Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12753 results about "Molten steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

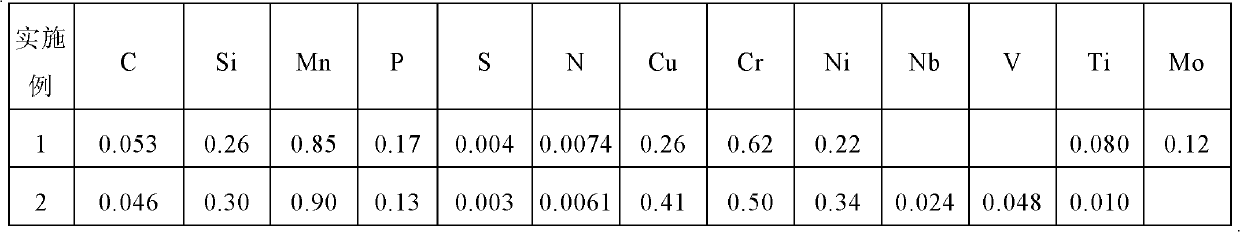

Method for improving performance of 700MPa grade V-N micro-alloying high-strength weathering steel

InactiveCN101161849AImprove low temperature impact toughnessGood formabilityTemperature control deviceMetal rolling arrangementsChemical compositionHigh intensity

The invention discloses a method for improving the performance of 700 MPa grade V-N microalloyed high strength weathering steel. The method is specific to the characteristics of the sheet billet continuous casting and tandem rolling technology and metallurgy component, and adopts an electric furnace or a revolving furnace to smelt, refine, continuously cast sheet billet which directly enters into a roller hearth to heat after a casting blank concretes, or soaking furnace, hot rolling, laminar flow cooling and wind-up process flow. The chemical composition of molten steel is :C occupies less than or equal to 0.08Wt. percent, Si occupies from 0.25 to 0.75Wt. percent, Mn occupies from 0.2 to 2.0Wt.percent, P occupies less than or equal to 0.025Wt. percent, S occupies less than or equal to 0.040Wt. percent, Cu occupies from 0.25 to 0.60Wt. percent, Cr occupies from 0.30 to 1.25 Wt.percent, Ni occupies less than or equal to 0.65Wt. percent, V occupies from 0.02 to 0.20Wt. percent and N occupies from 0.015 to 0.030 Wt. percent. The invention takes full advantages of the characteristics of the sheet billet continuous casting and tandem rolling short flow process and adopts the V-N microalloyed technique to produce 700 MPa grade high strength weathering steel under the thinning function of VN and V (C, N) nanometer scale precipitate on crystal grain in casting blank of the sheet billet continuous casting and tandem rolling flow and the theory of precipitation strength. By the optimization design of the metallurgy component of V-N microalloyed 700MPa grade high strength weathering steel, the invention increases the low temperature impact ductility of coil of strip and improves the shaping property.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Method for producing 700Mpa V-N microalloyed high-strength air corrosion-resistant steel based on sheet bar continuous casting tandem rolling process

InactiveCN1884608AHigh strengthGood formabilityTemperature control deviceMetal rolling arrangementsSheet steelChemical composition

This invention exposed the producing method of V-N microalloyed high strength weathering steel which produced with near net shape con-casting technology. It is smelted in electric furnace or converter, refined, con-casted, casted, then directly sent into roller hearth furnace or soaking pit, hot-rolled, laminar cooled, coiled. The liquid steel's chemical elements are (Wt.%): C: <=0.08%, Si: 0.25- 0.75%, Mn: 0.8-2.0%, P: 0.070-0.150%, S: <=0.040%, Cu: 0.25-0.60 %, Cr: 0.30-1.25 wt%, Ni: <=0.65%, V: 0.05-0.20%, N: 0.015-0.030%. This invention can get the high intensity, formation, weathering, joining character stably. The alloying cost is relatively low. So it can be used to produce container, carriage, and other industry facility.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Multi-purpose, multi-oxy-fuel, power burner/injector/oxygen lance device

InactiveUS20030075843A1Reduce the numberSmall sizeTuyeresCharge manipulationSteelmakingLiquid medium

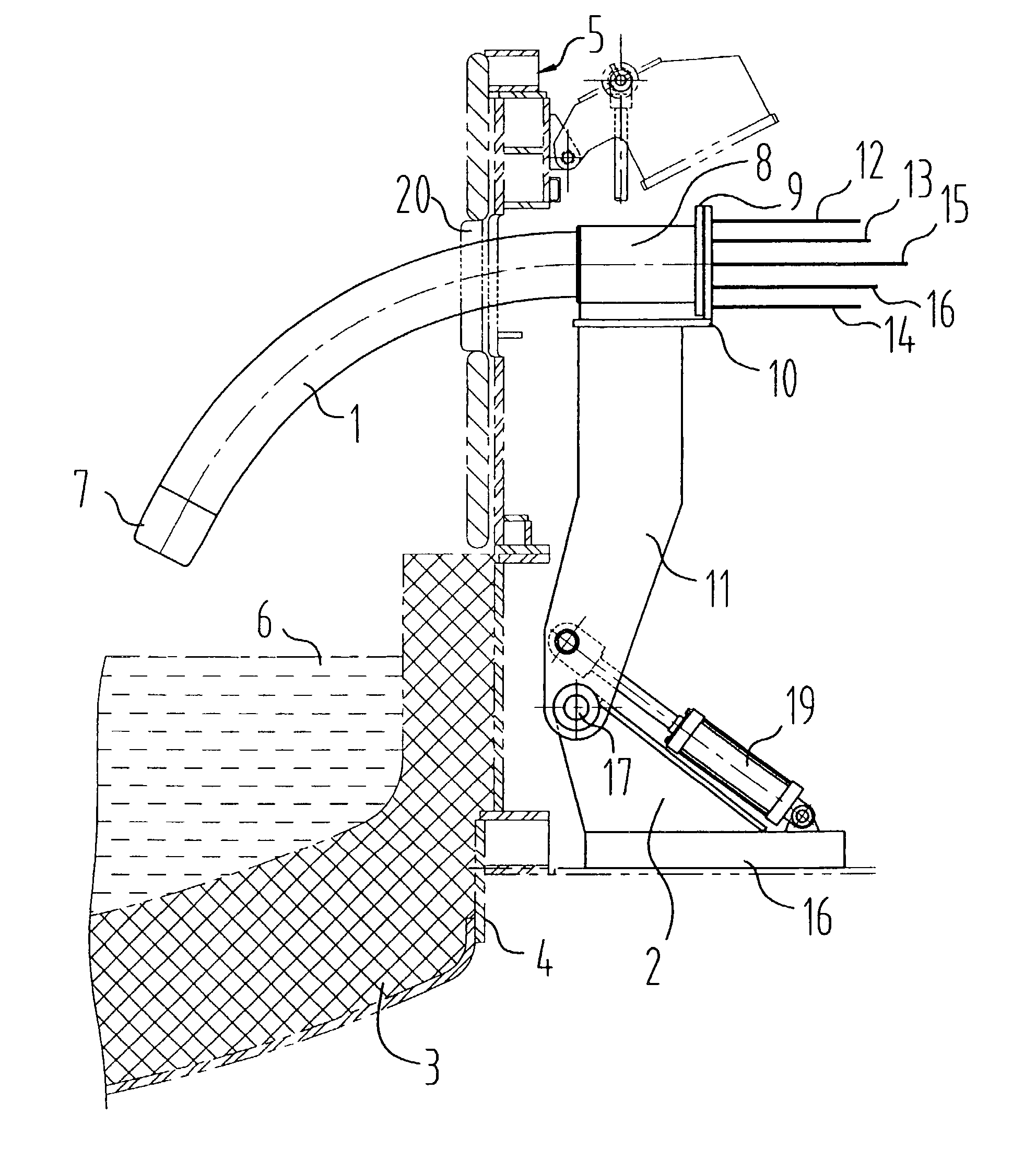

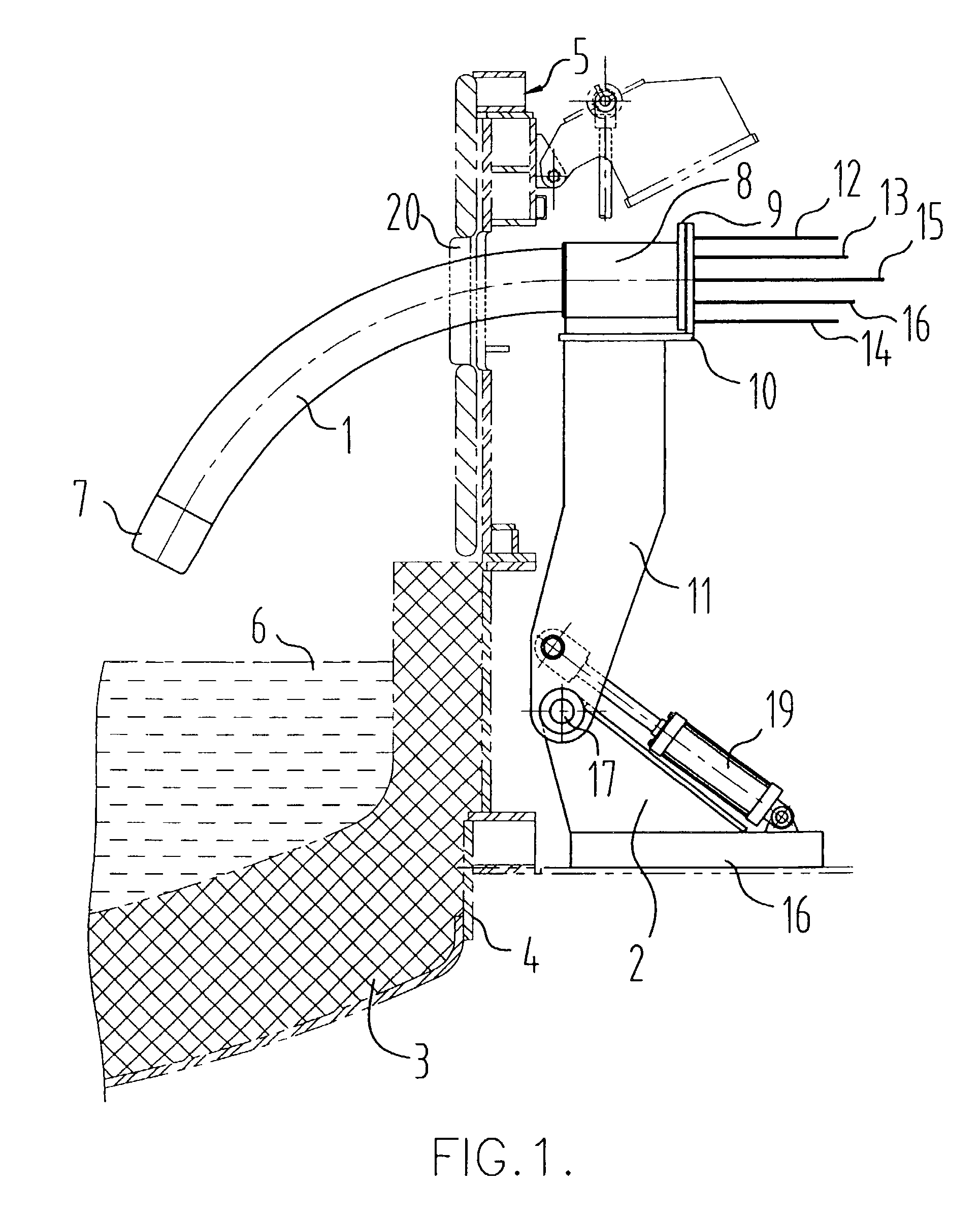

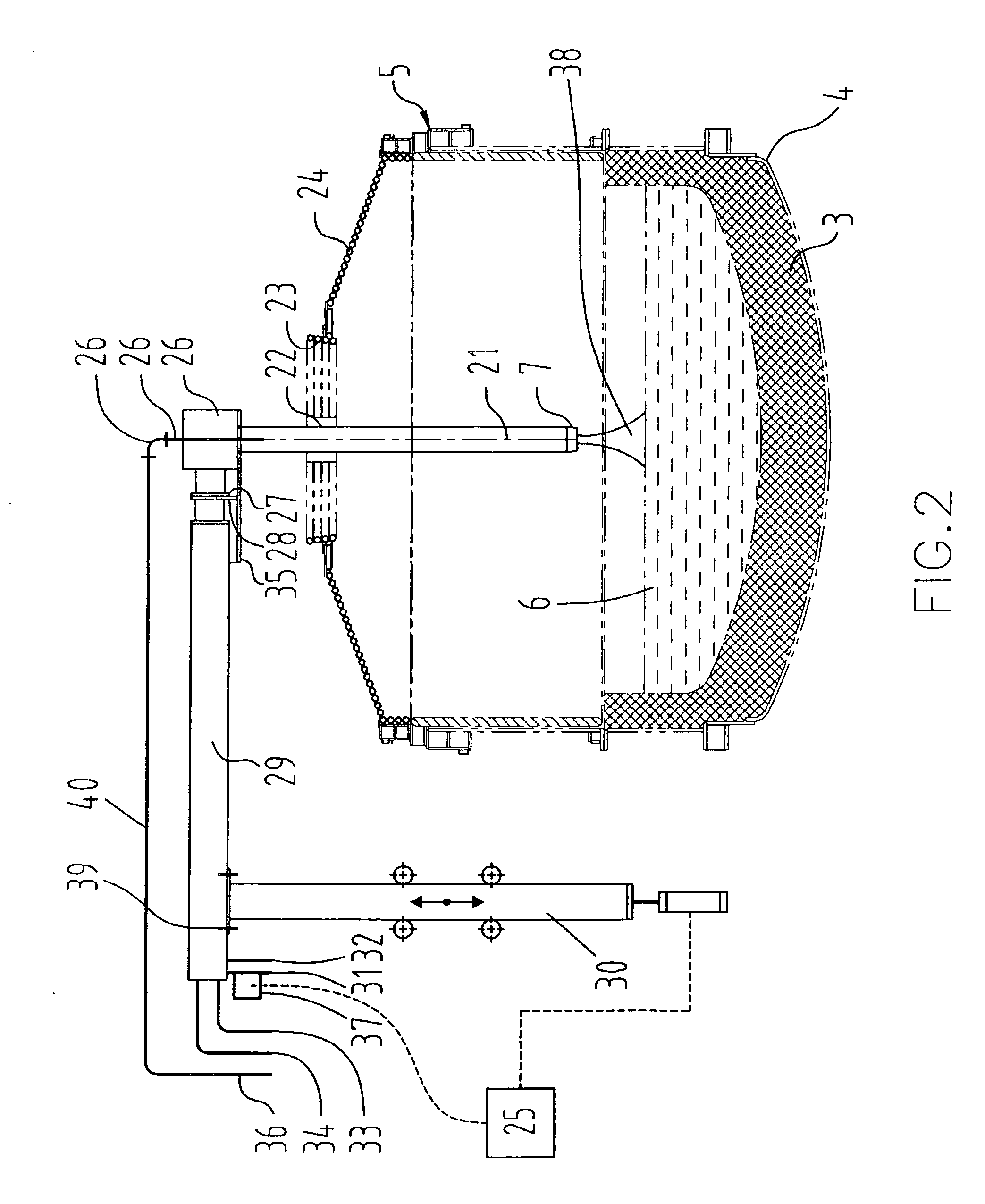

A multi-purpose, multi-oxy-fuel High Temperature Power Burner / Injector / Oxygen Lance, Mechanical System Apparatus Device, for steelmaking from recycled scrap and / or virgin ferrous charge, which can be employed in multi-oxy-fuel (natural gas; pulverized carbonaceous matter; heavy oil), especially by Oxygen Combusted mixture of Natural Gas / Pulverized Carbonaceous Matter in High Temperature Power Burner Mode, for efficient and rapid melting of solid ferrous charge (cold or preheated) in a special steelmaking Metallurgical Furnace or Open Hearth Furnace, Tandem Furnace, BOF, EAF, as its augmenting or only source of thermal energy; more than one Device in Oxygen-Natural Gas / Pulverized Carbonaceous Matter Power Burner Mode, can be employed as the only source of thermal energy in a modified, originally Electric Arc Furnace, as total replacement of Graphite Electrodes and Electric Arc System, the replacement being noticeably more primary energy efficient than the thermal energy provided by Graphite Electrode / Arc System; it also can be employed in an Solid Particles Injector Mode, for injecting of adequately granulated carbonaceous materials or lime into the molten steel for its carburizing or for foamy slag control; further it can be employed in a natural gas shrouded, pulsating oxygen stream, for vertically to the charge oriented soft blow supersonic Oxygen Injection Lance Mode, for decarburization of the molten metal contained in the hearth of the metallurgical furnace and foamy slag control; in one of the embodiments-generally arcuate-pivotally mounted, liquid media cooled composite body, is pivoted into and out of a furnace vessel through a small opening in the shell wall for auto-regulated constant optimal positioning of the Composite Body Tip against solid or molten charge, in each and all multi-purpose modes; furthermore, when inserted into the furnace vessel, the arcuate composite body can be rotated about its longitudinal axis for directing the oxy-fuel high temperature flame towards unmolten charge in the furnace; in an other-generally linear-embodiment, the liquid cooled composite body is attached to the mast type carrier allowing vertical movement of the composite body which enters the furnace vessel through a small opening in the furnace roof; the bimetallic, liquid cooled special tip assembly of both-arcuate and linear embodiments-of the composite body includes easy replaceable, independent, multi-opening nozzles, mounted in a protective, retracted position inside of the liquid cooled special tip assembly.

