Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

162results about How to "Increase nucleation density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

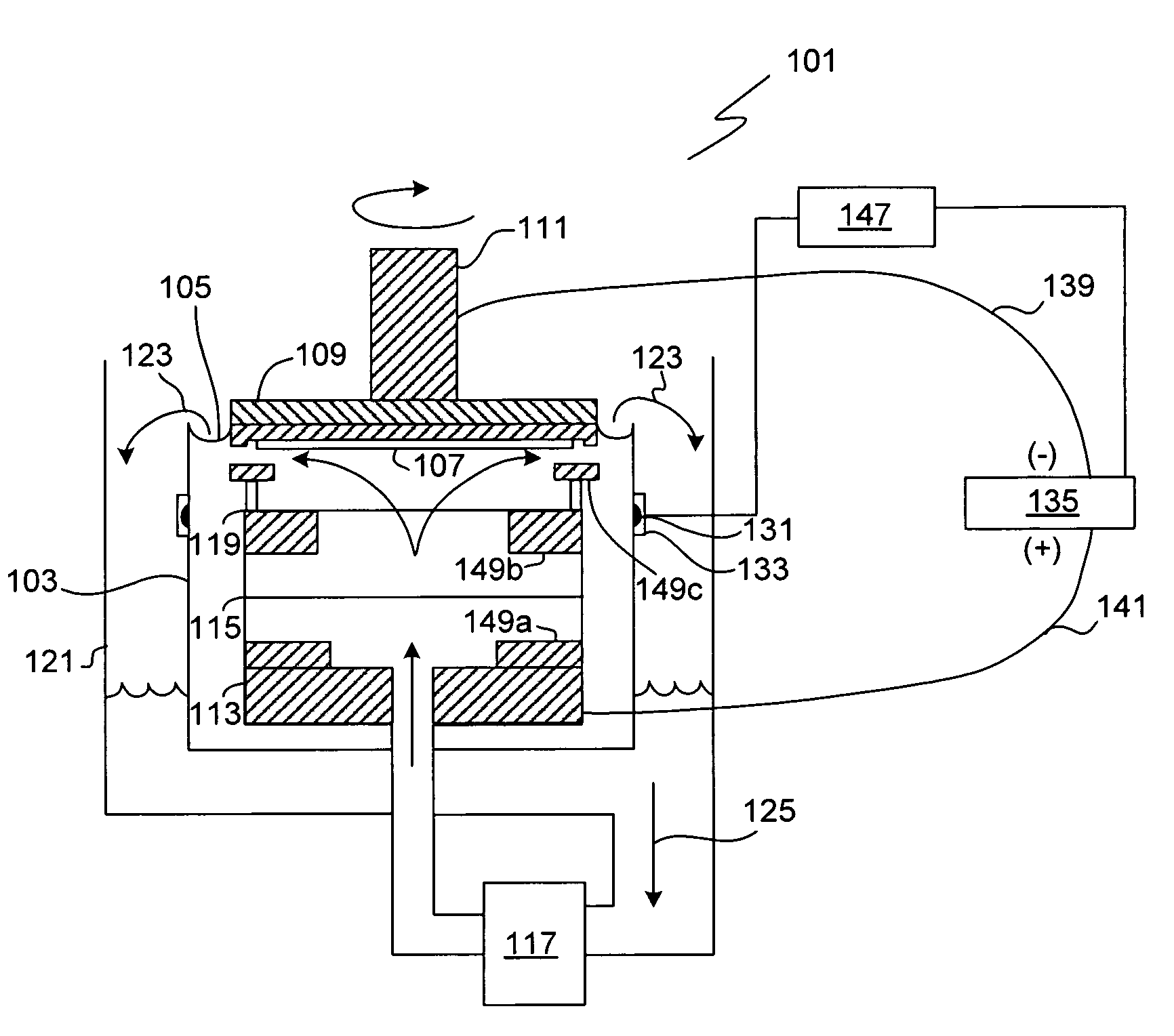

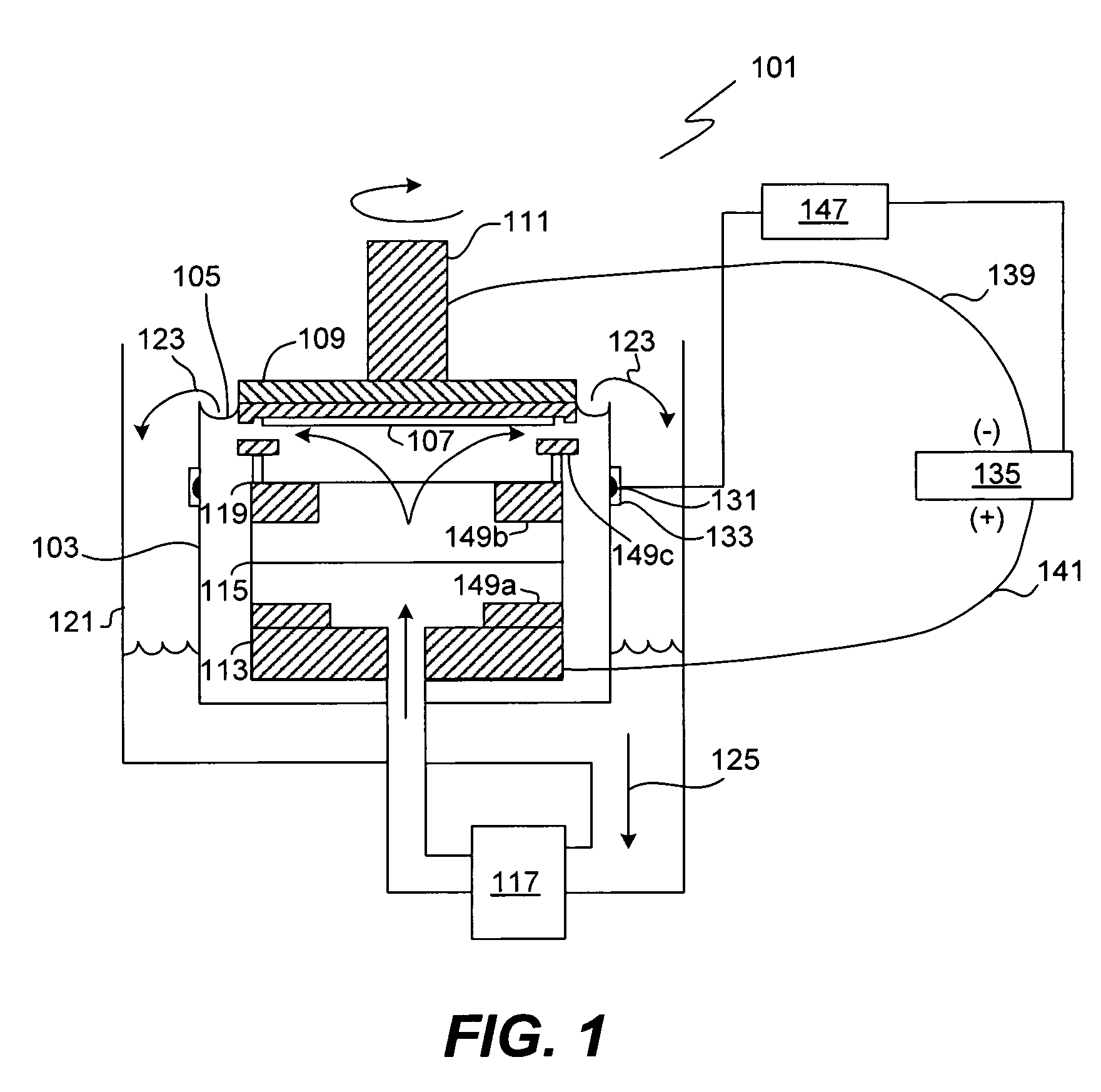

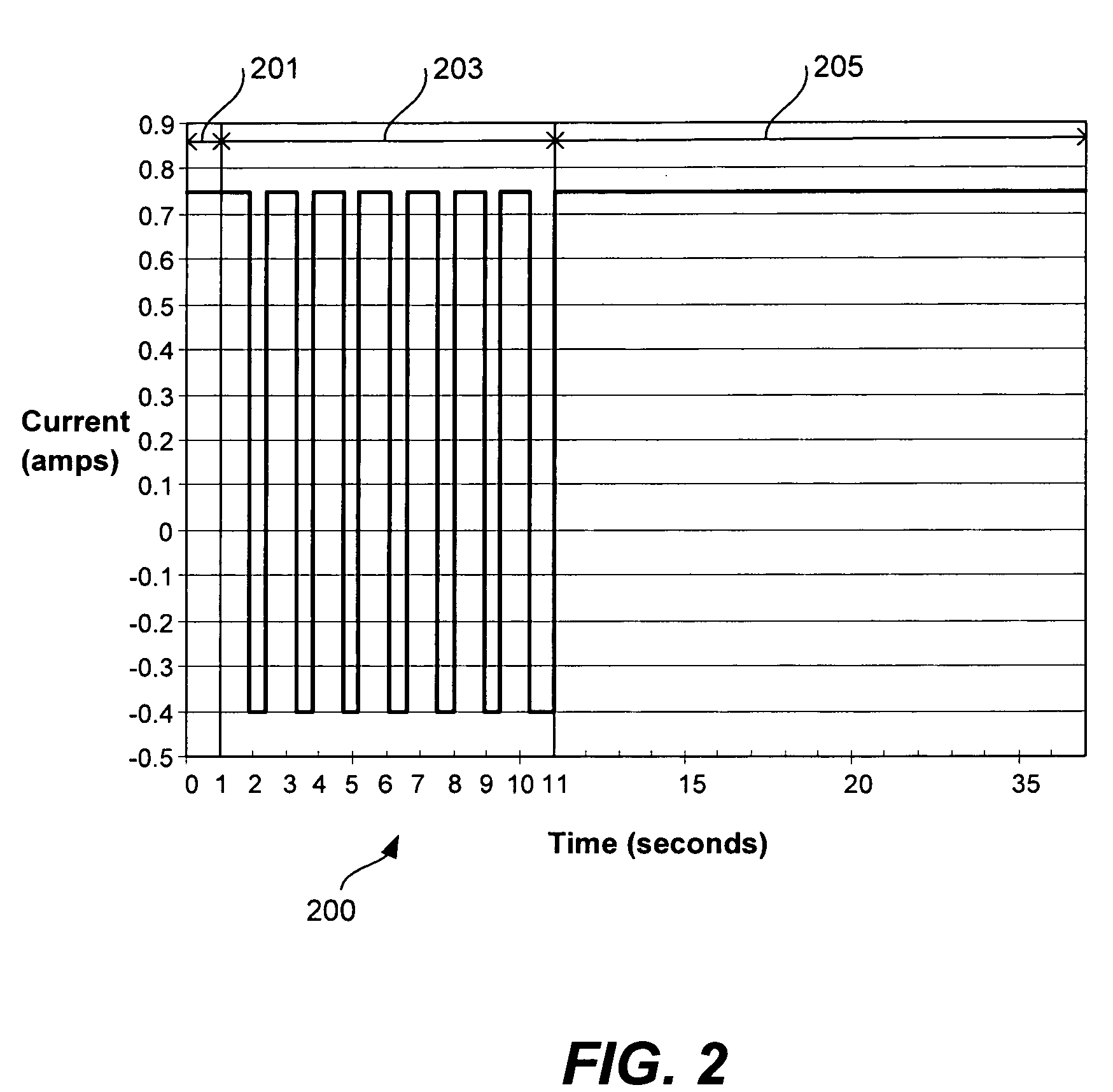

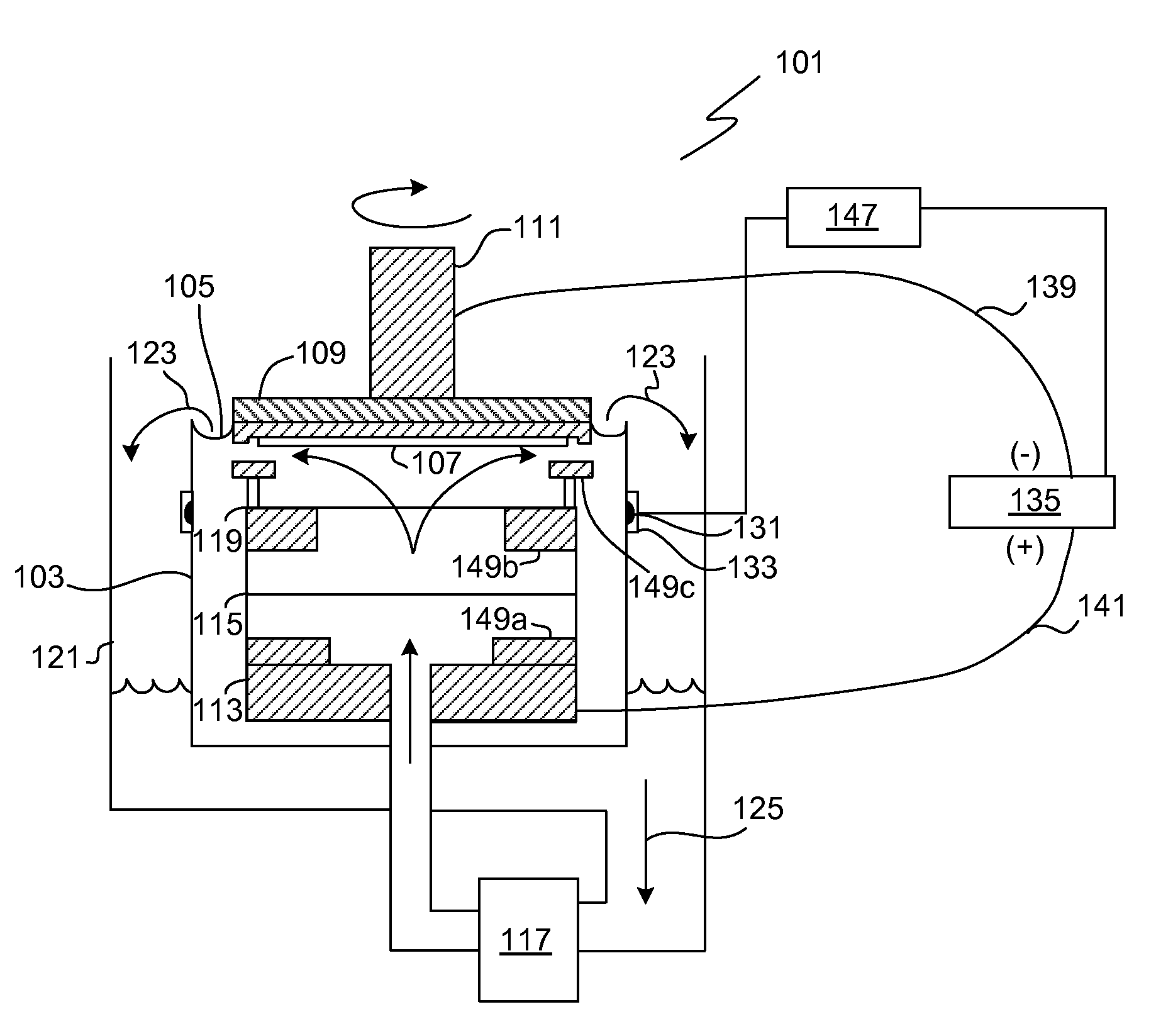

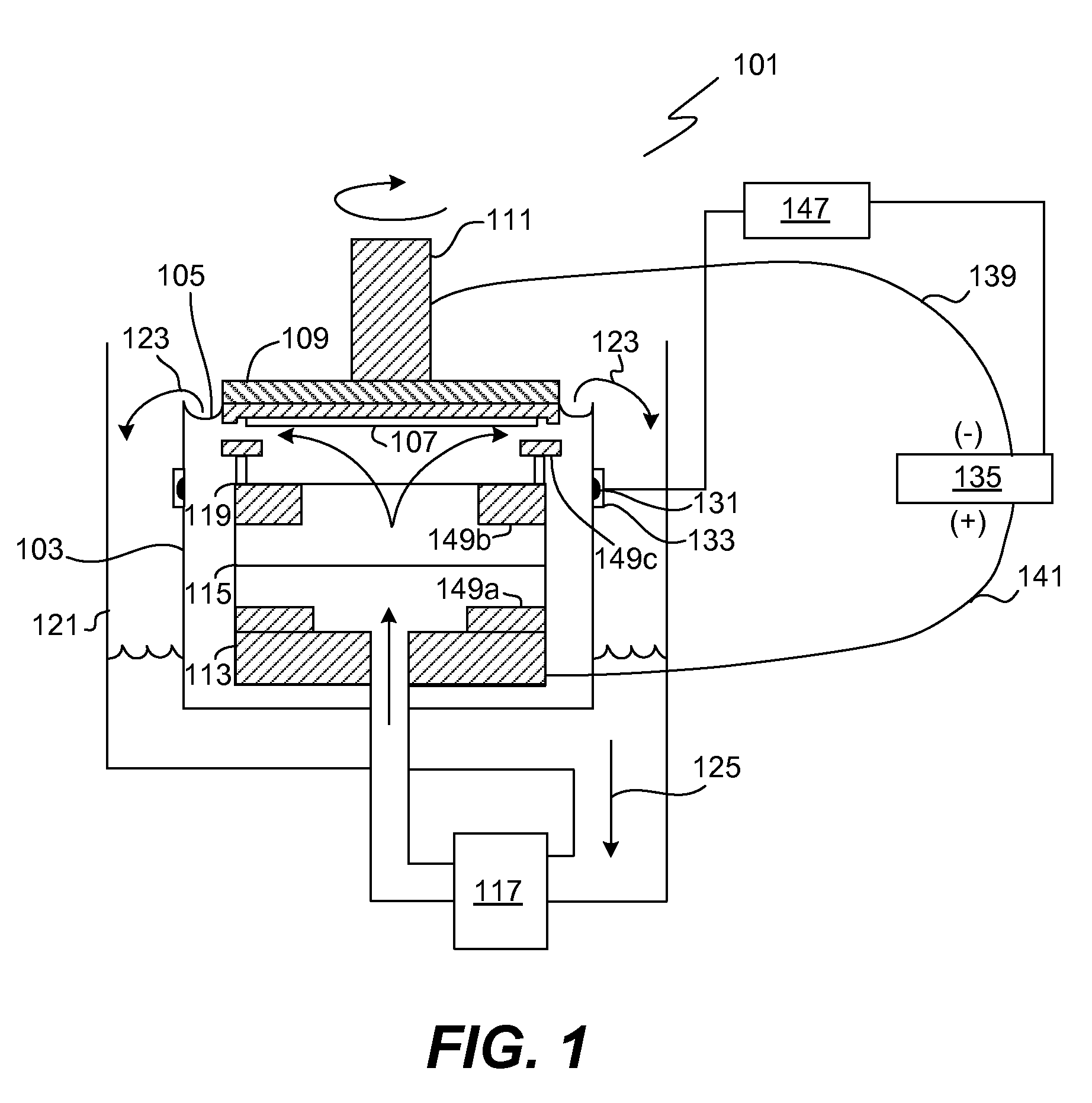

Two step copper electroplating process with anneal for uniform across wafer deposition and void free filling on ruthenium coated wafers

