Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43610 results about "Sulfuric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulfuric acid (alternative spelling sulphuric acid), also known as vitriol, is a mineral acid composed of the elements sulfur, oxygen and hydrogen, with molecular formula H₂SO₄. It is a colorless, odorless, and syrupy liquid that is soluble in water and is synthesized in reactions that are highly exothermic.

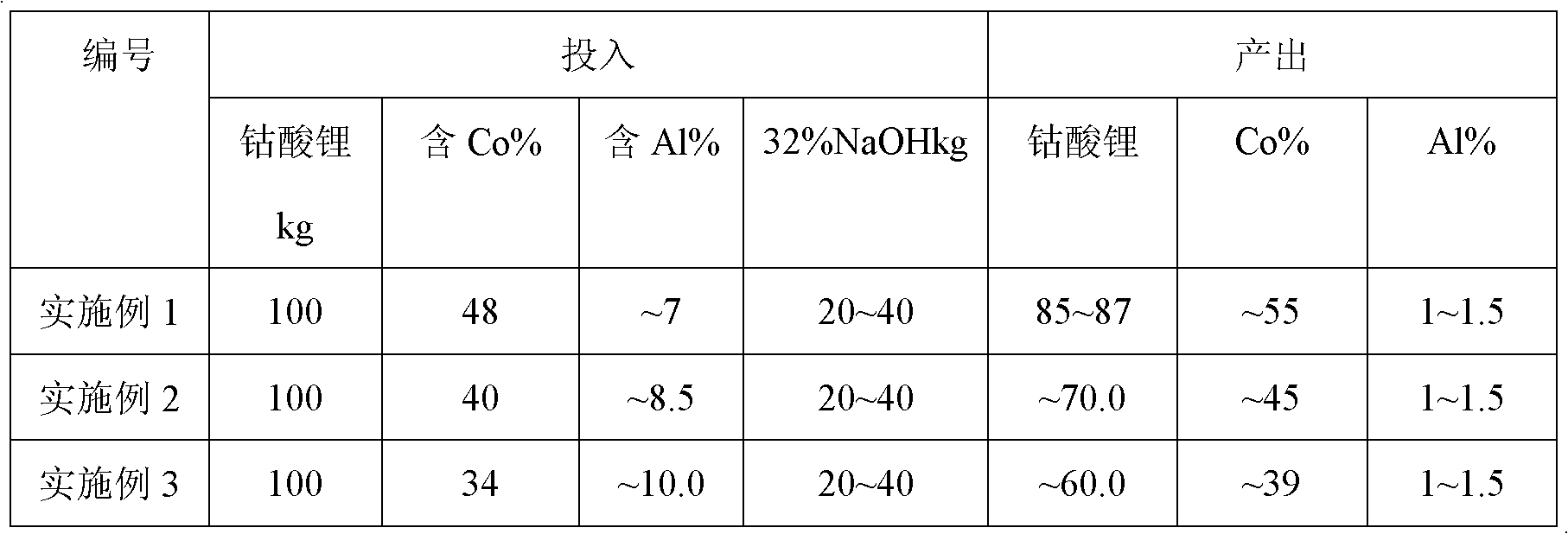

Method for preparing lithium cobaltate by directly using invalid lithium ion battery

InactiveCN102030375AReduce dispersionHigh purityCell electrodesCobalt compoundsElectrical batteryPotassium hydroxide

The invention provides a method for preparing lithium cobaltate by directly using an invalid lithium ion battery. The method comprises the following steps: crushing the invalid lithium ion battery or scraps generated when a lithium cobaltate battery is produced by a mechanical crusher at normal temperature; adding water and one or more of acetic acid, sulfuric acid, hydrochloric acid or nitric acid to produce mixed aqueous solution of the battery scraps and acid; filling the mixed aqueous solution into a hermetic pressure reactor, and controlling the temperature in the reactor to be between 50 and 150 DEG C; introducing or adding one leaching additive of sulfur dioxide or hydrogen, or adding hydrazine hydrate; stirring and leaching, cooling, and filtering; adding one precipitator of sodium carbonate, potassium carbonate and ammonium carbonate, or adding composite precipitator consisting of one of the sodium carbonate, the potassium carbonate and the ammonium carbonate and one of sodium hydroxide and potassium hydroxide to obtain mixture of lithium carbonate, cobalt carbonate and cobalt hydroxide; drying and calcining at high temperature to produce a lithium cobaltate product. The method is particularly suitable for the treatment scale of medium-sized and small enterprises, and is an effective method for directly materializing cobalt secondary resources.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Immobilizing mediator molecules via anchor molecules on metallic implant materials containing oxide layer

A mediator molecule is immobilized on the surface of a metallic or ceramic implant material. An anchor molecule such as a dialdehyde having a functional group that covalently binds the mediator molecule is covalently bound to the surface, and the mediator molecule is coupled to the functional group of the anchor molecule. The implant material may be composed of titanium, titanium alloy, aluminum, stainless steel or hydroxylapatite. Oxide units on the surface of the implant material can be increased preferably by treating with hot chromic-sulphuric acid for 0.5 to 3 hours at a temperature between 100 to 250° C. prior to binding the anchor molecule. Also, prior to binding the anchor molecule, the surface of the implant material can be activated by reacting with a silane derivative. Mediator molecules include BMP protein, ubiquitin and antibiotics, and the implant material may be an artificial joint or coronary vessel support such as a stent.

Owner:MORPHOPLANT

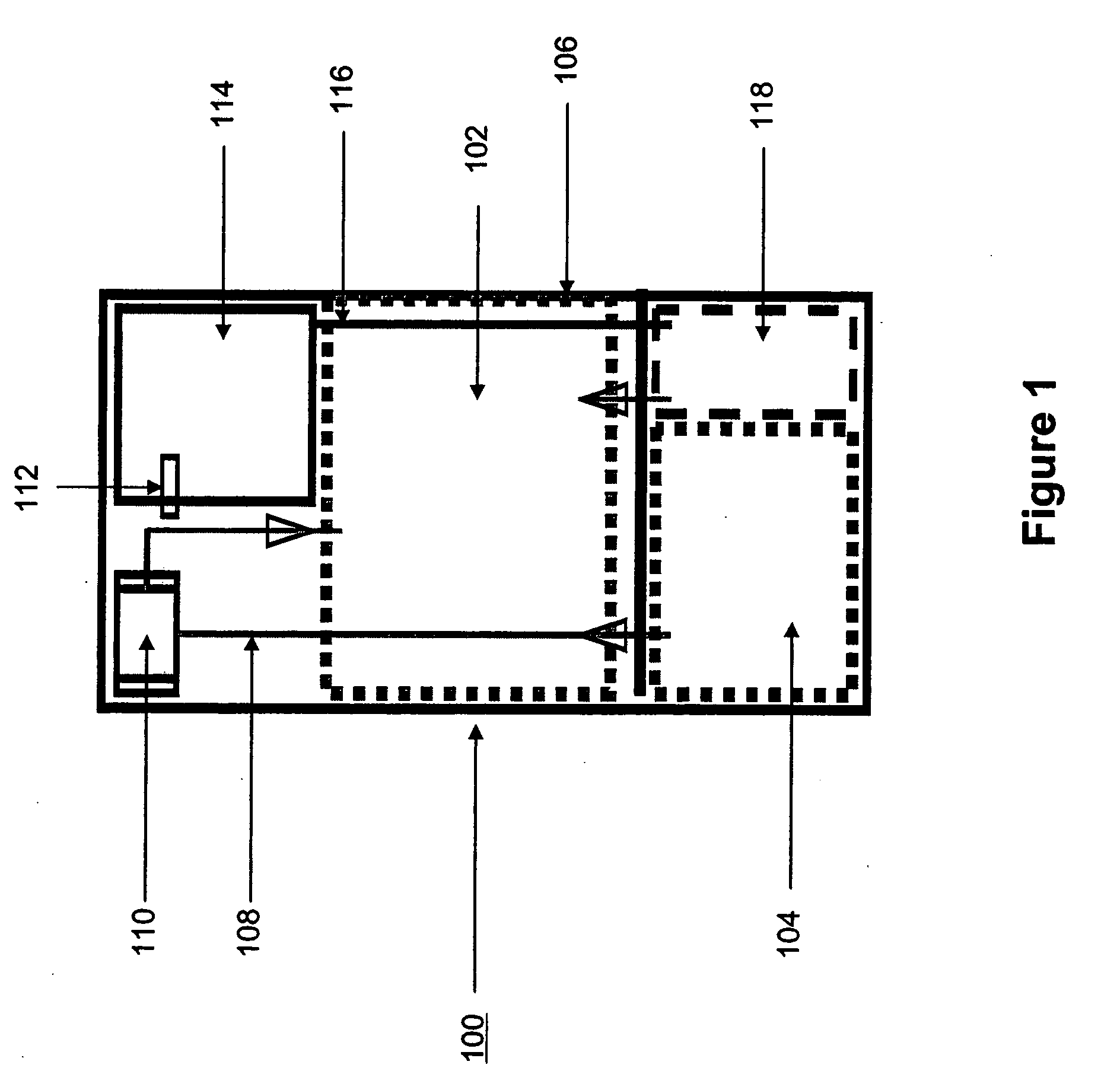

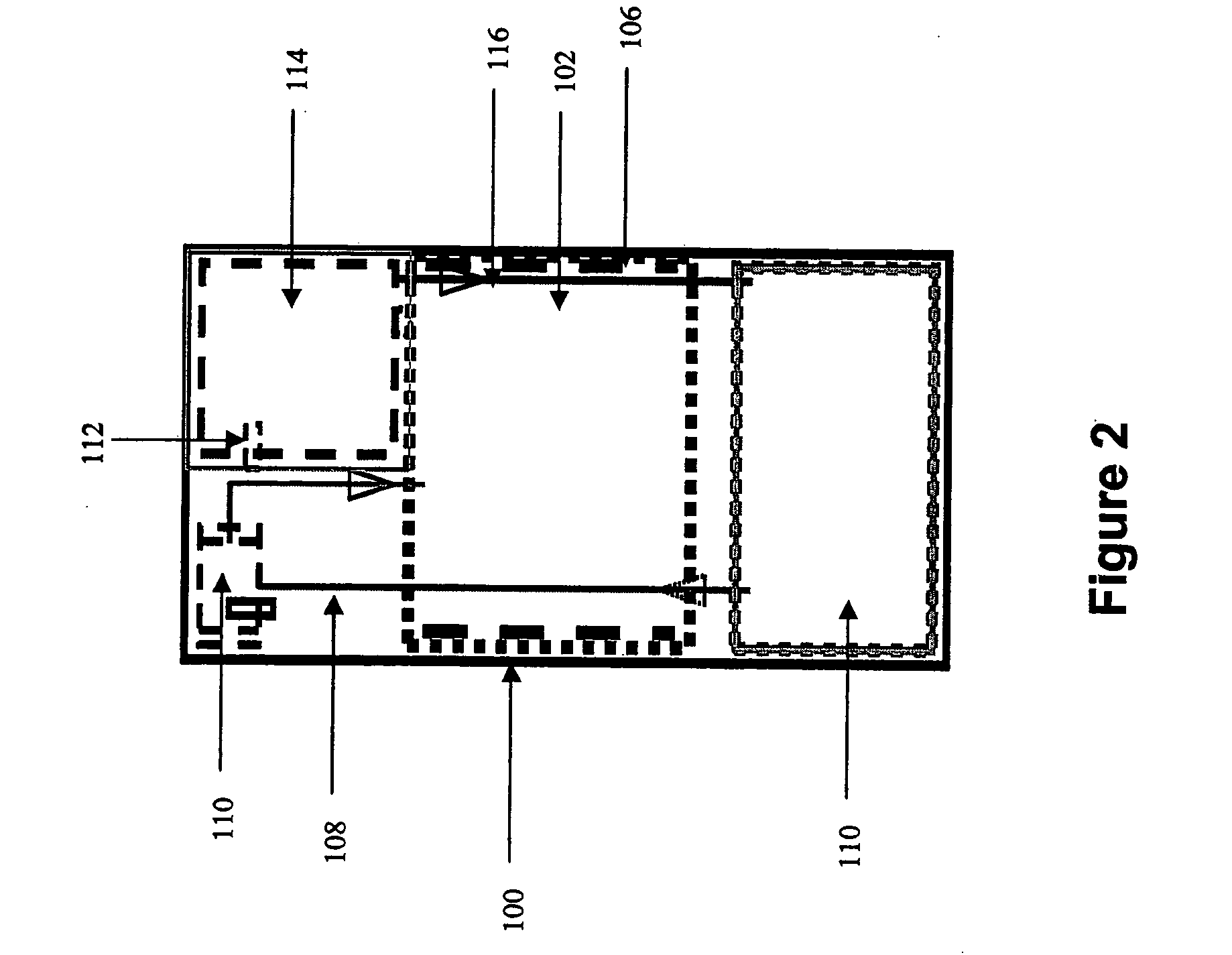

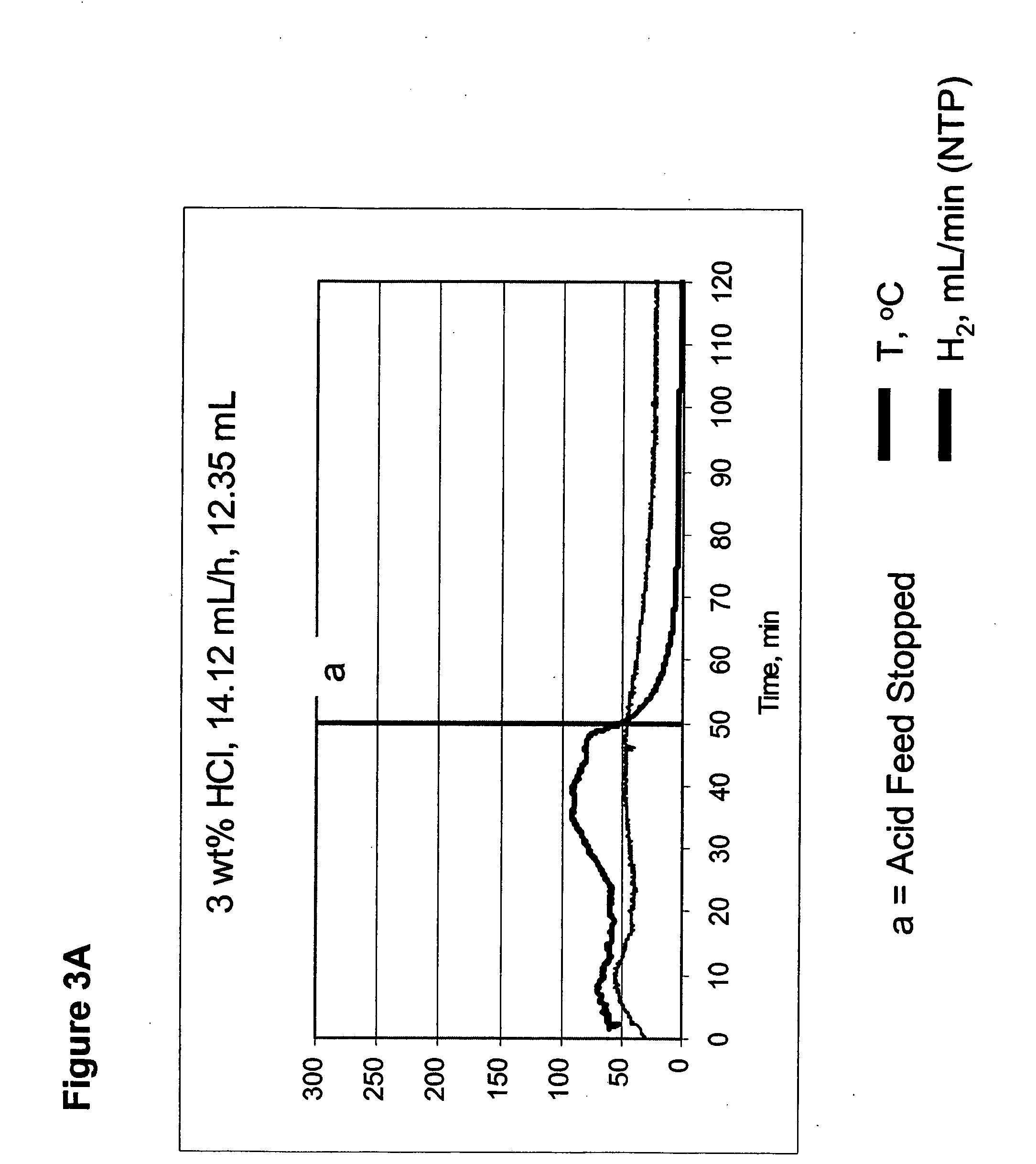

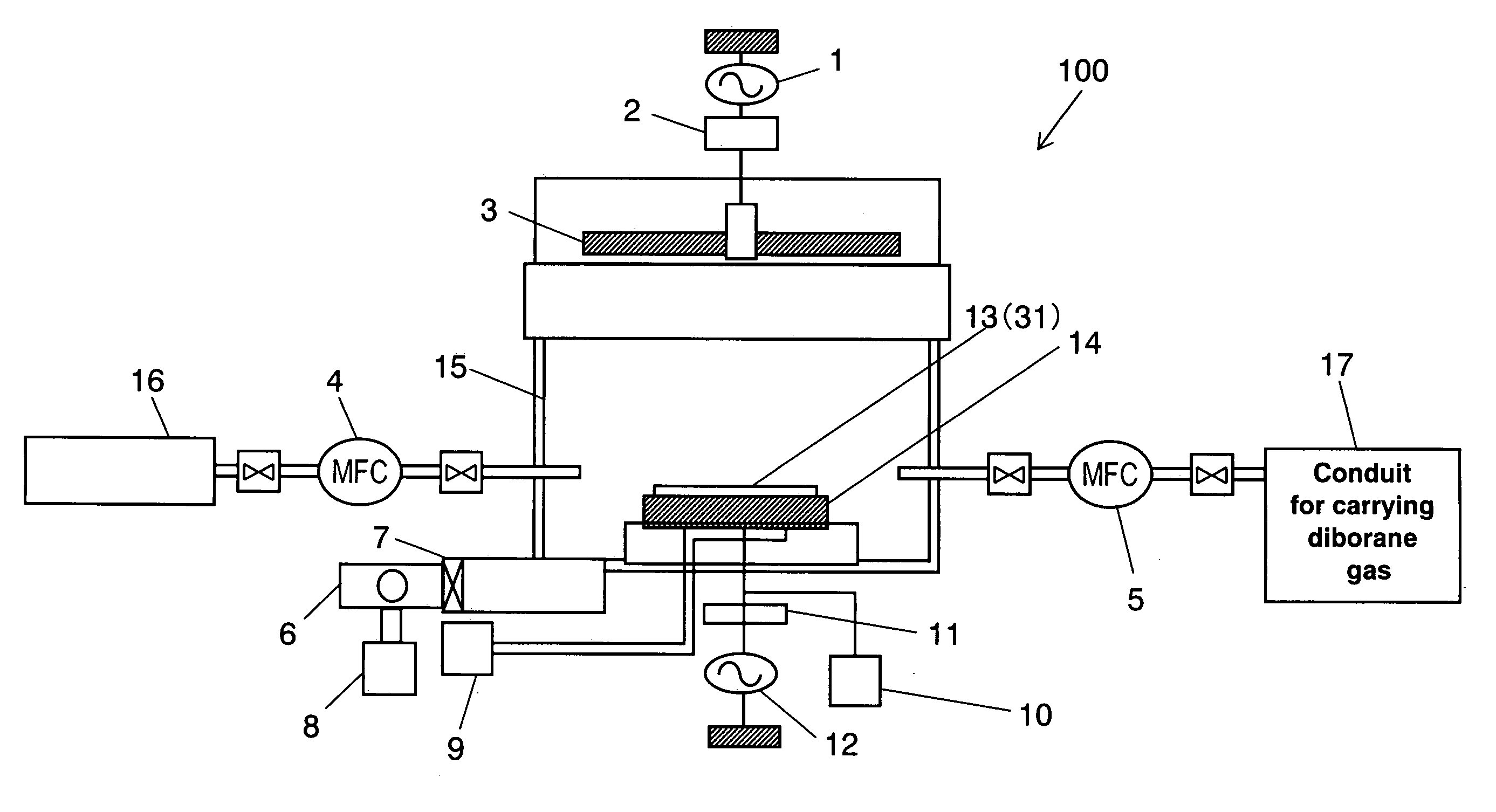

Systems and methods for hydrogen generation from solid hydrides

InactiveUS20050238573A1Regulate rateReactant parameters controlHydrogen productionO-Phosphoric AcidAlkaline earth metal

A system is disclosed for hydrogen generation based on hydrolysis of solid chemical hydrides with the capability of controlled startup and stop characteristics wherein regulation of acid concentration, acid feed rate, or a combination of both control the rate of hydrogen generation. The system comprises a first chamber for storing a solid chemical hydride and a second chamber for storing an acidic reagent. The solid chemical hydride is a solid metal borohydride having the general formula MBH4, where M is selected from the group consisting of alkali metal cations, alkaline earth metal cations, aluminum cation, zinc cation, and ammonium cation. The acidic reagent may comprise inorganic acids such as the mineral acids hydrochloric acid, sulfuric acid, and phosphoric acid, and organic acids such as acetic acid, formic acid, maleic acid, citric acid, and tartaric acid, or mixtures thereof.

Owner:MILLENNIUM CELL

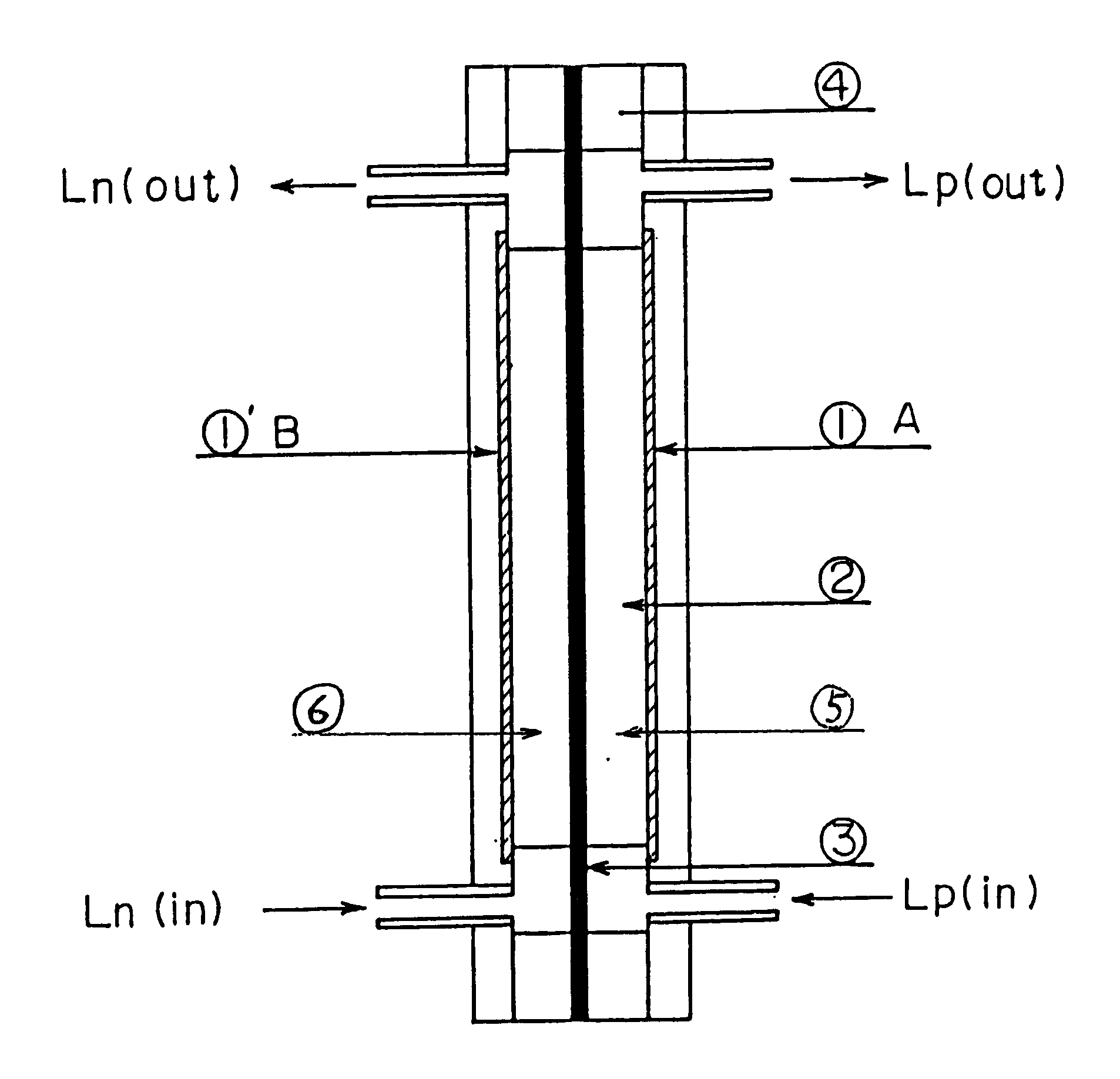

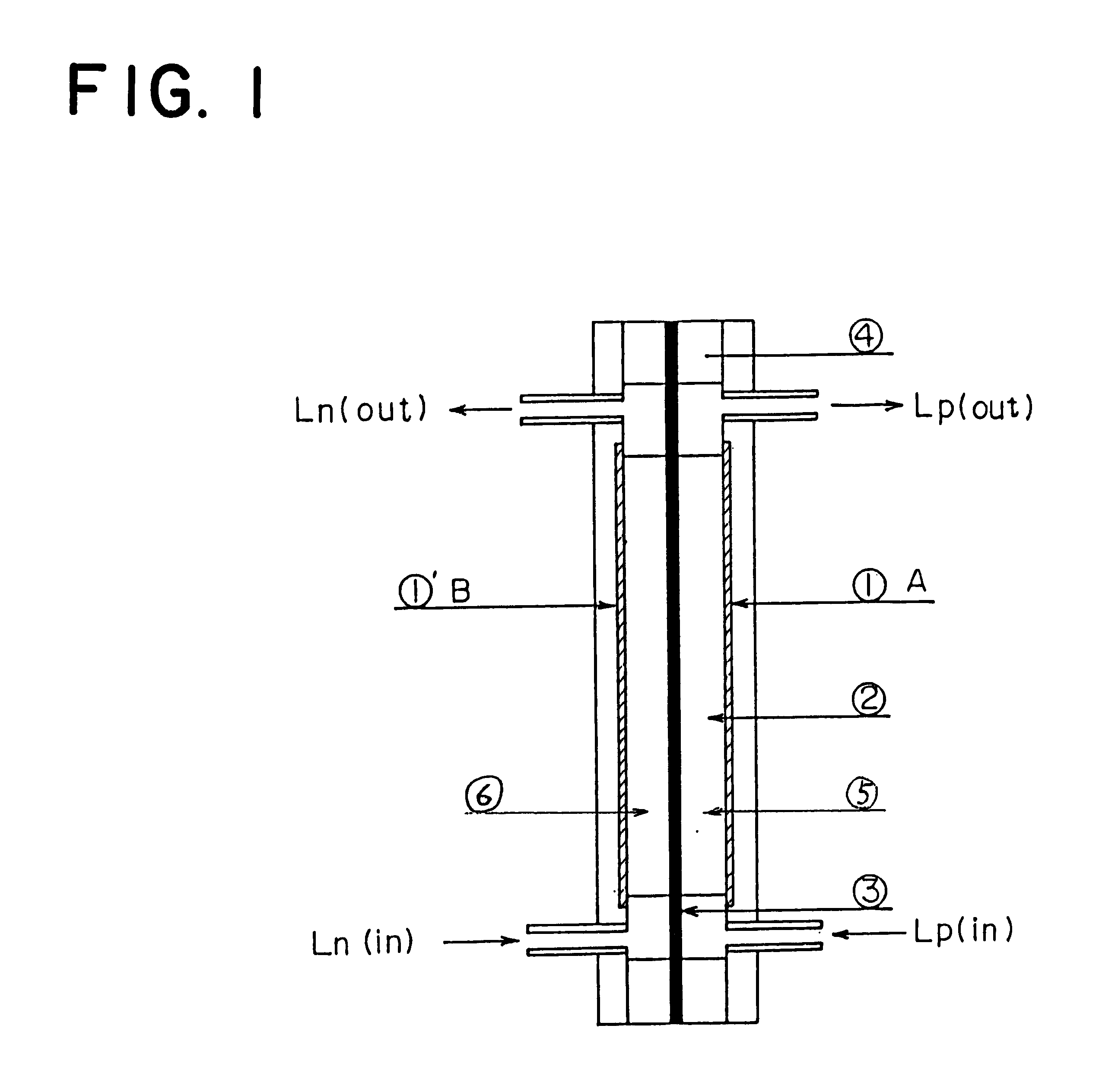

Redox flow battery

InactiveUS6764789B1Reduce capacityReduce frequencyElectrolyte holding meansCell electrodesRedoxAqueous solution

The present invention provides a redox flow type battery which a liquid-circulating battery comprising a battery cell and storage tanks for positive and negative electrolytes, wherein the battery cell is separated by a membrane to provide a positive cell and a negative cell, each cell having a liquid-permeable porous electrode disposed therein, wherein the positive and negative electrolytes are sulfuric acid aqueous solutions with vanadium ion concentrations of 0.5 mol / l to 8 mol / l and the electrolyte which migrates through the membrane over cycles of charge and discharge is returned from the storage tank where the liquid increases to the storage tank where the liquid decreases in order to keep the change in the amounts of the positive and negative electrolytes in a certain range while charge and discharge are carried out.

