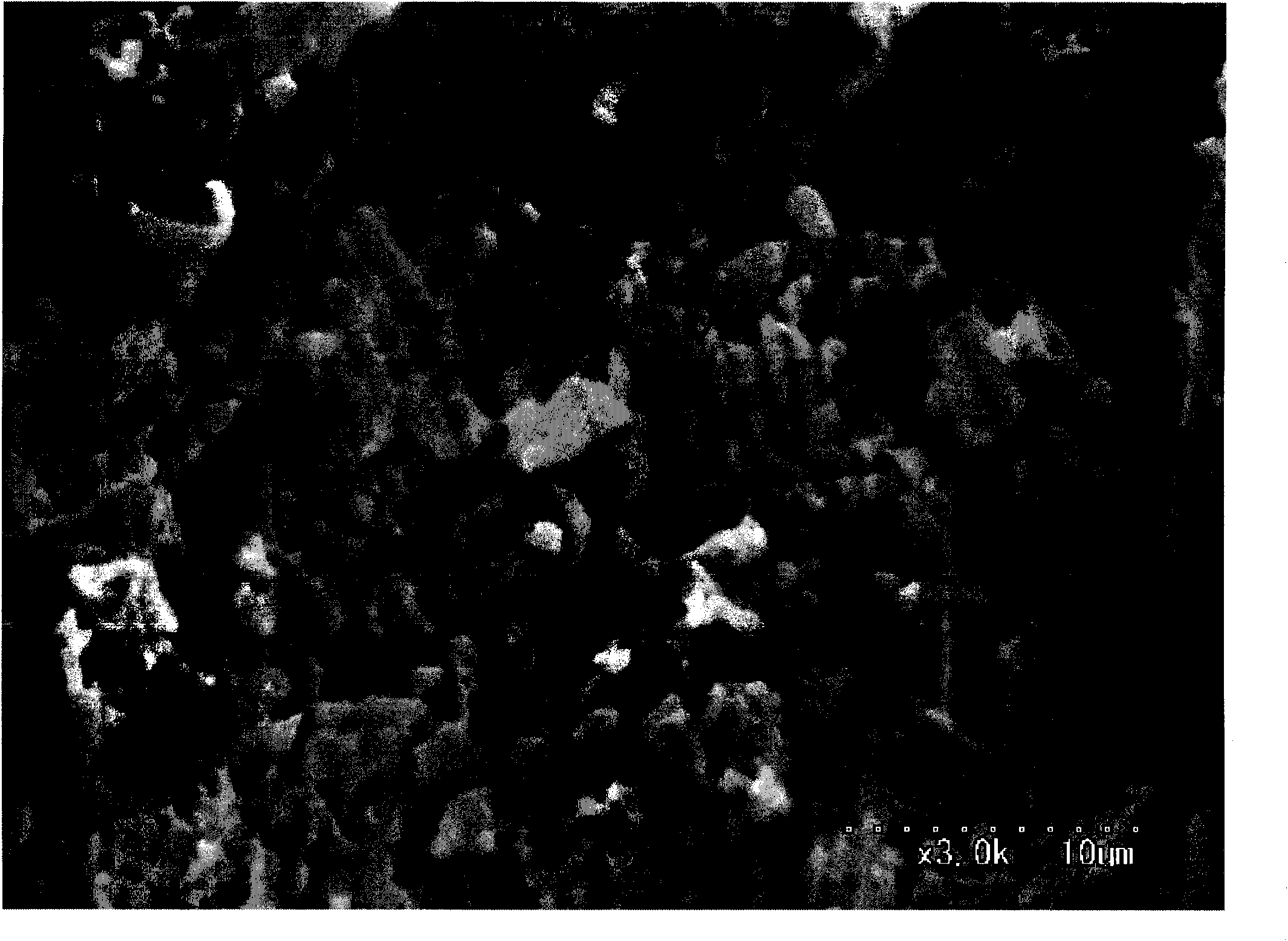

Resource-saving glazed ceramic tile having antiskid effect on surface and preparation method thereof

ActiveCN105837172AAchieve anti-slip effectGood quality glazeCeramic materials productionClaywaresBrickSludge

