Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

625results about How to "Increase nucleation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of controlling drug release from a coated medical device through the use of nucleating agents

InactiveUS20060088566A1Reduced nucleation rateSmall sizeSurgeryPharmaceutical delivery mechanismControlled drugsDrug release

A coated medical device have a drug and a nucleating agent thereon. Also provided are methods of increasing or decreasing the size of drug particles on a coated substrate through the use of nucleating agents to thereby increase or decrease the release rate of the drug from the coated substrate.

Owner:BOSTON SCI SCIMED INC

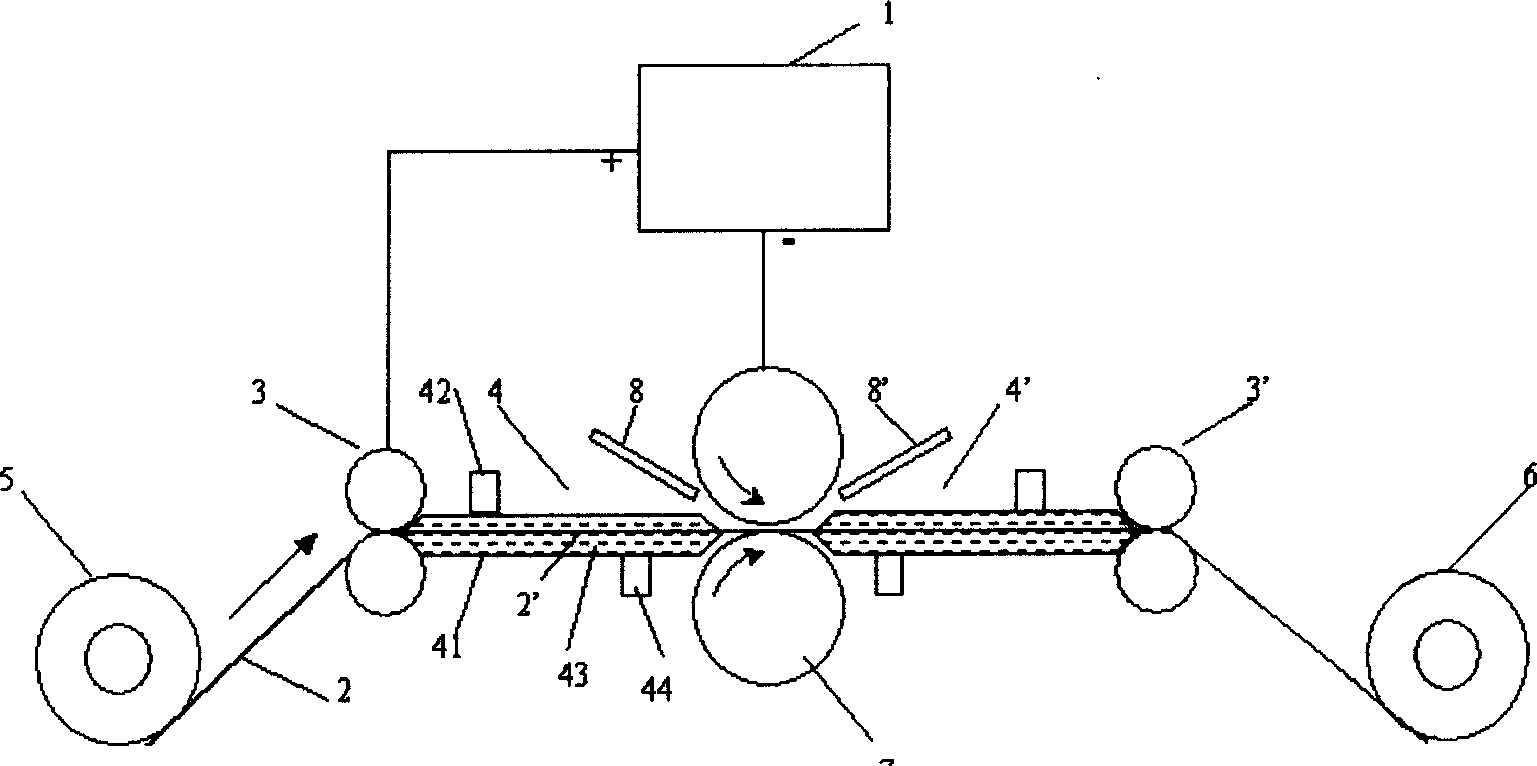

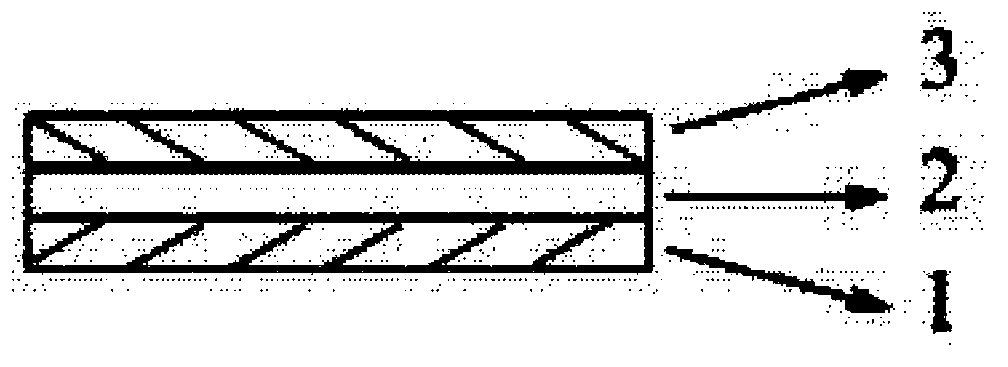

Electroplastic rolling method and apparatus for deformable magnesium alloy sheet, band and wire rod

This invention relates to an electro-plastic rolling method and a device for deformed Mg alloy thin plates, strips and wires including: inducing the deformed Mg alloy plates, strips and wires in single-way instant high energy continuous pulse current directly in the process of rolling, the current passes through a pair of electric contact devices with their distance adjustable to apply on the moving Mg materials, and the roller is the negative in it, necessary cooling and lubrication measures should be taken when rolling, this time, the rolling deformation ability of the Mg material is increased greatly and the resistance is reduced to avoid high temperature oxidation and poor accuracy in size.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV +1

Method for controlling center porosity of large section heavy rail steel casting blank

The invention relates to the technical field of ferrous metallurgy, in particular to a method for controlling the center porosity of a large section heavy rail steel casting blank. The method comprises the following steps of controlling the superheat degree of medium-package molten steel; controlling the pulling speed in the normal pouring process; pressing down the final solidification end in the pouring process; setting the stirring strength and stirring frequency of electromagnetic stirring of a crystallizer; setting the stirring strength and stirring frequency of electromagnetic stirring at the final solidification end; controlling the cooling water yield and the secondary cooling specific water yield of the crystallizer. The center porosity of the large section heavy rail steel casting blank produced by adopting the method can be effectively controlled, and the remaining internal quality of the casting blank can be effectively guaranteed.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

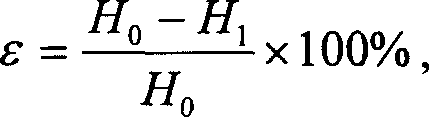

Added material manufacturing method under vibration condition

ActiveCN105458264AImprove manufacturing precisionGrain refinementAdditive manufacturing apparatusIncreasing energy efficiencyLean manufacturingMetal

The invention proposes an added material manufacturing method under a vibration condition. In an arc wire feeding added material manufacturing or laser powder feeding melting added material manufacturing process, mechanical vibration with a certain frequency is synchronously introduced, so that parts are located in a micro vibrating state; and the mechanical vibration acts on a micro liquid-state molten bath formed in the added material manufacturing process to refine grains, so that the structure becomes more uniform, and such phenomenon as air holes, inclusions and incomplete fusion is reduced or even eliminated. Meanwhile, the vibration acts on metal just condensed, so that the stress generated by vibration and residual stress generated in the added material manufacturing process are superposed to generate local plastic deformation to achieve the purpose of reducing residual stress and deformation of added material manufacturing parts, and the added material manufacturing parts under vibration condition are more excellent in performances.

Owner:HUAZHONG UNIV OF SCI & TECH

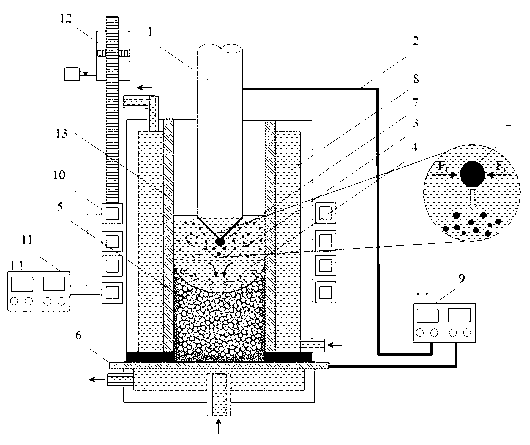

Method and device for preparing high-performance aluminum-base composite material under the action of pulsed magnetic field

The invention provides a method and a device for preparing high-performance aluminum-base composite material under the action of the pulsed magnetic field with the in situ crystallization method, belonging to the technical field of material preparation. The method comprises the following steps: smelting to synthesize compound material melt at the temperature of 10-200 DEG C higher than the compound material melt liquidus temperature and pouring the compound material melt into a specially-designed crystallizer to make the compound material melt solidify under the action of the pulsed magnetic field. The pulsed magnetic field has the key parameters of the pulse width of 1-500 ms and the amplitude strength of 0.1-50T. The pulsed electromagnetic force is applied to the process of solidifying the compound material melt under the action of the pulsed magnetic field so as to refine the matrix structure and the particle reinforced phase of the compound material at the same time, control the growth of the particle reinforced phase in cluster, increase the bonding strength of the interface of the particle reinforced phase and the matrix and obviously improve the performance of the composite material.

Owner:JIANGSU UNIV

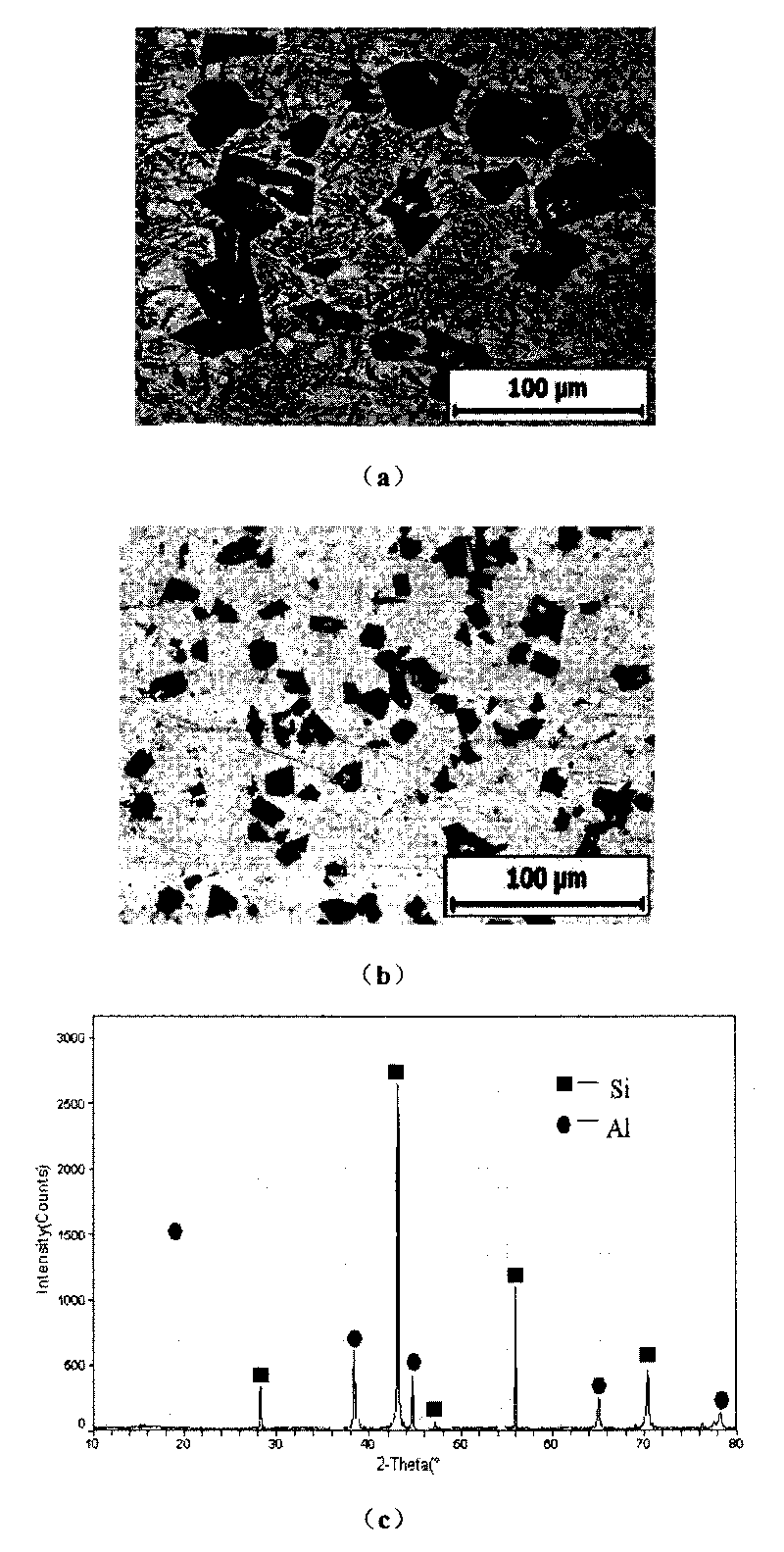

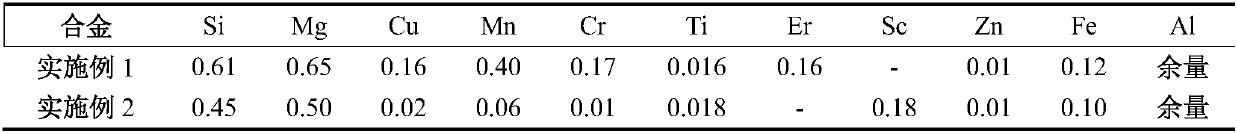

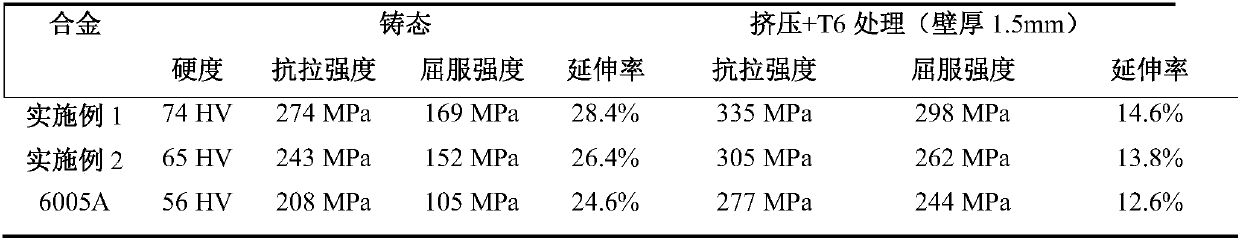

High performance Al-Mg-Si aluminum alloy extrusion material and preparation method thereof

ActiveCN110669964AImprove performanceStrong precipitation strengtheningRare-earth elementSingle element

The invention belongs to the technical field of aluminum alloy materials, and relates to a high performance Al-Mg-Si aluminum alloy extrusion material and a preparation method thereof. The high performance Al-Mg-Si aluminum alloy extrusion material is prepared from the following element components in percent by weight: 0.4-0.7% of Si, 0.5-0.7% of Mg, 0.01-0.2% of Cu, 0.05-0.45% of Mn, 0.01-0.3% ofCr, 0.01-0.02% of Ti, 0.05-0.30% of rare earth elements, less than or equal to 0.1% of Zn, less than or equal to 0.15% of Fe and the balance Al, wherein the content of single elements is less than orequal to 0.05%, the total content of impurities is less than or equal to 0.15%, and any one or two of the rare earth elements Er and Sc are mixed. The preparation method can optimize the alloy components obviously, balance and refine crystal grains, purify and clean a melt, reduce the casting flaws and improve the quality of a cast ingot greatly. In addition, the surface quality of an extruded profile can be better improved, and the extrusion speed and the thermal treatment comprehensive mechanical property of the extruded profile product are improved.

Owner:CHINA ZHONGWANG

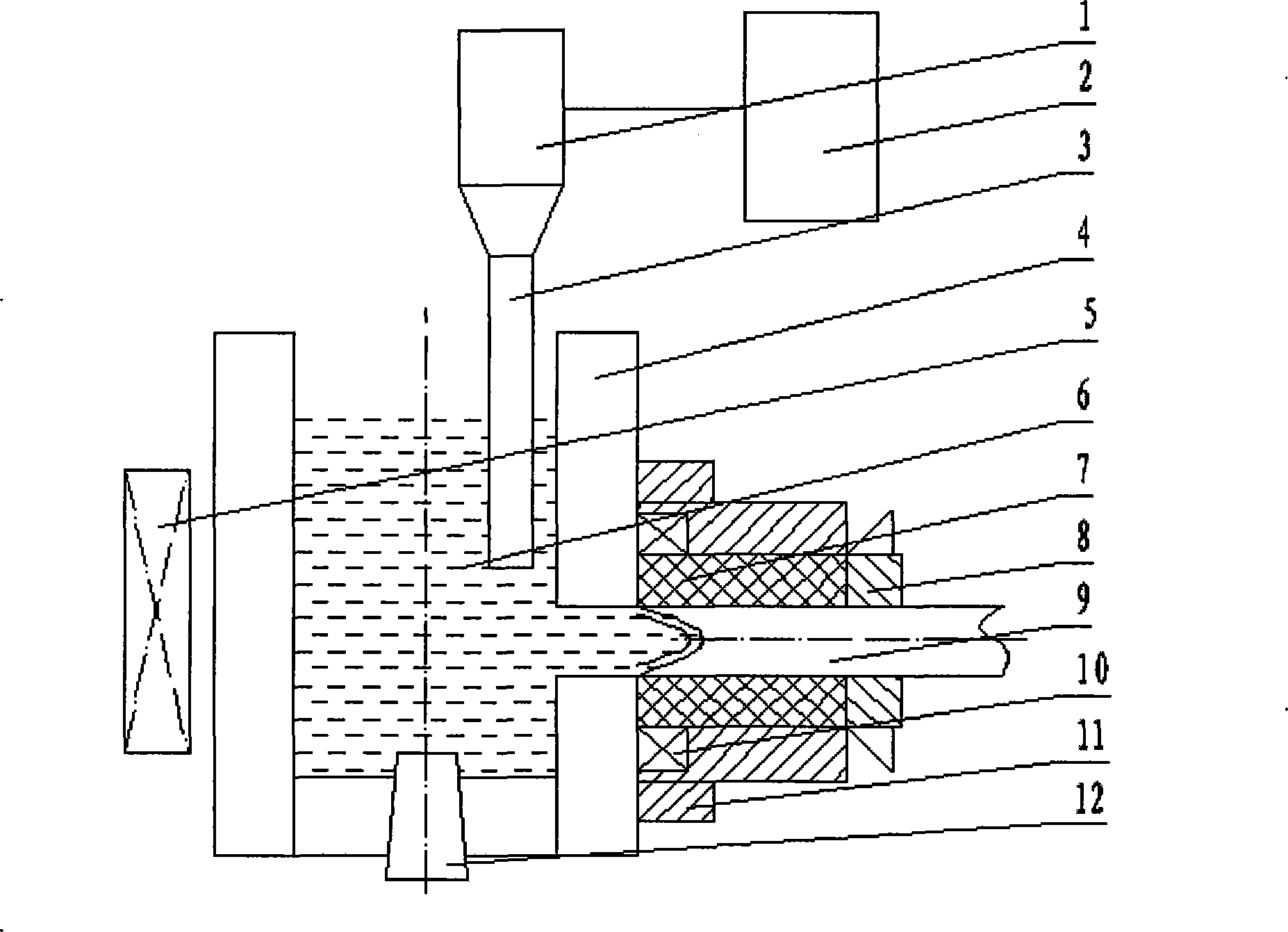

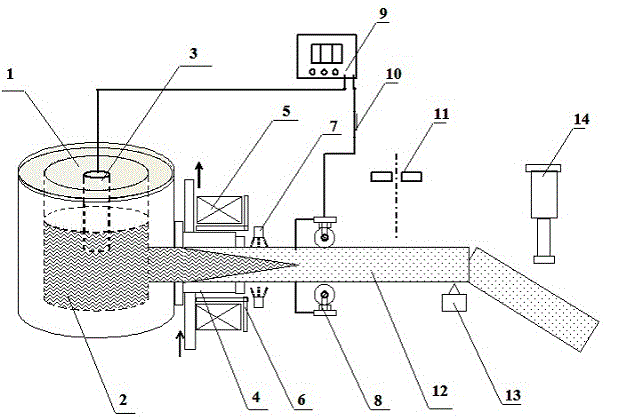

Method and apparatus for improving horizontal continuous casting billet quality by applying composite field

The invention relates to a quality improving method for horizontal continuous casting blanks by applying complex field and the device, belonging to the technical field of preparation of metal material, in particular to the technology of applying complex electromagnetic field and ultrasonic field in the continuous casting process of metal casting blanks. The device is characterized in that a generator of inert gas is arranged at the center of the bottom of a holding furnace; a generator of traveling wave magnetic field is arranged on the side of the holding furnace; a power ultrasonic device is arranged on the holding furnace close to the water port; a restriction electromagnetic coil is arranged on the outer side of a crystallizer. The device has the advantages that: firstly, the production technology is simple, the operation is easy, and the efficiency is high; secondly; the disadvantages of easy broken in rolling and drawing process of casting blank due to more impurity and pores is solved; thirdly, the solidification structure of the casting blanks is uniform, the crystal grain is fine, and the casting blanks can be rolled directly at casting state. The quality improving method and the device are mainly used for the field of metal continuous casting.