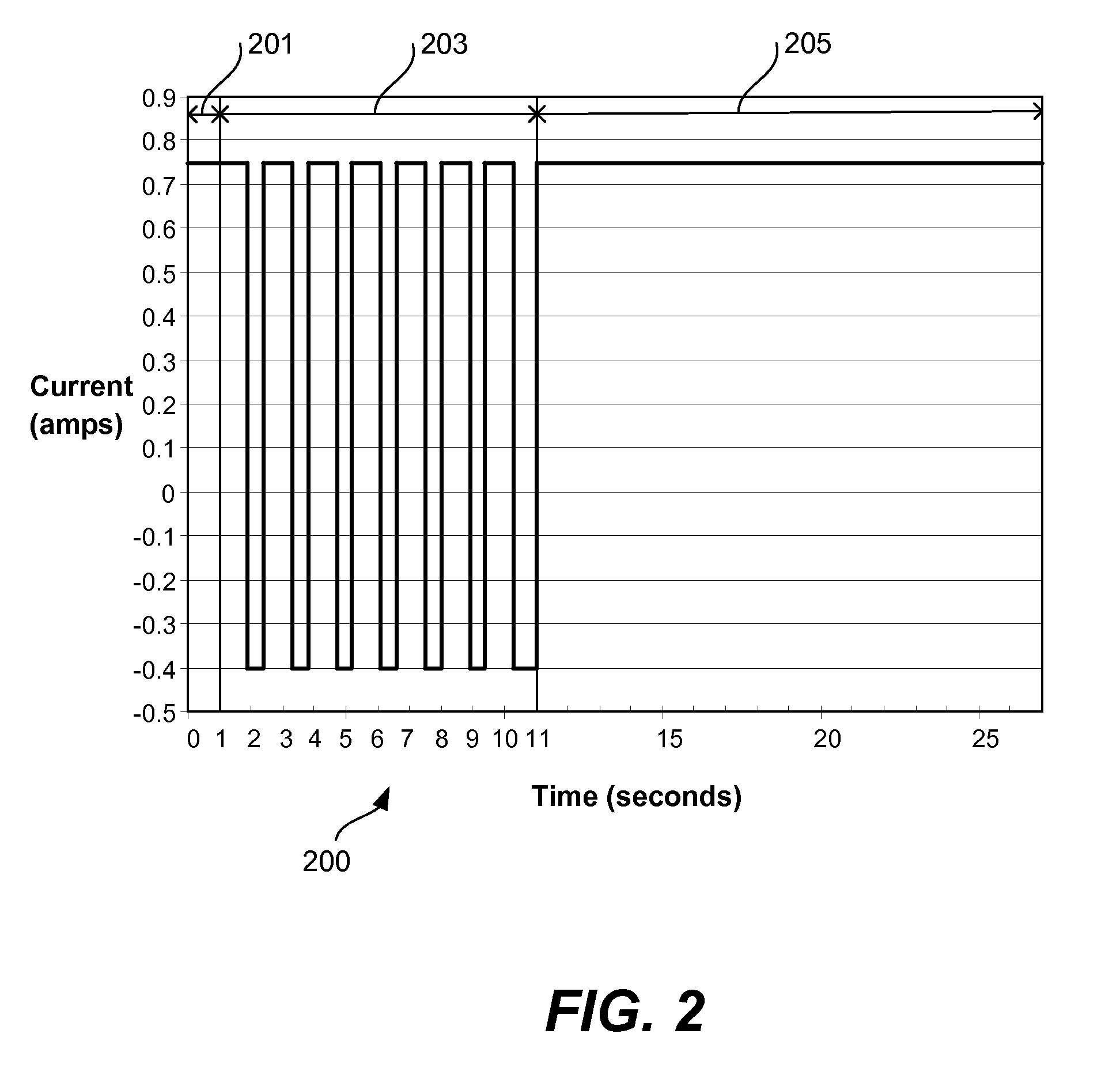

ActiveUS7964506B1Reduce the possibilityLow resistivityElectrolysis componentsSolid-state devicesCopper interconnectHigh density

A two-step semiconductor electroplating process deposits copper onto wafers coated with a semi-noble metal in manner that is uniform across the wafer and free of voids after a post electrofill anneal. A seed-layer plating bath nucleates copper uniformly and conformably at a high density in a very thin film using a unique pulsed waveform. The wafer is then annealed before a second bath fills the features. The seed-layer anneal improves adhesion and stability of the semi-noble to copper interface, and the resulting copper interconnect stays void-free after a post electrofill anneal.

Owner:NOVELLUS SYSTEMS

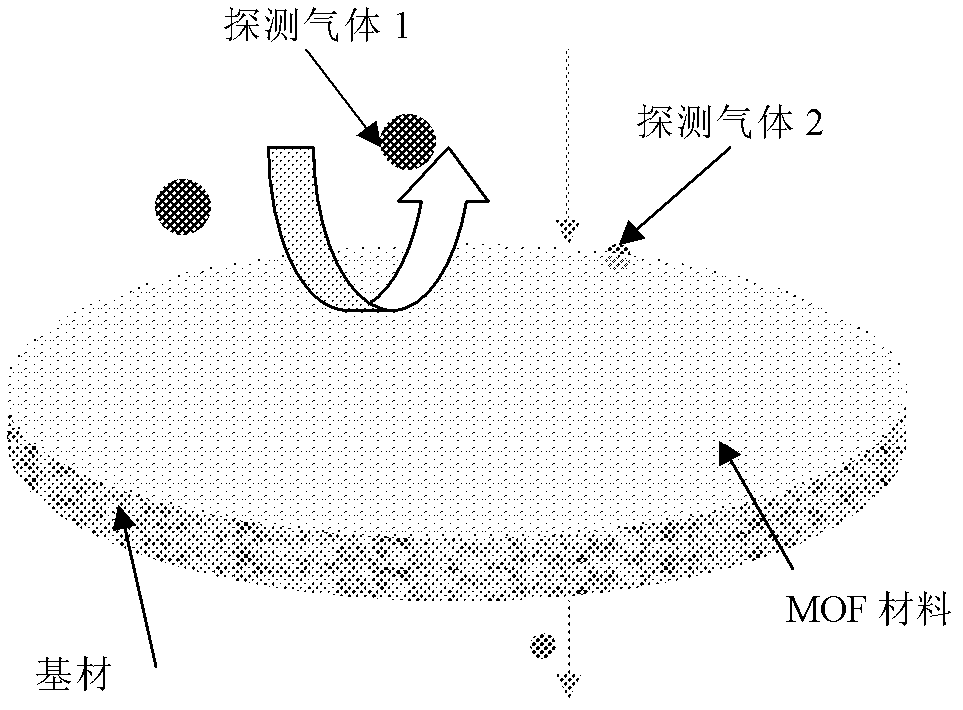

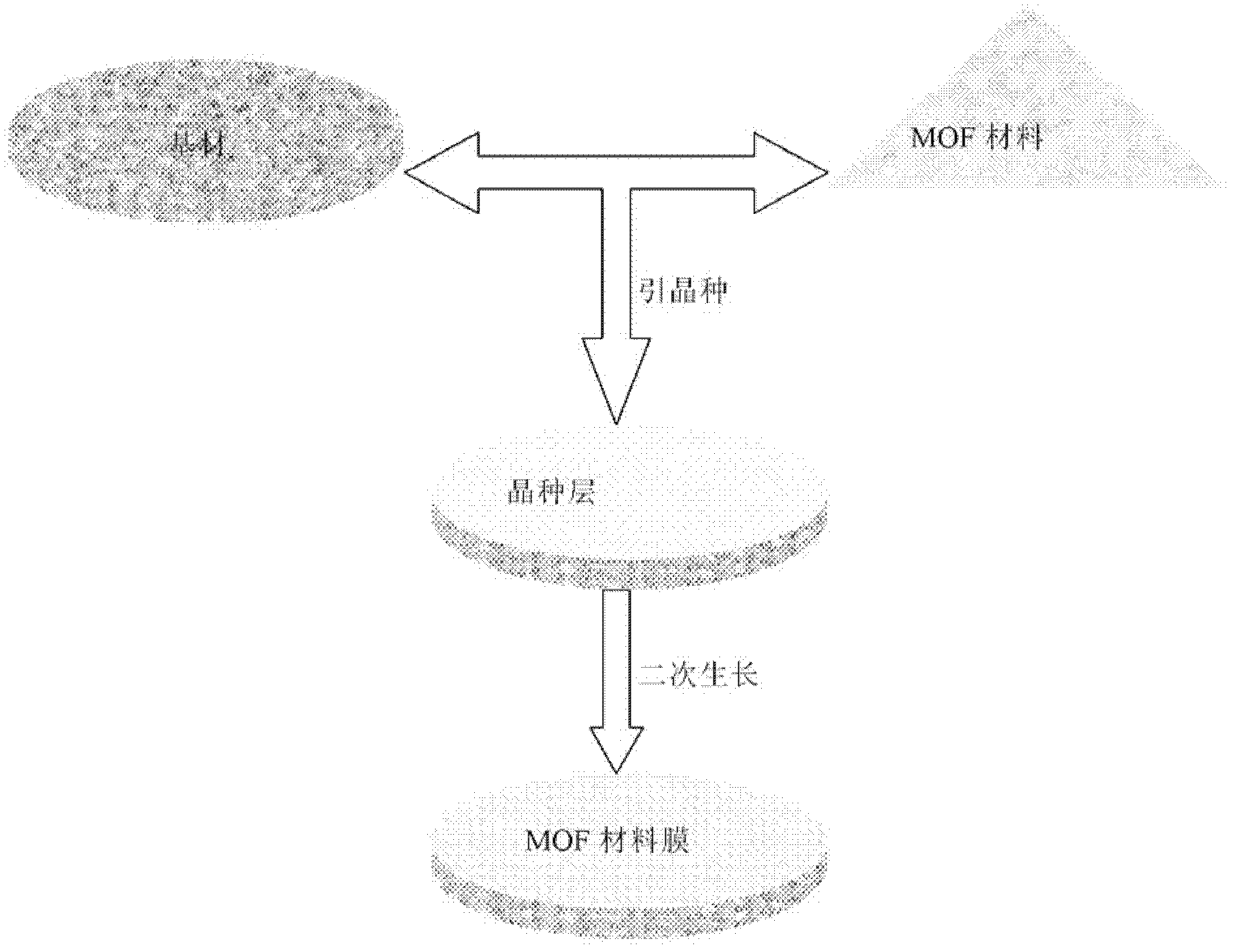

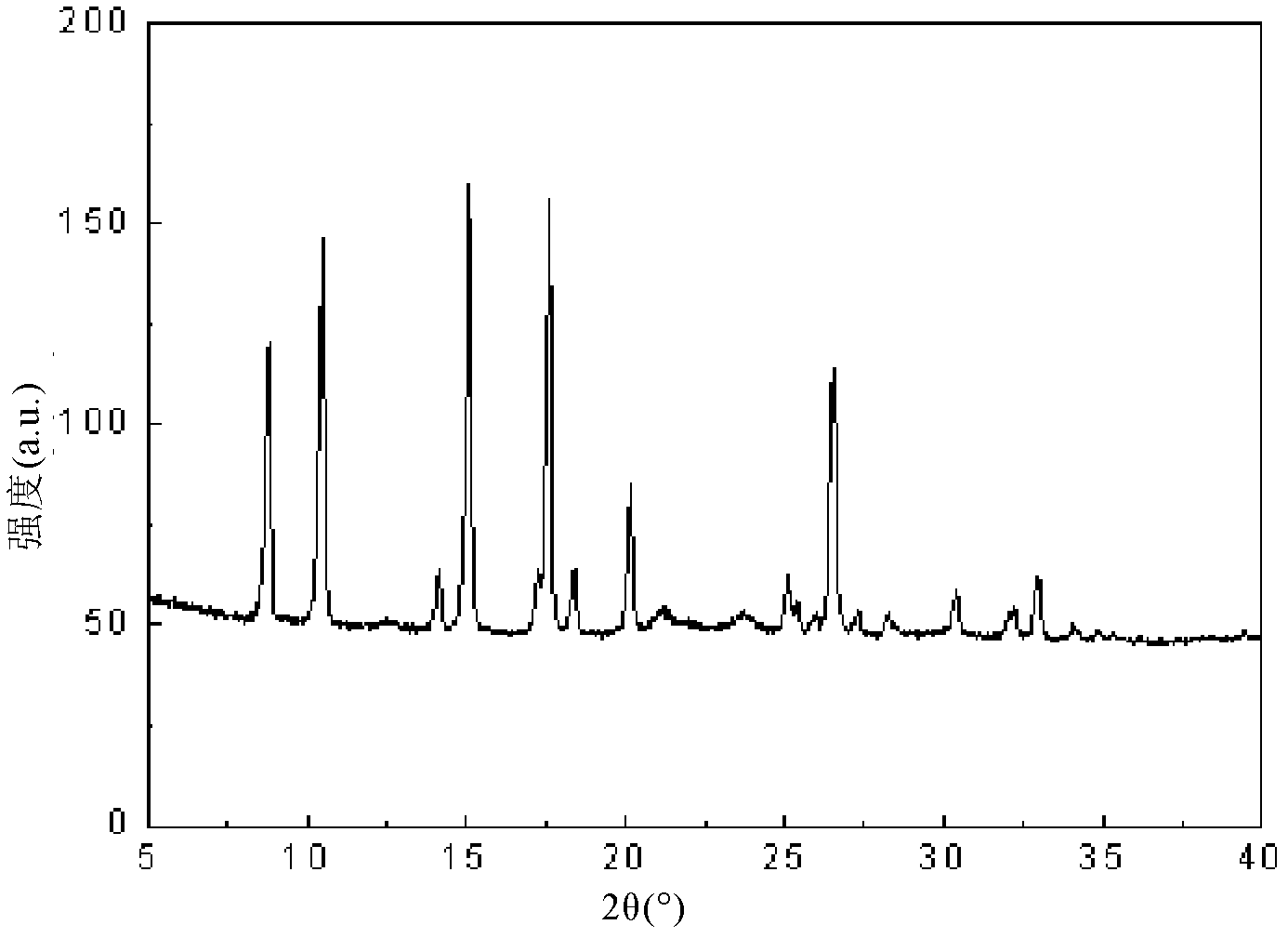

Metal-organic framework (MOF) material for permeating and separating gases and preparation method thereof

ActiveCN102489183AEasy to manufactureWell formedSemi-permeable membranesDispersed particle separationMetal-organic frameworkPermeation

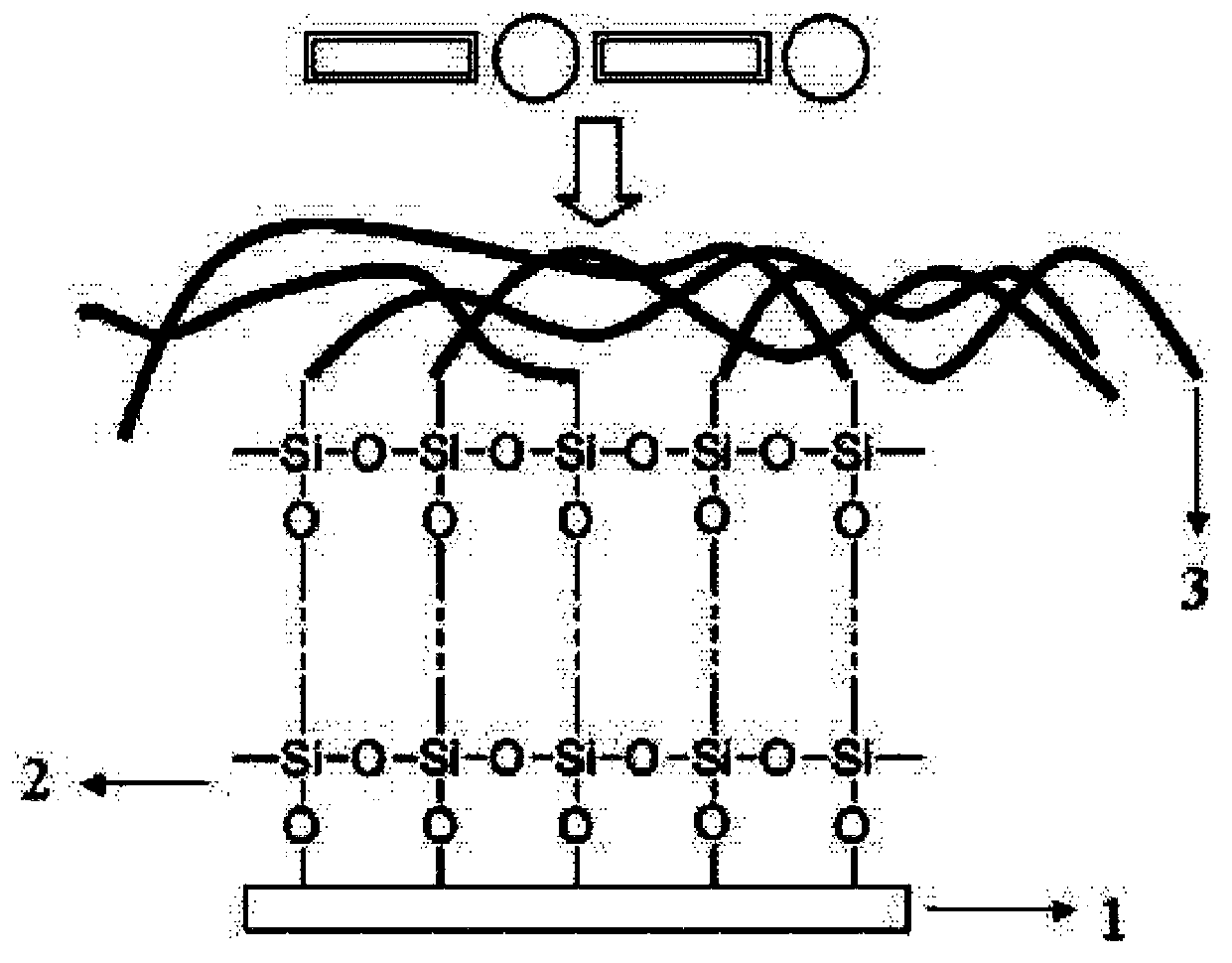

The invention discloses a metal-organic framework (MOF) material for permeating and separating gases and a preparation method thereof. Specifically, an MOF film disclosed by the invention is provided with a functional group, which contributes to nucleating on a substrate, increase the nucleating density on the substrate and contributes to the growth of a dense film; and the functional group can coact with certain specific gases, so that selective permeation of gases is facilitated. Due to the adoption of a film preparation method disclosed by the invention, the growing process of the film is simplified, the structure and shape of the film are optimized simultaneously, and film permeating and separating performance is enhanced. The MOF film prepared with the method has the advantages of high permeation amount, high separating coefficient, low energy consumption and avoidance of secondary pollution, and is particularly suitable for permeating and separating gases such as H2, CO2, CH4 and the like.

