Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3018 results about "Composite ceramic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

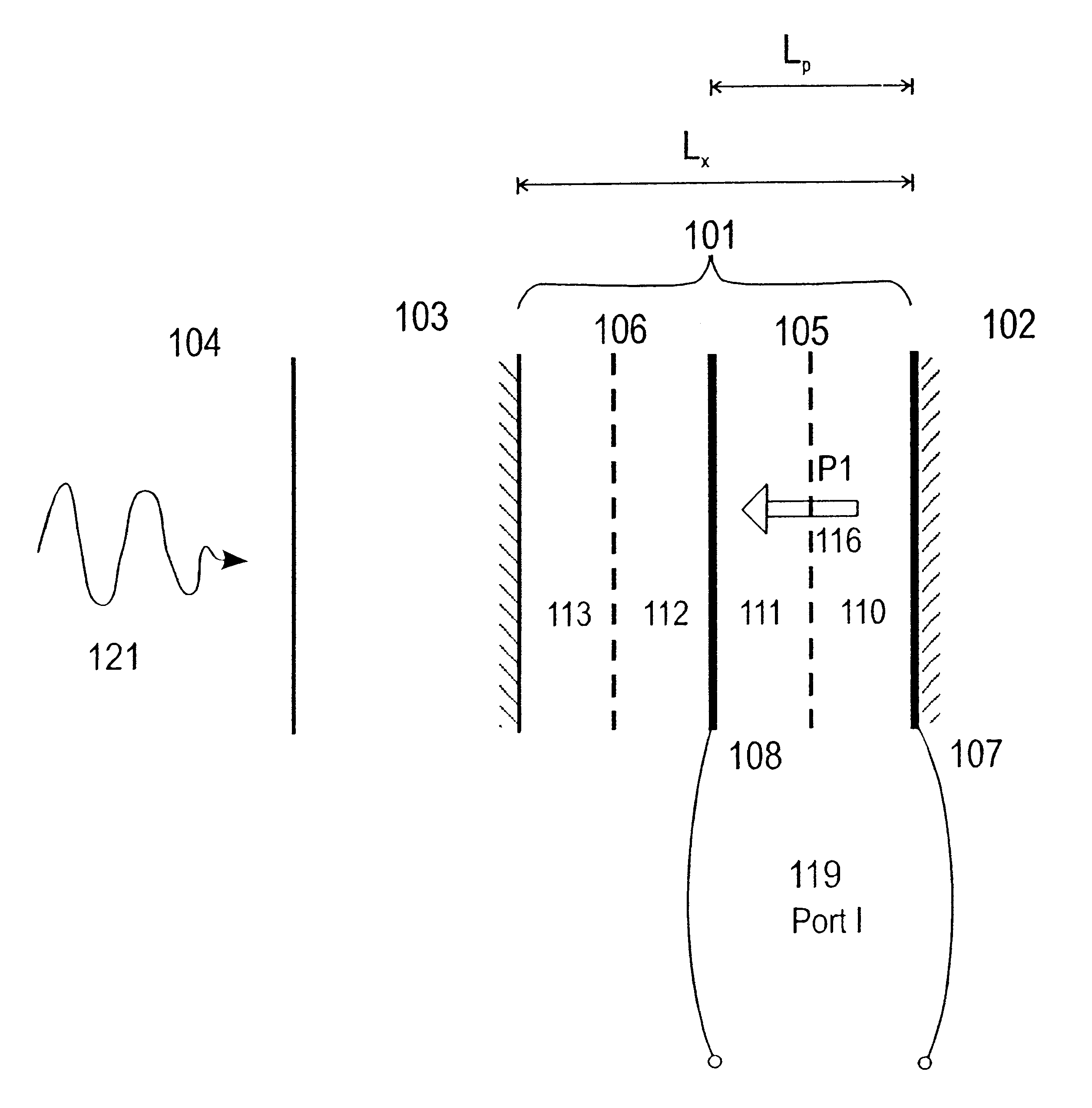

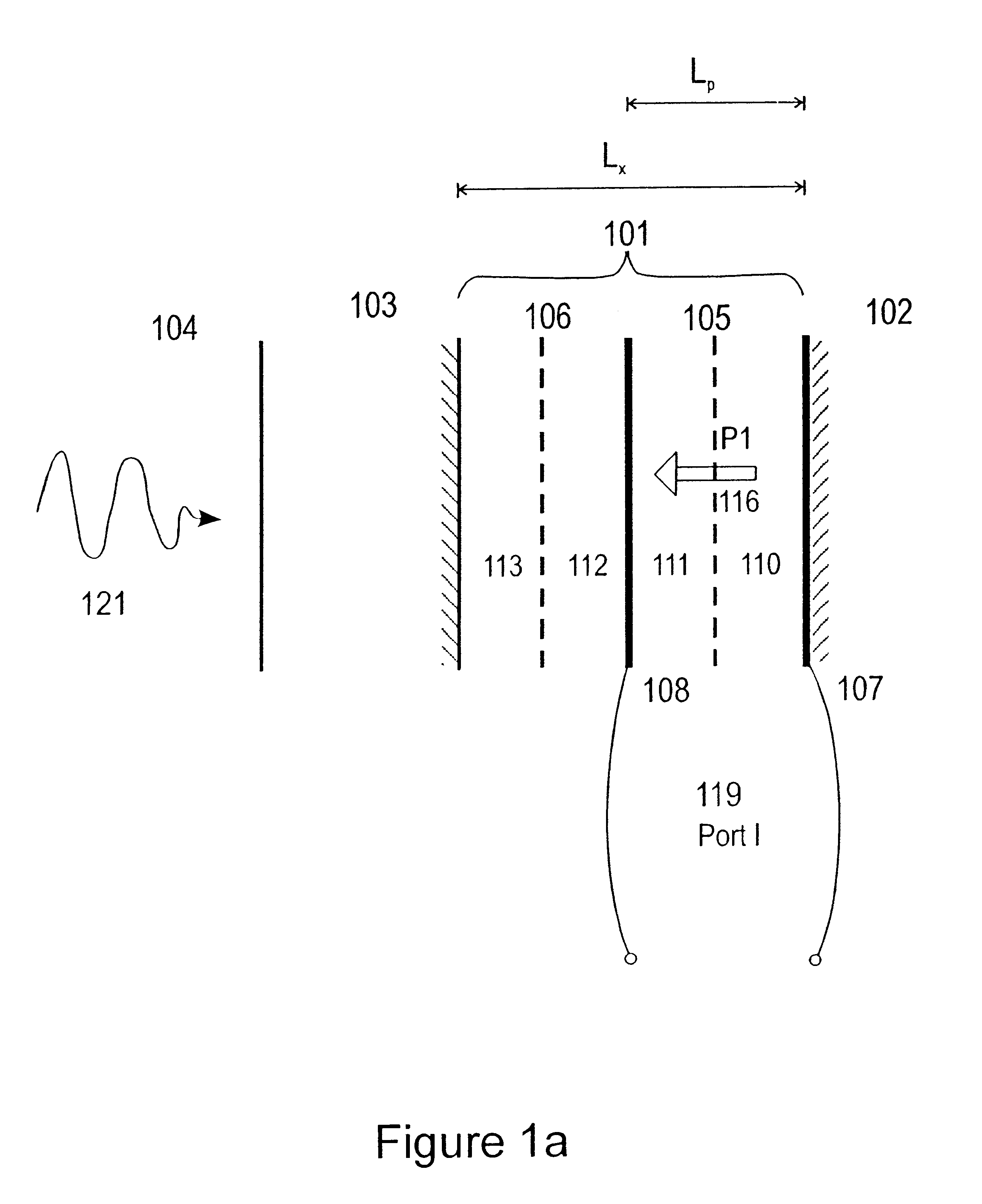

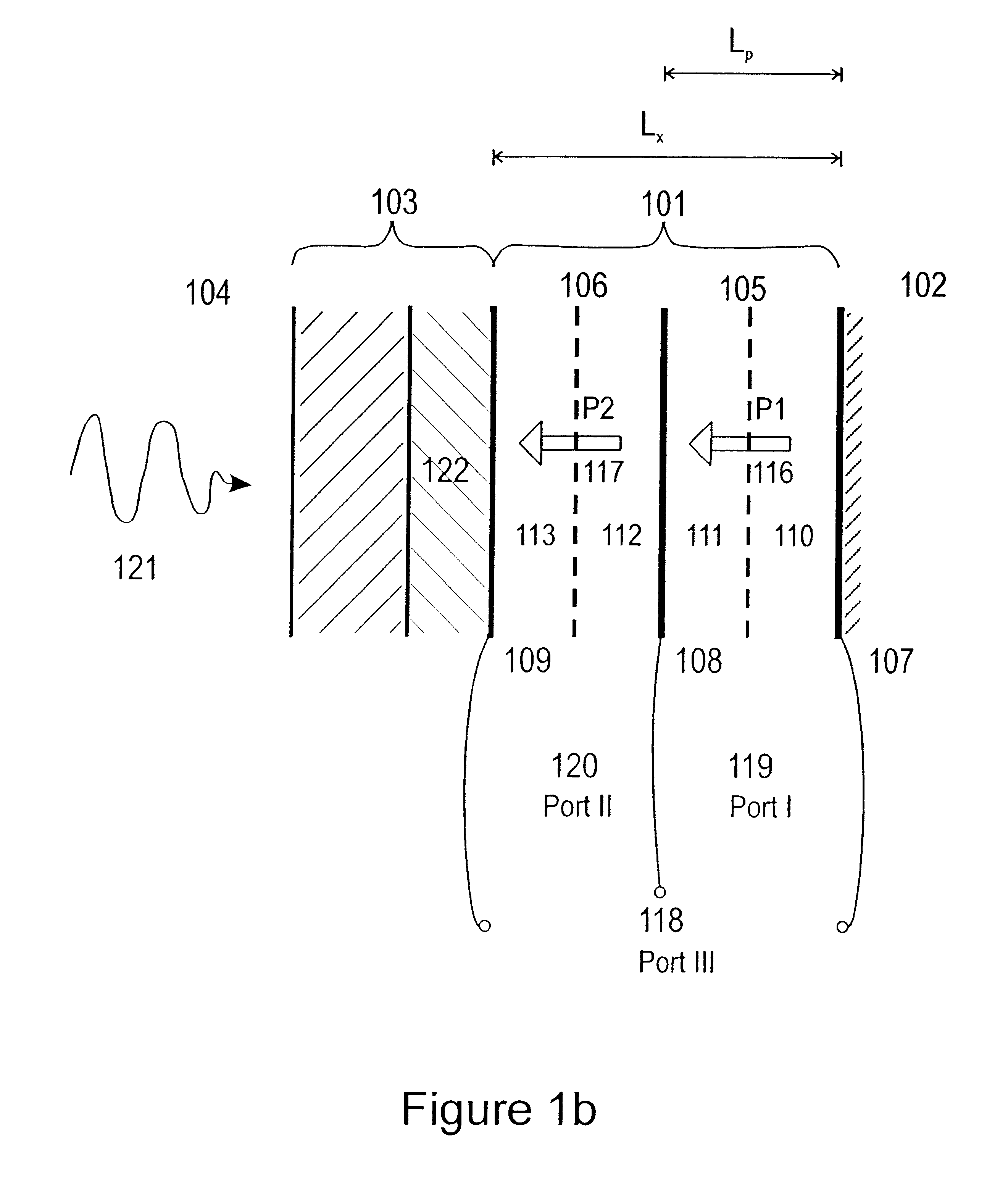

High frequency and multi frequency band ultrasound transducers based on ceramic films

InactiveUS6761692B2Maximizing electromechanical couplingImprove stabilityUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesMulti bandTransceiver

A design and a manufacturing method of ultrasound transducers based on films of ferro-electric ceramic material is presented, the transducers being particularly useful for operating at frequencies above 10 MHz. The designs also involve acoustic load matching layers that provides particularly wide bandwidth of the transducers, and also multiple electric port transducers using multiple piezoelectric layers, for multi-band operation of the transducers over an even wider band of frequencies that covers ~4 harmonics of a fundamental band. A transceiver drive system for the multi-port transducers that provides simple selection of the frequency bands of transmitted pulses as well as transmission of multi-band pulses, and reception of scattered signals in multiple frequency bands, is presented. The basic designs can be used for elements in a transducer array, that provides all the features of the single element transducer for array steering of the focus and possibly also direction of a pulsed ultrasound beam at high frequencies and multi-band frequencies. The manufacturing technique can involve tape-casting of the ceramic films, deposition of the ceramic films onto a substrate with thick film printing, sol-gel, or other deposition techniques, where manufacturing methods for load matching layers and composite ceramic layers are described.

Owner:PREXION

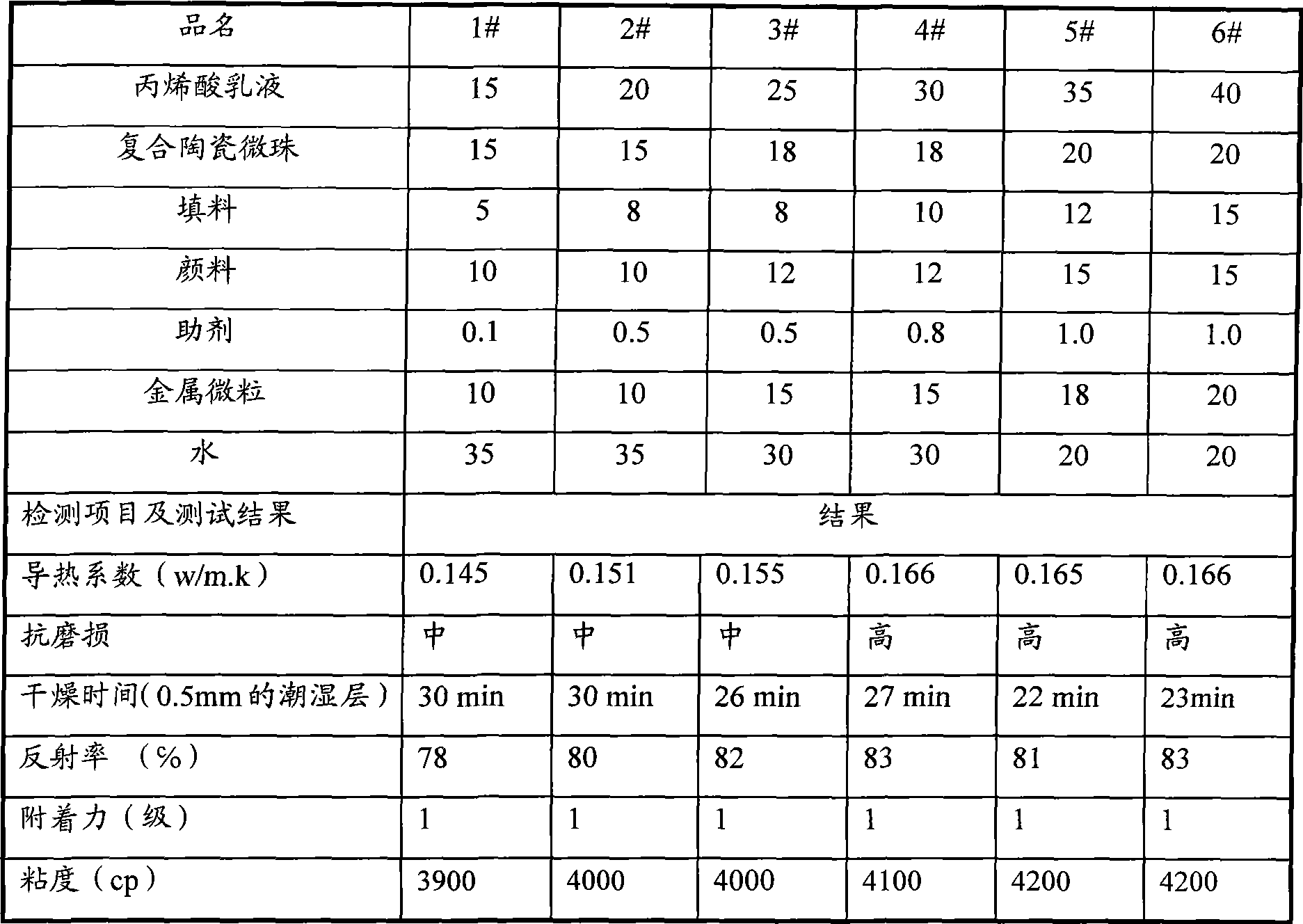

Watery acrylic acid insulating mould coating

InactiveCN101519560AImprove friction and scrub resistanceImprove insulation effectFireproof paintsElectricityWeather resistance

The invention relates to a watery acrylic acid insulating mould coating comprising the following components with the parts by weight:10-40 of acrylic acid latex, 12-20 of composite ceramic microballon, 5-15 of fillers, 1-15 of pigment, 0.1-1 of accessory ingredient and 15-35 of water. The watery acrylic acid insulating mould coating takes the watery acrylic acid latex as a carrier and contains a large amount of composite ceramic microballon, thereby enhancing the friction resistance and scrub resistance; a coating film generated by the watery acrylic acid latex has the capacities of heat insulation, heat preservation, water prevention, corrosion resistance and sun protection, thereby the watery acrylic acid insulating mould coating can be widely used for metal roofing materials, building materials, pipeline materials, and the like and can effectively reduce the electricity consumption and enhance the comfort level of work and environment. Besides, the watery acrylic acid insulating mould coating has the advantages of good heat insulation and preservation effects, innocuity, environmental protection, simple construction (the same as the construction technology of common water paint), friction resistance, acid-alkali resistance, water resistance, weather resistance, good dirt resistance, high cohering degree, powerful scrub resistance function and longer service life.

