Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39291 results about "Smelting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Smelting is a process of applying heat to ore in order to extract a base metal. It is a form of extractive metallurgy. It is used to extract many metals from their ores, including silver, iron, copper, and other base metals. Smelting uses heat and a chemical reducing agent to decompose the ore, driving off other elements as gases or slag and leaving the metal base behind. The reducing agent is commonly a source of carbon, such as coke—or, in earlier times, charcoal.

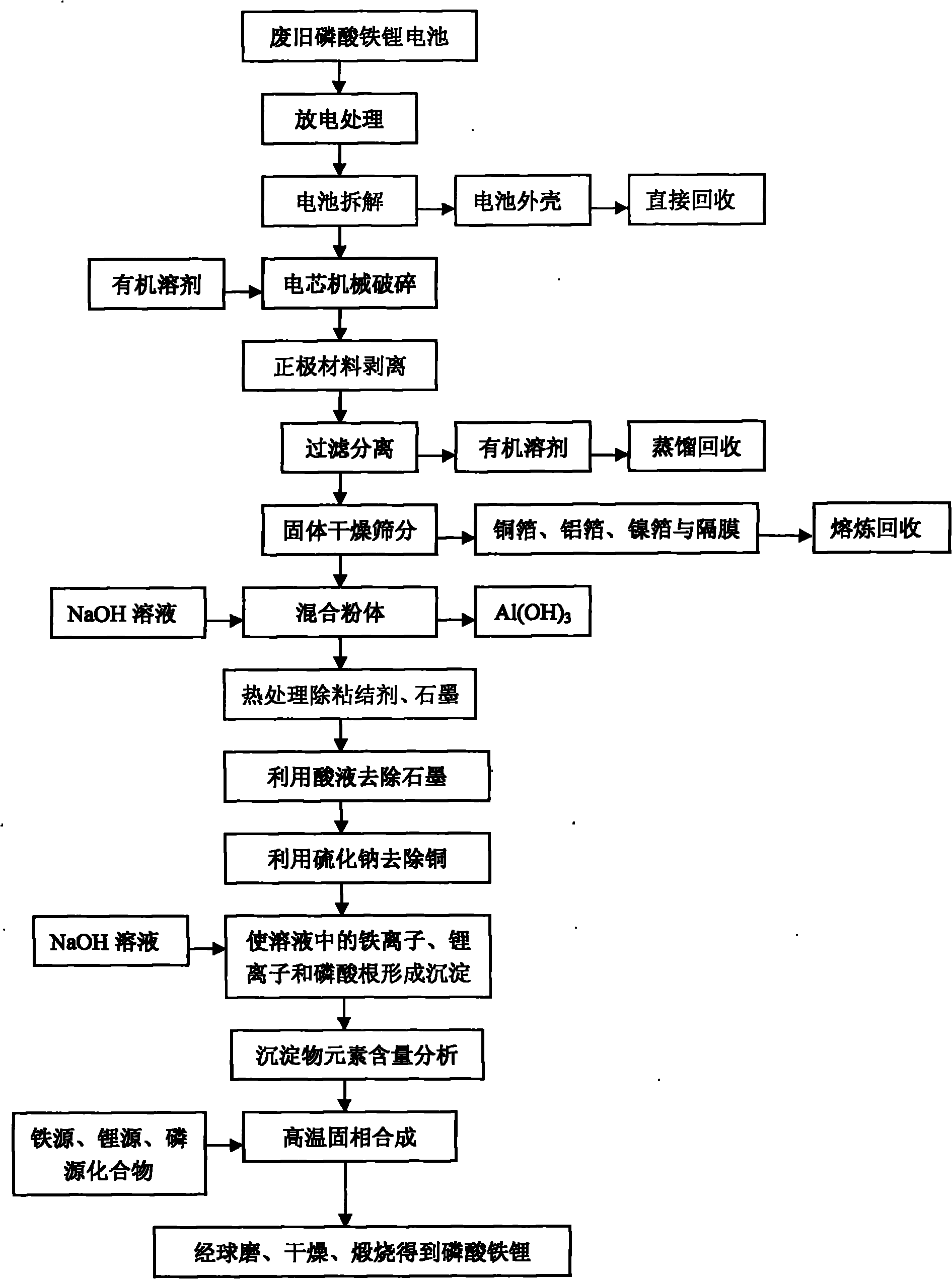

Comprehensive recovering method of waste lithium iron phosphate battery

InactiveCN101847763AImprove performanceLow priceWaste accumulators reclaimingProcess efficiency improvementAdhesiveCalcination

The invention provides a comprehensive recovering method of waste lithium iron phosphate batteries, which has simple and reasonable process, low recovering cost and high added value. The method comprises the following steps: utilizing an organic solvent to dissolve an adhesive on battery cell fragments, and realizing the separation of lithium iron phosphate material and clean aluminum and copper foils through screening, wherein the aluminum and copper foils are recovered by smelting; utilizing a NaOH solution to remove residual aluminum foil scraps in the lithium iron phosphate material, and removing graphite and remaining adhesive by heat treatment; after dissolving the lithium iron phosphate with acid, utilizing sodium sulphide to remove copper ions, and utilizing the NaOH solution or ammonia solution to allow iron, lithium and phosphorus ions in the solution to generate sediments; adding iron source, lithium source or phosphorus source compounds to adjust the molar ratio of iron, lithium and phosphorus; and finally adding a carbon source, and obtaining a lithium iron phosphate cathode material through ball milling and calcination in inert atmosphere. After the treatment of the steps, the recovery rate of valuable metals in the batteries is more than 95%, and the comprehensive recovery rate of the lithium iron phosphate cathode material is more than 90%.

Owner:CHERY AUTOMOBILE CO LTD

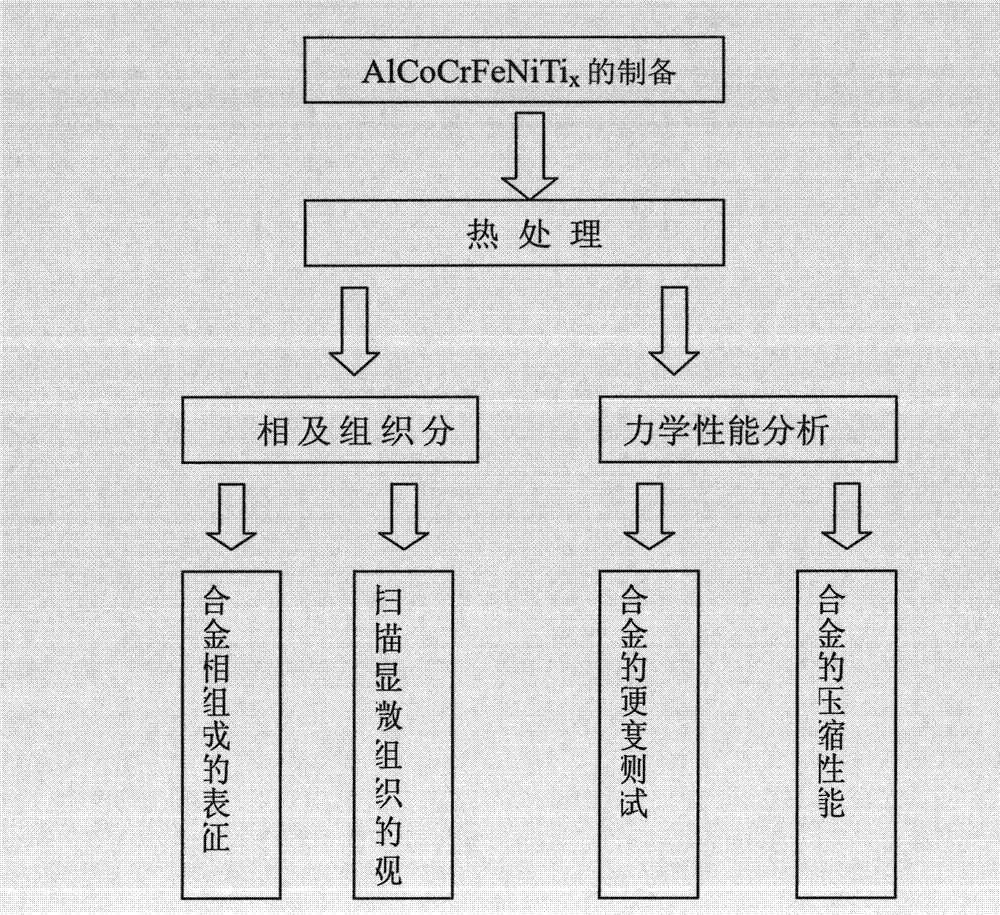

AlCoCrFeNiTix high-entropy alloy material and method for preparing same

The invention relates to a high-entropy alloy material and a method for preparing the same. The component of the high-entropy alloy material is AlCoCrFeNiTix, wherein x represents a molar ratio, and the value range is between 0.1-0.4. The method for preparing the material comprises: preparing raw materials, adopting the alloy smelting raw materials including Al, Co, Cr, Fe, Ni and Ti, and accurately weighing and proportioning according to the molar ratio; then, purifying oxide on a metal surface; putting the prepared raw materials into a tank in a water-cooling copper-formed mold smelting pool, vacuumizing, filling argon, controlling smelting current to be at about 250 ampere and smelting time for 30-60 seconds, turning an alloy block after alloys are fully mixed, putting an alloy ingot into a tank of a water-cooling copper-formed mold, regulating the smelting current, opening a suction casting air suction valve after the alloys are uniformly smelted, utilizing the negative pressure in a pump for suction casting, and taking out the alloy ingot after an alloy mould is cooled. Compared with the conventional crystalline state alloy, the high-entropy alloy material has relative high thermal stability, hardness, yield strength, breaking tenacity, plastic deformation and work hardening capacity.

Owner:TAIYUAN UNIV OF TECH

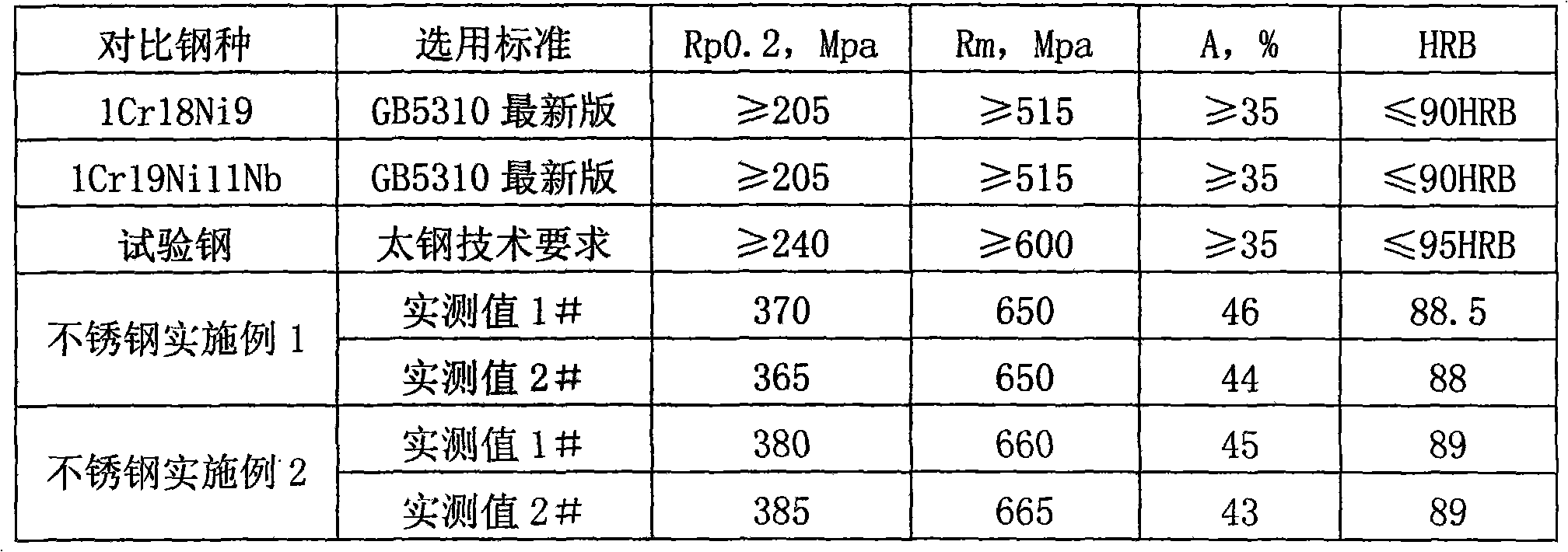

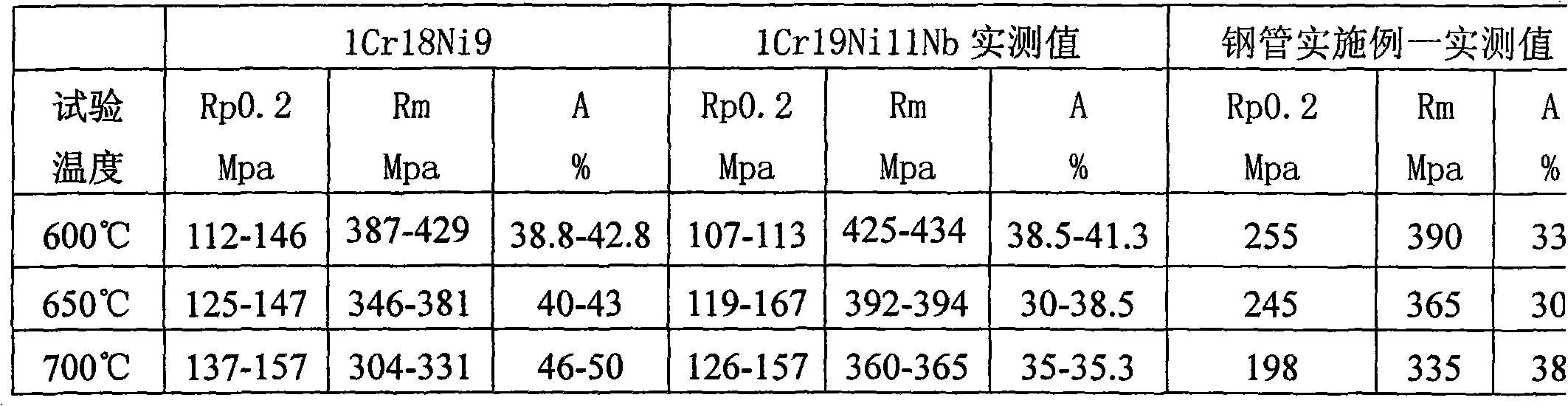

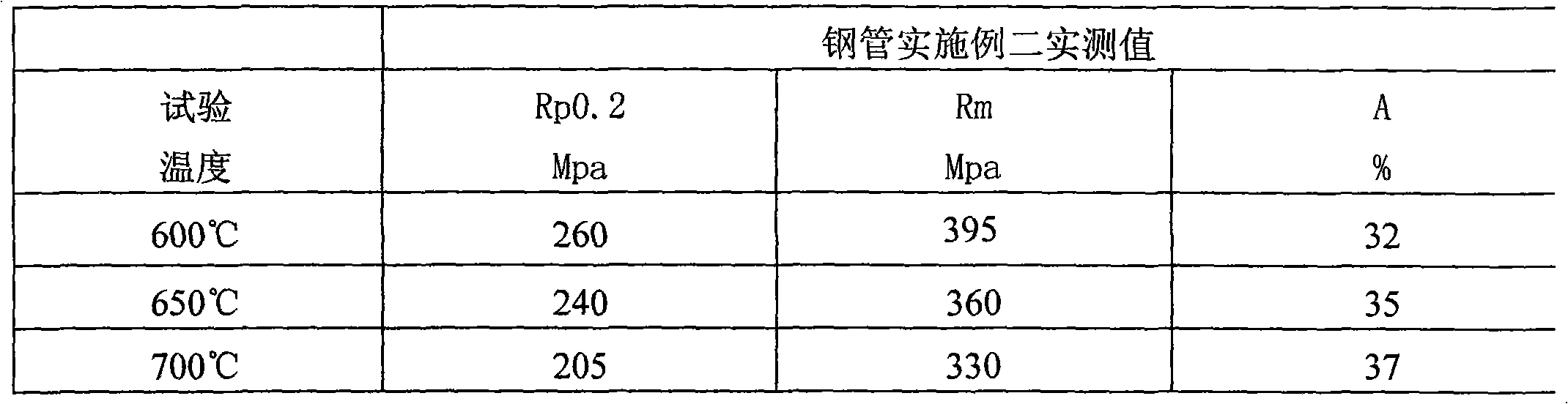

Austenitic stainless steel, steel tube thereof and manufacturing method thereof

ActiveCN101633999AImprove high temperature creep resistanceExcellent resistance to high temperature steam corrosionTemperature control deviceManufacturing convertersSS - Stainless steelIngot

The invention relates to an austenitic stainless steel, a steel tube thereof and a manufacturing method thereof, wherein the austenitic stainless steel and the stainless steel tube comprise the components by mass percent: 0.060-0.14% of C, more than 0 and less than or equal to 0.50% of Si, more than 0 and less than or equal to 1.00% of Mn, less than 0.040% of P, less than 0.015% of S, 17.00-20.00% of Cr, 8.00-11.00% of Ni, 2.50-4.00% of Cu, 0.30-0.60% of Nb, 0.15-0.50% of Mo, 0.15-0.50% of Co, 0.05-0.14% of N, 0.001-0.01% of B, the rest of Fe and unavoidable impurity. The manufacturing method of the steel tube comprises: smelting and pouring to form steel ingots or continuously cast bloom, processing bar material, preparing tubular billet and further processing the steel tube; the method comprises the steps: the heating temperature of processing the bar material is 1250-1270 DEG C, heating temperature of preparing the tubular billet is 1100-1220 DEG C, and the finished product solid solution temperature is 1120-1190 DEG C. The austenitic stainless steel tube has high temperature creep strength and corrosion resisting performance at the high temperature.

Owner:SHANXI TAIGANG ENG TECH +1

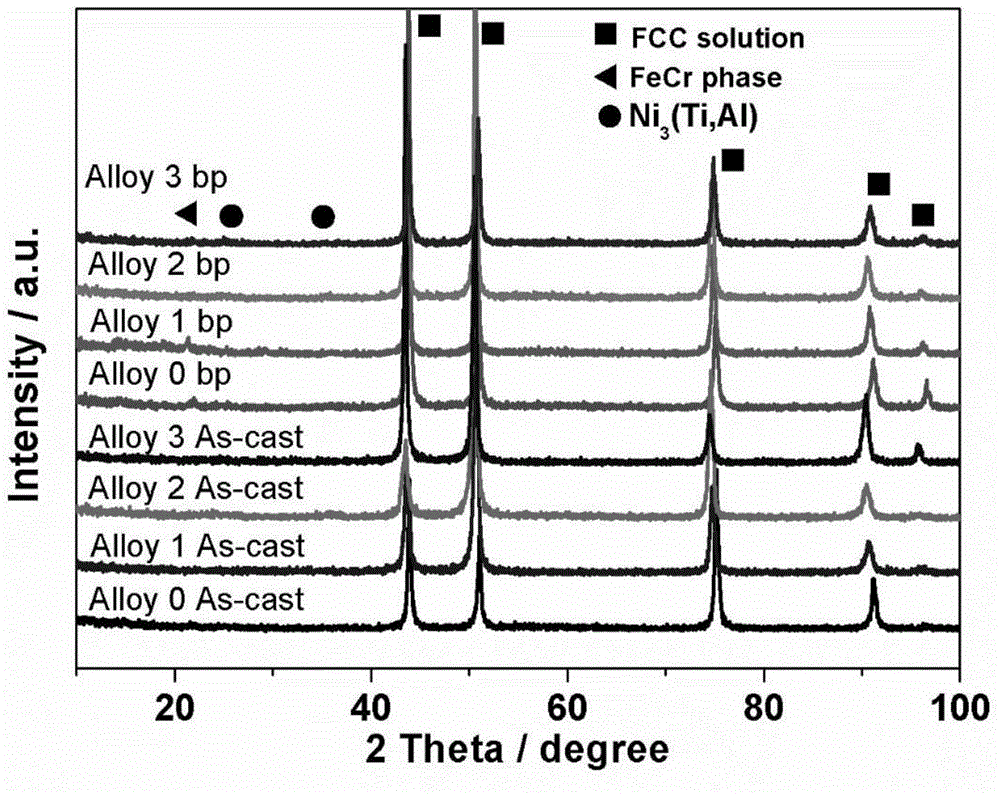

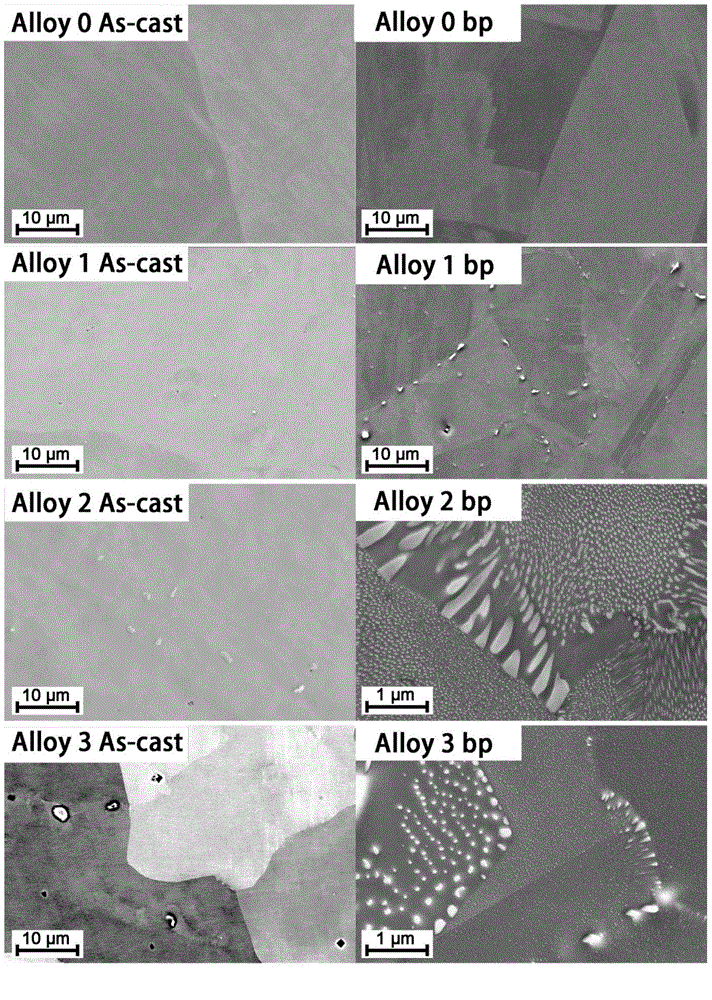

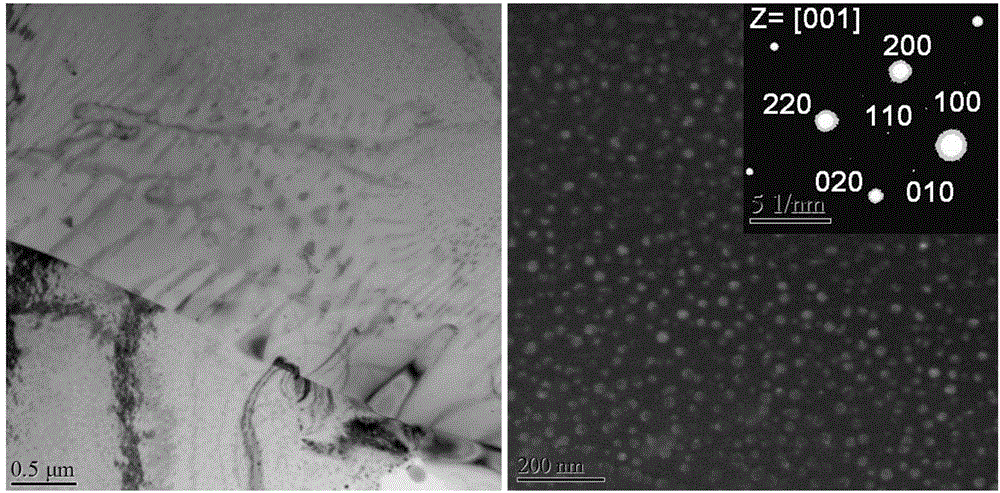

High-entropy alloy with dispersion nano-sized precipitate strengthening effect and preparing method thereof

