High-strength and high-hardness gray cast iron material and method for casting same into casting

A casting, high-hardness technology, applied in the field of casting, can solve the problems of inability to cast strength, hardness requirements, increase the difficulty of chemical composition, weaken the magnetic field of the intermediate frequency furnace, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

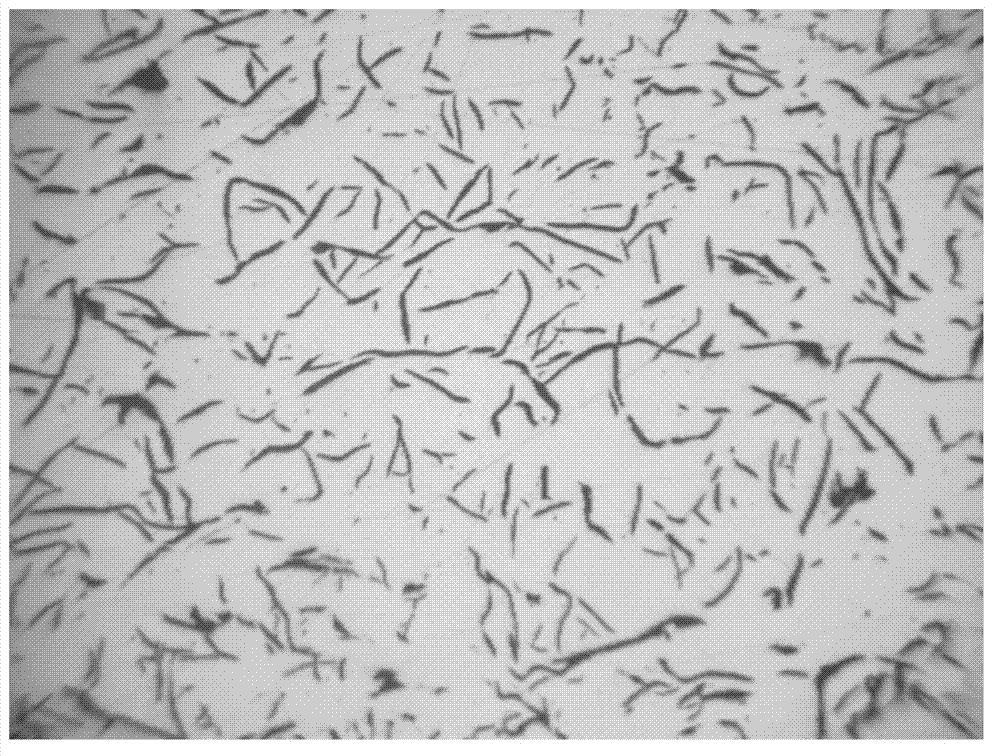

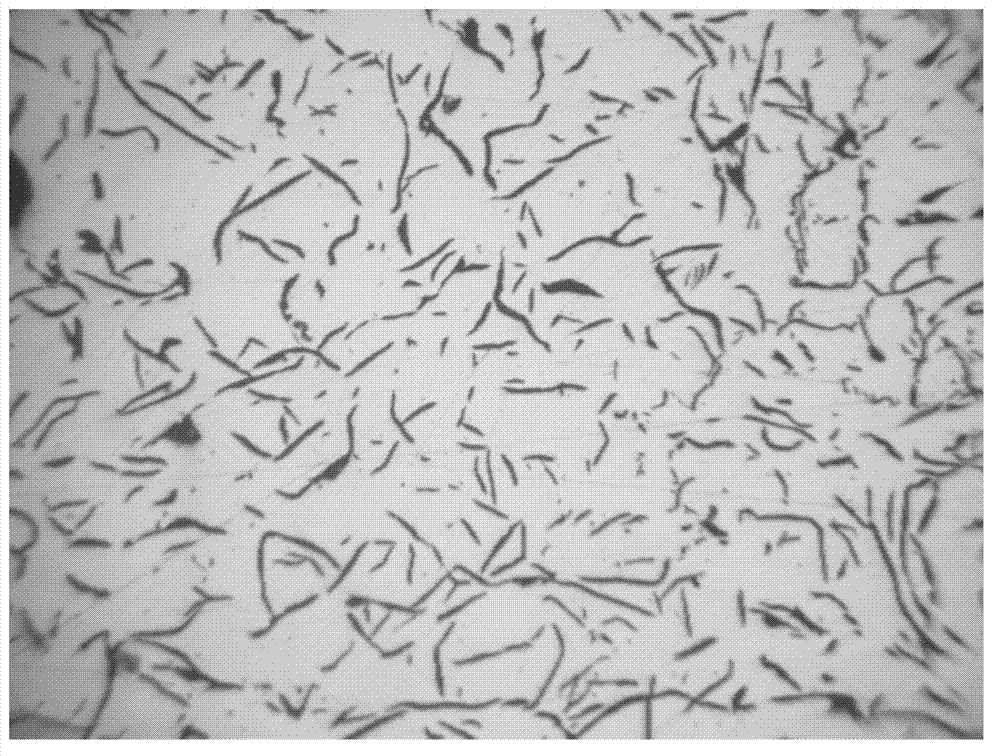

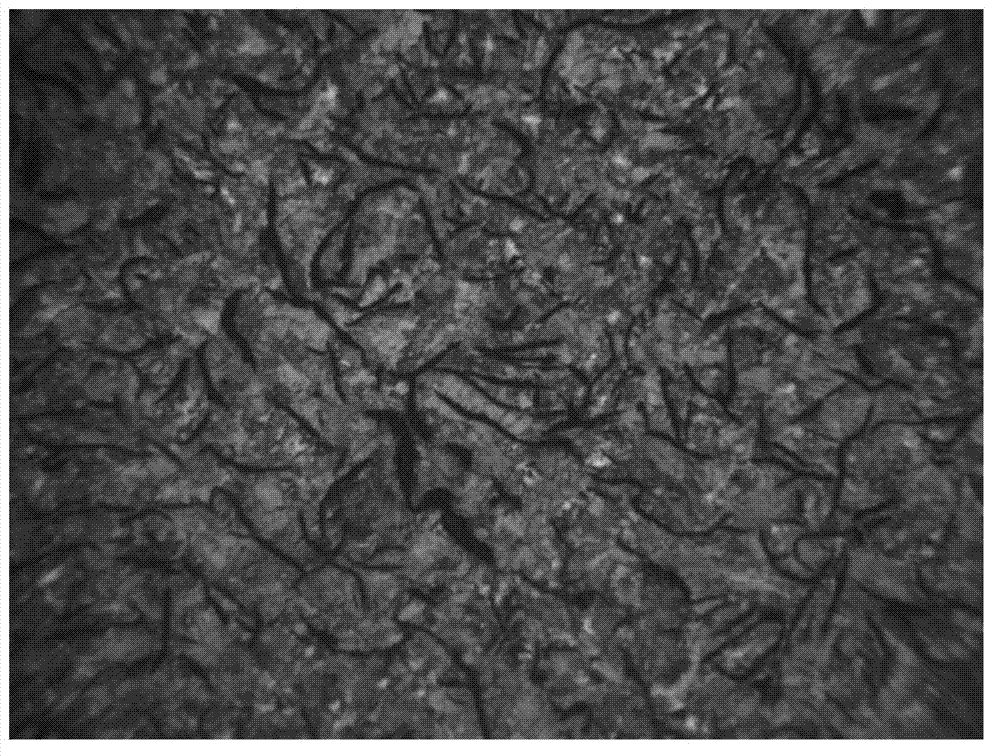

Image

Examples

Embodiment 1

[0032] The method for casting castings of the high-strength and high-hardness gray cast iron material of embodiment 1 may further comprise the steps:

[0033] 1) The raw materials are weighed and proportioned. The composition of each raw material includes: scrap steel 60wt%, iron filings 20wt%, returned iron 15.95wt%, recarburizer 1.5wt%, ferromanganese 0.6wt%, silicon 1.00wt% iron, 0.5wt% copper alloy, 0.05wt% tin, and 0.4wt% silicon-barium inoculant, wherein the mass percentage of silicon in the silicon-barium inoculant is 72%.

[0034] 2) Preheat the induction furnace (preferably 500kg) of the acid intermediate frequency furnace, and add the carburant after heating up to 200-300 degrees. When the carburizer becomes liquid, continue to heat up to 1250-1300 degrees.

[0035] 3) Add about 1 / 3 of the weight of steel scrap in the batching, add about 1 / 3 of the weight of iron filings in the batching after melting, add about 1 / 3 of the weight of returned iron in the batching after...

Embodiment 2

