Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

913 results about "Graphite carbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium ion battery silicon-based composite anode material, preparation method thereof and battery

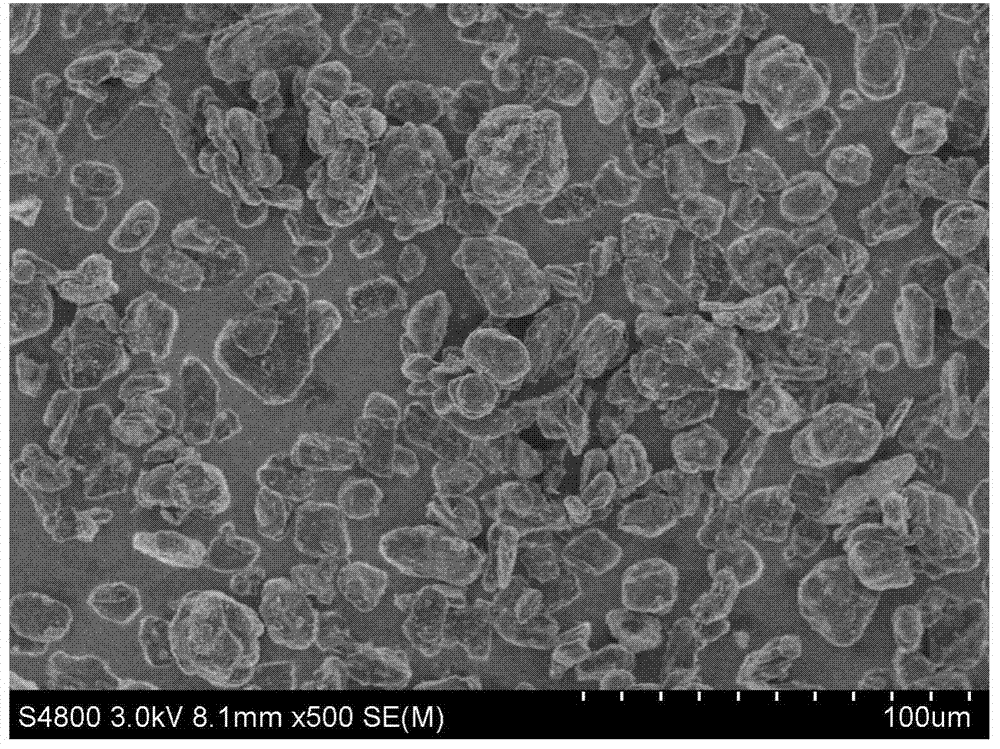

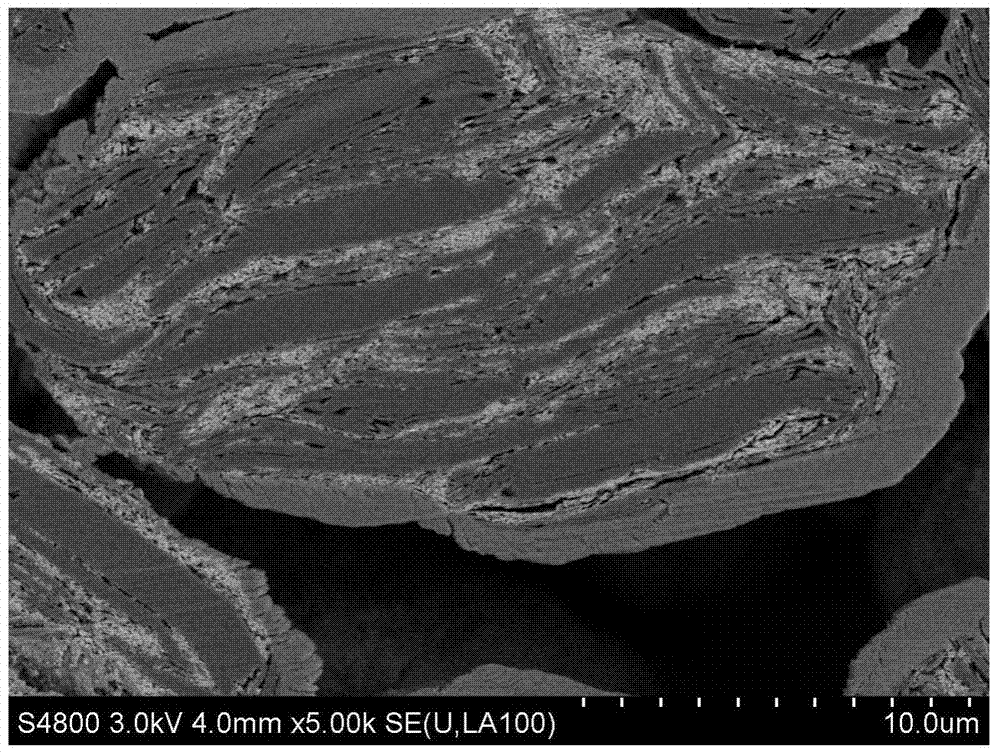

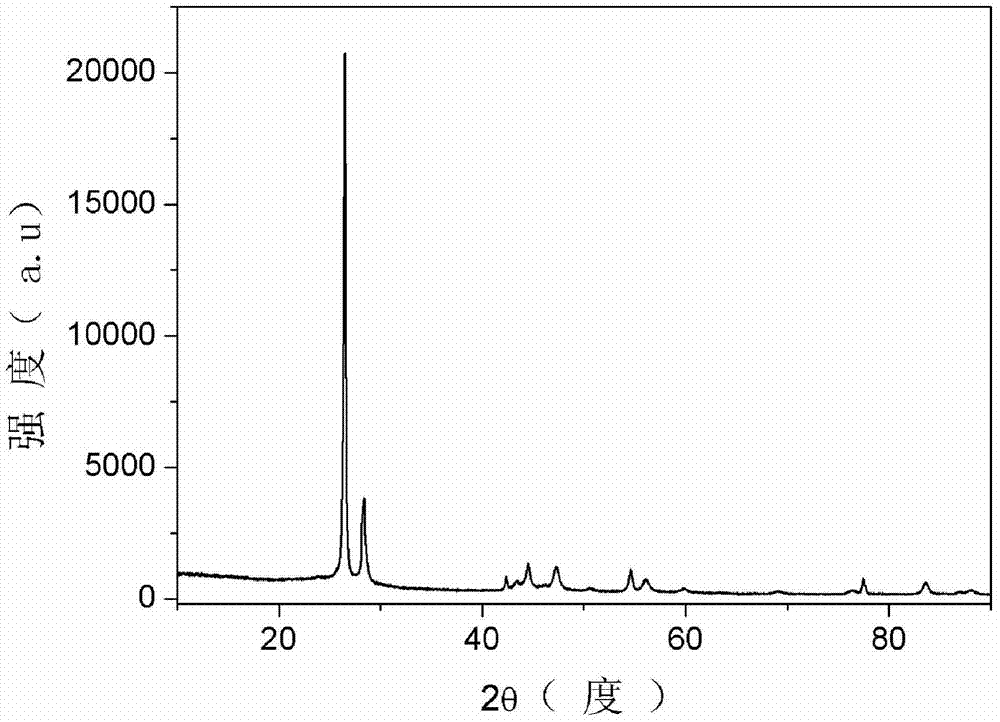

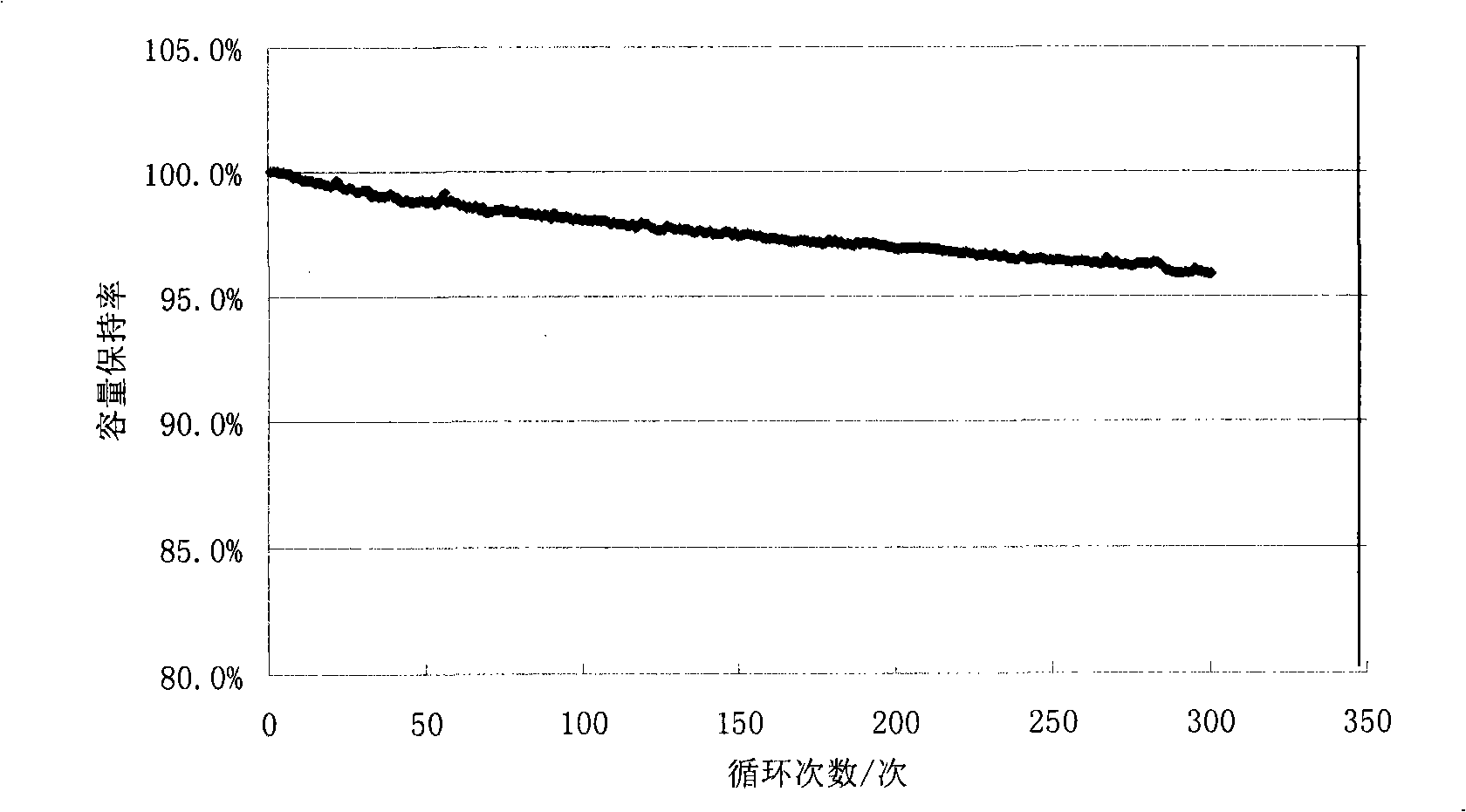

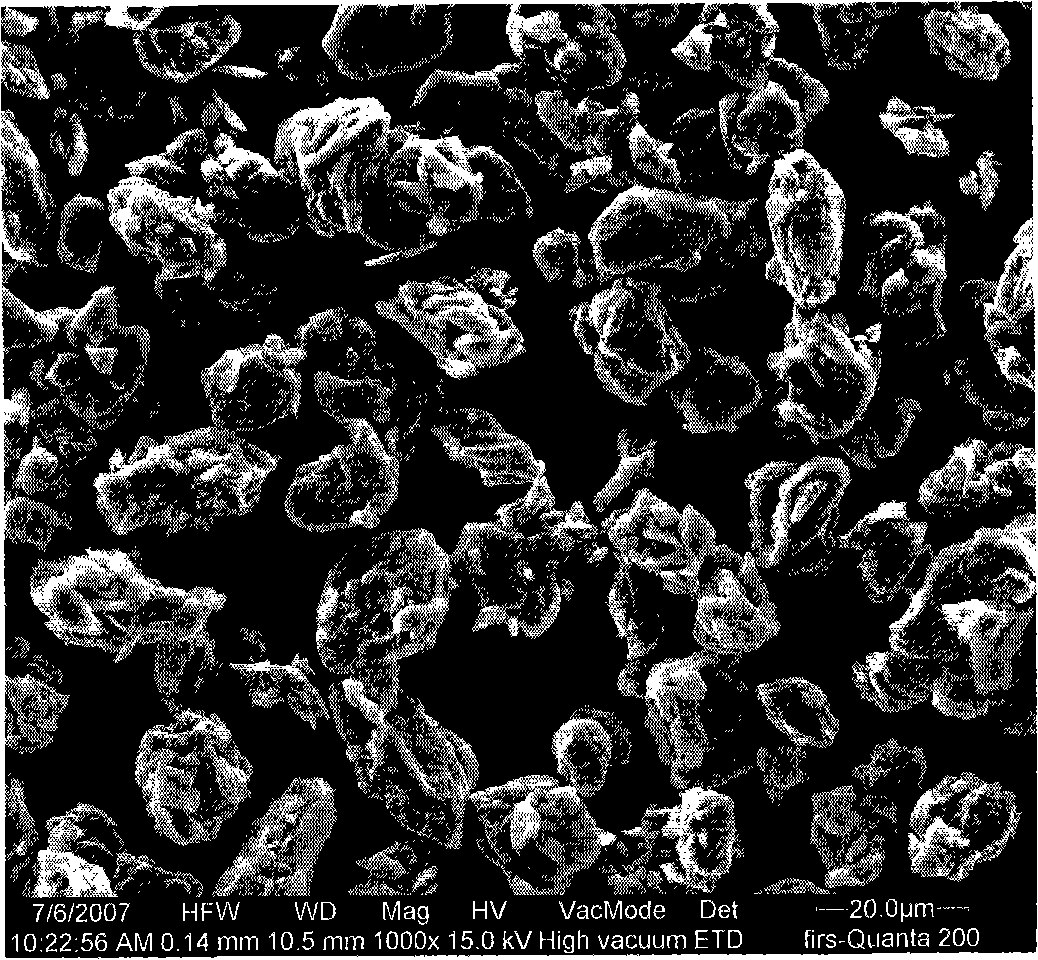

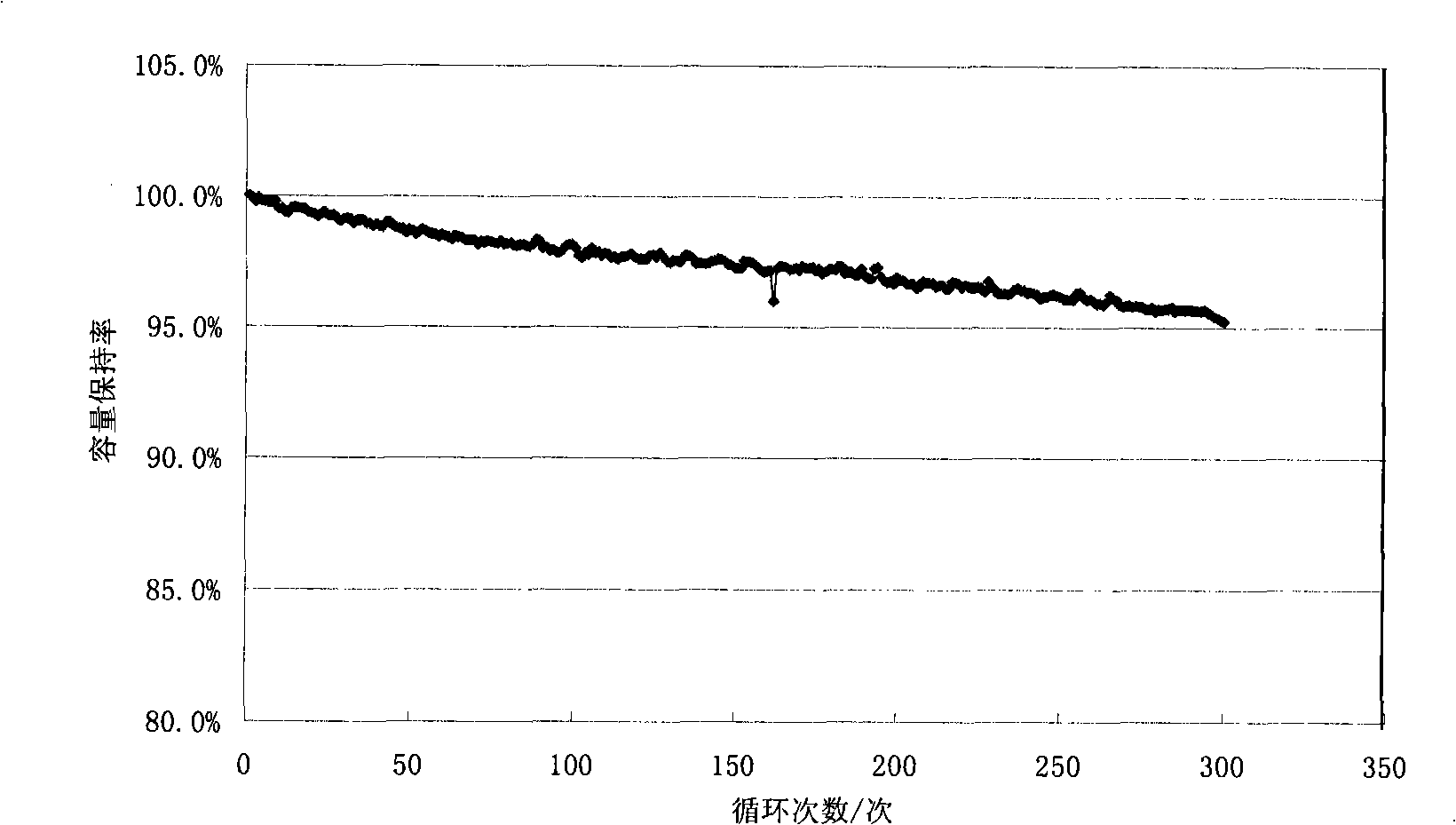

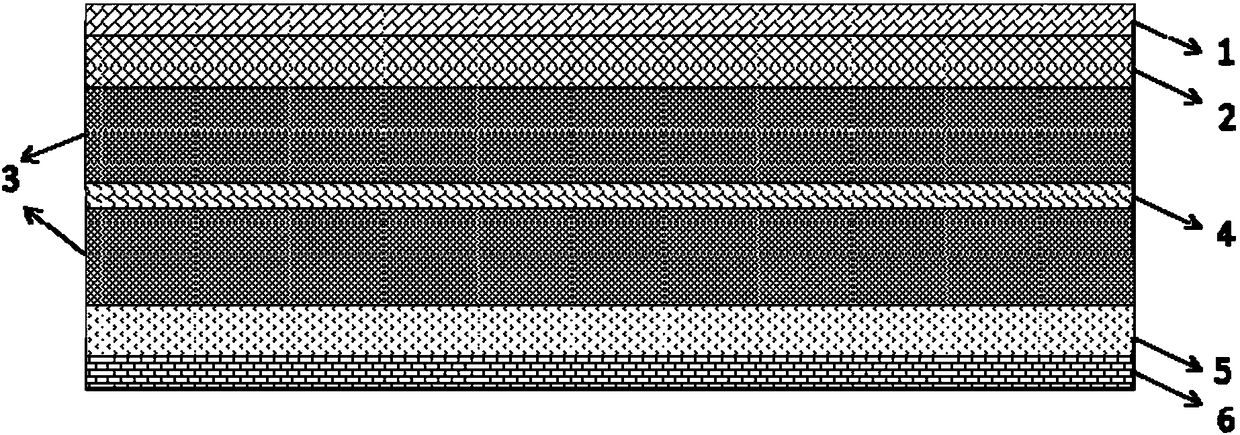

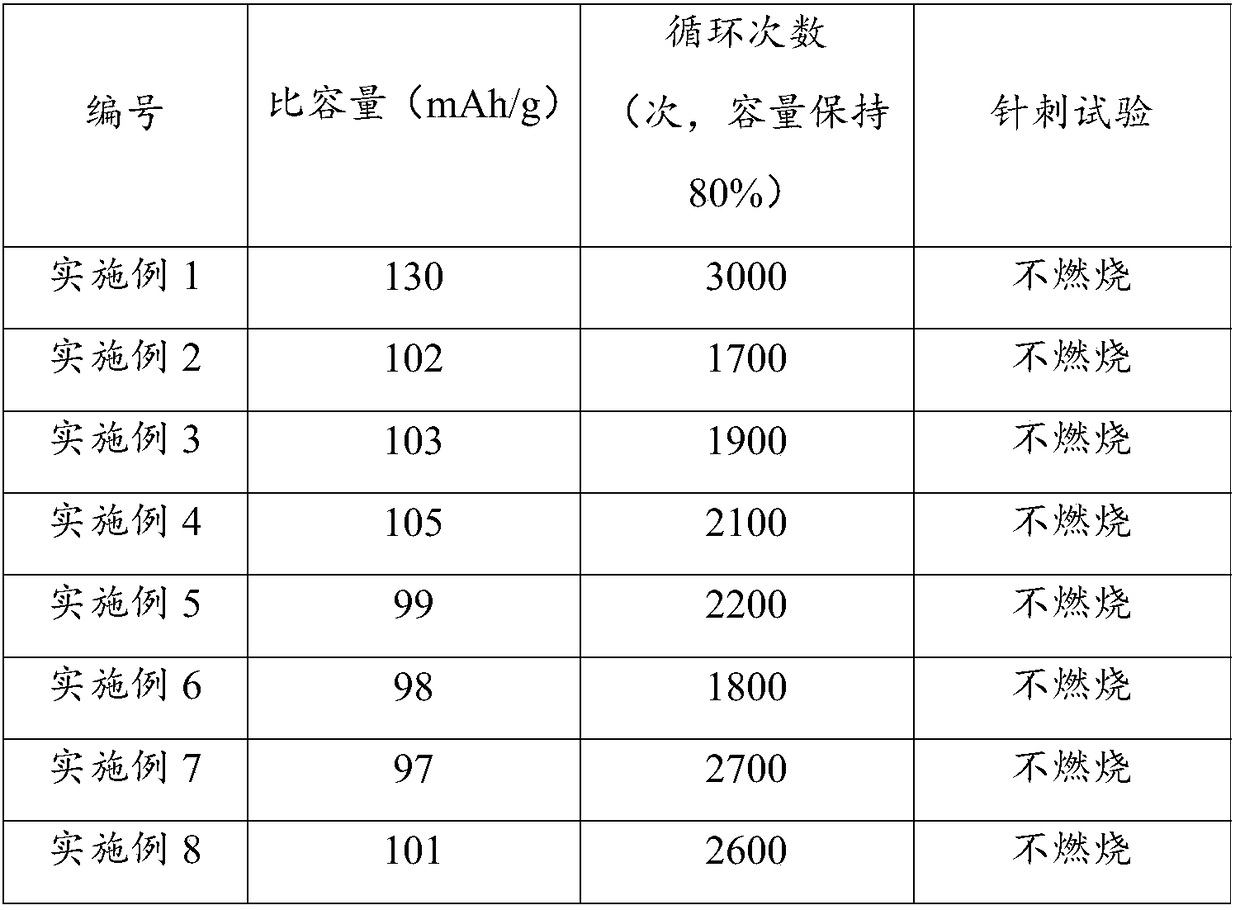

ActiveCN103682287AGood dispersionInhibit swellingCell electrodesSecondary cellsCarbon coatingRetention ratio

The invention relates to a lithium ion battery silicon-based composite anode material, a preparation method of the lithium ion battery silicon-based composite anode material, and a battery. The lithium ion battery silicon-based composite anode material adopts an embedded composite core-shell structure, a core has a structure formed by embedding nano silicon particles into a gap of an inner layer of hollowed graphite, and a shell is made from a non-graphite carbon material. According to the silicon-based composite anode material, mechanical grinding, mechanical fusing, isotropic compression processing and carbon coating technologies are combined, so that the nano silicon particles can be successfully embedded into the inner layer of the graphite and the surfaces of graphite particles are uniformly coated; the high-performance silicon-based composite anode material is obtained and is excellent in cycle performance (the 300-times cycle capacity retention ratio is more than 90%) and high in first efficiency (more than 90%); in addition, the silicon-based composite anode material is high in specific energy and compaction density, and can meet the requirements of a high-power density lithium ion battery; the preparation process is simple, the raw material cost is low, and the environment is protected.