ActiveCN104694808AWide range of ingredientsControl mechanical propertiesElectric arc furnaceHigh entropy alloys

The invention discloses high-entropy alloy with the dispersion nano-sized precipitate strengthening effect and a preparing method thereof. The method comprises the steps of removing oxidized skin of a metal material, and then conducting weighing and burdening accurately according to a ratio; conducing smelting in an electric-arc furnace in an argon shield atmosphere of titanium absorbed oxygen to obtain an initial high-entropy alloy ingot, and conducting cold rolling, wherein rolling reduction is 20-50%; placing the ingot in a heat treatment furnace with a temperature ranging from 900 DEG C to 1000 DEG C for heat preservation for 0.5-2 hours, and conducting quenching; placing the ingot in a heat treatment furnace with a temperature ranging from 700 DEG C to 800 DEG C for heat preservation for 2-18 hours, and conducting quenching. By means of precipitation strength, on the premise that high plasticity is kept, yield strength and tensile strength are improved greatly. The room-temperature tensile strength of (FeCoNiCr)94Ti2Al4 in the final state reaches 1094 MPa, plastic elongation is 35%, work hardening effect is remarkable, comprehensive room-temperature mechanical property is prominent, high-temperature tensile strength can reach 400 MPa at the temperature of 800 DEG C and strain rate of 10<-3>, steady creep rate is smaller than or equal to 10<-8> under the stress of 100 MPa and at the temperature of 750 DEG C, and high-temperature tensile strength and creep mechanical property are excellent.

Owner:UNIV OF SCI & TECH BEIJING

Investment precision casting technology for producing automobile I-shaped front axle

InactiveCN101147954ALess investmentReduce manufacturing costFoundry mouldsFoundry coresSteelmakingWax

The present invention relates to a fusible pattern precision casting process for producing automobile H-shaped front axle. Said casting process includes the following steps; (1), preparing wax pattern; (2), applying coating material onto the wax pattern surface for several times, spreading sand and making the coating material hardened pattern shell be primarily formed, removing wax and forming pattern shell; (3), firing pattern shell; (4), pouring the molten steel into the pattern shell, before steel-smelting having to make analysis of charge mixture ratio, in the course of smelting steel having to make on-the-spot sample analysis and furnace rear analysis, adding required additive and deoxidant so as to make the molten steel be reached to the defined chemical components requirement; (5), removing pattern shell from obtained automobile H-shaped front axle casting, cleaning sand and cutting spure; (6), grinding, finishing and checking casting; (7), making quenching and tempering, heat treatment; (8), making correction and shot blasting treatment; and (9), making metalworking treatment.

Owner:NANPING AUTO FORGING & STAMPING FACTORY

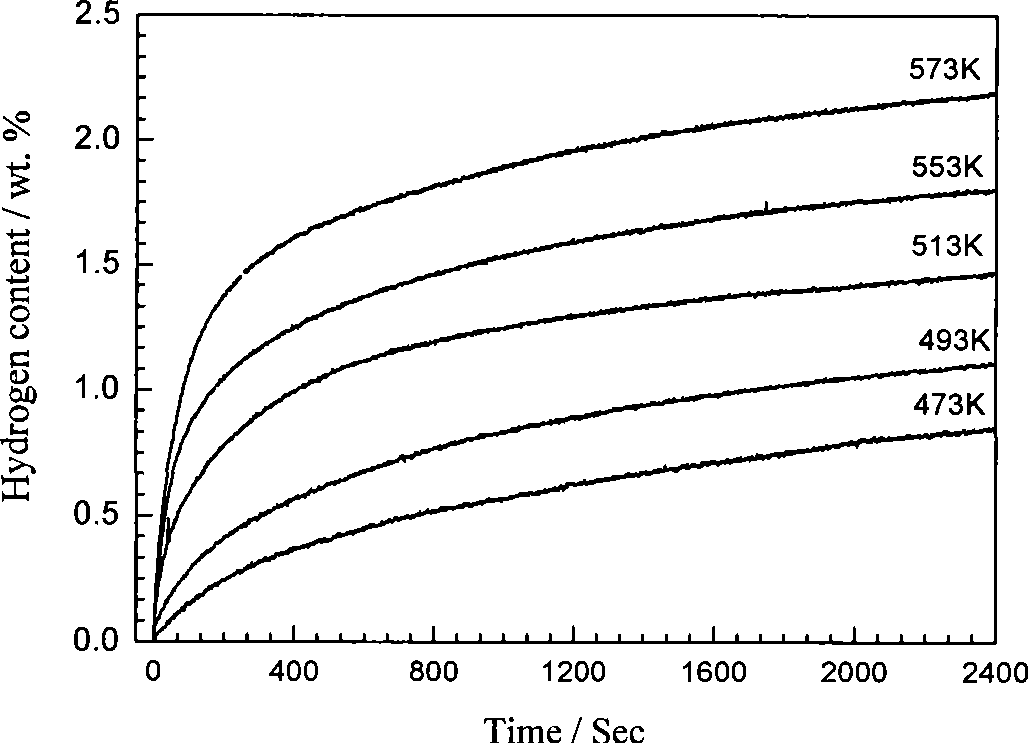

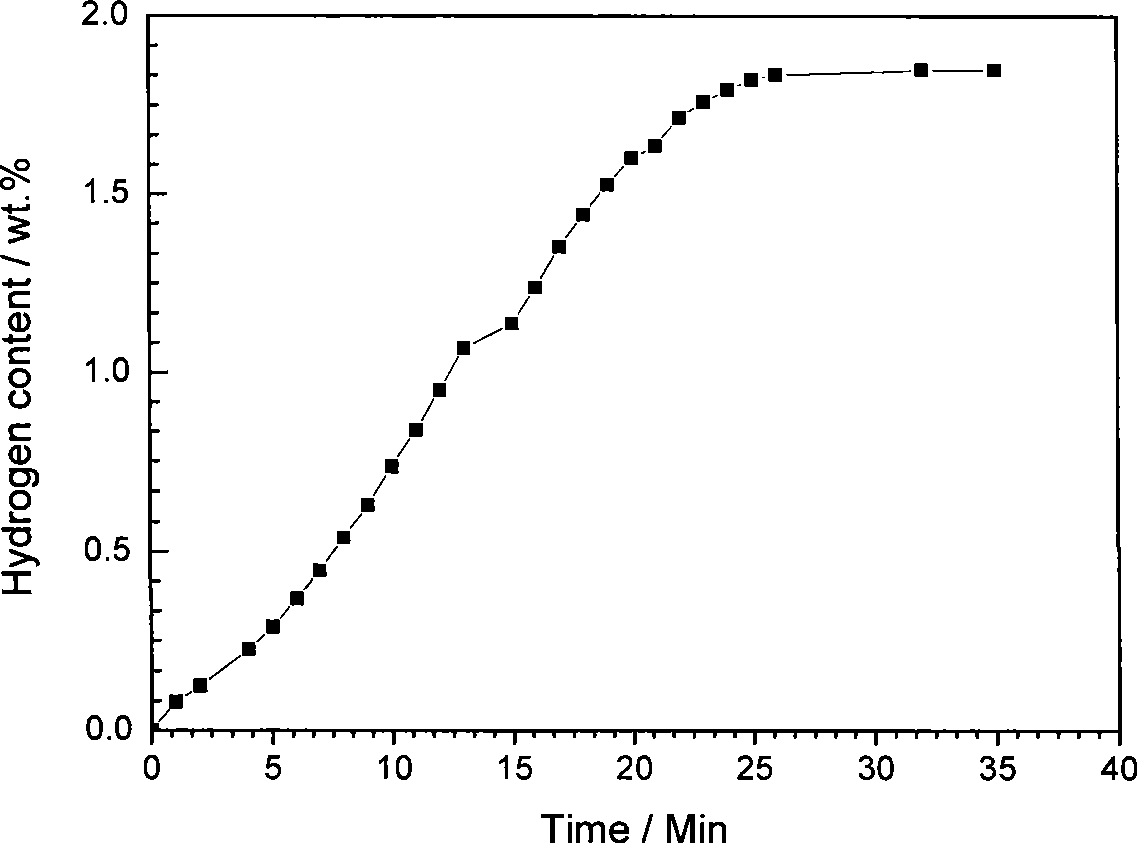

Magnesium base composite hydrogen storage material and preparation method

The invention discloses a magnesium-based composite hydrogen storage material comprising the following compositions by weight percent: 1.0-10.0% of Al, 1.0-5.0% of Ni, and the balance of Mg. A preparation method thereof comprising the following steps: at first, smelting block-shaped metal Mg and Al by a medium frequency induction to prepare Mg17Al12 alloy which is crushed to 300 meshes; hydrogenising Mg powder at 340 DEG C under a hydrogen atmosphere of 4.0MPa to prepare MgH2; then blending Mg17Al12, MgH2, Ni powder in accordance with contents by weight percent for ball-grinding for 60 to 100 hours under an atmosphere of argon. The magnesium-based composite hydrogen storage material can reversely absorb and release hydrogen at low temperature, and has high hydrogen storage capacity, excellent activation performance and superior hydrogen absorbing and releasing kinetics property. The magnesium-based composite hydrogen storage material can be used for manufacturing hydrogen source to facilitate purification and storage and transportation of hydrogen, and can also used for hydrogen storage material for fuel cells.

Owner:ZHEJIANG UNIV

Wax dielectric for heating temperature control valve and its preparing method

InactiveCN1458241ALow pricePhysical stabilityHeating/cooling contact switchesMineral wax recovery/refiningTemperature controlDielectric

The present invention relates to wax dielectric for heating temperature control valve and its preparation process. The destination product is prepared with fluid wax, wax paste, soap wax, etc containing C9-C20 components and through decompression distillation in 5-20 deg.c fraction width, sweating of the fractions in the smelting point temperature as the ultimate temperature, equal weight ratio mixing, refining and other technological steps. The product may be used in heating temperature controlling valve for temperature control in 5-30 deg.c and has basically the same stroke each degree of temperature. The product may be also used in other automatic temperature controlling devices.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-performance refractory weather-resisting building steel and its production method

InactiveCN1354273AImprove fire resistanceHigh yield strengthManufacturing cost reductionHeat-affected zone

The present invention relates to a high-performance fire-resistant weather-resisting building steel and its production method. Said invention steel contains C, Si, Mn, P, S, Mo, Ti, Al, N, O, Cr, Ni, Cu, Ca, B and one or more than one kind of Nb, V and RE and the rest is Fe. After having been undergone the processes of smelting, rolling and heat treatment, said building steel possesses high strenght, high toughness and excellent fire-resisting and weather-resisting properties. The building steel can be used for providing various steel structural members whose thickness is 4-100 mm in the fields of building, civil engineering and marine structure. Under the large linear energy (50-100 kJ / cm) welding condition of gas-arc welding, electroslag welding and high-frequency resistance welding, its heat affected zone (HAZ) still possesses excellent toughness so as to greatly raise welding efficiency of engineering structure and reduce its manufacture cost.

