Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

392results about How to "Overcoming brittleness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fire-proof adhesive and application thereof

ActiveCN104099028AReduce total calorific valueImprove thermal conductivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesCombustionAdhesive

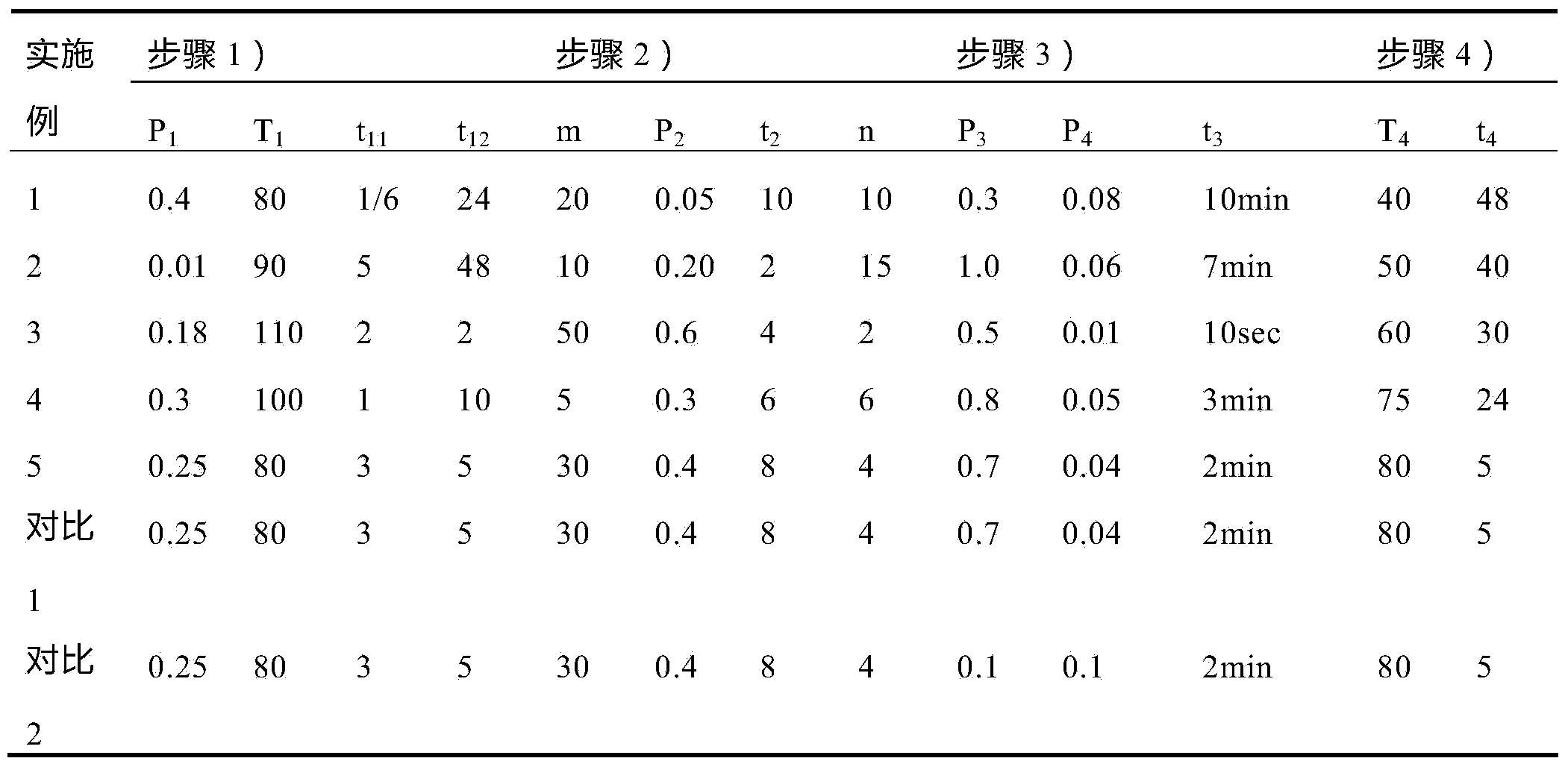

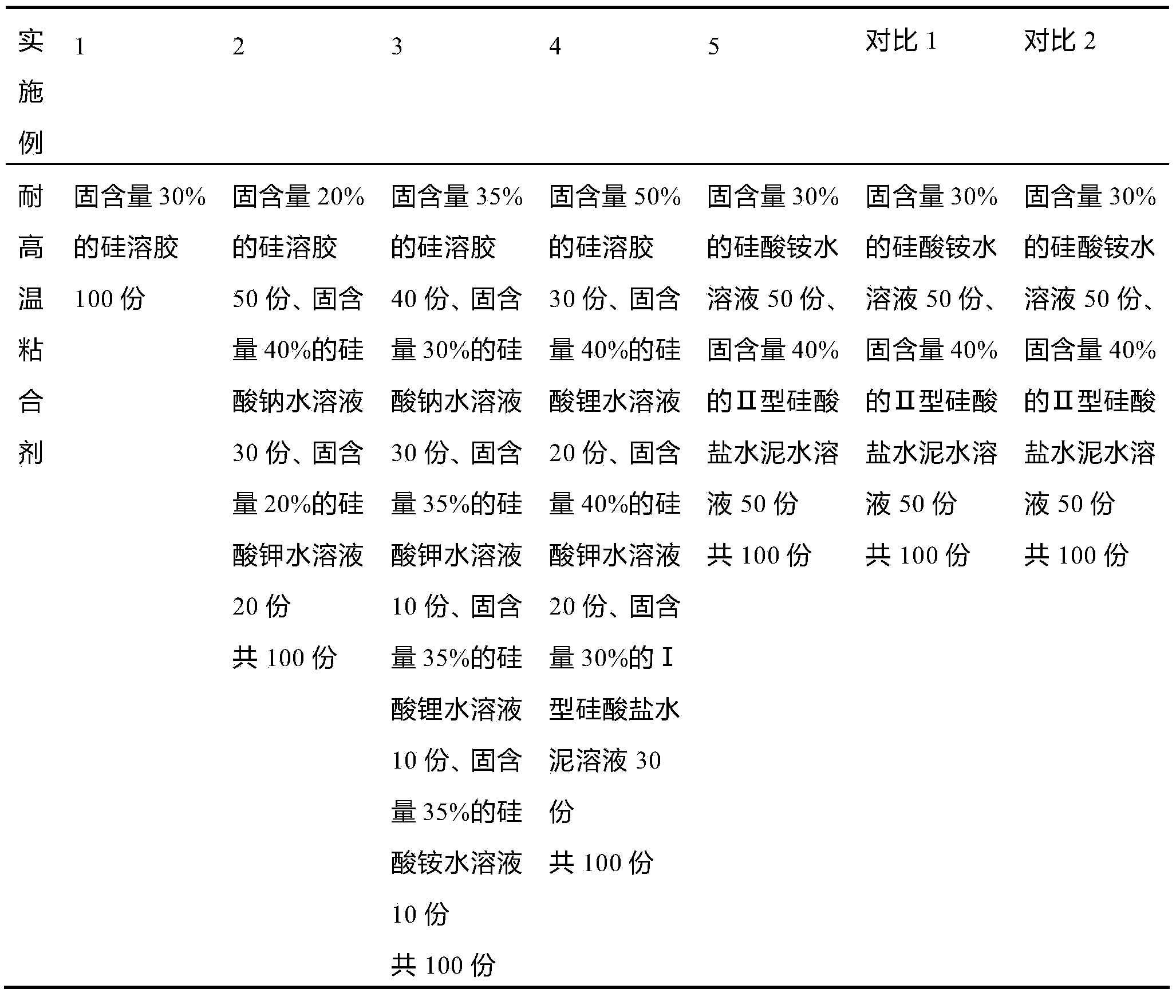

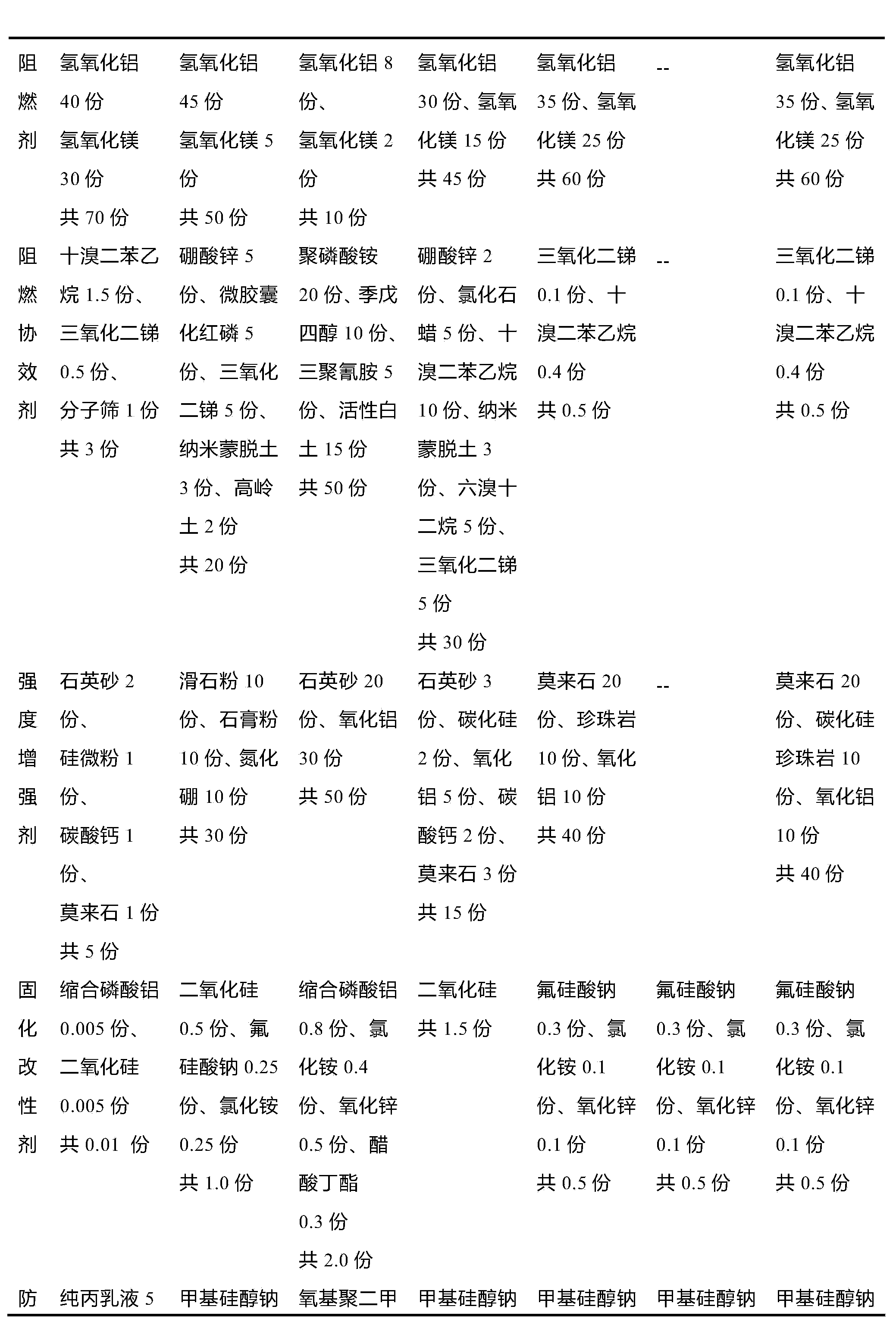

The invention discloses a fire-proof adhesive and application thereof. The fire-proof adhesive comprises the following components by parts: 100 parts of high-temperature bonding agent, 10-70 parts of fire retardant, 0.5-50 parts of flame retardant synergist, 5-50 parts of strength enhancer, 0.05-20.0 parts of water-proof modifying agent and 0.01-2.0 parts of curing modifying agent. By adopting the fire-proof adhesive and a preparation method of a fire-retardant EPS (Expandable Polystyrene) foam heat-insulating plate, the combustion performance and physicochemical performance of the fire-retardant EPS foam heat-insulating plate can be improved remarkably. For example, the heat-conducting coefficient can be lowered below 0.055w / m.k, the specific gravity can be lower than 150Kg / M<3>, the compressive strength is higher than 150KPa, and the heat value is less than 3MJ / kg.

Owner:应急管理部四川消防研究所

Modified epoxy resin adhesive and its preparation process

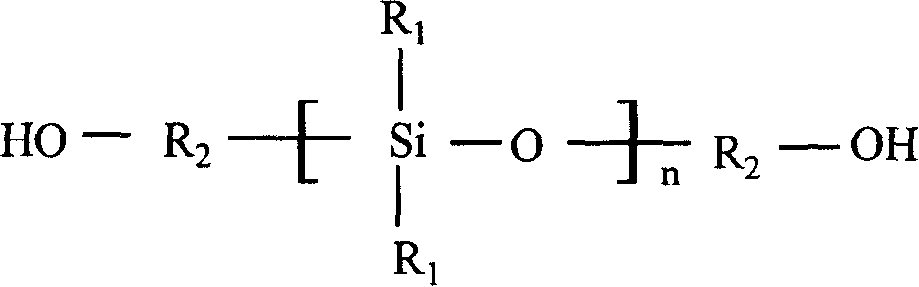

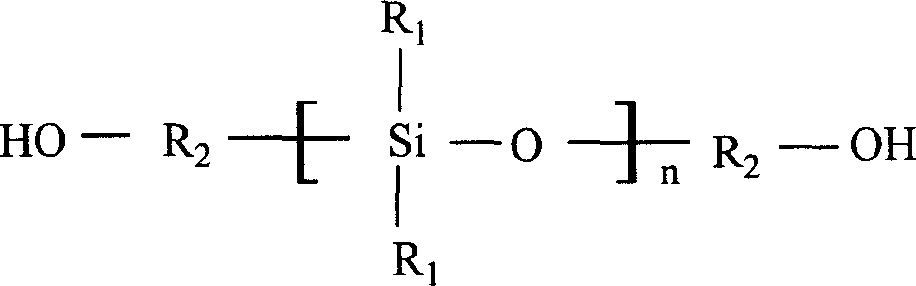

The invention relates to a modified epoxide resin adhesive agent and its preparation process to overcome the disadvantage such as brittleness and bad temperature resistance of common epoxide resin adhesive agents, which comprises: mixing the epoxide resin (component A) modified by polyurethane prepolymer and curing agent (component B) produced by author in the proportion of between 10:1 to 1:1 to prepare the curing system of fire resistant, good toughness and large reaction, wherein the polyurethane prepolymer is polysiloxane polyurethane prepolymer capped by isocyanate groups which are produced by the reaction of hydroxy-terminated polysiloxane and diisocyanate in a definite proportion, then using the said polyurethane prepolymer to modified treat epoxide resin. The said curing agent produced by author is made of diamine, imidazolinium compounds, silane coupling agents, mineral filler and catalyst. The said modified epoxide resin adhesive agent can be cured in room temperature and has the good characteristics of oil resistant, water resistant, acid and alkali resistant and resistance to organic solvent, also can adhere to the damp face, oil face, metal, plastic, ceramic, hard rubber and wood and so on.

