Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3010results about "Non-insulated conductors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

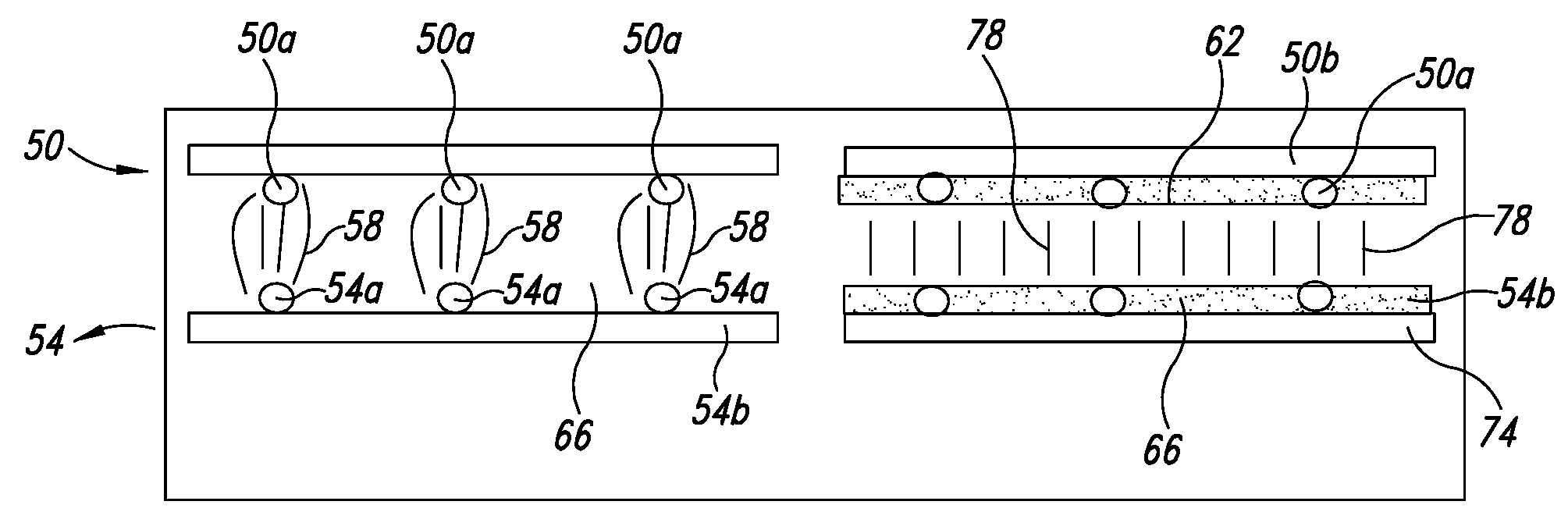

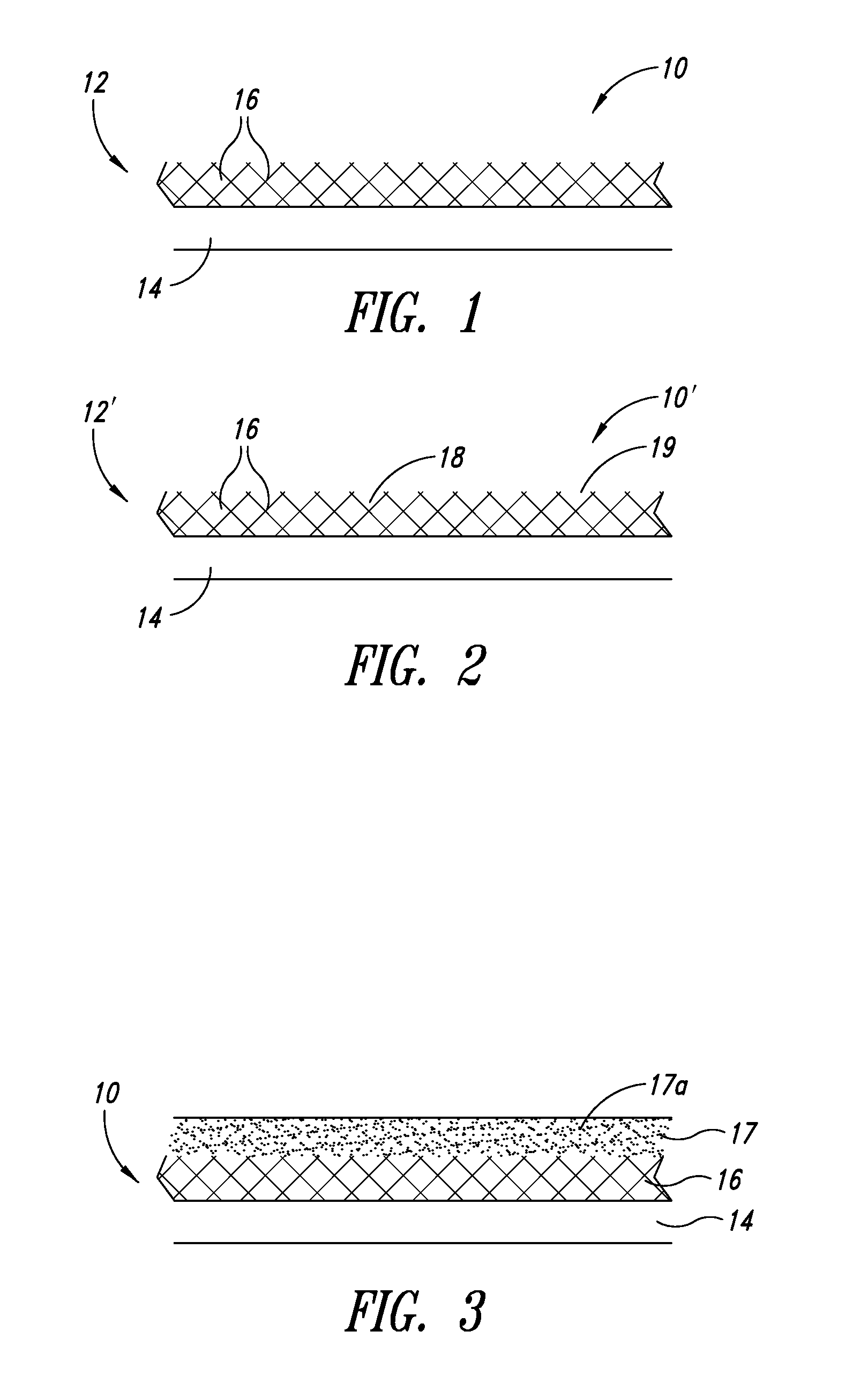

Composite transparent conductors and methods of forming the same

ActiveUS20080259262A1Improve drawing legibilityMaterial nanotechnologyNon-insulated conductorsMaterials scienceMetal nanowire

Composite transparent conductors are described, which comprise a primary conductive medium based on metal nanowires and a secondary conductive medium based on a continuous conductive film.

Owner:CHAMP GREAT INTL

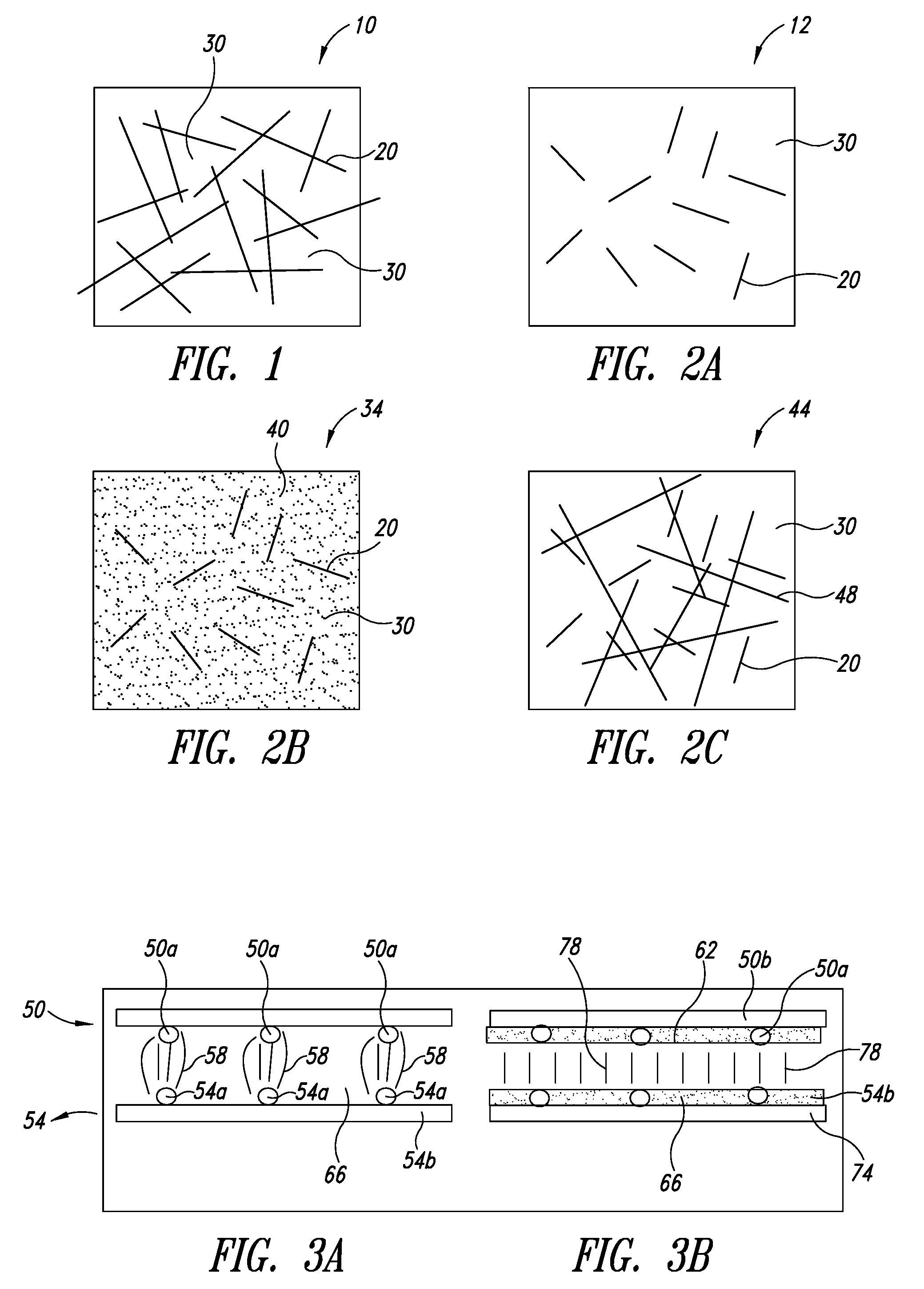

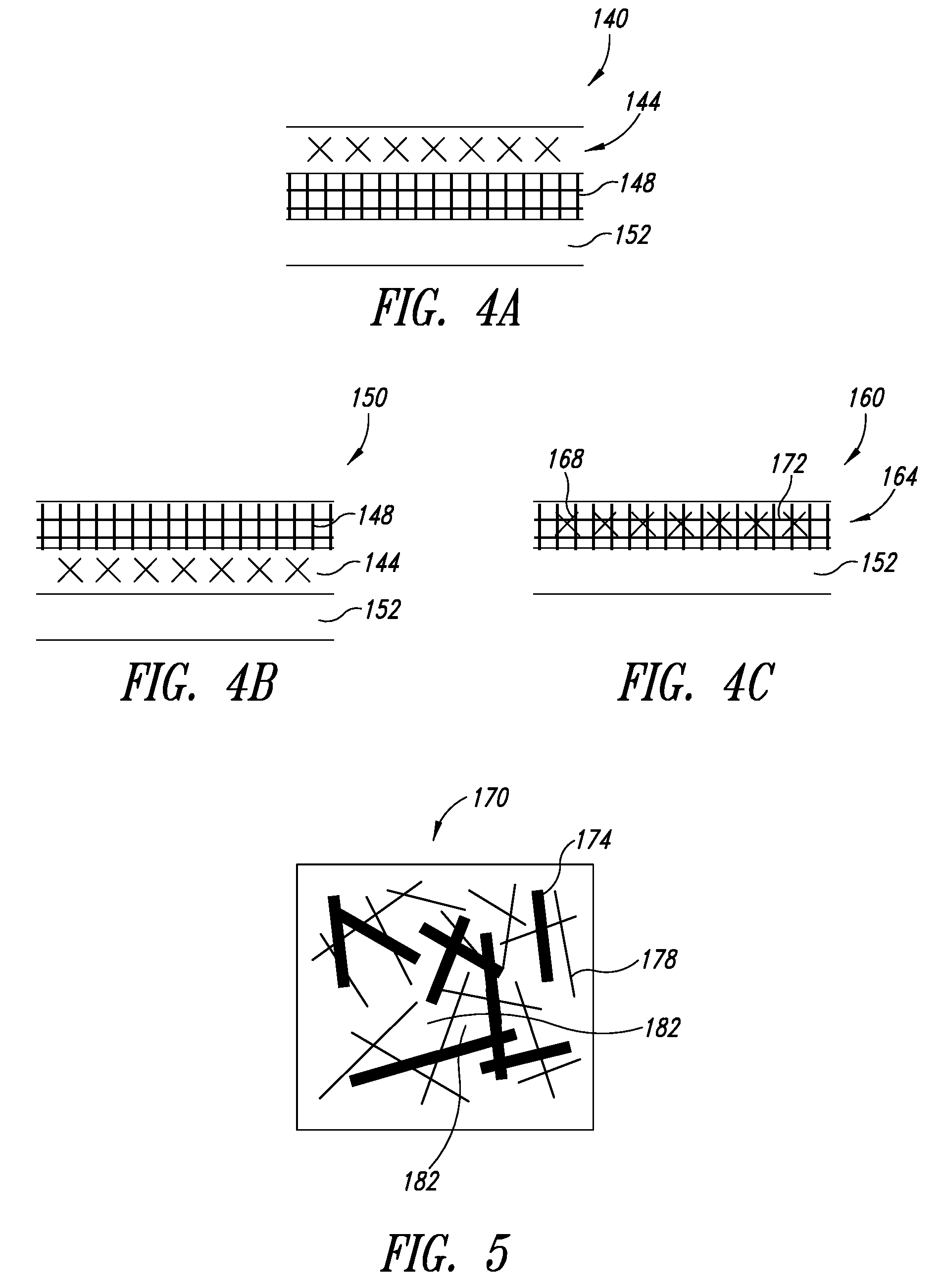

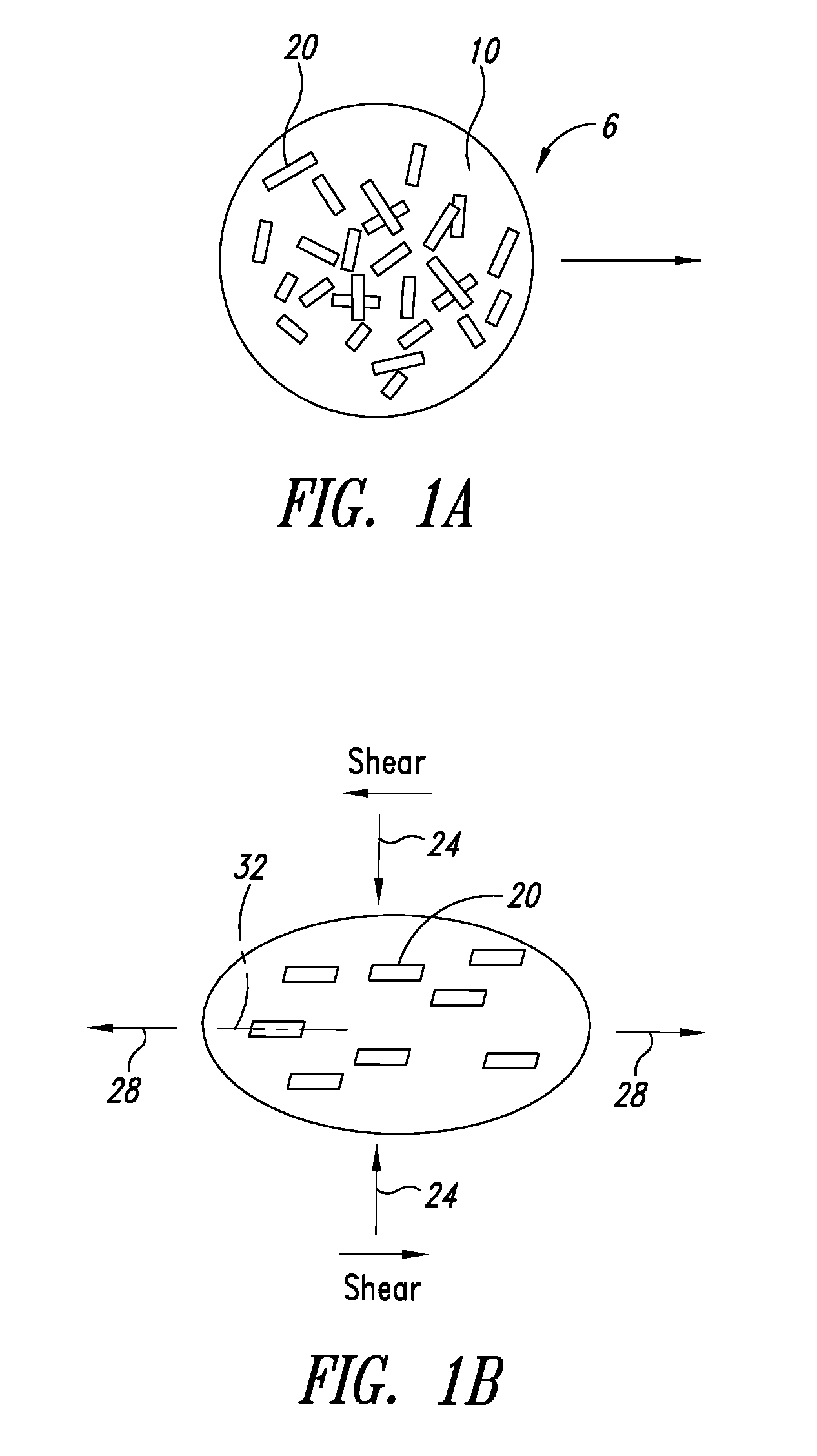

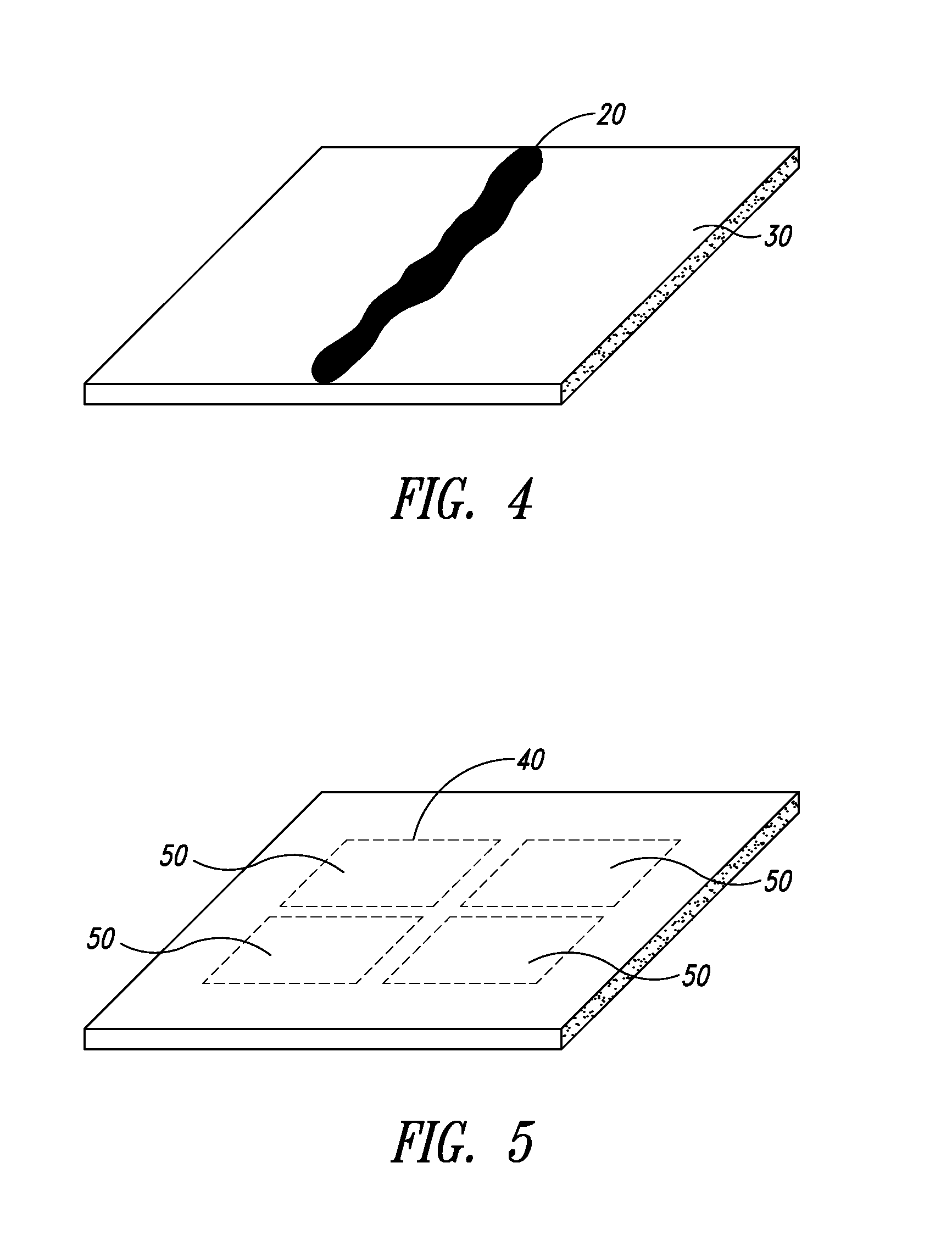

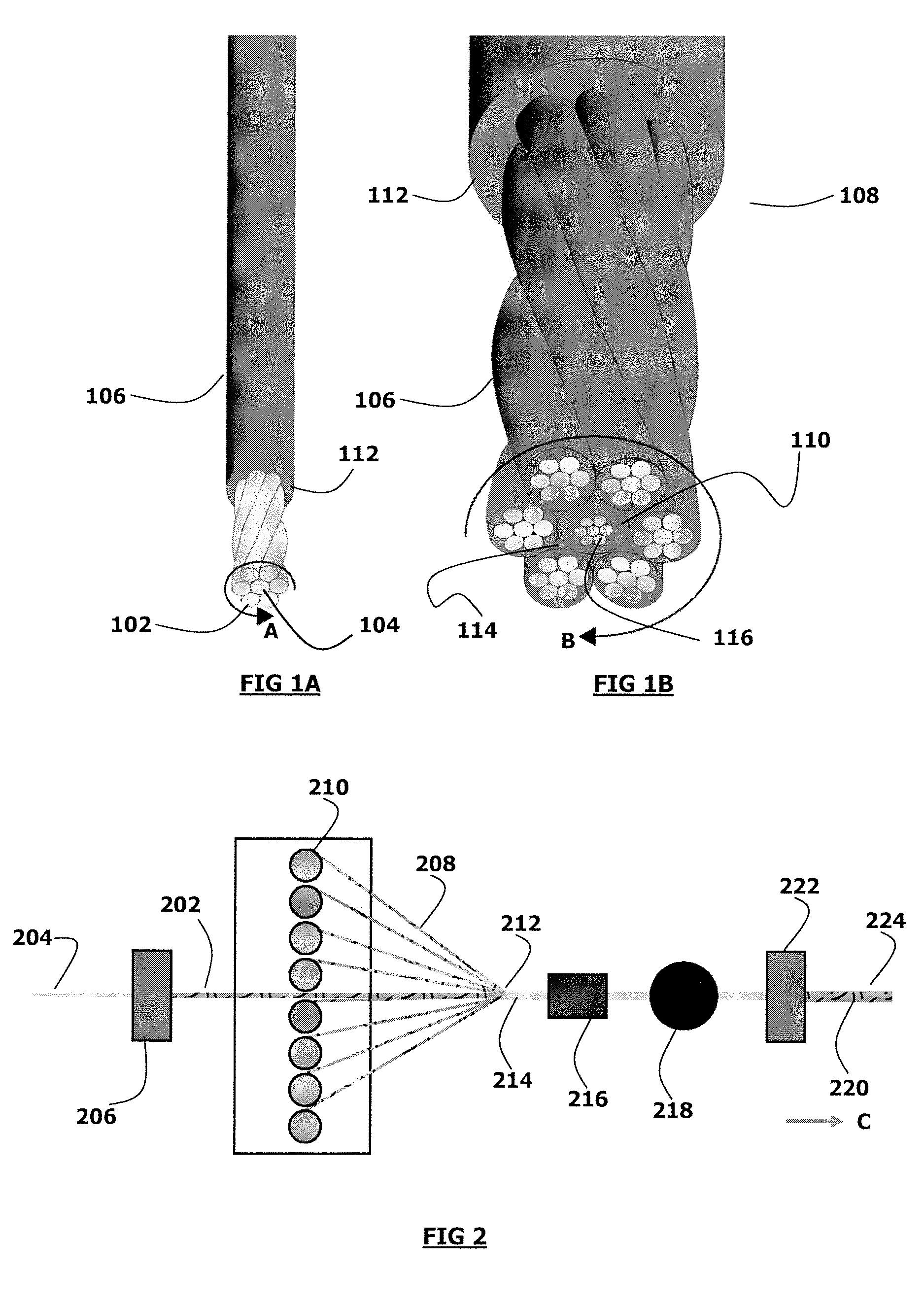

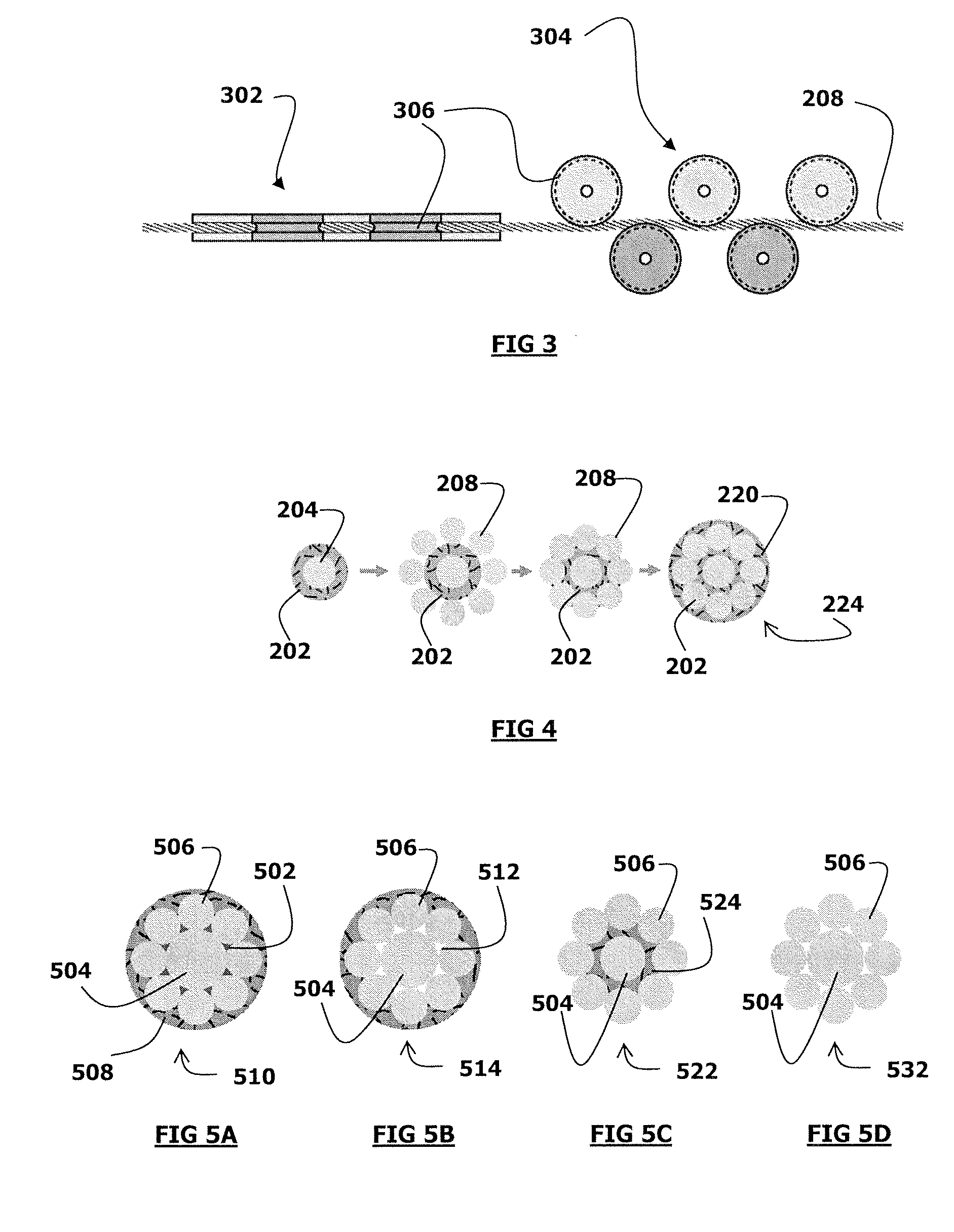

Functional films formed by highly oriented deposition of nanowires

InactiveUS20090052029A1Reduce manufacturing costIncreased durabilityMaterial nanotechnologyNon-insulated conductorsNanowireNanometre

Optical films formed by deposition of highly oriented nanowires and methods of aligning suspended nanowires in a desired direction by flow-induced shear force are described.

