Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90 results about "Isothermal crystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biaxially oriented polypropylene film with high heat seal strength

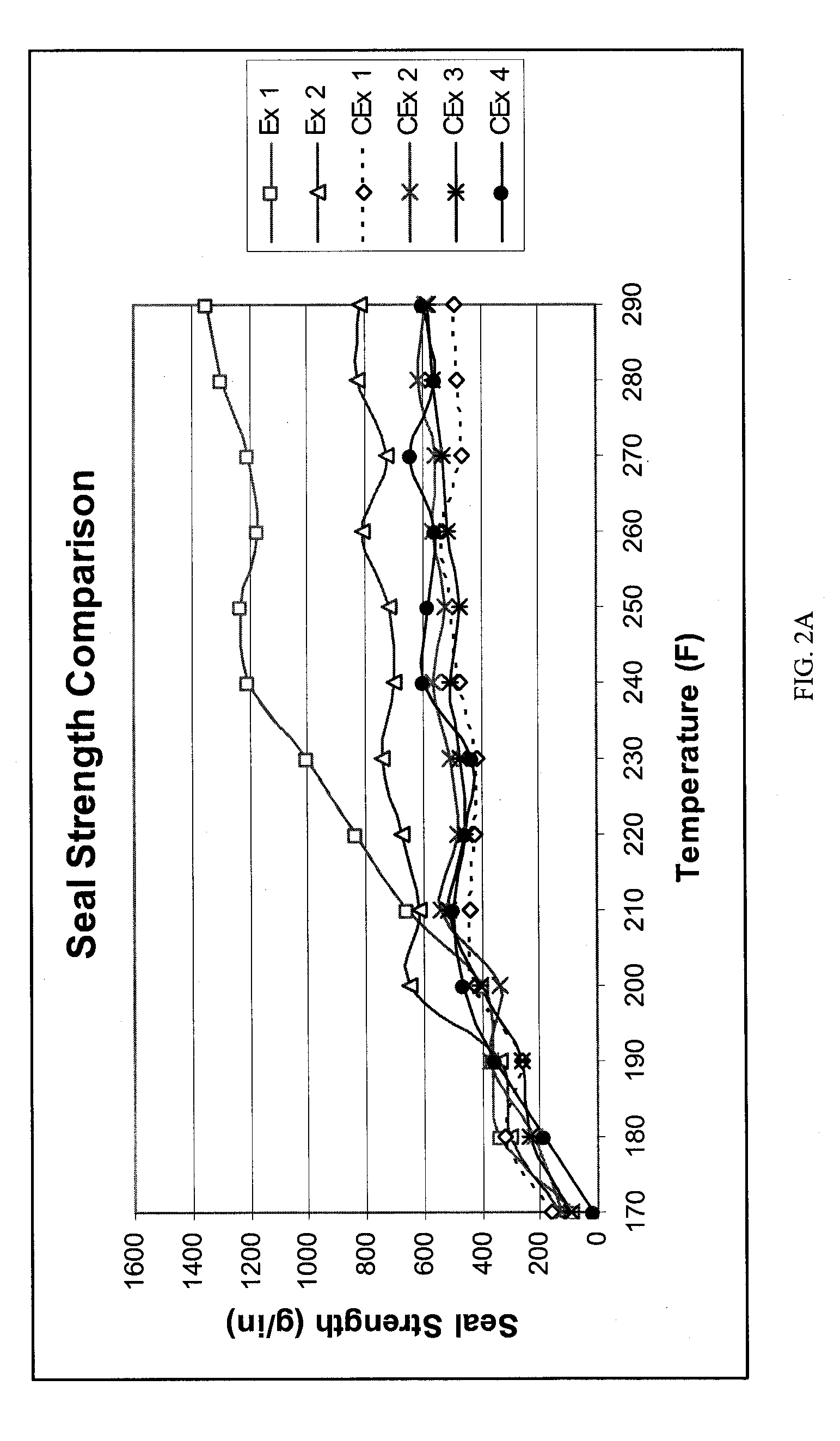

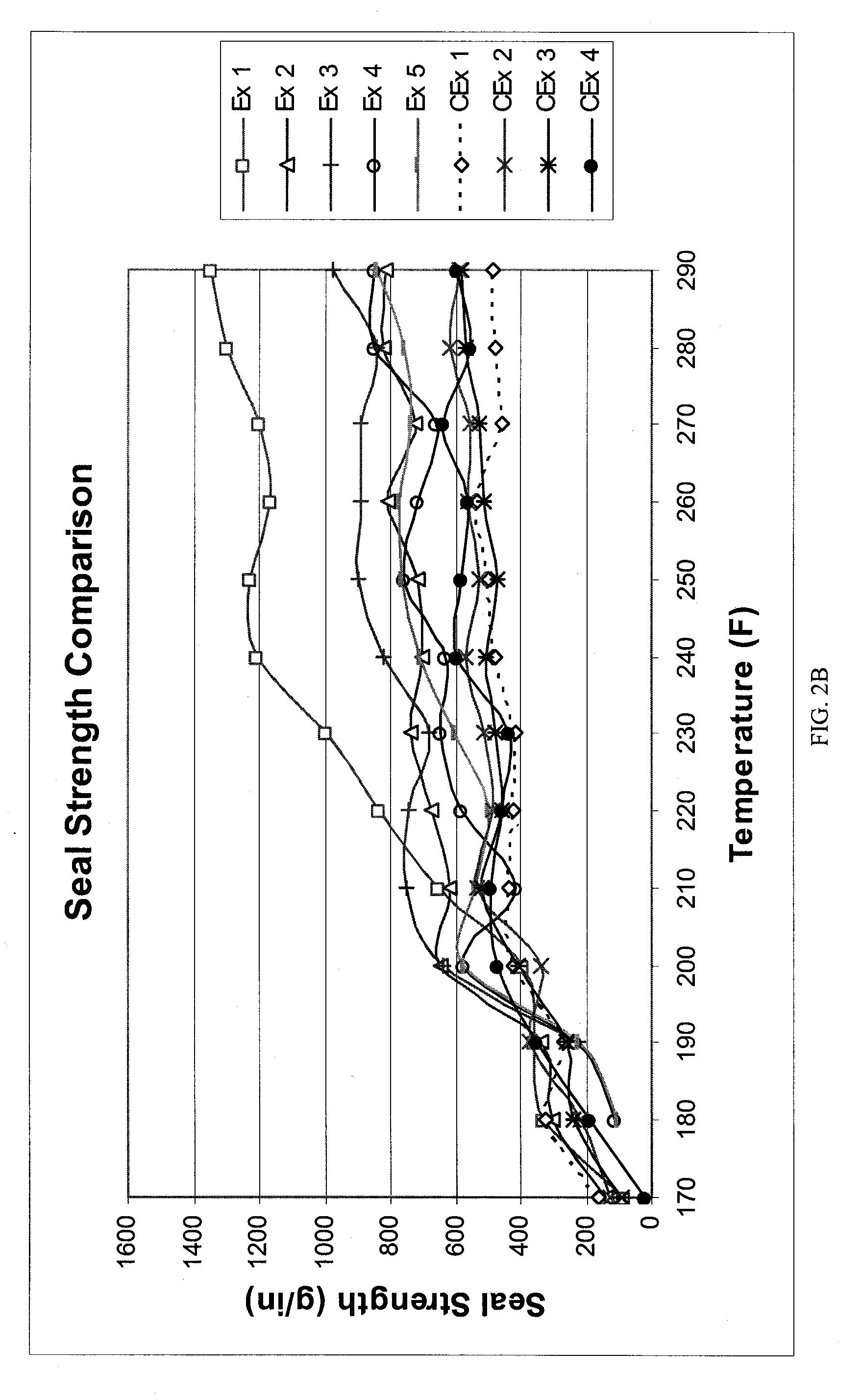

ActiveUS20090087648A1Easy to processImprove seal strengthLamination ancillary operationsLayered product treatmentPolyolefinThermoplastic elastomer

A laminate film including a first polyolefin heat sealable resin layer and a second core layer including of a blend of 5-15 wt % of a metallocene-catalyzed butene-propylene or ethylene-propylene thermoplastic elastomer or ethylene-propylene plastomer or blends thereof which exhibit an isothermal crystallization temperature of 60° C. or less and 95-85 wt % of a crystalline propylene homopolymer is disclosed. The laminate film may include additional layers such as a third polyolefin resin-containing layer disposed on the side of the core layer opposite the heat sealable layer, a metal layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

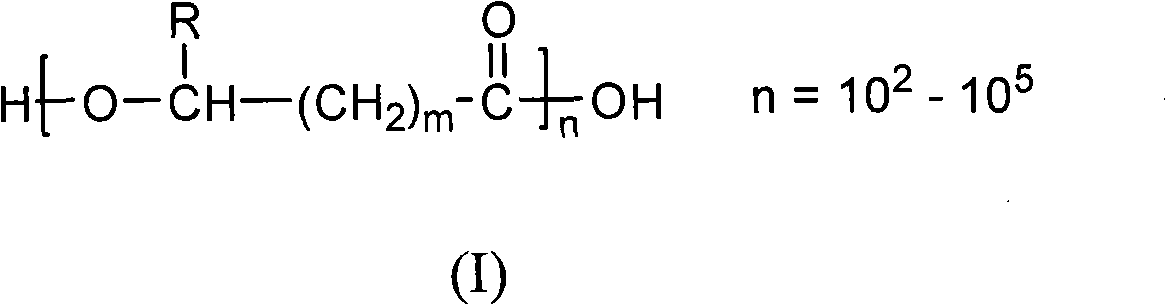

Polyhydroxyalkanoates fiber and preparation method thereof

InactiveCN101538750AArrange straight and neatHigh crystallinityMonocomponent copolyesters artificial filamentConjugated synthetic polymer artificial filamentsFiberBiocompatibility Testing

The invention relates to a fiber and a preparation method thereof, in particular to a degradable fiber and a preparation method thereof. The fiber contains polyhydroxyalkanoates, and the preparation method thereof comprises the steps of melting and extruding a base material, obtaining a sample band, cold-stretching or pre-stretching the sample band, quenching, performing isothermal crystallization and the like. The fiber disclosed by the invention has the advantages of good biocompatibility, biodegradability, high strength and / or good toughness.

Owner:TIANJIN GREENBIO MATERIAL CO LTD +1

Process for in-situ quiclely preparing crystalline polyester using nano silicon dioxide

The present invention relates to composite material preparing technology. The production process of nano composite silica / polyester material includes the following steps: coating nano silica as crystallizing nucleartor with organic matter for surface modification to make it capable of distribute well in ethylene glycol as one monomer for polyester; high temperature pre-treating compounded nano silica / ethylene glycol slurry to make nano silica possess average size smaller than 100 nm; and polymerization or copolymerization between nano silica / ethylene glycol slurry and other monomer for polyester inside reactor to obtain in-situ nano composite silica / polyester material. The composite material with 1 wt% of nanometer silica contained has non-isothermal crystallization melting peak temperature raised to 213.4 deg.c and 4-8 times raised isothermal crystallization rate at 185-200 deg.c.

Owner:SHANGHAI JIAO TONG UNIV

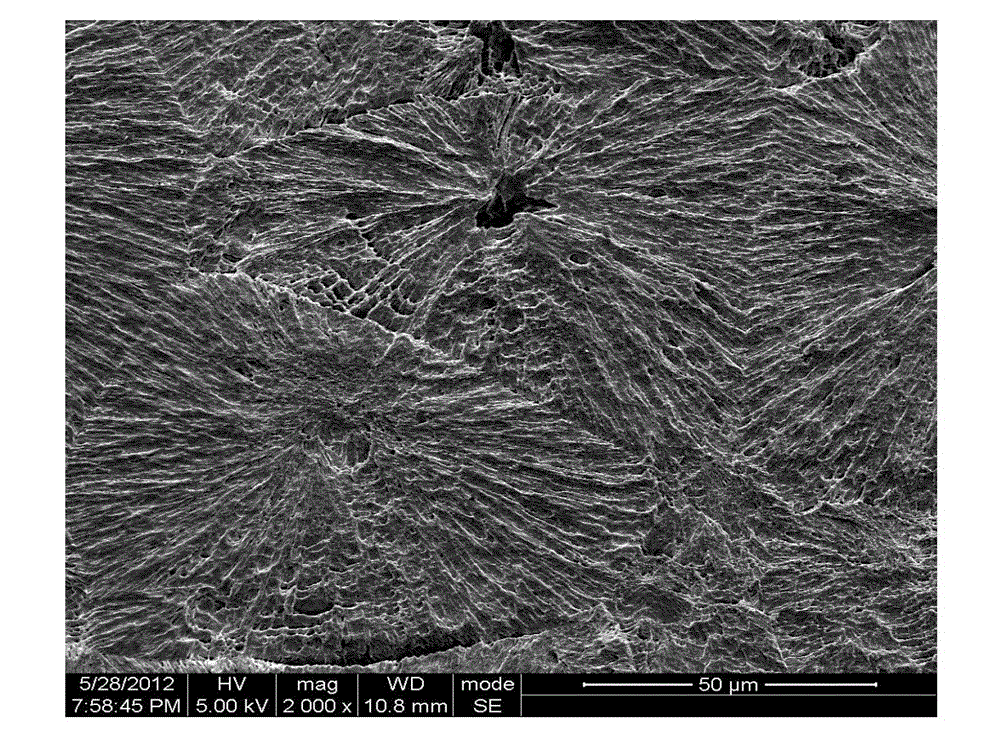

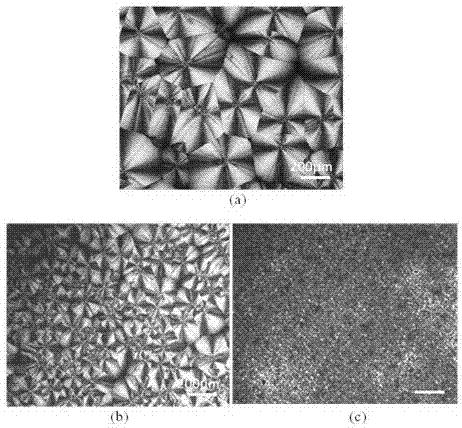

Method for preparing high-oriented gamma phase polyvinylidene fluoride PVDF thin film

