Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

279results about How to "Excellent discoloration resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mixtures of phenolic and inorganic materials with antimicrobial activity

InactiveUS6585989B2Excellent discoloration resistanceMaintain physical propertiesBiocideHeavy metal active ingredientsFiberAntibacterial activity

Plastic films, fibers and articles are provided long-term antimicrobial activity with a combination of certain phenolic and inorganic antimicrobial agents. The plastic films, fibers and articles with antimicrobial activity exhibit superior resistance to discoloration, may be processed at high temperature, and maintain physical properties upon weathering, especially upon exposure to ultraviolet radiation.

Owner:BASF SE

A kind of antibacterial composition and its application

InactiveCN102258064AExtended cleaning cycleTo achieve the effect of saving waterBiocideAntifouling/underwater paintsSodium PyrithioneNonwoven fabric

The invention relates to an antibacterial composition, comprising an organic antibacterial component containing at least one pyrithione salt, a pyrithione complex or an adduct thereof, an aqueous solution containing one or more metal ions or its The inorganic antibacterial component of the complex aqueous solution or its nanometer metal hydrosol or its nanometer metal oxide hydrosol and its composition, and the mass ratio of the organic antibacterial component to the inorganic antibacterial component is 1:100-50:1, It also includes other auxiliary agents, and its mass percentage in the antibacterial composition described in the patent is 0.001-20%. The antibacterial composition of the present invention can form a nanoparticle film on the surface of base materials such as natural fabrics, non-woven fabrics, clothing, bedding, toiletries, household items, medical care supplies, and filter screens, and realize its antibacterial properties through the nanoparticle film. Antibacterial, anti-mite, deodorizing and self-cleaning functions. The antibacterial composition of the invention is safe to use and can be used in medical treatment and life to protect people's health.

Owner:赵正坤

Mixtures of phenolic and inorganic materials with antimicrobial activity

InactiveUS20020106413A1Good additionExcellent discoloration resistanceHeavy metal active ingredientsBiocideFiberUltraviolet radiation

Plastic films, fibers and articles are provided long-term antimicrobial activity with a combination of certain phenolic and inorganic antimicrobial agents. The plastic films, fibers and articles with antimicrobial activity exhibit superior resistance to discoloration, may be processed at high temperature, and maintain physical properties upon weathering, especially upon exposure to ultraviolet radiation.

Owner:BASF AG

Inorganic antiseptic of RE activated silver carrying matter and its prepn

ActiveCN1739356AImprove antibacterial propertiesExcellent discoloration resistanceBiocideAnimal repellantsRare-earth elementInorganic Chemical

The present invention is inorganic antiseptic of RE activated silver carrying matter and its preparation, and belongs to the field of inorganic antiseptic purifying material technology. The present invention adopts compound phosphate as the porous carrier for inorganic silver antiseptic to carry several kinds of antiseptic ions, such as Ag, Zn and Cu ions simultaneously, and RE element, such as La, Y, etc. with activating characteristic to improve antiseptic performance and color change resistance. The antiseptic has powerful antiseptic performance, good ultraviolet ray radiation resistance, and less color change and blackening. It may be added into various kinds of plastic, paint, building ceramic material to produce antiseptic products for furniture and household decoration.

Owner:SHANGHAI UNIV

Anti-yellowing flame-retardant weather-resistant polypropylene composition and preparation method thereof

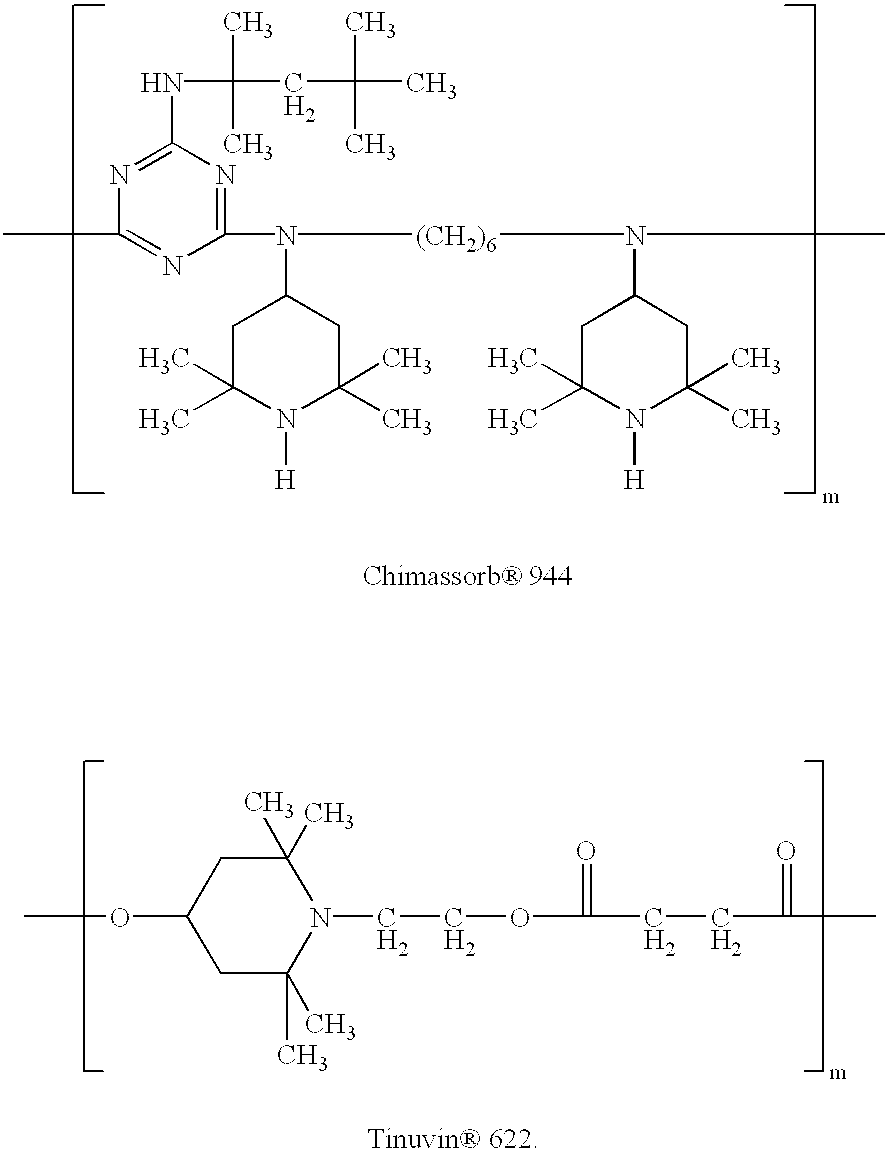

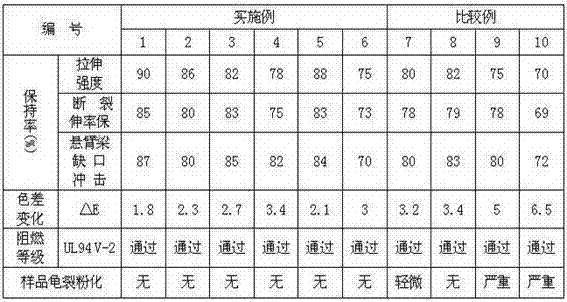

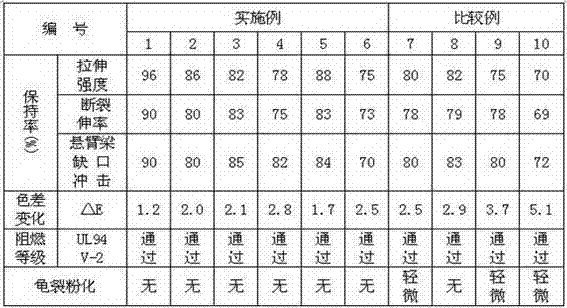

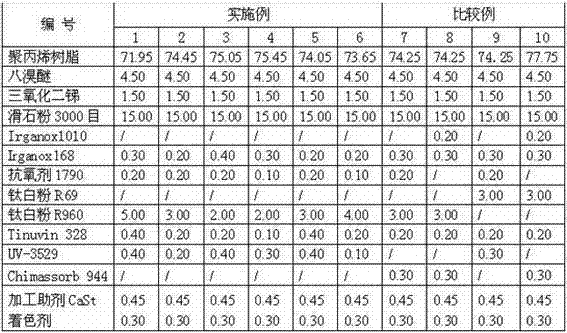

The invention discloses an anti-yellowing flame-retardant weather-resistant polypropylene composition and a preparation method thereof. The anti-yellowing flame-retardant weather-resistant polypropylene composition consists of the following components in percentage by weight: 58.5-82.7 percent of polypropylene, 3-8 percent of halogen-series flame retardant, 1.5-4 percent of flame-retardant synergist, 10-20 percent of mineral intensifier, 2-5 percent of light screener, 0.1-1 percent of light absorbing agent, 0.1-1 percent of hindered anime light stabilizer, 0.1-0.5 percent of main antioxidant, 0.1-0.5 percent of auxiliary antioxidant, 0.3-1 percent of processing aid and 0.1-0.5 percent of coloring agent. The flame retardant rating of the polypropylene composition provided by the invention is up to UL94V-2, high mechanical performance can be kept under long-term outdoor or ultraviolet ray irradiation, the yellowing degree is low, and the weather resistance of the material is greatly improved. The anti-yellowing flame-retardant weather-resistant polypropylene composition is mainly applied to home appliance components, large-sized outdoor stadium plastic seats, automobile parts and the like which are influenced by ultraviolet rays.