Owner:CAMBRIOS TECH +1

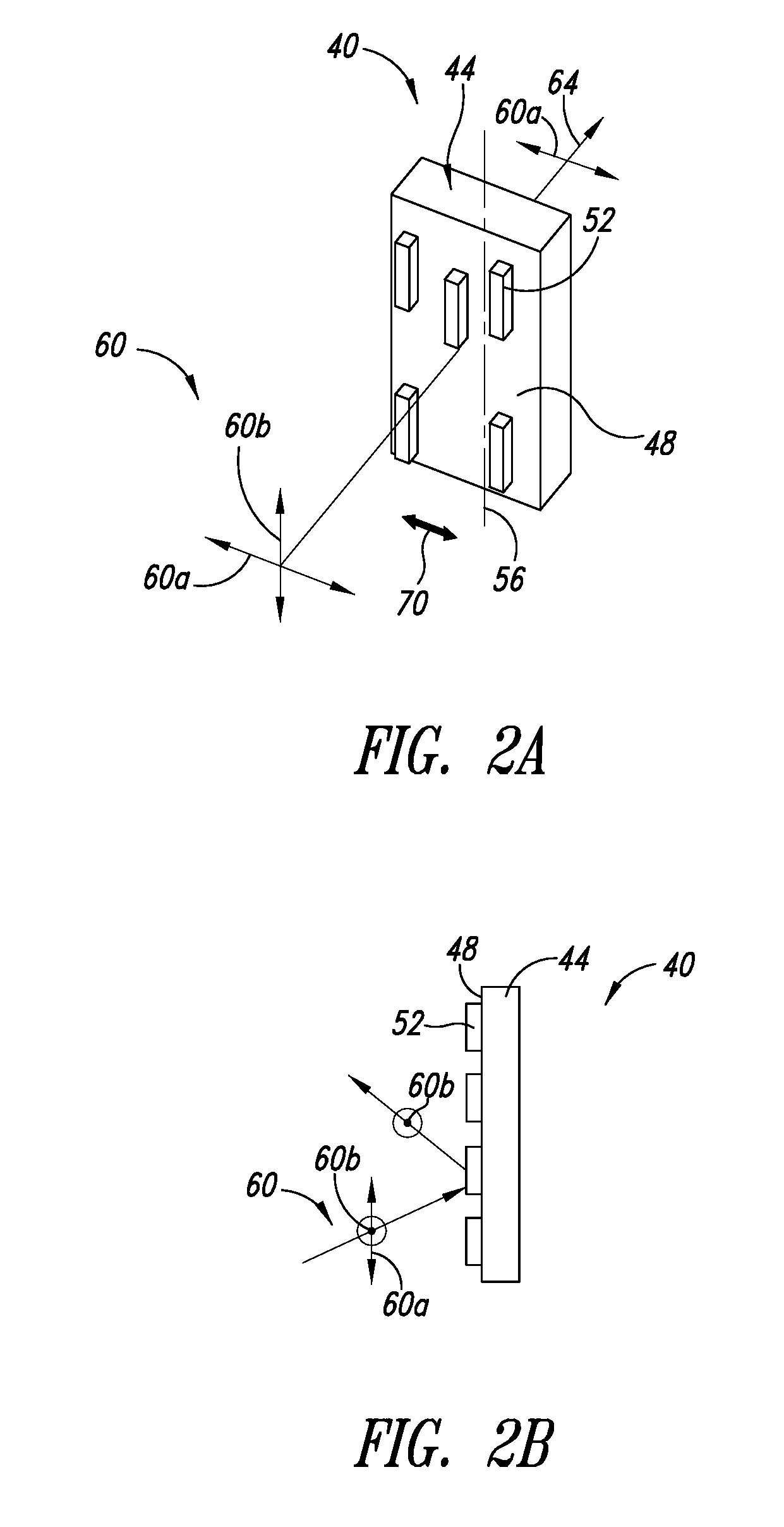

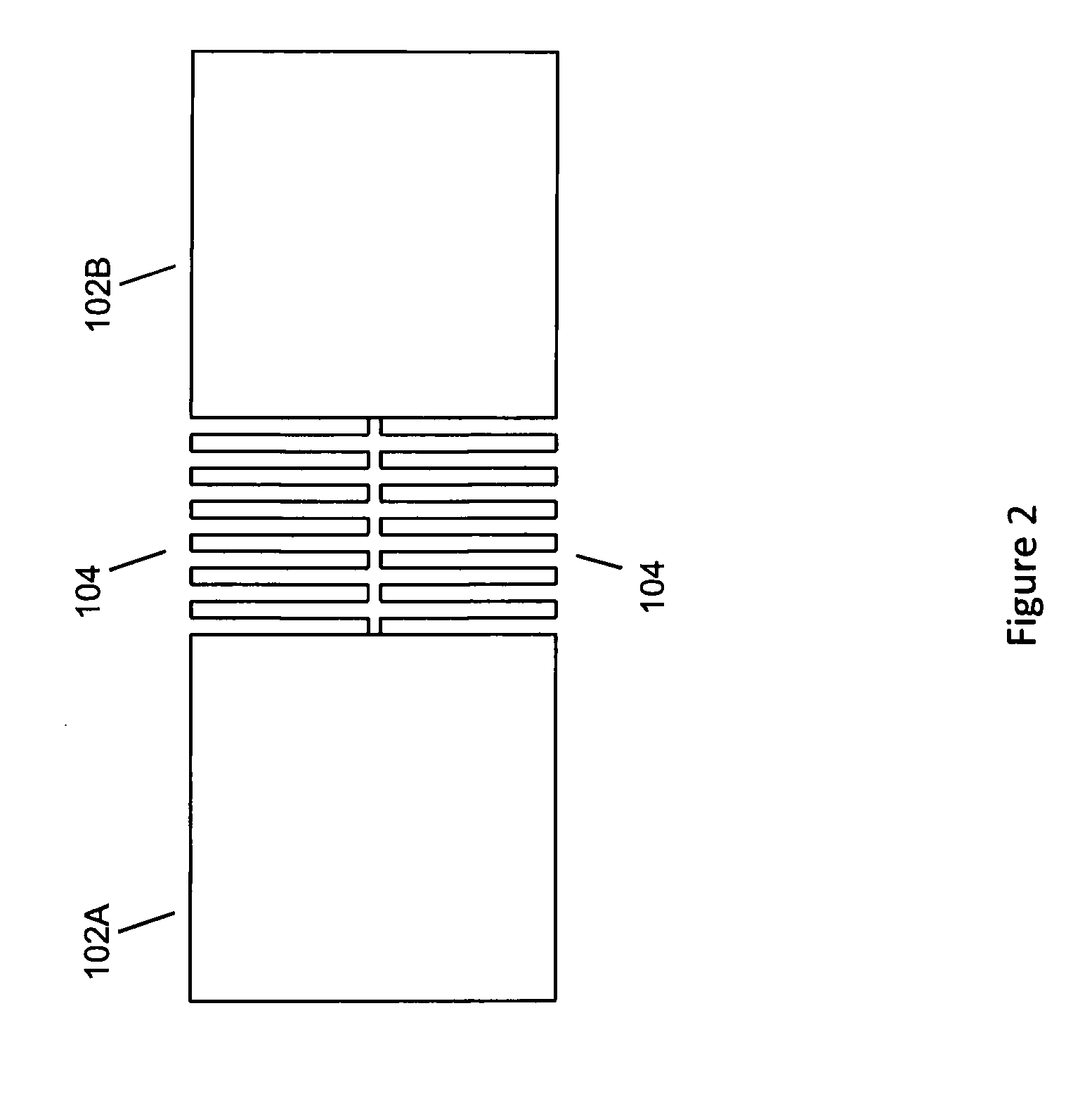

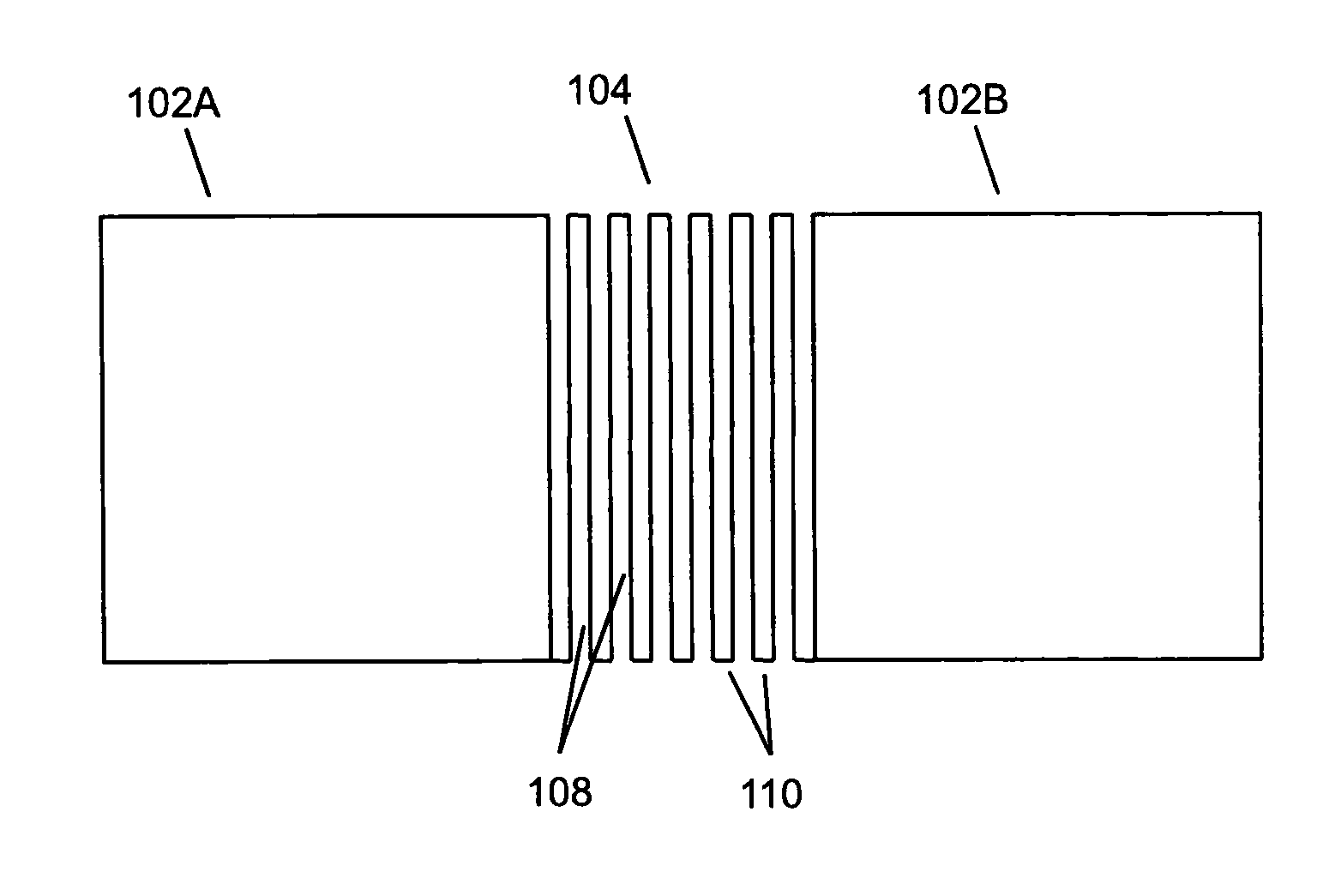

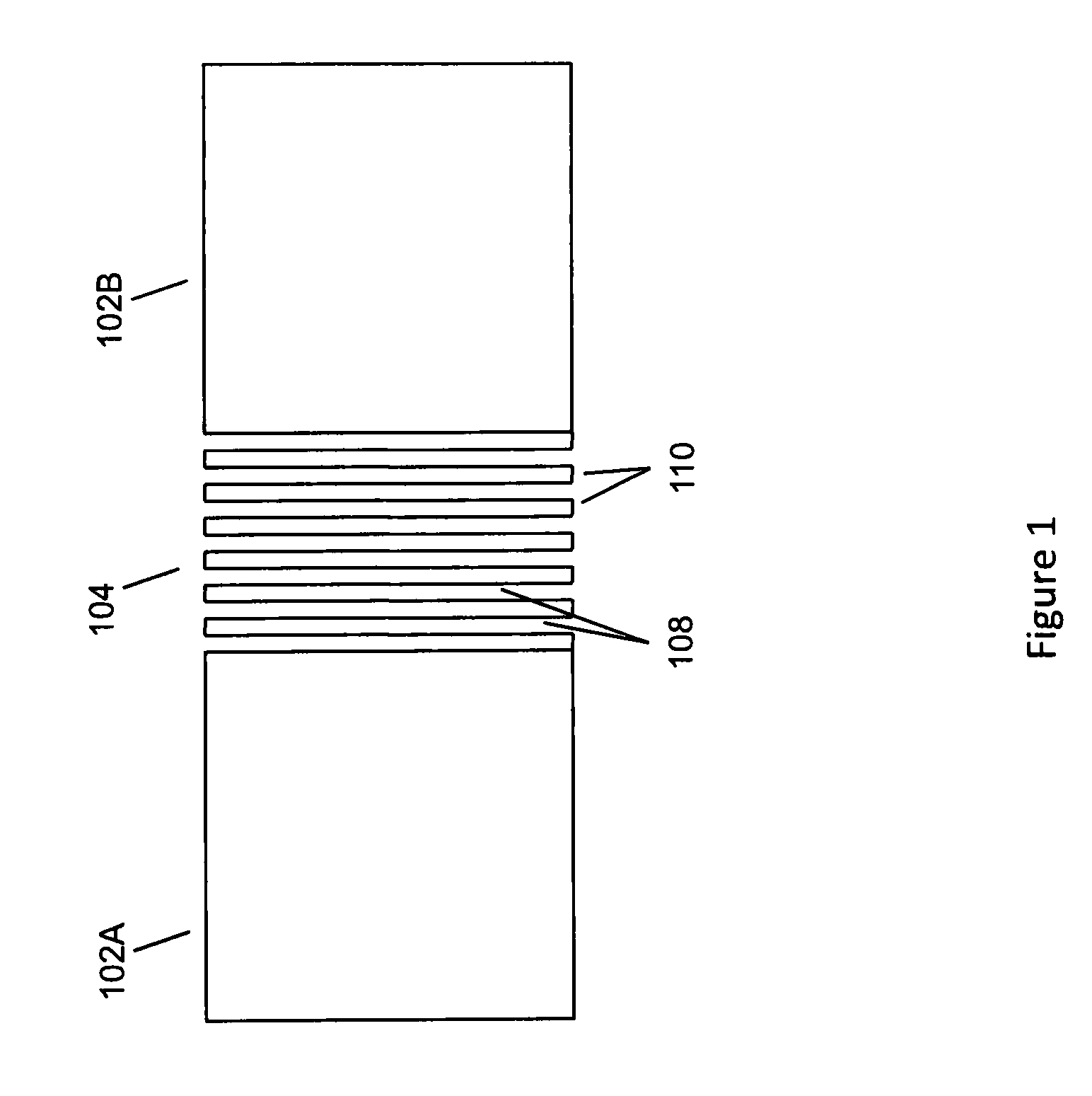

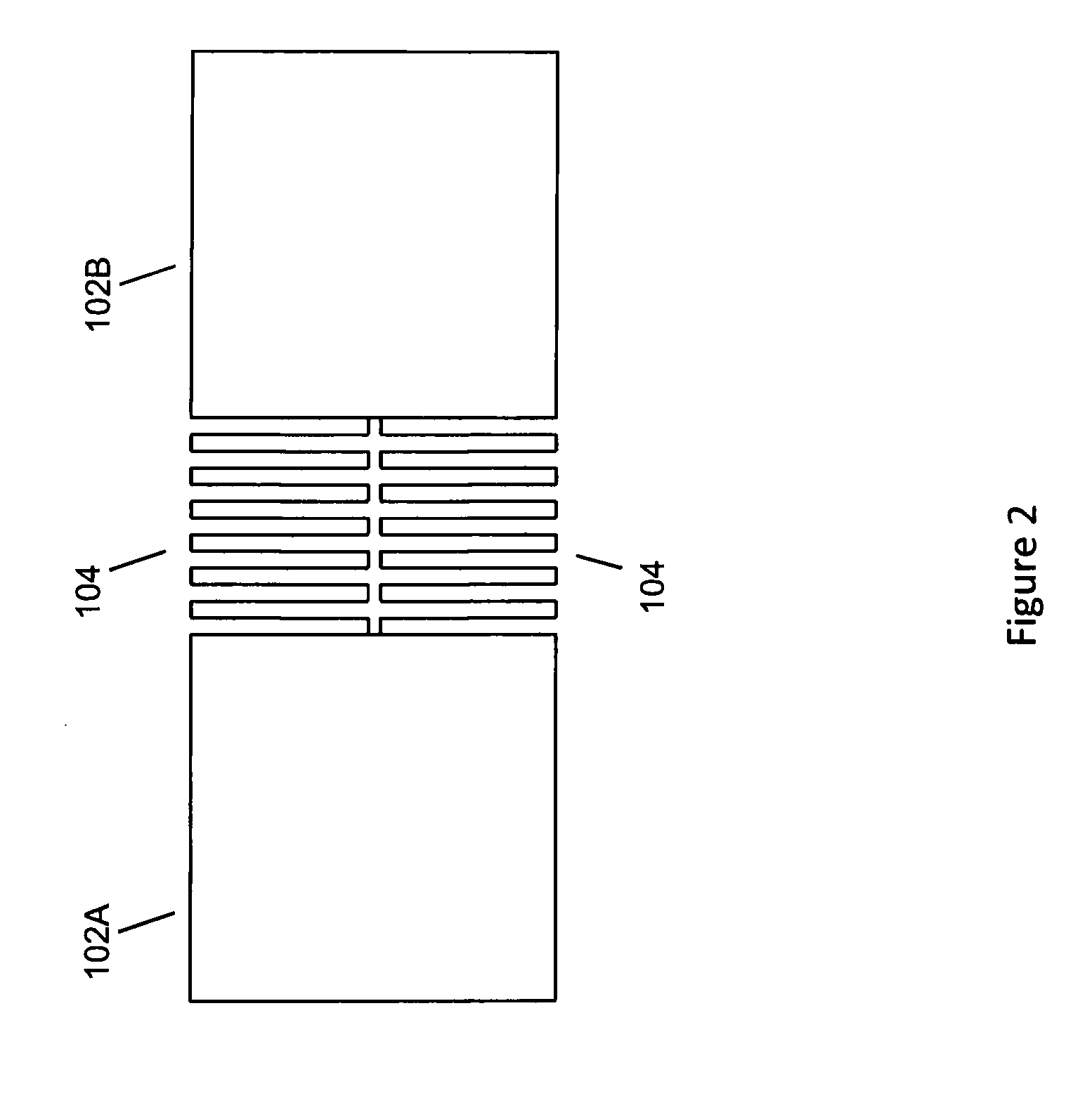

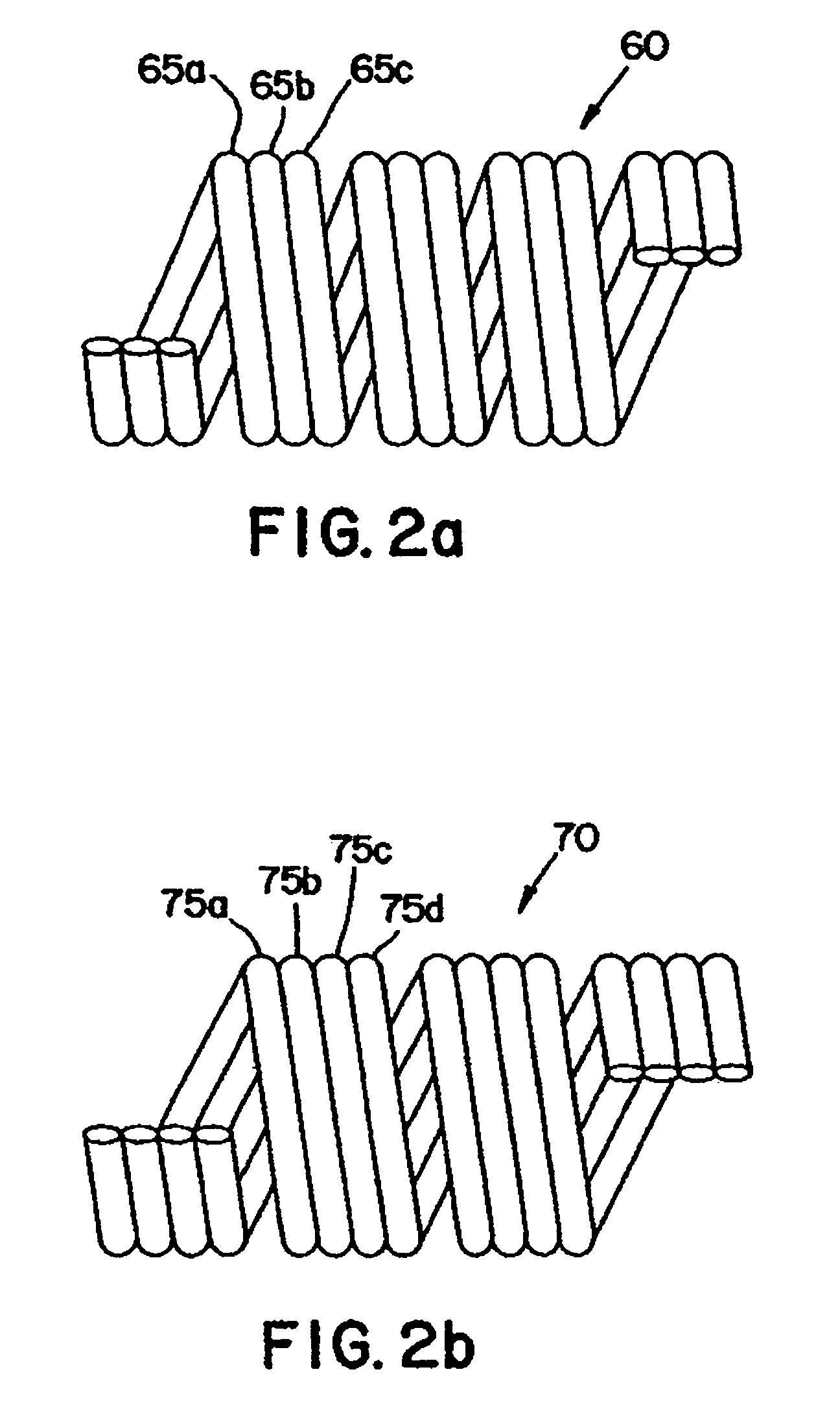

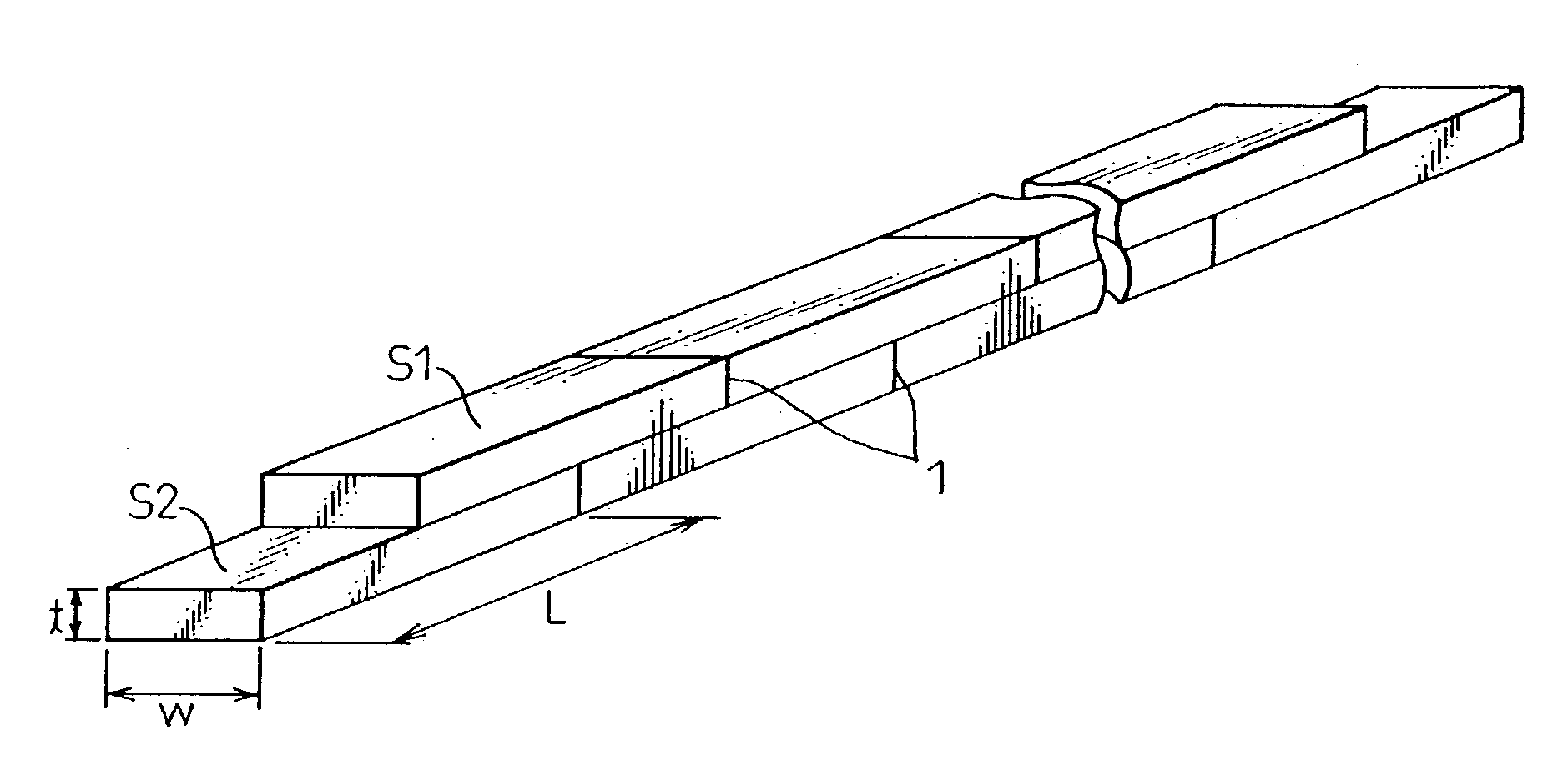

Extremely stretchable electronics

ActiveUS8389862B2Non-insulated conductorsContact member manufacturingStretchable electronicsElastomer

In embodiments, the present invention may attach at least two isolated electronic components to an elastomeric substrate, and arrange an electrical interconnection between the components in a boustrophedonic pattern interconnecting the two isolated electronic components with the electrical interconnection. The elastomeric substrate may then be stretched such that the components separate relative to one another, where the electrical interconnection maintains substantially identical electrical performance characteristics during stretching, and where the stretching may extend the separation distance between the electrical components to many times that of the unstretched distance.

Owner:MEDIDATA SOLUTIONS

Extremely stretchable electronics

ActiveUS20100116526A1Minimal strainNon-insulated conductorsContact member manufacturingStretchable electronicsElastomer

In embodiments, the present invention may attach at least two isolated electronic components to an elastomeric substrate, and arrange an electrical interconnection between the components in a boustrophedonic pattern interconnecting the two isolated electronic components with the electrical interconnection. The elastomeric substrate may then be stretched such that the components separate relative to one another, where the electrical interconnection maintains substantially identical electrical performance characteristics during stretching, and where the stretching may extend the separation distance between the electrical components to many times that of the unstretched distance.

Owner:MEDIDATA SOLUTIONS

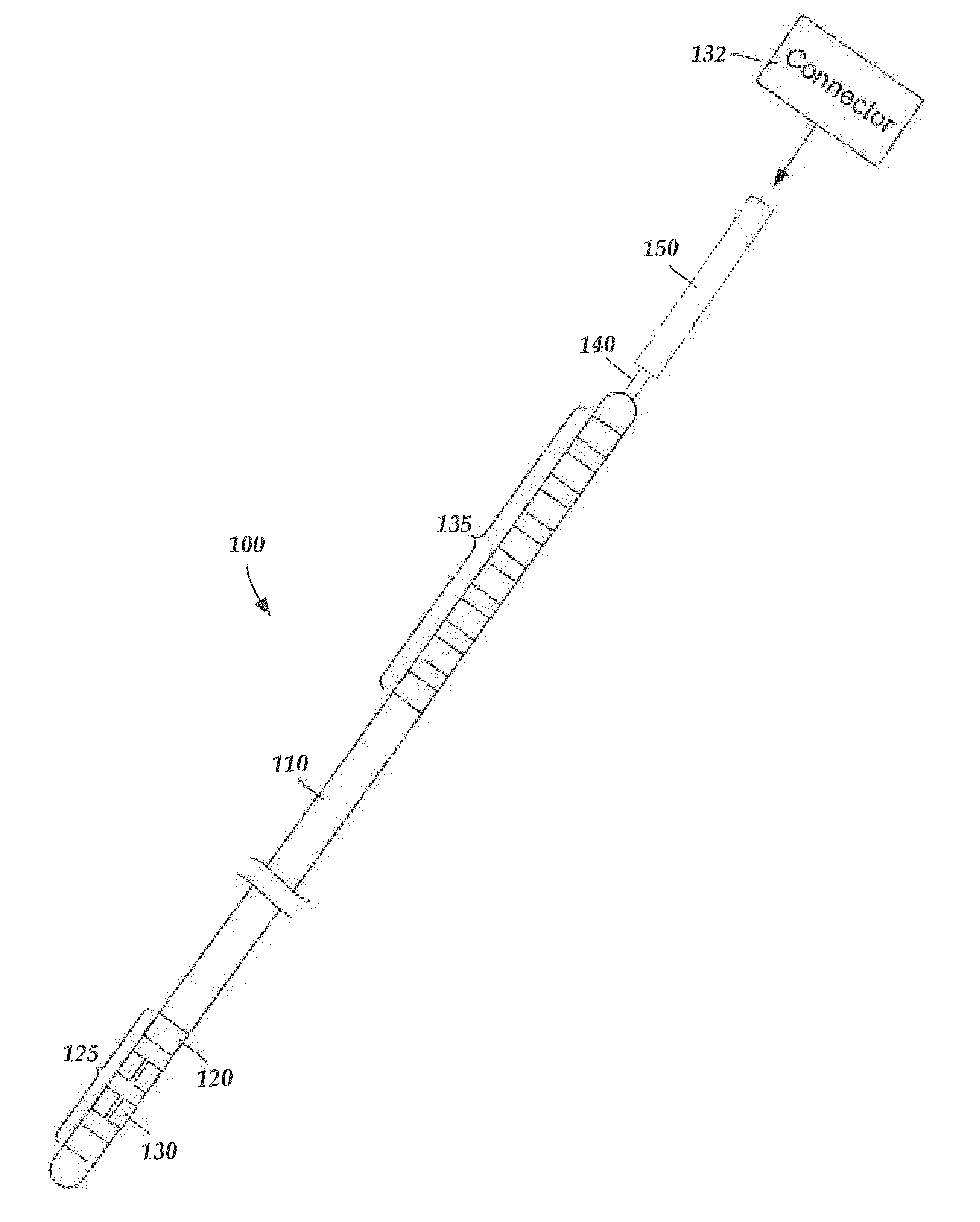

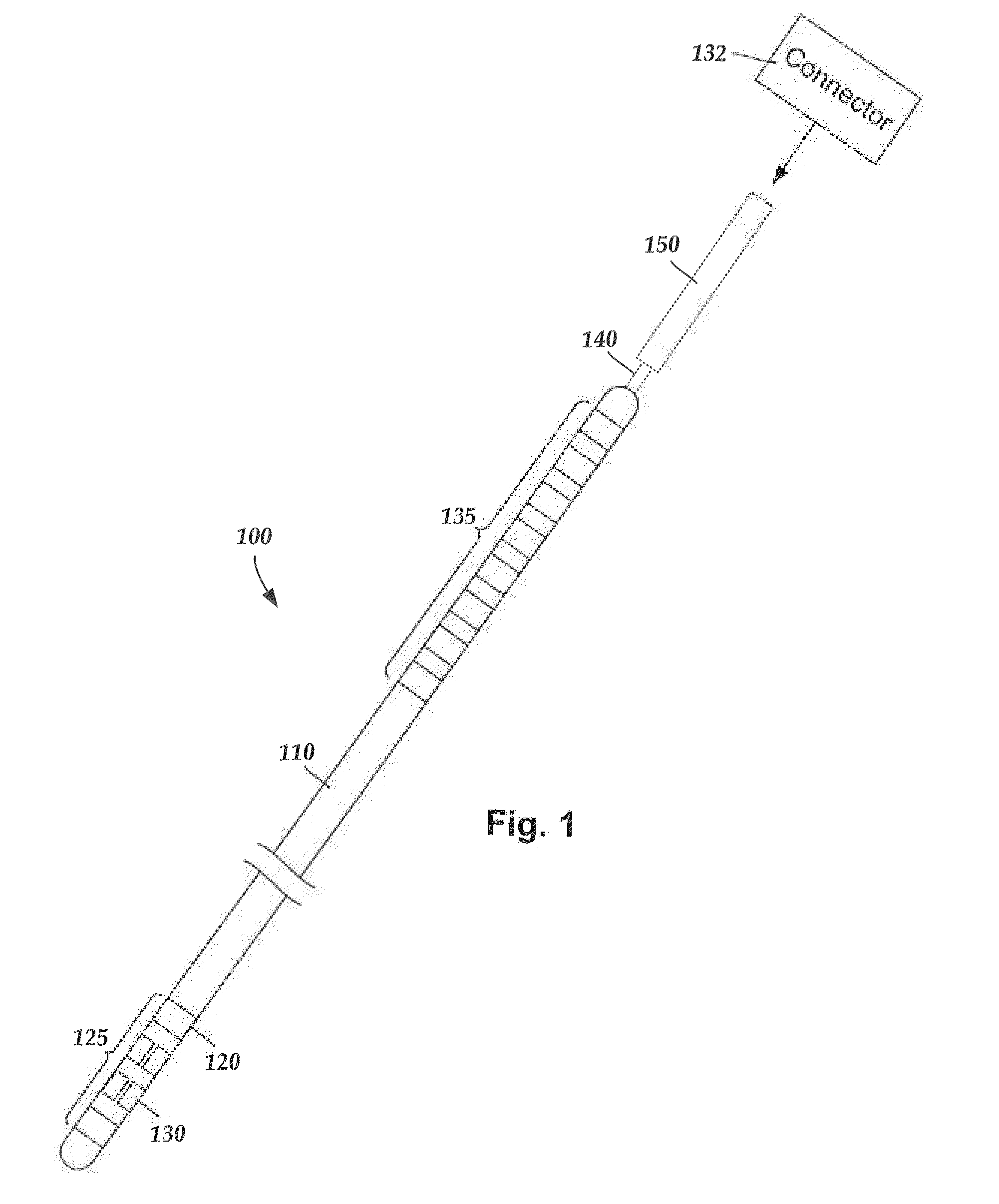

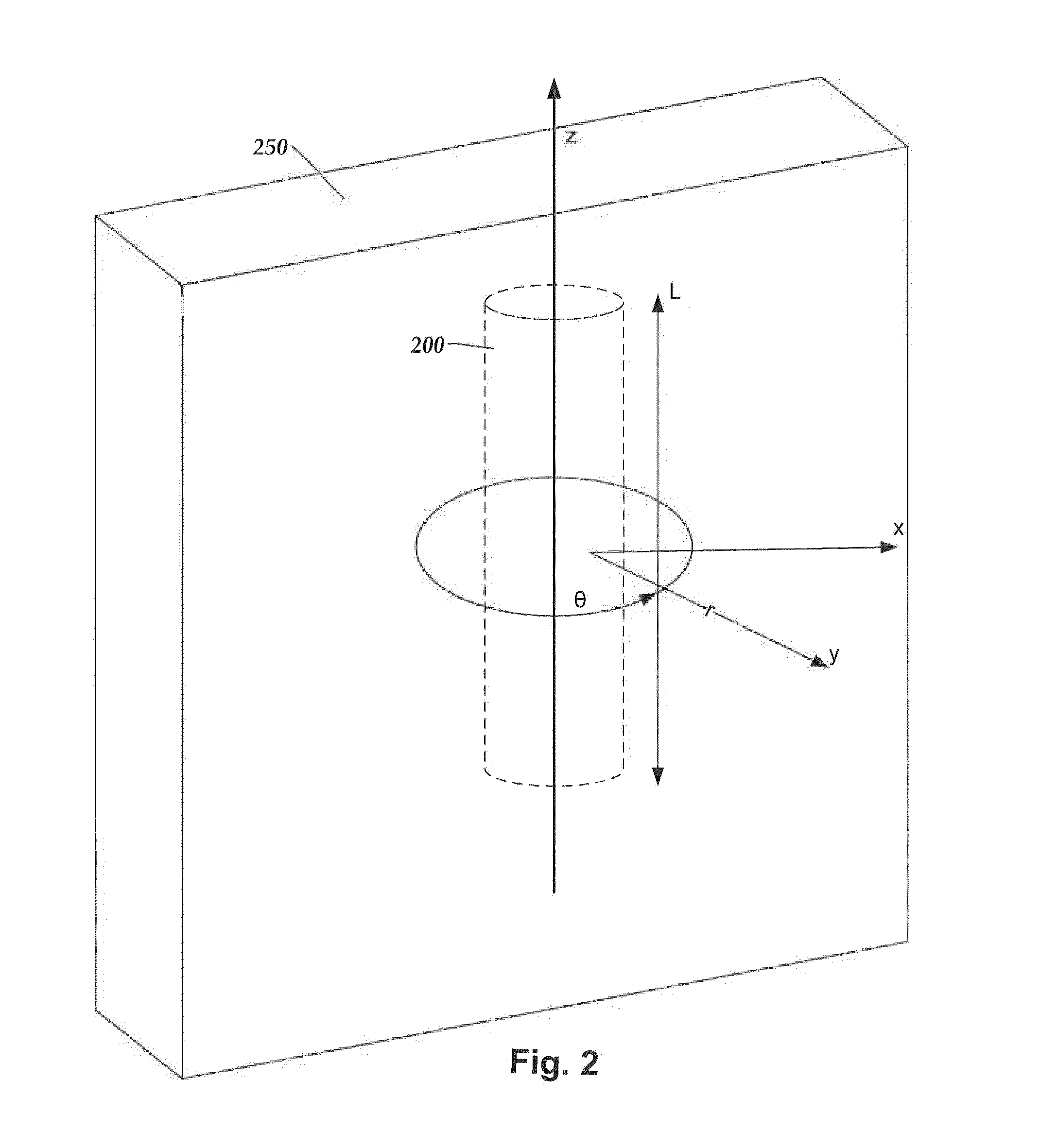

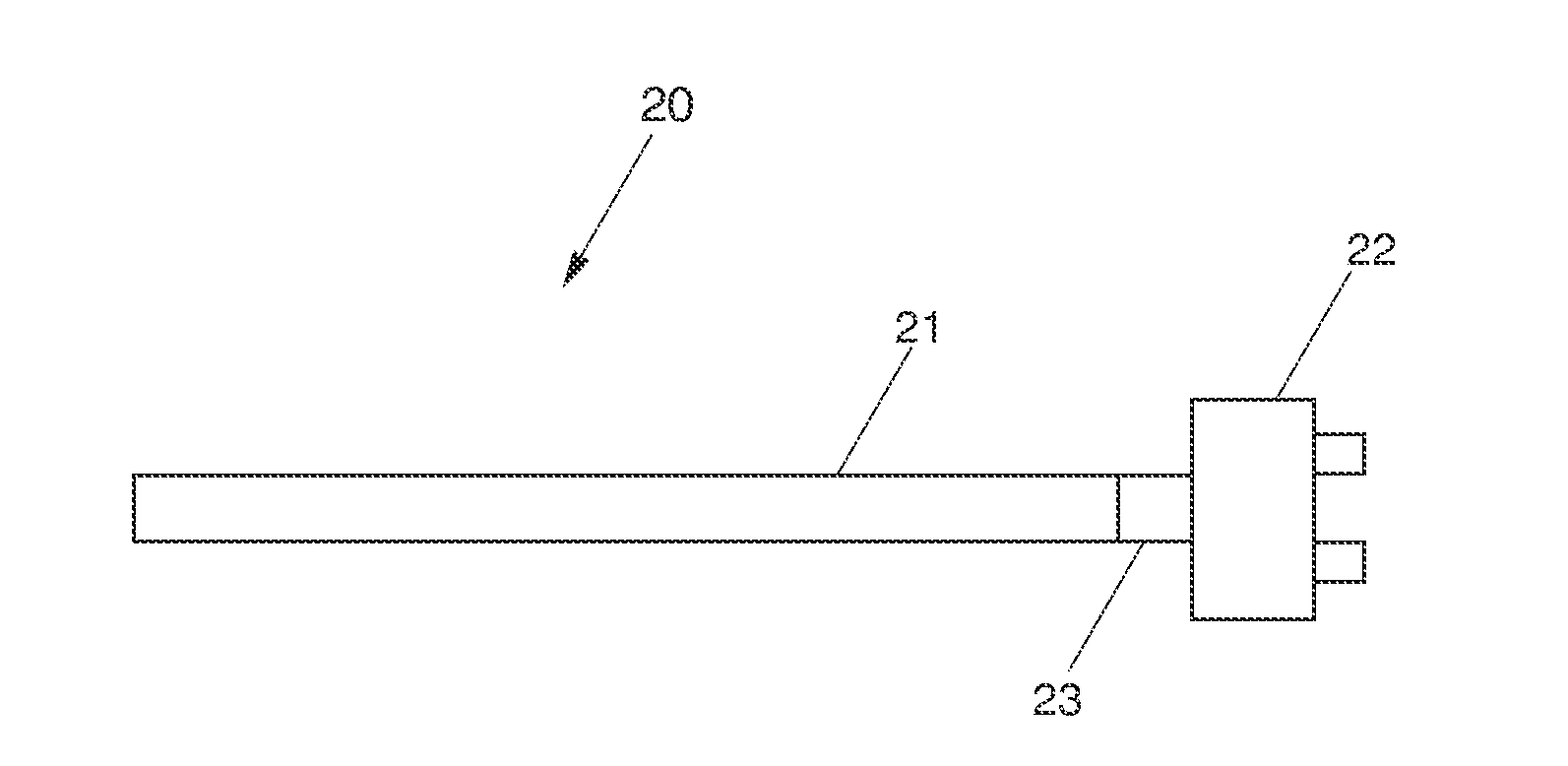

Leads containing segmented electrodes with non-perpendicular legs and methods of making and using

A method of making an electrical stimulation lead method includes attaching a pre-electrode to a lead body. The pre-electrode is a single, unitary, undifferentiated construct with a ring-shaped exterior. The method further includes attaching a plurality of conductor wires to the pre-electrode; and, after coupling to the lead body, removing an outer portion of the pre-electrode to separate remaining portions of the pre-electrode into a plurality of segmented electrodes spaced around the circumference of the lead body. When separated, each of the segmented electrodes includes a body and at least one leg extending inwardly from the body. The body defines an external stimulating surface and each of the at least one leg has an outer surface. For at least one of the at least one leg, the outer surface of the leg forms a non-perpendicular angle with the external stimulating surface of the body.

