Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Prolonged oxidation induction period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biological diesel modifying agent and preparation method thereof

InactiveCN101082004AImprove Oxidation StabilityProlonged oxidation induction periodLiquid carbonaceous fuelsFuel additivesChemistryAntioxidant

The present invention relates to one kind of biodiesel oil modifier and its preparation process. The biodiesel oil modifier is compounded with antioxidant 1-10 weight portions, antioxidant synergist 0-5 weight portions, biodiesel oil of rape seed oil 50-100 weight portions, and low temperature flow improver 5-50 weight portions. The biodiesel oil modifier can raise the stability of biodiesel oil and improve its low temperature flow performance effectively, and has convenient use, wide adaptability, long storage period, capacity of being used in low temperature and low cost.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

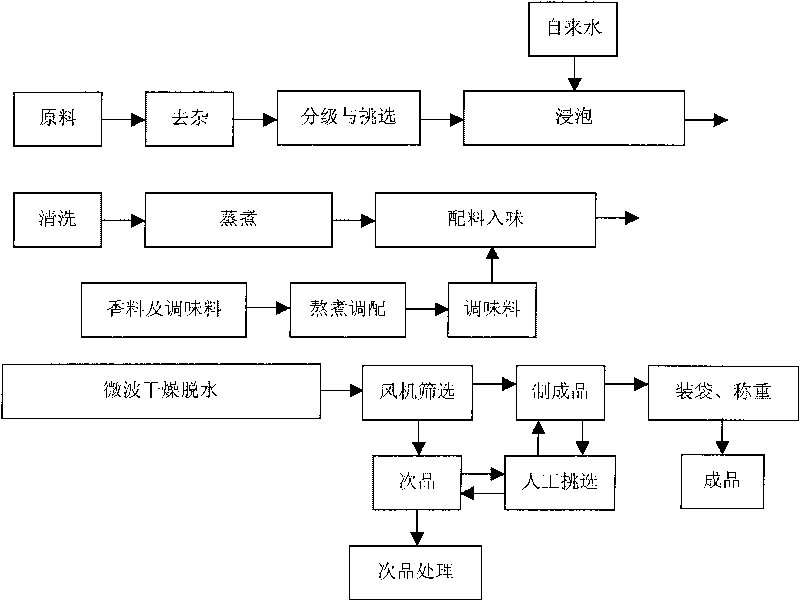

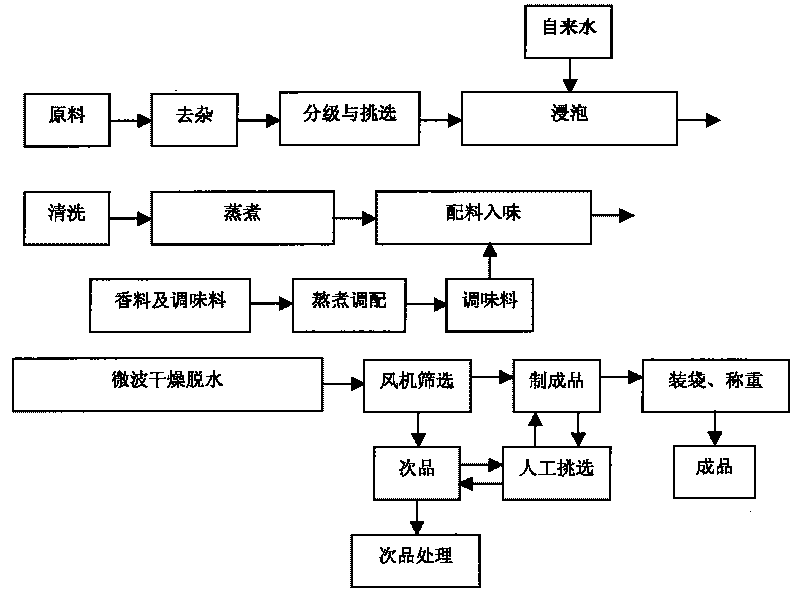

Method for producing dried salted peanuts

InactiveCN101703282AShorten drying timeShorten the production cycleFood preparationAir separationMicrowave power

The invention relates to a method for efficiently producing dried salted peanuts, which comprises the of selecting peanuts, cooking the peanuts, seasoning the peanuts, dehydrating the peanuts and performing air separation on the peanuts, wherein the peanuts are dehydrated in a microwave drying machine (furnace), the microwave power is between 1,000 and 6,000 W, and the microwave drying time is 4 to 10 minutes. The method can shorten the drying time from 50 to 70 hours of the conventional art to 4 to 10 minutes to significantly shorten the production period of products, improve the production efficiency, and simultaneously reduce the production energy consumption and production cost and reduce the pollutant discharges. The dried salted peanuts produced by the method are fragrant and crisp and have a good flavor mouthfeel, and particularly, the bad products generated in the drying process are reduced, the oxidation stability of the products is good, the oxidation induction period is prolonged to over 11 hours from 9 hours of the conventional art, and the shelf life is obviously prolonged. The method is convenient to produce various dried salted peanut products with different flavors.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

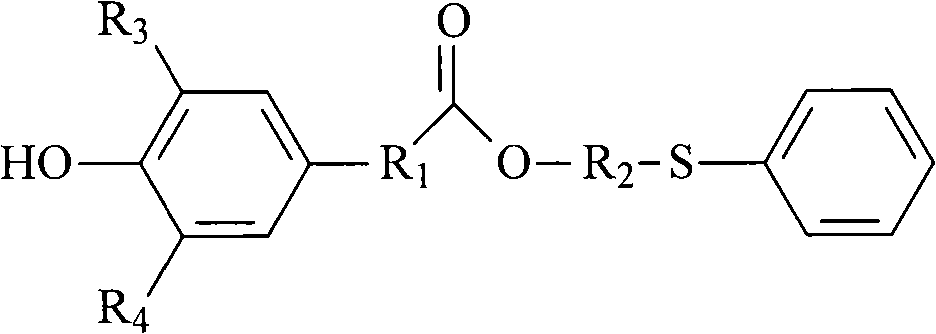

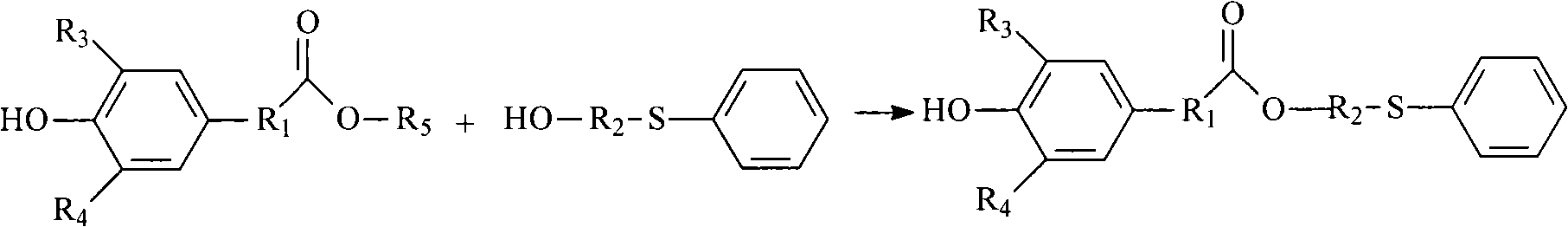

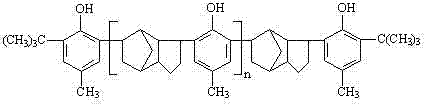

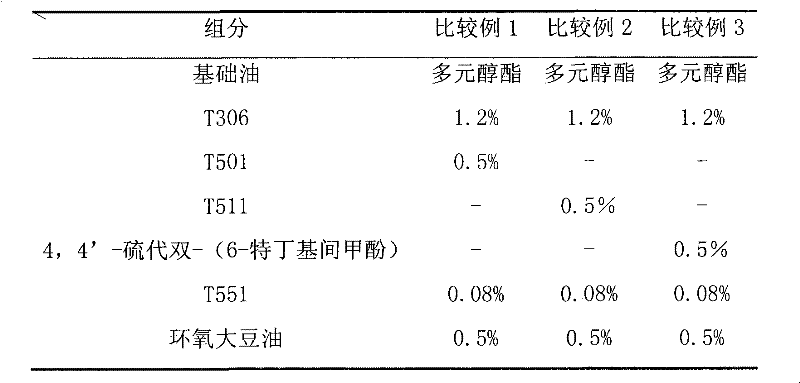

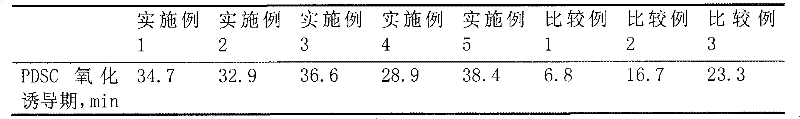

Refrigerator oil composition

InactiveCN101851545AImprove Oxidation StabilityProlonged oxidation induction periodAdditivesPolyolesterPentaerythritol

The invention relates to a refrigerator oil composition, which comprises polyol ester, (3,5-dialkyl-4-hydroxyphenyl) carboxylic thiophenyl alkyl ester, an antiwear agent, a metal passivator and an acid catching agent, wherein the polyol ester is pentaerythritol tetranitrate generated by reacting pentaerythritol with a mixture of isononanoic acid and diethyl caproic acid. The refrigerator oil composition provided by the invention has excellent oxidation stability. Compared with that of the refrigerator oil using the conventional antioxidant, the oxidative induction time of the refrigerator oil composition is obviously prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of emulsion antioxidant product

The invention provides a preparation method of an emulsion antioxidant product and belongs to the technical field of preparation of synthetic material antioxidant products. The emulsion antioxidant product is used for acrylonitrile butadiene styrene acrylonitrile butadiene styrene (ABS) grafting powder by means of an emulsion polymerization technology. Phenolic antioxygen Wingstay-L, an active ion radical trapping agent and a methylene di-sulfo ester compound are compounded according to the proportion to form a complex antioxidant, the complex antioxidant, isotridecyl alcohol polyoxyethylene ether or nonyl phenol polyoxyethylene ether and a dilution dispersing agent are mixed and stirred through a high speed shearing machine at the heating condition of 80-120 DEG C to form a homogeneous mixed liquid, and quantitative deionized water and an anionic surface active agent are added to continue to perform high speed shearing and stirring so as to obtain the antioxidant product having a water-soluble particle emulsion state, namely the emulsion antioxidant product.

