Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2882results about How to "Uniform particles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boiling bed hydrogenation treatment catalyst and its preparing process

ActiveCN101240190AThe reaction equipment is simpleReduce operating costsRefining to eliminate hetero atomsLow speedSpherical shaped

The invention relates to a boiling bed hydrogenation catalyst and a preparation method. The boiling bed hydrogenation catalyst of the invention is spherical shape which diameter is 0.1mm to 0.8mm, and has appropriate amount of additives and hydrogenation of metal components, and has reasonable hole distribution. The catalyst preparation method of the invention is spherical carrier impregnation, the process of spherical carrier preparation is following: making catalyst carrier raw material which is in appropriate temperature into appropriate size grain, then spheroidizing the grain, heating the conglobation and making them into spherical catalyst carrier. The process for making the catalyst carrier raw material into the appropriate size grain is that wet stock passes screen stencil by mechanical action and generates grain. Between the processes of the making grain and nodularization, granular material primely is placed for a period of time or operates in low-speed in nodularization device for a period of time. The catalyst of the invention appropriately conducts the boiling bed hydrogenation for heavy oil, residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Phosphate film-coated powder and preparation method thereof

InactiveCN101045828AUniform particlesParticle size distribution andNon-macromolecular adhesive additivesOther chemical processesDepolymerizationDouble decker

This invention relates to a method of preparing envelope powder. The shattering, depolymerization and coating processed at same time, and solid phase acid-base reaction participate the method. This envelope powder possess double-decker or three-layer structure, inner core is composed by oxide or hydrate or inorganic oxysalt, crust composed by inorganic oxysalt, envelope by aluminum phosphate or boron phosphate. This low cost powder be able to used as fortifier, power stuff, colorant and so on, applied to plastic, rubber, ceramics, dope, binder and paper, set foundation for popularization of ultramicro and nanometer powder.

