Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

25606results about How to "Ease of industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

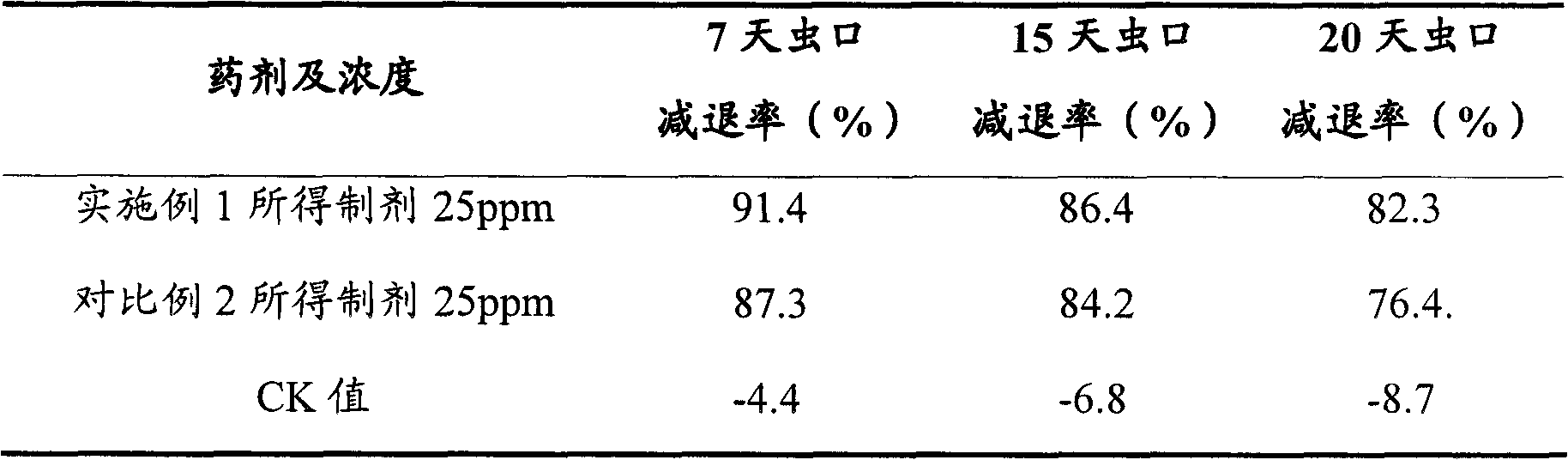

A kind of antibacterial composition and its application

InactiveCN102258064AExtended cleaning cycleTo achieve the effect of saving waterBiocideAntifouling/underwater paintsSodium PyrithioneNonwoven fabric

The invention relates to an antibacterial composition, comprising an organic antibacterial component containing at least one pyrithione salt, a pyrithione complex or an adduct thereof, an aqueous solution containing one or more metal ions or its The inorganic antibacterial component of the complex aqueous solution or its nanometer metal hydrosol or its nanometer metal oxide hydrosol and its composition, and the mass ratio of the organic antibacterial component to the inorganic antibacterial component is 1:100-50:1, It also includes other auxiliary agents, and its mass percentage in the antibacterial composition described in the patent is 0.001-20%. The antibacterial composition of the present invention can form a nanoparticle film on the surface of base materials such as natural fabrics, non-woven fabrics, clothing, bedding, toiletries, household items, medical care supplies, and filter screens, and realize its antibacterial properties through the nanoparticle film. Antibacterial, anti-mite, deodorizing and self-cleaning functions. The antibacterial composition of the invention is safe to use and can be used in medical treatment and life to protect people's health.

Owner:赵正坤

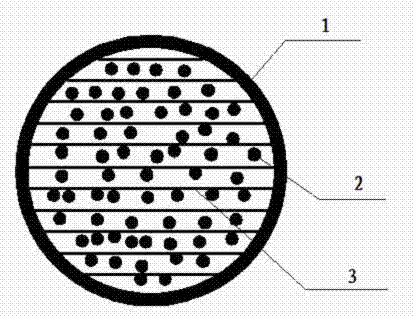

Electrode plate for lithium ion battery and manufacturing method thereof

InactiveCN101710619AChange the conductive contact interfaceImprove conductivityCell electrodesAdhesiveEngineering

The invention discloses an electrode plate for a lithium ion battery and a manufacturing method thereof, and particularly relates to the electrode plate for the lithium ion battery taking multi-layer graphene as a conductive agent and a manufacturing method thereof. The electrode plate of the invention consists of a positive electrode or negative electrode active substance, the conductive agent and an adhesive. The method comprises the steps of: using the positive electrode or negative electrode active substance, the conductive agent and the adhesive as raw materials to obtain electrode slurry through stirring and dispersing, and then obtaining the electrode plate through coating, drying and tabletting. The conductive agent adopted by the invention has the advantages of high dispersivity, high electric conductivity, good filling effect and the like; and the method has the advantages of simplicity, low production cost and convenient popularization and application. The method can remarkably improve the electric conductivity, electrochemical capacity and enhance charge-discharge capability of electrode materials by multiples, so the method can be widely applied to the preparation of electrode plates of lithium ion batteries.

Owner:CHONGQING UNIV

Method for removing pollutants in sewage

The invention belongs to the technical field of environmental protection, and discloses a method for removing pollutants in sewage. A composite microbial inoculant is used in the method and comprises rhodococcusrhodochrous, thiobacillus denitrificans, pseudomonas stutzeri, sphingomonas, bacillus pumilus and phanerochaete chrysosporium. According to the method, the pollutants are mainly treated by using microorganisms, so that the pollutants containing ammonia, nitrogen, sulfur and phosphorus can be effectively removed, and the investment cost is low; the method has broad application prospect.

Owner:JIANGSU LV CHUAN ENVIRONMENTAL PROTECTION TECH

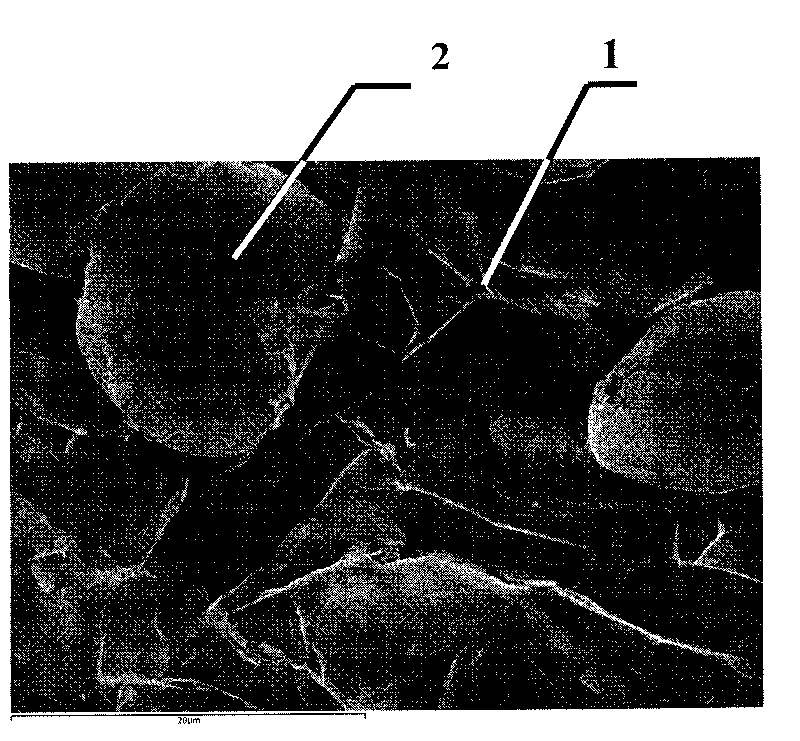

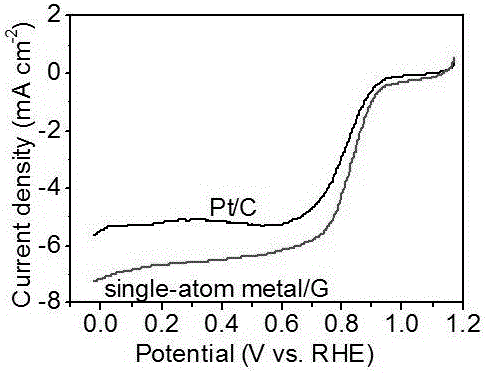

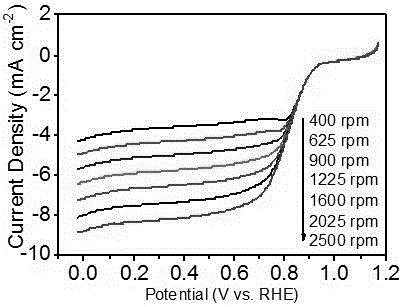

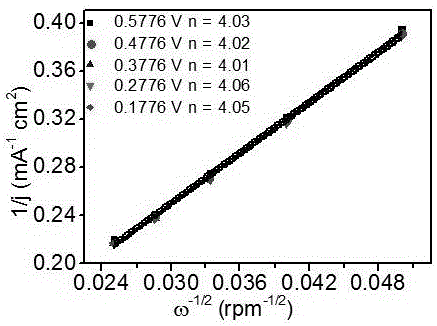

Monodisperse metal atom/graphene composite catalyst and preparation method and application thereof

ActiveCN106694007ALow costSimple stepsCell electrodesCatalyst activation/preparationCvd grapheneChemistry

The invention discloses a monodisperse metal atom / graphene composite catalyst and a preparation method and application thereof. The catalyst is formed by loading monodisperse metal atoms on / in graphene, wherein the content of the monodisperse metal atoms is 0.0001wt%-5.0wt%; the content of heteroatom doped graphene is 95wt%-99.9999wt%; and the content of heteroatom in graphene is 0wt%-90wt%. The monodisperse metal atom / graphene composite catalyst is obtained through an electrochemical method, and the preparation method is simple, easy to operate and control, low in cost, high in efficiency, good in quality, high in security and favorable for industrial production. The composite catalyst has the characteristics of high activity and good stability when being applied to electro-catalytic oxygen reduction, and has better comprehensive performance and good application prospects relative to commercial 20wt% of Pt / C.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method for preparing ethanol by hydrogenation of acetic ester

ActiveCN102093162AHigh activityImprove stabilityOrganic compound preparationHydroxy compound preparationReaction temperatureBULK ACTIVE INGREDIENT

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

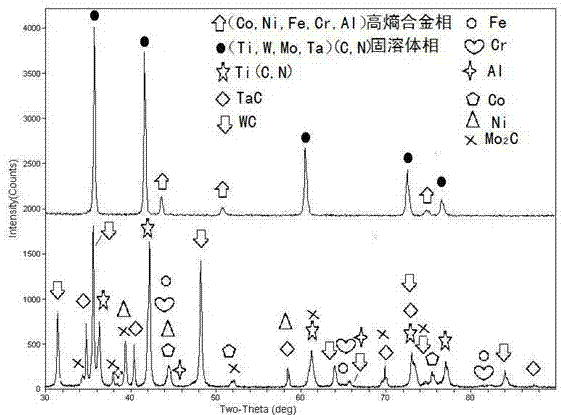

Titanium carbonitride based metal ceramic based on high-entropy alloy binder phase and preparation method of metal ceramic

InactiveCN102787266AImprove corrosion resistanceImprove wear resistanceRare-earth elementHigh entropy alloys

Disclosed is a titanium carbonitride based metal ceramic material based on a high-entropy alloy binder phase. The binder phase of the titanium carbonitride based metal ceramic material is high-entropy alloy, the hard phase of the titanium carbonitride based metal ceramic material is carbonitride solid solution, the high-entropy alloy binder phase includes at least four of ferrum, cobalt, nickel, chromium, aluminum, vanadium, titanium, copper, zirconium, molybdenum, manganese and rare earth elements, and the molar content ratio of each element ranges from 5% to 35%. In a preparation method, the titanium carbonitride based metal ceramic material based on the high-entropy alloy binder phase comprises raw materials including, in weight percent, 3-30% of the high-entropy alloy binder phase, 0-30% of second carbide powder and the balance carbonitride solid solution powder, the carbonitride solid solution powder includes at least one of Ti (Cx, N1-x), (Ti, M1...) and (Cx, N1-x), the M1 component of the (Ti, M1...) and (Cx, N1-x) includes at least one of W, Mo, Ta, Nb, V, Cr, Zr, Hf, Y and lanthanide, and 0<x<1 in the Ti (Cx, N1-x), (Ti, M1...) and (Cx, N1-x). The preparation method includes the process steps of (1) ball-milling mixing, (2) forming and (3) low-pressure sintering.

Owner:SICHUAN UNIV

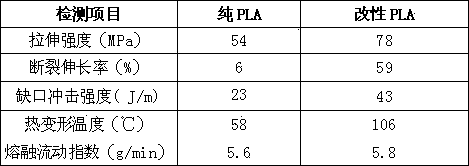

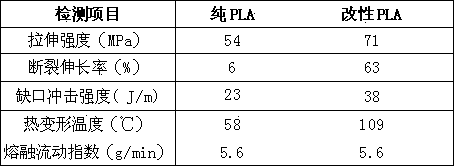

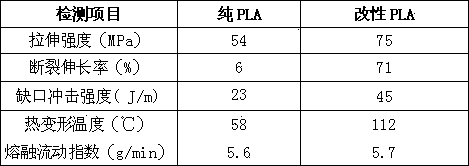

3D printing modified polylactic acid material and preparation method thereof

InactiveCN103467950AIncrease profitSelf-performance has not declinedMonocomponent polyesters artificial filamentArtifical filament manufactureHeat deflection temperaturePolymer science

A 3D printing modified polylactic acid material comprises, by weight, 70-85 parts of polylactic acid, 1-5 parts of chain extenders, 1-5 parts of cross-linking agents, 0.5-1 part of nucleating agents, 5-10 parts of polymers with low molecular weights, 5-10 parts of flexibilizers, 1-5 parts of fortifiers and 0.3-0.8 part of antioxidants. According to the 3D printing modified polylactic acid material, a low-temperature smashing hybrid reaction technology is utilized, modified processing is carried out on polylactic acid, toughness, impact strength and the heat distortion temperature for the polylactic acid are improved to a large extent, and the polylactic acid can have wider application prospects in 3D printing materials.