Owner:KINGFA SCI & TECH CO LTD +2

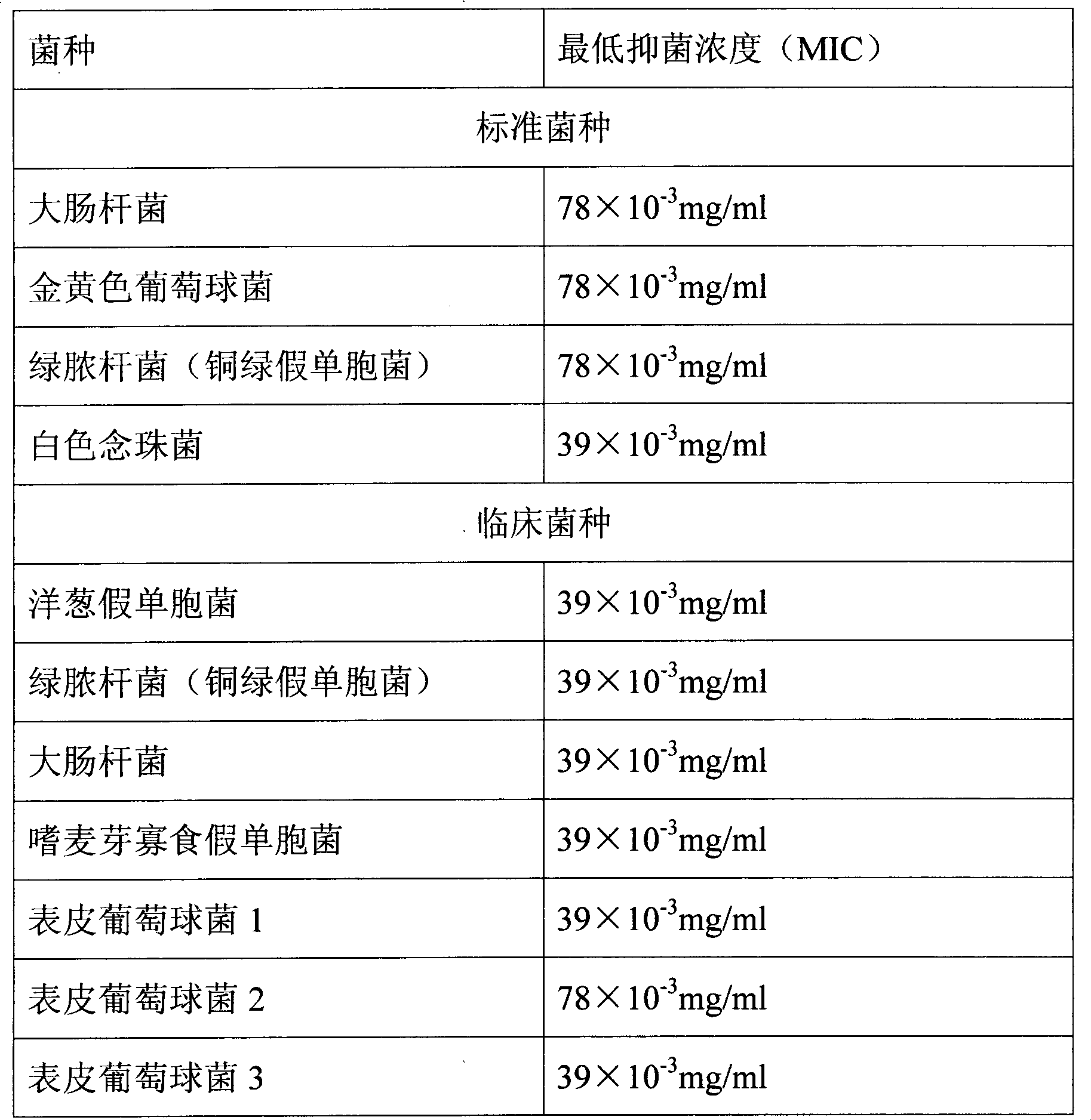

Slowly released type antibiotic medical catheter and preparation method thereof

The invention relates to the technical field of medical apparatus and instruments, which discloses a sustained release type antibacterial medical catheter and a preparation method thereof. A silver inorganic antimicrobial is characterized by high content of silver, safety and the like, and the silver inorganic antimicrobial which adopts zirconium phosphate as a carrier is selected and mixed into catheter material to prepare the sustained release type antibacterial medical catheter that is most widely applied to clinic, such as an antibacterial catheter, an antibacterial central venous catheter, an antibacterial trachea cannula and the like. The catheter has high use safety, wide antibacterial spectrum, good antibacterial effects, antimicrobial constituent sustained release and long duration of antibacterial effects, and can reduce the frequency of replacing medical catheters so as to have safe and convenient clinical use, effectively reduce nosocomial infections related to catheters due to the use of the medical catheters, greatly reduce medical expenses related to anti-infection, and the like, and save medical resources.

Owner:HUADONG HOSPITAL +1

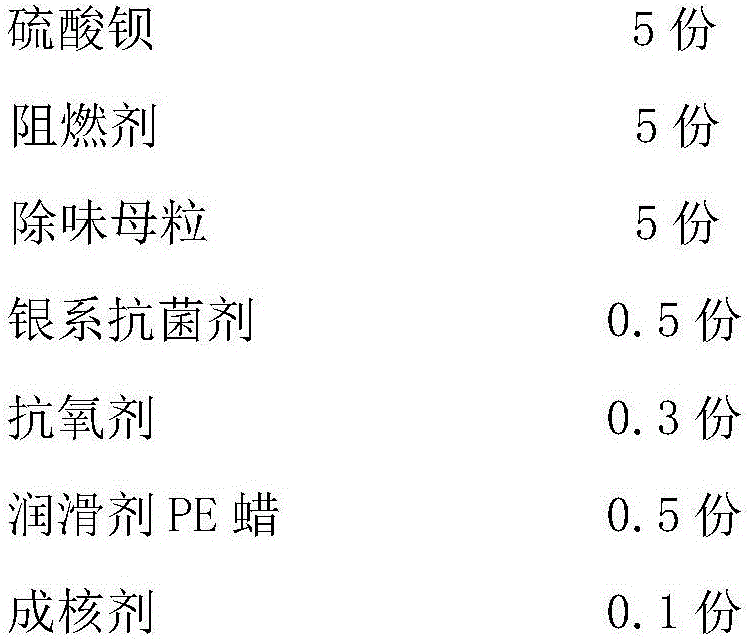

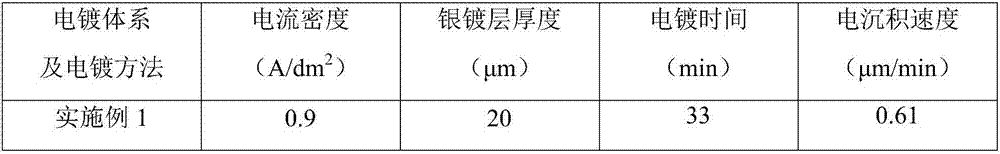

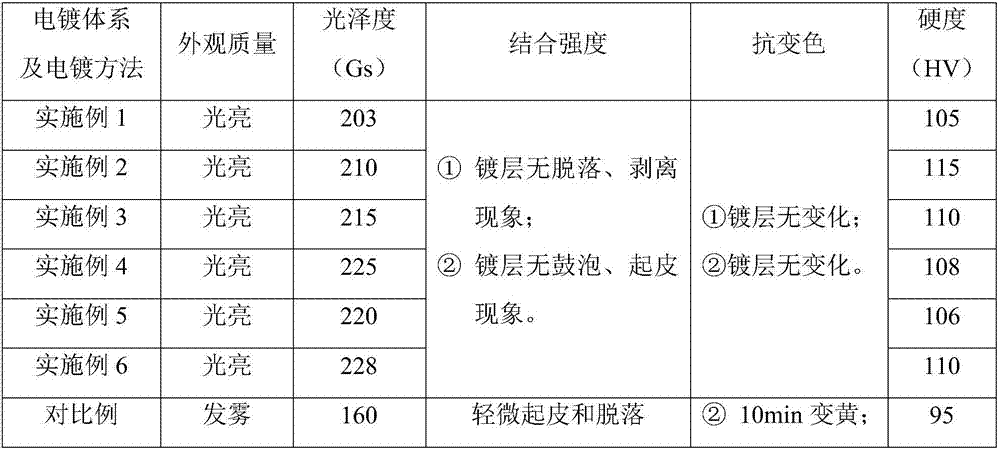

Cyanide-free silver plating electroplating solution and preparation method and electroplating method thereof

The invention discloses a cyanide-free silver plating electroplating solution and a preparation method and an electroplating method thereof, belonging to the field of electrosilvering. The invention aims at solving the technical problems of poor stability and narrow current density scope of an electroplating solution in the traditional cyanide-free silver plating system. The cyanide-free silver plating electroplating solution is prepared from glycolyurea derivatives, pyridine substances, silver nitrate, potassium carbonate, potassium hydroxide and deionized water. The cyanide-free silver plating electroplating solution is prepared by adopting a mixing method. Silver plating is performed according to the electroplating method. The electroplating solution of the invention has the dispersibility ranging from 65% to 75% and good stability so that the newly-prepared electroplating solution and the electroplating solution subsequent to electroplating are free from deposition, color change and other situations after being placed for 2 months and can still be continuously used to acquire an excellent plating layer. A copper replacement experiment finds that the cyanide-free silver plating electroplating solution in the embodiment can withstand the replacement time up to more than 5 minutes. The acquired plating layer is bright and consistent in appearance, compact and flat, small in crystalline grains and strong in color change resistance. Electroplating can be performed when the current density is 0.8 to 2.0A / dm<2>.

Owner:HARBIN INST OF TECH

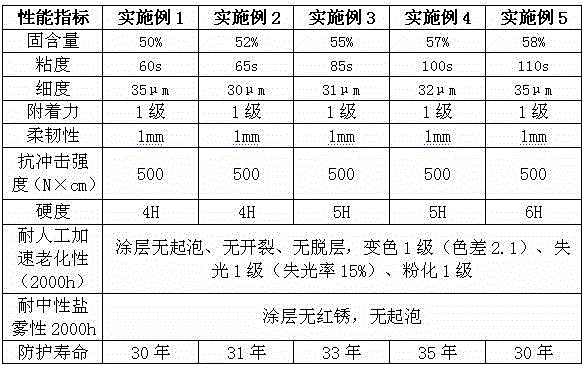

Acrylic polyurethane silicofluoride coating as well as preparation method and application method thereof

ActiveCN104017480AImprove adhesionGood flexibilityAntifouling/underwater paintsPretreated surfacesPolymer scienceAcrylic resin

Owner:湖南惠电科技有限公司

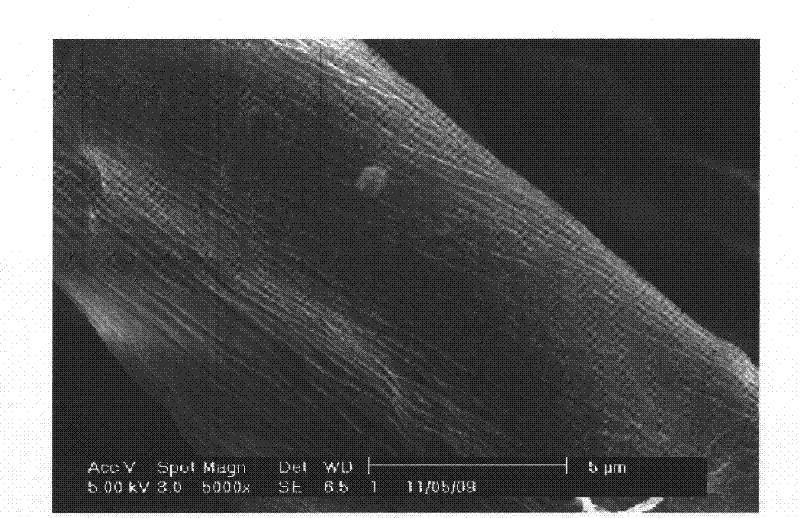

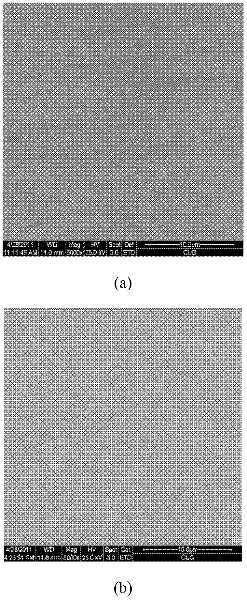

Method for double-pulse electrodeposition of nanocrystalline nickel-cobalt alloy

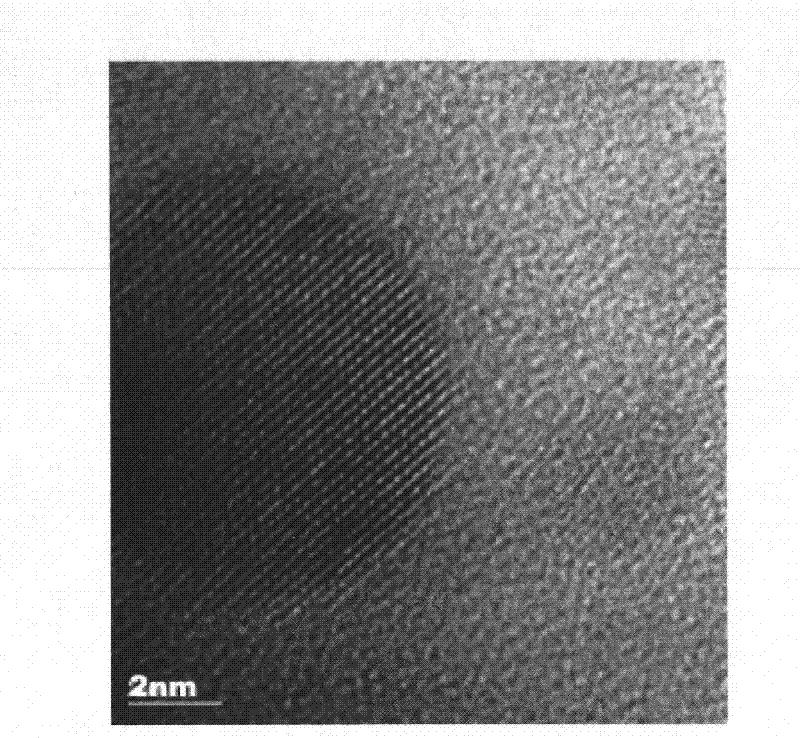

InactiveCN102260891AUniform crystallizationCrystal fineMaterial nanotechnologyPhotography auxillary processesElectroplatingNickel ions