Owner:武钢集团有限公司

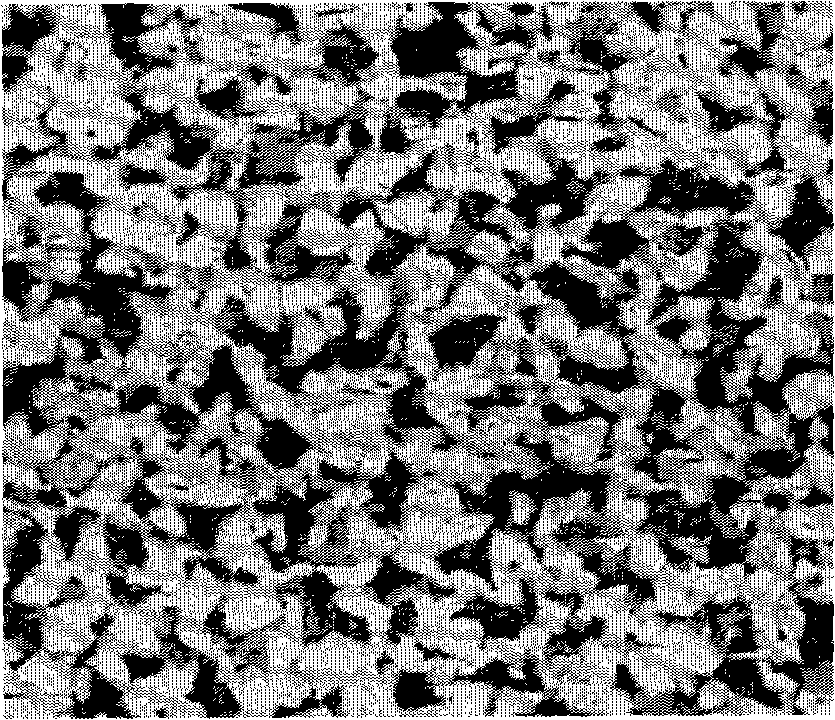

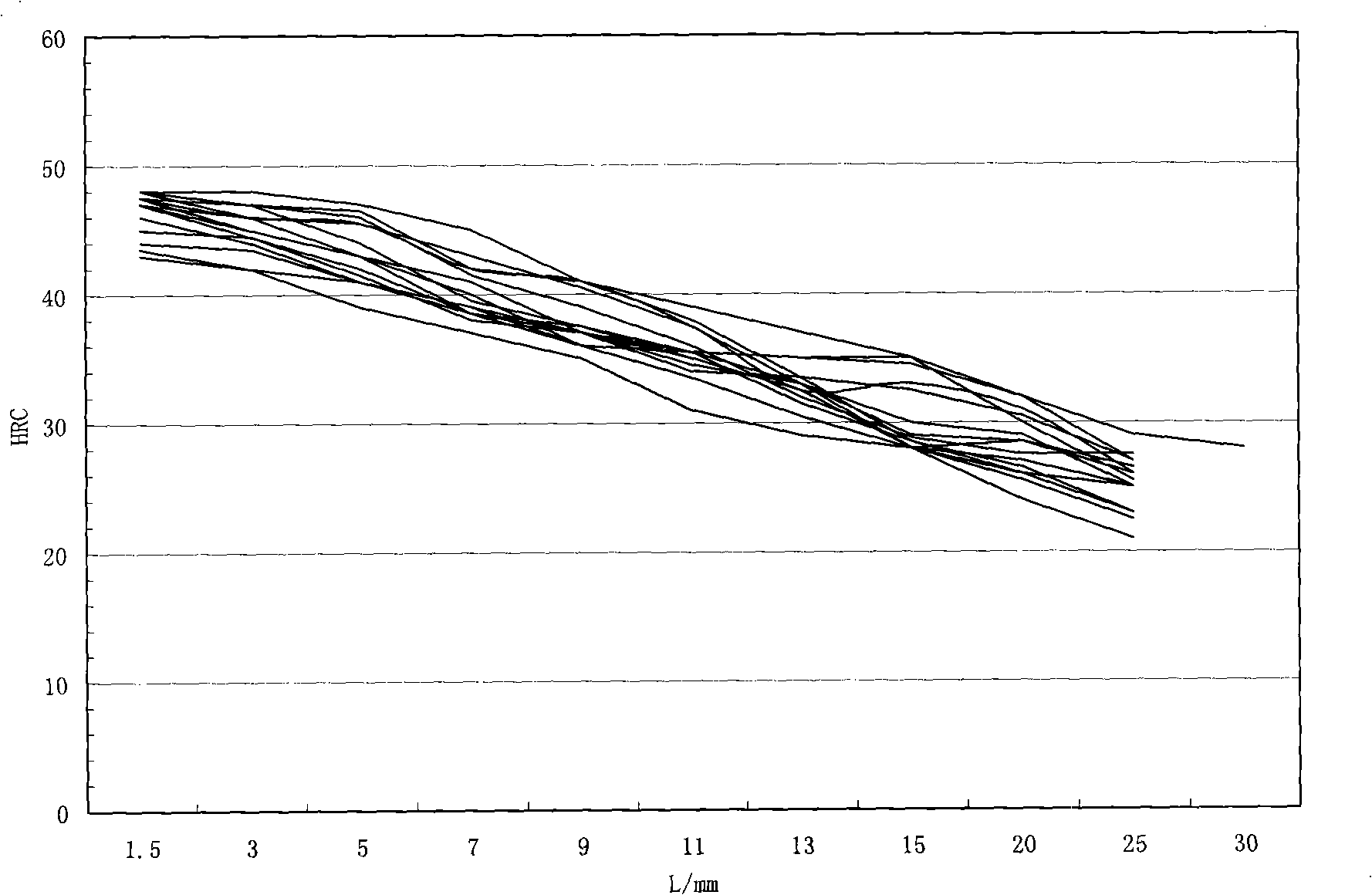

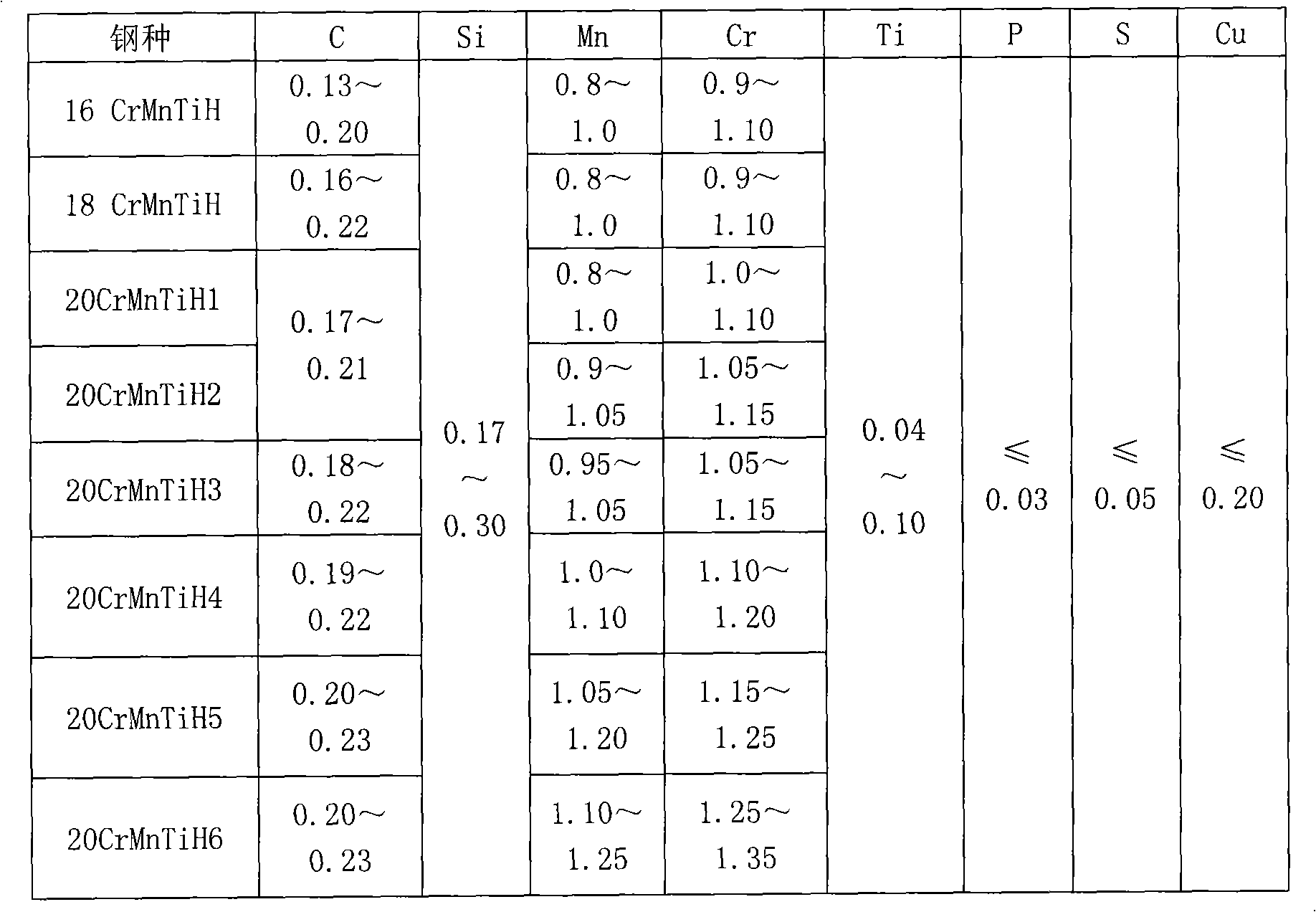

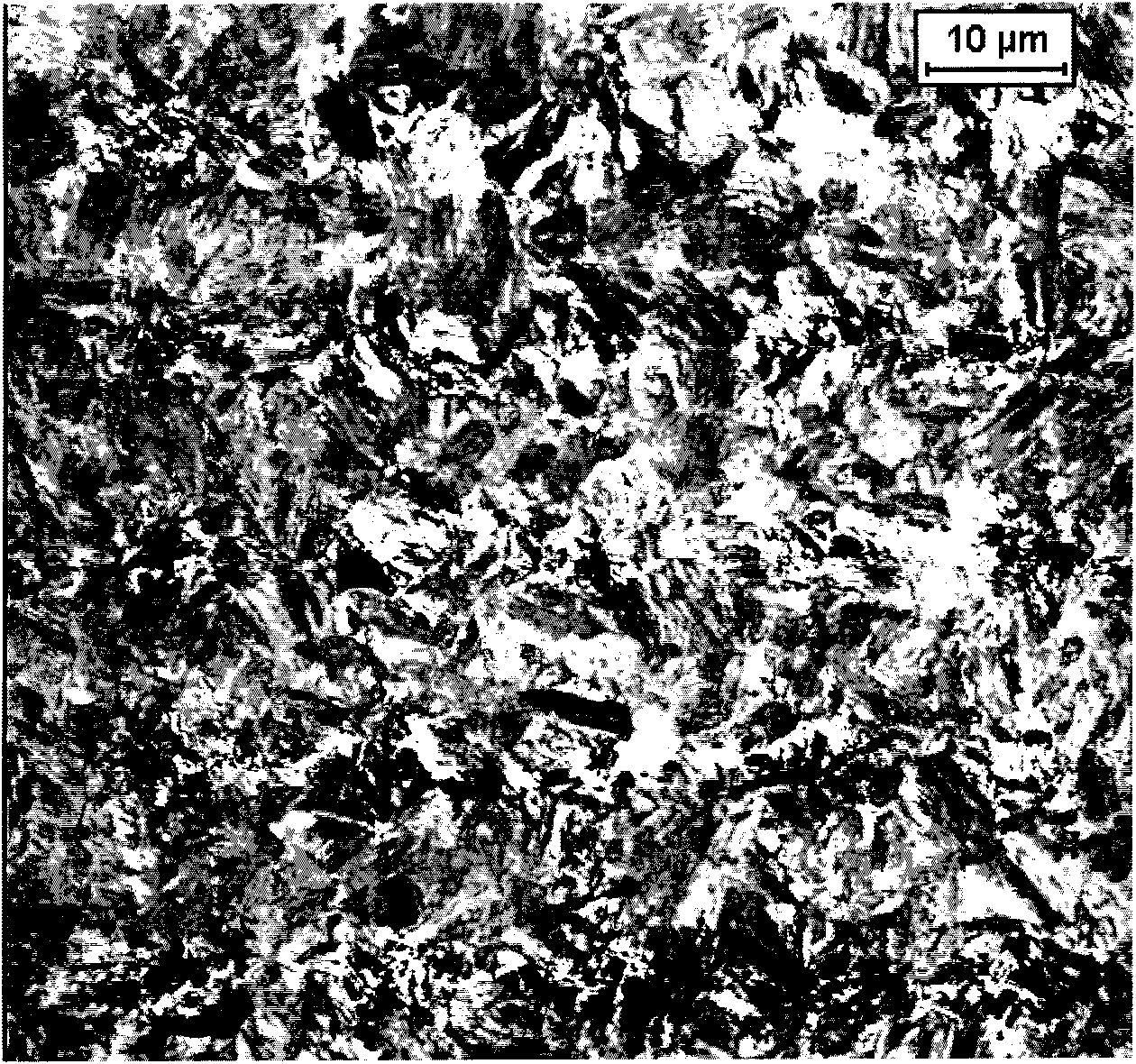

CrMnTi narrow hardenability strip pinion steels and method of manufacture

InactiveCN101289731AGuaranteed narrow hardenability band requirementsTemperature control deviceMetal rolling arrangementsChemical compositionPinion

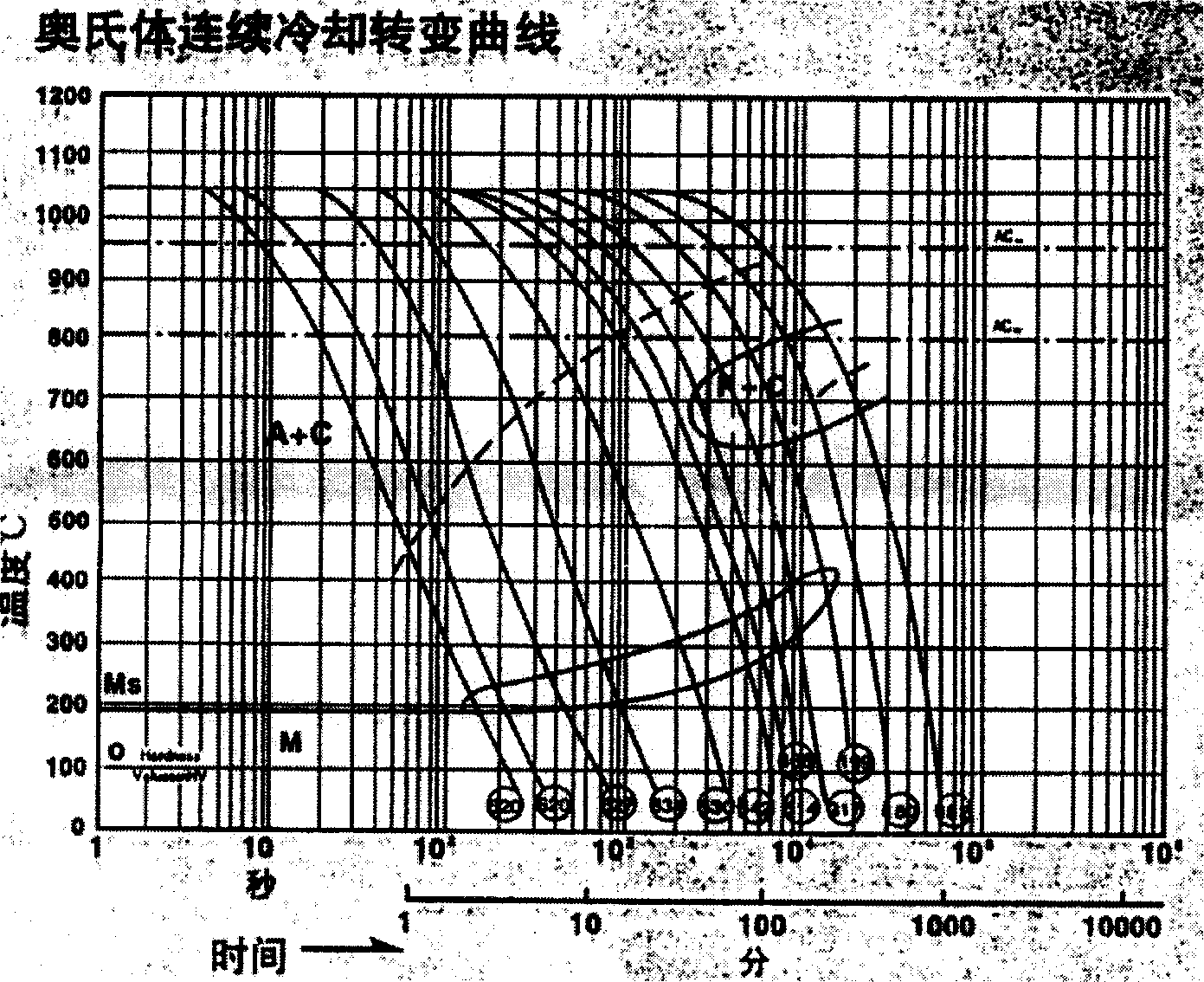

The invention relates to CrMnTi narrow-hardenability gear steel and a method for manufacturing the same, belonging to the gear steel material and the production process thereof technical field. The chemical composition in percentage by weight of the gear steel is: 0.13-0.23 percent of C, 0.17-0.30 percent of Si, 0.80-1.25 percent of Mn, 0.04-0.10 percent of Ti, 0.90-1.35 percent of Cr, less than or equal to 0.20 percent of Cu, less than or equal to 0.050 percent of S, less than or equal to 0.030 percent of P, less than or equal to 0.05 percent of Mo, less than or equal to 0.25 percent of Ni, [O] less than or equal to 20x10<-6>, [H] less than or equal to 2.5x10<-6>, and the balance being Fe and inevitable impurities. The manufacturing method comprises the following process steps of smelting, continuous casting, rolling and hot rolling, wherein in the step of continuous casting, the superheat degree of a tundish is controlled between 10 and 30 DEG C, and the casting speed is between 0.50 and 0.85 m / min; in the step of rolling, the heating temperature is between 1130 and 1280 DEG C, the start rolling temperature is more than or equal to 1100 DEG C, and the finish rolling temperature is between 850 and 980 DEG C. The gear steel and round steel in the specification between phi 30 and 160 mm can be produced by adopting the manufacturing method. By adopting narrow-composition steel grade design, electric furnace burden structure optimization, electric furnace end point control, grain-refining and banded structure control and other reasonable technological measures, the method effectively realizes hardenability narrowing and other objectives.

Owner:SHANDONG IRON & STEEL CO LTD

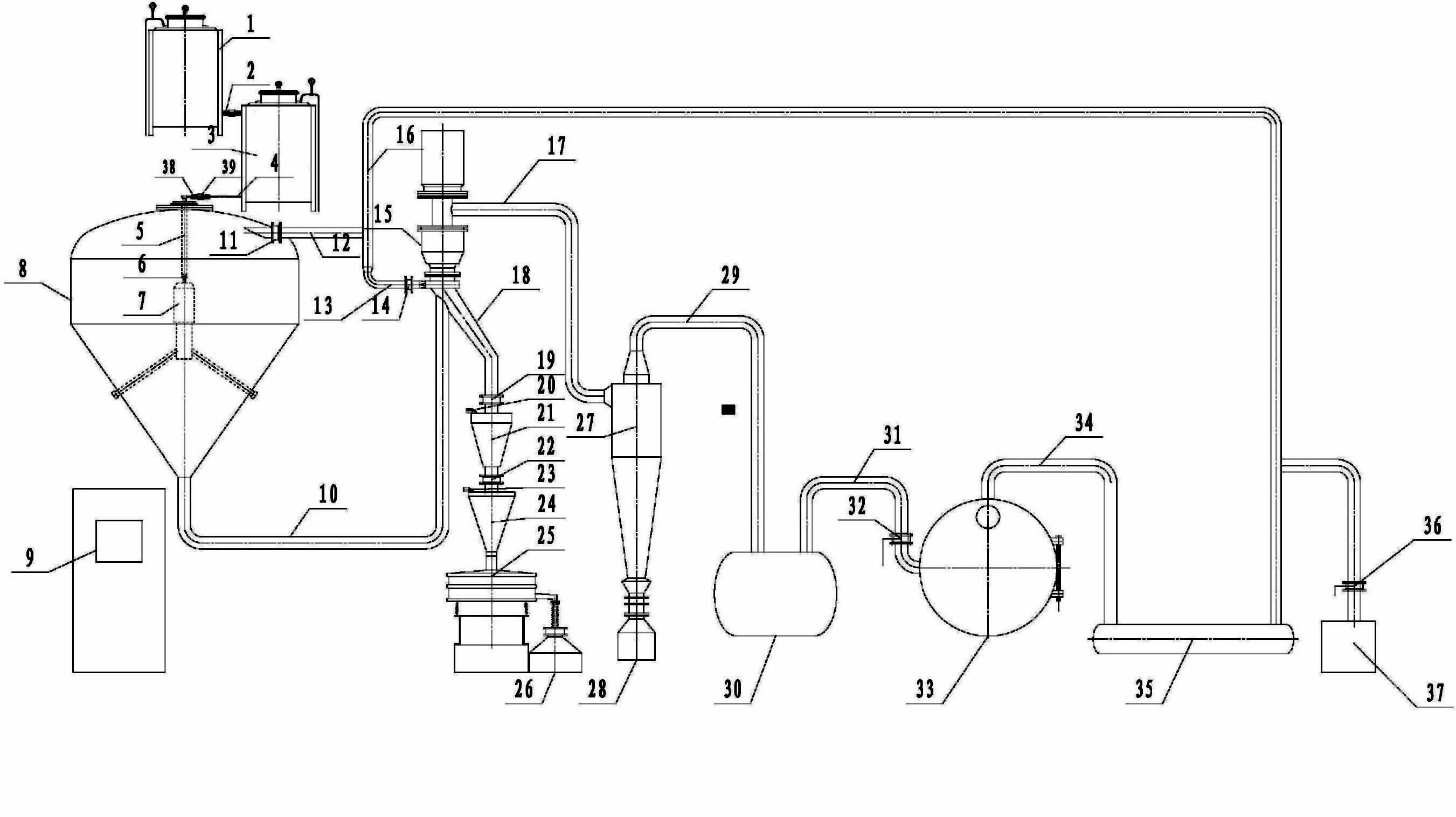

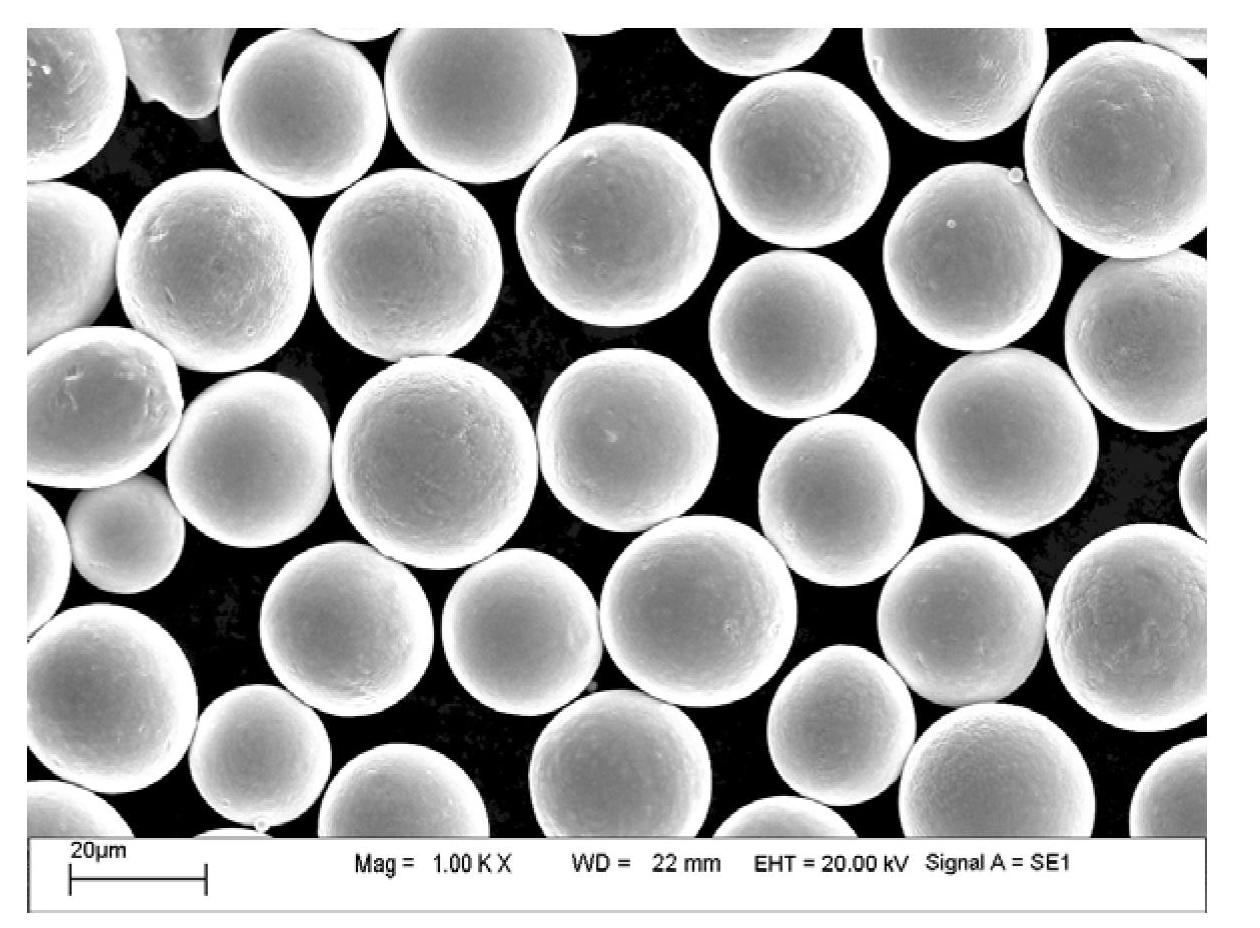

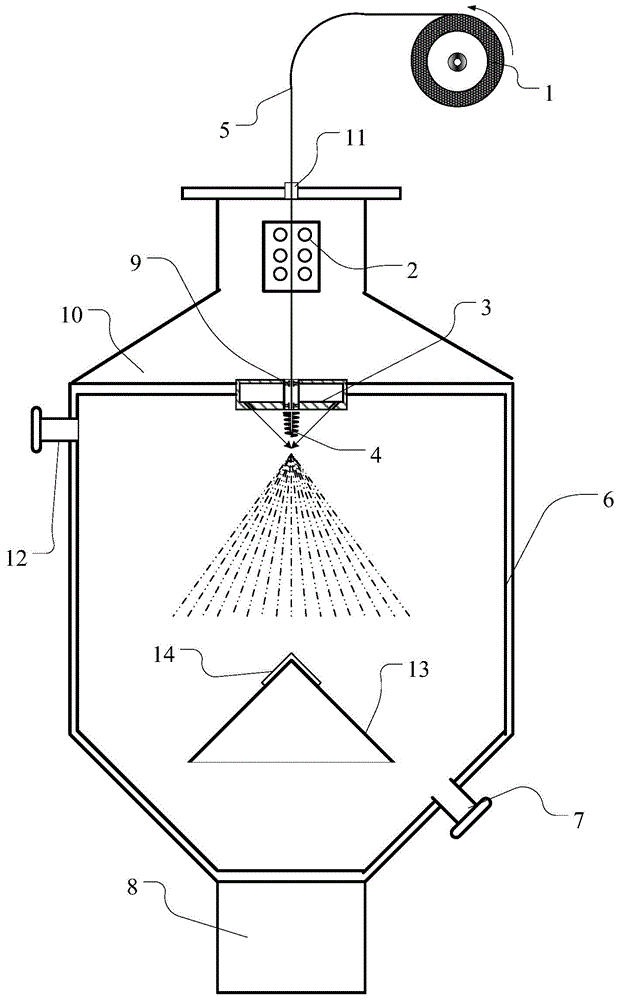

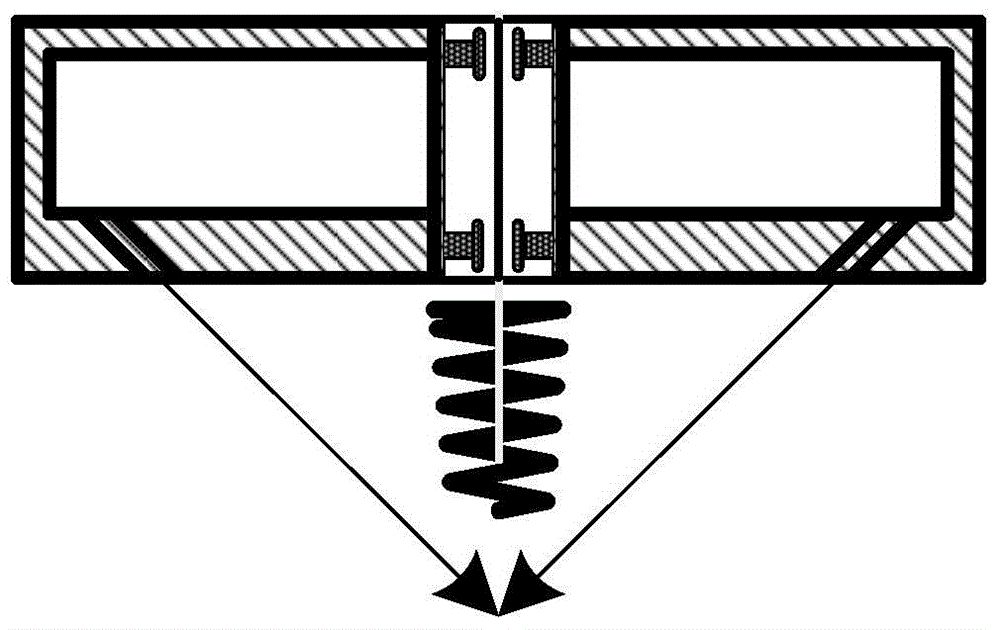

Metal powder preparation device and method therefor

The invention relates to a metal powder preparation device and method therefor. The device comprises an atomization furnace, a heater, a cooler, an atomization chamber, an atomizer, a pneumatic classifier, a middle bin, a sieving funnel, a screening machine, a deduster, a balance tank, a shell-and-tube heat exchanger, a vacuum obtaining device, a control system, an infusion tube, a conduit, a pipeline, a gas channel, a pneumatic butterfly valve, an electromagnetic valve and the like. The method comprises atmosphere preparation, metal smelting, infusion, centrifugal atomizing, pneumatic classification, mechanical screening, gas purification, cooling and the like, the metal is smelted and treated so as to be poured onto the atomizer for centrifugal atomization to form powder, the powder is classified by the pneumatic classifier, after classification, rough powder is screened by the mechanical screening so as to obtain the finished powder, fine powder is sent into the deduster by airflow for purification, the purified gas is driven by a high pressure centrifugal fan so as to be speeded up to be atomized and classified again after being subjected to heat exchange through the shell-and-tube heat exchanger. The device can be used for continuous production of spherical powder below -320 meshes, and the oxygen content is less than or equal to 80ppm.