Owner:佛山市斯太克科技有限公司

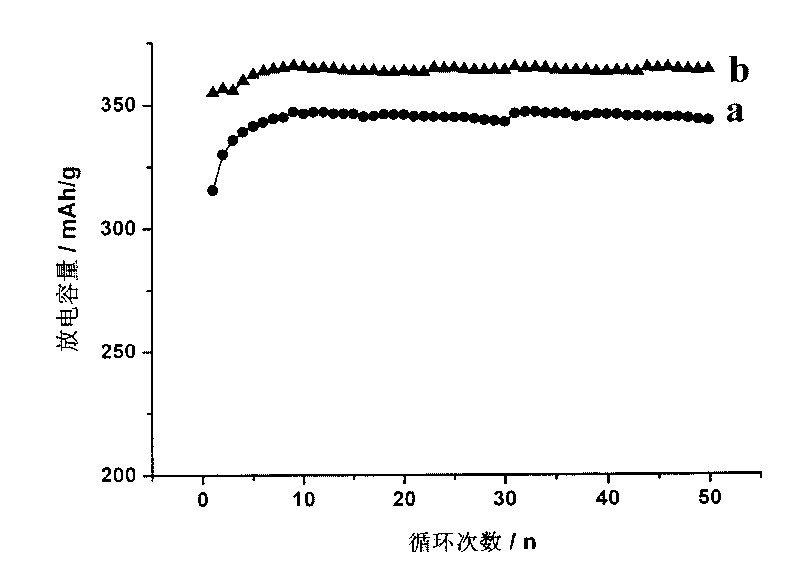

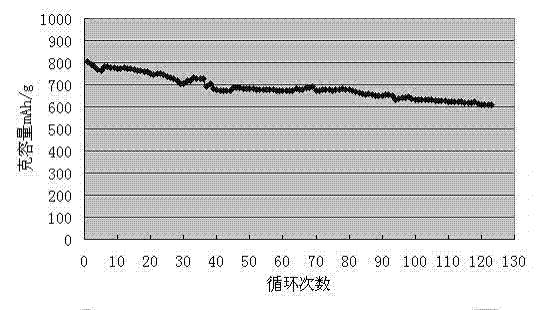

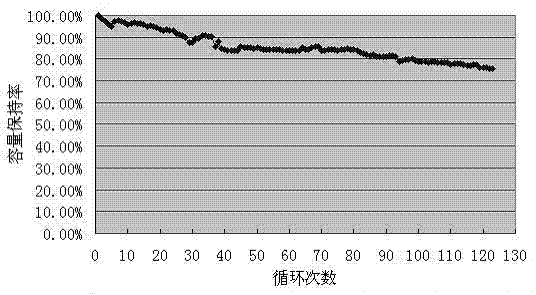

Preparation method of high power capacity lithium ion battery cathode material

ActiveCN102769139AHigh specific capacityImprove cycle stabilityCell electrodesNanotechnologyCyclic stability

A preparation method of a high power capacity lithium ion battery cathode material uses natural spherical graphite to serve as raw materials, uses concentrated sulfuric acid to serve as an inserting layer agent, uses potassium permanganate to serve as an oxidizing agent, conducts expansion treatment at high temperature to obtain micro-expanded graphite, then enables the micro-expanded graphite in different proportions to be mixed with nanometer ganister sand, conducts ultrasonic dispersion, suction filtration and dying to obtain the micro-expanded graphite with the nanometer ganister sand inserted in layers, enables the micro-expanded graphite to be mixed and coated with carbon source carbon source according to certain proportion, and finally conducts carburizing sintering under inert gas shielding to prepare completely coated silicon carbon composite cathode material with sufficient obligated obligate inside. Electrochemistry shows that the silicon carbon composite material prepared by the preparation method has high specific capacity and cycling stability and is the ideal high power capacity lithium ion battery cathode material.

Owner:内蒙古斯诺新材料科技有限公司

Method for finishing bacterium fixation by utilizing polyvinyl alcohol-borate secondary crosslinking

The invention relates to a method for finishing bacterium fixation by utilizing polyvinyl alcohol-borate secondary crosslinking, belonging to the field of water treatment. The method comprises the steps of: after mixing polyvinyl alcohol and bacteria in proportion, putting the mixture into saturated borate solution and carrying out first crosslinking fixation, after the fixation, taking out supernate and regulating pH of the supernate, carrying out second crosslinking fixation on the polyvinyl alcohol by utilizing the supernate in which the pH is regulated, and cleaning the polyvinyl alcohol after the fixation, so as to finish the whole fixation process. The method has the advantages that the damage to the bacteria in the fixation process is greatly reduced, and the phenomena of adhesion, water solubility and expansion are effectively reduced as well, thus providing conditions for large-scale industrial application of biologic active fillers and biologic active filter materials based on the polyvinyl alcohol.

Owner:BEIJING UNIV OF TECH

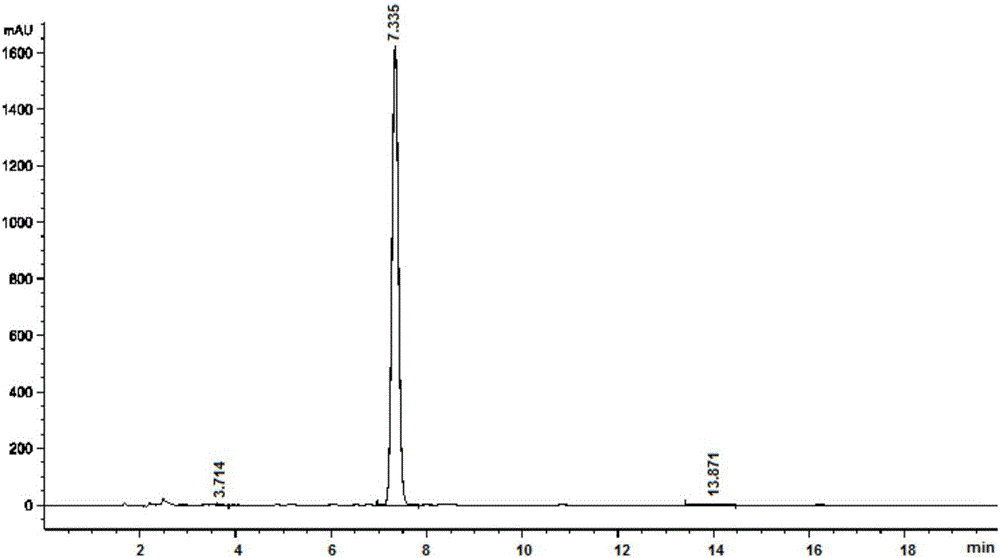

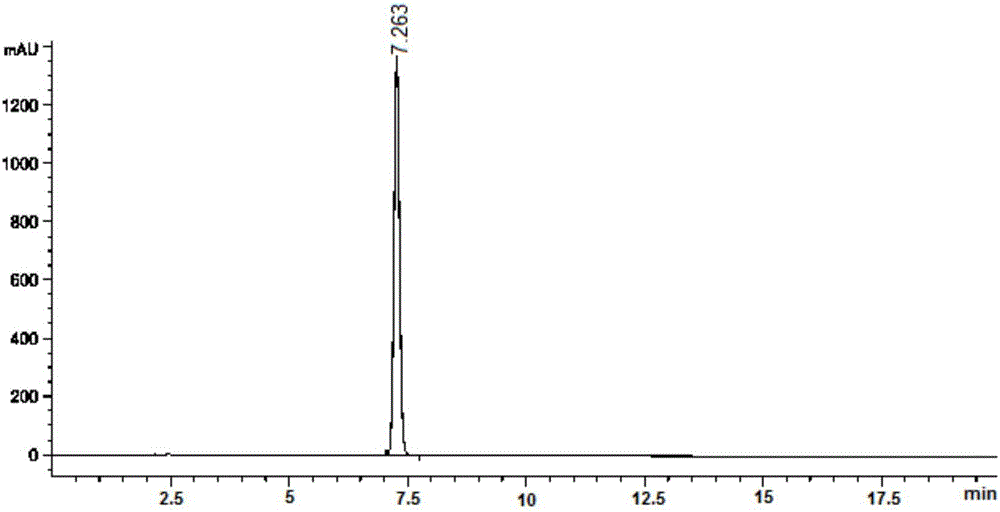

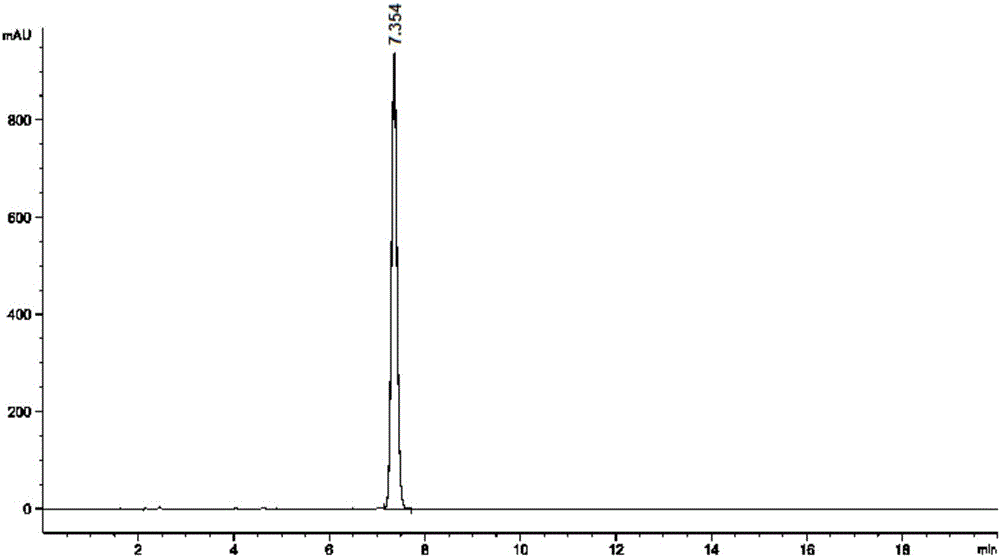

Method for extracting cannabidiol from cannabis

ActiveCN106831353AHigh yieldHigh purityOrganic chemistryOrganic compound preparationAlcoholExtraction Fraction

The invention discloses a method for extracting cannabidiol from cannabis. The method comprises the following steps: smashing and drying extraction fractions of cannabis to obtain medicine material powder; extracting the medicine material powder with 30% to 100% (V / V) of ethanol to obtain an extracting solution; concentrating the extracting solution to obtain an extract; carrying out water precipitation on the extract, and removing impurities to obtain a water precipitation solution; centrifuging the water precipitation solution and adding 10% to 100% (V / V) of ethanol into an obtained precipitate, and dissolving the precipitate to obtain an alcoholic solution of the precipitate; carrying out column chromatography on the alcoholic solution of the precipitate; eluting an obtained eluant after the concentration column chromatography, and adding ethanol for supersaturated dissolution to obtain a crystal substance; adding the crystal substance into purified water or ethanol for washing to obtain a primary product; blending the primary product with purified water, and drying to obtain the cannabidiol. Only highly safe ethanol is adopted as a solvent, the purity of the cannabidiol in a finished product is improved, and the psychotoxic component of tetrahydrocannabinol is also removed, so that the product safety is improved, and the method is applicable for industrial production.

Owner:YUNNAN HANSU BIO TECH CO LTD

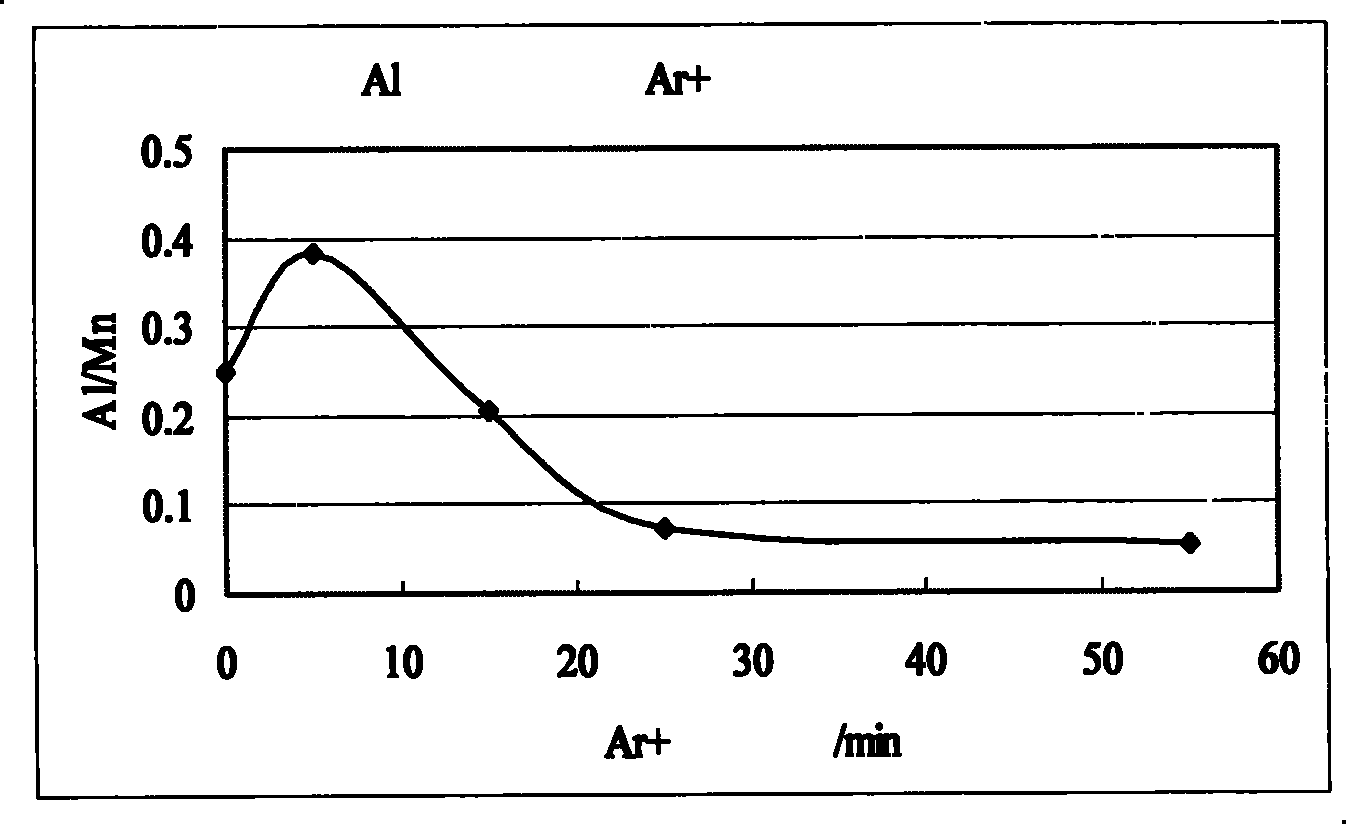

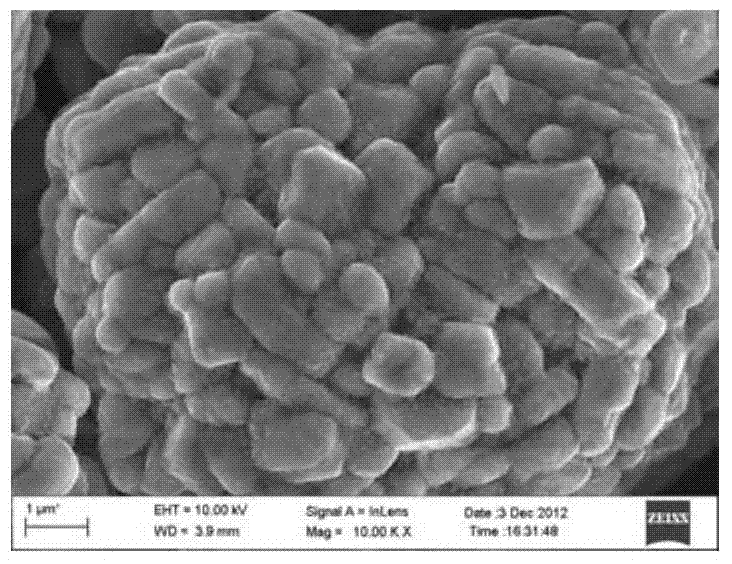

Lithium manganese oxide material and preparation method thereof

InactiveCN102054985AEasy to prepareNormal temperature is goodCell electrodesHigh temperature storagePhysical chemistry

The invention discloses a lithium manganese oxide material and a preparation method thereof, in particular to a high-crystallinity lithium manganese oxide material and a preparation method thereof, wherein the high-crystallinity lithium manganese oxide material is used for coating a lithium ion battery. The lithium manganese oxide material is obtained by being coated on a lithium manganese oxide precursor with the one-time crystal particle of 0.01-20mum and has the general formula of LiaMn2-b-cMbGcO4-d-eXdZe, wherein M and X are doped elements, G and Z are coating elements of which the concentration is distributed in a decreasing gradient from outside to inside, a is not less than 0.9 and is not more than 1.2, b is not less than 0 and is not more than 0.2, c is more than 0 and is not more than 0.2, d is not less than 0 and is not more than 0.2, and e is not less than 0 and is not more than 0.2. The material serves as the positive pole material of the lithium ion battery, has better normal-temperature and high-temperature cycle performance and excellent high-temperature storage performance, is simple in preparation and easy to operate, control and carry out industrial production.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