Owner:BTR NEW MATERIAL GRP CO LTD

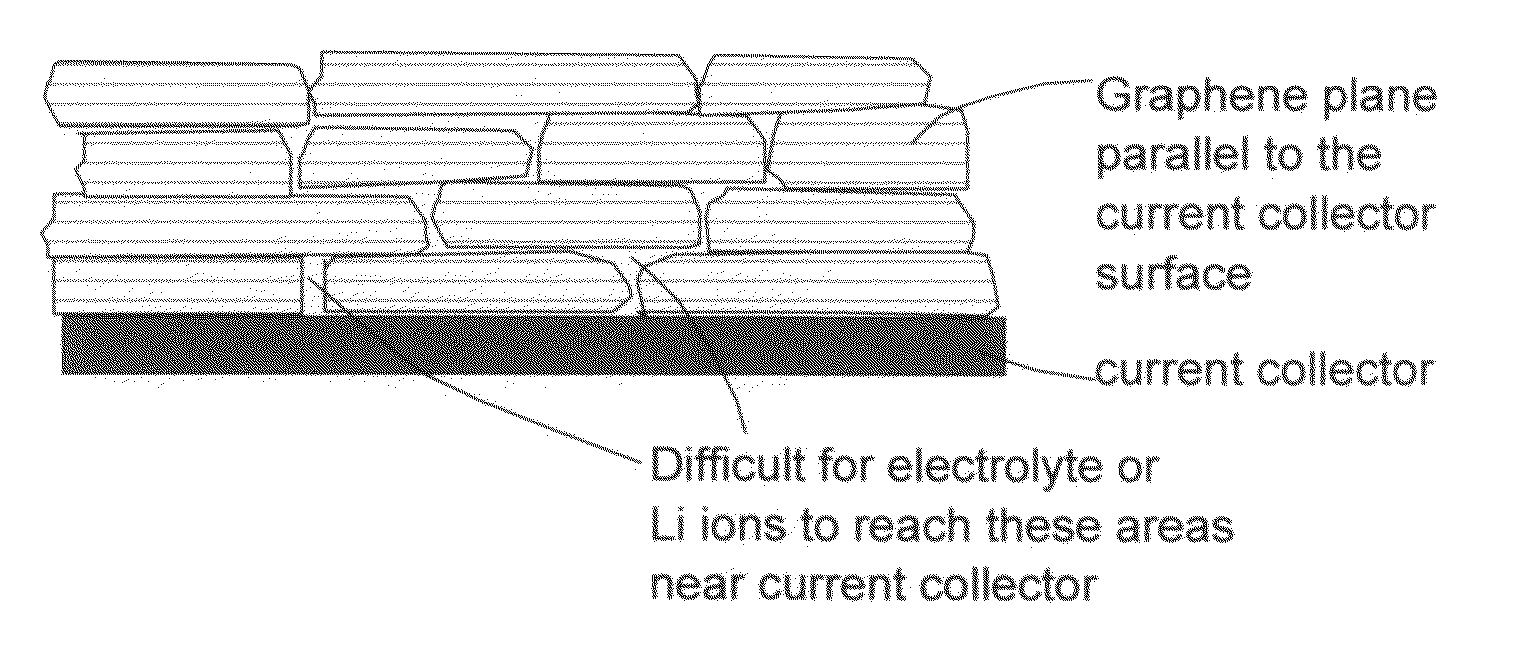

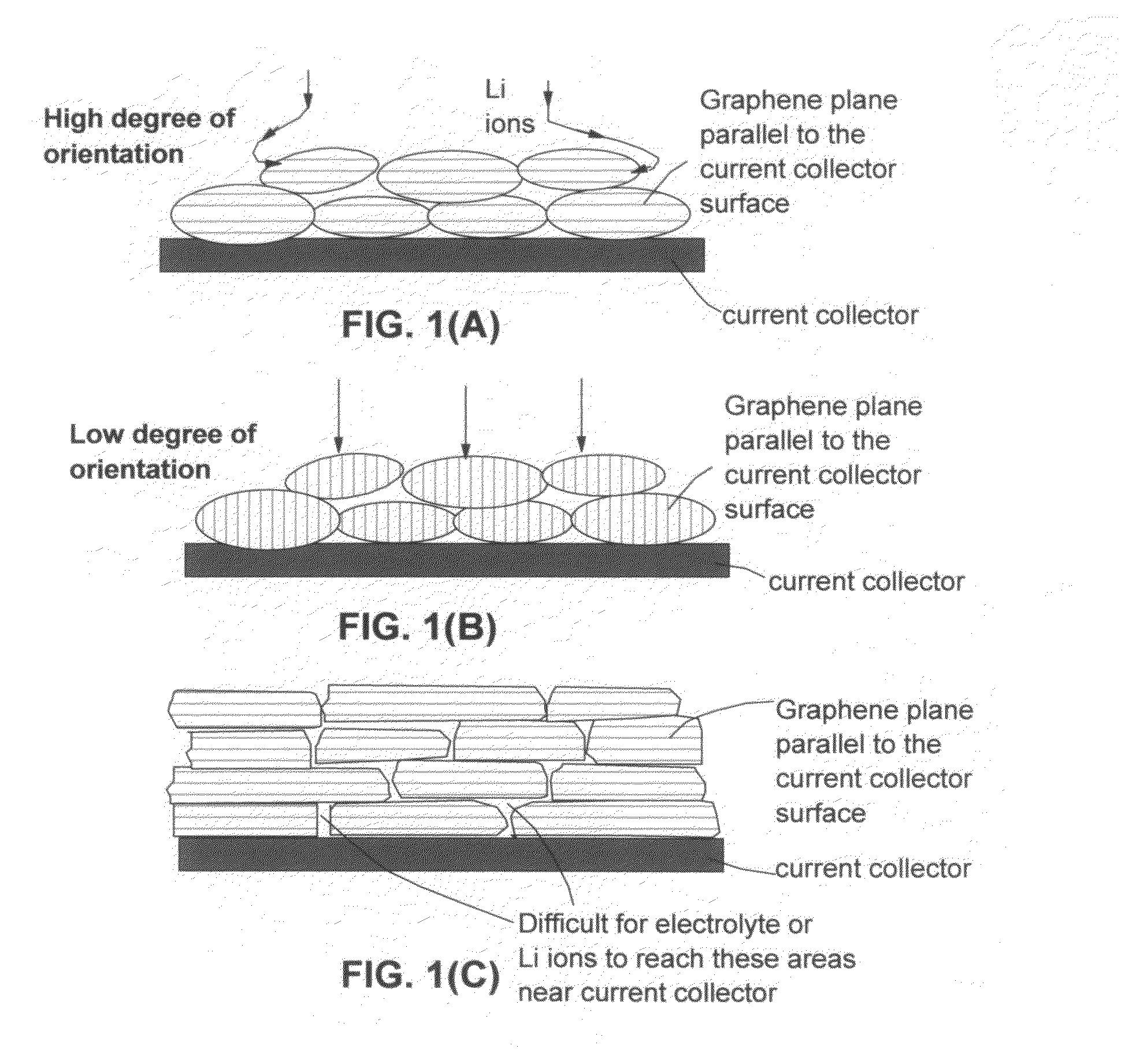

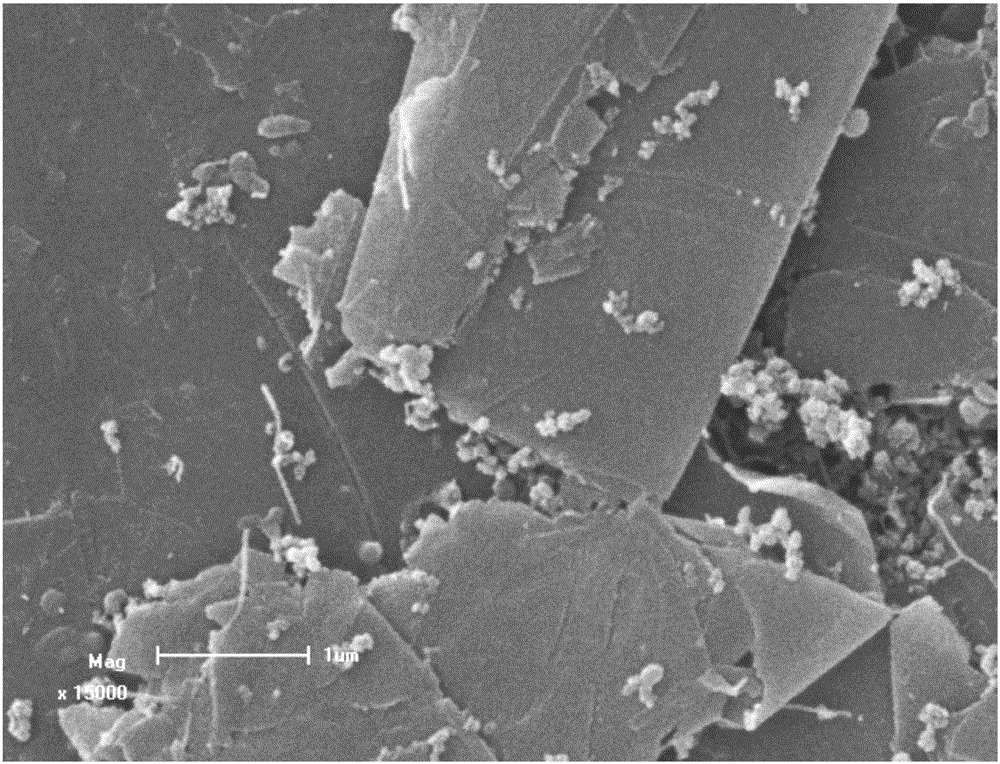

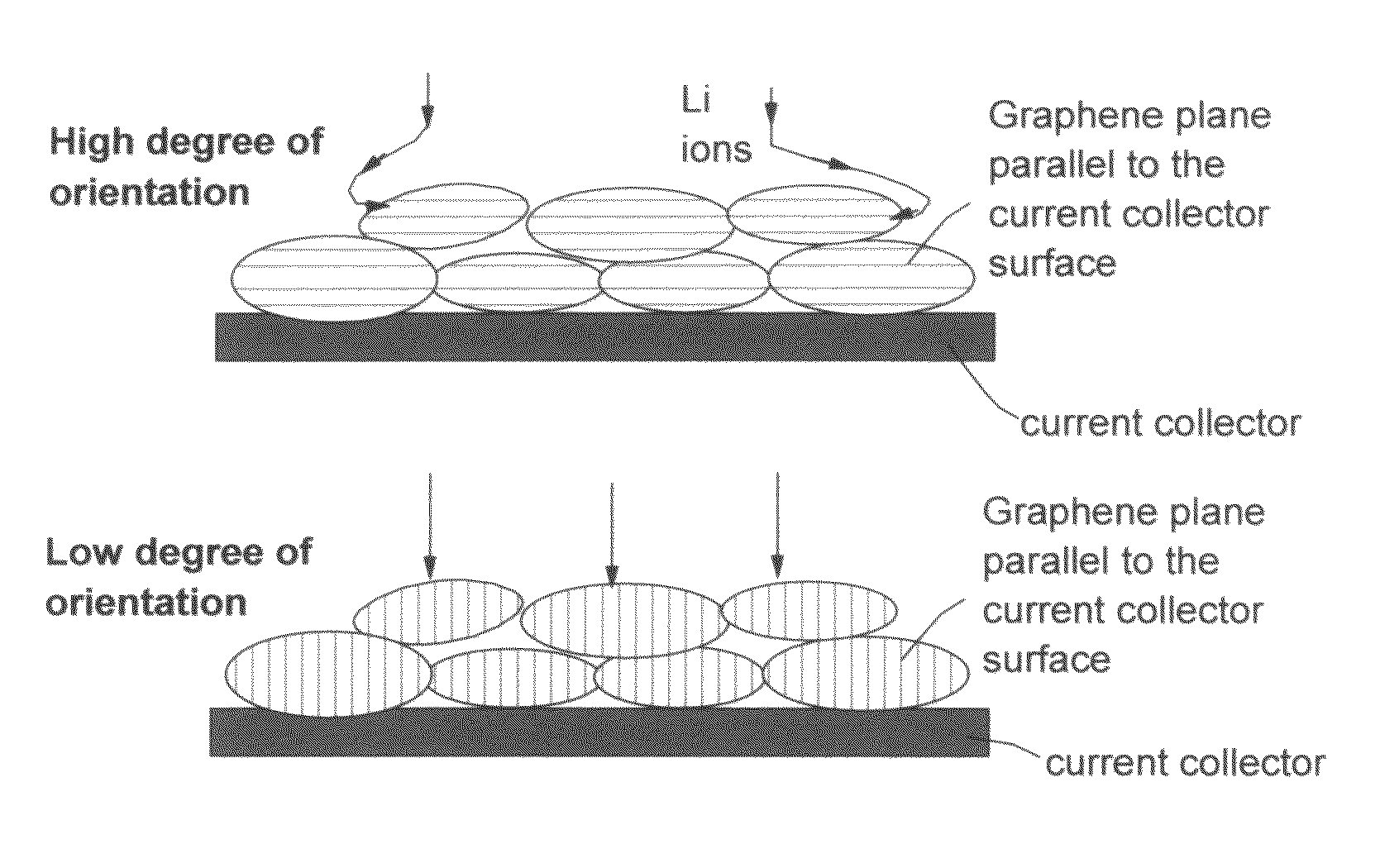

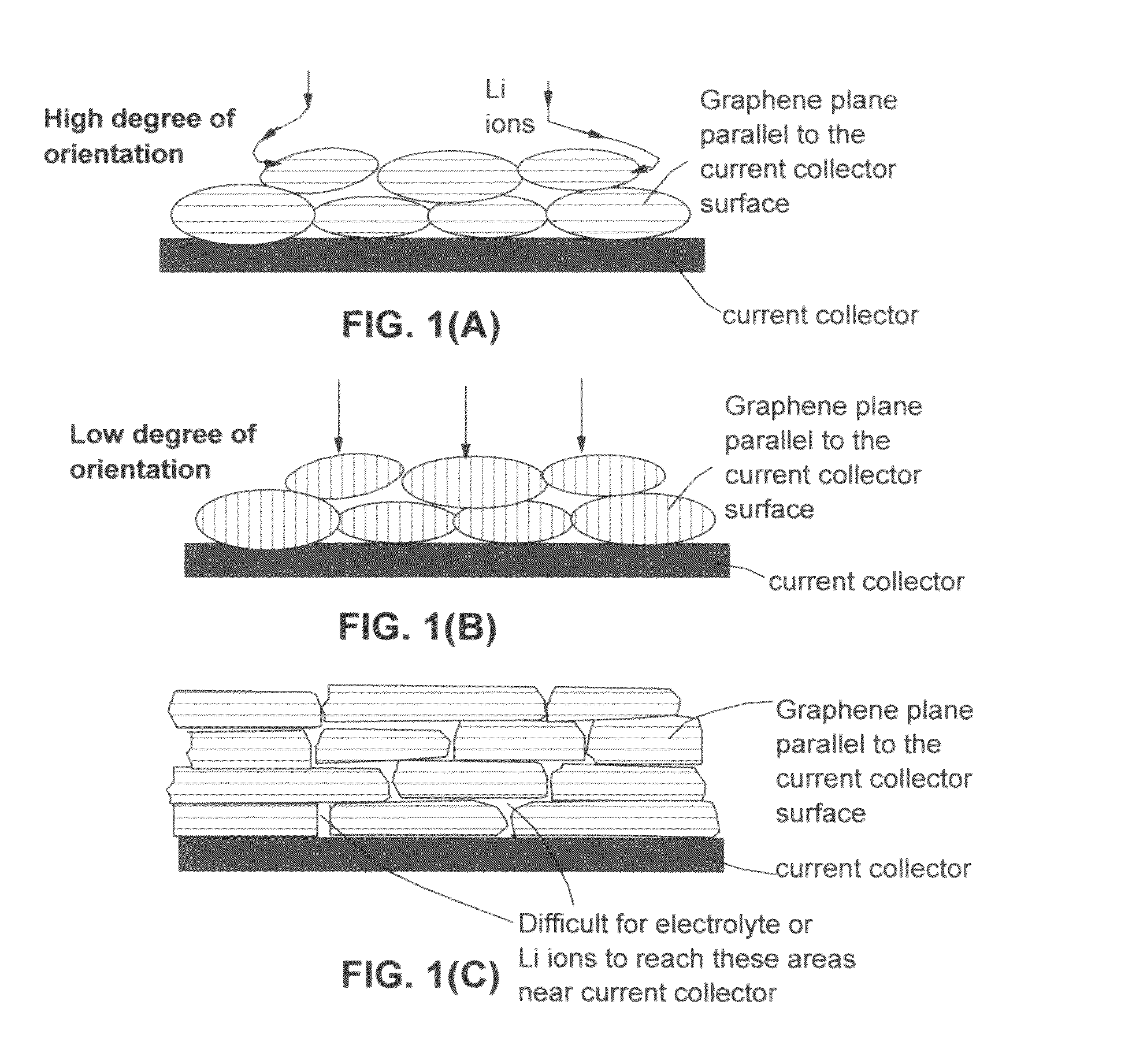

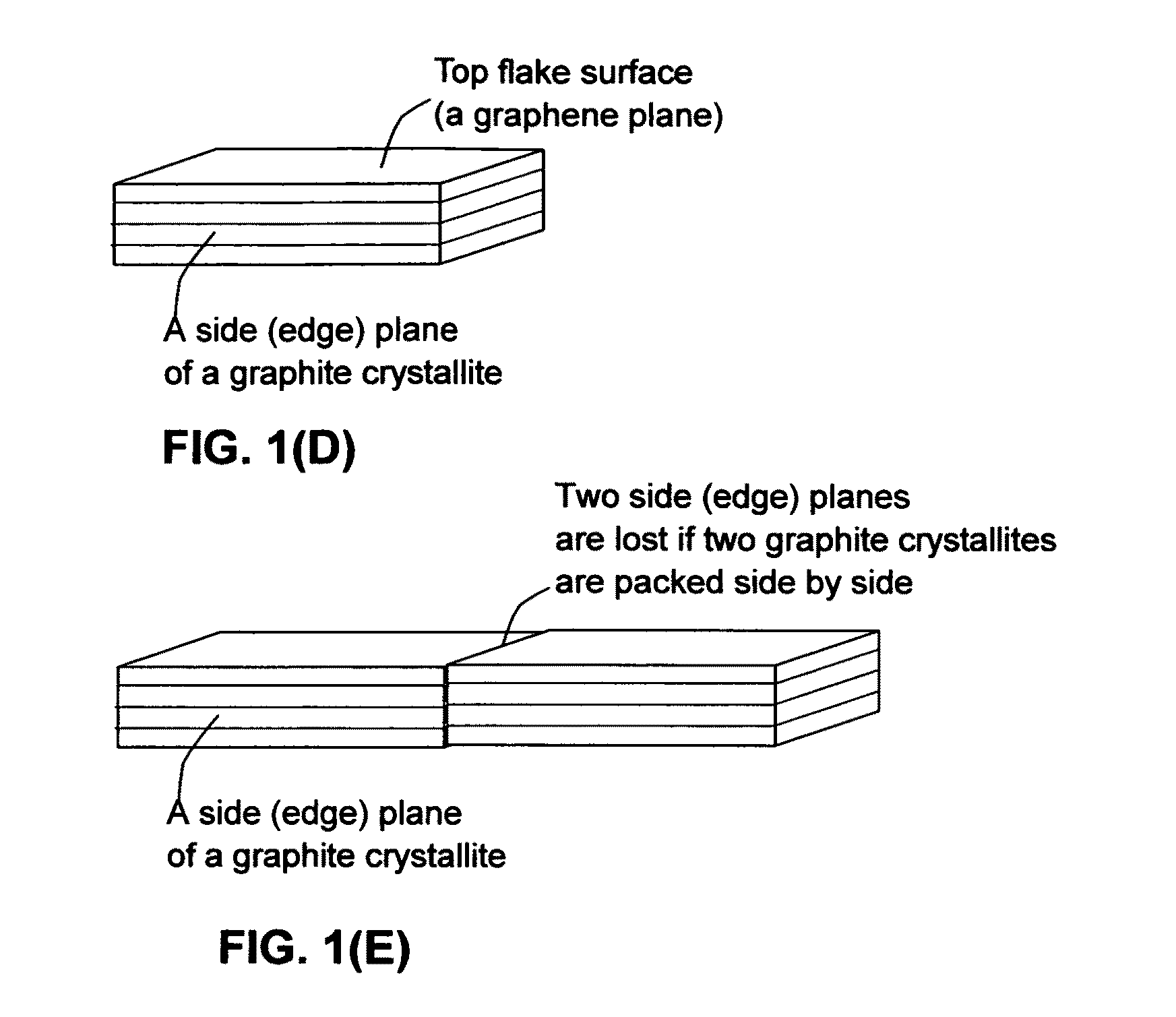

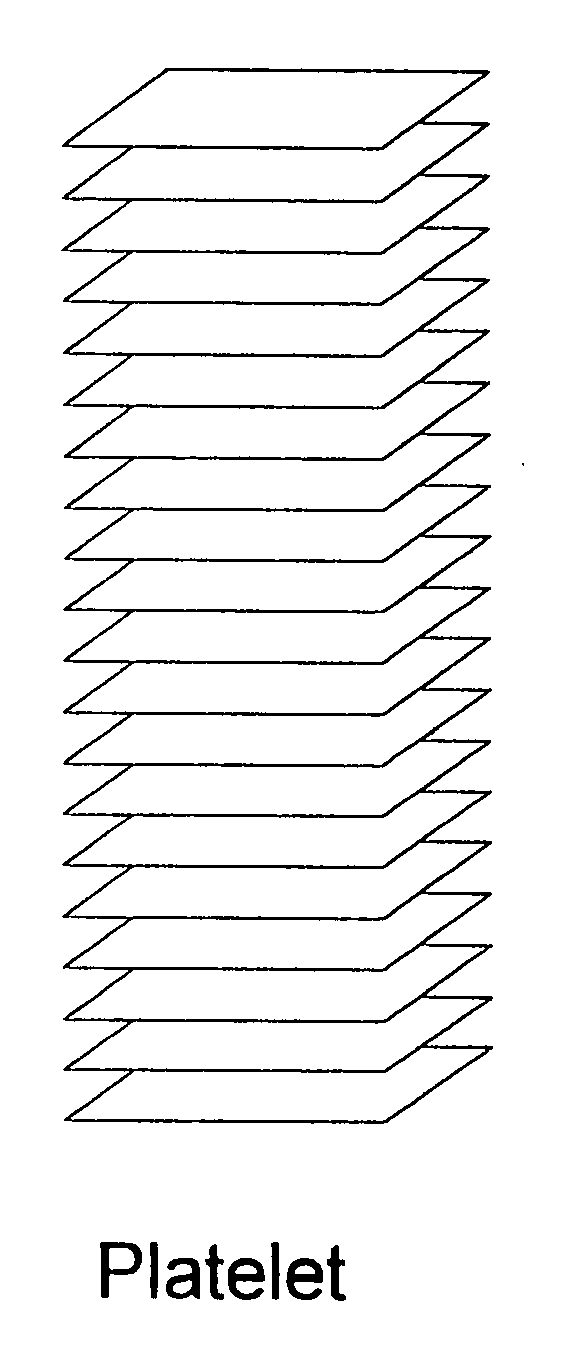

Graphite or carbon particulates for the lithium ion battery anode

This invention provides a graphite or graphite-carbon particulate for use as a lithium secondary battery anode material having a high-rate capability. The particulate is formed of a core carbon or graphite particle and a plurality of satellite carbon or graphite particles that are each separately bonded to the core particle wherein the core particle is spherical in shape, slightly elongate in shape with a major axis-to-minor axis ratio less than 2, or fibril in shape, and wherein the satellite particles are disc-, platelet-, or flake-like particles each containing a graphite crystallite with a crystallographic c-axis dimension Lc and a lateral dimension. Preferably, Lc is less than 100 nm and the flake / platelet lateral dimension is less than 1 μm. The core particle may be selected from natural graphite, artificial graphite, spherical graphite, graphitic coke, meso-carbon micro-bead, soft carbon, hard carbon, graphitic fibril, carbon nano-fiber, carbon fiber, or graphite fiber. Preferably, the flat-shaped particles are randomly oriented with respect to one another.

Owner:GLOBAL GRAPHENE GRP INC

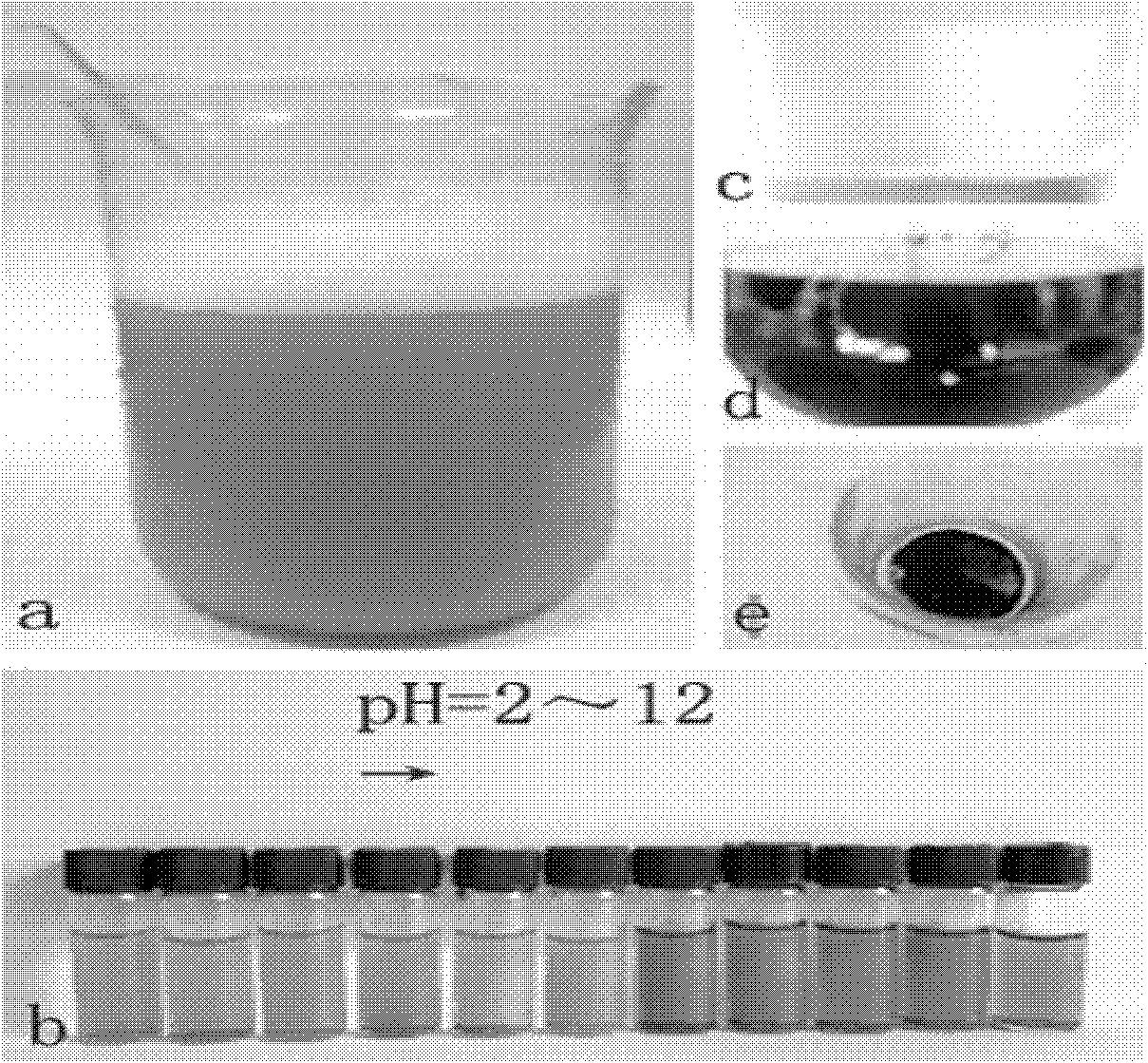

A kind of preparation method of graphene material

The invention discloses a preparation method of a graphene material. The preparation method comprises the following steps of: with graphite carbon as a raw material, adding potassium hypermanganate and concentrated sulfuric acid in batches in different stages to control an oxidation process of graphite; adjusting the pH value of the oxidized solution to obtain graphene oxide colloidal dispersing solutions (GOS) with different concentrations; dropwise adding the GOS on the surface of a carrier or spreading out the GOS on a non-intersolubility liquid / liquid interface and drawing into a grapheneoxide thin-film (GOF); carrying out high-speed centrifugation and drying treatment on the GOS to obtain graphene oxide solid powder (GOP); reducing the