Owner:深圳市方浩实业有限公司

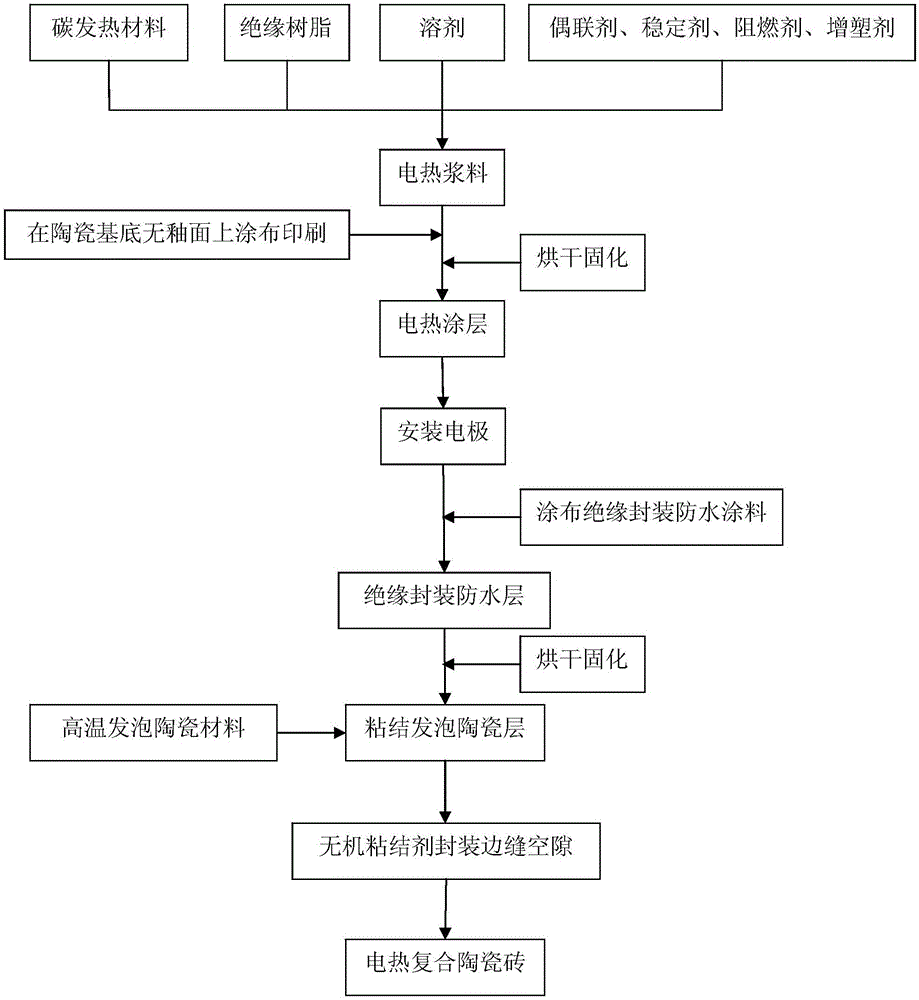

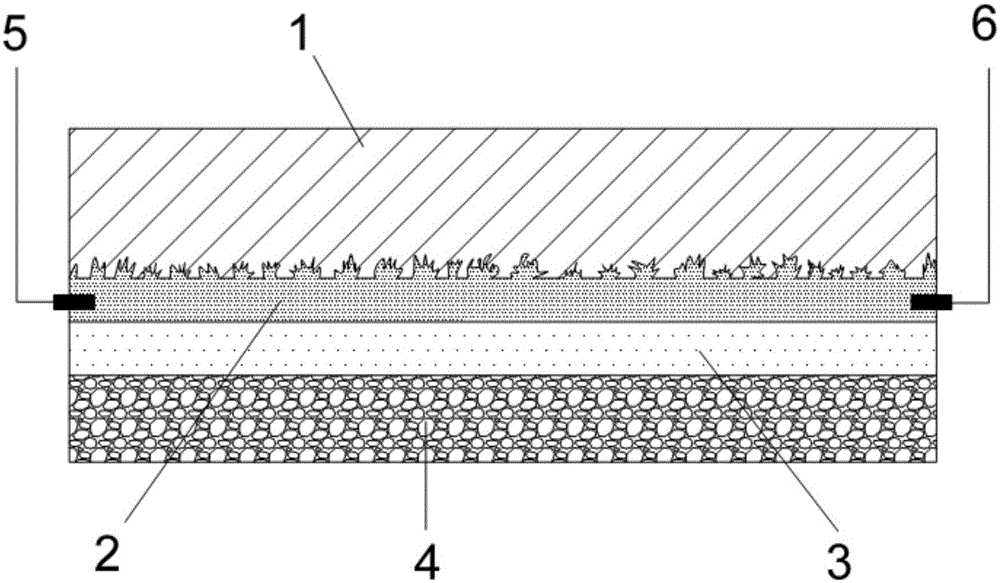

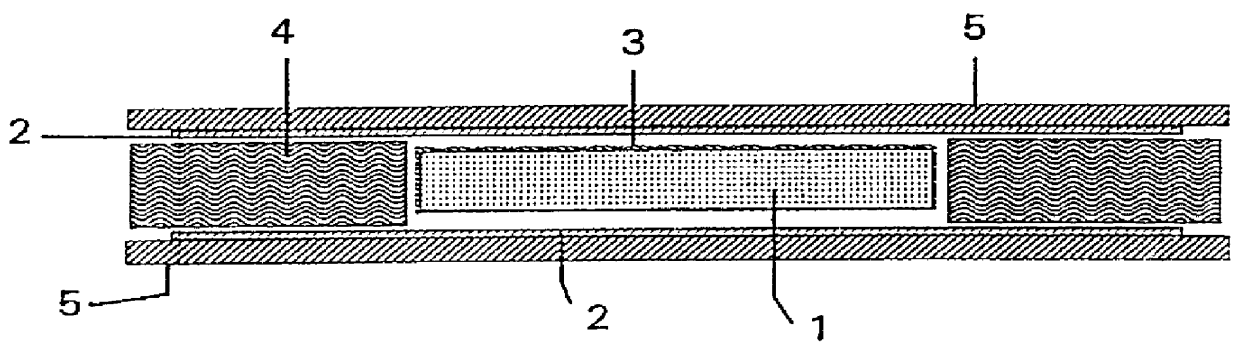

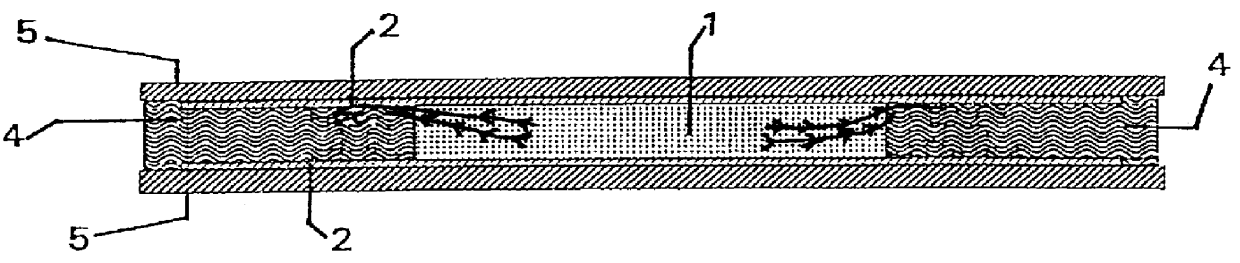

Electrothermal composite ceramic brick and preparation method thereof

The invention discloses an electrothermal composite ceramic brick and a preparation method thereof. An electrothermal coating layer, a guiding-out wiring electrode, a coating insulation packaging waterproof layer and an application foaming ceramic layer coat an unglazed surface of a ceramics substrate in order. The electrothermal coating layer coats the unglazed surface of the ceramics substrate in an electrothermal slurry form, the electrothermal slurry permeates the green body of the ceramics substrate, and the penetration depth is less than the thickness of the ceramics substrate and more than 0.5mm. Because of the penetration, the electrothermal coating layer of the electrothermal composite ceramic brick is combined with the ceramics substrate tightly, a surface heating mode is achieved, the thermal efficiency is high, normal and safe usage can be achieved under a voltage of 24-380V, the heating power is 90-120w / m<2>, and the temperature of the ceramics substrate can reach 18-50 DEG C through a temperature control device. The insulation packaging waterproof layer and the foaming ceramic layer outside the electrothermal coating layer can prevent heat from outward transmission effectively, heat loss is lowered, and the whole safety and reliability of the ceramic brick are raised.

Owner:GUANGDONG TIANBI CERAMICS

Composite ceramic filter core and preparation method thereof

InactiveCN102924067AGood mesoporous materialHas a hydrophobic surfaceFiltration separationCeramicwareActivated carbonComposite ceramic

The invention relates to a composite ceramic filter core and a preparation method thereof, in particular to a low-temperature sintering and high-strength diatomaceous earth composite ceramic filter core containing multi-walled carbon nanotubes and a preparation method thereof. The composite ceramic filter core comprises, by mass, 60-80% of refined diatomaceous earth, 12-20 parts of activated carbon, 4.5-9 parts of dispersing agent, 2-6 parts of sintering additives, 1-3 parts of antibacterial agents and 0.5-2 parts of carbon nanotubes. According to the low-temperature sintering and high-strength diatomaceous earth composite ceramic filter core containing the carbon nanotubes, due to the fact that the multi-walled carbon nanotubes are evenly distributed in the composite ceramic filter core, mechanical performance of the ceramic filter core can be improved, and the multi-walled carbon nanotubes are of mesoporous structures simultaneously and can perform effective adsorption on remove heavy metal ions in water. In addition, the sintering temperature is reduced to be below 950 DEG C by adding micron-sized metal aluminum powder, natural nano micropores of the diatomaceous earth are reserved, the mechanical strength of the ceramic filter core is further improved, and the compression strength is above 0.5GPa.

Owner:珠海启月生物科技有限公司

Manufacture method of environment friendly composite ceramic water-permeable brick

ActiveCN1919564AHigh strengthImprove wear resistanceSolid waste managementMixing operation control apparatusBrickComposite ceramic

The invention discloses a manufacturing method of environment-friend composite ceramic permeable brick, which comprises the following steps: adopting industrial slag with combustible substance as bottom aggregate and waste ceramic particle as layer aggregate, sieving at 10-20 order to obtain 55-65% material, sieving at 20-30 order to obtain 35-45% material, adding high-temperature adhesive and organic adhesive CMC, allocating, aging, moulding, drying, sintering.

Owner:JINGDEZHEN CERAMIC UNIV

Metal-foil-clad composite ceramic board and process for the production thereof

InactiveUS6113730APorous dielectricsSemiconductor/solid-state device detailsPorosityComposite ceramic

A metal-foil-clad composite ceramic board produced by impregnating a sintered substrate (II) of an inorganic continuously porous sintered body (I) having a true porosity of 12 to 50% and an open porosity of at least 10%, with a thermosetting resin (R) under vacuum, to form a resin-imprgnated sintered substrate (IIR), stacking a metal foil on the resin-impregnated sintered substrate (IIR) and press-forming the resultant laminate, wherein the stacked metal foil has a 10-point average surface roughness Rz of 10 mu m or less, and the resin-impregnated sintered substrate (IIR) and the metal foil have substantially no adhesive layer therebetween or have an adhesive layer having a thickness of 10 mu m or less therebetween.