Owner:BEIJING COMPO ADVANCED TECH

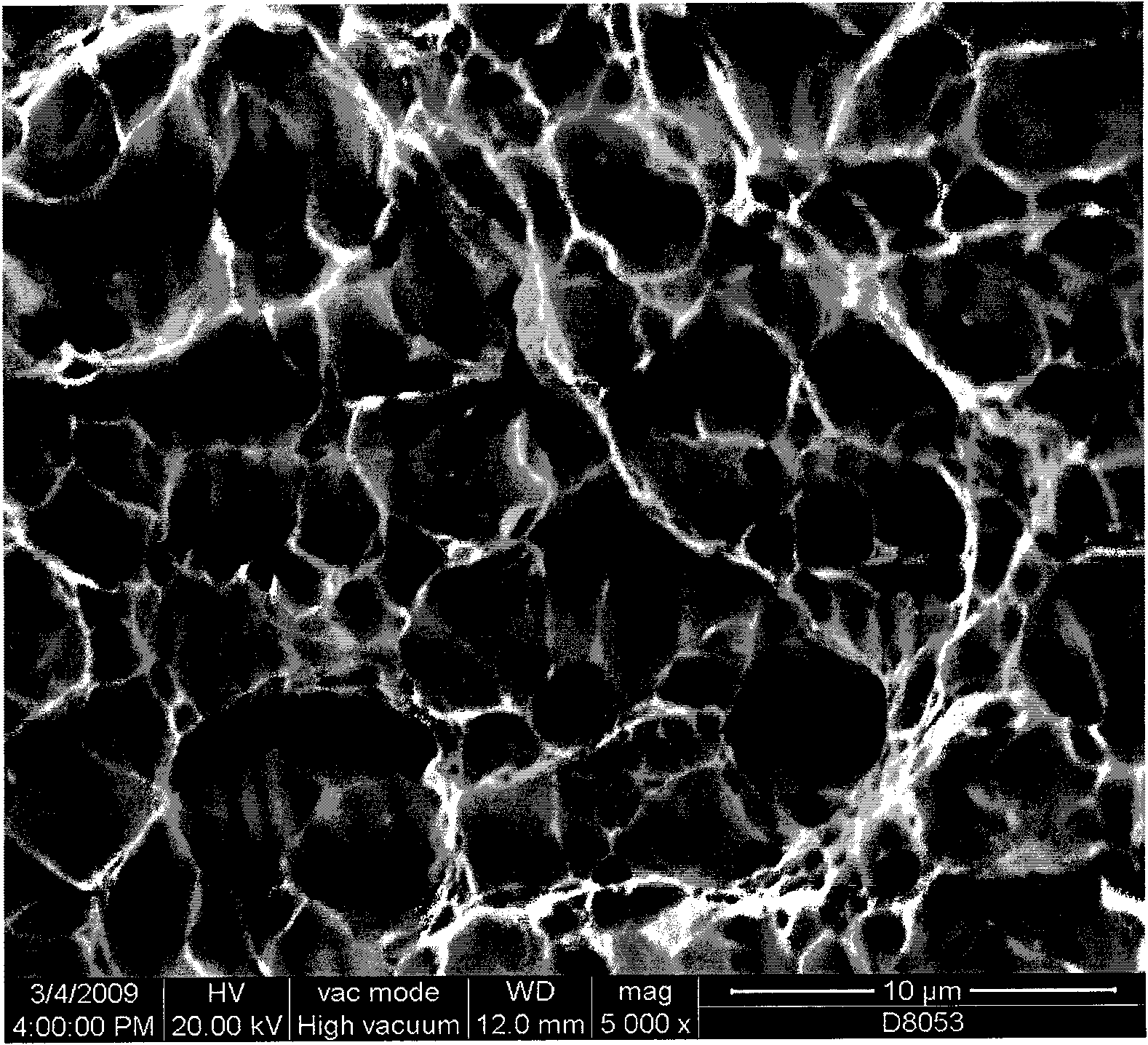

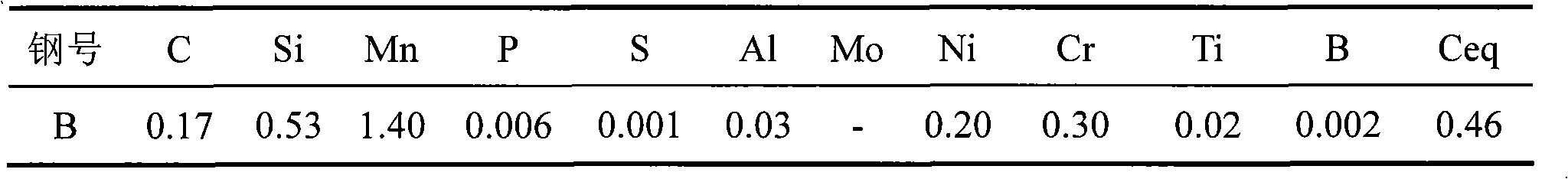

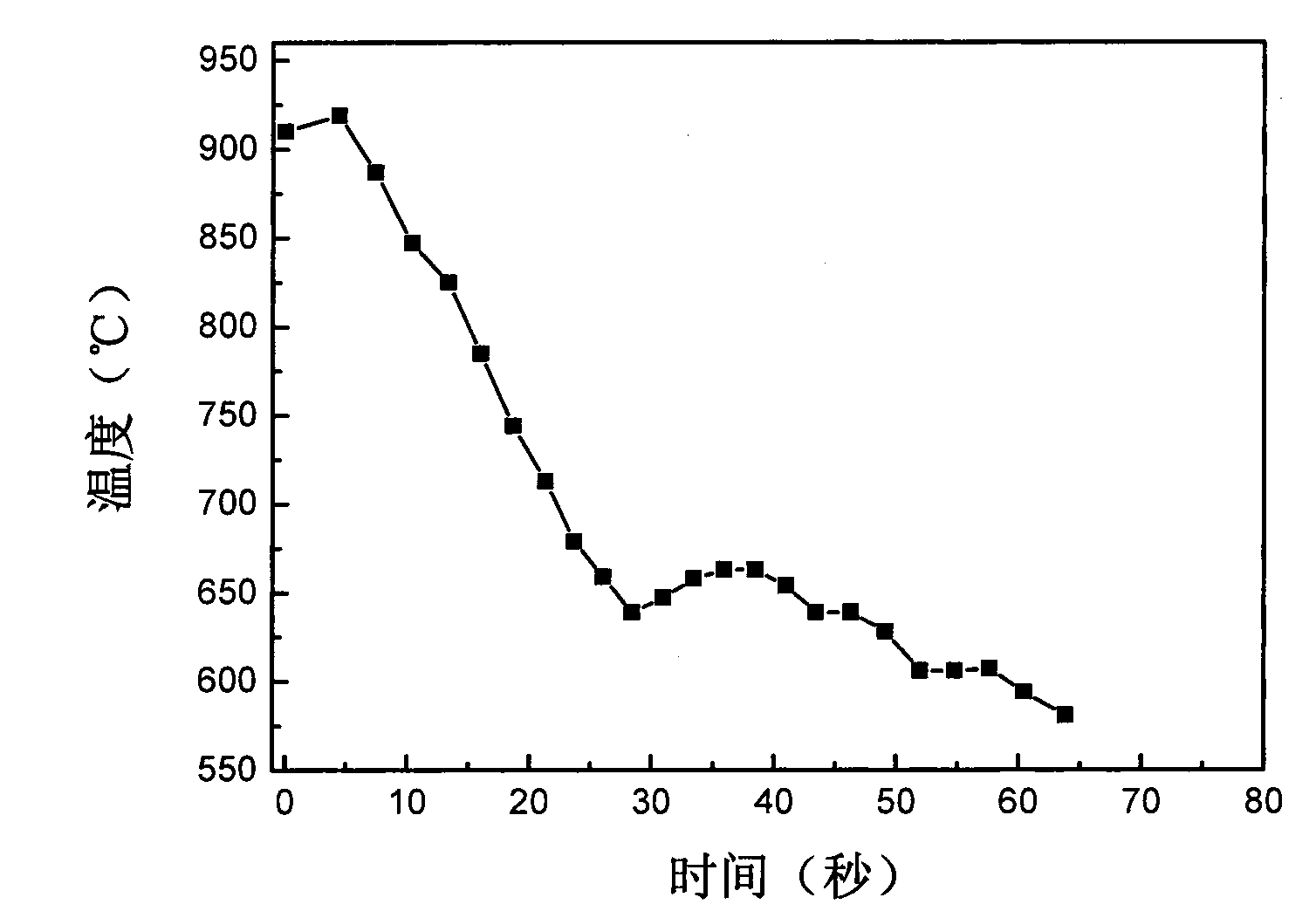

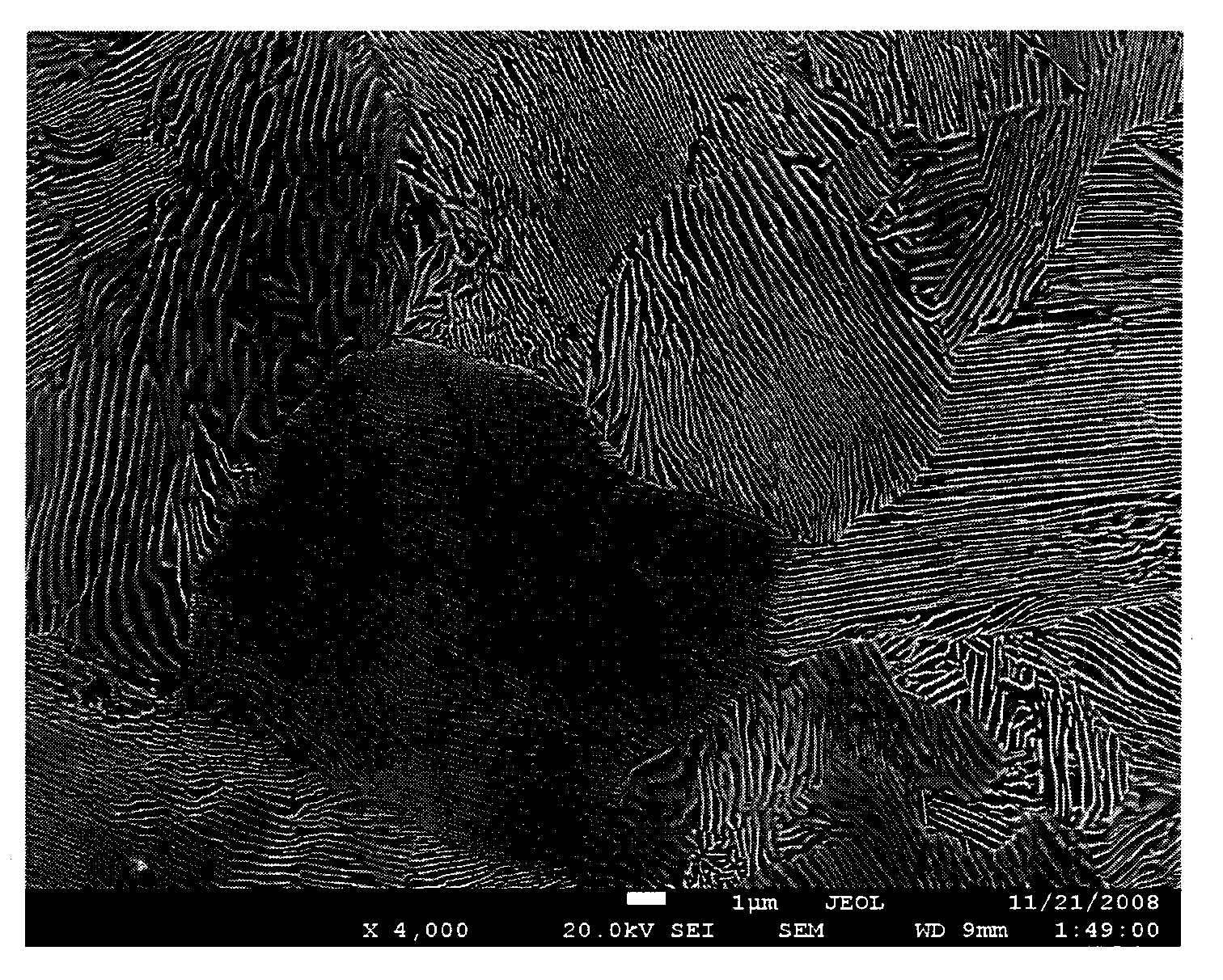

High-toughness and ultrahigh-strength wear-resistant steel plate and production method thereof

InactiveCN101638755AGood toughness matchGood welding performanceManufacturing convertersChemical compositionWear resistant

The invention provides a high-toughness and ultrahigh-strength wear-resistant steel plate and a production method thereof. The steel comprises the following chemical compositions by mass percent: 0.15-0.26% of C, 0.20-0.55% of Si, 1.0-1.60% of Mn, P less than or equal to 0.020%, S less than or equal to 0.010%, 0.00-0.60% of Mo, 0.00-0.50% of Ni, 0.20-1.00% of Cr, 0.01-0.05% of Ti, 0.02-0.04% of Als, 0.0005-0.004% of B and the balance Fe and inevitable impurities. The production method of the steel comprises the following steps: high clean steel smelting, hot metal desulphurizing, converter top-bottom blowing, vacuum processing and blank casting, in particular to plate blank heating, rough rolling, finish rolling and heat treatment technology parameter controlling. The chemical compositionsof the steel contain no V, Mo or Ni, or contain less Mo and Ni, therefore, the steel plate is low in alloy content and fine in toughness and can be widely applied to the mines and construction machinery products, which feature bad working conditions and have high requirements on steel properties.

Owner:NORTHEASTERN UNIV

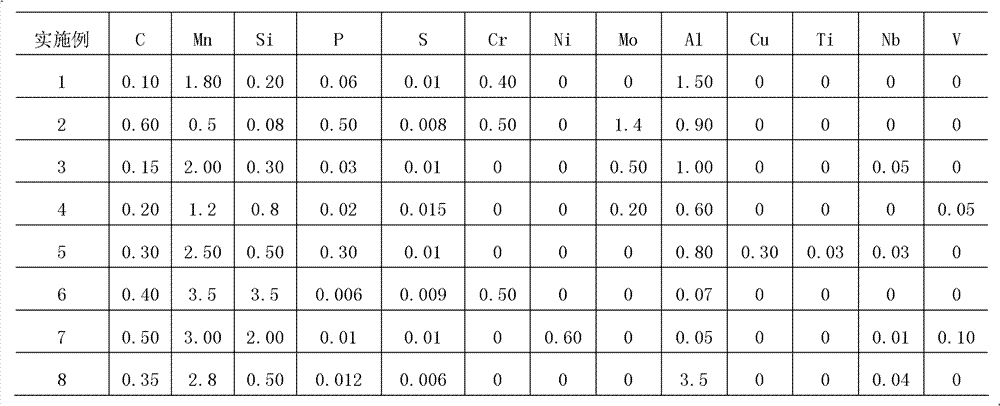

High carbon steel wire rod and preparation method thereof

ActiveCN101649416AImprove mechanical propertiesLess alloying elementsTemperature control deviceManufacturing convertersWire rodTemperature control

The invention relates to a high carbon steel wire rod with tensile strength of more than 1,200 MPa and surface shrinkage of more than 35 percent and a preparation method thereof. The high carbon steelwire rod comprises the base components of C, Si, Mn, Cr and the like, selective components of Ni, Cu, Al, B, Ti, Nb, Mo and the like, and the balance of Fe and impurities. The preparation method comprises the following procedures of smelting, casting, rolling and cooling control sequentially, wherein the rolling-starting temperature of the rolling procedure is controlled between 1,000 DEG C and 1,100 DEG C, the spinning temperature is 870-930 DEG C, the cooling controlling procedure is carried out by adopting Steyr cooling control, rapid cooling is adopted before the phase change and at the earlier stage of the phase change, and the slow cooling is adopted at the later stage of the phase change. The high carbon steel wire rod has excellent mechanical performance, less alloy elements and low cost; and meanwhile, the preparation method is realized by only less adjusting the prior production process of the high carbon steel wire rod without nearly adding any production cost.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

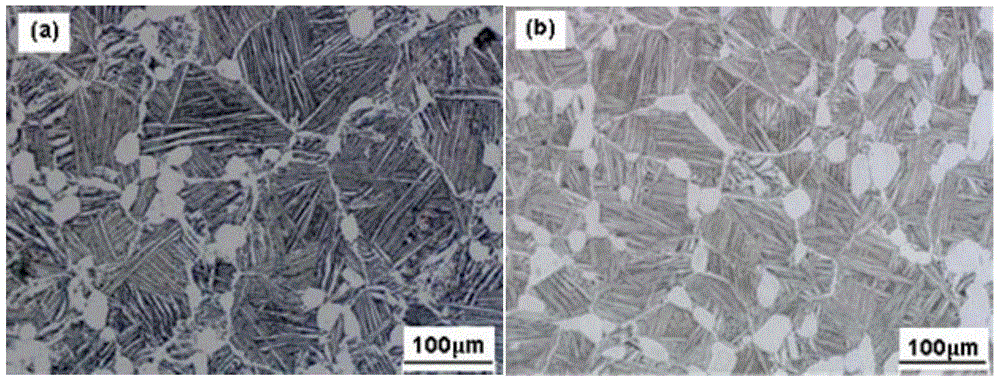

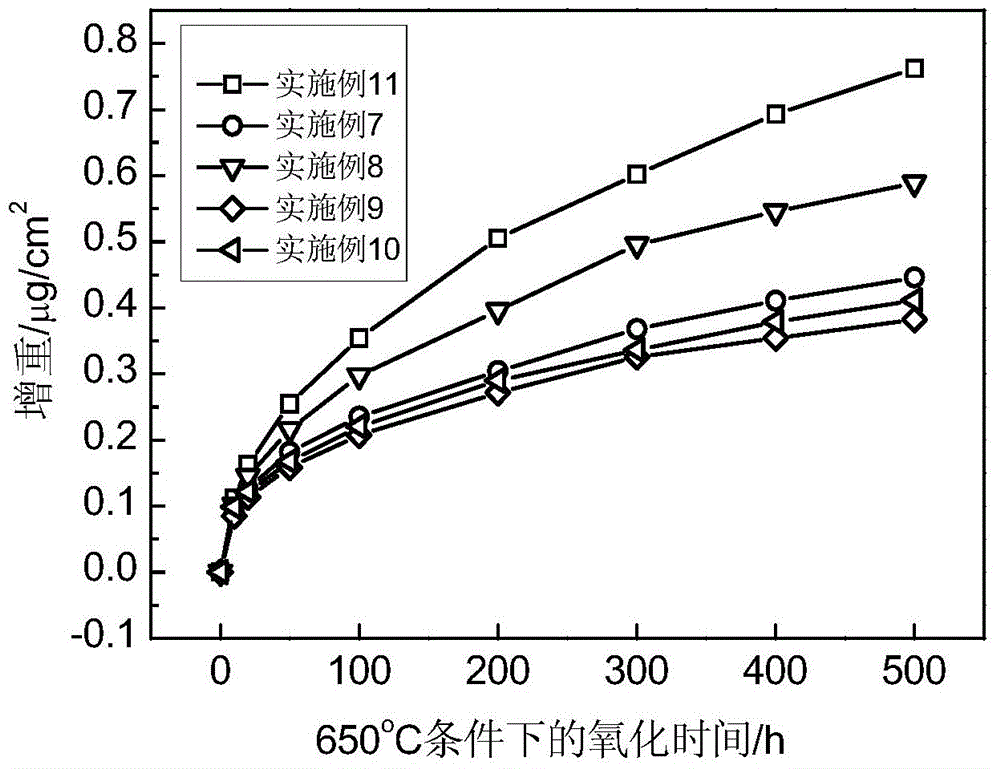

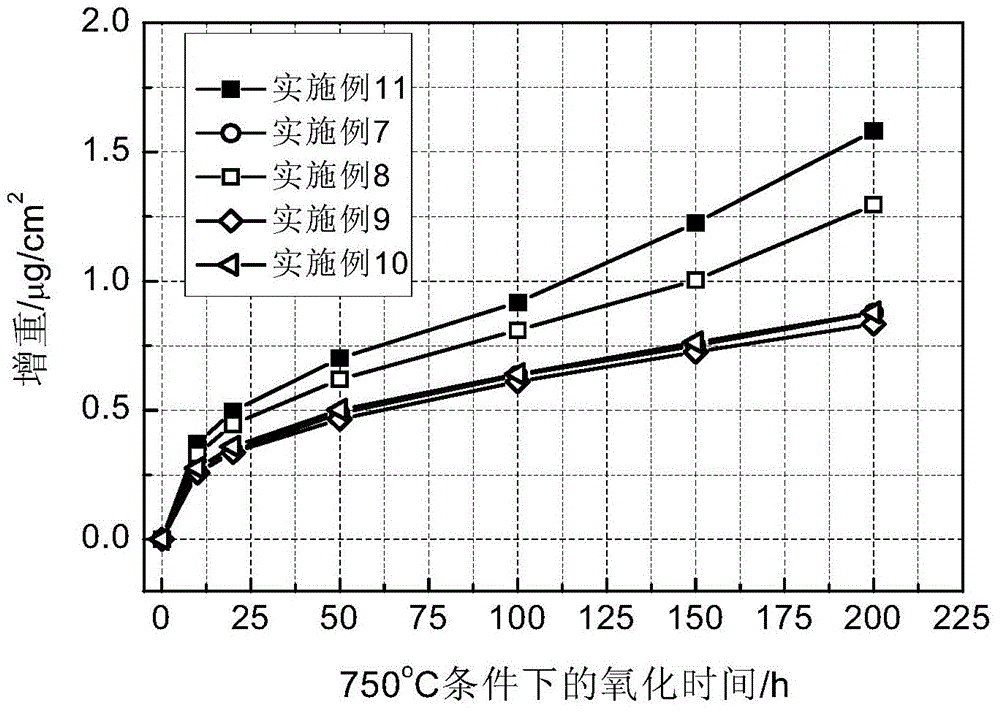

Novel heat-resisting titanium alloy and processing and manufacturing method and application thereof