The invention relates to a method for electrodepositing a nanocrystalline nickel-cobalt alloy by double-pulse. The method for electrodepositing the nanocrystalline nickel-cobalt alloy by double-pulse is characterized by comprising the following processing steps: in a plating solution with a pH value of 5-6, a nickel ion concentration of 0.68-0.95 mol / L and a cobalt ion concentration of 1.9*10<-2>to 3.8*10<-2> mol / L, taking a soluble nickel plate after the soluble nickel plate is subjected to surface treating as a anode, taking an iron sheet after the iron sheet is subjected to surface treating as a cathode and electroplating a nanocrystalline nickel-cobalt alloy layer by using double-pulse electrodepositing technology, wherein the time for electrodepositing is 15-20 min, the positive-going pulse current density is 1.0-2.0 A / dm<2>, the positive-going duty ratio is 60-80%, the working time of the positive-going pulse is 50-100 ms and the positive-going cycle is 40-60 ms; and the negative-going pulse current density is 0.1-0.2 A / dm<2>, the negative-going duty ratio is 60-80%, the working time of the negative-going pulse is 10-20 ms, the negative-going cycle is 1-2 ms and the workingtime of the positive-going pulse is 5-10 times of that of the negative-going pulse. The nickel-cobalt alloy coating prepared by the method has the advantages of smooth surface, compact structure, fine and even crystal, good smoothness, no crack and excellent corrosion resistance.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

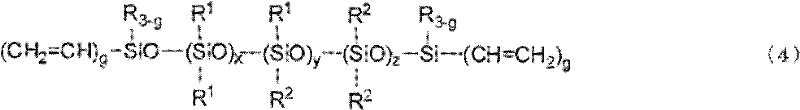

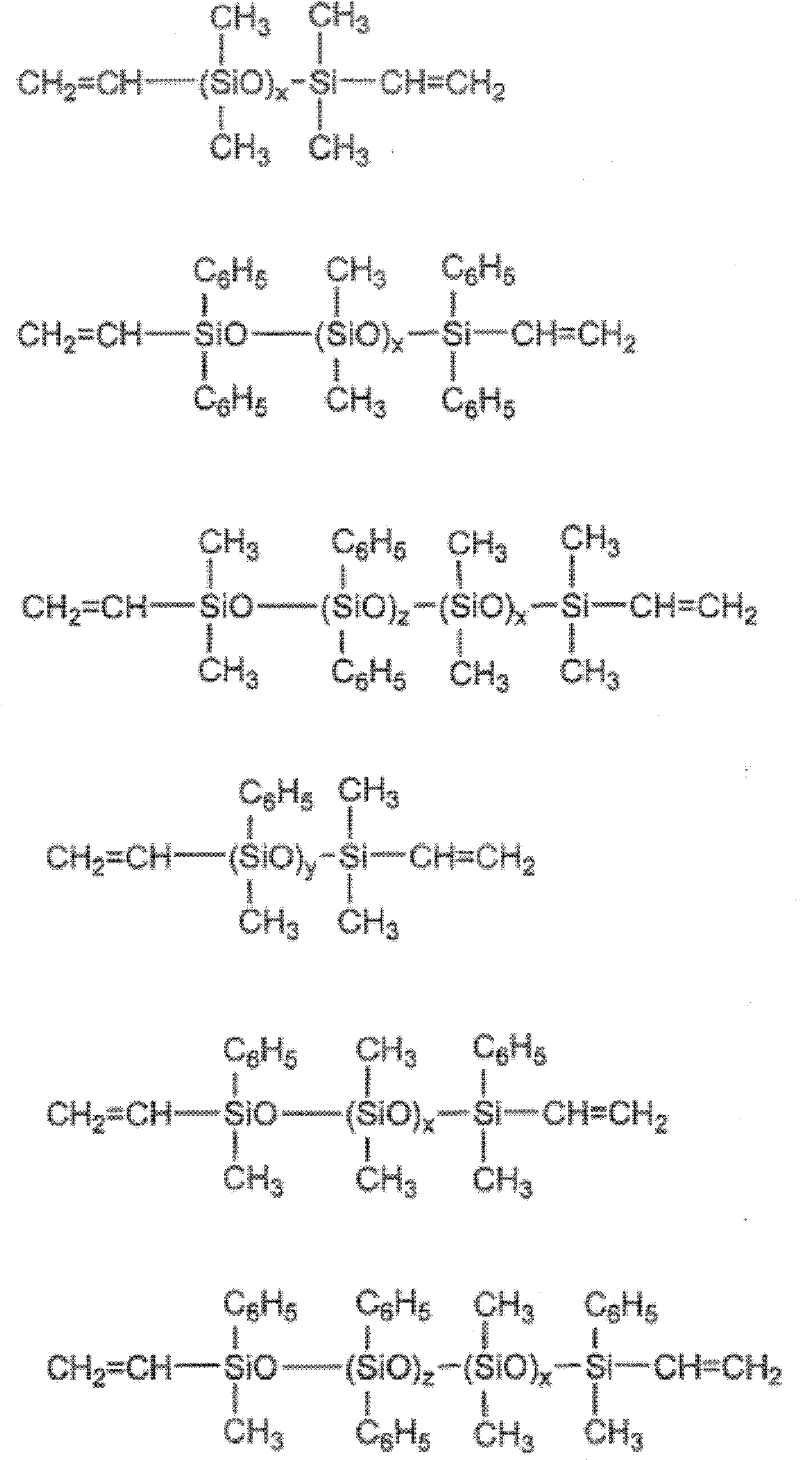

High adhesiveness silicone resin composition and an optical semiconductor device provided with a cured product thereof

The object of the present invention is to provide a silicone resin composition for encapsulating an optical semiconductor element which has strong adhesiveness to a substrate and provide an optical semiconductor element which has high reliability. The present invention provides a silicone resin composition comprising an organopolysiloxane (A) having at least two alkenyl groups per molecule, a liner organohydrogenpolysiloxane (B-1) which has hydrogen atoms each bonded to a silicon atom at the both terminals and a liner organohydrogenpolysiloxane (B-2) which has a hydrogen atom bonded to a silicon atom at one terminal and a hydroxyl or alkoxy group bonded to a silicon atom at the other terminal, a branched organohydrogenpolysiloxane (C) having at least three hydrosilyl groups per molecule, a catalytic (D), and a condensation catalyst (E).

Owner:SHIN ETSU CHEM IND CO LTD

Antibacterial shading medical polyvinyl chloride plastic and preparation method thereof

The invention discloses antibacterial shading medical polyvinyl chloride plastic and a preparation method thereof. The antibacterial shading medical polyvinyl chloride plastic comprises, by weight, 100 parts of polyvinyl chloride, 5-90 parts of a plasticizer, 5-15 parts of an auxiliary plasticizer, 1-6 parts of a heat stabilizer, 0.1-3 parts of a ultraviolet light absorbent, 1-20 parts of a migration inhibitor, 0.1-10 parts of toner, 0.1-10 parts of titanium dioxide, 0.1-5 parts of an antibacterial material and 0.1-1 part of a lubricant. The migration inhibitor is beta-cyclodextrin. The antibacterial shading medical polyvinyl chloride plastic can effectively inhibit migration or decoloring of micromolecule substances such as a plasticizer and toner, can improve transfusion apparatus safety after disinfection, can guarantee patient usage safety, can thoroughly prevent light-avoiding agent migration and illumination-caused influence on a medical agent, does not influence drug use efficiency, has excellent dyeing resistance and anti-tarnishing performances in processing or use and does not influence PVC material transparency.

Owner:上海新上化高分子材料有限公司

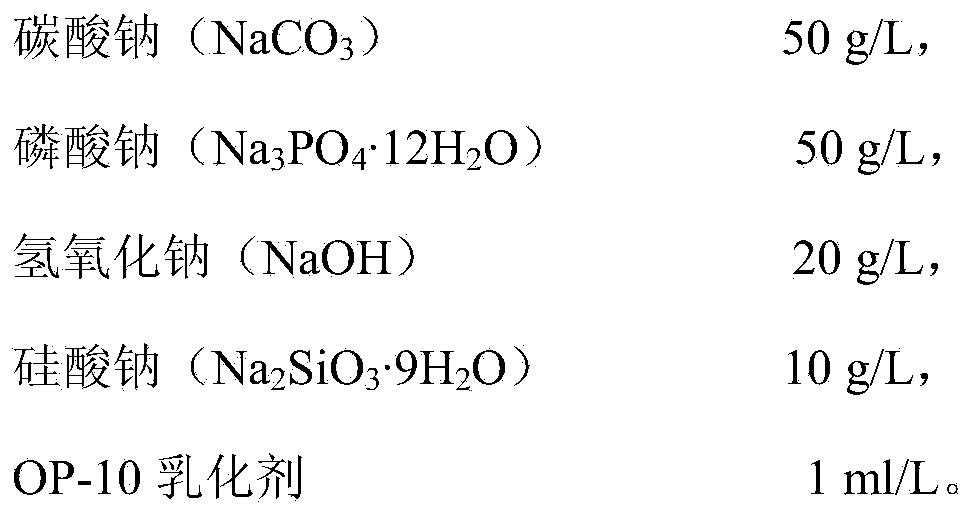

Aluminum and aluminum alloy cleaning agent and using method thereof

ActiveCN101012411AImprove cleaning rateImprove cleaning efficiencyInorganic/elemental detergent compounding agentsSurface-active detergent compositionsCleansing AgentsPhenol

The invention discloses an aluminium and aluminium alloy abluent, which comprises the following parts: 5-25W% alkyl phenol polyoxyethylene ether, 5-25W% aliphatic alcohol polyoxyethylene ether, 1-10W% cationic modified alkyl phenol polyoxyethylene ether, 2-10W% propanediol butyl ether, 2-8W% glucose, 1-8W% sodium bisilicate and 40-80W% water. The product displays light yellow transparent liquid with density at 1.05+-0.02 g / cm3, which simplifies normal disposal technique.

Owner:DALIAN SANDAAOKE CHEM

Brightening agent for cyanogen-free silver-plating and its preparing method

9This invention refers to a kind of brightener of non-cyanogen deposited silver. To more specifically speaking, it is about the brightener which is used in the technology of AgNO3 - thiosulfate series non-cyanogen depositing silver. It belongs to the field of silver electro-plating technology. The components and their contents are: diaminothiourea 35-55 g / L, orthophenanthroline 10-20 g / L, dodecyl-dephenyl oxide-mahogany 1-5 g / L, fluorocarbon sufactant 3-10 g / L, polyethylene glycol 15-30g / L. Then dilute these substances with water or distilled water until the volume reaches 1L. The we will get the brightener. You can fill this brightener into AgNO3 - sodium thiosulfate series non-cyanogen deposition silver solution, and by electric deposition in the way of impulse, you can get mirror surface bright deposited plate whose surface is smooth, and whose performance of keeping color is excellent. Also, the plate is hard enough to resist corrosion and sanding, and it has strong binding force with the base body.

