Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

179 results about "Polyolester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

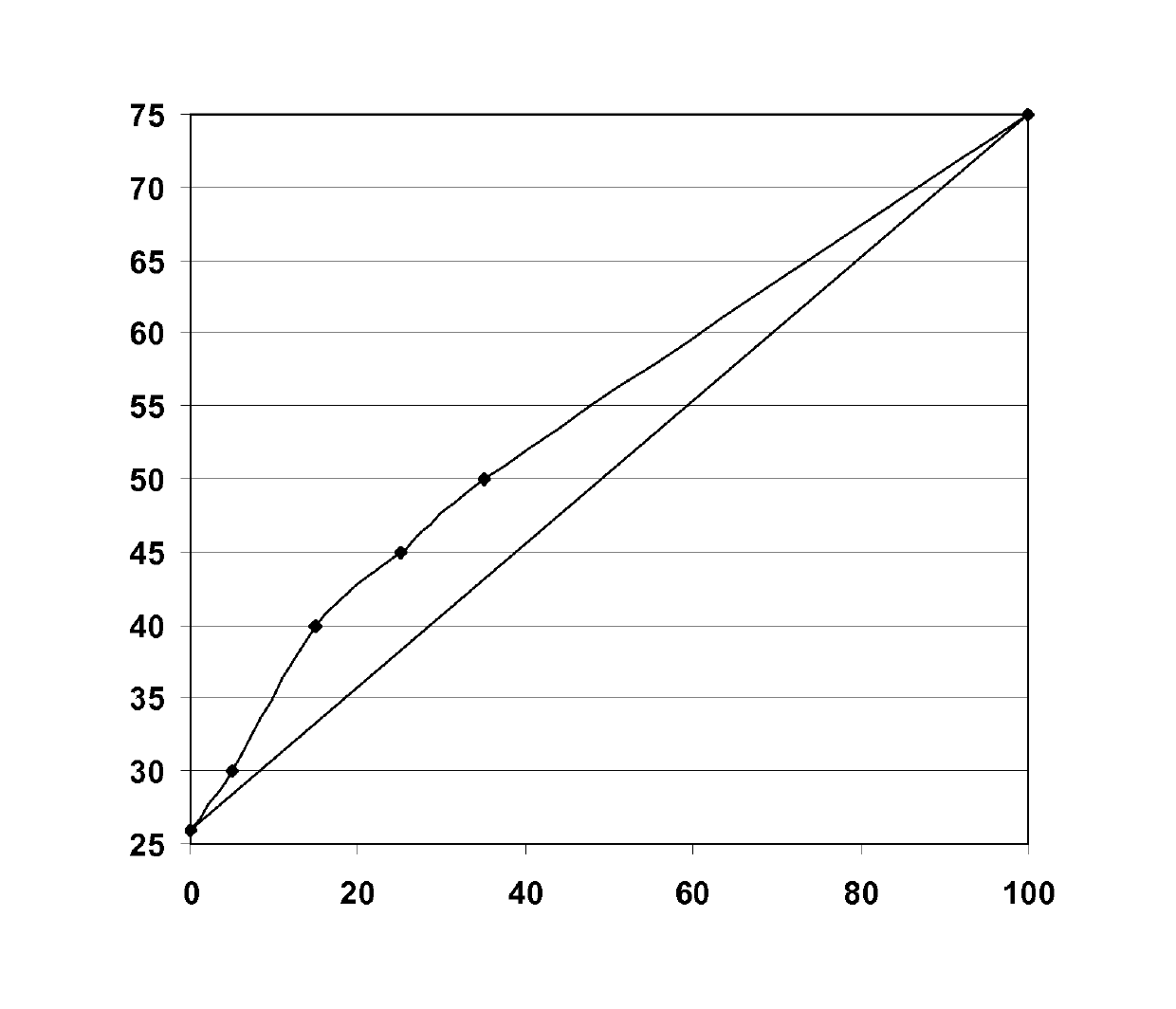

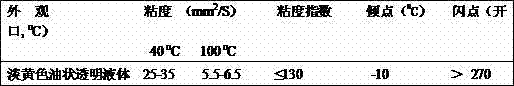

Polyolester oil (POE oil) is a type of synthetic oil used in refrigeration compressors that is compatible with the refrigerants R-134a, R-410A and R-12. It is recommended by experts as a replacement for hydrofluorocarbons (HFCs). Along with R-134a, POE oil is recommended as a replacement for R12 mineral oil as R134a does not mix well with mineral oil. These wax-free oils are suggested for use with chlorine free HFC systems as they provide better lubrication and stability and are more miscible with HFC refrigerants. They can meet the lubricity requirements to those of mineral oils used with CFCs and HFCs. They are compatible with most lubricants in the market. It is noted that the viscosity of the oil decreases with temperature. The dispersion behavior of this oil has also been the subject of a lot of study. It is also considered by some to be a good additive to engine oil.

Lubricant and additive formulation

InactiveUS20030119682A1Improve the lubrication effectImprove engine performanceBiocideLiquid carbonaceous fuelsPolyolesterChemical composition

Owner:ASHLAND OIL INC +1

Lubricating oil composition

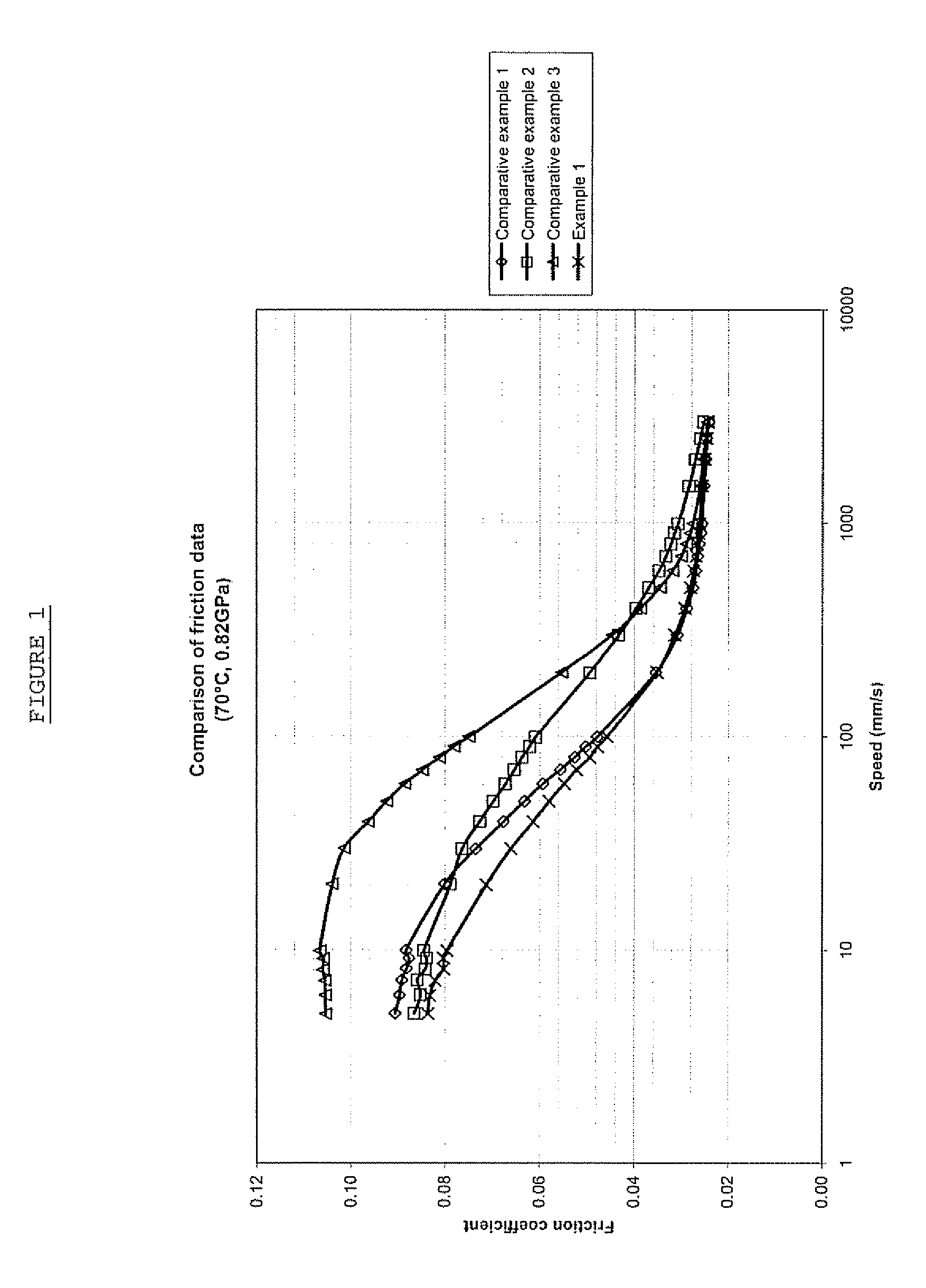

ActiveUS20080280795A1Good friction reductionImprove fuel economyOrganic chemistryAdditivesChemical compositionViscosity index

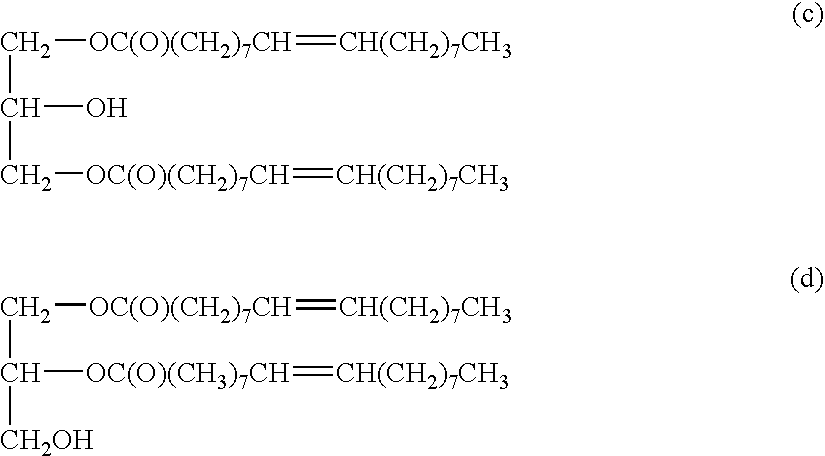

A lubricating oil composition comprising base oil, one or more glycerol esters selected from glycerol monooleate and / or glycerol dioleate, optionally in combination with glycerol trioleate, wherein said composition further comprises one or more dispersant-viscosity index improver compounds and an additive amount of one or more additional polyhydric alcohol esters; and a method of lubricating an internal combustion engine comprising applying said lubricating oil composition thereto.

Owner:SHELL USA INC

Heat transfer compositions with a hydrofluoroalkene, an iodocarbon and additives

The invention pertains to heat transfer compositions, particularly to automobile refrigerants comprising a hydrofluoroalkene, an iodocarbon, a polyol ester and at least one compound comprising trifluoromethane, methyl iodide, heptafluorobutane or propene.

Owner:HONEYWELL INT INC

Lubricating oil composition for refrigerators

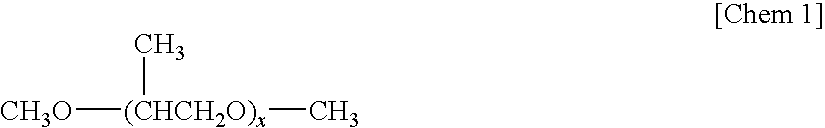

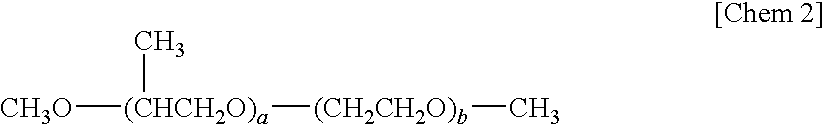

InactiveUS20100108936A1Low global warming potentialImprove sealingHeat-exchange elementsBase-materialsPolyolesterPolar structure

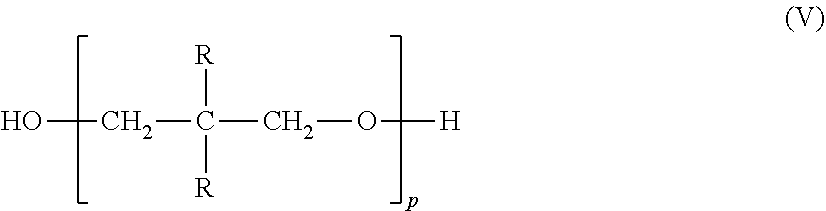

Provided is a lubricating oil composition for a refrigerator which uses a base oil including as the main component at least one kind of oxygen-containing compounds selected from polyoxyalkylene glycols, polyvinyl ethers, copolymers of poly(oxy)alkylene glycols or monoethers thereof and polyvinyl ethers, polyol esters, and polycarbonates. The lubricating oil composition for a refrigerator is used for a refrigerator that uses, as a refrigerant, a fluorine-containing organic compound, which is a refrigerant applicable to current car air conditioner systems or the like and has a specific polar structure, and has favorable sealing property, a low coefficient of friction factor in a sliding part, and excellent stability as well as excellent compatibility with the refrigerant.

Owner:IDEMITSU KOSAN CO LTD

Lubricating oil composition and watch using the same

InactiveUS6858567B2Long lifeChange propertiesLiquid carbonaceous fuelsHorological bearingsEtherViscosity index

The first lubricating oil composition of the invention comprises a polyol ester (A) as a base oil, a specific amount of a viscosity index improver (B) and a specific amount of an anti-wear agent (C), and the second lubricating oil composition of the invention comprises a paraffinic hydrocarbon oil (F) having at least 30 carbon atoms and a specific amount of a viscosity index improver (B), so that these compositions exert effects that they enable a life of watch battery to last long, they enable a watch to operate in the temperature range of −30 to 80° C. with one kind of a lubricating oil, and they are free from change of properties over a long period of time. The third lubricating oil composition of the invention comprises an ether oil (G) as a base oil, a specific amount of an anti-wear agent (C) comprising a neutral phosphoric ester and / or a neutral phosphorous ester, and an antioxidant (E), so that this composition is free from change of properties over a long period of time and is favorable as a watch lubricating oil. The watch of the invention is a watch having a movable portion for which at least one composition selected from the above compositions is used.

Owner:CITIZEN WATCH CO LTD

Heat transfer compositions having improved miscibility with lubricating oil

ActiveUS20150027146A1Low GWPImprove energy performanceCompression machines with non-reversible cycleHeat-exchange elementsPolyolesterPolyol

A composition including 2,3,3,3-tetrafluoropropene and a lubricating oil including a polyalkylene glycol and a polyol ester, the polyol ester content in the lubricating oil being less than or equal to 25%. A method of lubricating a vapor compression circuit, the method including using a mixture including a polyalkylene glycol and a polyol ester as lubricating oil in the vapor compression circuit, in combination with a heat transfer fluid comprising 2,3,3,3-tetrafluoropropene, the content of polyol ester in the lubricating oil being less than or equal to 25%. Further, the use of said composition in methods for heating or cooling.