The invention belongs to the field of titanium-based alloys, and particularly relates to a novel heat-resisting titanium alloy and a processing and manufacturing method and application thereof. The processing and manufacturing method comprises the composition elements of alloy components, smelting, heat processing, heat treatment and the like, wherein the alloy components are as follows (in percentage by weight): 5.4%-6.3% of Al, 3.0%-5.0% of Sn, 2.5%-6.4% of Zr, 0.0%-0.96% of Mo, 0.25%-0.5% of Si, 0.2%-0.5% of Nb, 0.3%-3.4% of Ta, 0.2%-1.6% of W, 0.0%-0.07% of C, less than or equal to 0.17% of O, less than or equal to 0.03% of Fe and the balance of Ti and inevitable impurity elements. The novel heat-resisting titanium alloy disclosed by the invention can obtain different matching of tensile strength, plasticity, permanence, creep strength and heat stability through the combination of different heat processing process and heat treatment processes, can be used for manufacturing parts, namely blades, coil assemblies and the like which are positioned on the high-temperature parts of an advanced aircraft engine, is used for a long time within a range of 600-650 DEG C, can also be used for manufacturing high temperature-resistant structural members, namely aerospace craft skin and the like, is used for a short time at about 700 DEG C and can be used as a material and the like used for high temperature-resistant corrosion-resistant valves of an automobile and a boiler.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

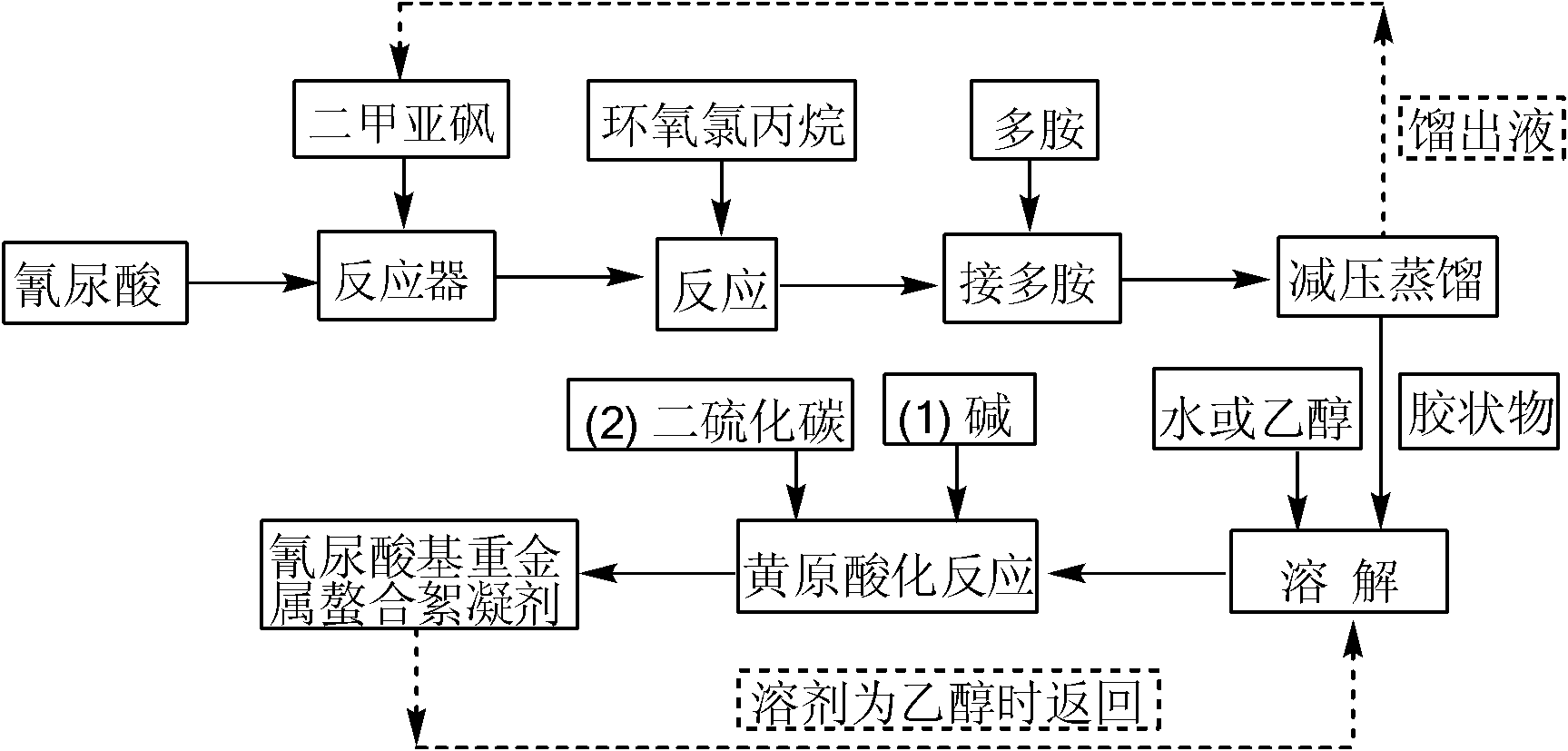

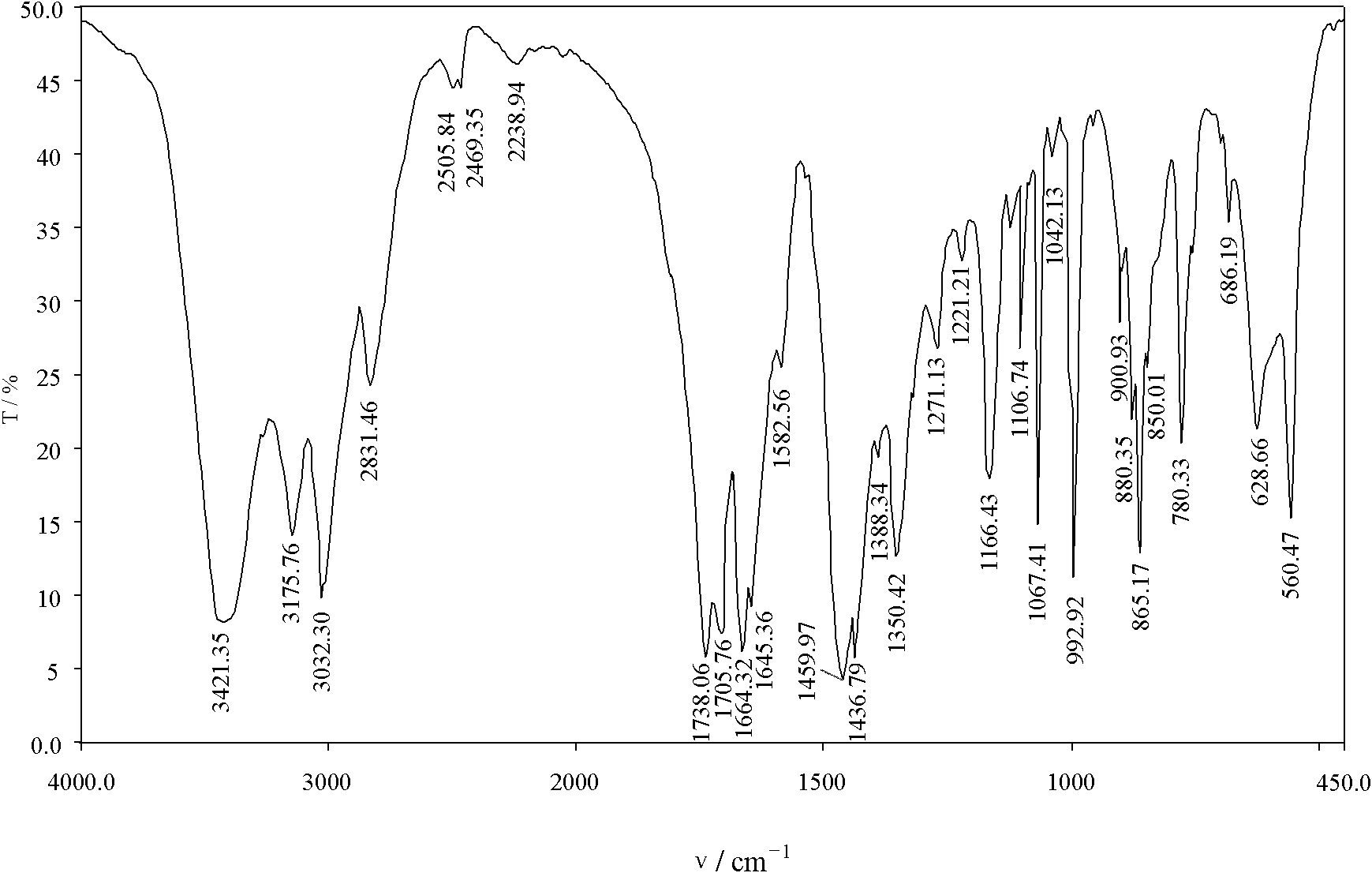

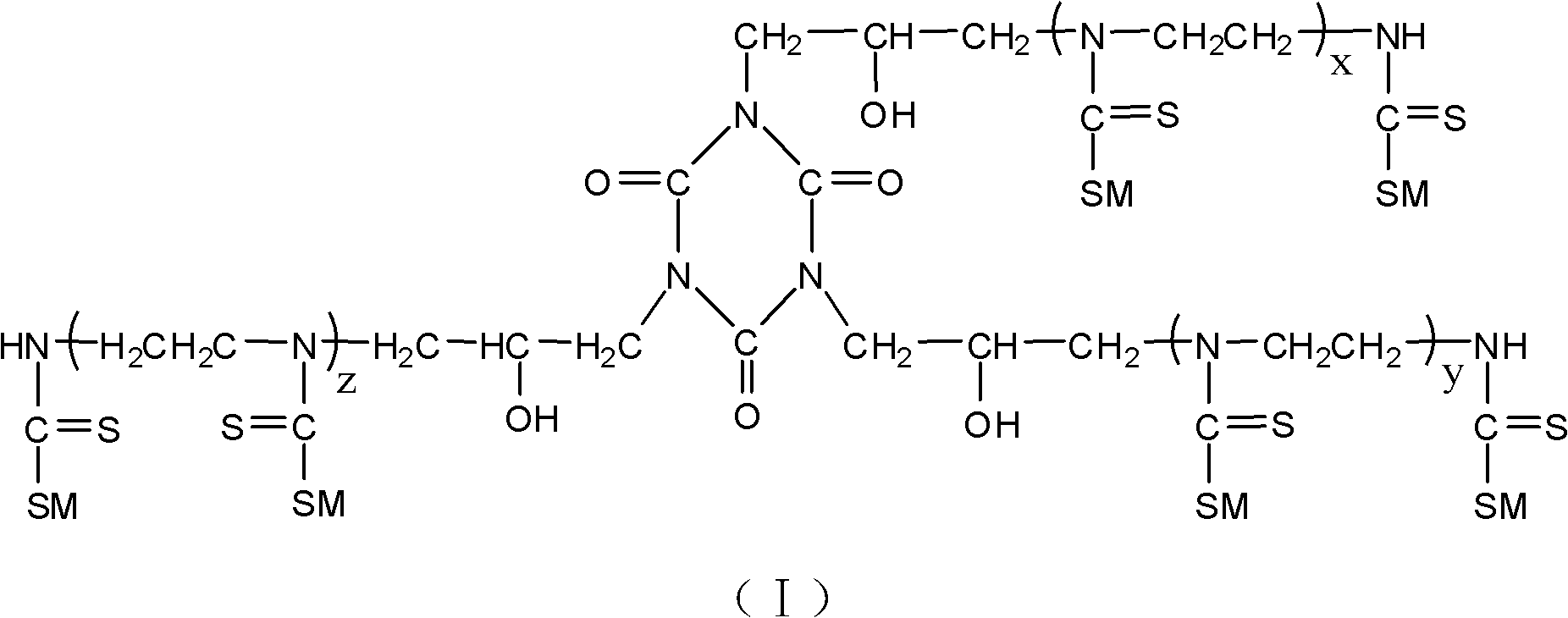

Cyanuric acid-based heavy metal chelating flocculant and preparation method thereof

InactiveCN101863544AOvercome the defect that the ion concentration is difficult to reach the standardIncrease steric hindranceWater/sewage treatment by flocculation/precipitationEpoxyHeavy metal chelation

The invention belongs to the technical field of heavy metal wastewater treatment, and in particular relates to cyanuric acid-based heavy metal chelating flocculant and a preparation method thereof. In the method, cyanuric acid is adopted as a basic framework; and polyamine is connected to a molecule through epoxy chloropropane, and reacts with carbon disulfide in an alkaline condition to prepare the heavy metal chelating flocculant of which the molecule contains a plurality of branches and a plurality of dithio formate functional groups. The method overcomes the defects that the conventional monofunctional flocculant has small flocculating body, and poor precipitation performance, and when polymeric chelant chelates heavy metals, steric clash is great, and the residual heavy metal ion concentration is difficult to meet the standard and the like. The flocculant has the advantages of simple preparation process, mild condition, easy operation and control, high yield, high raw material utilization, less three waste discharge and environmental protection of technical process, convenient popularization and industrialization realization and suitability for treatment of various types of heavy metal wastewater, such as smelting wastewater, electroplating wastewater, nonferrous metals processing wastewater, mining and beneficiating wastewater, printed circuit board wastewater, battery plants and the like.

Owner:HUNAN UNIV OF SCI & TECH

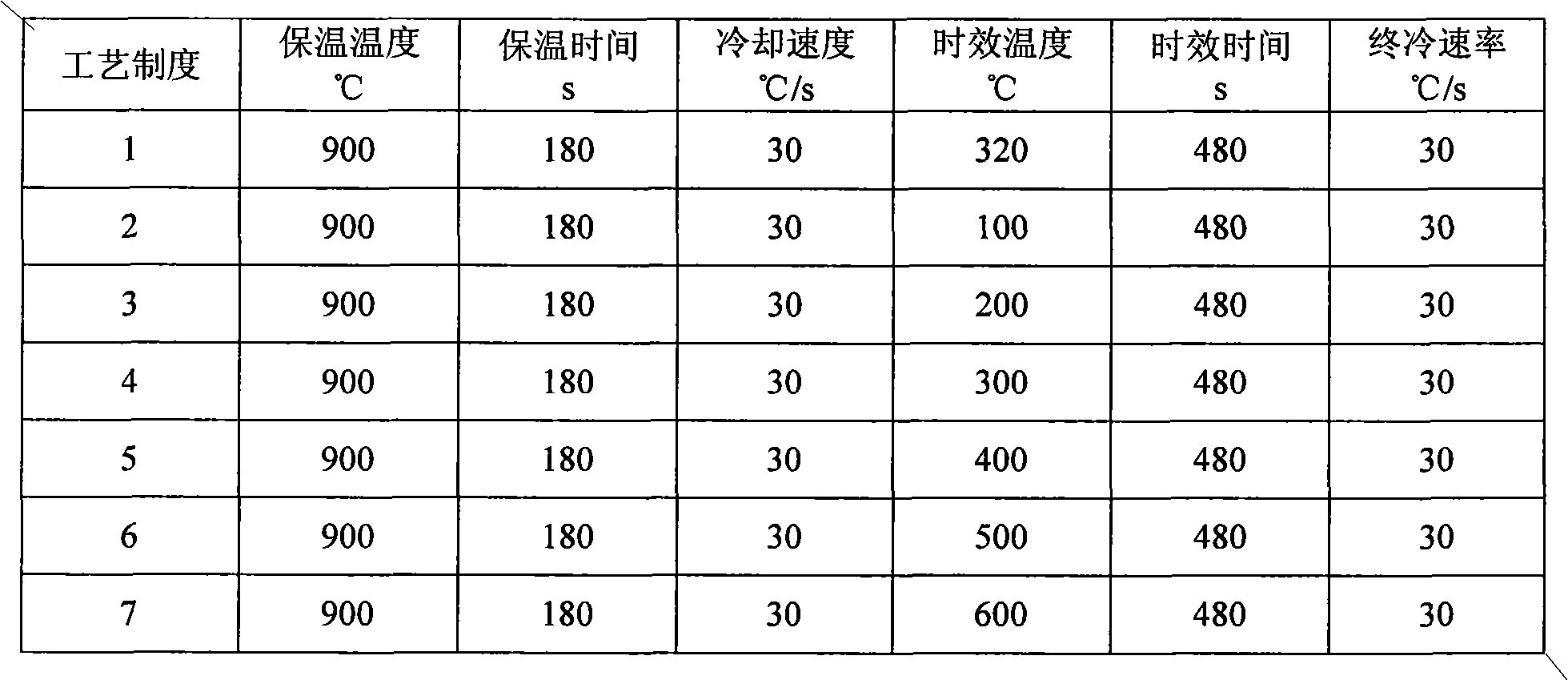

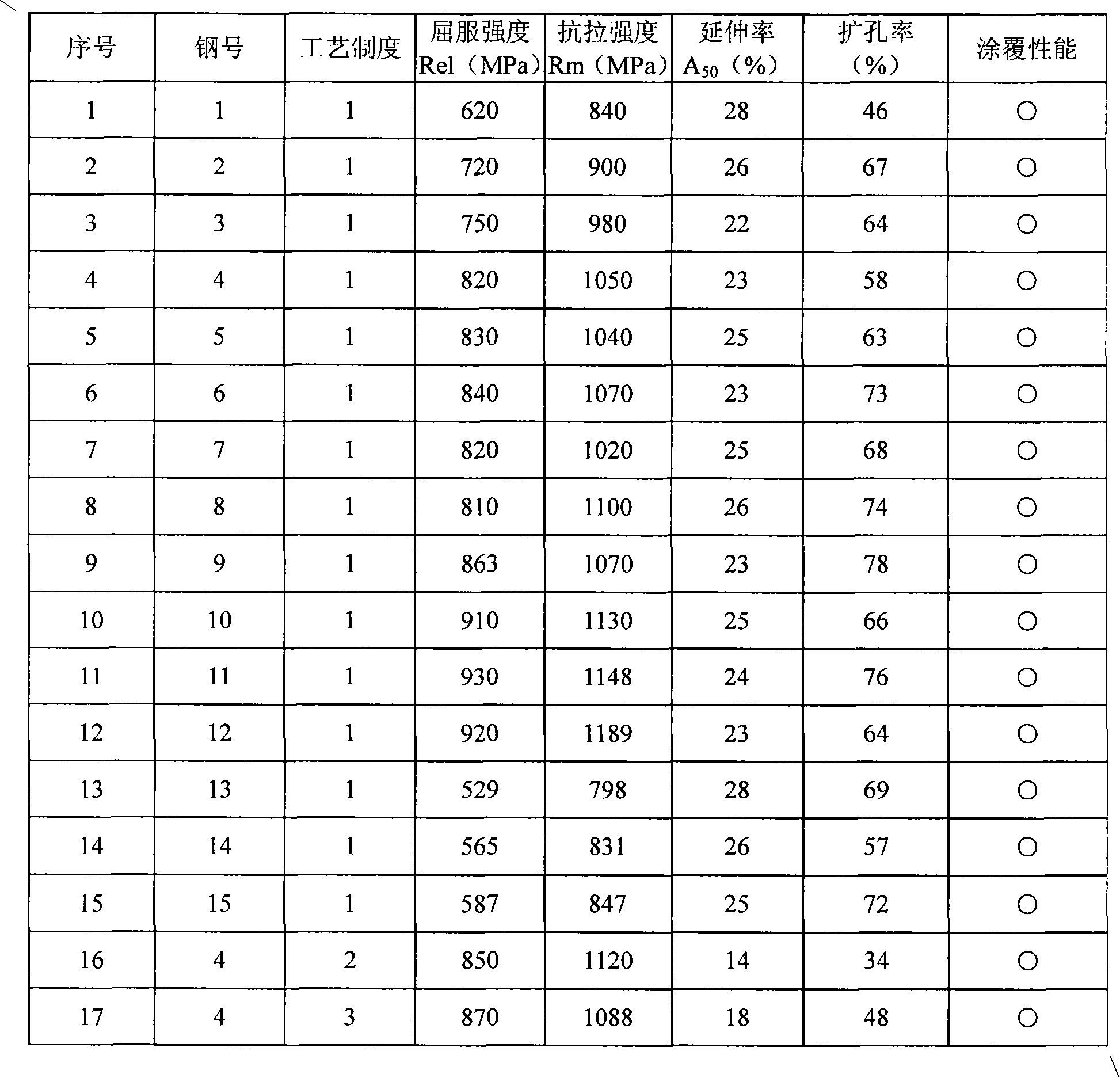

High-strength cold-rolled plate with favorable forming property and preparation method thereof

The invention provides a high-strength cold-rolled plate with favorable forming property and a preparation method thereof. The high-strength cold-rolled plate comprises the following chemical components: 0.05-0.6% of C, being more than or equal to 0.3% and being less than 0.8% of Si, 0.5-4.0% of Mn, being more than ore equal to 0.2% of P, being more than or equal to 0.002% of S, being more than or equal to 0.1% of Al, being more than or equal to 0.01% of N, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: smelting, continuous-casting, hot-rolling, cold-rolling and continuous-annealing, wherein annealing temperature is higher than that of Ac3, holding time is 3-30 minutes; quickly cooling to 100-600 DEG C at the rate of 30-100 DEG C / s, keeping the temperature for 3-30 minutes, and finally cooling to room temperature at the rate of 5-30 DEG C / s. The invention adopts low-silicon low-aluminum component design and heat treatment technique; the strength level of the produced bainite TRIP steel is greater than 780 MPa; and the produced bainite TRIP steel has favorable strength, plasticity, extensibility, chambering property and coating property.