Owner:MITSUBISHI GAS CHEM CO INC

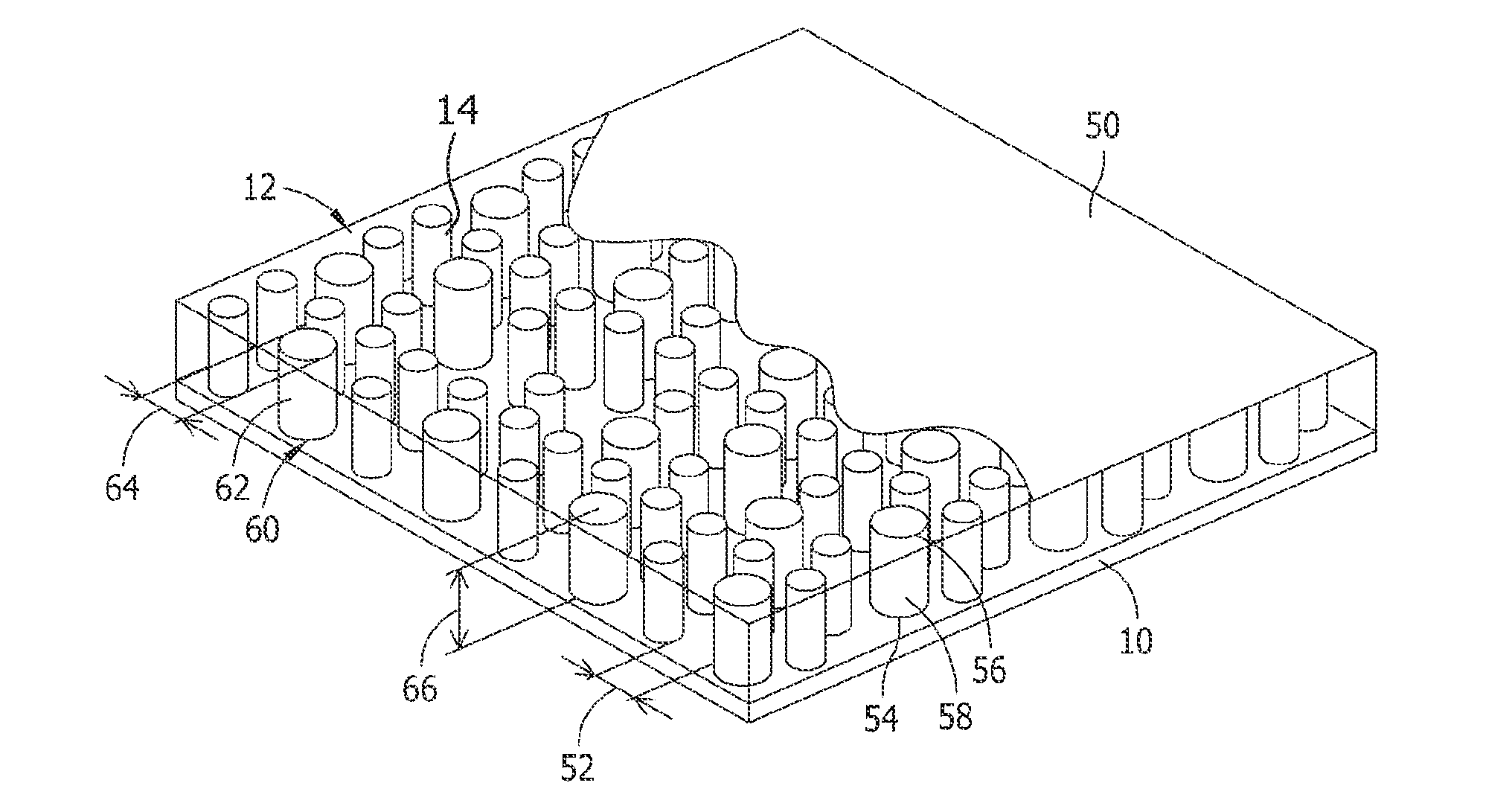

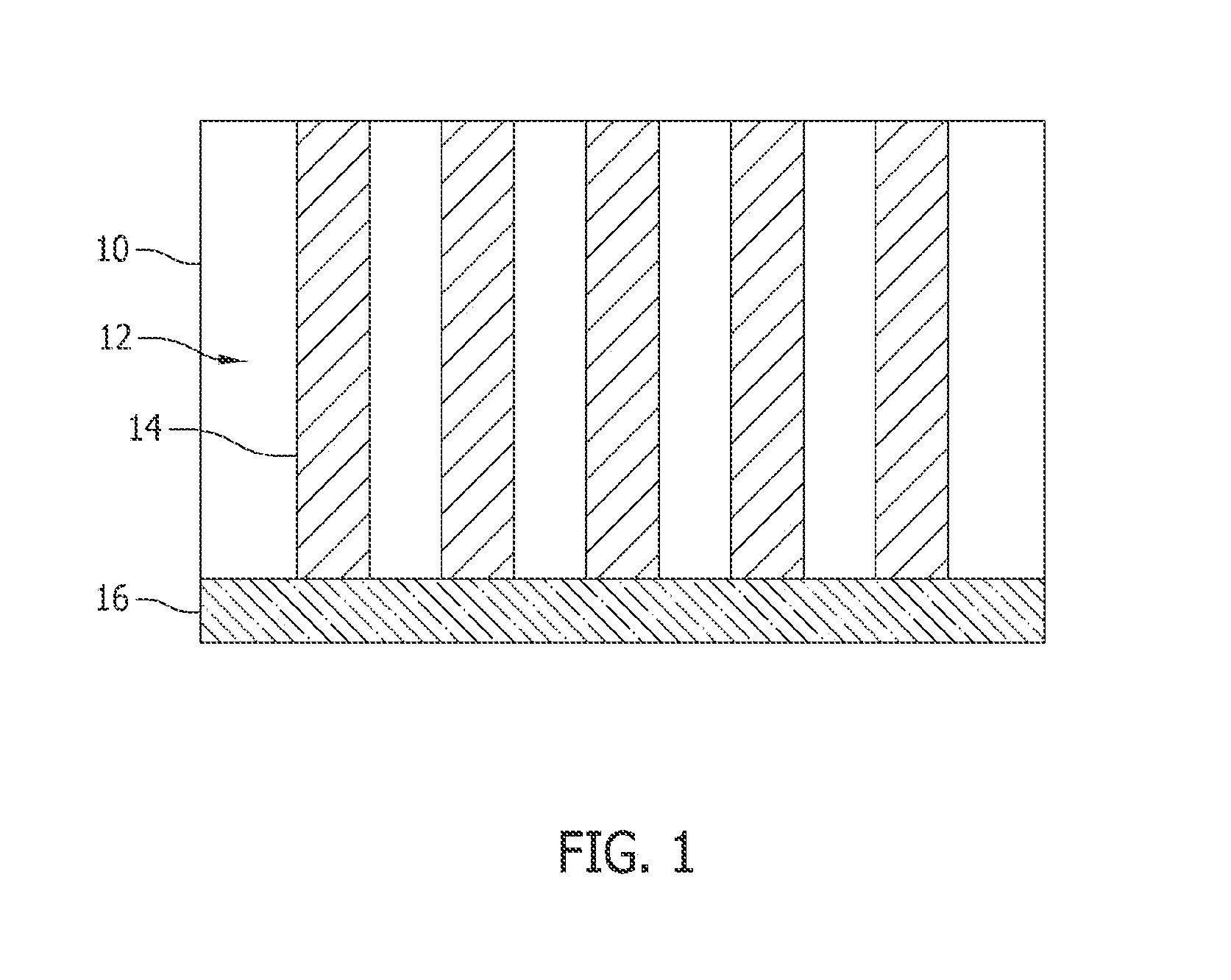

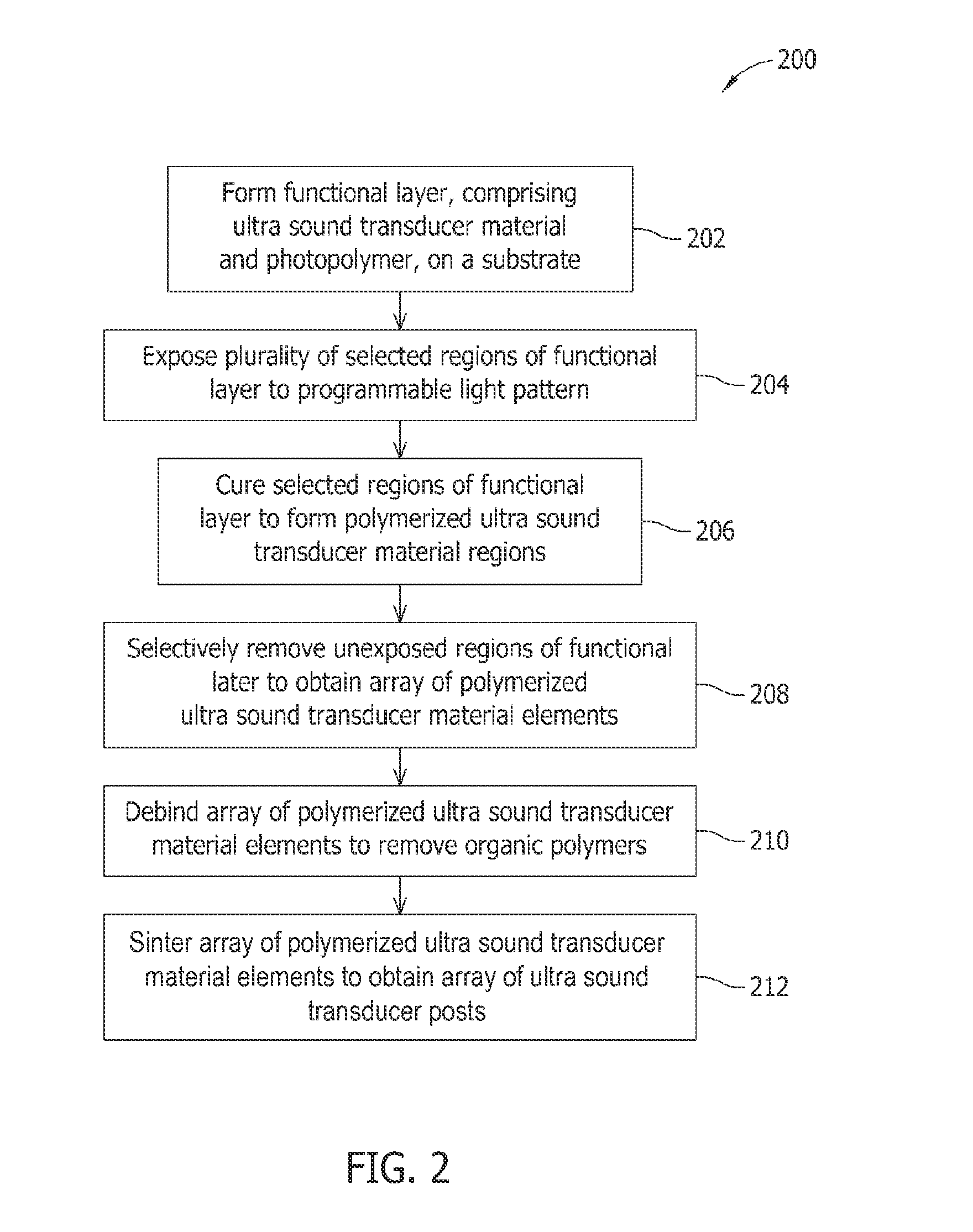

Transducer structure for a transducer probe and methods of fabricating same

ActiveUS20130076207A1MiniaturizationEasy to shapePiezoelectric/electrostrictive device manufacture/assemblyMaterial analysis using sonic/ultrasonic/infrasonic wavesComposite ceramicTransducer

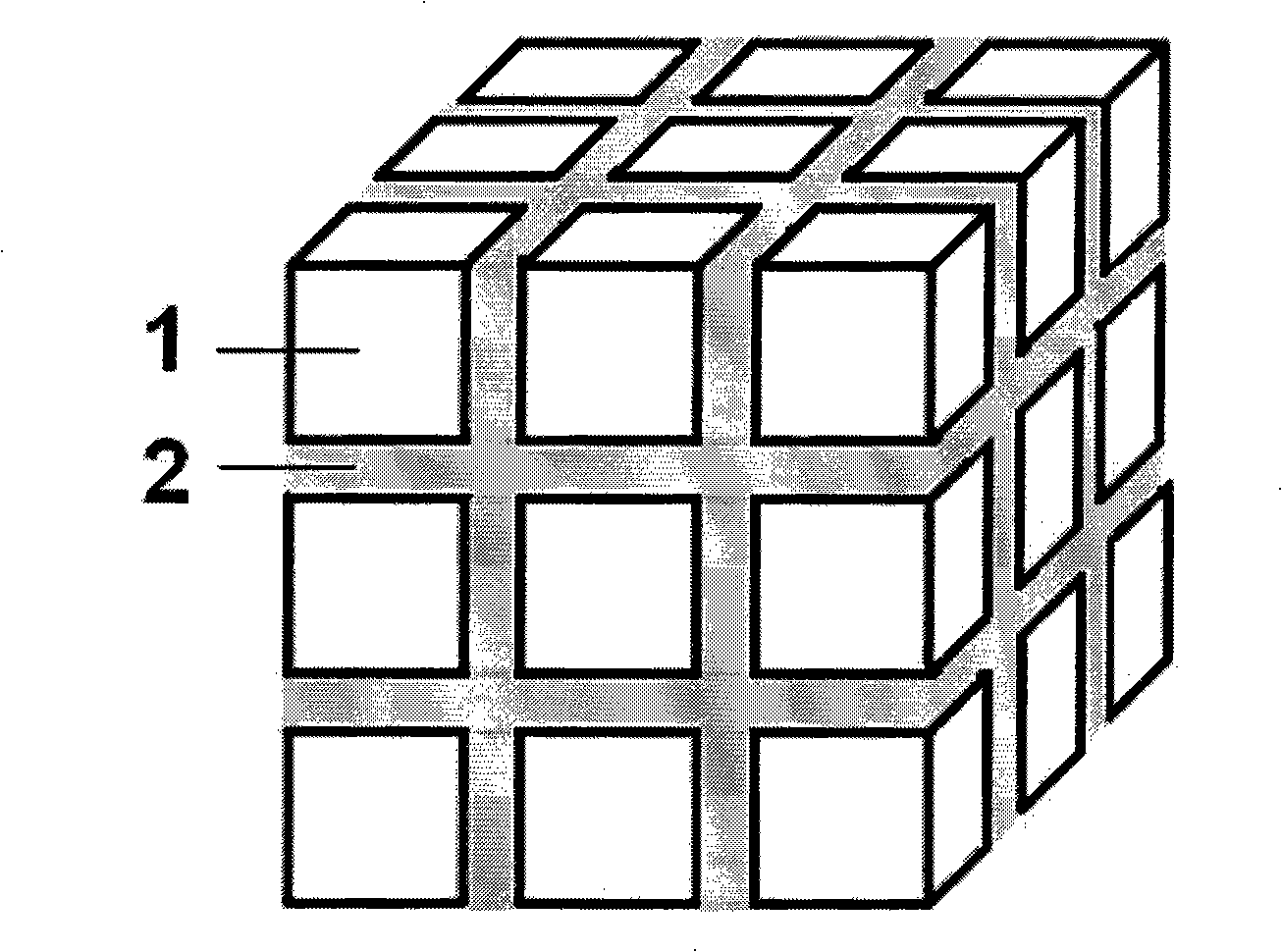

A composite ceramic transducer structure for use in the construction of an ultrasound probe includes a substrate and a plurality of piezoelectric transducer posts. The plurality of piezoelectric transducer posts are controllably formed on the substrate in a plurality of spatial positions located on an X-Y plane of the substrate. The plurality of piezoelectric posts includes a plurality of shapes defined in an X-Y-Z plane of the substrate, wherein the plurality of piezoelectric transducer posts are configured to facilitate minimizing shear waves within the ultrasound probe.

Owner:BAKER HUGHES INC

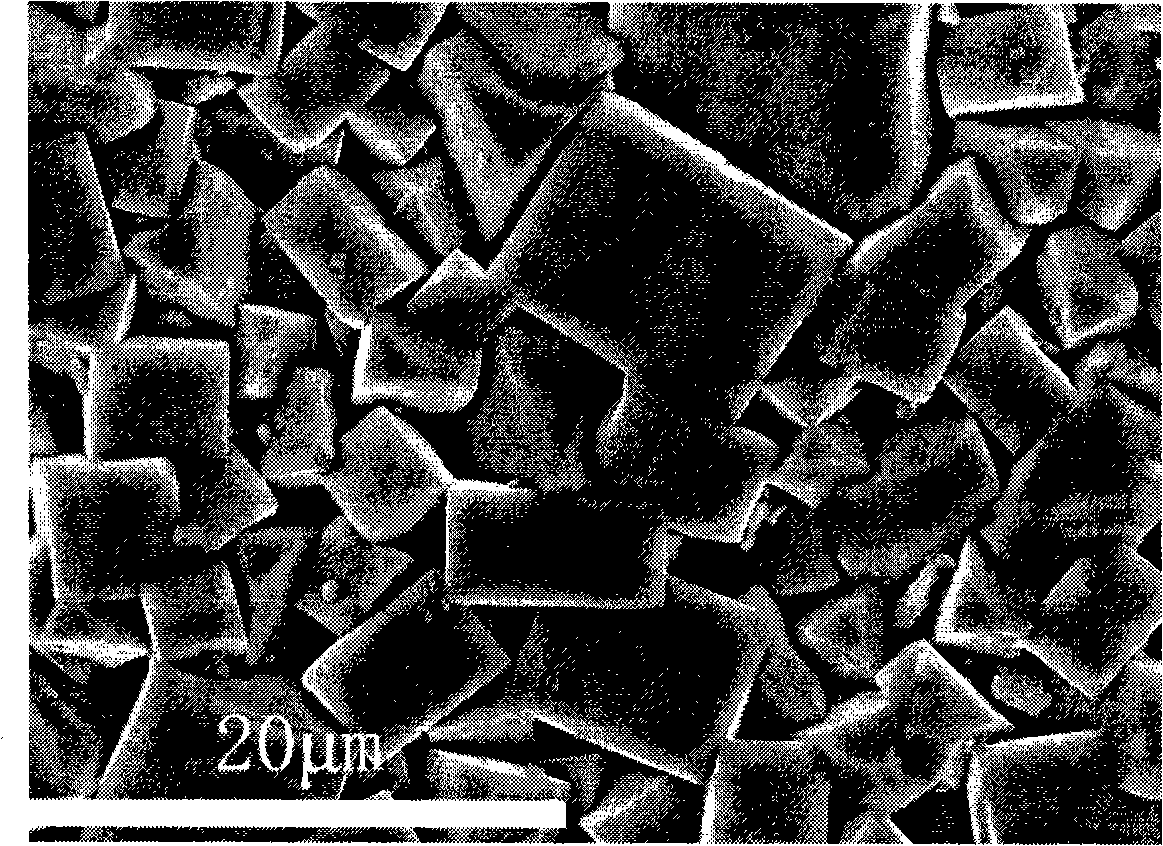

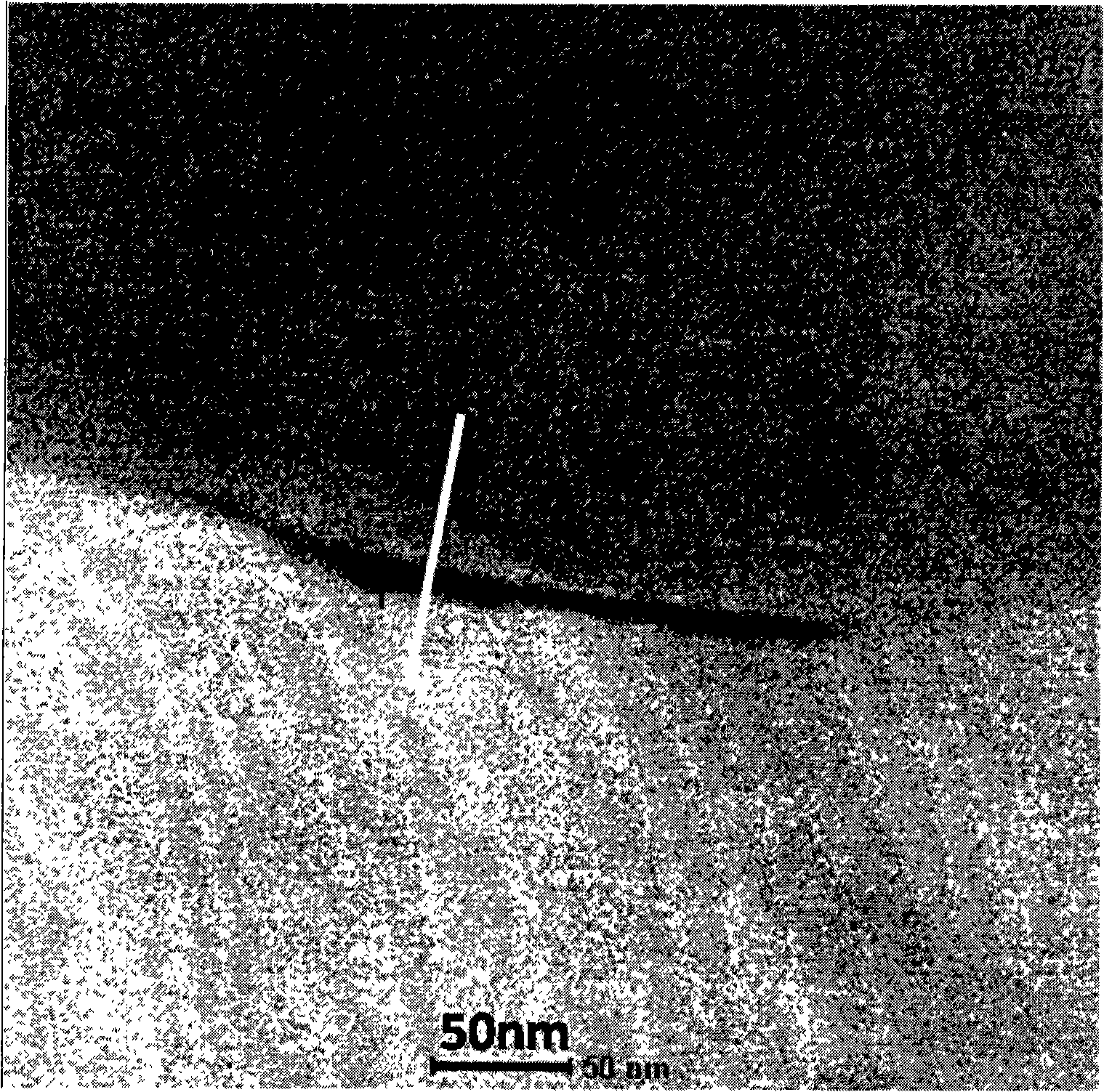

Lithium lanthanum titanium oxygen LLTO composite solid-state electrolyte material and synthesizing method thereof