Owner:SHANGHAI UNIV

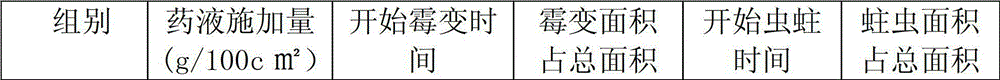

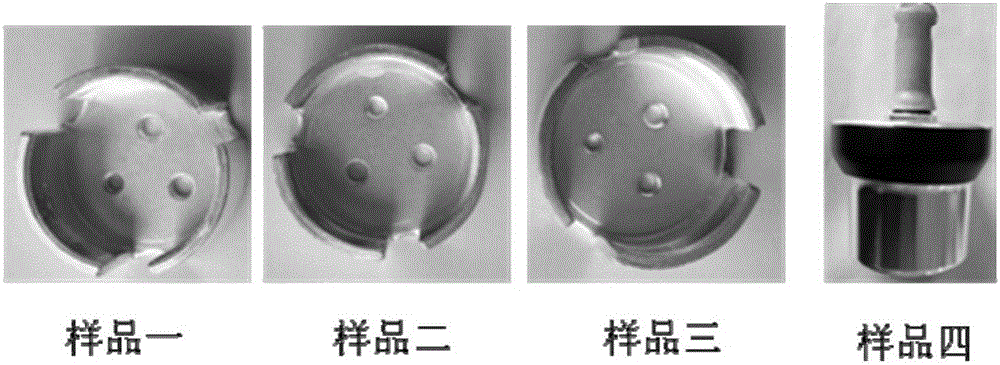

Wood preservative

InactiveCN102941606AImprove bindingGood insect repellentWood impregnation detailsPreservativePolyethylene glycol

The invention discloses a wood preservative. The preservative comprises the following components, by weight, borate 15-45%, quaternary ammonium salt 6-15%, chlorothalonil 5-10%, cosolvent 4-10% and the balance solvent, wherein the solvent is one or a plurality of dimethylbenzene, glycerol and water, and the cosolvent is polyethylene glycol, urea formaldehyde preshrinking liquid or ethylene. The wood preservative is colorless, odorless, safe and environment-protection, simultaneously has the functions of corrosion prevention, mold prevention, insect prevention and antitarnish, and can rest assured use indoor and outdoor.

Owner:东兴市观福古典红木家具有限公司

Anticorrosion white Cu-Mn alloy and method for making its wire material

An anticorrosion white Cu-Mn alloy contains Mn (9-15 wt.%), Zn (4-15 wt.%), Al (0.5-1.5 wt.%), Sn (0-1.5 wt.%) rare-earth element (less than 0.2 wt.%), and Cu (the rest). Said alloy can be used to make wire material through non-vacuum smelting, horizontal conticasting and cold drawing or cold rolling. Its advantages are high machinability and anticorrosion nature and stable lustre. It can replace Ni-contained white Zn-Cu alloy.

Owner:中铜(上海)铜业有限公司 +1

Novel cyanide-free silver plating electroplating liquid and electroplating technology

InactiveCN105088293AImprove solderabilityExcellent discoloration resistanceSilver plateSurface-active agents

The invention provides novel cyanide-free silver plating electroplating liquid and an electroplating technology. The cyanide-free silver plating electroplating liquid comprises, by mass concentration, 1.5-4 g / L of silver nitrate, 2-50 g / L of potassium carbonate, 2-100 g / L of hydantoin, 0.1-100 g / L of potassium gluconate, 0.1-100 g / L of potassium malate, 0.1-150 g / L of citric acid, 0.1-280 g / L of hydantoin, 0.1-280 g / L of butynediol and 0.001-20 g / L of alkyl sulfonic acid surface active agent. The electroplating technology comprises the steps of pretreatment, washing, activating, washing, beforehand silver plating, silver plating, recycling, washing, adjusting treatment, washing, hot water washing (80 DEG C), washing and silver protective agent treatment. The novel silver plating technology has the main beneficial effects that firstly, the plating liquid is very stable and easy to control, the current efficiency of the plating liquid is high, and the dispersing capability and covering capability are good; secondly, a cyanide-free formula is adopted in the electroplating liquid, potential danger of cyanide is eliminated, and pollution to the environment is greatly reduced; and thirdly, the various properties of a plating layer are not lower than those of cyaniding silver plating, and a functional cyaniding silver plating technology can be thoroughly replaced.

Owner:CHONGQING LIDAO SURFACE TECH

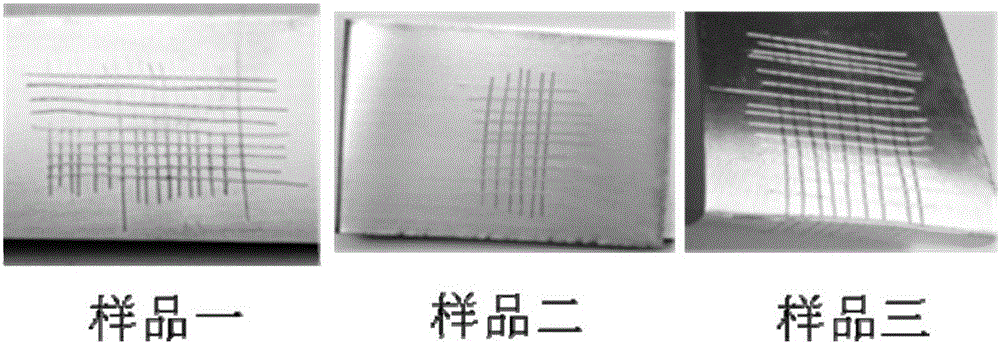

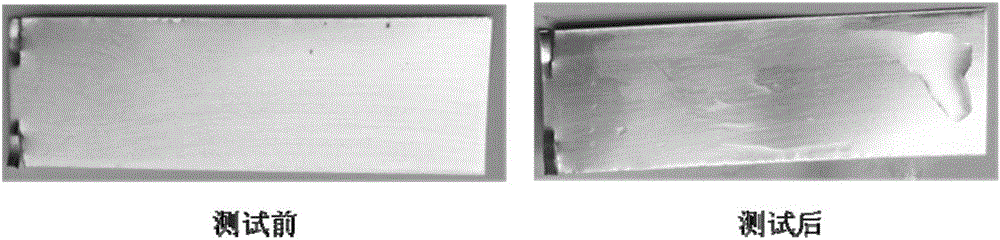

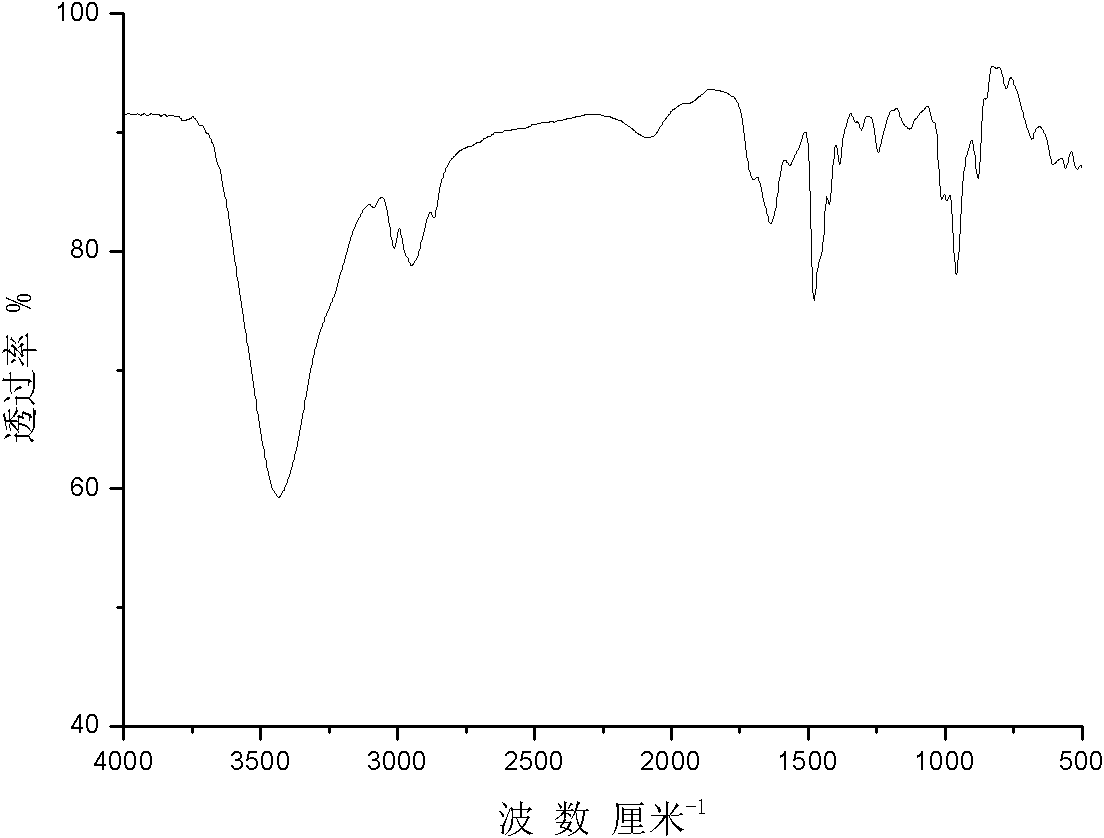

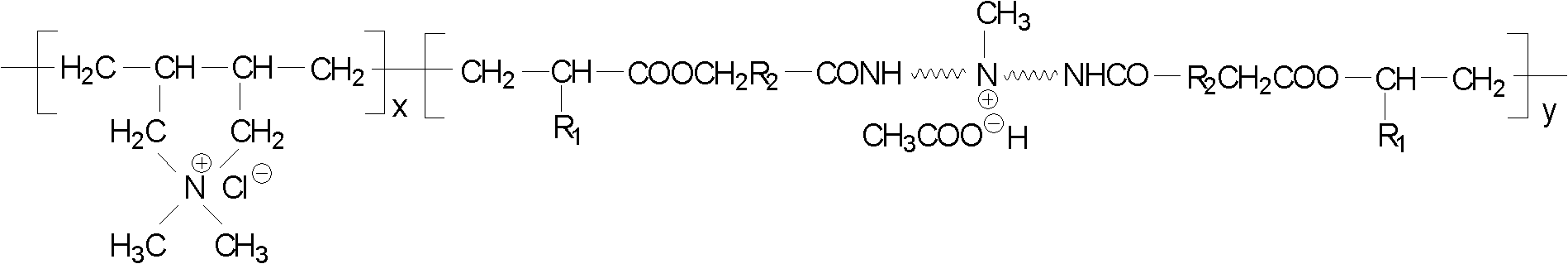

Method for preparing cationic poly(urethane-dimethyldiallylammonium chloride) color fixing agent

The invention discloses a method for preparing a cationic poly(urethane-dimethyldiallylammonium chloride) color fixing agent, which comprises: synthesizing vinyl terminated cationic polyurethane prepolymer by using isocyanate, polyol, N-methyldiethanolamine and acrylate functional monomers as polymerization monomers; hydrating and dispersing the vinyl terminated cationic polyurethane prepolymer, and performing reversed emulsion polymerization of the vinyl terminated cationic polyurethane prepolymer and dimethyl diallyl ammonium chloride in a water soluble initiator to obtain the formaldehyde-free poly(urethane-dimethyldiallylammonium chloride) color fixing agent. The cationic poly(urethane-dimethyldiallylammonium chloride) color fixing agent contains no formaldehyde, retains the property of a polyurethane material, realizes the organic combination of the high performance of the two kinds of resins due to the high positive charge density of a poly(dimethyl diallyl ammonium chloride) chain segment and can effectively improve the color fastness of the dyed fabrics. When the color fixing agent is used, the color fastness of the fabrics dyed with direct dye and active dye is as follows: the dry friction fastness is grade 5, the wet friction fastness is grade 3 to 4, and the brushing fastness is 4 to 5.