GOS by selecting an appropriate reducing agent,and centrifugally drying to obtain reduced graphene solid powder (GRP); dispersing a proper amount of GRP in an organic solvent to prepare a reduced graphene oxide colloidal dispersing solution (GRS); and dropwise adding the GRS on the surface of the carrier or spreading out on the non-intersolubility liquid / liquid interface and drawing into the reduced graphene thin-film (GRF). Various graphene materials prepared by the invention are easy to mutually transform; and the concentration of the colloidal solution and the thickness of the thin-film can be controlled in a certain range.

Owner:CENT SOUTH UNIV

Ball milling preparation method of graphene

The invention provides a ball milling preparation method of graphene. The ball milling preparation method comprises the following steps of: putting a mixture of graphite carbon and an alkyl six-membered aromatic ring or condensed ring polyether nonionic surfactant in the mass-volume ratio of 1: 2 to 1: 15, and deionized water in a ball milling jar, and fixing the ball milling jar on a ball mill for ball milling at a rotating speed ranging from 200 to 500 rpm for 5-30 hours; next, transferring the ball milled mixture to deionized water for centrifuging at a rotating speed ranging from 3000 to 8000 rpm for 10-30 minutes, and then obtaining a black upper-layer colloidal suspension for preparing graphene aqueous solutions with different concentrations. The graphene produced by the ball milling preparation method provided by the invention is dispersed in aqueous solutions and is high in concentration; the surfactant can be easily removed by using ethanol, which is friendly to environment and advantageous for wide application of graphene. The adopted ball milling equipment is simple, convenient to operate and safe to run; no new surface oxygen-containing functional group defect is introduced by ball milling; furthermore, the ball milling preparation method is mild and simple in preparation process, and high in yield.

Owner:CENT SOUTH UNIV

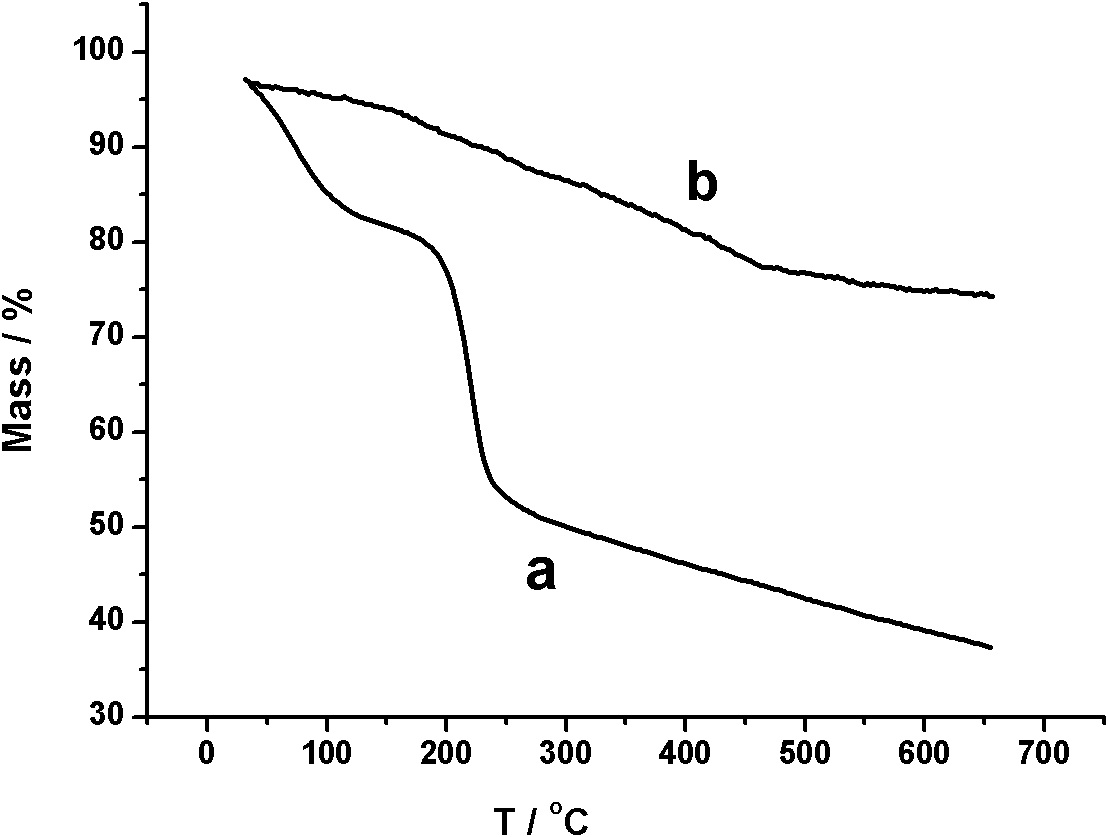

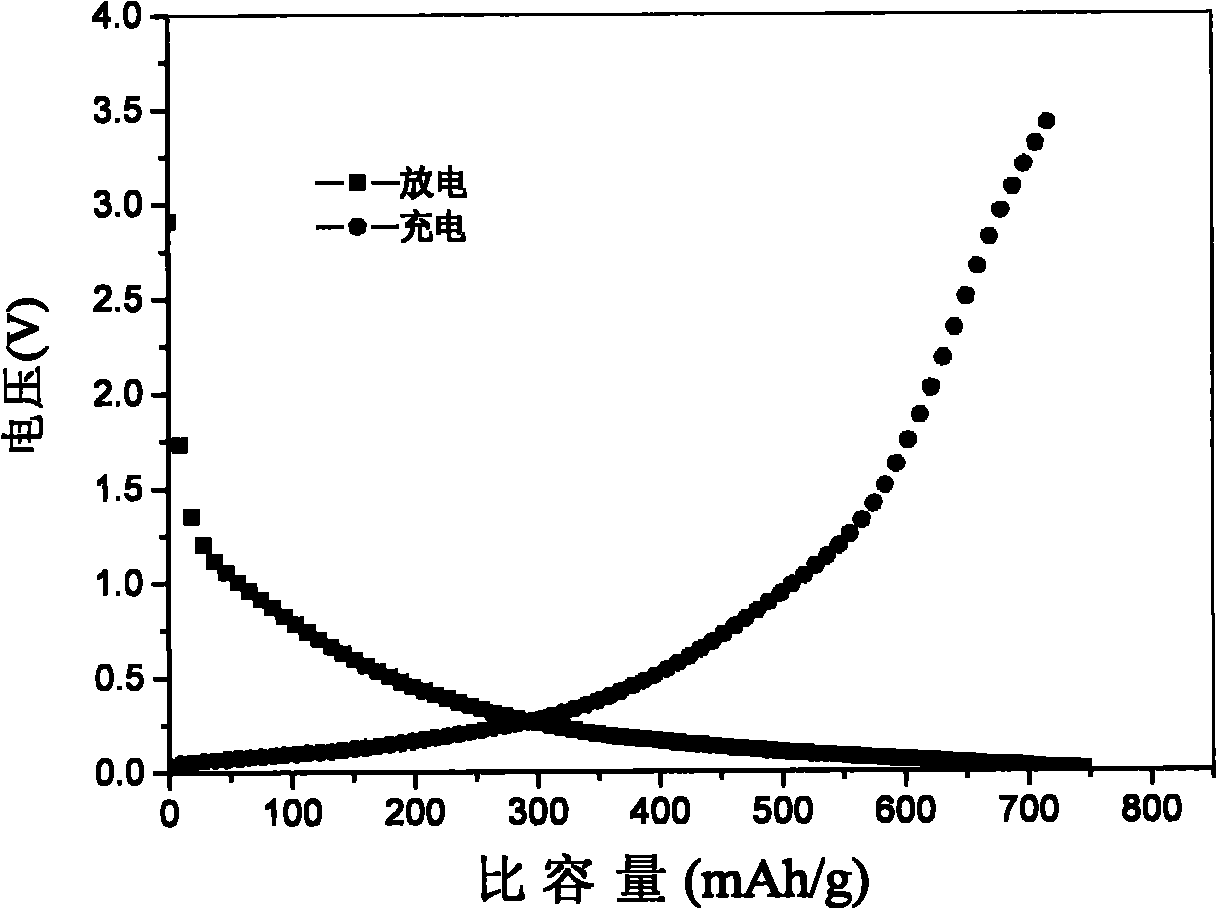

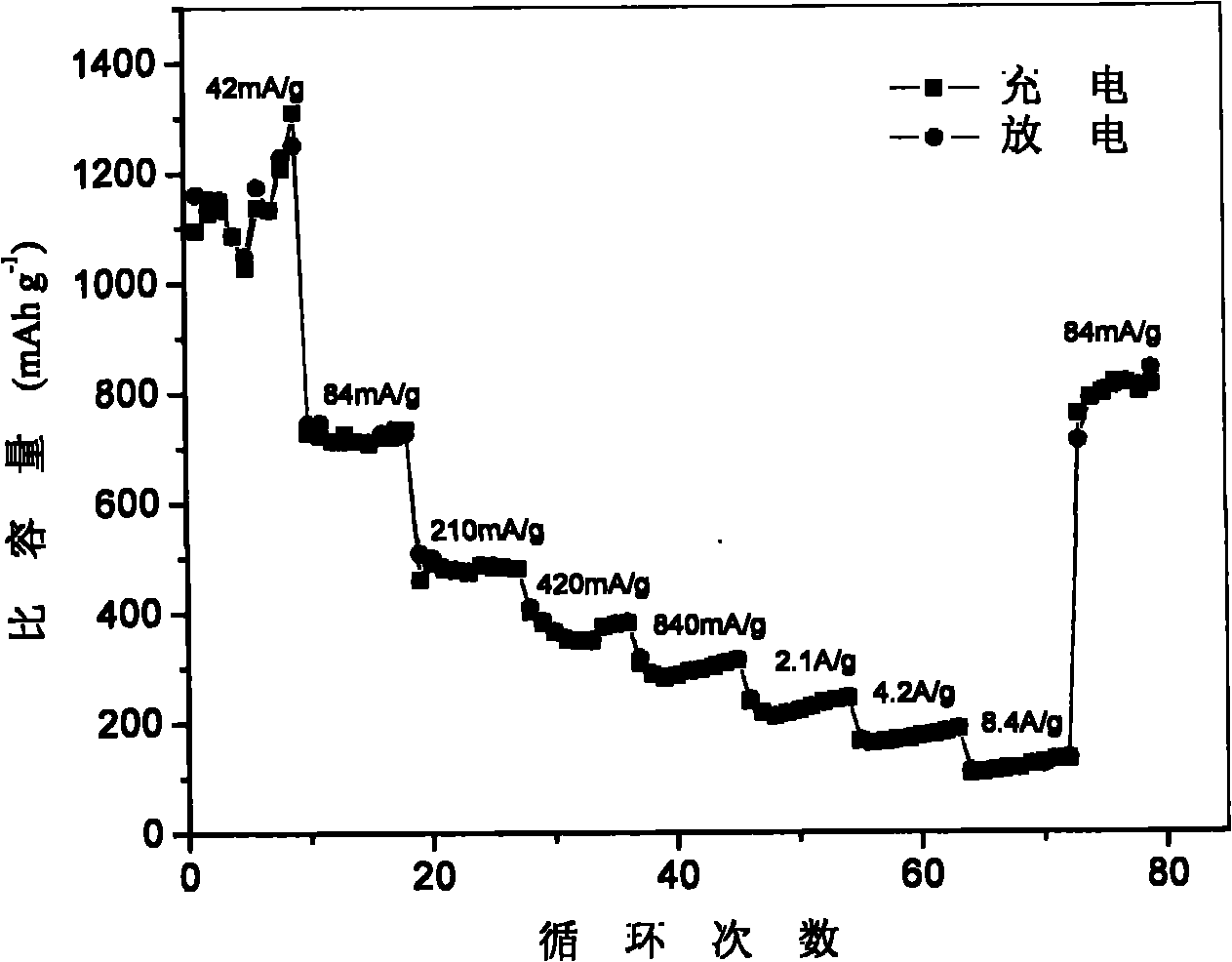

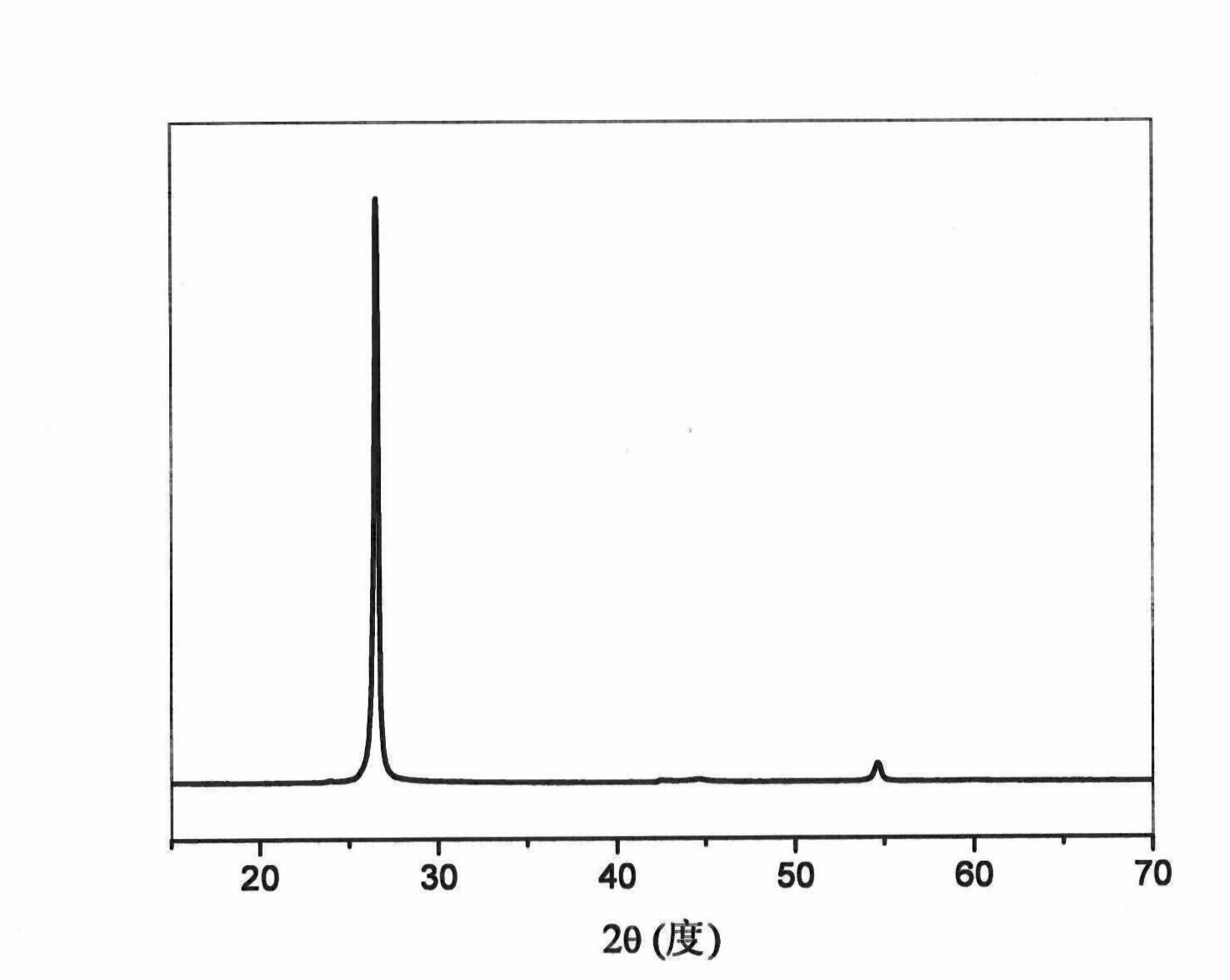

Nitrogen-doped graphite carbon serving as anode material of lithium ion battery, and preparation method and application thereof

