Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1216 results about "Synthetic oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synthetic oil is a lubricant consisting of chemical compounds that are artificially made. Synthetic lubricants can be manufactured using chemically modified petroleum components rather than whole crude oil, but can also be synthesized from other raw materials. The base material, however, is still overwhelmingly crude oil that is distilled and then modified physically and chemically. The actual synthesis process and composition of additives is generally a commercial trade secret and will vary among producers.

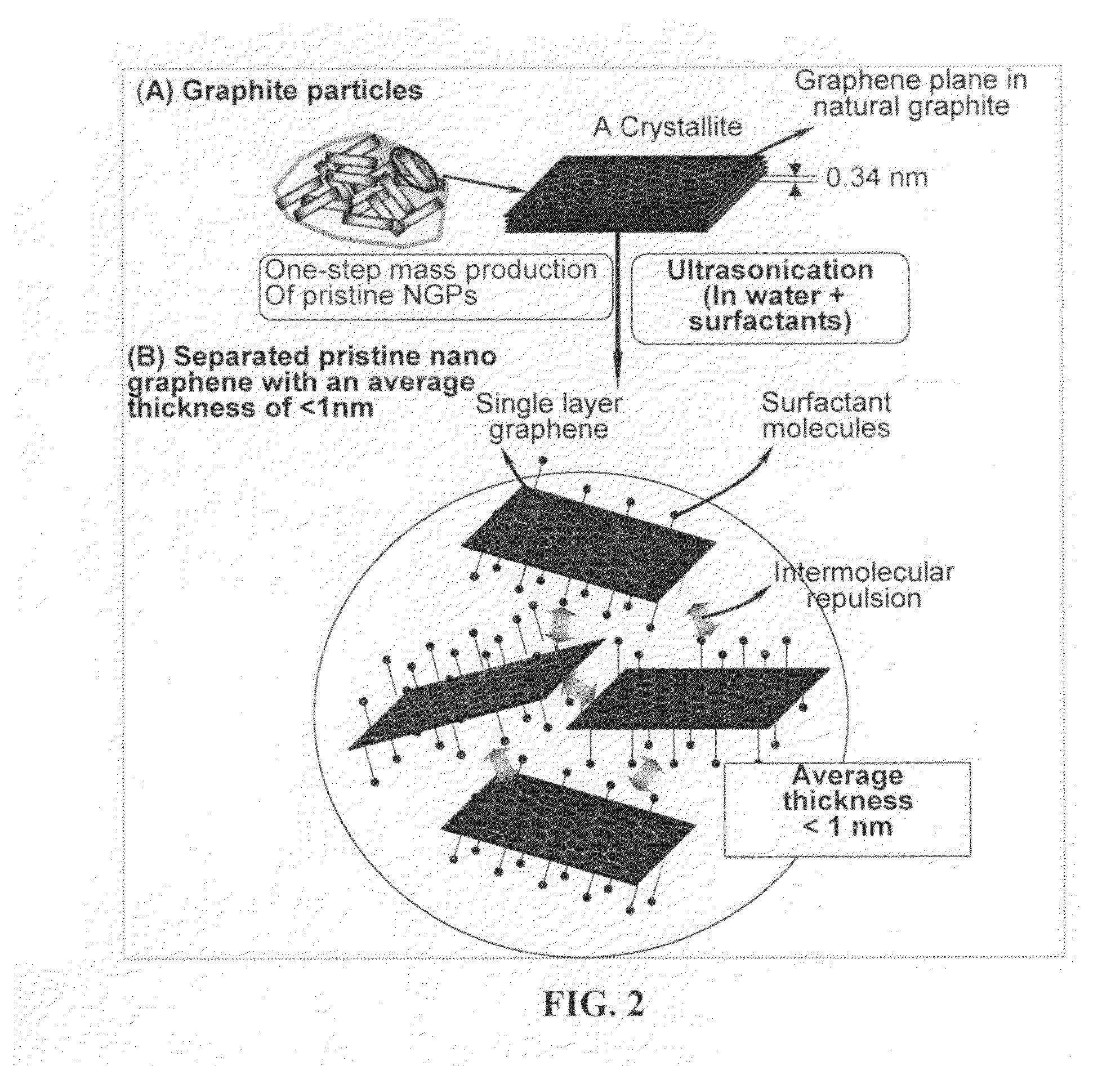

Nano graphene-modified lubricant

ActiveUS20110046027A1Modulate viscosityImprove the lubrication effectAdditivesBase-materialsCarbon nanotubeSingle layer graphene

