Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2034 results about "Pressure casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

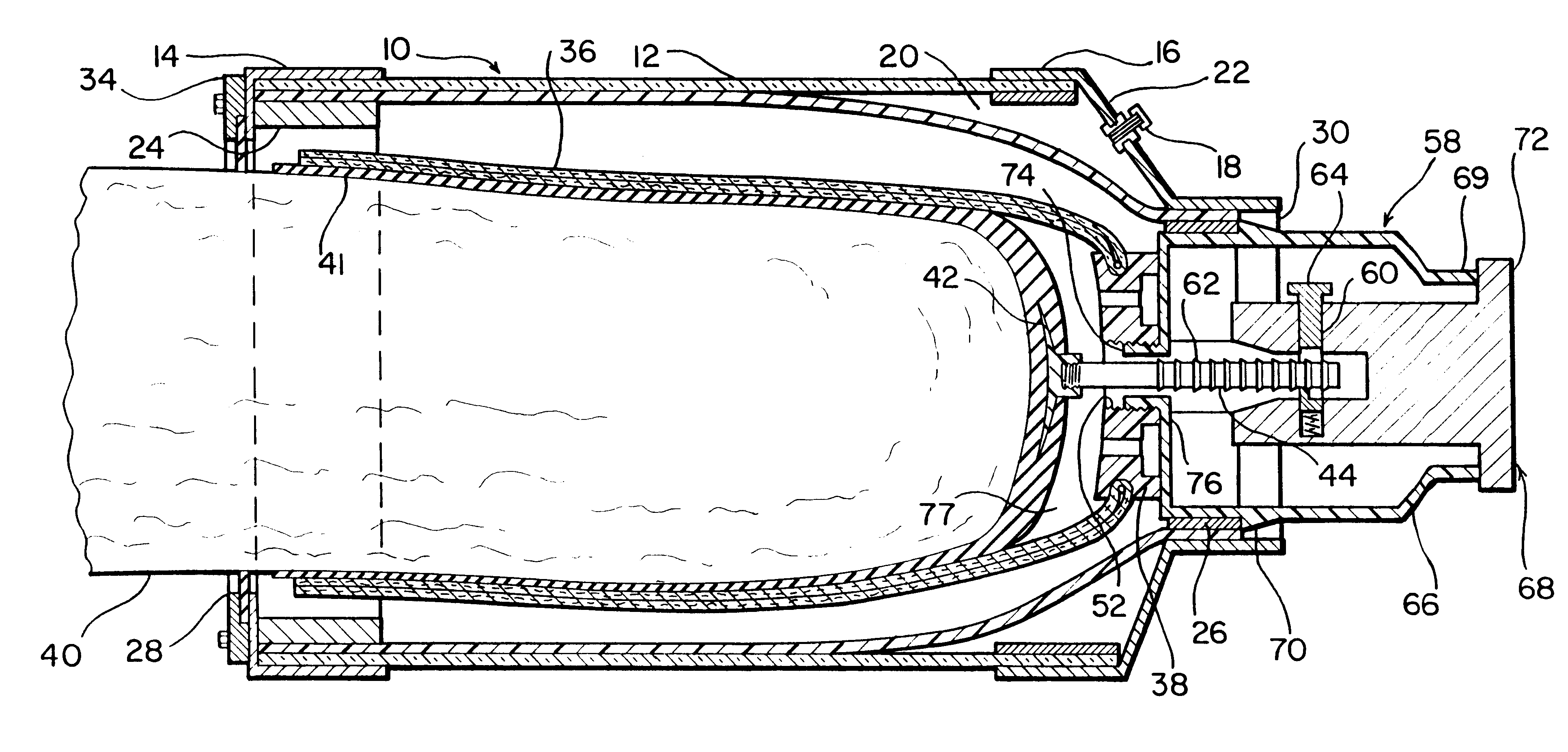

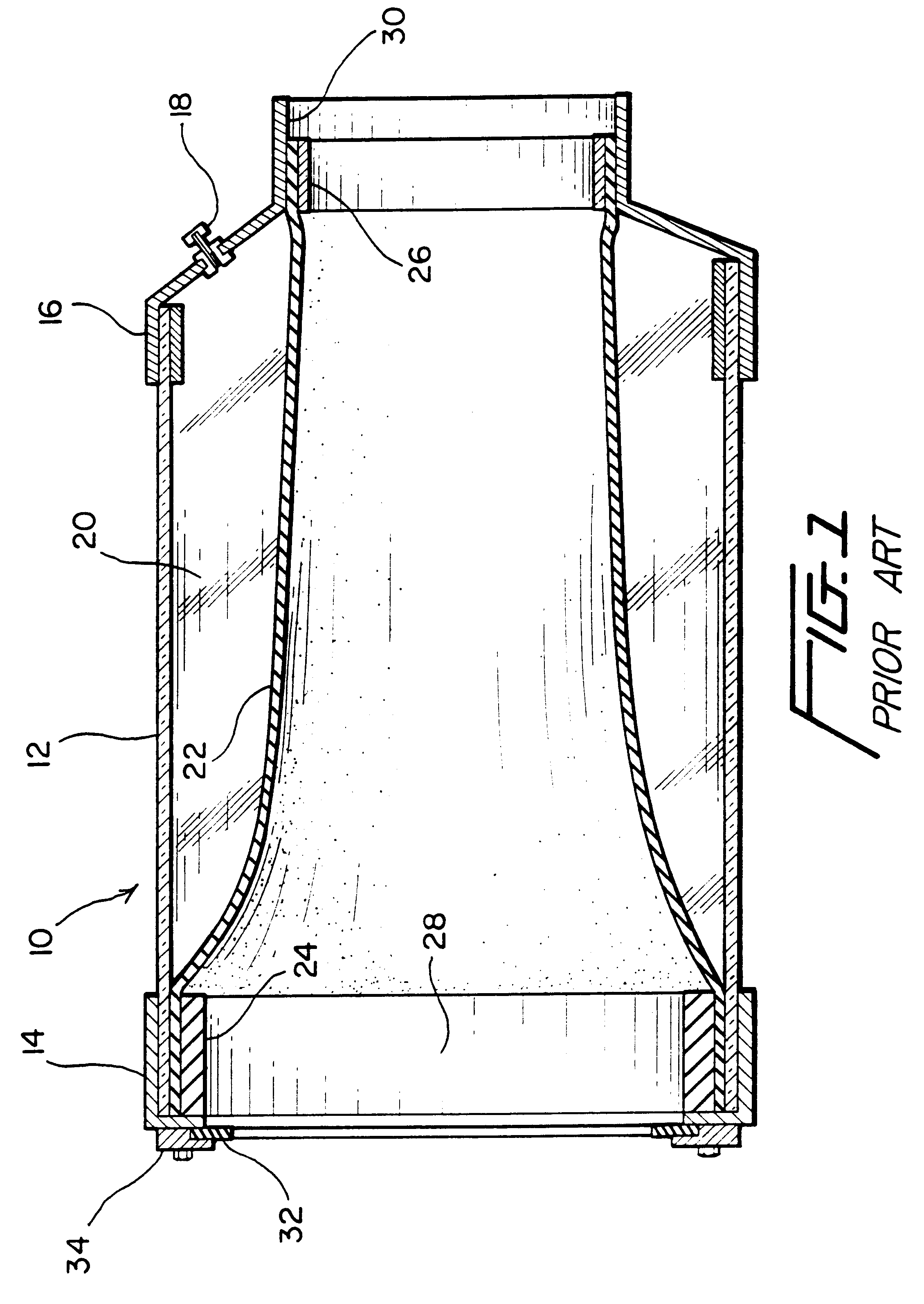

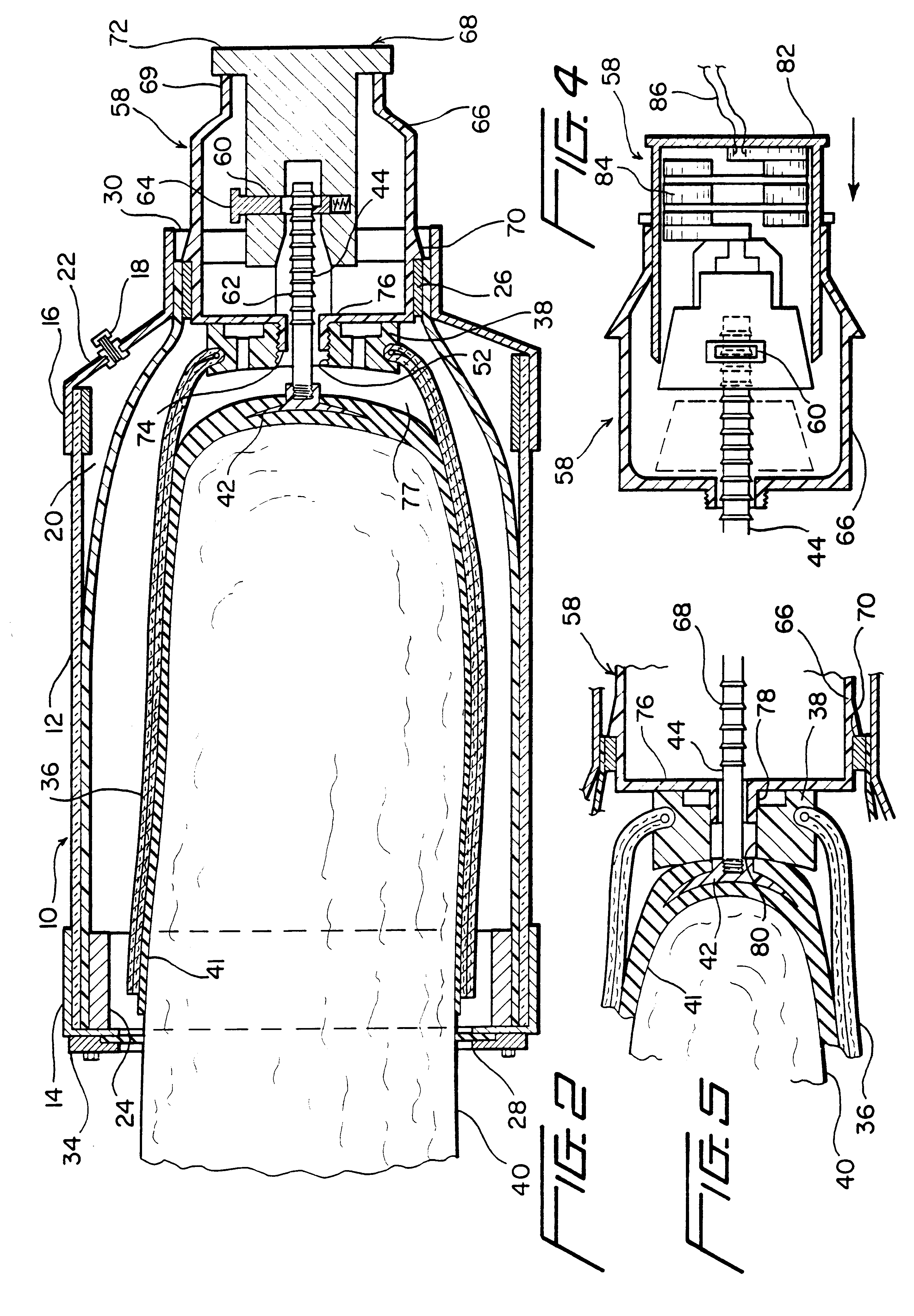

Method for making prosthetic residual limb socket

A definitive socket for residual limb prosthetic use is formed in a single molding step by compressive pressure casting or molding a pre-formed, moldable, hardenable socket material over a residual limb and curing the socket material to a load-bearing hardened condition while it is maintained under peripheral compressive pressure against the residual limb and while the residual limb is tensioned in a distal direction during the casting process. The combination of pressure casting the socket material and applying tension to the residual limb in a distal direction while the socket material is curing results in forming a definitive socket that fits well to the residual limb after curing without substantial rectification. Pressure relief formations, socket coverings, and a prosthesis coupler may be compression molded simultaneously with the socket.