Owner:浩瀚化学有限责任公司

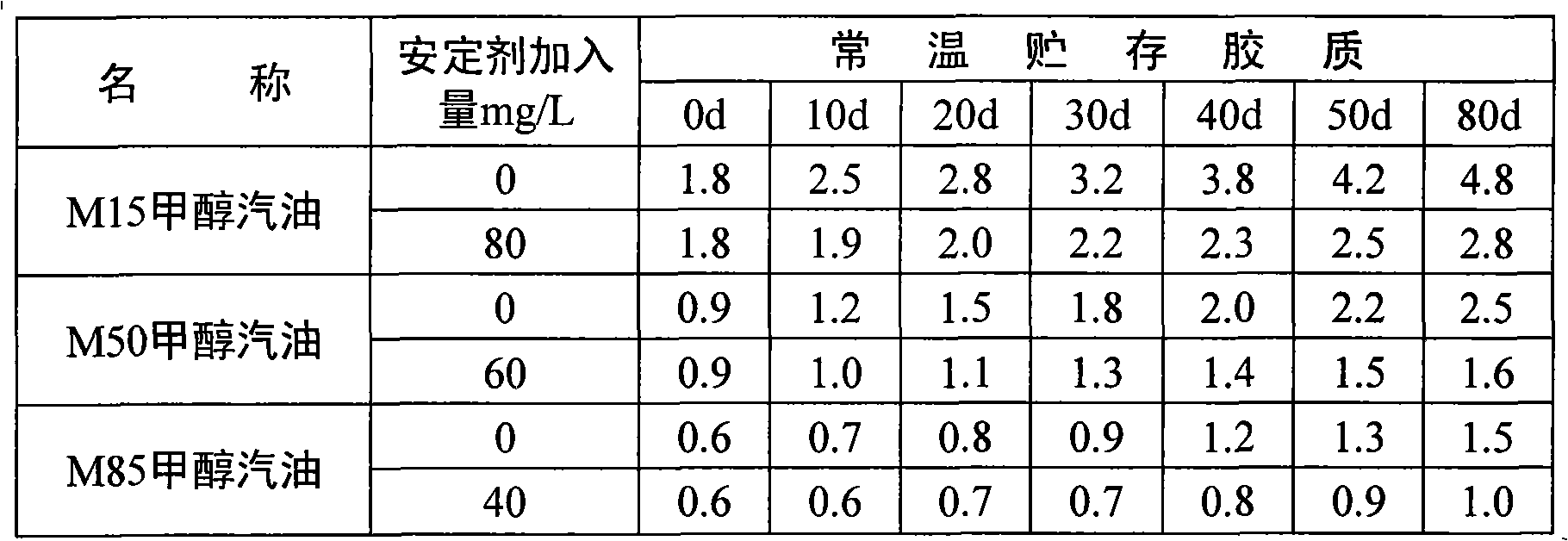

Stabilizer of methyl gasoline

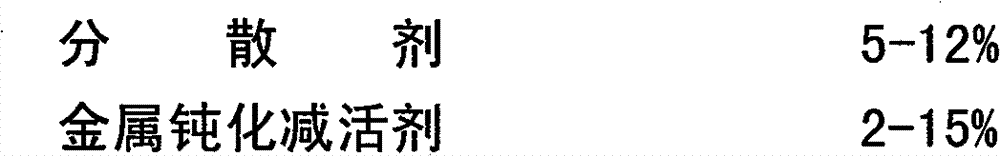

The invention relates to the field of additives of alcohol ether substituted fuel for vehicles, in particular to a stabilizer of methyl gasoline. The stabilizer of methyl gasoline is prepared from thefollowing components by weight percent: 40-70 percent of alkylamine, 18-50 percent of screen phenol, 5-12 percent of dispersant and 2-15 percent of metal passivator. The invention overcomes the defect of single component of antioxygen in the prior art, uses amine and phenol to resist oxygen, disperses the sediment particles, passivates and reduces the activity of soluble metal ion in oil according to the characteristics of combination of polarity and non-polarity of the methyl gasoline to restrain completely other than singly the oxidization and catalysis function to oil products. The four components are combined together to interact with each other to play a role of improving the stability of methyl gasoline. Tests prove that the invention has obvious effect on inhibiting the generationof colloid by storing the methyl gasoline at a normal temperature, and a batch test during an induction period shows that the methyl gasoline can reach the national GB17930-1999 standard in case of improving the induction period by 37 percent.

Owner:占小玲

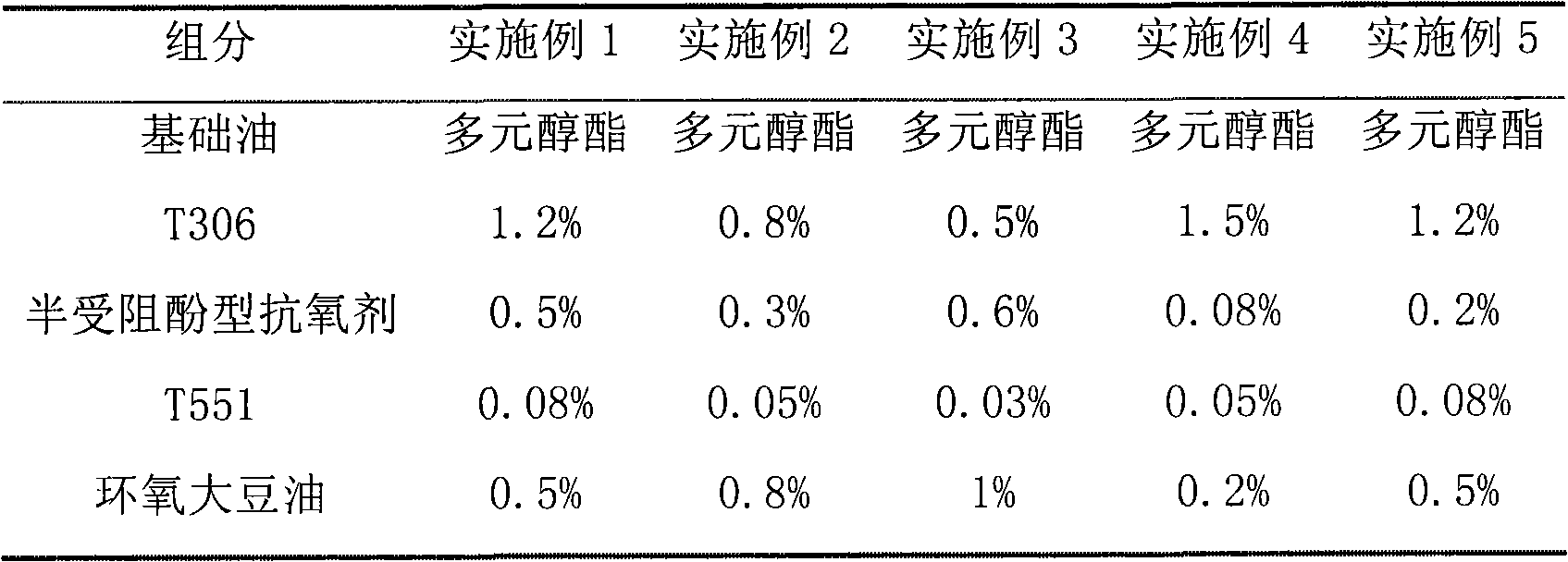

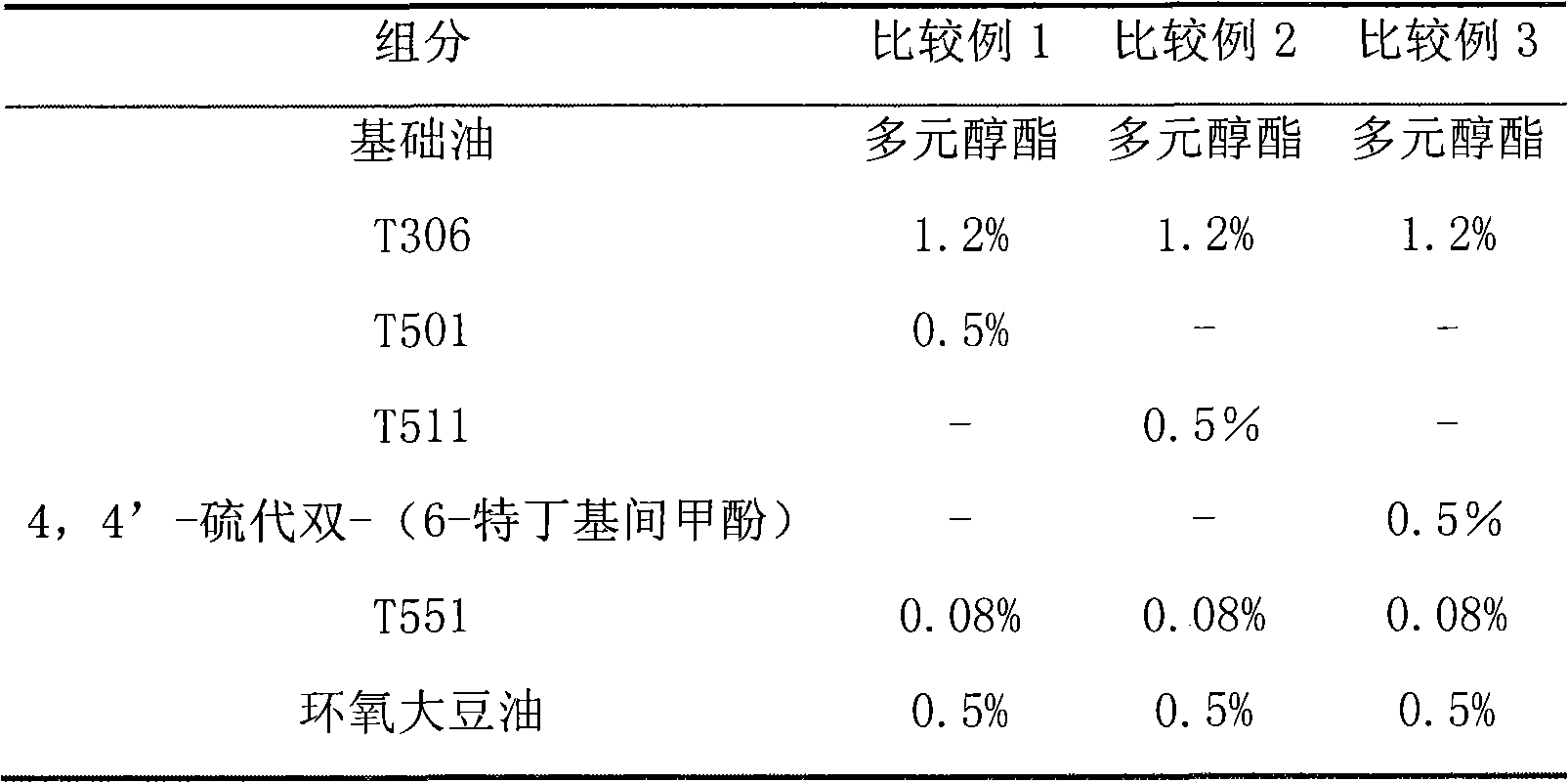

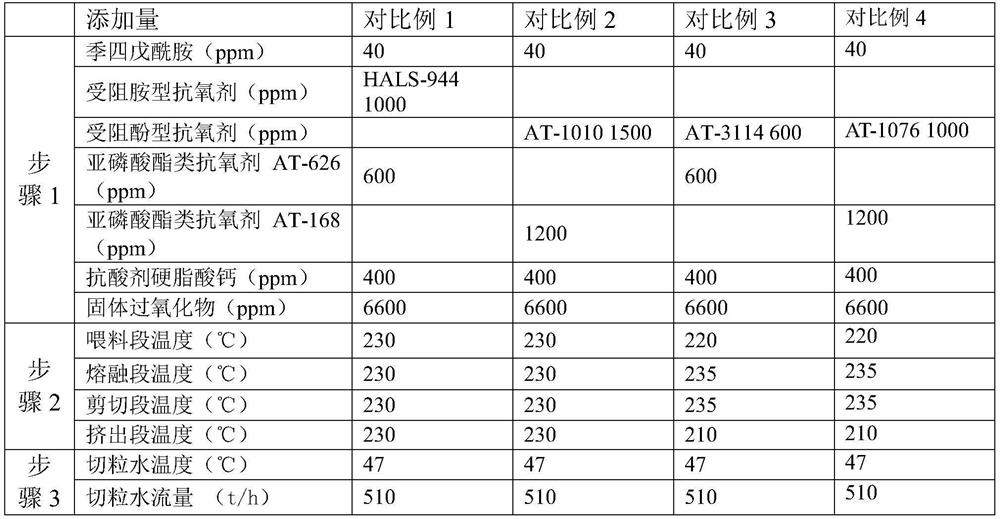

Refrigerating machine oil composition

ActiveCN101851546AImprove Oxidation StabilityProlonged oxidation induction periodAdditivesPentaerythritolOxidation stability

The invention relates to a refrigerating machine oil composition, comprising polyol ester, semi-hindered phenol type antioxidant, antiwear agent, metal deactivator and acid catcher; wherein the polyol ester is ester product of reaction of pentaerythritol with mixture of isononanoic acid and diethyl hexanoic acid. The refrigerating machine oil composition provided by the invention has good oxidation stability, and oxidation induction period thereof is obviously prolonged compared with the refrigerating machine oil utilizing conventional antioxidant.