Owner:张义纲 +1

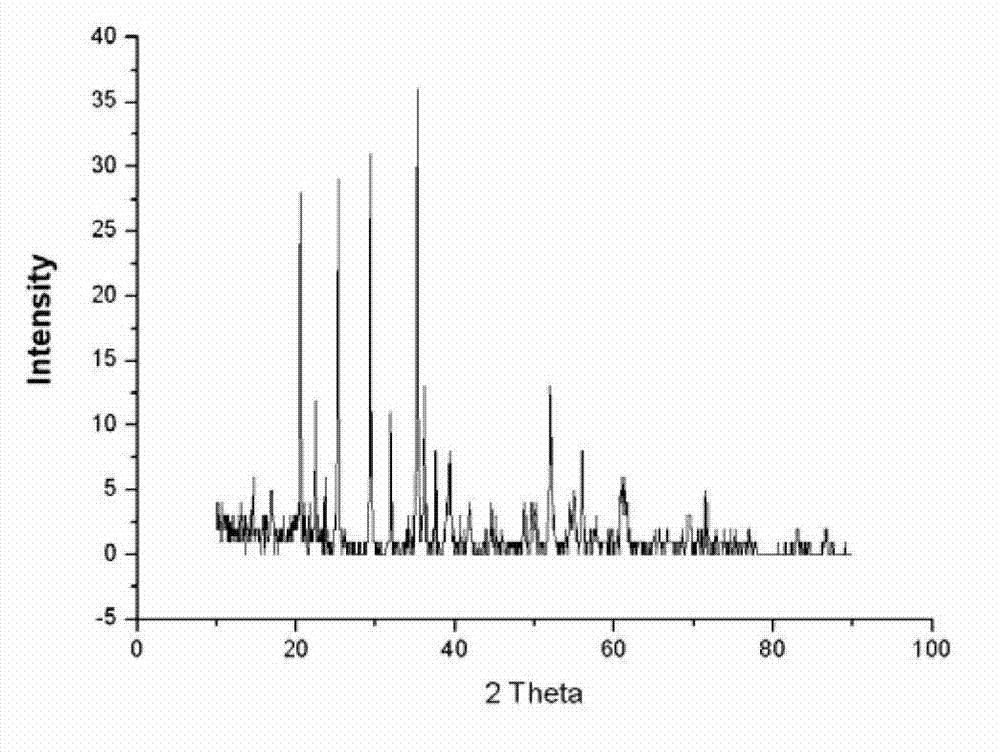

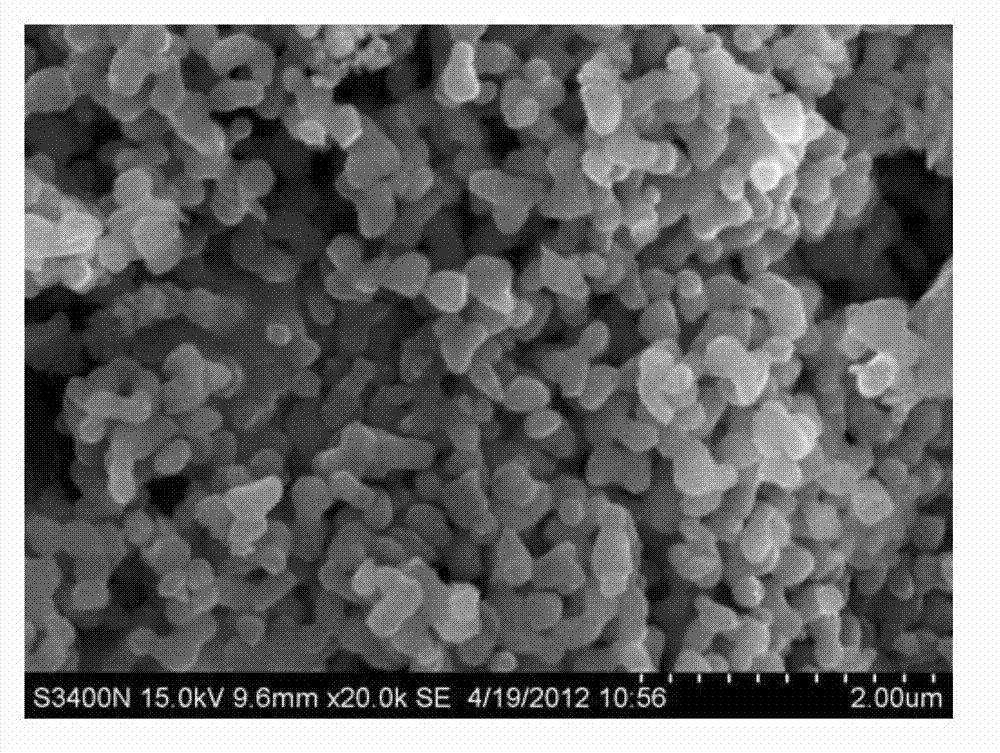

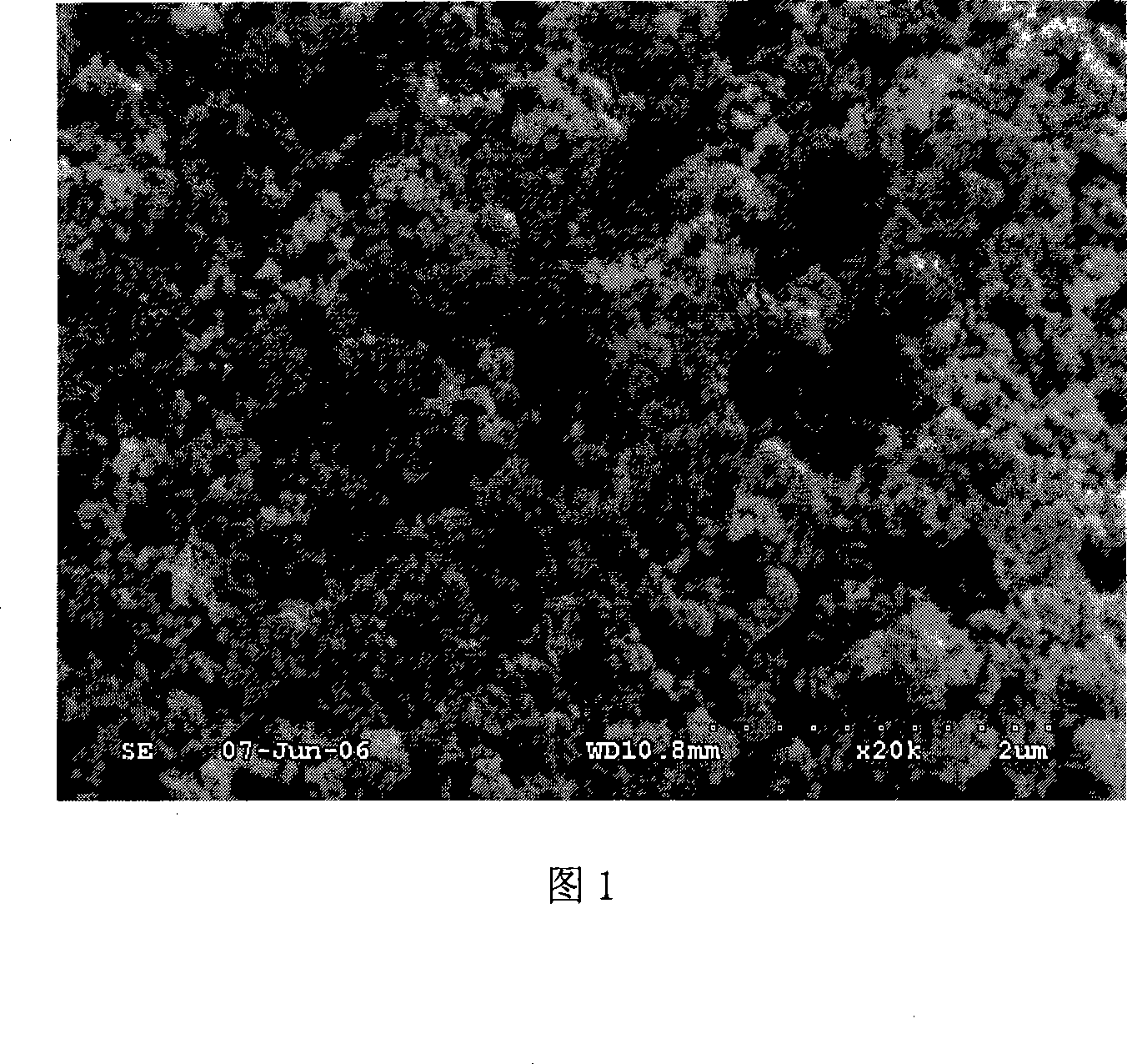

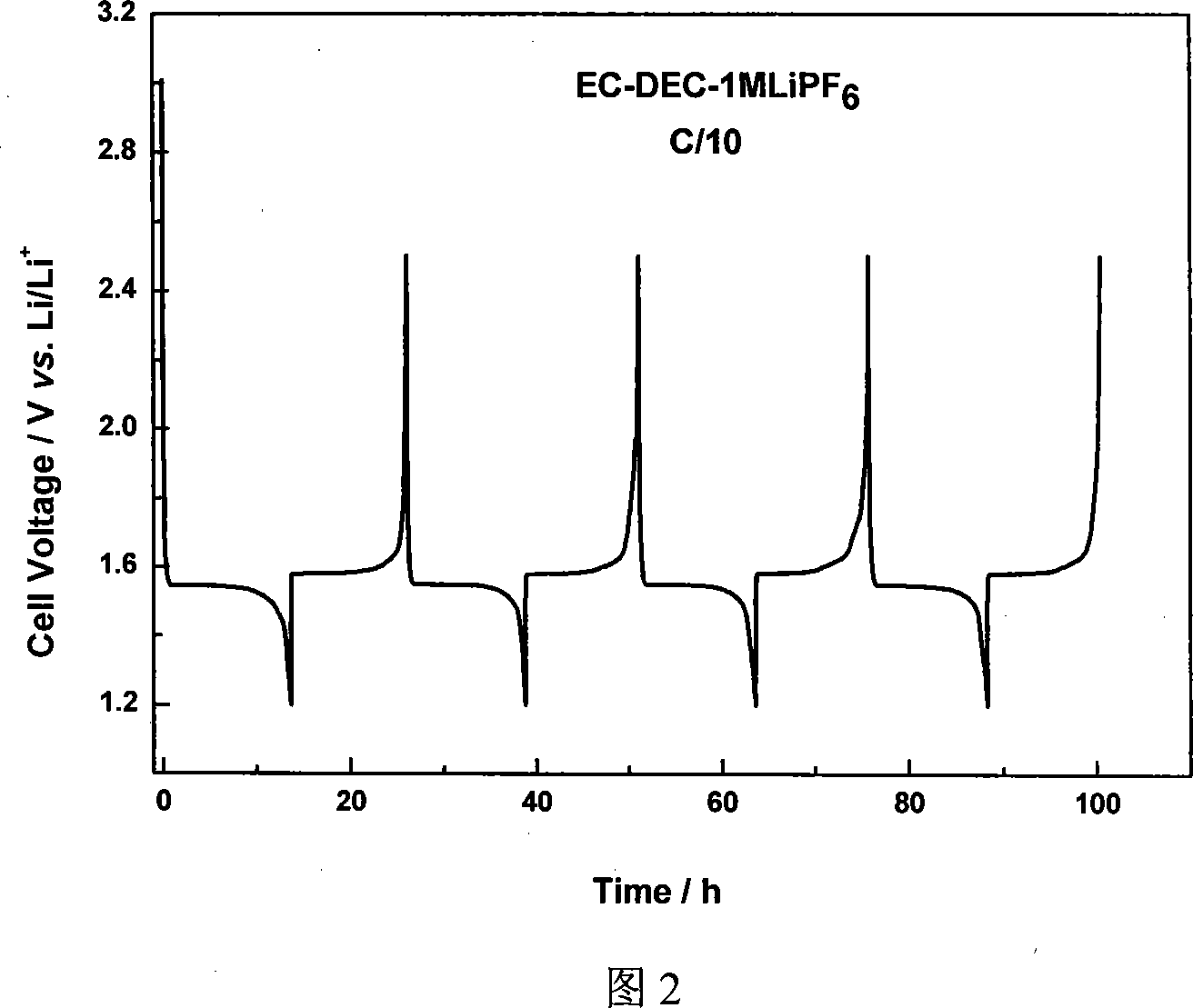

Nanoscale lithium titanate compound and preparation method thereof

ActiveCN101630732AEnabling molecular-scale mixingHigh purityElectrode manufacturing processesActive material electrodesLithium compoundCharge and discharge

