Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1548 results about "Friction reducing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Frictional force can be reduced in the following ways Use of lubricants: In machines, friction can be reduced by applying lubricants between the contact surfaces to fill the fine pores or depressions in the surfaces and make them smooth thereby reducing friction.

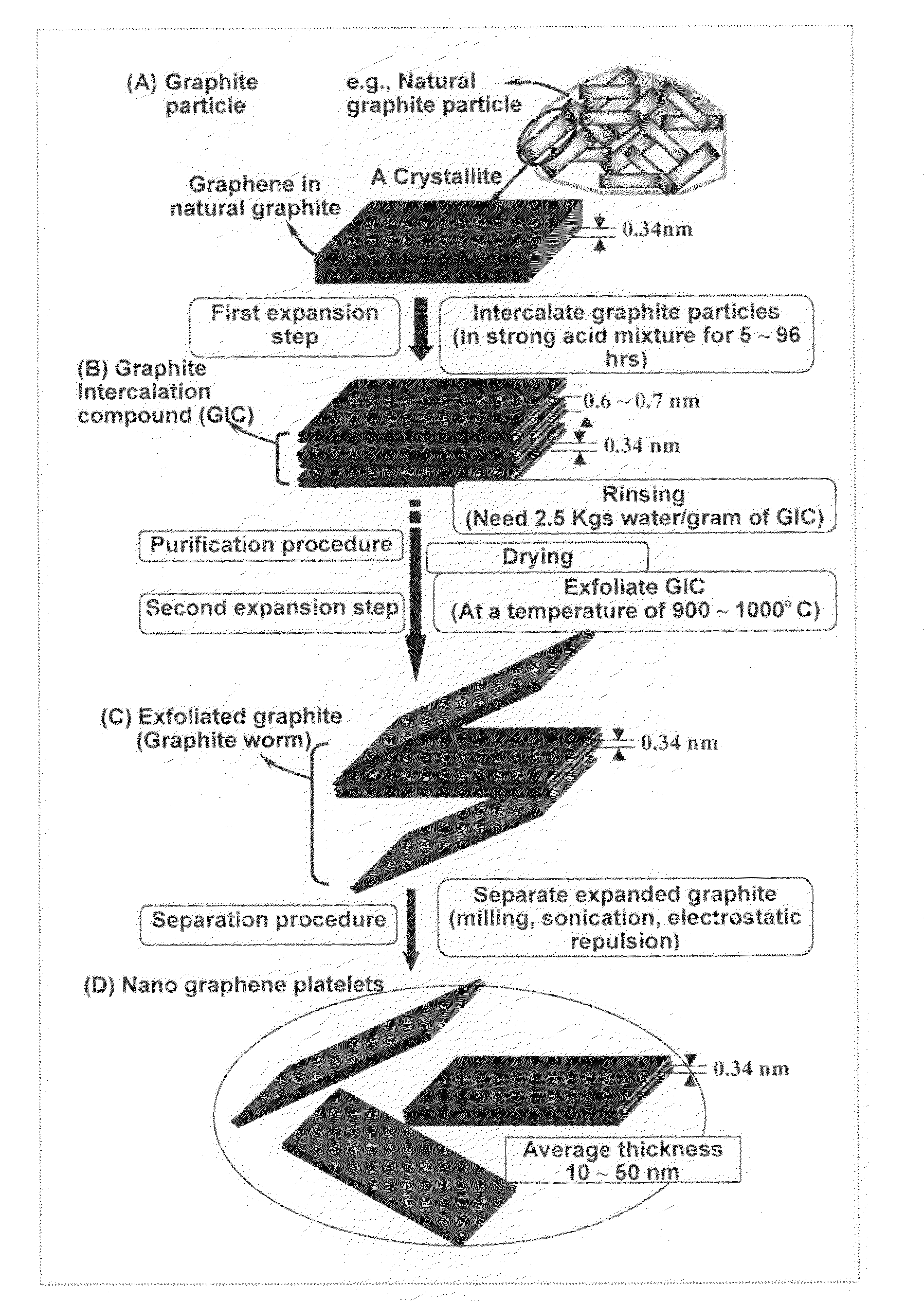

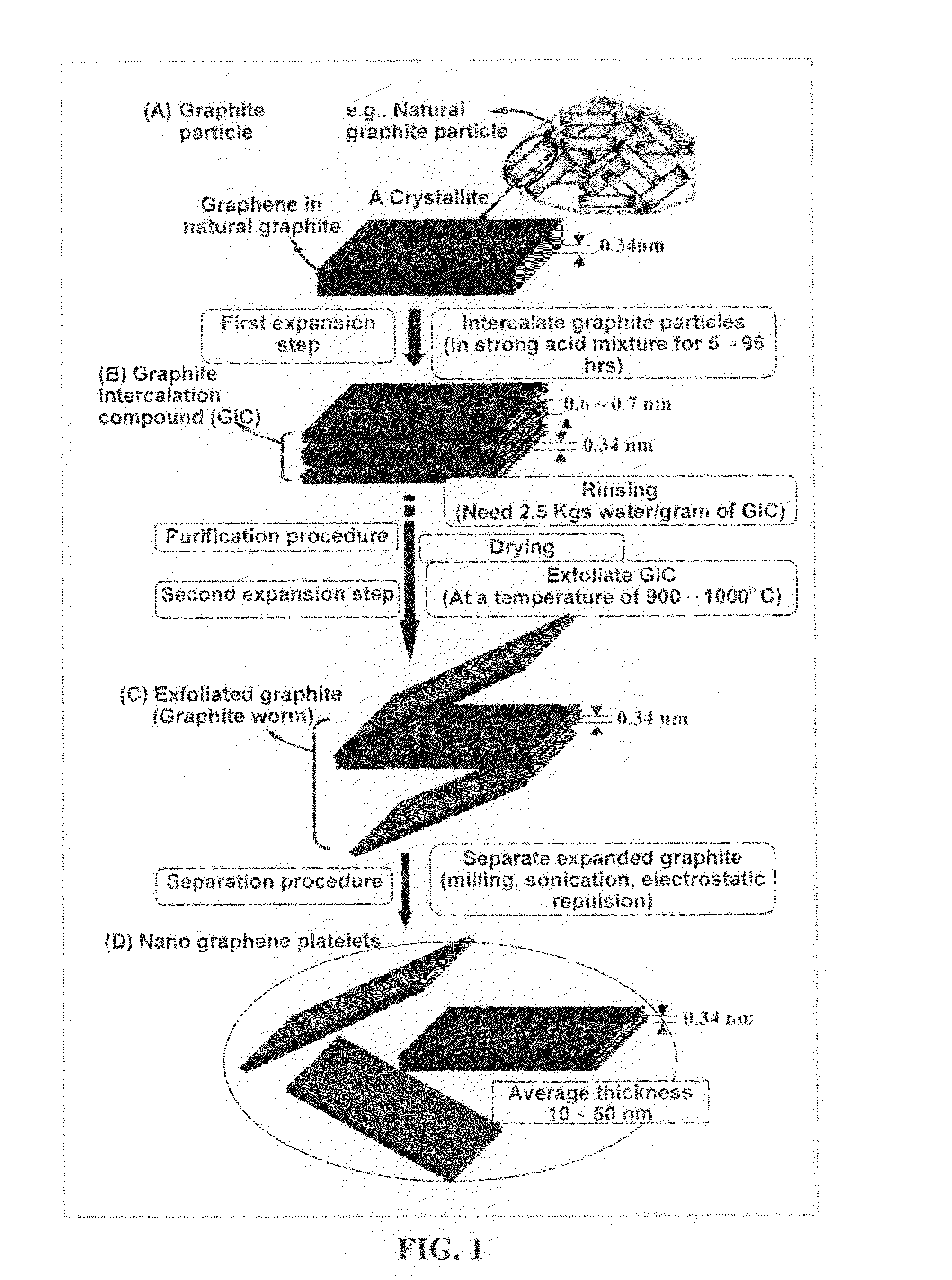

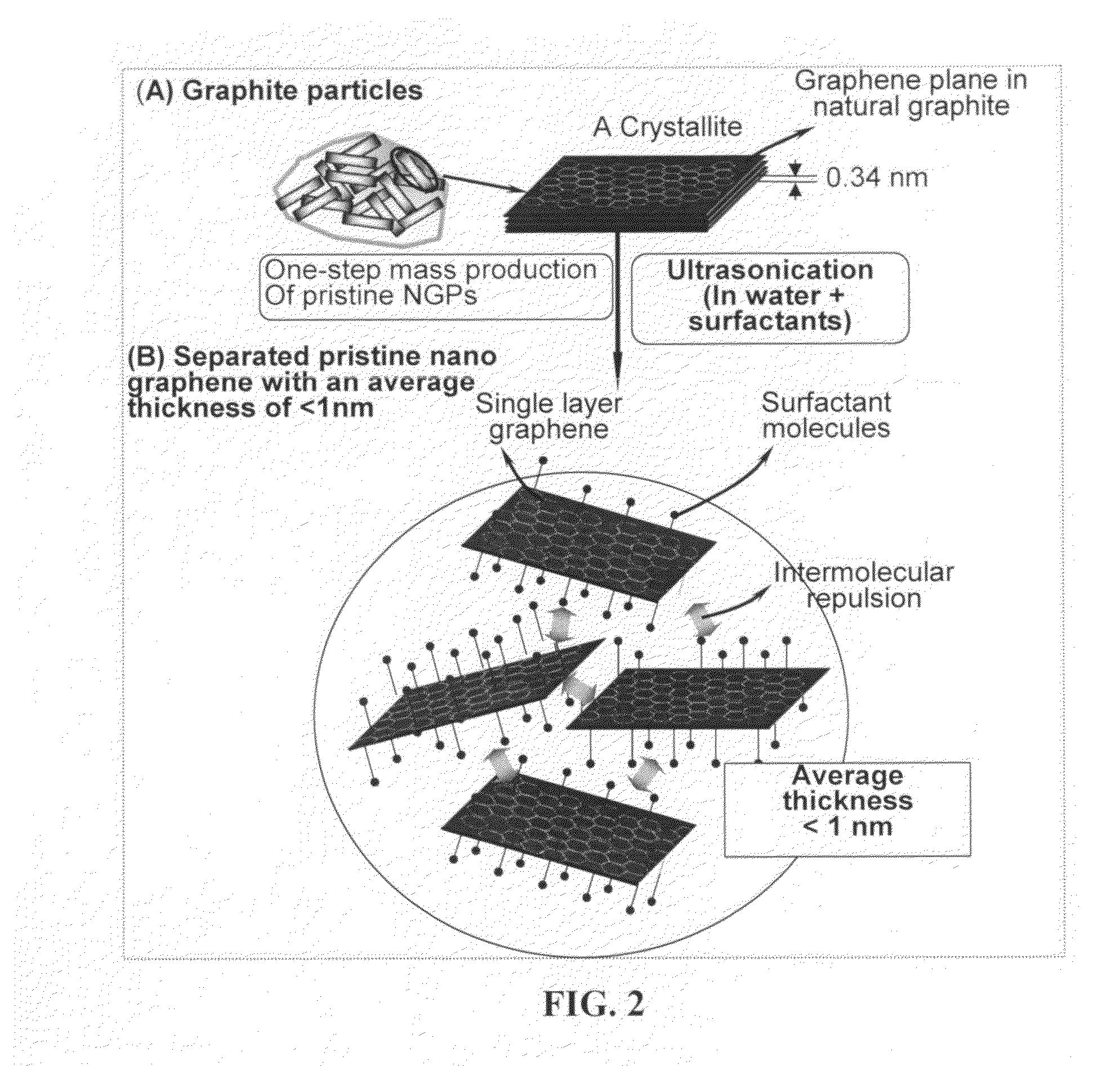

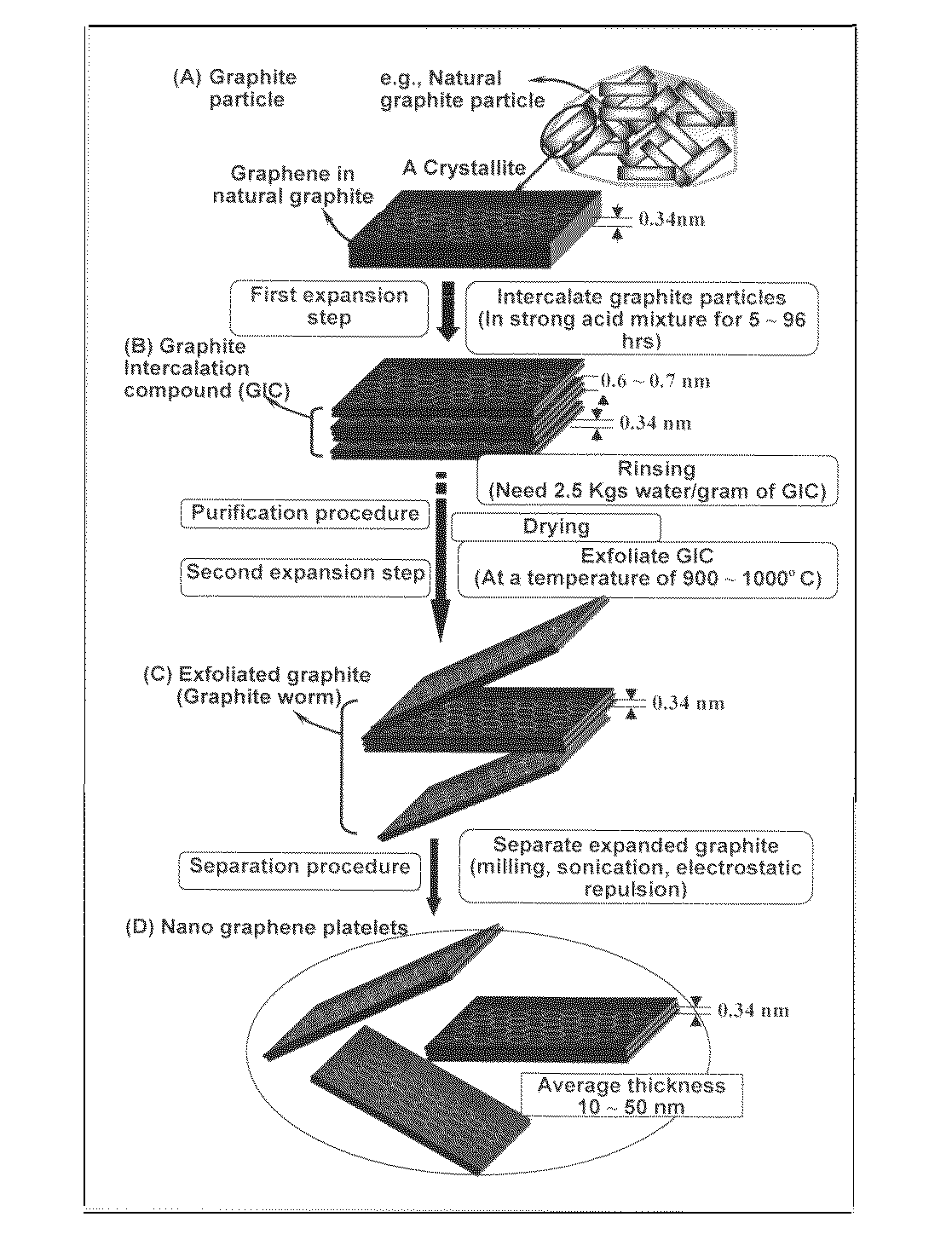

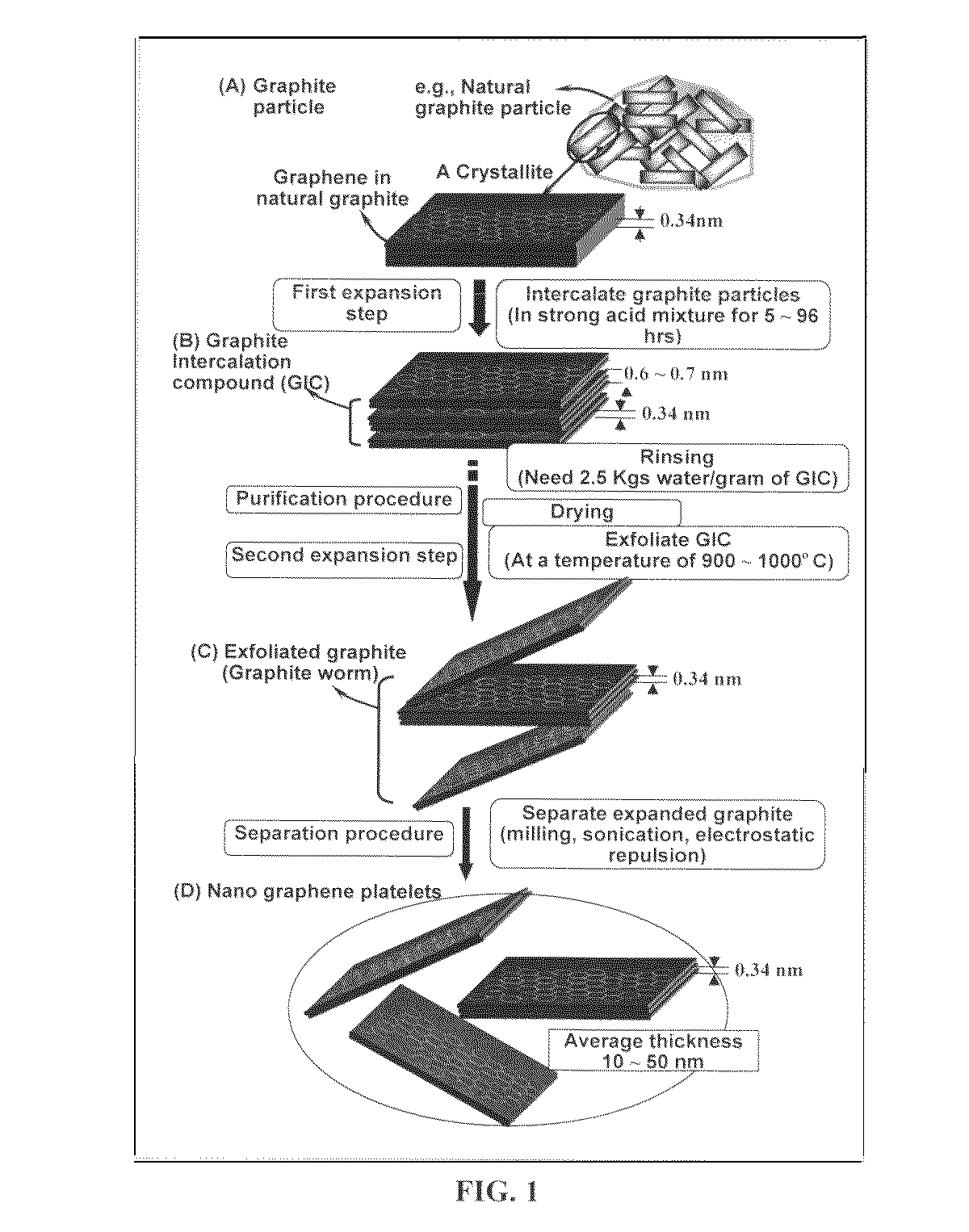

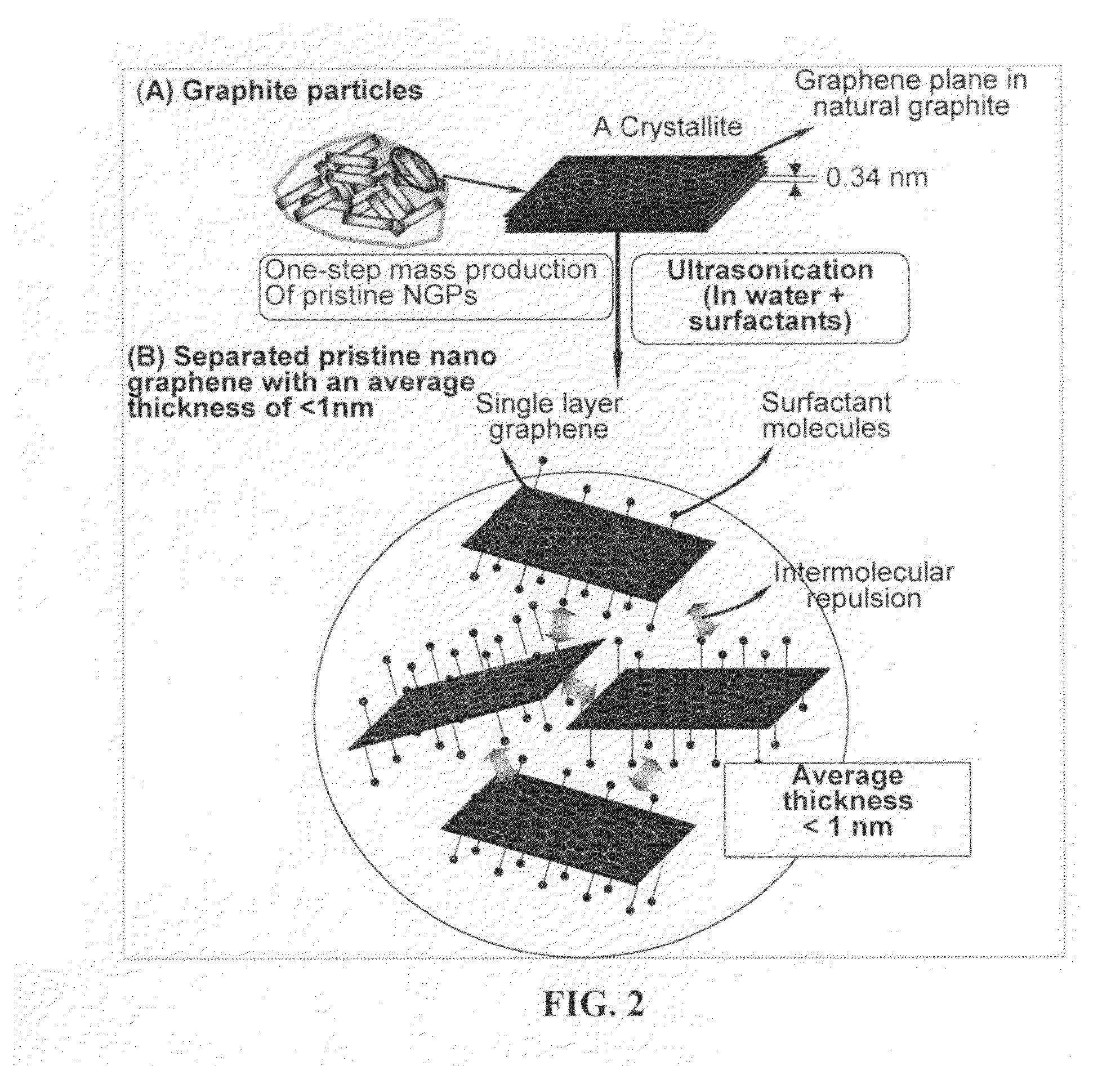

Nano graphene-modified lubricant

ActiveUS20110046027A1Modulate viscosityImprove the lubrication effectAdditivesBase-materialsCarbon nanotubeSingle layer graphene

A lubricant composition having improved lubricant properties, comprising:(a) a lubricating fluid; and (b) nano graphene platelets (NGPs) dispersed in the fluid, wherein nano graphene platelets have a proportion of 0.001% to 60% by weight based on the total weight of the fluid and the graphene platelets combined. Preferably, the composition comprises at least a single-layer graphene sheet. Preferably, the lubricating fluid contains a petroleum oil or synthetic oil and a dispersant or surfactant. With the addition of a thickener or a desired amount of NGPs, the lubricant becomes a grease composition. Compared with graphite nano particle- or carbon nanotube-modified lubricants, NGP-modified lubricants have much better thermal conductivity, friction-reducing capability, anti-wear performance, and viscosity stability.

