Lubricating grease for blast-furnace gun and preparation method thereof

A grease, mud gun technology, applied in the field of grease, to achieve the effect of improving rust resistance, long oxidation induction period and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further elaborated below by specific examples.

[0027] Each embodiment and comparative example preparation method:

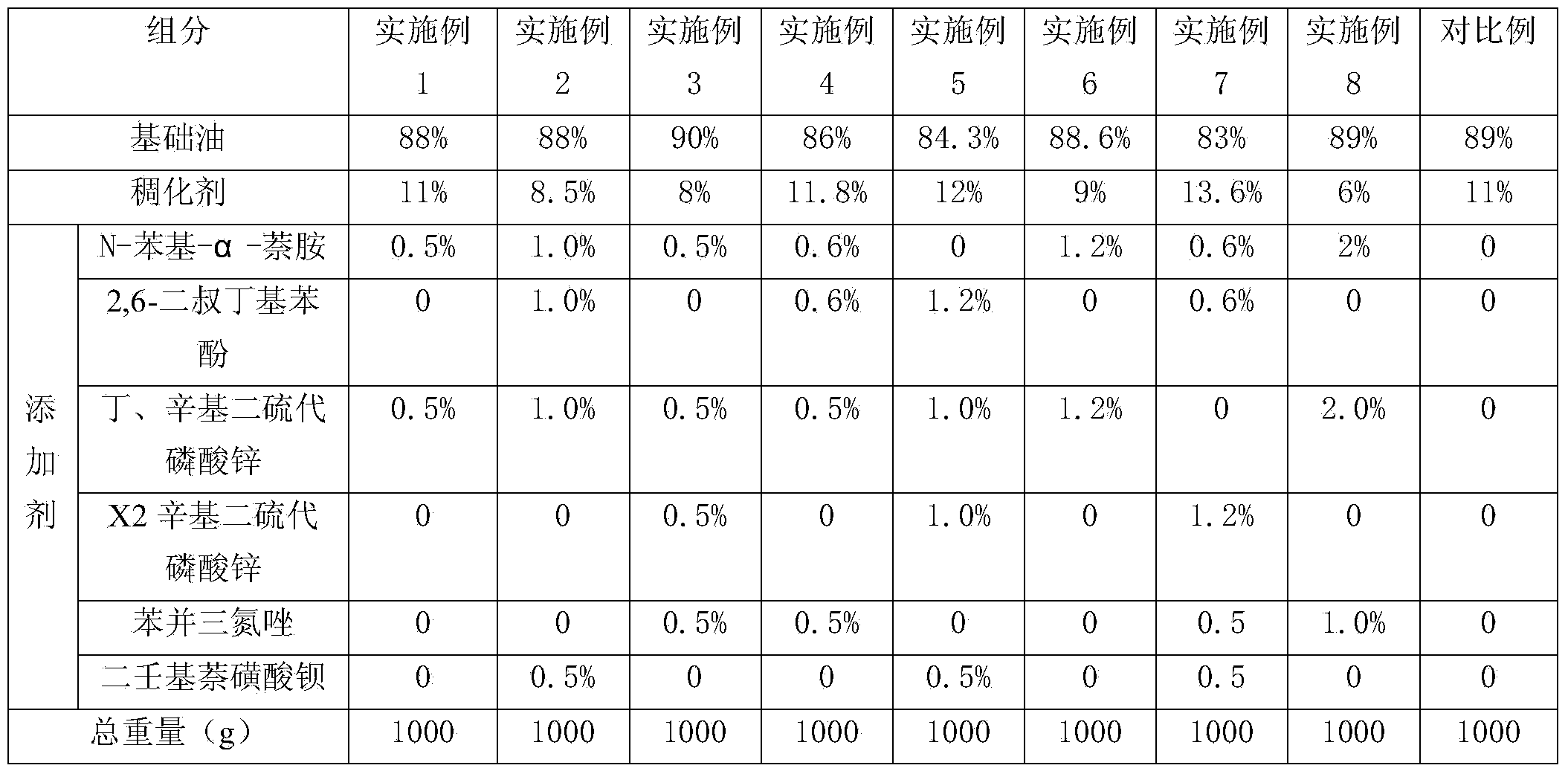

[0028] Embodiment 1-8 and comparative example

[0029] Add the thickener 12-hydroxystearate lithium, lithium borate, lithium sebacate complex soap and 45% base oil into the reaction kettle, stir and heat to 205-215°C, add 20% base oil to cool, continue Stir, add the remaining base oil, stir to lower the temperature below 90°C, add additives, stir and mix evenly. The composition is oil-pressed three times by a three-roller machine, and then packed in a finished product. Embodiment 1-8 component content and comparative example component content are shown in Table 1

[0030] Table 1 Example 1-8 component content and comparative example component content

[0031]

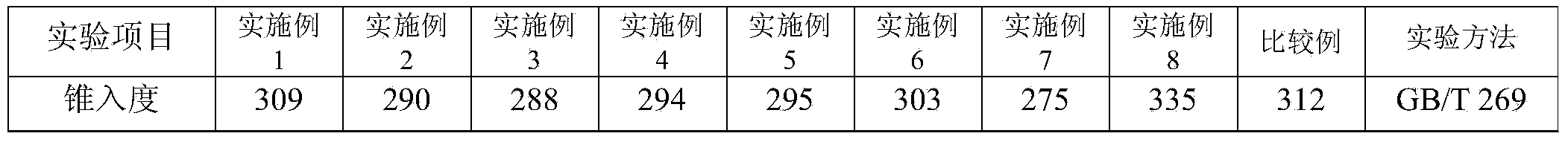

[0032] Embodiment 1-8 and comparative example performance data are shown in Table 2

[0033] Table 2

[0034]

[0035]

[0036] As can be seen from Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com