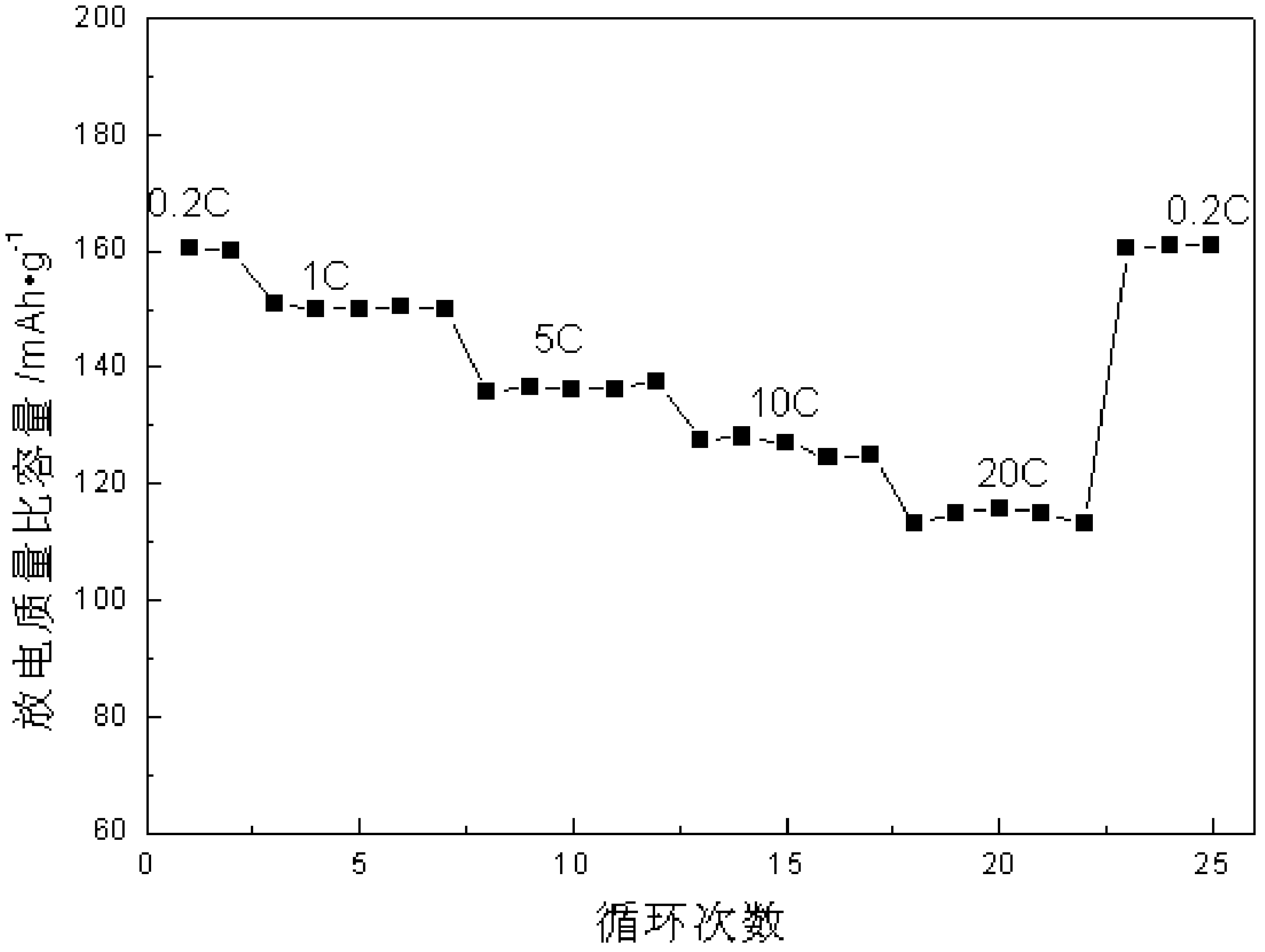

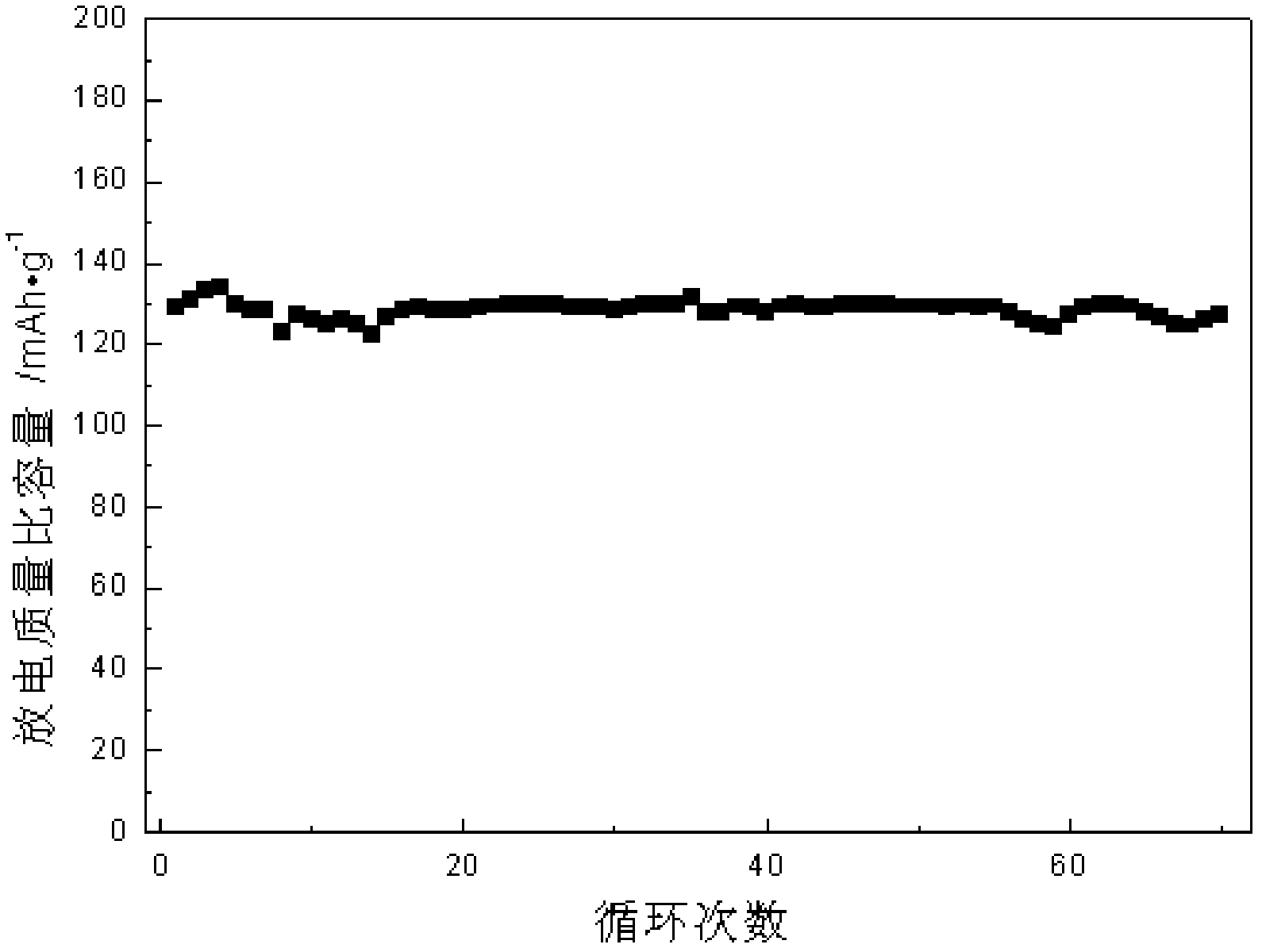

The invention relates to a nanoscale lithium titanate compound and a preparation method thereof. The nanoscale lithium titanate compound is prepared by following steps: a lithium compound, a titanium compound and a doped element compound are mixed according to a molar ratio of 0.75-0.80:1:0:0.05 of Li to Ti to doped elements so as to form a mixture A; the mixture A and a complexing agent are mixed according to a weight ratio of 1:0.1-10 and dissolved in water to form a mixture B; and the mixture B and a carbon nanotube dispersion C are mixed to form the nanoscale lithium titanate compound coated by carbon nanotubes with a nanoscale grain size. The preparation method comprises the following steps: mixing the mixture B and the carbon nanotube dispersion C; heating an obtained mixture in nitrogen at 100-200 DEG C for 1-2 hours to obtain gel; and sintering the obtained gel in inert atmosphere at 500-1,000 DEG C for 5-48 hours to obtain the powdered lithium titanate compound. The lithium titanate compound is nanoscale lithium titanate coated by the carbon nanotubes, has fine and even grain and high purity and has the characteristics of higher charge and discharge capacity, good rate discharge performance, good cycle performance and good safety performance, and the like, thus the lithium titanate compound is an ideal anode material for manufacturing a lithium ion battery.

Owner:SHENZHEN DYNANONIC

Preparation method of graphene-base tin dioxide composite anode material for lithium ion batteries

InactiveCN101969113AWell coveredExcellent electrochemical performanceNon-aqueous electrolyte accumulator electrodesElectrochemistryLithium electrode

The invention relates to a preparation method of a graphene-base tin dioxide composite anode material for lithium ion batteries, which belongs to the technical fields of material science and electrochemistry. The method for preparing graphene-base tin dioxide comprises the following steps: 1. dispersing graphite oxide nanosheets in an ethanol C2H5OH solution; 2. adding a certain amount of template agent cetyl trimethyl ammonium bromide (CTAB) into the suspension, adding a certain amount of tin tetrachloride hydrate (SnCl4.5H2O) and sodium hydroxide (NaOH) while vigorously stirring, and continuing stirring for 30 minutes; 3. after stirring, transferring the suspension into a high pressure reaction kettle, reacting in a baking oven at 160 DEG C for 20 hours, and washing the reaction product with ethanol and deionized water many times; and 4. carrying out vacuum drying on the product at 60 DEG C for 8 hours to obtain the graphene-base tin dioxide composite material.