Owner:GLOBAL GRAPHENE GRP INC

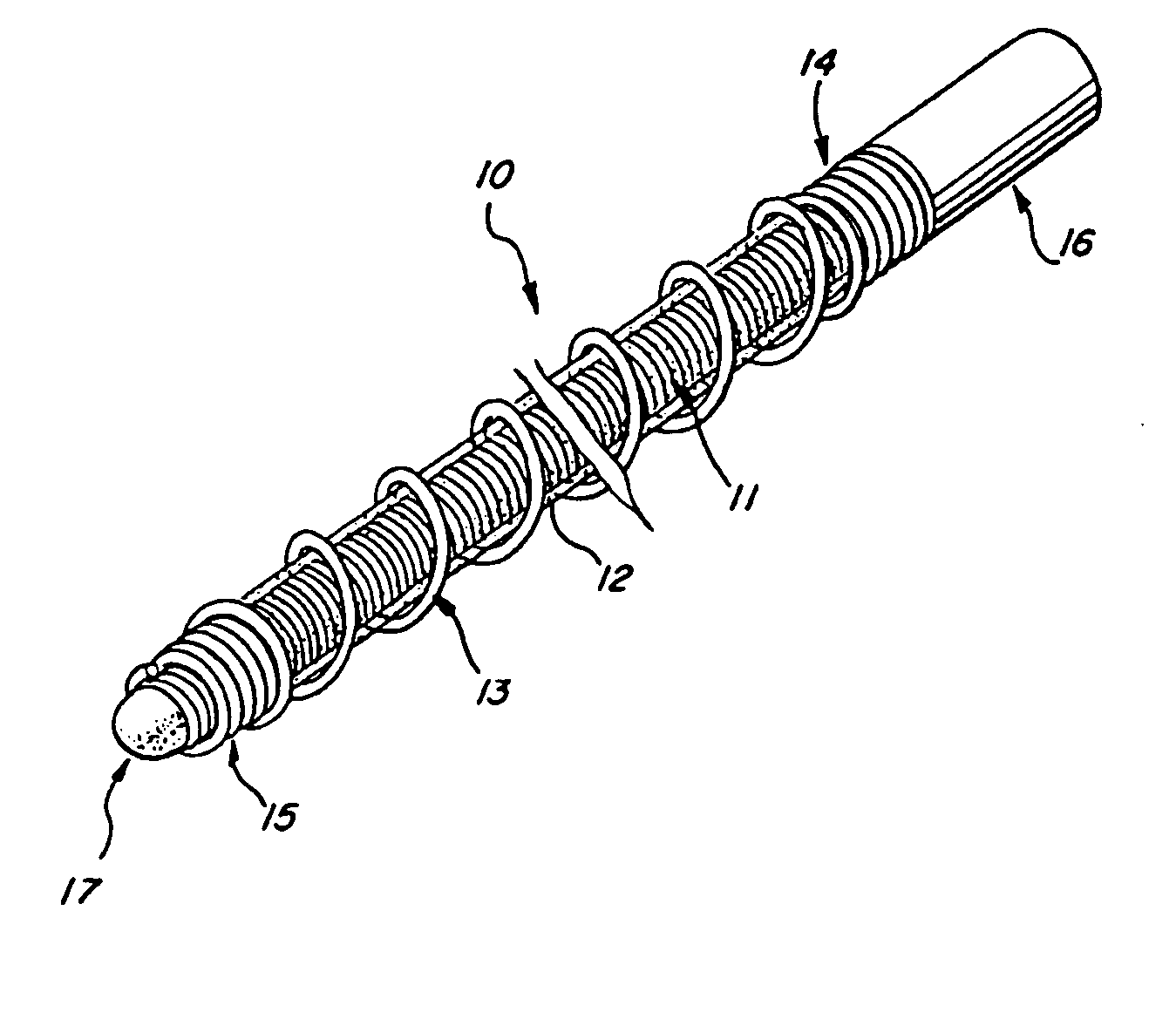

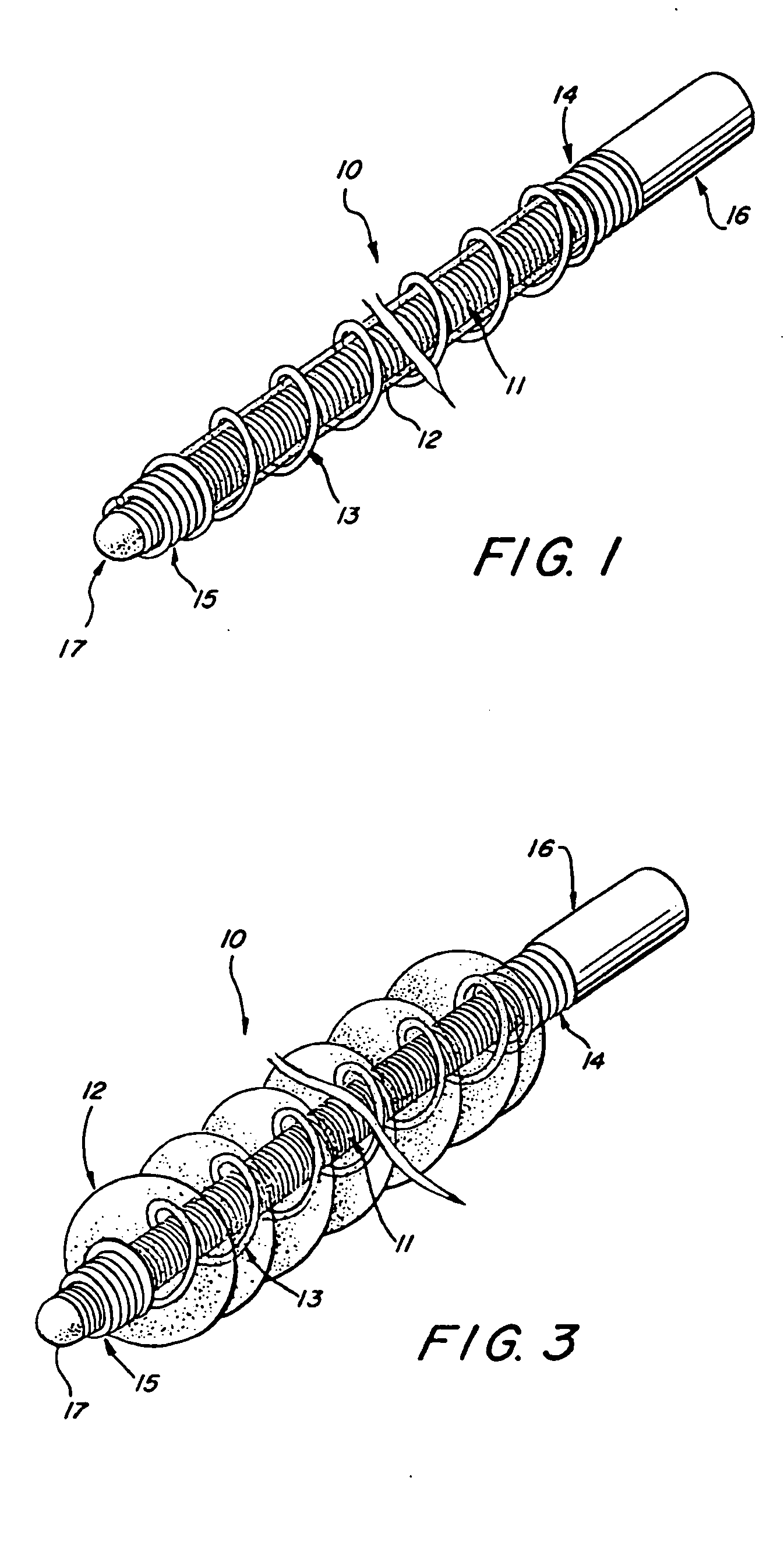

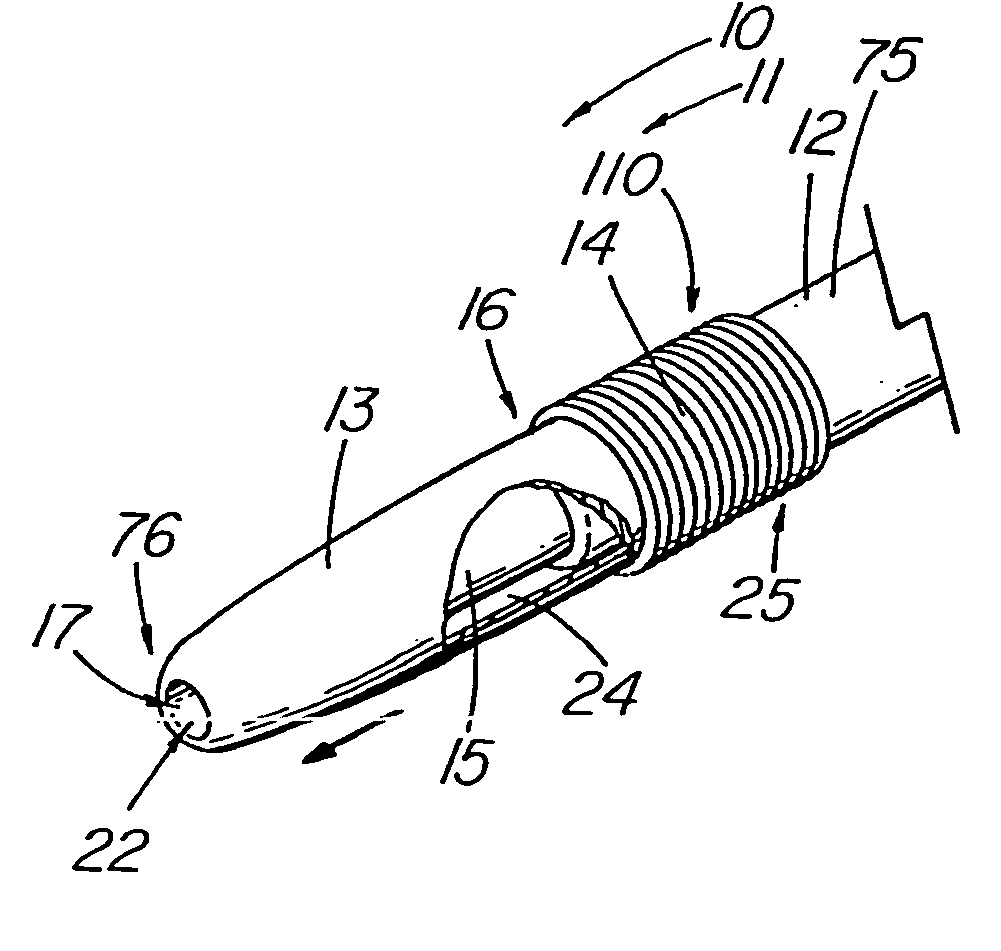

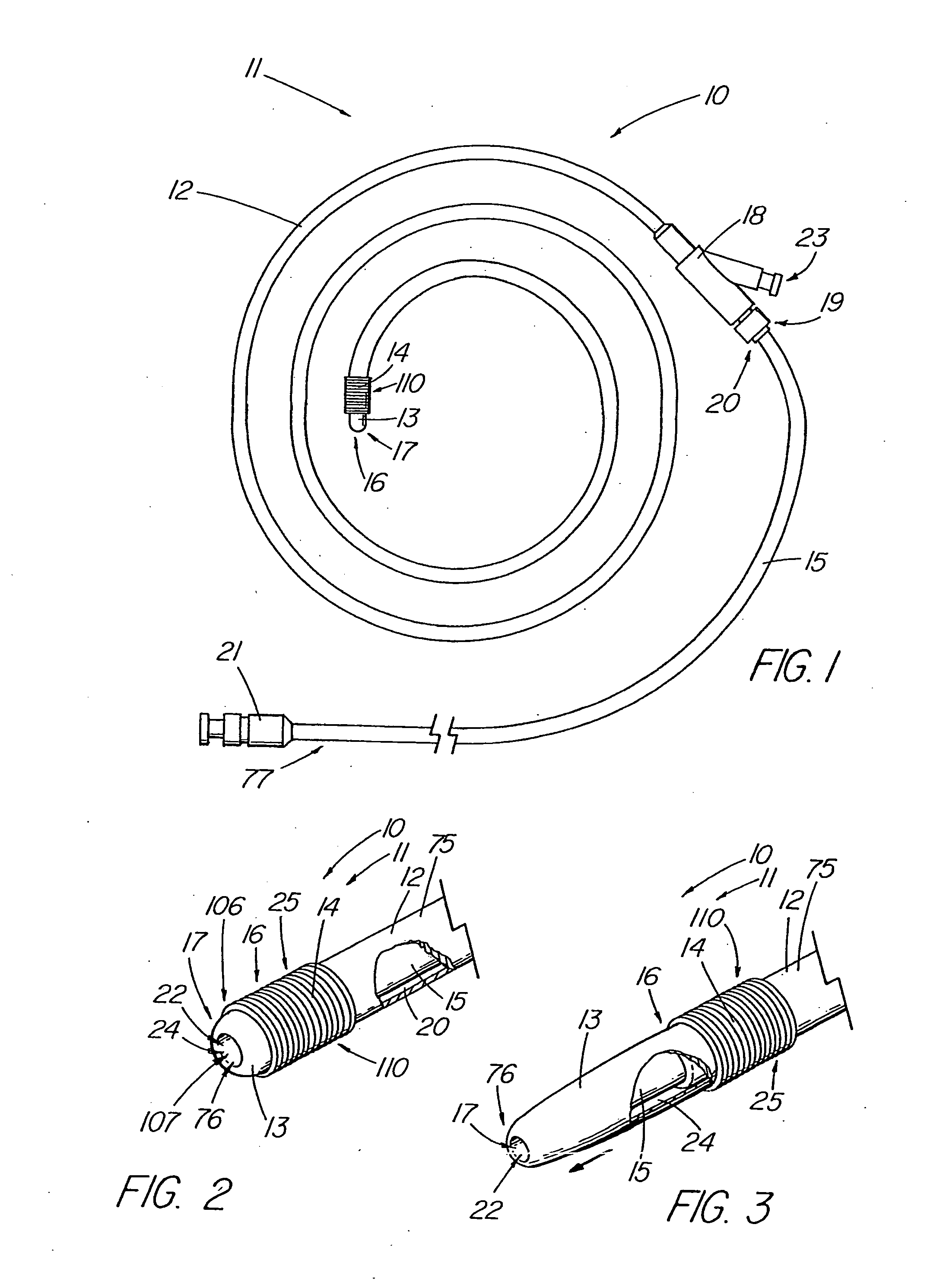

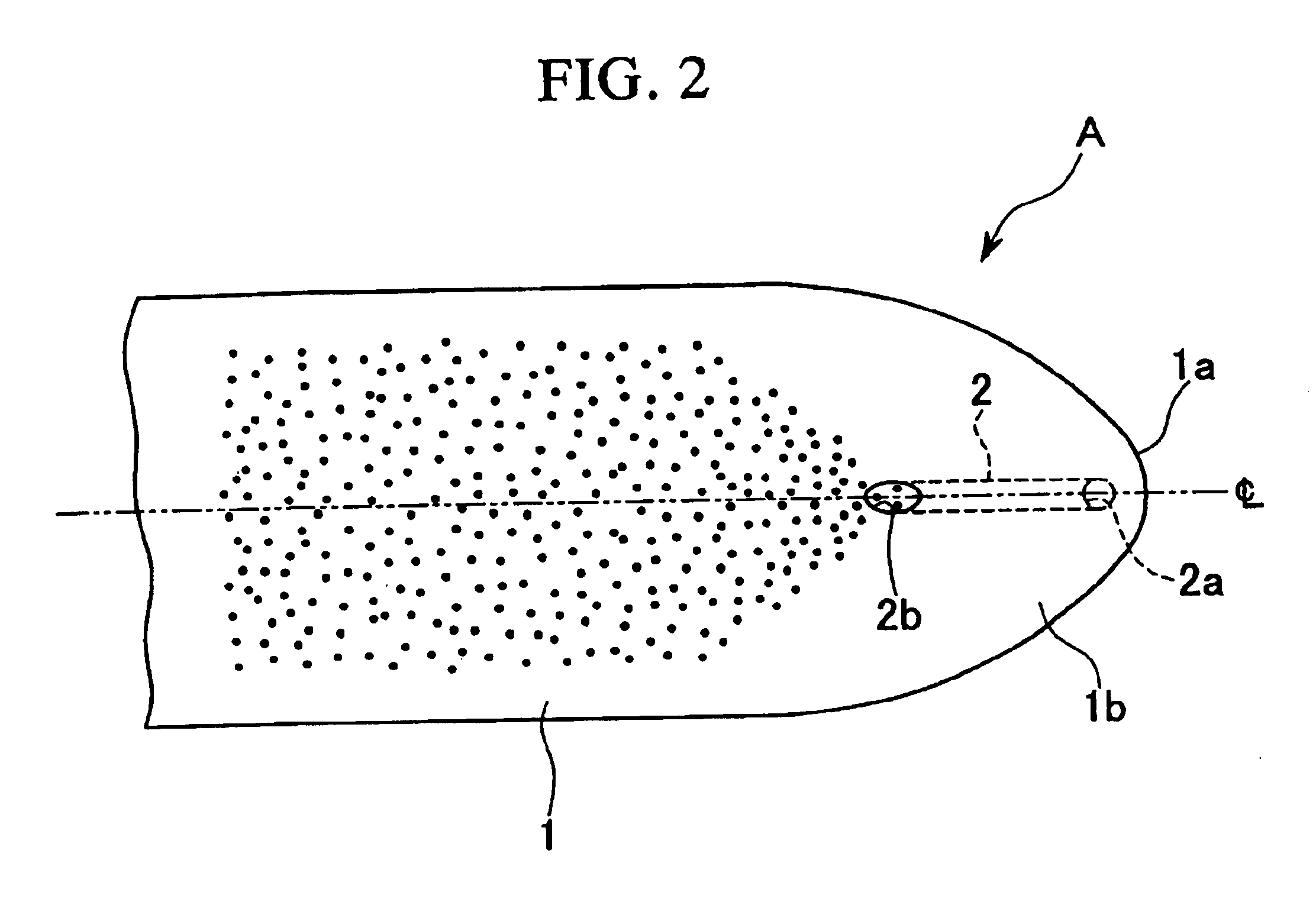

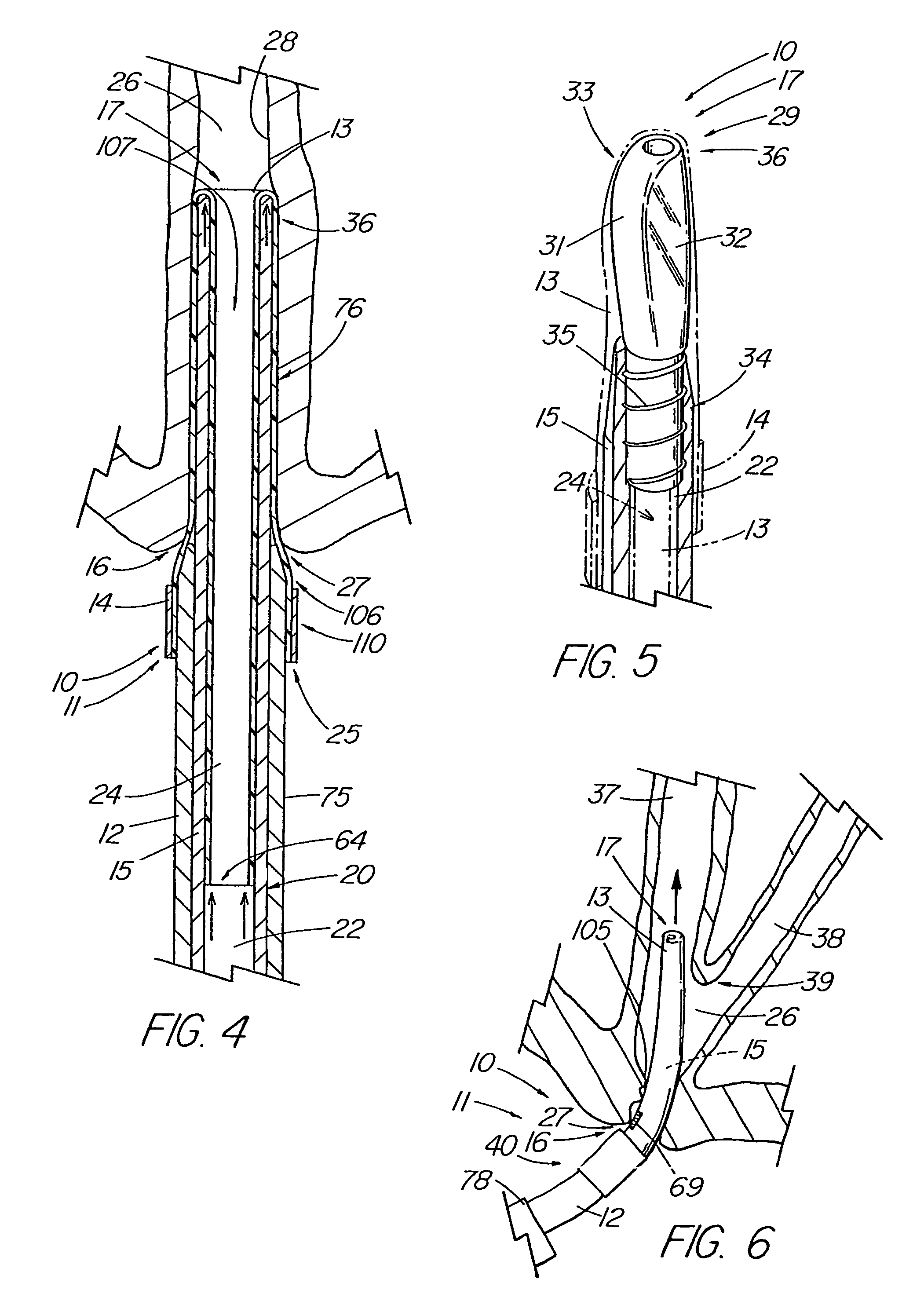

Multi-layer coaxial vaso-occlusive device

InactiveUS20050171572A1Reduces aggregate frictionDecreasing resistance to manipulationDilatorsCharacter and pattern recognitionMetallic materialsPliability

A vaso-occlusive device includes inner, intermediate, and outer elements arranged coaxially. The inner element is a filamentous element, preferably a microcoil. The intermediate element is made of a non-metallic material, preferably an expansile polymer. The outer element is substantially non-expansile and defines at least one gap or opening through which the intermediate element is exposed. In a preferred embodiment, when the intermediate element is expanded, it protrudes through the at least one gap or opening in the outer element and assumes a configuration with an undulating, convexly-curved outer surface defining a chain of arcuate segments, each having a diameter significantly greater than the diameter of the outer element. The expanded configuration of the intermediate element minimizes friction when the device is deployed through a microcatheter, thereby reducing the likelihood of buckling while maintaining excellent flexibility. The result is a device with enhanced pushability and trackability when deployed through a microcatheter.

Owner:MICROVENTION INC

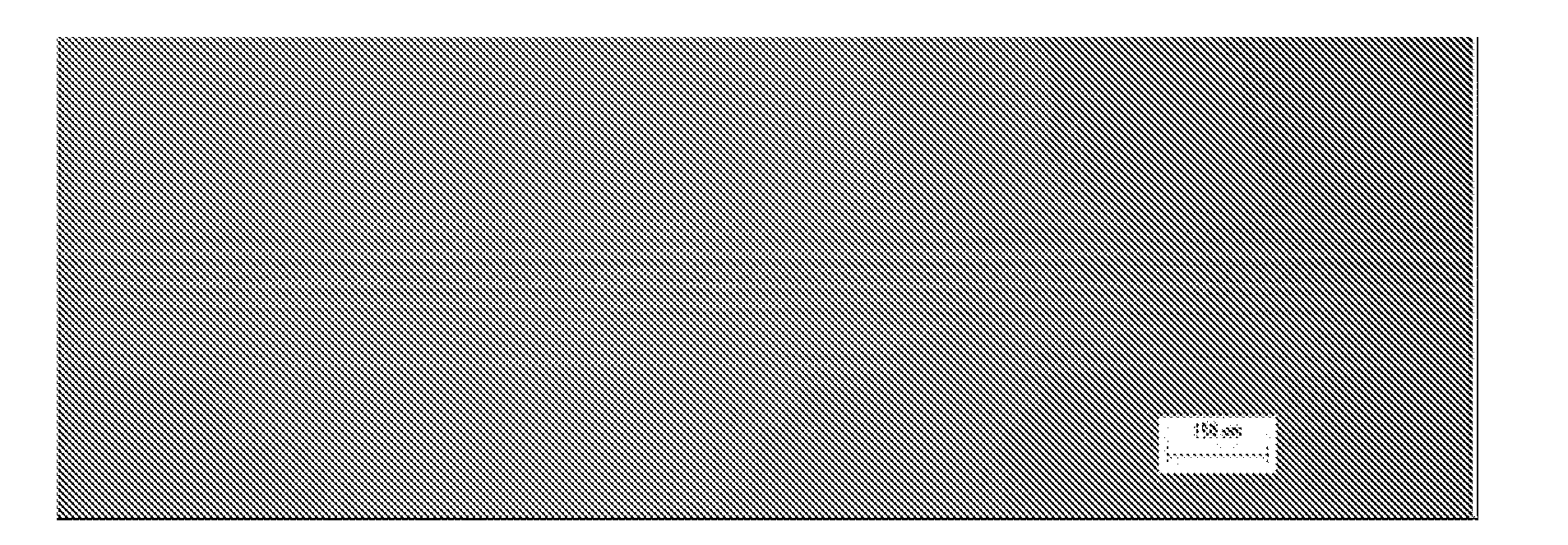

Glass with high frictive damage resistance

ActiveUS20120282449A1Improve initial strengthImprove the immunityDecorative surface effectsSynthetic resin layered productsPolymer scienceLayer thickness

A glass article exhibiting improved resistance to fictive surface damage and a method for making it, the method comprising removing a layer of glass from at least a portion of a surface of the article that is of a layer thickness at least effective to reduce the number and / or depth of flaws on the surface of the article, and then applying a friction-reducing coating to the portion of the article from which the layer of surface glass has been removed.

Owner:CORNING INC

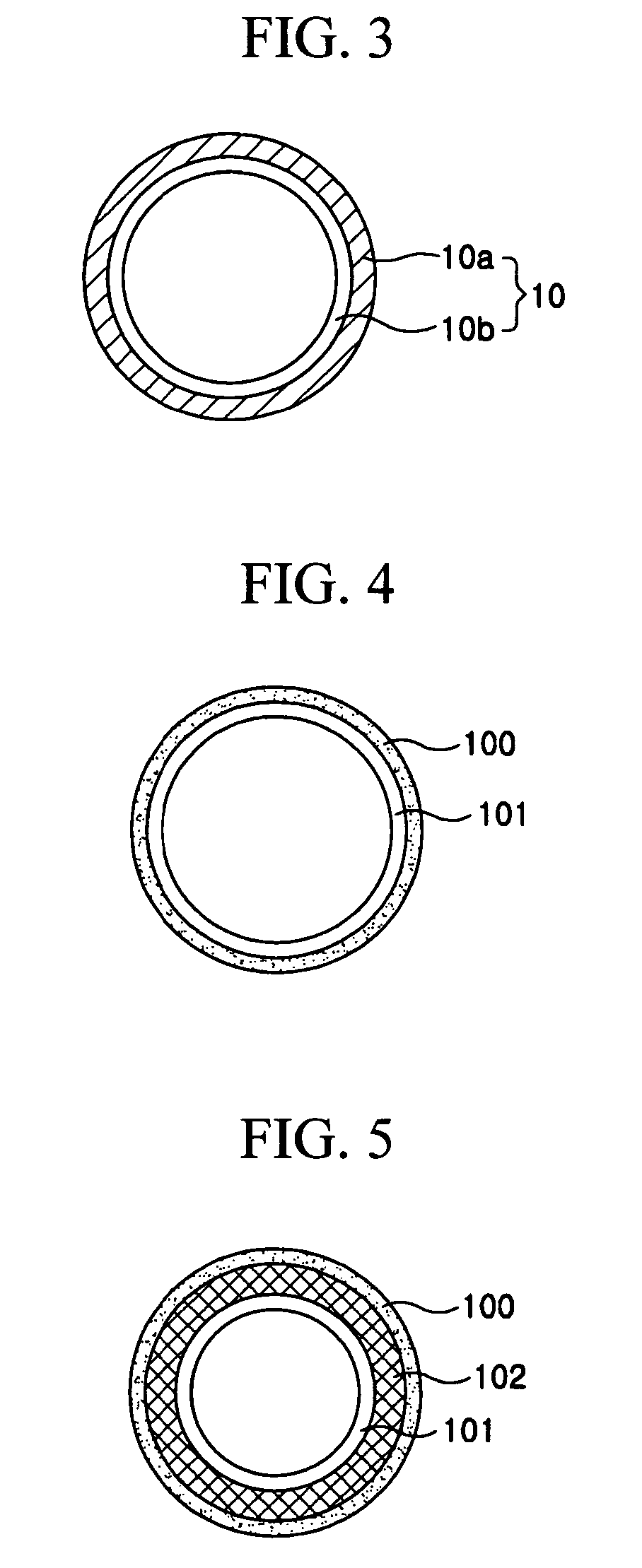

Non-expandable transluminal access sheath

InactiveUS20060253102A1Improved radiopaque characteristicMinimize potential for damageCannulasInfusion syringesFluid transportVisibility

A transluminal sheath is disclosed that permits instrumentation to be passed therethrough. The transluminal sheath comprises a composite structure with an inner layer, an outer layer, and a reinforcing layer. The materials comprising the inner and outer layer are plastically deformable and maintain their shape, once bent into a specific configuration. The reinforcing layer further has radiopacity enhancing coatings to improve visibility under fluoroscopy and a system of flutes running longitudinally, to enhance fluid transport and reduce friction.

Owner:ONSET MEDICAL CORP

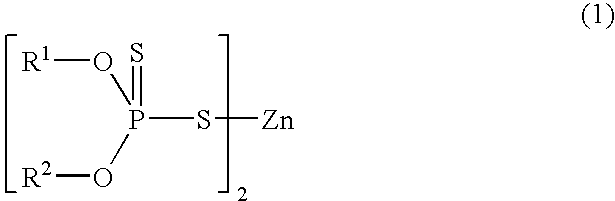

Low ash, low phosphorus and low sulfur engine oils for internal combustion engines

InactiveUS6730638B2Reduce friction and wearReduce frictionOrganic chemistryOrganic compound preparationCombustionSulfur

A lubricating composition for internal combustion engines especially useful with fuels having less than 350 ppm sulfur comprises a lubricating oil basestock, a boron containing ashless dispersant, a molybdenum containing friction reducing agent, a metal type detergent and zinc dithiophosphate.

Owner:EXXON RES & ENG CO

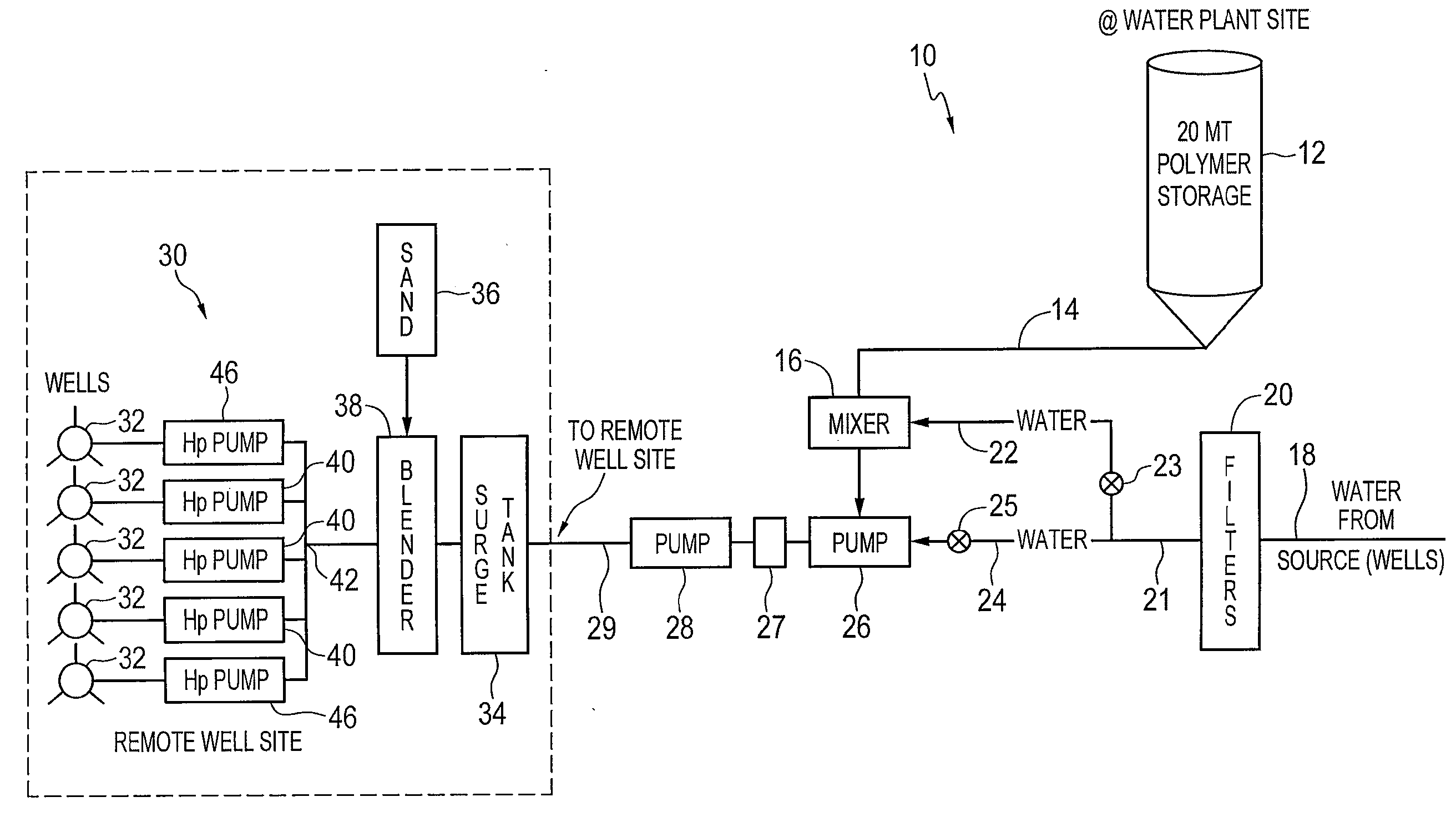

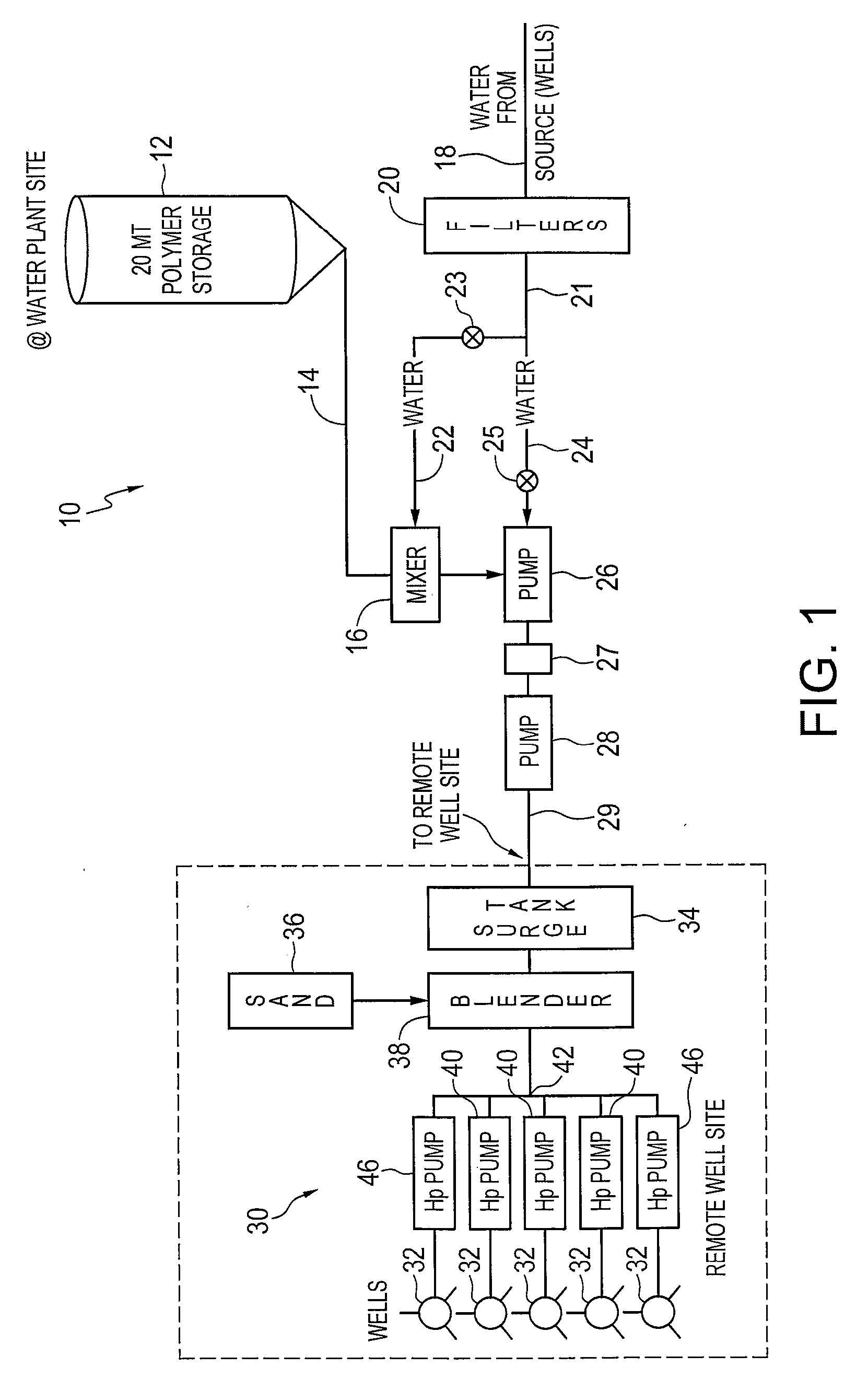

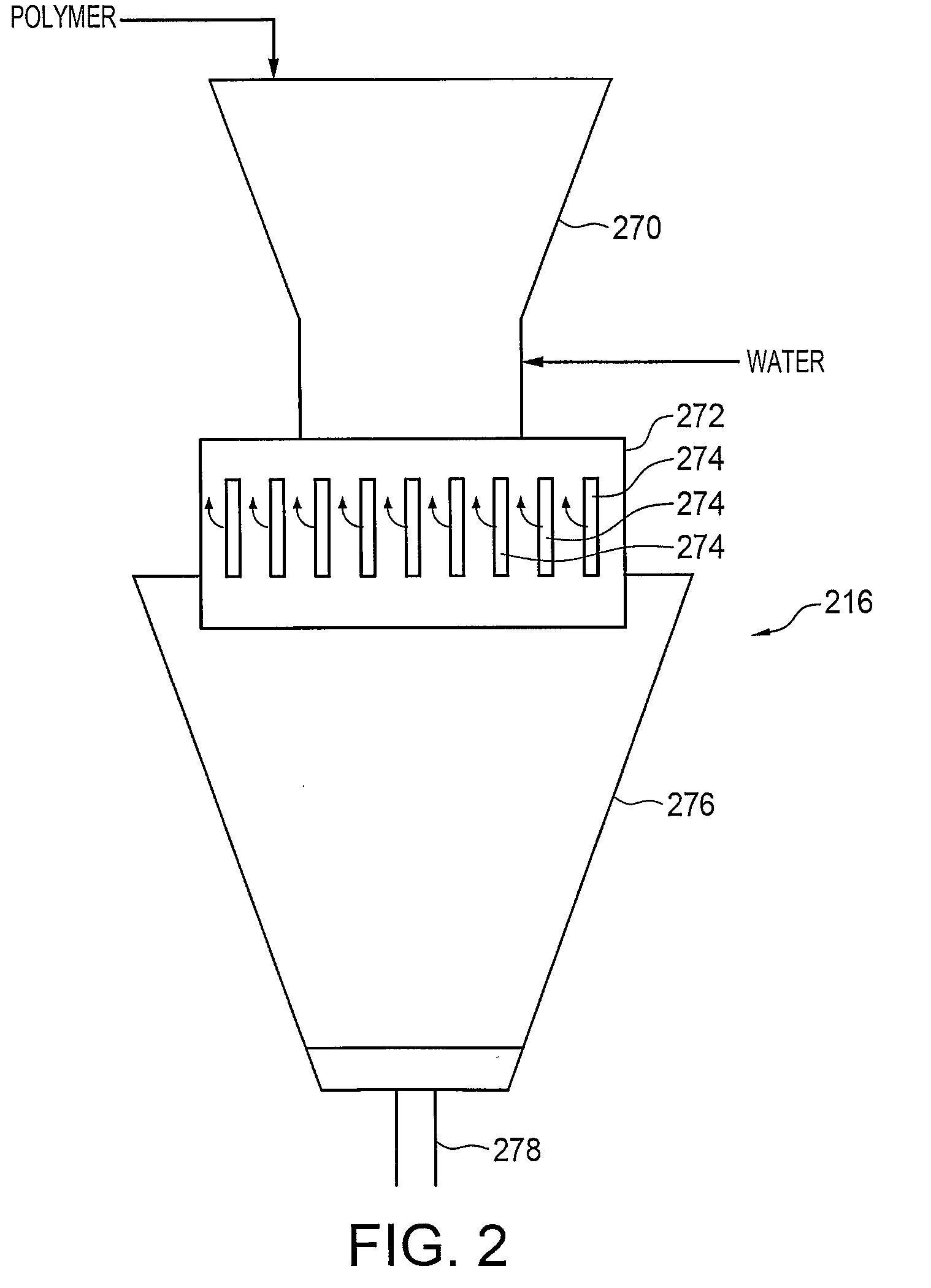

Process and process line for the preparation of hydraulic fracturing fluid

InactiveUS20100132949A1Drilling rodsTransportation and packagingFracturing fluidHydraulic fracturing

A process and process line is provided for preparing a friction-reduced hydraulic fracturing fluid at a central location which can be readily transported to an oil or gas well in a formation at a well site, comprising: preparing a mixture of polymer and water at the central location by shearing the polymer in the water in a high shear environment to create the friction-reduced hydraulic fracturing fluid; pumping the friction-reduced hydraulic fracturing fluid through a series of pumps and pipelines to the well site; and injecting the hydraulic fracturing fluid into the oil or gas well at a pressure sufficient to cause fracturing of the formation.