Owner:宁波大膜科技有限公司

Two step process for uniform across wafer deposition and void free filling on ruthenium coated wafers

ActiveUS7799684B1Increase nucleation densityLow resistivityElectrolysis componentsSemiconductor/solid-state device manufacturingHigh densityWafering

A two-step semiconductor electroplating process deposits copper onto wafers coated with a semi-noble metal in manner that is uniform across the wafer and free of voids. A plating bath nucleates copper uniformly and conformably at a high density in a very thin film. A second bath fills the features. A unique pulsed waveform enhances the nucleation density and reduces resistivity of the very thin film deposited in the nucleation operation. The process produces a thinner and conformal copper seed film than traditional PVD copper seed processes.

Owner:NOVELLUS SYSTEMS

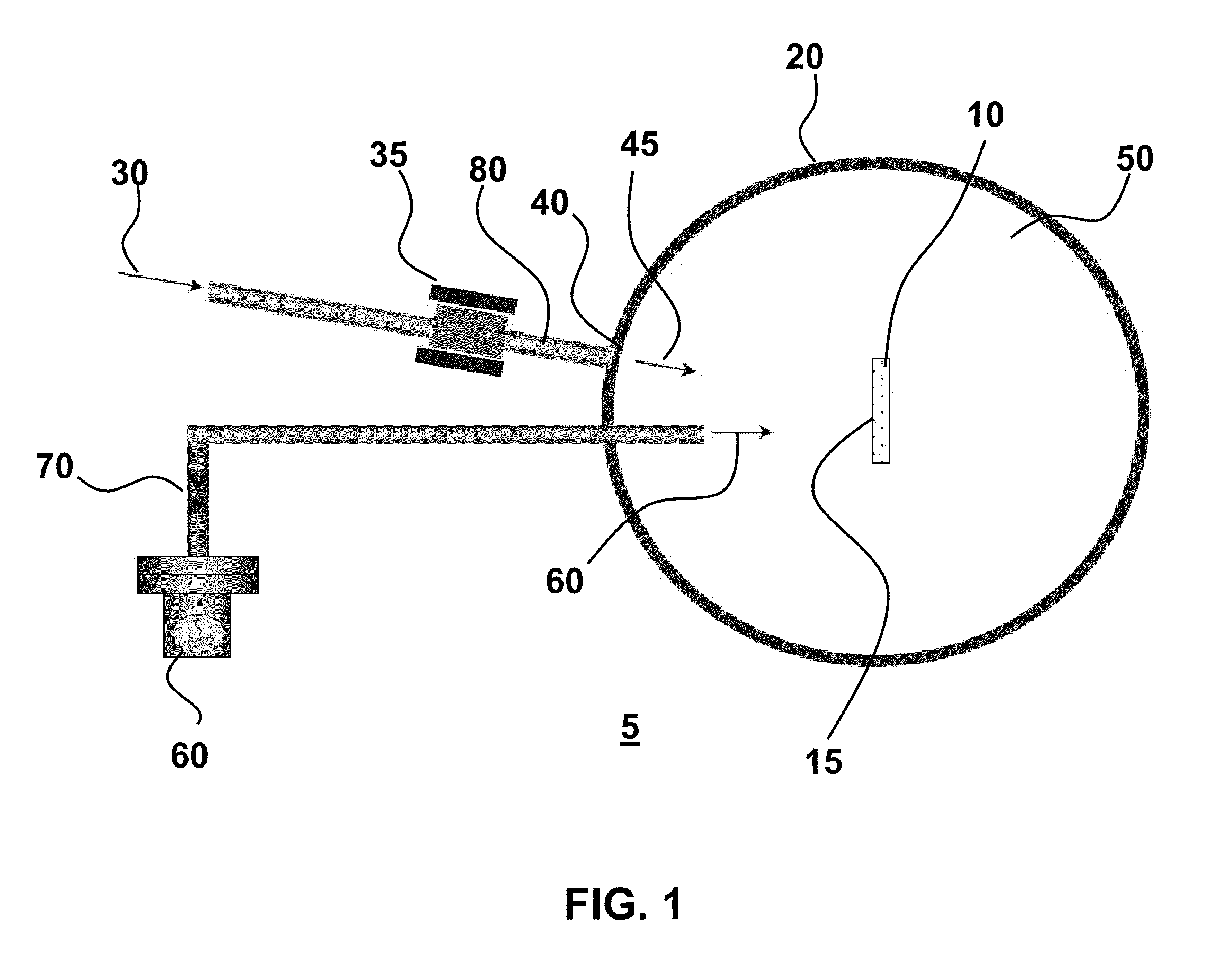

Surface preparation for thin film growth by enhanced nucleation

ActiveUS7943527B2Promote growthEnhanced nucleationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingRemote plasmaOptoelectronics

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

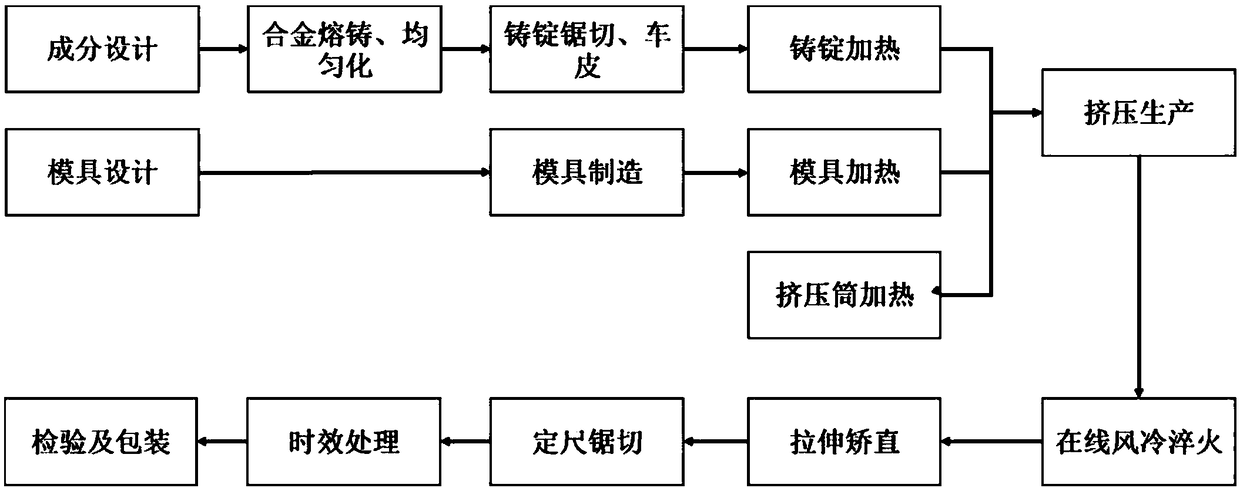

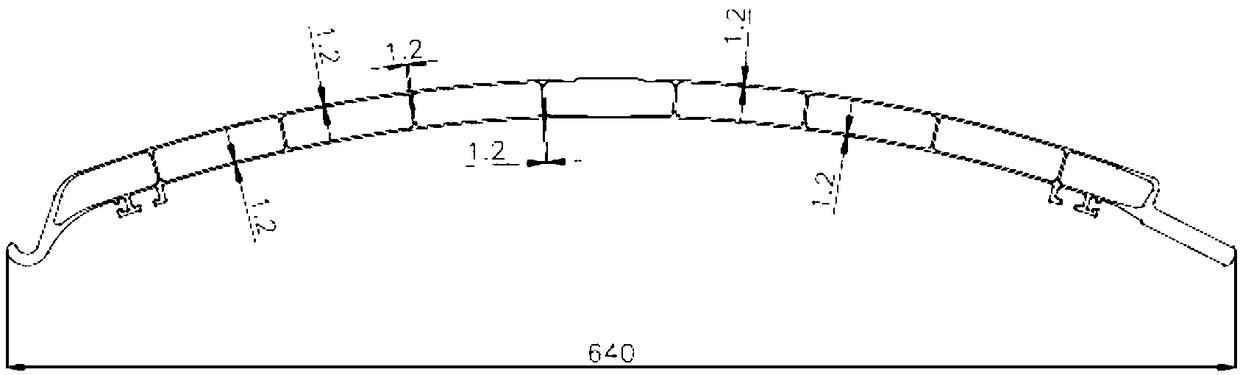

Wide-range thin-wall series-6 aluminum alloy section for high speed train and preparation method of wide-range thin-wall series-6 aluminum alloy section

ActiveCN108893661AHigh extrusion force per unit areaReduce deformation resistanceIngot castingUltimate tensile strength

The invention belongs to the technical field of preparation of aluminum alloy sections, and relates to a wide-range thin-wall series-6 aluminum alloy section for a high speed train and a preparation method of the wide-range thin-wall series-6 aluminum alloy section. Aluminum alloy comprises the following elements in percentages by weight: 0.50-0.65% of Si, less than or equal to 0.25% of Fe, less than or equal to 0.10% of Cu, 0.03-0.15% of Mn, 0.45-0.55% of Mg, less than or equal to 0.05% of Cr, less than or equal to 0.05% of Zn, less than or equal to 0.10% of Ti, less than or equal to 0.05% ofa single impurity, less than or equal to 0.15% of total impurities and the balance of Al. Deformation resistance and friction resistance in an extruding process are reduced by reasonably controllingthe temperature relationship of an ingot casting, an extrusion barrel and a die, the extruding speed is increased to be 8-13 m / min, the quenching temperature of the product is ensured, thus, any coarse grain rings are not generated when a thin-walled apron board is extruded at high speed, after being subjected to on-line quenching, the product is directly subjected to artificial ageing at the temperature of 175+ / - 5 DEG C for 4-8 hours, the mechanical property of the product can meet requirements in TB / T.3260.4-2011 TO 1.2 mm thin-walled sections, the actual tensile strength reaches 250-270 MPa, the yield strength reaches 210-230 MPa, the specific elongation is 8-10%, and the grade of the grain size of an aluminum section microscopic structure reaches and even exceeds 4.

Owner:中铝特种铝材(重庆)有限公司

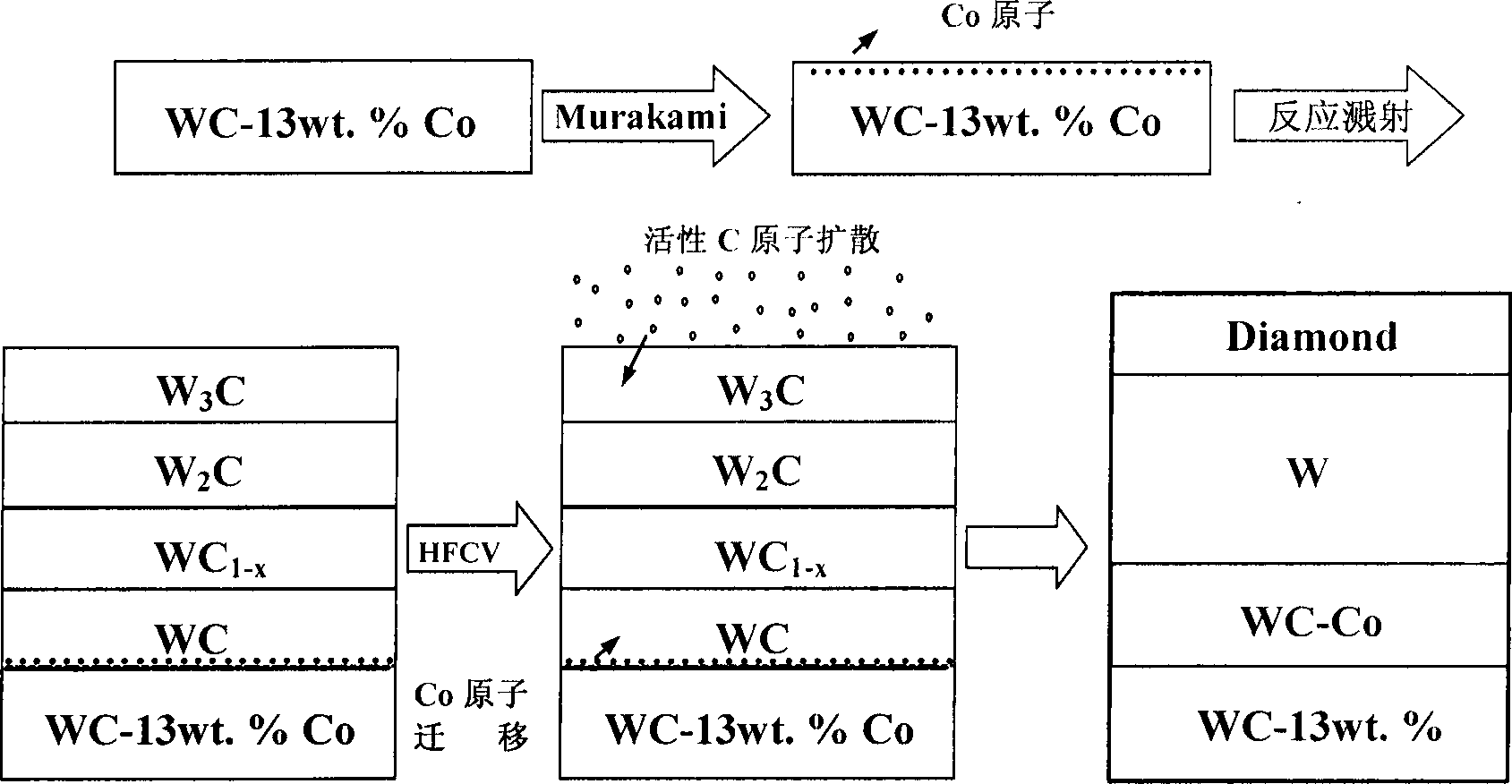

Diamond / W-C gradient structure composite coating and preparing method thereof

InactiveCN101487121AEliminate negative effectsStop the spreadVacuum evaporation coatingSputtering coatingCemented carbideTungsten

The invention discloses a composite coating of diamond / W-C gradient structure, and a preparation method thereof. The composite coating is characterized in that a composite coating which takes a W-C gradient structure as a transition layer and takes a diamond coating as a wearable coating is formed on a WC-Co hard alloy; the preparation method comprises the steps as follows: the hard alloy is used as a sample; a surface layer WC is dipped in Murakami reagent so as to form a Co-rich layer; subsequently, pure tungsten is taken as target material and argon and carbonaceous gas are used as reaction gases to prepare the W-C gradient structure of different structures as the transition layer by a reaction sputtering method by adjusting the concentration of carbonaceous active gas in the reaction gas, thus preparing the diamond wearable coating by a chemical vapor deposition technique. The composite coating solves the problem of the bonding strength of the film / substrate and ensures the surface smoothness of the diamond film.

Owner:CENT SOUTH UNIV

Thin-wall 6-series aluminum profile for rail transit vehicle body and preparation method thereof

The invention belongs to the technical field of aluminum alloy manufacturing, and relates to a thin-wall 6- series aluminum profile for a rail transit vehicle body and a preparation method thereof. The aluminum alloy comprises the following components in percentage by weight, 0.5-0.65% of Si, less than or equal to 0.25% of Fe, less than or equal to 0.10% of Cu, 0.03-0.15% of Mn, 0.45-0.55% of Mg,less than or equal to 0.05% of Cr, less than or equal to 0.05% of Zn, less than or equal to 0.10% of Ti, less than or equal to 0.05% of a single impurity, less than or equal to 15% of total impuritiesand the balance Al. The temperature of the homogenization treatment is 550-580 DEG C, the content of elements such as Mn and Cr is reduced, the recrystallization temperature in the alloy extrusion process is reduced, the nucleation density and the proportion of recrystallization of the aluminum profile in the wall thickness direction during extrusion of the aluminum profile are increased, the characteristic that recrystallization is easy to occur when the thin-wall sectional materials are extruded is fully utilized, a product with the uniform and consistent surface layer core grain structureis obtained in the extrusion process, and the method for improving the recrystallization temperature of the alloy by increasing the content of Mn and Cr elements is subverted.