Owner:DALIAN UNIV OF TECH

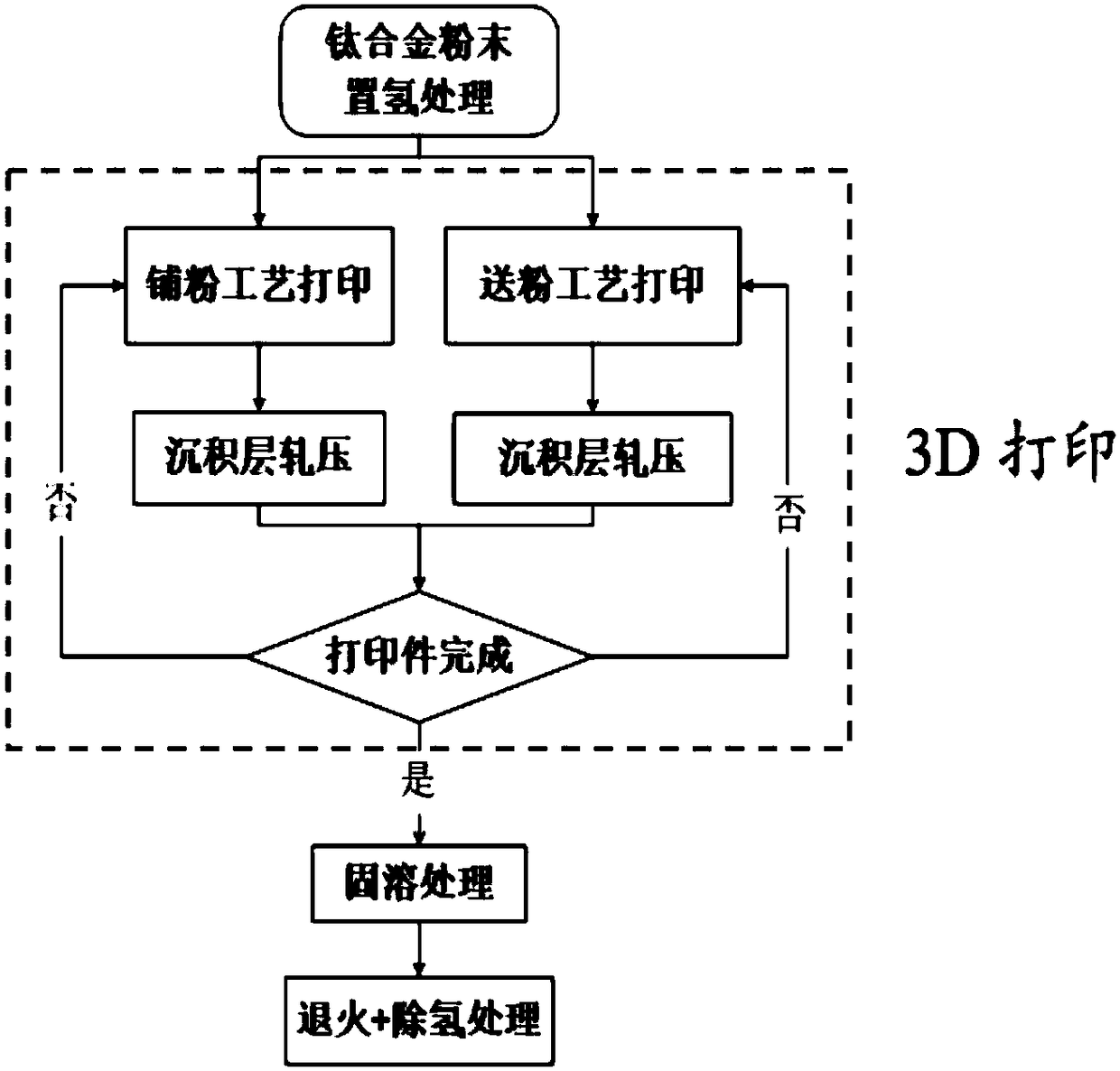

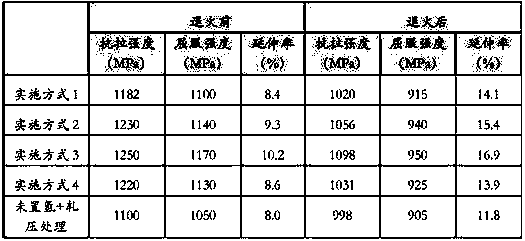

Hydrogen treatment roll compacting compound technology for improving additive manufacturing titanium alloy structure

ActiveCN108580884AFacilitated DiffusionIncrease subcoolingAdditive manufacturing apparatusTransportation and packagingCyclic processChemical composition

The invention provides a hydrogen treatment roll compacting compound technology for improving an additive manufacturing titanium alloy structure. The hydrogen treatment roll compacting compound technology for improving the additive manufacturing titanium alloy structure comprises the steps of during an additive manufacturing process, carrying out hydrogen treatment on titanium alloy powder, and roll compacting a printing piece layer by layer, so that the printing piece with structure being refined is prepared through a circulation process of printing-roll compacting-printing-roll compacting; and finally removing temporary alloying element hydrogen through vacuum annealing, so that the change of chemical components of a final material is avoided. During the process, the printing piece structure is refined and improved by utilizing hydrogen and the dislocation defects are increased by roll compacting at the same time, so that the capability of nucleation is reduced, the nucleation rate is improved, and the aims of refining grains and improving the structure without changing the alloy components are achieved.

Owner:SHANGI INST FOR ADVANCED MATERIALSNANJING CO LTD

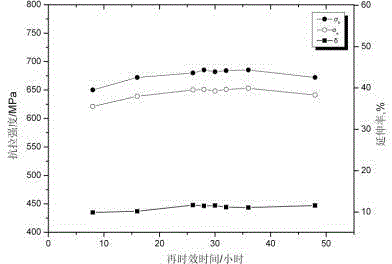

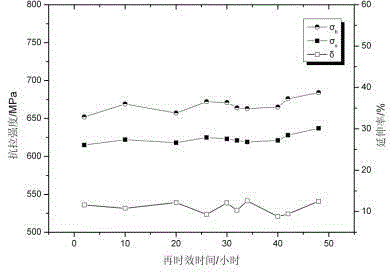

Ageing heat treatment method for low-purity Al-Zn-Mg-Cu alloy

ActiveCN104694860AIncrease nucleation rateImprove plastic deformation abilitySolution treatmentPlastic property

The invention discloses an ageing heat treatment method for a low-purity Al-Zn-Mg-Cu alloy. The method includes the steps that the low-purity aluminum alloy is treated in a solution mode at the temperature of 465 DEG C-480 EDG C for 1-2 h, then first-level ageing is carried out at the temperature of 90 DEG C-120 DEG C for 15-26 h, and air cooling is carried out; the alloy is treated in a regression mode at the temperature of 150 DEG C-210 DEG C for 2-120 min, and intragranular precipitates are redissoluted into a matrix through water cooling; natural ageing (RT) is carried out for 2-120 h, ageing is carried out at the temperature of 50 DEG C-120 DEG C for 2-90 h, and air cooling is carried out. The low-purity Al-Zn-Mg-Cu alloy comprises, by mass ratio, 5.8-7.5% of Zn, 0.2-0.6% of Mn, 1.7-2.5% of Mg, 1.2-2.0% of Cu, 0.08-0.25% of Cr or 0.05-0.15% of Zr, 0.1-0.6% of Fe, 0.1-0.6% of Si, and balance Al. By means of the four-level ageing technology, the low-purity Al-Zn-Mg-Cu alloy obtains highly-dispersed G.P. region granules and a few eta phase intragranular tissues and therefore has ultra-high strength, good plasticity and fatigue damage resistance.

Owner:CENT SOUTH UNIV

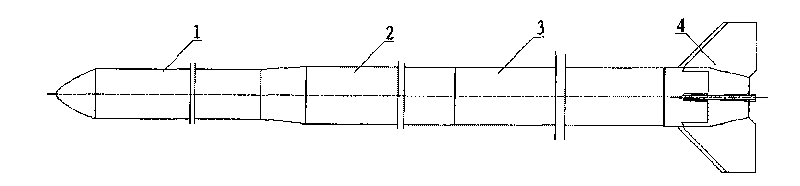

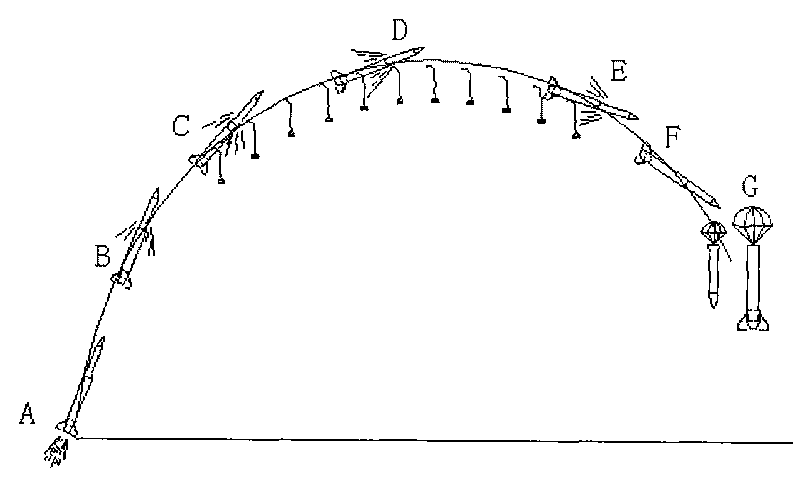

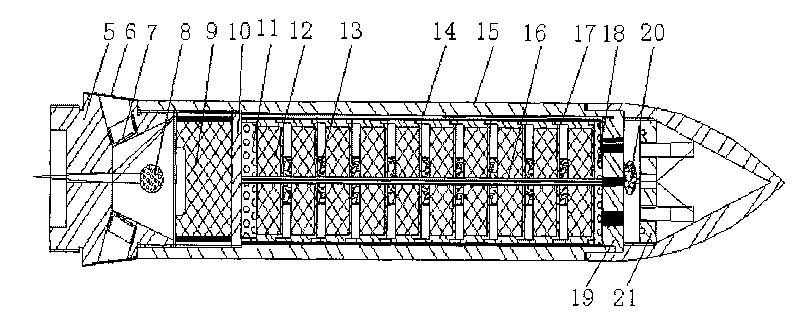

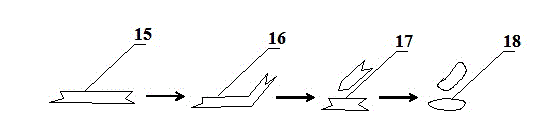

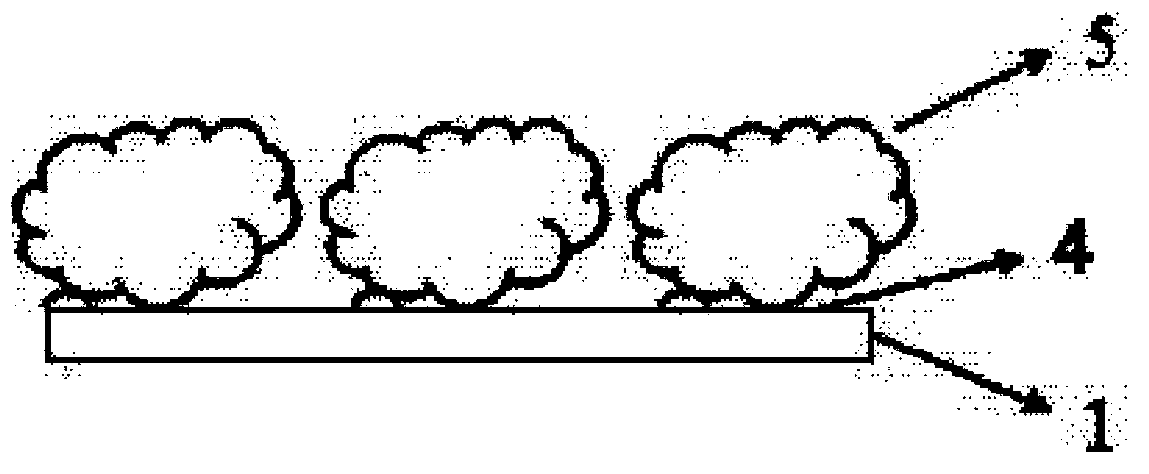

Multielement seeding combustion explosion type rainfall-increasing and anti-hail rocket

InactiveCN101726219ANo pollution in the processLarge coverage areaWeather influencing devicesSelf-propelled projectilesCombustionEngineering

The invention relates to a multielement seeding combustion explosion type rainfall-increasing and anti-hail rocket. In the rocket, one end of a safety system (2) is connected with a flame bullet seeding catalyst system (1), the other end is connected with the front end of a solid motor (3); the back end of the motor (3) sticks to an empennage; four catalyst seeding holes are evenly distributed in the middle part of a nozzle (5), a plurality of flame bullets (12) are sleeved together to be arranged in a shell (15), safety fuses (16) are arranged in the centre bores of the flame bullets (12), a propelling medicine (13) is filled to one end of each flame bullet (12); a cladding medicine block(9) is filled in the threaded connection section capsule of the shell (15), an ignition medicine package (8) is arranged in the counter bore of the cladding medicine block(9), and the ignition wire of the ignition medicine package passes through the centre bore of the nozzle (5). The invention adopts the flame bullet burning mode that catalyst is burnt and seeded continuously and a plurality of flame bullets are thrown along the parent trajectory, for seeding the catalyst, thus requiring that the flame bullets are thrown reliably and the burning is stable. The flame bullets of the invention adopt casting moulding for structure design, the technology is easy and stable, and the flame bullets are easy for the batch production.

Owner:SHAANXI ZHONGTIAN ROCKET TECH CO LTD

Titanium alloy and annular titanium alloy forge piece forming method

InactiveCN104148554AIncrease contentImprove high temperature strengthMetal rollingTitanium alloyUltimate tensile strength

The invention discloses titanium alloy and an annular titanium alloy forge piece forming method. The chemical element content of the titanium alloy comprises, by weight, 7.50%-7.80% of A1, 1.00%-2.00% of Mo, 2.60%-2.80% of Zr, 2.60%-2.80% of Sn, 0.50%-1.50% of W, 0.10%-0.25% of Si, no more than 0.15% of Fe, no more than 0.10% of Cu, no more than 0.10% of Cr, no more than 0.10% of C, no more than 0.15% of O, no more than 0.04% of N, no more than 0.012% of H, and the balance Ti. The annular titanium alloy forge piece forming method comprises the following steps that after the titanium alloy is fed, and blanking is conducted at the temperature 30 DEG C below the phase transformation point; forming is conducted at the temperature 20 DEG C above the phase transformation point, and water cooling is conducted till the allay reaches the indoor temperature; double annealing is conducted on the materials obtained through the above two steps. The annular titanium alloy forge piece has the high-temperature tensile strength which can meet the use conditions and is large in affluence measure at the temperature ranging from 500 DEG C to 550 DEG C and can replace TC 25 to be used for manufacturing compressor parts and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

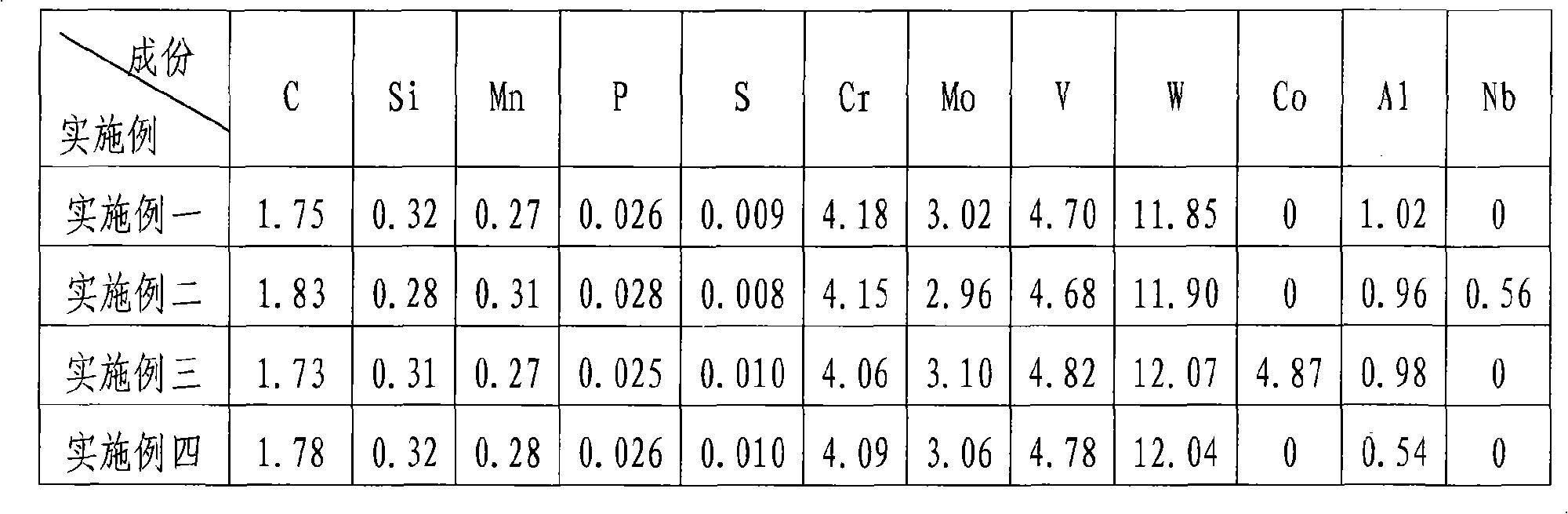

High-hardness high-wear-resistant powder metallurgy high-speed steel

The present invention relates to high-performance high-speed steel, and particularly to a high-hardness high-wear-resistant powder metallurgy high-speed steel which is manufactured according to a power metallurgy method and contains Al. The high-speed steel is composed of C, Si, Cr, Mo, V, W, Nb, Mn, Co, Al, Fe and impurities. The high-speed steel manufactured according to the technical solution has the following advantages: more than 67.5HRC of quenching-tempering hardness, better red hardness and wear resistance, stronger bending strength and lower cost.