A resource-saving glazed ceramic tile having an antiskid effect on surface and a preparation method thereof. Without great change on production process of the glazed ceramic tiles, formula composition of a blank body, composition of ground and cover glaze frits and formula composition of ground and cover glaze are regulated and optimized focusedly, so that the glazed ceramic tile, which has excellent performance and the antiskid effect, can be prepared even large quantity sludge residue is added to the blank body. Through a high-magnification scanning electronic microscopy for observing the surface of glaze on the product, it is found that projects which are hard and needle-like and look like aluminum spinel crystal are formed on the surface, and the glaze is 0.8 in antiskid coefficient and is R12 in antiskid level when a less quantity of water is sprayed on the glaze. The glazed ceramic tile has good antiskid effect, can reach 4000 r / four grade in wear-resisting revolution through detection, and has good anti-wear performance, surface anti-fouling performance and water permeation resistance. The glaze has no defects such as needle pores, bubbles and the like, has clear decorative pattern grains and is highly stone-simulated. The technology has strong adaptability and is easy to promote in the field.

Owner:GUANGDONG WINTO CERAMICS +3

Municipal sludge expanded ceramsite and preparation method thereof

InactiveCN101618971ALow costSave resourcesCeramic materials productionCeramicwareSludgeExpanded clay aggregate

The invention provides municipal sludge expanded ceramsite and a preparation method thereof. The municipal sludge expanded ceramsite is prepared from the following materials by mass percentage: 20% to 45% of municipal sludge, 50% to 70% of shale, tailings or clay, 1% to 5% of organic matter and 1% to 5% of iron powder, wherein, the tailings is one of pyrite tailings, gold tailings, lead-zinc tailings and aluminum tailings; and the organic matter is sawdust. The preparation method comprises the following steps: feeding the shale, tailings or clay into a crusher, and carrying out the screening treatment; adding and mixing the municipal sludge, the organic matter and the iron powder, feeding into an ageing silo and stirring; then, feeding into a granulating machine, granulating and calcinating in a rotary kiln; and finally, cooling and stacking the calcinated ceramsite by classification. By using a great amount of municipal sludge, the invention is resource-saving and environment-friendly; compared with the original cost, the overall cost of a building is reduced by 5% to 10%; and the prepared expanded ceramsite has the advantages of light weight, fire resistance, sound absorption, good heat insulating and preserving performance, simple process and low cost, so that the invention is suitable for industrialized production.