Owner:ARKEMA FRANCE SA

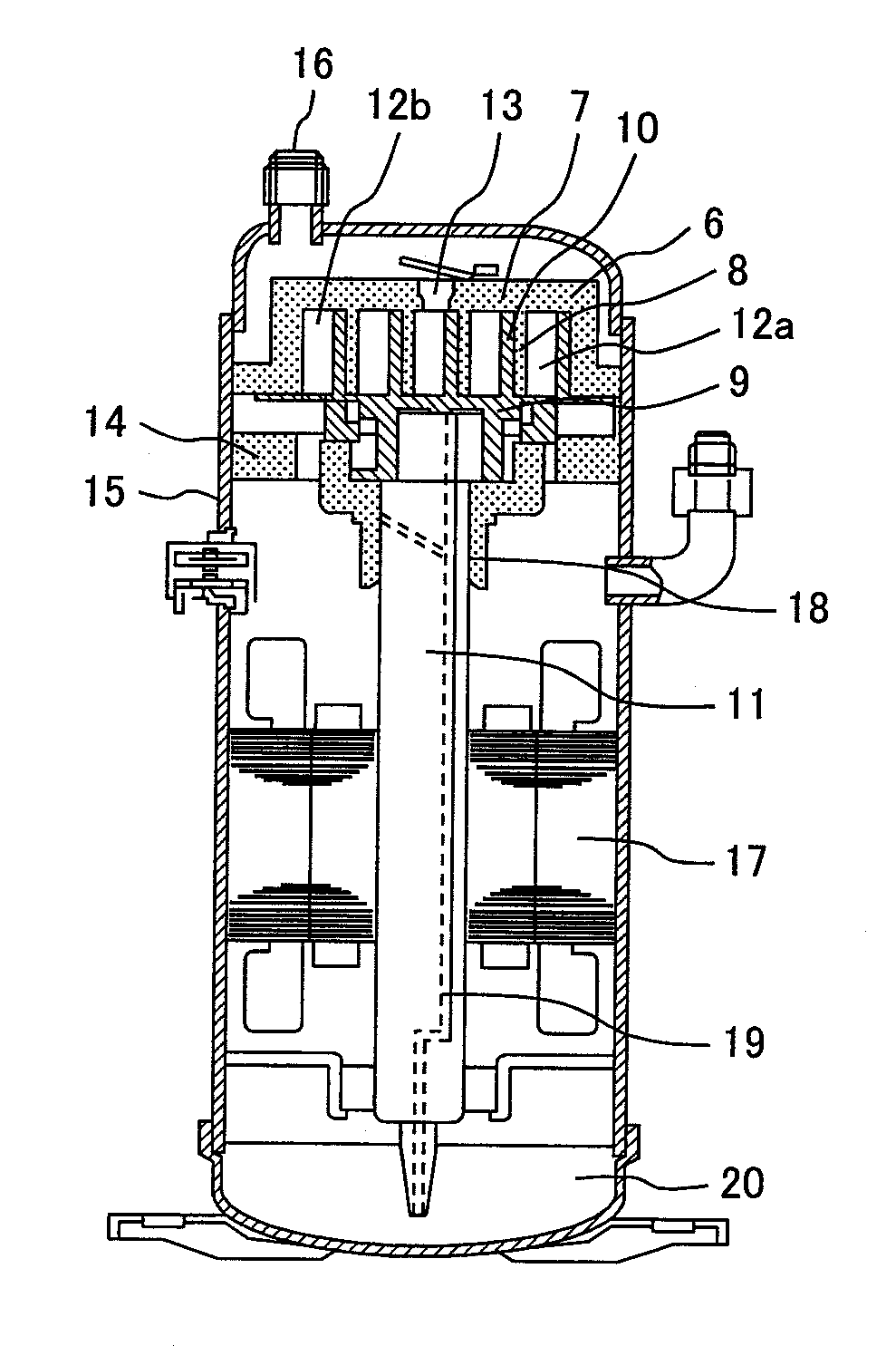

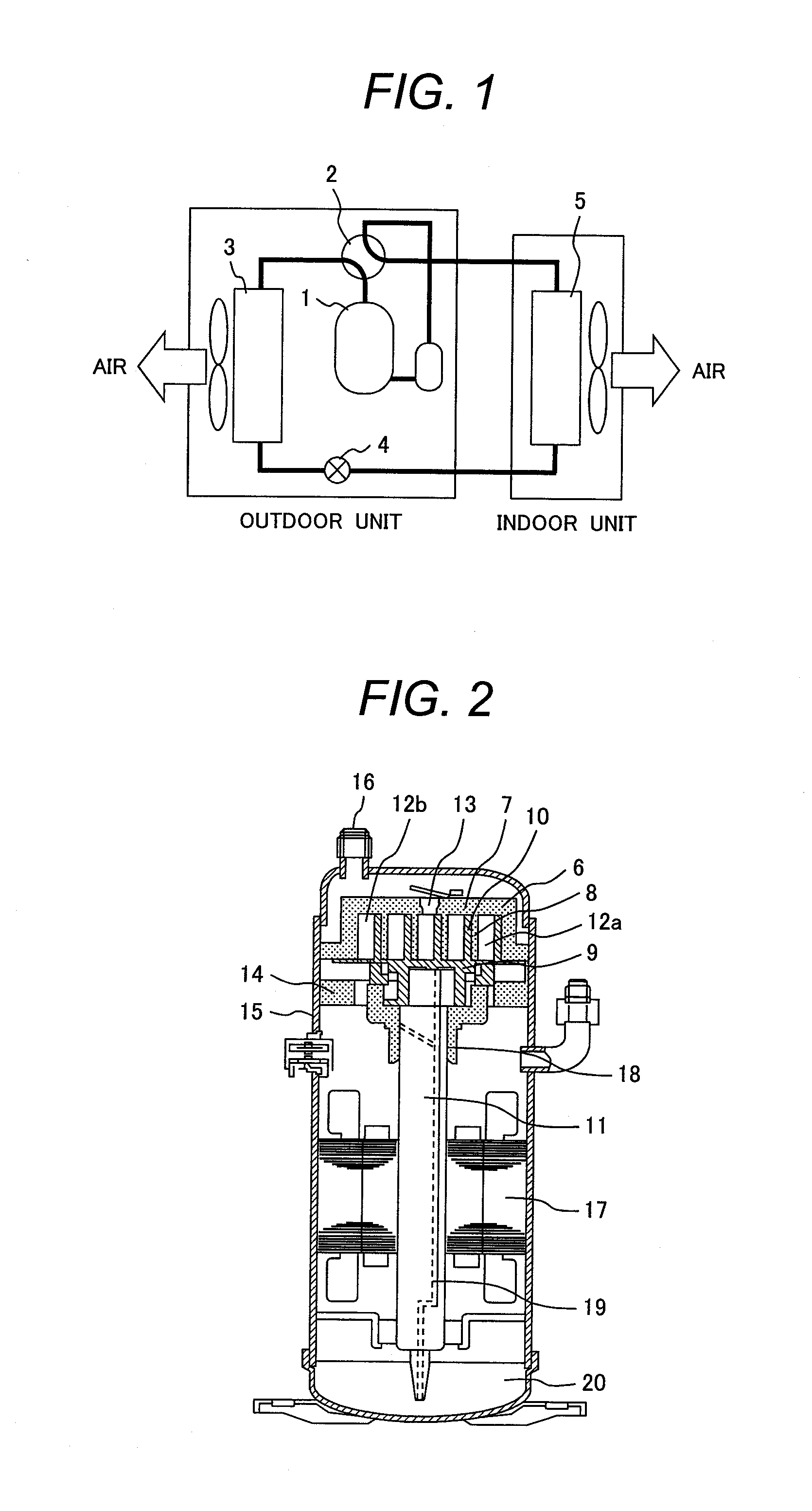

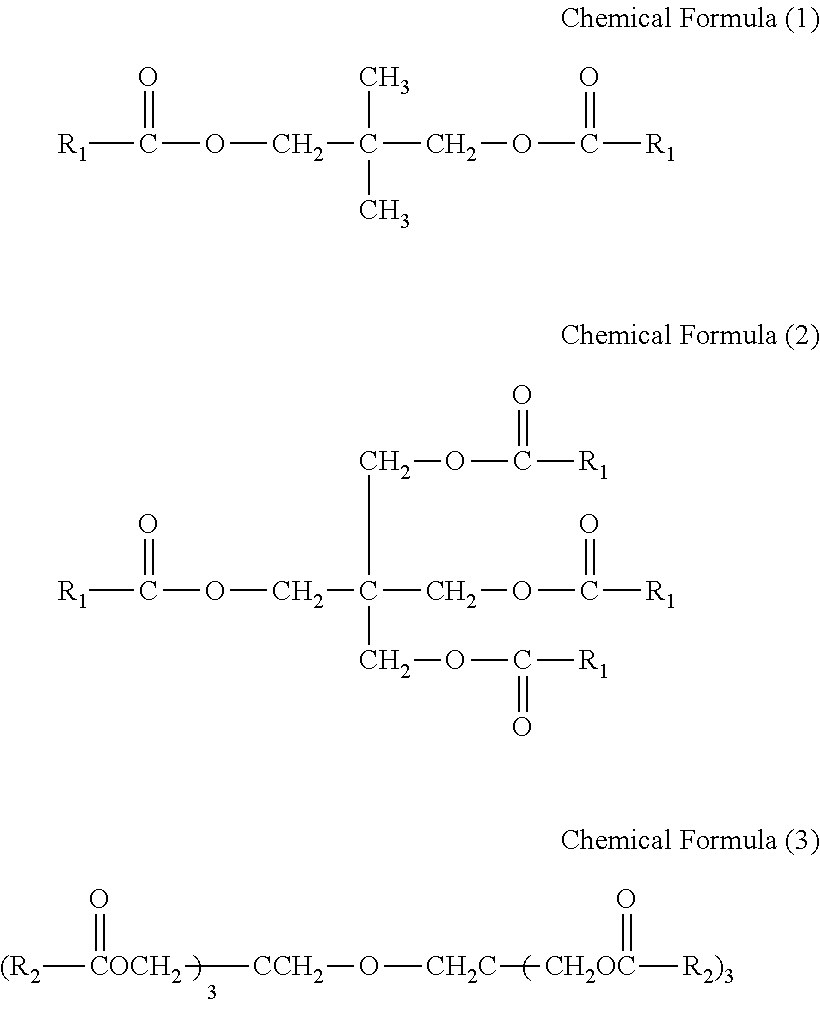

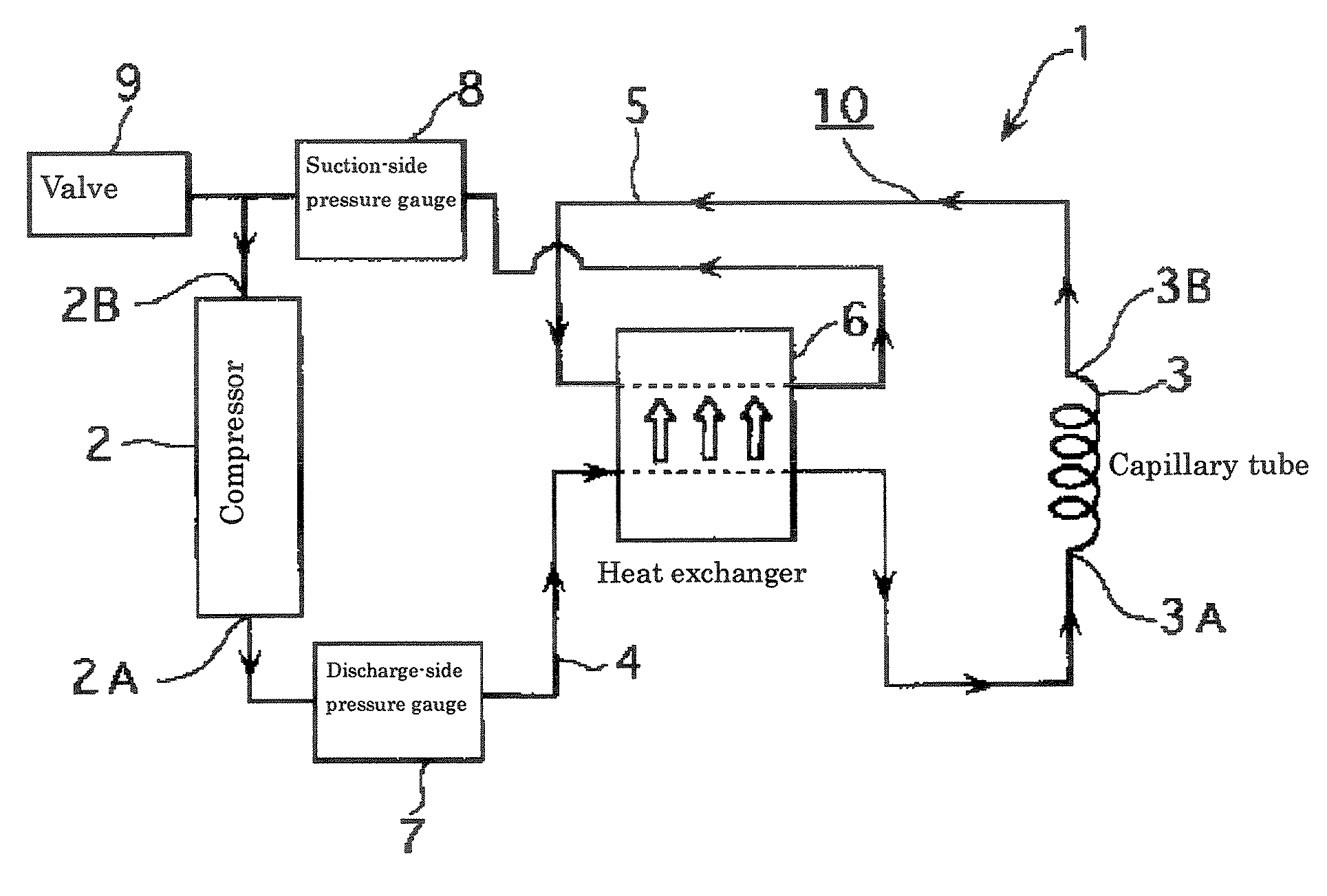

Compressor for refrigeration and air-conditioning and refrigerating and air-conditioning apparatus

InactiveUS20120024007A1Improve performanceGood miscibilityPositive displacement pump componentsCompression machines with non-reversible cyclePolyolPolyolester

A refrigerating machine oil including a refrigerating machine oil basis such as polyol ester oil and an additive polyol ester oil is mixed to a refrigerant including 2,3,3,3-tetrafluoropropene, 1,3,3,3-tetrafluoropropene or the like. A compressor for refrigeration and air-conditioning including the mixture charged therein is used. The composition of the additive polyol ester oil is 1 to 30 wt %.The wear resistance of the compressor is improved, and the efficiency of a refrigerating and air-conditioning apparatus using the compressor is enhanced.

