Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

263 results about "Porous anodic aluminum oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

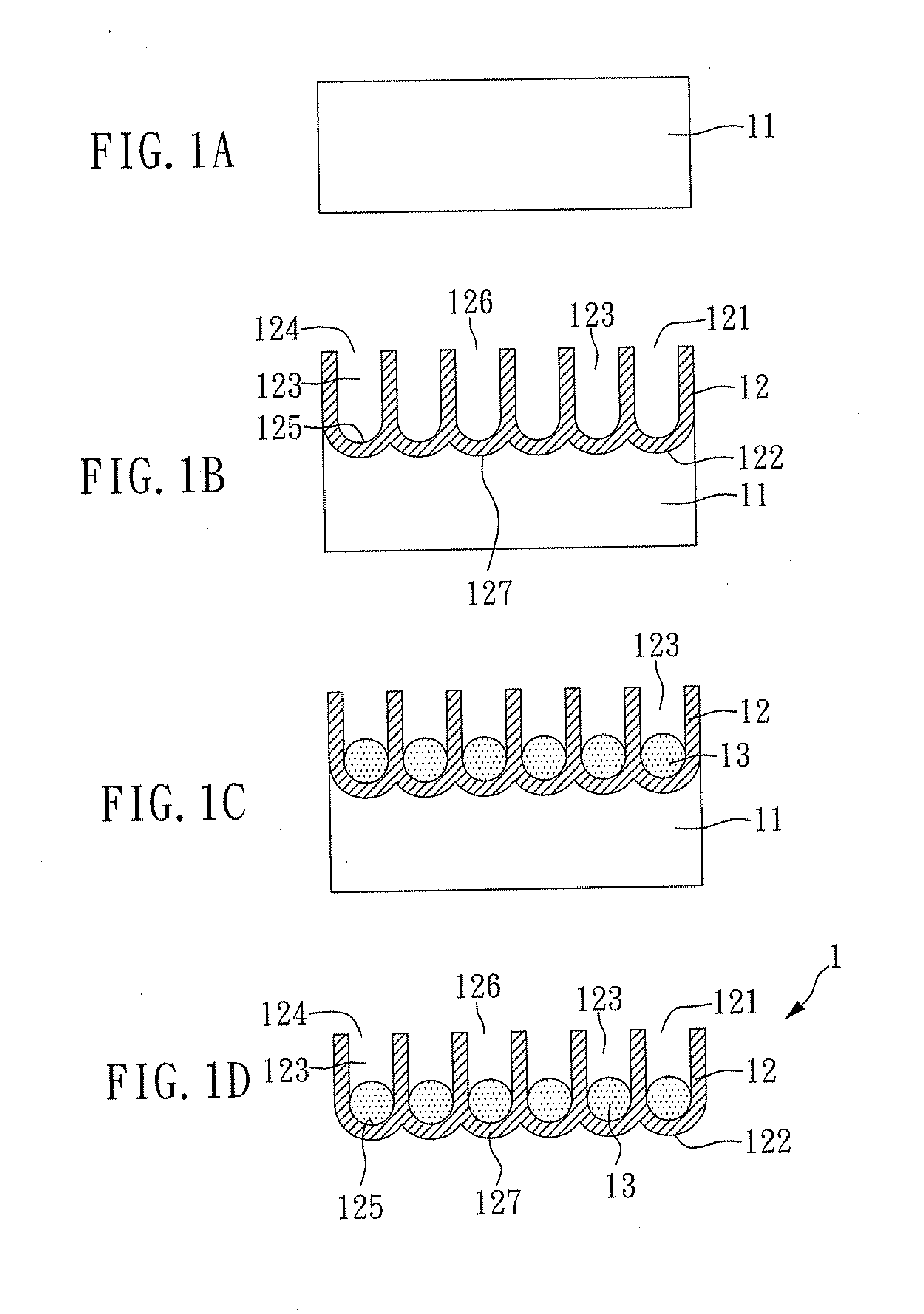

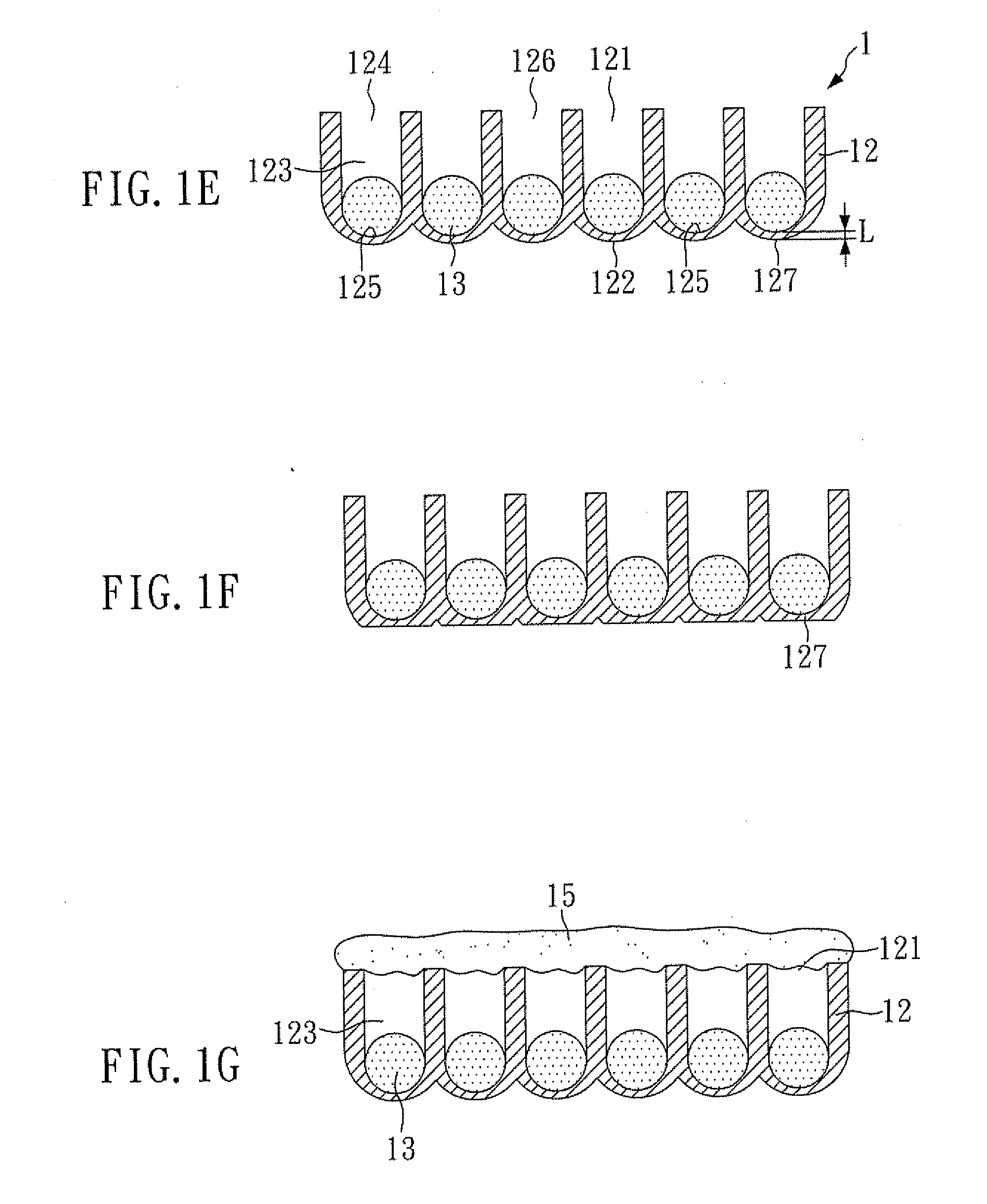

Method of manufacturing porous anodized alumina film

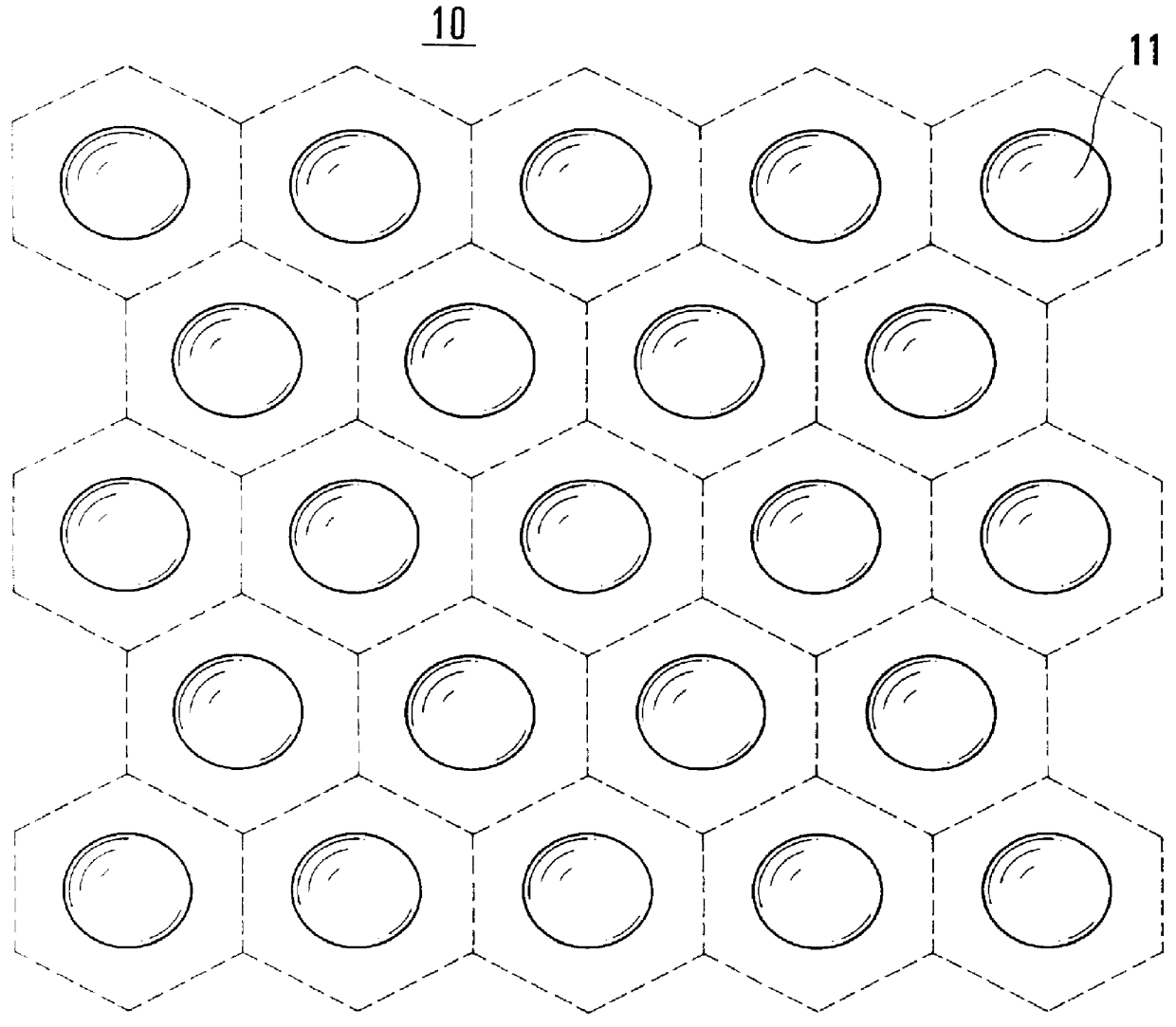

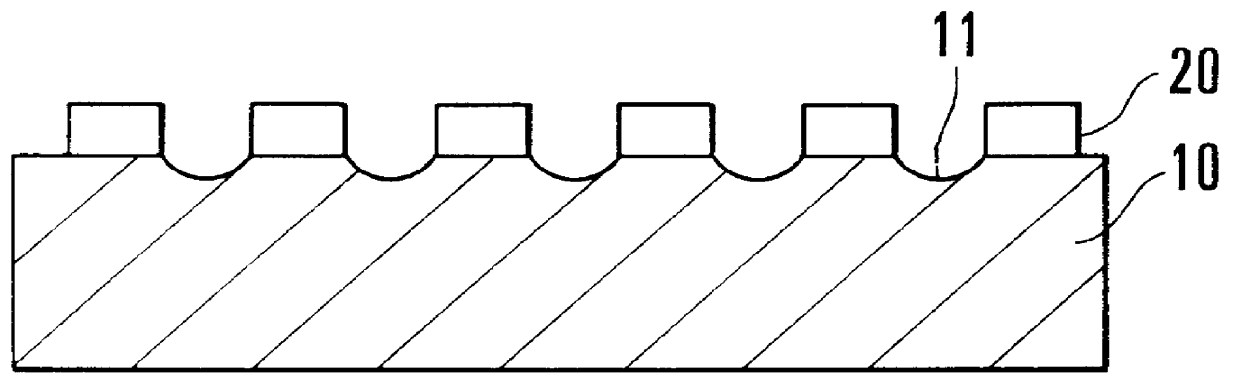

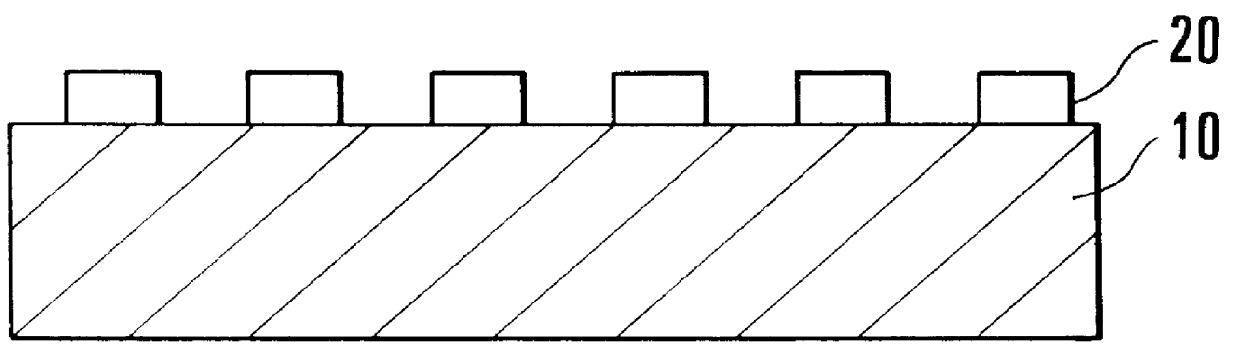

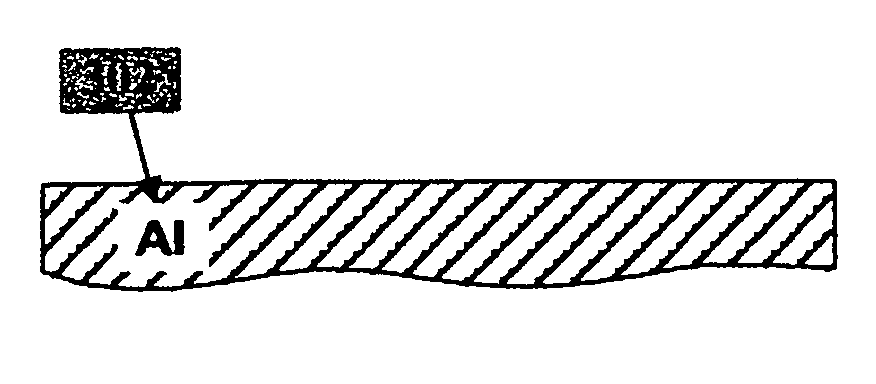

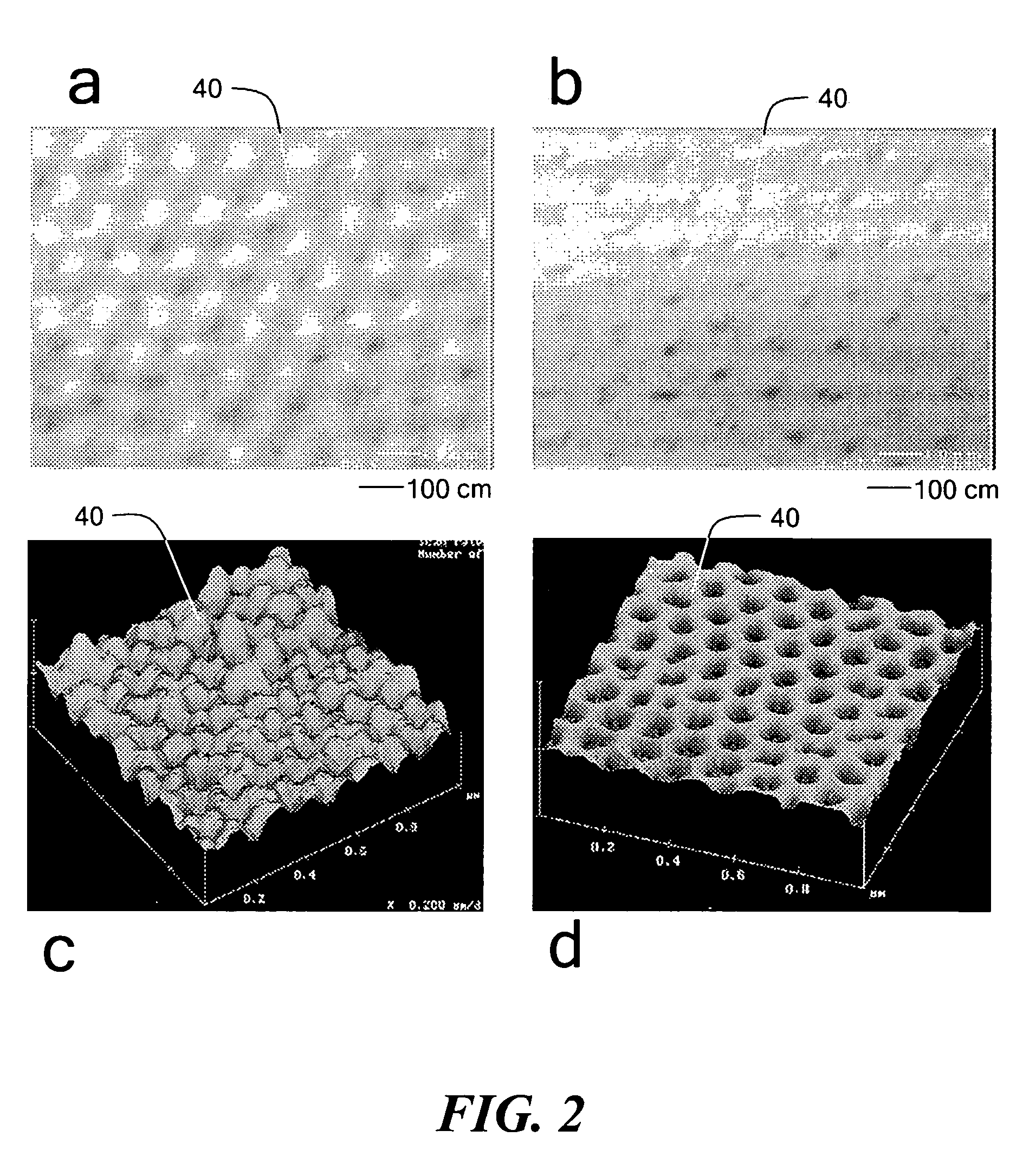

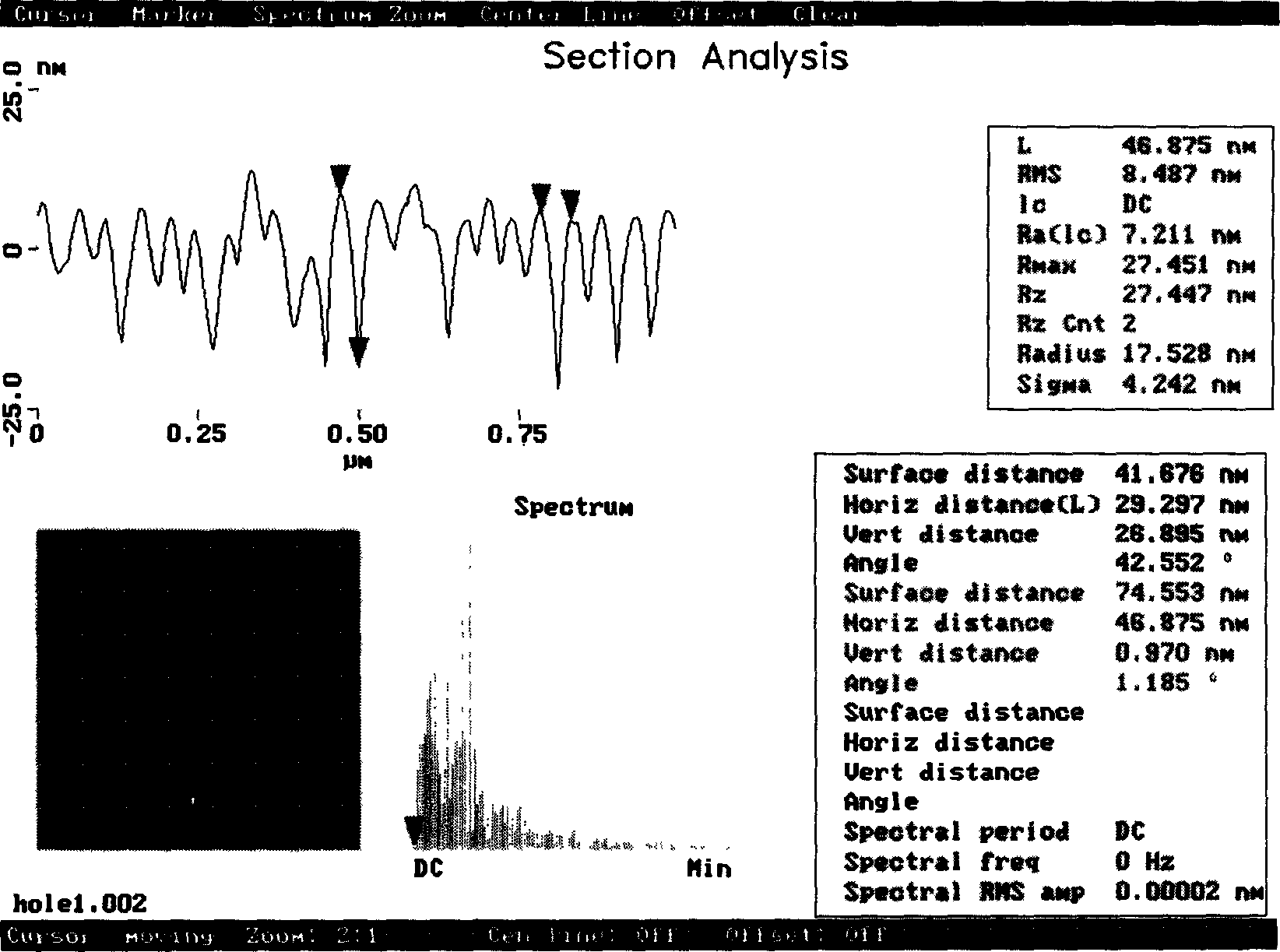

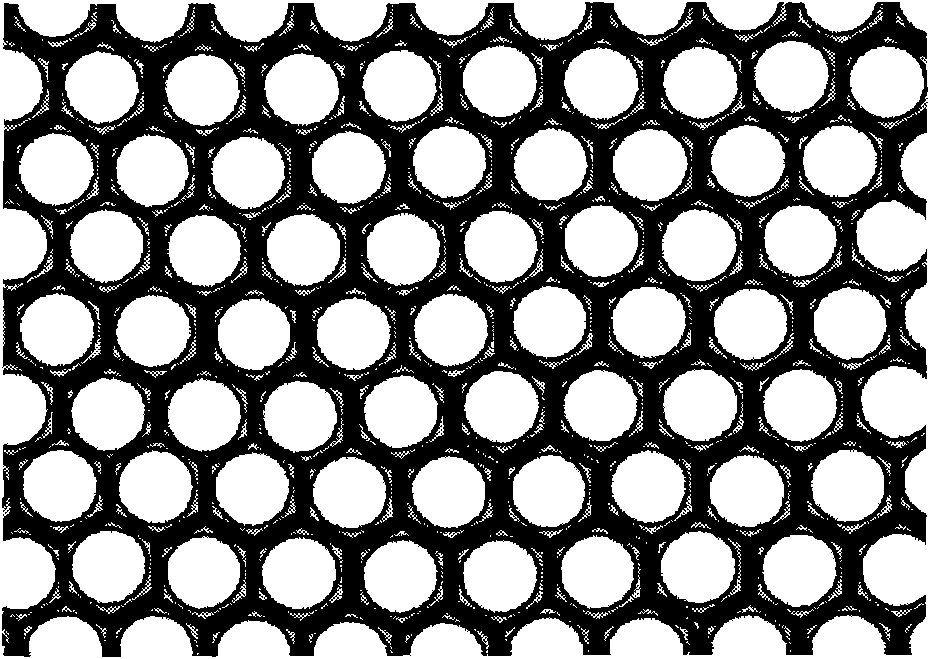

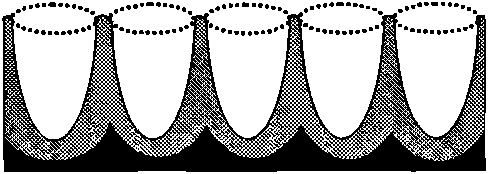

PCT No. PCT / JP97 / 02965 Sec. 371 Date Nov. 2, 1998 Sec. 102(e) Date Nov. 2, 1998 PCT Filed Aug. 26, 1997 PCT Pub. No. WO98 / 09005 PCT Pub. Date Mar. 5, 1998A plurality of recesses having the same interval and array as those of pores of an alumina film, which are to be formed in anodizing, are formed on a smooth surface of an aluminum plate in advance, and then, the aluminum plate is anodized. With this process, the roundness of the pores of the porous anodized alumina film and the uniformity of pore size are improved, and the pores are regularly arrayed at a predetermined interval. The recesses are formed by pressing a substrate having a plurality of projections on its surface against the aluminum plate surface to be anodized.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