Owner:ANGANG STEEL CO LTD

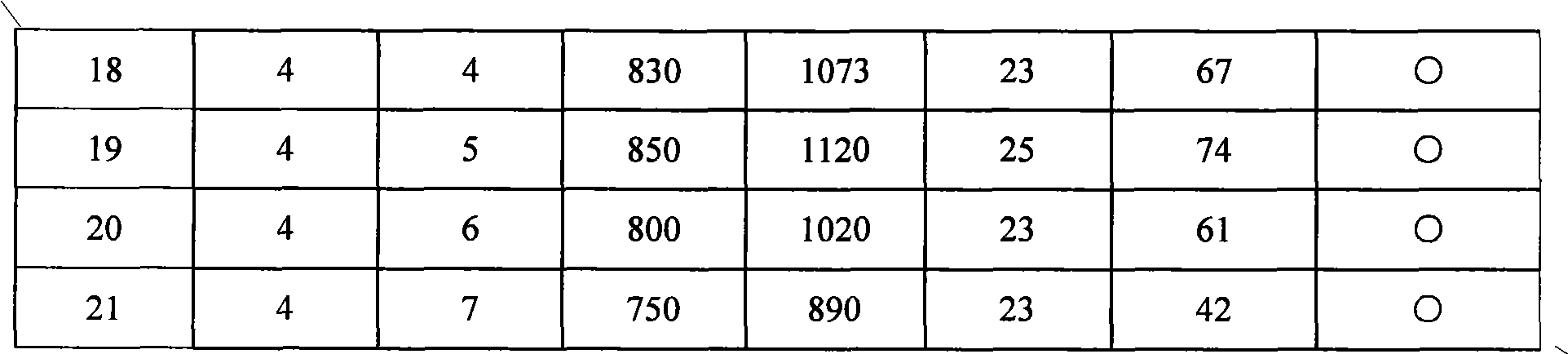

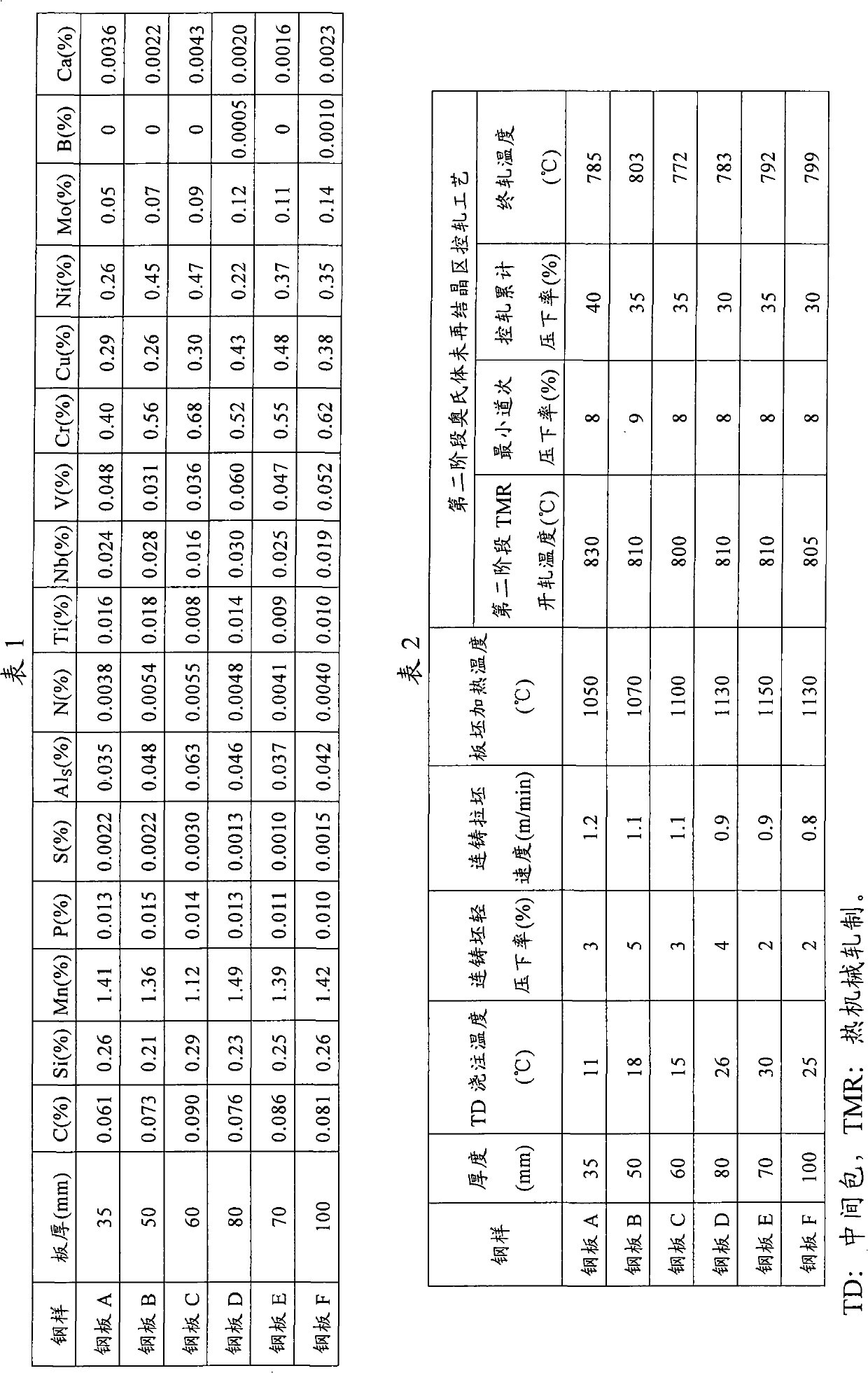

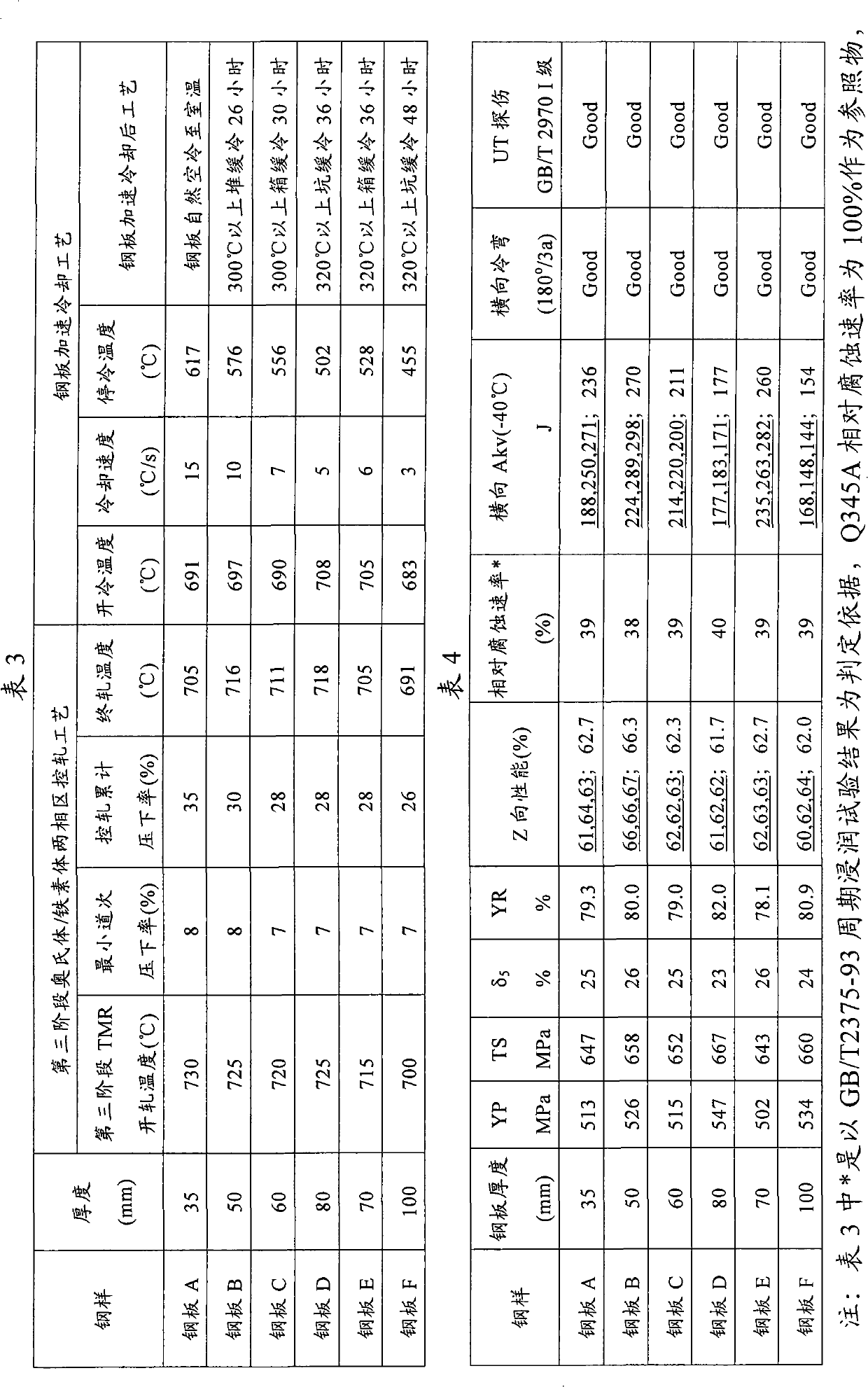

Weather resistant thick steel plate and manufacturing method thereof

A weather resistant thick steel plate comprises, by weight, 0.06%-0.9% of C, not more than 0.30% of Si; 1.10%-1.50% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.035%-0.065% of Als, 0.25%-0.50% of Cu, 0.20%-0.50% of Ni, 0.40%-0.70% of Cr, 0.50%-0.15% of Mo, 0.008%-0.018% of Ti, 0.030%-0.060% of V, 0.015%-0.030% of Nb, not more than 0.0055% of N, 0.001%-0.004% of Ca, 0.0004%-0.0010% of selectively added B, and the balance of Fe and unavoidable impurities. The manufacturing method includes deep desulfurization of molten iron, converter smelting, LF, RH, continuous casting, on-line finishing of slabs, cut-to-length torch cutting of slabs, heating, TMCP, and slow cooling of steel plates. The obtained weather resistant thick steel plate has balanced strong toughness and strong plasticity, low yield ratio, atmospheric corrosion resistance, excellent weldability and fatigue resistance, and is especially applicable to non-coating high-rise building structures and bridge structures.

Owner:BAOSHAN IRON & STEEL CO LTD

Production process of cold rolled orientation-free electrical steel plate with low iron loss and high magnetic induction

ActiveCN1887512ALow investment costReduce operating costsOther manufacturing equipments/toolsElectrical steelImpurity

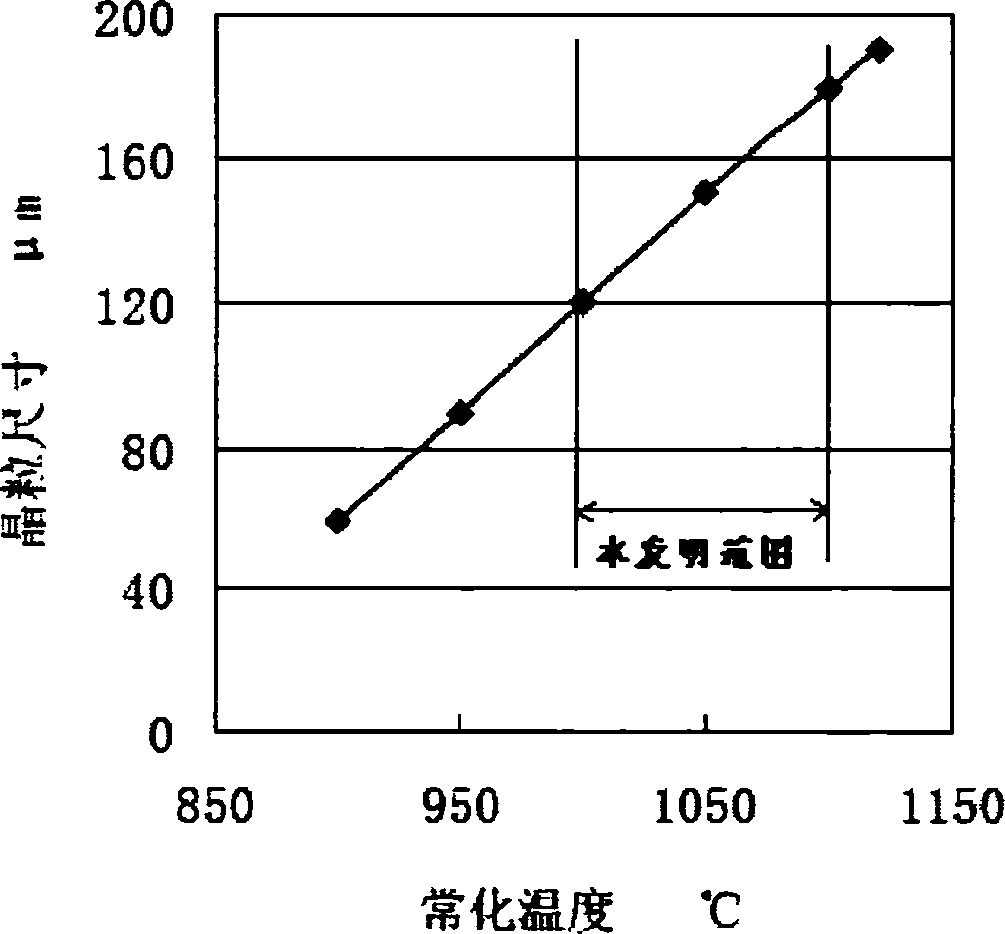

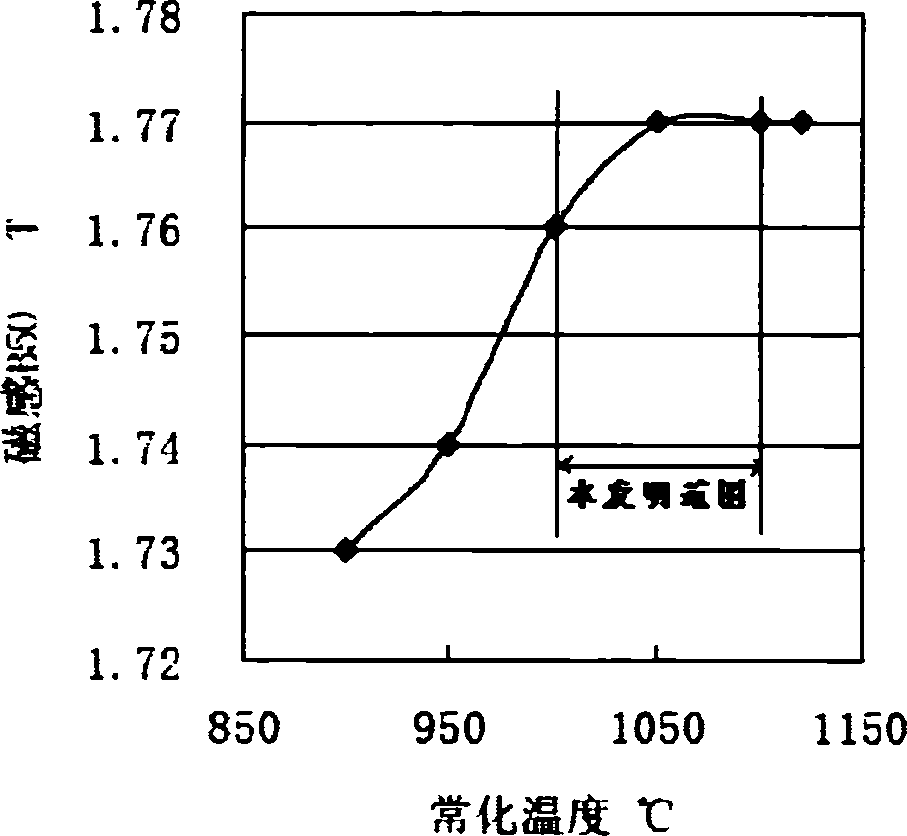

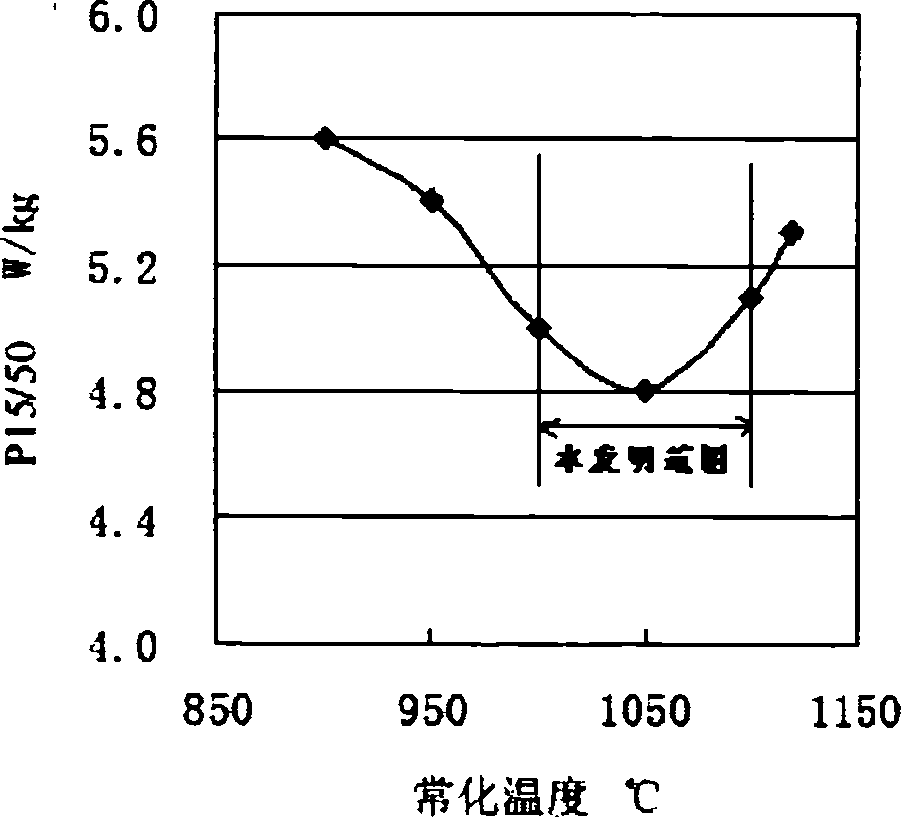

The production process of cold rolled non-orientation electric steel plate comprising C not more than 0.0050 wt%, Si not more than 2.50 wt%, Al not more than 1.0 wt%, Si+2Al not more than 2.50 wt%, Mn 0.10-1.50 wt%, P not more than 0.20 wt%, S not more than 0.005 wt%, N not more than 0.0025 wt%, Sn+Sb not more than 0.2 wt%, and Fe and inevitable impurities for the rest includes the following steps: 1. smelting, continuous casting and rolling; 2. normalizing treatment of the hot rolled plate through heating at heating rate of 5-15 deg.c / s to over Ac1, heat soaking at 1100 deg.c below for 10-90 s, cooling in two stages including cooling at the cooling rate belw 15 deg.c / s to below 650 deg.c and cooling at the cooling rate capable of ensuring the plate form to below 80 deg.c; 3. cold rolling; and 4. final annealing to form the cold rolled non-orientation electric steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD

600MPa level quake-proof twisted steel and manufacturing method thereof

The invention discloses 600MPa level quake-proof twisted steel and a manufacturing method of the steel. The twisted steel comprises one or the combination of more than two of the following components in percentage by weight: 0.21-0.26% of C, 0.61-0.80% of Si, 1.30-1.60% of Mn, 0.15-0.21% of V, 0.001-0.050% of Nb, 0.001-0.050% of Ti, 0.10-0.50% of Cr, 0.0001-0.0050% of B, 0.001-0.010% of Mo and the balance of Fe and unavoidable impurities, wherein the components of C, Si, Mn and V are basic components, and the components of Nb, Ti, Cr, B and Mo are optional components. A short-flow process of converter or electric furnace smelting and small billet continuous casting and rolling and cold bed cooling is adopted by the manufacturing method of the twisted steel. The tensile strength of the twisted steel produced by adopting the components and the method is more than 730MPa, the yield strength is more than 600MPa, the percentage elongation after fracture is more than 14%, the maximum force percentage of total elongation is more than 9%, and the yield ratio is more than 1.25, so the international requirement of quake resistance on the twisted steel can be met.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Treatment method of nickel-cobalt material

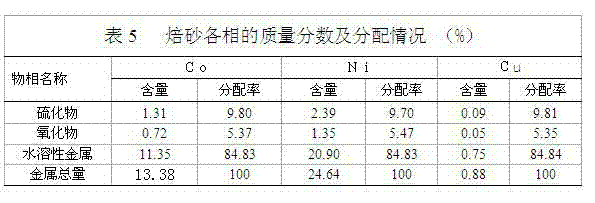

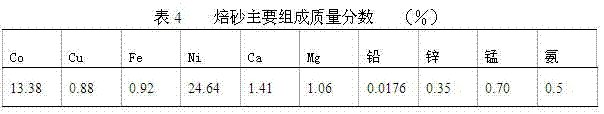

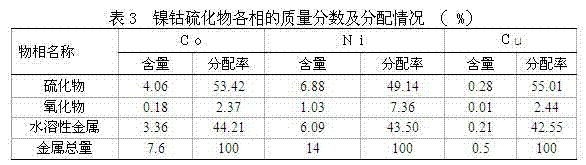

The invention provides a treatment method of a cobalt-containing material, belonging to the technical field of non-ferrous metal smelting. In the treatment method, through six steps such as peroxidation roasting, sulfuric acid leaching, N902 extraction of copper, chemical iron calcium magnesium removal, P204 extraction and impurity removal, P507 extraction and separation of nickel-cobalt, nickel,cobalt and copper in the nickel-cobalt material are extracted in high recovery, and impurities such as iron, zinc, manganese, calcium, magnesium and the like in the nickel-cobalt material are removed, thereby achieving nickel-cobalt-copper separation and resource comprehensive utilization. According to the treatment method provided by the invention, the process is simple and production cost is relatively low; the adaptability of the method on raw materials is strong and can be used for treating the nickel-cobalt material with complicated components and high copper-zinc-magnesium contents.