The invention discloses a nitrogen-doped graphite carbon, which is obtained by calcining a graphite carbon material in a nitrogen-containing micromolecule material or atmosphere of the nitrogen-containing micromolecule material. When a pole piece which is prepared from the nitrogen-doped graphite carbon material is used as an electrode material of the lithium ion battery, the specific capacity of the material reaches 450 to 1,100mAh / g, and the material has high multiplying power performance and cycle performance. A preparation method of the nitrogen-doped graphite carbon is convenient to operate, and is easy and practicable; the prepared material has stable and excellent performance, and is the anode material of the lithium ion battery, which has good application prospect.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

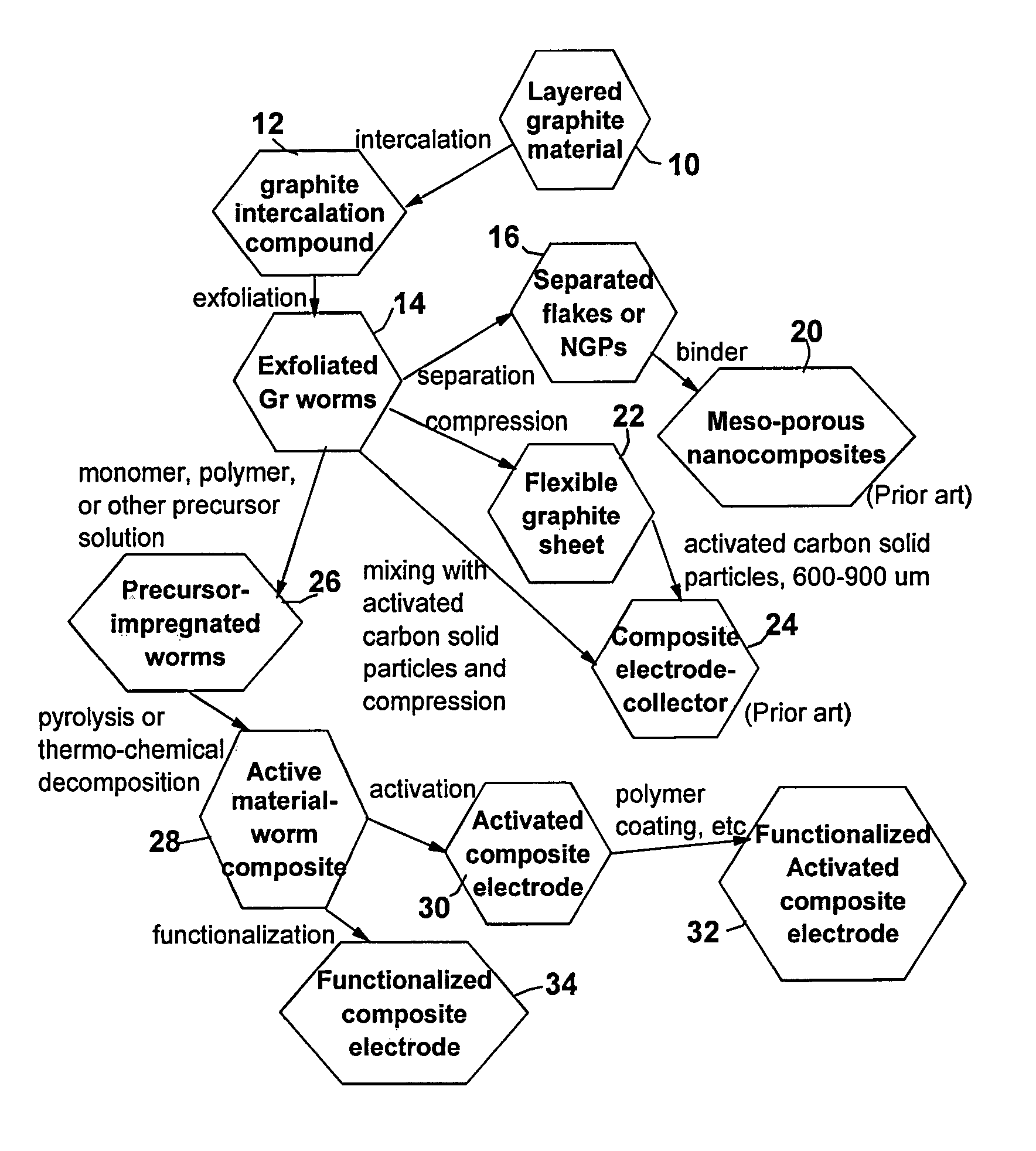

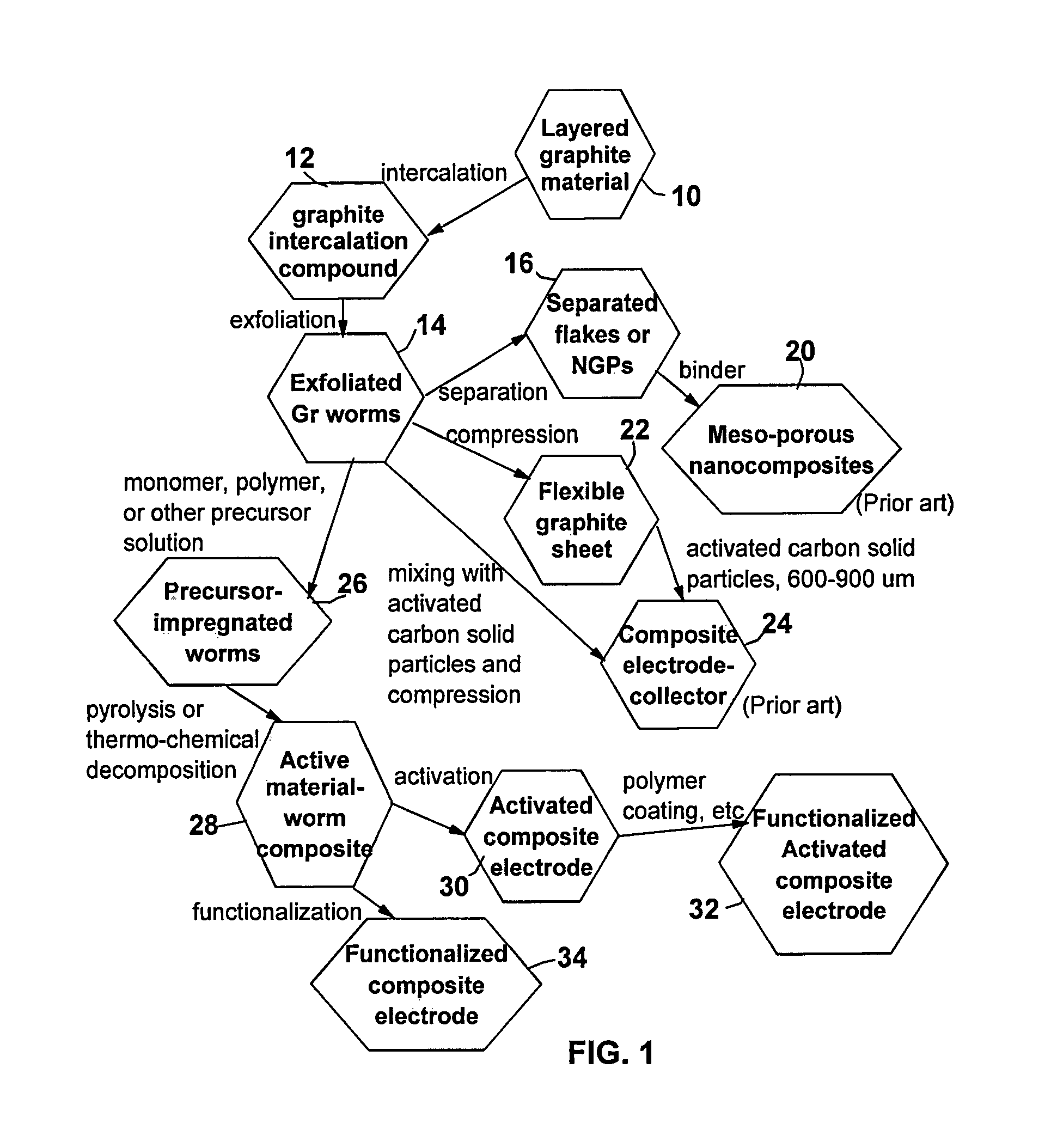

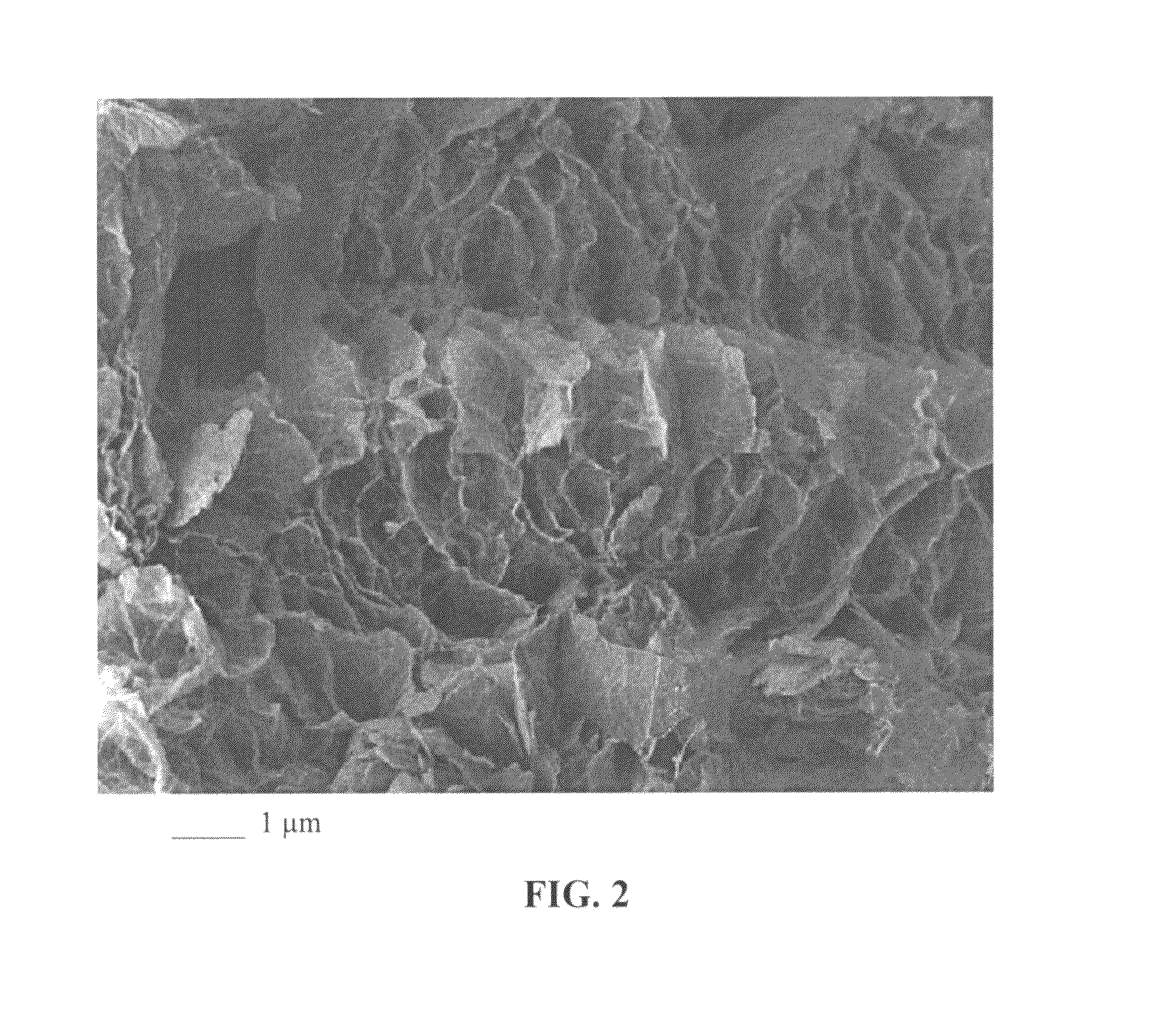

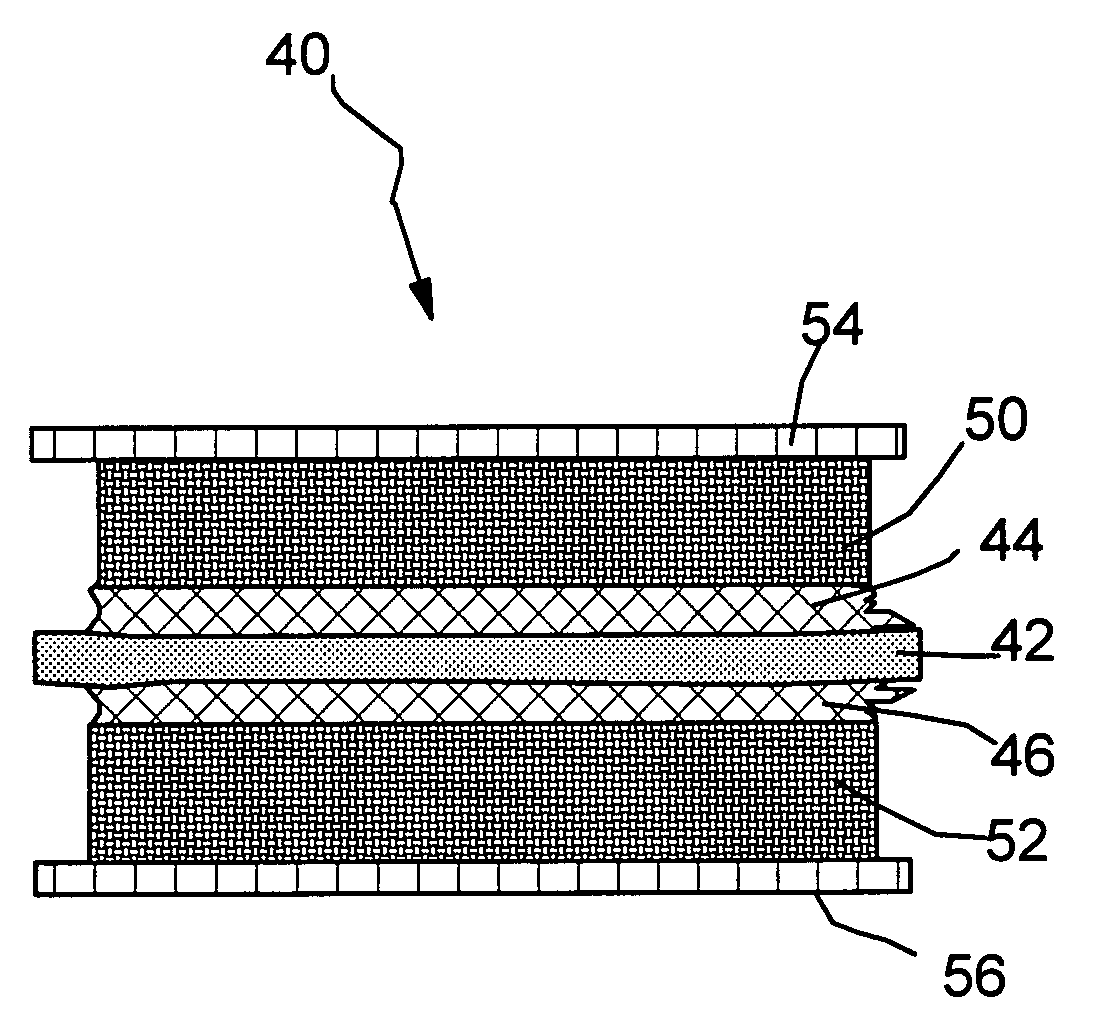

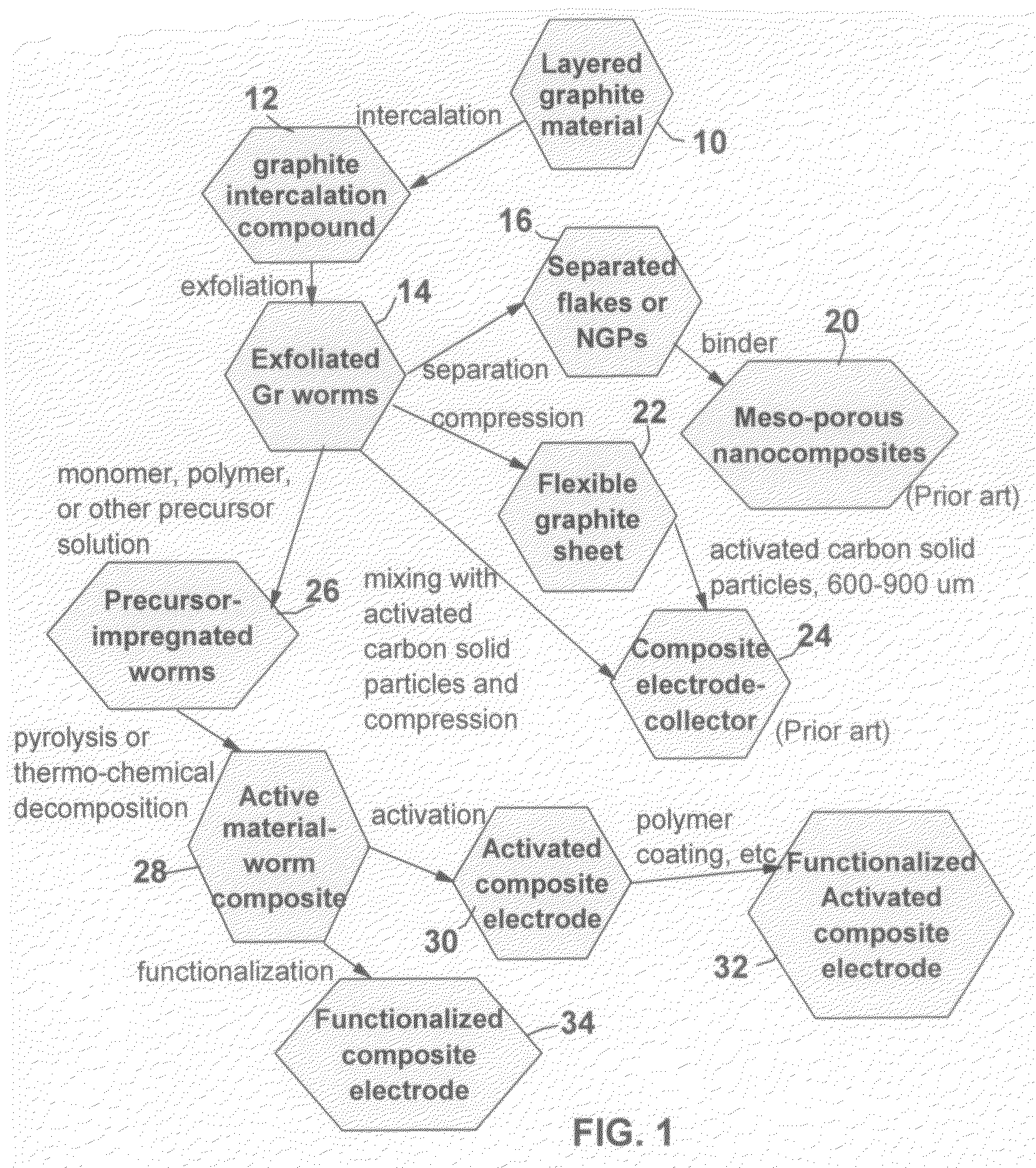

Method of producing graphite-carbon composite electrodes for supercapacitors

A method of producing a composite electrode having a specific surface area of at least 100 m2 / gm for use in an electrochemical capacitor. The method comprises (a) providing exfoliated graphite flakes that are substantially interconnected to form a porous, conductive graphite network comprising pores; and (b) incorporating an electrochemically active material into at least a pore of the graphite network to form the composite electrode. The exfoliated graphite flakes are preferably obtained from the intercalation and exfoliation of a laminar graphite material selected from natural graphite, spheroidal graphite, synthetic graphite, highly oriented pyrolytic graphite, meso-carbon micro-bead, carbon / graphite fiber, carbon / graphite whisker, carbon / graphite nano-fiber, carbon nano-tube, or a combination thereof. A supercapacitor featuring such a composite electrode exhibits an exceptionally high capacitance value and low equivalent series resistance.