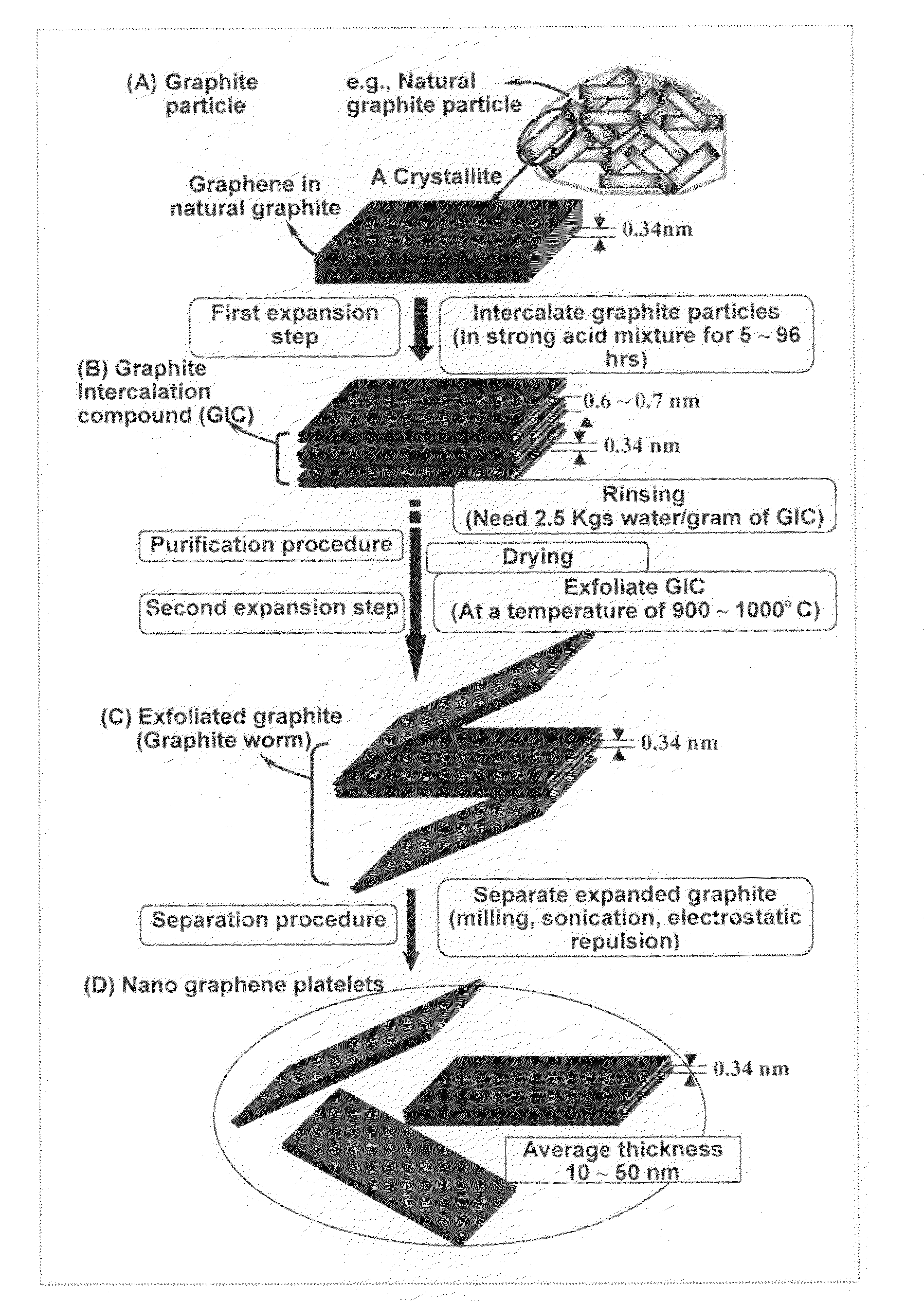

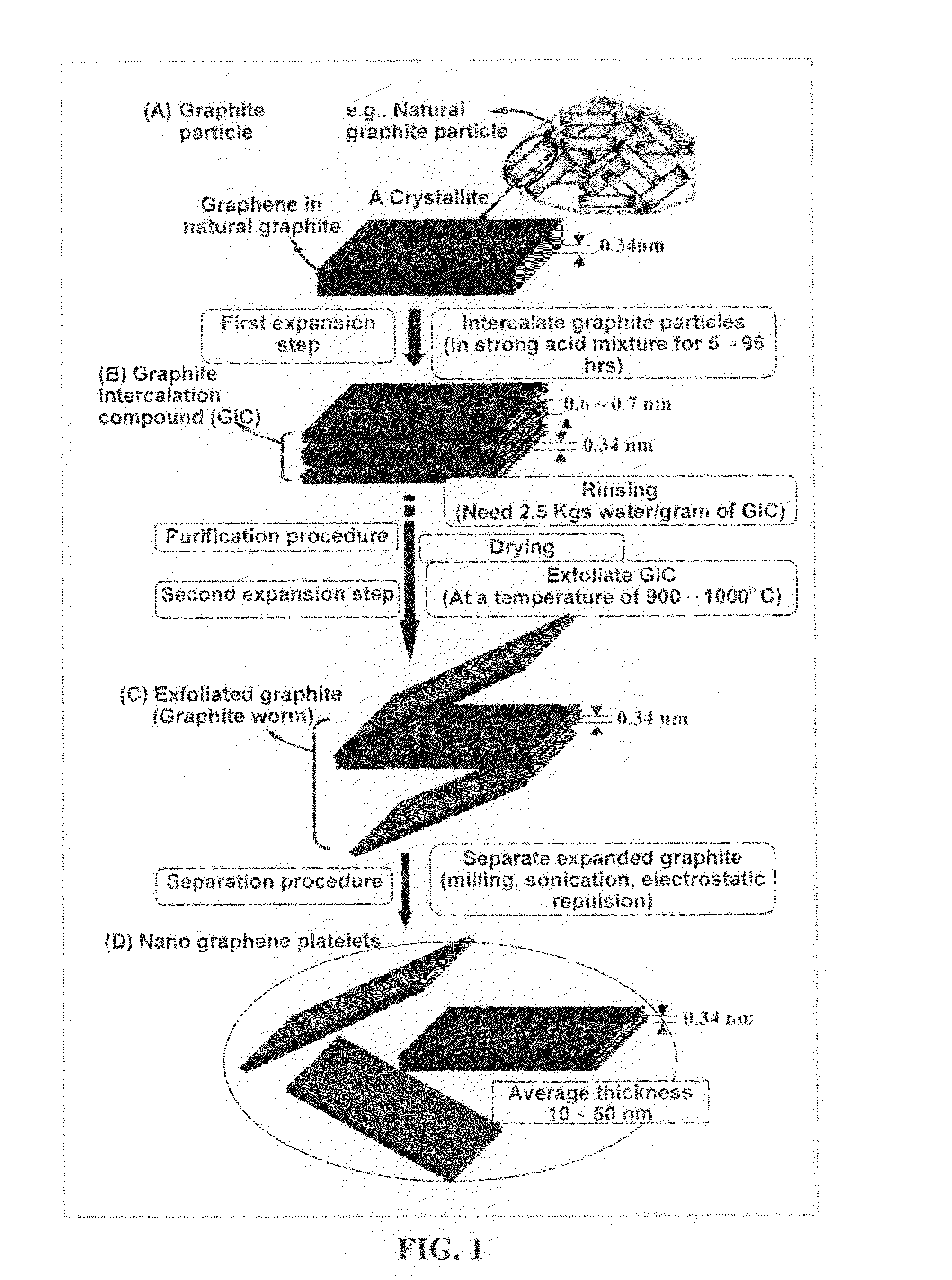

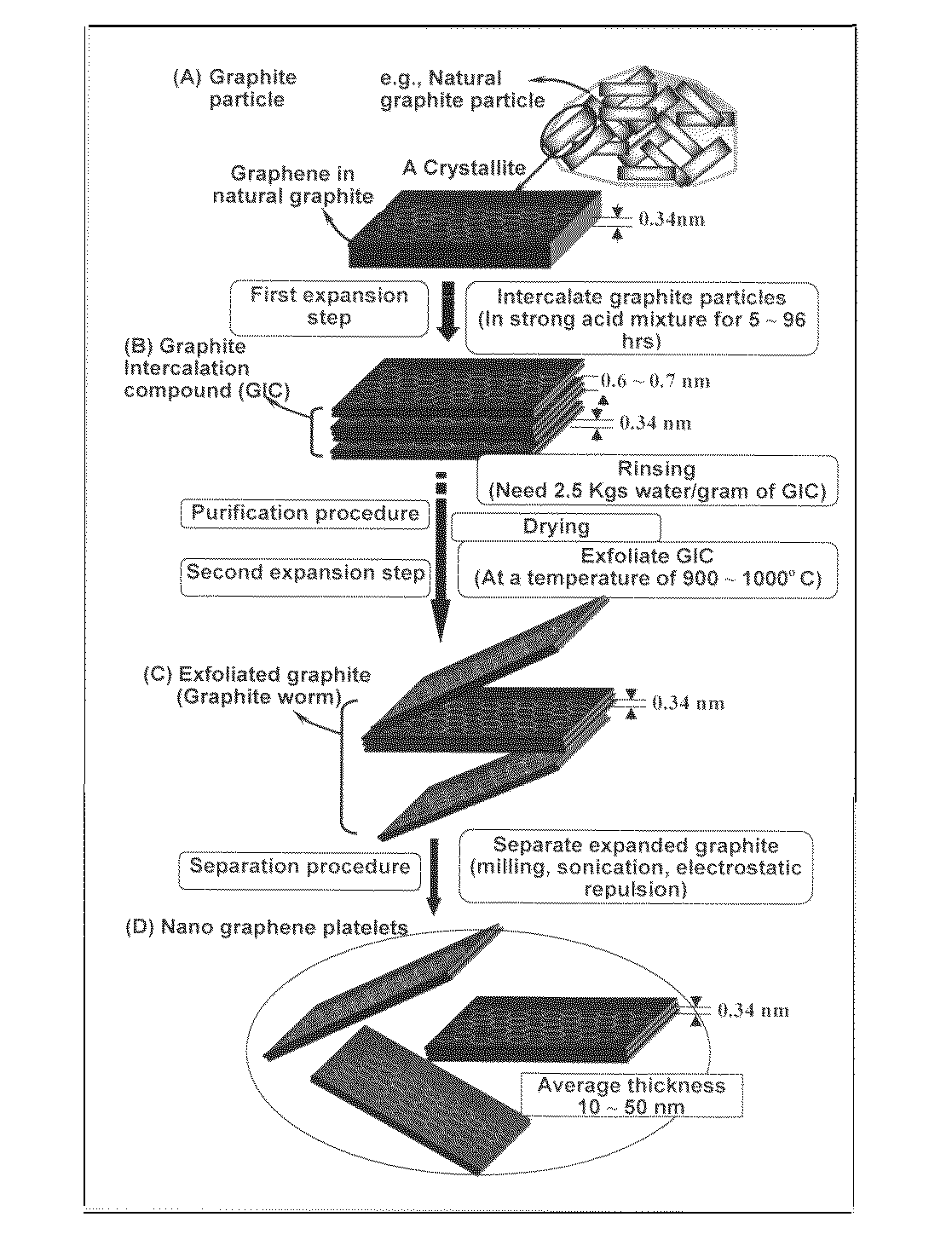

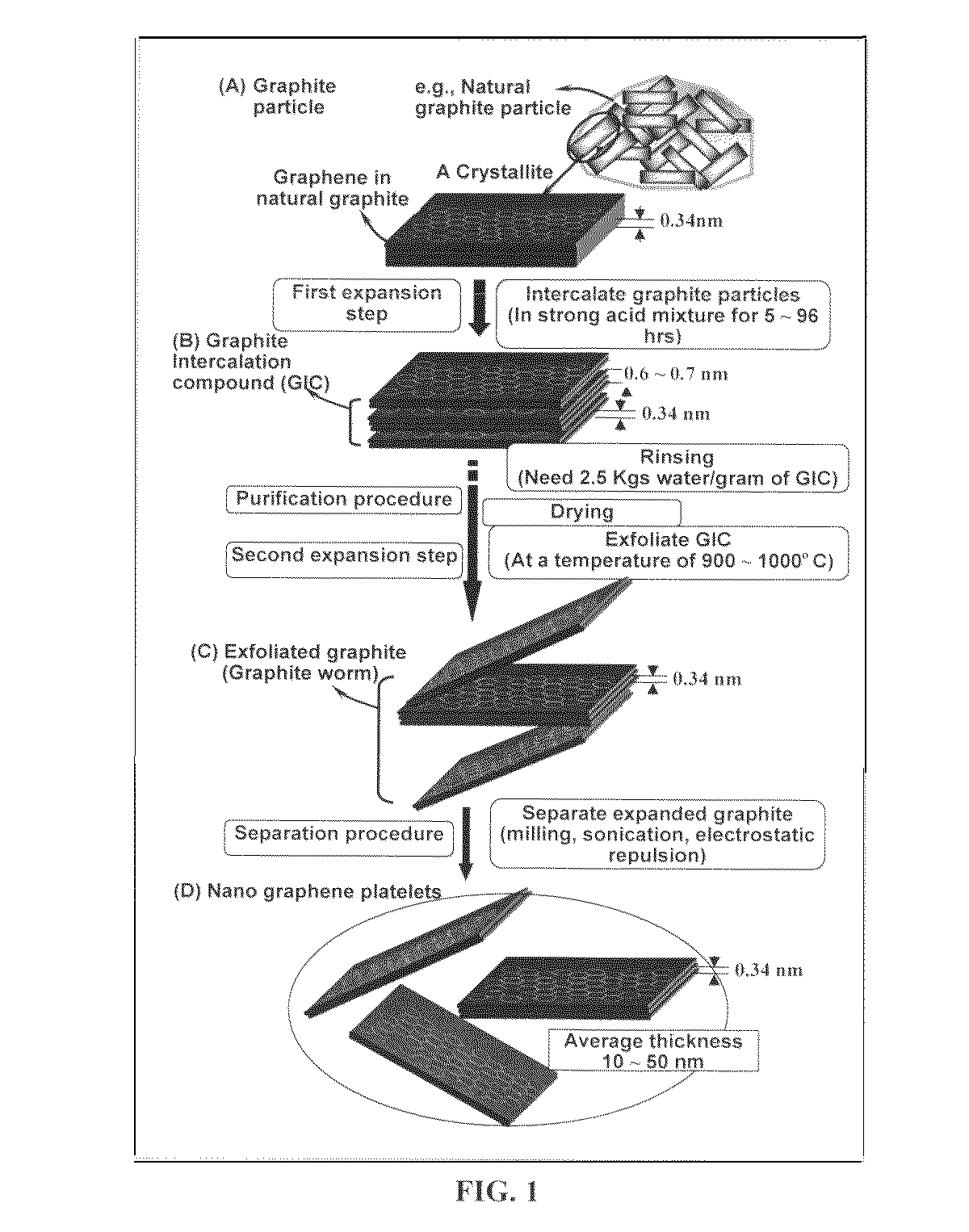

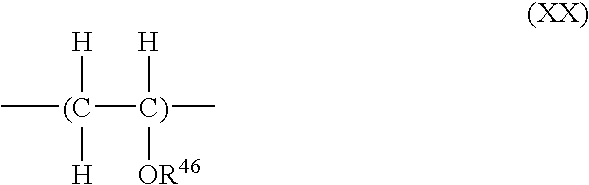

A lubricant composition having improved lubricant properties, comprising:(a) a lubricating fluid; and (b) nano graphene platelets (NGPs) dispersed in the fluid, wherein nano graphene platelets have a proportion of 0.001% to 60% by weight based on the total weight of the fluid and the graphene platelets combined. Preferably, the composition comprises at least a single-layer graphene sheet. Preferably, the lubricating fluid contains a petroleum oil or synthetic oil and a dispersant or surfactant. With the addition of a thickener or a desired amount of NGPs, the lubricant becomes a grease composition. Compared with graphite nano particle- or carbon nanotube-modified lubricants, NGP-modified lubricants have much better thermal conductivity, friction-reducing capability, anti-wear performance, and viscosity stability.

Owner:GLOBAL GRAPHENE GRP INC

Premium synthetic lubricants

InactiveUS6475960B1Refining to change hydrocarbon structural skeletonHydrocarbon purification/separationAntioxidantBoiling point

Premium synthetic lubricants comprise a synthetic isoparaffinic hydrocarbon base stock and an effective amount of at least one, and typically a plurality of lubricant additives such as a detergent, dispersant, antioxidant, antiwear additive, pout point depresant, VI improver and the like. The base stock is derived from a waxy, paraffinic, Fischer-Tropsch synthesized hydrocarbon feed fraction having an initial boiling point in the range of about 650-750° F. and continuously boiling up to at least 1050° F., by a process which comprises hydroisomerizing the feed and dewaxing the isomerate. The waxy feed has a T90-T10 temperature difference of at least 350° F. and is preferably hydroisomerized without any pretreatment, other than optional fractionation. The lubricant may also contain hydrocarbonaceous and synthetic base stock material. Lubricants, such as fully formulated multigrade automotive crankcase and transmission oils formed by adding a suitable additive package to the isoparaffinic base stock have exhibited performance superior to similar fully formulated oils based on both PAO and conventional, petroleum derived base stocks.

Owner:EXXON RES & ENG CO

Premium synthetic lubricant base stock (Law734) having at least 95% noncyclic isoparaffins

A premium synthetic lubricating oil base stock having a high VI and low pour point is made by hydroisomerizing a Fischer-Tropsch synthesized waxy, paraffinic feed wax and then dewaxing the hydroisomerate to form a 650-750° F.+ dewaxate. The waxy feed has an initial boiling point in the range of about 650-750° F., from which it continuously boils up to at least 1050° F. and has a T90-T10 temperature difference of at least 350° F. The feed is preferably hydroisomerized without any pretreatment, other than optional fractionation. The 650-750° F.+ dewaxate is fractionated into two or more base stocks of different viscosity.

Owner:EXXON RES & ENG CO

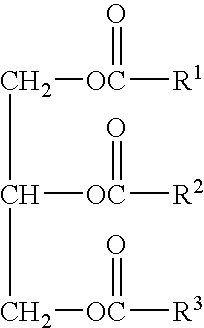

Lubricant and additive formulation

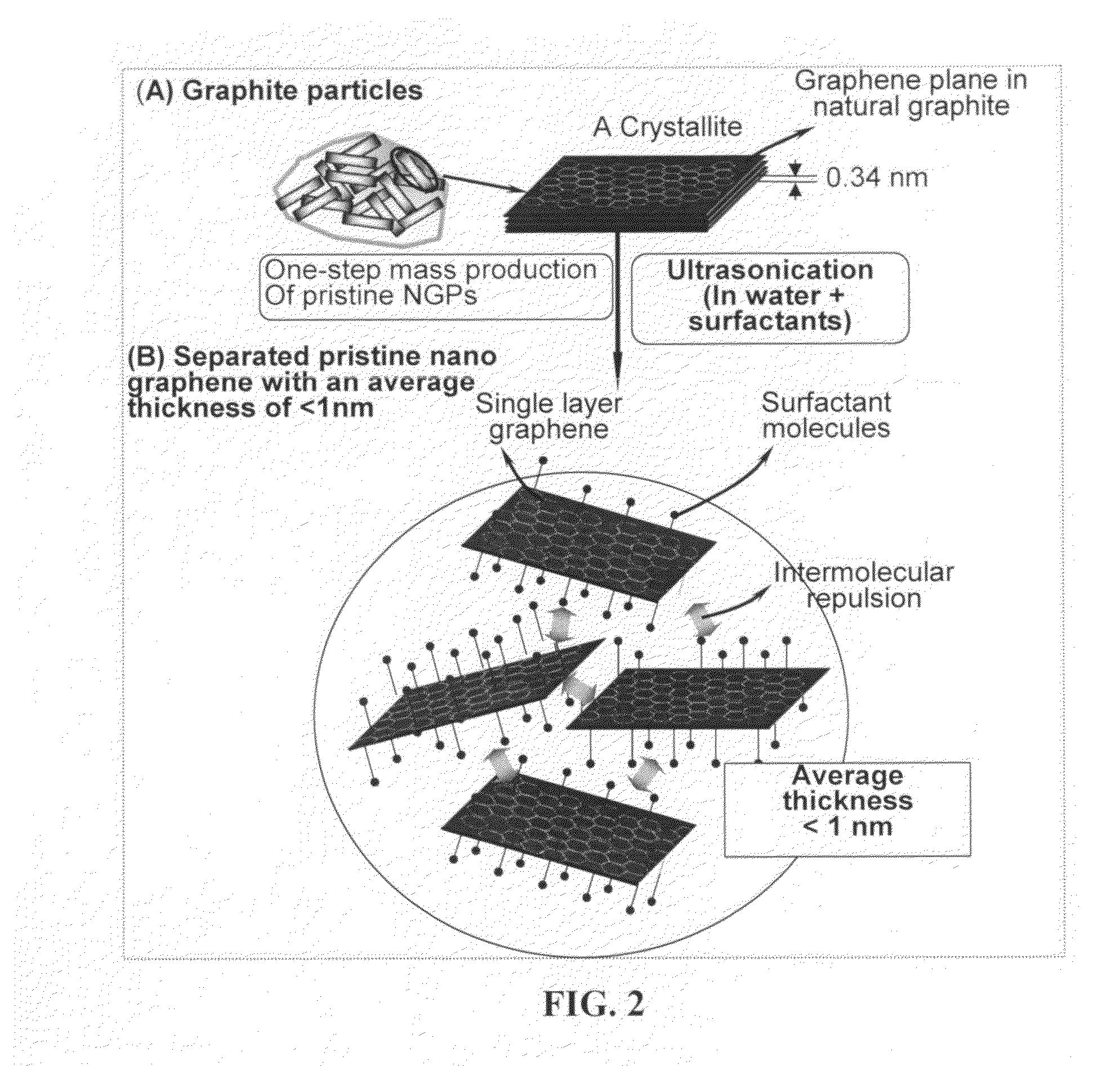

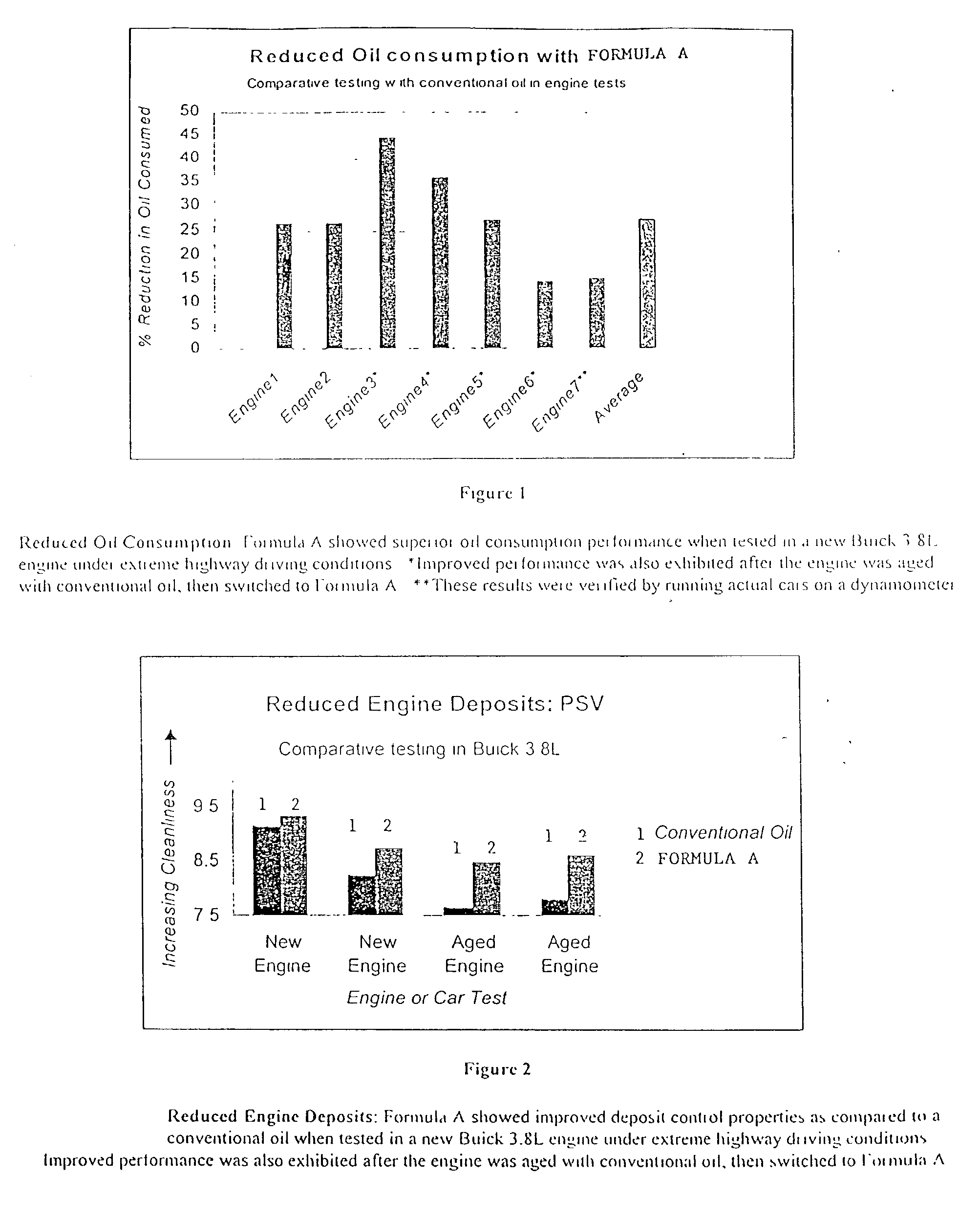

InactiveUS20030119682A1Improve the lubrication effectImprove engine performanceBiocideLiquid carbonaceous fuelsPolyolesterChemical composition

Owner:ASHLAND OIL INC +1

Method of using water-in-oil emulsion to remove oil base or synthetic oil base filter cake

ActiveUS7481273B2Improve breathabilityHighly efficient in breakingCleaning apparatusScale removal and water softeningParticulatesParaffin wax

Fluid producing or injecting wells may be treated with a water-in-oil emulsion for the removal or inhibition of unwanted particulates, including pipe dope, asphaltenes and paraffins. In addition, such emulsions are effective in the displacement of oil base drilling muds and / or residues from such muds from wells. The emulsion may also be used to break the interfacial and / or rheological properties of oil base mud and synthetic oil base mud filter cakes, and act as a demulsifier to break the water-in-oil emulsion present in such oil base and synthetic oil base muds. The water-in-oil emulsions may optionally contain a dispersing agent as well as a surfactant.

