Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

754 results about "Coumarones" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-solid anticorrosive coating composition, high-solid rapidly-curable anticorrosive coating composition, method of coating ship or the like, high-solid anticorrosive film and rapidly cured high- anticorrosive film obtained, and coated ship and underwater structure coated with these coating films

InactiveUS20090226729A1Improve anti-corrosion performanceIncrease contentLiquid surface applicatorsAntifouling/underwater paintsOrganic solventBoiling point

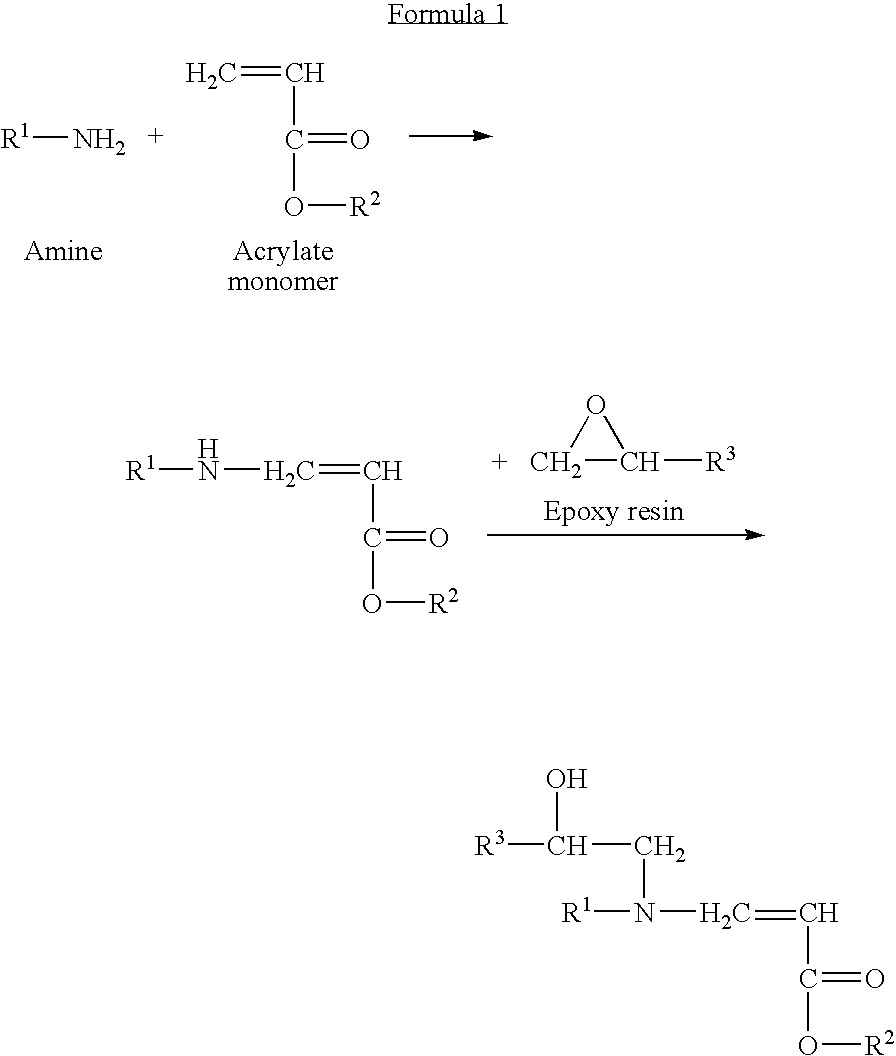

A high-solids anticorrosive coating composition which comprises a main ingredient (A) comprising an epoxy resin (a1) and a hardener ingredient (B) comprising an alicyclic amine hardener (b1) and / or a Mannich type hardener (b2), the ingredient (A) and / or the ingredient (B) containing at least either of an additive (a2) selected among epoxidized reactive diluents and modified epoxy resins and a coating film modifier (ab) selected among petroleum resins, xylene resins, coumarone resins, terpene phenol resins and vinyl chloride copolymers. The high-solids anticorrosive coating composition especially of the rapidly curable type is characterized by containing a high-boiling organic solvent having a boiling point exceeding 150° C. and containing substantially no organic solvent having a boiling point of 150° C. or lower.

Owner:CHUGOKU MARINE PAINTS

SBS modified asphalt high-self-adhesive waterproof coiled material and its preparing process

InactiveCN1621450AHigh peel strengthGood dispersionOther chemical processesBuilding insulationsPlasticizerBase oil

The adhesive waterproof coil material consists of alkyl asphalt, adhesive SBS, plasticizer naphthene base oil, stuffing calcium carbonate and composite tackifier of coumarone resin and terpene resin. It has the composition of: alkyl asphalt 35-40 wt%, adhesive SBS 10-13 wt%, naphthene base oil 3-5 wt%, stuffing 39-42 wt% and composite tackifier 5-13 wt%. It has high adhesion strength, and the production process has low power consumption, short time and low cost.

Owner:余建国

Polymer compositions

Owner:DOW GLOBAL TECH LLC

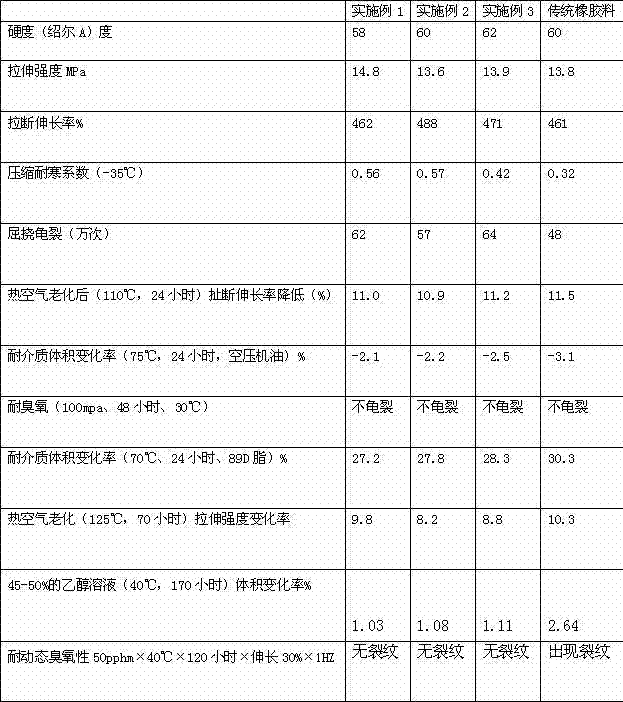

Vulcanized rubber for shoes capable of realizing high effective and fast vulcanization and preparation method and vulcanization process thereof

The invention discloses a vulcanized rubber for shoes capable of realizing high effective and fast vulcanization and a preparation method and a vulcanization process thereof. The vulcanized rubber isprepared from natural rubber, styrene-butadiene rubber, butadiene rubber, accelerator B, accelerator BM, accelerator DS, nanometer zinc oxide, rubber softening oil, sulphur, stearic acid, aging resister CD, carbon black N330, pine tar oil, solid coumarone, reclaimed rubber and pot clay. Compared with the prior art, the vulcanized rubber of the invention has suitable starting time of vulcanization,faster velocity of vulcanization and higher thermal oxidative aging property, the vulcanization efficiency is increased, and the heat-conducting property, processing safety and storage property of the rubber are increased in the vulcanization process; the provided vulcanization process can effectively shorten the vulcanization time, improve the vulcanization quality and increase the vulcanizationefficiency to 2-3 times of the original one.

Owner:JIHUA 3537 SHOE MAKING

Plaster-shape regenerated rubber and preparation method thereof

InactiveCN101100534ASimple processNo need to consume electricityPlastic recyclingFiberPolymer science

A creamed reclaimed rubber and its production are disclosed. It consists of 20-50 mesh vulcanized rubber powder 100 proportion, paraffin oil as solvent 70-90 proportion, solid coumarone 10-30 proportion as solvent, catalyst and catalyst accessory phthalic acid anhydride 2-5 proportion, methyl aldehyde aqueous solution 4-6 proportion, 1,3-benzenediol 0.2-0.5 proportion. The process is carried out by adding vulcanized rubber powder into vertical de-polymerizer, adding into solvent, catalyst and catalyst accessory successively, closing feeding open, agitating, raising temperature to 160-180 deg. C, controlling pressure to 0.5-0.7 MPa, reacting for 2-2.5 hrs, lowering temperature, releasing gas, discharging and filtering to obtain final product. It's simple, has stable quality, waterproof and antiseptic performances and no environmental pollution. It can be used to synthesize rubber with petrochemical asphalt and to paving road.