Owner:EMPCO (CANADA) LTD

Investment precision casting technology for producing automobile I-shaped front axle

InactiveCN101147954ALess investmentReduce manufacturing costFoundry mouldsFoundry coresSteelmakingWax

The present invention relates to a fusible pattern precision casting process for producing automobile H-shaped front axle. Said casting process includes the following steps; (1), preparing wax pattern; (2), applying coating material onto the wax pattern surface for several times, spreading sand and making the coating material hardened pattern shell be primarily formed, removing wax and forming pattern shell; (3), firing pattern shell; (4), pouring the molten steel into the pattern shell, before steel-smelting having to make analysis of charge mixture ratio, in the course of smelting steel having to make on-the-spot sample analysis and furnace rear analysis, adding required additive and deoxidant so as to make the molten steel be reached to the defined chemical components requirement; (5), removing pattern shell from obtained automobile H-shaped front axle casting, cleaning sand and cutting spure; (6), grinding, finishing and checking casting; (7), making quenching and tempering, heat treatment; (8), making correction and shot blasting treatment; and (9), making metalworking treatment.

Owner:NANPING AUTO FORGING & STAMPING FACTORY

Wear-resisting alloy steel with high boron, high chrome and low carbon and preparation method thereof

ActiveCN101660097AReduce manufacturing costElectric furnaceProcess efficiency improvementSilicon alloyCerium

The invention discloses a wear-resisting alloy steel with high boron, high chrome and low carbon and a preparation method thereof, which comprises the following chemical constituents in weight percent: 0.1-0.5% of C, 3-26% of Cr, 0.5-1.2% of Si, 0.5-1.5% of Mn, 0.3-2.8% of B, 0.3-2.6% of Cu, 0.2-0.6% of Ti, 0.02-0.15% of Ca, 0.03-0.25% of Ce, 0.02-0.18% of N, 0.05-0.3% of Nb, 0.04-0.09% of Al, 0.02-0.15% of Mg, 0.04-0.13% of K, less than 0.03% of S, less than 0.04% of P and the balance Fe and unavoidable impurity elements. The method comprises the following steps: melting steel scrap and chromium iron in an electric furnace; adding copper plates, ferrosilicon, ferromanganese into the melted steel scrap and chromium iron, heating the melt to 1560-1620 DEG C after the constituents are adjusted to be qualified in stokehold; adding calcium-silicon alloy and aluminium deoxidation into the melt; and then adding ferrotitanium and ferroboron in sequence, melting and discharging; roasting the compound inoculant composed of granular rare earth magnesium alloy with the diameter being less than 12mm and cerium metal, Si3N4, VN, Nb and K; placing the roasted compound inoculant at the bottom ofa steel ladle; carrying out modification and inoculation processes on the smelted liquid steel by pour-over method in the steel ladle, wherein, the pouring temperature of the liquid steel is 1400-1450DEG C; heating castings to 920-1150 DEG C and preserving heat for 2-4 hours; and air cooling the castings to room temperature to obtain the alloy steel in the invention. The alloy steel of the invention has the advantages of high strength, rigidity and toughness, good thermal fatigue resistance property, wear resistance, and low manufacture cost.

Owner:泰州海天机械配件有限公司

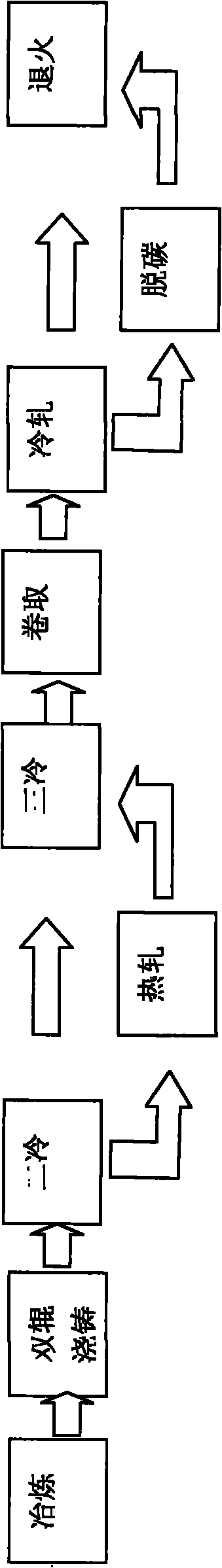

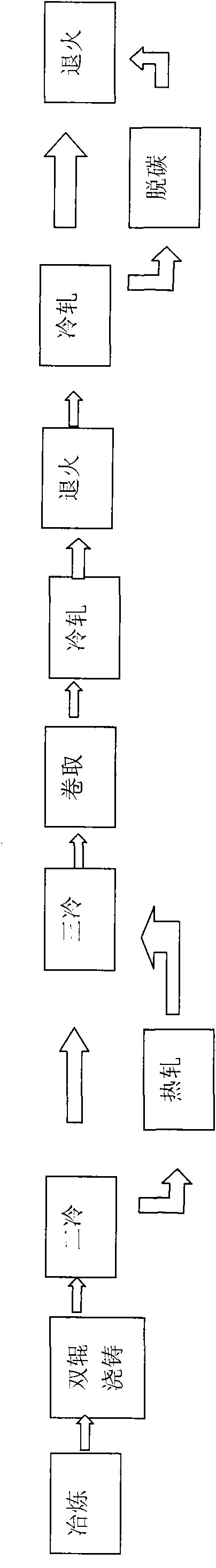

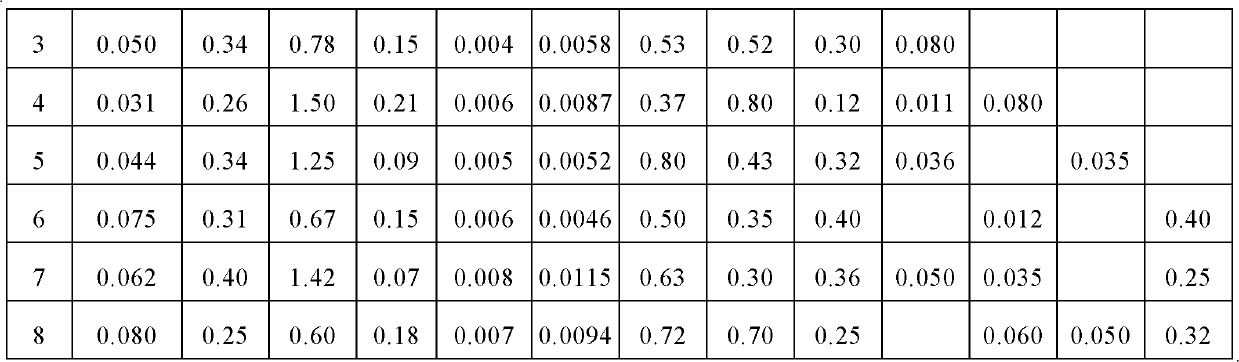

Manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel

ActiveCN102041367AMeet needsReduce processHeat treatment process controlMelting tankElectrical steel

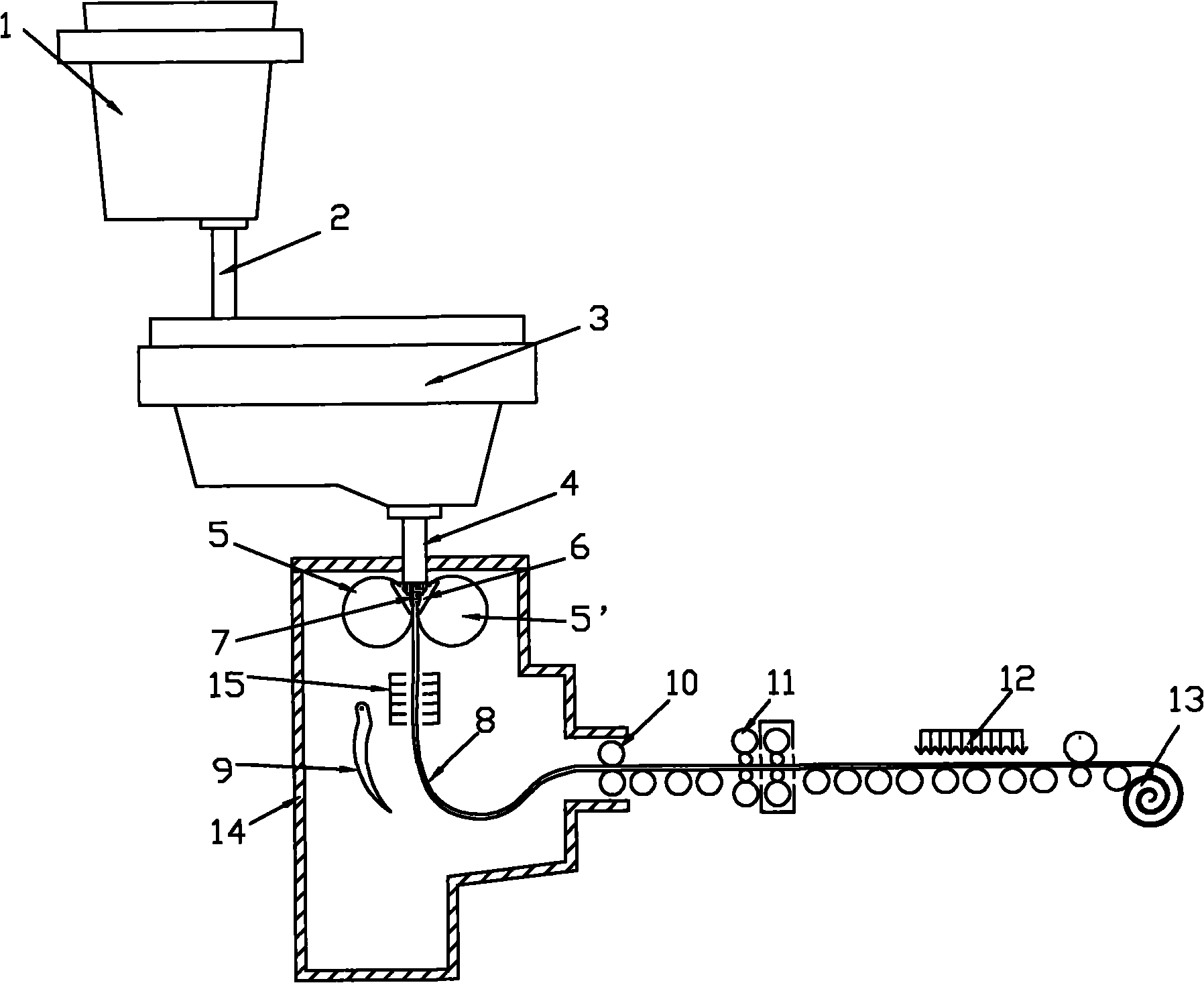

The invention relates to a manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel, comprising the following steps: smelting molten steel the temperature and components of which meet the requirements, casting the molten steel into a molten bath formed by a pair of water-cooling crystallizing rolls rotating at high speed, then cooling for the second time, hot rolling, cooling for the third time, coiling, cooling to room temperature, pickling, cold rolling, and finally annealing to obtain the cold rolled non-oriented silicon steel sheet with high magnetic induction and low iron loss. In the invention, the thin strip continuous casting process can eliminate the hot rolling thinning procedure in the traditional process, thus avoiding quality defect caused by the improper hot rolling process, simultaneously reducing the equipment loss, and reducing the maintenance and overhaul costs of equipment; the solidification process is controlled to improve the medium axialite proportion of the casting strip, thus improving the corrugation defect of the product in the cold rolling process; and the range of components of the non-oriented silicon steel smelting is widened by the characteristic of quick solidification of the continuously cast thin strip, and the smelting cost is lowered. The invention has the advantages of short process flow, low energy consumption, high efficiency, low production cost, simple manufacturing method and obvious energy saving and consumption reducing effects.

Owner:BAOSHAN IRON & STEEL CO LTD

Producing method of clean steel

The invention discloses a producing method of clean steel, which can further enhance the cleanliness and comprise the following steps of: pretreating with molten iron for desulfurizing until [S] is not more than 0.010%; then delivering to a converter for smelting; dephosphorizing and controlling sulfur; controlling finished molten iron in the converter to be with [P] of not more than 0.0080% and [S] not more than 0.010%; adding a ladle slag modifying agent to ladles in a steel tapping process for regulating and modifying the ladle slag, wherein after treating, in the molten iron, [P] is not more than 0.0060% to 0.0080%, [S] is not more than 0.0080% and roughing slag quantity is not more than 0.5%; controlling refined finished slag components in LF (Low Frequency) refining, wherein soft argon blowing time of the molten iron is not less than 5 minutes after LF refining, and the composition is qualified when [S] is not more than 0.0020%; carrying out VD (Vacuum Degassing) refining to ensure that [H] is not more than 1.5ppm; and continuously casting, wherein a double-layer high-alkalinity covering agent is adopted as a middle ladle, a seal ring and a long water gap are additionally arranged for argon-blowing protective casting, which is carried out at constant speed, and overheat delta T of the molten iron ranged from 15 DEG C to 30 DEG C. Under the condition that the producing cost is not increased basically, the cleanliness of the clean steel is further enhanced by the control of each procedure junction point, and the clean steel comprises the following components by weight percent: S not more than 20ppm, P not more than 100ppm, TO not more than18ppm, H smaller than 2.0ppm, N not more than 35ppm, and A, B, C and D types of impurities not more than 0.5 grade.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Method for producing low phosphorus steel by smelting semisteel

InactiveCN101696462APrevent rephosphorizationEasy to operateManufacturing convertersSteelmakingHigh magnesium

The invention belongs to the field of metallurgy, and relates to a method for producing low phosphorus steel by smelting semisteel, which solves the technical problem of controlling the steelmaking end point of a converter within 0.006 percent. The method is mainly realized by adjusting slag-making parameters of the converter smelting by adopting a single slag method, which comprises that: the slag-making materials added in the converter slag-making process consist of 40-50kg of active lime, 20-30kg of high-magnesium lime and 15-25kg of composite slag former based on per ton of tapping molten steel; and the slag-making materials are added in twice. In addition, by controlling an oxygen supply system and an end point control system, the dephosphorization rate of the converter can reach over 92 percent; molten steel containing less than 0.006 percent of phosphorus is obtained; steel ladle slag de-P and alloy re-P are controlled within 0.002 percent. The method can stably produce finished low phosphorus steel containing less than 0.010 percent of phosphorus, and is characterized by simple operation method, small investment on equipment and low production cost.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +3