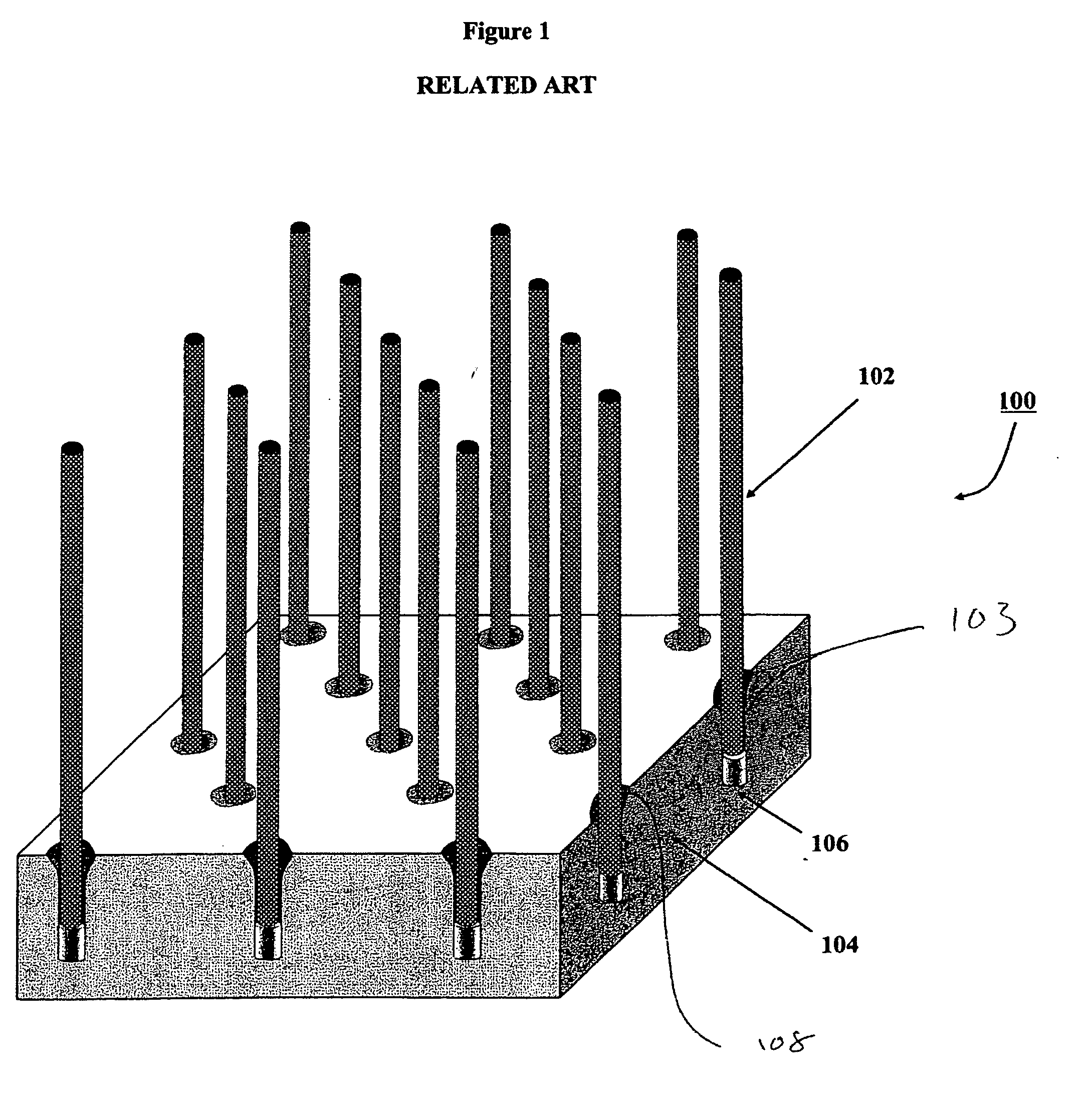

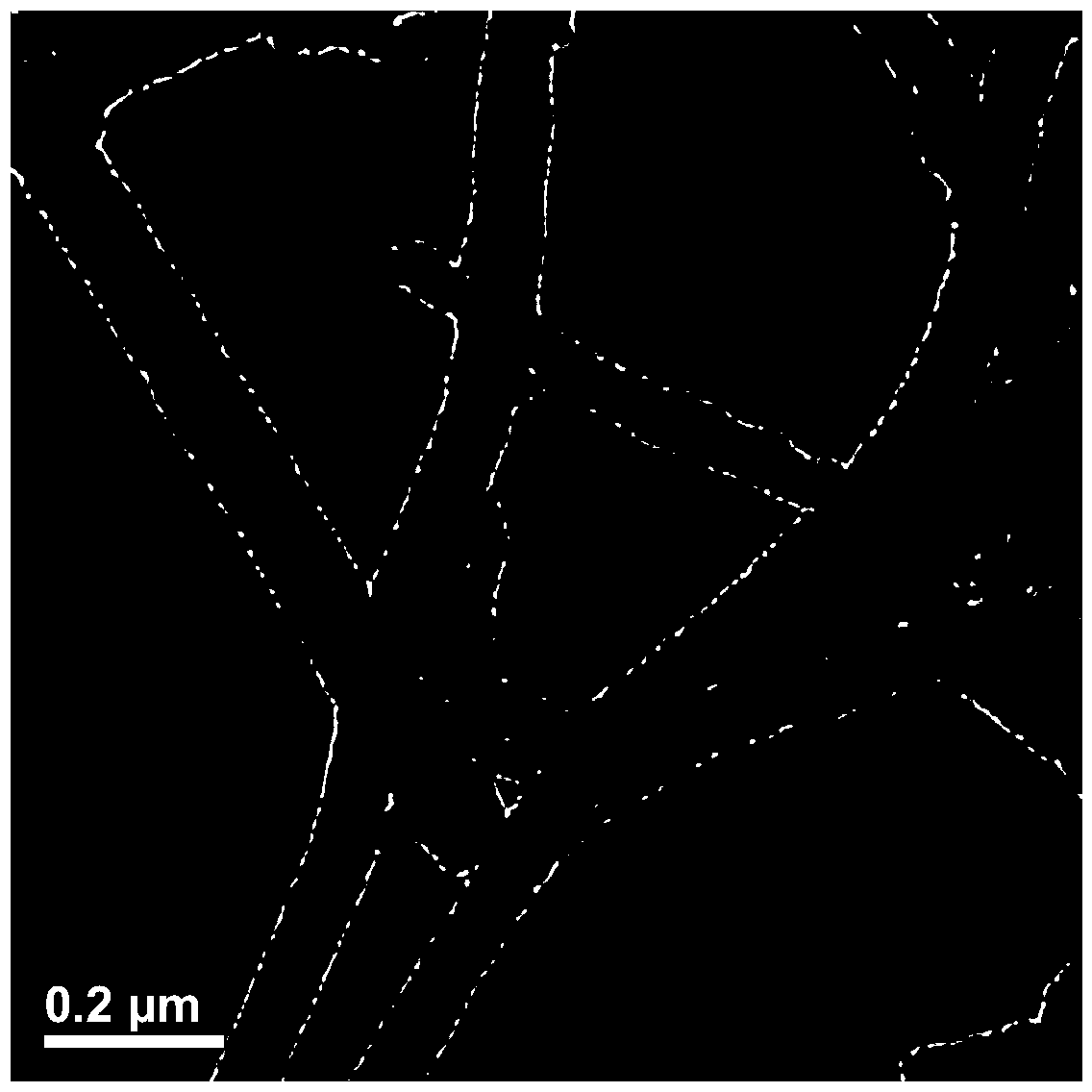

Method for fabrication of porous metal templates and growth of carbon nanotubes and utilization thereof

InactiveUS20050276743A1Large caliberSimple methodAnodisationMaterial nanotechnologyChemical speciesFuel cells

The present invention relates to controlled growth of carbon nanotube (CNT) arrays via chemical vapor deposition (CVD) using novel porous anodic aluminum oxide (AAO) templates, which have been seeded with transition metal catalysts. The resulting CNT bundles may be dense and long and can be used for numerous applications. Further, the porous AAO templates and the CNTs grown thereby, can be functionalized and used for separation of chemical species, hydrogen storage, fuel cell electrocatalyst and gas flow membranes, other catalytic applications, and as a bulk structural material.

Owner:BOARD OF RGT NEVADA SYST OF HIGHER EDUCATION ON BEHALF OF THE UNIV OF NEVADA RENO

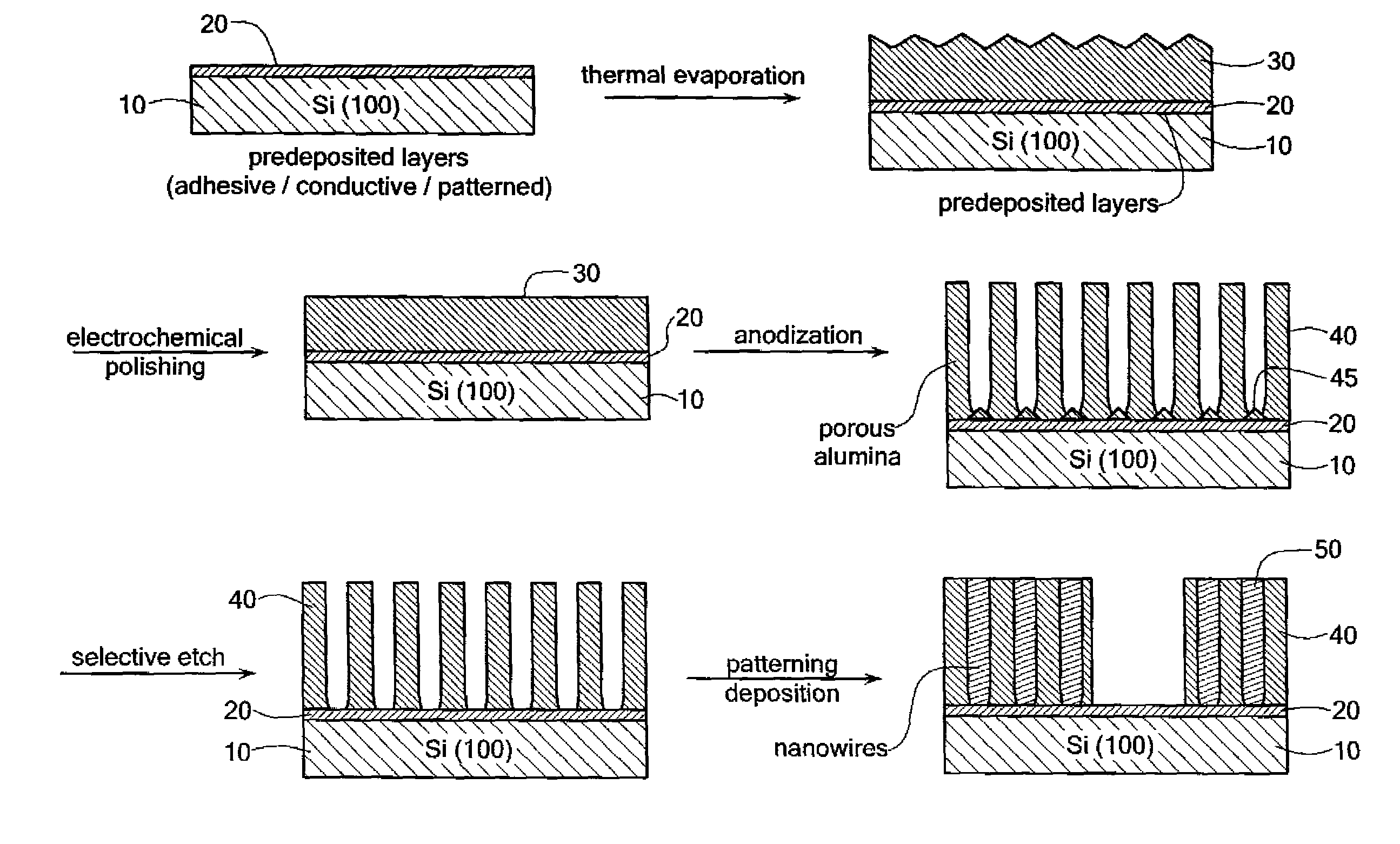

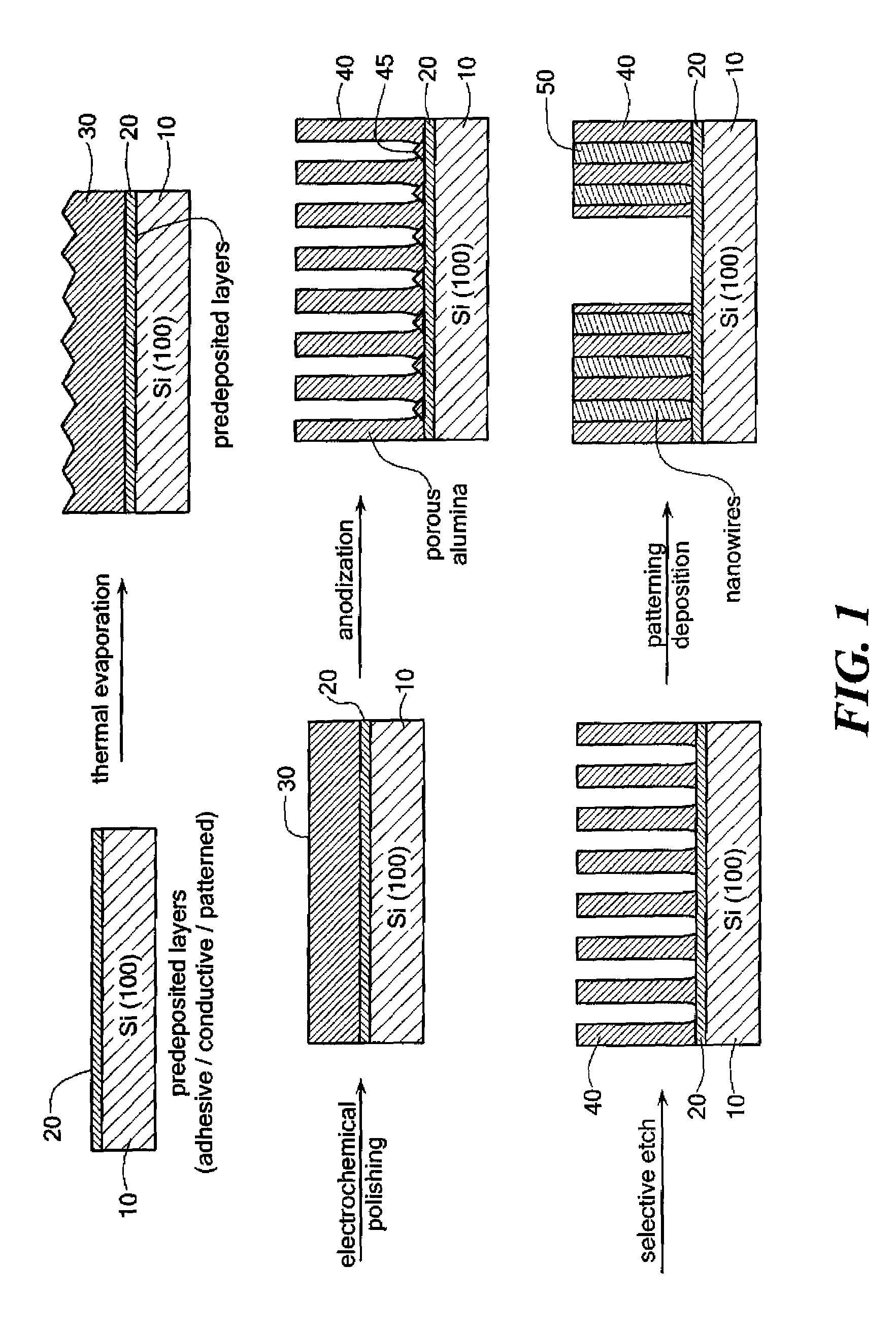

Thick porous anodic alumina films and nanowire arrays grown on a solid substrate

InactiveUS7267859B1Promote growthMore tractableMaterial nanotechnologyAnodisationSingle stageElectrochemistry

