Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

676 results about "Silicon iron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon Iron is predominately and Iron alloy with 2 – 4 % silicon added, exhibiting a saturation induction of approx. 21,000 Gauss, an initial permeability of 6,000 and a maximum permeability of 60,000. Silicon Iron exhibits high permeability at high induction, yielding superior magnetic shielding of high flux density magnetic fields. Quality.

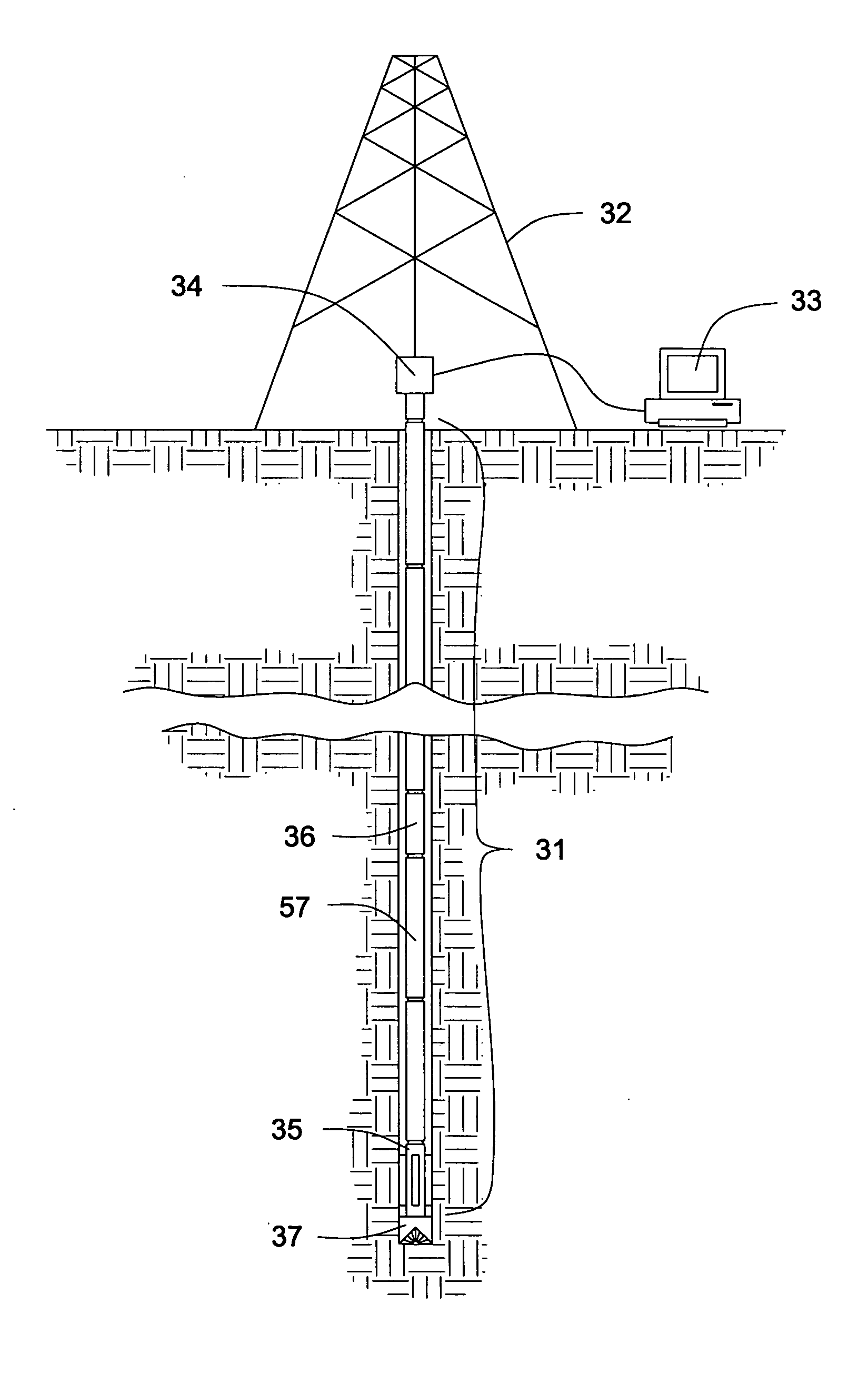

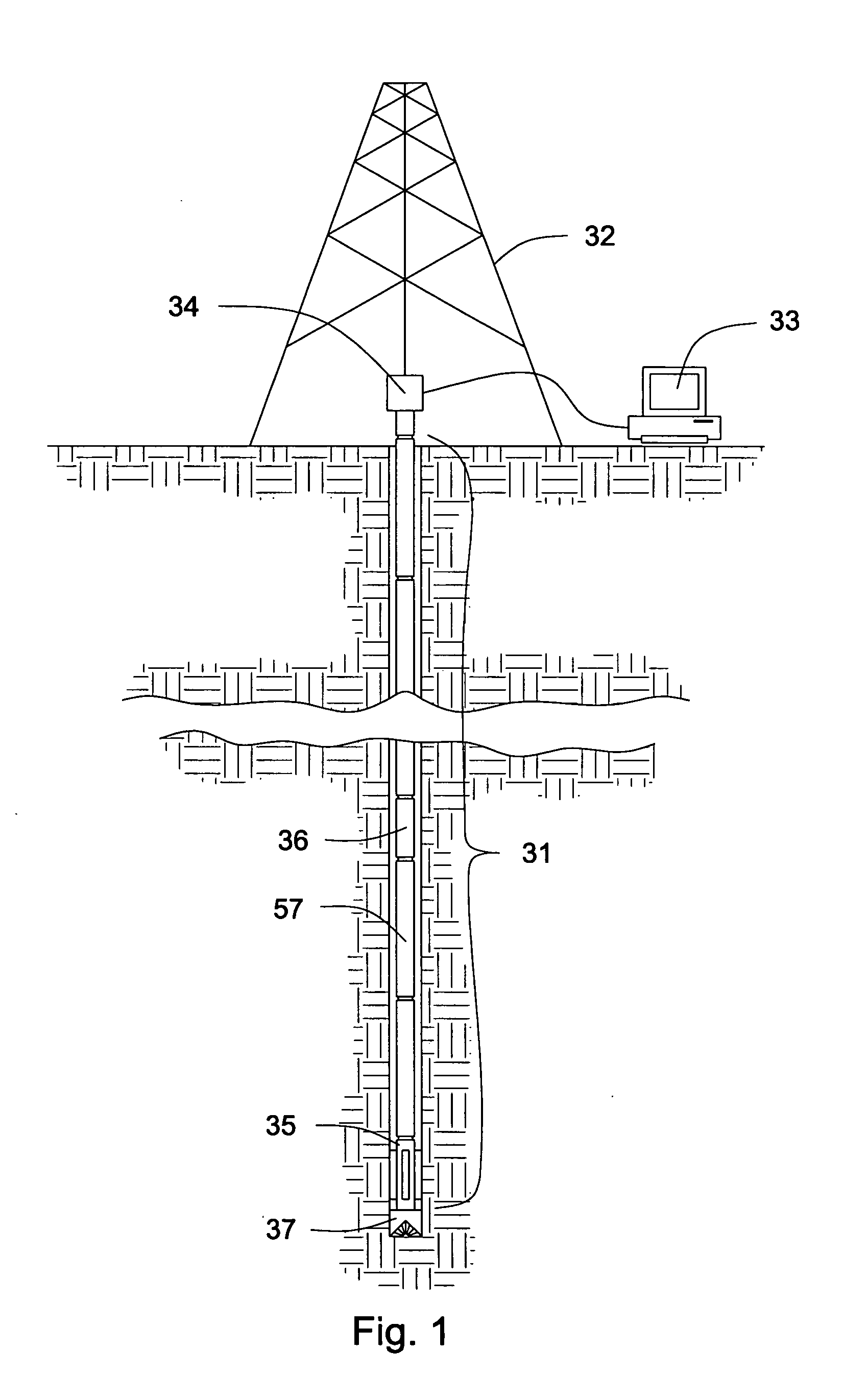

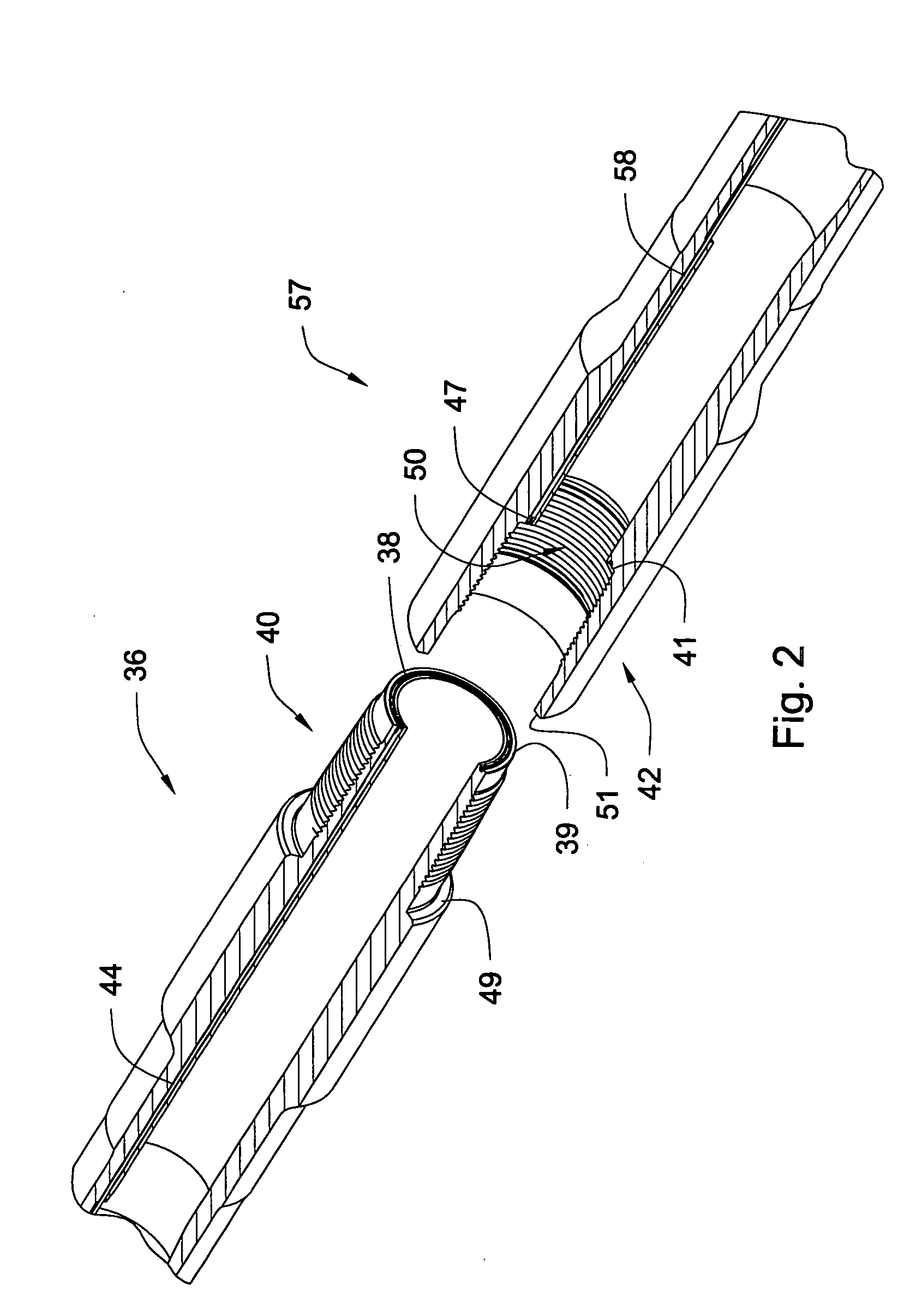

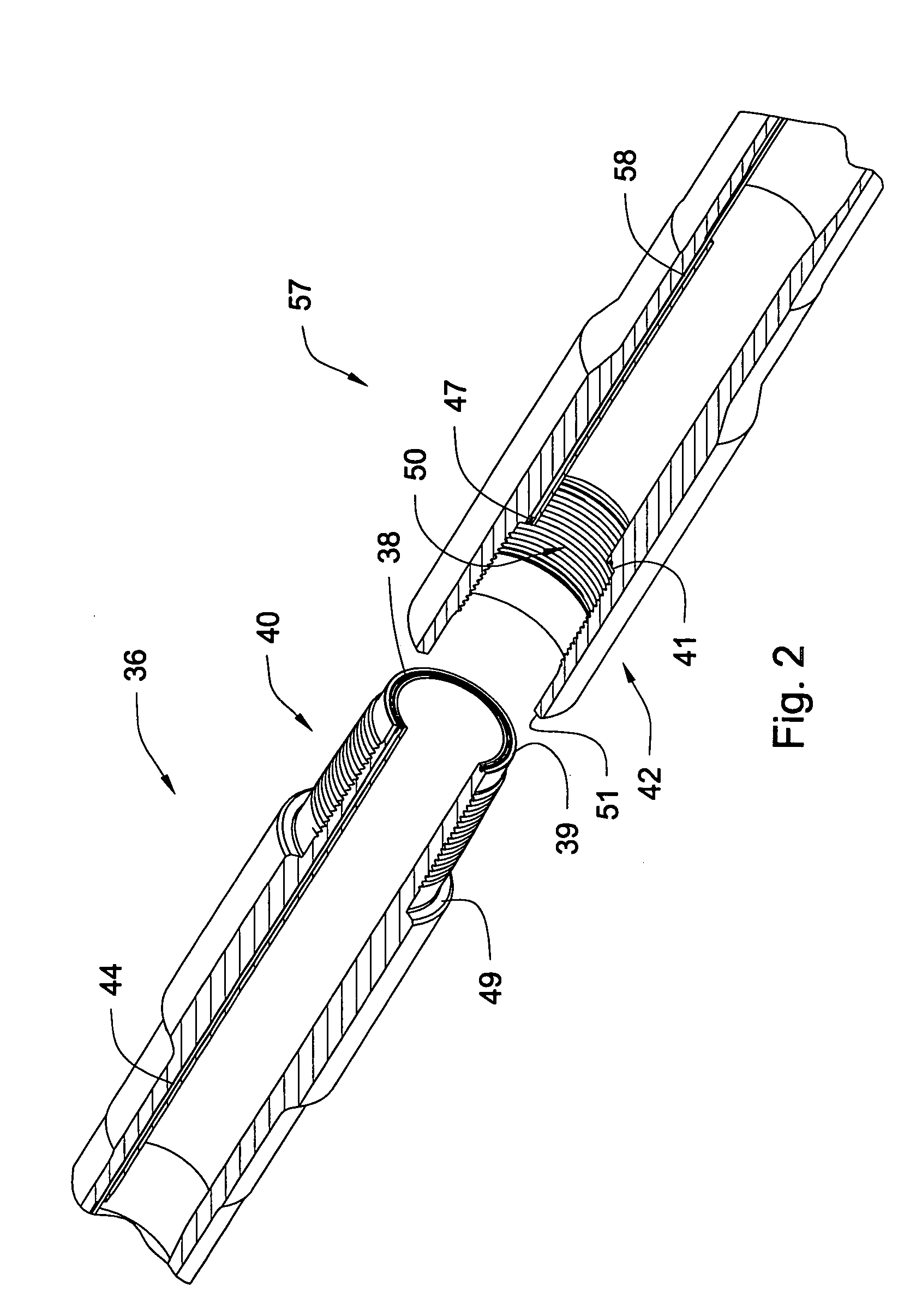

Element of an inductive coupler

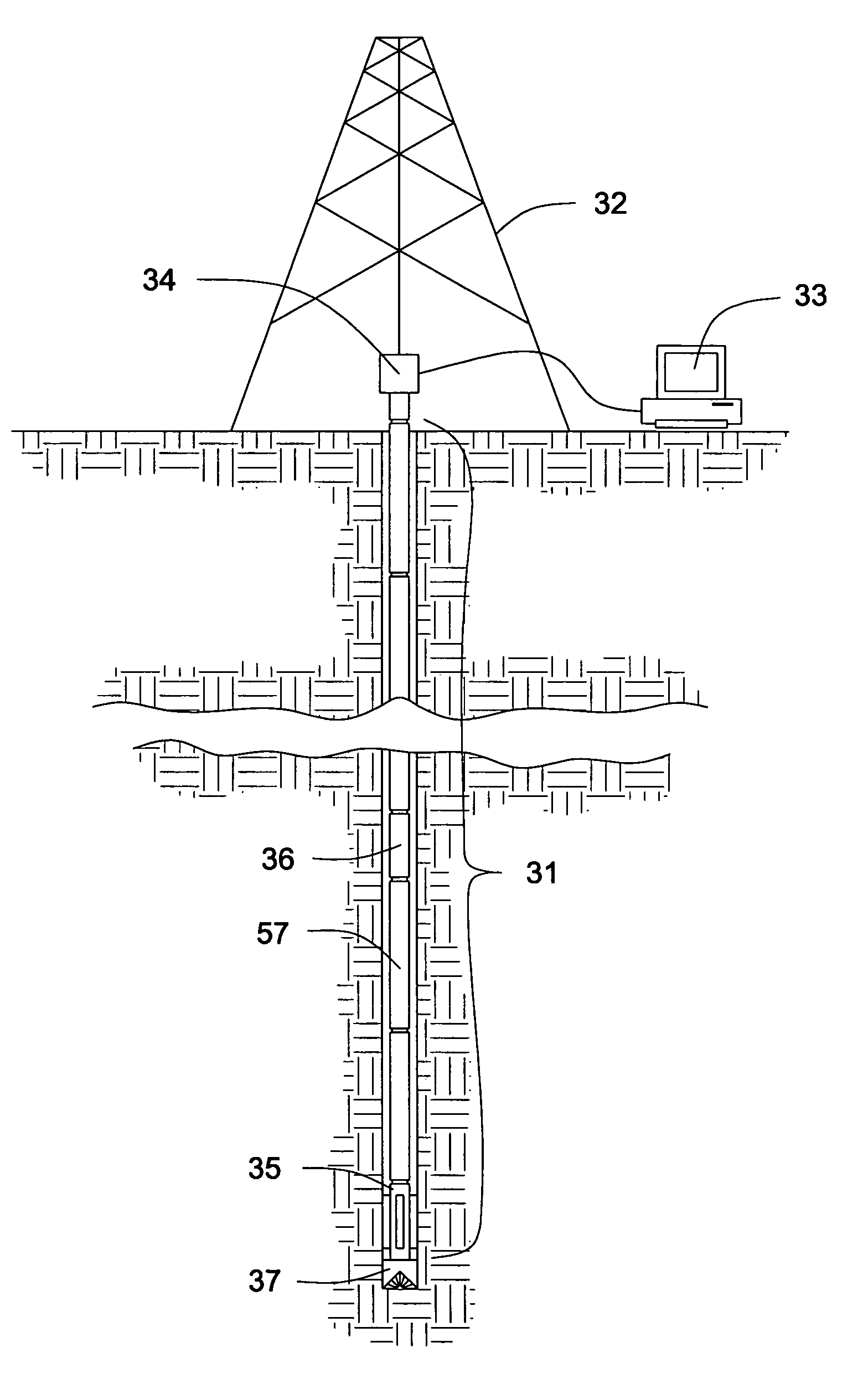

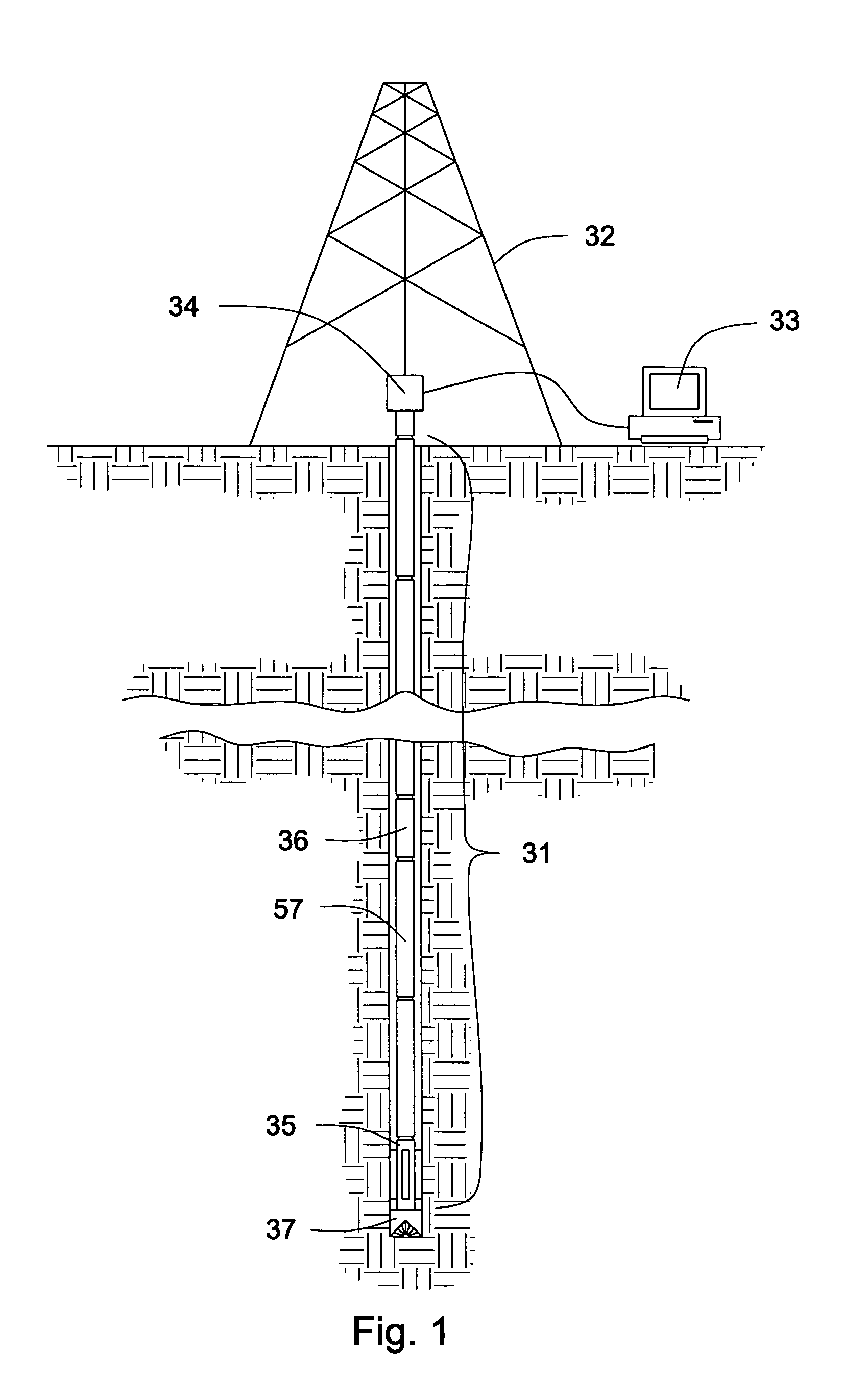

ActiveUS20050285705A1Reduce magnetic field strengthNear-field transmissionDrilling rodsAlloyConductive materials

An element for an inductive coupler in a downhole component comprises magnetically conductive material, which is disposed in a recess in annular housing. The magnetically conductive material forms a generally circular trough. The circular trough comprises an outer generally U-shaped surface, an inner generally U-shaped surface, and two generally planar surfaces joining the inner and outer surfaces. The element further comprises pressure relief grooves in at least one of the surfaces of the circular trough. The pressure relief grooves may be scored lines. Preferably the pressure relief grooves are parallel to the magnetic field generated by the magnetically conductive material. The magnetically conductive material is selected from the group consisting of soft iron, ferrite, a nickel iron alloy, a silicon iron alloy, a cobalt iron alloy, and a mu-metal. Preferably, the annular housing is a metal ring.