Owner:OVINTIV CANADA ULC

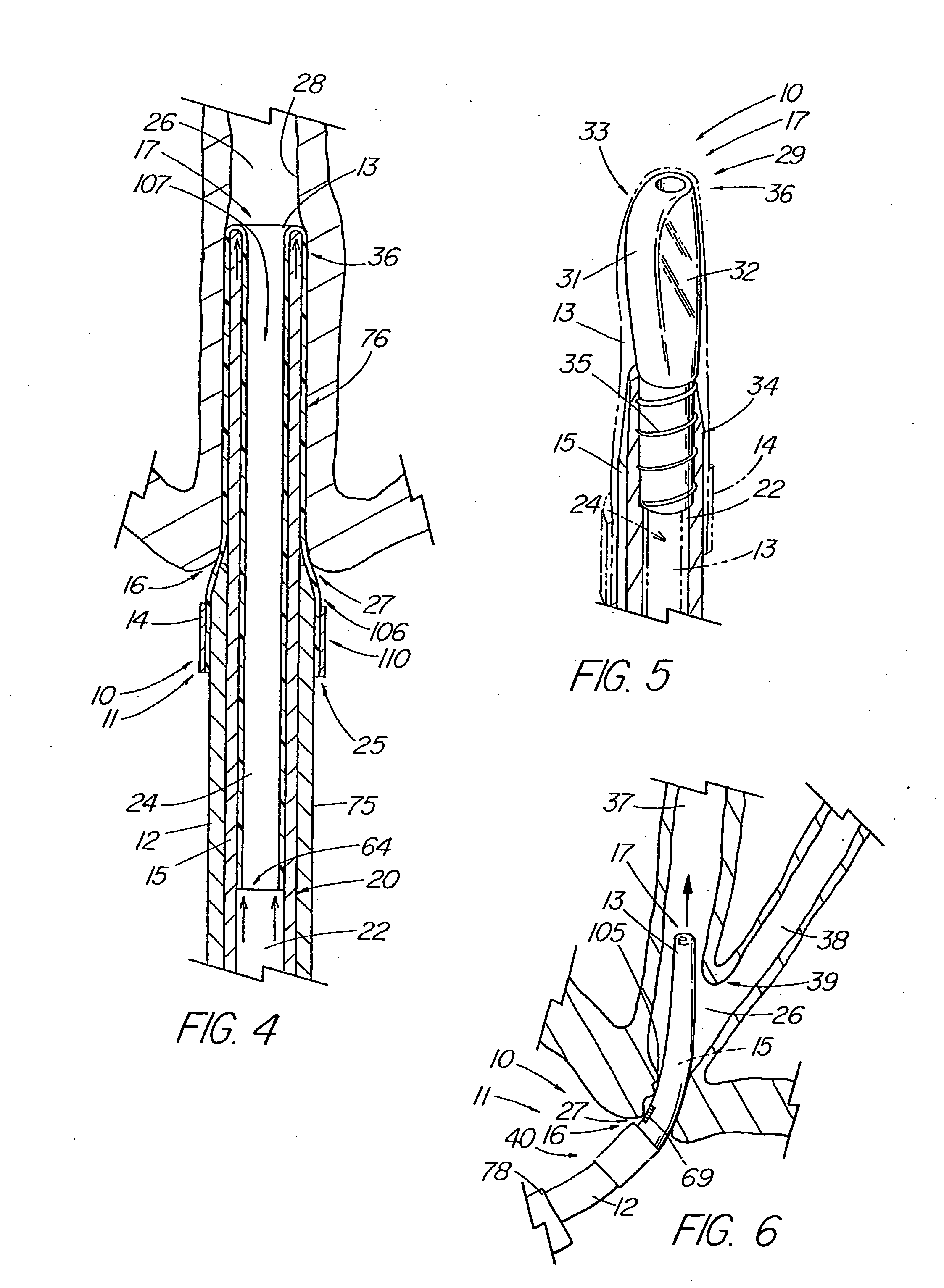

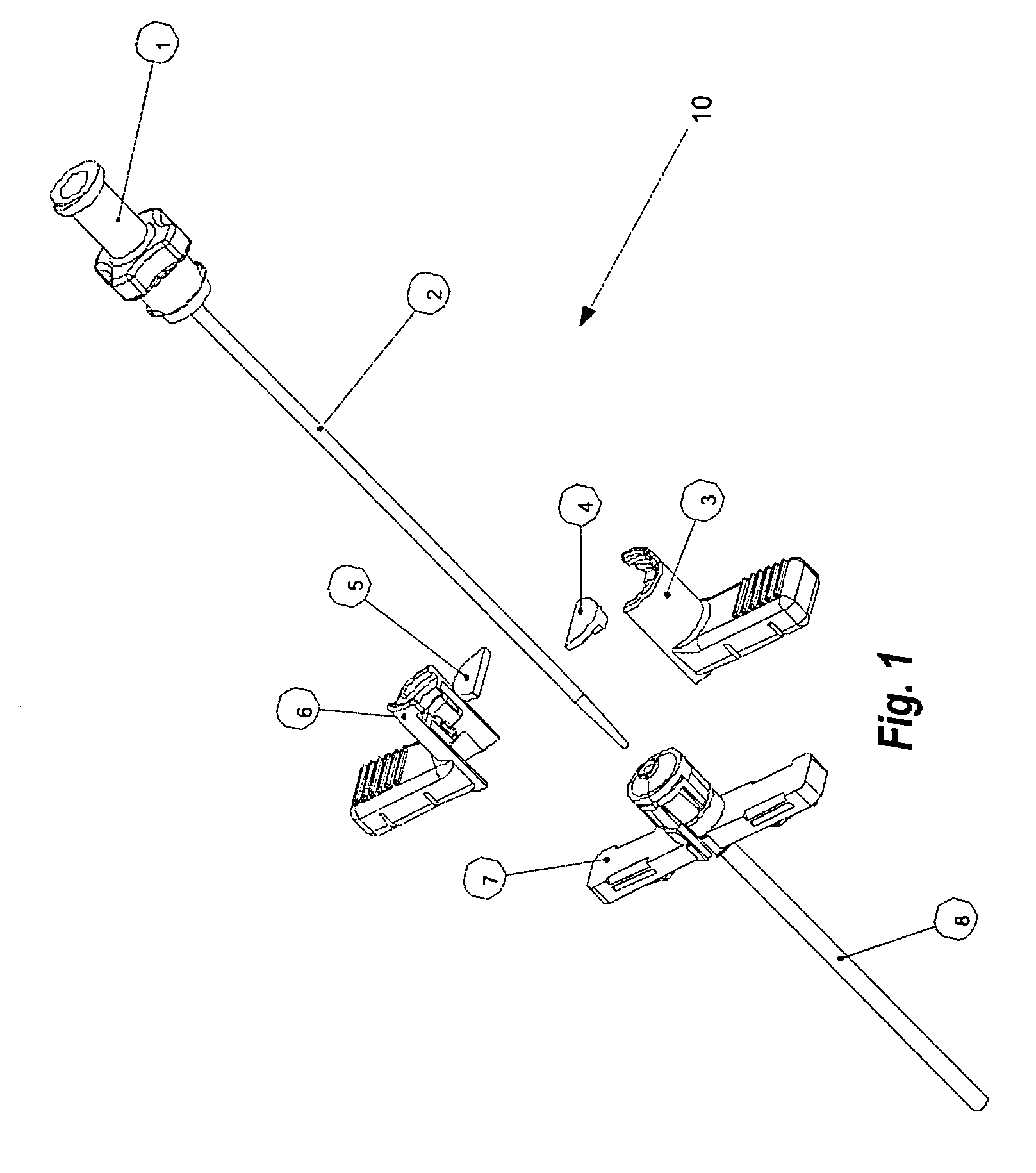

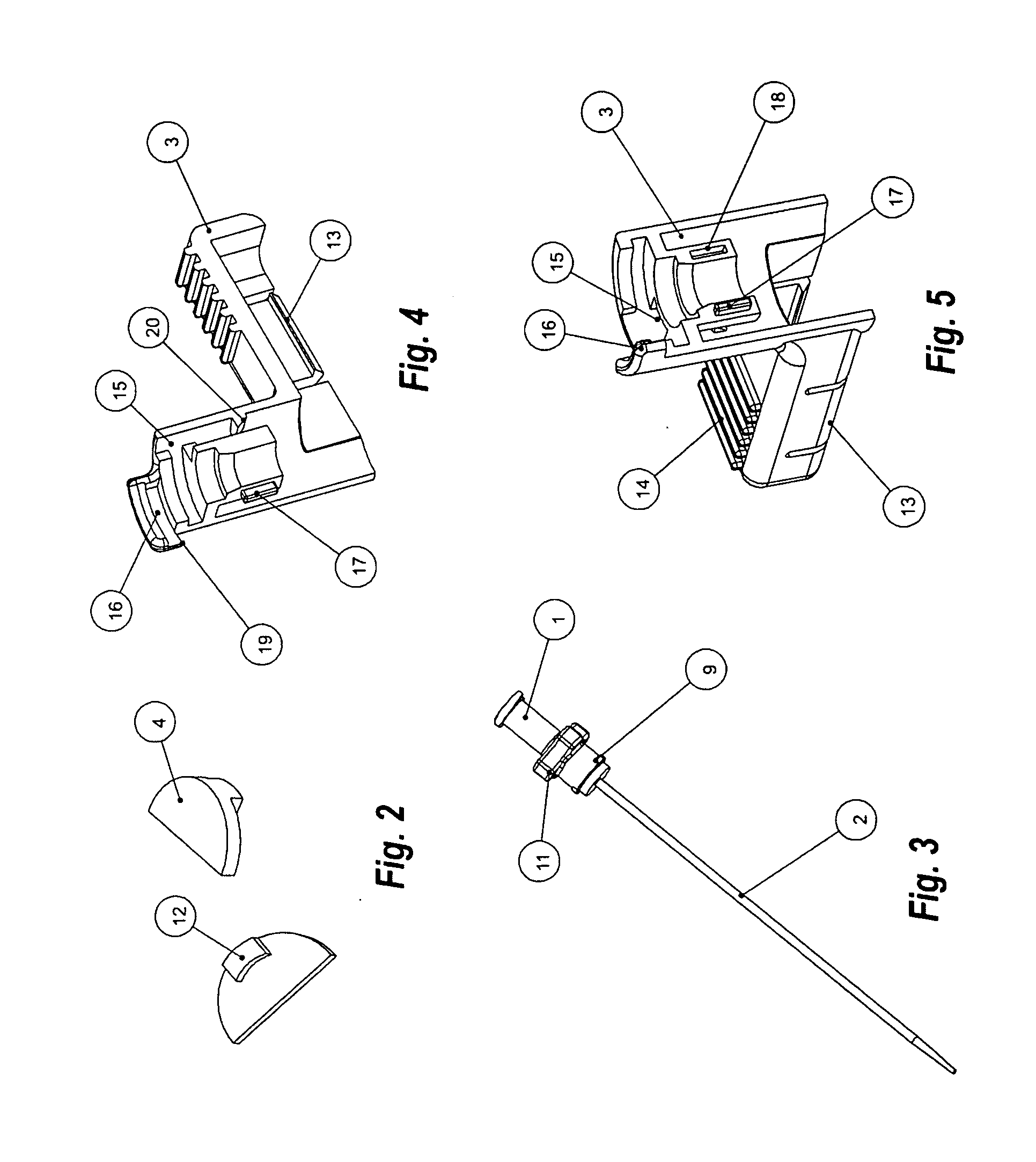

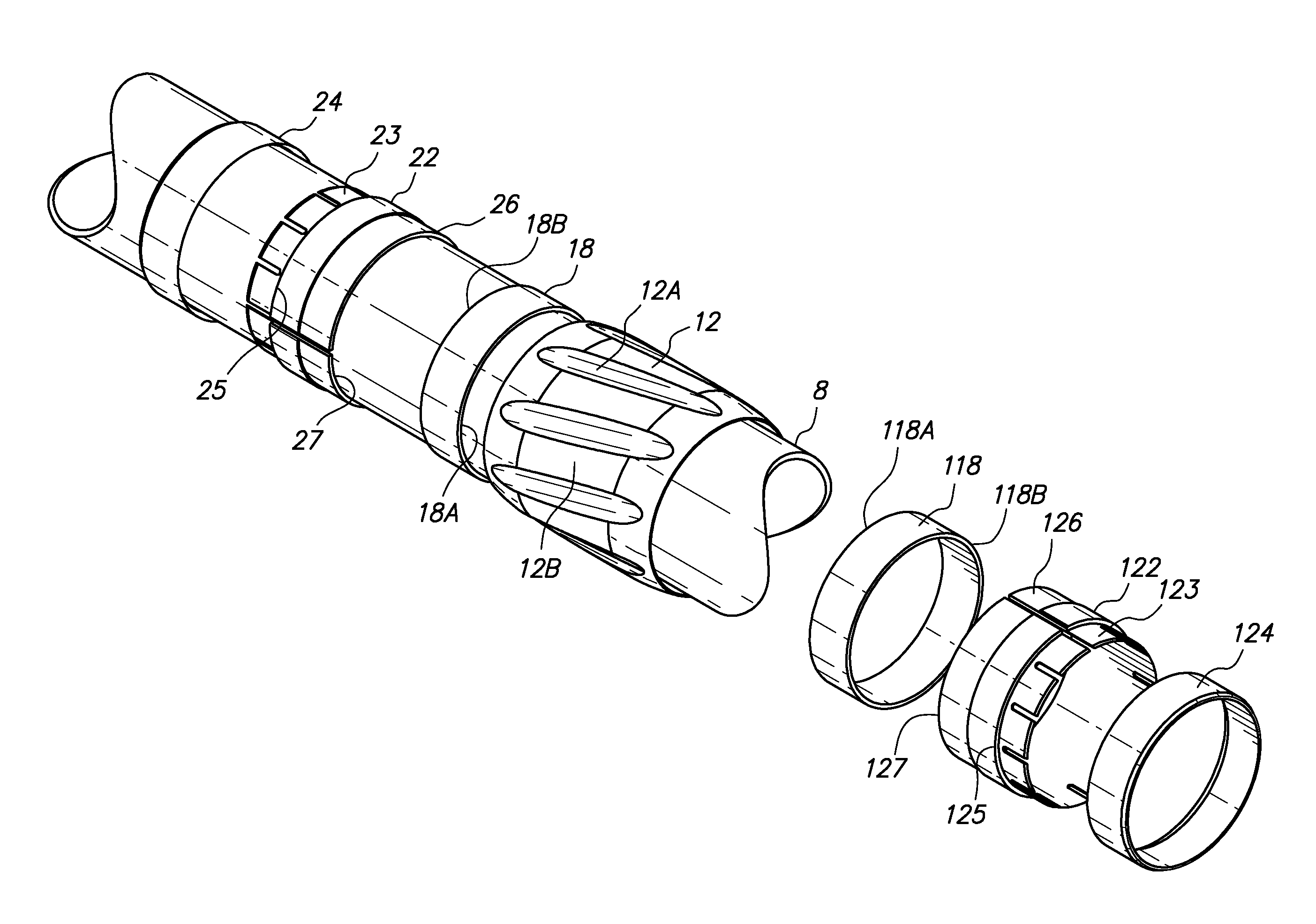

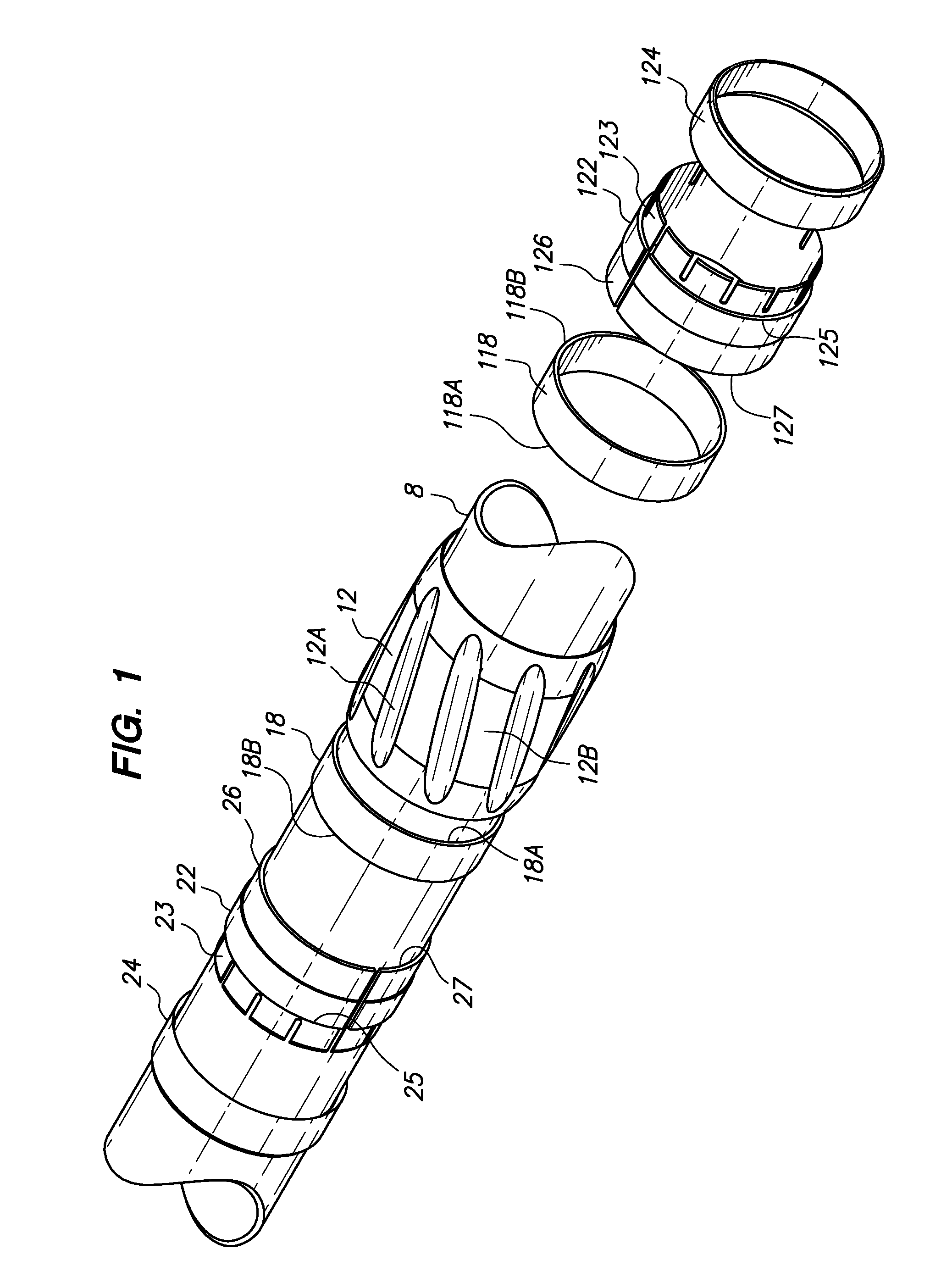

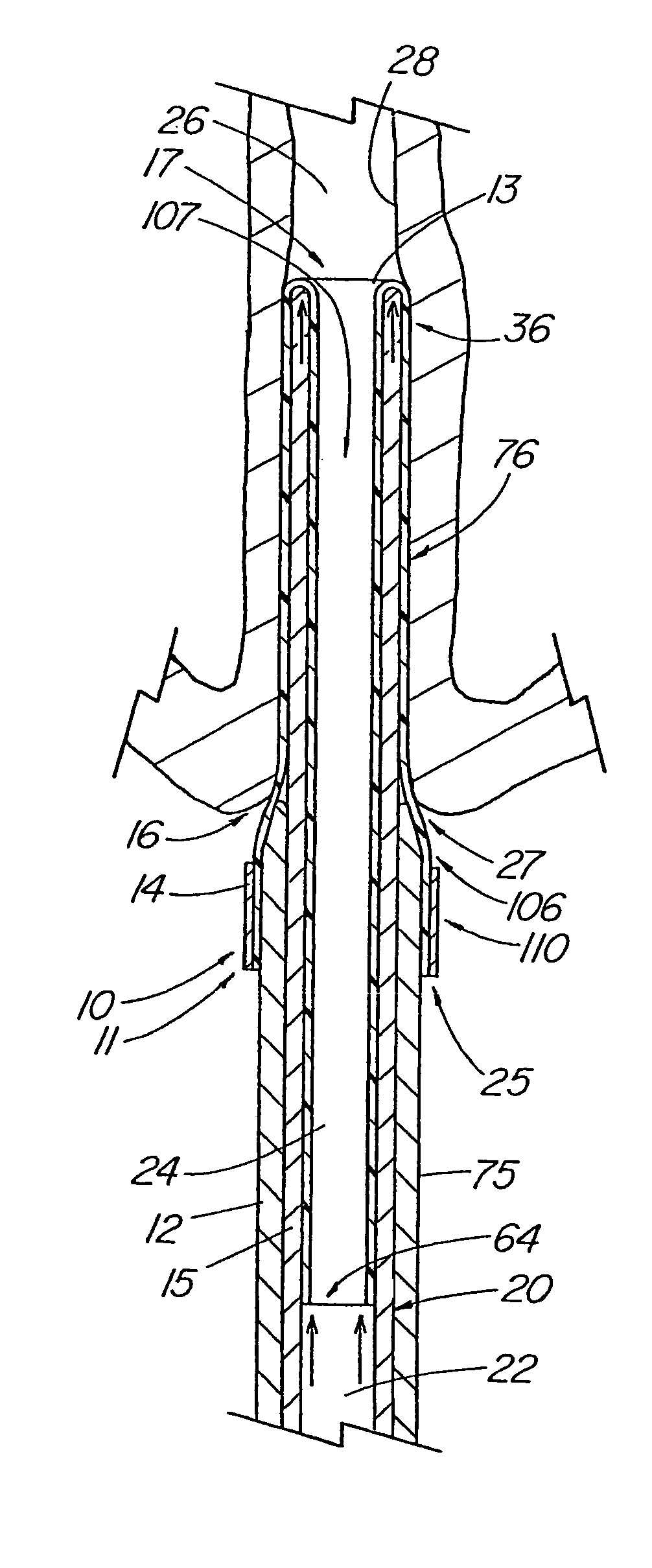

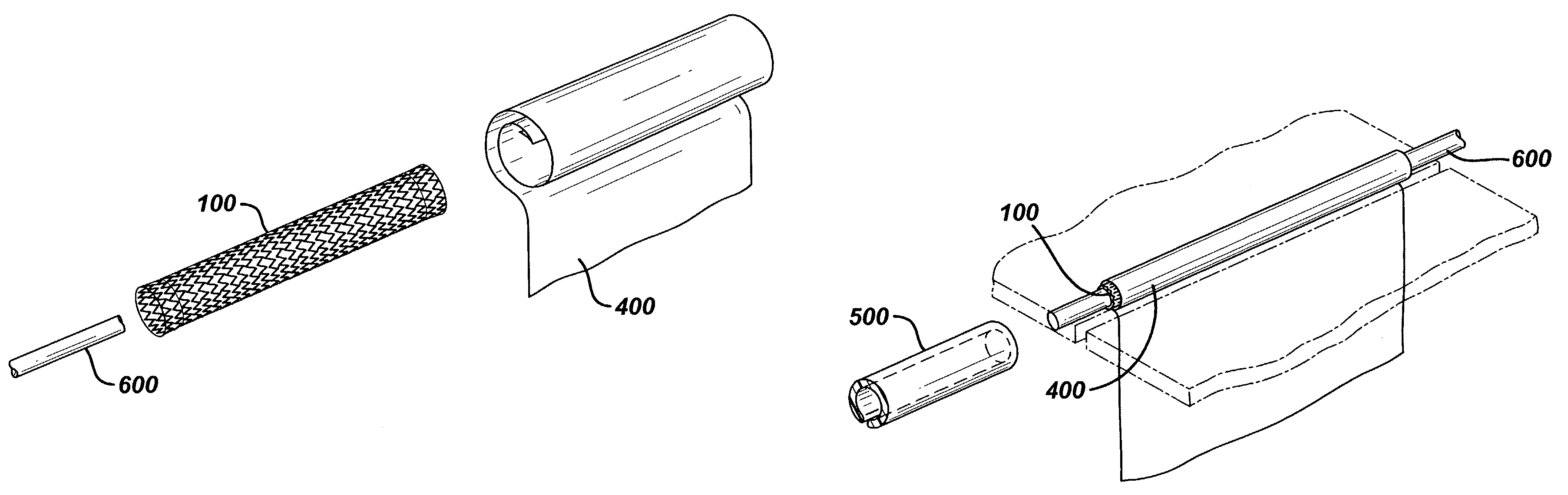

Introducer apparatus with eversible sleeve

InactiveUS20060173422A1Control expansionReduce patient discomfortGuide needlesStentsNasal passageNasal passages

Disclosed is an introducer apparatus comprising an sleeve fixation mechanism or introducer member, such as a catheter, introducer, or ring-like structure, which is attached to a protective sleeve comprising a thin flexible material such a polymeric film. The sleeve is inverted into the passageway of a second member, such as a catheter, feeding tube, introducer, etc., that is advanced through the passageway of the introducer member and is introduced into a bodily passage of a patient, such as the bile duct, nasal passages, colon, etc. The sleeve everts from the passageway of the second member during its advancement to lay down a friction-reducing surface. The sleeve prevents frictional contact between the second member and delicate or sensitive tissues.

Owner:COOK MEDICAL TECH LLC

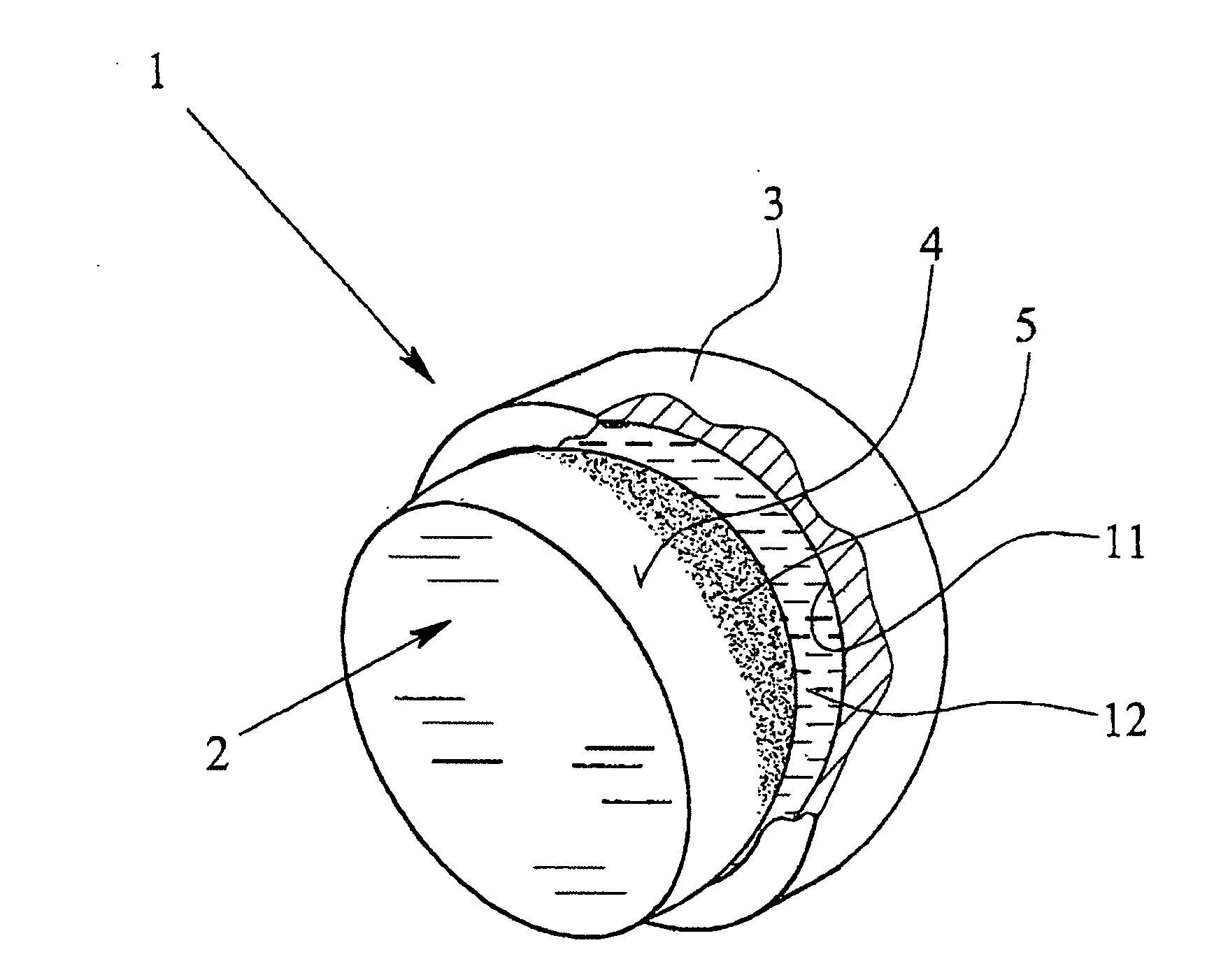

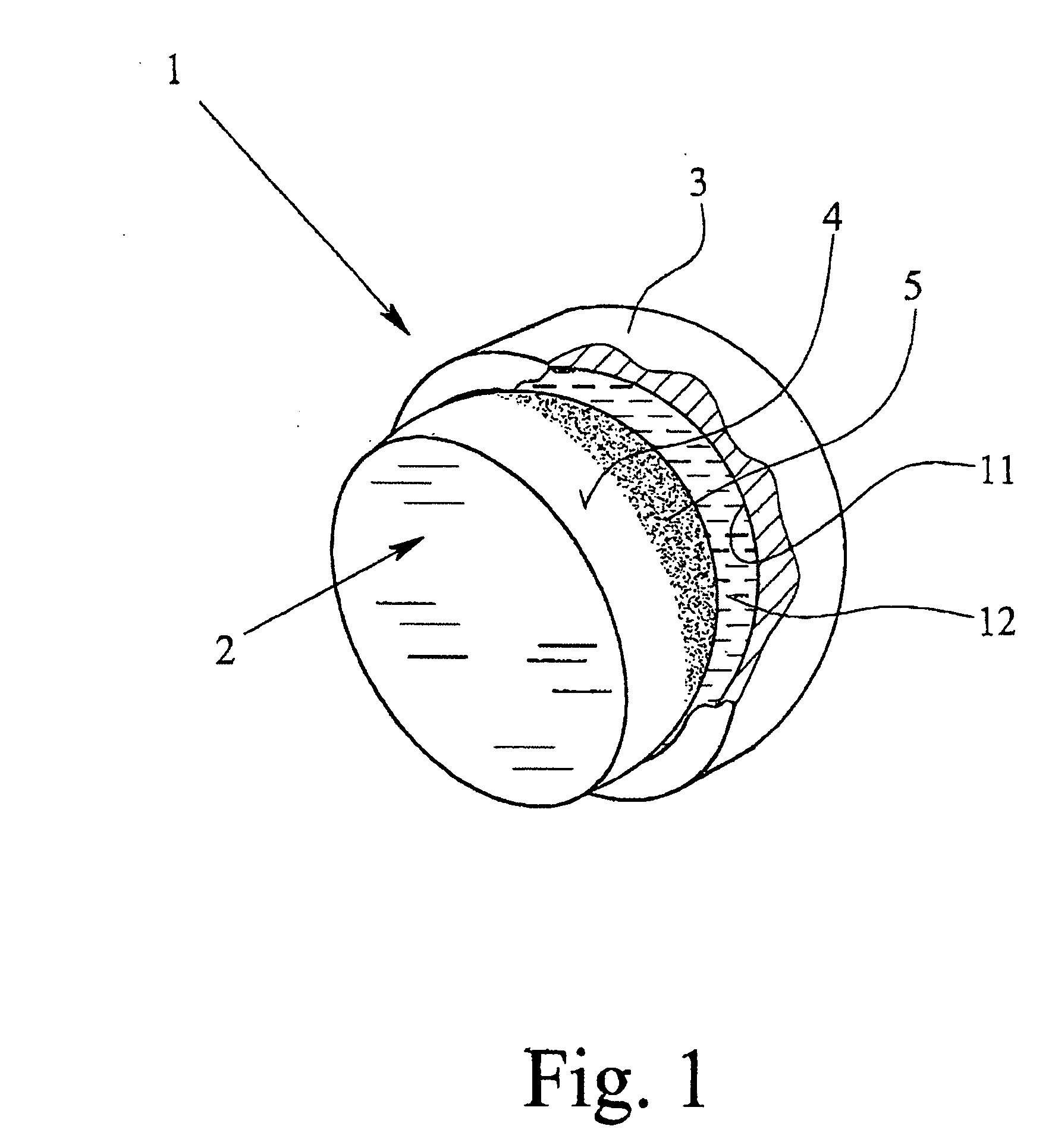

Bearing and composite structure

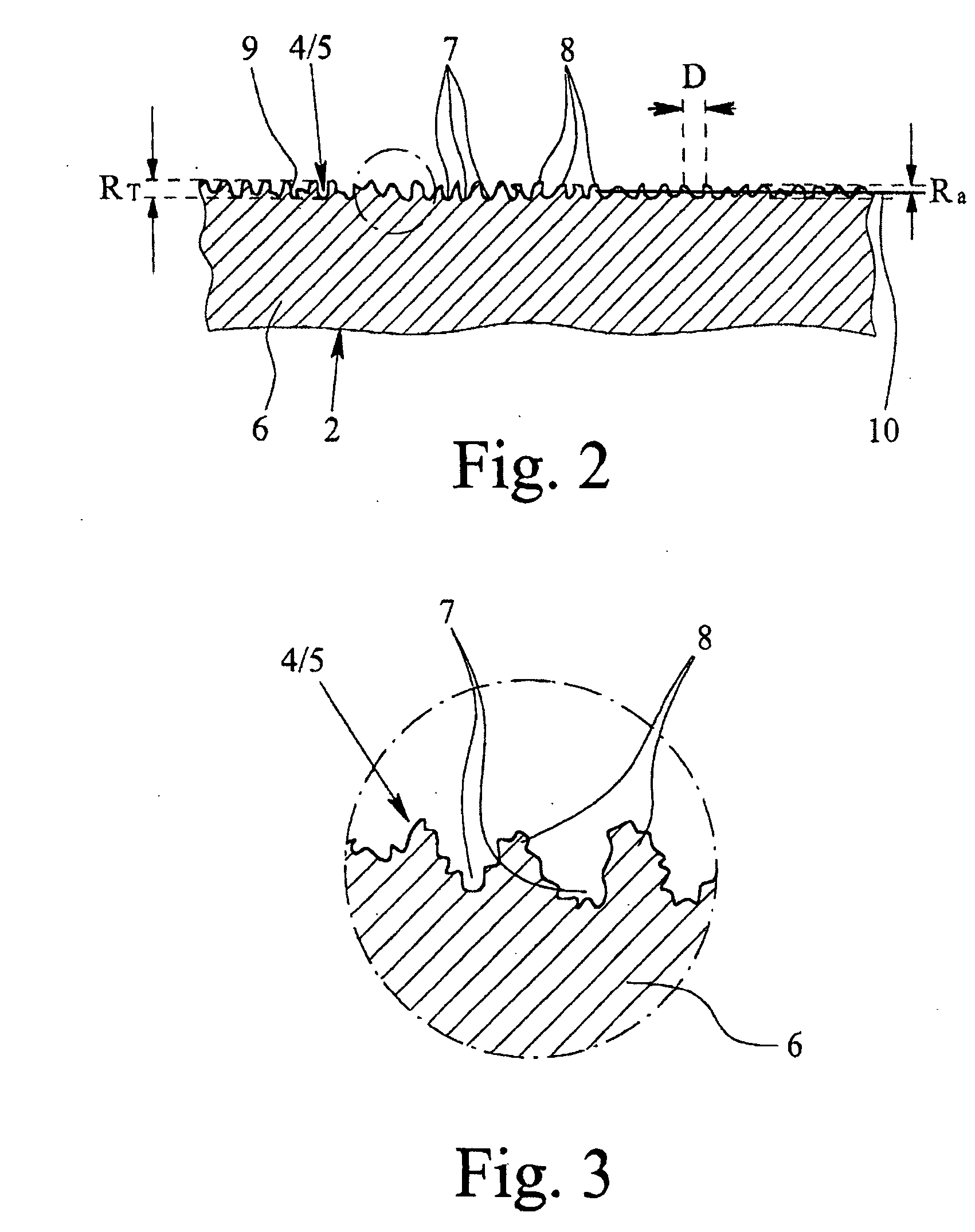

InactiveUS20050049716A1Minimize abrasionMinimize wearPharmaceutical delivery mechanismJoint implantsBearing surfaceMaterials science

A bearing, a composite structure, an implant and a method for producing a bearing with a micro-rough bearing surface are proposed. An improvement in the bearing properties—minimization of particle formation and reduction of friction—and a universally usable composite structure are achieved by the surface of the bearing or of the composite structure being roughened by etching and possibly provided with a coating, preferably consisting of plastic.

Owner:UNIV DUISBURG ESSEN

Friction reducing devices

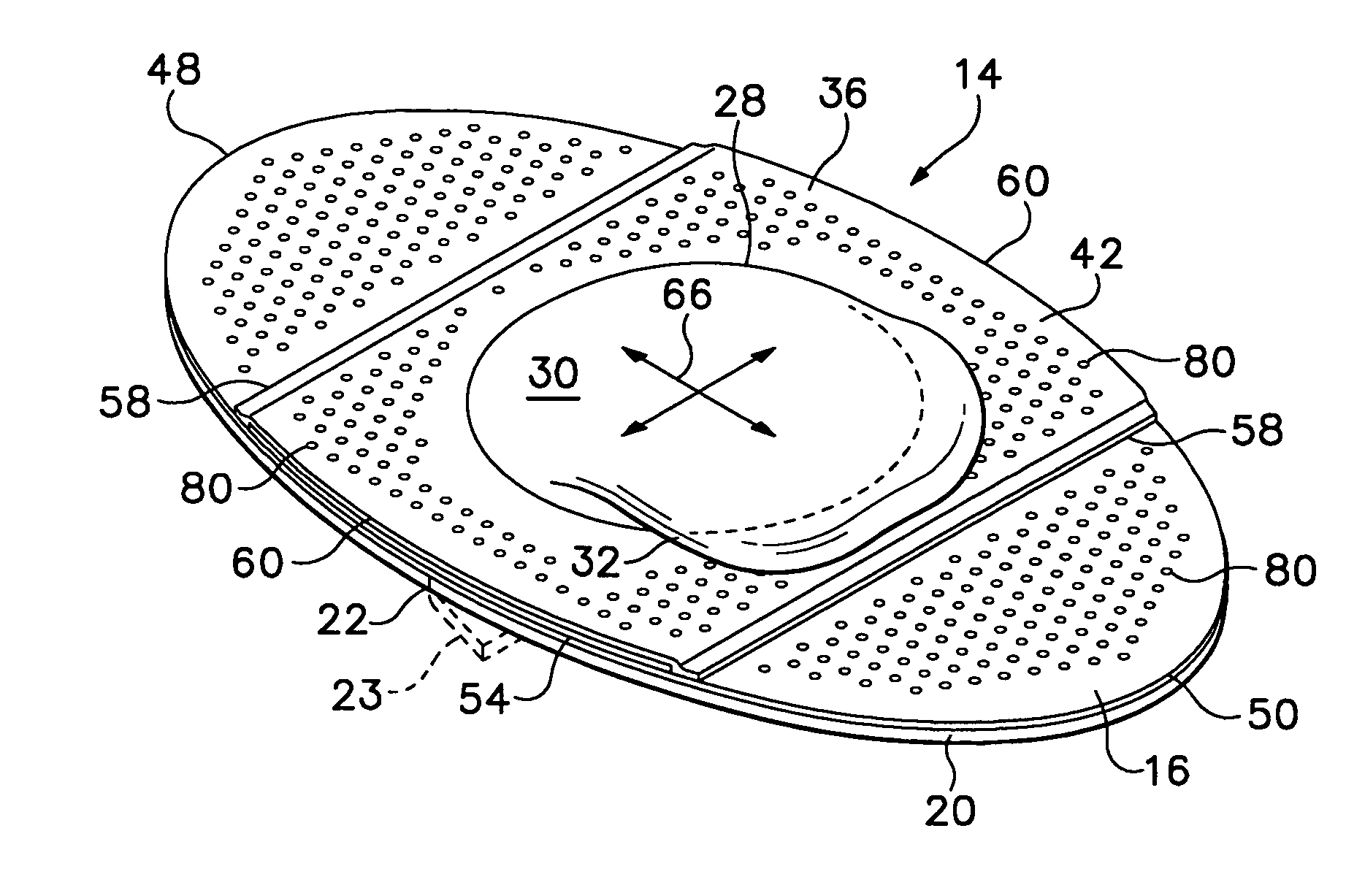

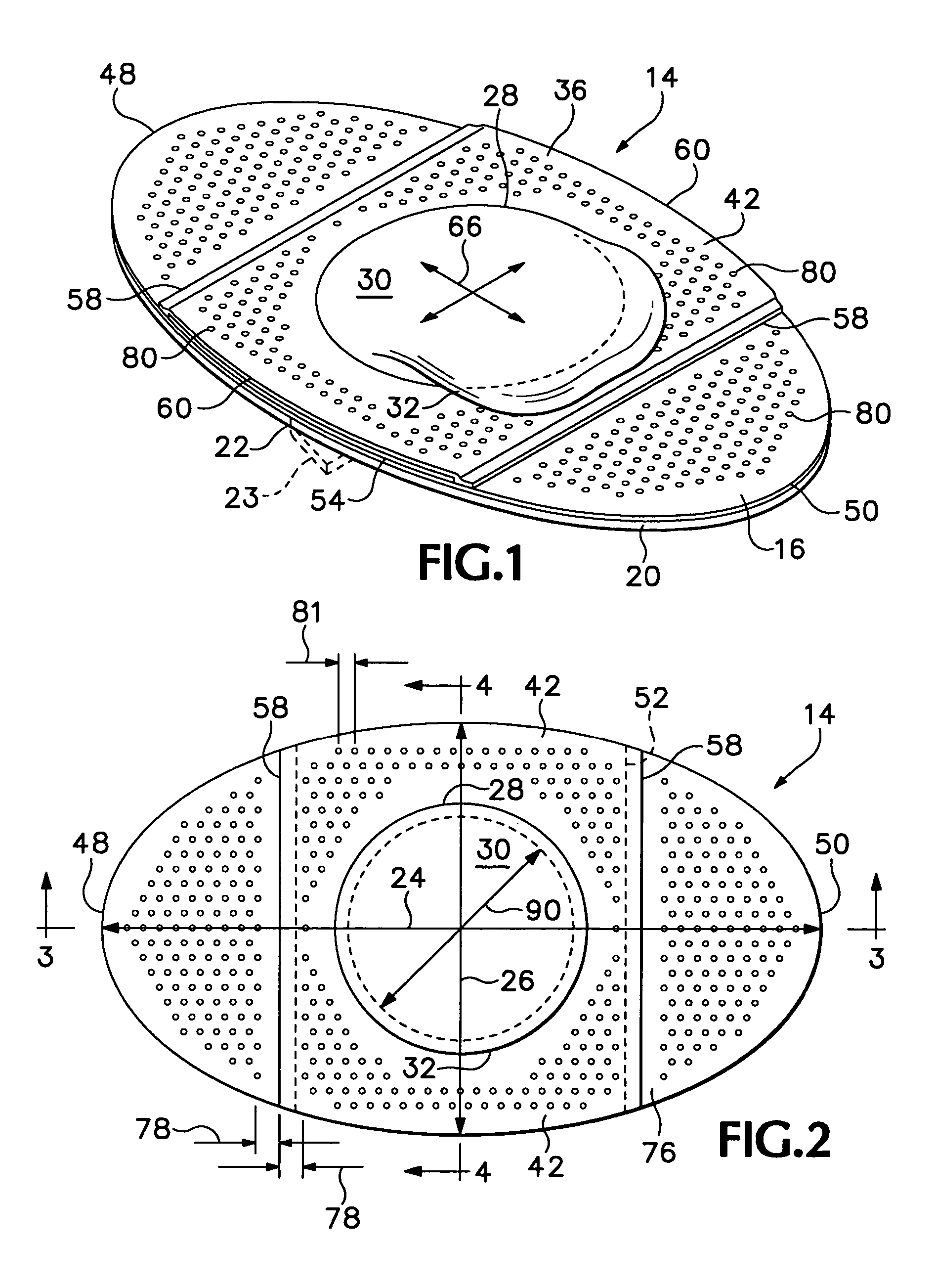

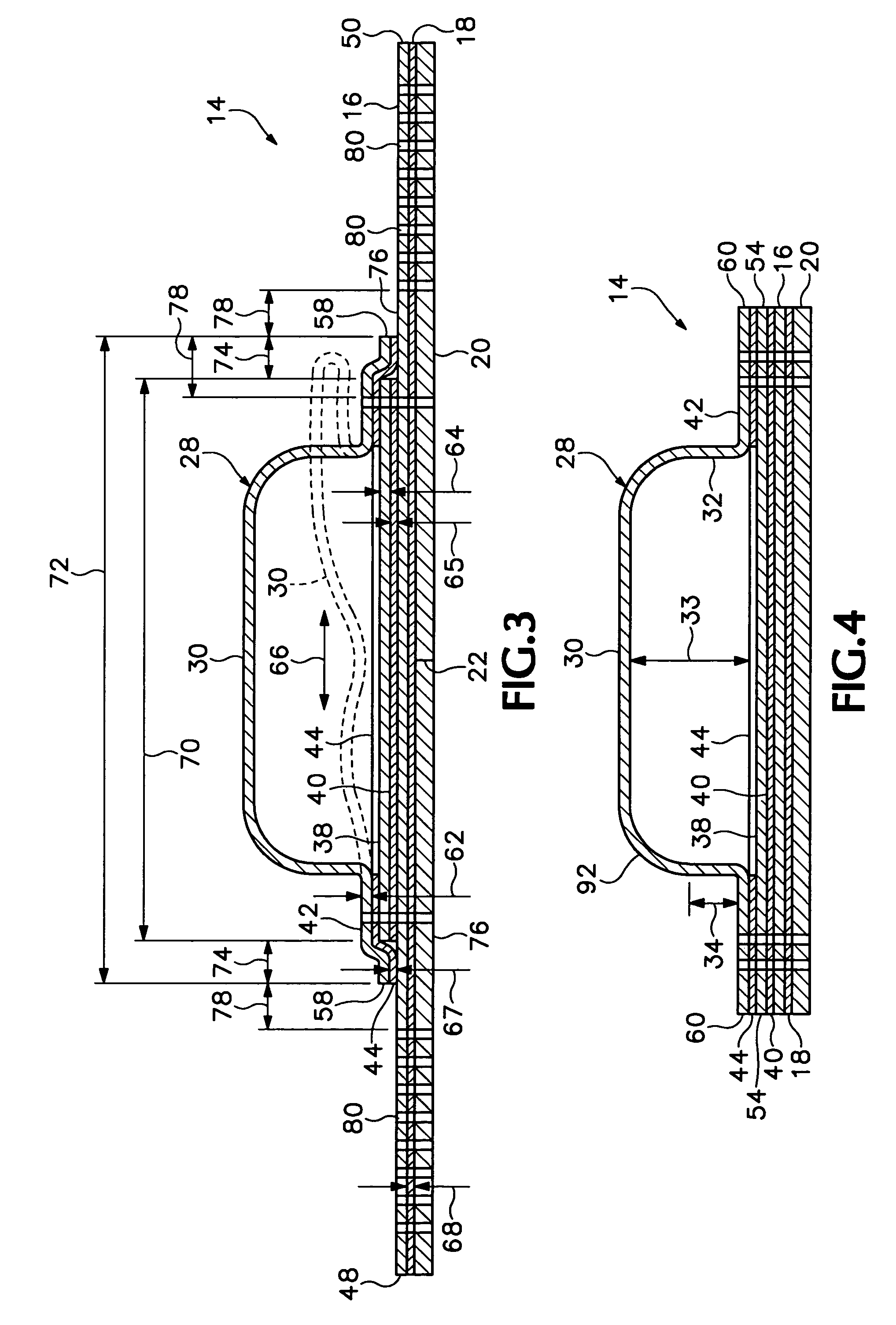

InactiveUS7087806B2Enhance moisture and vapor transferIncrease flexibilityFinger bandagesAdhesive dressingsSkin breakdownSkin contact

A self-adhesive bandage for prevention and treatment of skin breakdown by relief of friction and shear forces. The bandage includes a pair of thin film membranes, one of which is a portion of a dome and is free to move a limited distance with respect to the other. The dome is located on a skin contact layer that can be adhered to one's skin. A method of making such a bandage includes forming a dome in a flexible film and adhesively attaching a skirt surrounding the dome to a skin contact layer. Similar friction reducing devices may be incorporated in shoes, other clothing, or sports equipment.