Owner:ANHUI UNIVERSITY

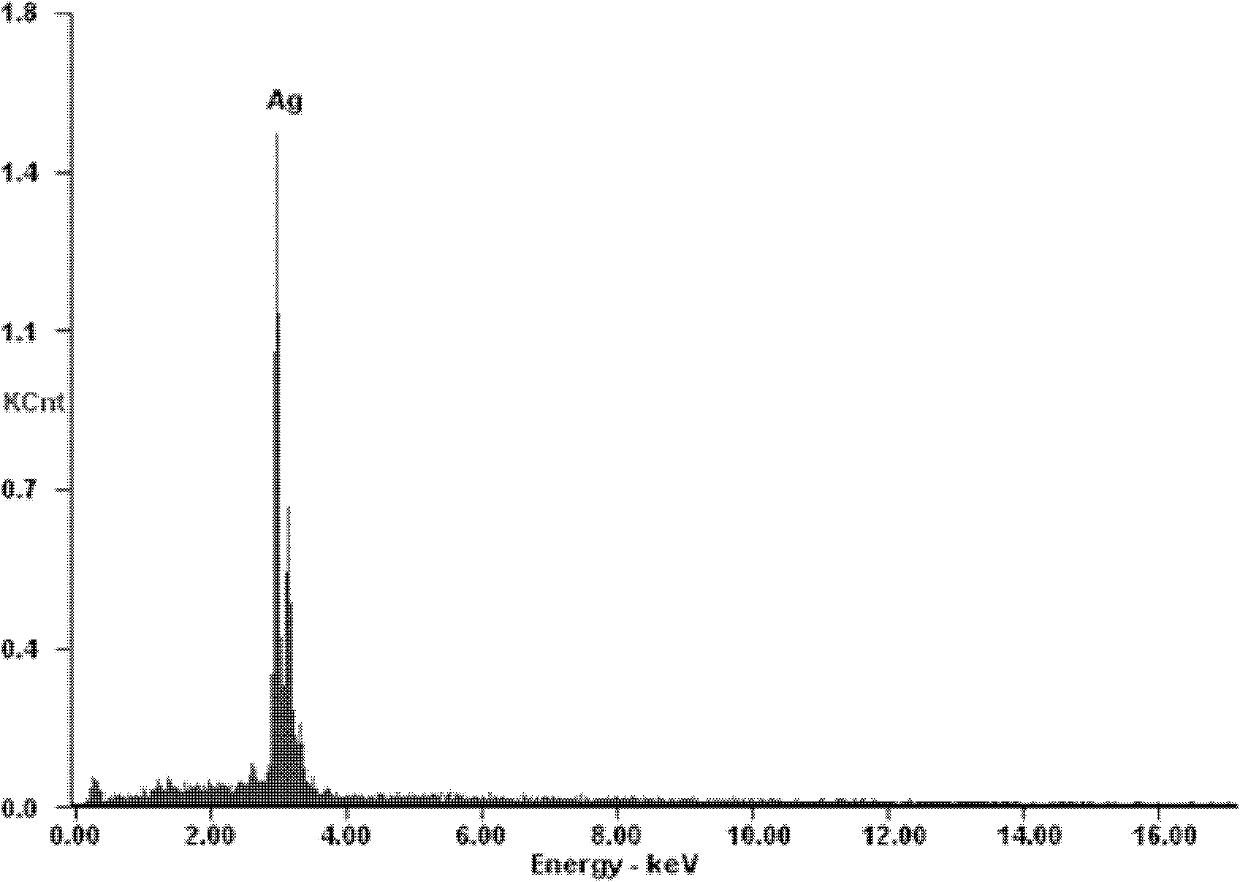

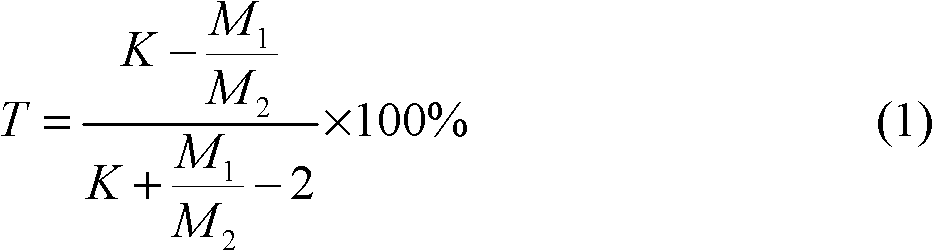

Method for preparing nano-silver antibacterial agent by utilizing microcapsule embedding technology

The invention discloses a method for preparing a nano-silver antibacterial agent by utilizing a microcapsule embedding technology and application thereof. In the preparation method, an oily nano-silver material is used as the core material of the nano-silver microcapsule particle, and the beta-cyclodextrin is used as a wall material; and in the reaction process, the nano-silver microcapsules of a core-shell structure, an inlaid structure, a shell-core structure, a shell-core-shell structure and other structures are prepared by a conjugate ultrasonic method. A supercritical drying method is adopted in the drying process, the shrinkage and collapse of the microcapsule in the drying process are avoided, the problem of agglomeration during the nano-powder drying process is improved, and the performance of sustained release, lasting and color change resistance of the nano-silver microcapsule is improved. The prepared nano-silver particle can be independently used as an antibacterial liquid, or be compounded with a high molecular material to prepare various antibacterial materials such as antibacterial plastic, an antibacterial PVA (Polyvinyle Acetate) film and antibacterial rubber, or be compounded with natural or chemosynthetic textile fabrics to prepare antibacterial fabric, or be compounded with ceramics to prepare various antibacterial ceramics. The method disclosed by the invention is simple; and the prepared nano-silver has the characteristics of small particle size, good dispersity, sustained-release bacteriostasis, wide application and the like.

Owner:HUNAN UNIV OF TECH

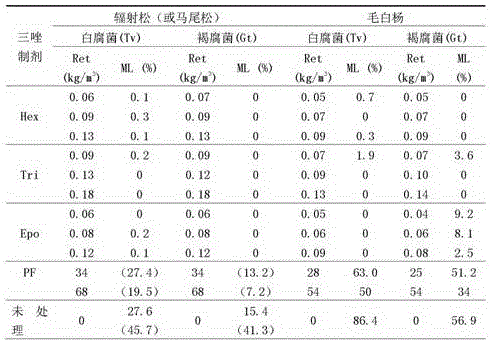

Wood bamboo material corrosion and discoloration prevention triazole composition and preparation method thereof

ActiveCN106003312AImprove anti-corrosion performanceImprove mildew resistanceWood treatment detailsReed/straw treatmentFatty alcoholHexaconazole

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Bicomponent silicofluoride acrylic polyurethane coating as well as preparation and application methods thereof

ActiveCN104017479AImprove adhesionGood flexibilityPretreated surfacesPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

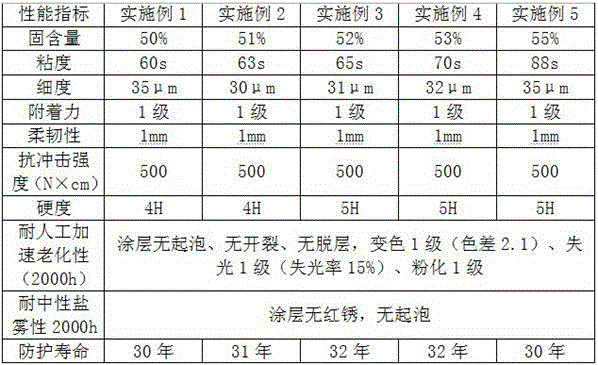

The invention relates to the technical field of protection coatings and in particular relates to a bicomponent silicofluoride acrylic polyurethane coating. The coating comprises a first component and a second component, wherein the mass ratio of the first component to the second component is (3 : 1) to (5 : 1); the first component comprises the following raw materials by weight parts: 50-70 parts of hydroxy acrylic resin, 15-24 parts of a solvent, 0.1-3 parts of fluorine-containing micropowder, 10-25 parts of a pigment, 1-3 parts of high-hardness oxide and 2-5 parts of aids; the second component comprises the following raw materials in parts by weight: 50-80 parts of a closed isocyanate curing agent and 20-50 parts of a solvent. According to the coating, the capability of protecting a steel structure can be improved; the coating has the characteristics of good ageing resistance, scratch resistance, corrosion prevention, color change prevention, pollution prevention and the like, and can achieve a very good long-acting protection effect on the steel structure by combination with other base paint and intermediate paint with excellent performance; and the protection life can be 30 years.

Owner:广东惠电科技发展有限公司

Corrosion-resistant coating sealing agent

ActiveCN103147104AImprove adhesionHigh anti-corrosion properties and strong adhesionAnti-corrosive paintsCopper platingMethyl-isothiazolinone

The invention discloses a corrosion-resistant coating sealing agent. The corrosion-resistant coating sealing agent with the volume of 1 liter comprises the following substances by weight: 2-3g of imidazole diketone urea, 1-2g of polydimethylsiloxane, 3-10g of polyquaternium-10, 1-5g of acrylic polymers, 1-3g of methylproline, 1-3g of methylisothiazolinone and the balance of water. The method comprises the following steps: adding 10-30ml of sealing agent into each liter of water, and uniformly stirring; washing the coated workpiece, putting the workpiece into the sealing agent at room temperature to seal for 10-60 seconds; and taking the workpiece out, washing by using percolating water, and drying in a drying box. The sealing agent is suitable for galvanization, nickel plating, chromeplating, copper plating, silver plating, gold plating, the neutral salt mist test resistance can reach over 72 hours, and the sealing agent is small in amount, low in cost, easy to operate and easy to maintain.

Owner:江苏增钬云表面处理有限公司

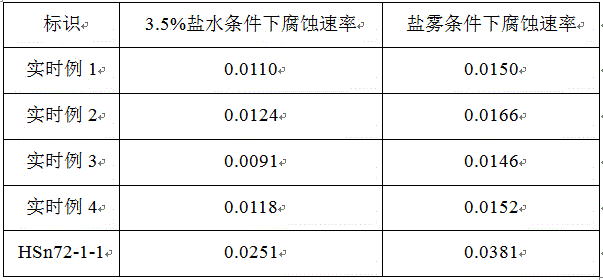

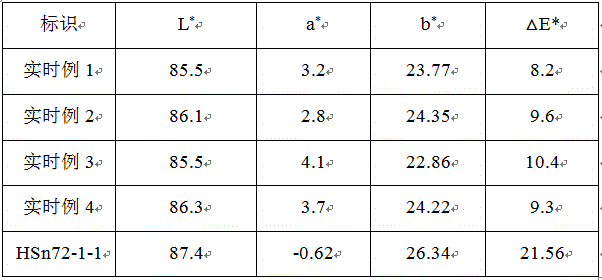

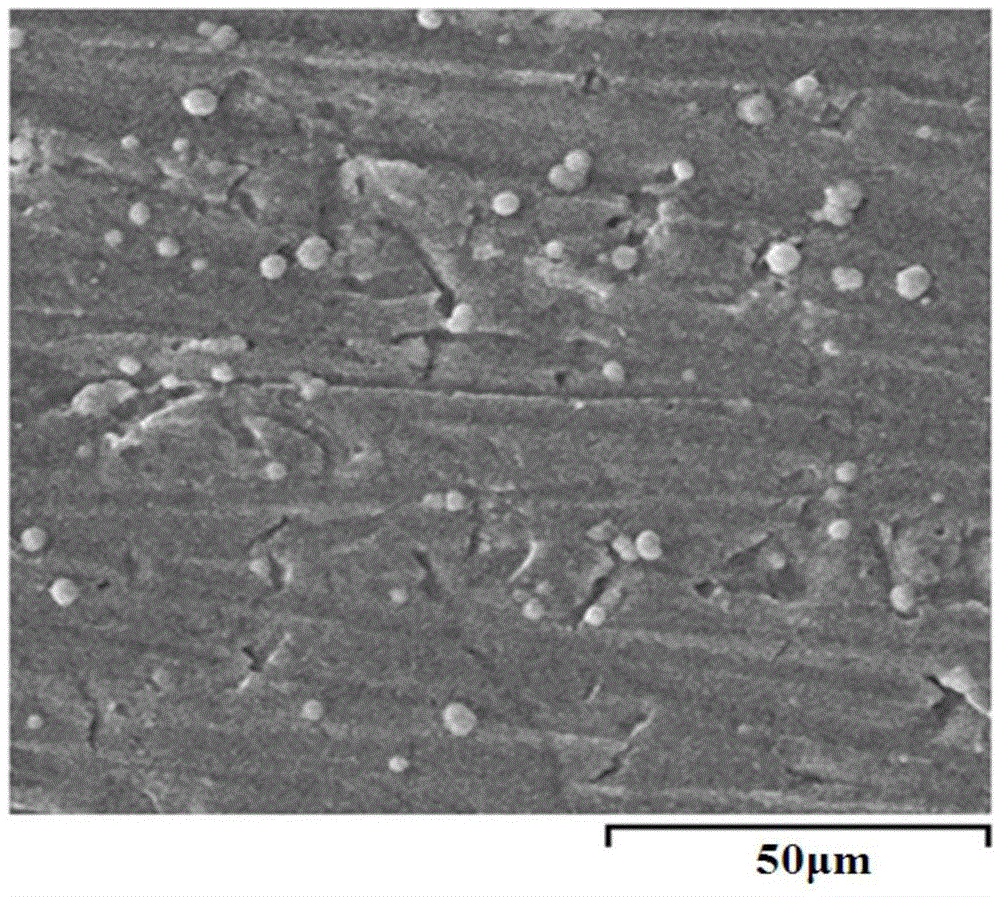

Tarnish-resistant gold imitation copper alloy material and preparation method thereof

The invention relates to a tarnish-resistant gold imitation copper alloy material, which comprises the following ingredients including 79 to 83 weight percent of Cu, 1.5 to 2.5 weight percent of Al, 0.5 to 1.0 weight percent of Ni, 0.3 to 1.0 weight percent of Sn, 0.2 to 0.5 weight percent of Fe, 0.01 to 0.05 weight percent of Ce and the balance of Zn and unavoidable impurities. The color and luster is golden yellow; the color and luster requires the brightness value L to be greater than or equal to 80, the red-green value a to be 1 to 4 and the blue-yellow value b to be 19 to 26. Compared with copper alloy such as the existing alloy HSn72-1-1, the produced alloy produced by the invention has the advantages that the tarnish-resistant performance and the corrosion-resistant performance are more excellent; the alloy ingredients are reasonable; the production process is simple; the alloy performance is excellent; the alloy can be applicable to the fields of various building decoration materials, commemorative coins, energy engineering, ocean engineering and the like.