Owner:CHINA PETROLEUM & CHEM CORP +1

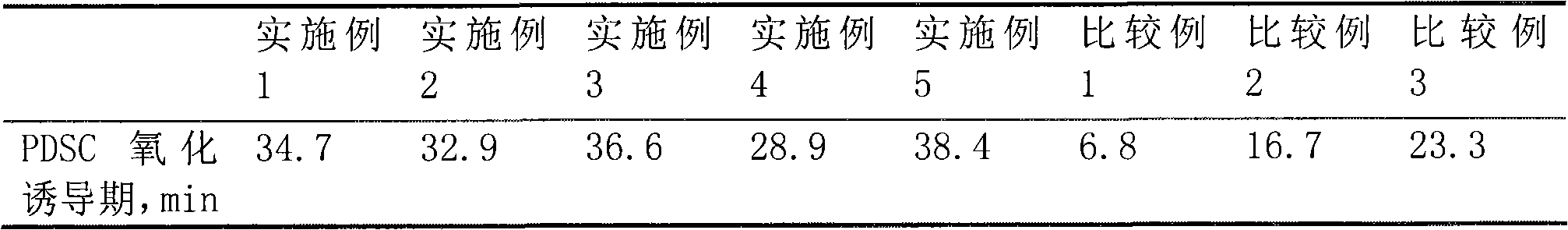

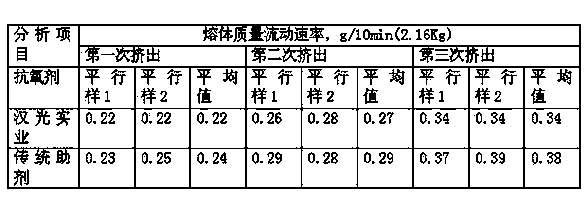

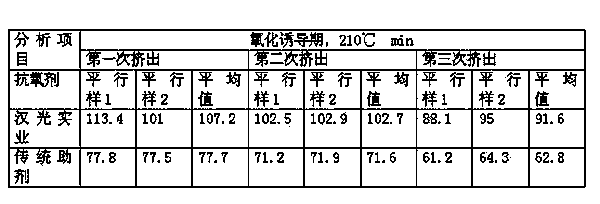

Formula and preparation method of special compound additive for polypropylene film material

InactiveCN104558826AProlonged oxidation induction periodHigh tensile strengthPolymer scienceColor index

The invention relates to a formula of a special compound additive for a polypropylene film material. The formula comprises an antioxidant 626, an antioxidant 1010, a deacidification agent DHT-4A and a nucleating agent HyperformHPN-20E. The preparation method comprises the following steps: mixing and stirring the components, throwing the uniformly mixed and stirred components into a squeezing granulator for granulation, and sieving the obtained granules by using 1-5 layers of sieves, wherein granules with apertures equal to or larger than 4mm are finished products, and the granules with apertures smaller than 4mm are recycled. The formula provided by the invention is low in production cost, can be used for increasing the oxidation induction time of the polypropylene film material to be equal to or more than 35 minutes, reducing the yellow color index, improving the fracture strain and increasing the tensile strength of the film, the transparency and stiffness of the special compound additive for the polypropylene film material are high, no dust pollution is generated, various addition procedures in a polypropylene device in the traditional working manner are replaced by one addition procedure, and the good performance of a single agent can be protected.

Owner:江苏汉光实业股份有限公司

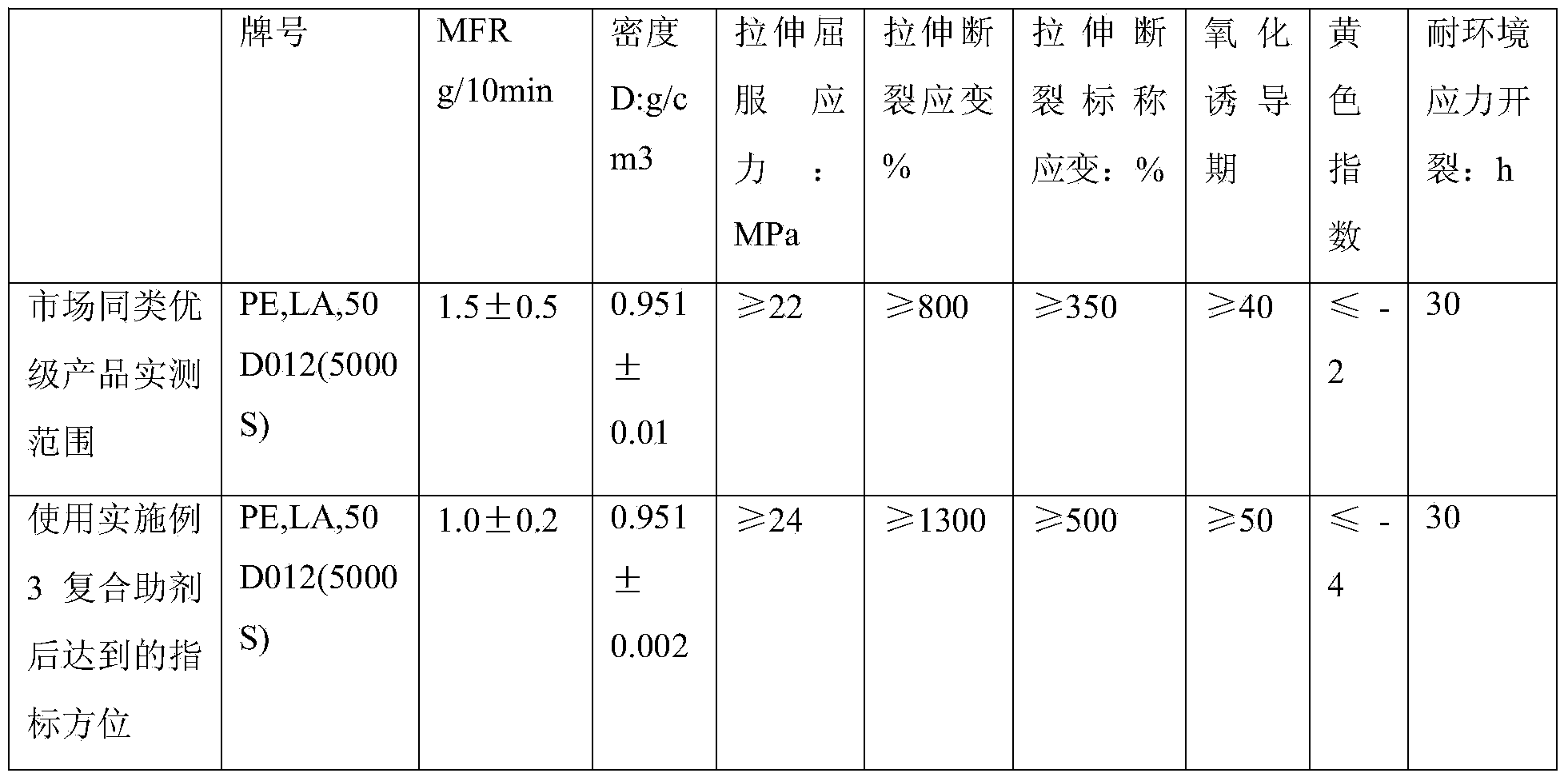

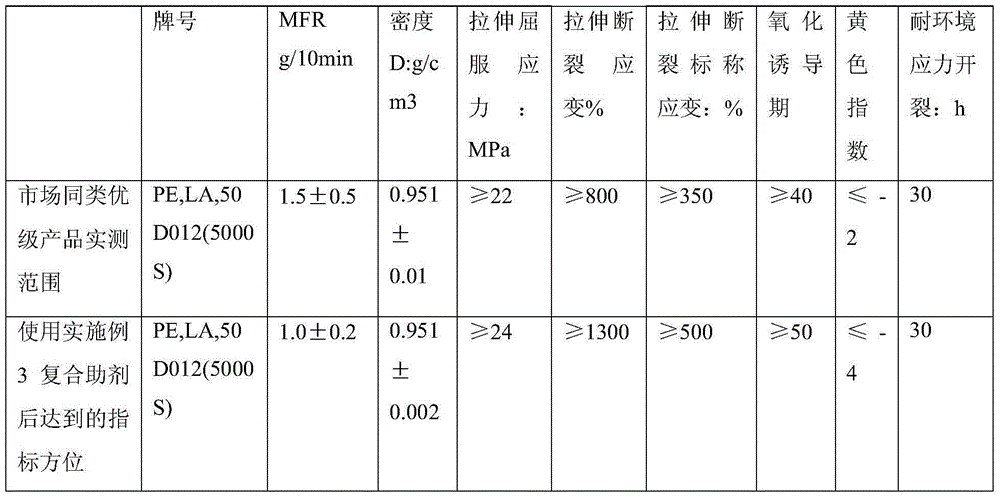

High-density polyethylene compound additive and preparation method thereof

The invention discloses a high-density polyethylene compound additive and a preparation method thereof, and belongs to the field of chemical engineering. The compound additive comprises an antioxidant, a nucleating agent, an acid acceptor and an antistatic agent, wherein the antioxidant comprises an antioxidant 330, an antioxidant 168 and an antioxidant 1076. The preparation method of the compound additive comprises the following steps: mixing the raw components, and uniformly stirring; granulating the uniformly mixed components so as to obtain granules; and sieving the obtained granules. The compound additive has the advantages that the 5000S-oxidation induction time can be prolonged to above 50 minutes through the synergistic effect among the additives, the yellow index is reduced, the fracture strain is improved, and the like.

Owner:江苏汉光实业股份有限公司

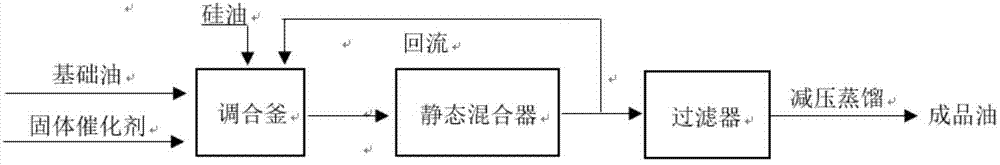

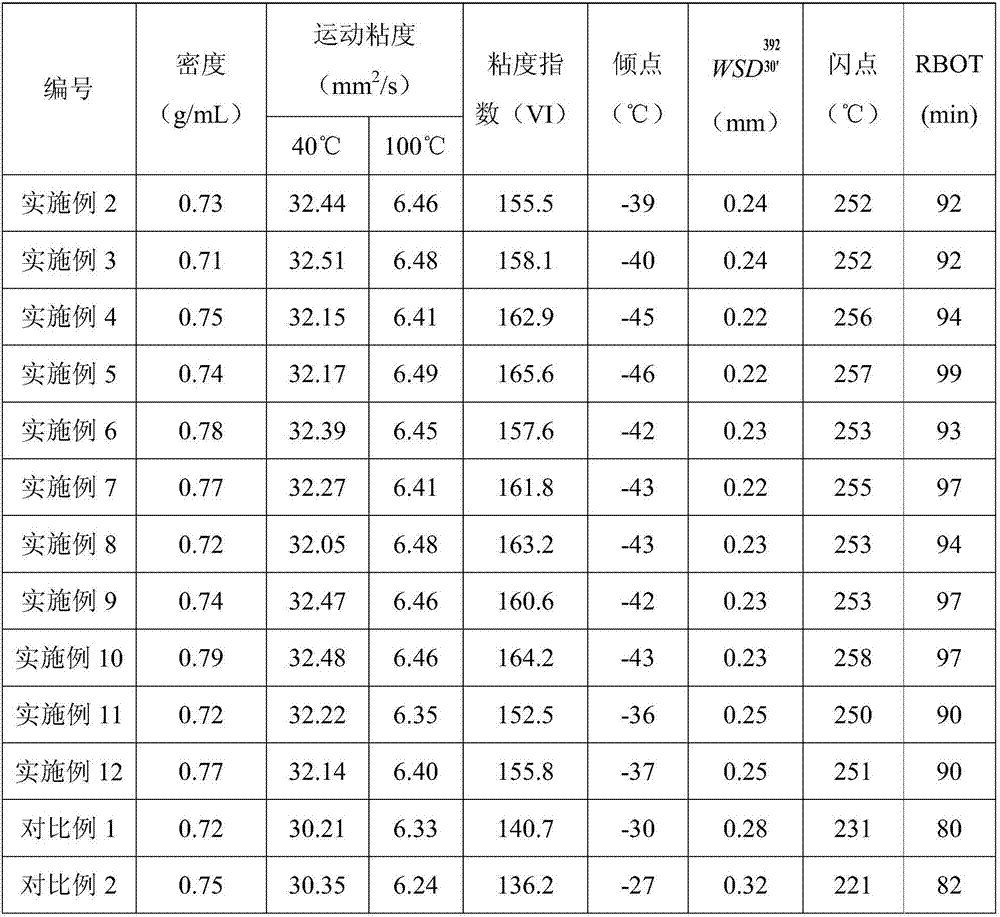

Lubricant base oil and preparation method thereof

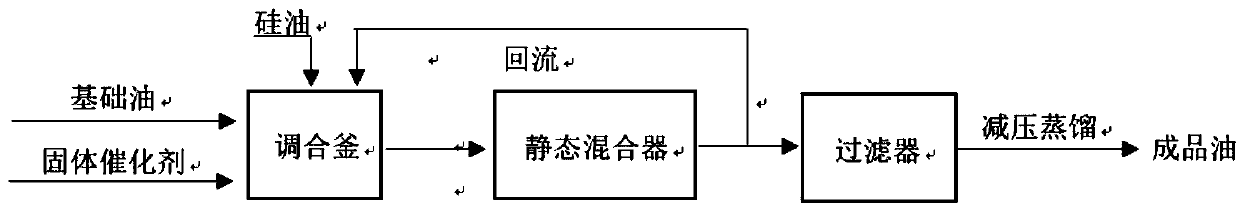

ActiveCN107325121ALow pour pointHigh flash pointGroup 4/14 element organic compoundsCatalyst activation/preparationDistillationReaction temperature

The invention discloses lubricant base oil and a preparation method thereof. The preparation method comprises the following steps: mixing silicone oil with a solid catalyst, stirring and heating to a reaction temperature, adding acetic acid vinyl ester to perform reaction, stopping reaction when an iodine value is smaller than 3.0g / 100g, separating the catalyst out and then performing reduced pressure distillation on obtained liquid to obtain the lubricant base oil. The preparation method of the lubricant base oil disclosed by the invention has simple technology, lower cost, low equipment requirement, no acid wastewater generation in a preparation process and no pollution to environment; the utilized platinum solid catalyst has higher catalyzing performance; the lubricant base oil synthesized by the acetic acid vinyl ester and the silicone oil has low pour point, high flash point, good viscosity-temperature property, good oxidation stability and excellent friction lubricating property.