Owner:ADVANCED WOUND SYST

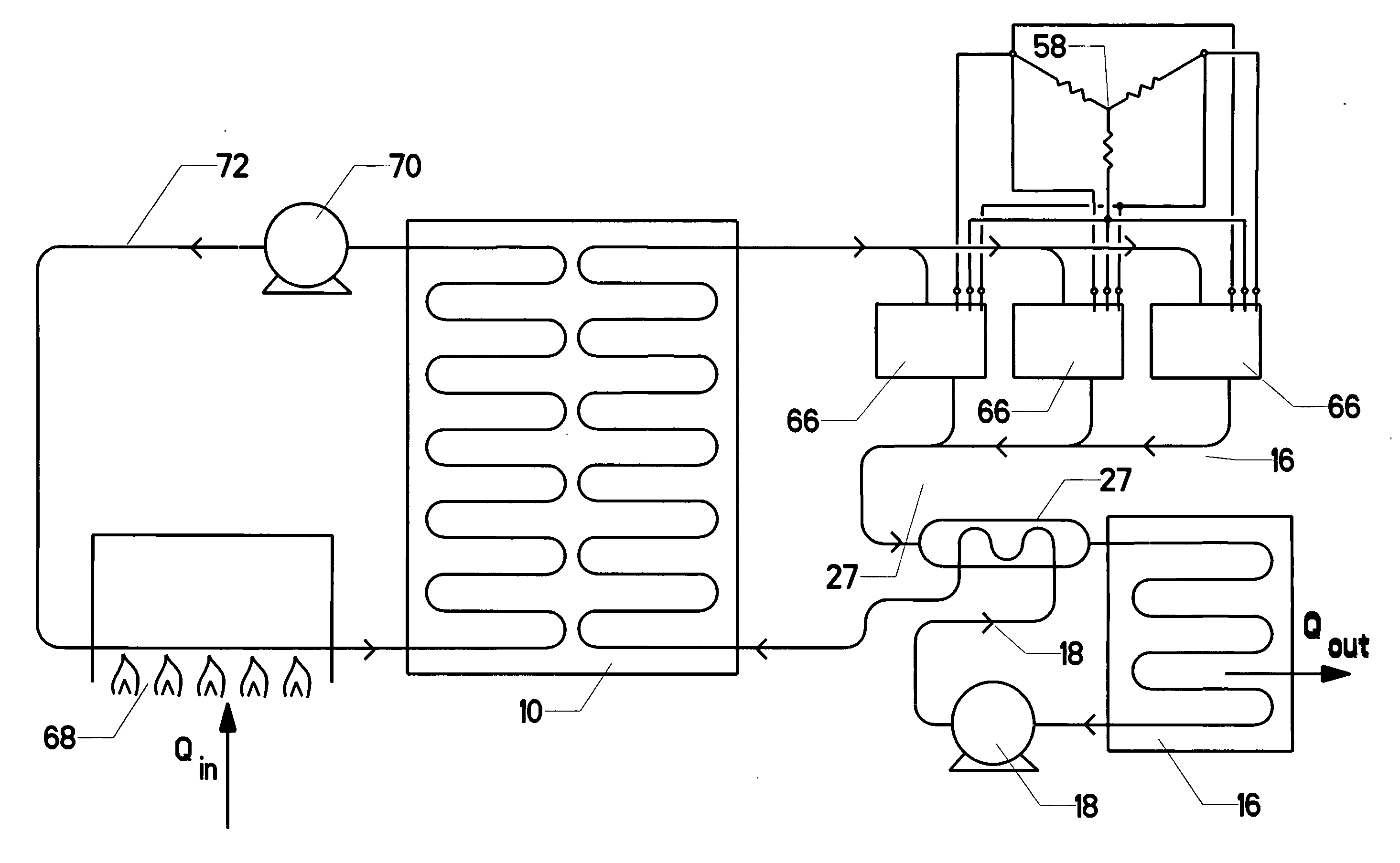

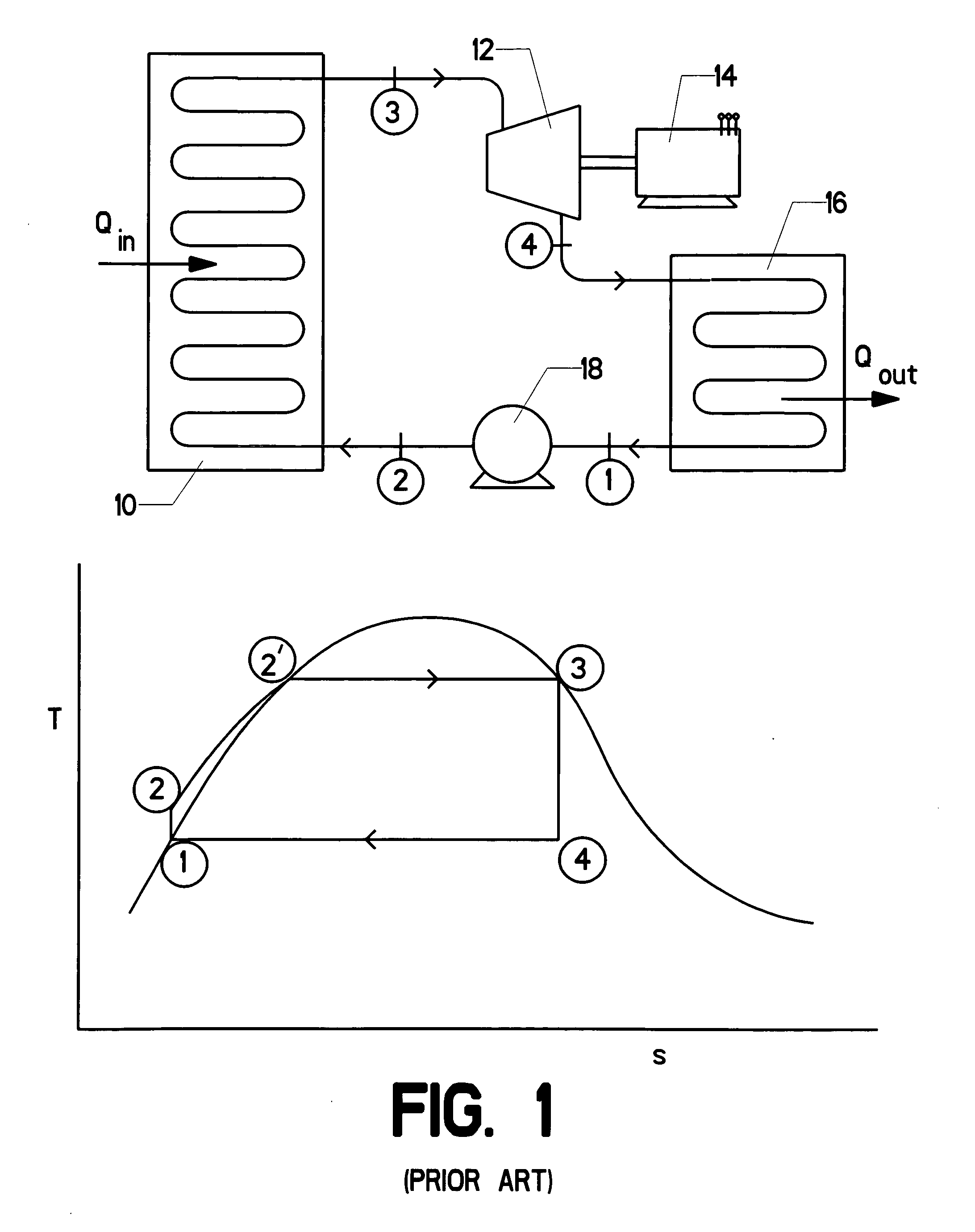

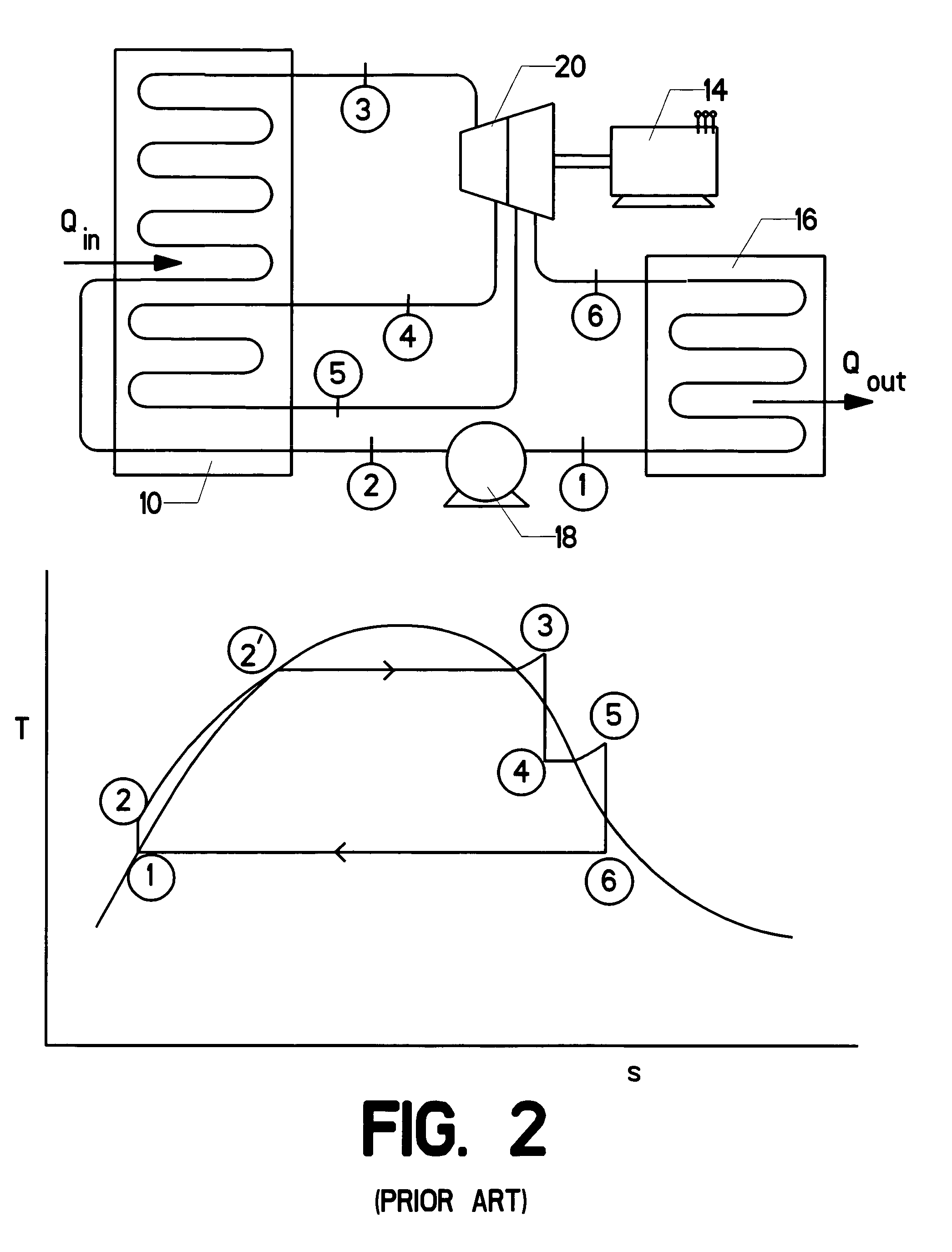

Rankine cycle heat recovery methods and devices

InactiveUS20090277400A1Minimize frictional lossIncrease speedLiquid coolingCoolant flow controlRecovery methodMagnetic bearing

An integrated expansion turbine / electrical generator assembly (collectively referred to as a “turbo-generator”) suitable for use in waste heat recovery and similar applications. The turbo-generator uses a common shaft mounting a one or more stage expansion turbine and a homopolar electrical generator. Magnetic levitating axial and thrust bearings are used to hold the common shaft in its proper position with a fixed housing. The magnetic bearings minimize frictional losses, allowing the common shaft to spin at a very high rotational velocity. Sensor rings continually monitor the common shaft's position. This information is used by control electronics to regulate the magnetic bearings in order to hold the rotating shaft's position. Electrical energy is extracted from the rotating shaft in the form of a direct current. Preferably integrated power-switching electronics are used to generate single or three-phase AC power, which can be phase-matched to an existing power grid or other application.

Owner:DANFOSS AS

Nano graphene-modified lubricant

ActiveUS8222190B2Improve the lubrication effectWider surface areaBase-materialsCarbon nanotubeSingle layer graphene

A lubricant composition having improved lubricant properties, comprising: (a) a lubricating fluid; and (b) nano graphene platelets (NGPs) dispersed in the fluid, wherein nano graphene platelets have a proportion of 0.001% to 60% by weight based on the total weight of the fluid and the graphene platelets combined. Preferably, the composition comprises at least a single-layer graphene sheet. Preferably, the lubricating fluid contains a petroleum oil or synthetic oil and a dispersant or surfactant. With the addition of a thickener or a desired amount of NGPs, the lubricant becomes a grease composition. Compared with graphite nano particle- or carbon nanotube-modified lubricants, NGP-modified lubricants have much better thermal conductivity, friction-reducing capability, anti-wear performance, and viscosity stability.