Owner:SUMITOMO ELECTRIC IND LTD

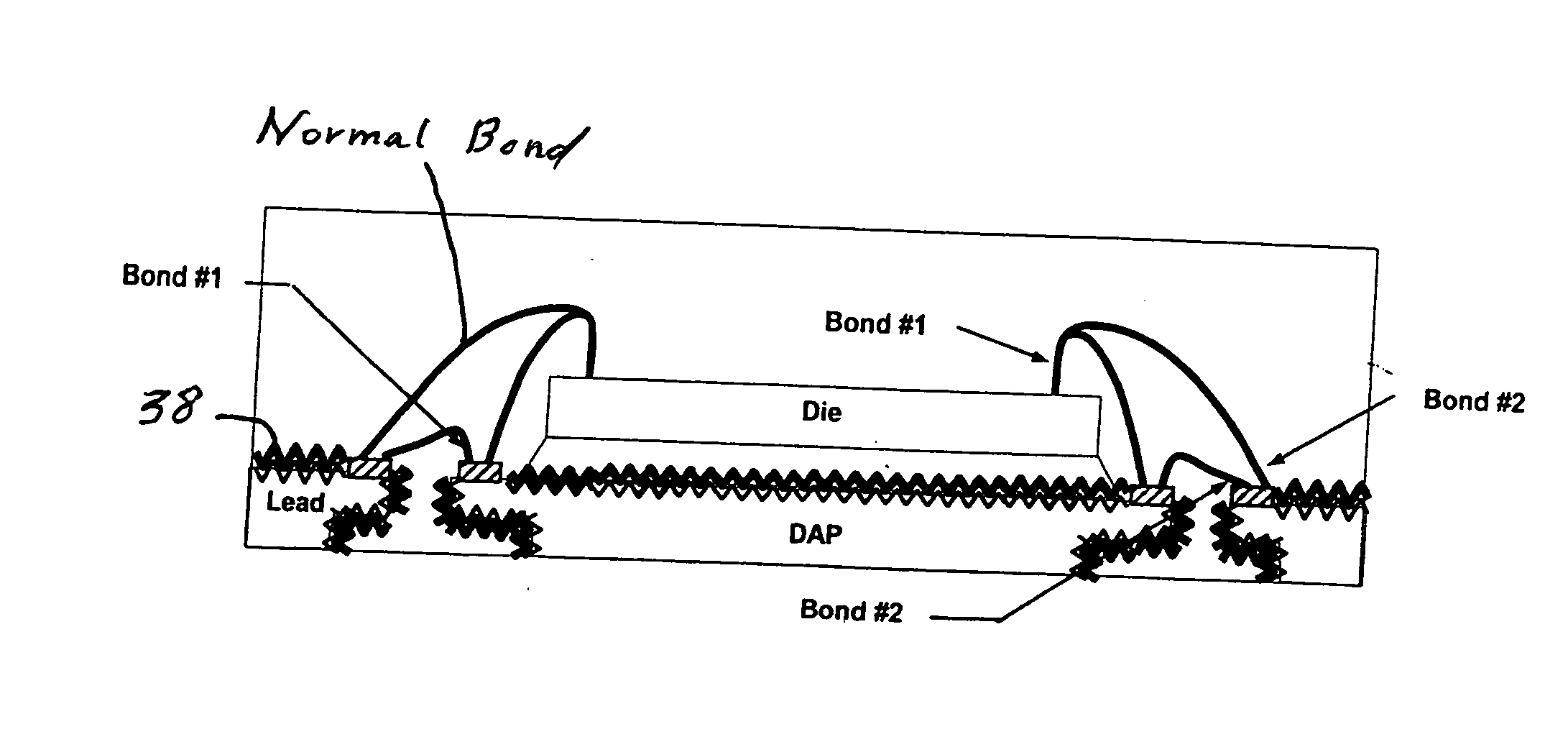

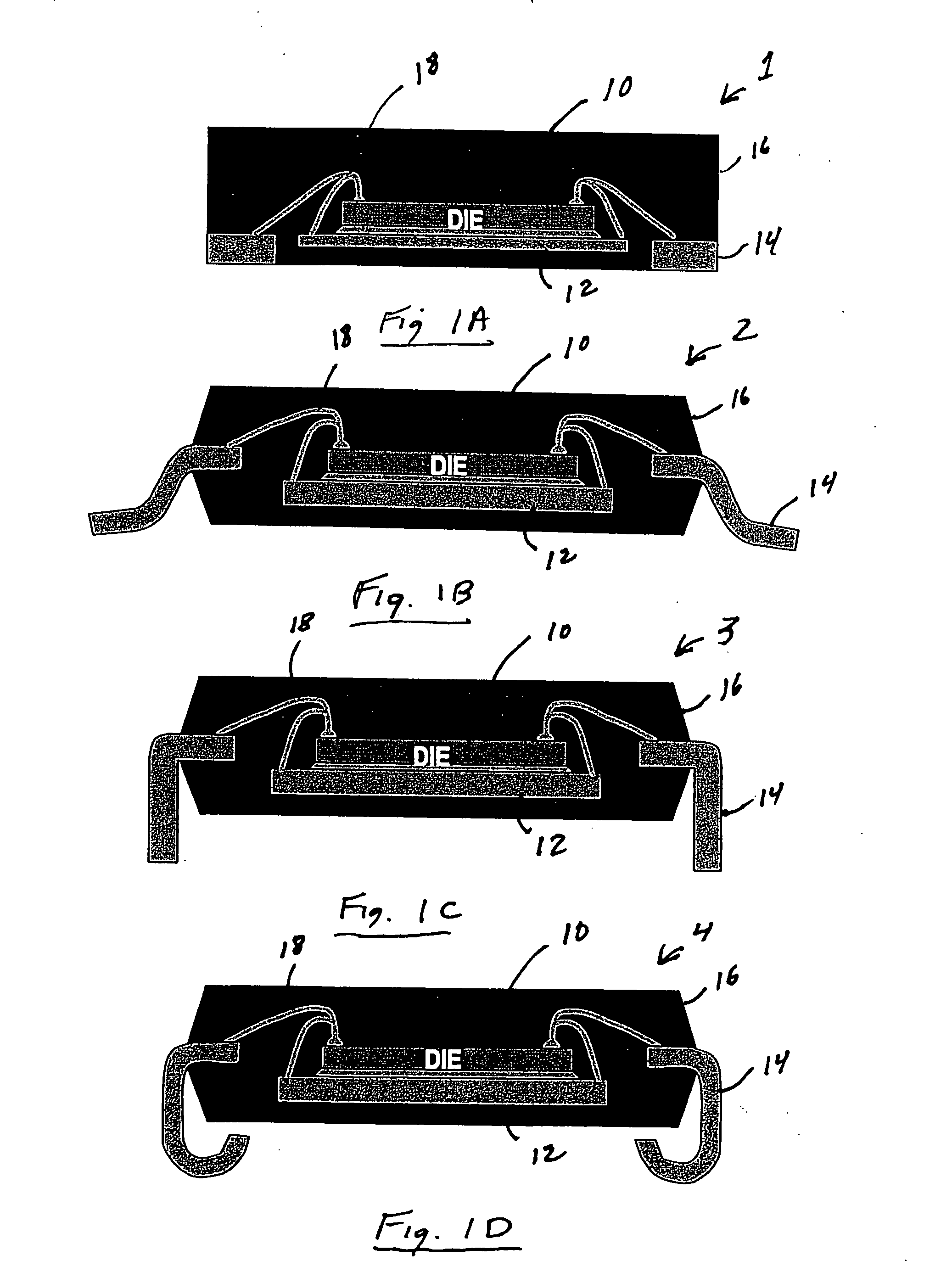

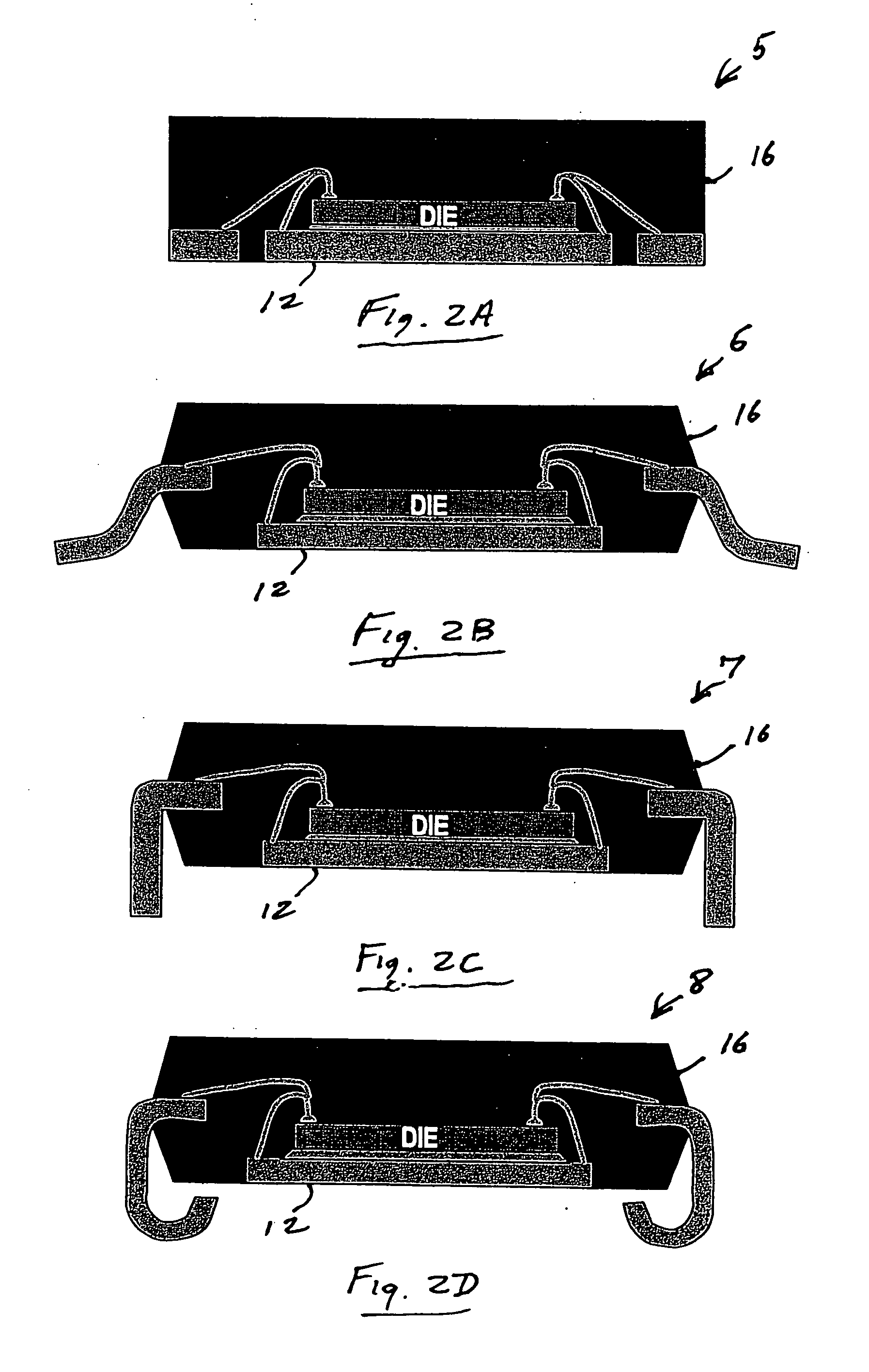

Semiconductor package including leadframe roughened with chemical etchant to prevent separation between leadframe and molding compound

InactiveUS20060097366A1Improve adhesionTrend downSemiconductor/solid-state device detailsSolid-state devicesCompound aSemiconductor package

A semiconductor package contains a metal leadframe that has been specially treated by roughening it with a chemical etchant. The roughening process enhances the adhesion between the leadframe and the molten plastic during the encapsulation of the leadframe and thereby reduces the tendency of the package to separate when exposed to moisture and numerous temperature cycles. In one embodiment, the leadframe made of copper is roughened with a chemical etchant that contains sulfuric acid and hydrogen peroxide.

Owner:UTAC HEADQUARTERS PTE LTD

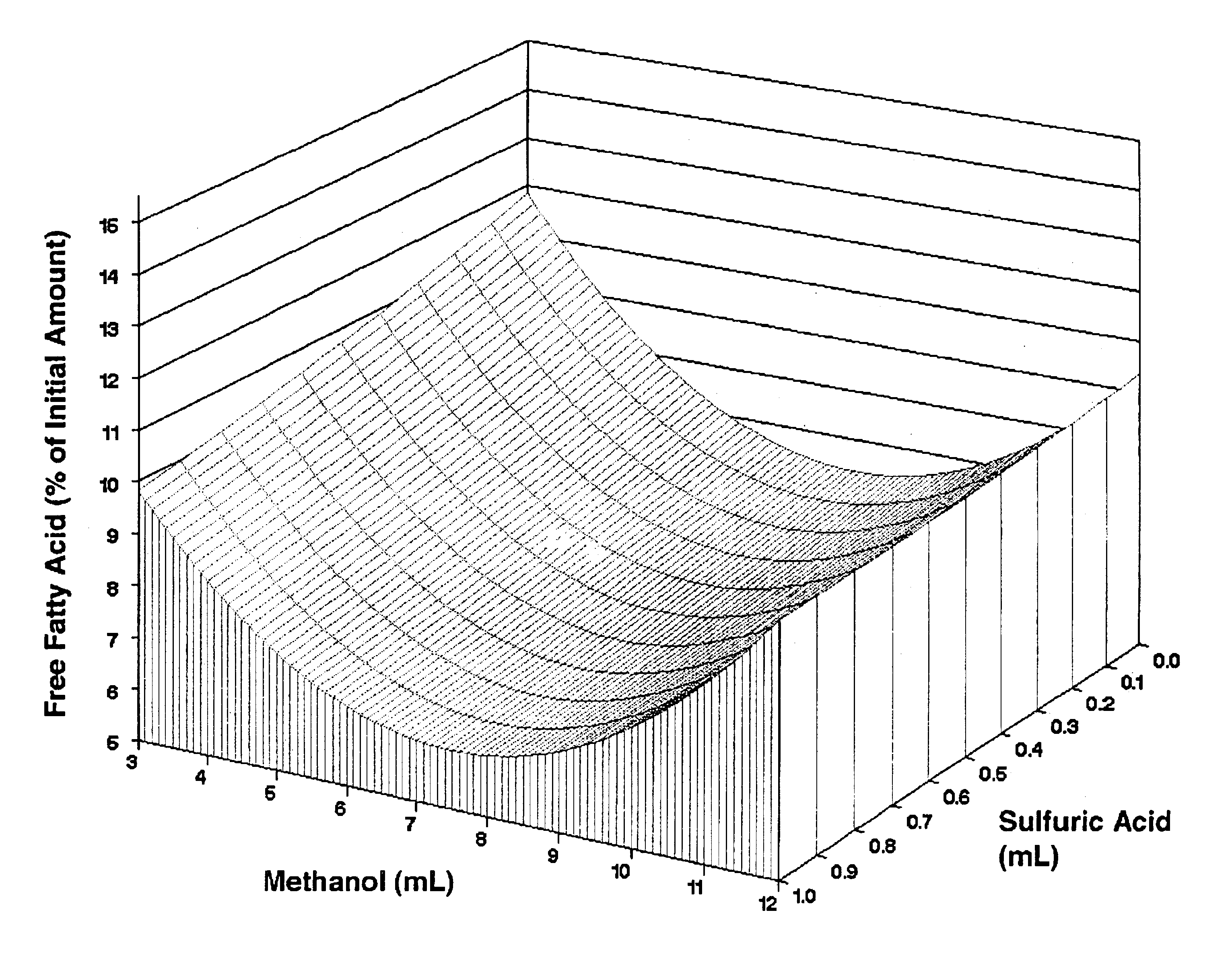

Lipid rich compositions, production of lipid rich compositions, production of fatty acid alkyl esters from heterogeneous lipid mixtures

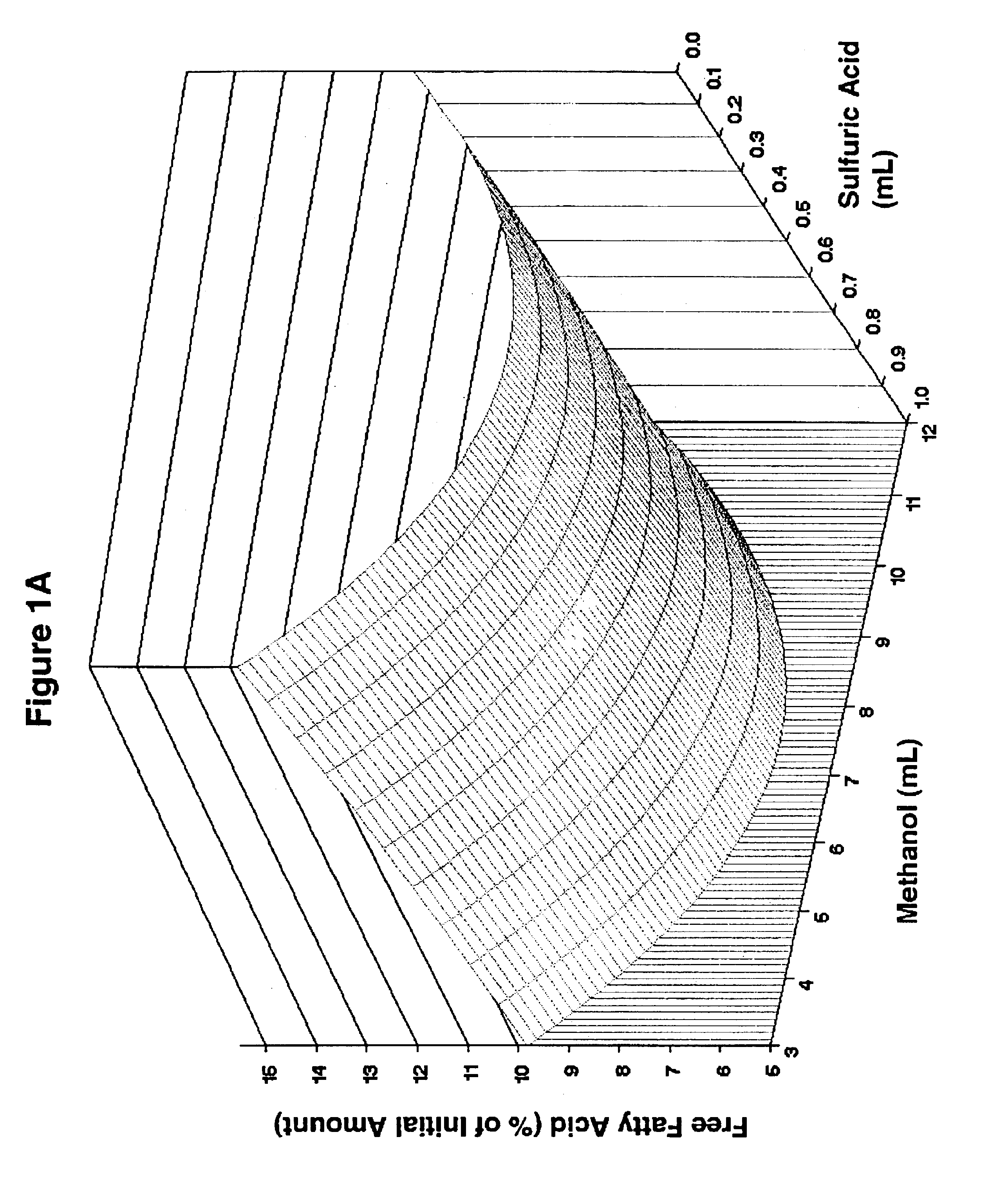

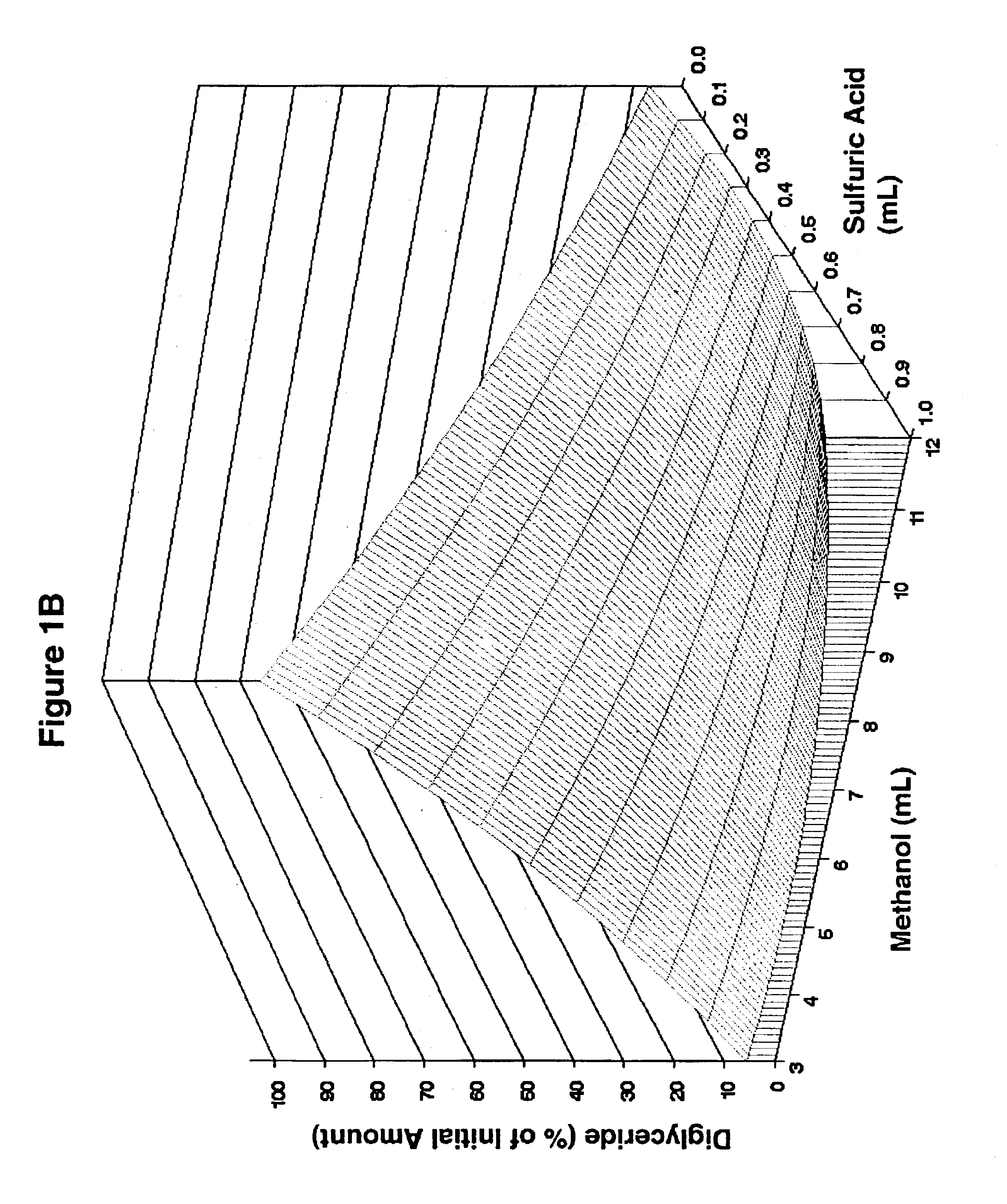

InactiveUS6855838B2Fatty oils/acids recovery from wasteFatty acid esterificationFatty acid esterSulfuric acid

The present invention relates to a method for producing fatty acid alkyl esters, involving esterifying a material containing free fatty acids (FFA) with an alcohol and an inorganic acid catalyst to form a product containing fatty acid alkyl esters, wherein (i) the material contains at least about 40% FFA and is produced by reacting a feedstock with steam and sulfuric acid at a pH of about 1-about 2 or (ii) the material contains at least about 80% FFA and is produced by reacting a feedstock with steam and alkali at a pH of about 11-about 13 and further reacting the feedstock with steam and sulfuric acid at a pH of about 1-about 2. The feedstock may be selected from the oils or soapstocks of soy, coconut, corn, cotton, flax, palm, rapeseed / canola, safflower, sunflower; animal fats; waste greases; and mixtures thereof; or other fully or partially hydrolyzed preparations of such feedstocks. The present invention also relates to a method for producing a lipid rich composition containing at least about 80% FFA, the method involving reacting a feedstock with steam and alkali at a pH of about 11-about 13 and further reacting the feedstock with steam and sulfuric acid at a pH of about 1-about 2. The feedstock may be selected from soy, coconut, corn, cotton, flax, palm, rapeseed / canola, safflower, sunflower, animal fats, waste greases, and mixtures thereof. The feedstock may be selected from the oils or soapstocks of soy, coconut, corn, cotton, flax, palm, rapeseed / canola, safflower, sunflower; animal fats; waste greases; and mixtures thereof; or other fully or partially hydrolyzed preparations of such feedstocks. Furthermore, the present invention concerns a lipid rich composition containing at least about 80% FFA.