Owner:苏州中色华人铜业有限公司

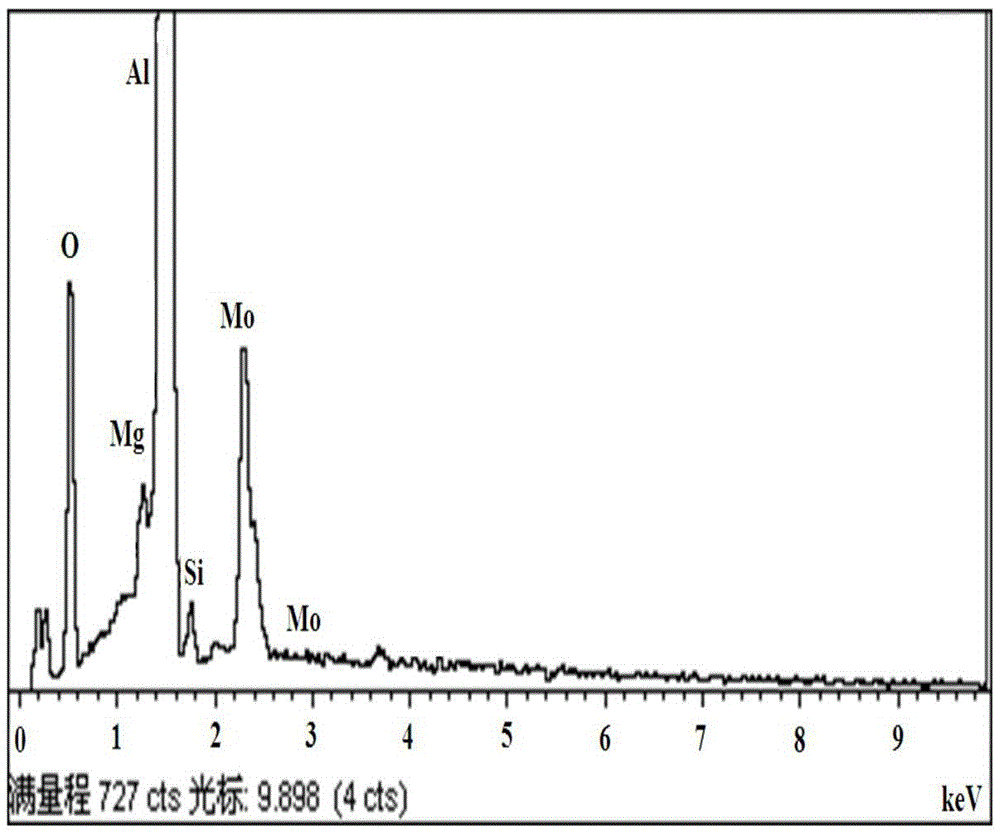

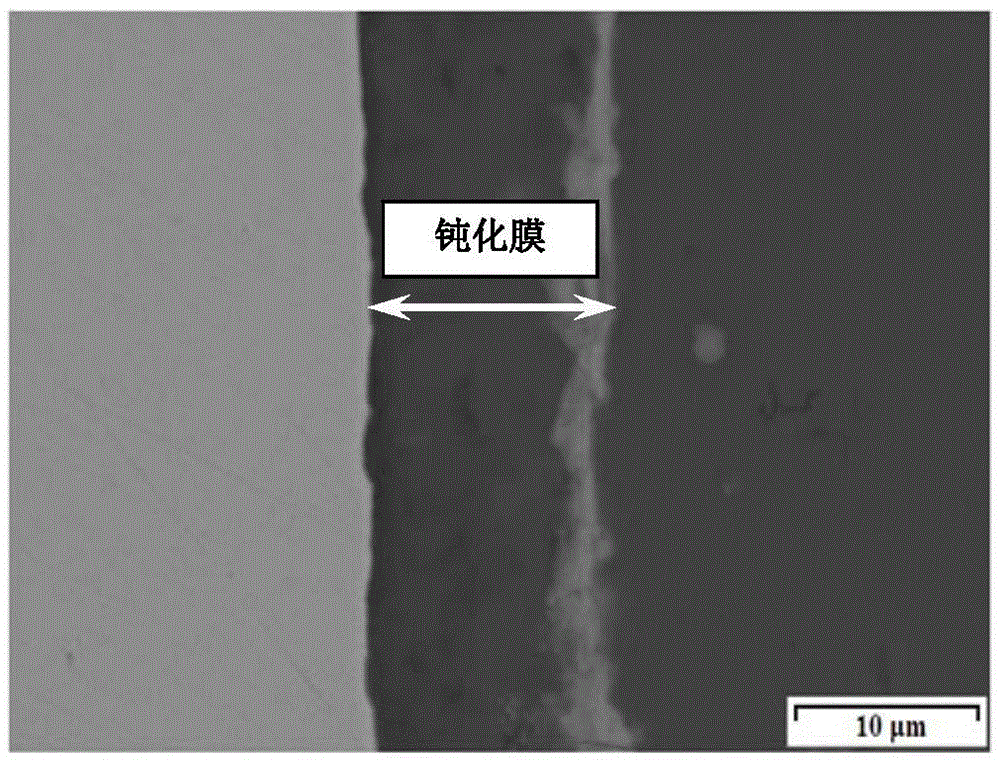

Normal-temperature alkaline chromium-free passivation solution and passivation method for aluminum alloy

ActiveCN105603409AEasy to detectStrong process controllabilityMetallic material coating processesChromium freeHydrogen

The invention belongs to the technical field of surface treatment on metal materials, and discloses normal-temperature alkaline chromium-free passivation solution and a passivation method for aluminum alloy. PH (potential of hydrogen) of chromium-free passivation solution is regulated by the aid of acid-alkali regulators until the chromium-free passivation solution is alkaline; the chromium-free passivation solution comprises molybdate, complexing agents, oxidizing agents, film-forming accelerators, surfactants and water. The passivation method includes carrying out alkali washing on the aluminum alloy and removing oil and dirt from the aluminum alloy; cleaning the aluminum alloy, then carrying out acid washing on the aluminum alloy and activating the aluminum alloy; cleaning the aluminum alloy, carrying out normal-temperature passivation treatment on the aluminum alloy, washing the aluminum alloy by the aid of water, drying the aluminum alloy by means of blowing or drying the aluminum alloy by the aid of ovens to obtain aluminum alloy passivation films. The normal-temperature alkaline chromium-free passivation solution and the passivation method have the advantages that the passivation films can grow fast and are excellent in discoloration resistance and corrosion resistance; various components of the normal-temperature alkaline chromium-free passivation solution are stable in chemical properties, accordingly, the normal-temperature alkaline chromium-free passivation solution is convenient to store and transport, low in cost and high in efficiency, processes are easy and convenient to implement, the aluminum alloy can be treated at the normal temperature, energy can be saved, and industrialization is easy to implement.

Owner:SOUTH CHINA UNIV OF TECH

Chemical deposition preparation method of piezoelectric composite metal electrode

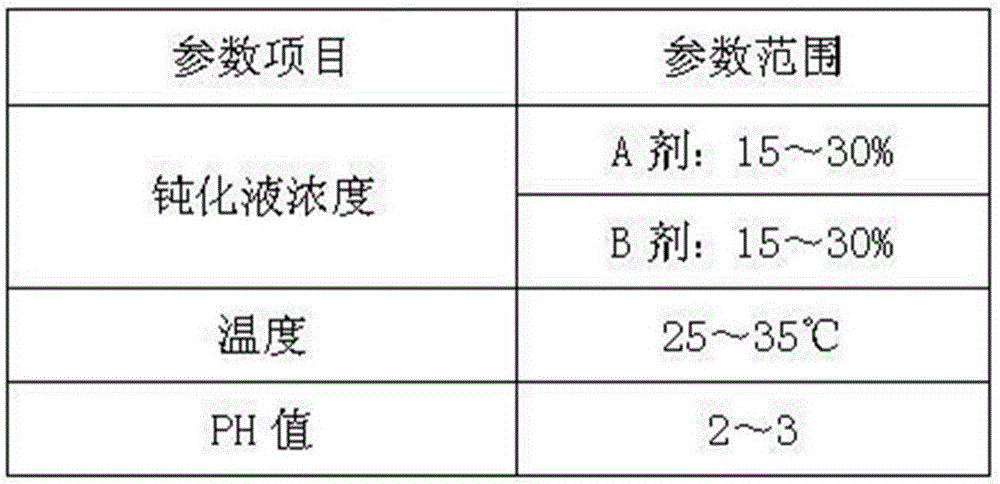

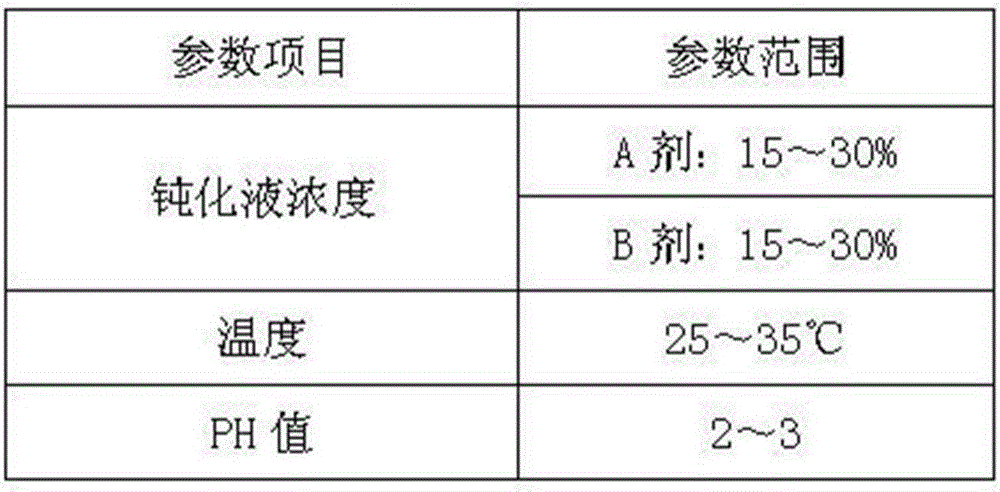

InactiveCN103938192ANo disengagementUniform coarseningLiquid/solution decomposition chemical coatingPolymeric surfaceChemical plating

The invention relates to a chemical deposition preparation method of a piezoelectric composite metal electrode. The chemical deposition preparation method particularly aims at a PZT ceramic and polymer coexisting composite material and comprises the following preparation steps: preparing a piezoelectric composite, cleaning, removing oil, wetting, carrying out primary coarsening, reducing, carrying out secondary coarsening, activating a colloid target, peptizing, carrying out chemical plating and passivating. According to the chemical deposition preparation method, a metal coating chemically deposited on the surface of the piezoelectric composite has a bright surface, is fine in crystallization, can uniformly cover the surfaces of ceramics and polymers and has good binding force with the ceramics and polymers. An adopted medium and low temperature technology is capable of ensuring that the piezoelectric composite metal electrode is free of deformation and material separation. The chemical deposition preparation method does not need expensive equipment and is low in cost and suitable for large scale production.