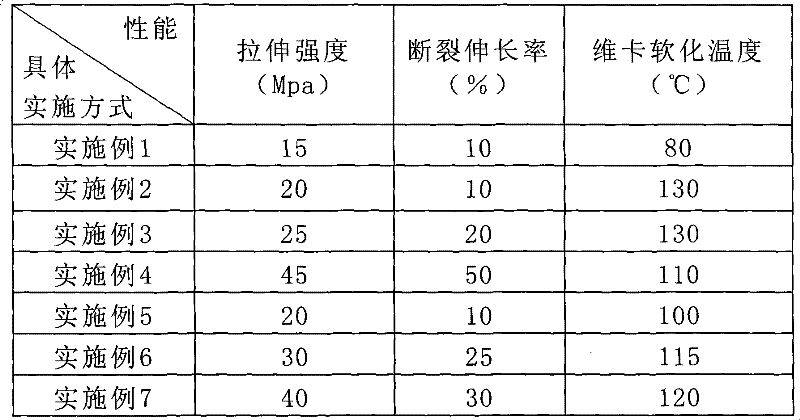

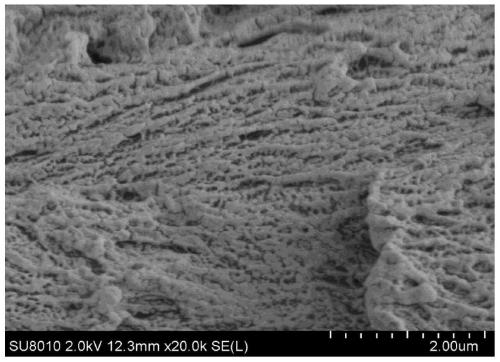

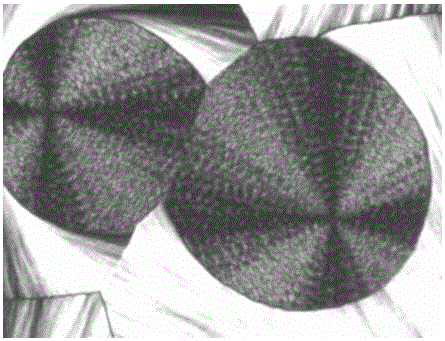

InactiveCN103113602AIncrease nucleation densityIncrease growth rateScanning electron microscopeIr microscope

The invention relates to a method for preparing a high-oriented gamma phase polyvinylidene fluoride PVDF thin film. The method comprises the following steps of: 1) first, casting a thin film for PVDF liquor to heat, insulate and eliminate thermal history, and quickly cooling the PVDF thin film at 50 DEG C / min to 160-170 DEG C; and 2) applying pressure to melt by a polymethylsiloxane plate to apply a shear stress, standing at 160-170 DEG C, wherein the crystallizing form at 160-163 DEG C is converted to alpha crystallizing form, and conversion from alpha crystallizing form to gamma crystallizing form occurs at 168-170 DEG C; the crystallizing crystal nucleus is alpha crystal nucleus at 164-167 DEG C, and the crystallizing form at 168-170 DEG C is gamma crystallizing form. A polarizing microscope, a scanning electron microscope and an infrared spectrometer represent crystallization of the melt in a shear stress field and a crystal structure after crystallization, so that the method is simple in process, and simple, convenient and accessible, and the problem that pure gamma phase PVDF thin film cannot be obtained by isothermal crystallization is solved. The gamma phase PVDF thin film which is high in purity, high in orientation and excellent in thermodynamic property can be prepared.

Owner:SHAANXI UNIV OF SCI & TECH

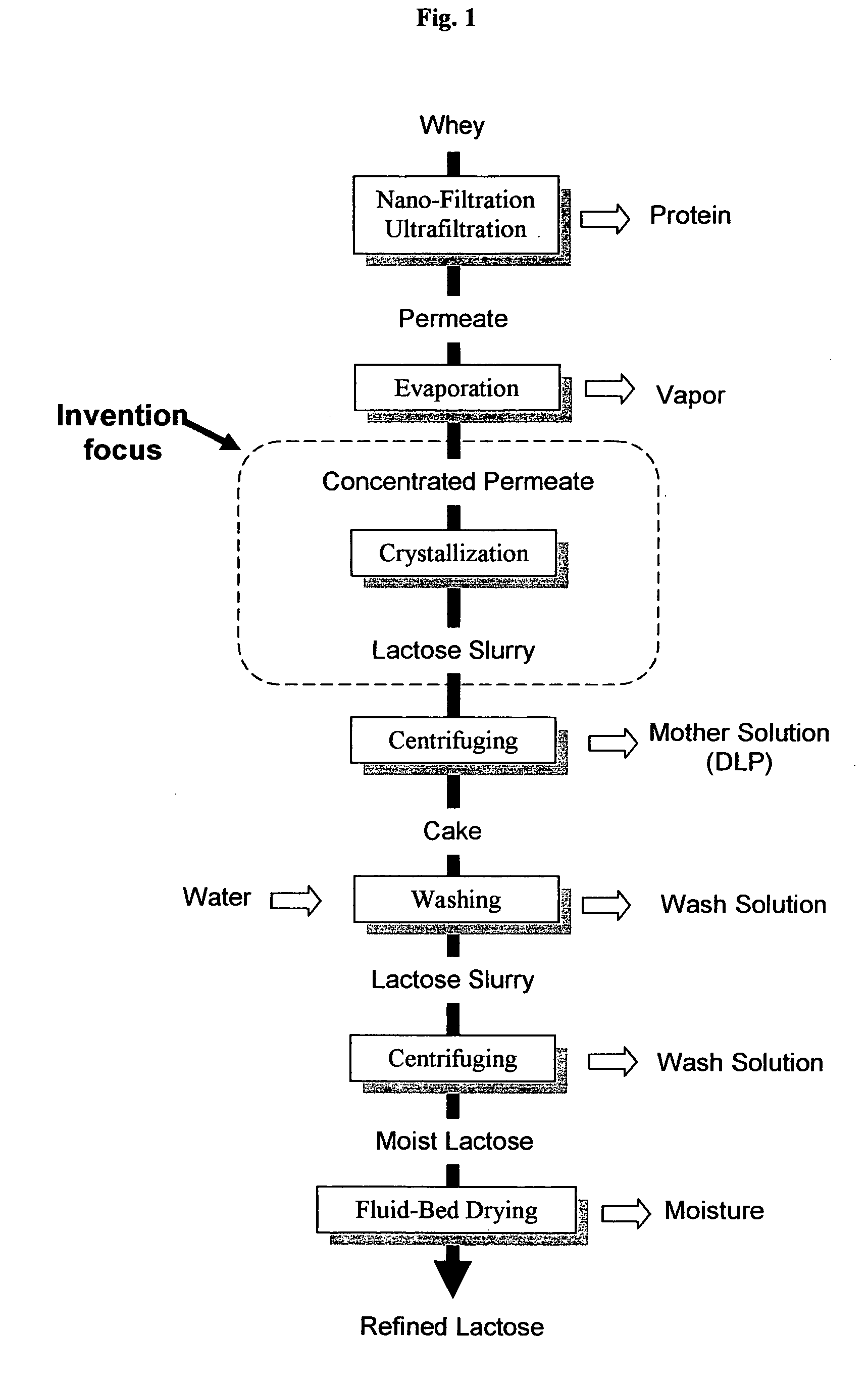

Crystal refining technologies by controlled crystallization

InactiveUS20060128953A1Short timeQuality improvementDisaccharidesProduct crystals bed crystallizationIsothermal crystallizationChemistry

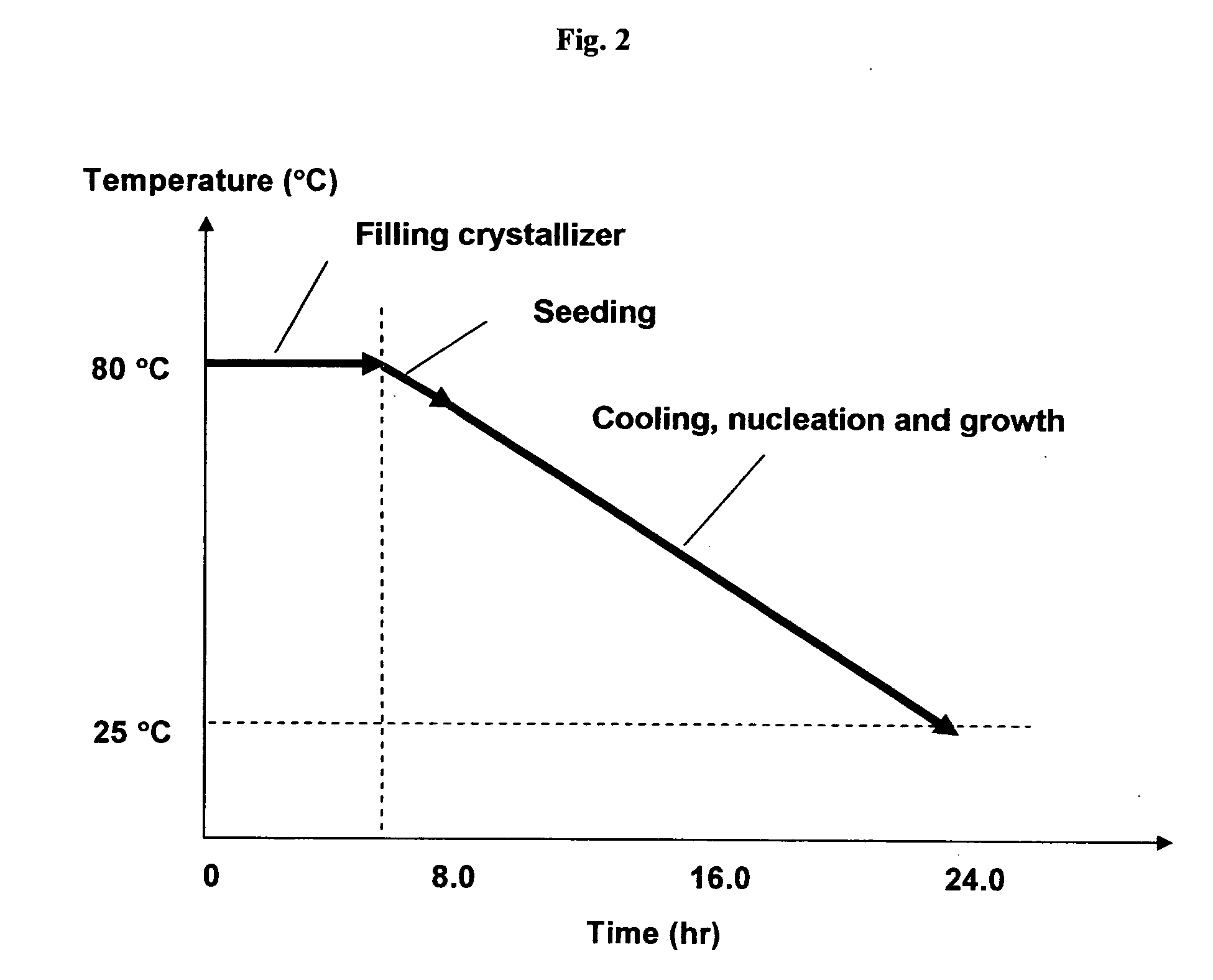

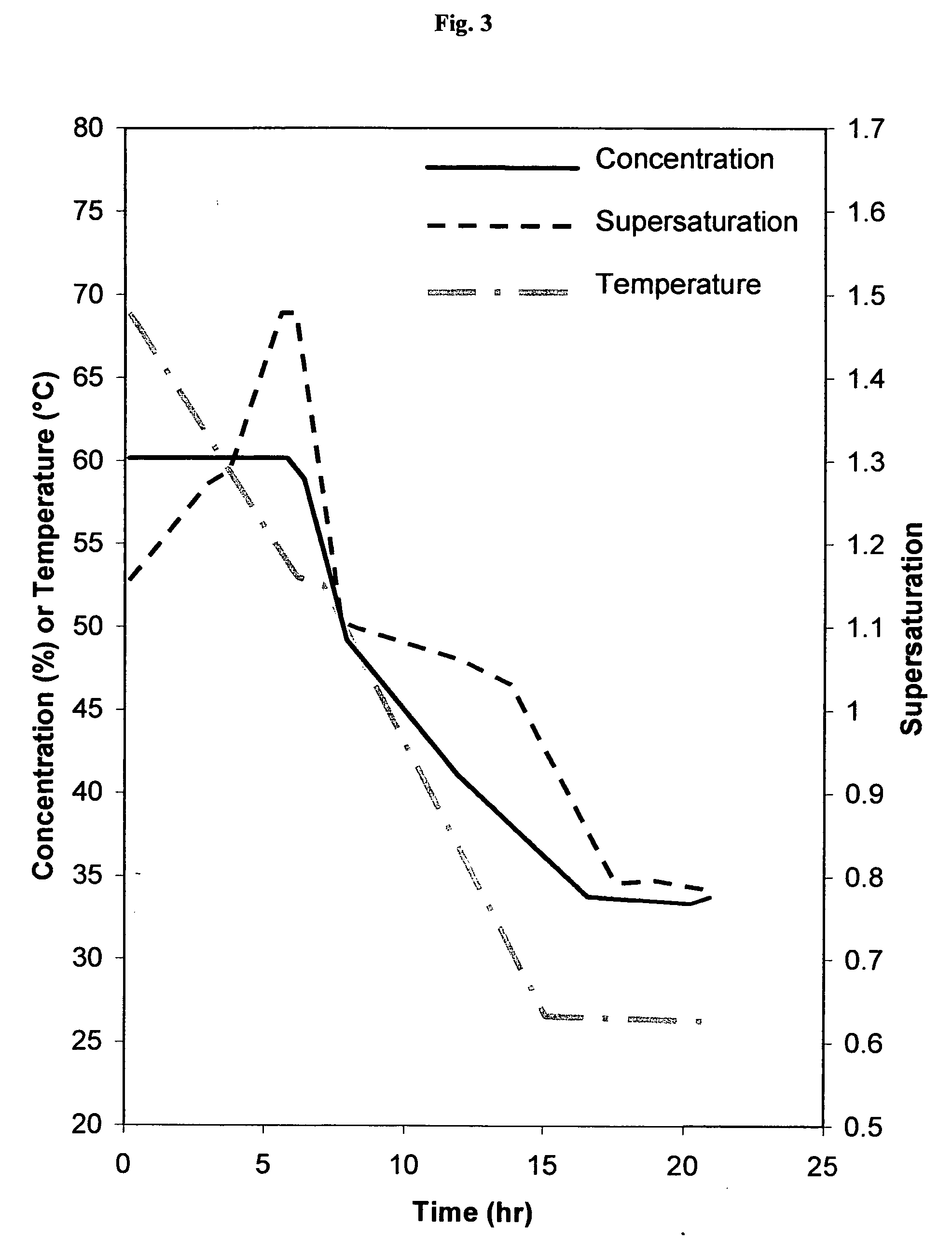

A method is provided for making large, uniform and individual crystals from aqueous solutions including the steps of obtaining a concentrated aqueous solution by means of evaporation; rapidly cooling the solution from a post-evaporation high temperature to a first lower temperature, wherein the first lower temperature is lower than the post-evaporation high temperature and further wherein the first lower temperature is an isothermal crystallization temperature of said solution; generating a batch of initial nuclei by inducing nucleation at the first lower temperature and starting crystal growth; uniformly spreading the initial nuclei into a bulk solution; maintaining simultaneous and rapid growth of crystals from the nuclei at the first lower temperature for a predetermined length of time; continuing the growth of the crystals to produce large, uniform and individual crystals for a predetermined length of time at a temperature that varies gradually from between a first lower temperature to a second lower temperature, wherein the second lower temperature is a temperature lower than the first lower temperature and further wherein the second lower temperature is an end temperature of crystallization; and recovering the large, uniform and individual crystals. Parameters and a system for producing lactose monohydrate crystals using the method are also provided.