Owner:RUNYON IND +1

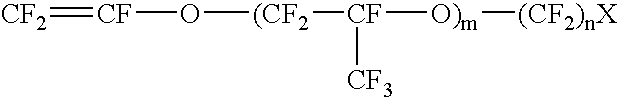

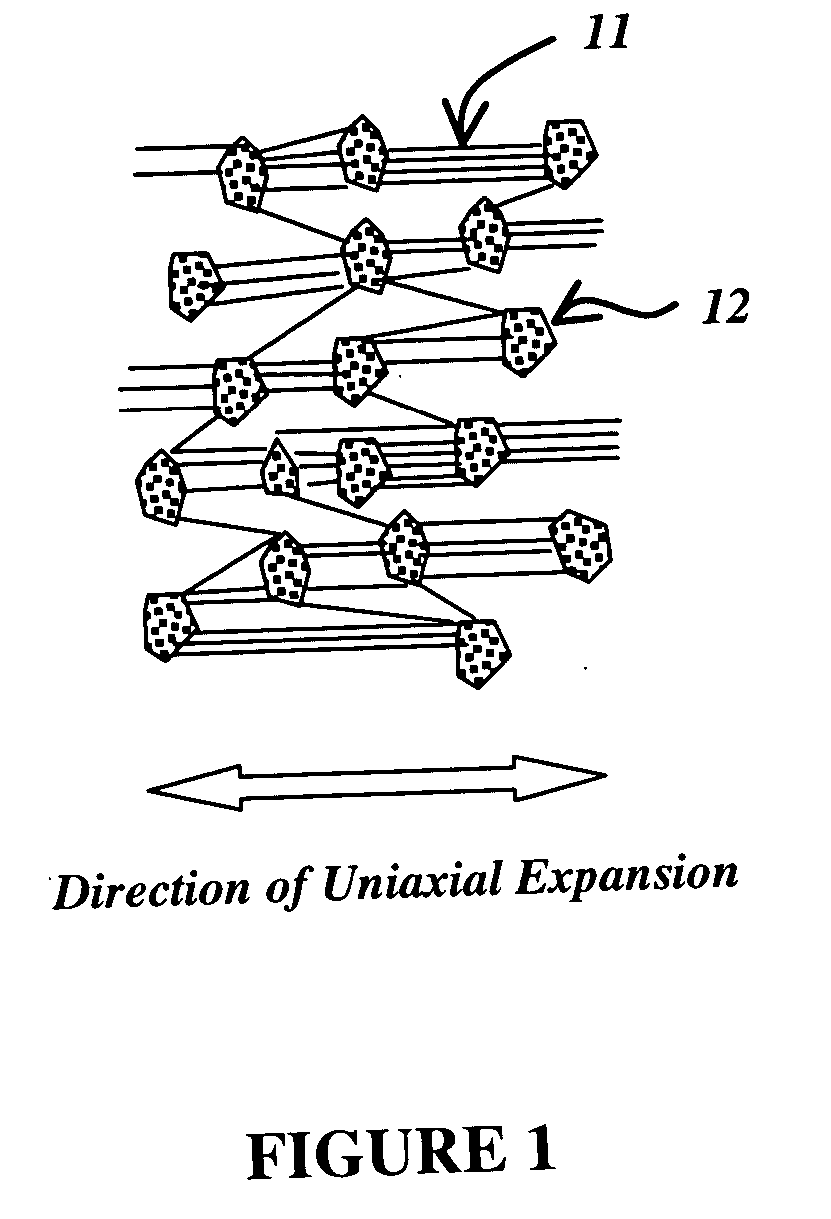

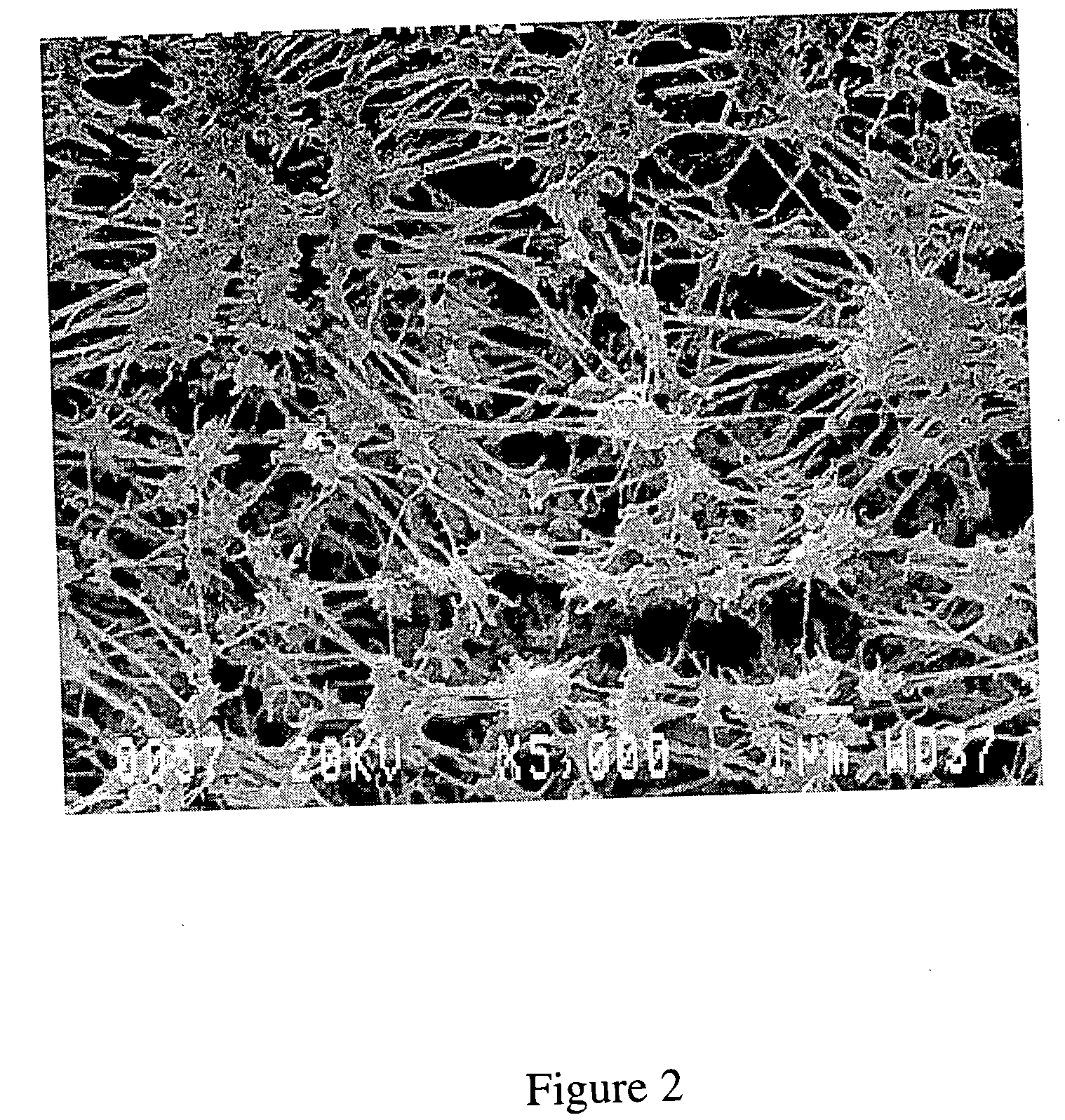

Flue gas purification process using a sorbent polymer composite material

ActiveUS20050019240A1Easy to fixImprove removal efficiencyGas treatmentNitrogen compoundsSorbentFluoropolymer

This invention provides a process of removing sulfur oxides, mercury vapor, and fine particulate matters from industrial flue gases that contain such pollutants. The pollutants are removed by modules, which contain microporous adsorbent (i.e., sorbent) material that is held within a polymer matrix. The preferred polymers are fluoropolymers. The composite material that contains the microporous absorbent material held within a polymer matrix removes sulfur oxides by converting them into high concentration sulfuric acids. It also removes mercury vapor by chemically adsorbing the mercury into the matrix. It also removes fine particulate matters by surface filtration. The sulfuric acid that is produced inside the composite material is automatically expelled onto the external surfaces of the composite material and is drained into an acid reservoir together with the fine particulate matters which are washed from the external surfaces of the composite material by the constant dripping of the sulfuric acid along the external surfaces of the composite material.

Owner:WL GORE & ASSOC INC

Anodizing Aluminum and Alloys Thereof

This invention encompasses methods of producing a colored oxide layer on an aluminum material by anodizing the aluminum material in an electrolyte comprising water, sulfuric acid and oxalic acid. The anodizing step comprises passing at least two sequential current densities through the electrolyte. Methods of making and using article with a colored oxide layer on an aluminum material make by the methods disclosed herein are also disclosed.

Owner:DURACOUCHE INT

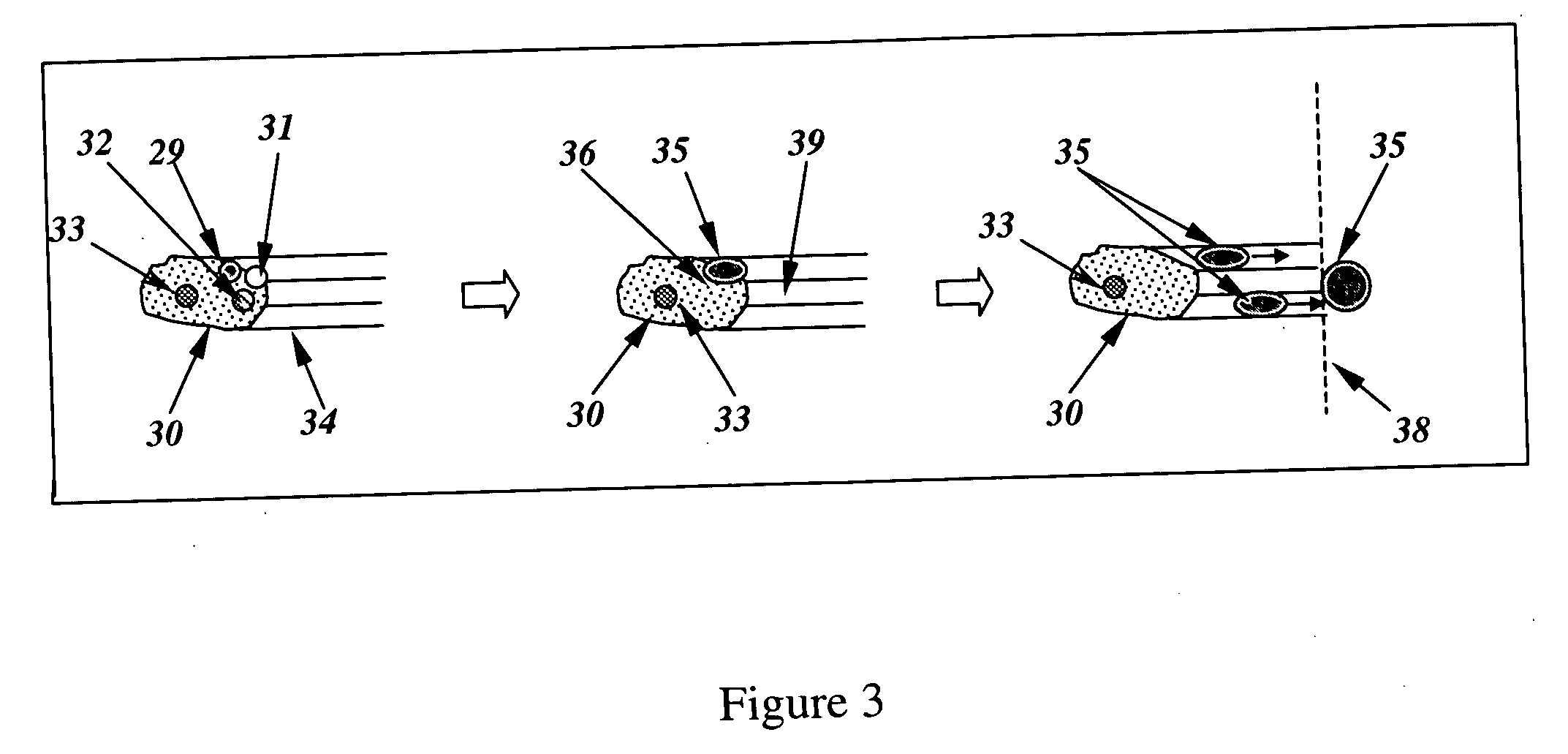

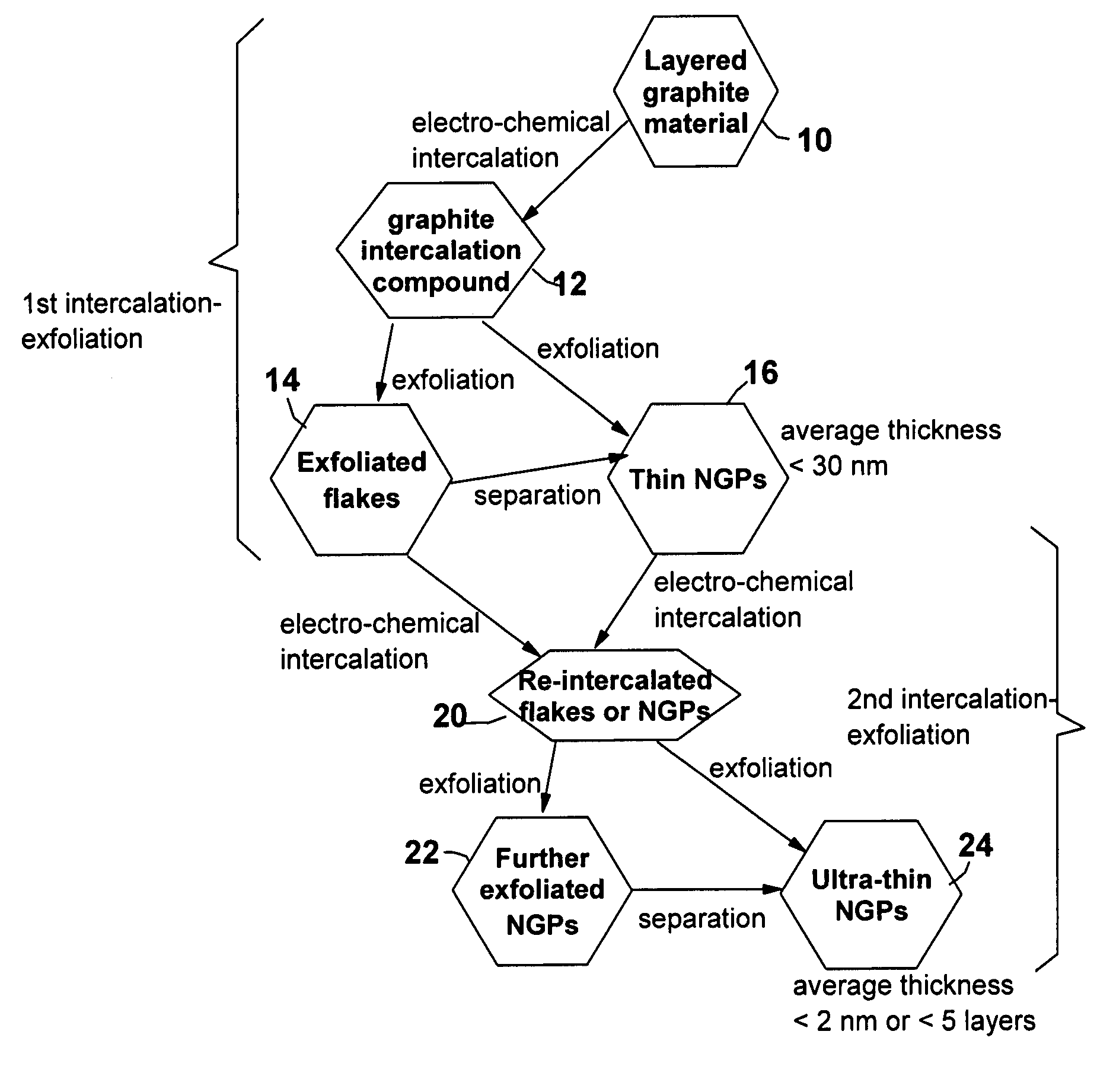

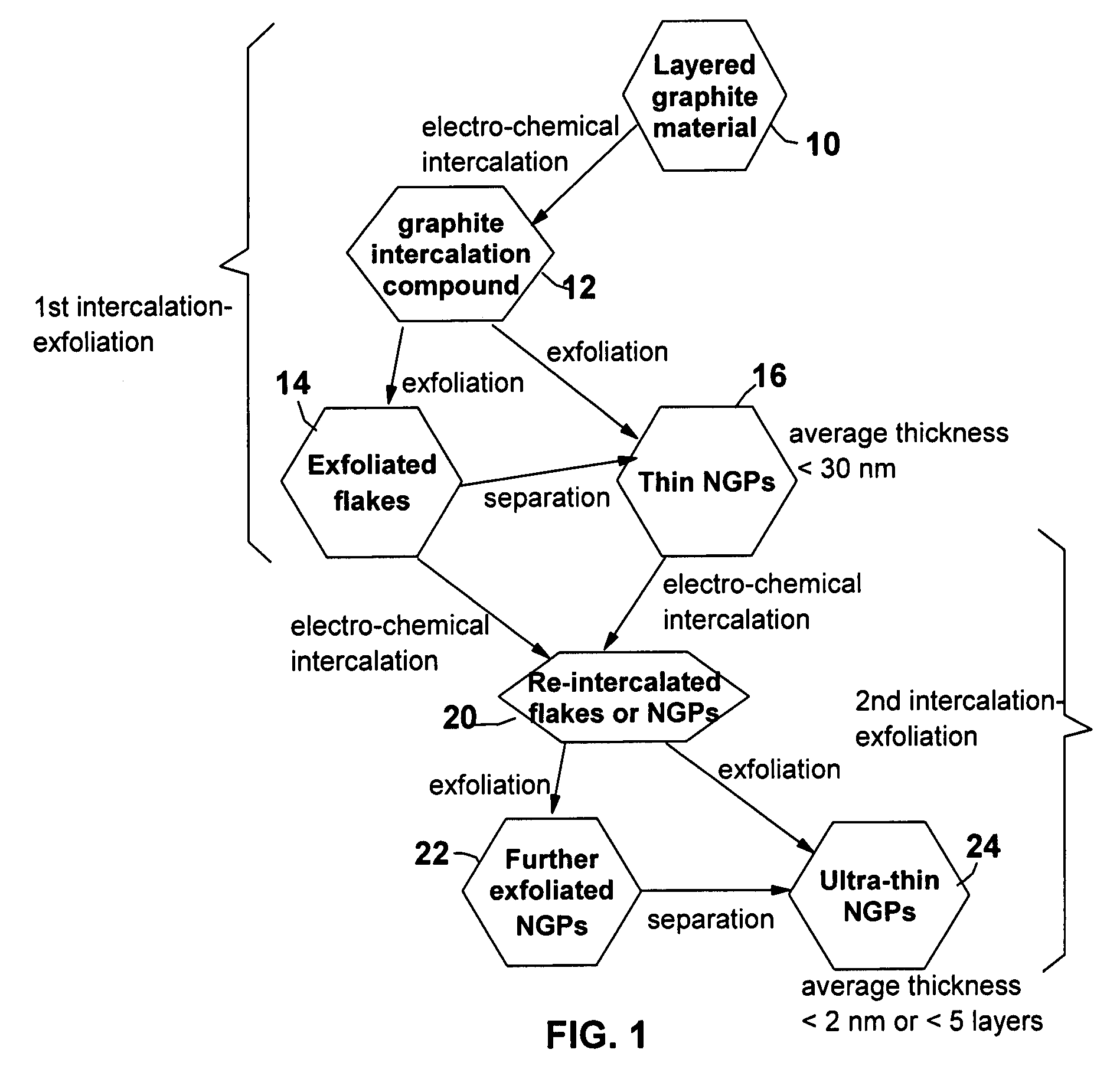

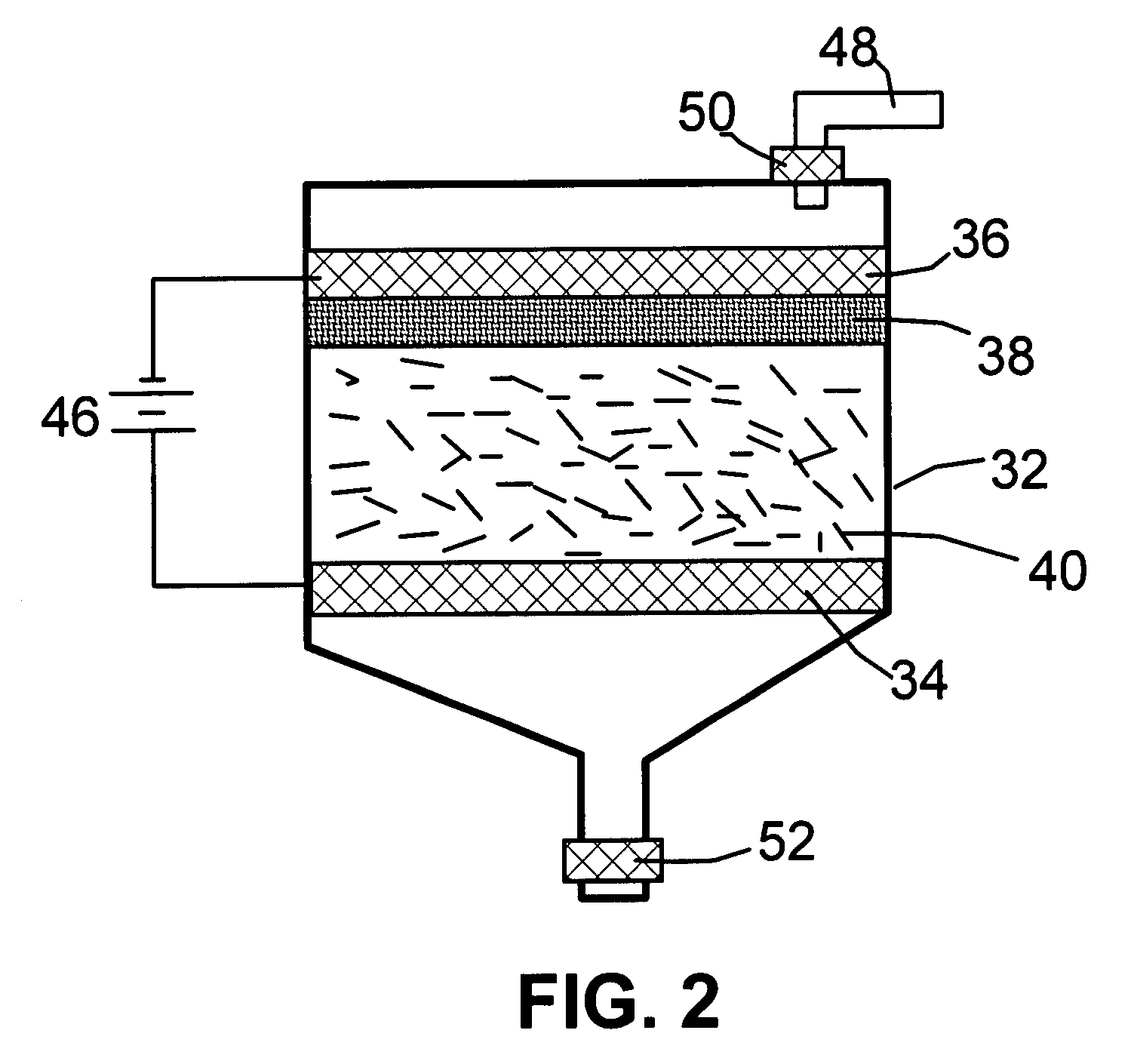

Electrochemical method of producing nano-scaled graphene platelets

A method of producing nano-scaled graphene platelets with an average thickness smaller than 30 nm from a layered graphite material. The method comprises (a) forming a carboxylic acid-intercalated graphite compound by an electrochemical reaction which uses a carboxylic acid as both an electrolyte and an intercalate source, the layered graphite material as an anode material, and a metal or graphite as a cathode material, and wherein a current is imposed upon the cathode and the anode at a current density for a duration of time sufficient for effecting the electrochemical reaction; (b) exposing the intercalated graphite compound to a thermal shock to produce exfoliated graphite; and (c) subjecting the exfoliated graphite to a mechanical shearing treatment to produce the nano-scaled graphene platelets. Preferred carboxylic acids are formic acid and acetic acid. The exfoliation step in the instant invention does not involve the evolution of undesirable species, such as NOx and SOx, which are common by-products of exfoliating conventional sulfuric or nitric acid-intercalated graphite compounds. The nano-scaled platelets are candidate reinforcement fillers for polymer nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:GLOBAL GRAPHENE GRP INC

