Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3692 results about "Structural material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Structural engineering depends on the knowledge of materials and their properties, in order to understand how different materials resist and support loads.

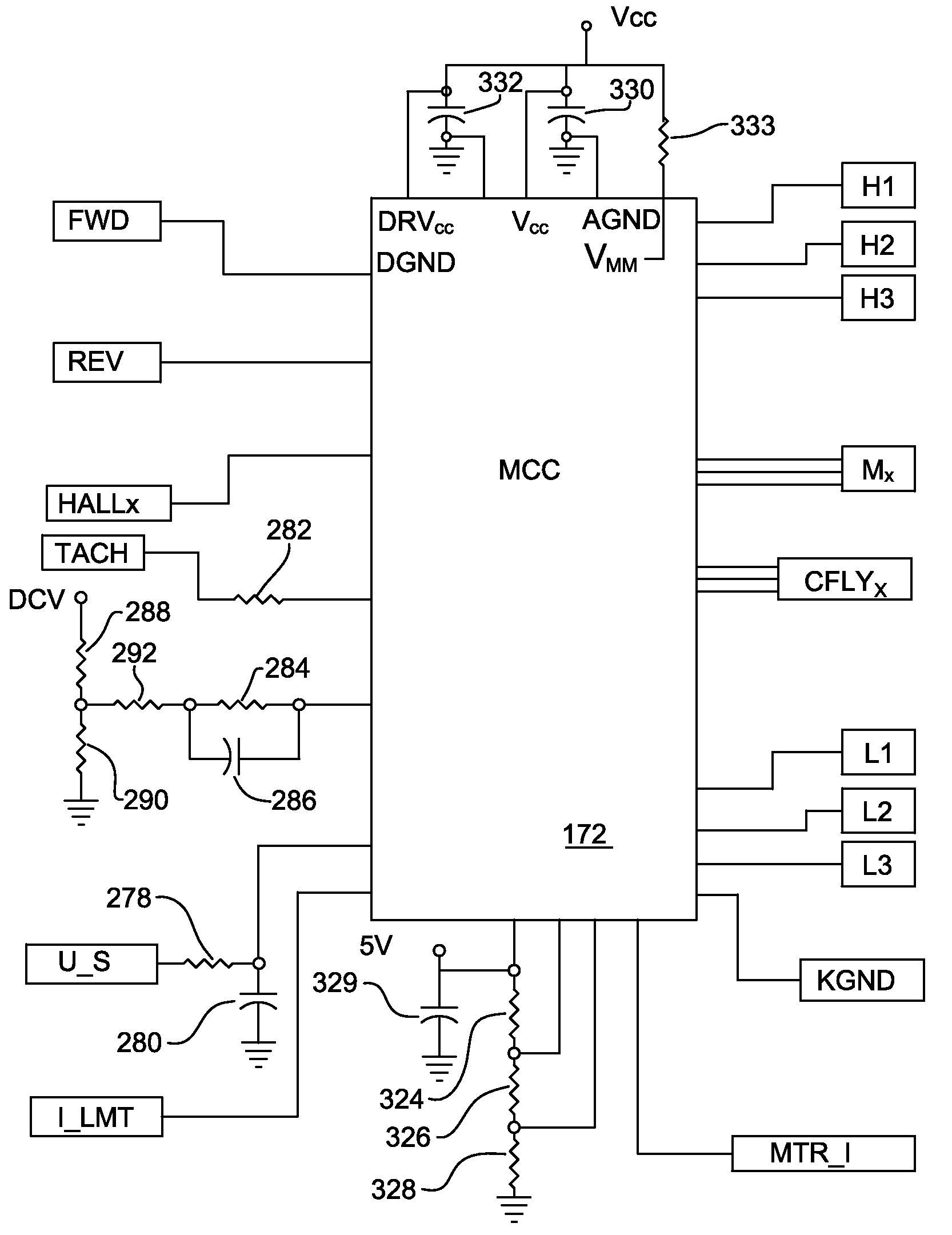

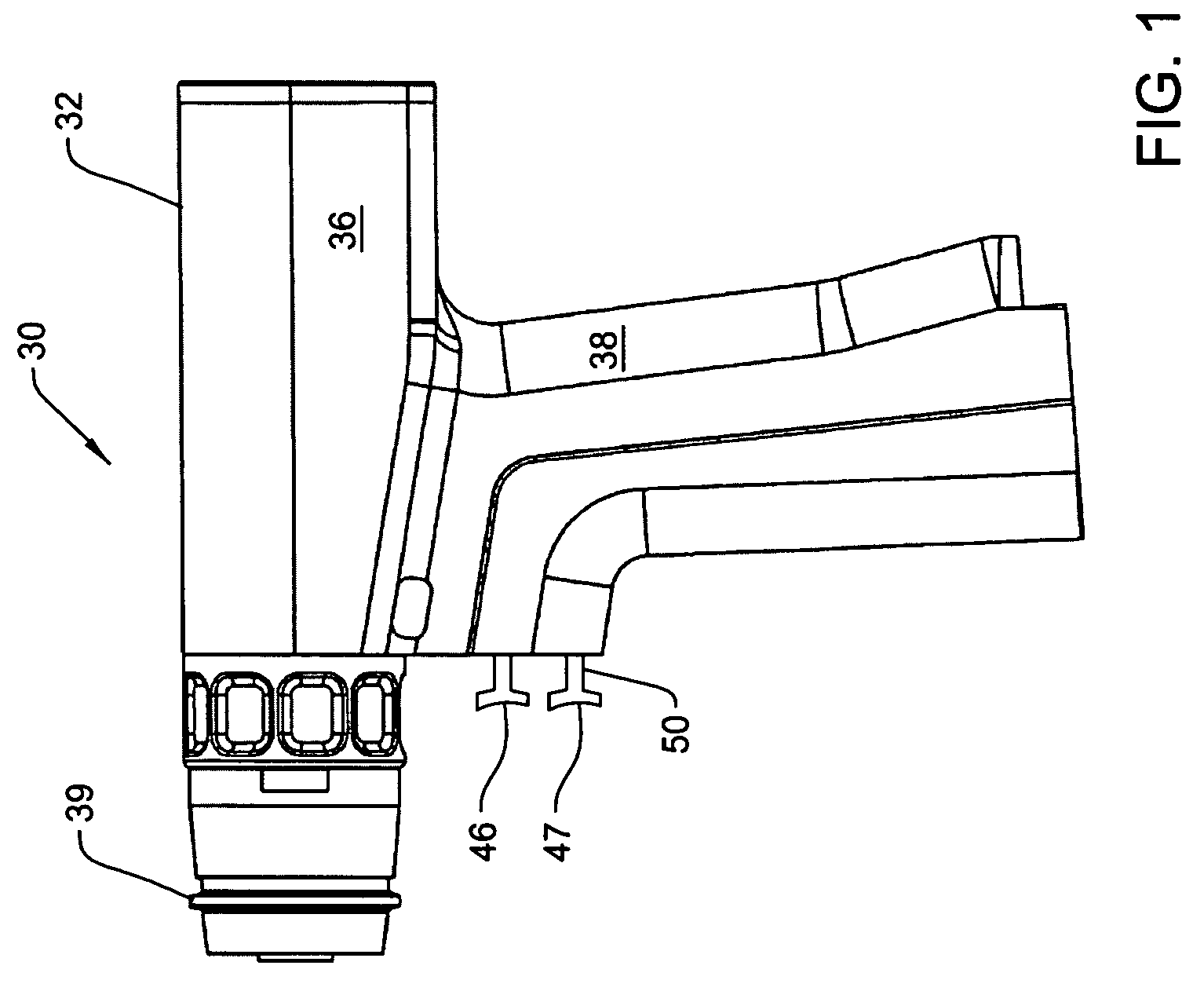

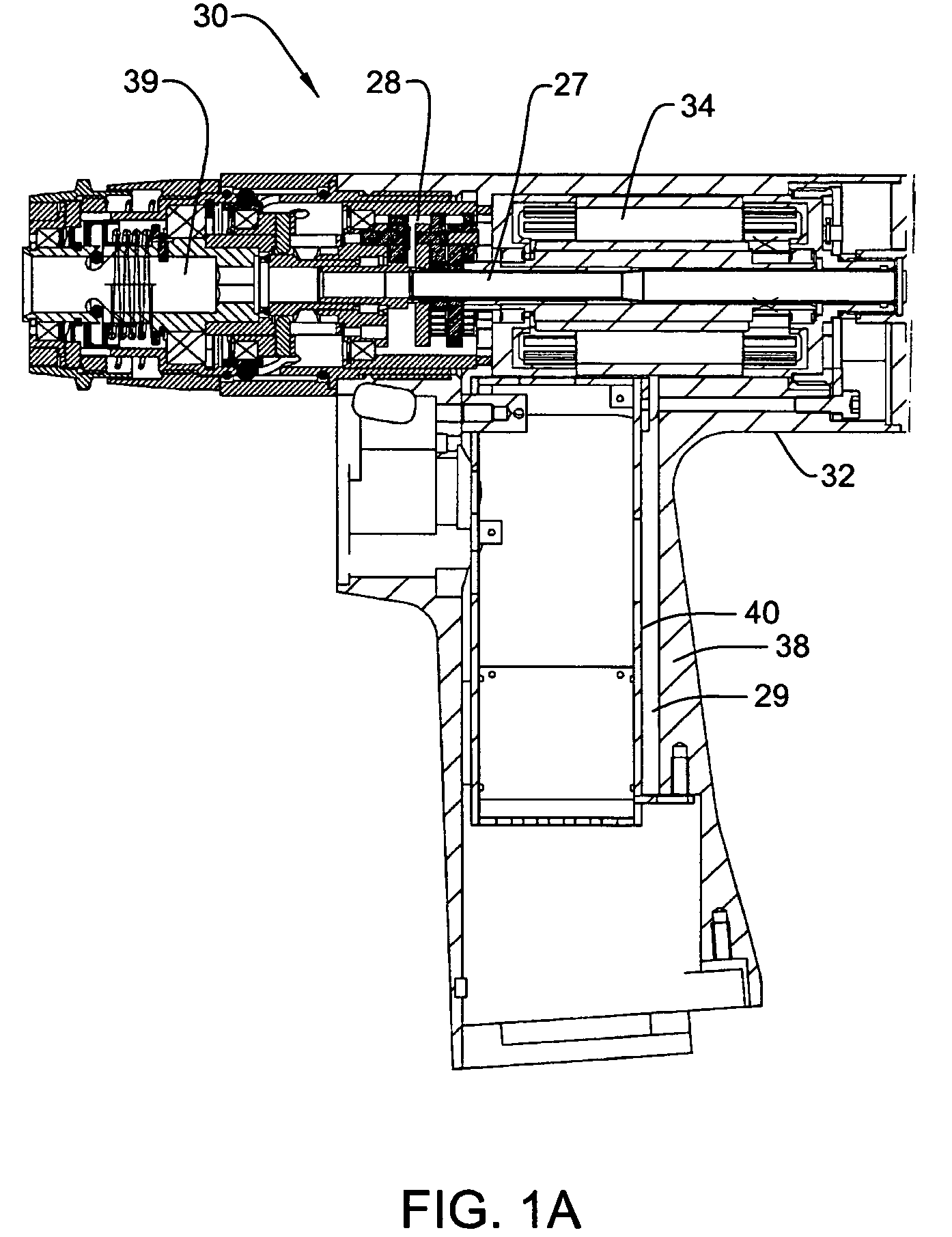

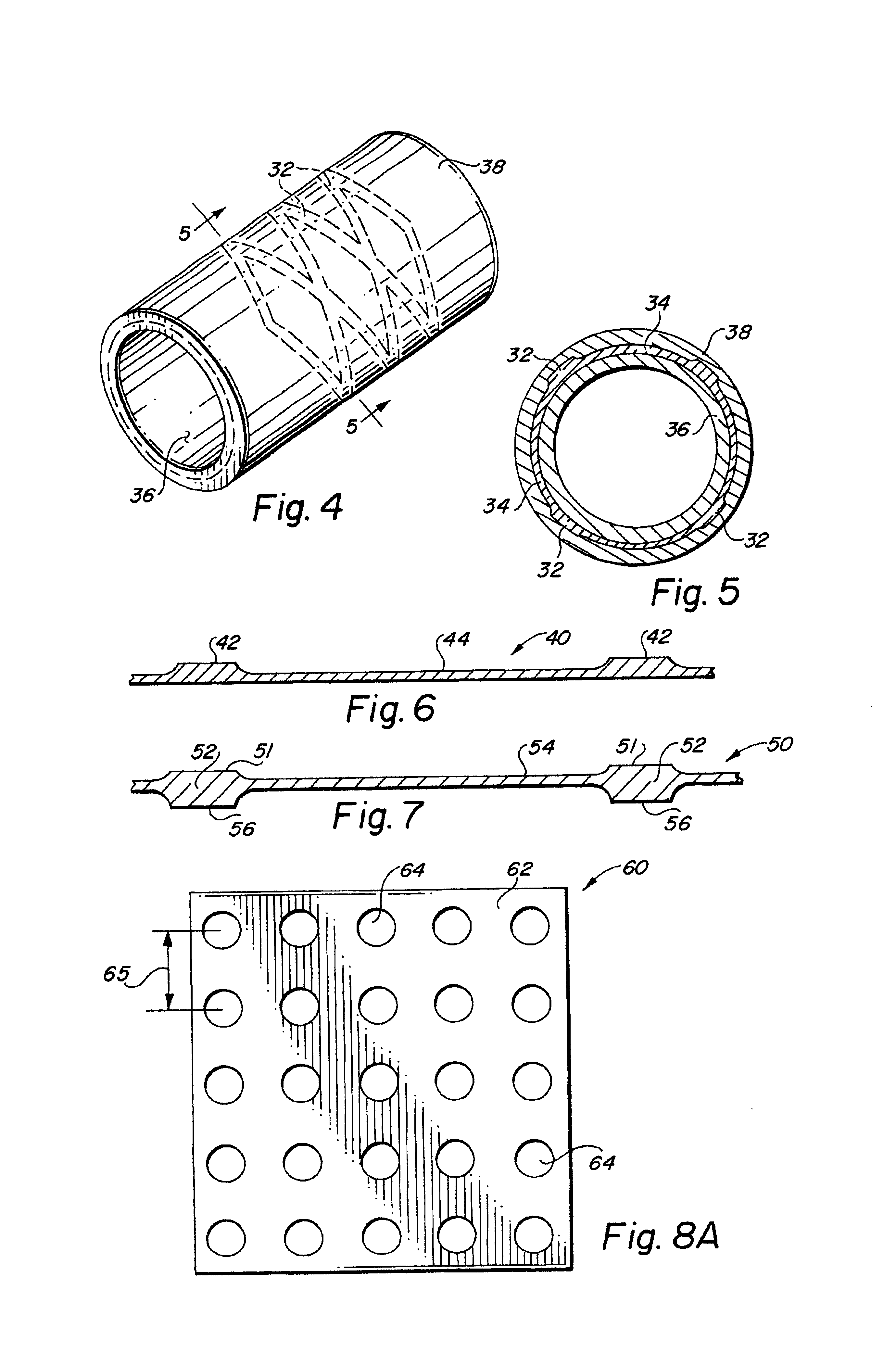

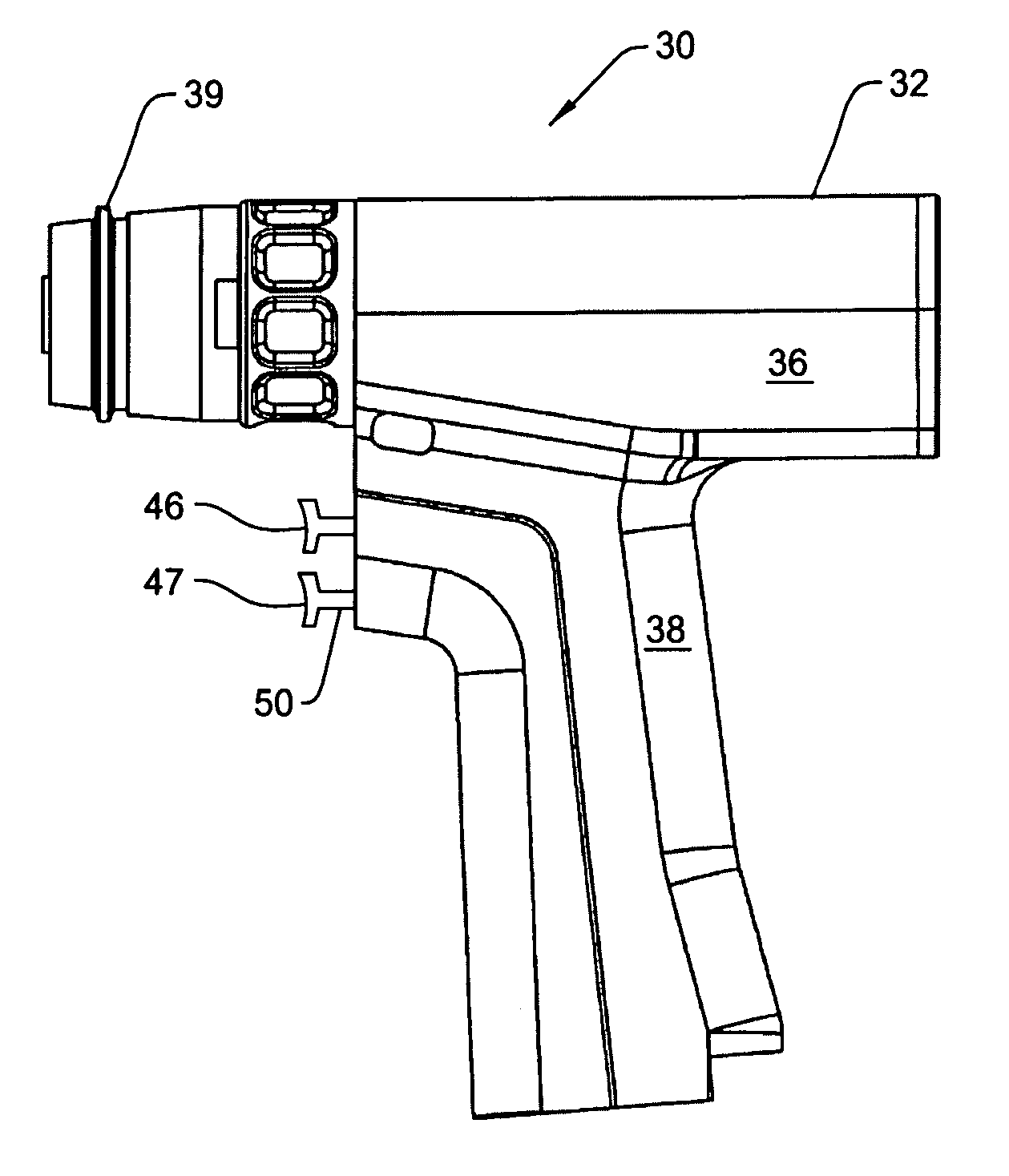

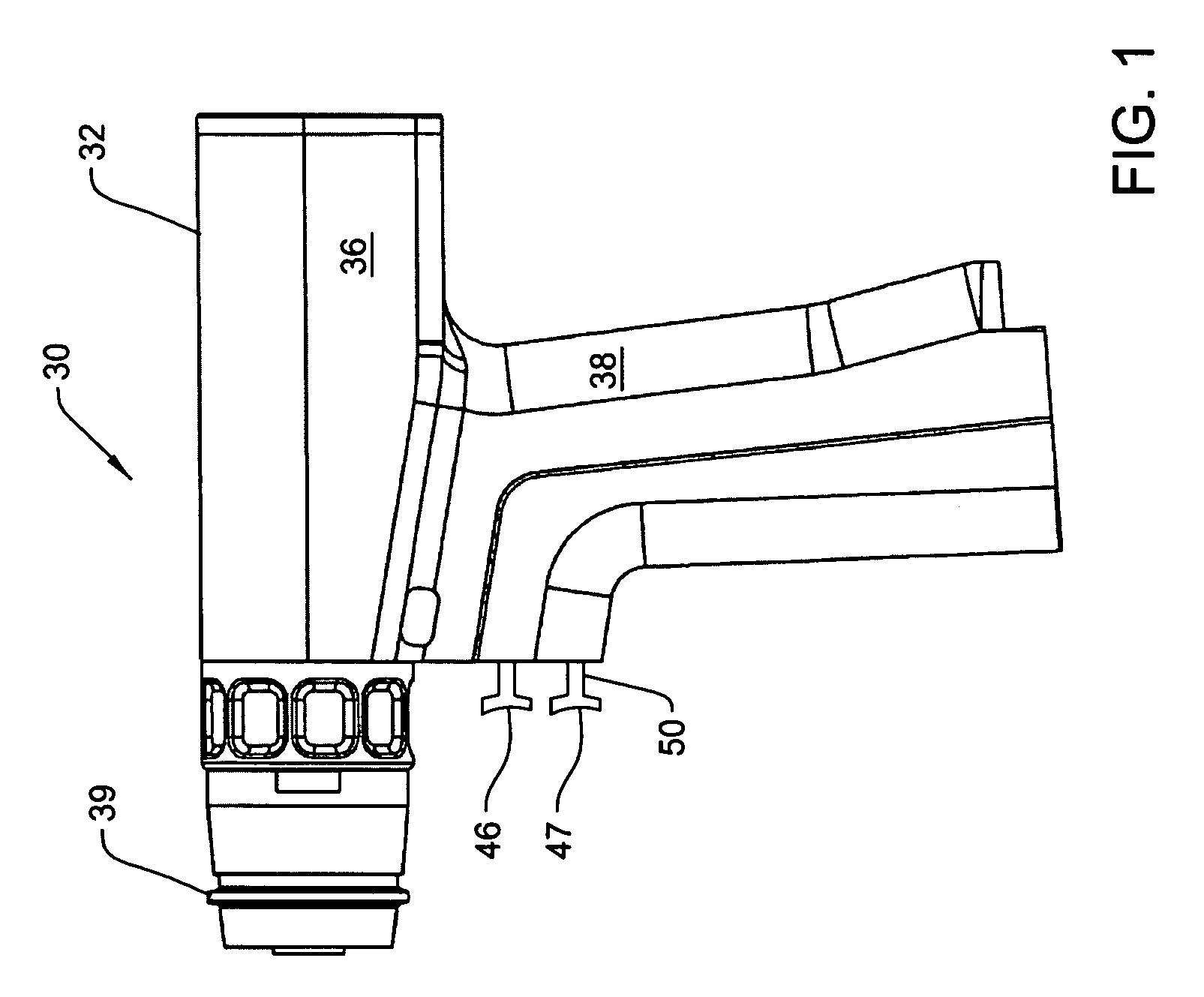

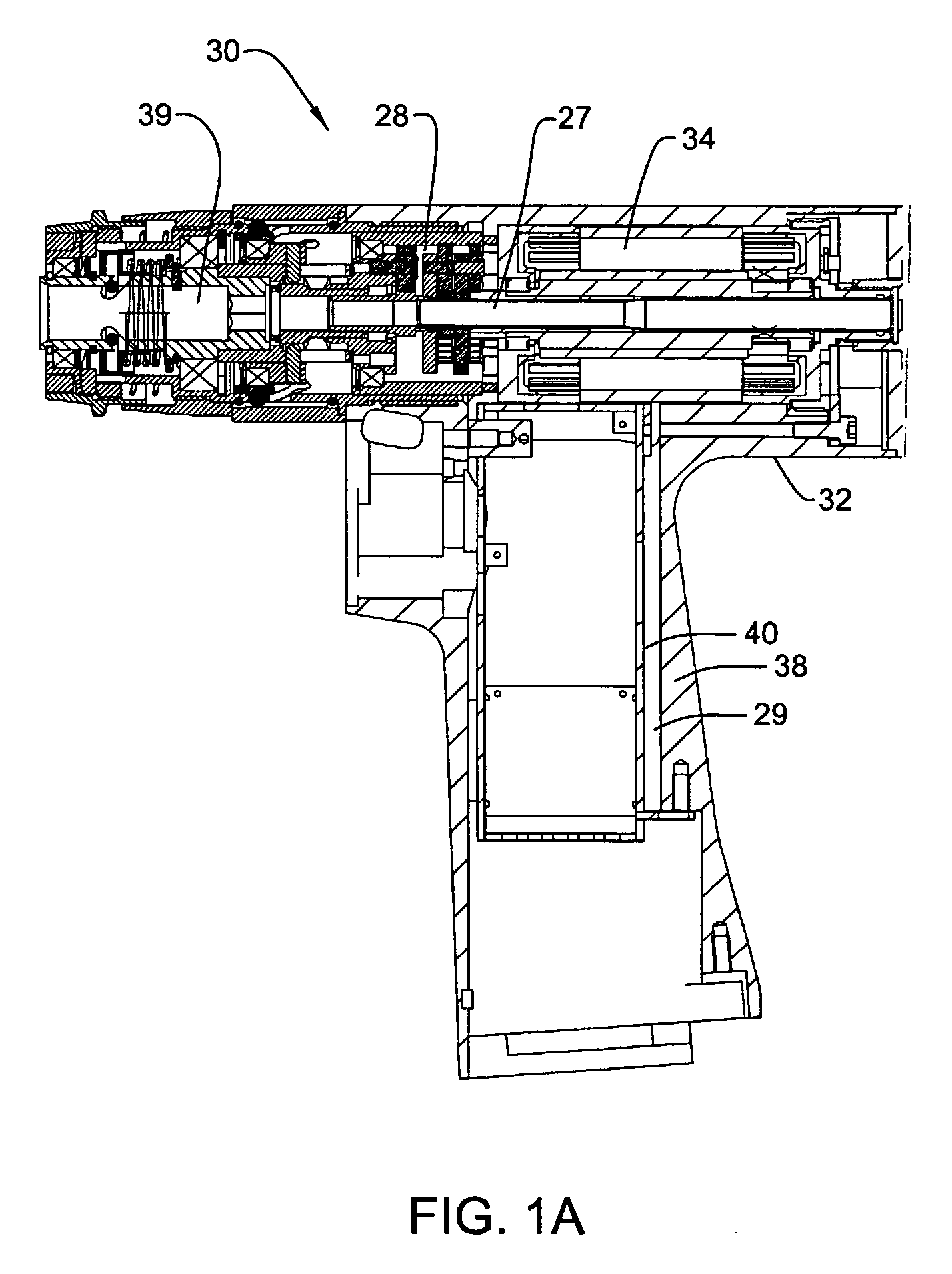

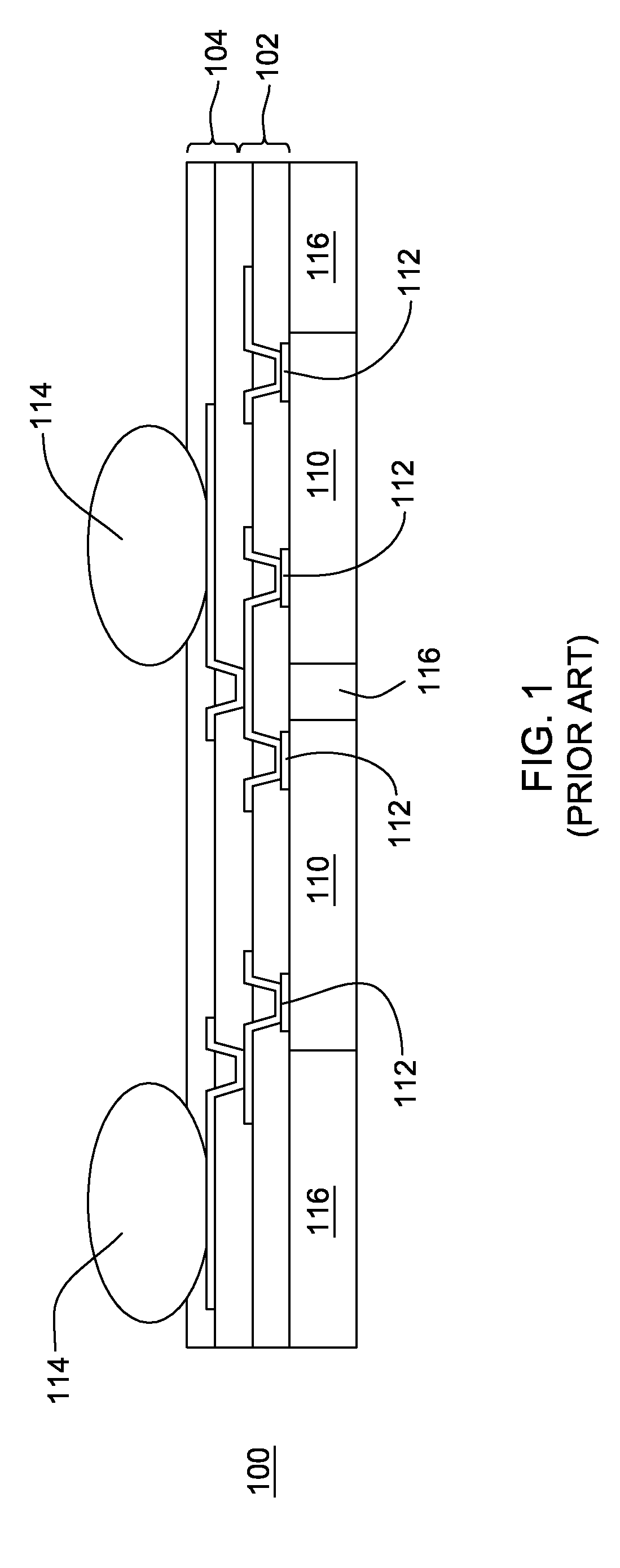

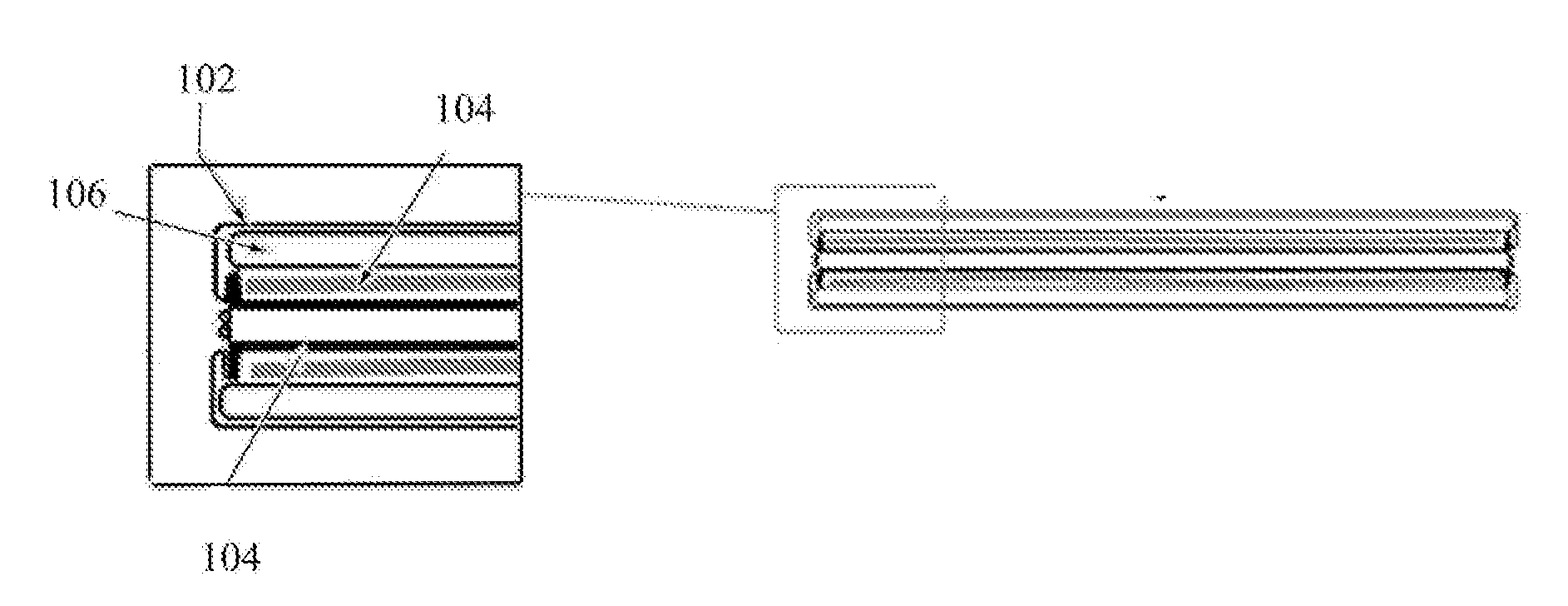

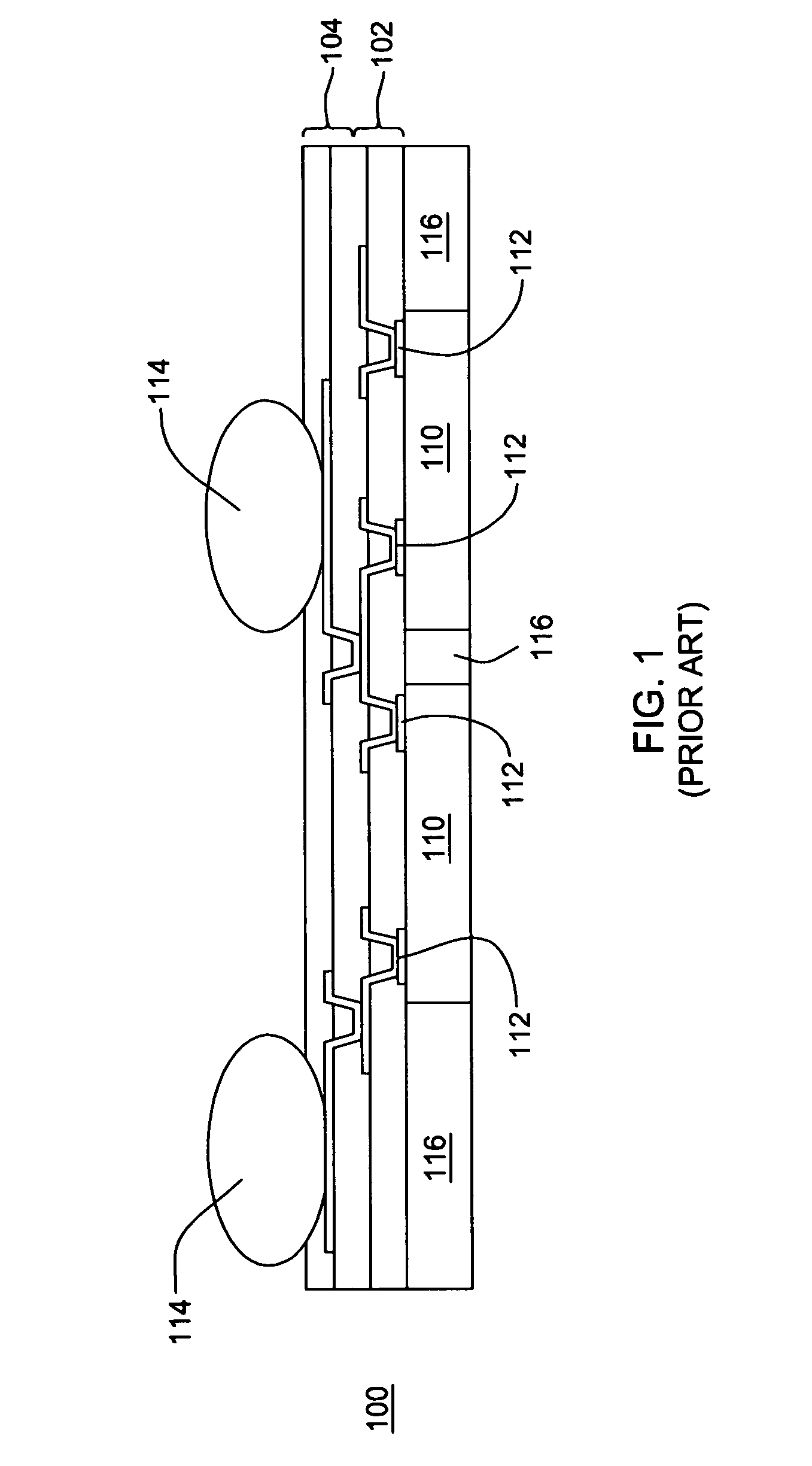

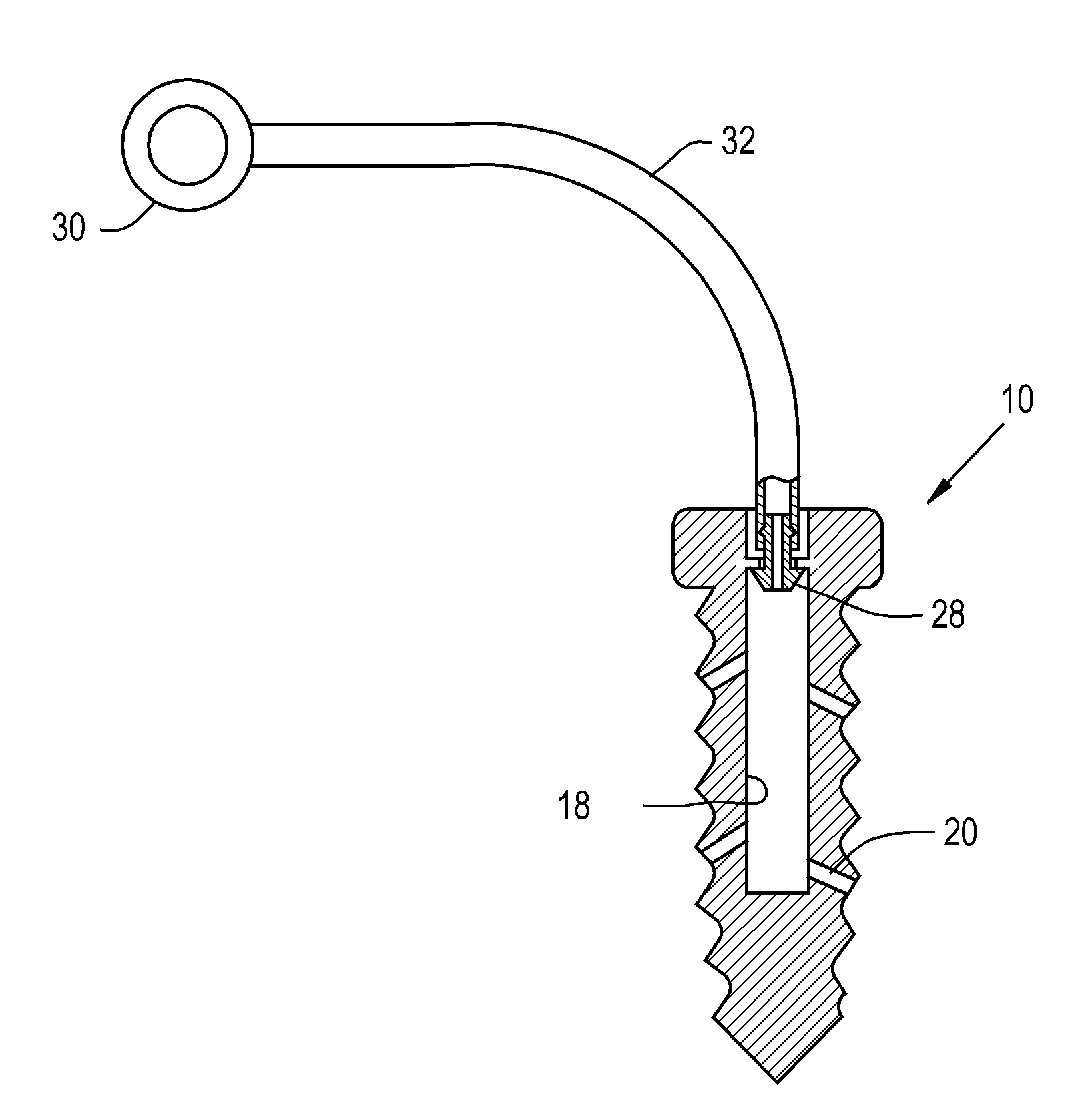

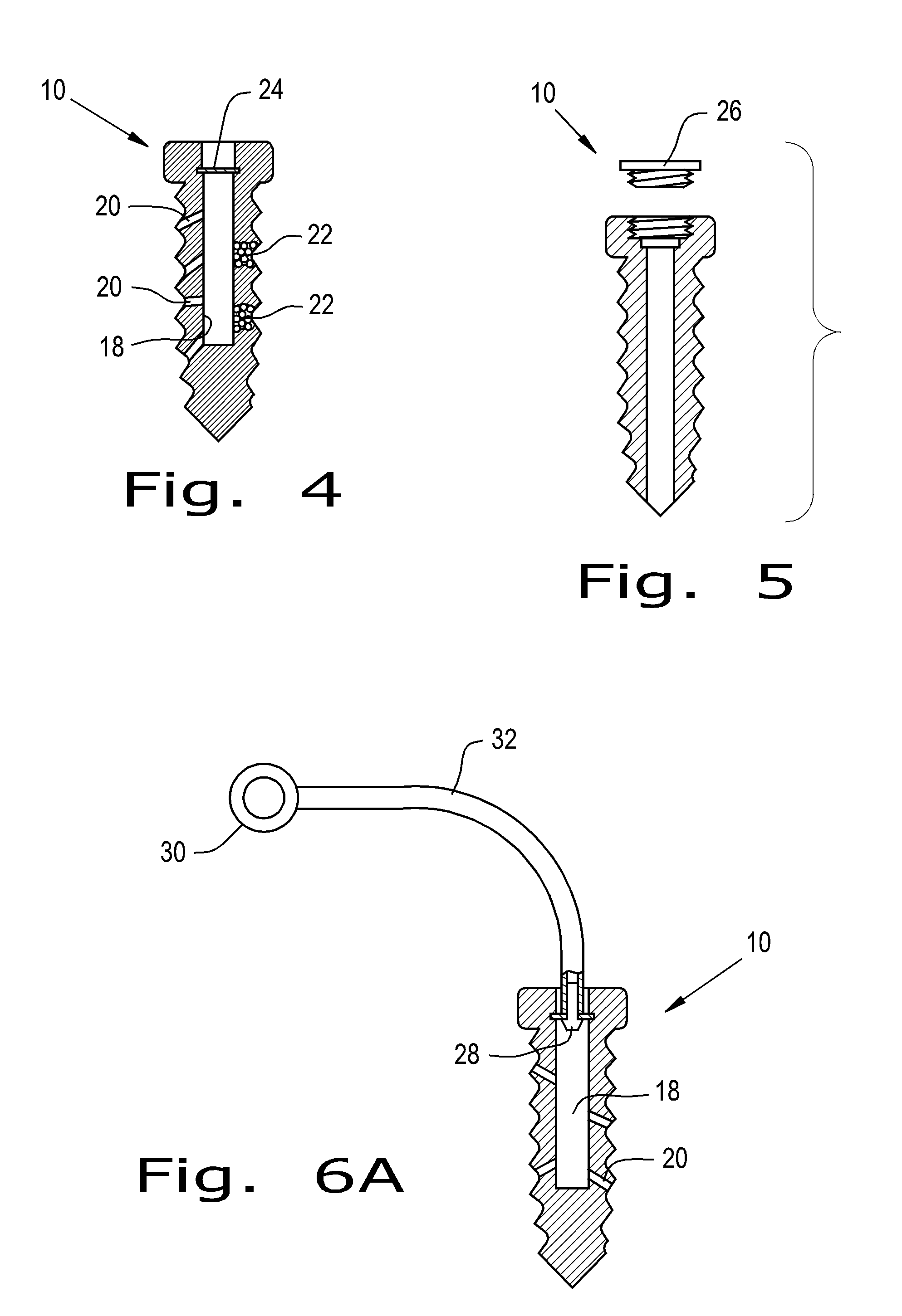

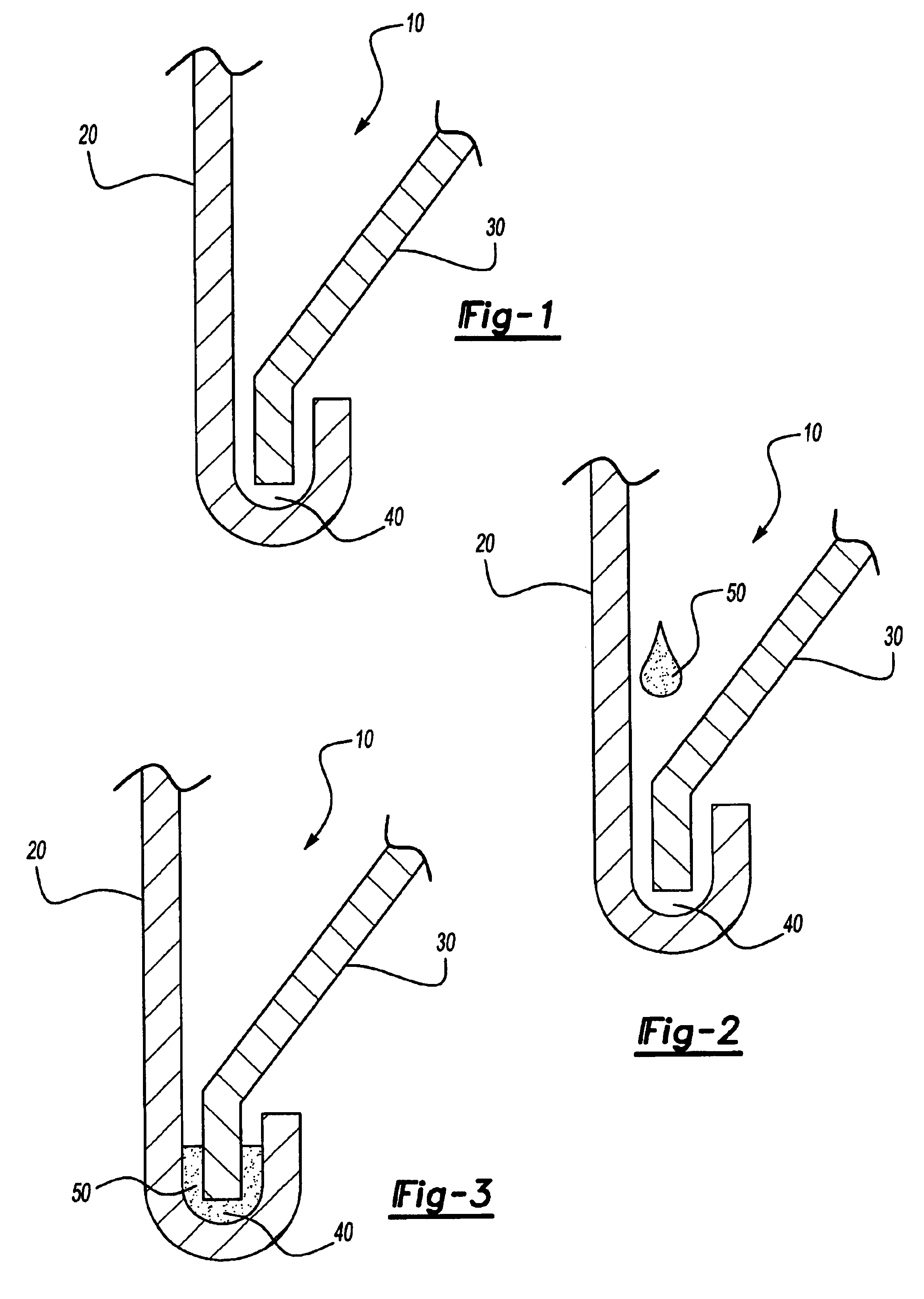

Powered surgical tool with control module that contains a sensor for remotely monitoring the tool power generating unit

ActiveUS7638958B2Shaking/oscillating/vibrating mixersTransportation and packagingEngineeringControl circuit

A powered surgical tool with a housing that contains a power generating unit such as a motor. A control module is disposed in a shell that is mounted in the housing. The control module contains a control circuit for regulating the actuation of the power generating unit. The power generating unit emits a signal representative of the operating state of the unit that is transmitted through the structural material forming the shell. Also internal to the control module shell