Owner:BAKER HUGHES INC

Stabilization of cosmetic compositions

A composition of matter is used as an ingredient in cosmetics comprising at least 0.5% by weight and preferably 1-30% by weight of highly refined cellulose fiber in a cosmetic composition. Additionally present in the composition are other conventional cosmetic ingredients as known in the art. This composition may include at least colorants (dyes and pigments), lipophilic materials, aqueous materials (water and aqueous solutions), waxes, binding agents (polymers, thickening agents), emollients, emulsifiers, thickening agents, antioxidants, natural and synthetic oils and extracts, clays, ultraviolet radiation absorbers, and the like.

Owner:FIBERSTAR BIO INGREDIENT TECH

Nano graphene-modified lubricant

ActiveUS8222190B2Improve the lubrication effectWider surface areaBase-materialsCarbon nanotubeSingle layer graphene

A lubricant composition having improved lubricant properties, comprising: (a) a lubricating fluid; and (b) nano graphene platelets (NGPs) dispersed in the fluid, wherein nano graphene platelets have a proportion of 0.001% to 60% by weight based on the total weight of the fluid and the graphene platelets combined. Preferably, the composition comprises at least a single-layer graphene sheet. Preferably, the lubricating fluid contains a petroleum oil or synthetic oil and a dispersant or surfactant. With the addition of a thickener or a desired amount of NGPs, the lubricant becomes a grease composition. Compared with graphite nano particle- or carbon nanotube-modified lubricants, NGP-modified lubricants have much better thermal conductivity, friction-reducing capability, anti-wear performance, and viscosity stability.

Owner:GLOBAL GRAPHENE GRP INC

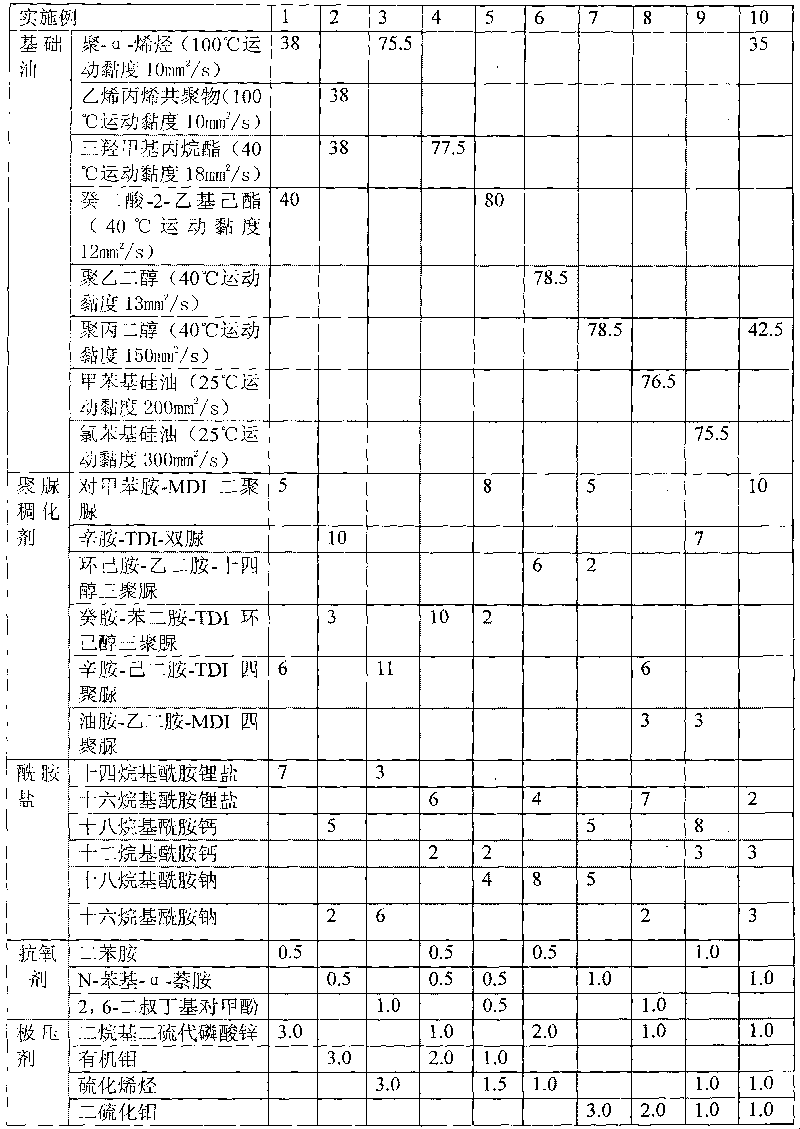

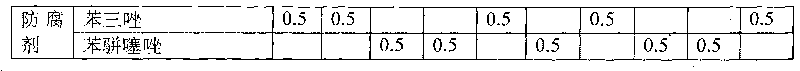

Synthetic high-temperature lubricating grease and production method thereof

InactiveCN101693851AGood colloidal stabilityGood shear stabilityThickenersAdditivesAntioxidantColloid

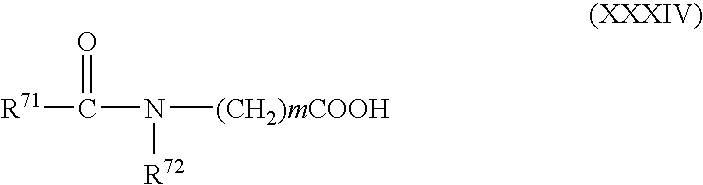

The invention discloses a synthetic high-temperature lubricating grease and a production method thereof. The synthetic high-temperature lubricating grease is produced by taking synthetic oil as base oil and mixing the base oil with thickening agents, an extreme-pressure additive, an antioxidant and an anticorrosive agent, wherein the weight ratios of all ingredients are as follows: 47-94% of base oil, 2-20% of polyurea thickening agent, 2-20% of acylamide thickening agent, 0.5-5.0% of antioxidant, 1.0-5.0% of extreme-pressure additive and 0.5-3.0% of anticorrosive agent. In the invention, the synthetic base oil, the polyurea thickening agent and the acylamide thickening agent all have excellent high-temperature performance, and the organic combination thereof leads the lubricating grease to obtain excellent high-temperature performance; the polyurea thickening agent endows the lubricating grease with good colloid stability, and the acylamide thickening agent endows the lubricating grease with excellent anti-shear stability, therefore, the organic combination of colloid stability and anti-shear stability leads the lubricating grease to have excellent high-temperature performance and good losing resistance, does not change to thin and avoids losing at high temperature. The extreme-pressure anti-wear additive endows the lubricating grease with excellent extreme-pressure anti-wear performance, and the bearing capacity is high.

Owner:CHINA PETROLEUM & CHEM CORP

Open-type gear grease composition

The invention provides an open gear grease composition, which comprises the following components and the weight percentage contents are that gelatinizer 2-6%, mineral oil 20-60%, synthetic oil 20-60%, antioxidant 0.3-1%, oil solubility anti-wear extreme pressure additive 1-15%, solid additive 3-20% and rust inhibitor 1-3%. The open gear grease composition of the invention does not contain dissolvent and bitumen, which has no harmless to environment, and solves the problems that bitumen-type open gear oil has bad pollution and low-temperature performance, and the flowability of open gear grease is bad. The open gear grease composition has outstanding water resistance, adhesiveness and antiwear and extreme pressure property.

Owner:益田润石(北京)化工有限公司

Method for improving solidifying point of Fischer-Tropsch wax

InactiveCN103980940AImprove stabilityHigh melting pointPetroleum wax recoveryChemical industryTwo step

The invention relates to a method for preparing high-melting-point refined wax capable of being applied to plastics, rubber processing, wood processing, food processing and other industries and particularly relates to a method for improving the solidifying point of Fischer-Tropsch wax. According to the method for preparing high-melting-point refined wax with excellent performances, distillation refining is carried out on light-weight oil serving as a raw material by means of continuous high-vacuum distillation, wherein the light-weight oil is produced by indirect coal liquefaction; According to the technical scheme, the method comprises two steps, namely, firstly, feeding the raw material in an evaporator by a feed pump so as to heat and evaporate the oil components and other low-boiling-point substances under the conditions of high temperature and high vacuum degree; secondly, feeding the coal-based synthetic oil without oil components and other low-boiling-point substances into a distiller, heating and evaporating the coal-based synthetic oil products by using heat-conduction oil under extremely high vacuum condition, condensing and capturing in a condenser to obtain the target product. The method disclosed by the invention can be widely used in the field of chemical industry.