Owner:BOSTON SCI NEUROMODULATION CORP

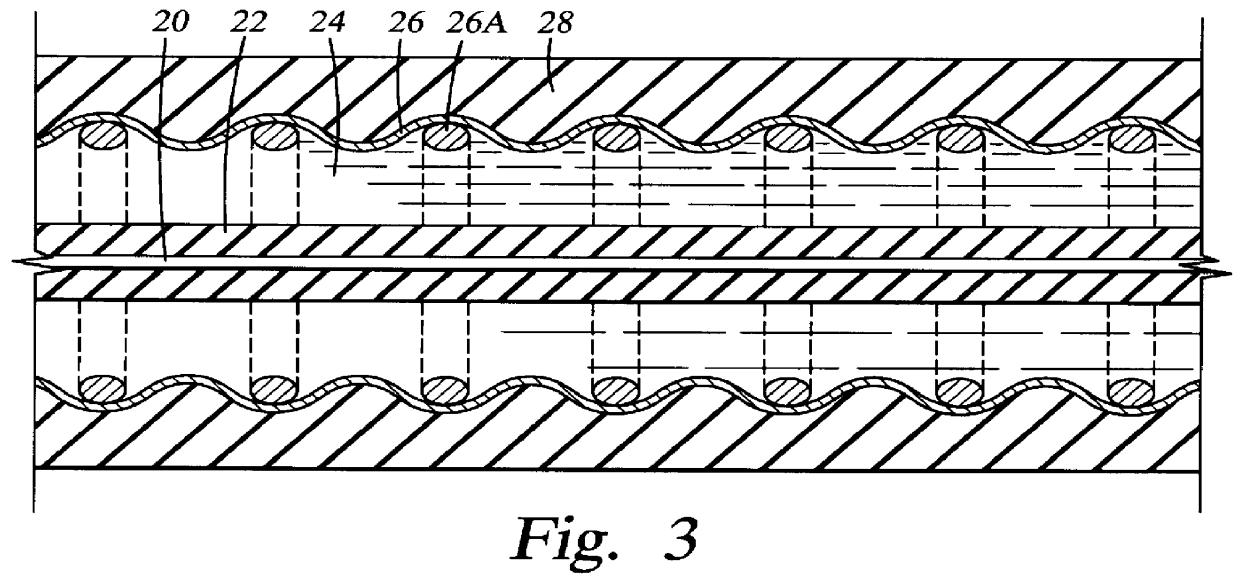

Fiber optic well logging cable

A well logging cable including an optical fiber and a pressure sealed enclosure surrounding the fiber. The enclosure is adapted to be able to be elongated to the maximum expected axial strain on the logging cable without permanent deformation. In one embodiment, the enclosure is a corrugated-wall tube surrounding the optical fiber. The tube contains toroidally shaped rings within the maximum diameter portions of the corrugations in the tube wall. The cable includes armor wires wound around the corrugated-wall tube. In the preferred embodiment, the tube is surrounded by an elastomeric jacket, and is filled with hydraulic oil or the like to prevent entry of wellbore fluids into the tube under hydrostatic pressure.

Owner:WESTERN ATLAS INTERNAIONAL INC

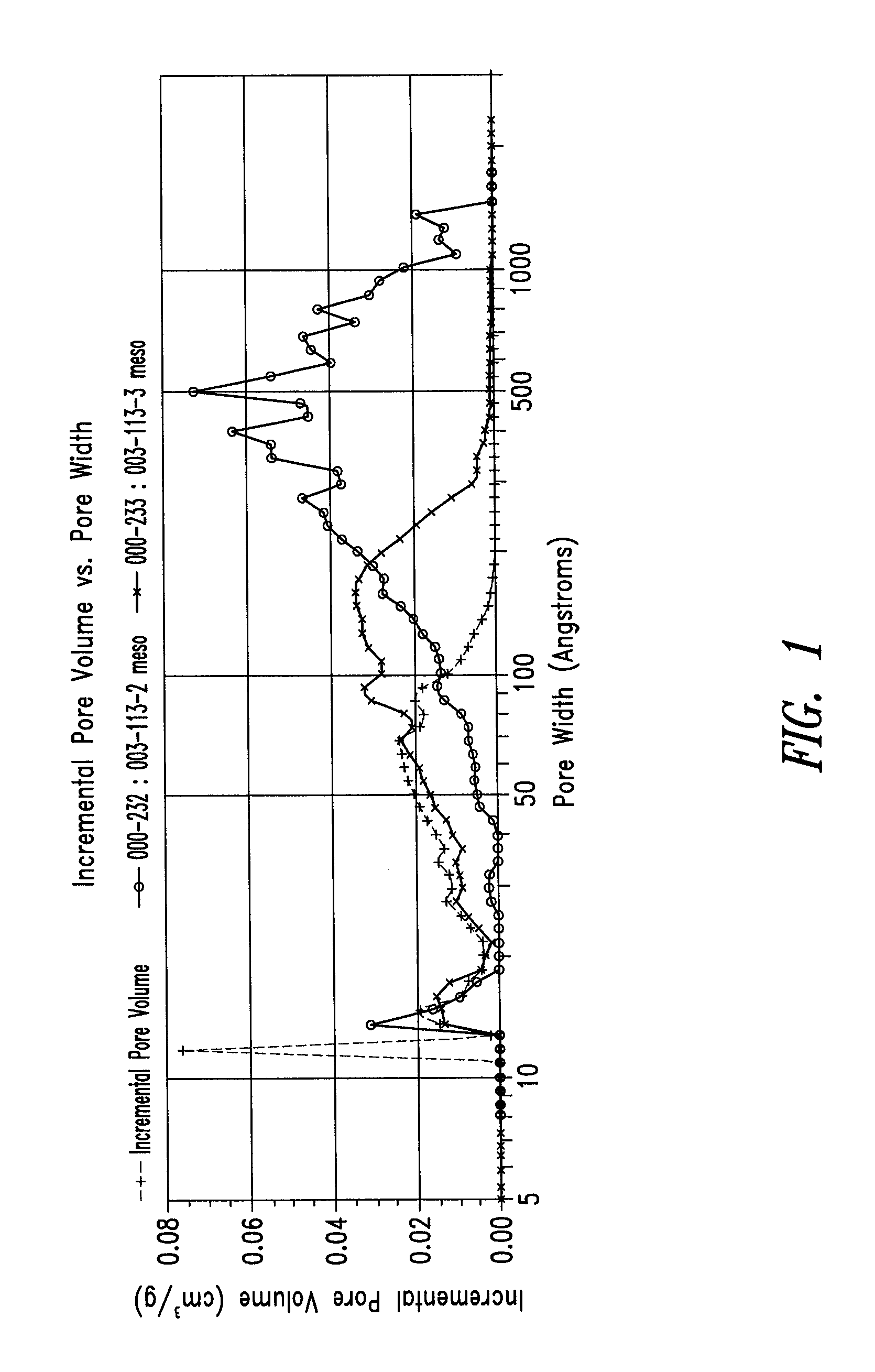

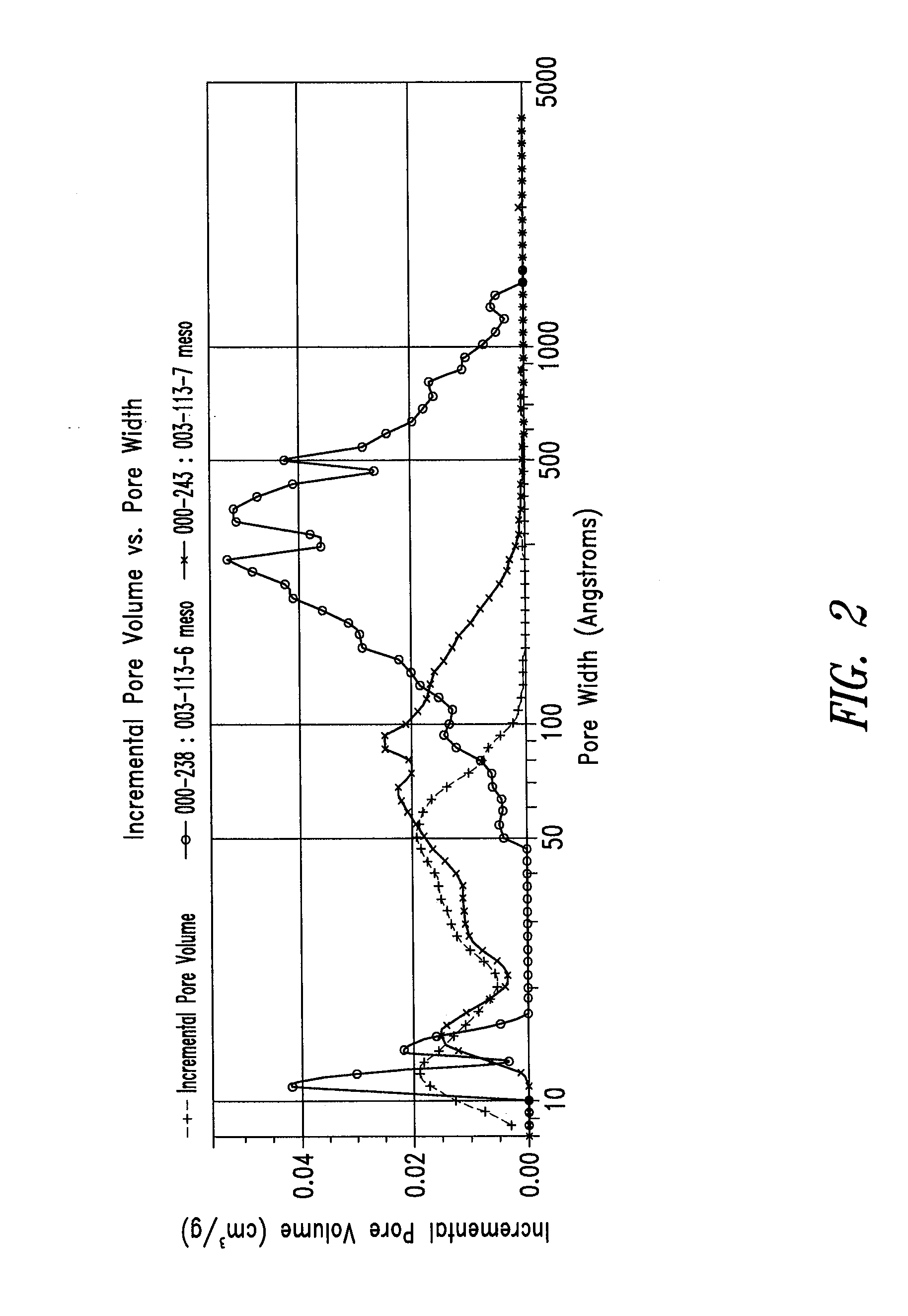

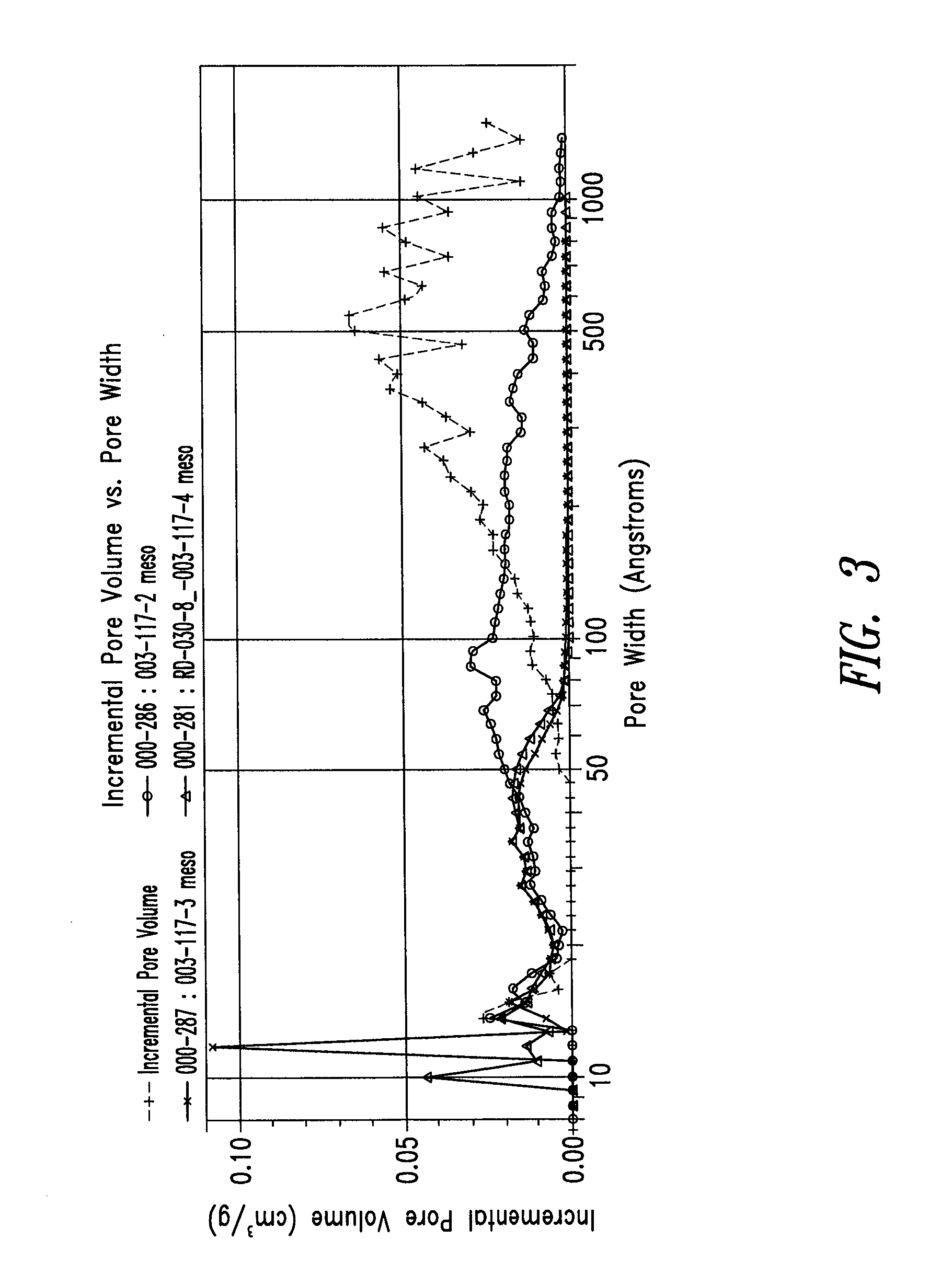

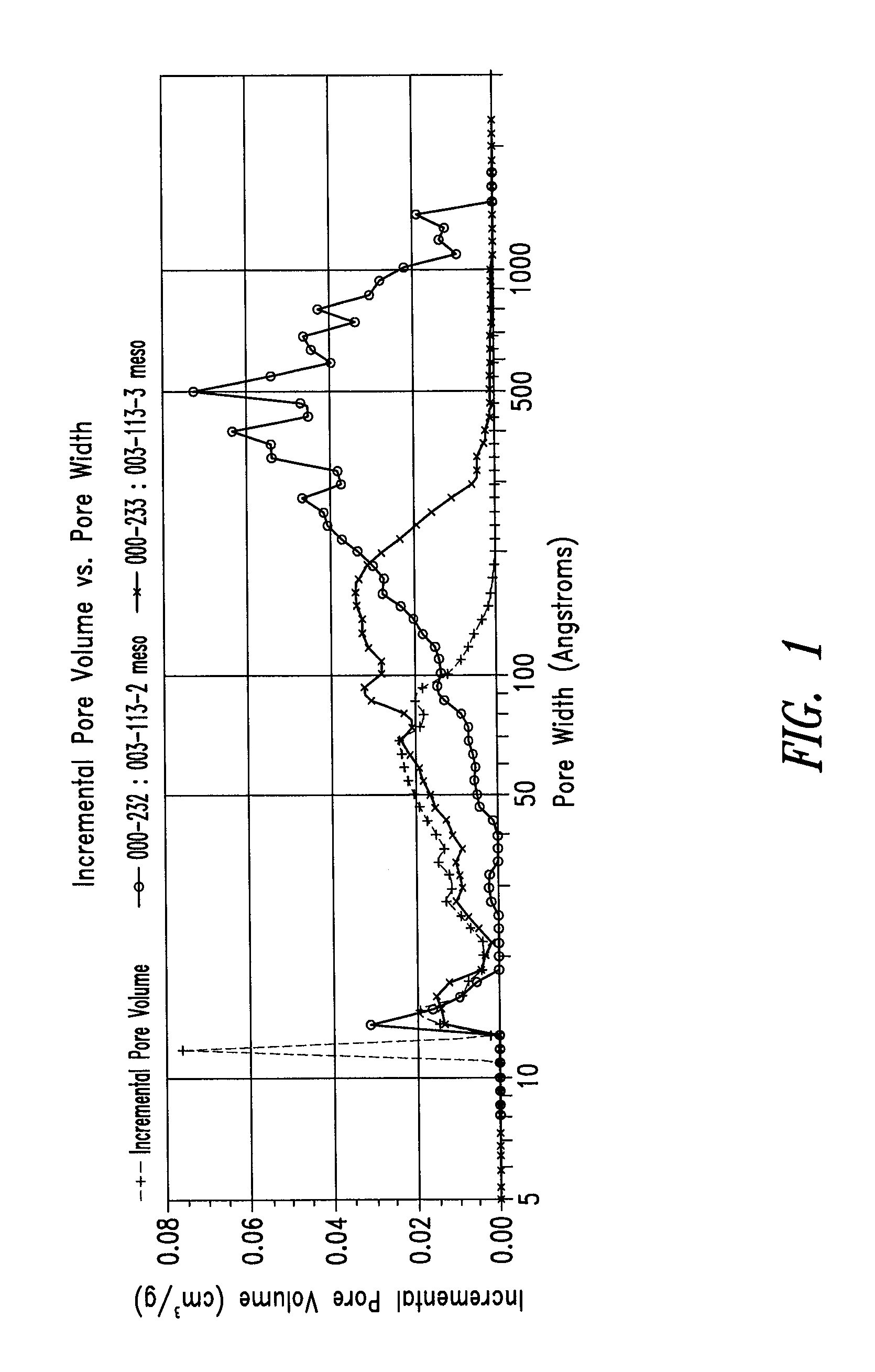

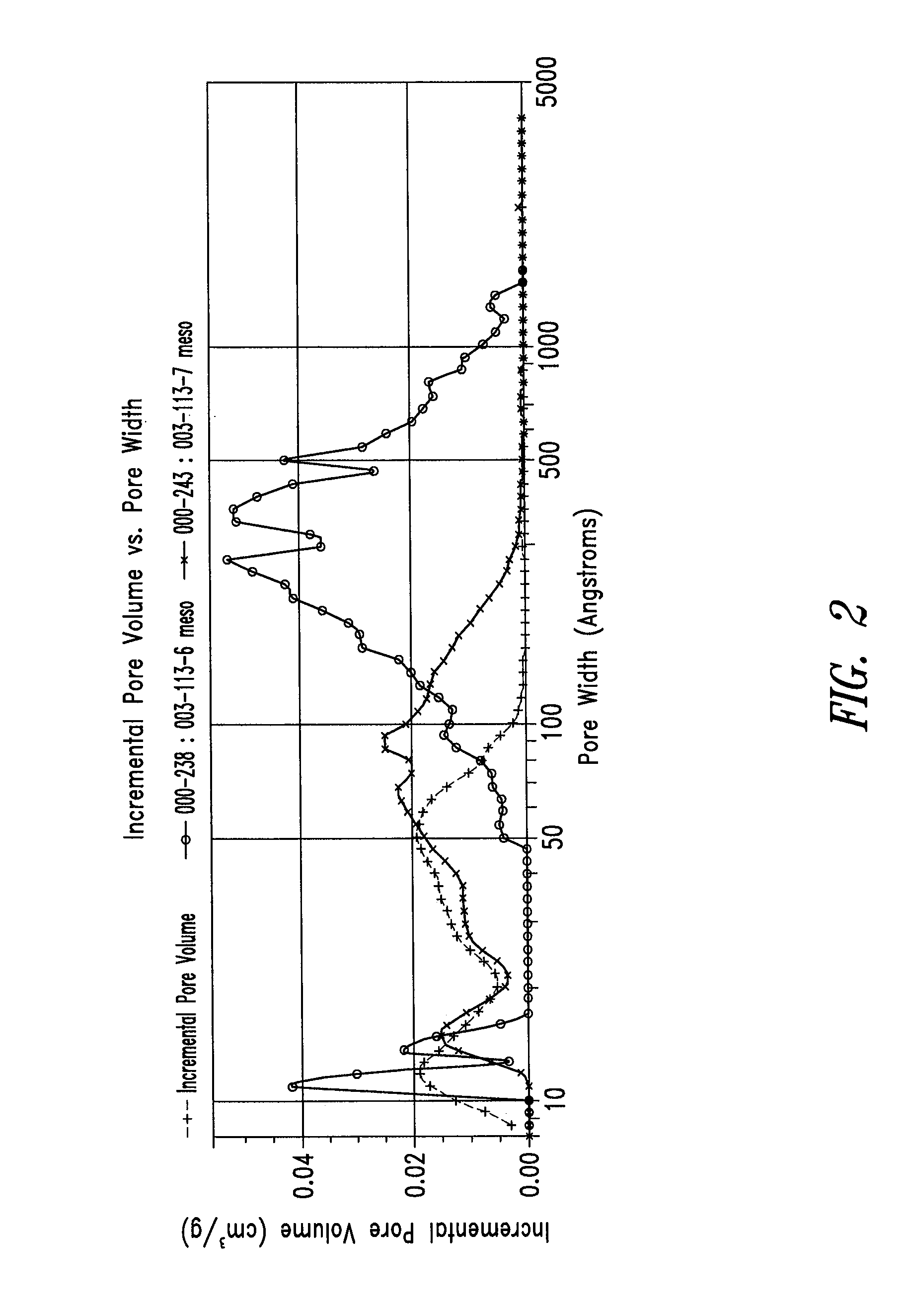

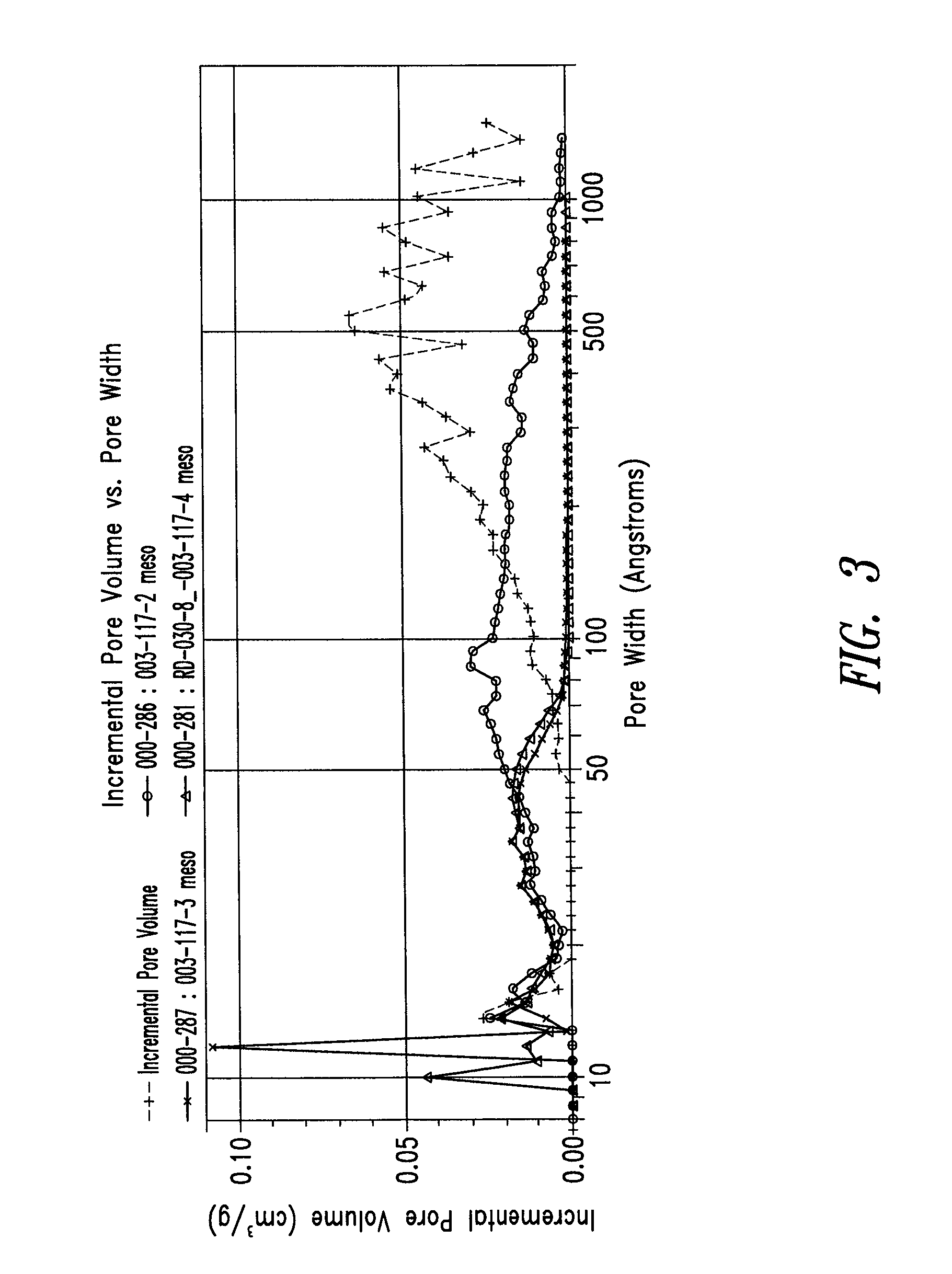

Ultrapure synthetic carbon materials

ActiveUS20110002086A1Short lifeEasy to operateNon-insulated conductorsElectrolytic capacitorsCapacitancePorosity

The present application is generally directed to ultrapure synthetic carbon materials having both high surface area and high porosity, ultrapure polymer gels and devices containing the same. The disclosed ultrapure synthetic carbon materials find utility in any number of devices, for example, in electric double layer capacitance devices and batteries. Methods for making ultrapure synthetic carbon materials and ultrapure polymer gels are also disclosed.

Owner:BASF AG

Ultrapure synthetic carbon materials

ActiveUS8404384B2Short lifeEasy to operateNon-insulated conductorsElectrolytic capacitorsPorosityPolymer science

The present application is generally directed to ultrapure synthetic carbon materials having both high surface area and high porosity, ultrapure polymer gels and devices containing the same. The disclosed ultrapure synthetic carbon materials find utility in any number of devices, for example, in electric double layer capacitance devices and batteries. Methods for making ultrapure synthetic carbon materials and ultrapure polymer gels are also disclosed.

Owner:BASF SE

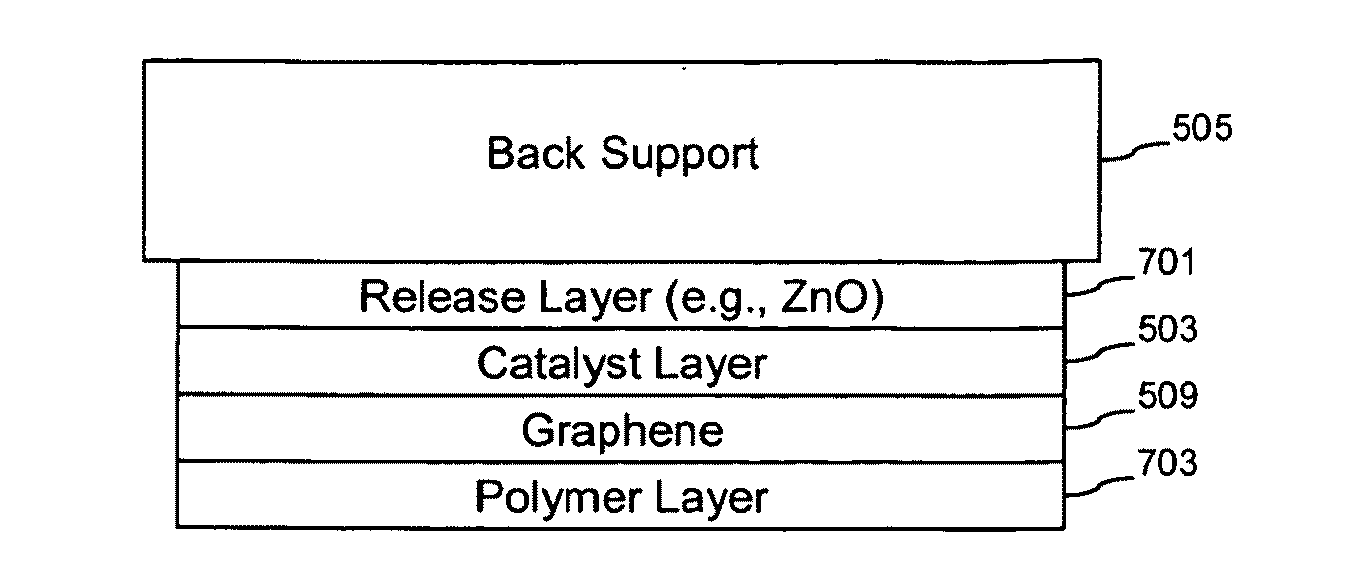

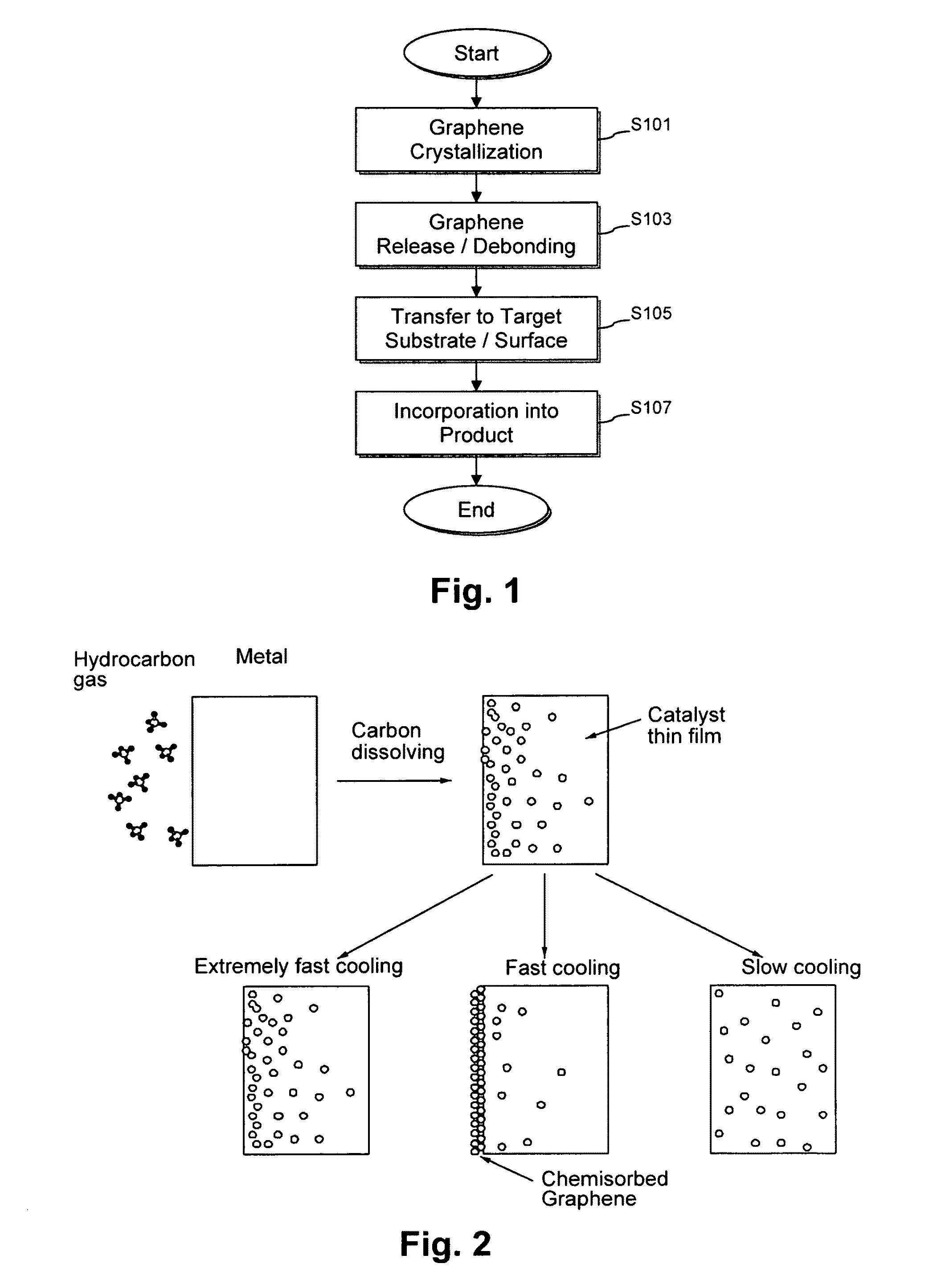

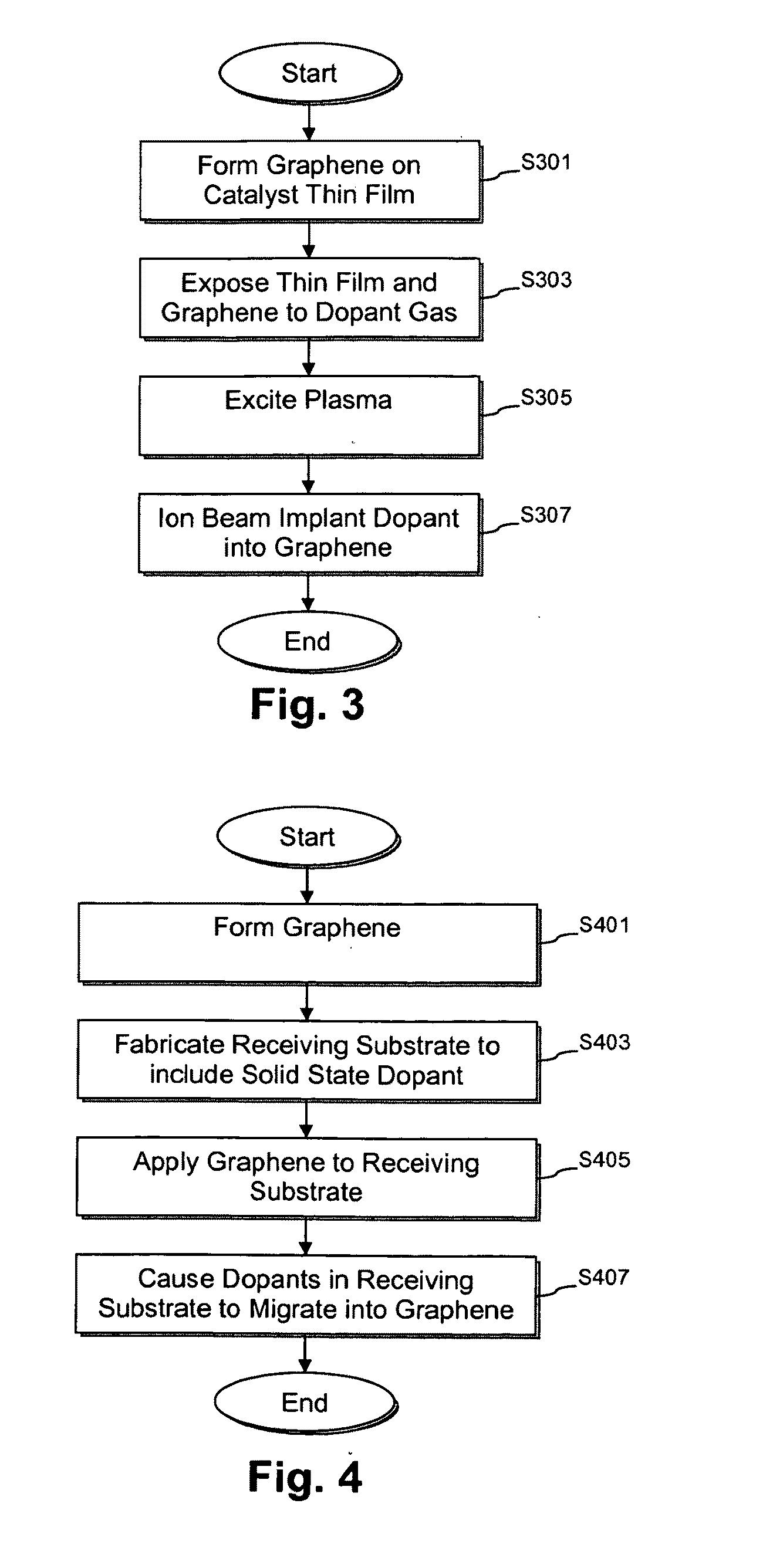

Large area deposition and doping of graphene, and products including the same

InactiveUS20110030991A1Reduced dimensionGood effectMaterial nanotechnologyNon-insulated conductorsConductive coatingTransmittance

Certain example embodiments of this invention relate to the use of graphene as a transparent conductive coating (TCC). In certain example embodiments, graphene thin films grown on large areas hetero-epitaxially, e.g., on a catalyst thin film, from a hydrocarbon gas (such as, for example, C2H2, CH4, or the like). The graphene thin films of certain example embodiments may be doped or undoped. In certain example embodiments, graphene thin films, once formed, may be lifted off of their carrier substrates and transferred to receiving substrates, e.g., for inclusion in an intermediate or final product. Graphene grown, lifted, and transferred in this way may exhibit low sheet resistances (e.g., less than 150 ohms / square and lower when doped) and high transmission values (e.g., at least in the visible and infrared spectra).