Owner:中铝特种铝材(重庆)有限公司

Surface Preparation for Thin Film Growth by Enhanced Nucleation

ActiveUS20100048029A1Superior film growthEnhanced nucleationVacuum evaporation coatingPretreated surfacesRemote plasmaProduct gas

Various processes and related systems are provided for making structures on substrate surfaces. Disclosed are methods of making a structure supported by a substrate by providing a substrate having a receiving surface and exposing at least a portion of the receiving surface to output from a remote plasma of an inert gas. The remote plasma has an energy low enough to substantially avoid etching or sputtering of the receiving surface but sufficient to generate a treated receiving surface. The treated surface is contacted with a deposition gas, thereby making the structure supported by the substrate.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Perfluoropolyether, touch screen and fingerprint-proof membrane containing perfluoropolyether membrane and preparation thereof

InactiveCN103724610AUnique structureGood anti-fingerprint effectVacuum evaporation coatingSputtering coatingPerfluoropolyetherDistillation

The invention provides a method for preparing perfluoropolyether through carrying out ring opening polymerization on tetrafluoro oxetane and the perfluoropolyether thereby. According to the method, the ring opening polymerization of the tetrafluoro oxetane is initiated by using fluoride salt as an initiator and a perfluoropolyether chemical compound F-(OCF2CF2CF2)n-CF2CF3 is collected through controlling the vacuum degree and the distillation temperature, where the n=2-30. The invention provides a method for applying the perfluoropolyether material to a fingerprint-proof membrane for touch screens at the same time. According the method, a buffer layer is formed on a glass substrate after being subjected to O2 glow discharge bombardment and a perfluoropolyether membrane is formed on the upper surface of the buffer layer, wherein the buffer layer is a PECVD (Plasma Enhanced Chemical Vapor Deposition)-deposited SiO2 film. A good adhesive force is provided between the SiO2 buffer layer and the glass substrate through depositing the SiO2 buffer layer by utilizing PECVD, so that the adhesive force between the perfluoropolyether fingerprint-proof membrane and the glass substrate is increased to a certain extent.

Owner:陈琦 +2

Nano-multicrystal phase glass ceramics and its production method

The present invention discloses a nano multicrystal phase glass-ceramic. Its composition includes (by wt%) 70% of silicon dioxide, 3.1%-4% of lithium oxide, 15% of aluminium oxide, 0.7%-1.2% of magnesium oxide, 0.8%-1.4% of zinc oxide, 0.4%-0.7% of calcium oxide, 0.2% of boron oxide, 1.8%-3.2% of titanium oxide, 1.5%-2.3% of zirconium oxide, 1.8%-2.1% of mixture of potassium oxide and sodium oxide, 0.1%-2.0% of lithium fluoride and / or phosphorus pentoxide and 0.8%-0.9% of mixture of arsenium oxide and antimony oxide. Its production method includes the following steps: grinding the above-mentioned components, uniformly mixing them to obtain mixed material, melting at 1350-1650deg.C, forming, annealing, nucleating for 1-4hr at 500-800deg.C, then heating to 700-1000deg.C and making crystallization treatment for 1-12hr so as to obtain the invented product.

Owner:ZHEJIANG UNIV

Method for recovering nickel in chemical nickel-plating ageing liquid

ActiveCN102212842AImprove wettabilityConvenient and quick escapePhotography auxillary processesThioureaPolyethylene glycol

The invention discloses a method for recovering nickel in a chemical nickel-plating ageing liquid, and the method comprises the following steps: (1) adding 1100-1300 parts by weight of the chemical nickel-plating ageing liquid into an electrolytic cell, and regulating the pH value of the ageing liquid to 8-10 by use of solid sodium hydroxide; (2) dissolving 0.01-0.03 part by weight of polyethylene glycol, 0.01-0.02 part by weight of 2-mercapto benzimidazole, 0.03-0.06 part by weight of thiourea, 0.005-0.03 part by weight of hide glue and 0.3-0.5 part by weight of sodium hypophosphite into 40-70 parts by weight of water, adding the mixture into the electrolytic cell, and adding 1-3 parts by weight of 5mol / L hydrochloric acid solution; (3) at normal temperature, on the basis of taking a stainless steel plate as a cathode and a reticular plate plated with iridium oxide titanium alloy as an anode, reacting for 8-10 hours at constant reaction current of 0.6-1.0A, thus obtaining a recoveredmetal nickel on the cathode. The method has the advantages of high recovery rate, simple equipment, low cost and the like, works at normal temperature and is easy to realize.

Owner:WUXI ZHONGTIAN SOLID WASTE DISPOSAL CO LTD

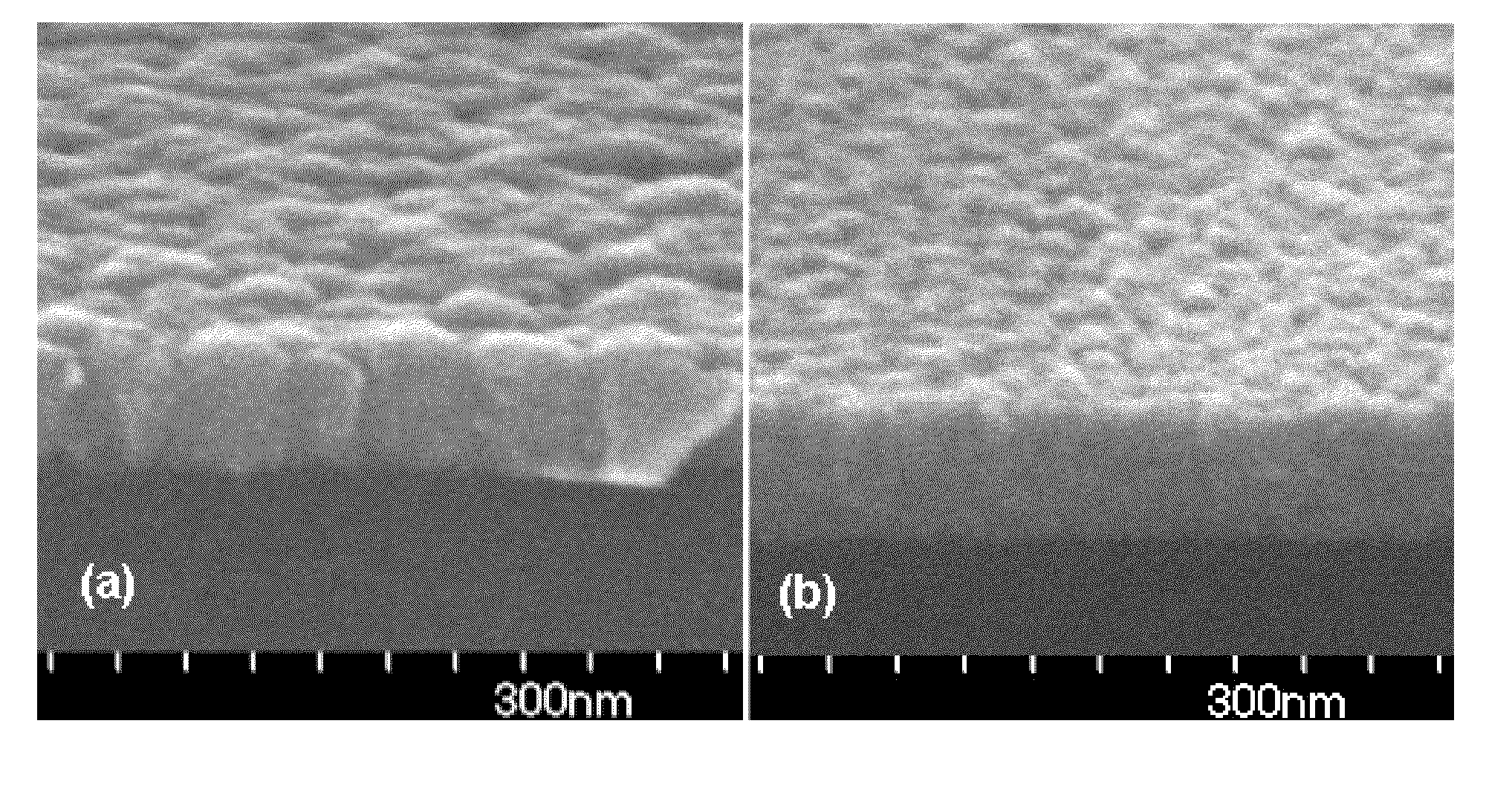

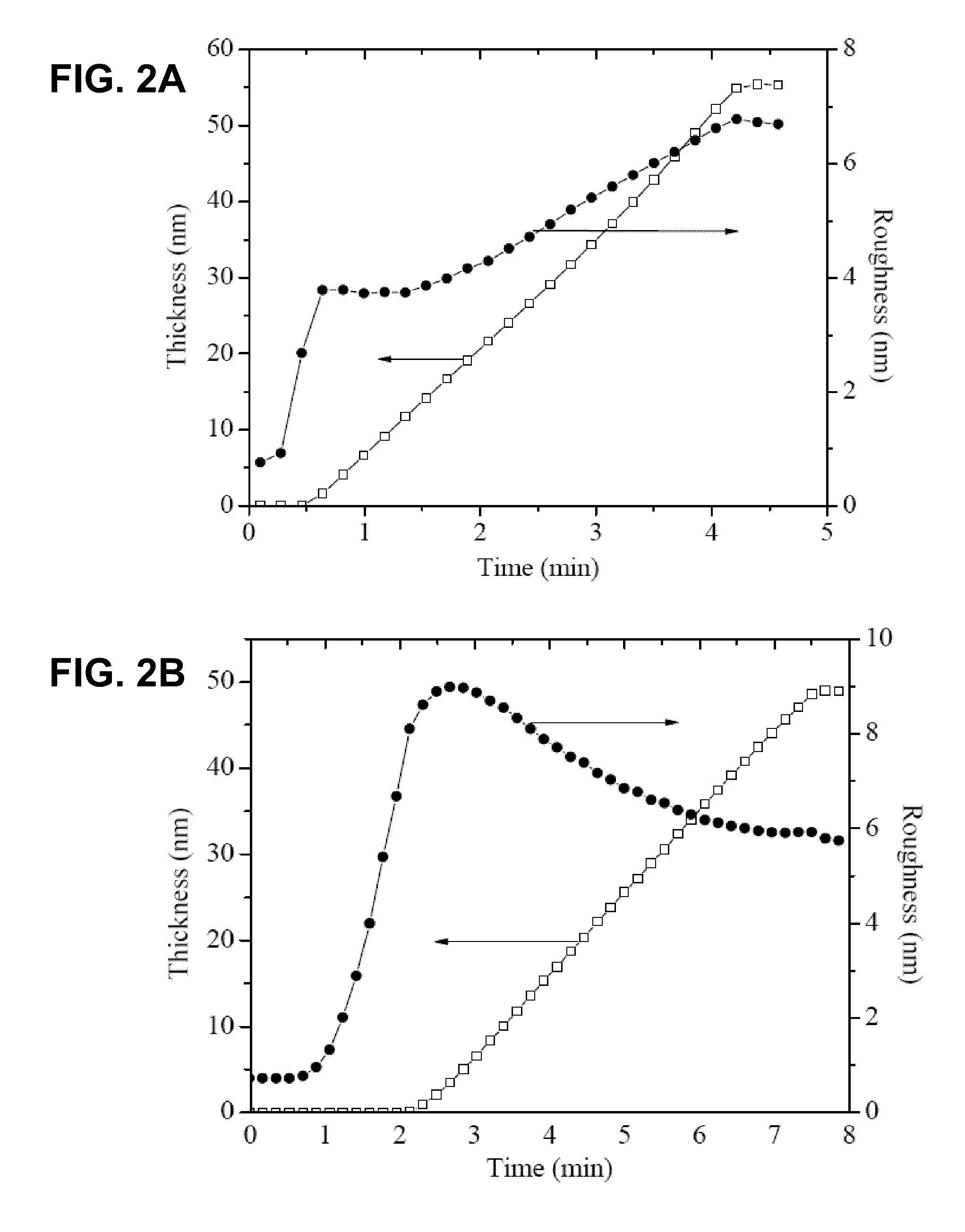

Smoothing Agents to Enhance Nucleation Density in Thin Film Chemical Vapor Deposition

ActiveUS20120107503A1High degree of smoothnessEnhance nucleation densityChemical vapor deposition coatingMicroelectronicsNano size

The present invention provides methods for making structures, including nanosized and microsized thin film structures that exhibit a high degree of smoothness useful for applications in microelectronics. Deposition processing of the invention utilize smoothing agents capable of selectively adjusting the relative rates of processes involved in thin film formation and growth to access enhanced nucleation densities resulting in smooth thin film structures, including ultrathin (e.g., <10 nm) smooth films.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

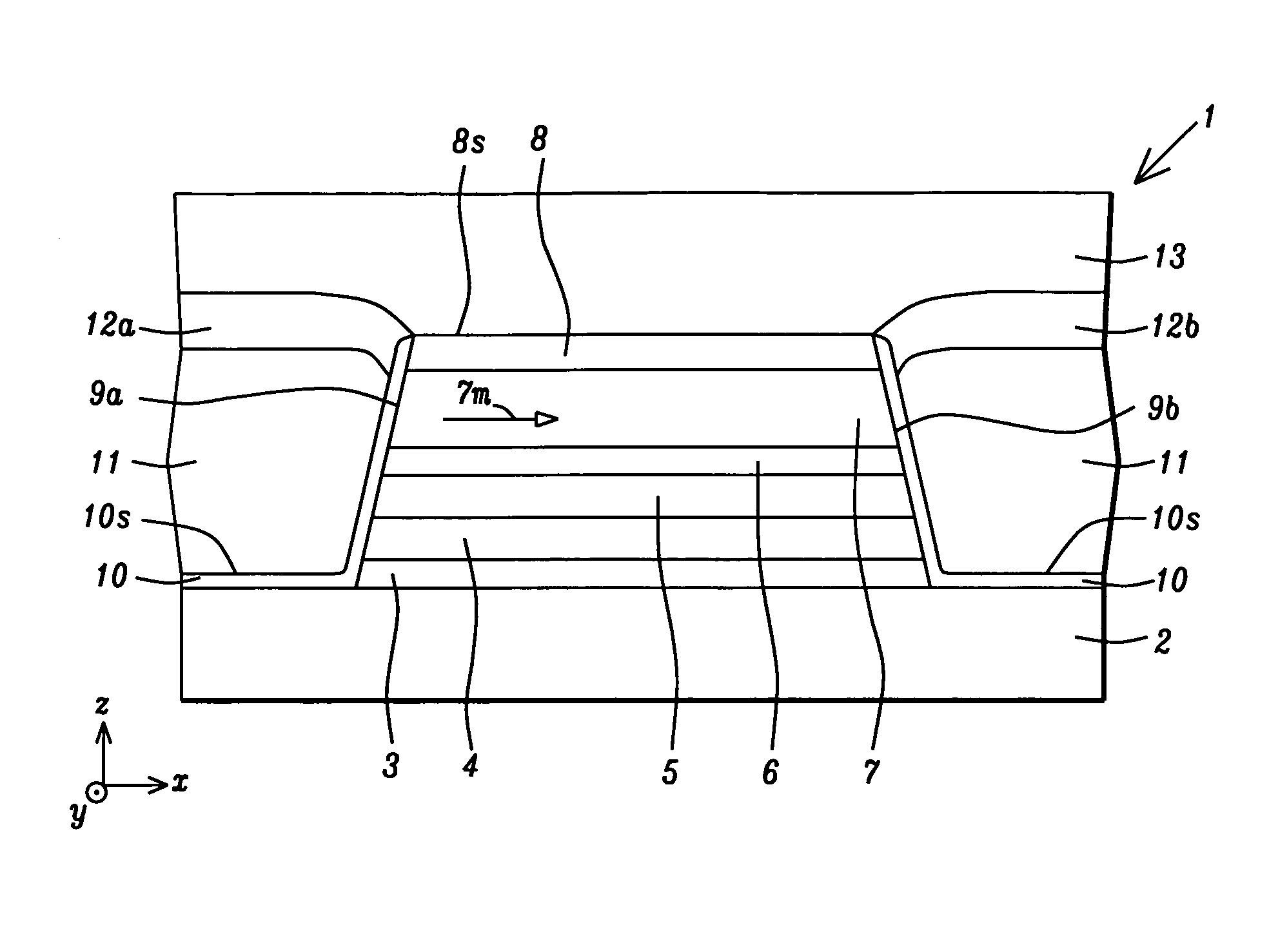

GaAs substrate-based gallium oxide thin film and growing method thereof

InactiveCN104962858AImprove crystal qualitySmall sizeVacuum evaporation coatingSemiconductor/solid-state device manufacturingSurface roughnessSemiconductor

The invention discloses a GaAs substrate-based gallium oxide thin film and a growing method thereof, and mainly solves the problems of poor surface appearance and small grain size of an existing gallium oxide thin film. The gallium oxide thin film comprises a GaAs substrate (1) and a gallium oxide epitaxial layer (3), and is characterized in that a gallium oxide buffer layer (2) of 6 to 12 nm is arranged between the GaAs substrate (1) and the gallium oxide epitaxial layer (3), and the crystal quality of the gallium oxide buffer layer is improved by utilizing thermal annealing. The surface roughness of a Ga2O3 thin film is reduced, the surface appearance of the Ga2O3 thin film is improved, and the Ga2O3 grain size is increased; the GaAs substrate-based gallium oxide thin film and the growing method can be used for making semiconductor power devices.

Owner:XIDIAN UNIV

Deposition from ionic liquids

InactiveUS20110266504A1Improve solubilityIncrease nucleation densityConductive materialSemiconductor/solid-state device manufacturingIonic liquidAtmosphere

A method to electrodeposit or electroless deposit material onto substrates from ionic liquids in vacuum or in a protective atmosphere after exposing the ionic liquid to vacuum and the resulting material. According to the invention, dense layers, free of unwanted components, can be produced in vacuum or in a protective atmosphere after exposing the ionic liquid to vacuum.