Owner:WISCONSIN ALUMNI RES FOUND

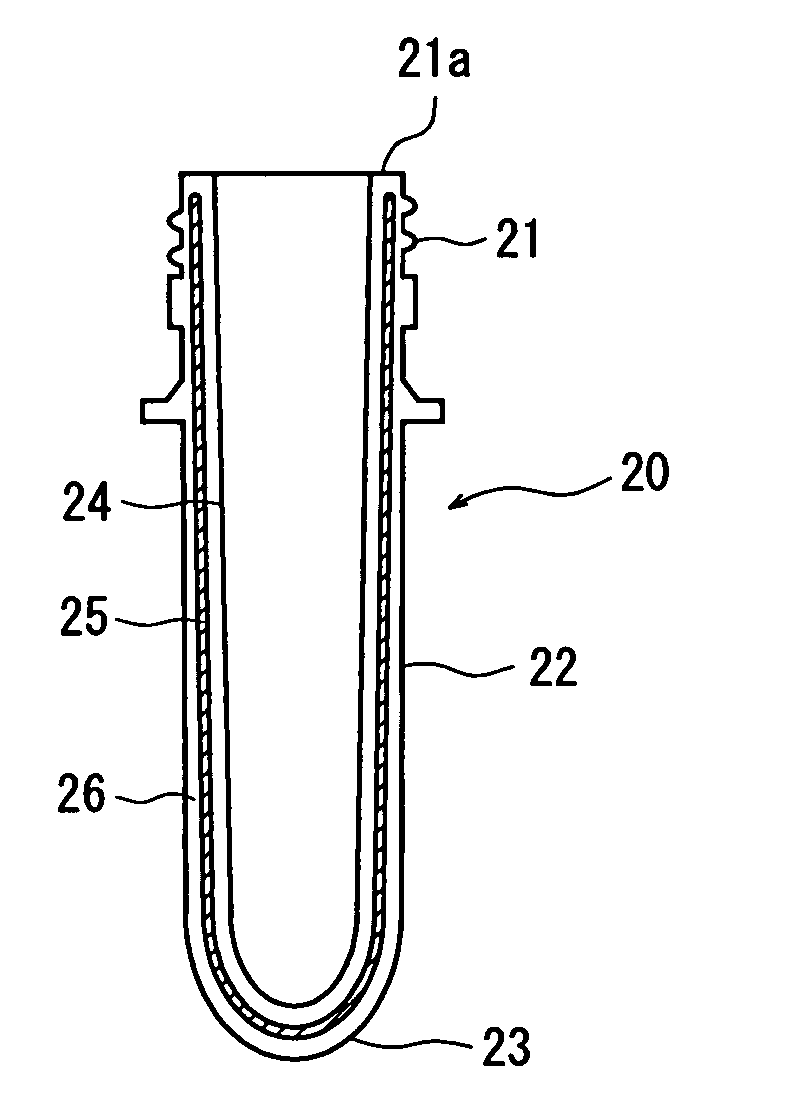

Preform, process for producing the same, and biaxially stretched container obtained from the preform

InactiveUS20060127615A1Low mechanical strengthImprove the problemSynthetic resin layered productsScrew-threads articlesCompression moldingPolyester resin

Owner:TOYO SEIKAN KAISHA LTD

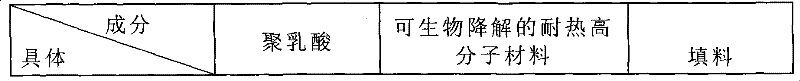

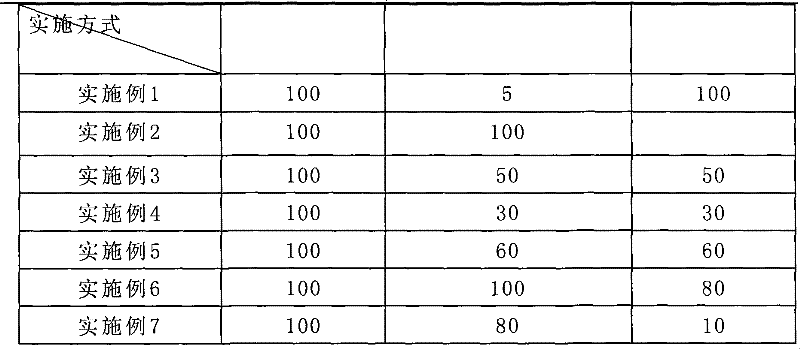

Heat-proof polylactic acid blend and preparation method thereof

The invention provides a heat-resistant polylactic acid blend and a preparation method thereof, pertaining to the polymer materials technique field, solving the problems of bad heat-resistant performance, weak mechanical performance and being not to be biodegraded, etc. The heat-resistant polylactic acid blend consists of the following components according to weight proportion: 100 parts of polylactic acid, 5 parts to 100 parts of heat-resistant polymer materials which can be biodegraded, 0 to 100 parts of fillers; the preparation method is that: A. blending; B. banburying; C. hot pressing forming; D. isothermal crystallization. The heat-resistant polylactic acid blend of the invention uses the polylactic acid which has a synergistic effect between crystallization and heat-resistant components, and therefore the invention has good heat-resistant performance. The invention adopts various components matching use, so the blend can not only be biodegraded, but also has good mechanical performance; the whole preparation method has simple technical process, good processing performance, low cost and can realize large-scale and industrialized production.

Owner:ZHEJIANG HISUN BIOMATERIALS +1

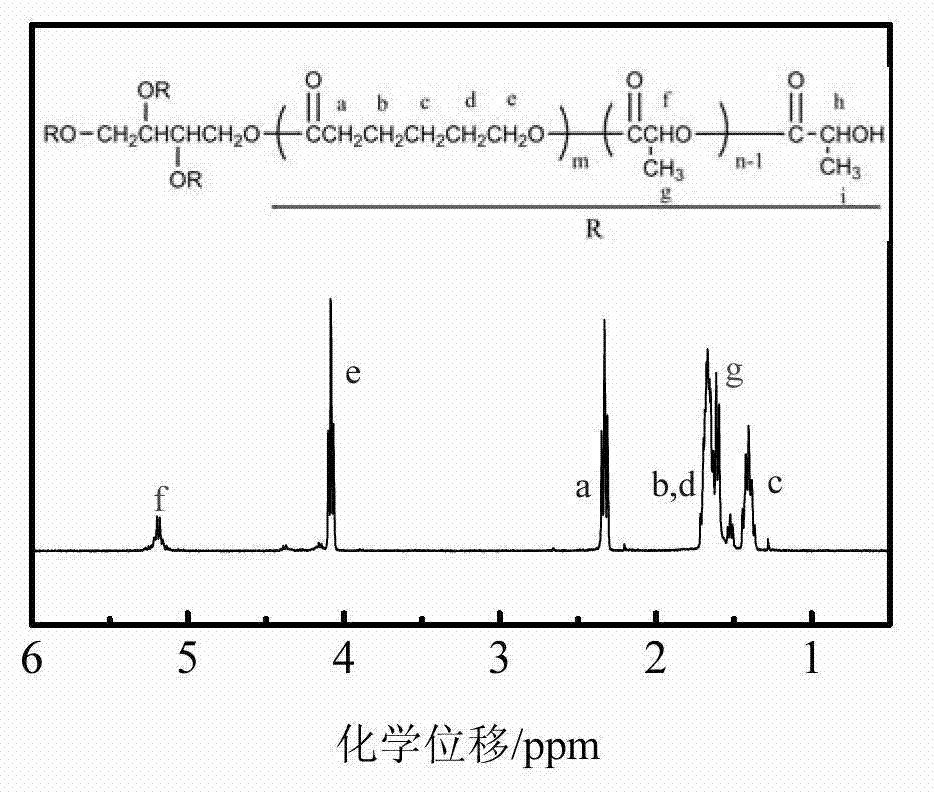

Multi-arm block copolymer, preparation method and application of multi-arm block copolymer in improvement of mechanical property of poly-L-lactic acid thereof

The invention discloses a multi-arm block copolymer and a preparation method as well as an application of the multi-arm block copolymer. Each arm of the multi-arm block copolymer is structured by a soft section and a hard section, wherein the soft section is poly-dl-lactide, or polycaprolactone or a copolymer of the poly-dl-lactide and the polycaprolactone; the hard section is poly-dextrolactic acid; a stereo composite crystal is formed through the poly-dextrolactic acid and the poly-dl-lactide of the multi-arm block copolymer and plays a role of a physical cross-link point; a multi-arm block copolymer system is fused and blended with the poly-dl-lactide, then a blend is formed by injection molding and a certain constant-temperature annealing treatment is carried out, so that the breaking elongation of the poly-dl-lactide can be obviously increased; and the multi-arm block copolymer can play a role of accelerating crystallization in the process of isothermal crystallization and still can retains good degradation and transparence properties, so that the important application prospects of the multi-arm block copolymer in modification of the mechanical property of the poly-L-lactic acid are shown.