Owner:HITACHI APPLIANCES INC

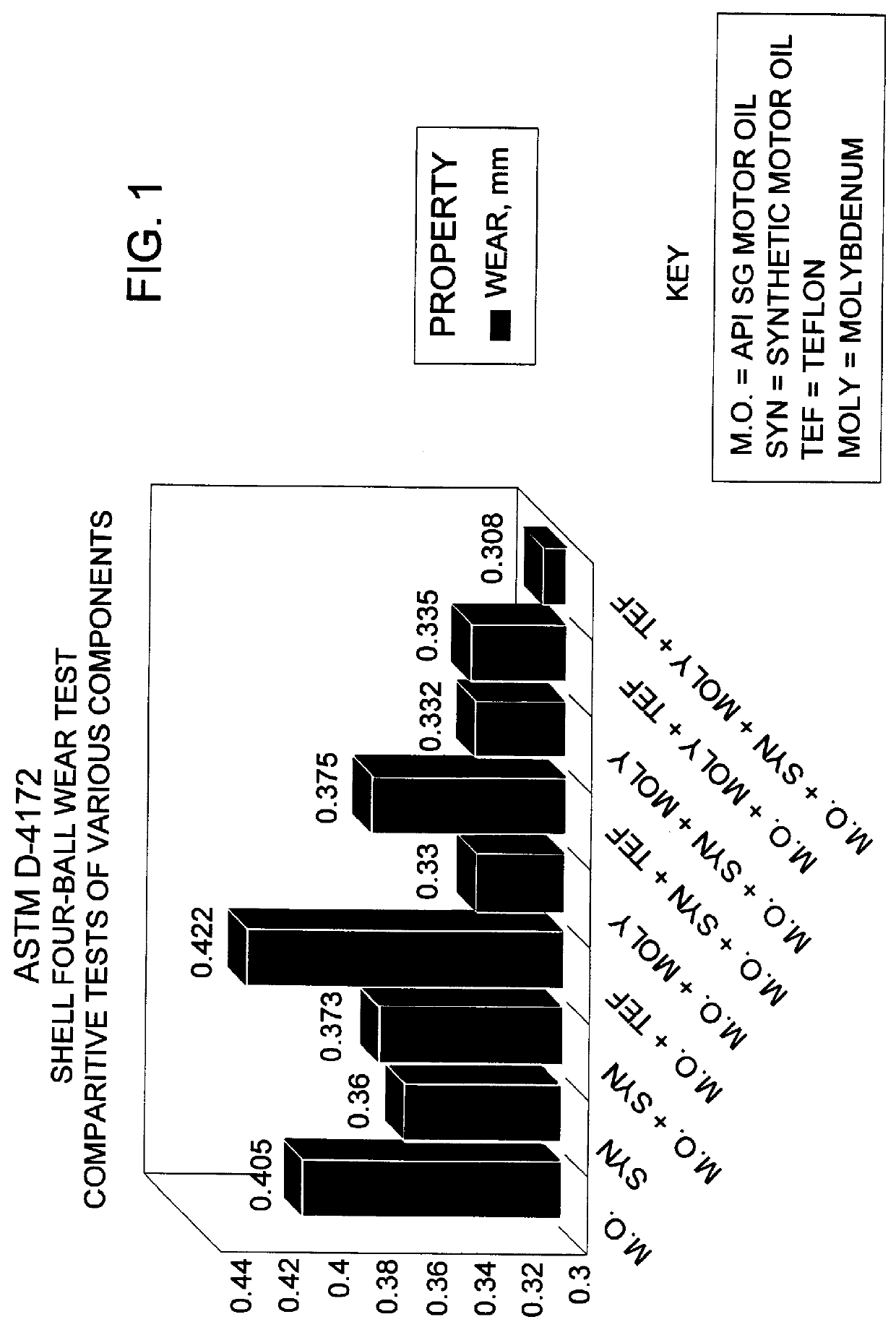

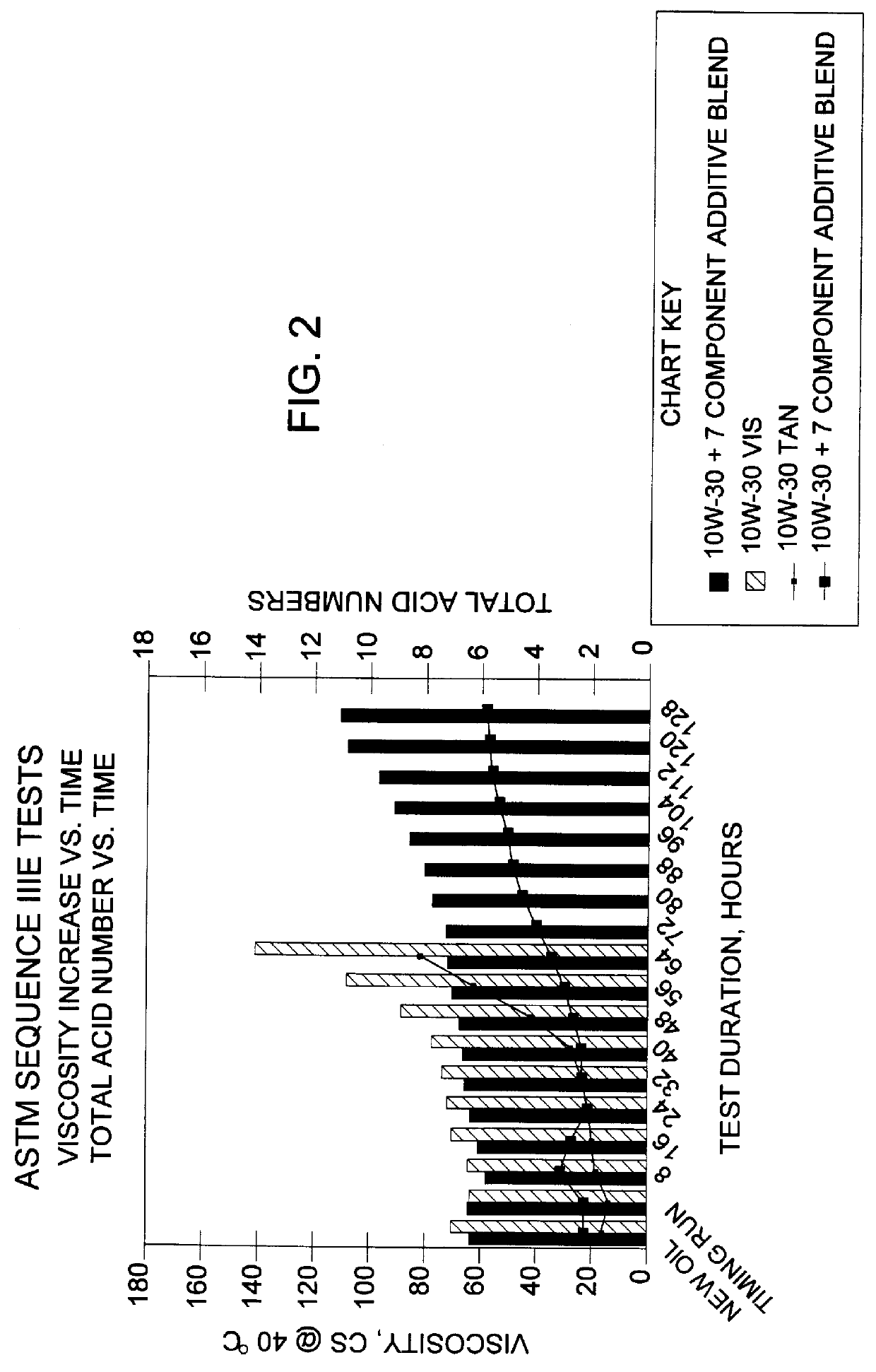

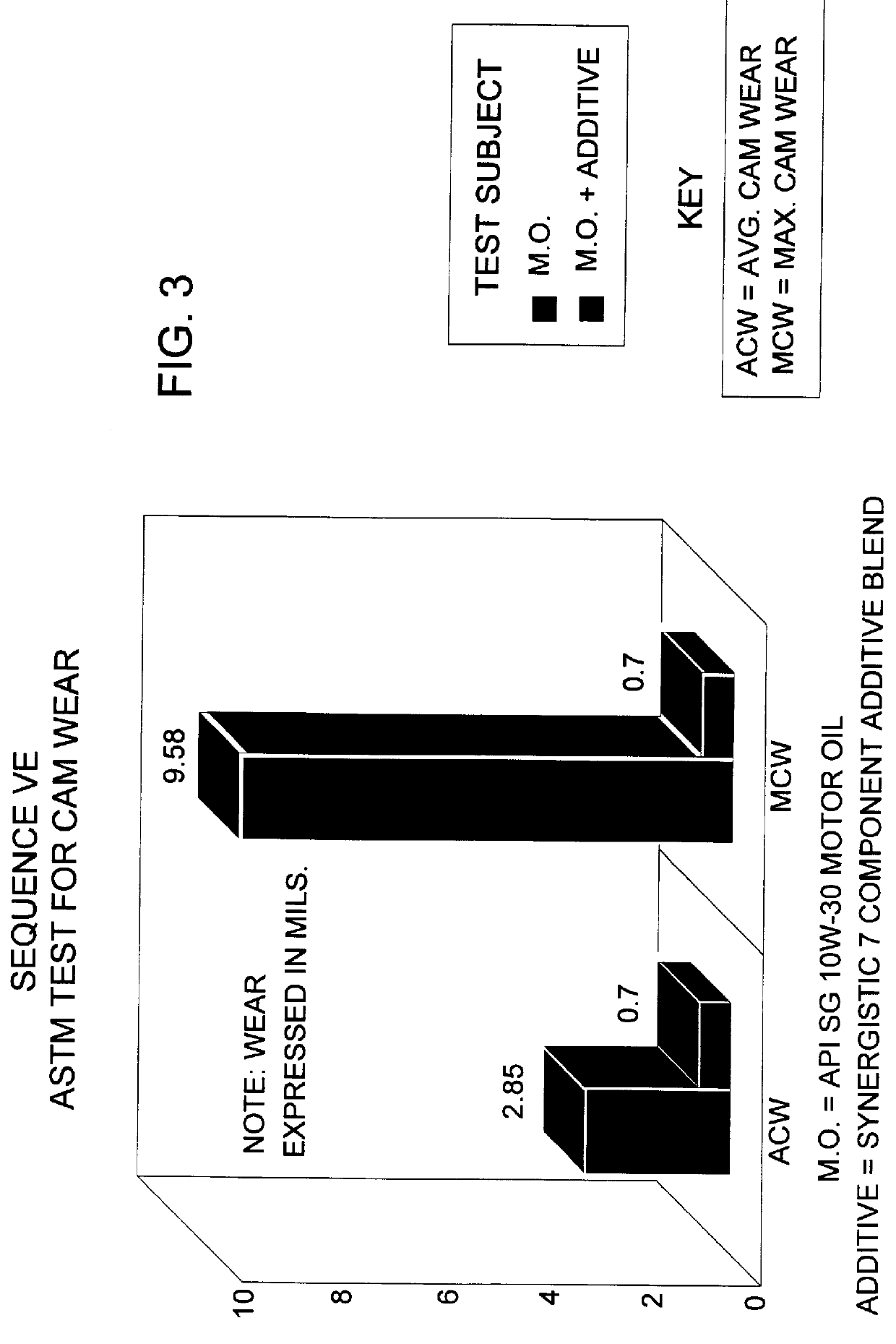

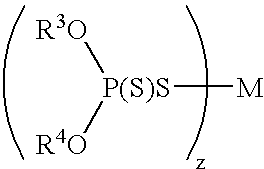

Lubricant additive formulation

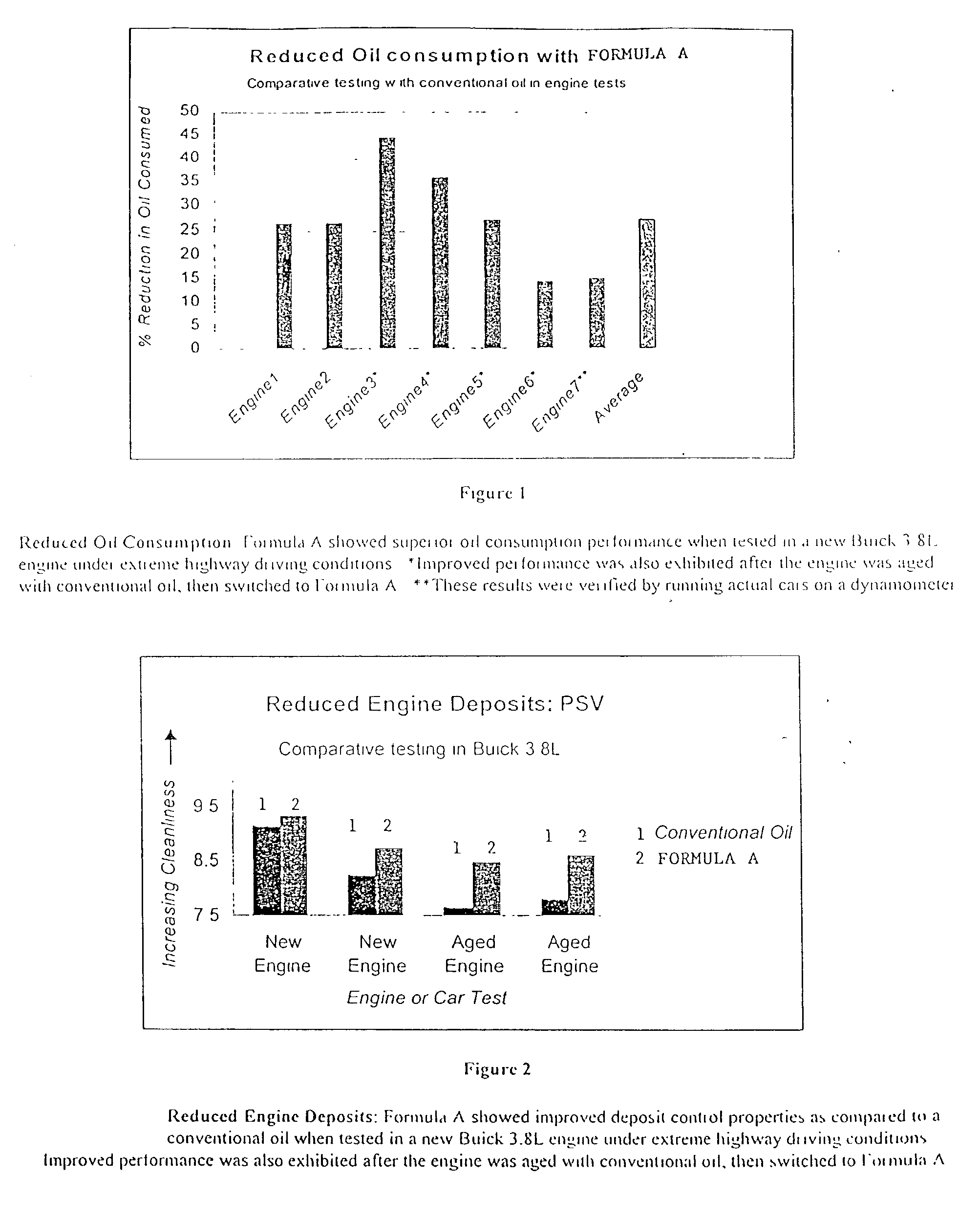

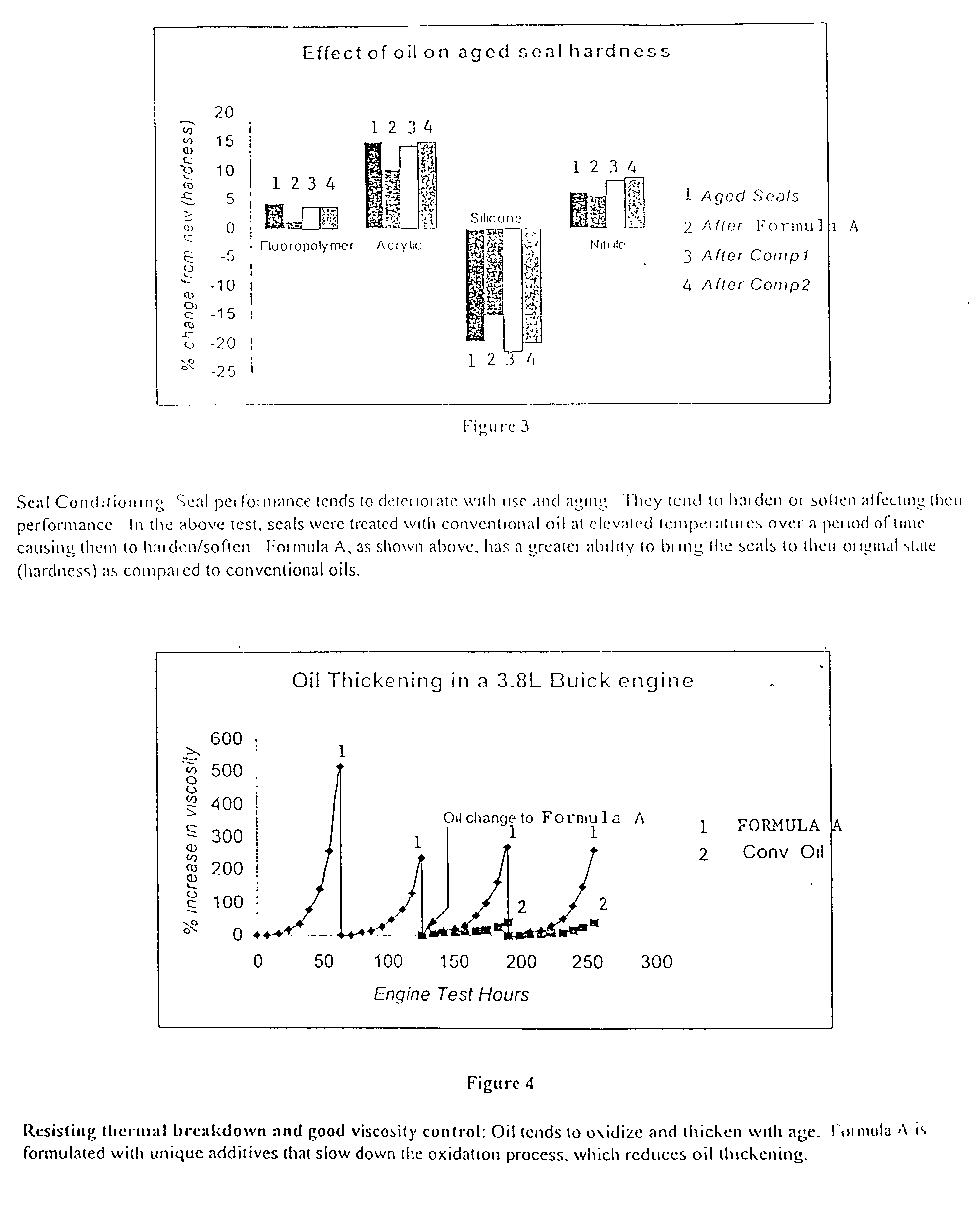

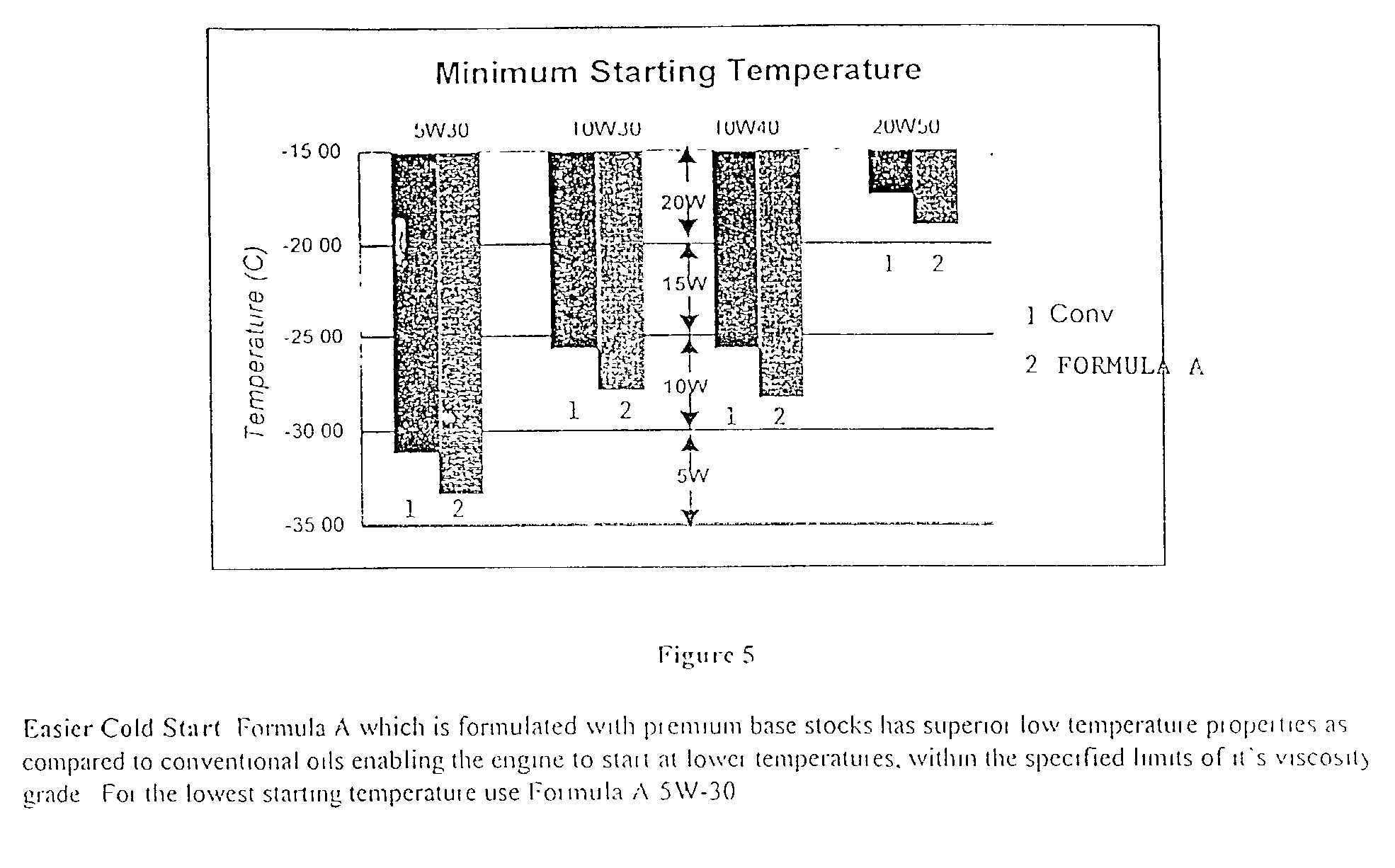

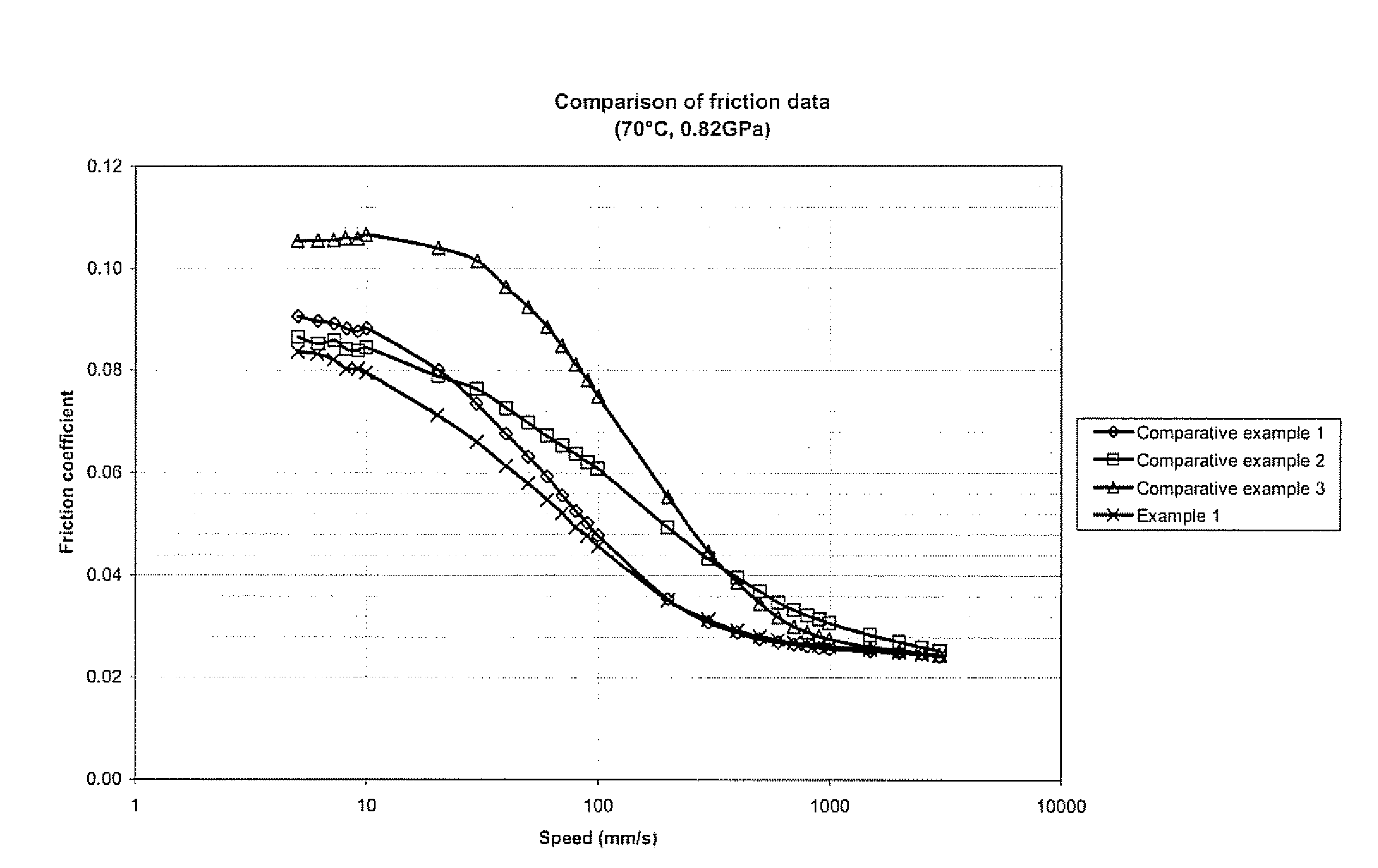

PCT No. PCT / US95 / 14186 Sec. 371 Date Aug. 27, 1997 Sec. 102(e) Date Aug. 27, 1997 PCT Filed Nov. 3, 1995 PCT Pub. No. WO96 / 15211 PCT Pub. Date May 23, 1996A lubricant additive formulation for addition to conventional motor oil to improve the lubricating properties of the engine oil and enhance the performance of the engine. The engine treatment oil additive comprises a synergistic blend of an oil soluble molybdenum additive, polyalphaolefin, ester such as a polyolester or diester, polytetrafluoroethylene, dispersant inhibitor containing zinc dithiophosphate, mineral oil base stock, viscosity index improvers, and borate ester used in combination with a conventional crankcase lubricant at about a 20 to about a 25% volume / percent. The improved performance of the engine additive in comparison with a conventional crankcase lubricants is attributable to the effect of optimizing the design parameters for each of the individual chemical constituents and combining the chemical constituents according to the present invention to obtain surprisingly good results including improved wear, oxidation resistance, viscosity stability, engine cleanliness, fuel economy, cold starting, and inhibition of acid formation.