Owner:INTELLISERV

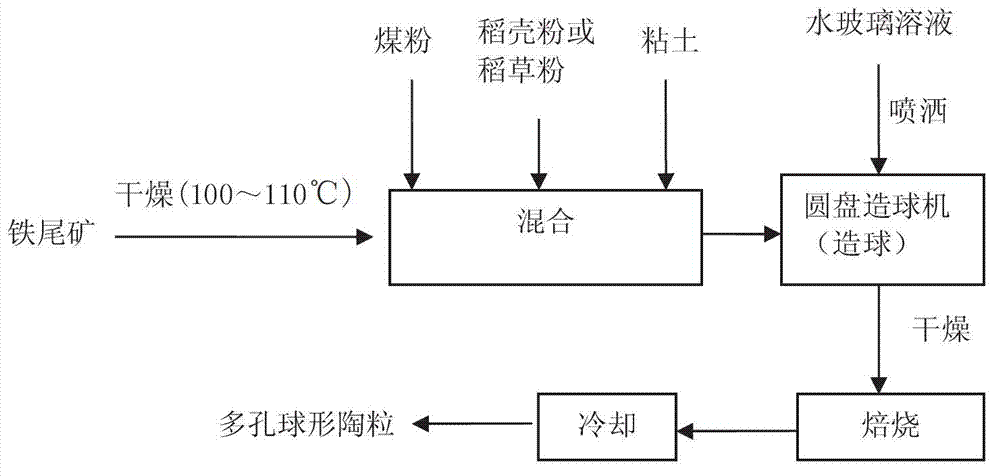

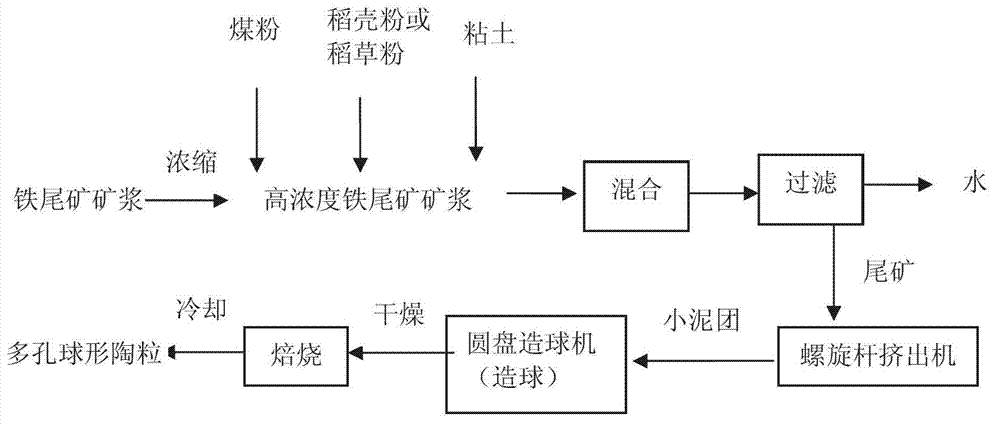

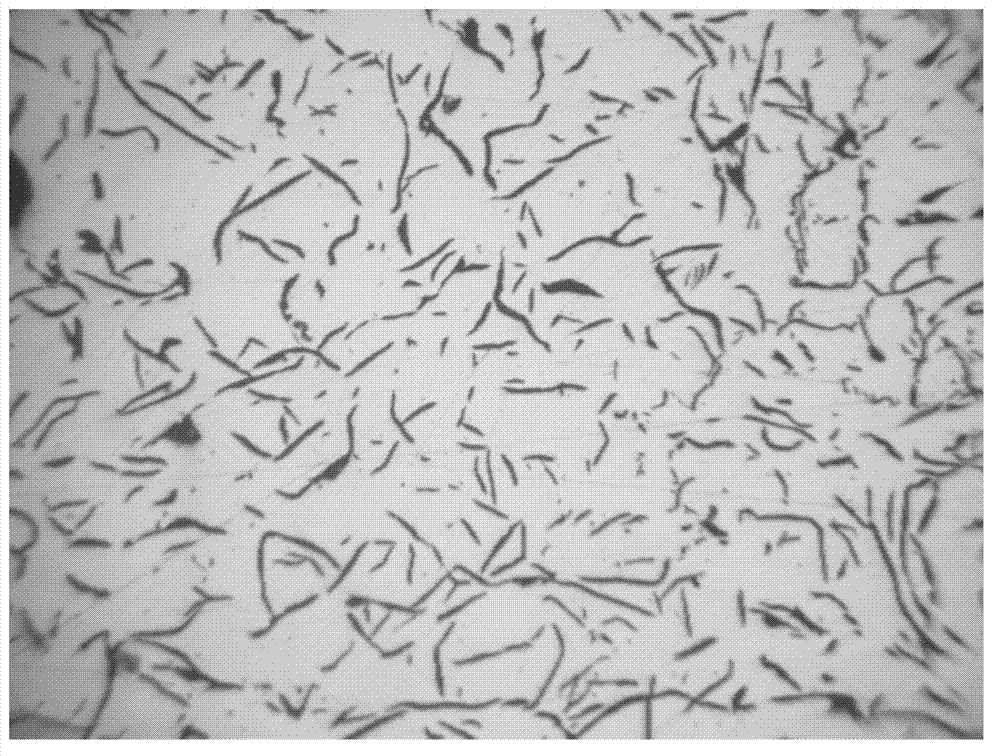

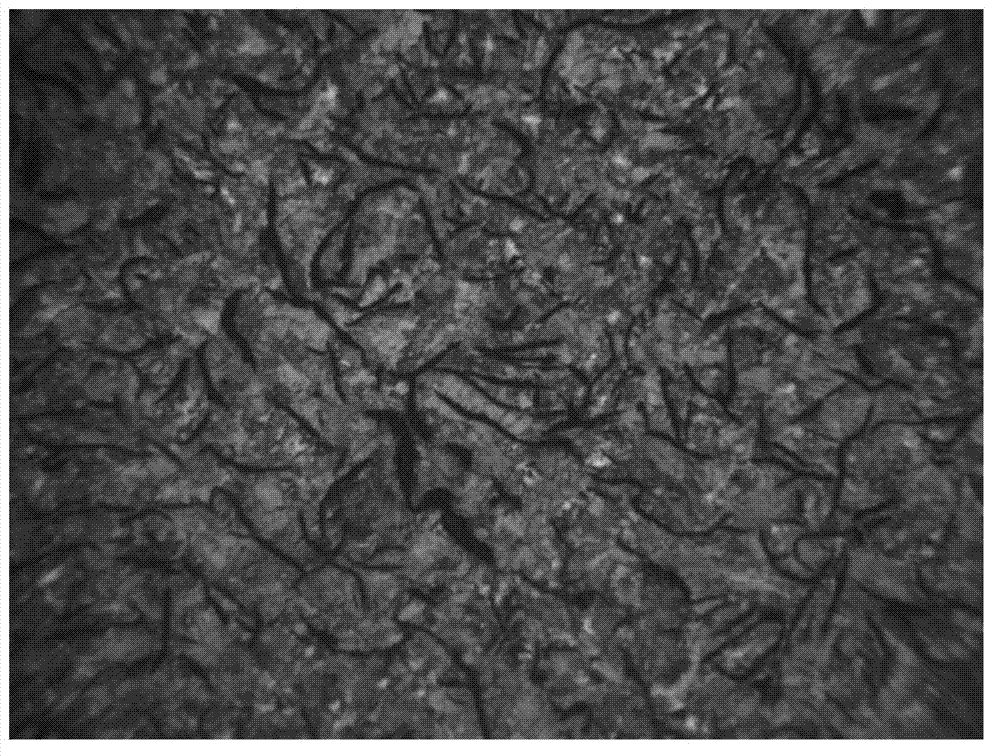

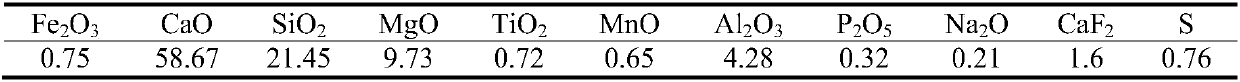

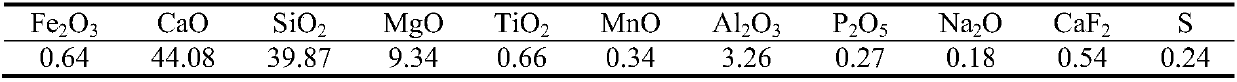

Porous ceramsite made of low-silicon iron tailings and preparation method of porous ceramsite

ActiveCN102815965AReduce usageLow costCeramic materials productionCeramicwarePorosityThermal insulation

The invention discloses porous ceramsite made of low-silicon iron tailings and a preparation method of the porous ceramsite. The porous ceramsite is prepared from, by weight, 75-90 parts of low-silicon iron tailing powder or low-silicon iron tailing pulp, 5-20 parts of pore-forming agents and 1-8 parts of clay, wherein the SiO2 content in the low-silicon iron tailing powder or low-silicon iron tailing pulp is lower than 40%. The method includes: weighing and mixing the iron tailings, the pore-forming agents and the clay, and granulating the mixture into green balls; and after the green balls are dried, calcinating the dried green balls for 40-60min at the temperature of 1100-1180 DEG C, so that the ceramsite made of the iron tailings is obtained. By the method, the porous ceramsite conforming to architecture application and water treatment application can be prepared respectively. The ceramsite prepared by the method has the advantages of high strength and apparent porosity, low density, good thermal insulation property, high cost performance and the like, and can be used for preparing various light, sound-insulation and thermal-insulation materials or used as light building aggregate, water treatment biological carriers and the like.

Owner:武钢资源集团有限公司 +1

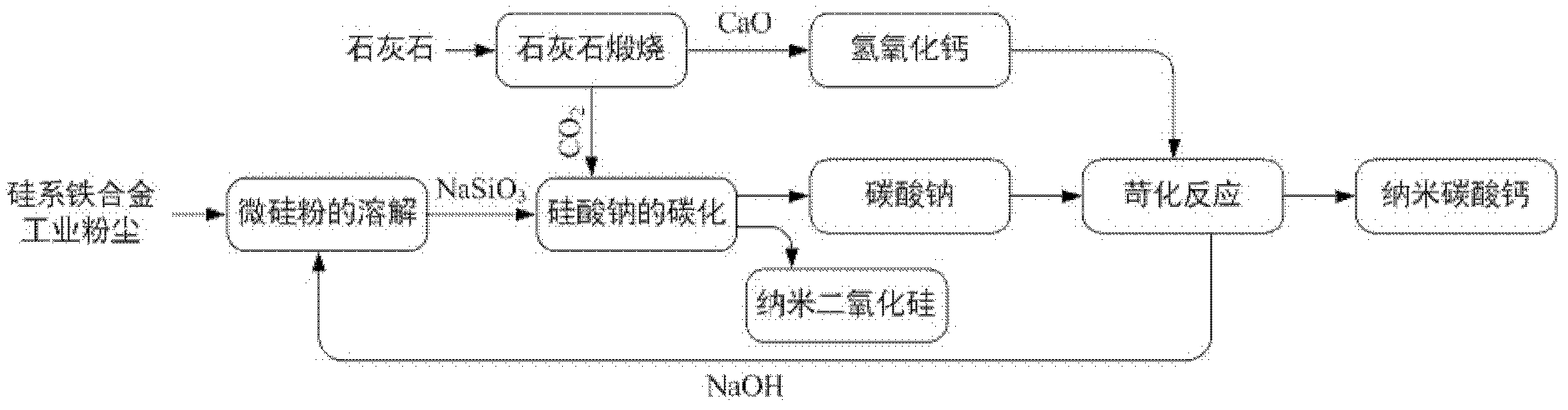

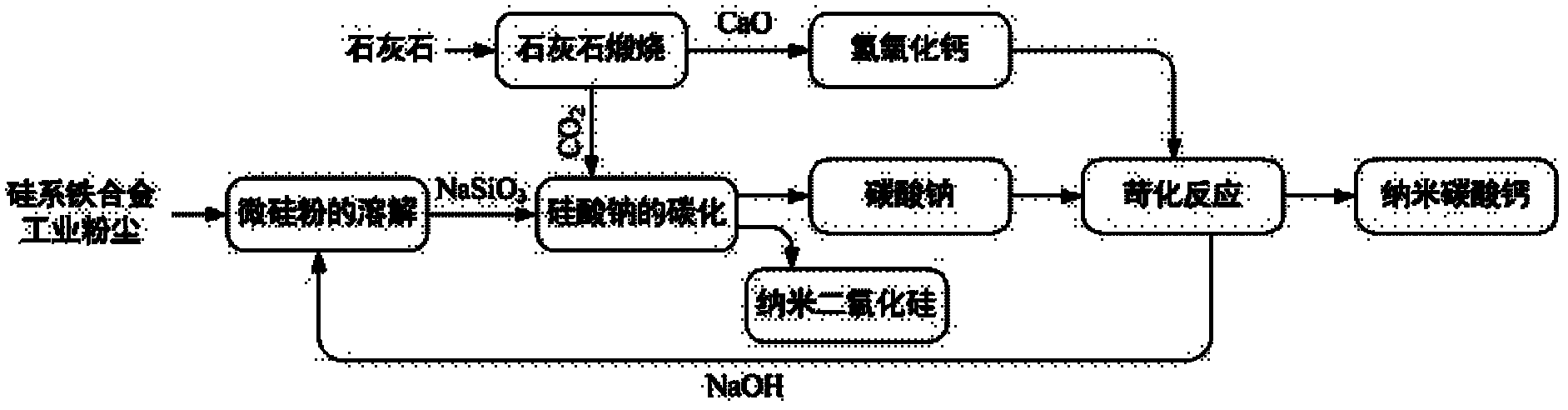

Method for preparing white carbon black cogeneration nanometer calcium carbonate by integrally utilizing micro silicon powder

InactiveCN102424392AReduce manufacturing costEmission reductionCalcium/strontium/barium carbonatesProductsCarbonizationCogeneration

The invention relates to a method for preparing white carbon black cogeneration nanometer calcium carbonate by integrally utilizing micro silicon powder, which belongs to the technical field of integrative utilization of silicon iron alloy industrial waste resources and industrial kiln gas carbon dioxide. The method comprises the following process steps that: micro silicon powder is dissolved by sodium hydroxide hot alkali for preparing water glass; lime is prepared through lime stone calcination, and carbon dioxide raw material gas is released; precipitated silica is prepared through water glass carbonization; carbonization filter liquid is subject to sodium carbonate causticization for preparing sodium hydroxide solution to coproduce nanometer calcium carbonate; and the sodium hydroxide solution is circulated to a hot alkali dissolving and boiling kettle for dissolving micro silicon powder to prepare water glass. The method has the advantages that the process circulation of integrally utilizing the micro silicon powder for preparing the white carbon black cogeneration nanometer calcium carbonate is realized, and a new method is provided for goals of changing metallurgy chemical industrial waste materials into resources and utilizing the waste materials at high value.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