Owner:JIANGSU ZHONGSHENG GAOKE ENVIRONMENTAL CO LTD

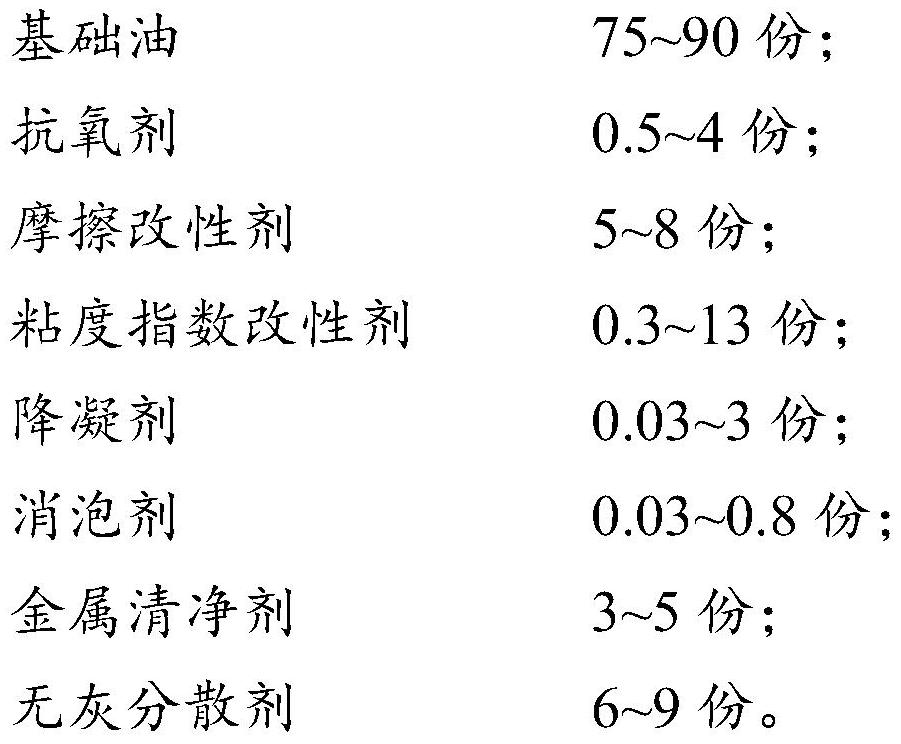

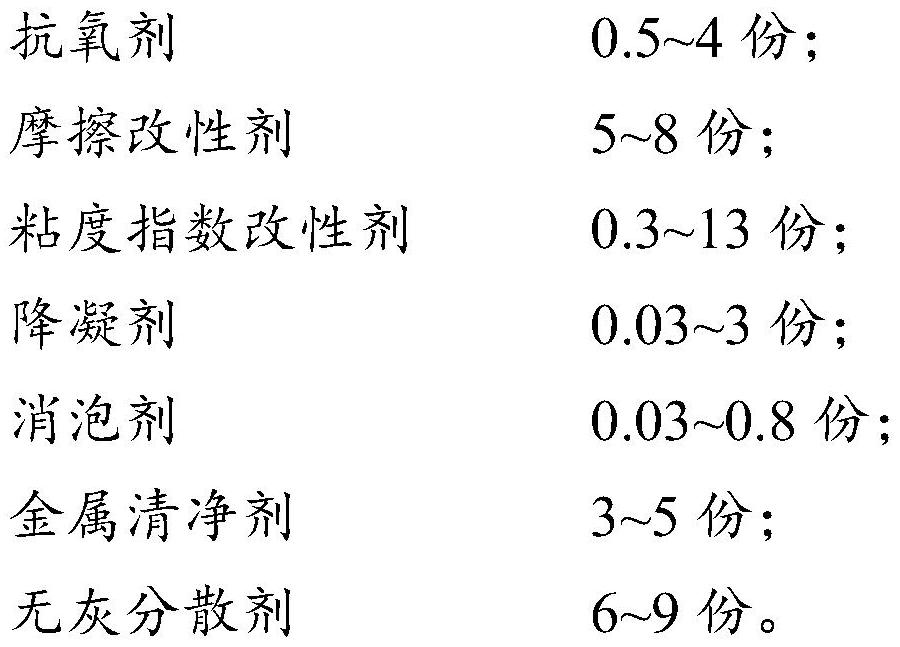

Engine lubricating oil and preparation method thereof

InactiveCN113046159AHigh flash pointIncrease temperatureLubricant compositionProcess engineeringViscosity index

The invention belongs to the technical field of lubricating oil. The invention provides engine lubricating oil. The engine lubricating oil comprises the following components in parts by weight: 75-90 parts of base oil; 0.5-4 parts of an antioxidant; 5-8 parts of a friction modifier; 0.3-13 parts of a viscosity index modifier; 0.03-3 parts of a pour point depressant; 0.03-0.8 part of a defoaming agent; 3-5 parts of a metal detergent; and 6-9 parts of an ashless dispersant. The invention also provides a preparation method of the engine lubricating oil. The lubricating oil disclosed by the invention is high in flash point and initial oxidation temperature, long in oxidation induction period and outstanding in high-temperature resistance and oxidation resistance; the pour point is low and the volatility is small; carbon deposit is not easy to generate at high temperature, and good capability of inhibiting generation of high-temperature sediments is achieved; the friction coefficient and the wear scar diameter are remarkably reduced, and excellent corrosion resistance and rust resistance are achieved; the service life of equipment is prolonged; the noise is low; fuel is saved, emission is reduced, and pollution is small.

Owner:雅士盾(天津)石油科技有限公司

Special plastic composite additive and granulation processing method for PPR pipe

InactiveCN103665545AProlonged oxidation induction periodReduce the use of additivesMetallurgyConveyor belt

The invention discloses a special plastic composite additive and a granulation processing method for a PPR pipe, which relates to the manufacturing of the PPR pipe and the preparation of the composite additive for the PPR pipe. Firstly, according to proportion, the composite additive disclosed by the invention is put into a high-speed mixer in proportion for stirring and mixing for 45-60 seconds; secondly, a mixture is conveyed to a pelletizer via a screw rod feeder to perform pelleting operation, the mixing temperature of the pelletizer is controlled below 25 DEG C, the two-stage temperature is controlled at 55 DEG C, the machine head temperature is controlled at 60 DEG C and the air cooling temperature is controlled at 25 DEG C; lastly, columnar material strips extruded out of the pelletizer are cooled via a conveyor belt air cooling device; after the material is cooled, powdery material is removed via a vibration and screening device, the product is obtained. According to the invention, the oxidation induction period of the PPR pipe can be increased to 100 minutes above, the high and low temperature impact strength and the high-temperature waterproof extraction performance of the PPR pipe are improved, the elastic capacity is enhanced, and the breaking elongation degree is increased.

Owner:江苏汉光实业股份有限公司

Preparation process of lubricating oil with high wear-resistant extreme pressure and wear-resistant antifriction property

The invention relates to a preparation process of lubricating oil with high wear-resistant extreme pressure and wear-resistant antifriction property. The preparation process comprises the following steps: mixing 35%-45% of hydroisomerization dewax type-III base oil with 35%-45% of poly-alpha olefin PAO, stirring at a uniform speed, heating the mixture to 48-58 DEG C within 10 minutes, and thermally insulating for 20 minutes, so as to obtain base oil; preparing a tungsten disulfide particle additive, adding the tungsten disulfide particle additive into the base oil, and stirring at a uniform speed for 15 minutes, wherein tungsten disulfide particles account for 1.5%-2.5% of the total components; preparing a nitrogen-containing boric acid ester additive, and stirring at a uniform speed for 15 minutes; adding a viscosity index improver, thermally insulating, stirring until the kinematic viscosity and the pour point meet standards, and continuing to thermally insulate; adding 2%-3% of a clean dispersing agent; adding 1.5%-2% of an oxidation and corrosion inhibitor; adding 0.3%-0.7% of a pour point depressant; adding 0.01% of an antifoaming agent; and continuing to stir at a uniform speed, heating to 62-66 DEG C within 10 minutes, and thermally insulate for 30 minutes, so as to obtain a finished product.

Owner:昆山中润信息科技有限公司

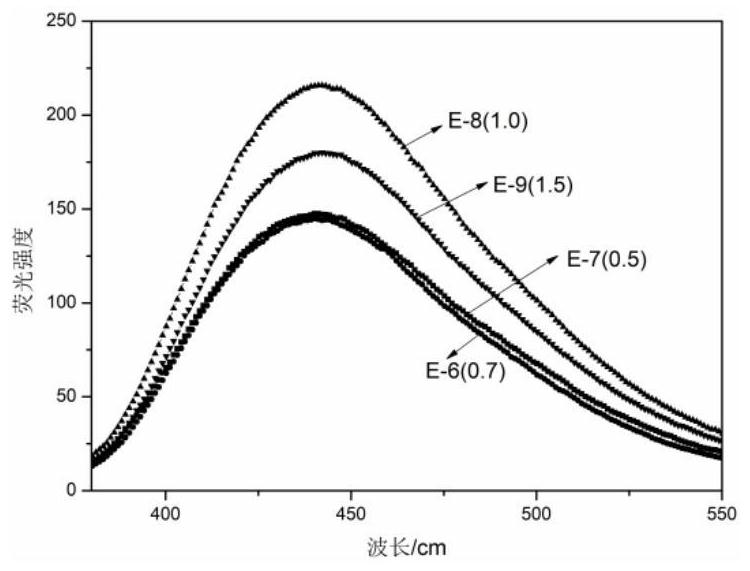

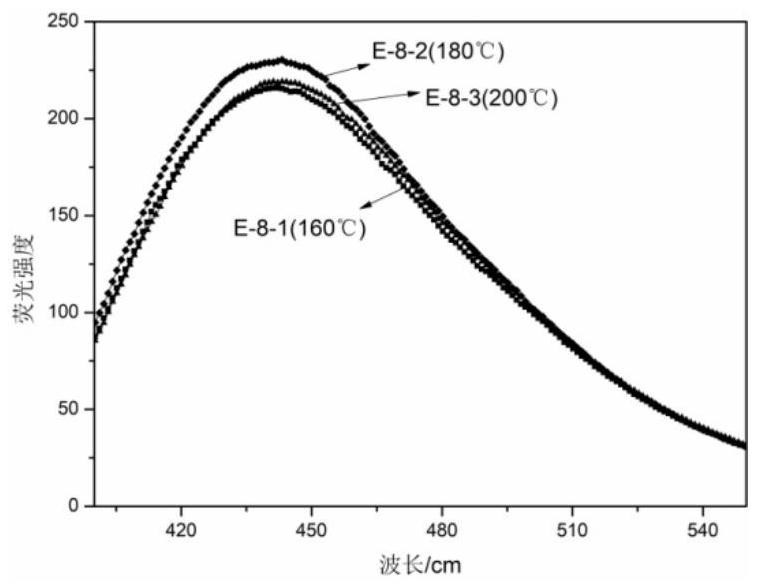

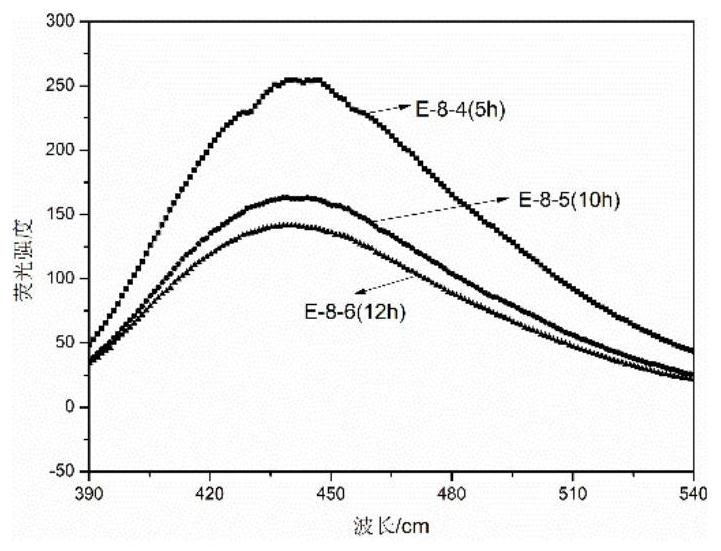

Modified lignin carbon dot and preparation method and application thereof

The invention provides a modified lignin carbon dot and a preparation method and application thereof, and relates to the technical field of nano materials. According to the preparation method of the modified lignin carbon dot, a lignin-based carbon source, water and a silane coupling agent are subjected to a hydrothermal reaction, and the modified lignin carbon dot is obtained; or hydrothermal reaction is performed on the lignin-based carbon source and water to obtain the lignin carbon dot, and hydrothermal reaction is performed on the lignin carbon dot, water and a silane coupling agent to obtain the modified lignin carbon dot. The silane coupling agent is utilized to modify the lignin carbon dot so that the dispersity of the lignin carbon dot is improved, the lignin carbon dot has multifunctionality, the high temperature resistance, oxidation resistance and scratch resistance of the composite material can be improved, and the friction coefficient of the composite material is reduced. Results of the embodiment show that when the modified lignin carbon dot is added into polypropylene, the degradation temperature of the composite material is increased by 20 DEG C, the oxidation induction period is 4.65 min, the friction coefficient is reduced to 0.164, and the scratch resistance is good.