Owner:TIANJIN YATENGDA RUBBER & PLASTIC PRODS DEV

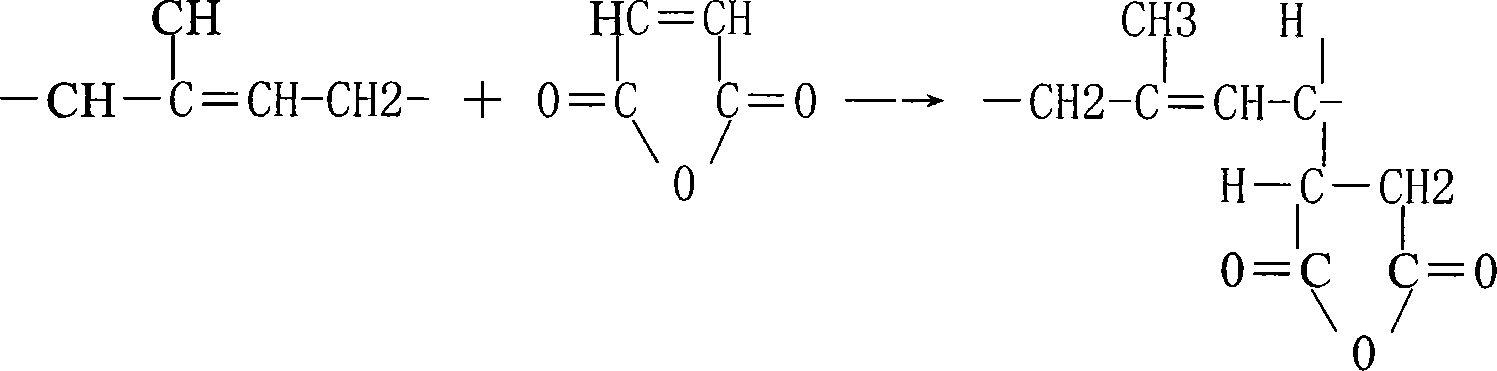

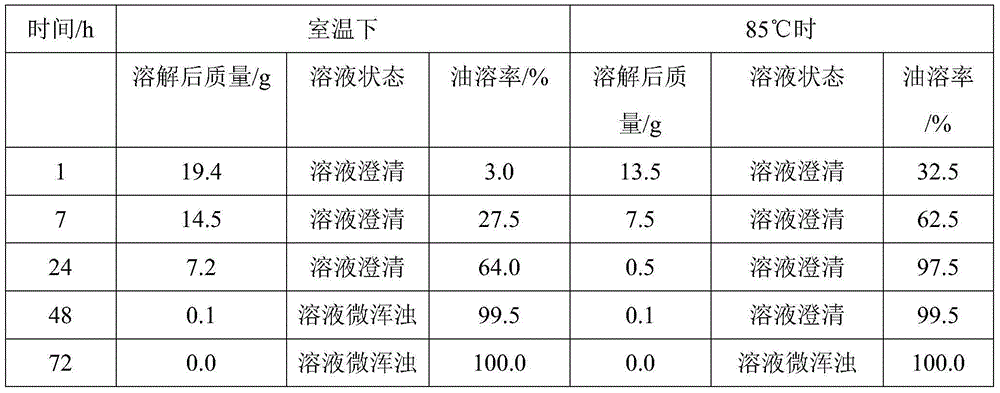

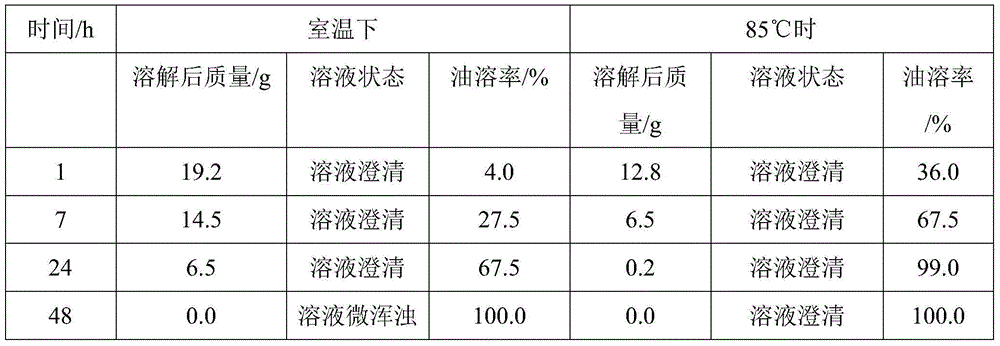

High-temperature oil-soluble temporary plugging agent and preparation method thereof

The invention relates to a high-temperature oil-soluble temporary blocking agent. The high-temperature oil-soluble temporary blocking agent is characterized by comprising the following components in percent by weight: 10-40% of asphalt, 20-50% of C9 petroleum resin, 15-50% of coumarone resin, 5-15% of a surfactant, 2-15% of a polymer fiber and 1-10% of a softening-point additive. The preparation procedures of the high-temperature oil-soluble temporary blocking agent are as follows: firstly, adding the asphalt into a reactor, heating to melt the asphalt, adding the C9 petroleum resin and the coumarone resin into the reactor, stirring continuously until the substances in the reactor are fully melted, continuously adding the surfactant, the polymer fiber and the softening-point additive into the reactor, stirring for 30 minutes to mix uniformly, stopping heating a mixture, cooling, then collecting particles, washing, and screening to obtain the high-temperature oil-soluble temporary blocking agent with different particle sizes. The high-temperature oil-soluble temporary blocking agent provided by the invention overcomes the defect that the traditional oil-soluble temporary blocking agent can not resist high temperature. The high-temperature oil-soluble temporary blocking agent has good oil solubility, acid and salt resistance and high-temperature degradation resistance. The added softening-point additive is capable of regulating the range of the softening point, and thus an oil layer can be protected.

Owner:TIANJIN DAGANG OILFIELD BINGANG GRP BOHONG PETROLEUM CHEM

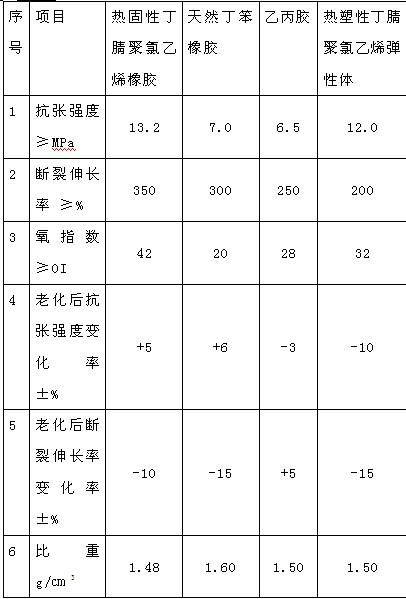

Flame-retardant thermosetting nitrile/polyvinyl chloride (PVC) rubber for wires and cables

ActiveCN102050971AHigh strengthGood elongationInsulated cablesInsulated conductorsThermoplasticParaffin wax

The invention discloses a flame-retardant thermosetting nitrile / polyvinyl chloride (PVC) rubber for wires and cables, which is characterized by comprising the following raw materials in parts by weight: 50-70 parts of nitrile rubber powder, 30-50 parts of PVC resin powder, 2-3 parts of vulcanizing agent, 2.5-4.5 parts of accelerant, 4-6 parts of zinc oxide, 2-3 parts of stearic acid, 1-3 parts of coumarone resin, 2-4 parts of anti-aging agent, 20-40 parts of chlorinated paraffin wax, 7-10 parts of antimony trioxide, 4-6 parts of zinc borate, 50-70 parts of aluminum hydroxide and 40-70 parts of carbon black. After exceeding a certain temperature, the flame-retardant thermosetting nitrile / PVC rubber disclosed by the invention can only be cured and charred, but can remain a certain insulating property; the strength, elongation and flame retardance of the flame-retardant thermosetting nitrile / PVC rubber are better than those of common rubber and thermoplastic nitrile / PVC rubber; and the flame-retardant thermosetting nitrile / PVC rubber also has the advantages of oil resistance, wear resistance and softness in the common rubber and thermoplastic nitrile / PVC rubber.

Owner:GUANGDONG RIFENG ELECTRIC CABLE

Aging-resistant and low-temperature-resistant EPDM (ethylene-propylene-diene monomer) rubber cable material

InactiveCN104610663AHigh strengthGood air aging resistanceRubber insulatorsPlastic/resin/waxes insulatorsCalcium silicateElastomer

The invention discloses an aging-resistant and low-temperature-resistant EPDM (ethylene-propylene-diene monomer) rubber cable material. The material comprises raw materials as follows: EPDM rubber, natural rubber, an ethylene-butene elastomer, superfine talc powder, nano calcium carbonate, modified superfine desulfurization ash, active calcium silicate, zinc methacrylate modified nano silicon nitride, pre-dispersed hollow phenolic microspheres, reinforcing fibers, zinc oxide, stearic acid, dicumyl peroxide, sulfur, N,N'-meta phenylene bismaleimide, diphenylmethane bismaleimide, DIPDIS, coumarone-indene resin, APP (ammonium polyphosphate), ADP, an MPE (metallocene polyethylene) elastomer, N-(4-anilino phenyl maleimide and 2-mercapto benzimidazole. The aging-resistant and low-temperature-resistant EPDM rubber cable material is high in strength, good in aging resistance and low-temperature resistance, excellent in insulating property and flame retardation and long in service life.

Owner:无为县华祥电缆材料有限公司

High-strength wearable floor rubber and process for preparing same

The high-strength flooring rubber mainly comprises (by mass portions) styrene-butadiene rubber 60-100 parts, natural rubber 40-60 parts, butylbenzene rubber with high styrene content 40-60 parts, stearic acid 3-8 parts, zinc oxide 3-6 parts, accelerating agent 3-7 parts, anti-aging agent 0.5-1.5 parts, Coumarone 3-8 parts, paraffin chloride 1-2 parts, pottery clay 100-200 parts, white carbon black 80-120 parts, light calcium 100-200 parts, coupling agent 3-8 parts, phenol resin 5-10 parts, HMT 0.5-1.0 part, sulfur 5-8 parts, decabromodiphenyl oxide 5-15 parts, antimony trioxide 5-15 parts, and aluminum hydroxide 30-100 parts. The preparation consists of plasticization, adaptation, pugging, calendaring, extrusion, modeling and sulfidization.