Owner:VALVOLINE LICENSING & INTPROP LLC

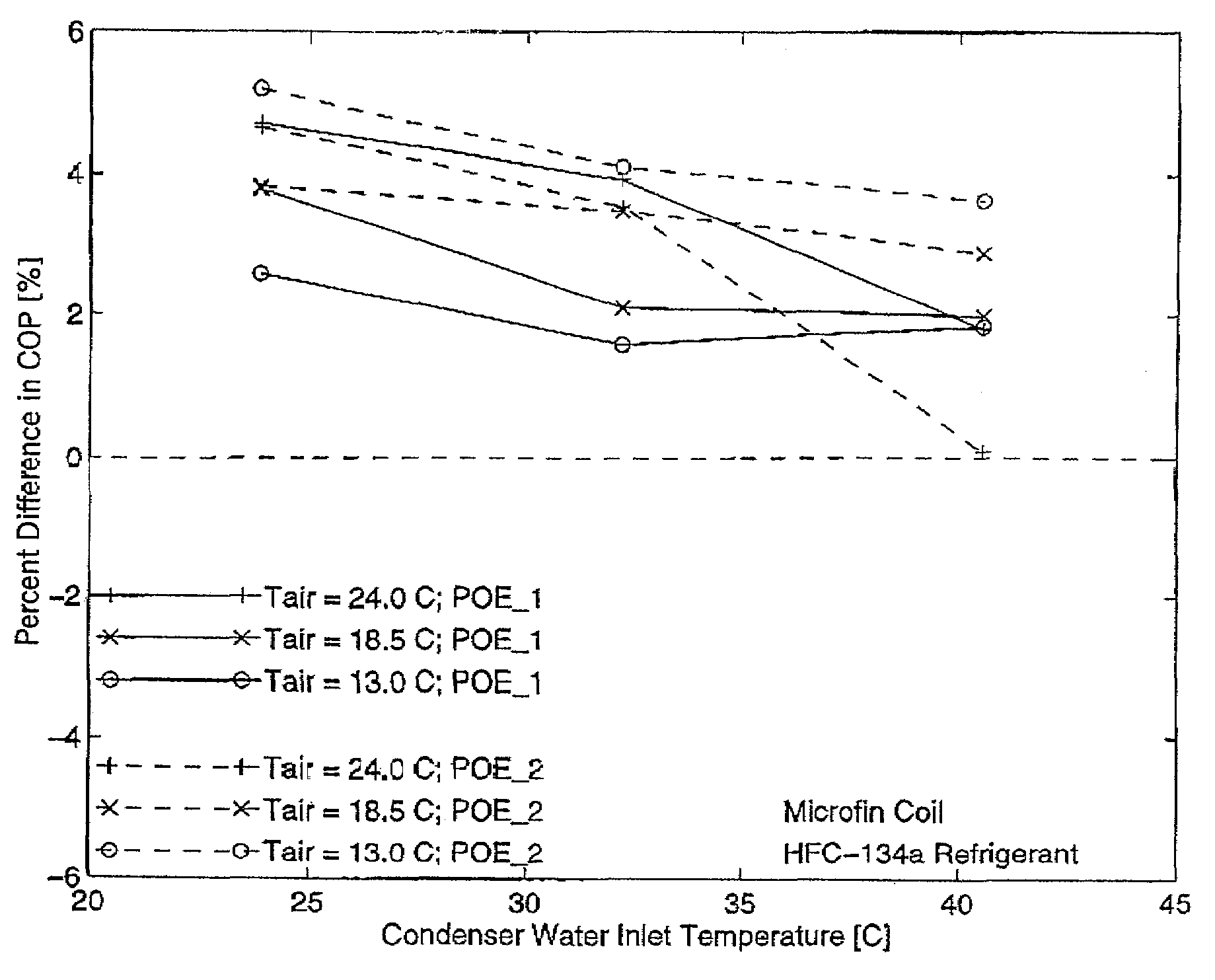

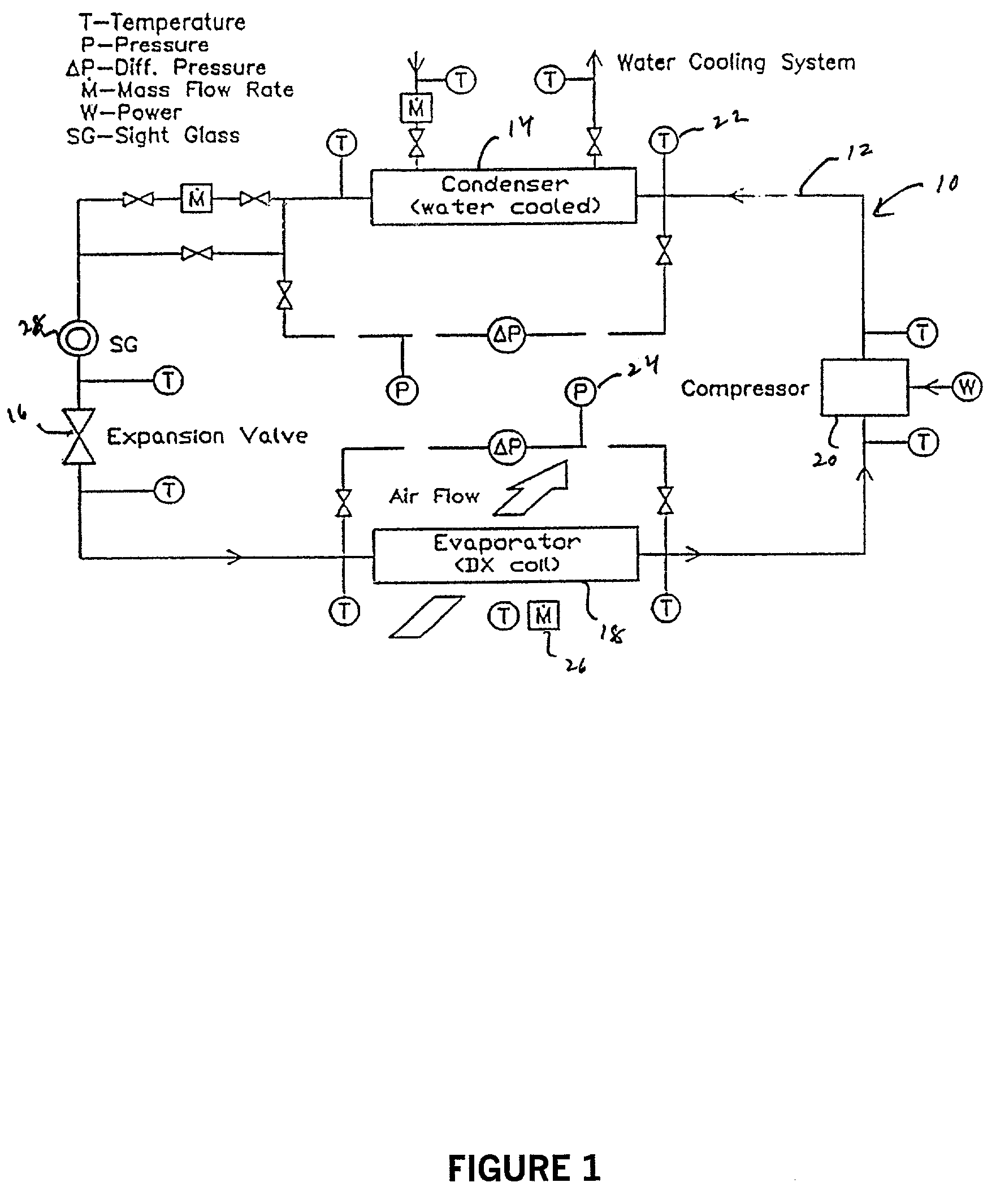

Method of improving performance of refrigerant systems

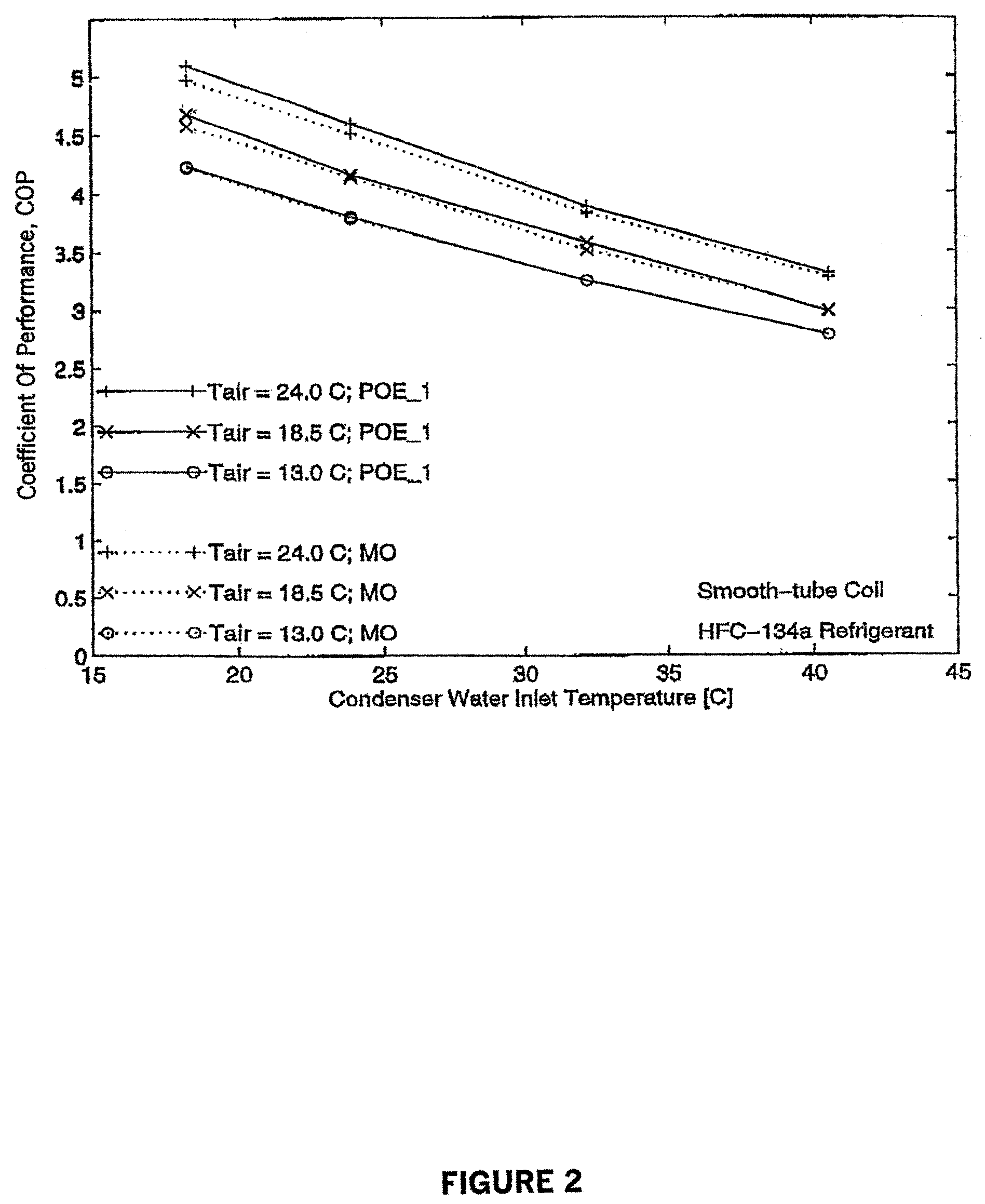

InactiveUS7018558B2Improve performancePerformance of a refrigerant system such as in air conditionerCompression machines with non-reversible cycleHeat-exchange elementsPolyolesterWorking fluid

A method of improving performance of refrigerant systems such as refrigerators and air conditioners that utilize a refrigerant working fluid. The working fluid consists essentially of a heat transfer fluid and a lubricant that is miscible and is otherwise compatible with the heat transfer fluid at all operating temperatures of the refrigerant system. The method is directed particularly to chlorine-free fluoro-group organic fluids and more particularly to hydrofluorocarbon heat transfer fluids. The preferred lubricants comprise polyol ester basestocks and compounded polyol esters that are highly miscible with such hydrofluorocarbon heat transfer fluids.

Owner:COGNIS IP MANAGEMENT GMBH

Polyol ester lubricants for hermetically sealed refrigerating compressors

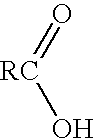

InactiveUS6221272B1Good hygroscopicityPromote undesirable corrosionOrganic chemistryPlastic/resin/waxes insulatorsNonanoic acidWorking fluid

A high quality lubricant for hermetically sealed domestic air conditioner and refrigerator compressors, especially those using chlorine free hydrofluorocarbon refrigerant working fluids, is provided by mixed esters of hindered polyols, most desirably pentaerythritol, with a mixture of carboxylic acids including at least some isopentanoic acid along with either or both of iso-nonanoic acid and dibasic acids such as adipic.

Owner:COGNIS IP MANAGEMENT GMBH

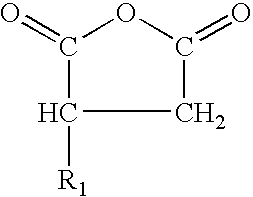

Lubricating oil composition for refrigerators and compressors with the composition

ActiveUS20100147016A1Improve compatibilityImprove sealingPositive displacement pump componentsHeat-exchange elementsPolyolesterCarboxylic acid

A lubricating oil composition for refrigerators comprising a base oil which comprises as a main component a polyol ester compound obtained from a polyhydric alcohol selected from among pentaerythritol, dipentaerythritol, trimethylolpropane, and neopentyl glycol and a C4 to C20 aliphatic monocarboxylic acid and which has an acid value of 0.02 mgKOH / g or less and a hydroxyl value of 5 mgKOH / g or less. A compressor using the lubricating composition. The lubricating oil composition is applicable to such refrigerators that use a refrigerant having a specific structure, such as an unsaturated fluorinated hydrocarbon compound, and being usable in current car air conditioner systems, and has excellent compatibility with the refrigerant, good sealing properties, capability of imparting a low coefficient of friction to sliding members and, yet, excellent stability. The compressor uses the lubricating composition.

Owner:IDEMITSU KOSAN CO LTD

Lubricating oil composition for refrigerators

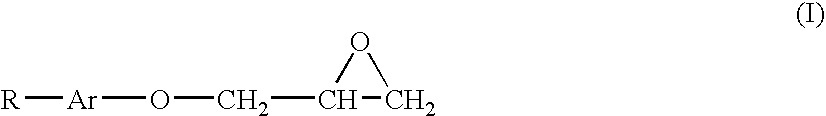

ActiveUS20100133463A1Improve compatibilityLow global warming potentialHeat-exchange elementsAdditivesPhosphorous acidScavenger

A lubricating oil composition for refrigerators including (A) a base oil containing as a main component a polyol ester compound obtained from a polyhydric alcohol selected from among pentaerythritol, dipentaerythritol, trimethylolpropane and neopentyl glycol and a C4 to C20 aliphatic monocarboxylic acid, (B) a phosphorus-based additive comprised of a phosphoric acid triester and / or a phosphorous acid triester, and (C) at least one acid scavenger selected from among glycidyl esters, glycidyl ethers and α-olefin oxides.The lubricating oil composition is applicable to such refrigerators that use a refrigerant having a specific structure, such as an unsaturated fluorinated hydrocarbon compound, and being usable in current car air conditioner systems, and has excellent compatibility with the refrigerant, good sealing properties, capability of imparting a low coefficient of friction to sliding members and, yet, excellent stability.