Owner:SHANGHAI UNIV

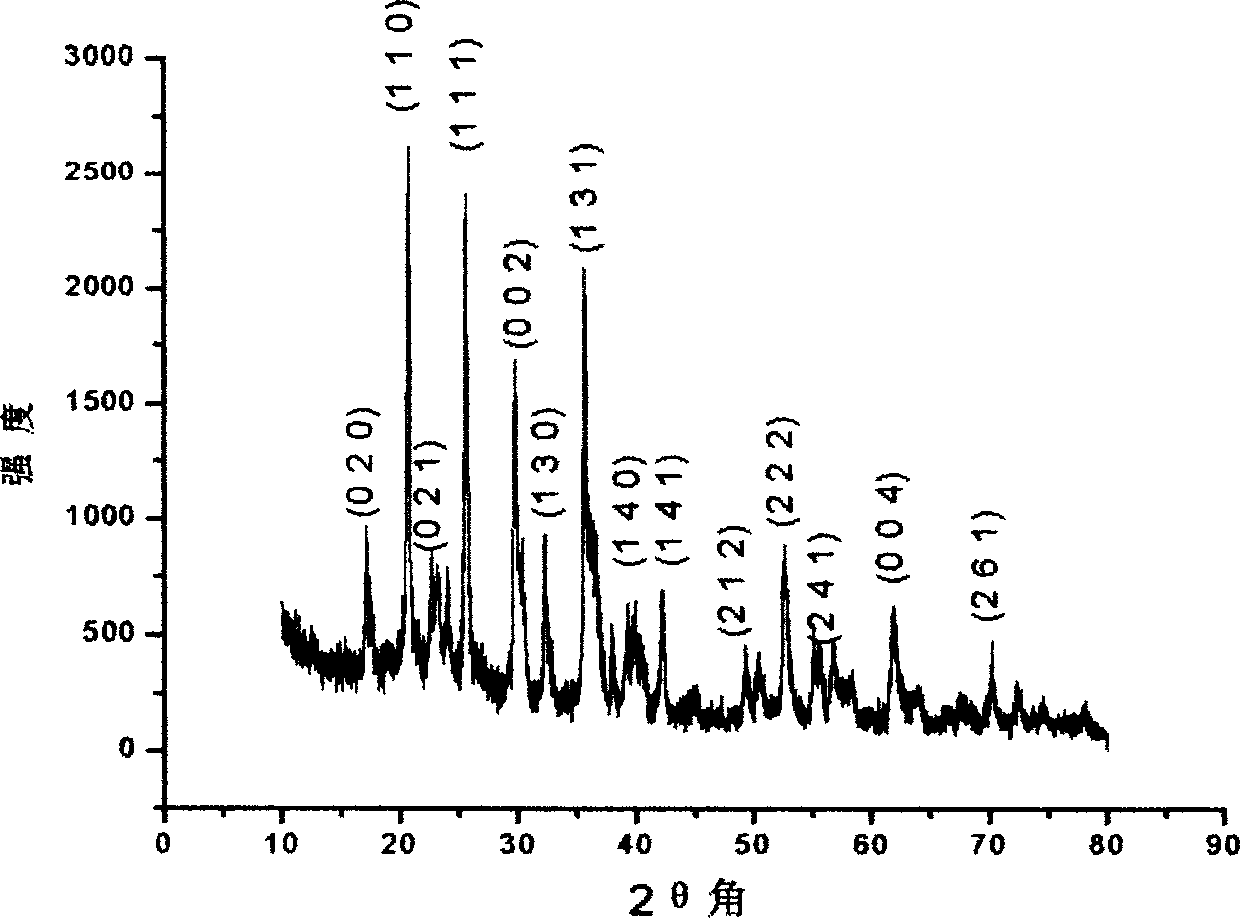

Preparation method of multicrystal LiFePO4 powder having olivine structure

InactiveCN1410349ASolve easy oxidationSolve precipitationCell electrodesRare earth metal compoundsOrganic acidGranularity

A polycrystalline LiFePO4 powder with olivine structure is prepared from Fe(Ac)2, FeSO4.7H2O, Ba(Ac)2 and organic acid by the sol-gel method. Its advantages are short period, low burning temp., low energy consumption, high purity and electric conductivity, and high granularity uniformity. It is suitable for making Li-ion battery.

Owner:TSINGHUA UNIV

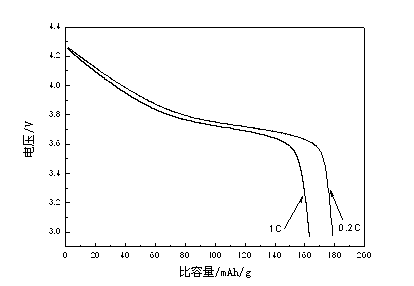

Nano lithium iron phosphate material and preparation method thereof

InactiveCN101546830ASolve the real problemSmall particlesElectrode manufacturing processesChemical/physical/physico-chemical processesChemical compositionLithium iron phosphate

The invention relates to a nano lithium iron phosphate material and a preparation method thereof. A lithium source, an iron source, a phosphate radical source and a doped element compound are dissolved in water solution containing a complexing agent according to a stoichimetric proportion and added with high-conductive carbon nano tubes scattered by assistant to form a cladding material, the obtained solution is sintered in an inert atmosphere furnace, the reaction temperature is between 500 and 900 DEG C, and the reaction time is 3 to 16 hours. The method effectively controls the chemical components, phase components and grain diameters of LiFePO4; and the obtained lithium iron phosphate is the nano lithium iron phosphate clad by the carbon nano tubes, has fine and even grains with high purity, high charge / discharge capacity, good multiplying power performance and good cycle performance, and is an ideal material for manufacturing lithium ion batteries.

Owner:SHENZHEN DYNANONIC

Multi-layer graphene/lithium iron phosphate intercalated composite material, preparation method thereof, and lithium ion battery adopting multi-layer grapheme/lithium iron phosphate intercalated composite material as anode material

InactiveCN102306783AImprove electronic conductivityReduced Diffusion ResistanceCell electrodesSecondary cellsHigh rateSlurry

The invention relates to a lithium iron phosphate intercalated composite material, a preparation method thereof and a lithium ion battery adopting the multi-layer graphene / lithium iron phosphate intercalated composite material as an anode material. In the prior art, the electronic conductivity of the lithium iron phosphate material is poor, high-rate charging / discharging capacity of the lithium ion battery adopting the lithium iron phosphate material as the anode material is poor. The purpose of the present invention is to solve the problems in the prior art, and improve the rapid charging capacity of the power lithium ion battery so as to meet the requirements of the pure electrocar. The composite material is prepared through the following steps that: a rheological phase reaction method is adopted for multi-layer graphene, a trivalent iron salt, a phosphorus compound, a lithium compound and carbon source of small organic molecule to obtain a composite precursor, then the precursor is sintered to obtain the multi-layer graphene / lithium iron phosphate intercalated composite material. The anode slurry of the lithium ion battery anode plate comprises the composite material, a conductive agent and polyvinylidene difluoride. The composite material is an intercalated structure, wherein the lithium iron phosphate particles are intercalated between the multi-layer graphene to form the intercalated structure. The trivalent iron salt is adopted as the raw material, such that the cost is reduced. The lithium ion battery has good charging / discharging cycle performance, wherein the specific capacity is more than 60 mA.h.g<-1> at the rate of 20C.