Owner:HEYE SPECIAL STEEL

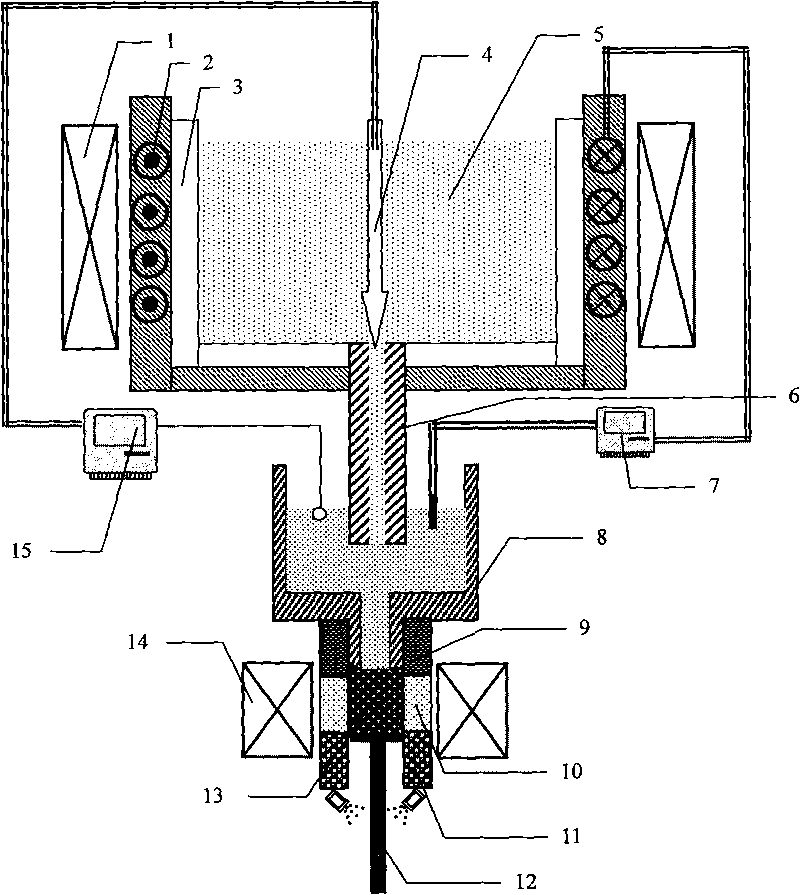

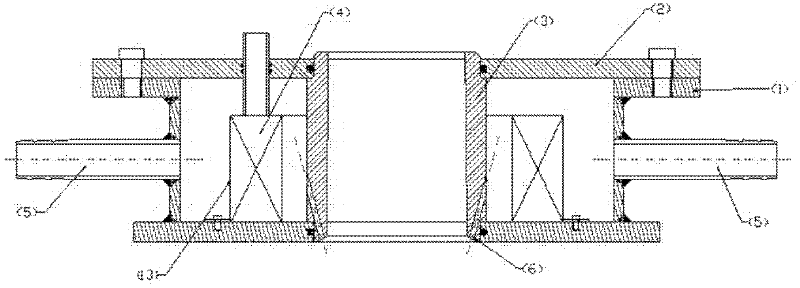

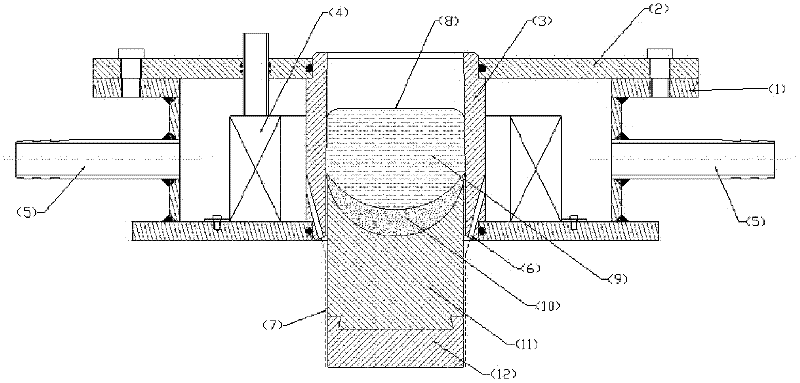

Method for controlling metal solidification phase texture in combined mode through external rotating magnetic field and current and fusion casting device of method

The invention discloses a method for controlling metal solidification phase texture in a combined mode through an external rotating magnetic field and current and a fusion casting device of the method. In a metal solidification process, firstly, the rotating magnetic field is exerted on a metal melt area on the front edge of a metal melt solidification interface, and meanwhile the current is exerted on metal melt nearby a solid-liquid interface area of a whole continuously cast bloom through an external power supply. Under the combined action of the rotating magnetic field and the current, electromagnetic combined stirring is conducted on metal liquid nearby the metal melt solidification interface, so that collision, friction and scour occur among primary grains of the metal melt and between the primary grains and the metal melt, fragmentation of the primary grains can be caused, and therefore the solidification texture of the continuously cast bloom is refined. The method is used for preparing high-quality metal materials.

Owner:SHANGHAI UNIV

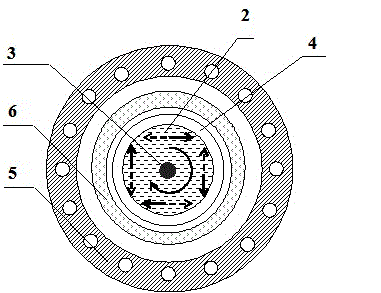

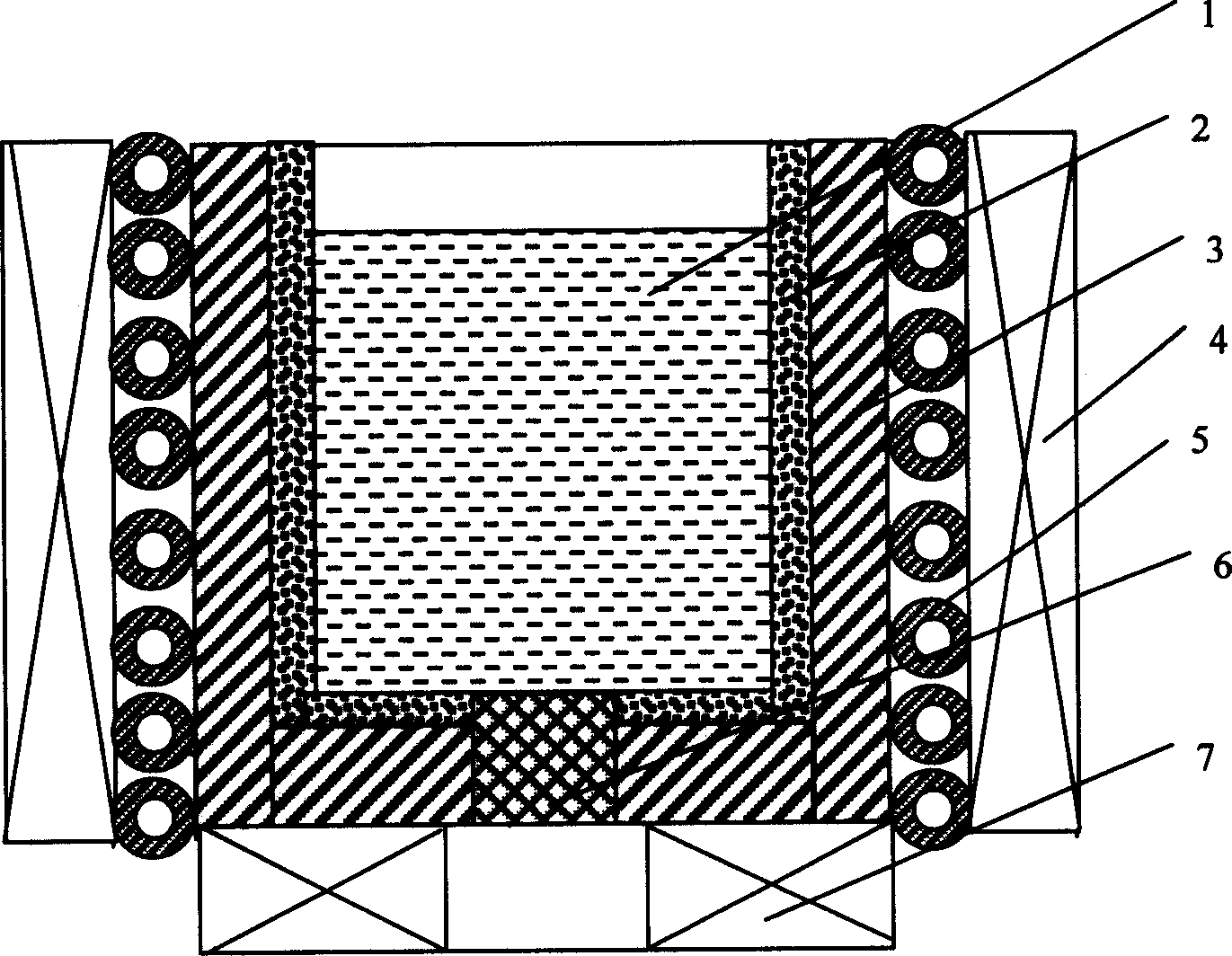

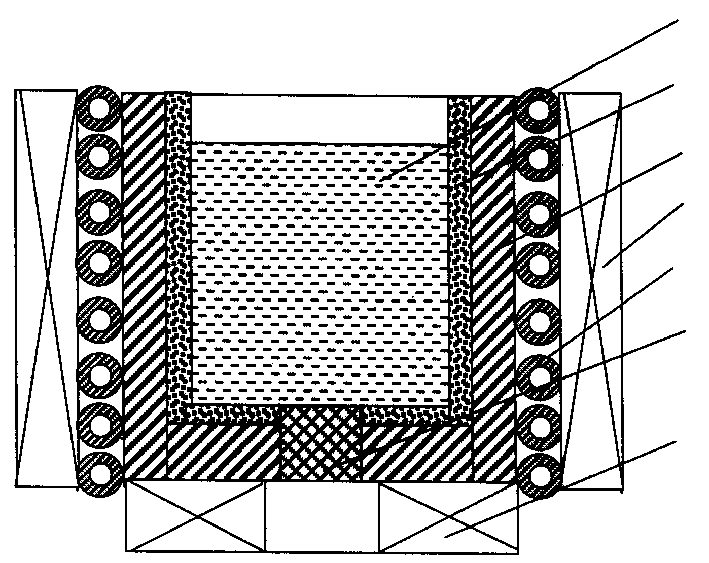

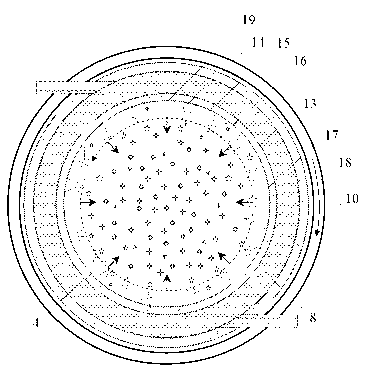

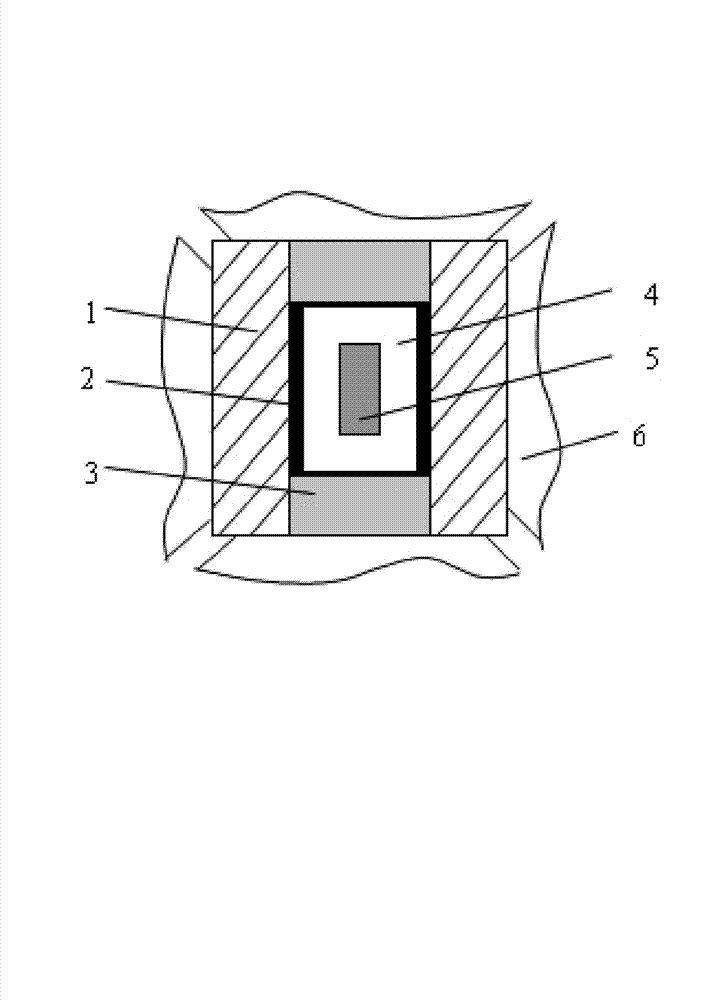

A magnesium alloy low-frequency pulsed magnetic field assisted semi-continuous casting mold and its application

The invention belongs to the field of the preparation of metal materials, and particularly relates to an auxiliary semi-continuous casting crystallizer for a low-frequency pulsed magnetic field of magnesium alloy and application thereof. The top of a casing of the crystallizer is provided with an upper cover of the crystallizer, the casing of the crystallizer and the position of a center hole of the upper cover of the crystallizer are provided with an inner sleeve of the crystallizer, a cooling water tank is formed between the casing of the crystallizer and the upper cover of the crystallizer, an excitation coil is arranged in the cooling water tank, the outer side of the casing of the crystallizer is provided with a water inlet communicated with the cooling water tank, and a secondary cooling water spraying hole communicated with the cooling water tank is arranged on the inner sleeve of the crystallizer. The casing and the upper cover of the crystallizer are made of stainless steel, and the inner sleeve of the crystallizer is made of a 4XXX family of aluminum alloy; and moreover, an upper opening of the inner sleeve of the crystallizer is higher than the upper surface of the upper cover, and a horn shape is formed between the upper opening and a lower opening. The auxiliary semi-continuous casting crystallizer for the low-frequency pulsed magnetic field of the magnesium alloyis used for the semi-continuous casting of the magnesium alloy, the forced convection of a melt is generated by utilizing pulsed electromagnetic force generated by the auxiliary semi-continuous casting crystallizer for the low-frequency pulsed magnetic field of the magnesium alloy to act on the melt of the magnesium alloy inside the crystallizer, bulky dendritic crystals are fragmented, the nucleation rate is increased, and the thinning effect of the crystal grains of a semi-continuous cast rod of the magnesium alloy is obvious.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

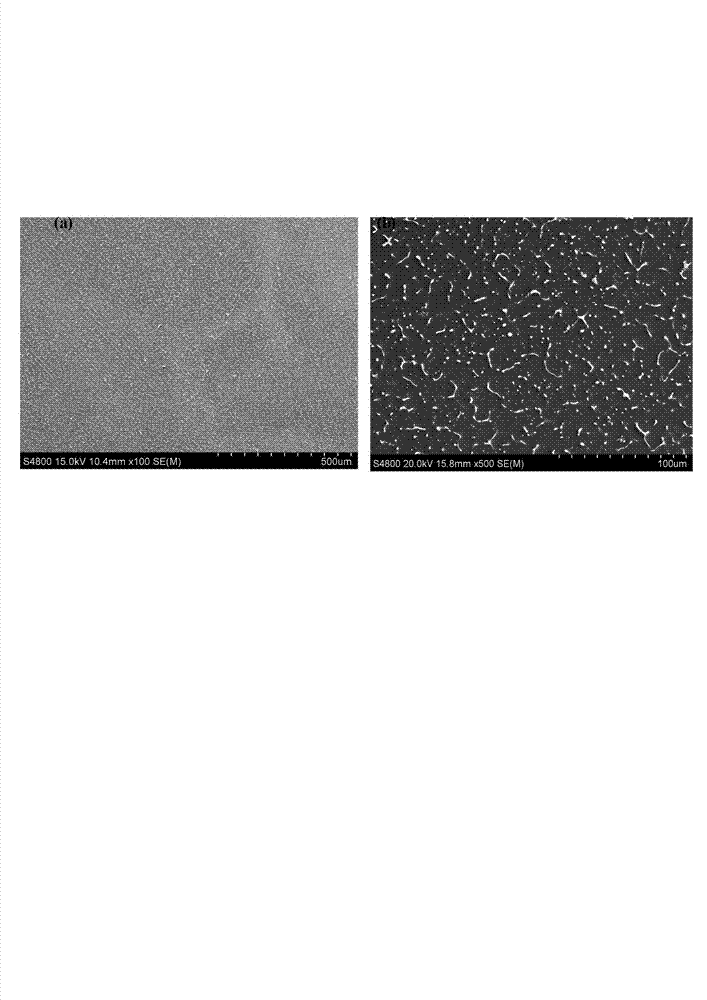

Preparation method of high-compactness corrosion-resistant and abrasion-resistant magnesium alloy micro arc oxidization film

InactiveCN108118380AImprove conductivityChangeable electrical propertiesAnodisationAluminatePlasma electrolytic oxidation

The invention provides a preparation method of a high-compactness corrosion-resistant and abrasion-resistant magnesium alloy micro arc oxidization film. An electrolyte of the preparation method is mainly composed of meta-aluminate and phosphate, and some adding agents capable of forming ceramic or insoluble salt are added in, so that different ceramic and insoluble salt can be formed. Due to the fact that the melting points of the ceramic or salt are different, the cooling times of the ceramic or salt are different in the micro arc oxidization process, in this way, holes left by melt cooled firstly can be filled with melt cooled later, and therefore the high-compactness micro arc oxidization film is formed. Little refractory solid oxide powder exists and can serve as a nucleating core during solidification, the nucleating rate can be increased, and therefore the micro arc oxidization film can be more uniform. The micro alloy micro arc oxidization film prepared through the preparation method has good compactness, abrasion resistance and corrosion resistance. The high-compactness corrosion-resistant and abrasion-resistant magnesium alloy micro arc oxidization film is good in corrosion resistant performance, stable in system, environment-friendly and non-toxic, low in cost, low in process temperature, simple in process and low in energy consumption, and industrialization can be achieved easily.