Owner:GLOBAL GRAPHENE GRP INC

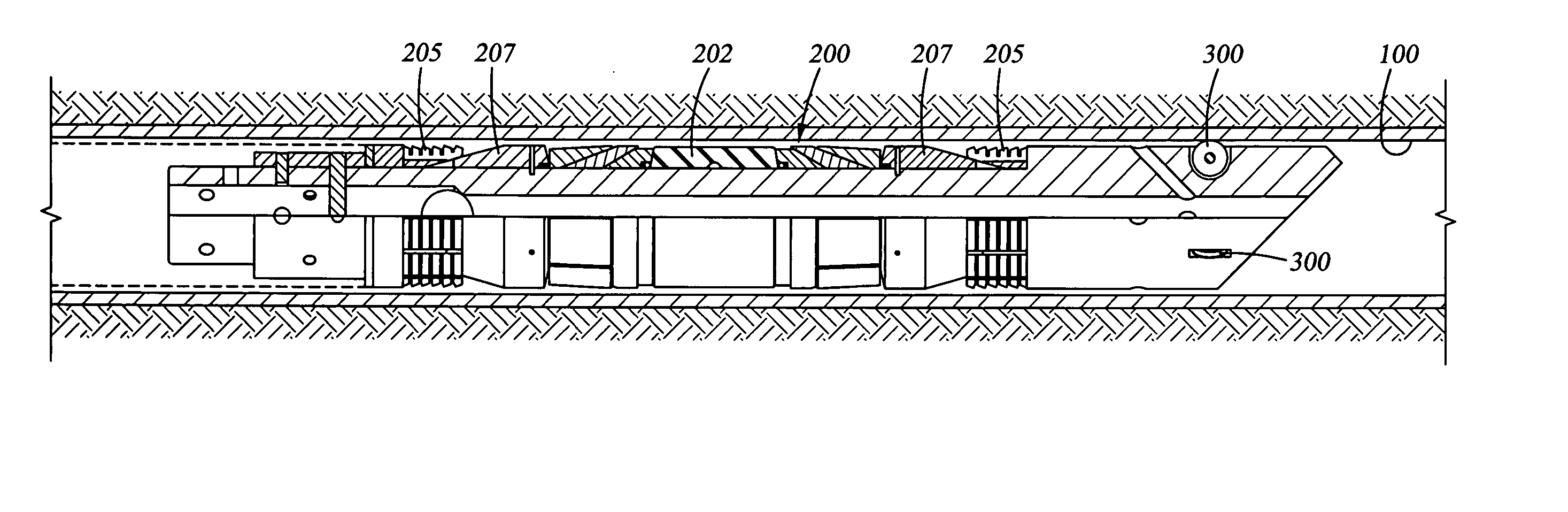

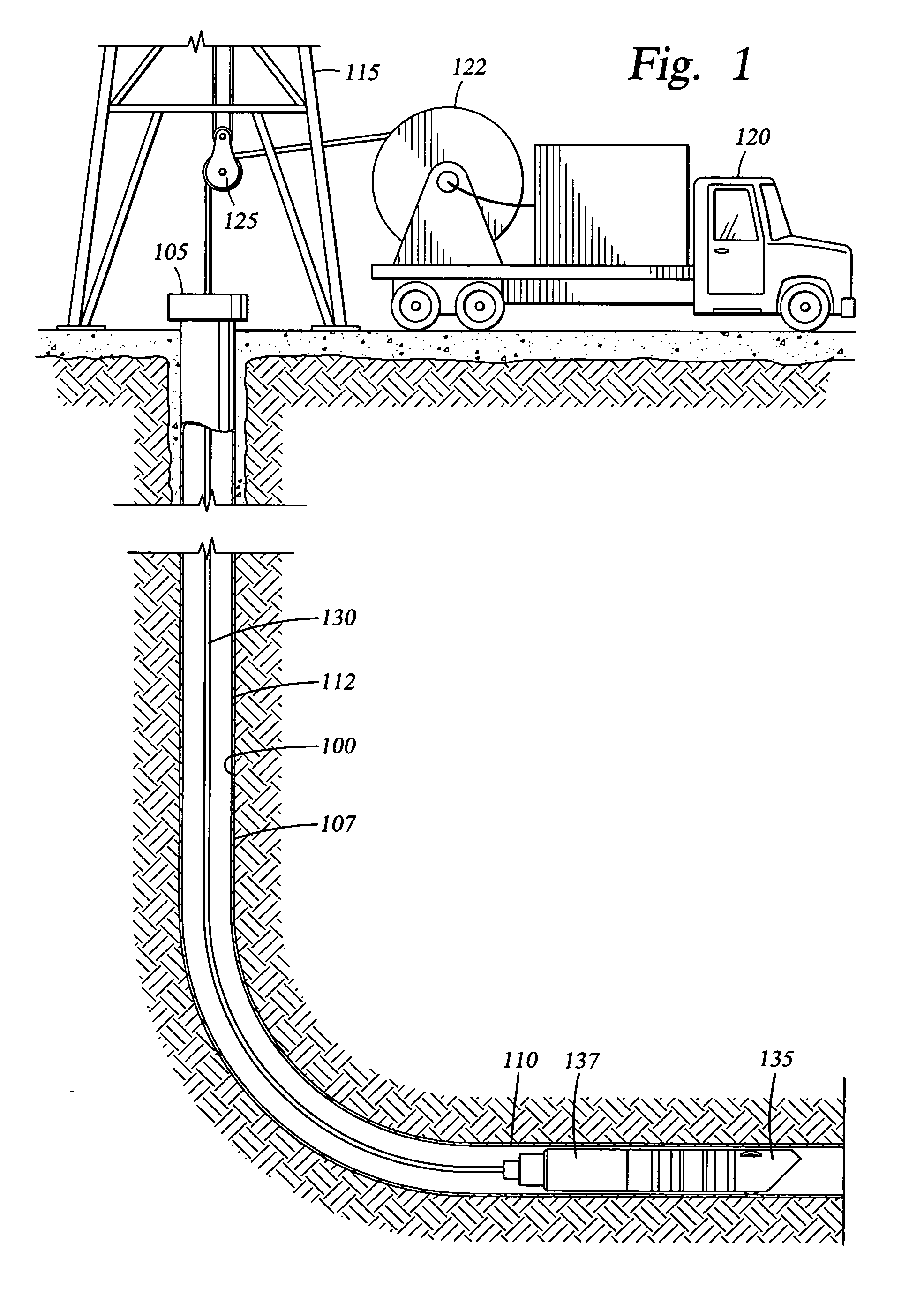

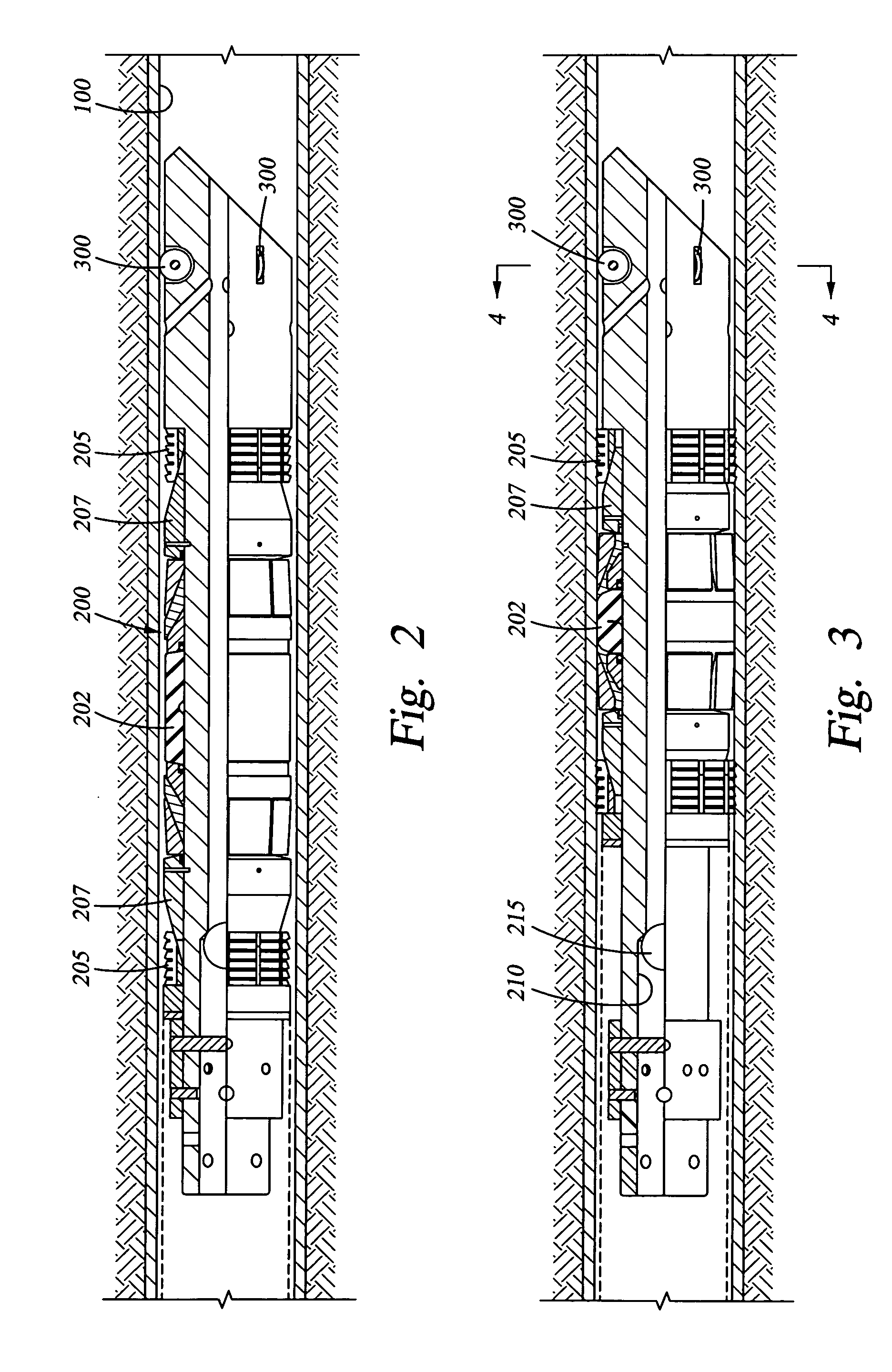

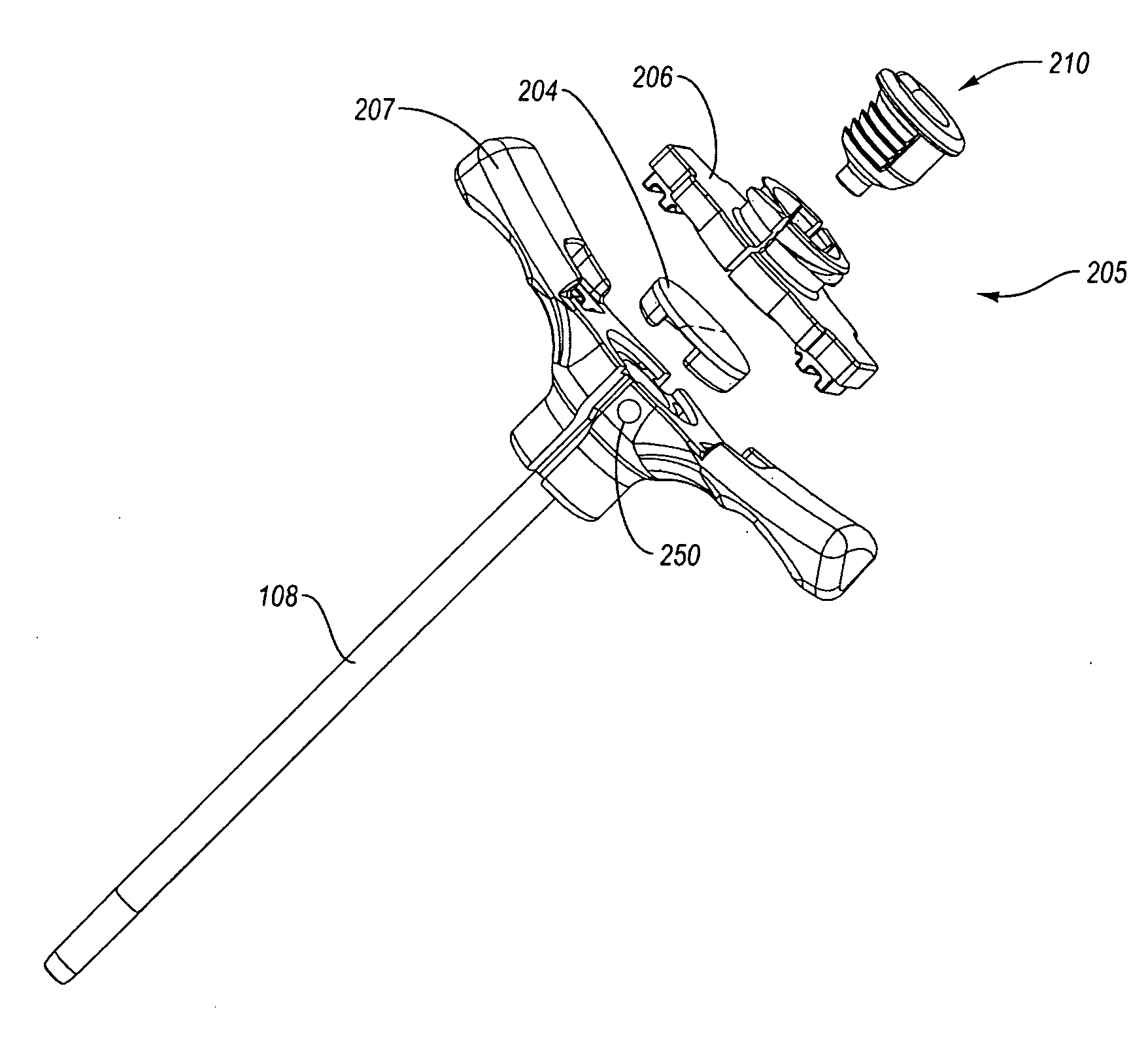

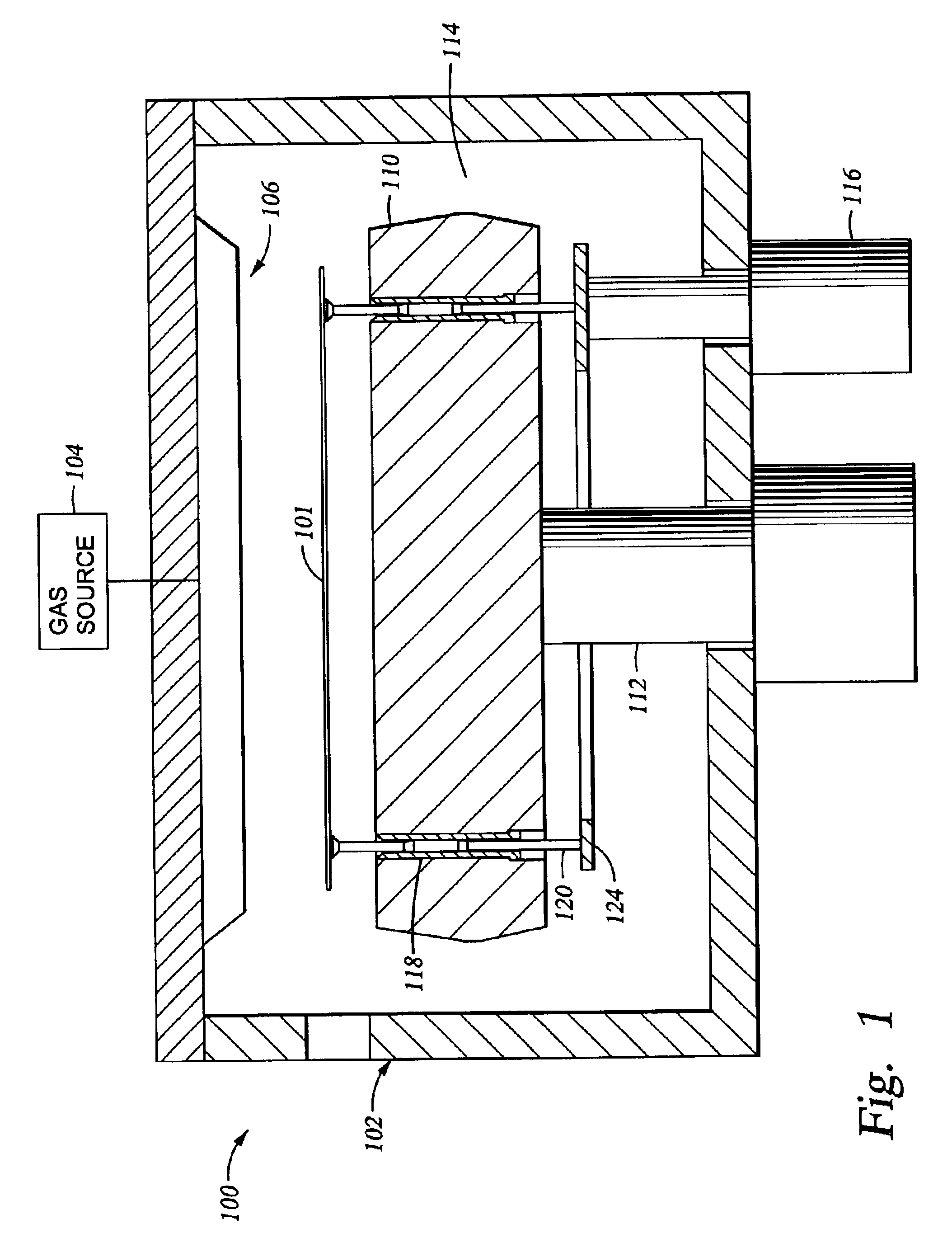

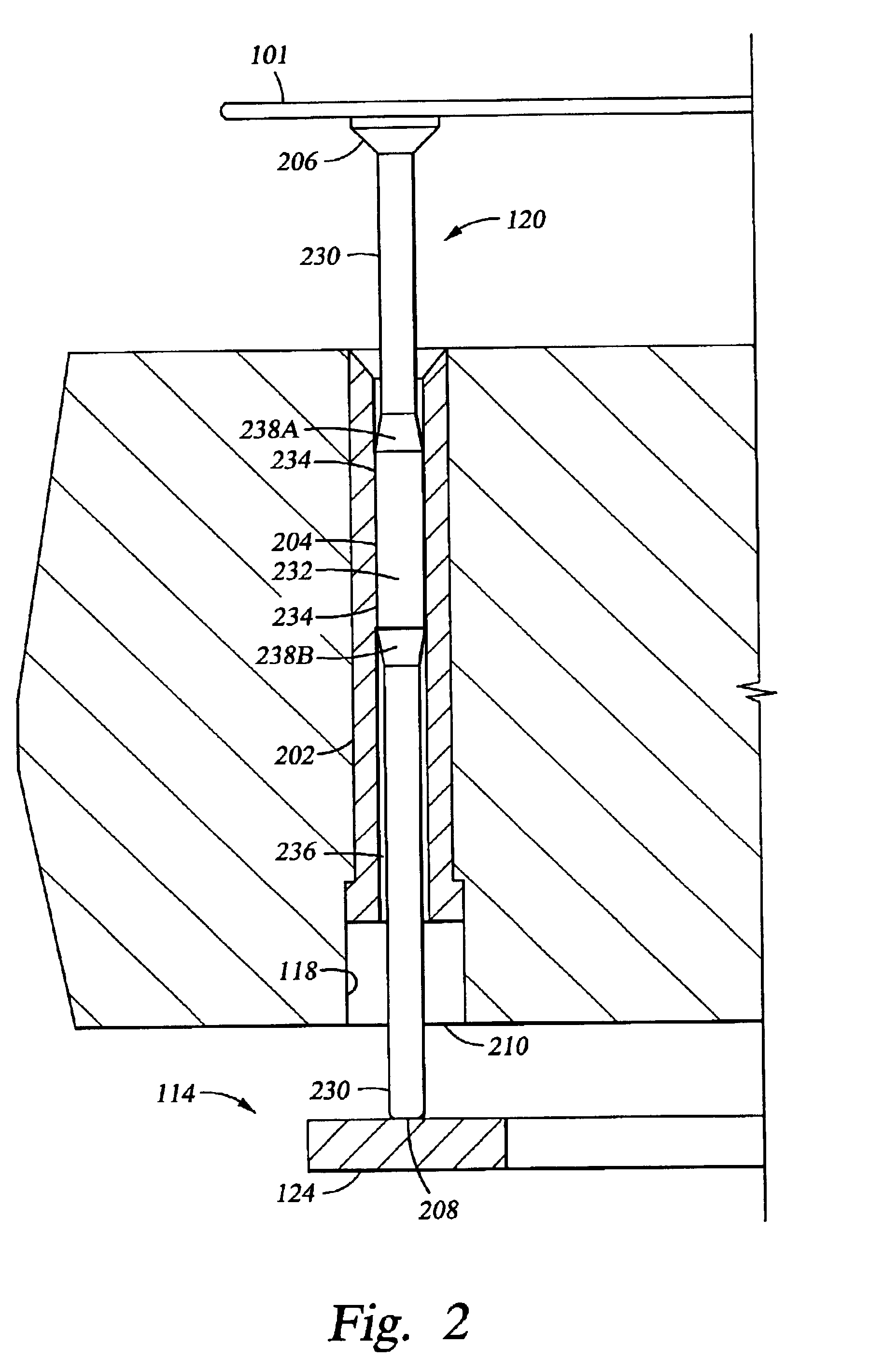

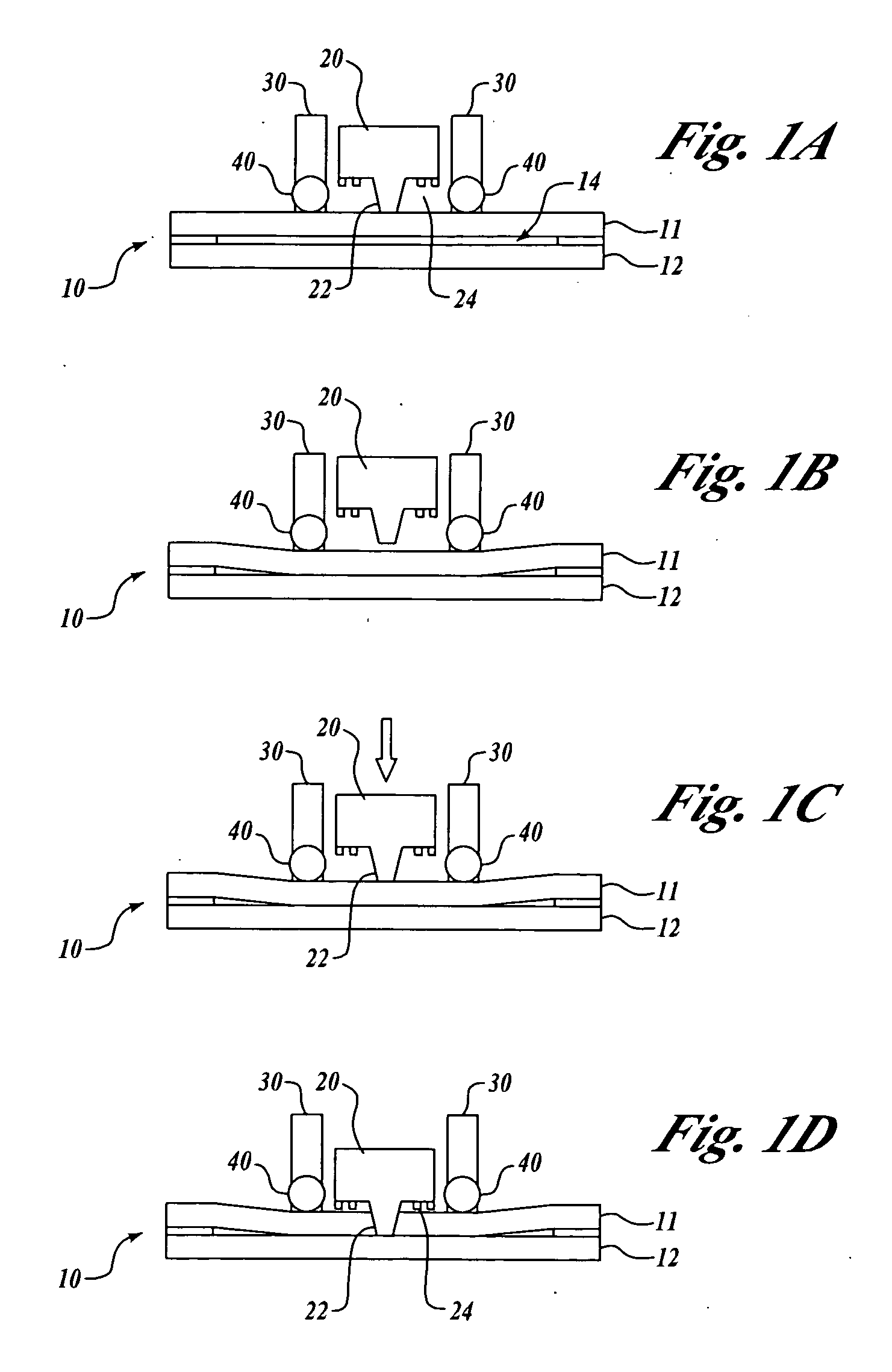

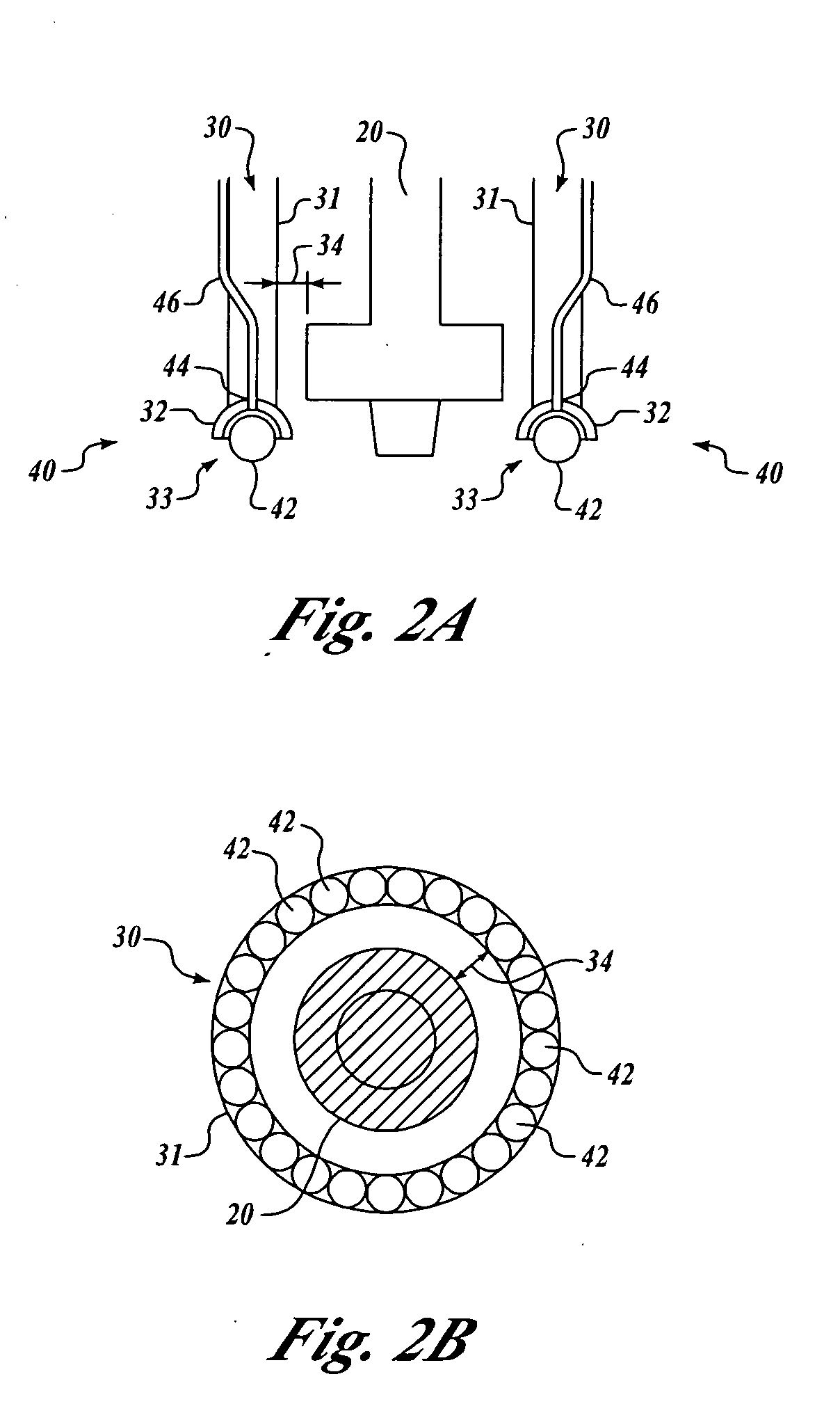

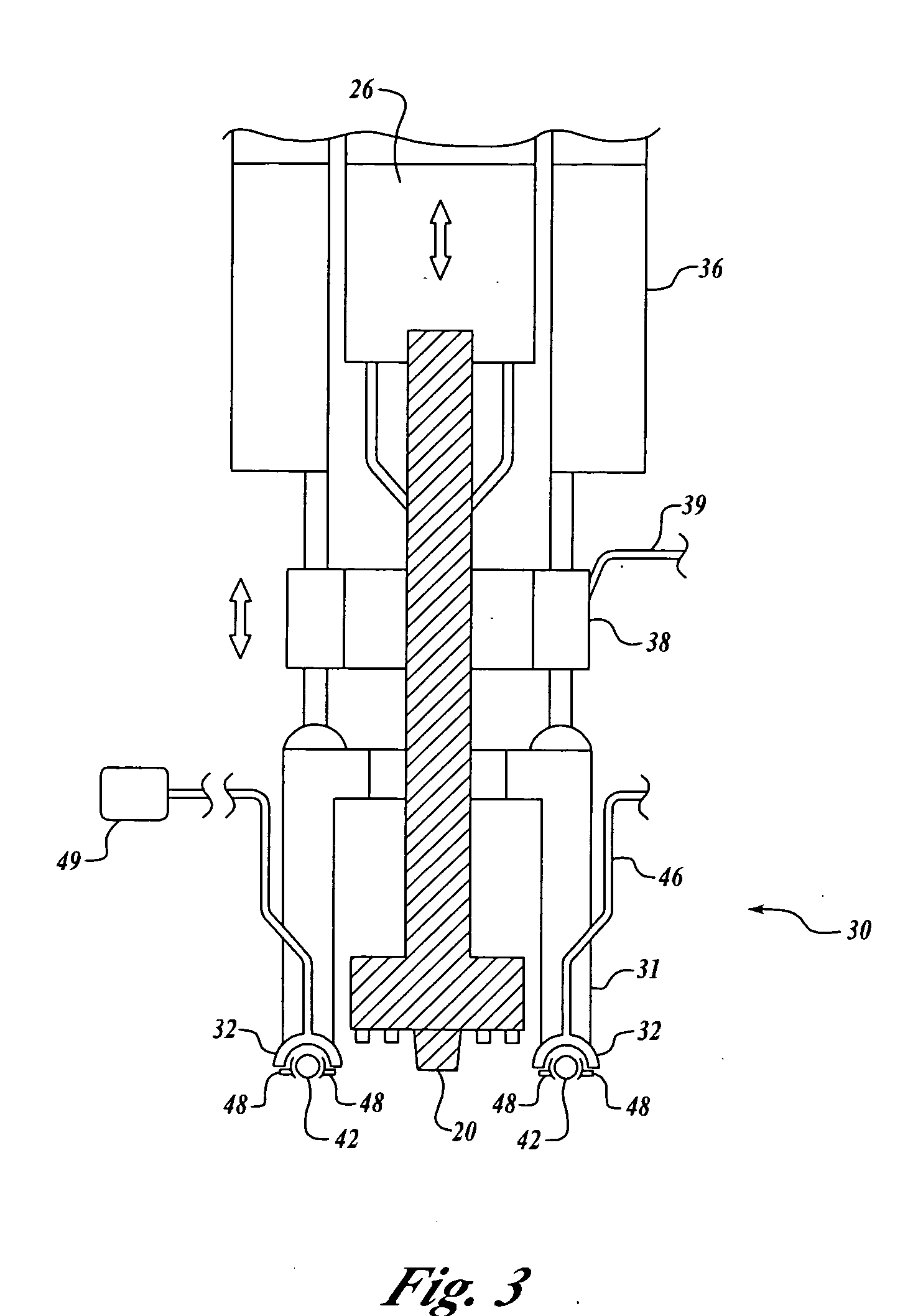

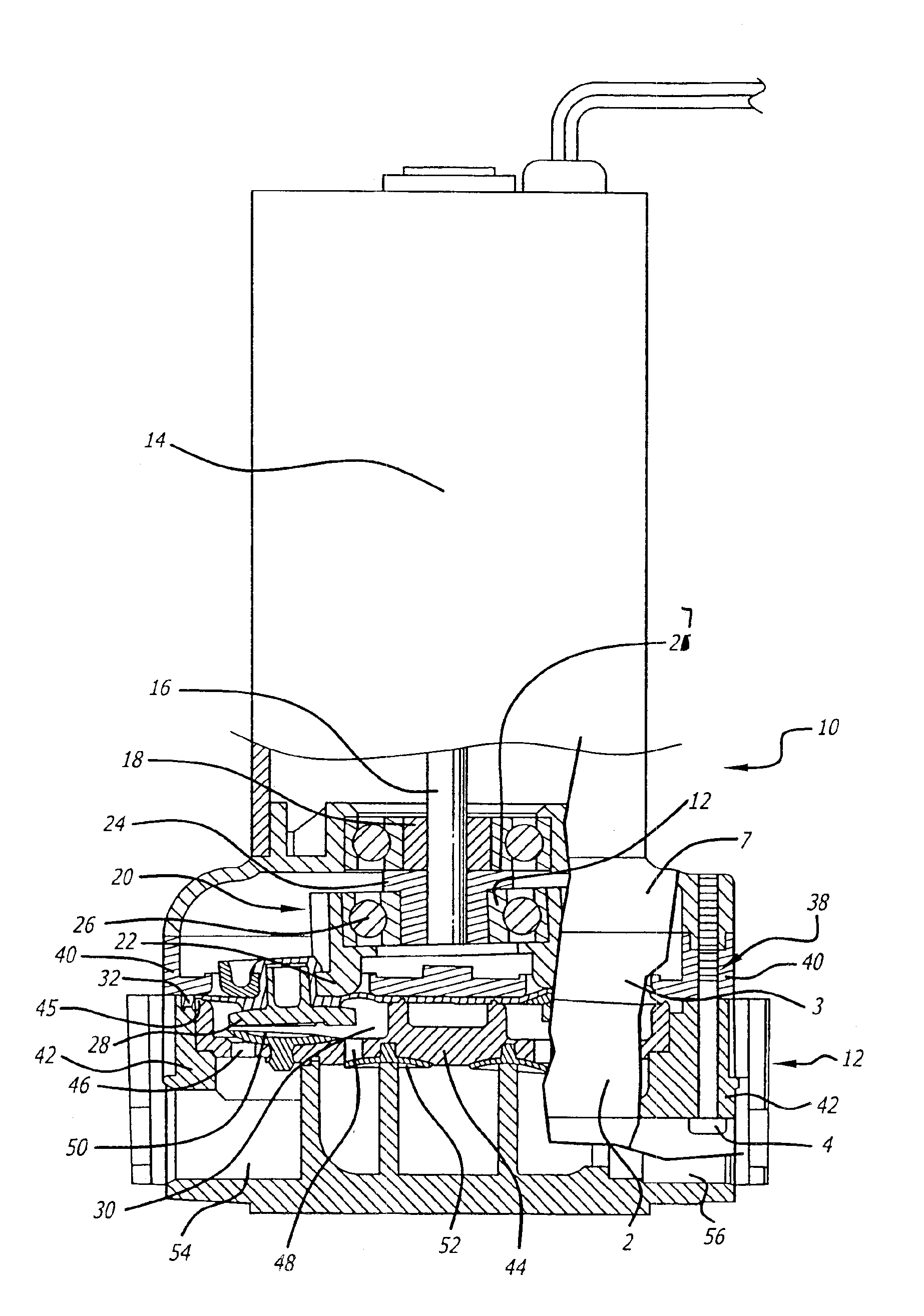

Method and apparatus for friction reduction in a downhole tool

A system for facilitating the insertion of a tool into a wellbore, especially a non-vertical wellbore. In one embodiment a tool is fixable in a wellbore and includes centralizing, friction-reducing members that serve to keep the body of the tool off the walls of the wellbore. In another embodiment the tool includes a wiper ring that partially fills an annular area formed between the centered tool and the wellbore walls. The surface of the ring facing the upper end of the wellbore provides fluid resisting piston surface and permits the centered tool to be pumped down the wellbore more effectively.

Owner:WEATHERFORD TECH HLDG LLC

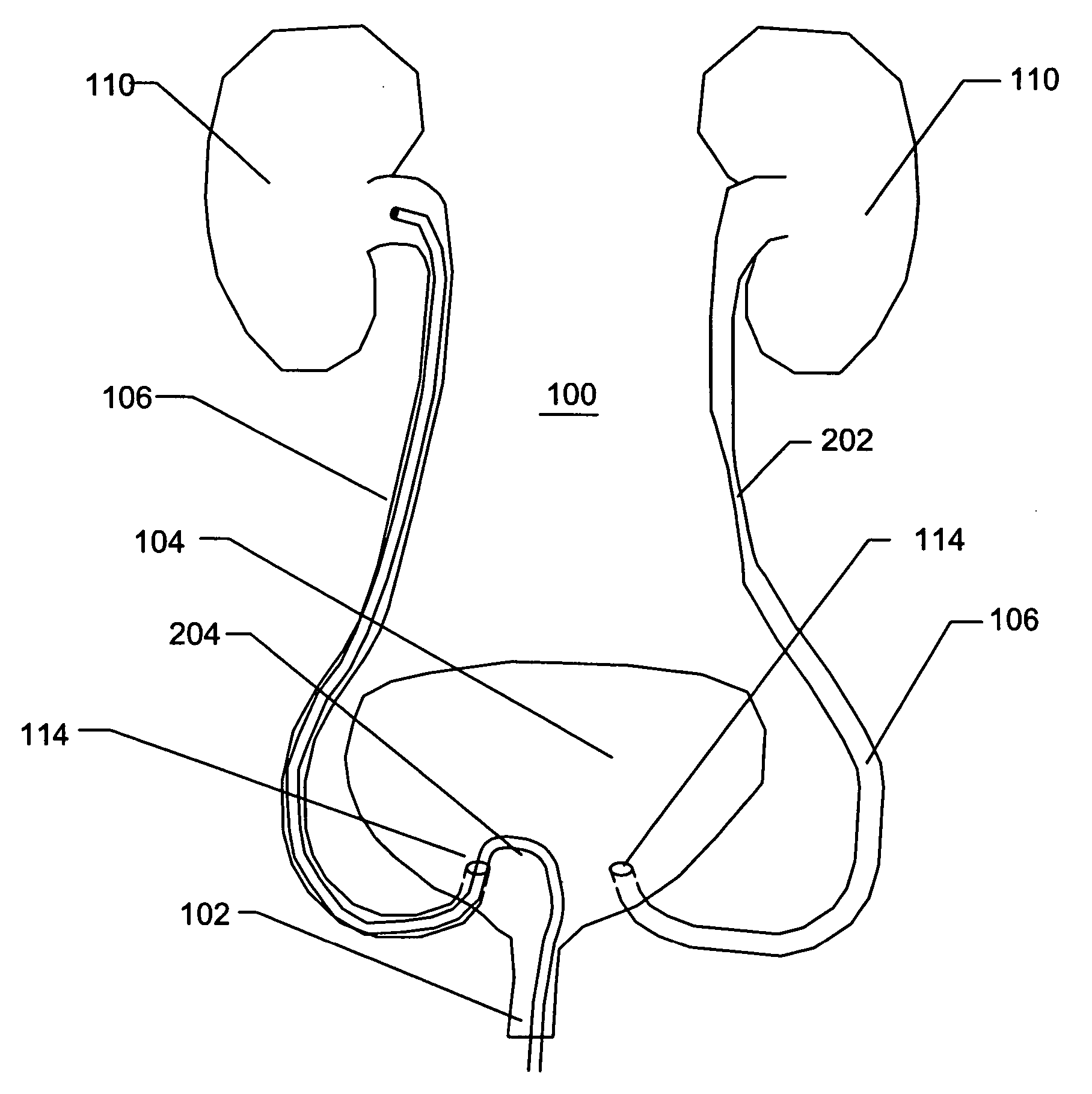

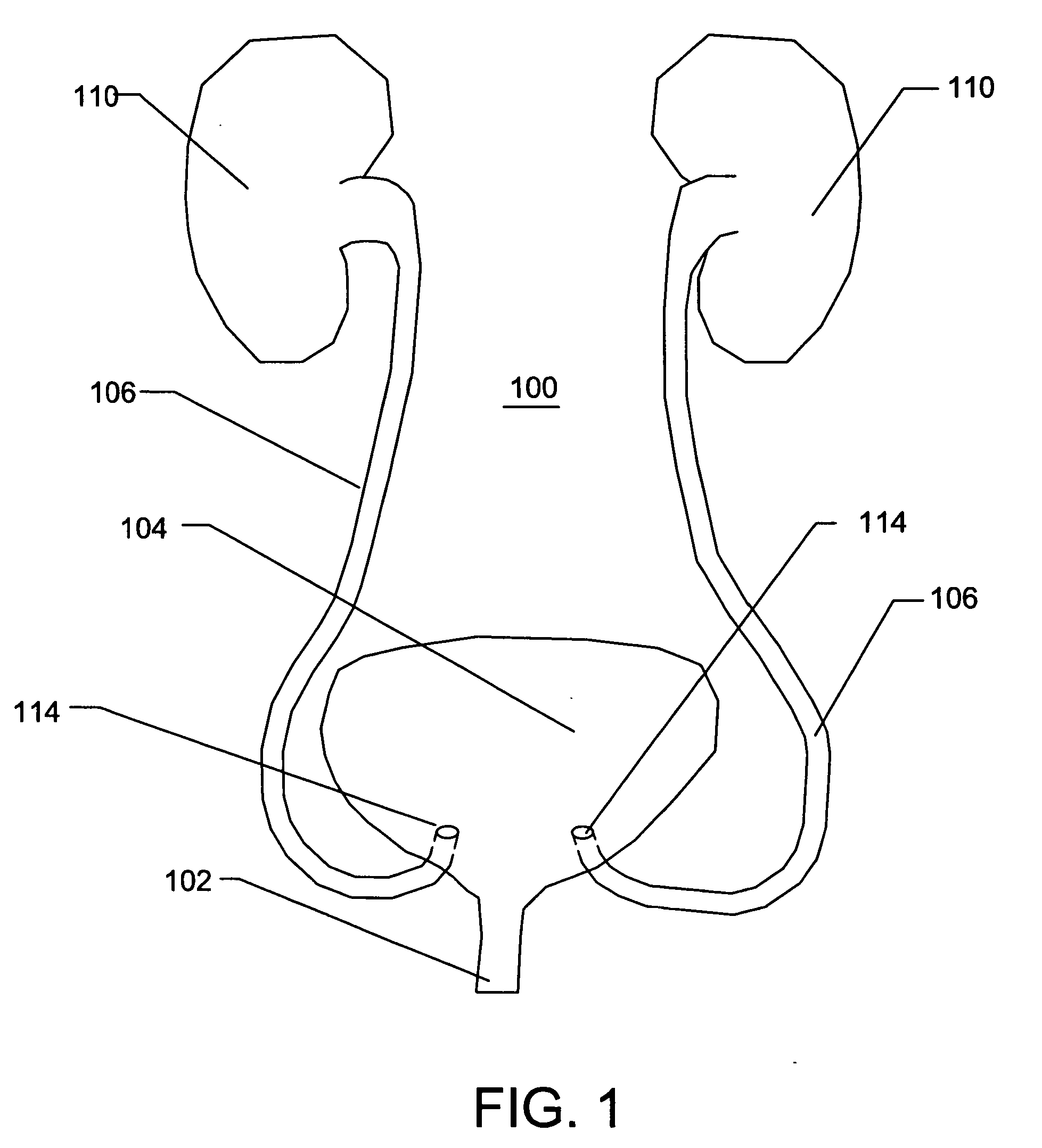

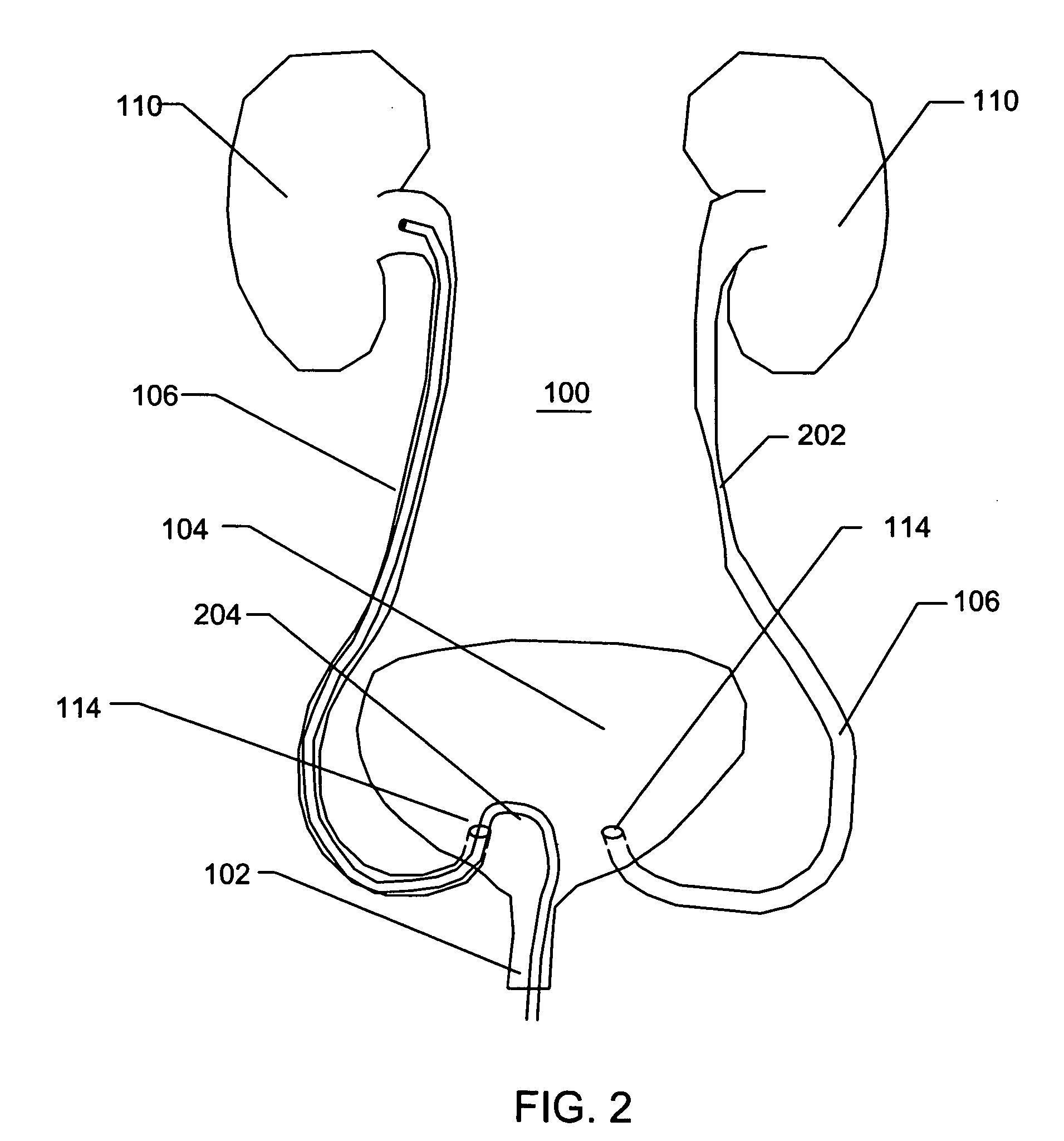

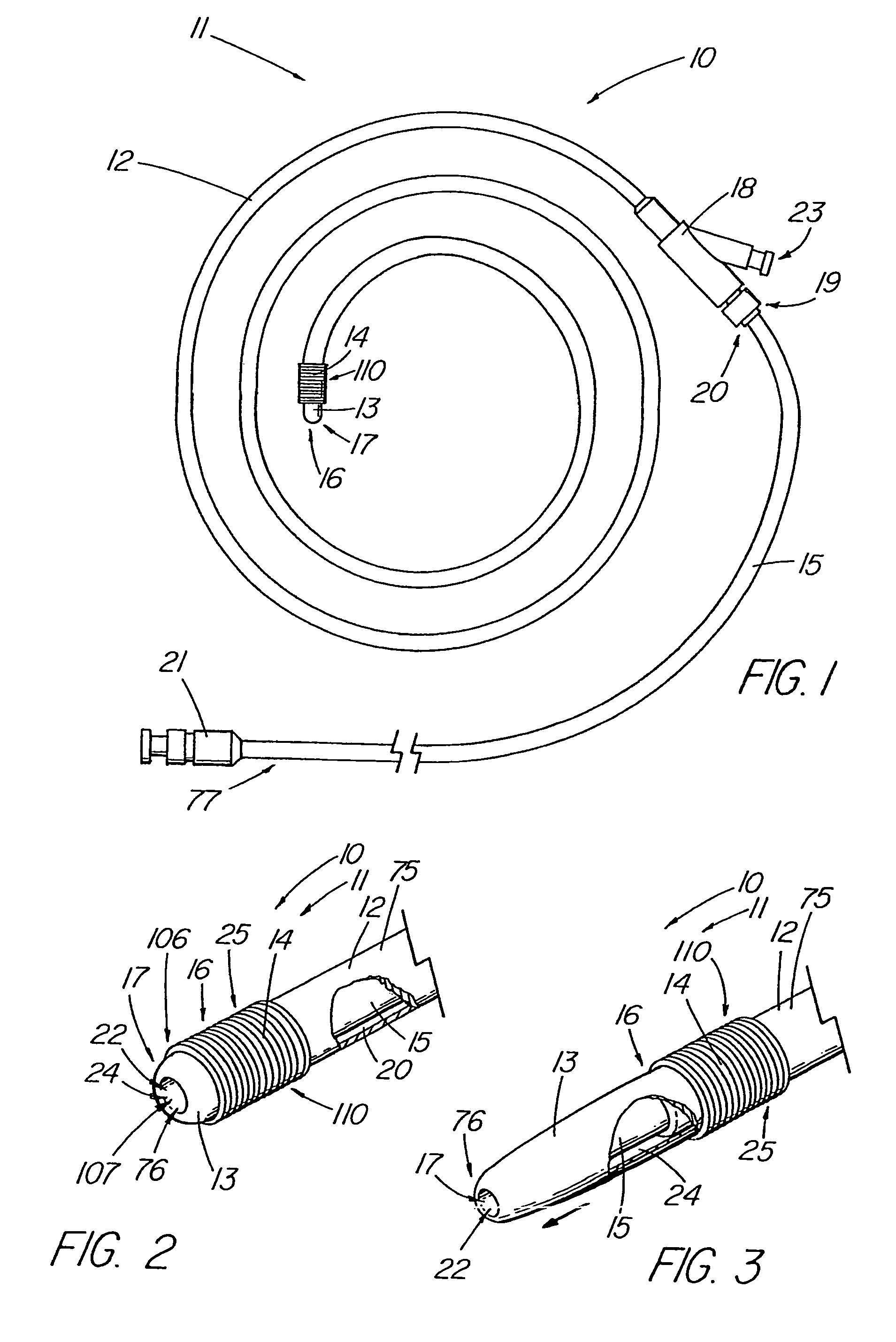

Reduced friction catheter introducer and method of manufacturing and using the same

ActiveUS20090177163A1Reduced and eliminated frictional forceGuide needlesInfusion syringesValve actuatorEngineering

Tear-away sheath introducers for catheters, methods for making such introducers, and methods for using such introducers are described. The sheath introducers contain movable valves that are encapsulated in a movable housing that allows the valve to move along the axis of the introducer. As the movable valve and housing travel along the axis, a portion of the hub protrudes past the valve and is exposed. As well, the sheath introducers can also contain a stationary valve and housing that can be opened to expose a portion of the hub when a conduit penetrates the stationary valve. The conduit can include a one-way valve actuator that can penetrate and open the valve, yet remain attached to a portion of the introducer when the introducer is split for removal from a patient. In both instances, the protruding portion of the hub contains a friction-free pathway for a catheter into the sheath introducer.