Owner:NANOTEK INSTR GRP LLC

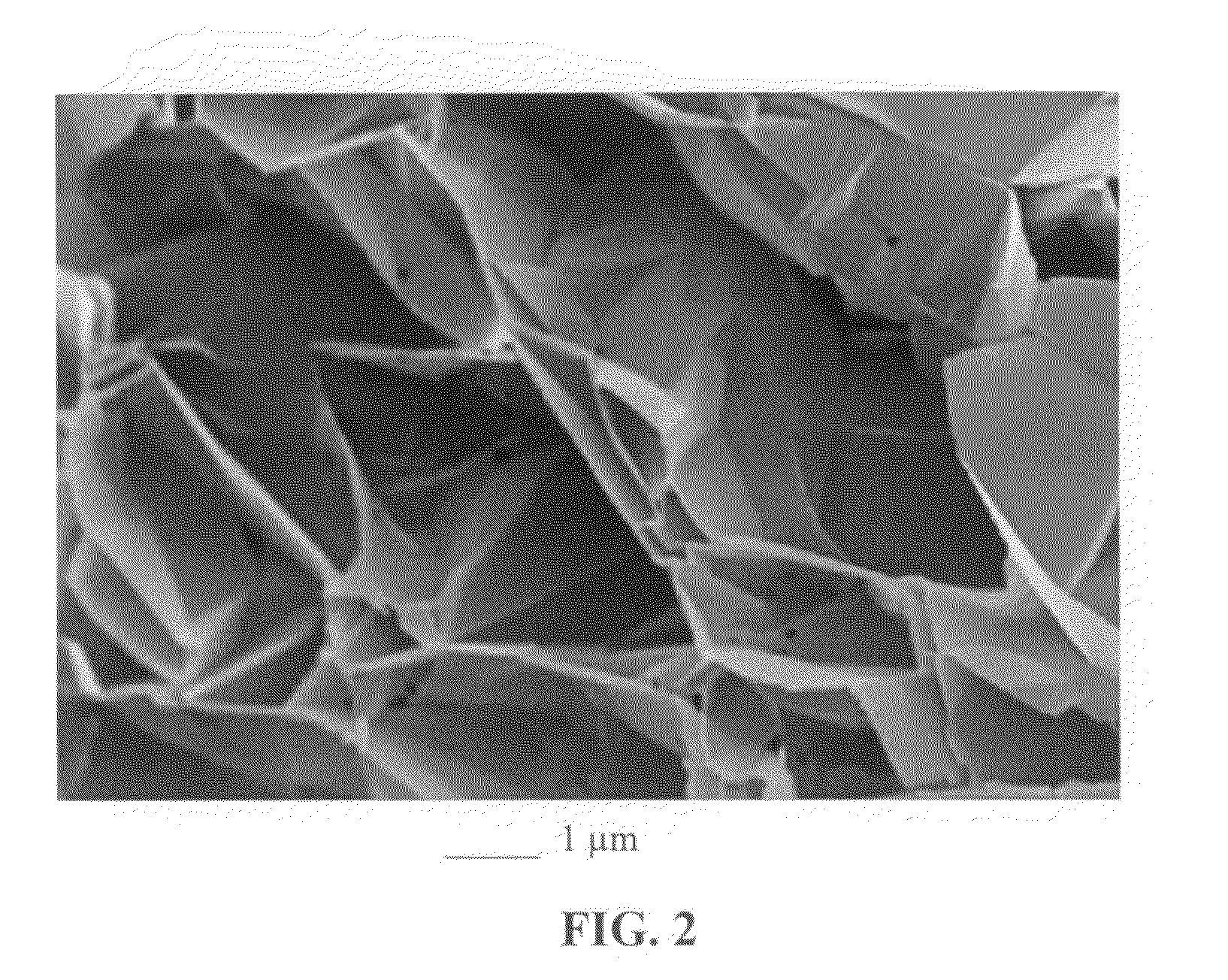

Graphite-carbon composite electrode for supercapacitors

A composite composition for use in an electrode for electrochemical capacitors, comprising: (a) an electrochemically active material; and (b) exfoliated graphite flakes that are substantially interconnected to form a porous, conductive graphite network comprising pores, wherein at least a portion of the active material resides in a pore of the network. The composite composition is characterized by having liquid accessible pores which provide a surface area greater than about 200 m2 / gm, preferably greater than 500 m2 / gm, more preferably greater than 1000 m2 / gm, and most preferably greater than 1000 m2 / gm. Also disclosed is a capacitor that includes at least an electrode comprising such a composite composition. A supercapacitor featuring such a composite electrode exhibits an exceptionally high capacitance value and high electrical conductivity.

Owner:SAMSUNG ELECTRONICS CO LTD +1

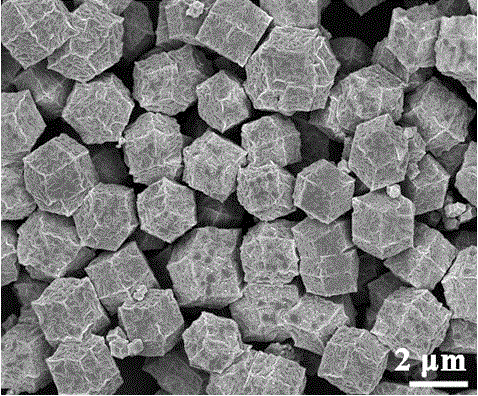

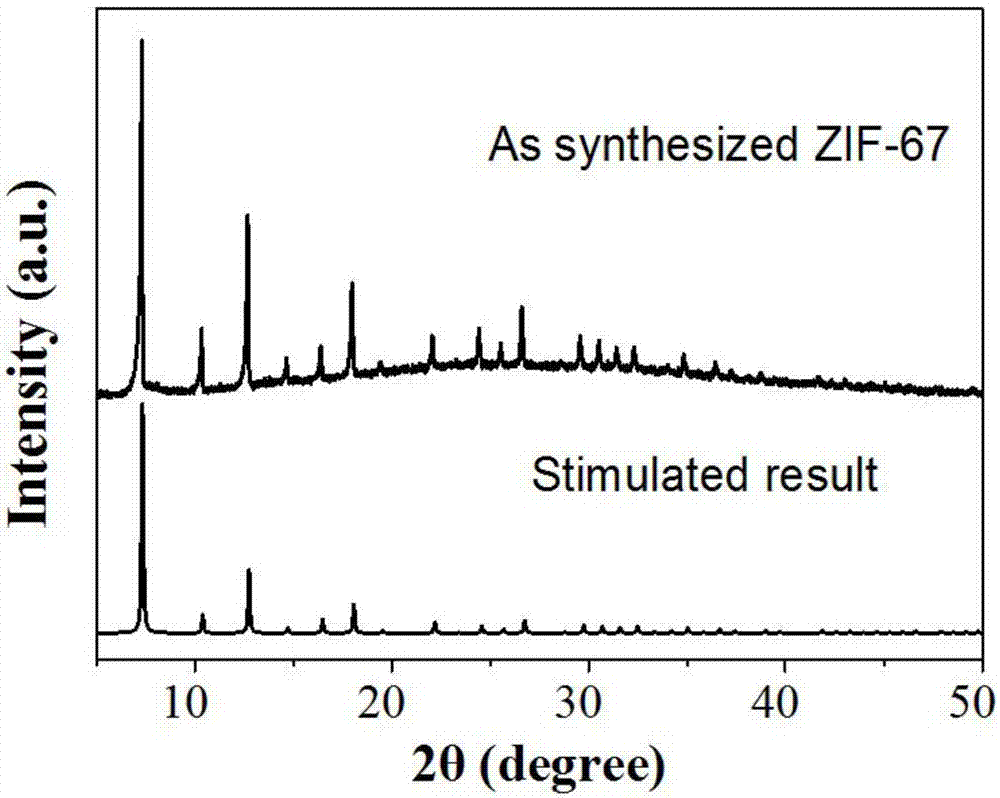

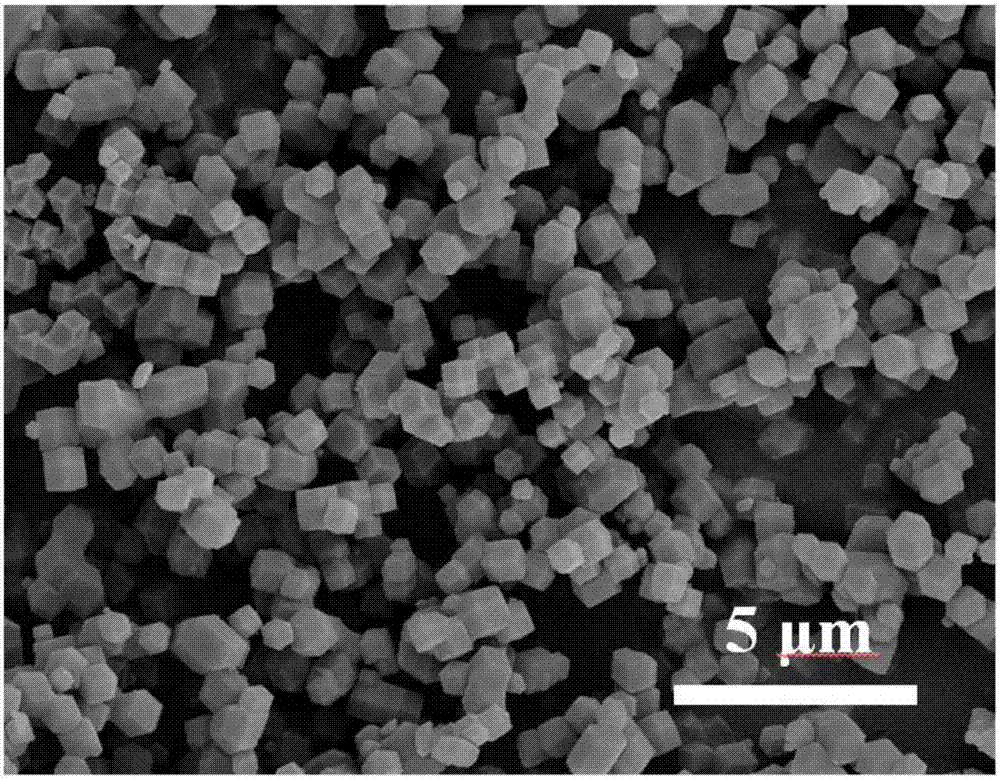

Polyhedron cobalt phosphide/graphite carbon hybrid material and preparing method and application thereof

ActiveCN105688958AHas a mesoporous structureLarge specific surface areaPhysical/chemical process catalystsOxygenOxygen evolution

The invention belongs to the technical field of materials and energy sources and particularly provides a metal phosphide / graphite carbon hybrid material and a preparing method and application thereof. A cobalt base-metal organic framework (ZIF-67) is utilized as a template and directly reacts with red phosphorus through heating, and the cobalt phosphide / graphite carbon hybrid material with the strong interface coupling effect is prepared in an in-situ mode. The hybrid material is formed by uniformly distributing and embedding cobalt phosphide nanometer particles in a polyhedron graphite carbon matrix. When used in the oxygen evolution reaction as a catalyst, the hybrid material shows high catalytic activity. The synthetic method is easy to operate, low in production cost and capable of achieving large-scale preparation, and is a novel efficient and economic preparing method.

Owner:FUDAN UNIV

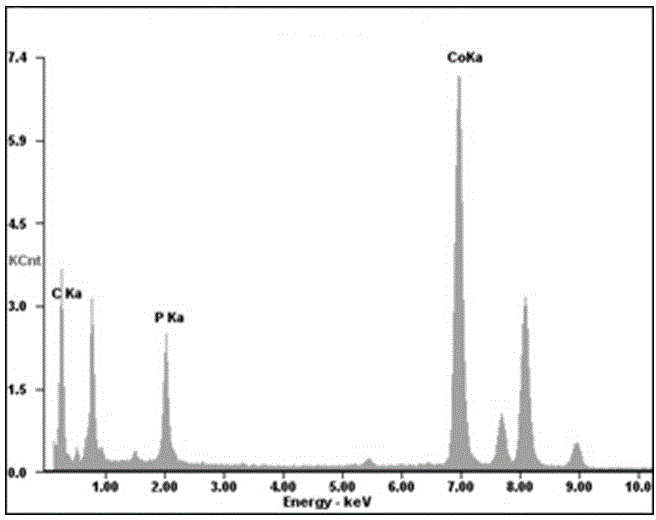

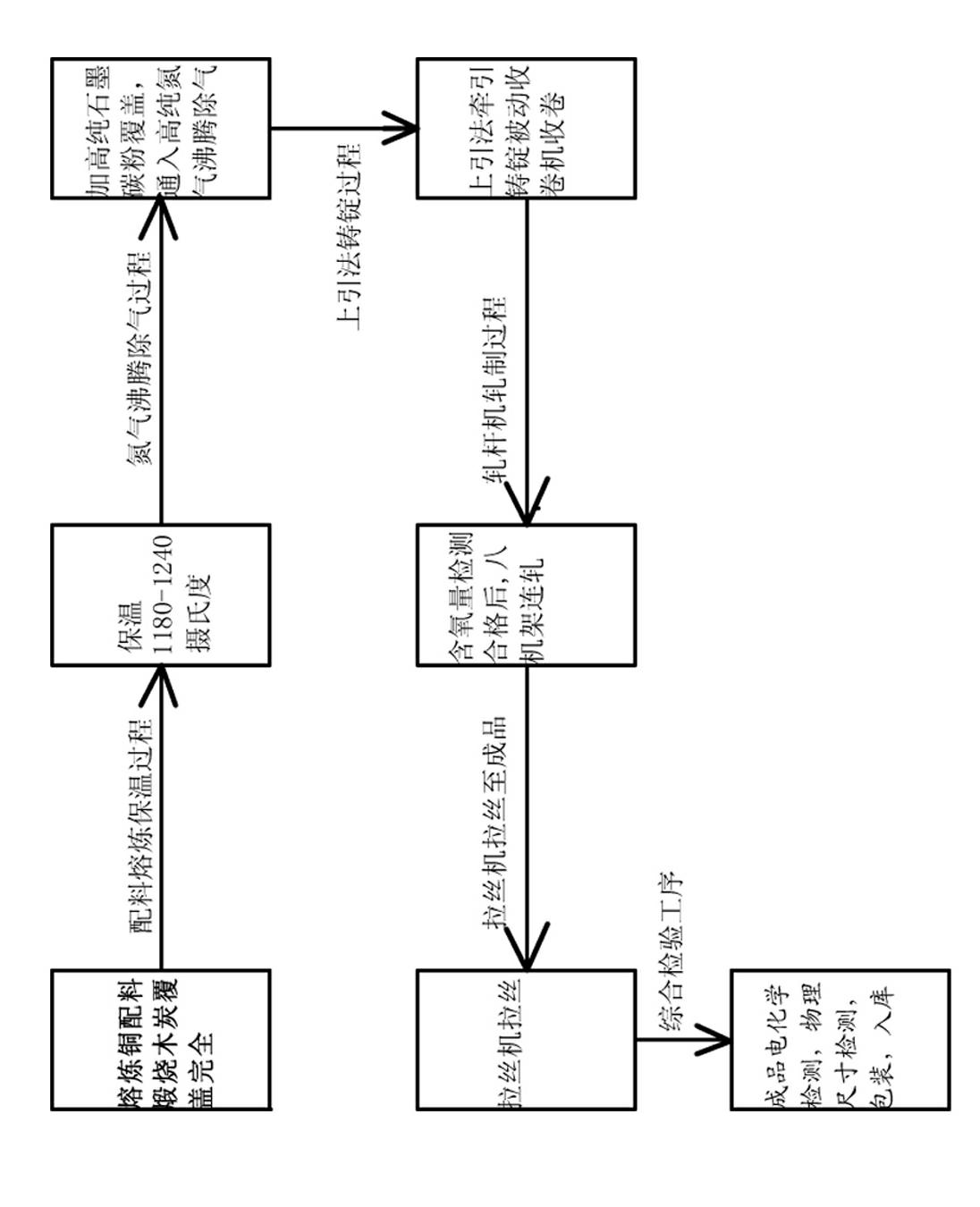

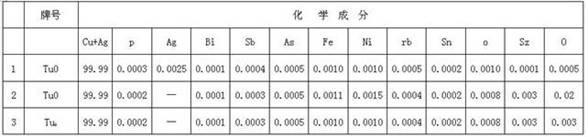

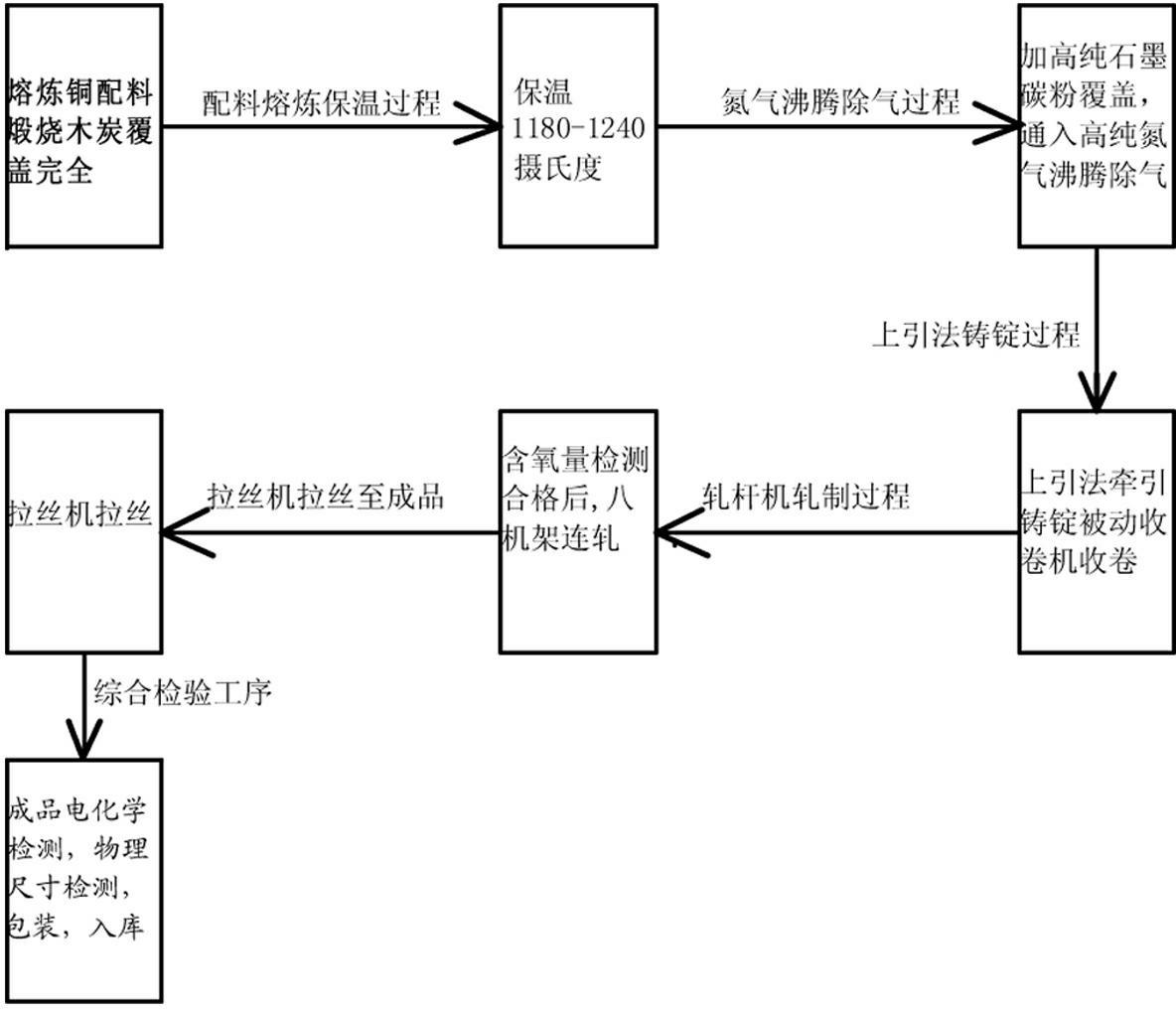

Upcast method for producing high-purity bright copper rod

ActiveCN102168180ALight weightFull reduction reactionProcess efficiency improvementGraphite carbonWinding machine

The invention relates to an upcast method for producing a high-purity bright copper rod. The method comprises the following steps of: drying smelting copper raw materials needed by smelting, mixing, adding the mixture into a smelting furnace, and covering firing charcoal with the thickness of between 100 and 150mm on starting molten copper until red copper is entirely molten, wherein molten copper constantly flows toward a heat preservation furnace under the action of fluid force; boiling the high-temperature molten copper and degassing before ingot guiding, adding prepared high-purity graphite carbon powder onto the liquid level of the molten red copper in the heat preservation furnace, and aerating high-purity nitrogen at the position which is 50 to 100mm lower than the liquid level of the heat preservation furnace; covering the firing charcoal after boiling and degassing, covering a furnace cover, performing draw casting operation, drawing a draw casting machine for draw casting bythe upcast method, cooling in a graphite crystallizer by the upcast method to obtain a qualified high-purity oxygen-free copper rod blank, and winding on a drawn cast ingot passive winding machine; and performing multi-pass rolling and fine-drawing on the high-purity oxygen-free high-brightness copper rod blank by an eight-rack rod cold rolling mill, and drawing the blank until the copper rod is obtained by a wire drawing machine, namely obtaining a finished product after the copper rod passes the inspection.