Owner:KATHOLIEKE UNIV LEUVEN

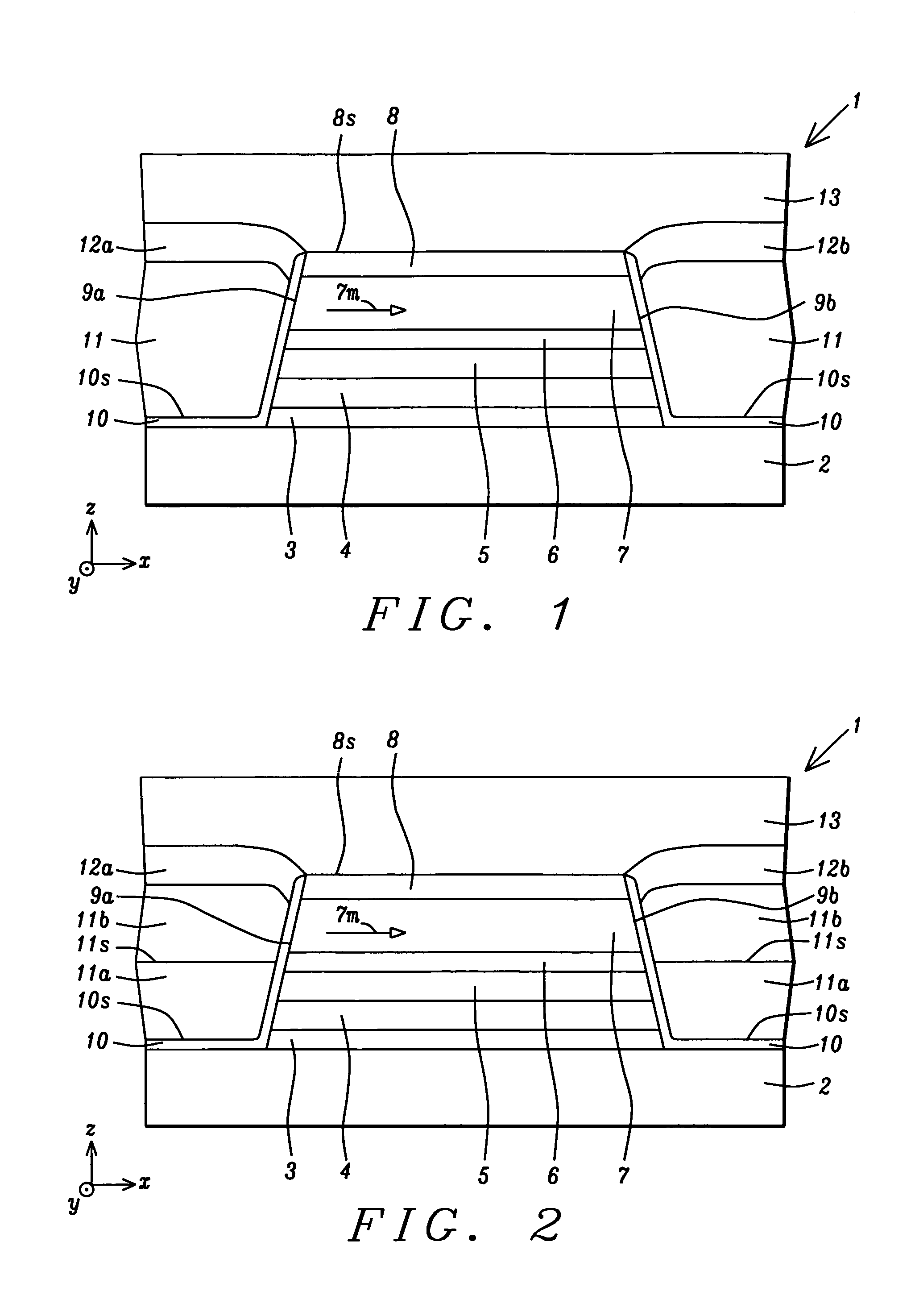

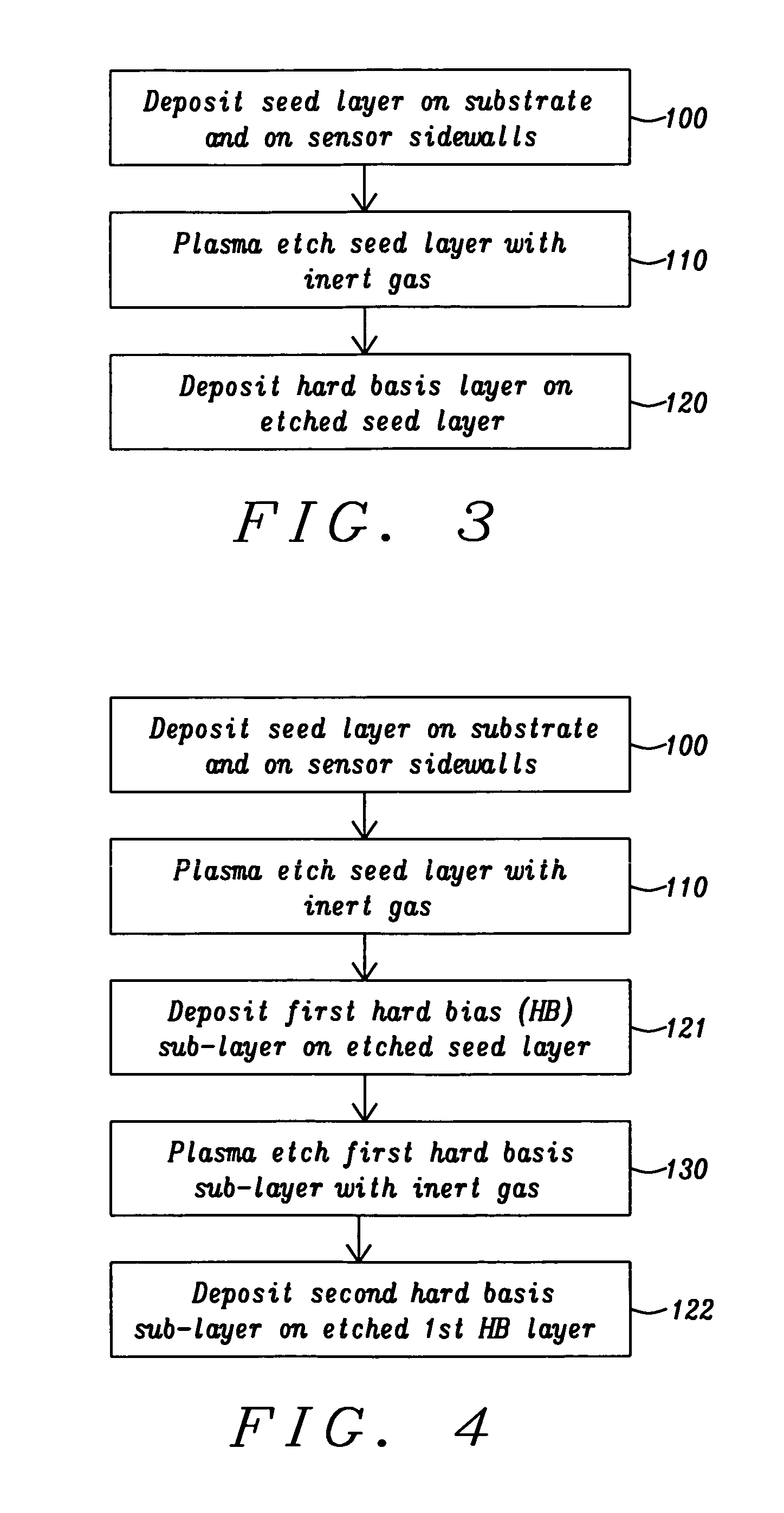

Method for fabricating a high coercivity hard bias structure for magnetoresistive sensor

ActiveUS20100276272A1High recording densityGreat coercivityMagnetic measurementsVacuum evaporation coatingCrystalliteHigh concentration

A hard bias (HB) structure for longitudinally biasing a free layer in a MR sensor is disclosed that includes a mildly etched seed layer and a hard bias (HB) layer on the etched seed layer. The HB layer may contain one or more HB sub-layers stacked on a lower sub-layer which contacts the etched seed layer. Each HB sub-layer is mildly etched before depositing another HB sub-layer thereon. The etch may be performed in an IBD chamber and creates a higher concentration of nucleation sites on the etched surface thereby promoting a smaller HB average grain size than would be realized with no etch treatments. A smaller HB average grain size is responsible for increasing Hcr in a CoPt HB layer to as high as 2500 to 3000 Oe. Higher Hcr is achieved without changing the seed layer or HB material and without changing the thickness of the aforementioned layers.

Owner:HEADWAY TECH INC

Sapphire substrate-based multilayer gallium oxide thin film and growing method thereof

InactiveCN105118851ASmall sizeIncrease coverageSemiconductor/solid-state device manufacturingSemiconductor devicesSurface roughnessSemiconductor

The invention discloses a sapphire substrate-based multilayer gallium oxide thin film and the growing method thereof, and mainly solves the problem of poor appearance and small crystal grain size of conventional gallium oxide thin films. The gallium oxide thin film comprises a sapphire substrate and gallium oxide epitaxial layers. and is characterized in that a plurality of epitaxial layers are provided, a 8-12nm of gallium oxide buffer layer is arranged under each gallium oxide epitaxial layer from top to bottom, and a composite structure of buffer layers and epitaxial layers alternatively formed is formed on the substrate. The surface roughness of a Ga2O3 is reduced, the surface appearance of the Ga2O3 is improved, and the crystal grain size of the Ga2O3 is increased. The sapphire substrate-based multilayer gallium oxide thin film can be used to manufacture a semiconductor power device.

Owner:XIDIAN UNIV

Coptis extract silicon slice texturing agent and preparation method thereof

InactiveCN105113017AControl corrosion rateImprove conversion efficiencyPolycrystalline material growthAfter-treatment detailsSodium CaseinateCoptis

The invention discloses a coptis extract silicon slice texturing agent. The coptis extract silicon slice texturing agent is characterized by being prepared from, by weight, 5-10 parts of coptis roots, 1.5-2.5 parts of sodium hydroxide, 3-5 parts of sodium tripolyphosphate, 0.3-0.5 part of lauryl sodium sulfate, 0.3-0.5 part of sodium lauroamphoacetate, 5-10 parts of texturing modifiers, 0.3-0.5 part of coconut oil, 0.5-1 part of sodium caseinate, 0.3-0.5 part of maltodextrin and 100-150 parts of water. By means of the silicon slice texturing agent, the texturing efficiency can be improved, the stability of the texturing technology can be improved, dosage of chemicals can be reduced, the silicon slice texturing agent is free of toxicity, harmless, green and environmentally friendly, the production cost is reduced, the transfer efficiency of a battery slice is effectively improved, good antibacterial and cleaning properties are achieved, and the product quality is stable.

Owner:安徽飞阳能源科技有限公司

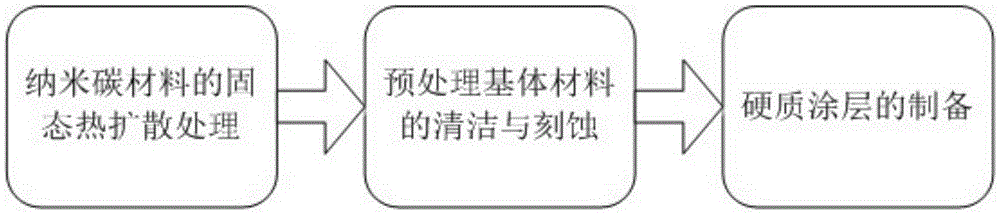

Hard coating preparation method with heat diffusion of carbon nanomaterials as pretreatment

ActiveCN105385983AImprove bindingGood surface nucleation conditionsSolid state diffusion coatingChemical vapor deposition coatingFiberGraphite carbon

The invention discloses a hard coating preparation method with heat diffusion of carbon nanomaterials as pretreatment. The preparation method comprises the steps of solid heat diffusion treatment of carbon nanomaterials, cleaning and etching of pretreatment base materials and preparation of a hard coating. In the step of solid heat diffusion treatment of the carbon nanomaterials, nanoscale diamond, carbon nanotubes, graphene, graphite and carbon fiber are used as carbon sources, solid heat diffusion treatment is carried out at a certain temperature, and the concentration of the nano carbon sources is distributed in a graded manner in the depth direction of the base materials. In the step of the cleaning and etching of the pretreatment base materials, the decontamination treatment, polishing, cleaning, etching of corrosive liquid and drying are carried out to enable the surface of the base materials to be flat, smooth and clean, and the nanoscale second-phase particles are exposed on the surface of a base body through etching of the specific corrosive liquid. In the step of preparation of the hard coating, substances in gas, liquid and solid states are used as carbon sources, and the diamond / diamond-like hard coating is prepared through physical / chemical vapor deposition, solid heat diffusion and high-energy spraying technologies.

Owner:CHINA UNIV OF MINING & TECH

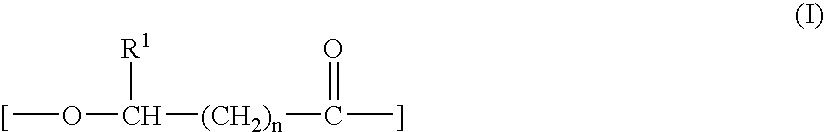

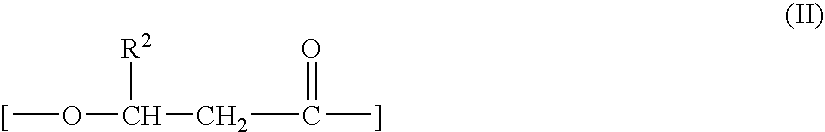

Biodegradable polyhydroxyalkanoate copolymers having improved crystallization properties

InactiveUS20030236358A1Extended processing methodIncrease ratingsEthylene HomopolymersPolymer chemistry

Compositions having improved crystallization properties and physical properties including a continuous phase of a first biodegradable polyhydroxyalkanoate comprising a copolymer, or a blend thereof, of at least two randomly repeating monomer units and having a melting point Tm1, and a second crystallizable biodegradable polyhydroxyalkanoate homopolymer or copolymer, which comprises at least one randomly repeating monomer unit and has a melting point Tm2, where Tm2 is at least about 20□C. greater than Tm1. The compositions are formed by solution or melt blending of the components and may be formed into shaped articles.

Owner:DANIMER IPCO LLC

Preparation method of high-temperature ultra-low sodium alumina powder material

PendingCN109607584AImprove thermal shock resistanceImprove insulation performanceAluminium oxides/hydroxidesAluminium hydroxideHardness

The invention provides a preparation method of a high-temperature ultra-low sodium alumina powder material. Firstly, industrial aluminum hydroxide is subjected to a drying pretreatment; secondly, an appropriate amount of mineralizer and a seed crystal are added to the pretreated aluminum hydroxide for high-temperature roasting; thirdly, the high-temperature roasting product is subjected to washingwith dilute acid; finally, the washed alumina powder is ball-milled to a certain particle size, and the high-temperature ultra-low sodium alumina powder material is obtained. By adopting the method,the sodium oxide content of industrial alumina can be can effectively reduced, and the thermal shock resistance, electrical insulation, hardness and strength of the alumina powder material can be remarkably enhanced.