Owner:GUARDIAN GLASS LLC

Etch patterning of nanostructure transparent conductors

Owner:CHAMP GREAT INTL

Metal nanowires, method for producing the same, and transparent conductor

InactiveUS20100078197A1Increased durabilityTransparencyMaterial nanotechnologyNon-insulated conductorsMetal particleNanometre

Owner:FUJIFILM CORP

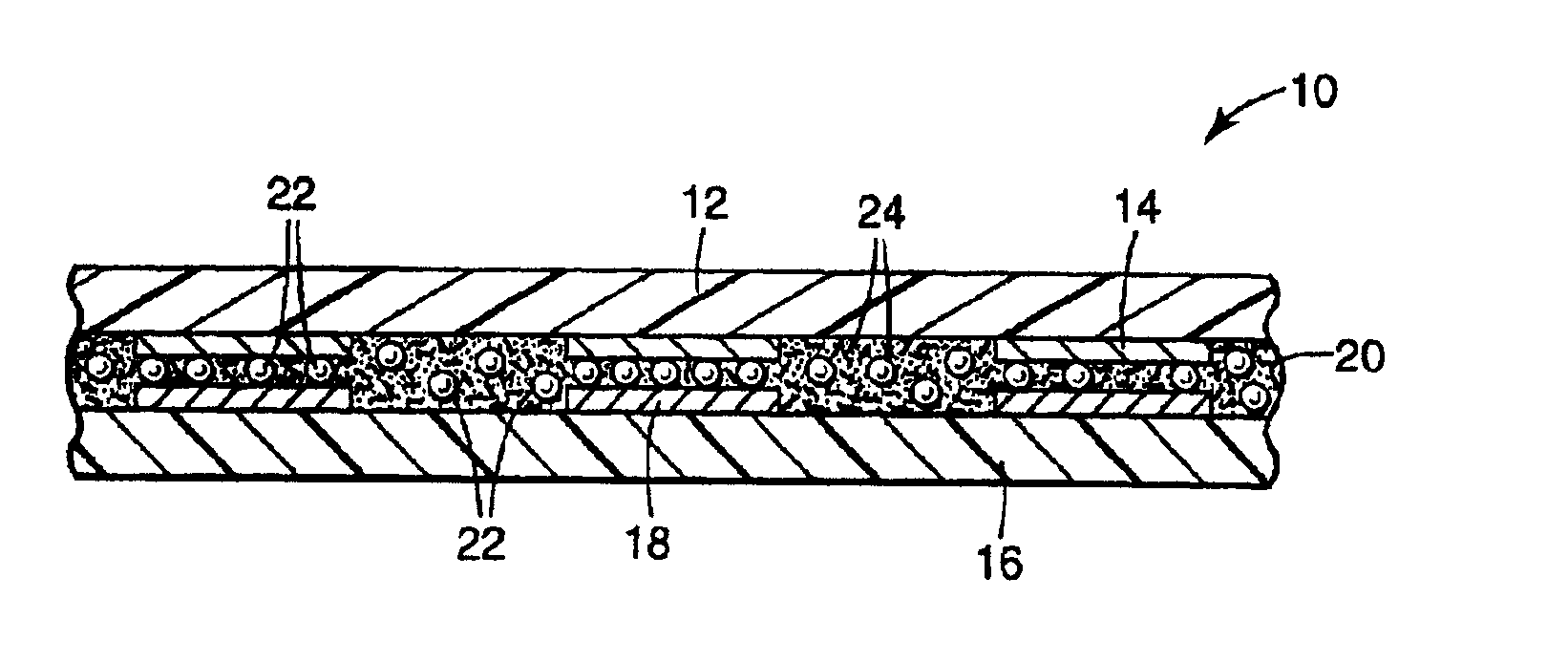

Curing resin composition, adhesive epoxy resin paste, adhesive epoxy resin sheet, conductive connection paste, conductive connection sheet, and electronic component joined body

ActiveUS20060154078A1Adhesion reliability is highIncrease flexibilityNon-insulated conductorsSynthetic resin layered productsEpoxyHeat resistance

It is an object of the invention to provide a curable resin composition excellent in mechanical strength, heat resistance, moisture resistance, flexibility, resistance to thermal cycles, resistance to solder reflow, dimensional stability, and the like after curing and providing high adhesion reliability and conduction reliability and an adhesive epoxy resin paste, an adhesive epoxy resin sheet, a conductive connection paste, and a conductive connection sheet using the curable resin composition, and an electronic component joined body. The invention relates to a curable resin composition, which contains an epoxy resin, a solid polymer having a functional group to react with the epoxy group and a curing agent for an epoxy resin, no phase separation structure being observed in a matrix of a resin when a cured product is dyed with a heavy metal and observed with a transmission electron microscope.