Owner:HUNAN UNIV OF TECH

A processing method of oxidation-resisting sesame oil

InactiveCN107779256ASolves bitter tasteImprove qualityFatty-oils/fats refiningFatty-oils/fats productionVitamin CFiltration

A processing method of oxidation-resisting sesame oil is disclosed. The method includes a step of soaking sesame in an enzyme solution, washing and peeling the sesame, drying the sesame and then performing microwave treatment to obtain pretreated sesame; a step of adding the pretreated sesame into a hydraulic oil press, and squeezing the sesame to obtain crude oil; a step of air drying honeysucklebud and flower, pomegranate rind, eucommia bark, Chinese star anise and fruits of pyracantha fortuneana, then crushing the honeysuckle bud and flower, the pomegranate rind, the eucommia bark, the Chinese star anise and the fruits of pyracantha fortuneana, adding ethanol into the crushed material, and performing ultrasonic extraction, filtration, concentration, drying and elution to obtain a plantextract product; a step of adding the plant extract product, loach polysaccharides, apple polyphenol, lotus oligomeric proanthocyanidins, oryzanol, phytic acid and vitamin C into the crude oil, fullystirring the mixture, decolorizing the mixture, allowing the mixture to stand, and filtering the mixture to obtain decolorized sesame oil; and a step of cooling the decolorized sesame oil to 0-7 DEGC, adding diatomite into the sesame oil, fully stirring the mixture, allowing the mixture to stand, and filtering the mixture. The method is simple in process, prone to industrial application and highin oil yield. The obtained sesame oil is light in color, high in transparency, good in oxidation resistance and long in shelf life.

Owner:BENGBU QIONGHUAI GRAIN & OIL

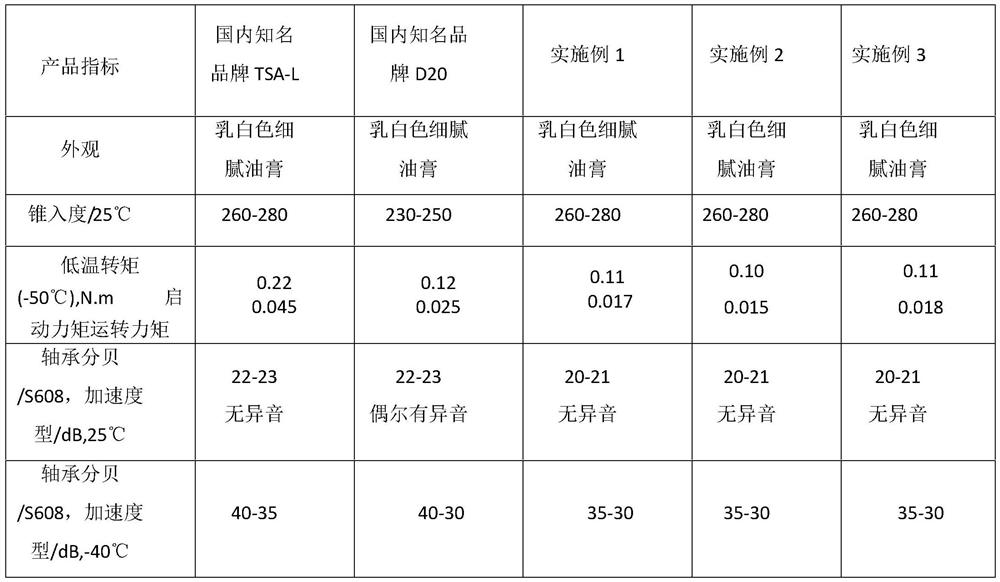

Ultralow-temperature mute bearing grease and preparation process thereof

ActiveCN111704951AMeet the need for low noiseLow starting/running torqueLubricant compositionMetallurgyLithium hydroxide

The invention discloses ultralow-temperature mute bearing grease, which is prepared from the following raw materials in parts by weight: 50 to 75 parts of PAO4 and PAO6 mixed oil, 7 to 12 parts of dodecahydroxyl stearic acid, 1.2 to 1.8 parts of lithium hydroxide, 5 to 15 parts of synthetic ester, 1 to 5 parts of an dditive and 1 to 10 parts of nanoscale PTFE powder. According to the invention, low-temperature starting of the bearing and normal-temperature bearing noise can reach a very high level, and the low-temperature starting of the bearing mainly reflects the starting condition and noisecondition of the bearing at a low temperature, such as -50 DEG C. The ester oil with low condensation point and high viscosity index and a nanoscale solid lubricant are added to improve the thickenerdistribution of the grease, enhance the oil film strength of the grease and lower the internal friction coefficient of the grease, thereby stabilizing the normal-temperature noise of the bearing andimproving the low-temperature start.

Owner:金鹰润滑材料(金湖)有限公司

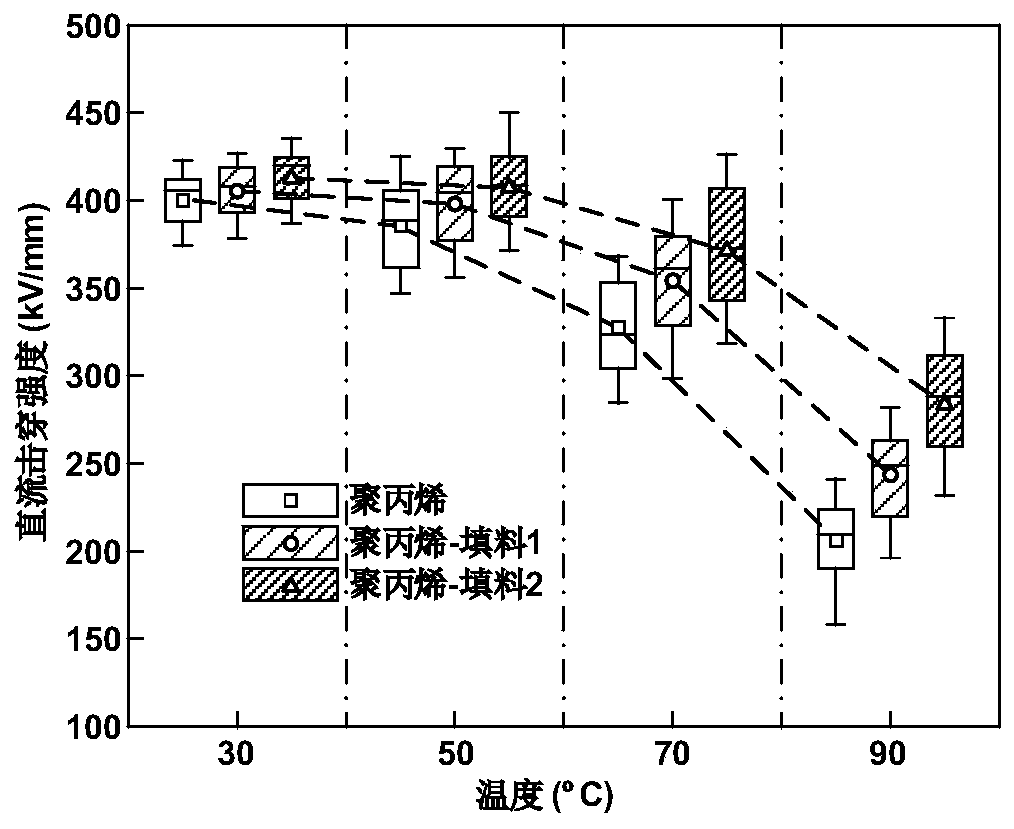

Polypropylene cable insulating material as well as preparation method and application thereof

InactiveCN111471236AExtended service lifeHigh breakdown strengthPlastic/resin/waxes insulatorsThio-High-voltage direct current

The invention discloses a polypropylene cable insulating material as well as a preparation method and application thereof. The polypropylene cable insulating material is prepared from, taking the massamount of the polypropylene cable insulating material as 100%, 99.5 to 99.9% of a polypropylene matrix and 0.1 to 0.5% of thio bisphenol compound filler. Wherein the thio bisphenol compound comprisesa hindered phenol unit and a sulfur-containing unit, the hindered phenol unit can capture free radicals generated in a matrix through proton transfer, and the sulfur-containing unit can efficiently decompose a hydroperoxide into a harmless product. The polypropylene cable insulating material with high thermal oxidation stability prepared by the invention has the characteristics of long oxidationinduction period, high direct-current breakdown strength, difficulty in accumulation of space charges and the like, and is suitable for high-voltage direct-current cables.

Owner:TIANJIN UNIV

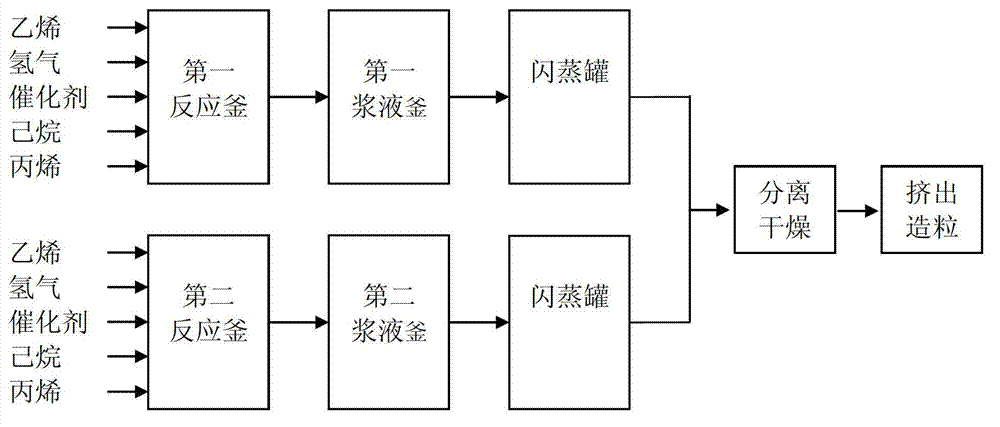

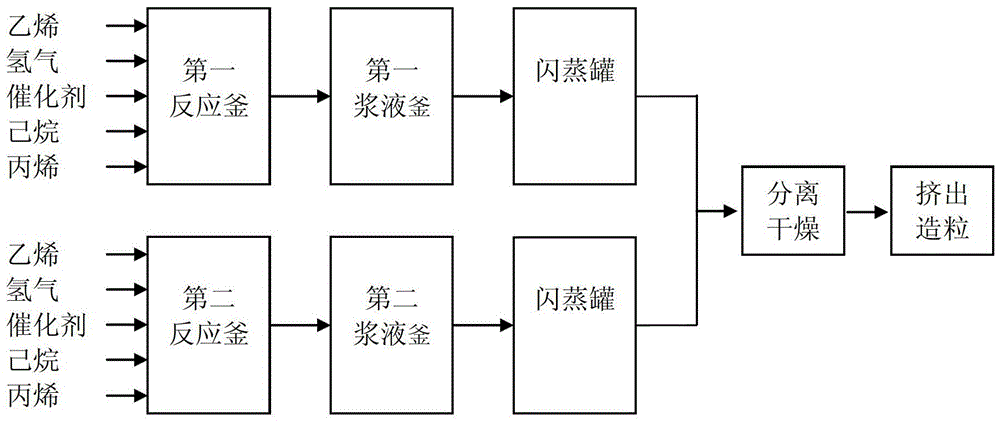

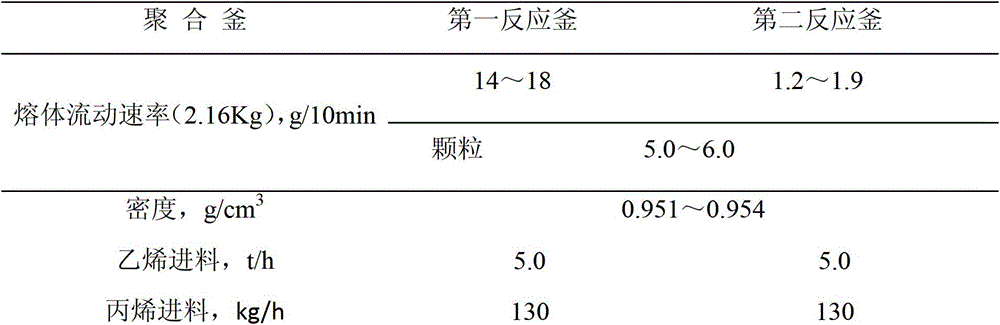

Injection molding grade high density polyethylene and preparation method thereof

ActiveCN103319639AGood molding effectEasy to processBulk chemical productionPolymer scienceHigh surface