Owner:HARBIN INST OF TECH

Catalyst for producing 1.4-butynediol and preparation method of catalyst

ActiveCN102950002AEasy to prepareSimple manufacturing methodOrganic compound preparationHydroxy compound preparationSlurry reactorPtru catalyst

The invention discloses a catalyst for producing 1.4-butynediol and a preparation method of the catalyst, belonging to the technical field of load type catalysts for a slurry reactor. The catalyst for producing 1.4-butynediol is characterized in that nanosilicon dioxide is used as a carrier, the nanosilicon dioxide has larger external specific surface area, copper and bismuth are absorbed on the carrier by adopting an impregnation and deposition-precipitation method, so that the catalyst contains 35-65 percent of copper oxide, and then a defined amount of silica sol is added, and through a specific forming method, the granularity of the catalyst is between 1micrometer and 50 micrometers. The prepared catalyst has the characteristics of good activity, high selectivity, high strength, easiness in separation, high particle uniformity, and difficulty in pulverization in a use process; and the preparation method of the catalyst is simple and easy to operate and good in repeatability.

Owner:河北瑞克新能源科技有限公司

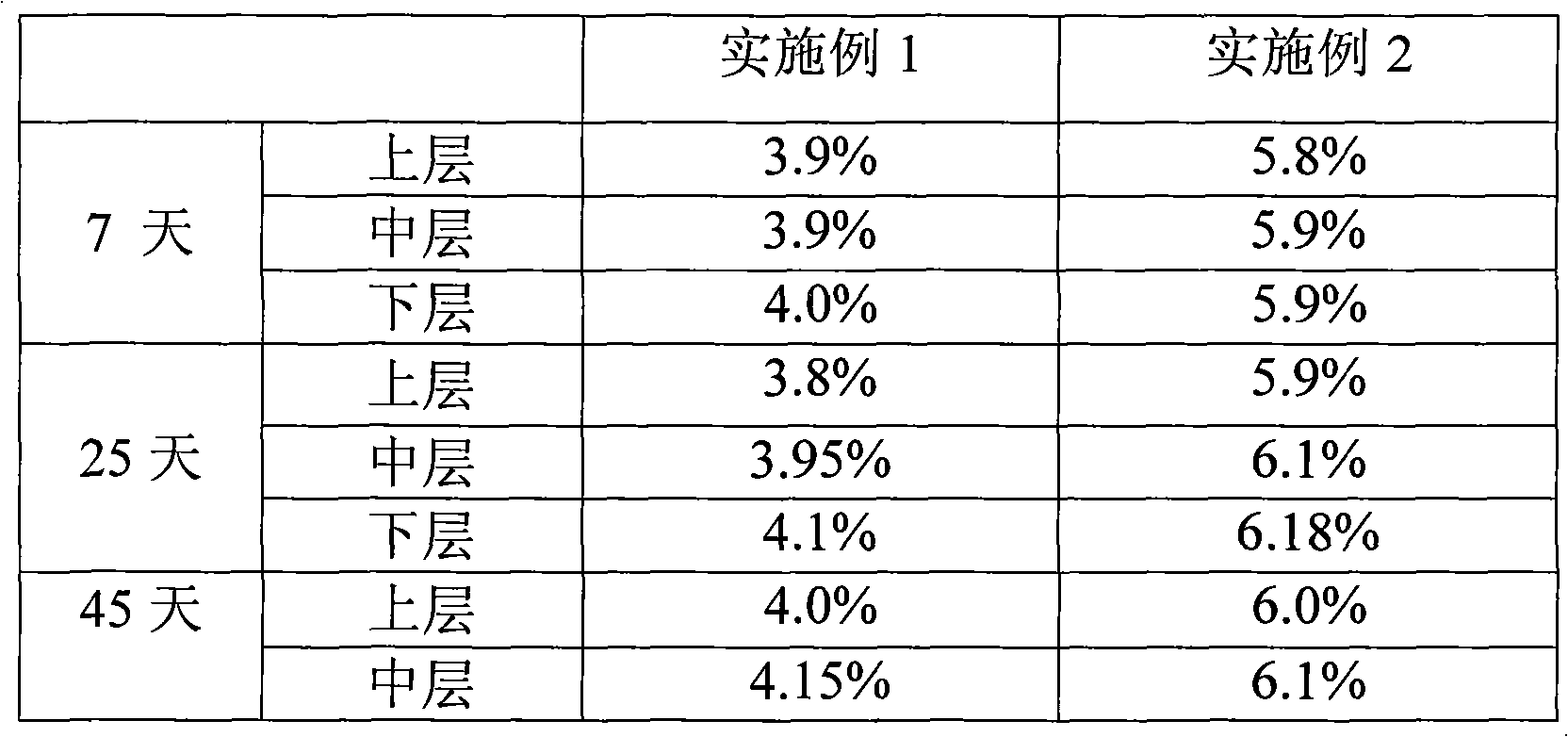

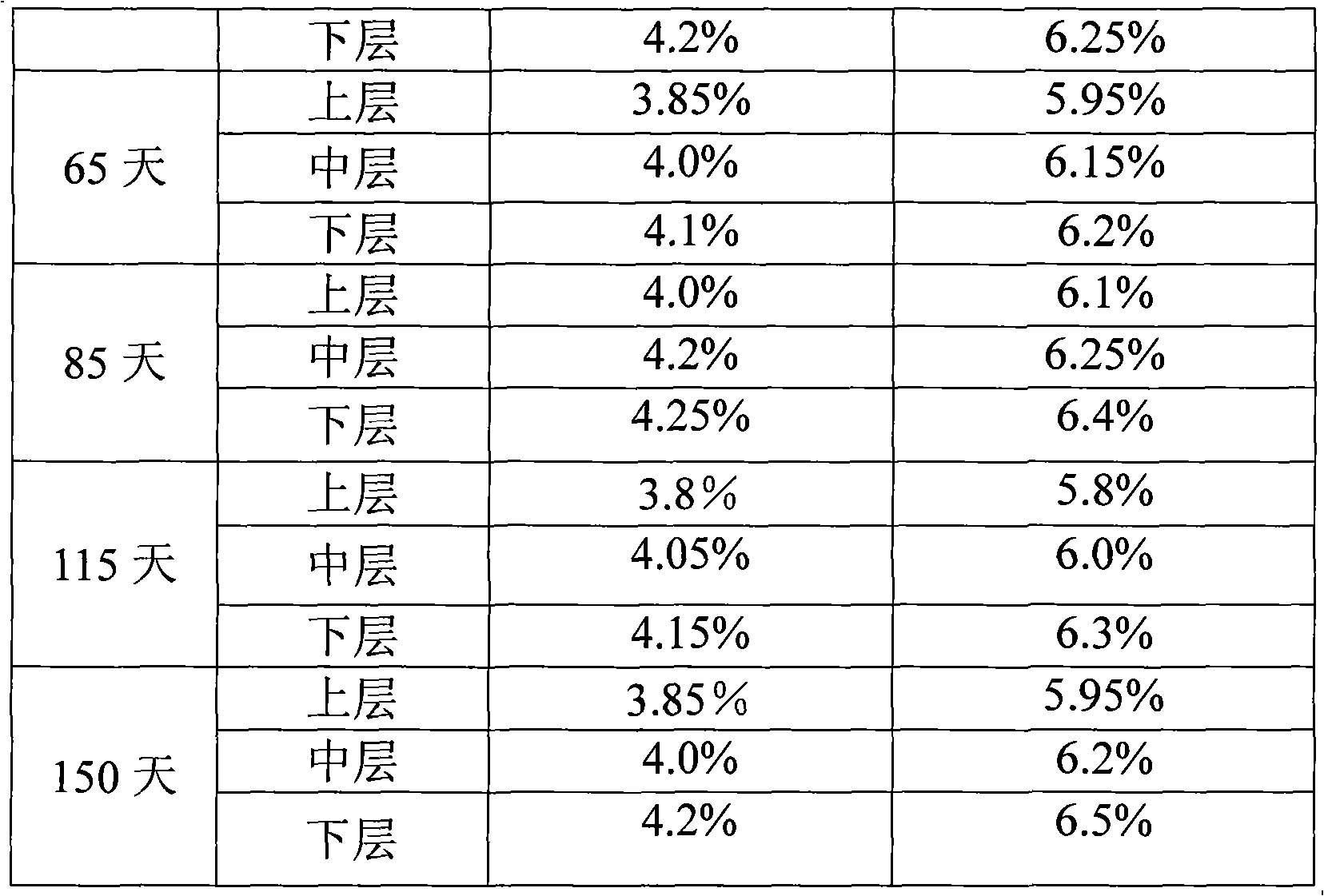

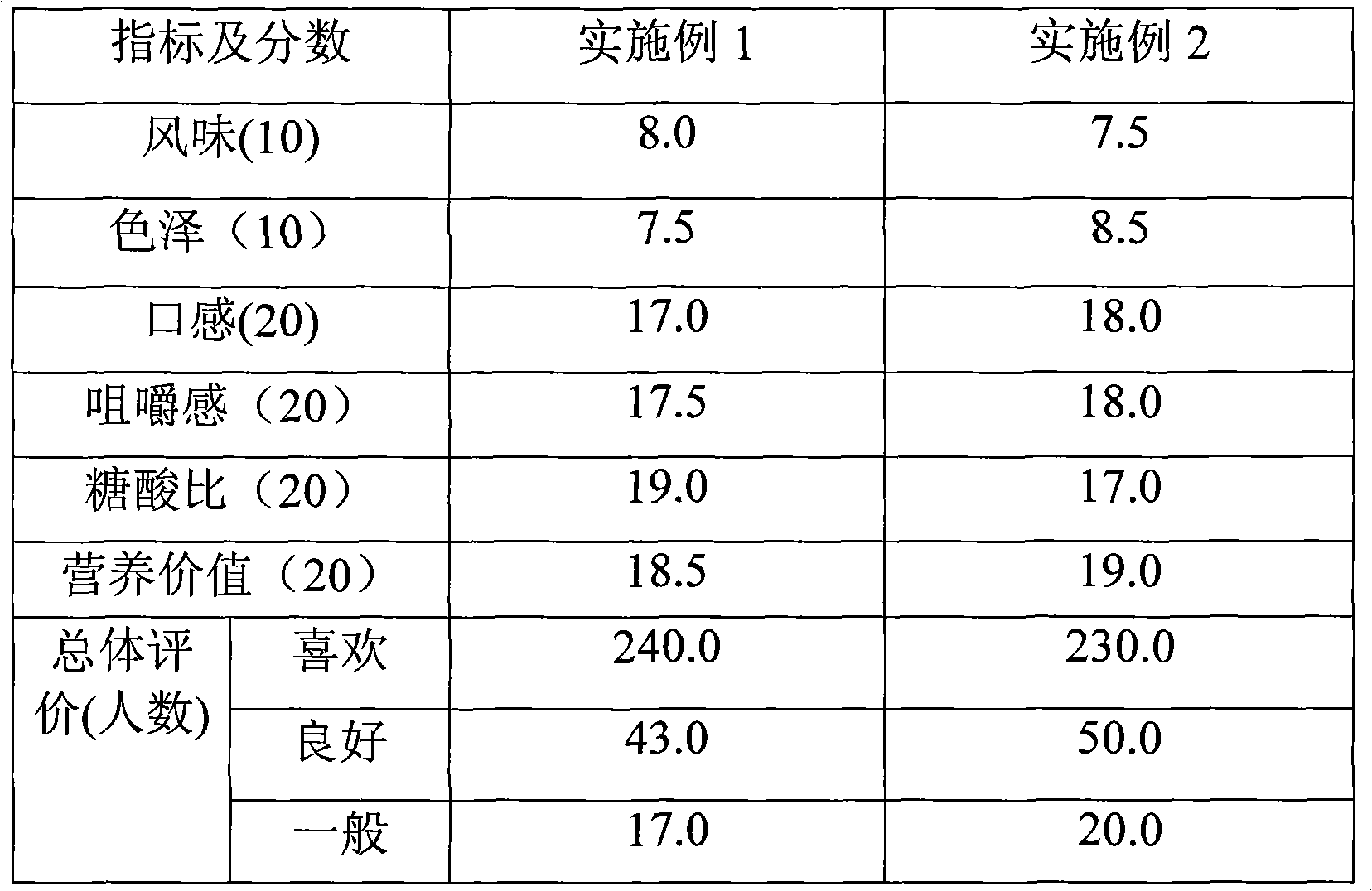

Milk and dairy food containing fruit granules and method for producing the same

The present invention relates to a diary product containing fruit granules. Every 100 weight parts of the diary product of the present invention contains 30 to 80 parts of milk and milk product, 1 to 15 parts of fruit granules, 0.2 to 1.0 part of stabilizer compound and 0.25 to 0.6 part of acidity regulator; wherein, the stabilizer compound contains modified bio-fermentation polysaccharide and thickener; the fruit granule contains coconut juice fermented polysaccharide granule and fruit vegetable granule. A production method of the diary product containing fruit granules is also related by the present invention.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