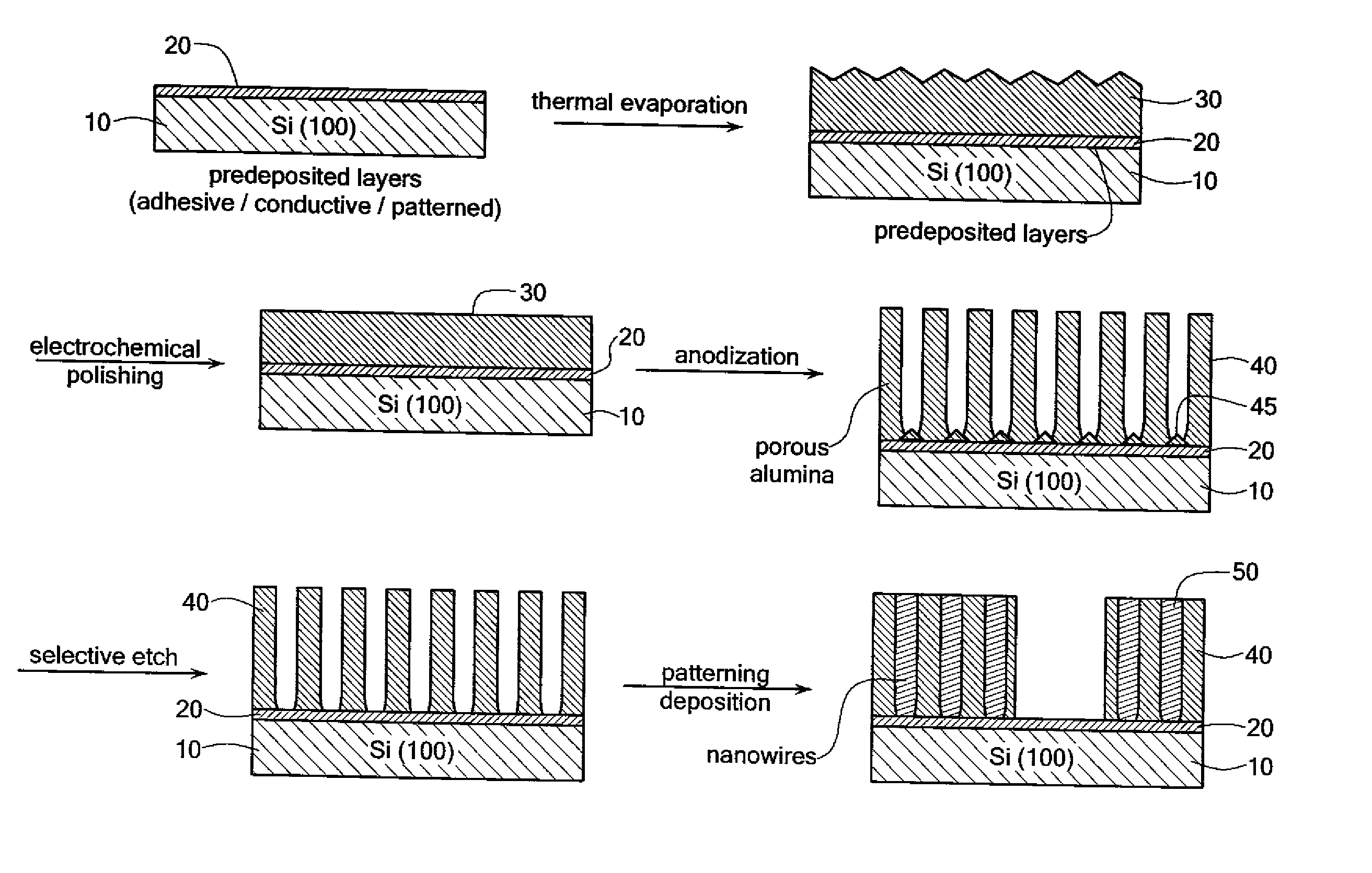

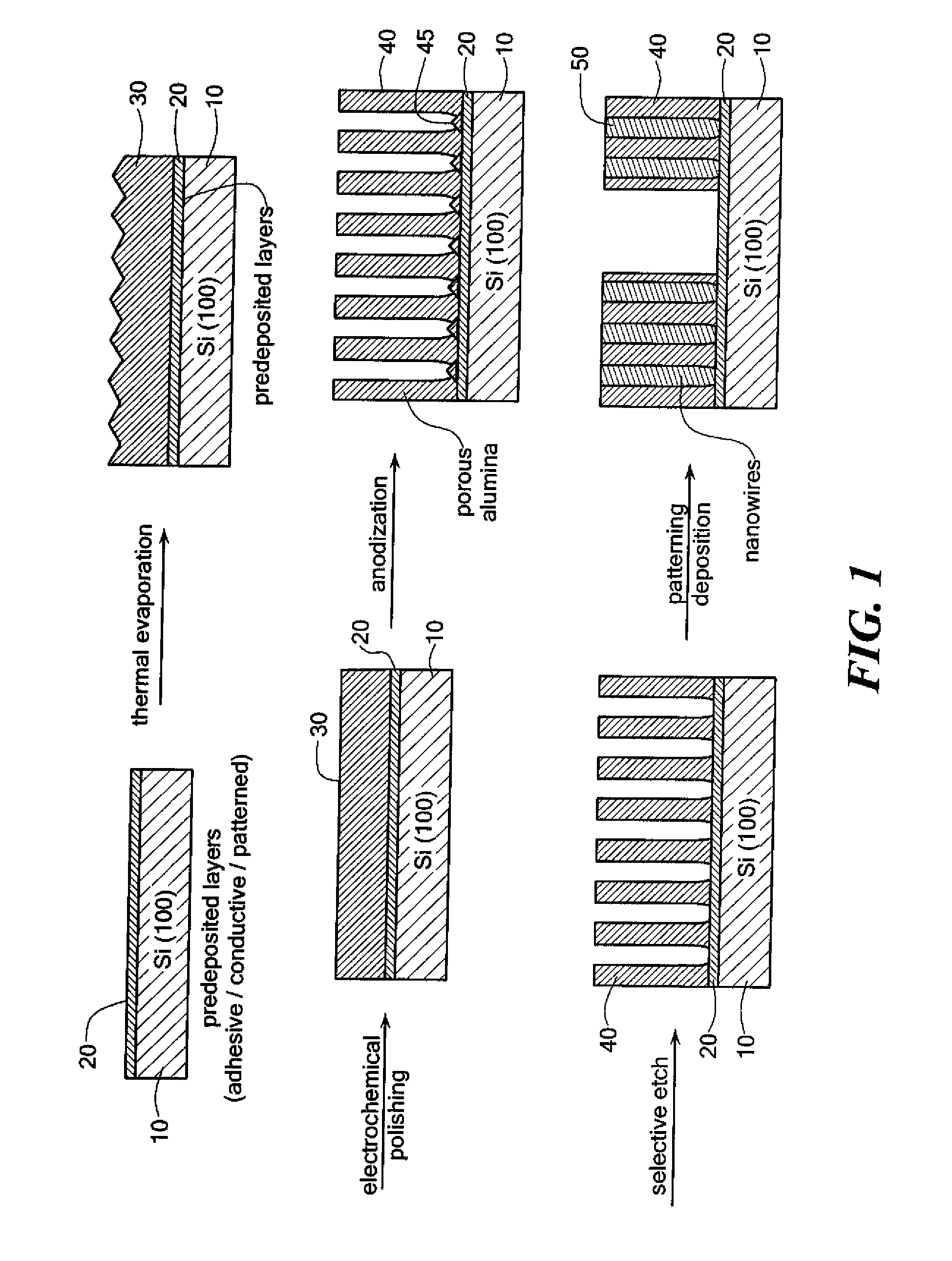

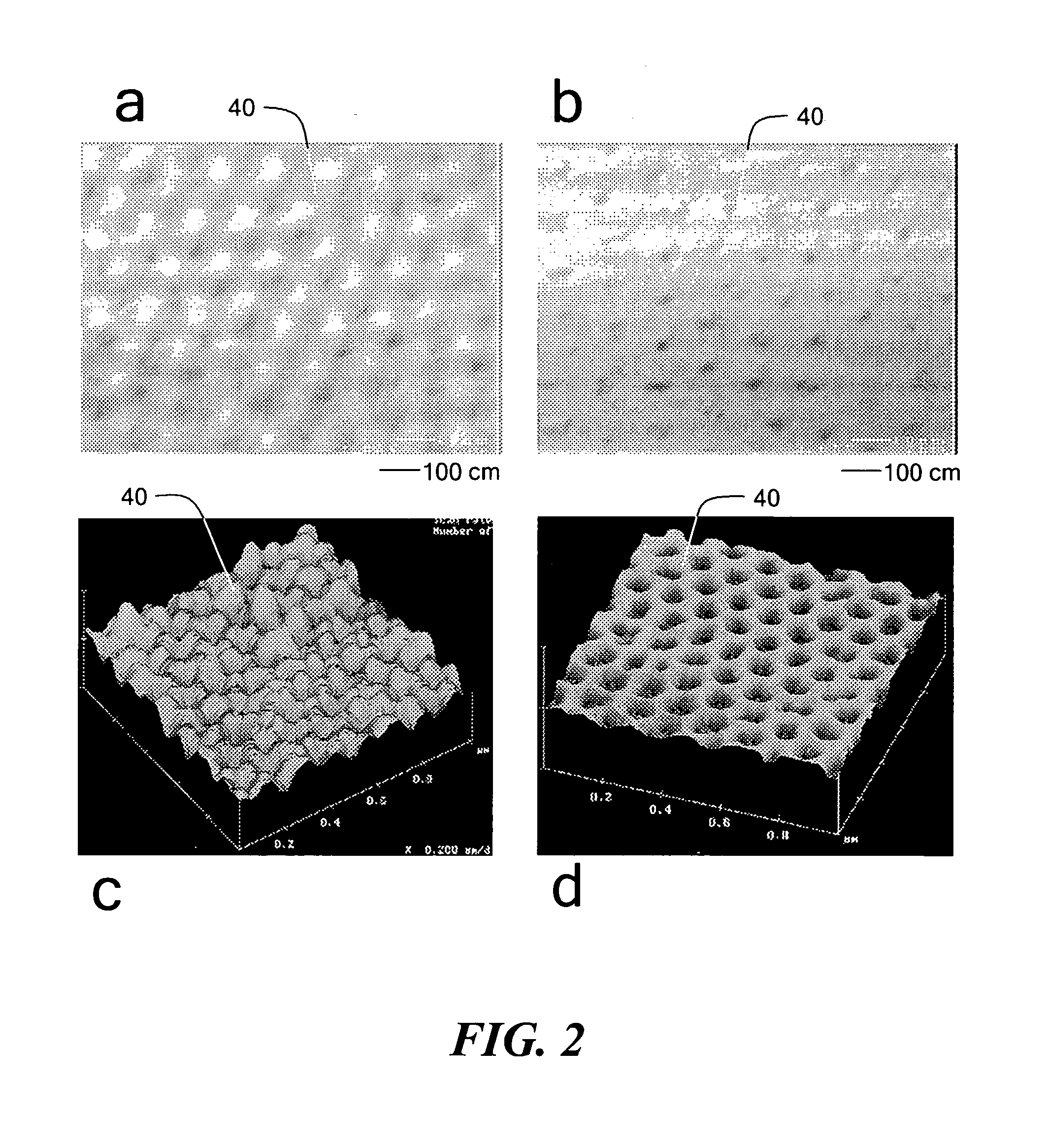

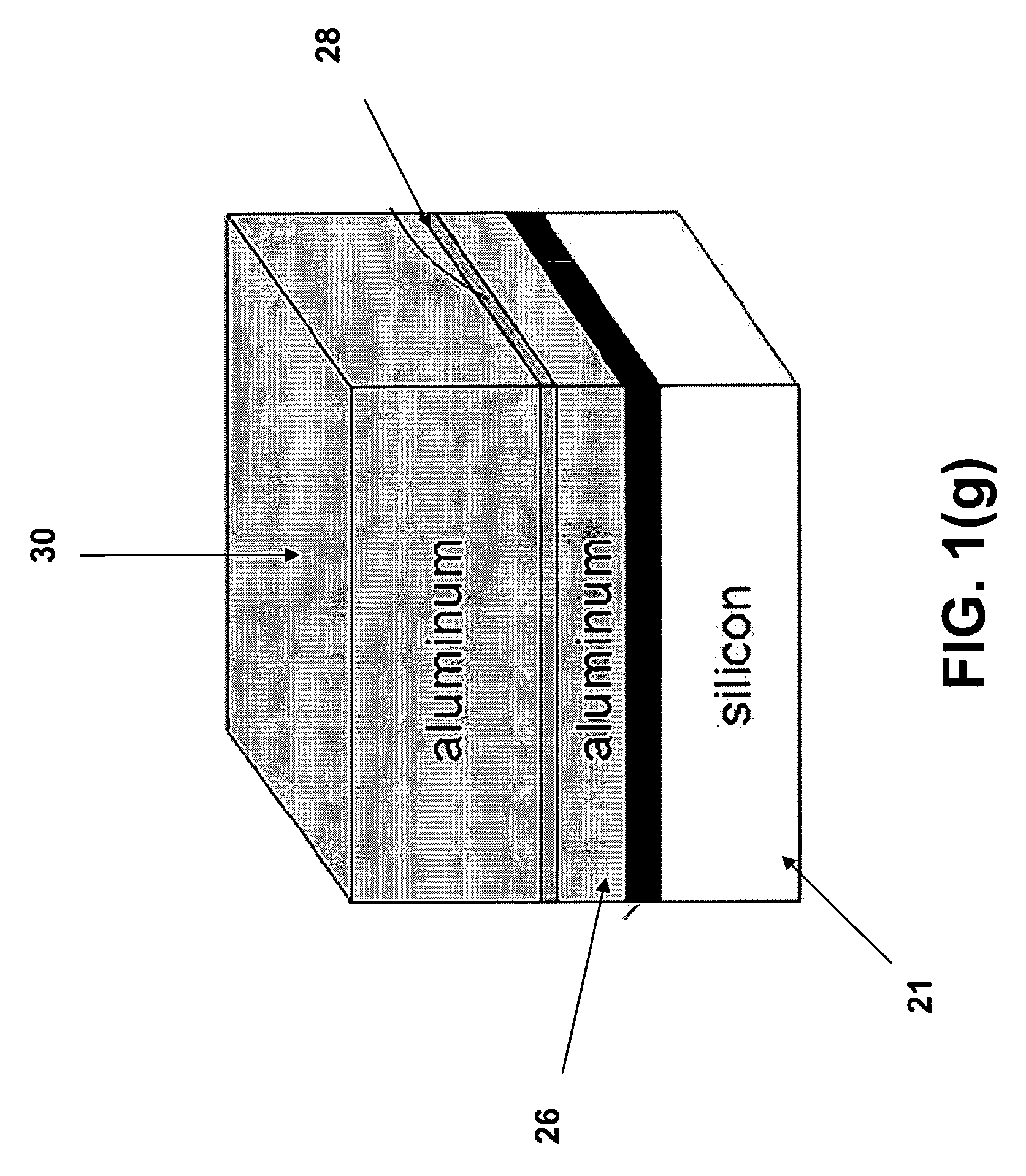

The presently disclosed invention provides for the fabrication of porous anodic alumina (PAA) films on a wide variety of substrates. The substrate comprises a wafer layer and may further include an adhesion layer deposited on the wafer layer. An anodic alumina template is formed on the substrate. When a rigid substrate such as Si is used, the resulting anodic alumina film is more tractable, easily grown on extensive areas in a uniform manner, and manipulated without danger of cracking. The substrate can be manipulated to obtain free-standing alumina templates of high optical quality and substantially flat surfaces PAA films can also be grown this way on patterned and non-planar surfaces. Furthermore, under certain conditions the resulting PAA is missing the barrier layer (partially or completely) and the bottom of the pores can be readily accessed electrically. The resultant film can be used as a template for forming an array of nanowires wherein the nanowires are deposited electrochemically into the pores of the template. By patterning the electrically conducting adhesion layer, pores in different areas of the template can be addressed independently, and can be filled electrochemically by different materials. Single-stage and multi-stage nanowire-based thermoelectric devices, consisting of both n-type and p-type nanowires, can be assembled on a silicon substrate by this method.

Owner:MASSACHUSETTS INST OF TECH

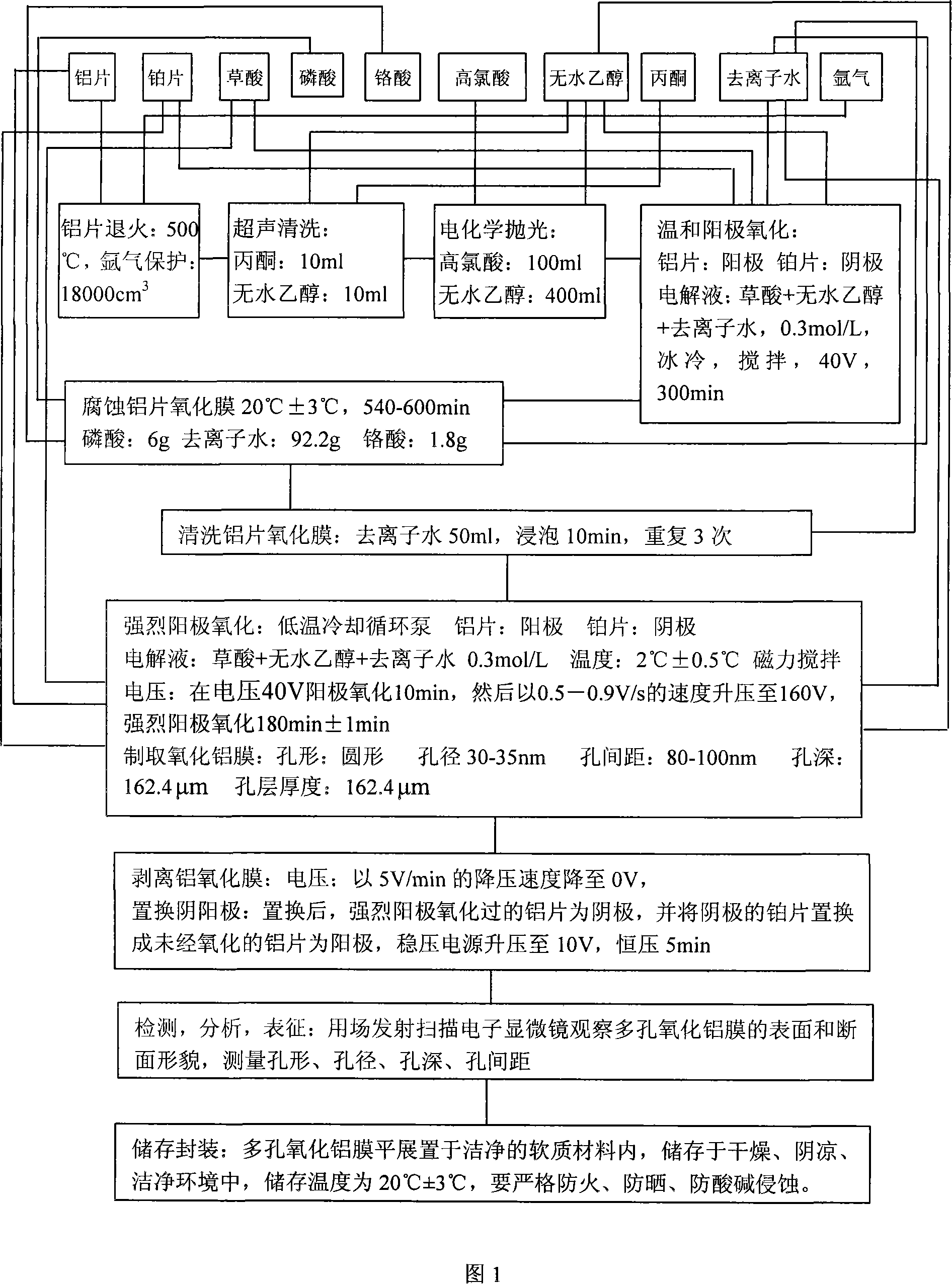

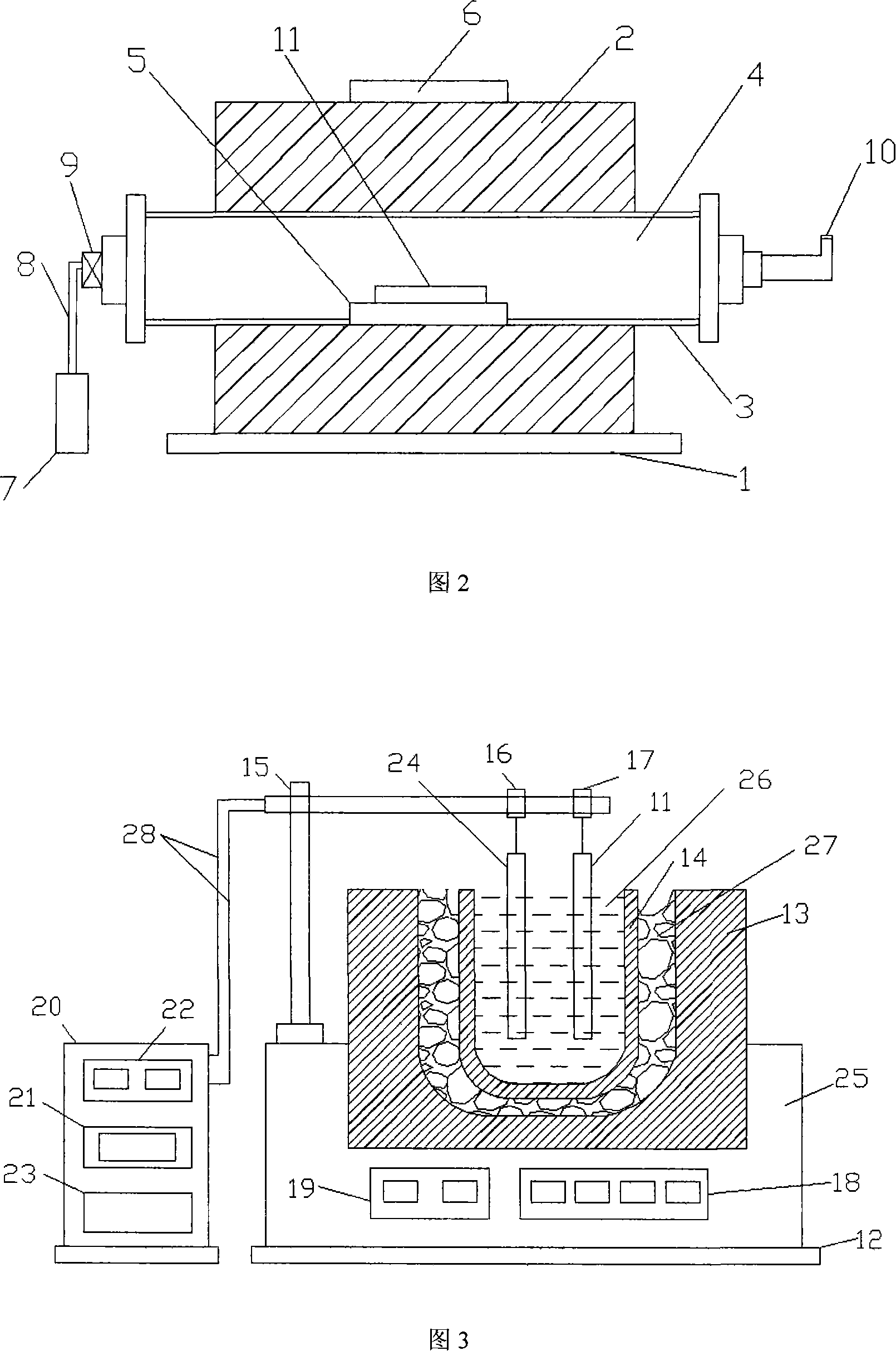

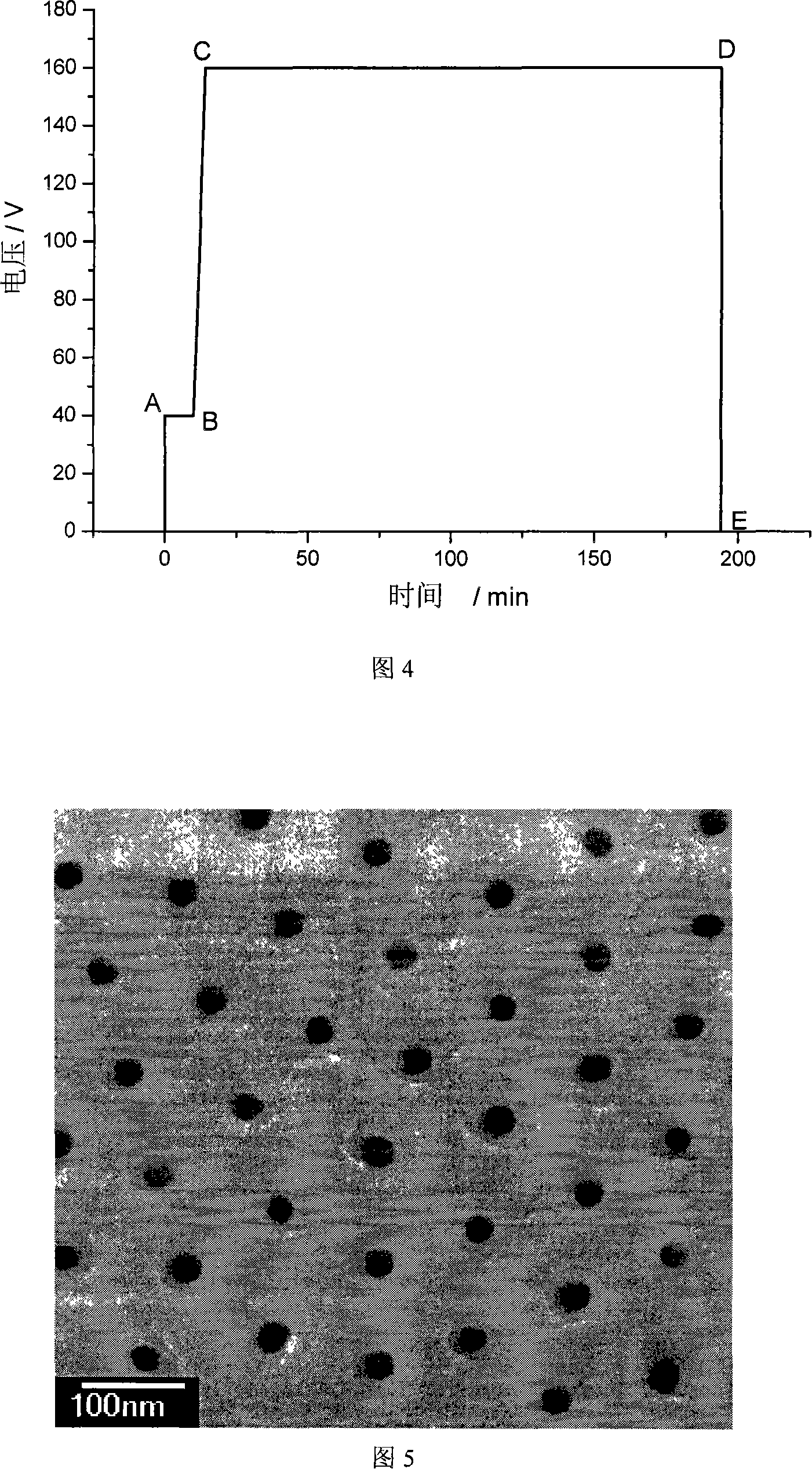

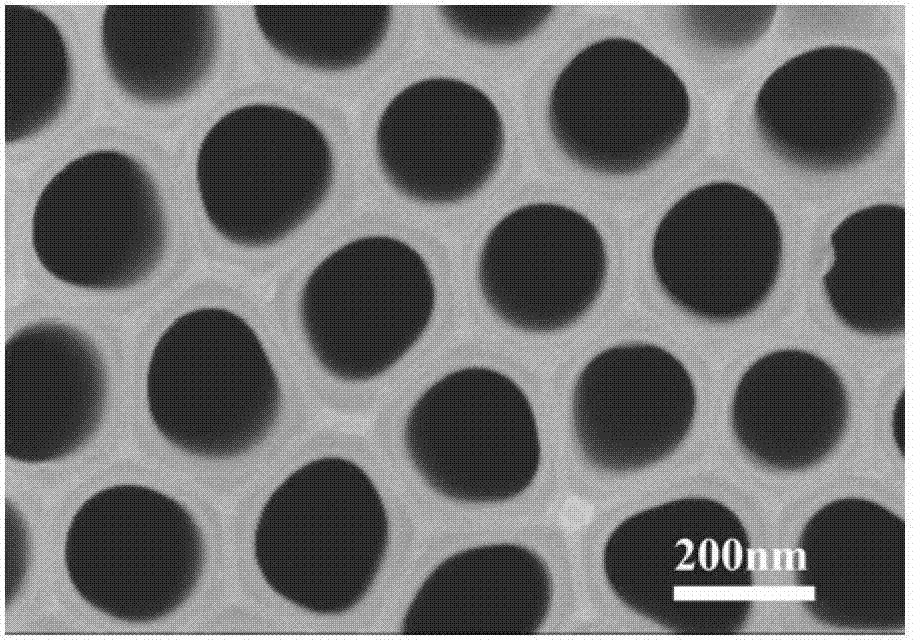

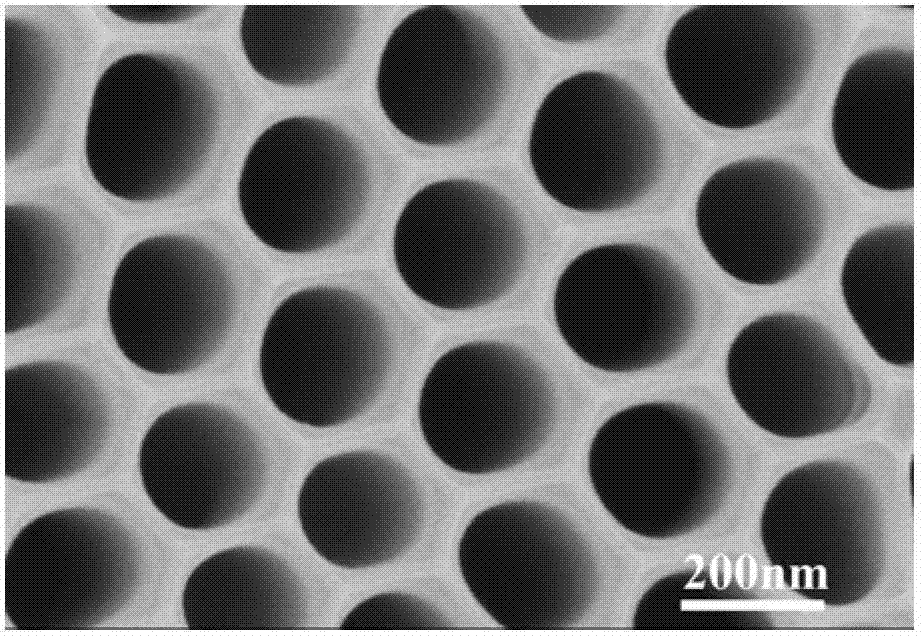

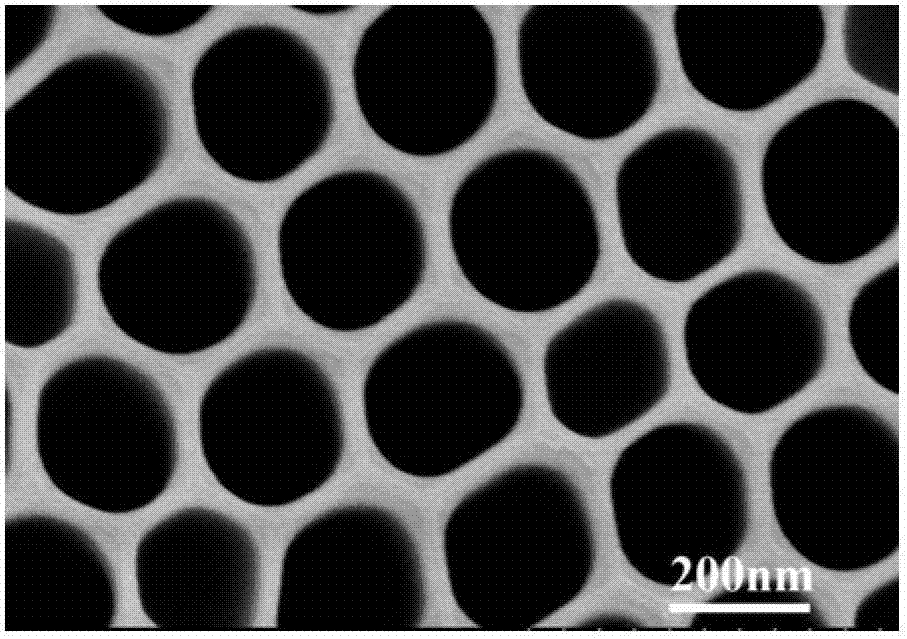

Strong anodic oxidation method for preparing porous pellumina

InactiveCN101139730AReduce pollutionRich sourcesSurface reaction electrolytic coatingShielding gasPhosphoric acid