Owner:李洁华

Composite phase-change energy storage material for microcapsule and preparation method thereof

InactiveCN101824307ANo leaksPlay the role of self-control temperature controlHeat-exchange elementsMicroballoon preparationCrack resistanceSolvent

The invention discloses a composite phase-change energy storage material for microcapsules and a preparation method thereof. The coating of the microcapsule is made of silicon dioxide, and the core of the microcapsule is made of a phase-change energy storage material, wherein the phase-change energy storage material is a paraffin organic solid-liquid phase-change energy storage material. 0.2 to 0.5 wt.% of dispersed emulsifier, 52.5 to 62.5 wt.% of solvent water, 18.75 to 31.5 wt.% of phase-change energy storage material and 15.5 to 18.75 wt.% of inorganic silica source are matched and put into a reactor for stirring for 5 to 8 hours; the mixture is uniformly dispersed and emulsified at the temperature 3 to 8 DEG C higher than that for solid-liquid phase change; hydrochloric acid aqueous solution catalyst with the pH value of 0.93 to 4.07 or sodium hydroxide aqueous solution catalyst with the pH value of 8.0 to 12.0 is added into the emulsion; the reacting solution is naturally cooled to room temperature and precipitation solution is obtained; the precipitate is washed with the combination of water and petroleum ether, wherein the mass percent of the petroleum ether is 30 wt.%; then the precipitate is washed with deionized water and is filtered, and the product is naturally aired. The invention improves the technology of phase-change energy storage and conservation, and has the function of automatic temperature regulation, favorable physical and chemical stability, crack resistance, flame retardancy, wear resistance and high thermal conductivity.

Owner:BEIJING UNIV OF CHEM TECH

Iron-based corrosion resistant wear resistant alloy and deposit welding material for obtaining the alloy

InactiveCN101505910AOvercoming brittlenessOvercome vulnerabilityWelding/cutting media/materialsSoldering mediaChromium carbideWear resistant

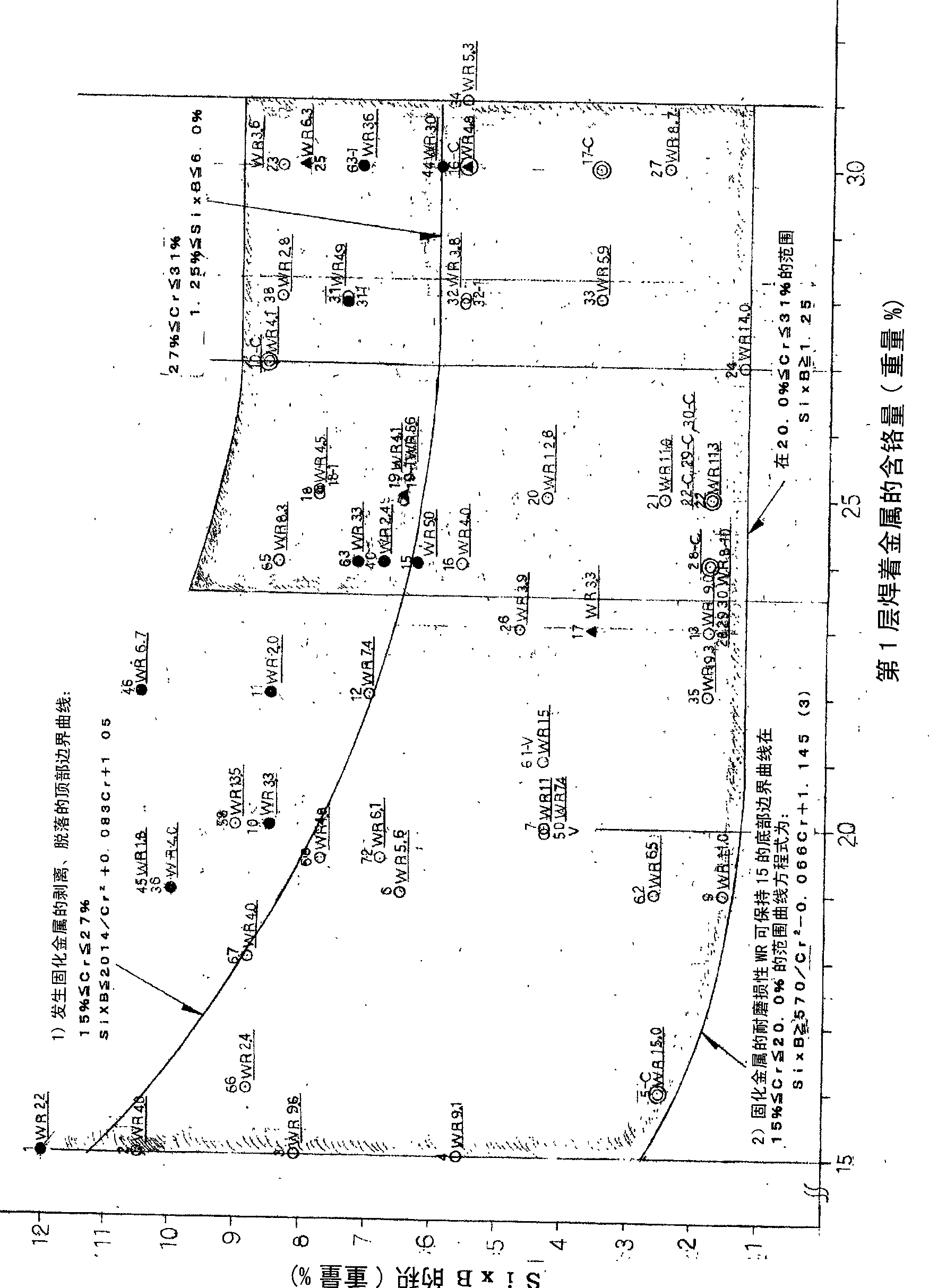

To provide a high-performance, inexpensive low C-high Si-high Cr-B-Nb type iron-based corrosion-resistant and wear-resistant alloy that is extremely superior in corrosion resistance and wear resistance to 304 stainless steel, high-chromium cast iron and high carbon-high chromium cast-iron-type materials, has a high corrosion-resistant property that would never be obtained from a high carbon-high chromium carbide precipitation-type iron-based wear-resistant alloy and at the same time, a wear-resistant property that is superior to these metals, and further hardly causes brittle peeling that is inherent to high Si-containing steel. This alloy contains, all percentages by weight, C: 0.5 to 2.5% by weight, Si: 2.5 to 4.5%, Mn: 0 to 10% or less, Cr: 15% to 31%, Ni: 0 to 16%, Cu: 7% or less, Mo: 10% or less, B: 0.5% to 3.5%, and 0+0.083Cr+1.05 is satisfied, within a range of 27% / =570 / Cr-0.066Cr+1.145 is satisfied, and within a range of 20% / =1.25 is satisfied.

Owner:ING SHOJI

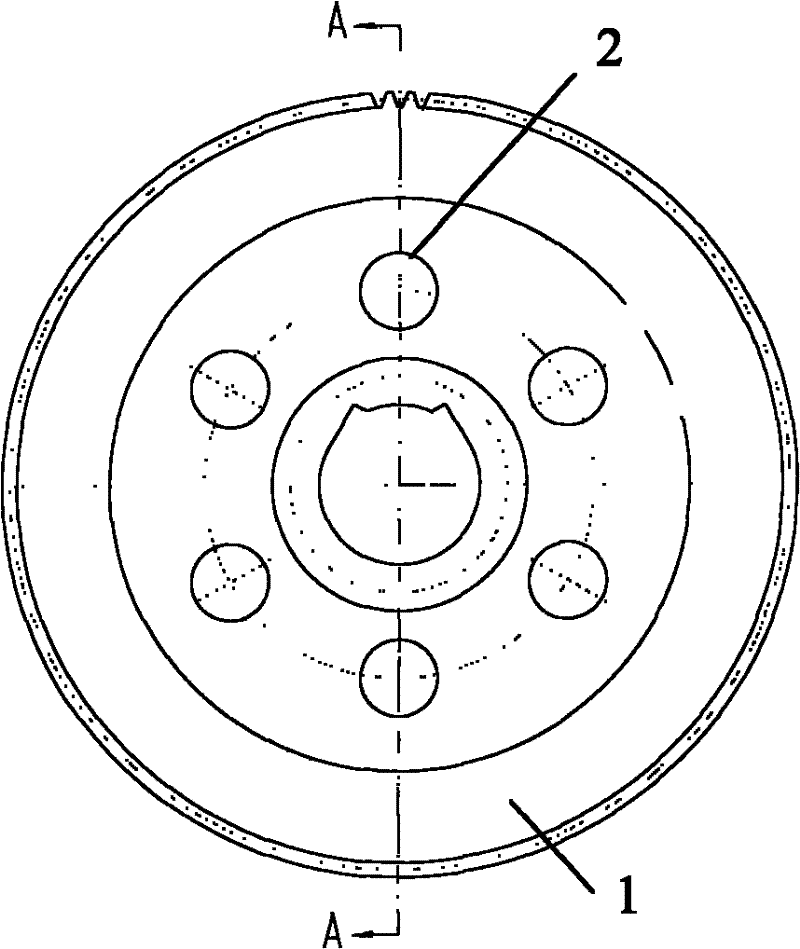

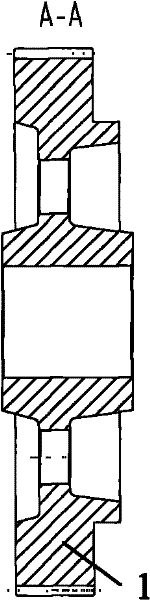

Flying-shear main-transmission gearwheel steel and preparation method thereof

ActiveCN102162069AReduce the effect of heat treatment distortionOvercoming brittlenessGear grindingHobbing

The invention discloses a flying-shear main-transmission gearwheel steel and a preparation method thereof. The flying-shear main-transmission gearwheel steel comprises the following elements in percentage by mass: 0.10-0.20% of C, 2.00-3.00% of Cr, 2.50-3.50% of Ni, 0.4-1.00% of Mo, 0.10-0.40% of Si, 0.40-1.00% of Mn, at most 0.25% of Cu, at most 0.1% of Al, at most 0.020% of P, at most 0.015% ofS, at most 30ppm of O, at most 100ppm of N and at most 2ppm of H. The preparation method comprises the following steps: (1) smelting according to the percentage by mass to obtain a forging stock; (2)forging; (3) carrying out normalizing heat treatment; (4) carrying out gear hobbing; (5) carrying out surface carburization quenching heat treatment; and (6) carrying out gear grinding. The inventionenhances the bearing capacity and reliability of the gearwheel, and satisfies the production demands of high-carbon high-alloy steel and enhanced specifications, thereby having wide popularization and application prospects.

Owner:BAOSHAN IRON & STEEL CO LTD

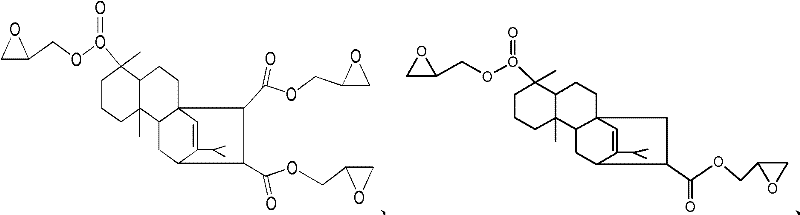

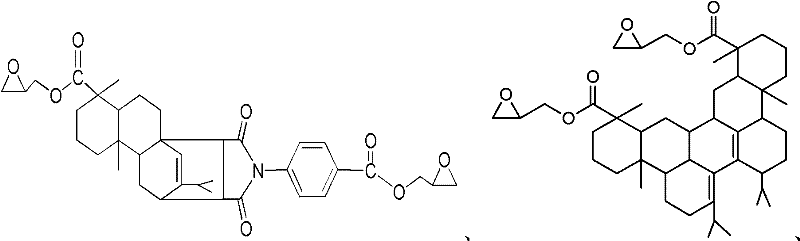

Full-biobased epoxy resin composition and condensate

ActiveCN102206324AGood environmental benefitsImprove flexibilityPlastic/resin/waxes insulatorsEpoxy resin adhesivesAging resistanceResin coating

The invention discloses a full-biobased epoxy resin condensate. The condensate is prepared by the following components in part by weight: 100 parts of abietyl-based epoxy resin base material, 50 to 300 parts of tung oil anhydride and 1 to 15 parts of catalyst, has the characteristics of higher mechanical property, high ultraviolet resistance, high aging resistance and the like and is particularlysuitable for preparing biobased composite material matrix resin and outdoor electric insulation materials. The invention also discloses a preparation method for the full-biobased epoxy resin condensate. The preparation method has a simple preparation process, is high in operability and process controllability and is easy to implement industrially. The invention also discloses a full-biobased epoxy resin composition and application thereof. The full-biobased epoxy resin composition is suitable for preparing a weather resistant epoxy adhesive, epoxy resin paint and an epoxy resin coating and has a good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Liquid photosensitive solder resist ink and preparation method thereof

The invention discloses liquid photosensitive solder resist ink, which comprises the components of a photosensitive resin, an acrylic monomer, a thermosetting resin, a pigment, a filler, a photoinitiator, accessories and a solvent, and is characterized by comprising the components in the following parts by weight: the photosensitive resin 20-80, the acrylic monomer 1-30, the thermosetting resin 5-30, the pigment 0.5-3, the filter 10-40, the photoinitiator 1-10, the accessories 0.1-5 and the solvent 10-30. The liquid photosensitive solder resist ink prepared in the invention has excellent heat resistance and flexibility. The liquid photosensitive solder resist ink has the advantages of simple process, reasonable formula and excellent performance.