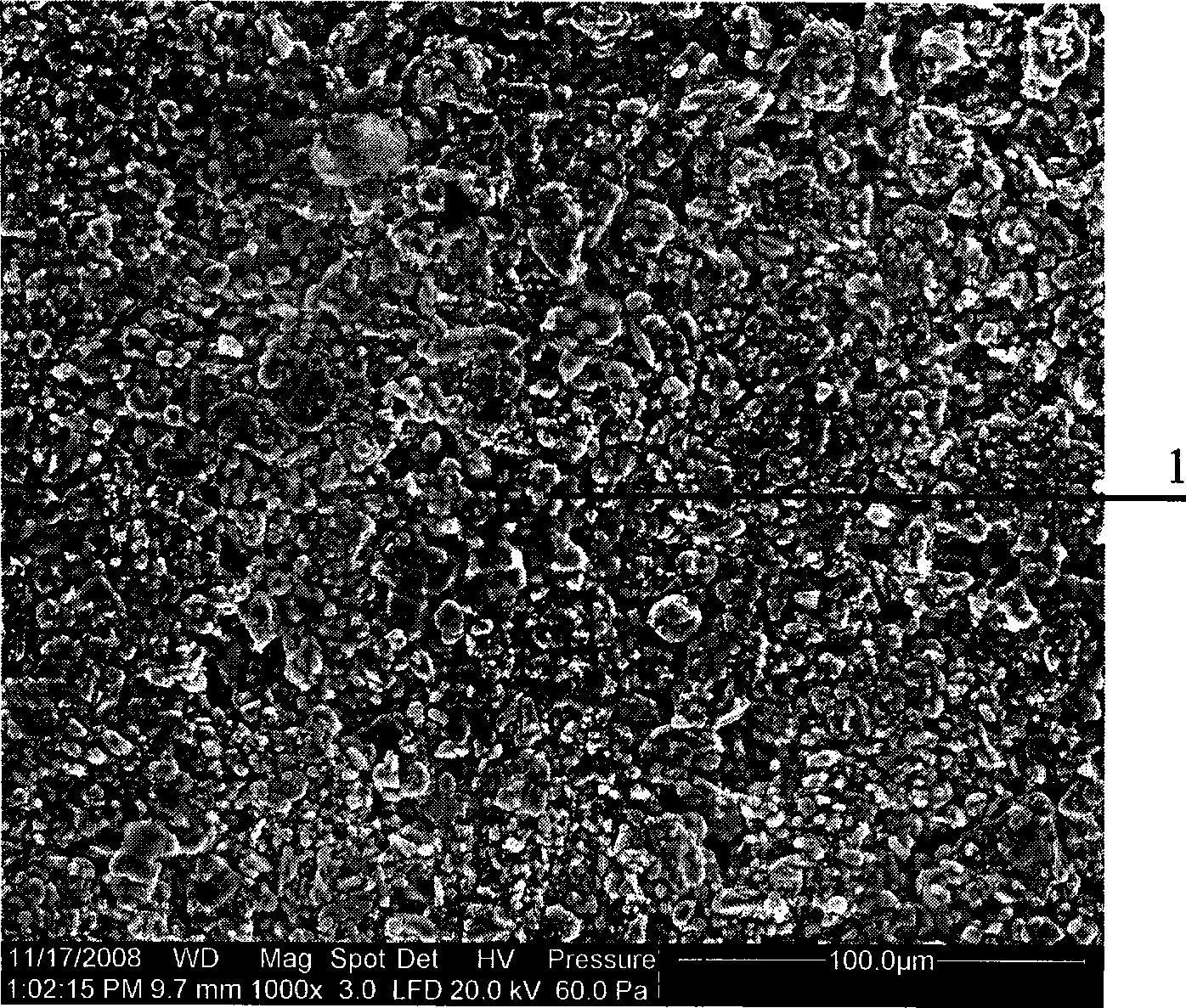

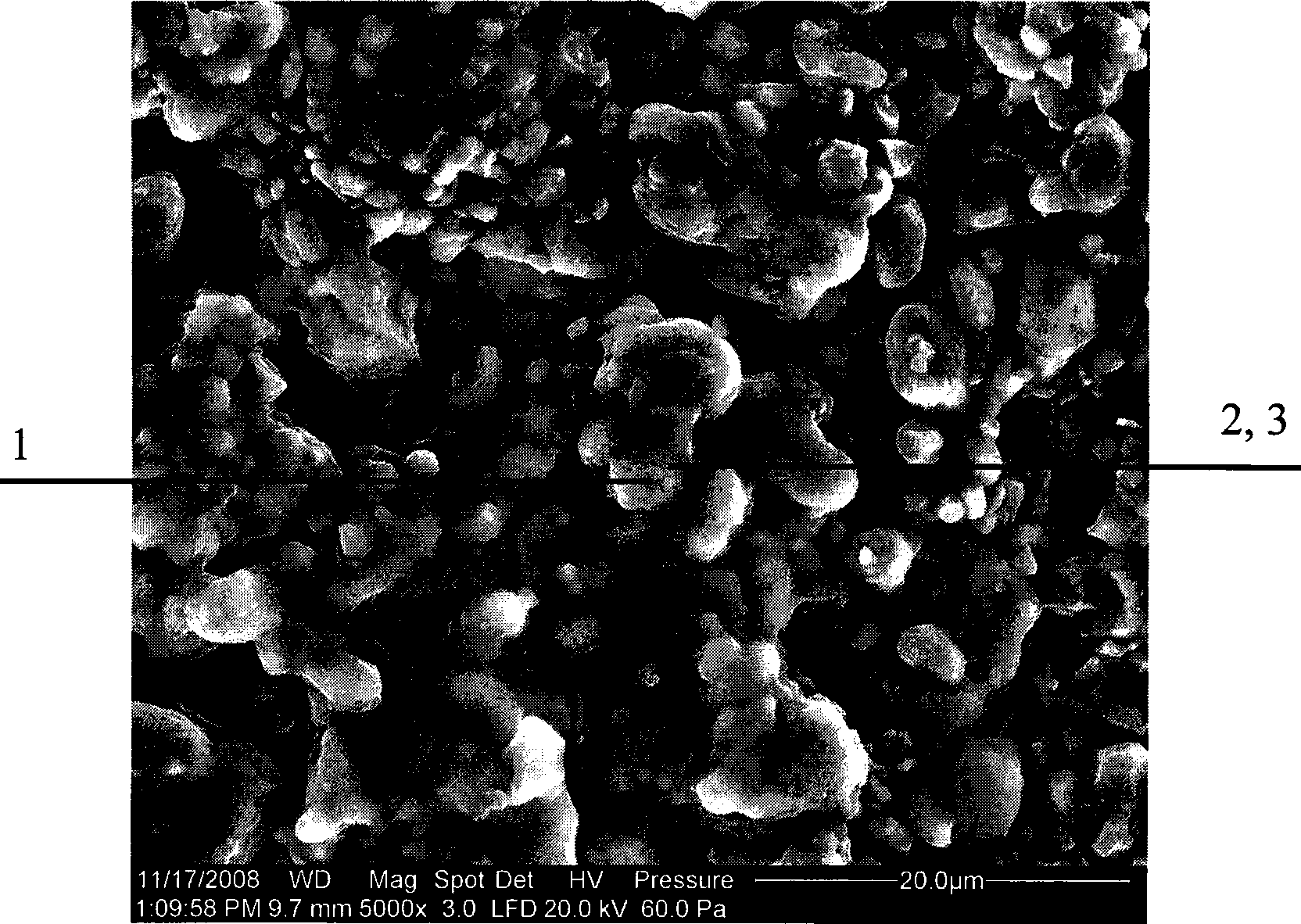

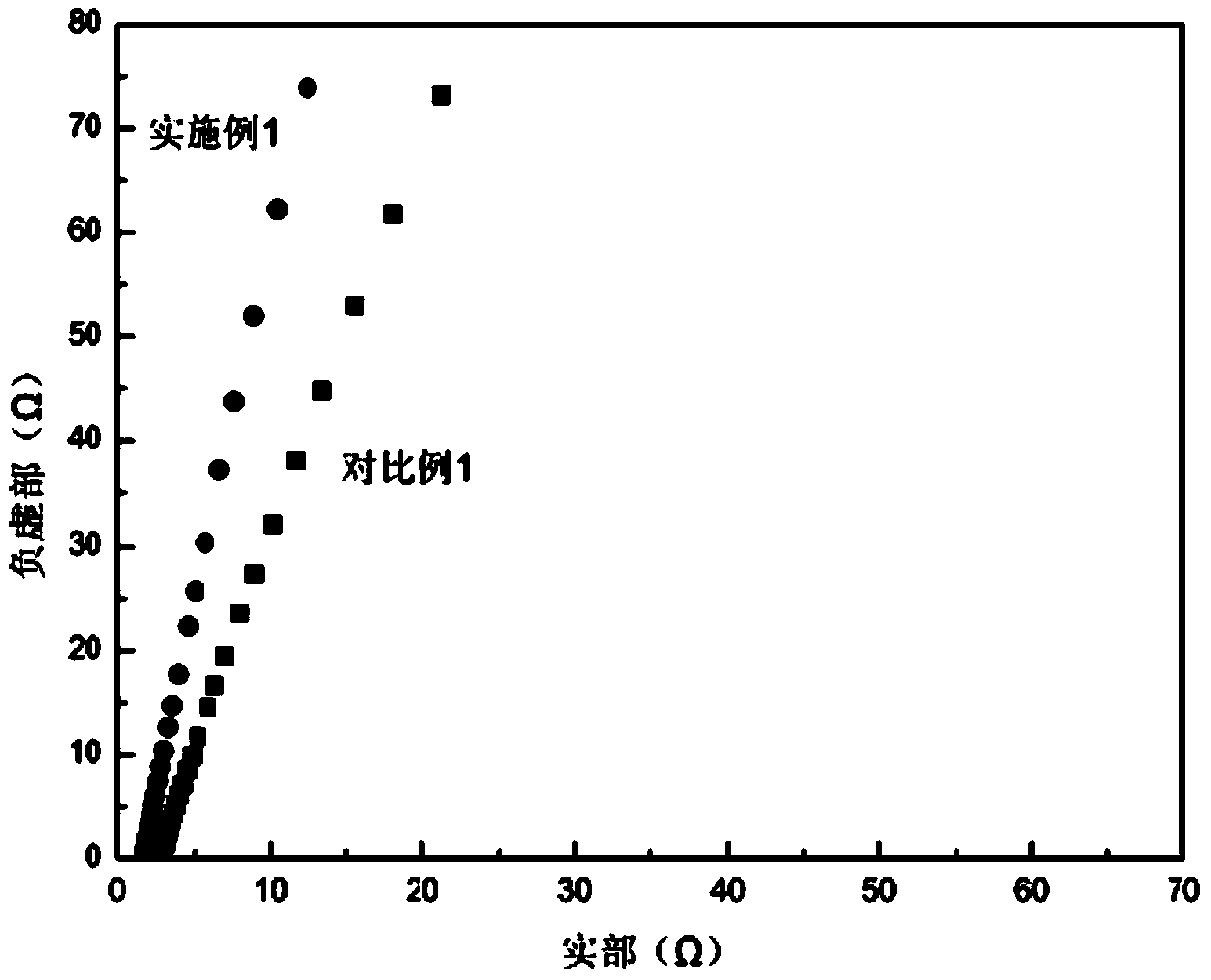

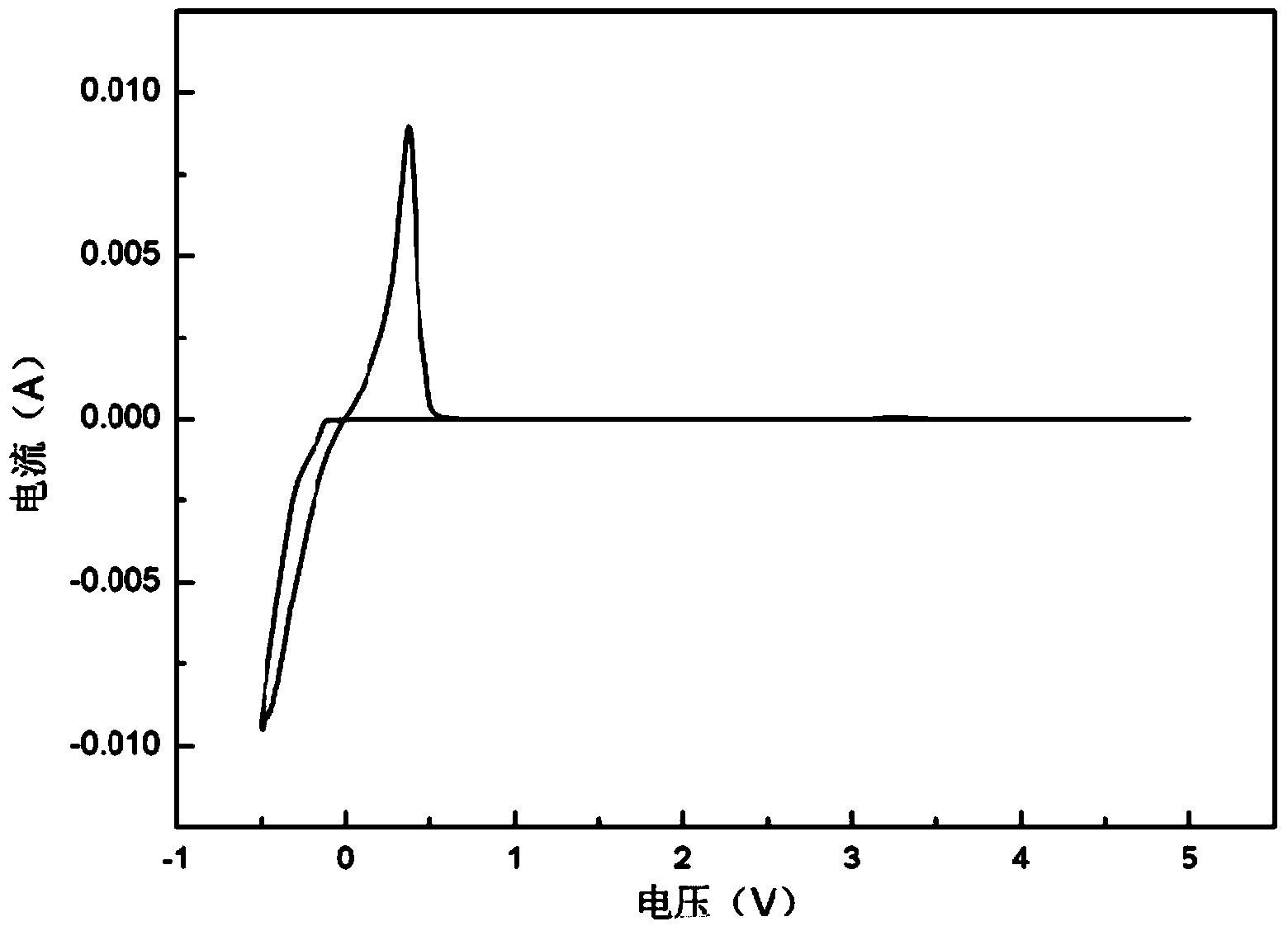

ActiveCN101325094AGood lifting effectSimple processSolid electrolyte cellsSecondary cellsSolid state electrolyteComposite ceramic

The invention provides a La-Li-Ti-O (LLTO) composite solid electrolyte material containing an amorphous silicon oxidate grain boundary layer and the synthetic method thereof, and belongs to the field of the lithium ion battery. The material is characterized in that: composite ceramics of an amorphous nano-silicon oxidate layer 2 are contained in the position of the grain boundary between materialcrystal grains, and the induction of the amorphous nano-silicon oxidate layer 2 is realized by adopting the wet chemical process, in the wet chemical process, inexpensive organic silicide is adopted as the additive to be added to the LLTO solid electrolyte material, and when the silicone content is 1 to 10 percent, the LLTO composite solid electrolyte material containing the amorphous silicon oxidate grain boundary layer can be synthesized through agglomeration. The electrical conductivity of the grain boundary is obviously improved, thereby improving the total electrical conductivity of the material. The composite solid electrolyte material has the advantages that the preparation process is simple, the operation is easy, the experimental period is greatly shortened, and the synthesis temperature is reduced, the energy consumption and the production cost are saved.

Owner:TSINGHUA UNIV +1

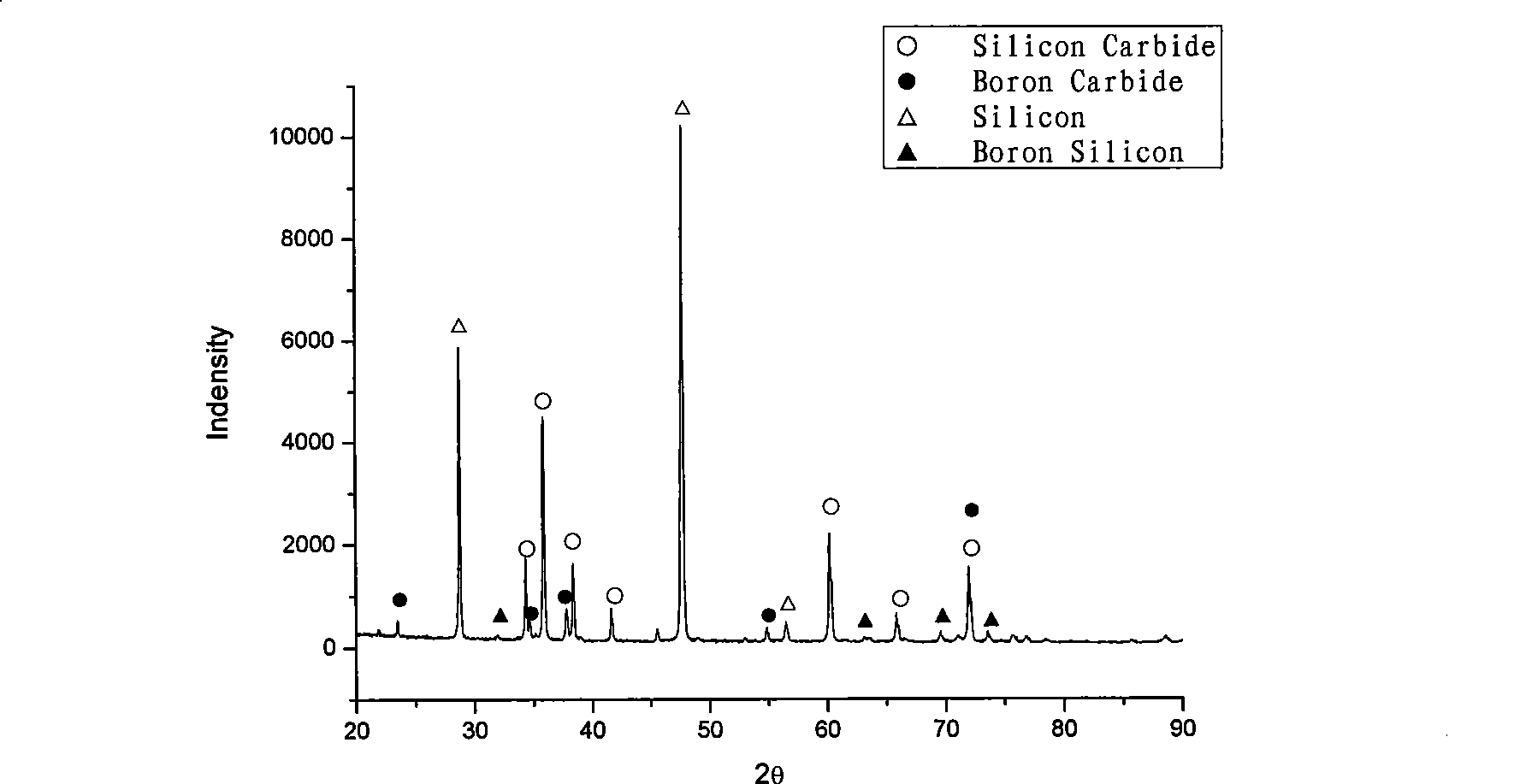

Boron carbide based bulletproof composite ceramic and preparation method thereof

The preparation method for boron carbide composite bulletproof ceramics comprises: selecting the material by weight ratio as 85~95 boron carbide, 1~15 carborundum whisker, 2~15 silicon powder, and 1~5 boride; with anhydrous alcohol as medium, grinding and mixing the material; then drying in vacuum to prepare the mixed powder and add into the graphite mould with layers separated by graphite spacer and graphite paper; hot pressing and sintering with pressure as 30~40MPa at 1700~2000Deg. This product has low density, high strength and elastic modulus.

Owner:SHANDONG UNIV

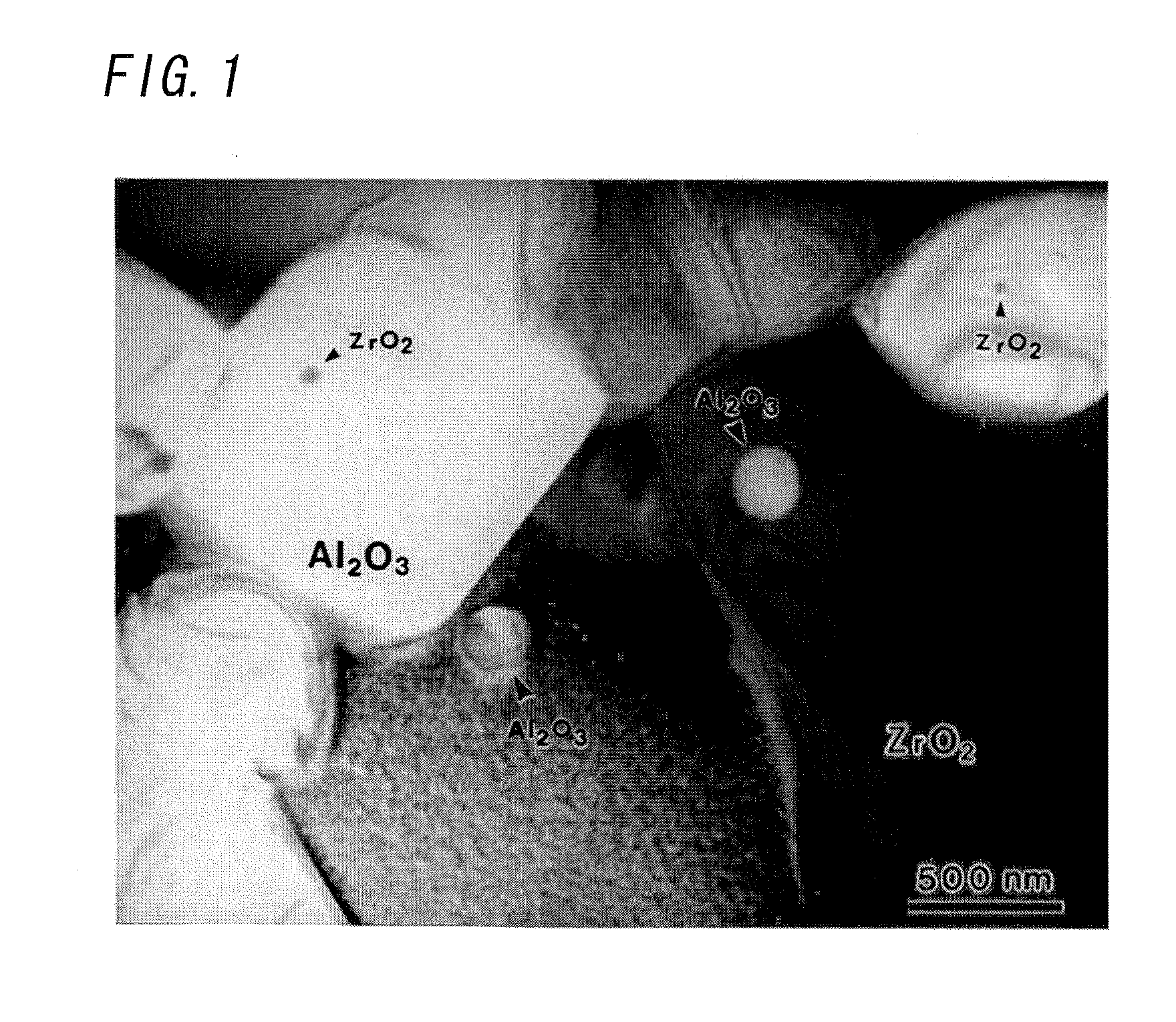

ZrO2-Al2O3 composite ceramic material

A ZrO2—Al2O3 composite ceramic material is provided, which is excellent in mechanical strength and toughness, and has the capability of preventing low temperature degradation. This ceramic material includes a first phase of ZrO2 grains having an average grain size of 0.1 to 0.8 μm, and containing 10 to 12 mol % of CeO2 and 0.005 mol % to less than 0.5 mol % of Y2O3, and a second phase of Al2O3 grains having an average grain size of 0.1 to 0.5 μm. The ZrO2 grains is composed of 90 vol % or more of tetragonal ZrO2, and a content of the second phase in the composite ceramic material is in a range of 20 to 60 vol %, and preferably 30 to 50 vol %.