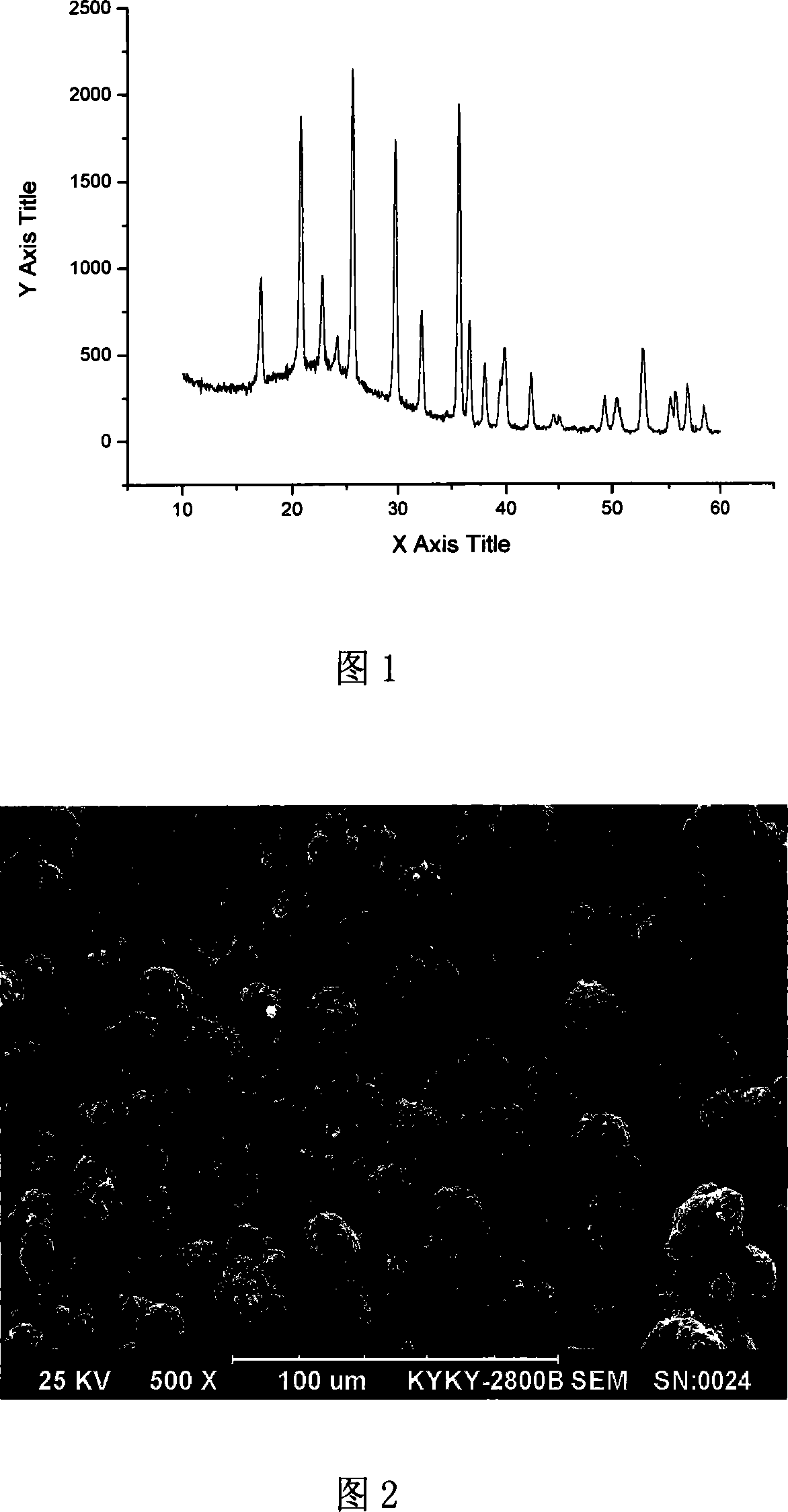

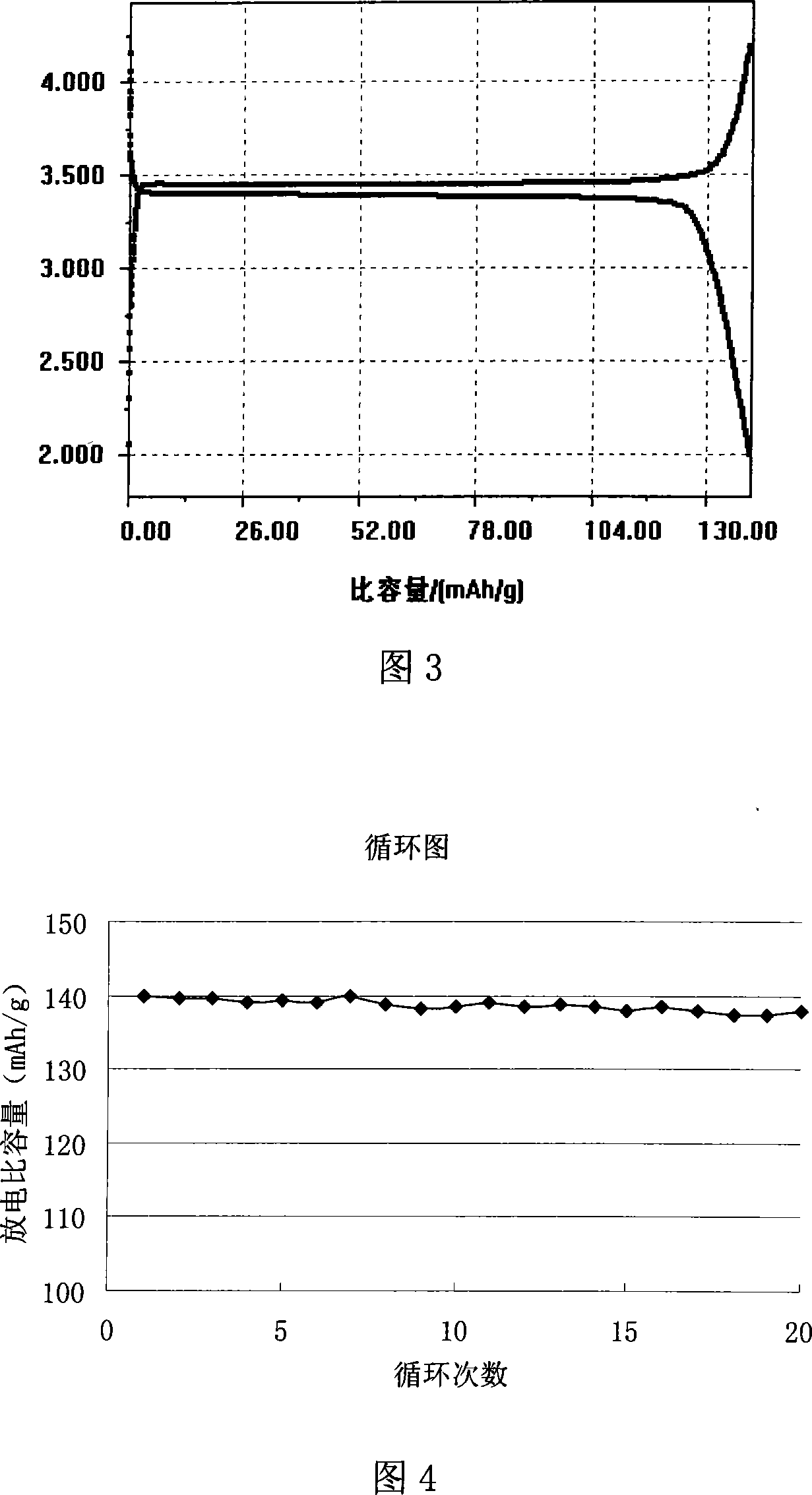

Ferric phosphate lithium material for lithium ion powder cell and preparation method thereof

ActiveCN101081696APromote crystallizationSingle structureElectrode manufacturing processesLithium compoundsCarbon layerLithium iron phosphate

The present invention discloses lithium iron phosphate material for lithium ion power cell and its preparation process, and dissolves the technological problem of raising the discharge power and safety performance. The lithium iron phosphate material is spherical or spheroid composite particle with one base body of lithium iron phosphate and doping and modifying agent and one coating carbon layer. Its preparation process includes wet ball milling the mixture comprising lithium salt, ferric salt, phosphoric acid, doping and modifying agent and dispersant, spraying to pelletize, heating for pre-treatment, maintaining temperature, cooling, pulverizing and shaping. Compared with available technology, the present invention has the features of high crystallization, single structure, average composite particle size of 5-60 microns, specific surface area of 8.0-15.0 sq m / g, bulk density of 1.4-1.7 g / cu cm, high specific capacity, high safety, etc.