Owner:新东方油墨有限公司

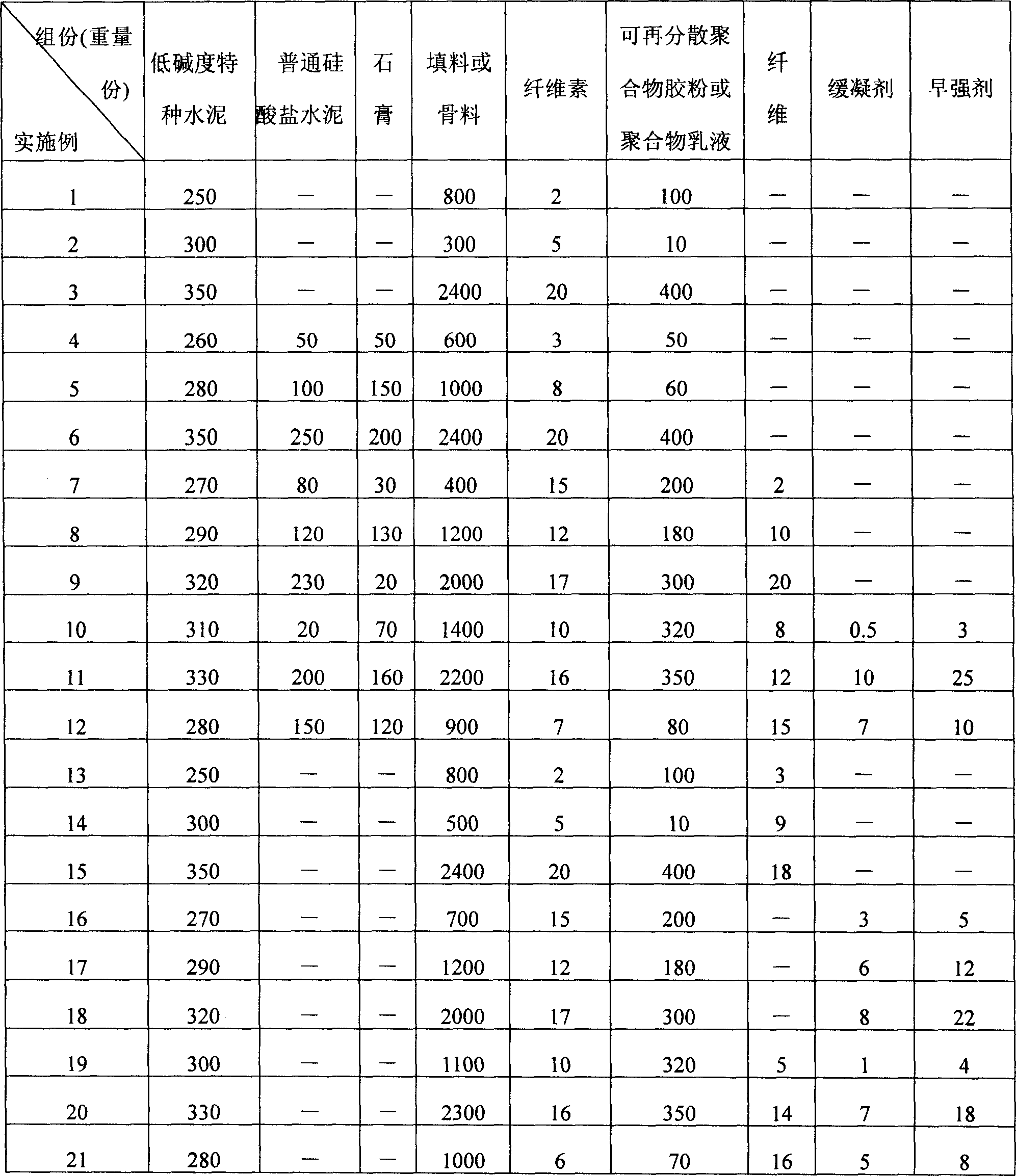

Mortar

InactiveCN1951858AOvercoming brittlenessOvercome defects such as cracking and drummingFiberCellulose

The invention discloses a mortar, which comprises the following parts: 250-350 parts of low-alkaline special typed cement, 0-250 parts of common silicate cement, 0-200 parts of calcium sulfate, 300-2400 parts of filler or aggregate, 2-20 parts of cellulose, 10-400 parts of redispersion polymer gel powder or 10-400 parts of polymer emulsion, 2-20 parts of fiber, 0.5-10 parts of retarder and 3-25 parts of instant coagulant. The low-alkaline cement contains the following clinker with 15%-35% C4A3S, 15%-35% C2S, 0%-35% C3S, 4%-15% CaSO4, 0%-15% C4AF and 0%-5% C3A . The mortar with low-alkaline cement and water can be preserved for 1-7d, whose pH value is 8-9.5.

Owner:王红

Composite material for pultrusion polyurethane resin and preparation method thereof

The invention discloses a composite material for pultrusion polyurethane resin and a preparation method thereof. The composite material is prepared from continuous fiber and polyurethane resin; the continuous fiber is selected from glass fiber or carbon fiber and is 60-85% of the total volume of the composite material in percentage by weight; and the polyurethane resin is 15-40% of the total volume of the composite material in percentage by weight. The resin disclosed by the invention has fast speed during curing, high degree of cross-linking, excellent mechanical property and good wettability to fiber reinforced materials.

Owner:南京聚发新材料有限公司

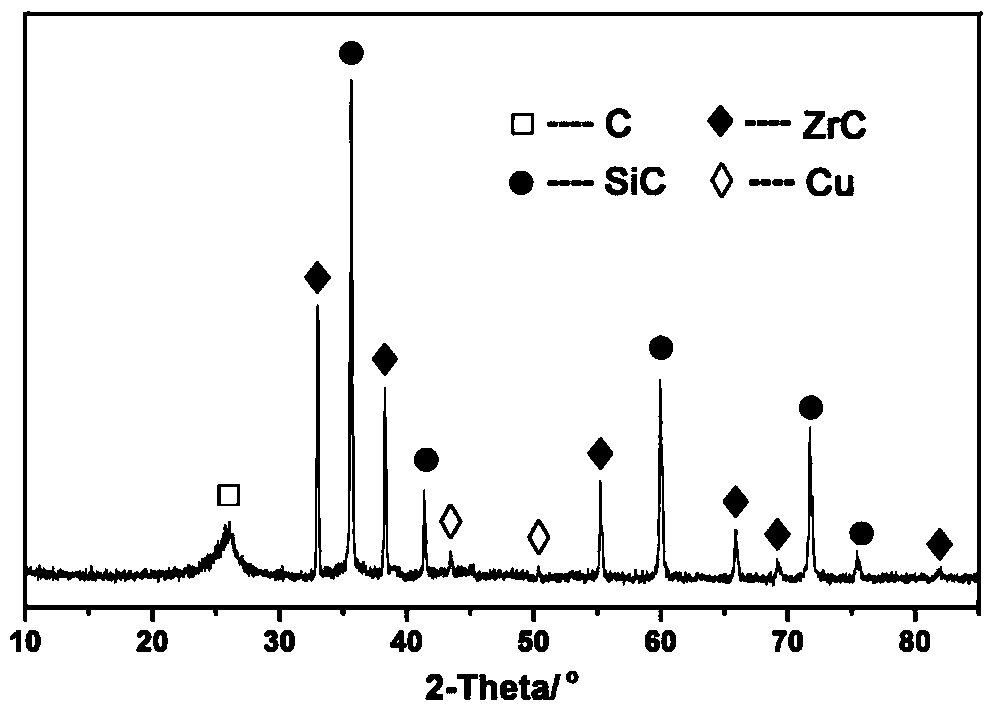

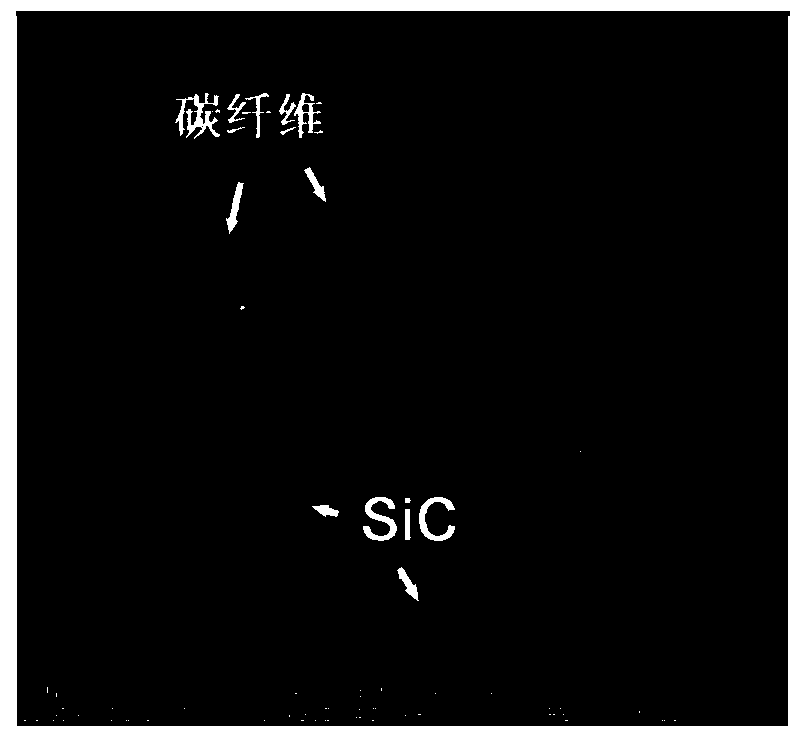

C/ZrC-SiC-Cu composite material and preparation method thereof

The invention discloses a C / ZrC-SiC-Cu composite material with spontaneous sweating function, and a preparation method thereof. The C / ZrC-SiC-Cu composite material takes carbon fiber as a reinforcement toughening phase, ZrC and SiC as matrixes and Cu as a diaphoretic, wherein the volume fraction of the carbon fiber is 10%-50%, the volume fraction of the ZrC is 5%-40%, the volume fraction of the SiC is 5%-20%, the volume fraction of the Cu diaphoretic is 5%-30%, the porosity rate is 3%-10%, the balance of impurities comprising less residual metal Zr and matrixes C and the like. The preparation method of the material comprises the steps of: by taking a carbon fiber prefabricated part as a fundamental, preparing C / C-SiC composite material, and then preparing the C / ZrC-SiC-Cu composite material by taking Zr-Cu binary alloy as a penetrating agent through metal infiltration reaction. The material is superhigh-temperature-resistant, good in fracture toughness, excellent in ablation resistance property, good in thermal shock resistance, and the preparation technique is simple, low in cost, corrosion-free for equipment, and free from environment pollution.

Owner:NAT UNIV OF DEFENSE TECH

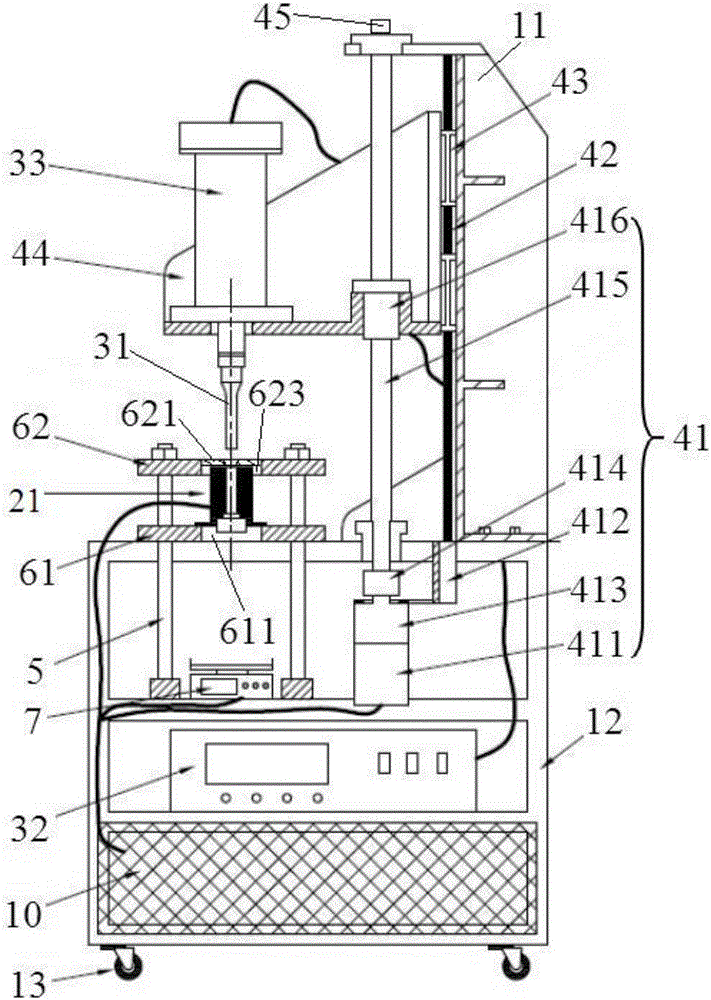

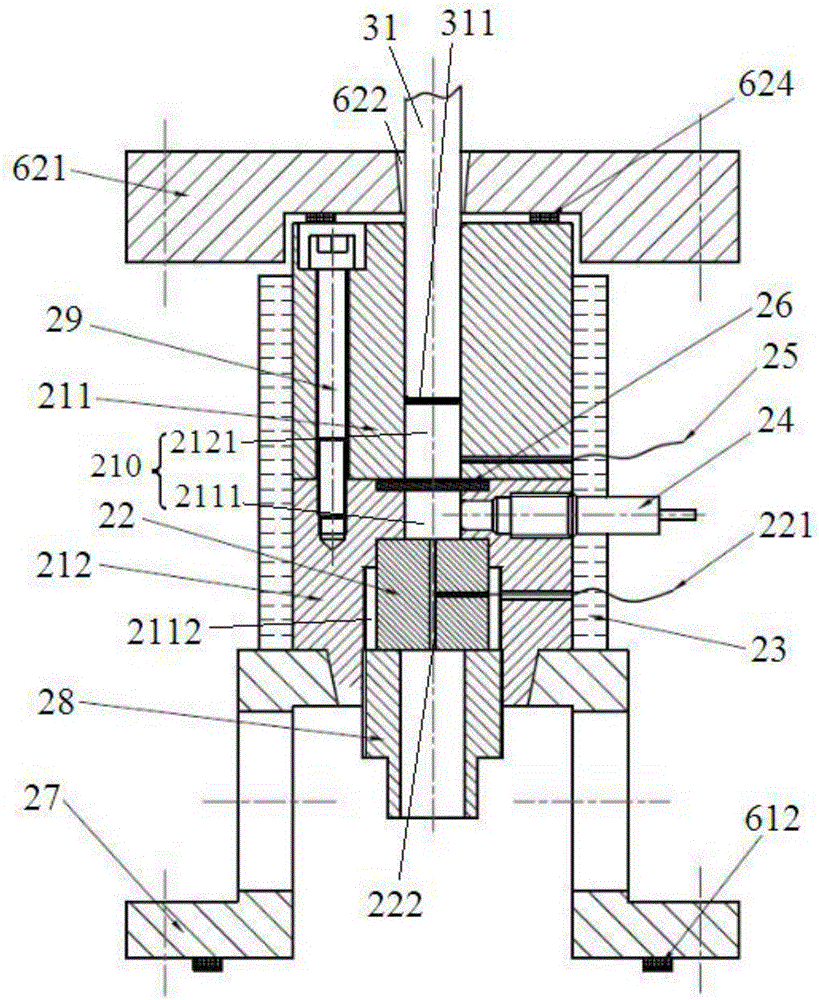

Ultrasonic plasticizing capillary rheometer and viscosity test method

ActiveCN106124362AImprove liquiditySimplify the delivery pathIndirect flow property measurementEngineeringPolymer