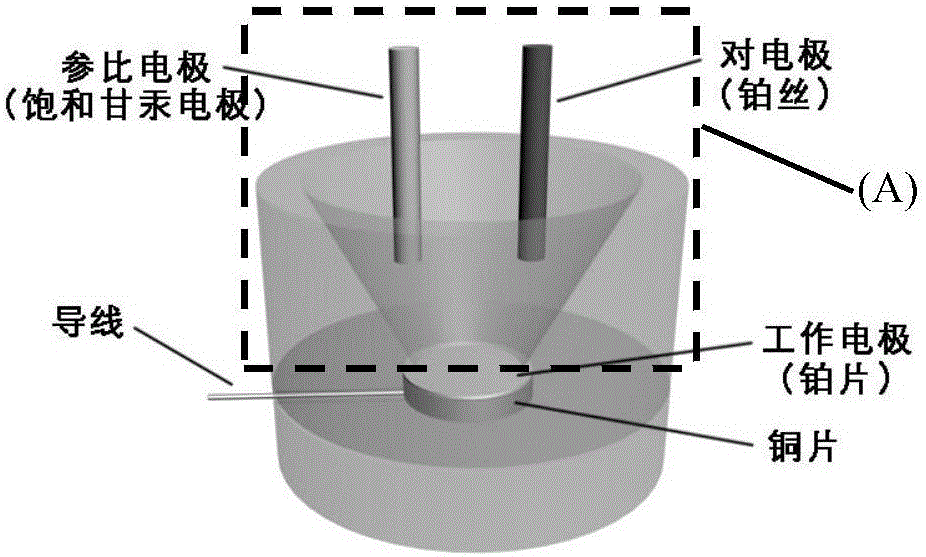

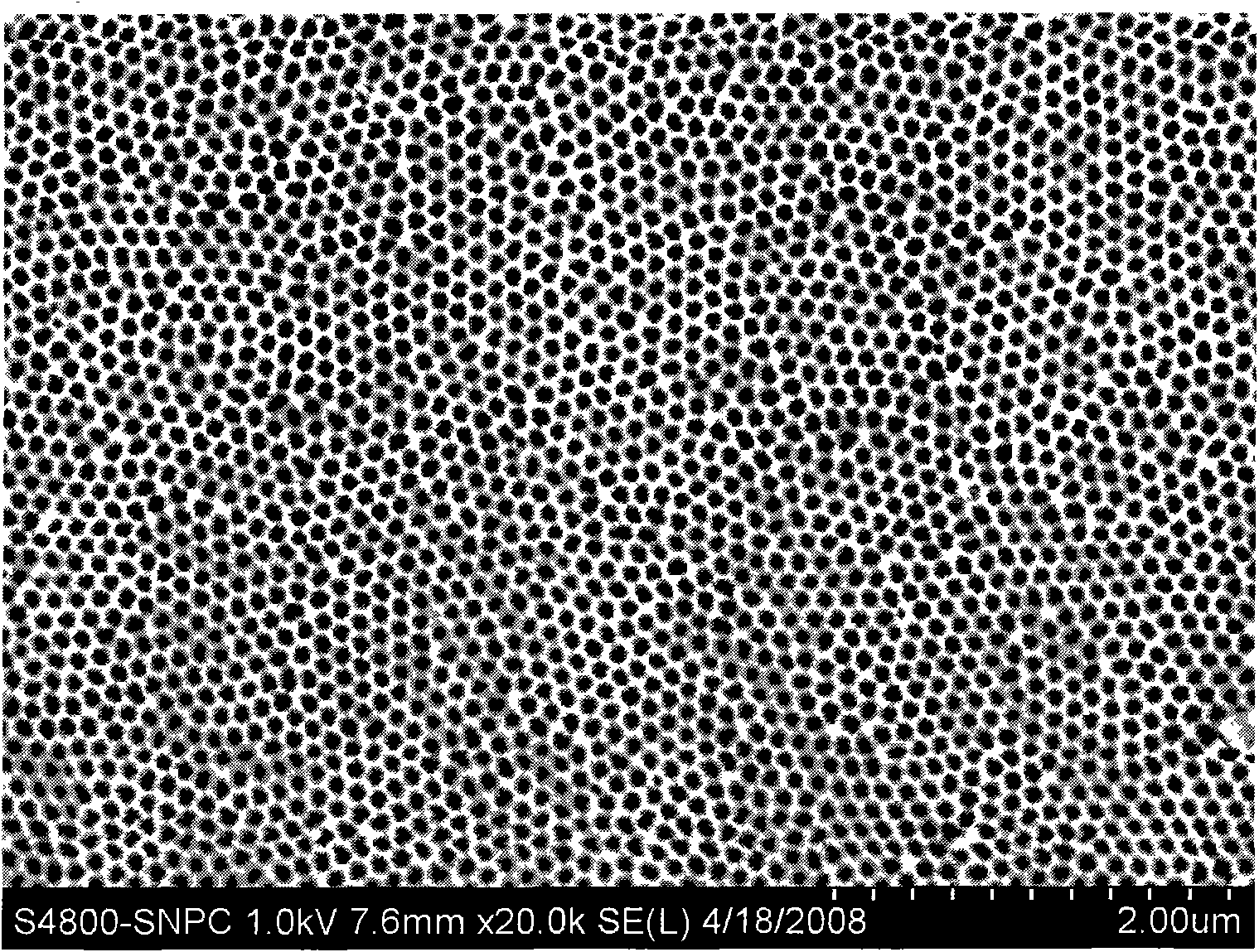

The invention relates to an intensive anodic oxidation process to prepare porous anodic alumina film. An aluminum sheet is as an anode; a platinum sheet as a cathode; argon as shielded gas; mixed solution of perchloric acid with absolute alcohol as electrochemical polishing compound for the aluminum sheet; mixed solution of oxalic acid, absolute alcohol and deionized water as electrolyte; and mixed solution of phosphoric acid, chromic acid and deionized water as alumina film corrodent. Through aluminum sheet annealing, purging, electrochemical polishing, mild anodic oxidation, corrosion on aluminum sheet oxide film, intensive anodic oxidation and stripping oxide film, and finally, pale yellow, high purity and ordered porous-structured nanometer-leveled alumina film is achieved; The alumina film pore is in circular shape sized in 30 to 35nm, pore distance in 80 to100nm and pore depth in 162.4 micrometers; growth rate of the alumina film is 54 micrometers / h, which is 27 times higher than 2 micrometers / h of growth rate of anodic oxidation aluminum film prepared through mild anodic oxidation process.