Owner:XIAMEN UNIV

Preparation method of nano-grade layered silver-carrying-amino acid complex antibacterial agent

InactiveCN102599164BImprove stabilitySolve technical problems that are prone to discolorationBiocideDisinfectantsSalt resistanceWater baths

The invention discloses a preparation method of a nano-grade layered silver-carrying-amino acid complex antibacterial agent. The method comprises the steps that: (1) silver salt, amino acid, and water are mixed according to a molar ratio of 1:1:2.7; the mixture is stirred for 30min under room temperature, and is stirred for 15min in a water bath with a temperature of 50 DEG C, wherein a stirring speed is 800r / min, such that a solution is prepared; (2) under a condition with a 50 DEG C water bath and a stirring speed of 800r / min, montmorillonite is added to the solution, and the mixture is stirred overnight under a hydro-thermal condition with a temperature of 50 DEG C, such that a material liquid is obtained; (3) solid-liquid separation is carried out; an obtained solid is dried under room temperature, such that a finished product antibacterial agent powder is obtained. The nano-grade layered silver-carrying-amino acid complex antibacterial agent is milk-white fluffy powder with excellent anti-tarnishing performance. With the method, the releasing-retardance and salt resistance of the antibacterial agent are improved. The antibacterial agent has a silver load of 18%. The antibacterial activity of the antibacterial agent is greatly improved. The method is suitable to be used in the technical field of chemical functional materials.

Owner:XIAN UNVERSITY OF ARTS & SCI

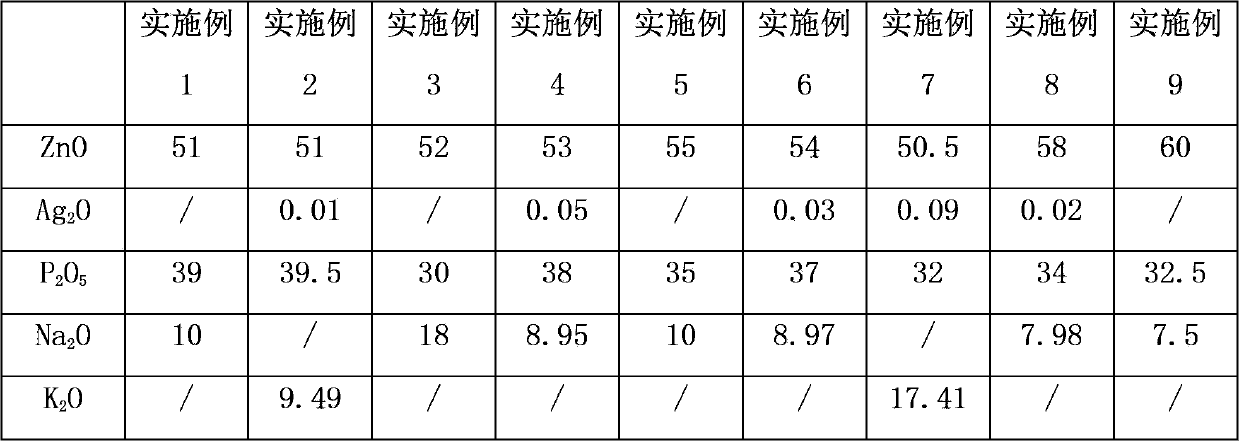

Antibacterial glass composition and preparation method thereof

ActiveCN103626399AImprove heat resistanceExcellent discoloration resistanceHeat resistanceAntibacterial activity

The present invention discloses an antibacterial glass composition and a preparation method thereof. The antibacterial glass composition comprises 50-60 wt% of ZnO, preferably 50-55wt%, and 0-0.09 wt% of Ag2O, preferably 0.01-0.05 wt%, and can further comprise 30-40 wt% of P2O5, preferably 35-40 wt%, and 6-18 wt% of Na2O or K2O, preferably 8-10 wt%. The preparation method comprises: carrying out high temperature melting and cooling on the components or hydroxides and salts corresponding to the components to prepare the antibacterial glass composition. The antibacterial glass composition has characteristics of excellent heat resistance, discoloration resistance and efficient antibacterial activity, and can be used in a plurality fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

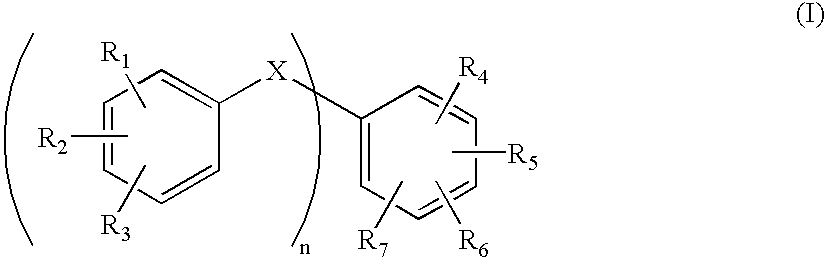

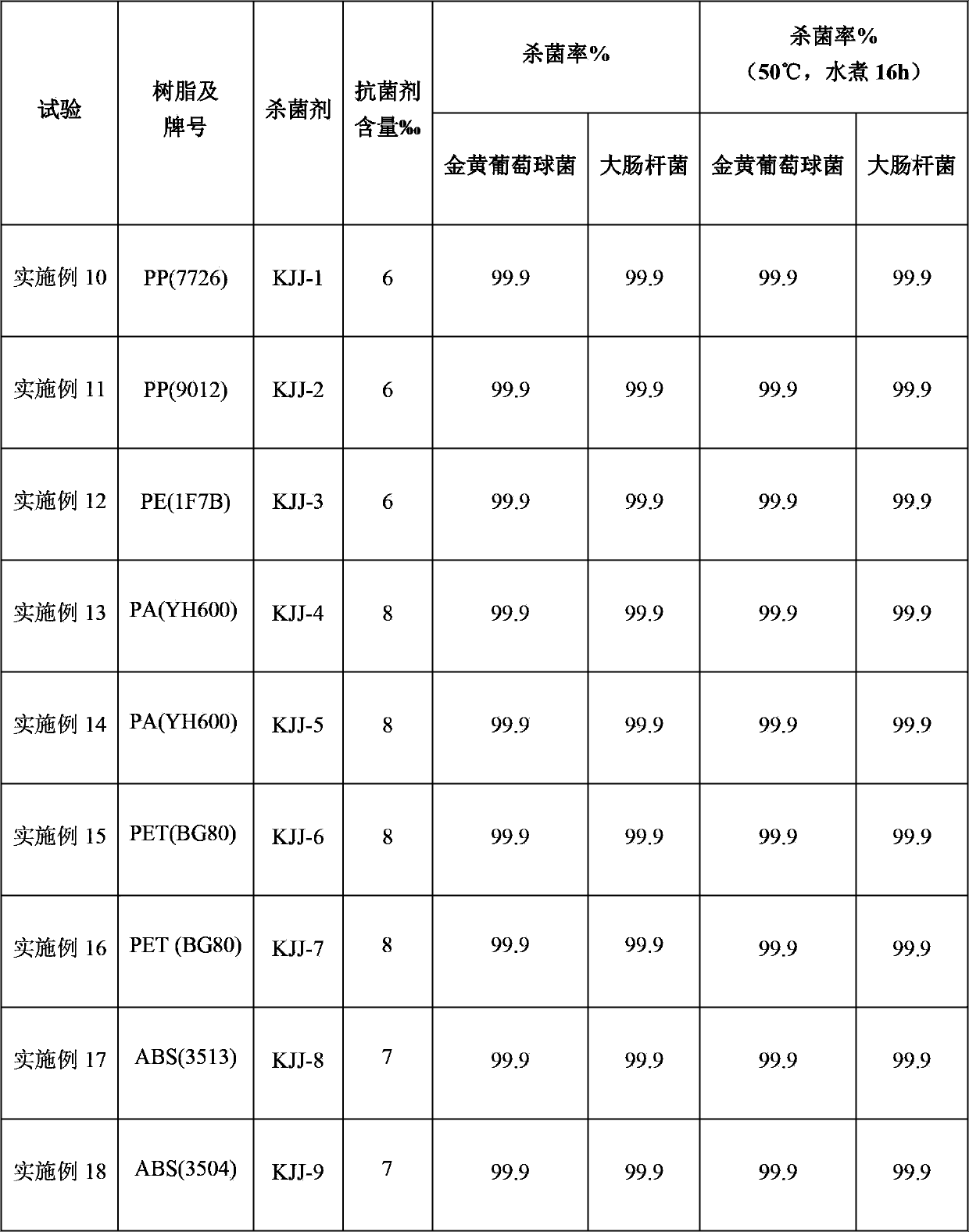

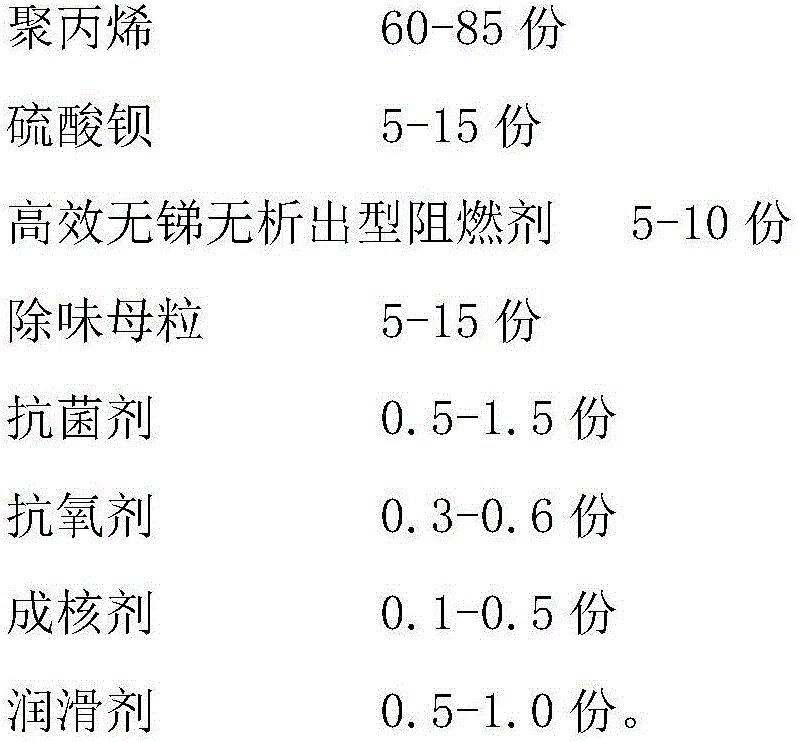

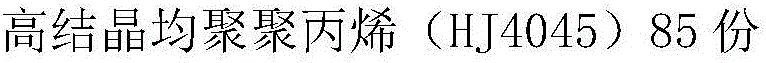

Antibacterial, low-odor and flame-retardant polypropylene composite material and preparation method for same

InactiveCN106832566APhysicochemically stableExcellent discoloration resistancePolypropylene compositesMasterbatch

The invention discloses an antibacterial, low-odor and flame-retardant polypropylene composite material and a preparation method for the same. The polypropylene composite material is prepared from the following components in parts by weight: 60 to 85 parts of polypropylene, 5 to 15 parts of barium sulfate, 5 to 10 parts of an efficient antimony-free and precipitate-free flame retardant, 5 to 15 parts of a deodorization masterbatch, 0.5 to 1.5 parts of an antibacterial agent, 0.3 to 0.6 part of an antioxidant, 0.1 to 0.5 part of a nucleating agent and 0.5 to 1.0 part of a lubricant. The prepared antibacterial, low-odor and flame-retardant polypropylene composite material has efficient antibacterial performance, and the antibacterial rate is over 99 percent. In addition, the odor level of the prepared antibacterial, low-odor and flame-retardant polypropylene composite material is lower than the 3.5 level, and the flame retardancy reaches the UL94 V-2 level.