Owner:SHANXI LUAN MINING GRP

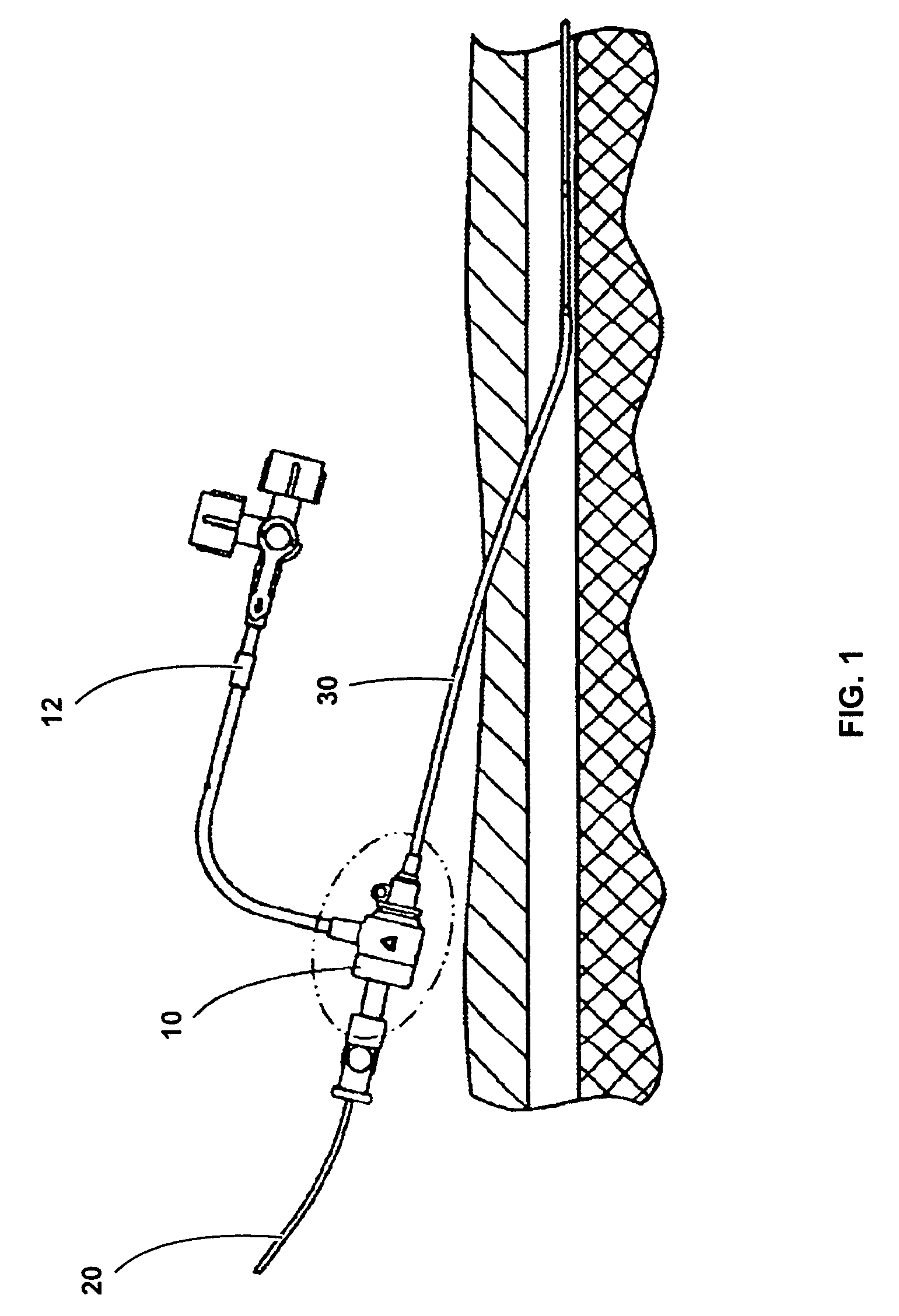

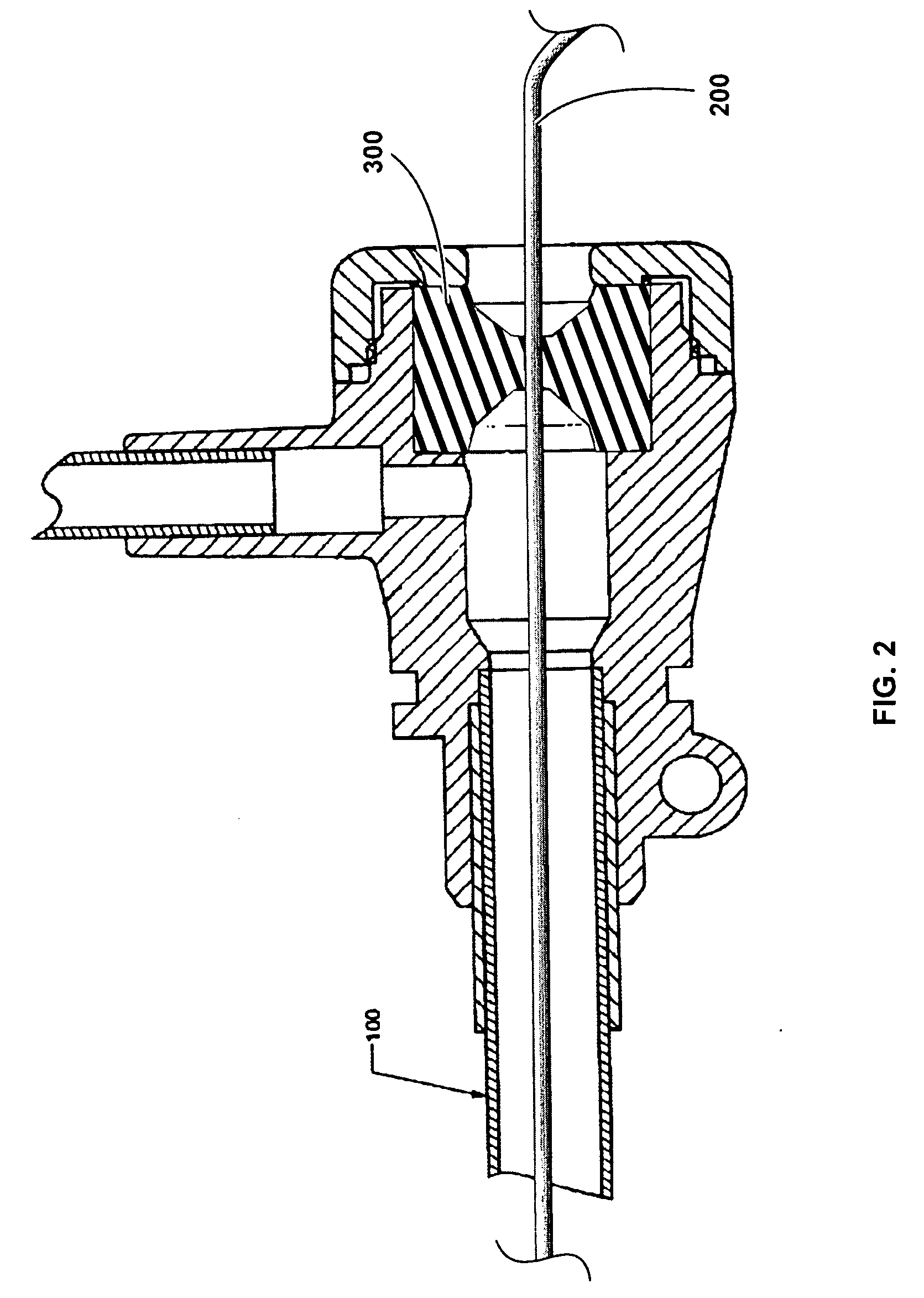

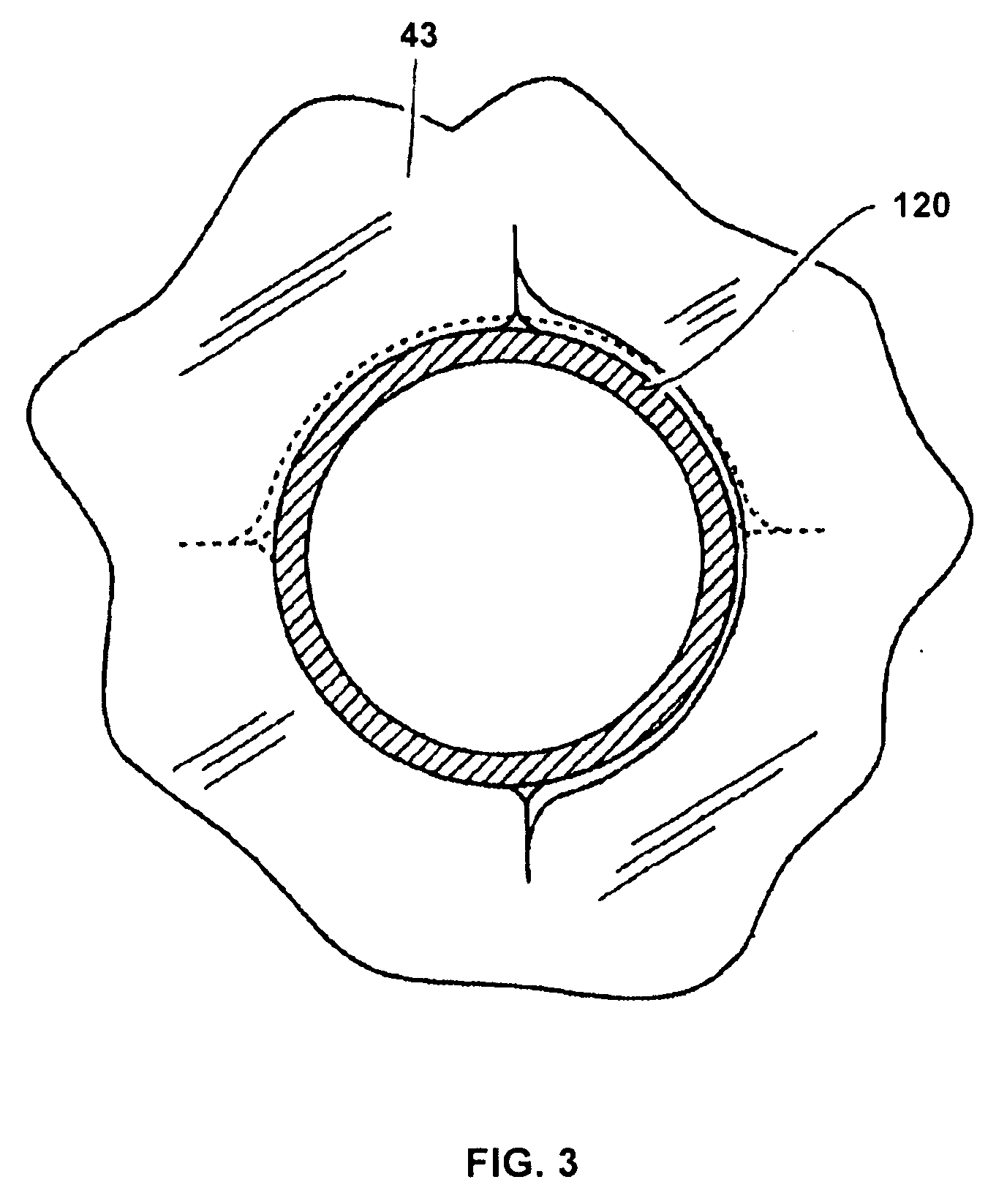

Biocompatible self-lubricating polymer compositions and their use in medical and surgical devices

InactiveUS20070254000A1Improve the lubrication effectReduce frictionMedical devicesCatheterSilicone ElastomersMedical device

The invention comprises self-lubricating polymer compositions that are especially useful in medical devices and valves and gaskets of medical devices. In a preferred embodiment, the polymer compositions comprise a thermosetting or thermoplastic silicone elastomer in combination with a lubricity enhancing polyfluoropolyether fluid or hydrocarbon-based synthetic oil. In other preferred embodiments, the polymer compositions contain only biocompatible components. The improved anti-friction properties of the self-lubricating polymers can be demonstrated over a course of insertion and withdrawal cycles, where conventional polymers have changing and mostly increasing force required for each insertion and withdrawal, while the polymer compositions of the invention remain stable.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

High temperature biobased lubricant compositions from boron nitride

InactiveUS20100105583A1Improve the lubrication effectEnhanced anti-wearBase-materialsBoron nitrideAlpha-olefin

This present invention discloses a method for the preparation of an improved high temperature engine lubricant composition comprising the steps of: 1) providing at least one biobased natural oil or biobased synthetic oil selected from the group consisting of natural or synthetic vegetable oil, natural or synthetic animal oil, genetically modified vegetable oil, genetically modified synthetic vegetable oil, natural or synthetic tree oil, and mixtures thereof; 2) providing at least one boron nitride; and 3) optionally, providing at least one base oil selected from the group consisting of a synthetic ester, solvent refined petroleum oil, a hydrocracked petroleum white oil, an all hydroprocessed synthetic oil, Fischer Tropsch oil, petroleum oil group I, group II, group III, a polyalphaolefin (PAO), and mixtures thereof; 4) optionally, providing at least one additive or combination of additives selected from the group consisting of anti-oxidant(s), corrosion inhibitor(s), metal deactivator(s), viscosity modifier(s), anti-wear inhibitor(s), friction modifier(s), and extreme pressure agent(s); 5) blending 1), 2), 3), and 4) in any sequence to form said composition.

Owner:RENEWABLE LUBRICANTS INC

Vegetable oil lubricant comprising all-hydroprocessed synthetic oils

InactiveUS20050059562A1Improve propertiesEnhanced microbial biodegradabilityLiquid carbonaceous fuelsAdditivesVegetable oilLubricant

The present invention discloses vegetable oil based compositions having an effective combination of properties including lubricity, rheology, electrical insulating value and microbial biodegradability making them particularly useful for the proper functioning of mechanical devices.

Owner:RENEWABLE LUBRICANTS INC

Lubricating oil composition for transmissions

InactiveUS20060135378A1Low viscosityImprove fatigue lifeAdditivesBase-materialsHydrogenOxidation stability

A lubricating oil composition for transmissions comprises a lubricating base oil comprising (A) a lubricating base oil so adjusted to have a kinematic viscosity at 100° C. of from 1.5 to 5 mm2 / s and a % CN of from 10 to 60 (B) a mineral lubricating base oil having a kinematic viscosity at 100° C. of from 10 to 50 mm2 / s and a sulfur content of from 0.3 to 1 percent by mass and (C) a synthetic oil composed of carbon and hydrogen and having a number average molecular weight of from 2,000 to 20,000, in respective specific amounts and (D) an extreme pressure additive of from 0.05 to 2 percent by mass, based on the total amount of the composition, of comprising a phosphorus-based extreme pressure additive, a sulfur-based extreme pressure additive and / or a phosphorus-sulfur-based extreme pressure additive, wherein in the composition, the phosphorus content (P) is from 0.01 to 0.05 percent by mass, the total sulfur content (S) is from 0.05 to 0.3 percent by mass, and the P / S ratio is from 0.10 to 0.40. The lubricating oil composition has both excellent fuel economy performance and satisfactory durability for gears and bearings and furthermore excellent low temperature viscosity and oxidation stability.