Owner:CR BARD INC

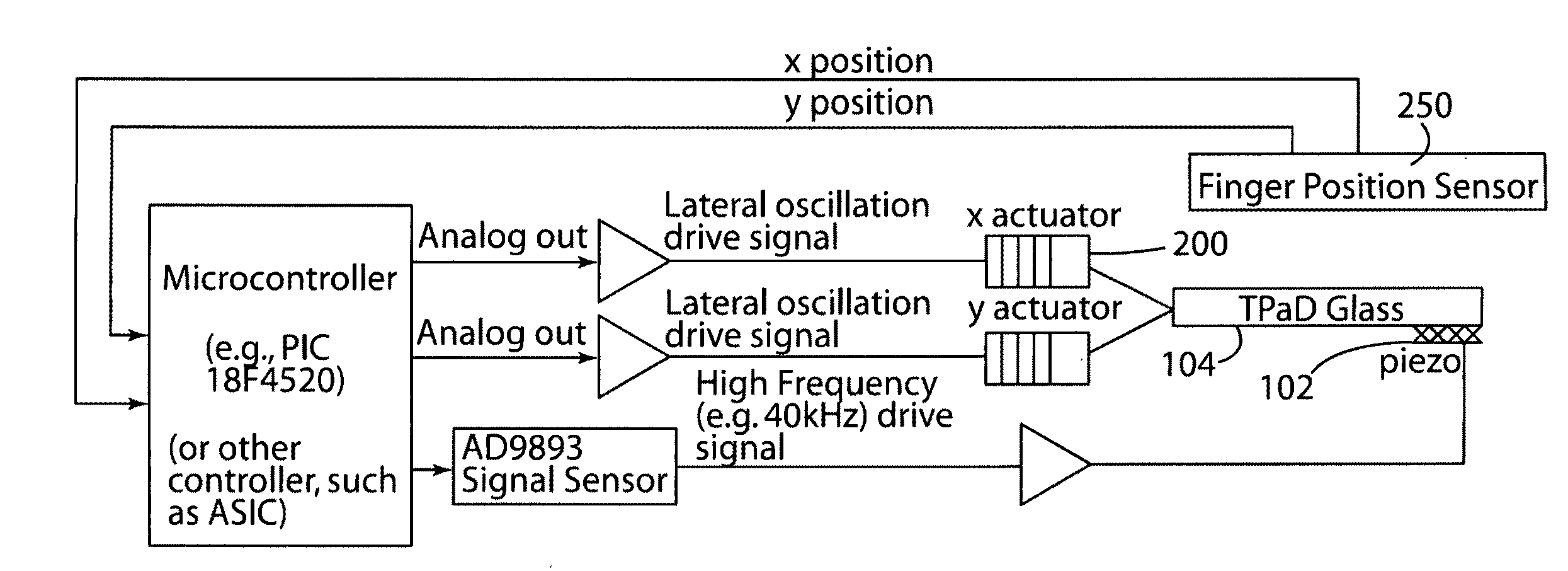

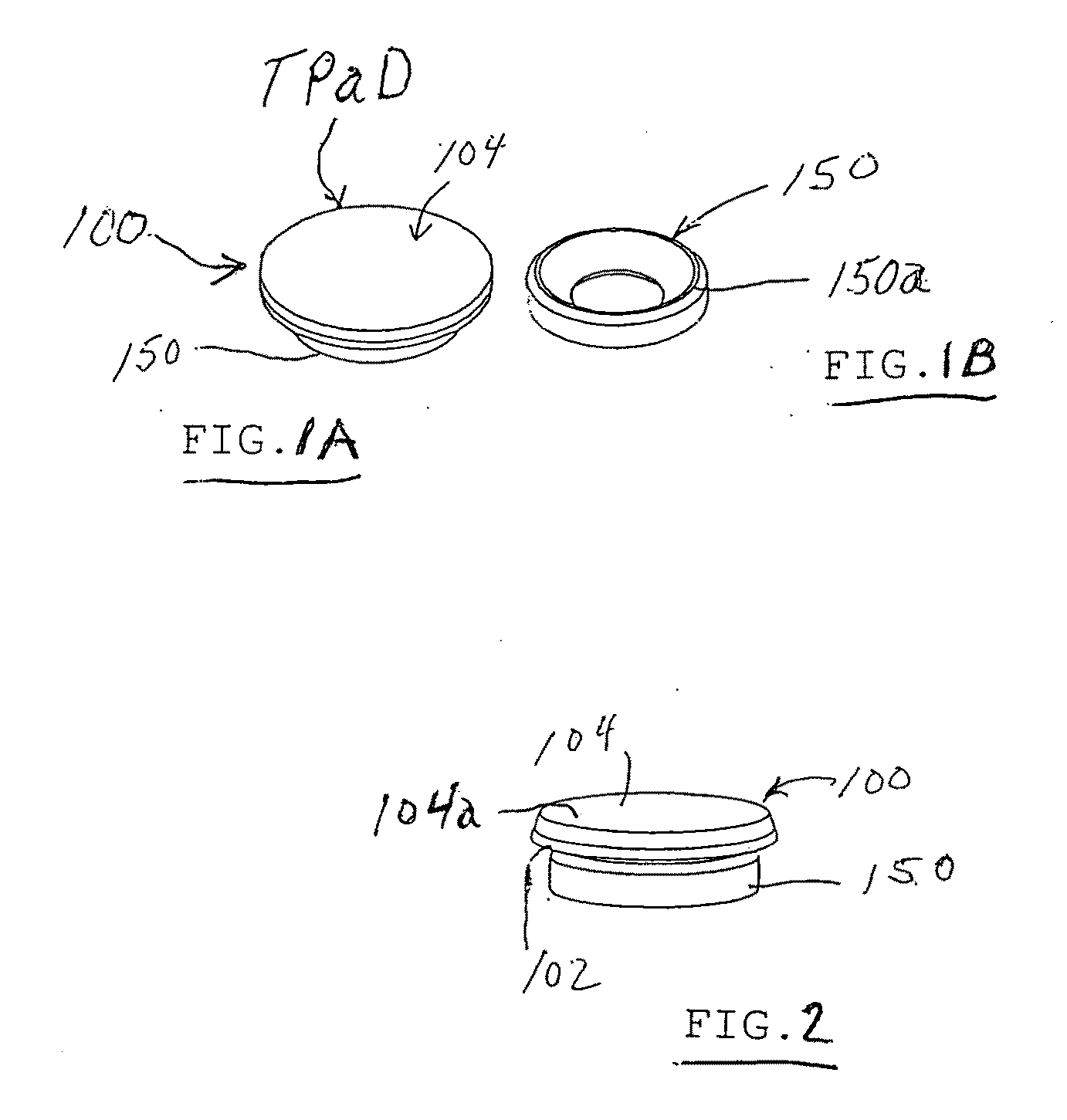

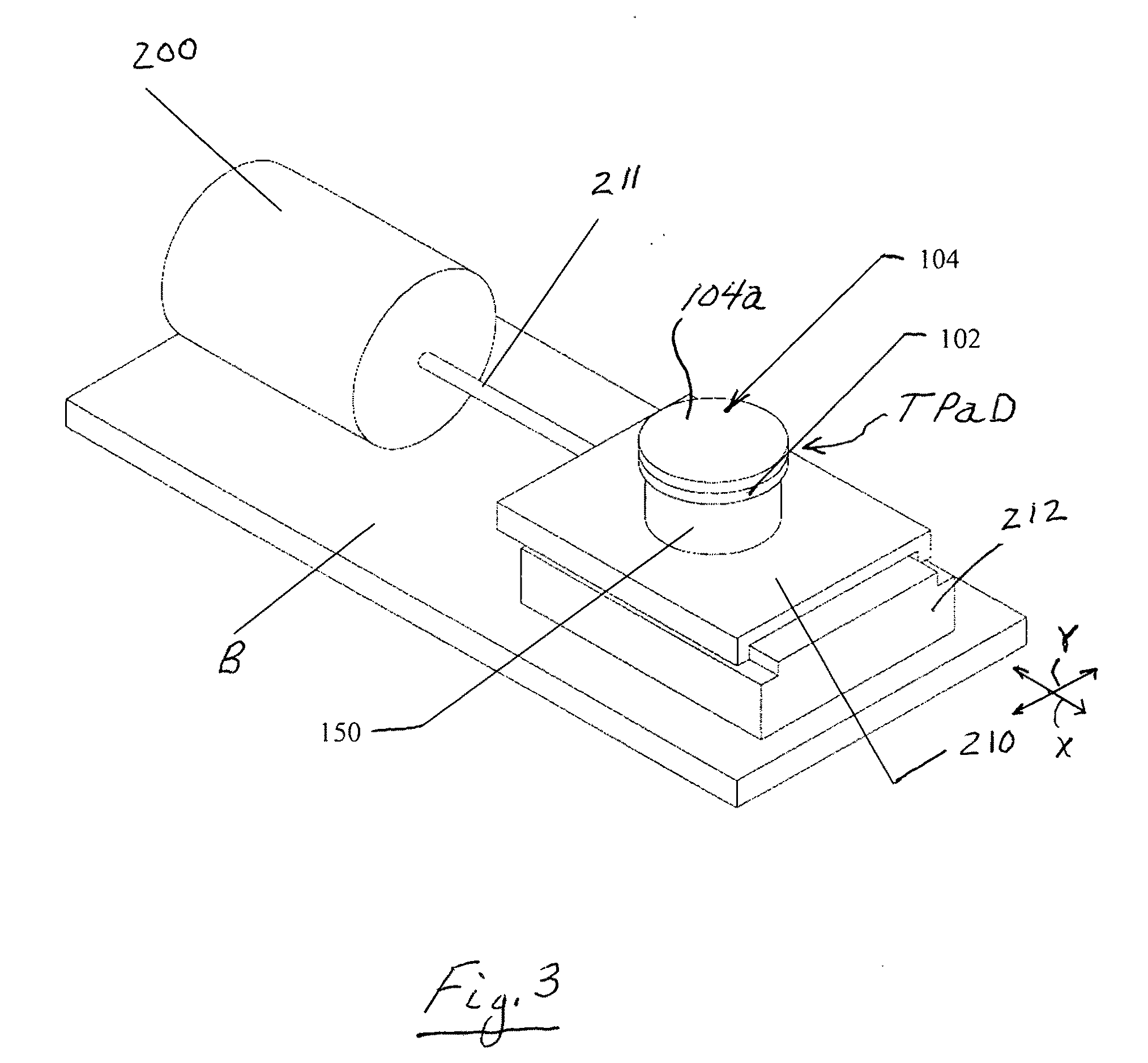

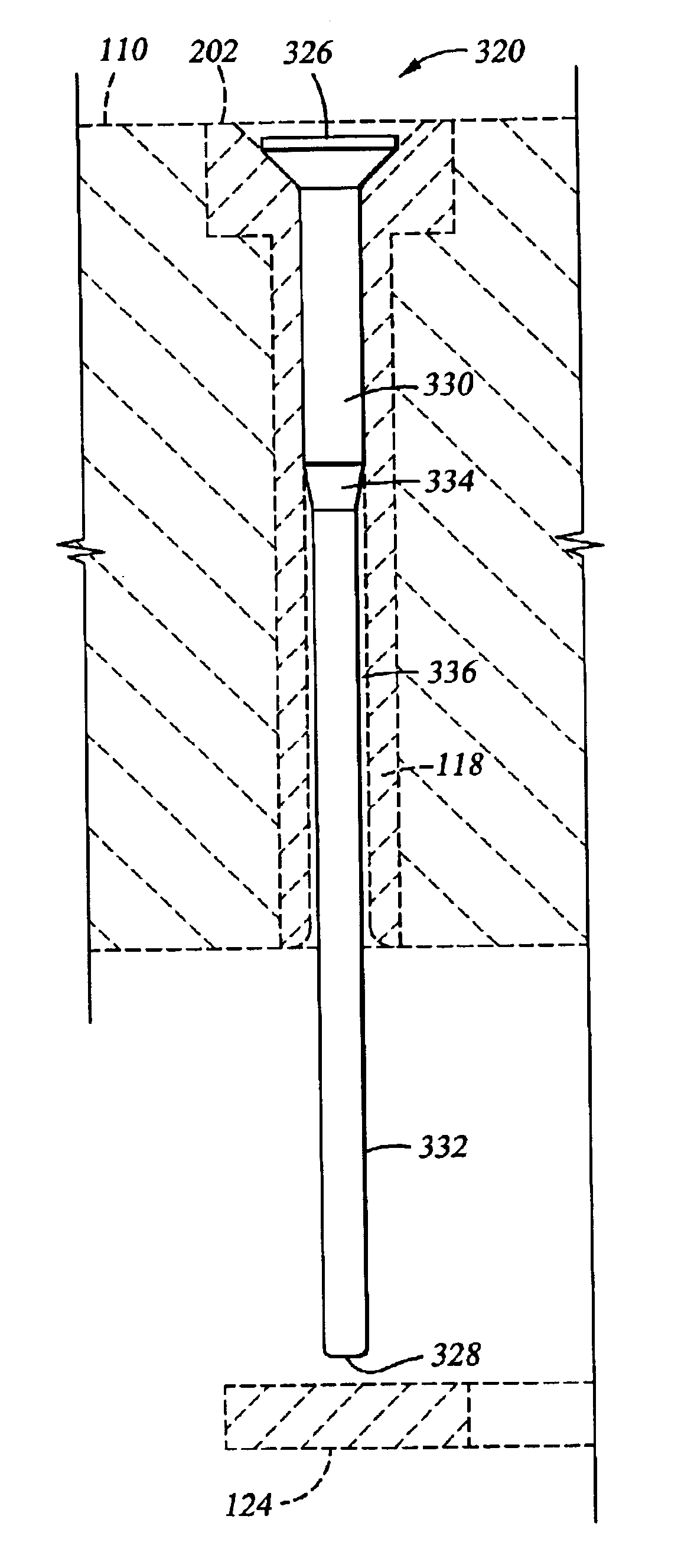

Haptic device with controlled traction forces

A haptic device includes a substrate that is subjected to lateral motion such as lateral oscillation with one or more degrees of freedom together with modulation of a friction reducing oscillation in a manner that can create a shear force on the user's finger or on an object on the device.

Owner:NORTHWESTERN UNIV

Reduced friction lift pin

InactiveUS6887317B2Increase design spaceReducing pin scratchingCellsLiquid surface applicatorsScratchingBiomedical engineering

A substrate support is provided that features a lift pin having at least one larger diameter shoulder section that forms a relief region between the lift pin and a guide hole disposed through a substrate support. The shoulder section minimizes contact between the substrate support and lift pin guide hole, thereby reducing pin scratching, particle generation, component wear, and increasing the useful life of the pin. In another embodiment, a flat-bottom tip is provided to promote self-standing of the lift pin, reducing pin tilting or leaning of the lift pin within the guide hole.

Owner:APPLIED MATERIALS INC

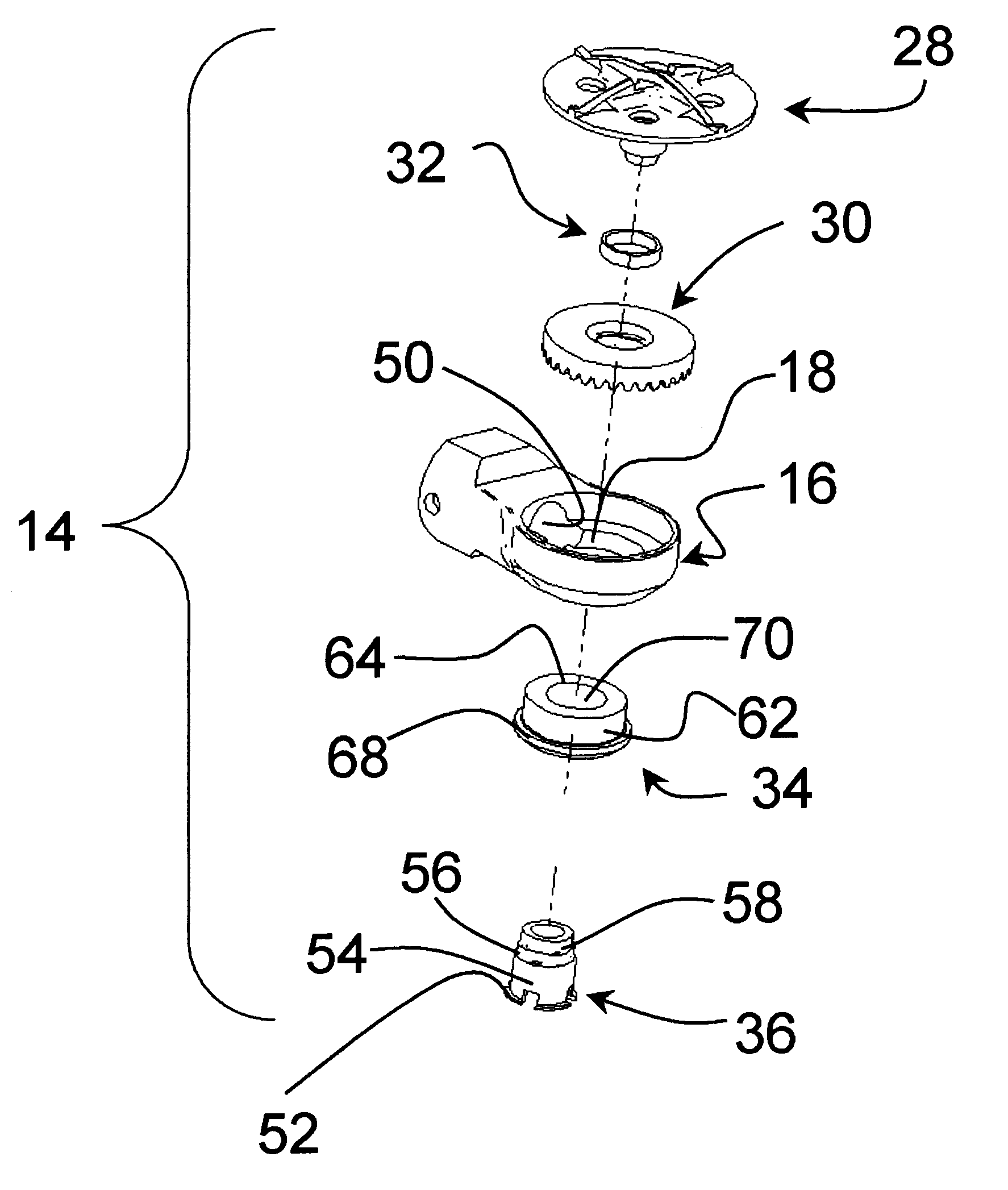

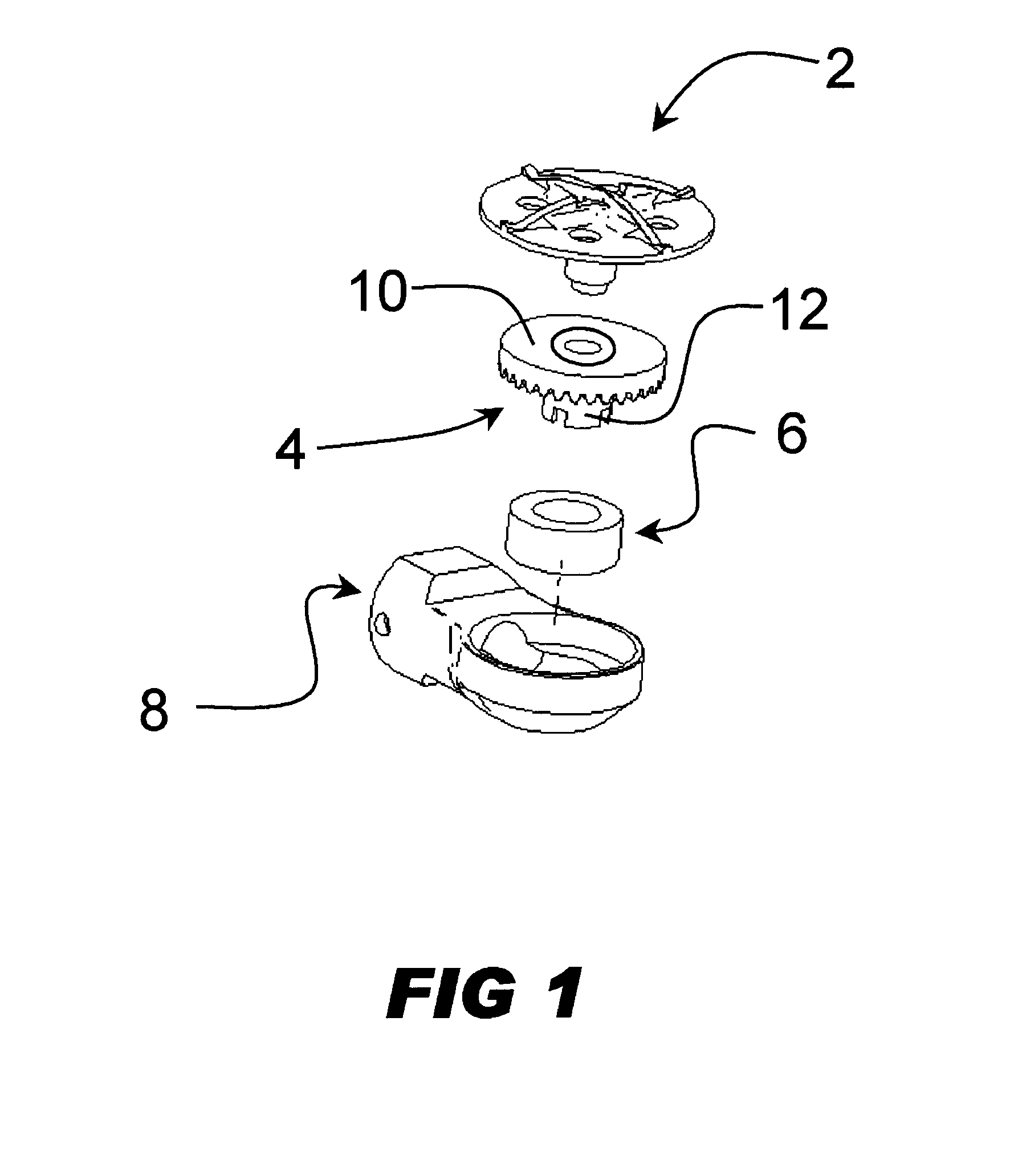

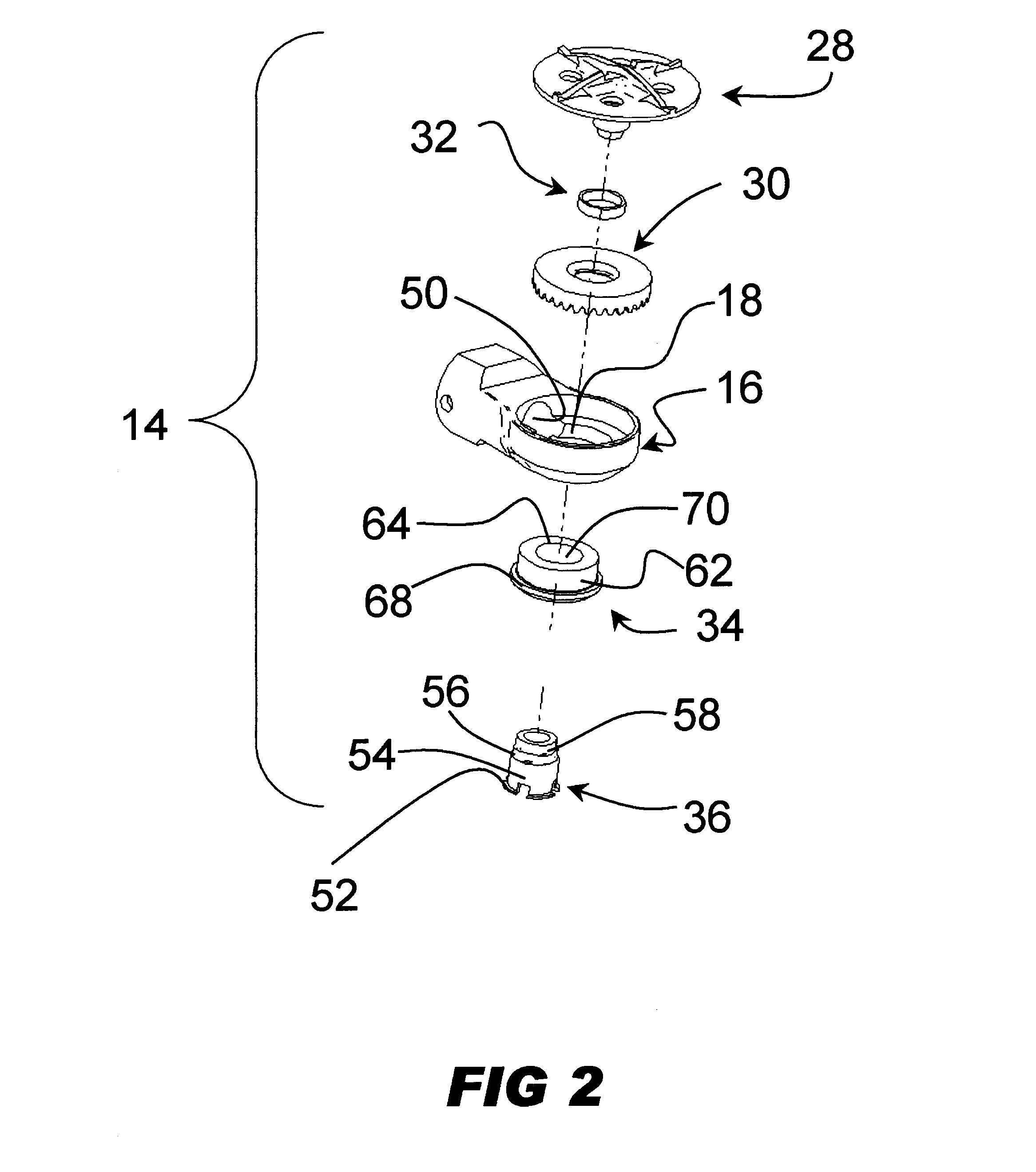

Machining apparatus

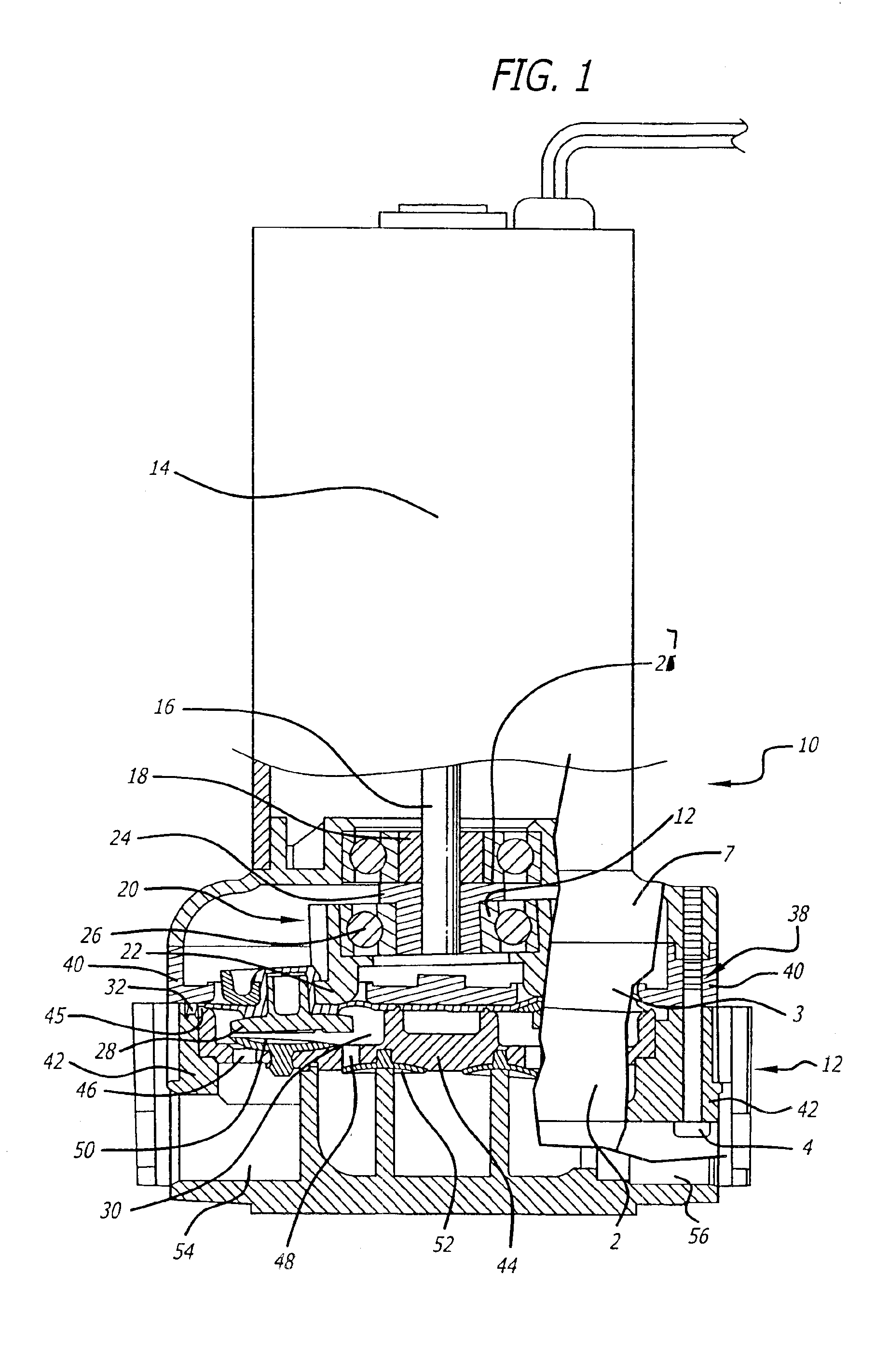

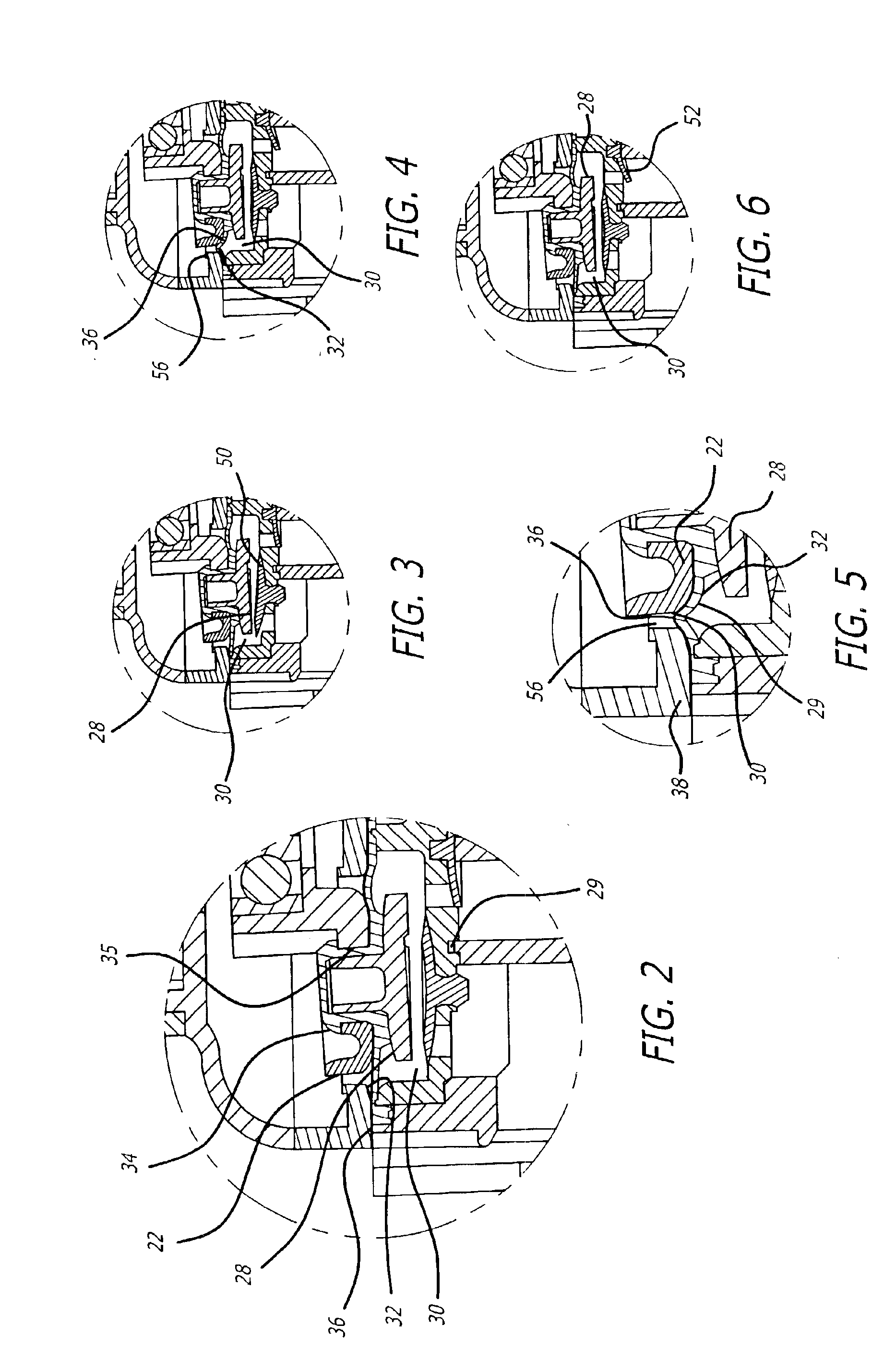

The invention relates to an apparatus for machining hard tissue and soft tissue associated therewith, having a housing, a rotating shaft having an axis essentially parallel to a longitudinal axis of the apparatus, and adapted to provide power to the apparatus by rotation of the shaft, a drive assembly, having a gear having a rotational axis oriented perpendicular to the longitudinal axis of the apparatus and adapted to mesh with the rotating shaft, a gear hub rigidly attached to the gear, which rotates when the gear rotates, and adapted to attached to a bearing assembly, a bearing assembly having a moveable member rigidly attached to the gear hub, a non-moveable member rigidly attached to the housing, and one or more friction reducing members disposed between the moveable and non-moveable members, and two or more locking members adapted to generate opposing forces helping to hold the drive assembly together, and a cutting element rigidly attached to the drive assembly, wherein the gear hub and bearing assembly are press fit together and the gear and gear hub each comprise complementary interlocking noncircular geometries.

Owner:COMPANION SPINE LLC +1

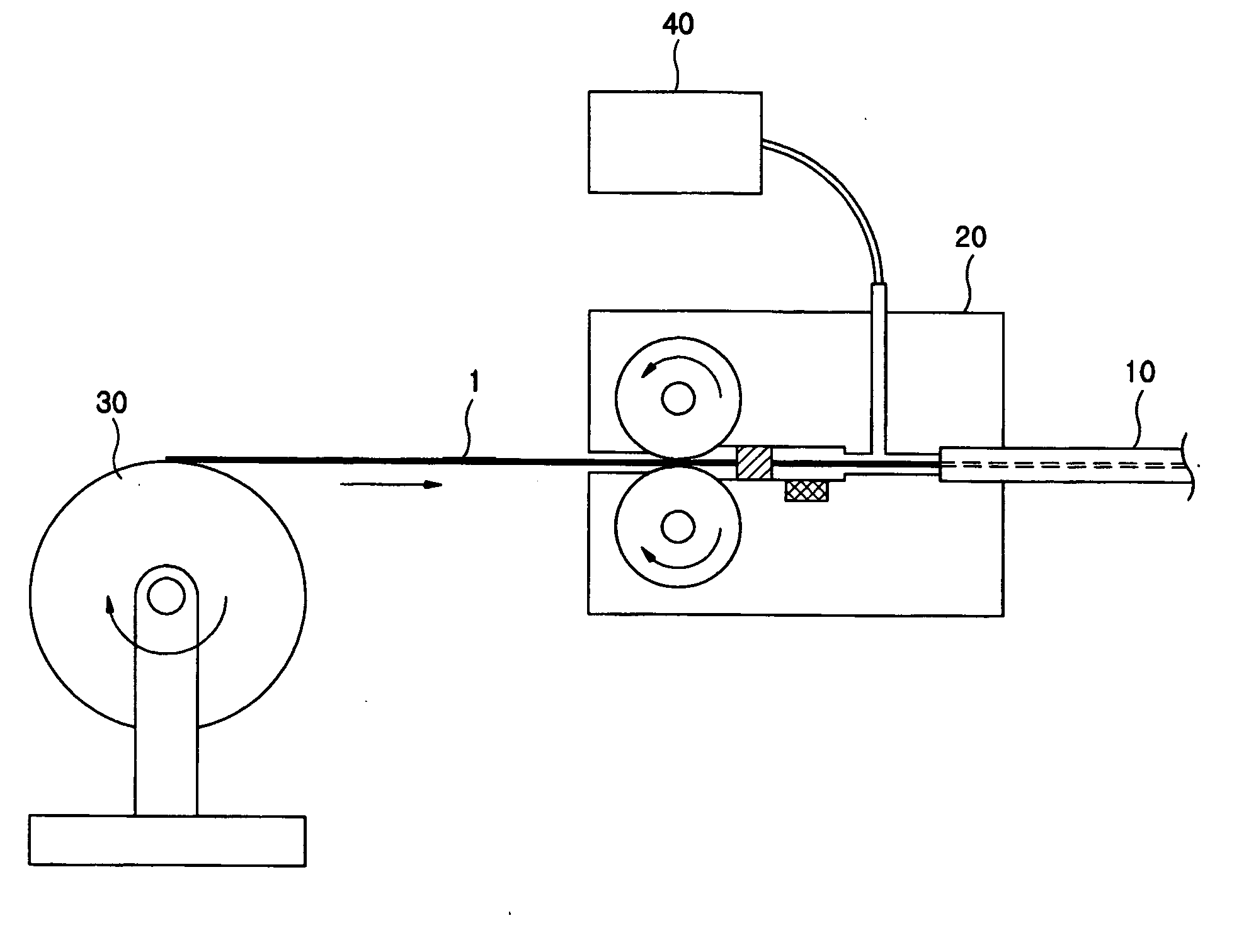

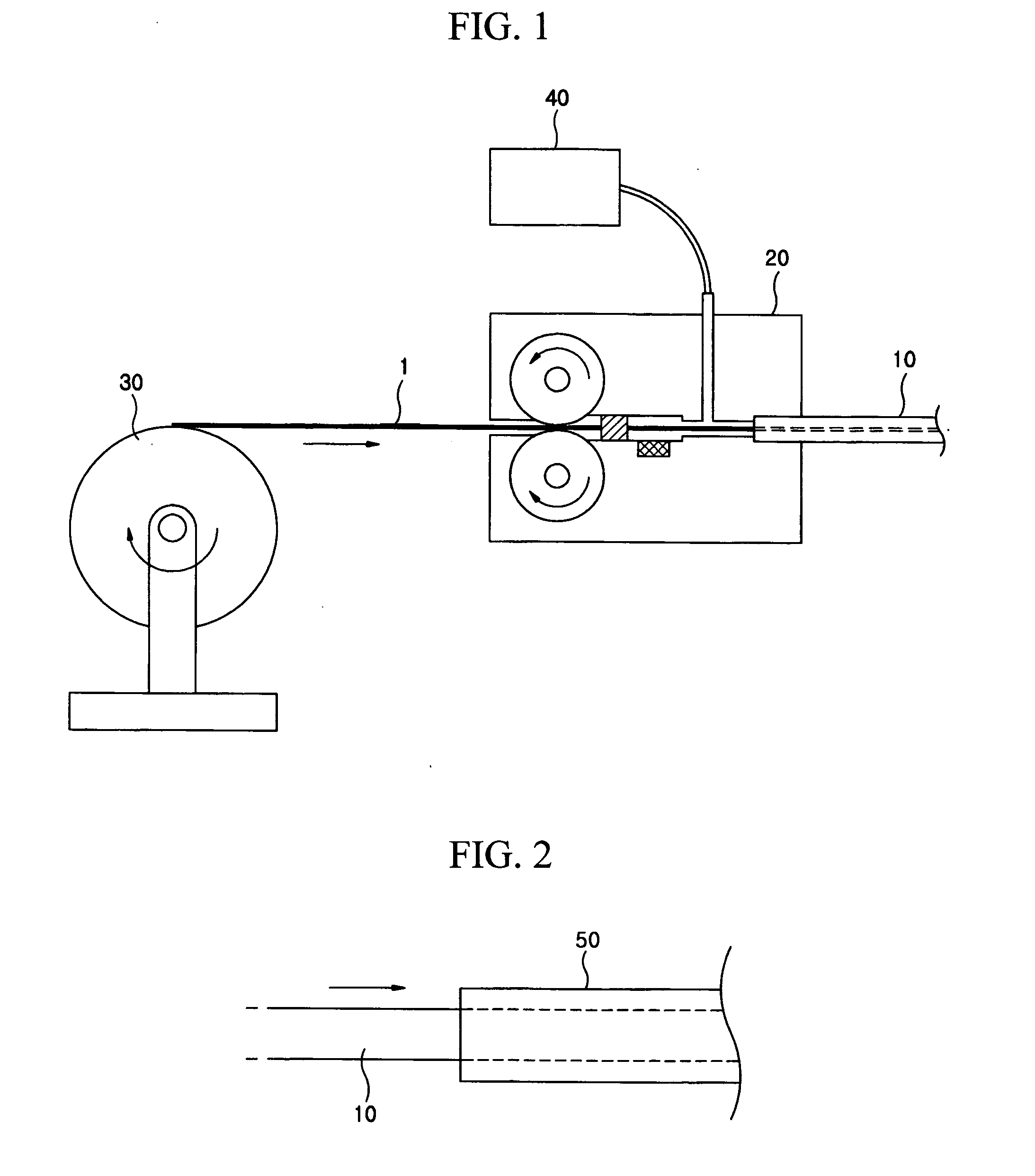

Tube for installing an optical fiber unit having a lubricous surface

InactiveUS20070098340A1Easy to installHigh strengthOptical fibre/cable installationFibre mechanical structuresEngineeringLubricant

Disclosed is a tube for installing an optical fiber unit having lubricous surface, which is installed in a communication pipe. The tube for installation includes an inner layer having lubricant components to decrease friction against an optical fiber unit, and an outer layer provided around the inner layer and composed of polymer having a lower friction coefficient than polyethylene so as to decrease friction when the tube is installed in the communication pipe. The tube is easier to install than the conventional one due to decreased friction against the communication pipe.