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

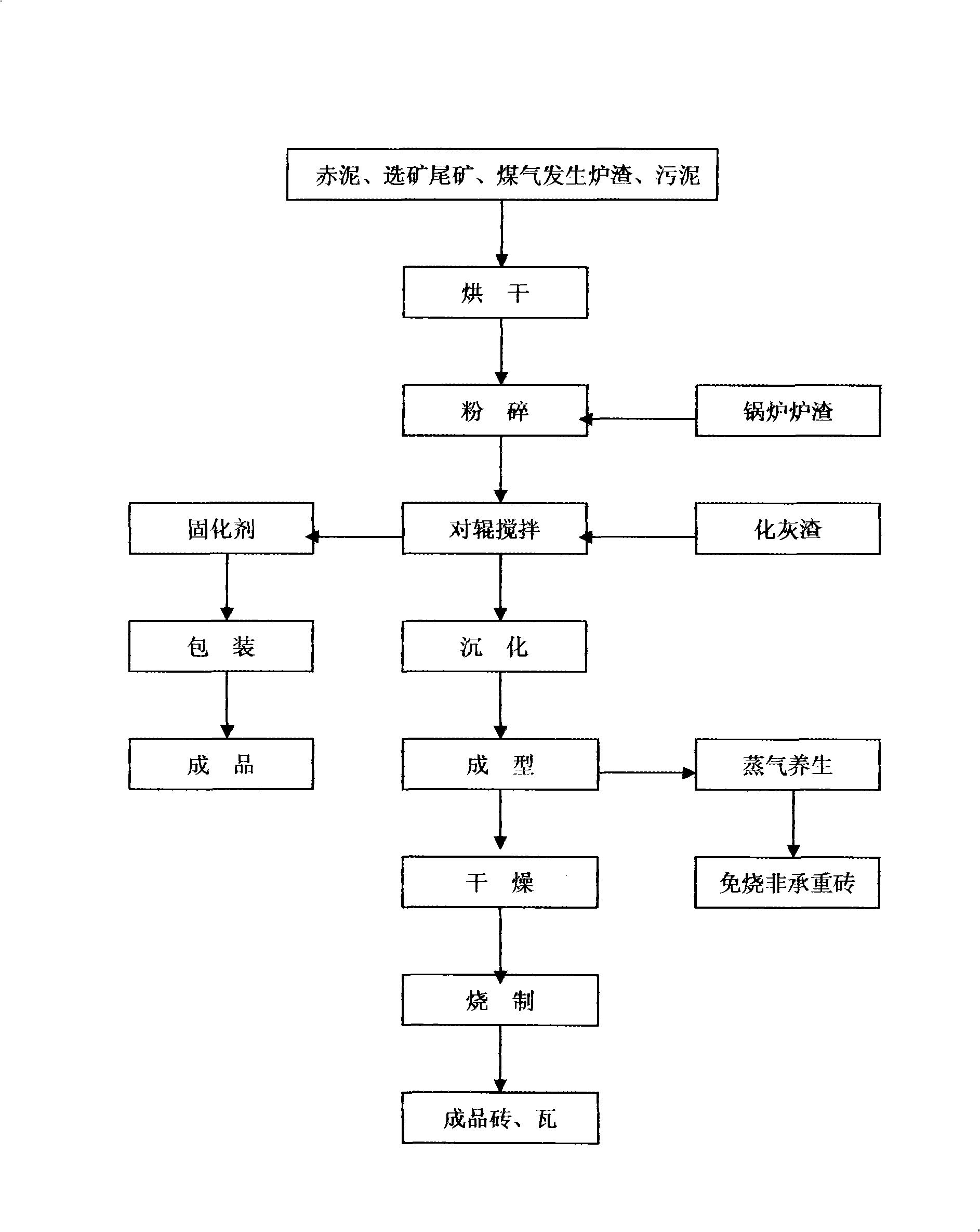

Process and method for converting waste slag wholly of aluminum industry into ecological building material

The invention belongs to a method for utilizing resources. The method utilizes the matter characteristics of solid wastes (six kinds of waste residues) such as red mud(the sintered method and the Bayer method), boiler slag, ore dressing tailings, ash and gas generation slag, which are generated during the manufacturing process in aluminum industry, and converts the solid wastes into a novel road material and construction walling material by the processes such as drying, crushing, reasonable proportioning, machine shaping(grinding and extrusion) and consolidation or sintering. The method is characterized in that the utilization ratio of the waste residues is 100 percent. The waste residues comprise the following compositions: (1) the produced road material-curing agent, which can be used to reinforce a highway subgrade and bases of road surface substrates(substrate and subbase) and buildings and completely replace cement, lime and sandstone materials, and the road material can meet prior national(industrial) standards and environmental protection standards in performance; and (2) the produced construction walling materials-non supporting brick, supporting brick, air brick, hollow building block, common tile, glazed roof tile and andorful tile, which are superior to the prior national standards in performance. The material obtained by the invention has the characteristics of energy conservation, thermal insulation, high strength, corrosion resistance, efflorescence resistance and no pollution.

Owner:王文举

Methods to solidify cremation ash

Residual bones, and ashes from the cremation process of deceased humans and animals are turned into solid objects containing glass, ceramics, clay based materials, or composites such as organic polymer matrix, metal matrix, or inorganic cementaceous matrix, or combination of thereof. In another embodiment, ash is mixed with at least a liquid phase such as paint or coating, which upon dying or heating the mixture becomes solid. The final solid product can be made into any shapes or forms that the matrix can be made into without the addition of the ash. The final form of the product thereof can range from abstractive non-functional to geometrical shapes or functional forms such as containers, vases, or in the form of jewelry stones. Or painting, drawing, coating, and glazing. The objects can be made to contain almost all ash, such as in the case of ceramics or partially loaded with ash as is the case for glass and composites. In one other embodiment, the cremation residue either in a solid form or powdery form can be encapsulated in glass, ceramics, and various composites to form a heterogeneous product. The finished products can be marked with identification formats such as bar codes which make them possible to be traced electronically in a data base environment.