is a sensor that monitors the signal emitted by the power generating unit. This signal output by the sensor is applied to the control circuit. The control circuit, based on the sensor signal regulates actuation of the power generating unit. Wherein the power generating unit is a motor, the signal emitted is the magnetic field that varies with rotor position. The sensor monitors the strength of this field.

Owner:STRYKER CORP

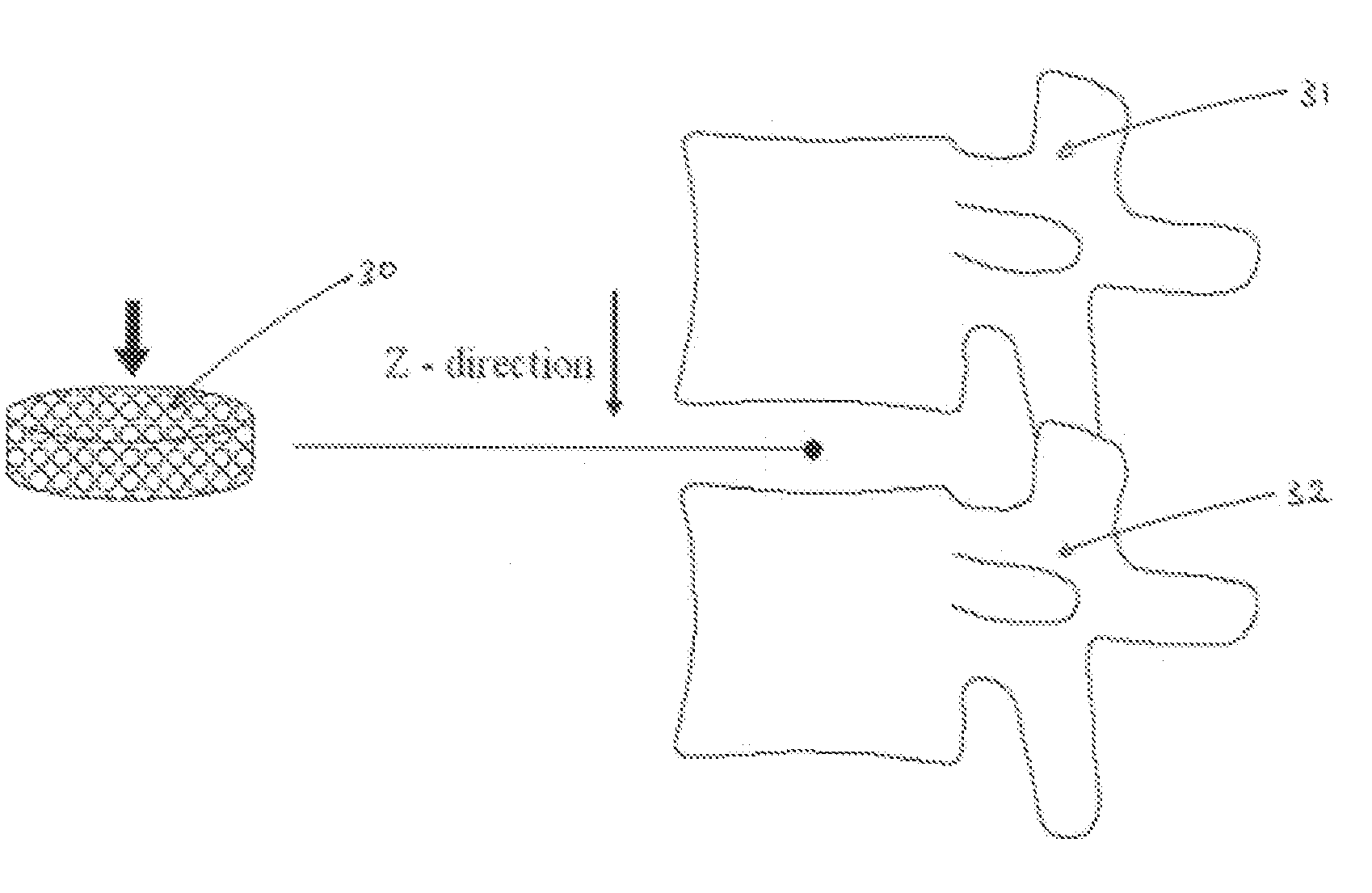

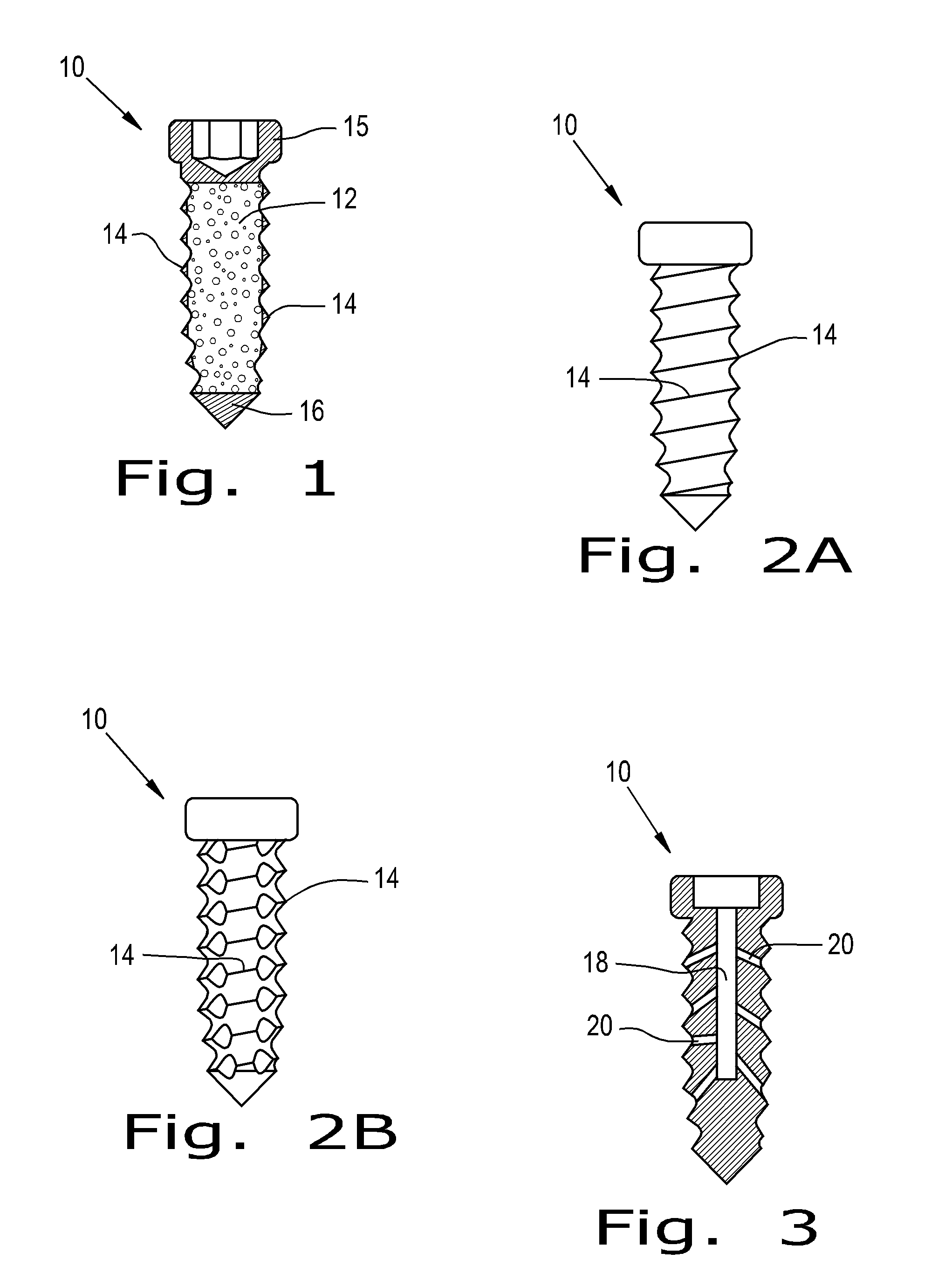

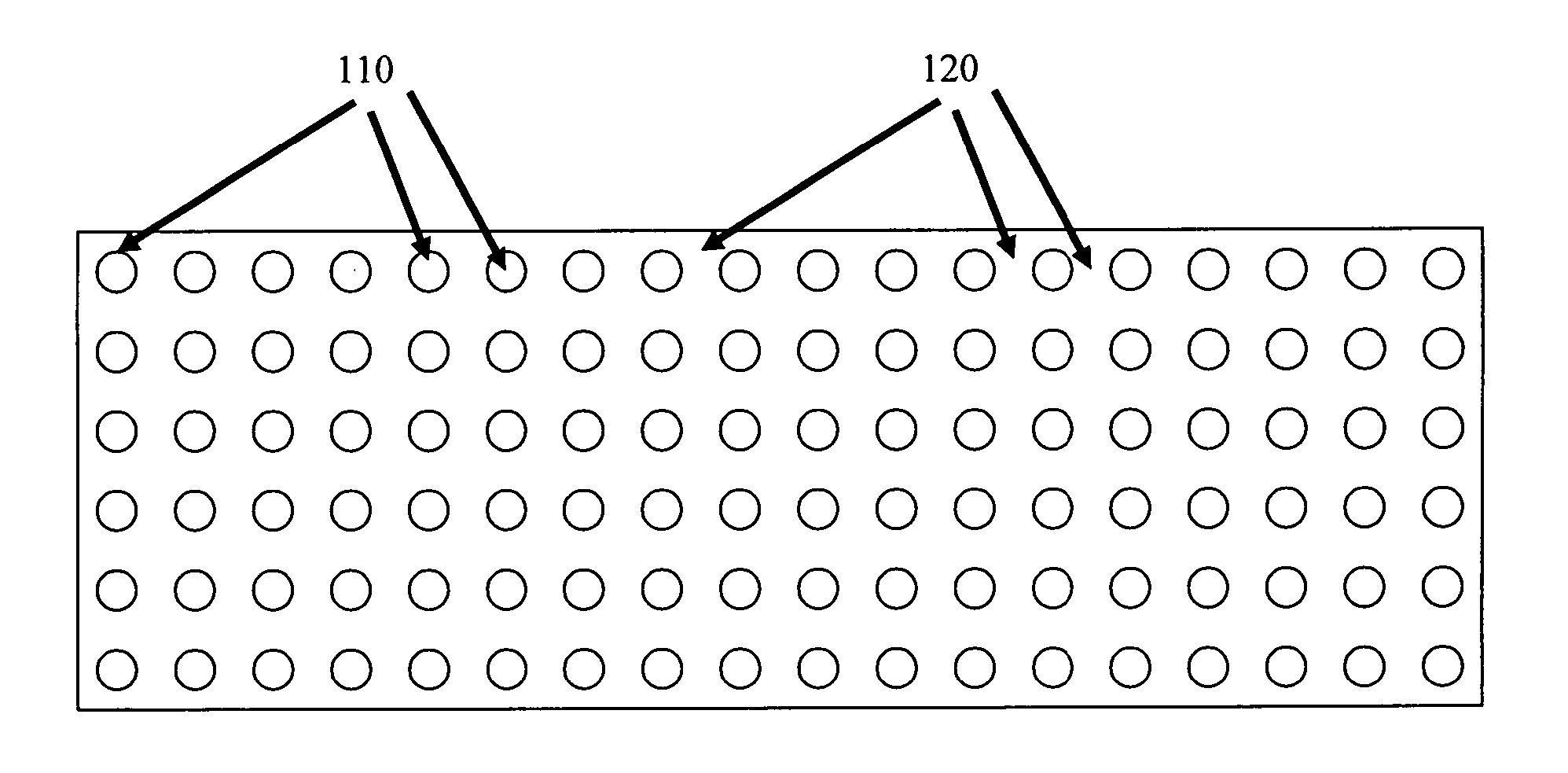

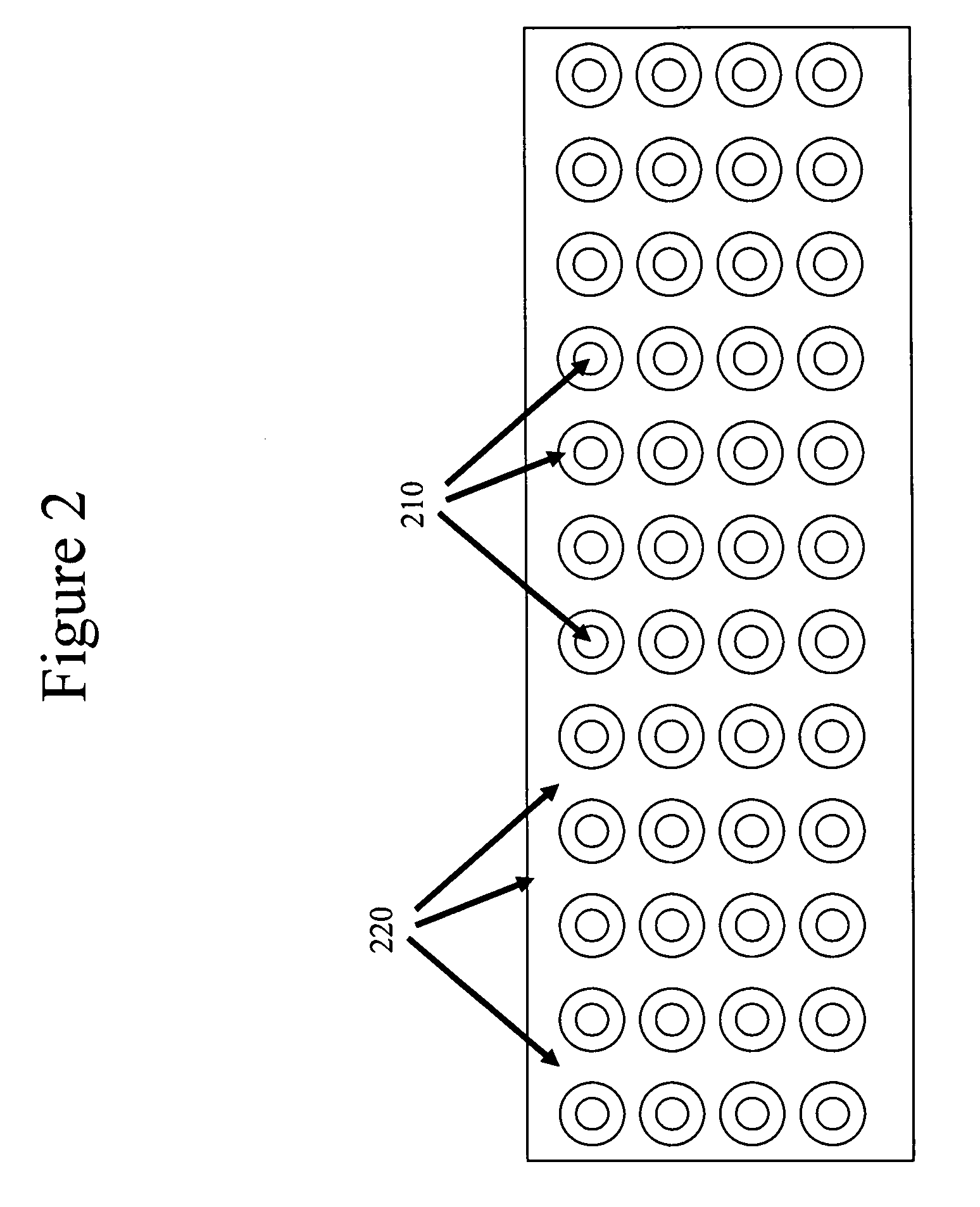

Porous Substrates for Implantation

InactiveUS20100137990A1Easy to integrateGood biocompatibilitySuture equipmentsDental implantsPorous substrateAnimal body

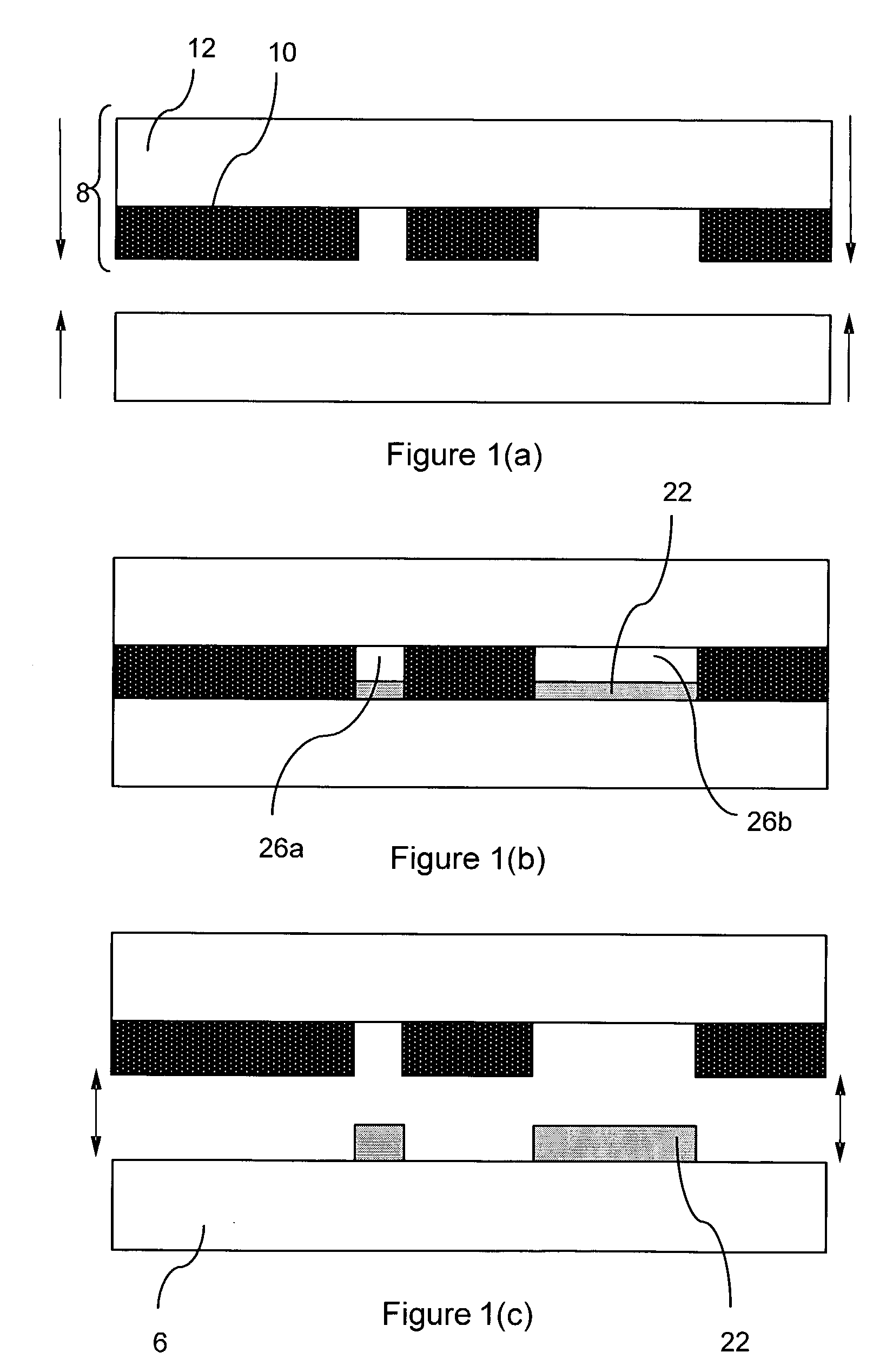

A porous substrate or implant for implantation into a human or animal body constructed from a structural material and having one or more regions which when implanted are subjected to a relatively lower mechanical loading. The region(s) are constructed with lesser mechanical strength by having a lesser amount of structural material in said region(s) relative to other regions. This is achieved by controlling pore volume fraction in the regions. A spacer is adapted to define an open-cell pore network by taking a model of the required porous structure, and creating the spacer to represent the required porous structure using three-dimensional modelling. Material to form the substrate about the spacer in infiltrated the scaffold structure formed.