Owner:KAUPTHING BANK

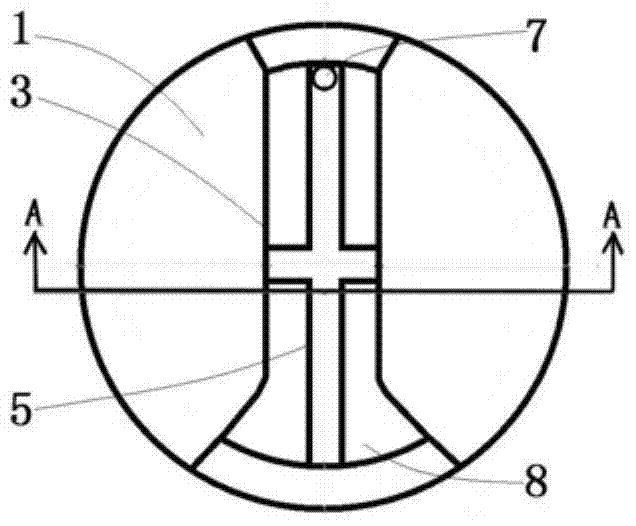

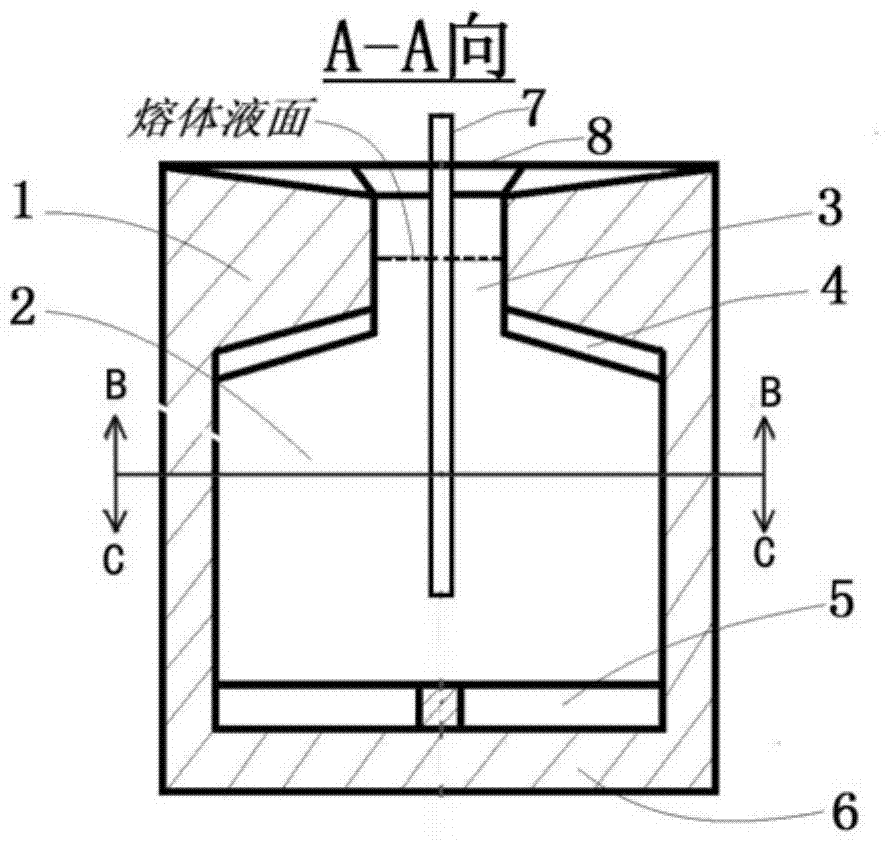

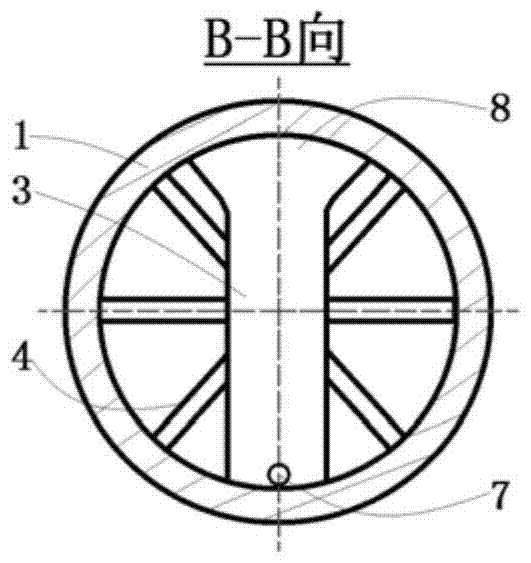

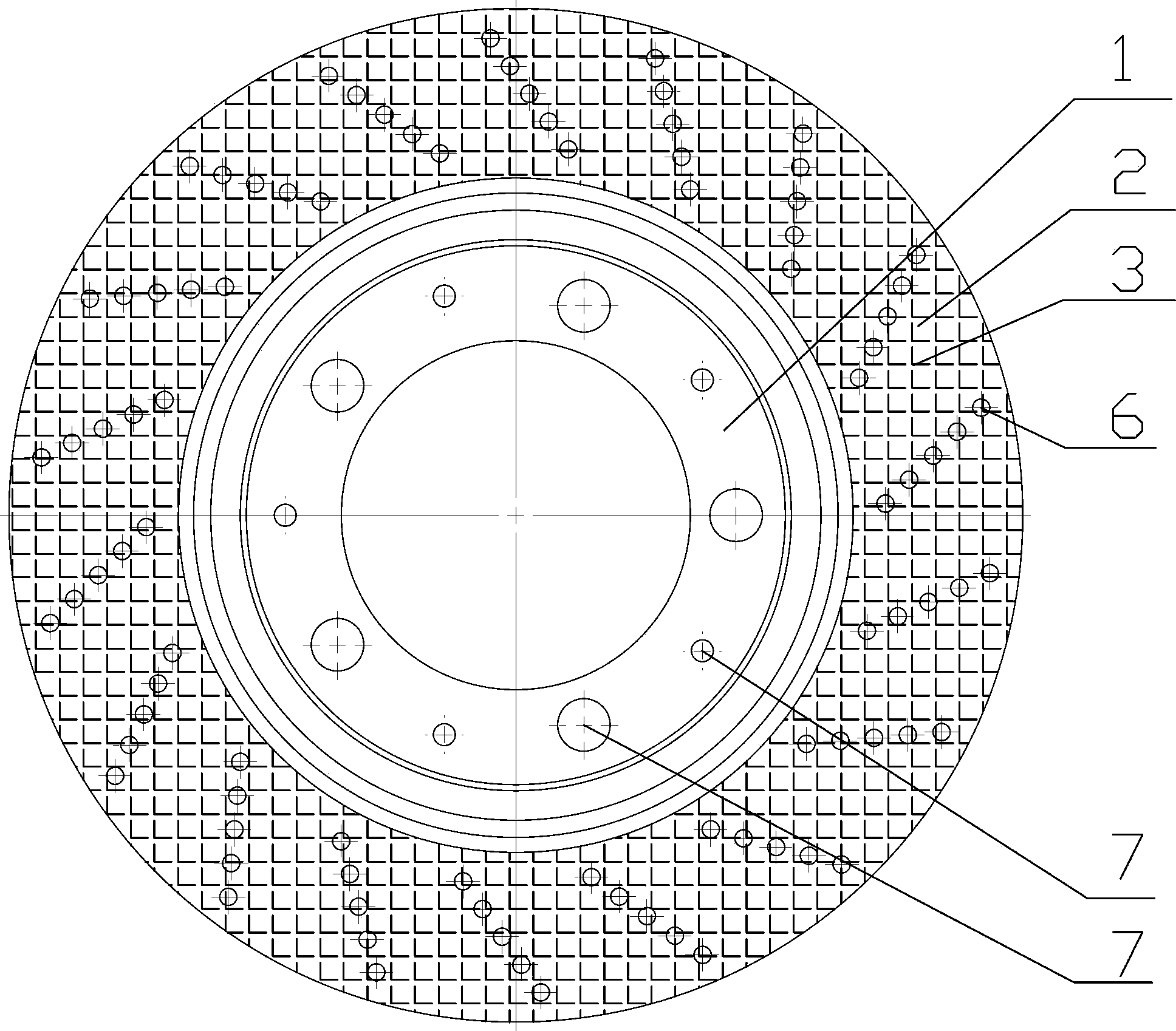

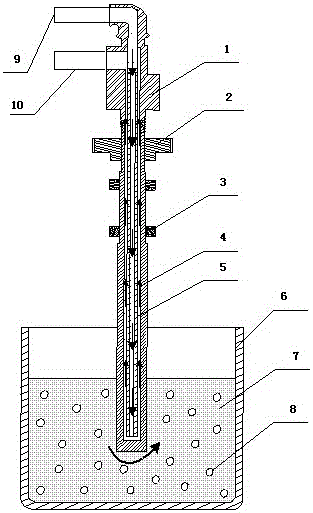

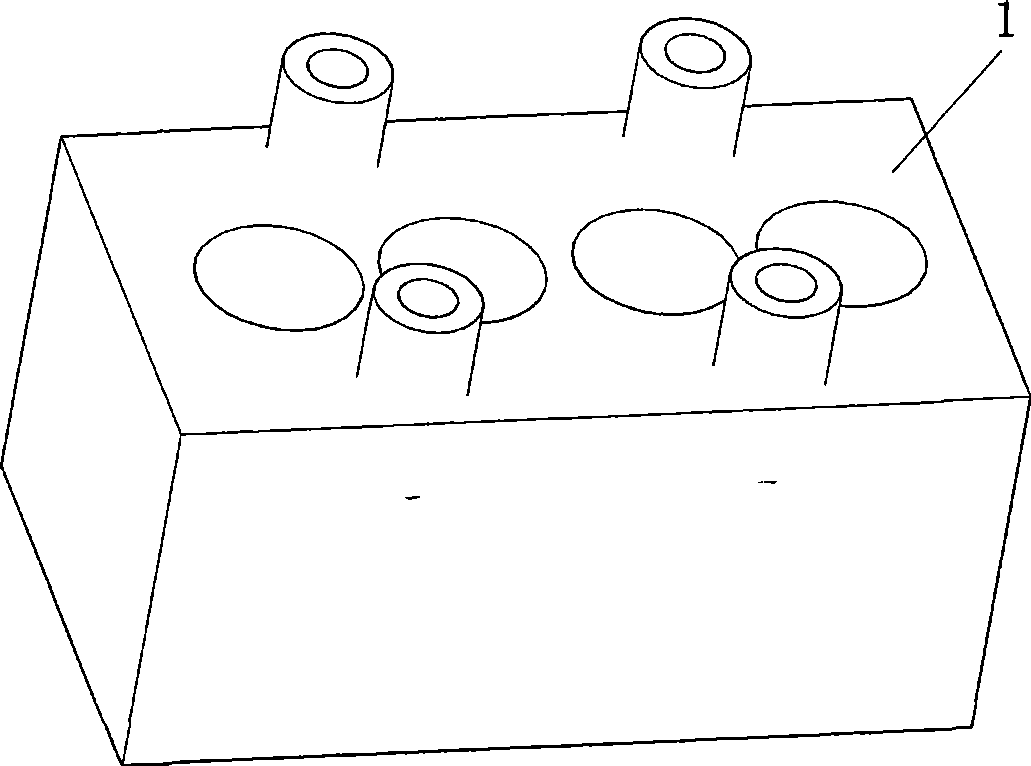

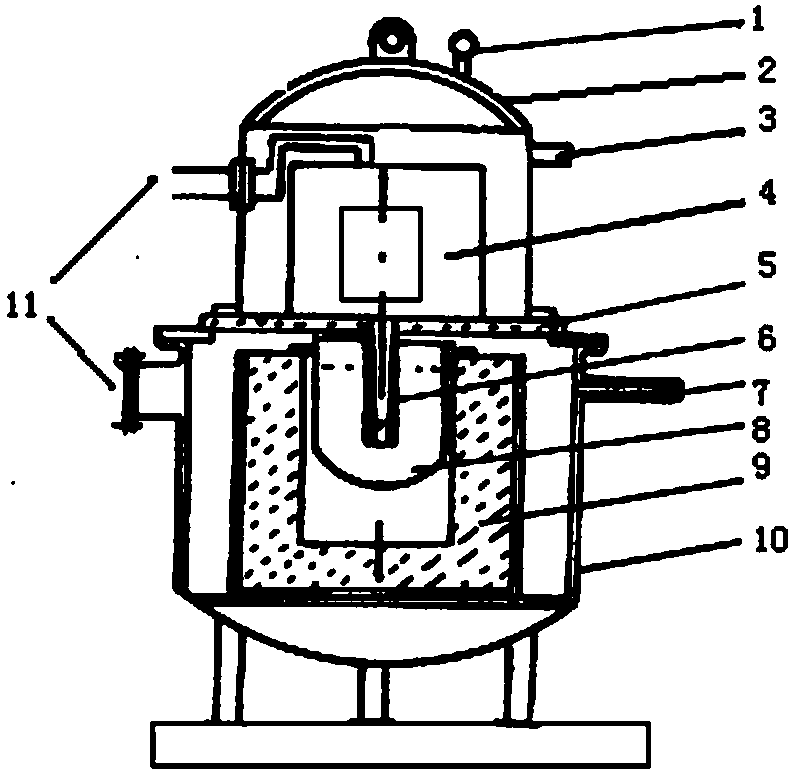

Stirring chamber for stirring molten metal and using method thereof

The invention discloses a stirring cavity used for stirring metal melt and a use method thereof, which belong to the field of material processing apparatuses for metallurgy, casting, chemical engineering and the like. The stirring cavity structurally consists of a melt container, a stirring cavity body, an upper stop opening, an upper blocking flange, a lower blocking flange, a lower bottom, a temperature sensor and a liquid taking / pouring port. According to the stirring cavity, the melt liquid level inside the stirring cavity is narrowed, so the stirring effect is effectively stopped from transferring to the liquid level, and the problems of melt oxidation and entrapped air risk are solved. The stirring cavity can be applied to various metal melt stirring and casting occasions; when the stirring cavity is used for batch-type casting such as pressure casting, the stirring cavity is adopted as the internal cavity structure of a pouring ladle; when the stirring cavity is used for continuous casting, the stirring cavity is adopted as the internal cavity structure of a melt hot top and can be directly connected with a continuous casting crystallizer; and full automation is realized in the whole process of melt stirring, chemical refining and casting in a pressure casting site.

Owner:GRIMAT ENG INST CO LTD

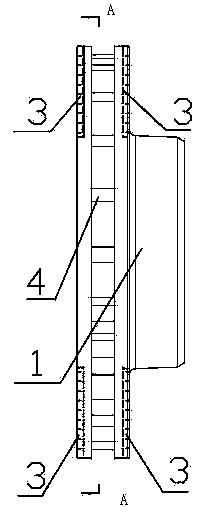

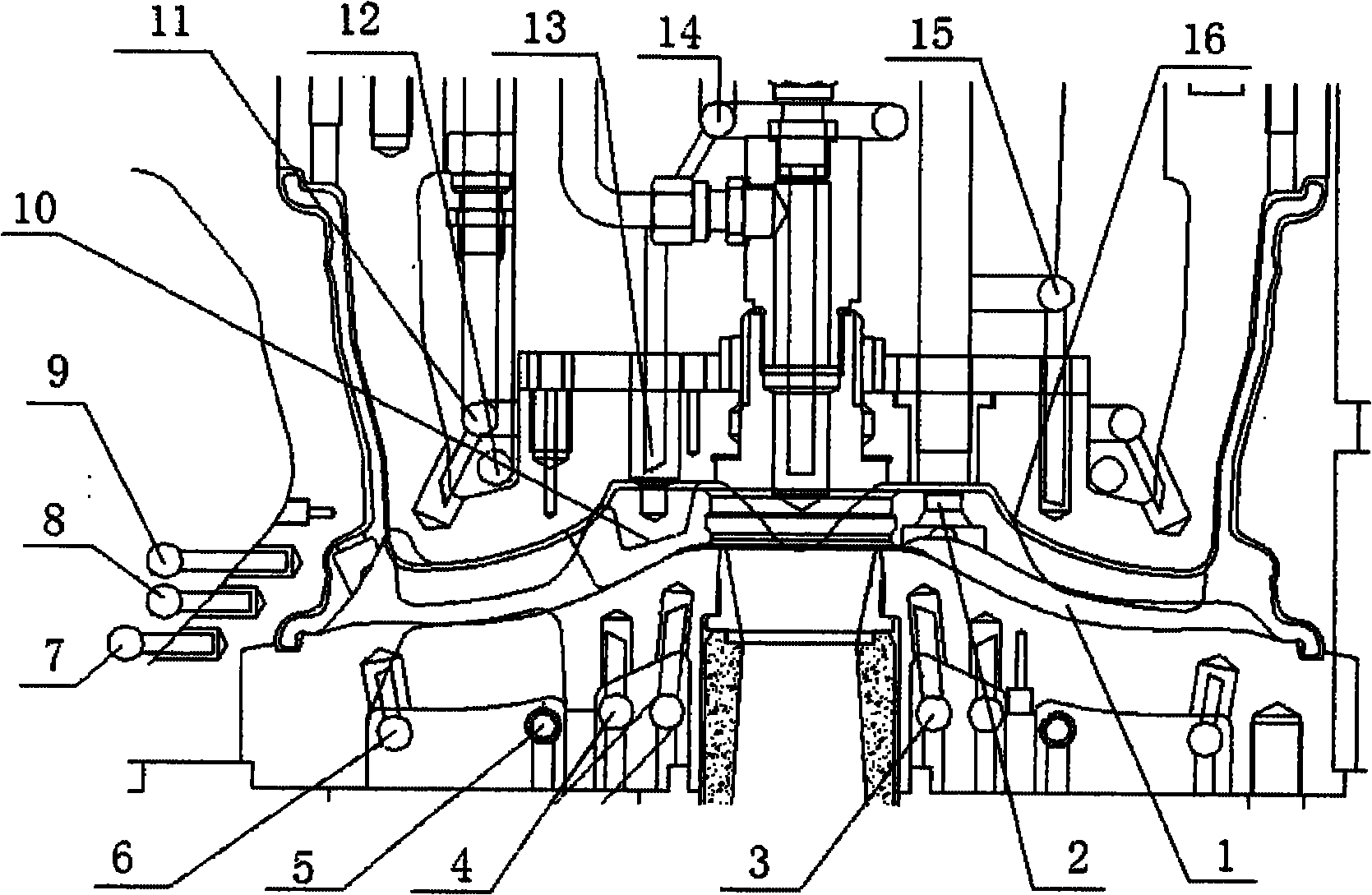

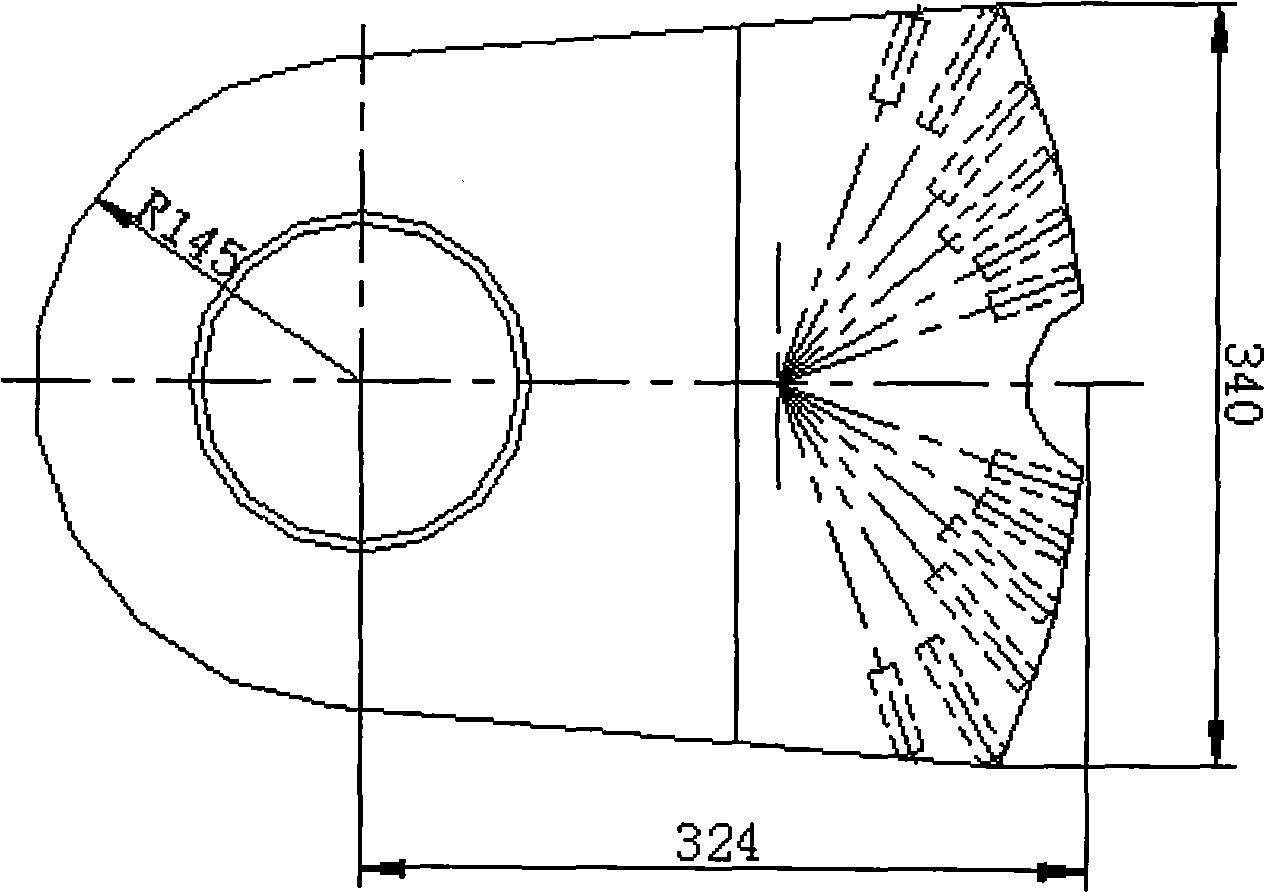

Low-pressure casting process and device for aluminum alloy wheel by bilateral pouring

The invention discloses a low-pressure casting process for an aluminum alloy wheel and a low-pressure casting device required for realizing the process. In the casting process, a casting manner of bilateral pouring is adopted; a pouring gate is formed on two sides of the wheel to allow aluminum liquid to enter from the wheel rim; and through the control of cooling, the aluminum liquid is crystallized from the wheel core to the wheel rim at a rapidly-cooled module temperature. The low-pressure casting device comprises a bilaterally-pouring module which is arranged on a machine bed platform below which a furnace cover of a low-pressure heat preserving furnace is arranged; and the furnace cover is arranged on the heat preserving furnace body which is connected with the bilaterally-pouring module through a liquid lifting pipe. In the process, as the bilaterally-pouring process is adopted for casting and symmetrical pouring gates are formed on two sides of the wheel, the aluminum liquid symmetrically enters from the two sides of the wheel rim to ensure a high casting composition consistency and a good mechanical property; in addition, the entire casting device has the advantages of simple device, identical process with that of the general low-pressure central casting, simple entire process and easy operation.