Owner:PANASONIC HEALTHCARE HLDG CO LTD

Multifunctional photocatalysis composite ceramic separation membrane as well as preparation method and use thereof

ActiveCN101497003AReduce loadIncrease loadSemi-permeable membranesWater/sewage treatment by irradiationMembrane permeabilityComposite ceramic

The invention belongs to the technical field of membrane and relates to a photocatalytic composite ceramic separation membrane using porous ceramic membrane as a carrier, a method for preparing the same and application of the separation membrane. The method is characterized in that a porous ceramic membrane substrate is used as the carrier to prepare hydroxyapatite sol and argent-titania composite sol through sol-gel technology; and a carrier membrane is subjected to secondary sol-gel dipping, drying and roasting sequentially to obtain the argent-carried titania / hydroxyapatite photocatalytic composite ceramic separation membrane with aperture of between 100 and 1,900 nm and porosity of between 20 and 55 percent. The photocatalytic composite ceramic separation membrane has biological adsorption and high photocatalytic activity and membrane permeability, improves separation of the composite membrane, photocatalytic degradation and sterilization, has remarkable effects of decontamination and sterilization, reduces the loss of porosity in the process of membrane preparation, has a simple preparation and application process, is easy for large-scale industrial production, integrates three units of membrane separation, photocatalytic degradation and sterilization and reduces investment and occupied area.

Owner:DALIAN UNIV OF TECH

Low-abrasion environment-friendly composite ceramic-based friction material

ActiveCN101619202ANo brake noiseReduce wear rateOther chemical processesFriction liningComposite ceramicBoron nitride

The invention discloses a low-abrasion environment-friendly composite ceramic-based friction material which comprises the following components in percentage by weight: 5 to 7 phenolic resin, 5 to 9 nitrile rubber, 2 to 5 aramid fiber, 2 to 6 silicon carbide, 15 to 20 ceramic fiber, 3 to 5 zirconia, 8 to 10 artificial graphite, 3 to 10 molybdenum disulphide, 5 to 15 zirconium silicate, 1 to 3 aluminum oxide, 8 to 10 potassium titanate whiskers, 5 to 15 precipitated barium sulfate, 1 to 3 magnesium oxide, 1 to 3 petroleum coke, 3 to 5 friction powder, 8 to 10 vermiculite and 4 to 9 boron nitride. The invention has the advantages that the friction material manufactured by using the components and the blending ratio has the advantages of no asbestos and brake noise, low wear rate, stable high-temperature brake performance, stable speed reduction brake, lower cost than the similar imported products, and the like.

Owner:CHONGQING HONGYU FRICTION PROD

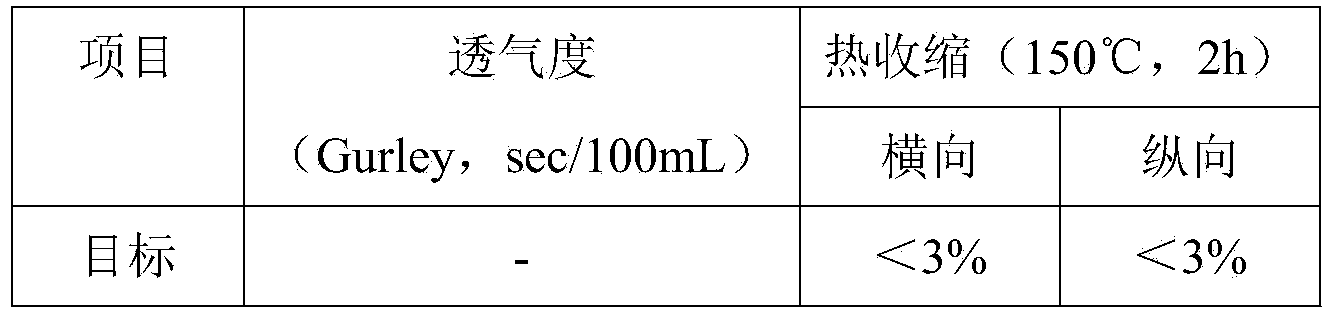

Composite ceramic coating, lithium ion battery composite ceramic diaphragm and lithium ion battery

InactiveCN104269508AImprove ionic conductivityImprove mechanical propertiesCell seperators/membranes/diaphragms/spacersMetallurgyComposite ceramic

The invention discloses a composite ceramic coating, a lithium ion battery composite ceramic diaphragm and a lithium ion battery. The composite ceramic coating comprises ceramic powder and solid electrolyte powder, wherein the mass ratio of the ceramic powder to the solid electrolyte powder is (1:19) to (1-9). The composite ceramic coating disclosed by the invention comprises ceramic powder and inorganic solid electrolyte powder, the ceramic powder is high-temperature resistant, the inorganic solid electrolyte powder is excellent in ionic conductivity, and when a composite ceramic layer is formed on the surface of a base film by using the coating, on one hand, the mechanical property and the high-temperature resistant shrinkage property of the diaphragm are improved, and furthermore the high-temperature stability and the safety of the lithium battery are improved; on the other hand, the ionic conductivity of the ceramic diaphragm is improved, the internal resistance of the lithium ion battery is effectively reduced, and the electrochemical performance of the lithium ion battery is improved.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

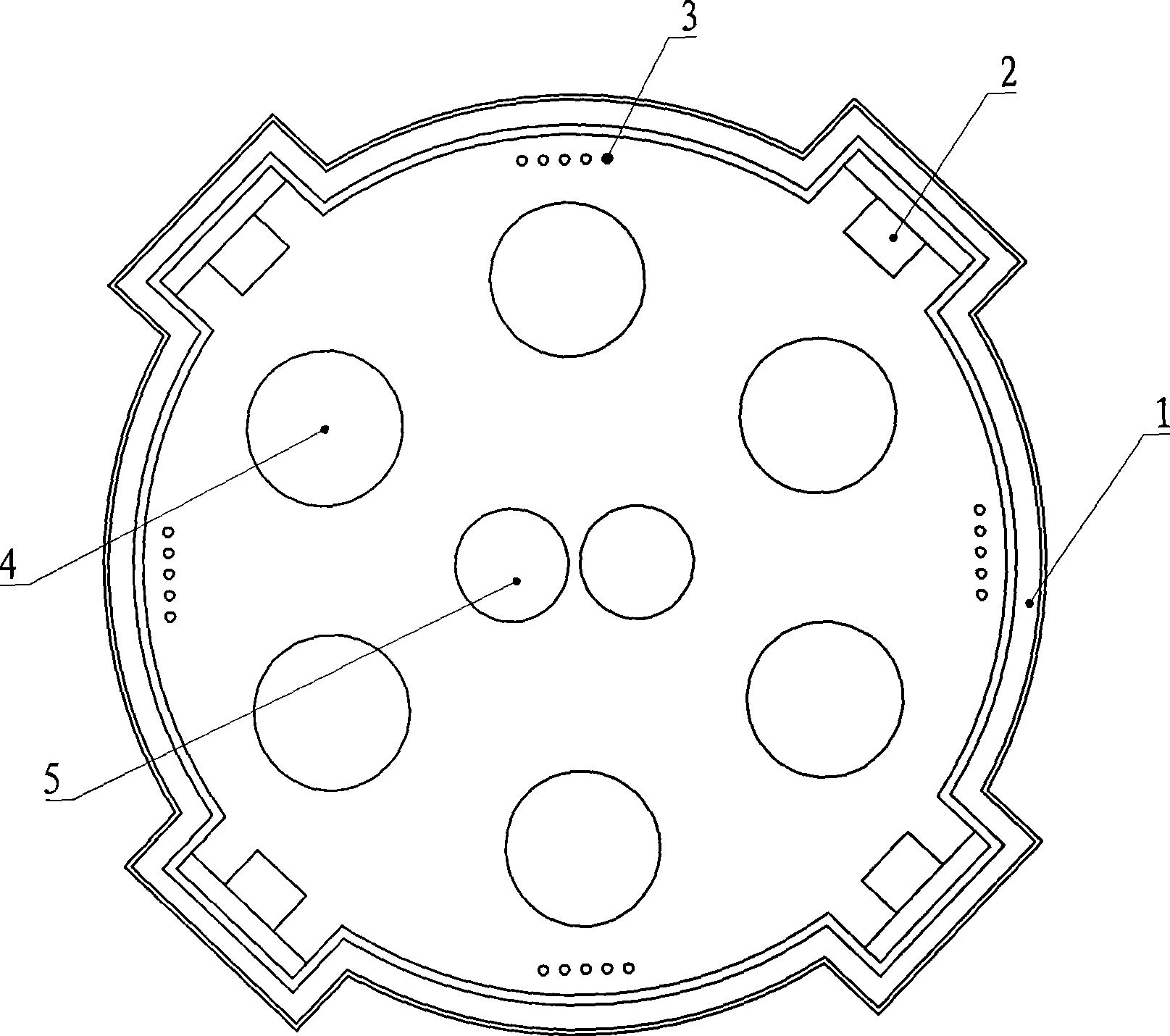

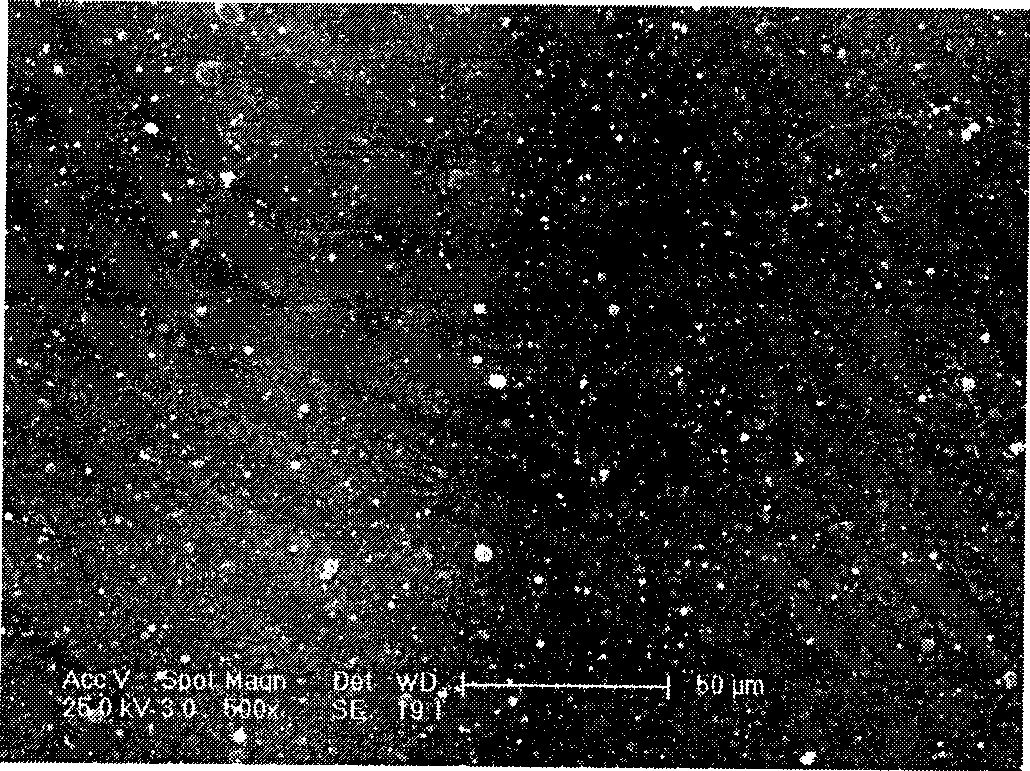

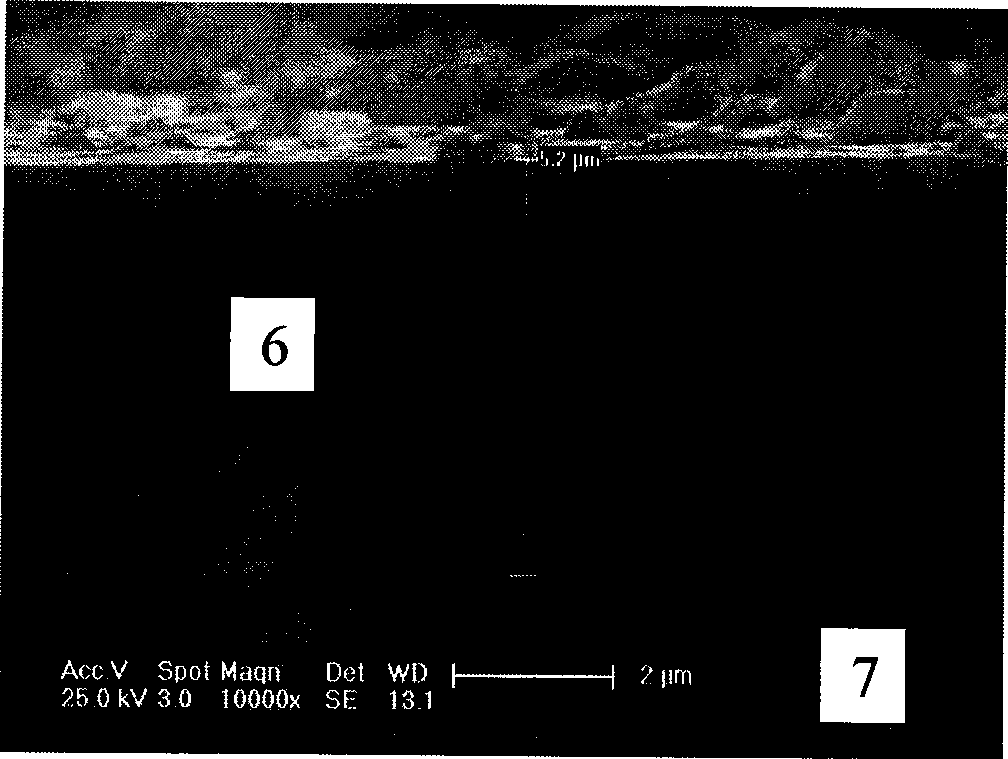

PVD nano composite ceramic coating screw and method for manufacturing same

InactiveCN101518935ASolve pollutionIncreased microhardnessLayered productsVacuum evaporation coatingCarbon filmDiamond-like carbon

The invention provides a PVD nano composite ceramic coating screw. A screw substrate (7) is coated with a coating (6) consisting of a bonding layer, a primary wear-resistance layer and a lubricating layer sequentially. The method for manufacturing the screw comprises the following steps: firstly, depositing a 50 to 100 nanometer thick transitional metal bonding layer at an air pressure of 0.1 Pa; secondly, depositing a 2 to 5 micrometer thick composite ceramic layer as the primary wear-resistance layer at a temperature of between 350 and 400 DEG C, a voltage of between -50 and -200 volts and an air pressure of 0.2 to 1Pa; and finally, depositing a 1 to 3 micrometer transitional metal doped diamond carbon film layer as the lubricating layer at a temperature of between 100 and 150 DEG C, a voltage of between -50 and -150 volts and an air pressure of 0.1 to 0.5Pa. Compared with the prior art, the screw has the advantages of having lubricating performance, along with high hardness (more than 40GPa Hv hardness) and excellent wear resistance (friction coefficient about 0.1). The method is free from pollution and the coating has strong adhesive force.

Owner:舟山市汉邦机械科技有限公司

Zr-Al-Si composite ceramic beads with high wear resistance and high strength and processing technique thereof

InactiveCN101723666AAdapt to a wide rangeDensity can be adjusted flexiblyMischmetalComposite ceramic

The invention provides a Zr-Al-Si composite ceramic bead with high wear resistance and high strength and a processing technique thereof. The Zr-Al-Si composite ceramic bead comprises the following components by weight percent: 2-65% of ZrO2, 2-60% of Al2O3, 10-50% of SiO2 and 5% of MgO and mischmetal. The production method comprises the following steps: firstly, evenly mixing zircon sand, zirconia, aluminia, magnesia, kaoline and mischmetal, then carrying out ball milling with a wet method, drying to prepare superfine pulverulent body, rolling and molding, sintering at high temperature, and polishing to obtain the Zr-Al-Si composite ceramic beads with high wear resistance and high strength with the diameter being Phi 0.2mm to Phi 15mm. The prepared ceramic bead has flexibly adjusted density, wide application, wear resistance, stable chemical property and simple process and is easy for scale production.

Owner:许兴康

Micro-nano composite ceramic die material and preparation method thereof

InactiveCN101164963AHigh strengthImprove toughnessCeramic shaping apparatusMicro nanoComposite ceramic

This invention relates to the micron nanometer composite ceramic die material, and its preparation method. In this invention, micron grade Al2O3 ceramic is used as basic material, added are nanometer grade Ti (C,N) ceramic hard granules as dispersing material, Mo, Ni and MgO as agglutinant assistant. The preparation steps are: the powder of Al2O3 and Ti(C,N) are dispersed in the unified dispersing medium, then being proceeded the ball-milling, drying and hot-pressing sintering. This invention method benefits the dispersing effect of the powder with advantages of: simple operation and low cost. This product can be used for making compressing die or drawing die and the like with its comprehensive mechanical properties and abradability being better than that of prior art ceramic die material.