Owner:HOJAJI HAMID

Ceramic material with multi-stage duct structure and manufacture method thereof

InactiveCN101885620ALow costMeet environmental protection requirementsSolid waste disposalFurniture waste recoveryMetallurgyDecomposition

The invention provides a ceramic material with a multi-stage duct structure and a manufacture method thereof. The ceramic material is characterized by being provided with a plurality of macropores with millimeter grade, tens of middle pores with millimeter grade exist on the walls of the macropores, micropores with sizes less than microns exist on the walls of the middle pores. The ceramic material is manufactured by using 10-50 percent by mass of waste and 20-60 percent by mass of natural porous mineral and matching with 10-30 percent by mass of clay through the steps of adding water for mixing, forming, drying, preheating and sintering at a temperature of 1000-1200 DEG C, wherein the waste can be expanded at high temperature or has large ignition lost and easy decomposition and volatilization. The ceramic material has excellent water-absorbing and water-retaining properties, better water permeability, excellent absorption and filtration and light weight, and can be used as a water-absorbing material, a water-retaining material, a water permeating material, a sound insulating material, a heat insulating material, an indoor deodorizing material, an absorbing material, a filtering material and the like to be widely applied to various fields.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

Cylindrical attapulgite flower ceramsite

ActiveCN102503537AHigh strengthLower sintering temperatureCeramic materials productionCeramicwareMetallurgyBentonite powder

The invention discloses cylindrical attapulgite flower ceramsite. The key points of the technical scheme are that the cylindrical attapulgite flower ceramsite consists of high-adhesion attapulgite clay powder, attapulgite clay tailing powder, red bentonite powder, sludge, diatomite tailing powder and rice husk powder. The cylindrical attapulgite flower ceramsite is produced by the following stepsof mixing the ingredients, pelleting, roasting, cooling, screening and packaging. The cylindrical attapulgite flower ceramsite has a rough and porous surface, is light in weight, high in strength andwater absorption rate, can be immersed in water throughout the year without cracking and can continuously and slowly release nutrition required by flowers. Moreover, the cylindrical attapulgite flower ceramsite is produced by comprehensively utilizing the sludge and tailings, so that the resource utilization rate is improved, waste is turned into wealth, and environment is protected. Besides, thecylindrical attapulgite flower ceramsite is applicable to cultivation of various flowers and vegetables.

Owner:江苏世澳非金属应用科技有限公司

Method for producing ceramic tile by metallurgical steel slag

The invention discloses a method for producing a ceramic brick by metallurgical steel slag, which comprises the following steps: crushing waste slag after metallurgical steel-making; adding clay, talc, quartz and other materials to the waste slag according to the requirement of formulation property to mold a blank by a dry pressing method through ball milling by a wet method, and powdering by slurry spraying; drying and placing the molded blank into a roller kiln for maturing; and producing the matured product into a finished product through edging, polishing, grading and packaging. The invention can be widely applied in decoration, has the characteristics of environmental production, high strength, corrosion resistance, good decoration effect and so on. The method provided by the invention is simple and feasible, and is beneficial to industrial production.

Owner:GUANGXI OCEANO CERAMICS CO LTD

Gravel attapulgite flower ceramsite

ActiveCN102503372AHigh strengthLower sintering temperatureCeramic materials productionCeramicwarePhysical chemistryMaterials science

The invention discloses gravel attapulgite flower ceramsite. The key point of the technical scheme is that the gravel attapulgite flower ceramsite consists of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, red bentonite powder, sludge, kieselguhr tailing powder and rice husk powder.t. The gravel attapulgite flower ceramsite is produced by the following steps of mixing the ingredients, pelleting, baking, cooling, smashing, sieving and packaging. The gravel attapulgite flower ceramsite is an irregularly-shaped granule, and has a rough and porous surface, light weight, high strength and high water absorption. The gravel attapulgite flower ceramsite can be soaked in water without being cracked and release nutrition required by flowers continuously and slowly. The gravel attapulgite flower ceramsite is produced by utilizing the sludge and tailings comprehensively, so that the utilization rate of resources is improved, waste materials are changed into wealth, and environment is protected. Besides, the gravel attapulgite flower ceramsite is suitable for planting the flowers and vegetables.