Owner:TAIYUAN UNIV OF TECH

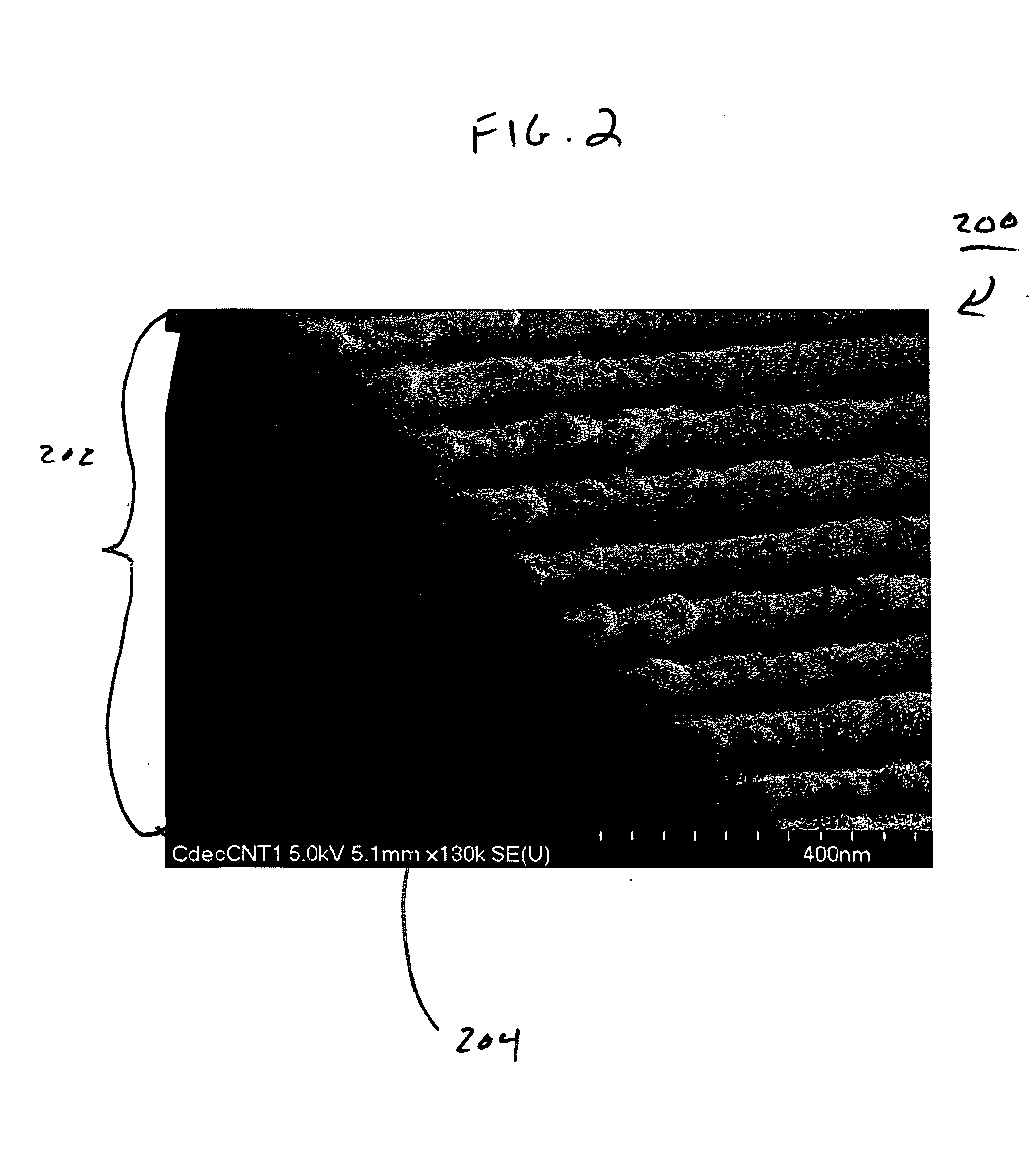

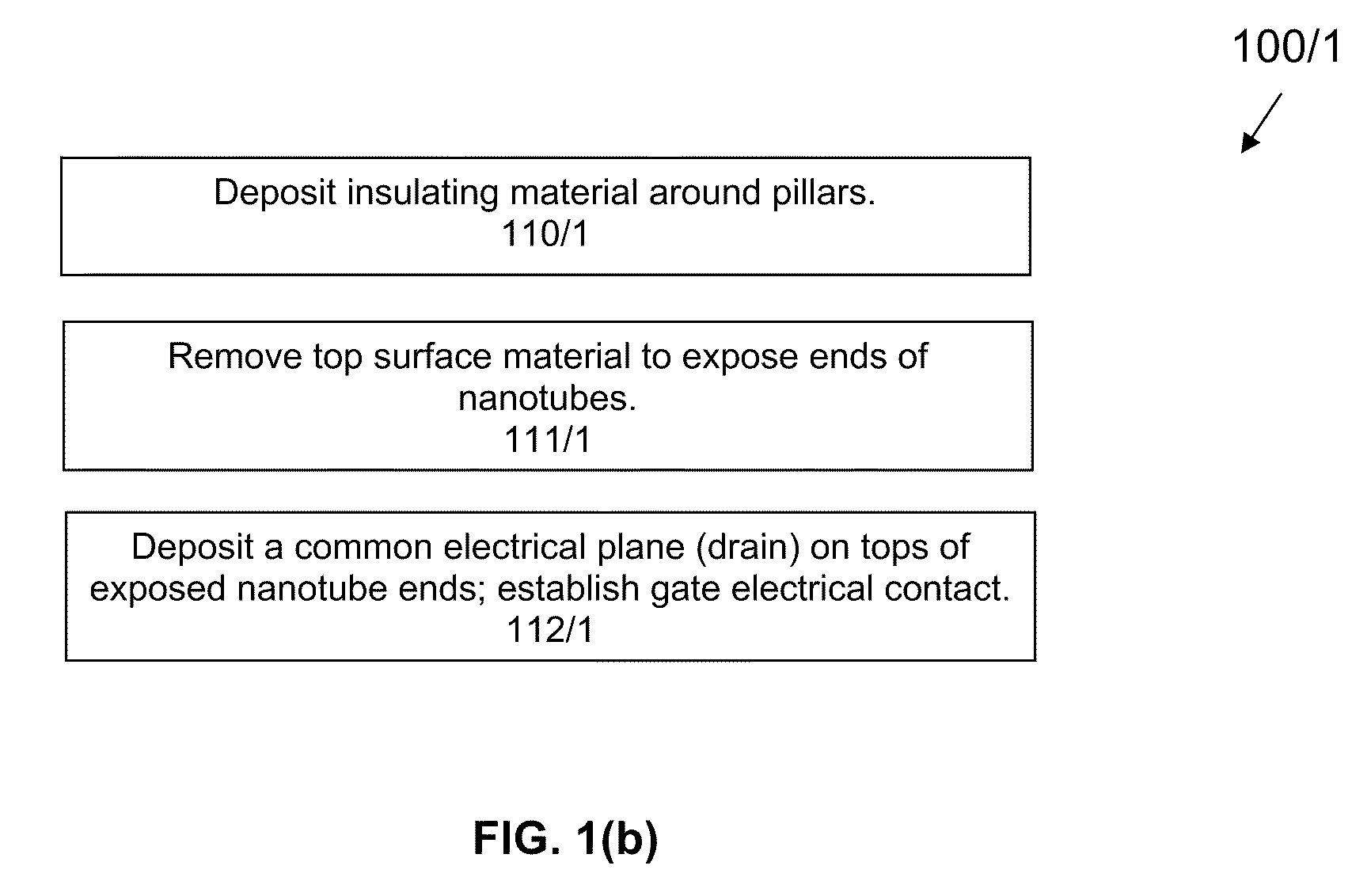

Contact metallization of carbon nanotubes

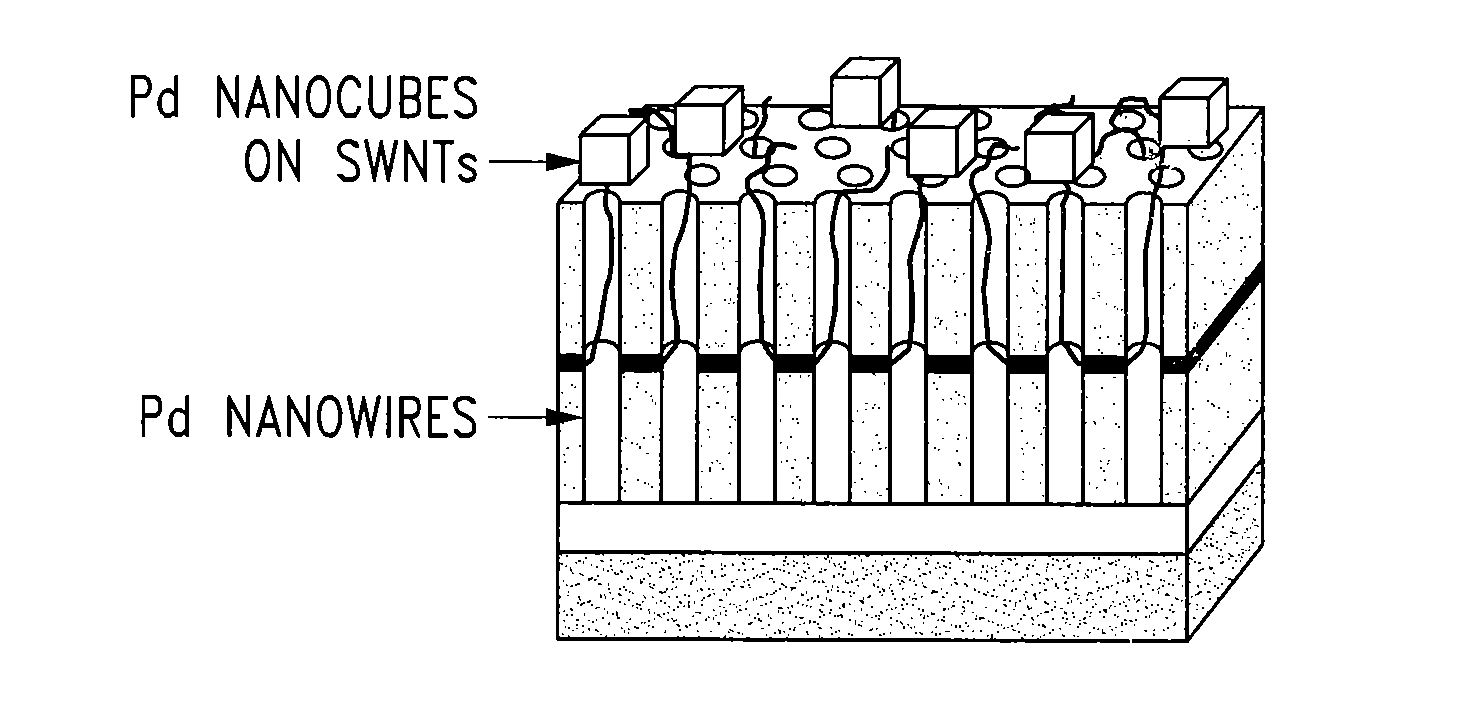

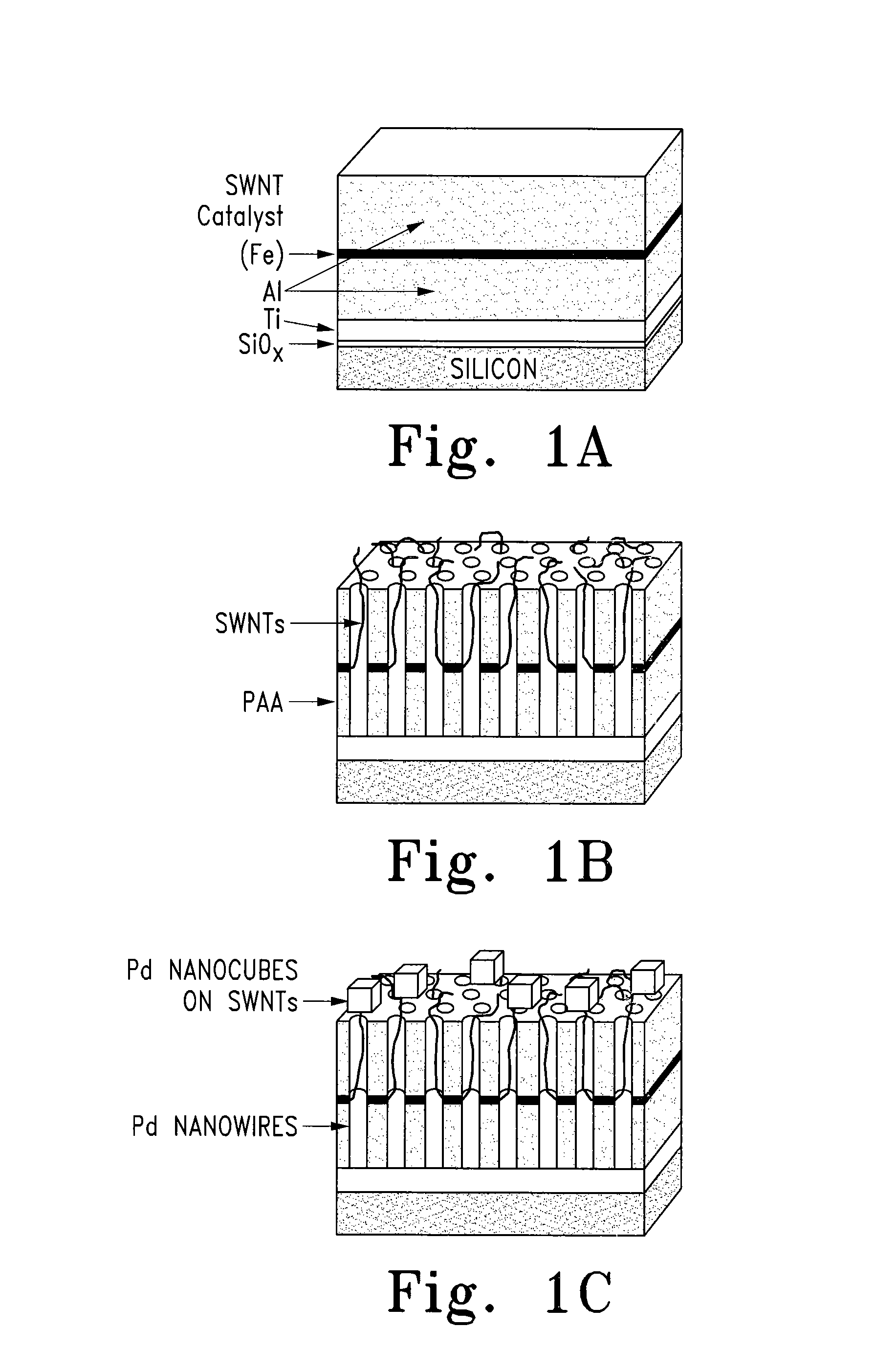

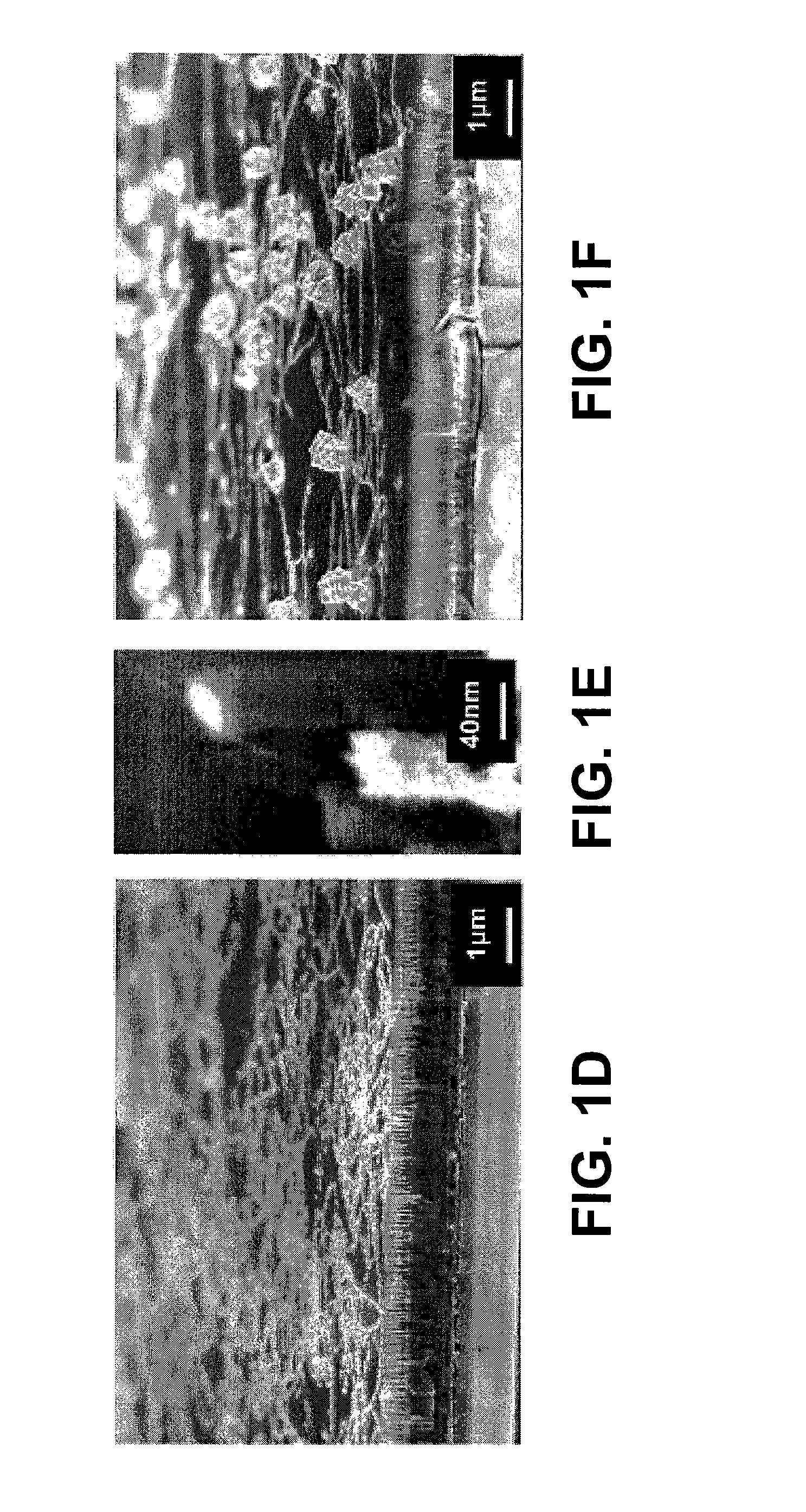

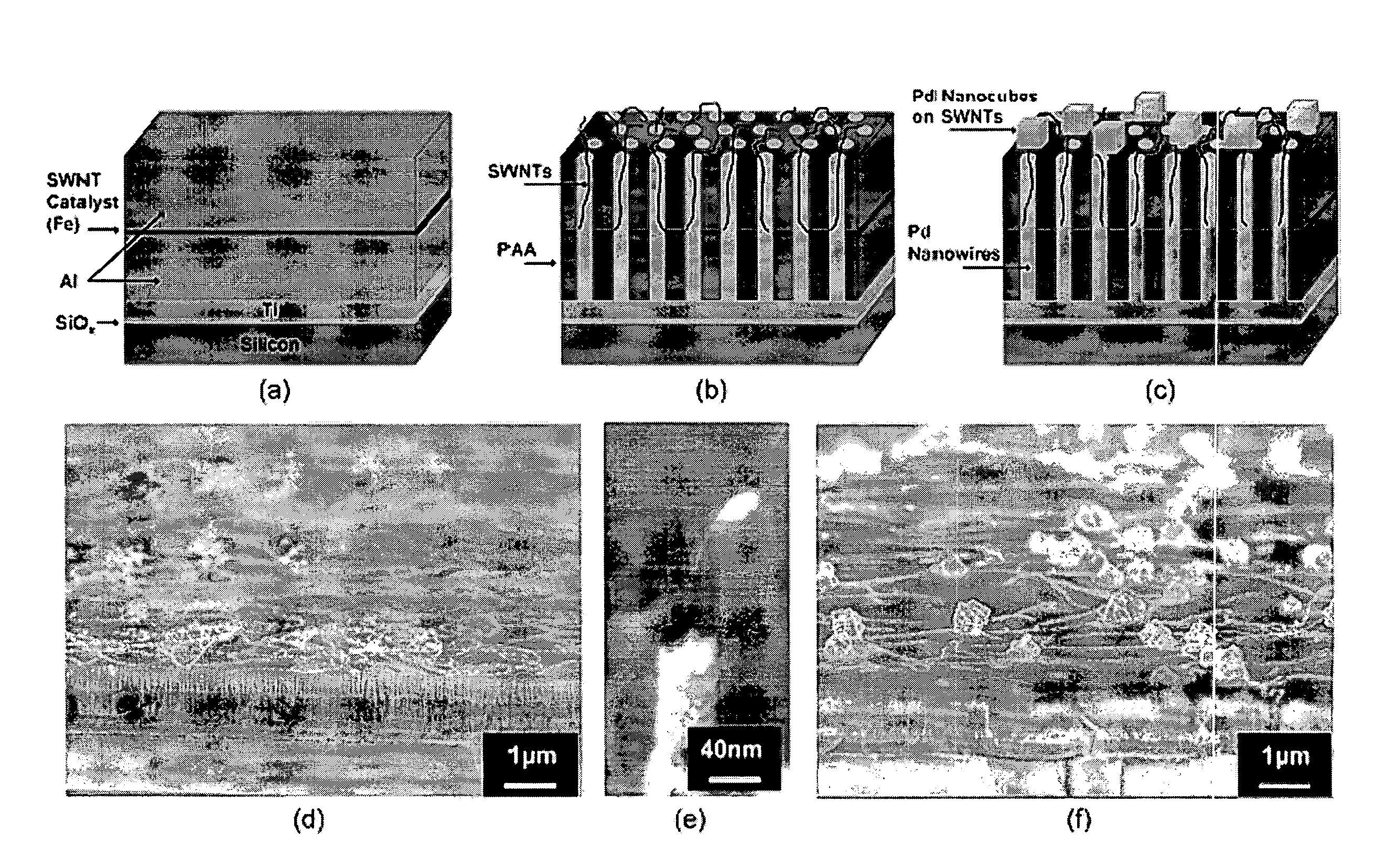

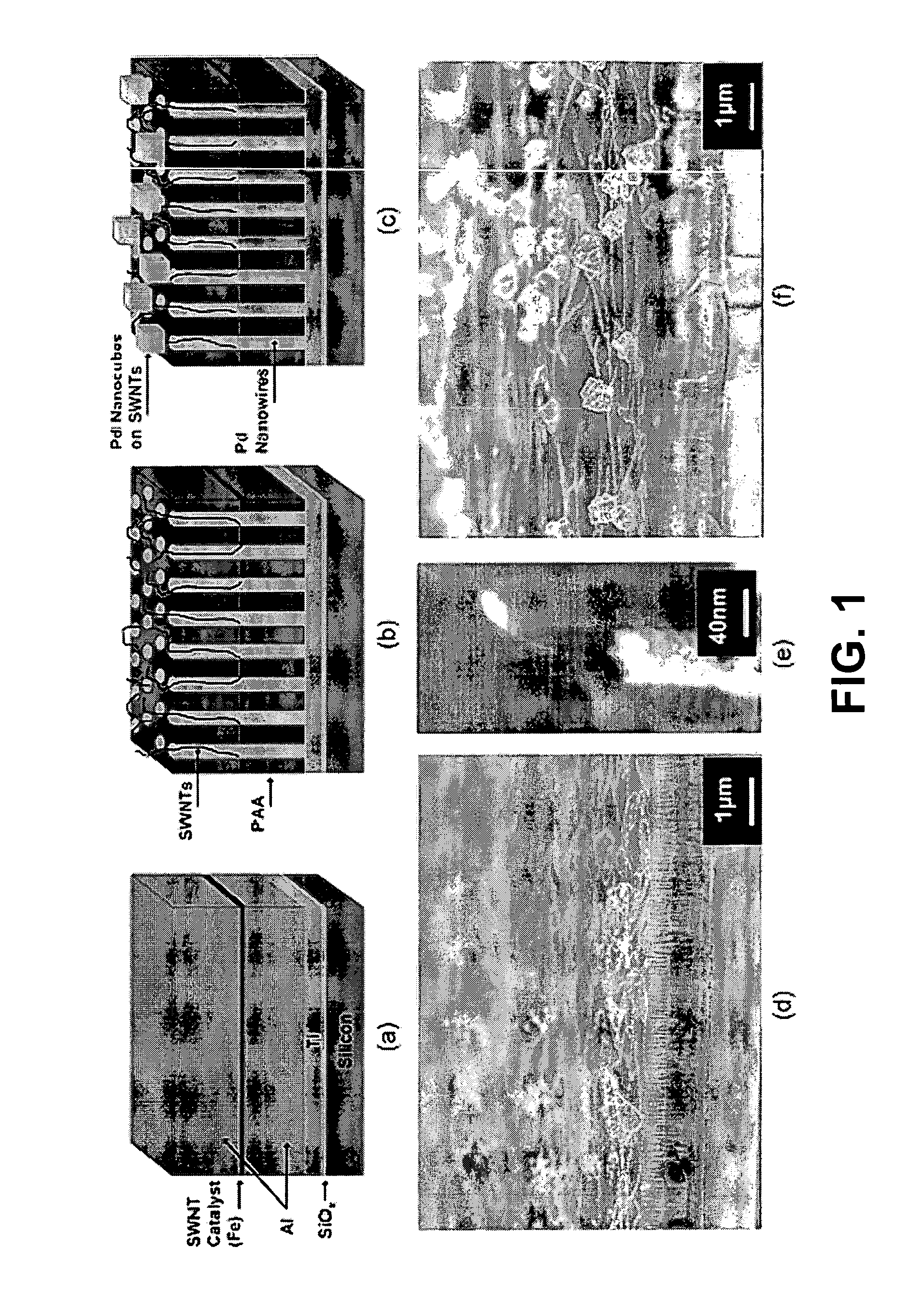

In one embodiment, SWNTs are synthesized from an embedded catalyst in a modified porous anodic alumina (PAA) template. Pd is electrodeposited into the template to form nanowires that grow from an underlying conductive layer beneath the PAA and extend to the initiation sites of the SWNTs within each pore. Individual vertical channels of SWNTs are created, each with a vertical Pd nanowire back contact. Further Pd deposition results in annular Pd nanoparticles that form on portions of SWNTs extending onto the PAA surface. Two-terminal electrical characteristics produce linear I-V relationships, indicating ohmic contact in the devices.

Owner:PURDUE RES FOUND INC

Process for producing ordered porous anodic alumina form

The present invention discloses one kind of ordered porous anode oxidized alumina template preparing process. Compared with available technology, the said process has the advantages of capacity one preparing great area highly ordered nanometer template, high template success rate and high template quality including raised nanometer pore arrangement orderliness, pore size homogeneity, depth uniformity and porosity.

Owner:DONGGUAN UNIV OF TECH

Modulation method for shape morphing of hole of anodic aluminum oxide template

The invention discloses a modulation method for shape morphing of a hole of an anodic aluminum oxide template, which comprises the following steps: I. removing grease and dirt of the surface of annealing-treated or untreated aluminium foil, and then carrying out electrochemical polishing treatment on the aluminium foil for later use; II. forming pit patterns on the surface of the aluminium foil by adopting an electrochemical oxidation method or a hard template mechanical pitting method; and III. carrying out noncontinuous oxidation and chambering on the aluminium foil the surface of which is provided with the pit patterns in an acid electrolyte to form various three-dimensional morphing-type aluminum oxide nanopore array structures by the combination control of electrolyte composition, electrolyte temperature, oxidation voltage, oxidation and chambering frequency and oxidation and chambering time. The modulation method uses existing equipment, has simple implementation and can manufacture various three-dimensional morphing shape-adjustable porous anodic aluminum oxide templates in manner of low cost and big area.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

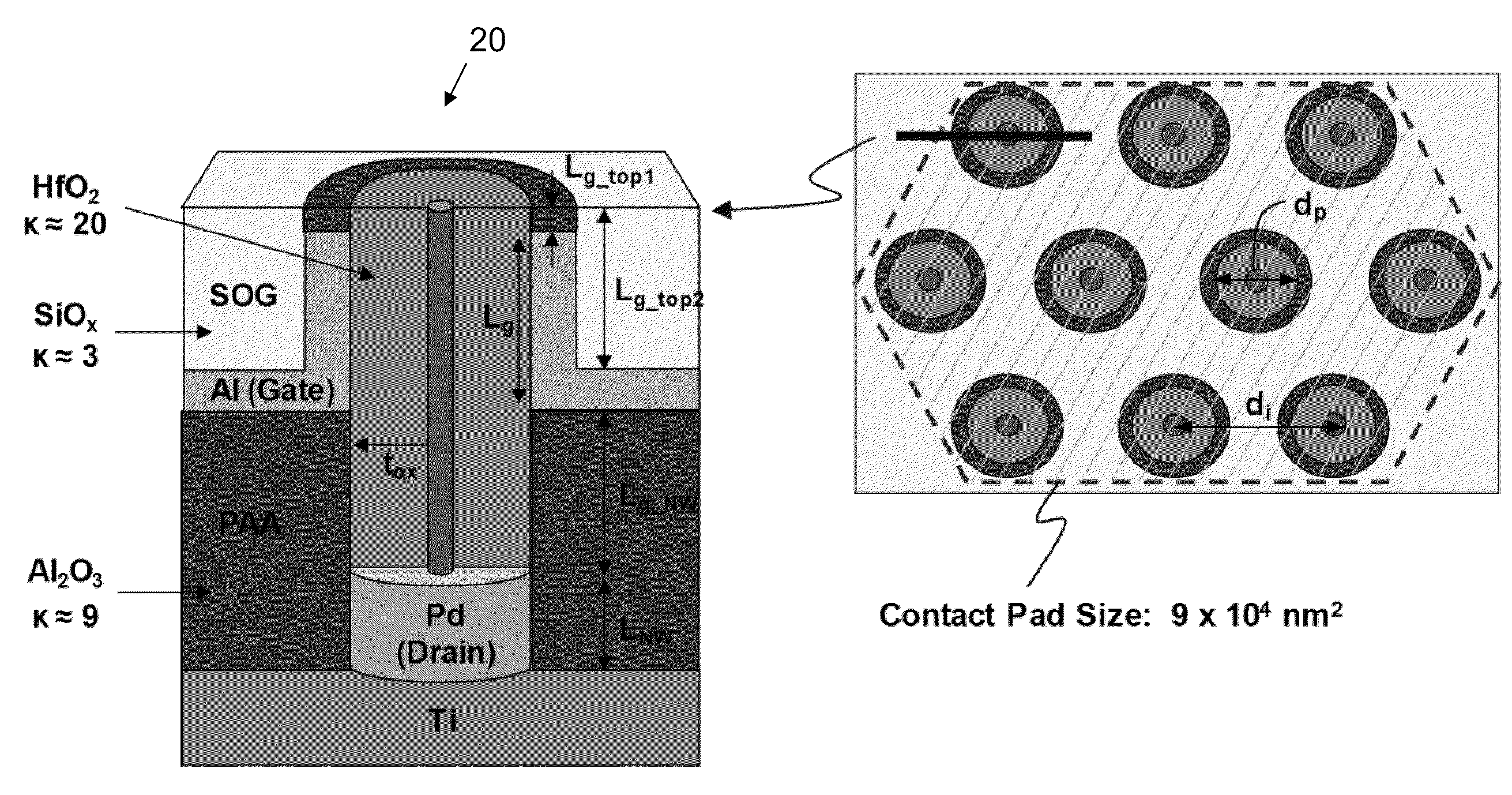

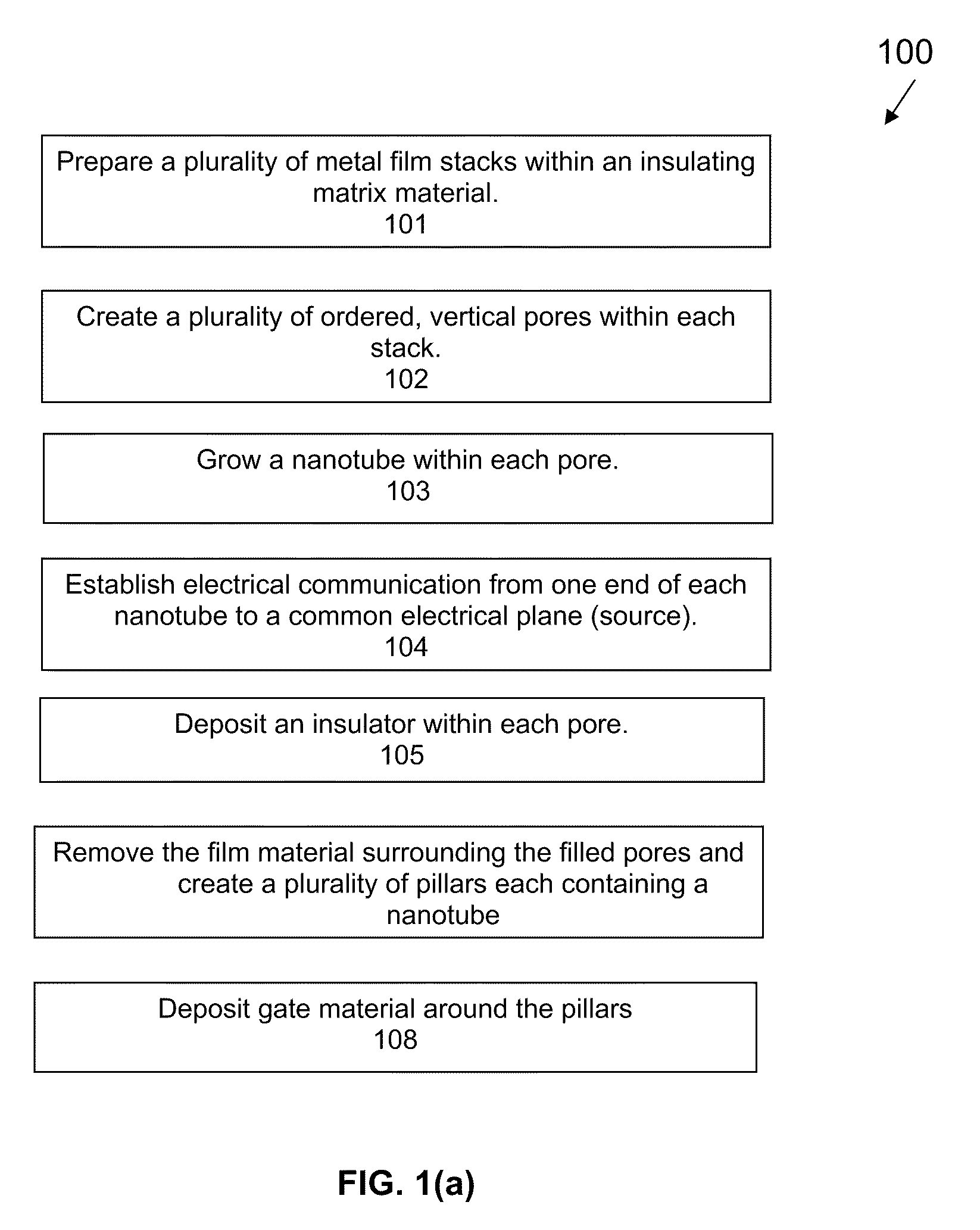

Vertical carbon nanotube device in nanoporous templates

InactiveUS20080176058A1Material nanotechnologyLayered productsCarbon nanotubePorous anodic aluminum oxide

A modified porous anodic alumina template (PAA) containing a thin CNT catalyst layer directly embedded into the pore walls. CNT synthesis using the template selectively catalyzes SWNTs and DWNTs from the embedded catalyst layer to the top PAA surface, creating a vertical CNT channel within the pores. Subsequent processing allows for easy contact metallization and adaptable functionalization of the CNTs and template for a myriad of applications.

Owner:PURDUE RES FOUND INC

Field effect transistor fabrication from carbon nanotubes

ActiveUS20100295023A1Semiconductor/solid-state device detailsNanoinformaticsSemiconductor materialsCarbon nanotube

Methods and apparatus for an electronic device such as a field effect transistor. One embodiment includes fabrication of an FET utilizing single walled carbon nanotubes as the semiconducting material. In one embodiment, the FETs are vertical arrangements of SWCNTs, and in some embodiments prepared within porous anodic alumina (PAA). Various embodiments pertain to different methods for fabricating the drains, sources, and gates.

Owner:PURDUE RES FOUND INC

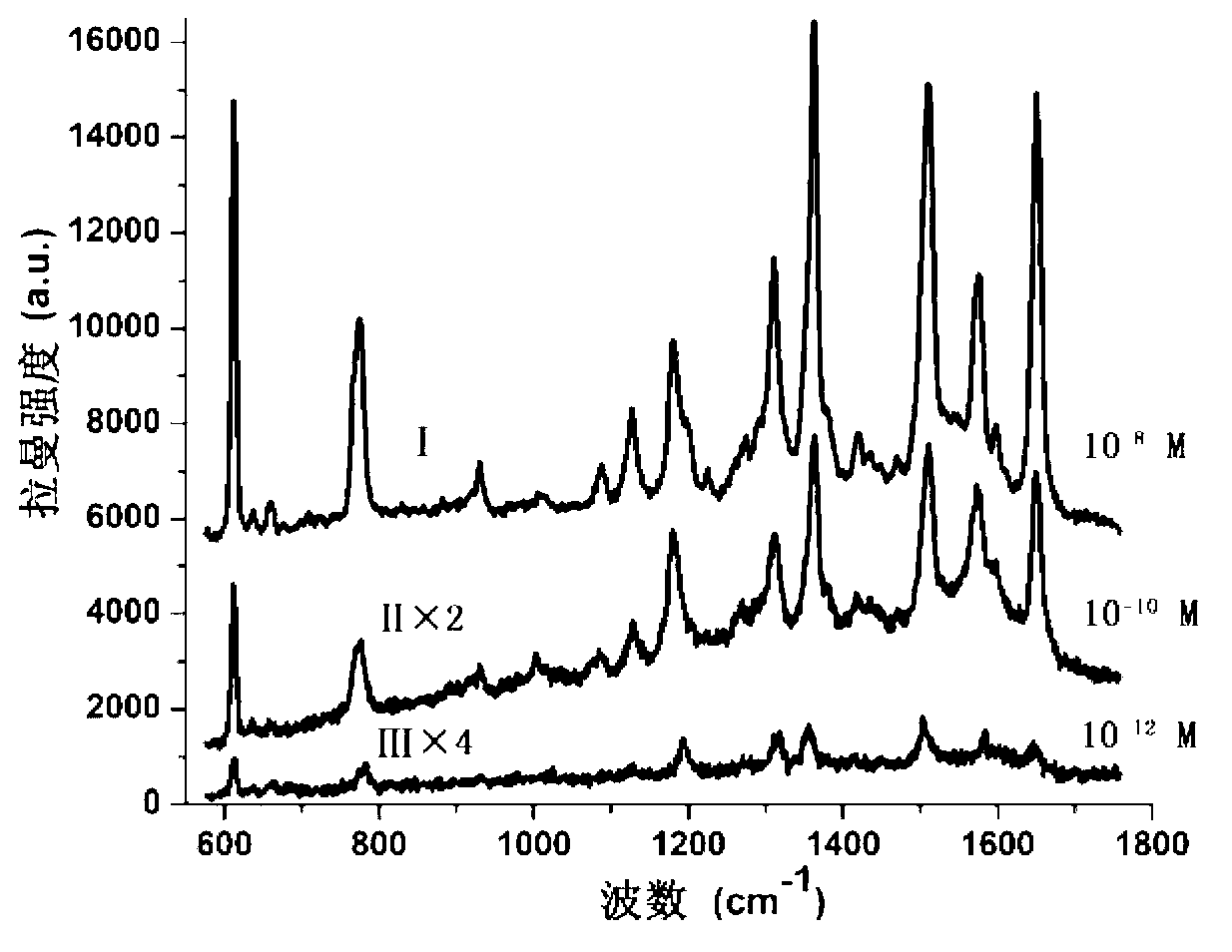

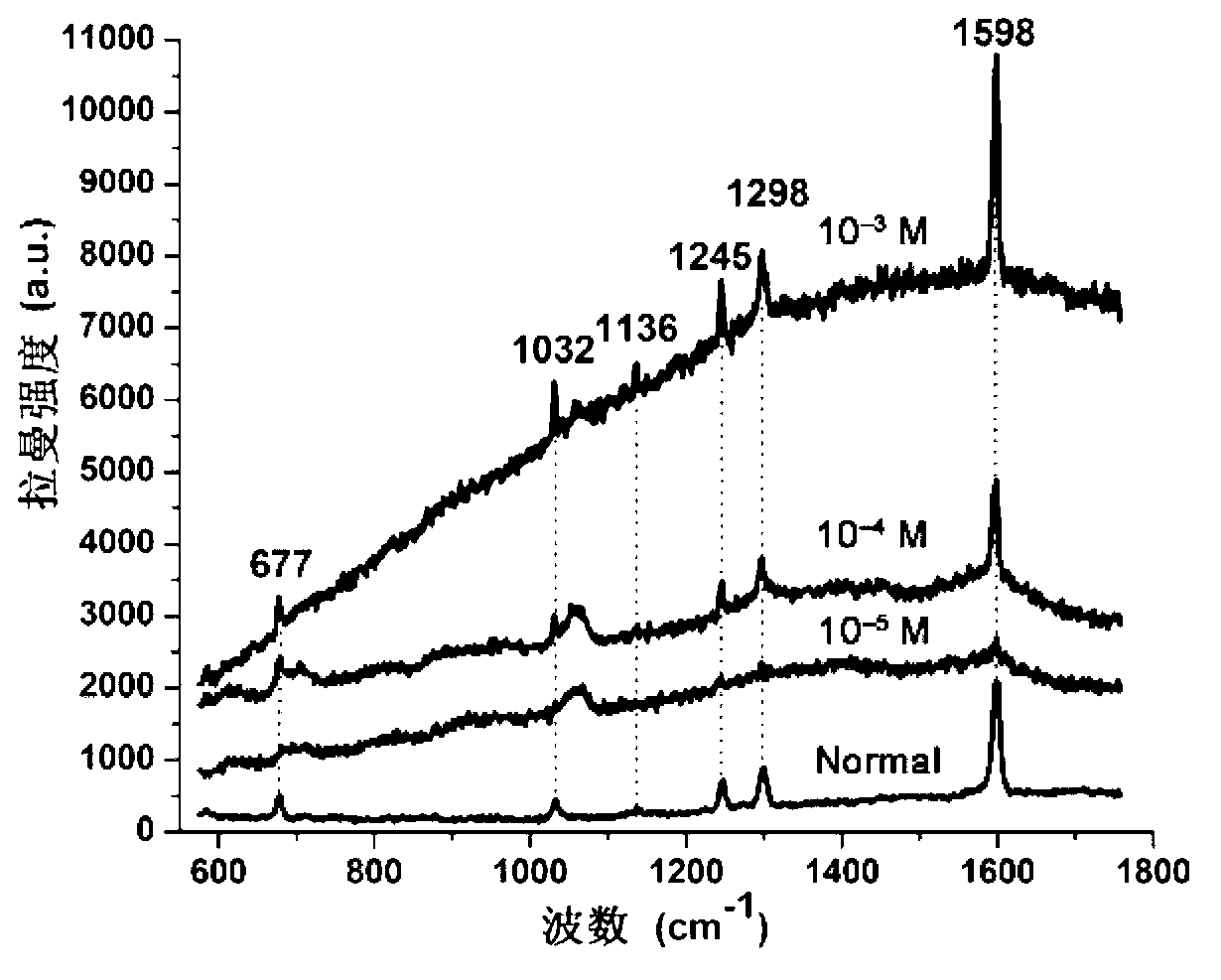

Silver nanometer column array erected on orifice of porous alumina template and preparation method and application thereof

InactiveCN103060878AMaintain propertiesHigh SERS activityVacuum evaporation coatingSurface reaction electrolytic coatingOXALIC ACID DIHYDRATEPhosphorus acid

The invention discloses a silver nanometer column array erected on the orifice of a porous alumina template and a preparation method and application thereof. The silver nanometer column array is characterized in that silver nanometer columns with the heights of 30-200 nanometers and the diameters of 30-60 nanometers are sequentially hexagonally arrayed on the periphery of the orifice of the porous anodic alumina template with taper holes; and silver nanometer particles with the particle size of 5-40 nanometers are attached to the walls of the taper holes. The preparation method comprises the following steps of: firstly placing an aluminum sheet into an oxalic acid solution, and carrying out anodization at direct-current voltage for at least 2 hours; then placing into a phosphorus-chromium acid mixed solution, and soaking for at least 3 hours to obtain an intermediate product; then firstly placing the intermediate product into the oxalic acid solution, carrying out the anodization at the direct-current voltage for at least 20 seconds, then placing the intermediate product into a phosphorus acid solution, and soaking for at least 1 minute; repeating the process for at least 10 times to obtain the alumina template with the holes in the shape of the taper holes; and then placing the alumina template into an ion sputter for silver sputtering so as to prepare a target product. The silver nanometer column array disclosed by the invention can be used as an active base of surface-enhanced Raman scattering; and the content of rhodamine or tetrachlorobiphenyl which is attached to the silver nanometer column array is measured by using a laser Raman spectrometer.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Method for preparing anode aluminum oxide thin film with thick barrier layer

InactiveCN101104945ALarge specific surface areaImprove breakdown voltageSurface reaction electrolytic coatingCapacitanceSolvent

A preparation method of anodic aluminum oxide film with thick barrier layer is provided, which belongs to the field of material technology. The method comprises: the first-step oxidation: placing an aluminum foil (without annealing and electrochemical polishing treatment) in an acid electrolyte containing water or ethylene glycol as solvent, performing the first-step anodic oxidation in a constant current or voltage mode to obtain a porous anodic aluminum oxide film; the second-step oxidation: performing the second-step oxidation of the porous anodic aluminum oxide film produced by the first-step oxidation in a neutral electrolyte containing water or ethylene glycol as solvent in a constant current mode until the breakdown voltage is reached. With this preparation method, the aluminum oxide film has high specific surface area and thick barrier layer and simultaneously exhibits larger electrostatic capacitance and higher breakdown voltage, and is widely used in field of high-performance aluminum electrolytic capacitor and other micro-electronics.