Owner:QILU UNIV OF TECH

Preparation method of high-toughness boride-carbide composite ceramic

A preparation method of a high-toughness boride-carbide composite ceramic relates to a preparation method of a boride-carbide composite ceramic and solves the problems that in the conventional preparation of the boride-carbide composite ceramic, due to high sintering temperature and high sintering pressure, the preparation cost is high and the prepared boride-carbide composite ceramic is poor in mechanical property and fracture toughness. The preparation method of the high-toughness boride-carbide composite ceramic comprises the following steps : adding a dispersing medium into boride and carbide; uniformly mixing the dispersing medium, the boride and the carbide; pressing the mixture into a blank material; and sintering the blank material in a two-section pressure-free sintering way at alow temperature and a high temperature sequentially. The sizes and the distribution of grain crystals in the boride-carbide composite ceramic which is prepared under the low-temperature pressure-freeconditions are uniform; the fracture toughness is as high as 5.0-13MPa.m<-1 / 2>; and the bending strength is as high as 400-1000 MPa; the boride-carbide composite ceramic with excellent comprehensive mechanical property can be prepared; the preparation cost is reduced; and the application range is widened.

Owner:吉林长玉特陶新材料技术股份有限公司

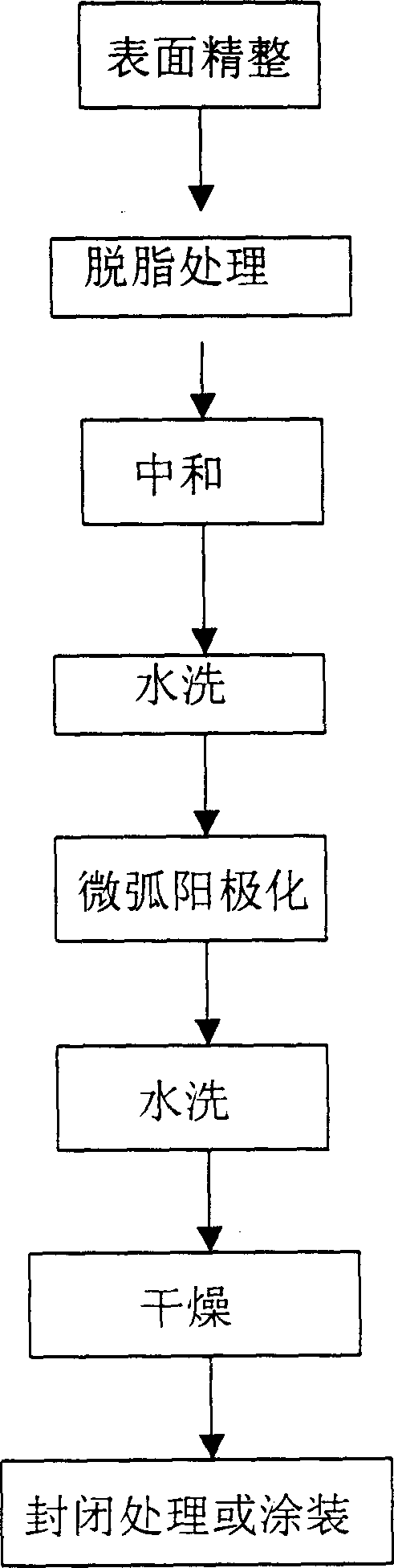

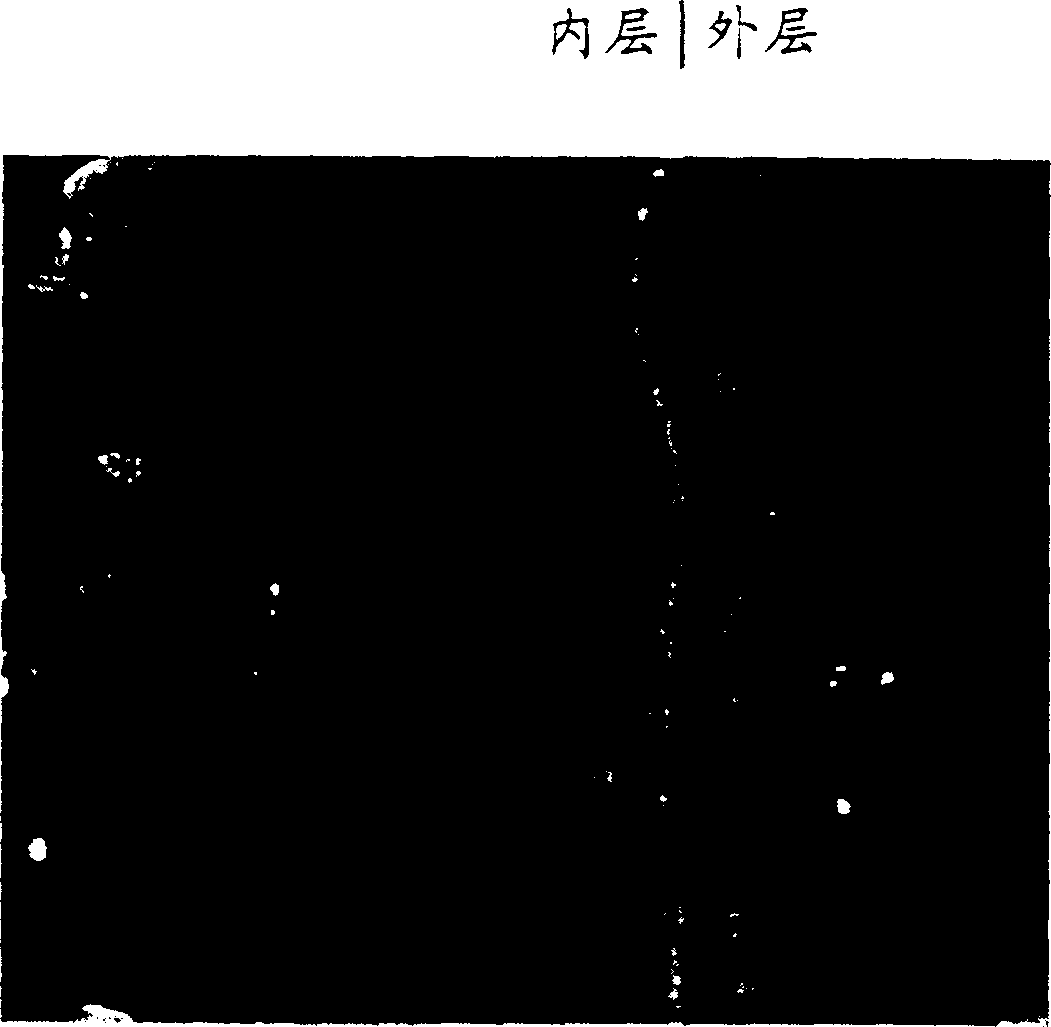

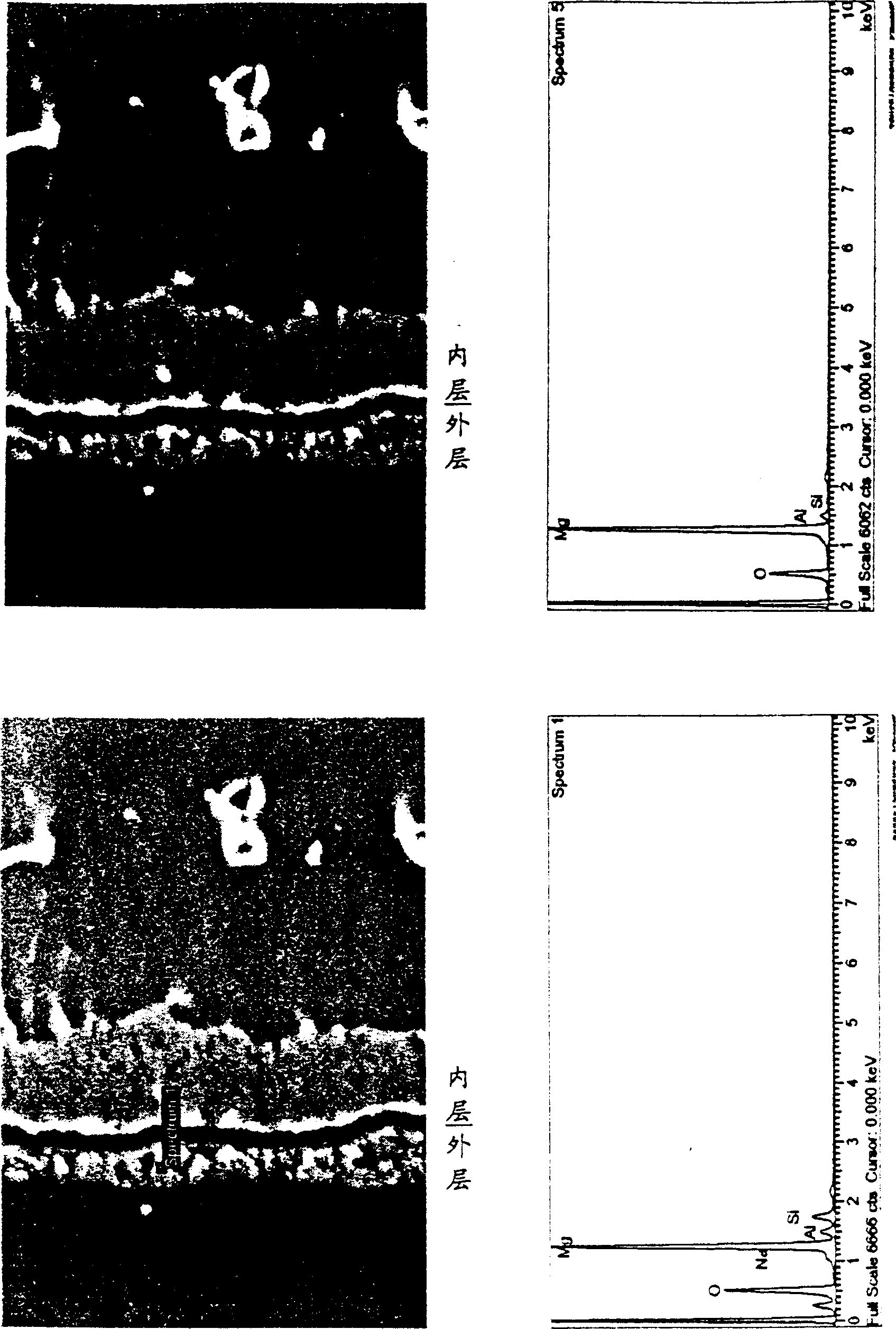

Composite ceramic film on surface of magnesium alloy and its forming process

InactiveCN1388272AOvercoming brittlenessOvercoming the formation of voids in the film layerAnodisationMicro arc oxidationPlasma electrolytic oxidation

The present invention features that the composite ceramic film consists of two layers, the inner layer film of silicon-containing composite Mg-Al oxide and the outer layer film of Mg-Al silico-oxide of 5-70 micron thickness each. The composite ceramic film is formed through surface treatment, degreasing, neutralizing, water washing, micro-arc anodizing, water washing, drying, closing treatment or painting. The composite ceramic film has no holes and cracks, high corrosion resistance, high wear resistance and smooth surface.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

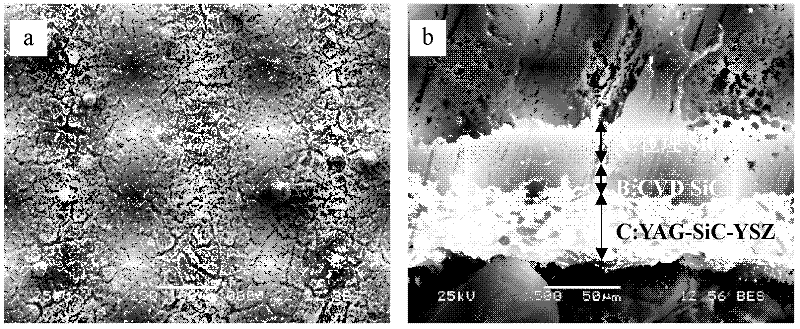

Turbine components with thermal barrier coatings

InactiveUS7226672B2Low thermal conductivityRare earth metal oxides/hydroxidesMolten spray coatingComposite ceramicSelf reinforced

A turbine component has a substrate formed from a ceramic material selected from the group consisting of a monolithic ceramic material and a composite ceramic material and a thermal barrier coating bonded to the substrate. In one embodiment, the ceramic material forming the substrate is selected from the group of silicon nitride and self-reinforced silicon nitride. In another embodiment, the ceramic material forming the substrate is selected from the group consisting of a silicon carbide-silicon carbide material and a carbon-carbon material. At least one bond coat layer may be interposed between the substrate and the thermal barrier coating.

Owner:RAYTHEON TECH CORP

Composite coating with friction-decreasing function and biological-foul and seawater resistances and its production

InactiveCN101074331AImprove the protective effectResistant to microbial foulingAntifouling/underwater paintsPaints with biocidesComposite ceramicAlloy

A composite coating against biological fouling and seawater corrosion and its production are disclosed. The composition consists of oxide based-phase ceramic powder 80-95 wt% and powder against biological fouling 5-20 wt% with Cu, CuO or Cu2O powders. The composite coating comprises binding bottom layer, composite ceramic coating and surface sealing layer; ZnNi alloy powder is sprayed on metal substrate of binding bottom layer by supersonic flame; Composite ceramic power against biological fouling and sea-water corrosion is sprayed on bottom of composite ceramic coating by plasma; Inorganic or organic sealer with low surface energy is sprayed on surface sealing layer. An insulating ceramic transient layer is added between binding bottom layer and composite ceramic coating when Cu powder is adopted. It's simple and cheap and can be used for industrial production.

Owner:WUHAN UNIV OF TECH

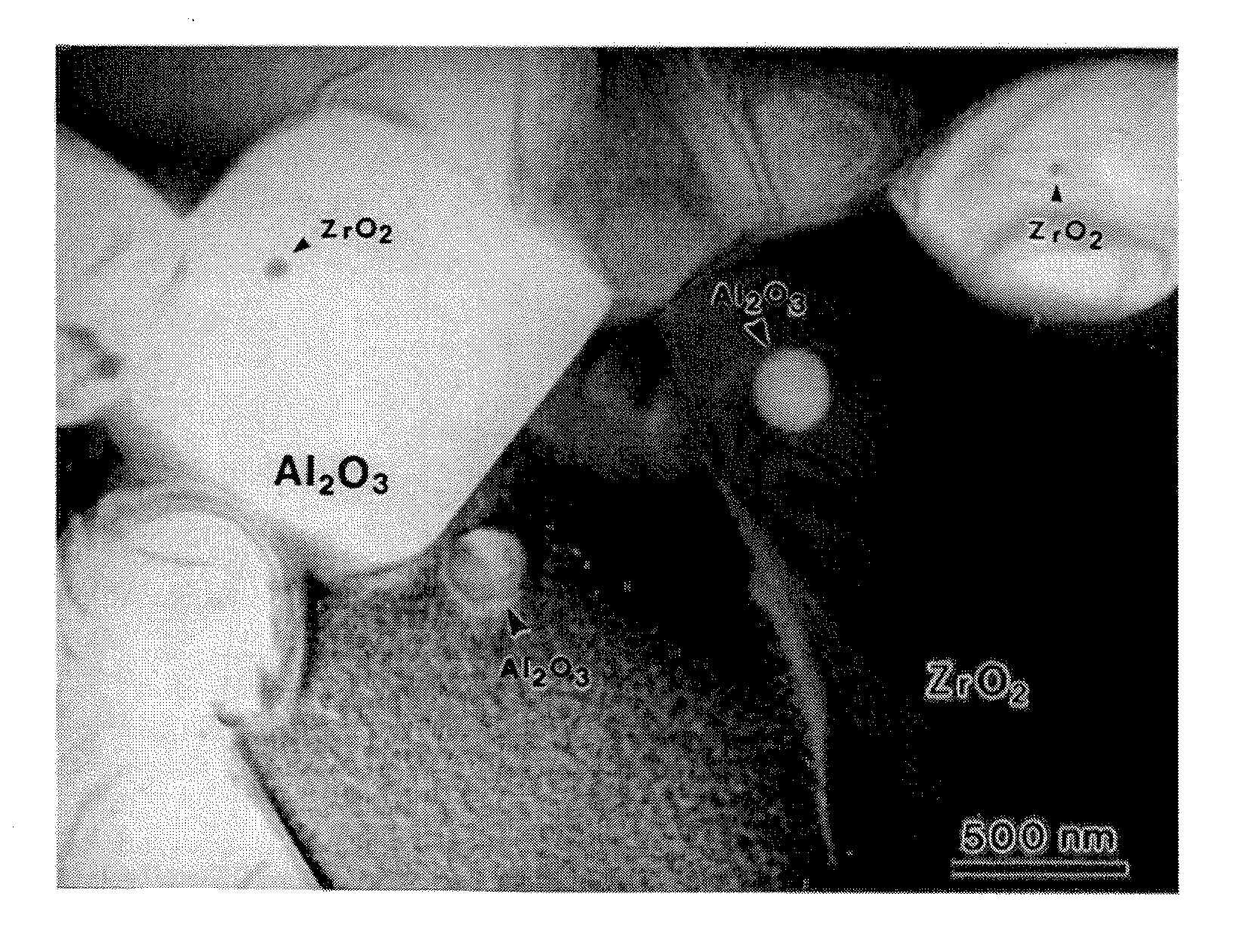

ZrO2-Al2O3 composite ceramic material and production method thereof

A ZrO2—Al2O3 composite ceramic material having high mechanical strength and toughness as well as excellent wear resistance and hardness is provided. This ceramic material includes a first phase of ZrO2 grains containing 10 to 12 mol % of CeO2 as a stabilizer and having an average grain size of 0.1 μm to 1 μm, and a second phase of Al2O3 grains having an average grain size of 0.1 to 0.5 μm. The ceramic material has a mutual nano-composite structure formed under a condition that a content of the second phase in the ceramic material is within a range of 20 to 60 vol % such that the Al2O3 grains are dispersed within said ZrO2 grains at a first dispersion ratio of 2% or more, and preferably 4% or more, which is defined as a ratio of the number of the Al2O3 grains dispersed within the ZrO2 grains relative to the number of the entire Al2O3 grains dispersed in the ceramic material, and the ZrO2 grains are dispersed within the Al2O3 grains at a second dispersion ratio of 1% or more, which is defined as a ratio of the number of the ZrO2 grains dispersed within the Al2O3 grains relative to the number of the entire ZrO2 grains dispersed in the ceramic material.