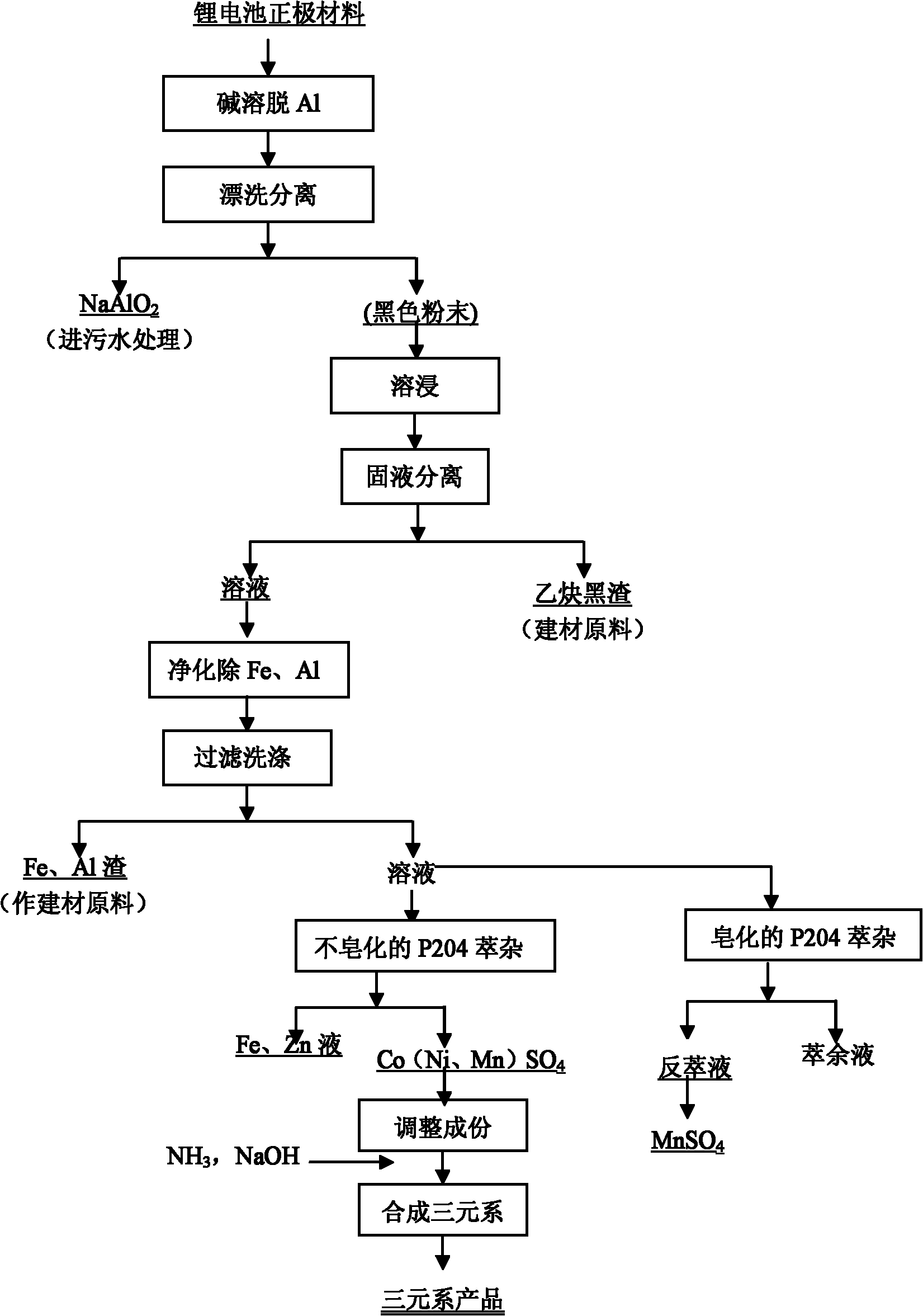

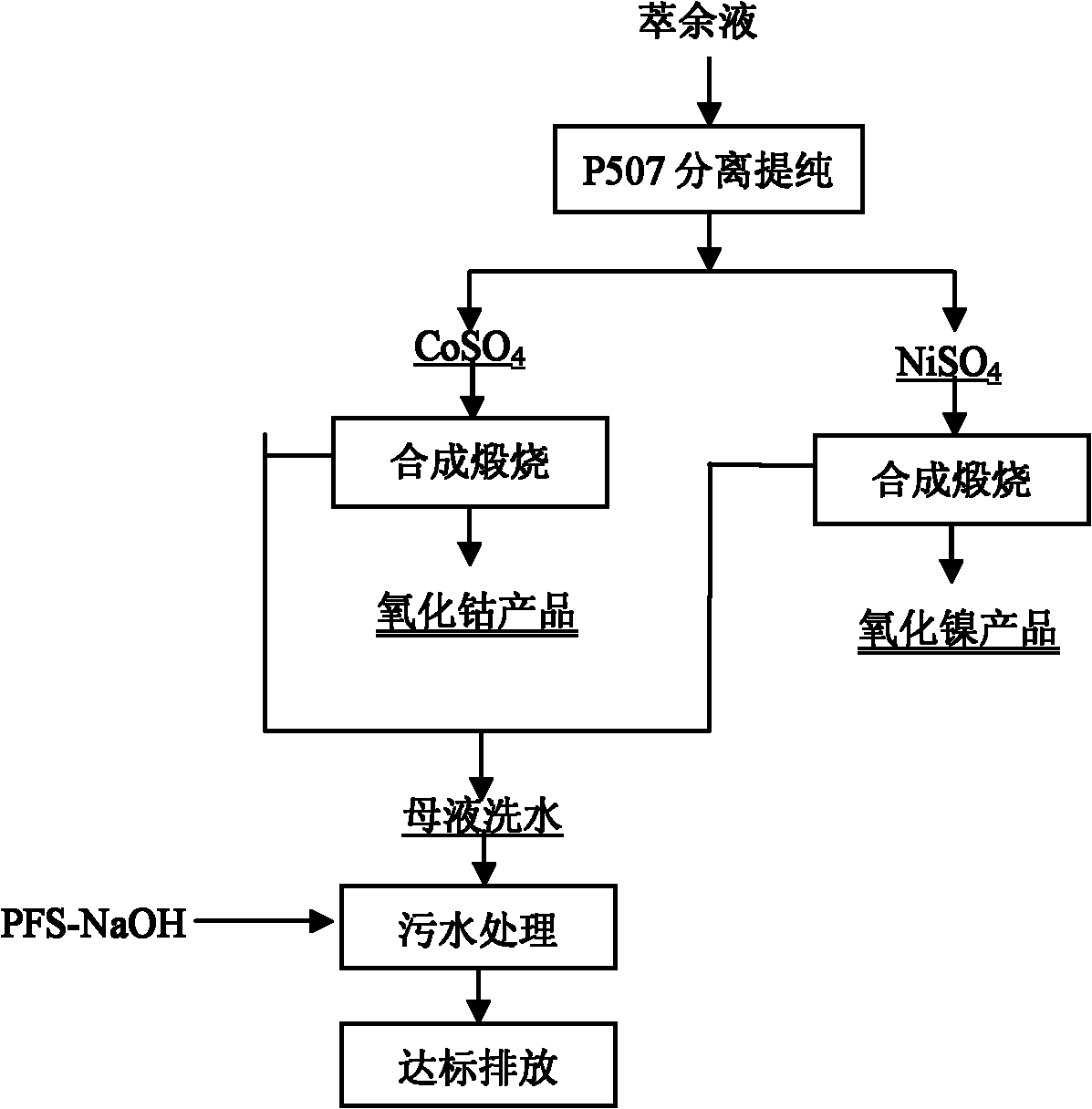

Method for recovering cobalt, nickel and manganese from waste lithium cells

ActiveCN101871048ANo pollution in the processReduce consumptionProcess efficiency improvementRecovery methodAlkaline earth metal

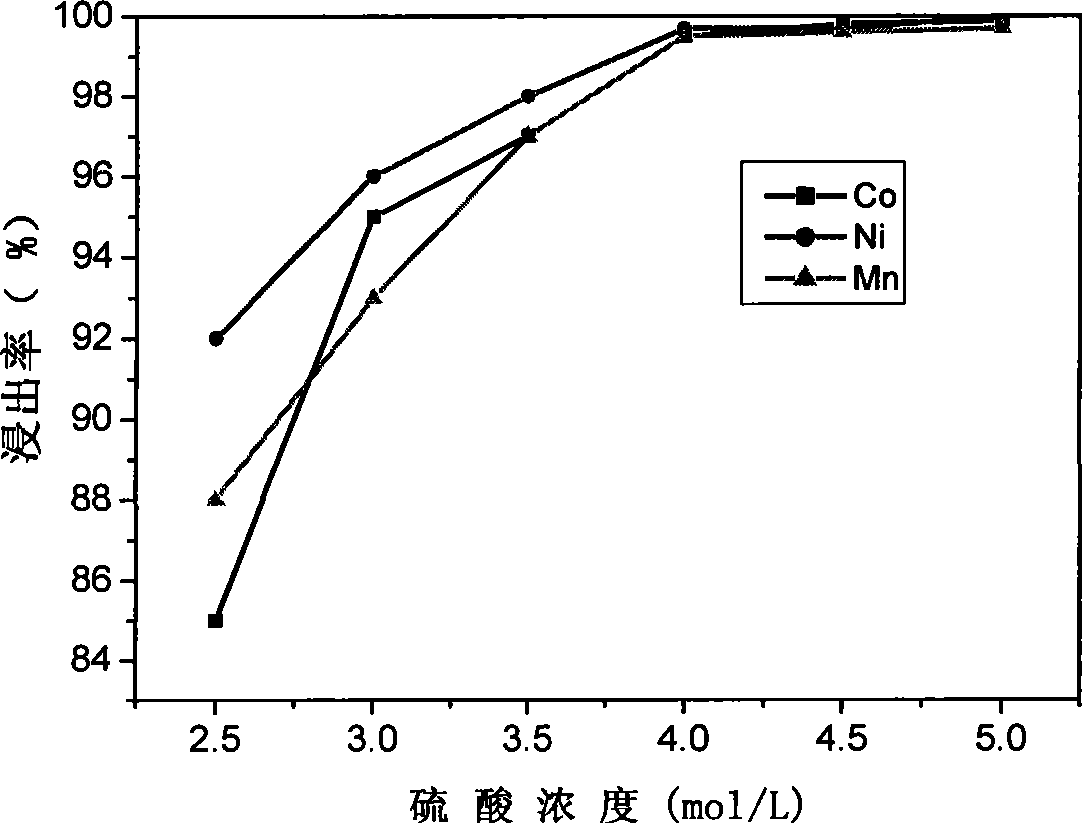

The invention discloses a method for recovering cobalt, nickel and manganese from waste lithium cells. Most of the conventional recovery methods can hardly guarantee the product quality. The technical scheme adopted by the invention is as follows: (1) the anode materials of waste lithium cells are immerged in low-concentration alkali solution, and because the anode materials do not react with the alkali solution, the anode materials shed from aluminum sheets to become black powder; (2) for the black powder, dilute sulfuric acid is first adopted for low-acid dissolution, Na2SO5 or Na2SO3 or Fe powder added with concentrated sulfuric acid is then adopted for reduction and dissolution, and finally, 3 to 6mol / L of sulfuric acid is adopted for high-acid dissolution; (3) solid-liquid separation is carried out on the substance obtained in step 2; (4) reagent is adopted for precipitating and deeply removing alkaline earth impurities. The method has the advantages of simple operation, low auxiliary material consumption, high product purity, high metal yield and no environment pollution, and is an ideal method for recovering cobalt, nickel and manganese from waste lithium cells.

Owner:ZHEJIANG HUAYOU COBALT +1

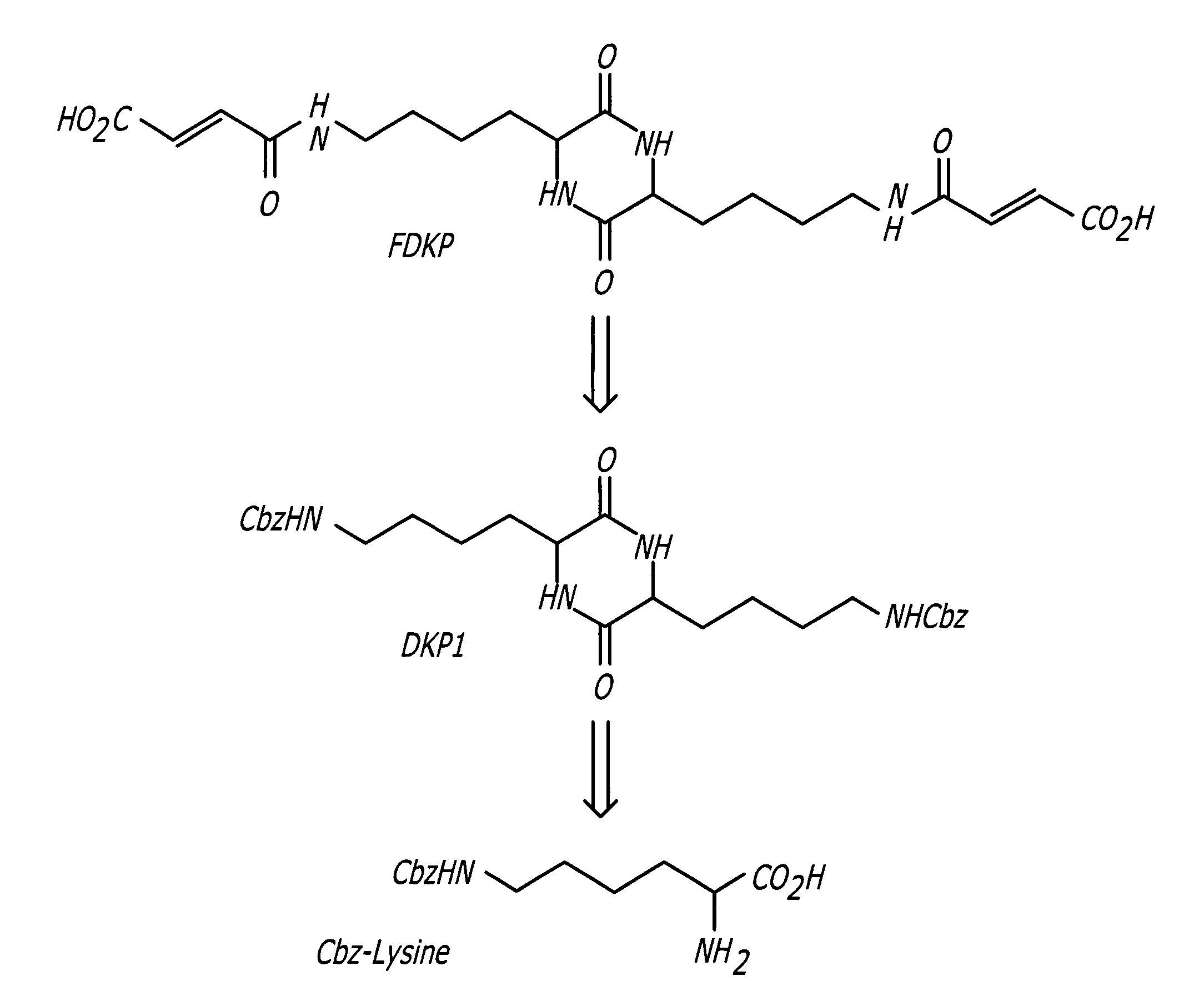

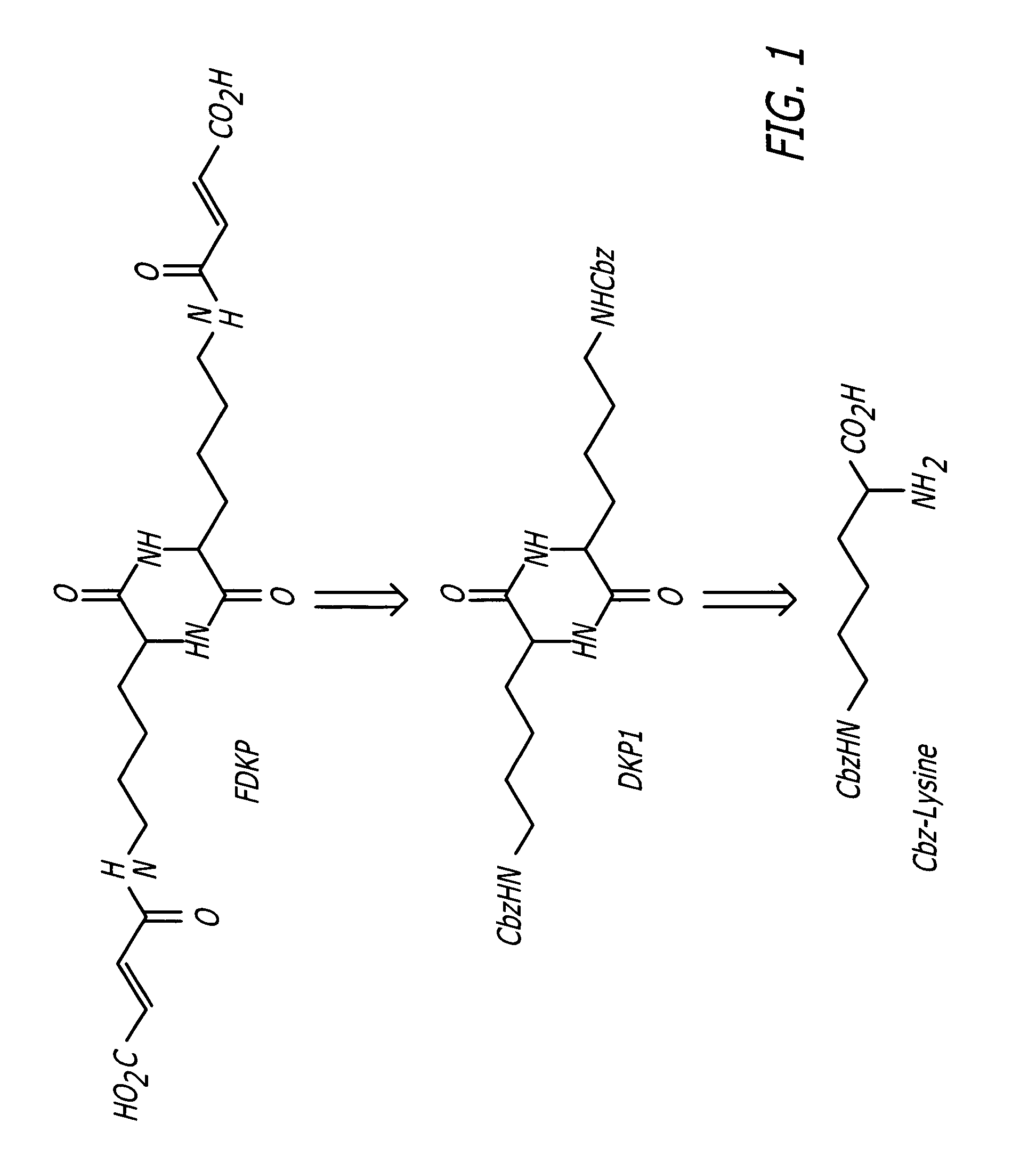

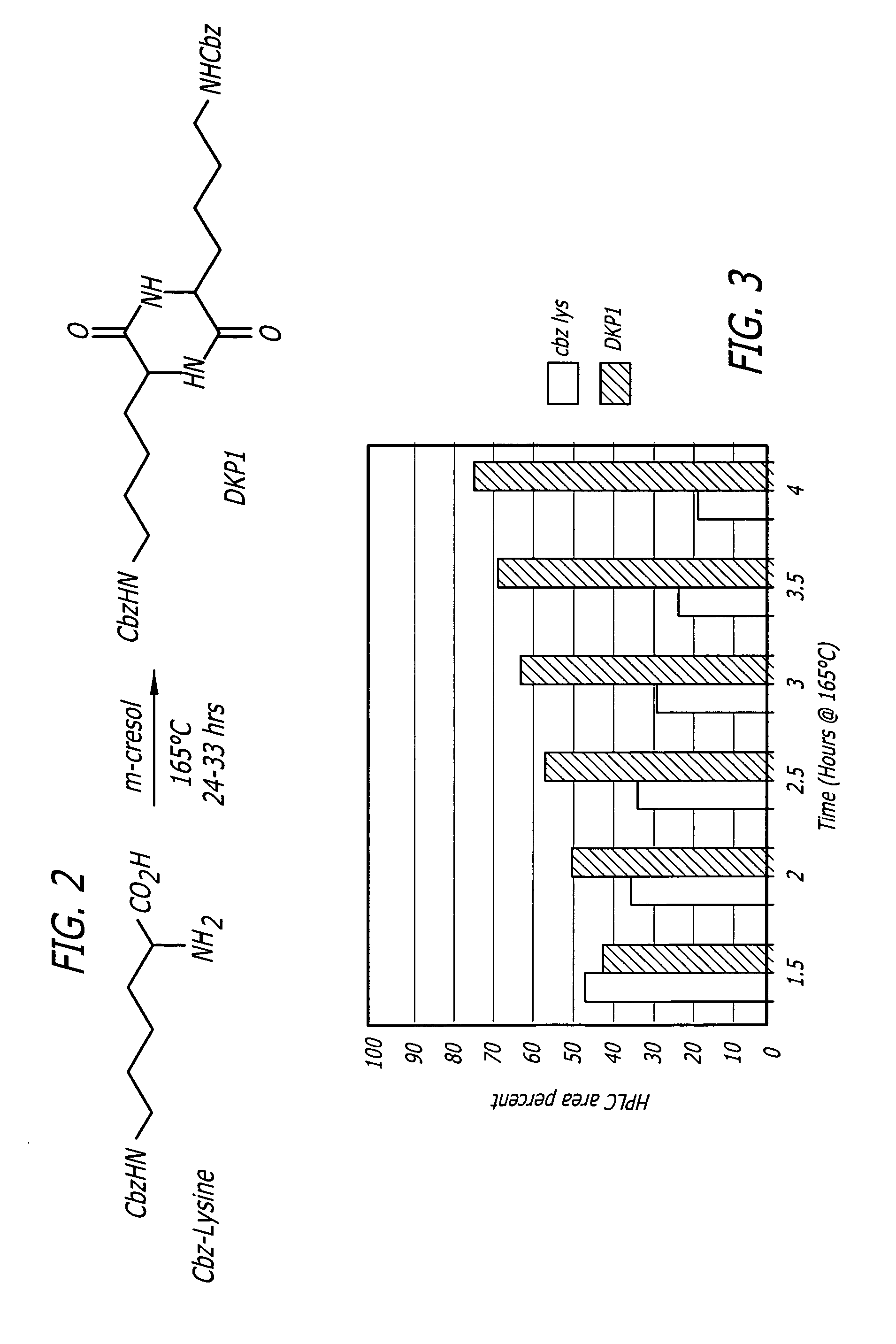

Catalysis of diketopiperazine synthesis

ActiveUS20060041133A1Fast reaction timeHigh yieldOrganic chemistryPhysical/chemical process catalystsPhosphoric acidDiketopiperazines

Provided is a method for the synthesis of N-protected bis-3,6-[4-aminobutyl]-2,5-diketopiperazine including the step of heating a solution of c-amino protected lysine in the presence of a catalyst selected from the group consisting of sulfuric acid, phosphoric acid, and phosphorus pentoxide.

Owner:MANNKIND CORP

Low-temperature smoke denitration SCR (silicon controlled rectifier) catalyst and preparation method

ActiveCN102114424ARich pore structureLarge specific surface areaDispersed particle separationCatalyst activation/preparationSilicon-controlled rectifierManganese oxide

The invention relates to a low-temperature smoke denitration SCR (silicon controlled rectifier) catalyst, which comprises a carrier, a manganese oxide, and composite oxide of one or more of Ce, Zr, Ti, Co, Fe and Cu, the mass content of manganese is 0.1-66 percent, and the total mass content of the Ce, Zr, Ti, Co, Fe or / and Cu is 0-50 percent; and glass fiber and / or kieselguhr is used as the carrier, wherein the glass fiber of the carrier is calcined for 2-4 hours at temperature of 400-600 DEG C, then placed in a nitric acid, sulfuric acid or hydrochloric acid solution with mass concentration of 5-40 percent for acidizing for 1-8 hours, washed by distilled water to be neutered, dried at temperature of 80-120 DEG C, and crushed to have the fineness of 20-325 meshes. The catalyst uses the glass fiber and the kieselguhr as the carriers, so that the dispersion effect of nanoparticles and specific surface area of the catalyst are increased, the high adsorptive capacity and strong heat resistance and corrosion resistance capacity are achieved, stronger toxic resistance capacity to sulfur dioxide and stream contained in the smoke is realized, the invention can be used for 10-200 DEG C of low temperature smoke denitration, and has strong water resisting and sulphur toxic resisting capacities.