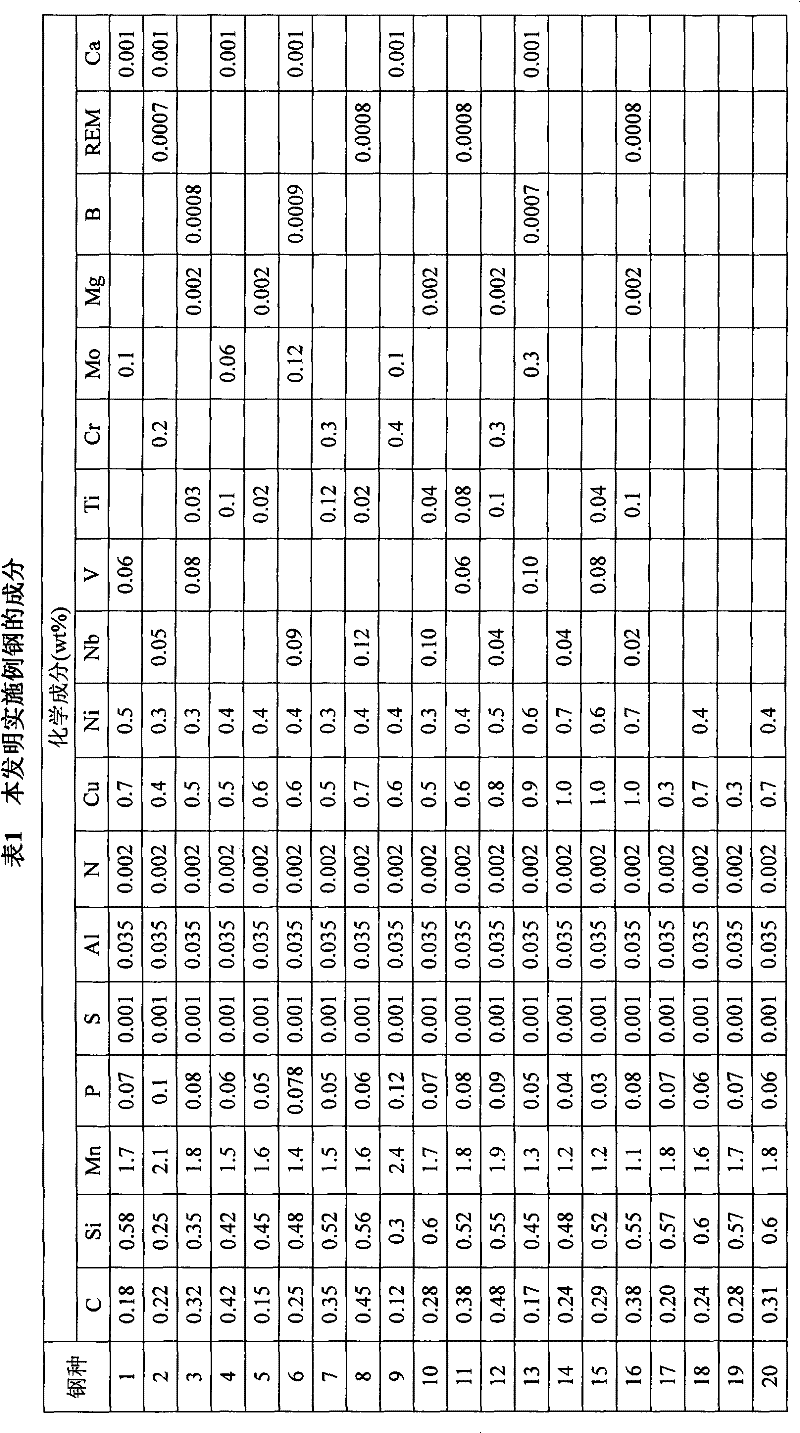

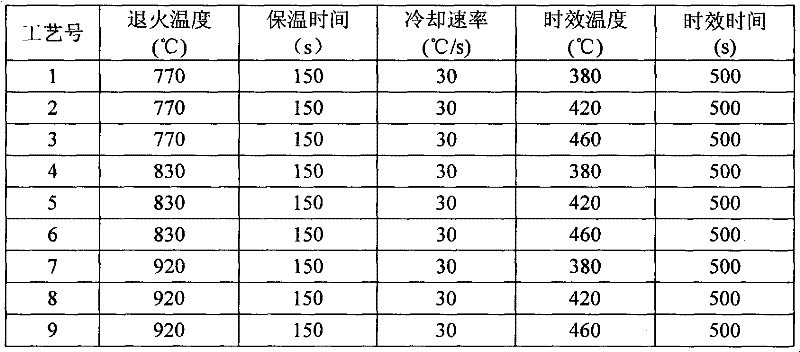

High-strength cold rolling transformation induced plasticity steel plate and preparation method thereof

InactiveCN102409235ASolve Surface Quality IssuesSolve the blockageTemperature control deviceFurnace typesSheet steelRoom temperature

The invention provides a high-strength cold rolling transformation induced plasticity steel plate and a preparation method thereof. The high-strength cold rolling transformation induced plasticity steel plate comprises the following components by weight percentage: 0.1%-0.5% of C, 0.1%-0.6% of Si, 0.5%-2.5% of Mn, 0.02%-0.12% of P, less than or equal to 0.02% of S, 0.02%-0.5% of Al, less than or equal to 0.01% of N, 0.1%-1.0% of Cu and the rest Fe. The preparation method comprises the following steps of: (a) refining molten steel meeting a component condition, and casting into a blank; (b) rolling, wherein the heating temperature is 1,100-1,250 DEG C, the heat preservation time is 1-4h, the initial rolling temperature is 1,100 DEG C, the final rolling temperature is 750-900 DEG C, the coiling temperature is less than 700 DEG C, the thickness of a hot rolled steel plate is 2-4mm, and the cold rolling accumulated pressing amount is 40-80%; and (c) continuous annealing, wherein the annealing temperature is 700-Ac3+50 DEG C, the heat preservation time is 30-360s, the cooling speed is 10-150 DEG C / s, the aging temperature is 250-600 DEG C, the aging time is 30-1,200s, and the hot roller steel plate is cooled at the speed of 5-100DEG C / s to be at the room temperature. The steel plate disclosed by the invention has the bending strength of 380-1,000 MPa, tensile strength of 680-1,280 MPa and elongation of 15-30%.

Owner:ANGANG STEEL CO LTD

High-strength, high-toughness and high-plasticity martensitic stainless steel and preparation method thereof

ActiveCN103614649AImprove the level of toughness and plasticityImprove stabilityMartensitic stainless steelRoom temperature

The invention discloses high-strength, high-toughness and high-plasticity martensitic stainless steel, and belongs to the technical field of metallurgy. The martensitic stainless steel comprises the following components in percentage by weight: 0.15 to 0.4 percent of C, 0 to 0.12 percent of N, 0.2 to 2.5 percent of Si, 0.4 to 3.0 percent of Mn, less than or equal to 0.02 percent of S, less than or equal to 0.02 percent of P, 13.0 to 17.0 percent of Cr, 0 to 5.0 percent of Ni, 0 to 2.0 percent of Mo, 0 to 0.3 percent of V, 0 to 0.2 percent of Nb, 0 to 0.05 percent of Ti, 0 to 0.8 percent of Al and the balance of Fe and inevitable impurities. A preparation method comprises the following steps of (1) smelting molten steel according to the set components, and solidifying the molten steel to form an ingot blank by using a continuous casting machine or a casting mold; (2) hot-rolling the ingot blank to form a hot-rolled plate blank; (3) heating the hot-rolled plate blank to 950 to 1100 DEG C, preserving heat for 0.5 to 2 hours, cooling the plate blank to 25 to 200 DEG C, heating the plate blank to 350 to 500 DEG C, preserving heat for 10 to 60 minutes, and air-cooling the plate blank to room temperature. According to the martensitic stainless steel prepared by the method, dispersed remaining martensite is introduced into a microscopic structure, so that the strength, toughness and plasticity of the martensitic stainless steel are greatly improved.

Owner:NORTHEASTERN UNIV

Large thickness quenched high strength steel and production method thereof

InactiveCN101363101AEquivalent lowGood welding performanceRoll mill control devicesMetal rolling arrangementsPower stationSheet steel

The invention belongs to the field of metal materials and discloses a large-thickness and high-strength quenched and tempered steel plate and a production method thereof. The steel plate mainly consists of the following chemical components by weight percentages: not more than 0.18% of C, 0.1-0.4% of Si, not more than 1.2% of Mn, 0.7-1.7% of Ni, 1.0-1.5% of Cr, 0.4-0.6% of Mo, 0.03-0.08% of V, 0.02-0.04% of Al, 0.0005-0.0020% of B, Fe and unavoidable impurities. The molten steel designed according to the components of the invention can be rolled into the large-thickness steel plate by smelting process, casting process, heating process, rolling process, water cooling process and quenching and tempering process. The steel plate has the advantages of reasonable component design, good comprehensive properties and low production cost, can be applied to off-shore oil production platform engineering, power stations, engineering scaffolds and other industries and has good application prospect.

Owner:WUYANG IRON & STEEL

Method for smelting ultra-low carbon steel

ActiveCN102719593AHigh carbon contentReduce carbon contentManufacturing convertersProcess efficiency improvementHigh carbonSlag

The invention provides a method for melting ultra-low carbon steel. The method adopts a desulfuration of molten iron-converter-RH-continuous casting process, wherein a sulfur content in the molten iron is 0.002%-0.006% after desulphurization; converter smelting controls oxygen blowing time, an oxygen gun flow, a bottom-blowing intensity and a smelting period, adopts slag-stopping tapping, steel tapping with a content of C being 0.06%-0.08% and with a temperature of 1650-1680 DEG C, and an oxygen content in the molten iron is 0.03%-0.05%; an RH adopts forced decarburization with a highest vacuum degree of 67-100 MPa and decarburization time of 15-27 min, and a carbon content in the molten iron is 0.0010%-0.0020% and a dissolved oxygen content in the molten iron is 0.025%-0.040% after the decarburization; the molten iron is recycled for 3-5 min after deoxidation by adding aluminium and recycled for another 3-5 min after adding other alloys; a nitrogen content in the molten iron is 0.0015%-0.0035%, and the temperature is 1590-1640 DEG C; and killed steel treatment is carried out for 10-30 min. The method adopts converter tapping with a high carbon and low oxygen content, can use less or not use slag modified agents during the tapping process, accelerates the production rhythm, makes the molten steel cleaner, and reduces the production cost.

Owner:ANGANG STEEL CO LTD

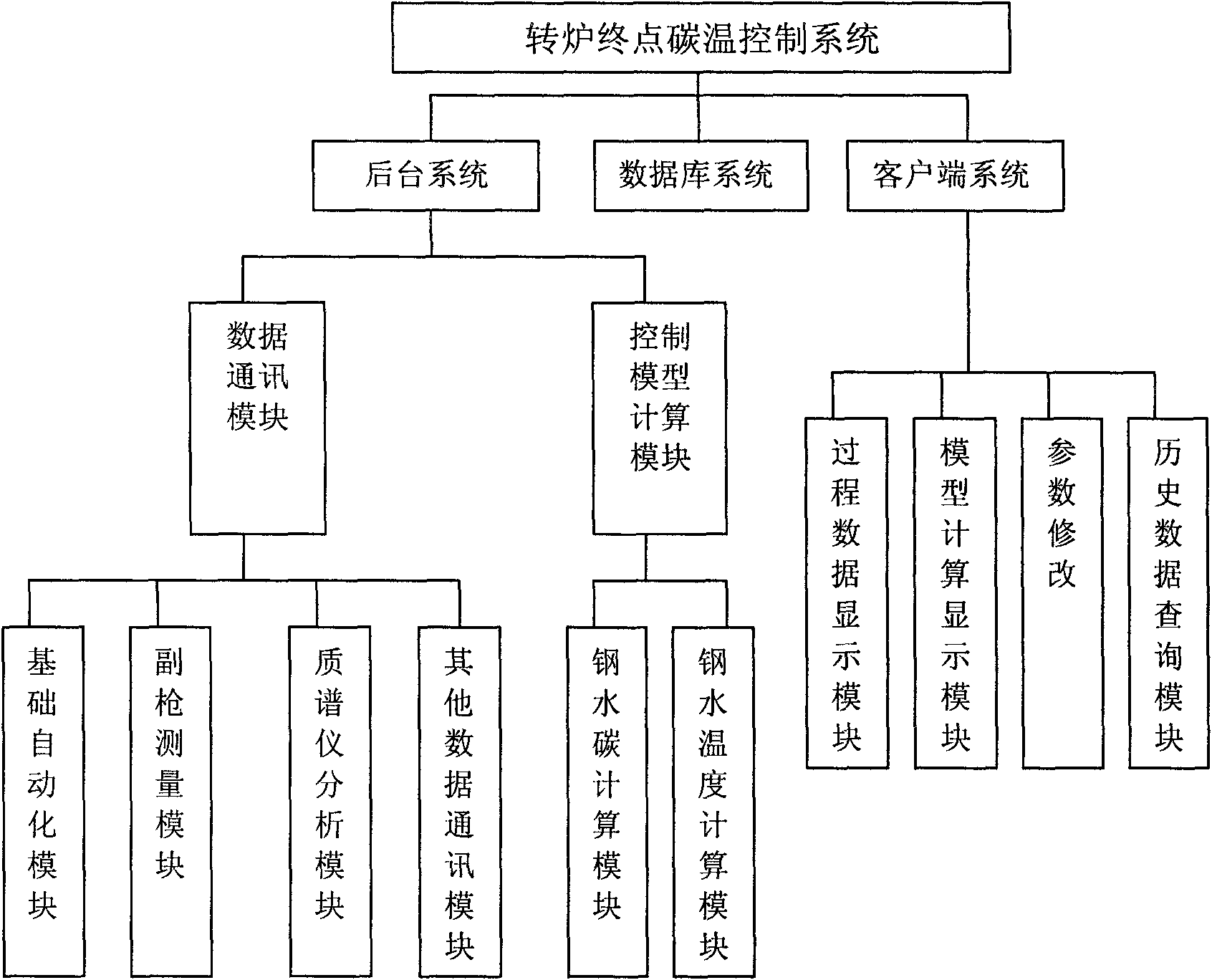

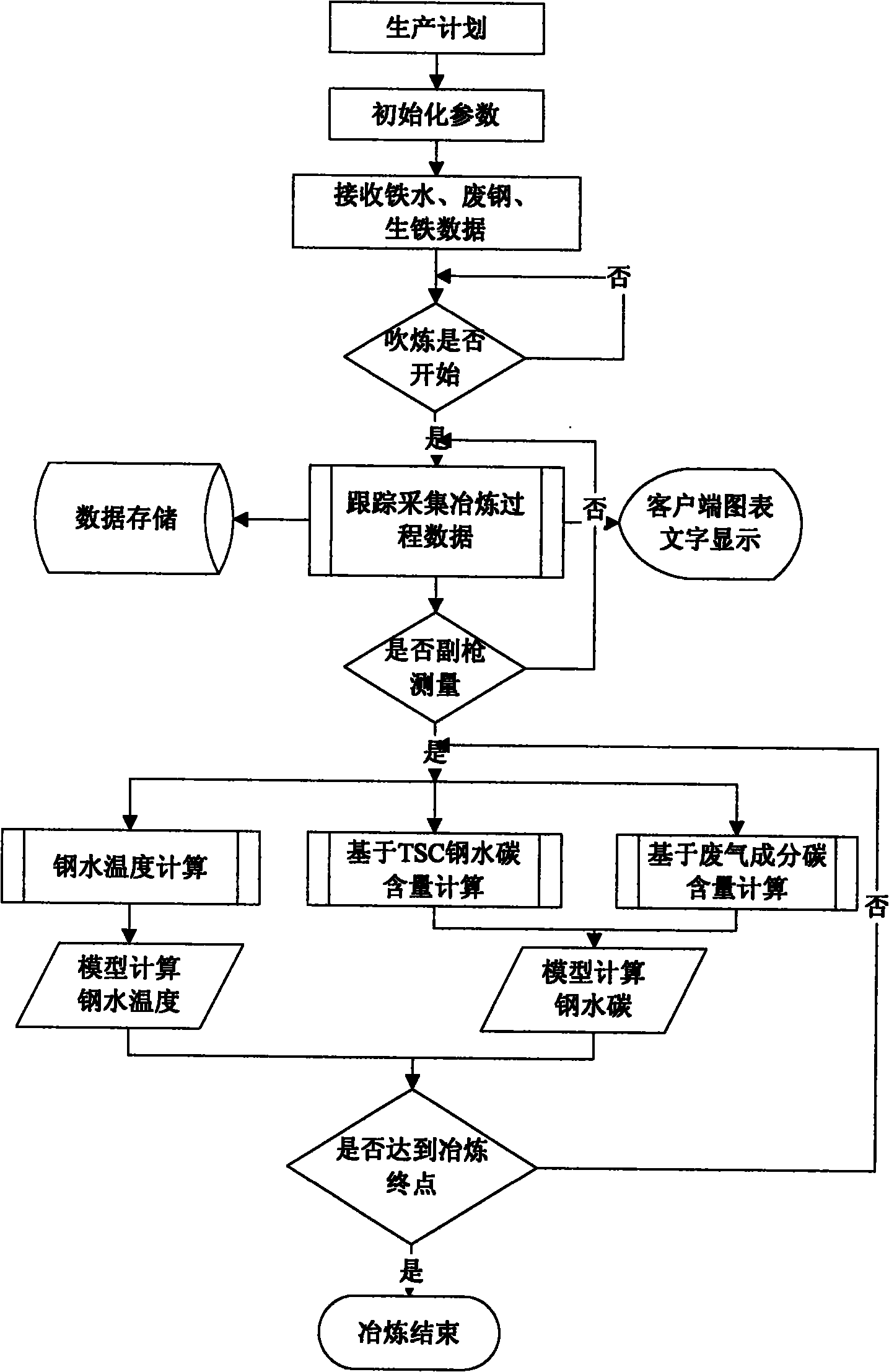

Converter smelting endpoint molten steel carbon and temperature control system and method thereof