Owner:JINCHUAN GROUP LIMITED

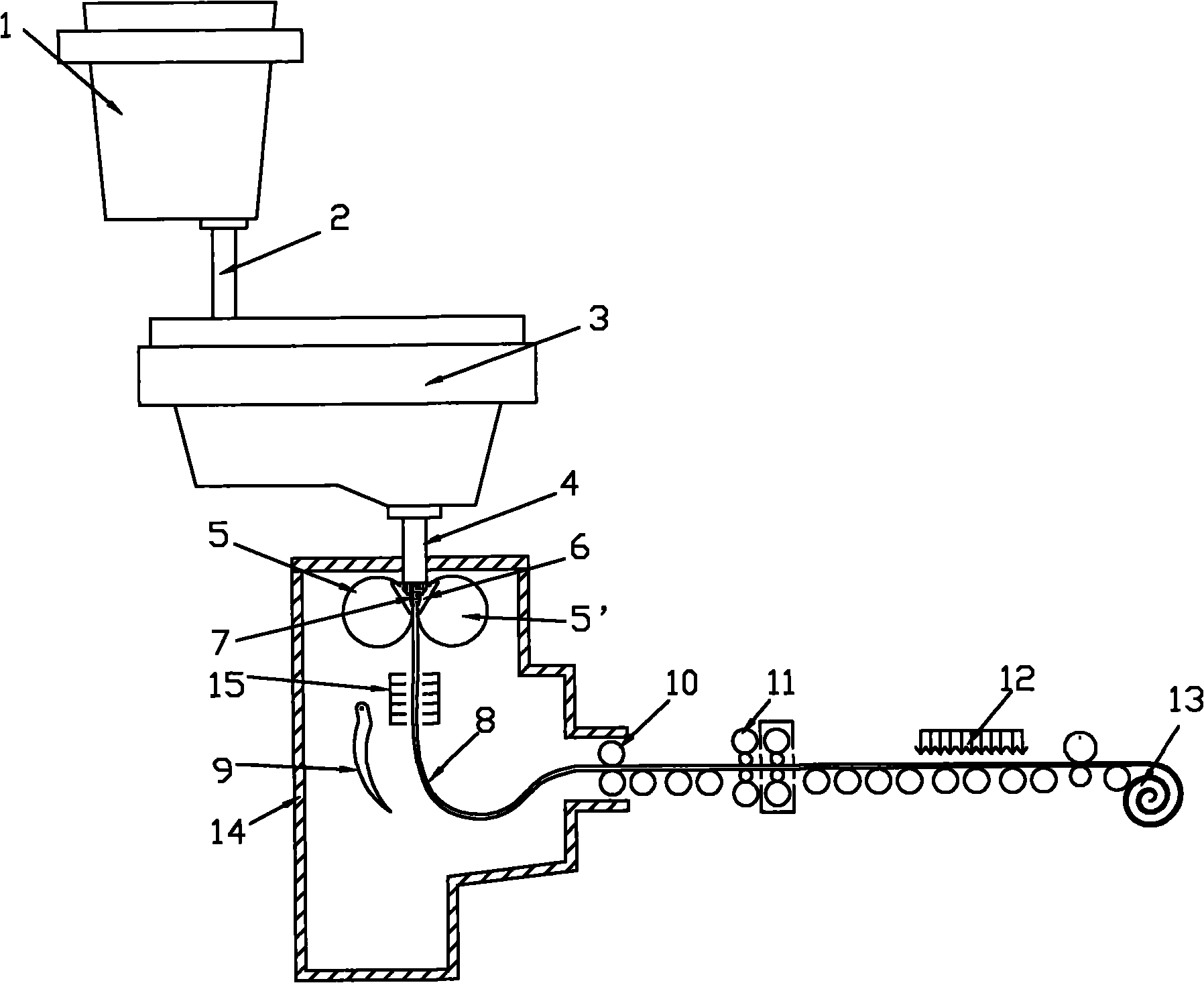

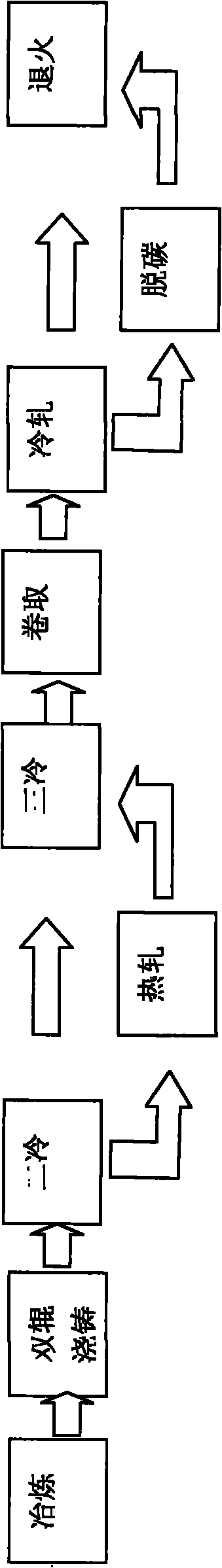

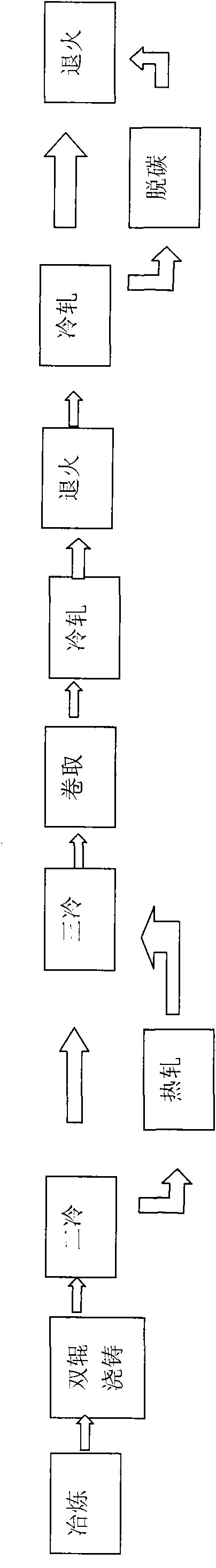

Manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel

ActiveCN102041367AMeet needsReduce processHeat treatment process controlMelting tankElectrical steel

The invention relates to a manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel, comprising the following steps: smelting molten steel the temperature and components of which meet the requirements, casting the molten steel into a molten bath formed by a pair of water-cooling crystallizing rolls rotating at high speed, then cooling for the second time, hot rolling, cooling for the third time, coiling, cooling to room temperature, pickling, cold rolling, and finally annealing to obtain the cold rolled non-oriented silicon steel sheet with high magnetic induction and low iron loss. In the invention, the thin strip continuous casting process can eliminate the hot rolling thinning procedure in the traditional process, thus avoiding quality defect caused by the improper hot rolling process, simultaneously reducing the equipment loss, and reducing the maintenance and overhaul costs of equipment; the solidification process is controlled to improve the medium axialite proportion of the casting strip, thus improving the corrugation defect of the product in the cold rolling process; and the range of components of the non-oriented silicon steel smelting is widened by the characteristic of quick solidification of the continuously cast thin strip, and the smelting cost is lowered. The invention has the advantages of short process flow, low energy consumption, high efficiency, low production cost, simple manufacturing method and obvious energy saving and consumption reducing effects.

Owner:BAOSHAN IRON & STEEL CO LTD

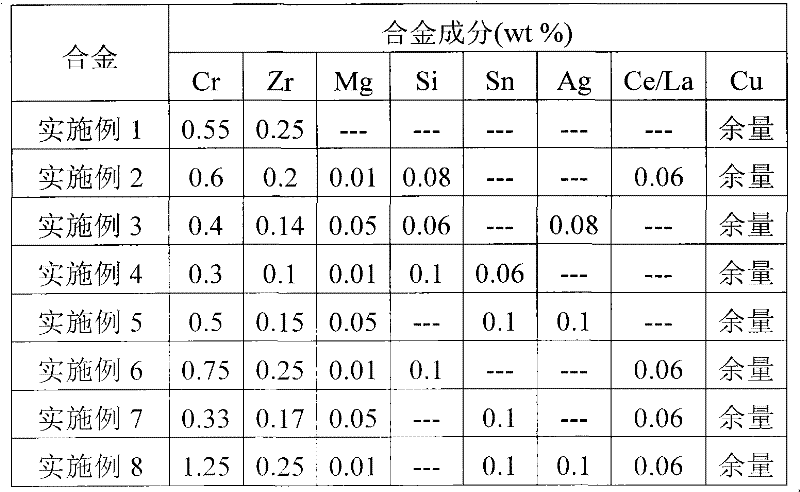

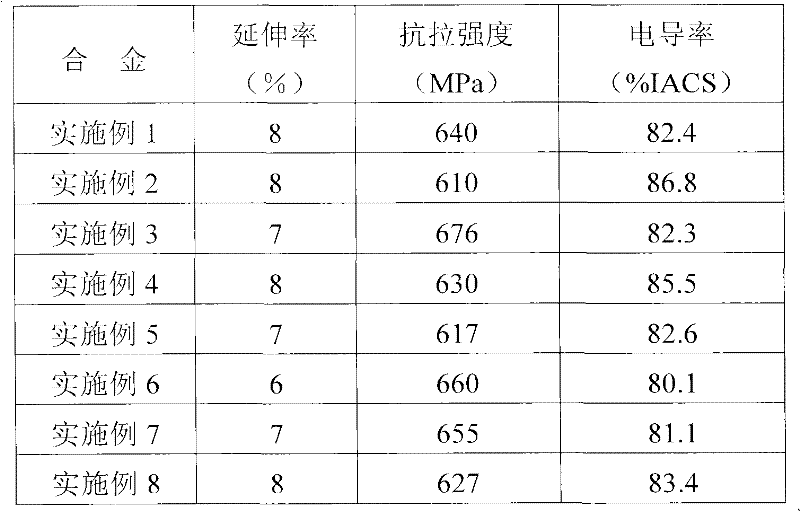

CuCrZr alloy with high strength and high conductivity, and preparation and processing method thereof

The invention relates to a CuCrZr alloy with high strength and high conductivity, and a preparation and processing method thereof. The alloy comprises the basic ingredients in percentage by mass: 0.3 percent to 1.4 percent of Cr, 0.02 percent to 0.25 percent of Zr and the balance Cu, wherein the ingredients in the CuCrZr alloy are needed to meet the following requirements: (a) Cr / Zr is less than or equal to 5 and is greater than or equal to 1.9; and (b) Cr+Zr is less than or equal to 1.5 percent and is greater than or equal to 0.4 percent. The preparation and processing method comprises the following steps of: a, compounding, feeding, smelting and casting according to mass percent; b, surface milling; c, hot rolling; d, solution treatment; e, primary cold rolling; f, primary aging; g, secondary cold rolling; and h, secondary aging. The CuCrZr alloy has the tensile strength sigma b being 600-700 MPa, the plasticity elongation rate delta being 4-10 percent, and the conductivity being greater than 80 percent of IACS (International Annealed Copper Standard), can be widely applied to occasions with high strength and high conductivity for preparing resistance welding electrodes, liners of crystallizers of continuous casting machines, integrated circuit lead frame and the like.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Device and method for preparing spherical titanium powder and titanium alloy powder through gas atomization

ActiveCN104475744AAvoid pollutionHigh sphericityGranulation by liquid drop formationHigh frequency powerTitanium alloy

The invention relates to a device and method for preparing spherical titanium powder and titanium alloy powder through gas atomization, which belongs to the field of powder metallurgy industry. The device comprises a vacuum chamber, a continuous feeder for titanium or titanium alloy wires / rods is arranged outside the vacuum chamber, a dynamic sealing device is arranged at the top of the vacuum chamber, a metal straightening device is arranged inside the vacuum chamber, an atomizing chamber is arranged below the vacuum chamber, a gas atomization nozzle is installed between the atomizing chamber and the vacuum chamber, the center hole of the nozzle is internally provided with a wire / rod guiding device, a high-frequency smelting coil is installed below the nozzle, wherein the dynamic sealing device, the straightening device, the guiding device and the high-frequency smelting coil are installed on the same axis; a heat dissipation cover is installed inside the atomizing chamber, a protective cover is arranged at the top of the heat dissipation cover, and the centers of the heat dissipation cover and protective cover and the center of the high-frequency smelting coil are on the same axis; a powder collecting pot is arranged below the atomizing chamber. By means of controlling the diameters of the wires, the atomizing gas pressure and the power of a high-frequency power supply, titanium and titanium alloy powder with different particle sizes and particle size distributions can be obtained.

Owner:有研增材技术有限公司

Production method of ultrahigh strength steel plate for cold forming and steel plate

The invention provides a production method of an ultrahigh strength steel plate for cold forming and the steel plate. The method comprises the steps of smelting, casting, hot rolling, cold rolling, heating the cold-rolled steel plate through a continuous annealing production line with rapid cooling treatment to the austenite temperature, holding the temperature for a certain time, carrying out quenching treatment, obtaining a steel plate with the main structure of M+A and carrying out distribution treatment in a bell type annealing furnace. The steel plate comprises the following components in percentage by mass: 0.02-0.60% of C, 0.05-3.5% of Si, 0.20-3.50% of Mn, P more than or equal to 0.005 but less than or equal to 0.50%, S not more than 0.05%, 0.02-3.00% of Al, Cr not more than 0.50%, Ni not more than 3.00%, Cu not more than 0.50%, Mo not more than 1.50%, V not more than 0.50%, Ti not more than 0.20%, Nb not more than 0.20% and the balance of Fe and unavoidable impurities. The steel plate produced by adopting the method provided by the invention has the advantages of high strength and capability of cold forming and the process route of Q&P steel industrial production is effectively solved.

Owner:ANGANG STEEL CO LTD

Spherical porous light haydite for treating waste water and its production method

InactiveCN1380137AHigh economic valueSolve the way outOther chemical processesSustainable biological treatmentPorosityEnvironmental resistance

The present invention relates to a kind of spherical porous loight-ceramsite produced by using industrial waste slag, steel-smelting rod mud and flyash as main raw material, using clay as binding agent, adding proper quantity of pore-forming agent and adopting high-temp., sintering process. Said invention also provides its production method, and said product can be specially used as filtration material for water treatment. Its product quality is as follows: specific surface area is 4-10 sq.m / g, average pore size is 50-250 micrometers, apparent density is 1.40-1.80 g / cu.cm and its voidage is 30-40%.

Owner:HUAQI ENVIRONMENT PROTECTION SCI & TECH

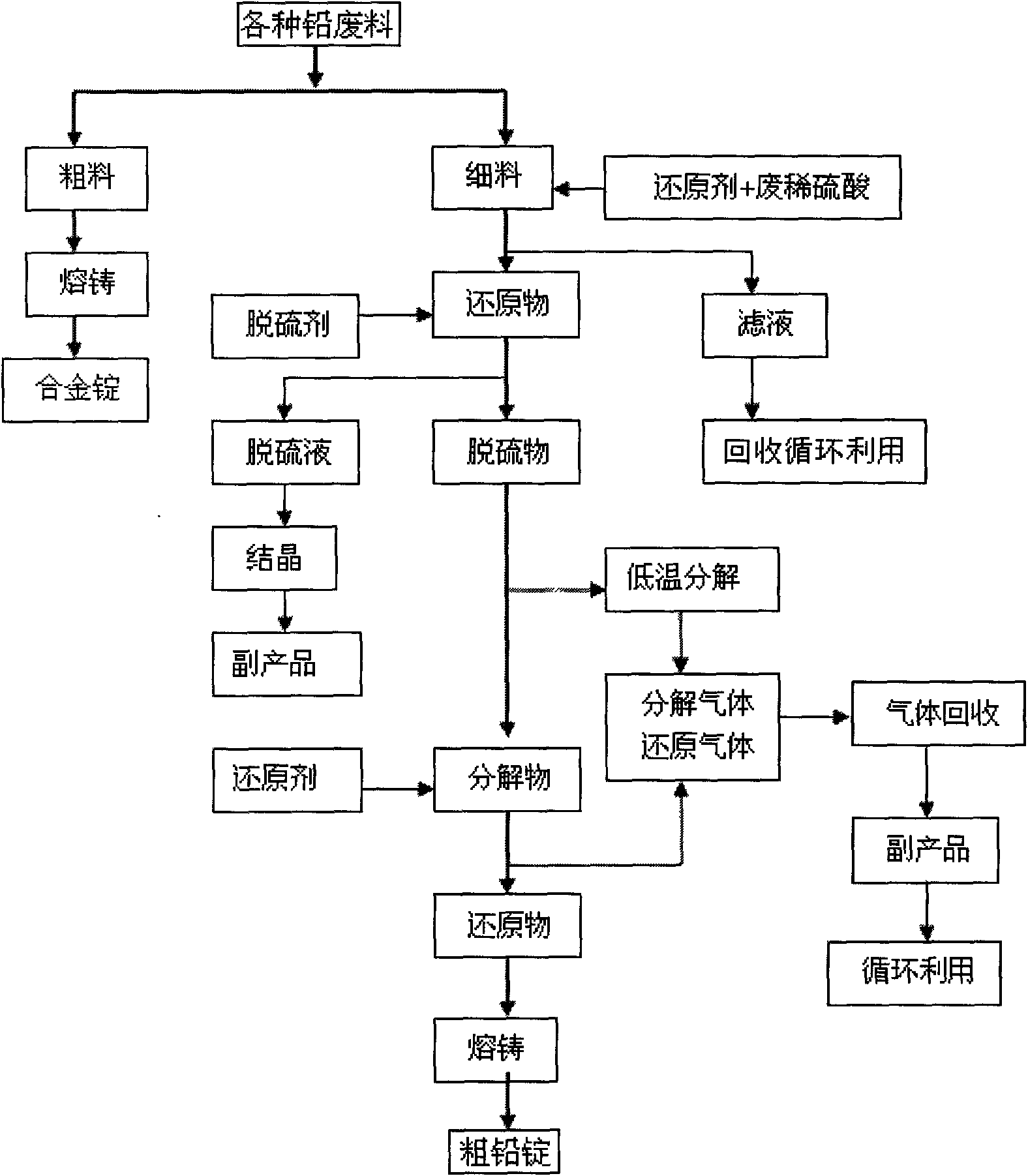

Waste lead recovering method for lead-acid storage batteries

InactiveCN101608264AAvoid harmLower decomposition temperaturePhotography auxillary processesProcess efficiency improvementLead dioxideEngineering

The invention discloses a waste lead recovering method for lead-acid storage batteries. The method comprises the following steps: fine stuff such as diachylon and the like are added in a reaction kettle with a stirring device; reducing agent (FeSO4) and dilute sulfuric acid are simultaneously added; stirring reaction is carried out at the temperature of 50-60 DEG C for 50-70 minutes so as to reduce lead dioxide into lead sulfate; the lead sulfate is added into the reaction kettle with the stirring device; water is simultaneously added into the reaction kettle for size mixing; then sodium carbonate is added; desulfuration is carried out at the temperature of 50-60 DEG C so as to obtain solid lead carbonate; the lead carbonate is put into a smelting furnace and then decomposed at the temperature of 320-350 DEG C so as to obtain lead oxide; and reducing agent (carbon) is added into the smelting furnace to reduce the lead oxide into metal lead at the temperature of 700-800 DEG C. The method recovers the lead by means of the combination of the wet and the dry processes, thereby avoiding the harm to the environment caused by lead dust, lead vapor, lead skim, sulfur dioxide gas, and the like by adopting fire smelting. The method has the advantages of high lead recovery rate, low energy consumption and no environment pollution.

Owner:张天任

Bulk depositing synthesis process of isotactic polybutylene-1

The present invention is bulk depositing synthesis process of isotactic polybutylene-1, and belongs to the field of polymer technology. The powdered isotactic polybutylene-1 product is obtained through bulk depositing polymerization of butylene-1 as the monomer and reactant medium at 0-70 deg.c in the presence of supported titanium catalyst, and the subsequent flash evaporation to eliminate unpolymerized monomer. The catalyst system may have organic aluminum AlR3 as co-catalyst, added electron donor compound, and hydrogen as molecular weight regulator. The polymerization reaction is performed in a polymerizing kettle with stirring screw belt. The present invention has simple technological process, high efficiency and low cost, and the prepared isotactic polybutylene-1 has high stereoregularity degree, crystallization degree higher than 60 %, and smelting point of 127.5 deg.c.