Owner:BAODING CITY LIZHONG WHEEL MFG

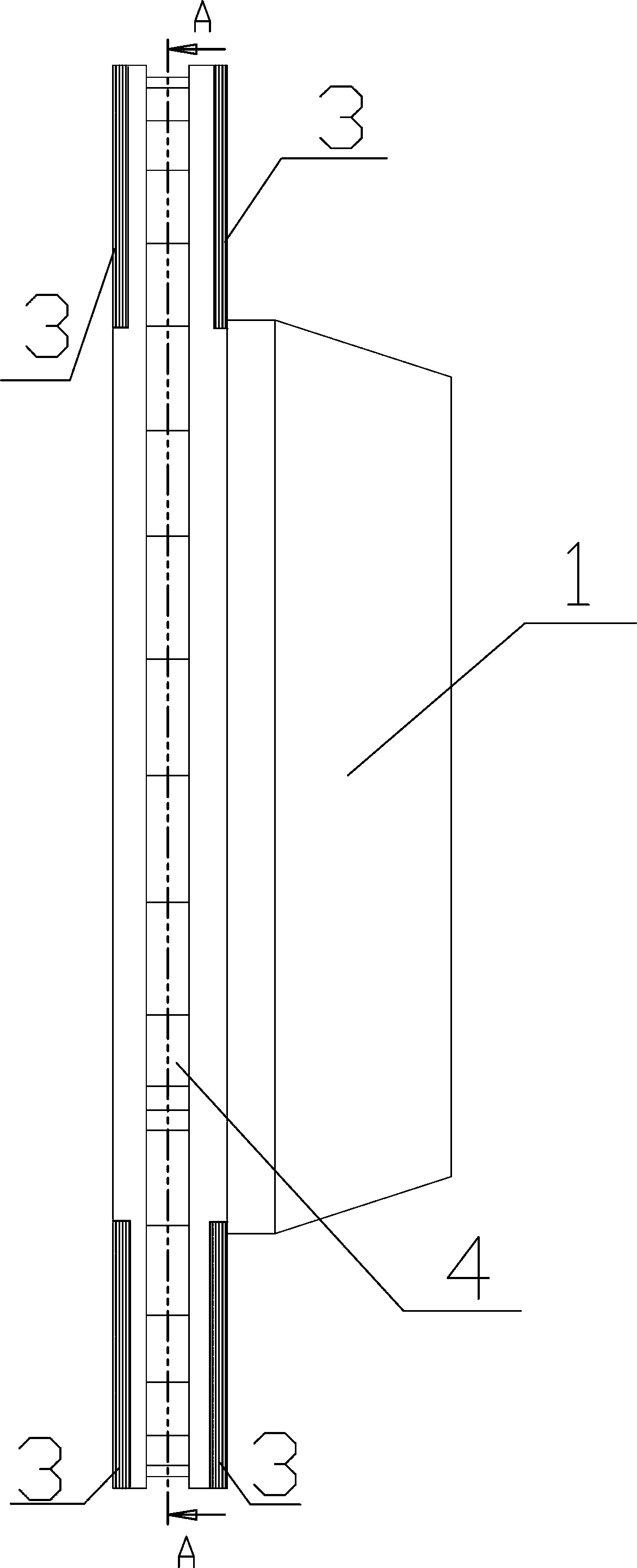

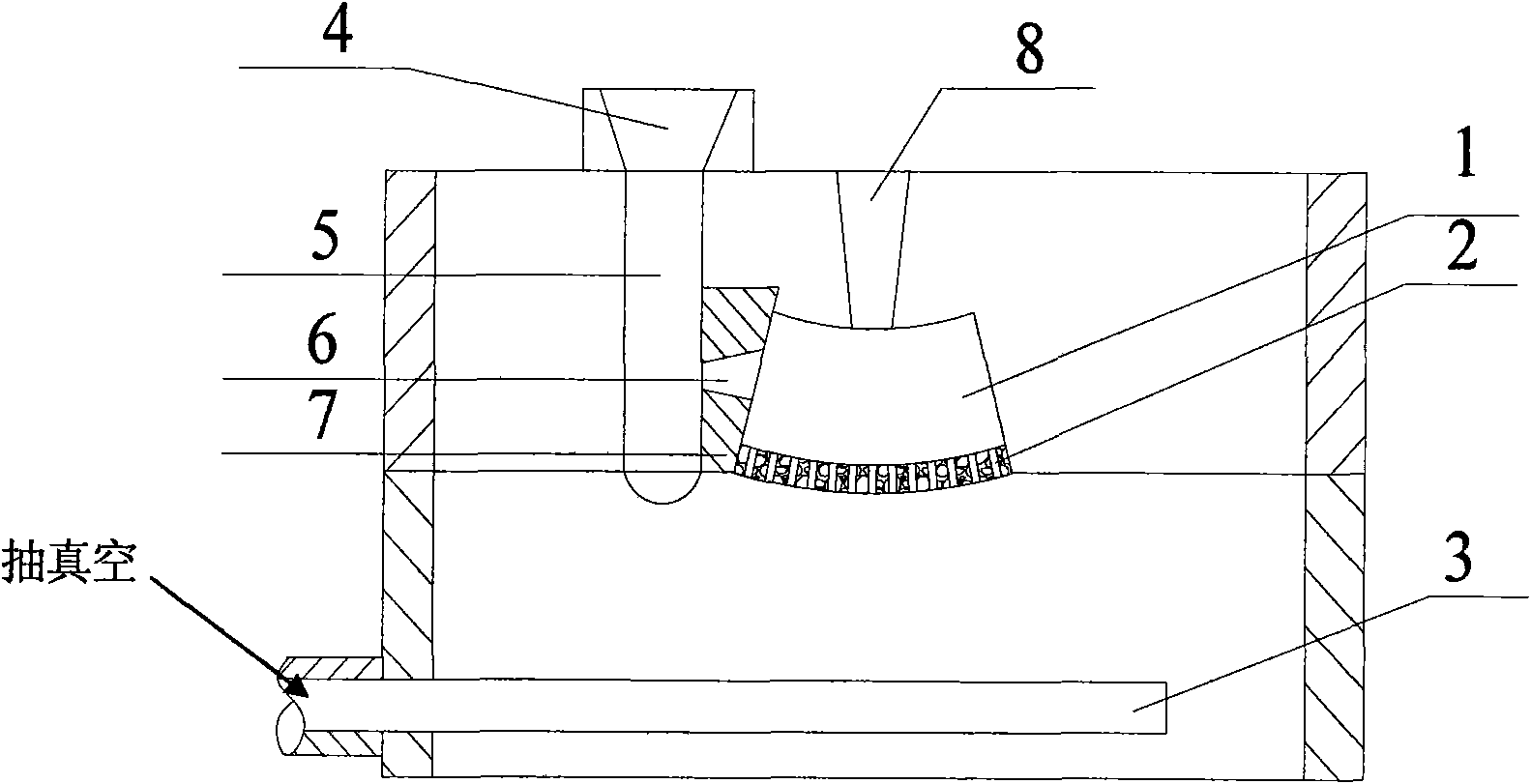

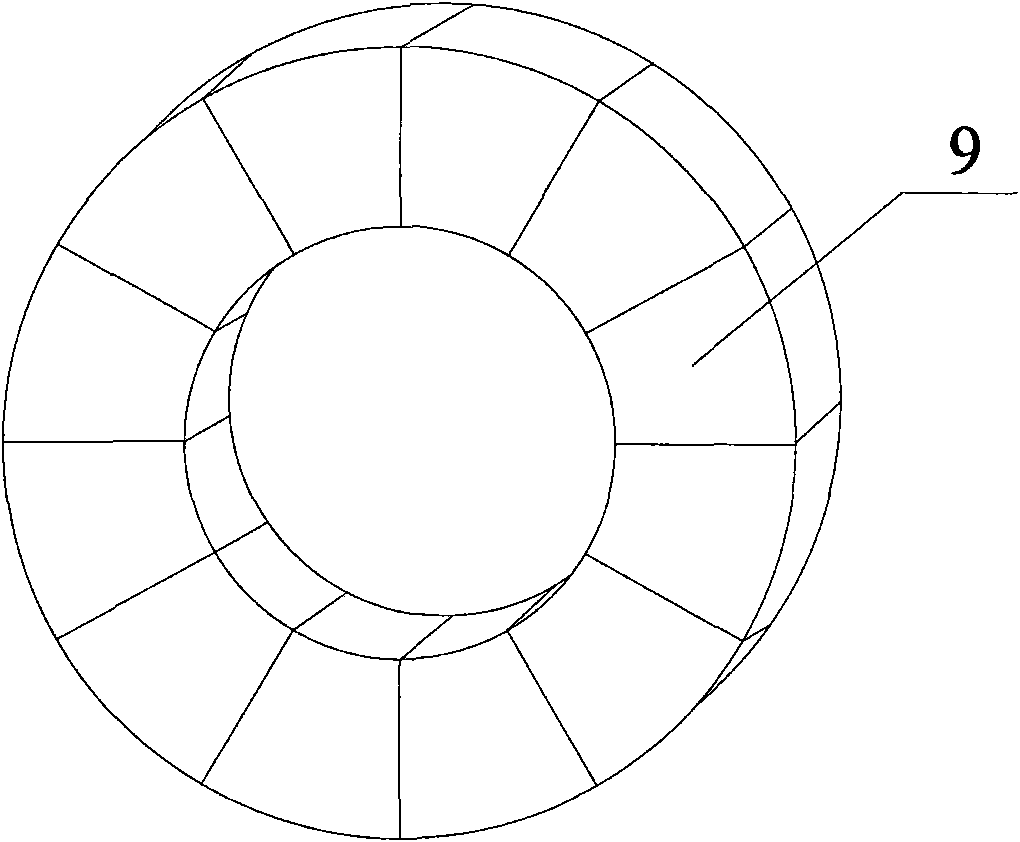

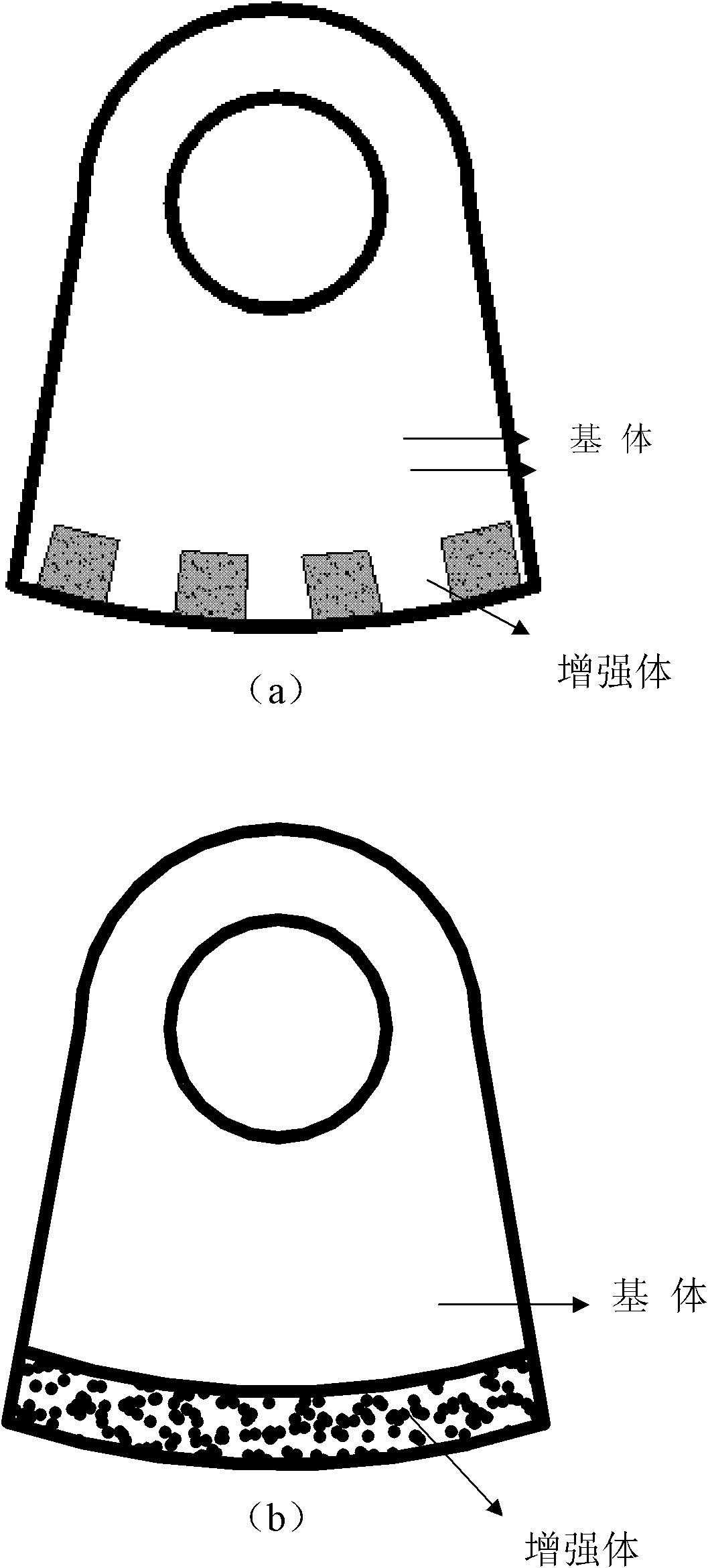

Road vehicle brake disc made of carborundum foamed ceramics/aluminum alloy composite materials and production method of road vehicle brake disc

ActiveCN104235237AReduce weightImprove feeding capacityBraking membersSlack adjustersNanoceramicAlloy composite

The invention discloses a road vehicle brake disc made of carborundum foamed ceramics / aluminum alloy composite materials and a production method of the road vehicle brake disc. The body of the reinforced-aluminum-alloy brake disc with a carborundum foamed ceramics framework is made of reinforced aluminum alloy materials such as aluminum alloy or nano ceramics particles or carbon nano-tubes. The carborundum foamed ceramics framework is integrally casted on two symmetrical friction surfaces of the brake disc, and heat dissipation grooves or air holes can be casted or do not need to be casted on the friction surfaces. A plurality of heat dissipation ribs are casted in the peripheral direction of non-friction surfaces. Mounting holes are formed in the disc body. The production method includes the steps of production of the carborundum foamed ceramics framework, preprocessing of the framework, design and production of a casting mold of the brake disc, lower-pressure casting of the brake disc, heat treatment of the brake disc, precision processing of the brake disc and storage of a finished product. The brake disc is simple in production technology, light in weight, high and stable in friction factor, high in heat conductivity, long in service life and applicable to existing road vehicles.

Owner:SHIJIAZHUANG DONGDA HUITONG NEW MATERIAL CO LTD

Low pressure casting process for aluminum alloy cylinder part

The invention discloses a low pressure casting process for an aluminum alloy cylinder part. The aluminum alloy used by the method comprises the following materials in percentage by mass: 6.0 to 7.0 percent of Si, 0.3 to 0.5 percent of Mg, 0.1 to 0.2 percent of Ti, 0.05 to 0.15 percent of Fe and the balance of Al. After melting, thining, modification, and refining, the materials are subjected to low pressure casting and pouring; and after low pressure casting process of liquid lifting, filling, pressure maintaining and pressure releasing, the materials form a cast in a die cavity; and after a cast blank is subjected to solution treatment, and heat treatment of incomplete artificial aging, the cast has the advantages that: the texture is compact, casting defects such as pores, shrinkage porosity, shrinkage cavity, slag inclusion, and the like are avoided, the quality of the cast is improved; meanwhile, the working allowance of the cast is less, so the material utilization is improved and the production cost is reduced.

Owner:王宏波

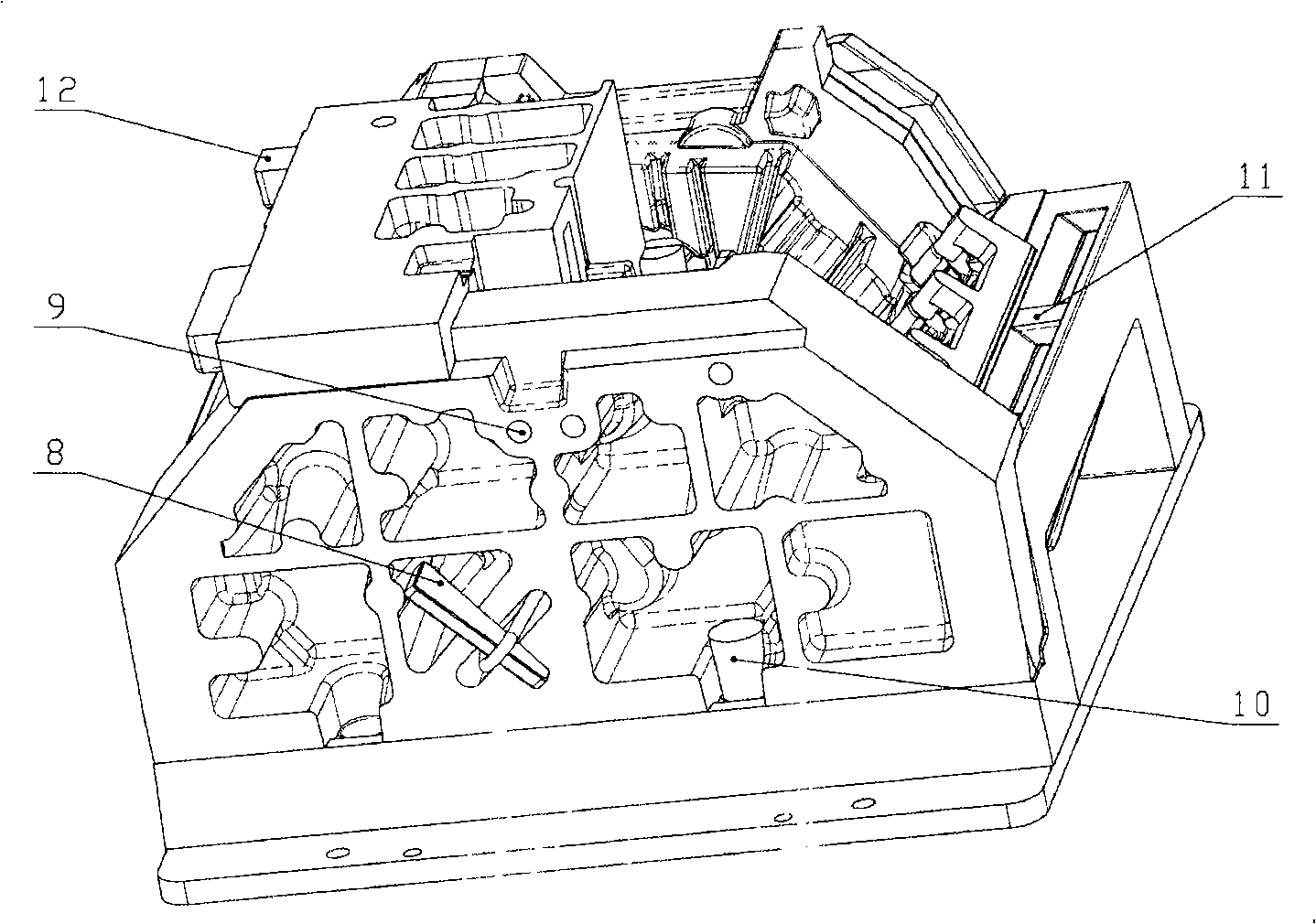

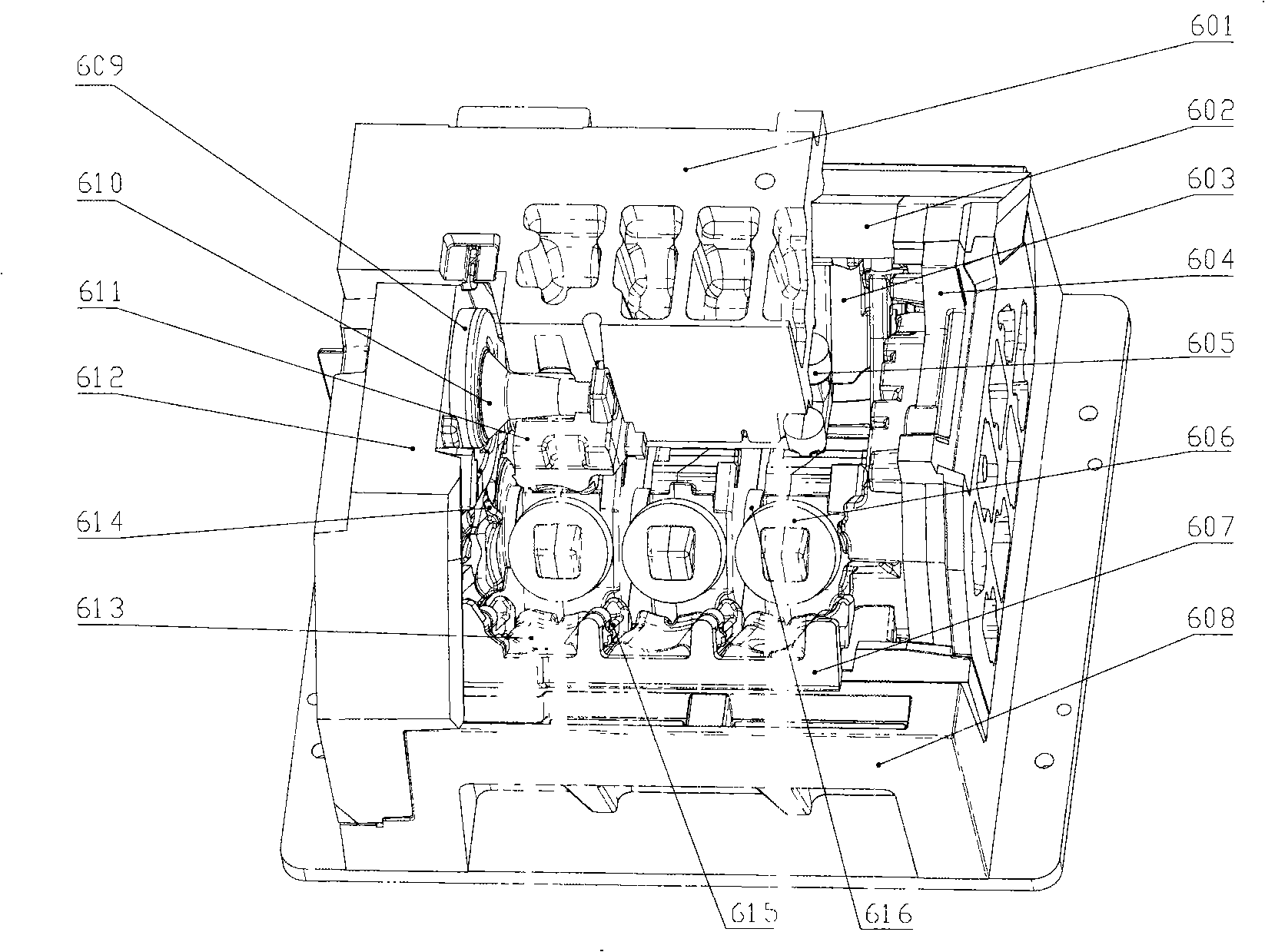

Low pressure multiple-core casting technique of engine V6 aluminum cylinder

InactiveCN101298091AImprove qualityLow costFoundry mouldsFoundry coresProduction lineHigh volume manufacturing

The invention discloses a low-pressure core assembly casting technique for V6 aluminum cylinder-block of engines, which is used for casting V6 aluminum cylinder-block of automobile engines. The casting technique adopted combines a low-pressure casting method and a core assembly method; the three-dimensional modeling of products is firstly carried out; according to the shape of the cast product, a crankcase is determined to be downwards and the aluminum liquid is let in from the baffle of the crankcase during casting course; the position of the sprue is selected and the size of the sprue is determined; a casting simulation software is adopted to carry out a simulation casting, the defects that are possible to occur are analyzed and a technical design scheme is made according to the analytic result, which essentially comprises the steps of : 1) making cores; 2) combining sand cores into a sand core group (6); 3) casting under low pressure. The casting technique of the invention can adopt flexible core assembly modes according to different shapes of engine blocks to produce aluminum cylinder-block cast products which are complex and of fine quality and has thin wall, meanwhile, the casting technique is applicable to the mass production with automatic production lines, thus having the advantages of low cost, high efficiency and high qualification rate.