Owner:恒昌(昆山)精密模具有限公司 +2

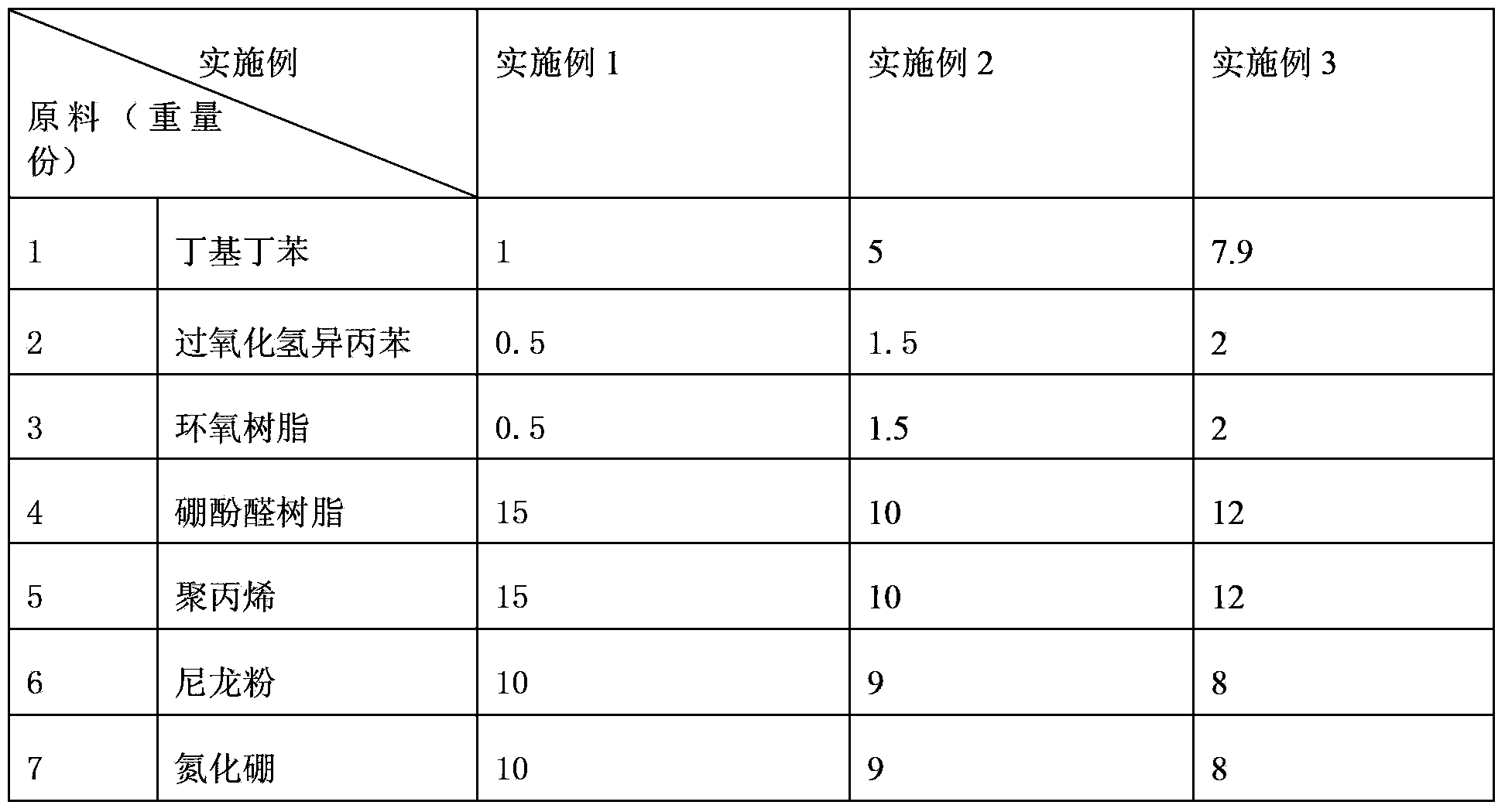

Brake pad

The invention discloses a brake pad which comprises a steel backing and friction materials. The friction materials are prepared from components including, by weight, 1-10 parts of butyl butylbenzene, 0.5-2 parts of cumyl hydroperoxide, 0.5-2 parts of epoxy resin, 1-15 parts of boron containing phenolic resin, 1-15 parts of polypropylene, 6-10 parts of nylon powder, 5-10 parts of boron nitride, 0.01-0.05 part of coupling agent, 1-5 parts of dicumyl peroxide, 1-2 parts of sulfur powder, 1-2 parts of benzoic acid, 1-2 parts of stearic acid, 1-2 parts of boric acid, 30-50 parts of graphite, 1-2 parts of reduced iron powder, 1-2 parts of barium sulfate, 0.5-2 parts of bauxite, 0.5-2 parts of feldspar powder, 0.5-2 parts of zinc oxide, 0.01-0.05 part of accelerator, 0.01-0.05 part of anti-aging agent, 0.5-2 parts of fluorite powder, 0.5-2 parts of silicon carbide and 0.5-2 parts of coumarone. The brake pad has the advantages of abrasion resistance, long service life, no spark, no smell, low noise and fine heat dissipation performance.

Owner:NINGBO JIA XUAN NEW MATERIALS

Abrasion-proof resin rubber cushion

The invention discloses a wear-resistant resin rubber pad, the weight part compositions of ingredients of the invention are as follows: 9-12 shares of natural rubber, 11-13 shares of styrene-butadiene rubber, 2.8-4.2 shares of cis-1,4-polybutadiene rubber, 4-8 shares of EVA, 3.2-4.3 shares of high styrene, 6.0-7.5 shares of light calcium, 0.5-1.0 shares of diglycol, 1.0-1.6 shares of coumarone, 1.0-2.0 shares of zinc oxide, 0.45-0.6 shares of stearic acid, 0.82 shares of accelerant, 7-10 shares of white soot, 0.8-1.2 shares of engine oil and 4-7 shares of sulfur. The invention is made by common technique with proper ratio of ingredients. The invention has prominent wear-resistance and greatly improves the service life of shoes, components and equipment. White soot is adopted to add colorant and meet the demands for colors, hence a widely applied invention.

Owner:孙振华

Self-adhesive butyl damping fin and preparation method thereof

InactiveCN108531101AImprove self-adhesivenessSimple processMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAcrylic resinVibration absorption

The invention provides a self-adhesive butyl damping fin, comprising a covering layer, an adhesive layer and an anti-sticking layer which are sequentially compounded, wherein the adhesive layer is prepared from the following raw materials by mass percent: 2-30wt% of butyl rubber, 1-20wt% of tackifying resin, 0.1-10wt% of carbon black, 50-80wt% of filler and 1-30wt% of tackifying liquid; the butylrubber refers to a copolymer containing most of isobutylene and a small amount of isoprene, is one or more selected from butyl rubber, chlorobutyl rubber, bromobutyl rubber, butyl recycled rubber, chlorinated butyl recycled rubber and brominated butyl recycled rubber; the tackifying liquid is one or more selected from liquid terpene resin, liquid rosin resin, polyisobutylene, polybutadiene, liquidC9 resin, liquid coumarone resin and liquid acrylic resin. The damping fin provided by the invention is higher in self-adhesion, light in weight, simple in process, low in production cost, suitable for industrial production, energy-saving and high in efficiency, and has good vibration absorption and noise reduction effects.

Owner:HANGZHOU ZHIJIANG SILICONE CHEM +1

Material for making piston rubber-rup of slurry pump

The invention is a material to make piston leather bowl of slurry pump, solving the problem of short life. Its characters: the components according to weight shares: natural glue 60-70, butyronitrile glue 30-40, zinc oxide 2-5, stearic acid 2-4, pine tar 4-6, anti-aging agent 2-4, accelerant DM 1.5-2.0, accelerant D 1.0-1.5, high-wearable carbon blacnk 50-90, sulphur 2-5, coumarone 4-9, dibutyl ester 2-10 and short fiber 5-20.

Owner:焦学明

Static conducting flame-retardant rubber for oil tank seal tape

ActiveCN101328290AMeet the requirements of static conduction and flame resistanceWith static conduction and flame retardant performanceOther chemical processesLarge containersParaffin waxPolymer science

The invention relates to a static electricity conductive flame retardant rubber for an oil tank sealing strip. The rubber takes butyronitrile rubber as a main raw material, which is mixed with stearic acid, zinc oxide, acetylene carbon black, semi reinforcing carbon black, aluminum hydroxide, decabromodiphenyl ether, antimony trioxide, chlorinated paraffin wax, antiager 4010NA, antiager A, sulfur, accelerant CZ, accelerant TMTM, coumarone and dioctyl phthalate, and the mixture undergoes the mixing by an internal rubber mixer, and the rubber is bonded on both sides of a gum dipping framework by a calender and is subject to the sulfuration to prepare the static electricity conductive flame retardant sealing strip. The surface resistance of the product is less than 3x10<8>Ohm, and the burning performance is no less than FV-1 class, the rubber of the invention meets the requirements of an steel oil tank on the static electricity conduction and the flame retardation of the rubber sealing strip.

Owner:ANQING SPECIAL RUBBER & PLASTIC PROD

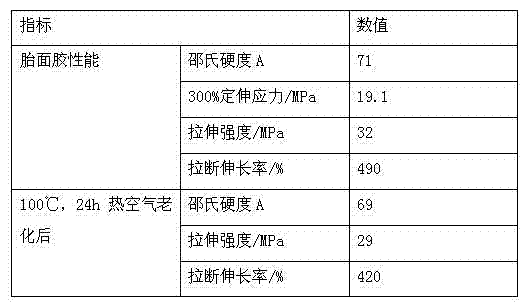

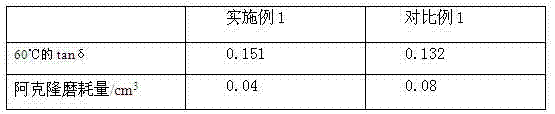

Automobile tire tread rubber

InactiveCN103483627AGood anti-aging performanceImprove wet skid resistanceSpecial tyresWear resistantEngineering

The invention specifically relates to an automobile tire tread rubber, which belongs to the field of tire manufacturing technology. The automobile tire tread rubber is characterized by comprising the following components: natural rubber, butadiene styrene rubber, polybutadiene rubber, brominated butyl rubber, stearic acid, sulphur, carbon black, paraffin, a coumarone resin, sixth line distillate, zinc oxide, pine tar, ISAF, a promoter DM, a promoter CZ, an anti-aging agent, highly wear-resistant furnace black and gas carbon black. The invention has the following beneficial effects: appropriate parts by weight of the above-mentioned components are employed for preparation of the tread rubber, so a tire has good wear resistance, ageing resistance and wet skid resistance; aging resistance of the natural rubber is inferior to that of the butadiene styrene rubber, so combination of the natural rubber and the butadiene styrene rubber and addition of the anti-aging agent enable the anti-aging performance of the rubber to be improved.