ActiveCN101845531AEffective controlUnderstand clearlyManufacturing convertersSteelmakingTemperature control

The invention discloses a converter smelting endpoint molten steel carbon and temperature control system and a method thereof, and belongs to the technical field of converter steelmaking automation control. The converter smelting endpoint molten steel carbon and temperature control system comprises hardware equipment and a software processing module, and is characterized in that: the hardware equipment comprises converter sublance measuring equipment and converter exhaust gas analysis equipment; the software processing module comprises a converter production process data acquisition module, a converter smelting endpoint carbon calculation module, a converter smelting endpoint temperature calculation module, and an information display module; the software processing module is operated on a computer; and the hardware equipment and the software module are connected with a converter production process database through an Ethernet to realize data interaction. The control system and the method thereof have the advantages of accurately controlling the converter smelting endpoint molten steel carbon content and the molten steel temperature, along with stable operation, cost conservation, and wide application range.

Owner:HEBEI SHOUGANG QIAN AN IRON & STEEL CO LTD +2

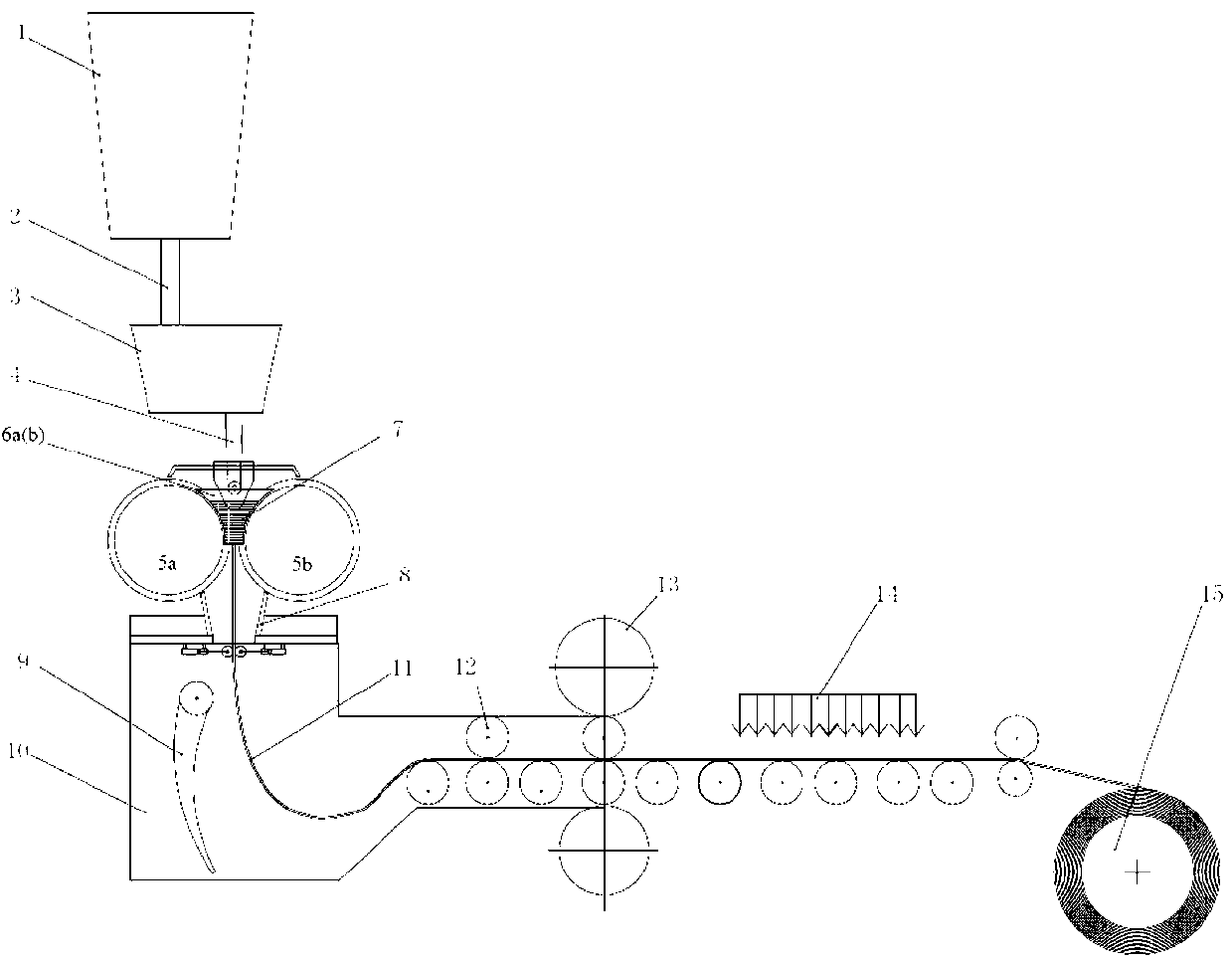

Method of sheet billet continuously casting and rolling to produce thin strip steel coil

ActiveCN101108394AShort production processSave construction investmentMetal rolling arrangementsProduction lineStrip mill

A method of using thin plate adobe continuous casting and rolling to producing thin band steel coil is provided, which belongs to rolling metal at once after continuous casting, in particular relating to thin standard band steel production method. The invention is characterized in that: a conticaster, a swing shear, a roller-hearth type heating furnace, a scale breaker, a vertical miller, 7 mill groups, laminar flow cooling device and reeling machine are connected to a CSP produce line, the produce line adopts reasonable temperature system, rolling equipment, rolling way and combining with cooling after rolling, the molten steel after continuous casting is a casting adobe of 50 to 70mm thick and 900 to 1300 wide, after cutting, heating, scale breaking, proceed continuous rolling to form a thin band of 1.2 to 1.5mm thick and 900 to 1300 wide, then after cooling to reel steel coil. The production flow is short, the equipment is few, the investment is less and the running expense is low; The technics and equipment is reasonable and high efficient, double locomotive and double flow casting, heating by two furnaces, seven rolling machines roll continuously, the production is smooth and saves energy with high production efficiency; the product performance is even and stable, the board shape is regular with high accuracy and good surface quality.

Owner:MAANSHAN IRON & STEEL CO LTD

Method for preparing aluminum oxide/carbon aerogel composite material

The invention discloses a method for preparing an aluminum oxide / carbon aerogel composite material. The method comprises the following steps: dissolving a water-soluble carbohydrate and a water-soluble high polymer in water in a closed container; adding an aluminum salt or aluminum hydroxide reacting at the temperature of 140-300 DEG C, drying, and calcining in an inert atmosphere of 300-1500 DEG C, thereby obtaining the aluminum oxide / carbon aerogel composite material. According to the method disclosed by the invention, the aluminum oxide / carbon aerogel composite material with low density and high porosity is prepared by adopting a one-pot process, the method disclosed by the invention has the advantages that the raw materials are readily available, the preparation process is simple, the cost is low and the like, and the prepared aluminum oxide / carbon aerogel composite material is light in weight and high in porosity and can be used for catalyst carriers, gas sensitive elements, solid electrolytic films and molten steel oxygen-measuring probe materials.

Owner:NORTHWEST UNIV(CN)

Non-oxide composite low-carbon magnesia-carbon brick

A non-oxide compound magnesite-graphite brick containing carbon less than 6% belongs to a fire resisting material. The material contains magnesia of 75-94%, carbon of 1-5%, non-oxide such as nitride and boride of 0.4-20%, additive of 0-5%, and binder containg carbon. Such magnesite-graphite brick with low carbon has a low heat conductivity, a small acierating to the molten steel and less pollution to the low carbon steel compared to the common magnesite-graphite brick. The magnesite-graphite brick has a good slag resistance because the magnesia is the primary component. And it also has a good heat shock capacity because the carbon is one of the primary components. The carbon prevents said non-oxide from being oxidated. The brick maintains a good heat and shock resistance and slag resistance when reducing the proportion of the carbon because said non-oxide has a low heat expansion and a wet resistance to the slag.

Owner:江苏苏嘉集团新材料有限公司

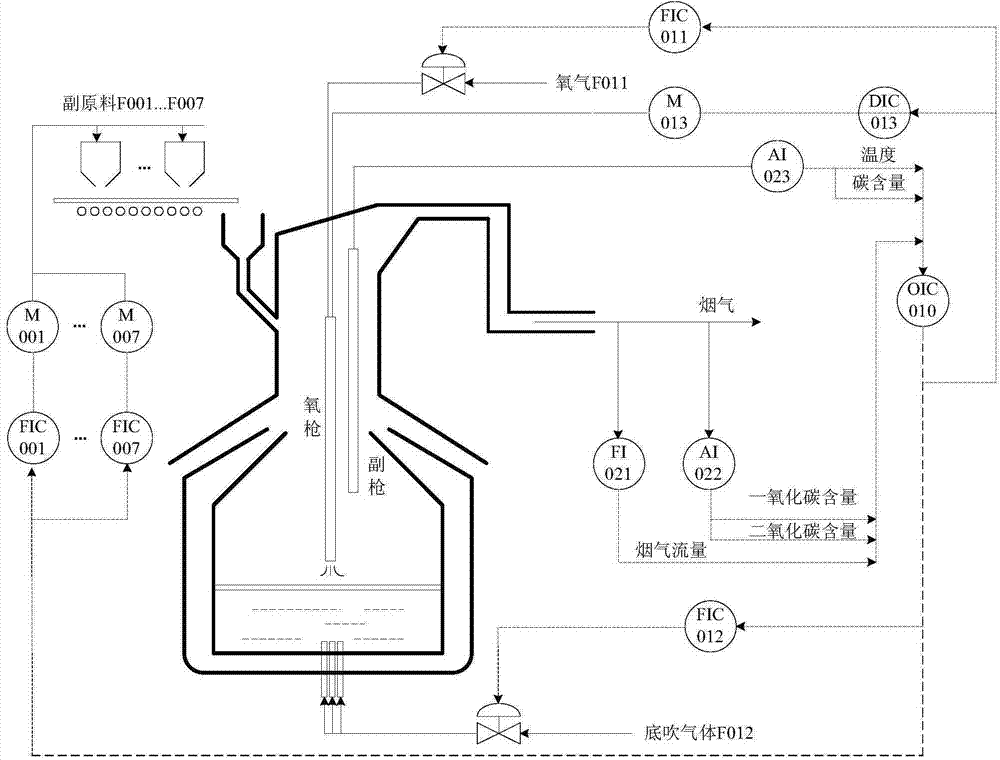

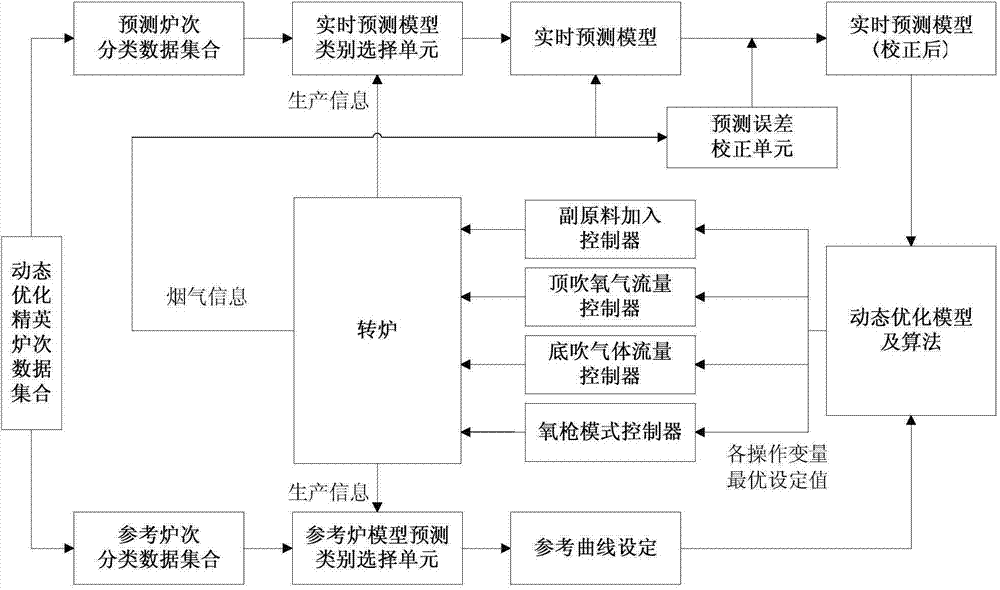

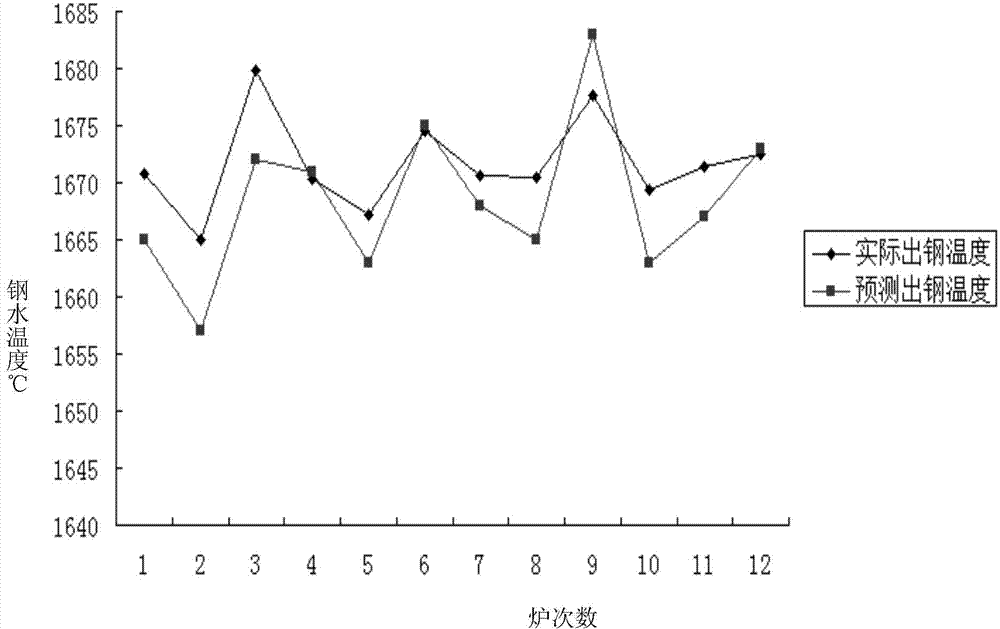

On-line dynamic optimization control method for converter steelmaking process based on data driving

ActiveCN103882176AImprove hit rateIncrease productivityManufacturing convertersSteelmakingDynamical optimization

The invention discloses an on-line dynamic optimization control method for a converter steelmaking process based on data driving. The method comprises the following steps: building an off-line prediction model database; building a liquid steel temperature prediction model and a carbon content prediction model by use of a data driving method to obtain a corresponding relationship between operating variables and the temperature and carbon content of liquid steel in the converter steelmaking process; selecting a melt data unit matched with the information of the current converter steelmaking production process and determining a control reference curve of the liquid steel temperature and carbon element content; building a real-time dynamic optimization model of the converter steelmaking process and determining an optimized set value unit of each operating variable; and selecting the set value of each operating variable from the optimized set value unit so as to carry out control operation. The method disclosed by the invention can be used for realizing real-time on-line control over the converter steelmaking process and providing convenience for an operator to set selection conditions according to actual working conditions, thus the production efficiency of a steelmaking plant is improved.