Owner:BTR (TIANJIN) NANO MATERIAL MFG CO LTD

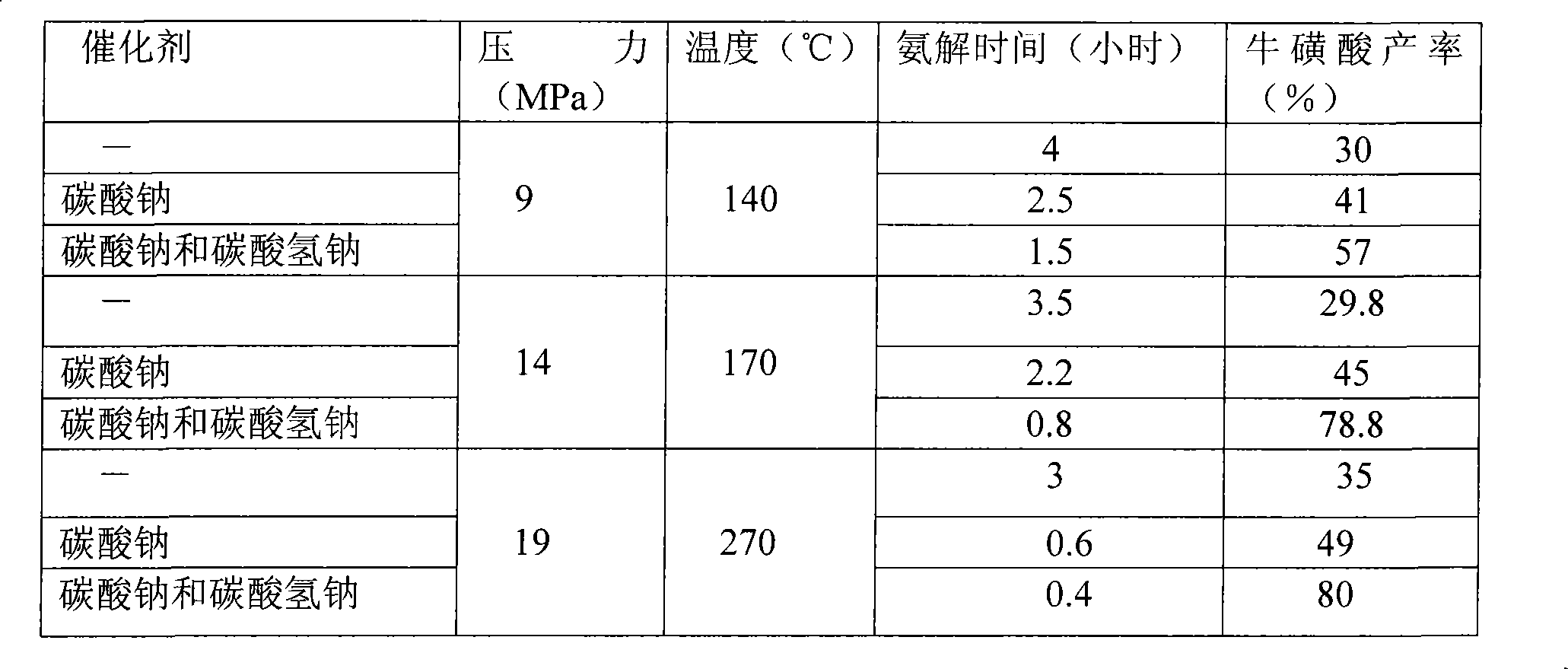

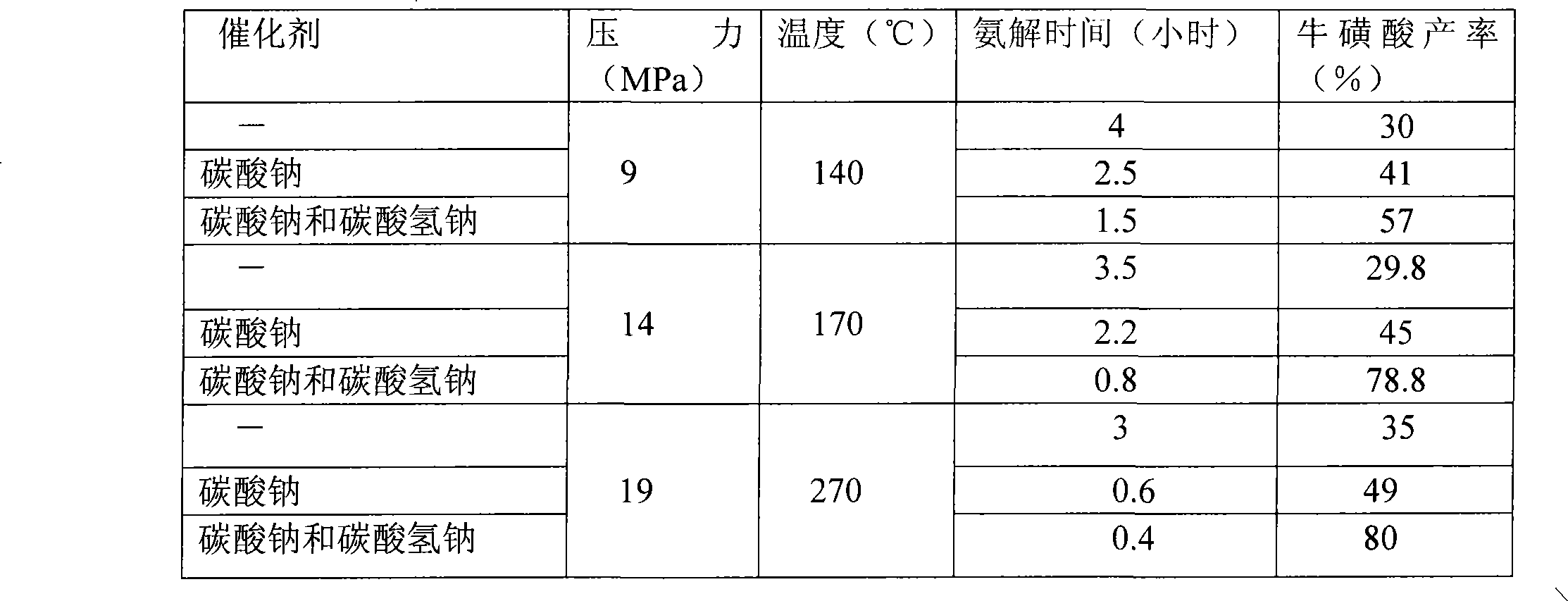

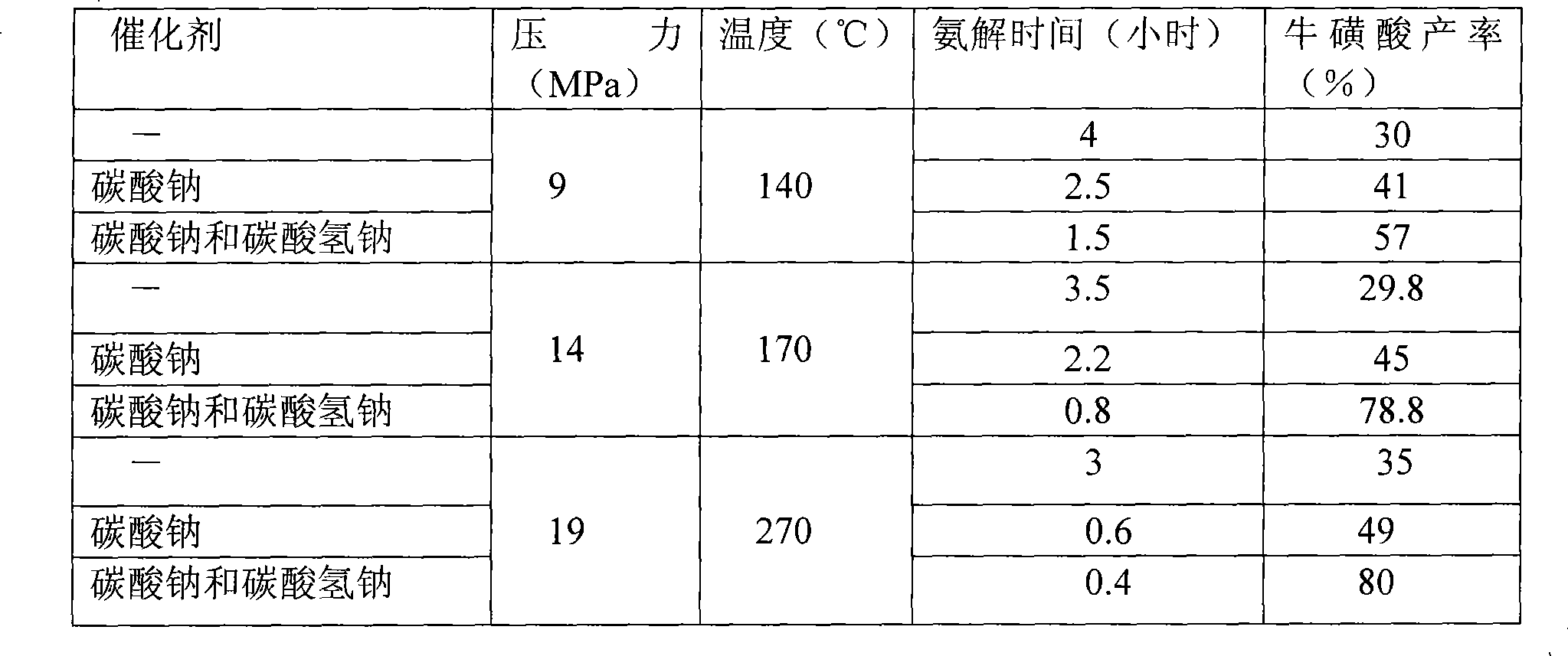

Synthesis of taurine

The invention relates to a method for synthesizing taurine, comprising the following steps: (1) according to the amount ratio of materials of 1:1 to 1:1.2, epoxy ethane and sodium bisulfite are subjected to addition reaction under 0.05 to 0.1MPa, with pH value of 6.5 to 7.5 and at a temperature between 75 and 85 DEG C to form hydroxyethyl sodium sulfonate; (2) the hydroxyethyl sodium sulfonate and liquid ammonia are subjected to ammonolysis reaction under 14 to 21MPa and at a temperature between 160 and 280 DEG C to generate sodium taurate, and the mass concentration of ammonia in the reaction liquid is 20 to 30 percent; and (3) neutralization: namely, the sodium taurate is neutralized by sulphuric acid to generate the taurine. The method for synthesizing the taurine has the advantages of short time, high yield and lower cost, and is easy for industrialized production.

Owner:王代龙 +1

Preparation method of ZrO2 nanotube supported B2O3 catalyst

InactiveCN102125825AGood for performanceSimple preparation processPhysical/chemical process catalystsChemistryAnode oxidation

The invention discloses a preparation method of a ZrO2 nanotube supported B2O3 catalyst, which comprises the following steps of: preparing aqueous solution containing NH4F with the concentration of 0.5 to 1.0%, boride with the concentration of 0.1 to 6% and (NH4)2SO4 with the concentration of 5 to 12%, taking the aqueous solution as reaction medium, taking a zirconium plate as anode and a platinum plate as cathode with the spacing of 1.5cm therebetween, adopting 10-30V direct current for anode oxidation for 3 to 5 hours at room temperature, stopping reaction, drying and roasting the resultant oxide to obtain the catalyst, wherein all the concentration percents are mass percents. The B2O3 / ZrO2 catalyst prepared according to the method of the invention has large specific surface area and volume simultaneously, and when the specific surface area thereof is the same as that of nano powder, the volume is ten thousand times as much as that of nano powder, thus the contradiction between specific surface area and volume of powder carrier is settled, and the defects caused by the fact that powder ZrO2 supports the B2O3 catalyst can be overcome.

Owner:HEBEI UNIV OF TECH

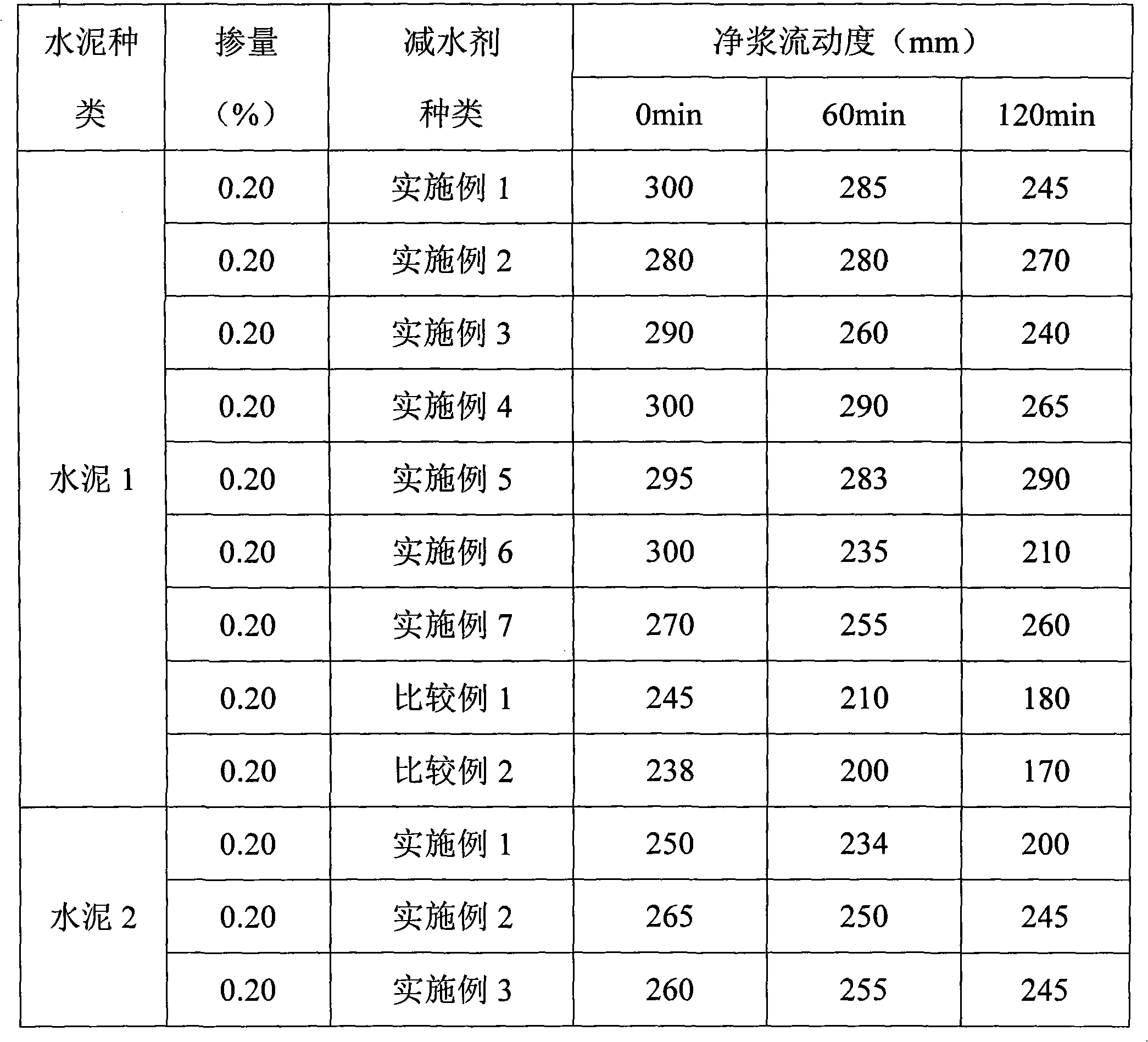

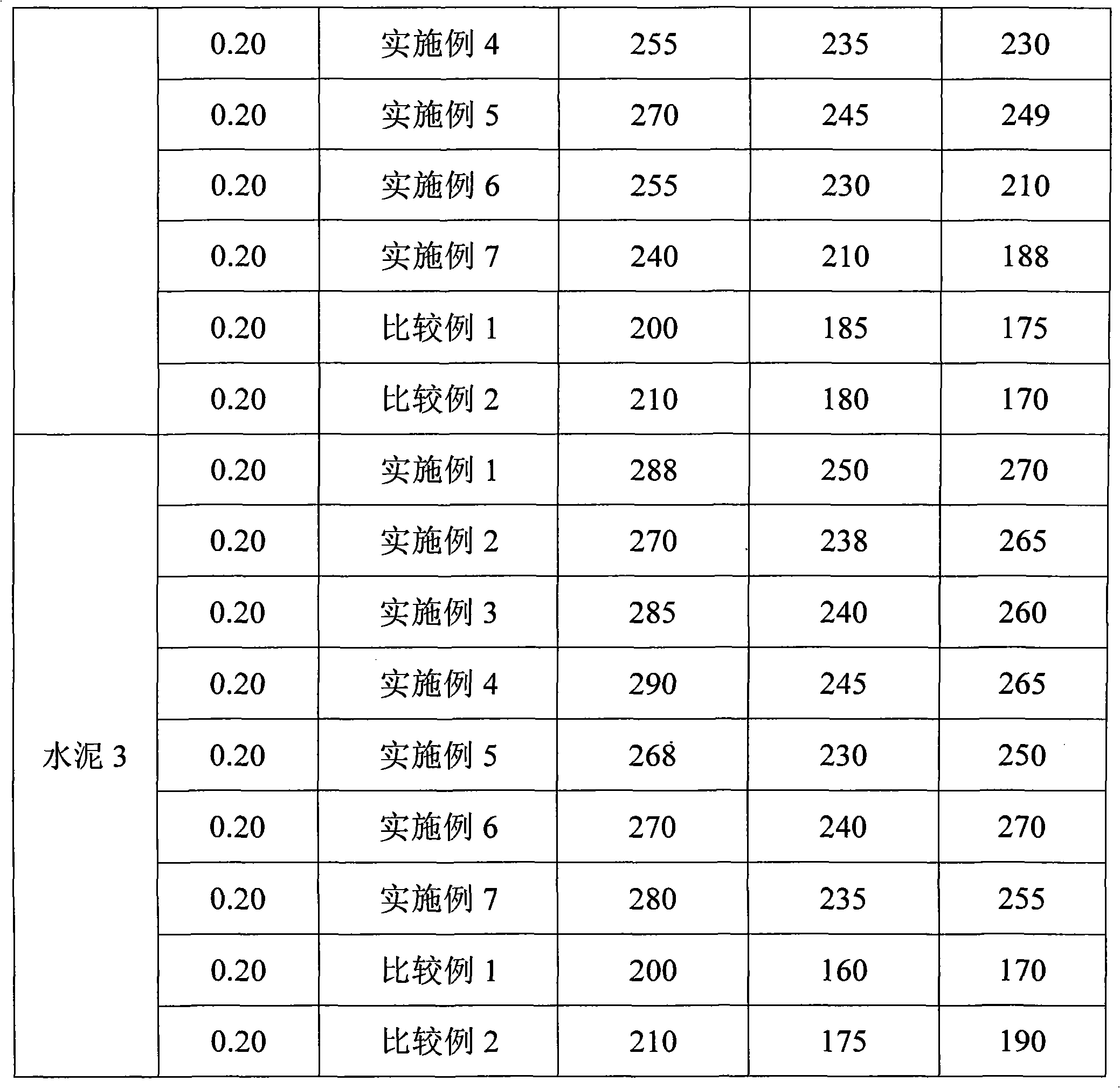

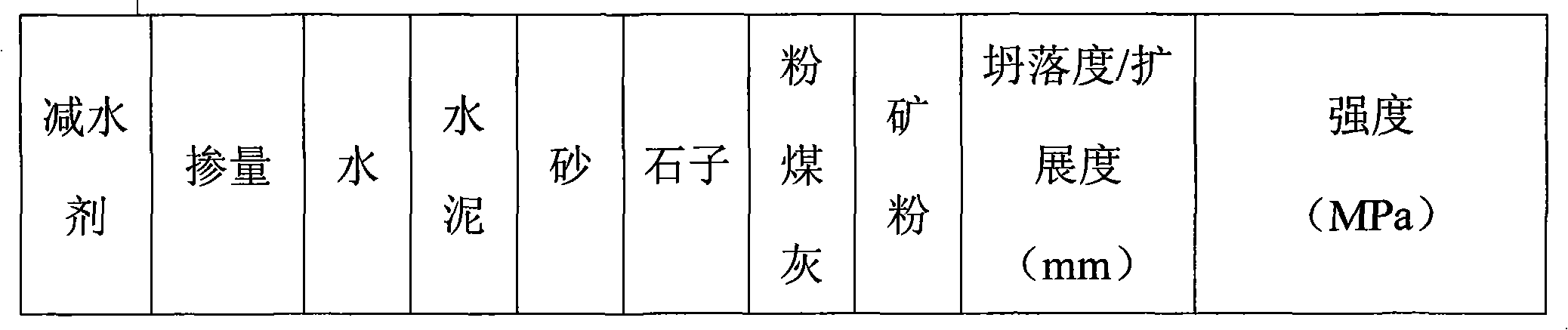

Normal-temperature synthesis method for polycarboxylic acid water-reducing agent

The invention discloses a normal-temperature synthesis method for a polycarboxylic acid water-reducing agent, and belongs to the field of cement concrete water-reducing agents. The water-reducing agent is prepared by the following steps of: copolymerizing polyoxyethylene ether monomer or polyoxyethylene ester monomer a containing unsaturated double bonds, unsaturated monocarboxylic acid and derivative monomer thereof b, unsaturated dicarboxylic acid c and unsaturated sulfonic acid or salt monomer thereof d in aqueous solution under the action of an oxidation reduction initiator, and finally neutralizing the solution by using alkali solution to obtain the water-reducing agent. The reaction can be performed at room temperature by adopting an oxidation reduction initiating system, and the appropriate reaction temperature is between 5 and 30 DEG C; and the synthesis process does not need heating, so energy is saved, and high-temperature side reaction is effectively controlled. The prepared polycarboxylic acid high-performance water-reducing agent has the characteristics of high water-reducing rate and good collapse protecting performance. The water-reducing agent has wide application range, and the method has low production process requirement and is suitable for industrialized large-scale production.

