Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8290results about How to "High elongation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

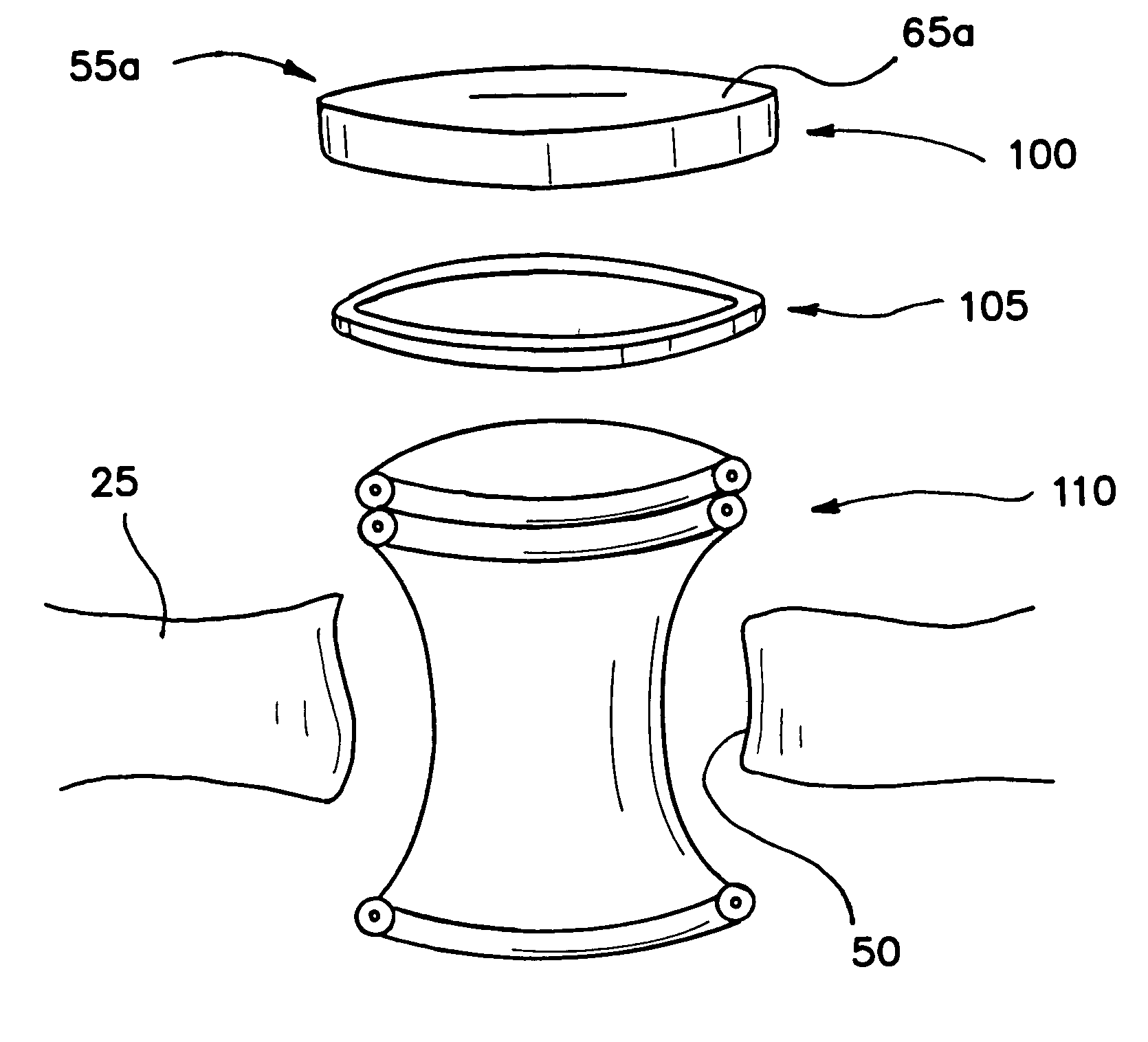

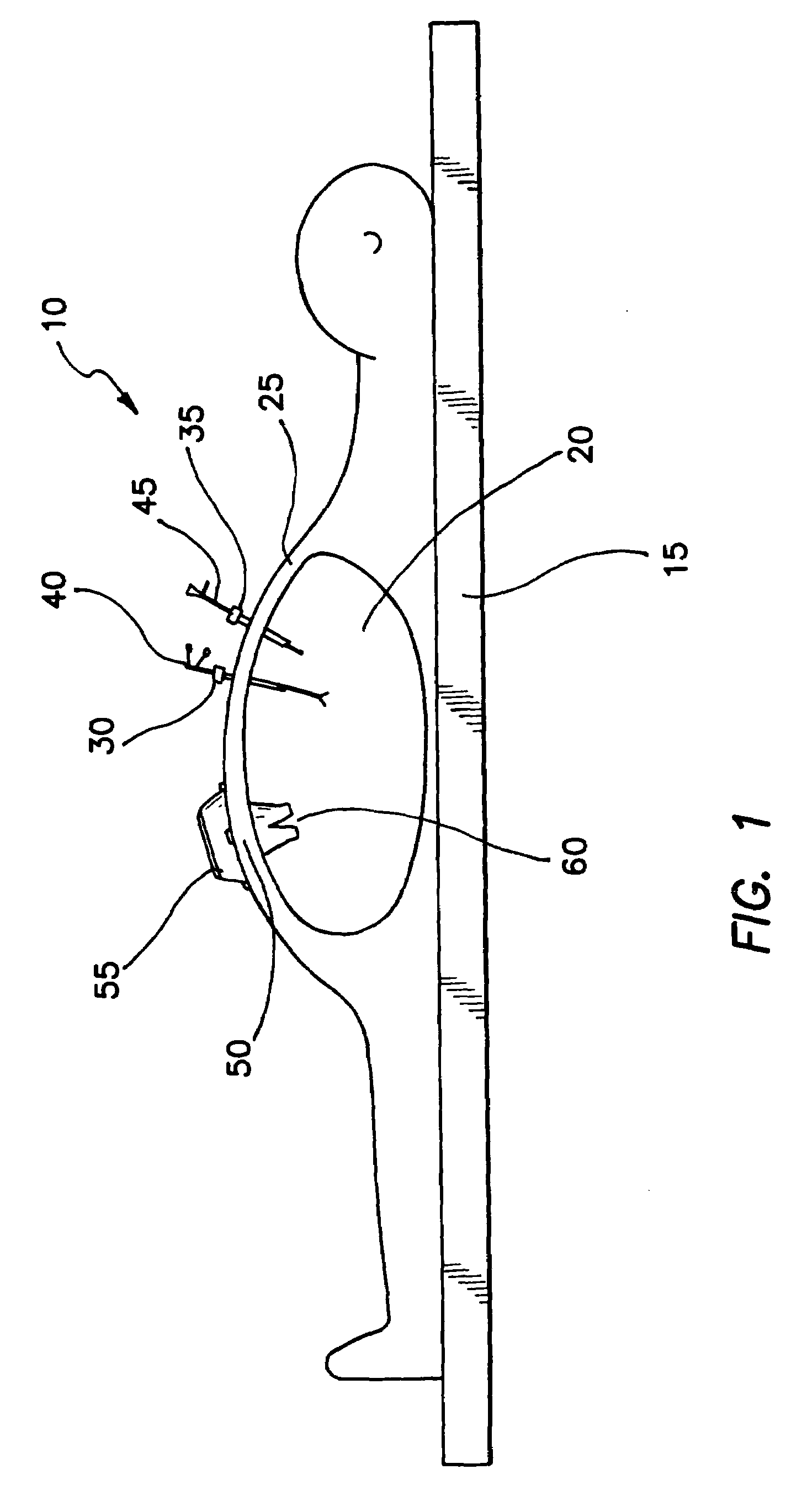

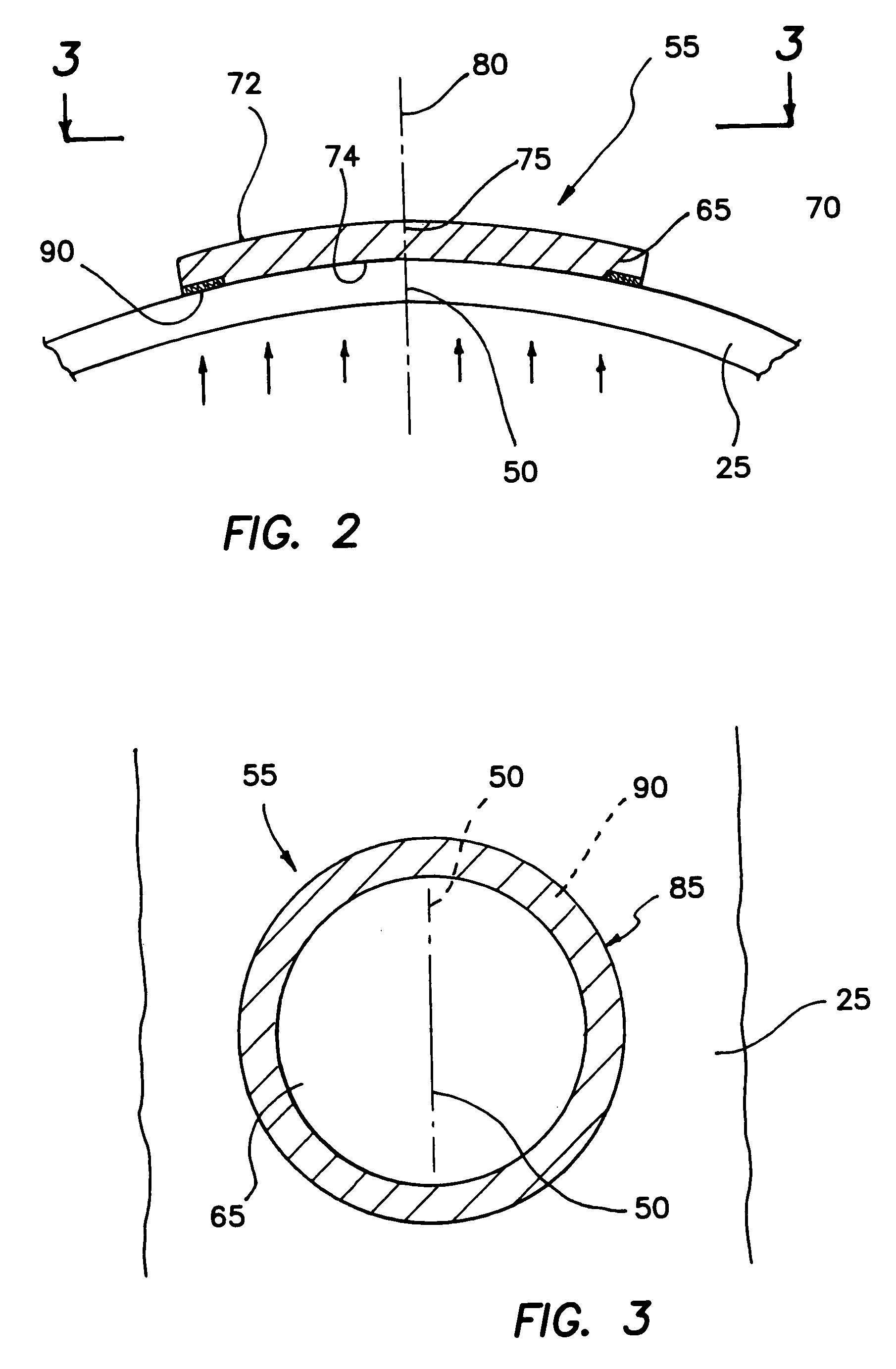

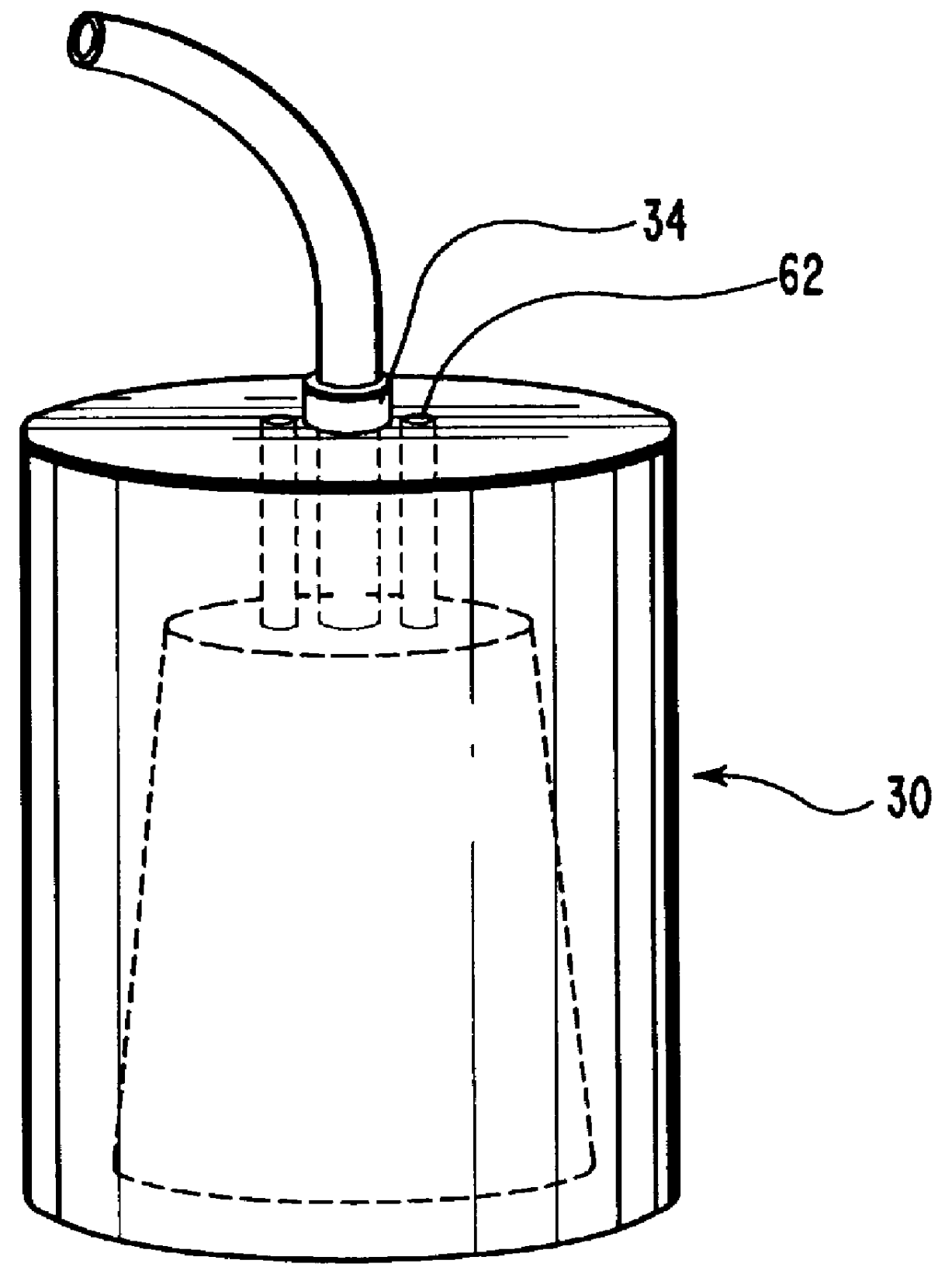

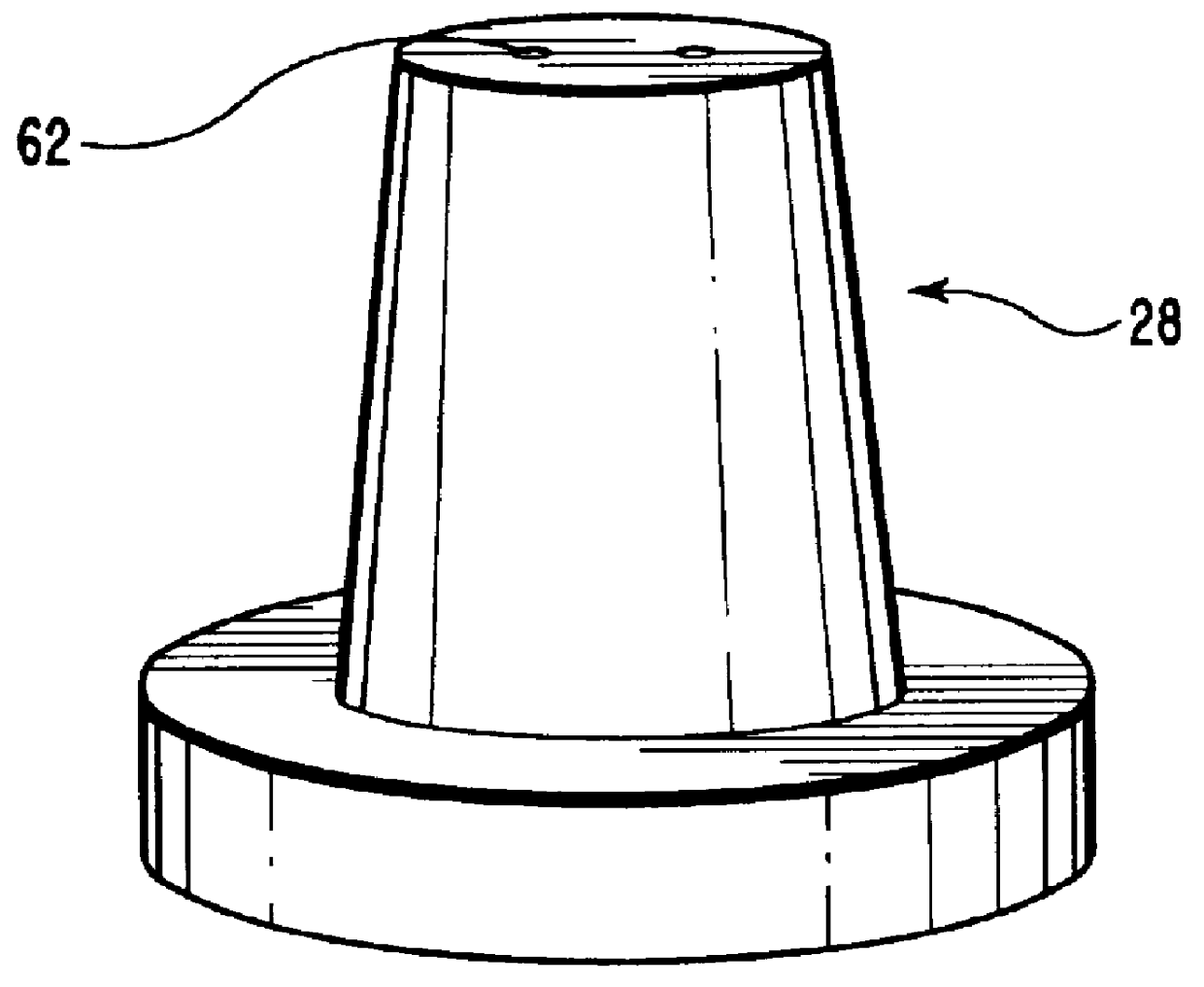

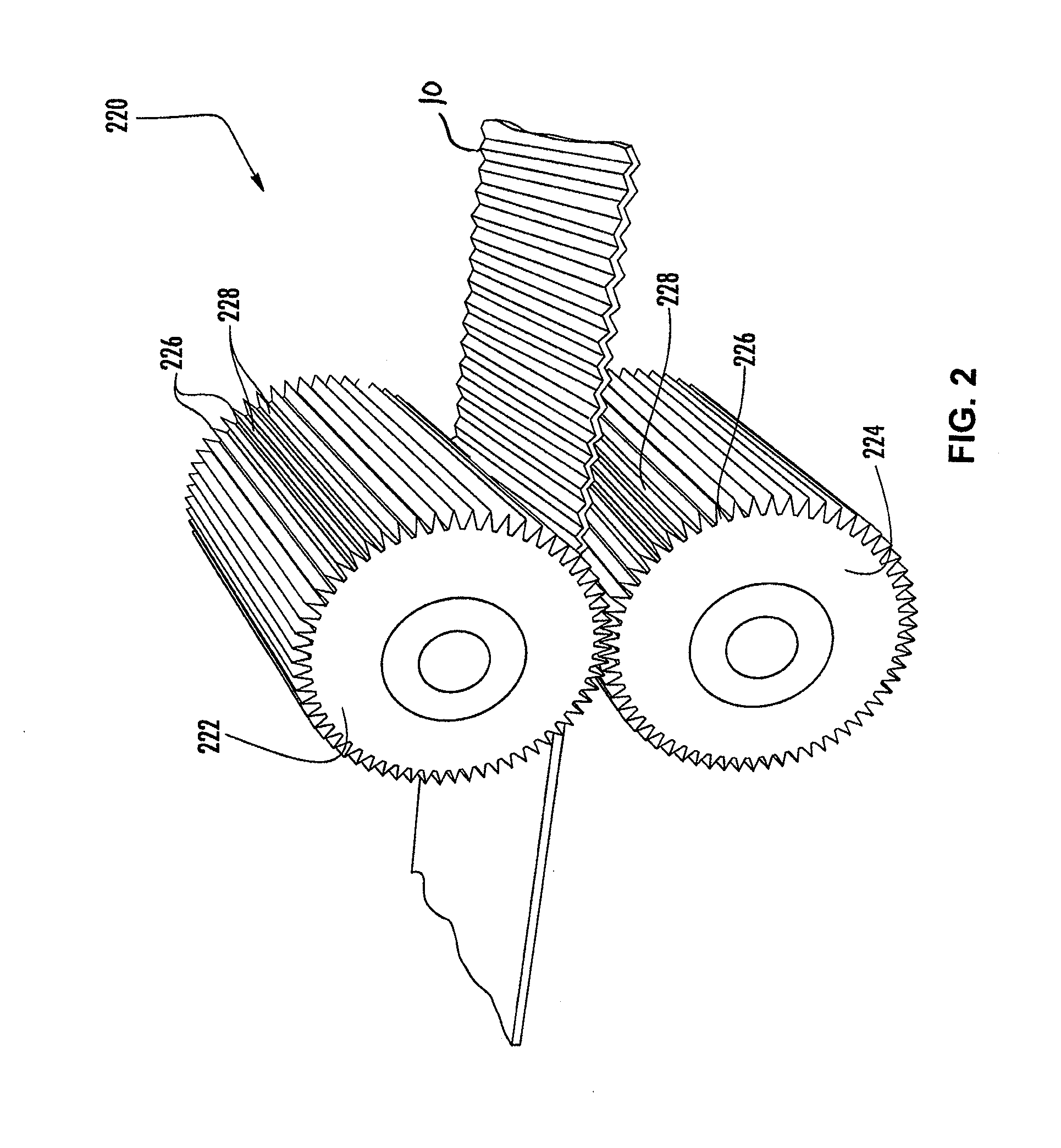

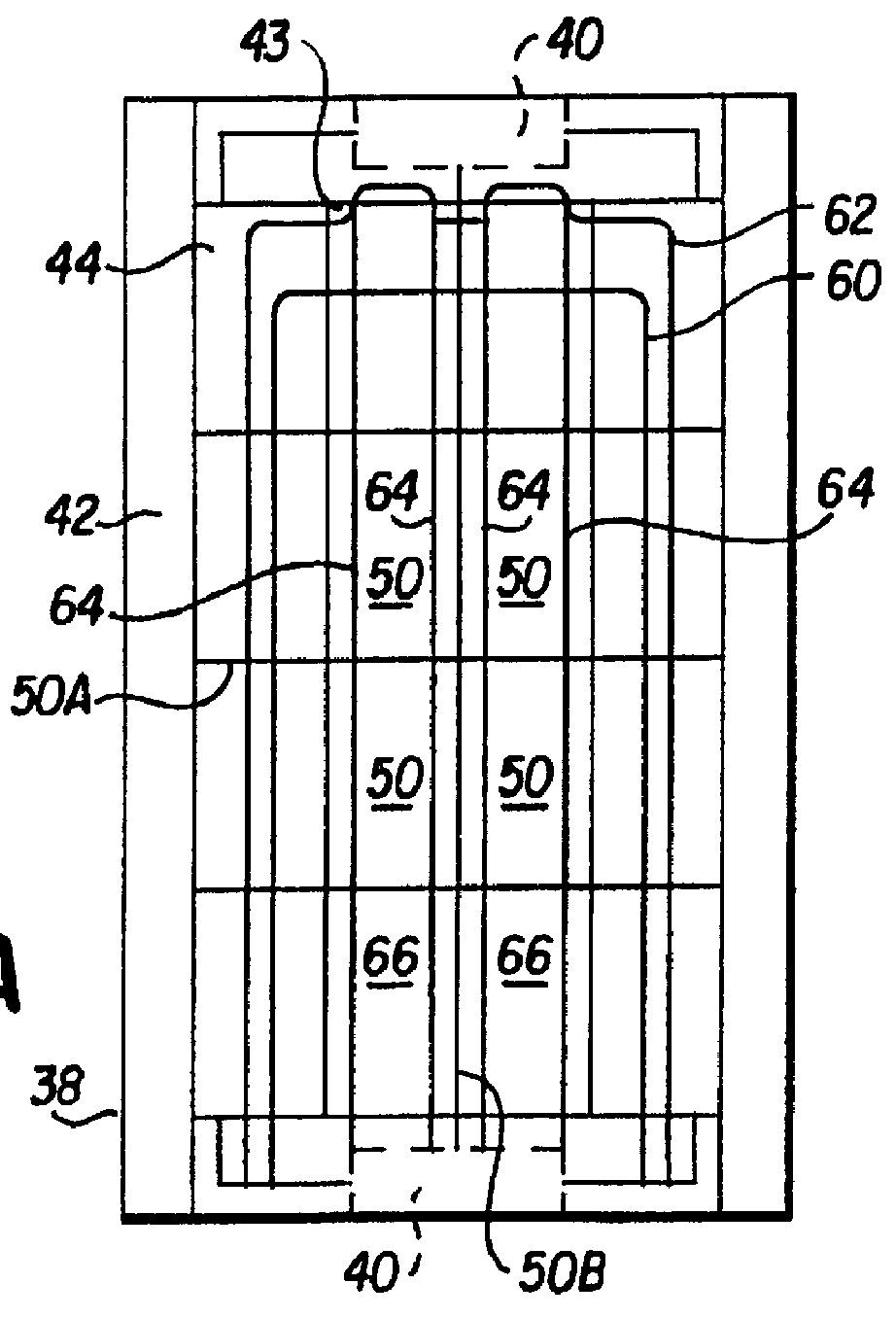

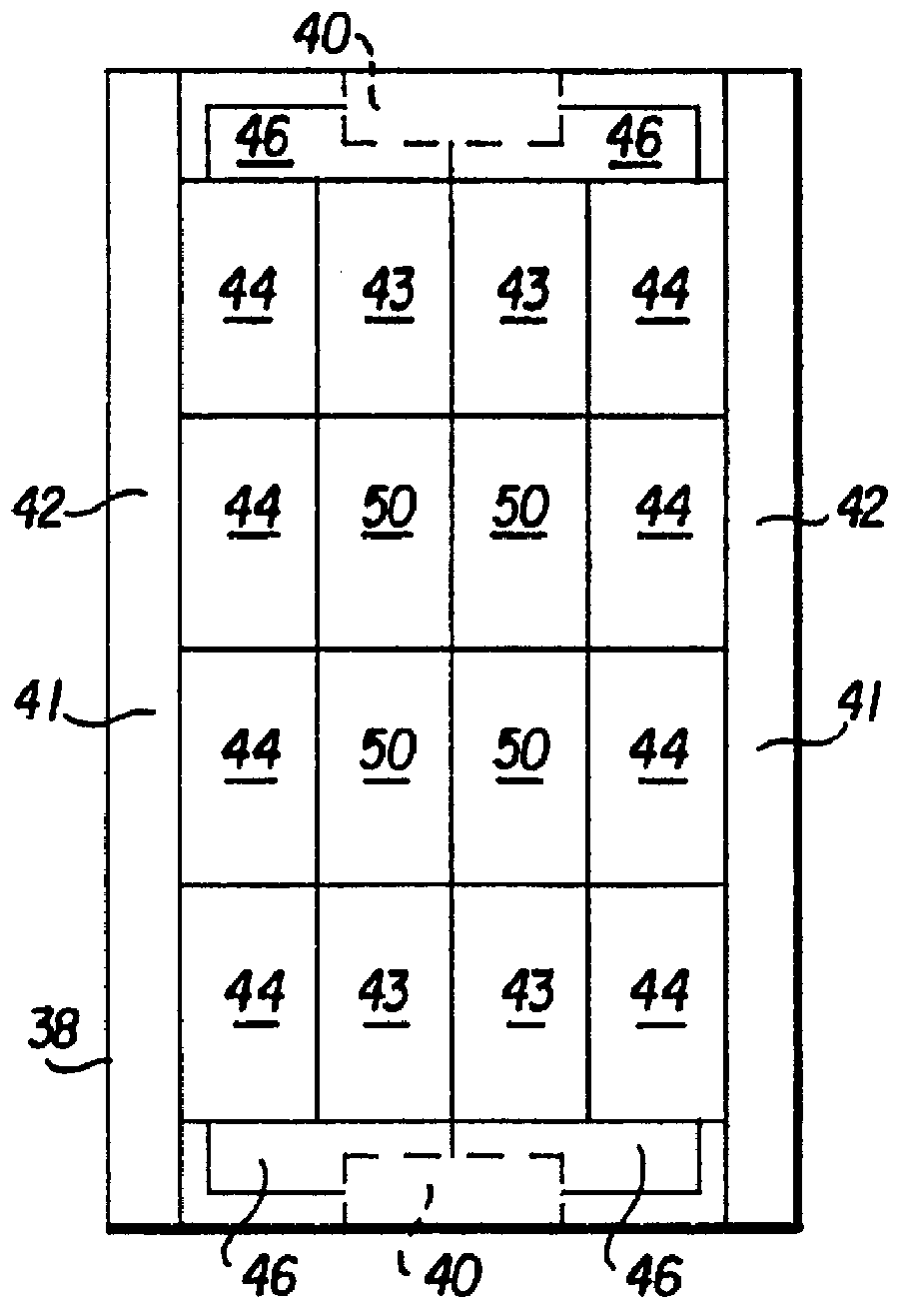

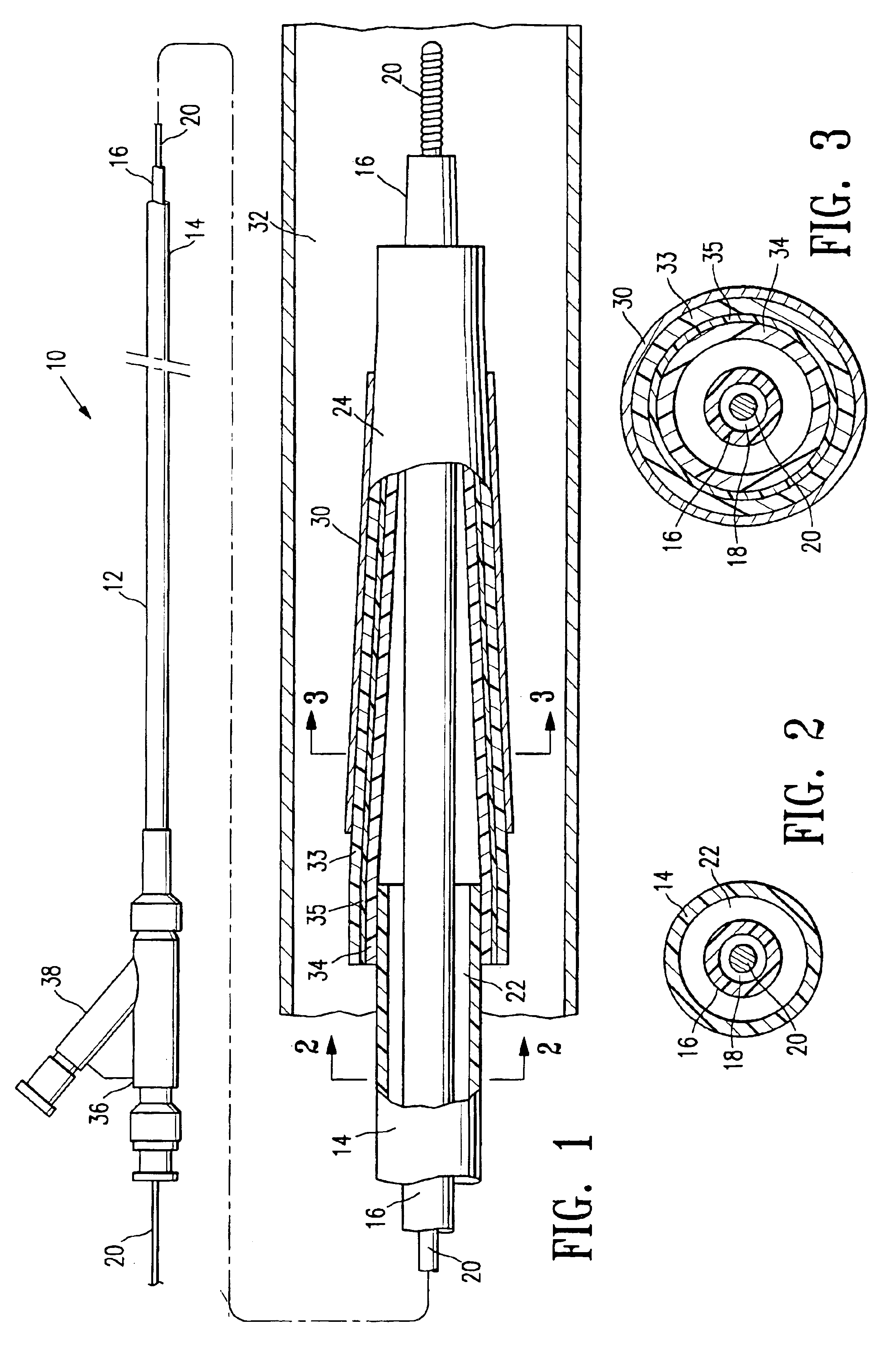

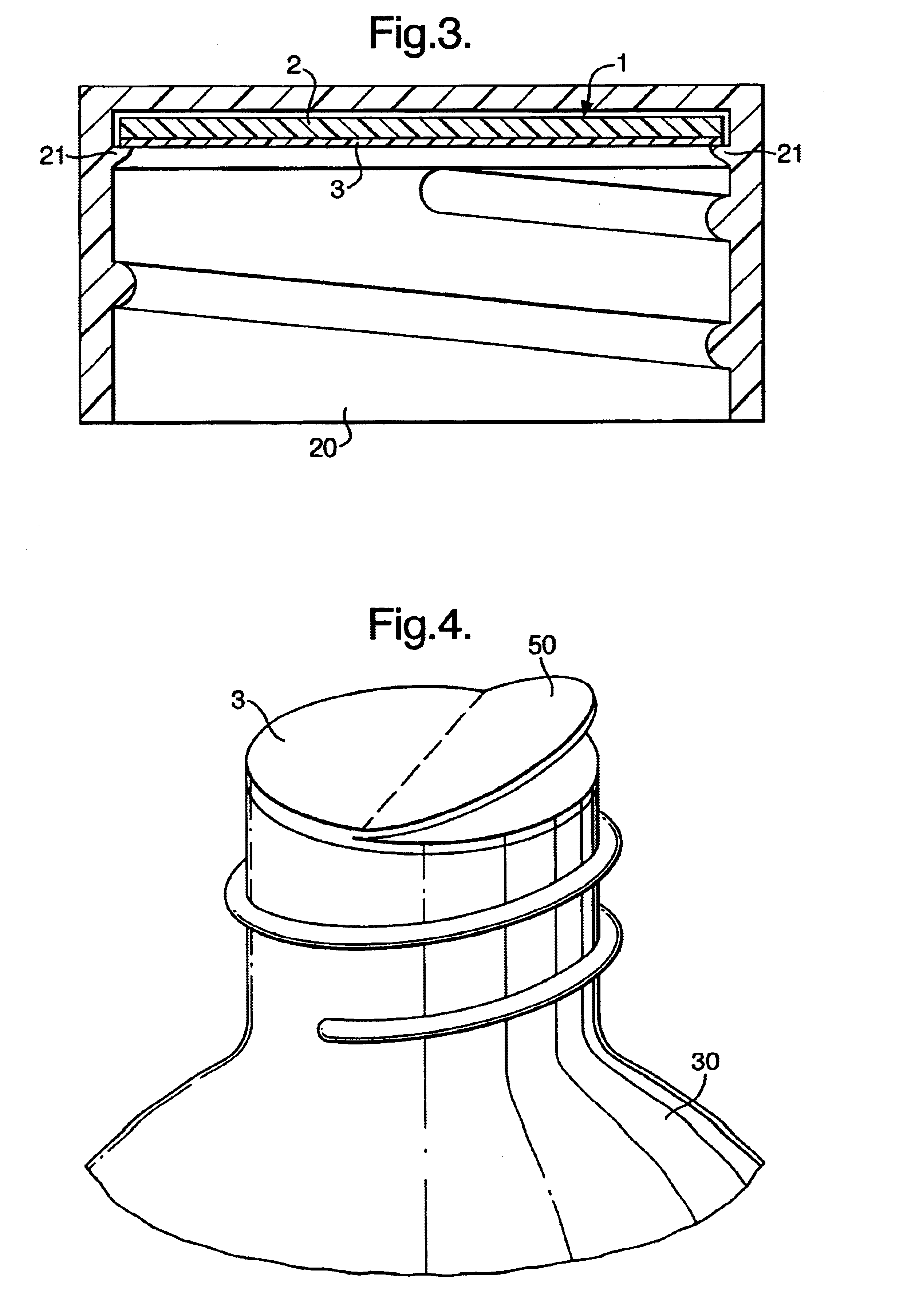

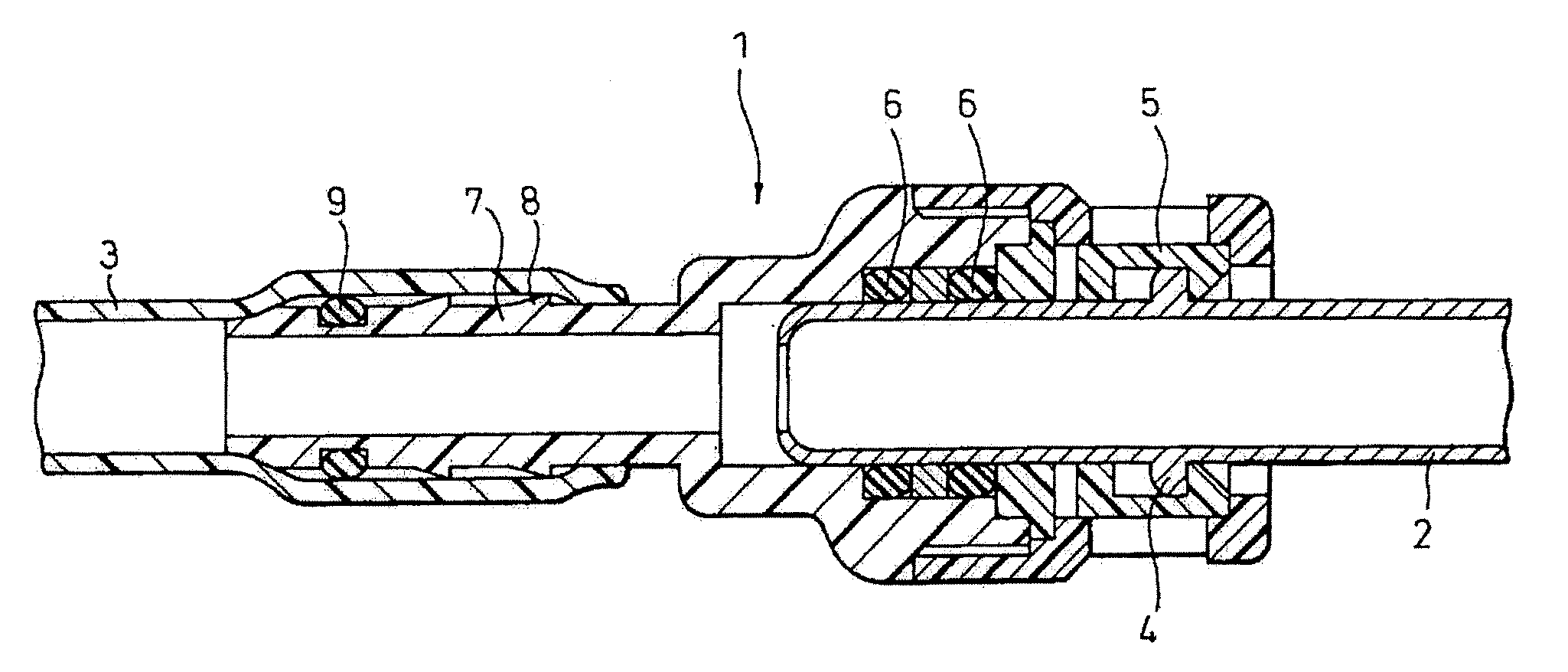

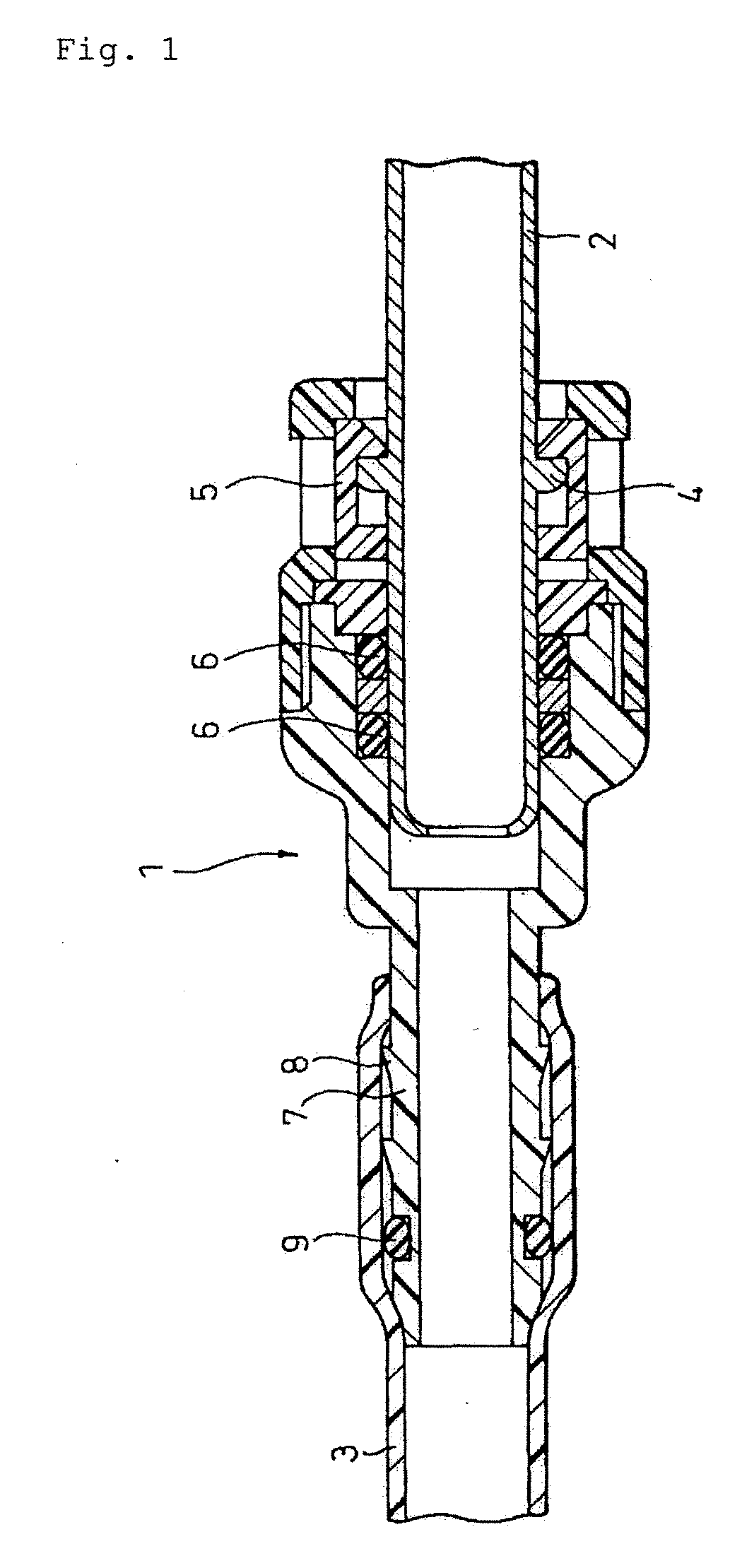

Surgical instrument access device

ActiveUS7163510B2High tear strengthHigh elongationCannulasInfusion syringesSurgical departmentVALVE PORT

A surgical access device includes a single valve that forms a seal with a body wall and provides an access channel into a body cavity. The valve has properties for creating a zero seal in the absence of an instrument as well as an instrument seal for an instrument having a diameter up to about 37 mm. The valve can include a gel material and the access channel can include a protective sleeve to provide for wound protection during insertion and withdrawal of a sharp surgical instrument. The valve