Low-pressure casting preparation method of heat resistant rare earth-magnesium alloy engine pistons

A low-pressure casting, rare earth magnesium technology, used in engine components, machines/engines, pistons, etc., to achieve excellent creep resistance, reduce vibration, and reduce fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The alloy composition (percentage by weight) of the magnesium alloy engine piston: 10% Gd, 3% Y, 2% Zn, 0.4% Zr, the impurity element is less than 0.02%, and the rest is Mg.

[0027] The specific steps of the melting process of the alloy are as follows:

[0028] (1) Configure the alloy according to the above ingredients, preheat the pure magnesium and the master alloy used to 200°C in an oven, and keep it warm for 2 hours;

[0029] (2) Mg smelting: Add industrial pure magnesium into the smelting furnace, heat and smelt, and protect it with a covering agent at the same time;

[0030] (3) Add Y and Gd: Add the dried Mg-Y and Mg-Gd master alloys to the magnesium liquid at a temperature of 730°C;

[0031] (4) Adding Zn: After the master alloy is completely melted, add industrial pure zinc at a temperature of 700°C;

[0032] (5) Adding Zr: Raise the temperature of the magnesium liquid to 760°C, then add the Mg-Zr master alloy, stir for 2 minutes to promote its full melting...

Embodiment 2

[0038] The alloy composition (percentage by weight) of the magnesium alloy engine piston: 11% Gd, 2% Y, 1% Zn, 0.2% Zr, the impurity element is less than 0.02%, and the rest is Mg.

[0039] The specific steps of the melting process of the alloy are as follows:

[0040] (1) Configure the alloy according to the above ingredients, preheat the pure magnesium and the master alloy used to 200°C in an oven, and keep it warm for 2 hours;

[0041] (2) Mg smelting: Add industrial pure magnesium into the smelting furnace, heat and smelt, and protect it with a covering agent at the same time;

[0042] (3) Add Y and Gd: Add the dried Mg-Y and Mg-Gd master alloys to the magnesium liquid at a temperature of 730°C;

[0043] (4) Adding Zn: After the master alloy is completely melted, add industrial pure zinc at a temperature of 700°C;

[0044] (5) Adding Zr: Raise the temperature of the magnesium liquid to 760°C, then add the Mg-Zr master alloy, stir for 2 minutes to promote its full melting...

Embodiment 3

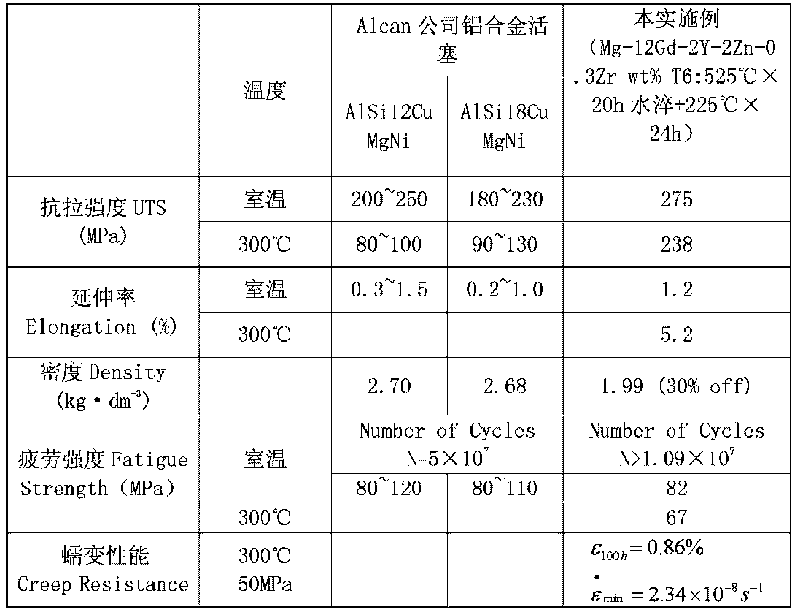

[0050] The alloy composition (percentage by weight) of the magnesium alloy engine piston: 12% Gd, 2% Y, 2% Zn, 0.3% Zr, the impurity element is less than 0.02%, and the rest is Mg.

[0051] The specific steps of the melting process of the alloy are as follows:

[0052] (1) Configure the alloy according to the above ingredients, preheat the pure magnesium and the master alloy used to 200°C in an oven, and keep it warm for 2 hours;

[0053] (2) Mg smelting: Add industrial pure magnesium into the smelting furnace, heat and smelt, and protect it with a covering agent at the same time;

[0054] (3) Add Y and Gd: Add the dried Mg-Y and Mg-Gd master alloys to the magnesium liquid at a temperature of 730°C;

[0055] (4) Adding Zn: After the master alloy is completely melted, add industrial pure zinc at a temperature of 700°C;

[0056] (5) Adding Zr: Raise the temperature of the magnesium liquid to 760°C, then add the Mg-Zr master alloy, stir for 2 minutes to promote its full melting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| fatigue strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com