Shaping device of solid hot extrusion magnesium alloy wheel hub and shaping method thereof

A magnesium alloy, hot extrusion technology, applied in the directions of wheels, transportation and packaging, vehicle parts, etc., can solve the problems of large grain size, unreasonable fiber distribution and complex manufacturing process of magnesium alloy wheel hubs, and achieve reasonable distribution of fiber structure, The effect of saving energy consumption, increasing productivity and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

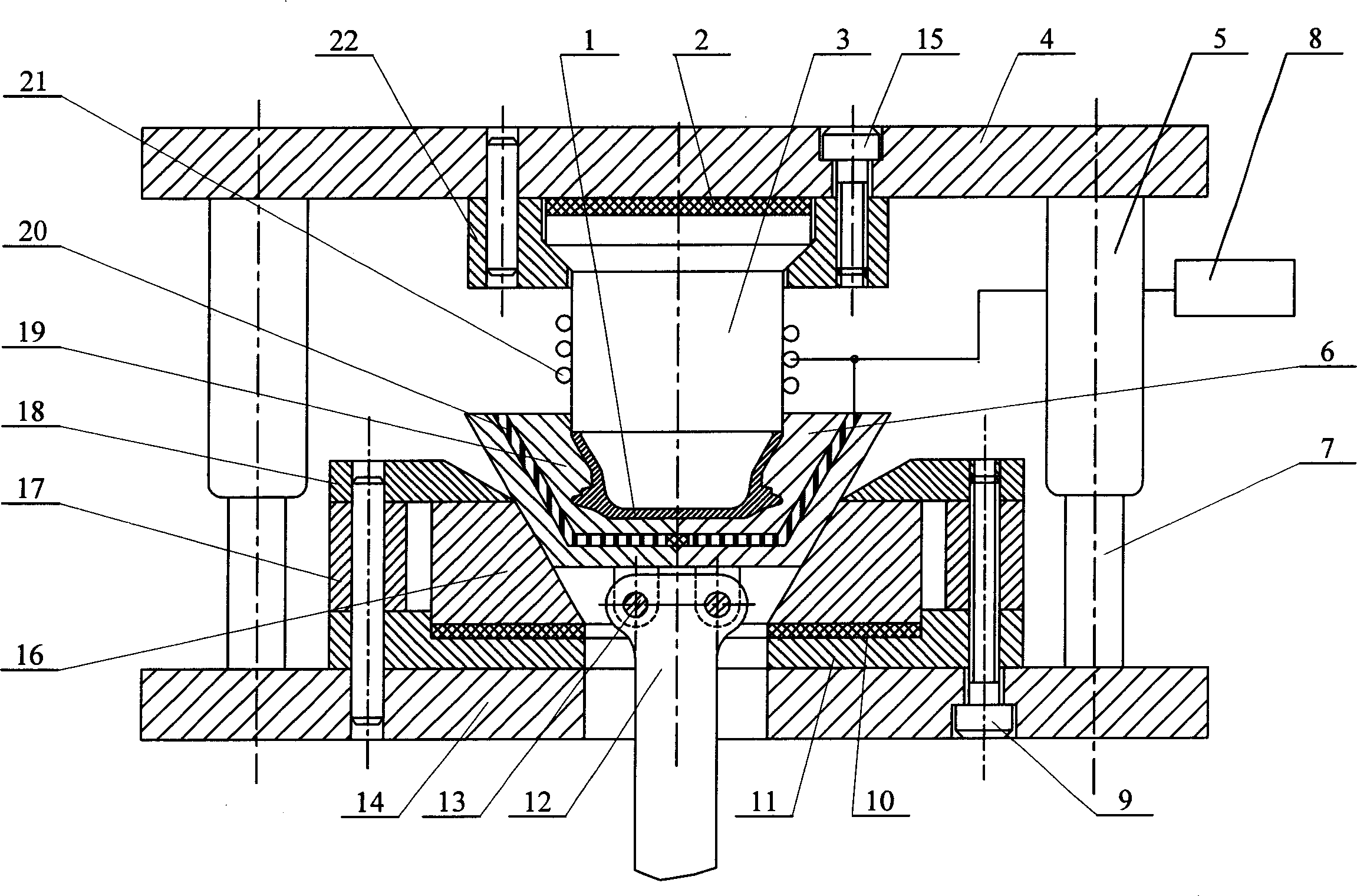

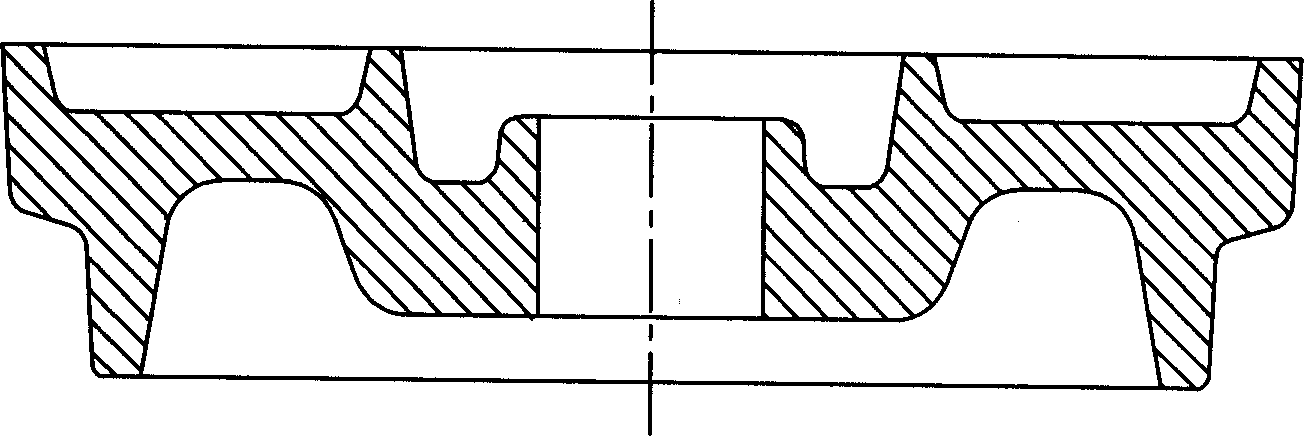

[0019] Specific embodiment 1: The forming device of the solid state hot extrusion magnesium alloy wheel hub of this embodiment consists of an upper template 4, a male die 3, a male die fixing plate 22, a pressing plate 18, a lower template 14, a female die 16, a support block 17, and a concave die. Mold pad 11, heat insulation board 2, punch heater 21, cavity heater 20, temperature controller 8, heat insulation pad 10, ejector rod 12, pin shaft 13, guide post 7, guide sleeve 5 , The upper end of the male mold 3 is embedded in the male mold fixing plate 22, the male mold fixing plate 22 and the upper template 4 are fixedly connected with screws 15, the support block 17 under the pressing plate 18 is seated on the female mold backing plate 11, the female mold backing plate 11 is placed on the lower template 14, the pressing plate 18, the support block 17, the die backing plate 11 and the lower template 14 are fixed and connected into one body with screws, the upper end of the guide ...

specific Embodiment approach 2