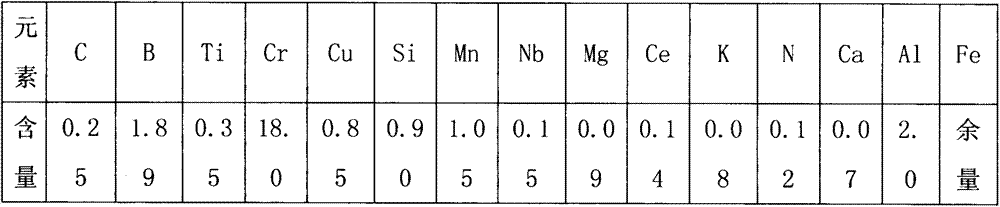

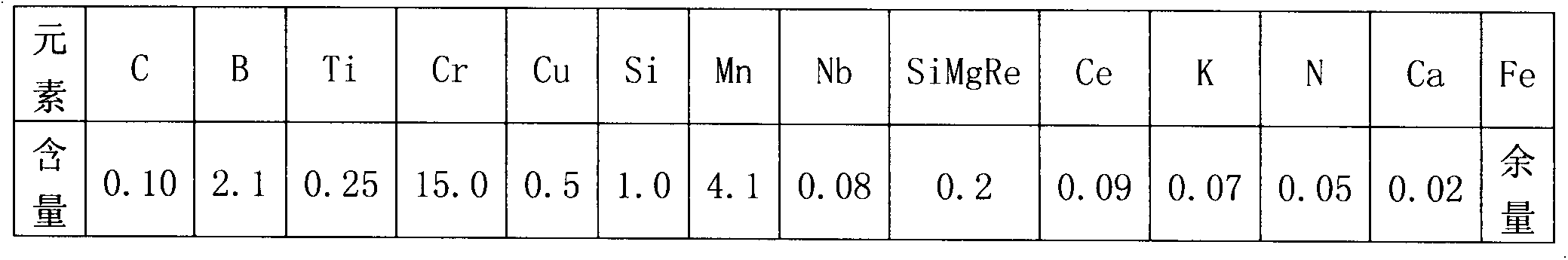

High-boron high-chromium low-carbon high-temperature-resistant wear-resisting alloy steel and manufacturing method thereof

InactiveCN103498107AReduce manufacturing costHigh heat and cold fatigue resistanceProcess efficiency improvementSilicon alloyCerium

The invention provides high-boron high-chromium low-carbon high-temperature-resistant wear-resisting alloy steel and manufacturing method thereof. The chemical content of the alloy steel includes, by weight, 0.10%-0.5% of C, 3%-26% of Cr, 0.5%-4% of W, 0.5%-1.2% of Si, 0.5%-1.5% of Mn, 0.7%-3.5% of B, 0.3%-2.6% of Cu, 1.5%-2.4% of Al, 0.8%-1.6% of Ti, 0.02%-0.15% of Ca, 0.03-0.25% of Ce, 0.02%-0.18% of N, 0.05%-0.3% of Nb, 0.12%-0.25% of Mg, 0.04%-0.13% of K, 0.05%-0.12% of Ca, 0.06%-0.15% of Ba, less than 0.03% of S, less than 0.04% of P and the balance Fe and unavoidable impurity elements. After steel scrap and ferrochromium are melted in an electric furnace, a copper plate, silicon iron and ferromanganese are added to the electric furnace, after content is qualified through pre-furnace adjustment, the temperature of a melt rises to 1560-1620 DEG C, calcium-silicon alloy and deoxidation aluminum are added, ferrotitanium, ferroboron and metal aluminum are sequentially added and poured out of the furnace after being melted, granular rare earth magnesium alloy with a diameter of less than 12mm and a composite inoculant composed of metal cerium, Si3N4, VN, Nb and K are placed at the bottom of a steel ladle after being roasted, metaphoric inoculation processing is carried out on smelt liquid steel in a in-ladle pouring mode, the liquid steel pouring temperature ranges from 1400 DEG C to 1450 DEG C, and a casting piece undergoes air cooling for 2-4 hours at the temperature of 920-1150 DEG C.

Owner:江苏盛伟模具材料有限公司

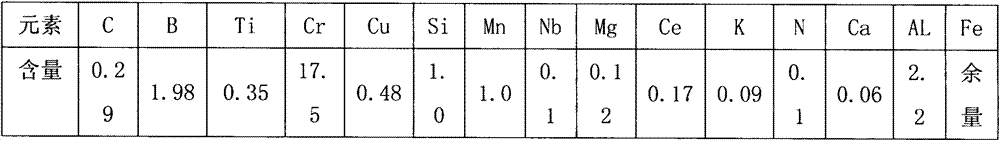

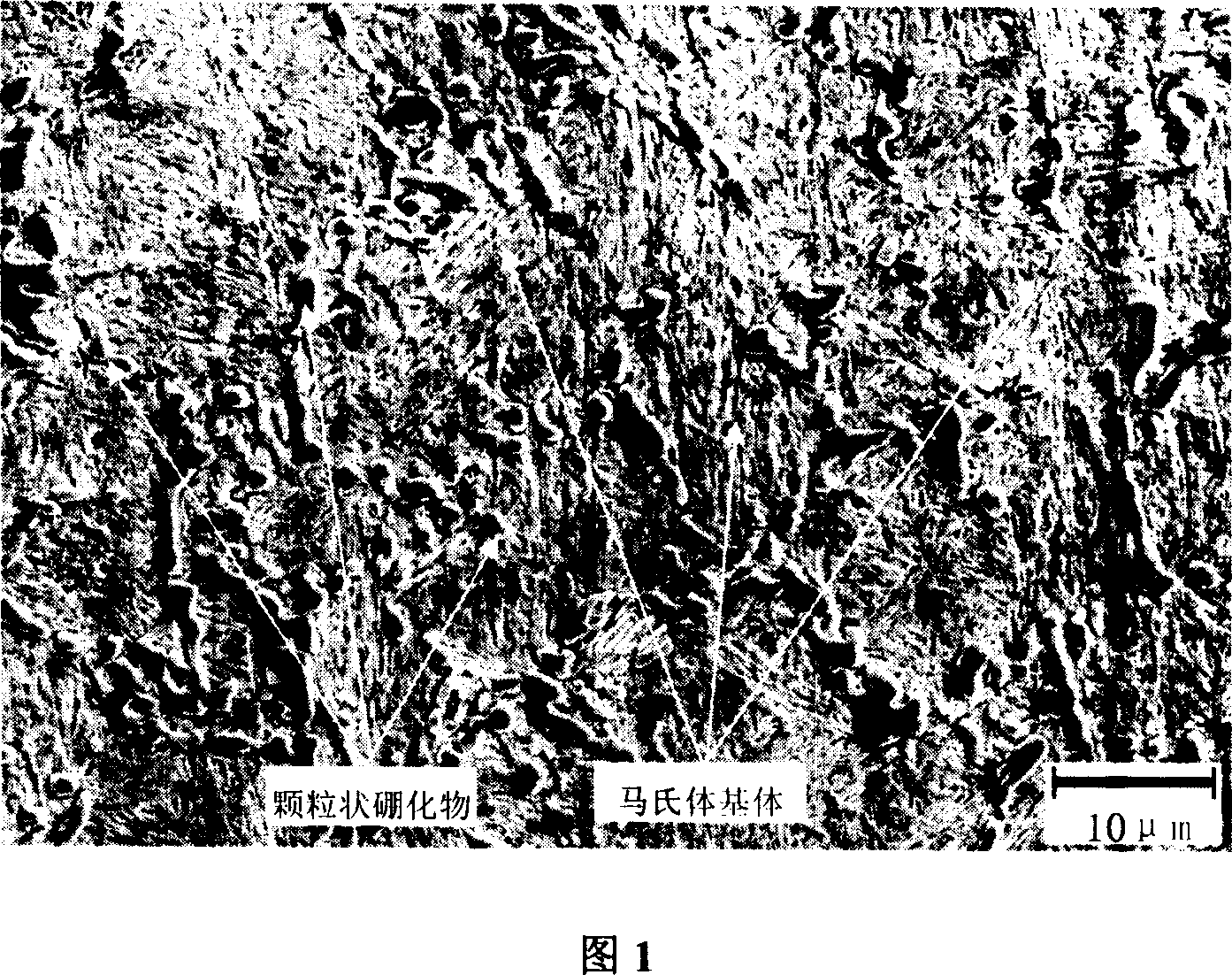

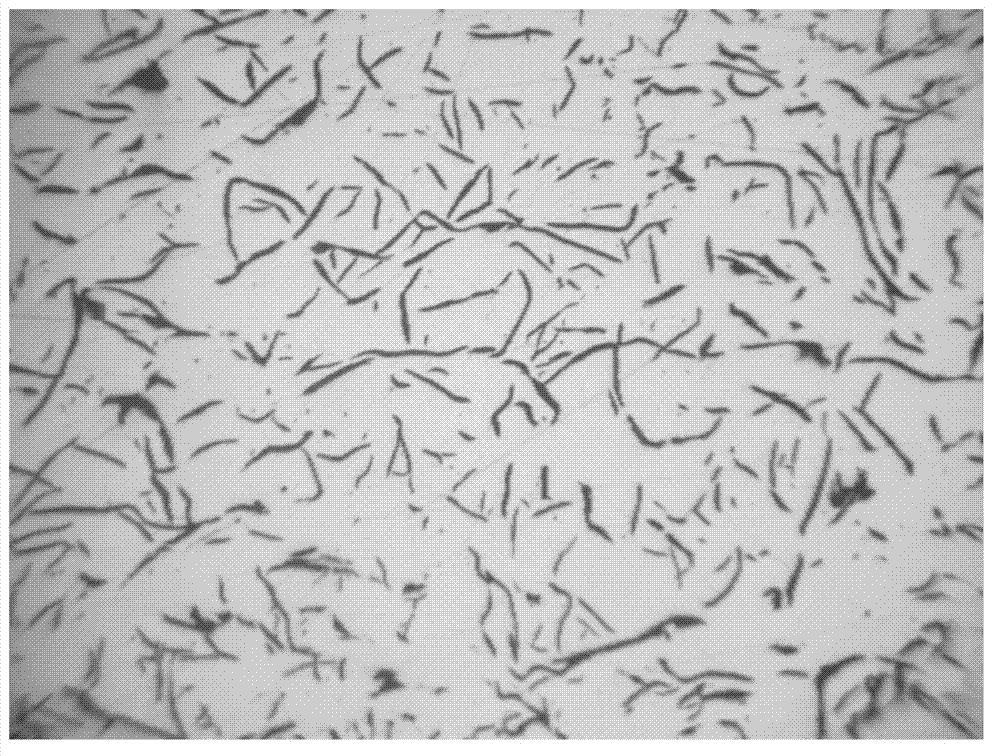

High-boron cast steel containing granular boride and preparing method thereof

The invention discloses a preparing method of granular boride high-boron cast steel, which comprises the following steps: allocating 0.15%-0.45% C,0.75%-2.70% B, 0.34 %-1.50% Ti, 0.80%-1.20% Cr, 0.50%-1.50% Si, 0.50%-1.50% Mn, 0.04%-0.12% Ce, 0.08%-0.20% Al, 0.03%-0.10% Ca, 0.01%-0.06 N, P<0.05%, S<0.05% and Fe; setting B / C=5.0-6.0, B / Ti=1.8-2.2; adopting electric stove to melt; mixing common scrap steel, pig iron and chromium iron; heating to melt; adding into silicon iron and manganese iron; adding into ferroboron and ferrotitanium before tapping; adjusting furnace-front element to be quality; heating-up; adding into silicon-calcium alloy; pre-deoxidizing; end-deoxidizing with aluminum; micro-alloying; proceeding composite deteriorating process outside of the furnace with cerium and nitrogen; keeping the temperature; proceeding oil-cooling quenching; tempering under the low temperature; getting the product. This invention possesses merits of high hardness and strength and good tenacity and resistance, which can increase the durability of wear resisting part.

Owner:XI AN JIAOTONG UNIV

Element of an inductive coupler

ActiveUS7091810B2Reduce magnetic field strengthNear-field transmissionDrilling rodsAlloyConductive materials

An element for an inductive coupler in a downhole component comprises magnetically conductive material, which is disposed in a recess in annular housing. The magnetically conductive material forms a generally circular trough. The circular trough comprises an outer generally U-shaped surface, an inner generally U-shaped surface, and two generally planar surfaces joining the inner and outer surfaces. The element further comprises pressure relief grooves in at least one of the surfaces of the circular trough. The pressure relief grooves may be scored lines. Preferably the pressure relief grooves are parallel to the magnetic field generated by the magnetically conductive material. The magnetically conductive material is selected from the group consisting of soft iron, ferrite, a nickel iron alloy, a silicon iron alloy, a cobalt iron alloy, and a mu-metal. Preferably, the annular housing is a metal ring.