Owner:GUIZHOU INST OF TECH

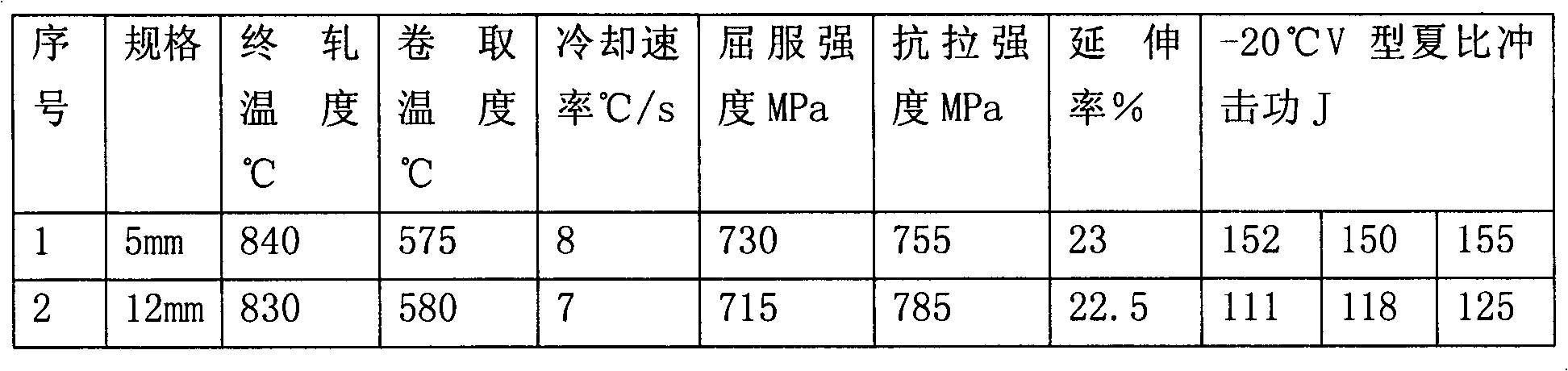

Steel for 600MPa-grade high-strength engineering machines and production method thereof

The invention relates to steel for 600MPa-grade high-strength engineering machines and a production method thereof, belonging to the technical field of steel for the engineering machines. The steel comprises the following chemical components by weight percent: C: 0.06-0.09%, Si: 0.15-0.25%, Mn: 1.4-1.6%, P: not more than 0.020%, S: not more than 0.010%, Alt: 0.020-0.060%, Nb: 0.040-0.060%, Ti: 0.09-0.12% and the balance of Fe and inevitable impurities. The steel has no expensive elements such as Mo, V and the like, 2 frames are adopted for rough rolling, and 6 frames are used for finish rolling, thereby carrying out controlled rolling; and 20-group laminar cooling is used for strictly controlling the cooling, and internal stress is eliminated by adopting a temperature-holding pit for slow cooling after being offline, thereby being capable of stably producing a hot rolled coil with excellent toughness and low cost, which has the thickness being 5-16mm, the yield strength being more than 600MPa, the V type Charpy impact energy at -20 DEG C being not less than 40J and is applicable to the field of the engineering machines and the like.

Owner:BEIJING SHOUGANG CO LTD

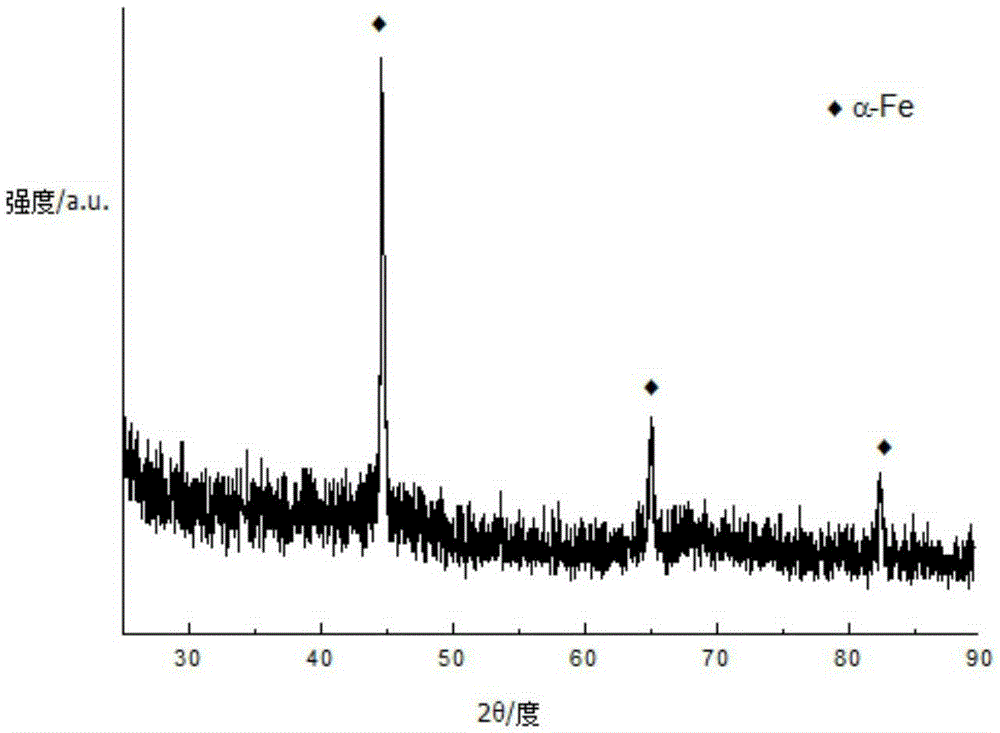

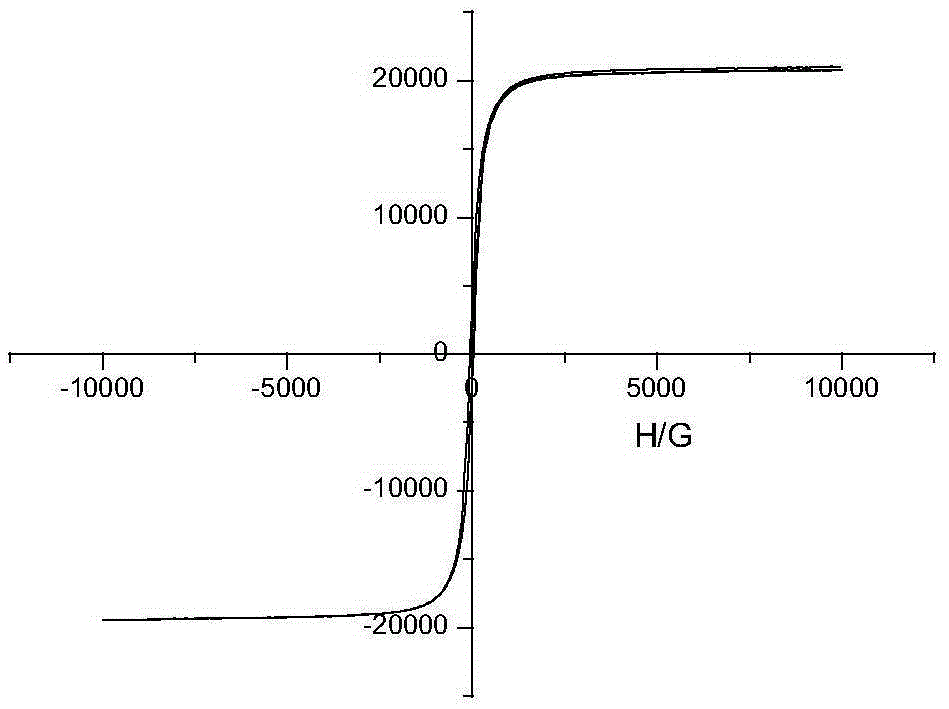

Fe-based amorphous and nanocrystalline soft magnetic alloy ribbon and preparation method thereof

InactiveCN105261435AHigh saturation magnetic inductionGood soft magneticInductances/transformers/magnets manufactureMagnetic materialsTransformerThermal stability

The invention provides a Fe-based amorphous and nanocrystalline soft magnetic alloy ribbon. Components of the Fe-based amorphous and nanocrystalline soft magnetic ribbon are as shown in FeSiB<c>P<d>Cu<e>Me<f>, wherein a, b, c, d, e and f respectively represent the content of Fe, Si, B, P, Cu and Me in the alloy ribbon on the basis of mass fractions of atoms; a is less than or equal to 90 and greater than or equal to 80; b is less than or equal to 5 and greater than or equal to 0.5; c is less than or equal to 12 and greater than or equal to 5; d is less than or equal to 9 and greater than or equal to 1; e is less than or equal to 2 and greater than or equal to 0.3; f is less than or equal to 3 and greater than or equal to 0.3; and a+b+c+d+e+f=100. According to the Fe-based amorphous and nanocrystalline soft magnetic alloy ribbon, by addition of microelements, the Fe-based amorphous and nanocrystalline soft magnetic alloy ribbon with high saturation flux density can be obtained without a heat treatment; and the alloy ribbon can be prepared in high vacuum or argon protection, has excellent soft magnetic property and high heat stability and is suitable for a transformer, an engine, a motor, a generator, a magnetic sensor and the like.

Owner:WANGWEI NEW MATERIALS (PIZHOU) CO LTD

Nano composite catalyzer for artificial weather affection and its production method

InactiveCN1557131AIncrease nucleation rateNucleation rate acceleratedWeather influencing devicesSilver iodideAdhesive

The nano composite catalyst is prepared with silver iodide, magnesium, aluminum, copper iodide, sliver iodate or other superfine particle, combustible component, adhesive, curing agent, plasticizer, cross-linking agent, anti-aging agent, speed regulator, etc. and through kneading, deairing and curing. In combustion or explosion, the nano composite catalyst produces composite AgI-NaCl-AgCl-KCl-CuI-NH4I kernels, which possess great specific surface area, high activity, and structure and crystal lattice constant similar to those of ice crystal. The catalyst has high kernel forming rate, fast kernel forming speed, excellent physical and chemical performance, less environmental pollution and easy maintenance and transportation, and is safe and efficient composite catalyst for rain making, preventing hail, eliminating cloud, and other weather modifications.

Owner:金德镇

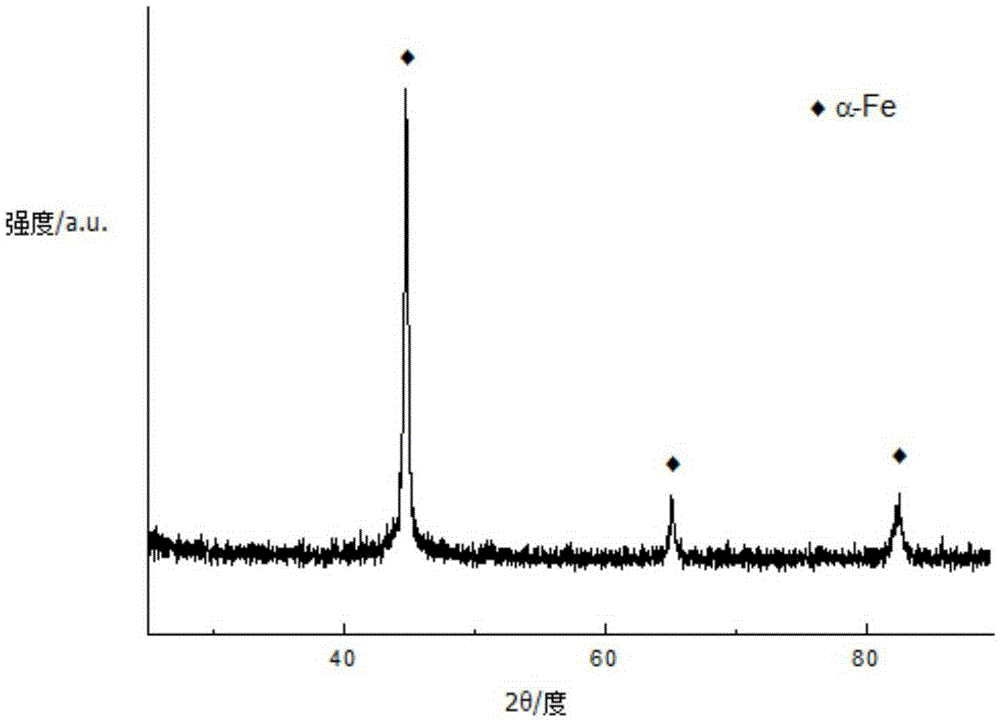

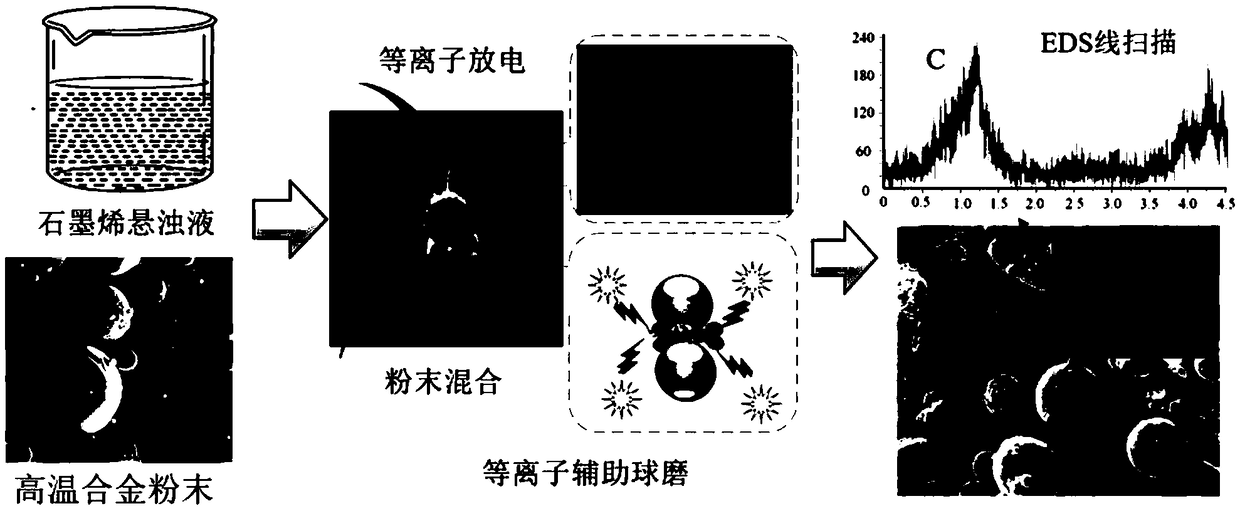

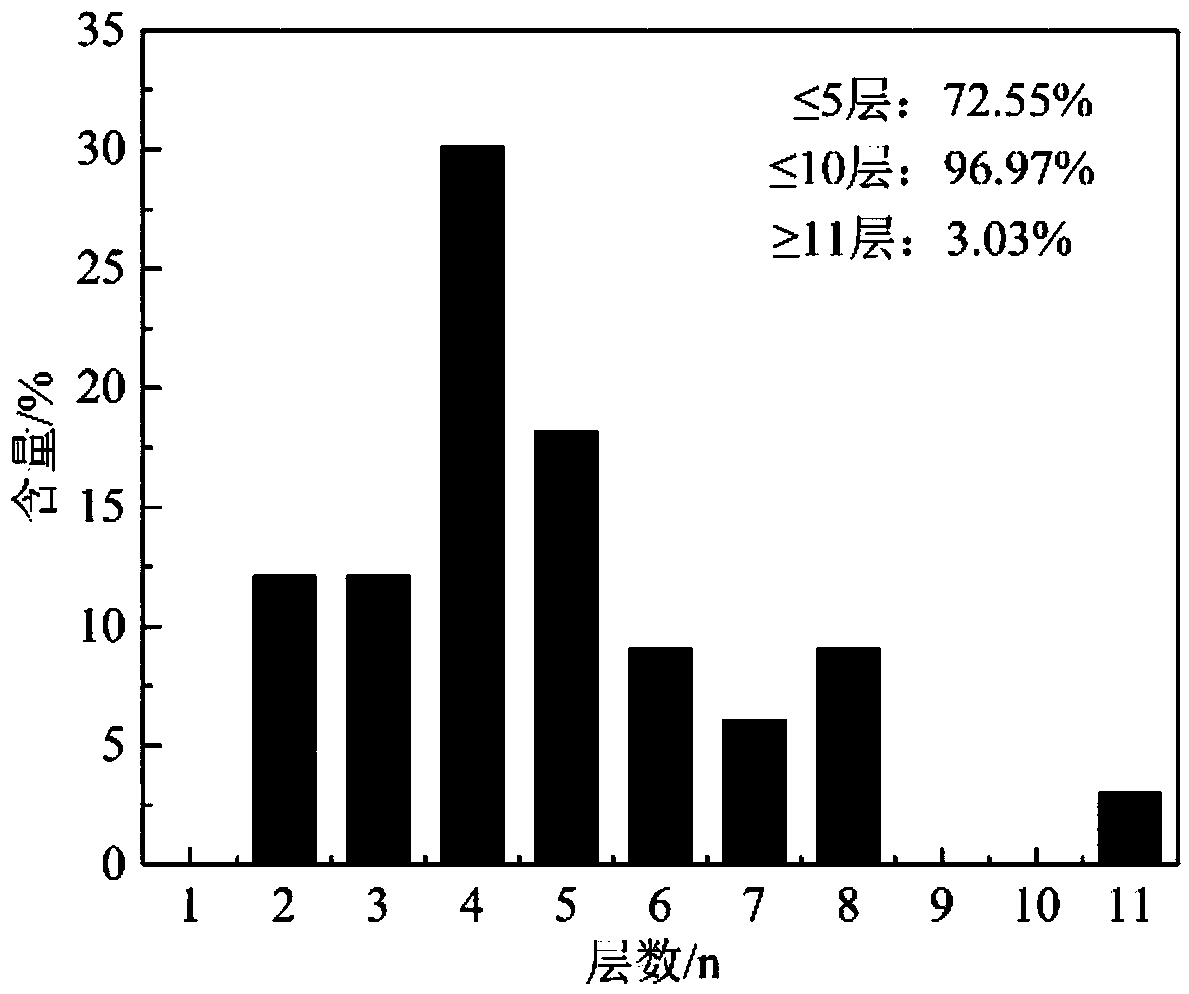

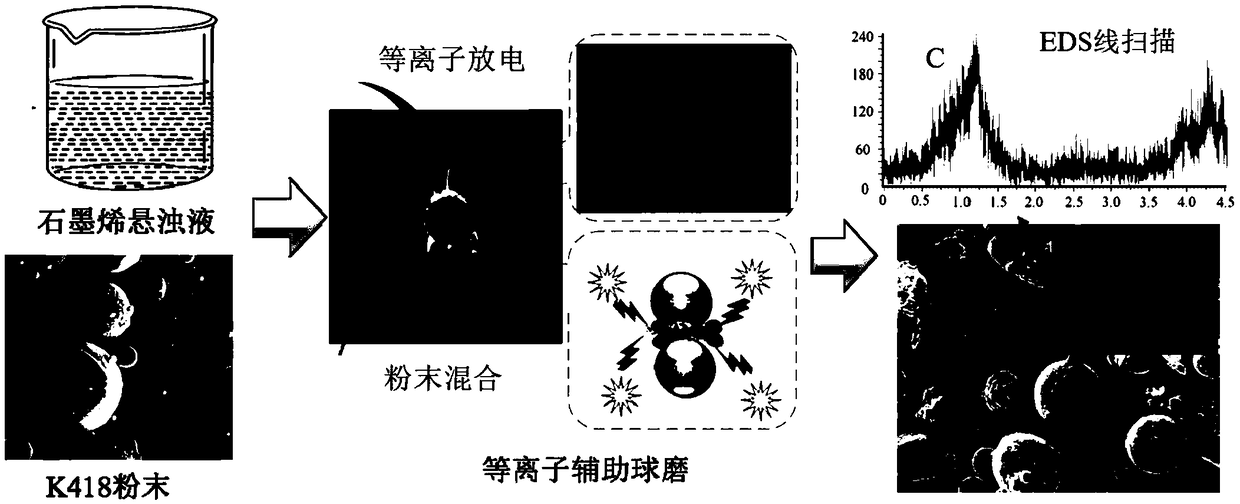

Preparation method of graphene alloy nanocomposite and SLM (Selective Laser Melting) forming process