Owner:NATIONAL UNIVERSITY OF IRELAND

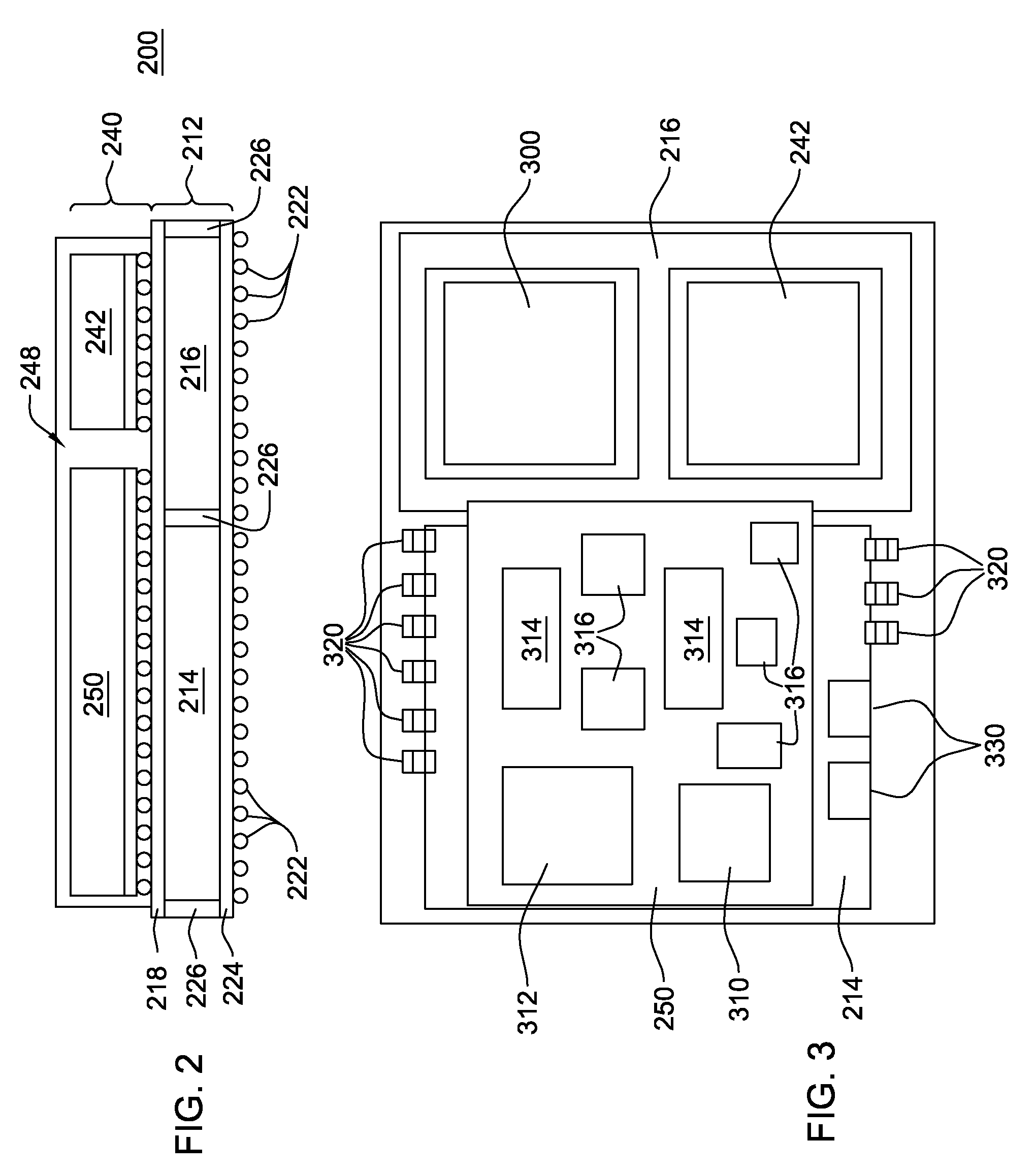

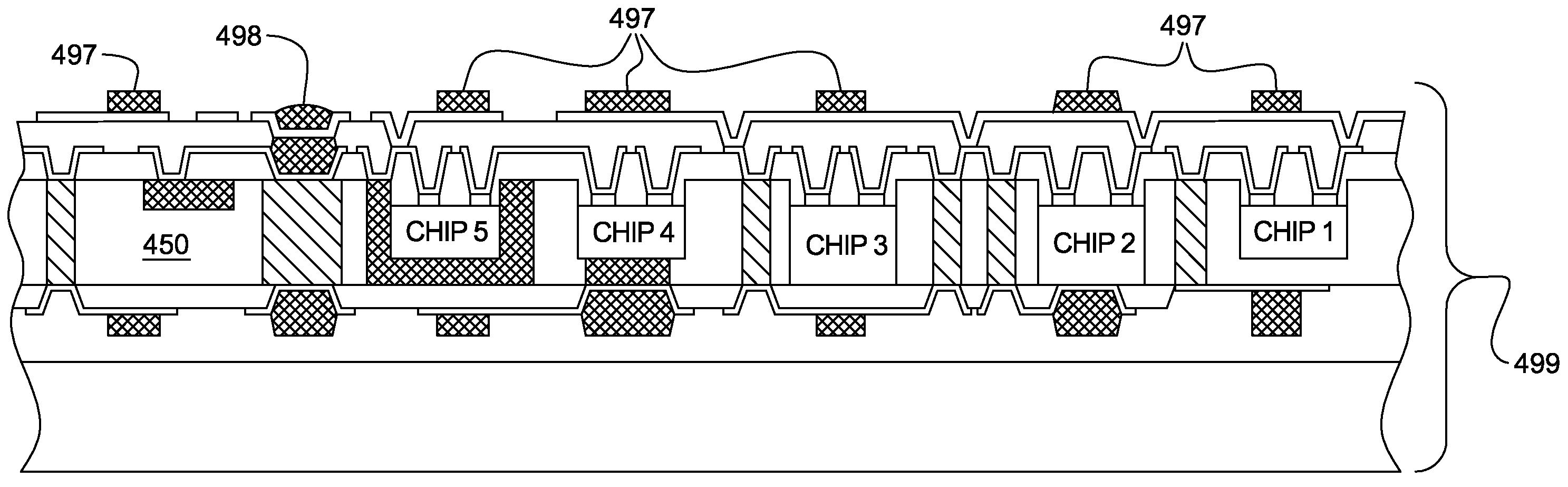

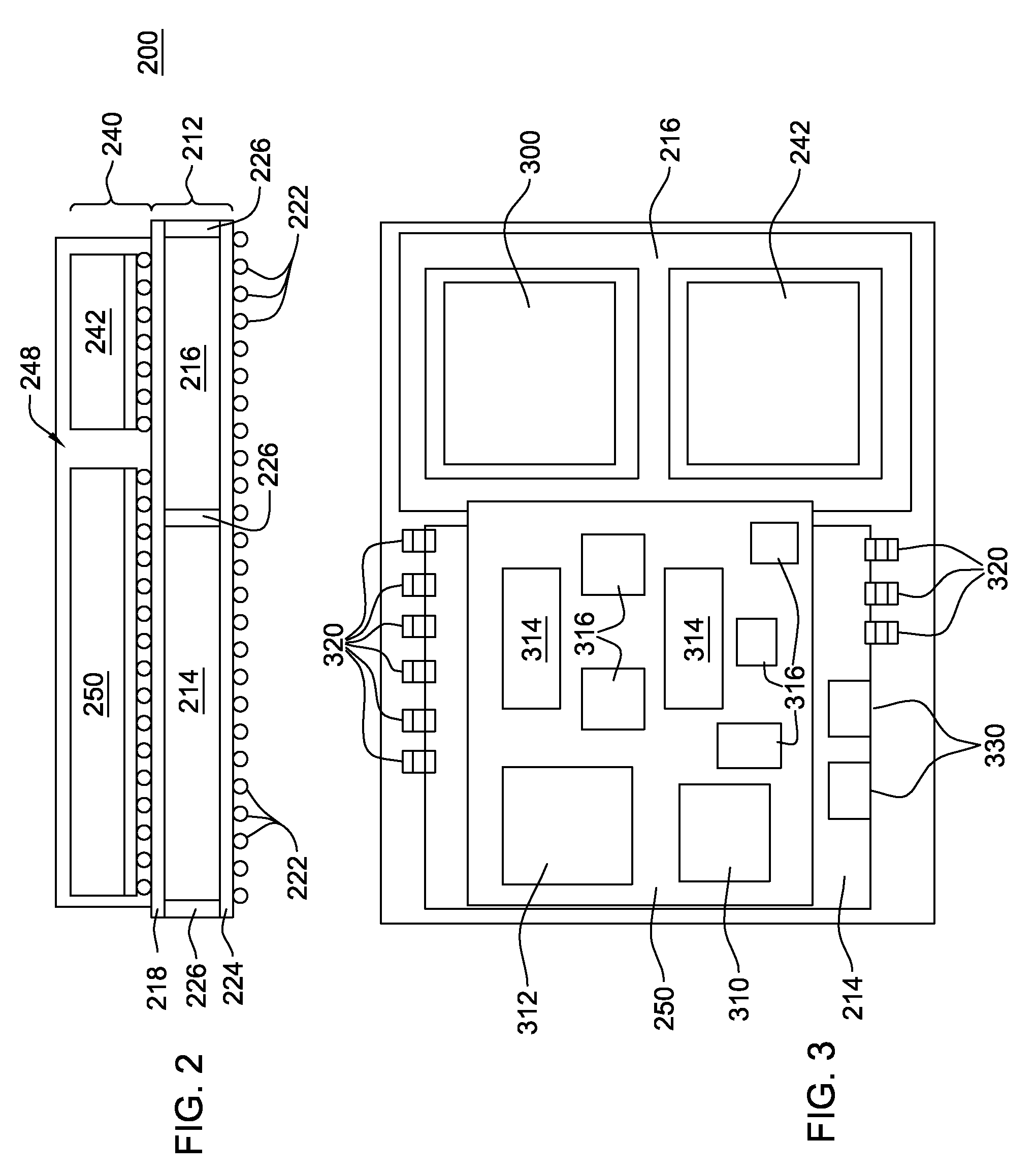

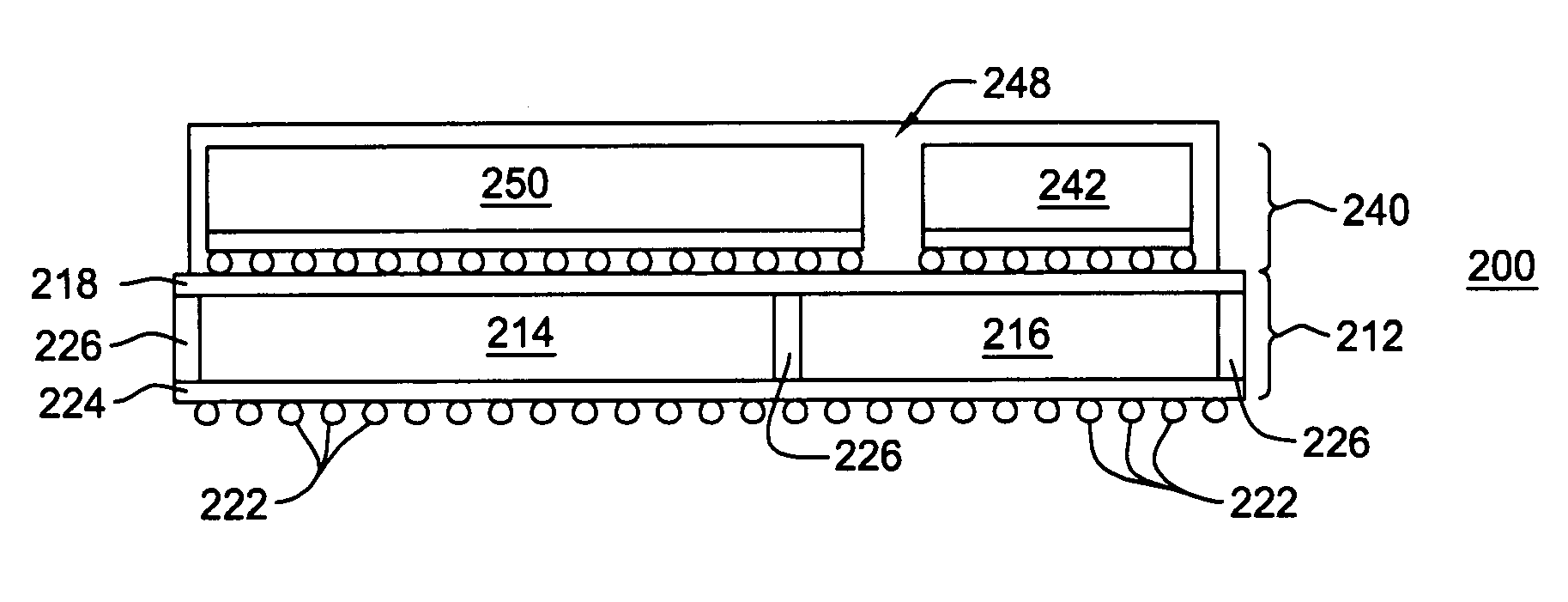

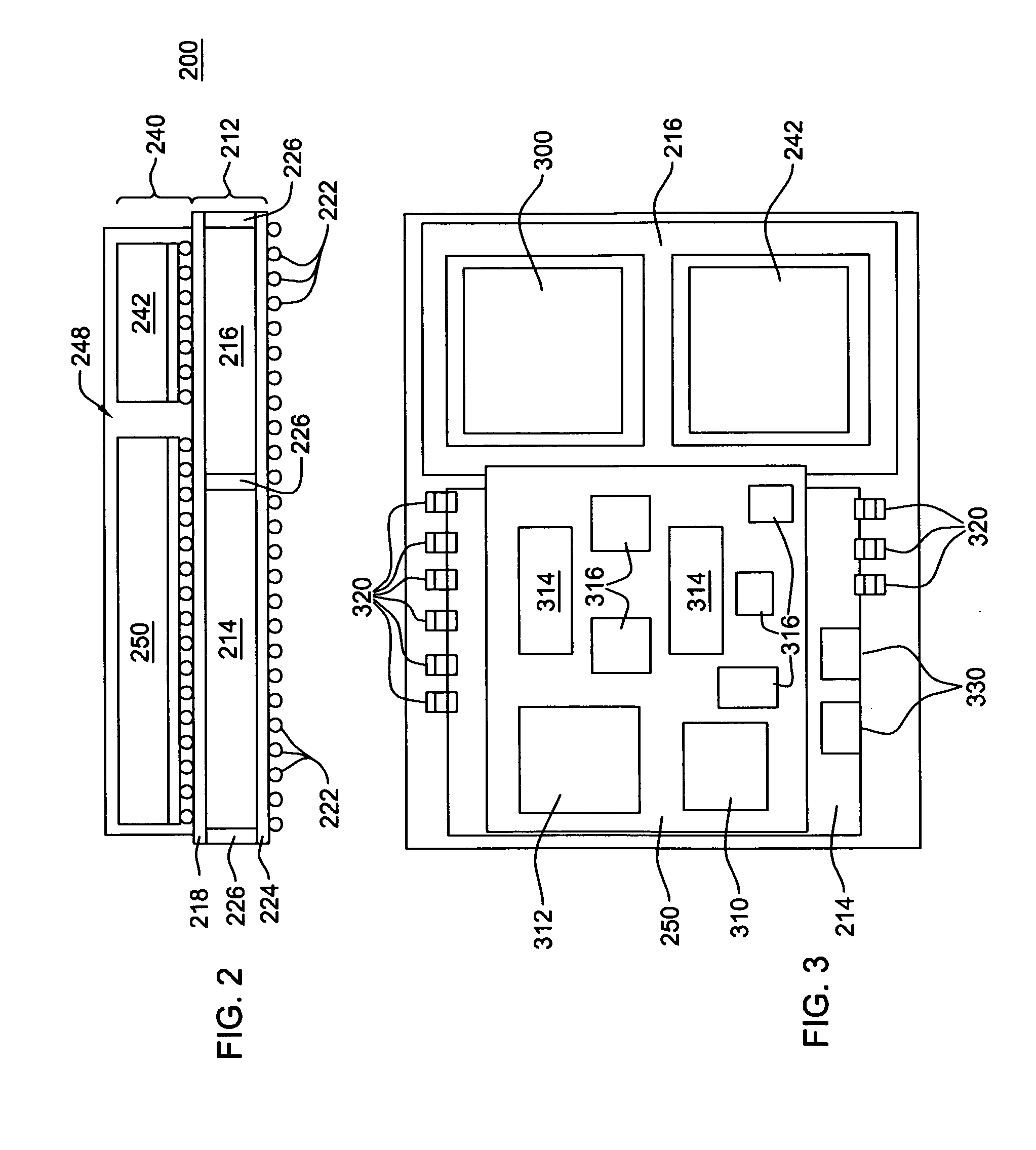

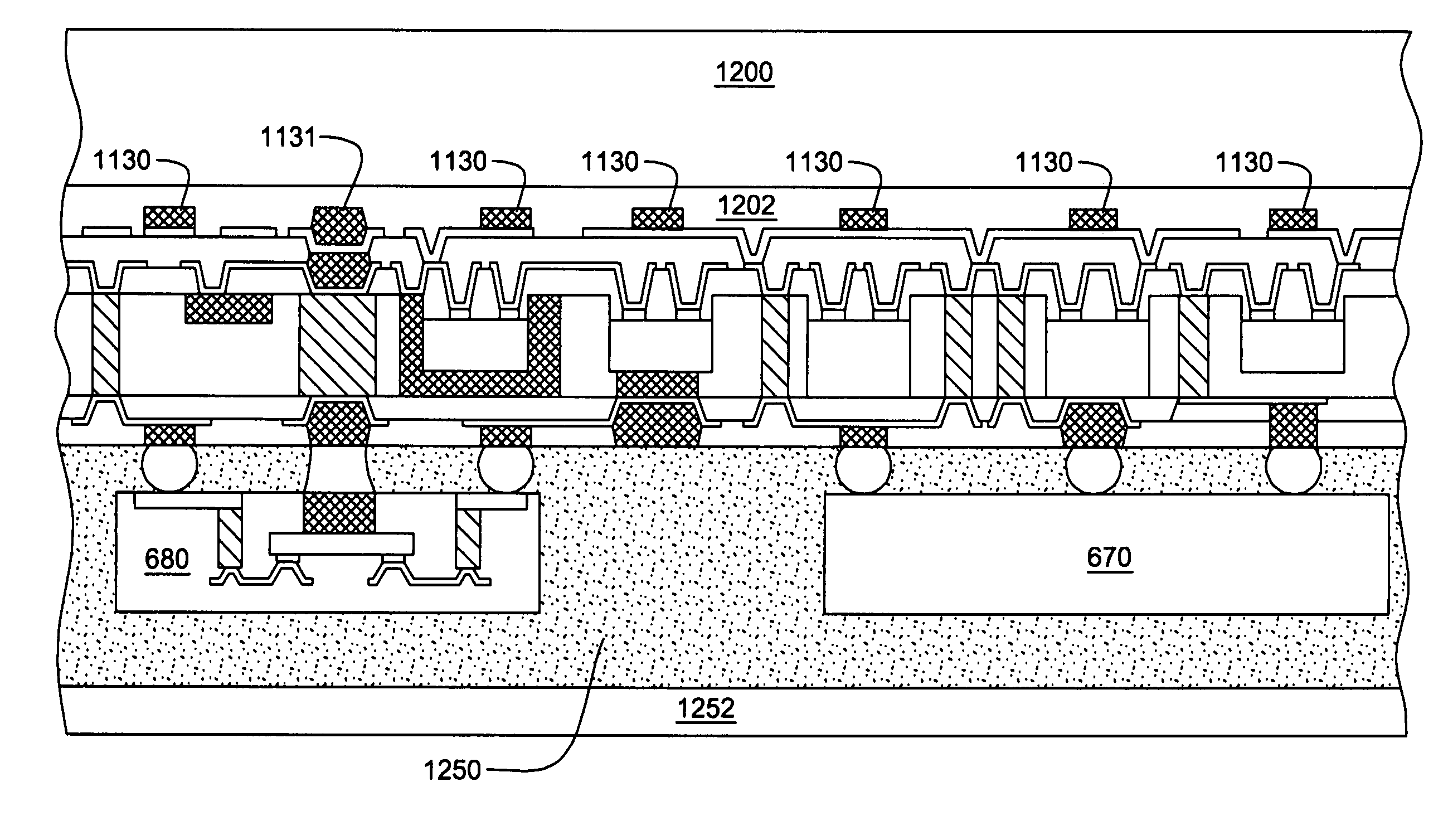

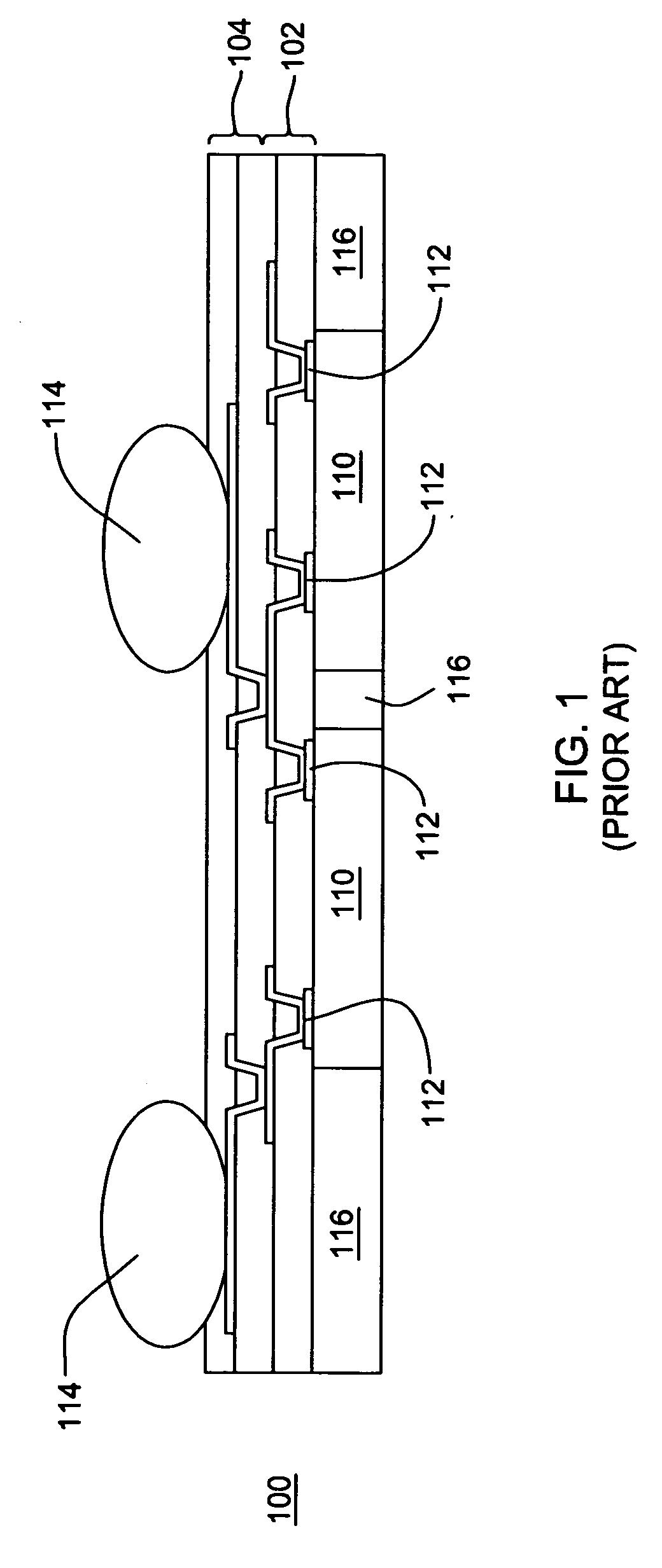

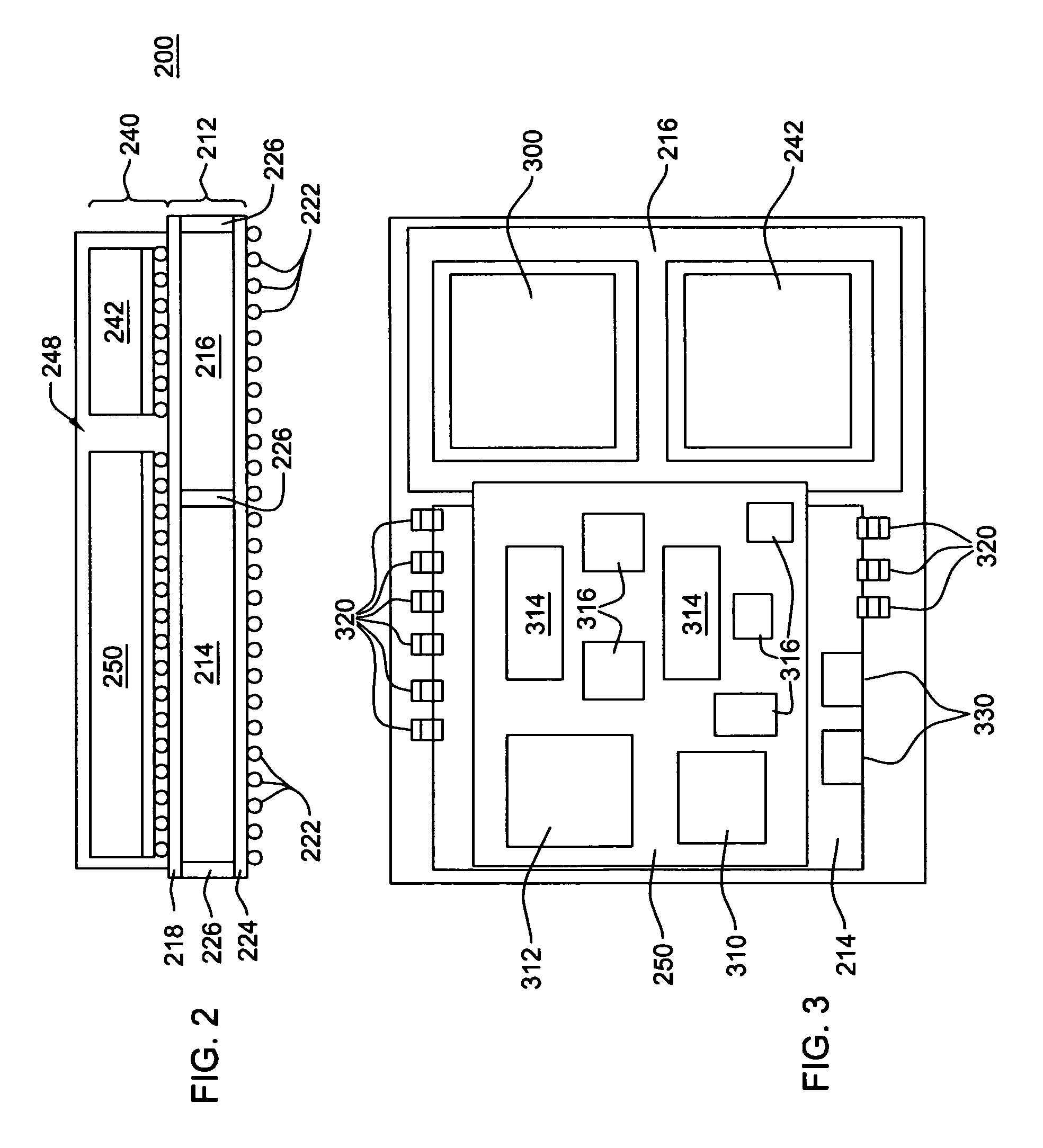

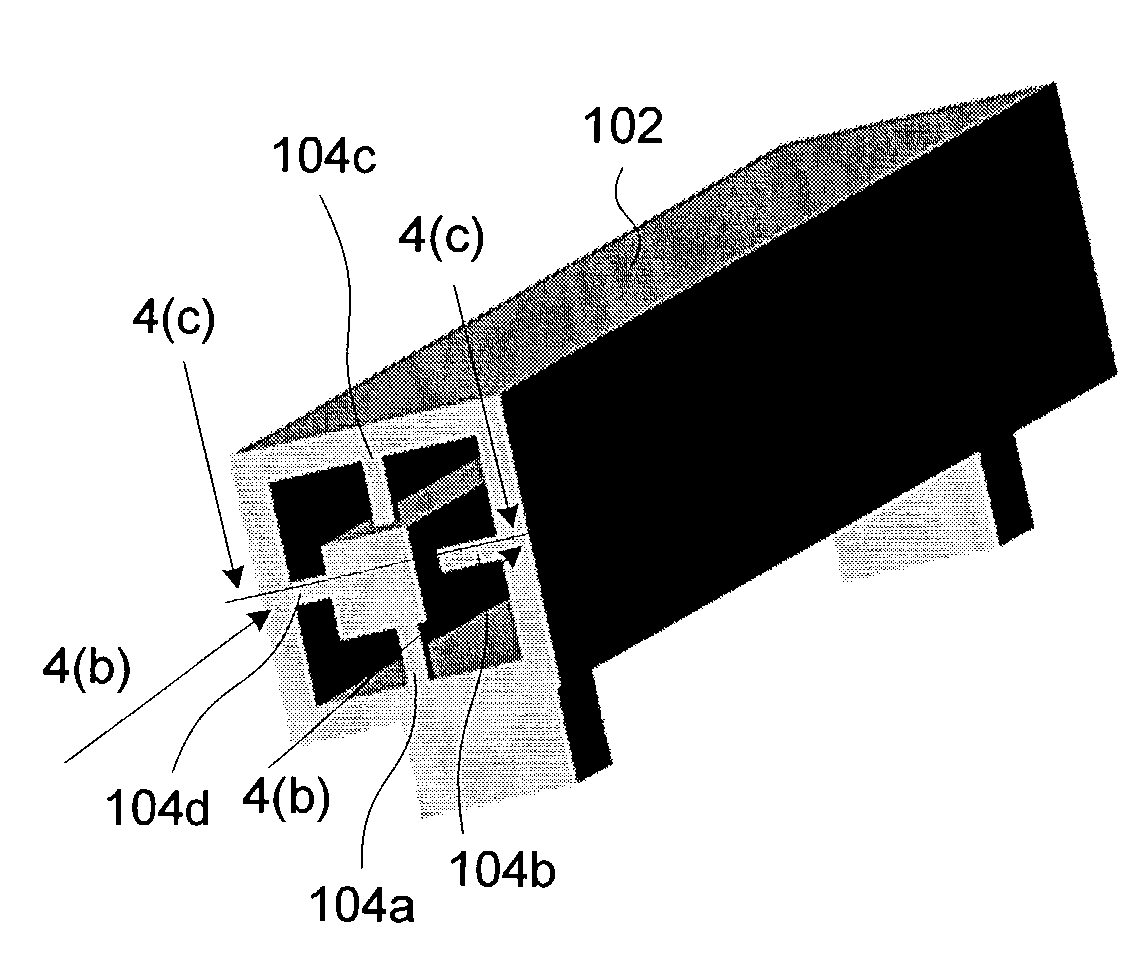

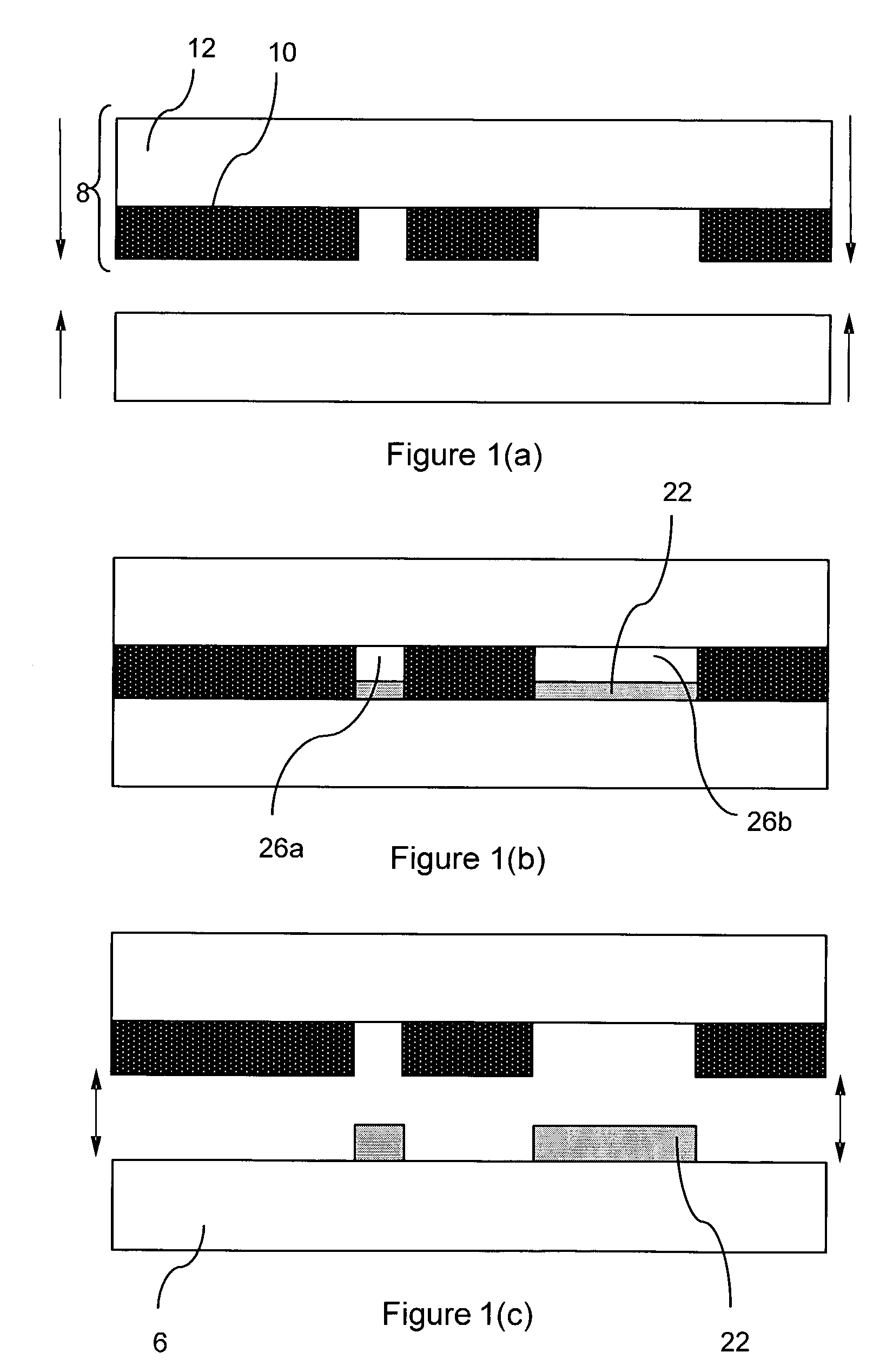

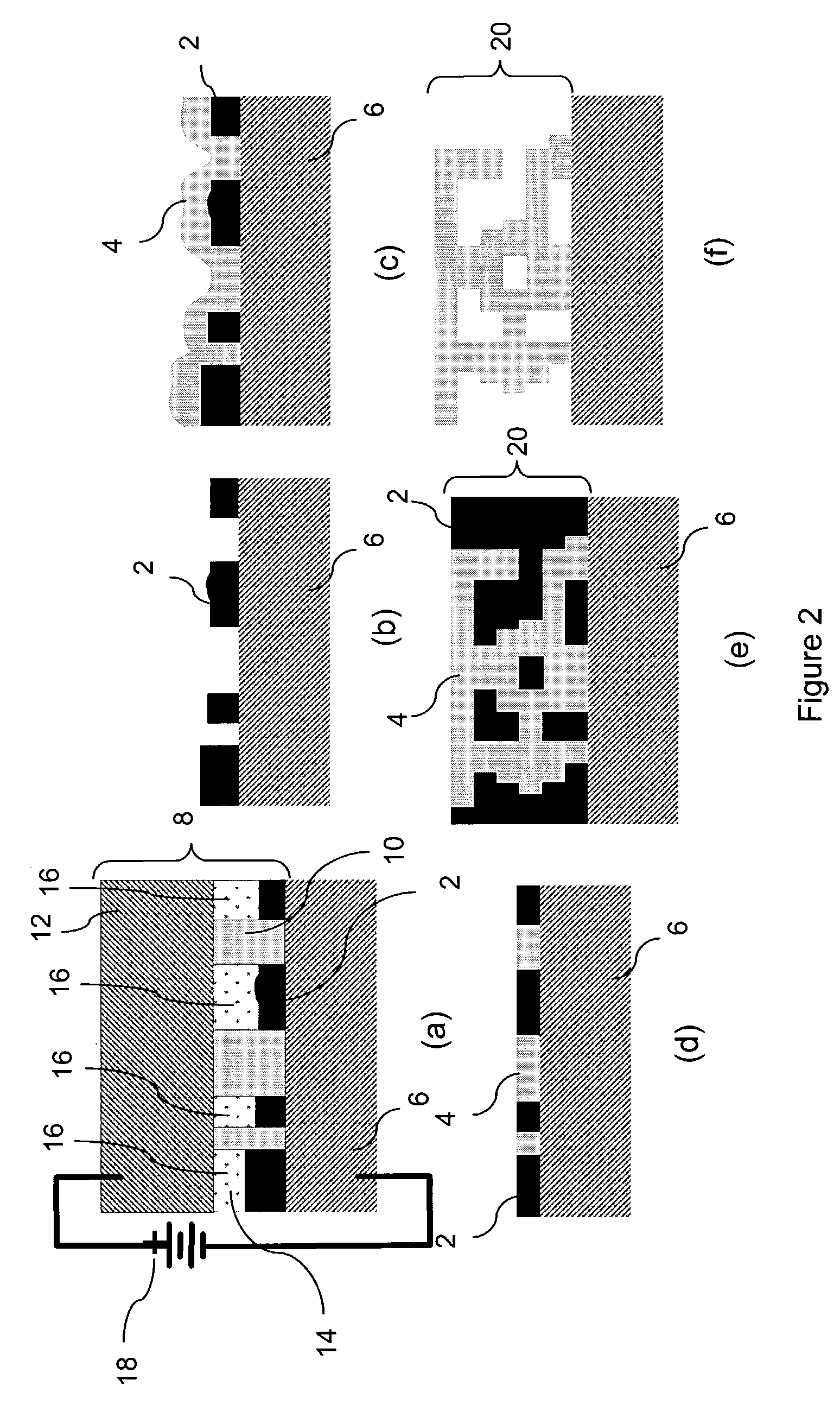

Integrated structures and fabrication methods thereof implementing a cell phone or other electronic system

ActiveUS7619901B2Semiconductor/solid-state device detailsSolid-state devicesElectronic systemsContact pad

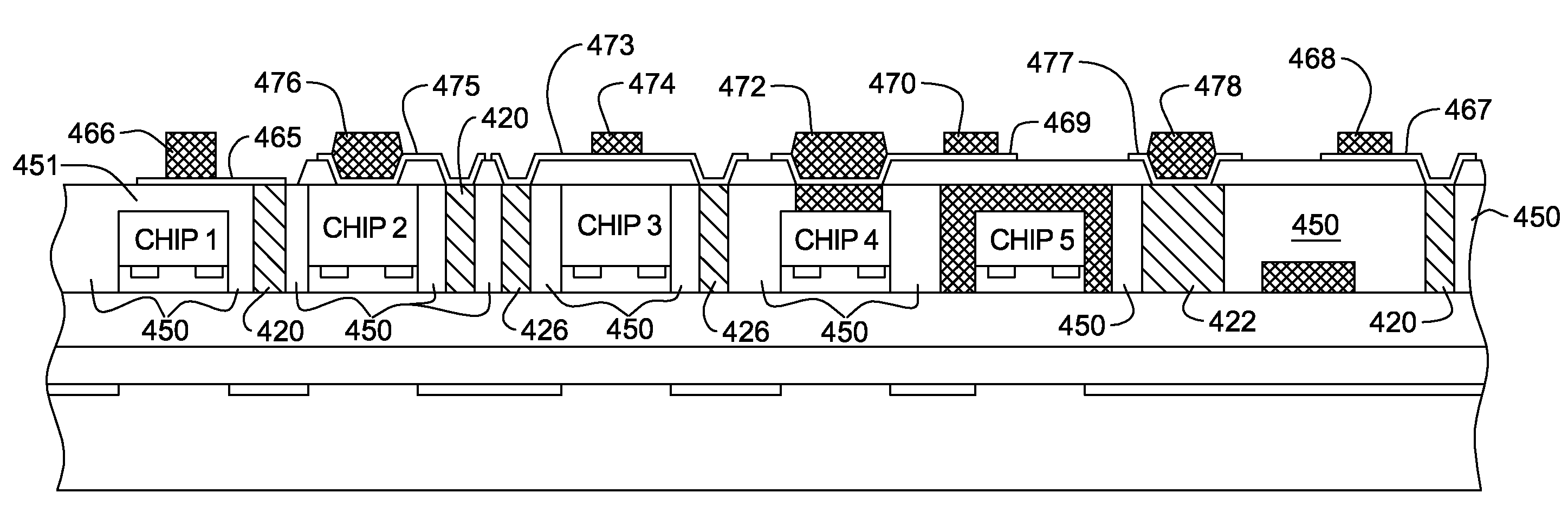

Circuit structures and methods of fabrication are provided for facilitating implementing a complete electronic system in a compact package. The circuit structure includes, in one embodiment, a chips-first multichip base layer with conductive structures extending therethrough. An interconnect layer is disposed over the front surface of the multichip layer and includes interconnect metallization electrically connected to contact pads of the chips and to conductive structures extending through the structural material. A redistribution layer, disposed over the back surface of the multichip layer, includes a redistribution metallization also electrically connected to conductive structures extending through the structural material. Input / output contacts are arrayed over the redistribution layer, including over the lower surfaces of at least some integrated circuit chips within the multichip layer, and are electrically connected through the redistribution metallization, conductive structures, and interconnect metallization to contact pads of the integrated circuit chips of the multichip layer.

Owner:EPIC TECH INC

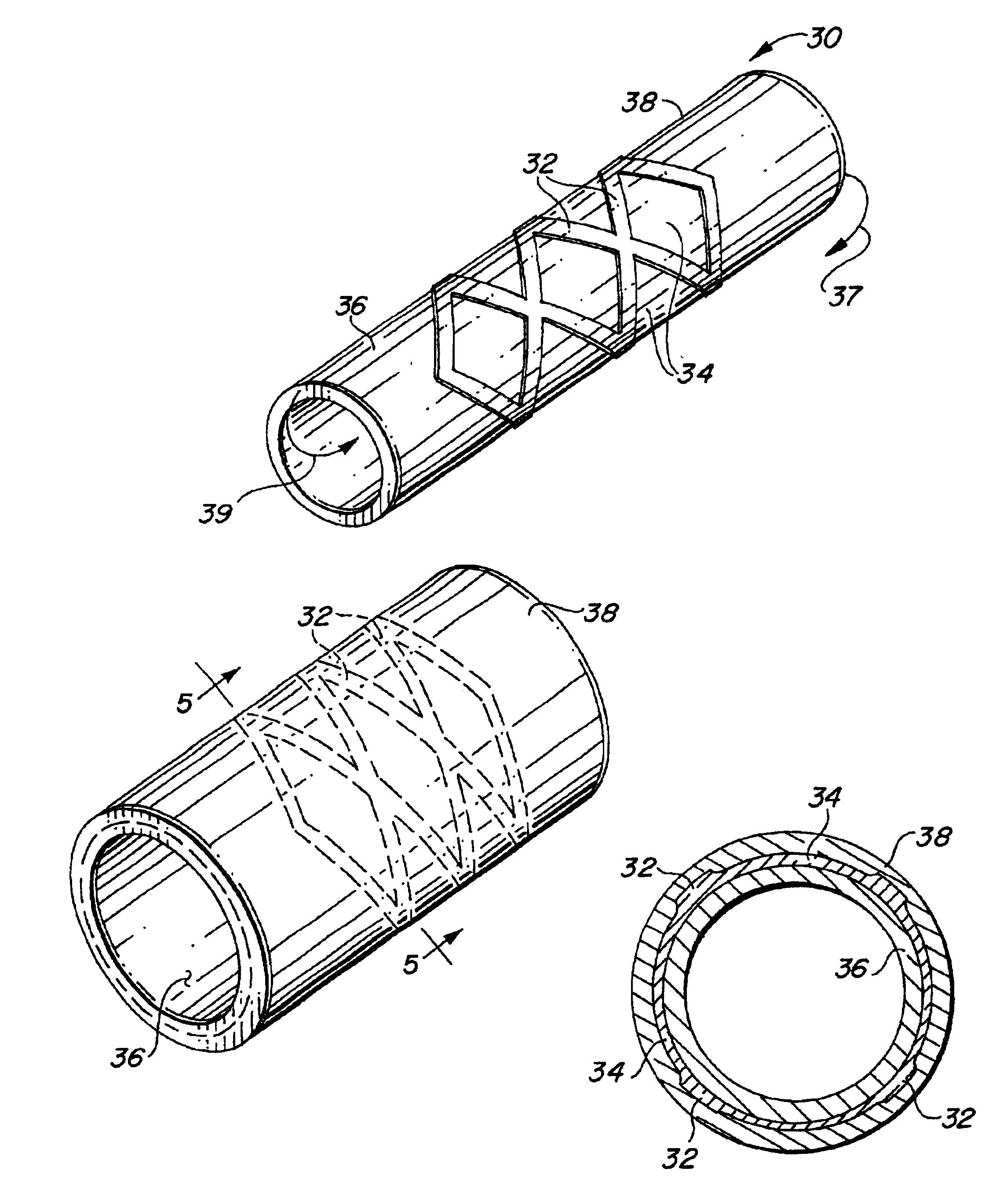

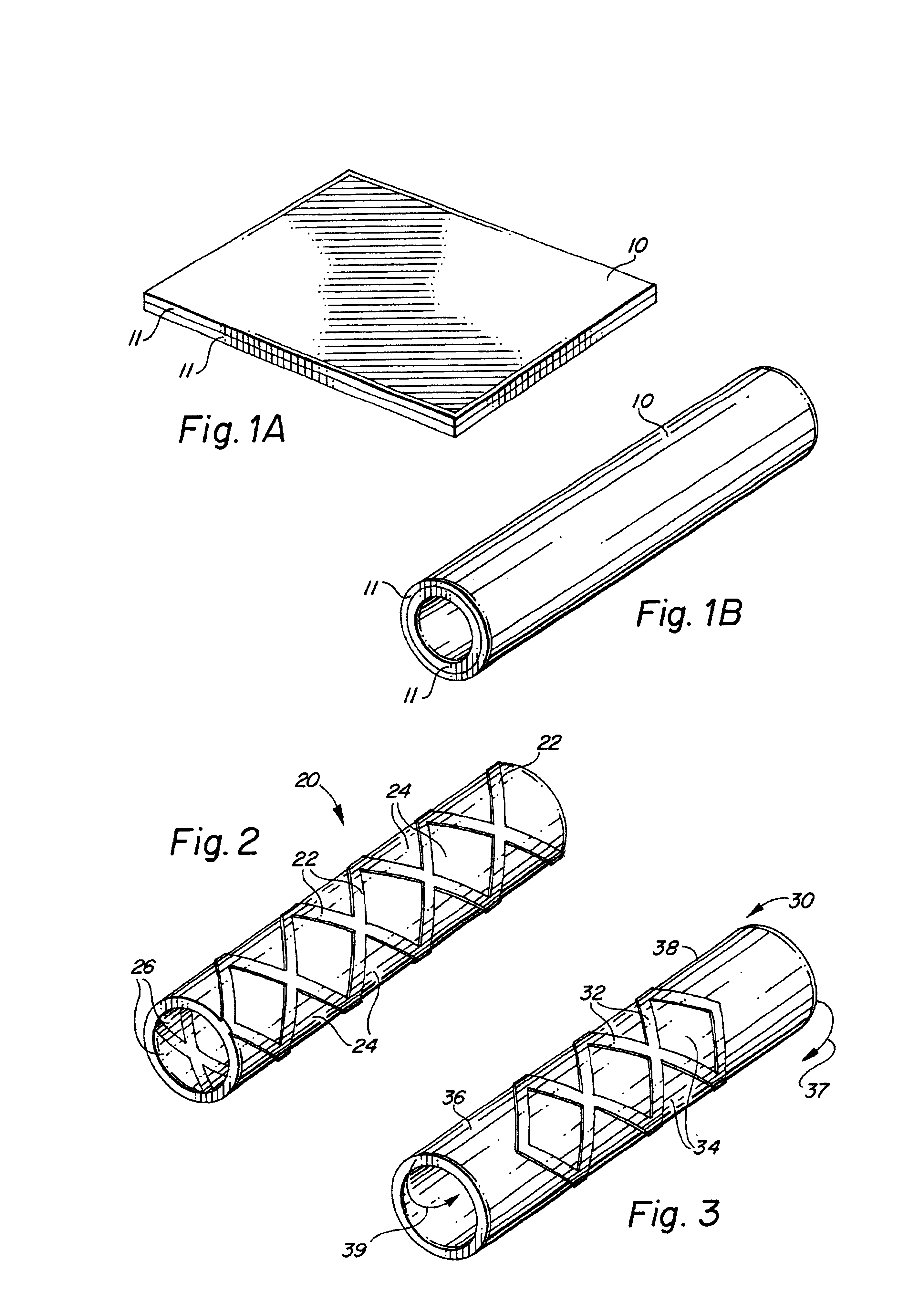

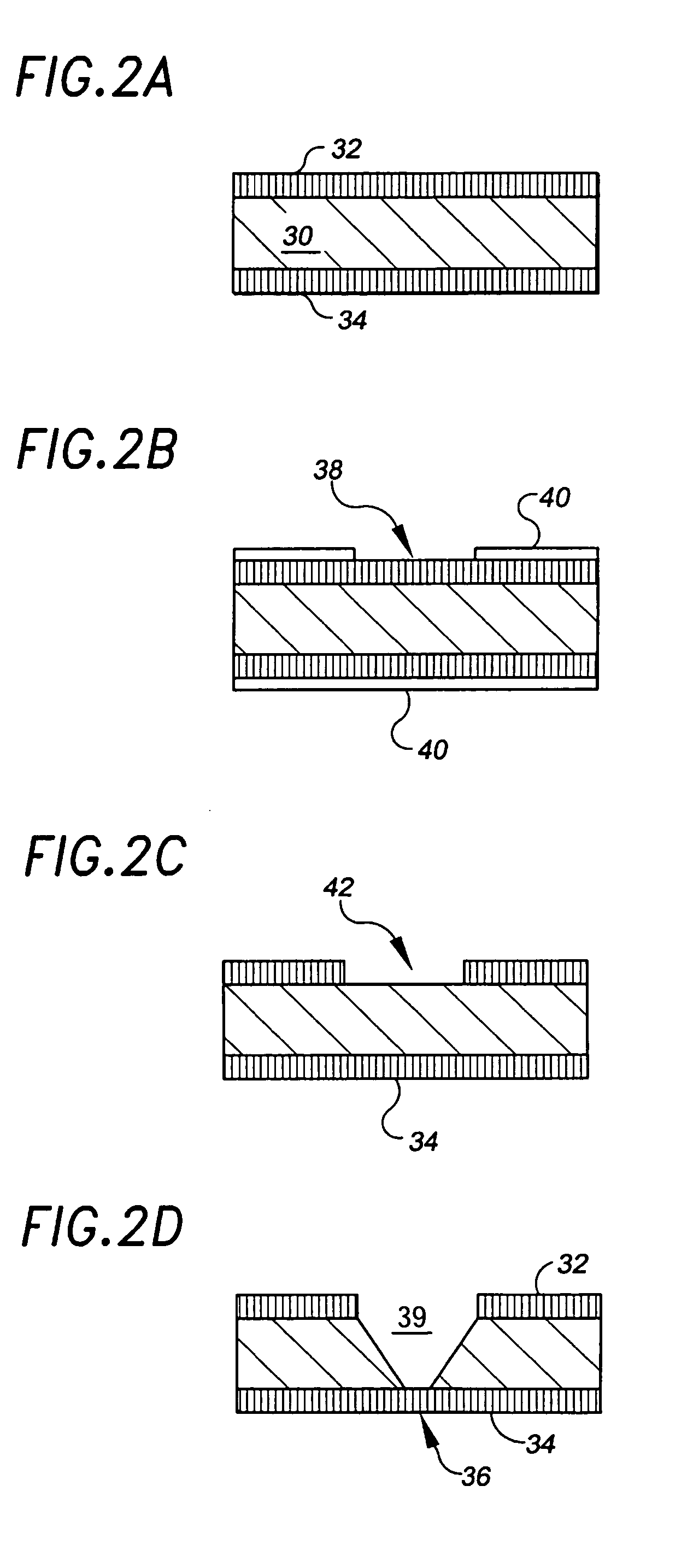

