Quasicrystal-strengthened Mg-6Zn-3Y alloy with ultrafine solidification texture and preparation method thereof

A technology of solidification structure and quasicrystal, applied in the field of autogenous quasicrystal reinforced alloy and its preparation, can solve the problem of few reports of quasicrystal scale, and achieve the effect of good thermal stability and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

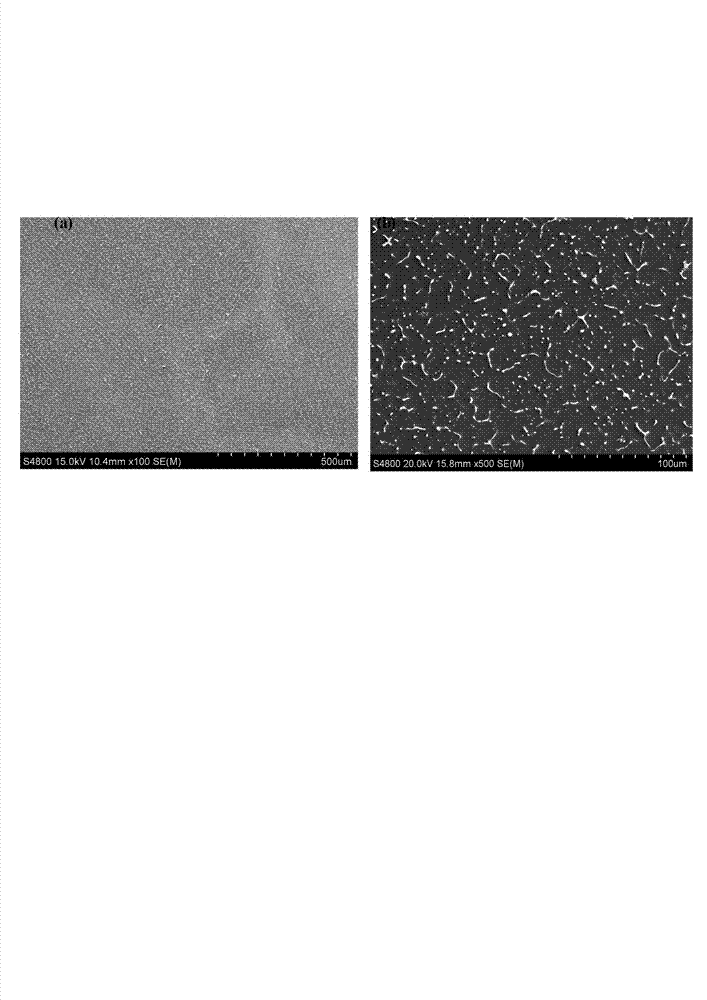

[0030] The technical solutions of the present invention are further described below through examples.

[0031] 1. In terms of melt mass percentage Wt%, weigh Mg: 91.0%, Zn: 6.0%, Y: 3.0%;

[0032] 2. Put the magnesium ingots, zinc ingots, and pure yttrium metal charges in the oven at 200°C for preheating and baking in a crucible with the above mass percentage;

[0033] 3. Set the heating temperature of the crucible resistance furnace to 780°C. When the temperature of the crucible rises to 380°C, add magnesium ingots and zinc ingots to the crucible, and start to feed CO2 / SF6 mixed gas as a protective gas, and continue to heat up. After the magnesium ingots and zinc ingots in the crucible are completely melted, add pure yttrium, stir for 2-5 minutes after the pure yttrium is completely melted, keep warm at 780°C for 10-15 minutes after the stirring is completed, and set aside;

[0034]4. Adjust the temperature of the Mg-Zn-Y alloy solution to 760°C, let it stand for 3 to 5 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com