Owner:SHANGHAI JIAO TONG UNIV

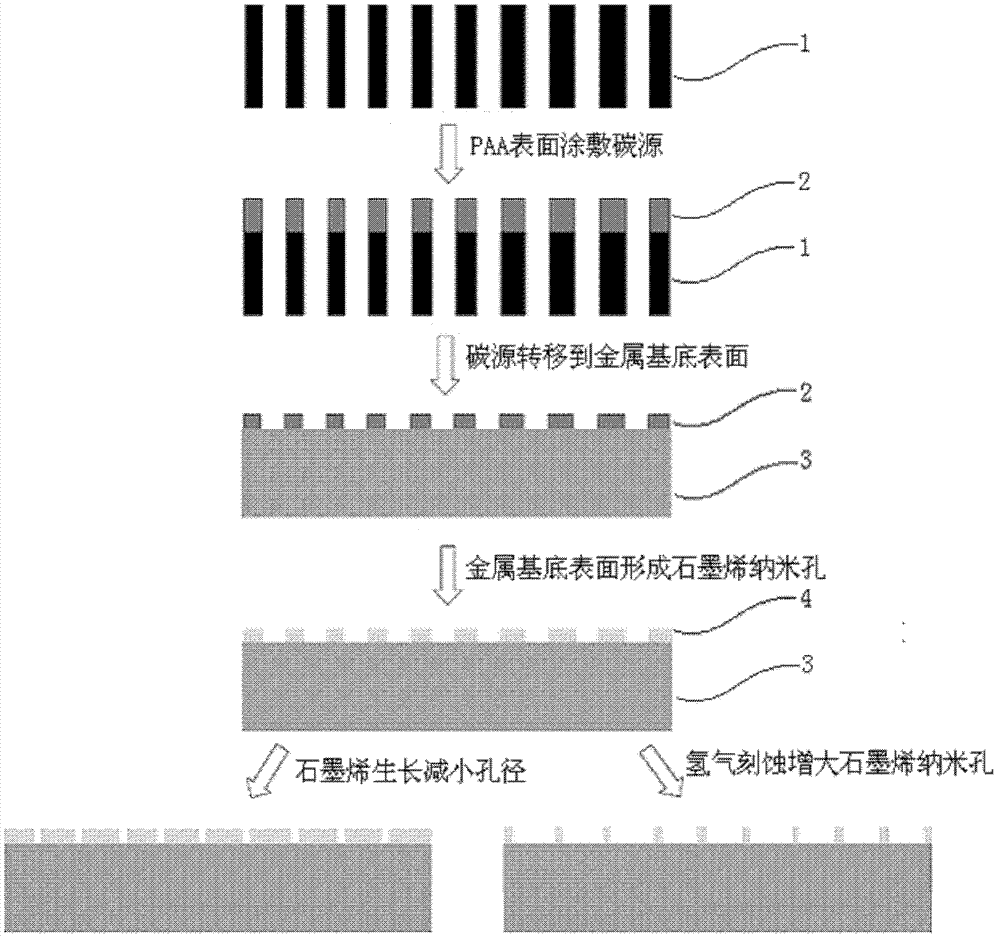

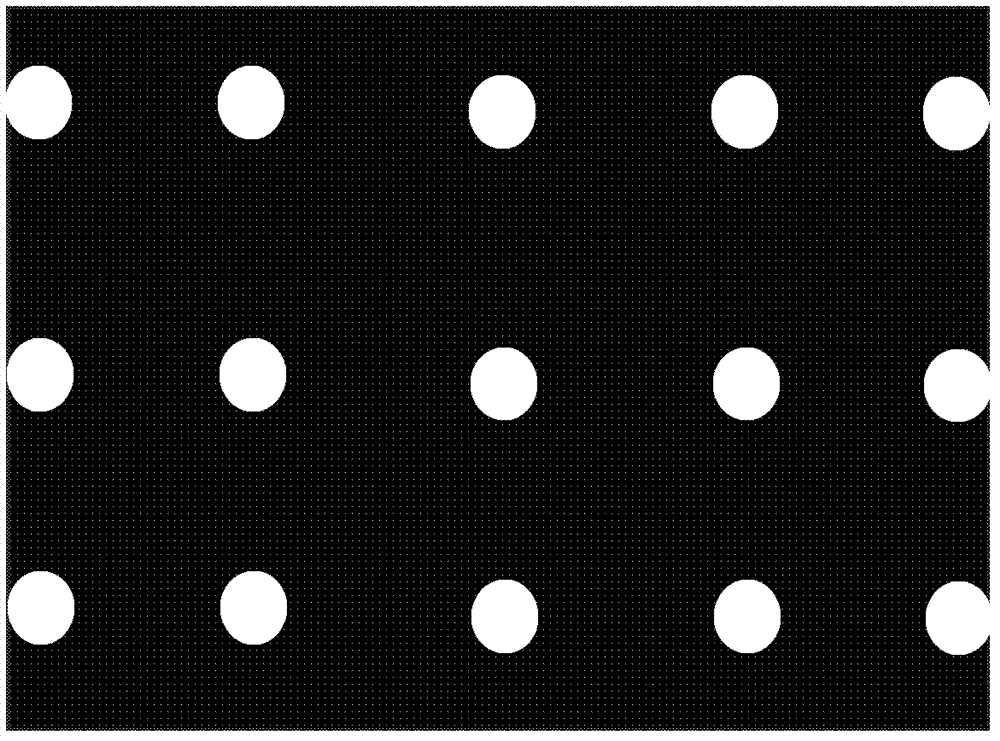

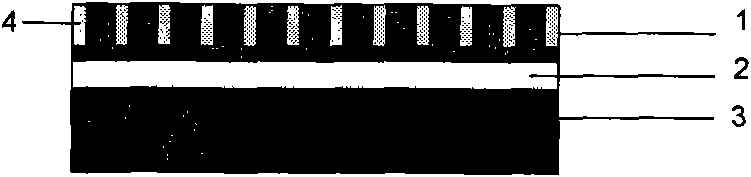

Method for preparing graphene nanopore array through chemical vapor deposition by using porous anodic alumina (PAA) as template

The invention provides a method for preparing a graphene nanopore array, which comprises the following steps: 1) coating a carbon source solution on the surface of a porous anodic alumina (PAA) template; 2) pressing the PAA template with the carbon source coated on the surface (obtained in the step 1)) on the surface of a metal base, peeling the PAA template, and ensuring that the carbon source is reserved on the surface of the metal base and the carbon source reserves a pattern which is consistent with that on the surface of the PAA template; and 3) performing annealing treatment on the obtained metal base in the presence of a mixed gas flow of hydrogen gas and argon gas, thus converting the carbon source into the graphene nanopore array. The nanopore array obtained by the invention is an interconnected nanopore array structure rather other a single nanopore or several nanopores; and the pore size of the nanopores can be regulated through the template effect of the PAA itself, and can be further regulated through growing and etching in the later stage. Thus, the pore size controllability is very excellent.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Thick porous anodic alumina films and nanowire arrays grown on a solid substrate

InactiveUS20070224399A1Promote growthMore tractableMaterial nanotechnologyPolycrystalline material growthSingle stageNanowire array

Owner:MASSACHUSETTS INST OF TECH

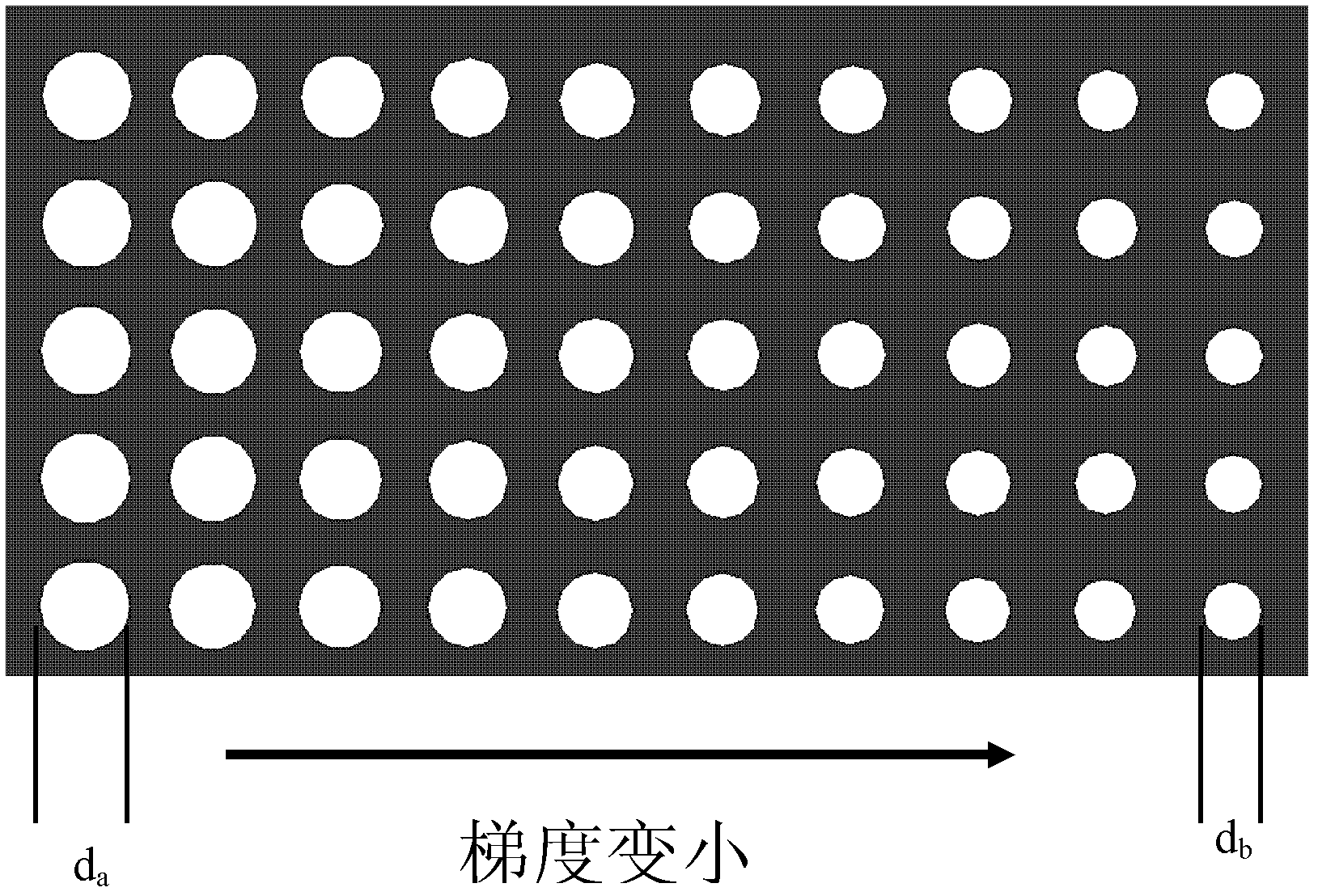

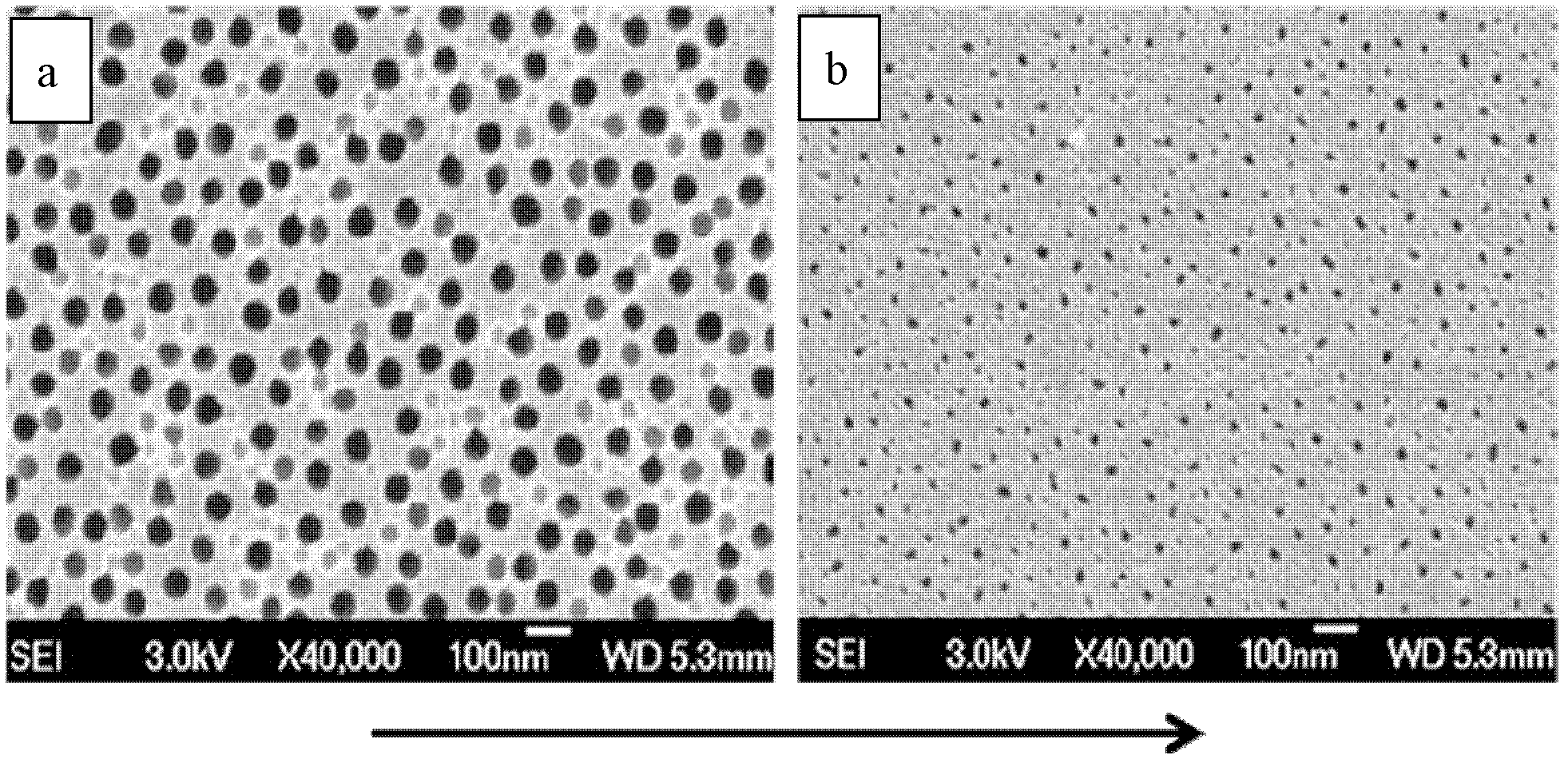

Preparation method for anode alumina template having gradient nanometer pore size

The present invention relates to the field of porous anode alumina templates, particularly to a preparation method for an anode alumina template having a gradient nanometer pore size. According to the preparation method, a porous anode alumina template is immersed in an inorganic acid aqueous solution, and then is rapidly pulled out of the inorganic acid aqueous solution to obtain the anode alumina template having a gradient nanometer pore size, wherein the gradient nanometer pore size has a characteristic of large lower portion and small upper portion. According to the present invention, the preparation method has characteristics of convenience and rapidness, and various anode alumina templates having different gradient pore size changes can be prepared by changing the concentration and the temperature of the inorganic acid aqueous solution, and the pulling-out time.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for preparing highly ordered porous anodic alumina films in superhigh speed

InactiveCN101654799AHinder dissolutionImprove conductivitySurface reaction electrolytic coatingWater bathsElectrolysis

The invention discloses a method for preparing highly ordered porous anodic alumina films in superhigh speed, relating to the application fields including the surface treating field of nonferrous metal and the preparation and application field of new materials in nanometer structures. Aluminum materials are used as anodes without high-temperature annealing or chemical polishing, a mixed solution containing oxalic acid, aluminum sulfate and ethylene glycol is used as an improved oxalic acid electrolyte system, the primary electrolysis is performed in the common technology, the secondary electrolysis is performed at the electrolyte temperature of 25 to 65 DEG C and under the direct-current electrolytic voltage of 30 to 50V after an oxide layer formed by the primary electrolysis is removed, and then the superhigh-speed growing method of porous anodic alumina films is directly realized; the growing speed is from 20 to 200 mum / h and is 10 to 50 times higher than that of the common technology for preparing the highly ordered porous anodic alumina films. The method does not need complicated thermal annealing and polishing, low-temperature requirements or high voltage and only needs a common water bath to stably prepare the highly ordered porous anodic alumina films in superhigh speed in a very wide temperature range.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Method for producing antireflection film of subwavelength structure

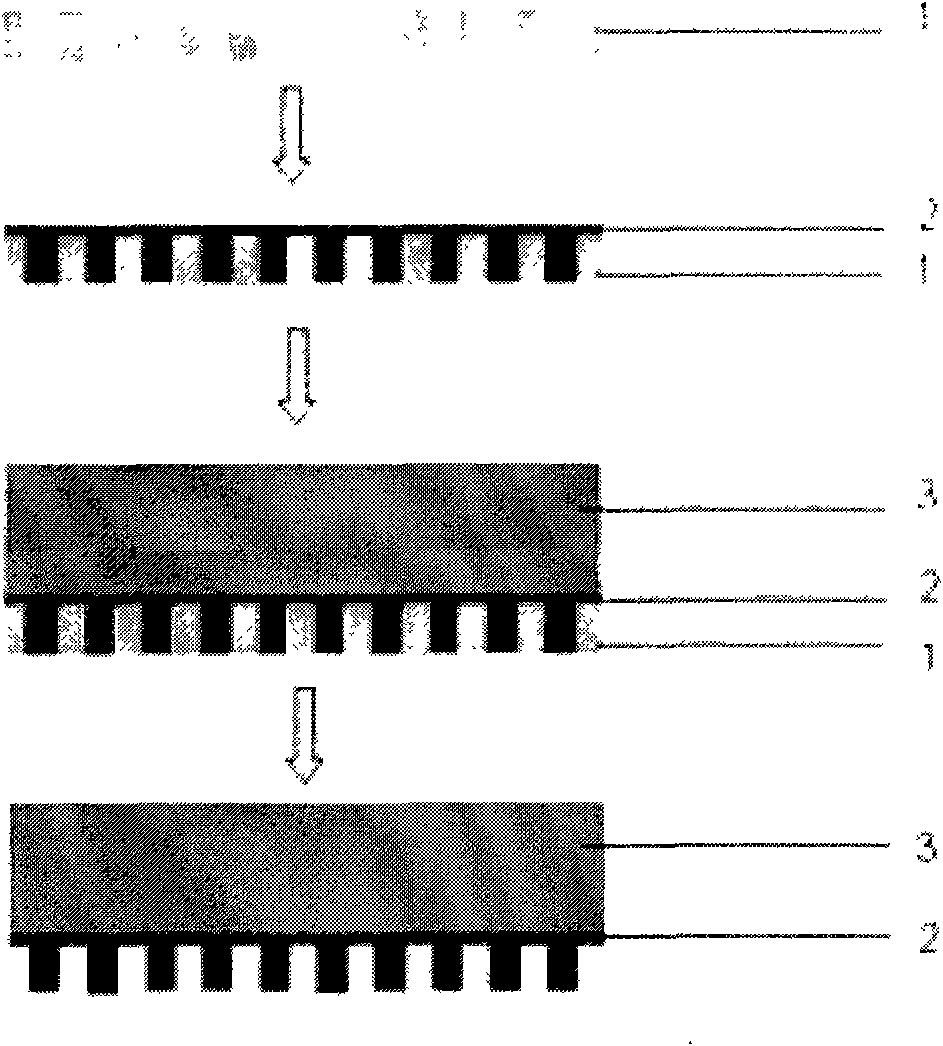

InactiveCN101398618AOvercome sizeOvercoming time-consuming disadvantagesPhotomechanical coating apparatusChemical industryUltraviolet lights

A preparation method of an anti-reflecting film with a sub-wavelength structure in the field of chemical industry comprises the following steps: step 1: a silicon chip is washed, heated and cooled to the room temperature; step 2: a porous anodic aluminum oxide template is washed and a release agent is coated on the porous anodic aluminum oxide template by vaporization; step 3: the silicon chip is slowly rotated to evenly spread a photoresist on the surface of the silicon chip, and then rotated at a high speed to remove the excessive photoresist and obtain the thinner and even photoresist; step 4: the porous anodic aluminum oxide template on the surface of which the release agent is coated by vaporization is aligned with the silicon substrate rotatably coated with the photoresist with even thickness, and then the porous anodic aluminum oxide template is pressed into the photoresist layer, and the photoresist is exposed and solidified with an ultraviolet light source; and step 5: after solidification, the porous anodic aluminum oxide template is scaled off, and the obtained photoresist is the anti-reflecting film. The anti-reflecting film prepared by the method has good antireflecting effect on broad band light.