Owner:INTELLISERV LLC

460MPa-level flux-cored wire for ocean engineering and application thereof

ActiveCN105269174AStable mechanical propertiesImprove crack resistanceArc welding apparatusWelding/cutting media/materialsCrack resistanceWeld seam

The invention provides a 460MPa-level flux-cored wire for ocean engineering. The 460MPa-level flux-cored wire comprises a carbon steel sheath and a flux core, wherein the carbon steel sheath accounts for 84-87% of the total mass of the flux core; the flux core accounts for 13-16% of the total mass of the flux-cored wire; the flux-cored wire consists of the following components in percentage by mass: 30-42% of rutile, 1-2% of sodium fluoride, 3-6% of feldspar, 3-5% of ferrotitanium, 1-3% of silicon iron, 0.5-1% of rear earth, 3-5% of magnesium powder, 5-10% of electrolytic manganese, 1-2% of aluminum powder, 7-9% of nickel powder, 4-7% of ferroboron, 0.2-0.5% of graphite, 3-6% of silicon-manganese alloy, 0.5-1% of zircon sand and the balance of Fe and inevitable impurities. By virtue of control in aspects of chemical components, diffusible hydrogen, low-temperature stability and the like, the 460MPa-level flux-cored wire meets the requirements of crack resistance and low-temperature impact resistance, is good in all-position welding process, attractive in welding seam and excellent in mechanical property, has seawater corrosion resistance; and content of diffusible hydrogen of deposited metal reaches ultralow hydrogen level.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

High-toughness high-boron medium-chrome low-carbon wear-resisting alloy steel and preparation method thereof

The invention relates to a high-toughness high-boron medium-chrome low-carbon wear-resisting alloy steel and a preparation method thereof. The high-toughness high-boron medium-chrome low-carbon wear-resisting alloy steel comprises the following chemical components by weight percentage: 0.20-0.5% of C, 5-12% of Cr, 0.5-1.2% of Si, 3.5-5.5% of Mn, 0.3-2.8% of B, 0.3-2.1% of Cu, 0.2-0.5% of Ti, 0.05-0.25% of Ca, 0.03-0.3% of Ce, 0.02-0.18% of N, 0.05-0.3% of Nb, 0.04-0.09% of Al, 0.1-0.5% of SiMgRe, 0.04-0.13% of K, less than 0.03% of S, less than 0.04% of P and the balance of Fe and inevitable impurity elements. The preparation method comprises the following steps of: adding a copper plate, silicon iron and ferromanganese iron after steel scrap and chromium iron are melted; after the component adjustment before furnace is qualified, increasing the temperature of the melt to 1560-1620 DEG C, adding a calcium-silicon alloy and aluminum for deoxidation, and orderly adding ferrotitanium and ferroboron, melting, and then discharging; putting a composite inoculant composed of granular rare-earth magnesium alloy with granule size being less than 12mm, metal cerium, Si3N4, VN, Nb and K at the bottom of a steel ladle after baking, and performing inoculation treatment on the molten steel by a rush-into-ladle method, wherein the casting temperature of the molten steel ranges from 1400 DEG C to 1450 DEG C; preserving the heat of castings for 4-6 hours at 700-780 DEG C, and then carrying out subcritical air quenching to obtain the alloy steel.

Owner:丁家伟

Flux-cored wire for stainless steel welding

ActiveCN103521951ASuitable for weldingWelding/cutting media/materialsSoldering mediaManganeseRare earth

The invention relates to a flux-cored wire for stainless steel welding, and particularly discloses the flux-cored wire for stainless steel welding. The flux-cored wire is composed of flux-cored powder and a stainless steel belt, wherein the flux-cored powder is wrapped by the stainless steel belt. The flux-cored wire for stainless steel welding is characterized in that the flux-cored powder accounts for15-25% of the total weight of the flux-cored wire, the flux-cored powder comprises, by weight, 30-38 parts of metal chromium powder, 6-15 parts of metal nickel powder, 3-10 parts of metal manganese powder, 20-35 parts of rutile, 1-6 parts of silicon iron, 1-7 parts of ferrotitanium, 2-10 parts of feldspar, 5-10 parts of quartz, 1-5 parts of rare earth fluoride, 1-5 parts of metal nitride powder and appropriate iron powder, and the total flux-cored powder is, by weight, 100 parts. A reduction jar of the flux-cored wire for welding is long in service cycle, and deposited metal formed by the flux-cored wire has the excellent effects of high temperature oxidation resistant capacity and high temperature sulphur corrosion resistant capacity.

Owner:BEIJING JINWEI WELDING MATERIAL +1

A kind of solder and its igniter for exothermic welding of grounding body in grounding system

InactiveCN102267024AWelding/cutting media/materialsAlumino-thermic welding apparatusHigh resistanceExothermic welding

The invention discloses a solder for exothermic welding of a grounding body in a grounding system and an ignition agent of the solder, relates to the solder for the exothermic welding and the ignition agent of the solder and solves the technical problem of poor welding performance caused by impurities contained in a welding joint which is obtained by the conventional exothermic welding hot-melting soldering agent. The solder for the exothermic welding of the grounding body in the grounding system consists of copper oxide powder, copper powder, industrial pure aluminum powder, zinc powder, zirconium powder, silicon iron powder, fluorite powder, marble powder and lanthanum cerium alloy powder. The ignition agent of the solder for the exothermic welding of the grounding body in the groundingsystem consists of magnesium powder, the copper oxide powder, the industrial pure aluminum powder, potassium permanganate powder and red phosphorus powder. When the solder and the ignition agent are used, the mass ratio of the solder for the exothermic welding of the grounding body in the grounding system to the ignition agent is (78-82):1. All elements in the solder and rare-earth elements can purify the welding joint. The invention is applicable to welding of copper, copper alloy, steel, galvanized steel, copper-clad steel, stainless steel and high-resistance heating source materials.

Owner:HEILONGJIANG PATENT TECH DEV

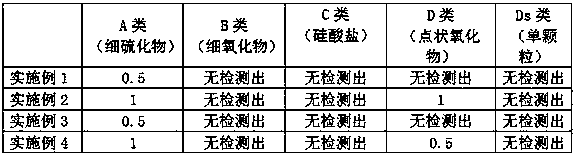

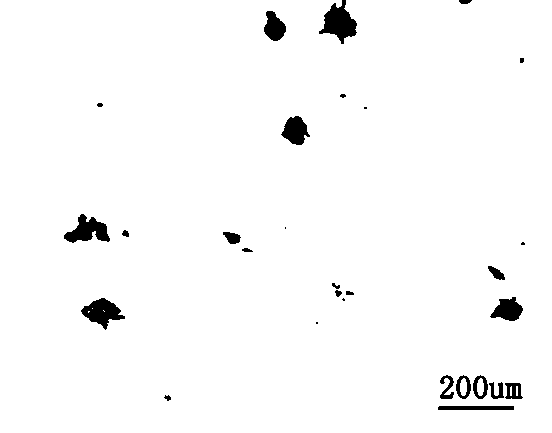

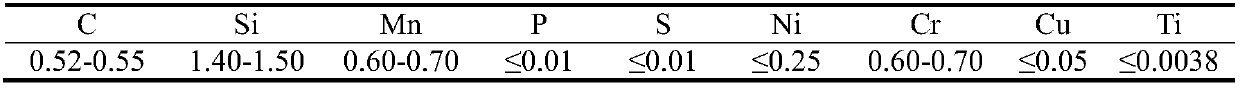

Production technology of spring steel 60Si2Mn hot-rolled wire rod for automotive suspension

ActiveCN109023059AGuarantee organizationGuaranteed performanceProcess efficiency improvementSlagDeoxygenation

The invention discloses a production technology of a spring steel 60Si2Mn hot-rolled wire rod for an automotive suspension. The production technology comprises the steps of a hot metal pretreatment working procedure, a converter smelting working procedure, an LF refining working procedure, an RH vacuum treatment working procedure, a continuous casting working procedure, a cogging working procedure, an ingot blank polishing working procedure and a wire rod rolling working procedure. According to the production technology, the generation of AL2O3 inclusion is controlled from the source by meansof hot metal pretreatment desulfurization, silicon iron deoxygenation, silicon carbide diffusion deoxygenation and wollastonite and active lime slag formation; by the adoption of special carburant andspecial silicon iron, the content of nitrogen and the content of titanium in steel are controlled, argon protection in the whole process and the sufficient standing time are adopted, the situation that the inclusion fully and upwards floats is guaranteed, and D and Ds inclusion in the molten steel is controlled; by means of large ladle slag detection and special covering slag, the phenomenon thatthe molten steel is subjected to secondary pollution can be completely eradicated, and a good effect of thermal-insulating adsorption of the inclusion can be achieved; by means of the stir and soft press operation of a large rectangular blank crystallizer, the internal quality of an ingot blank is ensured; and in the rolling process, due to the optimization of the rolling speed and the control over the rolling temperature, the structure and the performance of a finished product are guaranteed.

Owner:HANDAN IRON & STEEL GROUP +1

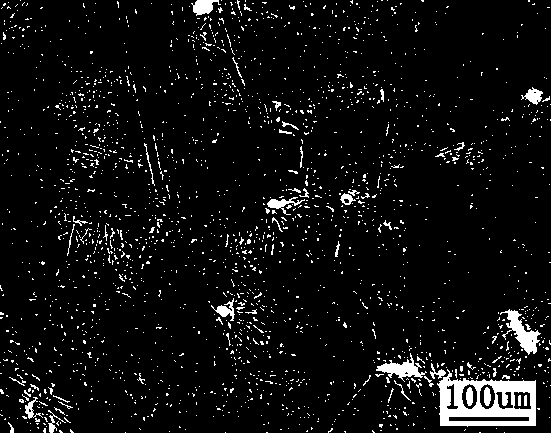

Roughing roll made of graphitizable steel material and manufacturing method thereof

ActiveCN103469109AReasonable designSmall drop in hardnessFurnace typesRollsCrack resistanceRare earth

The invention discloses a roughing roll made of a graphitizable steel material and a manufacturing method thereof. The roughing roll comprises the following alloy components by weight percent: 1.20-2.30% of C, 1.00-2.20% of Si, 0.50-1.20% of Mn, less than or equal to 0.03% of P, less than or equal to 0.03% of S, 0.40-3.50% of Cr, 0.20-2.00% of Ni, 0.20-1.00% of Mo, and the balance of Fe and inevitable impurities. The manufacturing method of the roughing roll comprises the steps of smelting, inoculation and spheroidization, casting and heat treatment, wherein in inoculation and spheroidization, an inoculator of aluminum and rare-earth silicon iron magnesium alloy is adopted, the inoculator is added by 1-3 Kg per one ton of liquid steel, and Fe-Si particles and Si-Ca particles are rushed into along with a steel flow in the steel tapping process; after the completion of steel tapping, argon blowing treatment is performed on the liquid steel in a steel ladle, and then standing is carried out for more than 10 minutes so that the temperature of the liquid steel reaches a casting temperature 50 DEG C higher than the melting point of the liquid steel; then casting is carried out. The roughing roll made of the graphitizable steel material provided by the invention has high abrasive resistance, and also has excellent thermal crack resistance and excellent accidental impact resistance.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Boron contg. multi-element low alloyed wearable cast steel and prepn. thereof

InactiveCN1834279AHigh strengthImprove wear resistanceHeat treatment process controlRare earthPotassium

This invention discloses a multi-element low alloy abrasion-resisting cast steel, which is composed of C 0.20-0.45 wt.%, Mn 1.1-1.8 wt.%, Si 0.8-1.5 wt.%, Cr 0.3-1.2 wt.%, B 0.05-0.20 wt.%, Ti 0.08-0.30 wt.%, N 0.03-0.20 wt.%, Ca 0.05-0.15 wt.%, K 0.04-0.15 wt.%, and the rest is Fe and inavoidable impurities. The cast steel is manufactured by: (1) mixing scrapped steel, silicon iron, chromium iron and manganese iron, (2) carrying out carburization by using scrapped graphite electrode or pig iron, (3) melting to obtain liquid steel and adjusting the components until being qualified, (4) heating the liquid steel to 1620-1660 deg.C, (5) adding Si-Ca alloy, boron iron, titanium iron and nitrogen-containing chromium iron, and then pouring out of the furnace, (6) pulverizing Y-based rare earth magnesium alloy and potassium-containing substances to granules whose sizes are less than 15 mm, (7) drying at 130-180 deg.C, (8) placing at the bottom of the ladle, (9) carrying out modification treatment by pour-over process, and casting at 1480-1520 deg.C, (10) austenitizing at 830-1050 deg.C for 0.5-4 h, (11) rapidly cooling, (12) keeping the temperature at 150-300 deg.C, and (13) cooling in a furnace or in the air.

Owner:XI AN JIAOTONG UNIV

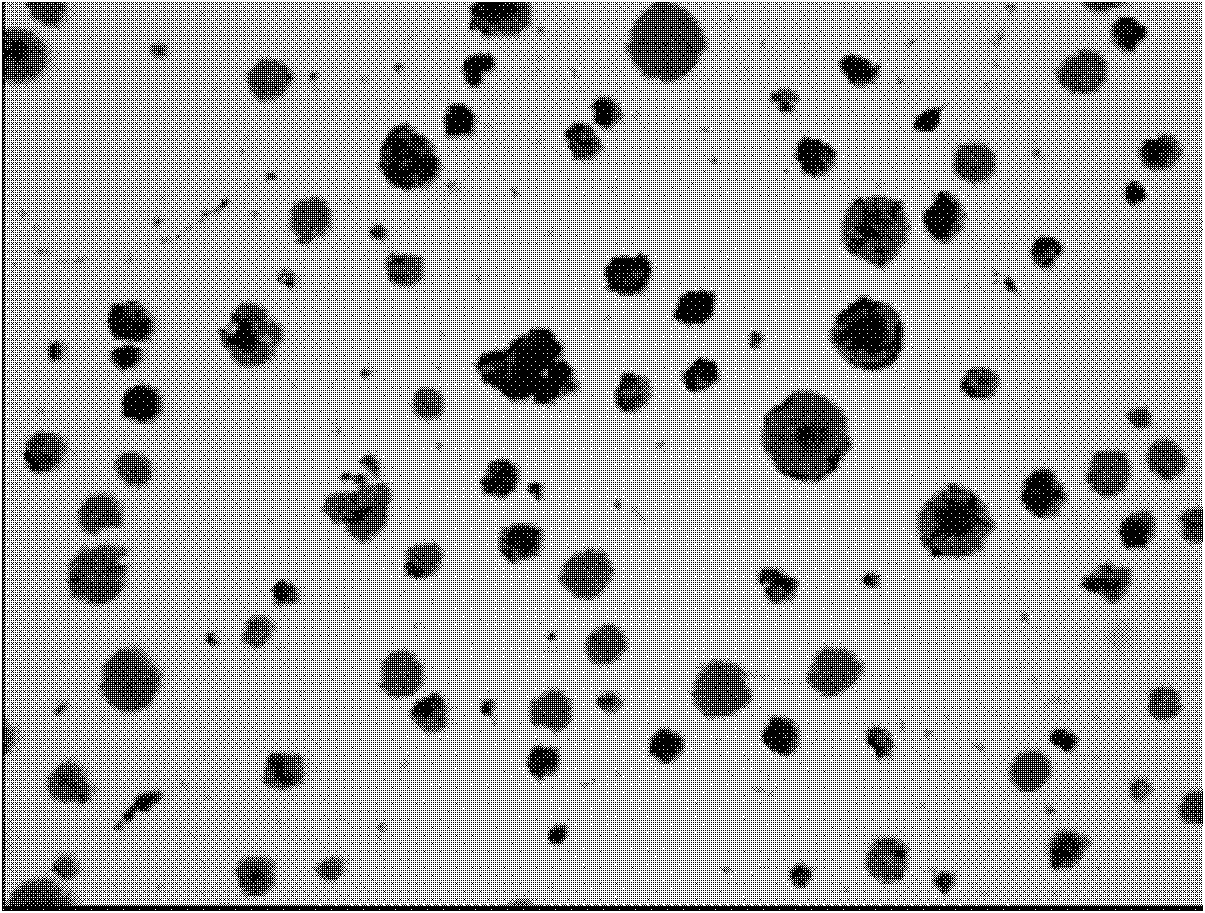

Nodular cast iron inoculant and preparation method thereof and application in smelting nodular cast iron