Owner:广州安耐特再生胶轮有限公司

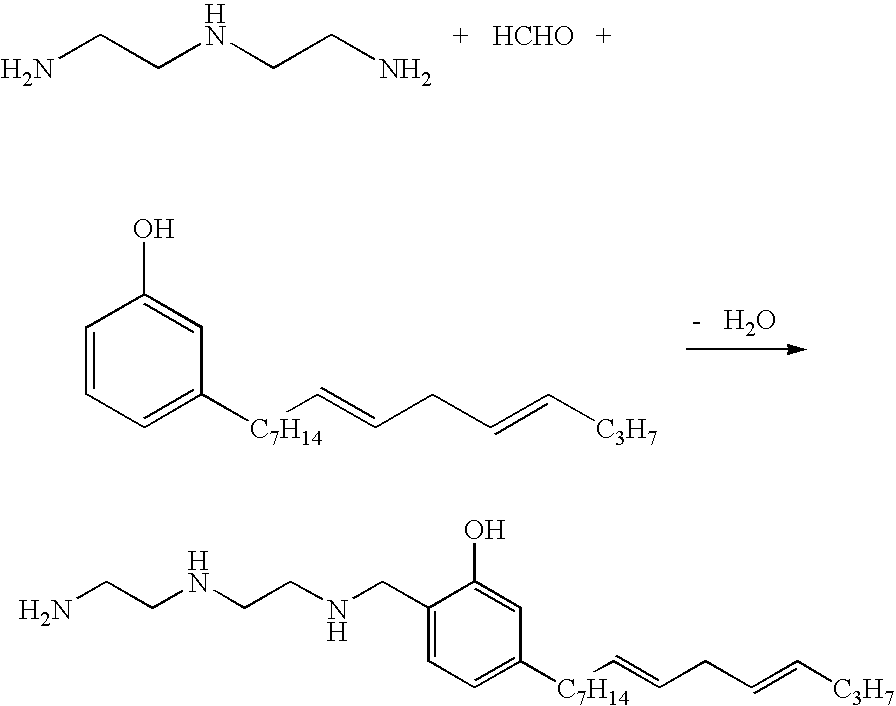

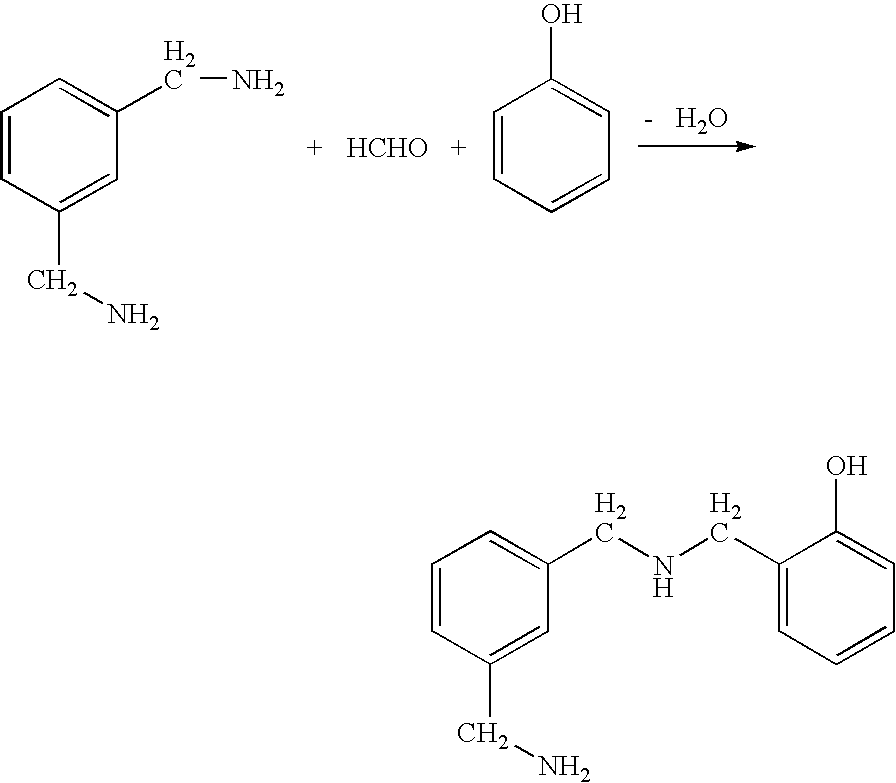

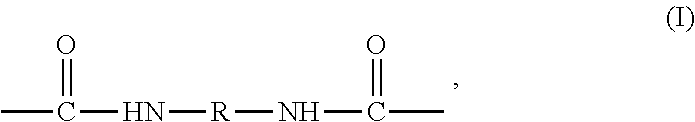

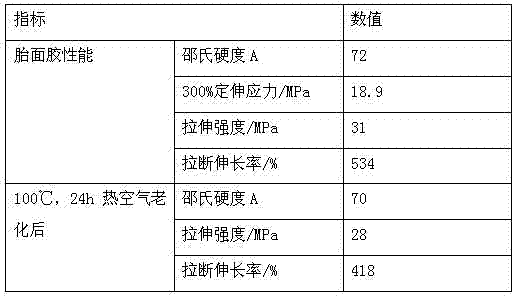

New use of medicine containing benzophen [C] anthridine alkaloid and its derivatives

The invention discloses a new use of phenanthridine biologic alcali of general formula I containing coumarone and its derivant in preparing anti-hepatitis b virus medicament.The biologic alcali has tumor cell apoptosis inducing effect, has strong inhibiting activity against to such pathogen, has antiviral effect, and is expected for treating liver cancer, wherein R1 to R10, R12 and R13 is hydrogen, hydroxy, carbon chain or naphthenic base with 1-12 carbon atoms, alkoxyl or acyloxy group, benzyloxy, chlorine and other halogen atoms, amino group, methylol, aldehyde group, carbonyl, acetonyl, carboxy, sulacyloxy, 4-methyl-benzenesulfonyloxyl, arylsulfonyloxy, diphenylphosphonoxyl and -OCONH2; R11 is hydrogen, methyl or oxygen atom; R14 and R15 are respectively hydrogen or methyl.

Owner:成都军区昆明总医院

Surface covering glue for high-temperature resistant wire rope core conveyer belt and preparation method of surface covering glue

InactiveCN102504726AExcellent thermal oxygen resistanceGood weather resistanceNon-macromolecular adhesive additivesSheet filmEngineering

The invention relates to a surface covering glue for a high-temperature resistant wire rope core conveyer belt. The surface covering glue can resist a test temperature not higher than 175 DEG C and the highest short-time running temperature at 300 DEG C, and reaches the T4 level of GB / T20021-2005 standard. The surface covering glue for the high-temperature resistant wire rope core conveyer belt is prepared by the steps of mixing ethylene-propylene terpolymer, cumyl peroxide DCP, zinc oxide, Triallyl Isocyanurate TAIC, zinc methacrylic acid ZDMA, stearic acid, anti-aging agent RD, anti-aging agent MB, anti-aging agent 6PPD, N330 carbon black, N550 carbon black, coumarone and paroline, forming glue sheets, molding and finally vulcanizing. The surface covering glue for the high-temperature resistant wire rope core conveyer belt prepared according to the method has excellent heat and oxidization resistance, weather resistance, ozone resistance, acid-base resistance and steam resistance, and can be used for a long term under the use conditions that the temperature is not higher than 175 DEG C and the highest short-time running temperature is at 300 DEG C.

Owner:WUXI BOTON TECH CO LTD

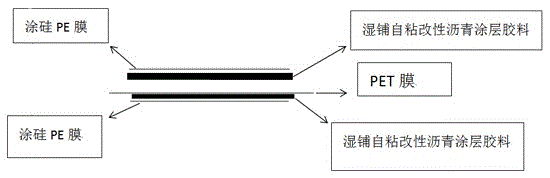

Double-sided adhesive asphalt-base and PET (polyethylene terephthalate)-carrier wet-laid waterproof roll and production process thereof

ActiveCN105619929AStrong stretchHigh peel strengthSynthetic resin layered productsLaminationPolyethylene terephthalate glycolAntioxidant

The invention provides a double-sided adhesive asphalt-base and PET (polyethylene terephthalate)-carrier wet-laid waterproof roll. The waterproof roll comprises a PET film, a modified asphalt layer and PE (polyethylene) film, wherein the PET film is 0.1-0.2 mm thick, the modified asphalt layer is 0.7-1.5 mm thick, and the PE film is 0.03-0.05 mm thick; raw material components of the modified asphalt layer comprise, in parts by mass, 245-260 parts of petroleum asphalt, 25-32 parts of second vacuum side-stream oil, 8-10 parts of SBS, 16-20 parts of SIS, 15-20 parts of SBR, 10-12 parts of petroleum resin, 2-4 parts of coumarone resin, 1-3 parts of an anti-stripping agent, 0.8-1.2 parts of an antioxidant, 50-60 parts of cement and 40-50 parts of talcum powder. The waterproof roll has good tensile property, high tearing strength and peeling strength, heat resistance and aging resistance.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL

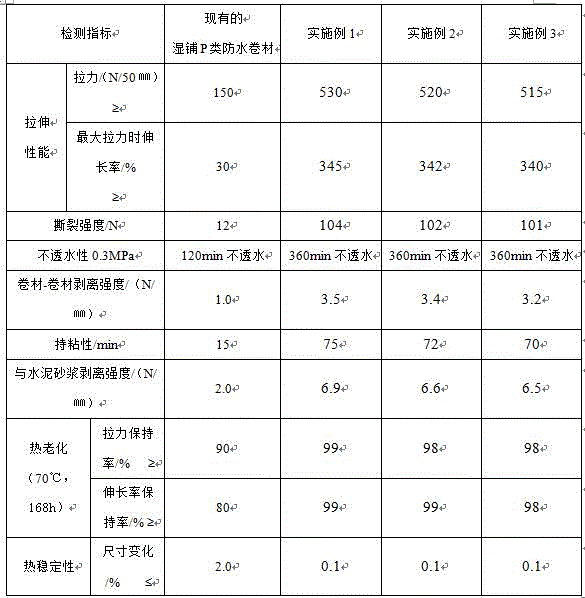

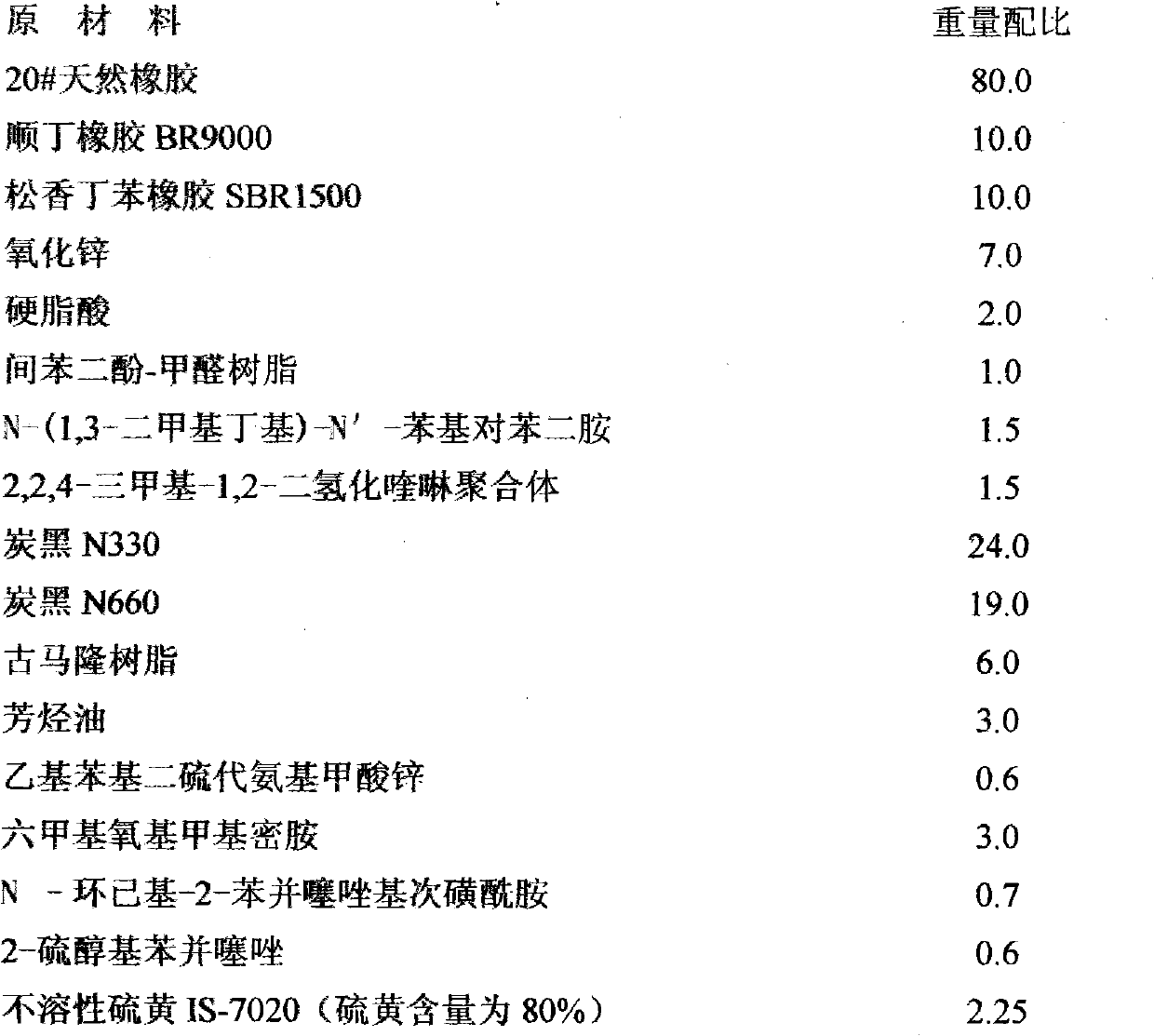

Intermediate adhesive material for retreaded tires

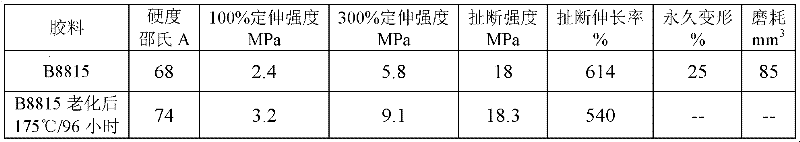

InactiveCN102086353AImprove adhesionImprove driving safetyNatural rubber adhesivesQuinolineHigh doses

