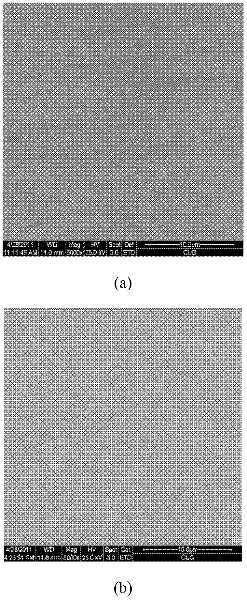

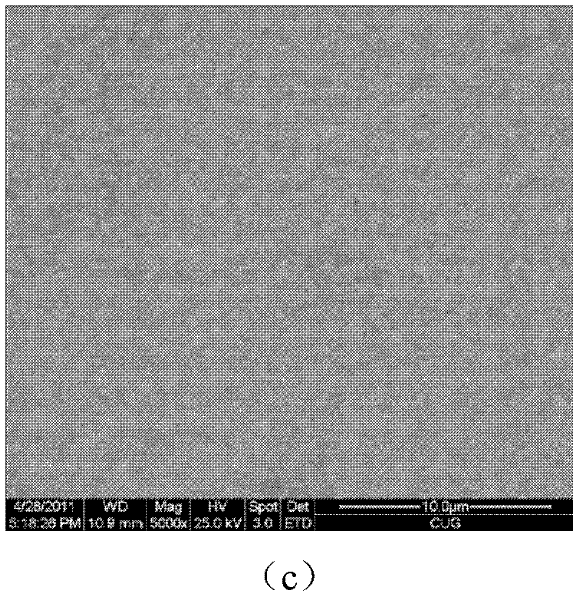

Method for double-pulse electrodeposition of nanocrystalline nickel-cobalt alloy

A nickel-cobalt alloy, electrodeposition technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as research on the influence of nickel-cobalt alloy coatings, and achieve good flatness and tight structure. , the effect of high finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 1) The soluble nickel plate with a purity greater than 99.99% is used as an anode plate after the following treatment: first use coarse sandpaper for preliminary grinding to remove the surface oxide layer, stains, etc., then wash it with distilled water, and after degreasing, use Rinse with distilled water, then clean the surface with absolute ethanol, and dry it with a hair dryer for later use;

[0057] 2) The iron sheet is used as the cathode plate after the following treatment. After the iron sheet is polished and polished with 600#, 1000#, 1200#, 2000# metallographic sandpaper in turn, it is cleaned by chemical degreasing, and then passed through Strong acid descaling, neutralization, weak etching Ⅰ, pre-nickel plating, weak etching Ⅱ, bright sulfate copper plating, weak etching Ⅲ, the process conditions of each surface treatment step are as follows:

[0058] basic component Concentration or Process Conditions sodium hydroxide 75g / L Sodiu...

Embodiment 2

[0104] 1) Treat the soluble nickel plate with a purity greater than 99.99% by the method of step 1) in Example 1 and use it as an anode plate;

[0105] 2) After the iron sheet is processed by the method of step 1) in Example 1, it is used as a cathode plate;

[0106] 3) Prepare the plating solution, the components and their contents in the plating solution are as follows:

[0107] Nickel Sulfate (NiSO 4 ·6H 2 O) 180g / L

[0108] Cobalt Sulfate (CoSO 4 ·6H 2 O) 5g / L

[0109] Sodium Chloride (NaCl) 10 g / L

[0110] Sodium Sulfate (Na 2 SO 4 ) 25~30 g / L

[0111] Boric acid (H 3 BO 3 ) 40g / L

[0112] Sodium formate (HCOONa) 40 g / L

[0113] Formaldehyde (HCHO) 2 g / L

[0114] Saccharin 1g / L

[0115] pH 5~6

[0116] 4) Inject the plating solution prepared in step 3) into the electrodeposition tank, use the soluble nickel plate after surface treatment in step 1) and the iron sheet after surface treatment in step 2) as the anode and cathode respectively, and adopt the dou...

Embodiment 3

[0131] 1) Treat the soluble nickel plate with a purity greater than 99.99% by the method of step 1) in Example 1 and use it as an anode plate;

[0132] 2) The iron sheet is used as a cathode plate after being processed by the method of step 1) in Example 1;

[0133] 3) Prepare the plating solution, the components and their contents in the plating solution are as follows:

[0134] Nickel Sulfate (NiSO 4 ·6H 2 O) 250g / L

[0135] Cobalt Sulfate (CoSO 4 ·6H 2 O) 10g / L

[0136] Sodium Chloride (NaCl) 15 g / L

[0137] Sodium Sulfate (Na 2 SO 4 ) 25~30 g / L

[0138] Boric acid (H 3 BO 3 ) 50g / L

[0139] Sodium formate (HCOONa) 50 g / L

[0140] Formaldehyde (HCHO) 2 g / L

[0141] Saccharin 1g / L

[0142]pH 5~6

[0143] 4) Inject the plating solution prepared in step 3) into the electrodeposition tank, use the soluble nickel plate after surface treatment in step 1) and the iron sheet after surface treatment in step 2) as the anode and cathode respectively, and adopt the doub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com