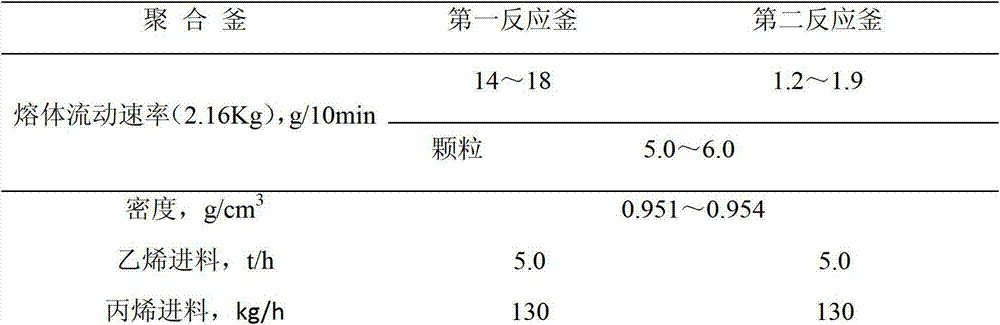

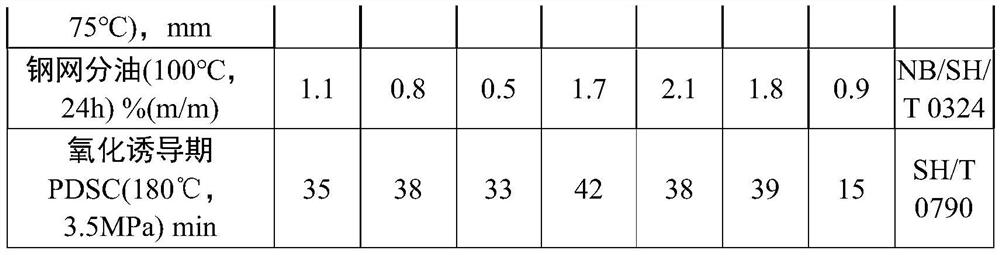

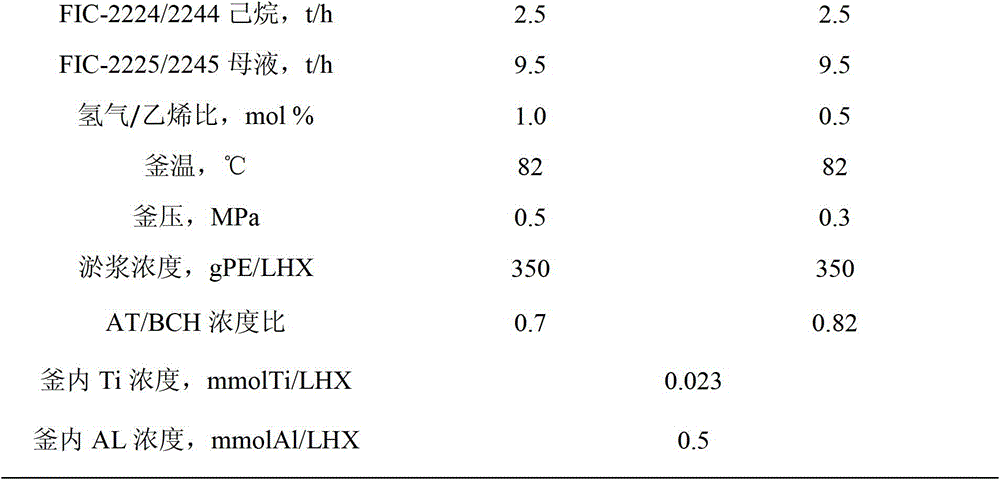

The invention discloses a preparation method for an injection molding grade high density polyethylene, and belongs to the field of special material preparation method of high density polyethylene. Reaction conditions are as following: using a Mitsui Chemicals high density polyethylene process unit, taking titanium trichloride and aluminum alkyl as catalysts, ethylene as a raw material, propylene as a comonomer, and hexane as a diluent; performing polymerization reaction in a polymerizing pot, at a temperature of 78 to 86 DEG C and under a pressure of 0.20 to 0.80 MPa; and ethylene flow quantity is 2 to 5 t / h, mole ratio of hydrogen / ethylene is 1.0 to 3.0m, and propylene flow quantity is 20 to 120 kg / h. The injection molding grade high density polyethylene of the invention possesses higher flow rate, small injection pressure, high rigidity, high surface glossiness, and long oxidation induction time. Processing and modeling are easy, distortion is difficult to happen, injection modeling is complete, weld-line strength is high, and defective index is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

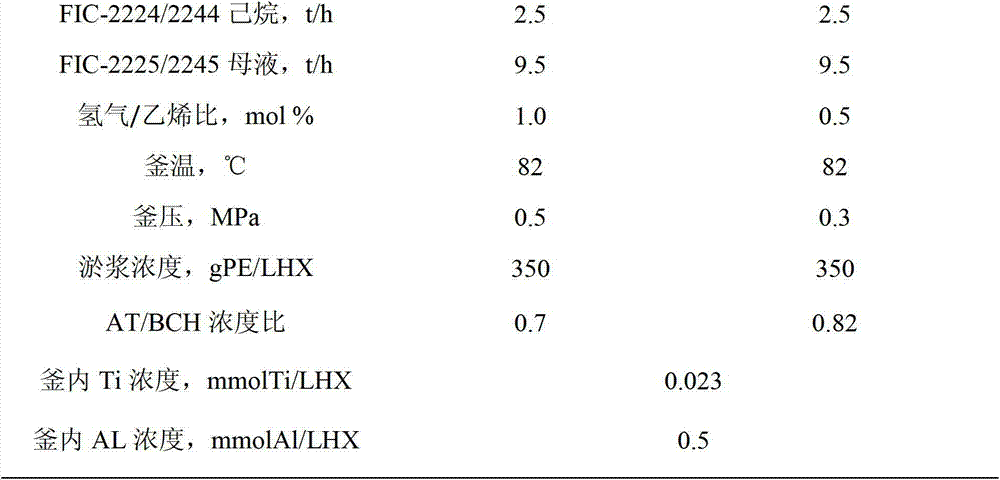

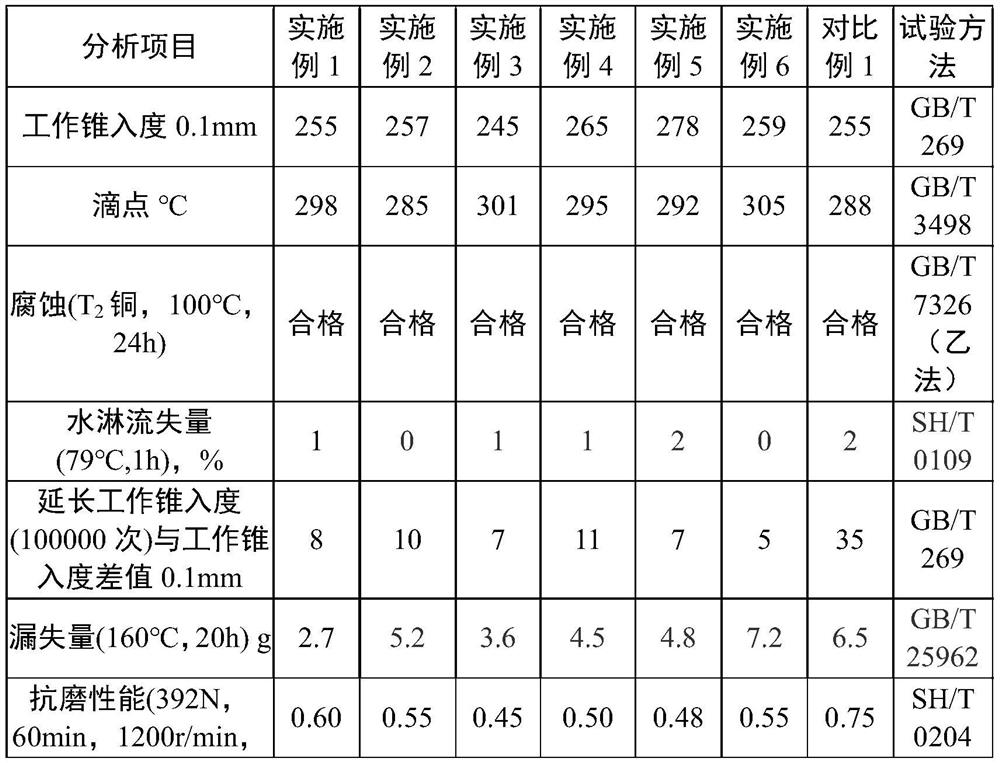

Composite soap-based lubricating grease composition and preparation method thereof

ActiveCN112522006AImprove water resistanceImprove high temperature performanceLubricant compositionLithium oxideLithium hydroxide

The invention provides a composite soap-based lubricating grease composition. The composition comprises base oil. The composition comprises the following components in parts by weight: 5-25 parts of athickening agent and 75 to 95 parts of the base oil, wherein the thickening agent is prepared by saponifying raw materials including 12-hydroxystearic acid, C6-C16 binary acid, lithium hydroxide anddivalent metal hydroxide, and a mass ratio of the lithium hydroxide to the divalent metal hydroxide is 1: 10 to 10: 1. The prepared lubricating grease has good water resistance, high temperature resistance, wear resistance and long oxidation induction period; in particular, the service life of the lubricating grease is 2-3 times the service life of common composite metal soap-based lubricating grease; and a low-temperature compounding process is adopted, so the lubricating grease has a high dropping point, greatly reduces working hours and energy consumption and has wide popularization value.

Owner:CHINA PETROLEUM & CHEM CORP

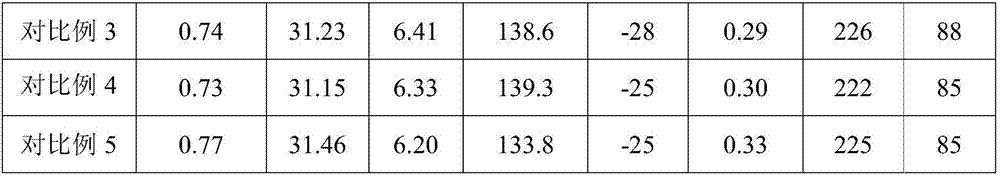

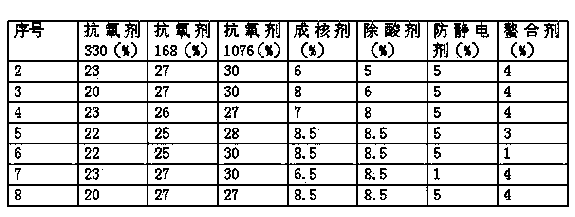

A kind of high-density polyethylene composite auxiliary agent and preparation method thereof

The invention discloses a high-density polyethylene compound additive and a preparation method thereof, and belongs to the field of chemical engineering. The compound additive comprises an antioxidant, a nucleating agent, an acid acceptor and an antistatic agent, wherein the antioxidant comprises an antioxidant 330, an antioxidant 168 and an antioxidant 1076. The preparation method of the compound additive comprises the following steps: mixing the raw components, and uniformly stirring; granulating the uniformly mixed components so as to obtain granules; and sieving the obtained granules. The compound additive has the advantages that the 5000S-oxidation induction time can be prolonged to above 50 minutes through the synergistic effect among the additives, the yellow index is reduced, the fracture strain is improved, and the like.