An ultrasonic plasticizing capillary rheometer comprises a frame, a rheological test unit, an ultrasonic vibration apparatus, and a tool head moving and loading unit. The ultrasonic vibration apparatus is provided with an ultrasonic tool head capable of extending into a plasticizing chamber along an axial direction, providing extrusion force for polymer in the plasticizing chamber, and providing ultrasonic wave energy required by the polymer for fusion from a solid state to a liquid state. In the ultrasonic plasticizing capillary rheometer, three steps including heating fusion, ultrasonic vibration for fluidity increase, and material extrusion are completed through the ultrasonic tool head and in the plasticizing chamber, thereby simplifying the conveying path. A heating ring providing the required initial temperature for the plasticizing process sleeves a material canister, provides a constant material canister temperature for the rheometer, and reduces the test error. A filter screen is arranged in the material canister, centralizes fused polymer, and improves the test accuracy. During a test process, a viscosity test method is accurate in heating, short in fusion time, and wide in application range, is slightly affected by the external environment, and can provide viscosity data high in accuracy.

Owner:CENT SOUTH UNIV

Preparation method for magnesium aluminum composite board

ActiveCN103586304AEffective oxidation protectionImprove bindingMolten spray coatingRoll mill control devicesComposite plateAluminum composites

The invention discloses a preparation method for a magnesium aluminum composite board, and relates to a preprocessing method for preventing the surface of die-cast magnesium alloy from being corroded. The method is characterized by comprising the following steps: carrying out acid washing, namely dipping preprocessed magnesium alloy in an acid solution for 25-30 seconds and washing by clear water when the metal luster of the alloy is generated; phosphating, namely processing the acid-washed magnesium alloy in a mixed solution of NaOH, Na3PO4 and Na3SiO4; carrying out film forming, that is, putting the acid-washed and phosphated magnesium alloy into a Na2O2 solution for processing to form a film. The method is simple in process, lower in cost and good in anticorrosion effect, and not only can provide a good anticorrosion bottom layer for subsequent surface treatment of the die-cast magnesium alloy but also can be directly used.

Owner:SHENYANG POLYTECHNIC UNIV

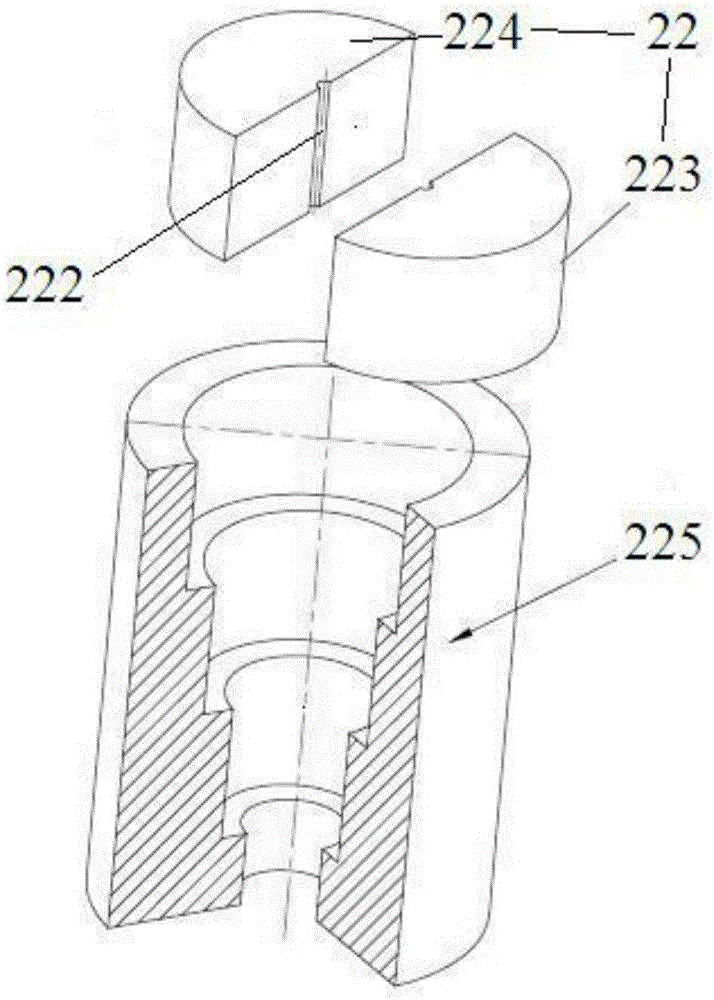

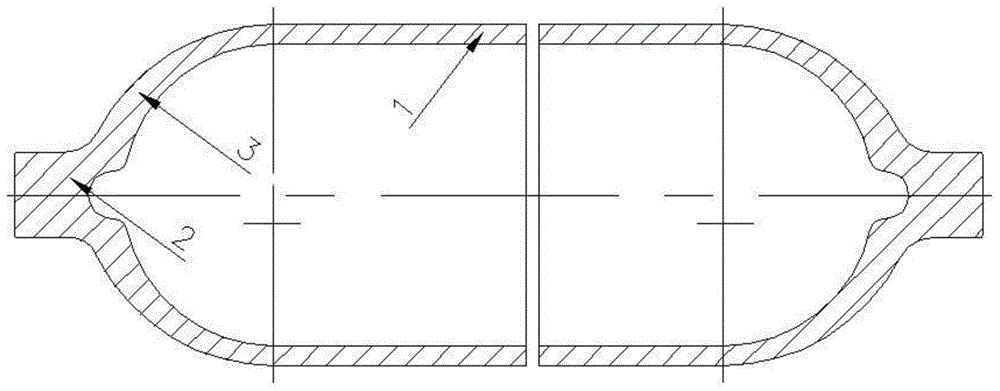

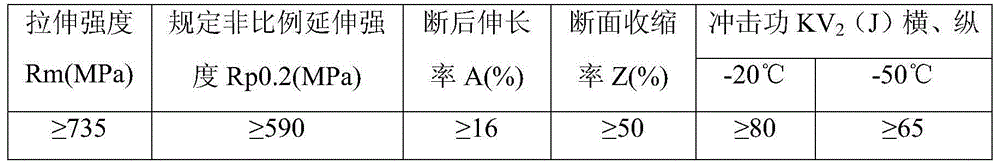

High-pressure seamless 10CrNi3MoV steel cylinder and manufacturing process thereof

ActiveCN104451419AImprove toughnessAvoid brittlenessFurnace typesHeat treatment furnacesHigh probabilityHigh pressure

The invention belongs to the field of machinery manufacturing, particularly relates to a high-pressure seamless 10CrNi3MoV steel cylinder and a manufacturing process thereof, and aims to solve the technical problems of difficulty in manufacturing process determination, poor low-temperature toughness of materials, high probability of deformation and cracking and the like of the current welded type high-pressure seamless 10CrNi3MoV steel cylinder. The scheme is that the high-pressure seamless 10CrNi3MoV steel cylinder adopting seamless 10CrNi3MoV steel pipes as raw materials is provided. The invention further provides a manufacturing process of the high-pressure seamless 10CrNi3MoV steel cylinder. A cylinder body and a seal head of the high-pressure seamless 10CrNi3MoV steel cylinder are seamlessly connected, so that the welding defect is overcome, and meanwhile, with the adoption of the manufacturing process, the low-temperature toughness of steel is further improved.

Owner:CHENGDU GREAT HIGH PRESSURE VESSEL

Dynamic sulfurated retardant composite material of polypropylene without halogen, and preparation method

InactiveCN101050290AHigh impact strengthImprove flame retardant performancePolypropylene compositesVulcanization

This invention relates to a method for preparing dynamic vulcanized polypropylene composite as halogen-free flame retardant. The dynamic vulcanized polypropylene composite is composed of: polypropylene 40-60 parts, ethylene-propylene terpolymerisate rubber 20-30 parts, halogen-free flame retardant system 50-100 parts, compatibilizer 10-30 parts, crosslinker 0.2-8 parts, and additives 1-10 parts. The method comprises: mixing the above components in a high-speed mixer, performing dynamic vulcanization by melt-blending in a twin screw extruder at 160-220 deg.C, extruding and granulating. The obtained dynamic vulcanizated polypropylene composite has good flame retardancy and mechanical properties, and can be used in the halogen-free flame-retarding environment.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Laminated NiAl material and preparation method thereof

InactiveCN103057203AOvercoming brittlenessSimple production processLaminationLamination apparatusRoom temperatureAlloy

The invention provides a laminated NiAl material and a preparation method of the laminated NiAl material, relates to the field of NiAl materials and preparation methods of the NiAl materials, and aims at solving the problems of an NiAl based alloy plate is difficult to prepare because of natural brittleness of the NiAl material prepared by the conventional preparation method. The laminated NiAl material is prepared by alternatively overlapping a Ni foil and an Al foil; and the grains of the laminated NiAl material are distributed in a lamination manner. The preparation method comprises the following steps: 1, preparing the Ni foil and the Al foil; 2, thermally pressing for the first time; and 3, thermally treating, and thermally pressing to obtain the laminated NiAl material. The laminated NiAl material with the coarse grains and fine grains distributed in the lamination manner, prepared by the preparation method of the laminated NiAl material, combines the advantages of the fine grain material at room temperature and the advantages of the coarse gain material at high temperature, and overcomes the shortcoming of natural brittleness. The laminated NiAl material is applicable to the field of high-temperature structural materials.

Owner:HARBIN INST OF TECH

Titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating and preparation method thereof

InactiveCN104760349AImprove high temperature oxidation resistanceAccelerated corrosionVacuum evaporation coatingSputtering coatingOxidation resistantThermal shock

The present invention discloses a titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating; an Al-rich deposition layer, an Al-Cr alloy layer and a Cr diffusion layer are successively arranged from surface to a titanium aluminum alloy substrate. The content of Al in the Al-rich deposition layer remains the same. The content of Al in the Al-Cr alloy layer gradually reduces outside-to-inside to 70%-100% of the content of Al in the titanium aluminum alloy substrate, and the rest in the Al-Cr alloy layer is Cr. The contents of Cr and Al in the Cr diffusion layer respectively gradually reduces outside-to-inside to same as the contents of Cr and Al in the titanium aluminum alloy substrate, and the rest in the Cr diffusion layer is other elements in the titanium aluminum alloy substrate, and the contents of other elements in the Cr diffusion layer respectively gradually rise to same as the contents of the other elements in the titanium aluminum alloy substrate from zero. The invention also discloses a preparation method of the titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating; the titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating can give titanium aluminum alloy excellent oxidation resistance and heat resistance corrosion performance under high temperature and long term service conditions, and due to the presence of the diffusion layer of the gradient components, the reliable binding strength and excellent thermal shock resistance can be realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Material for manufacturing modified phenolic fireproof insulating plate

The invention relates to the technical field of building materials, in particular to a material for manufacturing a modified phenolic fireproof insulating plate. The material for manufacturing the modified phenolic fireproof insulating plate comprises the following components in part by weight: 100 parts of expandable phenolic resin, 2 to 20 parts of polyurethane prepolymer, 2 to 4 parts of surfactant, 5 to 7 parts of foaming agent and 8 to 10 parts of curing agent. The material improves the closed porosity of the phenolic fireproof insulating plate, reduces the hygroscopicity, quickens the speed of curing and molding reaction, also improves the intensity and roughness of the phenolic fireproof insulating plate, reduces the crispness of phenolic foam, and meets the requirements on outer wall construction (an outer wall insulation system) of buildings.