further comprises a cap ring which may be inserted or molded with the gel material. The protective sleeve may be bonded or molded around an inner diameter of the cap ring. The protective sleeve may be a single tubular member, or may comprise a plurality of axially extending sleeve members having a plurality of axial slits. The protective sleeve and the cap ring may comprise of the same or different materials. The surgical access device further comprises at least one support ring disposed circumferentially of the valve forming a hollow space, and a wound retractor operatively placed in the hollow space. The wound retractor includes an inner ring, an outer ring, and a flexible sleeve connecting the inner ring and the outer ring.

Owner:APPL MEDICAL RESOURCES CORP

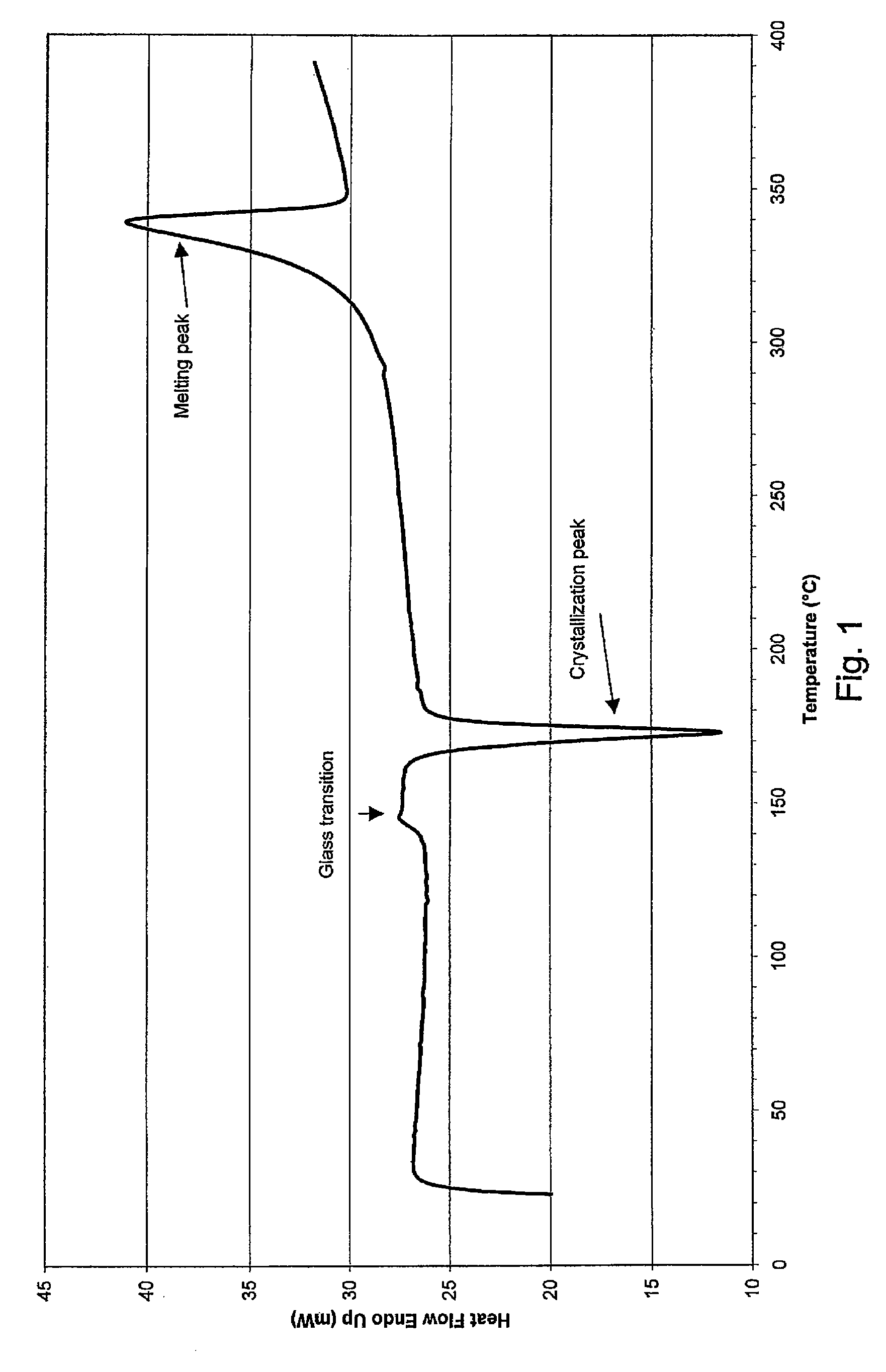

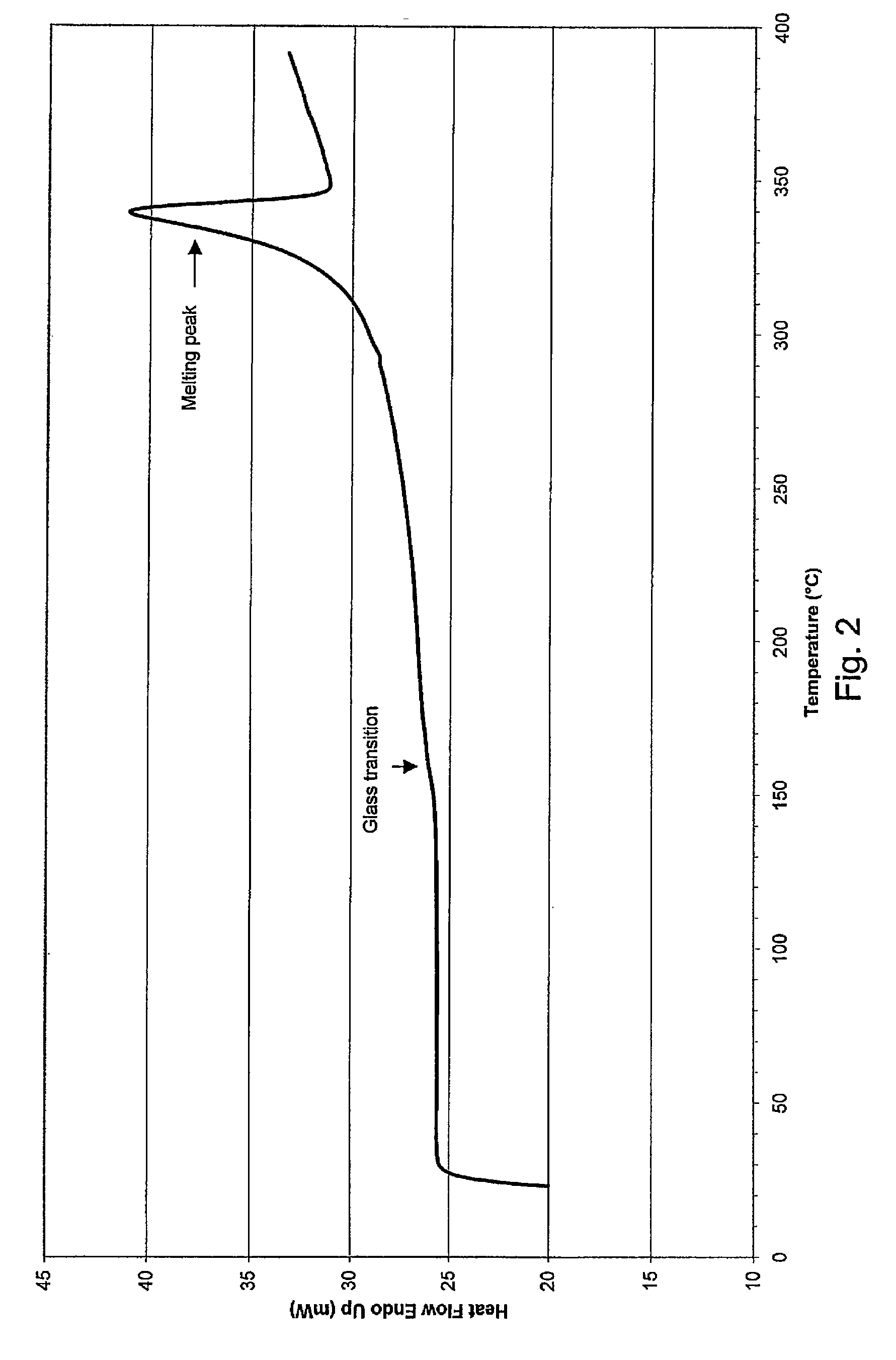

Surgical implant and manufacturing method

InactiveUS20070185488A1High elongationBone implantJoint implantsEthylene HomopolymersBiomedical engineering

A surgical implant and a method for manufacturing the same. The surgical implant has a body comprising polyaryletherketone (PAEK). Said polyaryletherketone is a homopolymer and a first section of the body comprises a polyaryletherketone that has a crystallization peak in its DSC-curve.