Owner:SEKISUI CHEM CO LTD

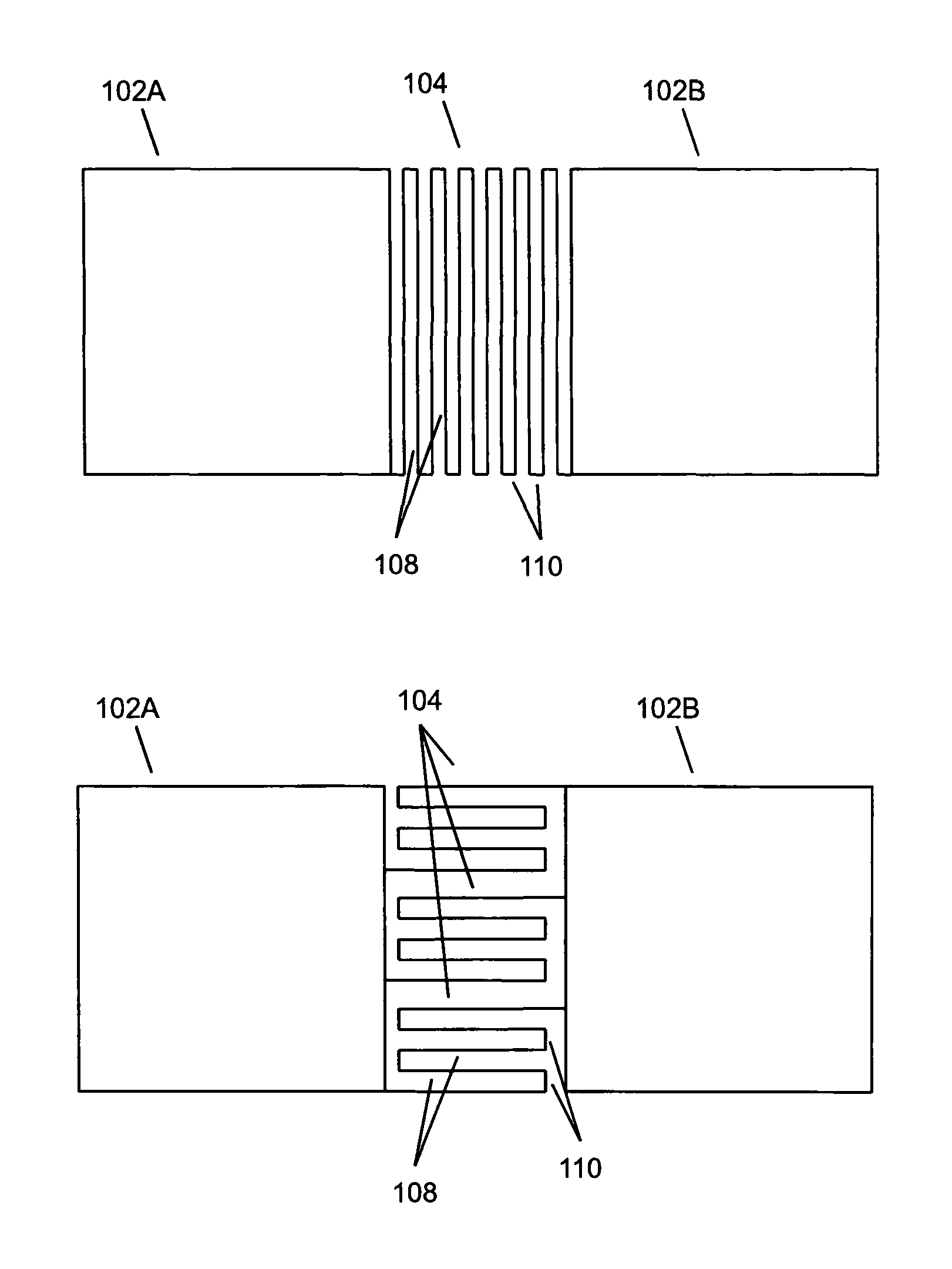

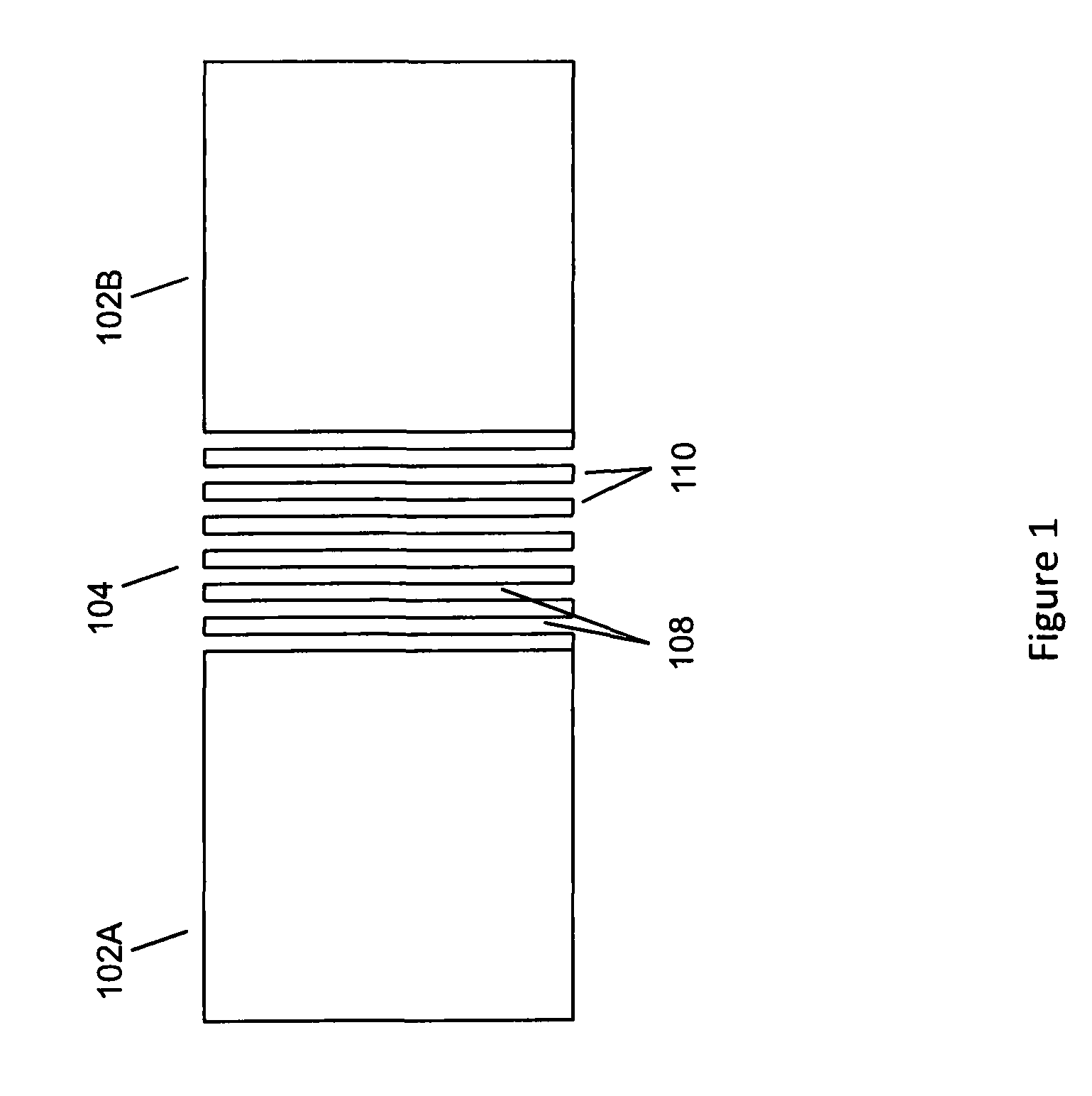

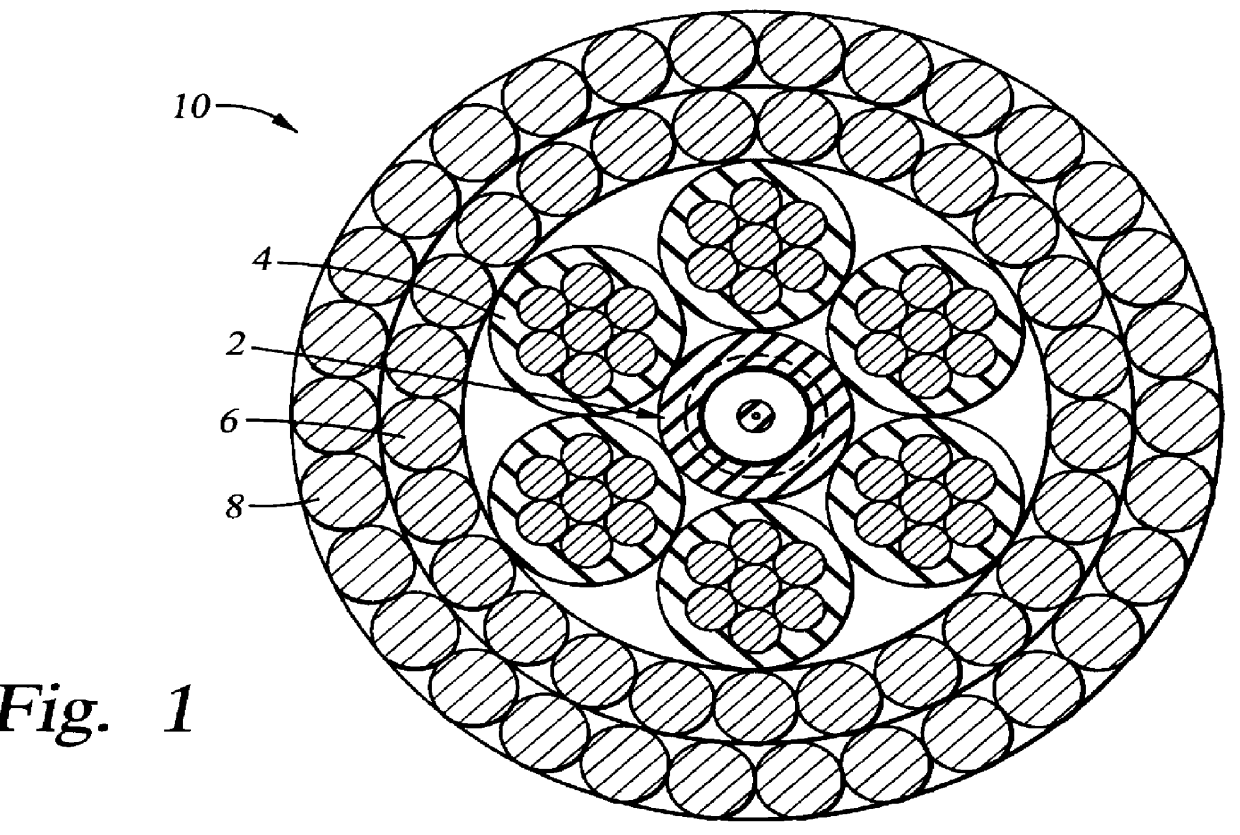

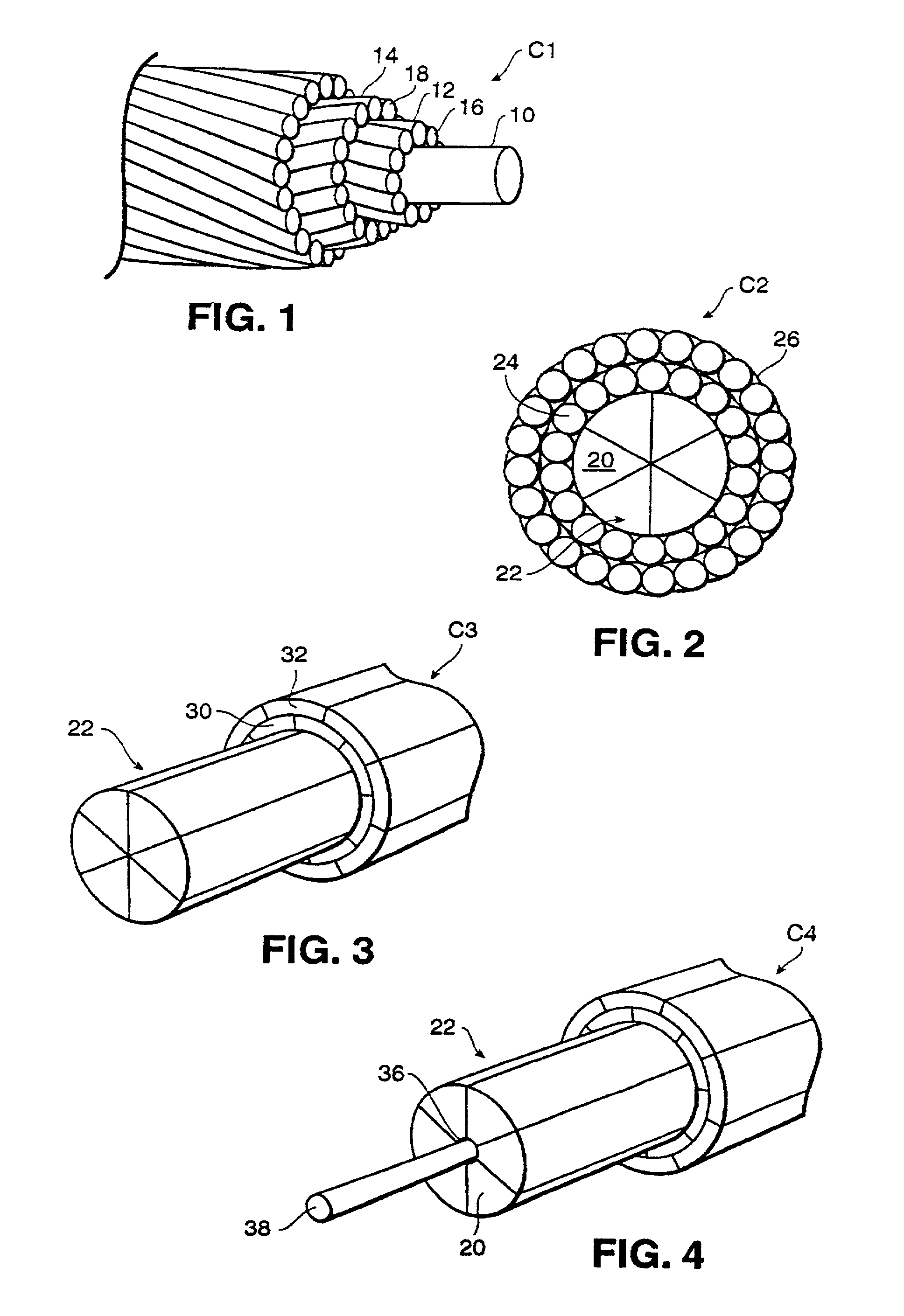

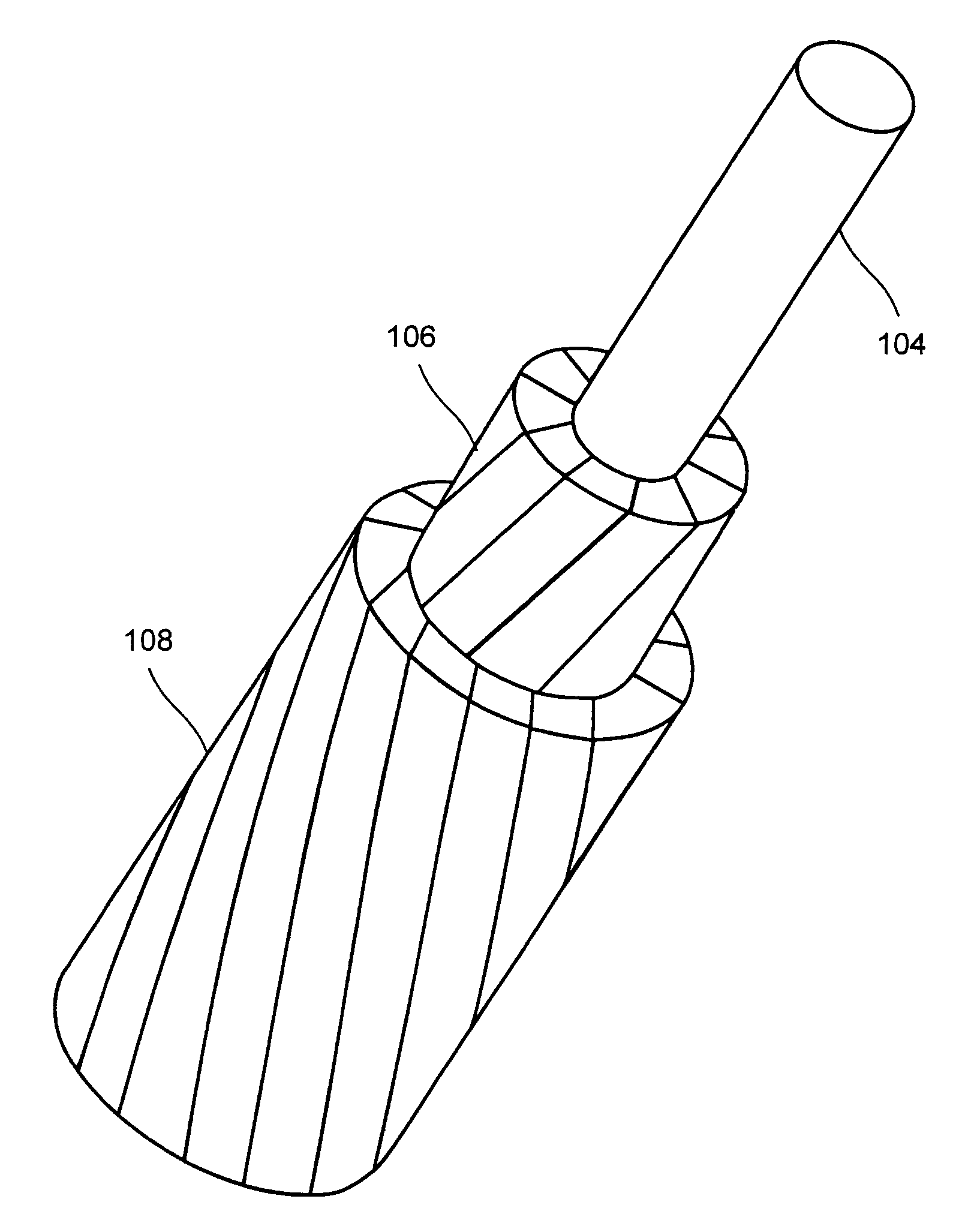

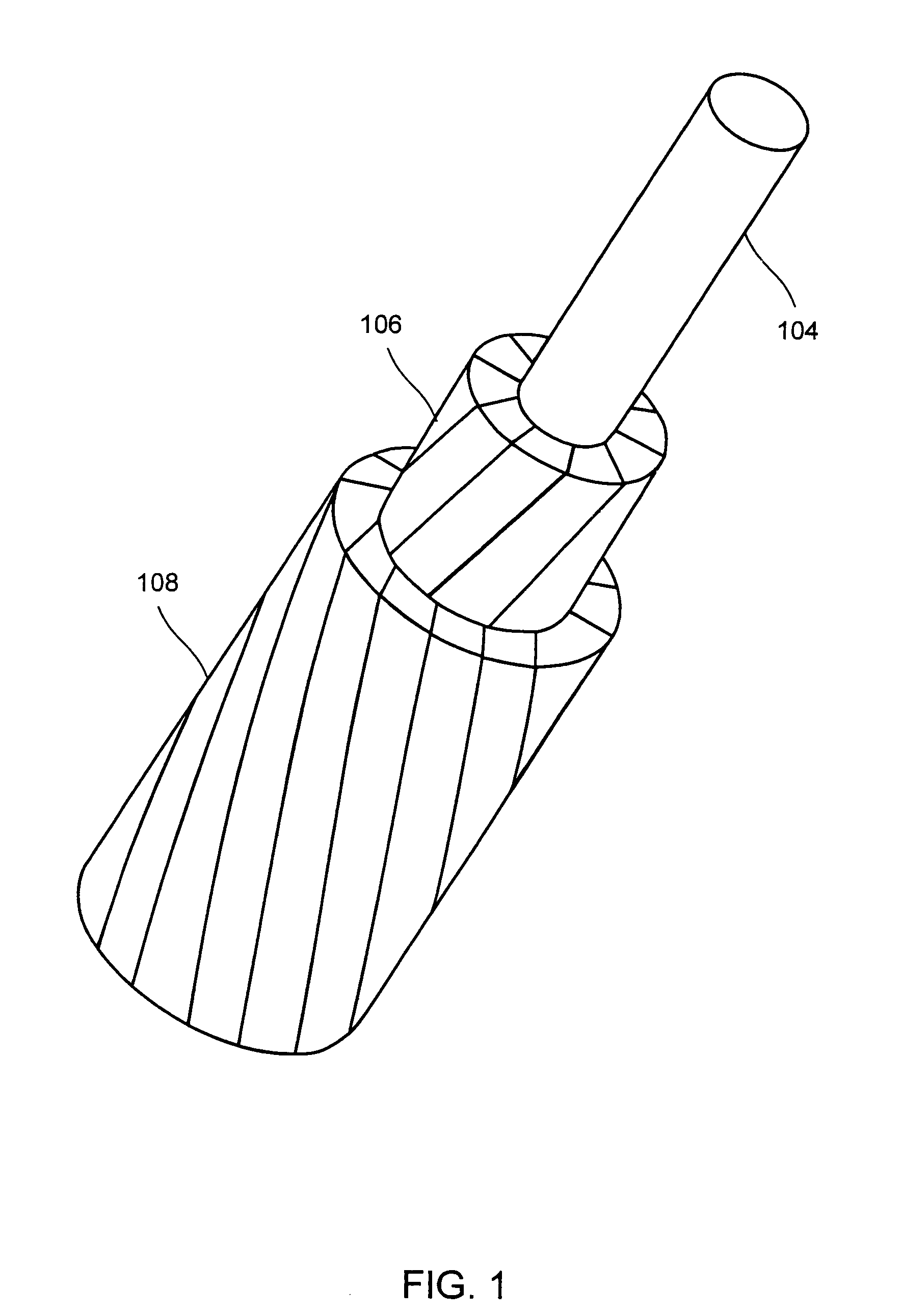

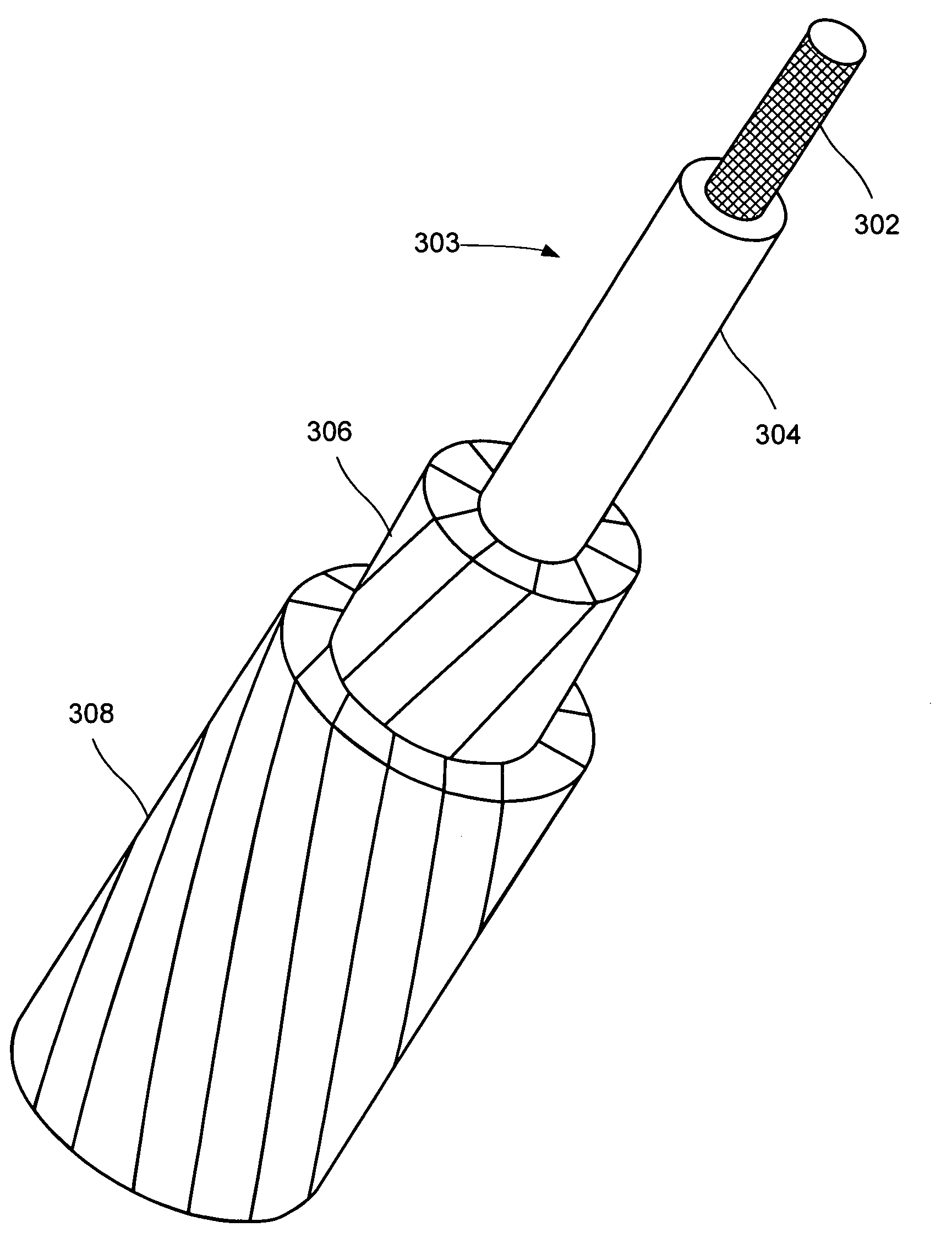

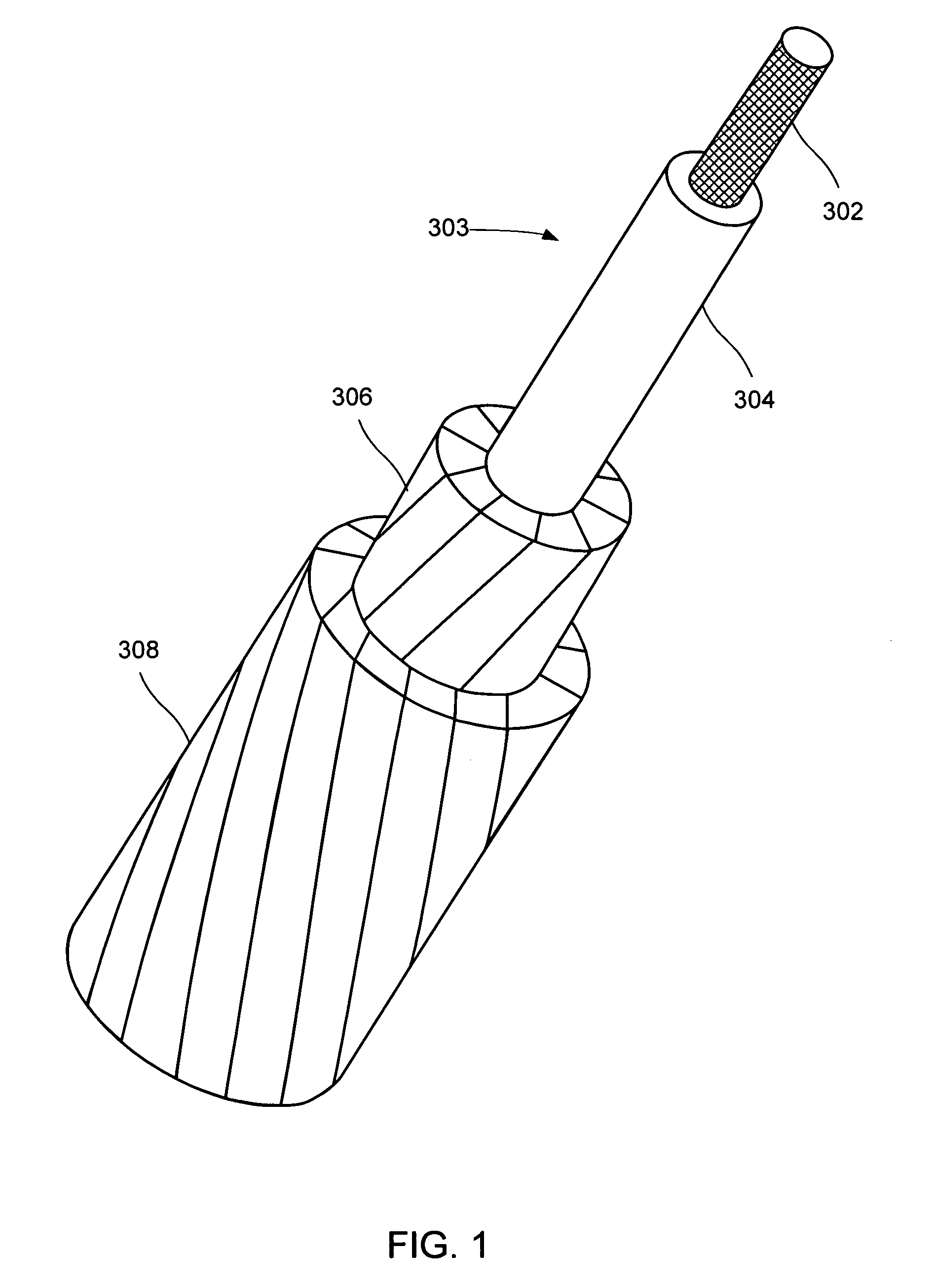

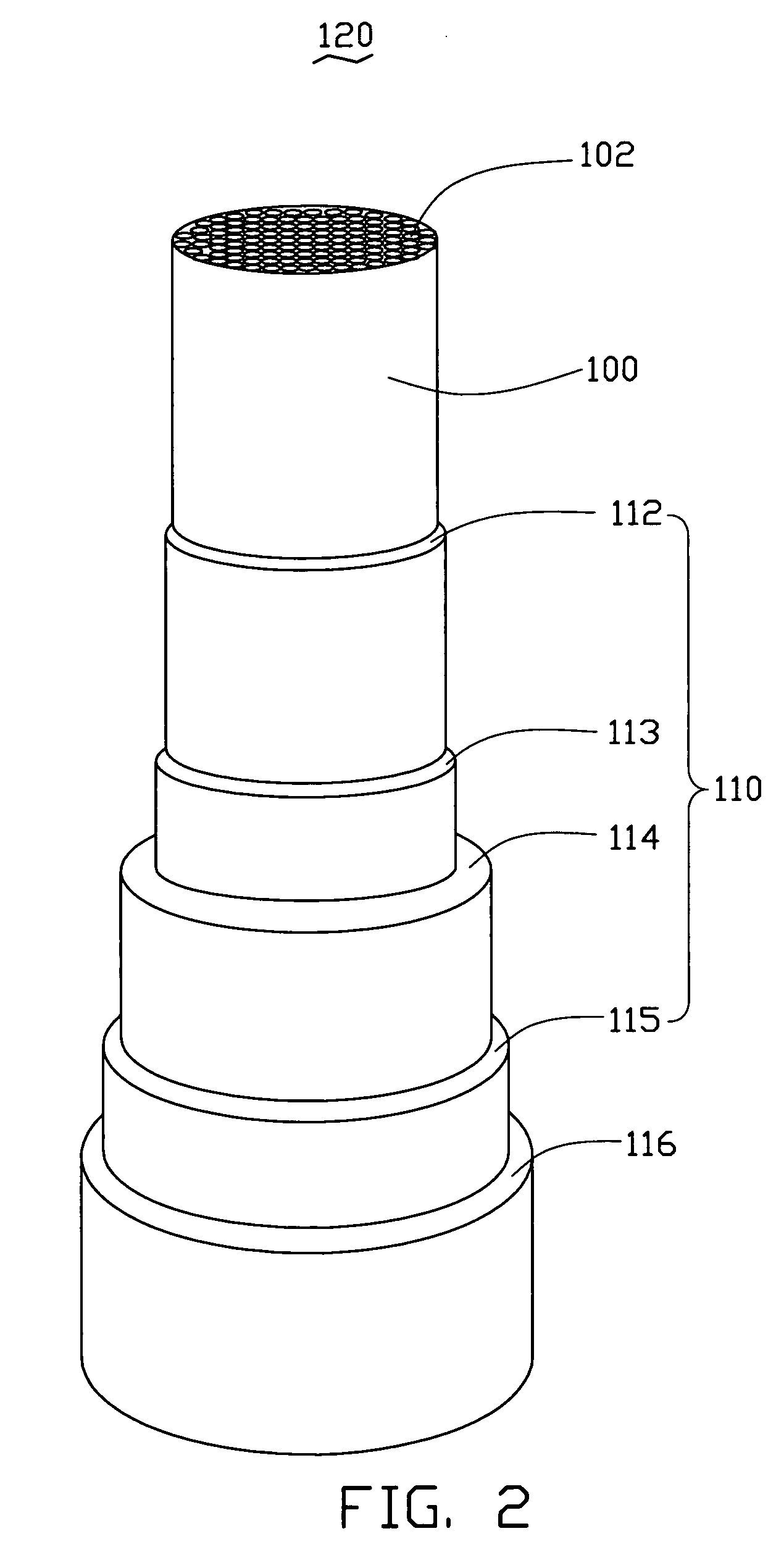

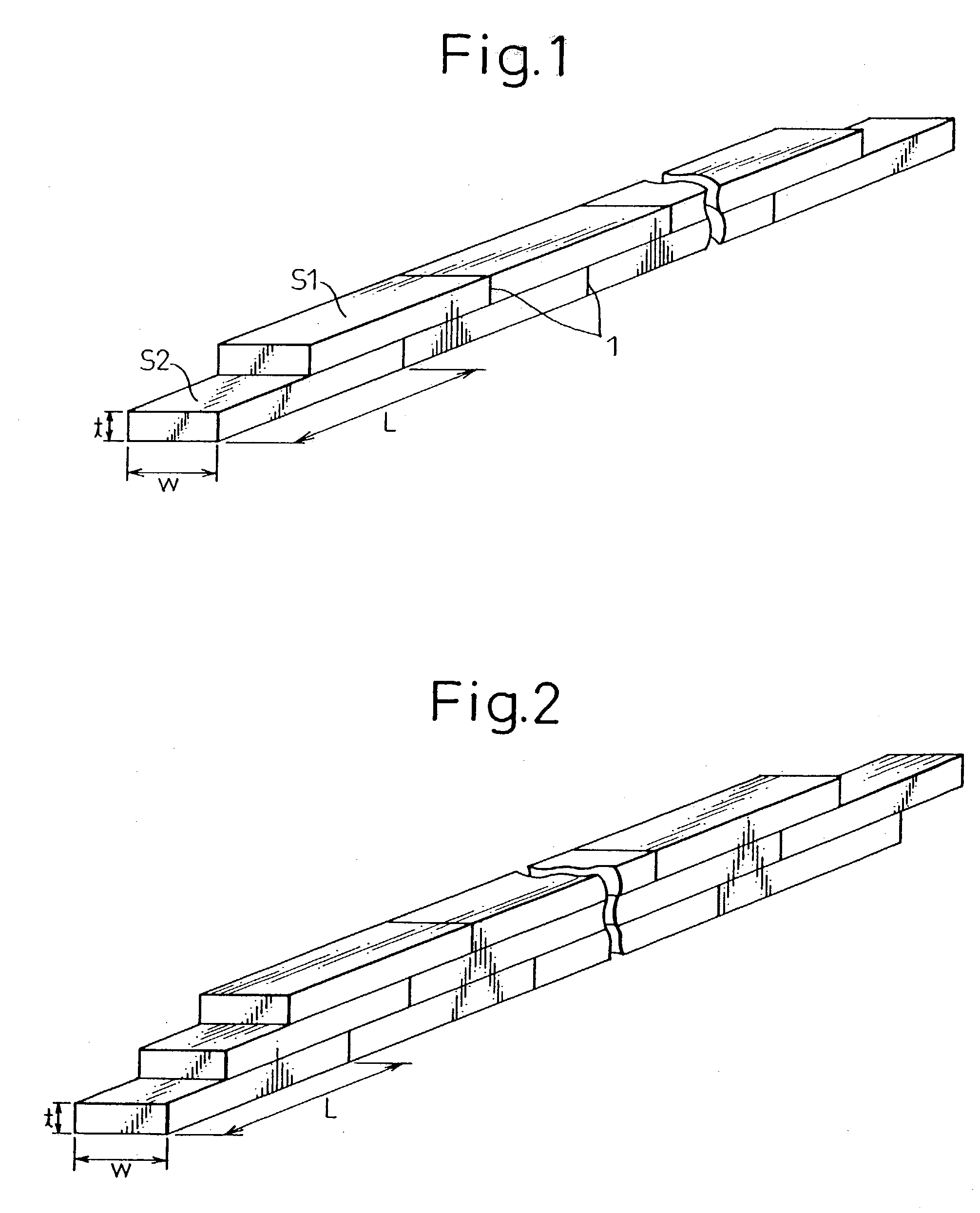

Composite reinforced electrical transmission conductor

InactiveUS7015395B2Avoid excessive labor intensityLow costNon-insulated conductorsPower cables with screens/conductive layersFiberElectrical conductor

A composite reinforced electrical transmission conductor primarily designed for transmission of electrical signals. The conductor is comprised of a reinforced plastic composite inner core along with an outer highly electrically conductive sheath therearound. In this way, the inner core provides the necessary strength and the outer sheath provides for transmission of the electrical signals. In a preferred embodiment, the reinforced composite core is comprised of individual sections which cooperate together to provide the necessary loading capabilities. Further, a fiber optic cable may also be carried by the composite reinforced core. A splicing arrangement for securing ends of the cable together is also provided.

Owner:GIFT TECH LP

Devices, compositions, and methods incorporating adhesives whose performance is enhanced by organophilic clay constituents

InactiveUS6884833B2Faster build-upImprove adhesionPrinted circuit assemblingNon-insulated conductorsOrganoclayHot melt

Incorporating organophilic clay into hot melt adhesive compositions, particularly those comprising semi-crystalline, thermoplastic polymers, greatly improves the adhesive properties in many respects. Some of these improvements are particularly beneficial to the specific use of hot melt adhesives filled with electrically conductive particles for use as electrically conductive adhesives.

Owner:3M INNOVATIVE PROPERTIES CO

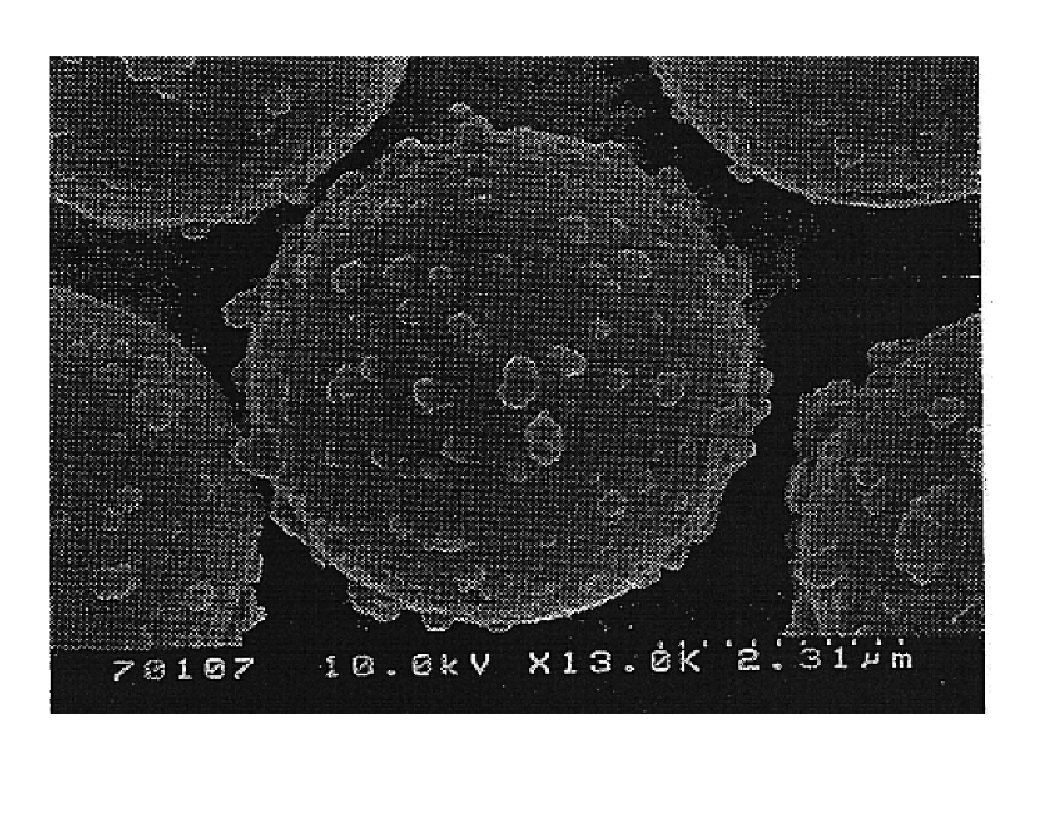

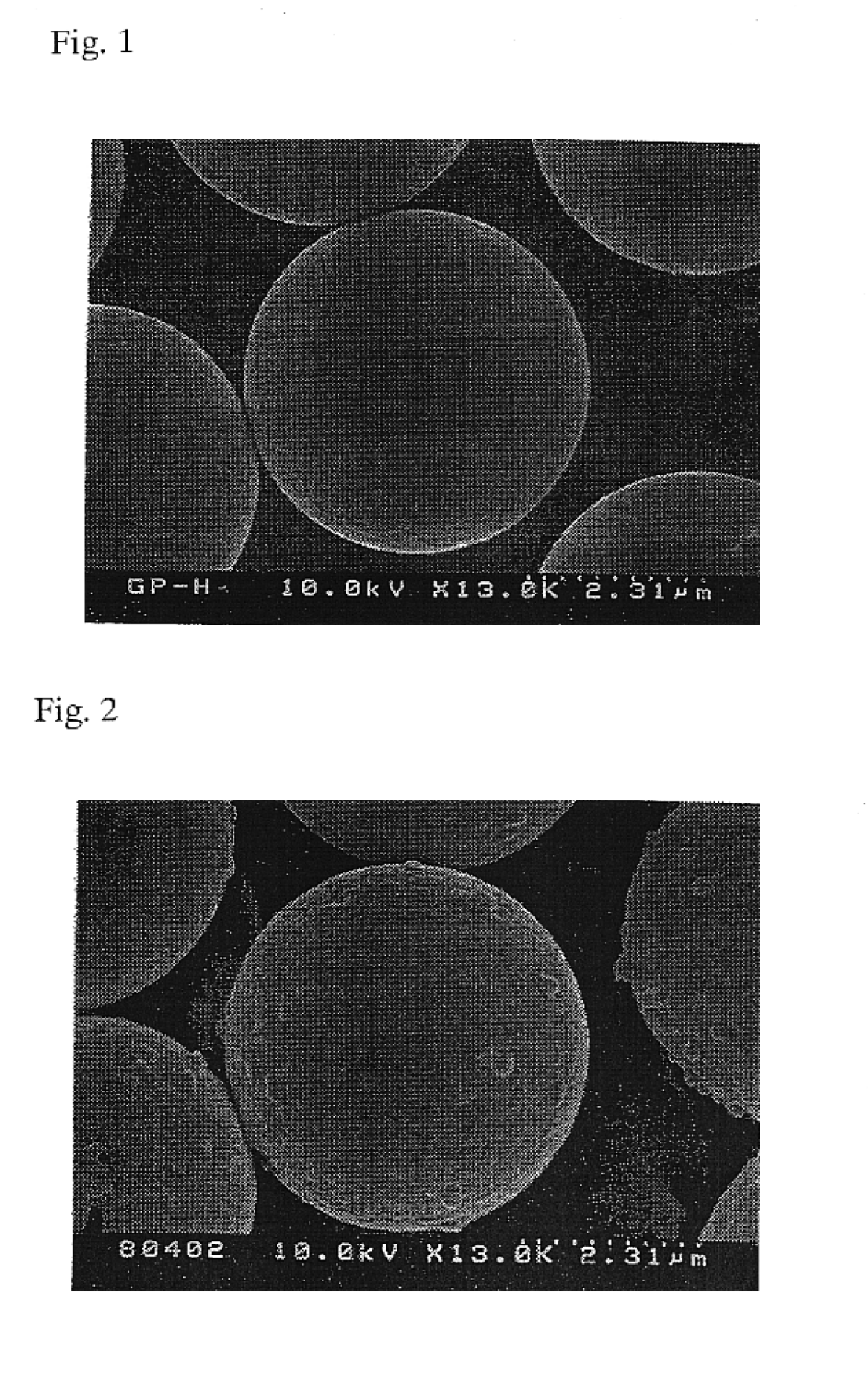

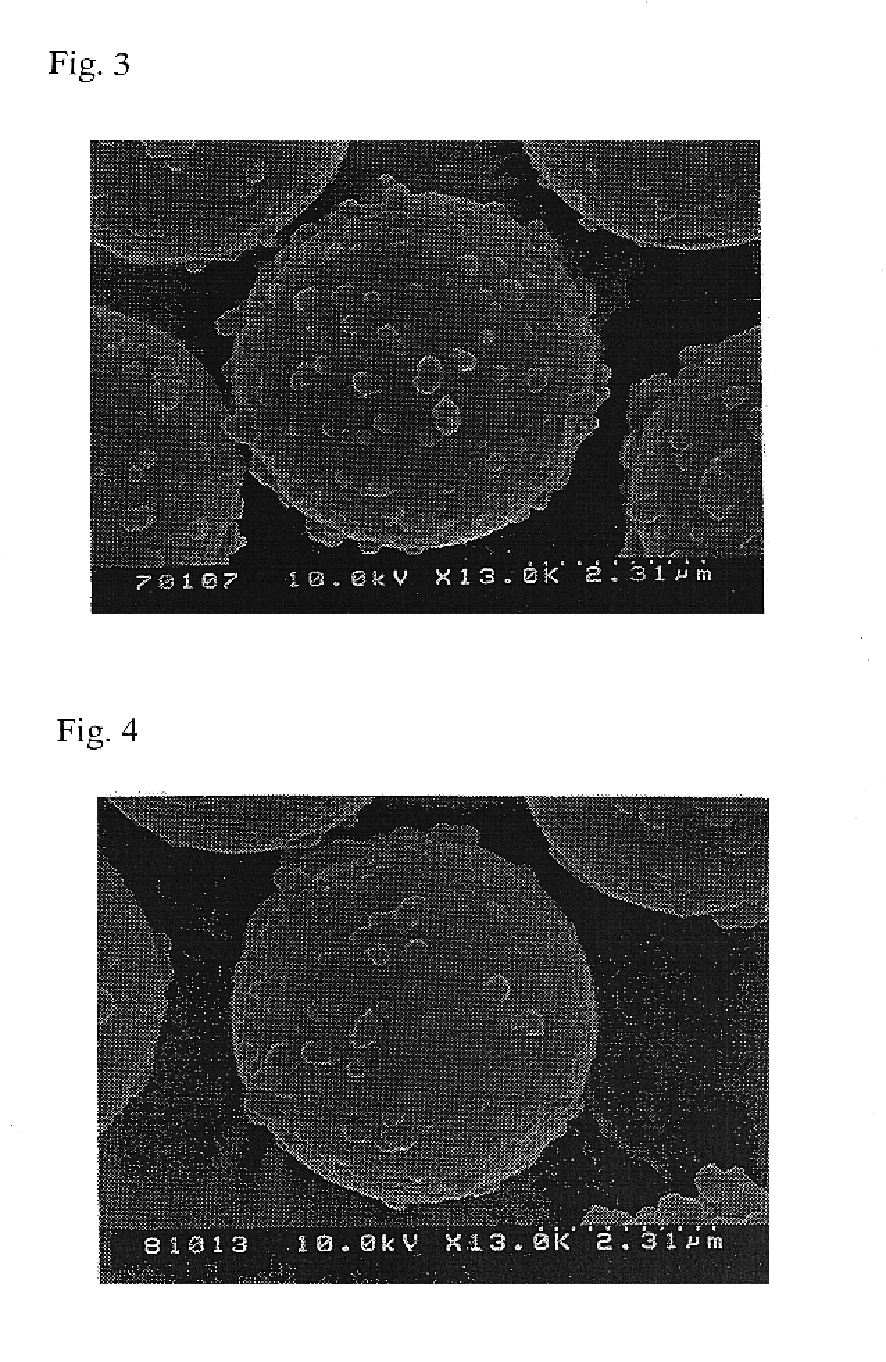

Conductive electrolessly plated powder, its producing method, and conductive material containing the plated powder

A conductive electrolessly plated powder used, for example, for bonding a small electrode of an electronic device, its producing method, and a conductive material containing the plated powder. Conventionally, there has been known, as conductive powders, metallic powders such as of nickel, carbon powders, and conductive plating powders the resin core particles of which are coated with a metal, e.g., nickel. However, there has been no conductive electrolessly plated powders having a good conductivity with respect to connection between conductive patterns having an oxide coating thereon or between electrodes and no methods for producing such powders industrially. The conductive electrolessly plated powder of the present invention consists of resin spherical core particles the average size of which is 1 to 20 mum and each of which has a nickel or nickel alloy coating formed by electroless plating. The coating includes small projections of 0.05 to 4 mum on its outermost layer and the coating is substantially continuous with the small projections. A method of producing such a powder is also disclosed.

Owner:NIPPON CHECMICAL IND CO LTD

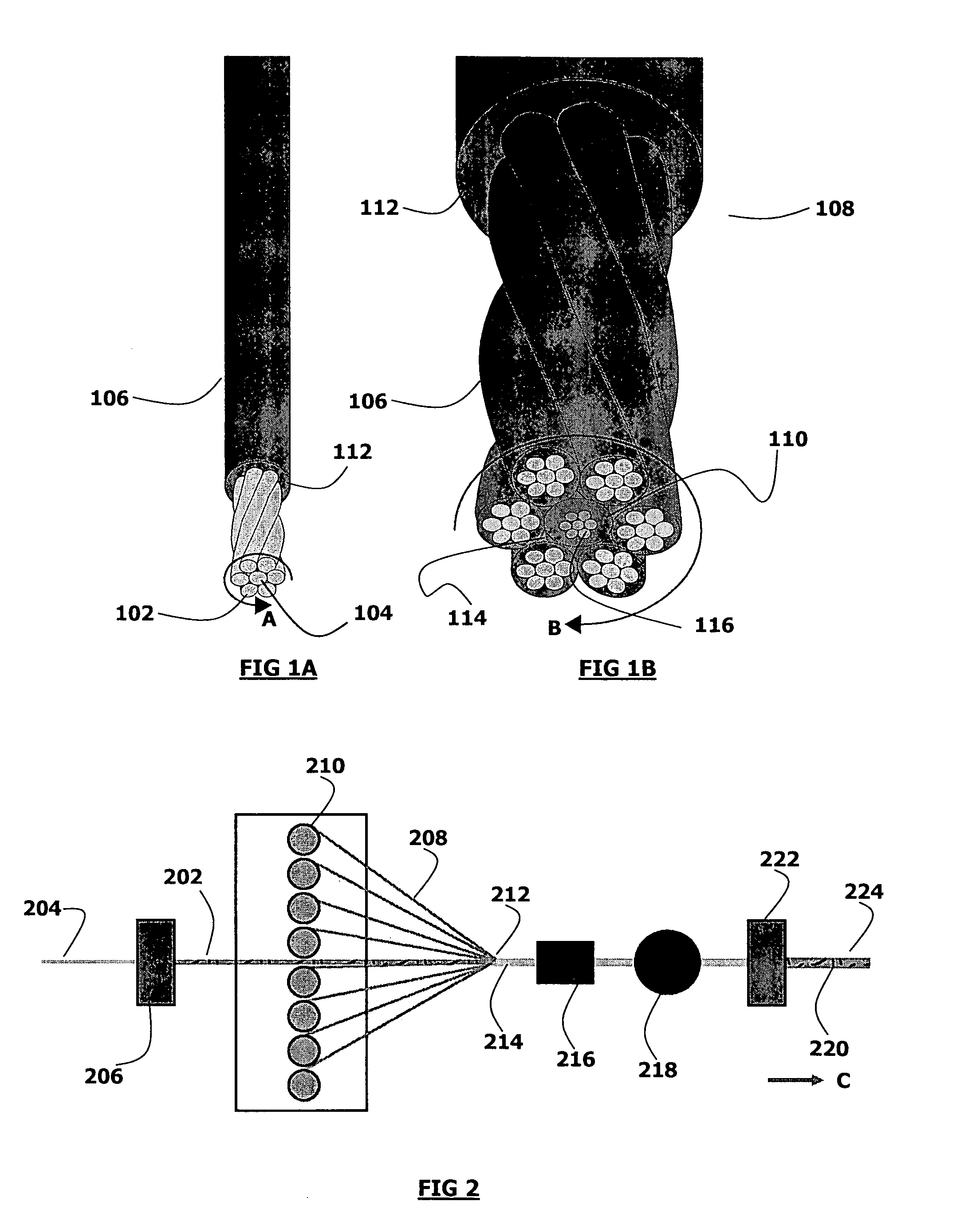

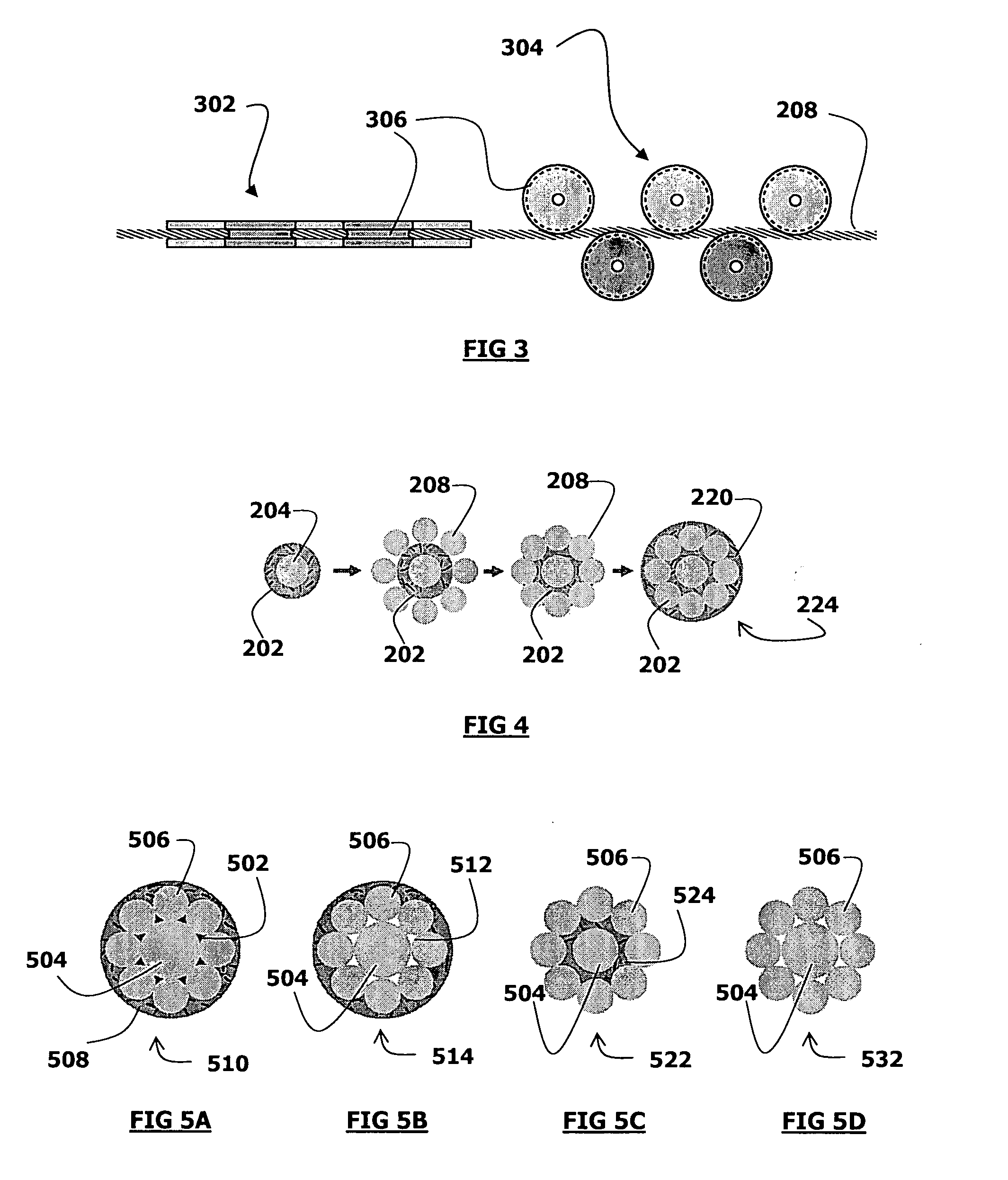

Hybrid Conductors and Method of Making Same

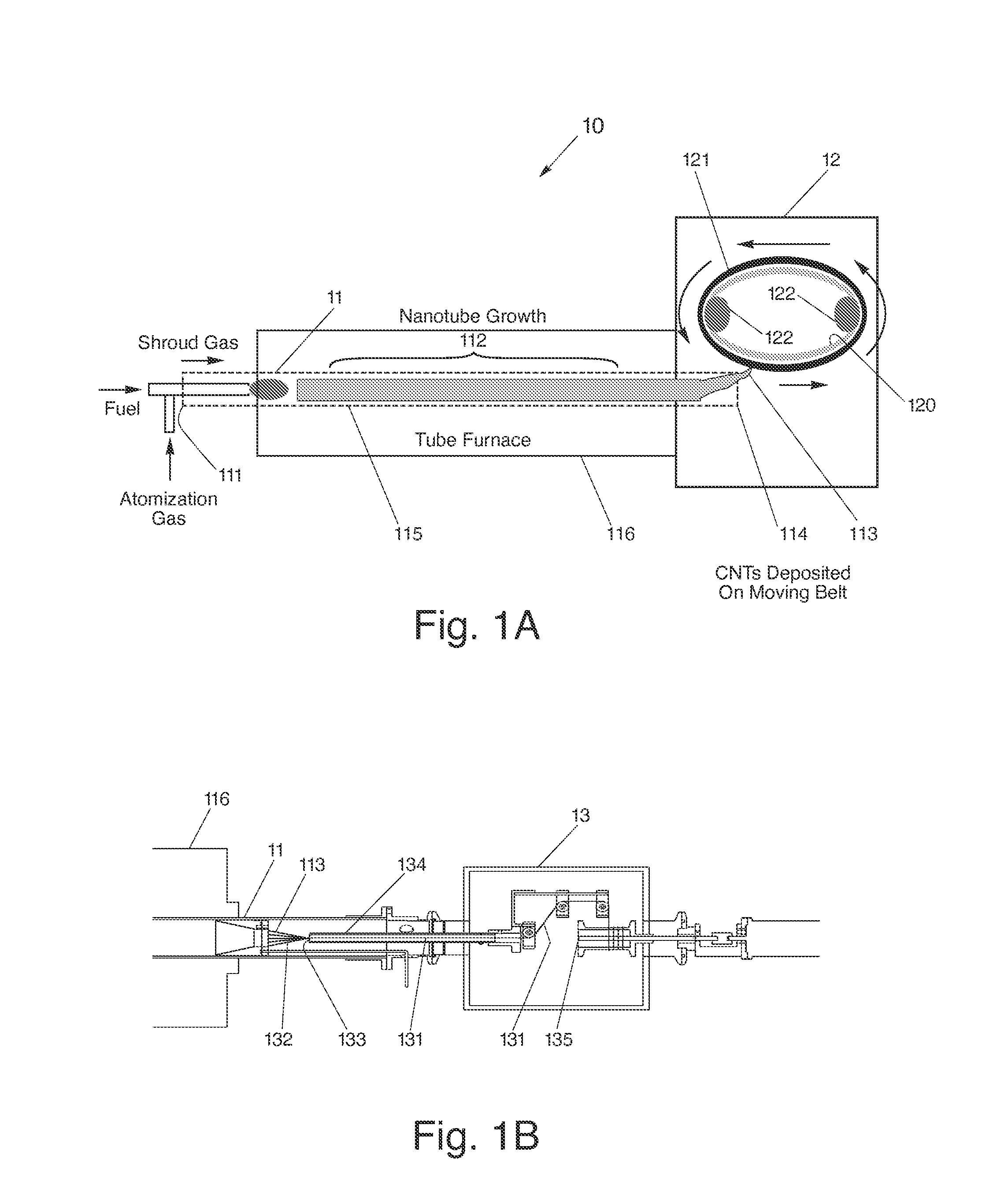

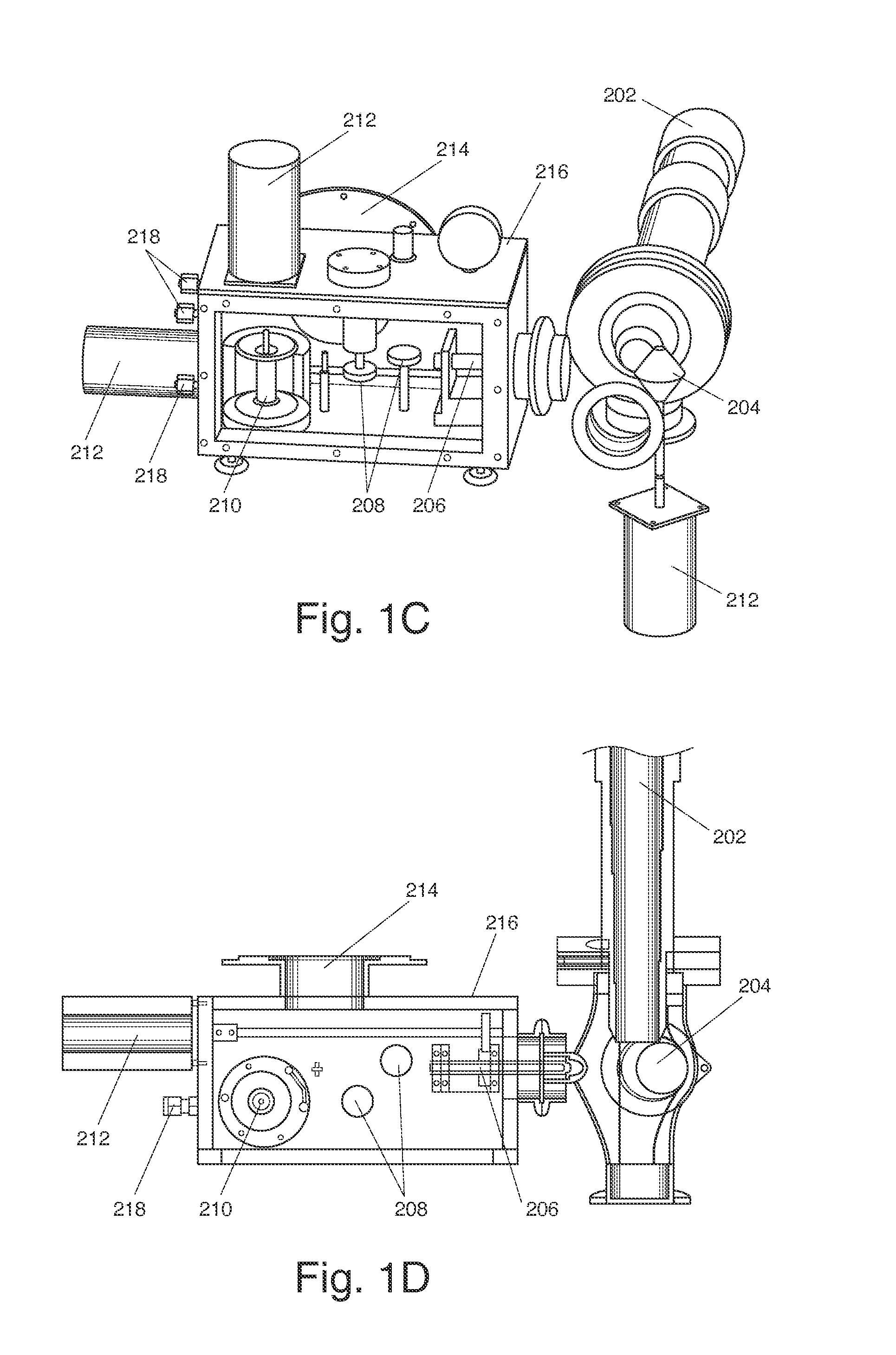

ActiveUS20110005808A1Improve conductivityLow resistivityNon-insulated conductorsConductive materialElectrical conductorCarbon nanotube

Hybrid conductors capable of achieving enhanced conductivity and current capacity over a wide range of frequencies are disclosed. The hybrid conductors may be used in electrical or thermal applications, or combinations of both. One method of fabricating such hybrid conductors includes complexing conductive metal elements (e.g., silver, gold, copper), transition metal elements, alloys, wires, or combinations thereof, with carbon nanotube materials. In the alternative, the hybrid conductors may be formed by doping the carbon nanotube materials in salt solutions.