Owner:上海雅达特种涂料有限公司

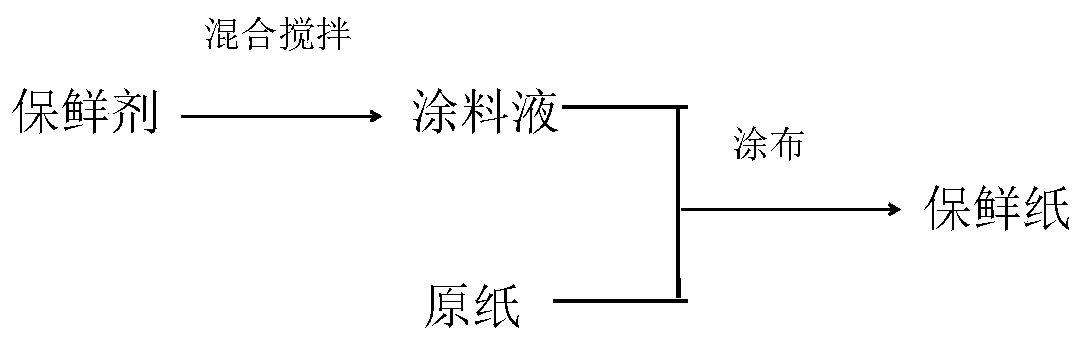

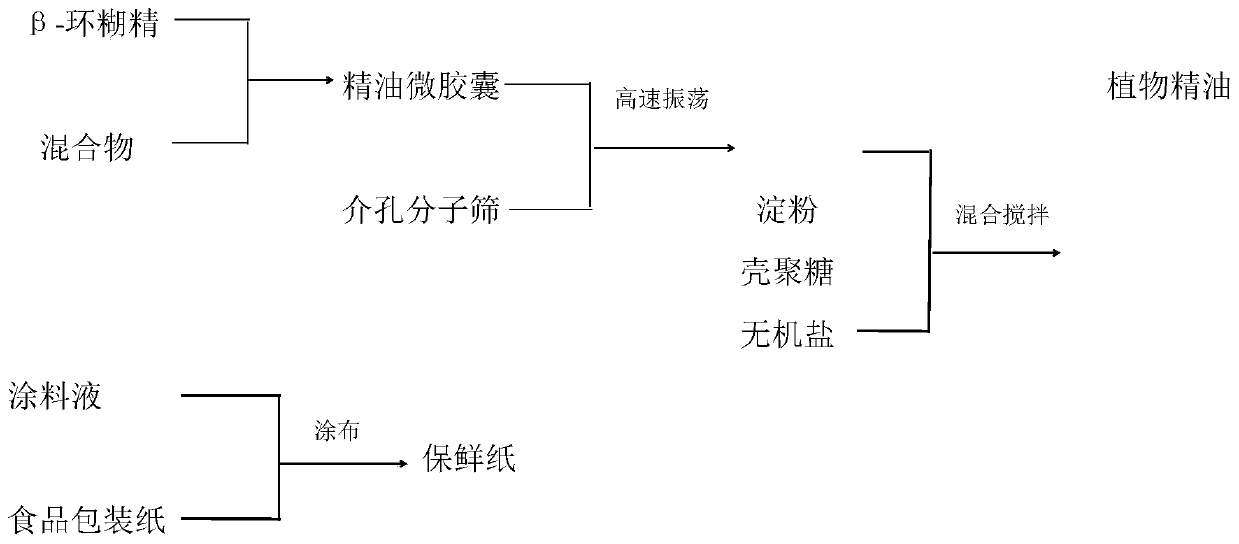

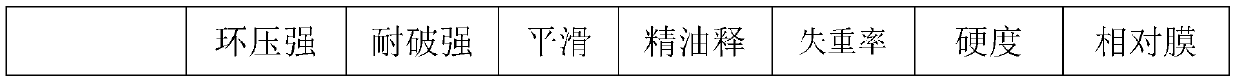

Preparation method of composite functional fresh-keeping paper based material with enhanced slow release function

ActiveCN110055820AExtended release timeGood sustained release effectFlexible coversWrappersInorganic saltsMolecular sieve

The invention discloses a preparation method of a composite functional fresh-keeping paper based material with enhanced slow release function. The preparation method comprises following steps: 1, beta-cyclodextrin and essential oil are weighed to prepare essential oil microcapsules; 2, the essential oil microcapsules and a mesoporous molecular sieve are mixed, water is added, and high speed oscillation treatment is carried out so as to obtain a molecular sieve loaded with the essential oil microcapsules; 4, the molecular sieve loaded with the essential oil microcapsules, a starch solution, a chitosan solution, and an inorganic salt solution are mixed and stirred at a ratio, deionized water is added to adjust the solid content to be 5 to 10% so as to obtain a coating solution; 5, the surface of food package body paper is uniformly coated with the coating solution; and 6, the coated paper is dried fully at room temperature so as to obtain the functional fresh-keeping paper based material. The fresh-keeping paper prepared using the above preparation method is capable of prolonging the storage period of packaged products, and the service life of the fresh-keeping paper can be prolongedat the same time.

Owner:ZHEJIANG UNIV OF TECH

Carbon fiber reinforced metal ceramic base composite material

The invention discloses a carbon fiber reinforced metal ceramic base composite material. The carbon fiber reinforced metal ceramic base composite material consists of a carbon fiber prefabricated body, an interface layer, a ceramic basal body and a metal basal body; metal is one of an aluminum alloy, a magnesium alloy, a copper alloy and a tin alloy; ceramic is SiC; the density of the composite material is 1.8-3.8 g / cm3; and the invention further discloses a method for preparing different alloy ceramic composite materials. The composite material has the advantages of short preparation period and adjustable density, overcomes the brittleness and low density of the ceramic, and can meet the demands on the ceramic base composite materials in multiple fields.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

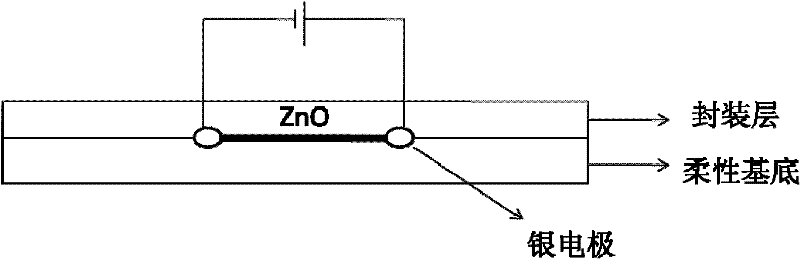

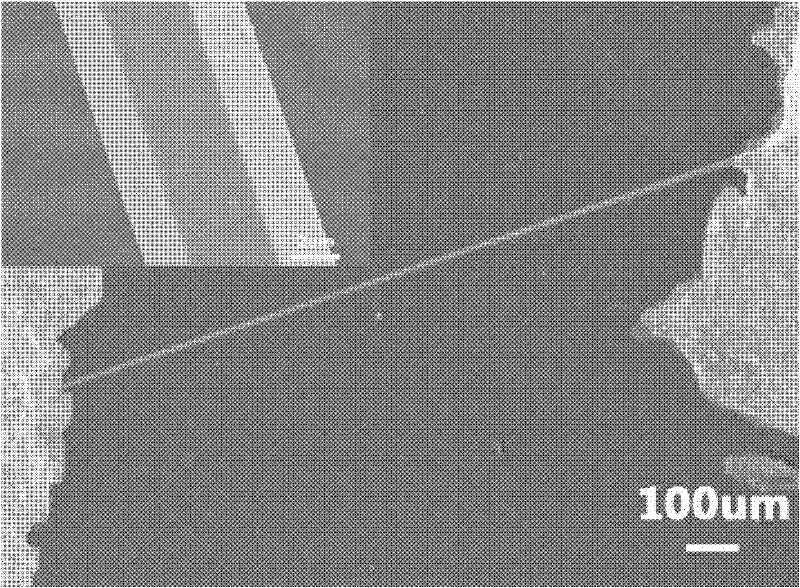

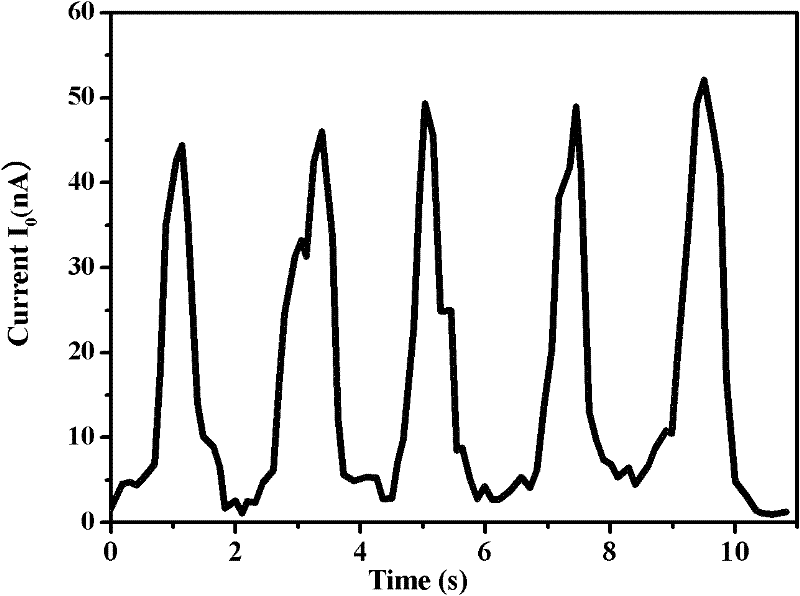

A construction method of zno micro/nano material flexible strain sensor

InactiveCN102285634AHigh crystallinityExcellent piezoelectric propertiesDecorative surface effectsChemical vapor deposition coatingSignal responseSilver electrode

The invention discloses a construction method of a flexible strain sensor based on ZnO micro / nano material, and relates to the technical fields of nanotechnology and semiconductor device manufacturing. The strain sensor provided by the invention includes: ZnO single crystal micro / nano material, silver electrode, encapsulation layer polydimethylsiloxane (PDMS) and flexible substrate (PDMS, polyimide PI thin film). Among them, the ZnO single crystal micro / nano material with a length of 2-8 mm and a diameter of 0.5-5 μm is prepared by a vapor phase method and transferred to a flexible substrate by a contact printing method. The packaged device can be used in corrosive environments such as acid / alkali, and has a high degree of fit for working surfaces with different roughnesses, and has a high signal response to small strains. It can be used for bridge detection, automobile shock absorption detection and biomedical devices, etc.

Owner:UNIV OF SCI & TECH BEIJING

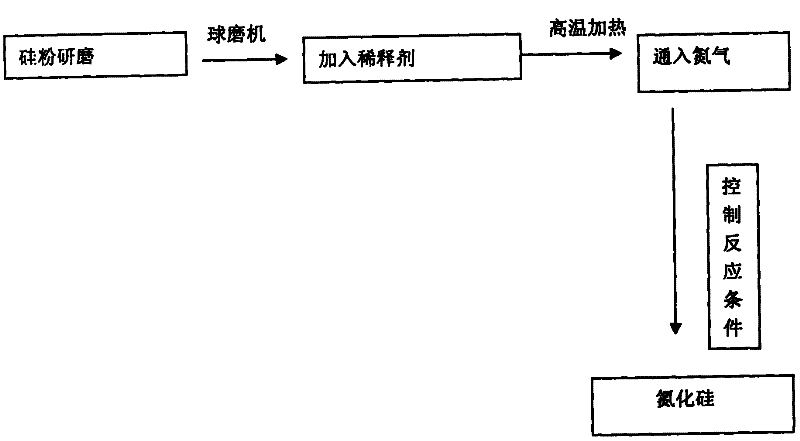

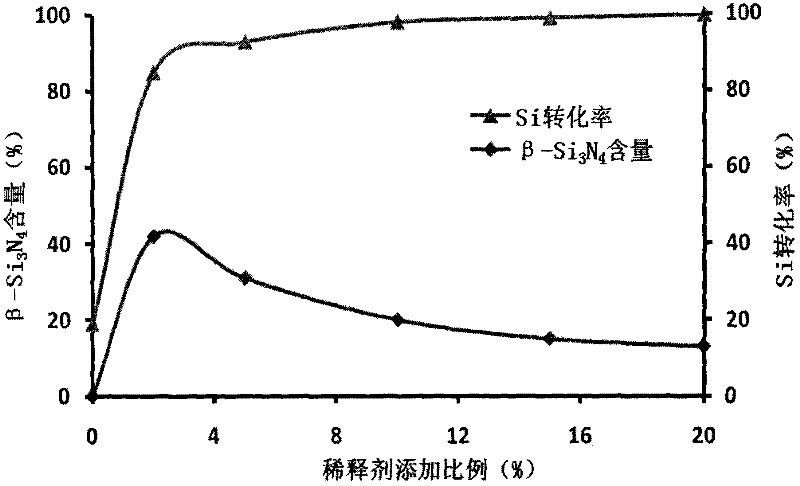

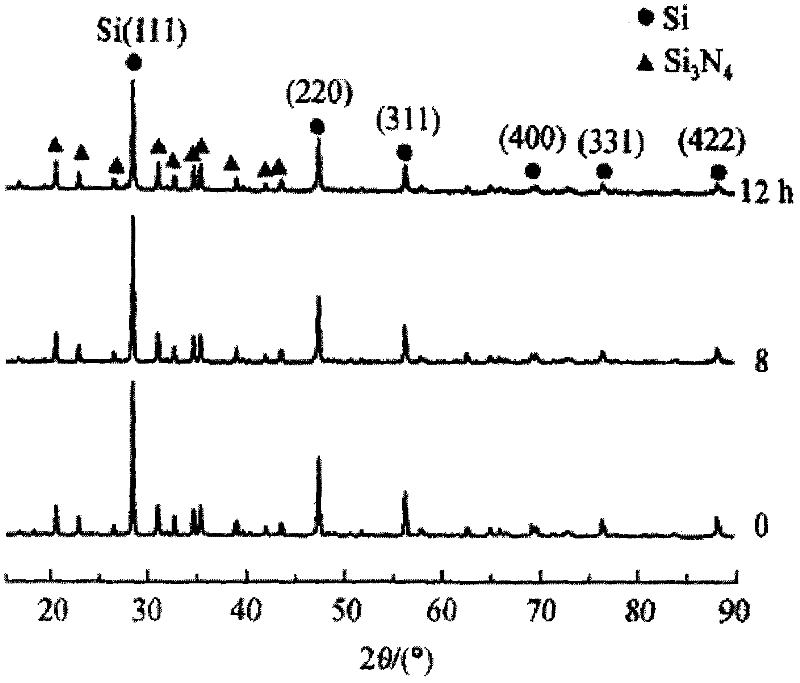

Production method of high-content alpha-crystal form silicon nitride powders

InactiveCN102173396ASmall granularityImprove defectsNitrogen compoundsChemical industryInorganic ChemicalSolid reaction

The invention discloses a production method of silicon nitride powders, in particular relates to a novel production method of silicon nitride powders with high content of alpha-Si3N4, and belongs to the technical field of inorganic chemistry. The method comprises the following steps: firstly pre-treating powdery raw materials by mechanical activation, and feeding a mixed diluting agent of alpha-Si3N4 and non-crystalline Si3N4 during the direct nitridation of silicon powders at a high temperature under normal pressure. By controlling the addition ratio of the diluting agent and the nitridation time and temperature, the silicon nitride powders with high content of alpha-Si3N4 are synthesized. The process improves the activity of solid-phase reactants, promotes the reaction between Si and N2, does not need high-temperature and high-pressure conditions, is easy to operate, adopts easily-available raw materials, increases the purity of products, has a low coat and a high efficiency, and is environment-friendly and energy-saving. The process is economical and highly-efficient and suitable for large-scale production.