ActiveCN103484749AIncrease the number of ballsIncrease the number ofTrace element compositionAdhesive

The invention relates to a nodular cast iron inoculant and a preparation method thereof and an application in smelting nodular cast iron. The nodular cast iron inoculant consists of 3-6% of Bi, 40-50% of Si, 0.5-3% of Ba, 0.1-3% of La, 10-18% of Ca, 1-3% of O, 0.5-3% of S and the balance of Fe and unavoidable trace elements. The nodular cast iron inoculant is prepared by the steps of mechanically mixing a metal oxide, a metal sulfide and a silicon iron-based alloy; adding an adhesive into a grinding device, and pressing the mixture into a cluster; breaking the cluster, screening and wrapping with an aluminum foil. In use, when the output molten iron accounts for about 1 / 2 of the lip-pour ladle, the inoculant is added to perform inoculation treatment on the nodular cast iron once or multiple times. The inoculant provided by the invention contains the trace elements such as O, S, Bi and the like and is low-silicon and efficient, and multiple heterogeneous nucleation mass points are formed in the iron liquid, thereby increasing the graphite quantity, improving the shock resistance, mechanical property and yield, increasing the utilization rate of foundry returns, and increasing the economic benefits.

Owner:宁波康发铸造有限公司

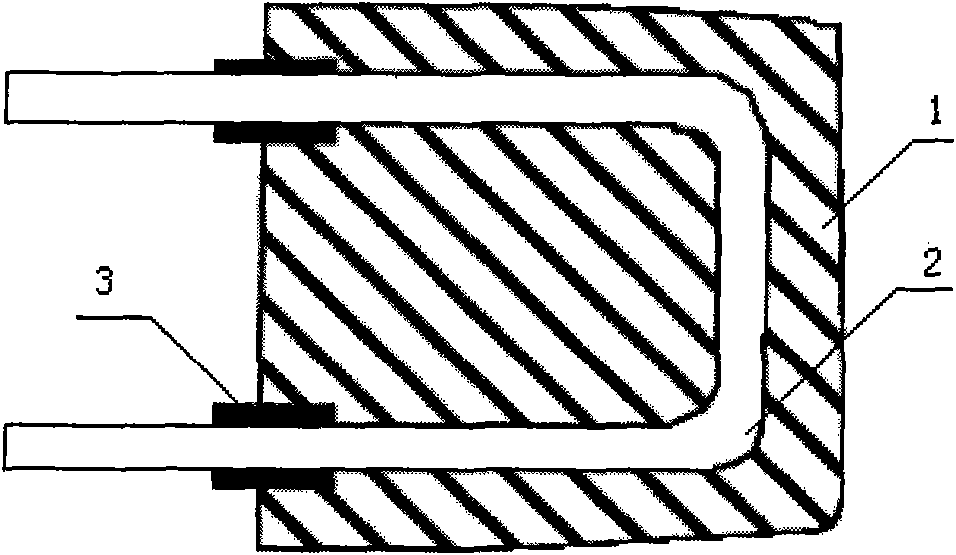

Casting method of cast steel cooling plate

InactiveCN101634520AImprove mechanical propertiesExtend your lifeFurnace cooling arrangementsProcess efficiency improvementCooling effectAlloy

The invention relates to a casting method of a cast steel cooling plate, which adopts a cast steel material to cast a cooling plate base body and a cooling water pipe. The casting method comprises the following steps: adding a slagging agent and a silicon iron alloy block in molten steel for casting steel; putting the cooling water pipe into a casting model, sheathing a pipe sleeve on the cooling water pipe and leading a liquid cold medium and a composite solid cooling medium to pass through the cooling water pipe; using molten steel for casting steel to cast the cooling plate base body, and casting the middle part of the cooling water pipe into the cooling plate base body; leading the casting model to be horizontal in the modeling process, leading a feeder head to be modeled lopsidedly toward one side and heightening one side of the feeder head of the model after the model is boxed; adopting an upper layer of inner sprue and a lower layer of lower sprue to carry out stepped casting so as to form sequential solidification; and cooling and disassembling the model. The casting method can effectively avoid the cooling water pipe from being penetrated in a fusing manner during the casting process, avoid air gaps from being generated between the base body and the cooling water pipe, avoids refusion and recrystallization, accurately realizes the microfusion of the outer surface of the cooling water pipe, prolongs the service life of the cooling plate, further prolongs the service life of a metallurgical high-temperature kiln, saves production cost and improves the cooling effect and the mechanical performance of the cast steel cooling plate.

Owner:江苏联兴成套设备制造有限公司

High-strength and high-hardness gray cast iron material and method for casting same into casting

The invention discloses a high-strength and high-hardness gray cast iron material and a method for casting the same into a casting. The gray cast iron material comprises the following components in percentage by weight: 3.00-3.20% of carbon, 1.45-1.80% of silicon, 0.75-0.95% of manganese, less than 0.1% of phosphorus, less than 0.08% of sulfur, less than 0.08% of chromium and iron. The gray cast iron material can further contain copper and tin. According to the method for casting the material into a casting, scrap steel, iron chips and returning iron are used as main furnace materials, and carburizing agent, silicon iron and manganese iron are used as auxiliary materials. The gray cast iron material obtained by the invention is small and dispersed in graphite in the tissue, fine in crystal grains, high in pearlite content, short in interlamellar spacing, high in strength, favorable in stability and low in effective cost.

Owner:宁国科博尔智能机床有限公司

High-performance flux-cored wire

InactiveCN106141485AImproved arc stabilityImprove densification performanceWelding/cutting media/materialsSoldering mediaCrack resistanceBoron carbide

The invention discloses a high-performance flux-cored wire which comprises a mild-carbon steel strip outer skin and a flux core, wherein the flux core is prepared from the following raw materials in weight percent: 3-5% of titanium dioxide, 1-5% of silicon dioxide, 1-5% of calcium carbonate, 1-2% of magnesia, 1-5% of sodium hexafluorozirconate, 0.5-3% of boron carbide, 1-5% of zirconium oxide, 0.1-2% of cobaltous oxide, 3-12% of manganese powder, 1-3% of nickel powder, 2-10% of chromium powder, 0.5-1.5% of molybdenum powder, 0.5-2% of vanadium powder, 0.05-0.5% of iron-cerium alloy, 1-5% of tungsten powder, 0.1-0.9% of copper powder, 1-3% of ferroboron, 0.2-1% of aluminite powder, 3-10% of Fe-Ti composite powder, 2-8% of silicon iron and the balance of iron powder. The high-performance flux-cored wire is stable in electric arc and slightly splashes; an obtained coating has high bonding strength with a substrate and is excellent in impact toughness and crack resistance; and soldering seam formation is attractive.

Owner:安徽飞弧焊业股份有限公司

Method for preparing nano-sized silicon and silicon/carbon composite material by using silica fume as raw material and application thereof

InactiveCN105084366AAbundant raw materialsLow priceMaterial nanotechnologyCell electrodesCarbon compositesNano structuring

A preparation method of nano-sized silicon and a silicon / carbon composite material is disclosed. A nano-sized silicon-containing by-product produced during the process of industrial smelting of metal silicon, silicon-iron alloy and the like is reduced directly by a metallothermic reduction process, so as to obtain a nano-sized silicon material; the nano-sized silicon material undergoes ball-milling along with a carbon material and / or is mixed with a carbon precursor; and through hydrothermal carbonization and solvent thermal treatment, pyrolysis carbonization, or chemical vapor deposition of carbon, the nano-sized silicon / carbon composite material is prepared. The nano-sized silicon and / or composite material can be used as an active negative material or used in an energy storage system. According to the preparation method, processes with disadvantages of tedious technology, complex equipment and energy consumption, such as removal of impurities in advance, nano-structuring and the like, are not required; raw material resources are rich, cheap and easily available; technology is simple; costs are low; and the method is easy for amplification.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Method for producing silicon deoxygenation low-sulfur high-carbon steel through LF refining double slag method

The invention relates to a method for producing silicon deoxygenation low-sulfur high-carbon steel through an LF refining double slag method. An electric furnace-LF-VD continuous casting technology isadopted. The method includes the steps that in the electric furnace tapping process, carbon powder is mixed firstly, then a silicon alloy and a manganese alloy are added for conducting deoxygenationalloying treatment, and lime, calcium carbide and aluminum-free refining slag are added for conducting modification treatment; secondly, after an LF enters a station, lime, calcium carbide, silicon iron and aluminum-free refining slag are added into the furnace for making high-alkalinity reducing refining slag; thirdly, low-alkalinity reducing slag is made, and the content of components in moltensteel is adjusted; and fourthly, the LF withdraws from the station after refining, VD and continuous casting processes are conducted in sequence, and the silicon deoxygenation low-sulfur high-carbon steel is obtained. The method is simple, reliable, high in operability and easy to achieve, the production cost of the whole process is reduced, the sulfur removing efficiency is high, the cleanlinesslevel of molten steel is high, the problem that when a non-molten-steel pretreatment sulfur removing process is adopted for producing high-quality silicon deoxygenation low-sulfur high-carbon steel, sulfur removing is difficult is solved well, and therefore the product quality is improved, and the economic benefits of a steel enterprise are increased.

Owner:CENT IRON & STEEL RES INST

Weather-proof flux core wire used for coating-free bridge steel and preparing method of weather-proof flux core wire

ActiveCN106475706AImprove mechanical propertiesStable welding arcWelding/cutting media/materialsSoldering mediaSlagManganese

The invention discloses a weather-proof flux core wire used for coating-free bridge steel and a preparing method of the weather-proof flux core wire. The weather-proof flux core wire is composed of a steel skin and a powder core. The powder core comprises, by weight percent, 2%-8% of ferro-boron, 0.01%-2% of ferromolybdenum, 1%-6% of fluoride, 1.5%-8% of zircon sand, 2%-7% of magnesium powder, 2%-5% of quartz sand, 2%-8% of silicon iron, 5%-19% of electrolytic manganese, 1%-5% of ferromanganese, 1%-6% of nickel powder, 1%-8% of chromium metal, 1%-8% of copper powder, 2%-9% of ferrotitanium, 0.1%-5% of feldspar, 2%-8% of sodium titanate, 20%-40% of rutile and the balance iron powder. Compared with the prior art, the weather-proof flux core wire is stable in welding arc and little in splashing, slag removing is easy, a welding joint is formed attractively, the weather-proof flux core wire is suitable for all-position welding, the mechanical performance of the welding joint is good, the impact toughness at the temperature of minus 40 DEG C is larger than 80 J, and very high corrosion resistance is achieved.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

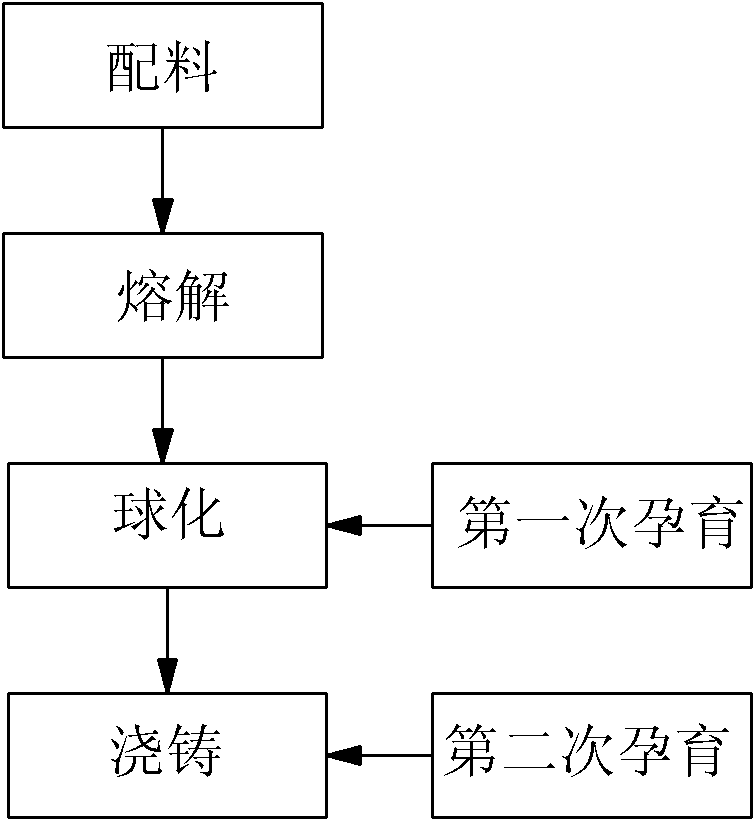

Smelting method for wind generating set casting

The invention relates to a smelting method for a wind generating set casting. The method comprises the steps of proportioning, smelting, nodulizing, primary inoculation, casting and secondary inoculation. The method specifically comprises the following steps of: smelting at the temperature of between 1,370 and 1,390 DEG C; heating molten iron to the temperature of between 1,410 and 1,430 DEG C, measuring carbon equivalent (CE) value, measuring spectrum, adding carburant and silicon iron, and adjusting the weight components of alloy to ensure that the content of carbon is 3.7 to 3.85 percent and the content of silicon is 1.3 to 1.5 percent; adding antimony alloy in an amount which is 0.003 to 0.005 percent of the total weight of the molten iron after raking out the slag; adding a nodulizing agent in an amount which is 0.9 to 1.2 percent of the total weight of the molten iron; adding primary inoculant in an amount which is 0.3 to 0.5 percent of the total weight of the molten iron; controlling the casting temperature of the molten iron at 1,300 to 1,340 DEG C; and performing secondary inoculation, namely stream inoculation, wherein the adding amount of the stream inoculant to 0.15 to0.25 percent of the total weight of the molten iron. By the method, the wind generating set casting has better mechanical property.