Owner:NORTHEASTERN UNIV

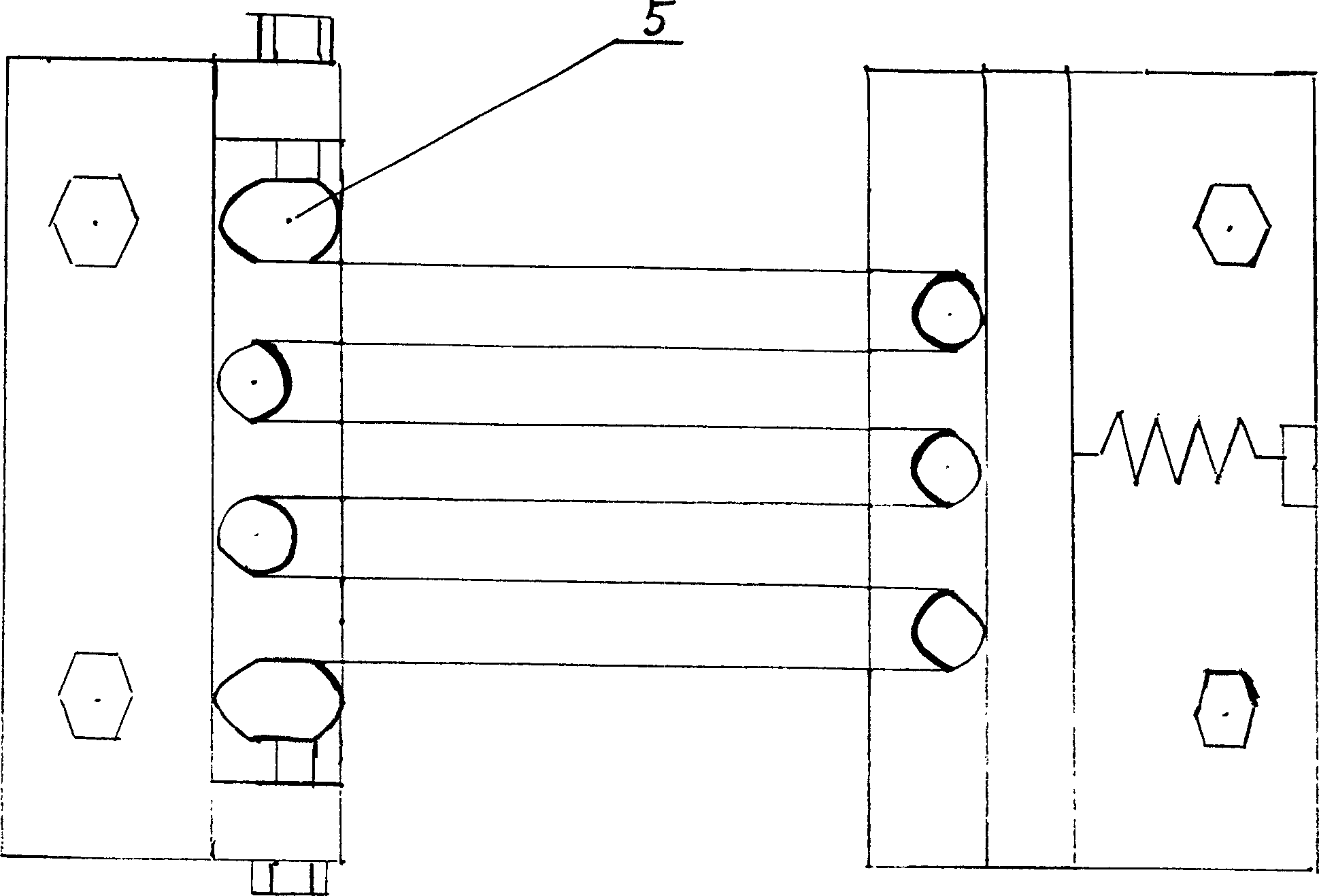

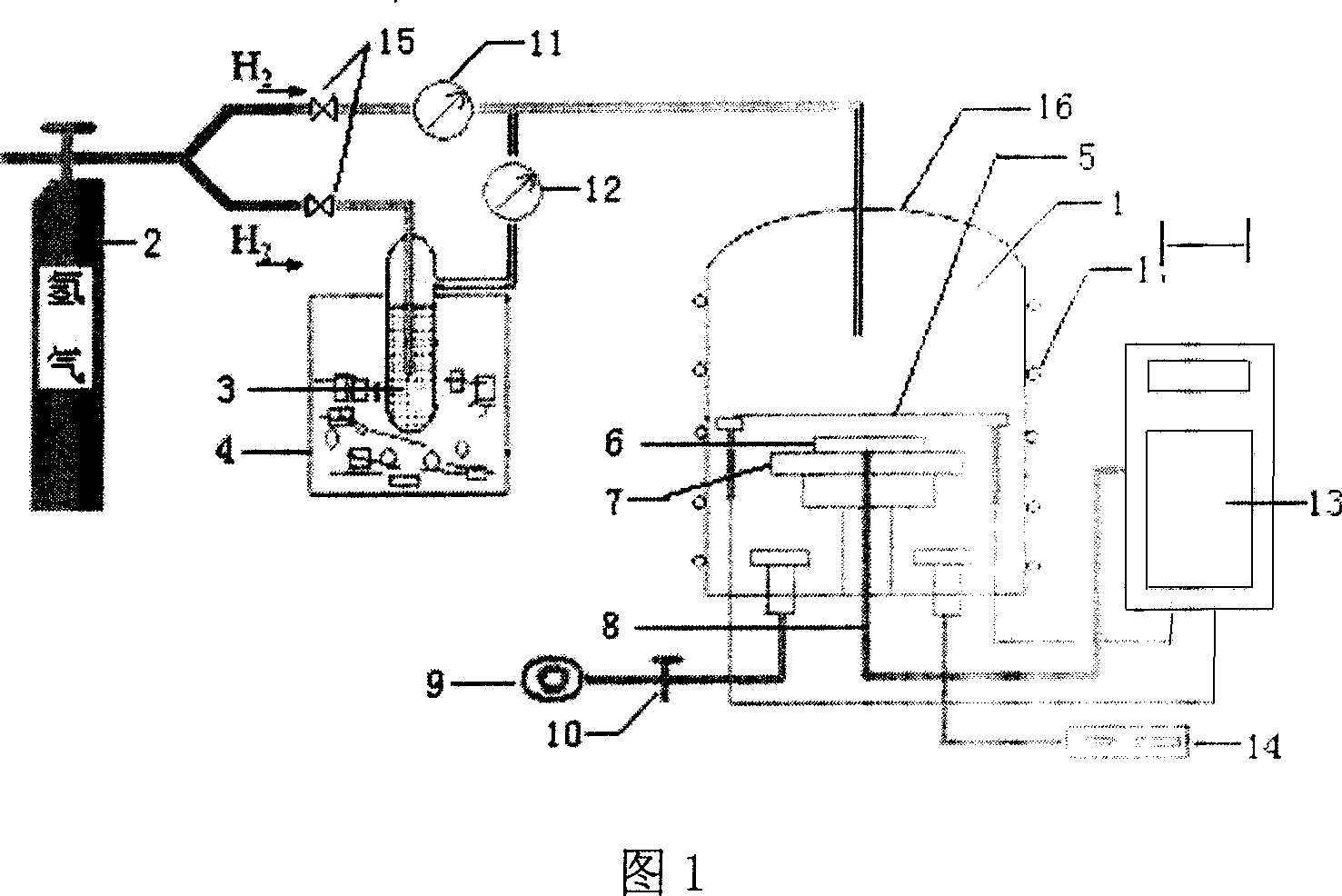

Hot wire for diamond film growth device and electrode structure thereof

InactiveCN1844450AReduced blocking cross sectionEasy to pass throughOhmic-resistance electrodesChemical vapor deposition coatingEngineeringProduct gas

This invention relates to the heater and electrode structure of diamond film growth device. This invention mainly includes a fixing electrode, a mobile electrode and corresponding heater, the character as follows: the fixing electrode is arranged with a group of electrode poles in equal space; and the mobile electrode is also arranged with a group of electrode poles, and the space is equal to the electrode pole space of the fixing electrode, the electrode pole is half space away from the electrode pole on the fixing electrode; the heater is a flat-shape heater, which is wrapped around the electrode pole of the fixing electrode and mobile electrode to form heater array. Comparing to the circular silk, the flat-shape structure increases the contact area and time of the reaction gas and heater, and improves the reaction gas decomposing rate, and save electric energy to decrease the growth cost of the diamond film.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Biodegradable polyhydroxyalkanoate copolymers having improved crystallization properties

Compositions having improved crystallization properties and physical properties including a continuous phase of a first biodegradable polyhydroxyalkanoate comprising a copolymer, or a blend thereof, of at least two randomly repeating monomer units and having a melting point Tm1, and a second crystallizable biodegradable polyhydroxyalkanoate homopolymer or copolymer, which comprises at least one randomly repeating monomer unit and has a melting point Tm2, where Tm2 is at least about 20□C. greater than Tm1. The compositions are formed by solution or melt blending of the components and may be formed into shaped articles.

Owner:DANIMER IPCO LLC

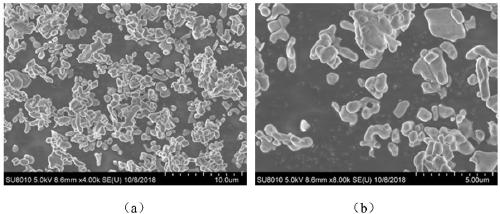

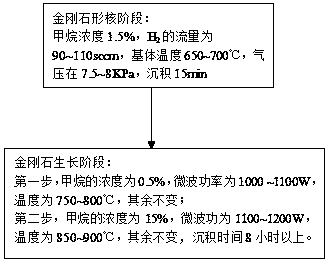

New method for preparing diamond coated cutting tool

InactiveCN104233217AEfficient removalPrevent proliferationChemical vapor deposition coatingMicrowaveAlloy

The invention belongs to the field of a material coating, and particularly provides a new method for preparing a high-quality diamond coated cutting tool by multilayered step-by-step deposition. The new method concretely comprises the following steps: firstly, plating a molybdenum layer on the surface of a hard alloy cutting tool by adopting an electroplating method or a physical vapor deposition method, wherein molybdenum is bound together with cobalt on the surface of a matrix to form a stable compound so as to form a transition layer on the surface of the matrix, so that not only can the influence of cobalt on the surface of the cutting tool to the diamond coating be reduced, but also the dispersion of cobalt towards the surface of the cutting tool from the depth position of the matrix is prevented; and then depositing a diamond coating by two steps through utilizing microwave plasma CVD (MPCVD) method, namely controlling corresponding parameters in diamond nucleation and growth stages to form a nanodiamond thin film with high quality and high stability.

Owner:JIANGSU UNIV

Method for preparing thickness controllable trilayer type diamond membrane

InactiveCN1928151ASolve Thickness ProblemsResolving Contradictions Between RoughnessesChemical vapor deposition coatingDeposition temperatureGas phase

The present invention is preparation process of three-layer diamond film in controllable thickness, belongs to the field of chemical vapor deposition technology of inorganic non-metal material, and aims at obtaining diameter film with proper roughness and thickness simultaneously. In an available chemical vapor deposition plant with hot filament and by means of regulating the carbon source concentration, depositing temperature, reaction pressure, applied bias and other parameters, three-layer diamond film is deposited on silicon chip. The present invention makes it possible to produce thick and flat diamond film without need of the post polishing treatment on the film.

Owner:SHANGHAI UNIV

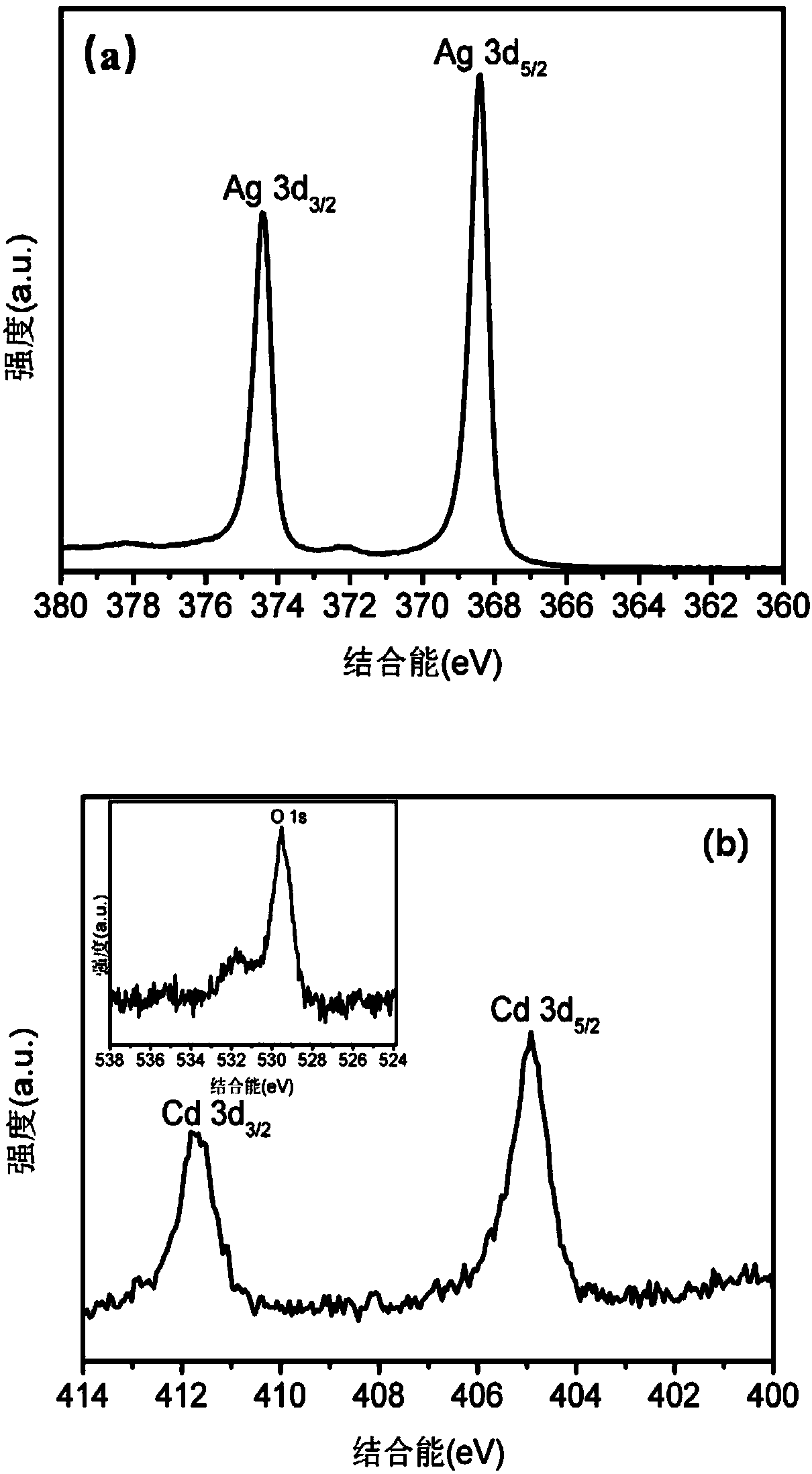

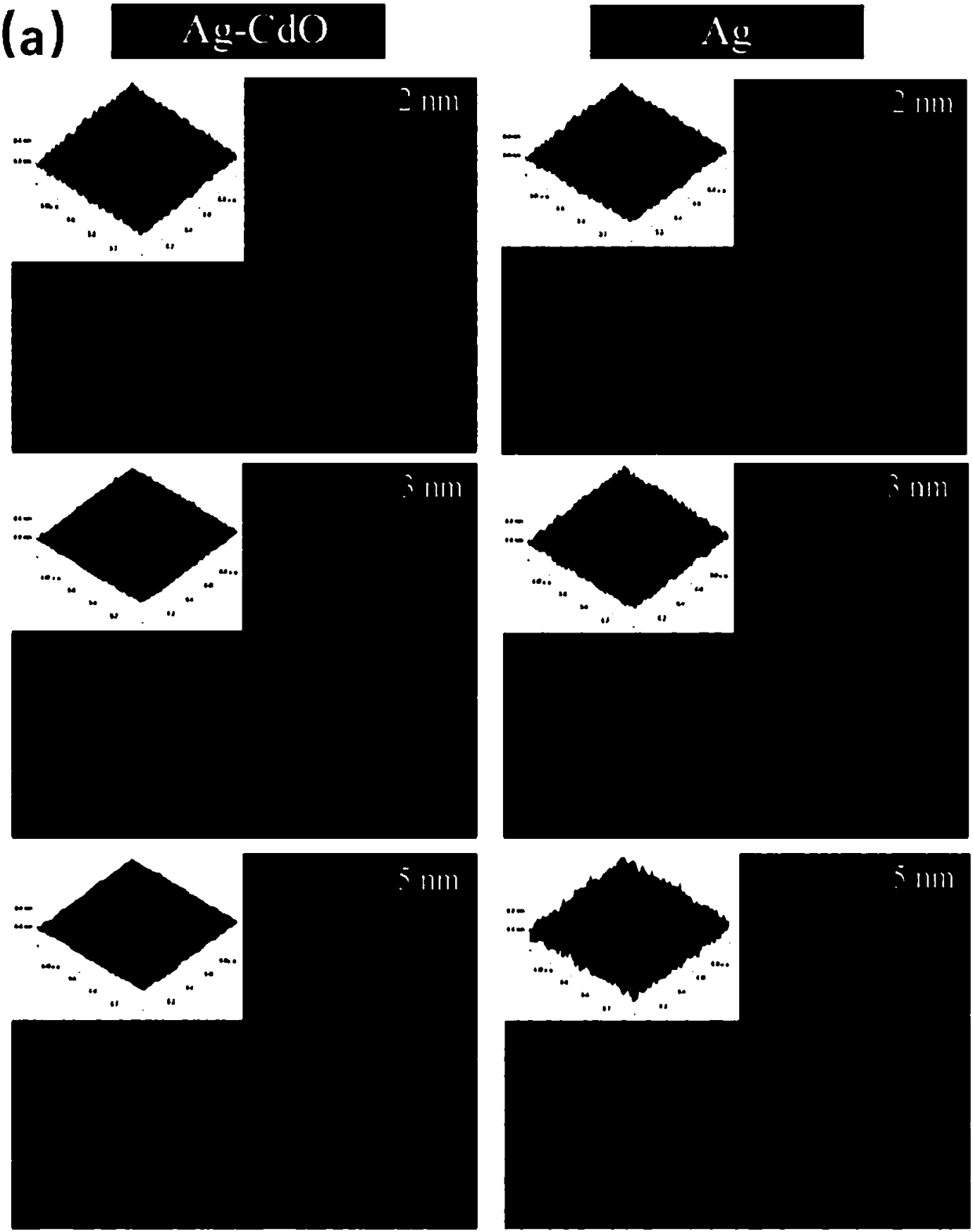

Transparent conductive film with single layer structure, preparation method and application thereof

ActiveCN108385072AImprove thermal stabilityImprove heat and humidity stabilityConductive layers on insulating-supportsVacuum evaporation coatingDirect current magnetron sputteringMaterial consumption

The invention discloses a transparent conductive film with a single layer structure, a preparation method and application thereof. The preparation includes: putting a cleaned substrate into a vacuum chamber of a vacuum magnetron sputtering device, filling argon when the vacuum degree of the chamber is 1*10<-4>-7*10<-4>Pa, and controlling the total air pressure at 0.16Pa, adjusting the sputtering power of a target material to 10-60W, then opening a sample baffle plate, and employing direct current magnetron sputtering technique for deposition on the substrate surface to obtain the transparent conductive film. The transparent conductive film is composed of silver and a metal oxide. By direct sputtering of an alloy target composed of silver and the metal oxide or co-sputtering of silver and ametal oxide target, the transparent metal conductive film with good continuity and stability under a small thickness can be prepared, thereby reaching the purposes of lowering the structural complexity and reducing material consumption.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Smoothing agents to enhance nucleation density in thin film chemical vapor deposition

ActiveUS8846146B2Reduce surface roughnessHigh degreeChemical vapor deposition coatingGas phaseNucleation

The present invention provides methods for making structures, including nanosized and microsized thin film structures that exhibit a high degree of smoothness useful for applications in microelectronics. Deposition processing of the invention utilize smoothing agents capable of selectively adjusting the relative rates of processes involved in thin film formation and growth to access enhanced nucleation densities resulting in smooth thin film structures, including ultrathin (e.g., <10 nm) smooth films.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Preparation method for ultrahigh molecular weight polyethylene microporous membrane

The invention relates to a preparation method for an ultrahigh molecular weight polyethylene microporous membrane. The ultrahigh molecular weight polyethylene microporous membrane comprises 10 to 30 weight parts of polyethylene resin, 0 to 1 weight part of fiber nucleating agent, 69 to 89.5 weight parts of latent solvent and 0.5 to 1 weight part of antioxidant. By the method, the fiber nucleating agent generates nanofibers in a polymer / latent solvent matrix; and the generated nanofibers are dispersed in the polymer / latent solvent matrix well. The ultrahigh molecular weight polyethylene microporous membrane prepared by the method has smaller aperture, uniform aperture distribution and higher porosity. The ultrahigh molecular weight polyethylene microporous membrane has prominent mechanical property, in particular high tearing strength. Therefore, the microporous membrane prepared by the method can be applied to preparation of food, medicines and ultrapure water and meets the requirements of separation, purification, concentration and purification.