Owner:GONGYI CITY HONGTAI SILICON NITRIDE MATERIAL

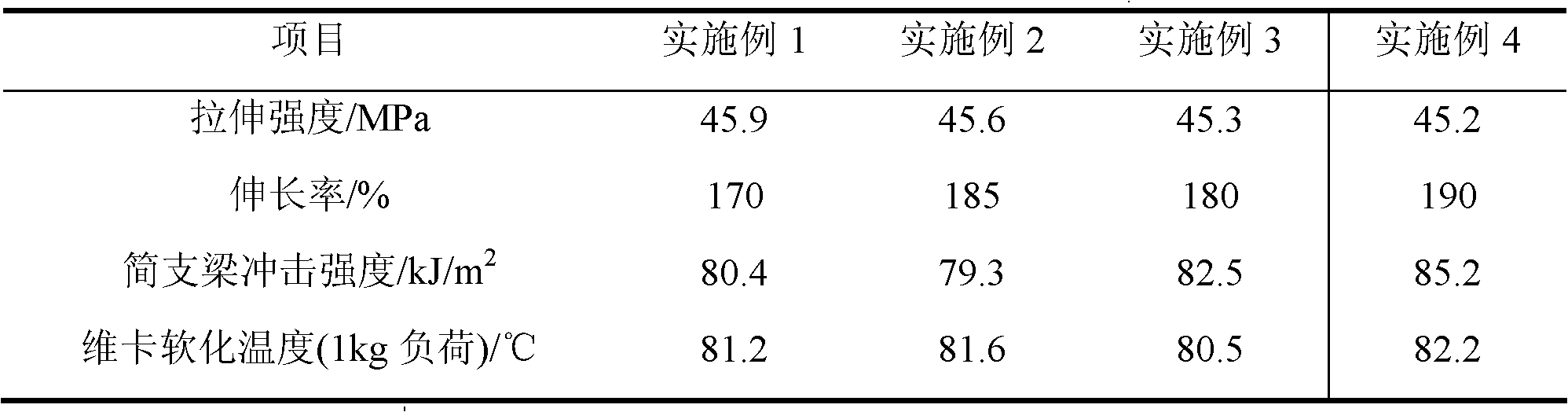

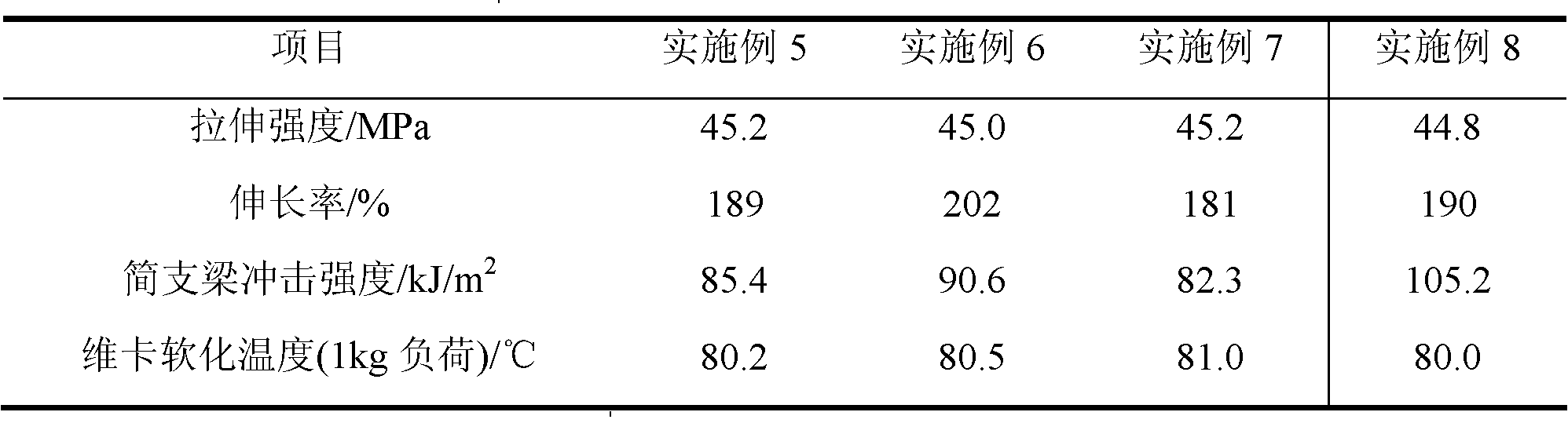

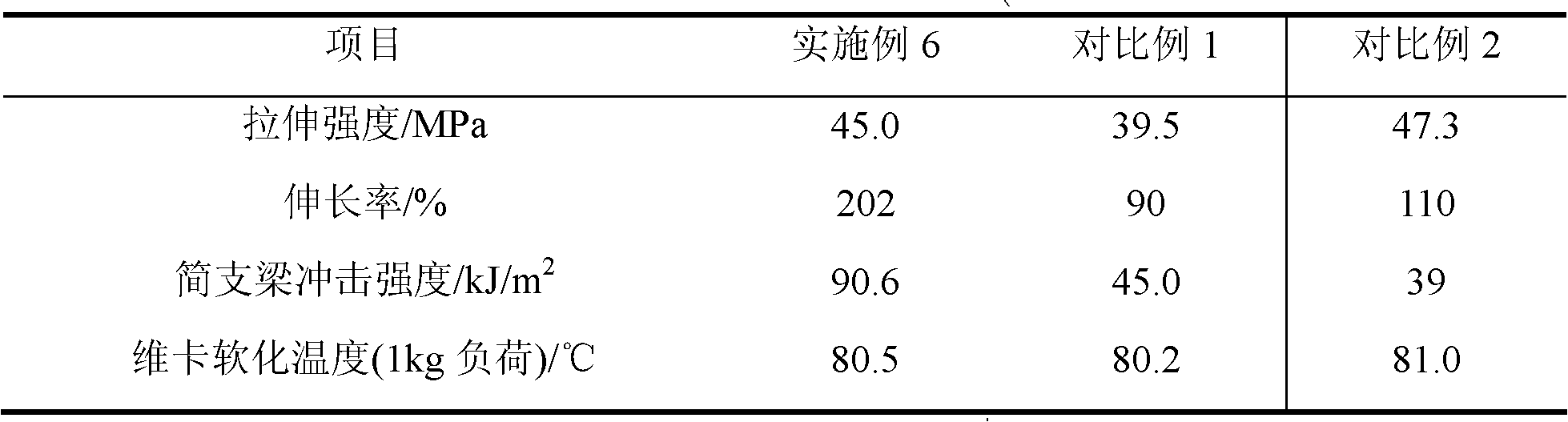

High-elongation high-shock resistance PVC tubular product composition and preparation method thereof

The invention discloses a high-elongation high-shock resistance PVC tubular product composition and a preparation method thereof, belonging to the technical field of plastic processing. The composition disclosed herein comprises 100 weight parts of PVC resin, 8-15 weight parts of IPN copolymer (ACM-M) of mild-chlorinated HDPE and acrylate, 0.8-3.0 weight parts of heat stabilizer, 1.8-3.5 weight parts of lubricant, 0-5 weight parts of filling agent, and 0-2 weight parts of coloring agent. According to the invention, the PVC tubular product produced by using the ACM-M modified high-elongation high-shock resistance PVC tubular product composition has an elongation being 202% and a simply-supported beam impact strength being 90.6kj / m<2>, has excellent shock resistance and high physical and mechanical properties, and the preparation method is simple, and the production cost is low.

Owner:CHINA PETROLEUM & CHEM CORP

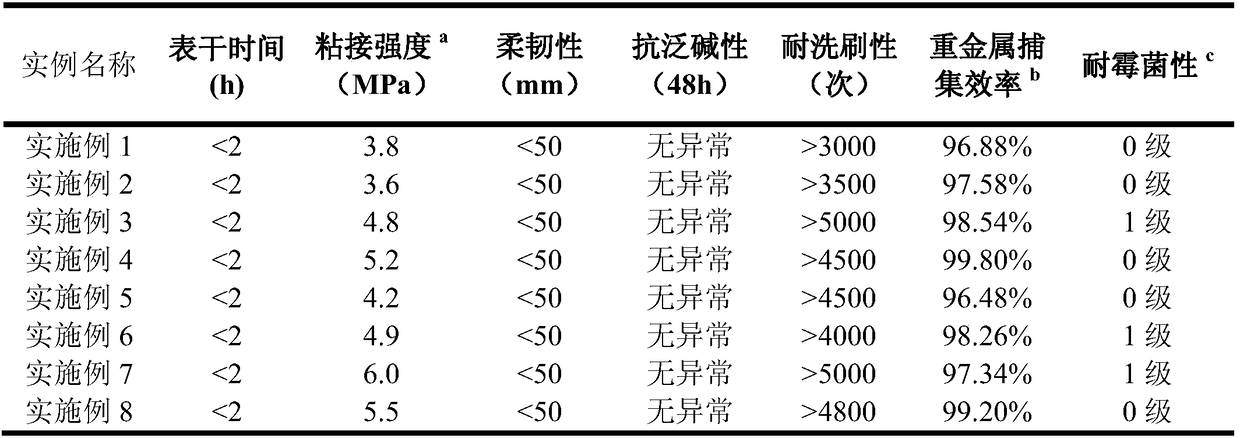

Geopolymer-based mold-proof antibacterial interior wall coating and preparation method thereof

InactiveCN108892978AReduce pollutionGood and long-lasting inhibitory effectAntifouling/underwater paintsPaints with biocidesWater basedBond strength

The invention discloses a geopolymer-based mold-proof antibacterial interior wall coating which is composed of a solid phase S and a liquid phase L, wherein the solid phase S comprises the following components in parts by weight: 10-90 parts of a gel binder, 5-85 parts of pigments and fillers, 0.1-5 parts of a film-forming agent, 0.5-10 parts of an anti-cracking additive and 0.4-5 parts of an anti-settling agent; and the liquid phase L comprises the following components in parts by weight: 5-90 parts of an alkali activator, 0.5-6 parts of a rheological modifier, 0.2-3 parts of an antifoaming agent and 2-90 parts of water. The invention further discloses a preparation method of the geopolymer-based mold-proof antibacterial interior wall coating. The geopolymer-based mold-proof antibacterialinterior wall coating disclosed by the invention realizes the zero-VOC (Volatile Organic Compound) advantage and high-efficiency mold-proof antibacterial functions of the novel water-based inorganicinterior wall coating, and has the advantages of being high in bonding strength with the base plane, excellent in scrubbing resistance, excellent in water resistance and penetration resistance, low inprice and the like, and the mold-proof antibacterial functions have long-term properties.

Owner:浙江航通舟新材料科技股份有限公司

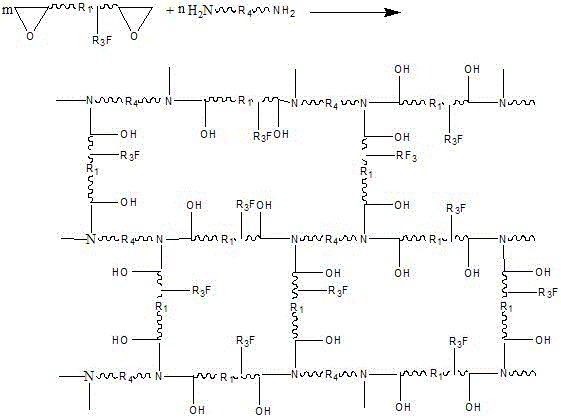

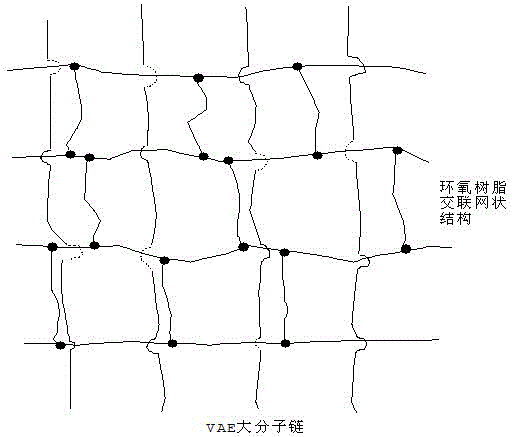

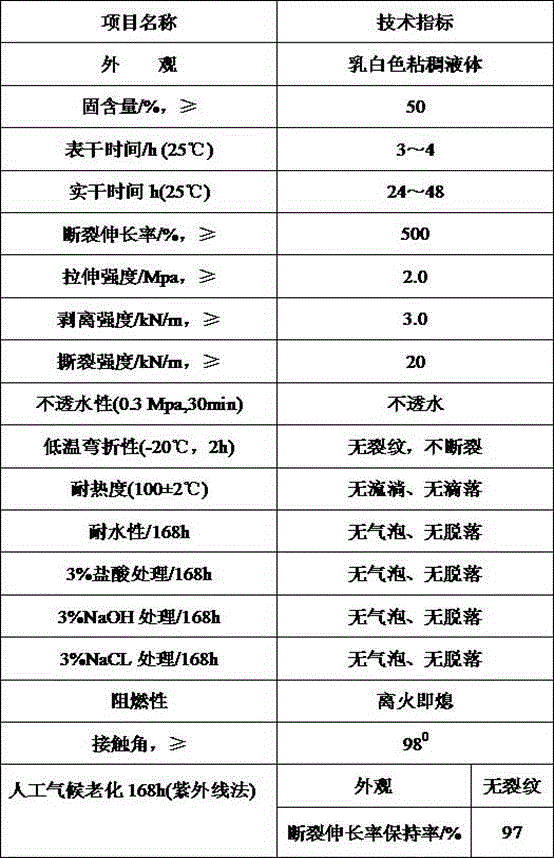

Epoxy resin modified VAE composite waterproof material and preparation method thereof

ActiveCN103555091AImprove water resistanceIncrease crosslink densityFireproof paintsAntifouling/underwater paintsPropanoic acidPhosphoric acid

An epoxy resin modified VAE composite waterproof material and a preparation method thereof. The composite waterproof material is composed of a component A and a component B. A preparation method of the component A is as below: adding a vinyl acetate-ethylene copolymer emulsion into a material canister, then adding an epoxy resin emulsion and a defoaming agent, stirring, then adding aluminum hydroxide, phosphoric acid tris(2-chloroethyl) ester, talcum powder, a polytetrafluoroethylene fine powder, tetra [beta-(3,5-di-t-butyl-4-hydroxy phenyl) propionic acid] pentaerythritol ester, 2-(2H-benzo triazoles-2-yl)-6-dodecyl-4-methylphenol and water, and stirring to obtain the component A. A preparation method of the component B is as below: under the protection of nitrogen, adding tetraethylenepentamine into a reactor, dropwise adding ethylene glycol diglycidylether and butyl glycidol ether for a thermal reaction, then adding water to dilute and stirring to obtain the B component. The component A and the component B are stirred according to a part ratio of 100: 5-8 and applied; and after curing, a flame retardant antifouling self-cleaning composite waterproof material with a semi-interpenetrating network macro-molecular structure is obtained.