Owner:PANASONIC HEALTHCARE HLDG CO LTD

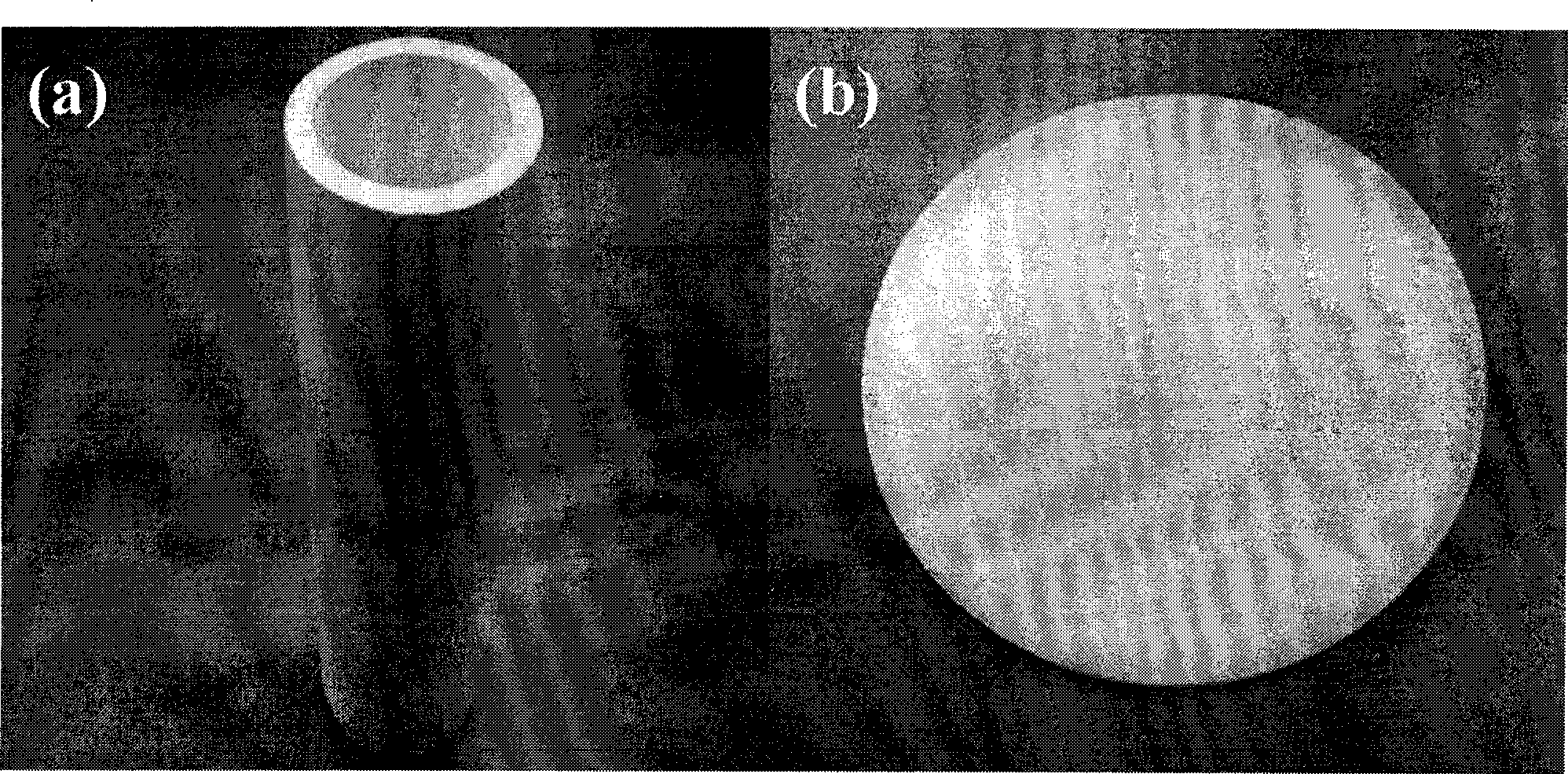

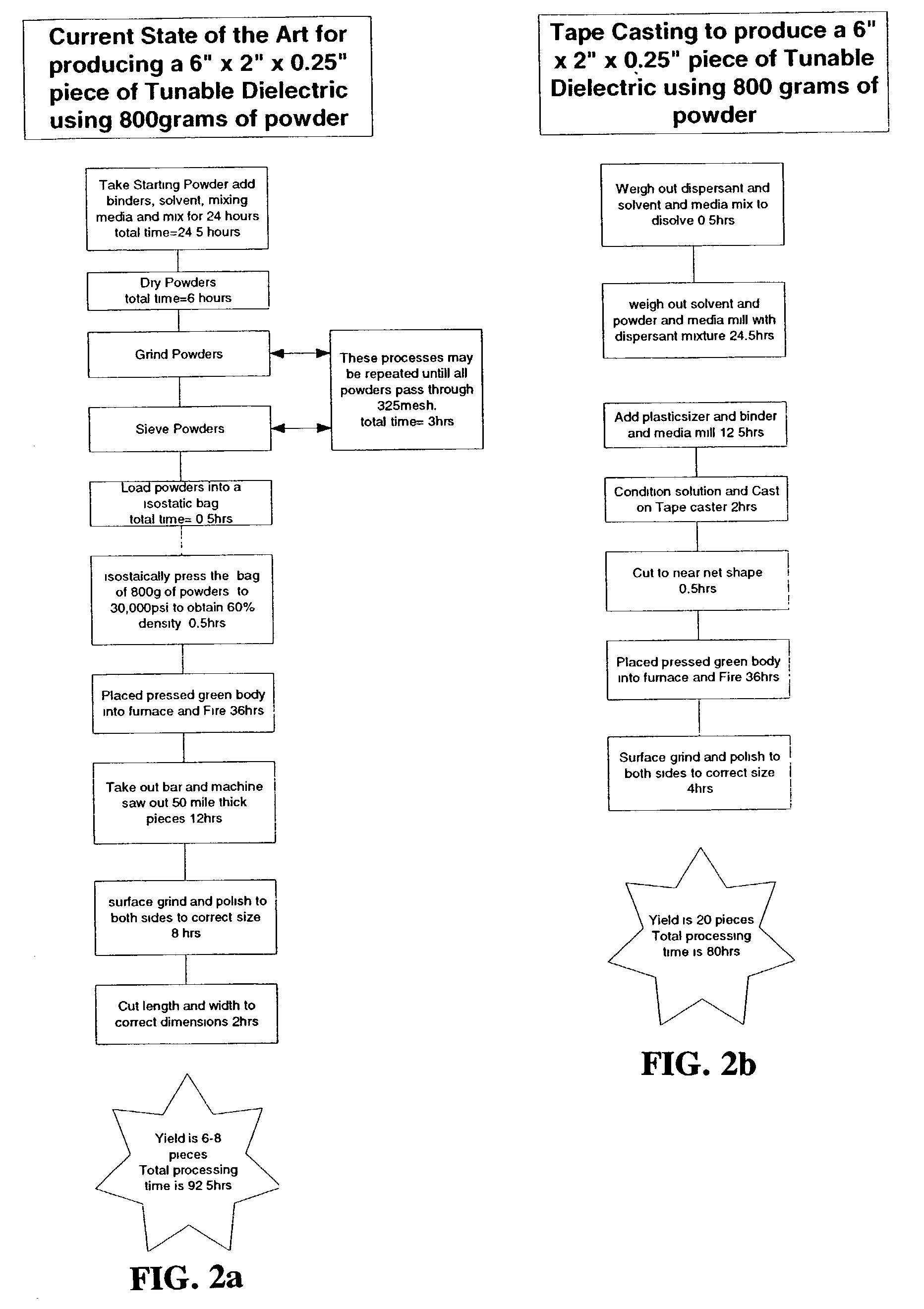

Method for producing low-loss tunable ceramic composites with improved breakdown strengths

InactiveUS20030119656A1Improved propertyLow cost productionLayered productsFixed capacitor dielectricBreakdown strengthMicrowave

The production of low-loss, tunable composite ceramic materials with improved breakdown strengths is disclosed. The composite materials comprise ferroelectric perovskites such as barium strontium titanate or other ferroelectric perovskites combined with other phases such as low-loss silicate materials and / or other low-loss oxides. The composite materials are produced in sheet or tape form by methods such as tape casting. The composite tapes exhibit favorable tunability, low loss and tailorable dielectric properties, and can be used in various microwave devices.

Owner:NXP USA INC

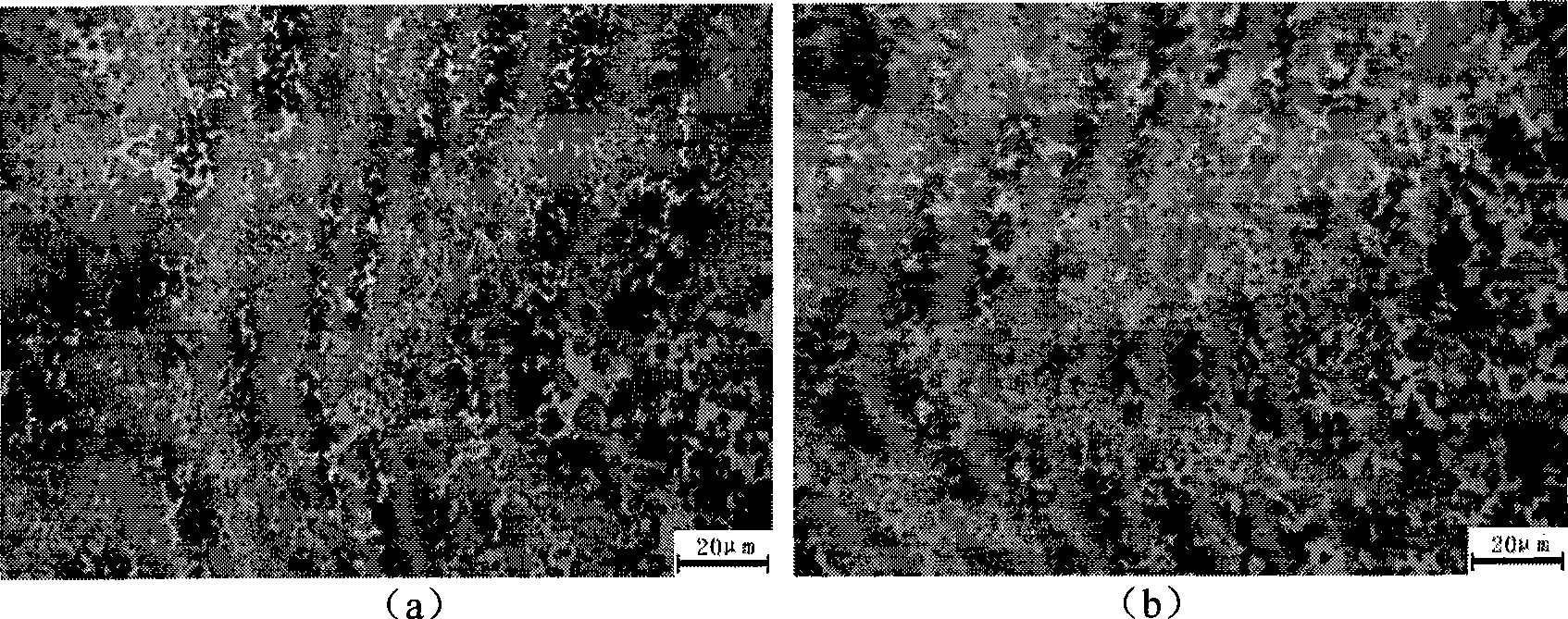

Silicon carbide based reinforced composite ceramic and preparation

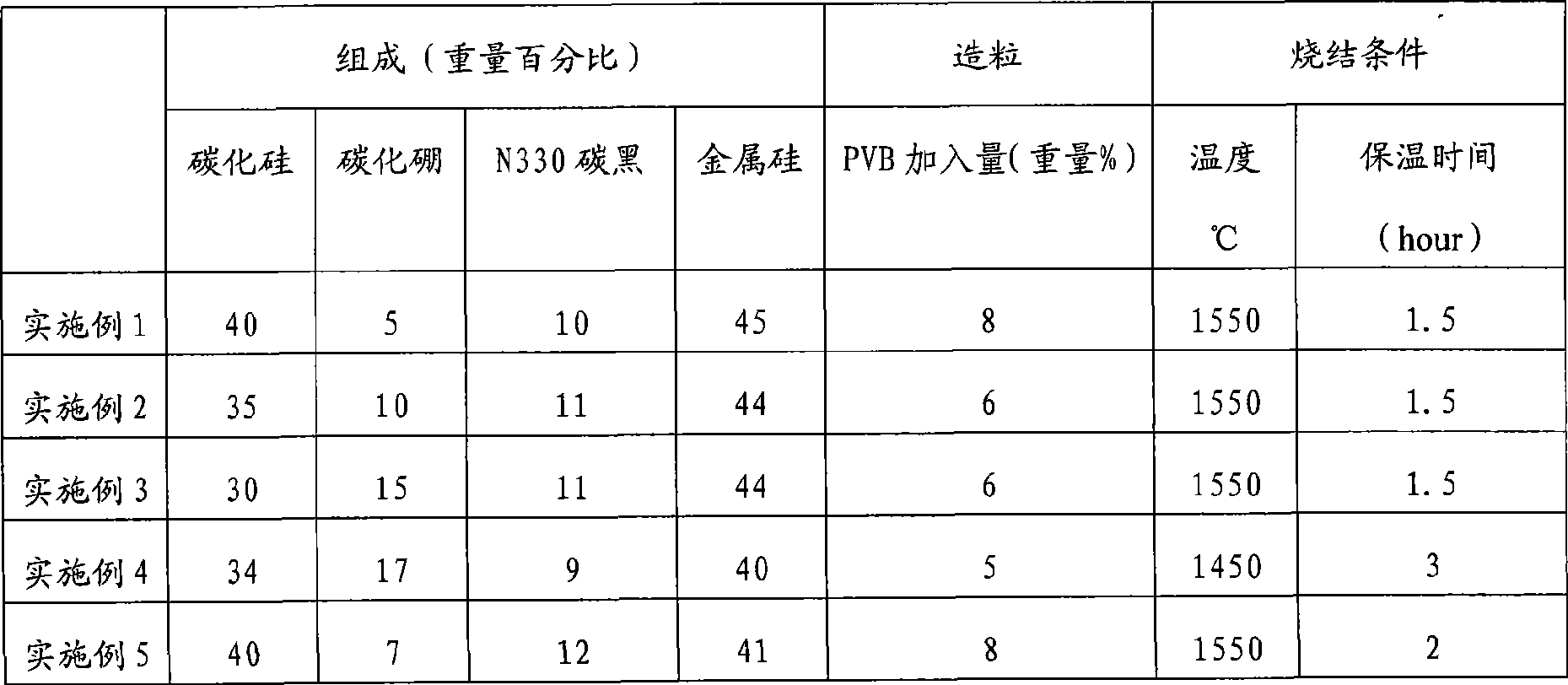

The invention discloses a reinforced silicon carbide-based composite ceramic and a preparation method thereof. The composite ceramic is characterized by comprising the following components based on weight percentages: 30%-40% of silicon carbide powder, 5%-17% of boron carbide powder, 9%-12% of nano carbon black and 40%-50% of silicon metal. The method comprises the following steps: firstly, ball milling and wet mixing are performed on the silicon carbide powder, the carbon black and the boron carbide powder to obtain mixed powder, and a bonding agent PVB is added for granulation, die pressing is performed for forming; then the formed green compact is dried and put in an air furnace for binder removal; and finally, the obtained green compact is put into a graphite crucible with silicon powder, and siliconizing and sintering are completed after 1-3h heat preservation at 1450-1550 DEG C under a vacuum environment, thus obtaining a sintering body. The boron carbide particle reinforced reaction sintered silicon carbide composite ceramic prepared by the method can be widely used as a structural material under high-temperature atmosphere and corrosive atmosphere, a frictional wear material and the like; and as the composite ceramic has better obdurability and hardness, the ceramic can be used as a substitute material of the traditional reaction sintered silicon carbide.