Owner:BEIJING UNIV OF TECH

Freezing beverage containing isomalt oligosaccharide and its preparation method

InactiveCN101057628AImprove gastrointestinal environmentHas a comprehensive nutritional effectFrozen sweetsIsomaltooligosaccharideFlavoring essences

The invention discloses a freeze beverage containing isomaltose hypgather and process for preparation, wherein the raw materials comprise the following constituents (by weight ratio): cow's milk and / or dairy product and / or dairy product analogues 0-90%, isomaltose hypgather 0. 01-10. 0%, sugar 4. 0-16. 0%, stabilizing agent 0. 1-1. 0%, sour flavor agent 0-0. 7%, edible flavoring essence 0. 01-0. 4% and balancing water.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Lithium nickel cobalt manganese positive electrode material and preparation method thereof

InactiveCN103490060AReasonable structureGood ability to withstand high voltageCell electrodesSecondary cellsRare-earth elementLithium

The invention discloses a lithium nickel cobalt manganese positive electrode material. The lithium nickel cobalt manganese positive electrode material comprises a lithium nickel cobalt manganese oxide contained core pure phase layer having a thickness of 5-8mum, a surface coat containing oxides, phosphates or fluorides of coating elements comprising Li, Al, Mg, Ti and Zr and having a thickness of 50-100nm, and a superficial doped transition layer positioned between the core pure phase layer and the surface coat, containing doping elements comprising Al, Mg, Ti and Zr or one of rare earth elements and having a thickness of 1-2mum. The lithium nickel cobalt manganese positive electrode material can inhibit the material dissolving in a cycle process without reducing a specific capacity, and has the characteristics of high capability excellent cycle and rate performances, and excellent thermal stability.

Owner:NINGDE AMPEREX TECH

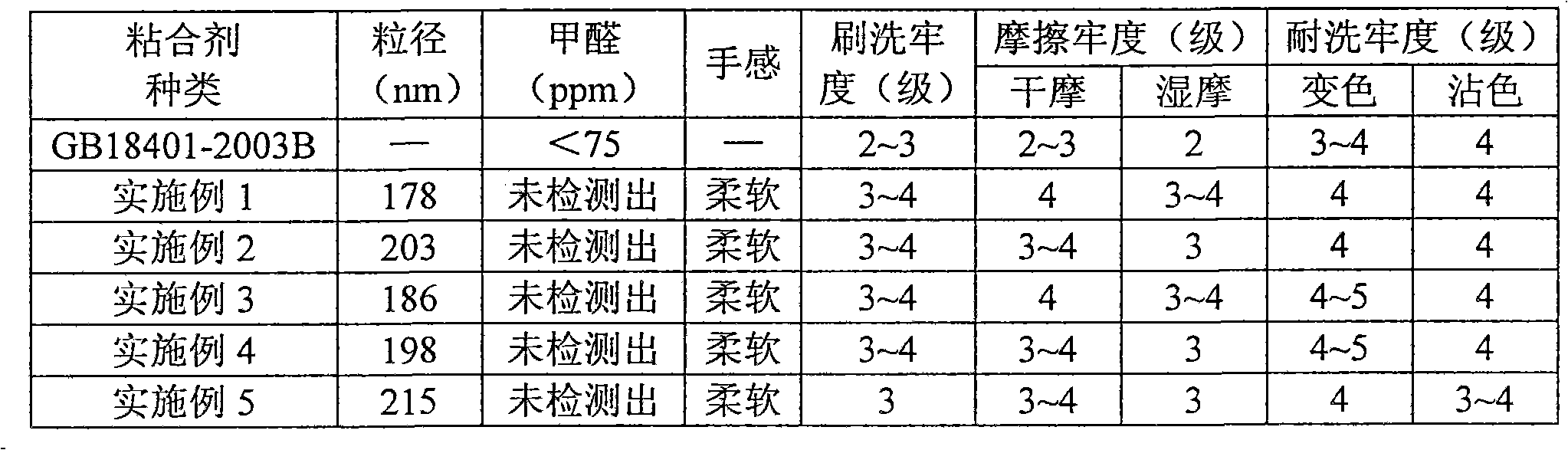

Low-temperature self-crosslinking polyacrylate pigment printing binding agent and preparation method thereof

InactiveCN102391411ALow viscosityIncrease the rate of polymerizationEster polymer adhesivesDyeing processKetoneCarbonyl group

The invention discloses a low-temperature self-crosslinking polyacrylate pigment printing binding agent and a preparation method thereof. The method comprises the following steps of: based on part by mass, preparing pre-emulsion from 70-90 parts of soft monomer, 10-30 parts of hard monomer, 5-10 parts of crosslinking monomer, 2-5 parts of ketone-containing carbonyl monomer, 0.6-3.0 parts of emulsifier and 50-70 parts of de-ionized water; adding 25-33 parts of de-ionized water, 0.2-1.0 part of emulsifier and 0.2-0.6 part of pH buffer; adding 14-16 parts of pre-emulsion and 2-2.5 parts of initiator solution; heating to 78-82 DEG C; dropwise adding remaining pre-emulsion and initiator solution after blue light occurs; heating to 85-90 DEG C and preserving heat for 0.5-1 hour; then cooling to be below 40 DEG C; adjusting pH value to be 6.5-7.0; and finally adding solution formed by dissolving 1-3 parts of hydrazide based monomer in 4-5 parts of de-ionized water. The agent is a formaldehyde-free environmentally-friendly product.

Owner:SOUTH CHINA UNIV OF TECH

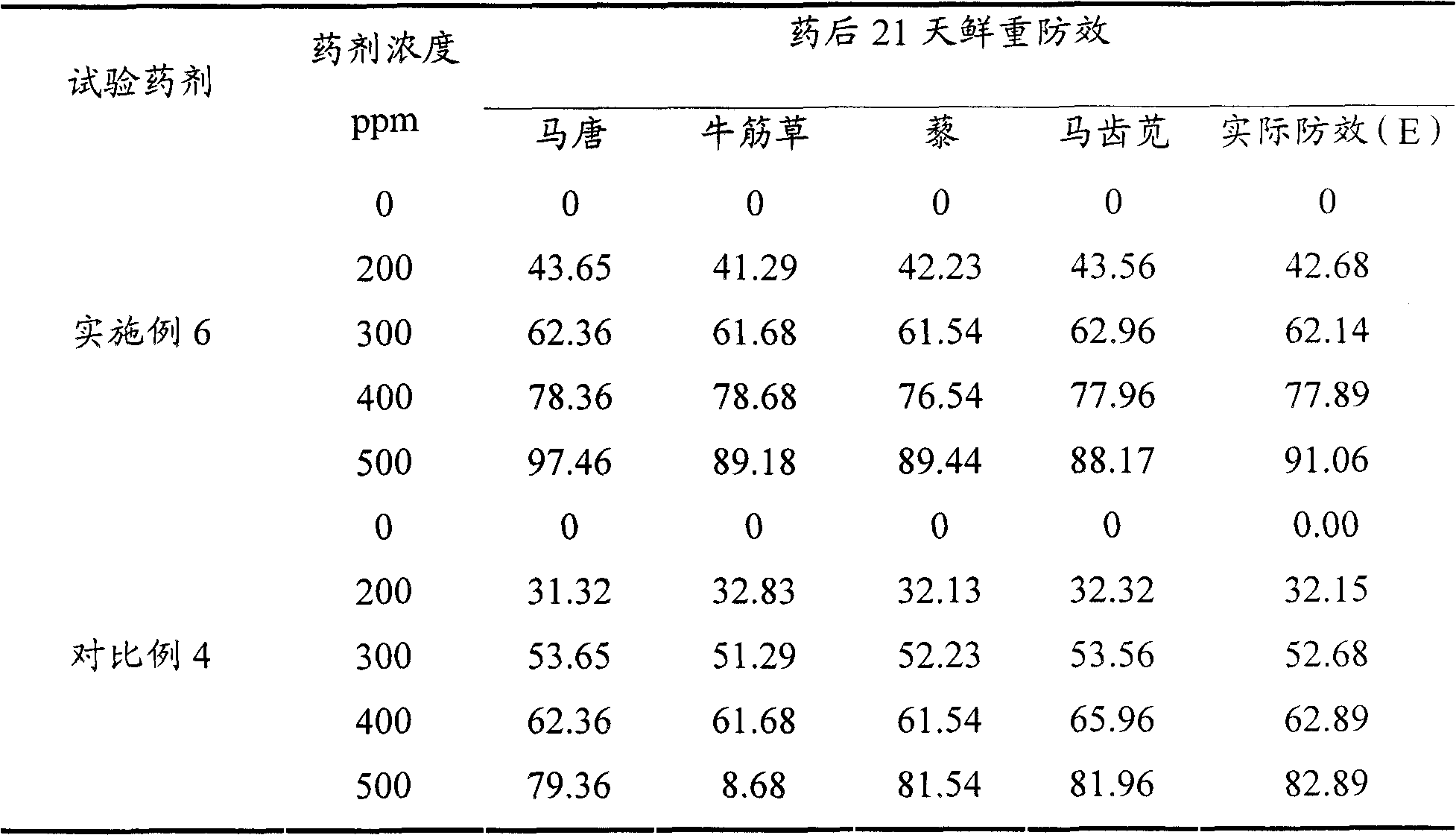

Pesticide oil suspension agent and preparation method thereof

ActiveCN101785455ASmall particle sizeGood spreadabilityBiocideFungicidesDispersion stabilityVegetable oil

The invention provides a pesticide oil suspension agent and a preparation method thereof; the pesticide oil suspension agent contains a pesticide active component, emulsifier, defoamer and a dispersion medium; and the dispersion medium is methyl oleate or the mixture of oil methyl ester and vegetable oil. The method for preparing the pesticide oil suspension agent comprises the following steps that: the dispersion medium and the emulsifier are mixed and emulsified; other components are added in to be mixed into pulp; and the pulp is ground by a grinder to prepare the oil suspension agent. Thepesticide oil suspension agent of the invention has small average grain size and high dispersion stability, has good extendibility and permeability on plant leaves, and improves the medicine effect of the product; and the preparation method of the pesticide oil suspension agent has simple process and low cost, facilitates industrial production, and has wide production application prospect.

Owner:SHENZHEN NOPOSION AGROCHEM

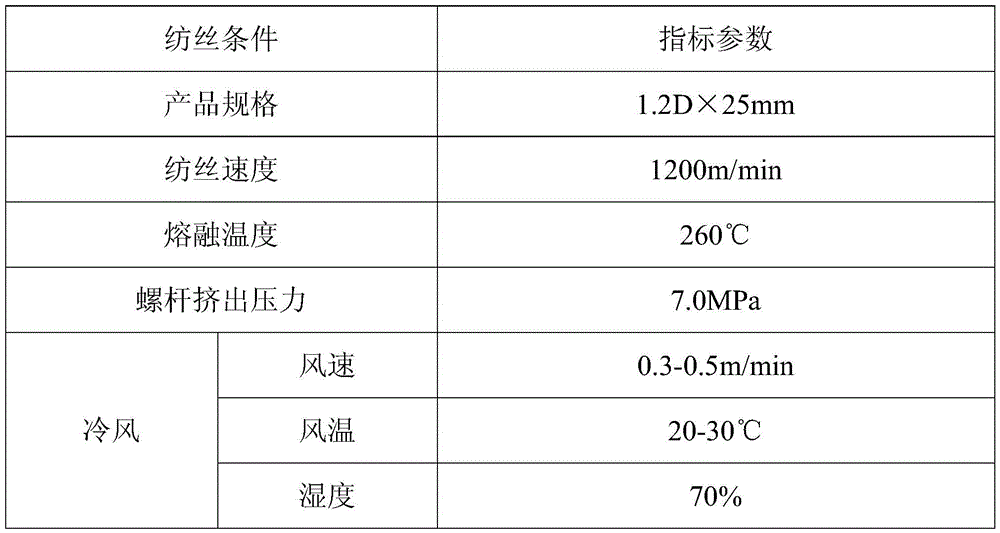

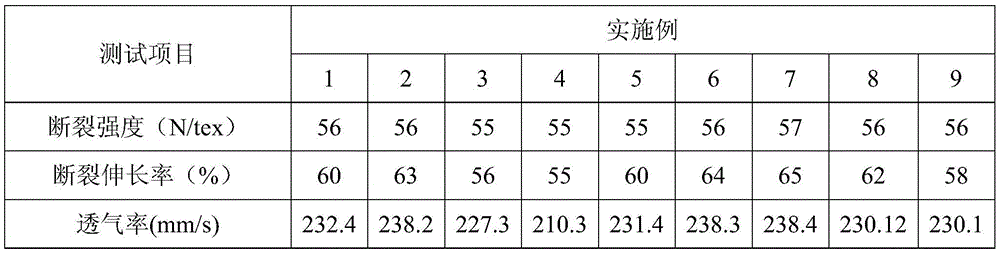

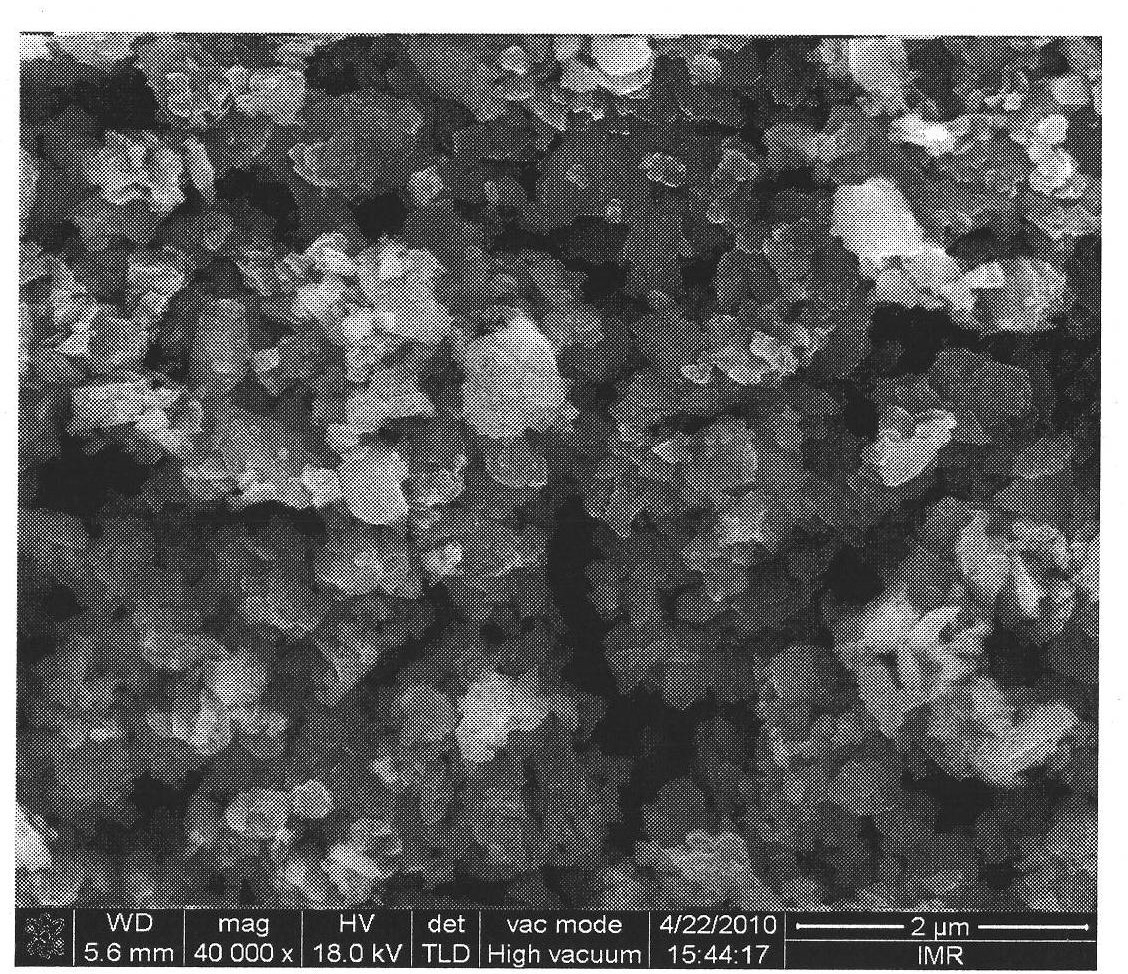

Modified chinlon fiber, preparation method and application

ActiveCN105586658AEvenly dispersedSimple processMelt spinning methodsArtifical filament manufactureFiberEmissivity