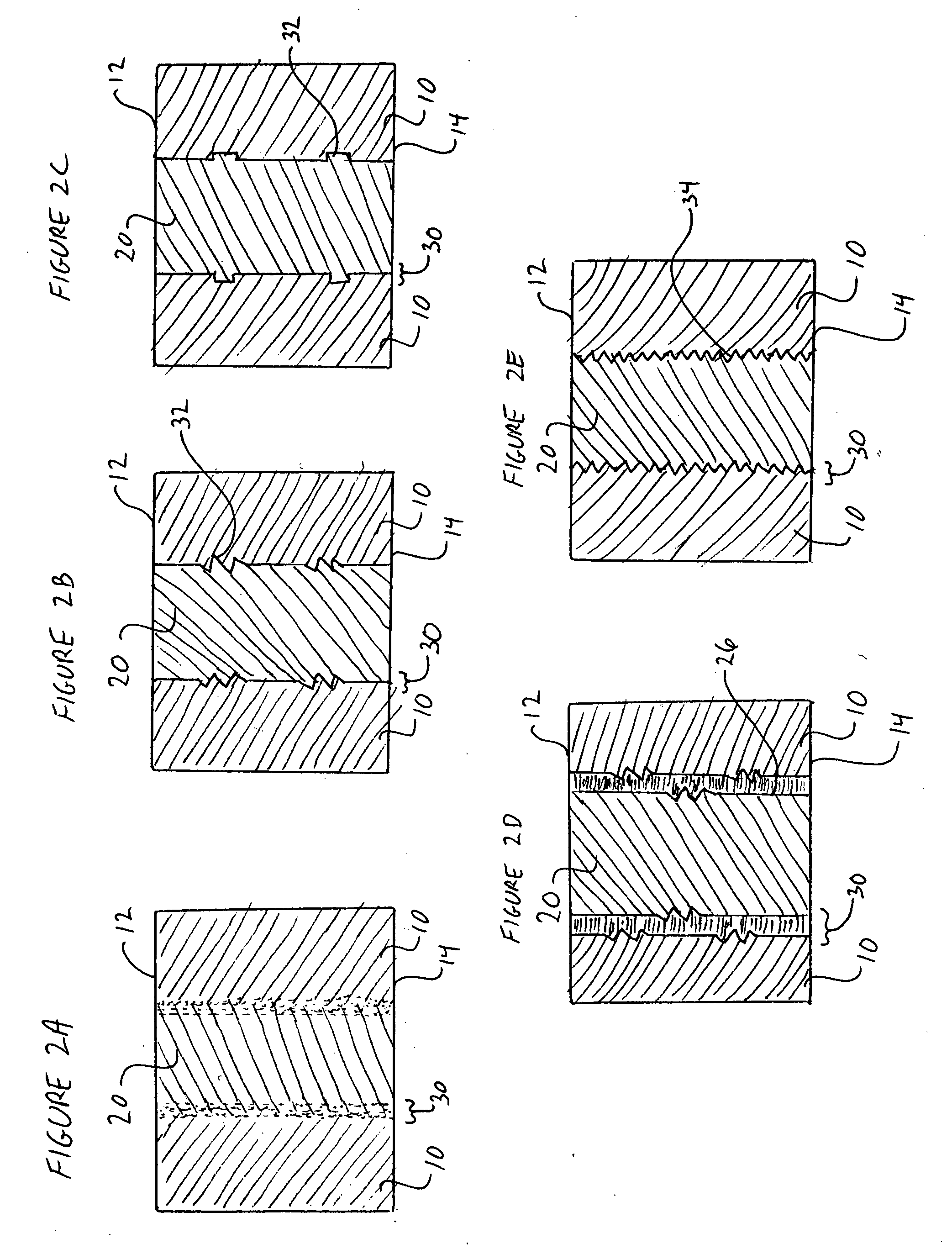

Self-supporting laminated films, structural materials and medical devices manufactured therefrom and methods of making same

Metal foils, wires, and seamless tubes with increased mechanical strength are provided. As opposed to wrought materials that are made of a single metal or alloy, these materials are made of two or more layers forming a laminate structure. Laminate structures are known to increase mechanical strength of sheet materials such as wood and paper products and are used in the area of thin films to increase film hardness, as well as toughness. Laminate metal foils have not been used or developed because the standard metal forming technologies, such as rolling and extrusion, for example, do not lend themselves to the production of laminate structures. Vacuum deposition technologies can be developed to yield laminate metal structures with improved mechanical properties. In addition, laminate structures can be designed to provide special qualities by including layers that have special properties such as superelasticity, shape memory, radio-opacity, corrosion resistance etc. Examples of articles which may be made by the inventive laminate structures include implantable medical devices that are fabricated from the laminated deposited films and which present a blood or body fluid and tissue contact surface that has controlled heterogeneities in material constitution. An endoluminal stent-graft and web-stent that is made of a laminated film material deposited and etched into regions of structural members and web regions subtending interstitial regions between the structural members. An endoluminal graft is also provided which is made of a biocompatible metal or metal-like material. The endoluminal stent-graft is characterized by having controlled heterogeneities in the stent material along the blood flow surface of the stent and the method of fabricating the stent using vacuum deposition methods.