Owner:IDEMITSU KOSAN CO LTD

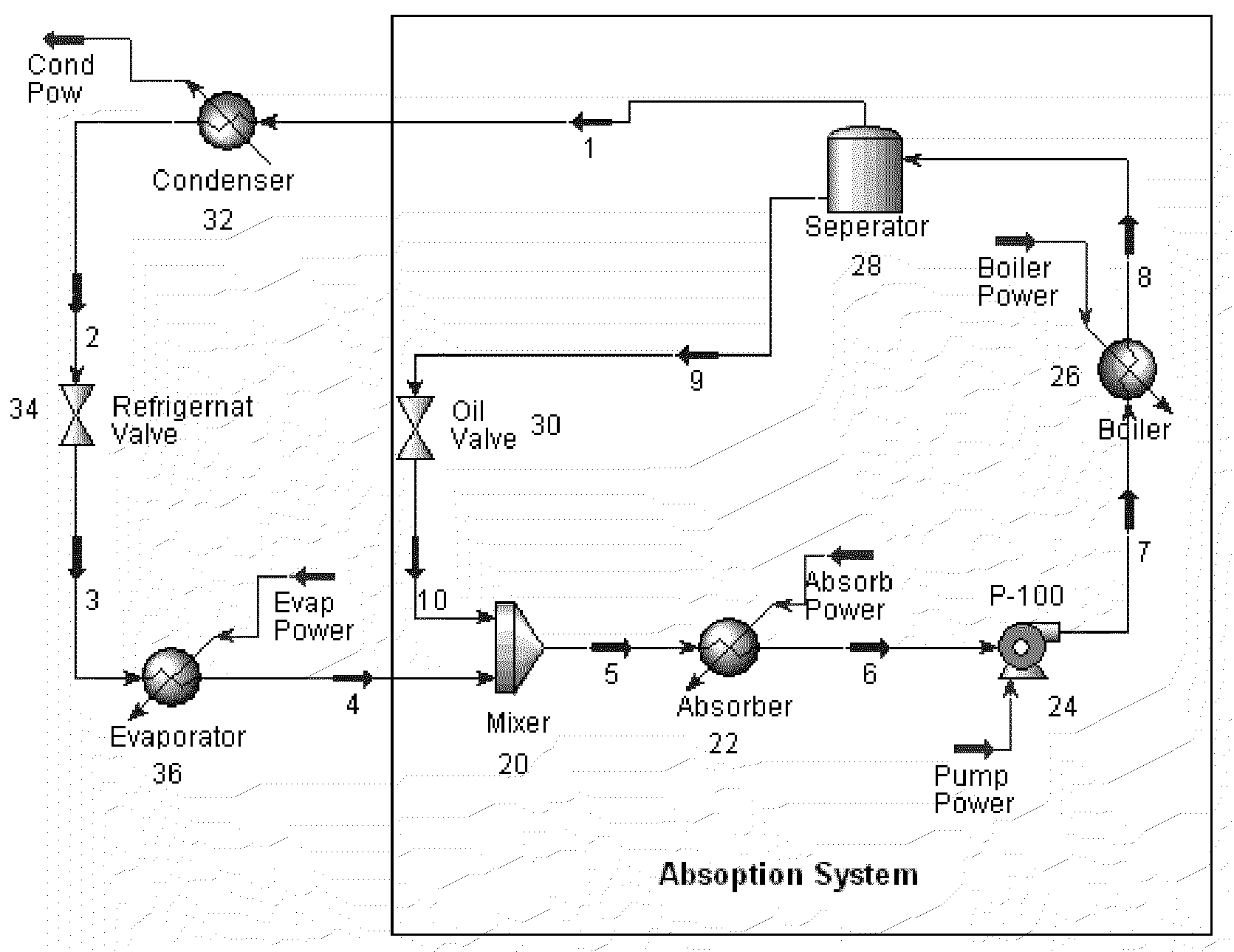

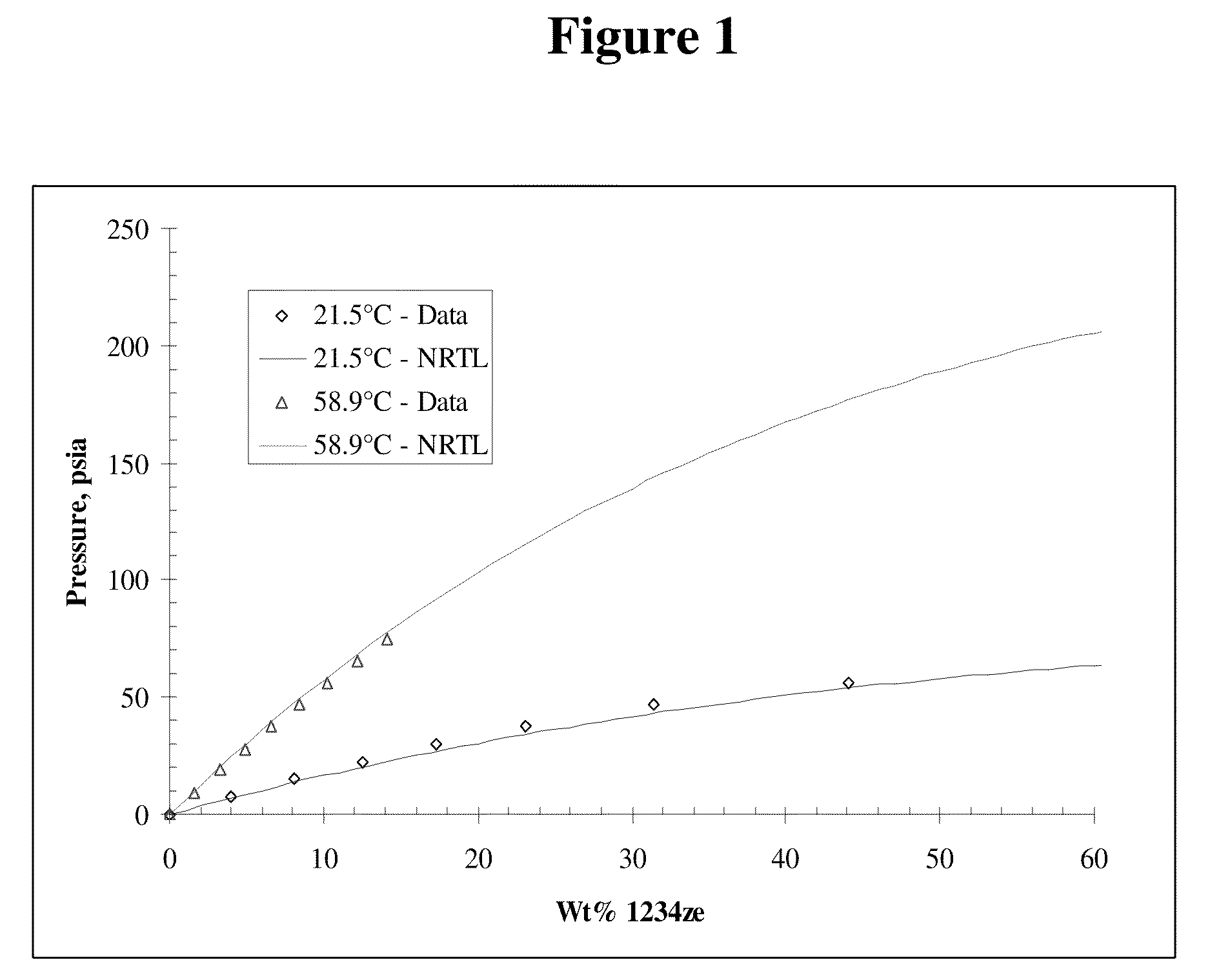

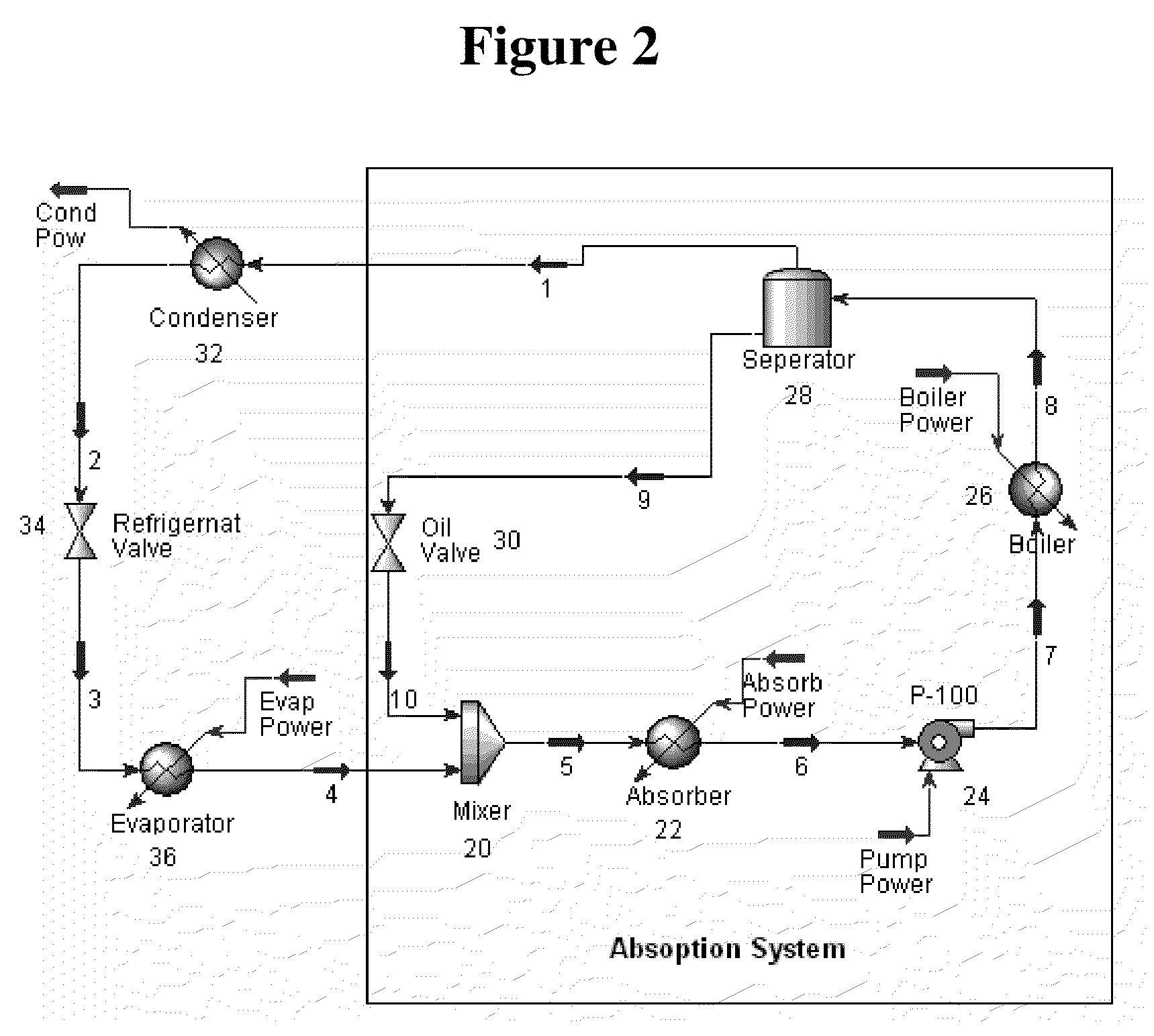

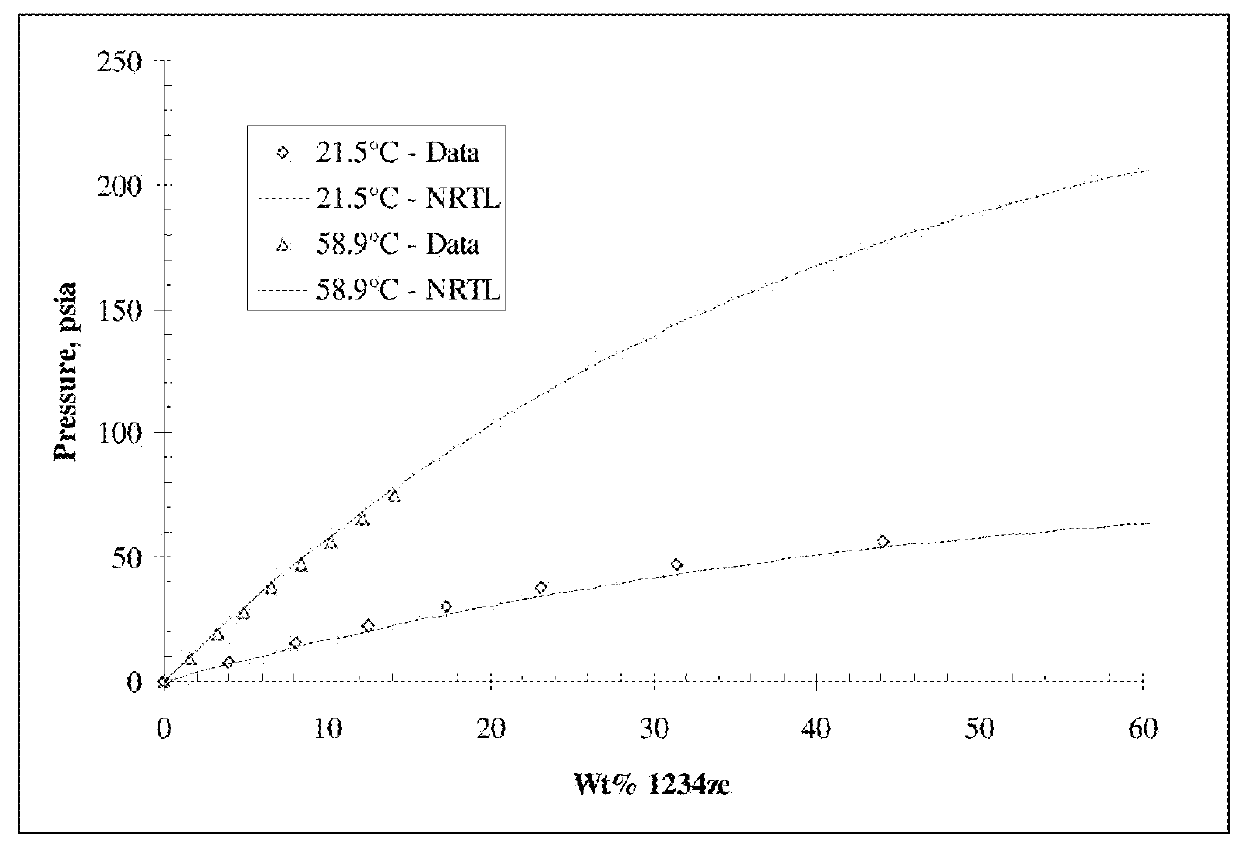

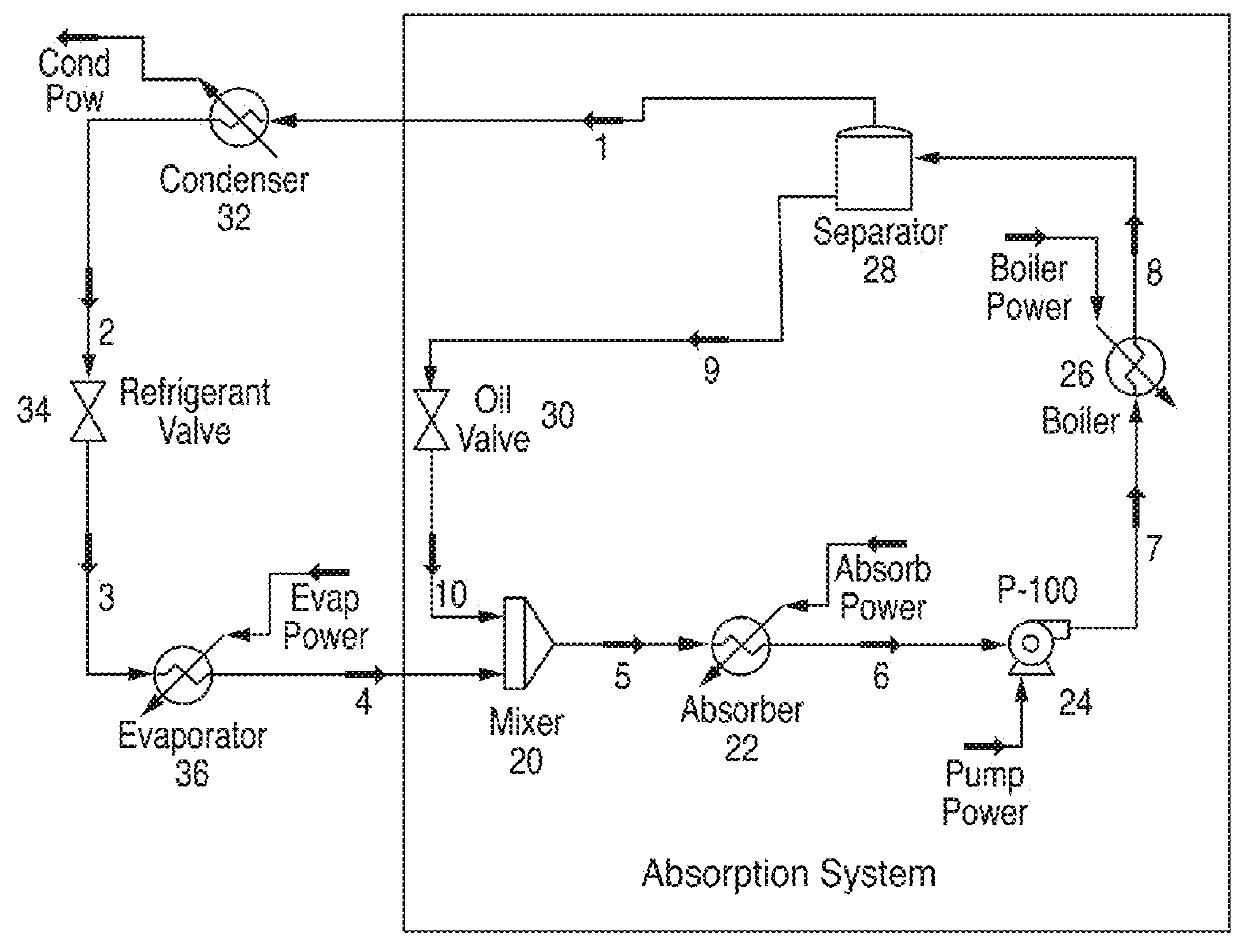

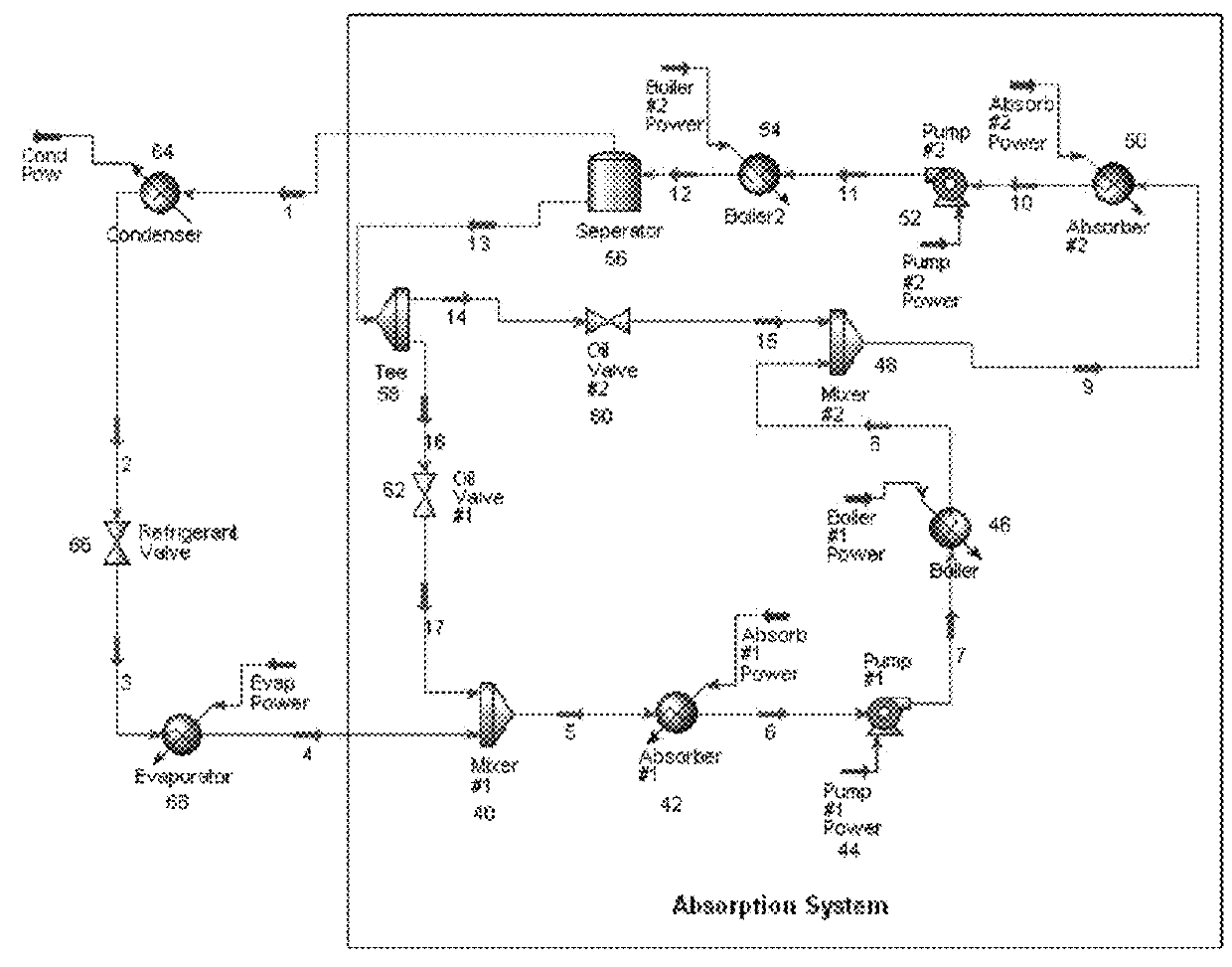

Absorption refrigeration cycles using a lgwp refrigerant

ActiveUS20090272134A1Improve heat transfer performanceEasy to separateEnergy efficient heating/coolingCompression machines with non-reversible cyclePolyolesterEngineering

An absorptive refrigeration method that employs a refrigerant comprising one or more hydrofluoroolefin or hydrochlorofluoroolefin refrigerants, and an oil selected from the group consisting of a polyalkyene glycol oil, a poly alpha olefin oil, a mineral oil and a polyolester oil.

Owner:HONEYWELL INT INC

Lubricating composition containing a blend of a polyol ester and an alkylbenzene

InactiveUS20050029488A1Low viscosityReduce attractionHeat-exchange elementsBase-materialsPolyolesterAir conditioning

The present invention relates to a lubricating basestock for the blends of hydrofluorocarbon and optionally hydrochlorofluorocarbon refrigerants comprising a blend of (A) at least one alkylbenzene and (B) at least one polyol ester. While alkylbenzenes are not miscible with the refrigerant blend at the desired operating temperature and pressure of refrigeration or air-conditioning systems, the addition of low concentration of polyol ester is found to greatly improve the miscibility of the alkylbenzene and polyol ester blend. An important criteria of the invention is that the lubricant blend of polyol ester and alkylbenzene are sufficiently miscible with the hydrofluorocarbon refrigerant blend both as a liquid and a gaseous refrigerant over the operational temperatures of the compression refrigeration system.

Owner:THE LUBRIZOL CORP

Base oil blends for conveyor chain lubricating compositions

InactiveUS20040014611A1Reduce volatilityConstant viscosityLiquid carbonaceous fuelsBase-materialsSludgeBase oil