Owner:INION

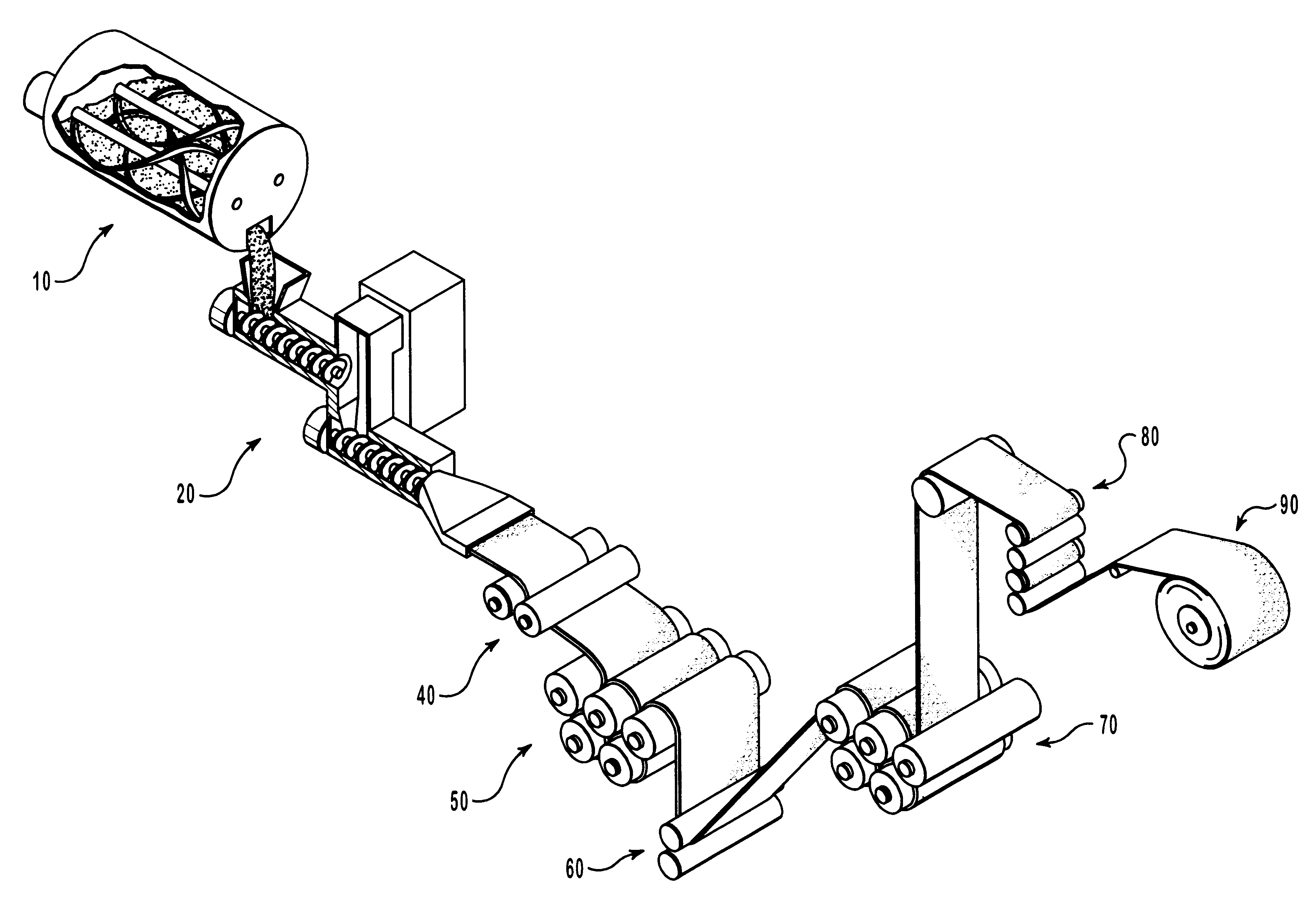

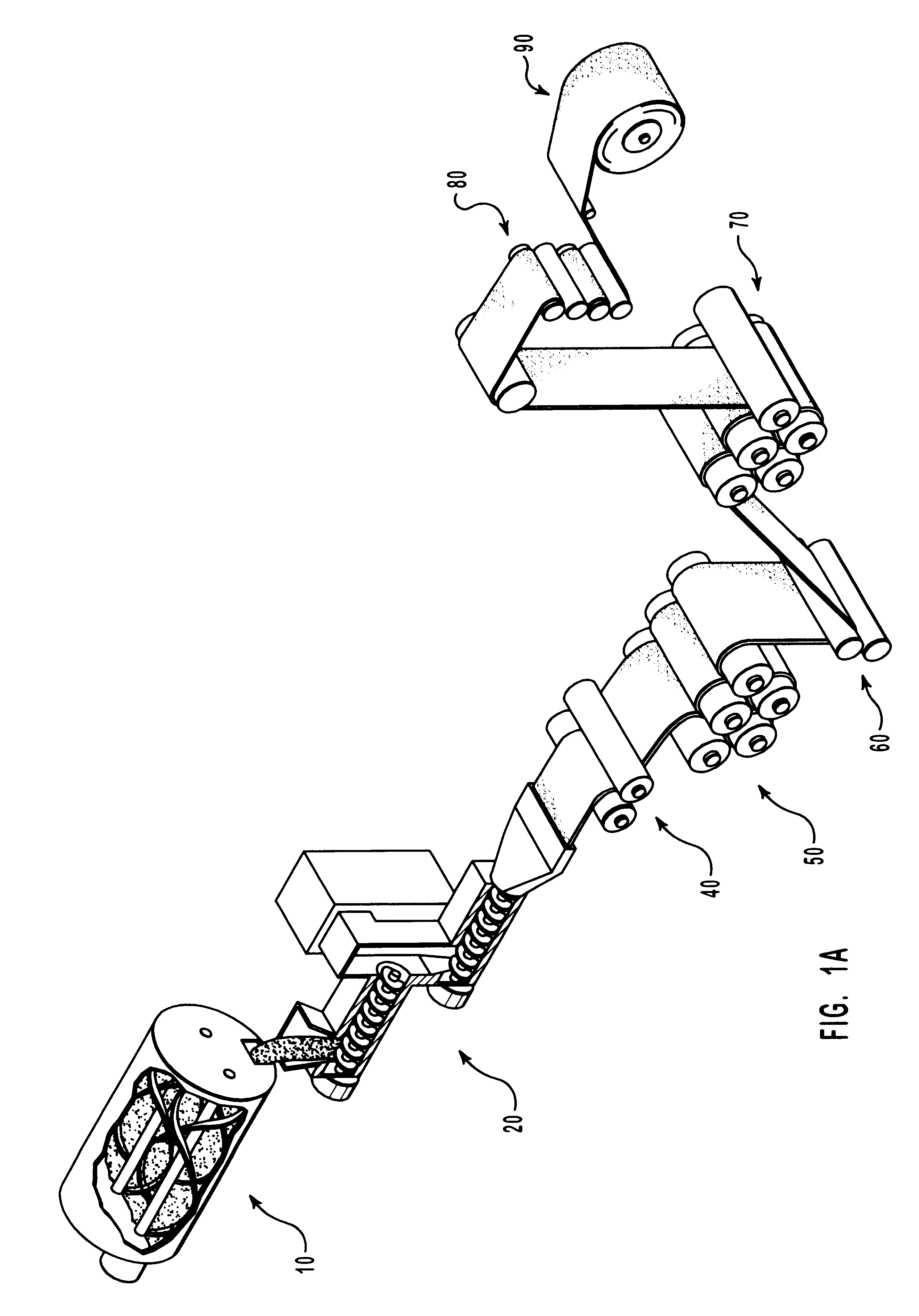

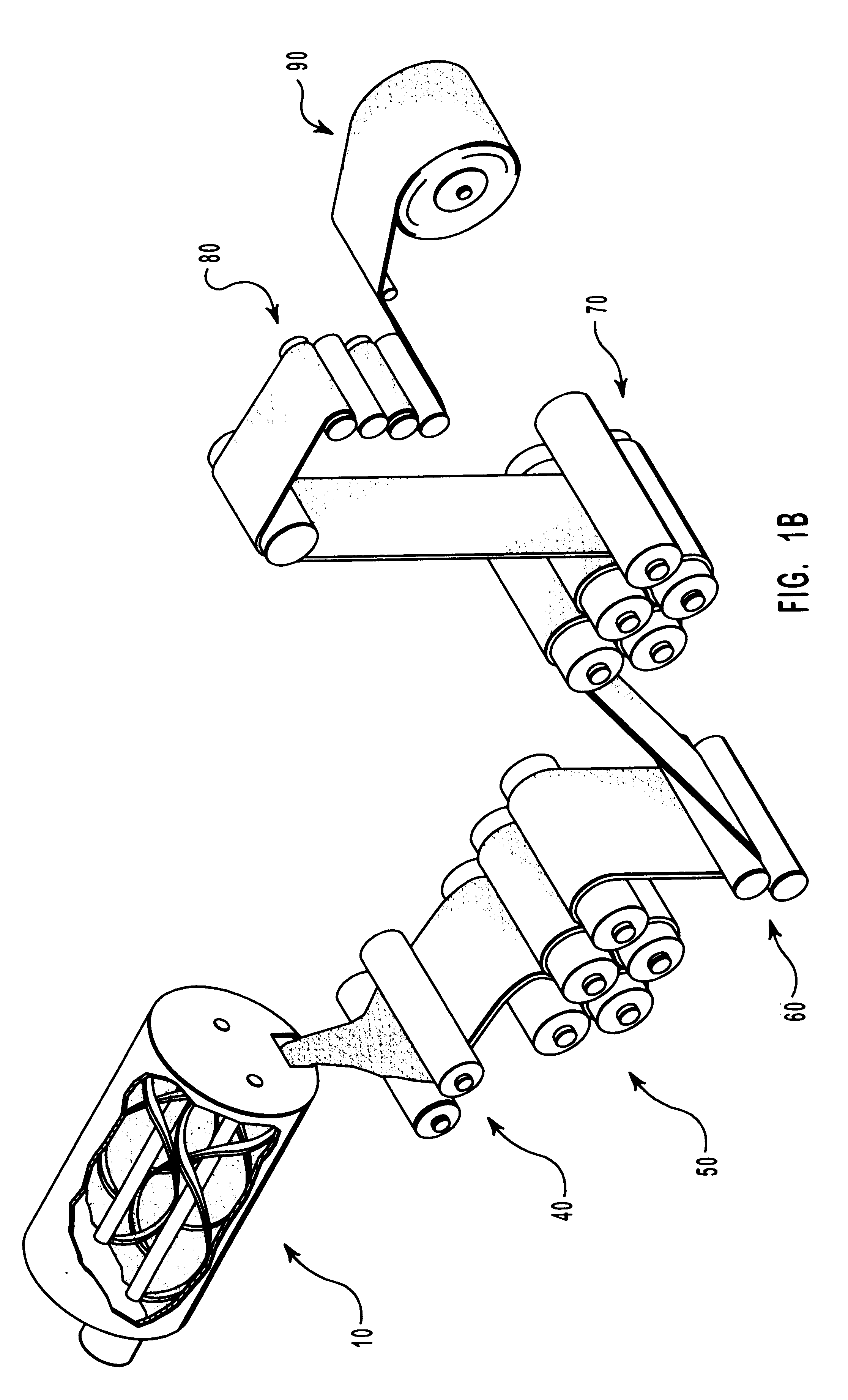

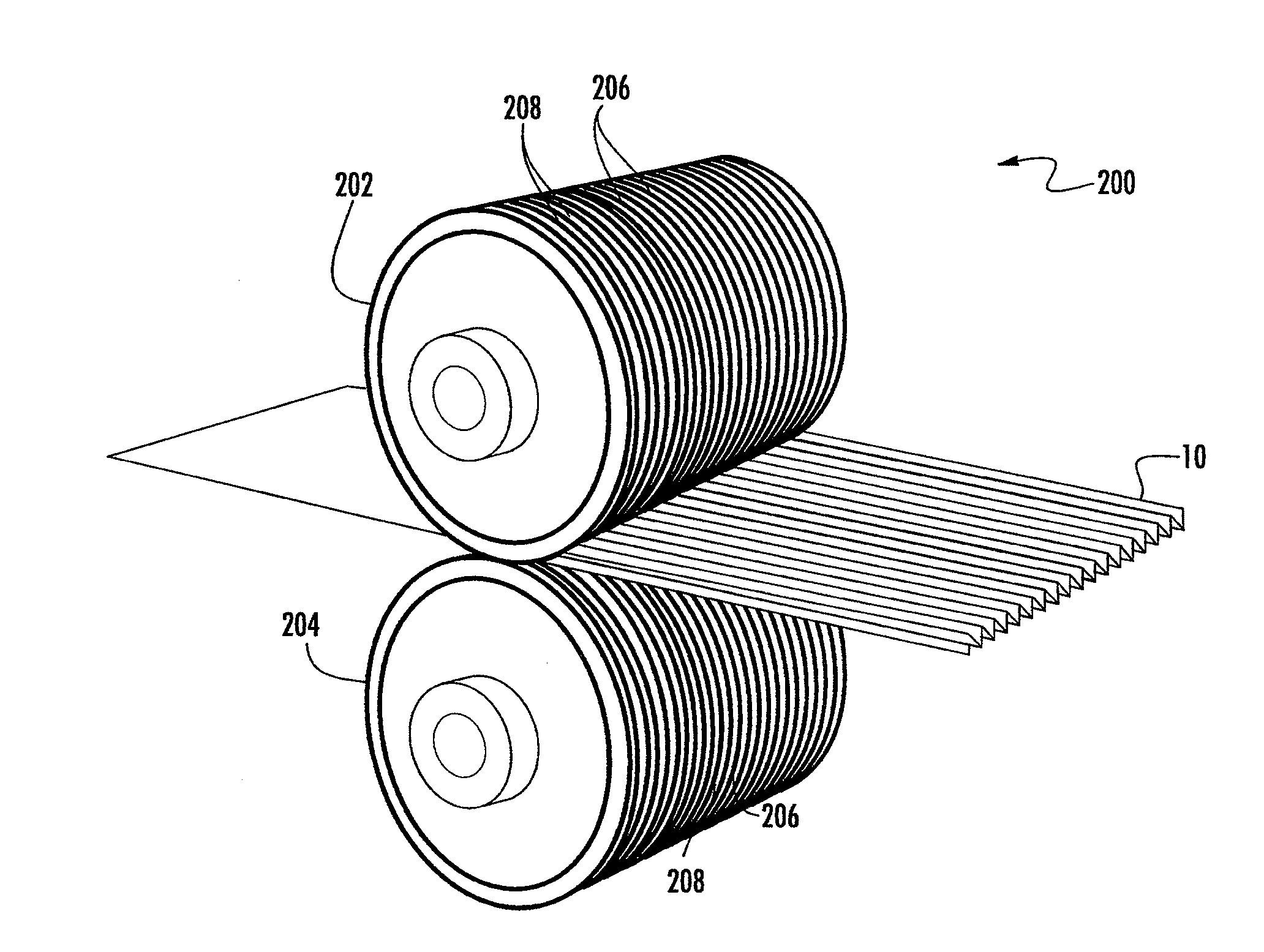

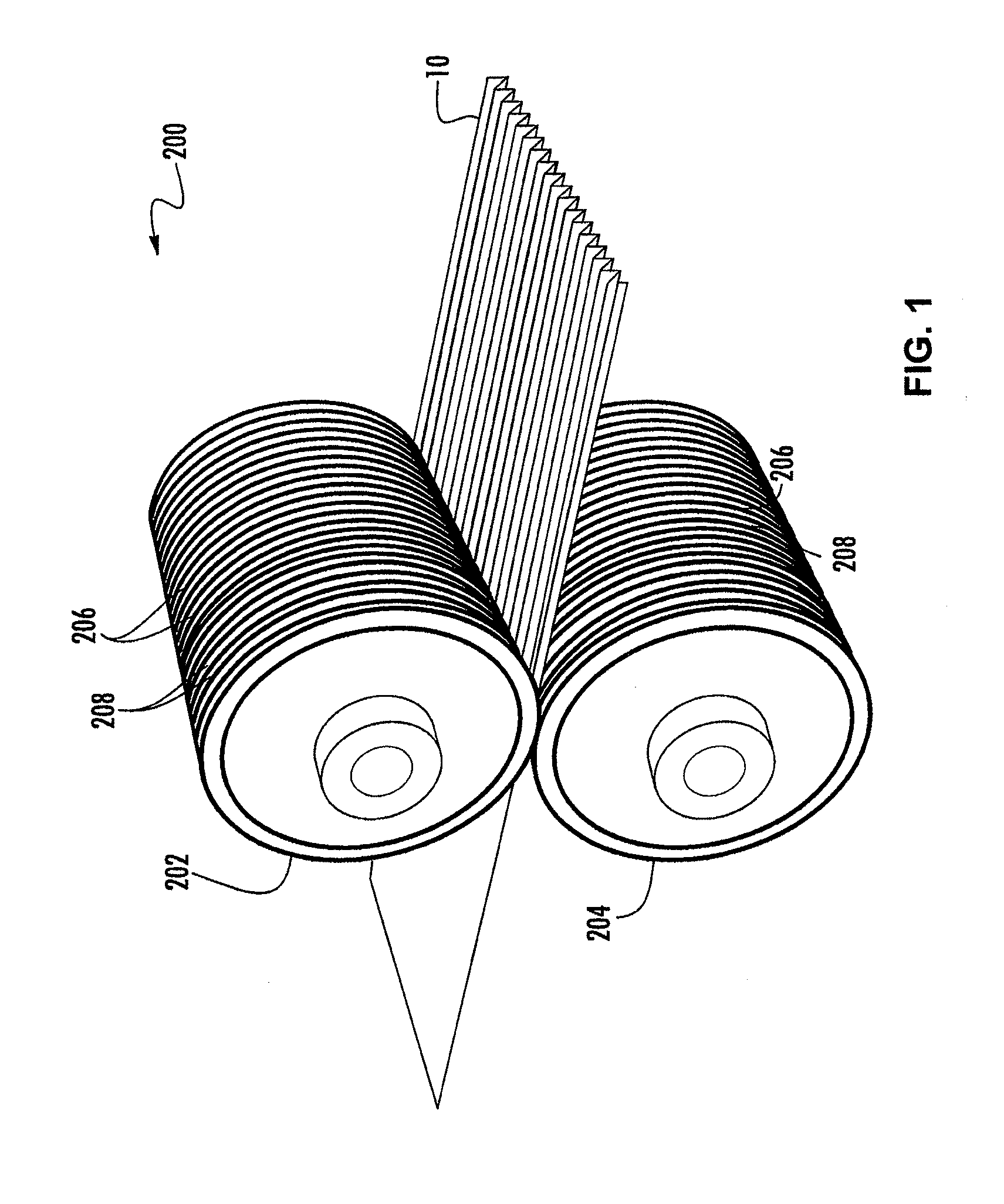

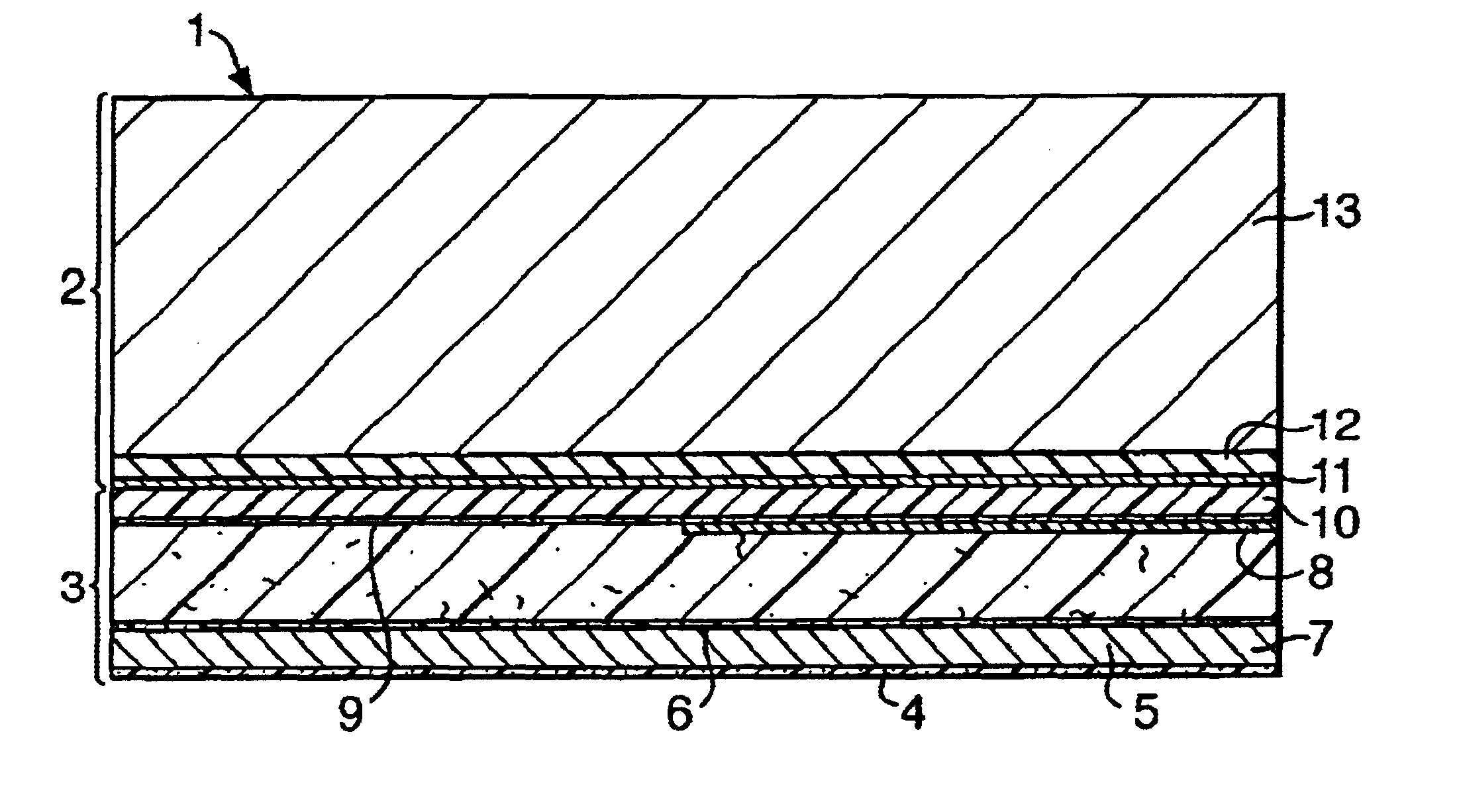

Methods for the manufacture of sheets having a highly inorganically filled organic polymer matrix

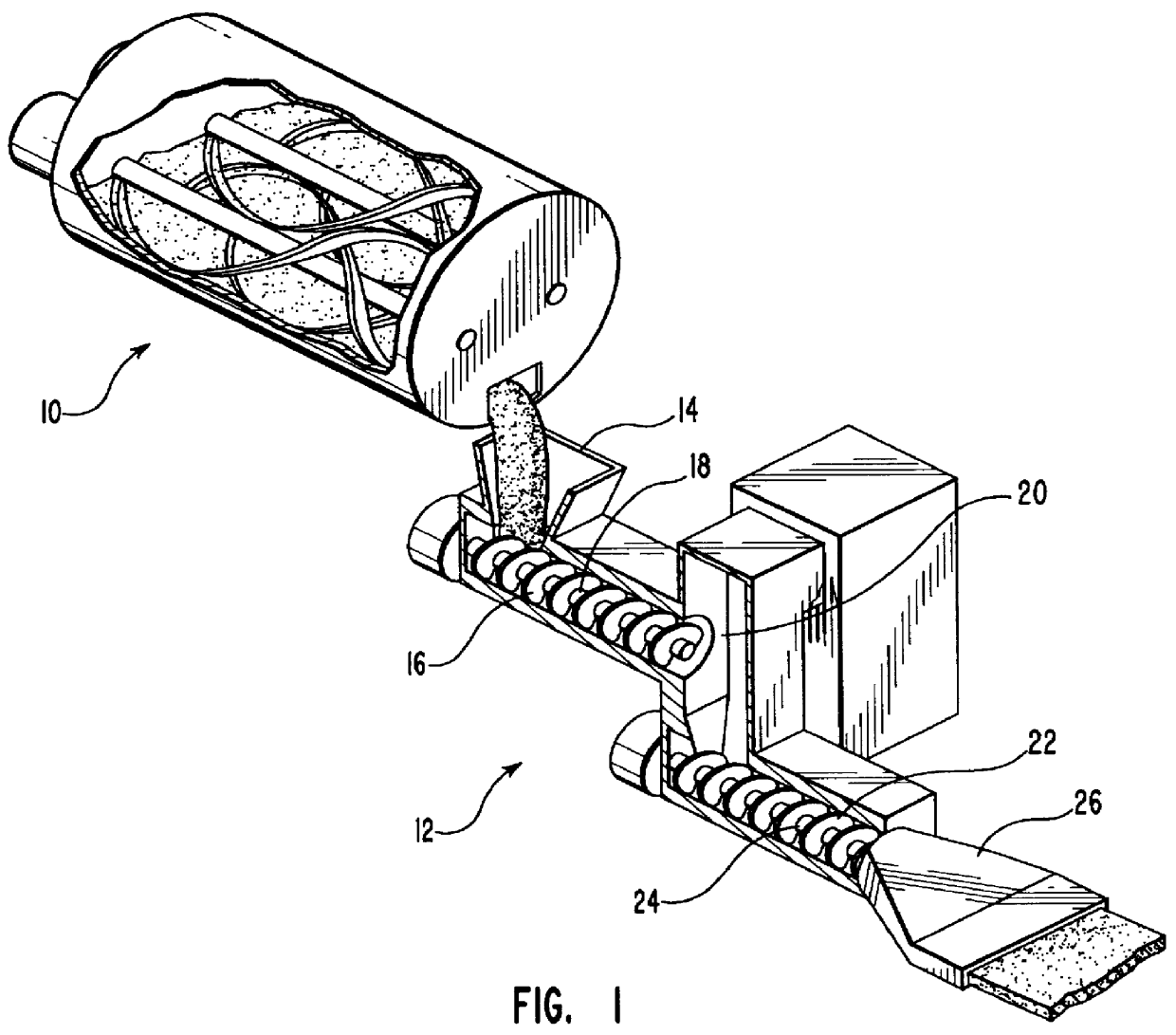

Compositions and methods for manufacturing sheets having a highly inorganically filled matrix. Suitable inorganically filled mixtures are prepared by mixing together an organic polymer binder, water, one or more inorganic aggregate materials, fibers, and optional admixtures in the correct proportions in order to form a sheet which has the desired performance criteria. The inorganically filled mixtures are formed into sheets by first extruding the mixtures and the passing the extruded materials between a set of rollers. The rolled sheets are dried in an accelerated manner to form a substantially hardened sheet, such as by heated rollers and / or a drying chamber. The inorganically filled sheets may have properties substantially similar to sheets presently made from traditional materials like paper, cardboard, polystyrene, plastic, or metal. Such sheets can be rolled, pressed, scored, perforated, folded, and glued. They have especial utility in the mass production of containers, particularly food and beverage containers.

Owner:E KHASHOGGI INDS

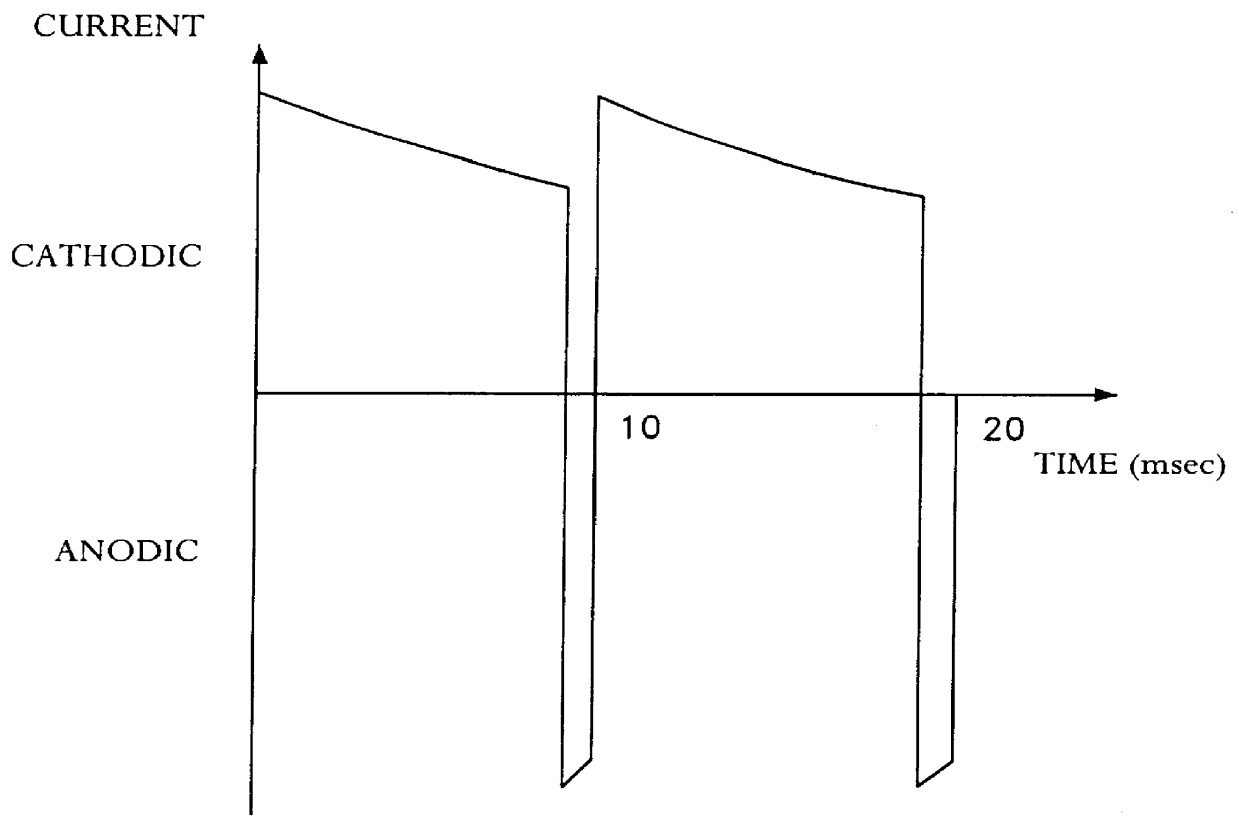

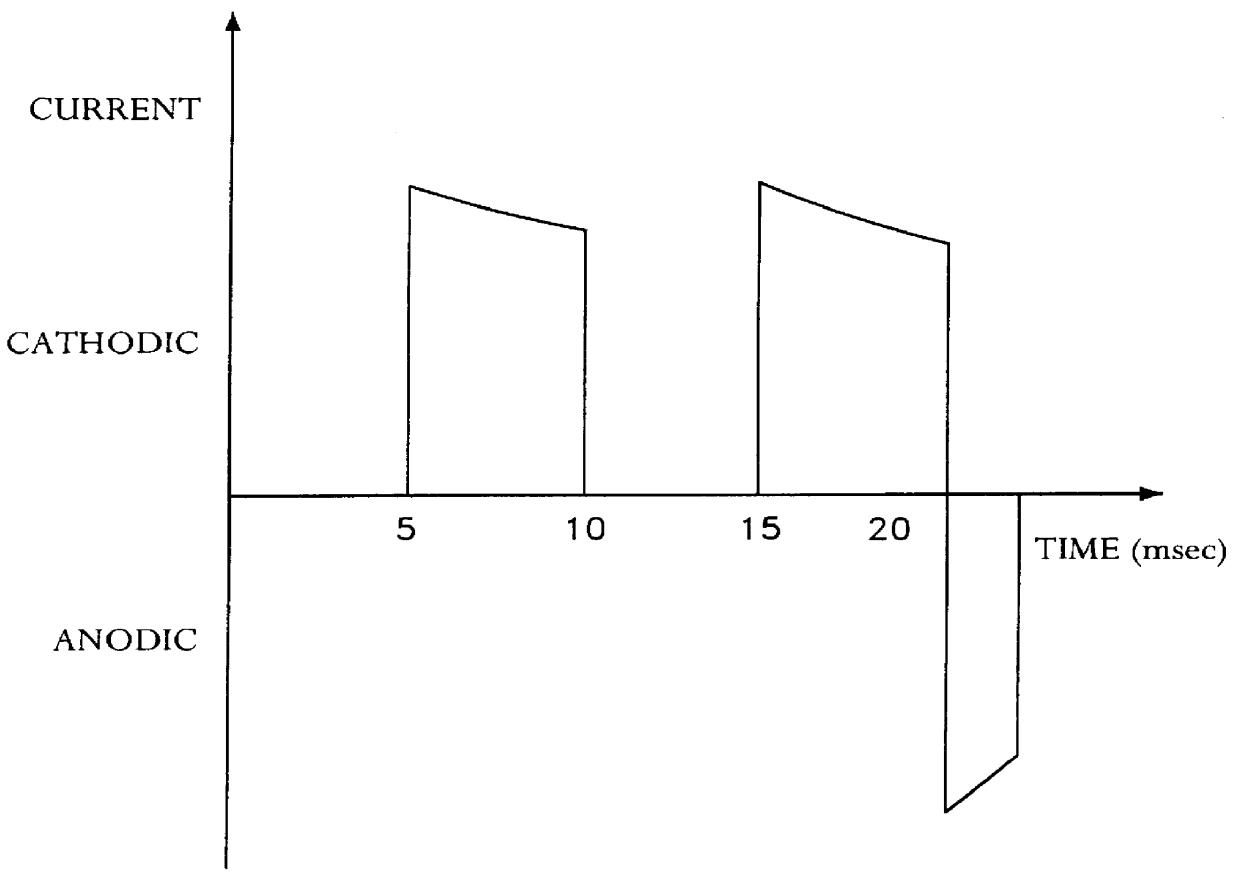

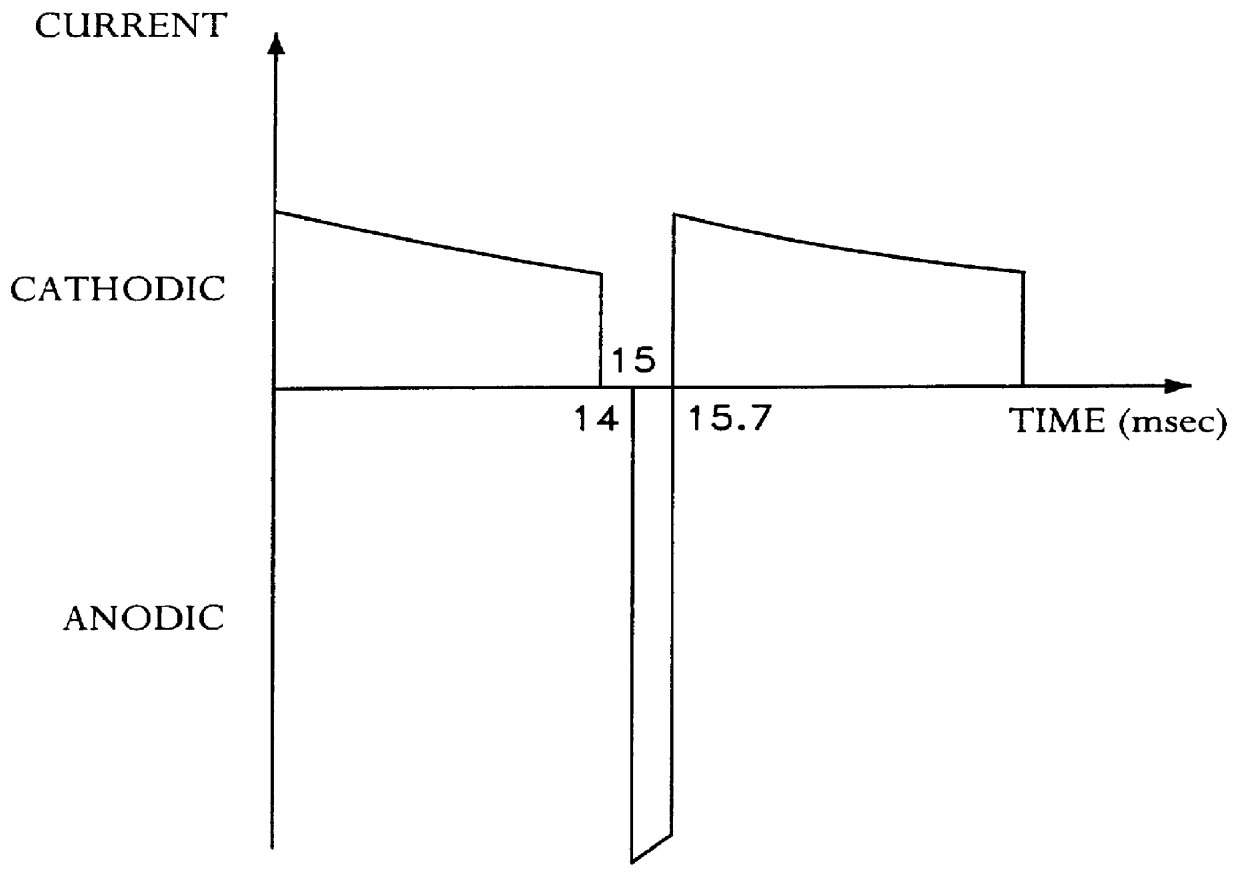

Process for the electrolytic deposition of metal layers

InactiveUS6099711AOptimize allocationImpairing propertyCellsElectrolysisHigh current densityMetal coating

PCT No. PCT / EP96 / 05140 Sec. 371 Date Apr. 23, 1998 Sec. 102(e) Date Apr. 23, 1998 PCT Filed Nov. 21, 1996 PCT Pub. No. WO97 / 19206 PCT Pub. Date May 29, 1997The invention relates to a method for the electrolytic deposition of metal coatings, in particular of copper coatings with certain physical-mechanical and optical properties and uniform coating thickness. According to known methods using soluble anodes and applying direct current, only uneven metal distribution can be attained on complex shaped workpieces. By using a pulse current or pulse voltage method, the problem of the coatings being of varying thickness at various places on the workpiece surfaces can indeed be reduced. However, the further problem of the geometric ratios being changed continuously during the depositing process by dissolving of the anodes is not resolved thus. This can be avoided by using insoluble anodes. In order to guarantee sufficient stability of the anodes and a bright coating even at those points on the workpiece surfaces, onto which the metal is deposited with high current density, it is essential to add compounds of an electrochemically reversible redox system to the depositing solution.