Owner:VACTRONIX SCI LLC

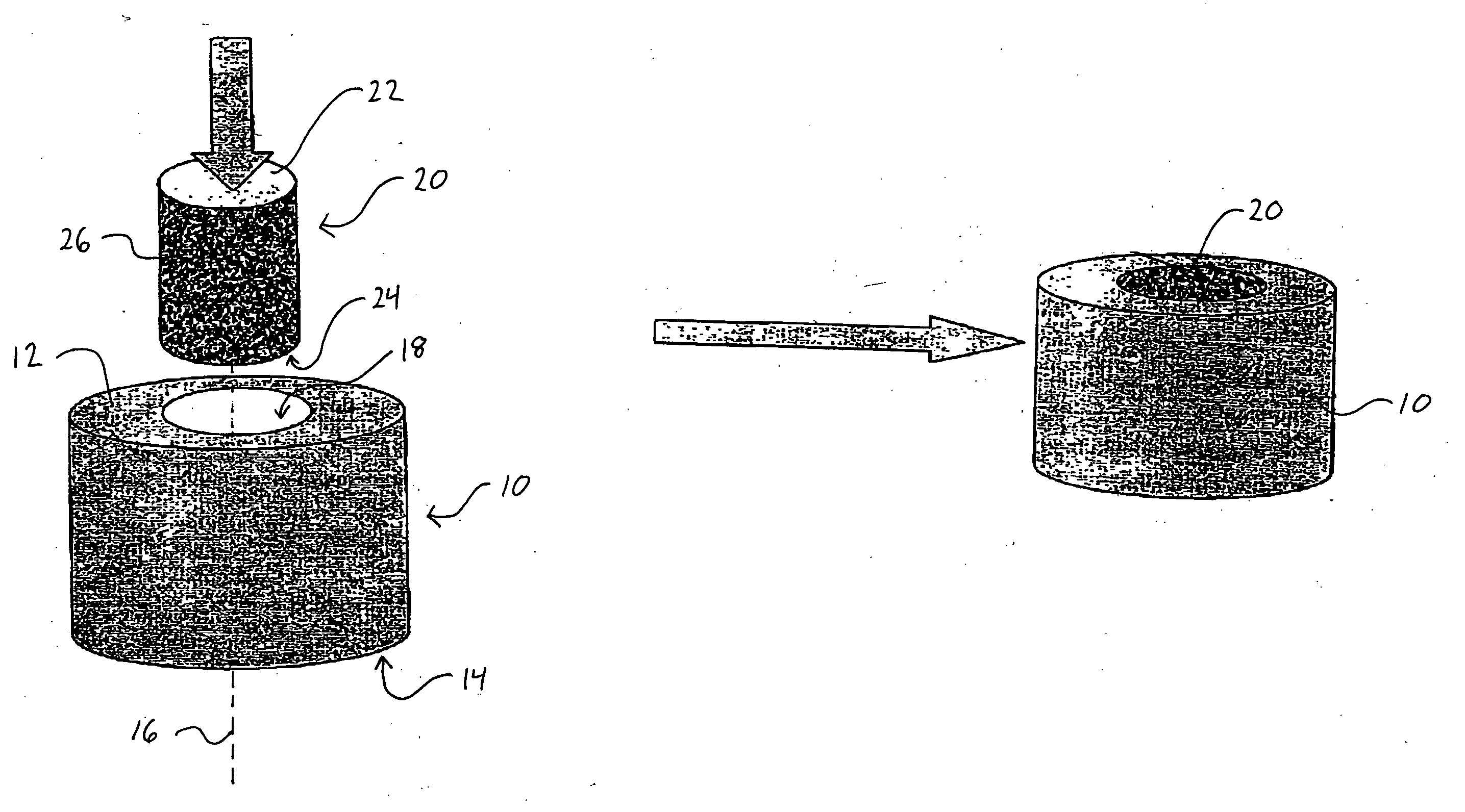

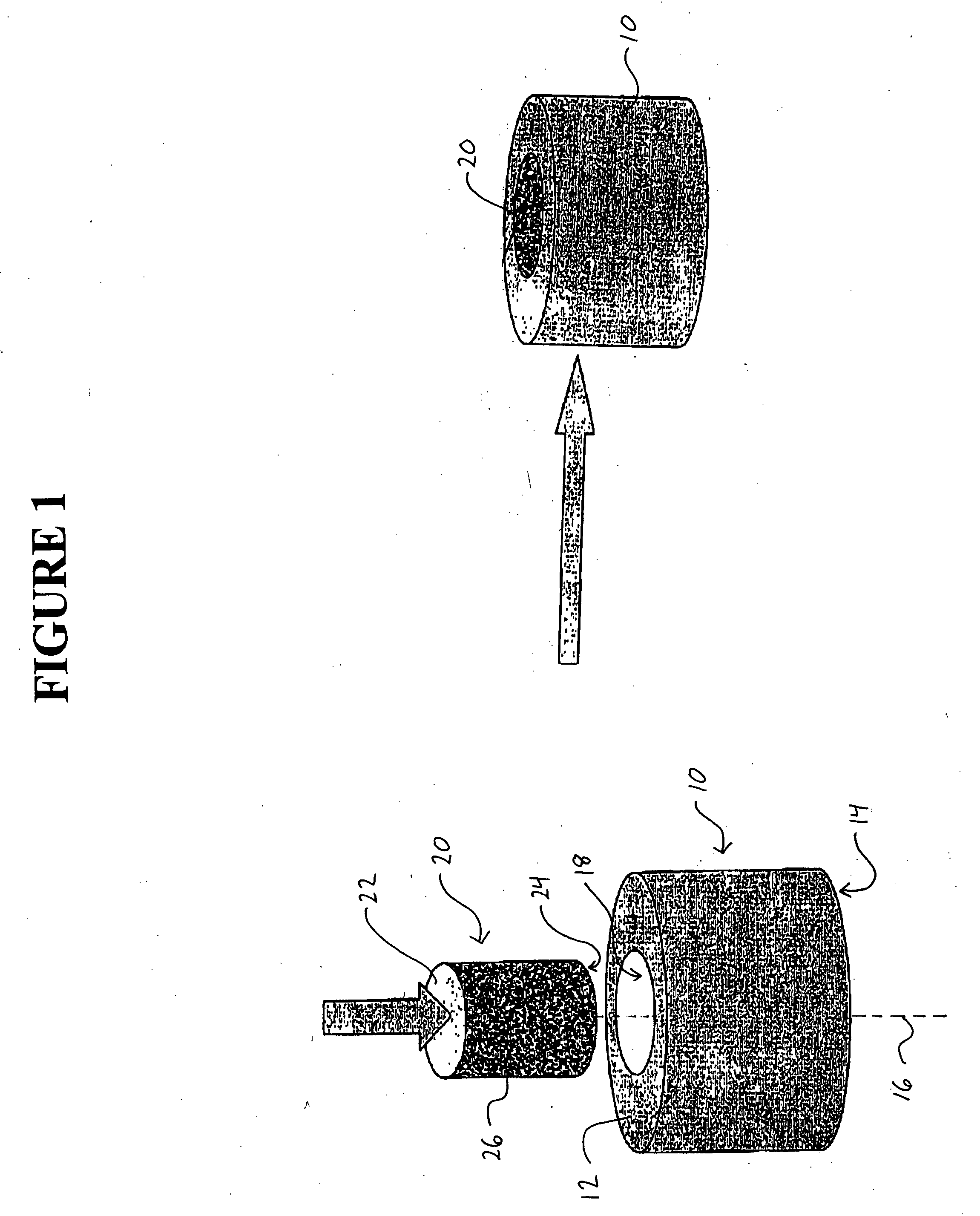

Topically applied clotting material

A composition, system, articles and method for the enhancement of clotting in wounds with extravascular blood flow, especially where the surface of the tissue has been broken is described. The system consists of biotolerable, porous particulates applied to the surface of a wound with liquid blood thereon. The porous nature of the particulate material, either free-flowing or packaged or restrained on or in a surface, enhances clotting. Chemical or biochemical agents, such as additional clotting agents, therapeutic agents, antibiotics, clot strengthening agents (such as fibrous structural materials), and the like may optionally be included on, with or within the porous particles. The particles may comprise such diverse materials as organics, metallics, inorganics, ceramics, and the like, both natural and artificial. It is generally preferred that the pore size distribution lies within a general range, and this range may vary from animal to animal and condition to condition, but generally falls within about 0.5 to 1000 nanometers or 3,000 to 200,000 Daltons.

Owner:MEDAFOR

Powered surgical tool with control module that contains a sensor for remotely monitoring the tool power generating unit

A powered surgical tool with a housing that contains a power generating unit such as a motor. A control module is disposed in a shell that is mounted in the housing. The control module contains a control circuit for regulating the actuation of the power generating unit. The power generating unit emits a signal representative of the operating state of the unit that is transmitted through the structural material forming the shell. Also internal to the control module shell is a sensor that monitors the signal emitted by the power generating unit. This signal output by the sensor is applied to the control circuit. The control circuit, based on the sensor signal regulates actuation of the power generating unit. Wherein the power generating unit is a motor, the signal emitted is the magnetic field that varies with rotor position. The sensor monitors the strength of this field.

Owner:STRYKER CORP

Integrated structures and fabrication methods thereof implementing a cell phone or other electronic system

ActiveUS20080316714A1Semiconductor/solid-state device detailsSolid-state devicesElectronic systemsContact pad

Circuit structures and methods of fabrication are provided for facilitating implementing a complete electronic system in a compact package. The circuit structure includes, in one embodiment, a chips-first multichip base layer with conductive structures extending therethrough. An interconnect layer is disposed over the front surface of the multichip layer and includes interconnect metallization electrically connected to contact pads of the chips and to conductive structures extending through the structural material. A redistribution layer, disposed over the back surface of the multichip layer, includes a redistribution metallization also electrically connected to conductive structures extending through the structural material. Input / output contacts are arrayed over the redistribution layer, including over the lower surfaces of at least some integrated circuit chips within the multichip layer, and are electrically connected through the redistribution metallization, conductive structures, and interconnect metallization to contact pads of the integrated circuit chips of the multichip layer.

Owner:EPIC TECH INC

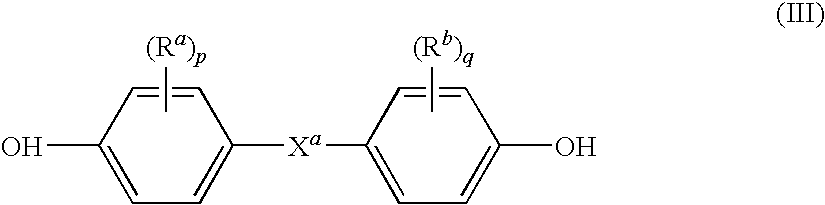

Flame retardant laser direct structuring materials

Flame retardant thermoplastic compositions that are capable of being used in a laser direct structuring process. The compositions include a thermoplastic resin, a laser direct structuring additive, and a flame retardant. The compositions offer flame retardant characteristics while also substantially maintaining the mechanical properties of the base thermoplastic resin, such as the impact strength and / or HDT of the composition. The compositions can be used in a variety of applications such as personal computers, notebook and portable computers, cell phone and other such communications equipment.

Owner:SHPP GLOBAL TECH BV

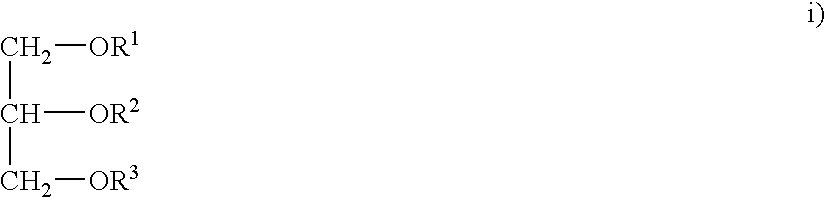

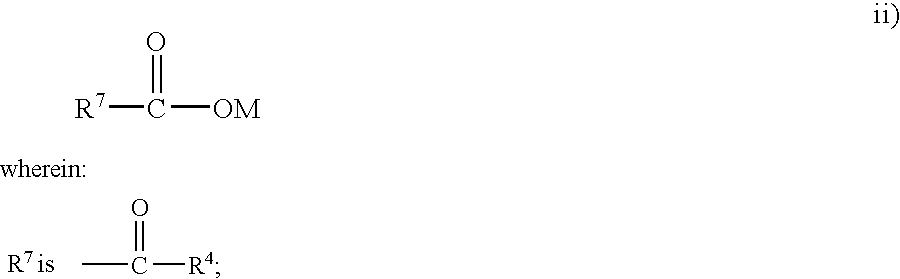

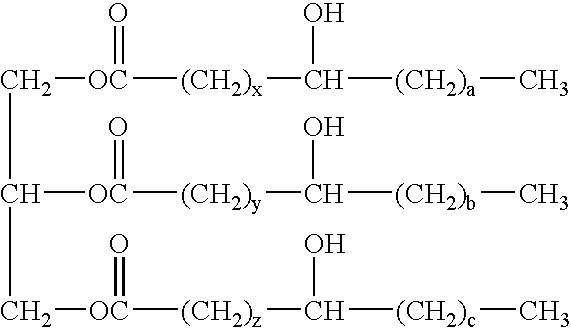

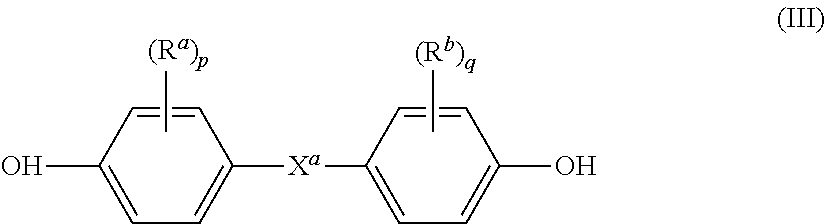

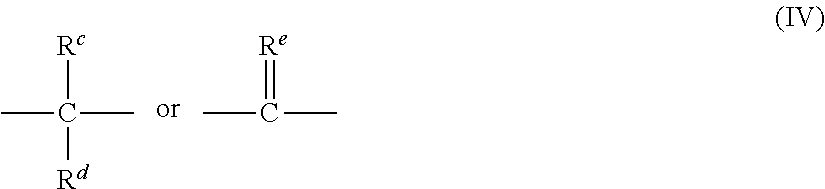

Structuring systems for fabric treatment compositions

InactiveUS20060205631A1Desirable stability and theological characteristicSuperior fabric care benefitCationic surface-active compoundsNon-ionic surface-active compoundsStructured systemsStructure system

The invention is directed to structuring systems suitable for incorporation into liquid fabric treatment compositions. Such structuring systems comprise, as added components, (A) a non-polymeric, crystalline, hydroxyl-containing structuring agent, which can crystallize to form a thread-like structuring network throughout liquid matrices; (B) a nonionic emulsifier; (C) an anionic emulsifier; and (D) a liquid carrier. The anionic emulsifier is present in such structuring systems, at concentrations from 0.1% to 8.0% by weight of the structuring system. The present invention also relates to processes for preparing such structuring systems and to the use of the structuring system of the present invention to control the particle size of a thread-like structuring material by mixing an anionic emulsifier with a structuring agent. Liquid fabric treatment compositions containing such structuring systems are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

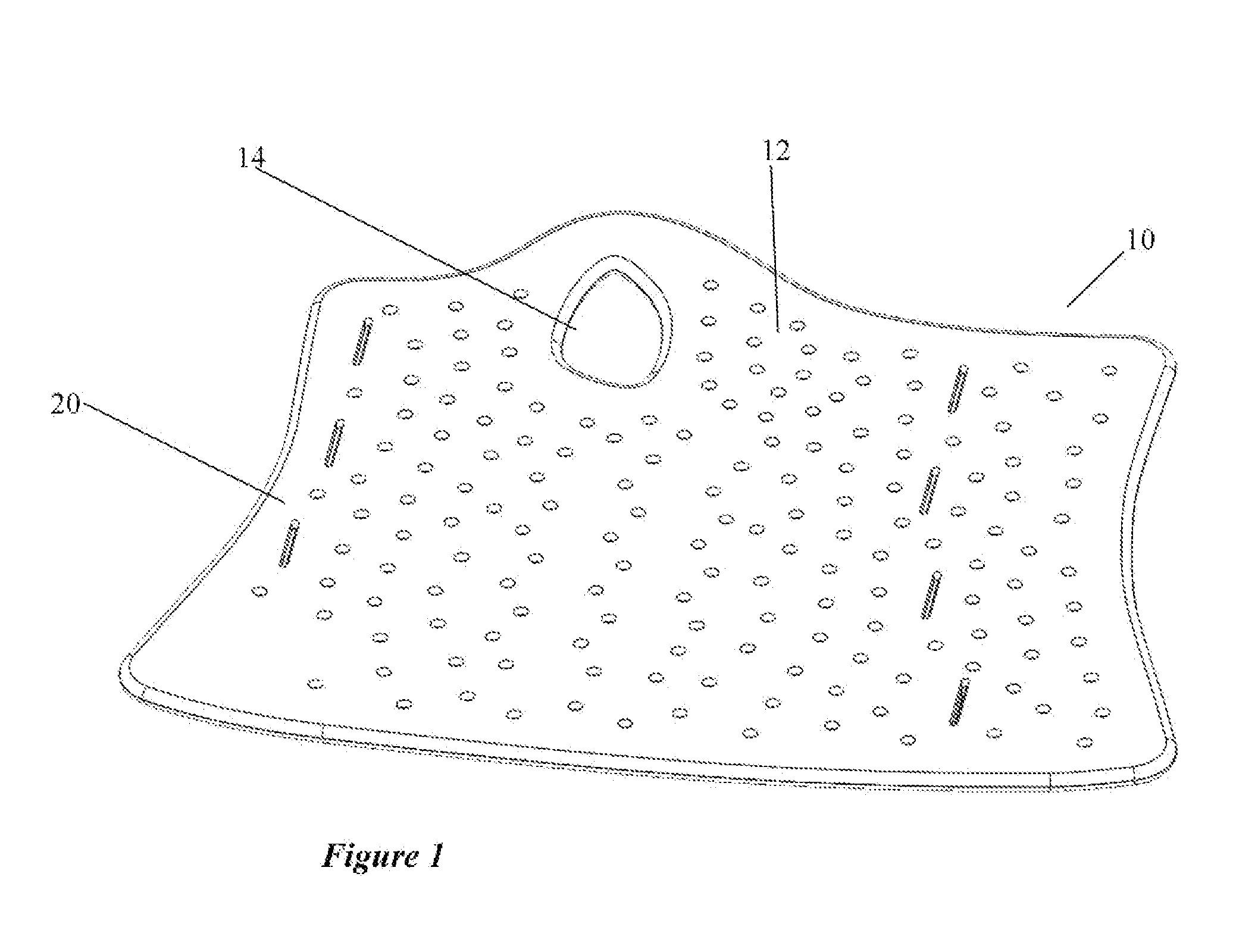

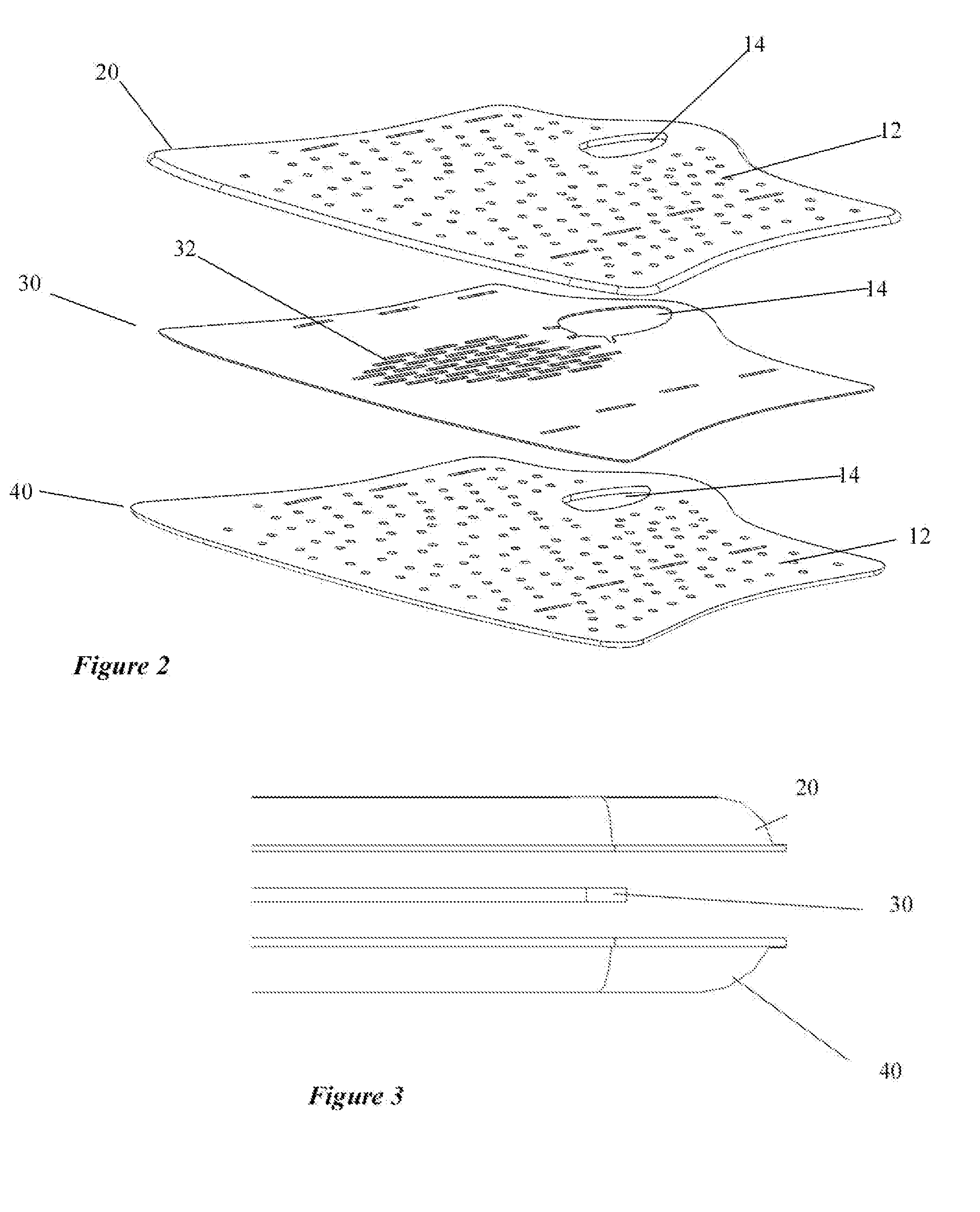

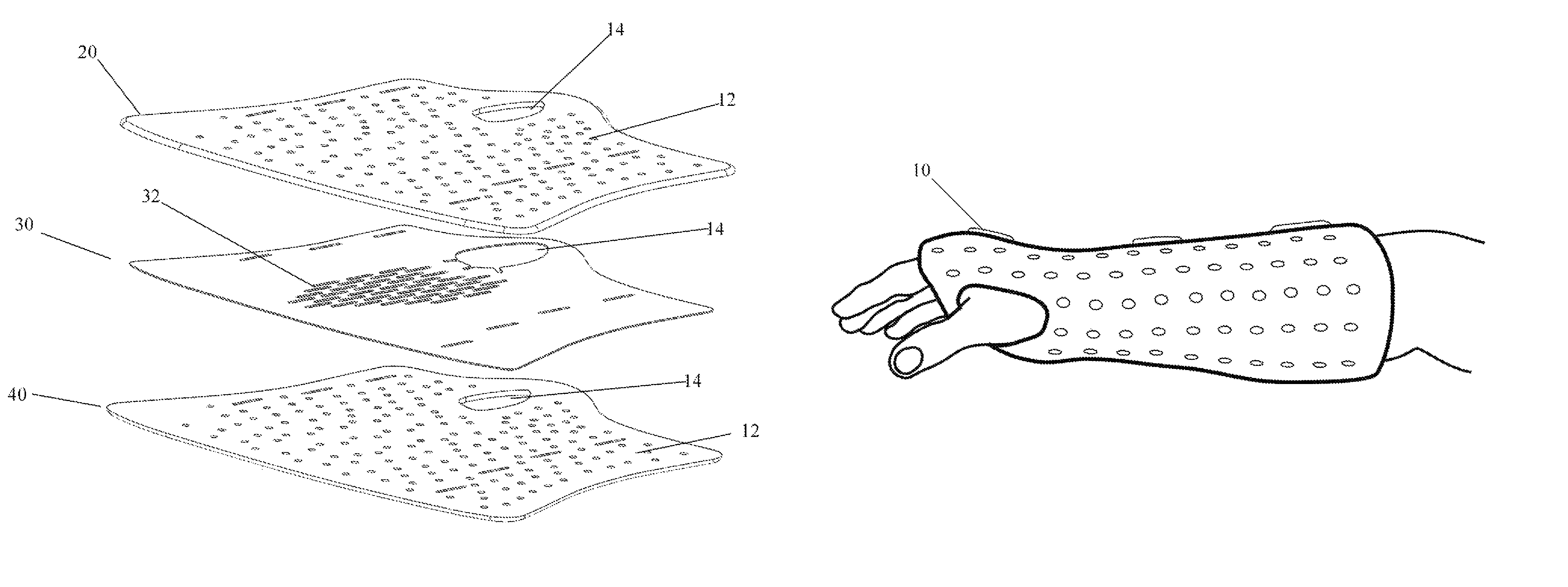

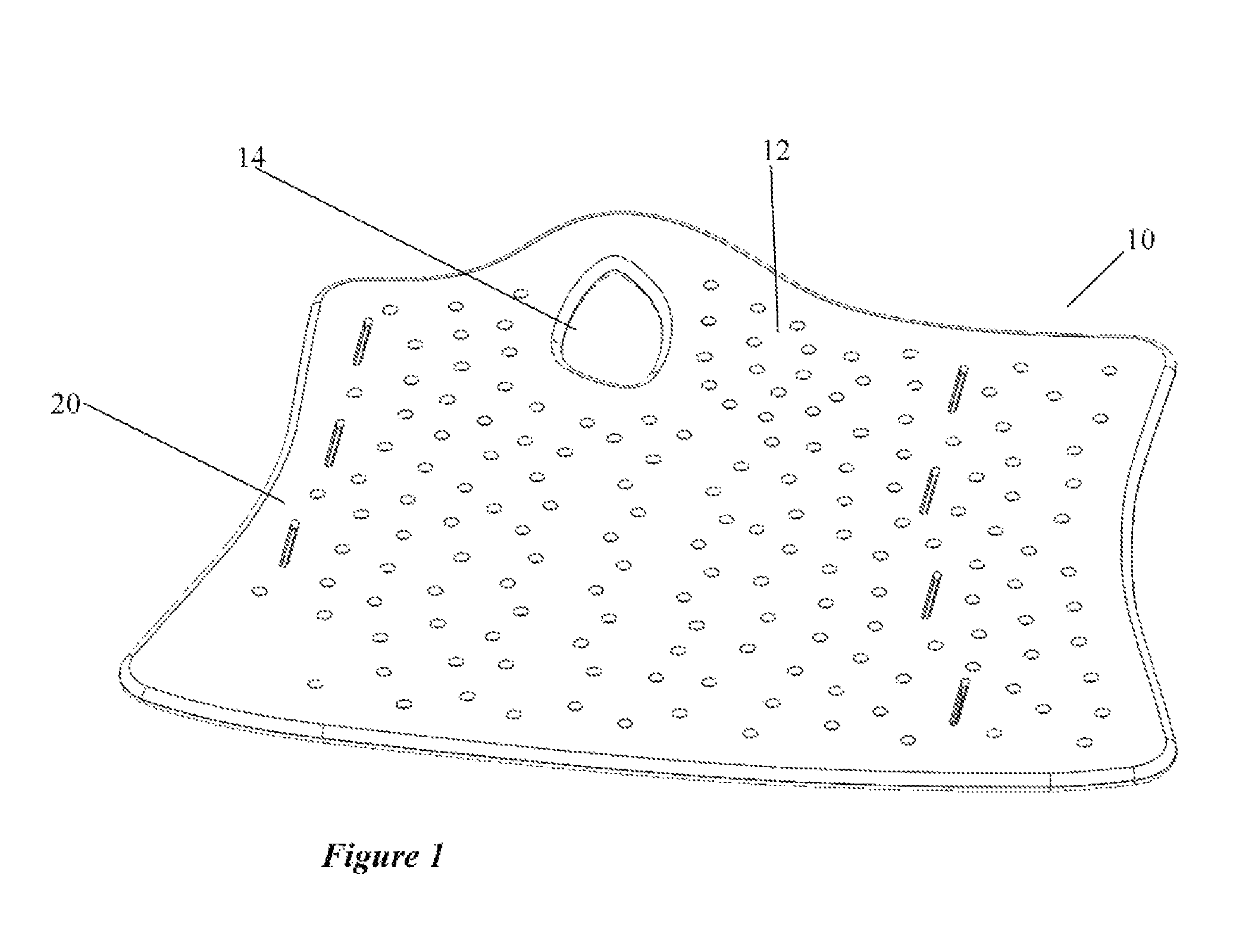

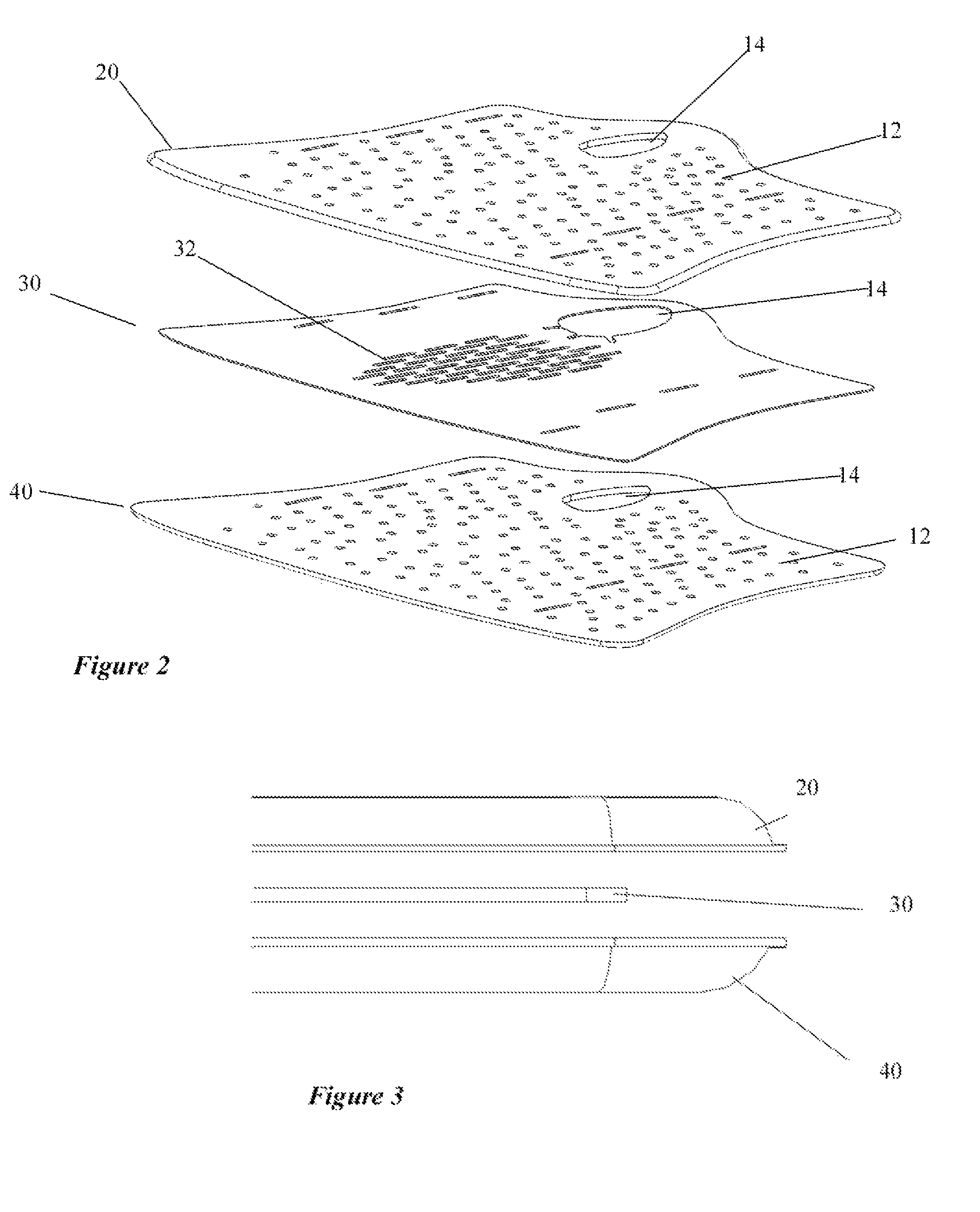

Orthopedic System for Immobilizing and Supporting Body Parts

ActiveUS20080319362A1Little timeLittle manipulationChemical protectionHeat protectionEngineeringStructural material

A unitized cast system for immobilizing and supporting a body part. The unitized casting system includes a first inner layer for padding and dissipating heat against the patient's skin. A second layer is formed from a thermoformable structural material such as perforated plastic. A protective third outer layer is provided to provide insulation for the second layer. These three layers are formed together to form a unitized cast system that is easily formed and applied to the patient.