Owner:江苏兴盛重工有限公司

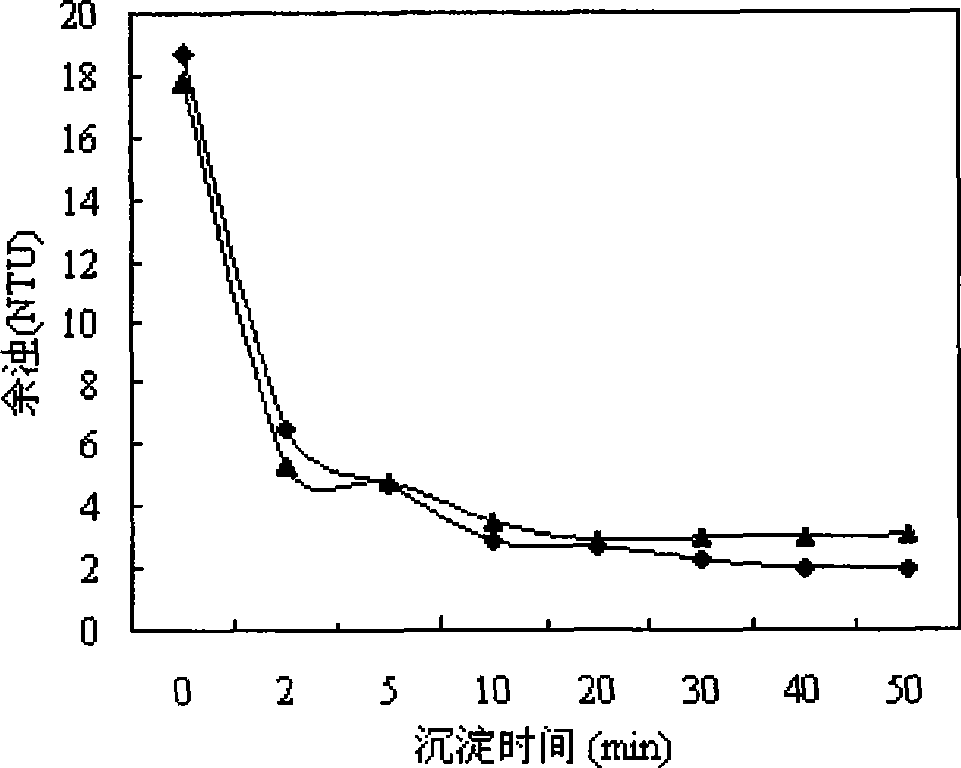

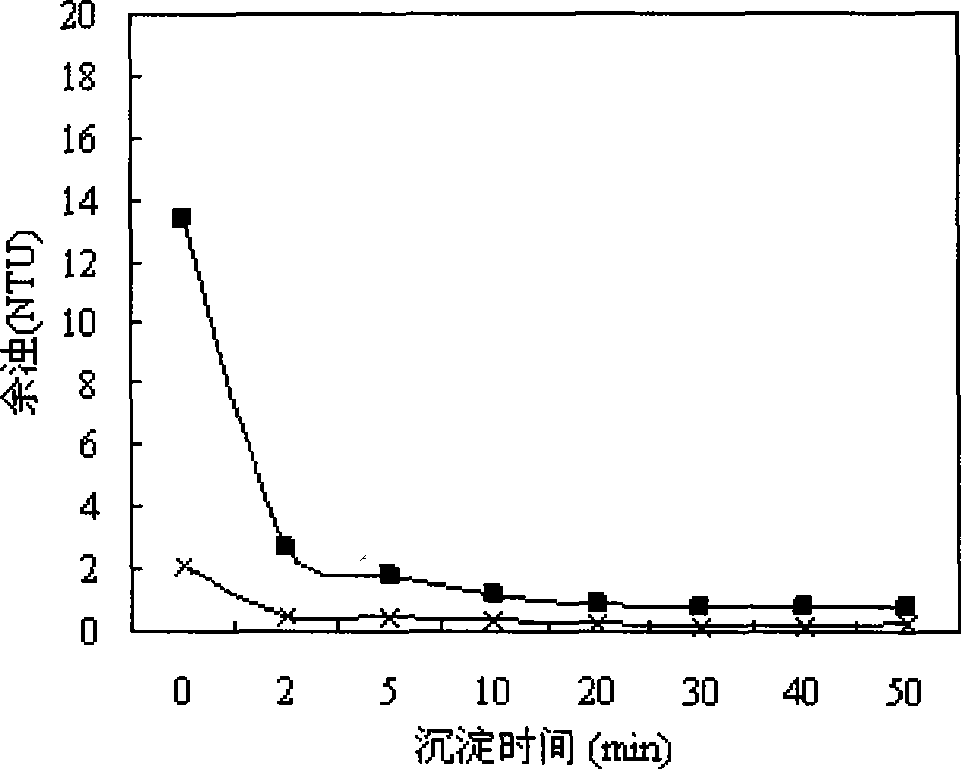

Poly ferrosilicium coagulant and preparation method thereof

ActiveCN101386435AReduce turbidityReduce CODWater/sewage treatment by flocculation/precipitationSodium chlorateSulfate

The invention discloses a poly silicon iron coagulating agent and a preparation method thereof, relates to an inorganic polymer coagulating agent and a preparation method thereof and solves the disadvantages of poor adaptability to low temperature and low turbidity water quality, high production cost, complex preparation technique and secondary pollution to the environment in the existing preparation process of poly silicon iron coagulating agent. The poly silicon iron coagulating agent of the invention is made from soluble glass, soluzione leggermente acida, ferrous sulfate and sodium chlorate. The preparation method of the poly silicon iron is as follows: step 1. raw materials are weighted; step 2. the soluble glass is added into the soluzione leggermente acida and activated silicic acid is prepared after the reaction; 3. the ferrous sulfate and the sodium chlorate are added into the rest soluzione leggermente acida and then the activated silicic acid obtained in step 2 is added, thus obtaining the poly silicon iron coagulating agent. The poly silicon iron coagulating agent is applicable to low temperature and low turbidity water quality and has the advantages of low preparation cost, simple preparation method and no pollution during the preparation process.