Owner:太原英可奥笔墨科技有限公司

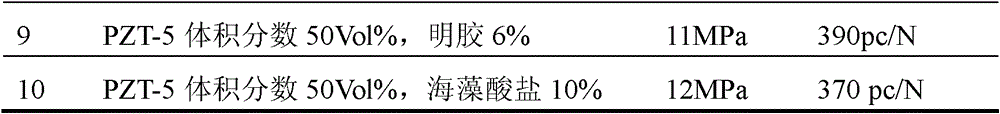

Preparation method of piezoelectric ceramics-polymer composite material

InactiveCN102745996AImprove reliabilityImprove electrical performanceRoom temperatureCeramic polymer composites

The invention relates to a preparation method of a piezoelectric ceramics-polymer composite material. The method is characterized in that ceramic powder, a dispersant and a curing agent system are added are added in water for mixing, a reaction is initiated to prepare the piezoelectric ceramics biscuit with the strength greater than 10 MPa, and processes of cutting and sintering are carried out. The method comprises the following steps: 1) removing water of the ceramic powder, the dispersant, the curing agent system and fully mixing, defoaming, performing a gel reaction on the ceramic slurry under certain temperature and solidifying to obtain the piezoelectric ceramics gel biscuit with strength greater than 10MPa; and 2) cutting the piezoelectric ceramics biscuit from the step 1), sintering, then filling the polymer, solidifying under room temperature and cutting a pedestal to obtain 1-3 or 2-2 piezoelectric ceramics polymer composite material. The method has the advantages of high reliability, simple required equipment, simple operation, and can be used for preparing the ceramic-polymer piezoelectric composite material with large area and less defect crack.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

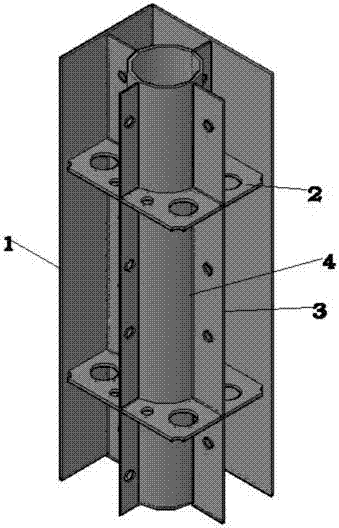

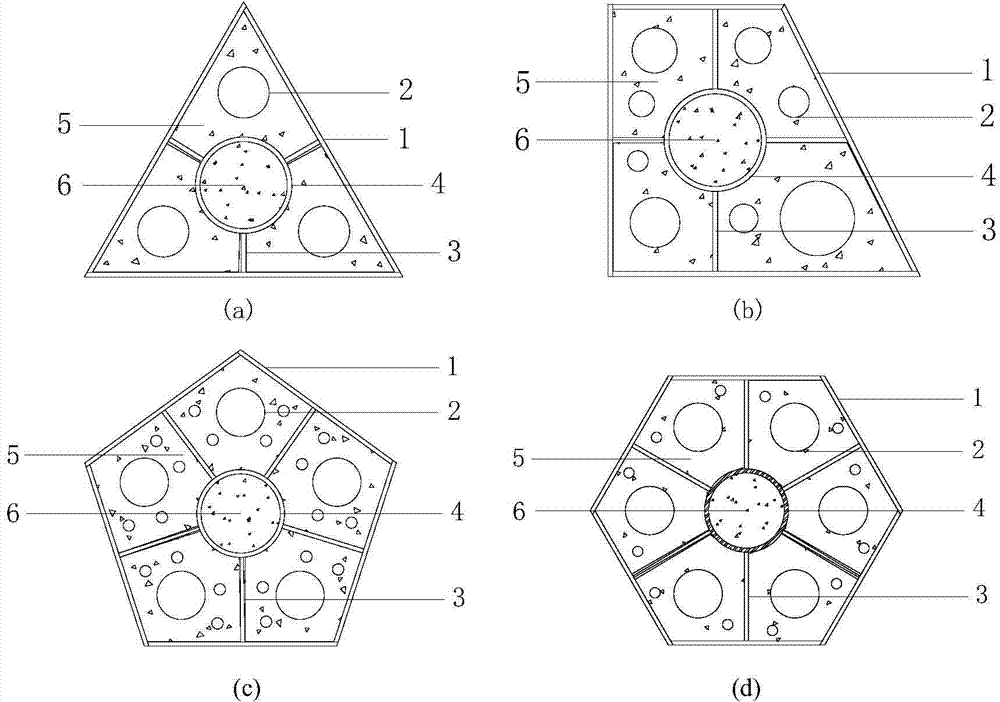

Combined giant column composed of irregular-section multi-cavity steel tube with built-in concrete-filled circular steel tube, and construction method thereof

ActiveCN104712099AImprove stabilityImprove bearing capacityStrutsPillarsHigh strength concreteStress concentration

The invention relates to a combined giant column composed of an irregular-section multi-cavity steel tube with a built-in concrete-filled circular steel tube, and a construction method thereof, and belongs to the field of building. The section form of the steel tube can be triangular, quadrilateral, pentagonal, hexagonal and the like, the composite giant column composed of the irregular-section multi-cavity steel tube with the built-in concrete-filled circular steel tube is formed under the combination or single use of different section forms. A diaphragm plate is welded with a square steel tube, a longitudinal stiffened rib is welded with the square steel tube and the diaphragm plate, and the circular steel tube is welded with the longitudinal stiffened rib and the diaphragm plate. High-strength concrete is poured in the steel tubes, the strength of concrete in the circular steel tube is higher than that of concrete in the square steel tubes, and recycled concrete can be poured in the circular steel tube. The bearing capacity of axial compression and partial compression of the irregular-section multi-cavity steel tube concrete giant column is improved; the combined giant column has an important significance on the improvement of stress concentration and hydration heat of concrete of the irregular-section multi-cavity steel tube concrete giant column; the method is simple, convenient, economical and effective and is beneficial to popularization and application in the design of building structures.

Owner:BEIJING UNIV OF TECH

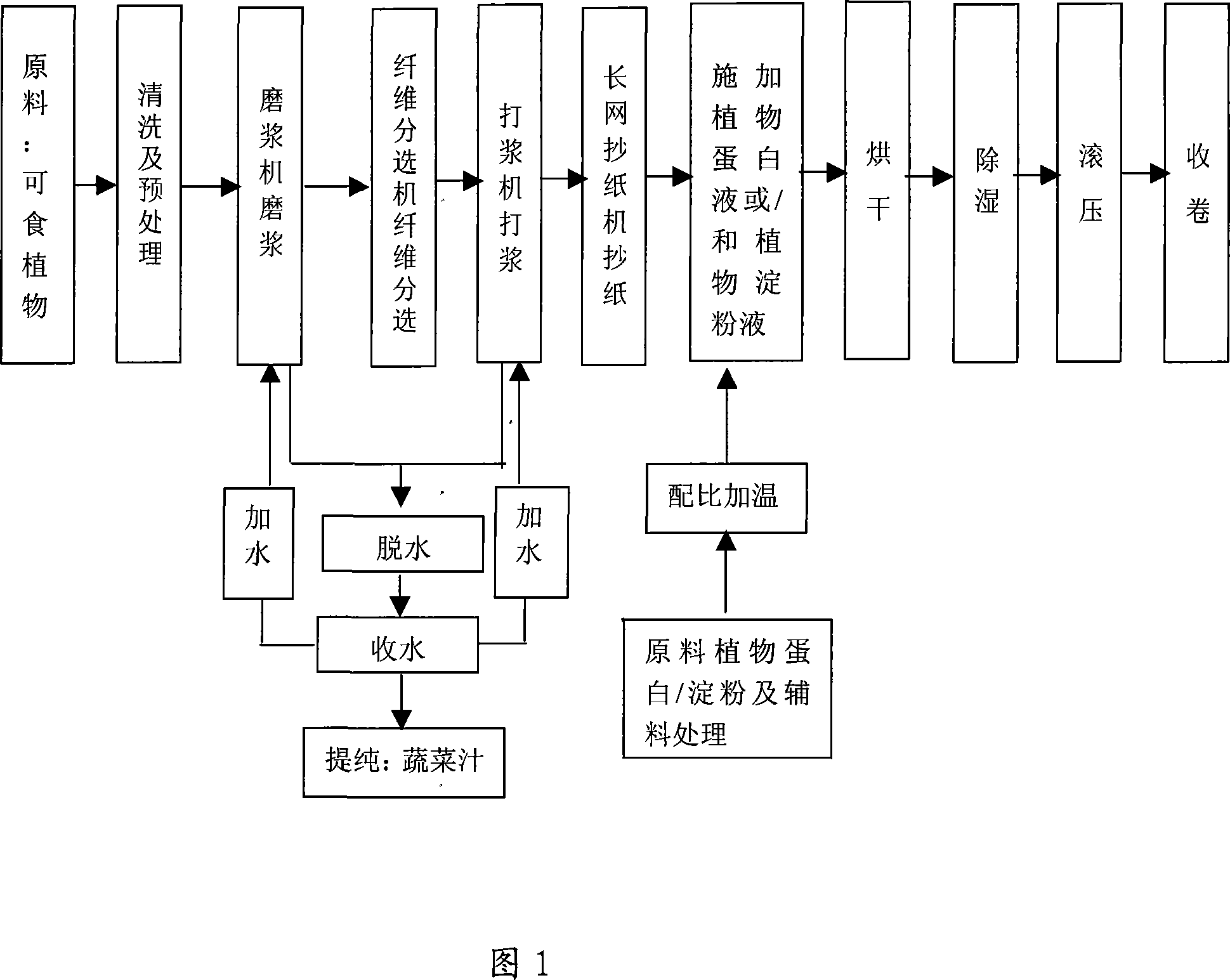

Edible mix paper film and production process mainly with papermaking technique thereof

InactiveCN101195976AFull of nutritionGreat tastePaper coatingSynthetic cellulose/non-cellulose material pulp/paperVegetable ProteinsFood item

The invention discloses edible mixed paper film and the producing method thereof taking the paper making process as main point. The invention aims to provide the edible mixed paper film which is made from eatable plants and vegetable protein or / and amylum and has multiple nutritive matters, and the producing method thereof. The mixed paper film of the invention comprises 40 to 70 percent of the eatable plants, 20 to 45 percent of the vegetable protein or / and amylum, and 5 to 15 percent of auxiliary materials according to the weight percentage. The invention also provides a method for preparing the mixed paper film through adopting the combination of fourdrinier making paper and sprayed liquid. The paper film of the invention is not only simple vegetable paper but also not simple protein film or starch film, the nutrition is plentiful, and the advantages of the physical and chemical characteristics of the vegetable paper and the protein film or the starch film are converged. In addition, the invention offers the producing method and the relevant technology taking the paper making process as the main, and the difficulties of the producing process and the technology are overcame. The mixed paper film can be used as an edible packaging of food, and also can be directly eaten as food.