Owner:GUODIAN SCI & TECH RES INST +1

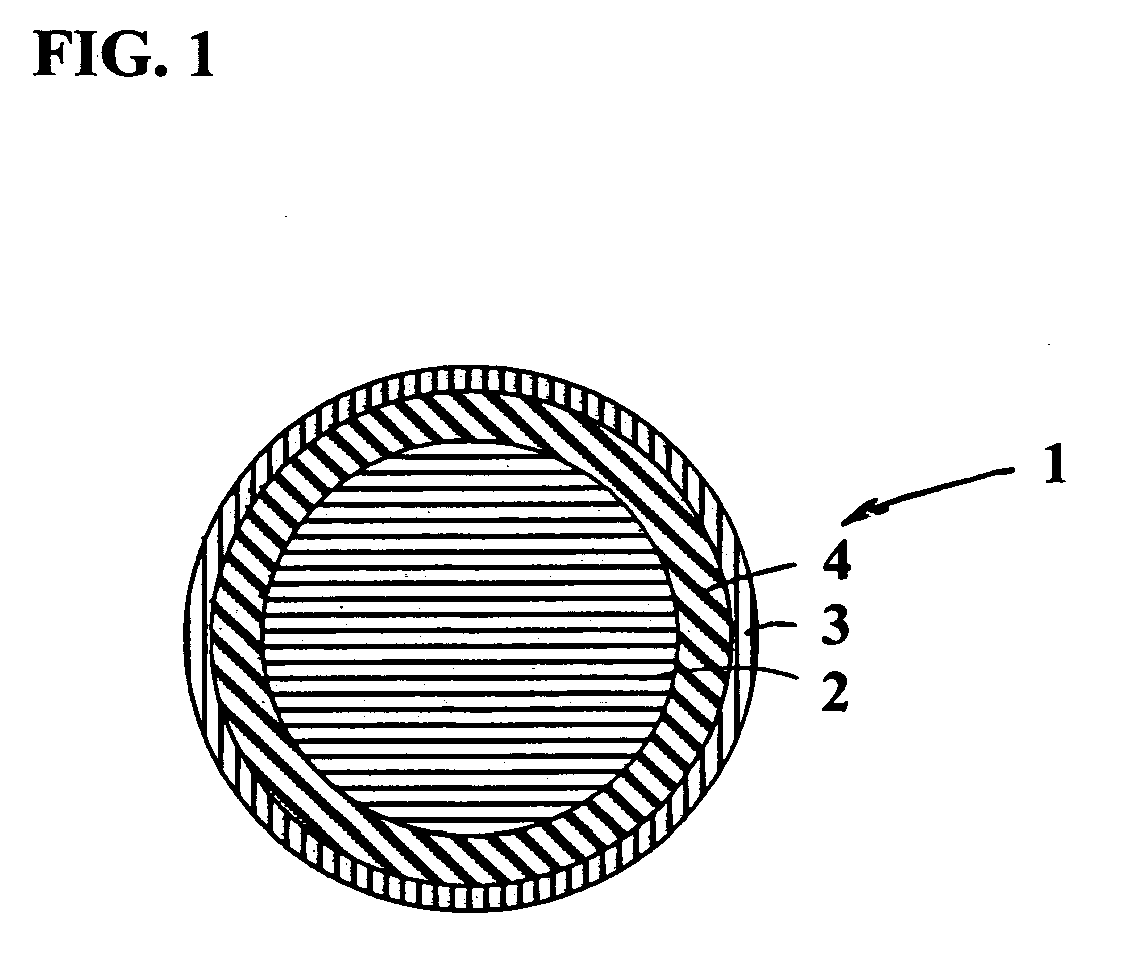

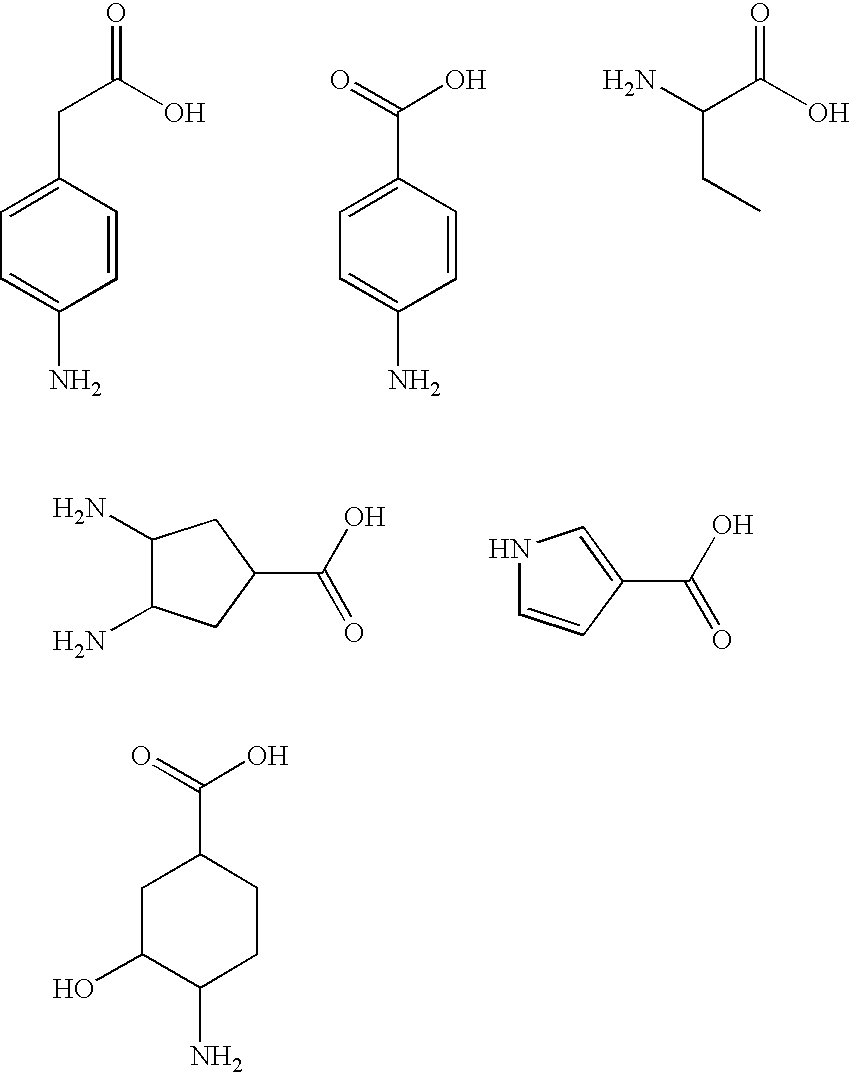

Composition for use in golf balls and sports equipment

The present invention relates to a novel blend composition suitable for use in sports equipment in general and in particular for use in golf ball manufacture. The composition is the reaction product of; A) a polymer of ethylene and / or one or more alpha olefins, and an acid, ester, or anhydride (“Component (A)”); and B) a compound comprising both an amine and a carboxylic acid in the same molecule which may be present in either a neutral or ionic or zwitterionic form (“Component (B)”); and C) a basic metal ion salt, capable of neutralizing the acid groups of Component (A) and / or Component (B). The metal ions including Li+, Na+, K+, Zn+, Co2+, Ca2+, Ni2+, Cu2+, Pb2+, and Mg2+, with Li+, Na+, Zn2+, Ca2+, and Mg2+ being preferred, and their salts include those of, for example, formic acid, acetic acid, nitric acid, sulfuric acid, carbonic acid, bicarbonic acid, as well as the metal oxides, hydroxides, and alkoxides (“Component (C)”). The present invention is also embodied in a blend composition including the reaction product of one or more ionomers and Component (B) which is a compound having a general formula (R2N)m—R′—(X(O)nORy)m, where R is either hydrogen, one or more C1-C20 aliphatic systems, one or more cycloaliphatic systems, one or more aromatic systems, or a combination of these. Also R′ is a bridging group comprising one or more unsubstituted C1-C20 straight chain or branched aliphatic or alicyclic groups, or one or more substituted straight chain or branched aliphatic or alicyclic groups, or one or more aromatic groups, one or more oligomers each containing up to 12 repeating units, and when X is C or S or P, m is 1-3. Also when X=C, n=1 and y=1, and when X=S, n=2 and y=1, and when X=P, n=2 and y=2. The present invention also resides in a golf ball including a core, an outer cover layer; and from 0 to 5 intermediate layers, wherein one or more of said core, outer cover, and / or intermediate layers, if present, includes the aforementioned blend compositions. Finally, the present invention is also embodied in sports equipment items comprising the aforementioned blend compositions.

Owner:TAYLOR MADE GOLF

Complex foam extinguishing agent for coal mine

InactiveCN102614615AHigh bonding strengthReduce the drainage rateFire extinguisherSodium bicarbonateMass ratio

The invention discloses a complex foam extinguishing agent for a coal mine and belongs to the technical field of fire prevention and extinguishing. The extinguishing agent is prepared from the following raw materials: main materials are 40 to 60 percent aqueous solution of ammonium bicarbonate or sodium bicarbonate and concentrated sulfuric acid in a solute mass ratio of 2:1-3:1, and auxiliary materials are a stabilizer and a foamer, wherein the auxiliary materials are 0.1 to 2 percent of the total weight of the main materials. Through a test, the extinguishing agent has the foaming coefficient of 20-200 and the foam stabilizing time of more than or equal to 2.5 hours. According to the foam extinguishing agent, the foam of inert gas carbon dioxide is applied to fire prevention and extinguishing of the coal mine, and the foam is diffused in a fire area and fills a fire space, so that the oxygen concentration in the fire area is rapidly reduced, fire is extinguished due to oxygen deficiency in the fire area, temperature is reduced and a fire extinguishing effect is good. The technology also can be applied to coal bed transformation, CO2 foam is easily absorbed by coal to displace partial methane, the recovery ratio of coal seam gas is improved, and CO2 is acid to reduce the generation of secondary precipitates, so that a gas drainage effect is improved. The complex foam extinguishing agent is simple and feasible, and low in cost.

Owner:抚顺正工矿业科技发展有限公司

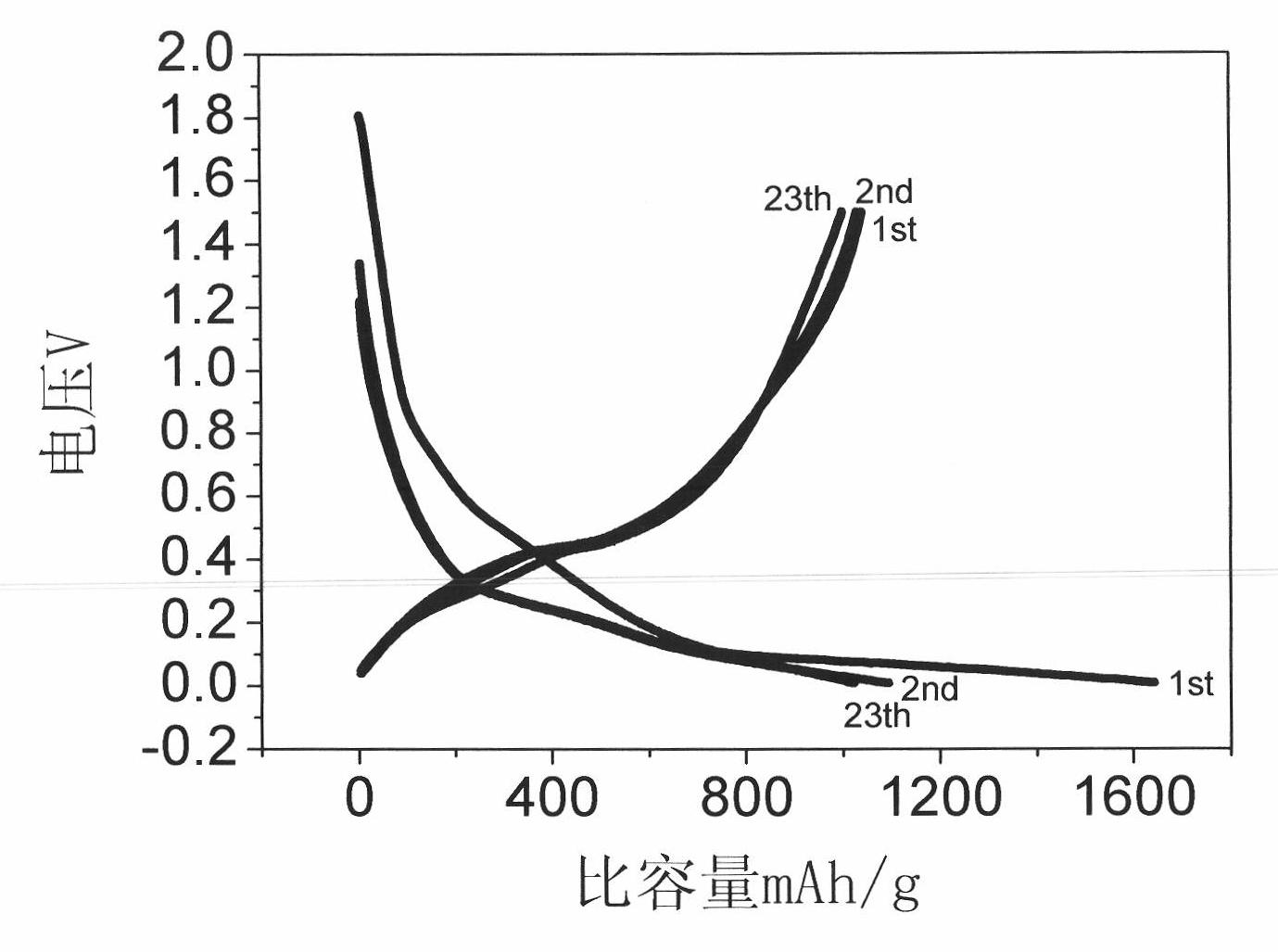

Graphene/silicon lithium ion battery cathode material and preparation method thereof

InactiveCN101924211AHigh specific capacityImprove cycle stabilityCell electrodesComposite filmNew energy

The invention discloses a grapheme / silicon composite material for a lithium ion battery cathode material and a preparation method thereof, belonging to the fields of electrochemistry and new energy materials. The method comprises the following steps of: using graphite as a raw material; oxidizing the graphite into oxidized graphite by adopting oxidants of concentrated sulfuric acid and potassium permanganate; then, ultrasonically stripping the oxidized graphite to prepare oxidized graphene; mixing oxidized graphene in different proportions with nano silicon powder; ultrasonically dispersing, filtering or directly drying into a cake / film; and roasting under a reduction atmosphere to prepare self-support graphene / silicon composite film materials in different proportions. Proved by electrochemistry tests, the graphene / silicon composite film material prepared by the method has higher specific capacity and cycle stability, simple preparation method and easy mass production and consequently is an ideal high-energy lithium ion battery cathode material.

Owner:UNIV OF SCI & TECH BEIJING +1

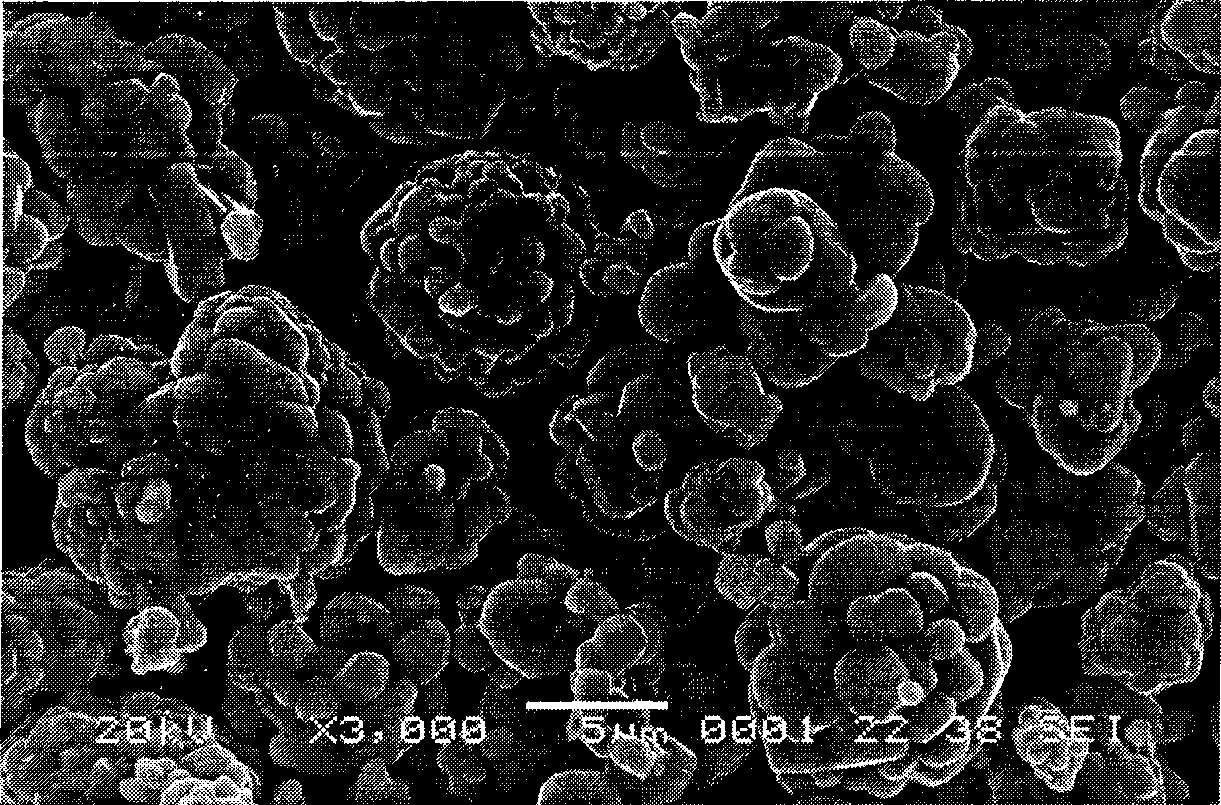

Recycling method for valuable metal from waste nickel-cobalt-manganese lithium ion battery

InactiveCN107653378AReduce lossesLess investmentWaste accumulators reclaimingProcess efficiency improvementSlagManganese

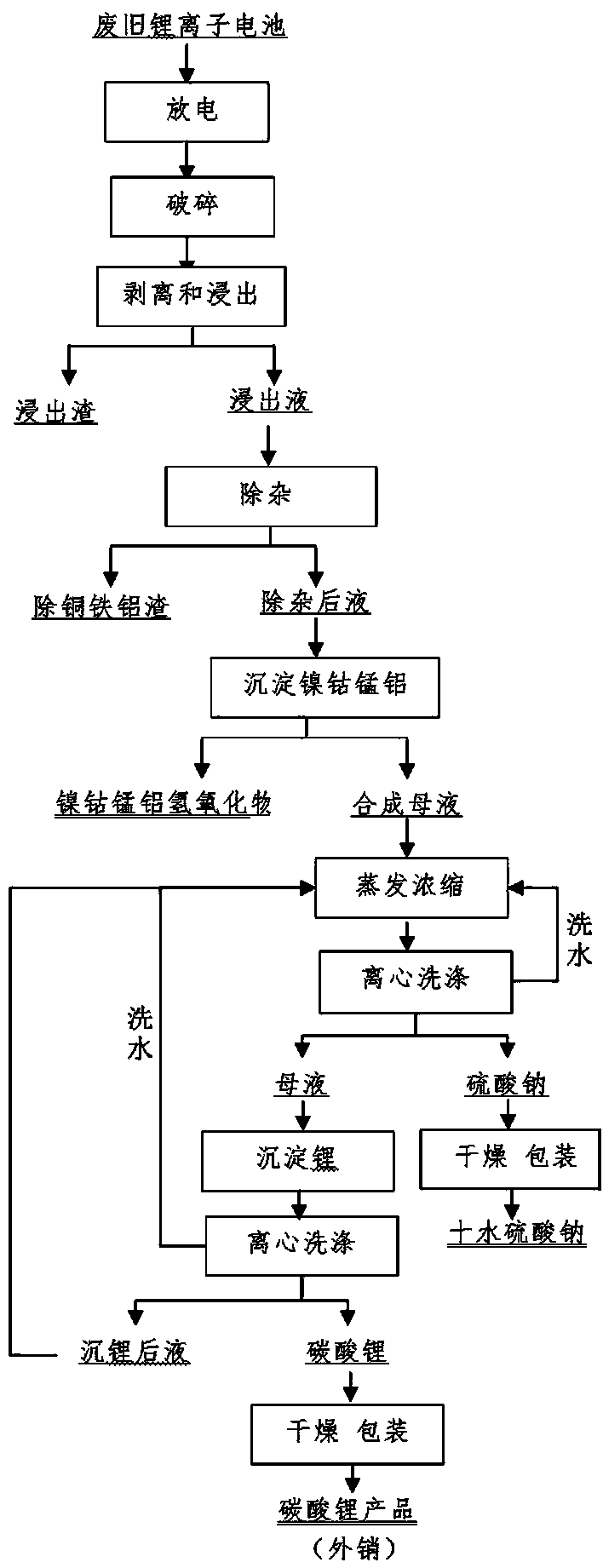

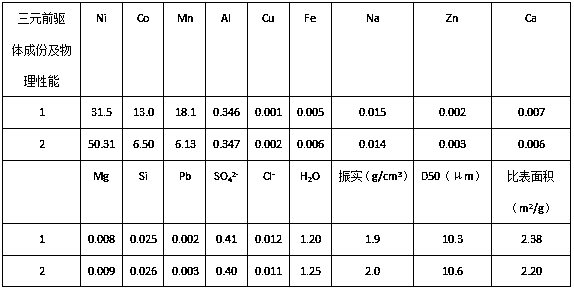

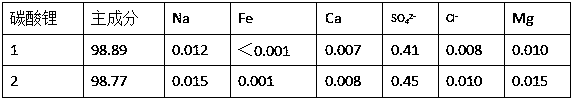

The invention relates to a method for recycling valuable metal from a waste nickel-cobalt-manganese lithium ion battery. The method comprises the following steps of: dismounting, discharging and crushing the battery, soaking crushed waste nickel-cobalt-manganese lithium ions into sulfuric acid with certain concentration, adding a reducing agent to strip positive and negative pole pieces, and leaching valuable metals of nickel, cobalt, manganese and lithium; and replacing leach liquor with iron powder to remove copper, carrying out hydrolyzing to remove iron and aluminum, and dosing an impurity-removed solution to synthesize an aluminum coated nickel, cobalt and manganese ternary positive electrode material precursor, evaporating and concentrating the synthesized solution, adding carbonateor introducing carbon dioxide to recycle lithium. According to the method disclosed by the invention, stripping and leaching are synchronously completed, chemical precipitation is performed to removecopper, iron and aluminum, slag amount is small, slag filter performances are good, and the impurity-removed solution is used for synthesizing the aluminum coated nickel, cobalt and manganese ternaryprecursor, so that the recovery rate of valuable metal is increased; and the recovery rate for nickel, cobalt and manganese is 96% or higher in the whole process, the total recovery rate of lithium is90% or higher, the technological process is short, operation is simple, equipment is less, and the cost is low.