Owner:NORTHEASTERN UNIV

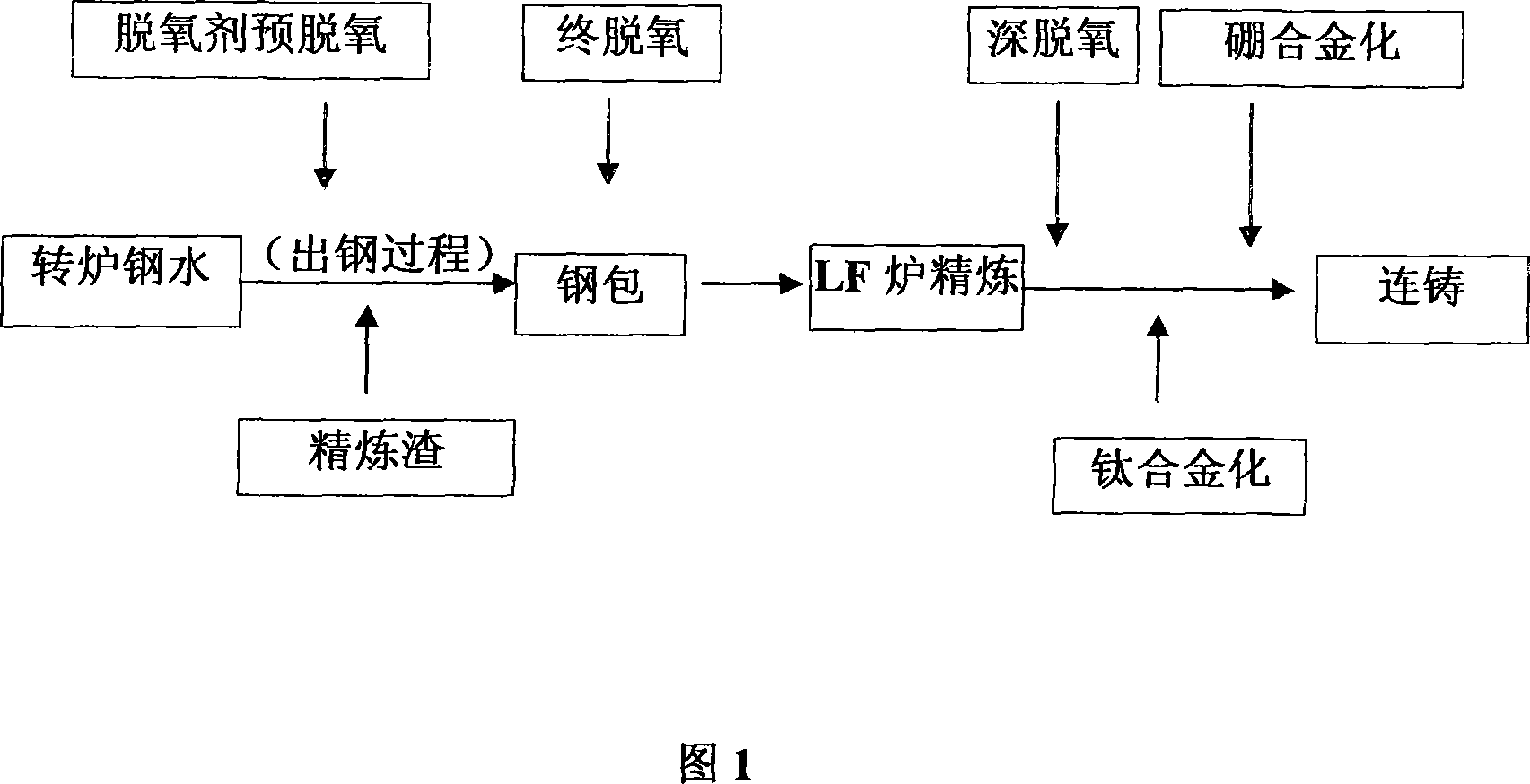

Boron steel producing converter smelting process

InactiveCN101045948ALow oxygen content in molten steelHigh yieldManufacturing convertersSmelting processMolten steel

The present invention belongs to the field of iron and steel smelting technology, and is especially boron steel producing process in a converter. The production process includes the steps of smelting in a converter, deoxidizing and refining in a ladle, and boron alloying. The boron steel producing process has low oxygen content in molten steel after refining, high boron steel yield of 69.4-91.8 %, and excellent application foreground.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

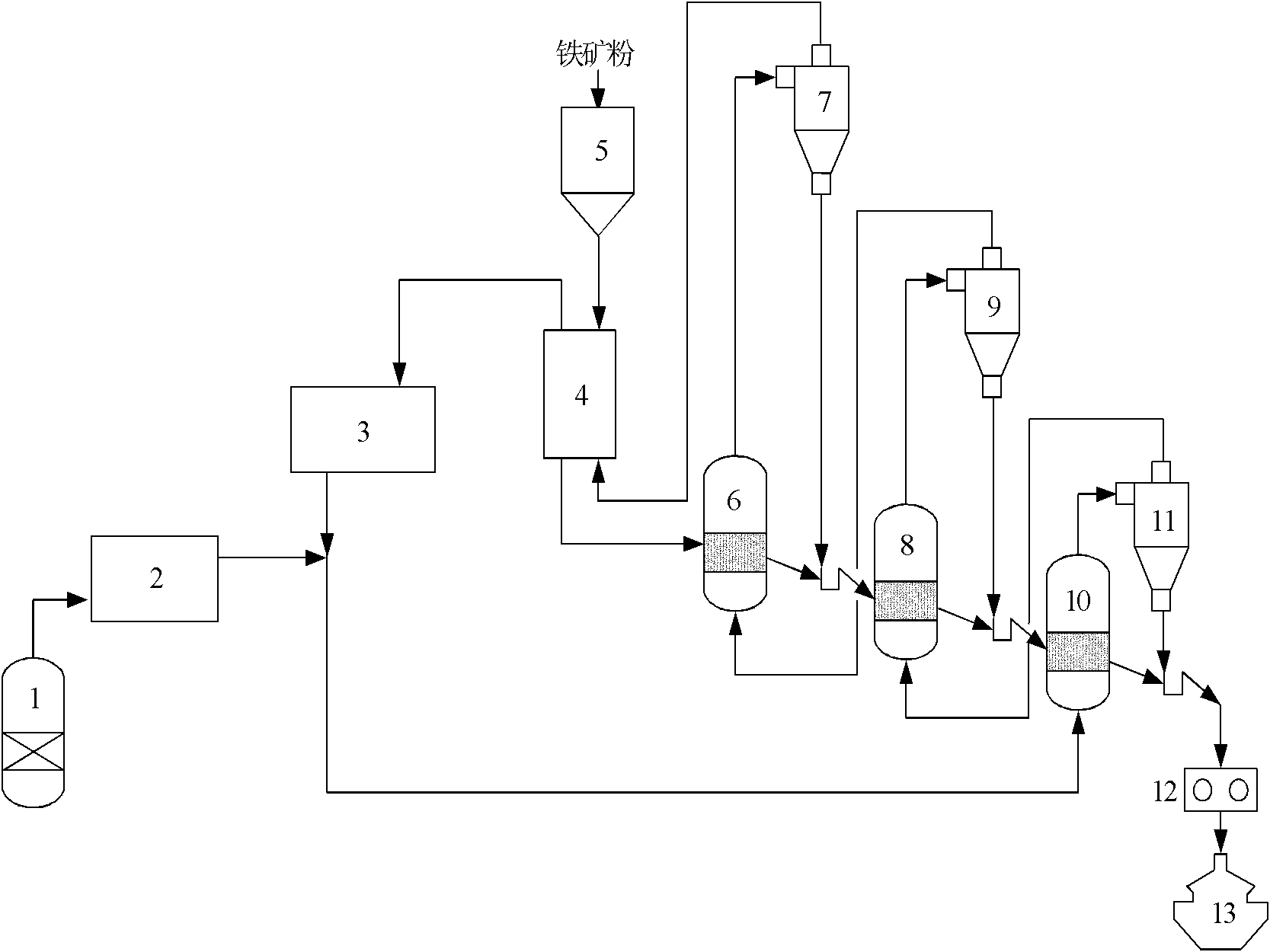

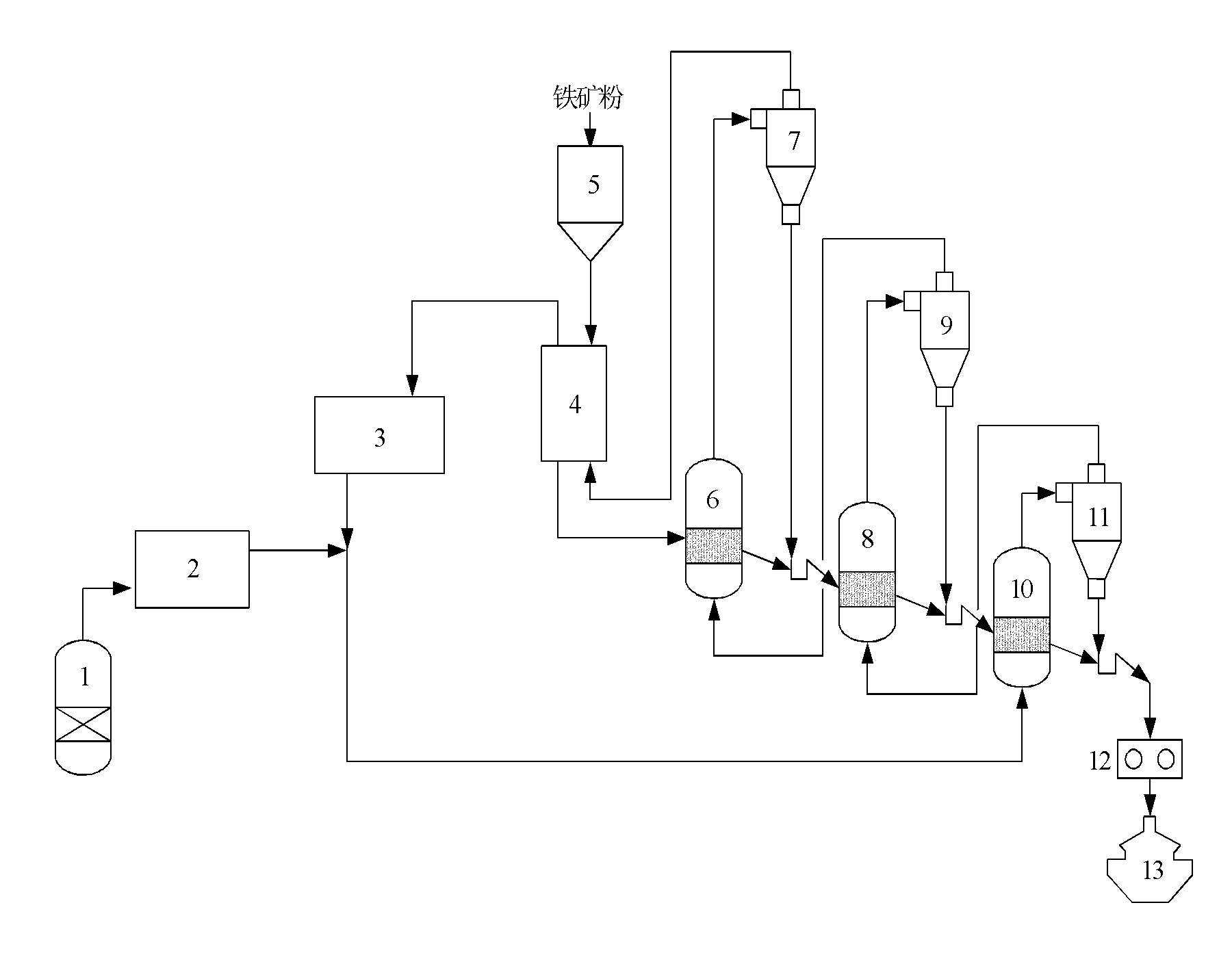

Method for reducing vanadium-titanium magnetite powder by coal reducing gas and fluidized beds

ActiveCN102127611AShort recovery timeHigh production heat efficiencyFluidised-bed furnacesProcess moduleMaterials science

The invention discloses a method for reducing vanadium-titanium magnetite powder by coal reducing gas and fluidized beds. High temperature coal gas produced by a coal reducing gas system is mixed with gas of a reducing exhaust gas purification system to form reducing gas, and the reducing gas enters third-stage, second-stage and first-stage reduction fluidized beds in turn; the preheated vanadium-titanium magnetite powder enters the first-stage, second-stage and third-stage reduction fluidized beds in turn and is fluidized and subjected to reduction reaction under the action of the reversely upward reducing gas; and the obtained directly reduced iron is briquetted, titanium slag is removed, vanadium slag is extracted, and the qualified molten steel is produced. The invention integrates process modules such as coal reducing gas, iron ore powder preheating, fluidized bed reducing, briquetting, electric furnace melting separation and the like, and has the advantages of high production thermal efficiency, low cost of preparing the reducing gas, short time of reducing the iron ore powder and the like.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