Owner:珠海亿特立新材料有限公司

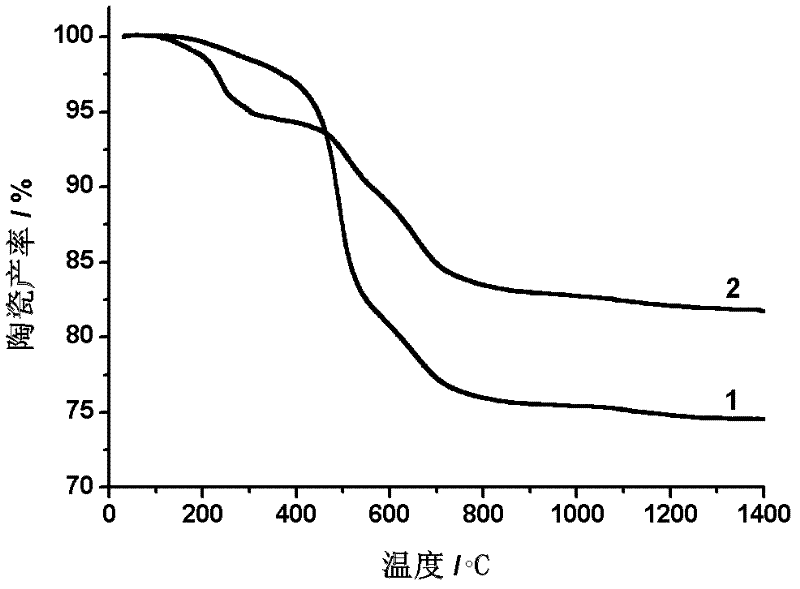

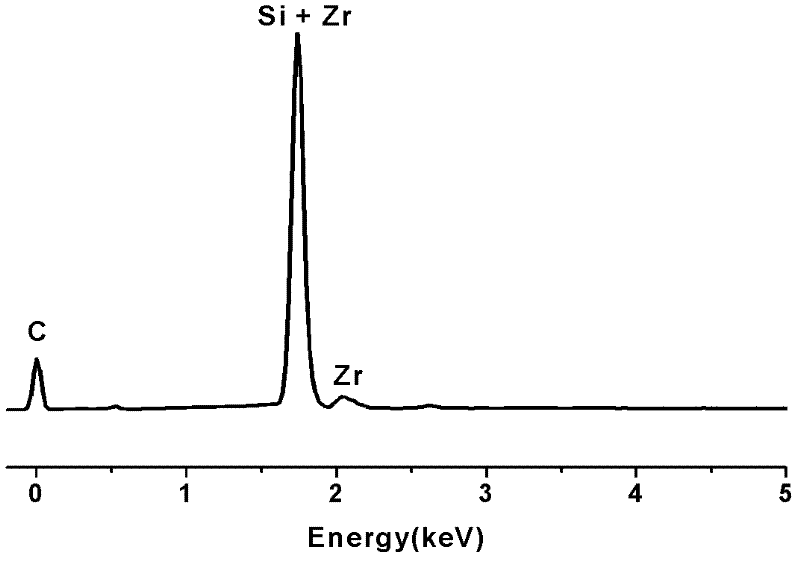

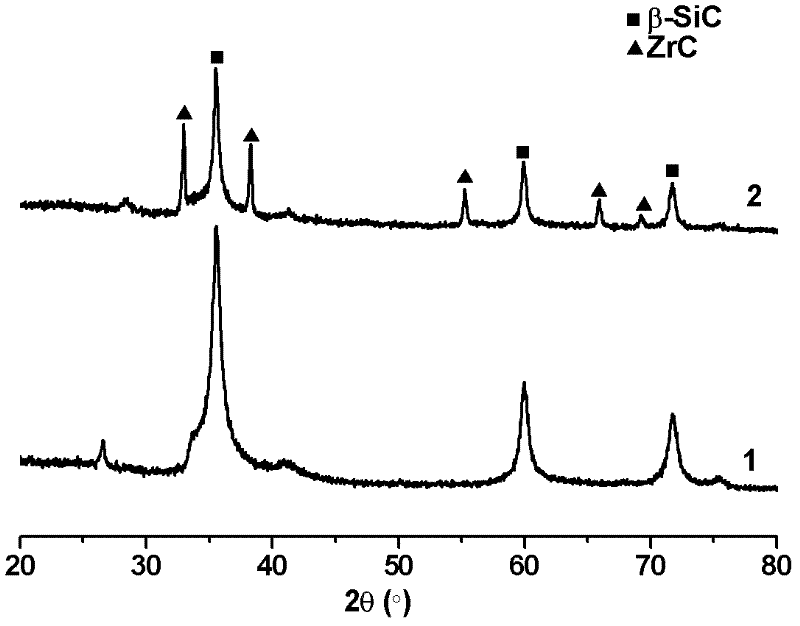

Preparation method of silicon carbide/zirconium carbide composite ceramic

The invention relates to a preparation method of silicon carbide / zirconium carbide composite ceramic, and relates to inorganic nonmetal material composite ceramic. The preparation method comprises the steps of: dissolving bis(cyclopentadienyl) zirconium dichloride with a solvent under the protection of inert atmosphere, and adding liquid hyperbranched polycarbosilane to obtain a mixture A; and distilling the mixture A under reduced pressure under the protection of inert atmosphere to remove the solvent, and carrying out cracking reaction in inert atmosphere to obtain the silicon carbide / zirconium carbide composite ceramic. According to the invention, bis(cyclopentadienyl) zirconium dichloride is used as a zirconium source, and is used for catalyzing the crosslinking reaction of liquid hyperbranched polycarbosilane, so as to increase ceramic yield; zirconium carbide can inhibit the growth of silicon carbide microcrystal grains, and improve high-temperature resistance and oxidation resistance of the composite material; the zirconium content in the composite ceramic can be controlled by controlling the content of bis(cyclopentadienyl) zirconium dichloride in a hybrid precursor; the liquid hyperbranched polycarbosilane / bis(cyclopentadienyl) zirconium dichloride hybrid precursor is free of oxygen, thus the gas escaped in the high-temperature cracking process is reduced; the ceramic has high compactness; and the preparation method is simple to operate, and is easy for engineering.

Owner:XIAMEN UNIV

Crystal glaze and its preparation method and use method

ActiveCN102659453AShorten the firing cycleTo achieve the purpose of industrialized mass productionBrickComposite ceramic

The invention discloses a crystal glaze and its preparation method and use method. The crystal glaze is prepared by uniformly mixing a basic crystal glaze and one or more coloring agents, wherein the weight of the one or more coloring agents is 0 to 10% of the total weight of the basic crystal glaze and the one or more coloring agents; and the basic crystal glaze mainly comprises 2 to 40 parts of spodumene, 5 to 20 parts of quartz, 5 to 25 parts of calcite, 5 to 25 parts of talcum, 5 to 20 parts of alumina, 1 to 5 parts of zinc oxide, 1 to 3 parts of sodium nitrate, 5 to 15 parts of zircon powder, 1 to 5 parts of bone ash, 1 to 5 parts of lithium carbonate and 5 to 15 parts of boric acid. In melting of the basic crystal glaze of the crystal glaze, the one or more coloring agents are used and thus a composite ceramic tile adopting the crystal glaze has a bright color and strong stereoscopic impression and produces crystal patterns having diameters of 3 to 4 centimeters. The preparation method greatly reduces a firing period of the traditional crystal glaze and realizes industrial production. An experiment proves that a crystal glaze surface with large crystal patterns can be obtained in a firing period of only 75 minutes.

Owner:JIANGSU BAIFU TECH CO LTD

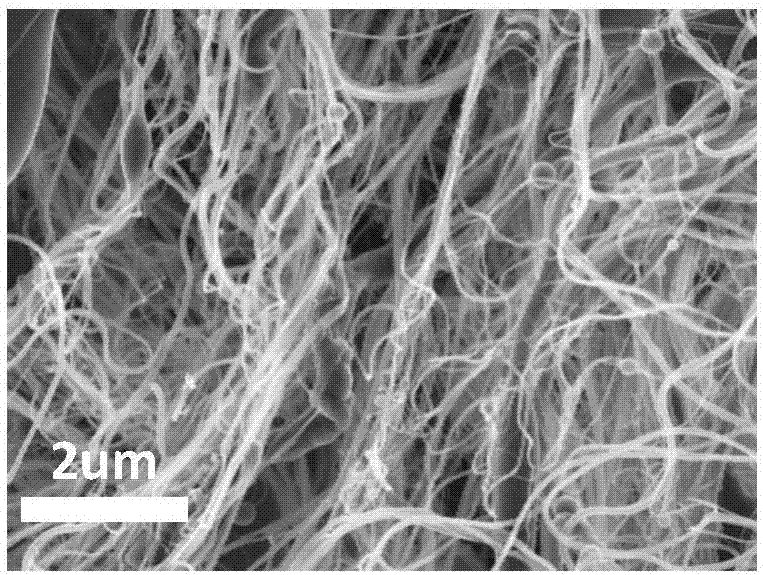

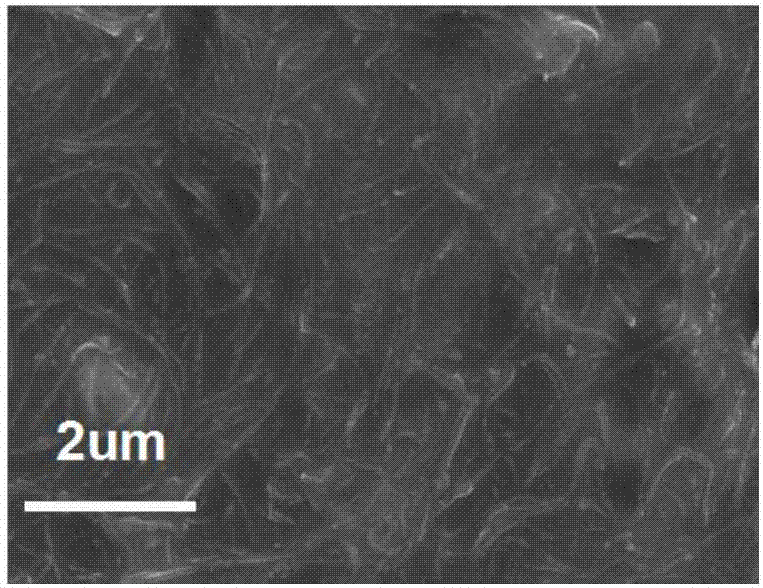

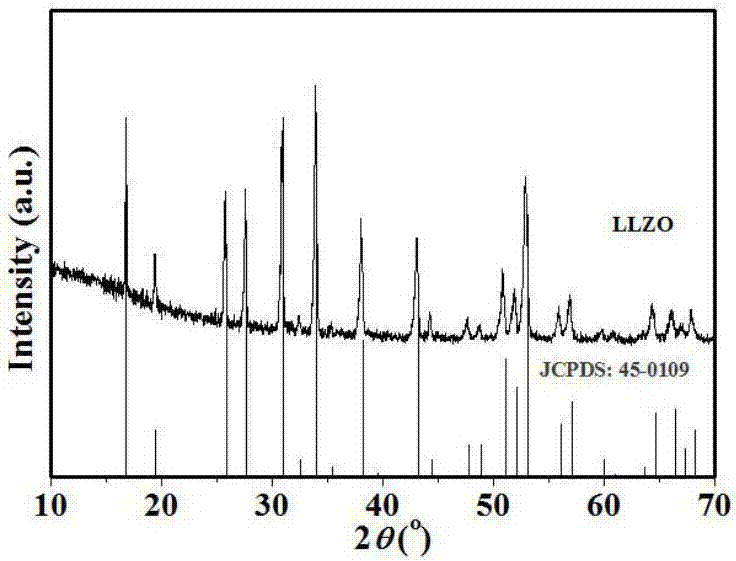

Preparation method of lithium lanthanum zirconium oxide nanometer fiber, preparation method of composite film and solid battery application

InactiveCN107316965AImprove cycle performanceImproved magnification performanceMaterial nanotechnologySecondary cellsComposite electrolyteInterface impedance

The invention discloses a preparation method of a lithium lanthanum zirconium oxide nanometer fiber, a preparation method of a composite film and solid battery application. Filamentation is carried out on a lithium lanthanum zirconium oxide precursor solution by using a jet airflow and a propelling plant, and the lithium lanthanum zirconium oxide nanometer fiber is obtained after heat treatment is carried out on the collected lithium lanthanum zirconium oxide fiber precursor. Superfine lithium lanthanum zirconium oxide nanometer powder or a lithium lanthanum zirconium oxide nanometer fiber film with certain mechanical property is obtained respectively by regulating the technological parameters and heat treatment temperature of an airflow spinning process. The method is simple in operation and low in cost, and can realize commercialized production. The composite film of the lithium lanthanum zirconium oxide fiber film and polymer provides a continuous lithium ion passage, so that higher ionic conductivity can be provided. The lithium lanthanum zirconium oxide nanometer fiber powder is used for composite ceramic films or composite electrolytes, blockage for membrane holes can be avoided, and higher ionic conductivity can be provided. A solid battery or lithium-ion battery prepared by using the lanthanum zirconium oxide nanometer fiber film or powder is stable in cycle performance, high in rate capability, low in interface impedance and high in stability.

Owner:UNIV OF SCI & TECH BEIJING

Long-term high-temperature oxidation-resistant multi-element composite ceramic coating for carbon/carbon composite material and preparation and application methods thereof

The invention provides a long-term high-temperature oxidation-resistant multi-element composite ceramic coating for a carbon / carbon composite material and preparation and application methods thereof. The long-term high-temperature oxidation-resistant multi-element composite ceramic coating is a composite coating on the surface of the carbon / carbon composite material and sequentially (from inside to outside) comprises a SiC connection layer prepared with an embedding method, a SiC sealing layer prepared with a chemical vapor deposition method and a SiO2-Y2Si2O7-ZrSiO4-Al2SiO5 ceramic layer prepared with a brush coating method and an in-situ oxidation reaction method, wherein the SiC connection layer is combined with a matrix and exerts the function of connecting the matrix, the SiC sealinglayer exerts the function of filling defects of an inner layer, and the outermost SiO2-Y2Si2O7-ZrSiO4-Al2SiO5 ceramic layer serves as an oxygen blocking layer and exerts the function of self-healing and oxygen blocking. The long-term high-temperature oxidation-resistant multi-element composite ceramic coating has the advantages of firmness in combination with the matrix, no run-through crack, long-term high-temperature oxidation resistance, and capability of being completely applied to the preparation of non-direct-ablation heat-resistant structural members around the head and of the wings ofa hypersonic aircraft and the preparation of a material for the tailpipe chamber of an aircraft engine.

Owner:CENT SOUTH UNIV

Thermal barrier coating systems

InactiveUS20110171488A1Highly preventive effectLow thermal conductivityMolten spray coatingBlade accessoriesComposite ceramicCoating system

This invention relates in part to thermal barrier coating systems that comprise at least one metallic or metallic / ceramic inner layer deposited onto a substrate, at least one ceramic intermediate layer deposited onto the inner layer, and at least one ceramic outer layer deposited onto the intermediate layer. The ceramic intermediate layer is a thermally sprayed coating having a plurality of macrocracks distributed throughout the intermediate layer. The ceramic outer layer is a thermally sprayed coating made from composite ceramic powder particles that include a zirconia-based component and an (alumina+silica)-based component. The ceramic outer layer is substantially free of macrocracks. This invention also relates in part to methods of forming thermal barrier coating systems, and articles coated with thermal barrier coating systems. The thermal barrier coating systems are suitable for protecting components exposed to high temperature environments, such as the thermal environment of a gas turbine engine.

Owner:PRAXAIR ST TECH INC

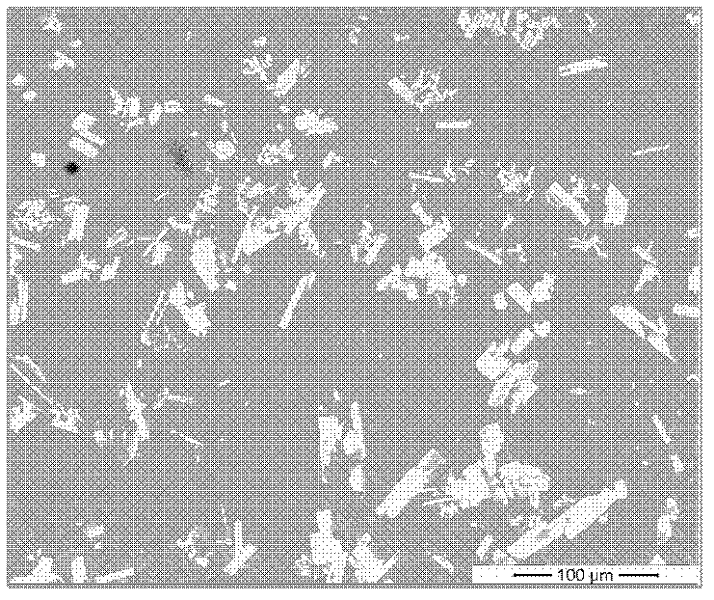

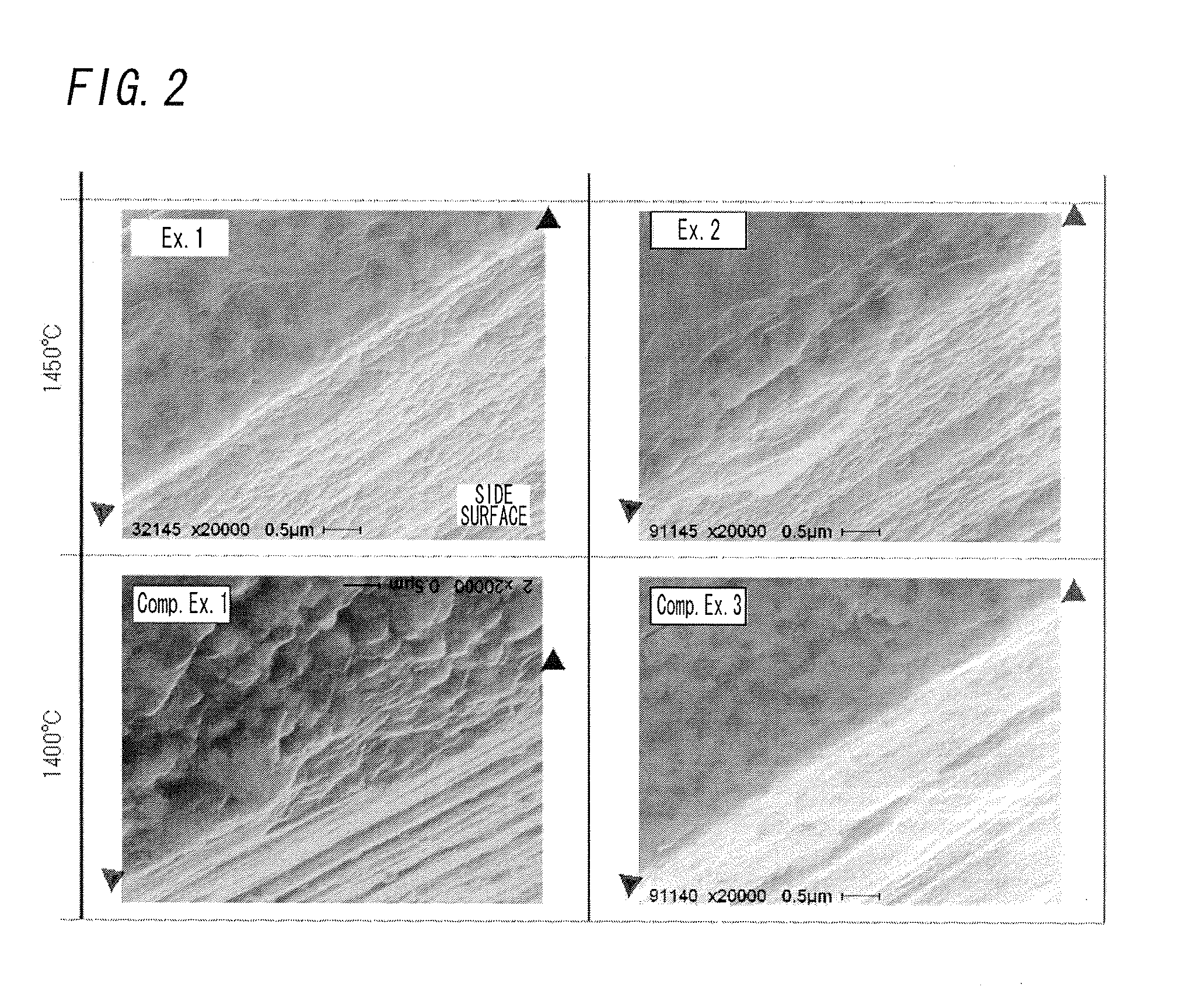

Method for producing zirconia-alumina composite ceramic material, zirconia-alumina composite granulated powder, and zirconia beads

InactiveUS20120295113A1High hardnessImprove wear resistanceMaterial nanotechnologySynthetic resin layered productsComposite ceramicCerium(IV) oxide

The present invention produces a zirconia-alumina composite ceramic material that exhibits an excellent wear resistance and hardness and that resists chipping at the particle edges. The zirconia-alumina composite ceramic material according to the present invention has a composite structure in which zirconia particles are dispersed in alumina particles and the alumina particles are dispersed in the zirconia particles. A first phase is formed of ceria-containing zirconia particles and a second phase is formed of alumina particles. An α-alumina powder having an average particle size of at least 0.1 μm and a γ-alumina powder having an average particle size of 0.01 to 0.1 μm are used in a proportion of 85:15 to 65:35 as the mass ratio for the alumina powder for producing the alumina particles of the second phase.

Owner:PANASONIC HEALTHCARE HLDG CO LTD

Infrared energy-saving coating of high-temperature kiln and preparation method thereof

Owner:CHINA SILICON ZIBOCERAMIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com