The invention discloses an intermediate adhesive material for retreaded tires. The adhesive material disclosed by the invention contains resorcinol-formaldehyde resin, hexamethoxy methyl melamine, zinc oxide (in high dose ratio), and N-ethyl-N-phenyldithiocarbamic acid zinc salt serving as a low-temperature promoter. The key points of the intermediate adhesive material include: the intermediate adhesive material is prepared from various raw materials including No.20 natural rubber, cis-1,3-butadiene rubber (BR)9000, abietic styrene butadiene rubber (SBR)1500, resorcinol-formaldehyde resin, zinc oxide (in high dose ratio), stearic acid, N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine,poly(1,2-dihydro-2,2,4-trimethyl-quinoline), poly(2-dihydroquinoline), carbon black N330, carbon black N660, coumarone-indene resin, aromatic oil, zinc ethylphenyl dithiocarbamate, hexamethoxy methyl melamine, N-cyclohexylbenzolthiazole-2-sulfenamide, 2-mercaptobenzothiazole, and insoluble sulphur (IS)-7020( the sulfur content is 80 percent). The adhesive material disclosed by the invention is mainly used in the intermediate adhesive layers of retreated diagonal tires and retreaded steel-belted radial tires and when the adhesive material disclosed by the invention is used, the tire tread and tire body adhering strength of the intermediate adhesive material is improved obviously; the H drawing force of the adhesive material with all-steel cords and nylon cords is improved to reduce the tire tread and tire body separation phenomenon of the finished retreaded diagonal tires and retreaded steel-belted radial tires; and thus, the driving safety and service life of the diagonal tires and the retreaded steel-belted radial tires are improved.

Owner:SICHUAN TYRE & RUBBER CO LTD

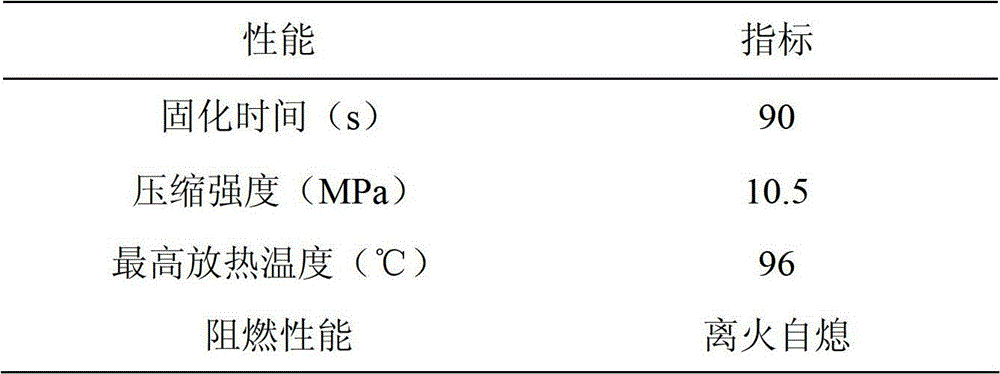

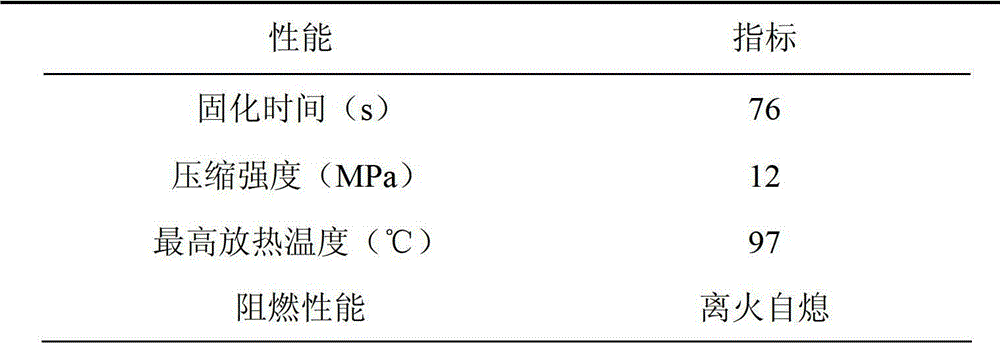

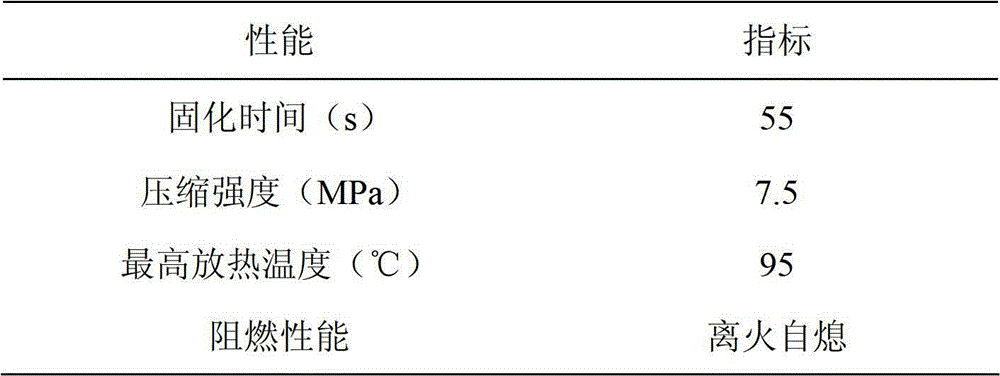

Low-heat-release polyurethane grouting reinforcement material and preparation method thereof

The invention discloses a low-heat-release polyurethane grouting reinforcement material and a preparation method thereof. The low-heat-release polyurethane grouting reinforcement material comprises the following raw materials in parts by mass: 100 parts of polymer polyol, 0.5 to 3.5 parts of amine catalyst, 0.5 to 3.5 parts of tin catalyst, 1 to 4 parts of foam stabilizer, 10 to 50 parts of fire retardant, 50 to 200 parts of adhesive coumarone-indene resin and 100 to 200 parts of isocyanate, wherein the polymer polyol is polyether polyol and / or polyester polyol. The preparation method is simple, the prepared grouting reinforcement material is low in cost and high in curing speed, the reaction heat release temperature is low in the curing process, and the solidification body formed by curing has excellent physical and mechanical properties and is particularly suitable for guaranteeing safety operation under a coal mine.

Owner:HEFEI UNIV OF TECH

EPT rubber waterproofing paint and process for preparing the same

InactiveCN101113262AImprove waterproof performanceImprove anti-agingReclaimed rubber coatingsAntifouling/underwater paintsVertical planePolymer science

The invention relates to an epdm rubber waterproof coating and a preparation method thereof. The total weight portions of dry raw material component of the waterproof coating are: epdm rubber 5-7, chlorinated polyethylene 10-15, reclaimed rubber 20-25, coumarone resin 2-3, naphthenic oil 5-10, carbon black 5-8, zinc oxide 0.5-0.7, stearic acid 0.1-0.3, sulfur 0.4-0.6, accelerator 0.5-0.9 and antioxidant 1-3. The waterproof coating adopts epdm rubber, reclaimed rubber and chlorinated polyethylene as film forming main bodies and also various modified promoter and fillings, which results in that the waterproof coating not only has excellent waterproof, ageing and cold resistance, but also has the advantages of convenient construction and low cost, and the components and construction thereof meet the requirements of national environmental standards. The invention has simple preparation process steps, is convenient to be widely industrially produced, and the store property and life service of the waterproof coating obtained is greatly prolonged. The waterproof coating can be widely applied to the waterproof construction in building, engineering, vertical plane and various waterproof datum planes.

Owner:北京立高科技股份有限公司

High flame retardance heat resistant low smoke no-halogen cable sheath and its production process

InactiveCN1772807AFeel goodHigh strengthInsulated cablesInsulated conductorsHigh resistanceExtensibility

The high flame retardance heat resistant low smoke no-halogen cable sheath material features its main materials including SEBS, white oil, PP, PS, maleic anhydride grafted SEBS, P-N fire retardant, coupler, tackified coumarone resin, superfine white carbon black, siloxane, antioxidant 1010 and PS802, and environment friendly color powder. The cable sheath material as one kind of green product contains no halogen, no heavy metal and other environment harming matter, and has high fire retarding performance, high strength, high extensibility and high heat resistance.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

Butyl rubber for wrapping capacitor case

The invention discloses a butyl rubber for wrapping a capacitor case, which is prepared from the following raw materials: butyl rubber (BBK232), LANXESS Deutschland 9650 ethylene propylene diene monomer, poly-4-methyl-1-pentylene, zinc oxide, nano fluorite powder, nano bentonite, attapulgite, anti-aging agent NBC, anti-aging agent OD, polyamide wax micropowder, accelerator TMTD, accelerator CZ, N-2-(aminoethyl)-3-aminopropyltrimethoxysilane, isopropyl tri(dioctylpyrophosphate)titanate, antioxidant 1035, carbon black N339, N660 carbon black 15-25, dibasic lead phosphite, tributyl citrate, stearic acid, coumarone, propanediol sebacate polyester, benzenesulfonyl hydrazide, ferrocene and modified kieselguhr. According to the reasonable raw material formula, the produced rubber has favorable comprehensive properties and strong binding property with metal; and the rubber has high mechanical properties, fatigue resistance, dynamic ozone resistance, aging resistance and the like, thereby providing a high-intensity protective function for the capacitor.

