High-toughness and ultrahigh-strength wear-resistant steel plate and production method thereof

An ultra-high-strength, wear-resistant steel plate technology, applied in the manufacture of converters, etc., can solve the problems of high carbon content, high cost, and low hardness, and achieve good strength and toughness matching, good welding performance, and cost savings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

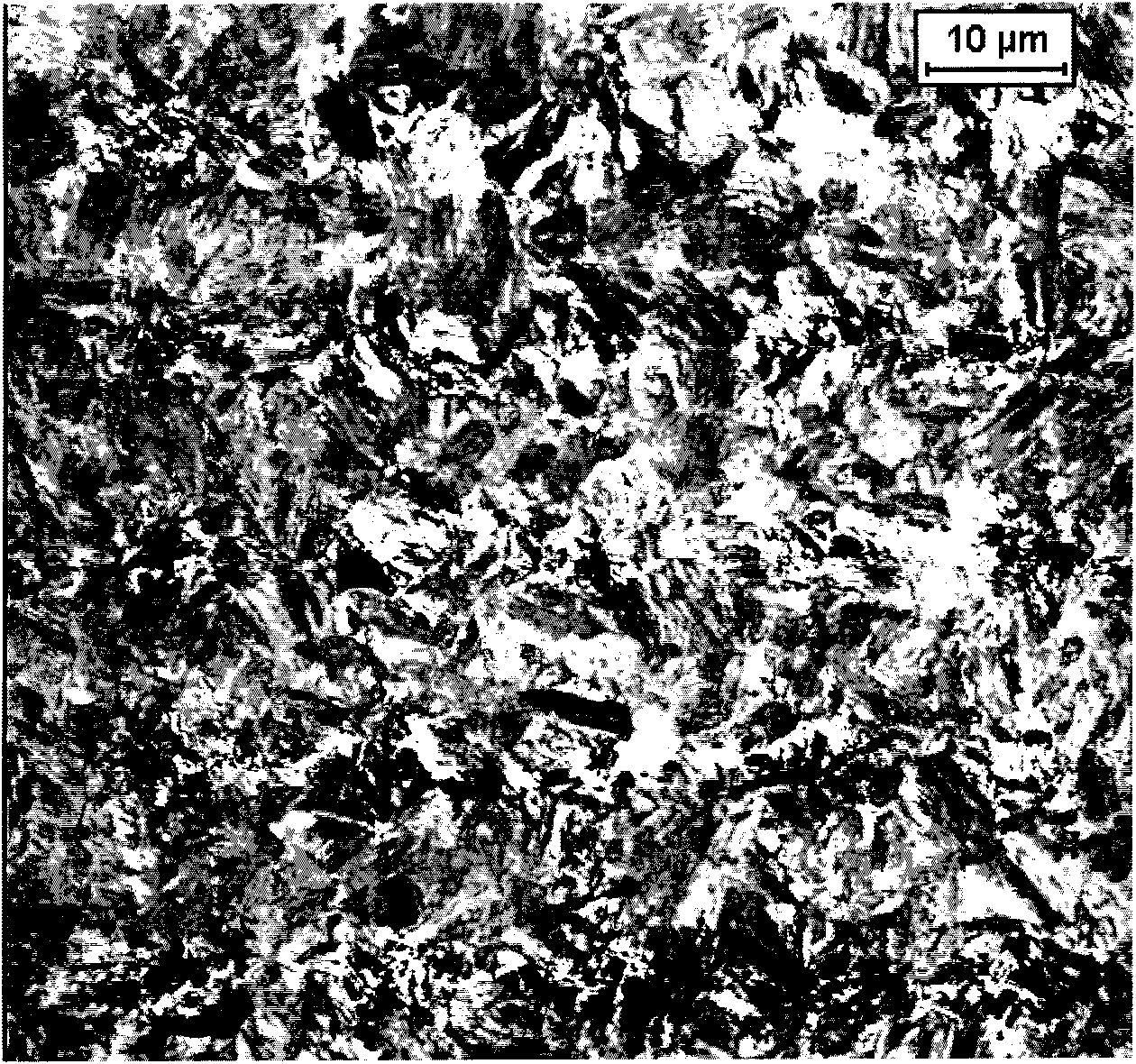

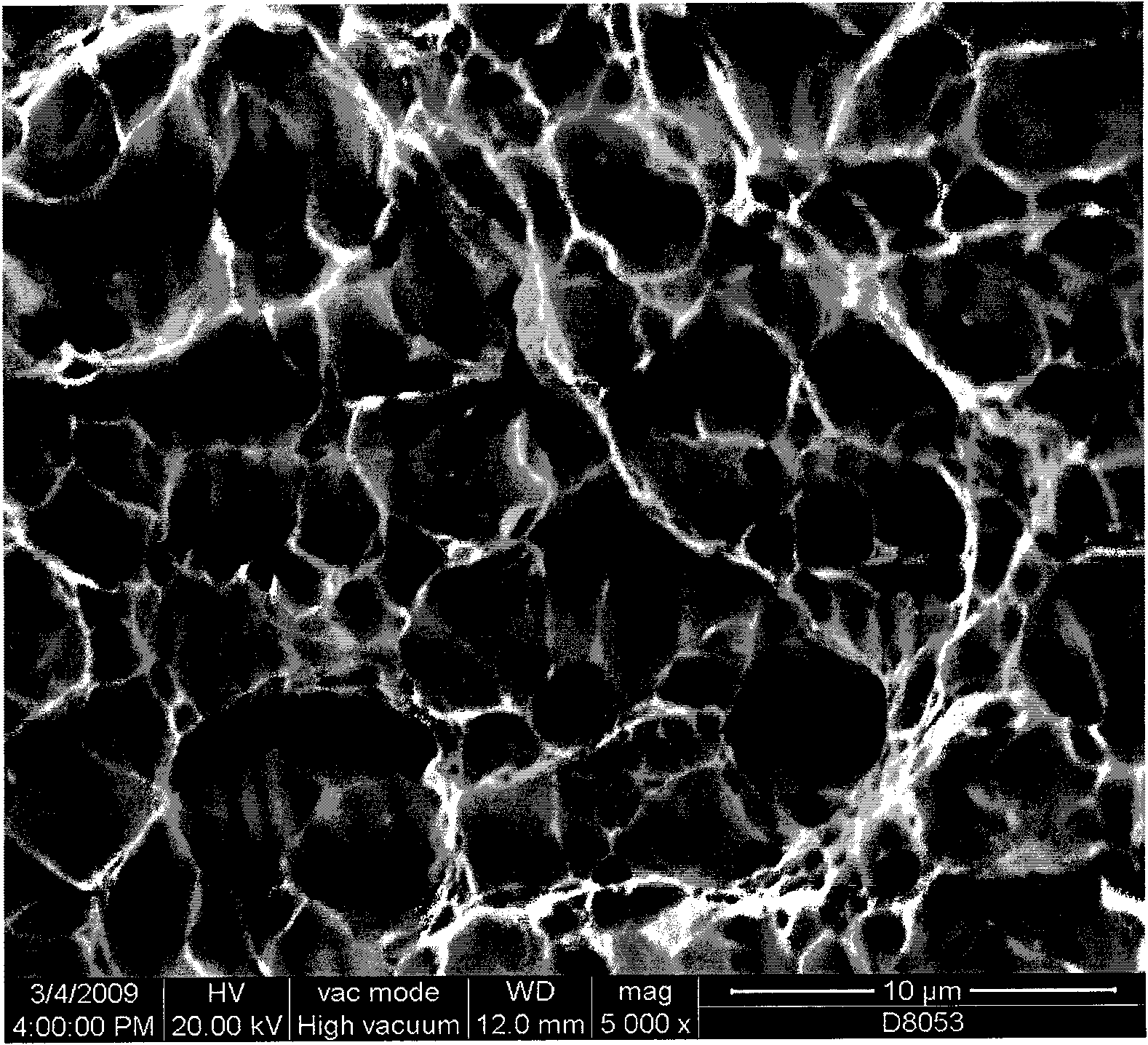

Image

Examples

Embodiment 1

[0024] The chemical composition of A test steel smelted according to the above scheme is shown in Table 1

[0025] Table 1 Chemical composition of experimental steel A (mass percent w%)

[0026]

[0027] Ceq=C+Mn / 6+(Cr+Mo+V) / 5+(Cu+Ni) / 15;

[0028] Produce table 1 composition A steel by the inventive method, it is characterized in that control following process parameter:

[0029] Slab heating stage: heat the smelted steel slab at 1200°C for 3 hours;

[0030] The starting temperature of rough rolling is 1080℃, and the finishing temperature of rough rolling is 1050℃;

[0031] The starting temperature of finish rolling is 940°C, and the finishing temperature of finish rolling is 910°C;