InactiveCN109454240AImproves Strength and ToughnessReduced hot cracking tendencyAdditive manufacturing apparatusIncreasing energy efficiencyCvd grapheneInterfacial reaction

The invention discloses a preparation method of a graphene alloy nanocomposite and an SLM (Selective Laser Melting) forming process. According to the preparation method, turbid liquid is prepared through the ultrasonic vibration of anhydrous ethanol, so that the graphene is uniformly dispersed in the anhydrous ethanol, the graphene is uniformly dispersed, then after the graphene anhydrous ethanolturbid liquid is mixed with high-temperature alloy in proportion, the graphene and partial residue are distributed in the grain boundary and crystals by participating in the interfacial reaction, so that the strength and toughness of a formed part are improved, and the hot cracking tendency is reduced; the addition of graphene changes the organization form of the material; and in the SLM forming process, the graphene in the graphene high temperature alloy nanocomposite is used as a heterogeneous nucleating agent, and increases the nucleation rate in the solidification crystallization process.The graphene high temperature alloy nanocomposite is prepared by the dielectric barrier discharge plasma-assisted ball milling technique. The plasma enhances the activity of powder, so that columnar crystals preferentially growing change to isometric crystals, grains are refined and the performances are improved.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

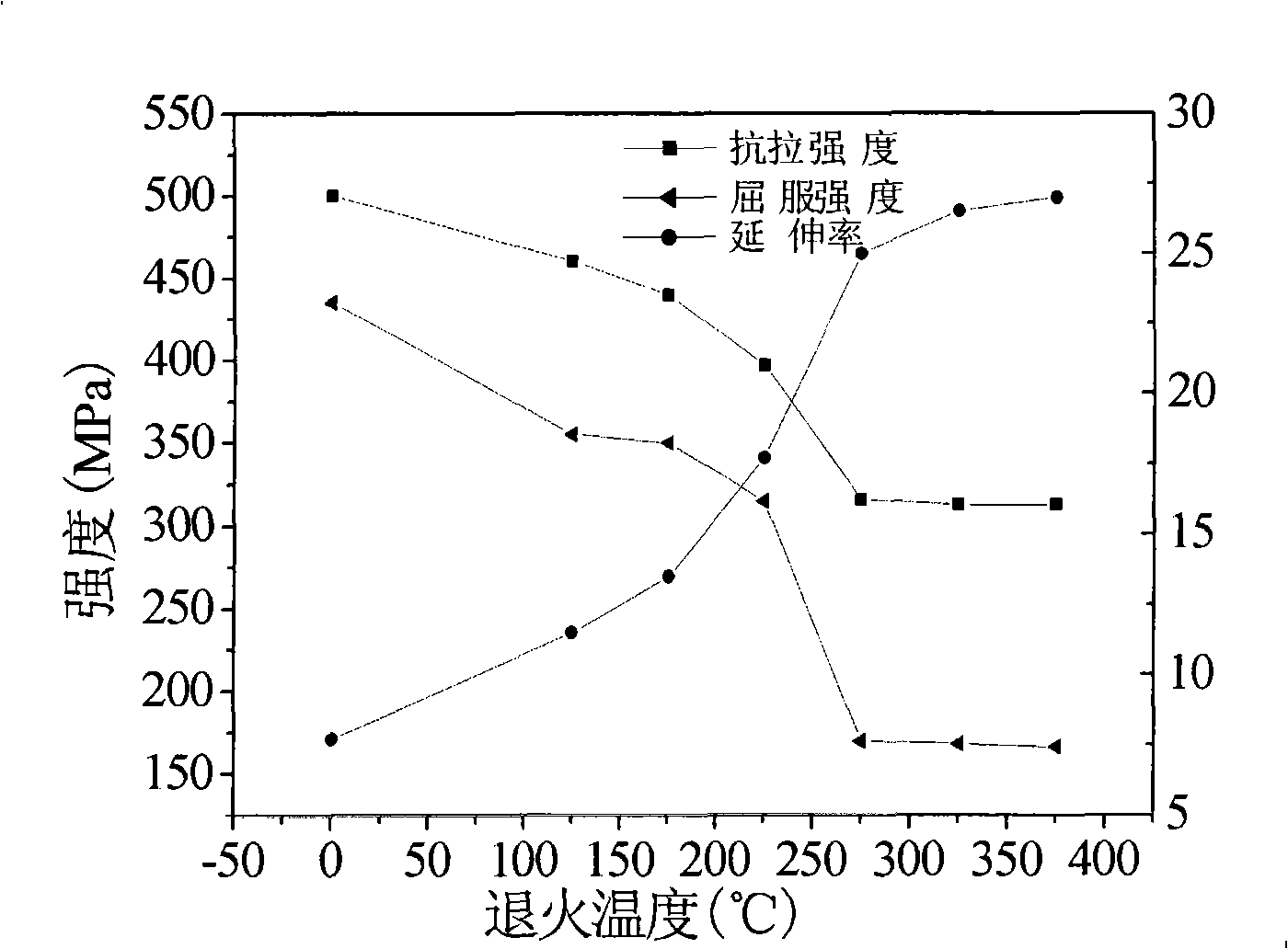

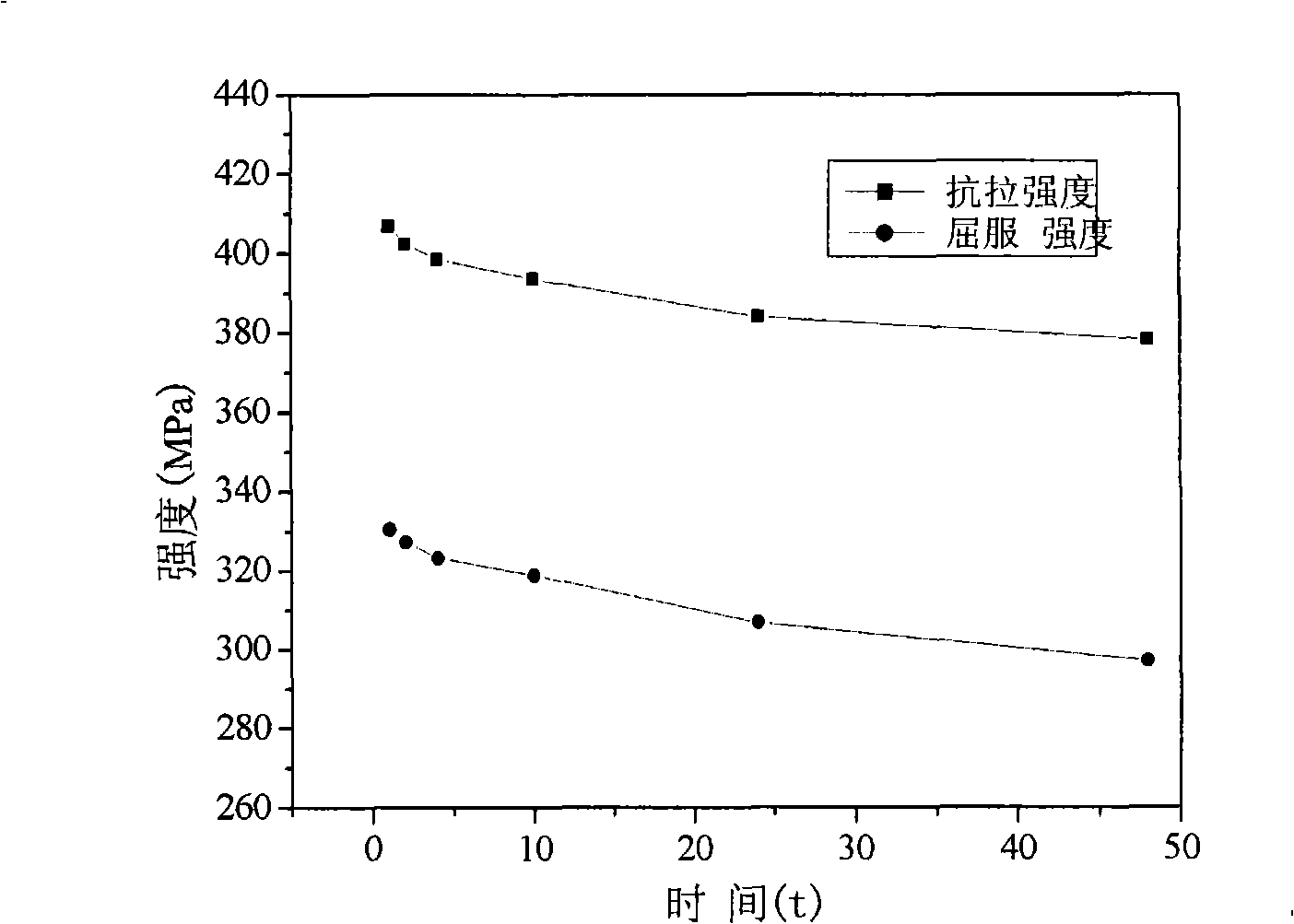

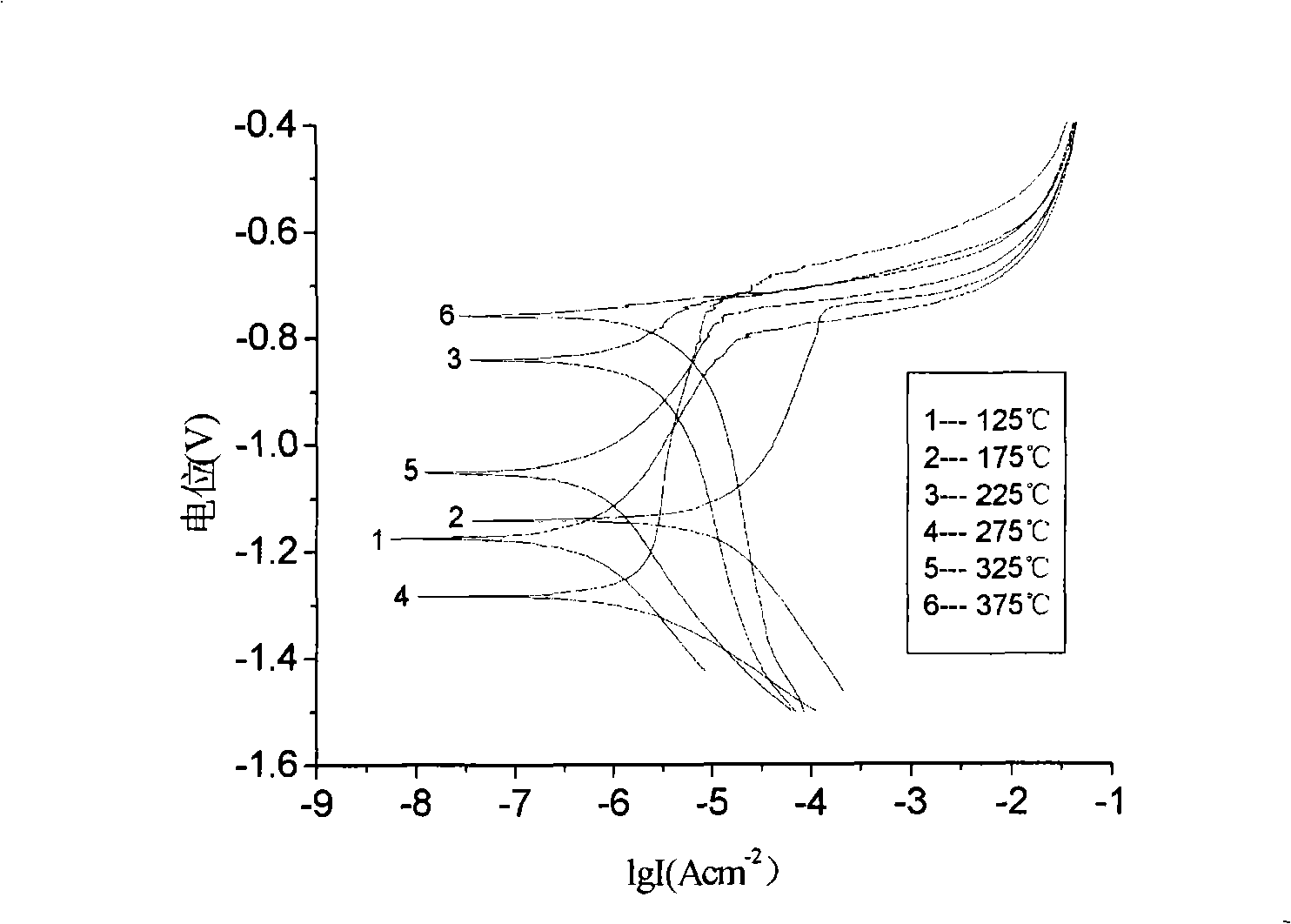

Thermal treatment process for erbium-containing aluminum-magnesium-manganese wrought aluminium alloy

The thermal treatment process for an aluminum-magnesium-manganese wrought aluminum alloy containing erbium belongs to the filed of metal alloys. The existing aluminum alloy thermal treatment process has the problems of strength reducing, corrosion resisting performance reducing after long term use, etc. The invention aims at providing the thermal treatment process for an aluminum-magnesium-manganese cold-rolled sheet containing erbium, which is realized by homogenizing annealing, hot rolling, cold rolling, stabilizing annealing and other process steps, wherein the stabilizing annealing process comprises the steps that, a cold-rolled sheet is annealed at the temperature of 100-400 DEG C and insulated for 1-48h; the annealing temperature and the insulating time are preferably 125-250 DEG C and 1-8h respectively. The thermal treatment process of the invention ensures the alloy to acquire excellent corrosion resisting performance under the condition that the high plasticity of the aluminum-magnesium-manganese cold-rolled sheet containing erbium is kept at a higher level; the treated alloy can be used for a long time with basically constant performance, and the service range of the alloy is wide.

