Hydrogen absorption fiber paste for optical fiber composite overhead ground wire (OPGW) optical cable and manufacture method thereof

A hydrogen-absorbing fiber paste and optical cable technology, applied in the direction of fiber mechanical structure, etc., can solve problems affecting optical fiber transmission performance, high drop point and flash point, increased fiber loss, etc., to improve transmission performance, reduce defects, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

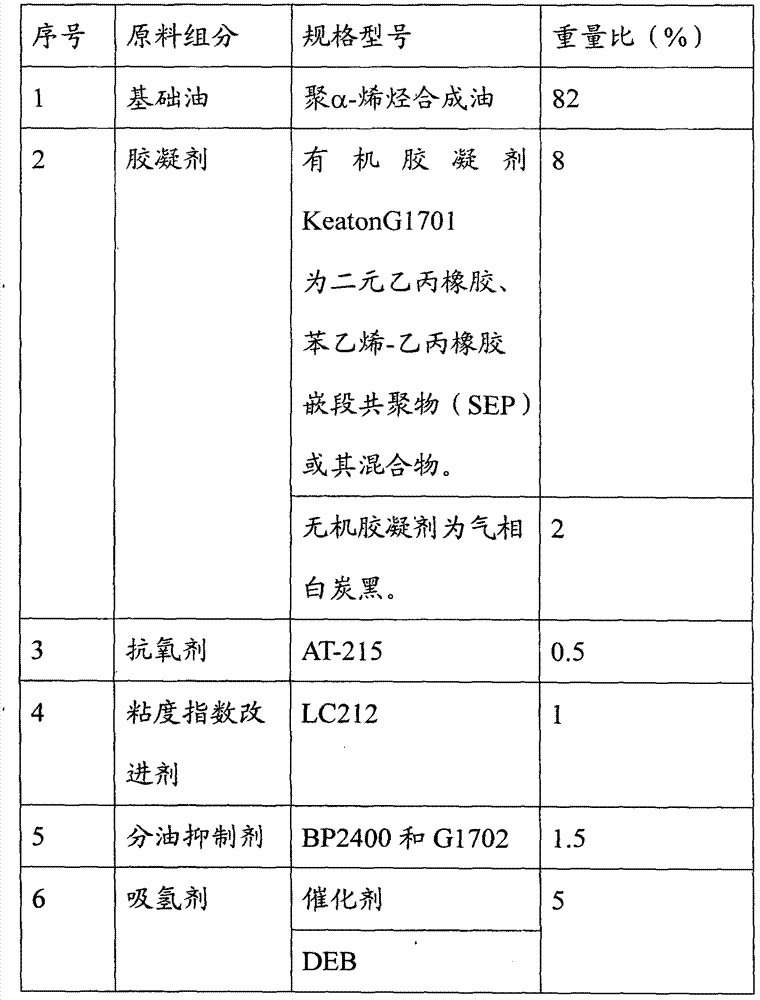

Embodiment 1

[0030] Step 1: Take 75 parts of poly-α-olefin synthetic oil, 1 part of viscosity index improver and 1.5 parts of oil separation inhibitor and add them together into a reaction kettle filled with nitrogen protection, heat up to 180°C and stir until fully uniform;

[0031] Step 2: Add organic gelling agent EPDM rubber, styrene-ethylene propylene rubber block copolymer or 15 parts of their mixture into the reaction kettle, and stir at 160°C until fully uniform;

[0032] The third step: Add 0.5 parts of antioxidant and 2 parts of inorganic gelling agent fumed silica and stir at 160°C until it is fully uniform, at this time it is the fiber paste matrix;

[0033] Step 4: Take activated carbon as the carrier, take 5 parts of the catalyst and mix with the organic hydrogen absorbing component for 2-3 hours until it is fully uniform, which is the hydrogen absorbing agent;

[0034] Step 5: Add the hydrogen absorbing agent to the fiber paste matrix in the reaction kettle by mechanical mix...

Embodiment 2

[0036] Step 1: Take 80 parts of poly-α-olefin synthetic oil, 1 part of viscosity index improver and 1.5 parts of oil separation inhibitor and add them together into a reactor filled with nitrogen protection, heat up to 180°C and stir until fully uniform;

[0037] Step 2: Add organic gelling agent EPDM rubber, styrene-ethylene propylene rubber block copolymer or 10 parts of their mixture into the reaction kettle, and stir at 160°C until fully uniform;

[0038] The third step: Add 0.5 parts of antioxidant and 2 parts of inorganic gelling agent fumed silica and stir at 160°C until it is fully uniform, at this time it is the fiber paste matrix;

[0039] Step 4: Take activated carbon as the carrier, take 5 parts of the catalyst and mix with the organic hydrogen absorbing component for 2-3 hours until it is fully uniform, which is the hydrogen absorbing agent;

[0040] Step 5: Add the hydrogen absorbing agent to the fiber paste matrix in the reaction kettle by mechanical mixing, the...

Embodiment 3

[0042] Step 1: Take 85 parts of poly-α-olefin synthetic oil, 1 part of viscosity index improver and 1.5 parts of oil separation inhibitor and add them together into a reactor filled with nitrogen protection, heat up to 180°C and stir until fully uniform;

[0043] Step 2: Add organic gelling agent EPDM rubber, styrene-ethylene-propylene rubber block copolymer or 5 parts of their mixture into the reaction kettle, and stir at 160°C until fully uniform;

[0044]The third step: Add 0.5 parts of antioxidant and 2 parts of inorganic gelling agent fumed silica and stir at 160°C until it is fully uniform, at this time it is the fiber paste matrix;

[0045] Step 4: Take activated carbon as the carrier, take 5 parts of the catalyst and mix with the organic hydrogen absorbing component for 2-3 hours until it is fully uniform, which is the hydrogen absorbing agent;

[0046] Step 5: Add the hydrogen absorbing agent to the fiber paste matrix in the reaction kettle by mechanical mixing, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com