Owner:ZHONGTIAN ALLOY TECH

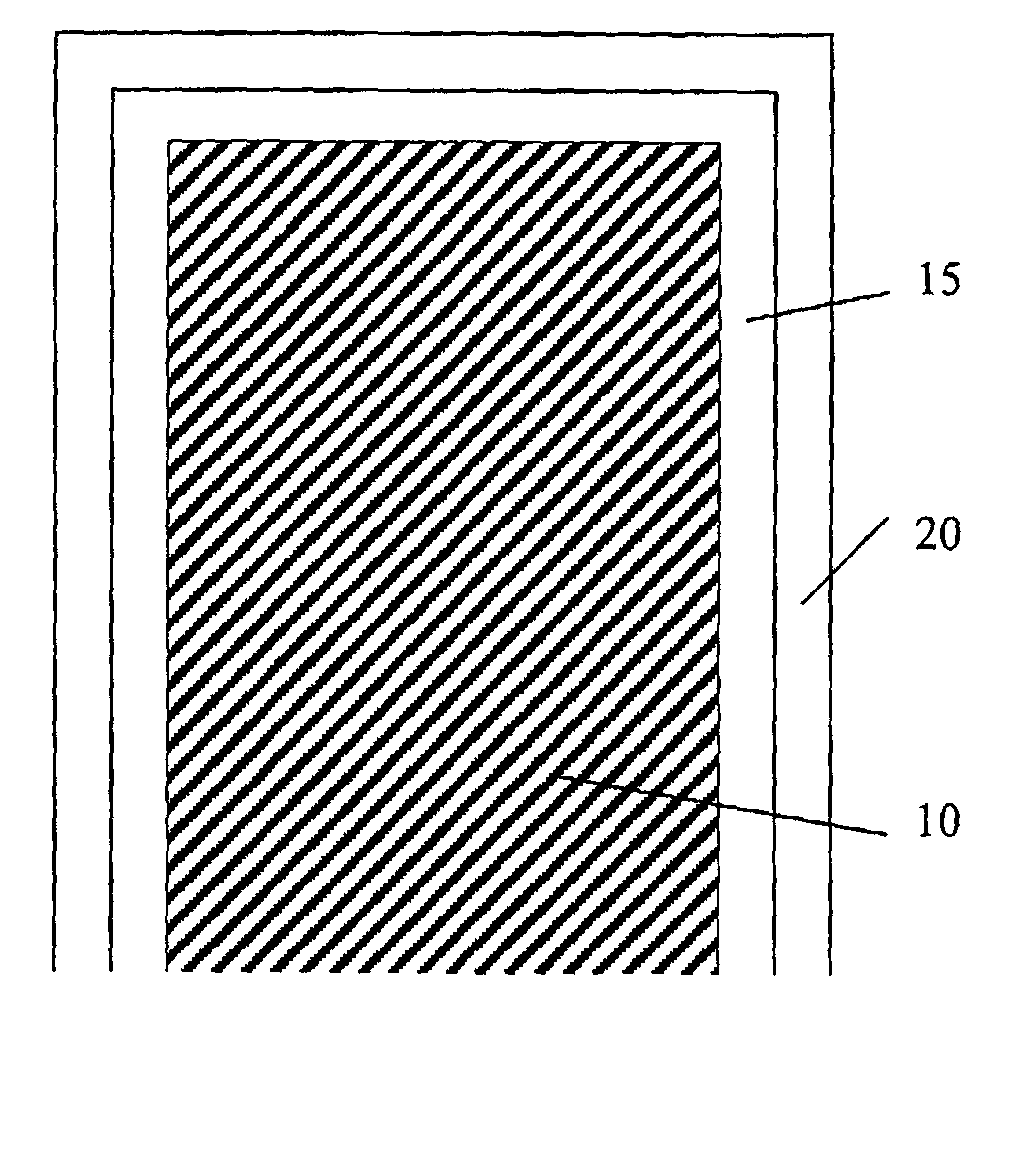

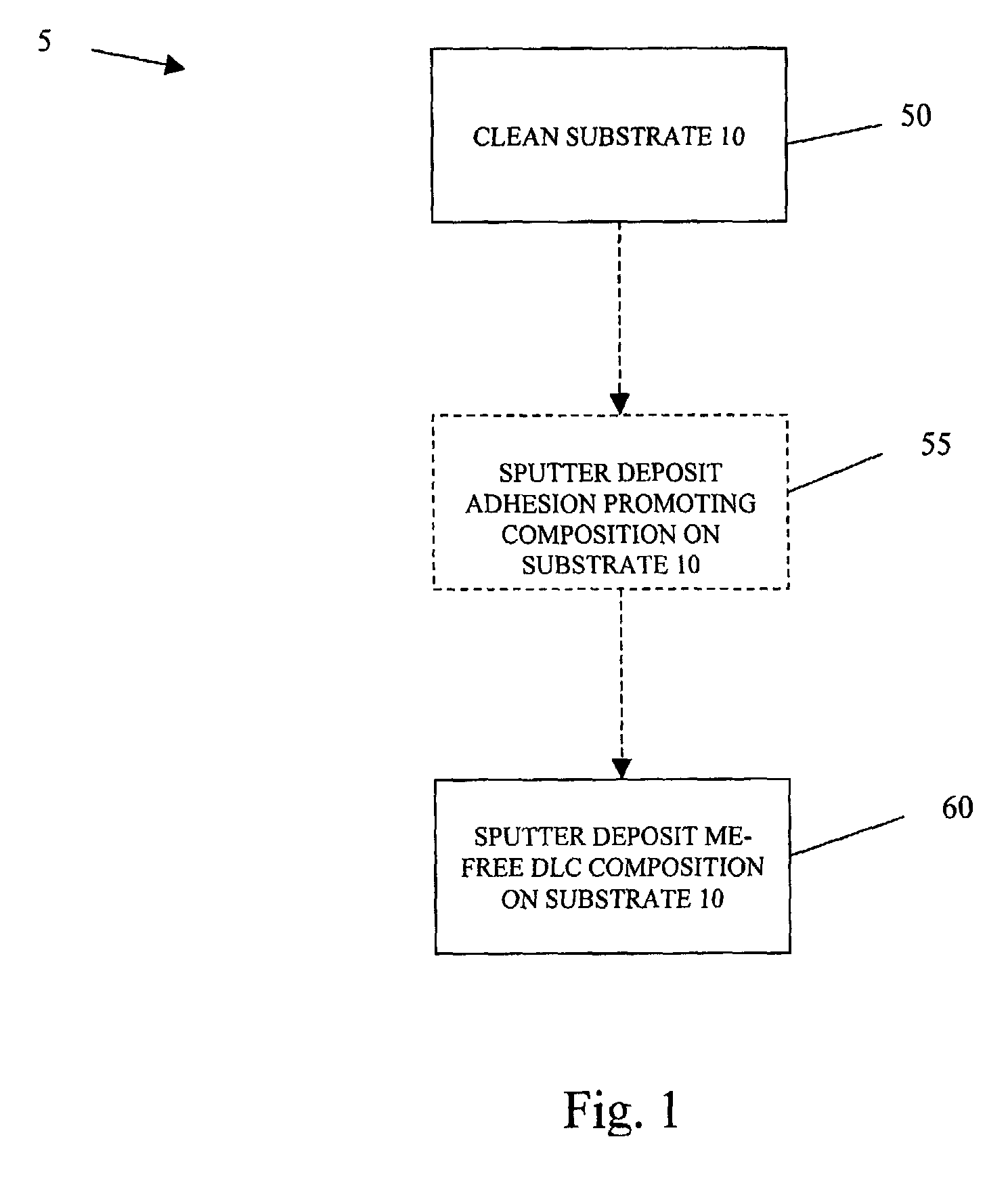

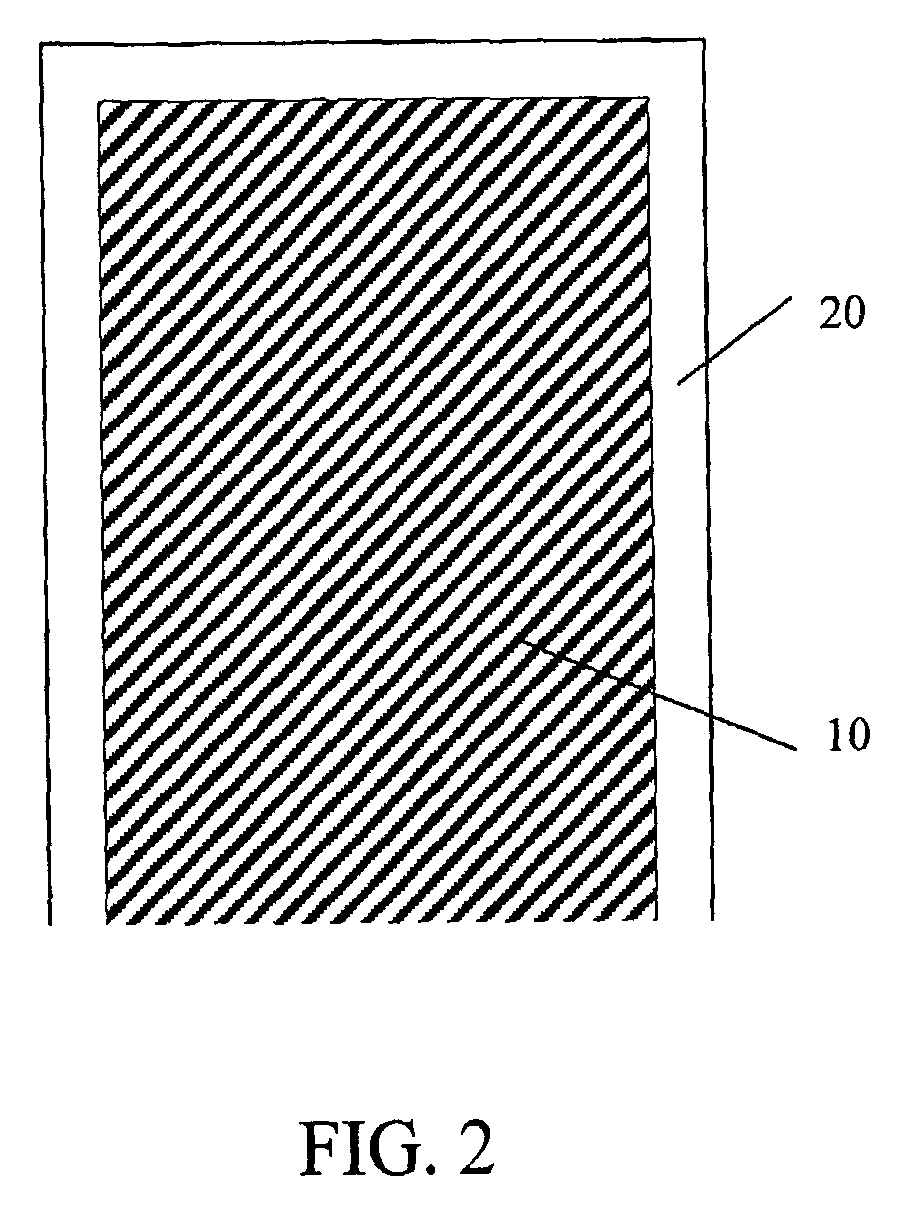

Metal-free diamond-like-carbon coatings

A coating (20) for a component of a power transmission system (10) and a method of coating a substrate is provided. The coating is substantially metal-free with a low hydrogen to carbon ratio. The method includes placing a graphite carbon target and the substrate in a magnetron sputtering chamber. The magnetron sputtering chamber is evacuated and filled with gas. The graphite carbon target is sputtered by the ionized inert and / or hydrogen gas so that the substrate is coated with a metal-free diamond-like-carbon coating.

Owner:RTX CORP

Purification method for obtaining high-purity carbon nano tube

InactiveCN101780951AImprove stabilityLow operating conditionsNanostructure manufactureGraphite carbonPurification methods

The invention relates to the technical field of carbon nano materials, in particular to a purification method for obtaining a high-purity carbon nano tube. The method combines liquid-phase oxidation, acid treatment and gas-phase oxidation, and simultaneously and fully utilizes the fluffy technology to increase the pore space and the specific surface area in a sample, thereby greatly improving the treatment efficiency of eliminating graphite carbon impurities and preparing the high-purity carbon nano tube. The method is specially suitable for purifying single-walled carbon nano tubes prepared by an arc process, has good stability and low requirements on operation conditions and can carry out industrialized amplification; both the productivity and purity of the obtained products reach or exceed the best result reported by recent literatures; and in addition, the method can also be applied to purifying various carbon nano tubes produced by other methods, and the obtained high-purity carbon nano tube has wide usable range.

Owner:PEKING UNIV

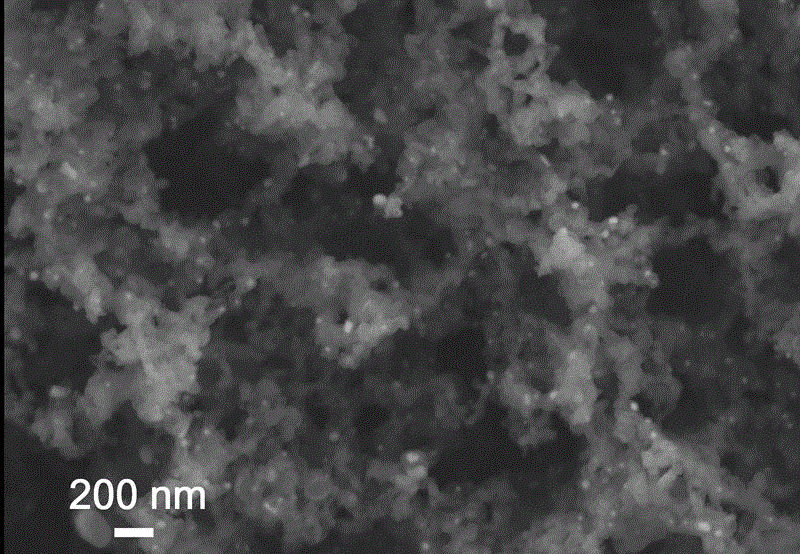

Preparation of nano graphite carbon colloidal SOL by pulse electrode process

InactiveCN1579932ASimple processReduce manufacturing costElectrolysis componentsVolumetric Mass DensityPulse period

The invention discloses a method to produce nanometer graphite sol. It supplies a system which includes highly pure graphite as anode, inert materials as cathode and electrolytical aqueous solution. There is an impulsing power source to connect the anode and cathode. The pulse period of the power source is 0.05-0.5 second, effective voltage 2-10V (3-5V is prelatered) and effective amphere density 15-75A (25-35 is prelatered). The efficiency of this invention is higher than common direct-current electrode method. The produced nanometer graphite sol is stable and disperses so it can produce nanometer graphite powder whose diameter is under 15nm.

Owner:华农纳米科技(天津)有限公司

Composite plumbago-carbon negative pole material and method of manufacturing the same

The invention discloses a method for preparing a composite graphite carbon cathode material, comprising the following steps that: 1. a step of adding and mixing materials, during which fine carbon powder and a caking agent with a weight ratio between 2:1 and 20:1 are added alternately in the stirring process, the mixture is stirred for 0.1 to 3 hours after adding the materials, the caking agent is selected from a thermoplasticity resin, asphalt and coal tar; 2. a step of increasing the temperature, during which the temperature is increased up to between 450 and 600 DEG C with a rate of 0.5 to3 DEG C per minute; 3. a step of keeping the temperature, during which the temperature of between 450 and 600 DEG C is kept constant for 1 to 10 hours; 4. a step of cooling to the room temperature; and 5. a step of graphitzation; wherein, the steps of 1 to 4 are performed without the protection of oxidation. The raw materials have high operating factor; the preparation method is environment-friendly and easy to implement; moreover, the composite graphite powder prepared has good isotropic properties and the characteristics of good high current performance, long cycle and low nonreversible capacity.

Owner:福建杉杉科技有限公司

Potassium-based dual-ion battery and preparation method thereof

ActiveCN108063217AReduce manufacturing costImprove power densityNon-aqueous electrolyte accumulatorsCell electrodesGraphite carbonPorous carbon

The invention discloses a potassium-based dual-ion battery and a preparation method thereof and relates to the field of electrochemical energy storage devices. The potassium-based dual-ion battery comprises a negative electrode, a positive electrode, a membrane between the positive electrode and the negative electrode and an electrolyte, wherein an active material of a negative electrode materialis a porous carbon material capable of reversibly absorbing and desorbing potassium ions; the active material of a positive electrode material is a graphite carbon material capable of reversibly intercalating and deintercalating anions in the electrolyte; and the electrolyte comprises a potassium salt and a non-aqueous solvent. The defects that an existing lithium-ion battery is limited in lithiumresource reserves and high in cost are alleviated, and the problems that an existing potassium-ion battery is limited in electrode material and not ideal in electrochemical properties are solved. According to the dual-ion battery disclosed by the invention, potassium is taken as an energy storage medium, the porous carbon material capable of absorbing and desorbing the potassium ions is taken asa negative active material and expanded graphite capable of being reversibly intercalated and deintercalated is taken as a positive active material, so that the potassium-based dual-ion battery has the advantages of high specific capacity, long cycle life and good security performance.

Owner:SHENZHEN INST OF ADVANCED TECH

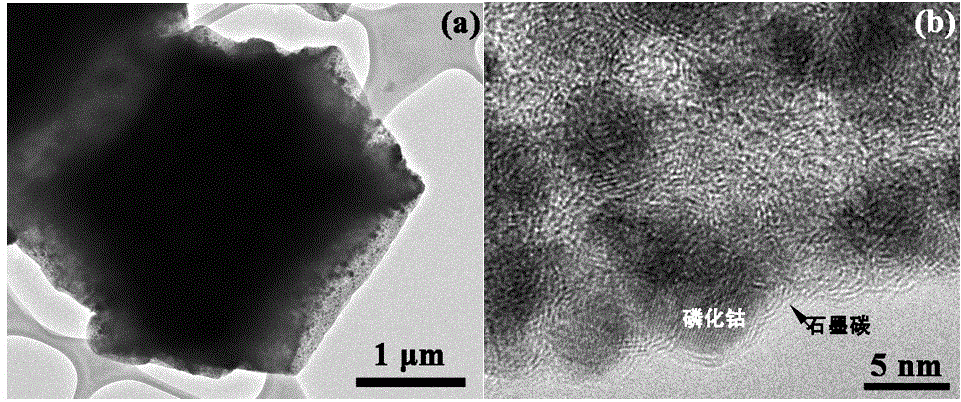

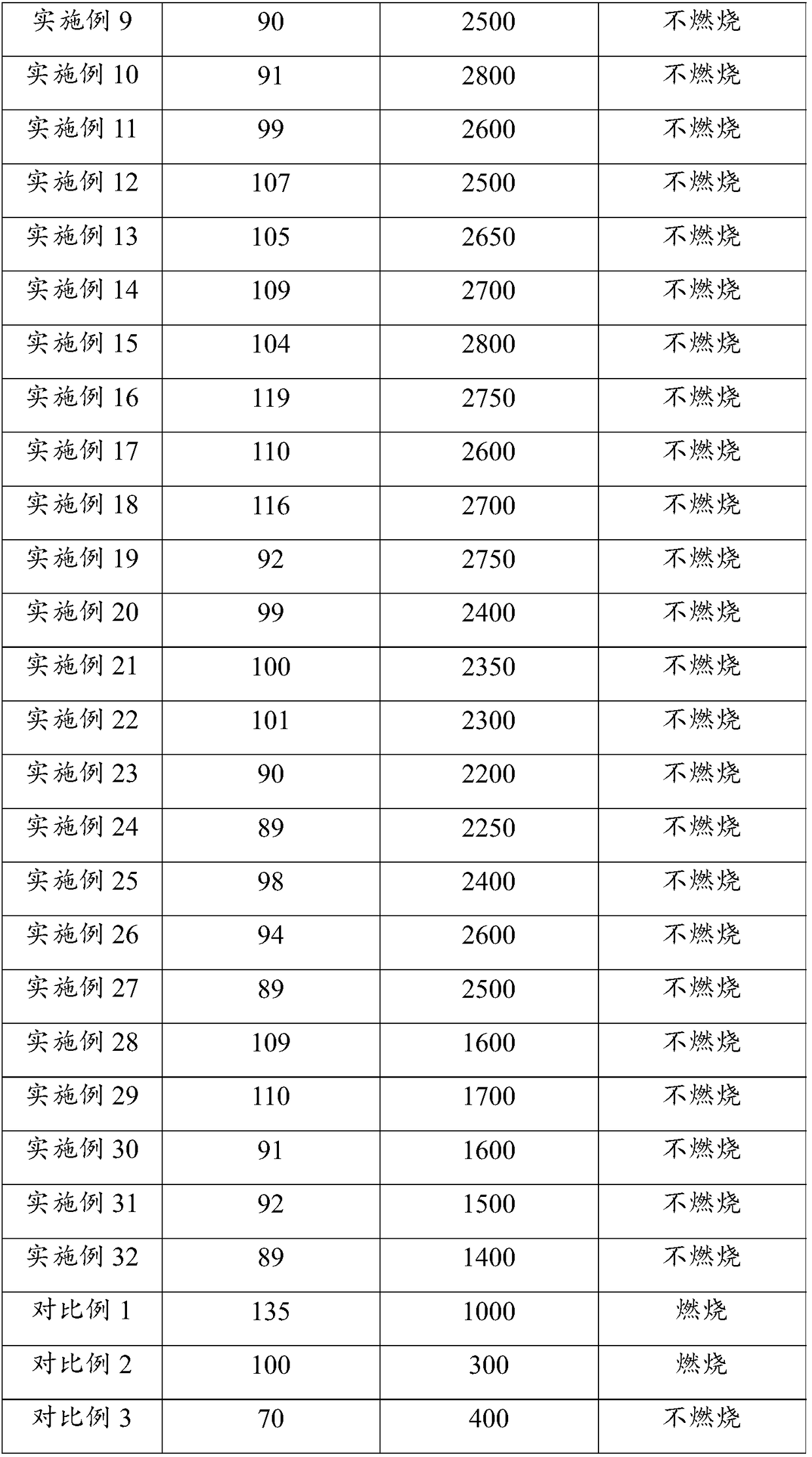

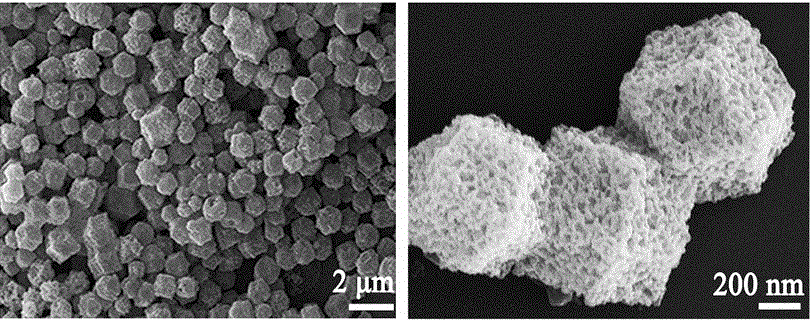

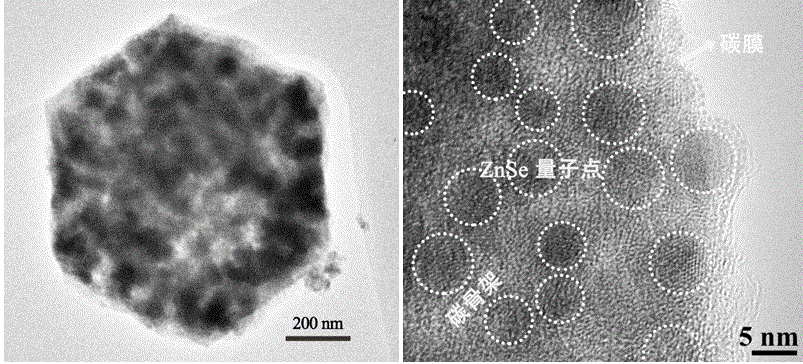

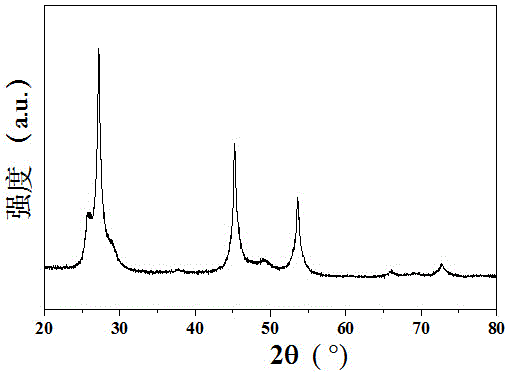

Three-dimensional porous carbon-coated zinc selenide material for lithium ion battery anodes and preparation method of material

ActiveCN106654221APreserve polyhedral shapeLarge specific surface areaMaterial nanotechnologyCell electrodesZinc selenidePorous carbon

The invention belongs to the technical field of material and energy and particularly relates to three-dimensional porous carbon-coated zinc selenide material for lithium ion battery anodes and a preparation method of the material. The preparation method comprises the specific steps of sintering zinc-based zeolite imidazate metal organic framework material (ZIF-8) as a precursor or template with selenium powder under the protection of an inert atmosphere at high temperature for a certain time, and carrying out synchronous selenization and carbonization to finally prepare the carbon-coated zinc selenide composite material. The composite material prepared herein and the preparation method thereof provide effective composition of zinc selenide and graphite carbon, the component ingredients generate great interfacial coupling effect, volume expansion effect of the zinc selenide material during charging and discharging can be effectively relieved and inhibited, the conductivity of the material is improved, and accordingly the composite material has very high specific capacity and excellent cycle stability and rate performance when applied as lithium ion battery anode material. The preparation process is simple, the preparation conditions are mild, and the cost is low.