Owner:NINGBO HELI TECH CO LTD

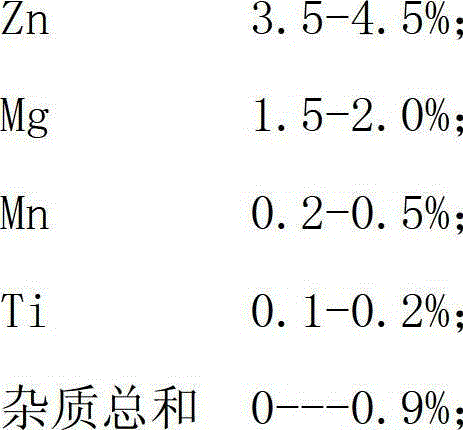

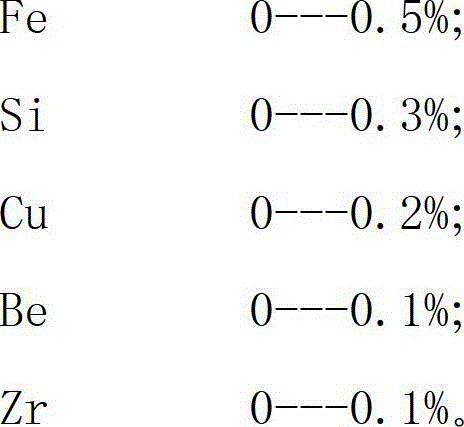

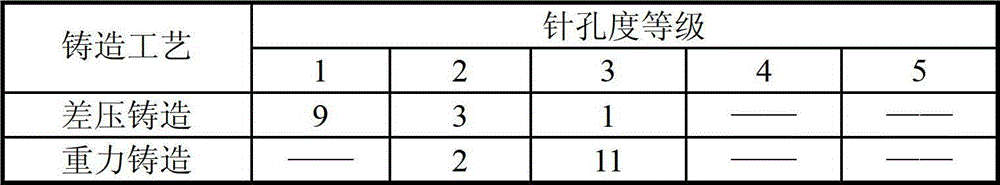

Counter-pressure casting process for ZL424 aluminum alloy castings

ActiveCN102873301AIncrease the speed of solidificationNot easy to precipitateCounter pressureShrinkage porosity

The invention relates to a counter-pressure casting process for ZL424 aluminum alloy castings. The process includes the steps: (1) alloy burdening; (2) using secondary refining and intermediate purifying for smelting alloy; (3) using a counter-pressure casting method for preparing ZL424 aluminum alloy castings; (4) cleaning the ZL424 aluminum alloy blank castings prepared at the step (3) before heat treatment; (5) checking the ZL424 aluminum alloy blank castings subjected to heat treatment. Blank castings prepared by the counter-pressure casting process overcome defects of ZL424 aluminum alloy castings obtained by traditional gravity casting methods, internal pinholes, microscopic shrinkage porosity and microcracks of castings are eliminated, and chemical component acceptability, mechanical performance and compactness of the castings are improved. In addition, the process has the advantages of high efficiency, high casting yield, low manufacturing cost and the like.

Owner:TIANJIN NAVIGATION INSTR RES INST

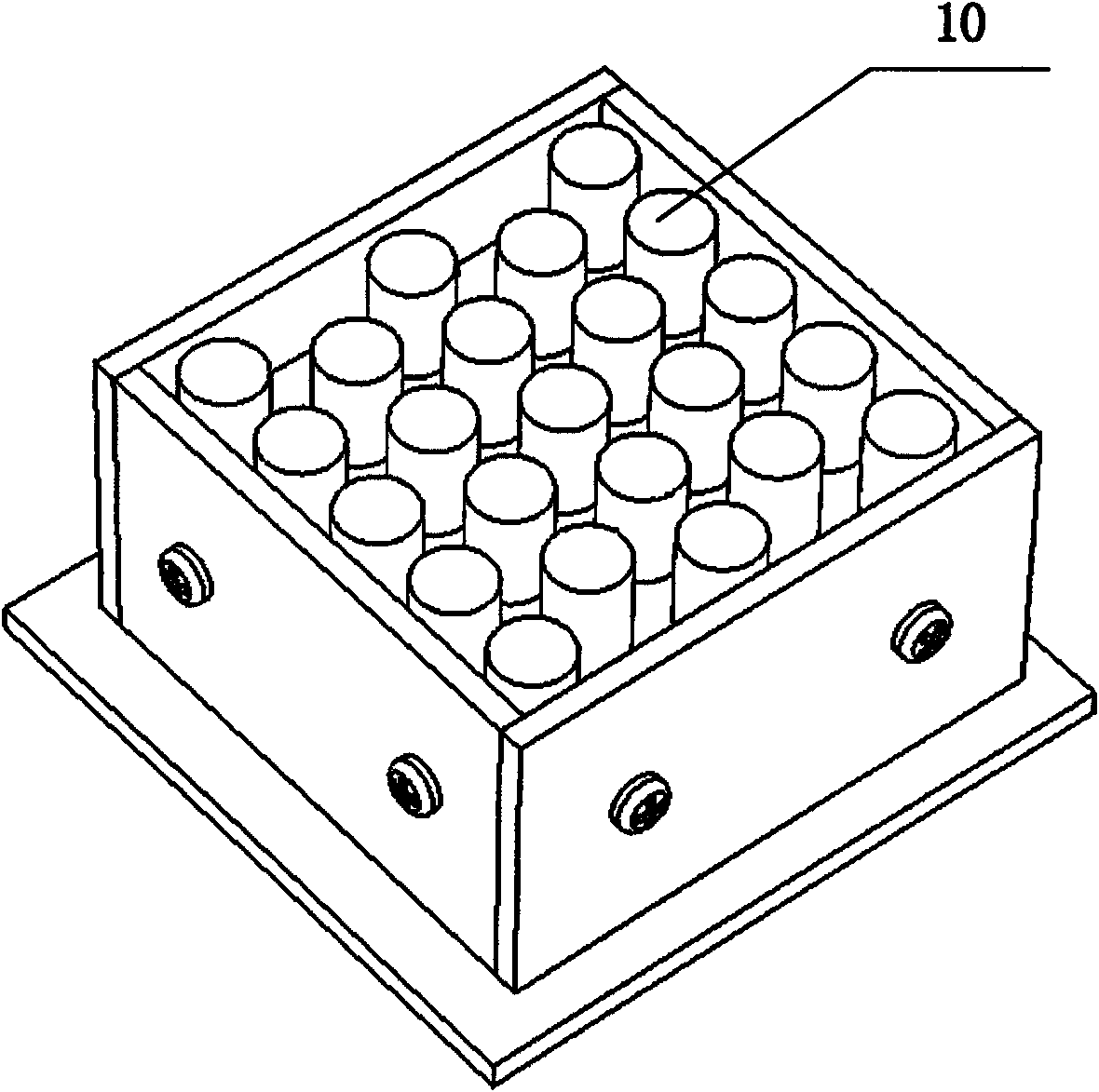

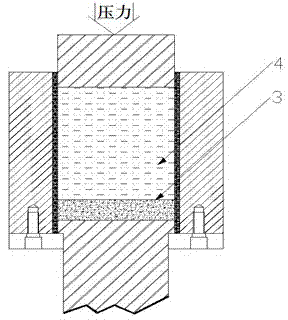

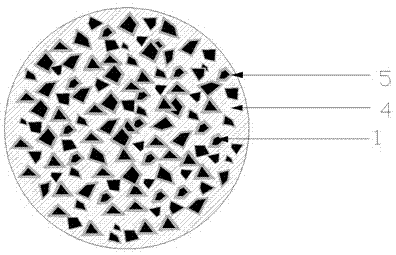

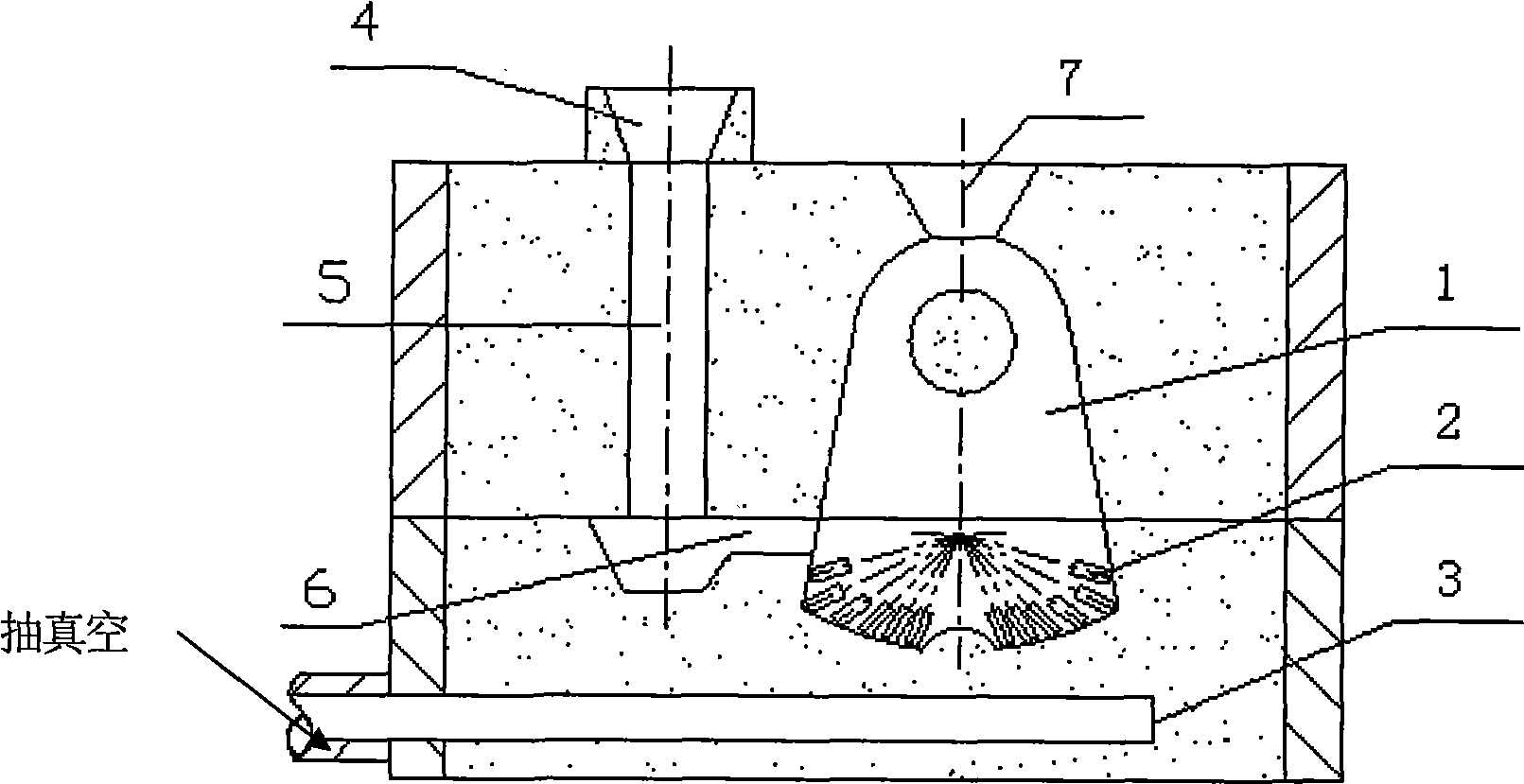

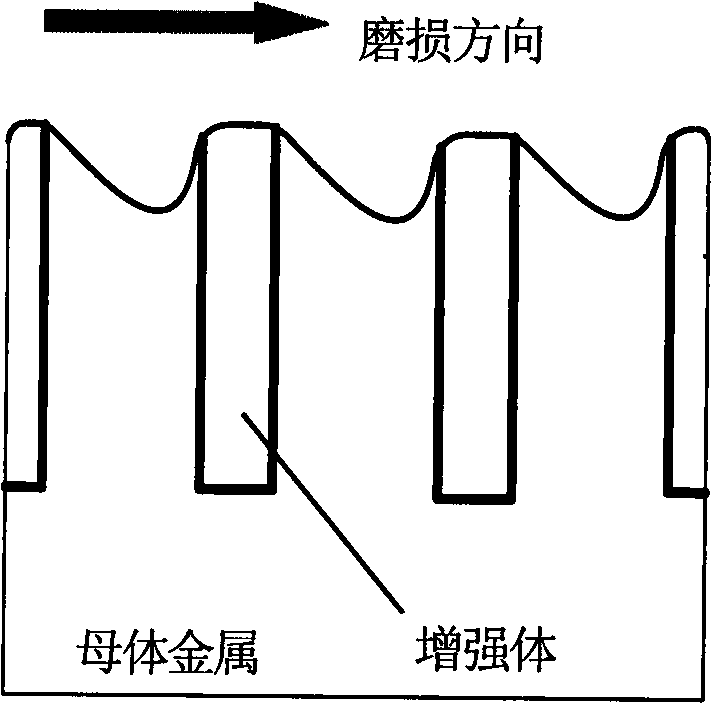

Composite-material grinding roller, grinding disc, and negative-pressure casting method thereof

InactiveCN101585081AQuality improvementHelps prevent scourGrain treatmentsShadow effectPressure casting

The invention provides a composite-material grinding roller, a grinding disc, and a negative-pressure casting method thereof. The method comprises: preparing WC particles and binder into paste; filling a mold with the paste to form a honeycomb-like prefabricated body; placing the prefabricated body on the side of the end face of a casting mold cavity; melting metal parent material to form molten metal; allowing the molten metal to enter the bottom of the casting mold cavity from a straight pouring channel and an inner pouring channel of a pouring cup; and forming the composite-material grinding roller and the grinding disc after the molten metal solidifies. As a reinforcement body of the invention adopts a honeycomb-like structure, on the one hand, the reinforcement body is favorable for blocking the scouring effect of the molten metal, benefiting the stable production of castings and reducing reject rate, and on the other hand, the honeycomb-like reinforcement body can realize macro-shadow effect during the service of the composite-material grinding roller, helps to improve the wear resistance of materials, and can also avoid the phenomena that the purely block-shaped reinforcement body peels off or falls.

Owner:XI AN JIAOTONG UNIV +1

Degradable open porous magnesium and magnesium alloy biomaterial and preparation method thereof

The invention discloses a degradable open porous magnesium and magnesium alloy biomaterial and a preparation method thereof. The magnesium and magnesium alloy biomaterial is in a completely open structure, the hole shape and size are controllable, holes are communicated by virtue of communicating holes, and the number and size of the communicating holes in hole walls are controllable; the holes are uniformly distributed and the porosity is adjustable. The preparation method comprises the following steps: sintering sodium chloride crystal particles to obtain an open porous sodium chloride prefabricated structure; pouring molten magnesium or magnesium alloy into a mould cavity with a sodium chloride prefabricated body, and performing seepage pressure casting; and removing magnesium or magnesium alloy block outer skin with the sodium chloride prefabricated body, washing with alkali, and filtering to remove sodium chloride to obtain the degradable open porous magnesium and magnesium alloy biomaterial. The preparation process is simple, convenient to perform and pollution-free; the prepared open porous structure is provided with the communicated and uniformly distributed holes, is controllable in hole shape and size, relatively high in porosity and strength, free of pore former residues and pore closing phenomenon and adjustable in degradation rate, and can serve as a new-generation degradable bone tissue engineering scaffold.

Owner:SHANGHAI INNOVATON MEDICAL TECH CO LTD

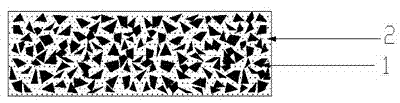

Method for preparing ceramic particle reinforcement of composite wear-resistant material

The invention relates to a method for preparing ceramic particle reinforcement of a composite wear-resistant material. The ceramic particle reinforcement is prepared by sintering WC ceramic particles in a vacuum high-temperature environment. By designing molds in different shapes and dimensions, a preformed body can be made into various required shapes, such as a block and a honeycomb, and the like. The preformed bodies are regularly arranged on an end face of a casting mold. After metals are cast by a negative pressure casting method, the liquid metal permeates the ceramic particle reinforcement (pores) of the preformed bodies to form the composite material under the action of casting infiltration; and a base metal on a working surface of a casting piece and the formed composite material coexist. Therefore, the ceramic particle reinforcement improves the wear resistance of a wear-resistant piece, and has certain impact resistance.

Owner:XI AN JIAOTONG UNIV +1

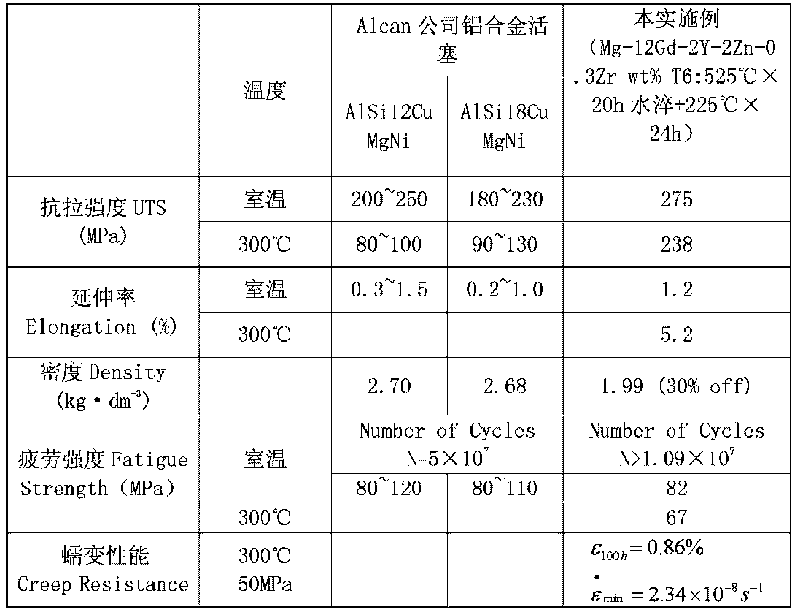

Low-pressure casting preparation method of heat resistant rare earth-magnesium alloy engine pistons

ActiveCN101693971AFine grainImprove creep resistanceMachines/enginesPistonsManufacturing technologyPressure casting

A low-pressure casting preparation method of heat resistant rare earth-magnesium alloy engine pistons in the field of the automobile manufacturing technology comprises preparing master alloy Mg-Y, Mg-Gd, Mg-Zr, industrial pure magnesium and industrial pure zinc, smelting alloy, obtaining magnesium alloy fused mass, squeezing and casting the magnesium alloy fused mass, obtaining the primary blank of a magnesium alloy piston, and obtaining a heat resistant tare earth-magnesium alloy engine piston through orderly carrying out the solid solution treatment, the cold treatment and the aging treatment. The method can prepare pistons with excellent high-temperature strength, fatigue strength and creep resistance performance through applying 0.2-0.8 atm pressure and selecting proper heat resistant rare earth-magnesium alloy, selecting proper low-pressure casting technical parameter and adjusting corresponding heat processing technology.