Owner:JINCHUAN GROUP LIMITED +1

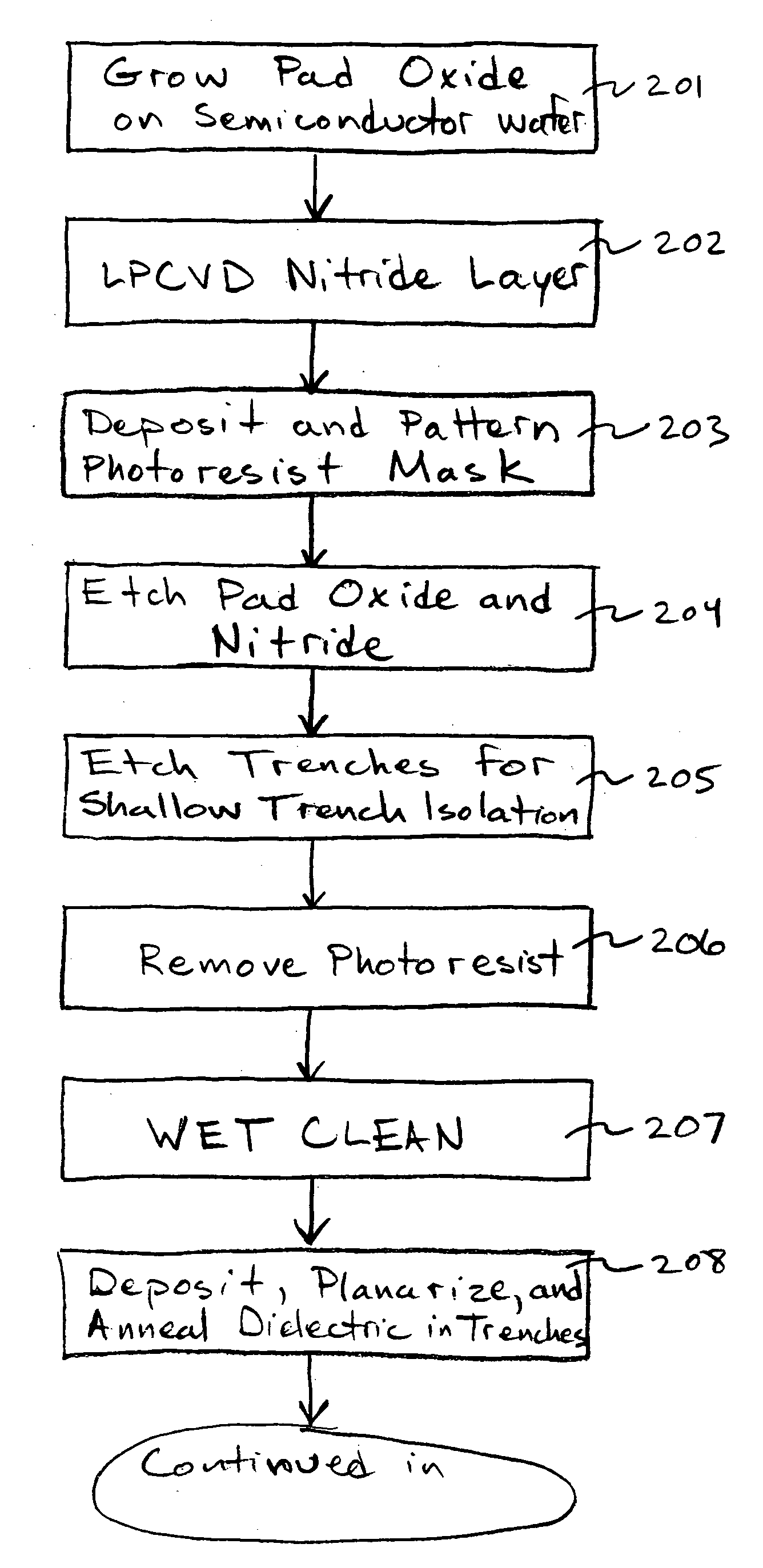

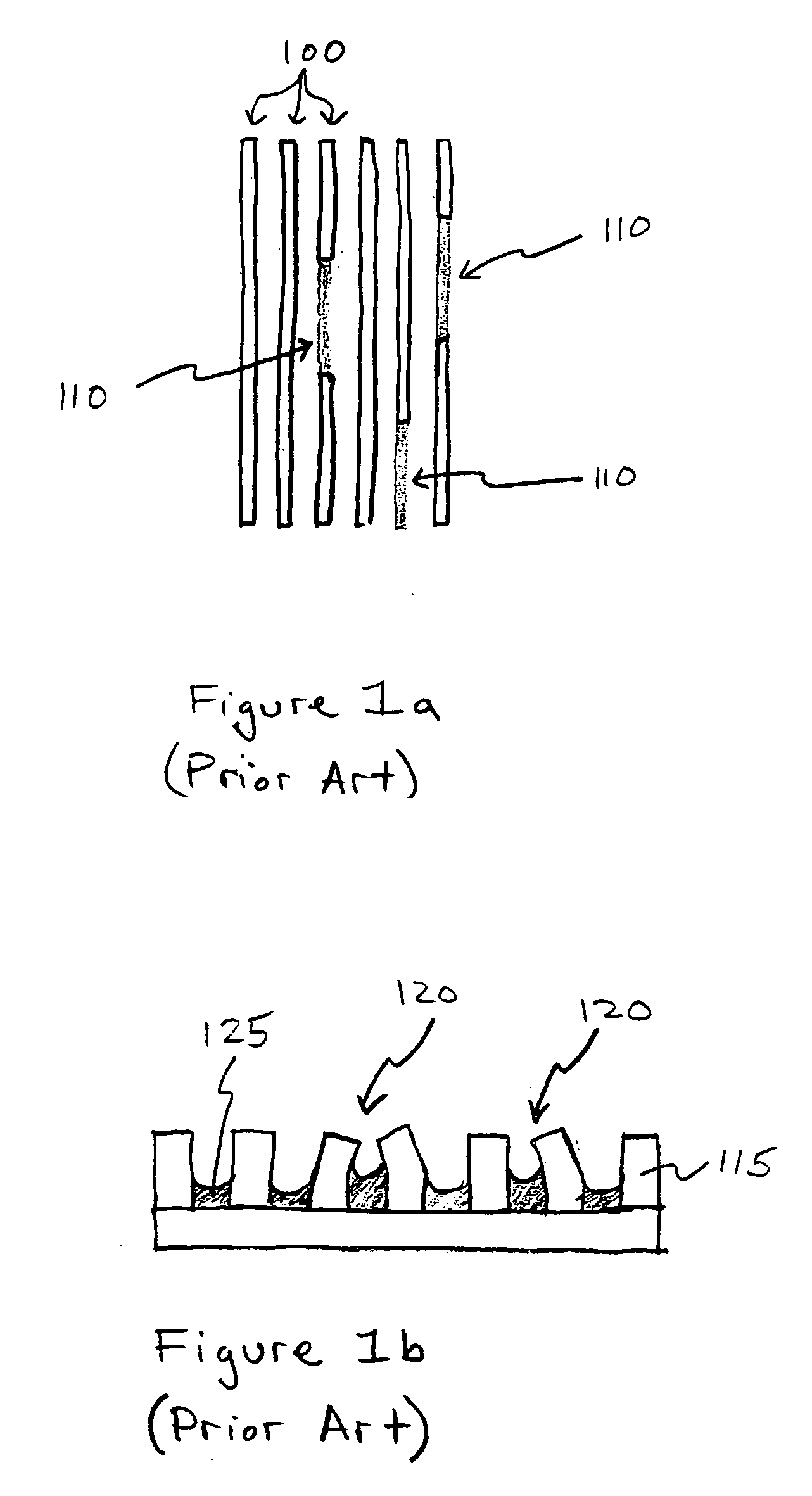

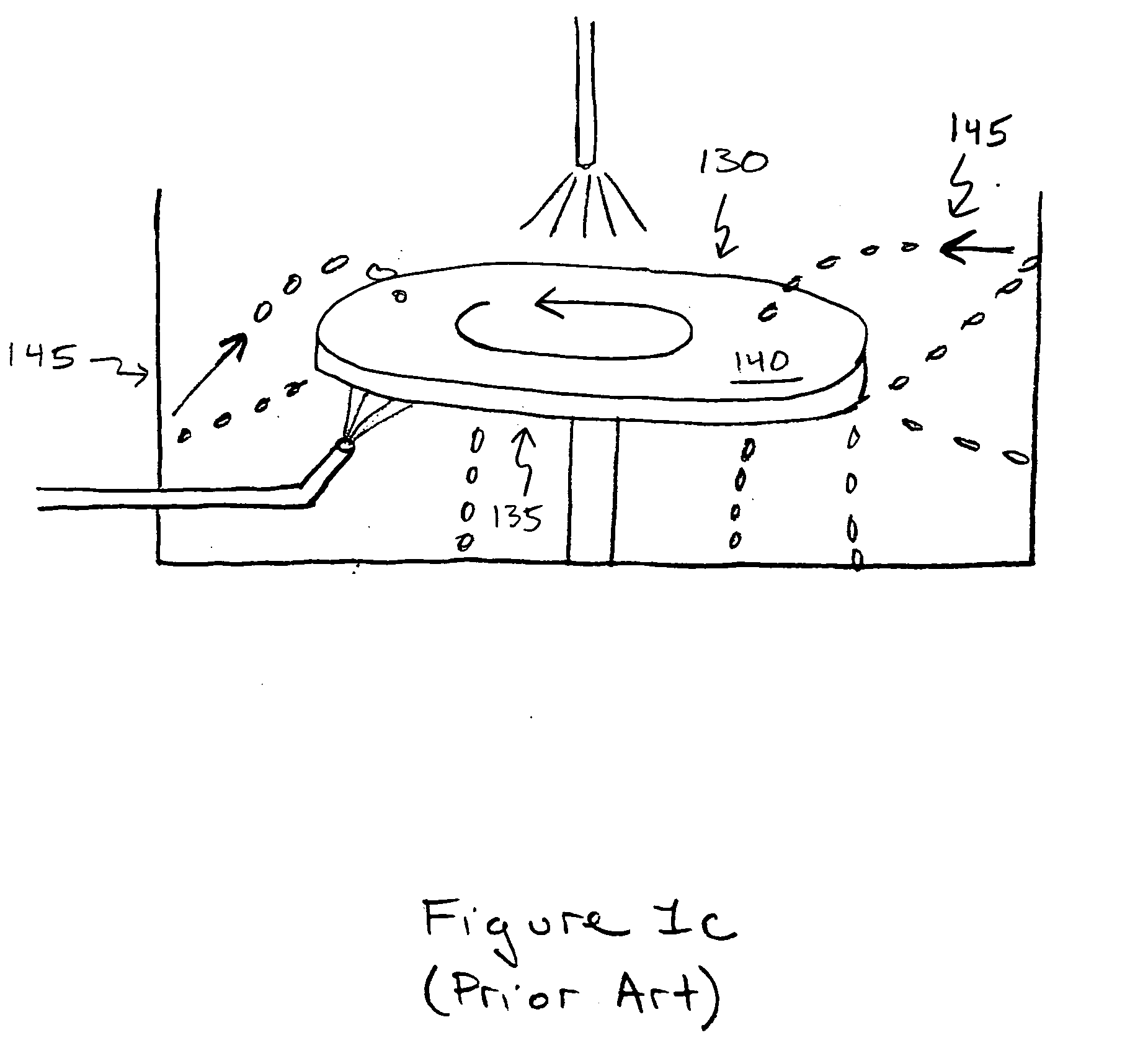

Cleaning submicron structures on a semiconductor wafer surface

InactiveUS20060042651A1Electrostatic cleaningSemiconductor/solid-state device manufacturingAcoustic energyPhysical chemistry

Cleaning solutions and cleaning methods targeted to particular substrates and structures in semiconductor fabrication are described. A method of cleaning fragile structures having a dimension less than 0.15 um with a cleaning solution formed of a solvent having a surface tension less than water while applying acoustic energy to the substrate on which the structures are formed is described. Also, a method of cleaning copper with several different cleaning solutions, and in particular an aqueous sulfuric acid and HF cleaning solution, is described. Also, methods of cleaning both sides of a substrate at the same time with different cleaning solutions applied to the top and the bottom are described.

Owner:APPLIED MATERIALS INC

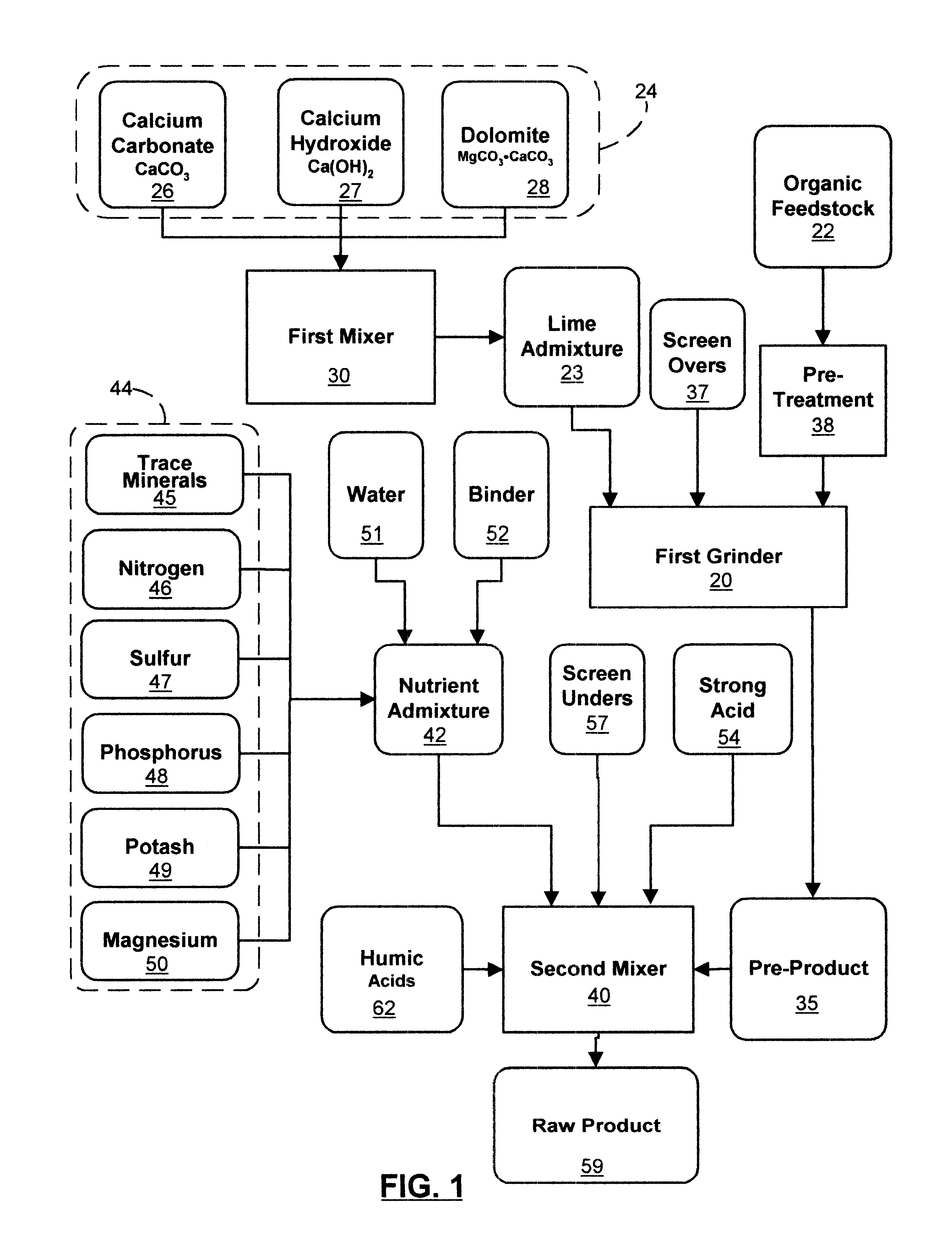

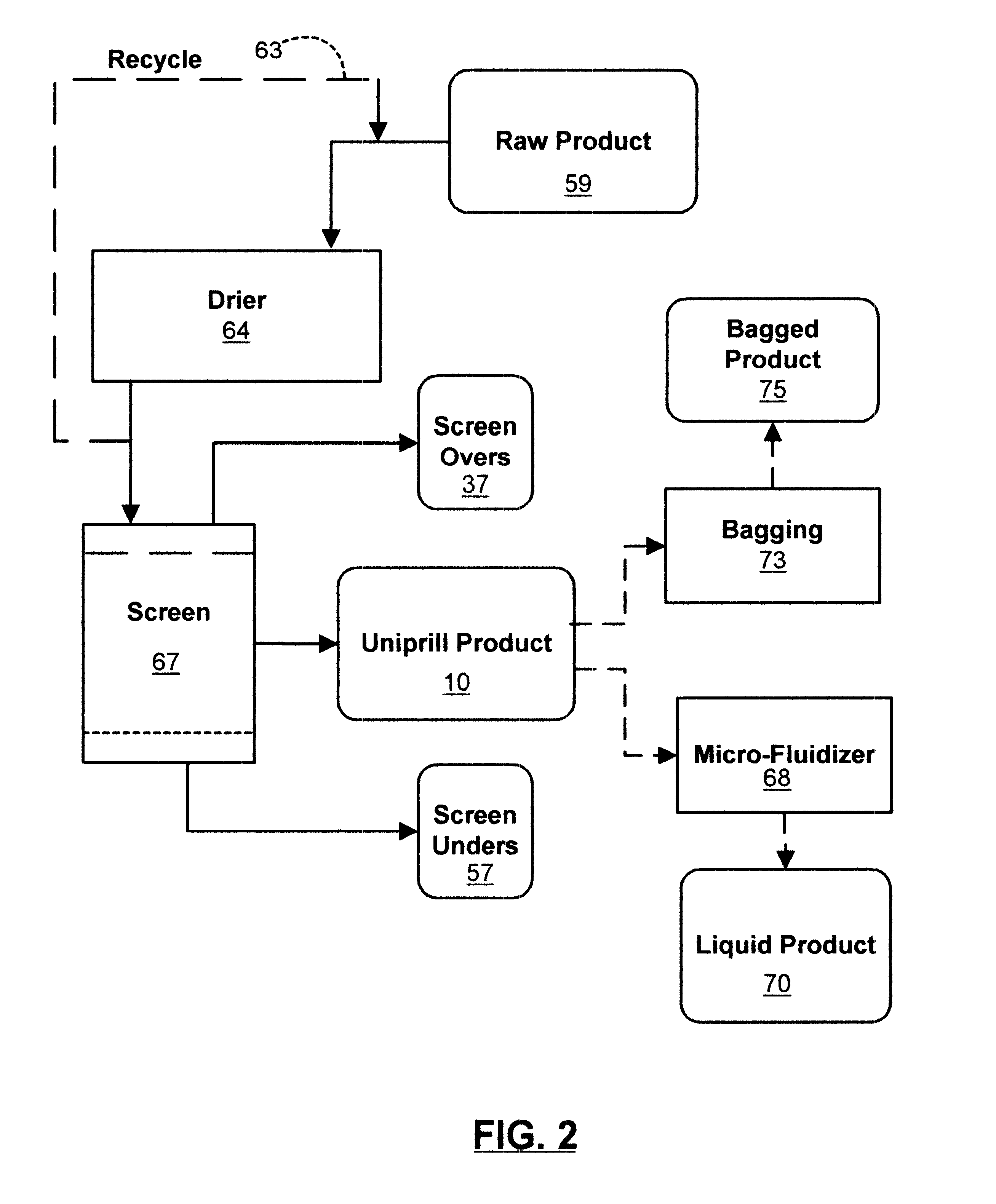

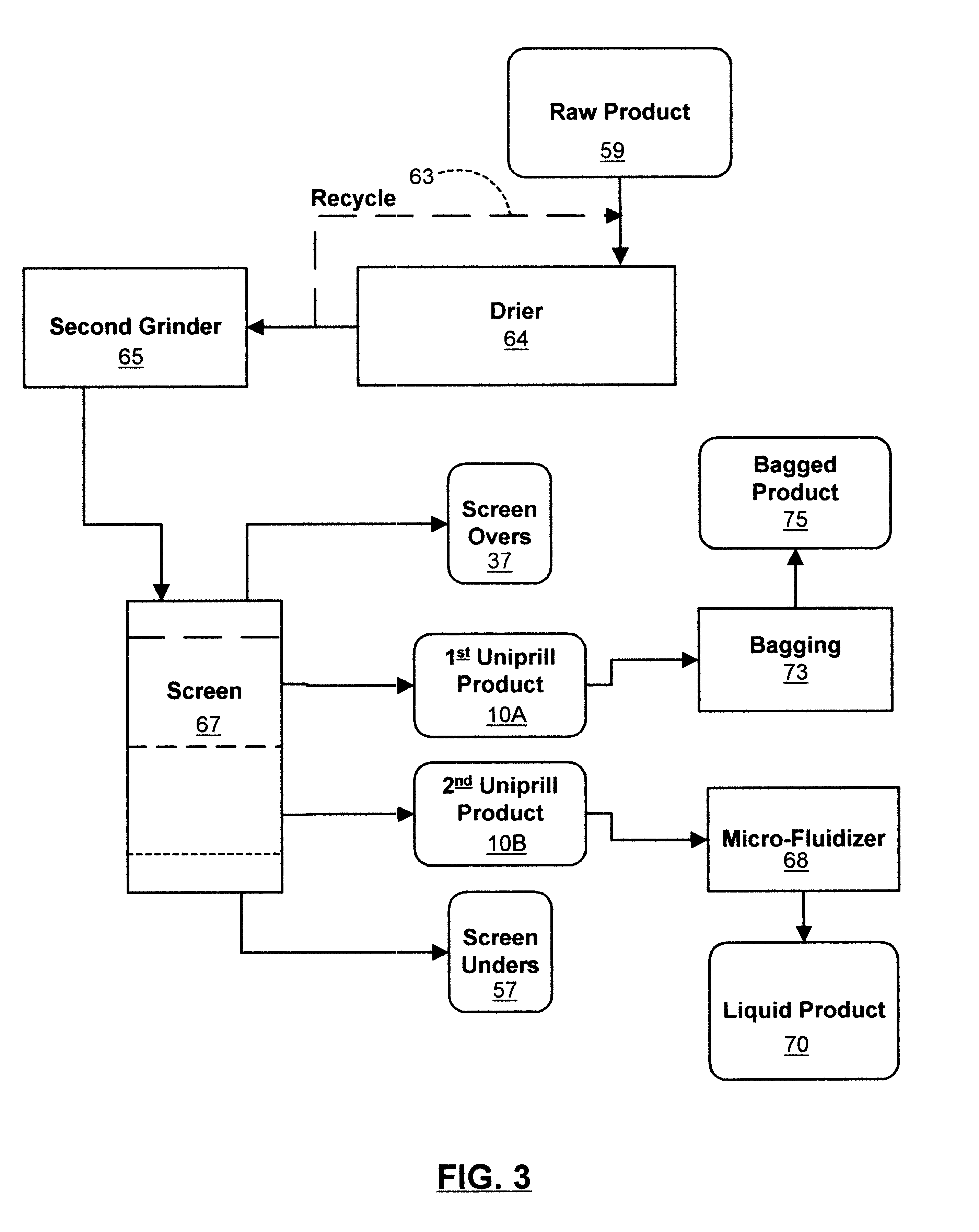

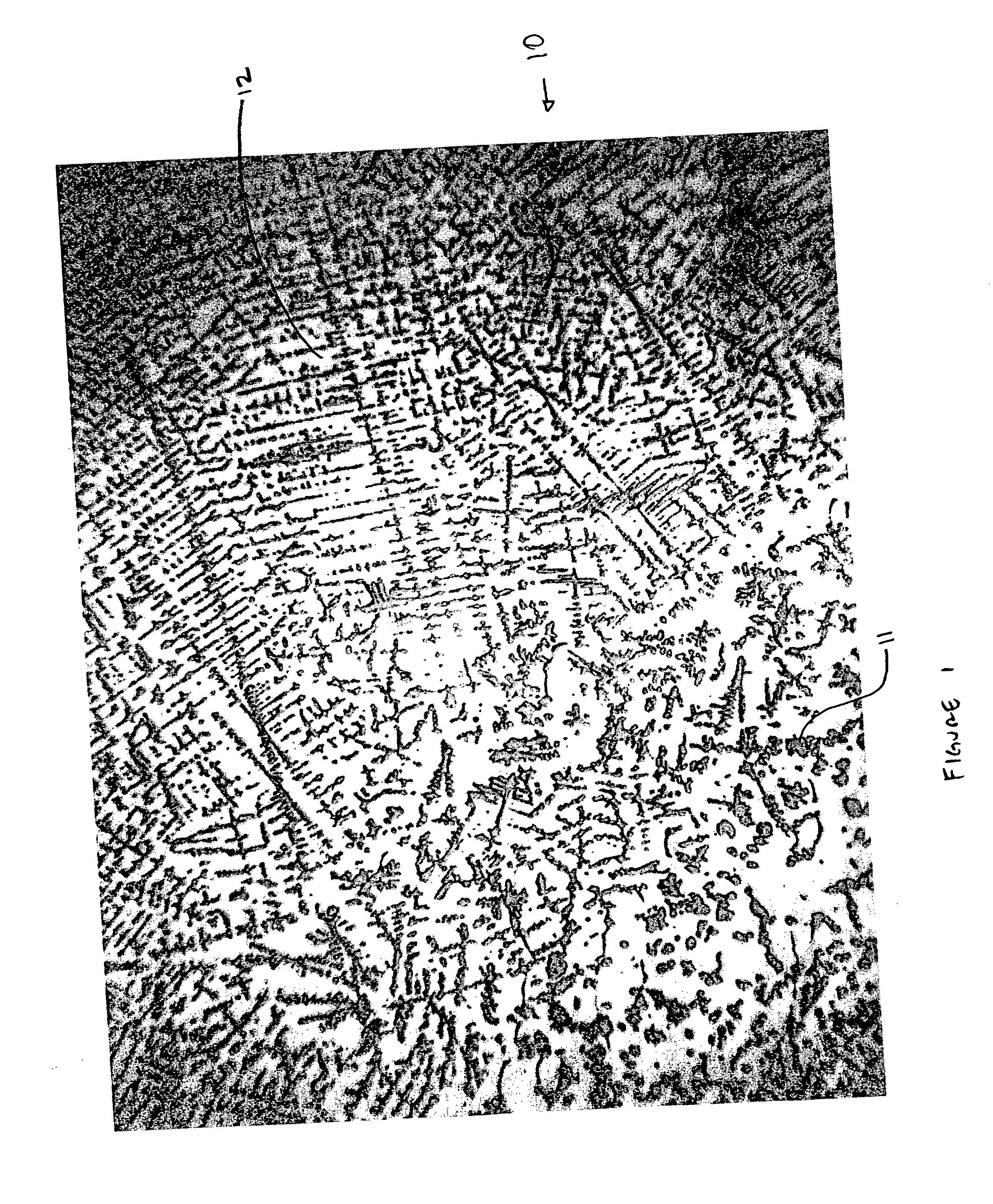

Organic material based uniprill fertilizer

InactiveUS6461399B1Reduce moisture contentIncrease speedCalcareous fertilisersBiocideOrganic basePhosphoric acid

An organic-based uniprill fertilizer is provided. To produce the fertilizer, organic matter is sequentially pre-treated by first mixing it in a first grinder with a lime admixture, then adding a slurry of reagents and binders, followed by a mixture of acids. The acids can include sulfuric and phosphoric acids, in addition to nitric acid and various organic acids such as citric and fulvic acid, depending on the end requirements of the fertilizer product. Following the mixing of the pre-product with the mixture of acids and reagents, the resultant raw product is preferably processed through a second grinder. This grinding further dries, mixes and granulates the raw product. The particle size of the completed fertilizer is reduced into a flowable, user safe uniprill product that can be further ground to reduce its moisture. Further drying may be necessary for bag or bulk product, or it can be liquified by high speed blending or micro-fluidized for sprinkler or drip applications. The uniprill fertilizer comprises small, preferably microscopic particles that are homogenous in nature, in that any single particle is substantially identical in composition to all other particles of the fertilizer. Additionally, each uniprill particle contains substantially all sixteen nutriments and minerals required for the growth of healthy plants.

Owner:GREEN TRIANGLE

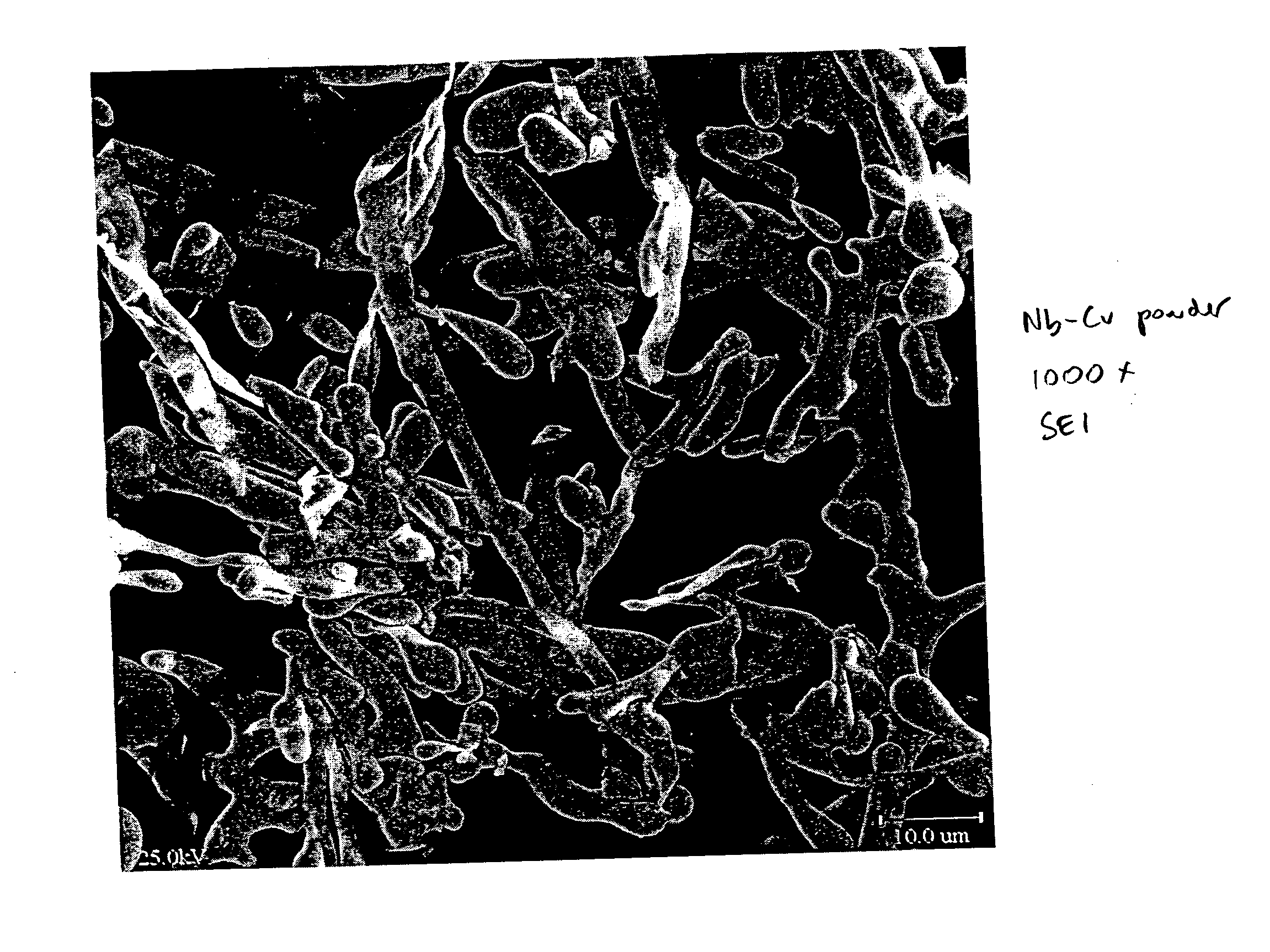

Method for producing metal fibers

InactiveUS20050000321A1Transportation and packagingMetal-working apparatusO-Phosphoric AcidMetal fibers

A method of producing metal fibers including melting a mixture of at least a fiber metal and a matrix metal, cooling the mixture to form a bulk matrix comprising at least a fiber phase and a matrix phase and removing at least a substantial portion of the matrix phase from the fiber phase. Additionally, the method may include deforming the bulk matrix. In certain embodiments, the fiber metal may be at least one of niobium, a niobium alloy, tantalum and a tantalum alloy and the matrix metal may be at least one of copper and a copper alloy. The substantial portion of the matrix phase may be removed, in certain embodiments, by dissolving of the matrix phase in a suitable mineral acid, such as, but not limited to, nitric acid, sulfuric acid, hydrochloric acid and phosphoric acid.