Owner:ATOTECH DEUT GMBH

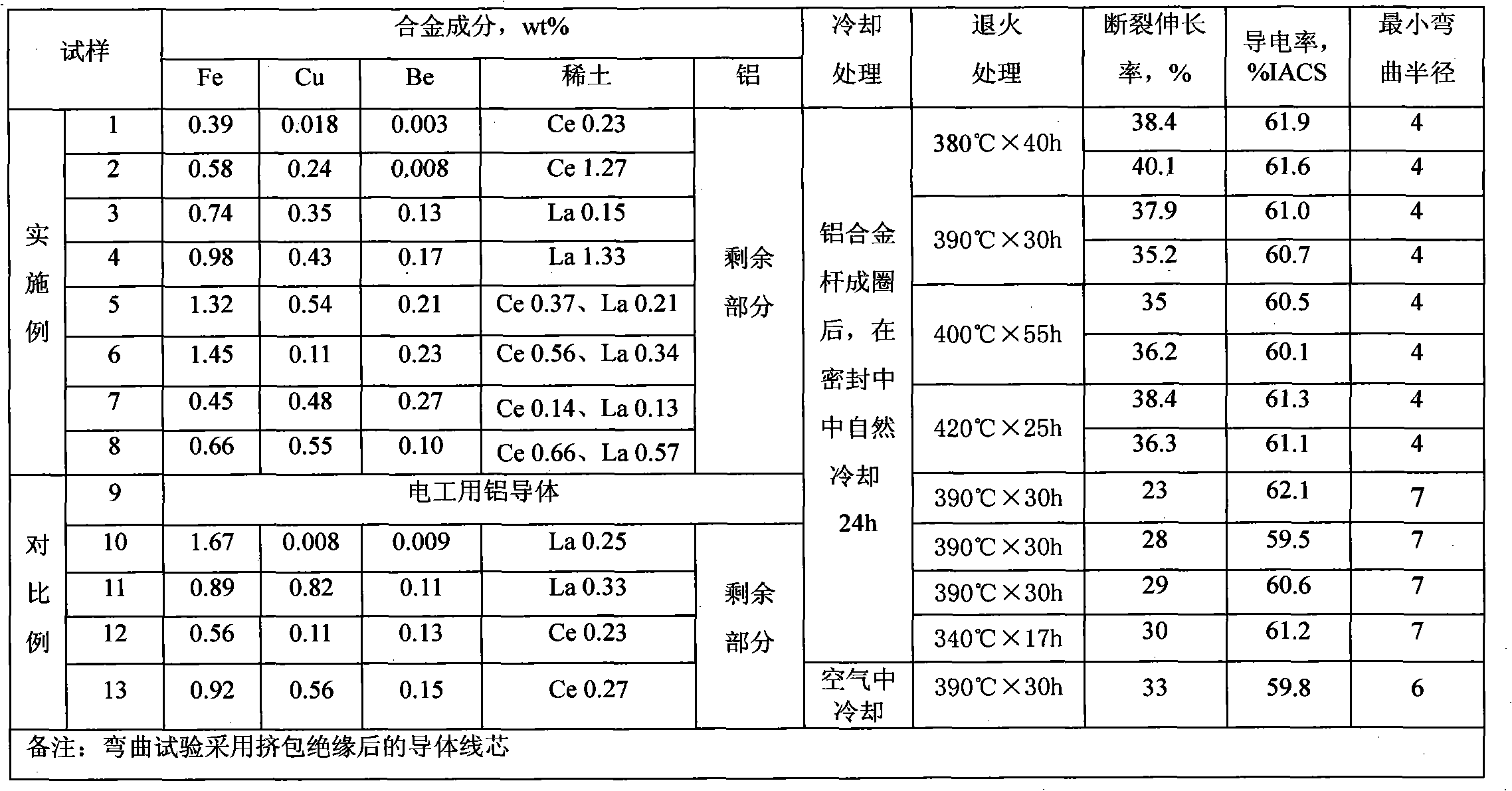

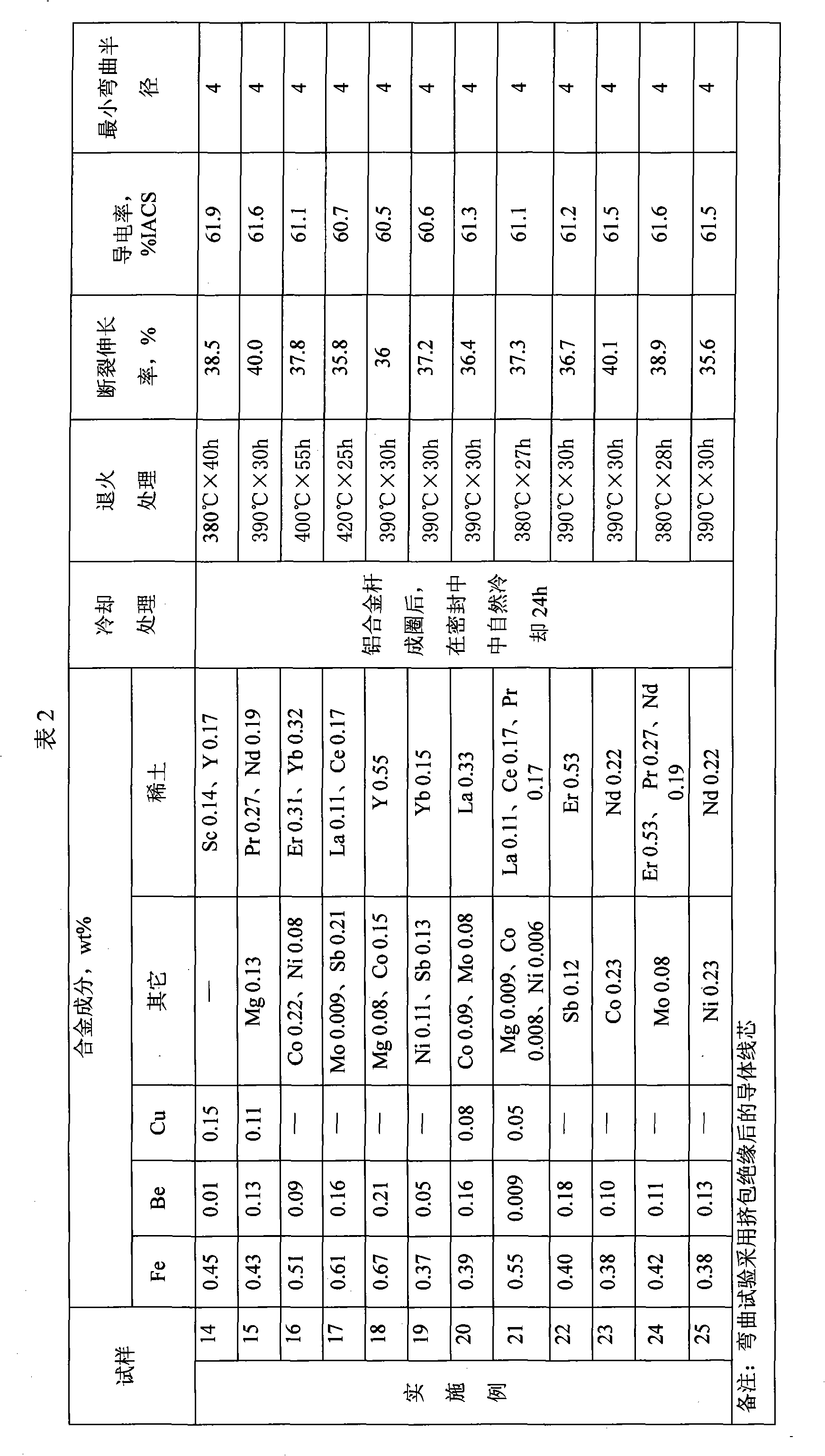

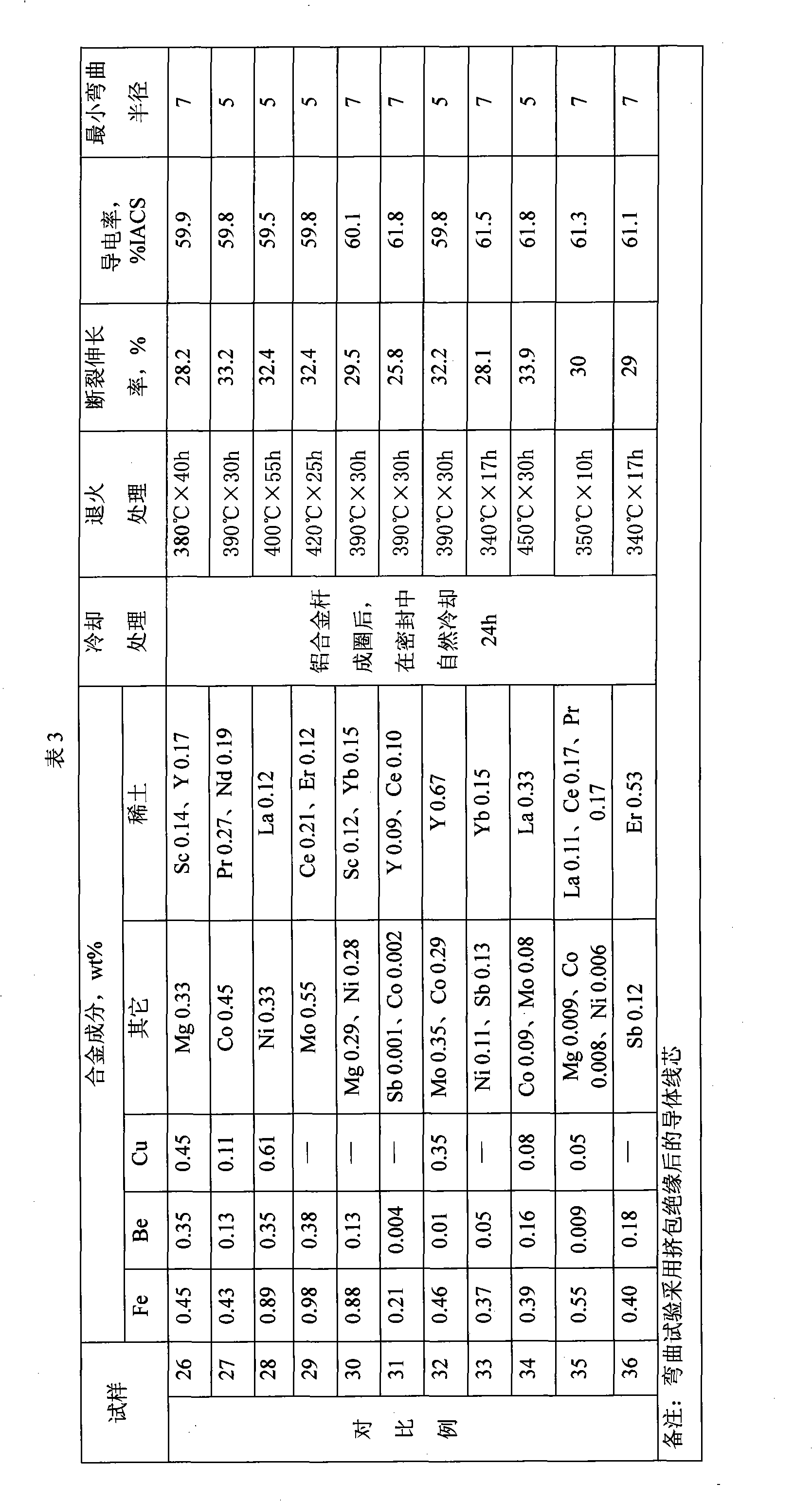

Super-soft aluminum alloy conductor and preparation method thereof

The invention provides a super-soft aluminum alloy conductor and a preparation method thereof. The aluminum alloy conductor comprises the following materials in percentage by weight: 0.3 to 1.5 percent of Fe, 0.001 to 0.3 percent of Be, 0.005 to 0.6 percent of Cu, 0.1 to 1.5 percent of rare earth, less than or equal to 0.08 percent of Si, less than or equal to 0.15 percent of total inevitable impurities, and the balance of aluminum. The aluminum alloy is drawn into an aluminum alloy wire by melting, continuous casting and continuous rolling, and the aluminum alloy wire is put into an annealing furnace and annealed for 20 to 40 hours at the temperature of between 380 and 420 DEG C to form the aluminum alloy conductor, wherein the annealing is performed in a sealed heat insulation device under the protection of nitrogen. The aluminum alloy has extremely good toughness and elongation performance, the coefficient of elongation reaches or exceeds 35 percent and even can reach 40 percent, and the electric conductivity can reach 60 percent IACS.

Owner:ANHUI JOY SENSE CABLE

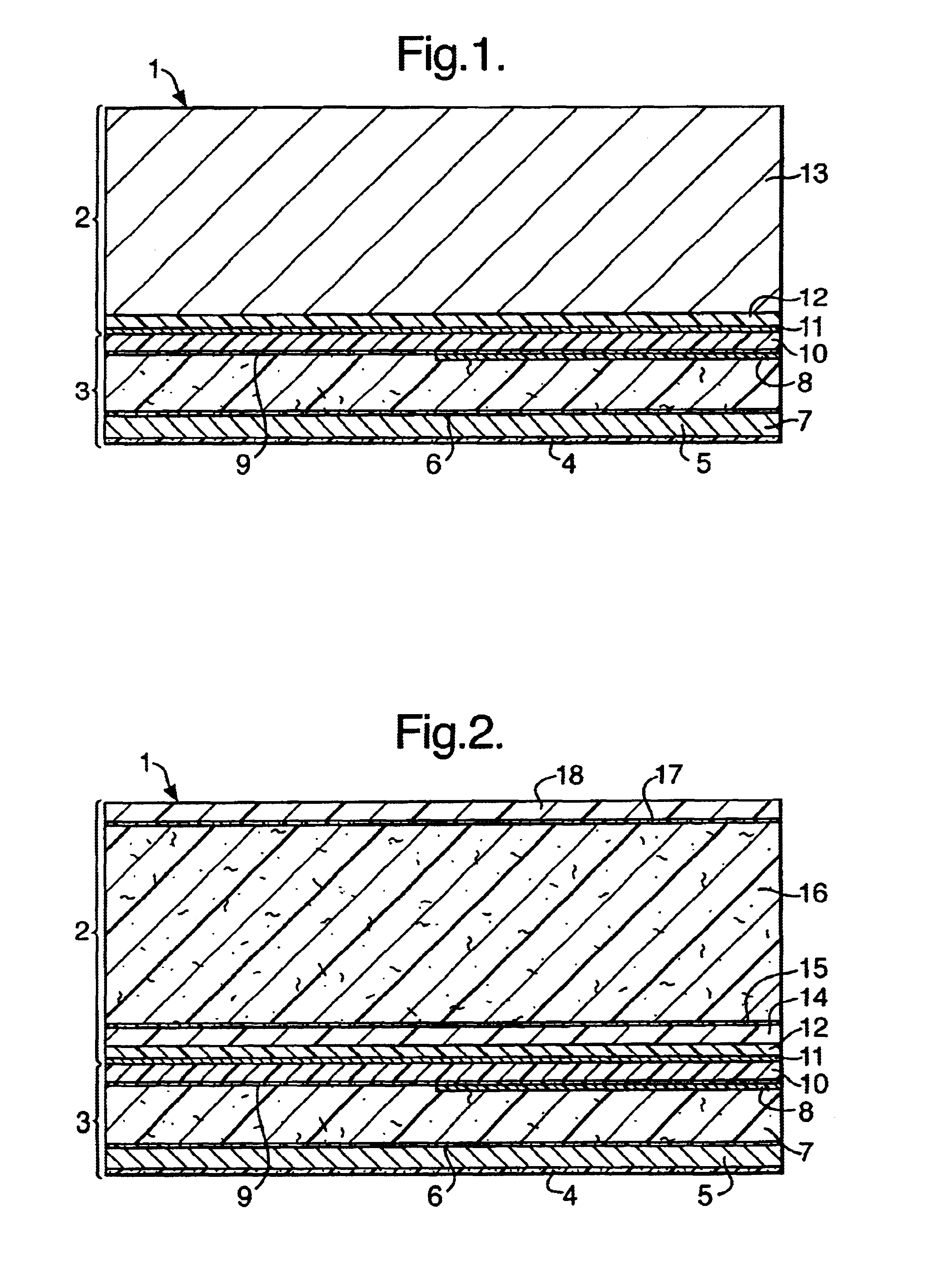

Compositions used in manufacturing articles having an inorganically filled organic polymer matrix

InactiveUS6090195AReadily and inexpensively mass producedHigh strengthClosure lidsWrappersFiberPolymer science

Compositions, methods, and systems for manufacturing articles, particularly containers and packaging materials, having a highly inorganically filled matrix. Suitable inorganically filled mixtures are prepared by mixing together an organic polymer binder, water, one or more aggregate materials, fibers, and optional admixtures in the correct proportions in order to form an article which has the desired performance criteria. The inorganically filled mixtures are molded to fashion a portion of the mixture into a form stable shape for the desired article. Once the article has obtained form stability, such as by heating to remove water by evaporation, the article is removed from the mold and allowed to harden to gain strength. The articles may have properties substantially similar to articles presently made from traditional materials like paper, paperboard, polystyrene, plastic, or metal. They have especial utility in the mass production of containers, particularly food and beverage containers.

Owner:EARTHSHELL SPE

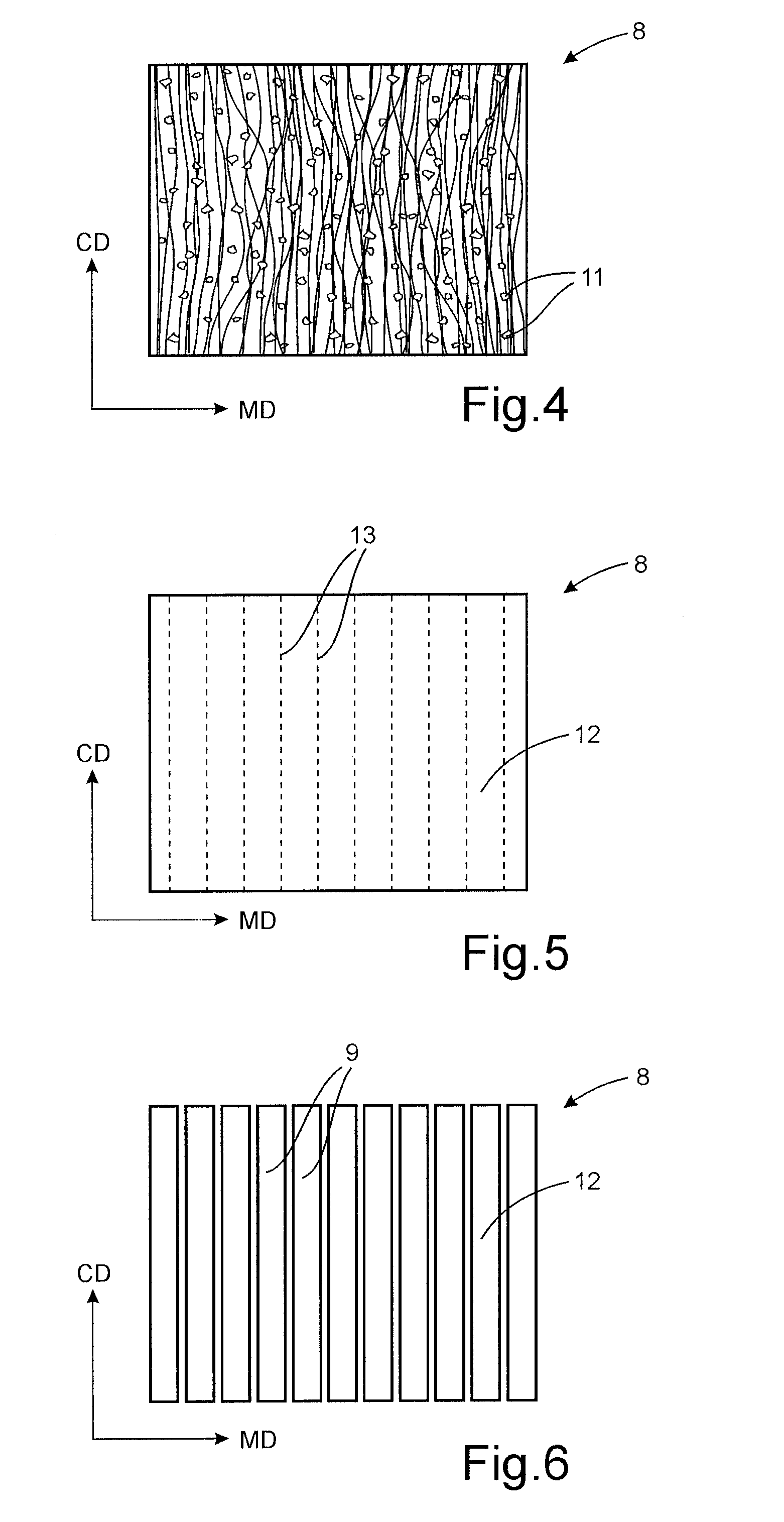

Extensible Nonwoven Fabric

ActiveUS20140276517A1High elongationImprovement in one or moreBaby linensWoven fabricsExtensibilityNonwoven fabric

Extensible nonwoven fabrics having improved elongation, extensibility, abrasion resistance and toughness. In particular, embodiments of the invention are directed to extensible spunbond fabrics comprising a polymeric blend of a metallocene catalyzed polypropylene, polyethylene, and a third polymer component.

Owner:FITESA GERMANY +1

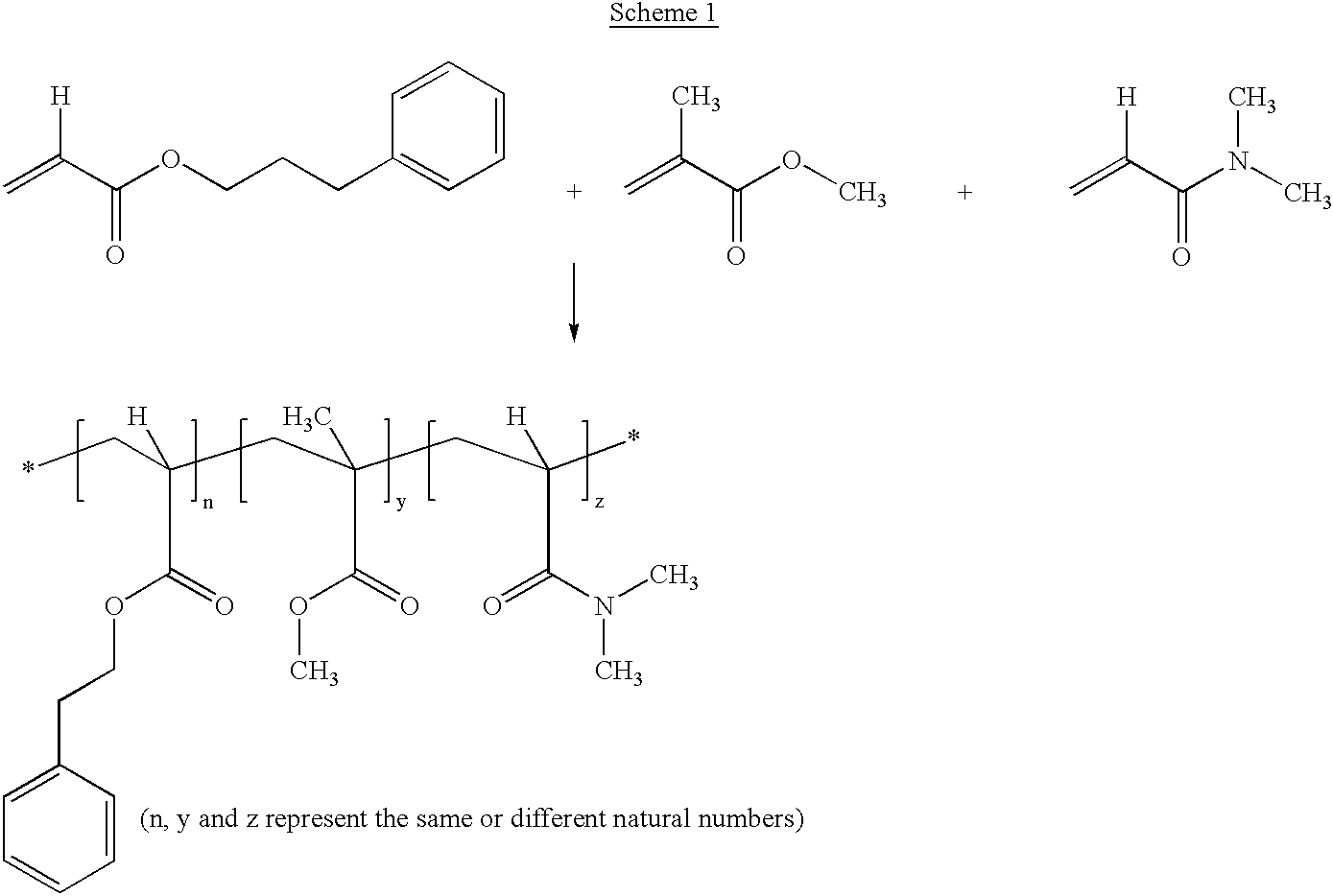

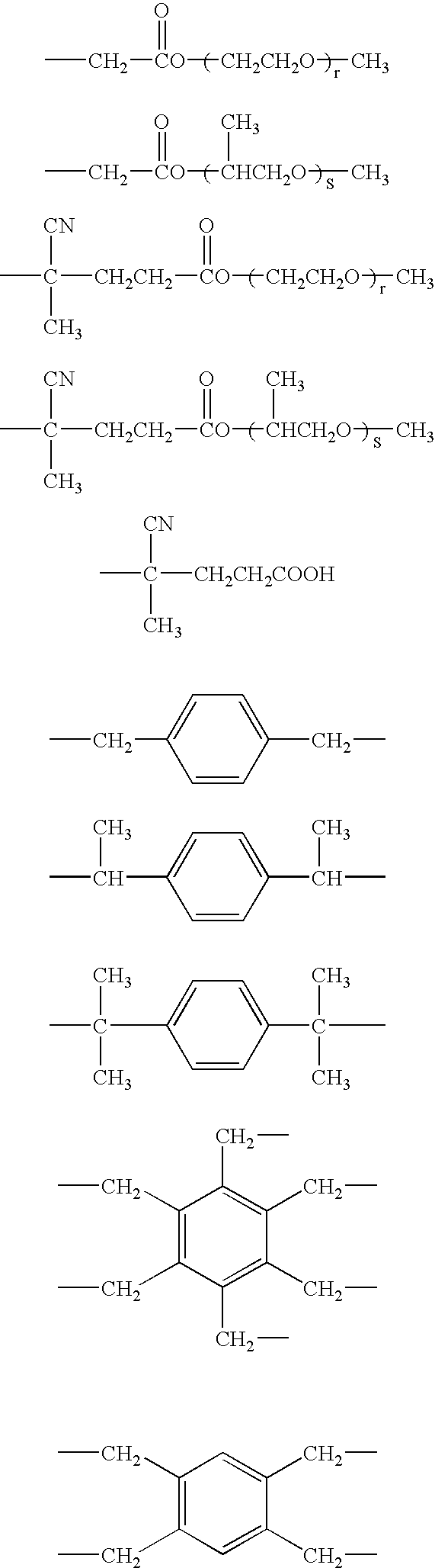

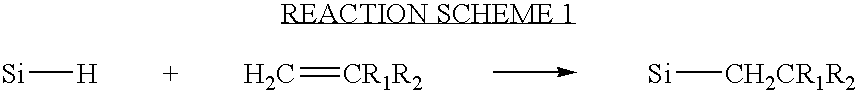

Low water content, high refractive index, flexible, polymeric compositions

InactiveUS6852793B2Ideal physical propertyHigh refractive indexOrganic dyesIntraocular lensHydrophilic monomerRefractive index

Optically transparent, relatively high refractive index polymeric compositions and ophthalmic devices such as intraocular lenses and corneal inlays made therefrom are described herein. The preferred polymeric compositions are produced through the polymerization of one or more copolymers with one or more hydrophilic monomers and optionally one or more aromatic-based monomers, hydrophobic monomers or a combination thereof.