Owner:NIPPON OIL CORP

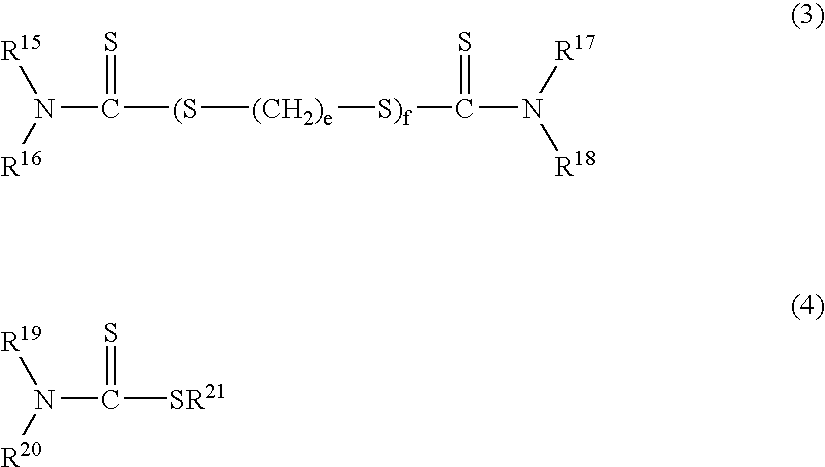

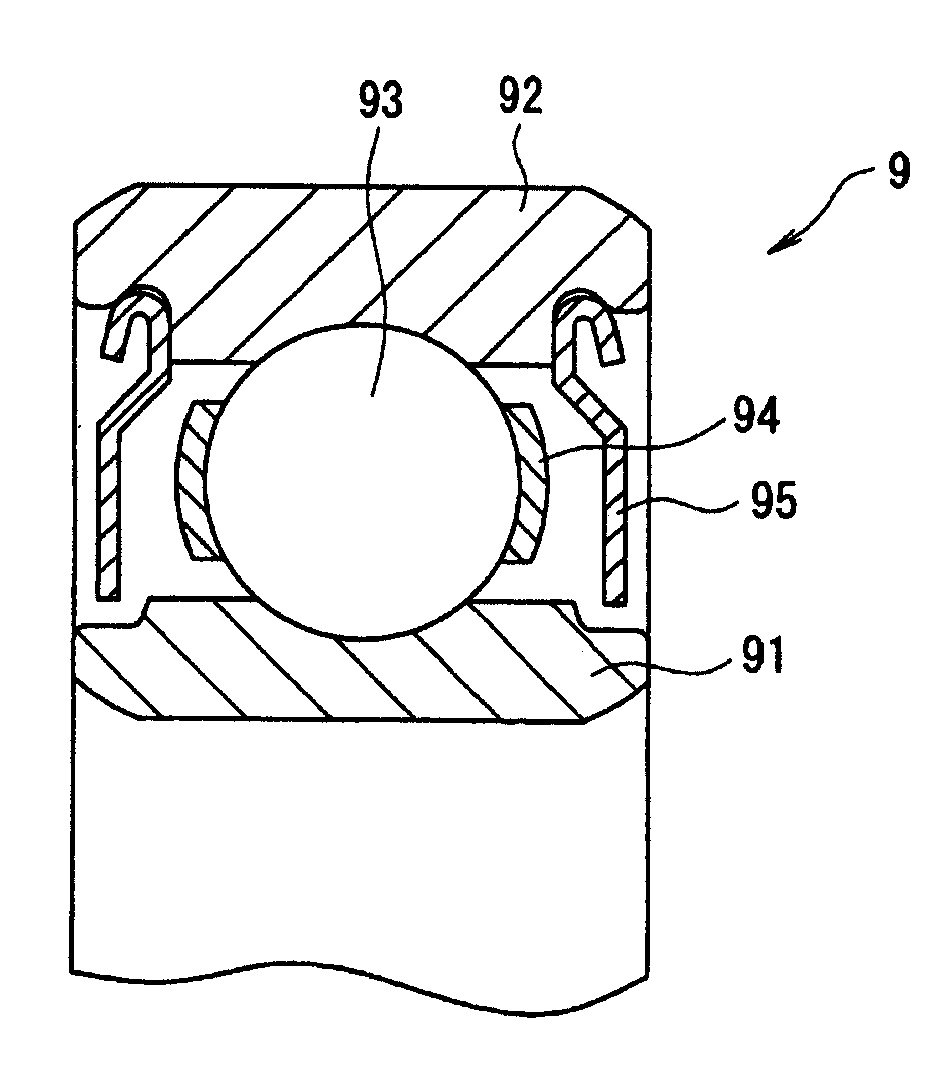

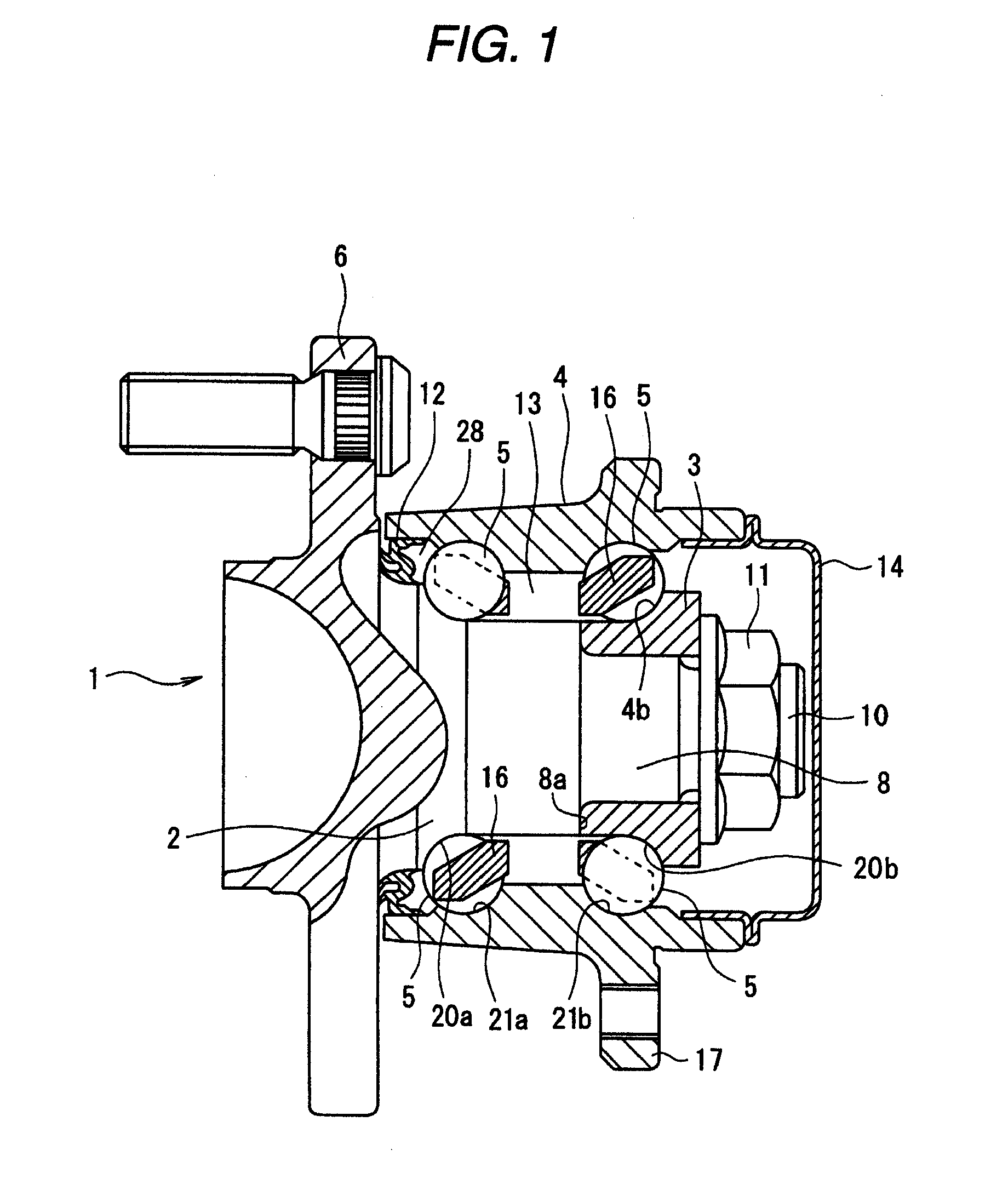

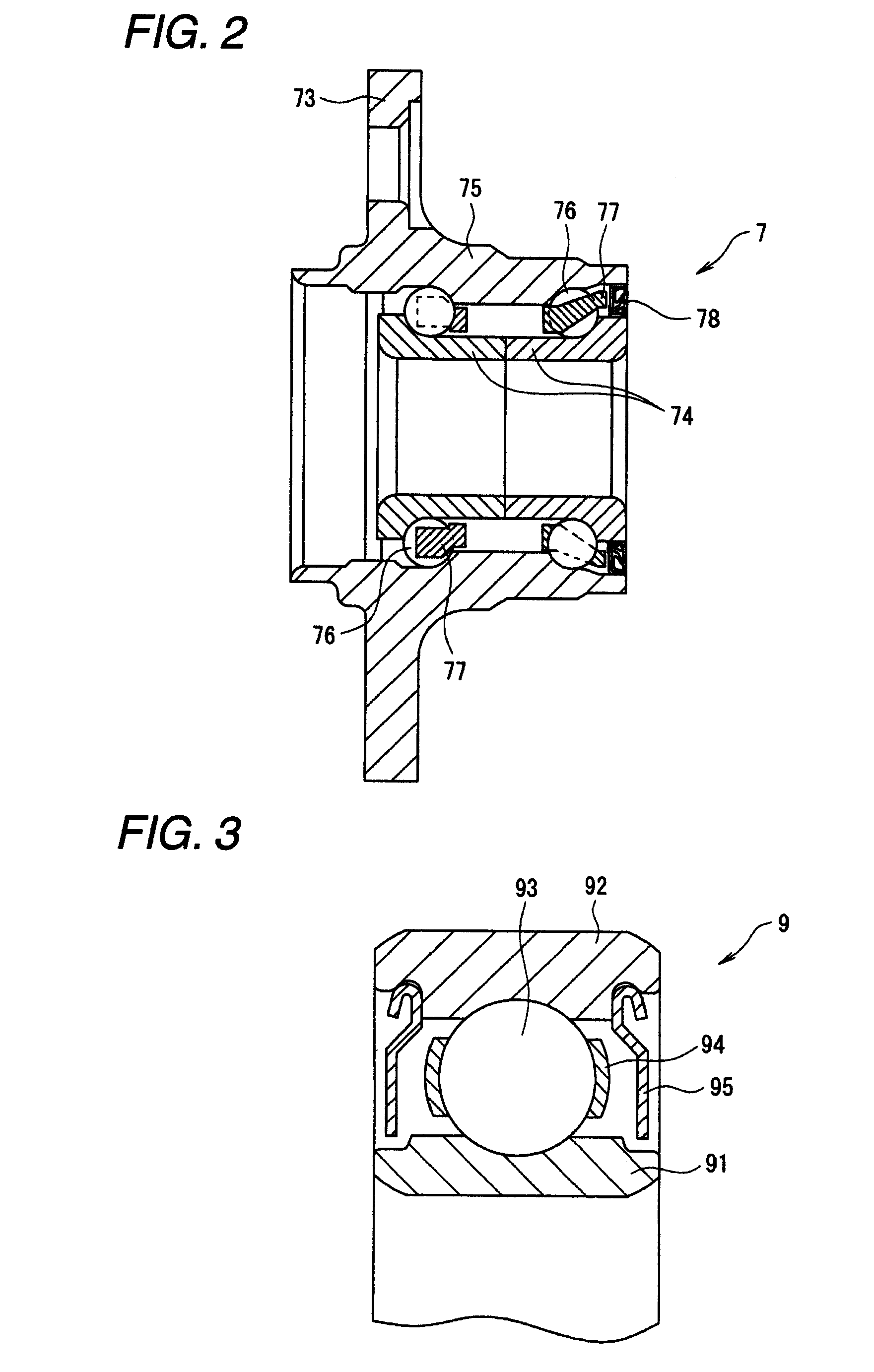

Grease Composition For Hub Unit Bearing, And Hub Unit Bearing For Vehicle

InactiveUS20090003742A1Improve peeling resistanceImprove the lubrication effectOrganic chemistryHubsRolling-element bearingAdditive ingredient

An object of the invention is to provide a grease composition capable of keeping a good lubrication condition for a long period of time even when water has mixed therein, thereby inhibiting white structure flaking and corrosion. Another object is to provide a vehicular hub unit bearing which hardly suffers from white structure flaking and corrosion even when used in an environment where water may penetrate into it and which therefore has a long life.The invention provides a rolling bearing with, sealed up therein, a grease composition containing a waterproof film-forming additive added thereto; a grease composition for hub unit bearings, containing a base oil that comprises at least one of mineral oil and synthetic oil as the main ingredient thereof, and a thickener and a flaking inhibitor; and a vehicular hub unit bearing with the grease composition sealed up therein.

Owner:NSK LTD +1

Combination of general gear oil

A universal oil composition for gear contains mineral lubricating oil or synthetic lubricating oil or their mixture, at least one viscosity index improver and / or pour depressor, at least one S-contained extreme-pressure agent, at least one P-contained antiwear agent, phosphate-type multi-effect agent, oil agent (1-hydroxyethylene-1, 1-biphosphonate), and at least one metallic deactivator and / or antirust agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fine particle dispersion compositions and uses thereof

InactiveUS20060027484A1Improve thermal conductivityChemical industryHydrocarbon oil crackingAir conditioningRefrigeration

The present invention relates to dispersion compositions comprising synthetic oils or other heat transfer fluids and fine particles. The compositions also comprise at least one dispersant. The dispersion compositions have improved thermal conductivity properties, which may translate to improved energy efficiency performance in a variety of heat transfer applications. Such applications include vapor compression air conditioning and refrigeration systems of all types, secondary heat transfer fluids, and other heating or cooling fluid applications.

Owner:EI DU PONT DE NEMOURS & CO

Method of Using Water-in-Oil Emulsion to Remove Oil Base or Synthetic Oil Base Filter Cake

InactiveUS20090114394A1Improve permeabilityImprove effectivenessCleaning apparatusFluid removalParaffin waxOil emulsion

Fluid producing or injecting wells may be treated with a water-in-oil emulsion for the removal or inhibition of unwanted particulates, including pipe dope, asphaltenes and paraffins. In addition, such emulsions are effective in the displacement of oil base drilling muds and / or residues from such muds from wells. The emulsion may also be used to break the interfacial and / or rheological properties of oil base mud and synthetic oil base mud filter cakes, and act as a demulsifier to break the water-in-oil emulsion present in such oil base and synthetic oil base muds. The water-in-oil emulsions may optionally contain a dispersing agent as well as a surfactant.

Owner:BAKER HUGHES HLDG LLC

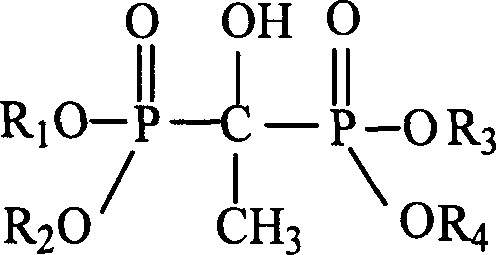

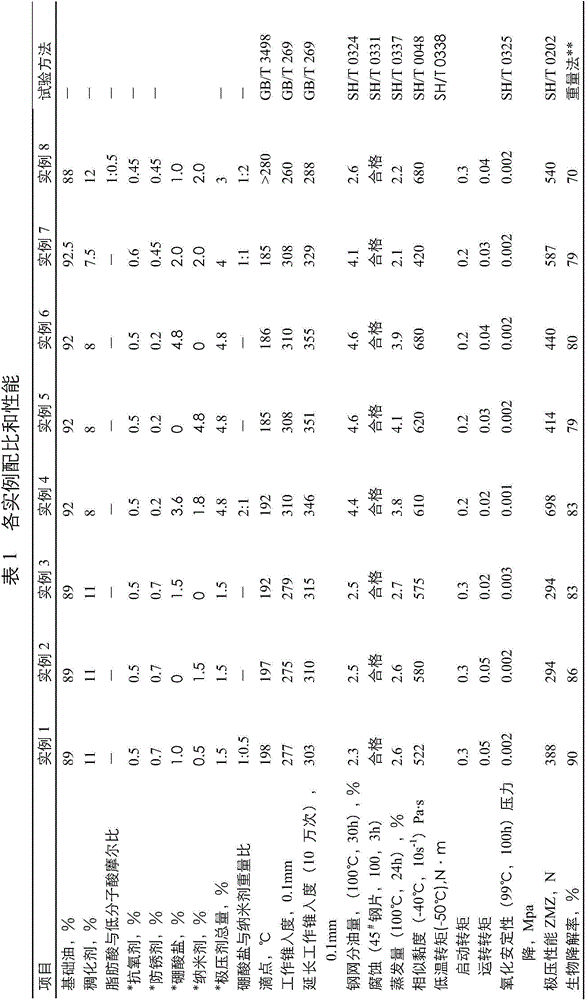

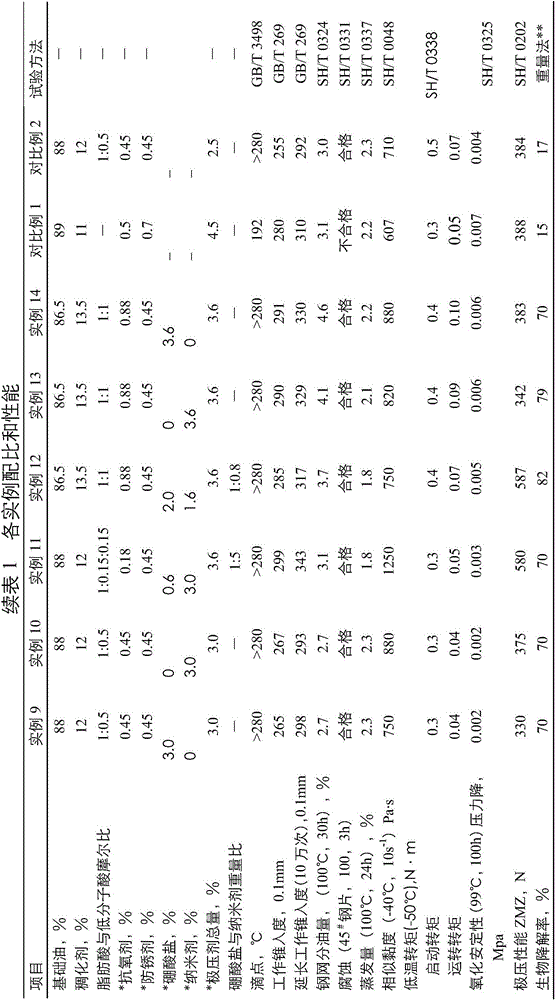

Environmentally friendly lubricating grease composition and preparation method thereof

InactiveCN104804842APromote degradationGood high and low temperature characteristicsLubricant compositionLithium soapAntioxidant

An environmentally friendly lubricating grease composition comprises base grease composed of base oil and a thickener, and an additive, wherein the base oil is selected form synthetic oil base oil, the thickener is a lithium soap or composite lithium soap thickener, and the additive at least contains an extreme pressure anti-wear agent selected from borate and a nanometer extreme pressure agent, an antioxidant and an antirust agent. The above lubricating grease has the advantages of good biodegradability, good high and low temperature characteristics, good extreme pressure anti-wear performances, and low starting torque and running torque, and is suitable for being used in railway switch machines.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for hyrogenating deoxidating and olefine saturating of Feather synthesizing oil and its mfg. process and application

ActiveCN1597859AImprove hydrogenation activityRefining by selective hydrogenationPtru catalystCopper oxide

The invention is a hydro-deoxidation and alkene-saturation catalyst of Fischer-Tropsch oil product and its components in weight percent: nickel oxide 5.0-18.0%, cobalt oxide 0-11.0%, copper oxide 0-6.0%, iron oxide 0-12.0%, titanium oxide 0-12.0%, lanthanum oxide 0-8.0% and carrier 46.0-85.0%. Its preparing method includes in turn carrier preprocessing and after-processing of supported active component and catalyst. It has higher activity to hydro-deoxidation and alkene saturation of the oil product, especially applied to the hydrofining process of the iron-base paste Fischer-Tropsch oil product with higher content of oxygen-containing compound and alkene.