Owner:DJO

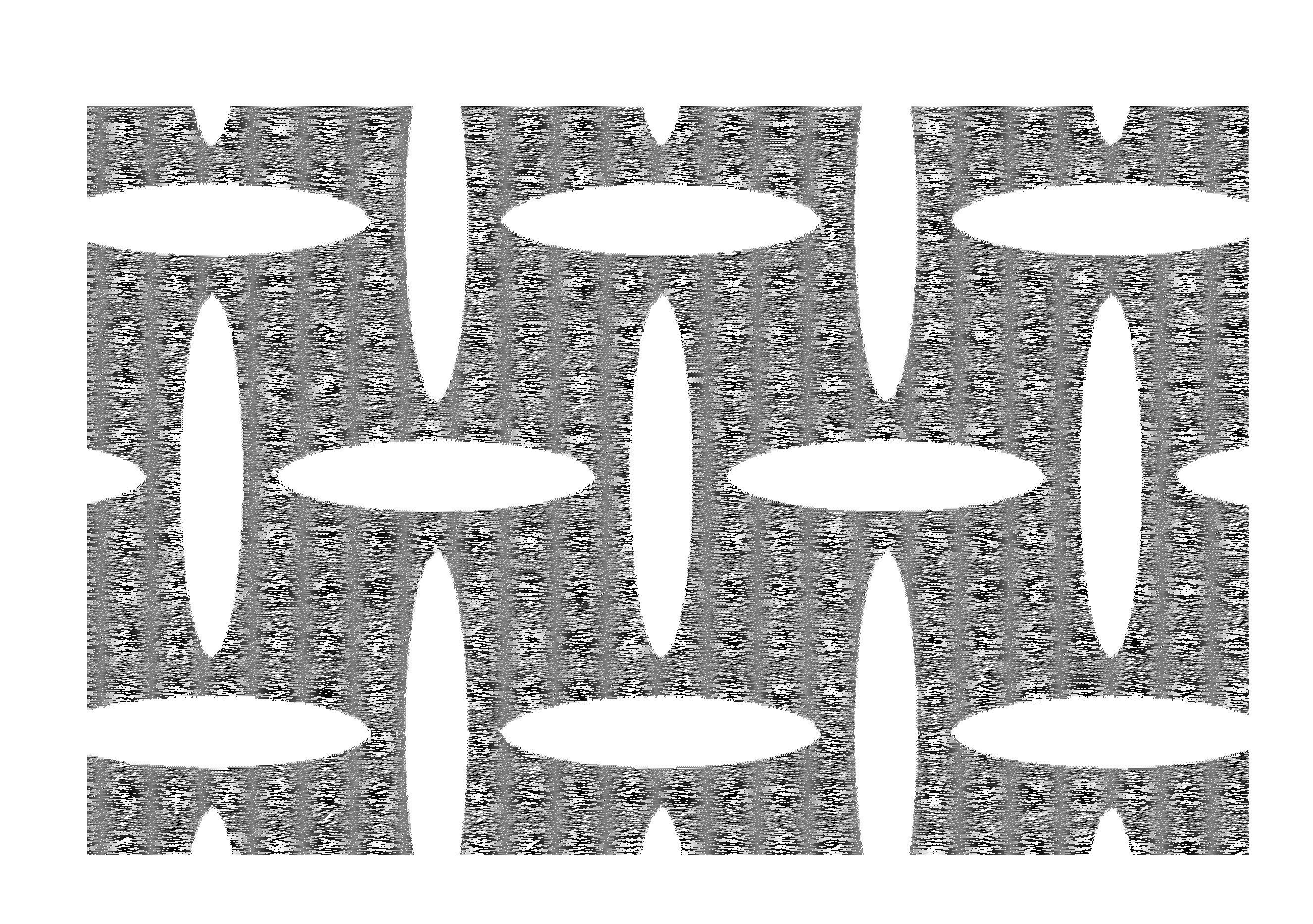

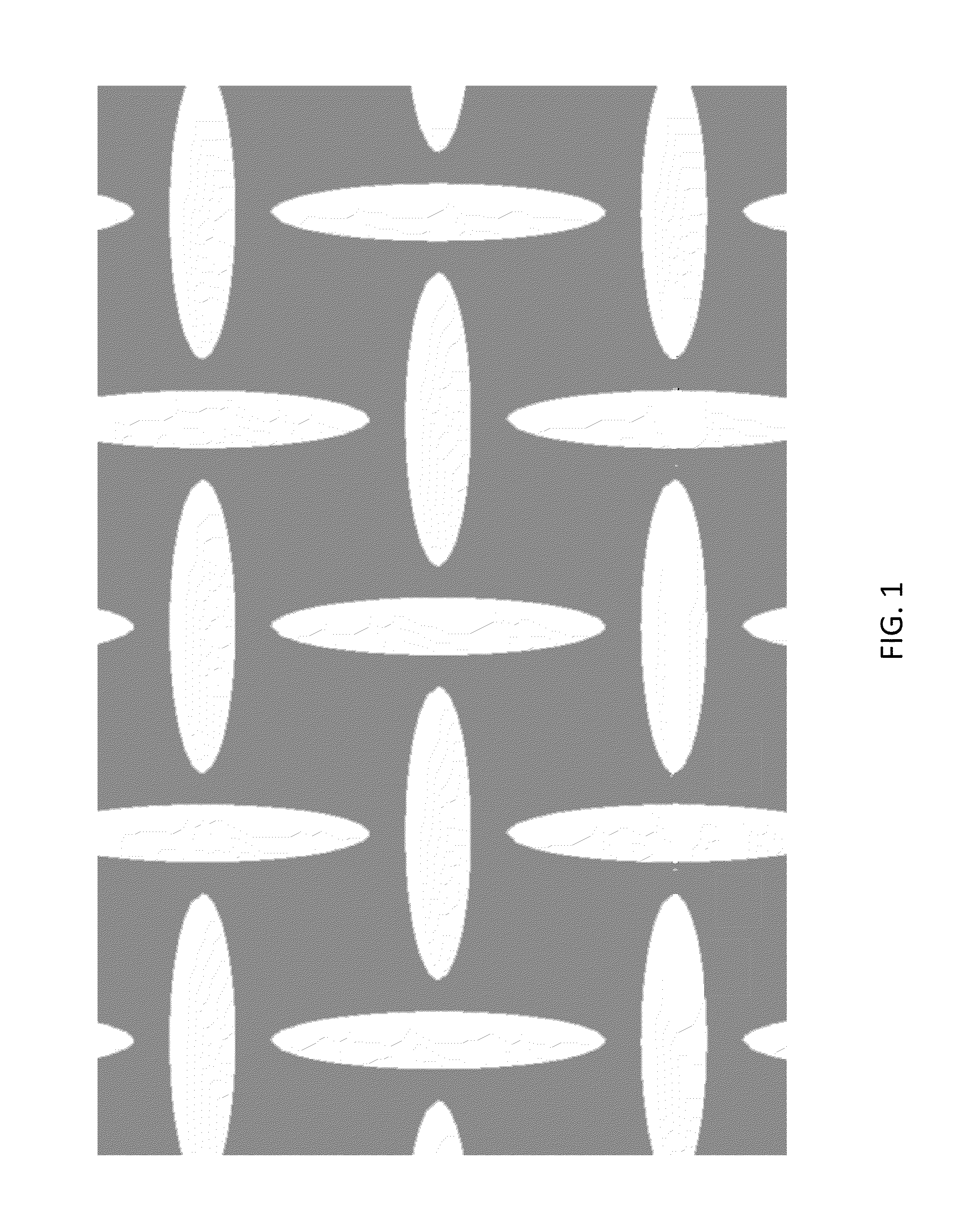

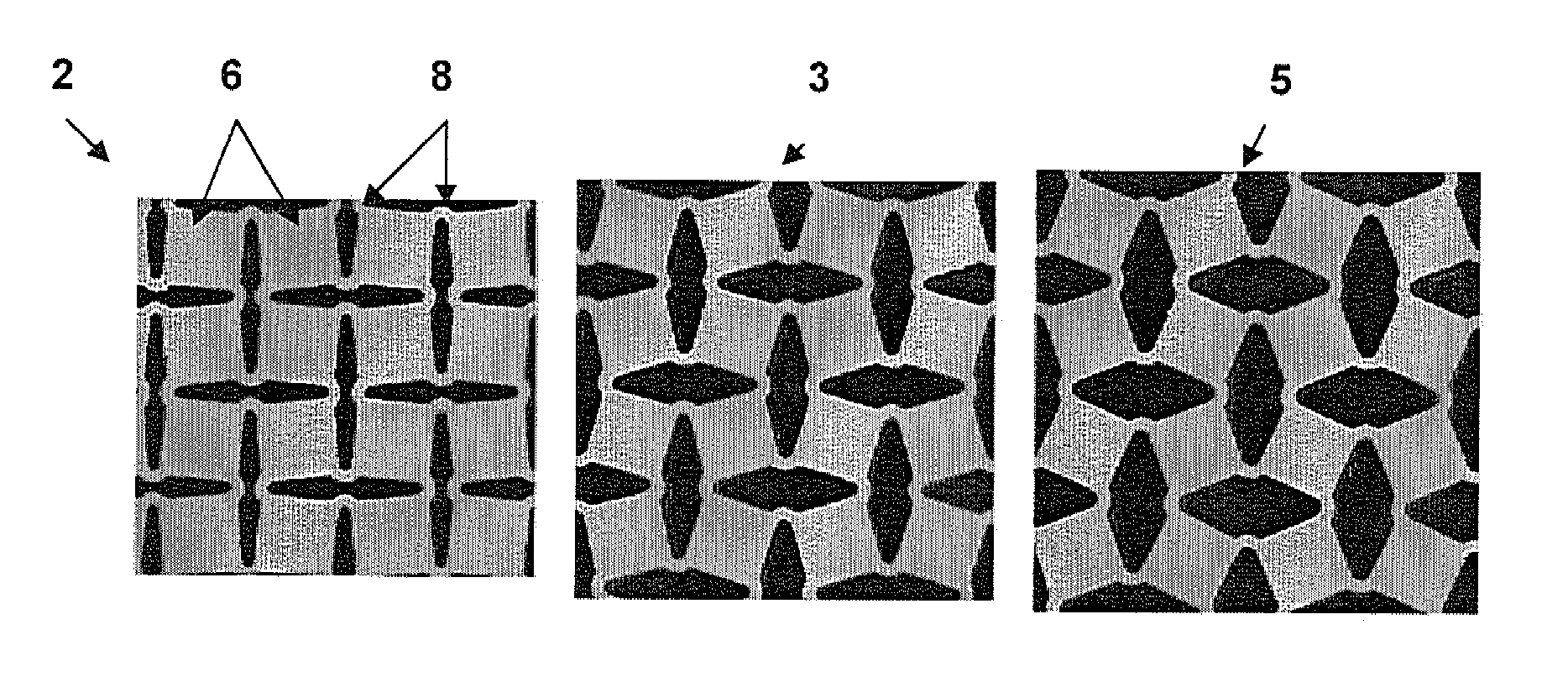

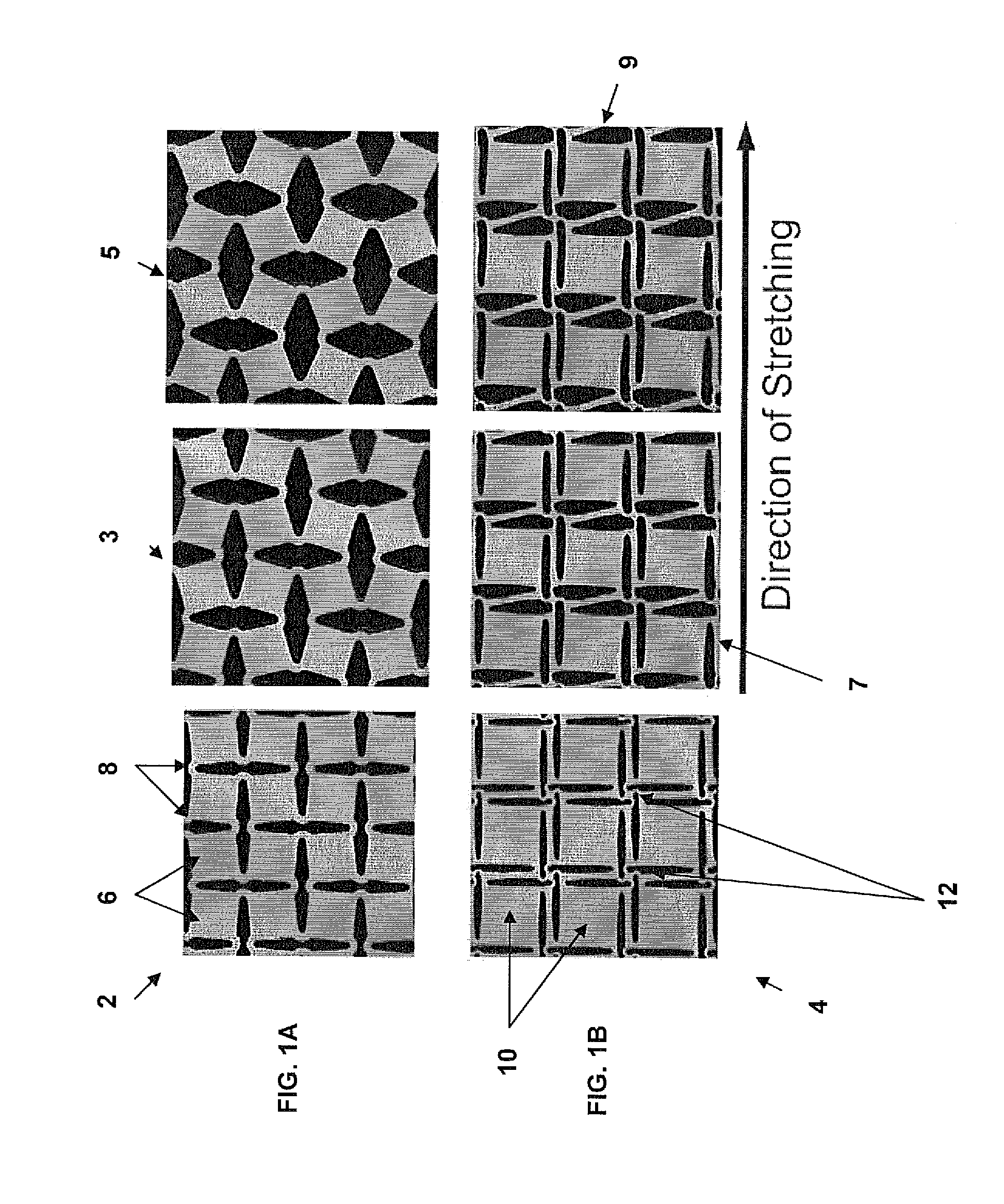

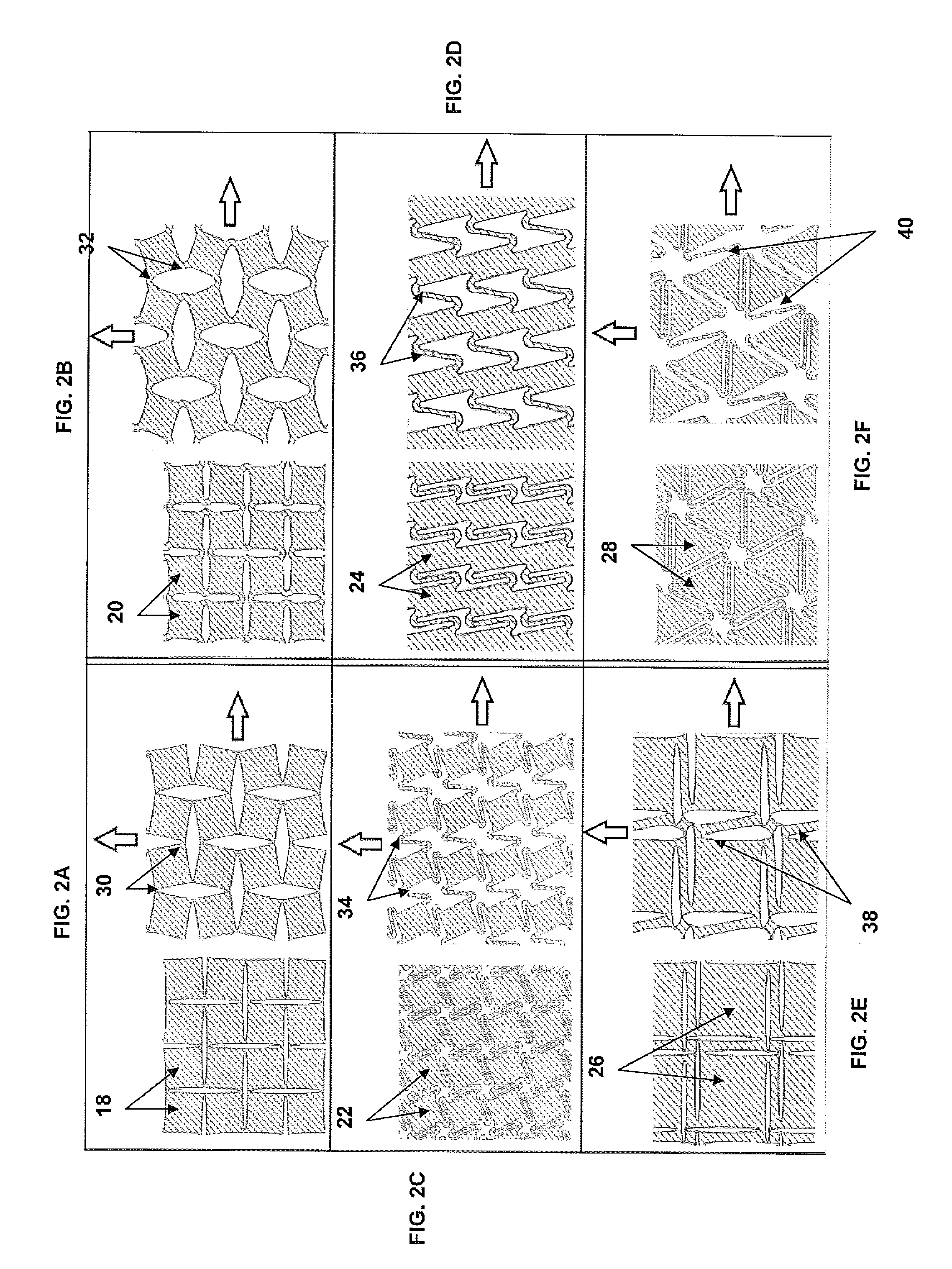

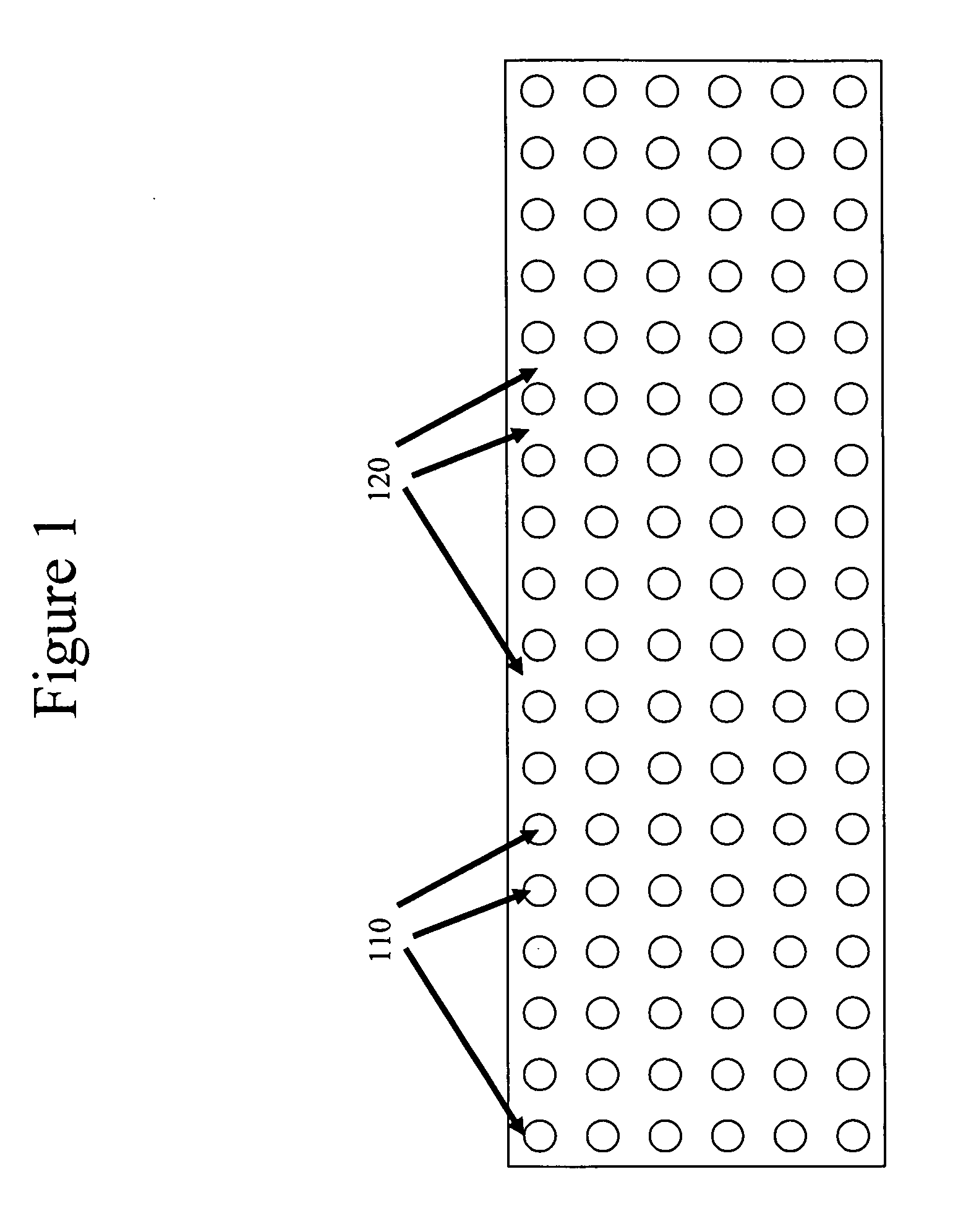

Structured materials with tailored isotropic and anisotropic poisson's ratios including negative and zero poisson's ratios

The invention described herein relates to structured porous materials, where the porous structure provides a tailored Poisson's ratio behavior. In particular, the structures of this invention are tailored to provide a range in Poisson's ratio ranging from a negative Poisson's ratio to a zero Poisson's. Two exemplar structures, each consisting of a pattern of elliptical or elliptical-like voids in an elastomeric sheet, are presented. The Poisson's ratios are imparted to the substrate via the mechanics of the deformation of the voids (stretching, opening, and closing) and the mechanics of the material (rotation, translation, bending, and stretching). The geometry of the voids and the remaining substrate are not limited to those presented in the models and experiments of the exemplars, but can vary over a wide range of sizes and shapes. The invention applies to both two-dimensional structured materials as well as three dimensionally structured materials.

Owner:BOYCE CHRISTOPHER M +3

High dielectric constant laser direct structuring materials

ActiveUS20090292051A1High dielectric constantReduce lossDuplicating/marking methodsLiquid/solution decomposition chemical coatingOptoelectronicsPersonal computer

High dielectric constant thermoplastic compositions that are capable of being used in a laser direct structuring process. The compositions include a thermoplastic base resin, a laser direct structuring additive, and at least one ceramic filler. The compositions provide a high dielectric constant, low loss tangent thermoplastic composition. The compositions can be used in a variety of applications such as personal computers, notebook and portable computers, cell phone antennas and other such communications equipment, medical applications, RFID applications, and automotive applications.

Owner:SHPP GLOBAL TECH BV

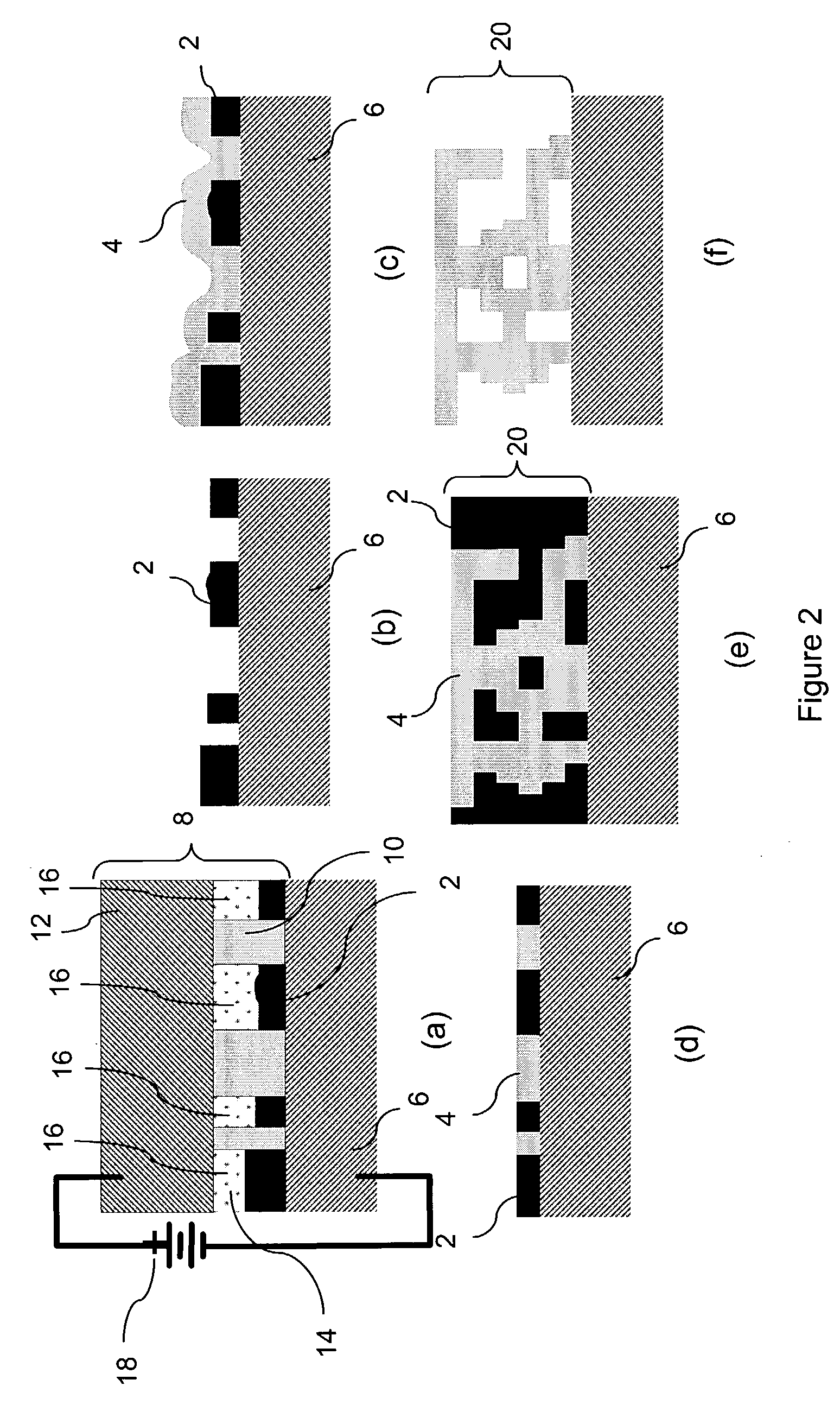

Structured material substrates for flexible, stretchable electronics

ActiveUS20100330338A1Reduce strainCircuit bendability/stretchabilityLayered productsStretchable electronicsPatterned substrate

A flexible and stretchable patterned substrate is provided having a strain-permitting material comprising a patterned conformation that allows the flexible patterned substrate to experience local strain or local strain domains lower than the macroscopic strain of the flexible and stretchable patterned substrate.

Owner:INFINITE CORRIDOR TECH

Integrated conductive structures and fabrication methods thereof facilitating implementing a cell phone or other electronic system

ActiveUS20080315375A1Printed circuit assemblingCross-talk/noise/interference reductionContact padElectronic systems

Circuit structures and methods of fabrication are provided for facilitating implementing a complete electronic system in a compact package. The circuit structure includes, in one embodiment, a chips-first multichip base layer with conductive structures extending therethrough. An interconnect layer is disposed over the front surface of the multichip layer and includes interconnect metallization electrically connected to contact pads of the chips and to conductive structures extending through the structural material. A redistribution layer, disposed over the back surface of the multichip layer, includes a redistribution metallization also electrically connected to conductive structures extending through the structural material. Input / output contacts are arrayed over the redistribution layer, including over the lower surfaces of at least some integrated circuit chips within the multichip layer, and are electrically connected through the redistribution metallization, conductive structures, and interconnect metallization to contact pads of the integrated circuit chips of the multichip layer.