Owner:BEIJING UNIV OF TECH

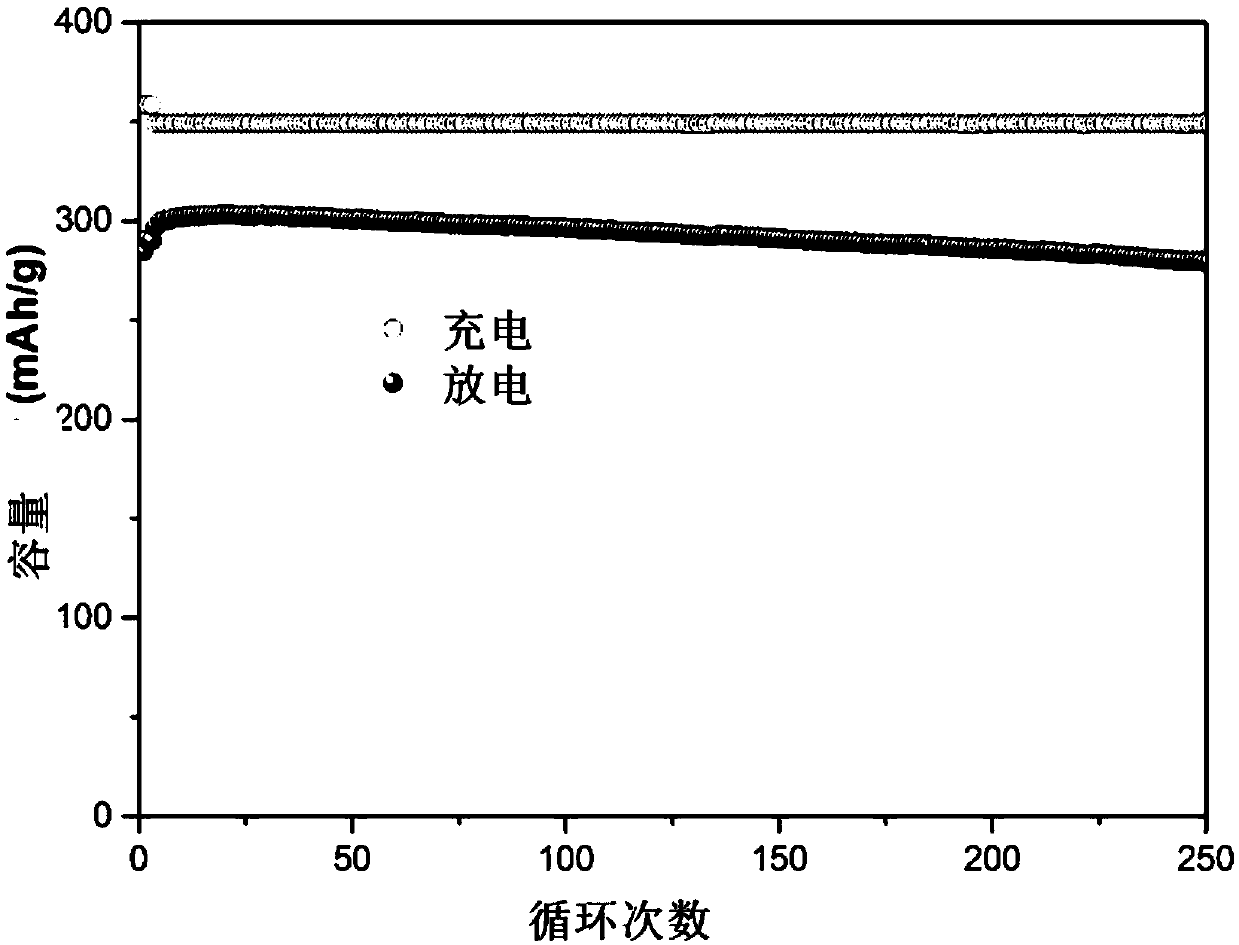

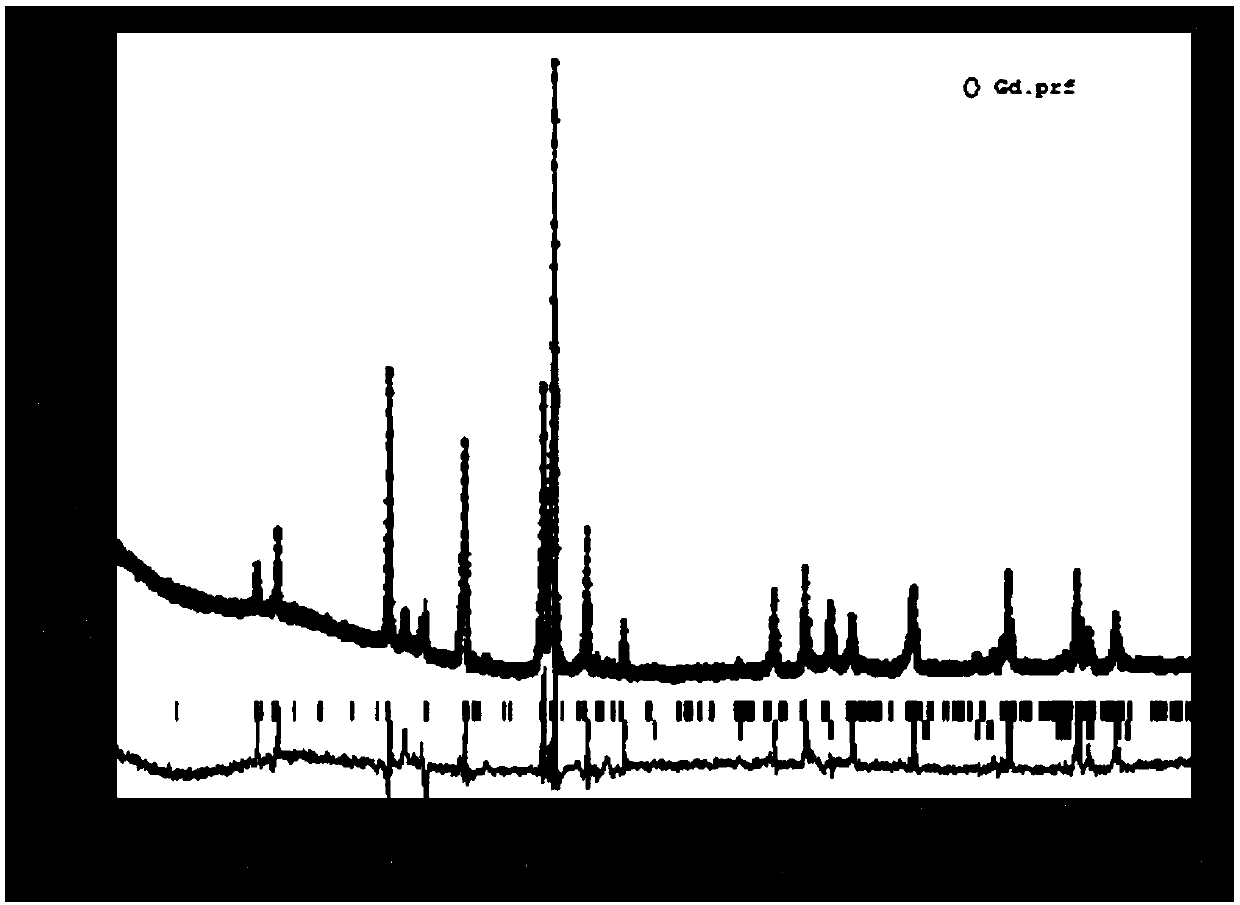

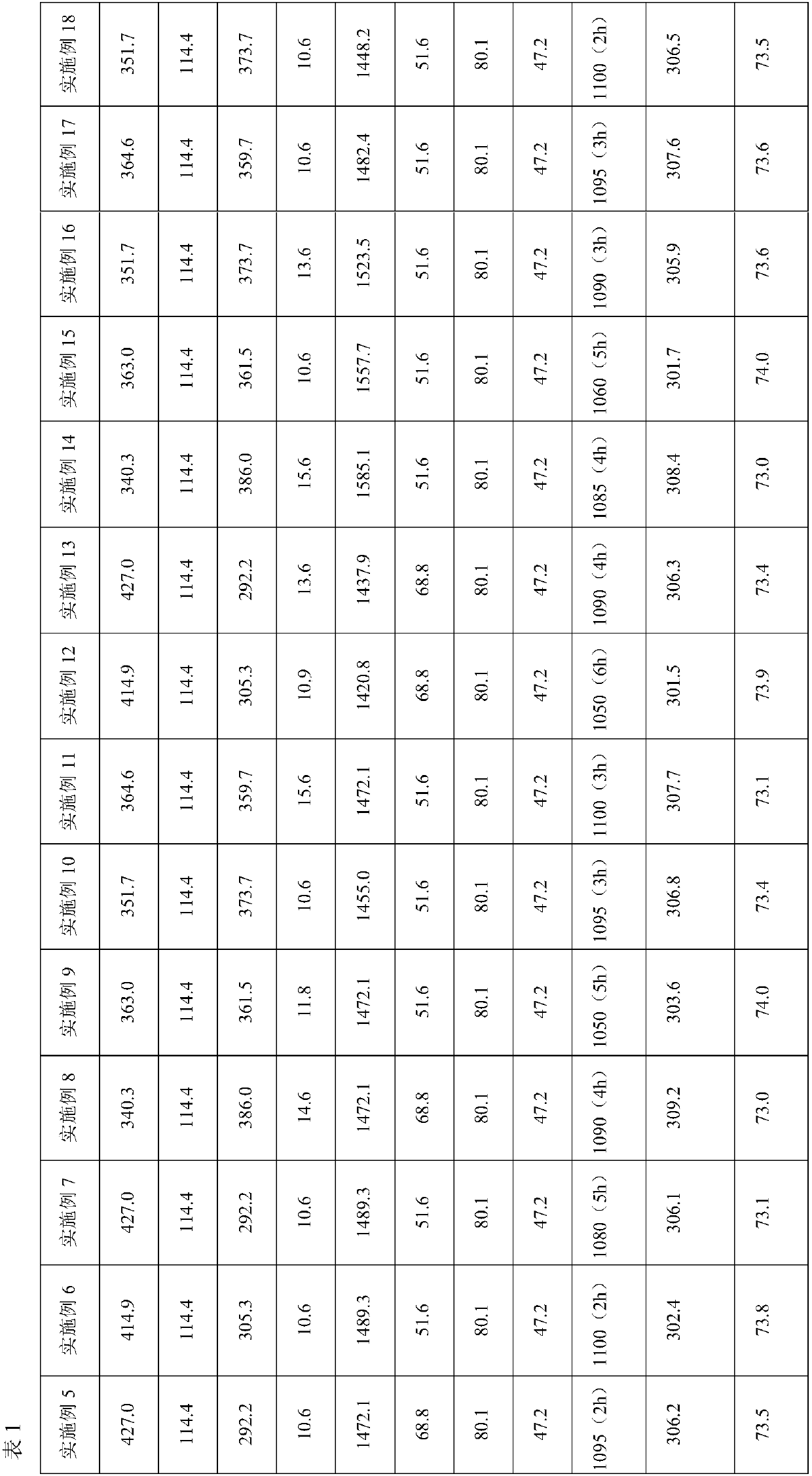

AB5-base hydrogen storage alloy, electrode for Ni-MH battery, secondary battery and method for preparing hydrogen storage alloy

ActiveCN109585790AMeet overcharge performanceSatisfy the charging and discharging dynamic performanceNegative electrodesAlkaline accumulator electrodesHigh rateCerium

The invention relates to a hydrogen storage alloy, an electrode for a Ni-MH battery, a secondary battery and a method for preparing the hydrogen storage alloy. The chemical composition of the hydrogenstorage alloy is represented by the general formula La(3.0-3.2)x CexZrySm (1- (4.0~4.2)x-y)NizCouMnvAlw, wherein x, y, z, u, v, w are molar ratios; 0.14 <= x <= 0.17; 0.02 <= y <= 0 .03; 4.60 <= z +u + v + w <= 5.33; 0.10 <= u <= 0.20; 0.25 <= v <= 0.30; and 0.30 <= w <= 0.40. The overcharge performance of the electrode material is satisfied by fixing a ratio of lanthanum (La) to cerium (Ce) to3.0 - 3.2. A large number of samarium (Sm) elements on a side A are replaced, namely, the ratio of Sm atoms accounts for 25.6 to 42% of the side A to overcome a decrease in service life caused by lowcobalt (Co). The equilibrium pressure is adjusted by changing the ratios of Sm and La to Ce in order to satisfy the charge and discharge dynamics performance of the electrode material. The nucleationrate of a solidification process is increased by adding zirconium (Zr) having an atomic ratio of 2 to 3% relative to the elements at the side A to the elements at the side A. The Ni-MH battery anode material obtained by using the hydrogen storage alloy has high overcharge resistance, high rate discharge performance and good cycle stability.

Owner:SOUTH CHINA UNIV OF TECH +2

Method and equipment for preparing semisolid fused mass of ferrous material

An apparatus for preparing the semi-solid molten body of iron and steel is composed of a special container for molten iron or steel, temp regulator, stirrer and bottom vibrator. The linear layer of said special container contains nucleation promoter. Its method includes pouring the molten iron or steel at the temp which is 5-10 deg.C, higher than the temp of liquid-phase line into said special container, and stirring or vibrating for 1-10 min.

Owner:BEIJING JIAOTONG UNIV

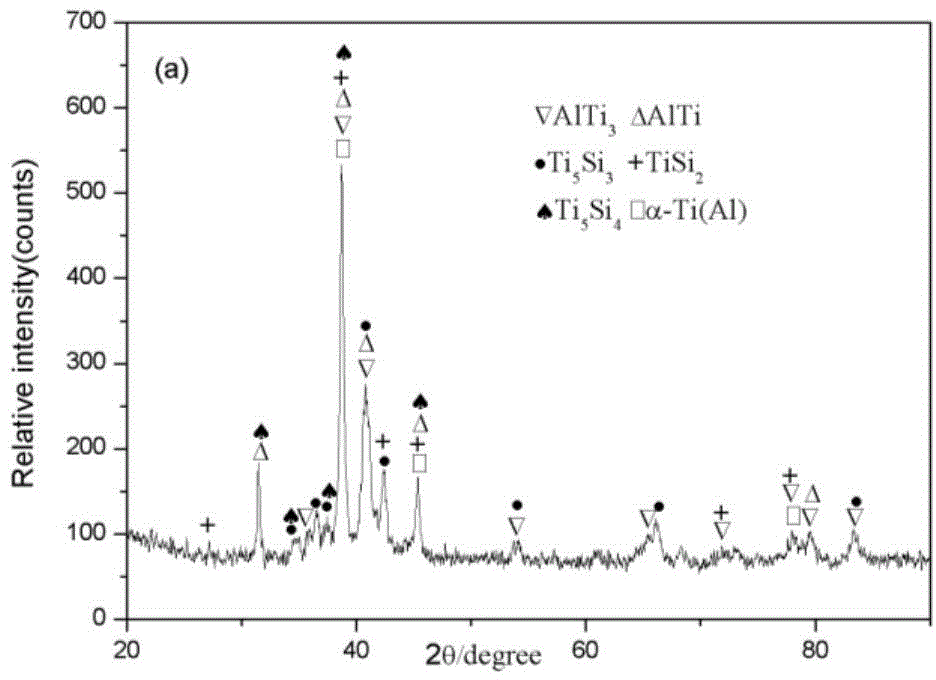

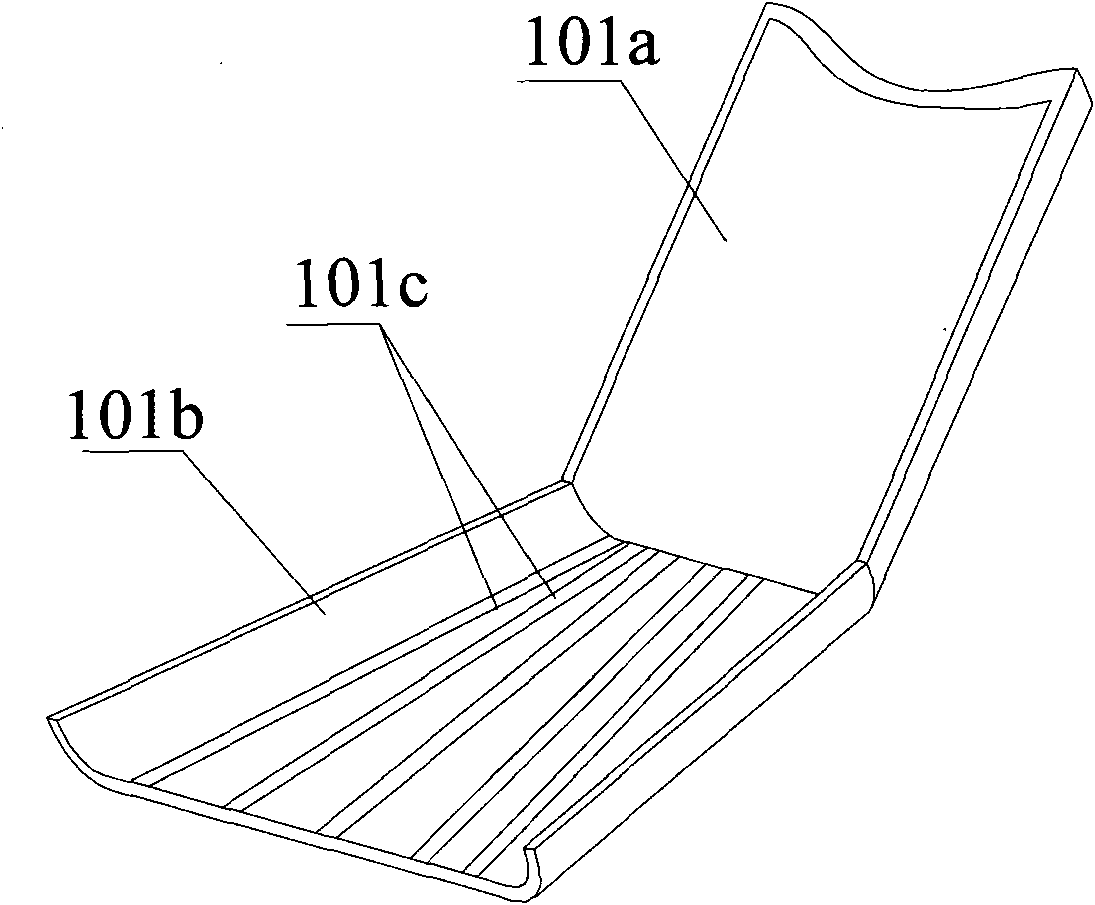

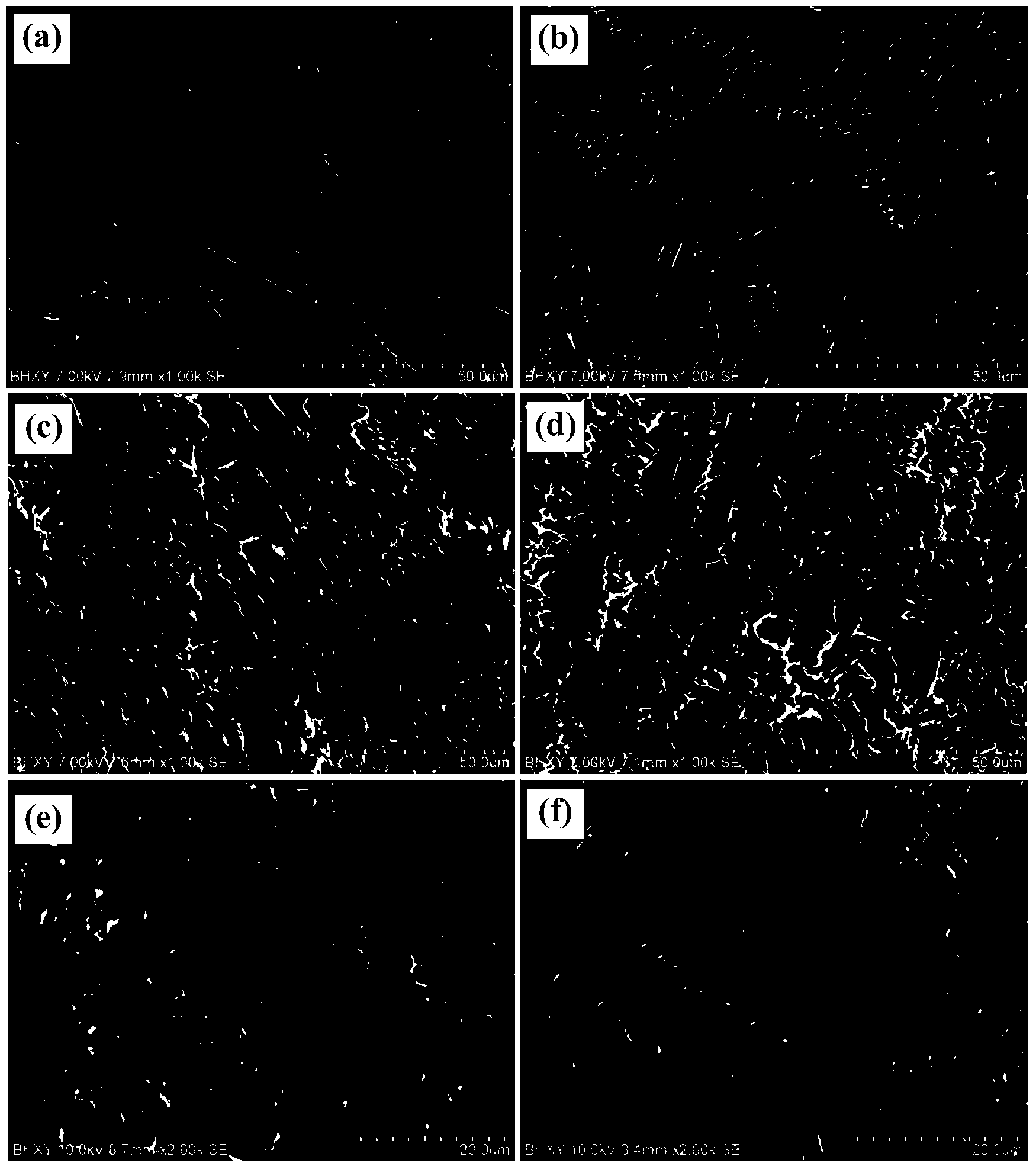

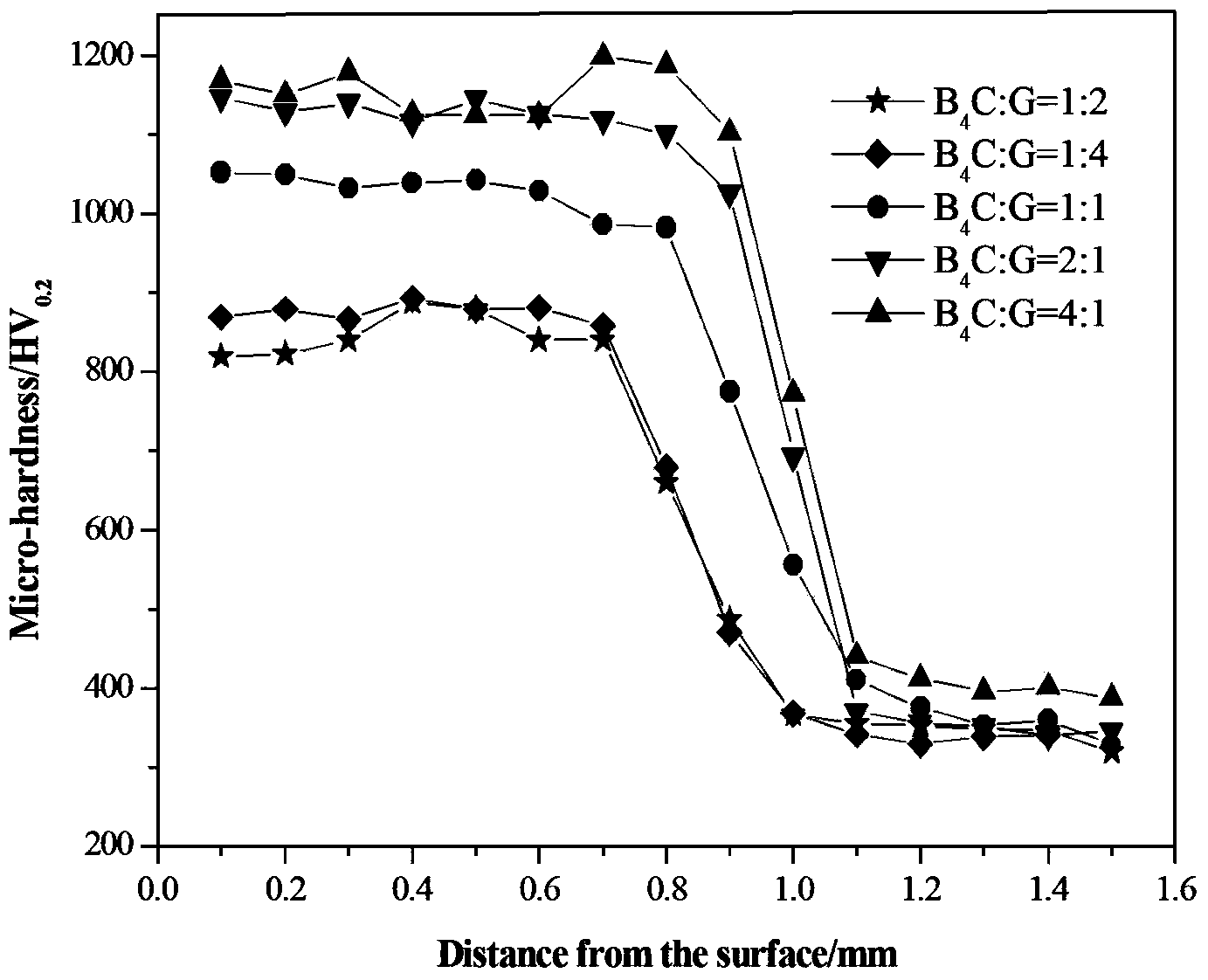

Preparation technology of intermetallic compound based ceramic composite coating on surface of titanium alloy

ActiveCN104152895AHigh hardnessGood metallurgical bondMetallic material coating processesCeramic compositeShielding gas

The invention discloses a preparation technology of an intermetallic compound based ceramic composite coating on the surface of a titanium alloy. The preparation technology comprises the following steps of: (1) uniformly mixing cladding material powder, preparing mixed powder into paste with a water glass solution, uniformly coating the surface of the titanium alloy with the paste with the coating thickness of 0.5-1.0mm, carrying out airing, and (2) carrying out laser cladding on the coating on the surface of the titanium alloy with the laser power of 800-1200W and the laser scanning speed of 2.5-7.5mm / s, and blowing argon for shielding with the shielding gas pressure of 0.2-0.4MPa, wherein a laser spot diameter is fixed at 4mm.The mixed cladding material powder comprises the following ingredients by mass percentage: 25-65% of Ti, 20-60% of Al, 5-30% of Si and 0-3% of Y2O3, or 25-65% of Ti, 20-60% of Al, 5-30% of Si, 2-40% of B4C and 0-3% of Y2O3, or 25-65% of Ti, 20-60% of Al, 5-30% of Si, 5-40% of TiC, and 0-3% of Y2O3. The composite coating prepared by the technology can significantly increase microhardness of the titanium alloy, improve wear resistance of titanium alloy components, and extend an application scope of titanium alloy spare parts.