Owner:SHANGHAI JIAO TONG UNIV

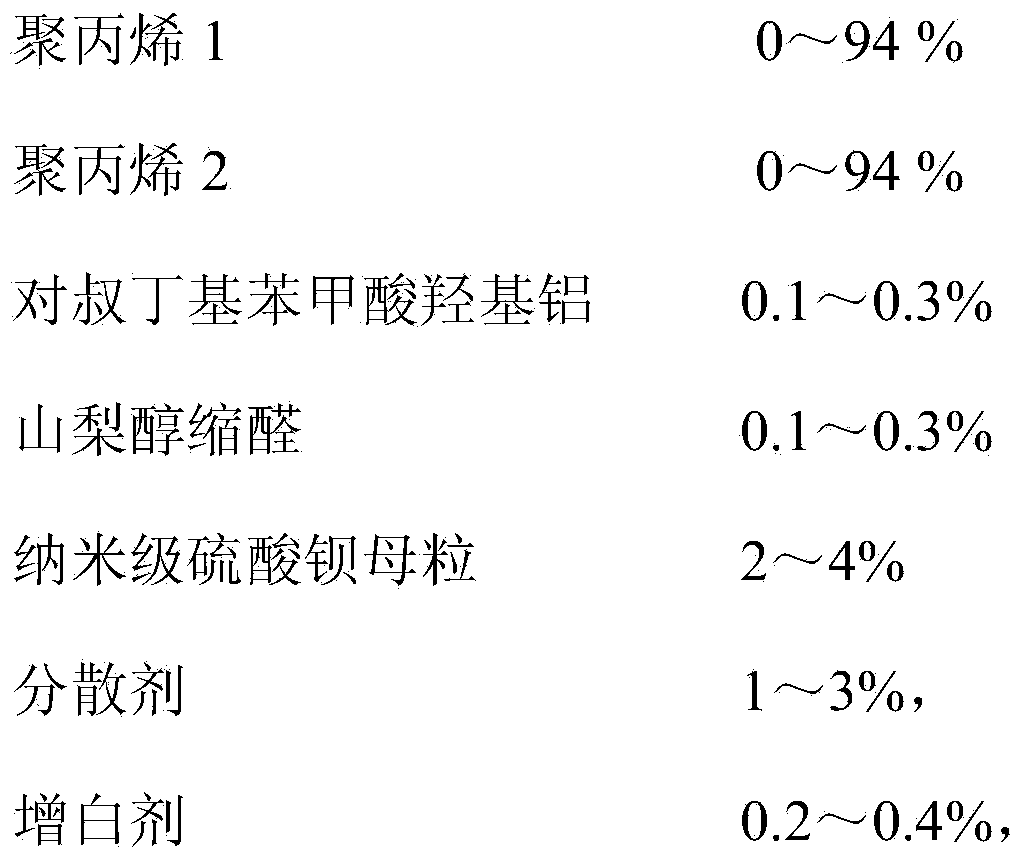

High-rigidity high-transparency polypropylene composite material

The invention discloses a high-rigidity high-transparency polypropylene composite material, and belongs to the technical field of high polymer alloy materials. The high-rigidity high-transparency polypropylene composite material is compounded by 2-4wt% of nanoscale barium sulfate master batch, 0.1-0.3wt% p-tertiary butyl hydroxyl aluminum benzoate and 0.1-0.3wt% sorbitol acetal as a nucleating agent of polypropylene. According to the high-rigidity high-transparency polypropylene composite material, the nanoscale barium sulfate master batch is added to achieve a certain compatible effect on two nucleating agents, so that the two nucleating agents are prevented from resisting against each other; and meanwhile, the effects of nucleating heterogeneously, promoting the polypropylene to quicken crystallization and refining spherocrystal effects are achieved, so that the rigidity and the transparency of a PP (polypropylene) product are further improved.

Owner:广东顺威赛特工程塑料开发有限公司

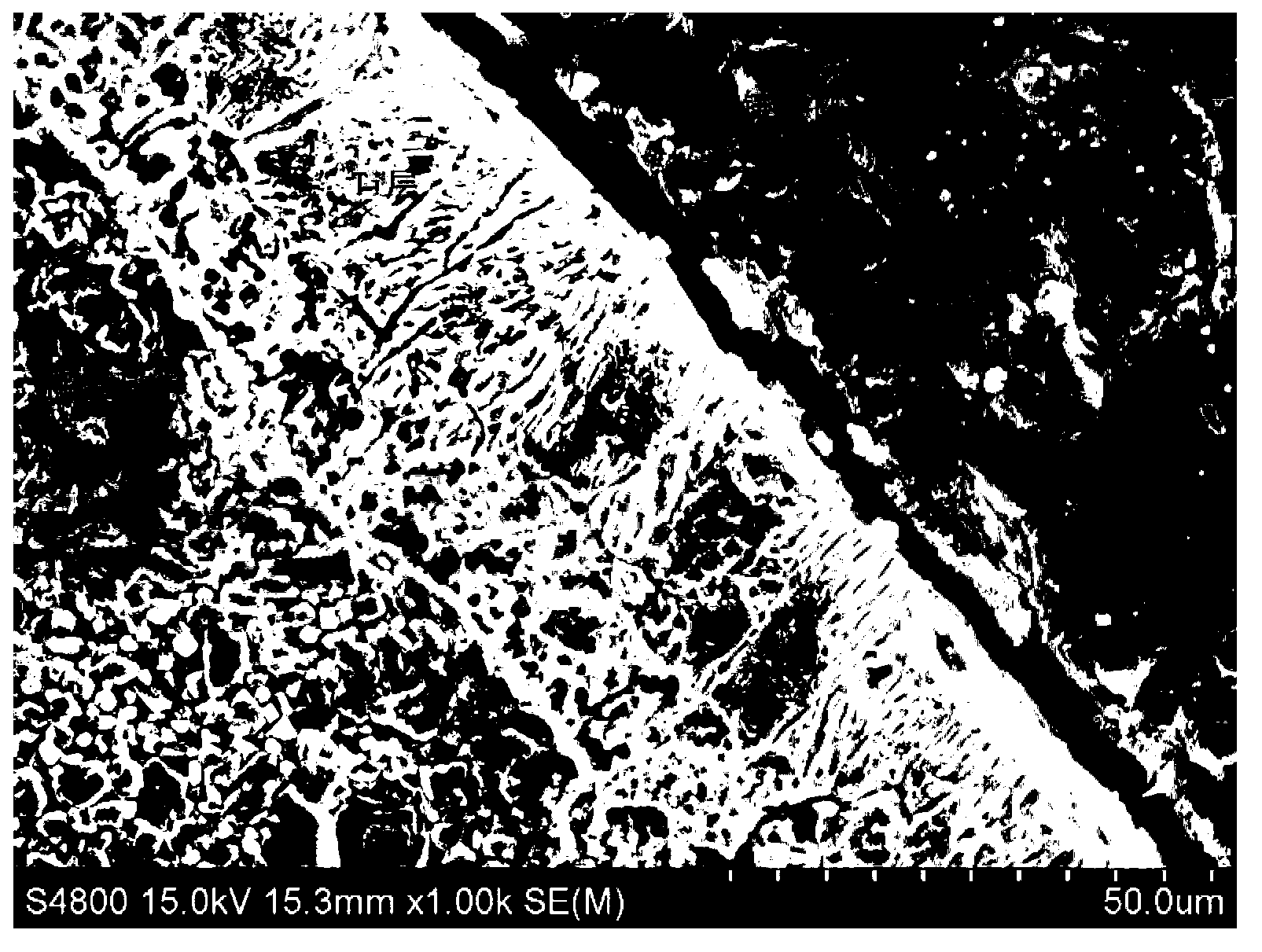

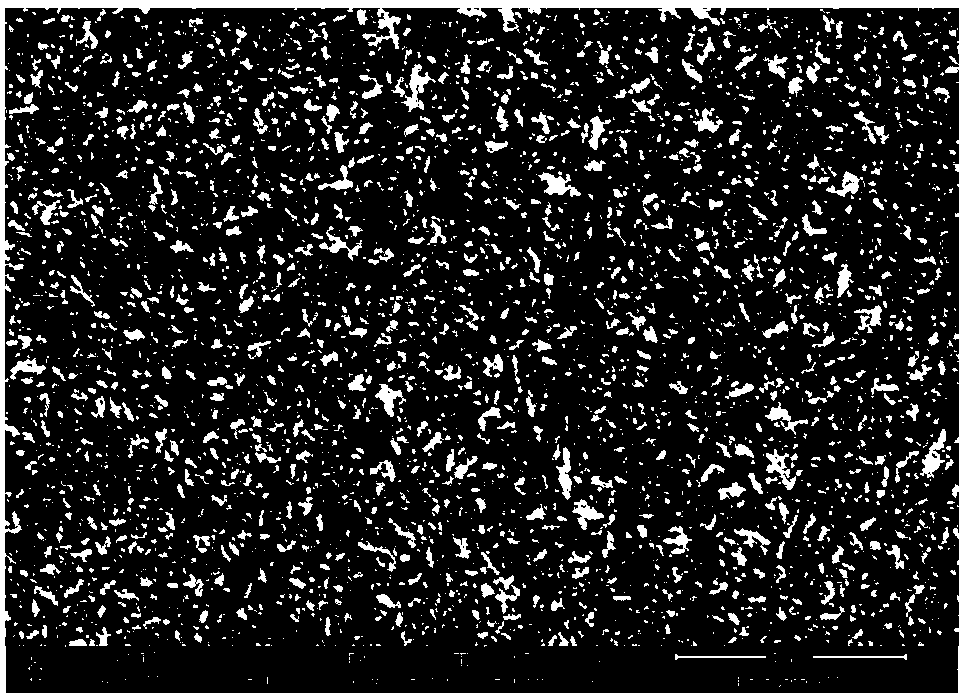

Method for preparing titanium metal coating on ceramic surface

The invention discloses a method for preparing a titanium metal coating on a ceramic surface. The method for preparing the titanium metal coating on the ceramic surface comprises the following steps of: firstly, placing ceramic the surface of which is treated into a quartz tube; then placing a mixture of titanium powder and iodine powder into a container, and placing the container into the quartz tube; then placing the quartz tube into a program control furnace, vacuumizing the program control furnace repeatedly, and introducing an inert gas, warming the program control furnace at the warming speed of 15-20 DEG C / min to 1030-1200 DEG C and carrying out heat preservation, and cooling, thereby obtaining the ceramic the surface of which is coated with the metal coating. The coating provided by the invention is high in purity, and has strong bonding force with base body ceramic, is uniform in distribution on the whole ceramic plane, can form a smooth deposition surface easily; and the device is simple, low in cost and simple to operate.