Owner:NANCOMP TECHNOLOGIES INC

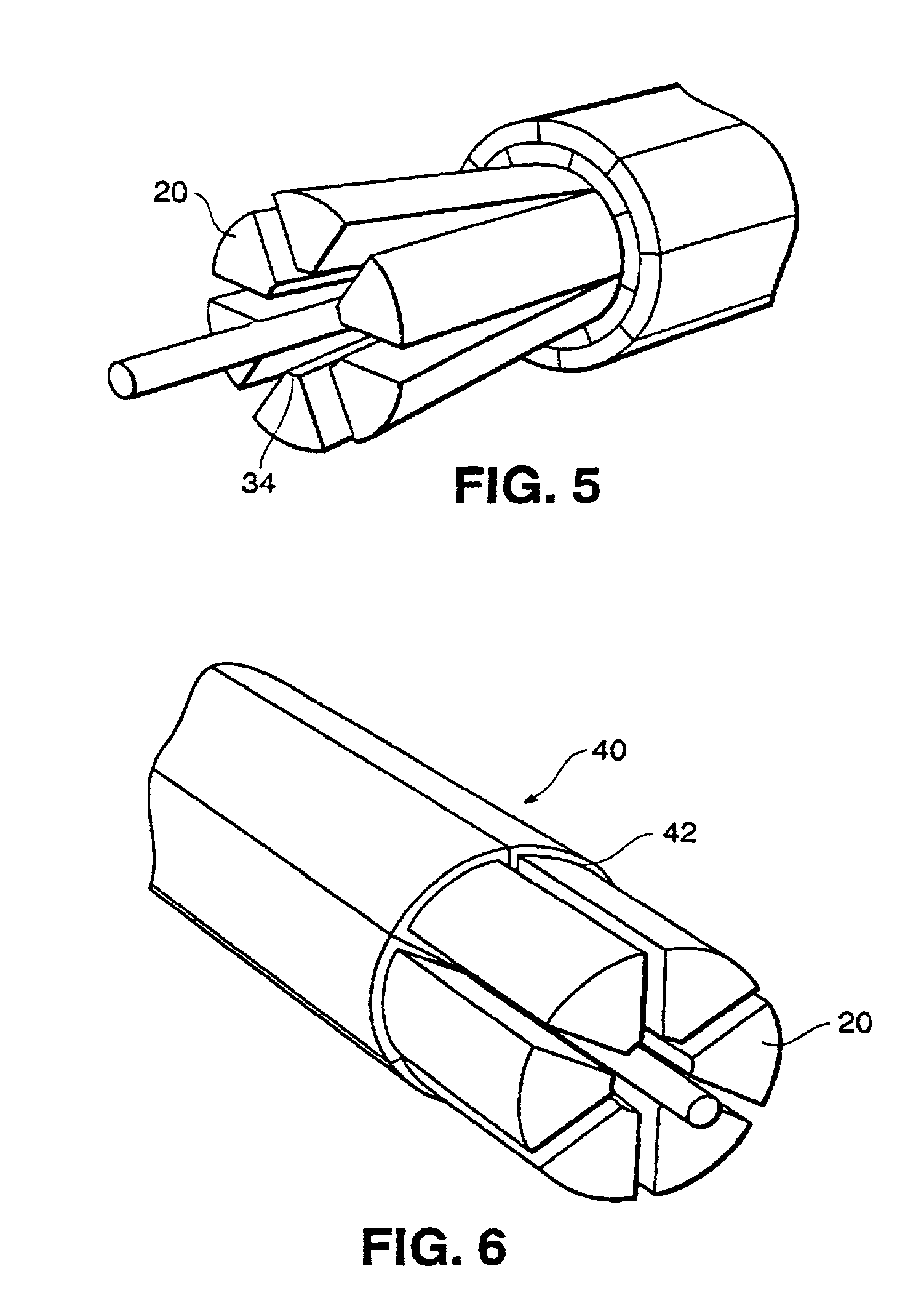

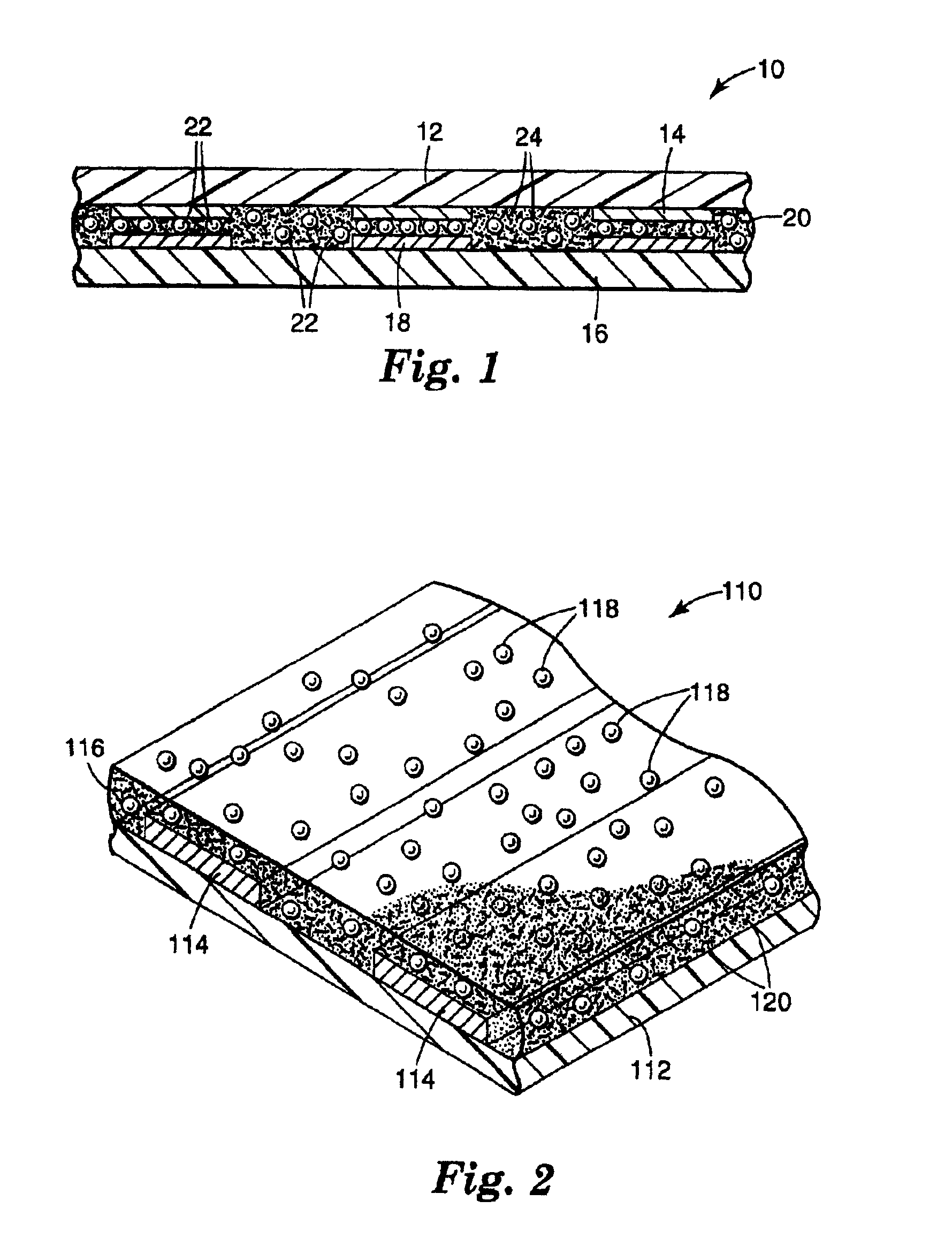

Aluminum conductor composite core reinforced cable and method of manufacture

InactiveUS7438971B2Non-insulated conductorsSynthetic resin layered productsElectrical conductorResin matrix

This invention relates to an aluminum conductor composite core reinforced cable and method of manufacture. The composite core comprises a plurality of longitudinally extending fibers embedded in a resin matrix. The composite core comprises the following characteristics: tensile strength ranging from about 250 to about 350 Ksi; a tensile modulus of elasticity ranging from about 12 to about 16 Msi; and a coefficient of thermal expansion less than or equal to about 6×10−6 cm / cm·° C. The composite core is further manufactured according to a one or more die pultrusion system, the system comprising tooling designed in accordance with the processing speed, selection of composite core fibers and resin and desired physical characteristics of the end composite core.

Owner:CTC GLOBAL CORP

Bonding wire for semiconductor device

ActiveUS20090188696A1Economical in material costSuperior in ball bondability bondabilityNon-insulated conductorsSolid-state devicesConcentration gradientControllability

The present invention provides a bonding wire improved in formability of a ball part, improved in bondability, good in loop controllability, improved in bonding strength of a wedge connection, securing industrial production ability as well, and mainly comprised of copper which is more inexpensive than gold wire, that is, provides a bonding wire for a semiconductor device comprised of a bonding wire having a core material having copper as its main ingredient and a surface covering layer over the core material and of a conductive metal of a composition different from the core material, characterized in that the surface covering layer has as its main ingredients two or more types of metals selected from gold, palladium, platinum, rhodium, silver, and nickel and the surface covering layer has a concentration gradient of one or both of a main ingredient metal or copper in the wire radial direction.

Owner:NIPPON STEEL CHEMICAL CO LTD

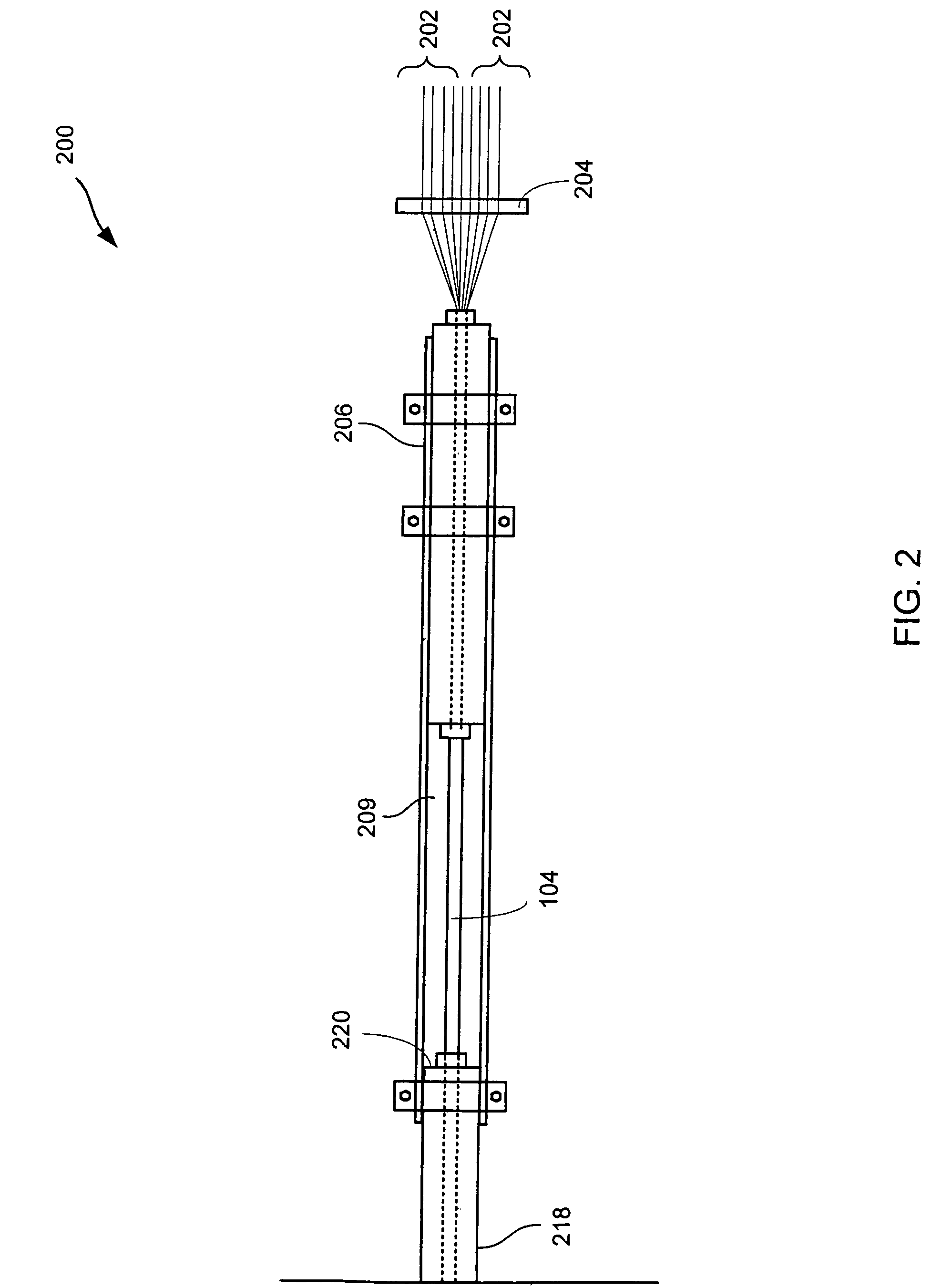

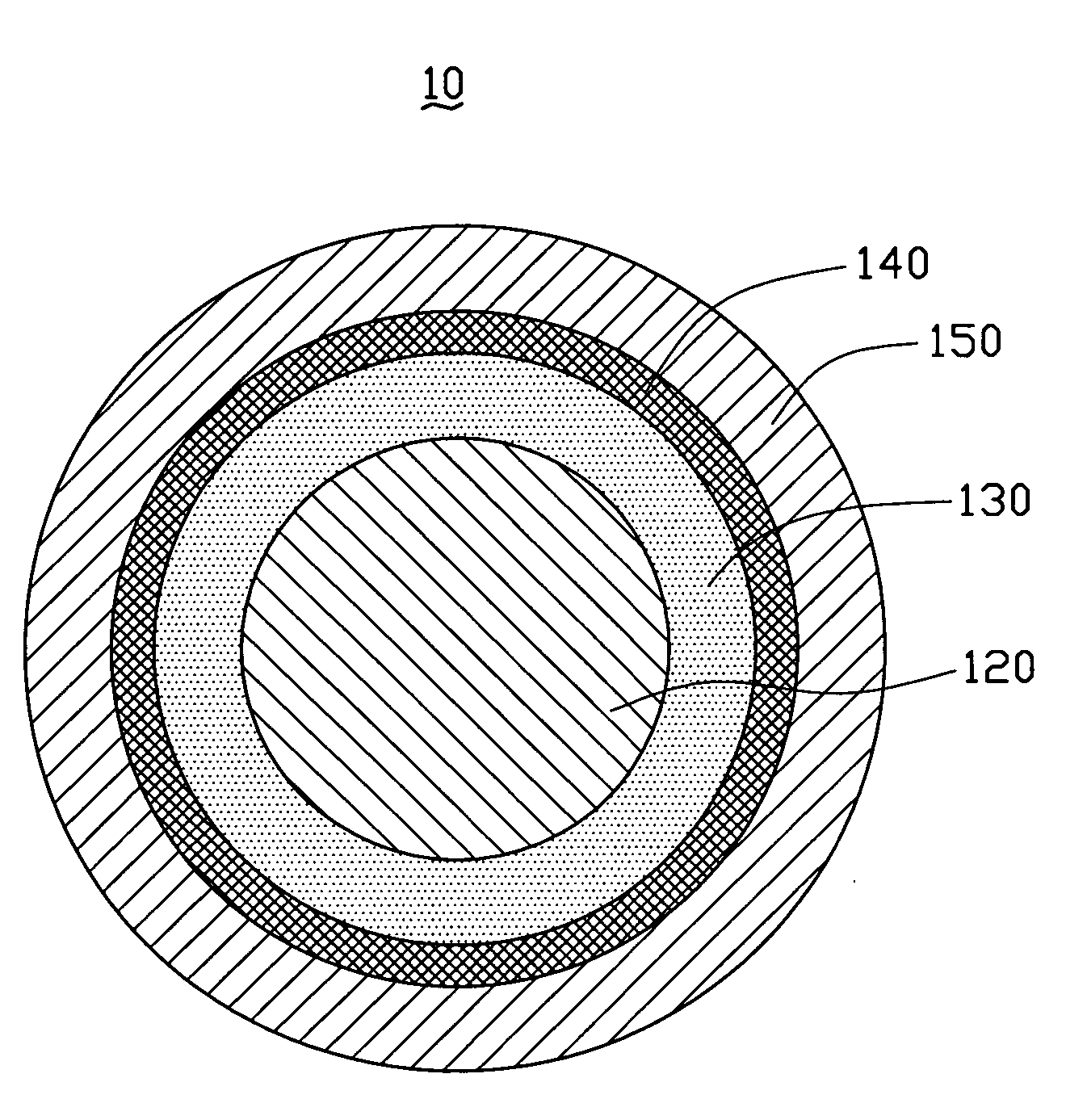

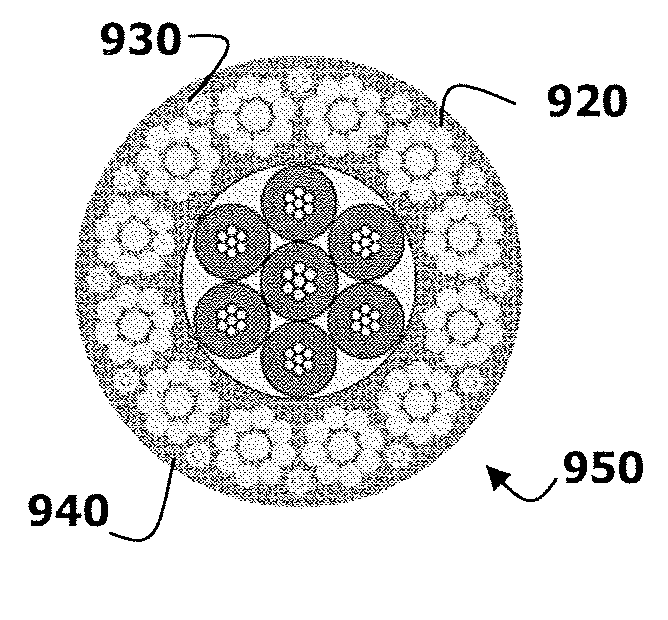

Aluminum conductor composite core reinforced cable and method of manufacture

InactiveUS7179522B2Change in weightMaintain stable propertiesNon-insulated conductorsSynthetic resin layered productsElectrical conductorThermal expansion

This invention relates to an aluminum conductor composite core reinforced cable (ACCC) and method of manufacture. An ACCC cable has a composite core surrounded by at least one layer of aluminum conductor. The composite core comprises a plurality of fibers from at least one fiber type in one or more matrix materials. The composite core can have a maximum operating temperature capability above 100° C. or within the range of about −45° C. to about 240° C. or higher, at least 50% fiber to resin volume fraction, a tensile strength in the range of about 160 Ksi to about 370 Ksi, a modulus of elasticity in the range of about 7 Msi to about 37 Msi and a coefficient of thermal expansion in the range of about −0.6×10−6 per deg. C. to about 1.0×10−5 per deg. C. According to the invention, unique processing techniques such a B-Staging and / or film-coating techniques can be used to increase production rates from a few feet per minute to sixty or more feet per minute.

Owner:CTC GLOBAL CORP

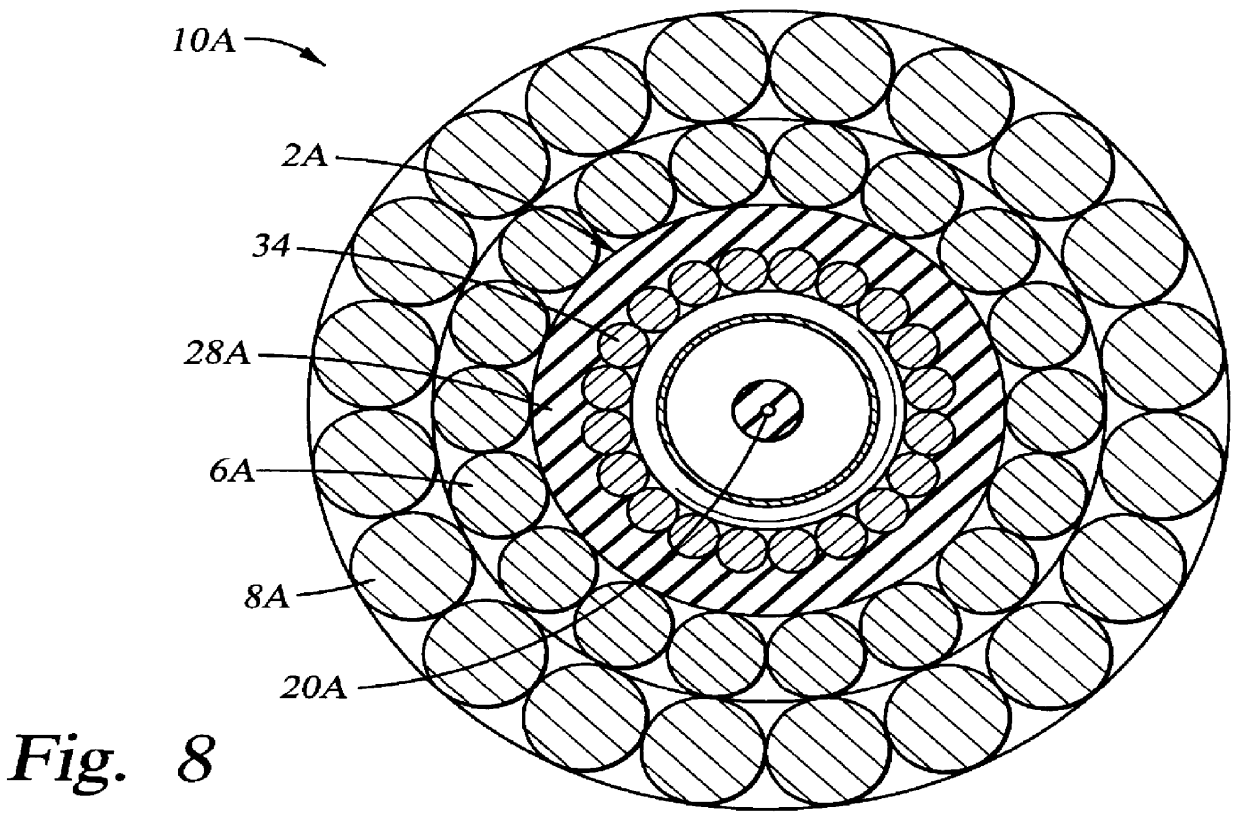

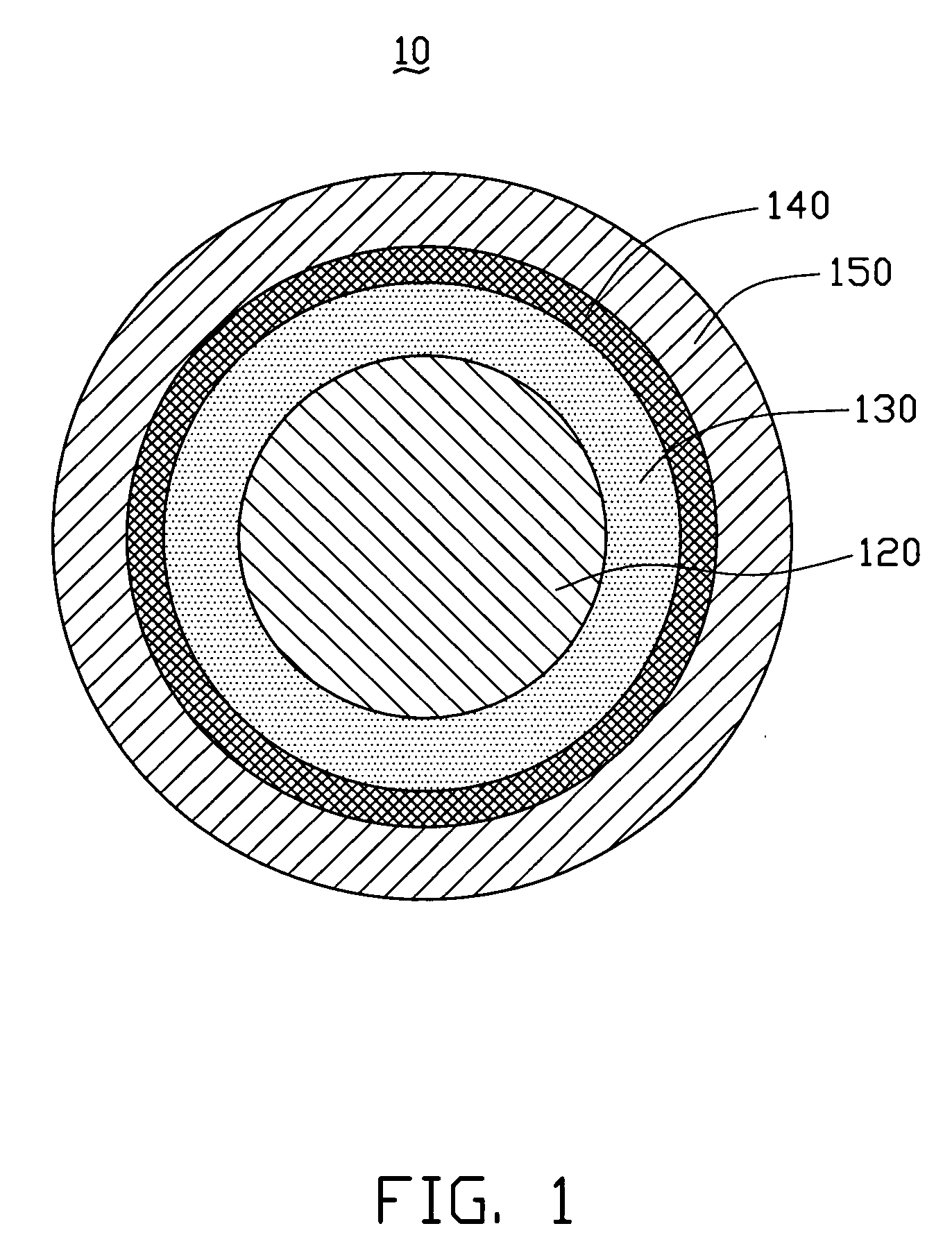

Coaxial cable

ActiveUS20090255706A1Reduce intensityGreat weight and diameterNon-insulated conductorsCable conductor constructionCoaxial cableCarbon nanotube

A coaxial cable includes a core, an insulating layer, a shielding layer, and a sheathing layer. The core includes a carbon nanotube wire-like structure and at least one conductive material layer is disposed on the outside surface of the carbon nanotube wire-like structure. The carbon nanotube wire-like structure includes a plurality carbon nanotubes orderly arranged.

Owner:TSINGHUA UNIV +1

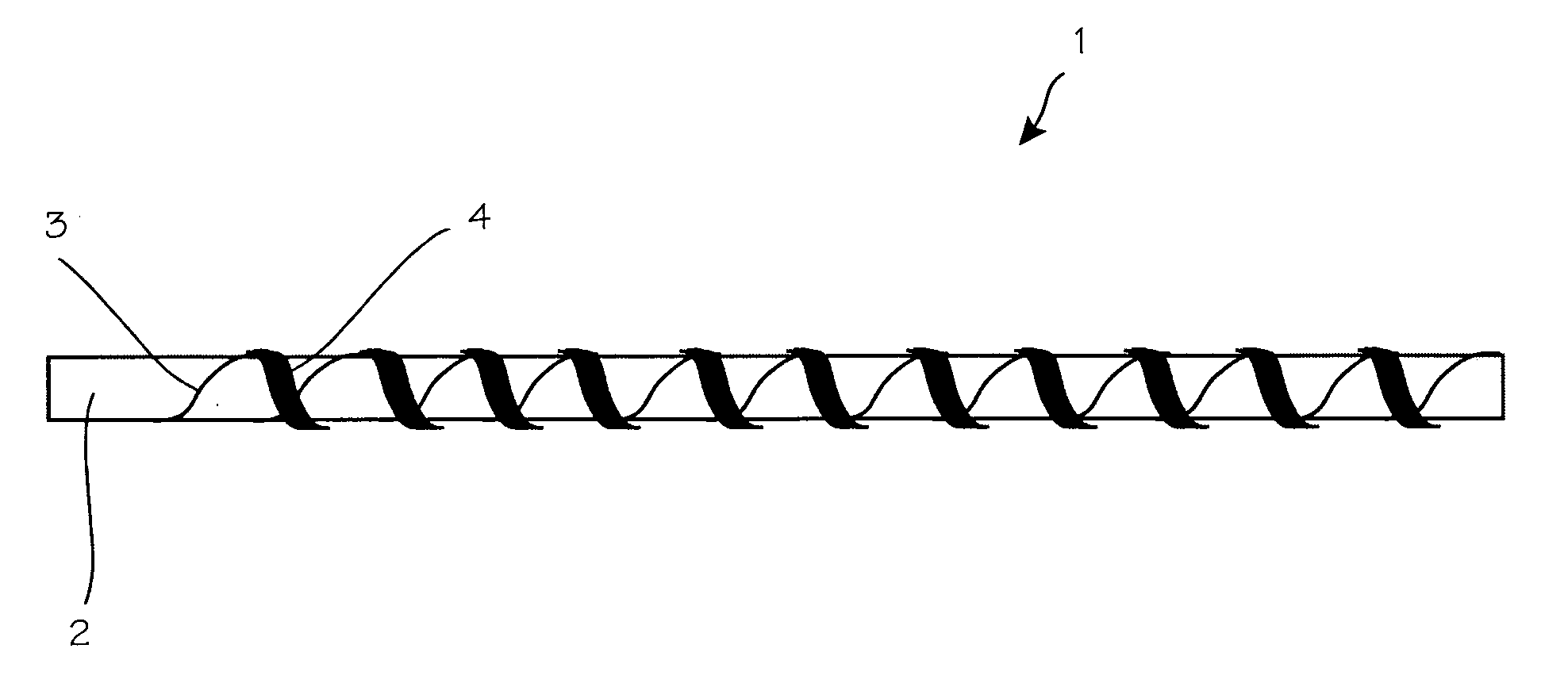

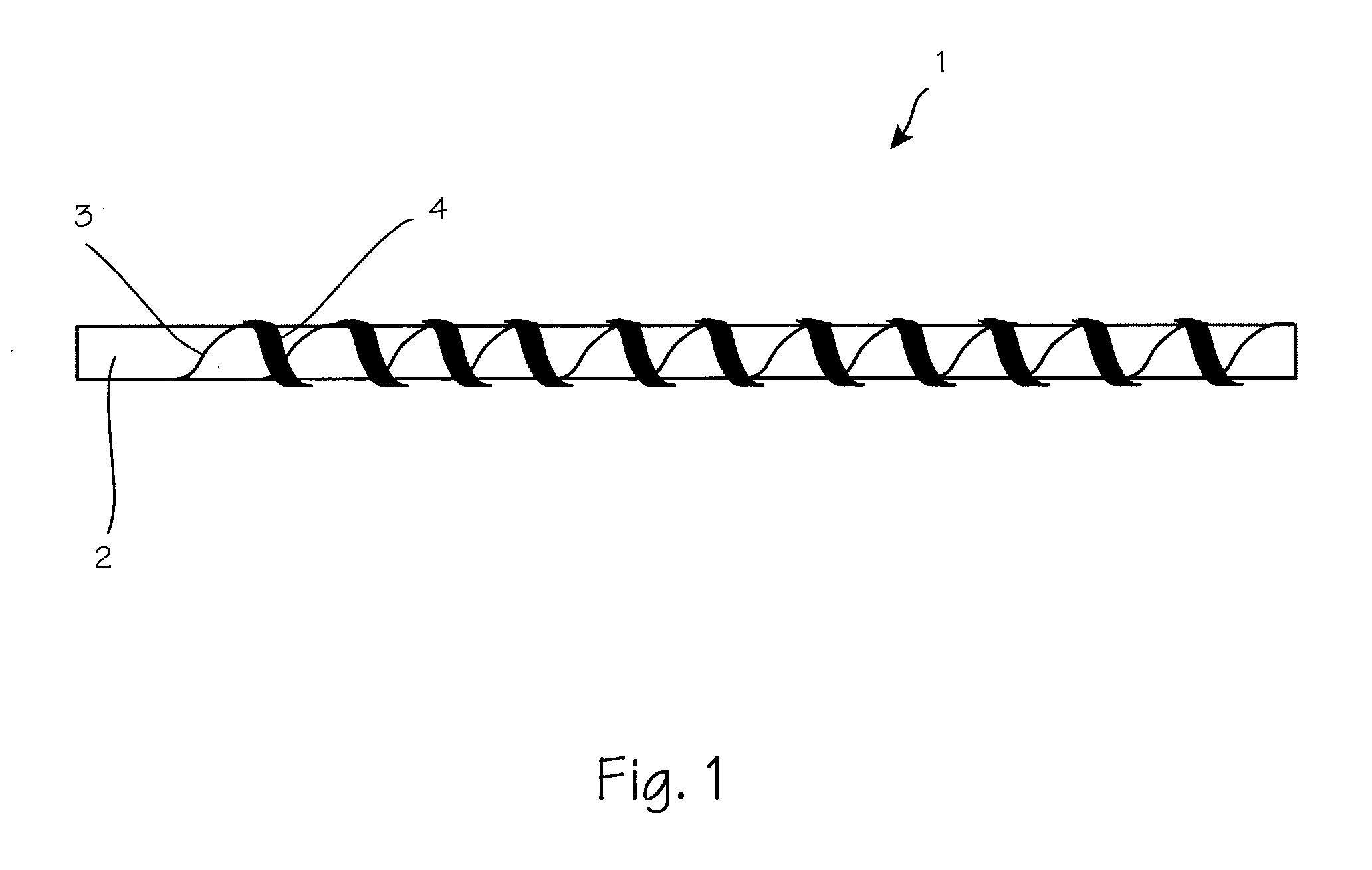

Electrically conductive yarn

InactiveUS20050282009A1Strong forcePrevent elongationNon-insulated conductorsHeating element shapesYarnEngineering

A yarn that is electrically conductive, that can be elongated considerably, at least briefly, without loss of conductivity, and that exhibits improved elongation properties.