Owner:江苏南翔橡胶制品有限公司

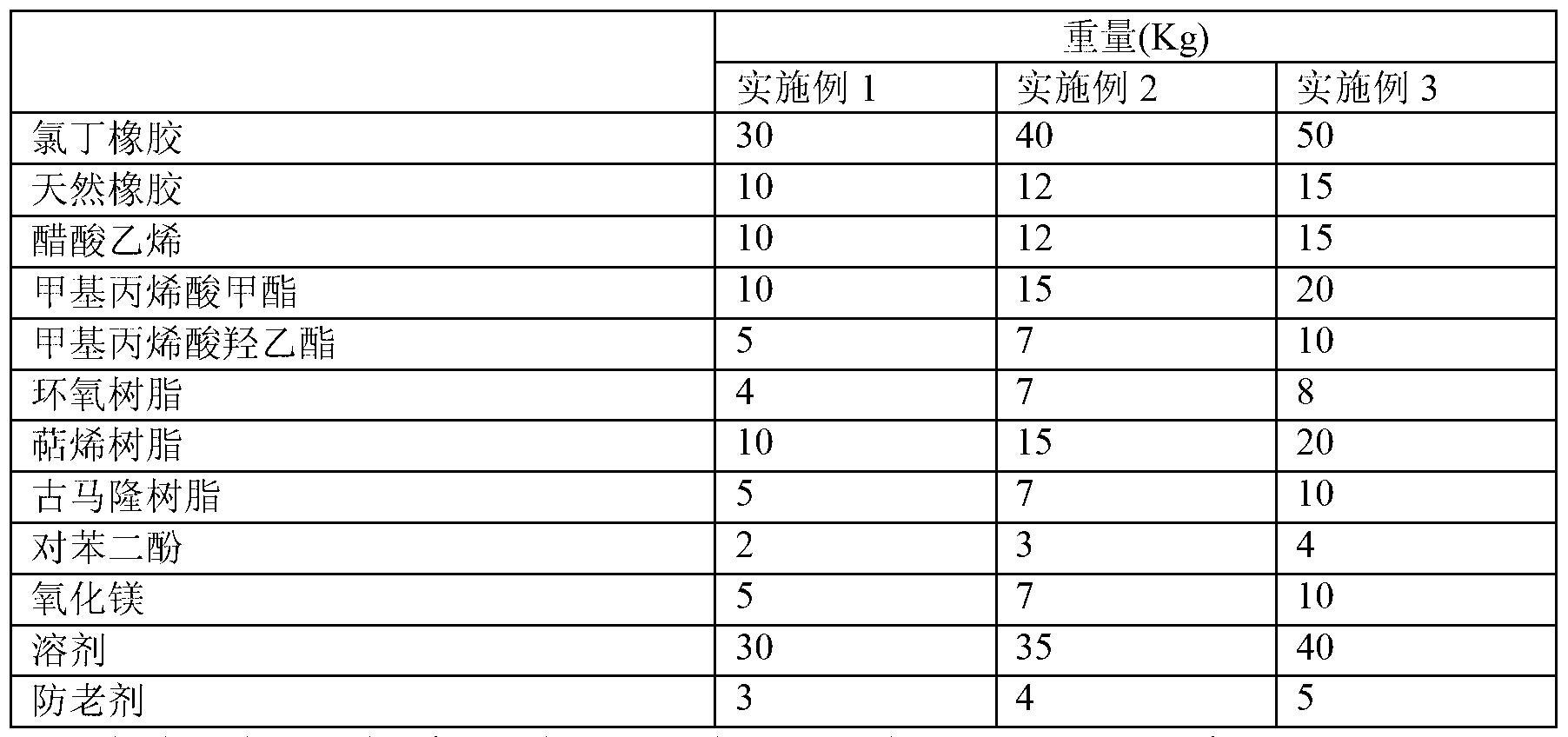

Solvent type chloroprene rubber adhesive with excellent weather ability and preparation method thereof

ActiveCN103265895AImprove cold resistanceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveEpoxyPolymer science

The invention provides an adhesive, particularly relates to a chloroprene rubber adhesive and belongs to the technical field of adhesives. The solvent type chloroprene rubber adhesive comprises the following constituents in parts by weight: 30-50 parts of chloroprene rubber, 10-15 parts of natural rubber, 10-15 parts of vinyl acetate, 10-20 parts of methyl methacrylate, 5-10 parts of hydroxyethyl methylacrylate, 4-8 parts of epoxy resin, 10-20 parts of terpene resin, 5-10 parts of coumarone resin, 2-4 parts of hydroquinone, 5-10 parts of magnesium oxide, 30-10 parts of solvent and 3-5 parts of anti-aging agent. The solvent type chloroprene rubber adhesive provided by the invention has better heat resistance and cold tolerance, the adhesive strength of the chloroprene rubber adhesive provided by the invention can be more than 130N / cm, after being placed for 7 days at minus 30 DEG C, the adhesive strength also can be 110N / cm, and after being placed for 7 days at 100 DEG C, the adhesive strength is more than 75N / cm.

Owner:广东硕成科技股份有限公司

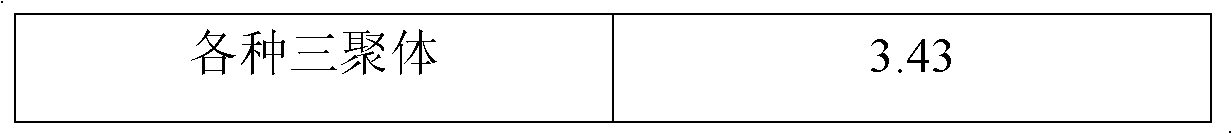

Nitrile-butadiene rubber bonded with fluororesin or fluororubber and application thereof in fuel pipe

ActiveCN102146173APerformance is not affectedAccelerated corrosionFlexible pipesPolymer scienceStearic acid

The invention relates to nitrile-butadiene rubber bonded with fluororesin or fluororubber and an application thereof in a fuel pipe. The rubber comprises the following components: raw nitrile-butadiene rubber, magnesium oxide, calcium hydroxide, stearic acid, an antiager RD, an antiager NBC, coumarone, an adhesive Ricobond 2031, fast extruding furnace black N550, high abrasion furnace black N330, white carbon black, trioctyl trimellitate, liquid nitrile-butadiene rubber 26, sulfur, an accelerator CZ and an accelerator TMTD (tetramethylthiuram disulfide). The experimental contrastive analysis on nitrile-butadiene rubber, epichlorohydrin rubber and ethyene-propylene rubber shows that the performances of the nitrile-butadiene rubber can fully meet the standard and the nitrile-butadiene rubber can replace epichlorohydrin rubber and ethyene-propylene rubber. A vehicle rubber pipe prepared from the nitrile-butadiene rubber can meet the normal production conditions and performance requirement, and simultaneously, the material cost can be reduced.

Owner:TIANJIN PENGYI GRP CO LTD

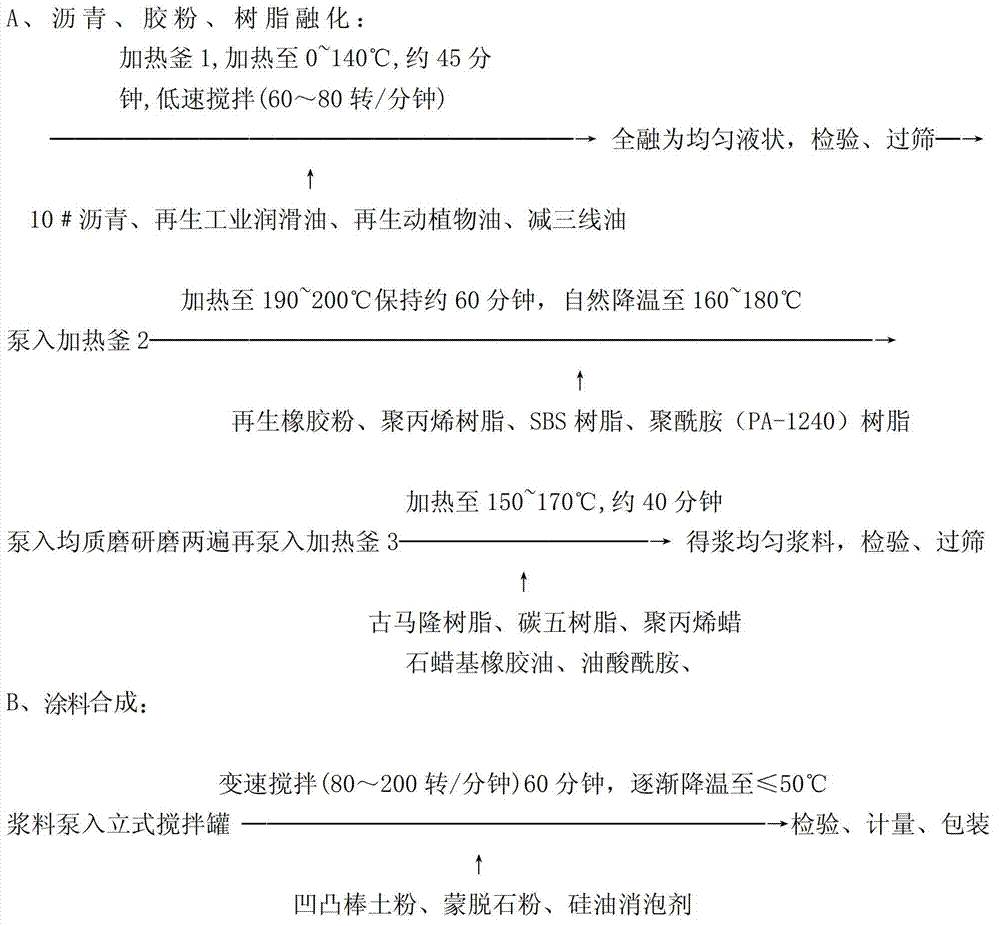

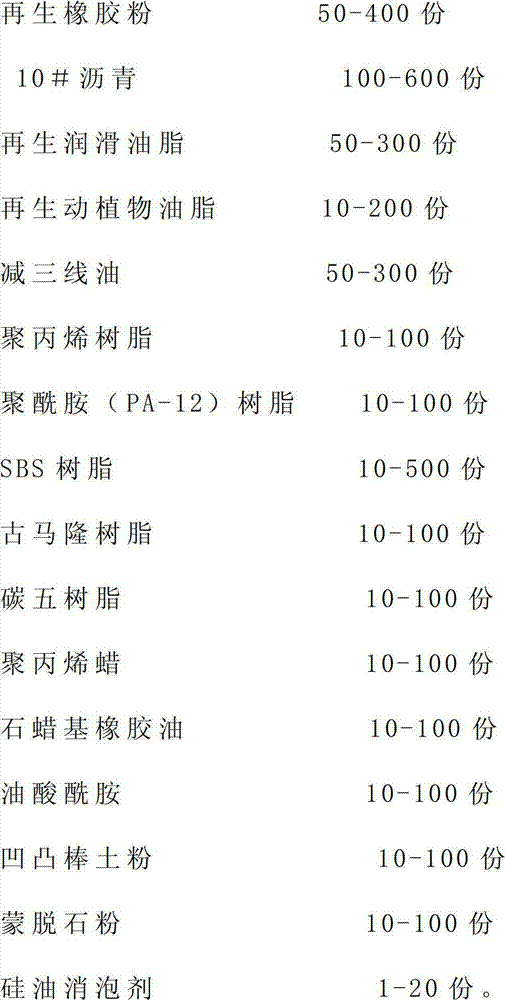

Non-solidifying rubber asphalt building waterproof coating

InactiveCN102925058AReduce pollutionImprove stabilityReclaimed rubber coatingsPolyamide coatingsDistilled oilFlora