Owner:EPIC TECH INC

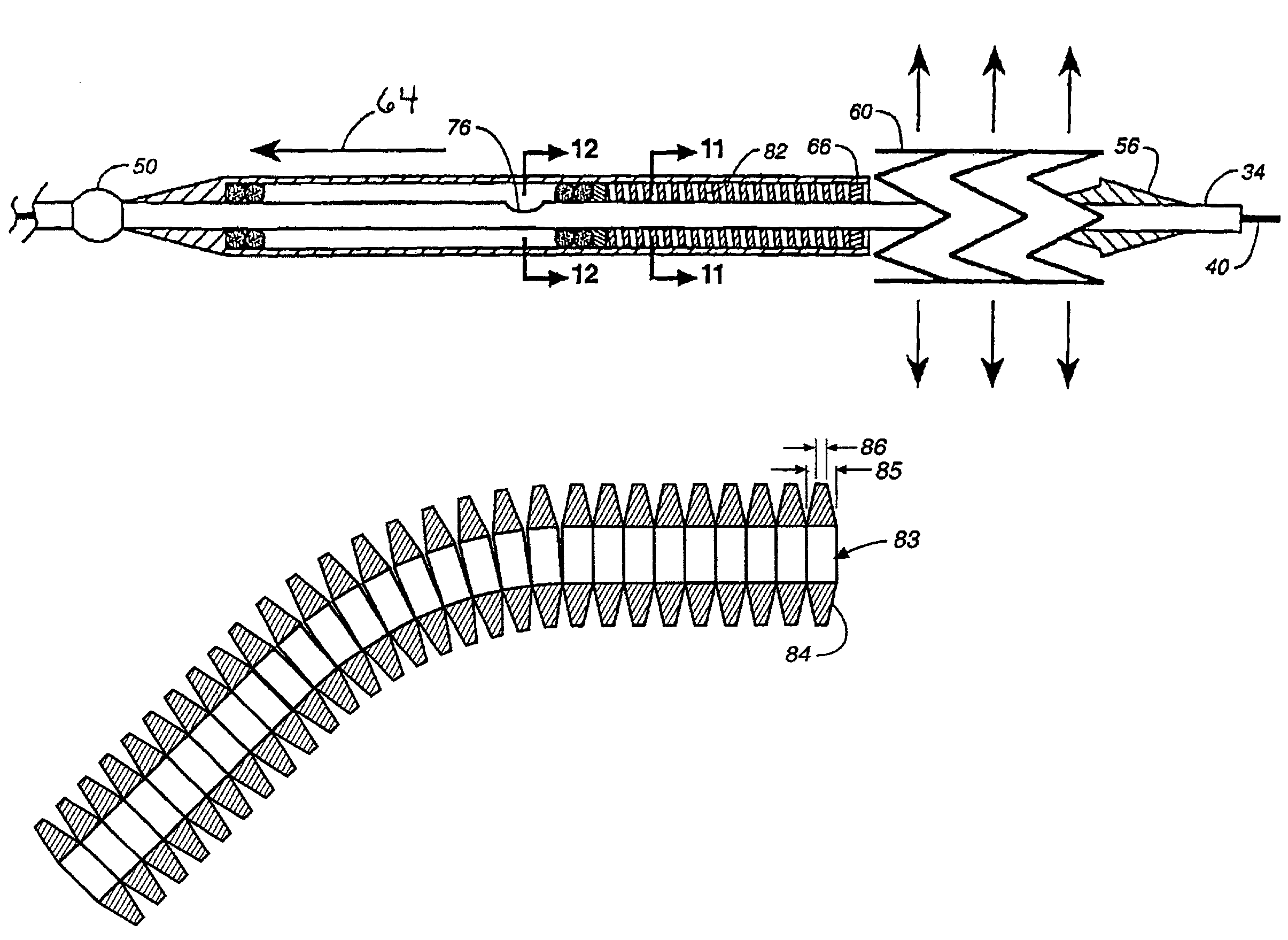

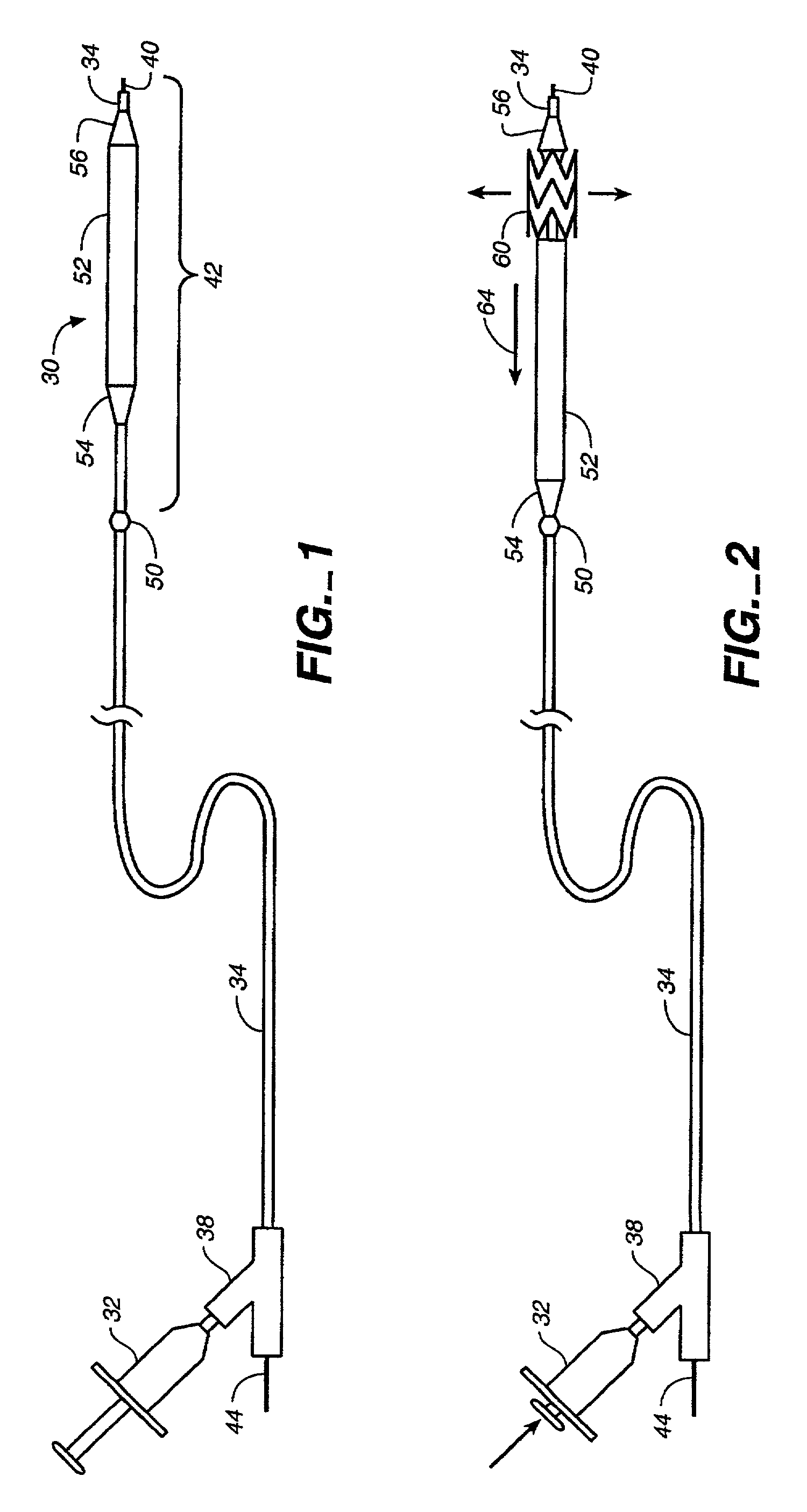

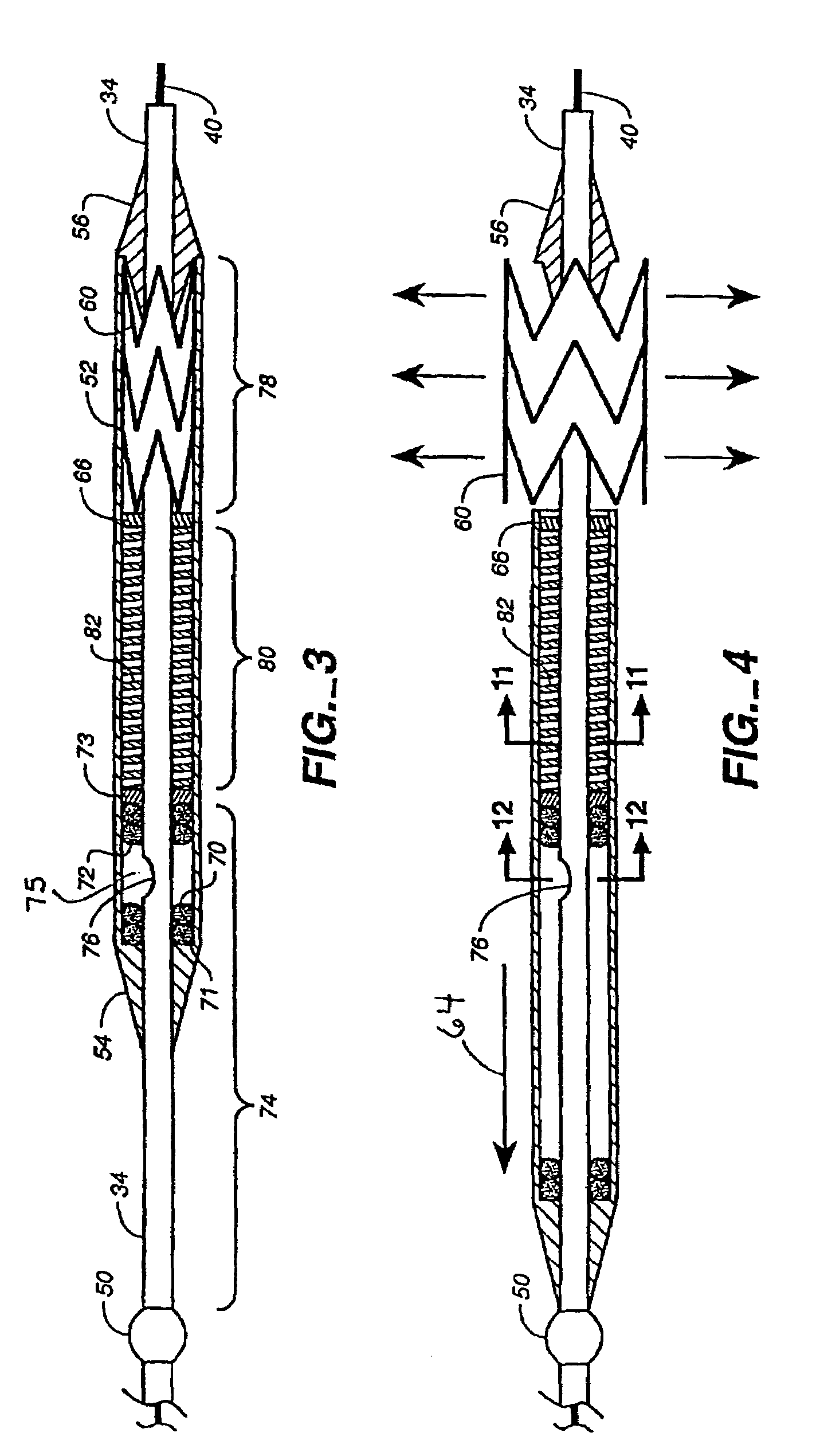

Stent delivery system with hydraulic deployment

A hydraulic stent and stent graft delivery system utilizing at least two different structural materials to effectuate the easy retention and release of the stent and stent graft, while maintaining structural and sealing integrity for a pressurizable fluid chamber. An anti kinking spacer is disclosed which prevents buckling / kinking of the otherwise unsupported sheath containment section when the catheter assembly is bent such as for insertion a movement to the delivery site. A configuration according to the invention provides a flexible small or dual diameter delivery system that uses fluid pressure within the catheter to retract the stent / stent graft containment sheath and allow the delivery and deployment of the stent / stent graft.

Owner:MEDTRONIC VASCULAR INC

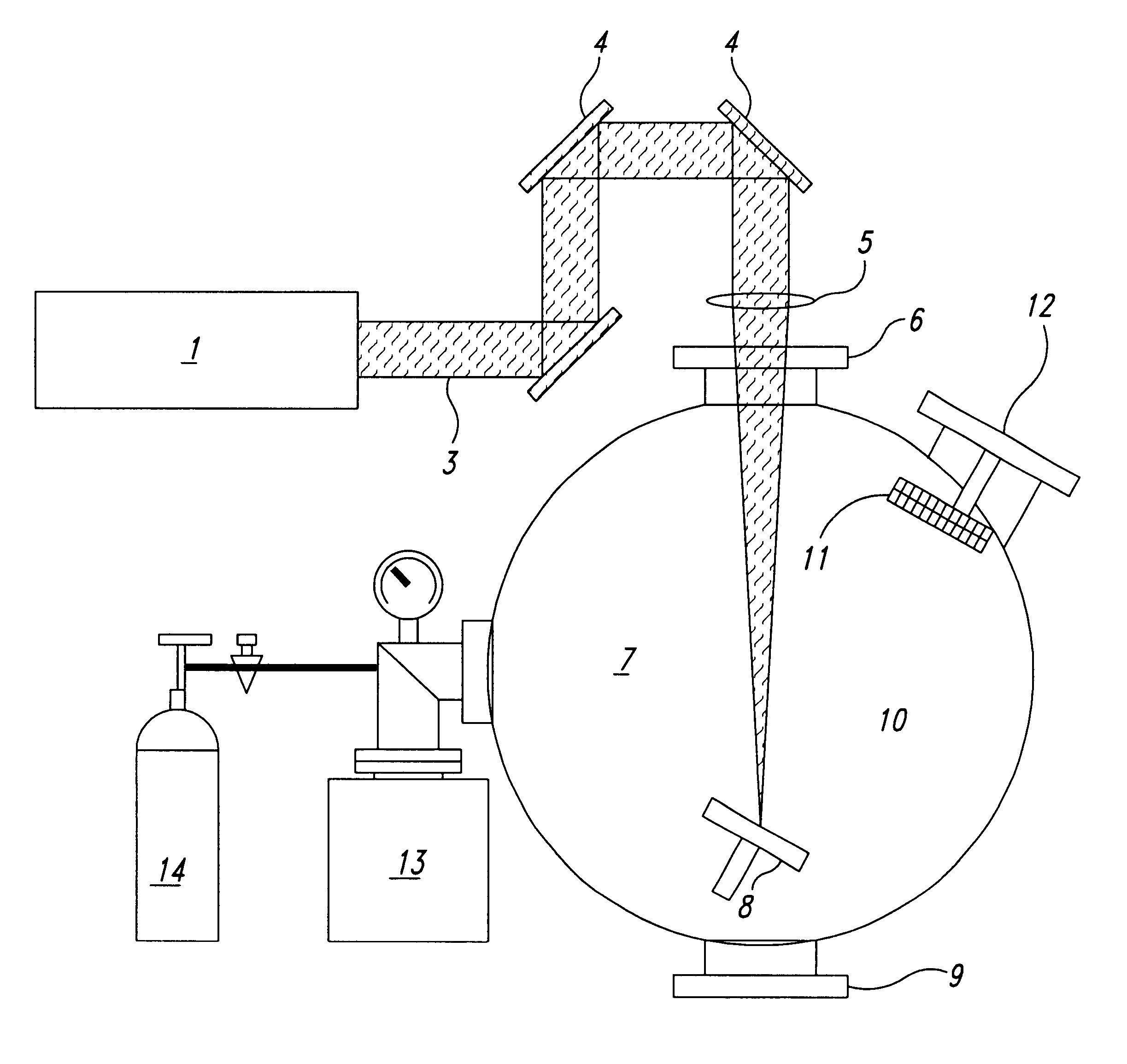

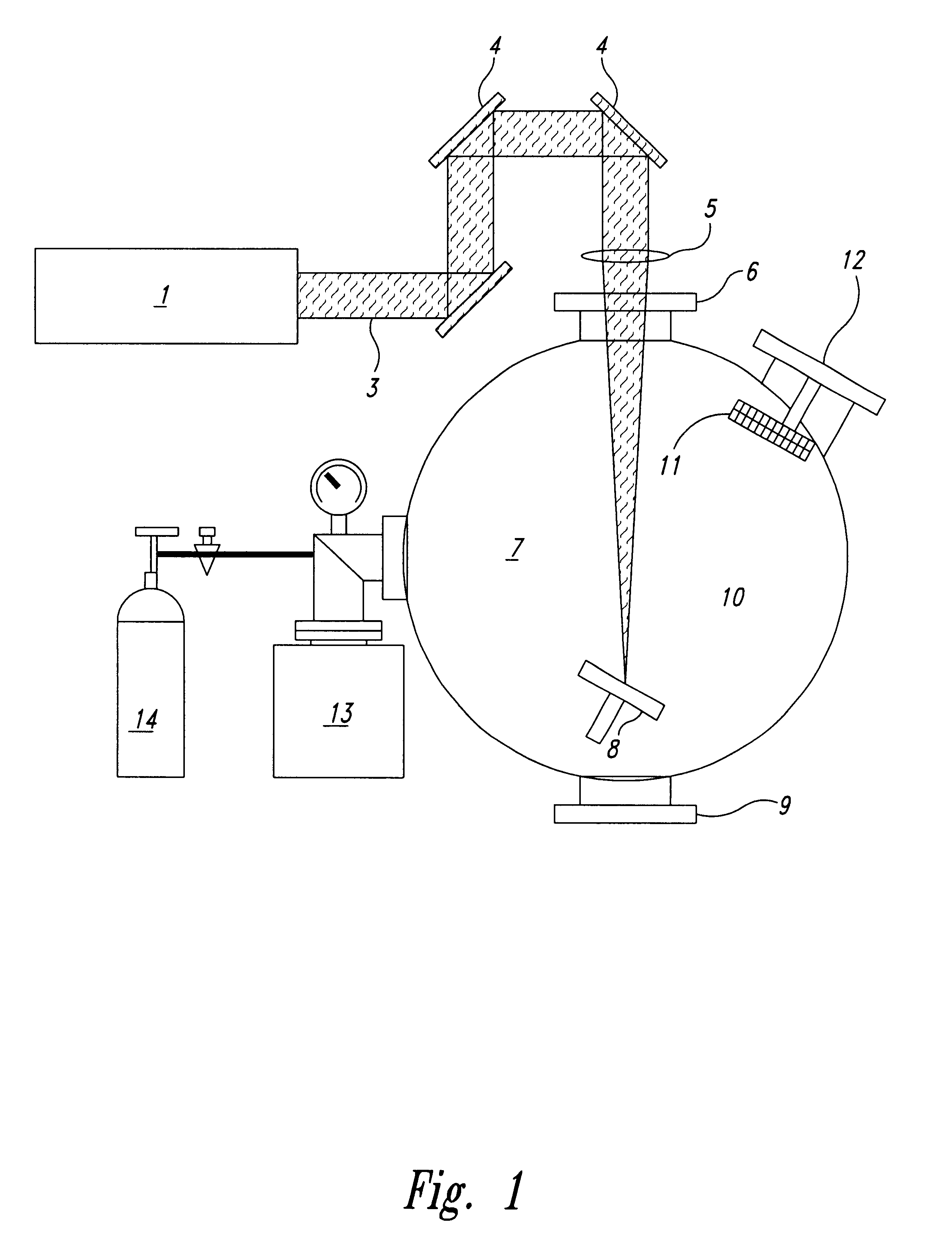

Method of deposition of thin films of amorphous and crystalline microstructures based on ultrafast pulsed laser deposition

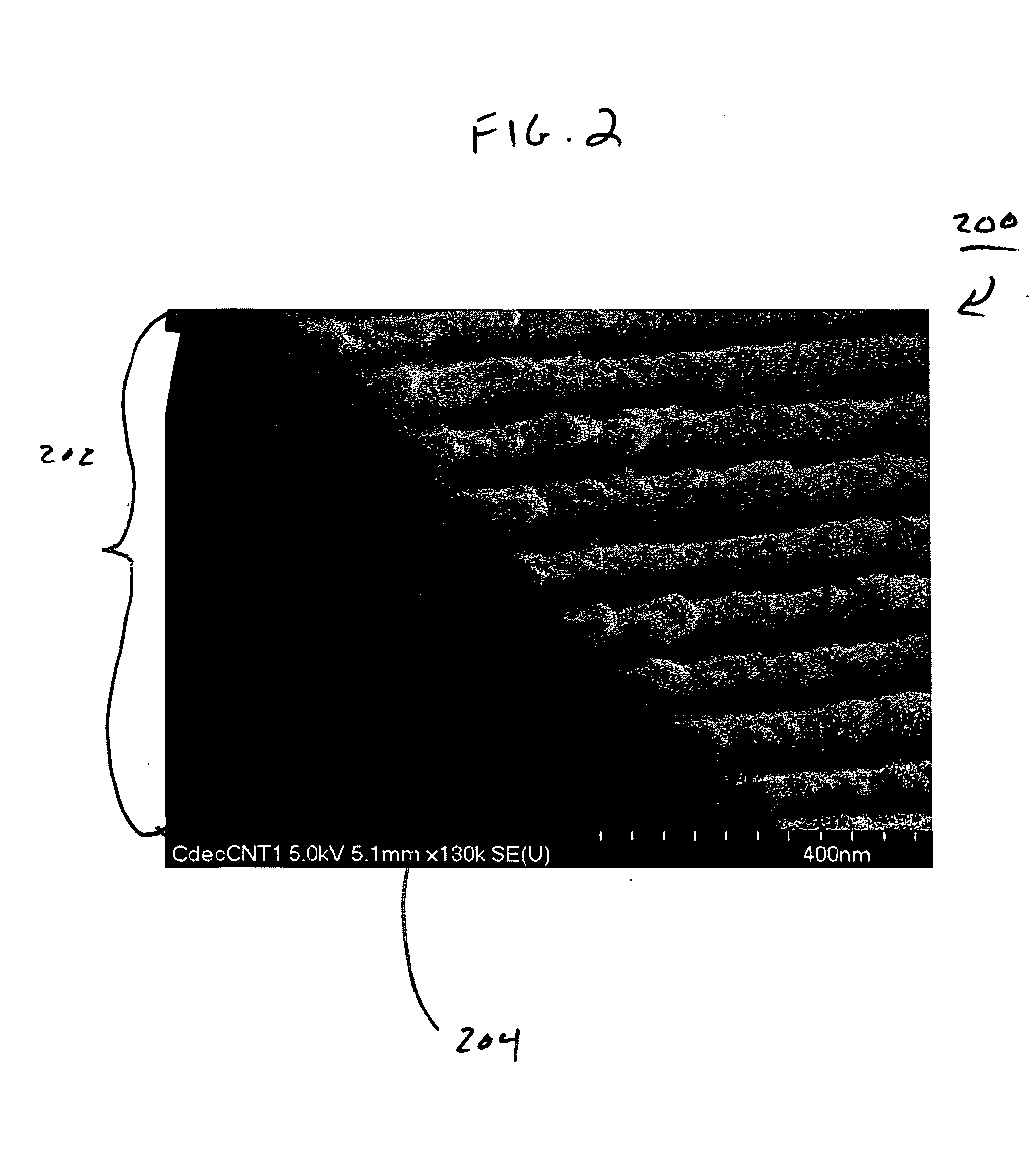

InactiveUS6312768B1Improve surface qualityImprove efficiencyMaterial nanotechnologyElectric discharge heatingMacroscopic scaleCarbon nanotube

Powerful nanosecond-range lasers using low repetition rate pulsed laser deposition produce numerous macroscopic size particles and droplets, which embed in thin film coatings. This problem has been addressed by lowering the pulse energy, keeping the laser intensity optional for evaporation, so that significant numbers of the macroscopic particles and droplets are no longer present in the evaporated plume. The result is deposition of evaporated plume on a substrate to form thin film of very high surface quality. Preferably, the laser pulses have a repetition rate to produce a continuous flow of evaporated material at the substrate. Pulse-range is typically picosecond and femtosecond and repetition rate kilohertz to hundreds of megahertz. The process may be carried out in the presence of a buffer gas, which may be inert or reactive, and the increased vapour density and therefore the collision frequency between evaporated atoms leads to the formation of nanostructured materials of increasing interest, because of their peculiar structural, electronic and mechanical properties. One of these is carbon nanotubes, which is a new form of carbon belonging to the fullerene (C60) family. Carbon nanotubes are seamless, single or multishell co-axial cylindrical tubules with or without dome caps at the extremities. Typically diameters range from 1 nm to 50 nm with a length >1 mum. The electronic structure may be either metallic or semiconducting without any change in the chemical bonding or adding of dopant. In addition, the materials have application to a wide range of established thin film applications.

Owner:AUSTRALIEN NAT UNIV

Orthopedic system for immobilizing and supporting body parts

ActiveUS8303527B2Reformed easilyImprove complianceChemical protectionHeat protectionEngineeringStructural material

A unitized cast system for immobilizing and supporting a body part. The unitized casting system includes a first inner layer for padding and dissipating heat against the patient's skin. A second layer is formed from a thermoformable structural material such as perforated plastic. A protective third outer layer is provided to provide insulation for the second layer. These three layers are formed together to form a unitized cast system that is easily formed and applied to the patient.

Owner:DJO

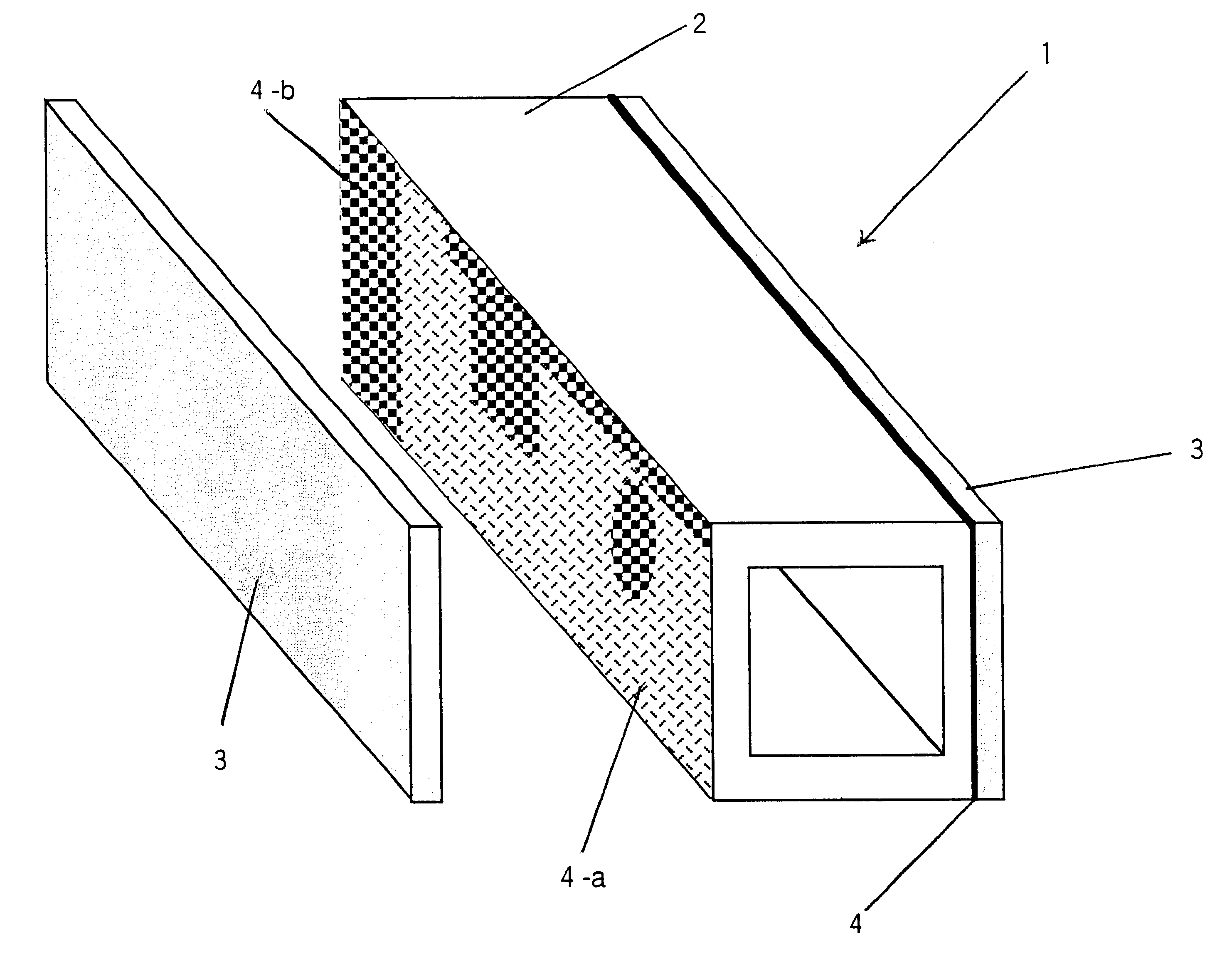

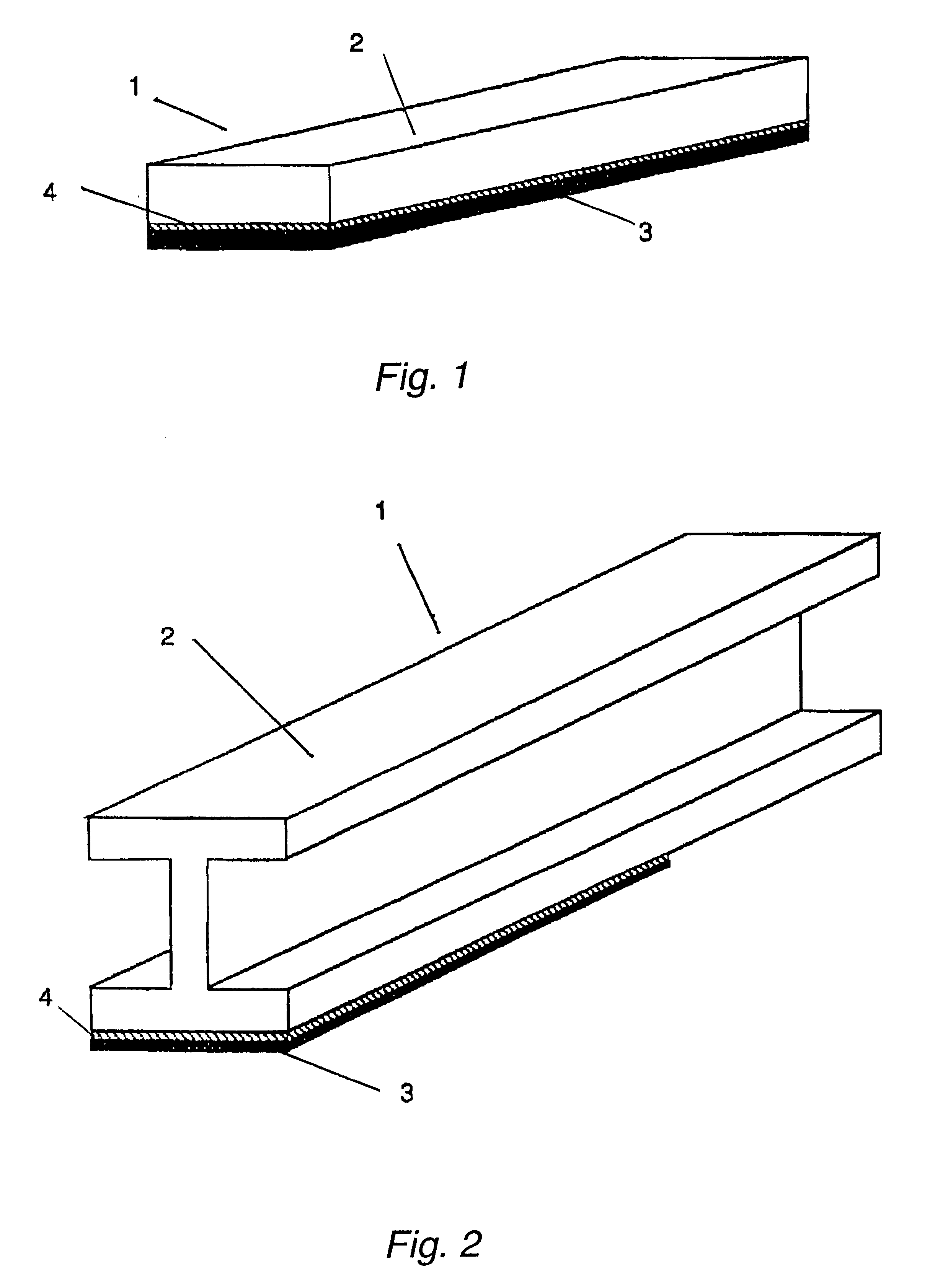

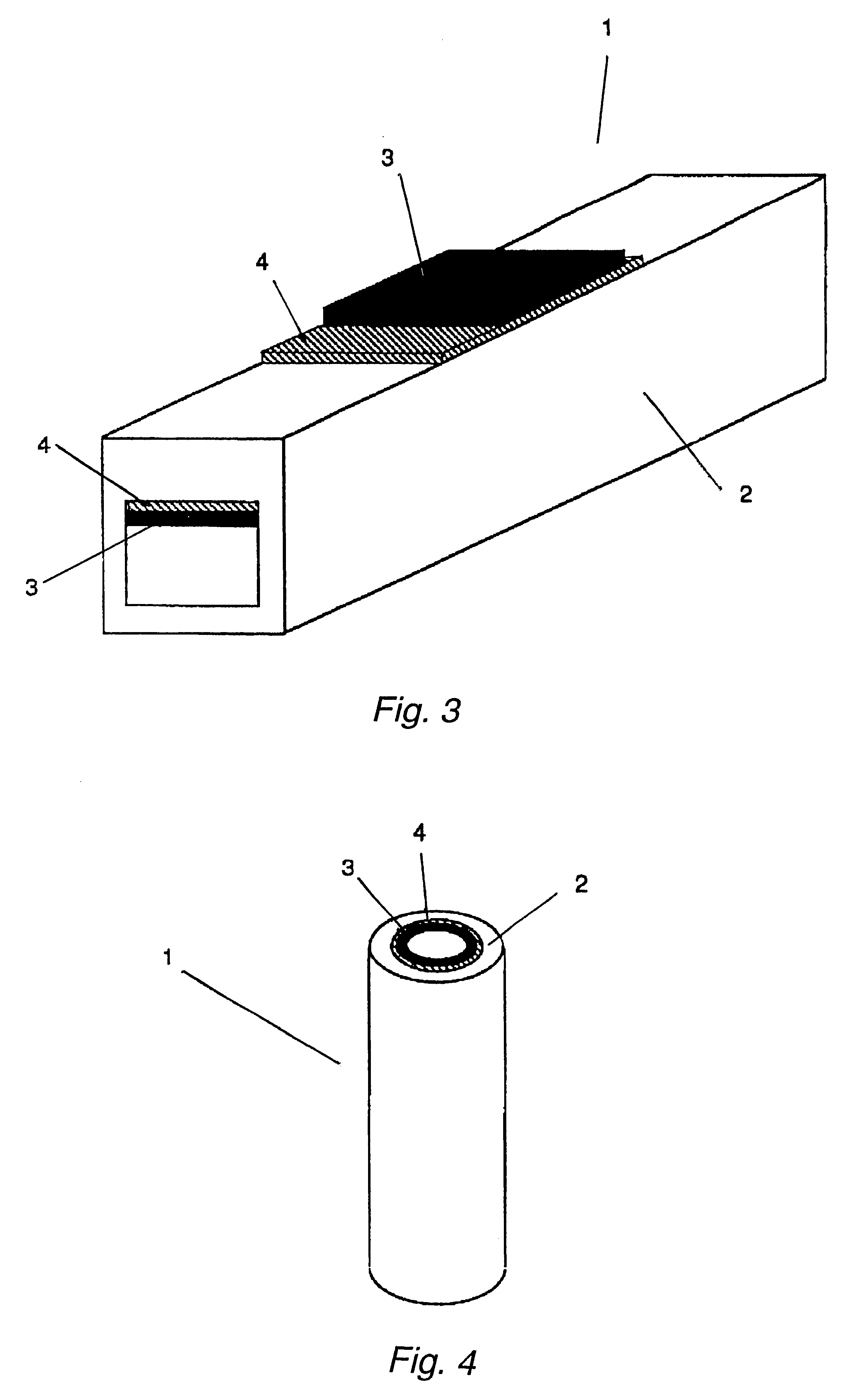

Light metal/CFRP structural member

InactiveUS6468613B1Prevent galvanic corrosionHigh structural reliabilitySynthetic resin layered productsCeramic shaping apparatusMetallic materialsRoom temperature

Light metal / CFRP-made structural members which are characterized in that they are structural materials in which a CFRP material is stuck to the surface of a light metal material via an adhesive agent layer of thickness at least 10 mum and up to 500 mum, and the volume resistivity of the adhesive agent layer between said metal material and said CFRP material is at least 1x1013 OMEGA.cm and, furthermore, the adhesive strength at room temperature is at least 15 MPa. In accordance with the present invention, since conventional light metal / CFRP structural materials can be made lighter and, furthermore, since the resistance to galvanic corrosion is outstanding and it is possible to markedly enhance the strength and the impact energy absorption performance, the development of applications and large-scale expansion into new fields becomes possible. Weight reduction and enhancing the durability and reliability of structures also makes a considerable contribution in terms of environmental protection.