Owner:W ZIMMERMANN

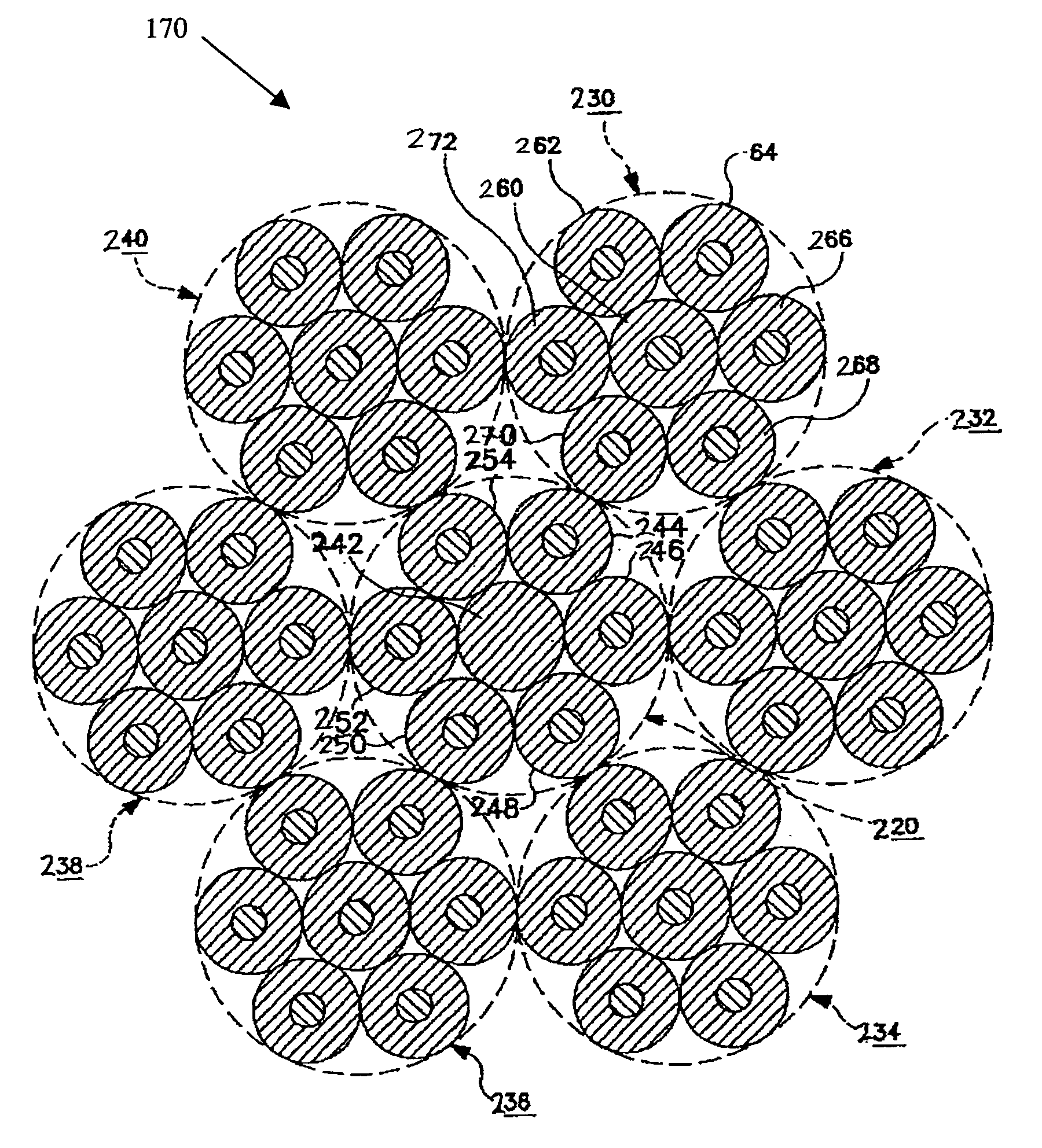

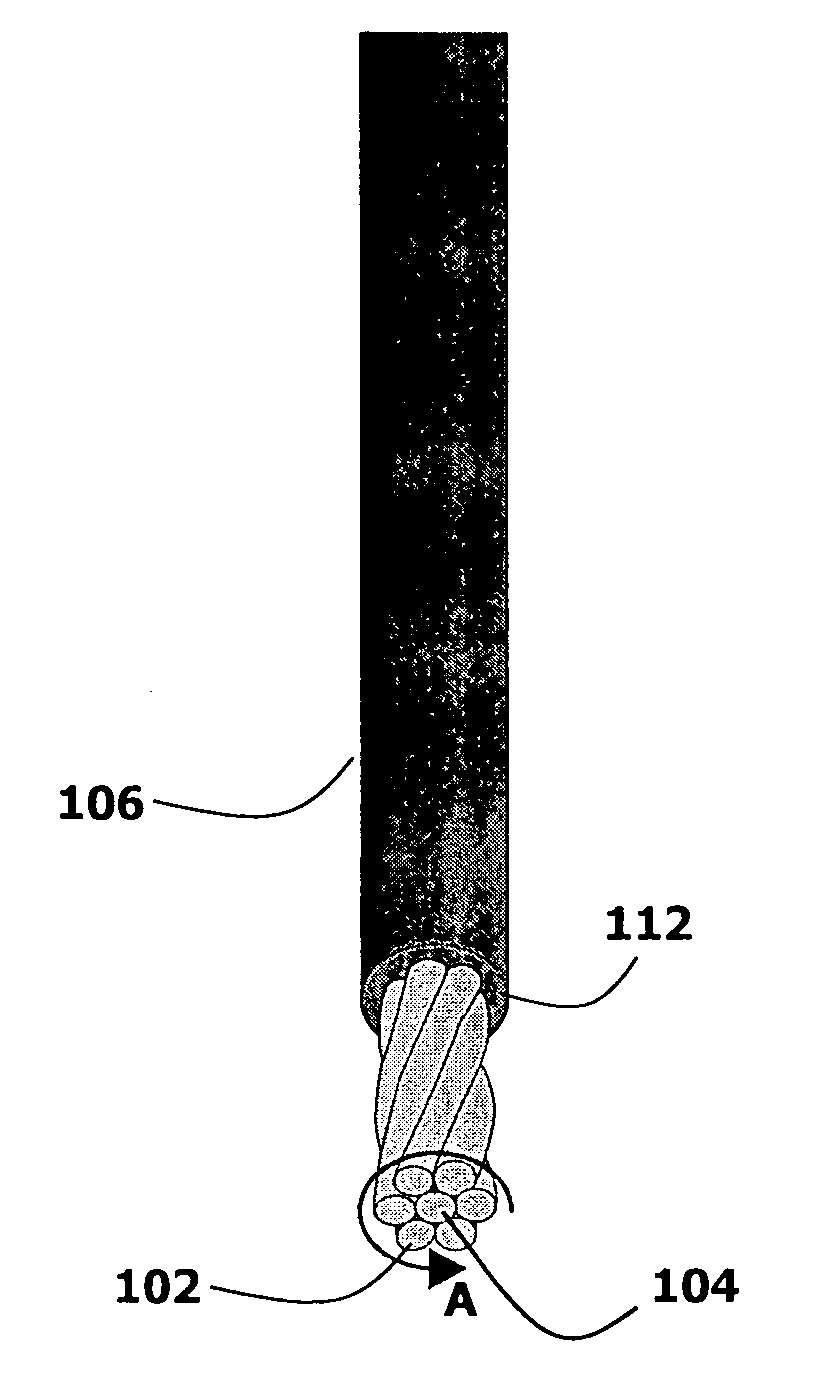

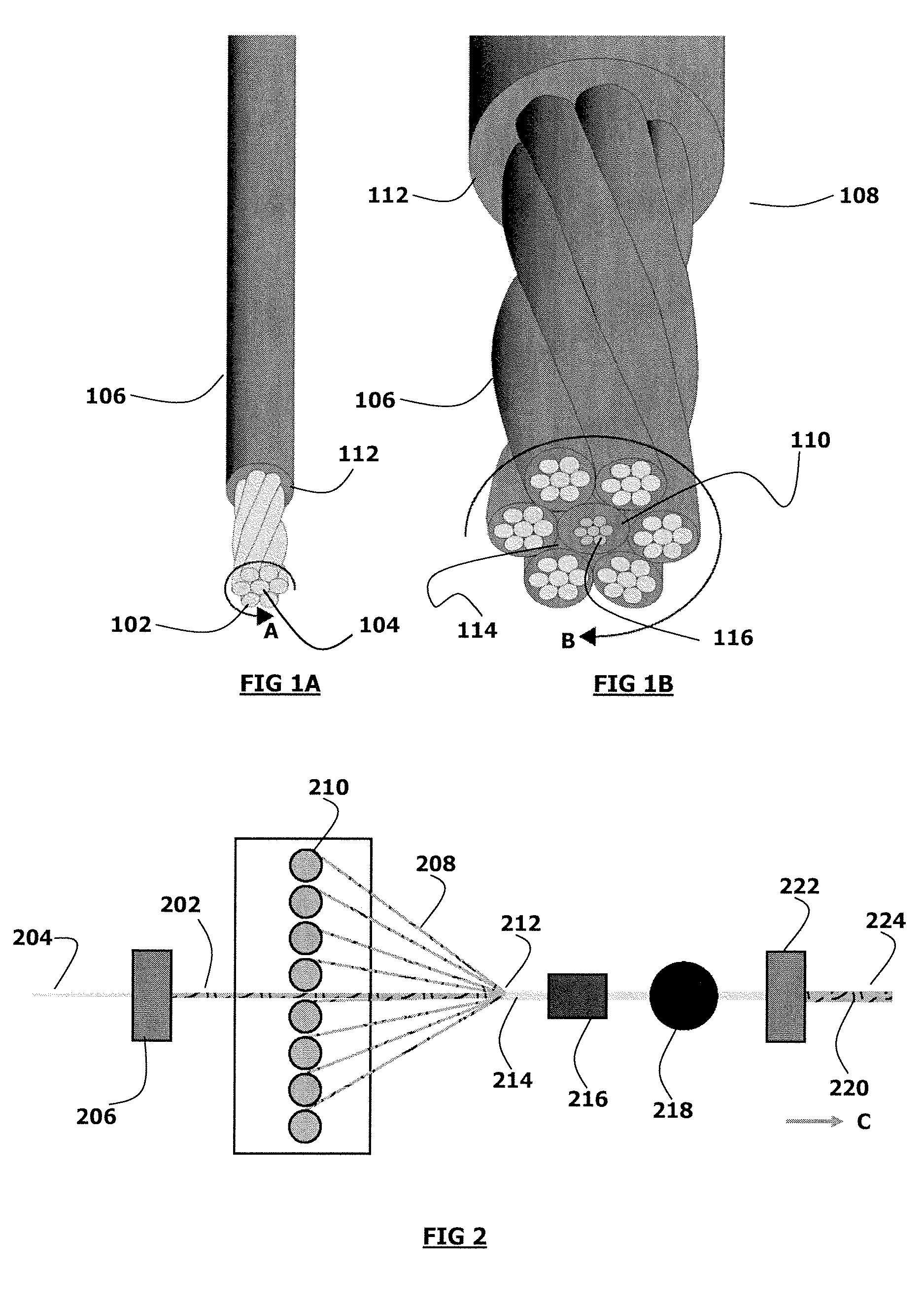

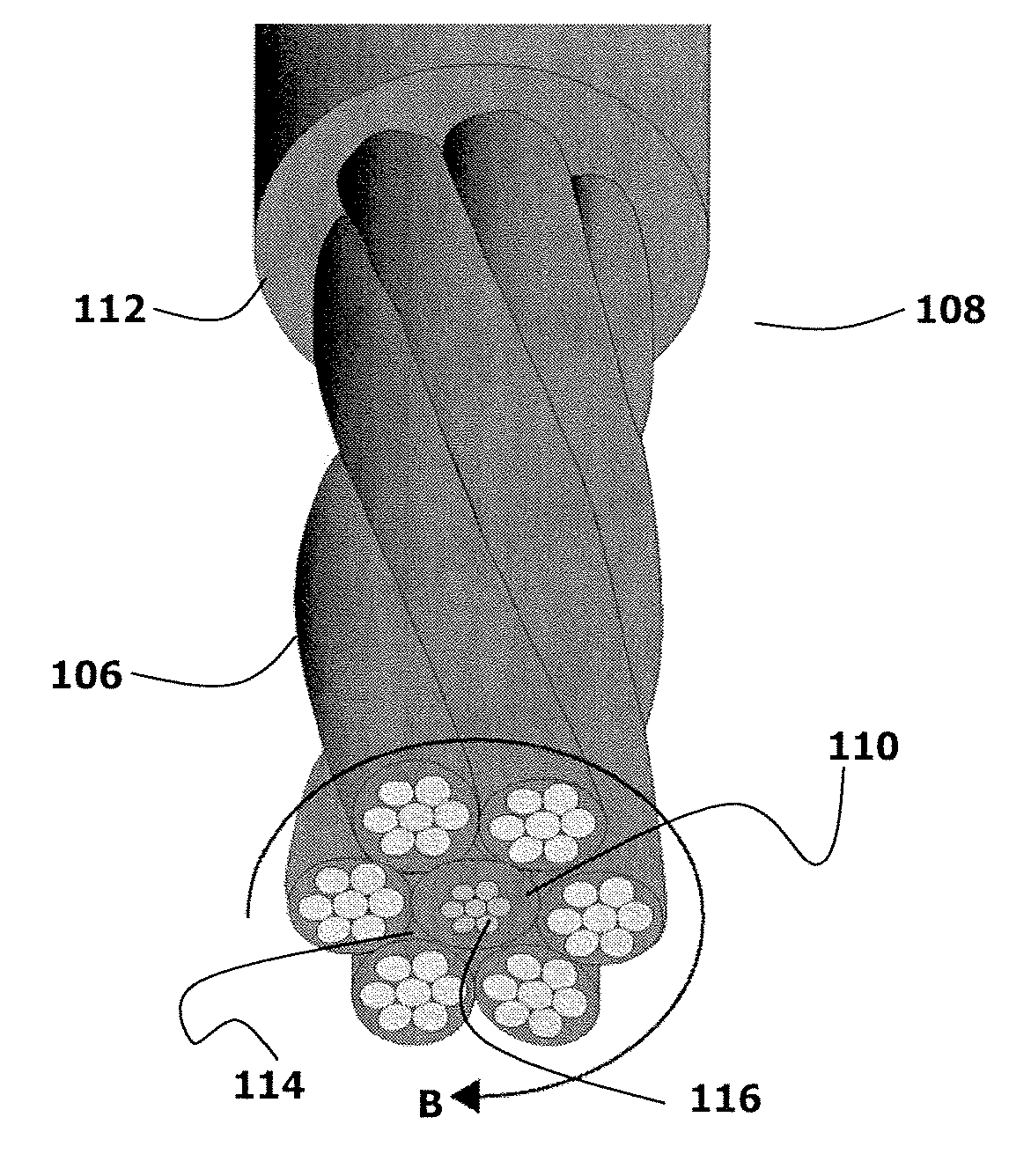

Electrical cables with stranded wire strength members

ActiveUS20070000682A1Improve corrosion resistancePrevent and minimize dangerous gas migrationNon-insulated conductorsPower cables with screens/conductive layersCoaxial cableEngineering

Disclosed are high strength wellbore electric cables, which are formed from a plurality of strength members. The strength members are formed from several stranded filament wires which may be encased within a jacket of polymeric material. The strength members may be used as a central strength member, or even layered around a central axially positioned component or strength member, to form a layer of strength members. Cables of the invention may be of any practical design, including monocables, coaxial cables, quadcables, heptacables, slickline cables, multi-line cables, etc., and have improved resistant to corrosion, torque balancing, and gas migration from a wellbore to the surface.

Owner:SCHLUMBERGER TECH CORP

Low resistance conductors, processes of production thereof, and electrical members using same

InactiveUS20030213611A1Low resistivityEconomical priceNon-insulated conductorsSuperconductors/hyperconductorsElectrical resistance and conductanceElectrical conductor

A conductor obtained by connecting a plurality of superconductors by normal conductivity or a conductor comprised of superconductors and normal conductors, said low resistance conductor using superconductors characterized in that an apparent specific resistance of said conductor at below a superconducting transition temperature of said superconductors is lower than the specific resistance of copper at that superconducting transition temperature.

Owner:NIPPON STEEL CORP

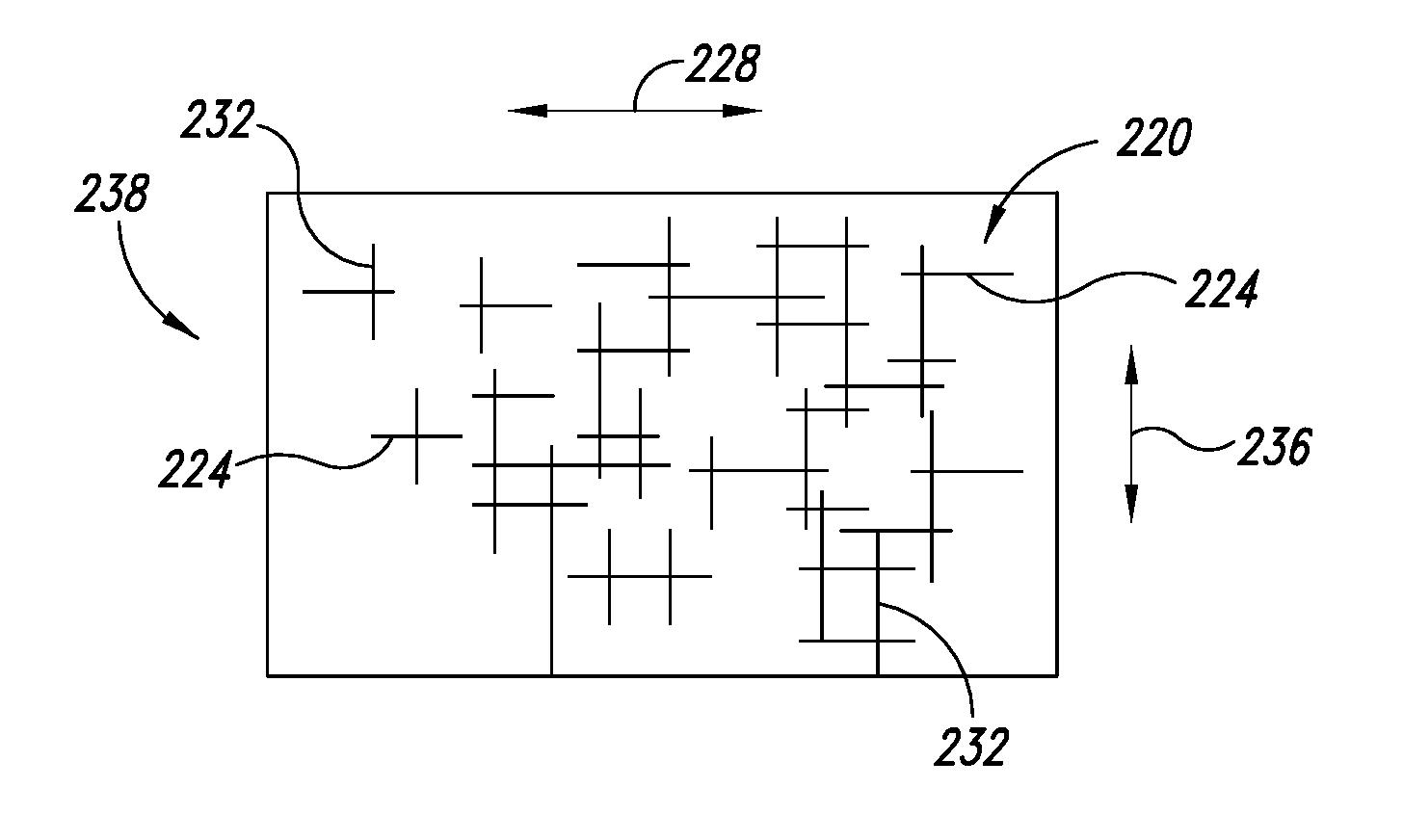

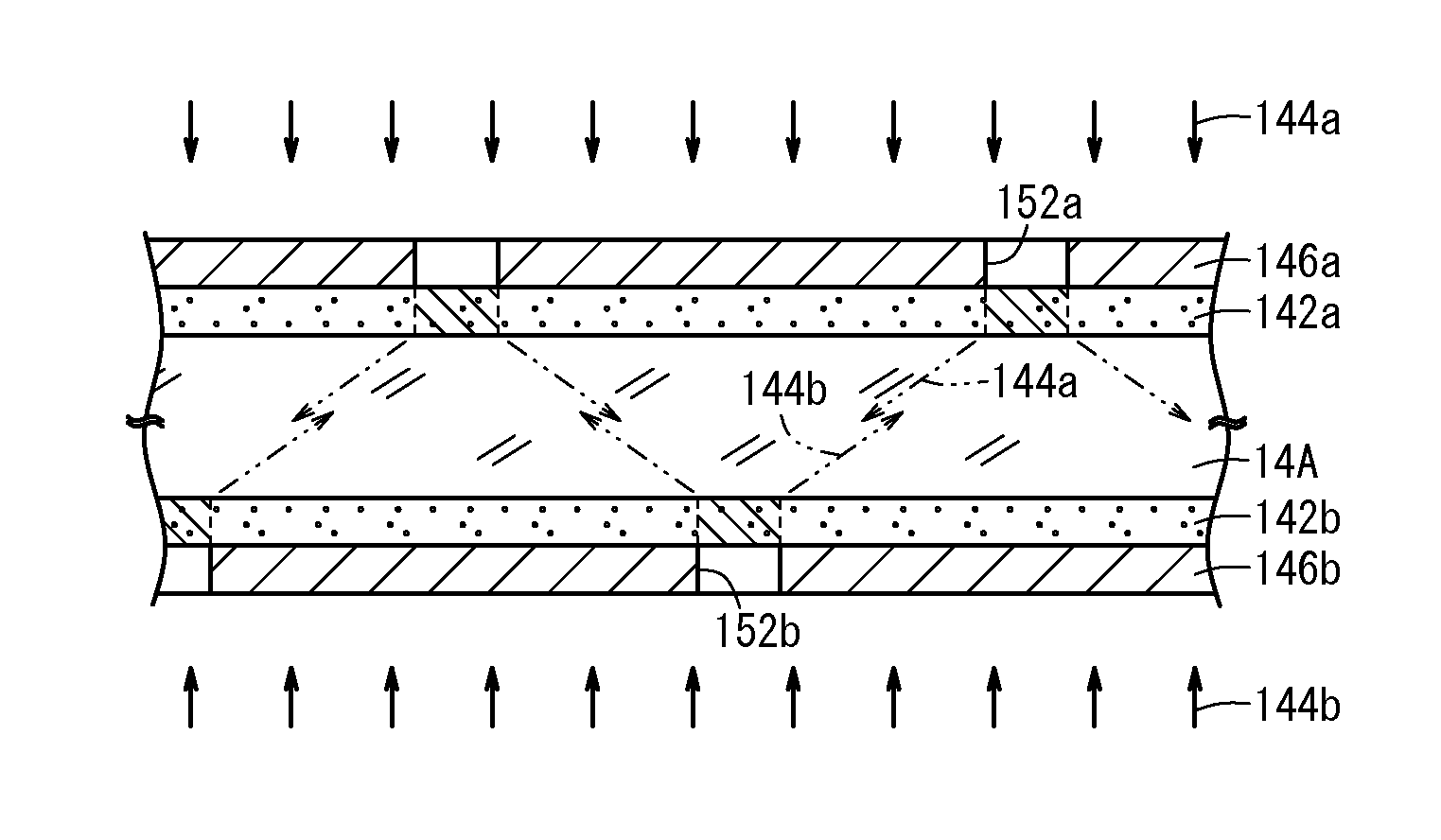

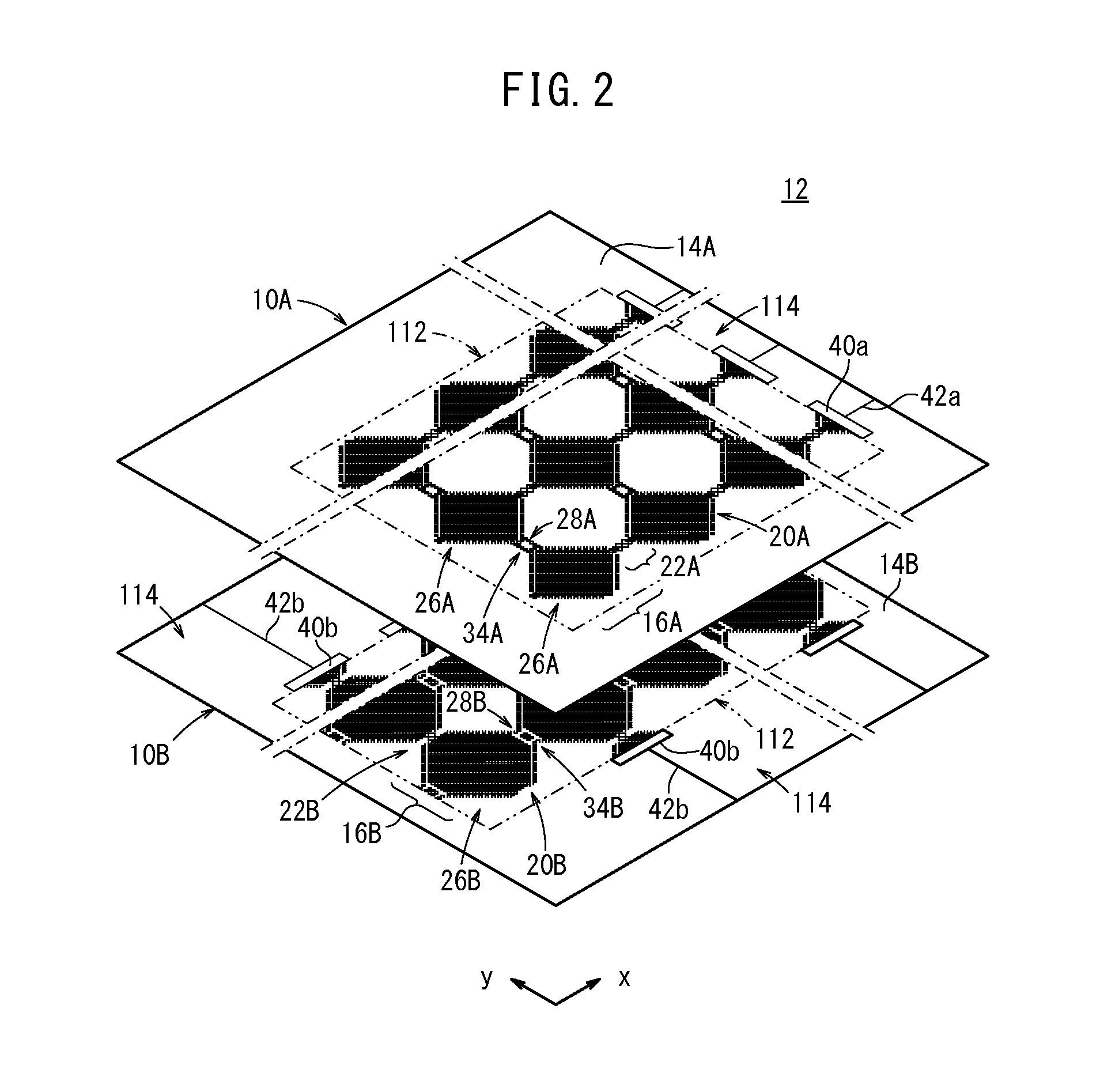

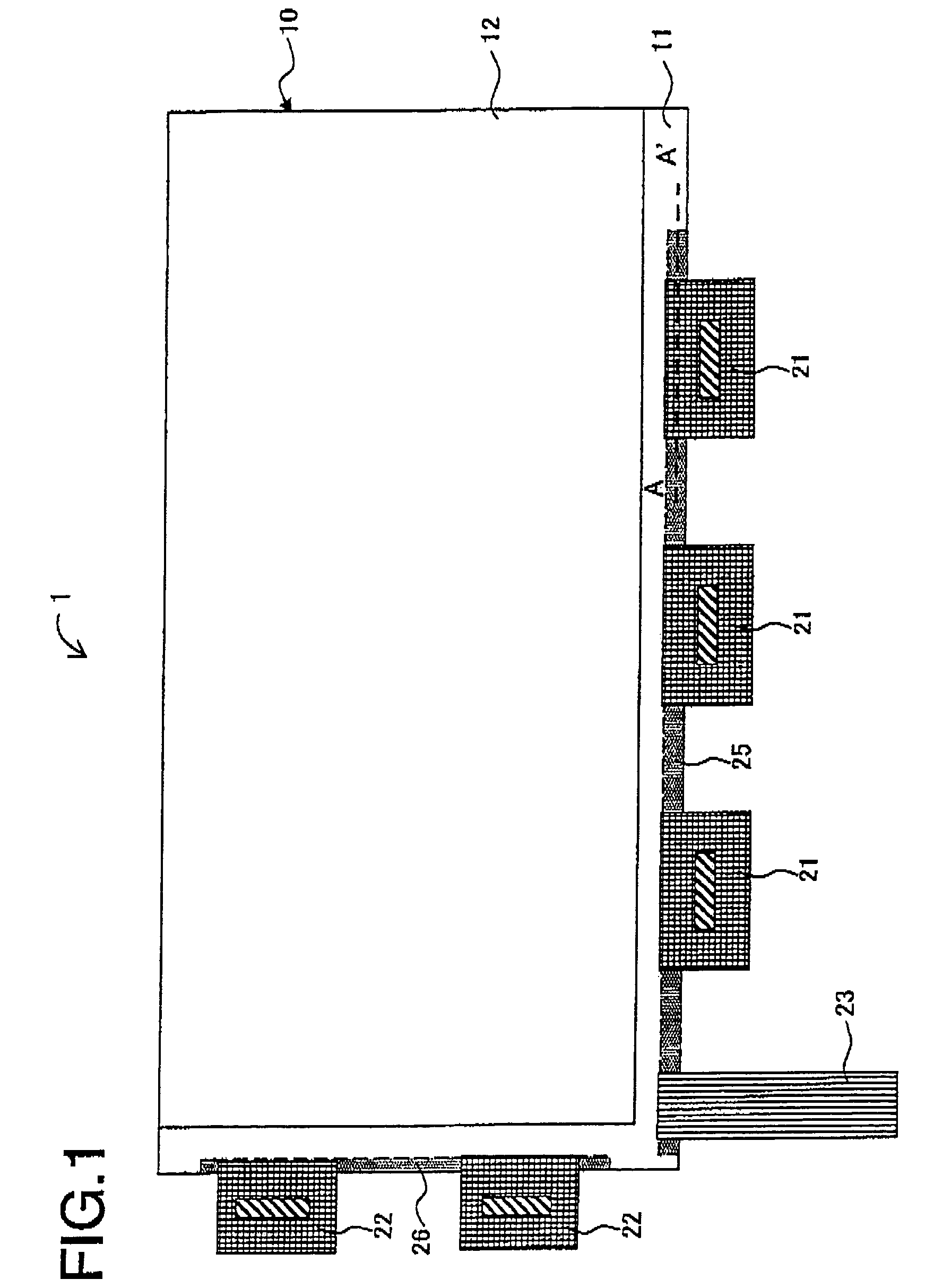

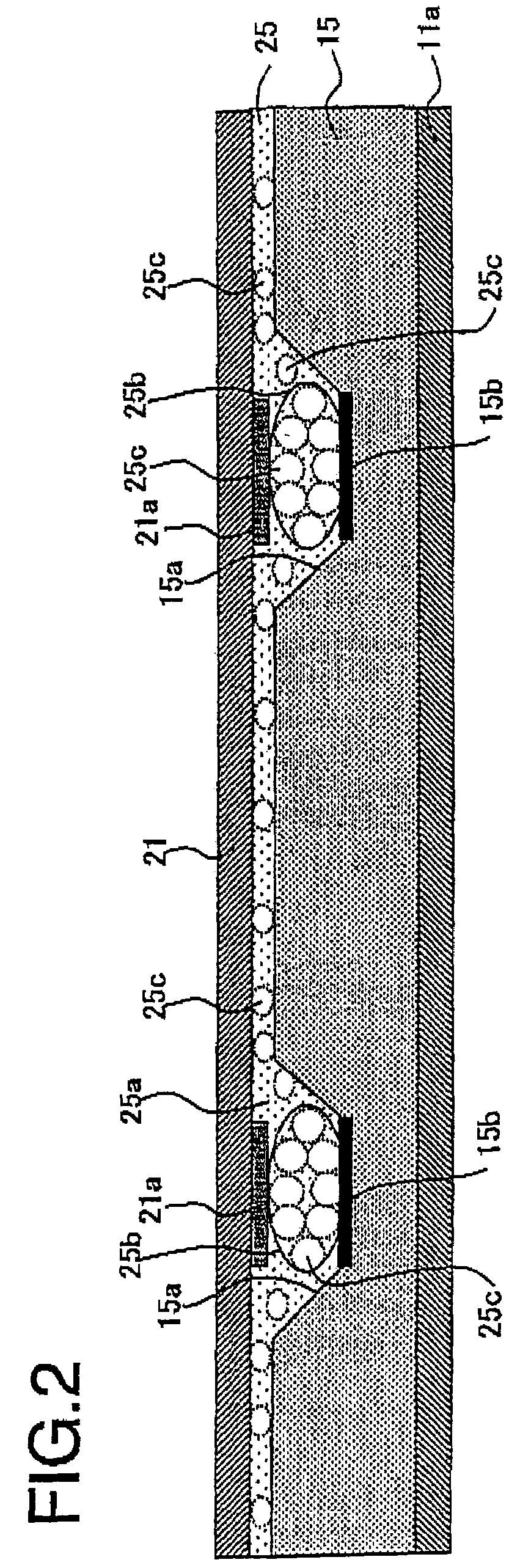

Electroconductive sheet and touch panel

ActiveUS20130327560A1High transparencyHigh detection sensitivityNon-insulated conductorsSuperimposed coating processThin metalEngineering

An electroconductive sheet and a touch panel having a first electroconductive section and a second electroconductive section, the second electroconductive section being disposed on the display-panel side. The first electroconductive section has a plurality of first electroconductive patterns arranged in the x-direction, a plurality of first large grids being respectively connected to the first electroconductive patterns. The second electroconductive section has a plurality of second electroconductive patterns arranged in the y-direction, a plurality of second large grids being respectively connected to the second electroconductive patterns. The area occupied by thin metal wires in the second electroconductive patterns is larger than the area occupied by thin metal wires in the first electroconductive patterns. The area occupied by thin metal wires in the second large grids is larger than the area occupied by thin metal wires in the first large grids.