Owner:SHANGHAI JIAO TONG UNIV

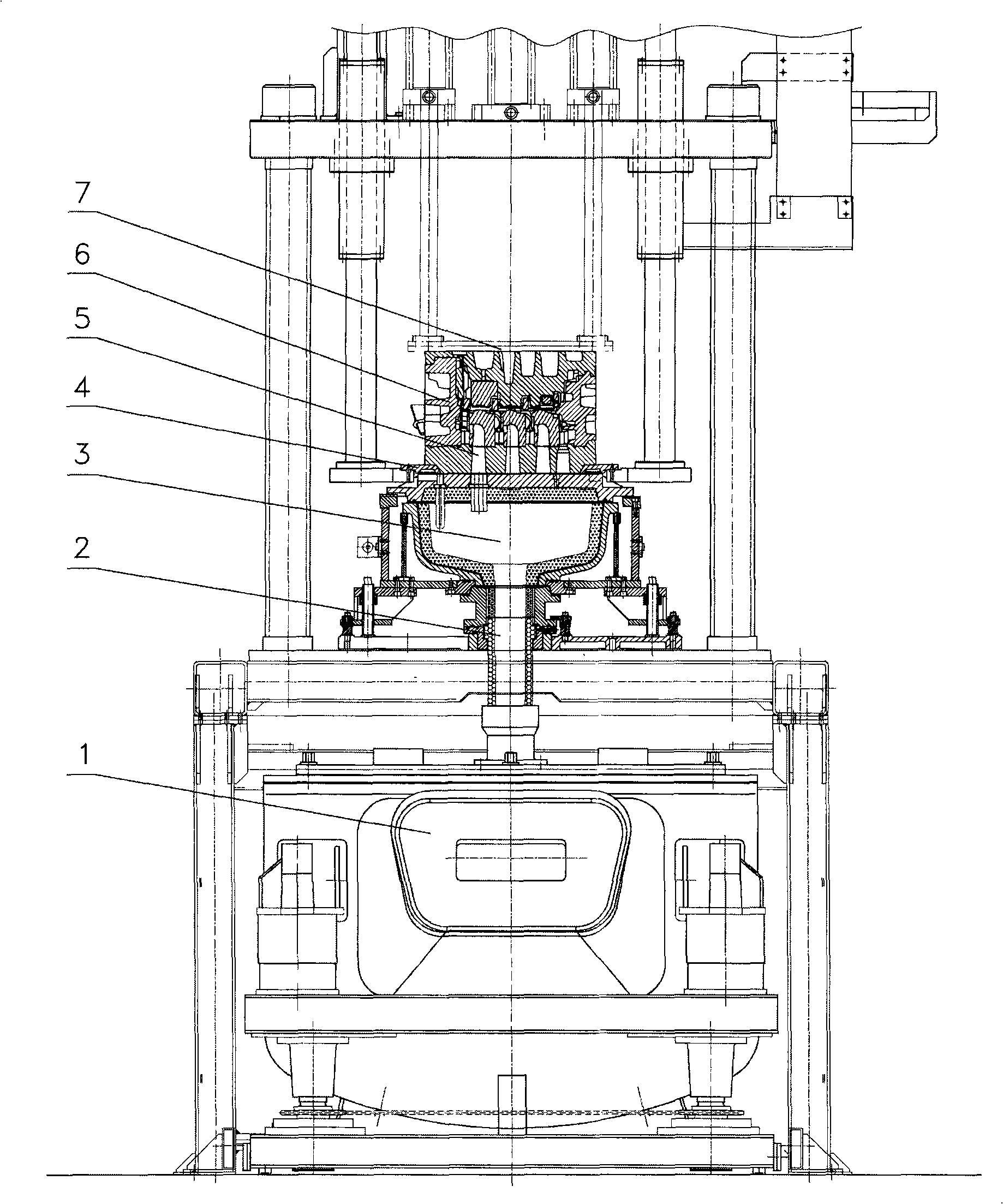

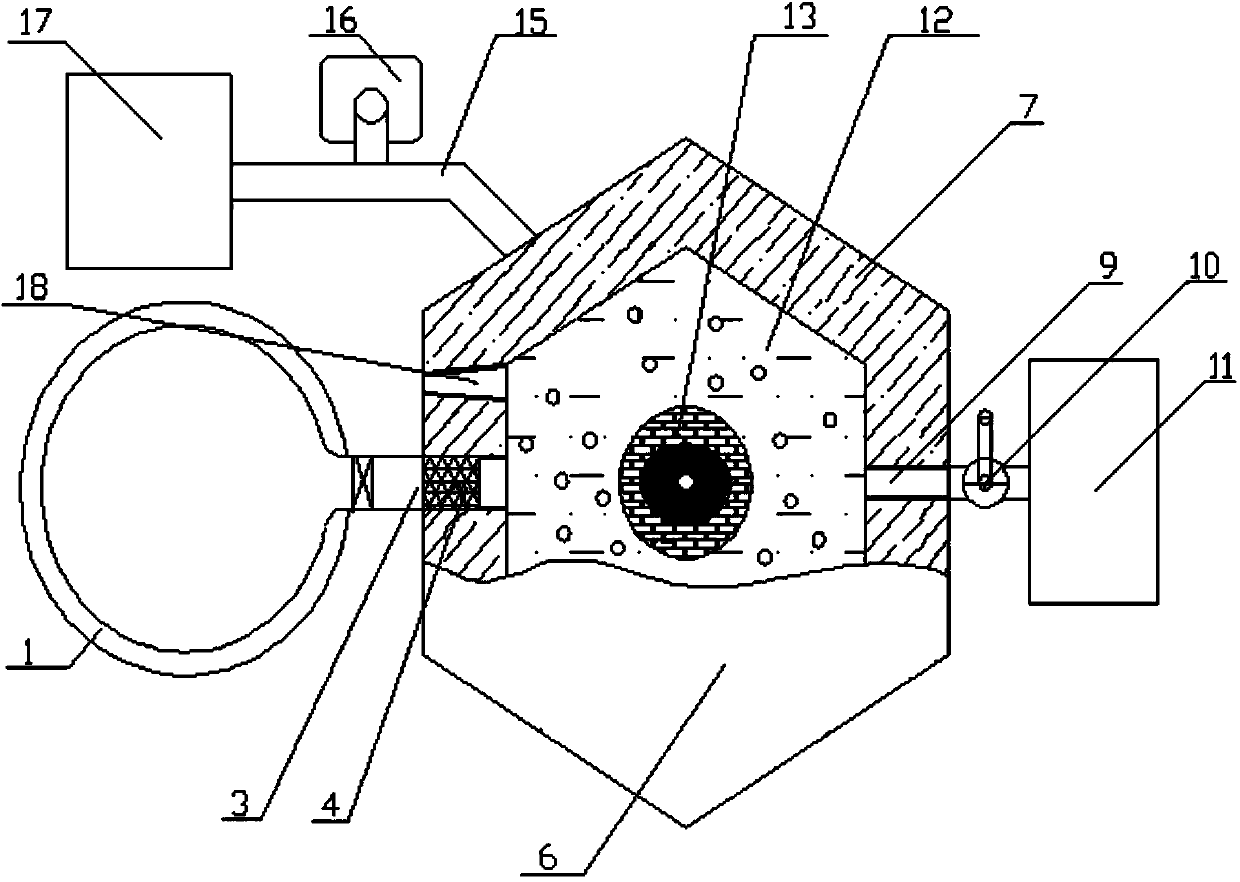

Vacuum low-pressure casting forming device for titanium alloy component

InactiveCN104028729AImprove feeding capacitySuppresses the tendency to segregate chemical componentsActuatorPressure difference

The invention provides a vacuum low-pressure casting forming device for a titanium alloy component. The vacuum low-pressure casting forming device for the titanium alloy component comprises a device body, a vacuum low-pressure casting pneumatic control system and an electronic control system. An upper chamber and lower chamber type structure is adopted by the device body, a water-cooled copper crucible is arranged in a lower chamber, a casting mold is arranged in an upper chamber, an intermediate separation plate is arranged between the upper chamber and the lower chamber, and a liquid lifting pipe is arranged on the intermediate separation plate. The vacuum low-pressure casting pneumatic control system is connected with the device body, a vacuum system and a protective gas source system, and digital combination valves are adopted as flow regulation actuators. The electronic control system is composed of an industrial control computer and a PLC. After the smelting process of titanium alloy is completed in a smelting chamber, the water-cooled copper crucible is lifted to a casting position through a lifting device, an upper chamber and lower chamber intercommunication valve is closed, the flow of protective gas fed into the lower chamber is controlled through the computer, the pressure difference between the upper chamber and the lower chamber is established, the liquid alloy is filled in the casting mold through the liquid lifting pipe under the action of the pressure difference, and the casting process is completed. Compared with traditional centrifugal casting and bottom leakage type suction casting, the mold-filling capacity and solidification feeding capacity of the titanium alloy can be improved, castings with better casting quality and thinner wall thicknesses can be obtained, and a new means is provided for batch production of minitype titanium alloy components.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

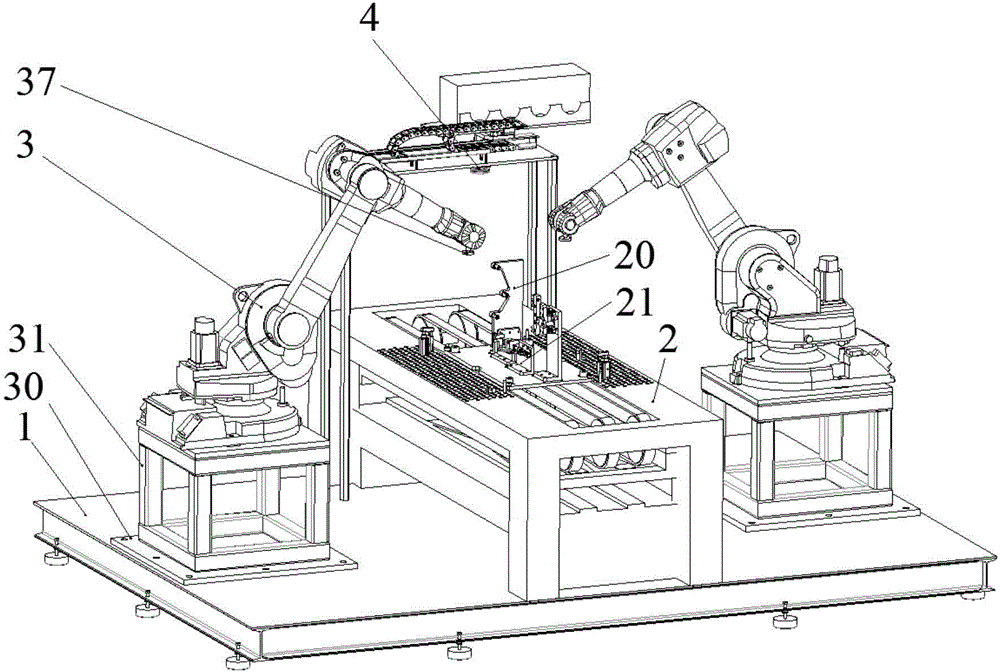

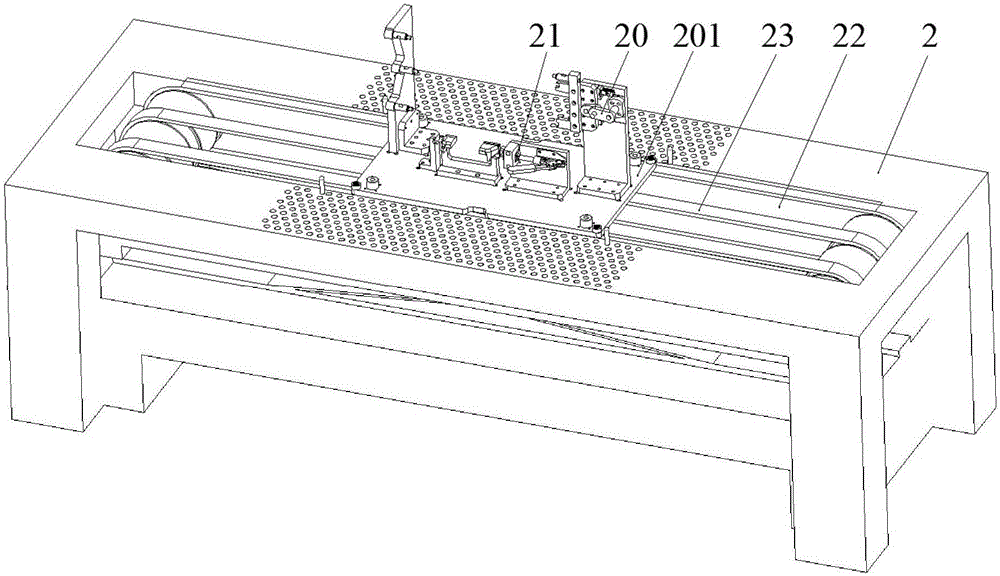

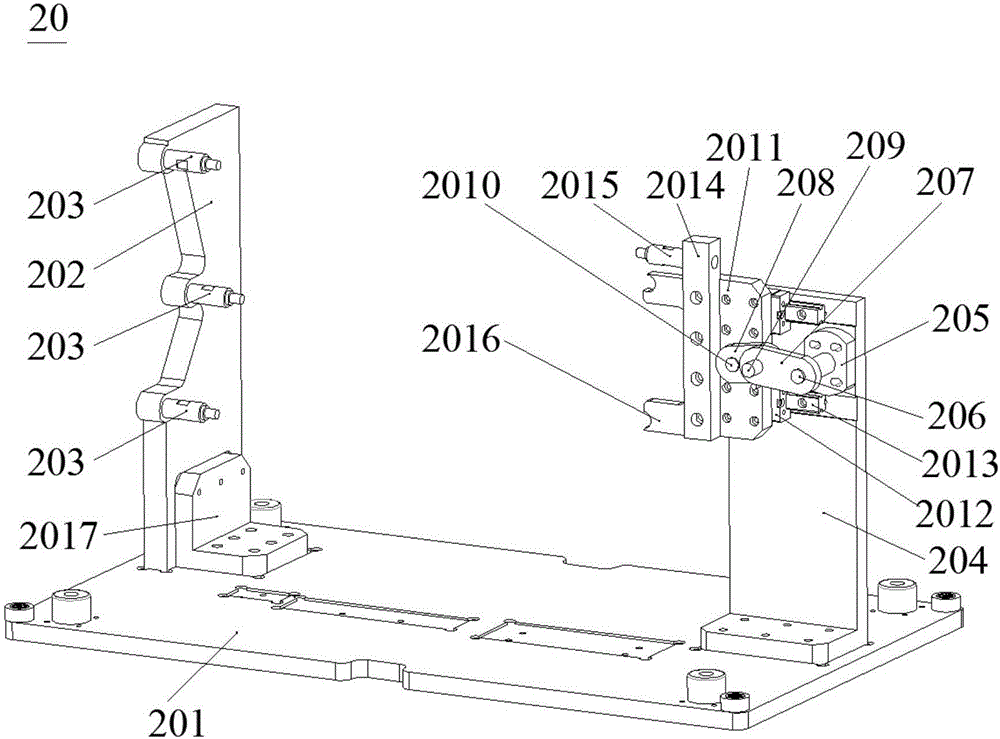

Multi-robot collaborative polishing device and method for pressure casting

ActiveCN106425790AOrderly and efficient grinding workCompact grinding processGrinding machinesGrinding feedersProduction linePressure casting

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

Low pressure casting wheel cooling technology

The invention discloses a mist-spraying cooling technology, which utilizes an electromagnetic type quantitative pump to pump water into an air and water mixing cooling channel so as to form water mist to be used as cooling medium, and is used for cooling a die by aiming at different air ducts via utilizing water mist cooling or air cooling, so the die is cooled to 430 DEG C-410 DEG C from 490 DEG C-470 DEG C within 40-60 seconds, and the temperature of the die is reduced about 40-80 DEG C. The invention utilizes the mist-spraying cooling technology to control the cooling rate so as to quench the die and can crystallize according to the progressive solidification principle, so an R angle is generated, and the shrinkage porosity defect probability of a rim part is smaller; and the cooling medium is the mixture of water and air and is directly acted on the surface of the die, so the mechanical property of a blank is correspondingly improved, the pinhole scrappage and rework rate are reduced, and the service life of the die is obviously prolonged at the same time.