Owner:INST OF CHEM CHINESE ACAD OF SCI

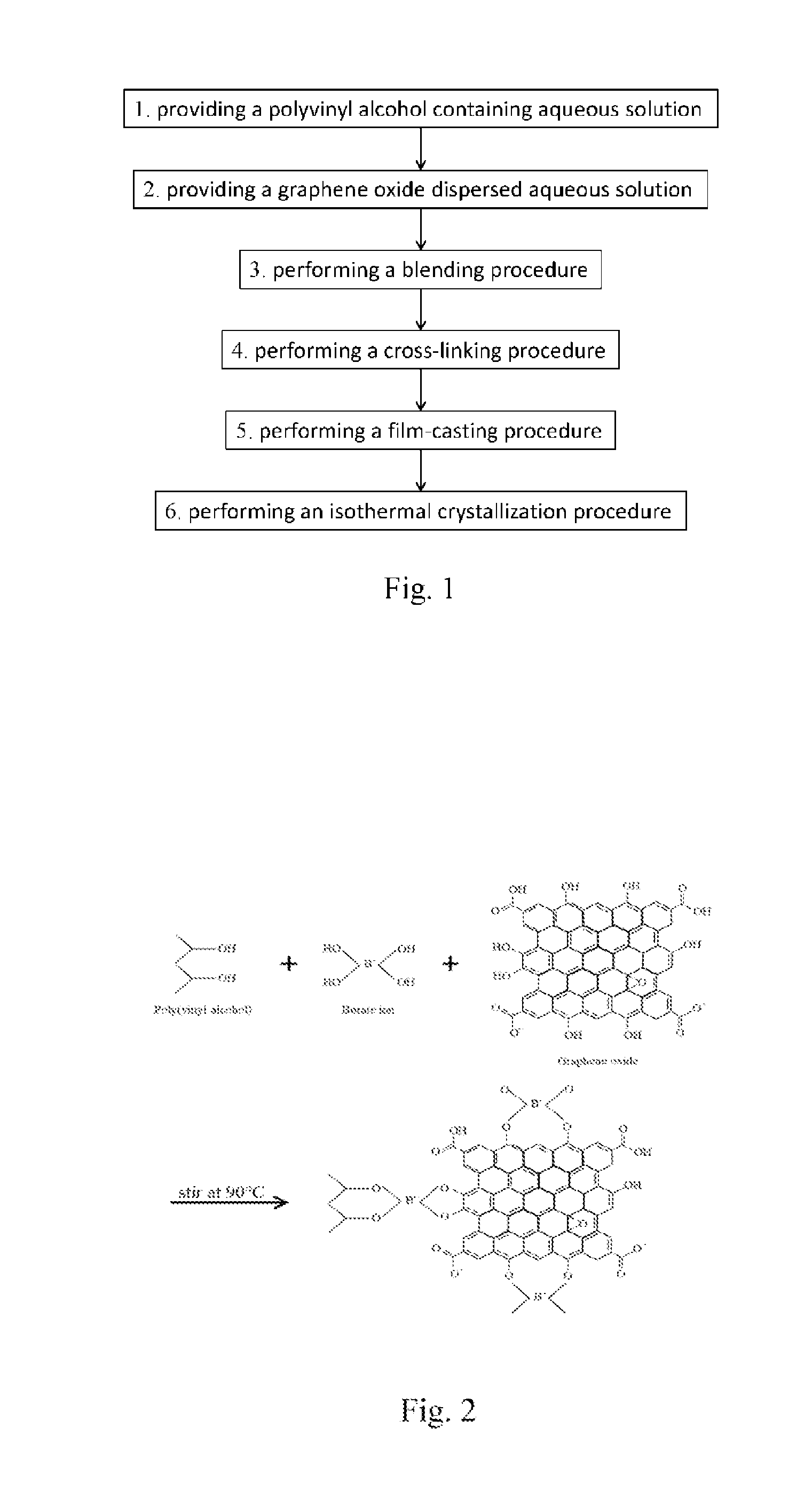

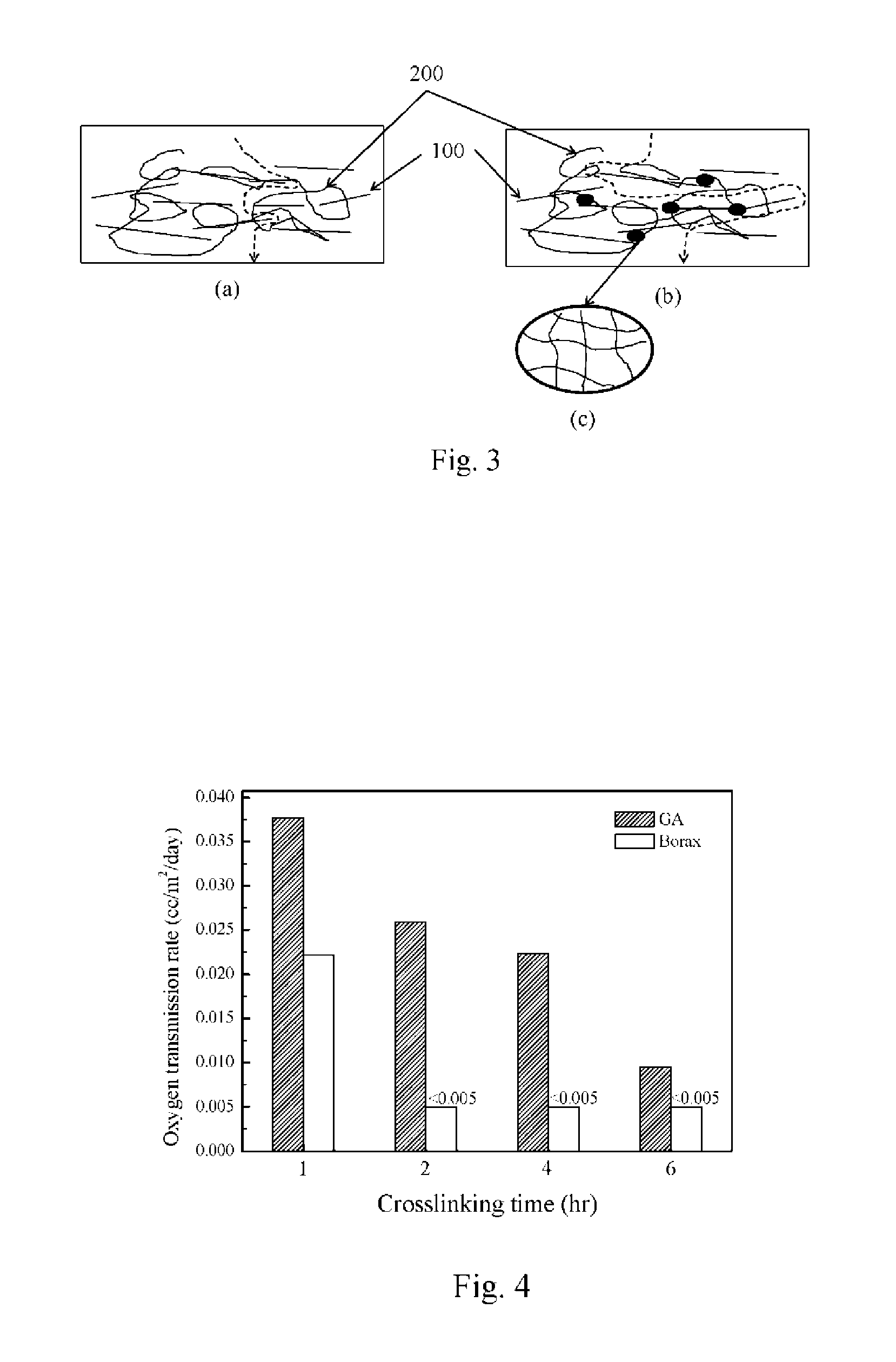

Transparent Gas Barrier Composite Film And Its Preparation Method

ActiveUS20160046773A1High light transmittanceEnhanced interactionPretreated surfacesCoatingsComposite filmPolyvinyl alcohol

The invention provides a transparent gas barrier composite film and its preparation method. The transparent gas barrier composite film is formed by having polyvinyl alcohol, graphene oxide and a crosslinking agent undergo blending, crosslinking, film casting and isothermal crystallization processes where a weight ratio of graphene oxide to polyvinyl alcohol is 0.1 wt %, graphene oxide induces crystallization of polyvinyl alcohol to form a hybrid structure compose of polyvinyl alcohol crystals, graphene oxide and the crosslinking agent, crystallinity of polyvinyl alcohol is more than 30%, transmittance of the composite film is more than 85%, and the oxygen transmission rate of the composite film is less than 0.005 cc / m2 / day.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

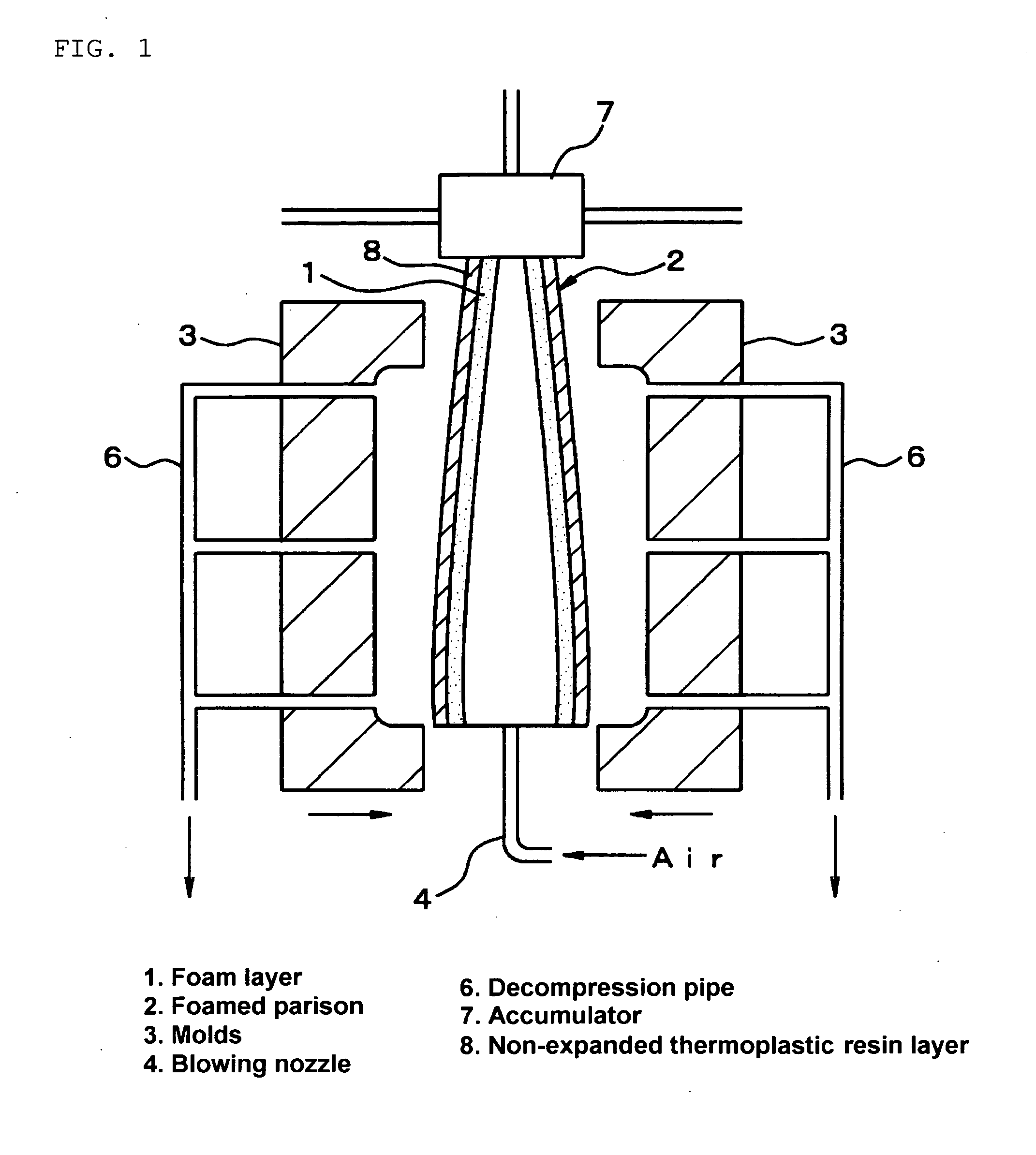

Polyethylene-based resin foamed blow molded article

InactiveUS20100279087A1High expansion rateSatisfactory mechanical propertyLayered productsDomestic articlesBlow moldingApparent density

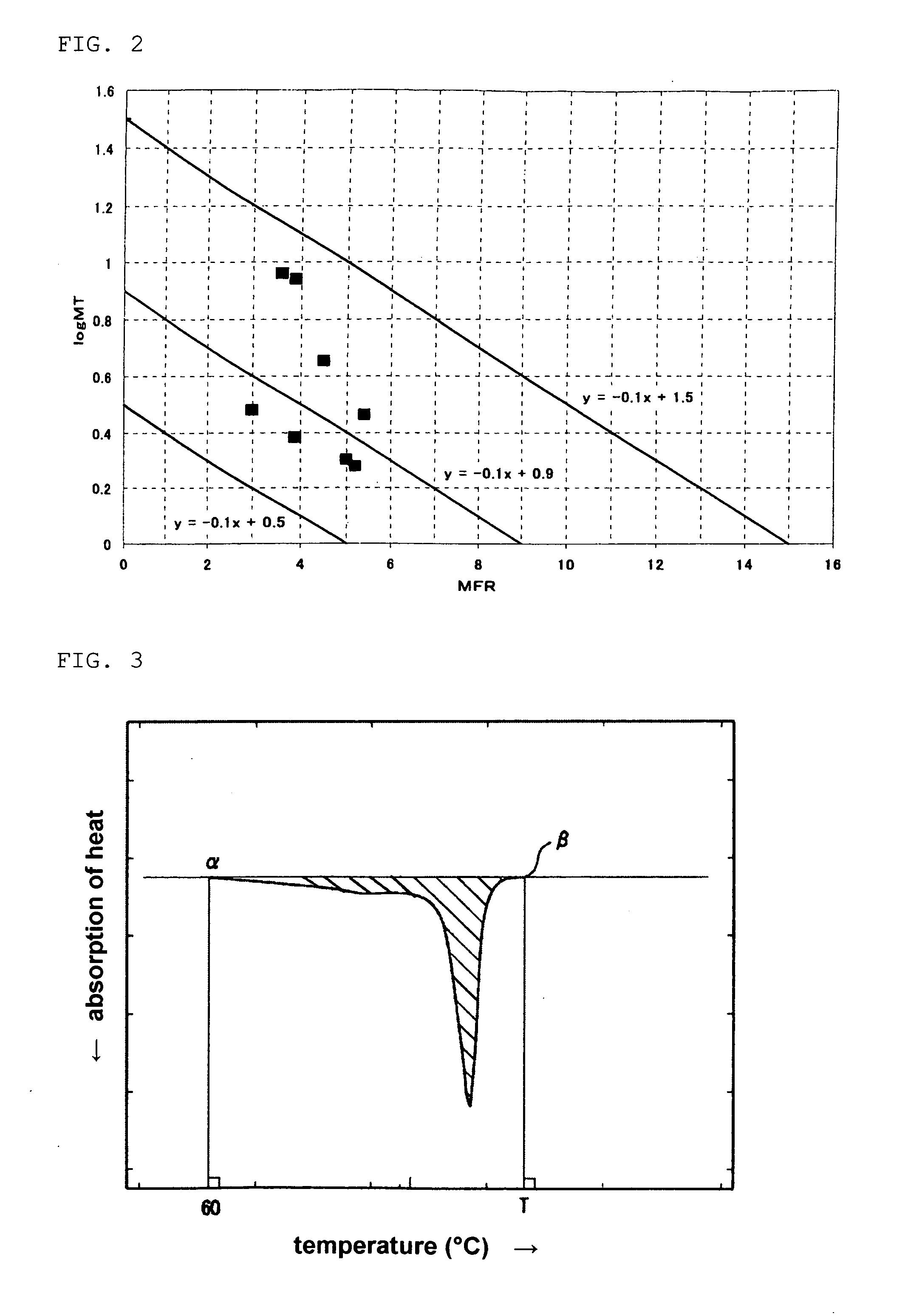

A polyethylene resin foamed blow molded article obtained by extruding a foamable resin melt to form a foamed parison, subsequently inserting the foamed parison in a mold, and blow molding the foamed parison,the foamed blow molded article having a foam layer having an apparent density of 0.1 g / cm3 or more to less than 0.7-g / cm3,wherein the resin composing the foam layer is:a polyethylene resin having a density of 0.935-g / cm3 or more,a melt tension of 0.7-cN or more at 190° C.,a melt flow rate (MFR) of 1 g / 10 min or more as measured at 190° C. under a load of 2.16-kg, andan one-quarter isothermal crystallization time of 40 seconds or longer, which is defined as the time required that an exothermic calorific value due to isothermal crystallization by measurement condition (I) becomes equal to one-quarter of a total endothermic calorific value by measurement condition (II).