Owner:CHANGAN UNIV

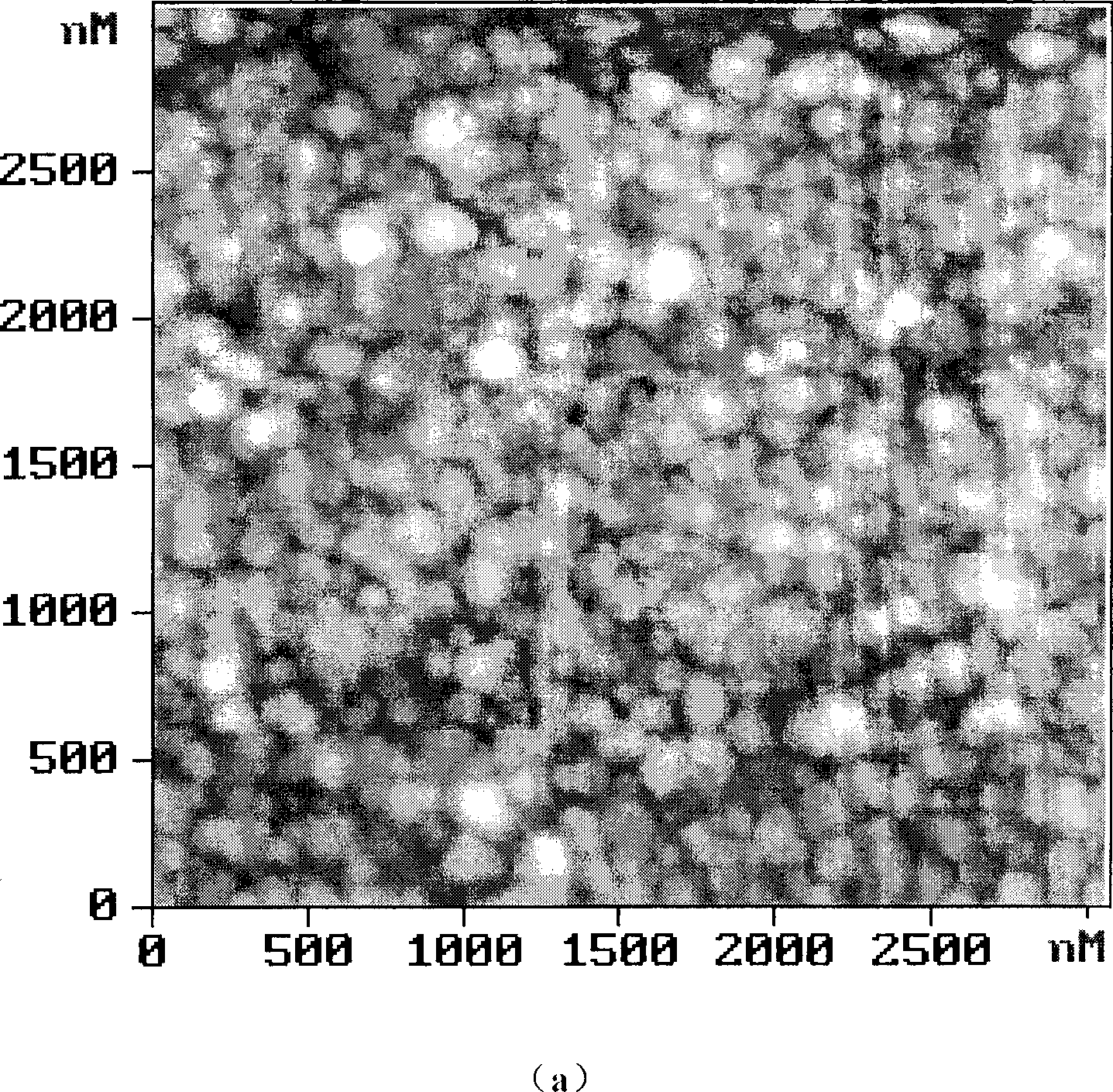

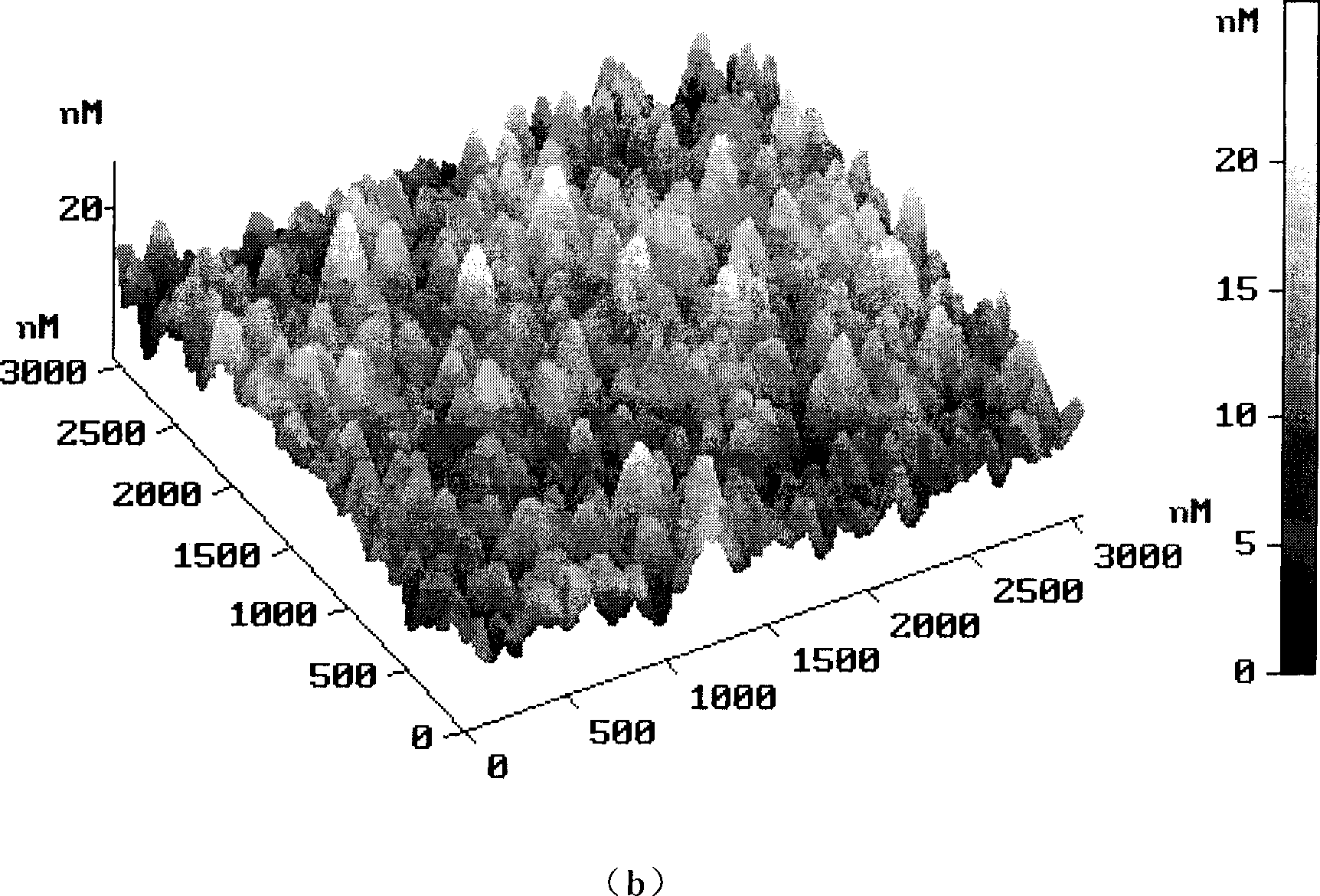

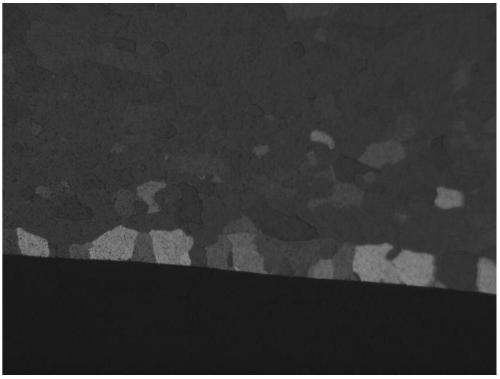

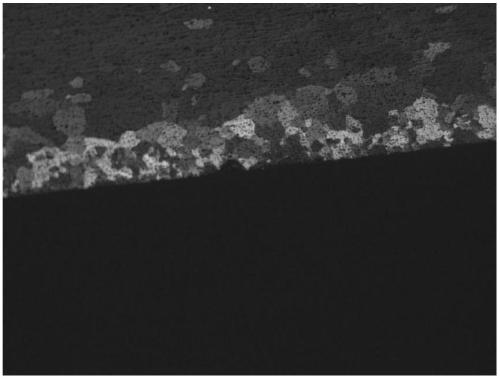

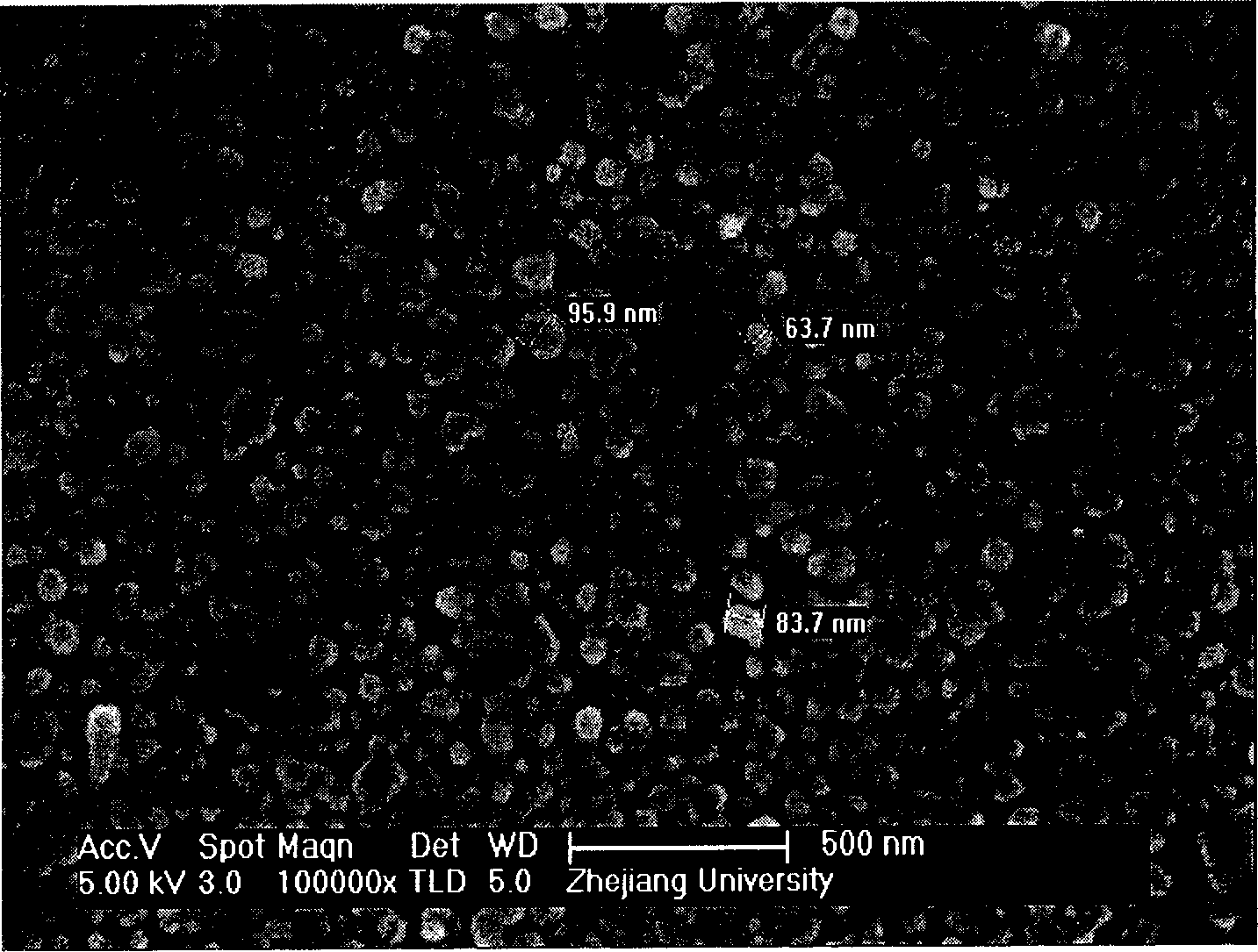

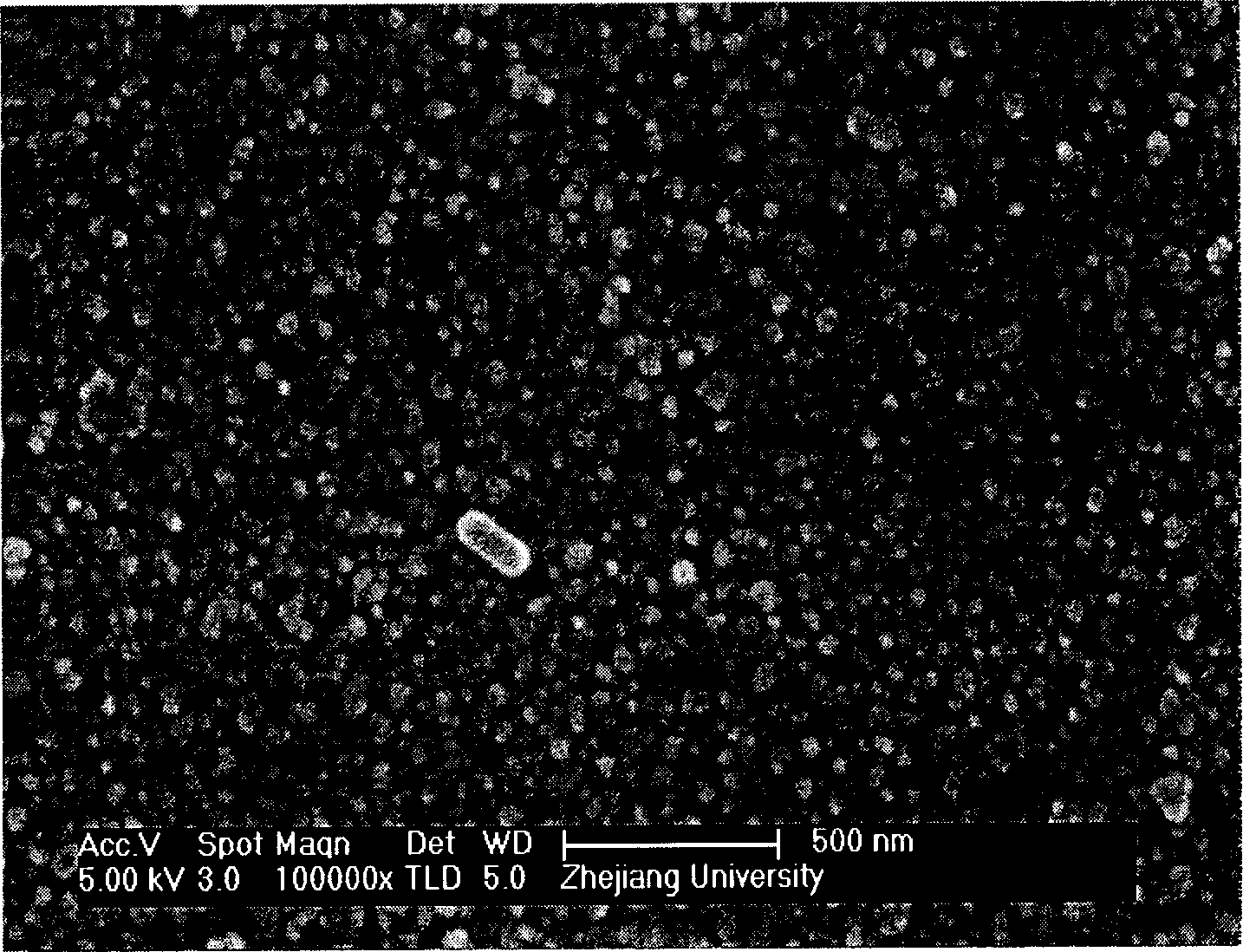

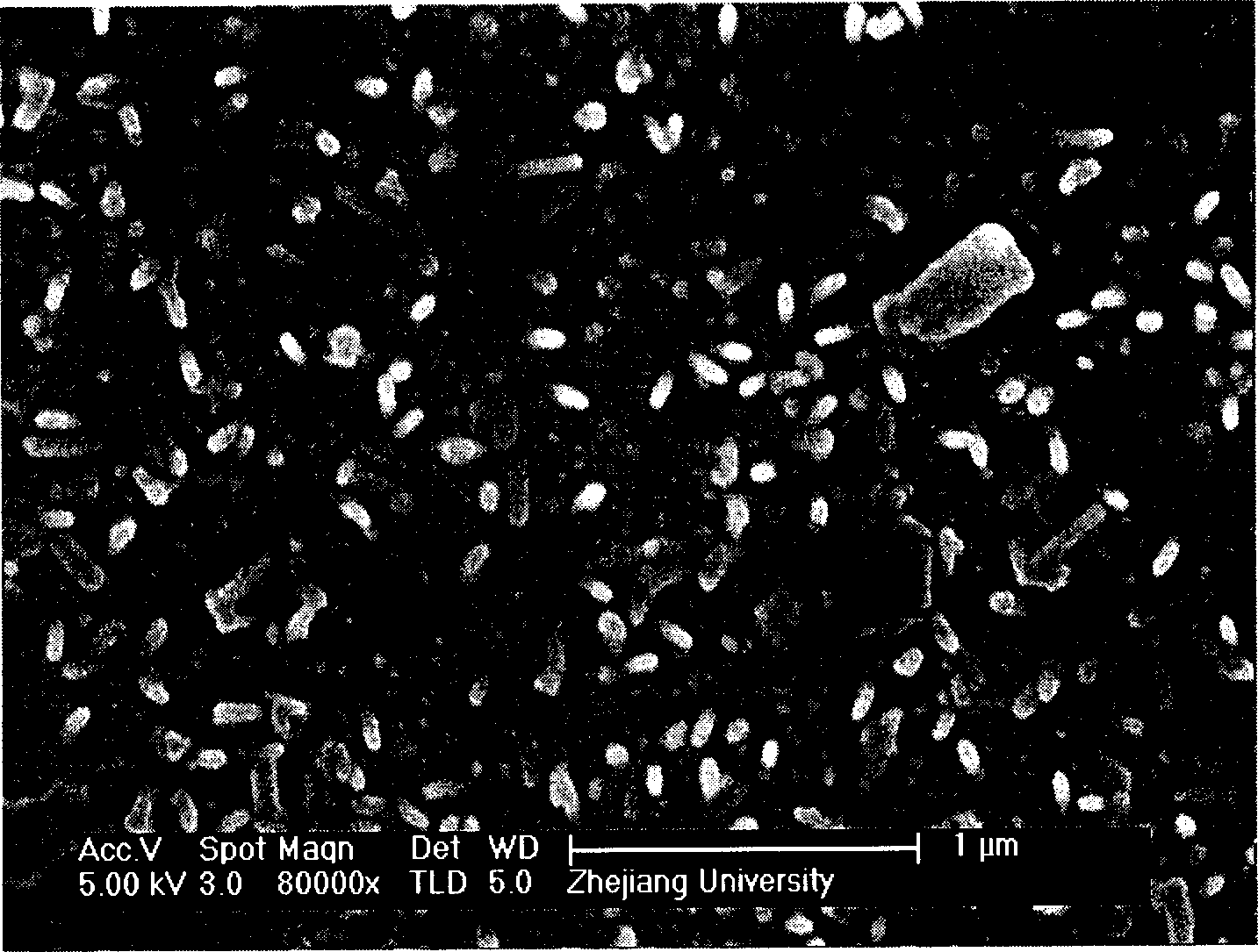

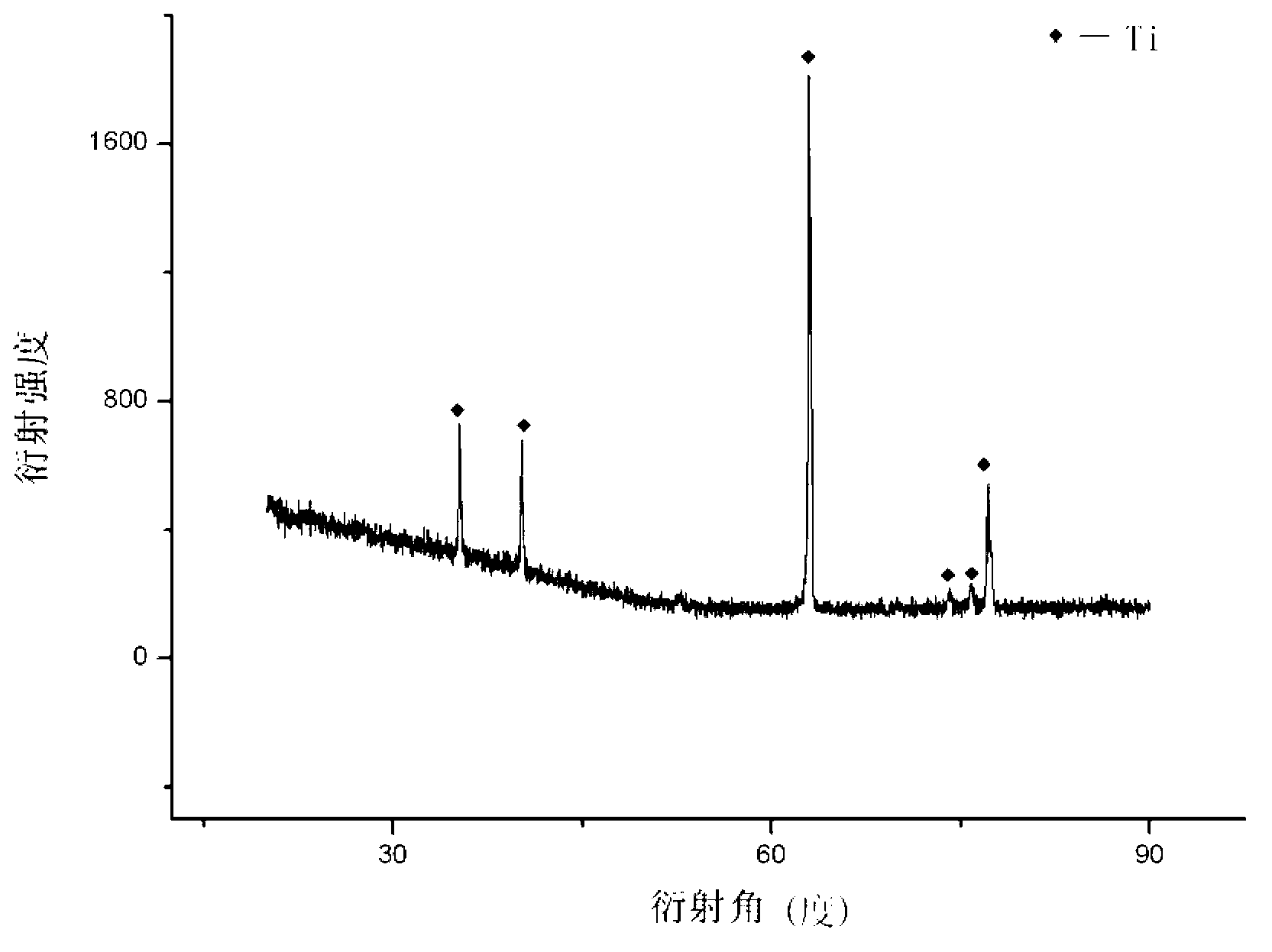

High-mobility n-type ultrathin nano diamond film and preparation method thereof

ActiveCN108531883AIncrease nucleation densityImprove n-type conductanceVacuum evaporation coatingSputtering coatingGas phaseLow vacuum

The invention discloses a high-mobility n-type ultrathin nano diamond film and a preparation method thereof. The preparation method comprises, through hot filament chemical vapor deposition (HFCVD), preparing an ultrafine nano diamond thin on a silicon substrate with a transitional layer deposed through physical vapor deposition (PVD), wherein the transitional layer is 50-100 nm thick; taking acetone as a carbon source, inletting the carbon source into a reaction cavity through hydrogen bubbling, and over a growth time around 10-30 minutes, preparing the ultrathin nano diamond film of a thickness of 200-300 nm; infilling donor impurity ions into the ultrathin nano diamond film, performing low-vacuum oxidizing annealing on the filled sample to obtain the high-mobility n-type ultrathin nanodiamond film in a novel microstructure. The high-mobility n-type ultrathin nano diamond film is of great significance and value to achieving application of diamond films to the fields of semiconductordevices, photoelectronics, field emission display and the like.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com