Owner:江苏世澳非金属应用科技有限公司

Method for preparing no-foaming and no-deformation ceramics by utilizing ceramic waste

InactiveCN101671160ARealize green productionEmission reductionSolid waste disposalCeramic materials productionFeldsparMaterials science

The invention discloses a method for preparing no-foaming and no-deformation ceramics by utilizing ceramic waste, comprising the following steps: all raw materials are mixed by weight percentage: 1-99percent of ceramic waste, 0-40 percent of ceramic clay, 0-30 percent of quartz, 0-35 percent of feldspar and 1-50 percent of aluminum oxide or aluminous rich matter; water is added by 50-150 percentof total weight of the raw materials, and 0.5-5 percent of grinding aids and 0.5-5 percent of binders are added to carry out ball-milling, the no-foaming and no-deformation ceramics can be prepared bydrying, formation and sintering. The technology provide by the invention not only solves the problem of the treatment of a great amount of ceramics in ceramic industry, but also solves excessive consumption problem of raw material resource in the ceramic industry, thereby greatly reducing the waste discharge in the ceramic industry and reducing environmental pollution caused by accumulation and land filling of the ceramic waste. The technology has the advantages of high waste utilization rate, simple process and low cost.

Owner:SOUTH CHINA UNIV OF TECH

Sewage sludge shale ceramic particle and preparation method thereof

InactiveCN101186485AHigh strengthLow water absorptionCeramic materials productionClaywaresLand resourcesBrick

Sewage sludge shale ceramsite and a preparation method thereof are provided, which relates to the light energy-saving ceramsite of building materials and a preparation method thereof. The ceramsite of the invention consists of sewage sludge, shale and admixtures; the method of the invention uses the sewage sludge, the shale and the admixtures as raw materials; first, the shale is grinded into shale powder and then the sewage sludge, the shale and the admixtures are mixed and wedged to be granulated into round particles and then enter into a kiln; the products are obtained after going through drying, preheating, barking and being taken out of the kiln for cooling. The ceramsite employs the sewage sludge discharged directly from sewage treatment plants and the shale as major materials, which greatly saves land resource and partial shale mine resource and provides an extremely good way for the non-hazardous and reclaiming treatment of sewage sludge; the method of the invention is simple, energy-saving and resources-saving and the density rank of the ceramsite is 300-700. The ceramsite of the invention can be widely applied in lightweight aggregate bricks, lightweight aggregate sheet materials, lightweight aggregate concrete, etc. and can also be taken as the filter material of sewage treatment, the water-retaining agent in cultivation, etc.

Owner:重庆三益污泥处理有限公司 +1

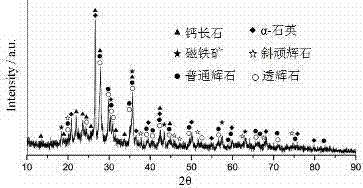

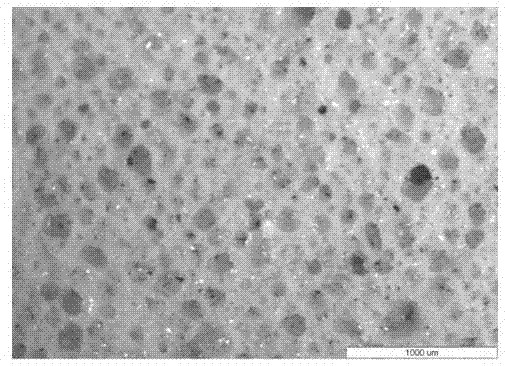

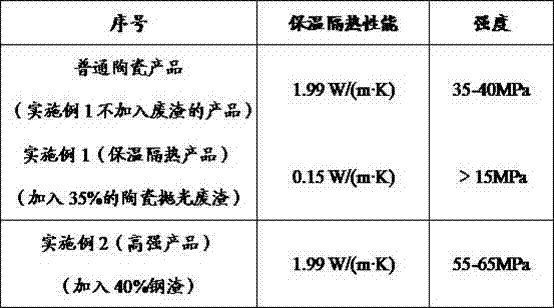

Architectural ceramic prepared from industrial solid waste through dry method and process for preparing architectural ceramic