Owner:TIANJIN UNIV OF COMMERCE

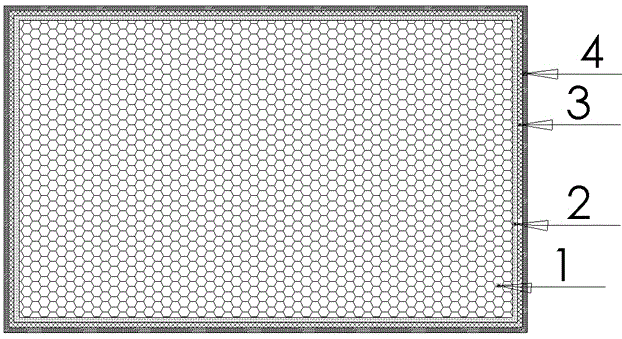

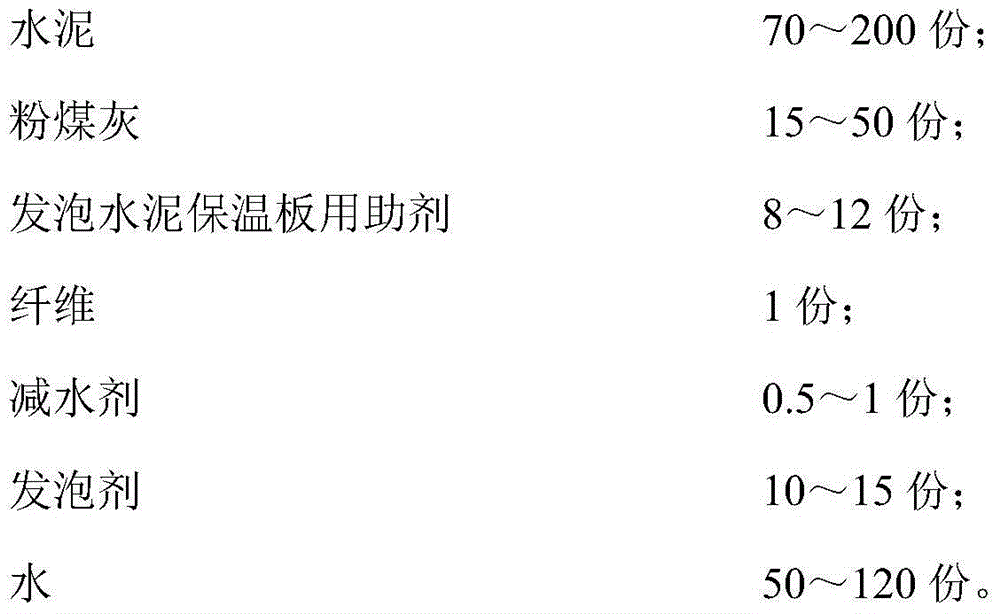

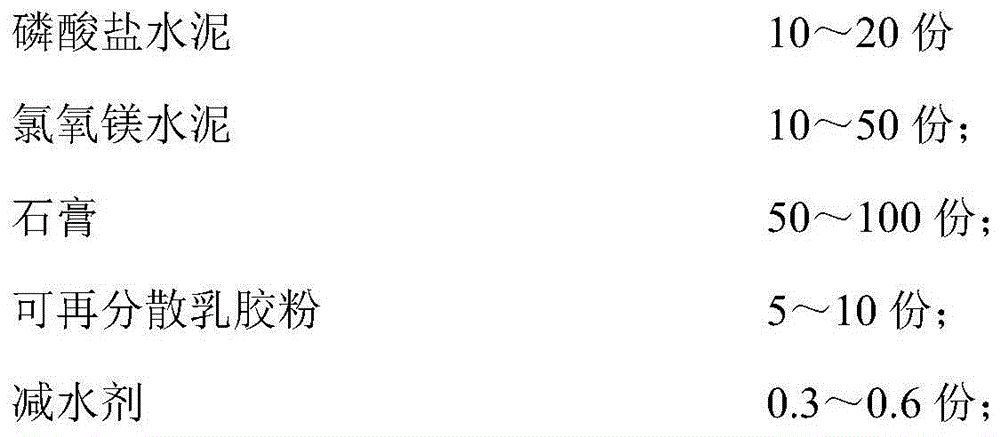

Low-alkalinity anti-crack mortar fiber reinforced foam cement heat-preserving plate

InactiveCN104790545ALow water absorptionImprove mechanical propertiesLaminationLamination apparatusFiberglass meshGlass fiber

The invention discloses a low-alkalinity anti-crack mortar fiber reinforced foam cement heat-preserving plate. The plate comprises a foam cement heat-preserving plate layer, alkali-resistant closed layers, a glass fiber mesh cloth layer and a low-alkalinity anti-crack mortar reinforced layer. The upper surface, the lower surface and the four side faces of the foam cement heat-preserving plate are coated with the alkali-resistant closed layers, and the glass fiber mesh cloth layer wraps and is attached to the upper surface, the lower surface and the four side faces of the foam cement heat-preserving plate coated with the alkali-resistant closed layers; the glass fiber mesh cloth layer is located between the alkali-resistant closed layers and the low-alkalinity anti-crack mortar reinforced layer; the upper surface, the lower surface and the periphery of the foam cement heat-preserving plate layer subjected to treatment of the alkali-resistant closed layers are coated with the low-alkalinity anti-crack mortar reinforced layer. The plate overcomes the defects that a traditional foam cement heat-preserving plate is large in fragility, prone to crack, high in water absorbing rate, severe in powder falling and the like. Meanwhile, flexibility of the plate is greatly improved, flexural strength is improved by 5-7 times, the plate in an ultra-large specification (> / =1200*1200 mm) can be manufactured, and the defects that corners of the plate in the ultra-large specification are prone to falling, and the plate is prone to damage or break are overcome.

Owner:CHONGQING SIBEIKEN ENERGY SAVING TECH DEV

Biologically degradable starch film and its prepn

InactiveCN1453303AHigh mechanical strengthGood heat sealing performanceCross-linkWater soluble polysaccharides

The biologically degradable starch film consists of starch polysaccharide hydrolyzing product 5-70 wt%, natural gelatin hydrolyzing product 0.2-3 wt%, PVA 18-85 wt%, cross linking agent 0.2-0.3 wt% and water 8-14 wt%, its preparation includes the following steps: mixing starch polysaccharide, natural gelatin, water and proper amount of polysaccharidase to obtain water soluble polysaccharide sol;mixing PVA and water to obtain PVA sol; mixing the polysaccharide sol and the PVA sol and adding proper amount of cross linking agent to form mixed sol; forming film with the mixed sol via dry curtain coating, drying, stretching, and hot setting to form the film with water content of 8-14 wt%. The film has the excellent performance similar to that of chemical plastic film, can be decomposed and absorbed by microbe in soil and has low production cost.

Owner:WUHAN JINBAO ENVIRONMENTAL BIOTECH

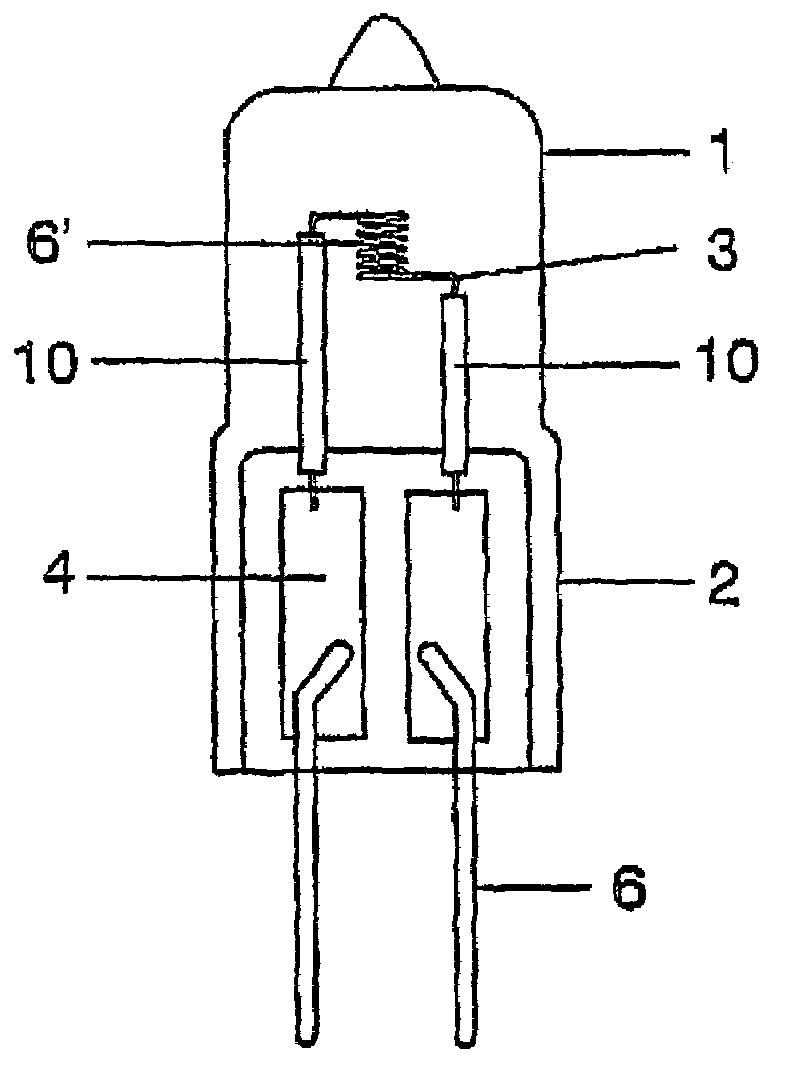

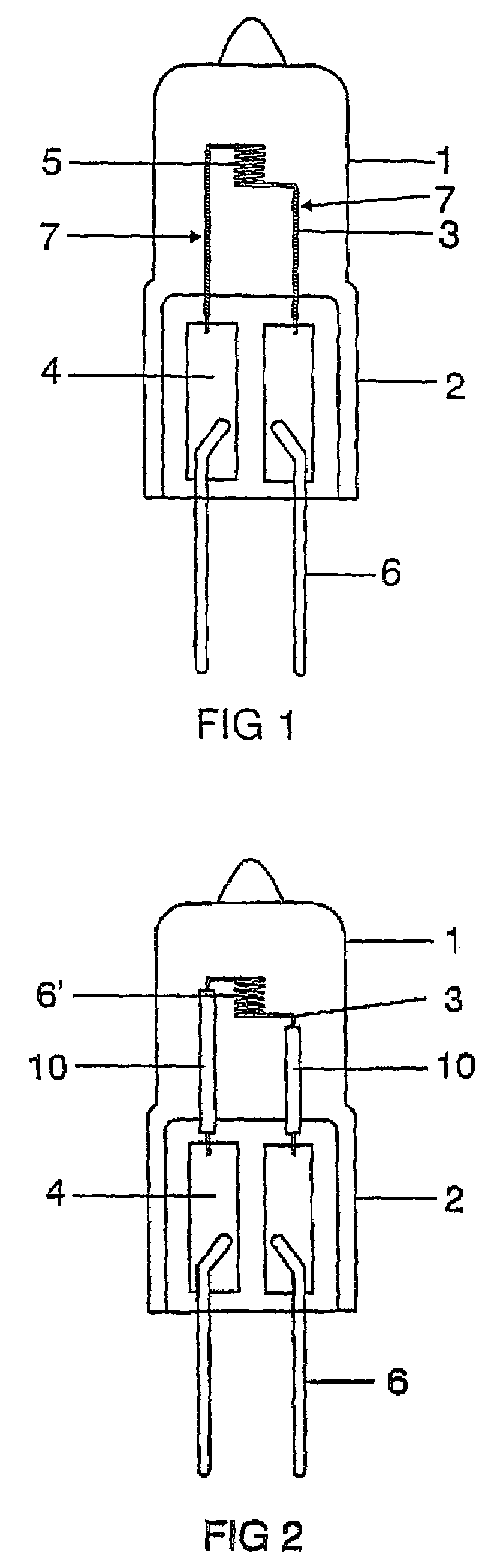

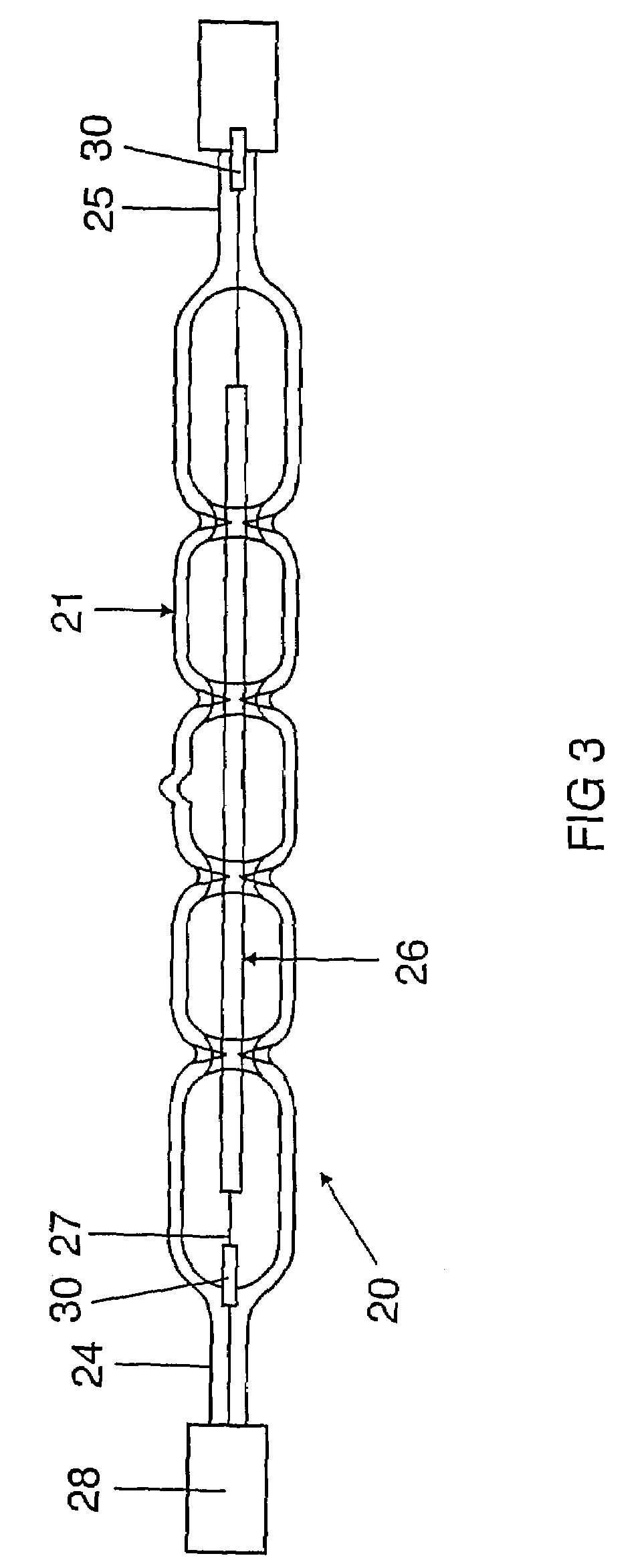

Incandescent lamp having a carbide-containing luminous element

InactiveUS7190117B2Easy to useOvercoming brittlenessIncadescent body mountings/supportLamp incadescent bodiesConductive coatingCarbide

The incandescent lamp is equipped with a luminous element which is hermetically inserted in a bulb together with a filling, the luminous element having a metal carbide whose melting point is above that of tungsten. The supply lead is fabricated integrally with the luminous element from a wire and provided with an electrically conducting coating which decisively improves the impact strength and make-proofness.

Owner:PATENT TREUHAND GESELLSCHAFT FUR ELECTRIC GLUEHLAMPEN MBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com