The invention relates to a modified chinlon fiber, a preparation method and application. Even dispersion of graphene particles in a chinlon base material is achieved through a physical method, the process is simple, no dispersing agent is needed, and industrial production is easy. Graphene, especially biomass graphene is introduced into chinlon, so that the modified chinlon fiber has a low-temperature far infrared function, and the far infrared normal emissivity of the modified chinlon fiber is 0.85 or above. The antibacterial property of the modified chinlon fiber is 90% or above, and the mechanical strength and breathability are excellent.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

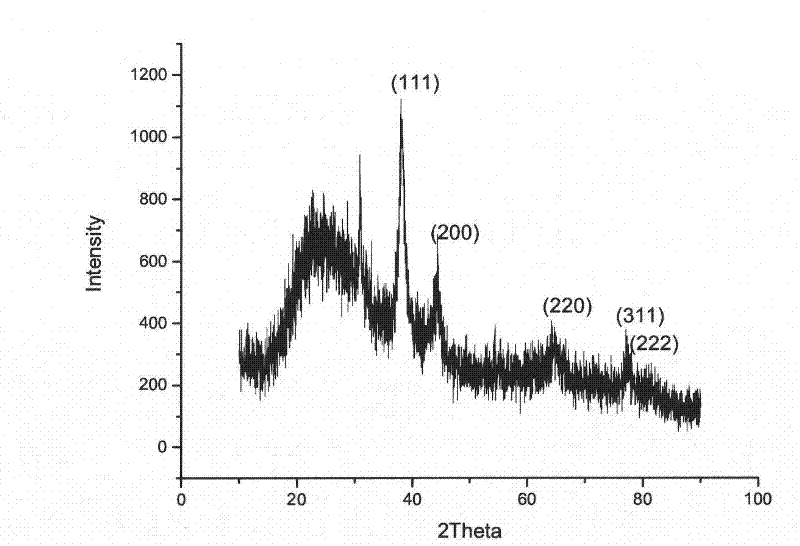

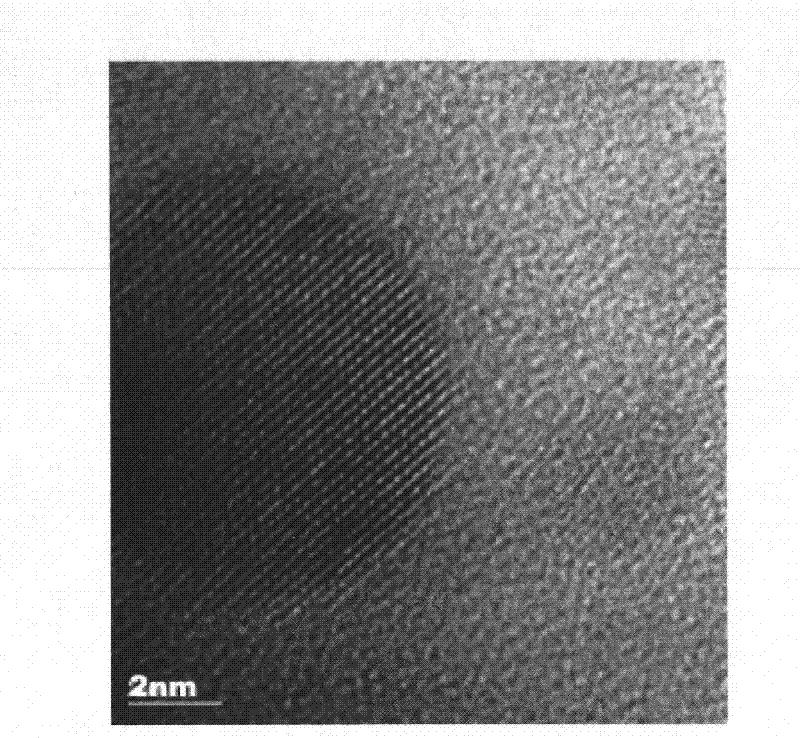

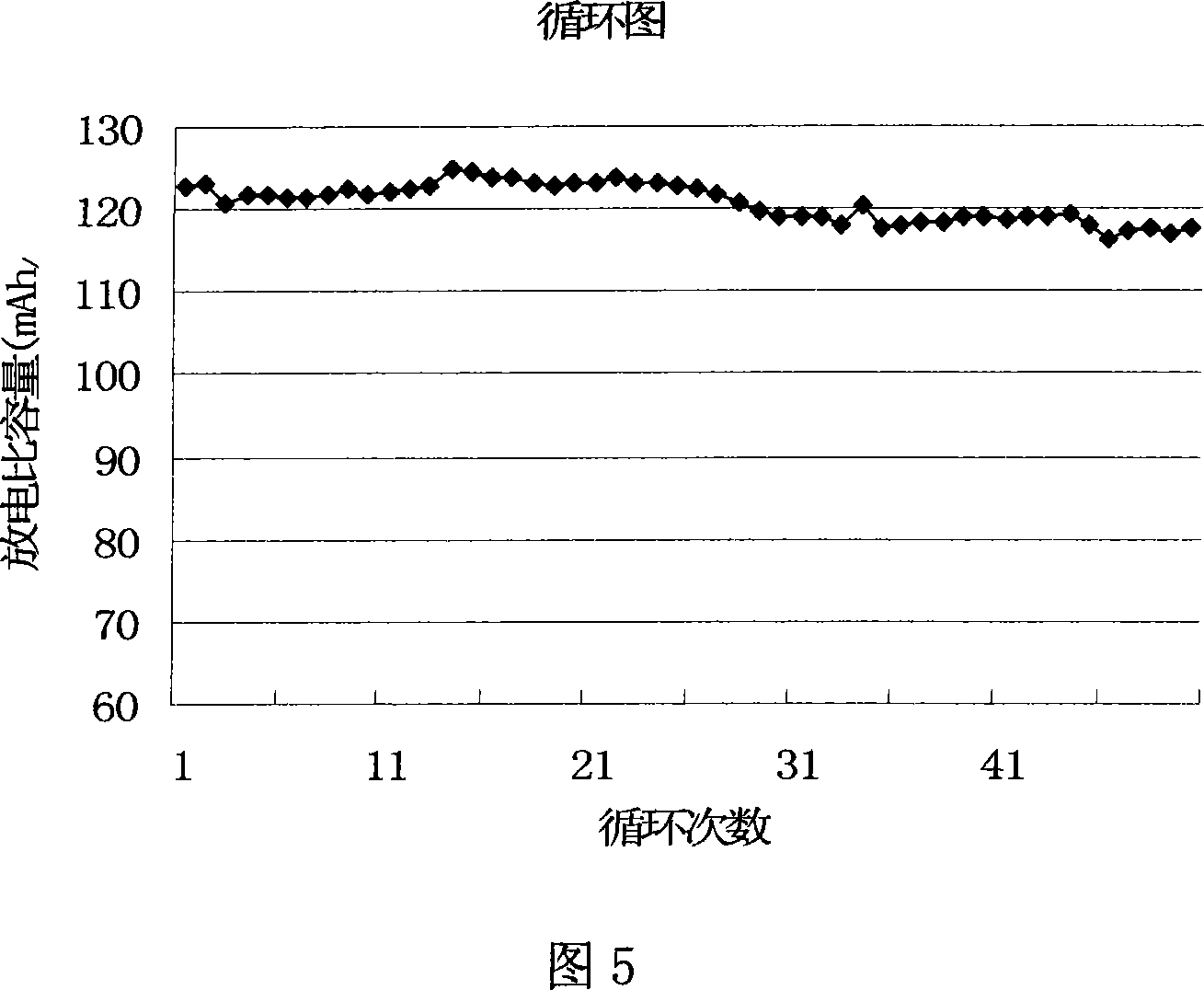

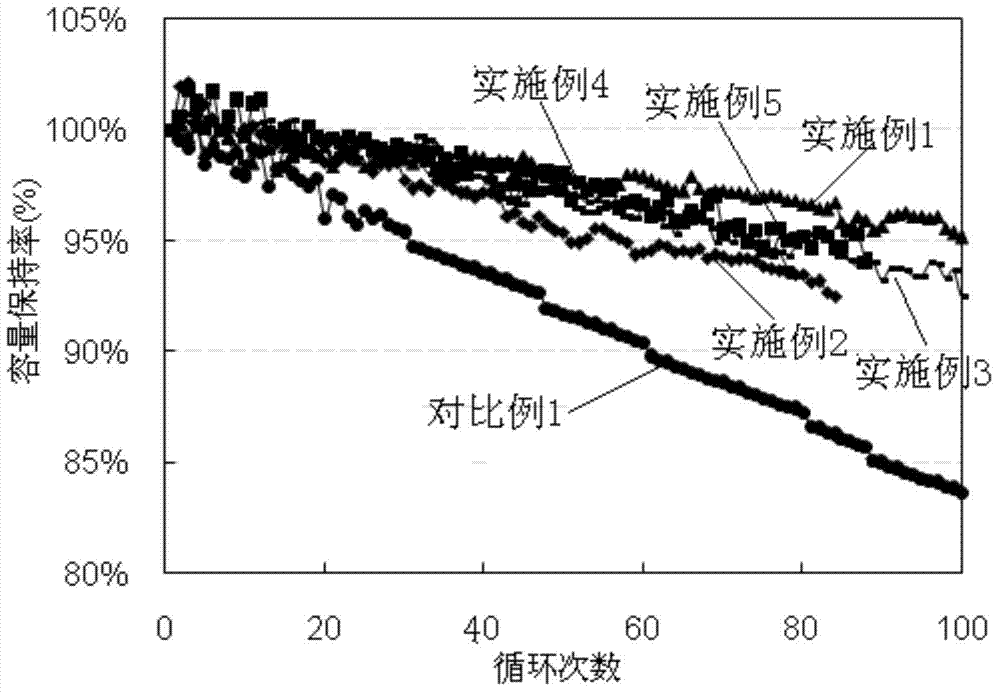

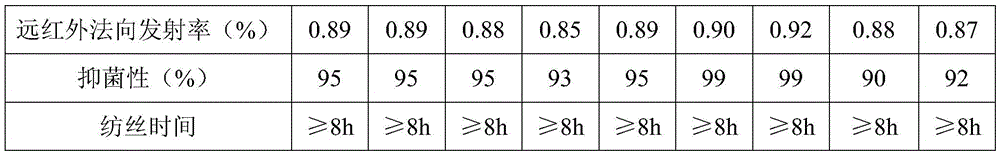

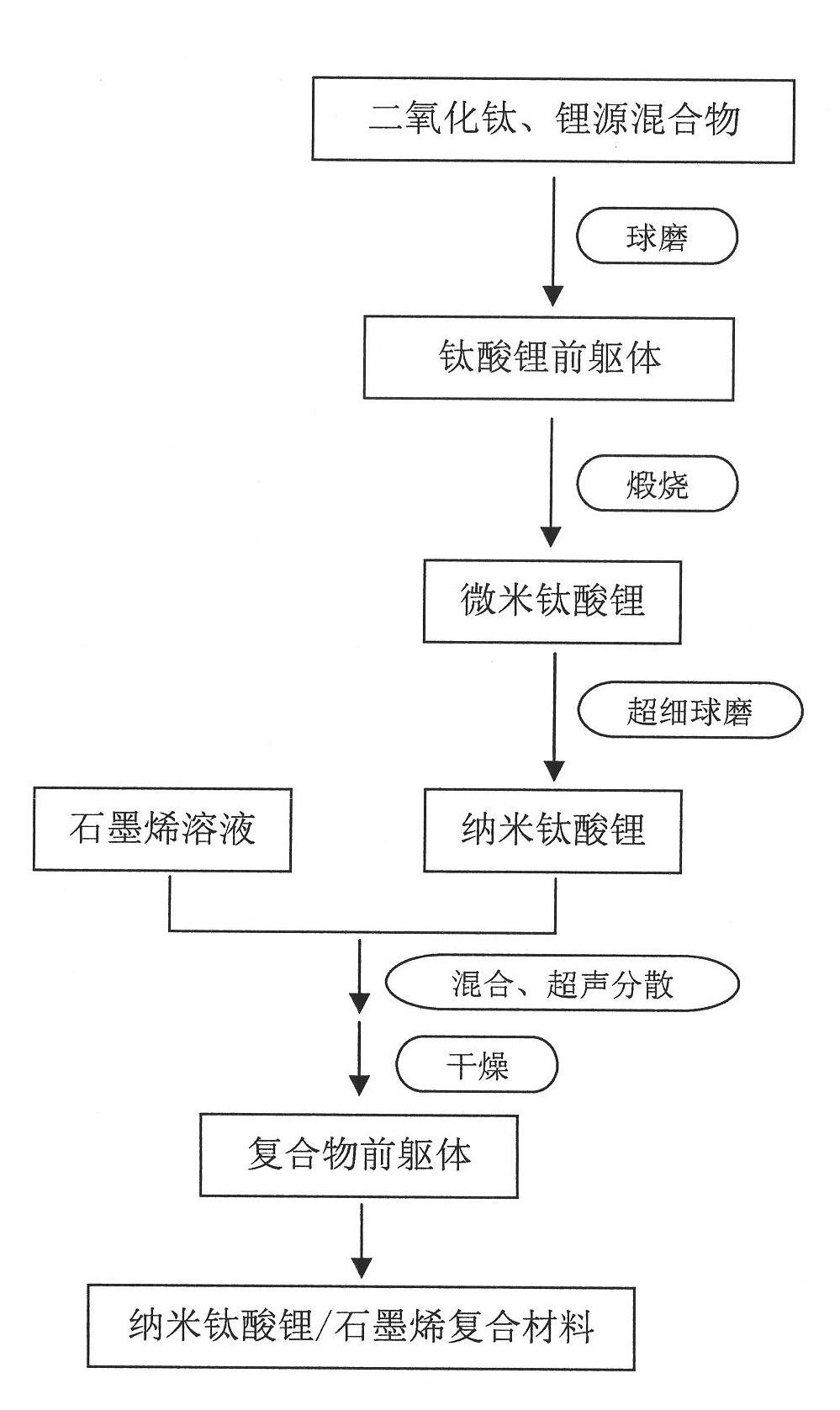

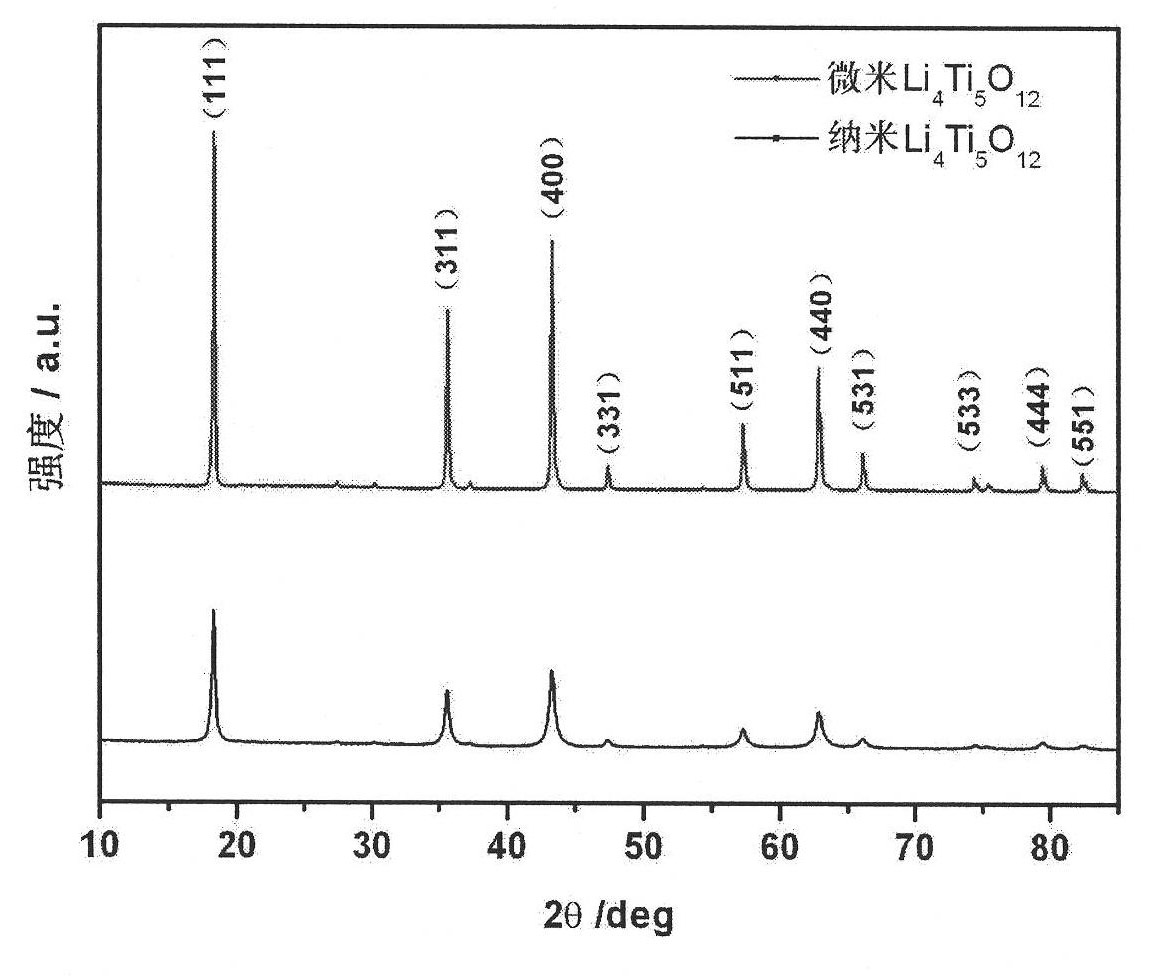

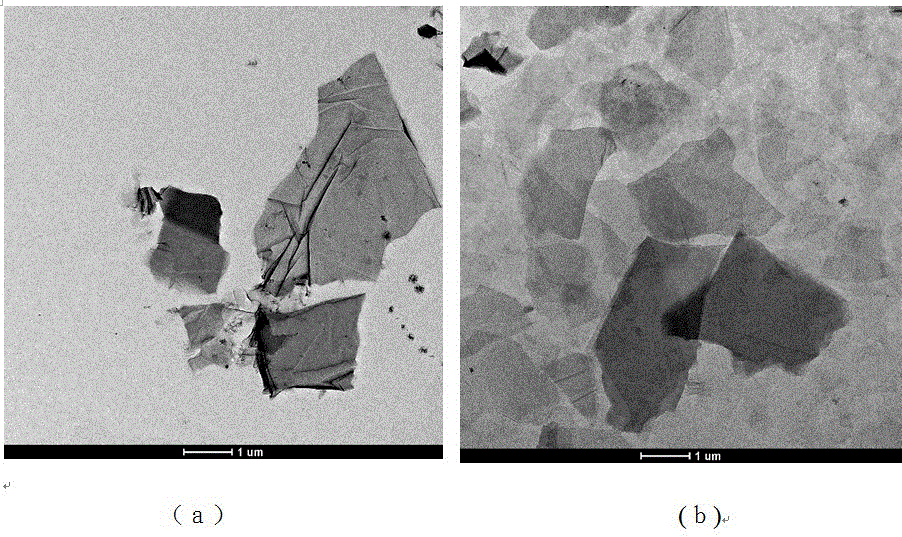

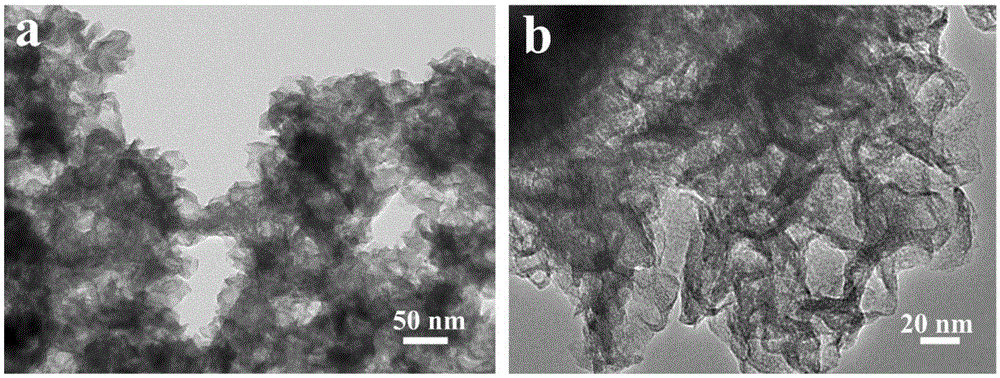

Nanometer lithium titanate/graphene composite negative electrode material and preparation process thereof

InactiveCN102376937AImprove electrochemical performanceAvoid defectsNon-aqueous electrolyte accumulator electrodesGrain treatmentsSodium-ion batteryCvd graphene

The invention relates to the field of negative electrode materials of lithium ion batteries, and specifically to a nanometer lithium titanate / graphene composite negative electrode material and a preparation process thereof. According to the invention, micron-sized lithium titanate prepared by the solid phase method is subjected to ultrafine ball milling to obtain nanometer powder, and the nanometer lithium titanate powder and graphene are uniformly compounded and subjected to heat treatment so as to obtain a high performance lithium ion battery negative electrode material; the invention is characterized in that uniform distribution of graphene in the nanometer lithium titanate powder is realized through in situ compounding; the weight of graphene in the composite negative electrode material accounts for 0.5 to 20%, and the weight of lithium titanate accounts for 80 to 99.5%. The lithium ion battery negative electrode material has good electrochemical performance, 1C capacity greater than 165 mAh / g, 30C capacity greater than 120 mAh / g and 50C capacity greater than 90 mAh / g. Nanometer lithium titanate in the lithium ion battery negative electrode material prepared in the invention has high phase purity; the preparation process of the material is simple and is easy for industrial production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

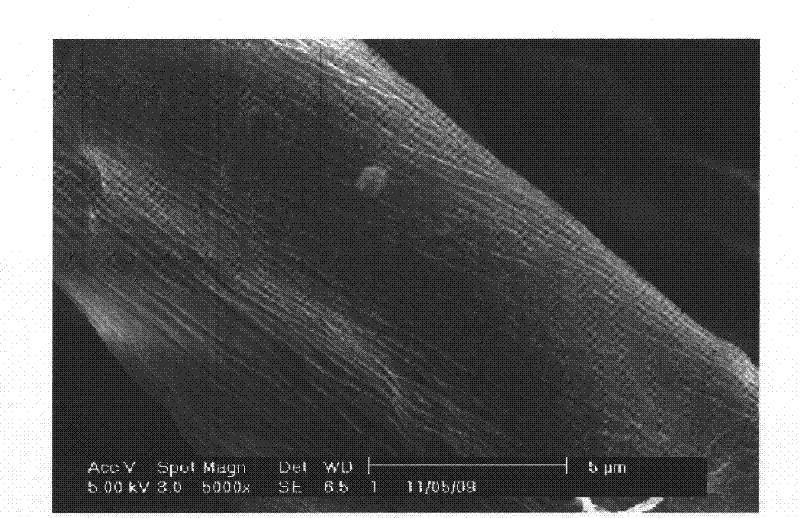

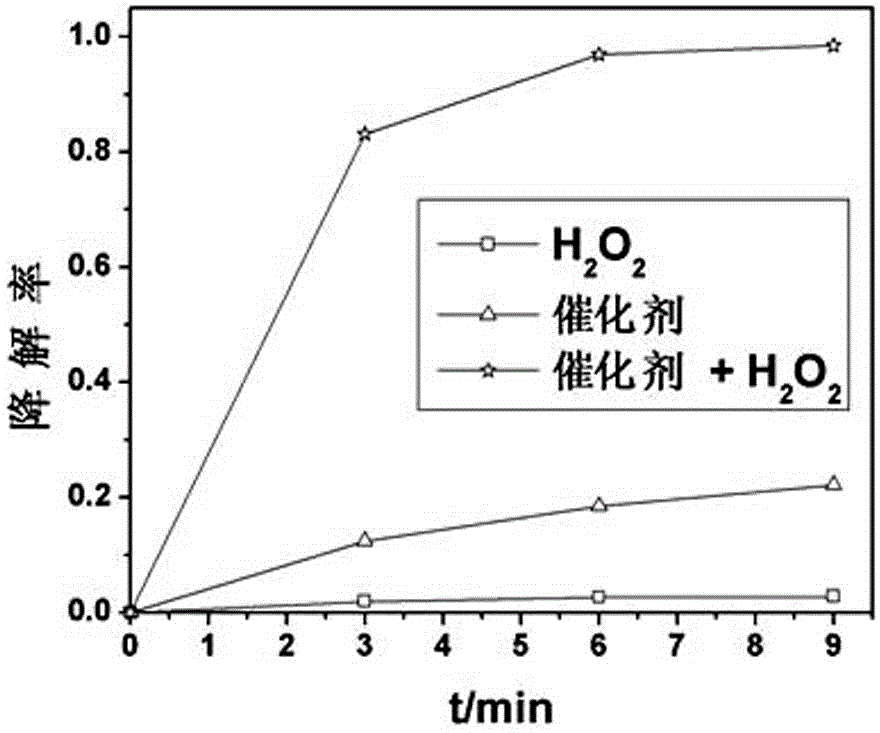

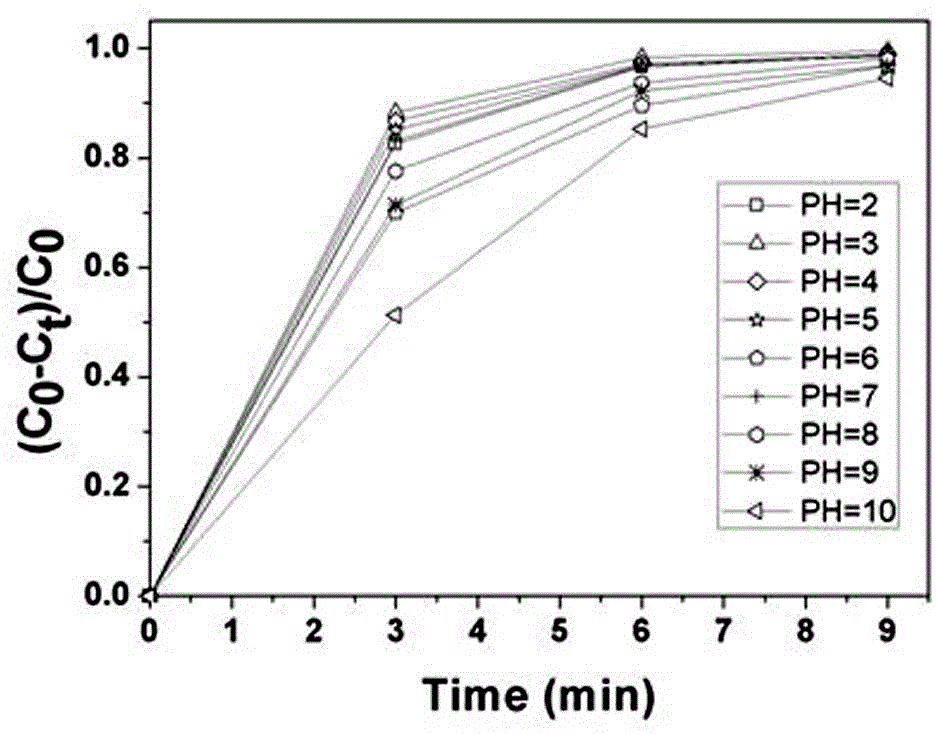

Preparation method and application of heterogeneous Fenton-like catalyst