Owner:LG CABLE LTD (KR)

Clamping apparatus and methods for manufacturing

InactiveUS20050092817A1Welding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The present invention is directed to apparatus and methods for clamping around a manufacturing tool engaging a work piece. In one embodiment, a clamp includes a moveable support arranged to at least partially surround a circumference defining a work area. A friction reducing element is attached to the support to apply pressure to the surface when the clamp is engaged with the work piece, and to allow the clamp to be moved with the manufacturing tool. In accordance with other aspects of the invention, the clamp co-annularly or partially surrounds the manufacturing tool. In another embodiment, the manufacturing tool is a friction stir welding tool.

Owner:THE BOEING CO

Enhanced wobble plated driven diaphragm pump

InactiveUS6892624B2Flexible wall reciprocating enginesFlexible member pumpsDiaphragm pumpThermal insulation

A pump that has a flexible liner located adjacent to a diaphragm. The liner provides structural support for the diaphragm. The flexible liner can slide relative to the diaphragm. This relative movement reduces the stiffness of the diaphragm / liner assembly. The diaphragm / liner assembly is therefore both flexible and strong. Additionally, the liner provides a thermal insulator for the diaphragm. The flexible liner may be constructed from a low friction material to lower the friction between the liner and a wobble plate of the pump. Lowering the friction reduces the heat generated within the pump. The structural reinforcement, thermal insulation and lower friction features of the liner increase the life of the diaphragm and the pump.

Owner:AQUATEC WATER SYST

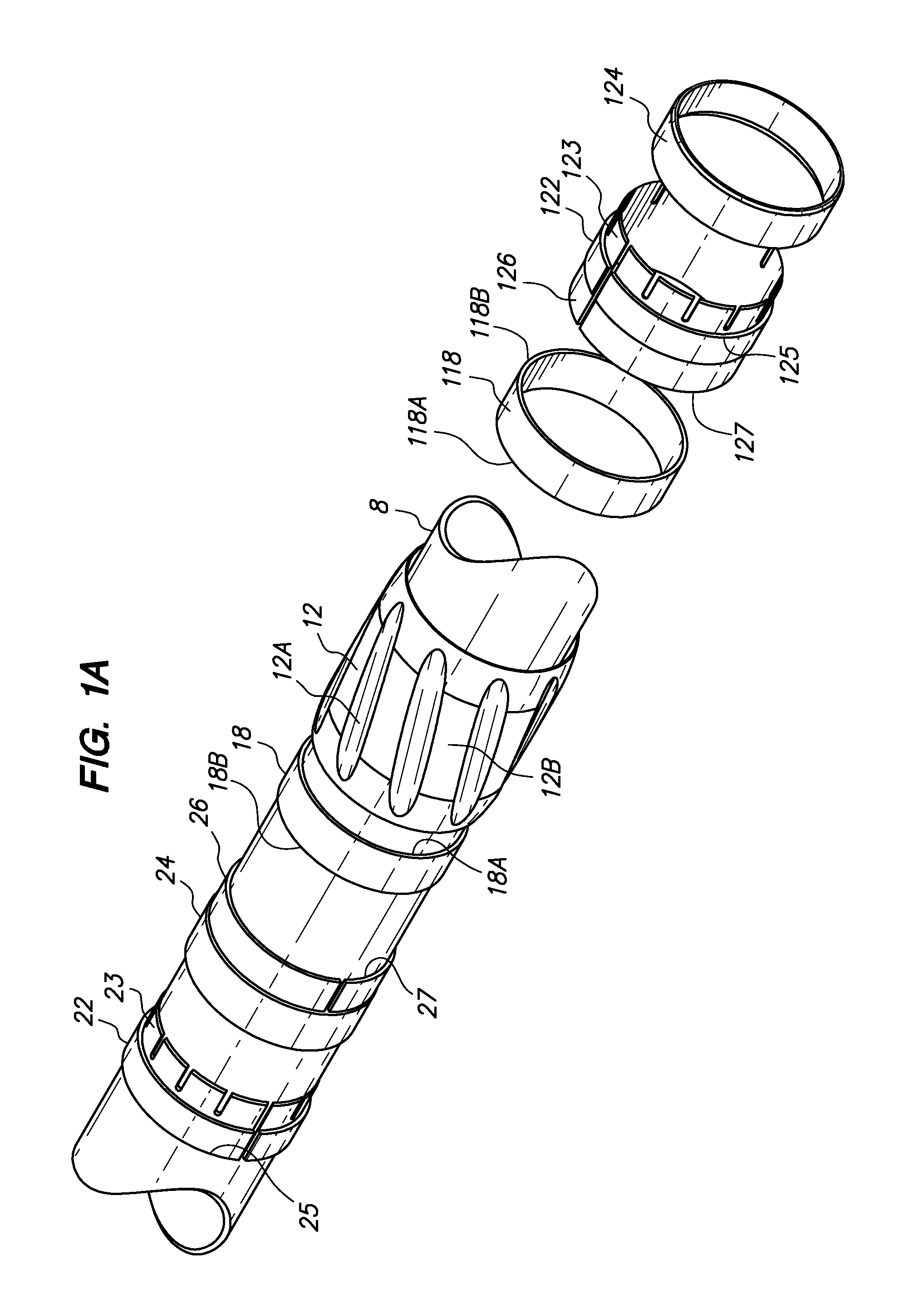

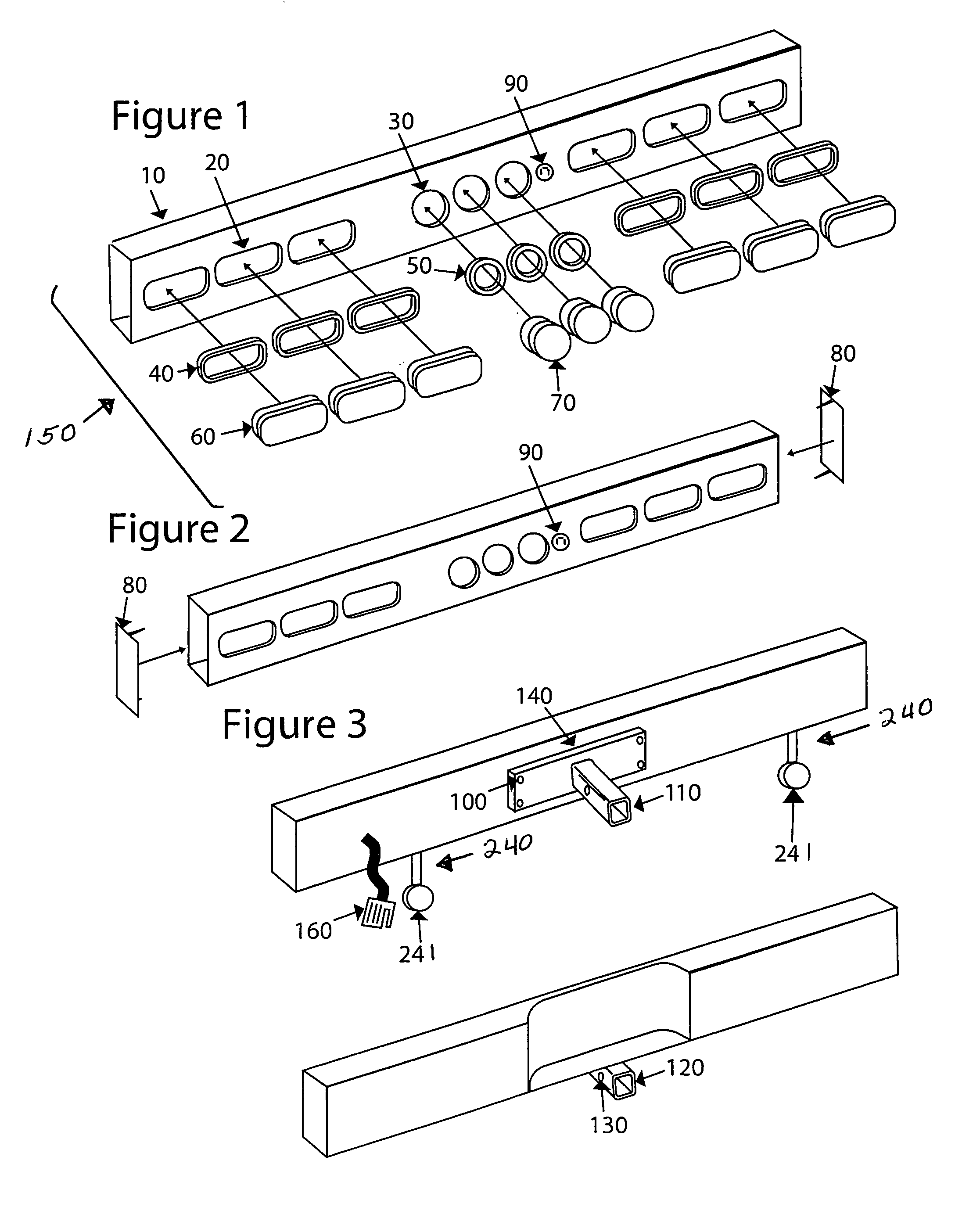

Combination safety light bar signal assembly and method

ActiveUS20050105296A1Facilitate telescoping ability of couplingReduce noiseLighting support devicesVehicle interior lightingEngineeringFlash light

The present invention relates to a full functioning safety light bar and signal assembly. A light system that utilizes a wiring harness assembly is further equipped with one or more of the following lights: driving, brake / signal, flasher / emergency, reverse, marker, strobe, fog or illuminating lights. Electric sensors in the body of the light bar unit control strobe and illuminating lights. The device compliments a vehicle by matching the various sizes, width and depth of their bumpers. Extension bars with the light fixture assembly can be attached to the light bar units to add greater illumination upon backing up and collars or strips of friction reducing materials are attached on the hitch components, e.g., such as the exterior of the male tongue insert and the interior cavities of the male tongue insert helping to limit vibration or noise. Locked protective covers keep the lights or lens in the light bar units from becoming scratched or damaged. Further, the ability to store an extra set of keys in a lockable security compartment is another safety feature provided with the safety light bar.

Owner:GREAT LAKES MFG

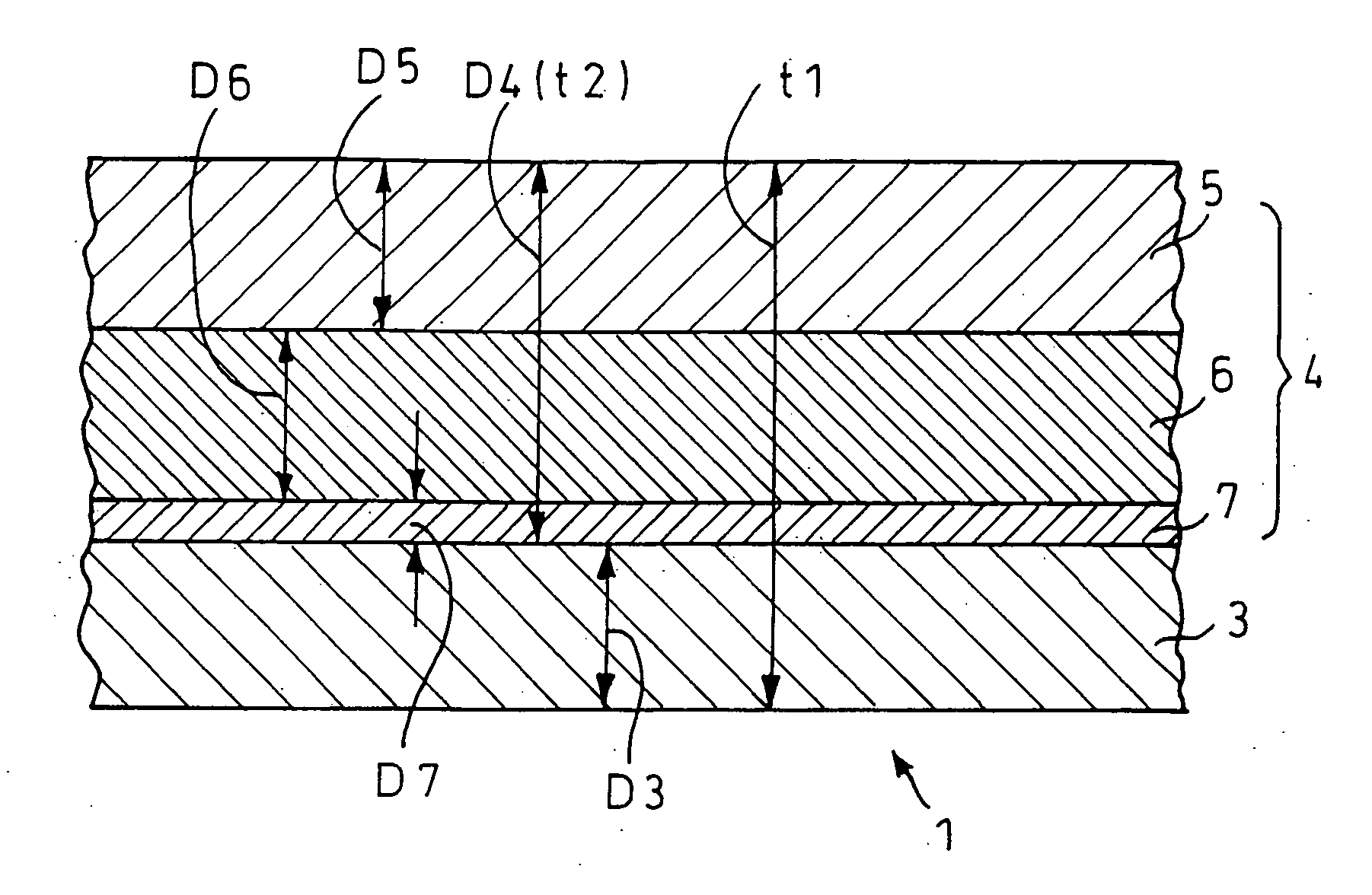

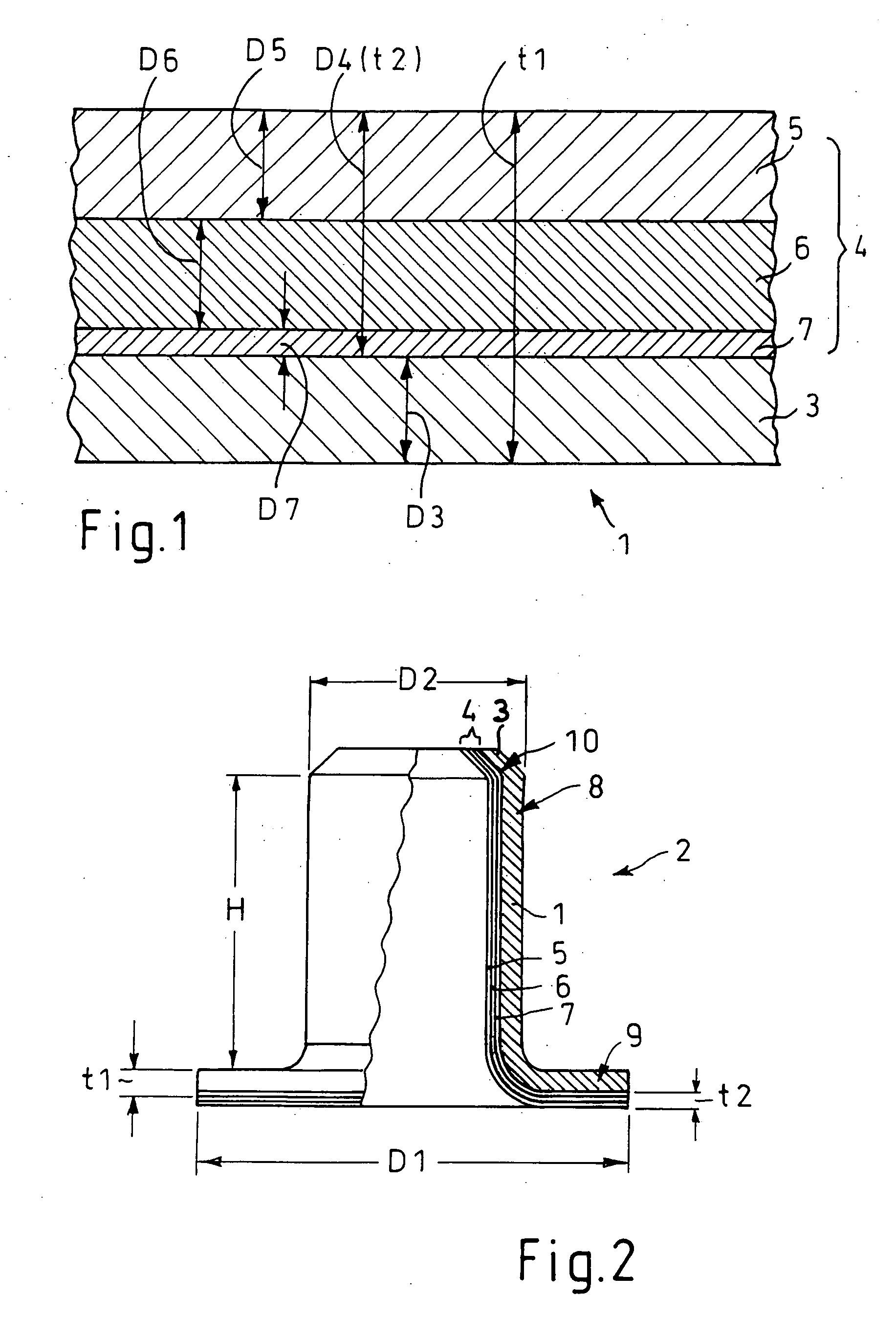

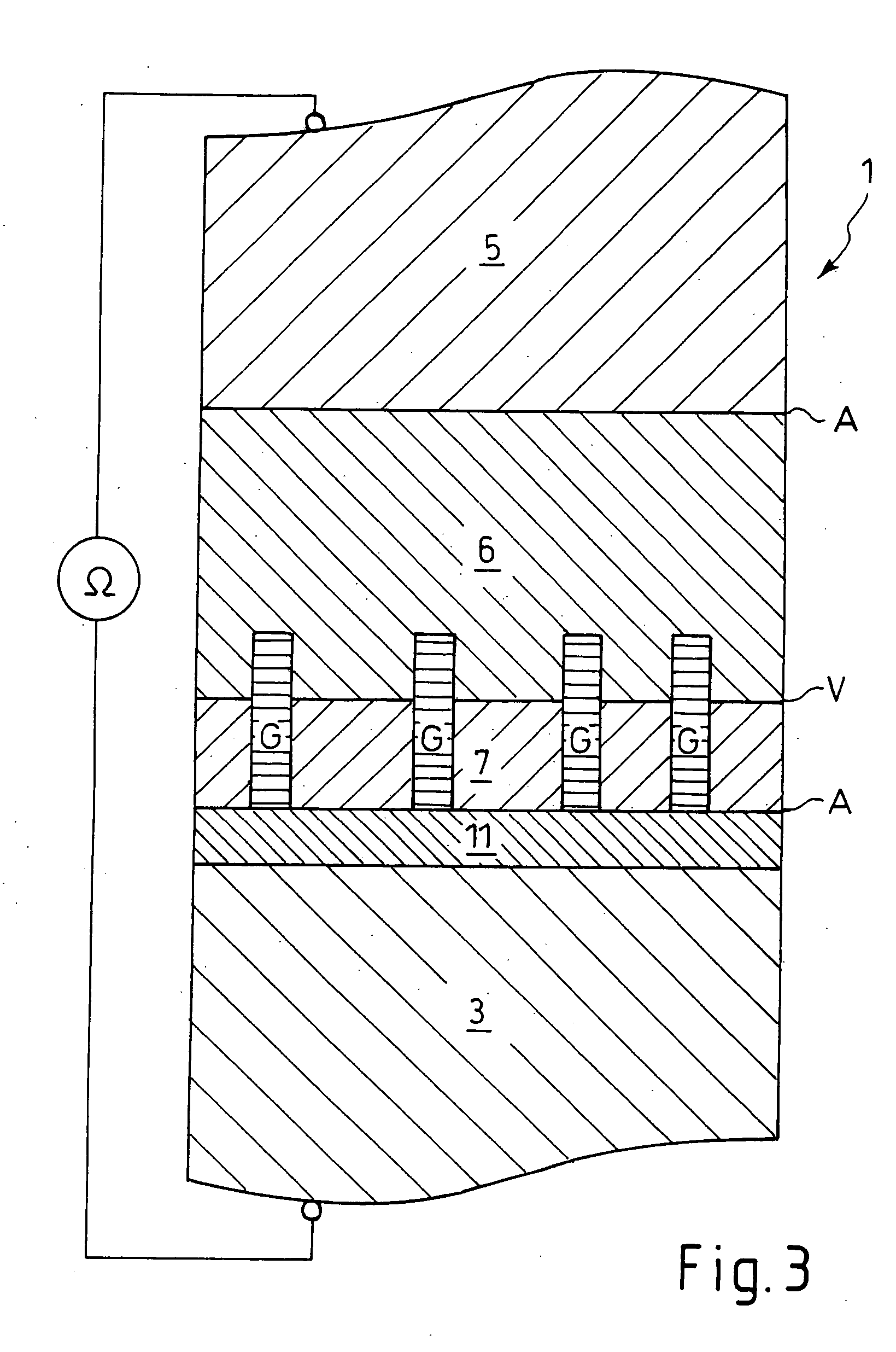

Composite system and bearing part with this system

InactiveUS20060251887A1Less complexReduce coefficient of frictionSynthetic resin layered productsBearing componentsElastomerEngineering

An antifriction composite system (1) for a bearing part (2), such as a sliding bearing part, with a metallic backing (3) and a functional coating (4), which comprises a top layer (5) with a friction-reducing effect. The functional coating (4) has an elastomer layer (6) lying directly under the top layer (5). The invention also relates to a bearing part (2) with an antifriction composite system (1) of this type.

Owner:HUHOCO METALLOBERFLACHENVEREDELUNG

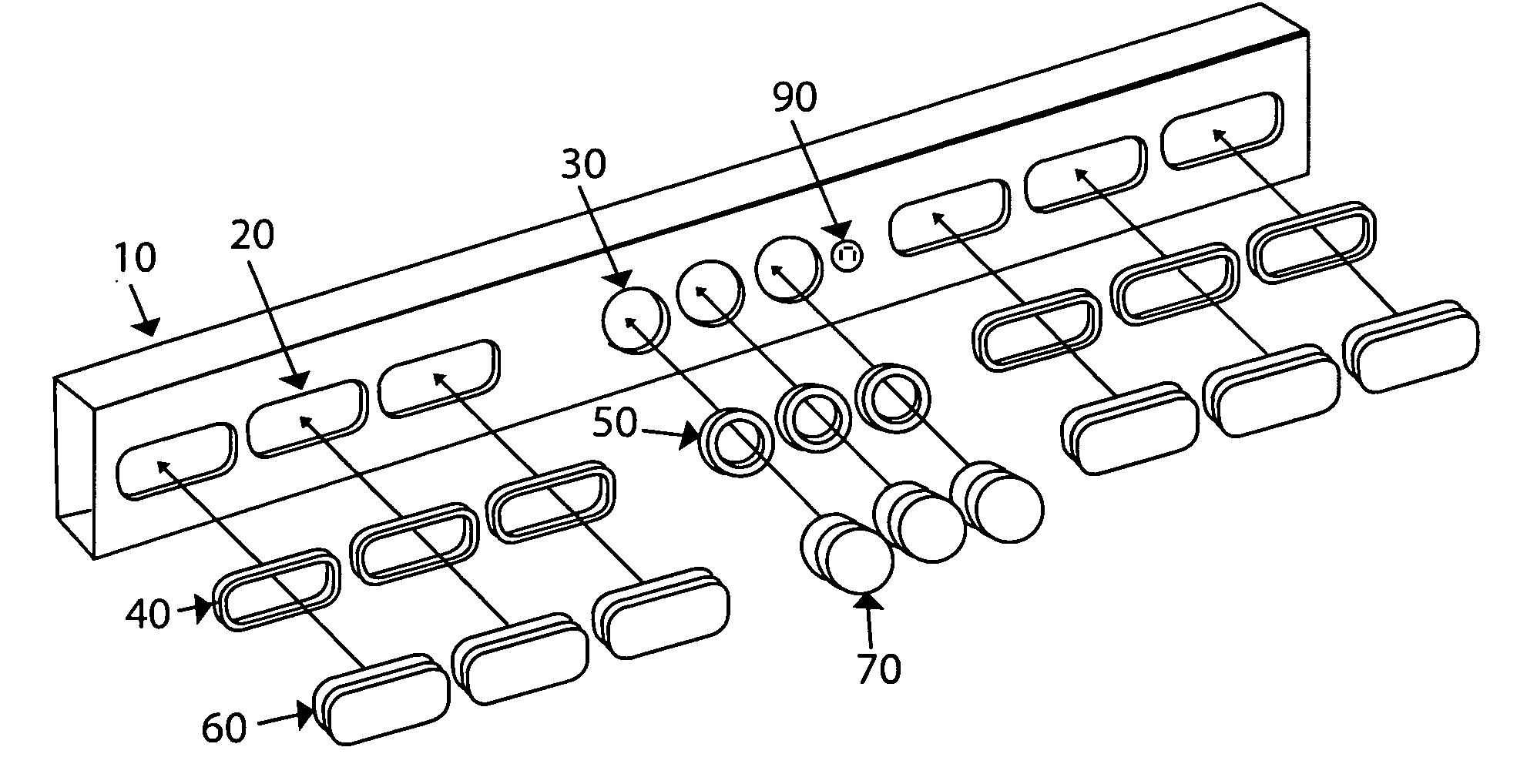

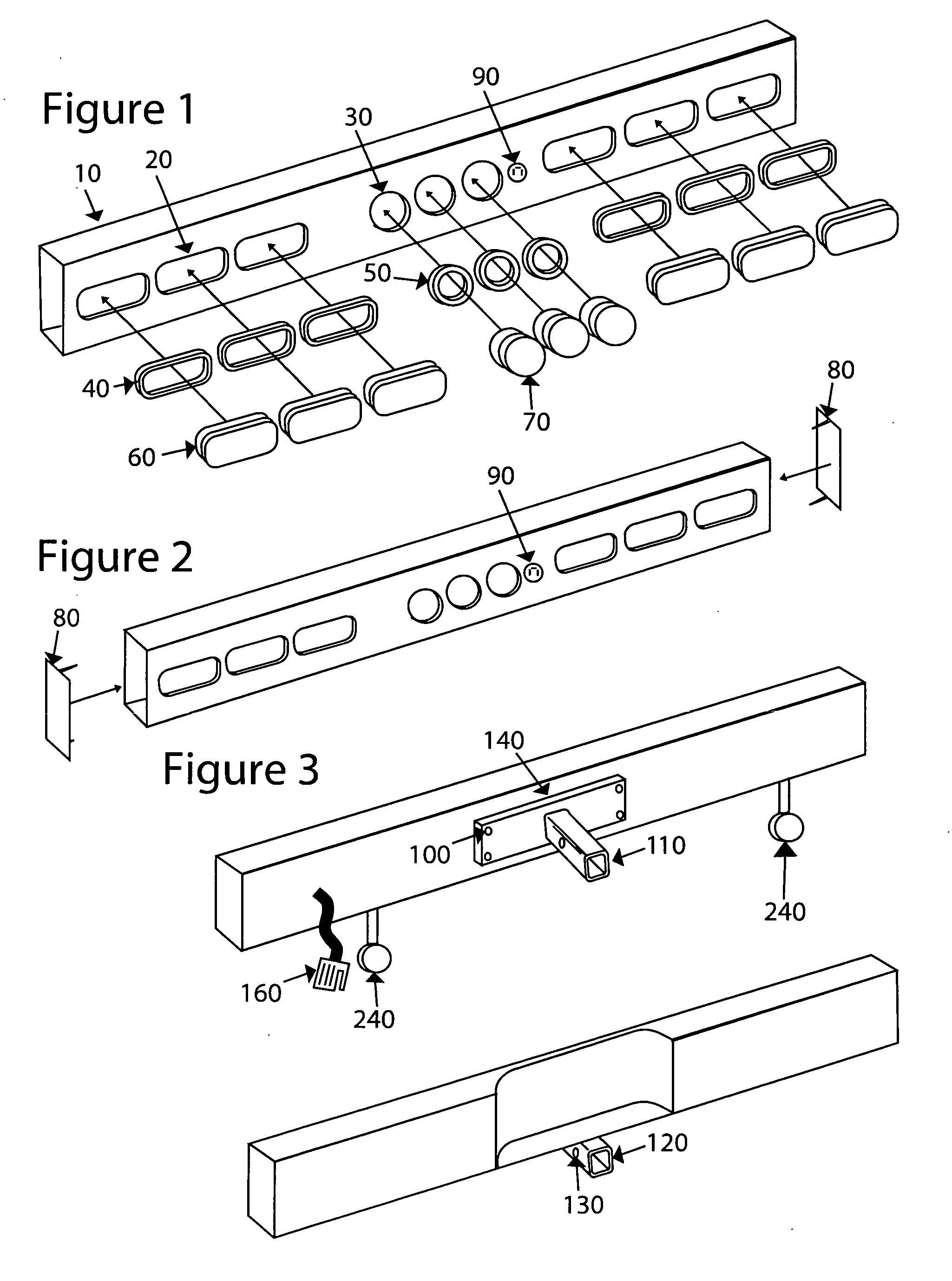

Friction reducing wear band and method of coupling a wear band to a tubular

ActiveUS20100252274A1Reduce frictional resistanceReduce resistanceDrilling rodsFluid removalFriction reducingFrictional resistance

In one embodiment, a wear band comprises a rotating element having a bore receivable on a tubular, the bore comprising first and second bore portions slidably receiving first and second sleeve bearings. Outer surfaces of the sleeve bearings slidably engage the bore portions and the bores of the sleeve bearings slidably engage the tubular. A first and a second stop collars may be received on the tubular to together straddle the rotating element and sleeve bearings to longitudinally secure the rotating element in a position on the tubular. The tubular may be included within a tubular string run into a borehole or into the bore of an installed casing, such as in casing while drilling. The rotating element provides stand-off between a tubular and the wall of a bore, reduces frictional resistance to longitudinal sliding and also to rotation of the tubular string within the bore.