Owner:江苏汉光实业股份有限公司

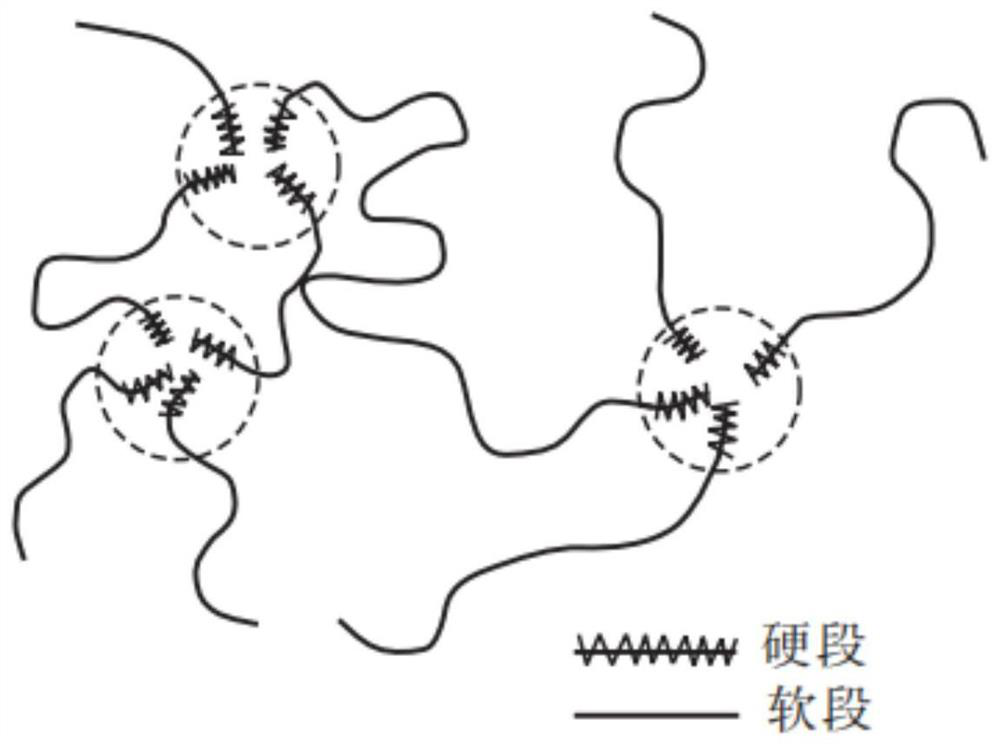

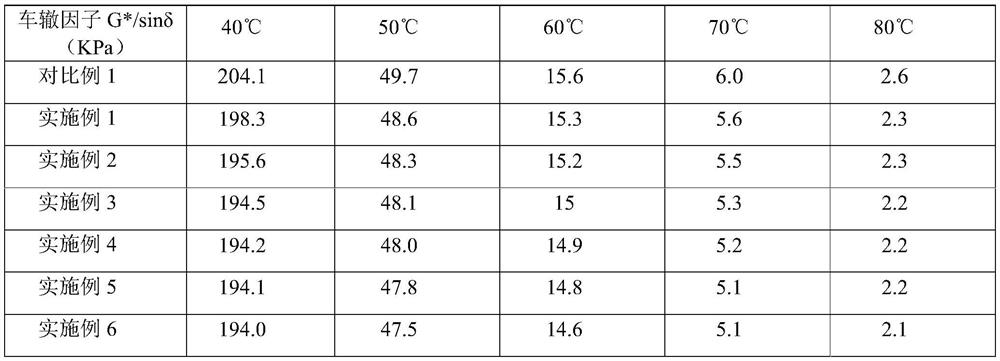

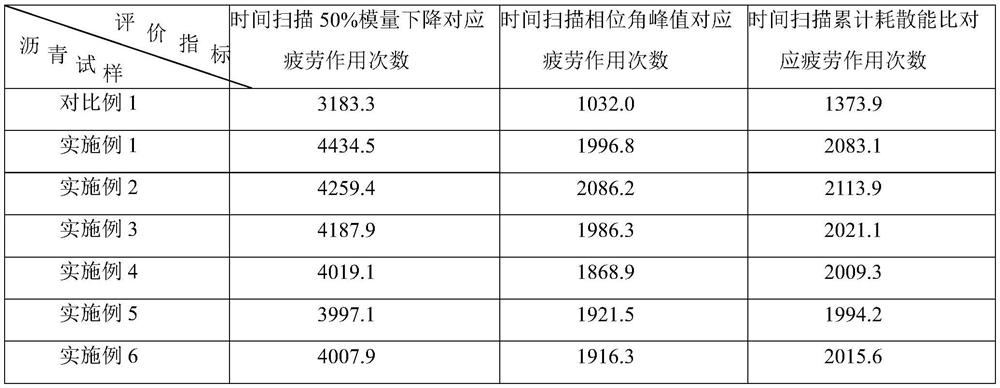

Oil-filled SBS as well as preparation method and application thereof

The invention discloses oil-filled SBS as well as a preparation method and application thereof. The oil-filled SBS comprises the following components in parts by weight: 36-41 parts of a styrene-butadiene-styrene block copolymer, 2-4 parts of zinc oxide, 1-3 parts of stearic acid, 2-4 parts of an antioxidant, 2-4 parts of tackifying resin, 2-4 parts of an accelerant, 1-2 parts of sulfur, 5-9 parts of carbon black and 35-45 parts of environment-friendly aromatic oil. The oil-filled SBS modified asphalt can be prepared by adding the prepared oil-filled SBS into matrix asphalt, the anti-fatigue performance of an existing cementing material in each temperature interval is effectively improved on the premise of ensuring the mechanical properties of the original asphalt cementing material, and the used raw materials are more environment-friendly compared with other oil-filled asphalt cementing materials; and the oil-filled SBS actively responds to the concept of environment-friendly pavements, and has industrial utilization value.

Owner:SOUTHWEST JIAOTONG UNIV

A kind of lubricating oil base oil and preparation method thereof

ActiveCN107325121BImprove catalytic performanceNo pollution in the processGroup 4/14 element organic compoundsCatalyst activation/preparationPtru catalystDistillation

Owner:JIANGSU ZHONGSHENG GAOKE ENVIRONMENTAL CO LTD

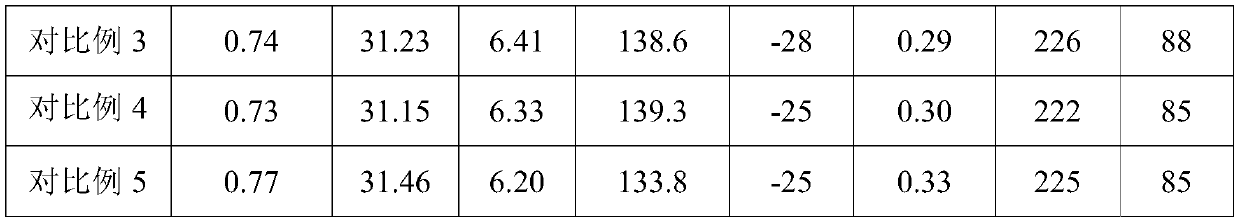

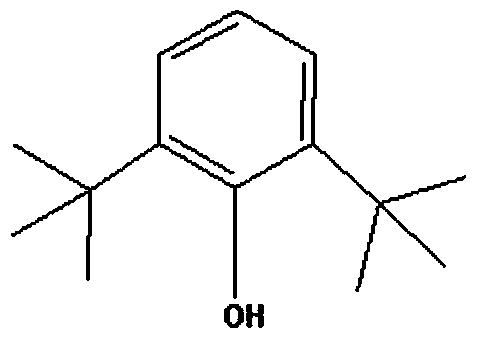

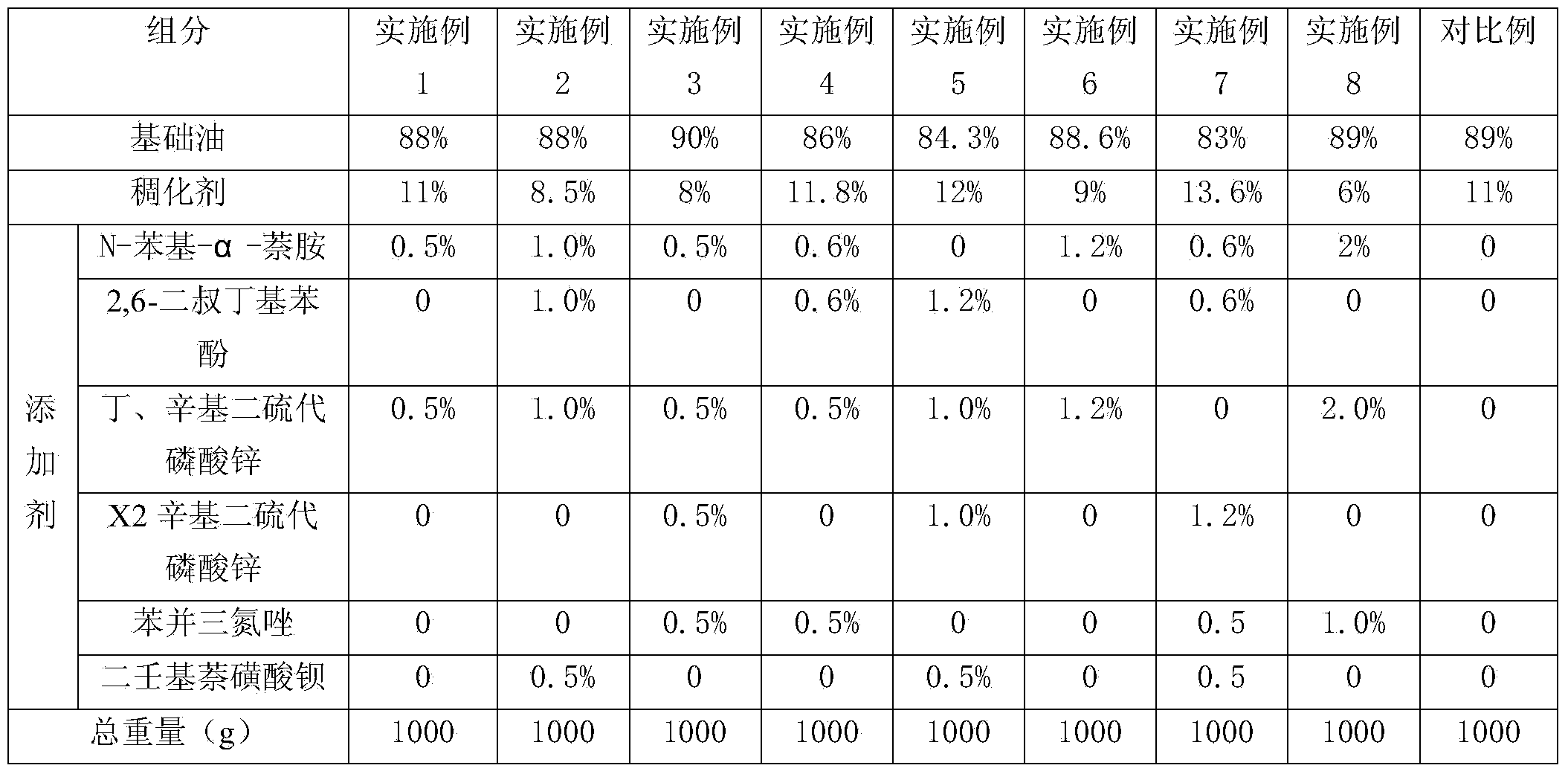

Lubricating grease for blast-furnace gun and preparation method thereof

The invention relates to lubricating grease for a blast-furnace gun and a preparation method thereof. The lubricating grease is prepared from the following components in percentage by weight: 6-13.6% of densifier, 83-90% of base oil and 1-5% of additives, wherein the kinematic viscosity of the base oil at 40 DEG C is 120-200mm<2> / s, and the viscosity index of the base oil is not less than 92 and the condensation point of the base oil is not higher than minus 10 DEG C; the additives comprise (a) 0.5-2% of antioxidant, (b) 0.5-2% of antiwear agent and (c) 0-1% of antirust agent. The lubricating grease produced by the method has a good high-temperature dropping point, long oxidation induction time, low long wear value under a certain load and good anti-corrosion performance in the presence of moisture. The wear scar diameter of the lubricating grease verified by an SH / T0204 method is not greater than 0.5mm. The oxidation induction time of the lubricating grease tested by SH / T0790 is greater than 13 minutes at 210 DEG C. The comprehensive problems that the lubricating grease simultaneously satisfies high temperature resistance, long service life, wear resistance, rust prevention, centralized pumping and the like are solved.