Owner:JSP CORP

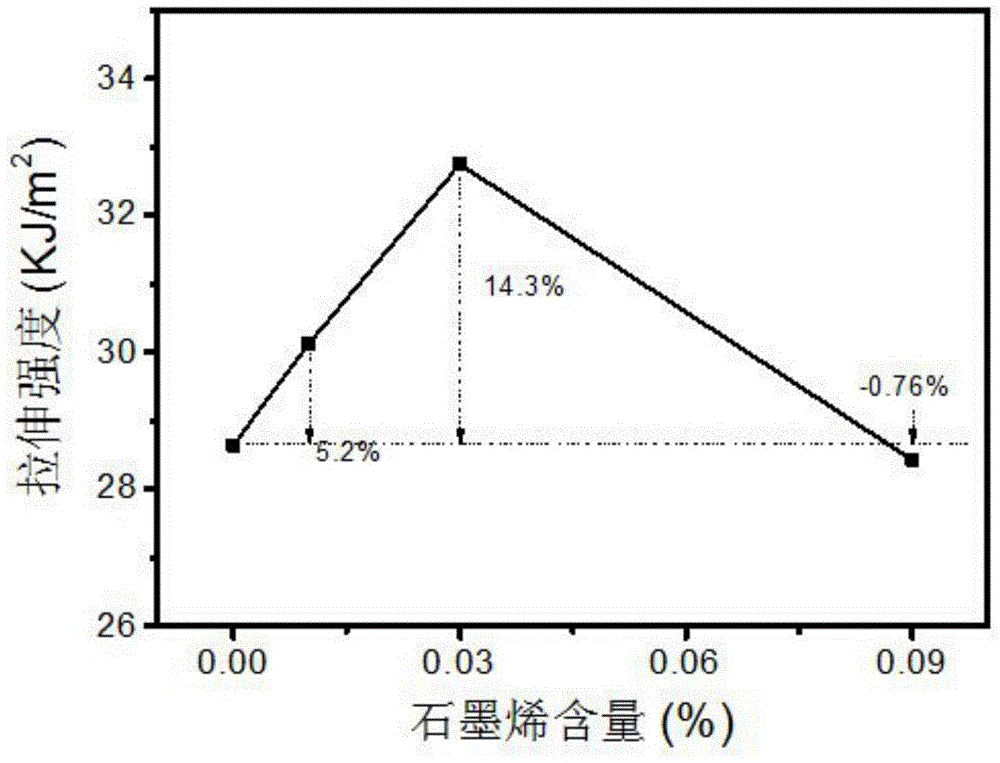

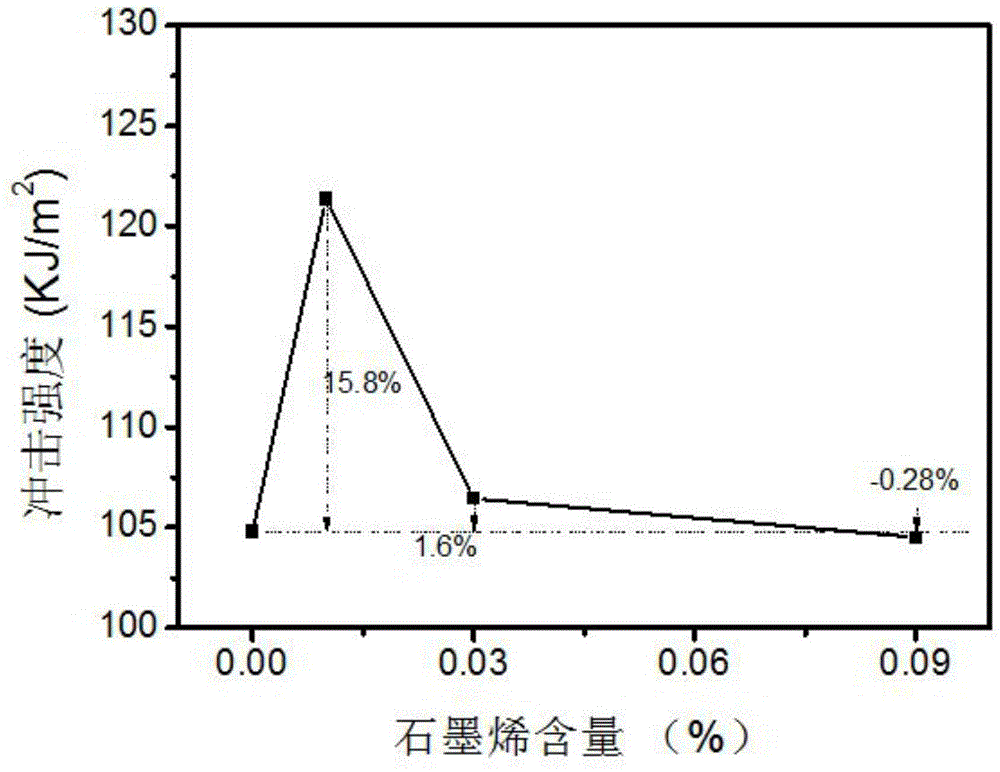

Method quickening II-I crystal form transformation of isotactic polybutylene-1 and applications in raising mechanical properties

The invention discloses a method quickening II-I crystal form transformation of isotactic polybutylene-1 and applications in raising mechanical properties. Graphene is added in isotactic polybutylene-1 in a fusion state, and after the mixture is mixed uniformly, isothermal crystallization is carried out. The crystal form transformation process is tracked by utilization of XRD, the result shows that addition of graphene promotes crystal form transformation of isotactic polybutylene-1, and in addition, the tensile strength and the impact performance of isotactic polybutylene-1 are raised after test of a universal stretcher and an impact tester.

Owner:TIANJIN UNIV

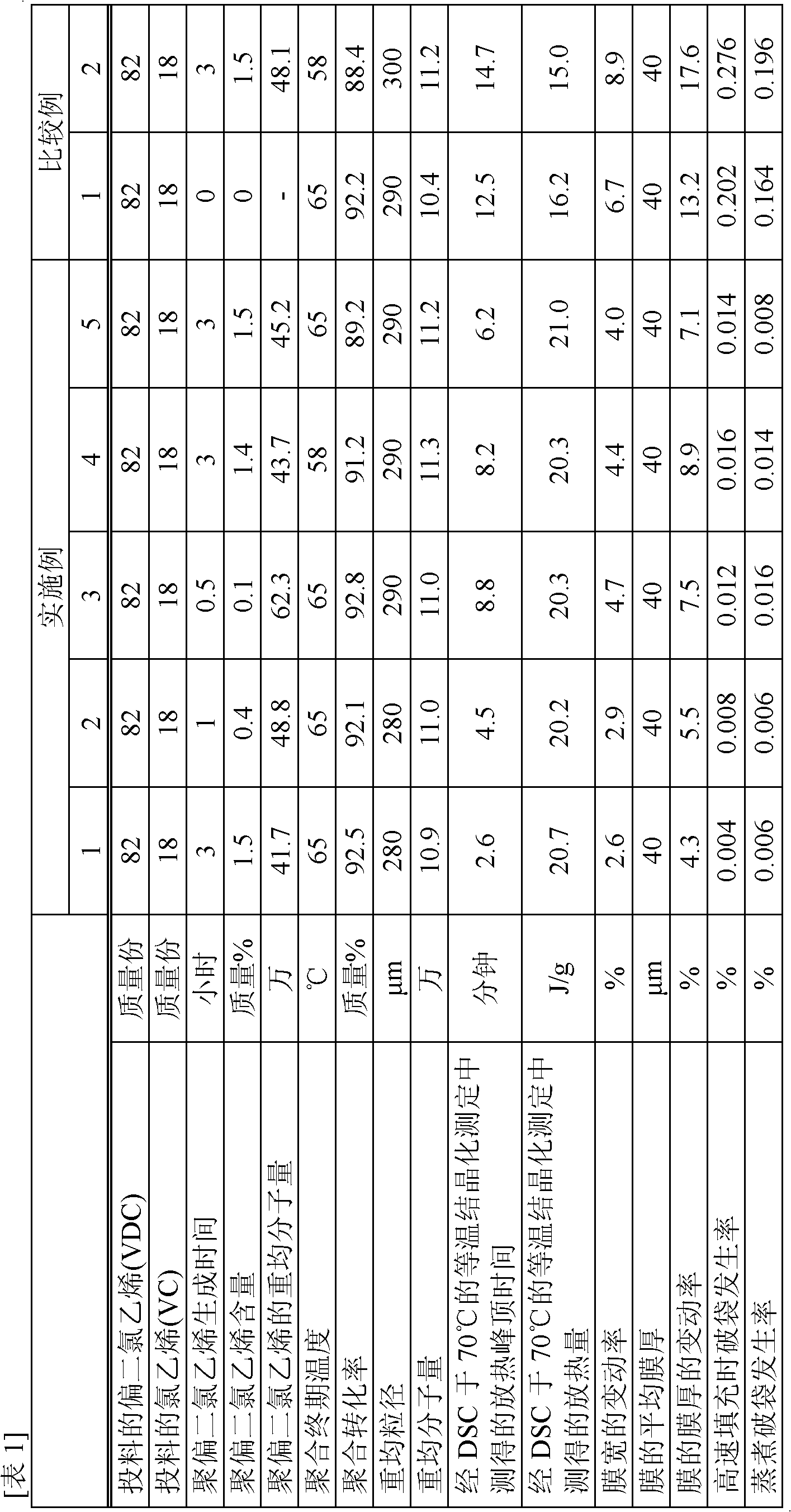

Vinylidene chloride copolymer, and its membrane or sheet material

ActiveCN103224582AExcellent adaptability to drawing processingImprove film thickness uniformityFlexible coversWrappersChlorideIsothermal crystallization

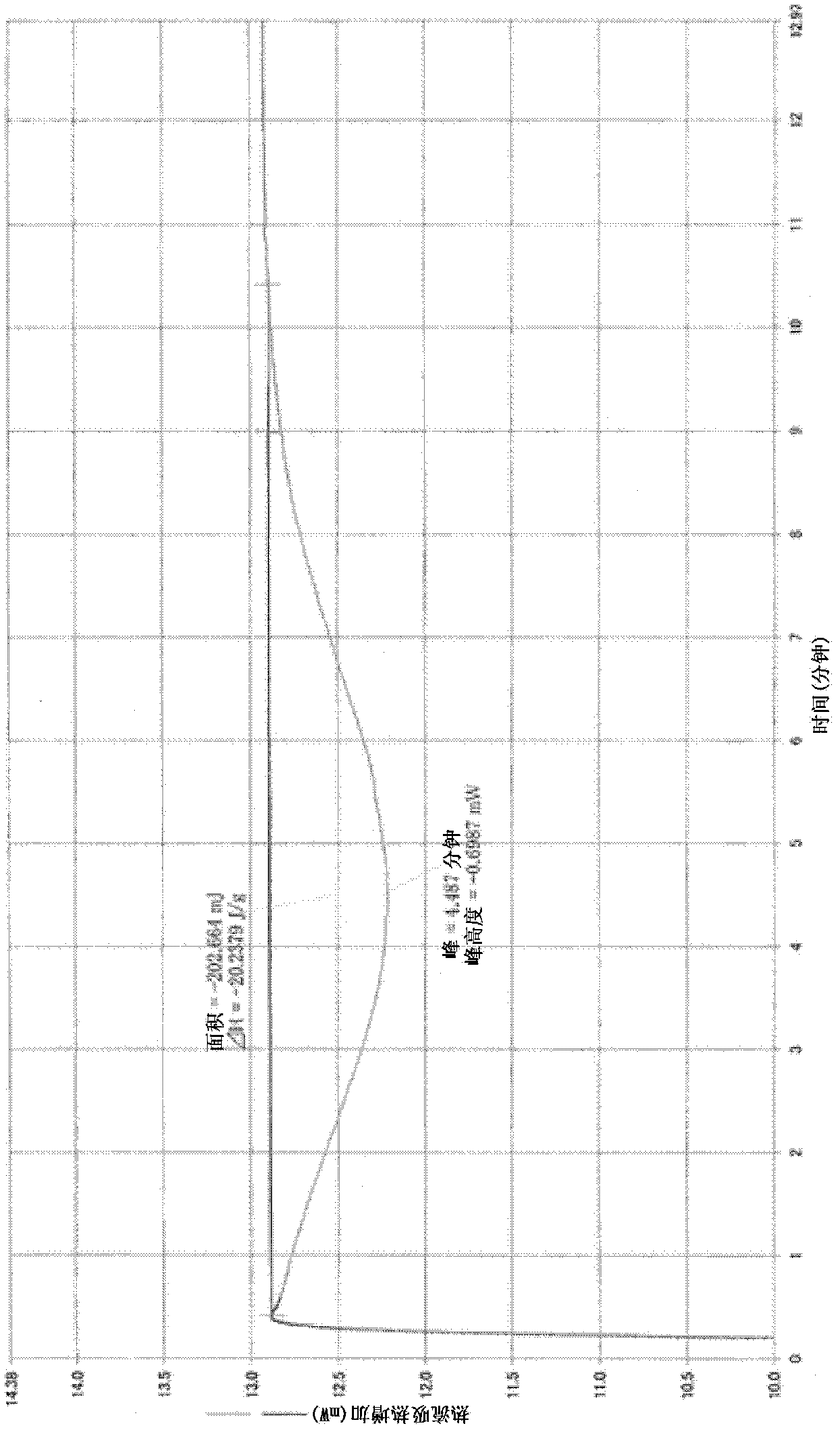

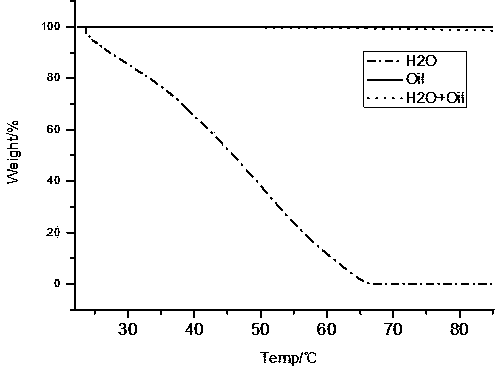

The invention relates to a vinylidene chloride copolymer composition, the stretch processing adaptability during a melt molding process is excellent, thereby membrane thickness uniformity of the obtained membrane or the sheet material is excellent, and the high frequency seal adaptability and heating pressurization sterilization adaptability (so-called boiling adaptability) of the provided membrane or the sheet material are excellent; The vinylidene chloride copolymer is the vinylidene chloride copolymer formed by vinylidene chloride and a polymerism vinyl monomer, wherein, through the differential scanning calorimetry thermal detection (DSC), and the heat release summit time of the vinylidene chloride copolymer detected in an isothermal crystallization detection at 70 DEG C is less than 10 minutes.