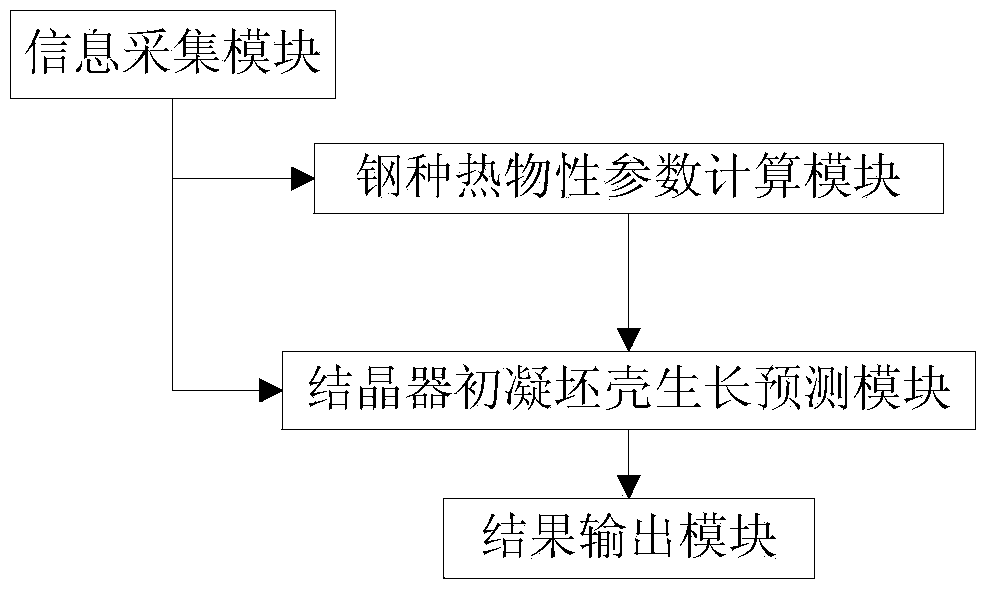

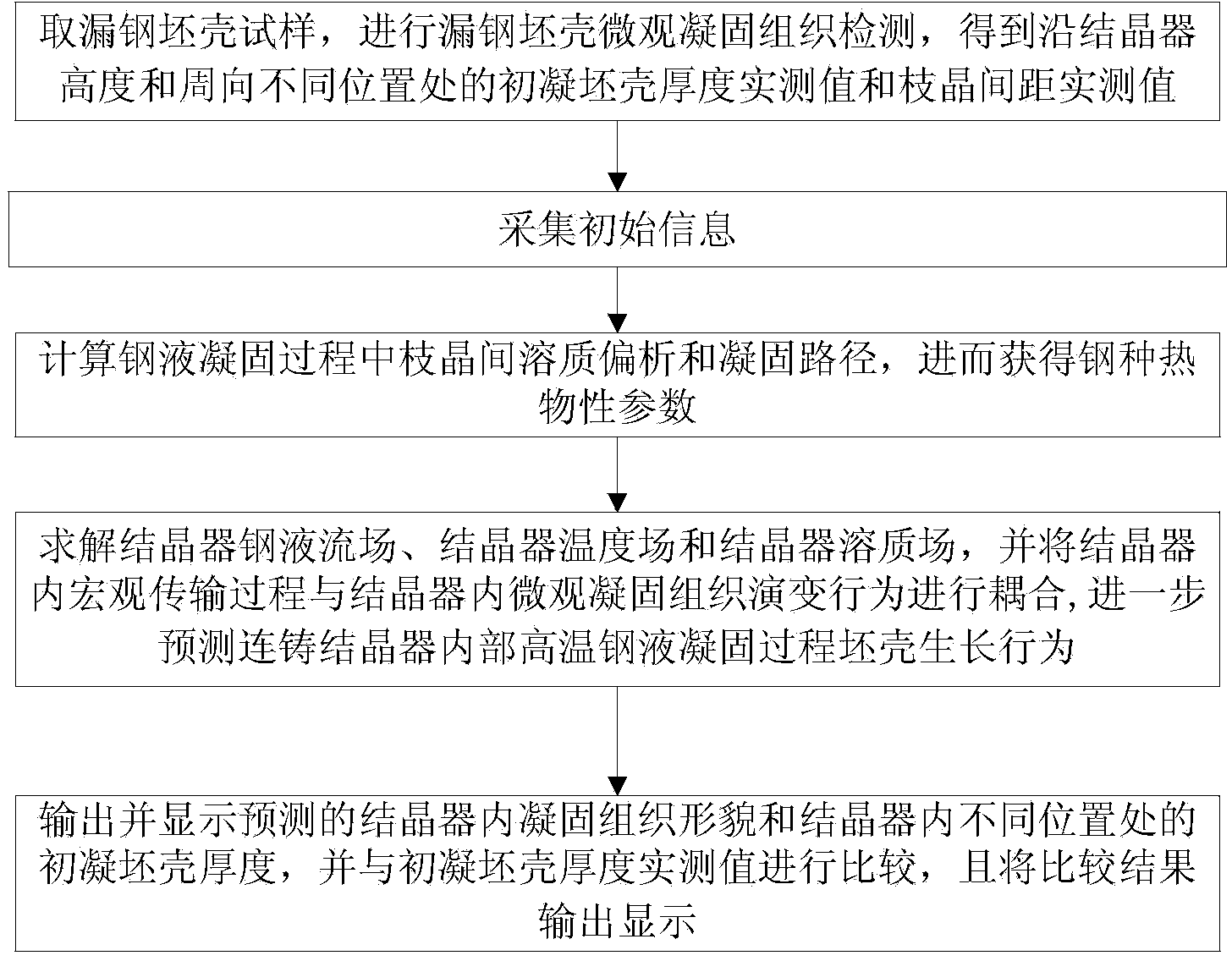

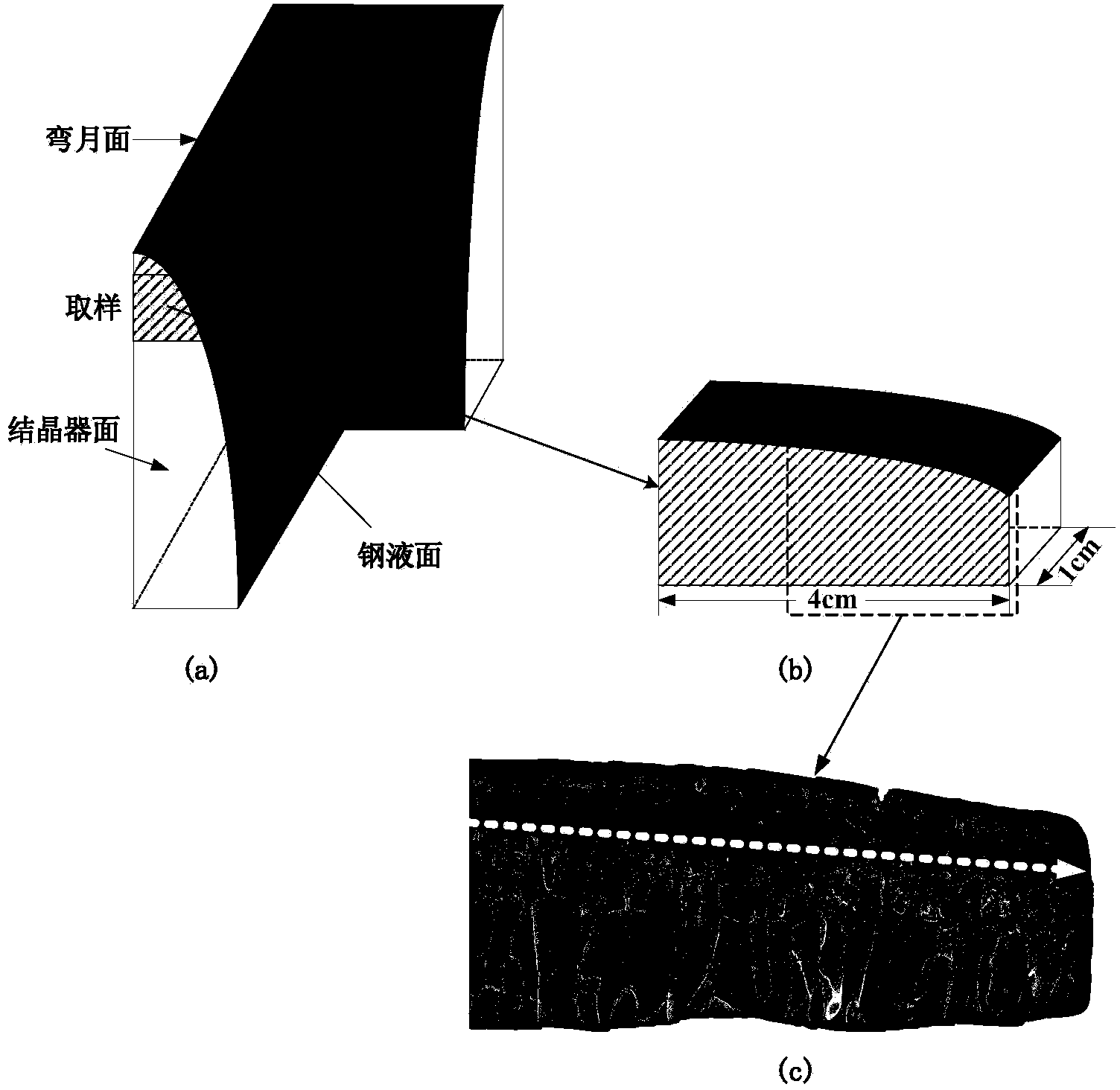

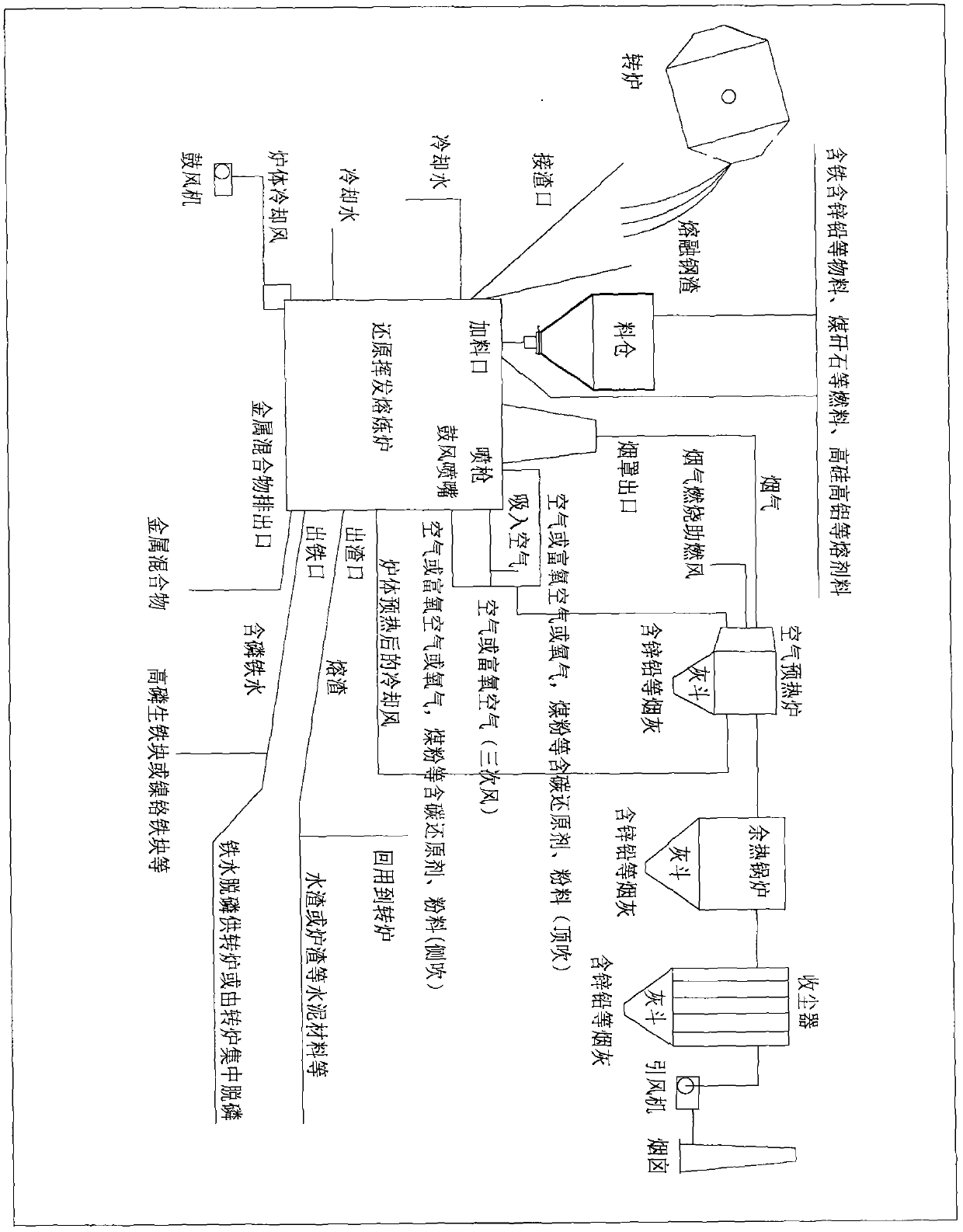

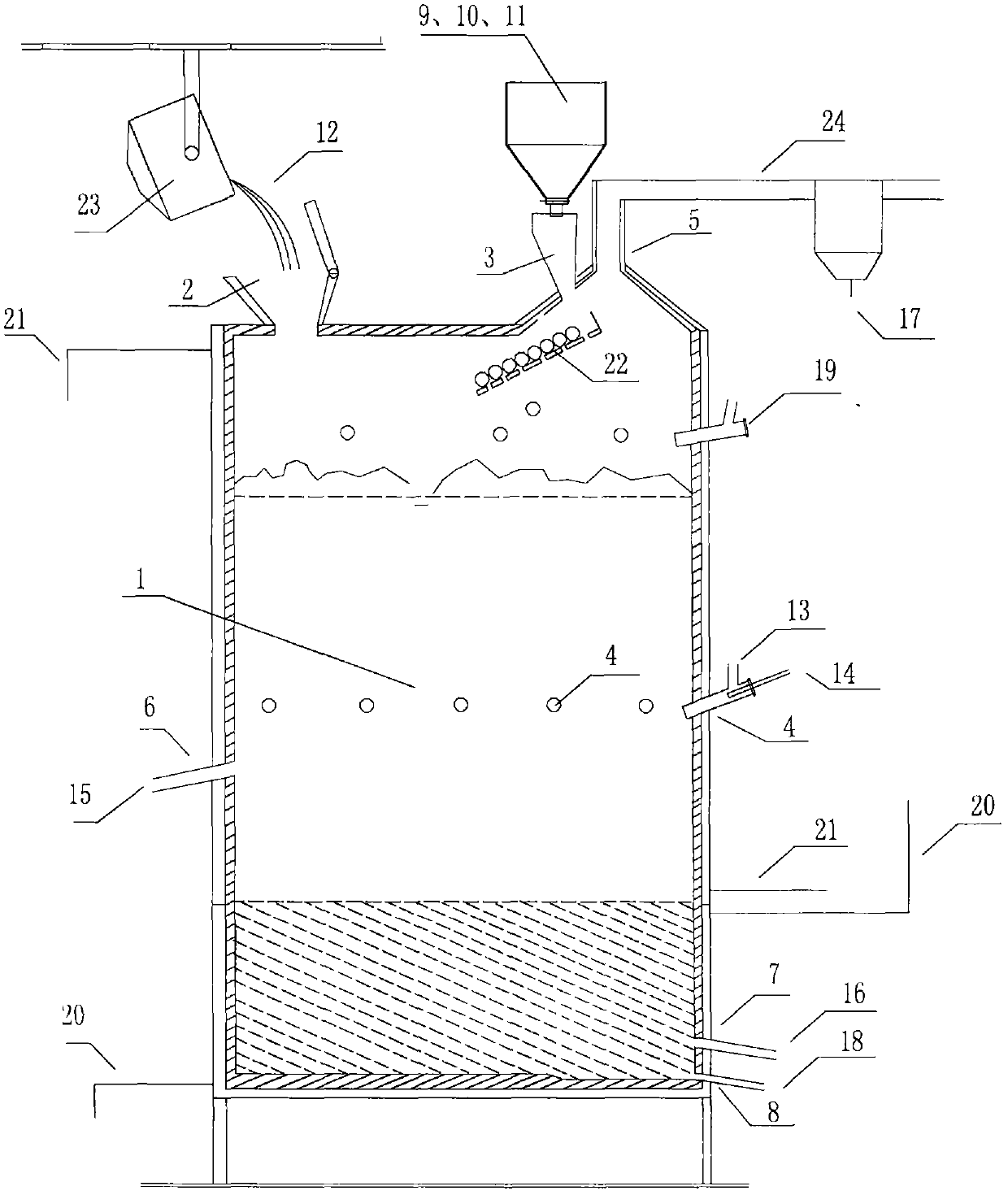

Prediction system and method for thickness of initially solidified shell in continuous steel casting crystallizer

ActiveCN104384469APredict growth behaviorPredicting Microscopic Solidification BehaviorMetallurgyPrediction system

The invention provides a prediction system and method for the thickness of an initially solidified shell in a continuous steel casting crystallizer. The system comprises an information collection module, a steel grade thermophysical parameter calculation module, a crystallizer initially solidified shell growth prediction module and a result output module. The method comprises the following steps: detecting a bleed-out shell microcosmic solidification structure; collecting initial information; computing the interdendritic solute segregation and solidification path in a molten steel solidification process to obtain a steel grade thermophysical parameter; solving a crystallizer molten steel flow field, a crystallizer temperature field and a crystallizer solute field, coupling a macroscopic transport process in the crystallizer and the evolution behavior of the microcosmic solidification structure in the crystallizer, and further predicting the shell growth behavior in the solidification process of high-temperature molten steel in the continuous steel casting crystallizer; outputting and displaying the comparative results of the predicted morphology of the solidification structure in the crystallizer, the predicted initially solidified shell thicknesses in different positions in the crystallizer and the actual thickness of the initially solidified shell. The system and the method can accurately predict the microcosmic solidification behavior of the initially solidified shell in the crystallizer.