Owner:BAUSCH & LOMB INC

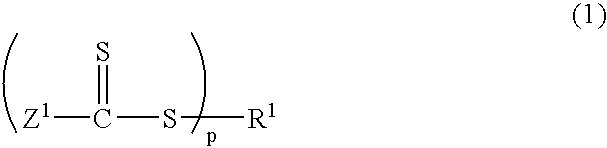

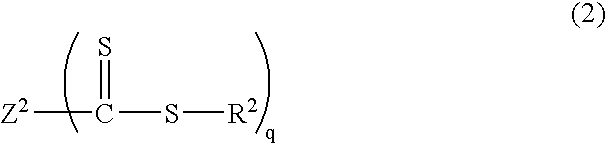

Thermoplastic resin composition and elastomer composition

Provided are a thermoplastic resin composition which is excellent in oil resistance, heat resistance, weatherability, impact resistance, transparency, and moldability, and which can be produced economically, an elastomer composition with low hardness and high tensile strength which is excellent in oil resistance and compression set, and a molded object produced by molding the thermoplastic resin composition or elastomer composition. The composition is produced by compounding a thermoplastic resin or an elastomer with a block copolymer having at least one methacrylic ester polymer block and at least one acrylic ester polymer block. Also provided are a process for producing a methacrylic ester-acrylic ester-methacrylic ester block copolymer which requires hardly any purification, which is excellent in heat resistance and weatherability, and in which the molecular weight and the molecular-weight distribution are controlled, and a methacrylic ester-acrylic ester-methacrylic ester block copolymer produced by the process.

Owner:KANEKA CORP

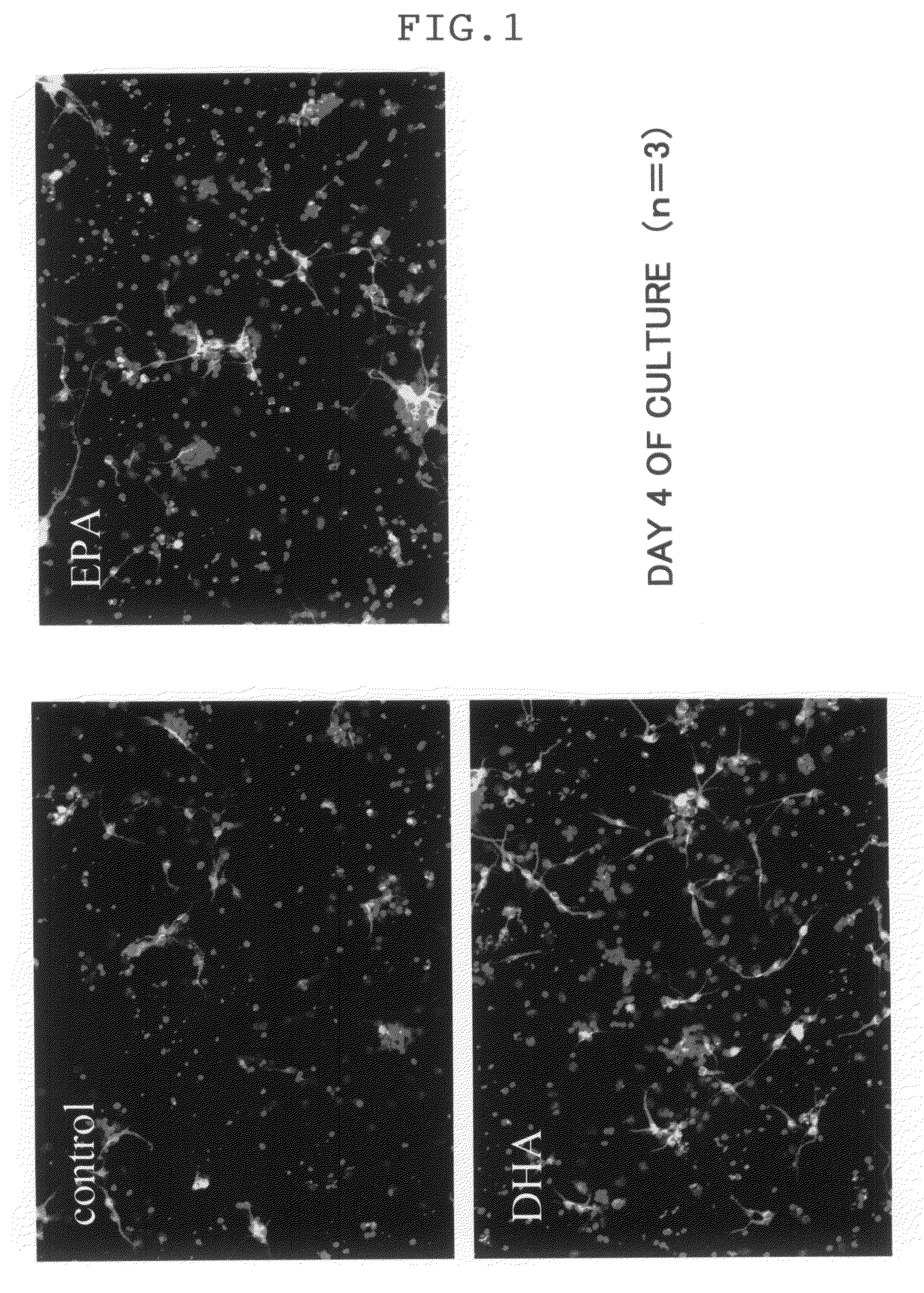

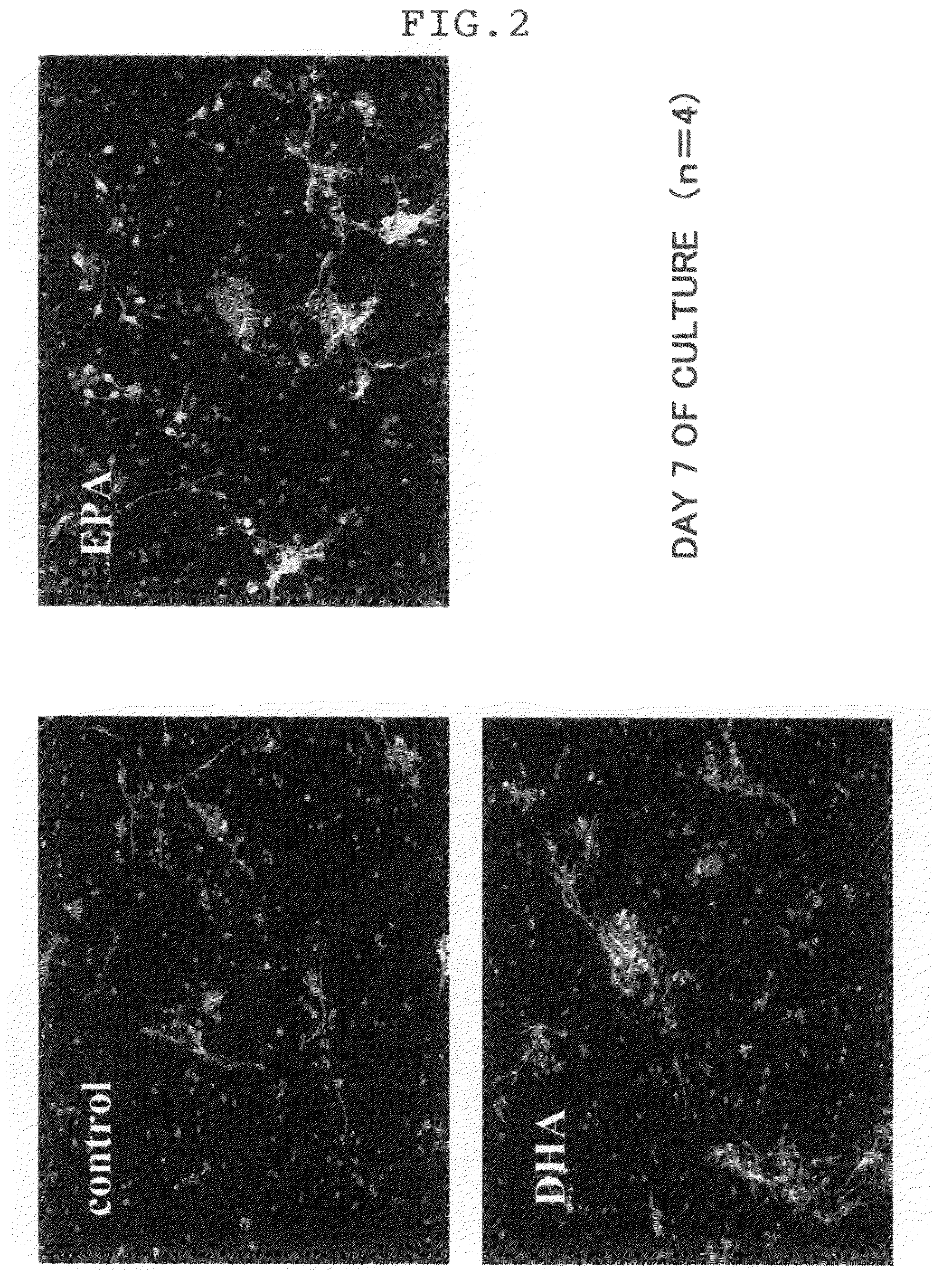

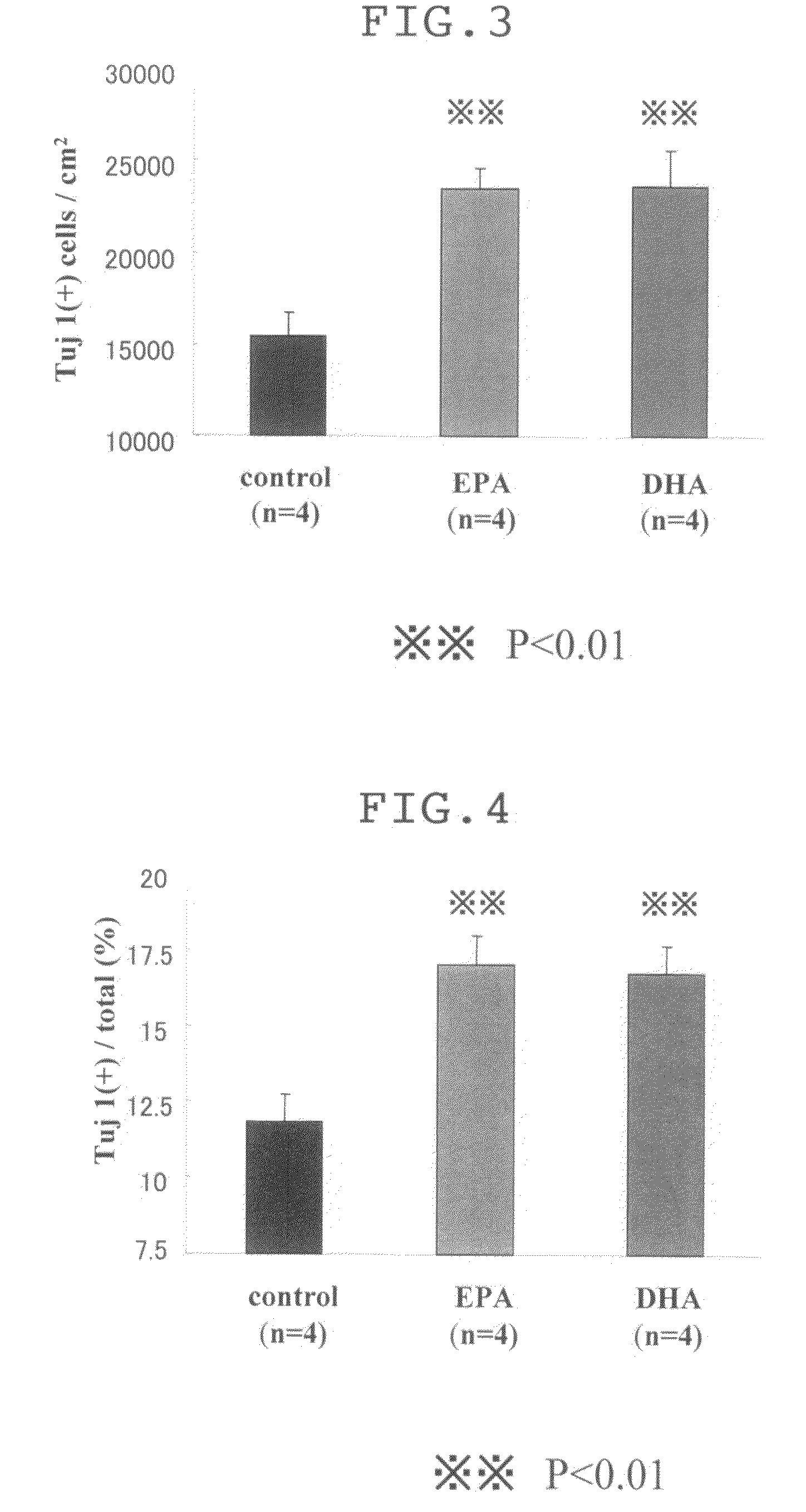

Nerve Regeneration Promoting Agent

InactiveUS20100254951A1Promote differentiationIncrease the number ofBiocideOrganic active ingredientsDiseaseBULK ACTIVE INGREDIENT

A neuronal differentiation promoting agent for neural stem cells comprising, as an active ingredient, at least one member selected from the group consisting of ω-3 unsaturated fatty acids and ω-6 unsaturated fatty acids having 18 to 22 carbon atoms, and derivatives thereof. The agent can be used for induction of differentiation of neural stem cells and is useful for treating and / or preventing a variety of neurological diseases, and in the fields of nerve transplantation and / or regenerative medicine for nerves.

Owner:MOCHIDA PHARM CO LTD +1

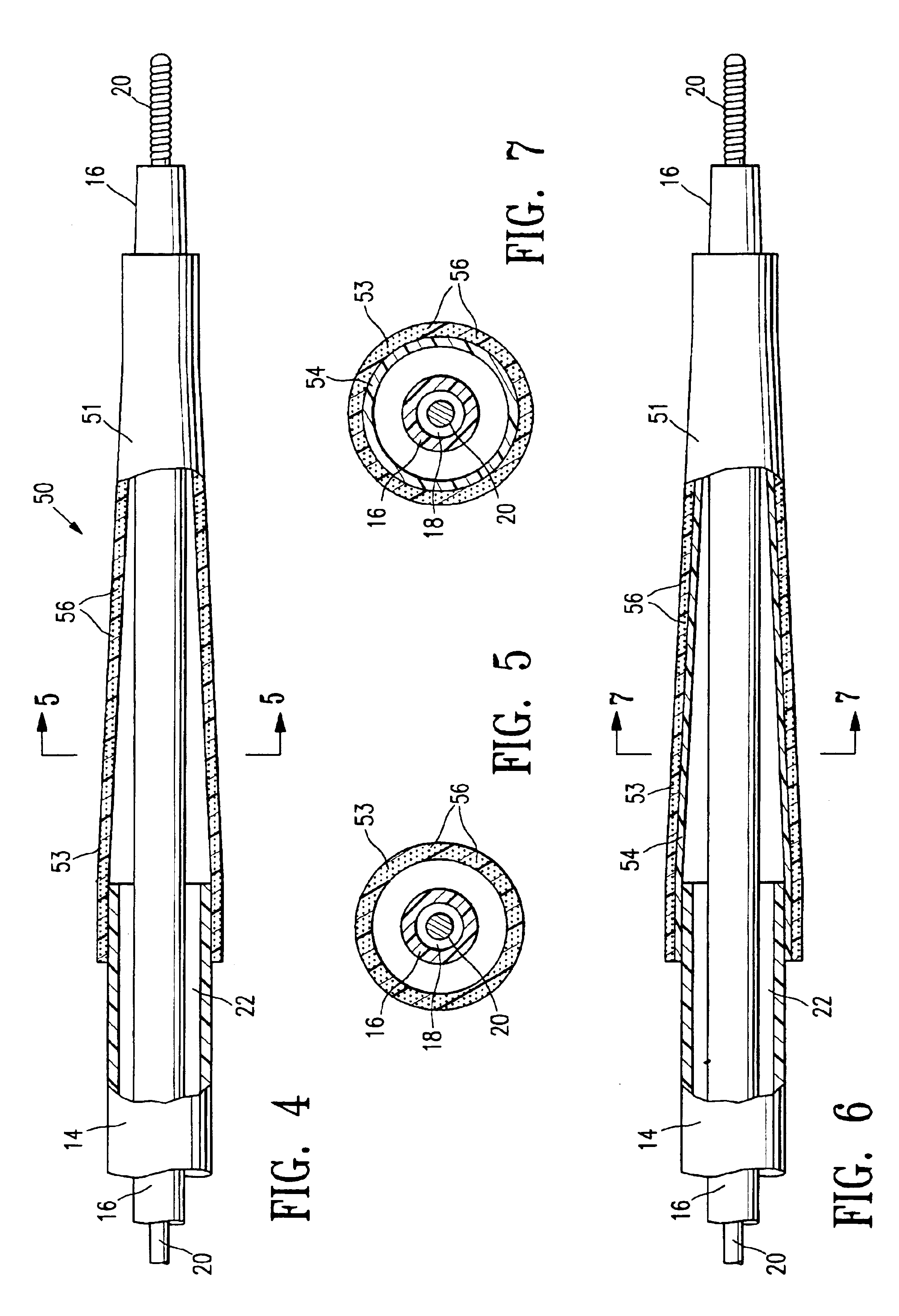

Coated optical fibers having strippable primary coatings and processes for making and using same

InactiveUS6014488ACleanly strippableHigh modulusGlass optical fibreGlass making apparatusFiberSilicon dioxide

PCT No. PCT / US98 / 01289 Sec. 371 Date Sep. 1, 1998 Sec. 102(e) Date Sep. 1, 1998 PCT Filed Jan. 23, 1998 PCT Pub. No. WO98 / 33081 PCT Pub. Date Jul. 30, 1998The invention relates to coated optical fibers which are coated with a particular radiation-cured primary coating layer composition. The fibers which are coated comprises a glass core and a glass cladding layer. The core, for example may comprises silica doped with oxides of germanium or phosphorous and the cladding, a pure or doped silicate such as fluorosilicate. Alternatively, the fibers may comprises a polymerclad silica glass core. Examples of such claddings include organosiloxanes such as polydimethylsiloxane or a fluorinated acrylic polymer.