[0041] A high-strength and high-hardness gray cast iron material, its composition content includes (weight percentage): carbon 3.20%; silicon 1.45%; manganese 0.95%; phosphorus 0.04%; sulfur 0.079%; chromium 0.03% and iron.

[0042] The high-strength and high-hardness gray cast iron material of Example 2 was obtained by the same method as that of Example 1. The difference is that the proportions of main furnace materials such as scrap steel, iron filings, and returned iron and auxiliary raw materials are appropriately adjusted. The weight percentages of each raw material are: scrap steel is 64.785wt%, iron filings is 20wt%, and returned iron is 10wt%. Carbon agent is 2wt%, ferromanganese is 0.9wt%, ferrosilicon is 1.25wt%, copper alloy is 0.55wt%, tin is 0.065wt%, silicon barium inoculant is 0.45wt%.

Embodiment 3

[0044] A high-strength and high-hardness gray cast iron material, its composition content includes (weight percentage): carbon 3.10%; silicon 1.60%; manganese 0.85%; phosphorus 0.07%; sulfur 0.06%; chromium 0.05% and iron.

[0045]The high-strength and high-hardness gray cast iron material of Example 3 was obtained by the same method as that of Example 1. The difference is to properly adjust the proportions of steel scrap, iron filings, returned furnace iron and other main furnace materials and auxiliary raw materials. The weight percentages of each raw material are: scrap steel is 60wt%, iron filings is 25wt%, and returned furnace iron is 10.69wt%. The carbon agent is 1.6wt%, the ferromanganese is 0.7wt%, the ferrosilicon is 1.1wt%, the copper alloy is 0.45wt%, the tin is 0.06wt%, and the silicon barium inoculant is 0.4wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com