Owner:ORINKO NEW MATERIAL CO LTD

Alkaline cyanide-free silver plating electroplating liquid and silver plating method

The invention relates to alkaline cyanide-free silver plating electroplating liquid and a silver plating method. The electroplating liquid is composed of the following components including 20 g / L-50 g / L of silver nitrate, 40 g / L-100 g / L of 5,5-dimethyl hydantoin, 70 g / L-100 g / L of potassium pyrophosphate, 0.8 g / L-1.2 g / L of 3,3'-dithiobis-1-propanesulfonic acid disodium salt, 0.10 g / L-0.15 g / L of benzotriazole, 10 mg / L-15 mg / L of N,N'-bi-oleoyl-Ethylenediamine-Sodium Diethyl sulfonate, 0.10 g / L-0.30 g / L of polyethylene glycol and the balance water, wherein due to a pH adjusting agent, the pH value of the system ranges from 8 to 12. By means of the alkaline cyanide-free silver plating electroplating liquid, all the components are matched and work collaboratively, stability is good, the copper replacement resisting performance is high, and the scattering capability of the plating liquid is high; crystal grains of a silver plated layer are fine, the crystal grains are densely and neatly arranged, the surface is flat and bright, glossiness is good, and the color changing resisting capability is high; and the hardness of the plated layer is high, the combining force with a base body is high, and the alkaline cyanide-free silver plating electroplating liquid is suitable for application and popularization.

Owner:佛山市南博旺环保科技有限公司

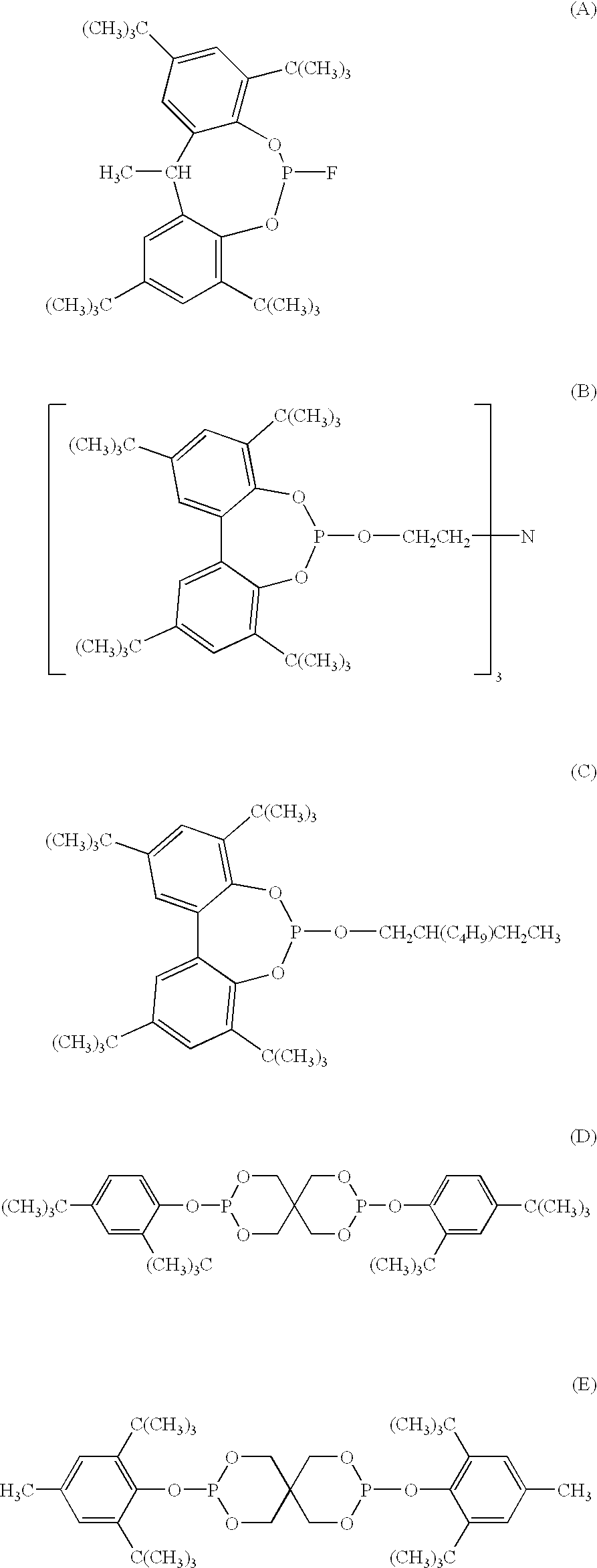

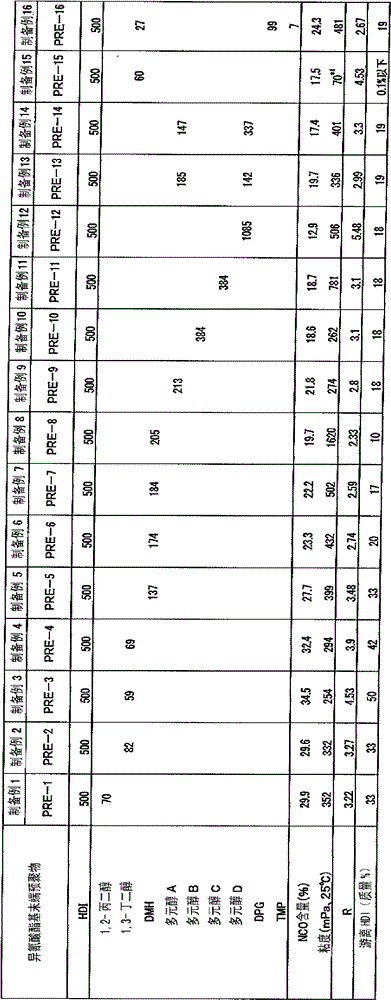

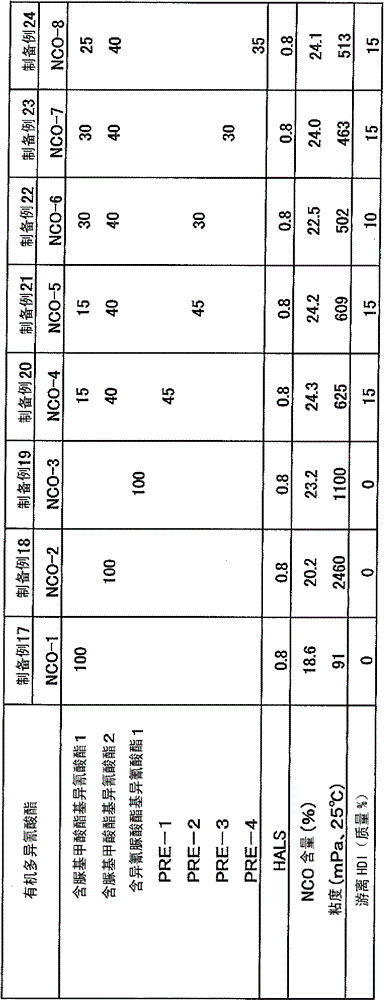

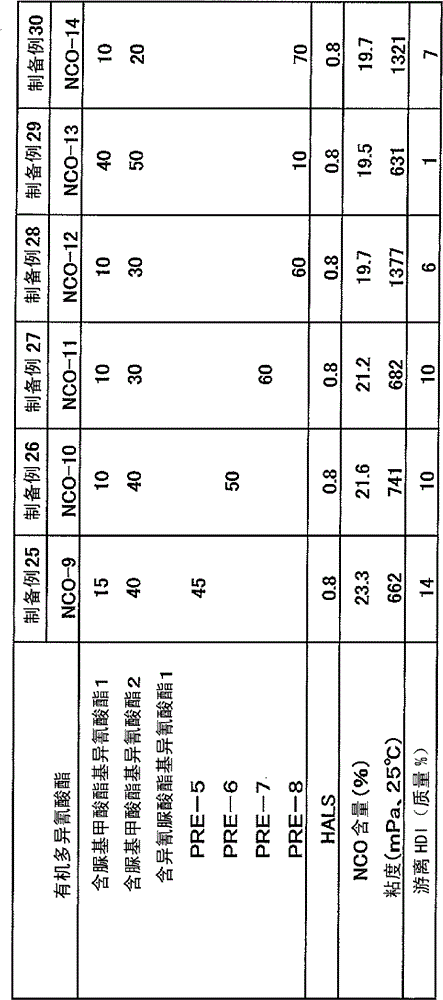

Flexible polyurethane?foam and manufacturing method thereof

InactiveCN102746485AUniform cell structureExcellent discoloration resistanceAbsorbent padsPackaging toiletriesAllophanePolyol

The invention provides a yellowing-proof flexible polyurethane?foam and a manufacturing method thereof. The manufacturing method of the flexible polyurethane?foam is a manufacturing method allowing reaction of an organic polyisocyanate (A), a polyalcohol (B), a catalyst (C), a foaming agent (D) and a foam stabilizer (E) to form and to be solidified, so as to obtain the flexible polyurethane?foam. The manufacturing method is characterized in that the organic polyisocyanate (A) is mixture of the following substances: an allophanate group-containing organic polyisocyanate composition (A1) which is generated by a monohydric alcohol and an aliphatic and / or alicyclic diisocyanate, an allophanate group-containing organic polyisocyanate composition (A2) which is generated by a hydroxyl group-containing compound having more than two hydroxyl groups and an aliphatic and / or alicyclic diisocyanate, and an organic polyisocyanate compound (A3) which is generated by reaction of an aliphatic and / or alicyclic diisocyanate and a polyalcohol component (a1).

Owner:NIPPON POLYURETHANE IND CO LTD

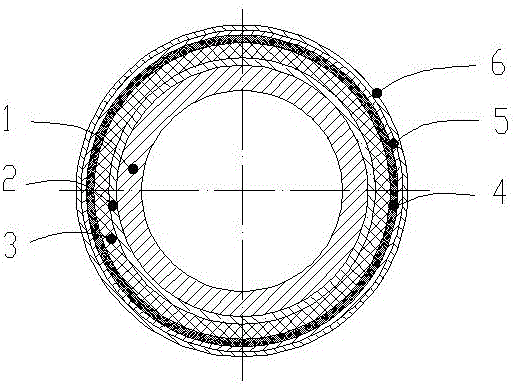

Composite galvanized army green steel pipe for refrigeration and manufacturing method of composite galvanized army green steel pipe

InactiveCN106544490AUniform thicknessImprove bindingHot-dipping/immersion processesFurnace typesZincWear resistance

The invention discloses a composite galvanized army green steel pipe for refrigeration and a manufacturing method of the composite galvanized army green steel pipe. The composite galvanized army green steel pipe comprises a steel pipe positioned on the innermost layer and is characterized in that a zinc-iron alloy layer is arranged on the outer surface of the steel pipe; a pure zinc layer is arranged on the outer surface of the zinc-iron alloy layer; an army green passivation layer is arranged on the outer surface of the pure zinc layer; a first closing layer and a second closing layer are separately arranged outside the army green passivation layer; and a product is obtained by the steps of carrying out deoiling, thermal treatment, composite galvanization, preheating, burnishing, washing with water, colored passivation, drying, closing for two time and drying. The composite galvanized army green steel pipe has a good binding force; a passivation bonding force among layers is high and weather fastness of the passivation layer is high; a finished product of the steel pipe has excellent wear resistance; the composite galvanized army green steel pipe has the advantages of good bright line, smoothness, anti-tarnishing property, rigorous process and high stability of the finished product; and when a condenser and a dew removable tube are manufactured, a protective heat shrink tube does not need to be added, so the working procedure is simple.

Owner:ZHEJIANG KANGSHENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com