Owner:HEXION INC

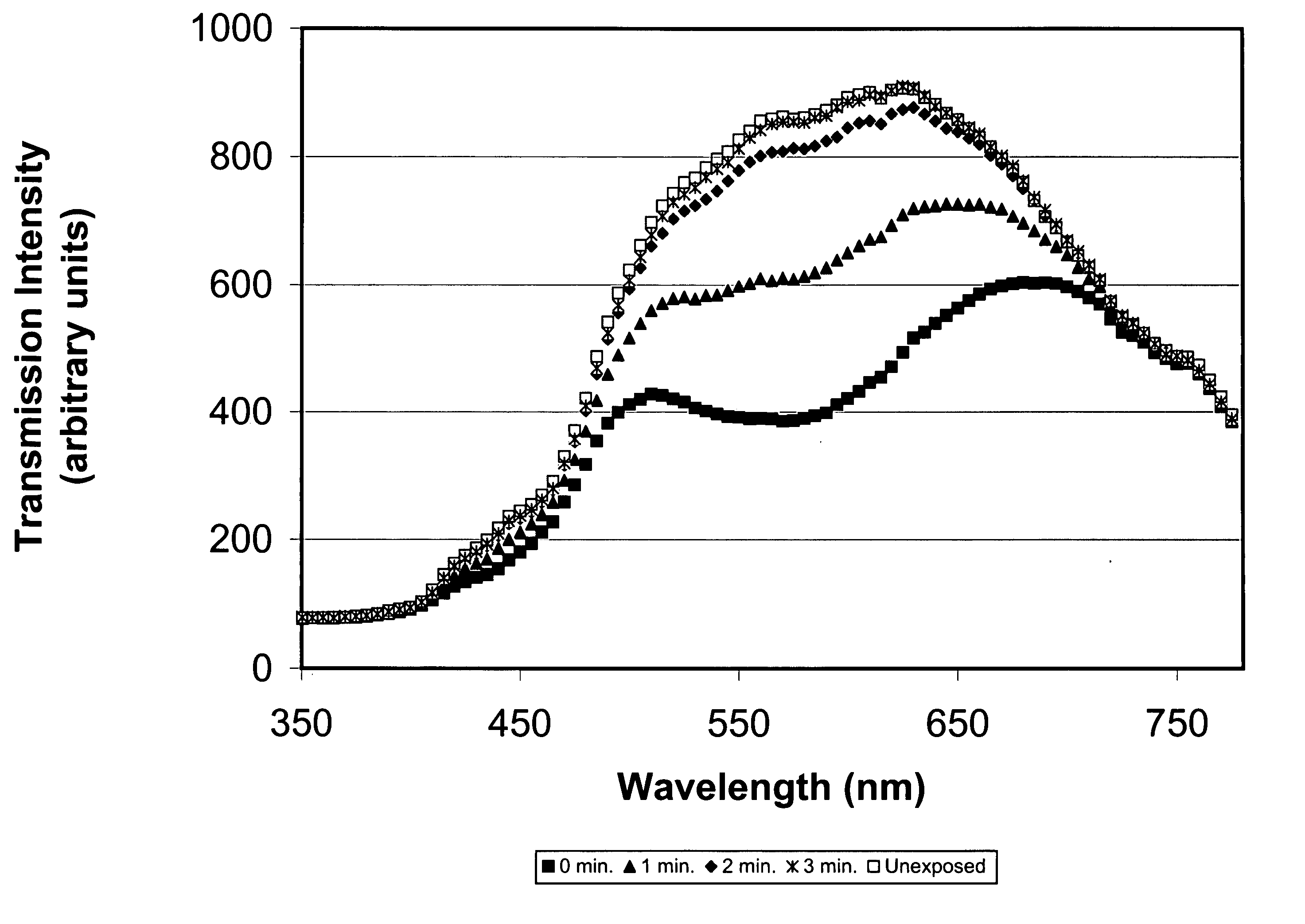

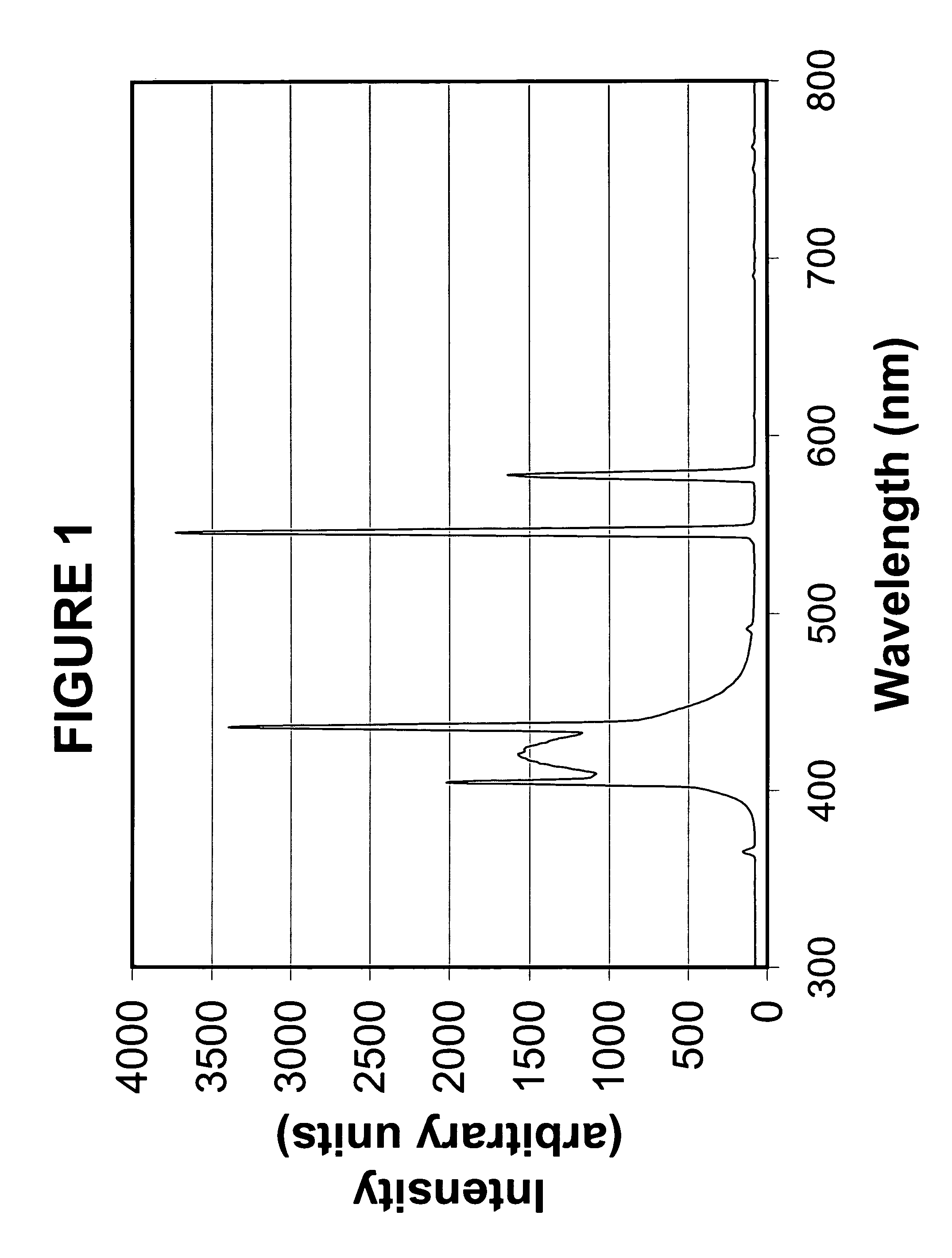

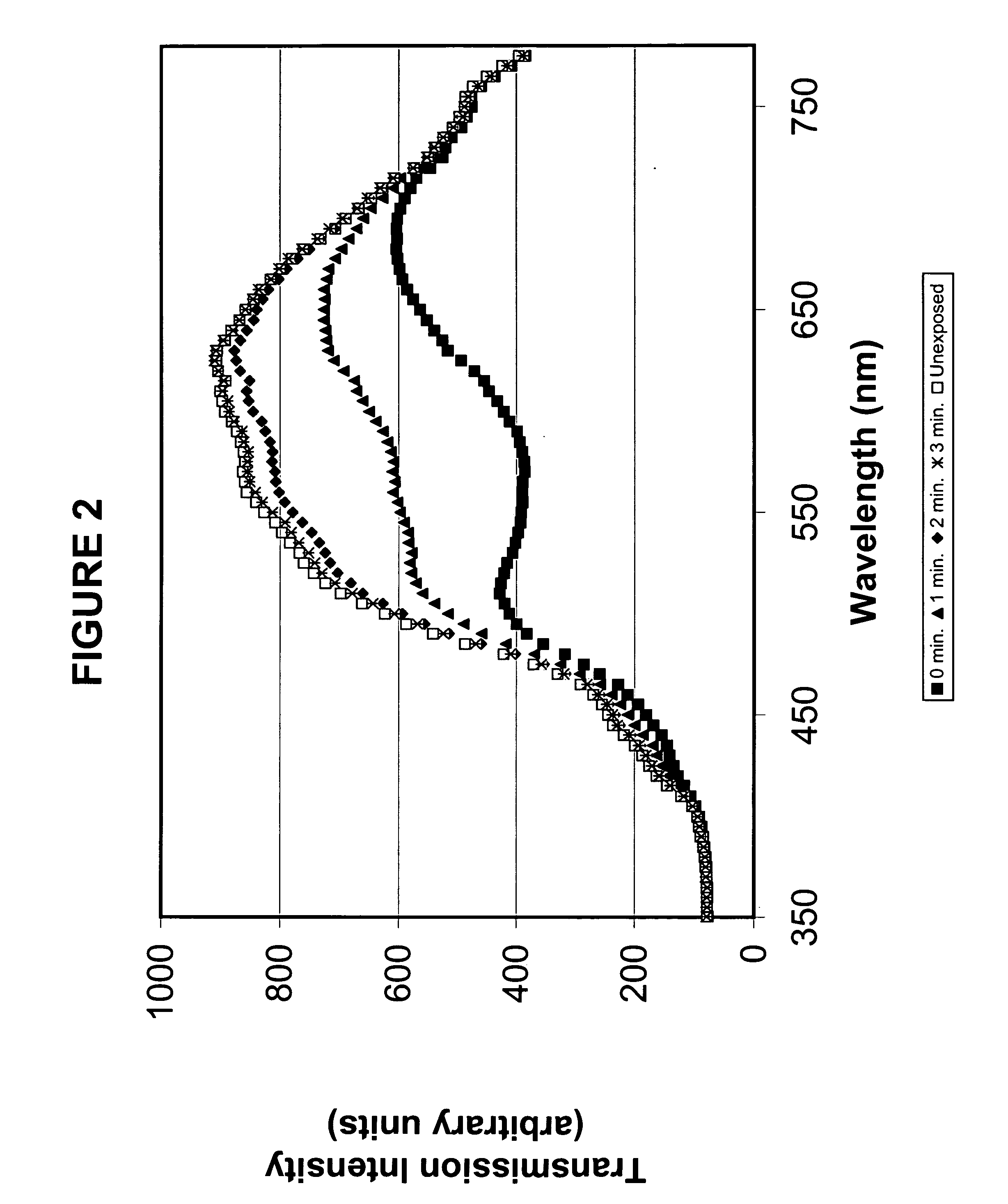

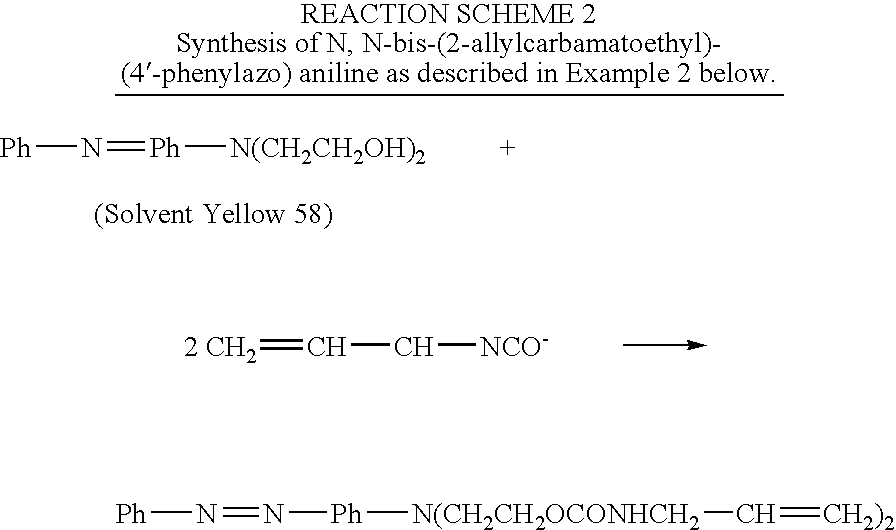

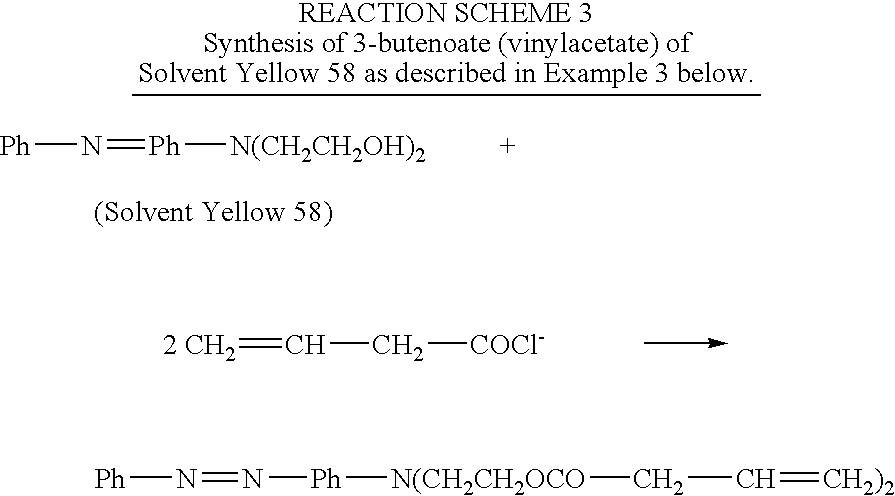

Photochromic blue light filtering materials and ophthalmic devices

InactiveUS20050254003A1High elongationHigh refractive indexPhotosensitive materialsTissue regenerationHost materialFilter material

Polymeric compositions have photochromic and blue-light filtering ability and are useful in the manufacture of ophthalmic medical devices. The polymeric compositions comprise a photochromic material incorporated into polymeric host materials and are activatable by blue light having a first wavelength range to become photochromic, and are thereby capable of absorbing blue light in a second wavelength range. Methods of making the compositions comprise incorporating a photochromic material into a polymeric host material.

Owner:BAUSCH & LOMB INC

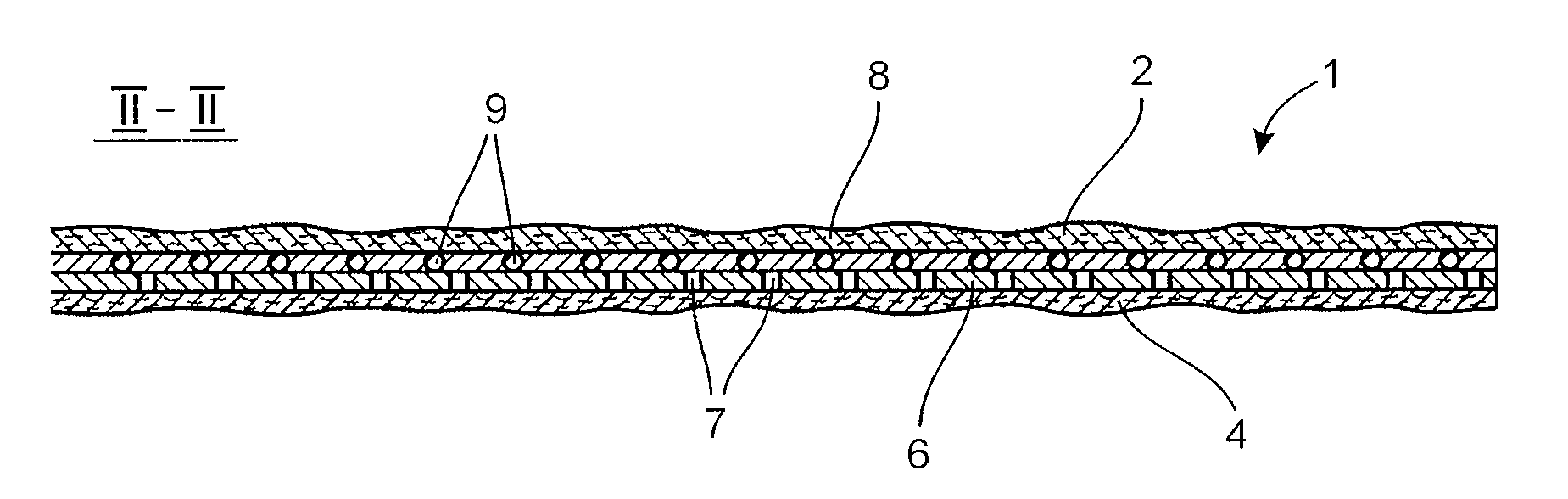

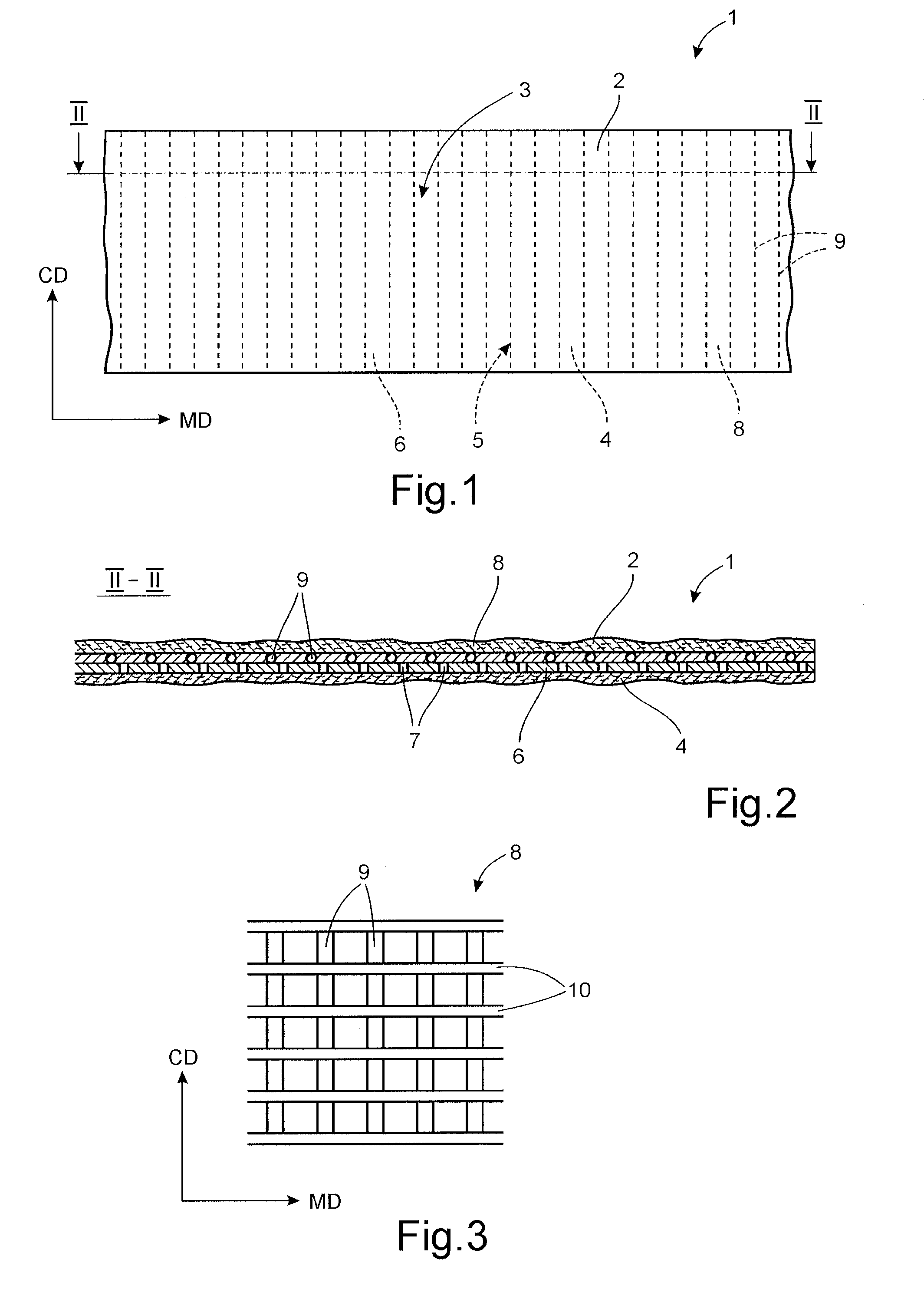

Elastic laminate and absorbent article comprising the laminate

ActiveUS20100076390A1Affects elasticityAffects flexibilitySynthetic resin layered productsLaminationFiberEngineering

Owner:ESSITY HYGIENE & HEALTH AB

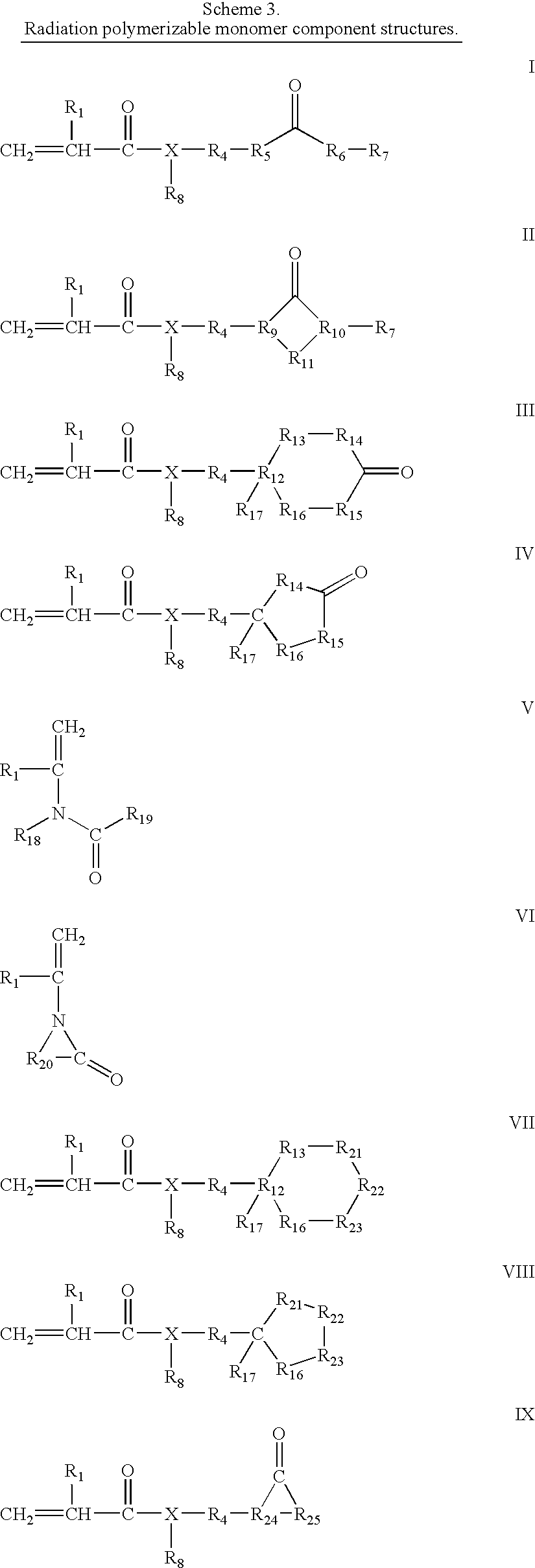

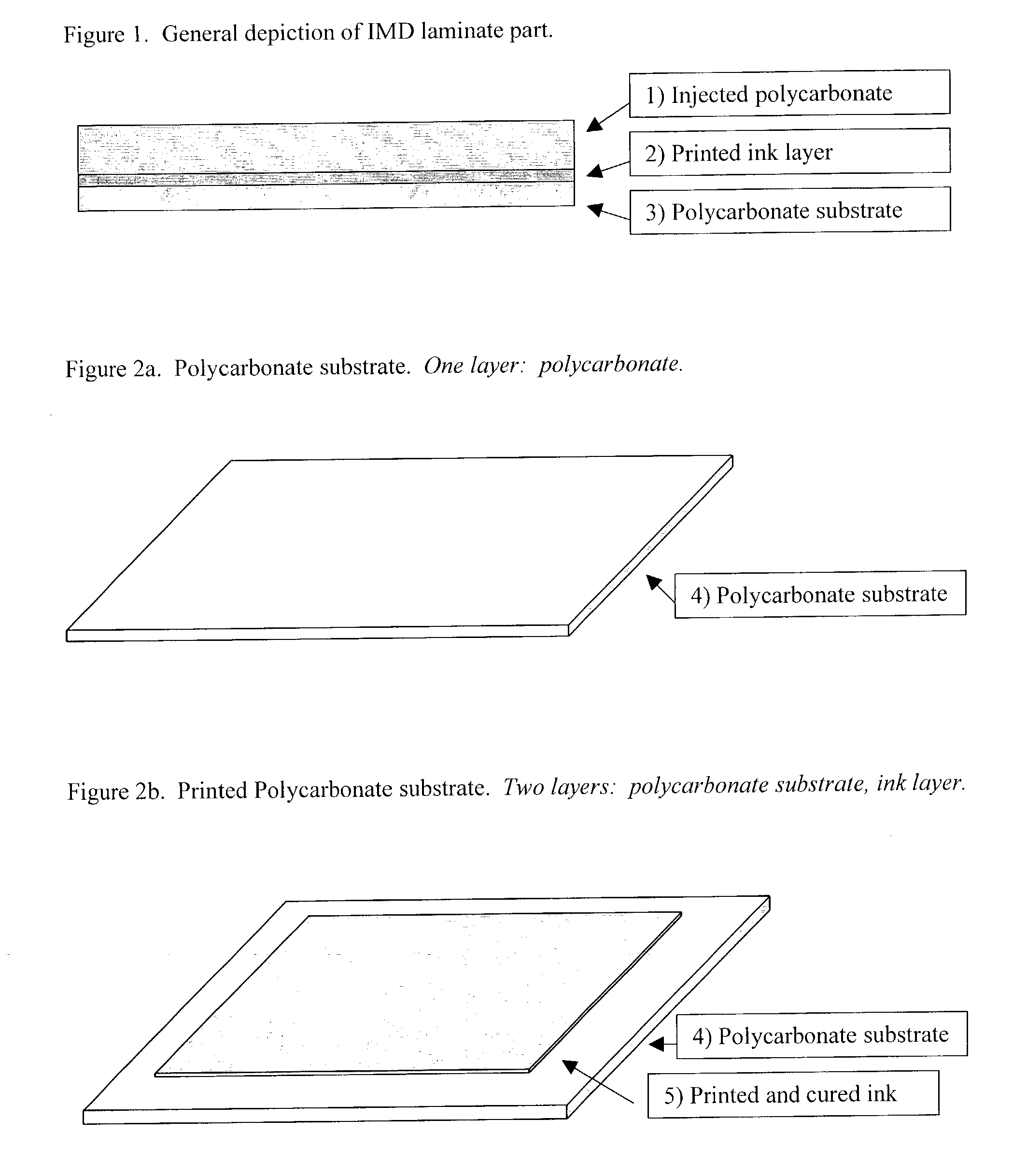

Flexible radiation curable compositions

InactiveUS20040152799A1Increase flexibilityReduce surface tackOrnamental textile articlesSynthetic resin layered productsMeth-Oligomer

Polymerizable compositions are described containing urethane (meth)acrylate oligomers and certain polymerizable monomers useful in thermoforming or in-mold decoration applications.

Owner:SURFACE SPECIALTIES

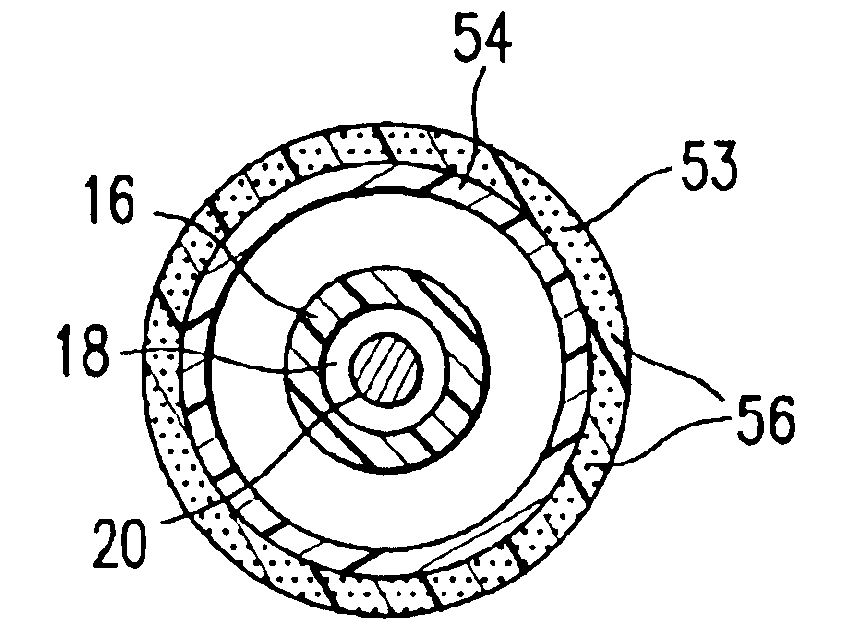

Catheter balloon formed of ePTFE and a diene polymer

InactiveUS6946173B2Improve performanceImprove adhesionEnvelopes/bags making machineryMouldsElastomerTetrafluoroethylene

A catheter balloon formed of a polymeric material such as expanded polytetrafluoroethylene (ePTFE) bonded to a second layer formed of a low tensile set polymer and / or impregnated with a low tensile set polymer. In a presently preferred embodiment, the low tensile set polymer is a silicone-polyurethane copolymer elastomer or a diene polymer elastomer. The low tensile set polymer has high strength, low modulus, high elongation, and low tensile set. The diene or silicone-polyurethane has a low tensile set, which facilitates deflation of the balloon to a low profile deflated configuration. One aspect of the invention provides improved attachment of the diene to the ePTFE. In one embodiment, the second layer is formed of a diene mixed with a bonding promoter such as a vulcanizing agent which is covalently bonded to the diene.

Owner:ABBOTT CARDIOVASCULAR

Curable composition

InactiveUS20090182099A1Good adhesivenessExcellent curabilityOther chemical processesEster polymer adhesivesNitrogen atomSiloxane

The present invention has its object to provide a curable composition which comprises an amidine compound as a non-organotin catalyst and shows good elongation, flexibility, surface curability, depth curability and adhesiveness; the above object can be achieved by a non-organotin curable composition which comprises: (A) an organic polymer containing a silyl group capable of crosslinking under siloxane bond formation, the silyl group being a group represented by the general formula (1): —SiR1X2; (B) an amidine compound (B-1) as a silanol condensation catalyst; and (C) a carboxylic acid, wherein the ratio between the number of moles (b) of all nitrogen atoms in the (B-1) component of the composition and the number of moles (c) of all carboxyl groups in the (C) component of the composition, namely the ratio (b) / (c), is higher than 2.

Owner:KANEKA CORP

High-strength heat-resisting magnesium alloy and its preparing method

This invention is a high-intensive heat-fast magnesium alloy and its preparation method, and the magnesium alloy has the following components with their weight percentages: 6-15%Gd, 1-6%Y, 0.35-0.8%Zr, 0-1.5%Ca, and impurity elements Si, Fe, Cu and Ni with their gross less than 0.02%, and the rest percentage is Mg. while melting, add Gd, Y, Zr in the Mg melt in Mg-Gd, Mg-Y, Mg-Zr forms, then carry out solution treatment to the magnesium alloy under 450-500deg.C for 6-12 hours, squeeze in in 350-450deg.C, treat in time the squeezing stick for 10-16 hours in 225deg.C to improve its strength.