A conveyor chain oil for use at elevated temperatures is described comprising a blend of a polyol ester, a poly(isobutylene), and a mineral oil. The blend has low volatility compared to the volatility of its individual components, suffers little change in viscosity with use, and resists the formation of undesirable sludge or varnish.

Owner:THE LUBRIZOL CORP

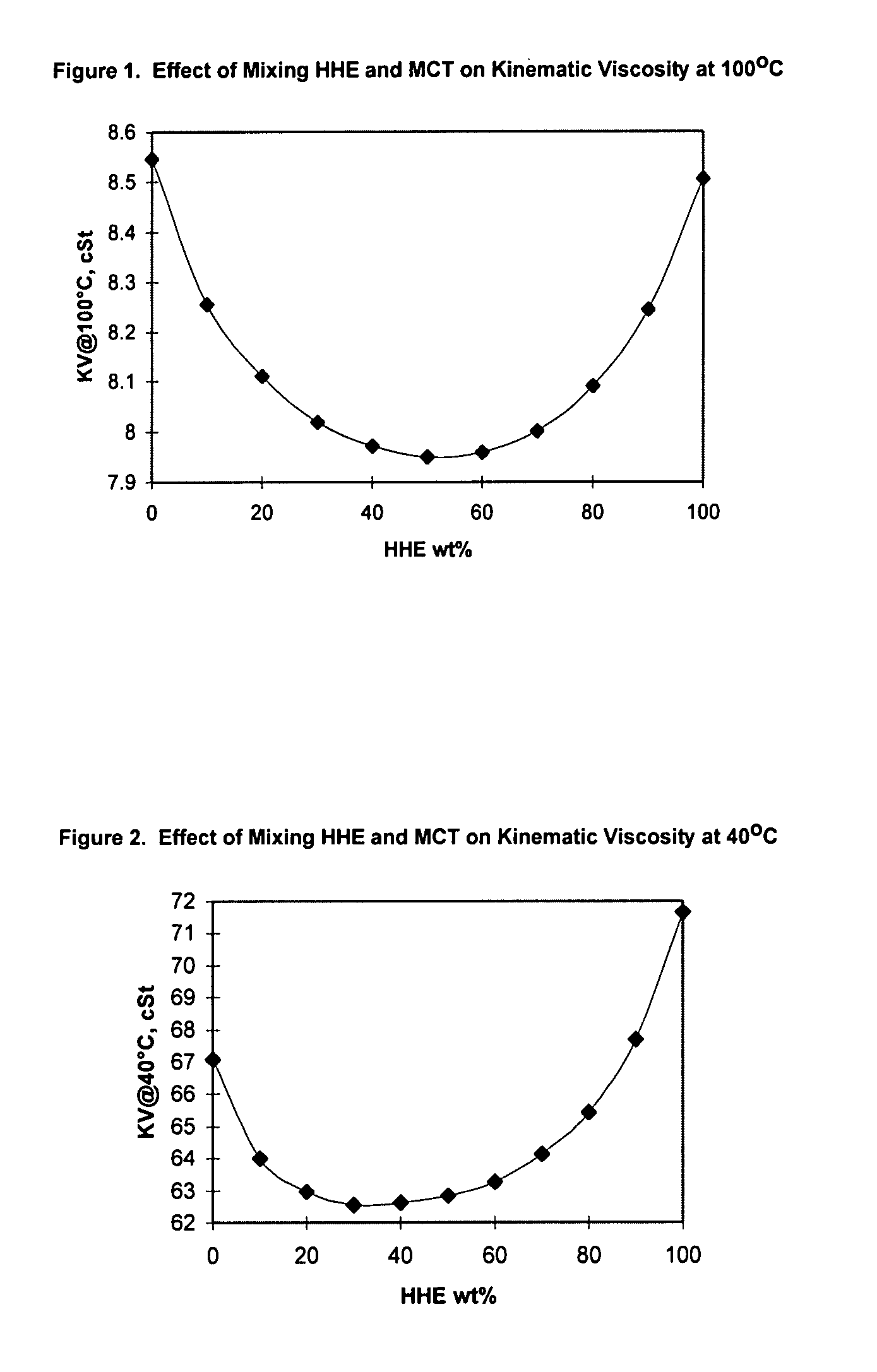

Blends of lubricant basestocks with polyol esters

A lubricating composition is provided comprising a polyol ester which is the reaction product of a neopolyol with linear or branched monocarboxylic acids and mixtures thereof having from 1 to about 25 carbon atoms and a natural or GTL oil of lubricating viscosity and mixtures thereof and wherein the weight ratio of the ester to oil will be sufficient to provide a composition having a viscosity less than the individual viscosities of the ester and oil.

Owner:GAO JASON Z +1

Polyol ester lubricants, especially those compatible with mineral oils, for refrigerating compressors operating at high temperatures

InactiveUS20010038088A1Good hygroscopicityPromote undesirable corrosionHeat-exchange elementsRefrigeration componentsSolubilityRefrigeration compressor

A high quality lubricant for compressors operated during at least part of their compression cycle at temperatures above normal human comfort temperatures, such as most automotive air conditioners, especially those using chlorine free hydro-fluorocarbon refrigerant working fluids, is provided by mixed esters of hindered polyols, most desirably pentaerythritol, with a mixture of carboxylic acids including at least some iso-pentanoic acid along with one or more of iso-nonanoic acid, isooctanoic acid, and dibasic acids such as adipic. When the mixture includes about 7% adipic and amounts of branched C8-9 and C5 monobasic acids in a ratio of at least 0.75:1.00, the esters formed have excellent solubility for paraffinic and naphthenic mineral oils and are therefore especially well suited for lubricating vehicle air conditioners formerly containing chlorine containing heat transfer fluids and mineral oil lubricants.