Owner:SHANGHAI JIAO TONG UNIV

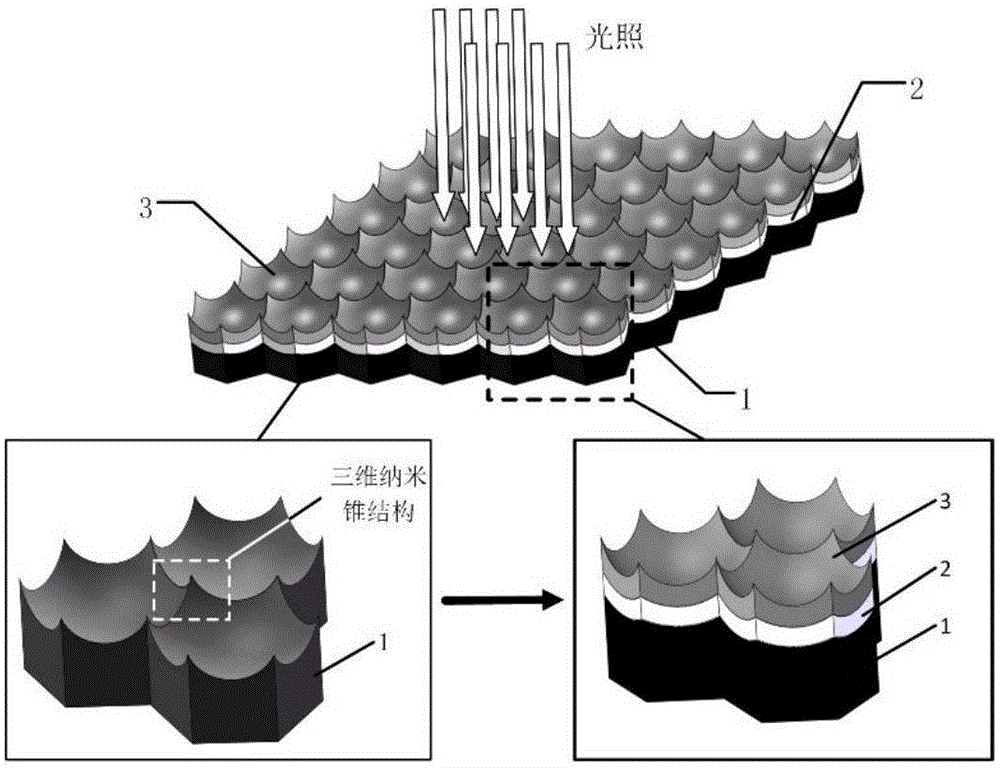

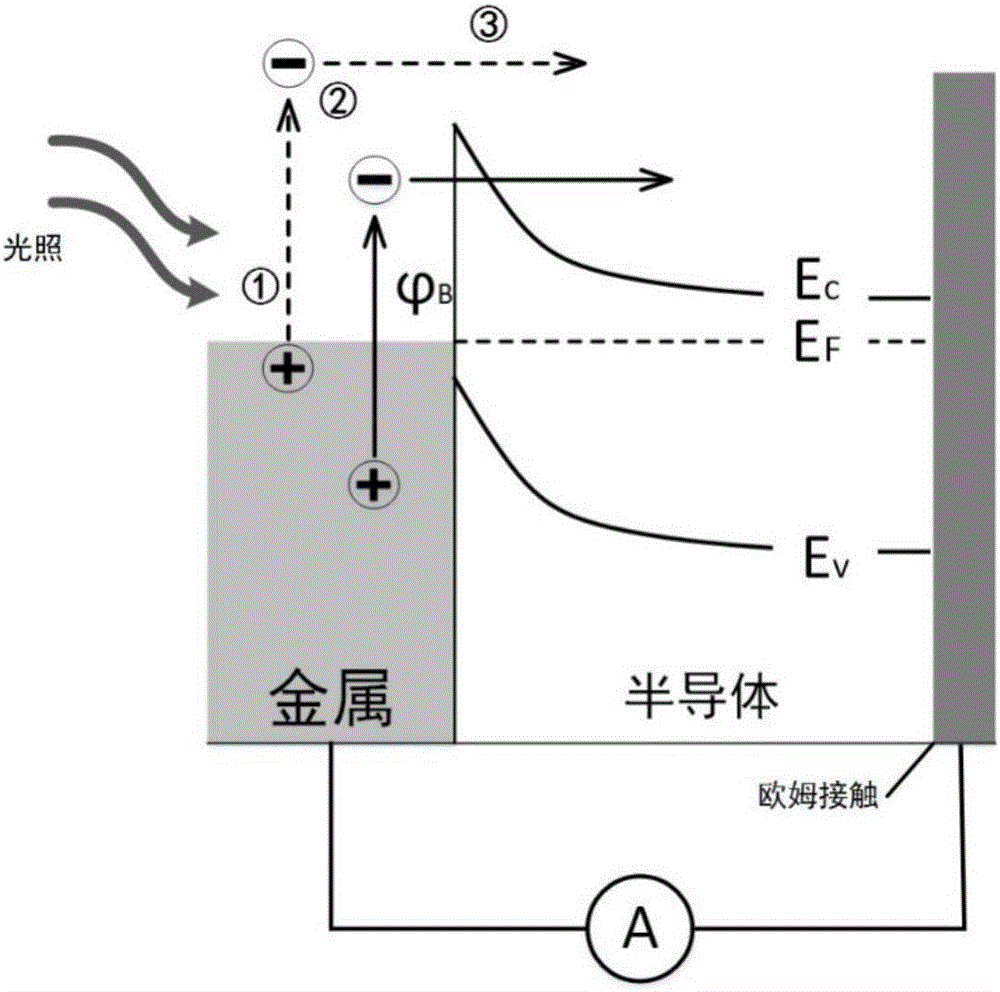

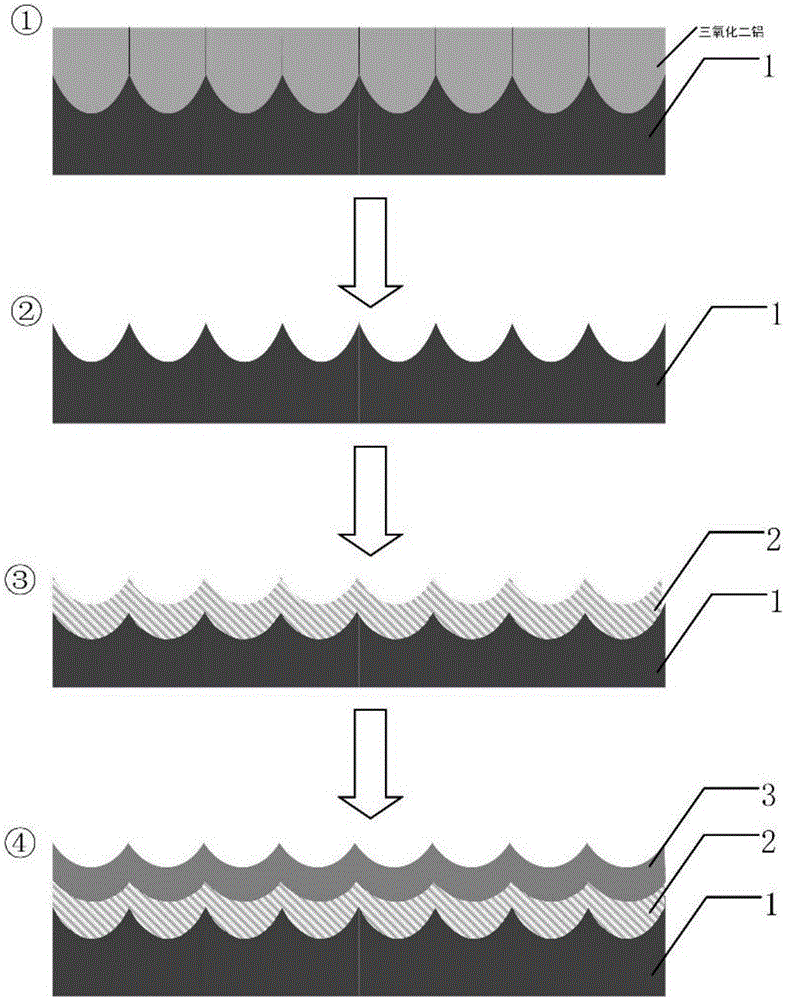

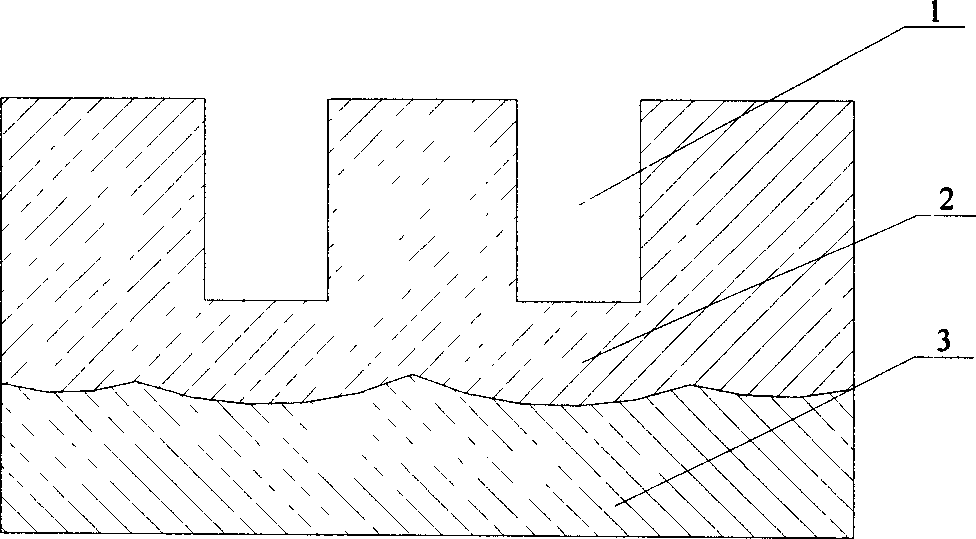

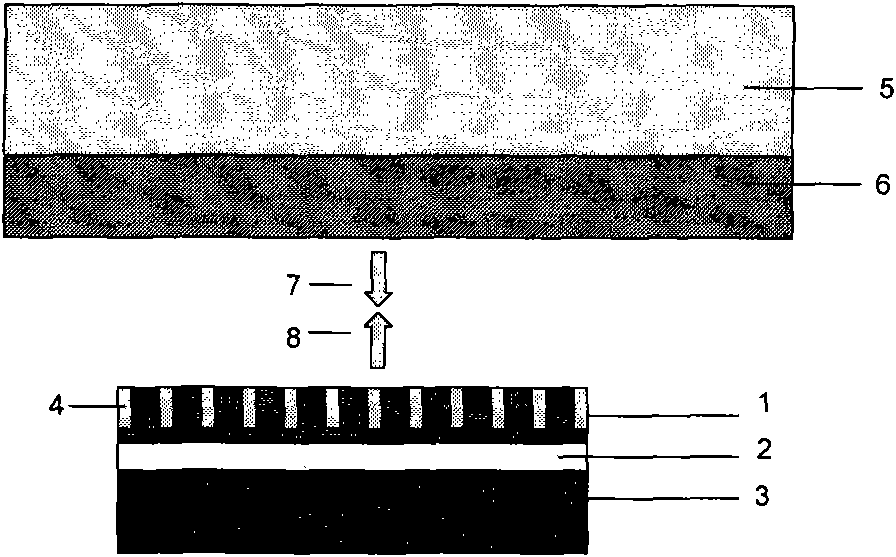

Tapered super-surface structure based photovoltaic photoelectric detector and preparation method thereof

ActiveCN106409938ARealize broadband photodetectionAvoid narrow-band absorption disadvantagesFinal product manufactureSemiconductor devicesMicro nanoOptoelectronics

The invention discloses a tapered super-surface structure based photovoltaic photoelectric detector and a preparation method thereof. The photoelectric detector comprises a metal substrate whose surface includes a 3D nanometer cone array structure, a semiconductor file layer whose forbidden band width is greater than incident photon energy, and a metal film layer; and the metal substrate, the semiconductor film layer and the metal film layer are arranged successively from bottom to top. The preparation method comprises that a porous anodised aluminum film is prepared on the aluminum substrate, the anodised aluminum film in the surface of the aluminum substrate is removed, and the semiconductor film layer and the metal film layer are prepared then. The metal substrate, the semiconductor film layer and the metal film layer for the super-surface structure, the thickness of the metal film layer, the material thickness of the semiconductor layer or a structural parameter of a nanometer cone is controlled to regulate and control the frequency range of super-absorption. The photoelectric detector is simple in preparation technology, convenience is provided for large-area preparation, complex micro nano processing is not needed, and high-effeminacy broadband wide-angle photoelectric detection can be realized.

Owner:SOUTHEAST UNIV

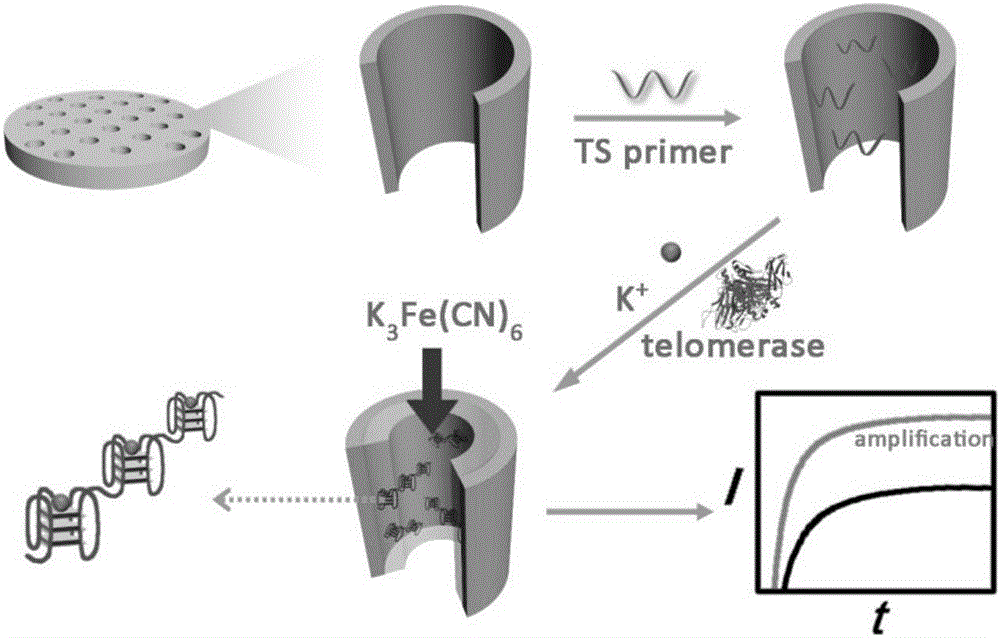

Method for quantitatively detecting telomerase activity based on nano pore channel and electrochemical sensing

ActiveCN105806912AAperture adjustableStable structureMaterial analysis by electric/magnetic meansTelomerasePower flow

The invention discloses a method for quantitatively detecting telomerase activity based on a nano pore channel and electrochemical sensing.The method comprises the following steps that firstly, a telomerase recognition sequence is connected to the inner wall of a porous anodic alumina template or a polyethylene terephthalate film to serve as a primer; secondly, telomerase amplifies the primer to form a G-rich sequence; a G-quadruplex is formed in the presence of potassium ions; electrochemical detection is conducted on the current produced through indicating molecules of the nano pore channel by utilizing an electrochemical workstation.The method does not need complex material preparation and DNA probe marking, and can avoid the defects of high detection cost, complicated operation and poor reproducibility caused by the complex material preparation and DNA probe marking and has the advantages of being low in cost, quick, simple, convenient, high in sensitivity and good in accuracy.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

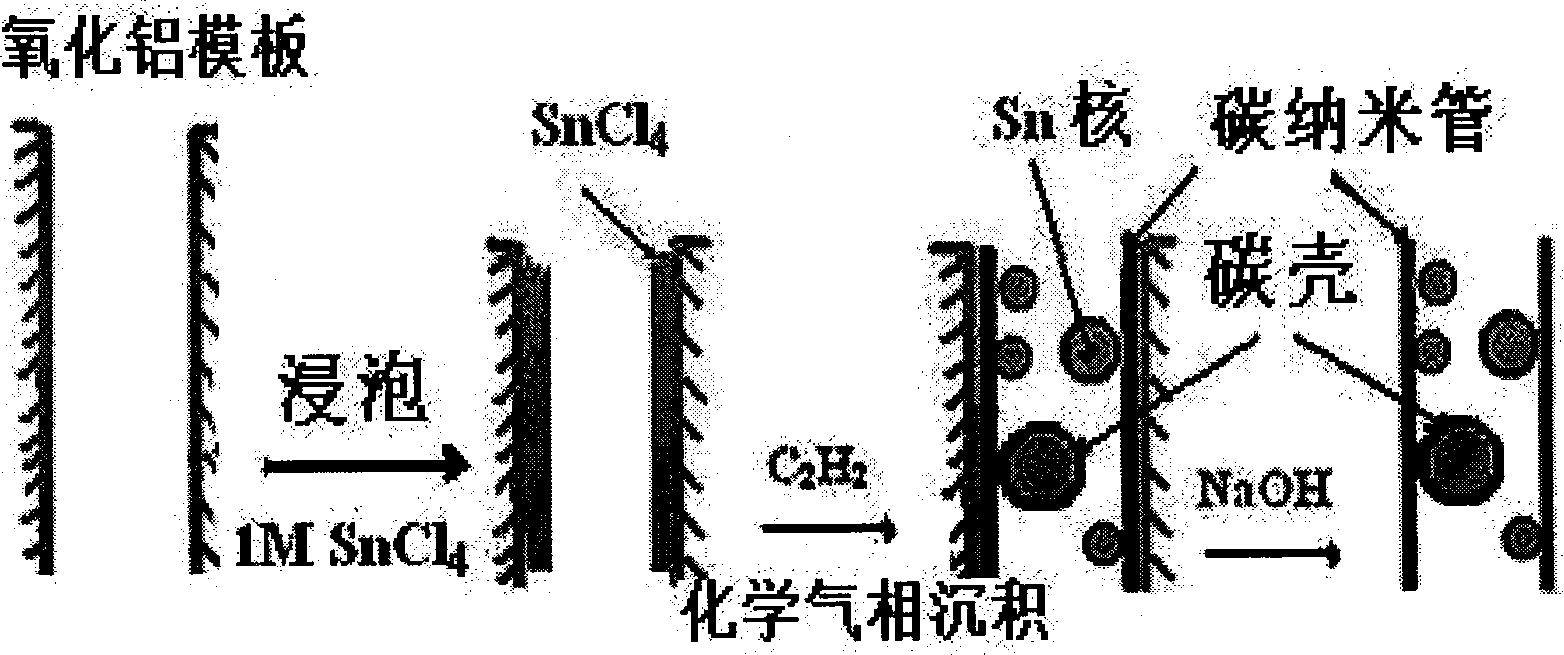

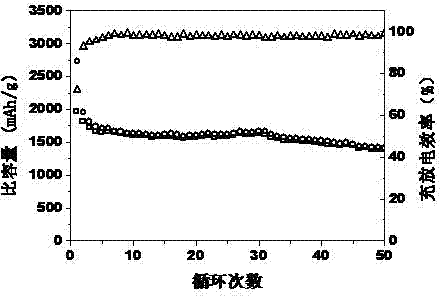

In-situ synthesis method for preparing tin-carbon/core-shell nano-particle fully filled carbon nano-tube composite anode material

InactiveCN101521273AOvercoming the drawbacks of low product structural purityIncrease in sizeElectrode manufacturing processesGas phaseSynthesis methods

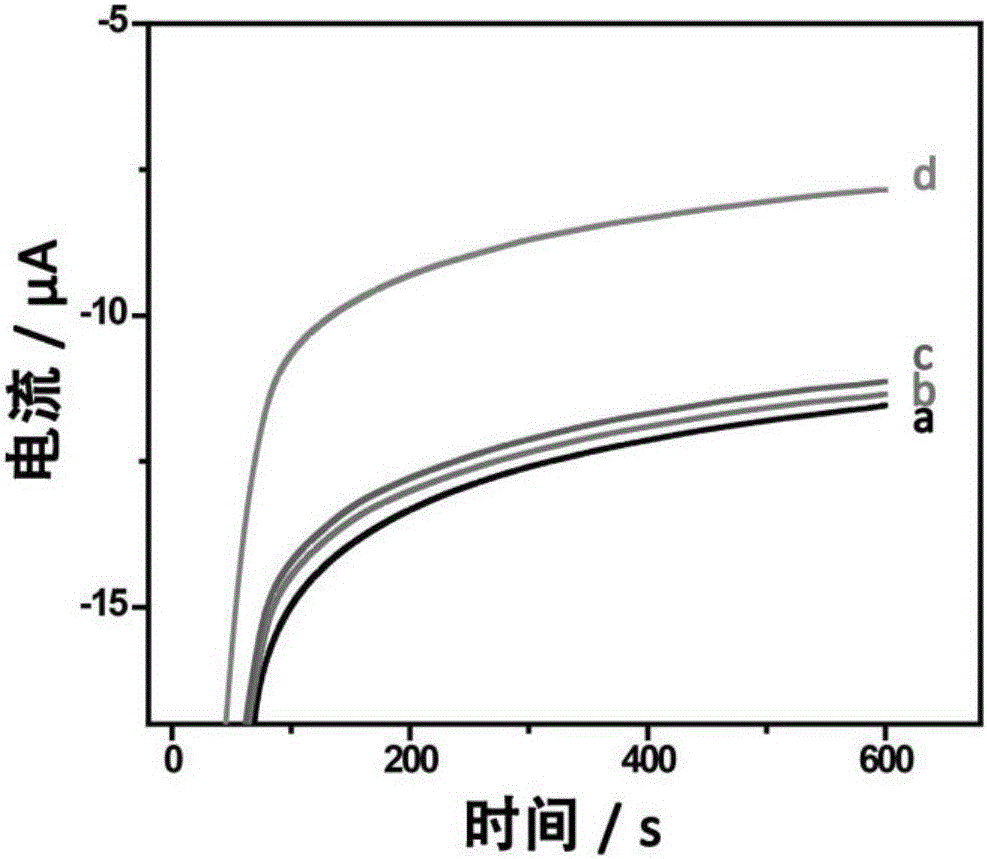

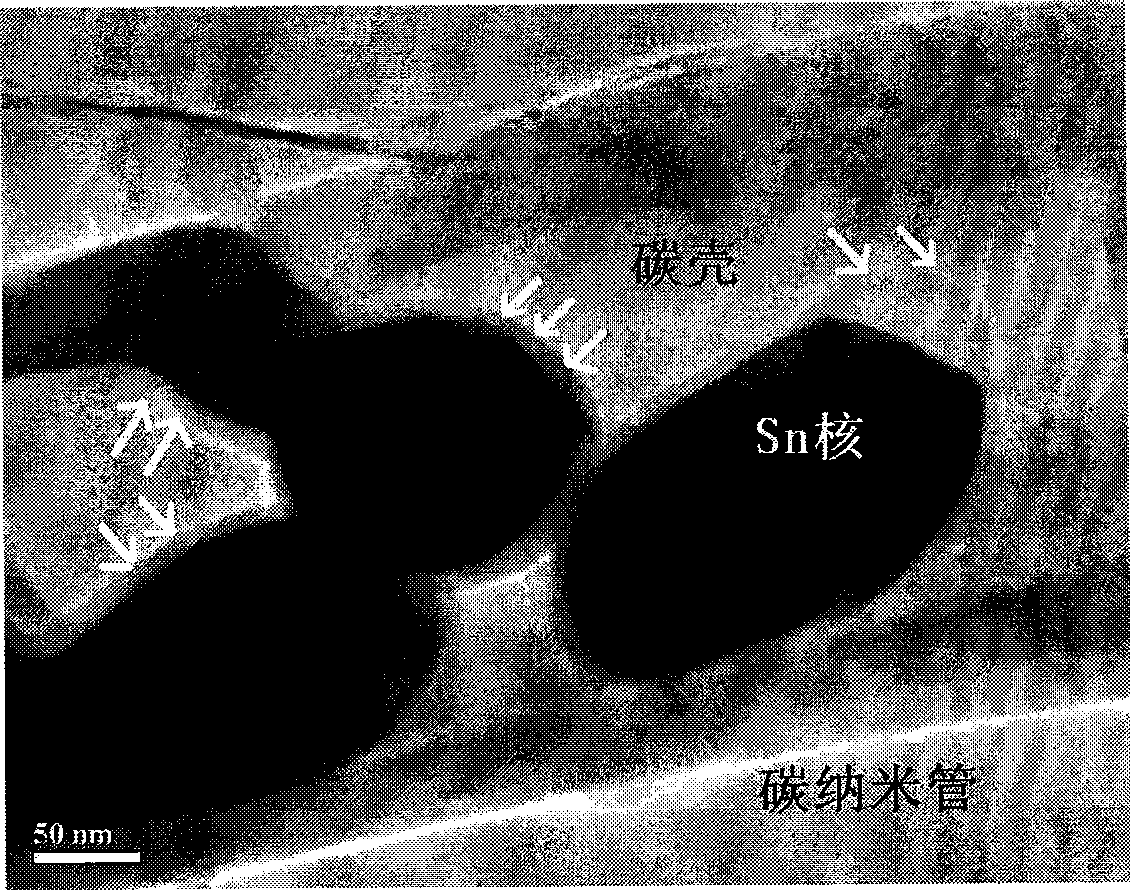

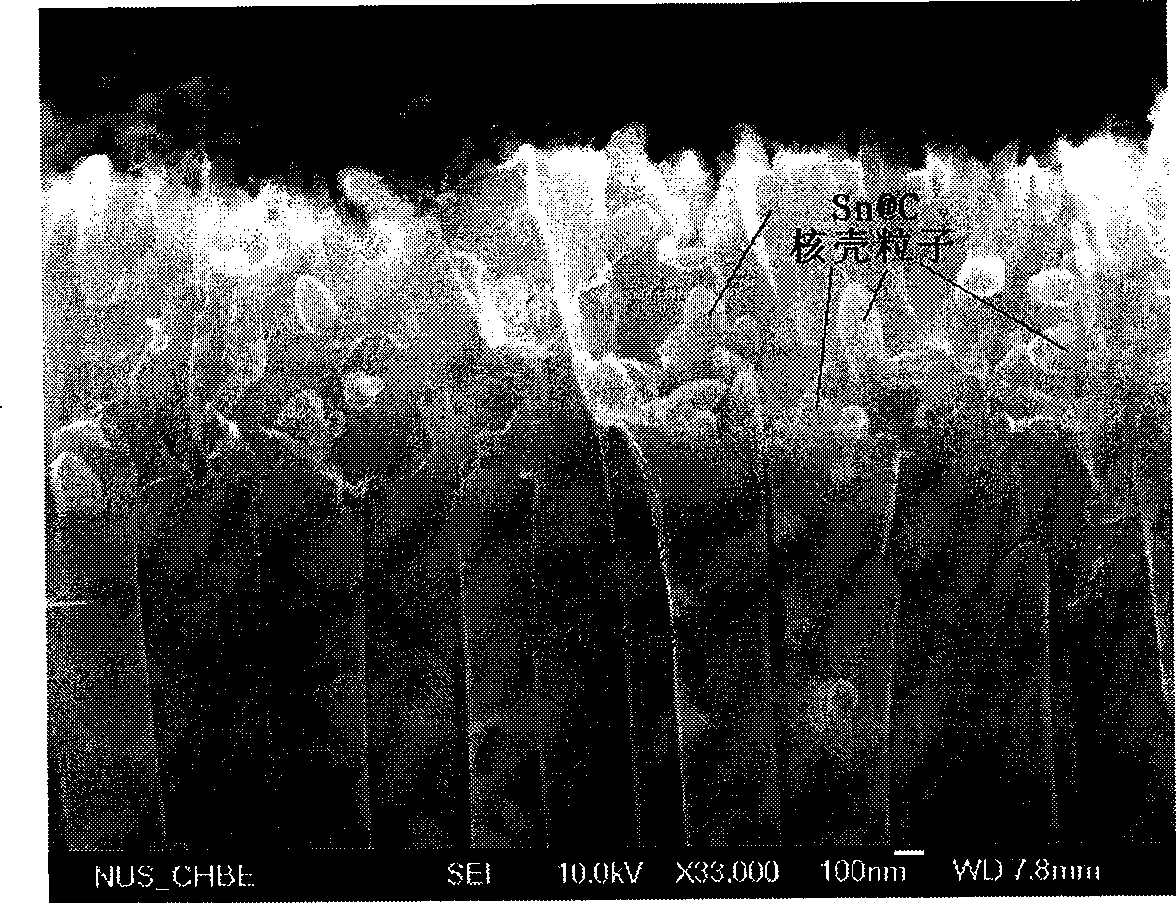

The invention provides a method for preparing a tin-carbon / core-shell nano-particle fully filled carbon nano-tube composite anode material, which comprises the following steps: a porous anodic alumina film is placed in a stannic chloride water solution for soaking, is dried and then is subjected to chemical vapor deposition and reduction reaction in mixed gas of C2H2 and N2 at high temperature to obtain the tin-carbon / core-shell nano-particle fully filled carbon nano-tube composite anode material. The size and morphology of filled particles of the invention are controllable, the filling efficiency of the method is high, the structural purity of a target product can approach 100 percent, the interference of incomplete filling on the one-to-one correspondence of a structure and performance of the product is avoided, and the reversible lithium-storage capacity of the carbon nano-tube composite anode material with the novel structure can reach more than 700 mAh / g.

Owner:SHANGHAI UNIV

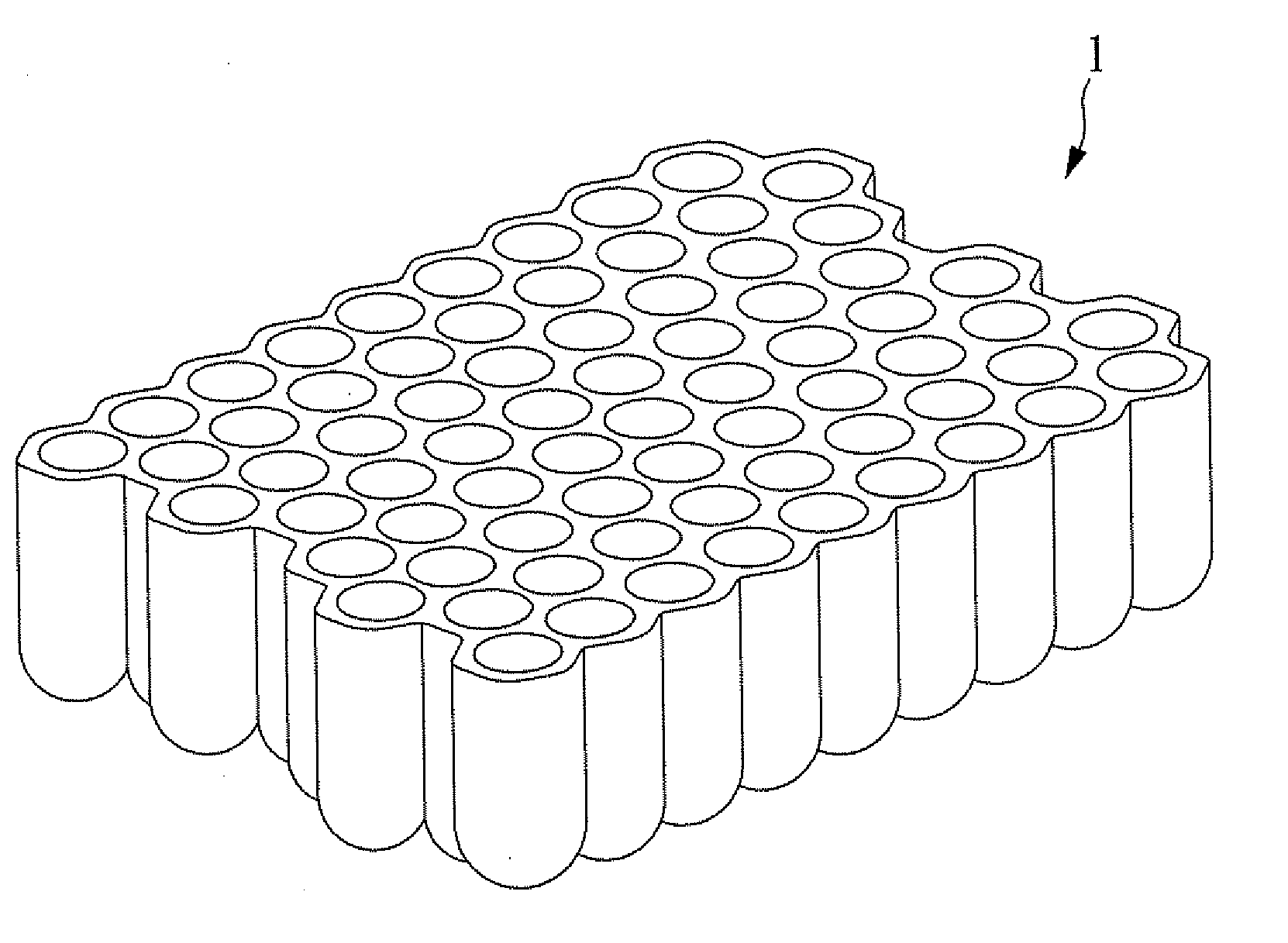

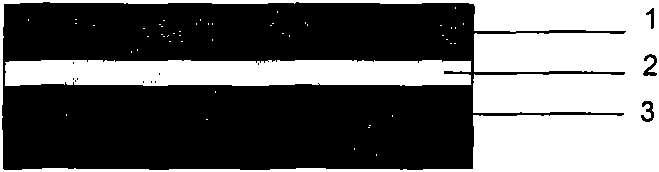

Sensor chip for biomedical and micro-nano structured substances and method for manufacturing the same

InactiveUS20120194813A1Easy to detectImprove signal-to-noise ratioRadiation pyrometryMaterial analysis by optical meansMicro nanoAnalyte

The present invention relates to a sensor chip for biomedical and micro-nano structured substances and a method for manufacturing the same. The sensor chip includes plural metal nanoparticles and a porous anodized aluminum oxide film. The plural metal nanoparticles are completely contained in holes of the porous anodized aluminum oxide film and located at the bottom of the holes, and an aluminum oxide layer covering the second end of the holes has a thickness of 1 nm to 300 nm. When analytes such as biomedical molecules are provided in contact with the sensor chip, a Raman signal can be detected based on the Raman spectroscopy. The structure of the sensor chip of the present invention is uncomplicated and the manufacturing steps thereof are simple, and therefore the sensor chip of the present invention is of great commercial value. Also, a method of manufacturing the above sensor chip is disclosed.