Owner:INNOVEX DOWNHOLE SOLUTIONS INC

Safety light bar with a light fixture assembly

ActiveUS7347597B2Facilitate telescoping ability of couplingReduce noiseLighting support devicesVehicle interior lightingEngineeringLighting system

Owner:GREAT LAKES MFG

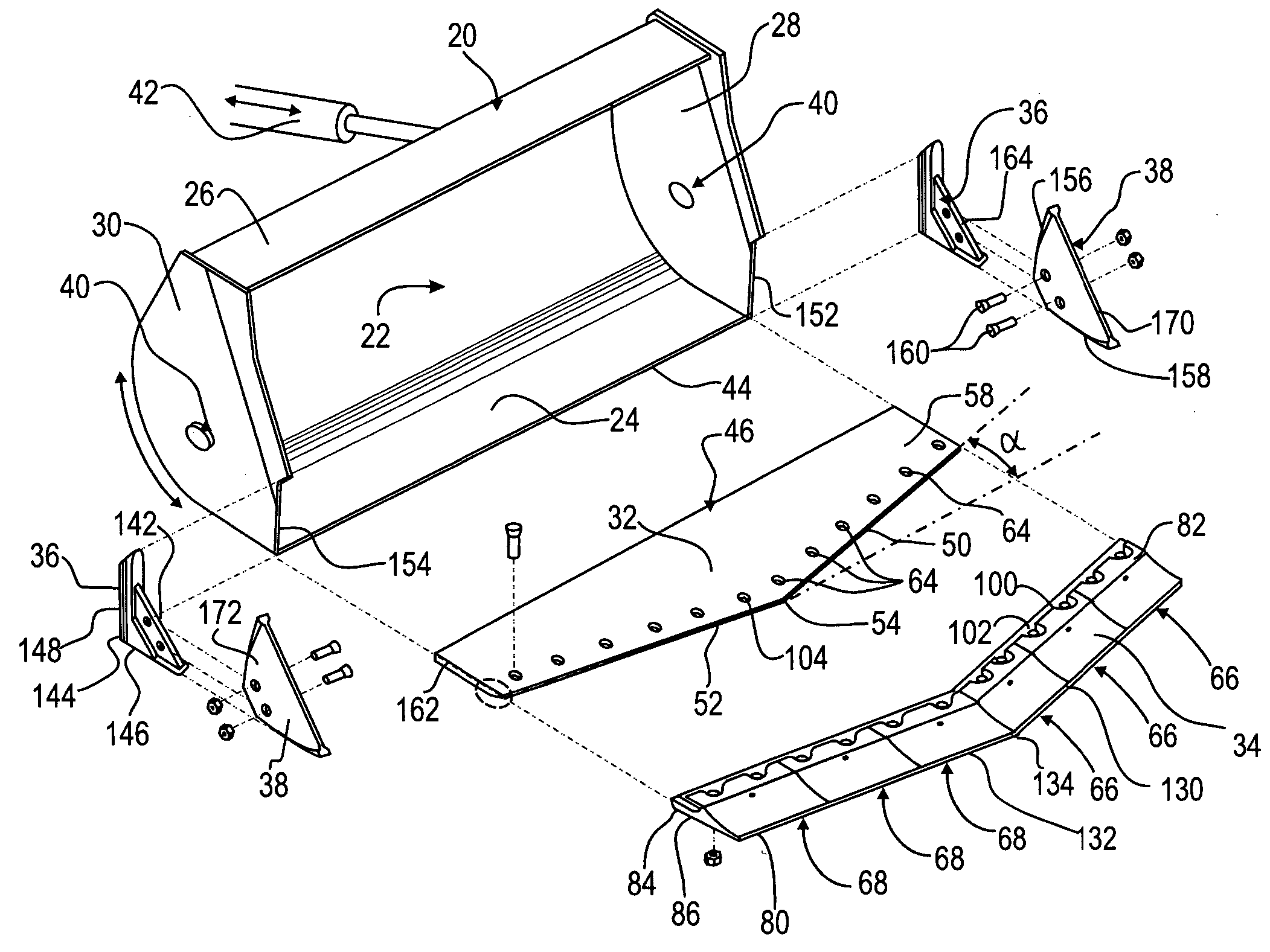

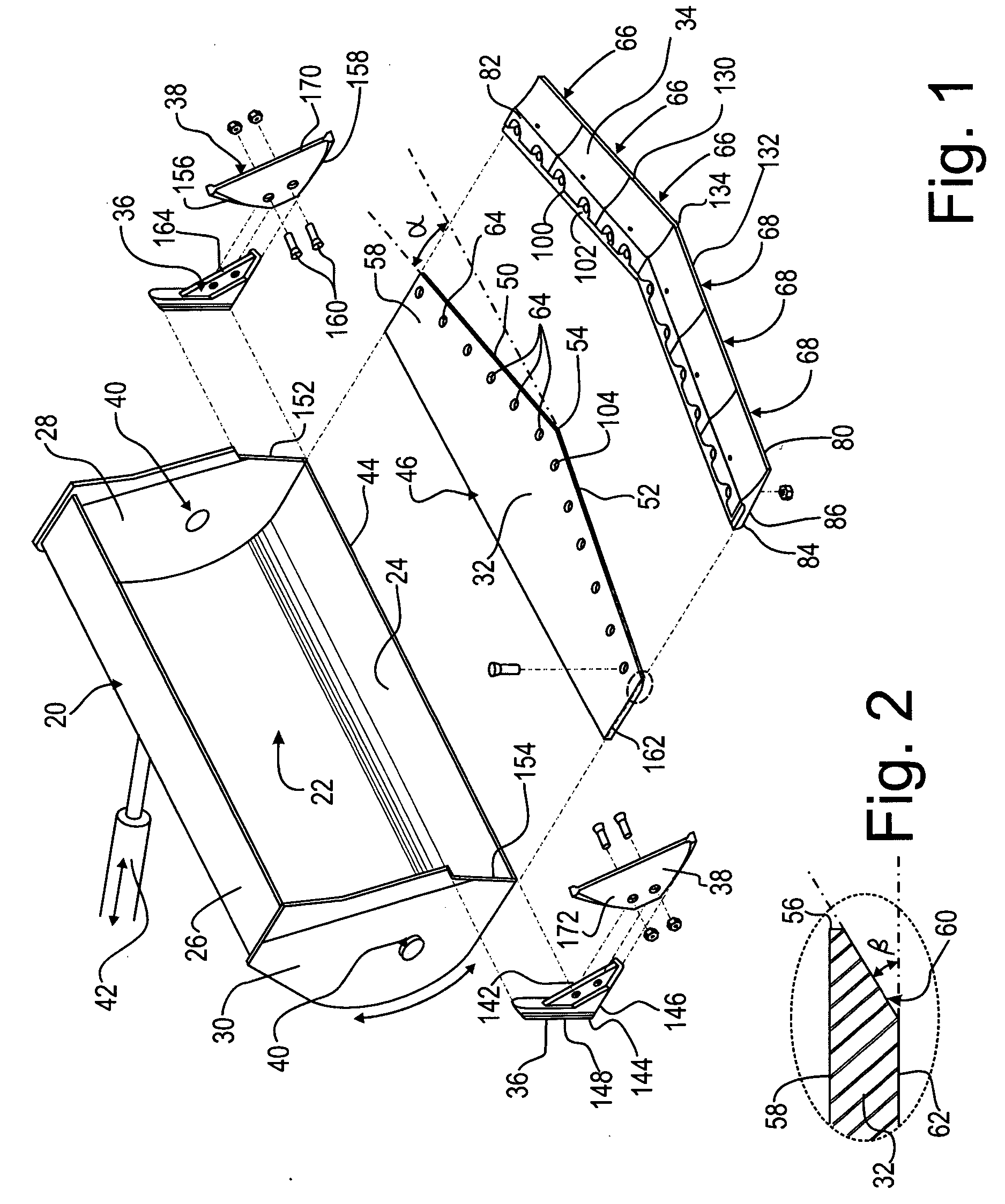

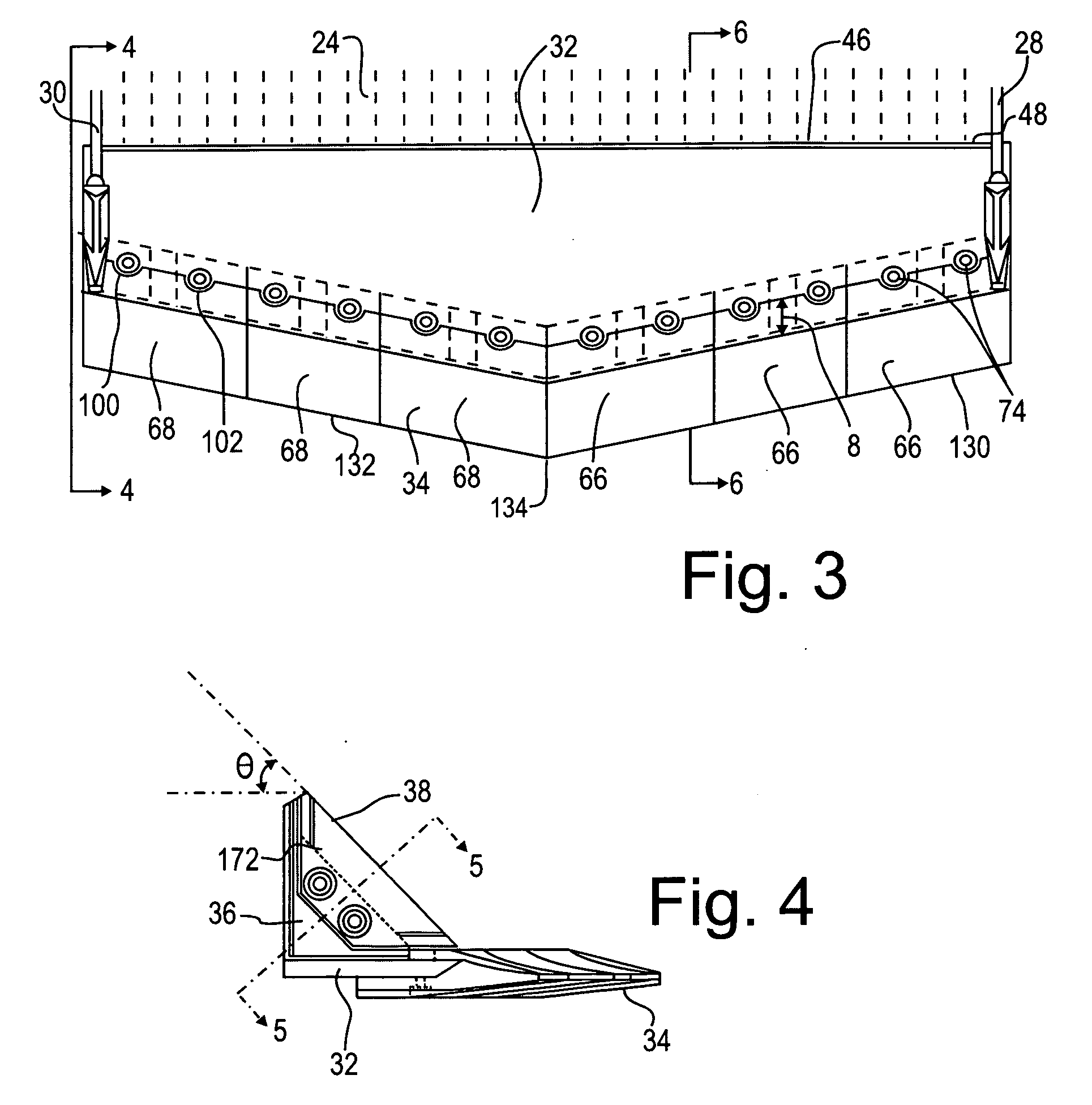

Wear plate assembly

InactiveUS20050172524A1Reduce and eliminate lip movementThicker wear lip sectionMechanical machines/dredgersLeading edgeEdge segment

A bucket assembly is provided with a kit that includes a base plate for permanent connection to a lower part of the bucket, and sacrificial, impermanent replaceable wear edge segments for the forward lip and corner leading edges of an excavator or loader bucket. These segments form a set of “bolt on” cast wear members and wing wear segments. The base plate and wear plates are drilled and machined to accommodate the precision fitting bolting on of the replaceable lips and cast wing segments. The cast lip segments are of both left and right hand configurations and come in a variety of widths that, in combination, may tend to fit a large number of different commercially available bucket sizes. The lip top and bottom faces are shaped in a profile that may tend to result in relatively uniform wear and a reduction in friction when digging into various materials.

Owner:PENINSULA ALLOY +1

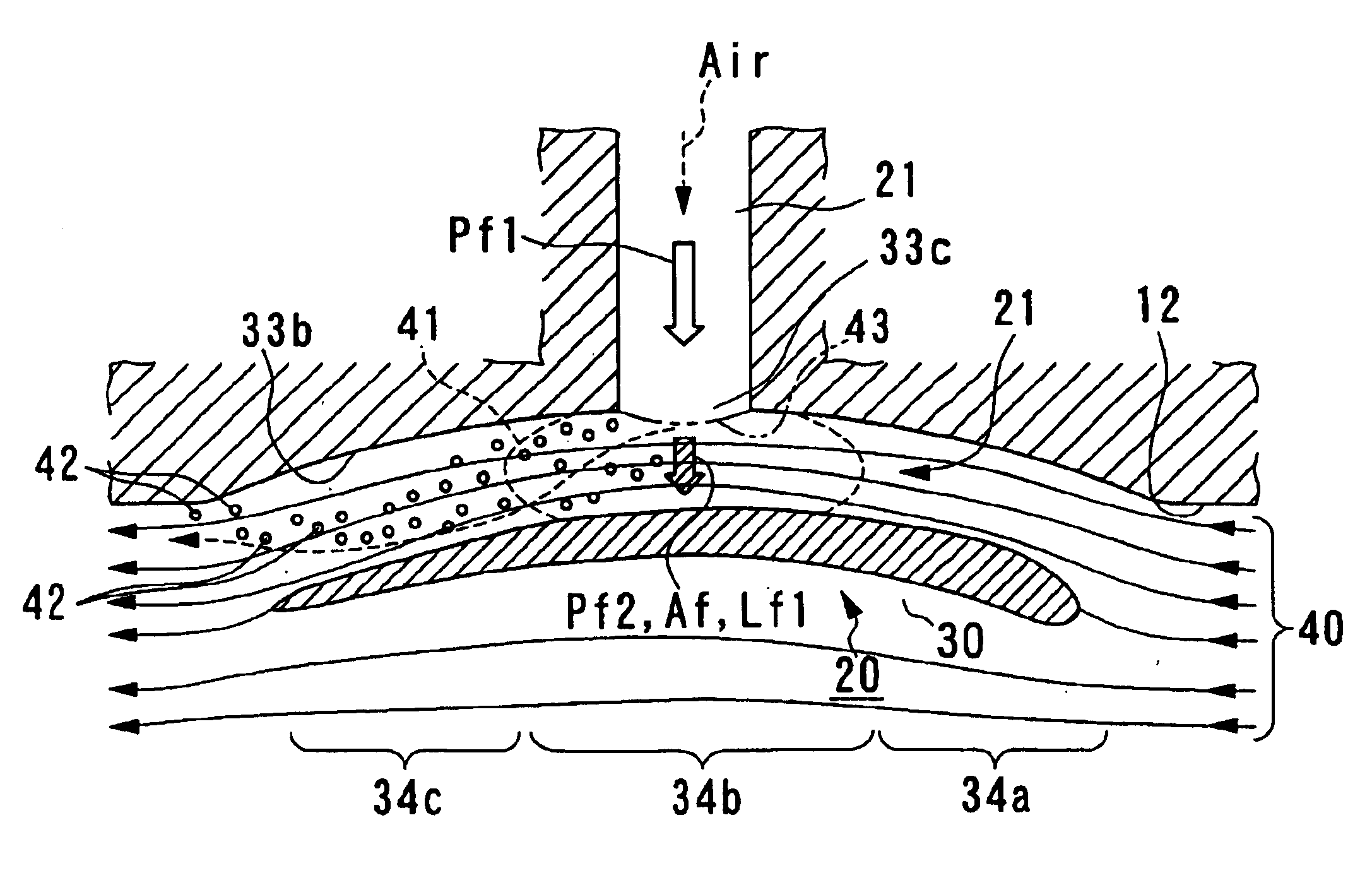

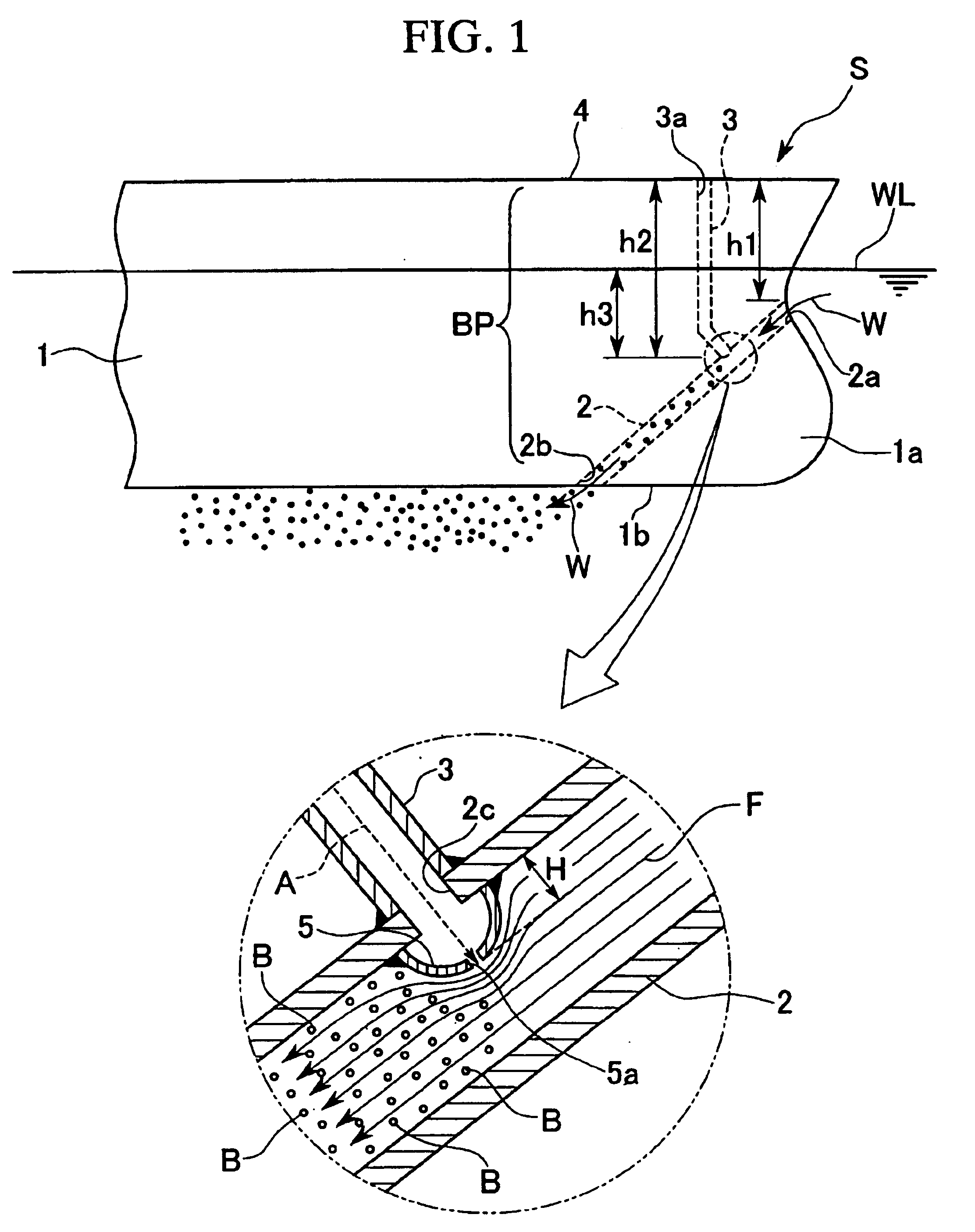

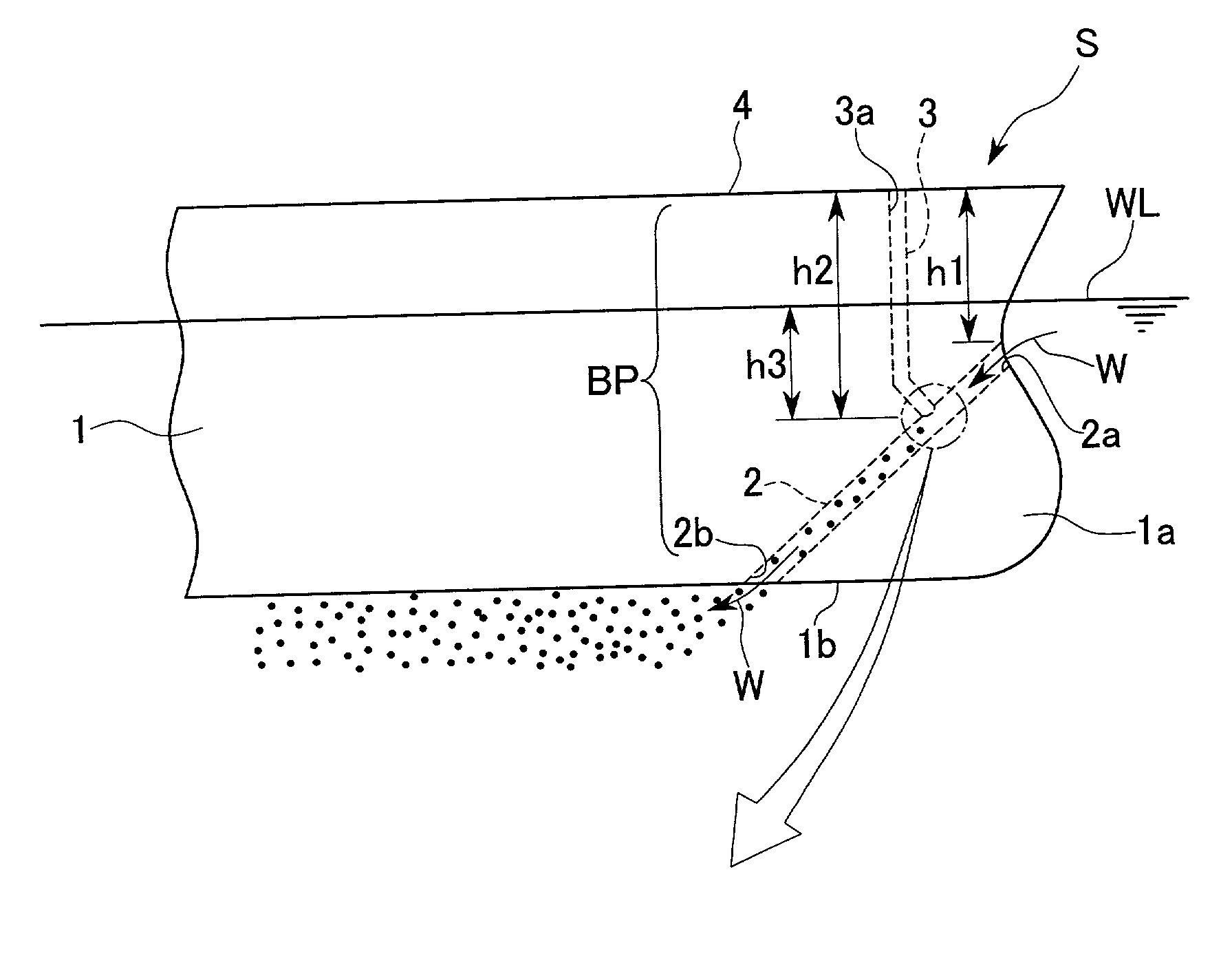

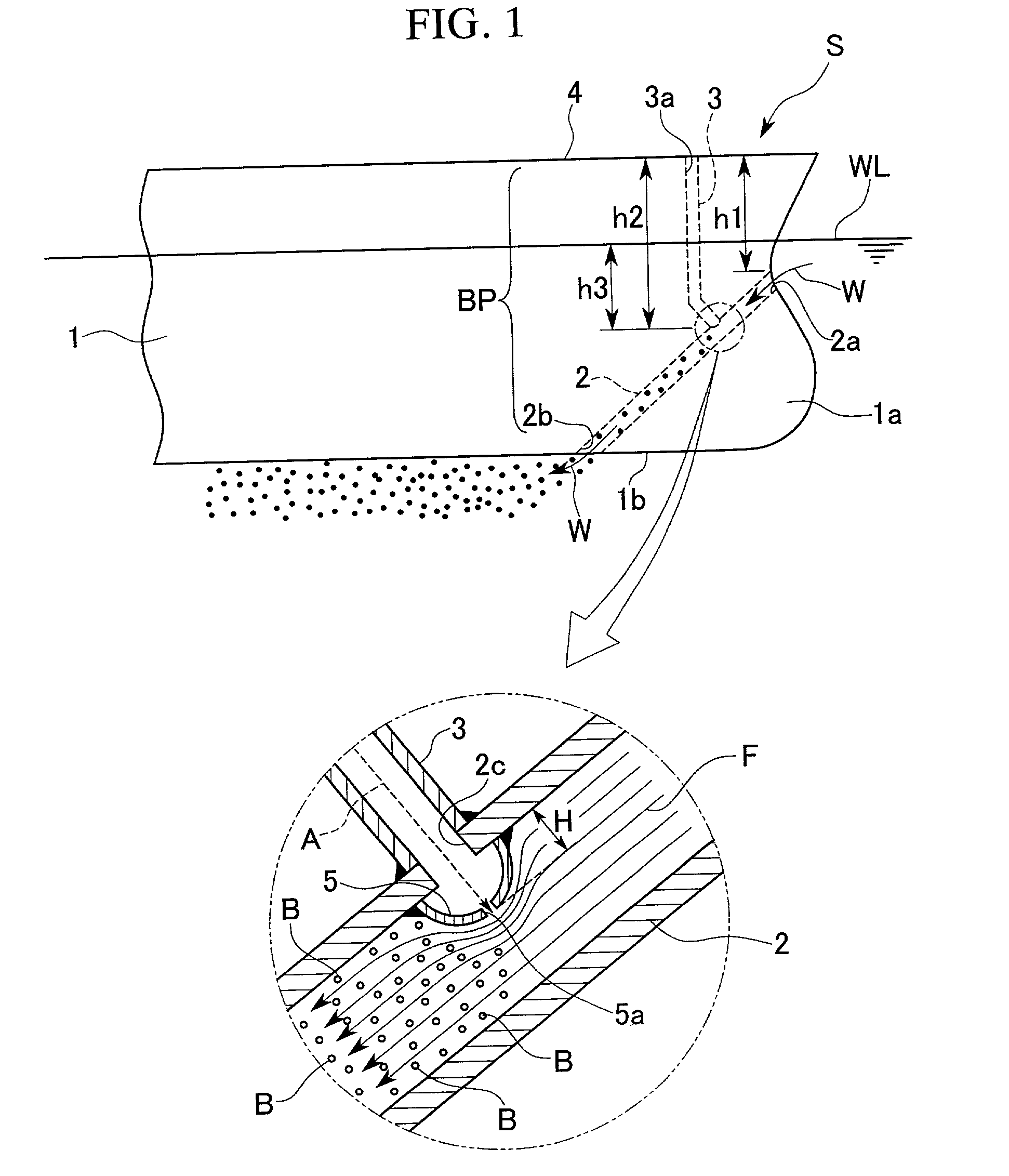

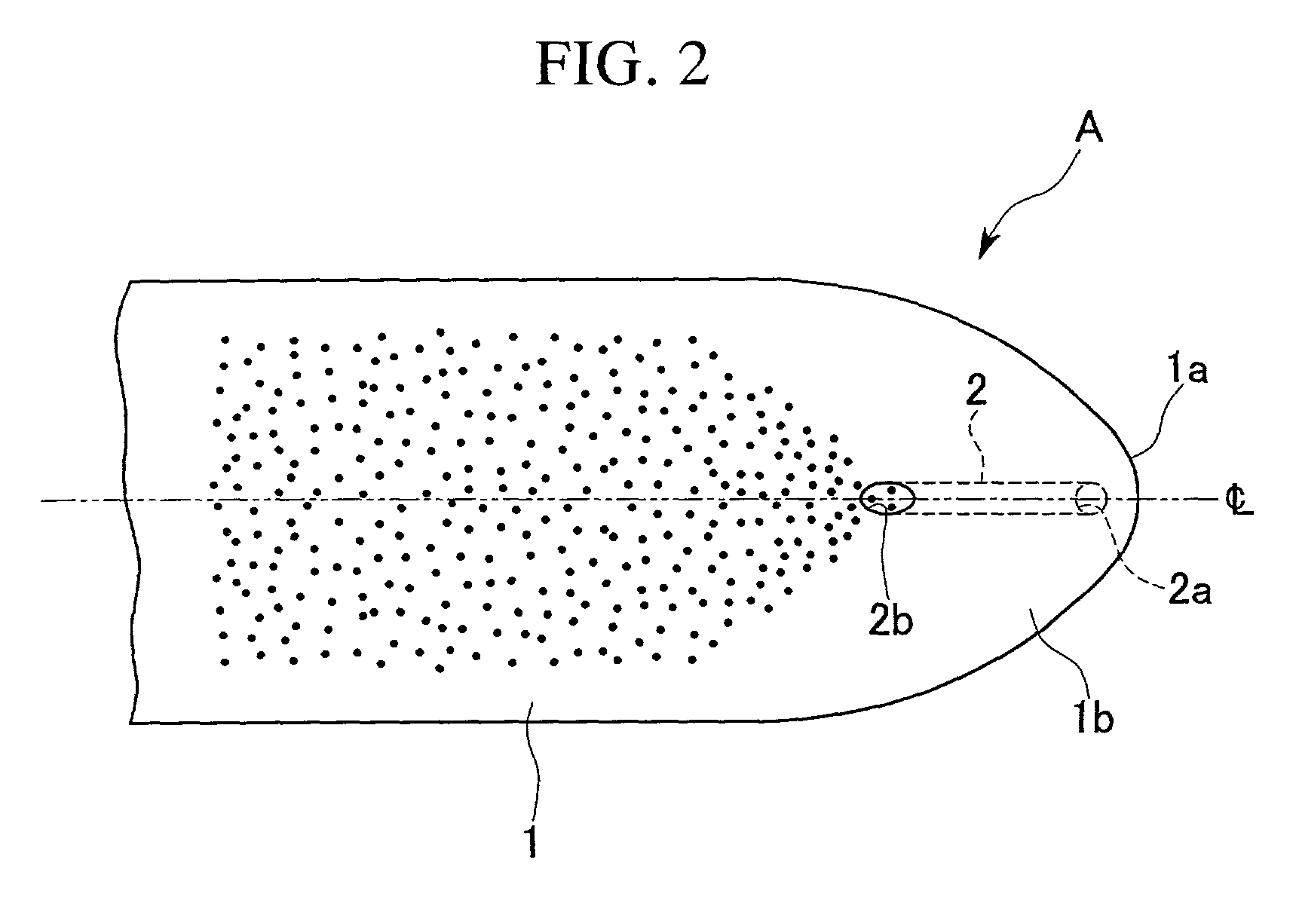

Friction reducing ship and method for reducing frictional resistance

InactiveUS6789491B2Reduce the power requiredReduce frictional resistanceWatercraft hull designJet pumpsWater dischargeAtmospheric air

A friction reducing ship reduces frictional resistance between the external hull plate 1 and water W by ejecting air A from the external hull plate 1 into water W to generate micro-bubbles B on the surface of the external hull plate 1. A structural feature of the ship is that micro-bubbles B are generated by creating a negative pressure region in the water W admitted in the water intake opening 2a, disposed below the waterline WL in the bow section 1a, so as to eject atmospheric air above the water into the water to generate micro-bubbles B, and discharging the micro-bubbles B together with water to the water discharge opening 2b provided in the bottom section 1b.

Owner:IHI MARINE UNITED INC

Composition for denaturing and breaking down friction-reducing polymer and for destroying other oil well contaminants

InactiveUS20070298979A1Onset of propertyIncreases hydrogen-bonding potentialOther chemical processesFluid removalOrganic compoundOxidizing agent

A composition and method for breaking down and denaturing friction-reducing compound introduced into the ground during the drilling of oil wells and for destroying other contaminants and biohazards naturally present within and artificially introduced into oil wells, which are formed as a result of the drilling and pumping processes. The composition comprises several species of oxidizing agent compounds that are effective in breaking down hydrogen sulfide produced by bacteria as well as the friction-reducing polymer used during drilling and several other organic compounds.

Owner:PERRY STEPHEN C +1

Coated body with nanocrystalline CVD coating for enhanced edge toughness and reduced friction

An improved coated body having a nanocrystalline CVD coating of Ti(C,N,O) is disclosed. The coating is formed using the MTCVD process and including, as part of the gaseous mixture, CO, CO2 or mixtures thereof. The use of this dopant during the coating results in a much smaller, equiaxed grain size. The method of forming the body is also disclosed.

Owner:SECO TOOLS AB

Introducer apparatus with eversible sleeve

Disclosed is an introducer apparatus comprising an sleeve fixation mechanism or introducer member, such as a catheter, introducer, or ring-like structure, which is attached to a protective sleeve comprising a thin flexible material such a polymeric film. The sleeve is inverted into the passageway of a second member, such as a catheter, feeding tube, introducer, etc., that is advanced through the passageway of the introducer member and is introduced into a bodily passage of a patient, such as the bile duct, nasal passages, colon, etc. The sleeve everts from the passageway of the second member during its advancement to lay down a friction-reducing surface. The sleeve prevents frictional contact between the second member and delicate or sensitive tissues.

Owner:COOK MEDICAL TECH LLC

Friction reducing ship and method for reducing frictional resistance

InactiveUS20020014192A1Reduce the power requiredWatercraft hull designJet pumpsMarine engineeringAtmospheric air

A friction reducing ship reduces frictional resistance between the external hull plate 1 and water W by ejecting air A from the external hull plate 1 into water W to generate micro-bubbles B on the surface of the external hull plate 1. A structural feature of the ship is that micro-bubbles B are generated by creating a negative pressure region in the water W admitted in the water intake opening 2a, disposed below the waterline WL in the bow section 1a, so as to eject atmospheric air above the water into the water to generate micro-bubbles B, and discharging the micro-bubbles B together with water to the water discharge opening 2b provided in the bottom section 1b.

Owner:IHI MARINE UNITED INC

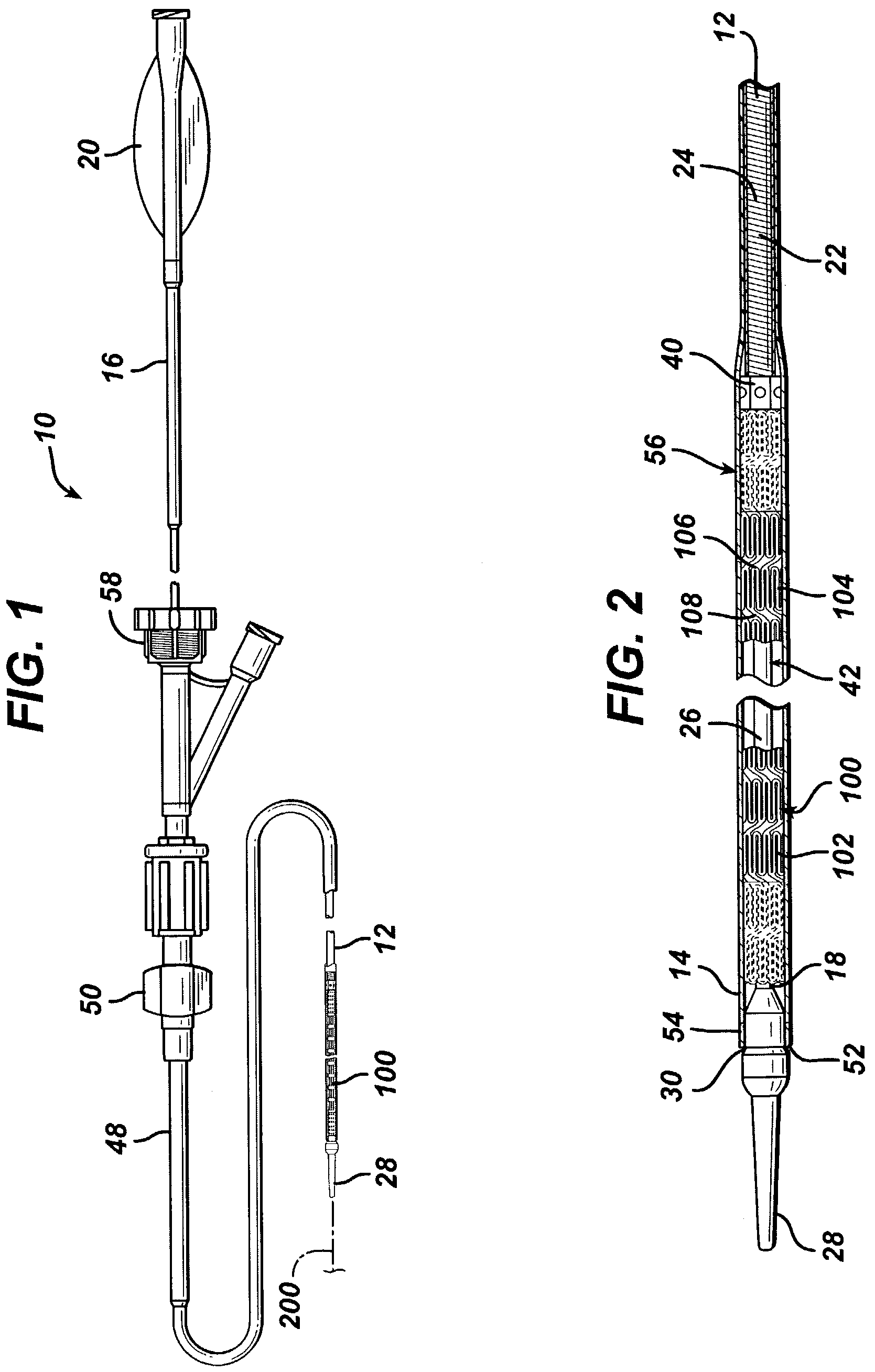

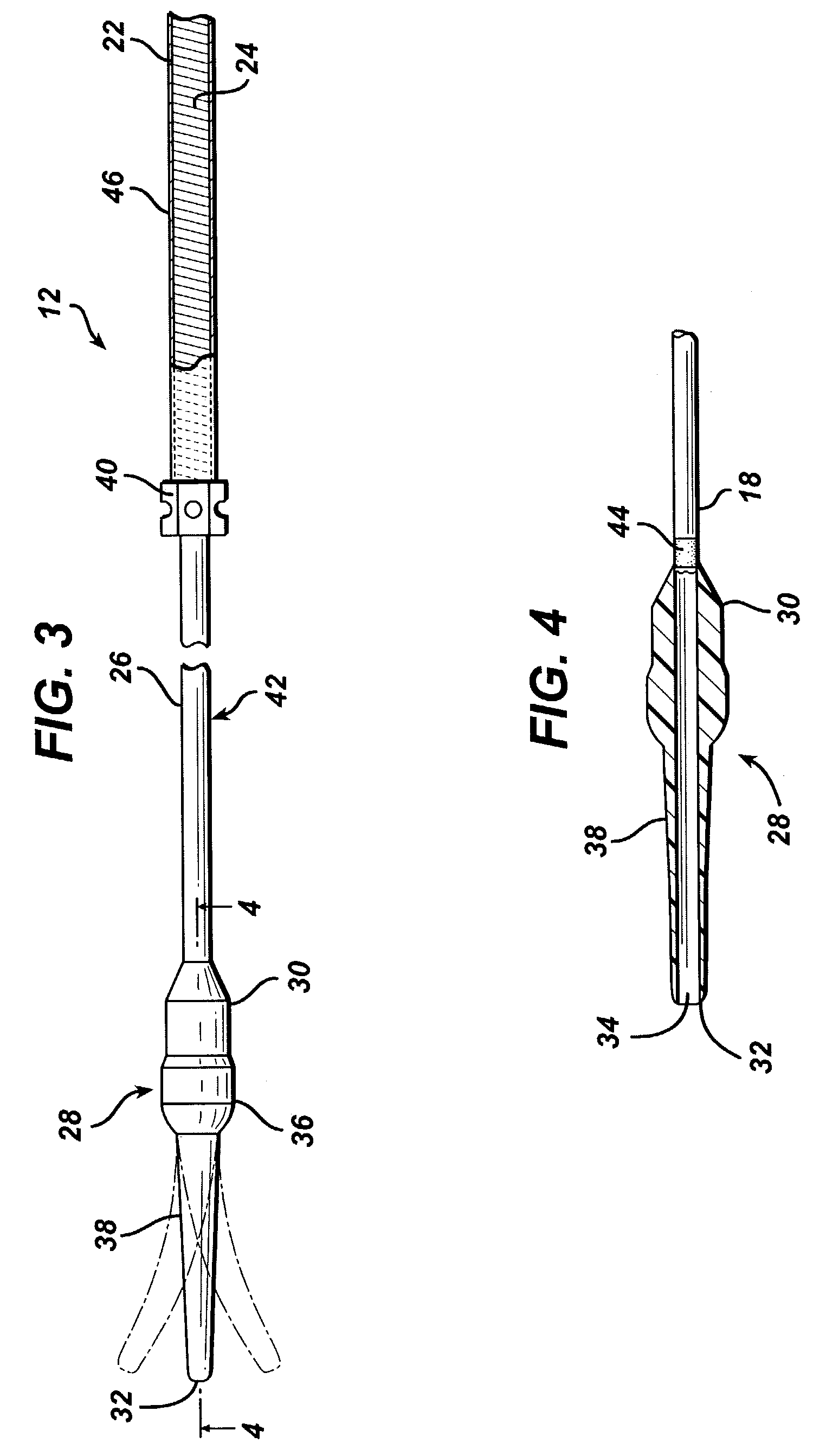

Friction reducing lubricant for stent loading and stent delivery systems

InactiveUS7309349B2Increase force inherent in loadingReduce frictionStentsBlood vesselsFriction forceDelivery system

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com