Owner:SYNFUELS CHINA TECH CO LTD

Detection of fuel contamination in lubricating oil

InactiveUS8643388B2Resistance/reactance/impedenceMaterial analysis by electric/magnetic meansCompound (substance)Engineering

Owner:VOELKER SENSORS

Electrically Conductive Oil Base Drilling Fluids Containing Carbon Nanotubes

Electrically conductive oil base drilling fuids with carbon nanotubes have either an organic base (oil) or a base that is an emulsion of water in oil (invert emulsion) and contains carbon nanotubes dispersed in oil. These drilling fluids may be prepared by either (1) the addition of electrically conductive dispersions of carbon nanotubes in oil to conventional oil base drilling fluids (unweighted or weighted) or (2) the sonication of the mixture of oil pre-wetted carbon nanotubes with unweighted conventional oil base drilling fluids. The electrically conductive dispersions of carbon nanotubes in oil may be prepared by sonication or by microfluidization. The oil may be a mineral oil, paraffin oil, synthetic oil, or diesel oil. The electrically conductive oil-based drilling fluids may further contain ionic, non-ionic or polymeric surfactants.

Owner:NEWPARK CANADA

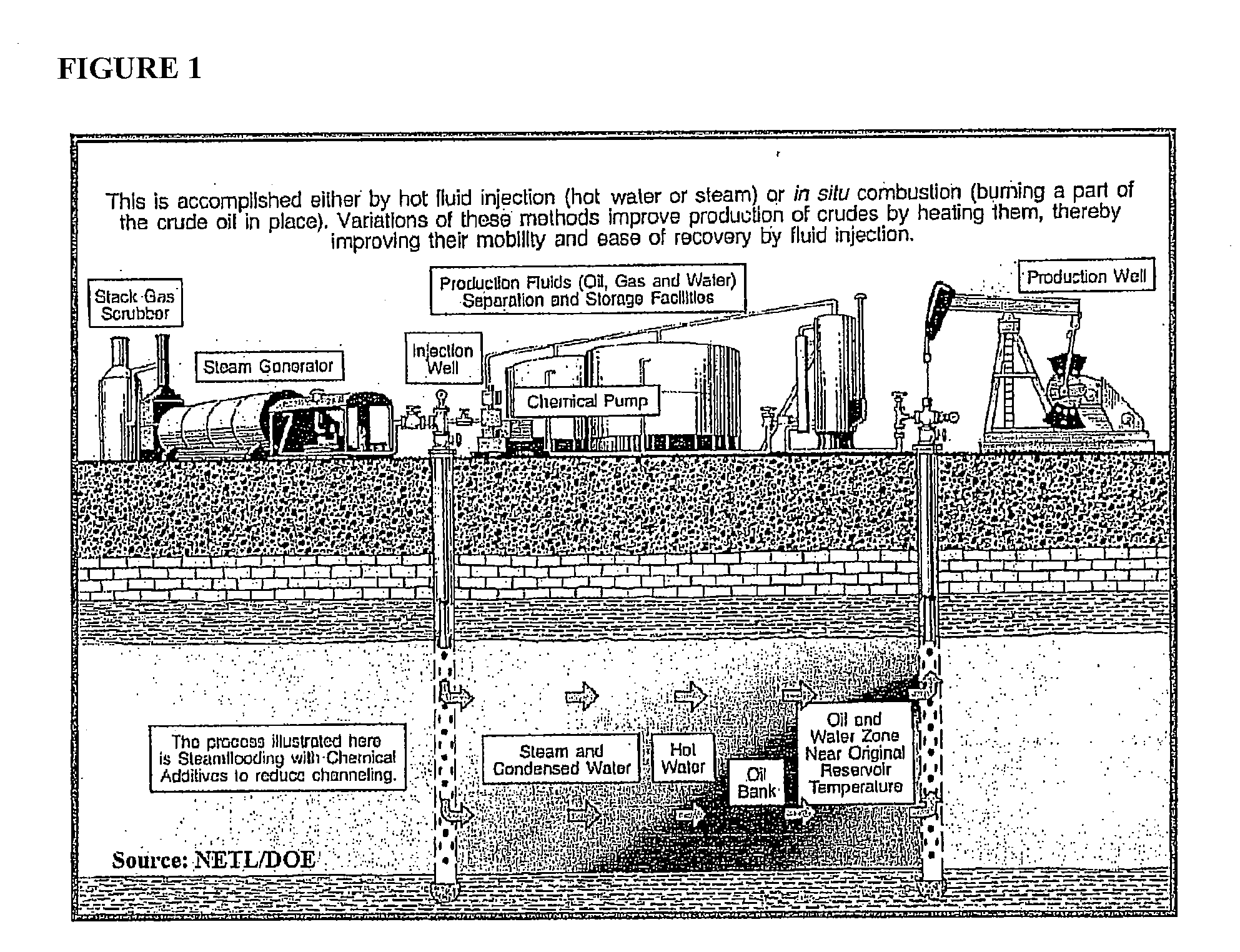

Apparatus and Method for Energy-Efficient and Environmentally-friendly Recovery of Bitumen

ActiveUS20100000733A1Minimize greenhouse gasLong operatingThermoelectric device with peltier/seeback effectInsulationElectrolysisEngineering

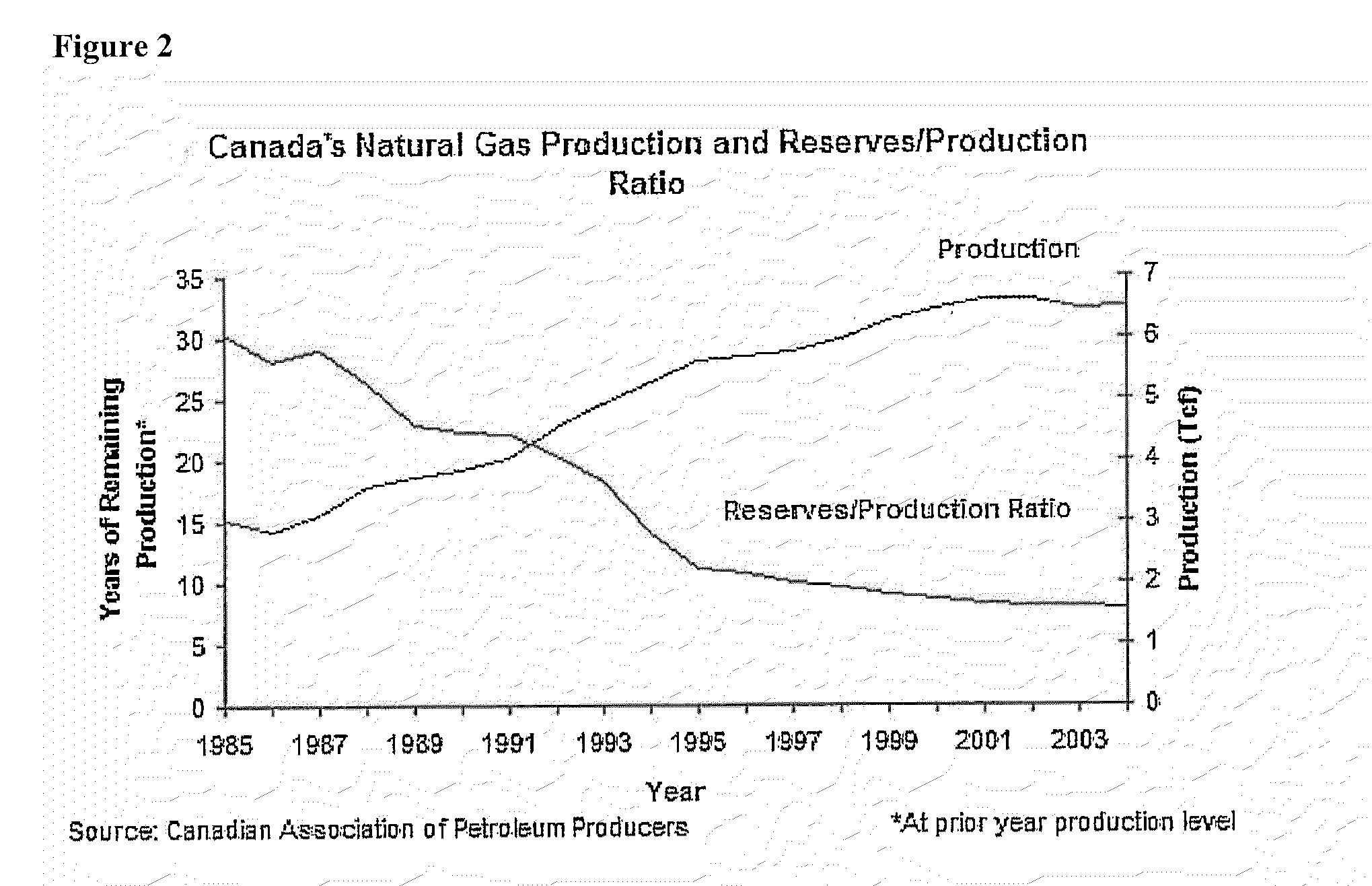

The present invention aims at recovering unconventional oil in an environmentally friendly and sustainable way that has the potential of eliminating the need of natural gas currently employed for steam production and power generation. Our invention aims at providing low temperature steam for the stimulation of the formation by means of solar radiation. In addition we propose a novel solution for hydrogen production that does not employ reforming of natural gas. We also illustrate how the use of thermoelectric devices in combination with low temperature steam can be employed to power an electrolysis plant to generate the hydrogen necessary to produce synthetic oil.

Owner:KHALIFA UNIV OF SCI & TECH

Low-dust unshaped refractory

The invention relates to a low-dust unshaped refractory, which comprises 0.1-1.0 wt percent of oil substances chosen from mineral oil, vegetable oil, synthetic oil, fluid wax or biodegradable petroleum to be used as the binder and combined materials calculated by the total weight of the refractory. The unshaped refractory is characterized by reducing dust in the carrying and instillation process. The unshaped refractory not only comprises spray coating, but also comprises compact and insulating refractory castables and dry materials. The low-dust unshaped refractory can reduce the dust suction quantity of the personnel exposed to the construction field by at least 70 percent, reduce the pollution to the environment and improve the life of the respirators used by the personnel.

Owner:ALLIED MINERAL PRODS TIANJIN

Refrigerating machine oil compositions

The invention provides a refrigerator oil composition comprising a base oil of a mineral oil and / or a synthetic oil, and containing (a) a partial ester of a polyalcohol and a fatty acid and (b) an acid phosphate or its amine salt; and a refrigerator oil composition comprising a base oil of a mineral oil and / or a synthetic oil, and containing any of (a) acid phosphates or their amine salts, (b) acetylene glycol alkylene oxide adducts, (c) potassium salts of fatty acids, etc., (d) organic acids, and (e) fatty acid amides. The refrigerator oil compositions have good lubricity and are especially effective for reducing the friction in both the oil region and the extreme-pressure region in the sliding area between aluminium materials and steel materials.