InactiveCN102909073ALow costEfficient degradationOrganic-compounds/hydrides/coordination-complexes catalystsWaste water treatment from textile industryFiberCarbon fibers

Disclosed are a preparation method and application of heterogeneous Fenton-like catalyst. The preparation method includes the steps of firstly, dissolving complexing agent and metal salt in distilled water to respectively prepare complexing agent and metal salt solutions; secondly dropwise adding the metal salt solution into the complexing agent solution under the action of a magnetic mixer, and mixing for 20-60 after dropwise addition to obtain metal complex solution; and thirdly, impregnating activated carbon fiber in the metal complex solution for 1-24h, and subjecting taken-out activated carbon fiber to distilled water washing and drying to obtain the heterogeneous Fenton-like catalyst. The preparation method is simple, and conditions are mild. Environment-friendly hydrogen peroxide is used as oxidant, no extra ultraviolet light or even visible light is needed, and the heterogeneous Fenton-like catalyst is capable of efficiently degrading organic pollutants such as dye within a wide pH range of 2-10. The heterogeneous Fenton-like catalyst is well repeatable, and secondary pollution of the homogeneous Fenton reagent caused by iron ions is avoided.

Owner:ZHEJIANG SCI-TECH UNIV

Graphene/polysiloxane composite coating material and preparation method thereof

ActiveCN106752926AImprove scratch resistanceImprove wear resistanceFireproof paintsAnti-corrosive paintsEpoxyResin-Based Composite

The invention provides a graphene / polysiloxane composite coating material and a preparation method thereof. The method comprises the following steps: modifying the graphene surface with active groups by a chemical modification technique to obtain modified graphene, mixing the modified graphene with a silane compound, a dispersion medium, a non-essential comonomer and a non-essential accelerator, and carrying out hydrolytic condensation or hydrolytic condensation-free radical polymerization to generate a graphene / polysiloxane composite resin in situ; and mixing the resin with a non-essential blend resin, a non-essential curing agent, a non-essential solvent, a non-essential pigment and filler and a non-essential aid, and carrying out physical blending, amino epoxy addition reaction, Michael addition reaction and the like to form a film, thereby obtaining the graphene / polysiloxane composite coating material. The uniformly dispersed graphene lamellae and polysiloxane have strong interface effects, also have the gas / liquid barrier and heat shielding effects, and endow the coating with excellent corrosion resistance, flame retardancy and the like, thereby greatly enhancing the mechanical properties, corrosion resistance, scratch resistance, wear resistance and the like of the coating.