Owner:SHANDONG UNIV

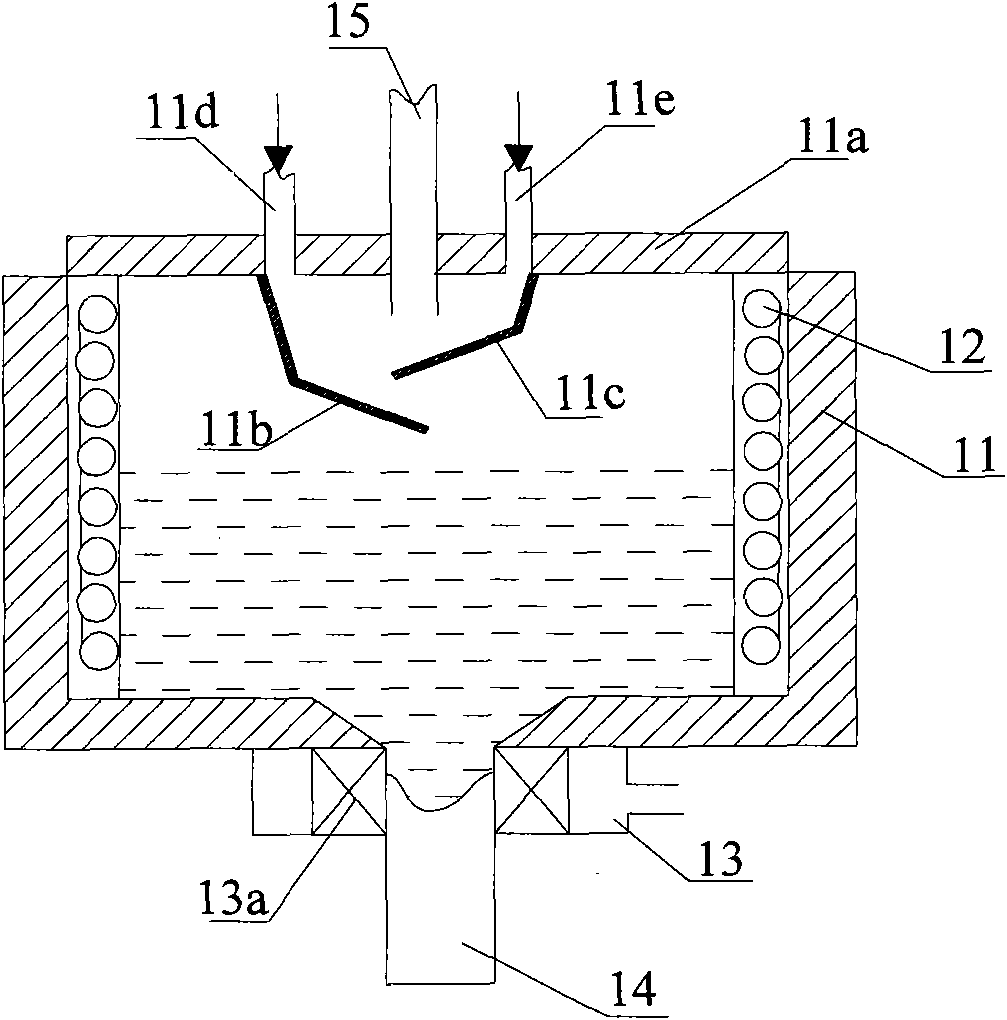

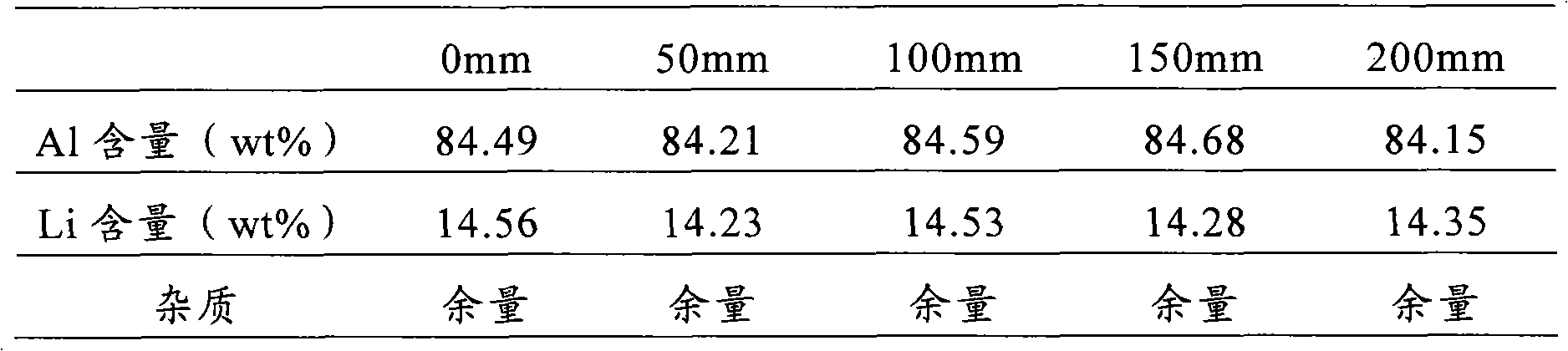

Preparation method of aluminium-lithium intermediate alloys

The invention discloses a preparation method of aluminium-lithium intermediate alloys, which comprises the following steps: preparing a lithium metal liquid; sending the lithium metal liquid and an aluminium metal liquid into a smelting furnace of a semicontinuous casting machine for mixing; and sending the mixed metal liquid into a crystallizer of the semicontinuous casting machine for casting ingots, wherein the magnetic density in the crystallizer is 0.01-0.05T and the casting temperature is 700-900 DEG C when casting the ingots. The lithium metal liquid and the aluminium metal liquid are together sent into the smelting furnace of the semicontinuous casting machine for mixing, and then an aluminium-lithium intermediate alloy is pulled out from the crystallizer of the semicontinuous casting machine. Under the action of a magnetic field of the crystallizer, low-frequency shock and stable circumfluence of the mixed liquid occur in, a better mixing function can be performed to the lithium metal liquid and the aluminium metal liquid, the nucleation rate is effectively improved, and the aluminium-lithium intermediate alloy with stable quality can be prepared.

Owner:SOUTHWEST ALUMINUM GRP

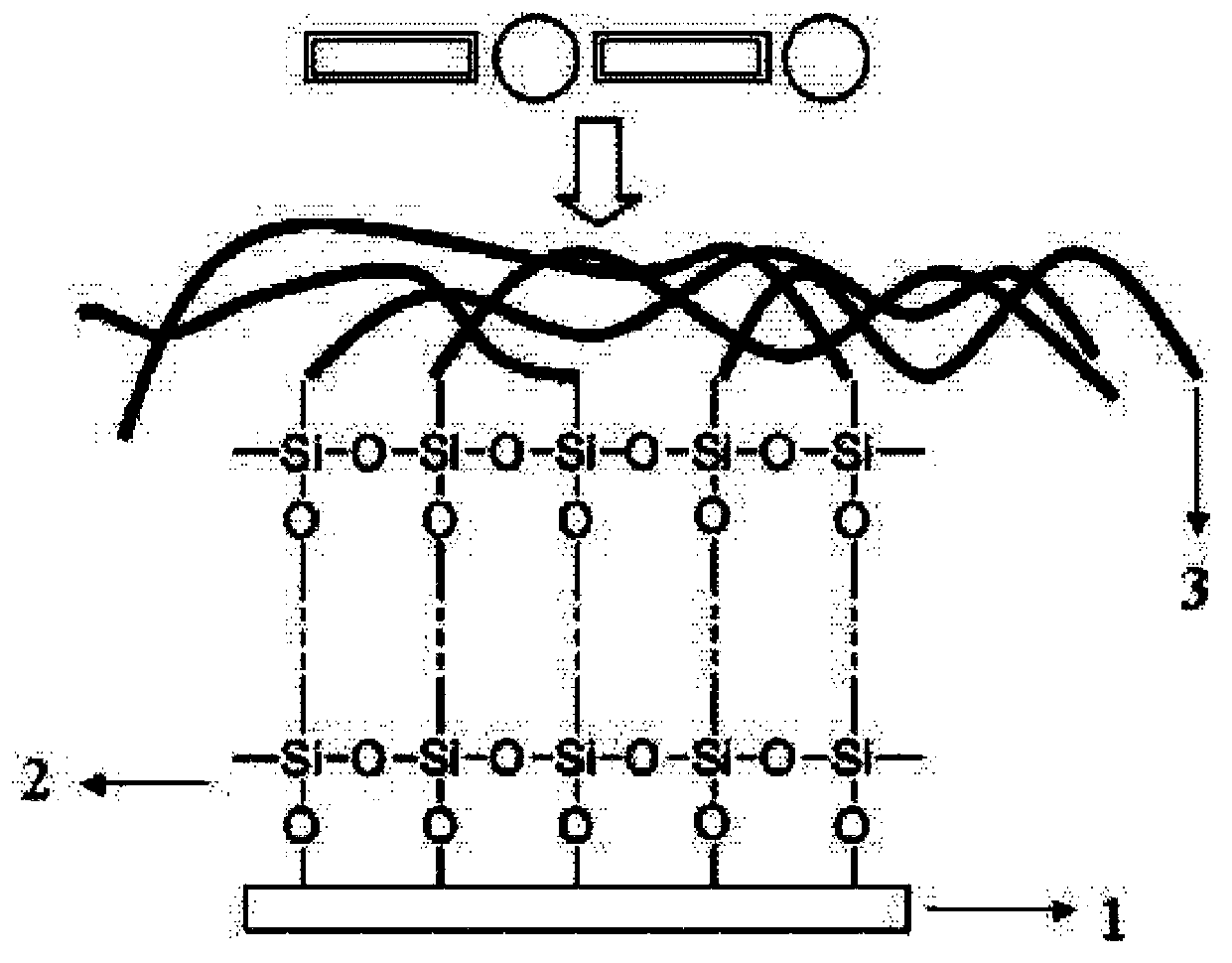

Perfluoropolyether, touch screen and fingerprint-proof membrane containing perfluoropolyether membrane and preparation thereof

InactiveCN103724610AUnique structureGood anti-fingerprint effectVacuum evaporation coatingSputtering coatingPerfluoropolyetherDistillation

The invention provides a method for preparing perfluoropolyether through carrying out ring opening polymerization on tetrafluoro oxetane and the perfluoropolyether thereby. According to the method, the ring opening polymerization of the tetrafluoro oxetane is initiated by using fluoride salt as an initiator and a perfluoropolyether chemical compound F-(OCF2CF2CF2)n-CF2CF3 is collected through controlling the vacuum degree and the distillation temperature, where the n=2-30. The invention provides a method for applying the perfluoropolyether material to a fingerprint-proof membrane for touch screens at the same time. According the method, a buffer layer is formed on a glass substrate after being subjected to O2 glow discharge bombardment and a perfluoropolyether membrane is formed on the upper surface of the buffer layer, wherein the buffer layer is a PECVD (Plasma Enhanced Chemical Vapor Deposition)-deposited SiO2 film. A good adhesive force is provided between the SiO2 buffer layer and the glass substrate through depositing the SiO2 buffer layer by utilizing PECVD, so that the adhesive force between the perfluoropolyether fingerprint-proof membrane and the glass substrate is increased to a certain extent.

Owner:陈琦 +2

Method for controlling electroslag melting casting by added transient magnetic field and electroslag smelting casting device

The invention discloses a method for controlling electroslag melting casting by an added transient magnetic field. The method includes adding a transient magnetic field to a melting end of an electroslag remelting mother electrode, a liquid slag tank and a metal melting tank so that the transient magnetic field acts on large metal molten drops which are generated by initial melting at the tail end of the electrode and are converging to become big; under joint action of alternating lorentz force and pressure waves generated by the transient magnetic field, dispersing the metal molten drops in a burst manner into small metal molten drop groups, and randomly dispersing the small metal molten drop groups into the liquid slag tank to sufficiently contact with liquid slag after passing the liquid slag tank; after washing, enabling included foreign substances and impurities in the small metal molten drops to enter the liquid slag quickly, slowly settling and converging the foreign substances and impurities into the metal melting tank below the liquid slag tank, and finally crystallizing and solidifying to form solidified cast ingots. The invention further provides an electroslag melting casting device. By adding the transient magnetic field during electroslag melting casting and fining the molten drops by the aid of unique electromagnetic effect of the transient magnetic field, the purposes of improving refining efficiency, fining crystalline grains and reducing segregation of cast ingots are achieved, and industrial application value is realized.

Owner:SHANGHAI UNIV

420MPa normalizing super-thick steel plate, and preparation method thereof

The invention discloses a 420MPa normalizing super-thick steel plate, and a preparation method thereof. The 420MPa normalizing super-thick steel plate comprises following chemical components, by mass, 0.14 to 0.16% of C, 0.30 to 0.40% of Si, 1.0 to 1.60% of Mn, 0.015 to 0.025% of Als, 0.005 to 0.025% of Nb, 0.065 to 0.10% of V, 0.010 to 0.02% of Ti, 0.2 to 0.45% of Ni, 0.05 to 0.30% of Cu, P less than 0.01% , S less than 0.005%, and the balance Fe and unavoidable impurities. The preparation method comprises following steps: continuous casting steel slab, which contains the above chemical components and possesses a thickness of 400mm, is subjected to two stages of rolling without water cooling, is discharged rapidly, and is subjected to stacking slow-cooling for 72h or more; and after steel plate shot blasting, the steel plate is obtained by normalizing plus accelerated cooling heat treatment process. The normalizing 100-120mm steel plate prepared by the preparation method possesses excellent strength and toughness; yield strength is more than 420MPa; and the normalizing 100 -120mm steel plate can be used for preparation of key force support elements of buildings, bridges and tower structures with large span frameworks.

Owner:SHOUGANG CORPORATION

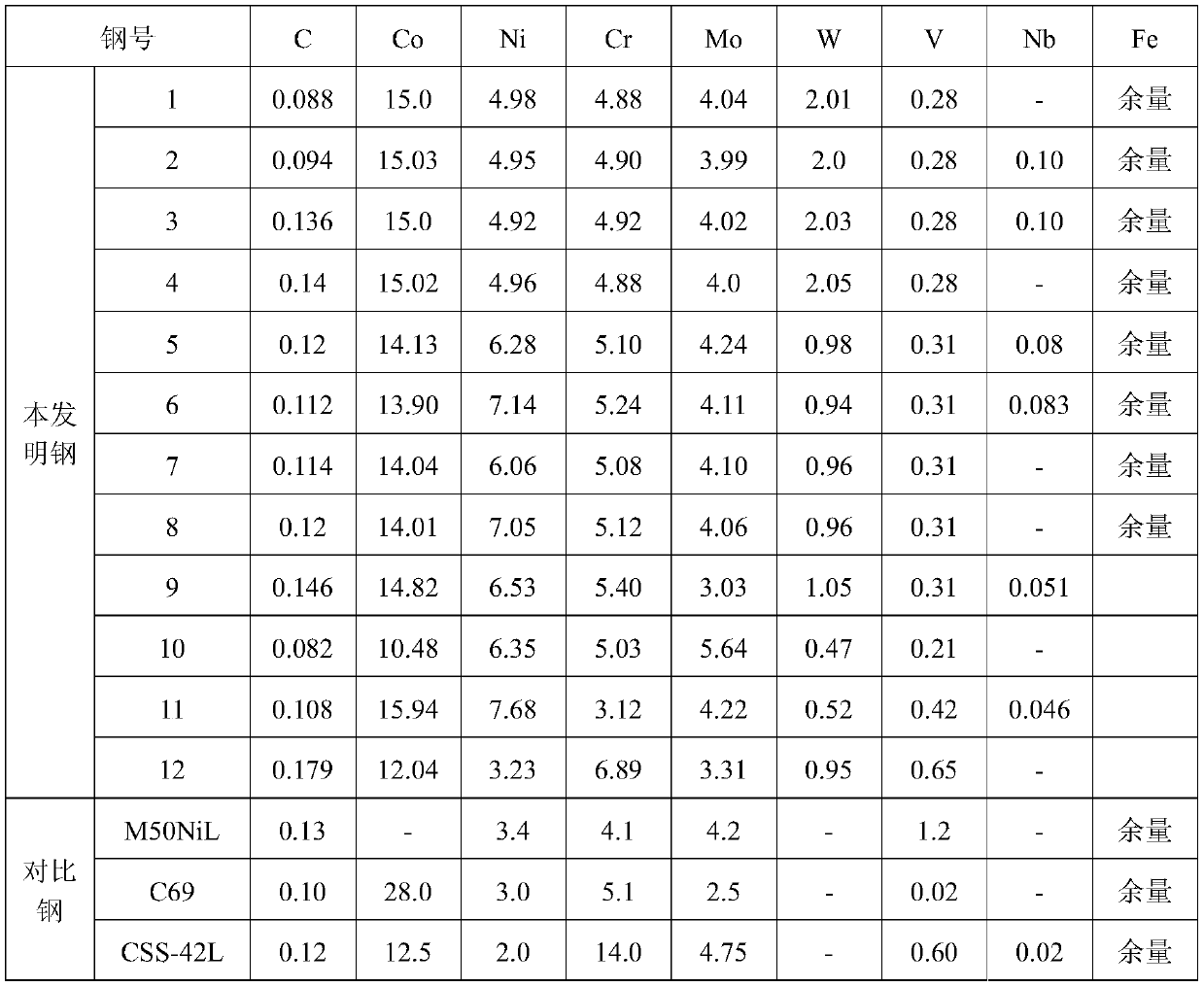

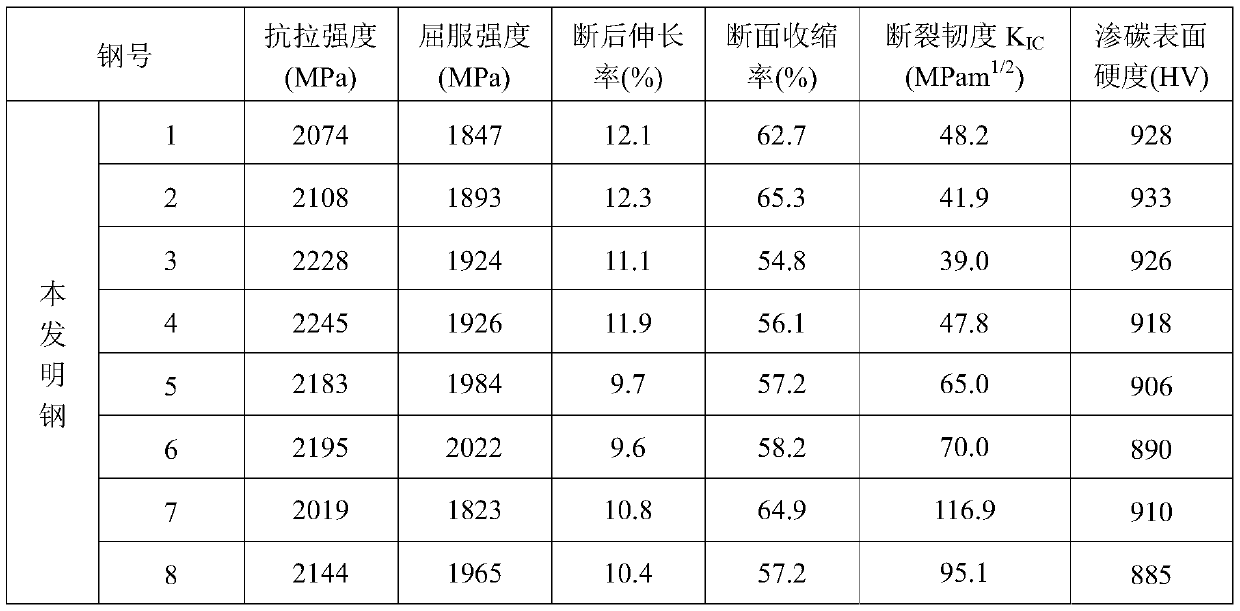

Ultra-high-strength heat-resistant gear bearing steel with ultra-hardened surface layer and preparation method thereof