Owner:IDEMITSU KOSAN CO LTD

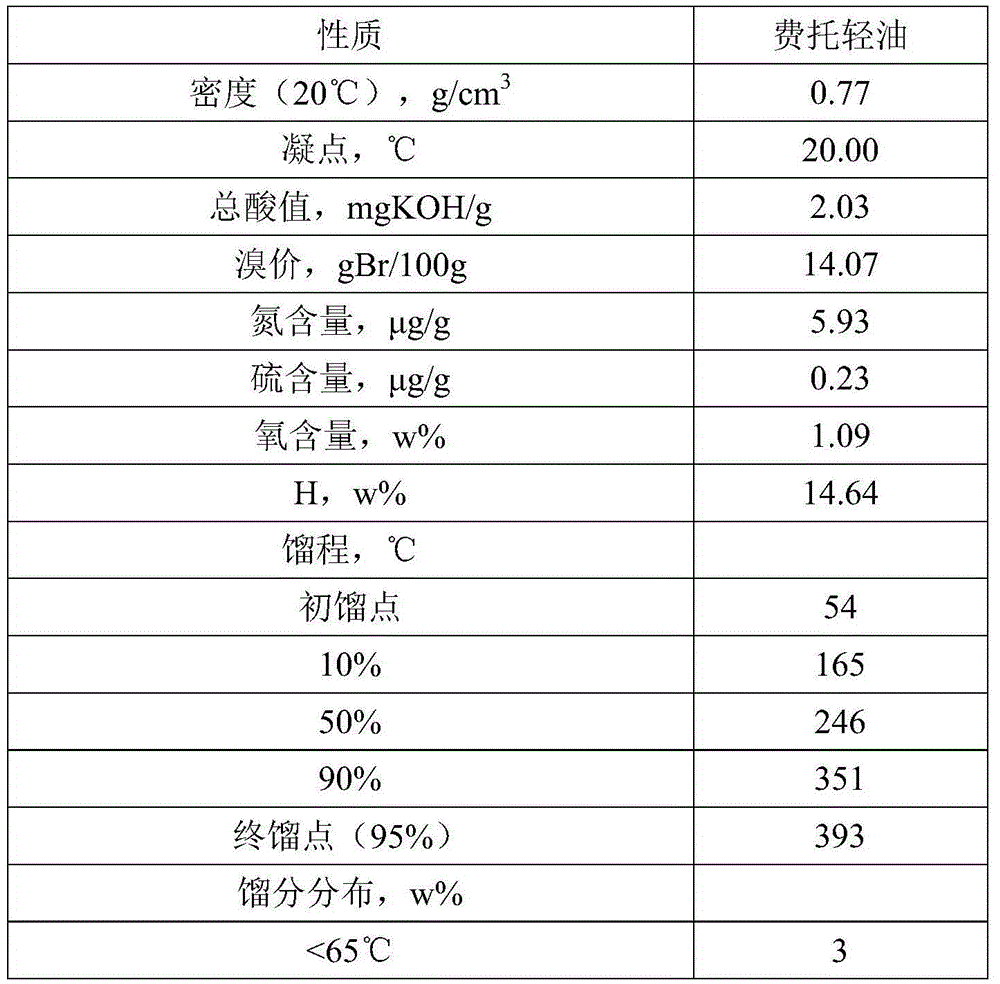

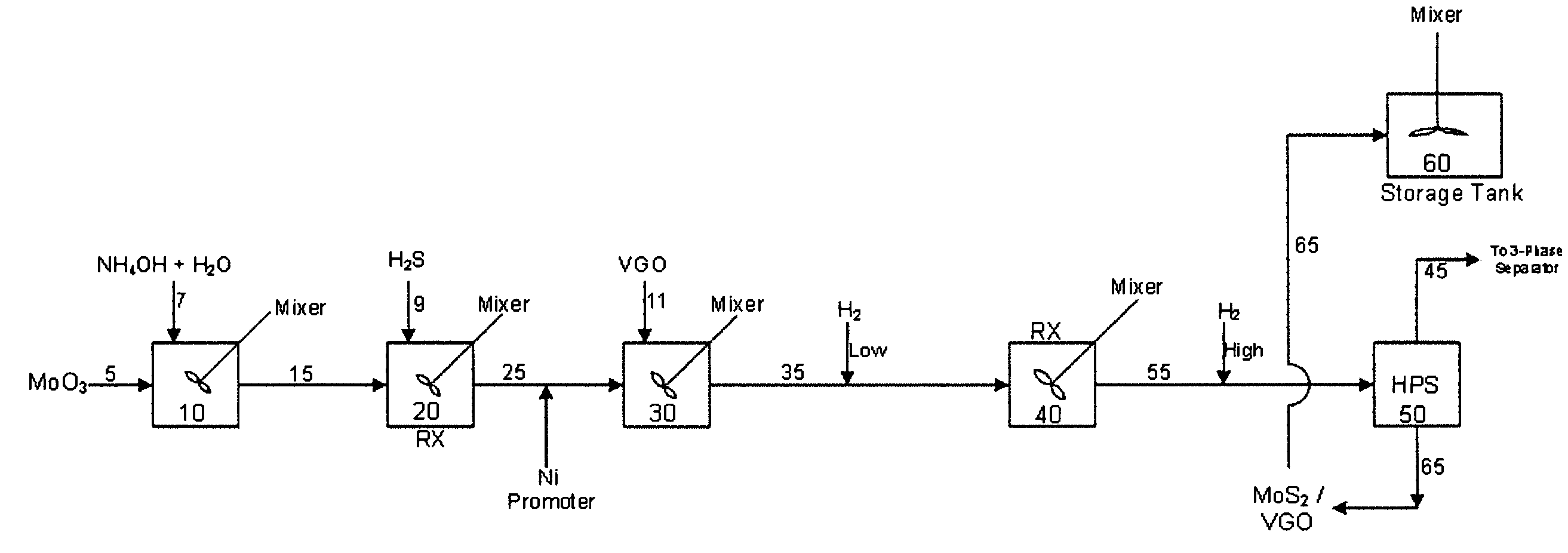

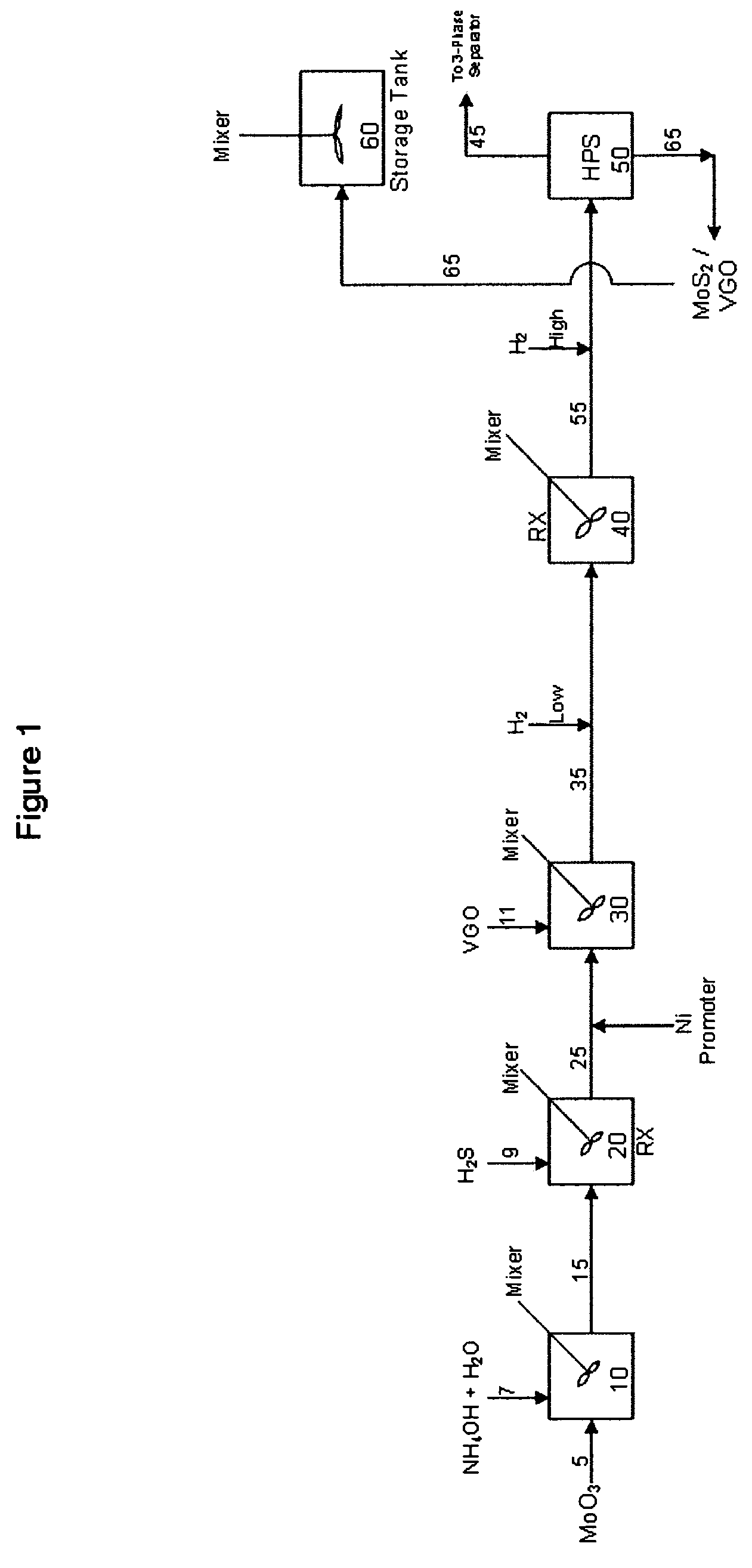

Production of intermediate fractional oil from Fischer-Tropsch synthetic oil

ActiveCN1854265ADifferent performanceLow priceTreatment with hydrotreatment processesHydrogenNaphtha

A kind of integrated hydrogenation improving quality method for the oil fractions from Fishcher-Tropsch synthesis process, it is used to gain high quality middle fraction oil. The all fractions and hydrogen contact with hydrofining catalyst, the middle fraction oil gained after isolation, naphtha and tail oil will be mixed by the reactant liquor of hydrofining and the reactant liquor of hydrocracking reactant liquor, the tail oil and hydrogen will be mixed and then circulate to isocracking reacktor and contact with hydrocracking and isocracking catalyst. The yield of the diesel oil is higher than 80% by the method, and the cetane number will be as high as 80, The water produced by hydrofining process can be prevented to go into the isocracking reacktor by this method, the availability and using periodic can also be improved. Moreover, the technological process of this method is high integrated; the equipment needed is fewer, so the cost of investment and operation can be decreased.

Owner:CHINA PETROLEUM & CHEM CORP +1

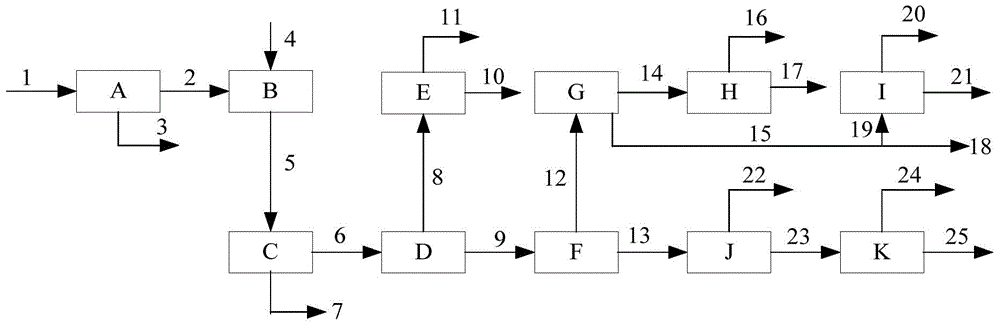

Method for producing n-alkane solvent oil from Fischer-Tropsch synthetic oil

ActiveCN104910960AMany modelsImprove qualityTreatment with hydrotreatment processesAlkaneDistillation

The invention relates to a method for producing n-alkane solvent oil from Fischer-Tropsch synthetic oil. According to the method, low-temperature Fischer-Tropsch synthetic light oil is adopted as a raw material, and is processed through upgrading and distillation separation processes with a fractionation tower, hydro-finishing, a degassing tower, a C6 / C7 cutting tower, a C5 / C6 cut tower, a C10 / C11 cutting tower, a C8 / C9 cutting tower, a C7 / C8 cutting tower, a C9 / C10 cutting tower, a C13 / C14 cutting tower, and a C17 / C18 cutting tower; such that various types of solvent oils such as n-pentane-rich, #6, #120, #140, #200, #D30, #D40, #D65, #D100 and #D120 solvent oils can be obtained. Compared to prior arts, all products produced with the method are n-alkane solvent oils. The method has the advantages of simple process flow, more produced solvent oil types, high solvent oil quality, and the like.

Owner:YANKUANG ENERGY R&D CO LTD

Lubricating grease special for constant-speed universal joint and preparing method thereof

ActiveCN101575548AImprove performanceImprove water resistanceThickenersAdditivesAntioxidantFriction modifier

The invention relates to lubricating grease special for a constant-speed universal joint and a preparing method thereof. The lubricating grease comprises base oil and thickener which is compounded by lithium-calcium composite and uramido composite, and the lubricating grease also contains: (a) borate extreme pressure anti-wear agent, (b) aliphatic amine derivative multi-effect friction modifying agent, (c) phosphoric extreme pressure anti-wear agent, (d) diphenylamine antioxidant and (e) viscosity index improver; wherein the base oil is mineral oil that accounts for 70 to 95 percent of the total weight of the lubricating grease, synthetic oil or the mixture of the mineral oil and the synthetic oil in optional proportion. The thickener which is compounded by the lithium-calcium composite and the uramido composite accounts for 1 to 25 percent of the total weight of the lubricating grease; and the lubricating grease has excellent extreme pressure anti-wear property, thermal stability, oxidation stability, water resisting property, mechanical stability, shear stability, anticorrosion property, and the like, and the lubricating grease can meet the lubricating demands of the constant-speed universal joint of automobiles and has low cost and high efficiency.