Owner:SHANGHAI JIAO TONG UNIV

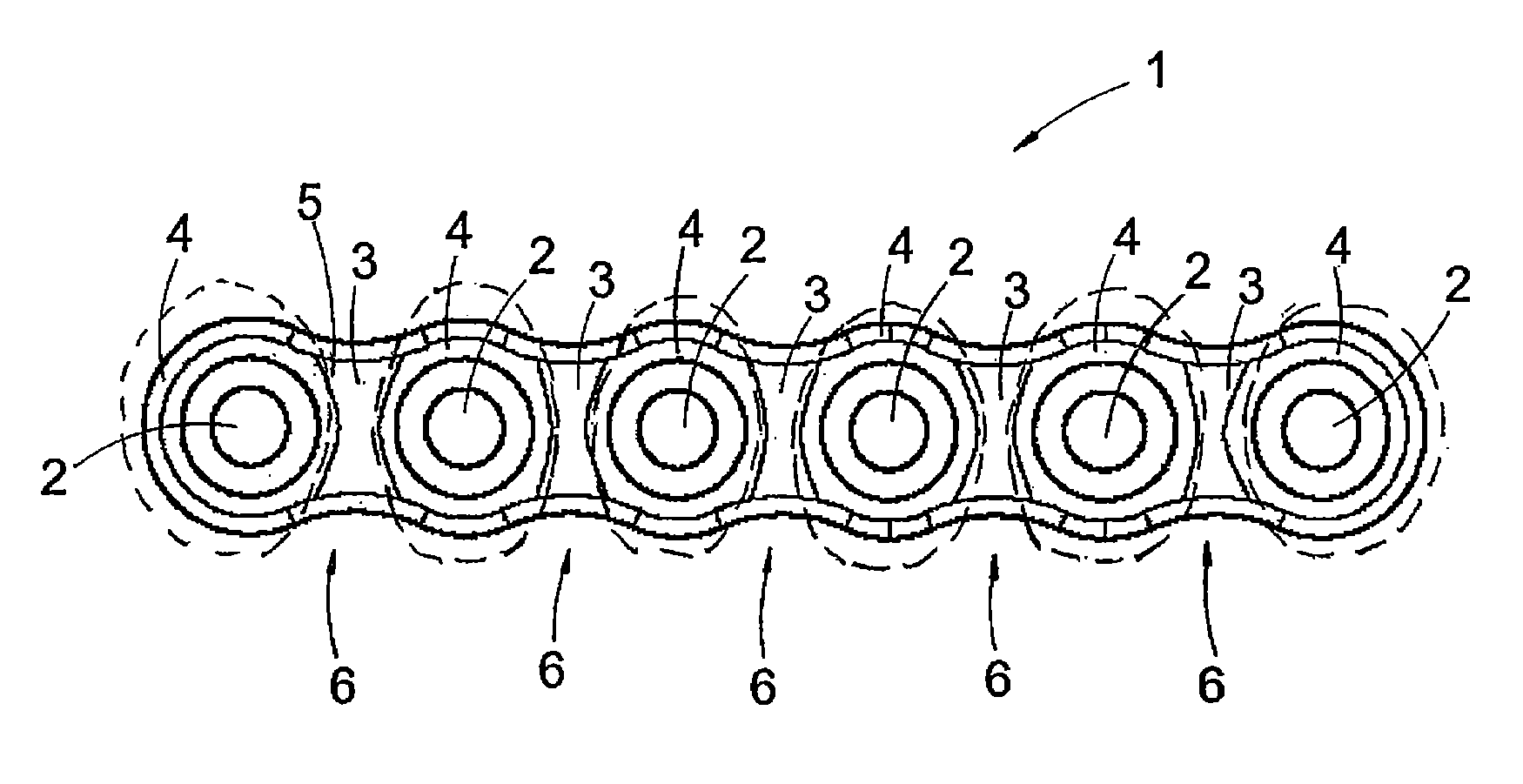

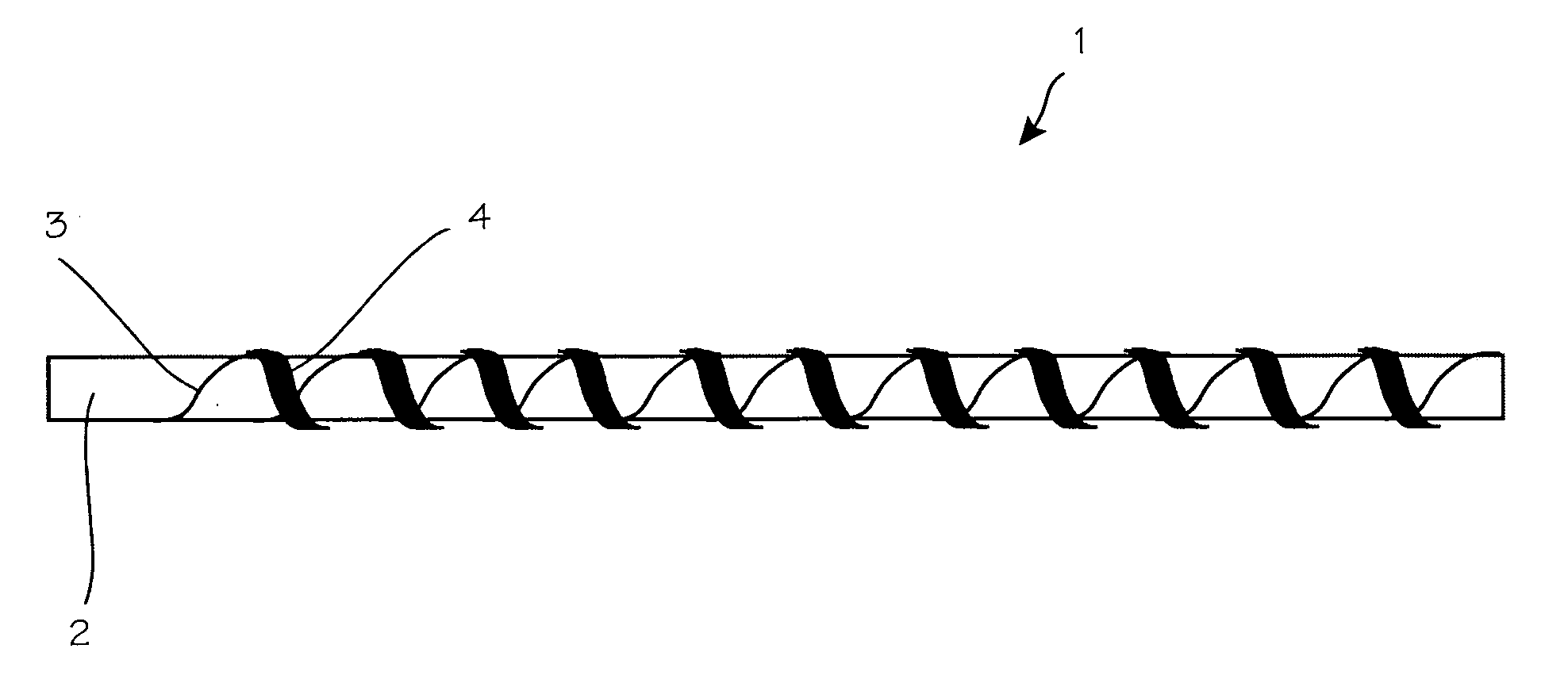

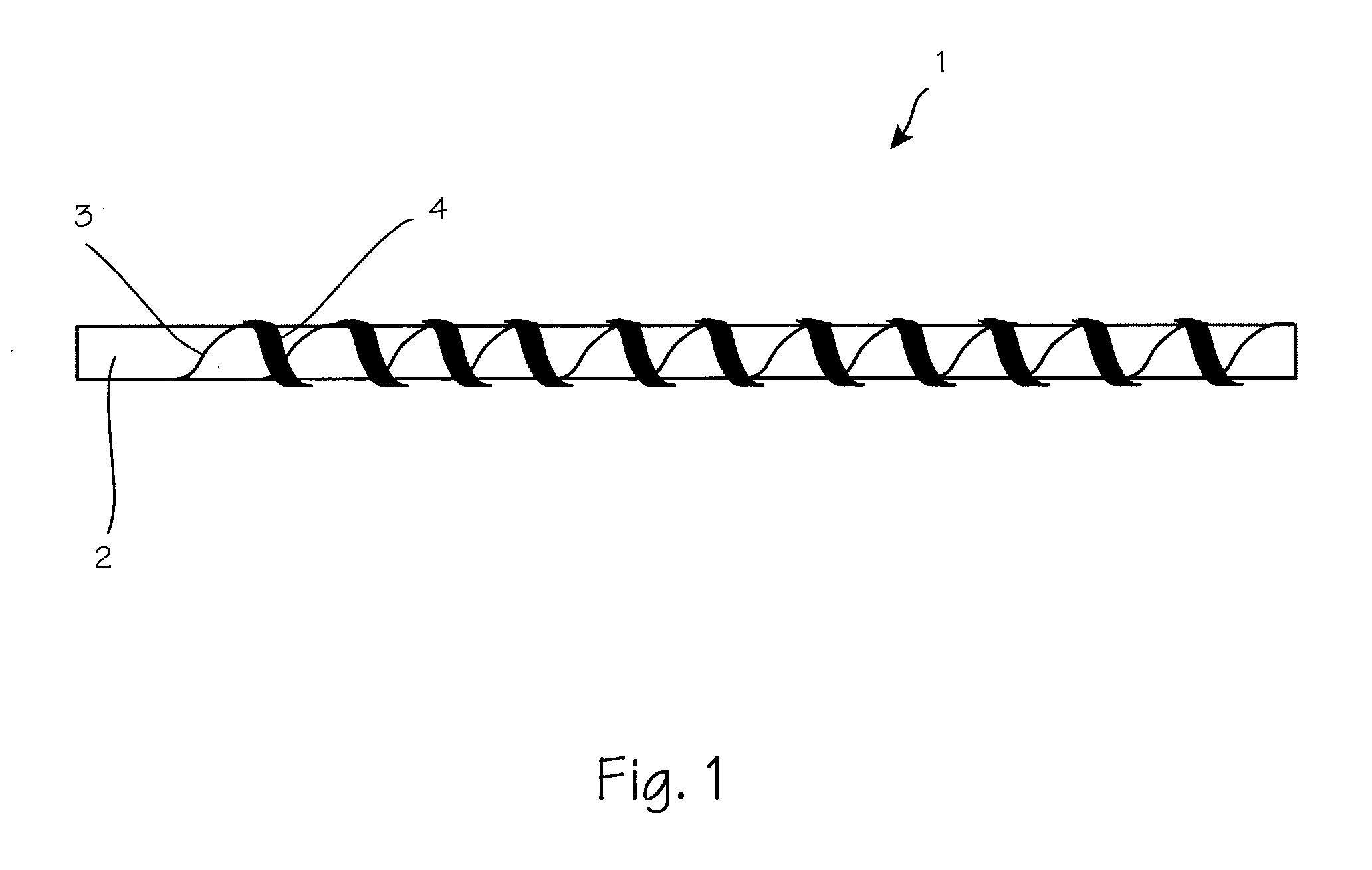

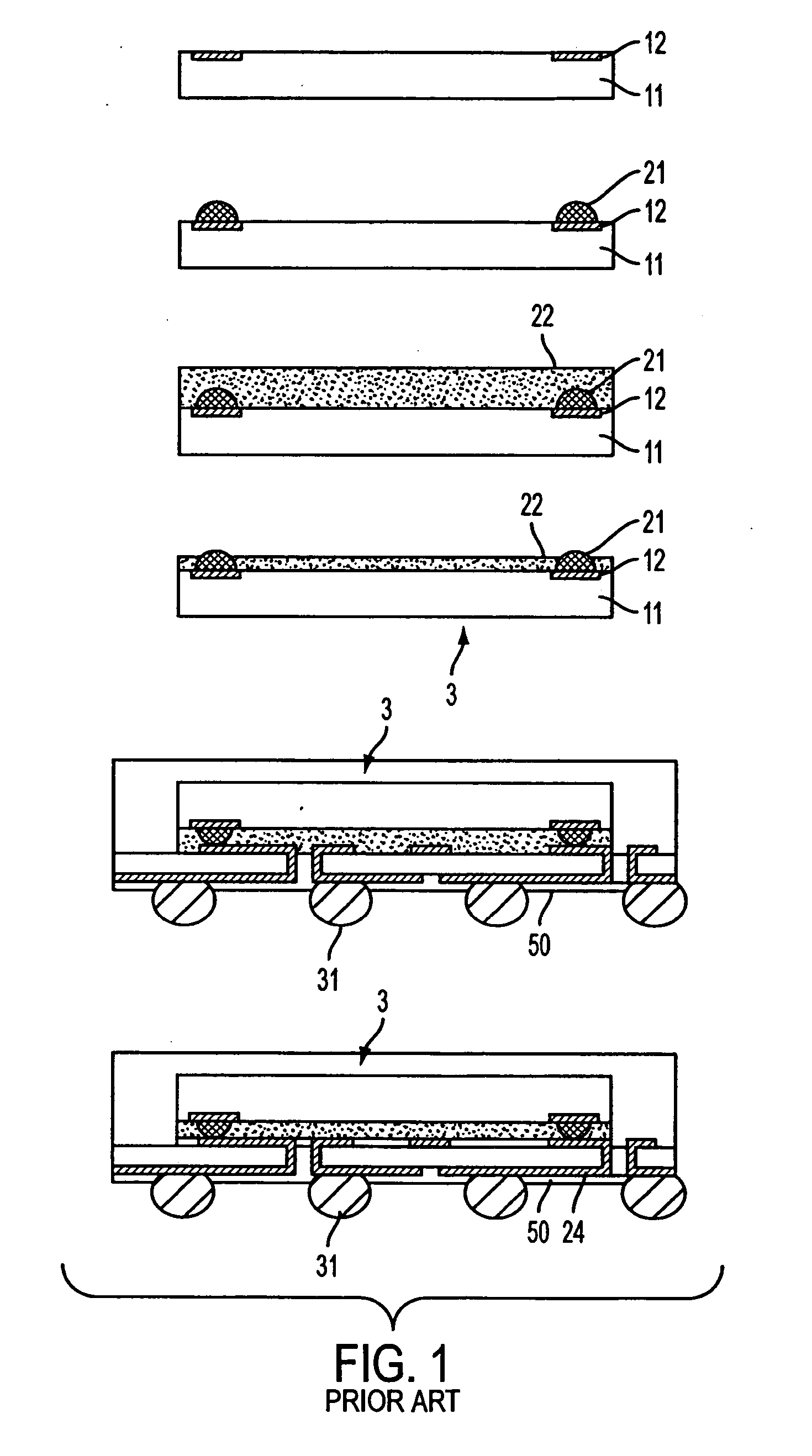

Container closure

InactiveUS6902075B2Achieve stabilizationHigh elongationCapsThreaded caps applicationWaddingEngineering

A one-component seal and wadding system (1) for a screw-cap includes a seal (3) having lower layers (4,5) forming an induction heating sealable system for attaching the seal (3) to the neck of a container, a seal substrate (6) including a free tab (50) lying wholly within the circumference of the seal, a layer of liner (2), and an attachment element (10,11,12) including a release layer (11) for attaching the seal substrate (7) including the tab (50) to the wadding (2).

Owner:SELIG SEALING PROD INC

Silicone intraocular lens with blue light absorption properties

InactiveUS7241312B2High elongationHigh refractive indexLiquid crystal compositionsTissue regenerationIntraocular pressureRetina

A process for producing silicone intraocular lenses (IOLs) capable of absorbing blue light. Intraocular lenses so produced block blue light from reaching the retina of an eye implanted with the IOL. By blocking blue light from reaching the retina, the IOL thereby prevents potential damage to the retina.

Owner:BARCLAYS BANK PLC AS SUCCESSOR AGENT

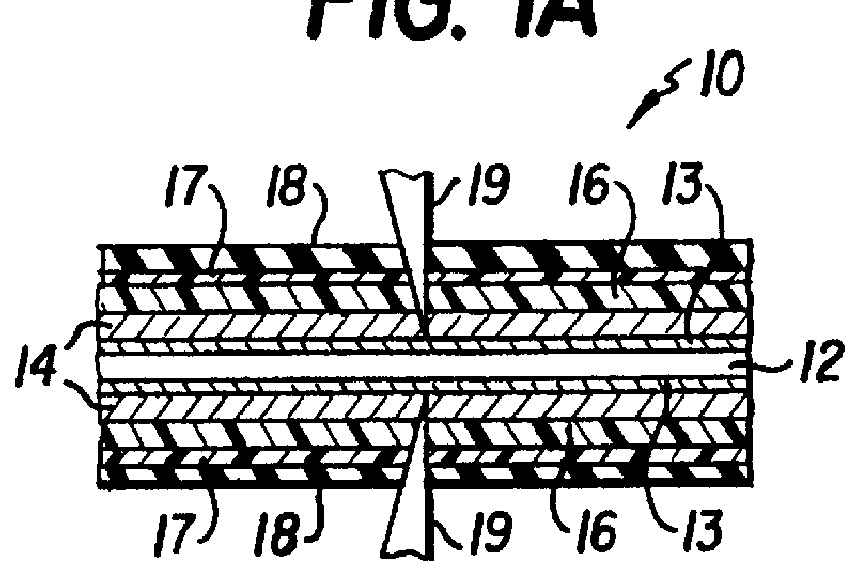

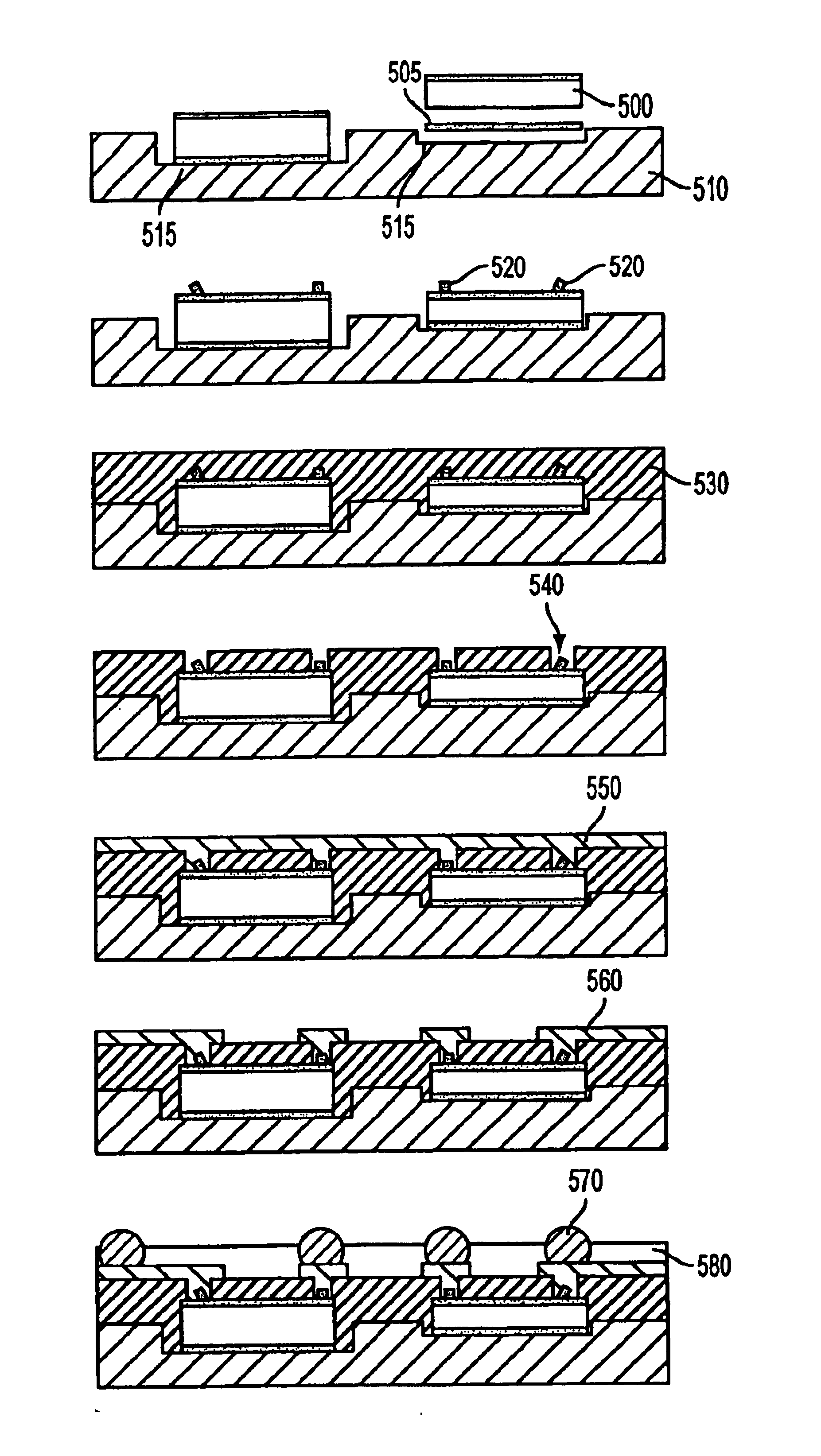

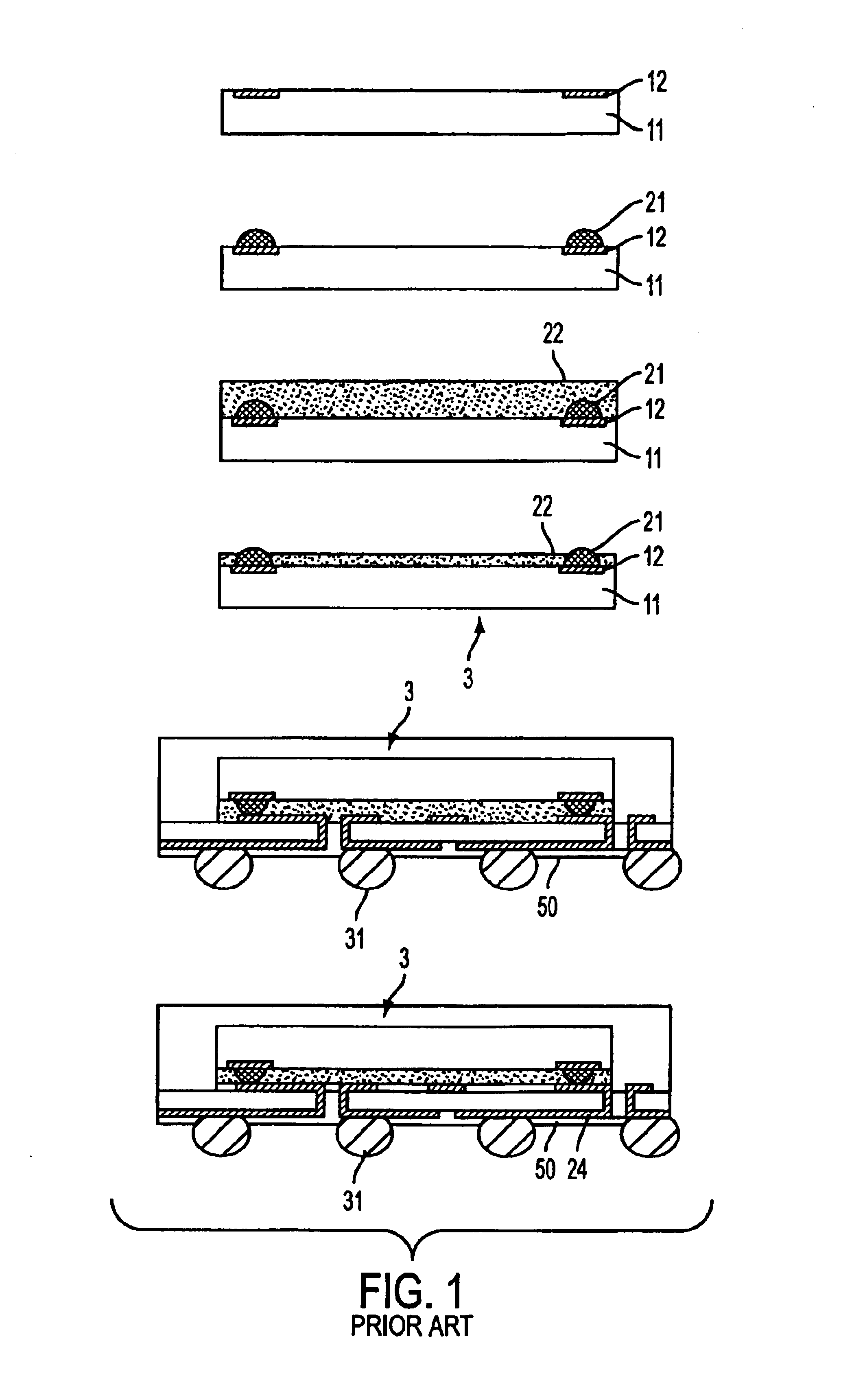

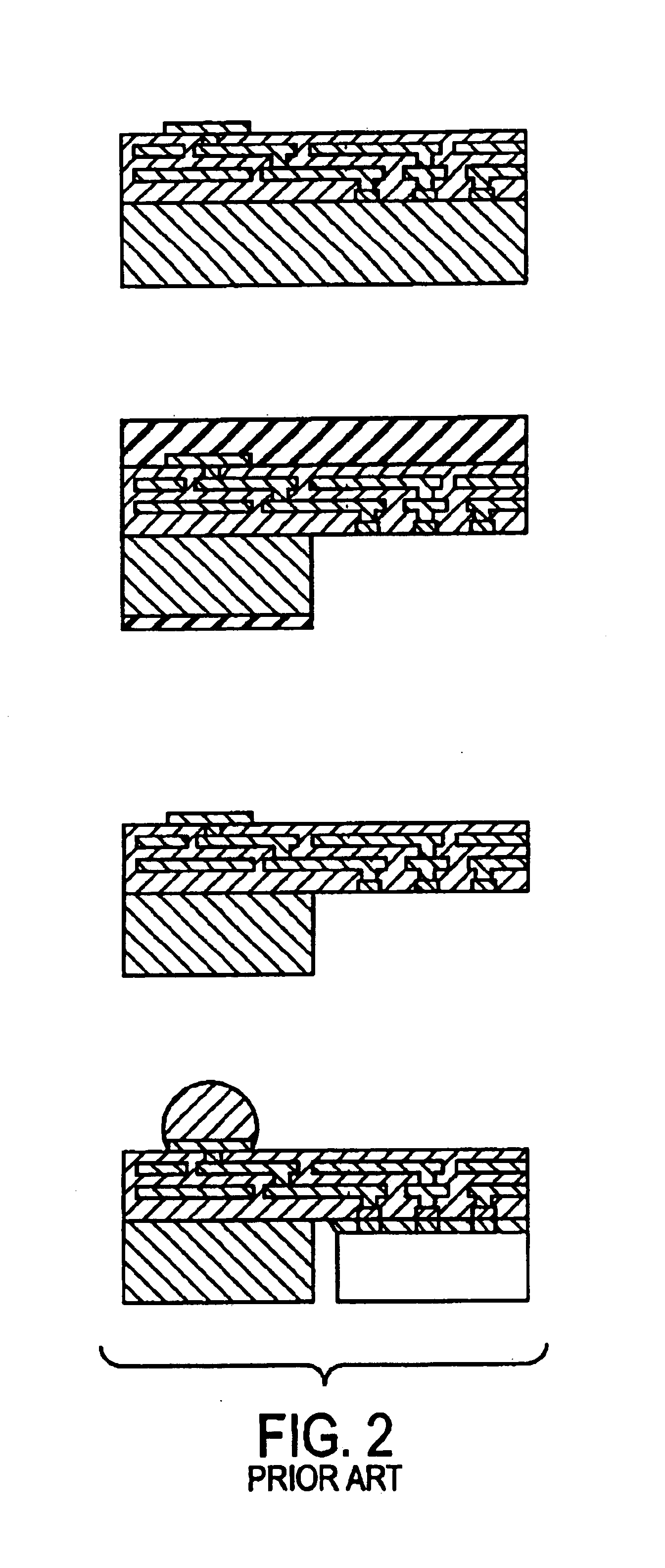

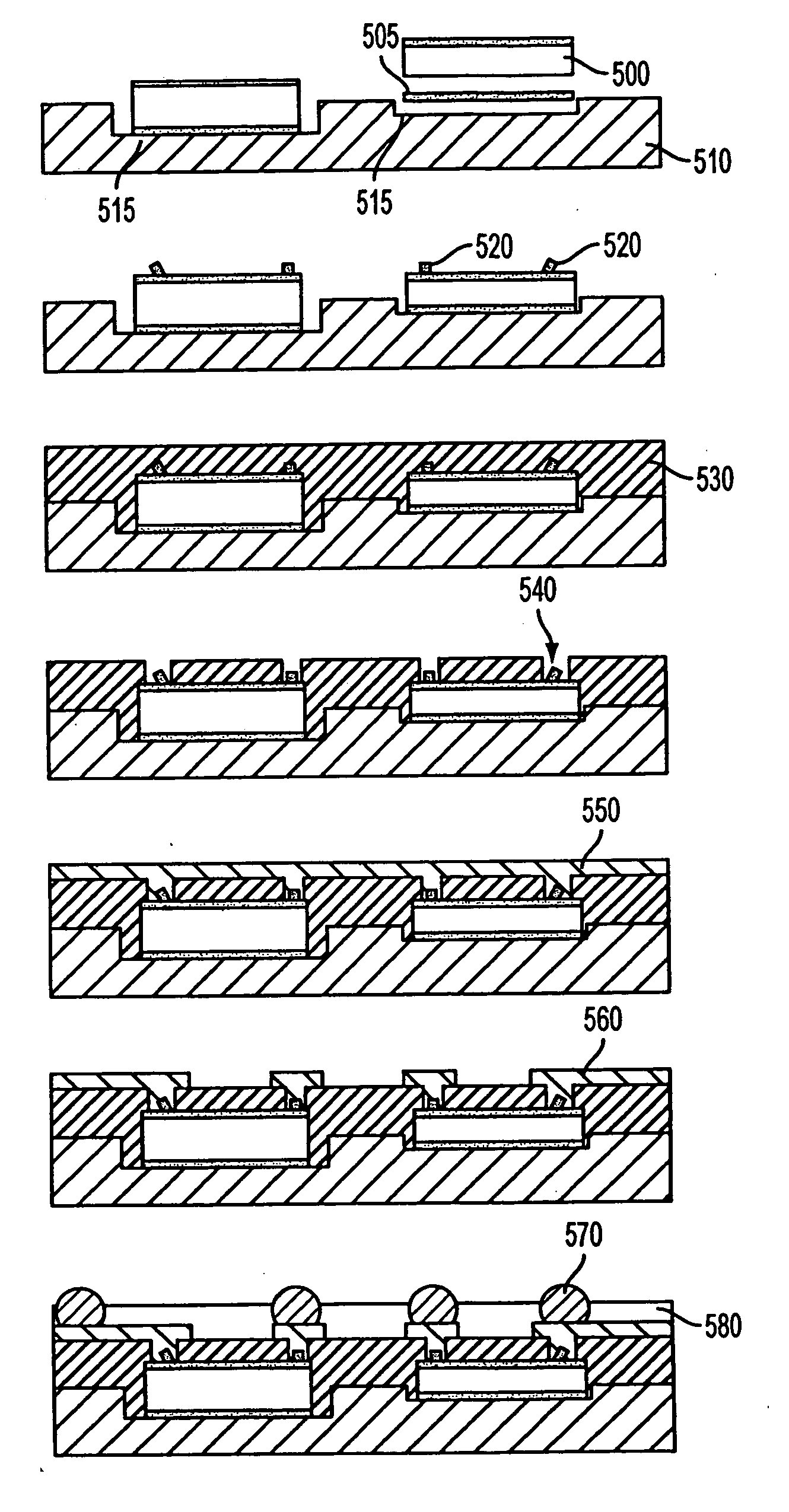

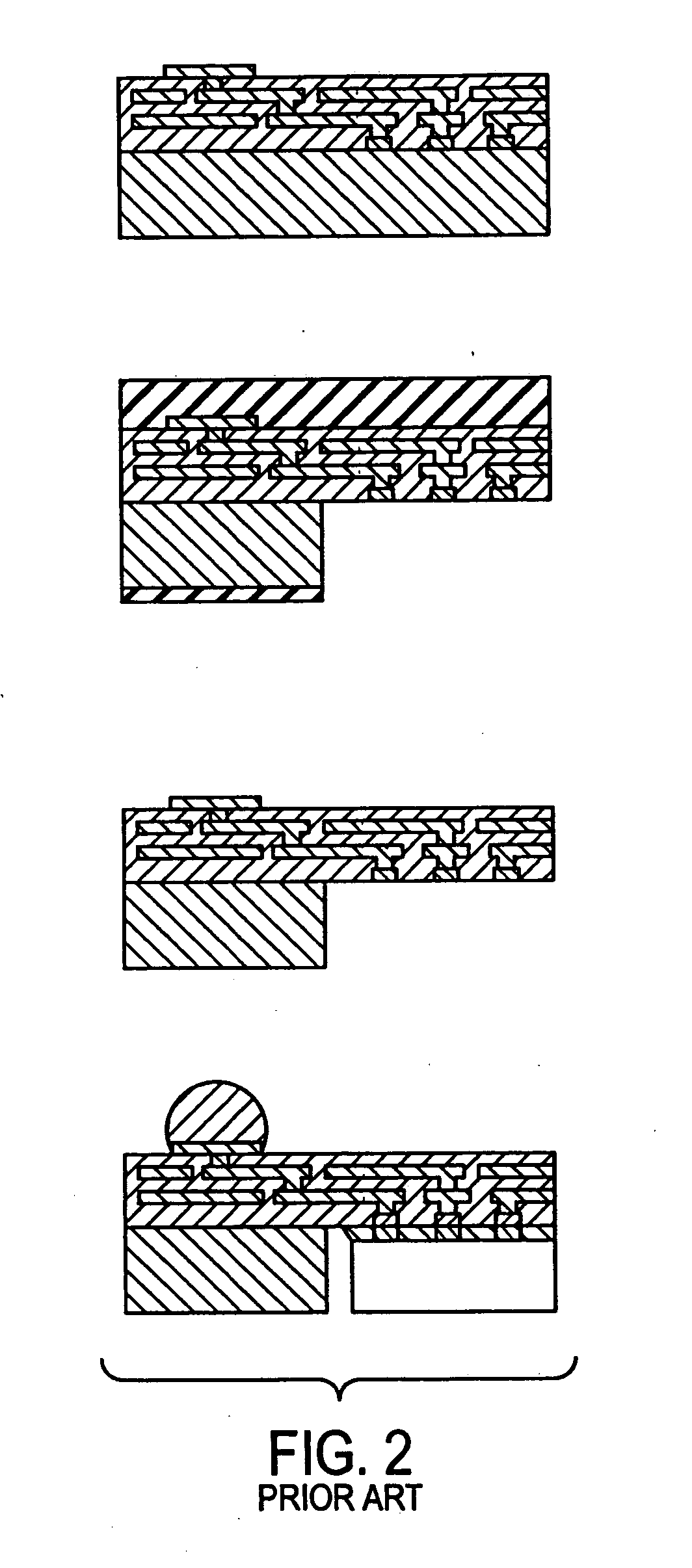

Build-up structures with multi-angle vias for chip to chip interconnects and optical bussing

InactiveUS6919508B2Improve performanceIncrease speedTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesAnisotropic conductive filmCopper interconnect

A build-up structure for chip to chip interconnects and System-In-Package utilizing multi-angle vias for electrical and optical routing or bussing of electronic information and controlled CTE dielectrics including mesocomposites to achieve optimum electrical and optical performance of monolithic structures. Die, multiple die, Microelectromechanical Machines (MEMs) and / or other active or passive components such as transducers or capacitors can be accurately positioned on a substrate such as a copper heatsink and multi-angle stud bumps can be placed on the active sites of the components. A first dielectric layer is preferably placed on the components, thereby embedding the components in the structure. Through various processes of photolithography, laser machining, soft lithography or anisotropic conductive film bonding, escape routing and circuitry is formed on the first metal layer. Additional dielectric layers and metal circuitry are formed utilizing multi-angle vias to form escape routing from tight pitch bond pads on the die to other active and passive components. Multi-angle vias can carry electrical or optical information in the form of digital or analog electromagnetic current, or in the form of visible or non-visible optical bussing and interconnections.