Owner:SHANDONG ORIENT HONGYE CHEM +1

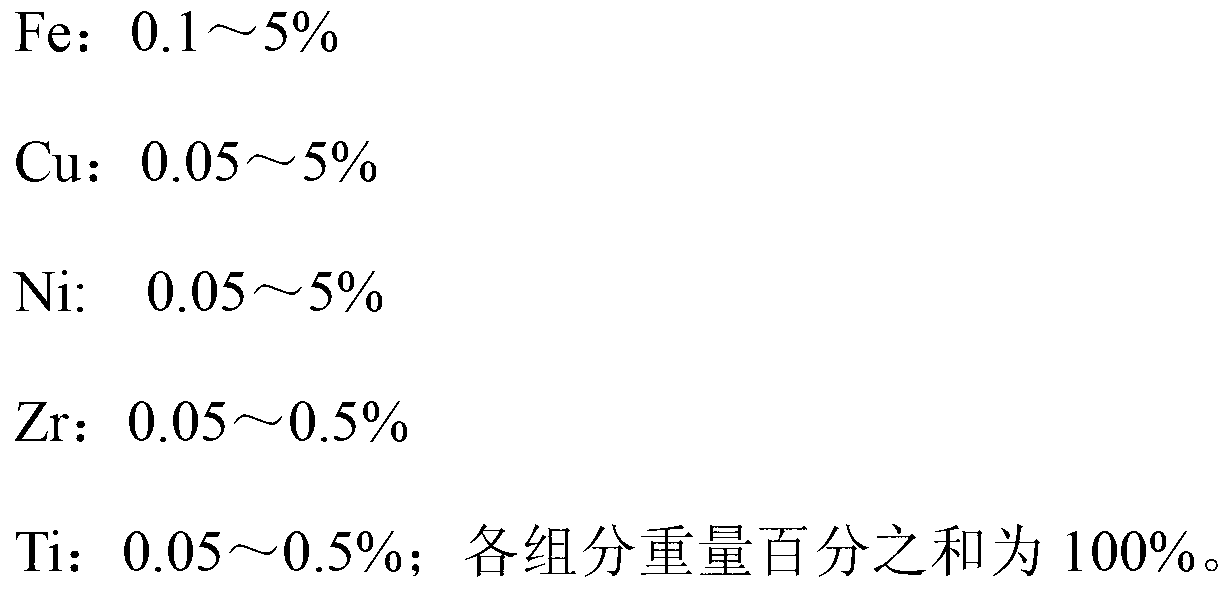

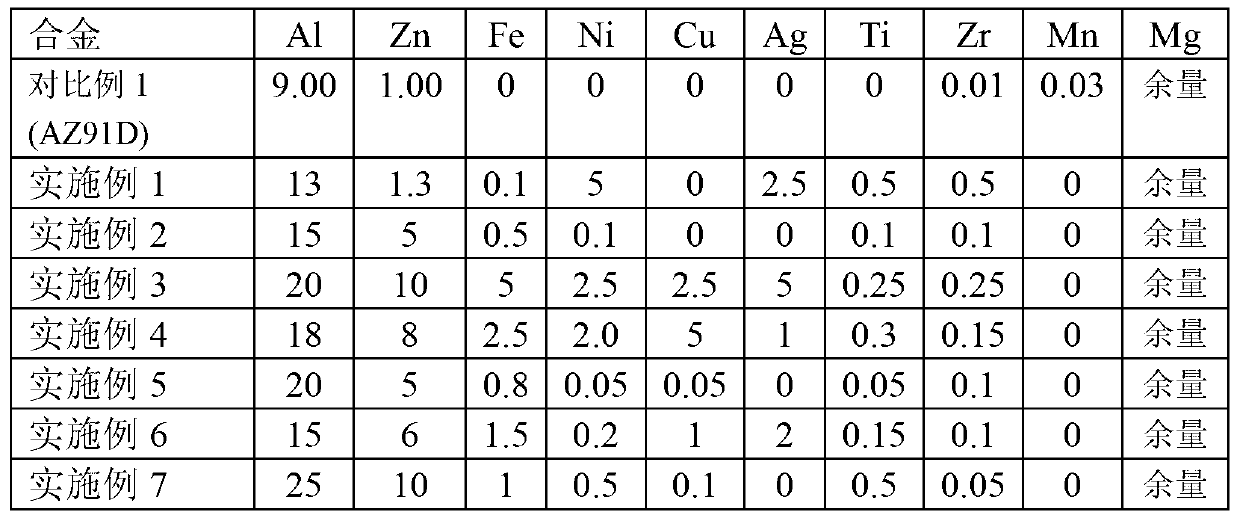

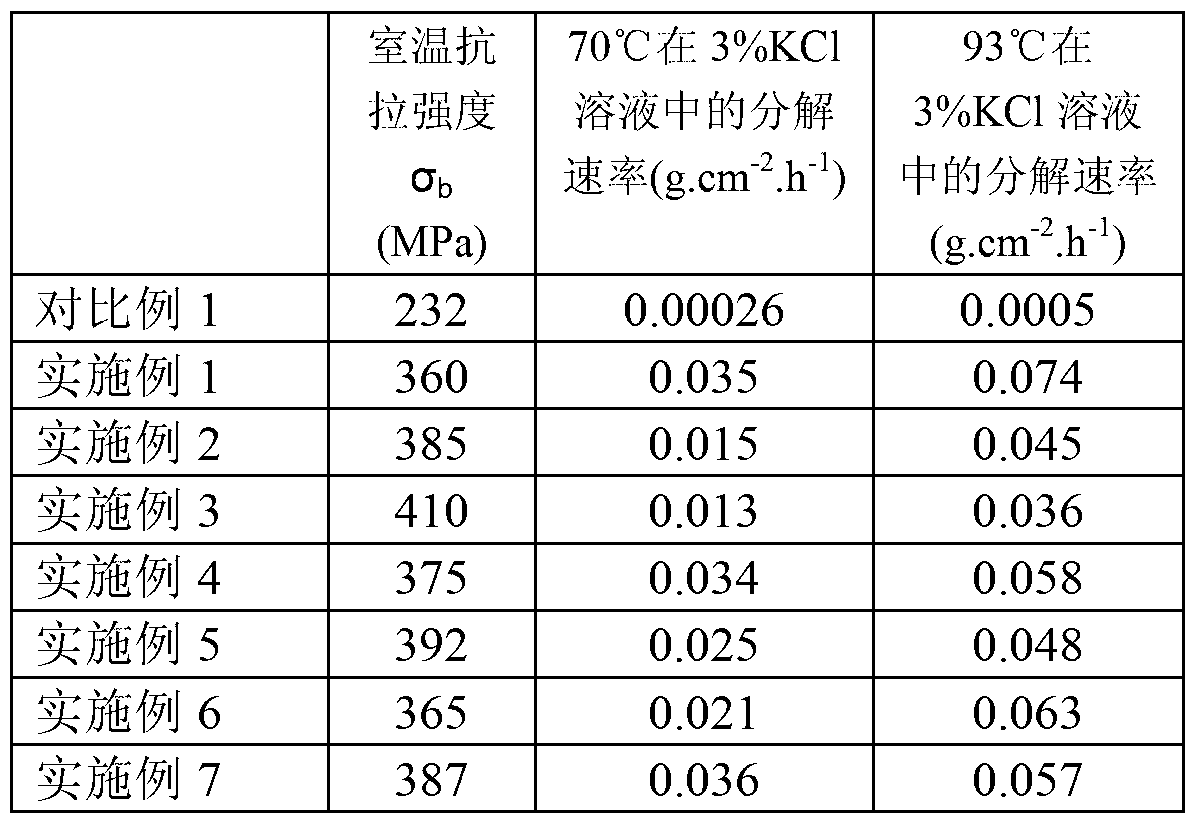

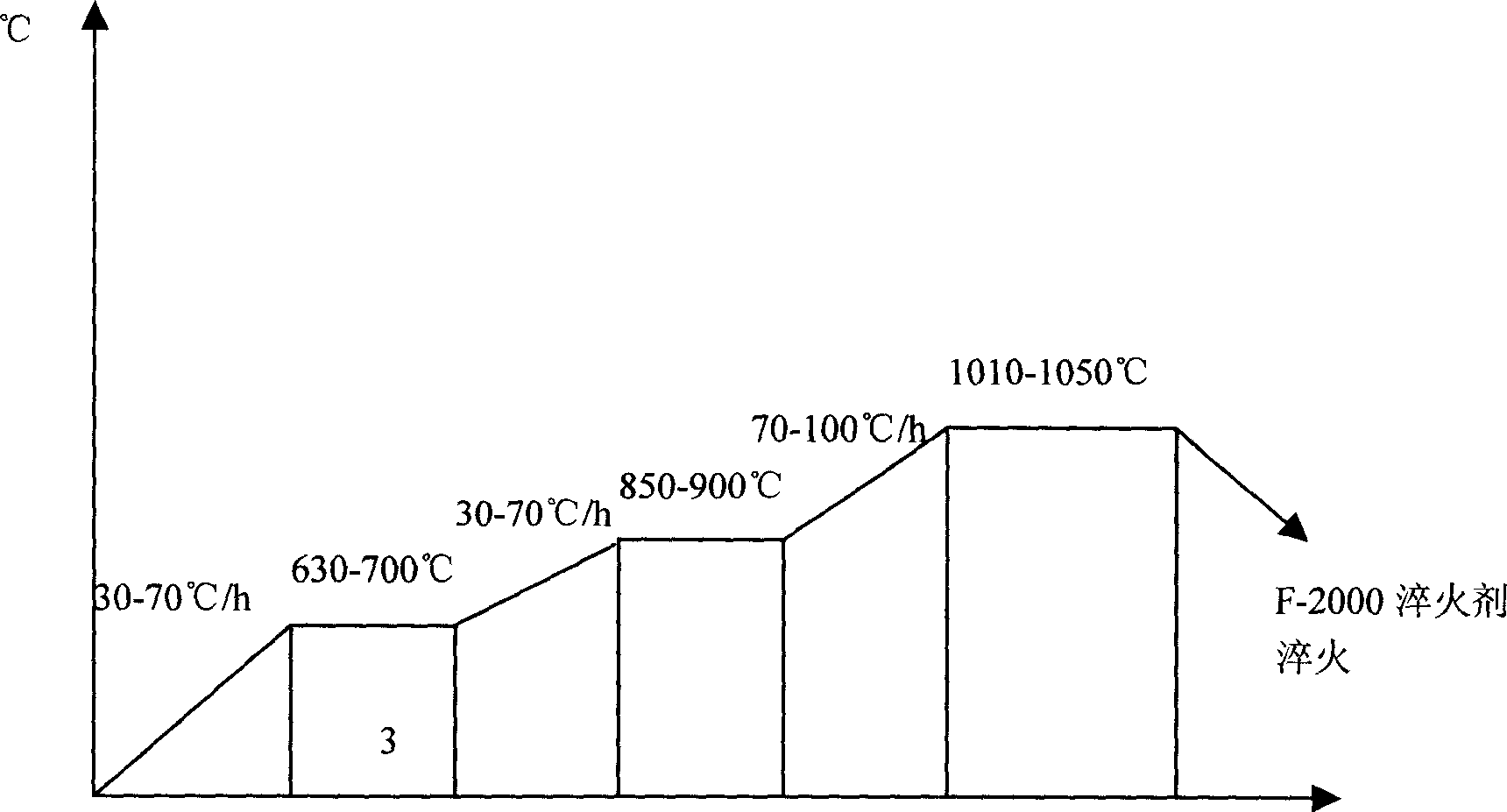

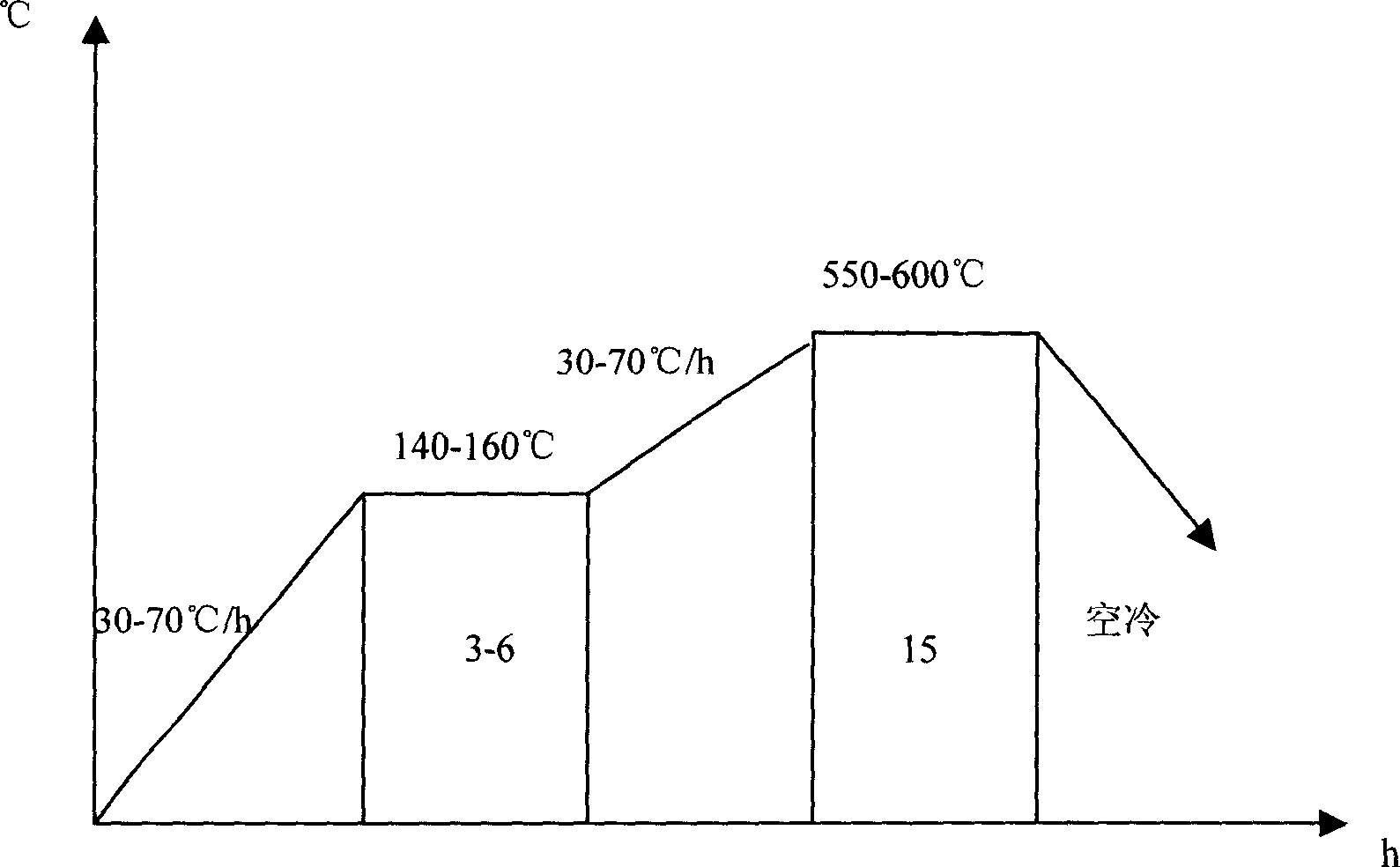

Light and pressure-proof fast-decomposed cast magnesium alloy

The invention discloses light and pressure-proof fast-decomposed cast magnesium alloy which can be used as a tripping ball material for a multi-stage sliding sleeve staged-fracturing technique. The light and pressure-proof fast-decomposed cast magnesium alloy is prepared from the following components: 13-25% of Al, 2-15% of Zn, 0.1-5% of Fe, 0.05-5% of Cu, 0.05-5% of Ni, 0-5% of Ag, 0.05-0.5% of Zr, 0.05-0.5% of Ti, and the balance of Mg. The preparation method comprises the following steps of: weighing the components according to the designed component ratio of the magnesium alloy; firstly, putting pure magnesium and pure aluminum into a smelting furnace, putting pure zinc and intermediate alloy of other components into magnesium-aluminum alloy melt after melting; refining, degassing, and stewing after warming to melt; then casting in a protective atmosphere. The light and pressure-proof fast-decomposed cast magnesium alloy is reasonable in component ratio, and simple in craft process; the light and pressure-proof fast-decomposed cast magnesium alloy can be obtained by controlling the ingredients of the alloy; the alloy decomposition performance exceeds that of the traditional cast magnesium alloy; the demands of the multi-stage sliding sleeve staged-fracturing technique on the decomposition performance of the tripping ball material can be met; industrialized application can be achieved; application of the magnesium alloy in the field of exploitation of petroleum and gas is expanded.

Owner:中山市宏镁科技有限公司

Producing method of clean steel

The invention discloses a producing method of clean steel, which can further enhance the cleanliness and comprise the following steps of: pretreating with molten iron for desulfurizing until [S] is not more than 0.010%; then delivering to a converter for smelting; dephosphorizing and controlling sulfur; controlling finished molten iron in the converter to be with [P] of not more than 0.0080% and [S] not more than 0.010%; adding a ladle slag modifying agent to ladles in a steel tapping process for regulating and modifying the ladle slag, wherein after treating, in the molten iron, [P] is not more than 0.0060% to 0.0080%, [S] is not more than 0.0080% and roughing slag quantity is not more than 0.5%; controlling refined finished slag components in LF (Low Frequency) refining, wherein soft argon blowing time of the molten iron is not less than 5 minutes after LF refining, and the composition is qualified when [S] is not more than 0.0020%; carrying out VD (Vacuum Degassing) refining to ensure that [H] is not more than 1.5ppm; and continuously casting, wherein a double-layer high-alkalinity covering agent is adopted as a middle ladle, a seal ring and a long water gap are additionally arranged for argon-blowing protective casting, which is carried out at constant speed, and overheat delta T of the molten iron ranged from 15 DEG C to 30 DEG C. Under the condition that the producing cost is not increased basically, the cleanliness of the clean steel is further enhanced by the control of each procedure junction point, and the clean steel comprises the following components by weight percent: S not more than 20ppm, P not more than 100ppm, TO not more than18ppm, H smaller than 2.0ppm, N not more than 35ppm, and A, B, C and D types of impurities not more than 0.5 grade.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Anticorrosion, wear-resistant plastic die steel 4Cr16Mo and its mirror large-die-block preparing and producing method

ActiveCN1676653AImprove lateral performanceMeet mirror polishing requirementsHeat treatment process controlProcess efficiency improvementChemical compositionWear resistant

It is a new preparation and production method of corrosion-resistant and anti-abrasive plastic die steel 4Cr16Mo and its big mirror module. The characteristic is about its chemical composition. There are 0.33-0.43%C, 0.30-1.00%Mn, 0.30-1.00%Si, less than 0.045%S, less than 0.045%P, 14-18%Cr, 0.10-1.00%Ni, 0.80-1.50%Mo besides Fe. The method includes double refinement consisting of the primer smelting in electric furnace and vacuum handling outside the furnace and electroslag remelting, and necessary stress relieving annealing static ingot and electroslag ingot to refine electroslag ingot of component-uniform. After that, it uses hot machining forging technology and necessary stress relieving annealing of module to make the electroslag ingot into big module (thickness: 500mm, width:1200mm, length: 2500mm). At last, special heat-treat module modified treatment technology is used to bring out big highly corrosion-resistant and highly anti-abrasive plastic die steel module. This kind of module has stable quality and the nature reaching the standard(dirty component A<=2.0, B<=2.0, C thinness<=2.0, C thickness<=1.5, D<=2.0). To sum up, it has significant economic and social efficiency.

Owner:宝武特种冶金有限公司

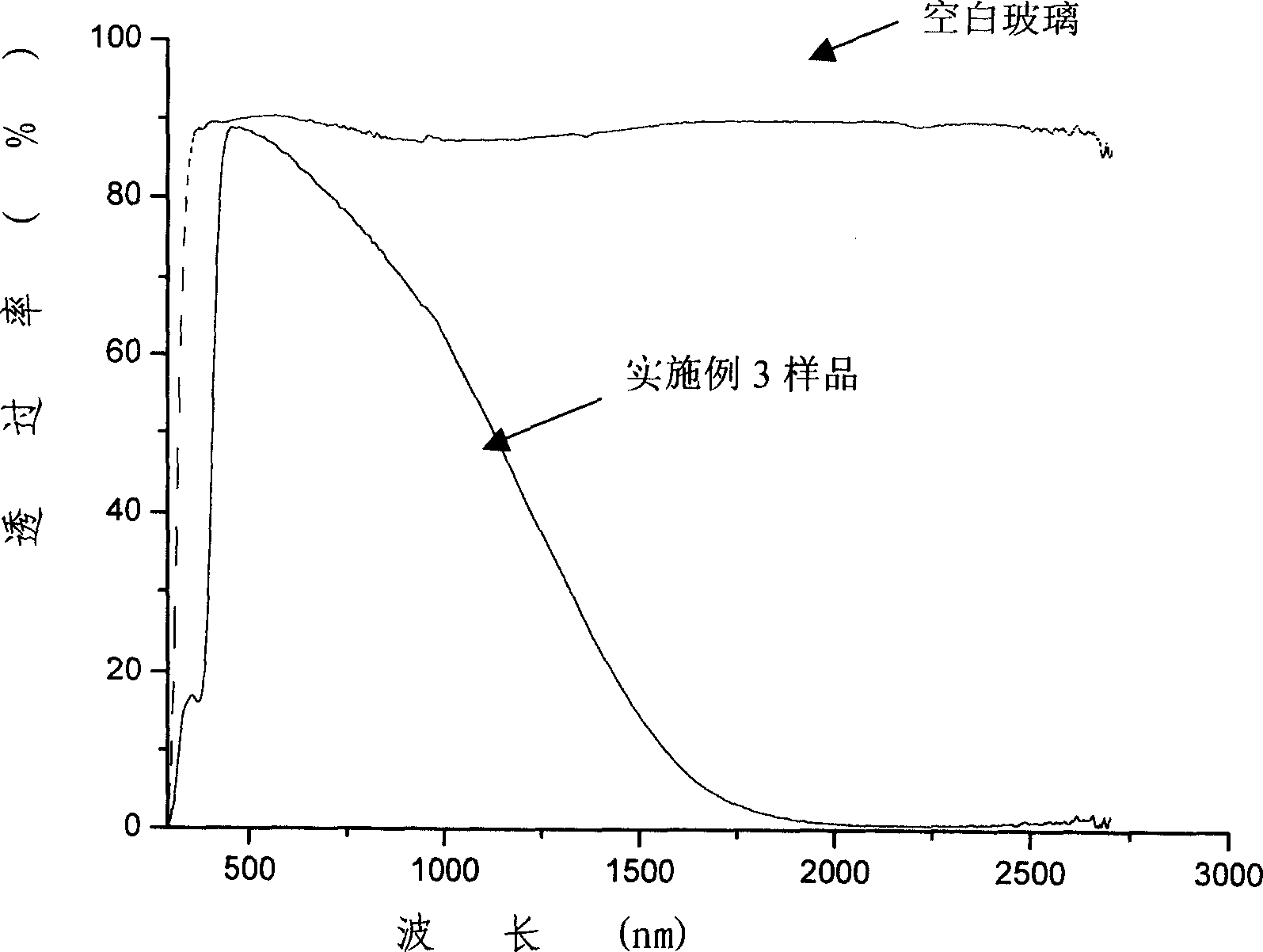

Sunlight controlled transparent film in low radiation, prepartion method and application

InactiveCN1916057AGood visible light transparencyPrevent penetrationDispersed mediaMetal oxide nanoparticles

This invention relates to a method for preparing low-radiation heat-insulating transparent film for controlling sunlight. The film is composed of: organic polymer 70-99.9 wt. %, doping metal oxide nanoparticles 0.1-30 wt. % and adjuvant 0-29.9 wt. %. The method comprises: (1) uniformly dispersing the doping metal oxide nanoparticles into a dispersing medium, mixing with the organic polymer and the adjuvant, and drying to obtain master batches; (2) plasticizing, smelting or extruding and blowing, calendaring, stretching, extruding and casting to obtain the film. The film can be used as the coating film for architecture glass, automobile window and ship window, and has such advantages as high visible-light permeability, good sunlight obstructing effect, good anti-electrostatic effect, and good electromagnetic radiation resistance.

Owner:长春迪高实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com