Owner:FUDAN UNIV

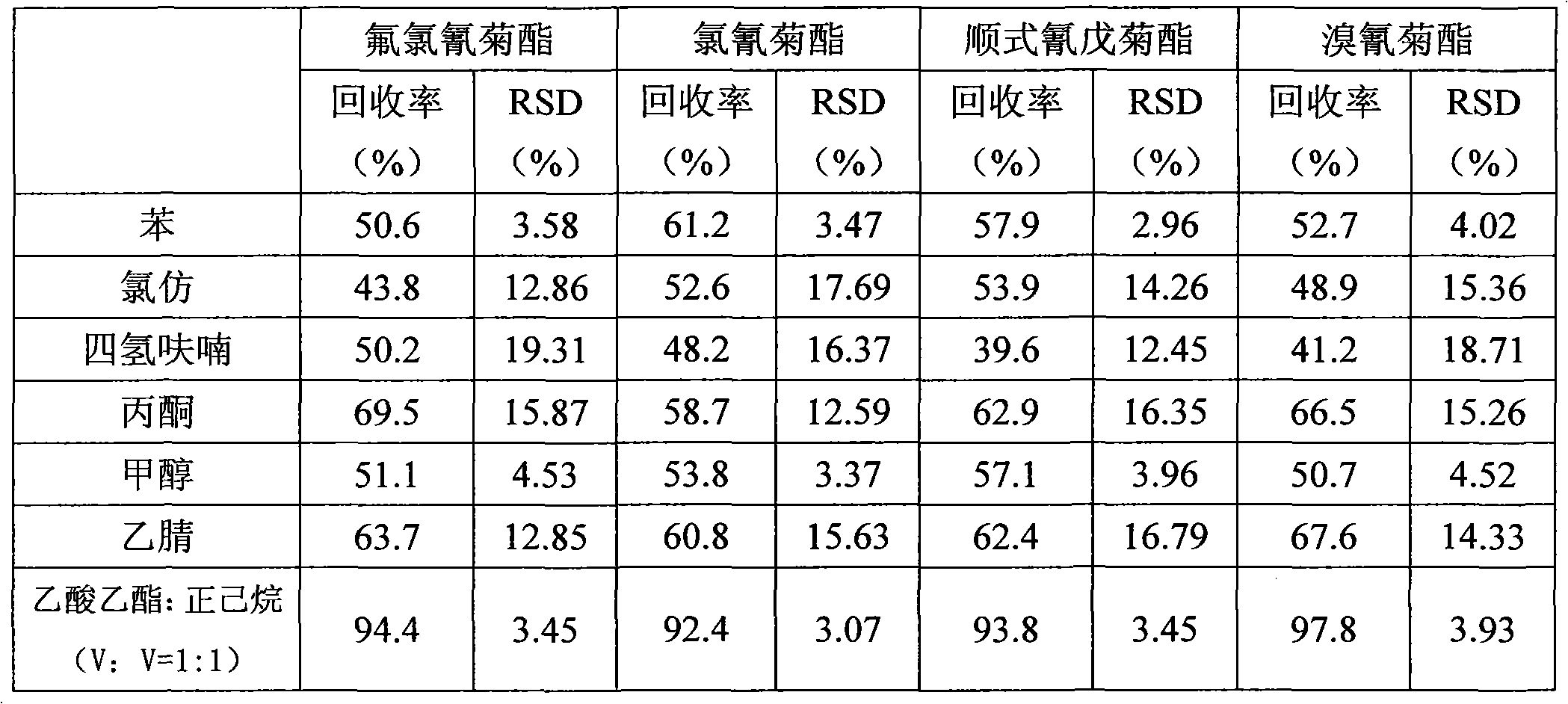

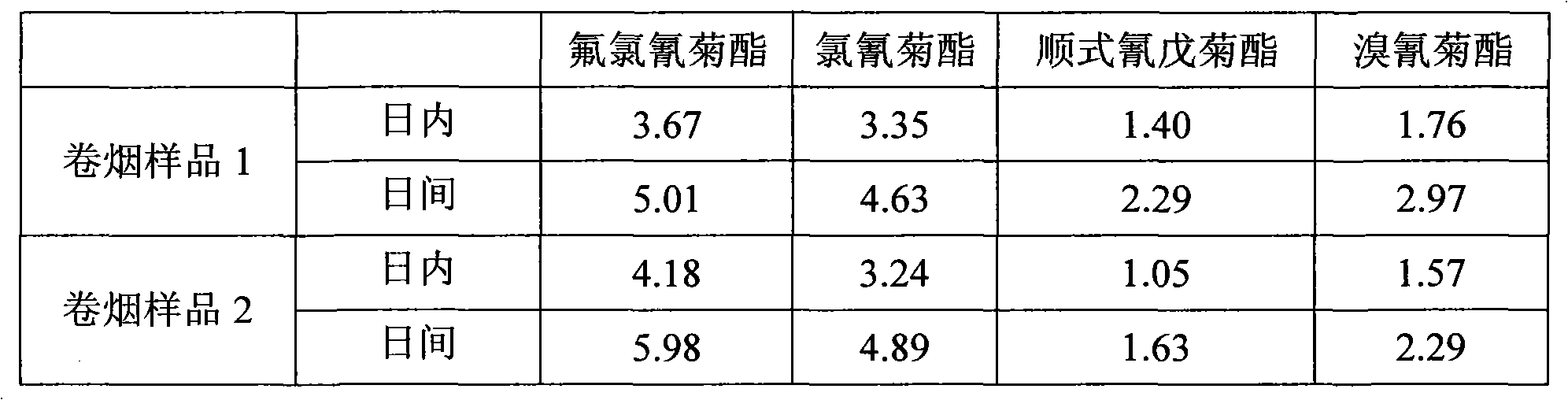

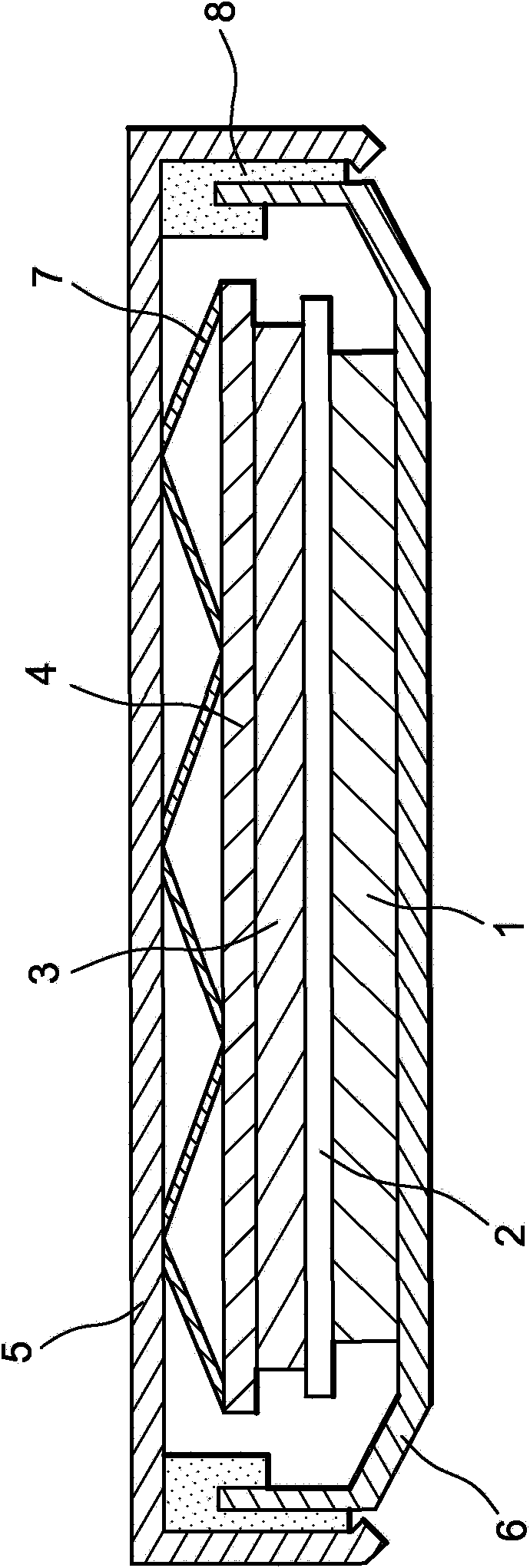

Method for detecting pyrethroid pesticide residue amount in smoke by cigarette filter

The invention discloses a method for detecting pyrethroid pesticide residue amount in smoke by a cigarette filter, belonging to the technical field of tobacco chemical analysis. The method comprises the following steps: placing a sucked filter tip at standard smoking condition into a 150ml of bottle with a tapered plug; adding 100mL of mixed solvent of ethyl acetate and cyclohexane with the volume ratio of 1:1; placing the bottle on an ultrasonic wave generator for extraction for 30min; concentrating to be 0.5mL on a rotary evaporator after drying by anhydrous sodium sulfate; setting the volume to be 2mL by normal hexane to be purified; placing a small graphite carbon black column on a solid phase extractor; activating by 3mL of acetone and 3mL of normal hexane in sequence; transforming the sample test solution to be purified into the small graphite carbon black column; eluting for two times by utilizing 2.5mL of mixed solvent of acetone and normal hexane, wherein the speed does not exceed 5.0mL / min; evaporating and concentrating eluent; setting the volume to be 1.5mL by acetone and normal hexane with the volume ratio of 2:8; and analyzing on GC-ECD. The method of the invention is simple and accurate, and can effectively determine pyrethroid pesticide residue amount in smoke by the cigarette filter.

Owner:YUNNAN RES INST OF TOBACCO SCI

Processing method for dipping graphite carbon envelope with oxide solution

The invention discloses an oxidation and abrasion resistant graphite material, which is characterized by the following: leaching oxide solution of graphite carbon sleeve in the cold-rolling silicon sheet continuous annealing furnace and other heat disposal furnace; improving oxidation and abrasion resistance for graphite carbon sleeve; making Al2O3, SiO2 and TiO2 into hyperfine powder; allocating; dispersing in the solution to make gel solution; adopting vacuum pressurizing leaching method to immerse oxide solution into graphite carbon sleeve; forming ceramic protecting film on the blank surface.

Owner:NANTONG QINGTIAN INDAL

Lithium-ion rechargeable accumulators including an ionic liquid electrolyte

The present invention relates to a lithium-ion rechargeable accumulator including a negative electrode in which the active material is graphite carbon, a positive electrode in which the active material is LiFePO4, and an ionic liquid electrolyte containing at least one ionic liquid of the formula C+A- in which C+ is a cation and A- is an anion, and at least one conducting salt, wherein the ionic liquid electrolyte further includes an organic additive consisting of vinyl ethylene carbonate (VEC).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

Iron-nitrogen-doped graphene porous material with dual-site catalytic oxygen reduction activity, and preparation method and application therefor

InactiveCN105609793ALarge specific surface areaMany active sitesCell electrodesPyrroleNitrogen doped

The invention belongs to the technical field of a nanomaterial, and specifically relates to an iron-nitrogen-doped graphene porous material with dual-site catalytic oxygen reduction activity, and a preparation method and an application therefor. The porous material is formed by embedding graphite-carbon-coated iron carbide into a nitrogen-doped porous graphene band network structure; the preparation method for the iron-nitrogen-doped graphene porous material comprises the steps of preparing a graphene oxide solution; adding a proper amount of conductive macromolecular pyrrole to the graphene oxide solution; obtaining uniform hydrogel through a hydrothermal process; performing oxidative polymerization on the hydrogel by ferric iron; then dispersing the hydrogel into a fresh ferric iron solution to complete adsorption; then performing drying and high-temperature carbonization thermal processing; and finally removing non-active and free iron phase from the reaction system by dilute acid so as to obtain the iron-nitrogen-doped graphene porous material. The porous material can be used as the negative electrode catalyst for a fuel cell, and shows quite high catalytic oxygen reduction activity, so that the porous material has quite important research meaning and bright application prospects.

Owner:FUDAN UNIV

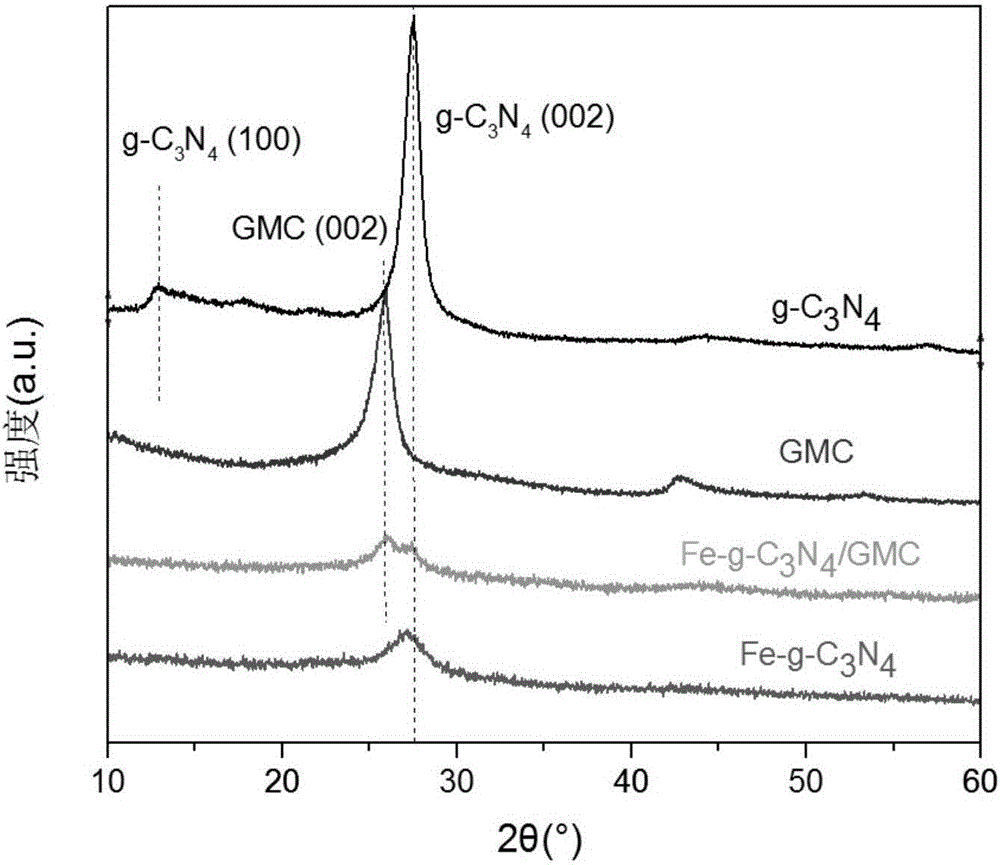

Preparation method of fe-doped carbon nitride/mesoporous graphite carbon composite catalyst and product and application

ActiveCN106076393AEfficient catalytic degradationHigh catalytic activityWater treatment compoundsOrganic-compounds/hydrides/coordination-complexes catalystsGraphite carbonTube furnace

The invention discloses a preparation method of a fe-doped carbon nitride / mesoporous graphite carbon composite catalyst. The method comprises the steps that 1, dicyandiamide is added into hot water, ferric salt is added for a period of time after the dicyandiamide is dissolved completely, mesoporous graphite carbon is added, continuous heating is performed till water is evaporated completely, and slight grinding is performed to obtain black powder; 2, the black powder is placed into a tube furnace to be calcined under the protection of nitrogen gas, and the fe-doped carbon nitride / mesoporous graphite carbon composite catalyst is obtained. The invention further discloses the catalyst obtained through the preparation method and an application method of the catalyst. Due to mutual effects of Fe, graphite phase carbon nitride and mesoporous graphite carbon, Fe is mainly dispersed into the catalyst in an N-coordinate mode, and the quite high Fenton-like catalytic activity can be shown.

Owner:ZHEJIANG UNIV

Preparation method of porous carbon nano rod with high specific area

InactiveCN104211040ALarge specific surface areaWell-developed pore structureMaterial nanotechnologyPorous carbonSolvent

The invention provides a preparation method of a porous carbon nano rod with a high specific area. The preparation method comprises the following steps (1) weighing zinc salts and trimesic acid according to a ratio of amount of substance of 0.5-5:1, dissolving the zinc salts and trimesic acid in an organic solvent, fiercely stirring for 0.5-3 hours at a room temperature, then carrying out a solvent heat treatment for 1 to 4 days at a temperature of 80 to 160 DEG C, filtering, washing, carrying out solvent exchange, and drying the obtained solid in vacuum to obtain white powder, wherein the ratio of amount of substance of the organic solvent to zinc salts is 20-200:1; (2) rapidly heating the white powder obtained in the step (1) to a temperature of 910 DEG C or more at a speed of 2-20 DEG C / min in a nitrogen gas atmosphere, maintaining the temperature for 1 to 12 hours, cooling to the room temperature so as to obtain the porous carbon nano rod with a high specific surface area. The provided preparation method has the advantages of economic route, low cost, simple operation, and mild conditions. The target product has a high specific area and narrow pore size distribution, and has an amorphous carbon structure and a graphite carbon structure at the same time.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Friction braking material and preparation method thereof

ActiveCN101423745AEvenly dispersedShort manufacturing timeOther chemical processesFiberGraphite carbon

The invention discloses a friction braking material, which contains resin carbon, graphite carbon, silicon, silicon carbide, and short carbon fiber. The invention also provides a method for preparing the friction braking material, wherein the method comprises the following steps: the short carbon fiber, an adhesive, silicon powder and graphite powder are mixed to obtain a mixture; the mixture is molded to obtain a molded blank; and the molded blank is sintered in inert atmosphere. The friction braking material can be obtained by only mixing and molding the short carbon fiber, the adhesive, the silicon powder and carbon powder into the molded blank and then sintering the molded blank in the inert atmosphere; compared with the prior method which needs high-temperature carbonization treatment, an isothermal CVD densification process and siliconizing treatment by a high-temperature reaction, the method greatly shortens the preparation time and simplifies the process. The material contains the short carbon fiber which is evenly dispersed; and compared with the prior friction braking material which adopts an integral felt or a braid, the material greatly reduces the cost.