ActiveCN103570340AReduce the cost of degummingSave the drying processCeramic materials productionClaywaresFluidized bed dryingThermal insulation

The invention discloses architectural ceramic prepared from industrial solid waste through a dry method and a process for preparing the architectural ceramic. The architectural ceramic comprises the following components in percentage by mass: 30-60% of solid waste, 40-70% of ceramic raw material and 1-3% of ceramic additive, wherein the ceramic raw material is selected from one or a composition of multiple of clay raw material, feldspar raw material or talc, and the ceramic additive is one or a combination of multiple of sodium tripolyphosphate, sodium silicate, ammonium chloride, ammonium citrate, sodium humate, sodium lignin sulfonate sodium, ethylenediamine tetraacetic acid disodium and edetic acid. After being pretreated, the granules of the solid waste are fine and are mixed evenly in a dry mixing manner and a spray drying manner and are directly used for pressing of green bricks or stored in a bin for standby, so that the ball milling energy consumption and the peptization cost are reduced, the humidification pelleting and fluidized bed drying procedures are omitted, the formula can be quickly adjusted according to the functional characteristics of the architectural ceramic, the process is simple and convenient to control, and the architectural ceramic has such good properties as heat preservation, thermal insulation and high strength.

Owner:FOSHAN OCEANO CERAMICS +1