[0020] The second embodiment: The difference between this embodiment and the first embodiment is: the punch heater 21 of the device is wound on the periphery of the punch 3 by a resistance wire, and the left half mold 19 and the right half mold 6 of the mold cavity Drill a hole for inserting the resistance wire of the solid cavity heater 20, insert the resistance wire into the hole, and the temperature controller 8 implements the punch 3, the left half mold 19 and the right half mold 6 of the mold cavity through a temperature measuring probe Temperature control with mold 1. The connection relationship in other components is the same as in the first embodiment.

specific Embodiment approach 3

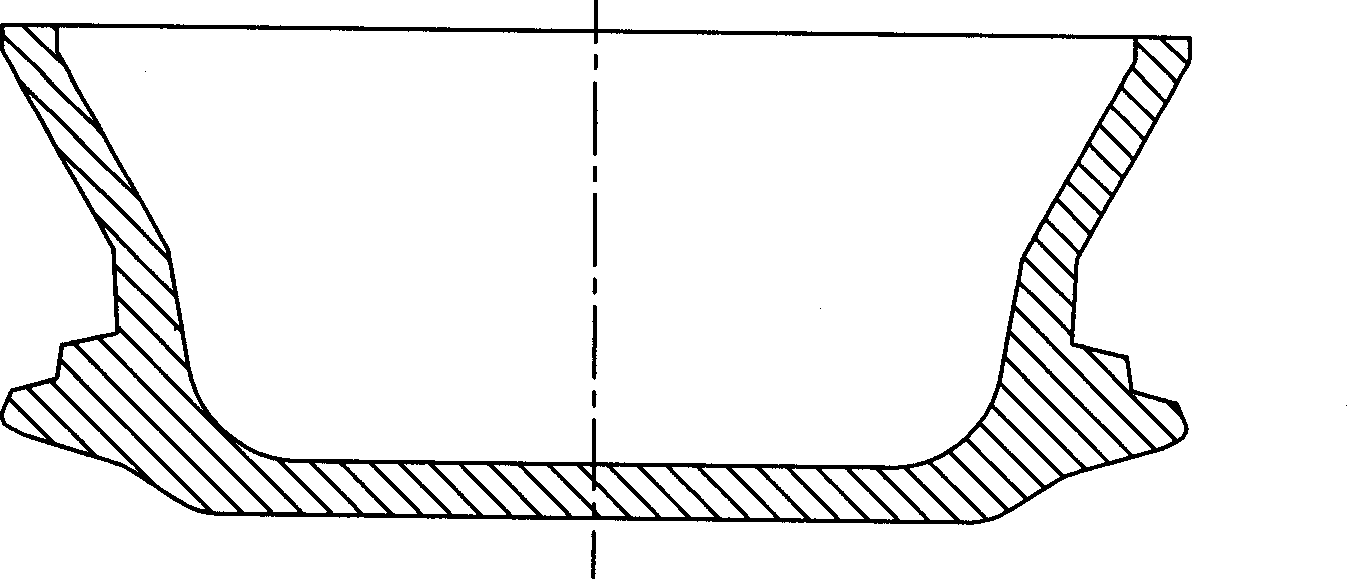

[0021] Specific embodiment 3: The device of this embodiment is equipped with an ejector rod 12 in the lower part of the mold cavity, and the upper end of the ejector rod 12 is provided with a pin 13 for the purpose of forming the mold by the ejector rod 12 under the action of a hydraulic mechanism. The semi-finished magnesium alloy wheel hub after being extruded in the cavity is lifted upwards. At this time, the left half mold 19 and the right half mold 6 of the mold cavity also follow upward movement. During the movement, under the action of eccentric gravity or external force, at the same time, Rotate to the outside around the pin shaft 13 and the final position is limited to the inclined surface of the pressing plate 18. The left half of the mold cavity 19 and the right half 6 are automatically divided. After the mold is divided, the small middle and large two ends of the extrusion can be smoothly taken out Round magnesium alloy car wheel blanks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com