Owner:BAODING CITY LIZHONG WHEEL MFG

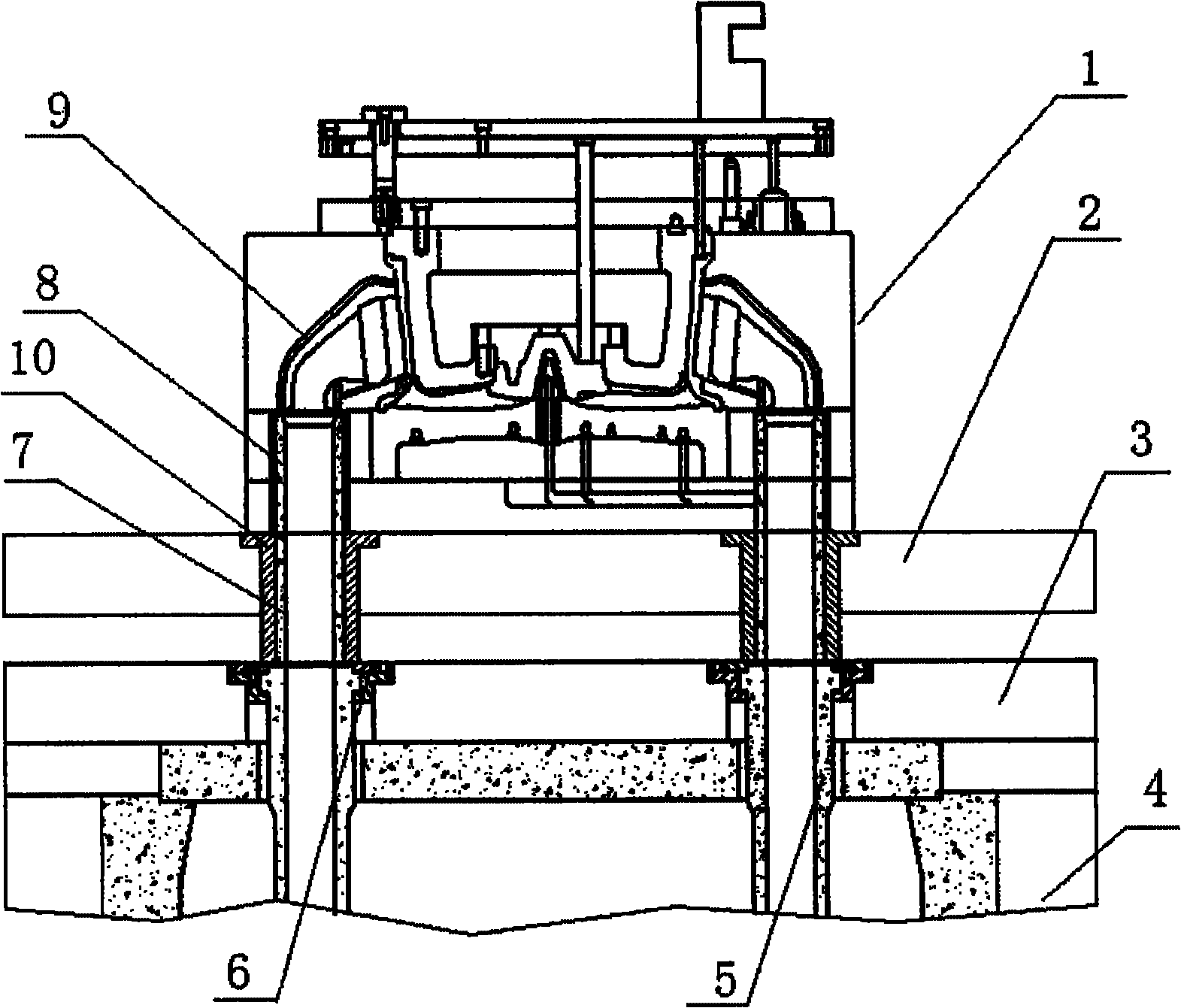

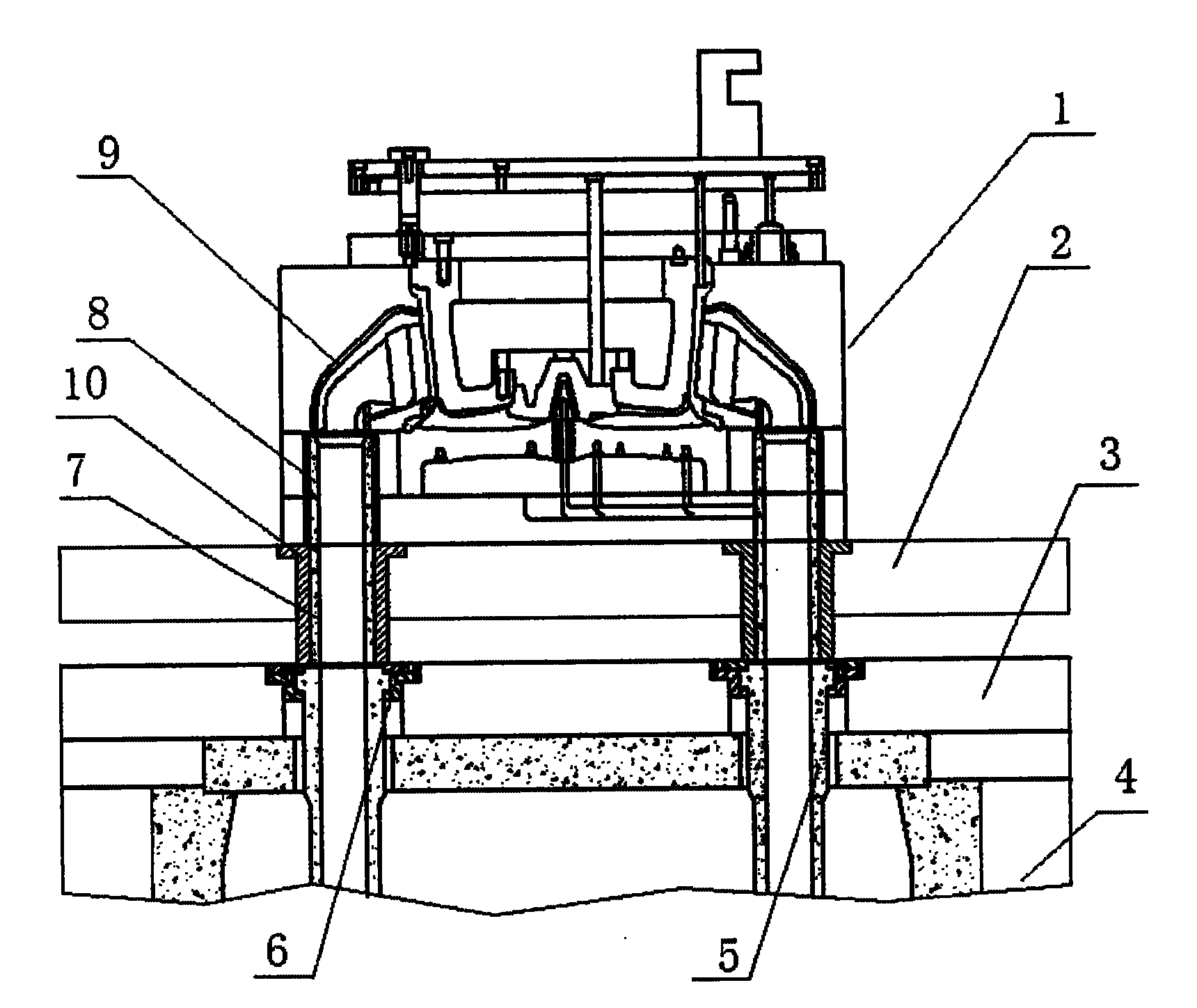

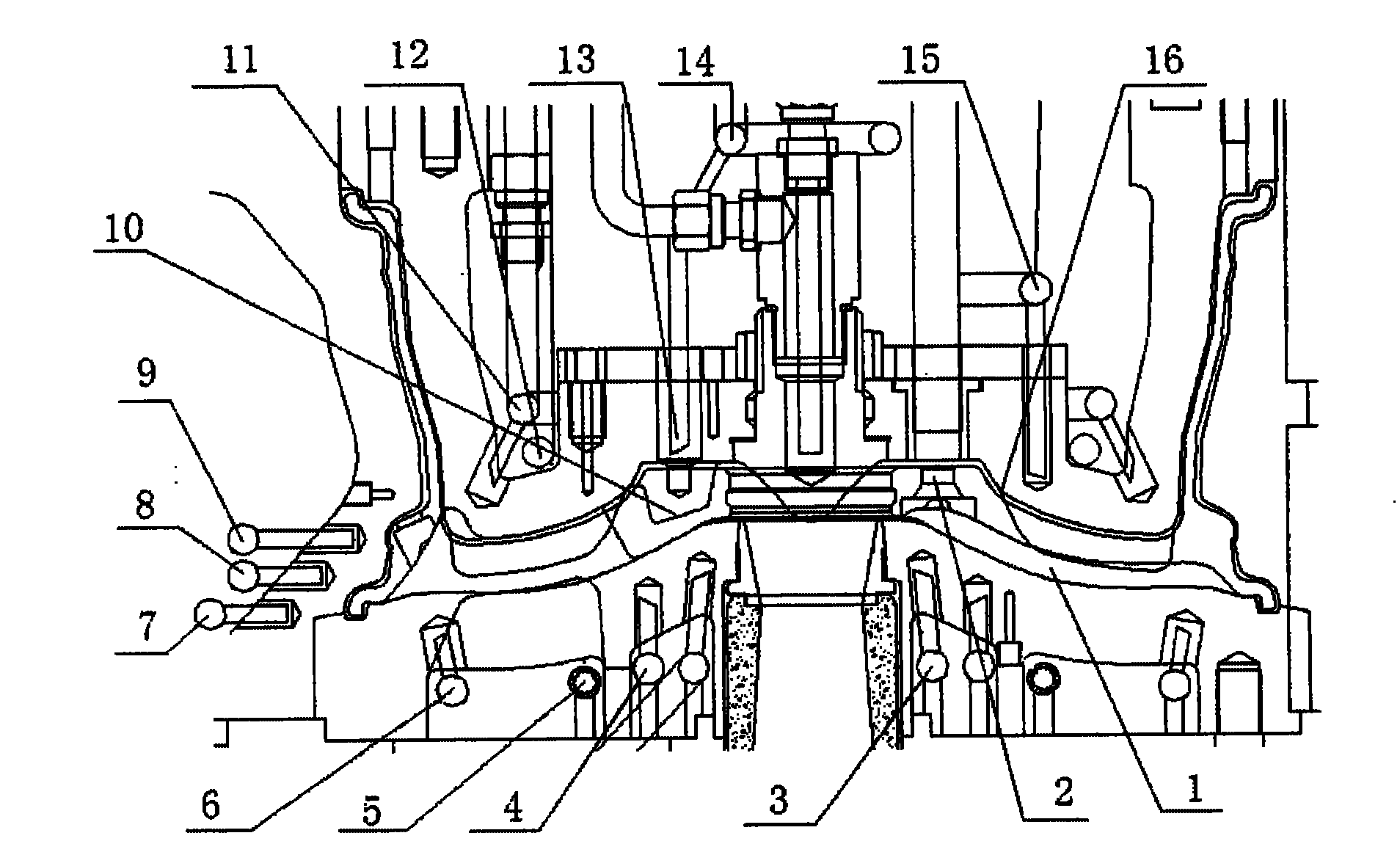

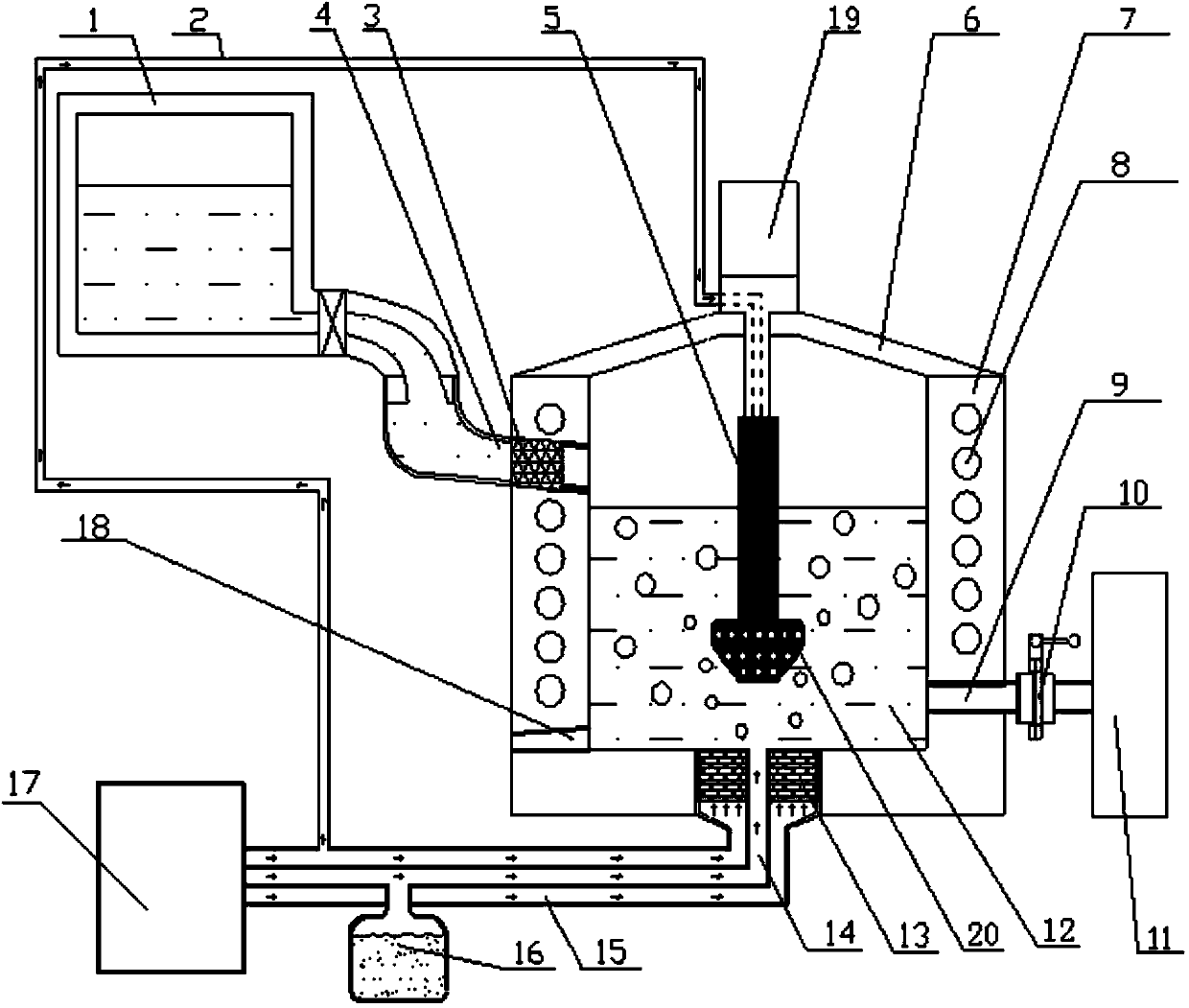

Method and device for preparing semi-solid state slurry through intensive cooling stirring

The invention discloses a method for preparing semi-solid state slurry through intensive cooling stirring. The method comprises the following steps: placing overheated alloy melt in a crucible or a casting ladle, descending a rotary stirring shaft internally introduced with a circular cooling medium in the alloy melt through a lifting device, driving the convection heat exchange of the alloy melt through stirring, continuously cooling the rotary stirring shaft through the circular cooling medium, stirring for a fixed period of time or cooling the melt to a set temperature, raising the rotary stirring shaft to prepare the semi-solid state slurry and form an ingot casting; closing the casting ladle containing the semi-solid state slurry to formation equipment and pouring the semi-solid state slurry into a cavity or material chamber of the formation equipment to take the shape; and taking out a formed part and moving the crucible or the casting ladle back to an original position and filling the overheated alloy melt to perform the next semi-solid state slurry preparation. The invention further provides a device for realizing the above method. Through the adoption of the method and device provided by the invention, large volume of semi-solid state slurry can be prepared once, and the semi-solid state slurry can be continuously produced in batch, and then the rheolytic formed part can be prepared through the combination of pressure casting, rolling, die-forging and other conventional formation equipment.

Owner:SHANGHAI INST OF TECH

Process for smelting and lower-pressure casting of aluminum alloy wheel hub

The invention discloses a process for the smelting and low-pressure casting of an aluminum alloy wheel hub, which comprises: 1, putting an aluminum alloy smelting material into a smelting furnace for smelting, and when the temperature in the smelting furnace reaches 740 to 760 DEG C, introducing nitrogen into the smelting furnace to blow a refining agent into the body of the furnace for refining;2, transferring the molten aluminum alloy to a tundish from the liquid outlet of the smelting furnace, adding an Al-Sr intermediate alloy, mischmetal (Re) and an Al-Zr intermediate alloy into the tundish to perform modification and refinement treatment under a condition of a temperature of 710 to 730 DEG C, and blowing nitrogen to the tundish to perform secondary degassing of the molten aluminum alloy; 3, transferring the molten aluminum alloy in the tundish to a casting holding furnace, adding a slag decomposing agent into the holding furnace to remove slag and blowing nitrogen into the holding furnace to perform tertiary degassing; and 4, pressing the molten aluminum alloy into a mold by a method of prepressing, pressure stabilizing, pressurizing and pressure keeping to perform casting.The process can effectively discharge slag and degas, has excellent modification and refinement effects and contributes to improvement in product quality.

Owner:ZHEJIANG ZENT AUTO WHEEL

Ceramics injection moulding automatic molding equipment

InactiveCN101229656AImprove balanceGuaranteed accuracyCeramic shaping apparatusPressure castingControl system

The invention discloses an automatic forming machine with a ceramic hot pressure casting, which includes a machine frame, a control system, a material storing bucket, a material conveying pipe, a constant temperature heating part, a guide pillar, an upper guide plate, a lower guide plate, a die and an air cylinder. The invention is characterized in that the feeding plate is firmly arranged on the bottom plate of a machine station and is sleeved with one end of the material conveying pie with the two ends open; the another end of the material conveying pipe is extended into the material storing bucket arranged below the bottom plate; the die consists of a panel, a frame board, a stripper, a fixed plate and a faller; a cavity arranged above the lower guide plate is used for embedding and wrapping the panel in the die neatly; the lower surface of the panel is provided with a feeding groove; the die prying devices are respectively arranged on the left side and the right side of the bottom plate; a plurality of copper pipes with cooling effect are passed through the frame board; in the device, type needles on the faller are inserted into type holes on the panel to resect waste material.

Owner:魏金富

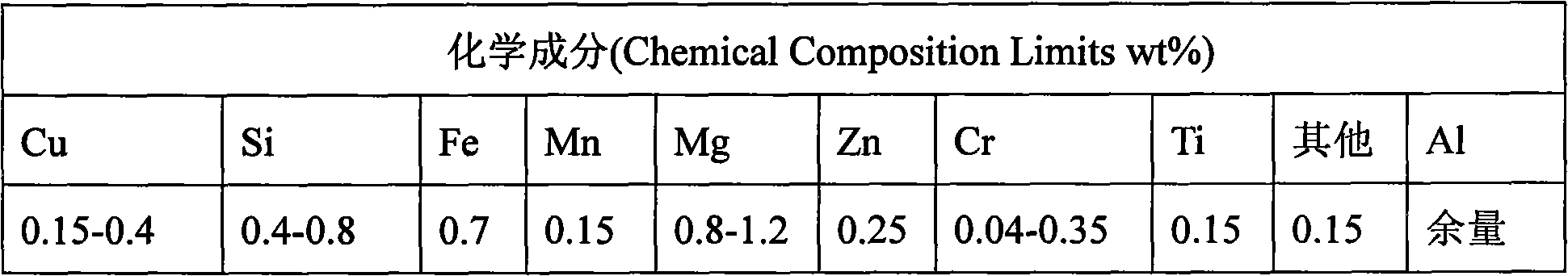

Low pressure casting aluminium alloy for cylinder cap of minicar engine

The present invention relates to a minicar engine cylinder cap low-pressure casting aluminium alloy, and its main chemical components are Si, Cu and Mg, in particular Cu and Mg control is better, and its harmful impurity element control is serious, and after said alloy is undergone the processes of modification treatment by means of modification agent and (T6) heat treatment, its tensile strength QbMPa is greater than or equal to 300, HB is about 110, and said alloy has enough strength and rigidity and good size stability, and said alloy can meet the requirements for miniature car engine cylinder cap low-pressure casting process and mechanical working process.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