Owner:COGNIS CORP

Absorption refrigeration cycles using a LGWP refrigerant

ActiveUS9994751B2Increase pressureLess energyCompression machines with non-reversible cycleEnergy efficient heating/coolingPolyolesterEngineering

Owner:HONEYWELL INT INC

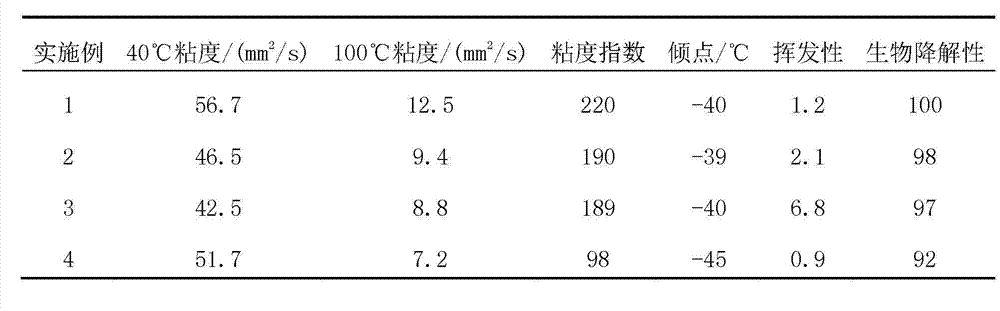

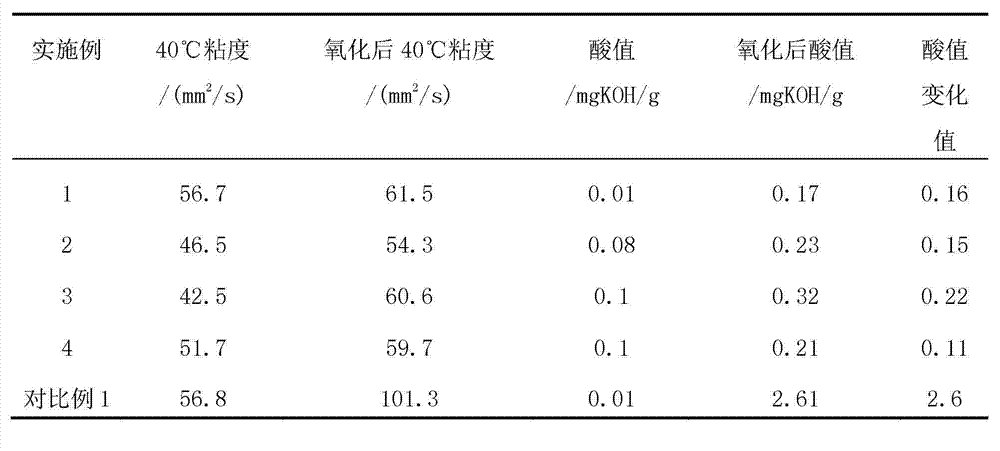

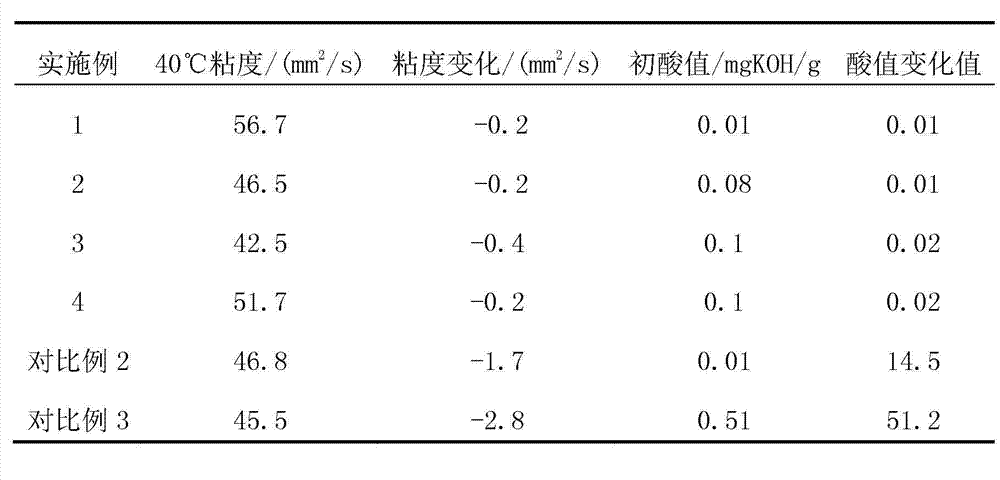

Wide temperature range polyol ester lubricating oil composition suitable for aircraft engine

InactiveCN102807908ASatisfy the operabilityFulfil requirementsAdditivesPolyolesterChemical composition

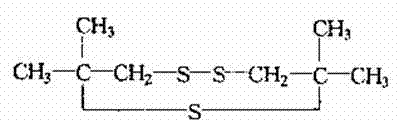

The invention relates to a wide temperature range polyol ester lubricating oil composition suitable for an aircraft engine. The wide temperature range polyol ester lubricating oil composition suitable for the aircraft engine consists of the following components in percentage by weight: 90-94 percent of polyol ester synthetic base oil, 2-5 percent of an organic polysulfide extreme-pressure wear-resisting agent, 0.5-1 percent of an antioxidant, 1-3 percent of a detergent dispersant and 0.5-1 percent of a corrosion inhibitor. Compared with traditional aircraft lubricating oil, the wide temperature range polyol ester lubricating oil composition has the advantages of excellent low-temperature starting performance, favorable thermal oxidation stability, strong hydrolytic stability, excellent lubricating performance, biodegradability and the like, and can meet the requirements of a modern aircraft engine on long-period rigorous working condition running and wide temperature range use.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Lubricating composition containing a blend of a polyol ester and an alkylbenzene

InactiveUS7208098B2Low viscosityImprove long-term stabilityHeat-exchange elementsBase-materialsPolyolesterAir conditioning

The present invention relates to a lubricating basestock for the blends of hydrofluorocarbon and optionally hydrochlorofluorocarbon refrigerants comprising a blend of (A) at least one alkylbenzene and (B) at least one polyol ester. While alkylbenzenes are not miscible with the refrigerant blend at the desired operating temperature and pressure of refrigeration or air-conditioning systems, the addition of low concentration of polyol ester is found to greatly improve the miscibility of the alkylbenzene and polyol ester blend. An important criteria of the invention is that the lubricant blend of polyol ester and alkylbenzene are sufficiently miscible with the hydrofluorocarbon refrigerant blend both as a liquid and a gaseous refrigerant over the operational temperatures of the compression refrigeration system.

Owner:THE LUBRIZOL CORP

Polyol ester lubricants for refrigerator compressors operating at high temperatures

InactiveUS6296782B1Good hygroscopicityPromote undesirable corrosionPlastic/resin/waxes insulatorsHeat-exchange elementsPolyolesterPentaerythritol

A high quality lubricant for compressors operated during at least part of their compression cycle at temperatures above and below normal human comfort temperatures, especially those using chlorine free hydrofluorocarbon refrigerant working fluids, is provided by mixed esters of hindered polyols, most desirably pentaerythritol, with a mixture of carboxylic acids including iso-pentanoic acid, trimethylhexanoic acid, and preferably n-pentanoic acid.

Owner:COGNIS IP MANAGEMENT GMBH

Heat transfer compositions having improved miscibility with lubricating oil

ActiveUS10450488B2Reduce the impact of heatLow GWPCompression machines with non-reversible cycleHeat-exchange elementsPolyolPolyolester

A composition including 2,3,3,3-tetrafluoropropene and a lubricating oil including a polyalkylene glycol and a polyol ester, the polyol ester content in the lubricating oil being less than or equal to 25%. A method of lubricating a vapor compression circuit, the method including using a mixture including a polyalkylene glycol and a polyol ester as lubricating oil in the vapor compression circuit, in combination with a heat transfer fluid comprising 2,3,3,3-tetrafluoropropene, the content of polyol ester in the lubricating oil being less than or equal to 25%. Further, the use of said composition in methods for heating or cooling.

Owner:ARKEMA FRANCE SA

Refrigerating machine oil

The invention provides refrigerating machine oil which comprises the following raw materials: 0.05wt%-0.1wt% of an antioxidant, 0.01wt%-0.05wt% of an anticorrosion agent, 1wt%-5wt% of an anti-wear agent, 0.0001wt%-0.005wt% of a defoaming agent and the balance of polyol ester, wherein polyol ester is obtained by esterification reaction of fatty acid and polyol; the polyol comprises one or two of pentaerythritol and dipentaerythritol. According to the refrigerating machine oil provided by the invention, polyol ester is adopted as base oil and is relatively high in viscosity and relatively good in compatibility with a refrigerant R134a at low temperature, so that the refrigerating machine oil is relatively high in viscosity and relatively good in compatibility with the refrigerant R134a at low temperature.

Owner:CHINA PETROLEUM & CHEM CORP

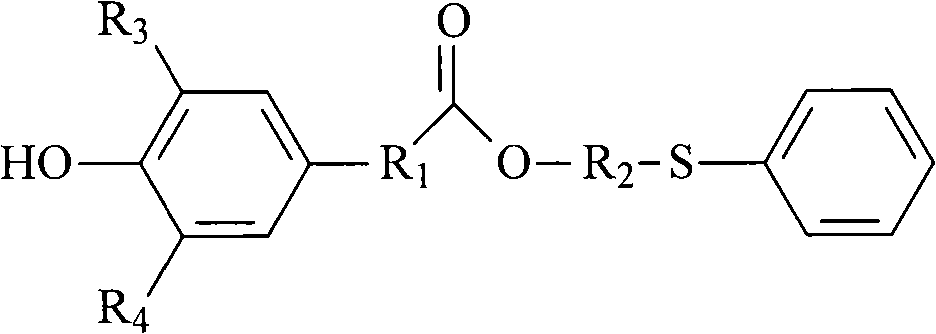

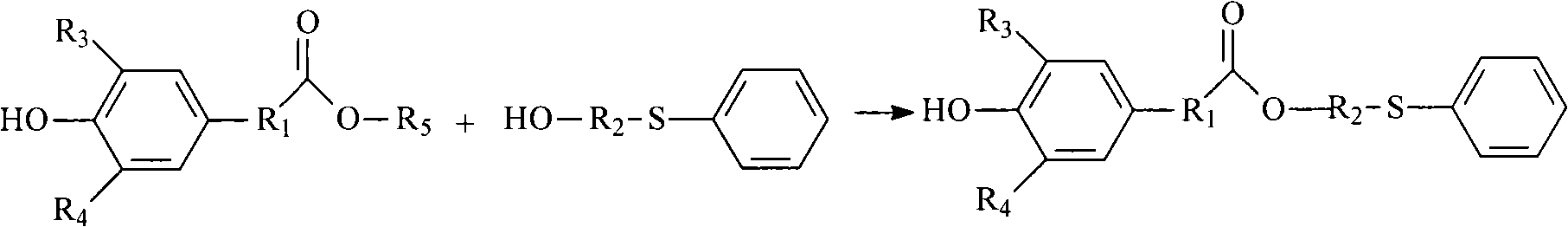

Refrigerator oil composition

InactiveCN101851545AImprove Oxidation StabilityProlonged oxidation induction periodAdditivesPolyolesterPentaerythritol

The invention relates to a refrigerator oil composition, which comprises polyol ester, (3,5-dialkyl-4-hydroxyphenyl) carboxylic thiophenyl alkyl ester, an antiwear agent, a metal passivator and an acid catching agent, wherein the polyol ester is pentaerythritol tetranitrate generated by reacting pentaerythritol with a mixture of isononanoic acid and diethyl caproic acid. The refrigerator oil composition provided by the invention has excellent oxidation stability. Compared with that of the refrigerator oil using the conventional antioxidant, the oxidative induction time of the refrigerator oil composition is obviously prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Use of tetrafluoropropene based compositions

The invention relates to the use of a composition comprising a polyol ester-based lubricant and a refrigerant F comprising at least one tetrafluoropropene and at least one hydrofluorocarbon, in a heat transfer system containing a vapour compression circuit comprising an oil separator.

Owner:ARKEMA FRANCE SA

Neopentyl polyol ester automobile gear lubricating oil containing sulphurized isobutylene

InactiveCN103756765AGood extreme pressure and anti-wear propertiesImprove carrying capacityAdditivesBase-materialsPolyolesterPolyol

The invention provides neopentyl polyol ester automobile gear lubricating oil containing sulphurized isobutylene. The neopentyl polyol ester automobile gear lubricating oil is prepared by taking neopentyl polyol ester as basic oil, adding the sulphurized isobutylene with the code of T321, dialkyl pentasulfide with the code of RC2540 and a composition of a phosphorus family with the code of P120, and uniformly mixing. The proportions of the composition are as follows: the weight percents of esters added by taking the neopentyl polyol ester as the basic oil are as follows: 0.05%-0.35% of T321, 0.03%-0.39% of RC2540 and 0.02%-0.32% of P120. The neopentyl polyol ester automobile gear lubricating oil containing the sulphurized isobutylene has very good extreme pressure abrasion resistance and the bearing capability is up to 3361N; the minimum grinding crack value is shown in description. The neopentyl polyol ester automobile gear lubricating oil can be used for preparing heavy-load vehicle gear oil and can also be used for heavy-load and middle-load industrial gear oil.

Owner:SHENYANG LIGONG UNIV

Refrigerator oil composition

The present invention provides a refrigerator oil composition including: a base oil (A) composed of at least one selected from a polyalkylene glycol, a polyol ester, a poly-α-olefin, an alkylbenzene, and an mineral oil; an organic sulfur compound (B) having a sulfur content of 35% by mass or less; and a refrigerant (C) composed of at least one selected from carbon dioxide gas, a hydrocarbon, and ammonia, in which the refrigerator oil composition has a total sulfur content of 0.01 to 0.1% by mass with respect to a total amount of the components (A) and (B). The refrigerator oil composition is novel, and is free from an environmental problem such as the ozone layer destruction or the global warming, can retain its lubrication property for a long period of time, and does not cause the clogging of a capillary in a refrigeration cycle.

Owner:IDEMITSU KOSAN CO LTD

Polymeric Polyol Esters Used in Metalworking Fluids

ActiveUS20070287645A1Improved solubility characteristicLow acid valueLiquid carbonaceous fuelsLubricant compositionMetalworking fluidPolyolester

Polymeric polyol ester additives for metal working applications are described that have lower pour points and improved solubility in API Group II and III basestocks. The polymeric polyol ester contains linear monocarboxylic acid, alkanedioic acid, alk(en)yl substituted succinic acid or anhydride, trihydric alcohol and pentaerythritol.

Owner:THE LUBRIZOL CORP

System and method for retrofitting a refrigeration system from hcfc to hfc refrigerant

ActiveUS20150377533A1Simple processPromote resultsCompressorDomestic cooling apparatusPolyolesterPolyol

A system and method for retrofitting a refrigeration system containing an HCFC refrigerant and a compatible lubricant, with an HFC refrigerant, comprising providing a transport container containing a mixture of a miscible lubricant and the HFC refrigerant, removing the HCFC refrigerant from the refrigeration system while maintaining at least a portion of a lubricant immiscible with the HFC refrigerant, and charging the refrigeration system with the mixture. The polyol ester lubricant may be present in a range exceeding about 5-15% by weight, e.g., 8%.

Owner:HUDSON TECHNOLOGIES

Synthetic automobile gear lubricating oil containing pentasulfide and animal oil

InactiveCN103756757AGood extreme pressure and anti-wear propertiesImprove carrying capacityAdditivesPolyolPolyolester

The invention discloses a synthetic automobile gear lubricating oil containing pentasulfide and animal oil. Neopentyl polyol ester is used as base oil for the lubricating oil, American product sulfurated extreme pressure agent polymeric pentasulfide TDPS532, lard oil CD-1 and P120 are added. Formula of the lubricating oil is shown as follows: neopentyl polyol ester is used as base oil, and 0.03-0.3% of TDPS532, 0.03%-0.36% of lard oil CD-1 and 0.02-0.32% of P120 by weight percentage of neopentyl polyol ester are added. The synthetic automobile gear lubricating oil containing pentasulfide and animal oil has superb extreme pressure abrasion resistance, bearing capacity is up to 2832N, wear scar is 0.426mm when load is 392N and abrasion time is 60min, and when load is 441N and abrasion time is 30min, the wear scar is 0.374mm. The synthetic automobile gear lubricating oil containing pentasulfide and animal oil can be used for preparing heavy load automobile gear oil, and also can be used for heavy load and medium load industrial gear oil.

Owner:SHENYANG LIGONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com