Owner:ATI PROPERTIES

Method for synthesizing polyoxymethylene dimethyl ether

The invention relates to a method for synthesizing polyoxymethylene dimethyl ether. The invention mainly solves the following problems of the prior art that: in the process of synthesizing polyoxymethylene dimethyl ether, catalyst separation is difficult, the material conversion rate is low, and product selectivity is poor. The method adopts methanol and trioxymethylene as materials, the reactiontemperature is 70 DEG C to 200 DEG C, the reaction pressure is 0.5MPa to 6MPa, the materials react with super solid acidic catalyst by way of contact, so that the polyoxymethylene dimethyl ether CH3O(CH2O)nCH3 is produced, wherein the used catalyst is selected from solid superacids. By weight part, the polyoxymethylene dimethyl ethe comprises the following components: (a) 20 to 70 parts of acid selected from sulfuric acid, hydrochloric acid or peroxosulfuric acid or at least one of salt thereof; (b) 30 to 80 parts of carrier selected from at least one of ZrO2, TiO2, SiO2, Fe2O3, SnO2, WO3 andAl203. The method effectively solves the problems, and can be used in the industrial production of polyoxymethylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

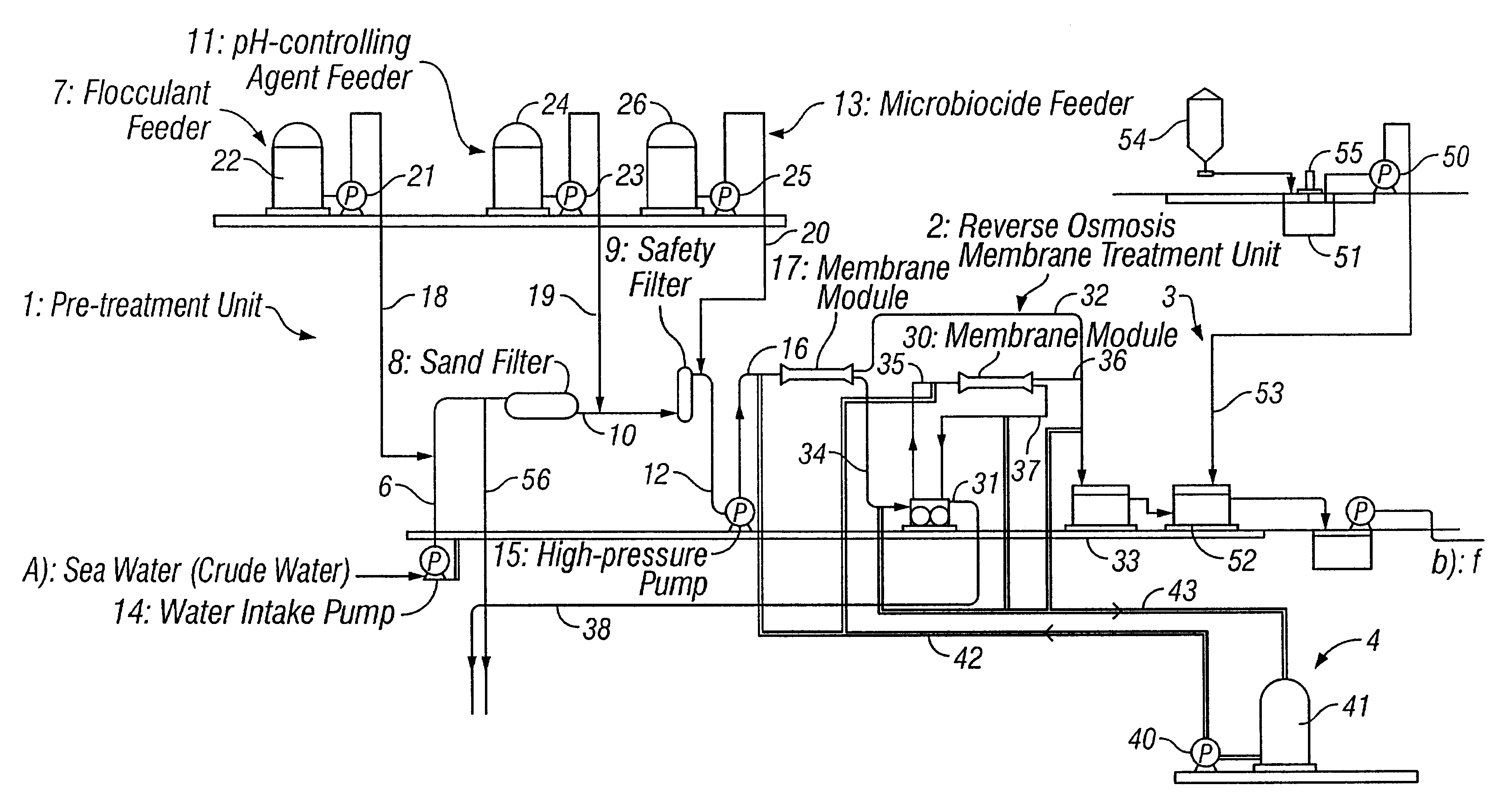

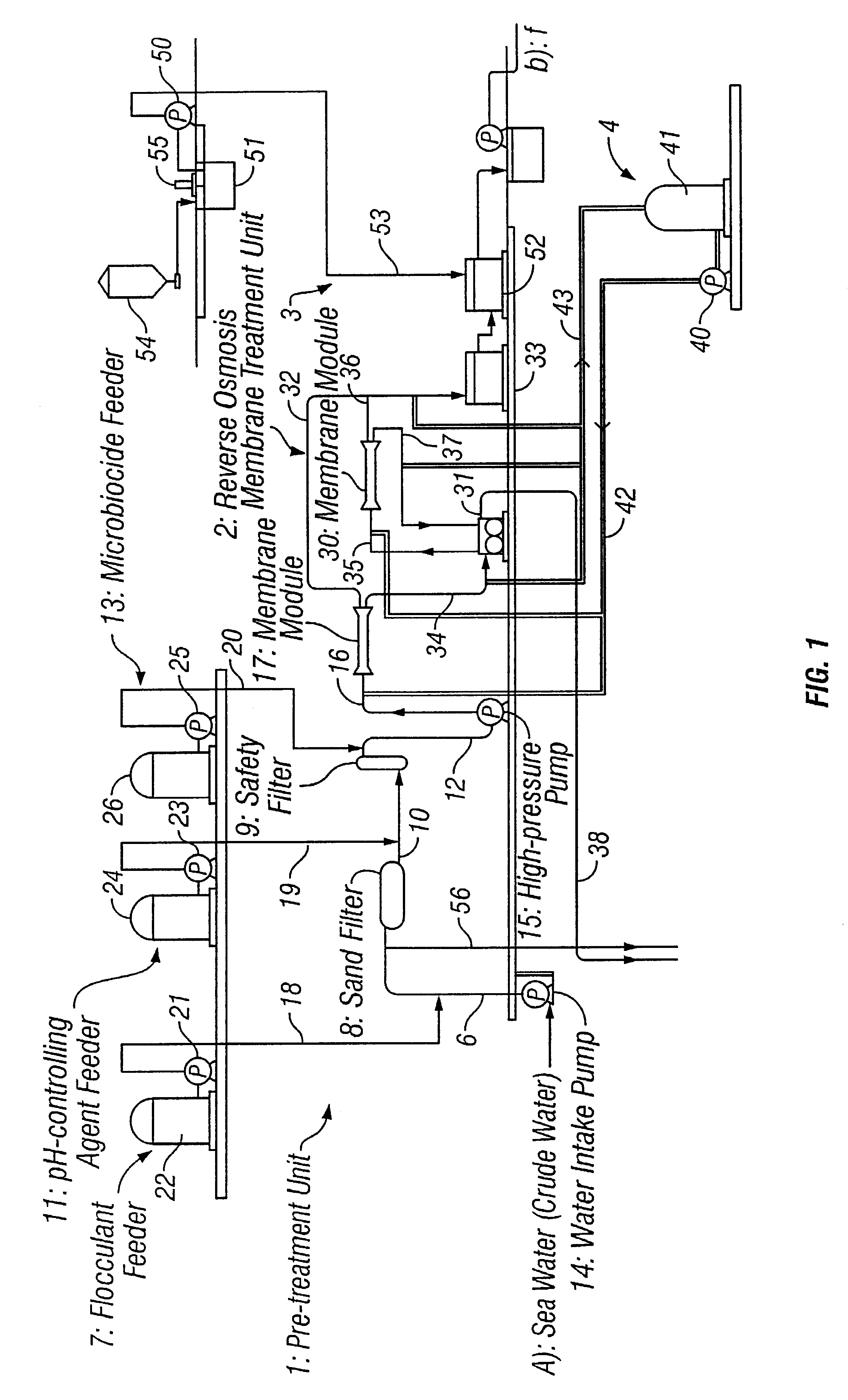

Method for inhibiting growth of bacteria or sterilizing around separating membrane

InactiveUS6468430B1Conserve costReduce the impactMembranesSolid sorbent liquid separationPre treatmentPermselective membrane

In the invention, the pipe lines around permselective membranes and the surfaces of permselective membranes are intermittently disinfected by adding an inexpensive acid such as sulfuric acid or the like to pre-treated crude water so as to make the water have a pH of 4 or lower. Accordingly, the invention provides a method of surely disinfecting the permselective membranes in membrane separation systems.

Owner:TORAY IND INC

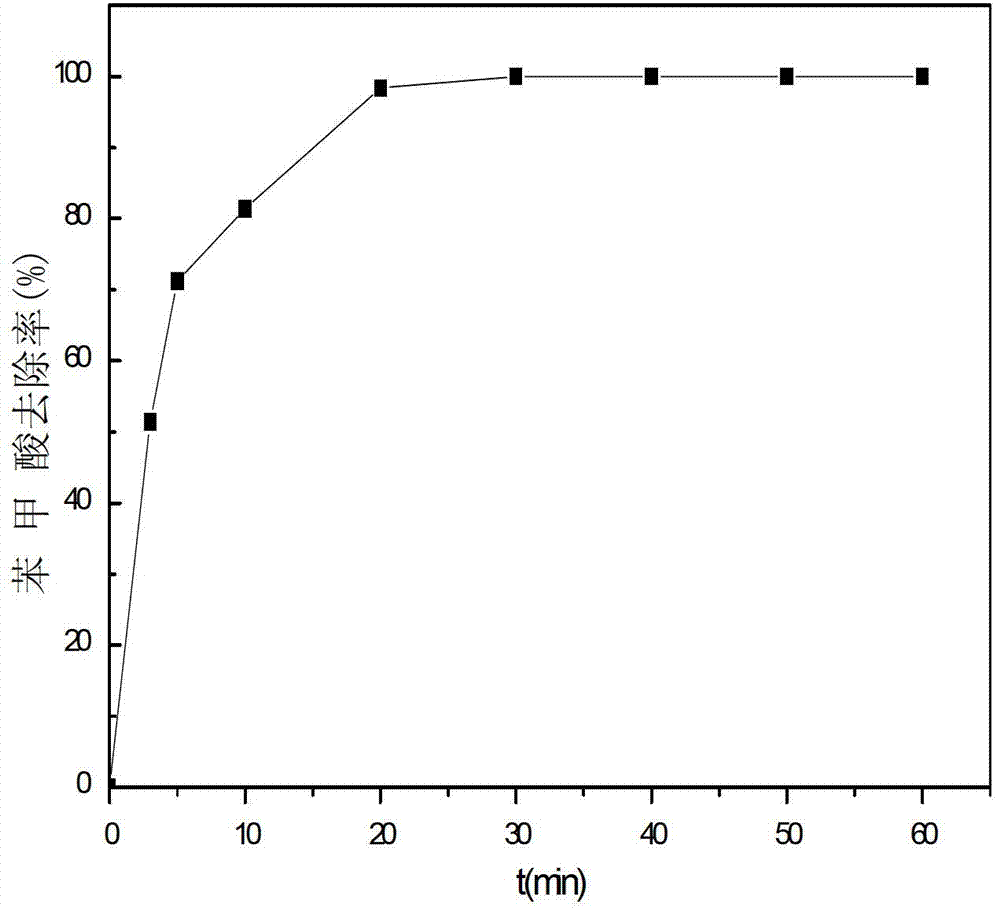

Application of spinel ferrite catalyst and method for urging persulfate to generate free radicals to catalytically degrade organic matters

InactiveCN103030208AStable structureHigh mechanical strengthSolid waste disposalWater contaminantsPersulfateSulfate

Application of spinel ferrite catalyst and a method for urging persulfate to generate free radicals to catalytically degrade organic matters relate to application of spinel ferrite catalyst and a method for degrading organic matters. The invention aims to solve the problems of high probabilities of oxygenolysis and breakage, low strength, impurity dissolution, low catalytic efficiency and difficulty in recovering in the existing catalyst as catalyst generated by sulfate free radicals and complex reaction system, rigor reaction conditions and higher cost in the existing activating technology. The spinel ferrite catalyst, as catalyst for urging the generation of persulfate free radicals, for urging persulfate or mono-persulfate to generate free radicals is applied; and the method comprises the following steps: the spinel ferrite catalyst is adopted as catalyst for urging the generation of persulfate free radicals to urge persulfate or mono-persulfate to generate free radicals; and then sulfuric acid free radicals are used for degrading the organic matters. The application and the method are mainly applied in catalytic degradation of the organic matters.

Owner:HARBIN INST OF TECH

Purification of carbon dioxide

SO2 and / or NOx are removed from gaseous CO2 at elevated pressure(s) in the presence of molecular oxygen and water and, when SO2 is to be removed, NOx, to convert SO2 to sulfuric acid and / or NOx to nitric acid. The sulfuric acid and / or nitric acid is / are then removed from the gaseous carbon dioxide to produce SO2-free, NOx-lean carbon dioxide gas. The invention has particular application in the removal of SO2 and / or NOx from carbon dioxide flue gas produced in an oxyfuel combustion process, for example, in a pulverized coal fired power station.

Owner:AIR PROD & CHEM INC

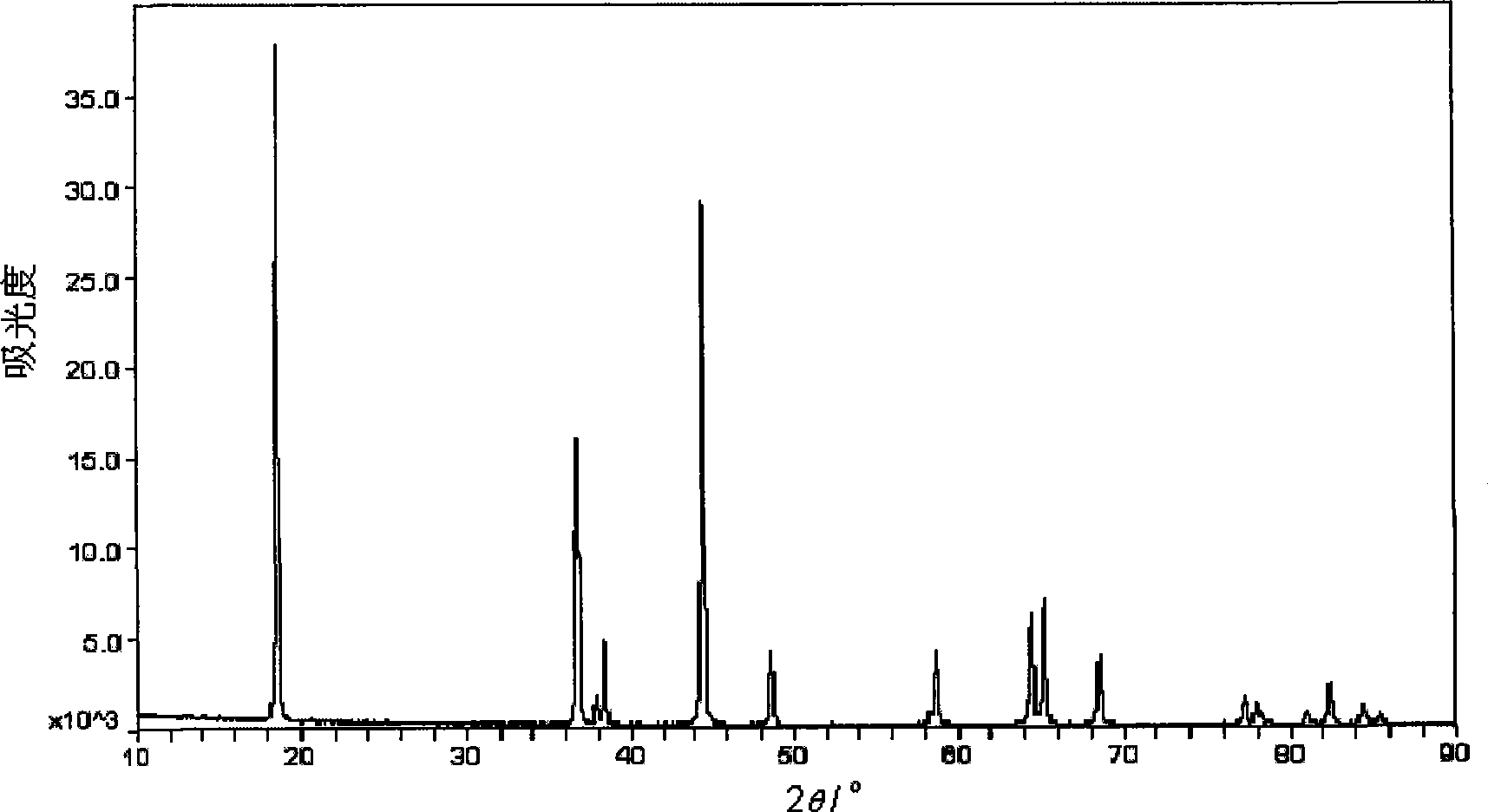

Method for preparing nickel and cobalt doped lithium manganate by using waste and old lithium ionic cell as raw material

InactiveCN101450815ASimultaneous recyclingShort processManganates/permanganatesManganateManganese oxide

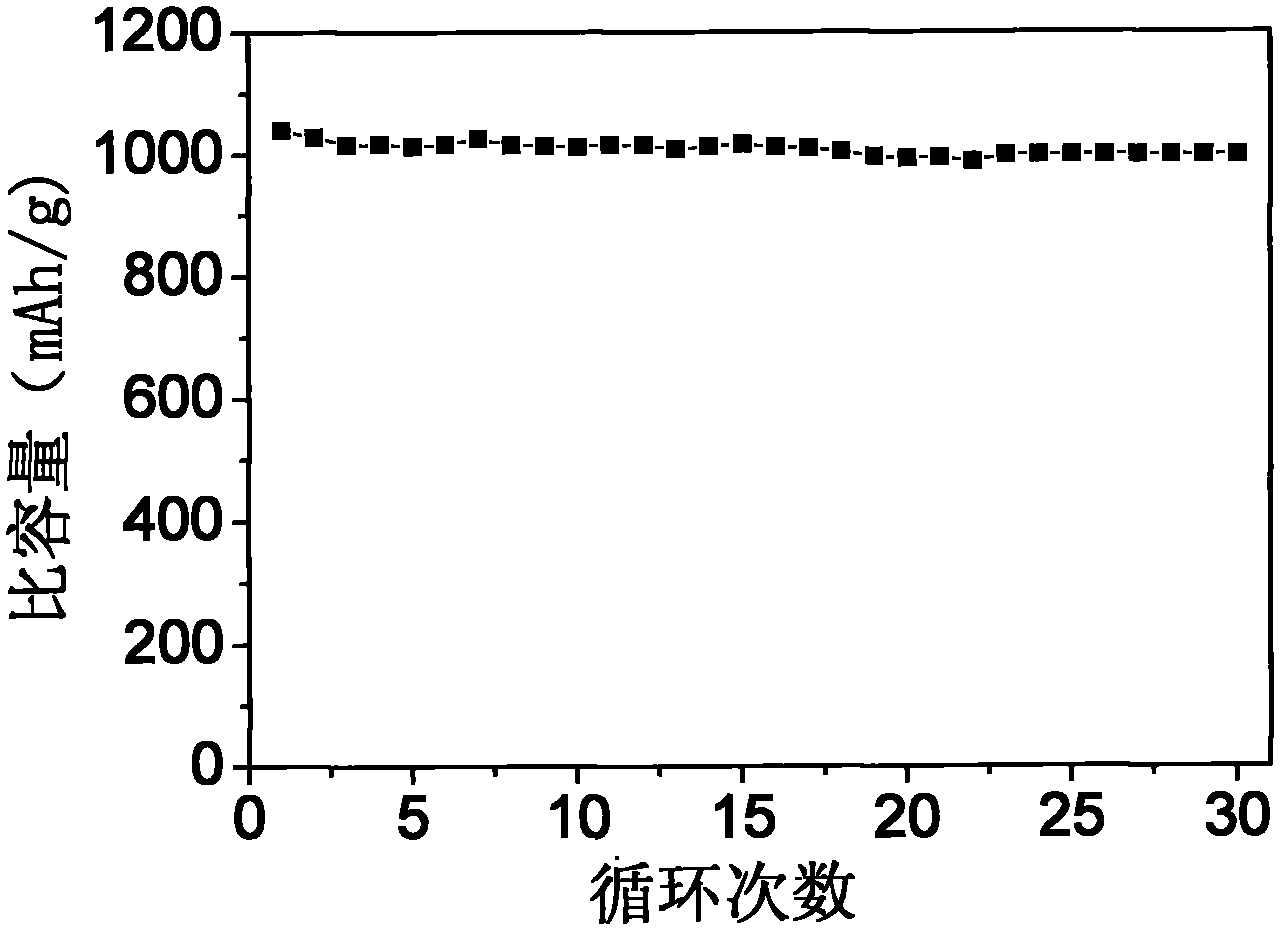

The invention discloses a method for preparing lithium nickel cobalt manganese oxide by taking a waste lithium ion battery as a raw material. The method is mainly characterized in that a waste lithium ion battery taking the lithium nickel cobalt manganese oxide, lithium nickel cobalt oxide and so on as a battery positive material is selected as the raw material and is pretreated through disassembly, separation, crushing, screening and so on, and then processes such as adhesive removal at high temperature and aluminum removal by sodium hydroxide are adopted to obtain an inactivated positive material containing nickel, cobalt and manganese; then a sulfuric acid and hydrogen peroxide system is adopted to leach, and P204 is adopted to remove impurities by extraction to obtain pure nickel, cobalt and manganese solution, and proper manganese sulfate, nickel sulfate or cobalt sulfate is blended to ensure that the mol ratio of nickel, cobalt and manganese elements in the solution is 1: 1: 1; and then ammonium carbonate is adopted to adjust the pH value to form a nickel cobalt manganese carbonate precursor, and then a proper amount of lithium carbonate is blended for high temperature sintering to synthesize a lithium nickel cobalt manganese oxide battery material. The first discharge capacity of the material is 150 mAh / g, the discharge capacity is still kept more than 130mAh / g after the circulation for 30 times, and the material has good electrochemical performance.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

Burning-free block brick prepared from bulky industrial waste residues

The invention relates to a burning-free block brick prepared from bulky industrial waste residues. The burning-free block brick is characterized in that the block brick comprises the following raw materials in parts by weight or volume: 10-80 parts of at least one of tailing, magnesium slag, basic slag, mountain flour, cinder, fly ash, coal gangue, oil shale waste and sulfuric acid slag, 0-80 parts of at least one of gravel, waste sand, construction waste, garbage to be burnt, steel slag, mineral slag, copper slag, iron slag with gold, ardealite, phosphorous slag and carbide slag, 0-50 parts of active cementing material, 0-30 parts of cement clinker, 2-15 parts of cement and a defined amount of water. The preparation method of all types of burning-free and steaming-free standard bricks, perforated bricks, hollow blocks, paving tiles, road edge bricks and fence railings which have low cost and high strength, is as follows: proportioning, stirring for 1-6 minutes, adding a defined amount of water to stir, placing in moulds to form in a machine and performing natural curing for 7-28 days. The burning-free block brick has high raw material selectability, simple technology and wide development and application prospects, and is environmental-friendly.