[0032] In the heat treatment stage, the quenching temperature is 930°C, the heating time is 30min (2.5min / mm×plate thickness), quenching is carried out in the laboratory test quenching machine, the cooling rate is about 60°C / s, the tempering temperature is 250°C, and the heating time It is...

Embodiment 2

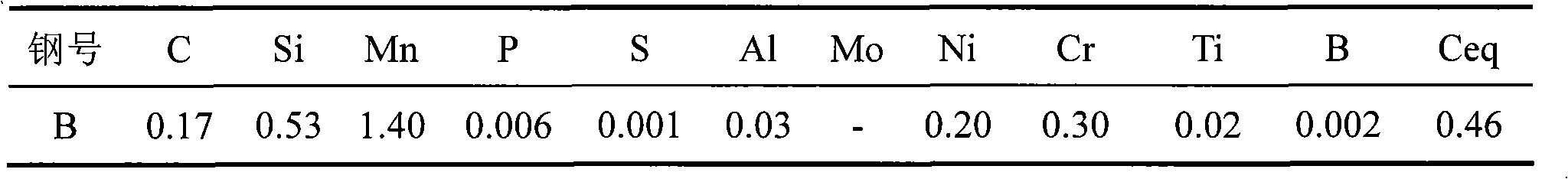

[0034] The chemical composition of the B test steel smelted according to the above scheme is shown in Table 2 below:

[0035] Table 2 Chemical composition of experimental steel B (mass percentage w%)

[0036]

[0037] Ceq=C+Mn / 6+(Cr+Mo+V) / 5+(Cu+Ni) / 15;

[0038] Produce the composition B steel of last table by the inventive method, it is characterized in that control following process parameter:

[0039] Slab heating stage: heat the smelted steel slab at 1200°C for 3 hours;

[0040] The starting temperature of rough rolling is 1100℃, and the finishing temperature of rough rolling is 1120℃;

[0041] The finish rolling start temperature is 930°C, and the finish rolling finish temperature is 880°C;

[0042] In the heat treatment stage, the quenching heating temperature is 900°C, the heating time is 36min (according to 3min / mm×plate thickness), quenching is carried out in the laboratory test quenching machine, the cooling rate is about 60°C / s, and the tempering temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com