Owner:CAPITALSOURCE FINANCE

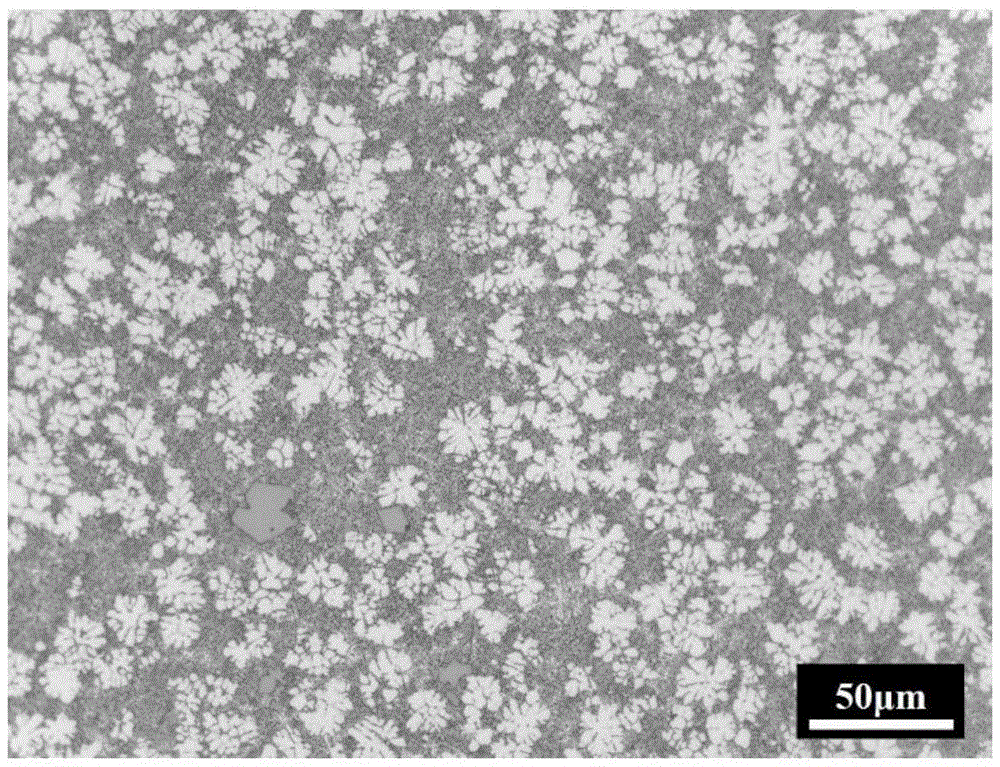

Centrifugal casting high-speed steel composite roll and manufacture method thereof

InactiveCN102615108AGood metallurgical bondHigh strengthRollsMetal rolling arrangementsNiobiumEconomic benefits

The invention relates to a centrifugal casting high-speed steel composite roll and a manufacture method thereof and belongs to the field of casting. The composite roll is composed of outer layer high-speed steel, middle layer graphitic steel and core high-strength nodular cast iron by centrifugal compounding. The centrifugal casting high-speed steel composite roll is based on the conventional high-carbon high-vanadium high-speed steel roll, the content of vanadium is appropriately reduced, niobium is added at the same time, and the Nb / V is controlled to be 0.3 to 0.5 so that Nb and V form complex carbide (V, Nb) C so as to avoid forming segregation under the action of centrifugal force. A roll core of the high-speed steel composite roll adopts high-strength nodular cast iron, and a multivariate graphite steel middle layer is poured between an outer layer and the roll core for preventing interfusing elements of Cr, B, and the like which cause embrittlement when the nodular cast iron is poured to be fused with the outer layer high-speed steel. Microalloying processing for refining the organization is carried out on a roll surface high-speed steel material and the middle layer graphitic steel so as to achieve the purpose of improving the thermal cracking capacity of the roll material. The centrifugal casting high-speed steel composite roll has high overall performance, long service life and good economic benefits.

Owner:BEIJING UNIV OF TECH

Electrically conductive yarn

InactiveUS20050282009A1Strong forcePrevent elongationNon-insulated conductorsHeating element shapesYarnEngineering

A yarn that is electrically conductive, that can be elongated considerably, at least briefly, without loss of conductivity, and that exhibits improved elongation properties.

Owner:W ZIMMERMANN

High-strength and high-corrosion-resistance cast aluminum alloy and pressure casting preparation method thereof

The invention provides high-strength and high-corrosion-resistance cast aluminum alloy and a pressure casting preparation method thereof. The alloy is prepared from, by a certain weight percent, Si, Mg, Fe, Mg, Zn, Sr, Cu, M and the balance Al, wherein M is at least one element of Ti, Zr and V, or the element RE is added in M. After the high-strength and high-corrosion-resistance cast aluminum alloy is subjected to pressure casting, the room temperature tensile strength sigma b of alloy not subjected to heat treatment is larger than or equal to 315 MPa, the room temperature ductility sigma of the alloy not subjected to heat treatment is larger than or equal to 3.0%, and good corrosion resistance is achieved; and the alloy can be applied to automobile parts without ageing or solid solution heat treatment, and the requirement for light automobile development is met.

Owner:SHANGHAI JIAO TONG UNIV

Low-smoke halogen-free flame retardant thermoplastic elastomer alloy for flexible wire rod and preparation method thereof

InactiveCN101225224AHigh tensile strengthHigh elongationInsulated cablesInsulated conductorsLow voltageAntioxidant

The invention discloses a low-smoke halogen-free flame-retarding thermoplastic elastomer alloy used for soft wires and a preparation method of the alloy, which is characterized in that: the material comprises thermoplastic polyurethane elastomer, thermoplastic styrene elastomer, compatilizer, phosphorus-nitrogen compound flame retardant, flame-retarding potentiating agent, lubricant, antioxidant and colorant; the weight ratio of the thermoplastic polyurethane elastomer, the thermoplastic styrene elastomer, the compatilizer, the phosphor-nitrogen compound flame retardant, the flame-retarding potentiating agent, the lubricant, the antioxidant and the colorant is 40 to 55 : 5 to 25 : 5 to 10 : 20 to 25 : 3 to 10 : 1.5 : 0.25 : 0.25; the preparation method is that the all components are evenly mixed in a high-speed mixer, and then extruded, drew and granulated at 170 to 210 degree centigrade, and then a low-smoke halogen-free flame-retarding thermoplastic elastomer alloy used for soft wires is obtained. The low-smoke halogen-free flame-retarding thermoplastic elastomer alloy used for soft wires has the advantages of achieving distinct flame-retarding effect at a small quantity of flame retardant dosage, satisfying the flame-retarding requirement of low-voltage wires, adjusting the Shore durometer number of the material between 80 to 95, good pliability, high physical mechanical property and according with the halogen-free and environment-friendly requirement.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

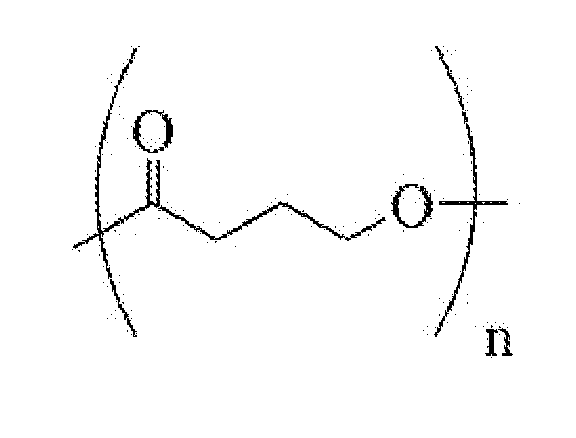

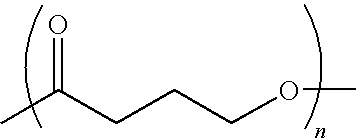

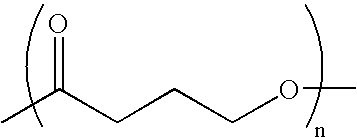

Toughened Polylactic Acid Polymers and Copolymers

InactiveUS20070182041A1Low tensile modulus valueMaintain good propertiesSuture equipmentsCatheterToughnessPolymer chemistry

Toughened compositions of PLA and PLA copolymers are disclosed, which also have low tensile modulus values and greater elongation to break. These toughened compositions are prepared by blending PLA and PLA copolymers with poly-4-hydroxybutyrate, and copolymers thereof. Blending of poly-4-hydroxybutyrate with PLA and its copolymers has been found to impart advantageous properties to the resulting blend. These compositions, and objects formed from these compositions, have improved toughness and lower stiffness than polylactic acid polymers or copolymers alone.

Owner:TEPHA INC

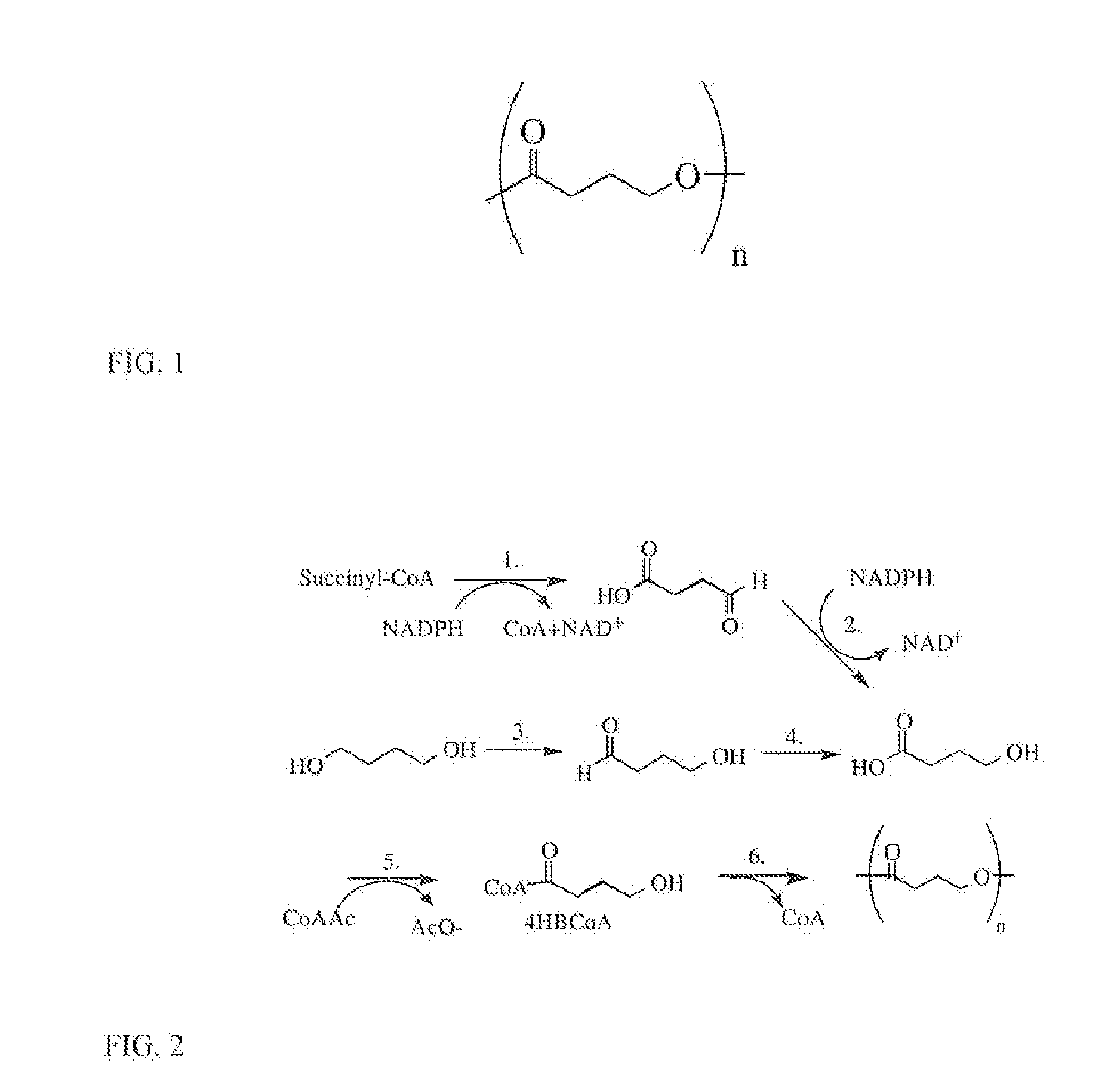

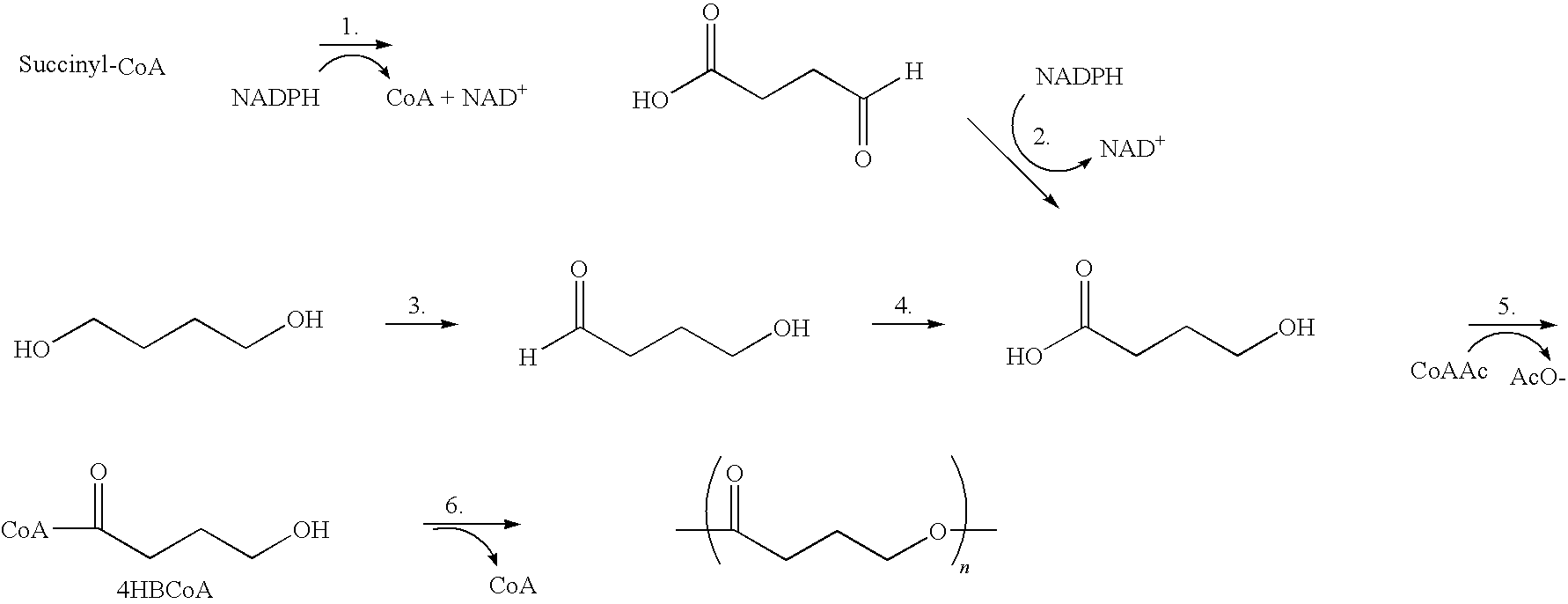

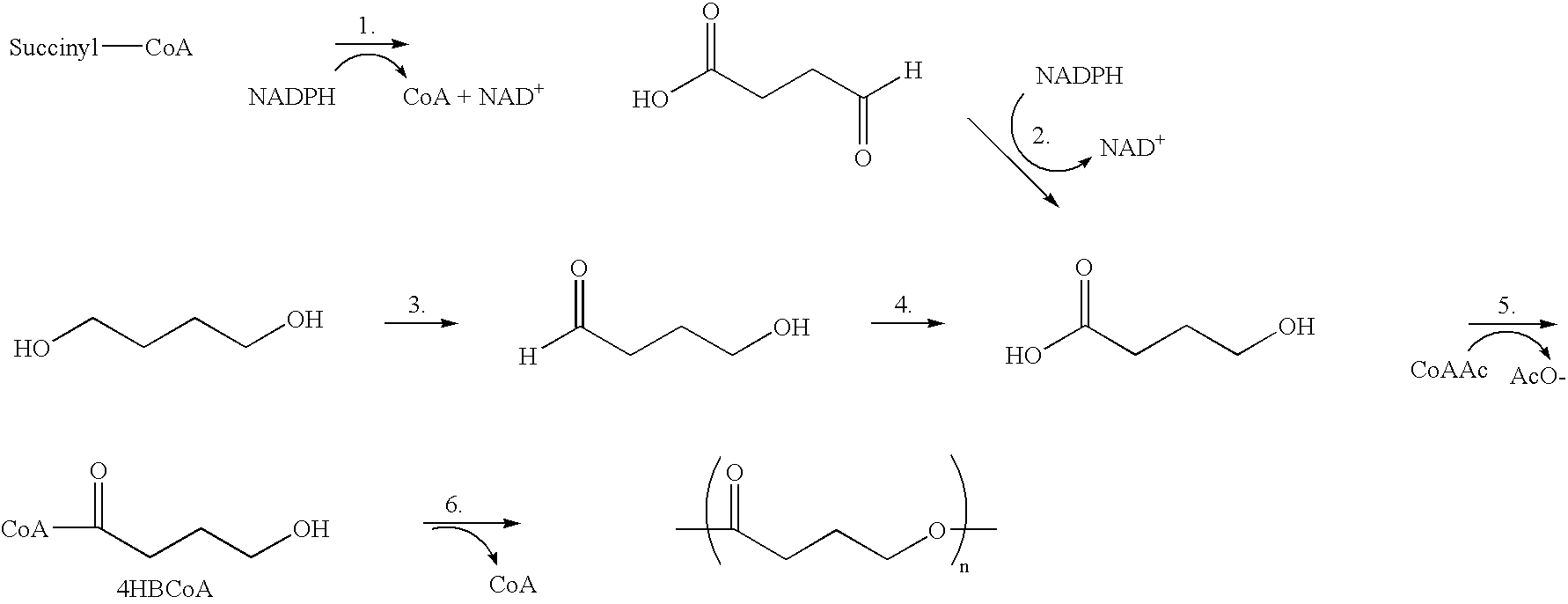

Method of making a polyhydroxyalkanoate filament

ActiveUS7641825B2Improve handlingImprove methodSuture equipmentsMovable spraying apparatusPolyesterFiber

Absorbable polyester fibers, braids, and surgical meshes with improved handling properties have been developed. These devices are preferably derived from biocompatible copolymers or homopolymers of 4-hydroxybutyrate. These devices provide a wider range of in vivo strength retention properties than are currently available and have a decreased tendency to curl, in the preferred embodiment, due to the inclusion of relaxation and annealing steps following methods are characterized by the following physical properties: (i) elongation to break from about 17% to about 85% (ii) Young's modulus of less than 350,000 psi, (iii) knot to straight ratio (knot strength / tensile strength) of 55-80% or (iv) load at break from 1100 to 4200 grams.

Owner:TEPHA INC

Non-curling polyhydroxyalkanoate sutures

ActiveUS20060058470A1Improve handlingSimple materialSuture equipmentsMovable spraying apparatusPolyesterFiber

Absorbable polyester fibers, braids, and surgical meshes with improved handling properties have been developed. These devices are preferably derived from biocompatible copolymers or homopolymers of 4-hydroxybutyrate. These devices provide a wider range of in vivo strength retention properties than are currently available and have a decreased tendency to curl, in the preferred embodiment, due to the inclusion of relaxation and annealing steps following extrusion and orientation of the fiber. Filaments prepared according to these methods are characterized by the following physical properties: (i) elongation to break from about 17% to about 85% (ii) Young's modulus of less than 350,000 psi, (iii) knot to straight ratio (knot strength / tensile strength) of 55-80% or (iv) load at break from 1100 to 4200 grams.

Owner:TEPHA INC

Build-up structures with multi-angle vias for chip to chip interconnects and optical bussing

InactiveUS20050087356A1Enhanced signalReduce in quantityTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesAnisotropic conductive filmEngineering

A build-up structure for chip to chip interconnects and System-In-Package utilizing multi-angle vias for electrical and optical routing or bussing of electronic information and controlled CTE dielectrics including mesocomposites to achieve optimum electrical and optical performance of monolithic structures. Die, multiple die, Microelectromechanical Machines (MEMs) and / or other active or passive components such as transducers or capacitors can be accurately positioned on a substrate such as a copper heatsink and multi-angle stud bumps can be placed on the active sites of the components. A first dielectric layer is preferably placed on the components, thereby embedding the components in the structure. Through various processes of photolithography, laser machining, soft lithography or anisotropic conductive film bonding, escape routing and circuitry is formed on the first metal layer. Additional dielectric layers and metal circuitry are formed utilizing multi-angle vias to form escape routing from tight pitch bond pads on the die to other active and passive components. Multi-angle vias can carry electrical or optical information in the form of digital or analog electromagnetic current, or in the form of visible or non-visible optical bussing and interconnections.

Owner:CAPITALSOURCE FINANCE

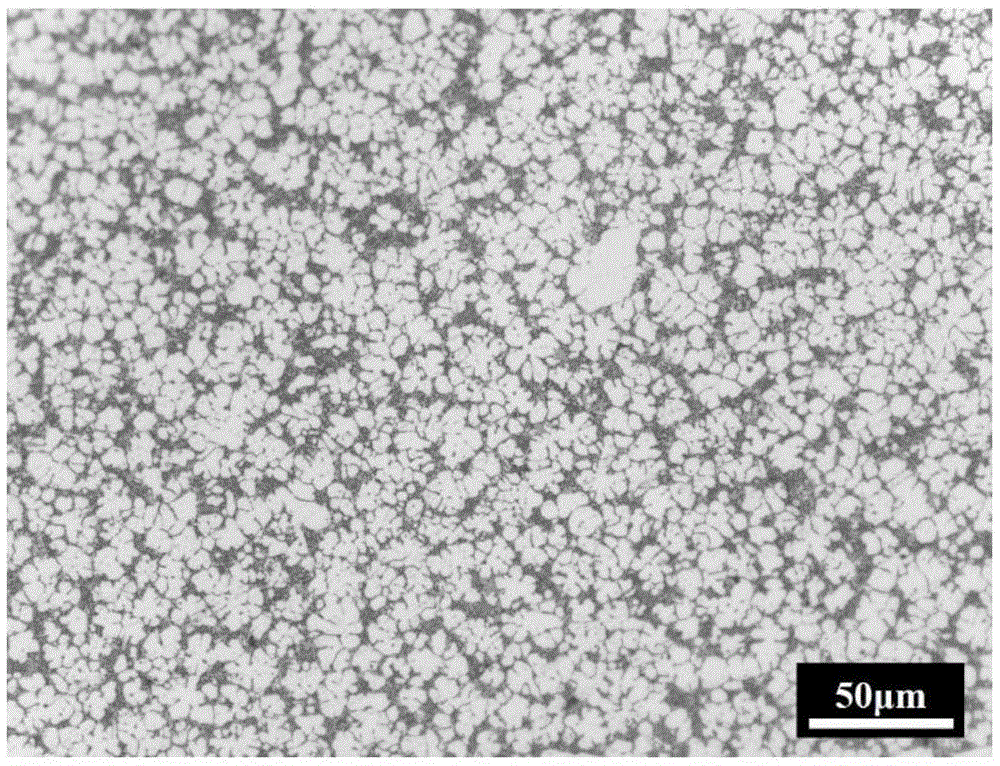

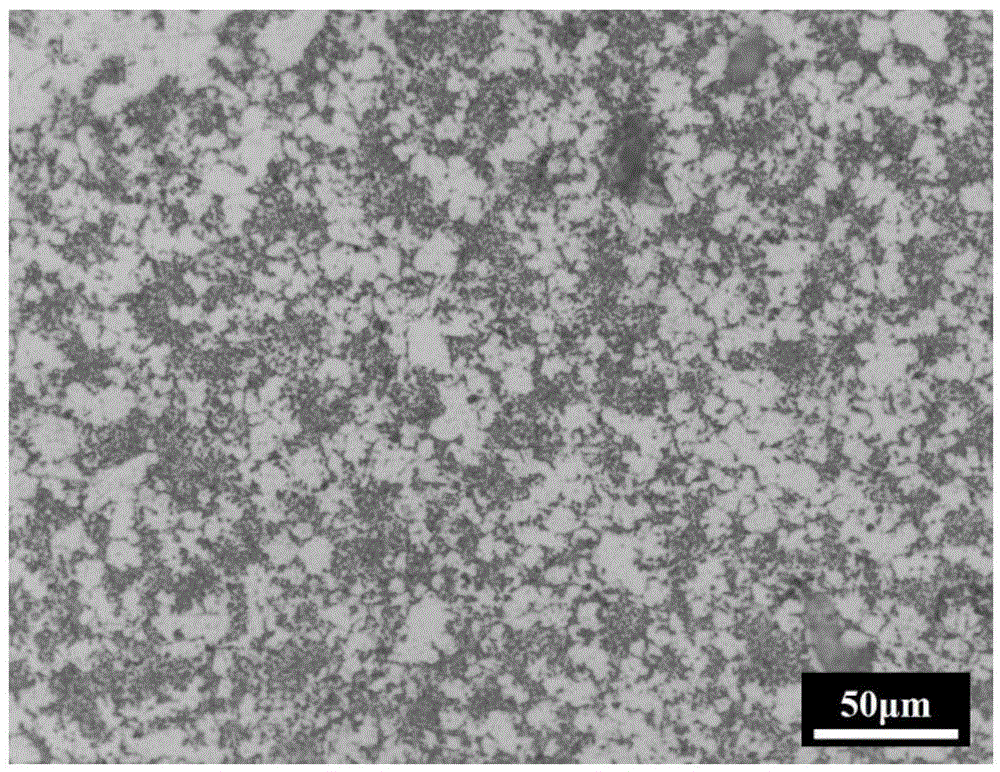

Wear-resistant sintered aluminum alloy with high strength and manufacturing method thereof

Disclosed is a wear-resistant sintered aluminum alloy with high strength and a manufacturing method thereof. The sintered aluminum alloy contains, by mass: 3.0-10% zinc; 0.5-5.0% magnesium; 0.5-5.0% copper; 0.1-10% hard particles; impurities; and aluminum. The metallographic structure has an aluminum alloy matrix in which the hard particles dispersed; and an intermetallic compound phase being dispersedly precipitated in the aluminum alloy matrix. Using an aluminum powder, a hard particles powder and other powders, a compact is formed and sintered at 580-610 degrees C., then cooled and subjected to heat treatment at a temperature of 460-490 degrees C., including water-quenching and aging at 110-200 degrees C.

Owner:ICHIKAWA JUNICHI +1

Semi-aromatic polyamide resin

InactiveUS20090098325A1Good adhesive propertyHigh residence stability and hot water resistanceSynthetic resin layered productsFlexible pipesDiamineCarboxylic group

A semi-aromatic polyamide resin is provided which has a high level of residence stability, hot-water resistance and chemical resistance and is also excellent in adhesive properties and compatibility with other resins and the like.The semi-aromatic polyamide resin comprises: dicarboxylic acid units in which 50 to 100 mol % of the dicarboxylic acid units are aromatic dicarboxylic acid units; and diamine units in which 60 to 100 mol % of the diamine units are aliphatic diamine units having 9 to 13 carbon atoms. Furthermore, at least 10% of terminal groups of molecular chains of the polyamide resin are blocked with a terminal-blocking agent, and the amount of terminal amino groups of the molecular chains is 60 μeq / g or more and 120 μeq / g or less. In addition, [NH2] / [COOH]≧6 is satisfied, where [NH2] (μeq / g) represents the amount of the terminal amino groups and [COOH] (μeq / g) represents the amount of terminal carboxyl groups.

Owner:KURARAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com