Surface covering glue for high-temperature resistant wire rope core conveyer belt and preparation method of surface covering glue

A steel cord core and surface covering technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of easy wear of covering glue, limited use of steel cord conveyor belts, cracks, etc., to improve dynamic performance Performance and wear resistance, excellent thermal oxygen resistance, effect of increasing crosslinking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

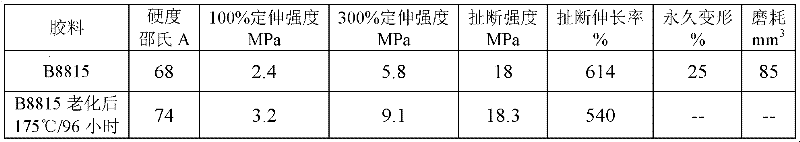

Image

Examples

Embodiment 1

[0017] The surface covering rubber of high heat-resistant steel cord conveyor belt, the formula ratio is as follows in parts by weight:

[0018] EPDM rubber: 100 parts, vulcanizing agent DCP (dicumyl peroxide): 4 parts, zinc oxide: 5 parts, vulcanization accelerator TAIC (triallyl isocyanurate): 2 parts, Cross-linking agent ZDMA (zinc methacrylate): 8 parts, stearic acid: 2 parts, antioxidant RD: 2 parts, antioxidant MB: 2 parts, antioxidant 6PPD: 2 parts, coumarone: 8 parts, Reinforcing carbon black N330: 25 parts, N550 carbon black: 25 parts, paraffin oil: 5 parts.

[0019] The preparation method of the surface covering rubber of the high heat-resistant steel cord conveyor belt is added according to the above formula, and the steps are as follows:

[0020] (1) Mixing: The internal mixer is mixed in two stages. In the first stage of mixing, EPDM rubber is added first, then Coumarone and paraffin oil are added, then N330 carbon black, N550 carbon black are added, and finally ...

Embodiment 2

[0029] A surface covering rubber for a high-heat-resistant steel cord conveyor belt, the formula ratio is as follows in parts by weight:

[0030] 70 parts of EPDM rubber; 3 parts of dicumyl peroxide DCP, 3 parts of zinc oxide, 1 part of triallyl isocyanuric acid TAIC, 5 parts of zinc methacrylate ZDMA, 1 part of stearic acid; 1 part of anti-aging agent RD, 1 part of anti-aging agent MB, 1 part of anti-aging agent 6PPD; 20 parts of N330 carbon black, 20 parts of N550 carbon black; 5 parts of coumarone, 5 parts of paraffin oil, after mixing, filming, molding and vulcanization Finally, the surface covering rubber of the high heat-resistant steel cord conveyor belt is obtained.

[0031] The preparation method of the surface covering rubber of the high heat-resistant steel cord conveyor belt is added according to the above formula, and the steps are as follows:

[0032] (1) Mixing: The internal mixer is mixed in two stages. In the first stage of mixing, EPDM rubber is added first,...

Embodiment 3

[0038] A surface covering rubber for a high-heat-resistant steel cord conveyor belt, the formula ratio is as follows in parts by weight:

[0039] 200 parts of EPDM rubber; 9 parts of dicumyl peroxide DCP, 8 parts of zinc oxide, 3 parts of triallyl isocyanuric acid TAIC, 10 parts of zinc methacrylate ZDMA, 4 parts of stearic acid 4 parts of antioxidant RD, 4 parts of antioxidant MB, 4 parts of antioxidant 6PPD; 30 parts of N330 carbon black, 30 parts of N550 carbon black; 10 parts of coumarone, 10 parts of paraffin oil, through mixing, filming, molding and After vulcanization, the surface covering rubber of the high heat resistant steel cord conveyor belt is obtained.

[0040] The preparation method of the surface covering rubber of the high heat-resistant steel cord conveyor belt is added according to the above formula, and the steps are as follows:

[0041] (1) Mixing: The internal mixer is mixed in two stages. In the first stage of mixing, EPDM rubber is added first, then C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com