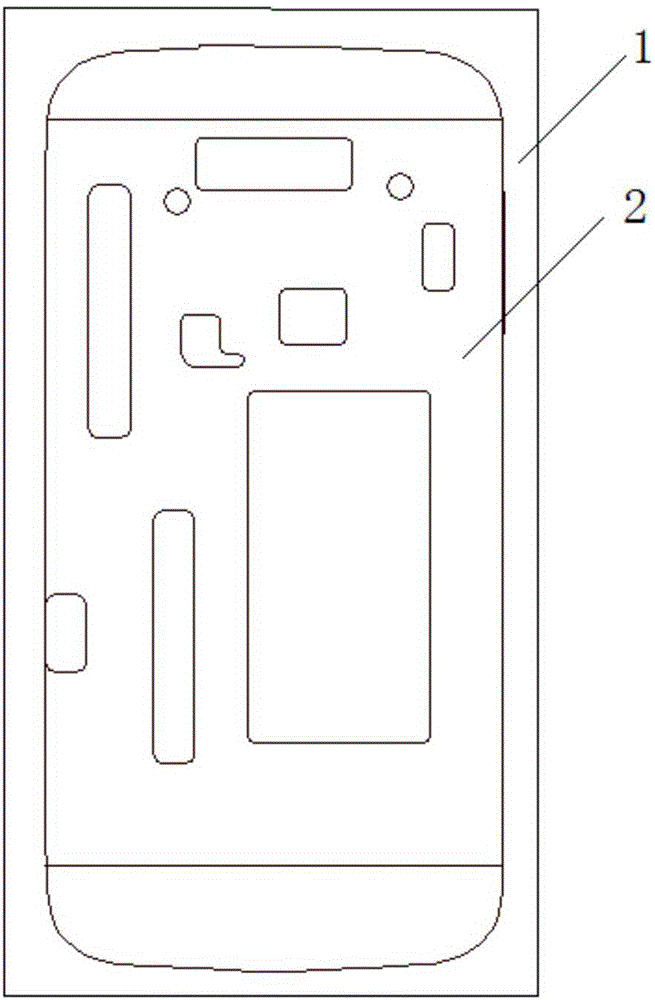

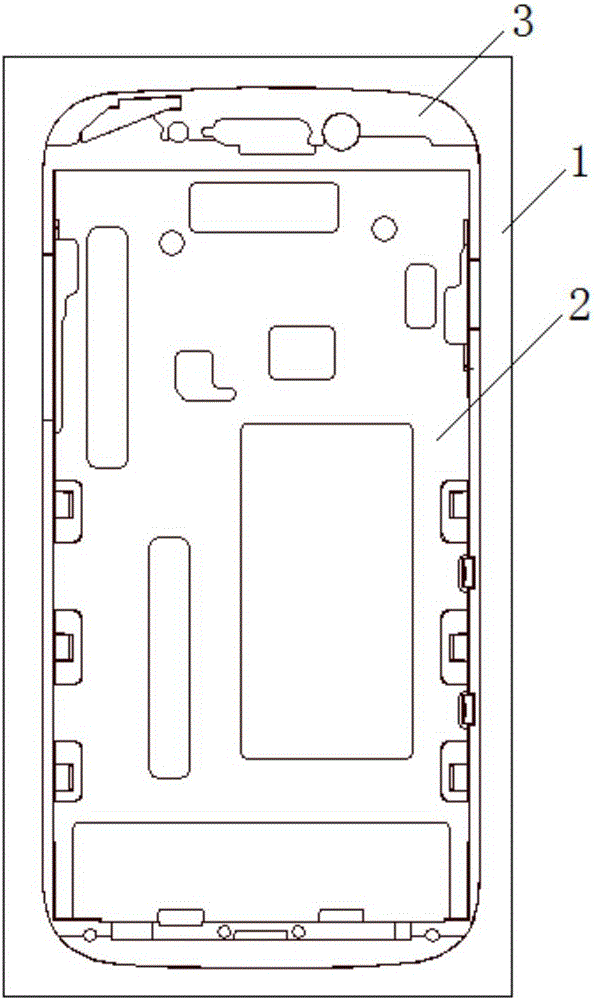

Manufacturing method of mobile phone middle frame

InactiveCN106435686AAvoid corrosion onlyReduce the amount of processingAnodisationDomestic articlesPressure castingMachining

The invention discloses a manufacturing method of a mobile phone middle frame. The manufacturing method comprises the following steps: S1, preparing a stainless steel rim; S2, putting the stainless steel rim into a pressure casting die, then adding smelted aluminum alloy liquid into the pressure casting die for pressure casting to form an aluminum alloy middle plate, and integrally forming an aluminum alloy-stainless steel middle frame from the aluminum alloy middle plate and the stainless steel rim; S3, covering the aluminum alloy middle plate with protective rubber capable of resisting corrosion of acidic liquid and alkaline liquid, putting the aluminum alloy-stainless steel middle frame into microhole treatment liquid for corrosion to form micro holes, and then removing the protective rubber; S4, forming a plastic structural member on the aluminum alloy-stainless steel middle frame through injection molding; and S5, performing post machining treatment on the aluminum alloy middle frame. The manufacturing method can avoid the problem that only the aluminum alloy is corroded, but the stainless steel cannot be corroded due to different activities of metals in the manufacturing process. According to the method, the machining amount of the whole structure of the middle frame can be reduced, the appearance effect is good, and the yield is high.

Owner:GUANGDONG JANUS SMART GRP CO LTD

Al-Si-Cu-Mg cast aluminum alloy and preparation method thereof

InactiveCN104073699AImprove performanceAccurate element content control valuePressure castingAutomotive industry

The invention relates to metal smelting technology and particularly relates to a Al-Si-Cu-Mg cast aluminum alloy and a preparation method thereof. The cast aluminum alloy comprises 89.5-90.5wt% of aluminum (Al) and the balance of 6.5-7.5wt% of silicon (Si) and 0.02-0.04wt% of modificator strontium (Sr), wherein according to the alloy, the content of copper (Cu) is 1.5-2.5wt%, the content of magnesium (Mg) is 0.35-0.65wt% and 0.05-0.25wt% of zirconium (Zr) and 0.1-0. 5wt% of cadmium (Cd) are both added into the alloy. The preparation method comprises the steps of smelting, refining, carrying out modification treatment, adding 0.04wt% of Sr, standing for 40-60 minutes, carrying out low pressure casting by using an electromagnetic pump and carrying out T6 heat treatment on castings to obtain the corresponding castings. Since more accurate element content control values and reliable operation process parameters are provided by the scheme, the high-performance cast aluminum alloy, especially suitable for the automotive industry can be prepared based on the optimized configuration of trace elements in AlSi7Cu2Mg.

Owner:QUZHOU COLLEGE OF TECH

Manufacturing device for light alloy or light metal semi-solid slurry and manufacturing method

The invention discloses a manufacturing device for light alloy or light metal semi-solid slurry and a method for manufacturing the semi-solid slurry through the device. The manufacturing device for the light alloy or light metal semi-solid slurry comprises a smelting furnace, a runner, a mechanical stirring device, an inert gas stirring device, a powder spray device and a heating device. The semi-solid slurry manufacturing device reasonable in structure is designed, continuity for manufacturing the semi-solid slurry is good, and products can be cast industrially and continuously in a large scale by applying a semi-solid pressure casting or squeeze casting forming method. According to the manufacturing method for the semi-solid slurry, efficiency for manufacturing the light alloy or light metal semi-solid slurry is high, energy consumption is less, cost is low, and the manufactured semi-solid slurry cannot generate oxide inclusions, and is even in organization and excellent in quality.

Owner:机械科学研究总院(将乐)半固态技术研究所有限公司

Cylinder block made from wearable aluminum alloy and manufacturing technique

InactiveCN1563456ADense internal organizationImprove air tightnessCylindersManufacturing technologyChemical composition

This invention discloses an abrasion Al arroy cylinder and its manufacture technology, which chemical composition in weights is Si 7.6-8.3% Cu2.5-3.5% 0.3-0.5%Mg, Mn 0.2-0.4%, rest is Al. The technology is that the Al alloy raw material matched in terms of the above mentioned proportion is smelted in a thermal insulation furnace, refined, gas cleaned-up and modificated with dust refinery agent and the solution temperature is monitored by a dogmatic thermometer via a thermal coupler, then an alloy iron cast cylindrical jacket is put on the position of its mold to pour the solution onto the mold cavity to be casted with low pressure casting so as to integrate the jacket with the solution finally it is finished by the process center.