Owner:司密花 +2

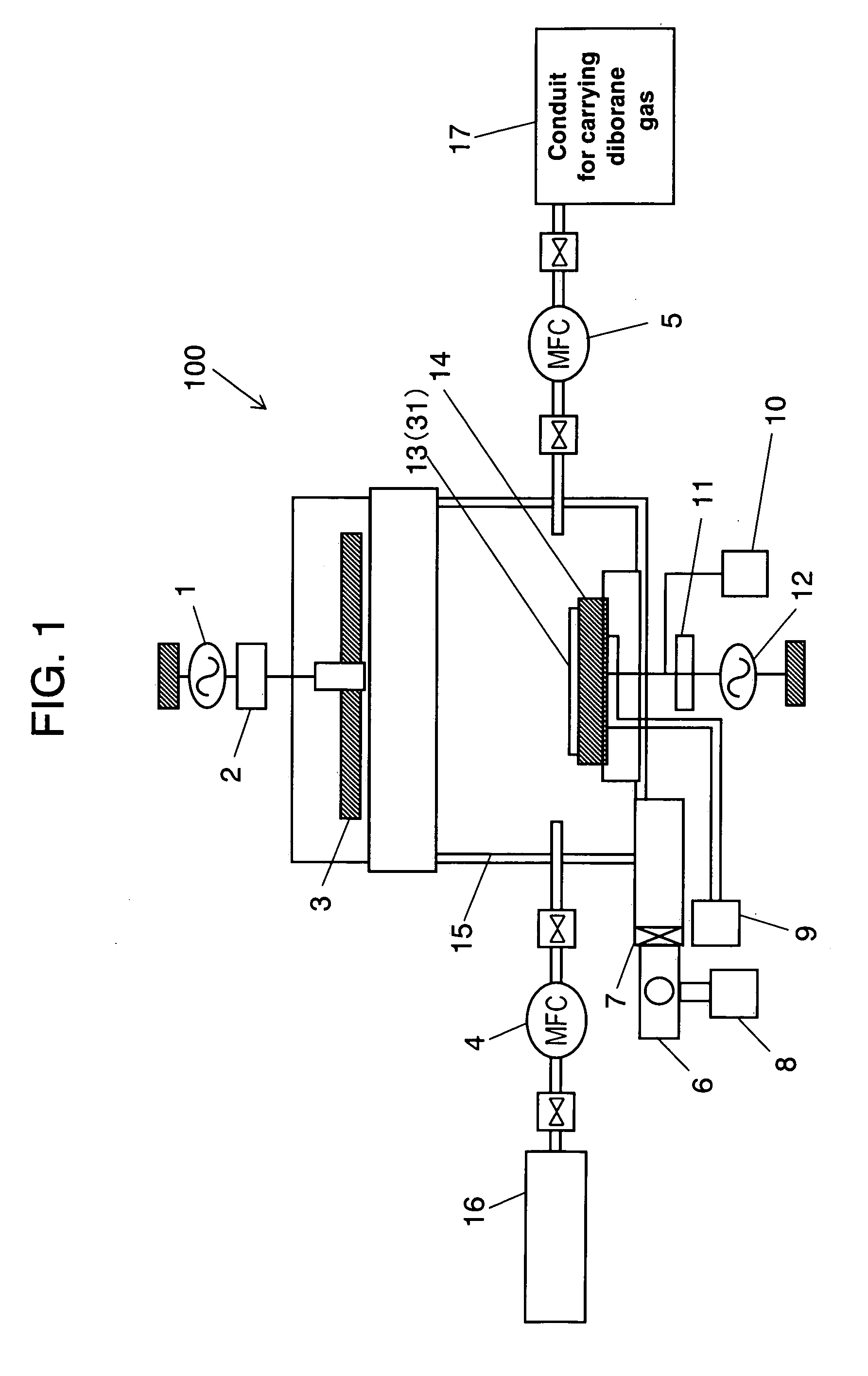

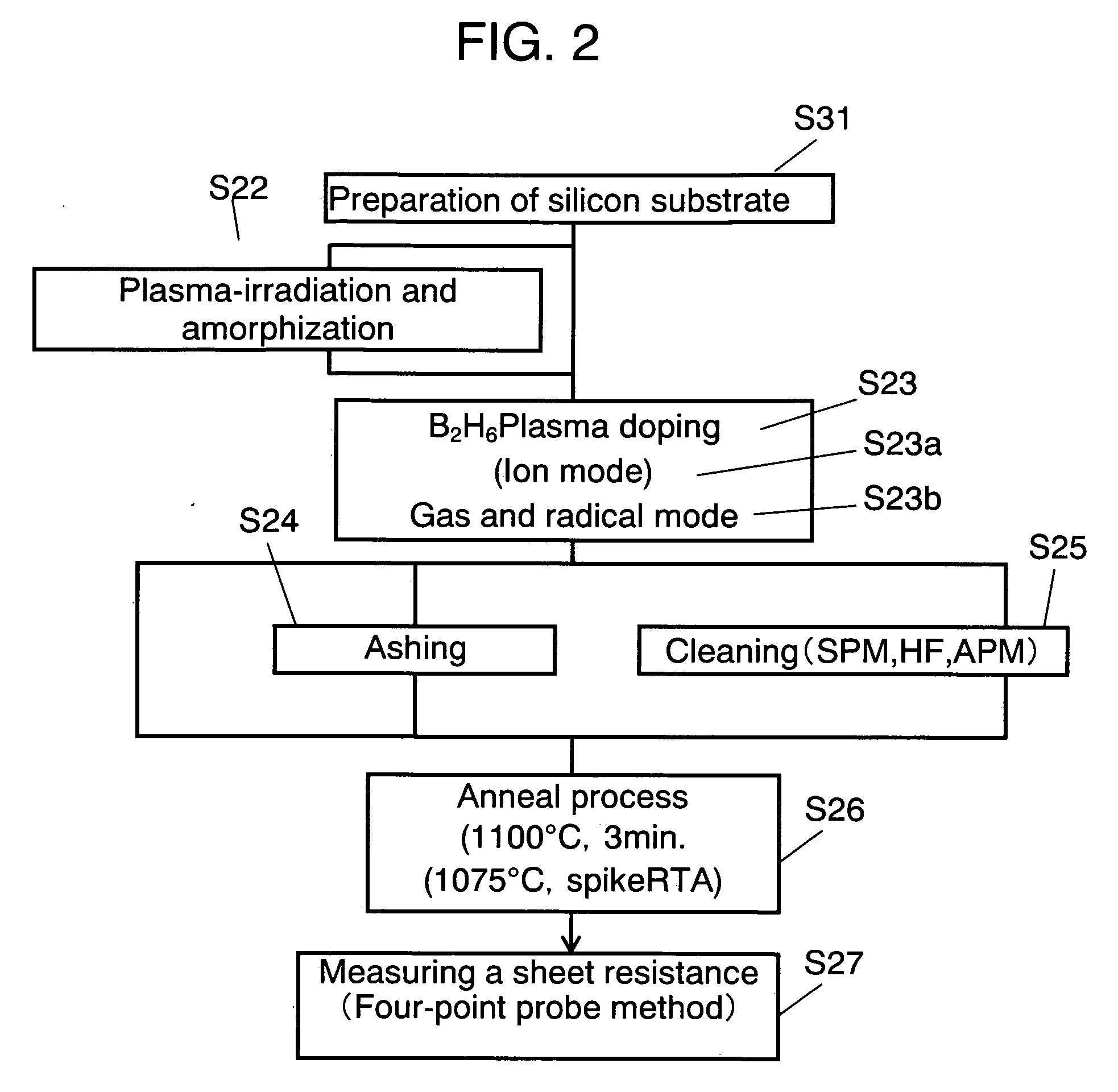

Method for formng impurity-introduced layer, method for cleaning object to be processed apparatus for introducing impurity and method for producing device

A method of forming an impurity-introduced layer is disclosed. The method includes at least a step of forming a resist pattern on a principal face of a solid substrate such as a silicon substrate (S27); a step of introducing impurity into the solid substrate through plasma-doping in ion mode (S23), a step of removing a resist (S28), a step of cleaning metal contamination and particles attached to a surface of the solid substrate (S25a); a step of anneal (S26). The step of removing a resist (S28) irradiates the resist with oxygen-plasma or brings mixed solution of sulfuric acid and hydrogen peroxide water, or mixed solution of NH4OH, H2O2 and H2O into contact with the resist. The step of cleaning (S25a) brings mixed solution of sulfuric acid and hydrogen peroxide water, or mixed solution of NH4OH, H2O2 and H2O into contact with the principal face of the solid substrate. The step of removing a resist (S28) and the step of cleaning (S25a) can be conducted simultaneously by bringing mixed solution of sulfuric acid and hydrogen peroxide water, or mixed solution of NH4OH, H2O2 and H2O into contact with the principal face of the solid substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

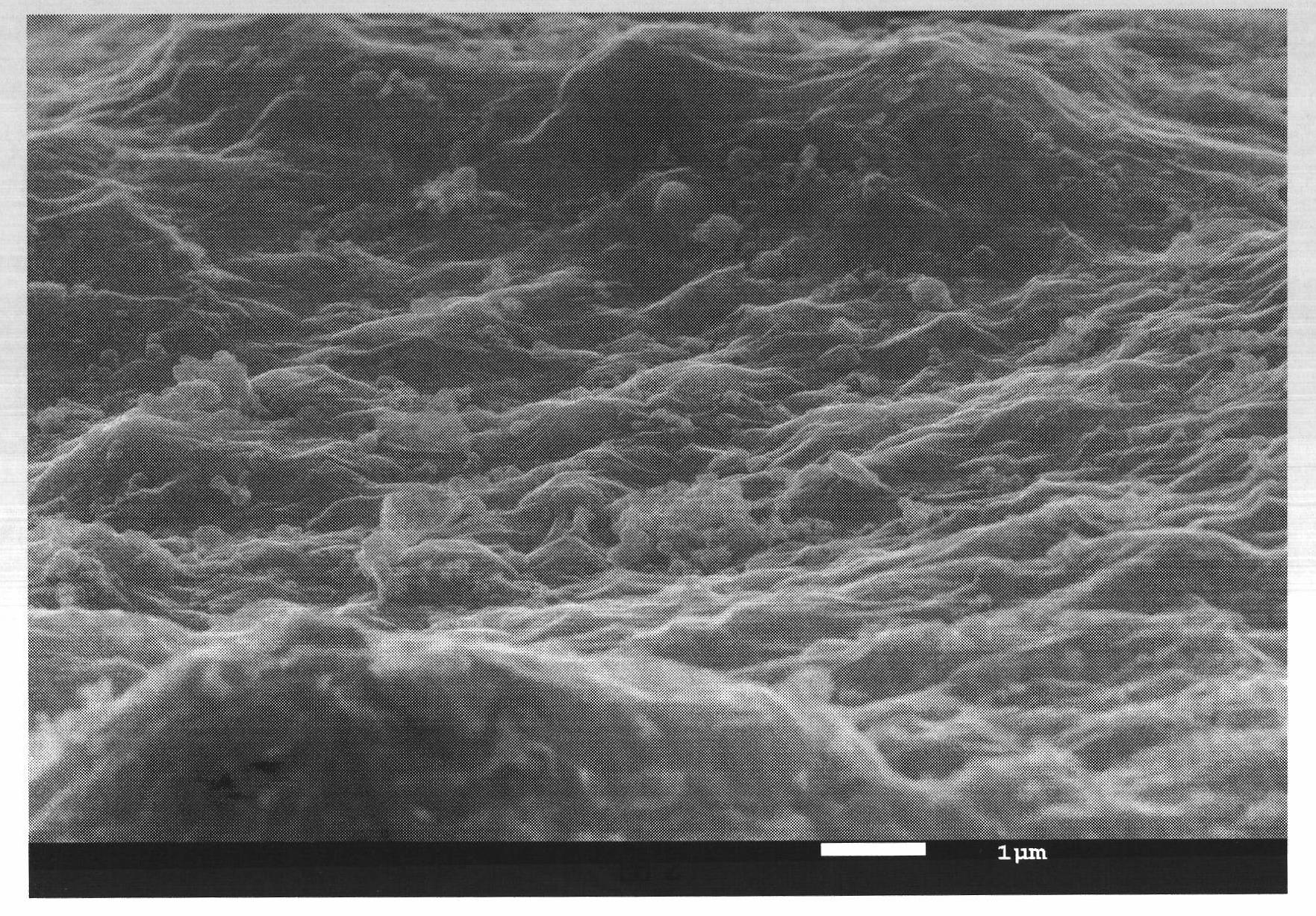

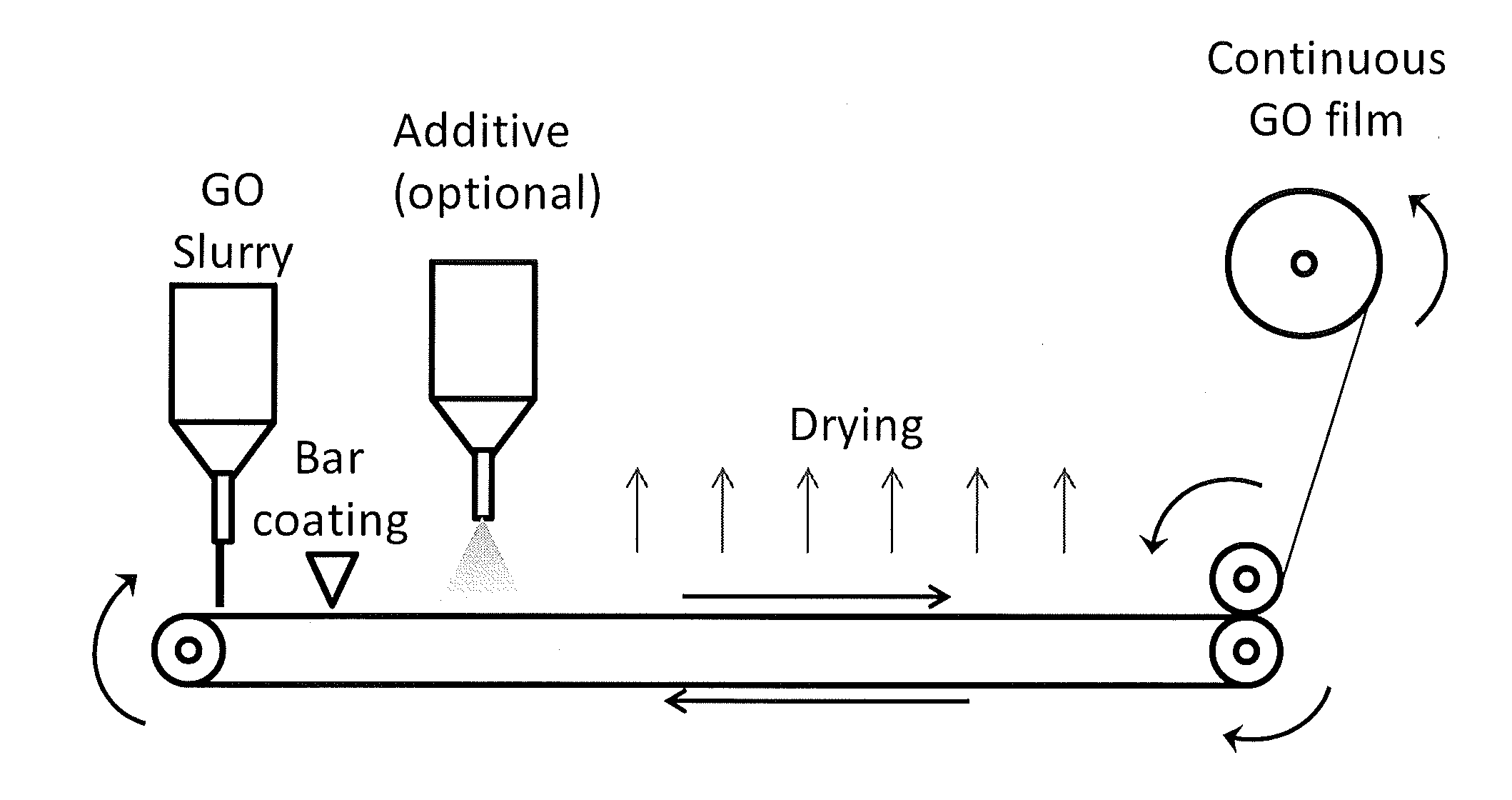

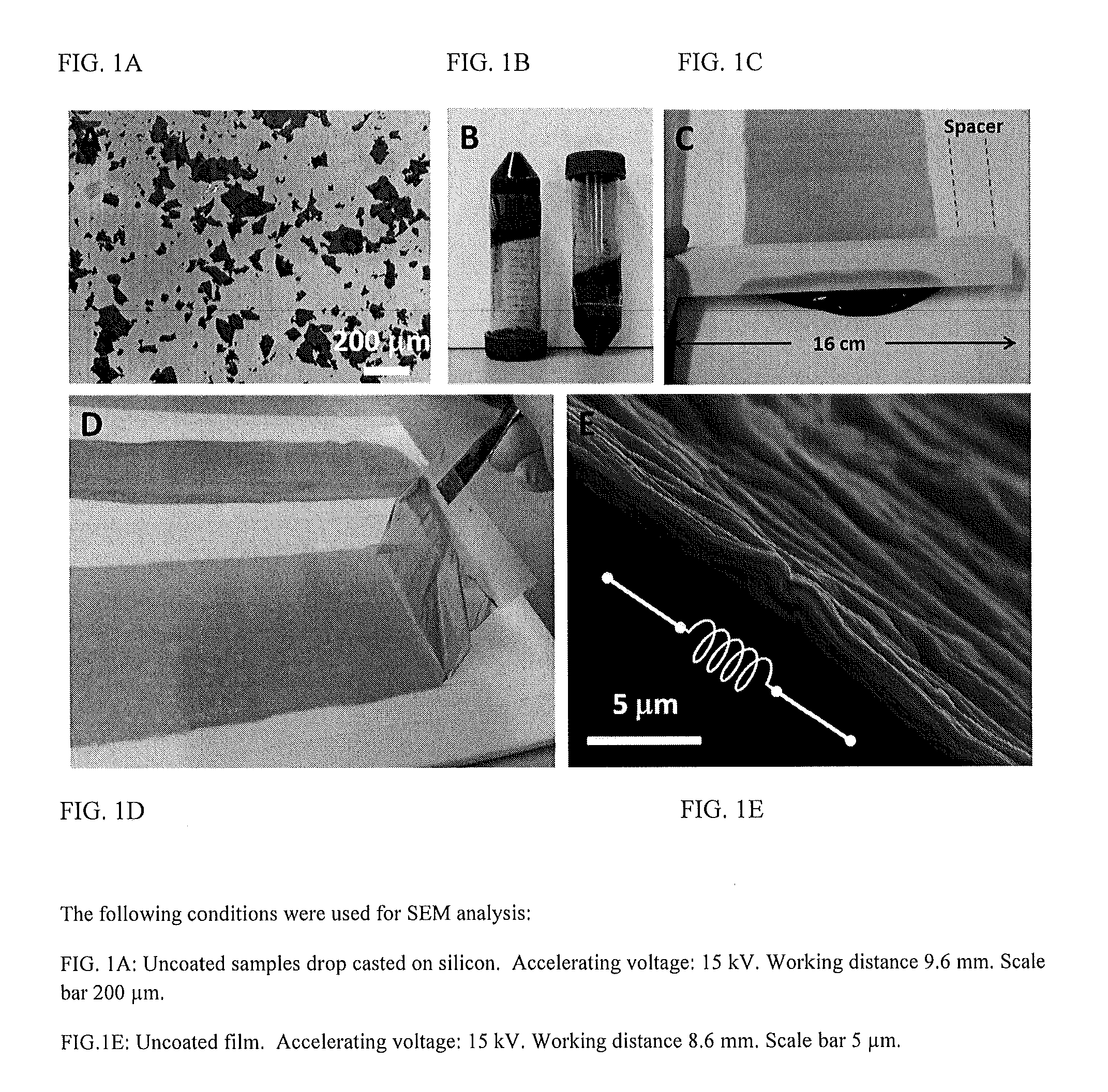

Method for preparing graphene oxide films and fibers

ActiveUS20150111449A1Improve conductivityHigh densityCarbon compoundsFilament/thread formingFiberSolid content

We report a method of preparation of highly elastic graphene oxide films, and their transformation into graphene oxide fibers and electrically conductive graphene fibers by spinning. Methods typically include: 1) oxidation of graphite to graphene oxide, 2) preparation of graphene oxide slurry with high solid contents and residues of sulfuric acid impurities. 3) preparation of large area films by bar-coating or dropcasting the graphene oxide dispersion and drying at low temperature. 4) spinning the graphene oxide film into a fiber, and 5) thermal or chemical reduction of the graphene oxide fiber into an electrically conductive graphene fiber. The resulting films and fiber have excellent mechanical properties, improved morphology as compared with current graphene oxide fibers, high electrical conductivity upon thermal reduction, and improved field emission properties.

Owner:PENN STATE RES FOUND +1

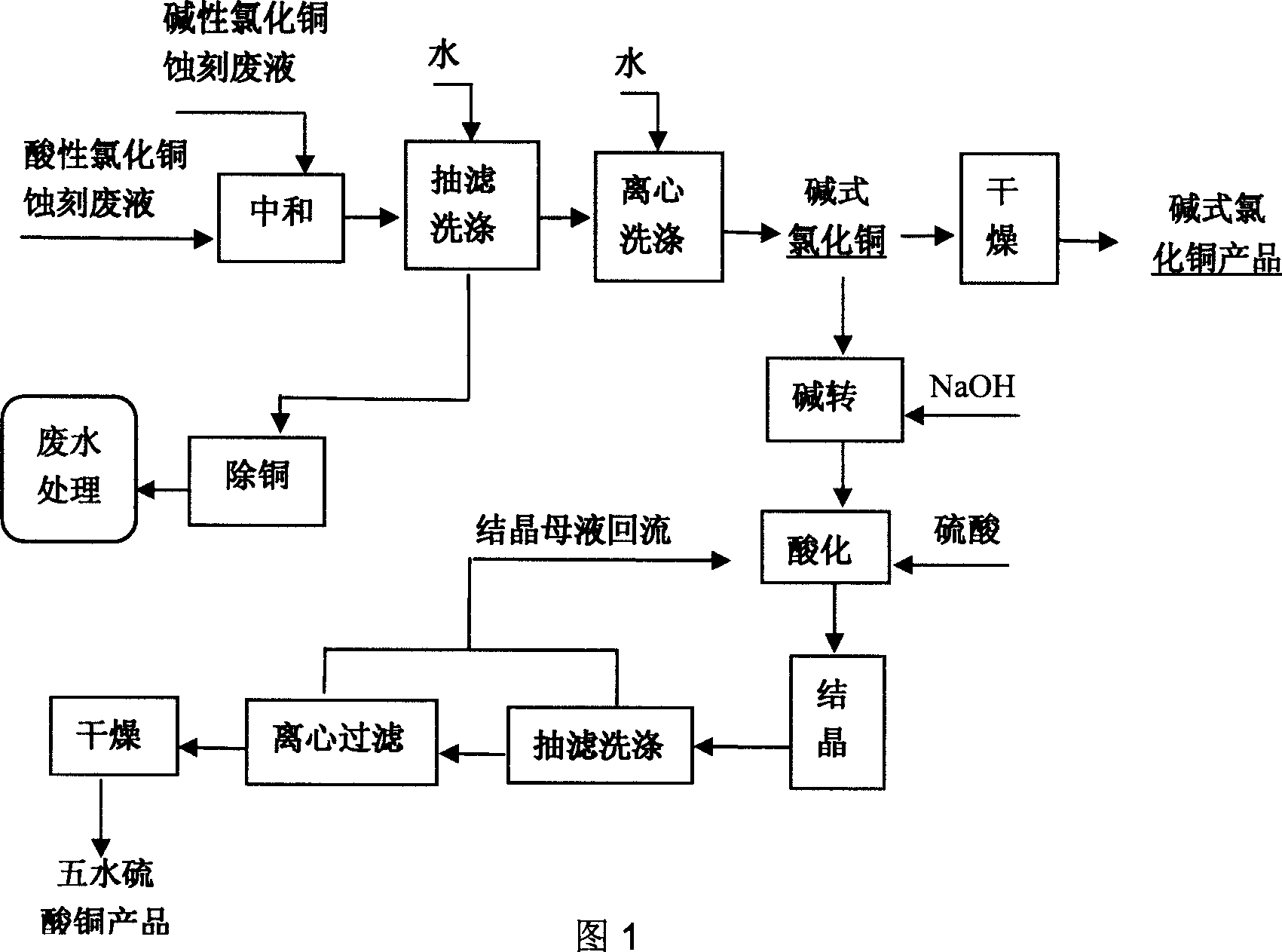

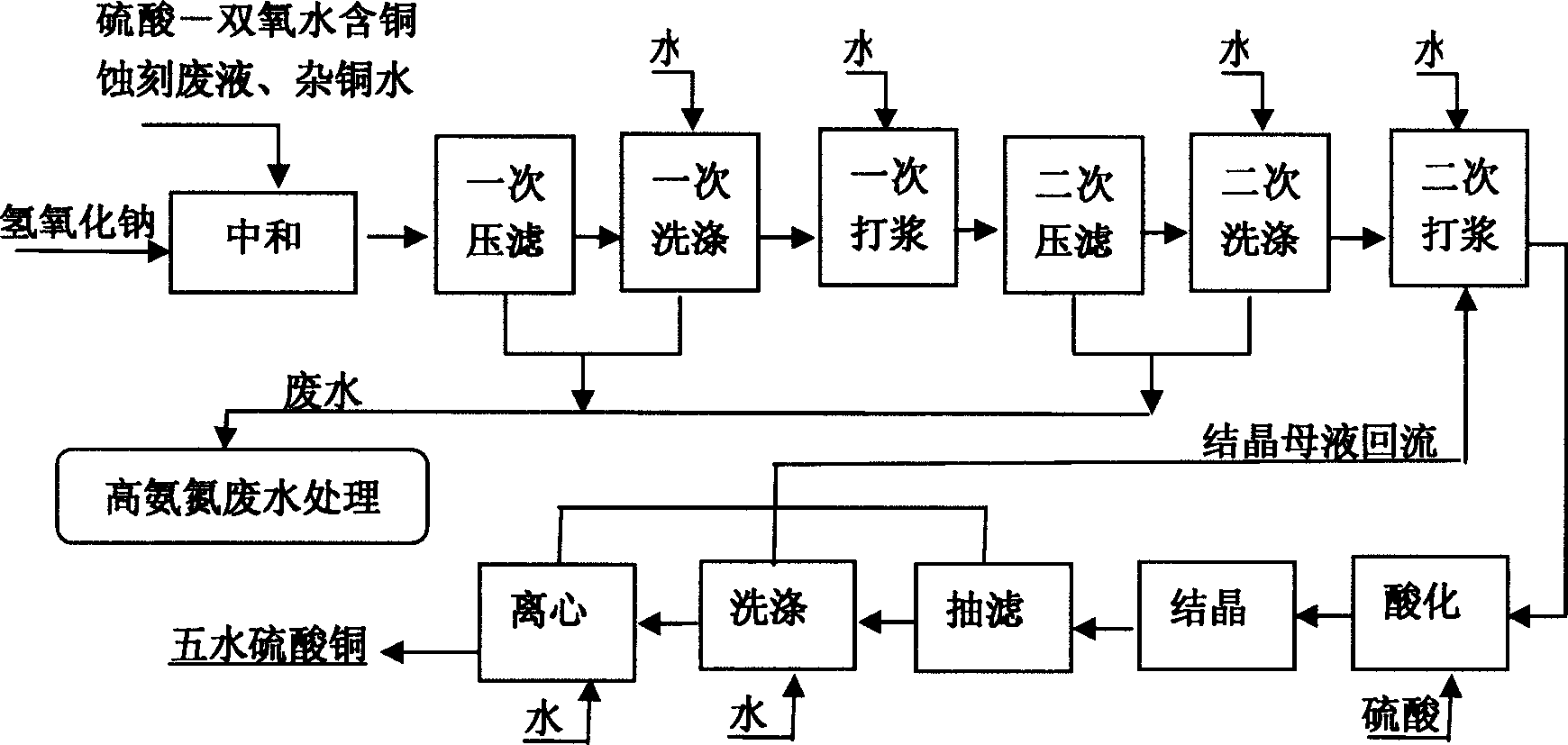

Method for producing basic copper chloride, cupric sulfate pentahydrate from copper-containing etching waste liquid

ActiveCN101391800AEfficient removalImprove product qualityCopper chloridesMultistage water/sewage treatmentCopper chlorideSulfate

The invention relates to a method for producing copper chloride hydroxide and blue vitriod by using cupriferous etching wastewater; the method comprises the following steps: acidic copper chloride etching wastewater and alkaline copper chloride etching wastewater are neutralized and crystallized to get acidic copper chloride crystal under the condition of strictly controlling filling liquid and the Ph range of a reaction kettle, and then pumped and filtrated, and centrifugated; part of the obtained alkaline copper chloride crystal is dried to obtain finished products while the other is added with NaOH solution for alkali conversion to obtain copper oxide, and then is acidulated by sulphuric acid, crystallized, washed, centrifugated, and dried to obtain blue vitriod products. The method for producing blue vitriod by directly using sulphuric acid-oxyful etching wastewater includes the following steps: sulphuric acid-oxyful etching wastewater and composition brass wasterwater in a PCB manufacture are blended together and added with NaOH to form cupric hydroxide precipitation which filtrated, washed, and then acidulated by sulphuric acid to obtain copper sulphate solution; after the copper sulphate solution is cooled, crystallized, centrifugated and dried, and the blue vitriod is obtained.

Owner:HUIZHOU DONGJIANG ENVIRONMENTAL PROTECTION TECH

Acidified attapulgite clay

Owner:XUYI BOTU ATTAPULGITE CLAY HIGH TECH DEV

Lubricating oil compositions

Disclosed are lubricating oil compositions excellent in friction reducing effect and long drain properties and particularly suitable for internal combustion engines, which comprise a lubricating base oil, a specific phosphorus compound in an amount of 0.005 to 0.5 percent by mass in terms of phosphorus based on the total mass of the composition, and at least one additive selected from the group consisting of (C) metallic detergents, (D) ashless dispersants, and (E) anti-oxidants, and further contains (F) a sulfur-containing organic molybdenum complex and (G) an ashless friction modifier and which satisfy prescribed requirements and have a sulfated ash content not exceeding a specified level.

Owner:NIPPON OIL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com