Owner:NAT CHENG KUNG UNIV

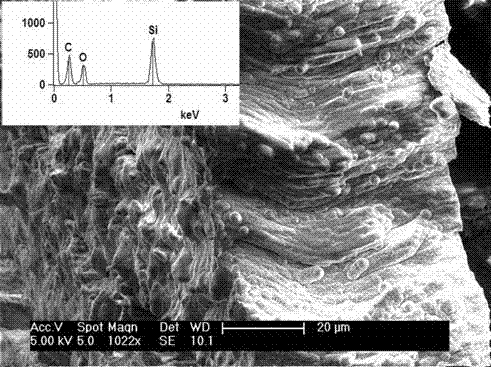

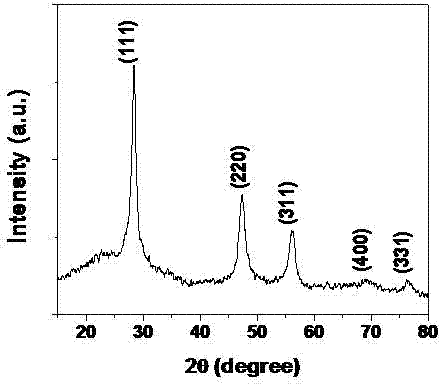

Preparation method for silicon-carbon composite nano tube array

InactiveCN103618072APipe diameter controllableControllable managementCell electrodesSecondary cellsCarbon compositesGas phase

The invention belongs to the field of lithium ion batteries and discloses a preparation method for a silicon-carbon composite nano tube array. The preparation method for the silicon-carbon composite nano tube array is characterized by comprising the following steps: raising the temperature of a porous-anode aluminum oxide template under inert gas; introducing acetylene gas; generating a carbon nano tube array on the surface of the template by high-temperature gas-phase decomposition of acetylene; vacuumizing and introducing the inert gas, hydrogen and silane after the temperature is raised; decomposing silane to obtain a coaxial carbon nano tube and silicon nano tube array in the template; and removing silicon oxide on the surface of the template by using a hydrofluoric acid aqueous solution and drying to obtain the silicon-carbon composite nano tube array. According to the preparation method for the silicon-carbon composite nano tube array, the silicon-carbon composite nano tube array with controllable pipe diameter, pipe length and wall thickness, and uniform size can be obtained by two-step chemical vapor deposition and hydrofluoric acid corrosion; in a whole production process, complicated equipment is not used and process steps are simple, so that large-scale industrial production is facilitated; the stability of the silicon-carbon composite nano tube array is good.

Owner:山东玉皇盛世化工股份有限公司

Process for preparing porous anode aluminium oxide mould of height ordered by mixed acid electrolyzing liquid

InactiveCN1793437AOxidation voltage decreasedReduce thicknessSurface reaction electrolytic coatingAnodic Aluminum OxideAnode

The invention relates to a method used mixed acid electrolyte to manufacture high ordered multi-hole anodic alumina die plate. In order to further reduce oxidation voltage, barrier layer thickness, and increase nanometer hole array orderliness, the alumina die plate is manufactured as follows: using the mixed acid of sulfuric acid and oxalic acid as electrolyte; their content are 100-200g / L and 50-150g / L; de-oiling; oxide layer removing; electro polishing; double steps anodic oxidation manufacturing multi-hole anodic alumina die plate. The invention reduces reduce oxidation voltage and barrier layer thickness to make nanometer hole diameter rise from 20nm to 45-55nm. This is good for the further application of multi-hole alumina die plate.

Owner:HARBIN INST OF TECH

Self-assembly preparation method and application of solid/liquid interface of graphene oxide hydrogel

ActiveCN102153073AImprove electrochemical energy storage performanceEasy to prepareHigh pressureGraphite oxide

The invention discloses a self-assembly preparation method and application of a solid / liquid interface of graphene oxide hydrogel. The method comprises the following steps of: preparing graphite oxide powder and deionized water into a solution with the concentration of 1-7 mg / mL; and immersing a porous anodic alumina film or an aluminum sheet, an aluminum foil or a copper sheet treated by a mixed liquid of concentrated sulfuric acid and hydrogen peroxide in a water solution of graphene oxide at 0-80 DEG C to form graphene oxide hydrogel on the surface of the porous anodic alumina film, the aluminum sheet, the aluminum foil or the copper sheet. The graphene oxide hydrogel is used for preparing graphene oxide aerogel and graphene aerogel and is also a coating of the graphene oxide hydrogel. The preparation method provided by the invention is simple and does not require any high-temperature high-pressure process, and the water mass of the graphene oxide hydrogel is more than 99%.

Owner:TIANJIN UNIV

Contact metallization of carbon nanotubes

In one embodiment, SWNTs are synthesized from an embedded catalyst in a modified porous anodic alumina (PAA) template. Pd is electrodeposited into the template to form nanowires that grow from an underlying conductive layer beneath the PAA and extend to the initiation sites of the SWNTs within each pore. Individual vertical channels of SWNTs are created, each with a vertical Pd nanowire back contact. Further Pd deposition results in annular Pd nanoparticles that form on portions of SWNTs extending onto the PAA surface. Two-terminal electrical characteristics produce linear I-V relationships, indicating ohmic contact in the devices.

Owner:PURDUE RES FOUND INC

Method for preparing porous anodic alumina film by using industrial pure aluminum

The invention discloses a method for preparing a porous anodic alumina film by using industrial pure aluminum. By controlling process conditions such as voltage, electrolyte category, temperature, concentration and the like, a nano-scale porous alumina template with narrow diameter distribution range is prepared. The method is carried out in ice-water bath, and has the advantages of low used raw material cost, simple equipment, convenient operation and easy control; and the hole diameter of the alumina template obtained by the method is about 50 to 60 nanometers, and is evenly distributed.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

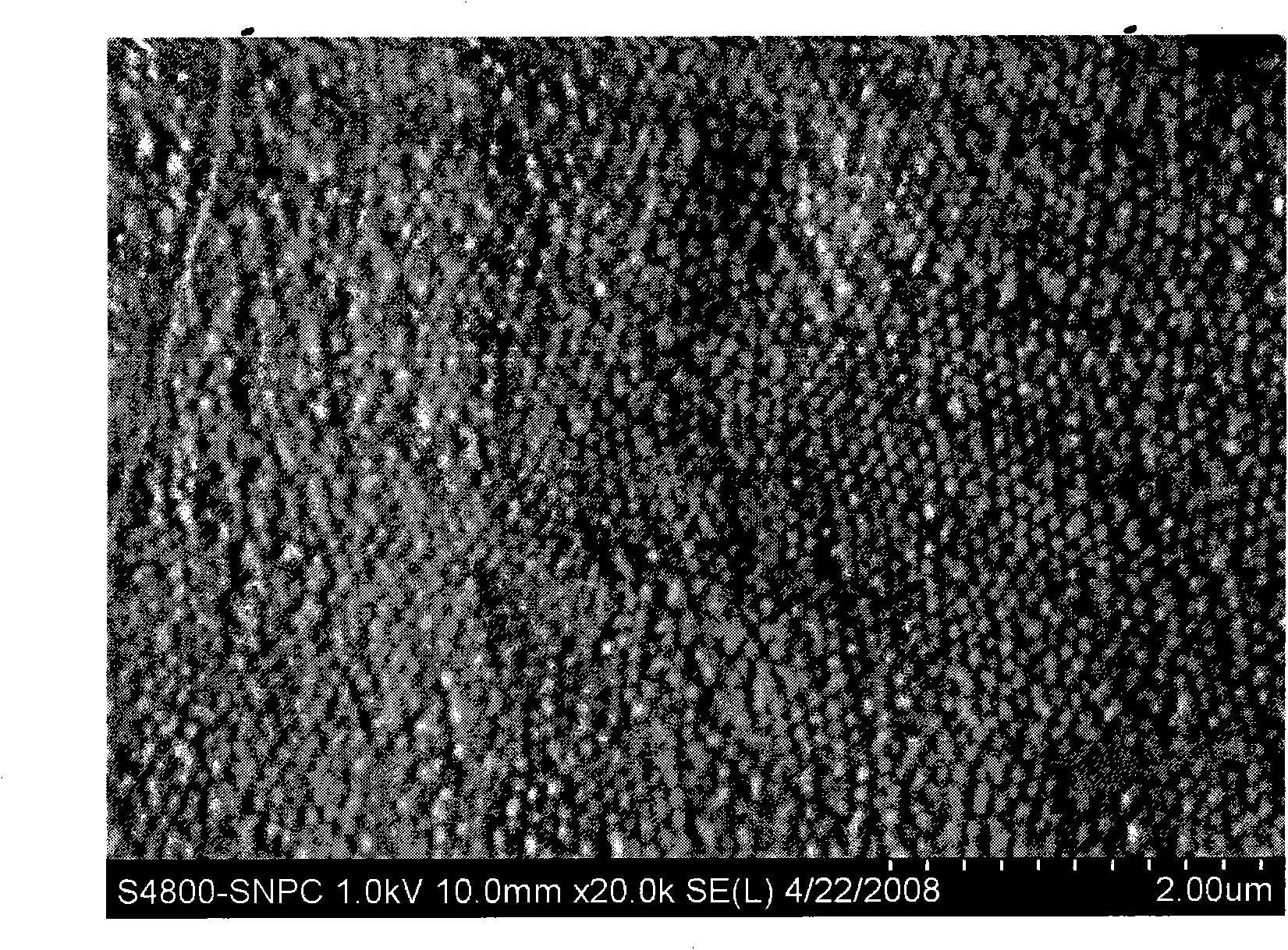

Fabricating method of soft template with nanometer structure

InactiveCN101581878ASimple methodReduce manufacturing costPhotomechanical apparatusPore diameterNanostructure

The invention relates to a fabricating method of a soft template with a nanometer structure, which is characterized in that the soft template is duplicated by a porous anodic aluminum oxide template. The pore diameter of porous anodic aluminum oxide is usually 10-500 nm, holes of the porous anodic aluminum oxide are straight and are evenly distributed, the porous anodic aluminum oxide template can be used as a mother template and can be duplicated to form the soft template with high resolution and high duplication accuracy, therefore, the fabricating cost and the fabricating period of the template are reduced. The invention has the remarkable characteristics of low fabricating cost of the template, short period and simple process, and can realize large-area impression because the duplicated soft template can be repeatedly used.

Owner:SHANGHAI NANOTECH PROMOTION CENT +1

Impressing hard template in nanostructure

The invention relates to an impressing hard template in a nanostructure, which belongs to the field of nano manufacturing and is characterized in that a porous template with a hard material substrate is prepared by the porous AAO (anodic aluminum oxide) membrane technology and can be directly used as an impressing (from top to bottom) template after the hard substrate is added and the surface modification treatment is carried out. A porous AAO membrane can self-organize and grow into an ordered six-site symmetrical porous structure, and steep holes are uniformly distributed. When the porous AAO membrane is used as the template, various nanostructures and devices with optical, electrical and magnetic properties can be prepared by a processing method of directional assembling from bottom to top such as thermal evaporation, sputtering, deposition and electrochemical assembling. As the hard material substrate is added and the surface modification treatment is carried out, the AAO template technology is transplanted into the field of top-to-bottom surface micro-structure processing. Compared with the present technical method of the common electron beam direct writing, the manufacturing method for the impressing hard template with a nano-grade high-density structure not only has the obvious characteristics of low cost, short period and simple processing, but also can be widely used in the processing as well as researching of the nano-grade high-density surface nanostructure and particularly has broad prospects in the fields of semiconductor lighting and high-density storage. Meanwhile, as the hard substrate is increased, the shortcomings of the present brittle and fragile AAO template are overcome, thereby being more beneficial for duplication of the soft template.

Owner:SHANGHAI NANOTECH PROMOTION CENT +1

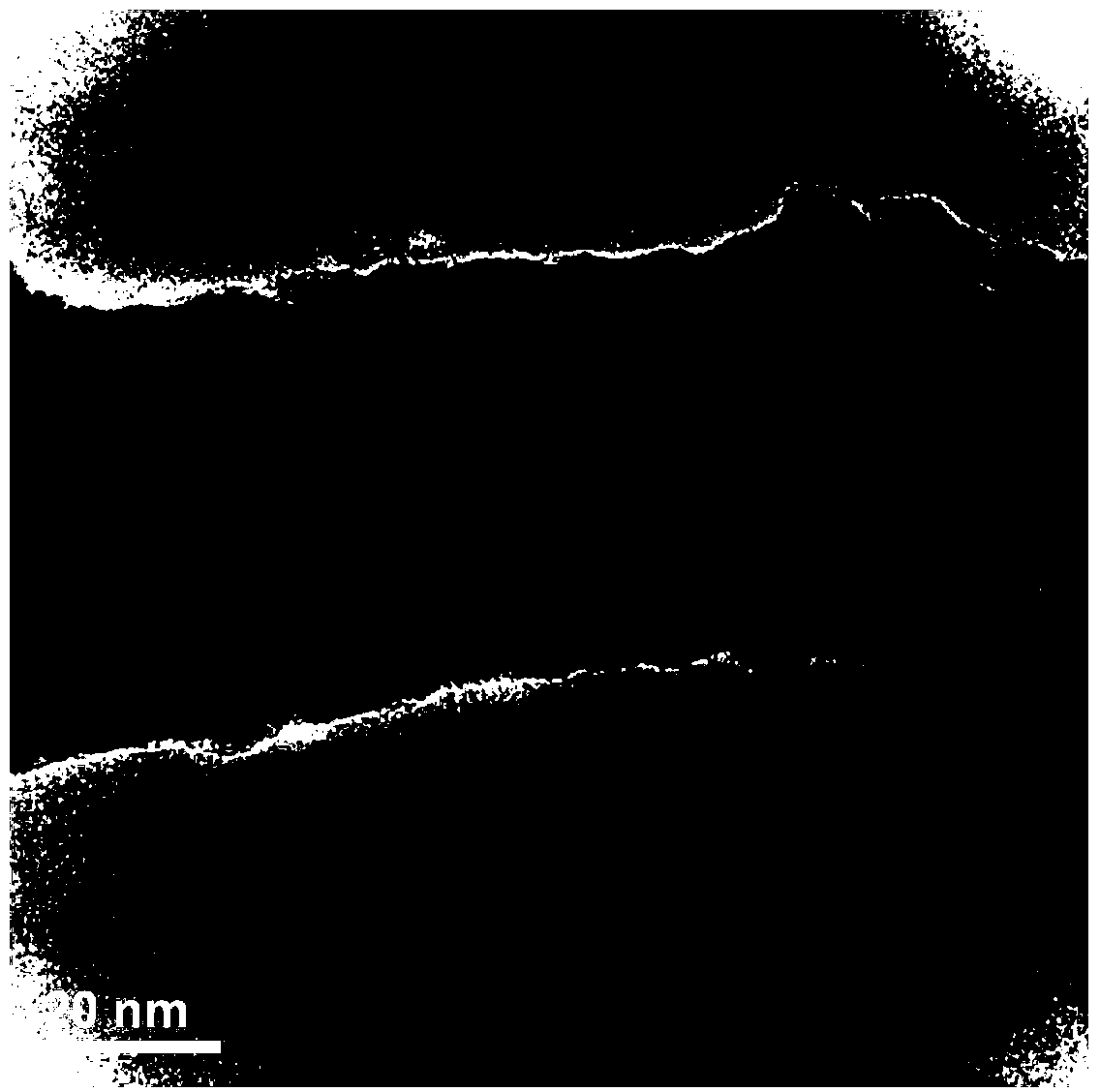

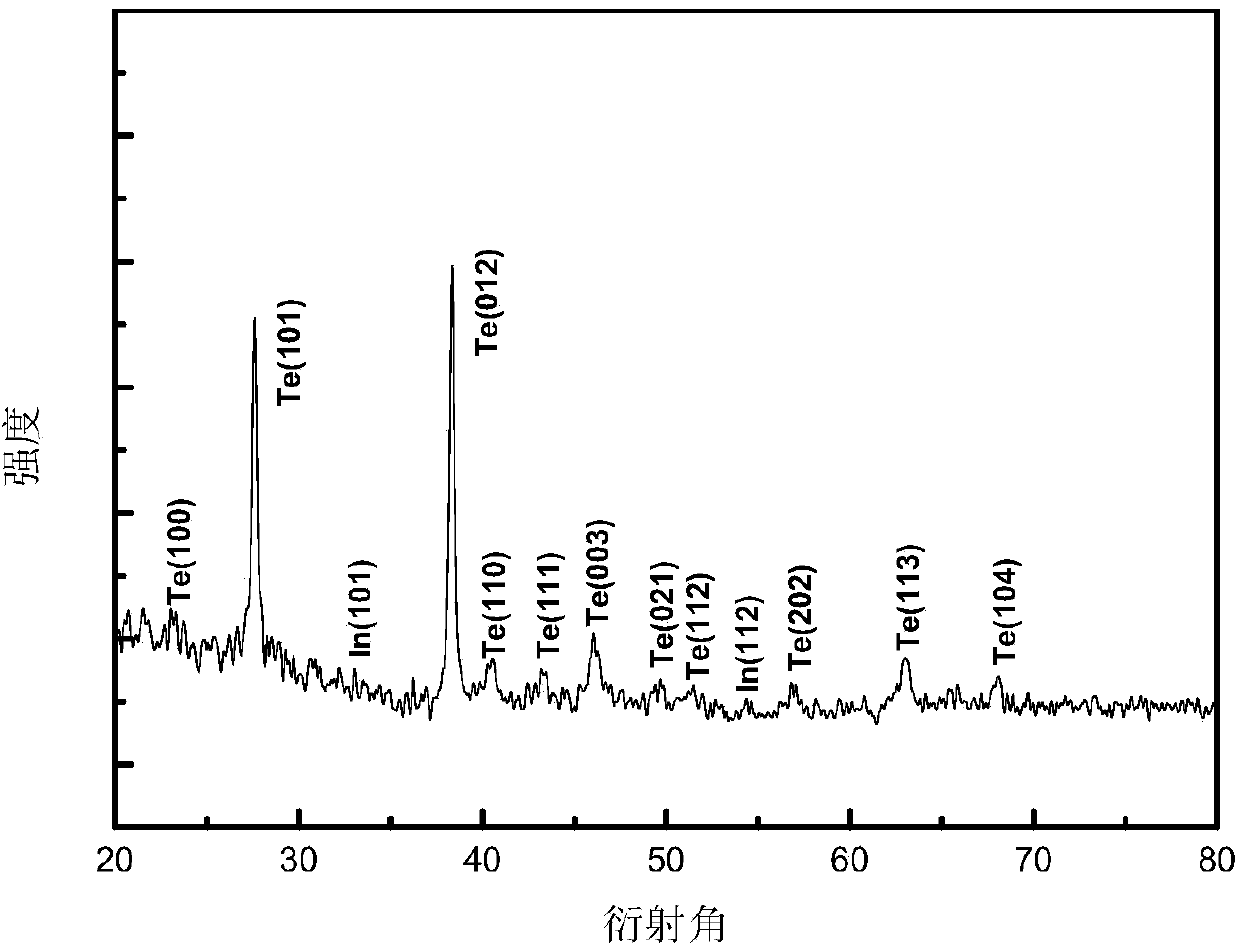

Method for preparing indium/tellurium porous nanowire array

The invention discloses a method for preparing an indium / tellurium porous nanowire array, and belongs to the technical field of preparation of porous materials and nano materials. The method is characterized by comprising the following steps: preparing a porous anode alumina template (PAA) by using a two-step anodization method, preparing an electrolytic deposition solution consisting of a high-purity In salt or compound, a salt or compound of Te, a pH conditioning agent, an additive and deionized water, and performing electrochemical deposition on In and Te elements in pore canals of the alumina template by adopting a pulse electrochemical deposition technology, using the electrolytic deposition solution containing the In and Te elements and taking metal-sprayed PAA template as an anode and graphite as a cathode under certain deposition parameters and conditions, so as to finally obtain a one-dimensional ordered In / Te porous nanowire array. The method has the effects and benefits that the preparation is simple, the cost is low, and components and structures are easy to regulate and control; the array has a significant potential application prospect in fields of energy, catalysis, adsorption, thermoelectricity, optics, electrics and the like, and particularly has great values in application of sensors.

Owner:DALIAN UNIV OF TECH

Method for preparing ordered macroporous anodic alumina film by two-step anodic oxidation

InactiveCN103243370AAperture continuously adjustableArranged in orderSurface reaction electrolytic coatingIce waterPhosphoric acid

The invention relates to a method for preparing an ordered macroporous anodic alumina film by two-step anodic oxidation. The method comprises the following steps of: carrying out hard anodizing on aluminum which is subjected to high temperature annealing, ultrasound deoiling and electrochemical polishing treatments in modified oxalic acid electrolyte, so as to obtain a porous anodic alumina film; removing an irregular porous alumina layer which is formed after first anodic oxidation by using a mixed solution of chromic acid and phosphoric acid; then carrying out second anodic oxidation, namely carrying out mild anodic oxidation on the aluminum sheet with the alumina film removed in the modified phosphate electrolyte in a constant voltage manner, wherein the voltage in the second anodic oxidation is completely the same as the voltage in the first anodic oxidation; and finally chambering the test sample subjected to anodic oxidation in a phosphoric acid solution to obtain the ordered macroporous anodic alumina film. The preparation method is carried out under an ice-water bath condition without the requirement on a very low temperature or a high voltage; the cost of used raw materials is low; and equipment is simple and is convenient to operate and easy to control, and therefore the method has a bright application prospect in the modern industry and high and new technology field.

Owner:DONGHUA UNIV

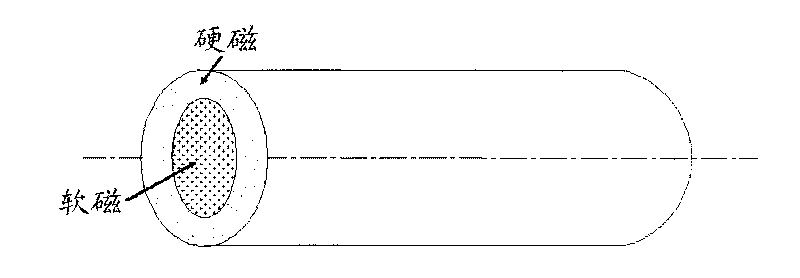

One-dimensional permanent magnetic nano-material, in which hard magnetic tubes are coated with soft magnetic wires and preparation method thereof

InactiveCN101692364AImprove permanent magnet performanceInorganic material magnetismMagnetic phaseElectrochemistry

The invention provides a one-dimensional permanent magnetic nano-material, in which hard magnetic tubes are coated with soft magnetic wires and a preparation method thereof. The material has a composite structure that hard magnetic nano-tubes prepared from hard magnetic phase FePt or CoPt alloy are coated with soft magnetic nano-wires prepared from soft magnetic phase pure metals including Fe, Co and Ni or binary and ternary alloy, wherein, the diameter of the one-dimensional permanent magnetic nano-material is 10nm to 220nm; the diameter of the soft magnetic phase nano-wires is 4nm to 60nm; and the wall thickness of the hard magnetic phase nano-tubes is 3nm to 80nm. The preparation method of the material comprises the following steps: firstly, preparing the hard magnetic alloy nano-tubes in a porous anodic alumina template by using the template wetting method; and then, growing the soft magnetic nano-wires in the nano-tubes by using the electrochemical deposition method. The invention has the advantages that the size of the one-dimensional permanent magnetic nano-material is controllable and the preparation method is simple.

Owner:CENT IRON & STEEL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com