Owner:WENZHOU RUIMING IND

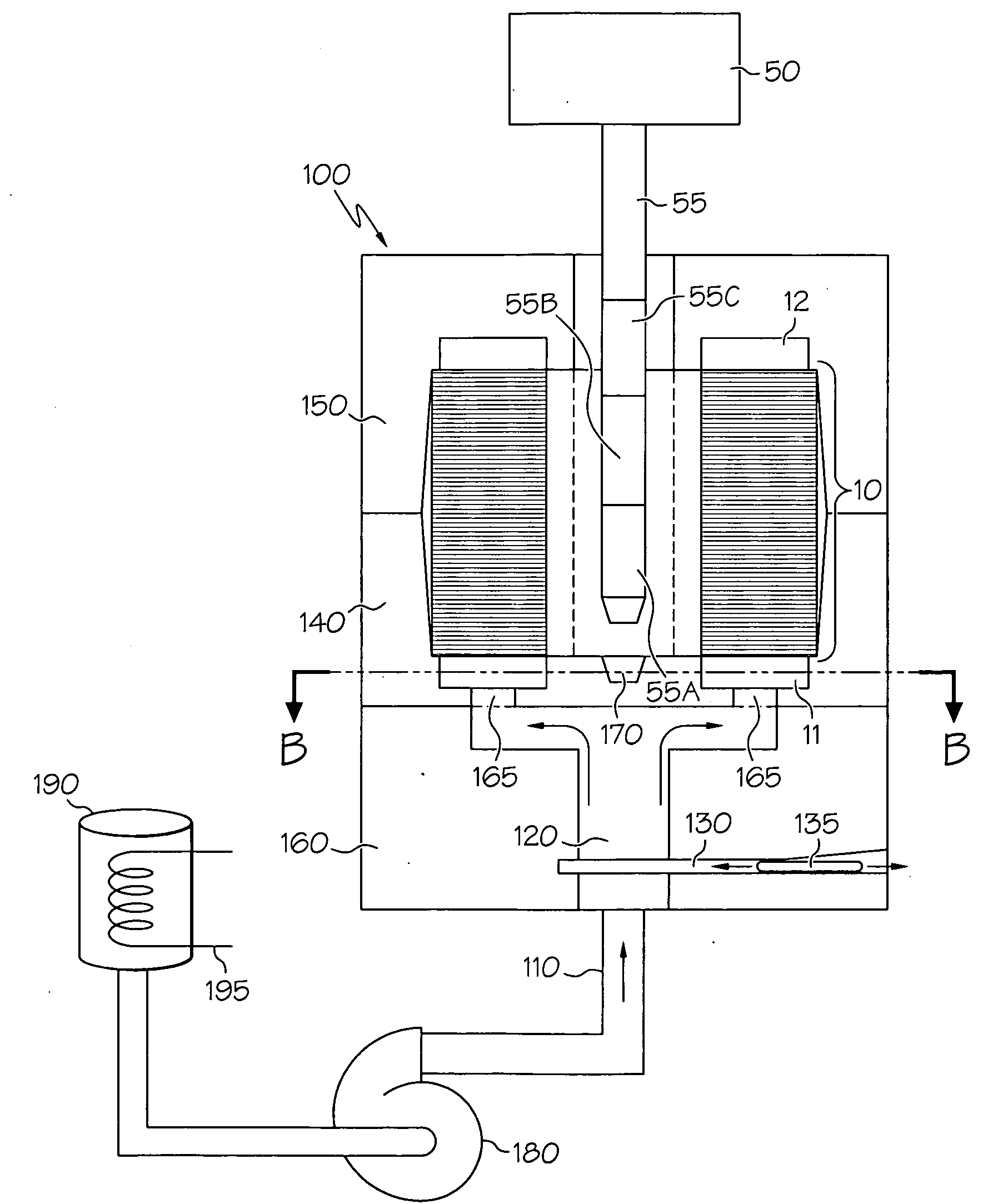

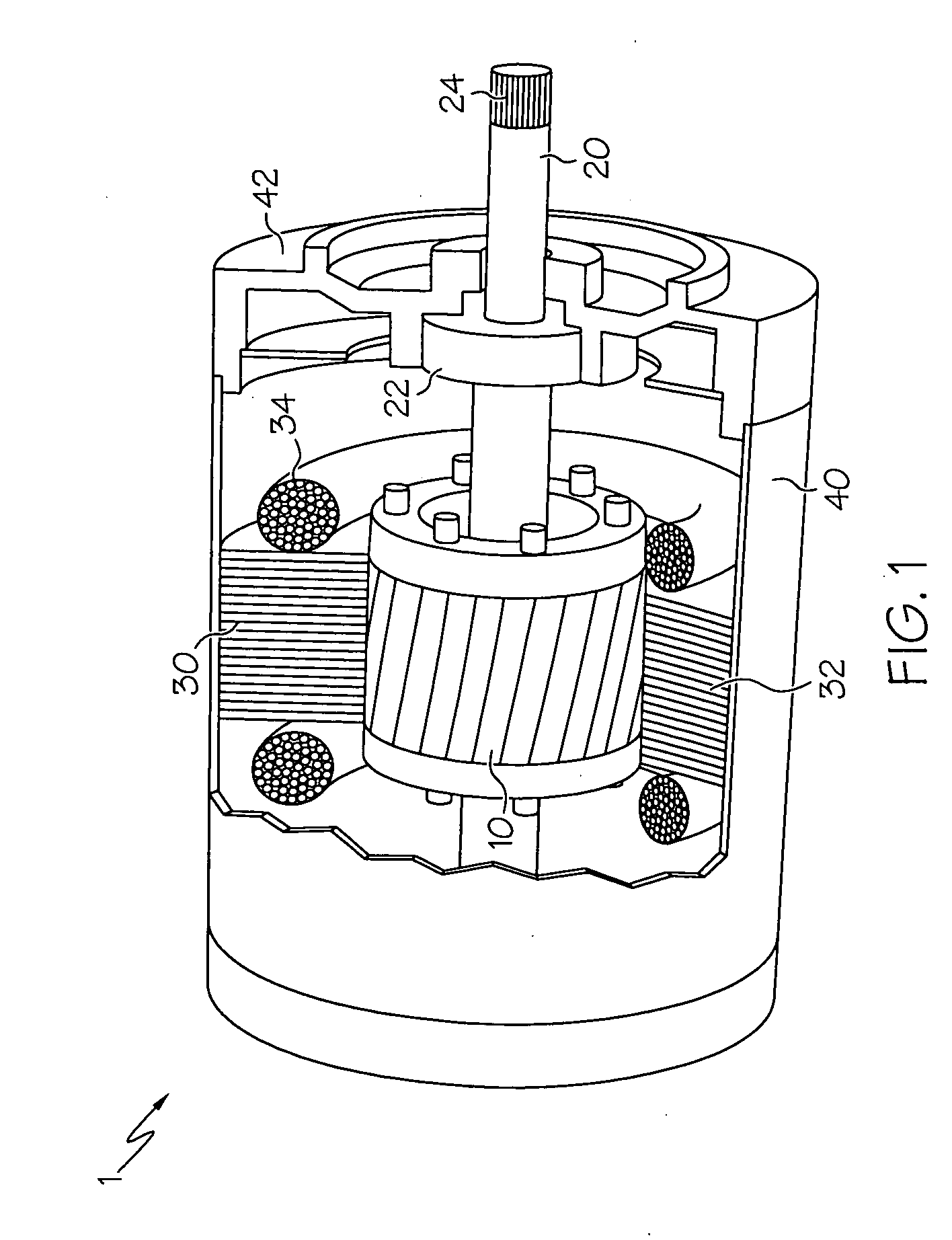

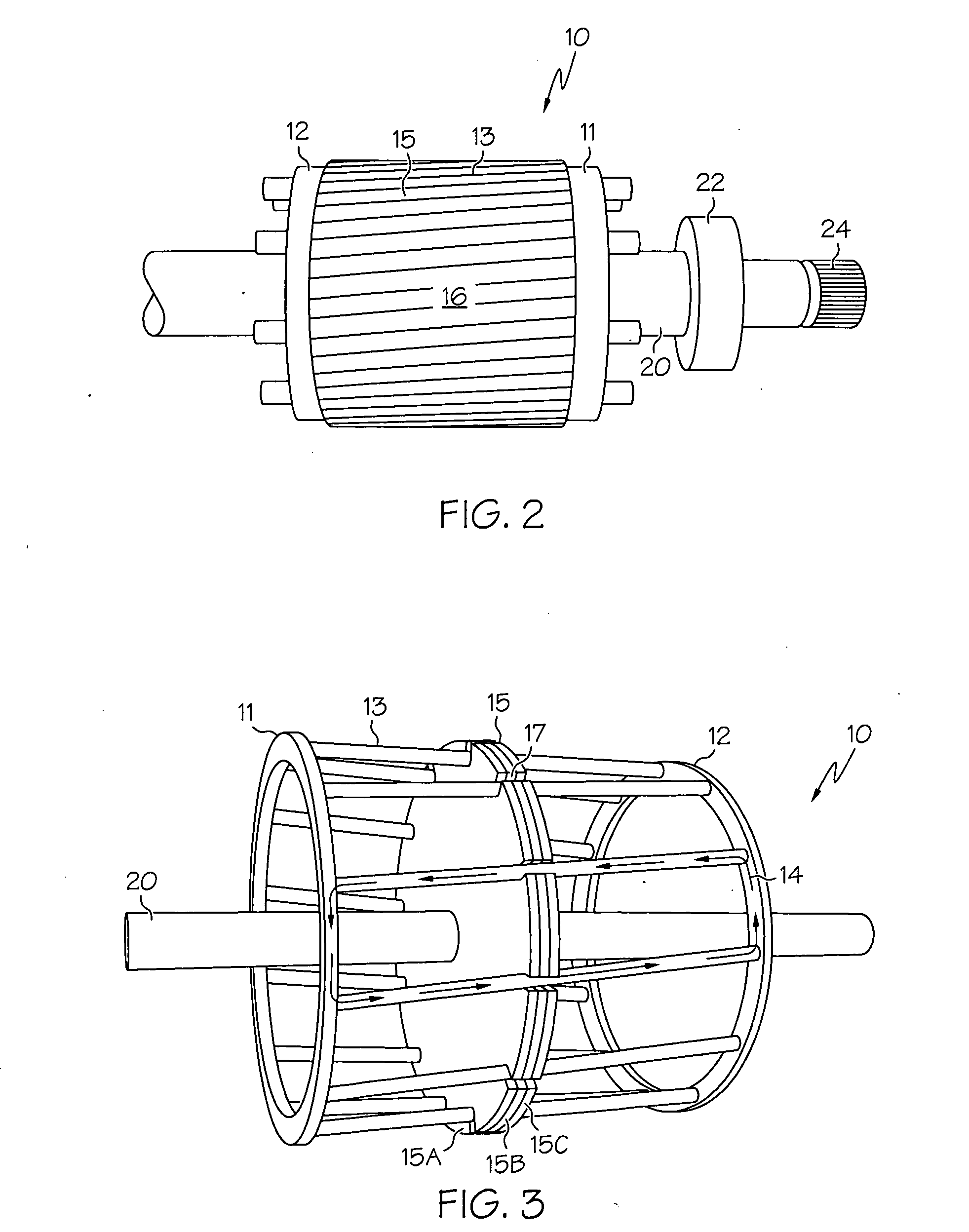

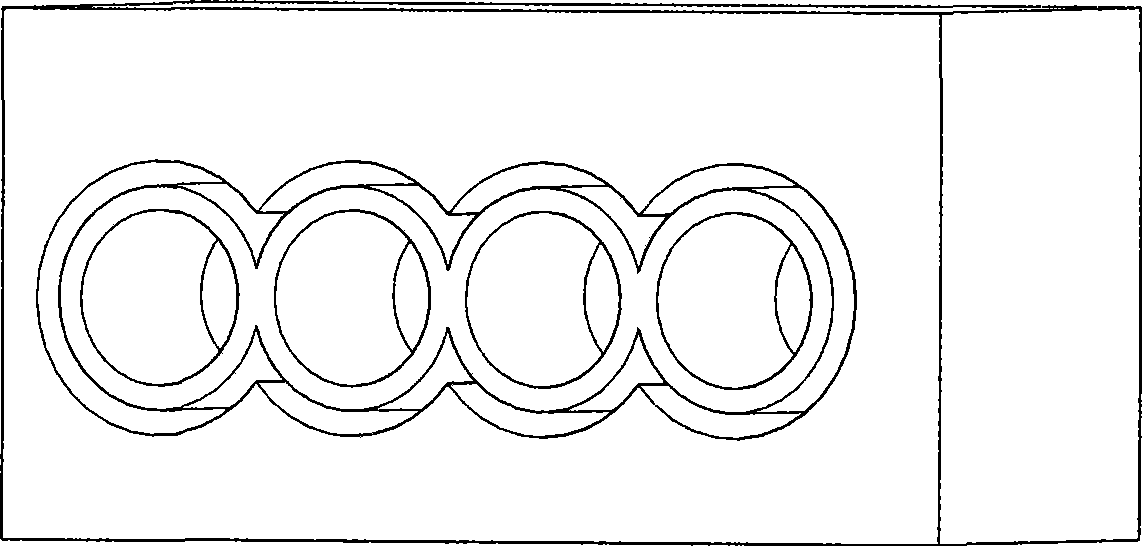

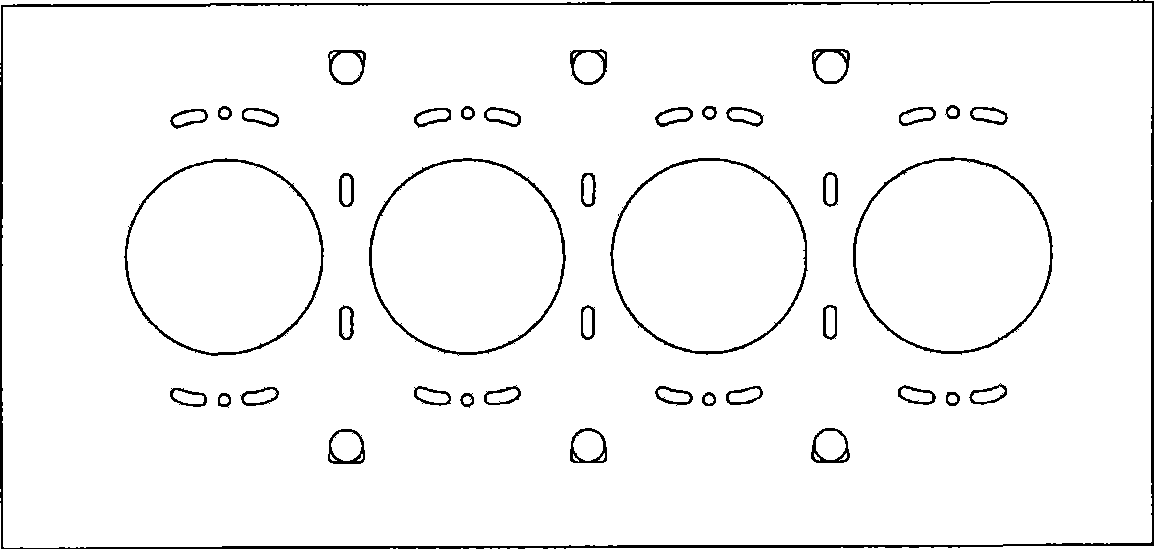

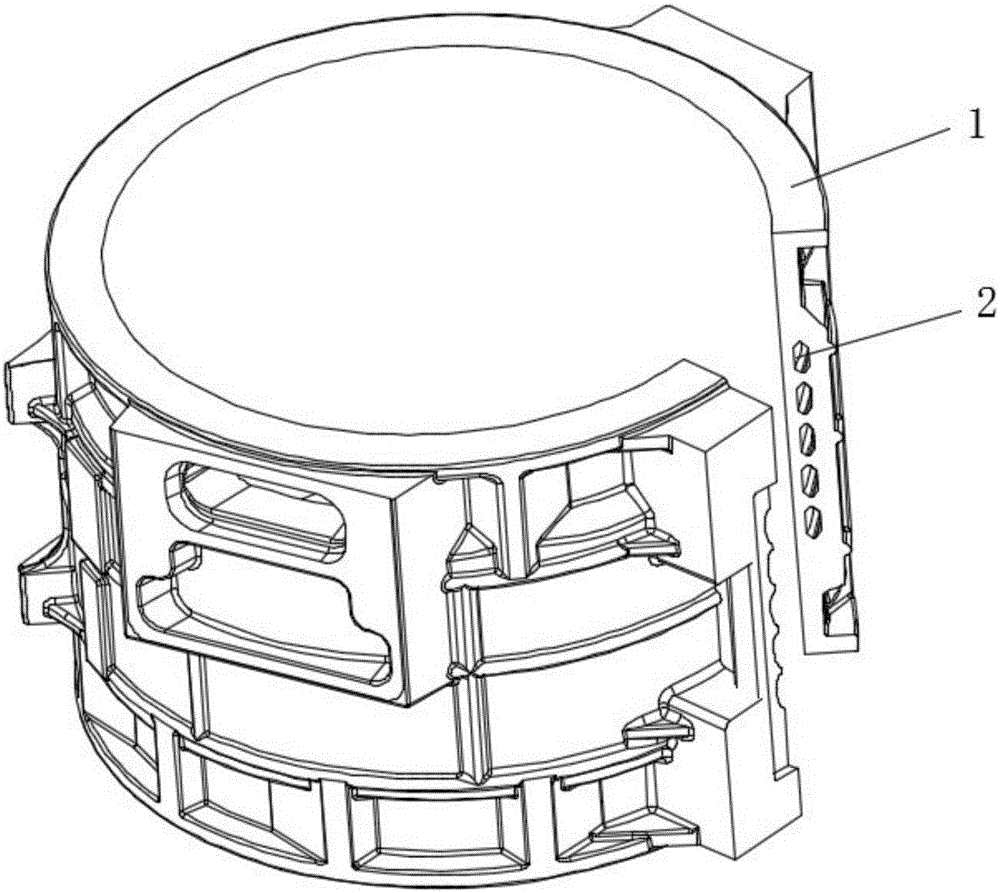

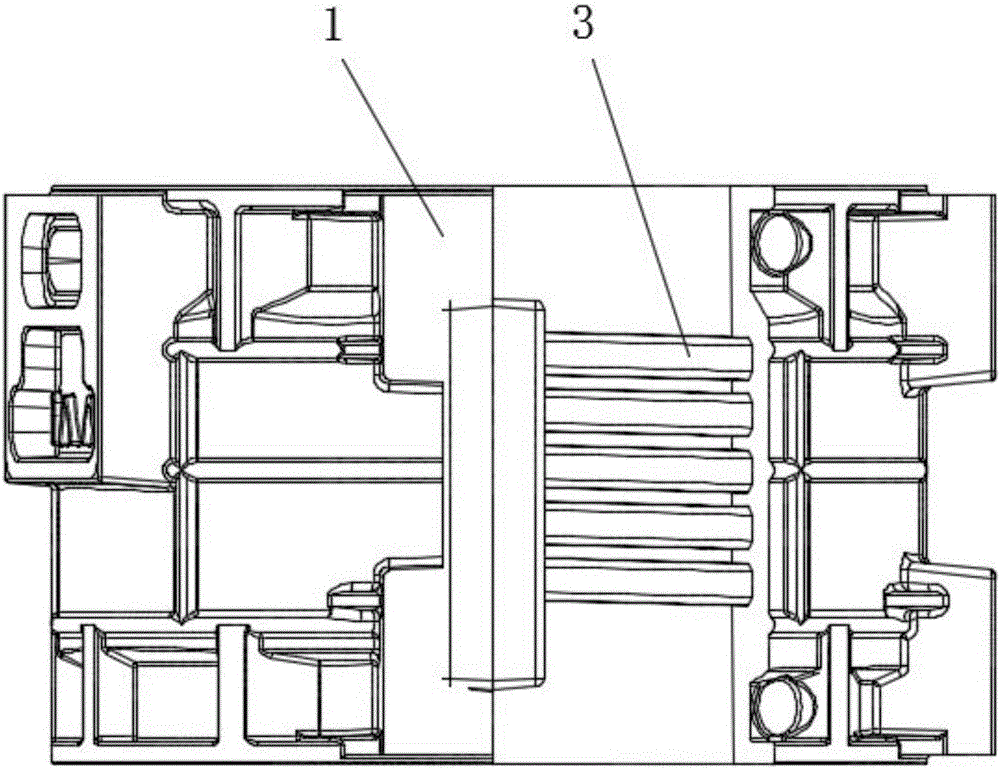

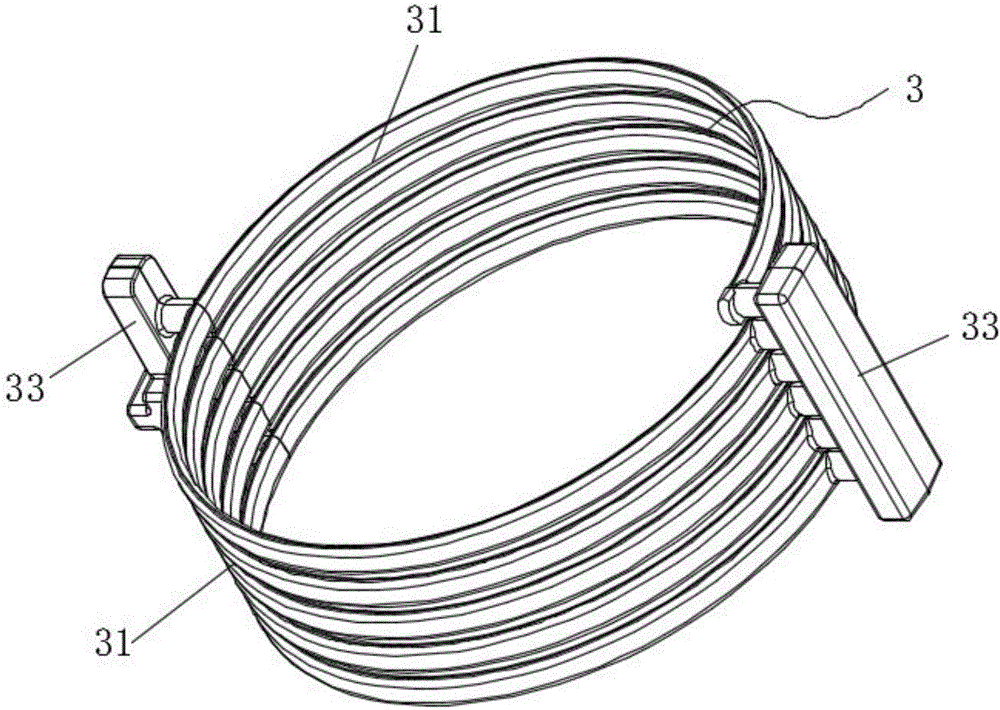

Pressure casting of electric rotors

InactiveUS20100243197A1Sufficient pressureInhibited porositySynchronous motorsFoundry mouldsMolten statePorosity

A rotor for an induction motor and a method of preparing same. The method includes making a squirrel-cage rotor made up of a cage and a laminate stack by forming a mold around the stack, heating the stack and introducing a molten metal into the mold such that the molten metal substantially fills a space defined in the stack that corresponds to the cage. In one form, the space includes slots or related channels formed in the stack that upon filling with the molten metal become longitudinal bars that form electric current loops with end rings of the cage. By heating the stack and maintaining it at a temperature high enough to keep the molten metal in a substantially molten state at least long enough for it to flow through the slots of the stack, premature freezing of the molten metal is avoided. In addition, by providing low pressure to the molten metal in conjunction with the elevated temperature in the stack, flow is promoted to ensure a substantially porosity-free, fully dense squirrel-cage for the rotor.

Owner:GM GLOBAL TECH OPERATIONS LLC

Diesel motor aluminium alloy cylinder metal mould low-pressure casting method

ActiveCN101497121AGuaranteed StrengthPromote prolapseFoundry mouldsFoundry coresProduction ratePressure casting

The invention relates to a method for metal mold low-pressure casting of an aluminum alloy cylinder body of a diesel engine, which adopts a metal casting die and a low-pressure full metal mold casting method to cast the aluminum alloy cylinder body and comprises the steps of low-pressure pouring, sand vibration, primary processing and heat treatment, wherein in the step of low-pressure pouring, a water jacket and an oil duct are cast by adopting an oil duct sand core and a water jacket core respectively, and a cylinder sleeve is cast in an embedding mode; and the whole cast adopts a mode that the surface of a cylinder barrel is on the upside while the surface of a crankshaft is on the downside, an aluminum liquid is introduced from the cylinder barrel, and the temperature for casting the aluminum liquid is between 670 and 690 DEG C. The method combines the advantages of pressure casting and gravity casting, and adopts a low-pressure casting technique so that a cylinder body cast reaches the requirement of high mechanical property of the diesel engine, and simultaneously ensures high technical production rate, saves energy source, and has simple and convenient casting process.

Owner:SHANGHAI AISHIDA AUTOMOTIVE COMPONENTS

Preparing method of interface modification layer of ceramic particle enhanced metal base composite material

The invention discloses a preparing method of an interface modification layer of a ceramic particle enhanced metal base composite material, and belongs to the technical field of a metal base composite material. The method comprises the following steps that ceramic particles and modification element particles are uniformly mixed according to a certain proportion, are pressed into a prefabricated body and are sintered, then, the sintered prefabricated body is placed into a casting die cavity, a metal substrate with the melting point lower than the melting point of the modification elements is cast on the sintered prefabricated body, next, the metal base composite material is prepared by adopting a pressure casting method, the melting point of the modification elements is a little higher than the melting point of molten liquid, so the modification elements are in a molten state when the molten liquid is cast into the die cavity, then, the modification elements move together with the molten liquid under the pressure effect, when meeting the blocking effect of the ceramic particles, the modification elements and the molten metal can go around the surface of the ceramic particles for forming a micrometer level interface modification layer on the surfaces of the ceramic particles, and the bonding intensity of the ceramic particles and the metal interfaces can be improved. When the method provided by the invention is adopted, great significance can be realized on the preparation of high-performance and low-cost metal base composite material.

Owner:KUNMING UNIV OF SCI & TECH

Manufacturing method for aluminium alloy automobile hub with high performance and big size

InactiveCN101579818AImprove fuel economyImprove riding performanceOther manufacturing equipments/toolsWhole bodyPressure casting

A manufacturing method for an aluminium alloy automobile hub with high performance and big size relates to the mechanical manufacturing method. The semi-solid state thixocasting is used for extruding an alloy automobile spoke with the designed shape and diameter, high mechanical property and fatigue performance on a large scale extruder; aluminium alloy plank stuff is rolled and spun to be a wheel felloe with the definite shape and diameter; after precision work and amendment, the spoke and the wheel felloe are welded together by inert-gas arc welding or laser-inert-gas arc welding to form a whole body and superficially processed. The aluminium alloy automobile hub has the advantages of light weight, high mechanical property and fatigue performance and the like, can replace a steeliness welding cartwheel used by a commercial vehicle for the moment and a low-pressure casting aluminium alloy cartwheel used by a passenger car, simultaneously increases the fuel economical efficiency and structural strength, is suitable for the cartwheel manufacture of all automobiles and motorcycles and especially suitable for large scale light car wheels and custom car wheels.

Owner:马鸣图 +6

Low-pressure casting method for automobile motor casing and motor casing structure

ActiveCN104999051AMeet normal workGuaranteed cooling effectSupports/enclosures/casingsPressure castingElectric machinery

The invention discloses a low-pressure casting method for an automobile motor casing. The low-pressure casting method for the automobile motor casing includes the following steps that (1) a sand core structure of a spiral water channel is manufactured; (2) the sand core structure is placed on a lower mold body of a die-casting mold; (3) the automobile motor casing with the sand core structure of the spiral water channel is cast through a low-pressure casting device; (4) heat treatment is conducted on the automobile motor casing, then sand is vibrated out, and the automobile motor casing is provided with the complete spiral water channel; and (5) holes formed in the original sand core structure portion of the sidewall of the automobile motor casing are filled up through welding, so that the complete automobile motor casing with the spiral water channel is formed. The invention further discloses a motor casing structure. Through the low-pressure casting method for the automobile motor casing, the aluminum alloy low-pressure casting process is adopted and the spiral water channel is cast through the sand core of the spiral water channel, so that the cooling effect on a motor is guaranteed, the service life of the motor is greatly prolonged, the requirement for long-time working of an automobile can be met, and the weight of the whole motor is reduced by about 60%.

Owner:HUIZHOU WEISHENG IND

Composite material hammerhead of crusher and negative pressure casting method thereof

The invention discloses a composite material hammerhead of a crusher and a negative pressure casting method thereof. The negative pressure casting method comprises that: firstly, a metal parent material is subjected to electric smelting to form molten metal; WC particles and a bonding agent are mixed and prepared into paste, the paste is filled in a columnar metal screen which is then baked in a sealed mode to form a prefabricated body, and the prefabricated body is placed on the end face side of a mould cavity; a vacuum pump is started 5 minutes earlier than the tapping of the molten metal, and then the molten metal is tapped off for casting; and the vacuum pump is switched off after 4 minutes of the casting completion. The composite material hammerhead hammer body obtained by the preparation method is made of high manganese steel, alloy steel or common carbon steel; a hammer end, namely a working face or a striking face consists of a metal matrix and columnar reinforcers uniformly distributed in the metal matrix, wherein the columnar reinforcers are made of a composite material formed through infiltration of a ceramic particle prefabricated body and mother liquor metal, and have the hardness of HRC55-67 and excellent impact abrasion resistance; and the interface of the columnar reinforcers and the metal matrix, and the interface of the WC particles in the reinforcers and a substrate have good metallurgical bonding and high bonding strength.

Owner:XI AN JIAOTONG UNIV

Plaster casting method for large-sized complex thin-walled magnesium alloy part

ActiveCN104209497ASolve Oxidation ProblemsImprove filling abilityFoundry mouldsFoundry coresVacuum castingMold filling

The invention relates to a plaster casting method for a large-sized complex thin-walled magnesium alloy part. The method comprises the following steps of coating the surface of an assembled form with a coating in situ, and arranging shapeless cold iron on a hot spot part, wherein a mixture for manufacturing the shapeless cold iron comprises the following components in percentage by mass: 1.25 percent of phenolic resin, 0.4 percent of toluenesulfonic acid, 1 to 1.5 percent of boric acid, 2 percent of bentonite and the balance of 70 to 140-mesh chromite sand; pouring a casting in an adjustable pressure casting device, arranging a plaster mold poured by the form at the casting position of the adjustable pressure casting device, filling a tank with dry air or a CO2 atmosphere with SF6 content of 0.1 to 1.0 percent, and performing vacuum casting and pressurized solidification, wherein the casting temperature is 710 to 750 DEG C, vacuum degree for primary mold filling is minus 0.6Mpa to minus 0.8Mpa, and the solidification pressure is 0.020 to 0.025Mpa. According to the method, oxidization can be prevented, the mold filling capability can be improved, shrinkage cavities and shrinkage porosities in the casting are reduced, and the obtained magnesium alloy casting is higher in density.

Owner:山西银光华盛镁业股份有限公司

Oil pan machining process

The invention discloses an oil pan machining process and relates to the field of automobile engine accessories. The oil pan machining process comprises the seven process procedures of smelting, pressure casting, degating, heat treatment, cutting, flash removing and sealing testing. According to the oil pan machining process, smelting and impurity removing are conducted on aluminum alloy according to a certain ratio; through vacuum constant-temperature pressure casting, stability in the pressure casting procedure can be guaranteed, and the porosity of an oil pan can be smaller than 4%; local high-frequency quenching is conducted on the bottom of the oil pan, large-area quenching is avoided, the elongation percentage, shock resistance and local hardness of the oil pan can be further improved, engineer specification requirements are met, the process is simple, and a high automation degree can be achieved by applying the oil pan machining process to flow line production.

Owner:中山市鸿程科研技术服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com