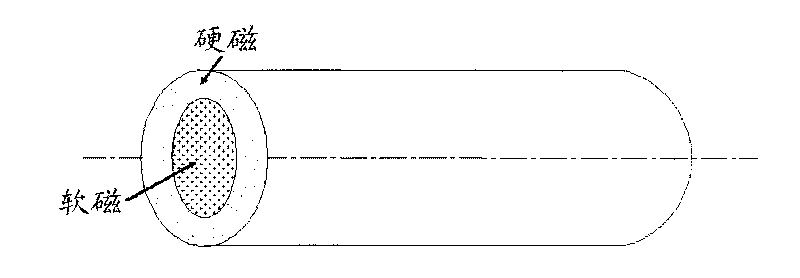

One-dimensional permanent magnetic nano-material, in which hard magnetic tubes are coated with soft magnetic wires and preparation method thereof

A permanent magnet material and coating technology, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of unfavorable device miniaturization, low maximum magnetic energy product, and expensive equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] The high-purity aluminum sheet was annealed in vacuum at 400°C for 4 hours. The annealed aluminum sheet was placed in absolute ethanol for 1 minute and then placed in 0.3 mol / L NaOH for 3 minutes, washed with deionized water, and dried. Put the treated aluminum sheet into a mixture of absolute ethanol and perchloric acid (4:1) and conduct electropolishing for 1.5 minutes with a current of 1A. Take out the aluminum piece and wash it, put it into 0.3mol / L H 3 PO 4 Electrochemical oxidation is carried out in the solution, the oxidation voltage is 120V, and the oxidation time is 3 hours to obtain a porous alumina template. Immerse the alumina template into the prepared mixed solution of chloroplatinic acid and ferrous chloride (molar ratio 1:1) for about 30 minutes, take out the template and put it into a quartz tube filled with hydrogen, put the sample into the tube Reduction in a furnace at 560°C for 2 hours. Repeat the soaking, reduction process three times. FePt na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com