ActiveCN110423955AHigh tensile strengthImprove plasticitySolid state diffusion coatingCarburizingVacuum arc remelting

The invention belongs to the technical field of materials, and relates to an ultra-high-strength heat-resistant gear bearing steel with ultra-hardened surface layer and a preparation method thereof. The chemical composition of the steel comprises the following chemical components of, in percentage by mass, 0.08-0.18% of C, 10.0-16.0% of Co, 3.0-8.0% of Ni, 3.0-7.0% of Cr, 3.0-6.0% of Mo, 0.5-2.0%of W, 0.2-1.0% of V, 0-0.1% of Nb, and the balance Fe and impurity elements. According to the method, vacuum induction melting, vacuum induction melting and vacuum arc remelting or vacuum induction melting and electroslag remelting are adopted for smelting. Steel ingots are diffusion annealed and forged into steel products. Steel samples are subjected to preliminary heat treatment, carburization and final heat treatment, the tensile strength of the steel is not less than 1900 MP a, the yield strength is not less than 1600 MP a, and the carburized surface hardness is not less than 850 HV (equivalent to 66 HRC). The method has the advantages that compared with the prior art, the method has higher tensile strength, yield strength and relatively good plasticity, toughness and heat resistance,has excellent surface carburization super-hardening performance and fatigue performance, and achieves good matching of the core super-toughening and surface super-hardening.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

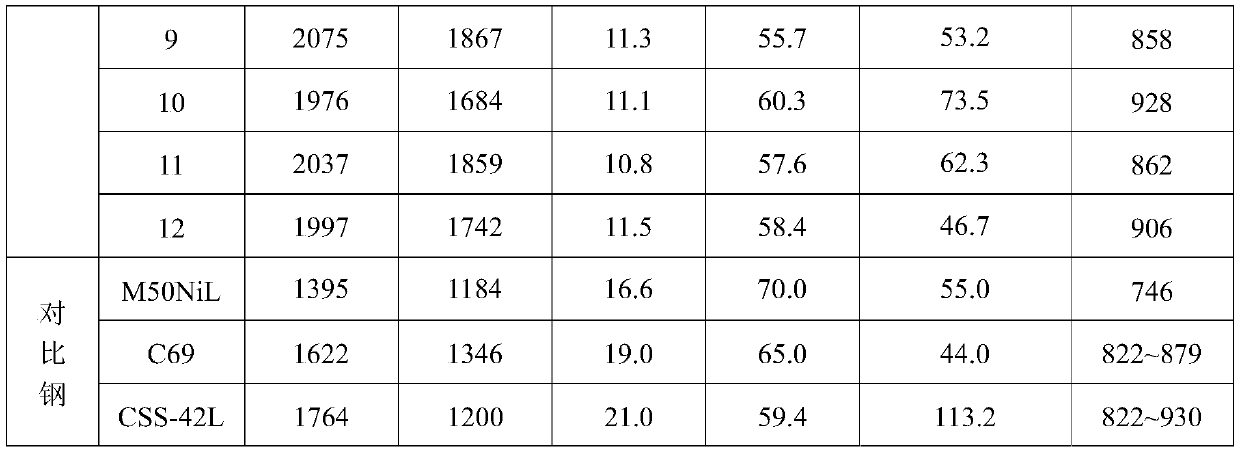

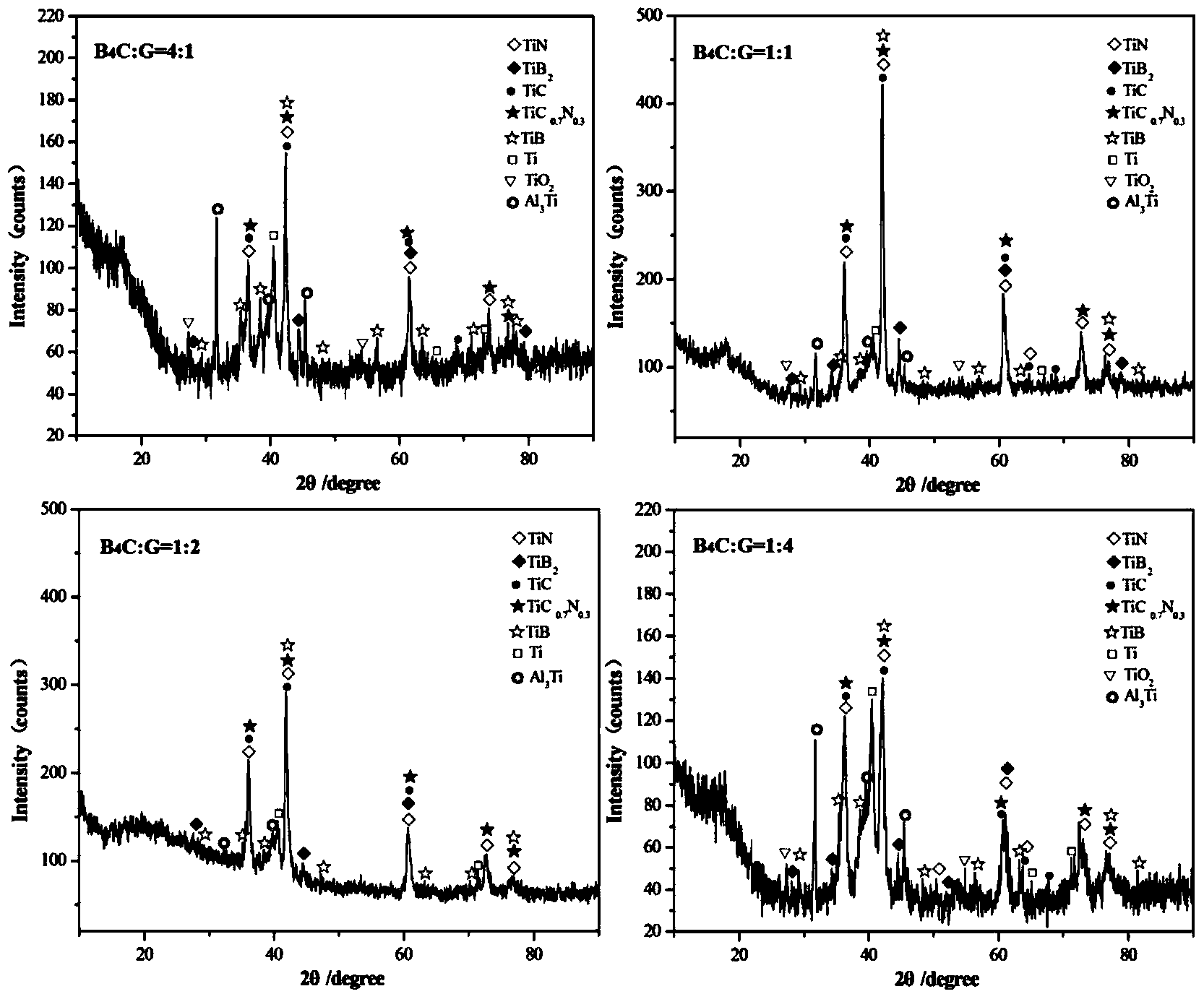

Titanium alloy surface multi-element laser alloyed layer and preparation method thereof

ActiveCN103966598AGood metallurgical bondImprove wettabilityMetallic material coating processesWear resistantComposite ceramic

The invention relates to a titanium alloy surface multi-element laser alloyed layer and a preparation method thereof. The preparation method comprises the following steps: by using titanium alloy as a base material, applying mixed powder of B4C, graphite, Ti powder and rare-earth oxides Y2O3 used as a coating material onto the titanium alloy surface, and carrying out laser scanning while blowing nitrogen gas to perform alloying, wherein the coating material comprises the following components in percentage by mass: 10-90% of B4C, 10-90% of graphite powder, 0-50% of Ti powder and 0-4% of Y2O3.In an open N2 environment, the B4C and graphite powder are subjected to boron-carbon-nitrogen multi-element composite laser alloying on the titanium alloy surface to prepare the high-hardness wear-resistant composite ceramic coating. The simultaneous addition of the Ti powder and rare-earth oxides Y2O3 is beneficial to enhancing the microhardness and wear resistance of the alloyed layer; and the proper amount of Ti can promote the in-situ reaction in the alloyed layer, and the Y2O3 can refine the structure, thereby enhancing the comprehensive mechanical properties of the coating.

Owner:SHANDONG UNIV

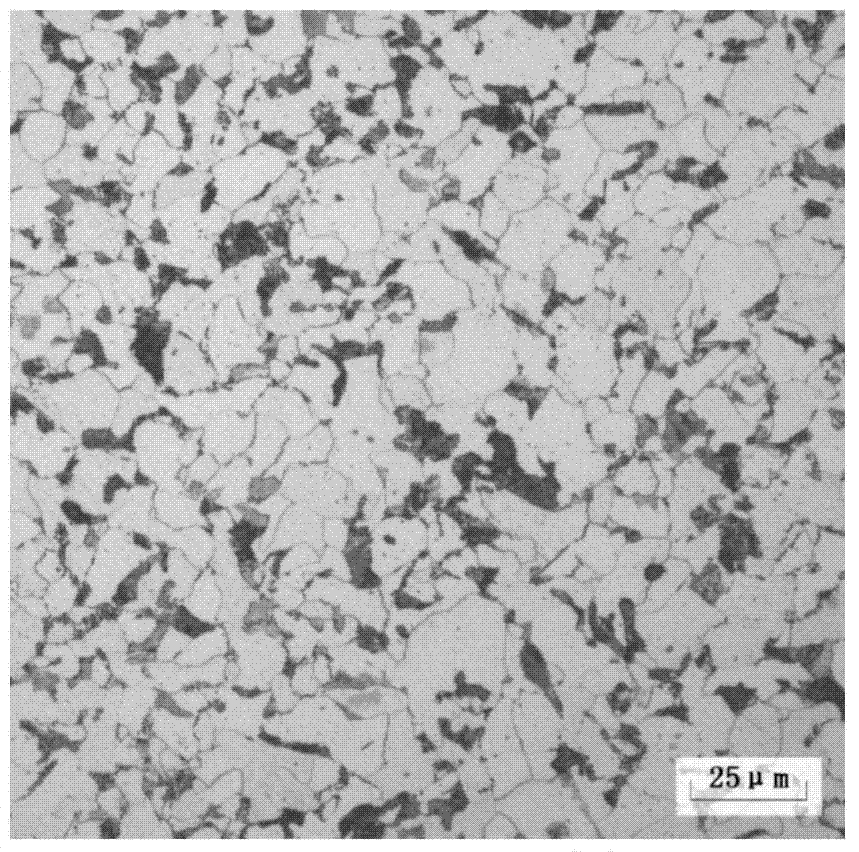

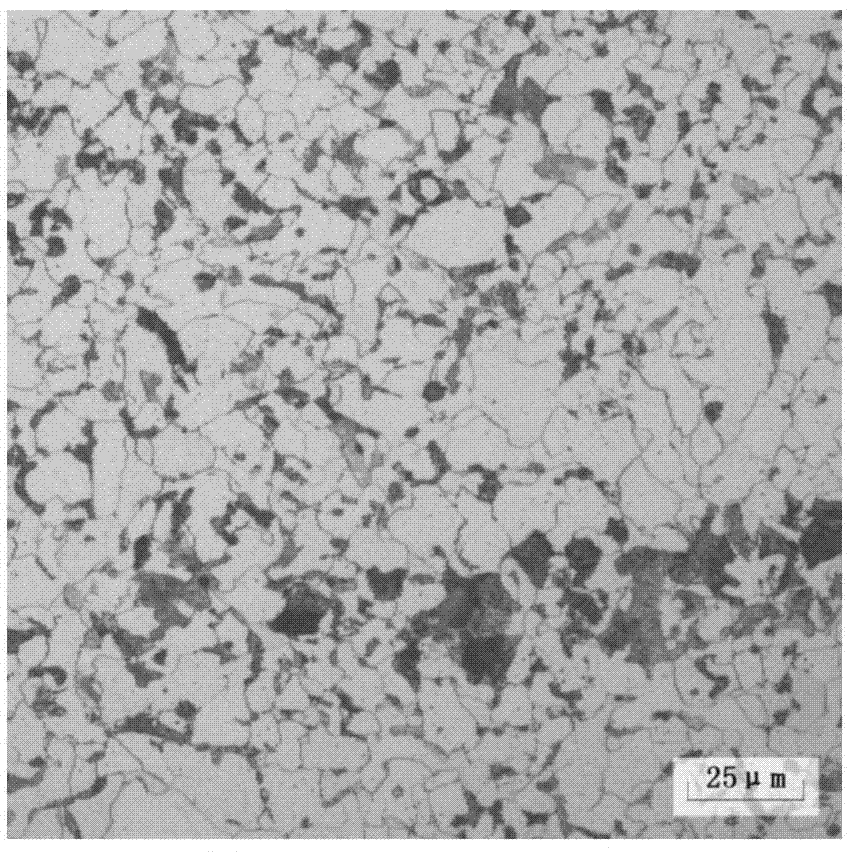

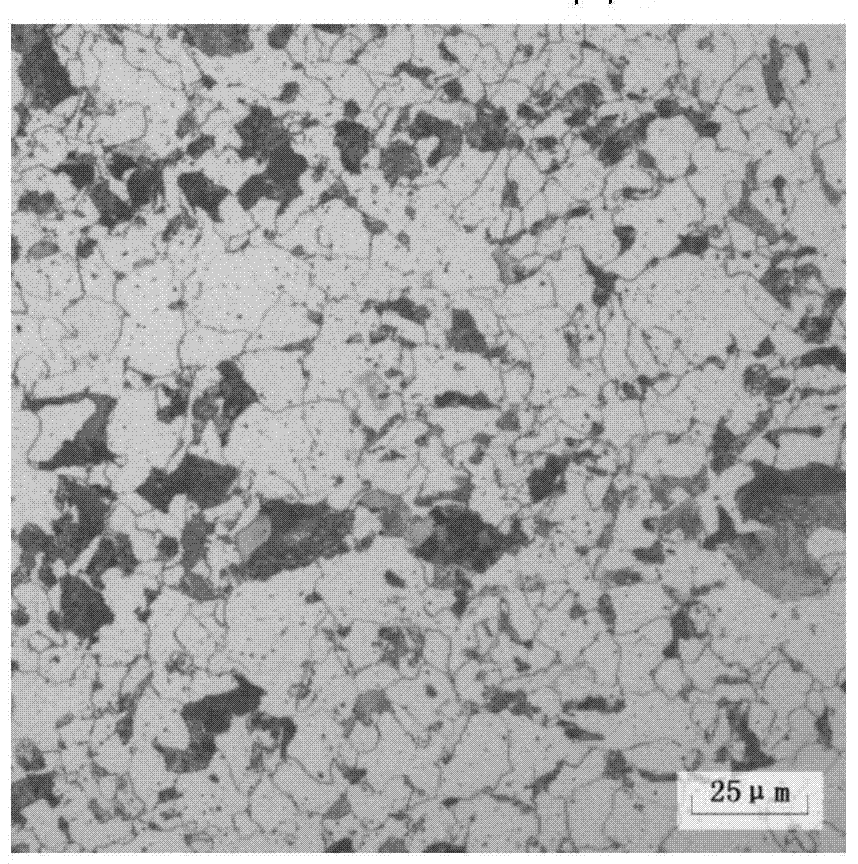

Quasicrystal-strengthened Mg-6Zn-3Y alloy with ultrafine solidification texture and preparation method thereof

The invention discloses a quasicrystal-strengthened Mg-6Zn-3Y alloy with an ultrafine solidification texture and a preparation method thereof. The quasicrystal-strengthened Mg-6Zn-3Y alloy consists of the following chemical components in percentage by weight: 87.0 to 93.0 percent of Mg, 3.0 to 10.0 percent of Zn and 0.5 to 3.0 percent of Y. The Mg-6Zn-3Y alloy with the ultrafine solidification texture, which contains nanoscale granular quasicrystals, is prepared from normal-pressure as-cast Mg-Zn-Y alloy material under GPa-level ultrahigh pressure as solidification pressure, temperature and solidification cooling rate are controlled. The as-cast texture is characterized in that: the granular quasicrystals are evenly and dispersely distributed on the ultrafine Alpha-Mg matrix, wherein the secondary dendrite arm spacing between Alpha-Mg dendrites is 7Mu m to 10Mu m, the diameter of the granular quasicrystal is 50nm to 100nm, and the volume of the granular quasicrystals accounts for 25 to 35 percent of the total volume of the alloy. The invention adopts a cubic press, solidification process parameters are controlled, i.e., the solidification pressure is 6GPa, the solidification temperature is 1300DEG C, and the solidification rate is 300K / S. Theultrafin quasicrystal-strengthened Mg-6Zn-3Y alloy has high mechanical properties and good thermal stability.

Owner:东北大学秦皇岛分校

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com