Owner:HARBIN INST OF TECH

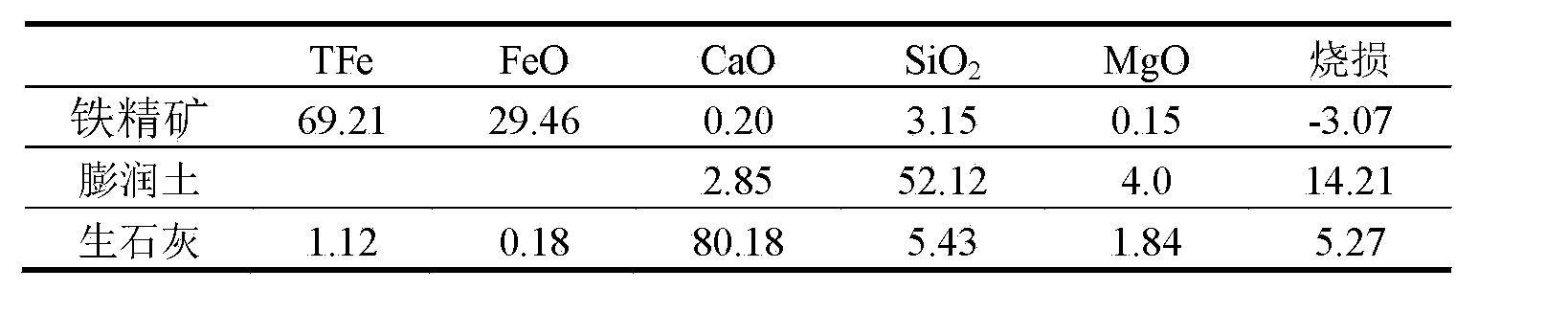

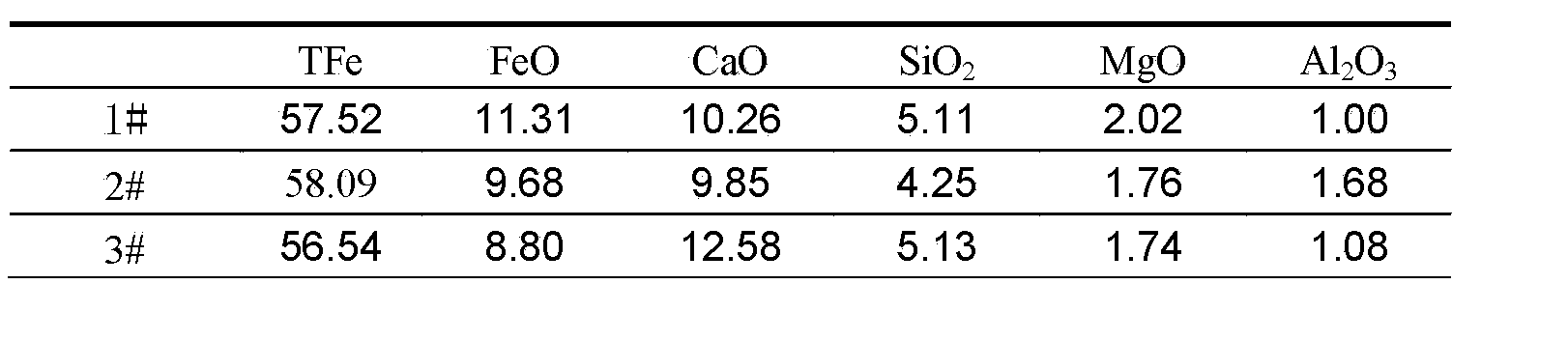

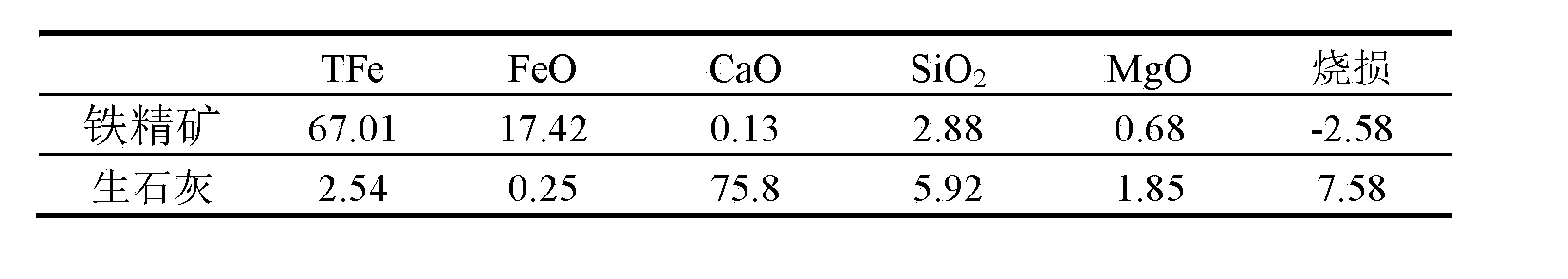

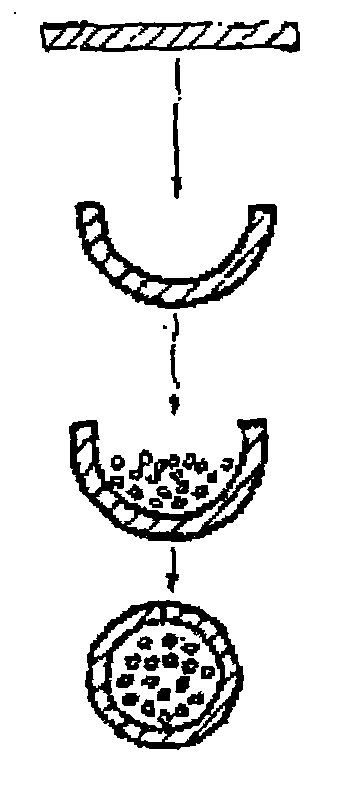

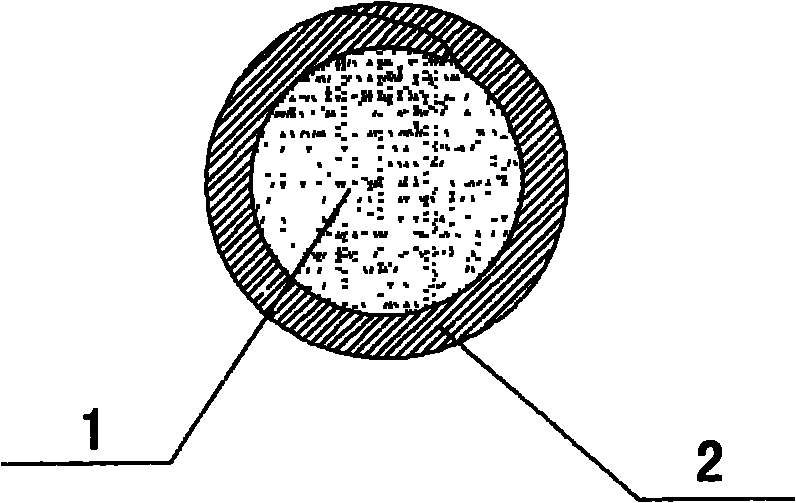

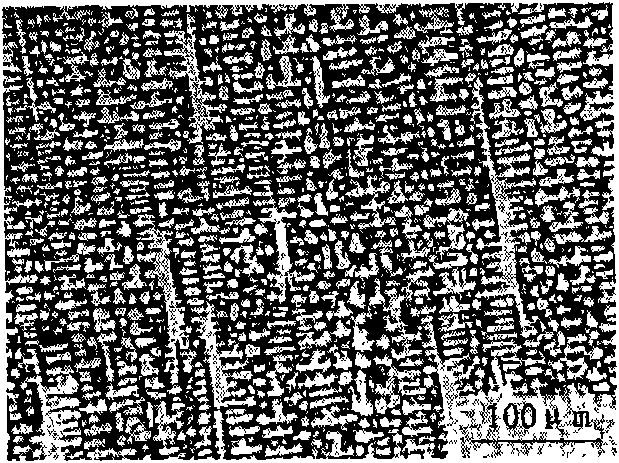

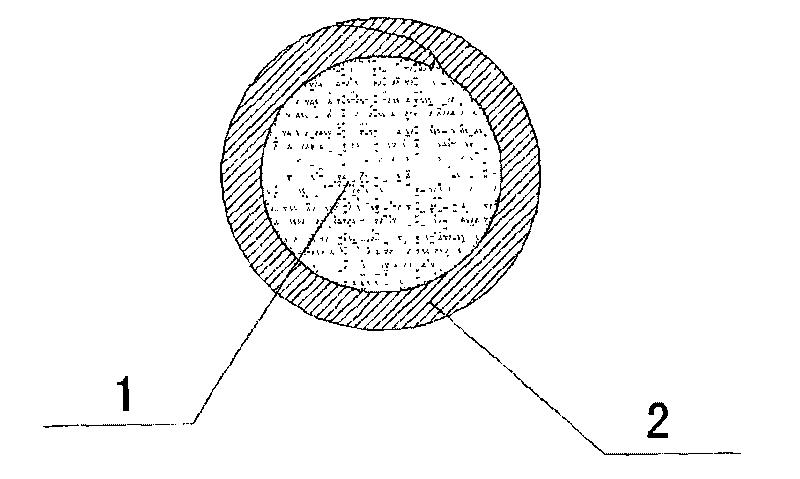

Producing method of fluxed composite pellet

A producing method of a fluxed composite pellet is disclosed. The method includes: (1) mixing a iron material, a flux, and an adhesive to obtain a material mixture with the iron material being high-iron low-silicon iron ore powder, the flux being quicklime powder and the adhesive being bentonite, water glass or sodium humate, etc., adjusting the content of the quicklime powder to make the alkalinity of the material mixture to be 0.6-1.0, adding water into the material mixture to wet the material mixture and uniformly mixing; and (2) wetting high-alkalinity sintering return mine, subjecting the material mixture in the step (1) to primary pelletizing in a disk pelletizer to produce raw pellets by adopting the return mine as a pelletizing core, and calcinating according to fluxed composite pellet calcinating rules to obtain the fluxed composite pellet finished product with double alkalinity for one pellet. The composite pellet having advantages of high-alkalinity sintering ore and advantages of pellets is produced. The metallurgical performance of pellets is enhanced. A novel utilization route of the sintering return mine is provided.

Owner:ANGANG STEEL CO LTD

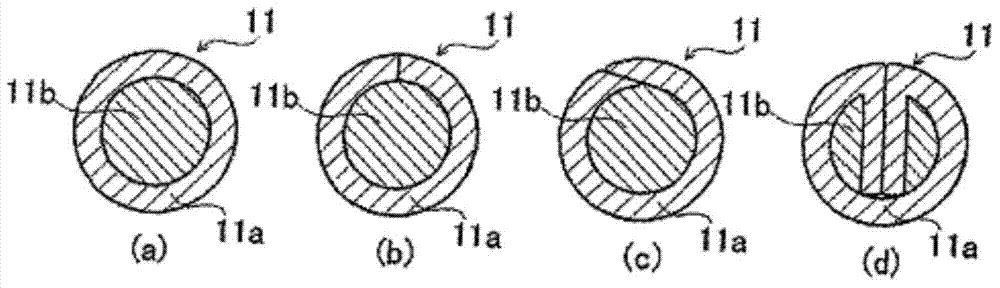

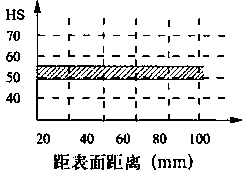

Semi-process cold-rolling non-oriented electrical steel and production process thereof

The invention discloses a semi-process cold-rolling non-oriented electrical steel and a production process thereof, which mainly solves the technical problems that the prior art is high in energy consumption, large in pollution and high in cost. According to the technical scheme, the semi-process cold-rolling non-oriented electrical steel is a special steel which comprises the following ingredients by mass: not more than 0.01% of C, not more than 0.015% of P, not more than 0.012% of S, not less than 0.4% and not more than 0.60% of Si, not less than 0.6% and not more than 0.8% of Mn, not less than 0.15% and not more than 0.25% of Al, and the balance of Fe. The production process comprises the following steps: smelting molten steel, continuous casting, hot-rolling, punching and annealing, and specifically comprises the following steps: pretreating molten iron, smelting in a rotary furnace, blowing argon over the whole process, conducting RH (Rockwell Hardness) fine smelting, conducting CSP (Cast Steel Plate) continuous casting, putting in a CSP heating furnace, conducting CSP hot-continuous-casting, pickling and cold-rolling and annealing, wherein in the smelting process in the rotary furnace, silicon iron, ferromanganese iron and an aluminum alloy are added to conduct alloying so as to manufacture an alloy steel. The semi-process cold-rolling non-oriented electrical steel is mainly used in a production process of a motor iron core.

Owner:HUNAN XUEBAO ELECTRIC APPLIANCE

Submerged-arc welding flux for low-alloy-steel narrow-gap welding and preparation method thereof

ActiveCN104668816AExcellent transition abilityEasy transitionWelding/cutting media/materialsSoldering mediaSlagMechanical property

The invention relates to a submerged-arc welding flux for low-alloy-steel narrow-gap welding and a preparation method thereof. A high-alkalinity MgO-CaO-Al2O3-CaF slag system is adopted, and the submerged-arc welding flux is mainly made from raw materials including calcium fluoride, aluminum oxide, wollastonite, marbles, silicon iron and ferromanganese iron. The preparation method of the submerged-arc welding flux mainly comprises the steps of 1 dry mixing in proportion, 2 impurity removal, 3 bonding agent adding for wet mixing and 4 baking and high-temperature sintering. The alkalinity of the welding flux ranges from 2.0 to 3.0, low-hydrogen and low-oxygen deposited metal containing ultra low P and S impurity contents can be obtained through welding, and accordingly it can be ensured that the deposited metal has excellent comprehensive mechanical property. When the submerged-arc welding flux is matched and welded with a low-purity low-alloy steel welding wire, S and P are not added into the deposited metal by adopting the welding flux. The submerged-arc welding flux has excellent alloy transition capacity.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

High-hardness self-protecting cold roll build-up welding flux-cored wire

The invention discloses a high-hardness self-protecting cold roll build-up welding flux-cored wire, and belongs to the field of welding in material processing. The flux-cored wire is mainly applied to build-up welding repair of cold rolls of steel mills. The flux-cored wire is characterized in that: the outer surface of the powder cored wire is an H08A cold rolling steel strip; and the powder of the powder cored wire comprises the following components in percentage by mass: 25 to 45 percent of high carbon ferrochrome, 5 to 15 percent of chromium metal, 4 to 8 percent of ferromolybdenum, 5 to 10 percent of manganese metal, 4 to 8 percent of No.75 silicon iron, 4 to 10 percent of aluminum magnesium alloy, 6 to 12 percent of ferrocolumbium, 4 to 10 percent of ferrotungsten, 4 to 12 percent of nickel powder and 4 to 18 percent of iron powder. A coating prepared by build-up welding has high hardness (Rockwell hardness (HRC): 55 to 60) and excellent abrasion resistance; and a self-protecting build-up welding mode is adopted, namely a protective gas source and a flux are not needed in the build-up welding process, and slag knocking is not needed in the build-up welding process, so automatic production is easy to realize.

Owner:BEIJING SURYEE SCI & TECH

Self-protected flux-cored wire

InactiveCN101722378ALow priceThe material is cost-effectiveWelding/cutting media/materialsSoldering mediaRare earthSilicon iron

The invention provides a self-protected flux-cored wire, relating to a welding technology. The self-protected flux-cored wire is used for surfacing, repairing and bottoming a quick-wear part of manganese steel material, wherein the diameter of the quick-wear part is Phi 2.8mm. The core comprises the following components based on parts by percentage: 0.2-0.6% of C, 16-53% of Mn, 17-40% of Cr, 2-9% of Ni, 1.5-10% of Mo, 1-5% of heavy rare earth silicon iron, 0-6% of V, 0-6% of Nb, 0-6% of Co and 20% of mineral substance. A steel band adopts 0.3*14, and proportion is less than or equal to 48%. The flux-cored wire has low price, high material cost performance, can be directly surfaced on the surface of the high manganese steel, does not need transition material, and has wide application prospect.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Low-cost high-hardness self-protection build up welding flux-cored wire

ActiveCN103753052ASolve the problem of self-protectionHigh hardnessWelding/cutting media/materialsWelding/soldering/cutting articlesSlagFilling rate

The invention provides a low-cost high-hardness self-protection build up welding flux-cored wire which comprises a mild-carbon steel strip and a flux core. The flux core is filled into the steel strip. The flux core comprises, by weight, 85-92% of high carbon ferro-chrome, 2-5% of manganese powder, 1-2% of aluminum magnesium alloy, 0.5-1.5% of silicon iron, 1-3% of graphite, 0.5-2% of ferro-boron and 0.5-1.5% of sodium fluorosilicate. The filling rate of the flux core in a cored solder wire is 58-65%. The low-cost high-hardness self-protection build up welding flux-cored wire is low in cost, high in hardness, good in abrasion resistance, needless of slag removal in a multi-layer welding mode, and extremely small in air hole sensibility.

Owner:北京力佳利焊接材料有限公司

Slag-free self-protection flux-cored wire for niobium-titanium compound reinforcement hardfacing

InactiveCN103785967AHigh hardnessImprove thermal stabilityArc welding apparatusWelding/cutting media/materialsSlagFerrotitanium

The invention discloses a slag-free self-protection flux-cored wire for niobium-titanium compound reinforcement hardfacing. The slag-free self-protection flux-cored wire for niobium-titanium compound reinforcement hardfacing comprises a mild-carbon steel strip and a flux core, and the steel strip is filled with the flux core. The flux core contains, by mass, 55-65 percent of high carbon ferro-chrome, four to eight percent of ferroniobium, four to eight percent of ferrotitanium, three to five percent of graphite, two to three percent of ferroboron, eight to fourteen percent of deoxidizing agent and the balance of iron powder, wherein the deoxidizing agent is a mixture of aluminum-magnesium alloy, manganese powder and silicon iron, the mass ratio of the aluminum-magnesium alloy, the manganese powder and the silicon iron is (2-3):(5-8):(1-4), the weight percent of the manganese powder is larger than or equal to the sum of the weight percent of the silicon iron and the weight percent of the aluminum-magnesium alloy, and the ratio of the weight of the flux core to the total weight of the flux-cored wire is between 49 percent and 56 percent. The flux-cored wire is low in cost; (Nb,Ti)C double carbide is dispersed and separated out in the welding process, and the flux-cored wire is low in cost, high and uniform in rigidity, good in abrasion resistance, free of slag clearing in multi-layer welding, low in pore sensitivity and good in welding processing property.

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com