Owner:ASAHI KASEI KK

Preparation method of amorphous alloy gradient composite material

ActiveCN112935251AEasy to manufactureSimple processImage analysisChemical processes analysis/designNerve networkIsothermal crystallization

The invention belongs to the field of amorphous alloy composite material preparation, and particularly relates to a preparation method of an amorphous alloy gradient composite material. According to the preparation method of the amorphous alloy gradient composite material, an isothermal crystallization rule of an amorphous alloy matrix is obtained through an experiment, and a nonlinear mapping relation between sintering process parameters and reinforcement phase characteristic parameters is established through a neural network; a required temperature field is reversely deduced by combining reinforcement phase distribution characteristics of a target amorphous alloy gradient composite material, and then a sintering mold is designed by taking amorphous alloy powder or a block as a raw material and adopting a spark plasma sintering technology and combining numerical simulation, and spark plasma sintering treatment is carried out on the amorphous alloy powder under the required sintering process parameters and temperature field to obtain the amorphous alloy gradient composite material with continuous gradient distribution of the reinforced phase. According to the preparation method of the amorphous alloy gradient composite material, flexible design and preparation forming of the large-size bulk amorphous alloy gradient composite material can be achieved, the process is simple and efficient, a reinforced phase is obtained in an in-situ endogenous mode, and the interface bonding state is good.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for synthesizing polylactic acid

The invention provides a method for synthesizing polylactic acid. The method comprises the following steps: taking and putting 75-95 percent by mass of lactic acid solution in a reaction container andde-watering at a temperature of 90-120 DEG C and a pressure intensity of 1-2 kpa till the moisture content is 0.1-1 percent by weight; adding a zinc catalyst in the reaction container, increasing thetemperature to 120-150 DEG C and reacting for 5-15 hours at a pressure intensity of 0.001-2 kpa to prepare a lactic acid prepolymer; performing isothermal crystallization on the lactic acid prepolymer at a temperature of 90-140 DEG C, crushing, adding pentaerythritol and p-toluene sulfonic acid and reacting for 2-6 hours at a pressure intensity of 5 kpa and a temperature of 90-150 DEG C in a molecular sieve environment; and then reducing the pressure intensity to 0.001-2 kpa and reacting for 3-6 hours at a temperature of 130-170 DEG C to prepare a polylactic acid product. The method for synthesizing the polylactic acid can obtain the polylactic acid with more dealer molecular weight and solve the problems of tedious solvent recovery steps and solvent residue in the product, thereby improving the reaction rate, shortening the reaction time and facilitating large-scale industrial production.

Owner:SHANGHAI CHANGFA NEW MATERIAL CO LTD

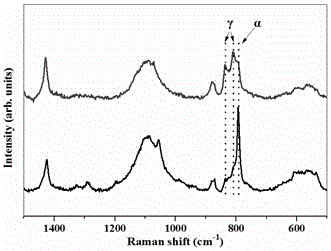

Method for promoting alpha-to-gamma crystal transformation of vinylidene fluoride

The invention discloses a method for promoting alpha-to-gamma crystal transformation of vinylidene fluoride. The method for promoting alpha-to-gamma crystal transformation of the vinylidene fluoride comprises adding graphene into the vinylidene fluoride for melt-mixing to fully mixing the graphene and the vinylidene fluoride; extracting tablets, and performing melt isothermal crystallization; performing DSC (differential scanning calorimetry) testing on fully-crystallized samples, analyzing change of the crystal structure of the samples. The method for promoting alpha-to-gamma crystal transformation of the vinylidene fluoride discovers that adding in the graphene can improve the alpha-to-gamma crystal transformation rate of the vinylidene fluoride, and the higher the added content of the graphene is, the more significant the improvement is.

Owner:TIANJIN UNIV

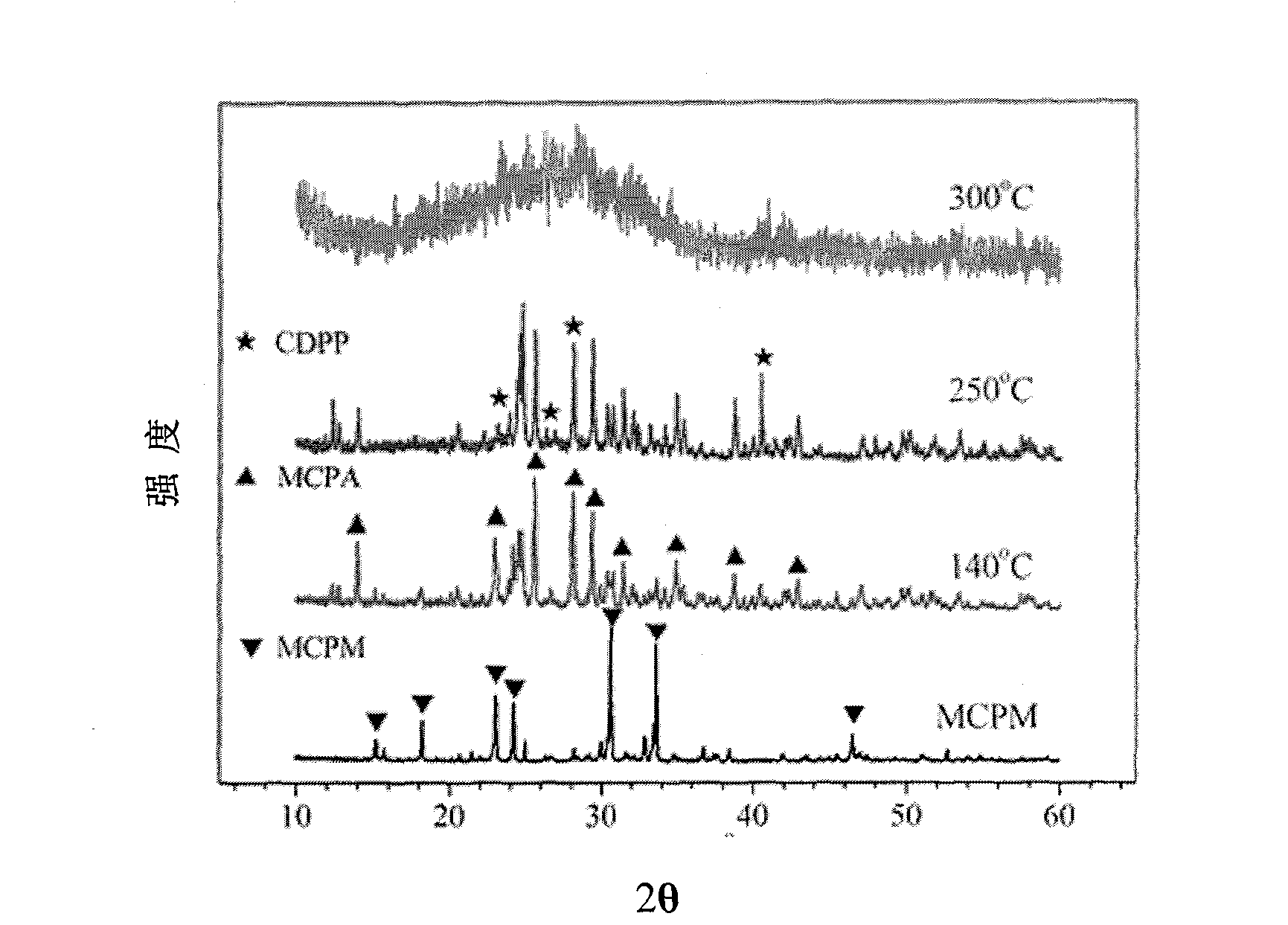

Preparation method of calcium metaphosphate porous bioceramic

The invention relates to a preparation method of calcium metaphosphate porous bioceramic. The preparation method is characterized by using calcium oxide and phosphoric acid as initial reactants to synthesize monocalcium phosphate monohydrate (Ca(H2PO4)2.H2O, MCPM) powder by means of isothermal crystallization chemical precipitation according to the formation mechanism of calcium metaphosphate; carrying out thermal treatment on the powder at different temperatures respectively to synthesize monocalcium phosphate (Ca(H2PO4)2, MCPA) powder and calcium dihydrogen pyrophosphate (CaH2P2O7, CDPP) powder; preparing the calcium metaphosphate porous ceramic from the powder synthesized respectively in the condition of controlling the molding process and the sintering mechanism (such as the molding pressure of the sample, and the temperature raising rate of the initial thermal treatment). The gas released when different crystal water contained in the raw material is decomposed is used as a pore forming agent, and the synthesis method of the powder and the preparation process of the porous body are controlled to obtain the calcium metaphosphate porous ceramic prepared by adopting the preparation method disclosed by the invention.

Owner:NANJING UNIV OF TECH

High pressure forming method for increasing crystallinity of polylactic acid

The invention discloses a high pressure forming method for increasing crystallinity of polylactic acid. The method is as below: placing dried polylactic acid particles in a high pressure die; first heating to 185 DEG C and maintaining for long enough to completely eliminate the thermal history; slowly cooling with a speed of 2.5 DEG C / min to a forming temperature (120-185 DEG C); applying a pressure of 300-1500MPa and maintaining for 0.5- 24 h for isothermal crystallization; and eventually releasing pressure until temperature decreases to room temperature. A polylactic acid product prepared by the method gains significantly improved crystallinity behavior, crystallinity as high as 66.3%, and obviously improved heat resistance and mechanical properties. The invention can further broaden application value and use range of polylactic acid.

Owner:SICHUAN UNIV

Heat-proof polylactic acid blend and preparation method thereof

Owner:ZHEJIANG HISUN BIOMATERIALS +1

Method for accelerating crystallization of isotactic poly 1-butylene by shear flow

The invention discloses a method for accelerating crystallization of isotactic poly 1-butylene by shear flow, when the temperature is reduced from heat treatment temperature to the crystallization temperature, the isotactic poly 1-butylene is applied with shear flow, and is fully crystallized by maintaining for enough time. The heat treatment temperature is 200 DEG C, and thermal history can be eliminated by maintaining for 5min at the heat treatment temperature. The isothermal crystallization temperature is 85 DEG C, the shear rate is 10-40s<-1>, and the shear time is 5S. According to the method, macromolecular chains in mesomorphic phase are in directional arrangement along flow direction, the entropy of crystallization can be reduced, the number of crystal nucleus is increased significantly, and the crystal growth period is decreased to accelerate the crystallization of 1-butylene.

Owner:TIANJIN UNIV

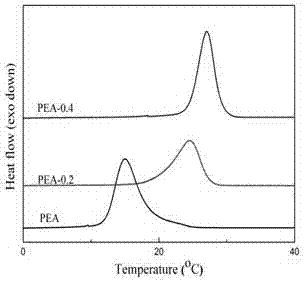

Method for preparing polyhexamethylene glycol/ terminal hydroxyl multi-wall carbon nanotube nanocomposite film

InactiveCN107236262ARaise the crystallization temperatureIncrease added valueSolventIsothermal crystallization

The invention discloses a method for preparing polyhexamethylene glycol / terminal hydroxyl multi-wall carbon nanotube nanocomposite film. The method comprises the following steps of 1, taking the terminal hydroxyl multi-wall carbon nanotube nanocomposite film out after drying for 3 days, weighing different weights of terminal hydroxyl multi-wall carbon nanotube nanocomposite film and putting into 10mL N,N-dimethylformamide solvent and ultrasonically dispersing for 1h; 2, weighing different weights of polyhexamethylene glycol to dissolve into 10mL DMF; 3, mixing solution acquired in the step 1 and the step 2 in proportion, ultrasonically dispersing for 2h after mechanical stirring to acquire cast film solution; 4, moving the cast film solution to cure on a constant temperature heating stage to form film; and 5, cooling the blended film prepared by in the step 4 to 25-35 DEG C for isothermal crystallization until complete crystallization. The method is simple in technology, convenient to operate, short in preparation period, and capable of being used as a degradable functional high polymer material, and has potential application value in aspects of capacitors, sensors and biological medical instruments.

Owner:SHAANXI UNIV OF SCI & TECH

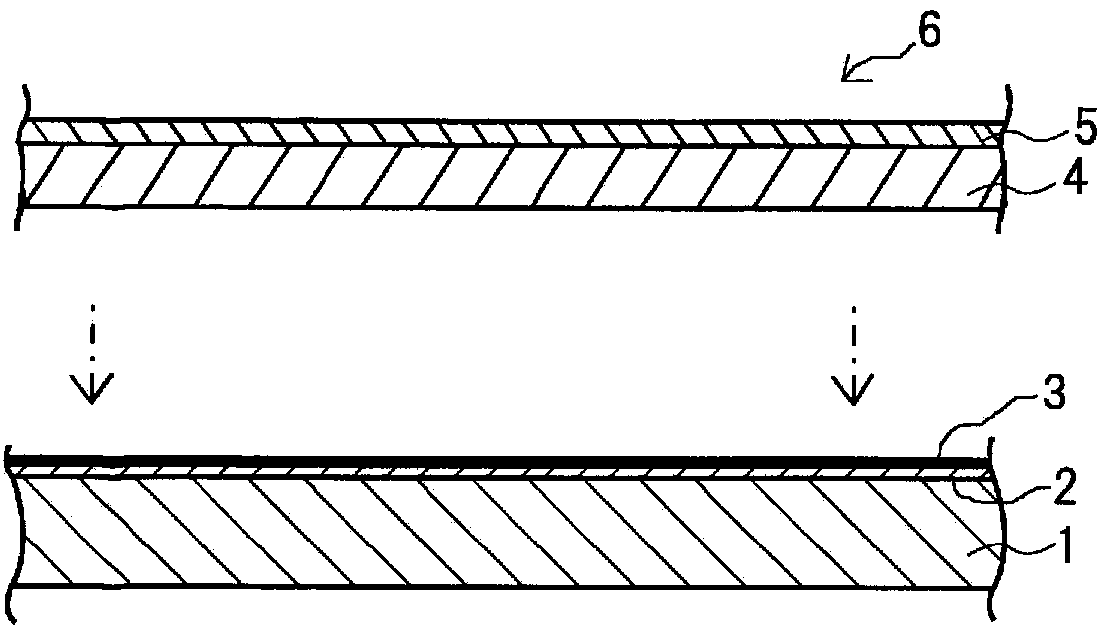

Resin-coated aluminum plate, and outer container for electronic components

InactiveCN103998234APrevent appearance changesShort semi-crystallization timeLiquid surface applicatorsSynthetic resin layered productsPolyamideAdipic acid

Provided is a resin-coated aluminum plate, which does not undergo the deterioration of appearance quality which may be caused by the crystallization of a coating resin during storage, and in which the adhesion between an aluminum plate and a resin layer is high and the resin layer has excellent alcohol resistance. An resin-coated aluminum plate produced by coating an anodically oxidized surface of an aluminum plate that has been subjected to an non-porous anodic oxidation treatment with a polyamide resin layer, wherein the polyamide resin layer comprises 100 parts by mass of a resin component and 0.01 to 10 part by mass of a crystallization-accelerating agent, the resin component comprises a mixed resin comprising 50 to 80 parts by mass of an aromatic polyamide (A) containing 90 mol% or more of a structural unit produced by the polycondensation reaction of metaxylylene diamine with adipic acid and 50 to 20 parts by mass of nylon-6 (B) (wherein the sum total of the components (A) and (B) is 100 parts by mass), the crystallization start temperature of the polyamide resin layer is 177 to 200 DEG C as measured by a DSC measurement in which the polyamide resin layer is heated and melted and then the melted product is cooled at a cooling rate of 10 DEG C / min, and the semi-crystallization time of the polyamide resin layer is 2 minutes or shorter as measured by a 120 DEG C isothermal crystallization test.