The invention discloses a non-solidifying (wriggling) rubber asphalt building waterproof coating and belongs to the field of chemical material building. The coating is prepared by processing the following raw materials: 50-400 parts of regenerated rubber powder, 100-600 parts of 10# asphalt, 50-300 parts of regenerated lubricating grease, 10-200 parts of regenerated flora and fauna grease, 50-300 parts of tertiary-distilled oil, 10-100 parts of polypropylene resin, 10-100 parts of polyamide (PA-12) resin, 10-500 parts of styrene butadiene styrene (SBS), 10-100 parts of coumarone resin, 10-100 parts of carbon 5 resin, 10-100 parts of polypropylene wax, 10-100 parts of paraffin base rubber oil, 10-100 parts of oleamide, 10-100 parts of attapulgite powder, 10-100 parts of smectite and 1 part to 20 parts of silicone oil defoamer. Inspections show that technical indexes of the non-solidifying (wriggling) rubber asphalt building waterproof coating are superior to JC / T864-2008 national material building industry standard of the 'polymer emulsion building waterproof coating', and stability and aging resistance of the coating are greatly improved.

Owner:刘力

Sealing ring for bottom and top cover of filter cleaner

ActiveCN102942723AImprove performanceImprove wear resistanceOther chemical processesPolymer scienceWear resistant

The present invention discloses a sealing ring for a bottom and a top cover of a filter cleaner. The sealing ring is composed of the following raw materials: chloroprene rubber CR121, hydrogenated nitrile rubber ZP2020 (Zeonex, Japan), zinc stearate, coumarone, 2-benzimidazolethiol, chlorinated paraffin, semi-reinforcing carbon black SRF, montmorillonite powder, adipate, an accelerator PZ, an accelerator TETD, a crosslinker TAC, an antiager RD, an antioxidant 1010, and modified diatomite. The sealing ring of the invention has good overall performance, high wear resistance, strong insulation, high corrosion resistance, especially high oil resistance, and low thermal deformation coefficient, and enhances functional effect of the filter cleaner. By adding a modified diatomite, rigidity and hardness of products are enhanced, the heat-resistant, wear-resistant and anti-aging performances of products are improved, and costs are significantly reduced.

Owner:ANHUI PUYUAN SEPARATION MACHINERY MFG CO LTD

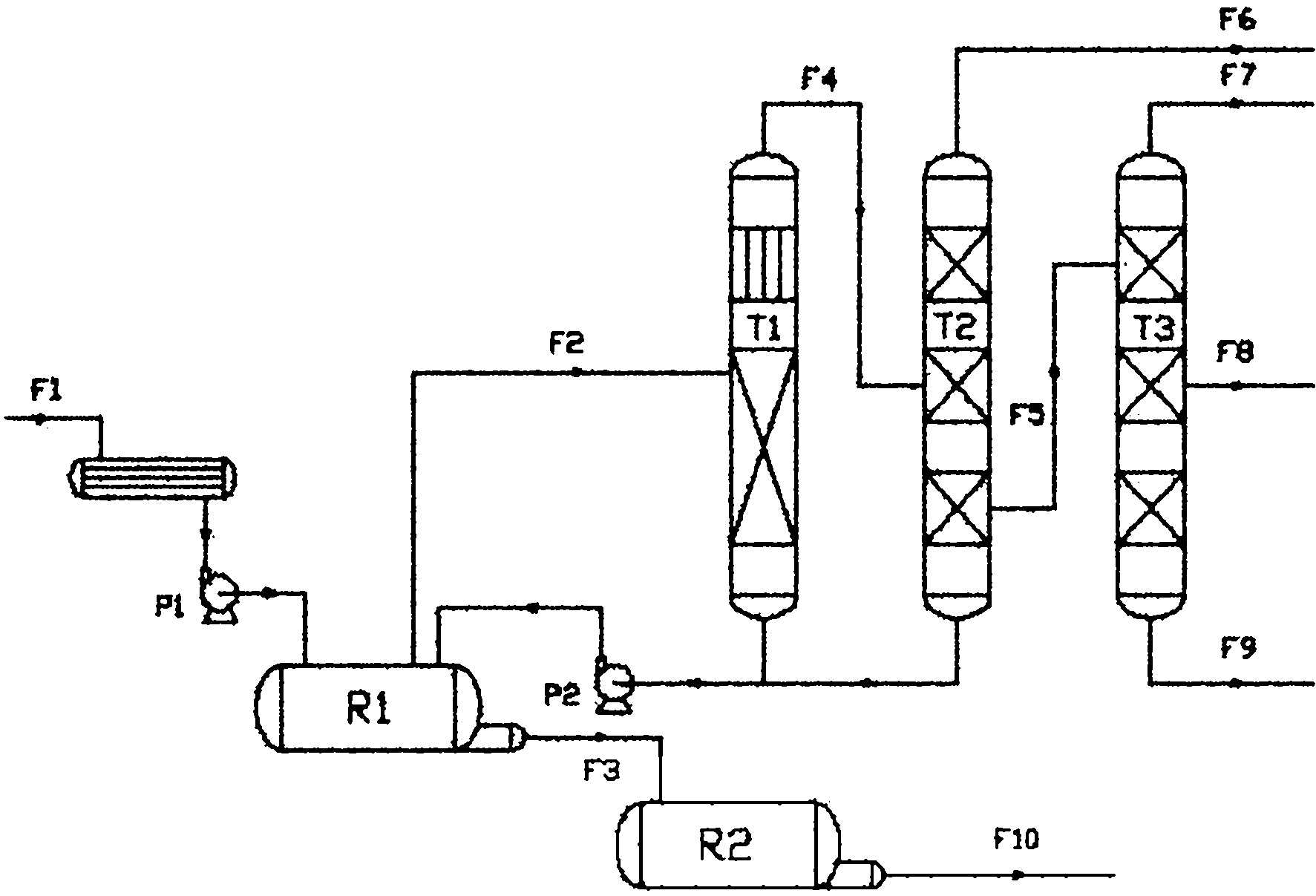

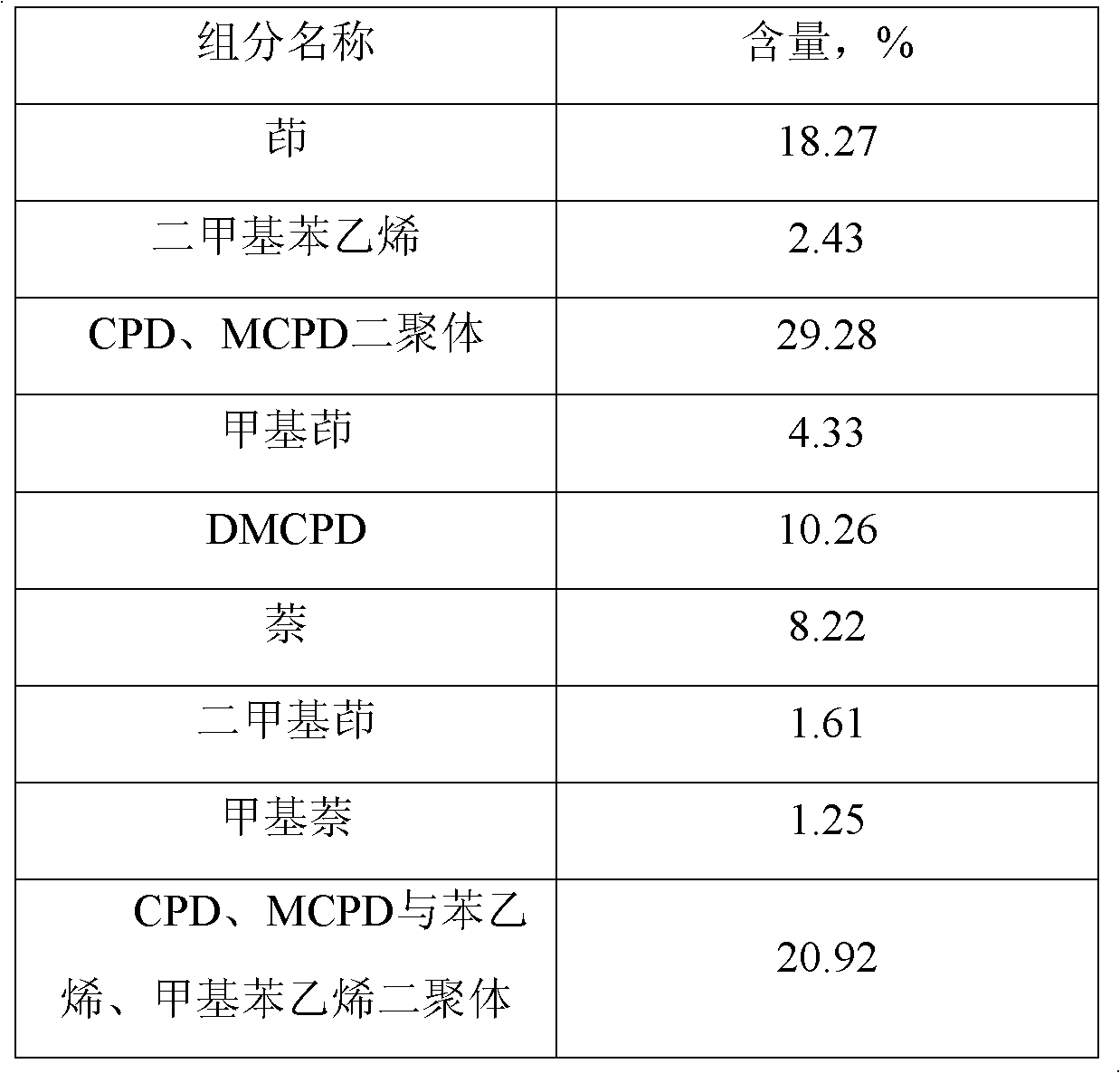

Method for extracting methyl cyclopentadiene from ethylene cracked C9 heavy fractions

ActiveCN102010285ANo preheating requiredIncrease profitDistillation purification/separationHydrocarbon by depolymerisationDepolymerizationGas phase

The invention relates to a method for extracting methyl cyclopentadiene from ethylene cracked C9 heavy fractions, which comprises the following steps of: (1) preheating C9 heavy fractions serving as a raw material and conveying to a depolymerizing reactor; (2) performing depolymerization reaction on the raw material; (3) adding a gas-phase material generated by depolymerization into a rectifying column T1; (4) adding a mixture of coarse cyclopentadiene and coarse methyl cyclopentadiene generated in the step (3) into a rectifying column T2 for further rectifying; (5) adding the residual material in the depolymerizing reactor into a coumarone resin reaction kettle to generate coumarone resin; (6) performing dimerization on the cyclopentadiene material to obtain dicyclopentadiene; (7) performing dimerization on the methyl cyclopentadiene material to obtain methyl cyclopentadiene dimer; and (8) adding the methyl cyclopentadiene dimer into a rectifying column T3, rectifying under reduced pressure, and removing light fractions on the tower top and heavy fractions at the tower bottom to obtain the methyl cyclopentadiene dimer on a side line. The method is simple and suitable for industrial application; and the purity of a product is not less than 98 percent.