Owner:CHINA PETROLEUM & CHEM CORP

Compressor oil composition

ActiveCN101397521BHigh viscosity indexImprove the lubrication effectAdditivesBase-materialsPhenolic antioxidantViscosity index

The invention provides a compressor oil compound which comprises the following materials on the basis that the weight of base oil is 100 percent: (1) a main amount of hydrogenization mineral oil base oil; (2) 1 to 15 weight percent of ashless dispersant; (3) 0.01 to 1 weight percent of the combination of half-hindered phenolic antioxidant or amine antioxidant and half-hindered phenolic antioxidant; (4) 0.05 to 2 weight percent of antiwear additive; (5) 0.01 to 0.5 weight percent of friction modifier; (6) 0.01 to 0.2 weight percent of metal passivator; and (7) 0 to 1000ppm of antifoamer. The compressor oil has the advantages of high viscosity index, excellent lubricating property and good oxidative stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

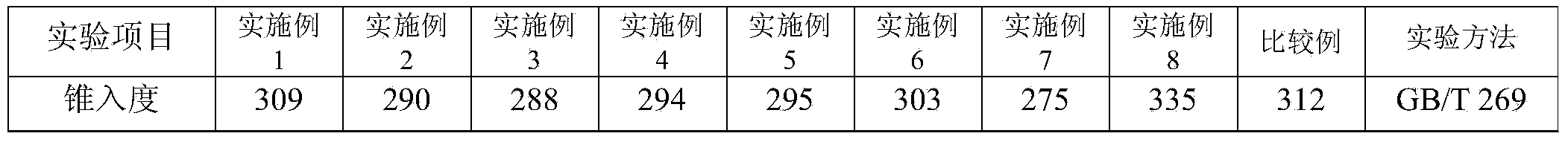

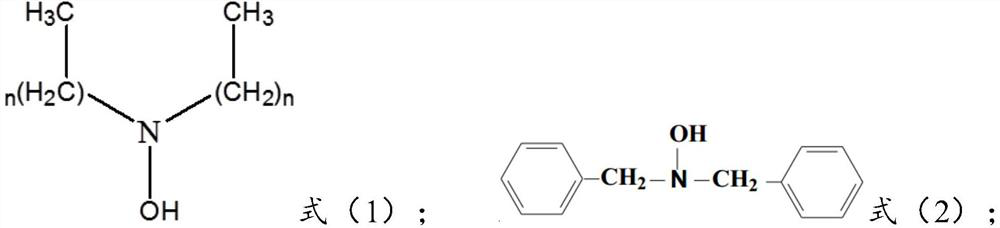

Anti-aging composition and BOPP film

ActiveCN112194824ALower dynamic/static coefficient of frictionProlonged oxidation induction periodPhosphoric Acid EstersPolymer science

The invention provides an anti-aging composition and a BOPP film. The anti-aging composition provided by the invention is prepared from the following components: an amine synergist, a hindered phenolantioxidant, a phosphite antioxidant, an acid acceptor and a processing aid, wherein the amine synergist is a compound shown as a formula (1) and / or a compound shown as a formula (2). The specific amine synergist shown as the formula (1) and / or the formula (2) is matched with the hindered phenol antioxidant, the phosphite antioxidant and the acid acceptor for combined action, and the processing aid is supplemented, so the problem that the end face of the BOPP film becomes red can be solved, the friction coefficient of the film can be reduced, antioxidant effect is improved, and a low ash content is kept.

Owner:SHANDONG LINYI SUNNY WEALTH CHEM CO LTD

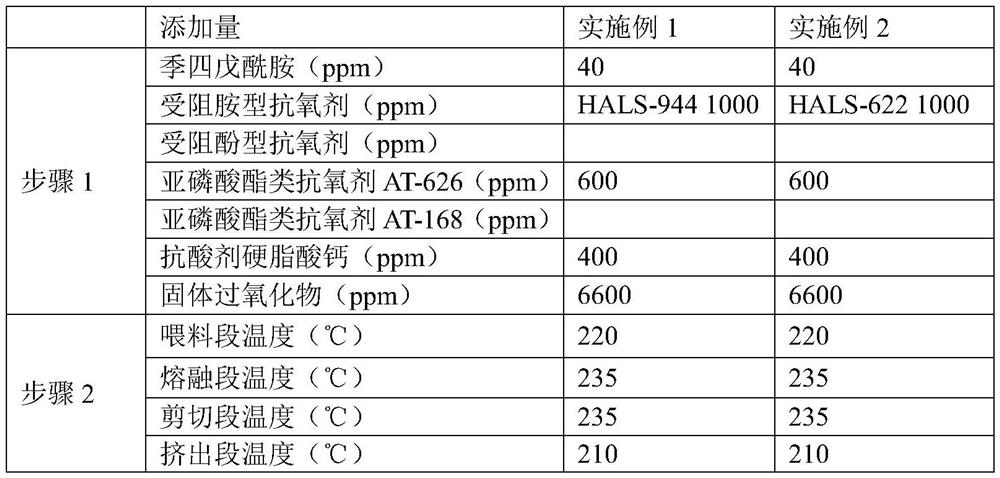

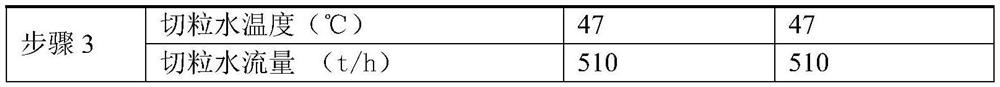

Special material for irradiation-resistant sterilizing polypropylene spun-bonded non-woven fabric and preparation method of special material

ActiveCN113388203AAvoid direct contactSmall mechanical propertiesMonocomponent polyolefin artificial filamentArtifical filament manufactureElastomerPolymer science

The invention belongs to the technical field of synthetic resin production, and particularly relates to a special material for an irradiation-resistant sterilizing polypropylene spun-bonded non-woven fabric and a preparation method of the special material. The preparation method specifically comprises the following steps: (1) on-line mixing of basic polypropylene powder, peroxide and additives; (2) controllable rheological reaction in a barrel of an extruder; (3) extrusion pelletizing and centrifugal drying; and (4) air conveying, product homogenization, packaging and delivery. According to the invention, a one-time hot working process is utilized, direct contact with oxygen in the processes of mixing and preparation is avoided, reduction in mechanical performance and optical performance caused by the hot working process is reduced, additional addition of an elastomer for toughening is not needed, and production cost is low. The produced special material provided by the invention can provide protection for polymer degradation induced by high-energy rays, and is long in oxidation induction period and not prone to discoloring.

Owner:CHINA PETROLEUM & CHEM CORP +1

Refrigerating machine oil composition

ActiveCN101851546BImprove Oxidation StabilityProlonged oxidation induction periodAdditivesPentaerythritolOxidation stability

The invention relates to a refrigerating machine oil composition, comprising polyol ester, semi-hindered phenol type antioxidant, antiwear agent, metal deactivator and acid catcher; wherein the polyol ester is ester product of reaction of pentaerythritol with mixture of isononanoic acid and diethyl hexanoic acid. The refrigerating machine oil composition provided by the invention has good oxidation stability, and oxidation induction period thereof is obviously prolonged compared with the refrigerating machine oil utilizing conventional antioxidant.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coloring masterbatch for cold hot water plastic pipe fittings

InactiveCN110724338AProlonged oxidation induction periodIncrease concentrationLinear low-density polyethyleneMasterbatch

The invention discloses a novel coloring masterbatch for cold hot water plastic pipe fittings, and belongs to the technical field of plastic additives. The coloring masterbatch for the cold hot waterplastic pipe fittings is characterized by including the following raw materials in percentages by weight: 25-55% of linear low-density polyethylene, 0-30% of linear polyethylene, 0-50% of carbon black, 0.5-2.5% of an antioxidant, 0.5-2% of a functional auxiliary agent, 0-36% of titanium dioxide, 0-8% of phthalocyanine blue, 0-4% of zinc iron yellow, and 0-0.001% of permanent violet. The coloring masterbatch provided by the invention is used for coloring of PP pipes and PPR pipes, and the prepared pipe fittings have the advantages of a long oxidation induction period and good weather resistance, and can meet the requirements of new standards, thereby promoting the sustainable development of the industry.

Owner:成都菲斯特新材料有限公司

A kind of manufacturing method of injection molding grade high-density polyethylene

ActiveCN103319639BHigh measured performanceHigh surface glossBulk chemical productionPolymer scienceHigh surface

Owner:CHINA PETROLEUM & CHEM CORP +1

Stabilizer of methyl gasoline

The invention relates to the field of additives of alcohol ether substituted fuel for vehicles, in particular to a stabilizer of methyl gasoline. The stabilizer of methyl gasoline is prepared from the following components by weight percent: 40-70 percent of alkylamine, 18-50 percent of screen phenol, 5-12 percent of dispersant and 2-15 percent of metal passivator. The invention overcomes the defect of single component of antioxygen in the prior art, uses amine and phenol to resist oxygen, disperses the sediment particles, passivates and reduces the activity of soluble metal ion in oil according to the characteristics of combination of polarity and non-polarity of the methyl gasoline to restrain completely other than singly the oxidization and catalysis function to oil products. The four components are combined together to interact with each other to play a role of improving the stability of methyl gasoline. Tests prove that the invention has obvious effect on inhibiting the generationof colloid by storing the methyl gasoline at a normal temperature, and a batch test during an induction period shows that the methyl gasoline can reach the national GB17930-1999 standard in case of improving the induction period by 37 percent.

Owner:占小玲

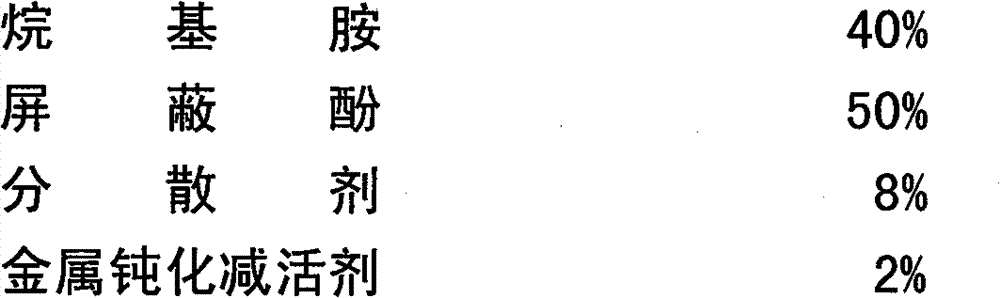

Additive composition for improving performance of lubricant, and preparation method and application method thereof

InactiveCN107779237AHas a cleansing and dispersing effectImprove anti-friction and anti-wear effectAdditivesFriction reductionHigh pressure oxygen

The invention relates to an additive composition for improving the performance of lubricant, and a preparation method and application method thereof. The preparation method comprises the following steps: performing hydroxylation reaction for C60 fullerene to obtain C60(OH)8-15 or C60(OH)24-26, then catalytically esterifying the hydroxyl by virtue of short chain carboxylic acid C1-5COOH to obtain an esterification product C60(OOC-R)8-15 or 24-26 which is adopted as a component A, wherein the additive composition also comprises an ester dissolving agent and an antioxidant synergistic agent, andthe weight ratio of the three components, i.e., a weight ratio of component A to ester dissolving agent to antioxidant synergistic agent is (0.1 to 10): (2 to 20): (10 to 40). The additive compositiondoes not comprise water, sulfur, phosphorus, chlorine and mechanical impurities and is environment-friendly; and the additive composition has good wear resistance and friction reduction performance:the friction coefficient of the lubricating oil is decreased by 18.8 percent to 34.3 percent, an average grinding spot diameter is reduced to 0.49, and the oxidation induction period is increased by one time or more in the existence of the high-temperature high-pressure oxygen. After the lubricating grease is added, when the device is in an idle state, the input current can be decreased by 16.3 to20.3 percent.

Owner:江苏凯尚碳科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com