Owner:NORTHEASTERN UNIV LIAONING

Cooperative processing and recycling method for material containing iron and/or zinc, lead, copper and tin, and the like and molten steel slag

PendingCN108676942AReduce outputEfficient recyclingRecycling and recovery technologiesProcess efficiency improvementMolten slagMaterials science

The invention discloses a process method for cooperatively and continuously processing waste containing iron and / or zinc, lead, copper and tin, and the like and molten steel slag on line, separating and recycling metal such as iron, zinc, lead, copper and tin as well as molten slag. The cooperative processing and recycling method is characterized in that pellets prepared from waste containing iron, zinc, lead, copper, tin and the like, particles, a blocky material containing iron, zinc, lead, copper, tin and the like and high-temperature molten steel slag are added into a reducing, volatilizing and smelting furnace, molten iron, which is obtained by air-blowing, adding of fuels such as coal gangues and flux such as high silicon and high aluminum, high-temperature reducing and volatilizingtreatment, is discharged from an iron outlet of the reducing, volatilizing and smelting furnace; volatilized substances such as zinc and lead and smoke gas are sucked into a dust collector for being collected and utilized; enriched metal such as gold, silver, copper, tin and lead is discharged from a discharge hole in the bottommost part of the reducing, volatilizing and smelting furnace for beingrecycled; and molten slag is discharged through a slag outlet, water slag and the like or the molten slag is returned into a converter for being recycled. Waste containing iron, zinc, lead, copper, tin and the like, molten steel slag and coal gangue waste slag and the like are cooperatively and continuously treated to separate and recycle useful metal, so that remarkable energy-saving environment-friendly social benefits and economic benefits are achieved.

Owner:湖南建鑫冶金科技有限公司

Metallic composite low carbon magnesium carbon brick for ladle slag wire and manufacture method thereof

The invention discloses a metal complex low-carbon magnesia carbon brick used for ladle slag lines, the weight percentage of the added materials is as following, 50 to 70 percent of magnesia particles, 25 to 35 percent of magnesia powder, and 3 to 6 percent of organic binder, furthermore, the following components are added which are produced by mixing, striating materials, forming and heat-treatment, 0 to 4 percent of flake graphite, 3 to 15 percent of metal powder, and 0.5 to 3 percent of antioxidant containing boron. The antioxidant properties, slag-resistance performance, high temperature strength and the thermal shock resistance of the ladle slag line used metal complex low-carbon magnesia carbon brick are greatly improved, the service life is prolonged, the consumption cost of each ton of refractories is lowered. The preparation method of ladle slag line used metal complex low-carbon magnesia carbon bricks is also disclosed, and the carbon content in the ladle slag line used metal complex low-carbon magnesia carbon bricks produced by the method is less than or equal to 6 percent, little carbon is added so as to reduce the pollution towards liquid steel, and residual strength ratio of the thermal shock resistance is kept at 70 to 80 percent.

Owner:ZHENGZHOU UNIV +1

Method for producing strong annealed steel hot-rolled sheet coil

ActiveCN101121992ANo investment requiredHigh strengthTemperature control deviceManufacturing convertersSlagManganese oxide

The invention discloses a method of manufacturing a tough steel hot rolled strip coil. The molten steel, waste steel, chromic oxide and molybdenum oxide are mixed into a rotating furnace, and a fluxing medium is added in; the manganese oxide or manganese ore is added in at the earlier stage of blowing; the manganese oxide or manganese ore and the reducing agent are added in by the end of blowing, and nitrogen or argon is blew from bottom during the whole process; tapping is conducted when the components and the temperature of the molten steel are appropriate; during tapping, the composite deoxygener and the reducing desulfurating refining slag are added in the molten steel during tapping, and nitrogen or argon is blew from bottom of a steel ladle during the whole process. The steel ladle adds the metal aluminum in the molten steel from the CAS position to conduct deep deoxidation and microalloying; and then the increasing nitrogen agent, vanadium iron and ferrocolumbium are added in, and nitrogen or argon blowing is kept. The steel ladle is sent to the position of an LF refining furnace, the lime and reducing desulfurating refining slag are added in the LF refining furnace, argon is blew, electricity is supplied, the temperature is raised and argon is blew again, and the calcium line and the boron filament are fed at the later stage of refining; CSP is supplied for continuous casting, and the charging temperature of a cast slab is is more than 950DEG C; the heating temperature, the initial billet temperature, the rolling finishing temperature and the coiling temperature are well controlled. The tough steel hot rolled strip coil manufactured with the method has high strength and good tenacity.

Owner:湖南华菱涟钢特种新材料有限公司 +1

Molten steel deoxidizing and carbureting method and steelmaking method

The invention relates to a molten steel deoxidizing and carbureting method which comprises the step of adding a carburant and a deoxidizer to a steel ladle in sequence in the process of leading molten steel obtained by smelting to enter the steel ladle through steel tapping. The invention further provides a steelmaking method which comprises the following steps: tapping the molten steel obtained by smelting to the steel ladle, deoxidizing and carbureting the molten steel during the steel tapping process and then externally refining the molten steel after being deoxidized and carbureted, wherein the method for deoxidizing and carbureting the molten steel is the molten steel deoxidizing and carbureting method. In the deoxidizing and carbureting method, the carburant is firstly added and then reacted with oxygen in the molten steel to generate spontaneous mixing gas while the content of carbon is adjusted. Later, the added deoxidizer can be completely and uniformly mixed with the molten steel under the agitation action of spontaneous mixing gas, so that the molten steel that has uniform temperature and ingredients and satisfies the refining requirements can be obtained, so as to create good conditions for the next procedure.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