Owner:HENGHE MATERIALS & SCI TECH CO LTD

Antifouling composition

An antifouling coating composition comprising: (I) a binder component comprising at least one hydrolysable copolymer and at least one hydrocarbon resin wherein the total amount of hydrocarbon resin forms 1 to 50 wt% of the binder component (I); and (II) at least one an antifouling agent; wherein said hydrocarbon resin comprises a resin formed by the polymerisation of at least one monomer selected from a C5 aliphatic monomer, a C9 aromatic monomer, an indene coumarone monomer, or a terpene.

Owner:JOTUN AS

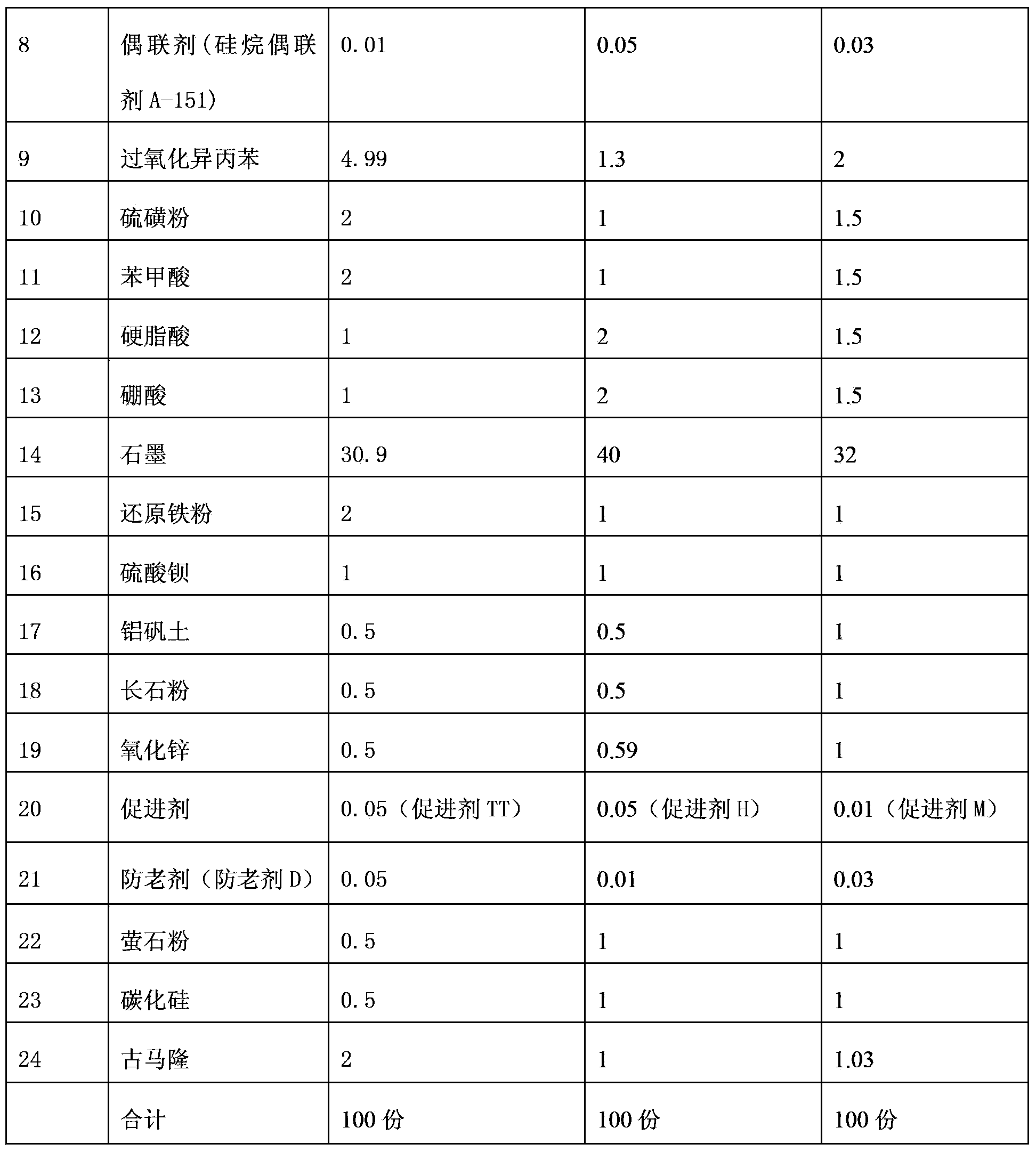

Automobile brake pad

ActiveCN103511512AFast heat conductionFlexibleOther chemical processesBraking membersEpoxyBenzoic acid

The invention provides an automobile brake pad which comprises a steel back and a friction material, wherein the friction material comprises the following materials in parts by weight: 1 to 10 parts of butylbenzene, 0.5 to 2 parts of cumyl hydroperoxide, 0.5 to 2 parts of epoxy resin, 1 to 15 parts of boric phenolic resin, 1 to 15 parts of polypropylene, 6 to 10 parts of nylon powder, 5 to 10 parts of boron nitride, 1 to 5 parts of dicumyl peroxide, 1 to 2 parts of sulphur powder, 1 to 2 parts of benzoic acid, 1 to 2 parts of stearic acid, 1 to 2 parts of boric acid, 50 to 60 parts of graphite, 5 to 8 parts of ceramic fibers, 0.5 to 1 part of potassium titanate, 1 to 2 parts of reduced iron powder, 1 to 2 parts of barium sulfate, 0.5 to 2 parts of bauxite, 0.5 to 2 parts of feldspar powder, 0.5 to 2 parts of zinc oxide, 0.5 to 2 parts of fluorite powder, 0.5 to 2 parts of silicon carbide and 0.5 to 2 parts of coumarone. The automobile brake pad is nuisanceless, pollution-free, noise-free, spark-free, wear-resistant and long in service life.

Owner:NINGBO JIA XUAN NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

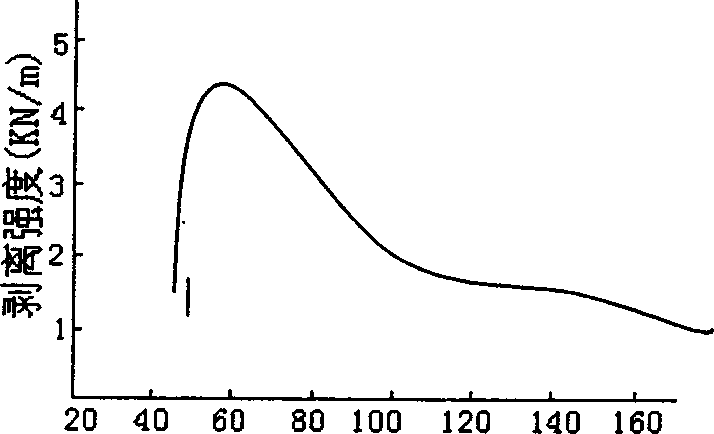

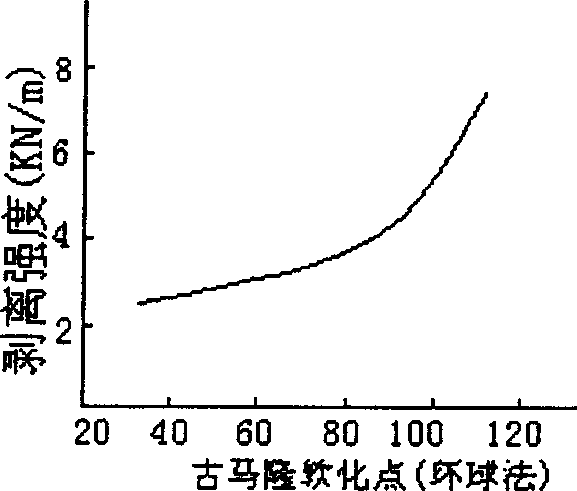

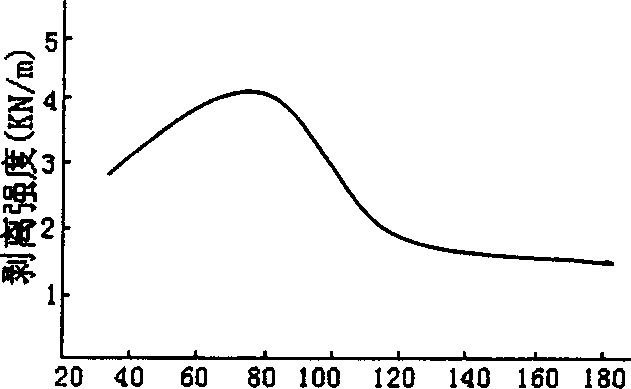

![New use of medicine containing benzophen [C] anthridine alkaloid and its derivatives New use of medicine containing benzophen [C] anthridine alkaloid and its derivatives](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/4747cdb9-f0b2-4fac-a997-a95d9b0a85ba/A20071006599500091.PNG)

![New use of medicine containing benzophen [C] anthridine alkaloid and its derivatives New use of medicine containing benzophen [C] anthridine alkaloid and its derivatives](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/4747cdb9-f0b2-4fac-a997-a95d9b0a85ba/A20071006599500101.PNG)

![New use of medicine containing benzophen [C] anthridine alkaloid and its derivatives New use of medicine containing benzophen [C] anthridine alkaloid and its derivatives](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/4747cdb9-f0b2-4fac-a997-a95d9b0a85ba/A20071006599500111.PNG)