Owner:FUDAN UNIV

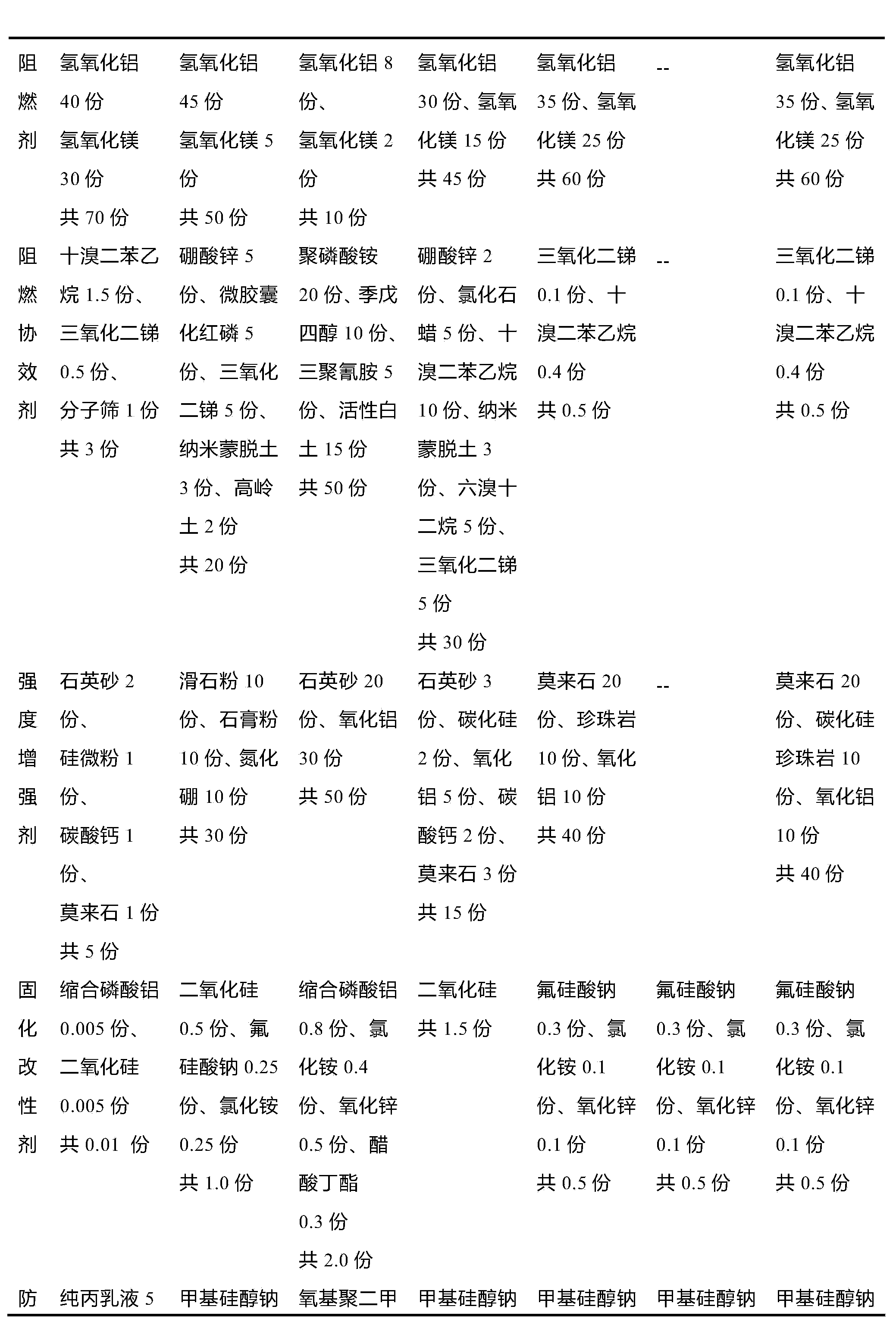

Fire-proof adhesive and application thereof

ActiveCN104099028AReduce total calorific valueImprove thermal conductivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesCombustionAdhesive

The invention discloses a fire-proof adhesive and application thereof. The fire-proof adhesive comprises the following components by parts: 100 parts of high-temperature bonding agent, 10-70 parts of fire retardant, 0.5-50 parts of flame retardant synergist, 5-50 parts of strength enhancer, 0.05-20.0 parts of water-proof modifying agent and 0.01-2.0 parts of curing modifying agent. By adopting the fire-proof adhesive and a preparation method of a fire-retardant EPS (Expandable Polystyrene) foam heat-insulating plate, the combustion performance and physicochemical performance of the fire-retardant EPS foam heat-insulating plate can be improved remarkably. For example, the heat-conducting coefficient can be lowered below 0.055w / m.k, the specific gravity can be lower than 150Kg / M<3>, the compressive strength is higher than 150KPa, and the heat value is less than 3MJ / kg.

Owner:应急管理部四川消防研究所

Method for preparing taurine

The invention relates to a method for preparing taurine, comprising the following steps: epoxy ethane and sodium bisulfite are reacted under 0.05 to 0.1MPa, with pH value of 6.5 to 7.5 and at a temperature between 75 and 85 DEG C to form hydroxyethyl sodium sulfonate; the hydroxyethyl sodium sulfonate and liquid ammonia are subjected to ammonolysis reaction at under 14 to 21MPa and at a temperature between 160 and 280 DEG C to form ammonolysis solution containing sodium taurate; and the ammonolysis solution is evaporated to remove ammonia, neutralized by sulphuric acid, concentrated, crystallized, separated, pre-dried in a boiling drying device or a vibration fluidization drying device, and then added into a microwave drying device to be dried and sterilized to obtain the taurine. The method for synthesizing the taurine has the advantages of short time, high yield and lower cost, and is easy for industrialized production. The water content of a taurine wet product can be reduced to below 0.30 percent through combined application of pre-drying of the boiling drying device or the vibration fluidization drying device and microwave drying, and simultaneously the device has the function of sterilizing.

Owner:王代龙 +1

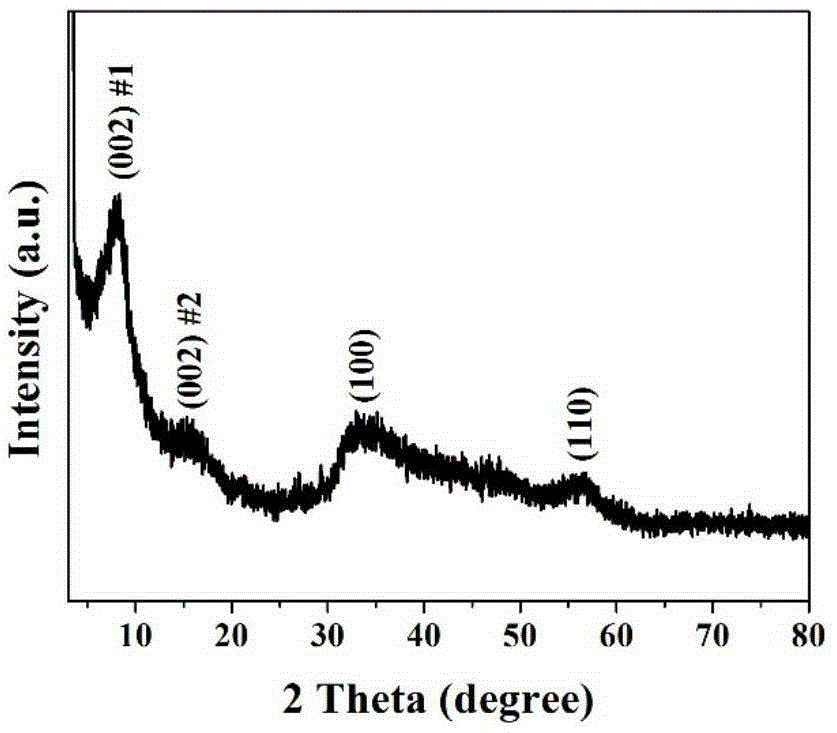

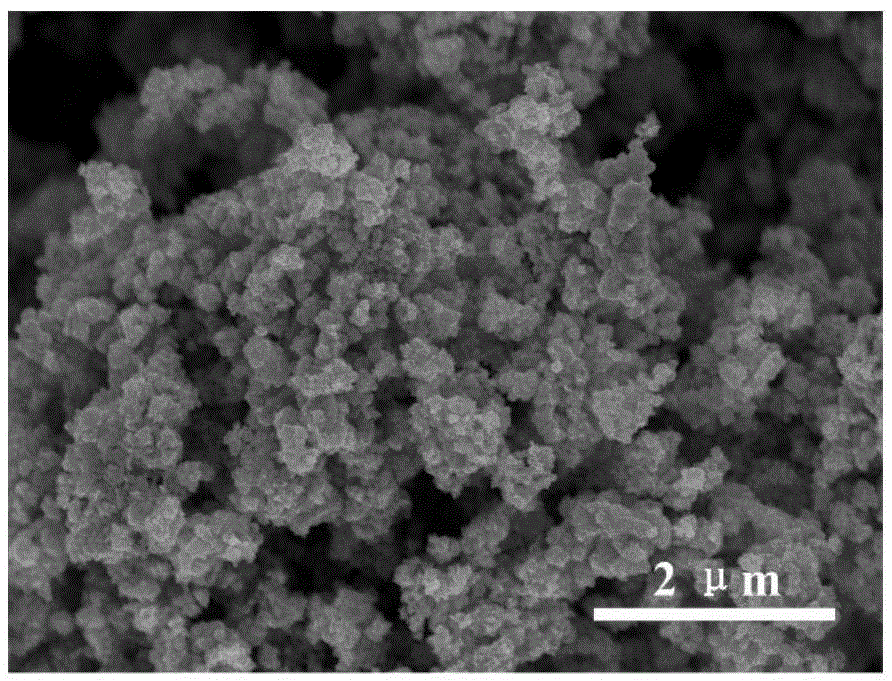

Cobalt-intercalated molybdenum sulfide secondary battery material and preparation method and application thereof

InactiveCN106611837AAvoid reunionAvoid stackingMaterial nanotechnologyHybrid capacitor electrodesLevel structureChemical solution

The invention relates to a cobalt-intercalated molybdenum sulfide secondary battery material and a preparation method and an application thereof. A three-dimensional cobalt-intercalated molybdenum sulfide multi-level structure is prepared by adopting a chemical solution method; firstly, a cobalt salt, a molybdenum salt and a sulfur source are dispersed into a solvent to prepare a reaction liquid; and then the prepared reaction liquid is subjected to solvent thermal treatment to obtain the three-dimensional cobalt-uniformly-intercalated molybdenum sulfide multi-level structure which is self-assembled by graphene-like ultra-thin nanosheets, wherein the size of the multi-level structure is about 100nm. The invention also discloses a preparation method for the multi-level structure. The secondary battery material prepared by the method is stable in nanomaterial performance, and long in cycle life when the secondary battery material is used as a negative electrode material of a lithium ion battery and an electrode material of a supercapacitor.

Owner:SHANGHAI JIAO TONG UNIV

Environmentally-friendly acrylic ester coating printing adhesive emulsion and preparation method

InactiveCN101928367AThe polymerization process is stableEvenly distributedEster polymer adhesivesDyeing processEpoxyFunctional monomer

The invention discloses environmentally-friendly acrylic ester coating printing adhesive emulsion and a preparation method. An emulsion polymerization process is adopted. The emulsion comprises the following raw materials in part by weight: 50 to 90 parts of soft monomer, 10 to 20 parts of hard monomer, 2 to 10 parts of functional monomer, 2 to 5 parts of emulsifying agent, 0.2 to 0.5 part of initiator, 0.2 to 0.5 part of pH buffer, 80 to 120 parts of deionized water and a proper amount of pH adjustor, wherein the total amount of the soft monomer, the hard monomer and the functional monomer is 100 parts by weight. The three monomers are cooperatively used as functional monomers for generating carboxyl crosslinking, hydroxy crosslinking, epoxy crosslinking and the like so that the obtained printing adhesive emulsion has excellent water tolerance and mechanical property. The crosslinking monomers and the emulsifying agent do not contain the components such as N-methylol acrylamide, APEO and the like, so the emulsion does not release formaldehyde during baking and using and is suitable for high-grade environmentally-friendly printing adhesive.

Owner:SOUTH CHINA UNIV OF TECH

Composite fiber as well as preparation method and application thereof

ActiveCN105603718ARetains the property of large specific surface areaAchieve reuseOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsFiberSpecific adsorption

The invention relates to a composite fiber. The composite fiber comprises a fiber carrier, and a graphene aerogel layer covering the outer side of the fiber carrier. According to the composite fiber provided by the invention, the relatively thin graphene aerogel layer covers the surface of the composite fiber, and a self surface shielding effect of existing graphene aerogel is overcome; the adsorption speed and adsorption efficiency of the graphene aerogel of the unit volume are improved; the fiber carrier of the composite fiber provided by the invention provides a bracket for the graphene aerogel and the mechanical strength is enhanced; when the composite fiber is used as an adsorption material, the composite fiber can be in seamless butt joint with an existing cigarette production process directly, and replaces an existing adsorption fiber so that the specific adsorption on benzopyrene polycyclic aromatic hydrocarbon type harmful substances can be realized; and meanwhile, other aromatic substances in smoke are kept so that the flavor and aroma of cigarettes are not influenced.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Mud resisting and slump retaining type polycarboxylic acids water reducer and preparation method thereof

ActiveCN105110687ASimple preparation processNo pollution in the processFunctional monomerCross linker

The invention discloses a mud resisting and slump retaining type polycarboxylic acids water reducer and a preparation method thereof. The mud resisting and slump retaining type polycarboxylic acids water reducer comprises, by weight, unsaturated polyoxyethylene ether 32.5% to 33.6%, unsaturated carboxylic acid 1.7% to 2.5%, functional monomer 3.25% to 3.36%, cross-linking agent 0.08% to 0.13%, oxidizing agent 0.12% to 0.32%, reducing agent 0.09% to 0.17%, chain transferring agent 0.03% to 0.06%, alkalinity modifier 0.86% to 1.22%, and water 60%. The water reducer in the invention has quite strong adaptability for sandstone with high silt content, good effect on mud resisting, large initial dispersibility, low cost and good slump retaining performance. Moreover, the preparation method in the invention reacts at normal temperature; has short reaction time, low energy consumption, low cost, high security coefficient, and no need to control the temperature in the whole production process; and is simple, without pollution, and suitable for commercial production.

Owner:厦门路桥翔通建材科技有限公司

Method of preparing taurine

The invention relates to method for preparing taurine, comprising the following steps: (1) reacting epoxy ethane with sodium sulfite under 0.05 to 0.1MPa, with pH value of 6.5 to 7.5 and at temperature between 75 and 85 DEG C to obtain hydroxyethyl sodium sulfonate; (2) carrying out ammonolysis reaction on the hydroxyethyl sodium sulfonate and liquid ammonia under 14 to 21MPa and at temperature between 160 and 280 DEG C to obtain ammonolysis solution containing sodium taurate; (3) introducing the ammonolysis solution into a single flash evaporator for primary flash evaporating at a temperature between 160 and 200 DEG C and under 1.3 to 2.0MPa; introducing the flash evaporated liquid into a secondary flash evaporating and falling film evaporator, using the primary flash vapor as a heating medium to carry out flash evaporating and falling film evaporating on the primary flash evaporated liquid in the secondary flash evaporating and falling film evaporator at a temperature between 110 and 140 DEG C and at 0.1 to 0.6MPa; evaporating and concentrating the flash evaporated liquid subjected to secondary flash evaporating and falling film evaporating with flash vapor and steam as heating media in a multi-effect flash evaporating and falling film evaporator; and (4) neutralizing the sodium taurate by sulphuric acid to obtain the taurine. The method for preparing the taurine has the advantages of short time, high yield and low cost, and is easy for industrialized production. In addition, by primary flash evaporating and secondary flash evaporating processes, almost all the ammonia and 40% to 60% of water in the flash evaporated liquid can be removed, thus having double effects of removing ammonia and condensing.

Owner:王代龙 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com