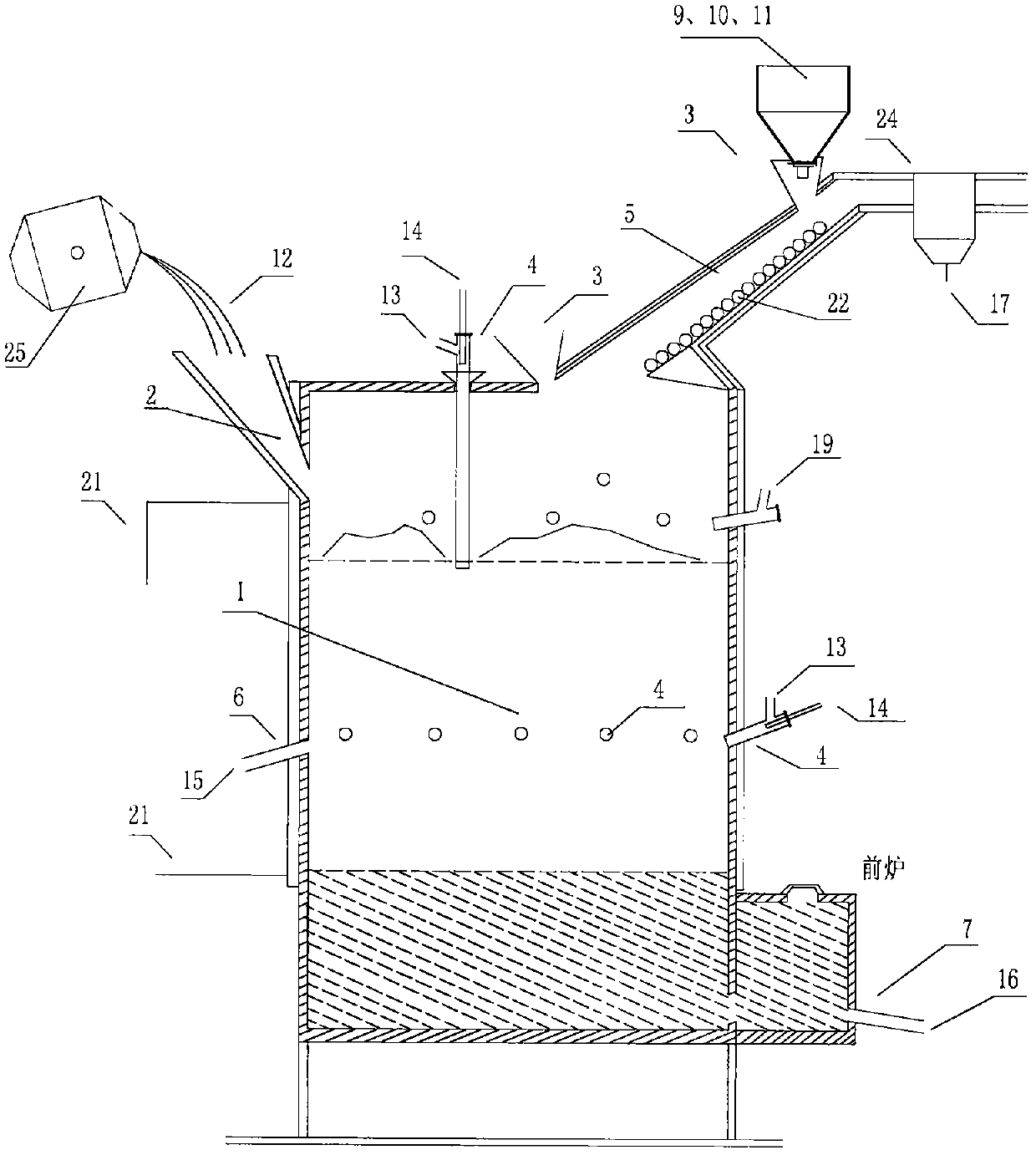

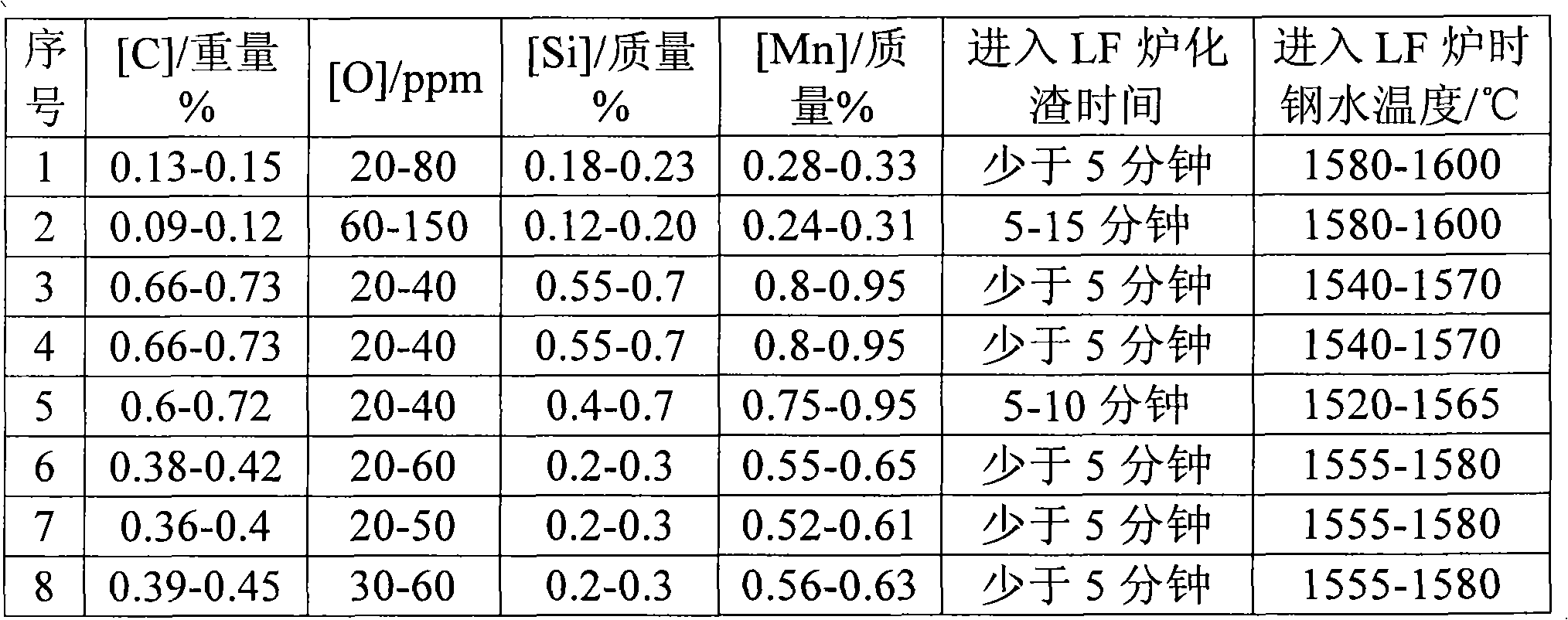

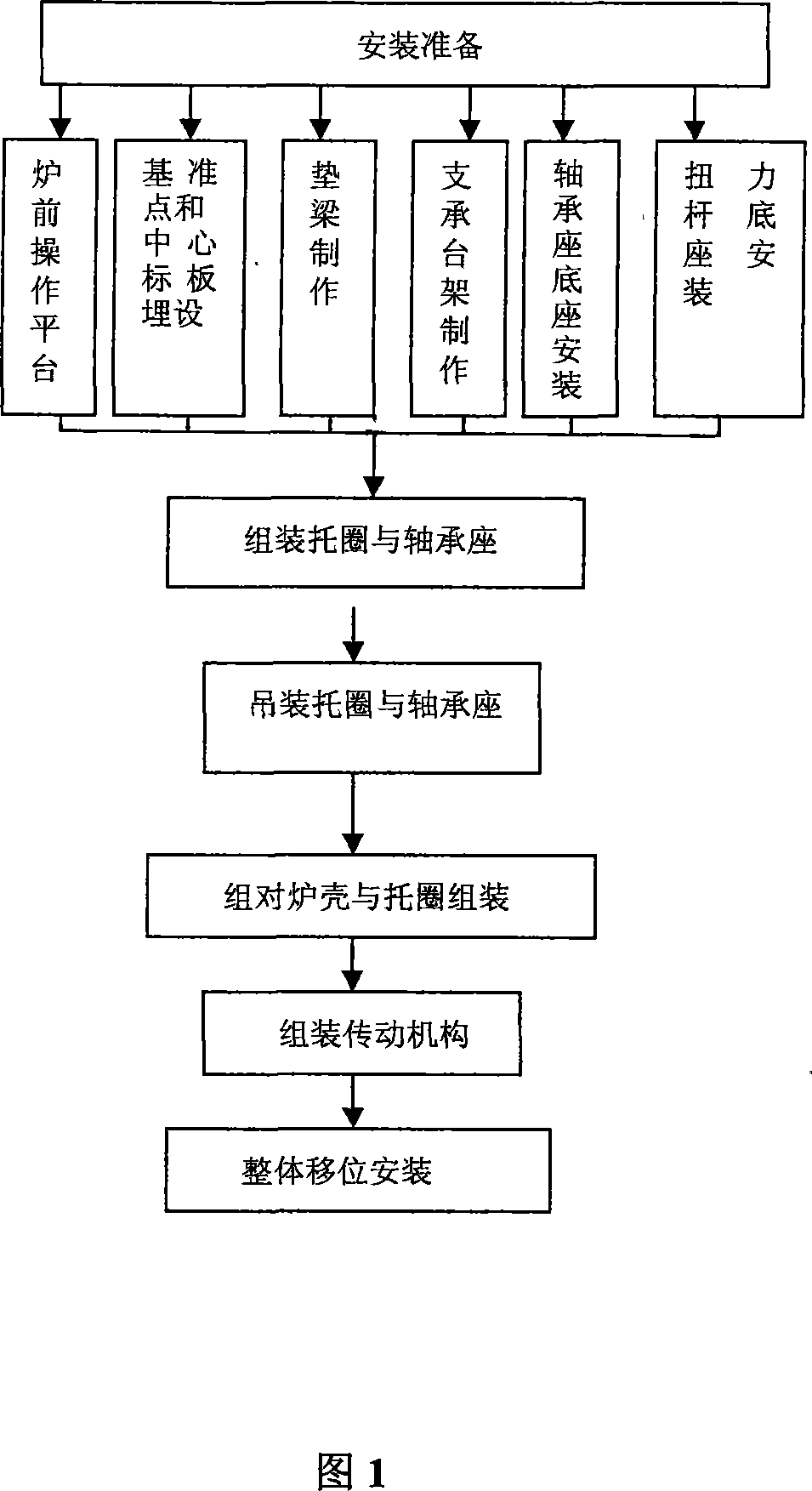

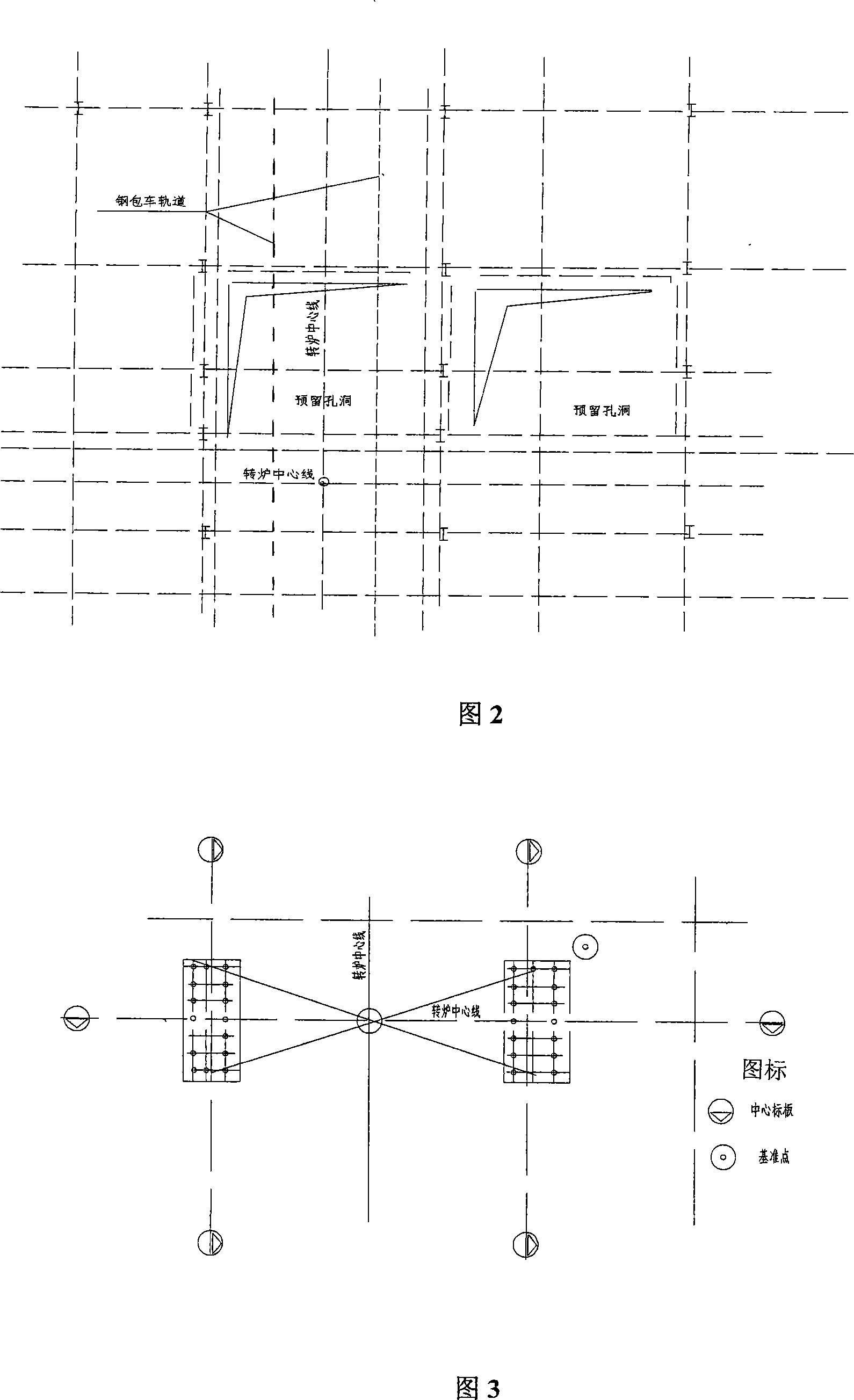

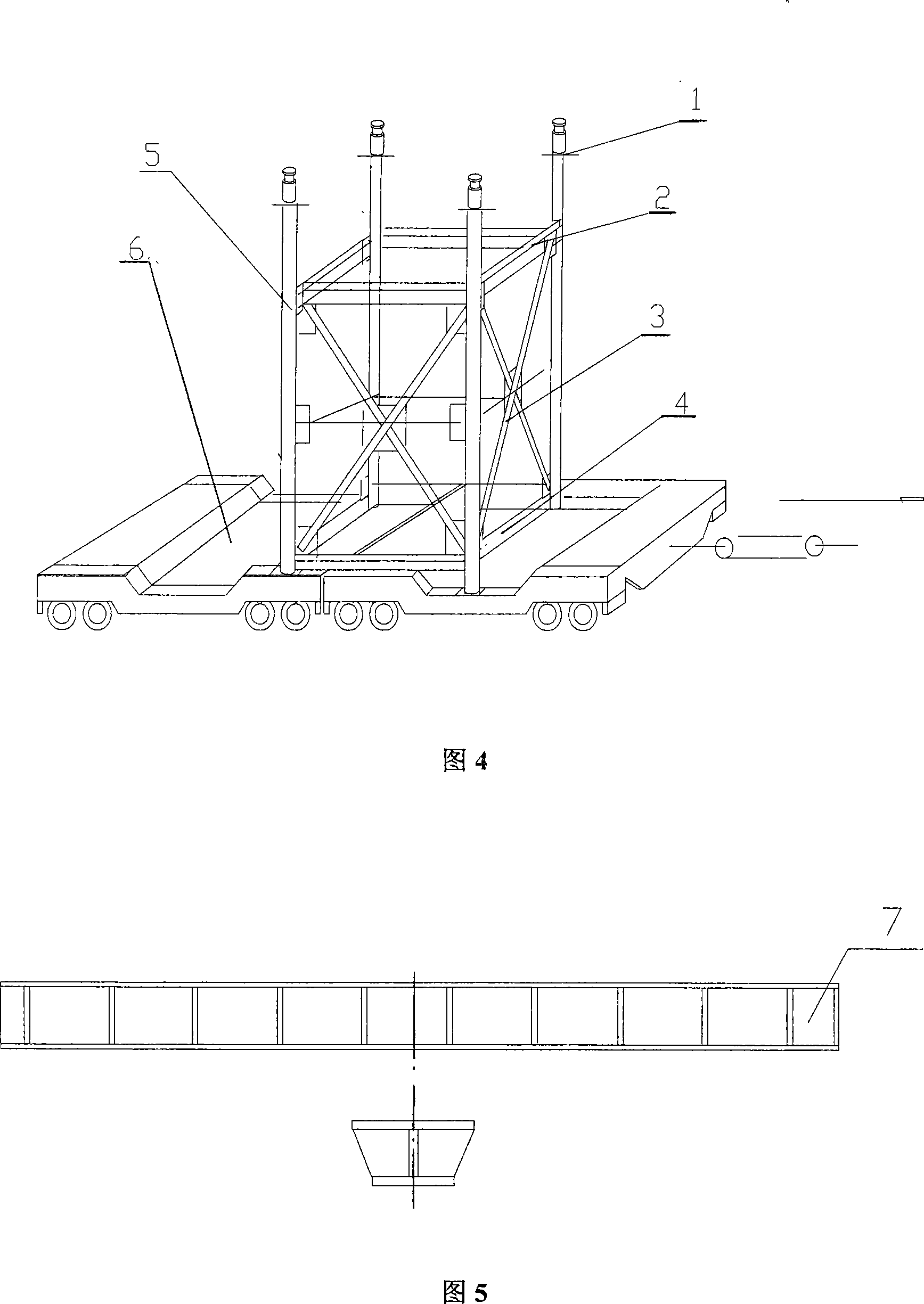

Combination method mounting technique for ultra-large type steel converter

ActiveCN101215615ASolve the installationEasy to operateAssembly machinesManufacturing convertersOperabilityEngineering

The invention relates to a combination method installation technology for an ultra large steel-smelting converter, belonging to the installation of steel-smelting devices, which is characterized in that respectively installing hydraulic presses and cylindrical safety cushion blocks on the upper portions of four vertical props of a supporting platform relatively to the chassis portions of bearing bases on the driving side and non driving side of the converter, installing pad beams which are respectively indentified with height marks of the chassis of the bearing bases and are integrated together on steel pillars or steel beams of the operational platform on the front of the converter, assembling three components of the converter on charging bays, suspending the three components on the hydraulic presses on the supporting platform and the pad beams which are provided with rolling rods and assembling integrally, regulating the hydraulic presses to make each supporting point with balance force, installing a winding engine and a main pulley block on the advancing end of a ladle car to drag the ladle car and the supporting platform, arranging a single-sheaved block on the driving lateral bearing base which is dragged by a line hook of a steel-melting bay, correcting directions by regulating the rolling rods, and slowly dragging the whole converter to the installation position of the steel-melting bay, which is safe and reliable, and has high effect and strong operability.

Owner:中国冶金科工股份有限公司

Ultra-high performance wearable high-manganese steel and producing method thereof

The invention provides ultra-high-performance abrasion-resistant high manganese steel and the production method thereof. The chemical compositions of the steel are that: carbon of 1.00 to 1.50 percent; manganese of 10.5 to 20.0 percent; silicon of 0.30 to 0.80 percent; chromium of 1.3 to 2.8 percent; sulfur of less than or equal to 0.040 percent; phosphorus of less than or equal to 0.070 percent; titanium of 0.06 to 0.20 percent; vanadium of 0.10 to 0.40 percent; boron of 0.002 to 0.010 percent; magnesium of 0.06 to 0.3 percent; rhenium of 0.08 to 0.4 percent; nitrogen of 0.05 to 0.2 percent; the remainder is iron. The production method is that: when the molten steel temperature reaches between 1500 and 1550 DEG C, the nitrogen and the calcium are added within 5 minutes after the molten steel is reduced, the aluminum is inserted and the vanadium (2 to 5 kg / t) and the titanium (4 to 10 kg / t) are added within 10 minutes before steel tapping, the rare earth magnesium (2 to 6 kg / t) is added into a tank when one-third steel is tapped, the rare earth silicon (1 to 4 kg / t) is added into the tank when one-second steel is tapped, the boron (0.1 to 0.3 kg / t) is added into the tank when two-third steel is tapped, the casting temperature of the molten steel is controlled between 1430 and 1460 DEG C. The invention adopts new alloying process, improves the abrasion- resistant performance and the comprehensive mechanical performance of the high manganese steel.

Owner:ANSTEEL GRP MINING CO LTD

Dynamic soft reduction technologies for bloom continuous casting of heavy rail

The invention discloses a process of continuous casting dynamic with less reduction heavy rail steel cogged ingot, the process is applied in the continuous casting of high carbon steel cogged ingot, which can not only evidently alleviate center segregation, center porosity, center line shrinkage, center crack and so on defects and prevent the casting ingot center crack, middle crack and so on underbead crack, but also can improve component homogenization of rail rolled by the casting ingot, stabilize and improve mechanical property and functional performance of the rail and reach technical requirements of the high speed rail. The technical measure as follows: controlling continuous casting pulling rate and molten steel temperature of the heavy rail steel, the continuous casting pulling rate is 0.60-0.80m / min, the molten steel superheating temperature is 15-40 DEG C; adopting even and assuasive control mode in the secondary cooling zone, the continuous casting ratio water amount is 0.25-0.30L / kg, the casting ingot surface temperature on the area with less reduction is 900-1020 DEG C; the reduction is controlled on the area with less reduction, the casting ingot solidification rate on the area with less reduction fs=30%-100%, total reduction is 1.6-7.0 mm.

Owner:PANZHIHUA IRON AND STEEL

Grinder hammerhead with ceramic wearing coat and casting method thereof

InactiveCN101314145ANot easy to wearAvoid breakingFoundry moulding apparatusGrain treatmentsSurface layerHardness

The invention discloses a crusher hammer with a ceramic abrasion-resistant layer and a casting method thereof. The hammer adopts high boron cast steel as a parent body and a ceramic particle composite layer as a surface layer of the hammer, and is produced through a shape casting method that evaporated pattern casting is combined with casting by a cast-penetration process, and high temperature molten steel is taken as a parent body and is penetrated into the ceramic particle composite layer to form metallurgical bonding. The produced hammer has good strength and toughness as well as high hardness and wearing resistance.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Method for controlling center porosity of large section heavy rail steel casting blank

The invention relates to the technical field of ferrous metallurgy, in particular to a method for controlling the center porosity of a large section heavy rail steel casting blank. The method comprises the following steps of controlling the superheat degree of medium-package molten steel; controlling the pulling speed in the normal pouring process; pressing down the final solidification end in the pouring process; setting the stirring strength and stirring frequency of electromagnetic stirring of a crystallizer; setting the stirring strength and stirring frequency of electromagnetic stirring at the final solidification end; controlling the cooling water yield and the secondary cooling specific water yield of the crystallizer. The center porosity of the large section heavy rail steel casting blank produced by adopting the method can be effectively controlled, and the remaining internal quality of the casting blank can be effectively guaranteed.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for manufacturing 550MPa-level high-strength atmospheric corrosion resistant steel strip through strip continuous casting

ActiveCN103305770AHigh strengthHigh elongationFurnace typesMetal rolling arrangementsReduction rateChemical composition

The invention provides a method for manufacturing a 550MPa-level high-strength atmospheric corrosion resistant steel strip through strip continuous casting. The method comprises the following steps of: 1) smelting, wherein molten steel comprises the following chemical components: 0.03-0.08% of C, not more than 0.4% of Si, 0.6-1.5% of Mn, 0.07-0.22% of P, not more than 0.01% of S, not more than 0.012% of N, 0.25-0.8% of Cu, 0.3-0.8% of Cr, 0.12-0.4% of Ni, at least one of microalloy elements including 0.01-0.08% of Nb, 0.01-0.08% of V, 0.01-0.08% of Ti and 0.1-0.4% of Mo, and the balance of Fe and inevitable impurities; 2) strip continuous casting: directly casting a cast strip with thickness of 1-5mm; 3) strip cooling, wherein the cooling rate is more than 20 DEG C / s; 4) online hot rolling of the cast strip, wherein the hot rolling temperature is 1050-1250 DEG C, the reduction rate is 20-50% and the deformation rate is more than 20s<-1>; online austenite recrystallization happens after hot rolling; and the hot-rolled strip is 0.5-3.0mm in thickness; and 5) cooling and coiling, wherein the cooling rate is 10-80 DEG C / s, and the coiling temperature is 570-720 DEG C. The microstructure of the obtained steel strip is mainly formed by fine polygonal ferrite and pearlite.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com