Owner:MITSUBISHI PLASTICS INC

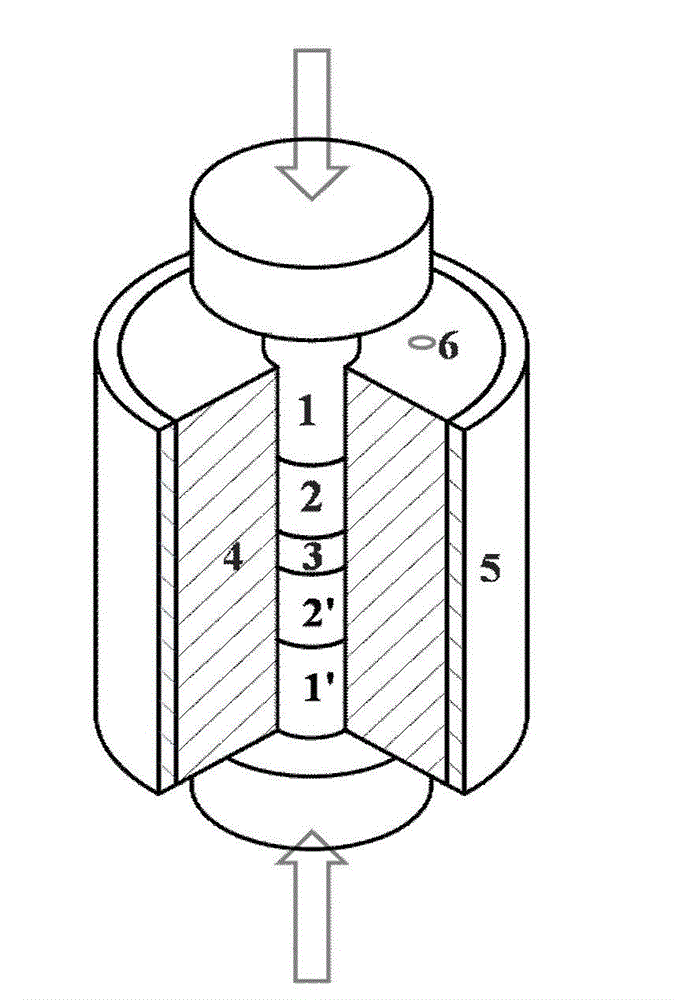

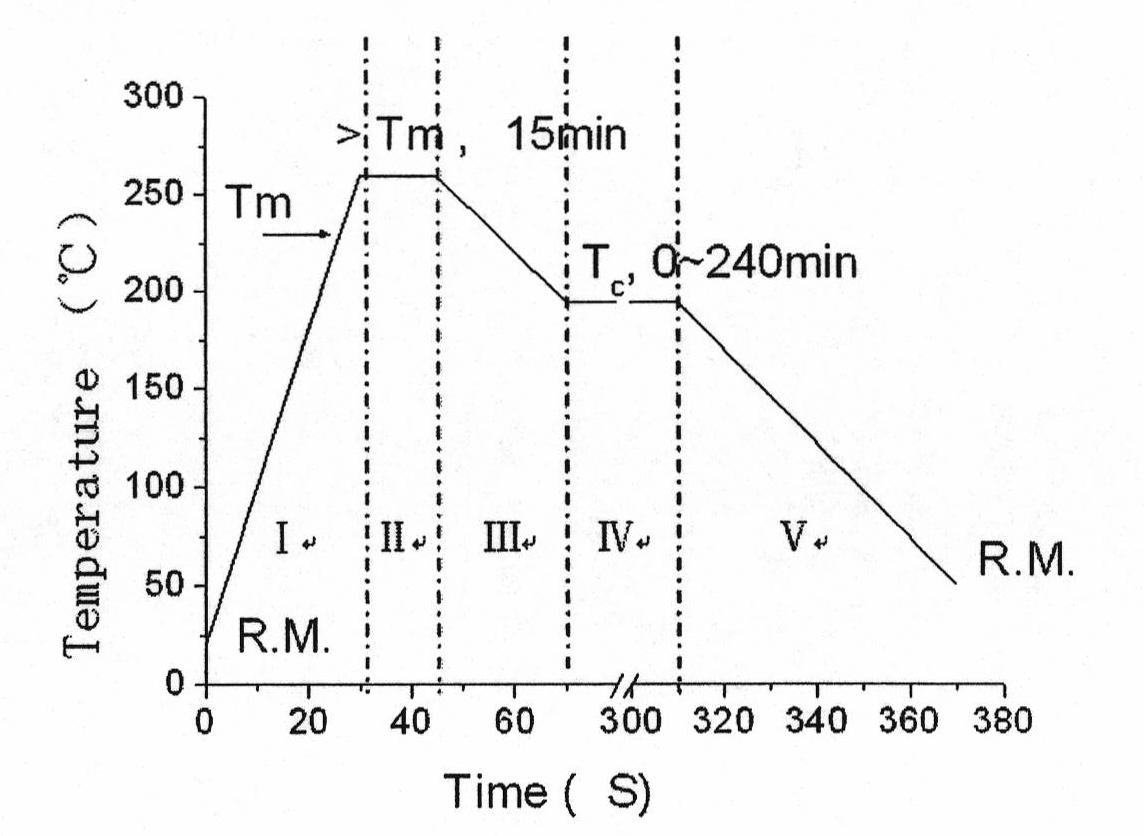

Method and device for regulating aggregate structure of thermoplastic semicrystalline polymer by using pulsed magnetic field

The invention relates to a method and a device for regulating an aggregate structure of thermoplastic semicrystalline polymer by using a pulsed magnetic field. The method comprises the following steps of: drying polymer; putting a polymer raw material under the pulsed magnetic field in inert atmosphere, or eliminating the thermal history of the polymer and putting the polymer under the pulsed magnetic field; controlling the intensity and frequency of the pulsed magnetic field; heating at the heating speed of 2 to 10 DEG C / minute to a temperature which is 20 to 30 DEG C higher than the melting point of the polymer, and keeping the temperature for 10 to 20 minutes; cooling at the cooling speed of 2 to 10 DEG C / minute to a temperature which is 75 to 95 DEG C lower than the melting point of the polymer, performing isothermal crystallization on the polymer for 5 to 240 minutes, and cooling at the cooling speed of 2 to 10 DEG C / minute to room temperature; or cooling at the constant cooling speed of 2 to 10 DEG C / minute to room temperature. By adopting the pulsed magnetic field, the crystallization action of the thermoplastic semicrystalline polymer can be changed so as to control the structure and optimize performance.

Owner:SHANGHAI UNIV

Completely stereotyped high-toughness polylactic acid stereocomplex and preparation method thereof

ActiveCN111393817AIncreased stereocomplex crystallinityImprove toughnessPolymer scienceCarvacryl acetate

The invention belongs to the field of polymer composite materials, and particularly relates to a completely stereotyped high-toughness polylactic acid stereocomplex and a preparation method thereof. The polylactic acid stereocomplex provided by the invention is prepared by carrying out melt blending on raw materials and then carrying out isothermal crystallization, wherein the raw materials comprise: 50 parts by weight of poly-L-lactic acid; 50 parts by weight of poly(D-lactic acid); 10-20 parts by weight of a compatible blend; and 10-20 parts by weight of a toughening agent; wherein the compatible blend comprises polyvinyl acetate and / or poly-racemic lactic acid; the toughening agent comprises a vinyl acetate-vinyl laurate copolymer and / or a racemic lactic acid-caprolactone copolymer; andthe temperature of isothermal crystallization is 90-140DEG C. According to the invention, the stereocomplex crystallinity and toughness of the polylactic acid stereocomplex are obviously improved bystrictly controlling the dosage ratio of the poly-L-lactic acid to the poly(D-lactic acid) in the raw materials, adding the compatible blend and the toughening agent and adopting an isothermal crystallization process.

Owner:云南利翀科技有限公司

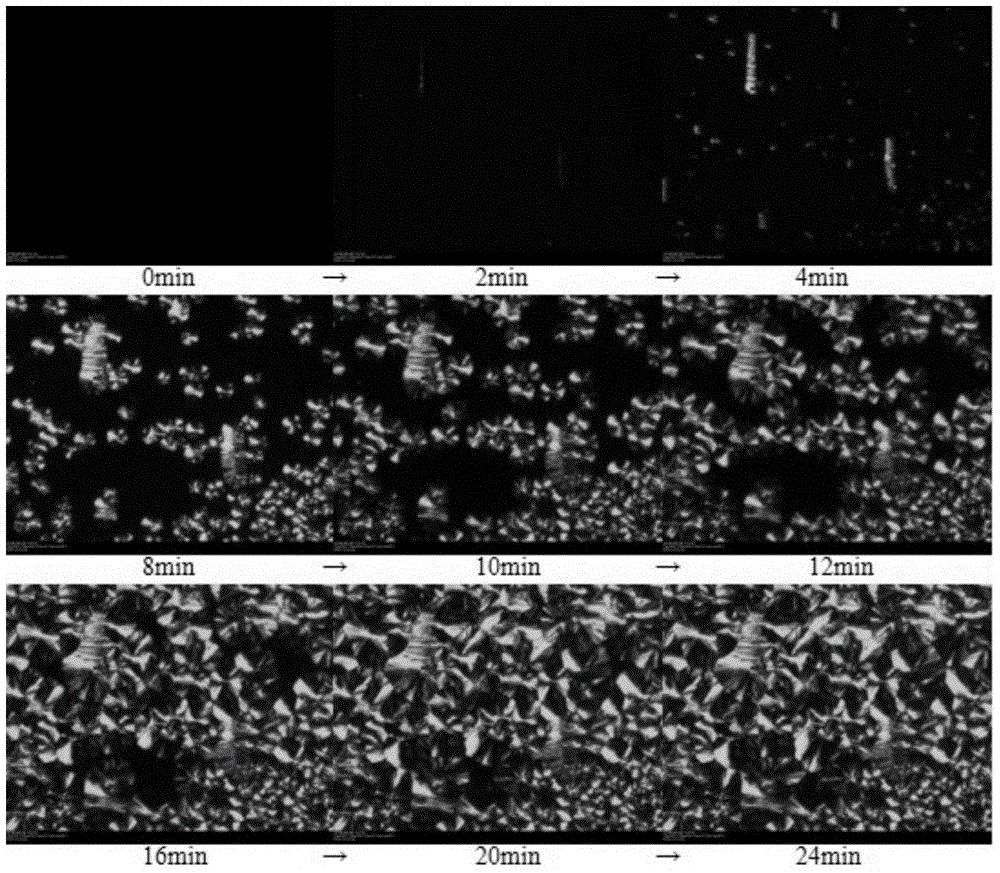

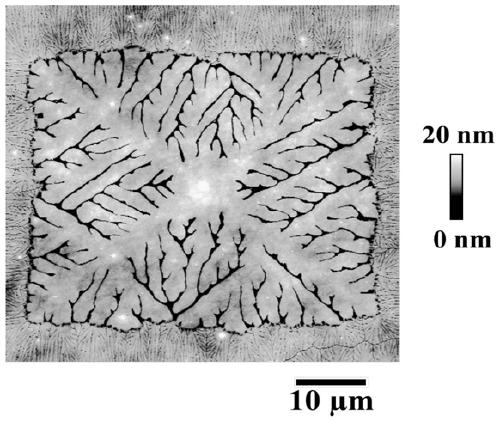

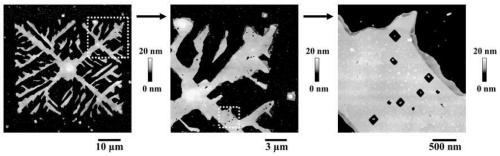

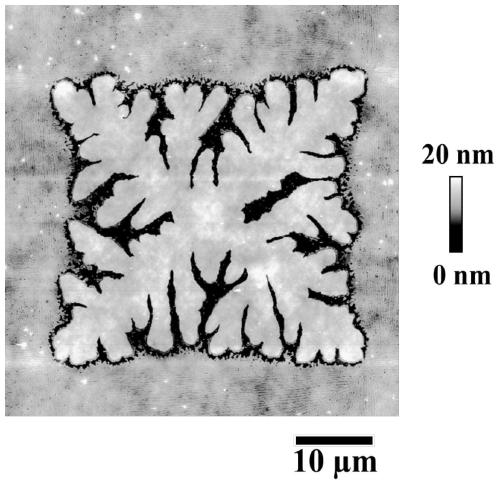

Method for constructing micro-nano patterns in high-molecule film lamellas through selective dissolution

The invention discloses a method for constructing micro-nano patterns in high-molecule film lamellas through selective dissolution. According to the method, polyoxyethylene is utilized as a raw material and is completely dissolved into an organic solvent to obtain a mixed solution; the mixed solution is spin coated to a silicon wafer to obtain a polyoxyethylene film; melting isothermal crystallization is performed on the polyoxyethylene film under a nitrogen protective atmosphere; the organic solvent is utilized to dissolve the film subjected to the isothermal crystallization; the solvent is blown and dried after the dissolution is finished, and the different patterns can be constructed in the film lamellas. The method is simple and easy to operate; the method can be applied to constructing the different structural patterns in the high-molecule lamellas, can judge stability of the inside in the lamellas through structures and can provide technical research contents of important theoretical support and the like for researching the high-molecule crystallization materials. The effects on high-molecule crystallization can be theoretically deepened, a crystallization state can be regulated in actual application, performance is optimized, materials and products with preset performance can be obtained, and very important significances are achieved.