Owner:TORAY IND INC

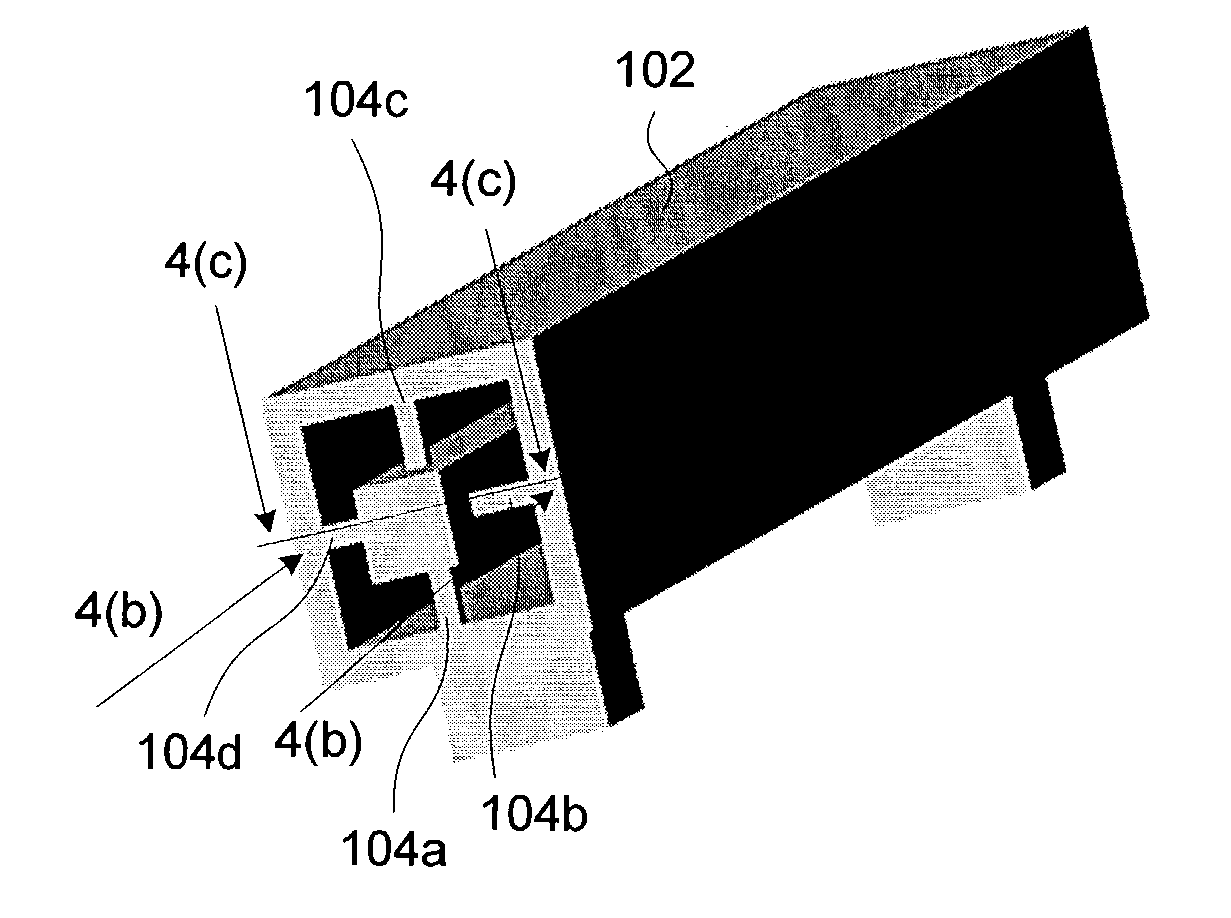

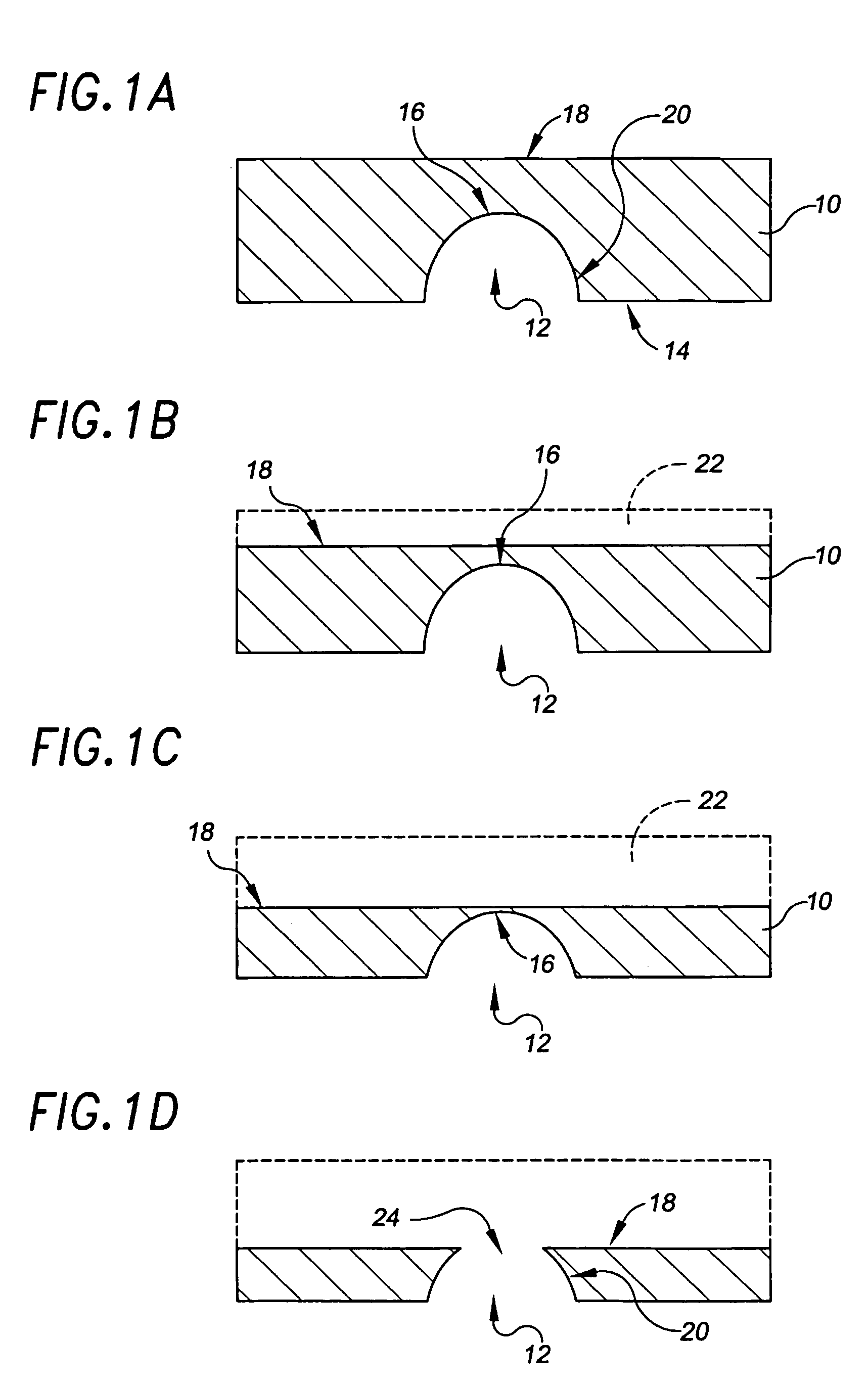

Miniature RF and microwave components and methods for fabricating such components

ActiveUS20030222738A1Add depthAcceleration measurement using interia forcesAdditive manufacturing apparatusElectricityInductor

RF and microwave radiation directing or controlling components are provided that may be monolithic, that may be formed from a plurality of electrodeposition operations and / or from a plurality of deposited layers of material, that may include switches, inductors, antennae, transmission lines, filters, and / or other active or passive components. Components may include non-radiation-entry and non-radiation-exit channels that are useful in separating sacrificial materials from structural materials. Preferred formation processes use electrochemical fabrication techniques (e.g. including selective depositions, bulk depositions, etching operations and planarization operations) and post-deposition processes (e.g. selective etching operations and / or back filling operations).

Owner:MEMGEN

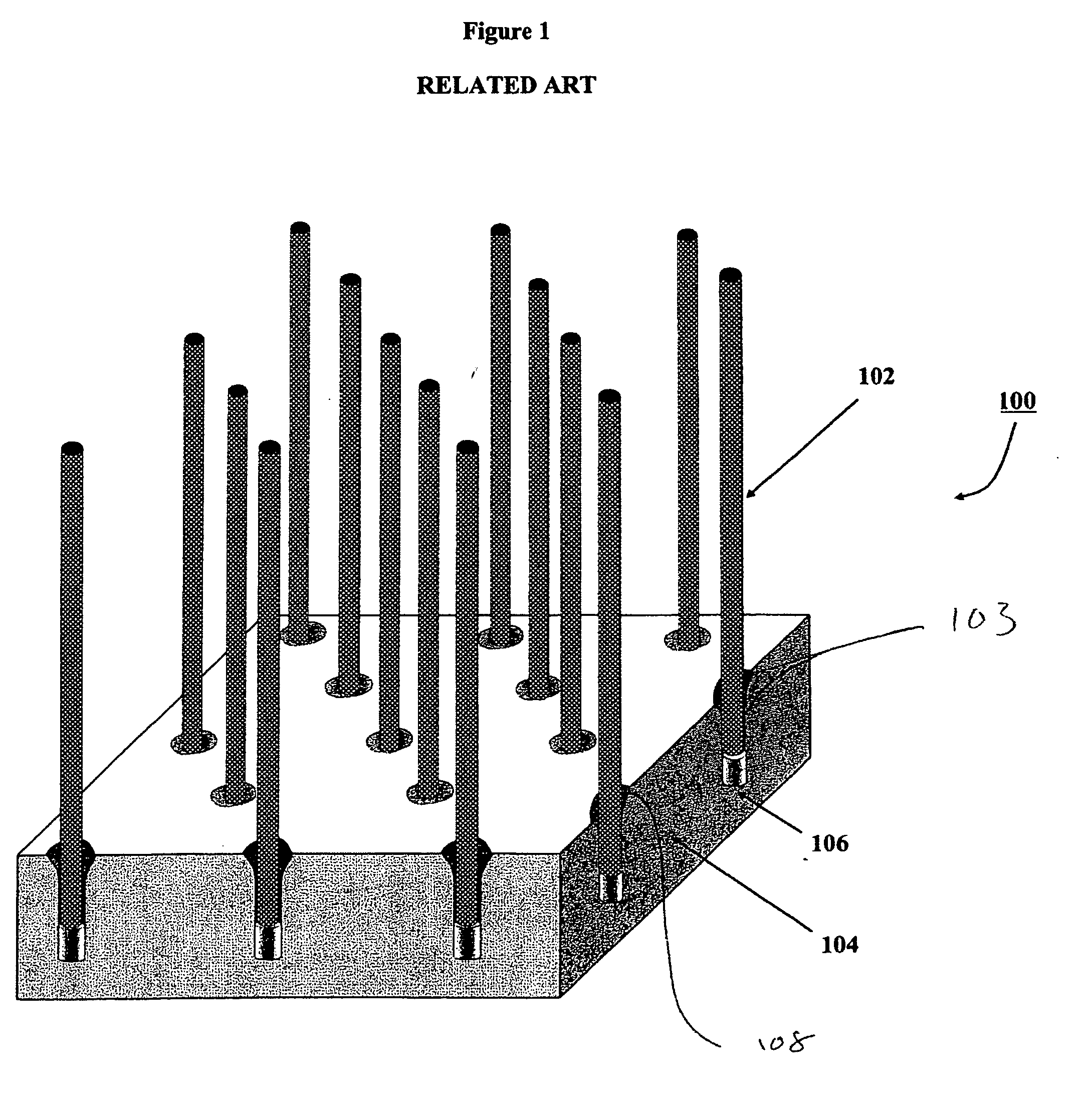

Method for fabrication of porous metal templates and growth of carbon nanotubes and utilization thereof

InactiveUS20050276743A1Large caliberSimple methodAnodisationMaterial nanotechnologyChemical speciesFuel cells

The present invention relates to controlled growth of carbon nanotube (CNT) arrays via chemical vapor deposition (CVD) using novel porous anodic aluminum oxide (AAO) templates, which have been seeded with transition metal catalysts. The resulting CNT bundles may be dense and long and can be used for numerous applications. Further, the porous AAO templates and the CNTs grown thereby, can be functionalized and used for separation of chemical species, hydrogen storage, fuel cell electrocatalyst and gas flow membranes, other catalytic applications, and as a bulk structural material.

Owner:BOARD OF RGT NEVADA SYST OF HIGHER EDUCATION ON BEHALF OF THE UNIV OF NEVADA RENO

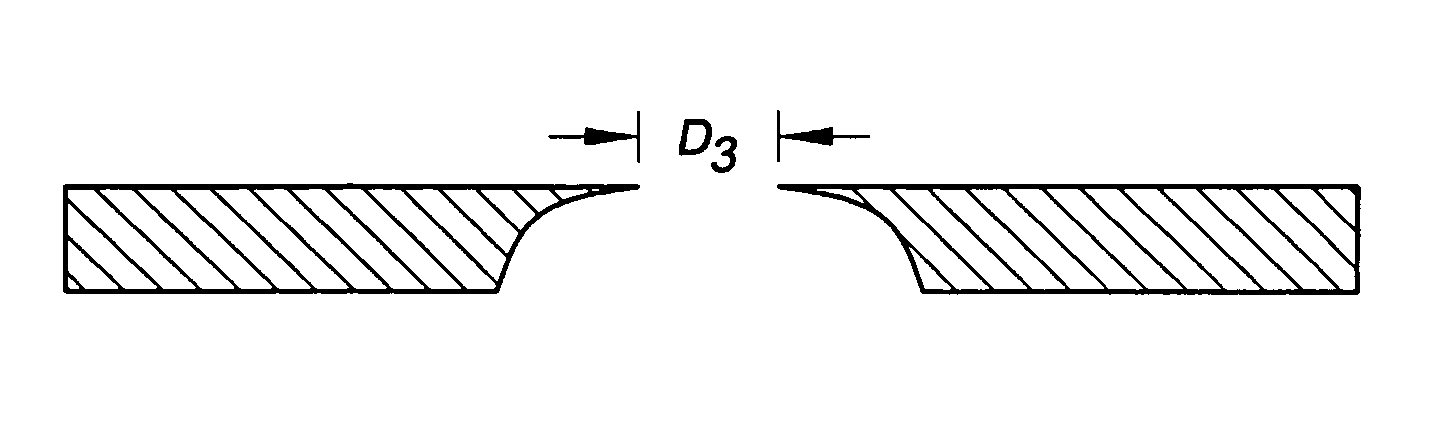

Pulsed ion beam control of solid state features

InactiveUS7118657B2Semiconductor/solid-state device testing/measurementFixed microstructural devicesSolid state structureIon beam

For controlling a physical dimension of a solid state structural feature, a solid state structure is provided, having a surface and having a structural feature. The structure is exposed to a first periodic flux of ions having a first exposure duty cycle characterized by a first ion exposure duration and a first nonexposure duration for the first duty cycle, and then at a second periodic flux of ions having a second exposure duty cycle characterized by a second ion exposure duration and a second nonexposure duration that is greater than the first nonexposure duration, for the second duty cycle, to cause transport, within the structure including the structure surface, of material of the structure to the structural feature in response to the ion flux exposure to change at least one physical dimension of the feature substantially by locally adding material of the structure to the feature.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Orthopaedic implant

ActiveUS20100042215A1Improve adhesion strengthStrong bonesSuture equipmentsInternal osteosythesisPlastic surgeryBiomedical engineering

An orthopaedic implant system includes an orthopaedic implant implantable at a selected location within a corporeal body. The implant includes a first structural material and a second structural material. The first structural material is non-resorbable relative to the corporeal body and is different relative to the second structural material. The implant is an internal fixation device.

Owner:SMED TATD

Packaged electronic modules and fabrication methods thereof implementing a cell phone or other electronic system

InactiveUS20080315377A1Printed circuit assemblingCross-talk/noise/interference reductionContact padRedistribution layer

Circuit structures and methods of fabrication are provided for facilitating implementing a complete electronic system in a compact package. The circuit structure includes, in one embodiment, a chips-first multichip base layer with conductive structures extending therethrough. An interconnect layer is disposed over the front surface of the multichip layer and includes interconnect metallization electrically connected to contact pads of the chips and to conductive structures extending through the structural material. A redistribution layer, disposed over the back surface of the multichip layer, includes a redistribution metallization also electrically connected to conductive structures extending through the structural material. Input / output contacts are arrayed over the redistribution layer, including over the lower surfaces of at least some integrated circuit chips within the multichip layer, and are electrically connected through the redistribution metallization, conductive structures, and interconnect metallization to contact pads of the integrated circuit chips of the multichip layer.

Owner:EPIC TECH INC

Osteoconductive integrated spinal cage and method of making same

The spinal cage comprises a structural component having sufficient strength to withstand the compressive loading between vertebral bodies. The structural component is integrated with an osteoconductive component to facilitate bone growth between the vertebral bodies. The structural component may comprise any of PEEK, PEKK, or other structural material. The osteoconductive component may comprise any of allograft, natural bone, tricalcium phosphate, hydroxyapatite or a blend of calcium carbonate, calcium lactate and other calcium salts. A method for making the spinal cage involves molding polymers around an osteoconductive component, heat staking, and may further include ultrasonically welding, snap fit or mechanically assembling and / or adhesively bonding components.

Owner:SPINAL ELEMENTS INC

Laser direct structuring materials with all color capability

InactiveUS20120276390A13D rigid printed circuitsRadiation applicationsPersonal computerMechanical property

Thermoplastic compositions that are capable of being used in a laser direct structuring process to provide enhanced plating performance and good mechanical properties. The compositions include a thermoplastic base resin, a laser direct structuring additive, and a mineral filler. The compositions can be used in a variety of applications such as personal computers, notebook and portable computers, cell phone antennas and other such communications equipment, medical applications, RFID applications, and automotive applications.

Owner:SABIC GLOBAL TECH BV

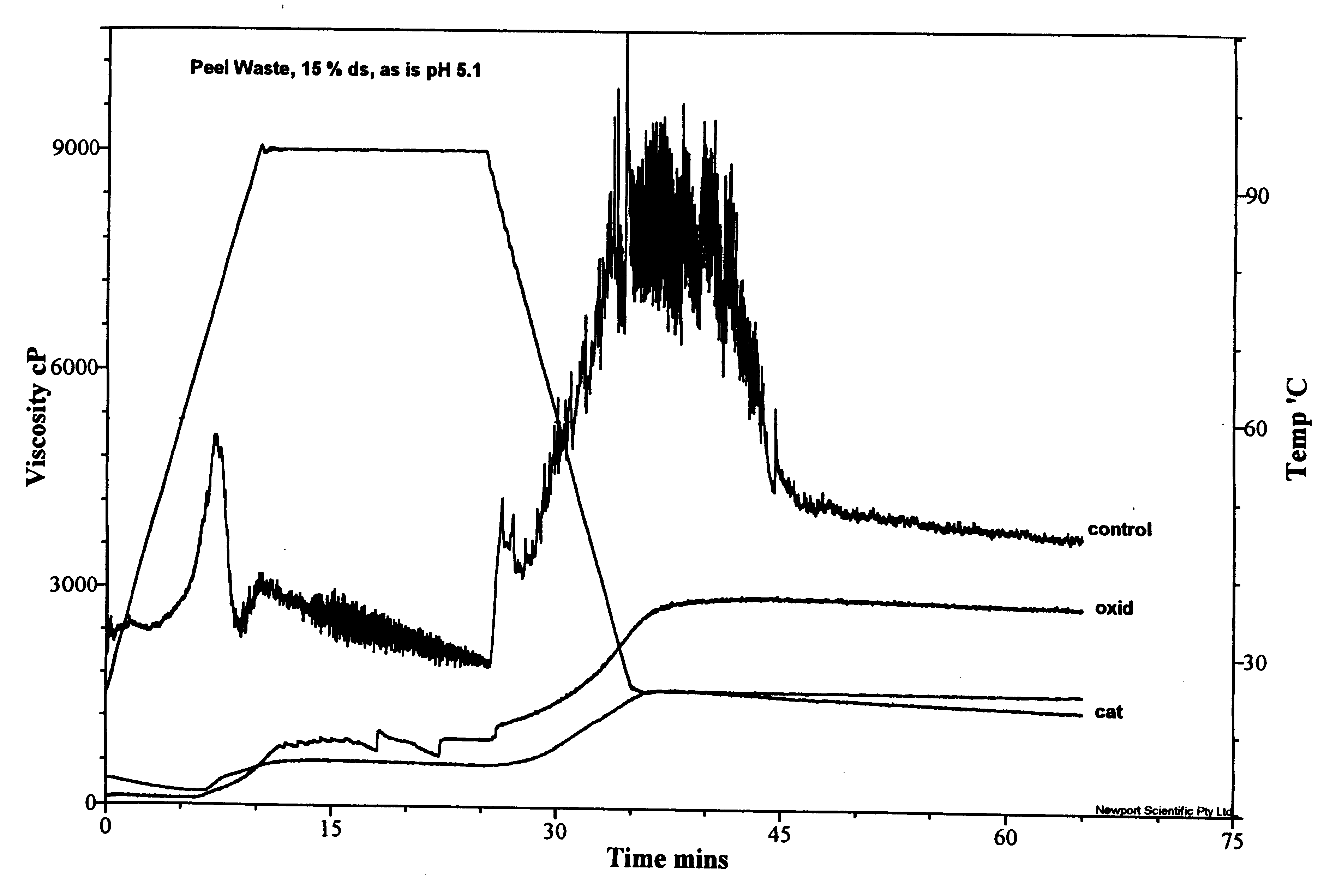

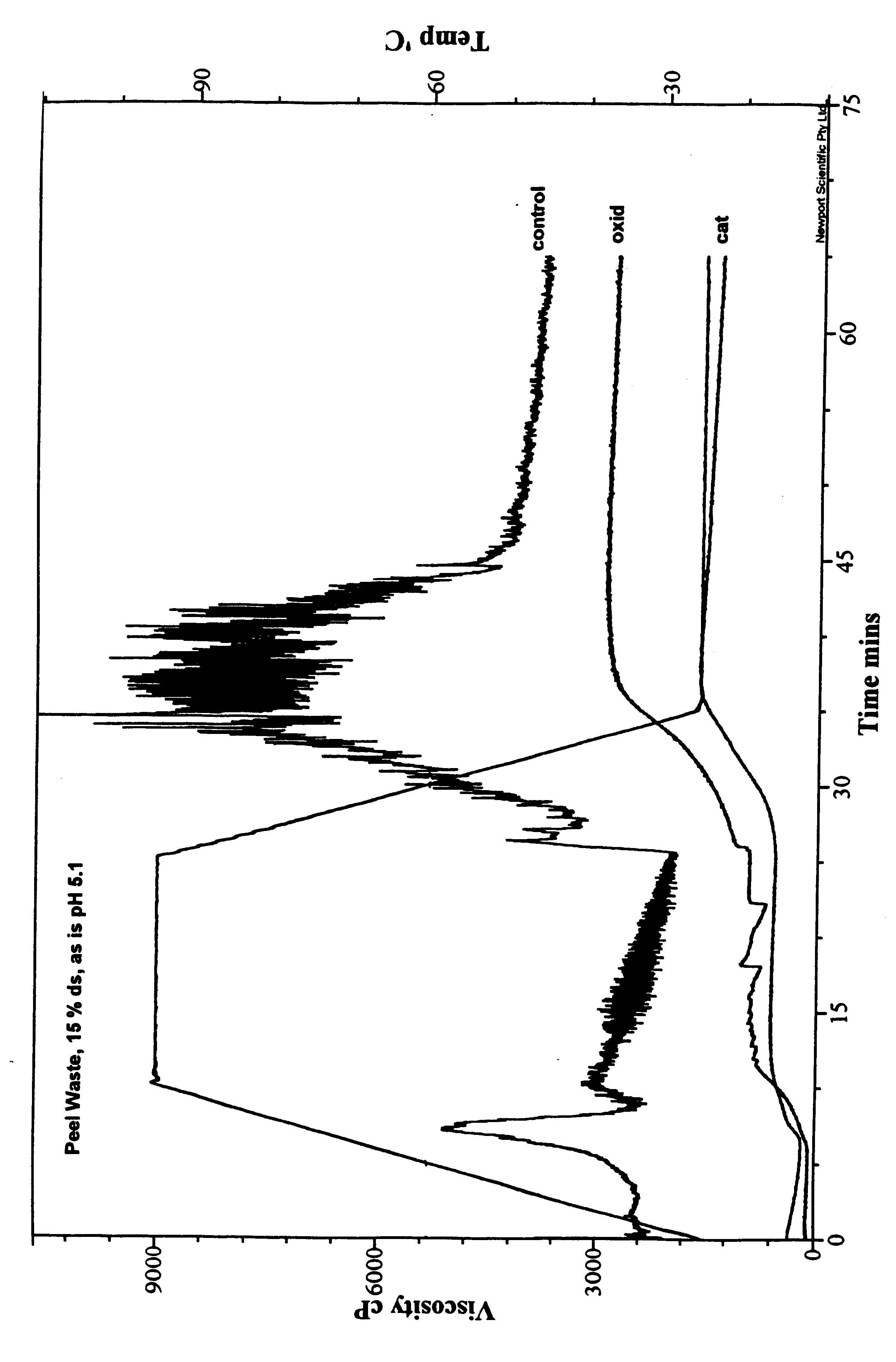

Packaging and structural materials comprising potato peel waste

InactiveUS6440204B1Inhibit migrationImprove stabilityProtein waste adhesivesLayered productsFiberAdhesive

Owner:HARRIS TRUST & SAVINGS BANK AS ADM AGENT +1

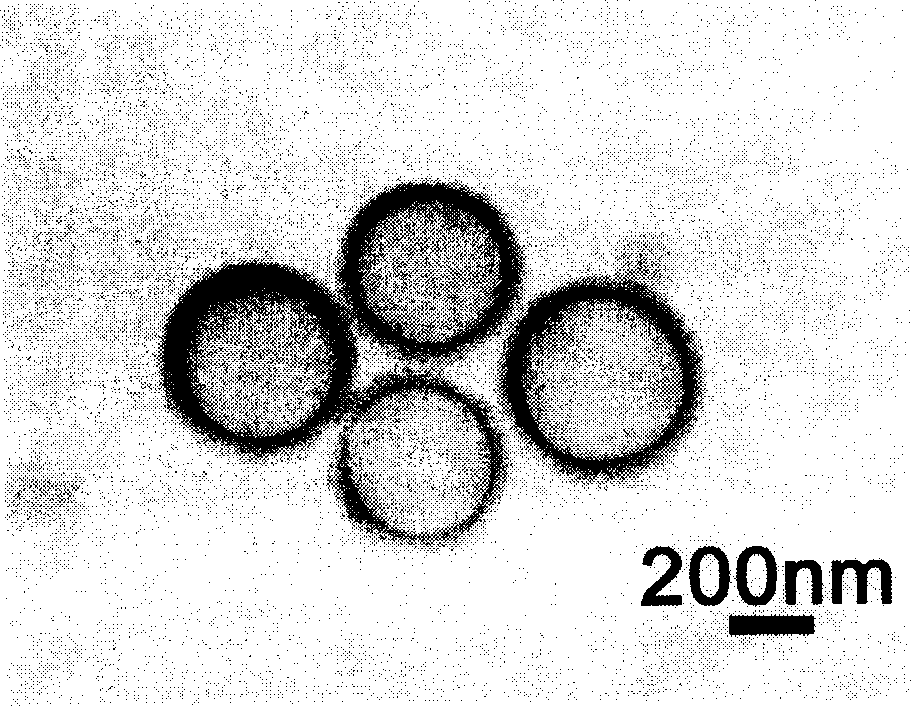

Template process of preparing hollow ball and composite hollow ball

InactiveCN1772363ARealize the intelligent switching processWide adaptabilityMicroballoon preparationMicrocapsule preparationPolymer scienceSolvent

The present invention belongs to the field of hollow material preparing technology, and is especially the preparation process of hollow ball of inorganic matter, metal, organic matter and composite structure with hollow polymer ball as template. The present invention prepares composite hollow ball through combining hollow polymer ball template with sol-gel, deposition reaction, oxidation-reduction process and through forced interface process or surface deposition process; and obtain hollow ball of inorganic matter, metal and organic matter through high temperature sintering or selective solvent extraction to eliminate template polymer. The control of hollow ball structure and size and the compounding of several kinds of matters may be realized through controlling reactant activity, material feeding mode, reactant concentration and circulating reaction process. The hollow ball has excellent dispersivity, high strength and size stability. The present invention also relates to the application of these hollow structure materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Miniature RF and microwave components and methods for fabricating such components

InactiveUS7259640B2Small sizeReduce manufacturing costAcceleration measurement using interia forcesAdditive manufacturing apparatusPhysical chemistrySelective deposition

Owner:MEMGEN CORP

Nanostructured material comprising semiconductor nanocrystal complexes for use in solar cell and method of making a solar cell comprising nanostructured material

InactiveUS20070012355A1Improve performanceLow costNanoopticsPhotovoltaic energy generationNanostructured materialsSolar cell

A solar cell includes a semiconductor base layer, a semiconductor nanocrystal complex over the semiconductor base layer, and a semiconductor emitter layer formed over the semiconductor nanocrystal complex. The semiconductor nanocrystal complex includes nanocrystal cores dispersed in an inorganic matrix material. A corresponding method is also disclosed.

Owner:EVIDENT TECH

Structural hot melt material and methods

InactiveUS6887914B2Reduce and eliminate stepAvoid corrosionAdhesive processesNon-macromolecular adhesive additivesEpoxyHot melt

The present invention relates to a material, method, and application for reinforcement of structural members, especially joints such as a hem flange joint of an automobile. The method and material of the present invention comprises of combining, in parts by weight: less than about twenty percent (<20%) ethylene copolymer, less than about forty percent (<40%) epoxy, less than about thirty percent (<45%) epoxy-based resin, less than about two percent (<2%) blowing agent and from about one percent (1%) to about five percent (5%) curing agent (and optionally add any of the following components: less than about two percent (<2%) curing agent accelerator, from about twenty-five percent (25%) to fifty-five percent (55%) filler, and less than about one percent (<1%) of coloring agent). The application of the present invention comprises of: (1) providing a structural member having two substrates forming a space to be joined; (2) placing the material of the present invention in proximity of the space to be joined; (3) exposing the material to a heat source causing it to flow, fill, and cure in the defined area or space to be joined.

Owner:ZEPHYROS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com