Owner:HAIAN JIAHE CHEM FIBER

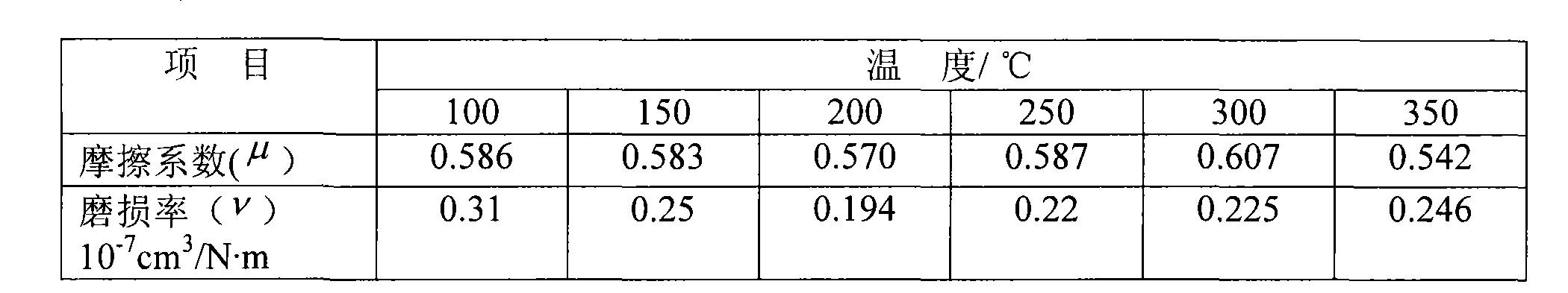

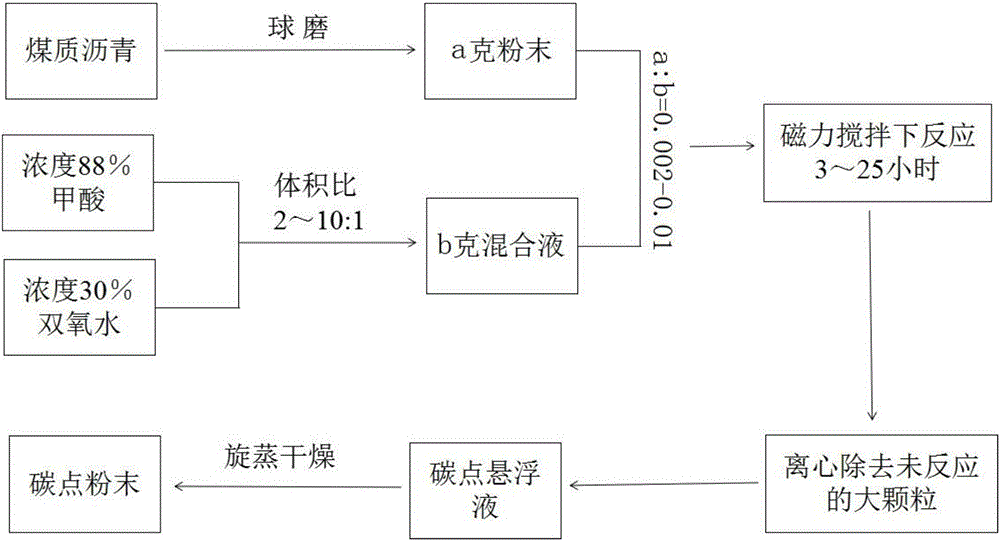

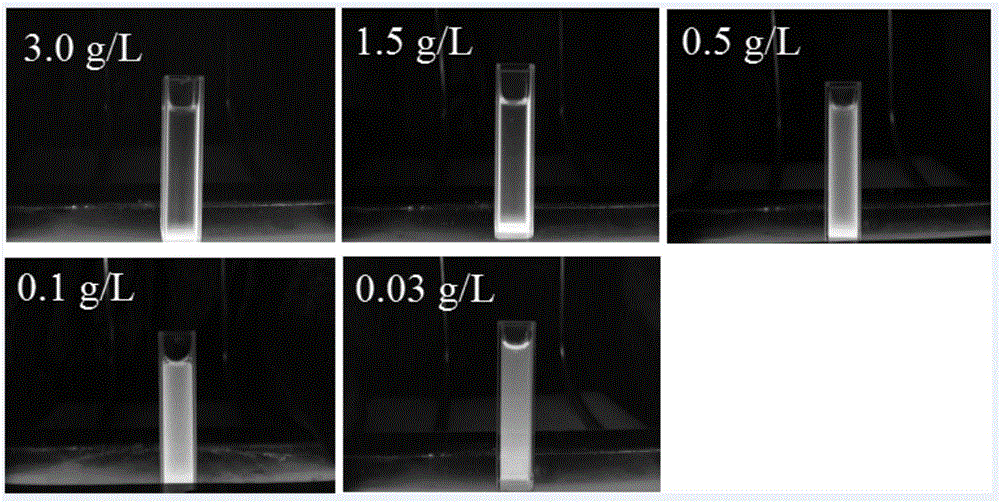

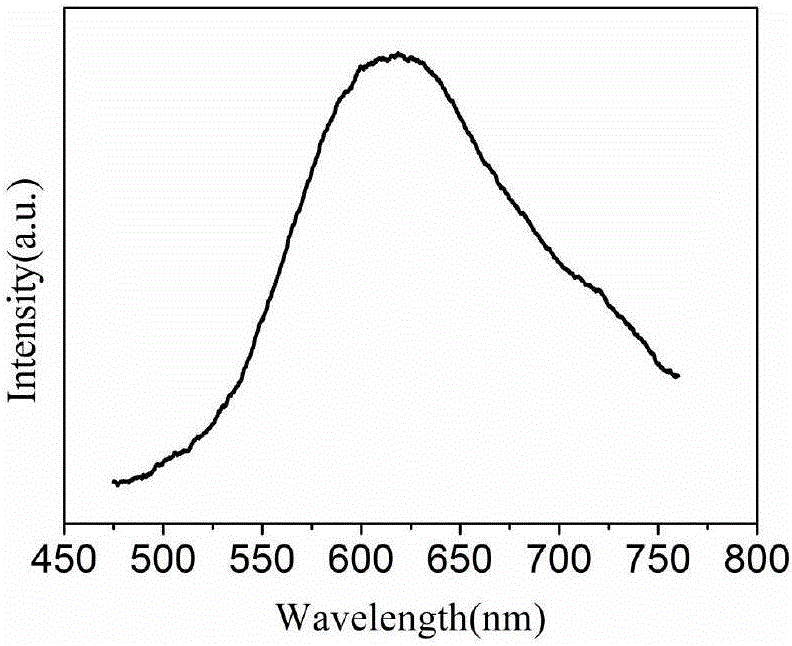

Method for preparing carbon dots with multiple luminescence colors adjusted from coal pitch

ActiveCN106167256AMild conditionsAbundant raw materialsMaterial nanotechnologyNanoopticsDehydrogenationDeoxygenation

The invention discloses a method for preparing carbon dots with multiple luminescence colors adjusted from coal pitch. According to the method, coal pitch in a solid state at the room temperature is broken into small pieces through oxidation by virtue of an oxidation reaction, and dehydrogenation and deoxygenation are carried out in reaction heat to convert an organic molecular structure to a graphite carbon structure. Luminous carbon dots are obtained at a high yield through utilization of a mixed liquid of formic acid and hydrogen peroxide. The luminescence colors of the obtained carbon dots are changed with the concentration. According to the method, a reaction can be conducted at the room temperature, and the method is mild in condition and requires no extra energy consumption. The method is abundant in raw materials, low in cost and wide in application.

Owner:ZHONGBEI UNIV

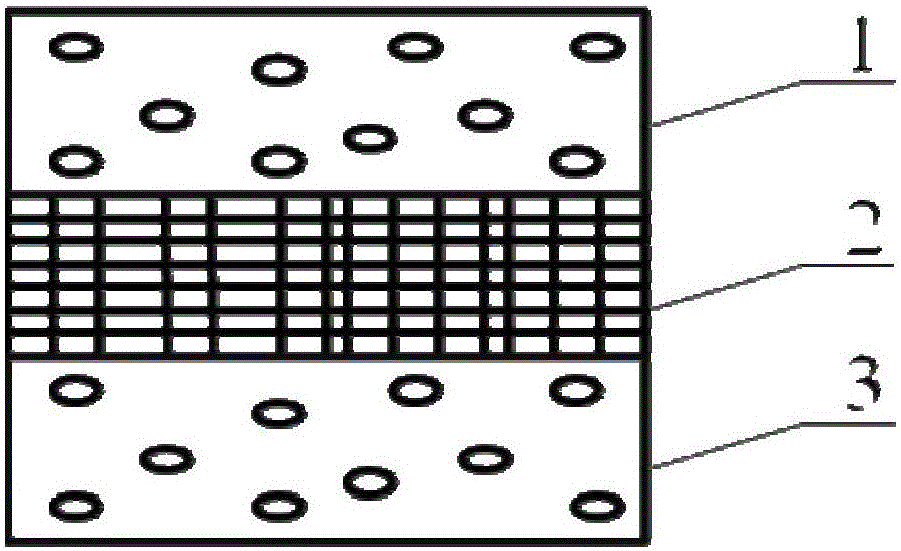

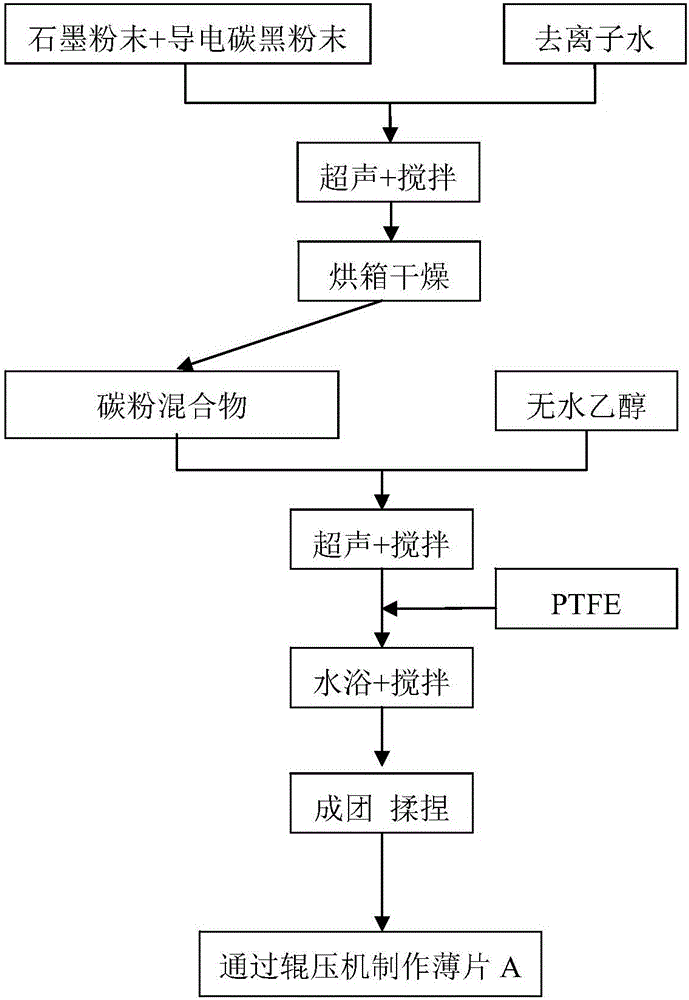

Preparation and application of graphite-carbon black mixed air diffusion cathode

ActiveCN105696018AIncrease the areaHigh porosityPhysical/chemical process catalystsElectrodesGraphite carbonAverage current

The invention discloses a preparation method of a graphite-carbon black mixed air diffusion cathode. The air diffusion cathode is of a composite layer structure composed of a diffusion layer, a stainless steel mesh and a catalyst layer which are laminated in sequence. The stainless steel mesh is a 60-mesh stainless steel mesh with the thickness being 0.1 mm. Catalyst layer materials are embedded in the stainless steel mesh. The preparation method of the graphite-carbon black mixed air diffusion cathode includes the steps that the 0.5 mm sheet-like catalyst layer formed by mixing graphite and conductive carbon black is prepared, the 0.5 mm sheet-like diffusion layer formed by pressing and sintering the conductive carbon black is prepared, the catalyst layer is embedded into the stainless steel mesh through rolling, the diffusion layer is attached to the other surface of the stainless steel mesh and then tightly combined with the stainless steel mesh after being rolled, and therefore the air diffusion cathode of the composite layer structure is prepared. The prepared air diffusion cathode is used for electro-catalysis synthesis of hydrogen peroxide, high catalytic efficiency is achieved, and average current efficiency is 80% or above.

Owner:TIANJIN UNIV

Preparation method for graphite carbon material

The invention provides a preparation method for a graphite carbon material, wherein, the graphite carbon material is prepared from the following required components in parts by weight:. 99-101 parts of calcined petroleum coke dry material and 20-25 parts of melting asphalt. The preparation method comprises the following steps: (1) mixing and kneading the dry material and an adhesive and then cooling and molding the mixture; (2) calcining for the first time; (3) soaking for the first time; (4) clacining for the second time; (5) soaking for the second time; (6) calcining for the third time; and (7) carrying out a graphitization process. The novel graphite carbon material prepared in accordance with the invention has the advantages of antioxidation, good heat and corrosion resistance, excellent conductivity and good thermal shock resistance, so that the lifetime is as over three times as that of a common graphite anode.

Owner:兴和县鑫源碳素有限公司 +1

CoTe2 electro-catalysis oxygen evolution composite material and preparation method and application thereof

InactiveCN107447231ARetains PorosityLarge specific surface areaElectrodesNew energyReaction temperature

The invention provides a CoTe2 electro-catalysis oxygen evolution composite material and a preparation method and application thereof, and belongs to the technical field of new energy nanomaterial synthesis. The CoTe2 electro-catalysis oxygen evolution composite material is formed in a manner that CoTe2 nano particles are loaded to an N-doped graphite carbon frame through recombination, the expression of the CoTe2 electro-catalysis oxygen evolution composite material is CoTe2@n-GC. A zeolite imidazate skeleton structure material ZIF-67 serves as a template and also serves as a cobalt source, elemental tellurium serves as a tellurium source, the reaction temperature and the reaction time are adjusted in an atmosphere of argon and hydrogen mixed gas, and accordingly imidazole carbonizing and tellurid processes are completed through a one-step manner, and the CoTe2 nano particle composite material with the N-doped graphite carbon frame as a support is obtained. By means of the synthetic method, the problems that according to an existing synthetic technology, the process is tedious, the period is relatively long and homogeneity is poor and other problems can be solved, and the study and development of telluride in transition metal chalcogenide are enriched. The CoTe2 electro-catalysis oxygen evolution composite material shows excellent electro-catalysis oxygen evolution performance and is suitable for the field of new energy development.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Graphite or carbon particulates for the lithium ion battery anode

This invention provides a graphite or graphite-carbon particulate for use as a lithium secondary battery anode material having a high-rate capability. The particulate is formed of a core carbon or graphite particle and a plurality of satellite carbon or graphite particles that are each separately bonded to the core particle wherein the core particle is spherical in shape, slightly elongate in shape with a major axis-to-minor axis ratio less than 2, or fibril in shape, and wherein the satellite particles are disc-, platelet-, or flake-like particles each containing a graphite crystallite with a crystallographic c-axis dimension Lc and a lateral dimension. Preferably, Lc is less than 100 nm and the flake / platelet lateral dimension is less than 1 μm. The core particle may be selected from natural graphite, artificial graphite, spherical graphite, graphitic coke, meso-carbon micro-bead, soft carbon, hard carbon, graphitic fibril, carbon nano-fiber, carbon fiber, or graphite fiber. Preferably, the flat-shaped particles are randomly oriented with respect to one another.

Owner:GLOBAL GRAPHENE GRP INC

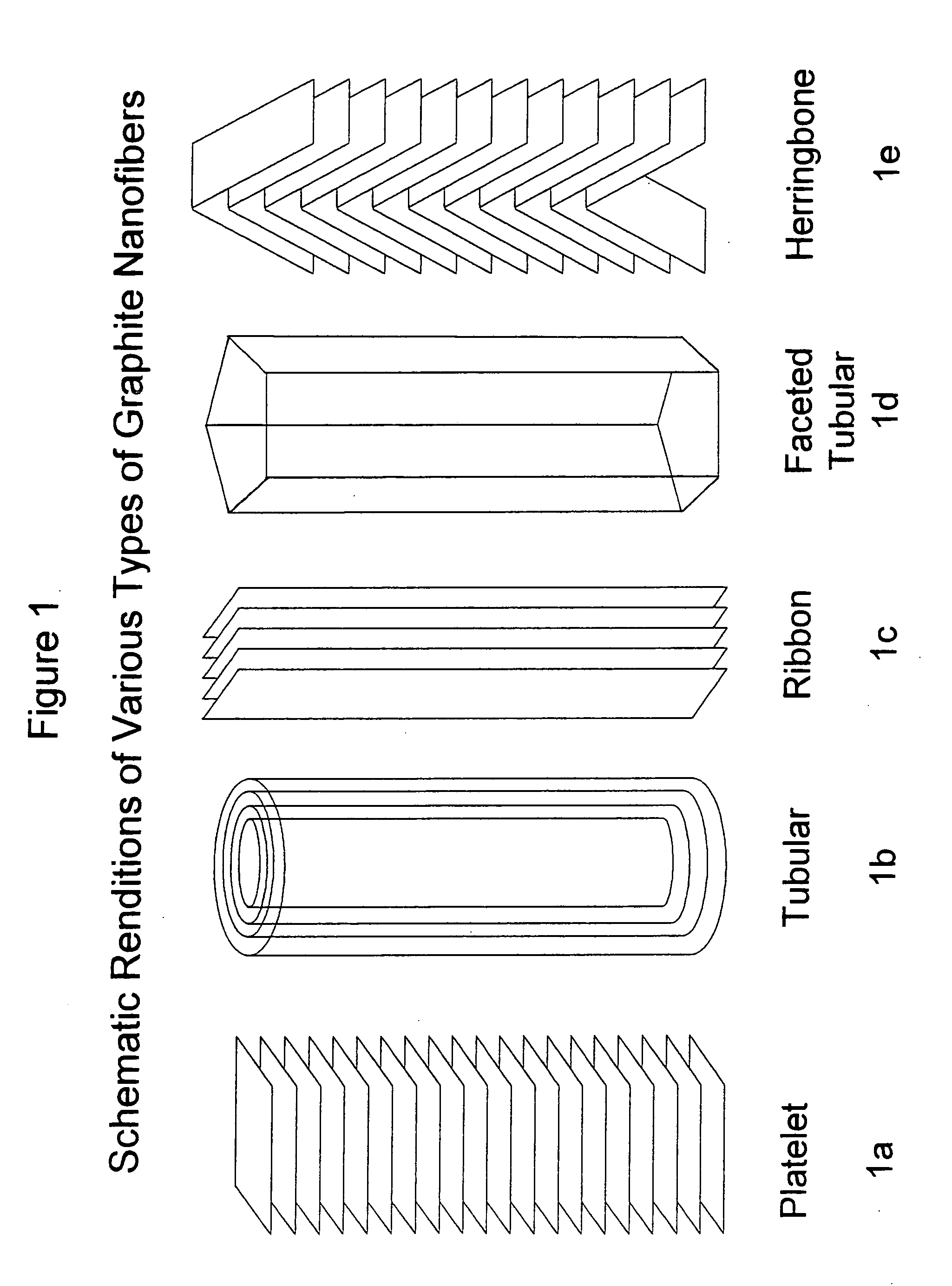

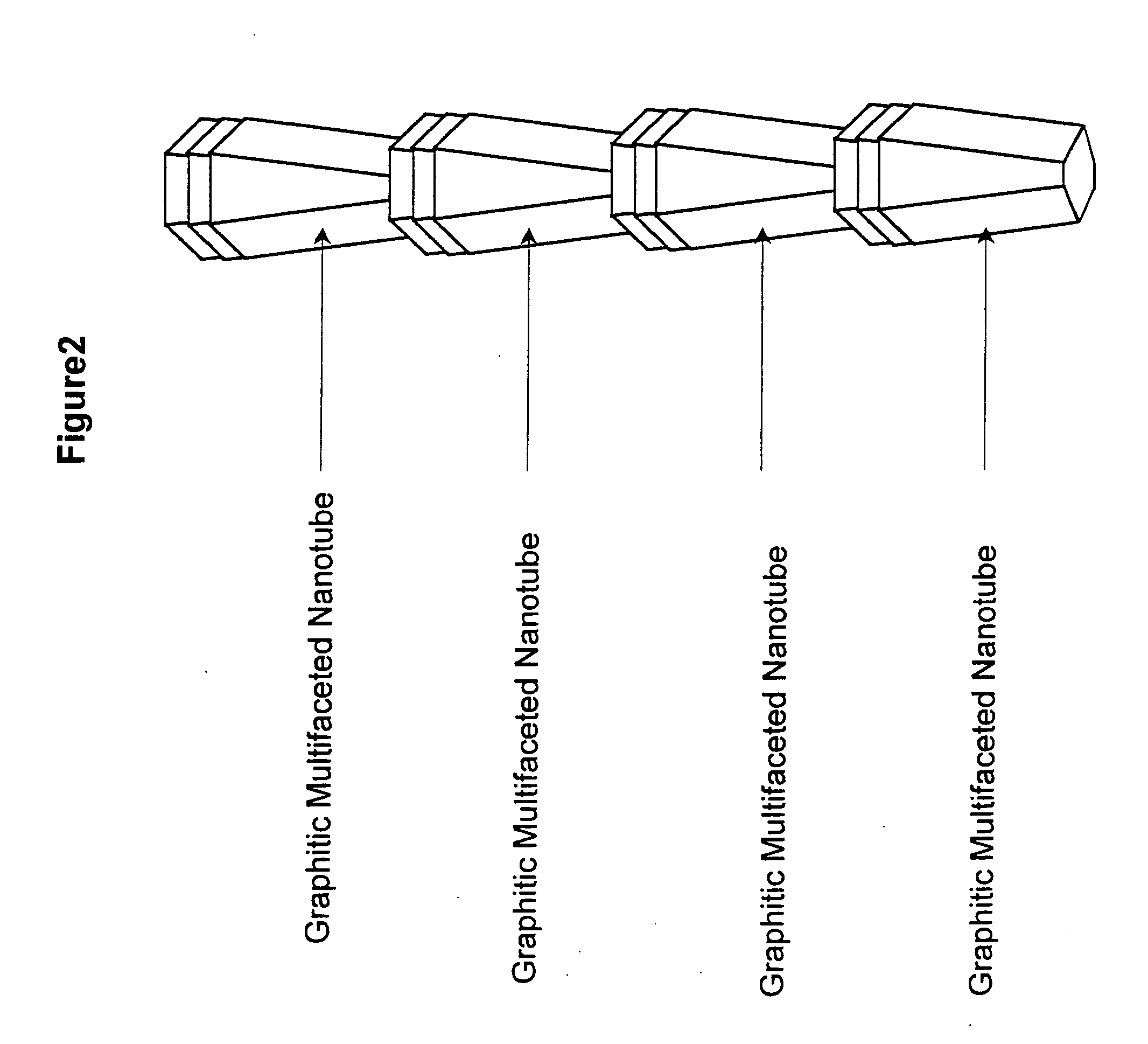

Conductive polymeric structures containing graphite nanofibers having graphite sheets parallel to the growth axis

Electrically conductive polymer composite materials comprised of: a) an effective amount of substantially crystalline graphitic carbon nanofibers comprised of graphite sheets that are substantially parallel to the longitudinal axis of the nanofiber, preferably wherein said grip sheets form a multifaceted tubular structure; and b) a polymeric component.

Owner:CATALYTIC MATERIALS

Method for the preparation of porous graphite carbon with high crystallinity using sucrose as a carbon precursor

InactiveUS20090041653A1High crystallinityHigh catalytic activityMaterial nanotechnologyCarbon compoundsSilica particleGraphite carbon

The present invention relates to a process for preparing a porous graphite carbon with high crystallinity, which comprises the steps of: (a) hydrothermally treating sucrose (i.e. carbon precursor), transitional metal precursor and uniform-sized silica particles at the same time to prepare a polymer; and (b) carbonizing the polymer, which can provide a porous graphite carbon with remarkably improved crystallinity suitable for a catalyst support for a fuel cell.

Owner:HYUNDAI MOTOR CO LTD

Graphene/C60/g-C3N4 heterojunction composite film and preparation method thereof

InactiveCN104174437AOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen productionHeterojunctionGraphite carbon

The invention relates to a photo-catalysis film material and a preparation method thereof, and belongs to the field of inorganic photo-catalysis materials. The photo-catalysis material comprises graphene, C60 and graphite carbon nitride. The photo-catalysis film material prepared by adopting the method has the photo-catalysis activity in a wavelength range of 400-800nm and is capable of photolyzing water under visible light or natural light radiation to produce hydrogen.

Owner:TIANJIN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com