Owner:ZHENGZHOU UNIV

Thermal analysis method of TiO2 crystallization by water supporting at low temperature

InactiveCN103822939AProtection against changes in the environment (e.g. concentration)Convenient and quick thermal analysis methodMaterial thermal analysisWarming processIsothermal crystallization

The invention discloses a thermal analysis method of TiO2 crystallization by water supporting at low temperature, which is characterized in that a DTA or DSC method is used for determining a crystallization process of TiO2 under water infiltration condition. The method comprises the following steps: a cover layer is added on the surface of a solution sample to overcome the moisture volatilization during a determination process; detection sensitivity is increased by taking water and a covering substance as references, an isothermal crystallization mode is used, and the influence of TiO2 water infiltration temperature and infiltration time to the TiO2 crystallization phase transition by water supporting at low temperature can be researched according to an exothermic peak on an isothermal curve. According to the invention, the moisture volatilization of an aqueous solution sample during a heating process is effectively overcome, influence of the experimental environment to the experiment result is reduced, and the detection sensitivity of thermal analysis is increased. The operation of the thermal analysis method is convenient, the determination result is visual, and the thermal analysis method is the effective method for researching the TiO2 crystallization characteristic by water supporting at low temperature.

Owner:NANJING NORMAL UNIVERSITY

Multilayered container

InactiveUS20100136271A1Excellent in solid-state molding processabilityEasy to processFlexible coversWrappersInter layerShell molding

Disclosed is a multilayered container having an intermediate layer comprising an oxygen-absorbable barrier resin composition showing excellent processability upon molding. Specifically disclosed is a multilayered container which comprises an inner layer and an outer layer each comprising an olefin resin and an intermediate layer provided between the inner layer and the outer layer and comprising an oxygen-absorbable barrier resin composition, wherein the oxygen-absorbable barrier resin composition has a cooling crystallization peak temperature lower than that of a base resin (an oxygen barrier resin) which constitutes the oxygen-absorbable barrier resin composition, the multilayered container is formed by a solid-phase forming process at a temperature lower by 1 to 15° C. than the cooling crystallization starting temperature (Tc2) of the base resin, and the body of the container shows a calorific value of less than 0.5 J / g by the isothermal crystallization after heating from 30° C. to 130° C. at a heating rate of 100° C. / min in a thermal analysis of the body.

Owner:TOYO SEIKAN KAISHA LTD

High-strength super-tough polylactic acid nano-pore foaming material and preparation method thereof

ActiveCN111574745ANo pollution in the processRetain degradabilityIsothermal crystallisationPolymer science

The invention discloses a high-strength super-tough polylactic acid nano-pore foaming material and a preparation method thereof. The method comprises the following steps: firstly, carrying out vacuumdrying on a polylactic acid raw material, then carrying out hot pressing on polylactic acid to form a plate, and carrying out isothermal crystallization at 100-120 DEG C for 3-5 hours; cutting the polylactic acid plate subjected to isothermal crystallization into small sample strips, putting the small sample strips into the middle of a pressure-induced flow forming mold, and carrying out low-temperature pressure-induced flow forming for 5-10 minutes under the conditions that the temperature ranges from 80 DEG C to 130 DEG C and the pressure ranges from 30 MPa to 300 MPa; and putting the samplestrips subjected to pressure-induced flow forming into a high-pressure kettle, performing sealing, adding a physical foaming agent, soaking for 4-12 hours under the conditions that the temperature ranges from 100 DEG C to 120 DEG C and the pressure ranges from 8 MPa to 20 MPa, and obtaining the polylactic acid nano-pore foaming material through rapid pressure relief. The polylactic acid preparedby the method provided by the invention has a large number of uniformly distributed nanopores, and has excellent mechanical properties.

Owner:HUBEI UNIV OF TECH

Preparation method of MgCl2-doped annular gamma-phase polyvinylidene-fluoride-base composite film

ActiveCN106009426AHigh gamma contentImprove electrical performanceComposite filmScanning electron microscope

The invention relates to a preparation method of an MgCl2-doped annular gamma-phase polyvinylidene-fluoride-base composite film. The preparation method comprises the following steps: 1) preparing a polyvinylidene fluoride / MgCl2 blend solution by using N,N-dimethylformamide (DMF) as a solvent; 2) preparing blend solutions with different mass percents into films on a hot stage, sandwiching each film between two transparent glass plates to prepare a sandwich structure; 3) eliminating the heat history of the blend films with different mass percents in the step 2), carrying out cooling and isothermal crystallization, and applying until the blend films completely crystallize; and 4) characterizing the gamma crystal form and gamma crystal form topographic characteristics of the blend films by using an infrared spectroscopy, a Raman spectroscopy, a differential scanning calorimeter, a polarized light microscope, a scanning electron microscope and other means. The method has the advantages of simple main technique and short preparation period, is convenient to operate, and can prepare the gamma-polyvinylidene-fluoride-base composite film with large size and special annular shape; and the gamma-polyvinylidene fluoride has the unique electric properties different from alpha-polyvinylidene fluoride.

Owner:SHAANXI UNIV OF SCI & TECH

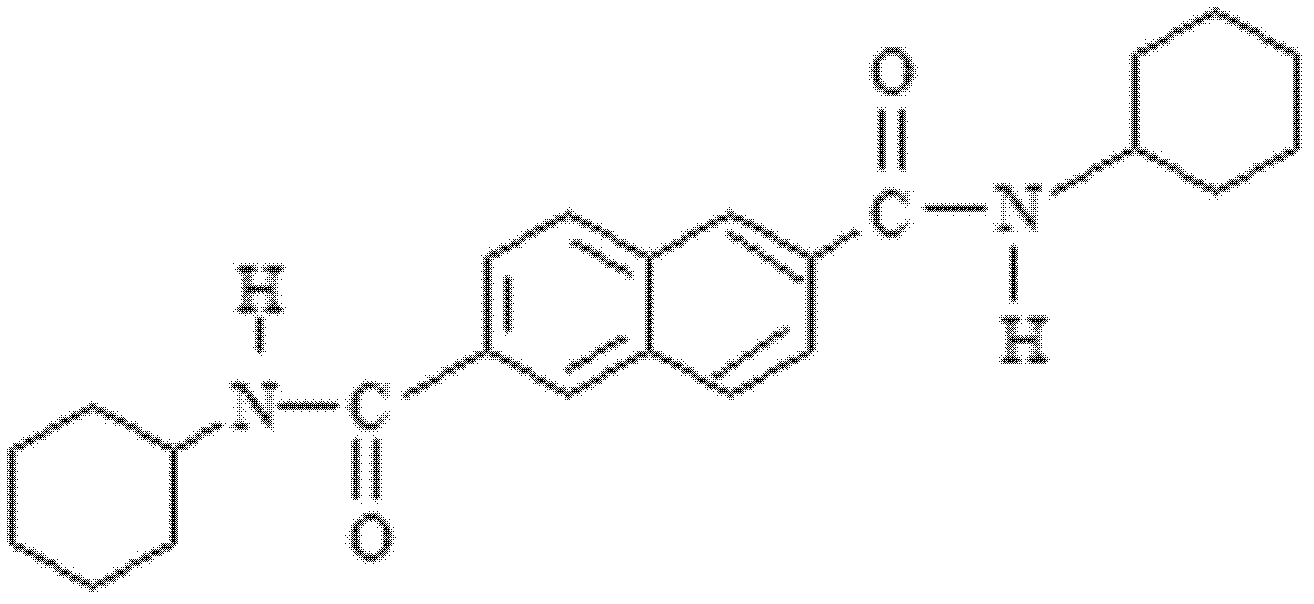

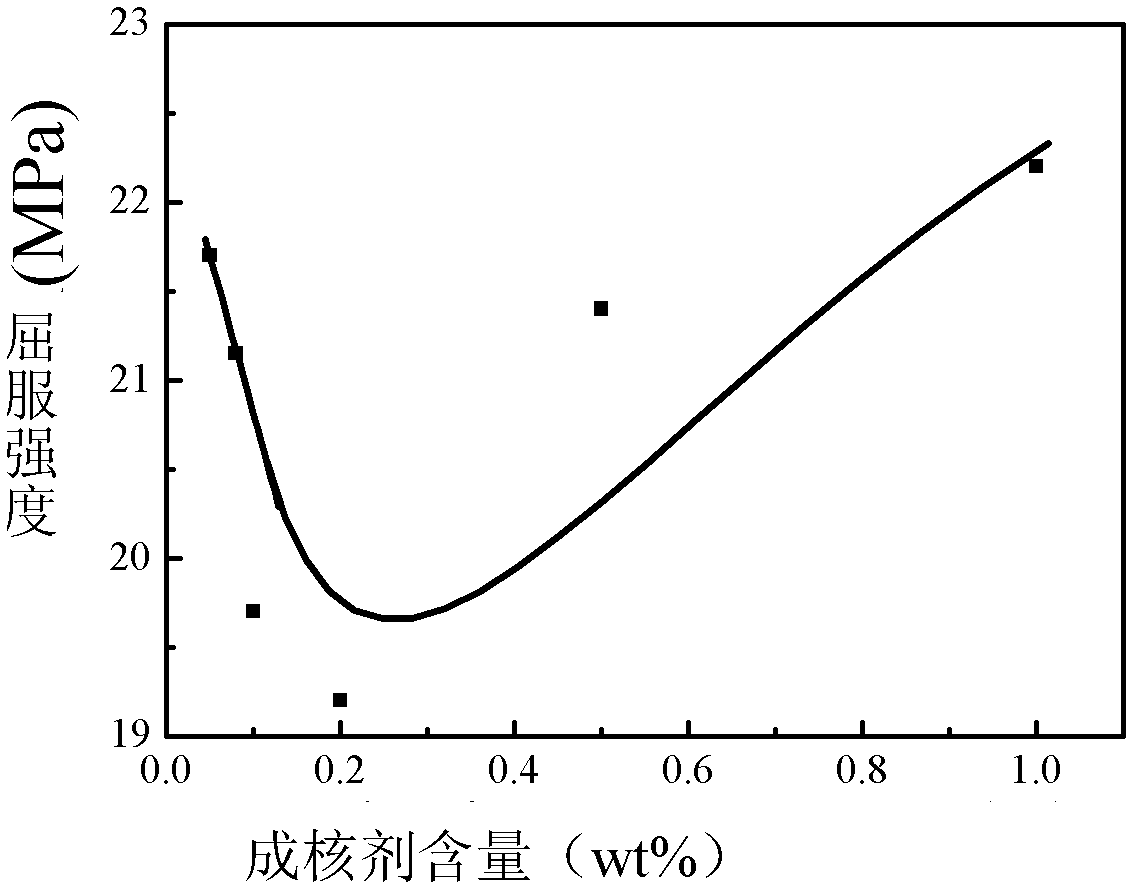

Improved polypropylene and method for improving yield strength and toughness of polypropylene

InactiveCN102516656AStrong yield toughnessYield Toughness ControlPolymer scienceIsothermal crystallization

The invention discloses an improved polypropylene and a method for improving yield strength and toughness of polypropylene. The improved polypropylene is characterized in that isotactic polypropylene and N,N'-dicyclohexyl-2,6-naphthalene dicarboxamide (DCNDCA) which is utilized as a single nucleating agent of isotactic polypropylene and has a molecular structural formula shown in the formula 1 are mixed uniformly, then are subjected to melt blending and are subjected to isothermal crystallization at a temperature of 135 to 140 DEG C, wherein an addition amount of the nucleating agent of DCNDCA is greater than 0 and is less than or equal to 1% of the mass of the isotactic polypropylene. Through adjustment of a nucleating agent content and isothermal crystallization at different temperatures, the optimum condition capable of improving yield strength and toughness of polypropylene is acquired. The method provided by the invention improves yield strength and toughness of polypropylene thereby promoting polypropylene material development and industrial application.

Owner:TIANJIN UNIV

Method for regulation and control of crystal form of isotatic polypropylene (iPP)-ethylene propylene diene monomer (EPDM) rubber-plastic blended material by double constant temperature heating stages

ActiveCN105295197ASimple methodEasy to operateEthylene-propylene-diene-monomerIsothermal crystallization

The invention discloses a method for regulation and control of a crystal form of an isotatic polypropylene (iPP)-ethylene propylene diene monomer (EPDM) rubber-plastic blended material by double constant temperature heating stages. The method comprises carrying out ultrasonic mixing dispersion on a beta nucleating agent, iPP, EPDM and a sulfuration auxiliary agent in a solvent, adding the mixture into a Haake torque rheometer, carrying out melt blending, carrying out melting on a temperature programmed control heating stage, and carrying out isothermal crystallization at a specific temperature so that the polypropylene crystal form of the iPP-EPDM blended material is selectively regulated and controlled and high-content beta crystal form is obtained. The method solves the problem that the prior art is difficult in polypropylene crystal form regulation and control, is convenient for polypropylene alpha crystal form and beta crystal form selective regulation and control and satisfies requirements on polypropylene crystal form regulation and control convenience.

Owner:ANHUI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com