Owner:杭州得润宝油脂股份有限公司

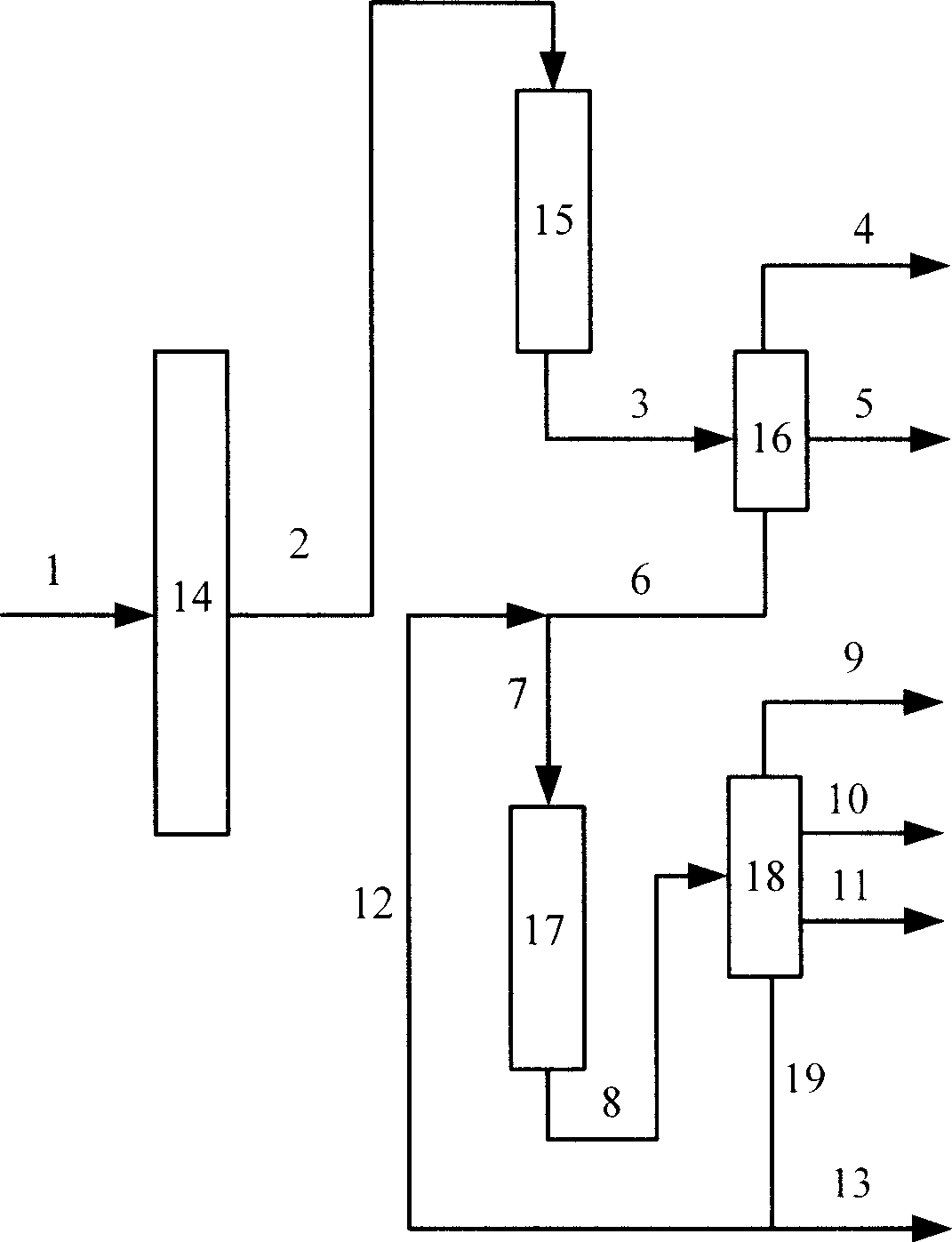

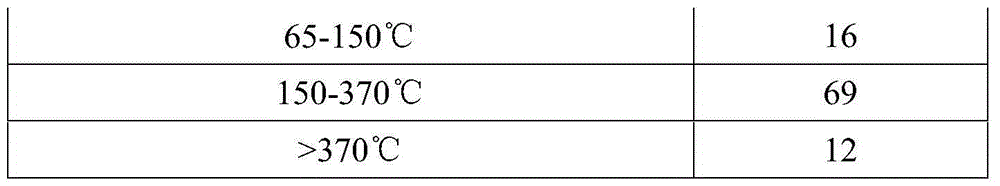

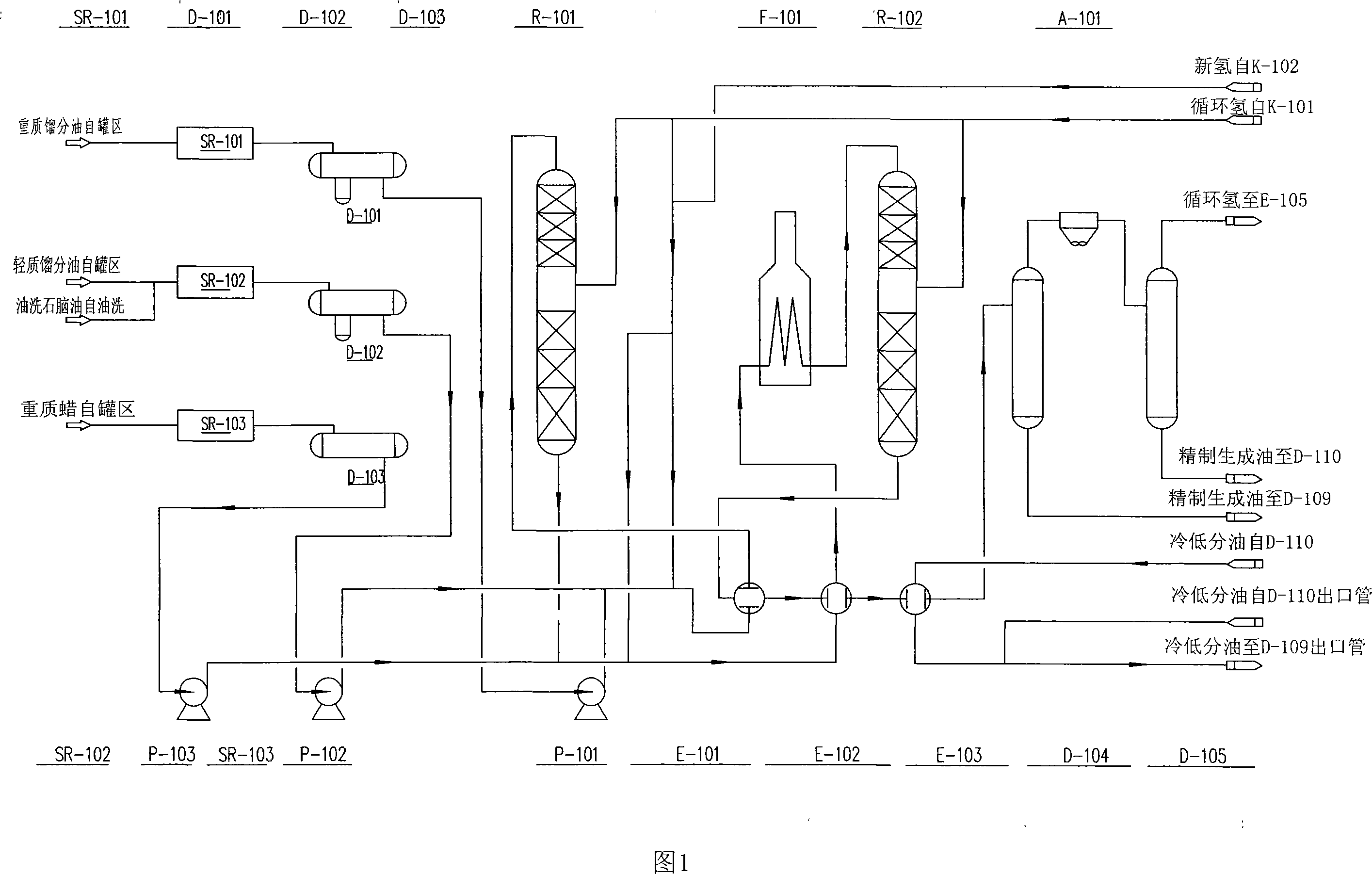

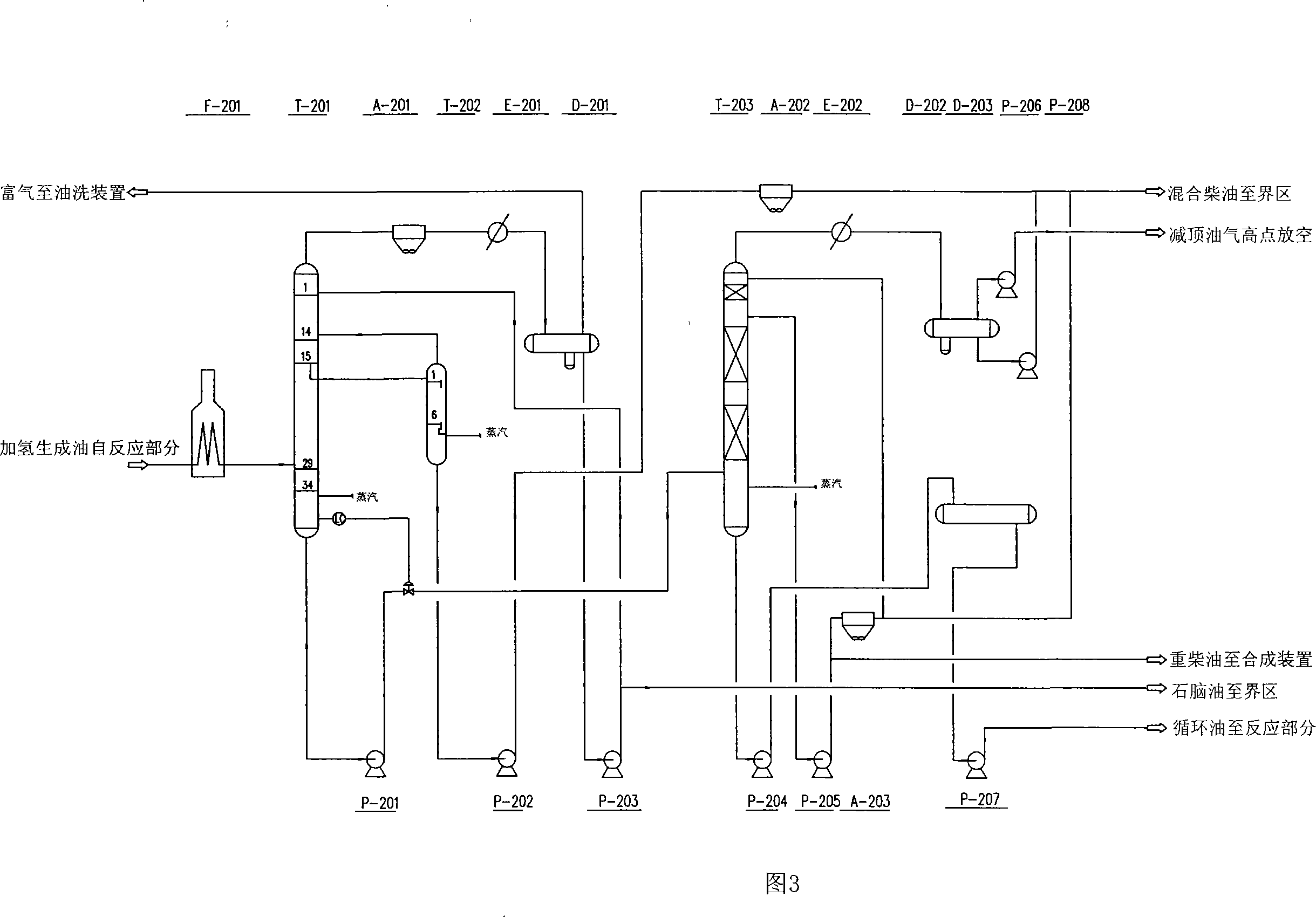

Feito synthetic oil processing line

ActiveCN101173190AReduce design flowStable temperature controlTreatment with hydrotreatment processesGas phaseMetal impurities

The invention relates to a processing flow of FT synthetic oil, which comprises hydrogenation, low-temperature oil washing, decarburization and PSA. The invention is characterized in that the synthetic oil is mixed with hydrogen via a filter, and enters a hydrogenated prerefining reactor after heat exchange, then enters a hydrogenated refining reactor after the synthetic oil is heated to 300 to 380 DEG C by a heating furnace; oxygen-containing compounds, unsaturated hydrocarbons and metal impurities in the raw material are extracted; the hydrogenated refined product enters a high thermal separator for separation of oil phase and gas phase after heat exchange, and enters a hydrocracking reactor for hydrocracking after heat exchange and heating of the heating furnace; the cracked product and the refined product are mixed to enter a fractionation system; a combined flow with two stages connected in series is adopted for the hydrogenated refining reactor and the hydrocracking reactor which share a recycle hydrogen system; a fractionation system is shared by the hydrogenated refined oil and the hydrocracked oil; and a three-column process flow is adopted for the fractionation system. The invention has the advantages of low gas consumption of the low-temperature oil washing process, high recovery of light hydrocarbons, less matching investment, and reduction of energy consumption and improvement of hydrogen recovery rate due to the decarburization process.

Owner:中国石油集团工程设计有限责任公司抚顺分公司

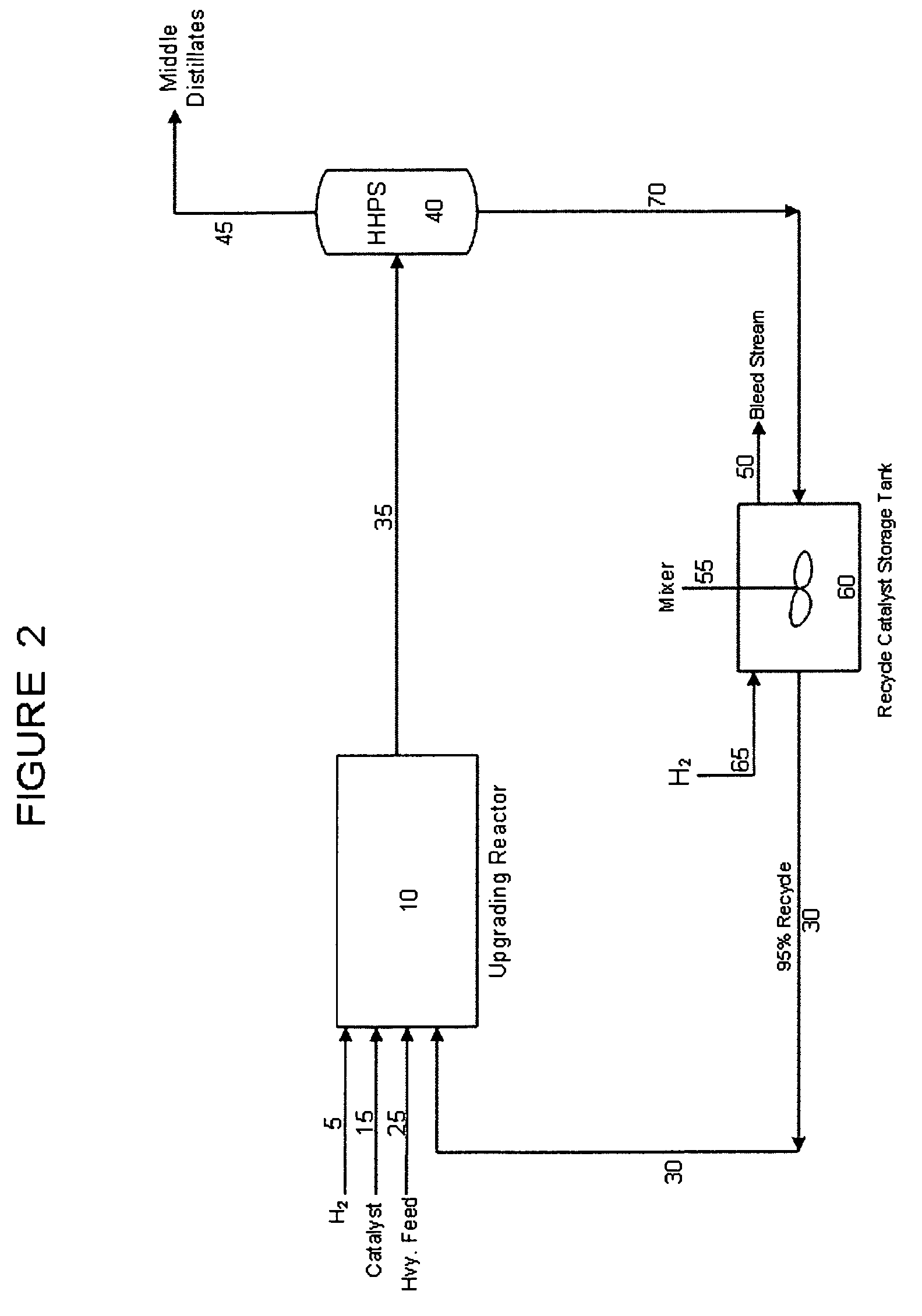

Process for producing tailored synthetic crude oil that optimize crude slates in target refineries

InactiveUS7799207B2Physical/chemical process catalystsHydrocarbon oil crackingFuel oilProcess engineering

The instant invention is directed to a process wherein a heavy oil feedstock upgrader alters its mode of operation of its full conversion hydroprocessing unit to create a custom tailored synthetic crude feedstock based upon data communicated from a target refinery and data communicated from the heavy oil feedstock upgrader. The data from the target refinery is data that represents refining process data and linear program modeling along with analysis by a refining planner to calculate the optimum “synthetic trim crude” that will optimize the effective use of the target refinery's capacity and equipment.

Owner:CHEVROU USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com