Owner:FUJIFILM CORP

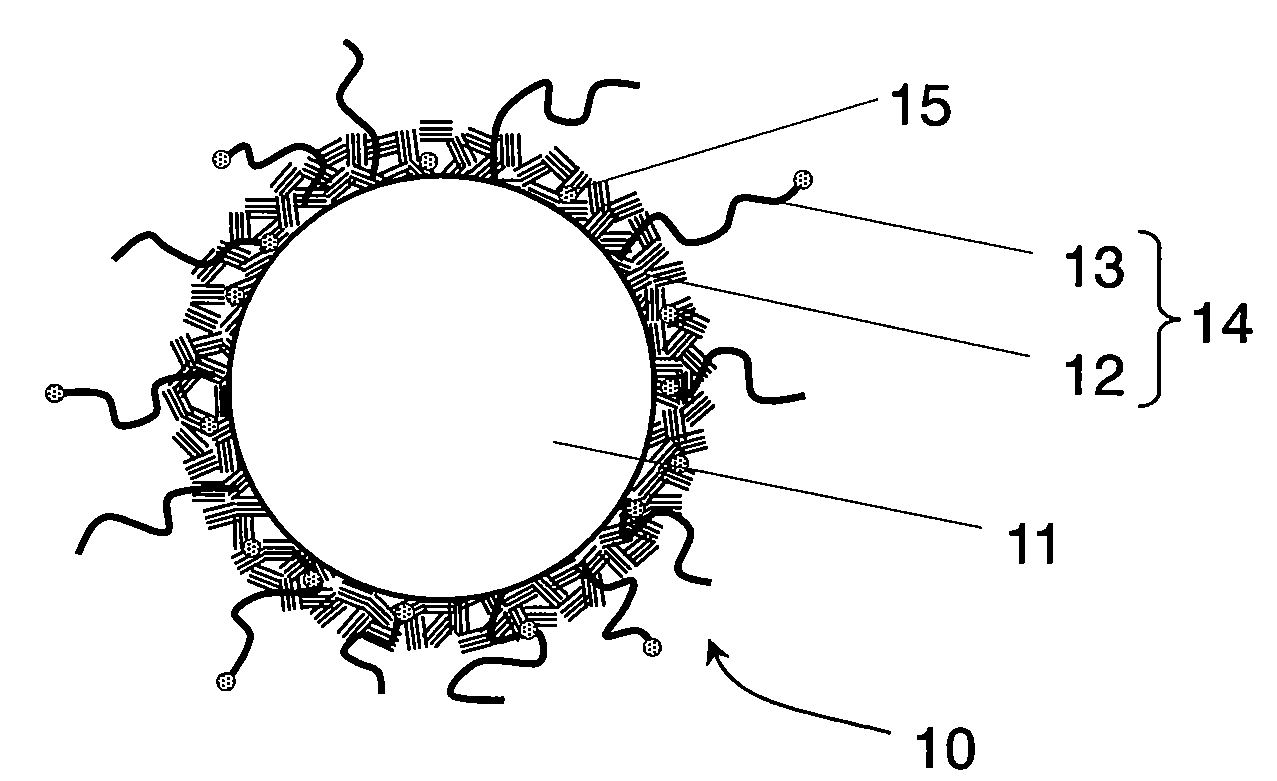

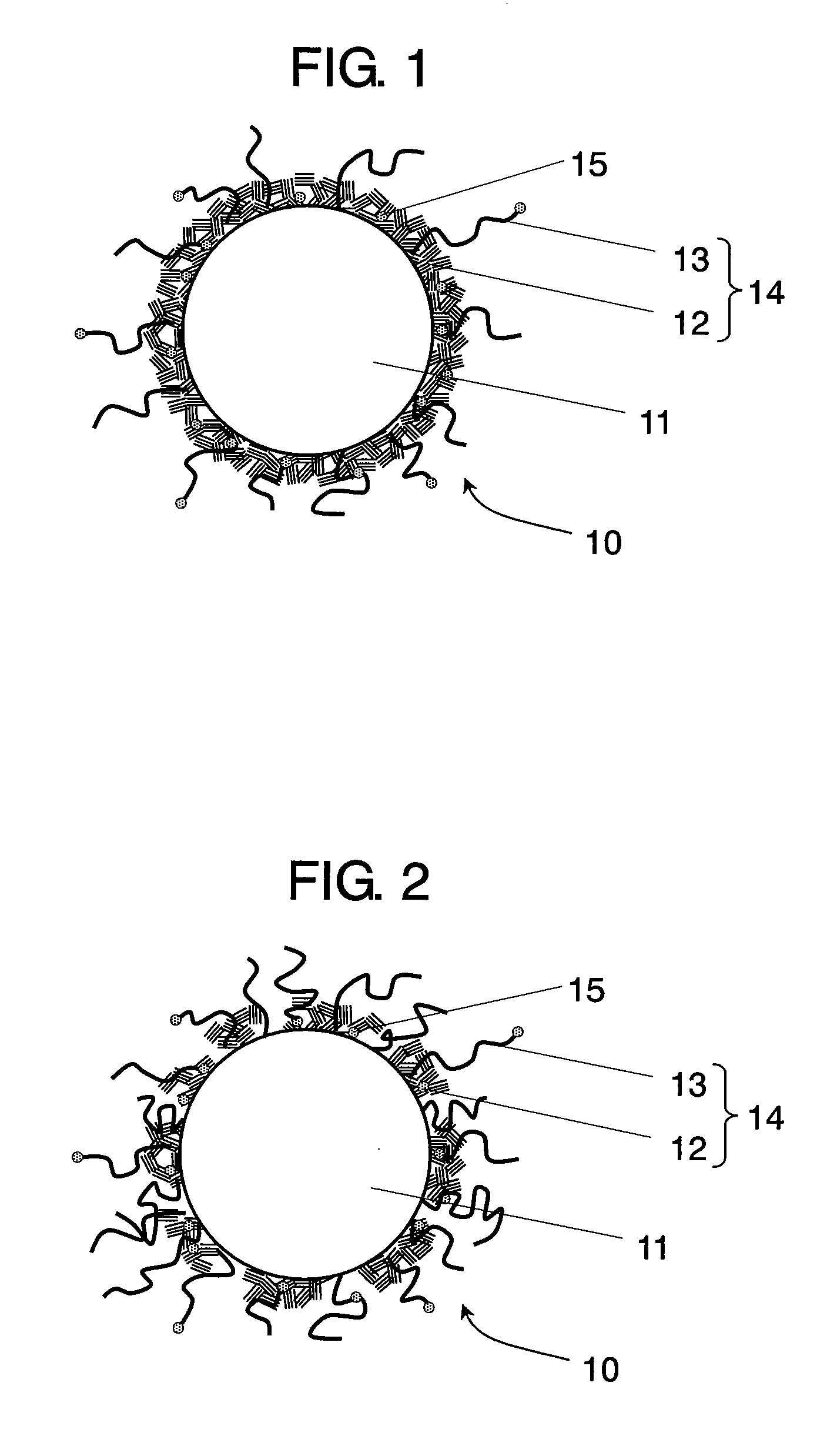

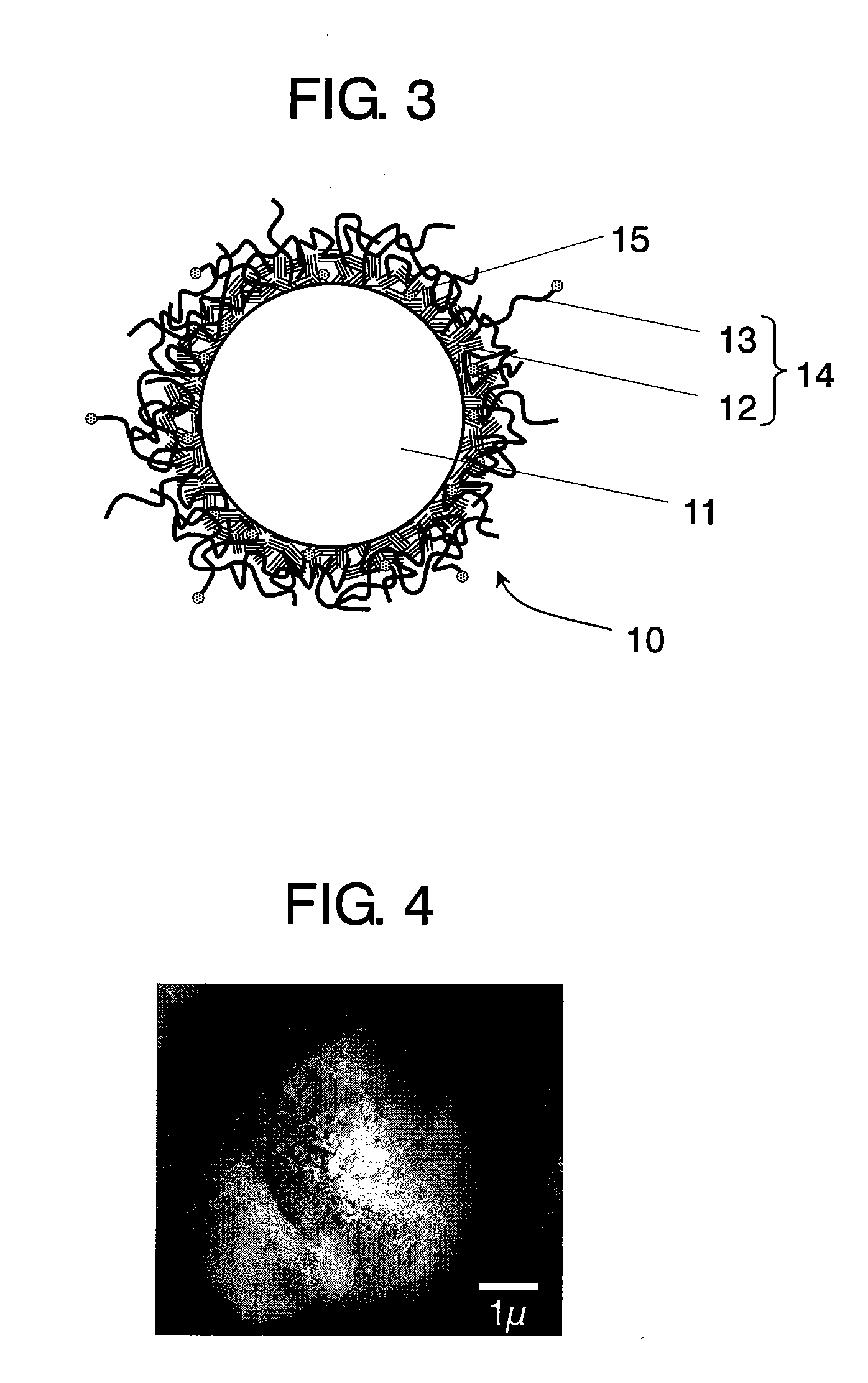

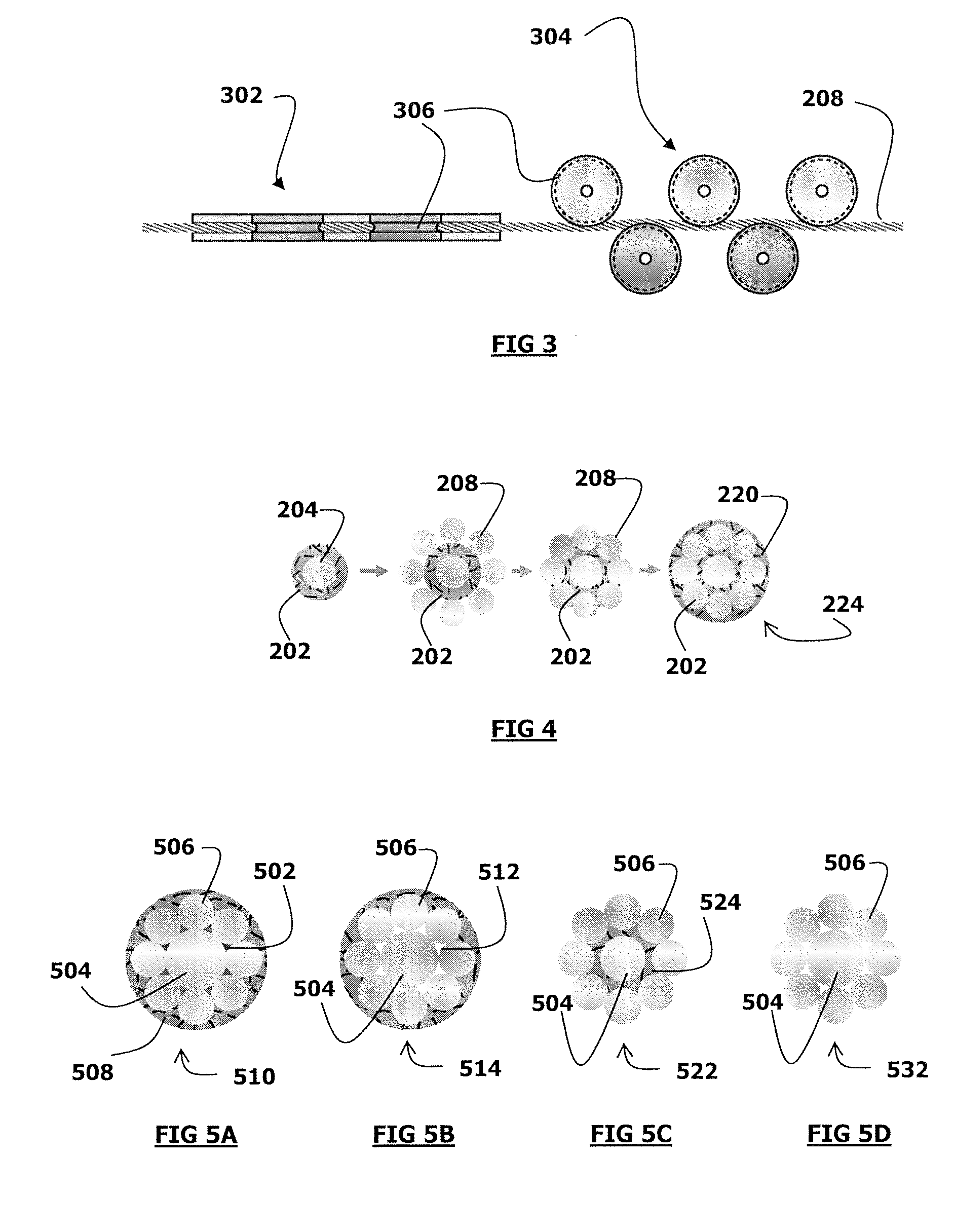

Conductive composite particle, method of manufacturing the same, electrode using the same, lithium ion secondary battery

In a manufacturing method of a conductive composite particle, a conductive composite particle is manufactured that is formed of an active material particle having a region capable of electrochemically inserting and desorbing lithium and a carbon layer joined to the particle surface. In the carbon layer, fine metal particles are dispersed. This method has the following three steps. In the first step, a polymer material containing the metal element composing the fine metal particles is prepared. In the second step, the active material particle surface is coated with the polymer material containing the metal element. In the third step, a carbon layer having a porous structure including a fibrous structure is formed as the surface layer section from the polymer material by a treatment where the active material particle coated with the polymer containing the metal element is heated in an inert atmosphere to carbonize the polymer material.

Owner:PANASONIC CORP

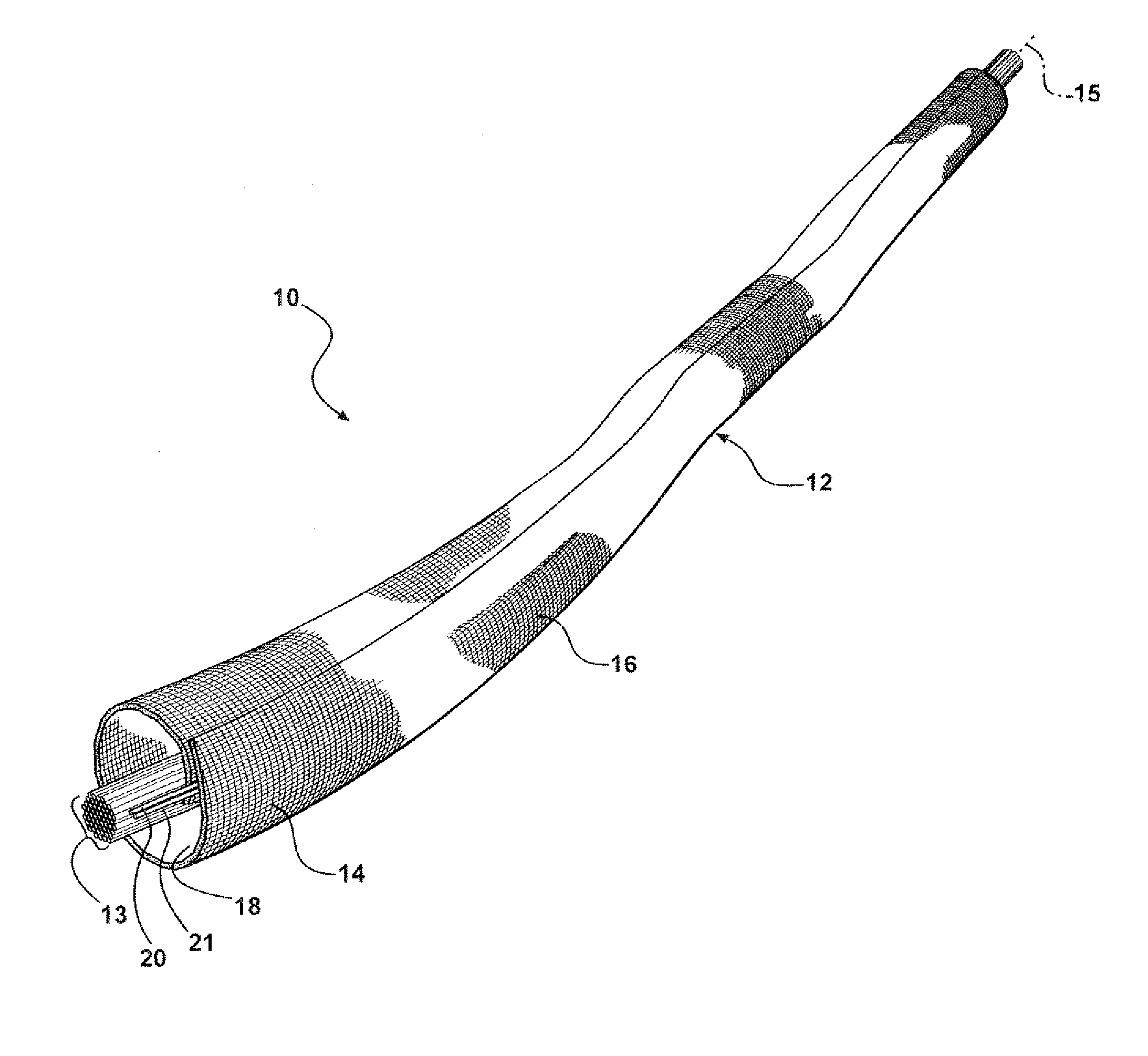

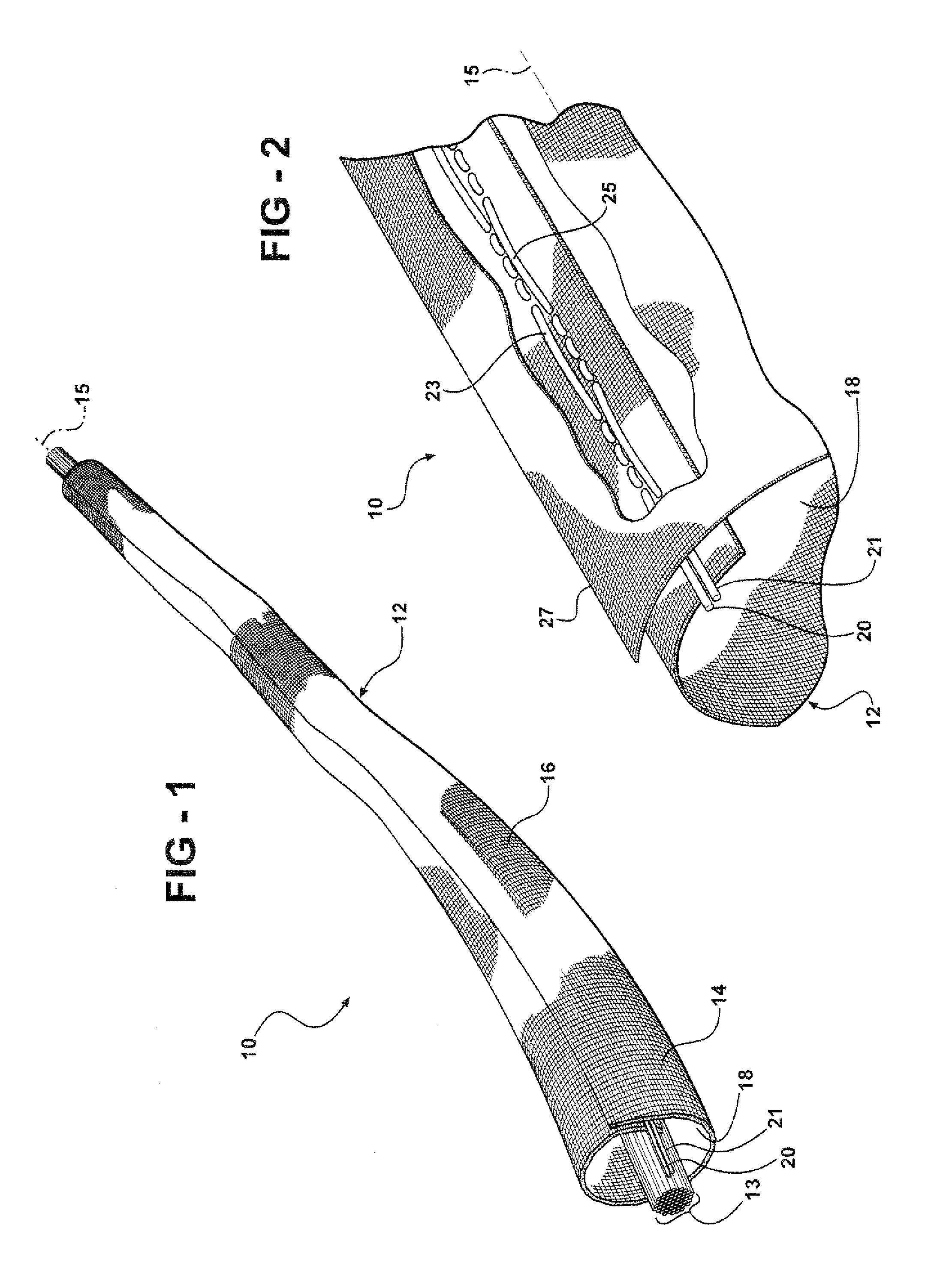

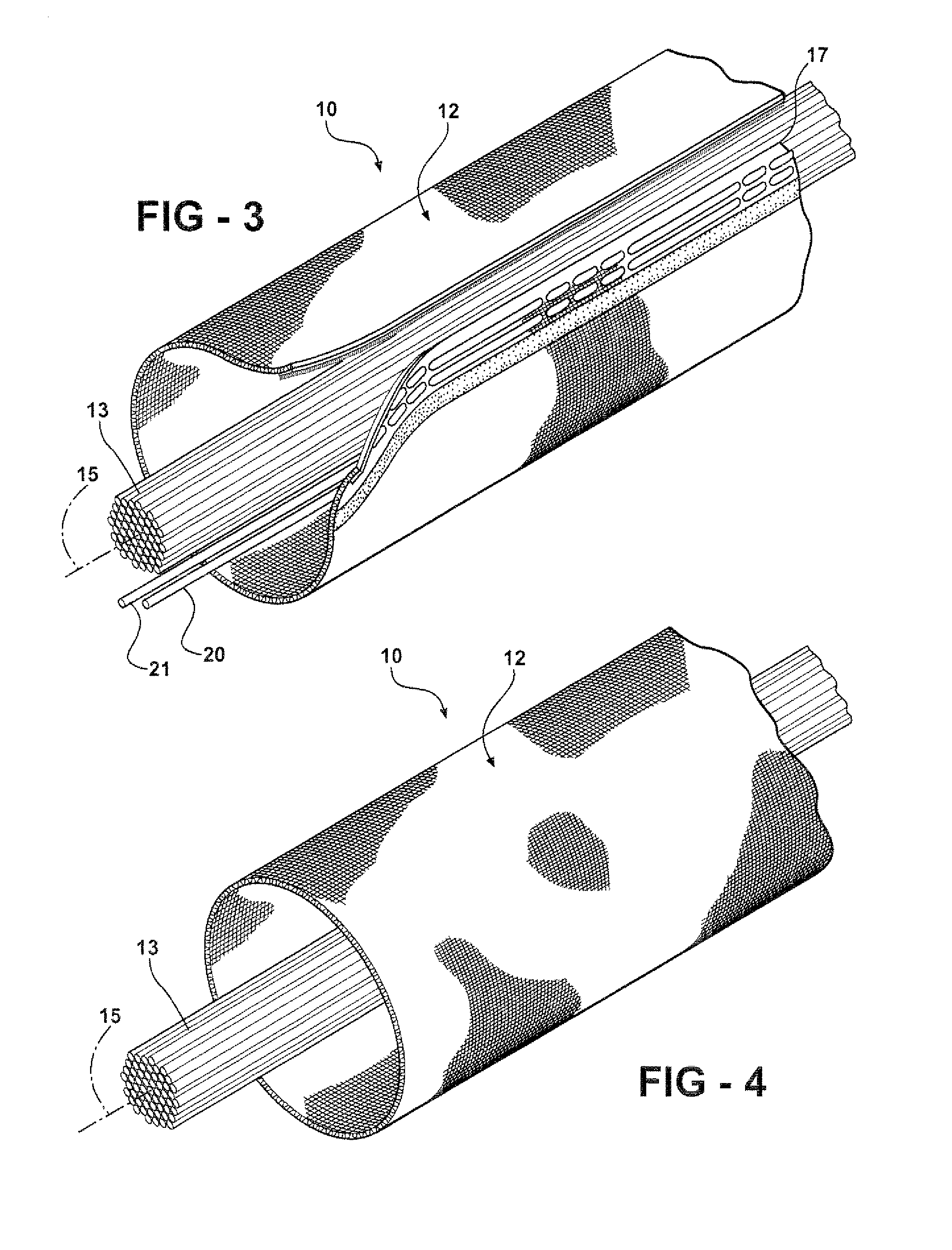

Protective sleeve fabricated with hybrid yard, hybrid yarn, and methods of construction thereof

ActiveUS20100084179A1Improve conductivityNon-insulated conductorsMagnetic/electric field screeningYarnArchitectural engineering

A hybrid yarn filament and sleeve constructed therefrom for protecting elongate members against at least one of EMI, RFI or ESD is provided, along with methods of constructing the hybrid yarn filament and sleeves. The hybrid yarn filament has a nonconductive filament and at least one conductive wire filament overlying an outer surface of the nonconductive filament. The hybrid yarn filament is arranged in electrical communication with itself or other hybrid yarn filaments during construction of the sleeve to provide uniform shielding against EMI, RFI, and and / or ESD.

Owner:FEDERAL MOGUL POWERTAIN LLC

Cables with stranded wire strength members

ActiveUS7326854B2Improve corrosion resistancePrevent and minimize dangerous gas migrationNon-insulated conductorsPower cables with screens/conductive layersCorrosion resistant alloyCoaxial cable

High strength cables formed from strength members. The strength members are formed from bimetallic filament wires which may be encased within a jacket of polymeric material. The bimetallic filament wires wherein the filaments include a high strength core and a corrosion resistant alloy clad forming the outer layer of the filament. The strength members may be used individually, as a central strength member, or even layered around a central axially positioned component or strength member, to form a layer of strength members. Cables of the invention may be of any practical design, including monocables, coaxial cables, quadcables, heptacables, slickline cables, multi-line cables, suspension cables, and the like.

Owner:SCHLUMBERGER TECH CORP

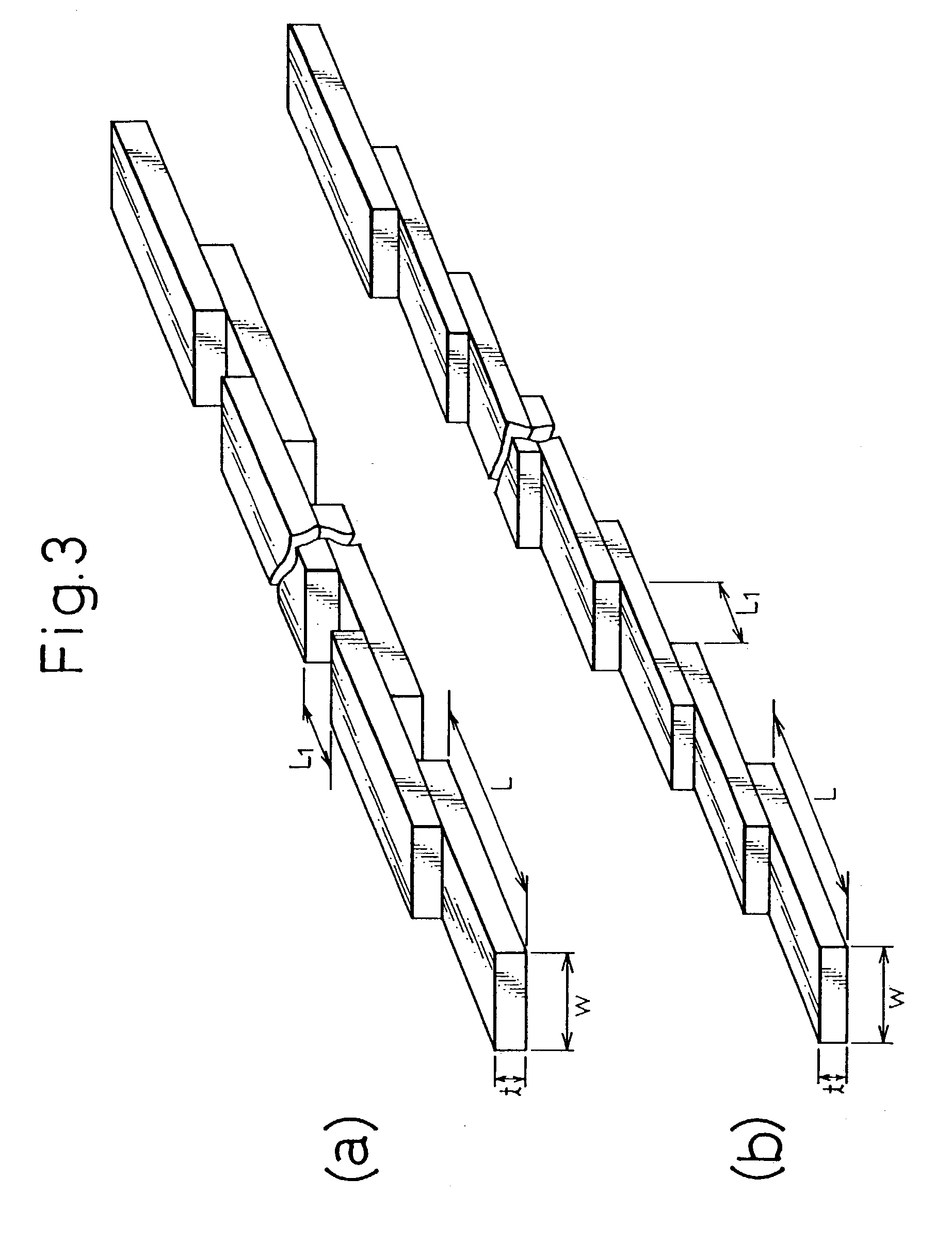

Anisotropic conductive material body, display apparatus, method for producing the display apparatus, and conductive member

ActiveUS7134879B2Improve mounting reliabilityImprove reliabilityCoupling device connectionsNon-insulated conductorsEngineeringConductive materials

Owner:SHARP KK

Cables with stranded wire strength members

ActiveUS20070044991A1Improve corrosion resistancePrevent and minimize dangerous gas migrationNon-insulated conductorsPower cables with screens/conductive layersCorrosion resistant alloyCoaxial cable

High strength cables formed from strength members. The strength members are formed from bimetallic filament wires which may be encased within a jacket of polymeric material. The bimetallic filament wires wherein the filaments include a high strength core and a corrosion resistant alloy clad forming the outer layer of the filament. The strength members may be used individually, as a central strength member, or even layered around a central axially positioned component or strength member, to form a layer of strength members. Cables of the invention may be of any practical design, including monocables, coaxial cables, quadcables, heptacables, slickline cables, multi-line cables, suspension cables, and the like.

Owner:SCHLUMBERGER TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com