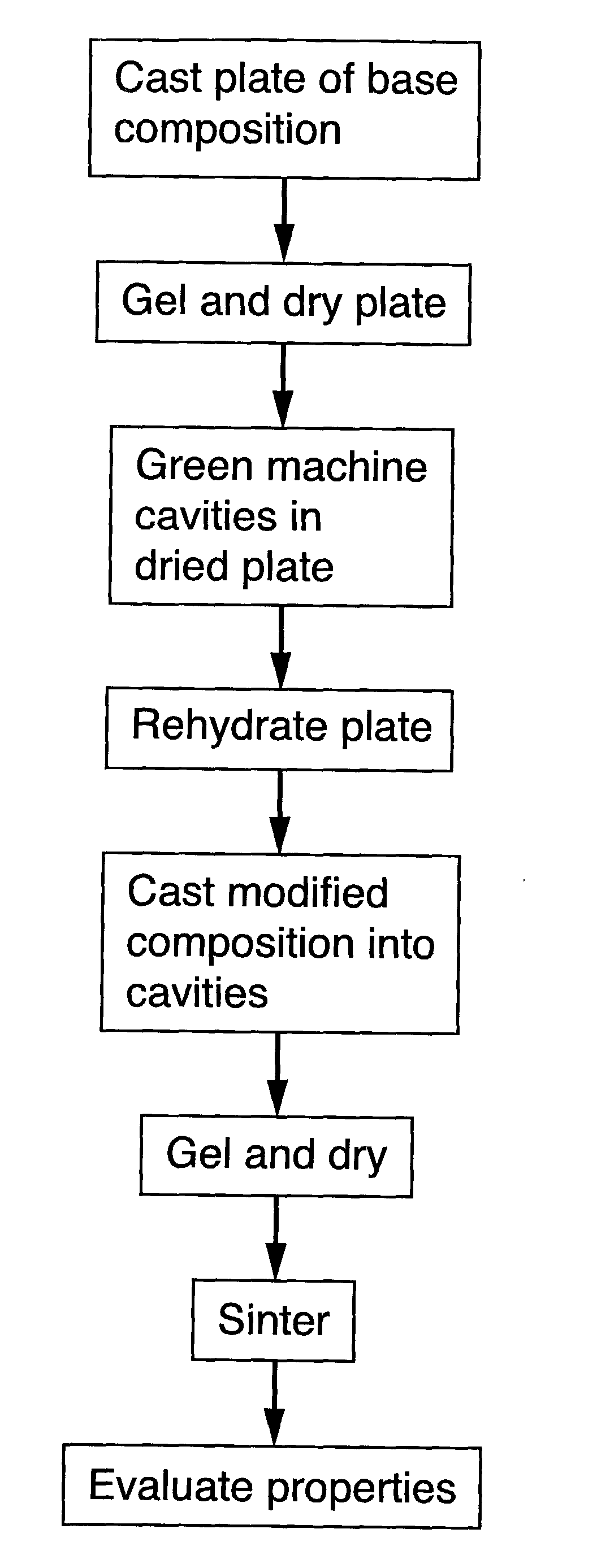

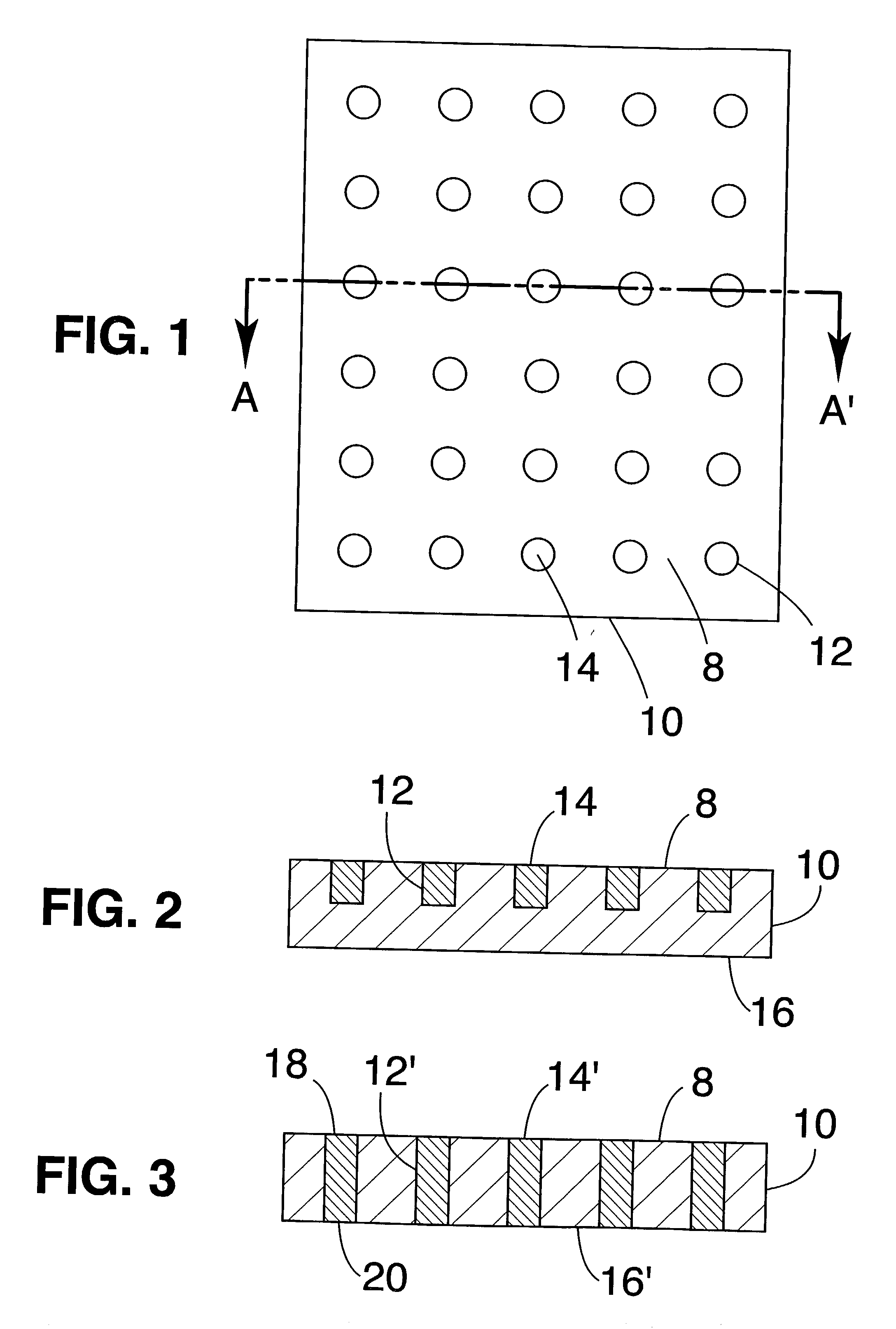

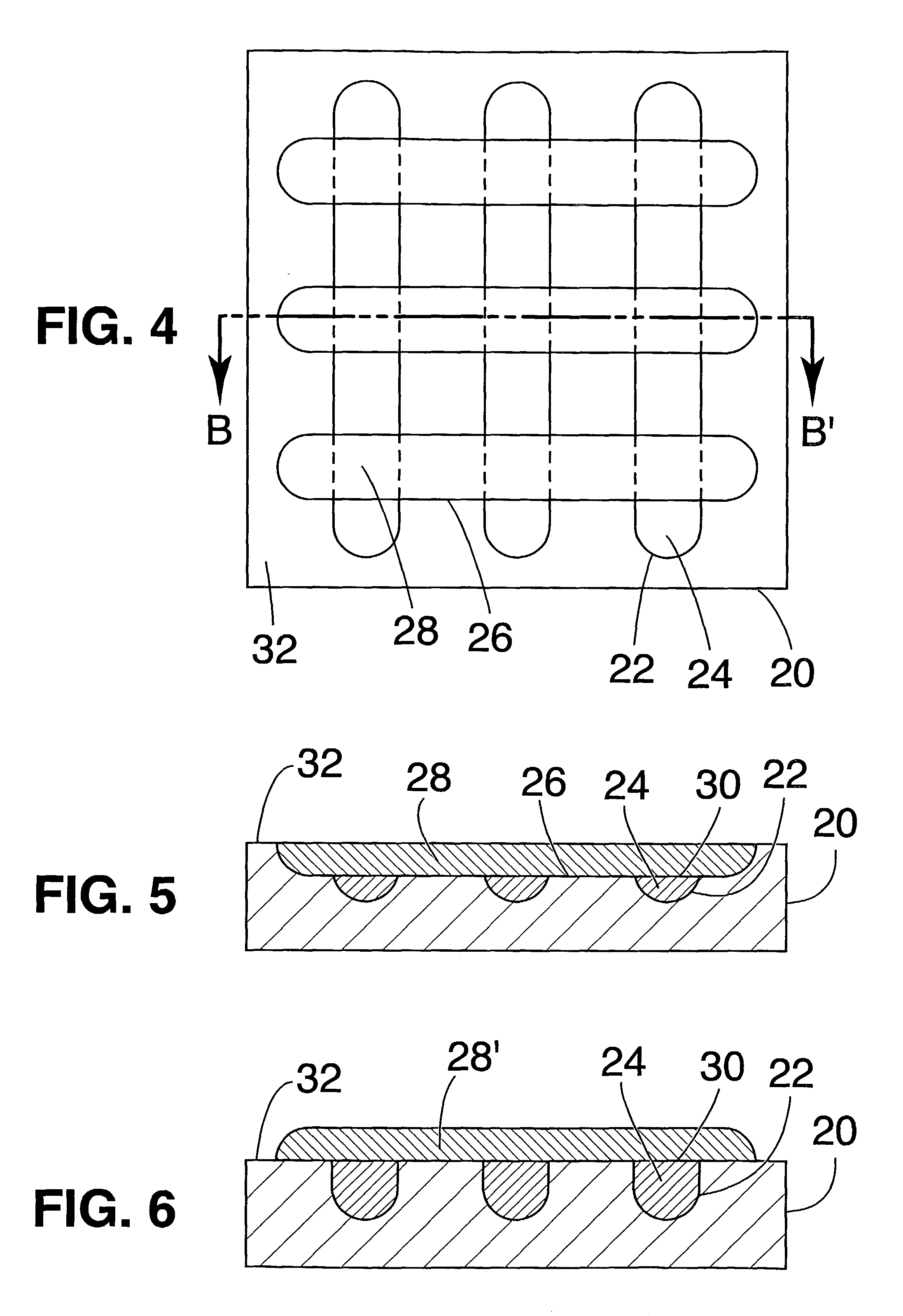

Combinatorial synthesis of ceramic materials

InactiveUS20040062911A1Overcome limitationsRealistic and physical propertyButtonsLayered productsTest materialCombinatorial synthesis

A combinatorial library includes a gelcast substrate defining a plurality of cavities in at least one surface thereof; and a plurality of gelcast test materials in the cavities, at least two of the test materials differing from the substrate in at least one compositional characteristic, the two test materials differing from each other in at least one compositional characteristic.

Owner:UT BATTELLE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com