TiO2 supported manganese-cerium composite oxide catalyst and preparation method thereof

InactiveCN101352680AHigh catalytic activityUniform particlesDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsDispersityAdditive ingredient

The invention discloses a manganese-cerium complex oxide catalyst loaded by TiO2, which takes nanometer titanium dioxide as a carrier and the manganese-cerium complex oxide loaded on the carrier as an active ingredient. The mole ratio of each ingredient is that Ti: Mn: Ce is equal to 1: (0.05 to 1): (0.05 to 1). The invention also discloses a preparation method of the catalyst, which adopts sol-gel preparation technology to promote the dispersity and strength of the two ingredients of manganese and cerium on a TiO2 carrier. Furthermore, the catalyst prepared by adopting the preparation method has the advantages of high catalytic activity and uniform particles; active substances is good in dispersity and is hard to sinter; when used in low-temperature SCR reaction, the catalyst can greatly lower the operation temperature and the operation cost of the SCR since the catalyst has a very high removal rate of NO at the temperature about 120 DEG C.

Owner:ZHEJIANG UNIV

Preparation method of nano-grade lithium manganese phosphate anode material

The invention discloses a preparation method of a nano-grade lithium manganese phosphate anode material, comprising the following steps of: preparing a lithium source, a manganese source, a phosphorus source and a doping element compound into a solution in a mol ratio of Li: Mn: P: the doping element of (0.9-1): (0.9-1): (0.9-1): (0-0.1); adding a complexing agent and adding a carbon source into the solution to obtain a uniform colloid; drying the colloid to obtain precursor powder; heating the precursor powder under a protective atmosphere to obtain nano powder; and sintering the nano powder under a protective atmosphere to obtain the nano-grade lithium manganese phosphate anode material. The method belongs to one of a liquid-phase method; each element is at an ion or molecule state in a synthesizing process and the mixing is more uniform; on the basis of the existing liquid-phase method, the synthesizing time is further shortened, a production process is simplified and the cost is reduced; and the nano grade and the purity of a synthesized product are high, the grain diameter is 10-400 nm and the electrochemical performance is good.

Owner:FOSHAN DYNANONIC

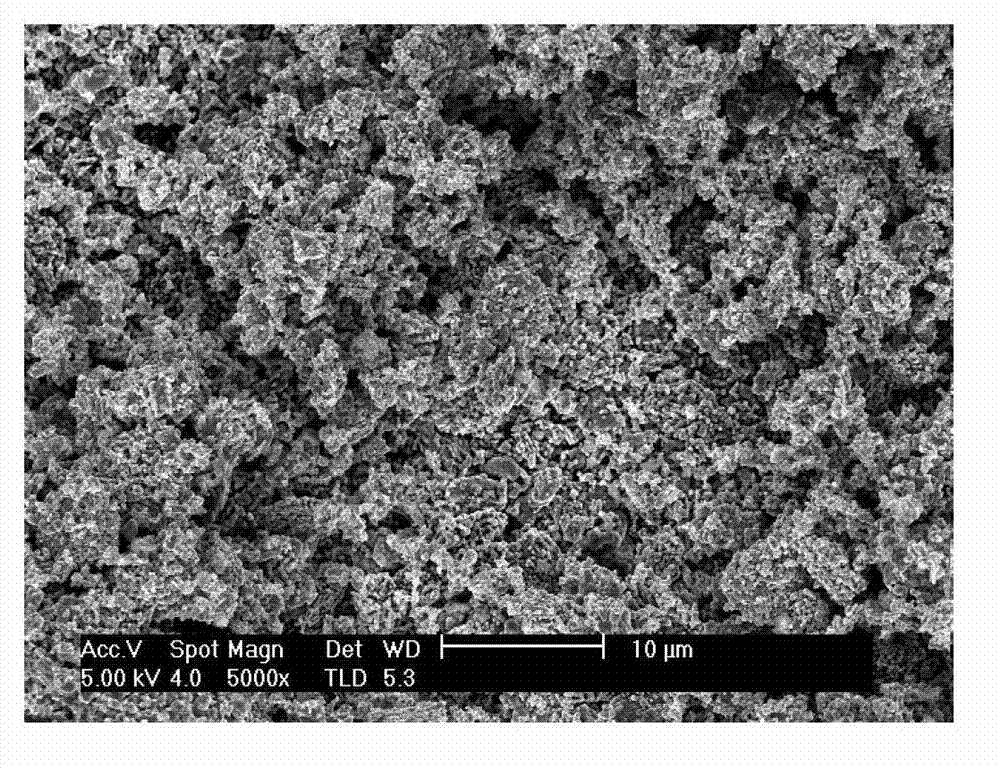

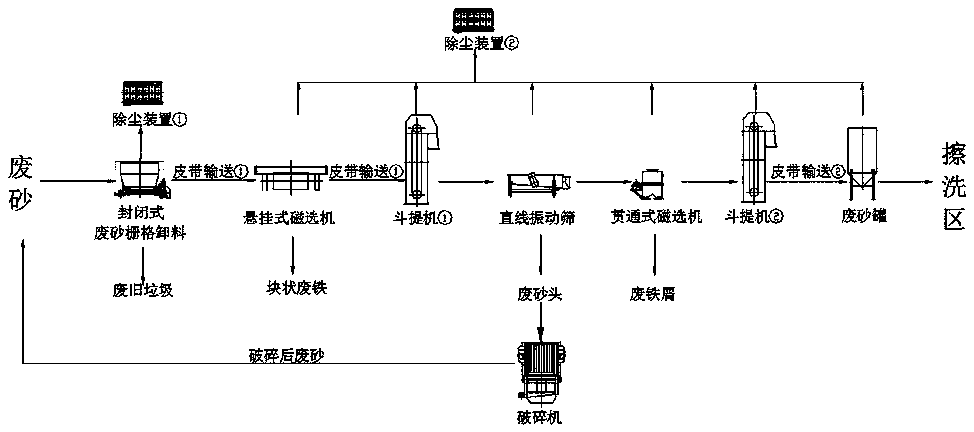

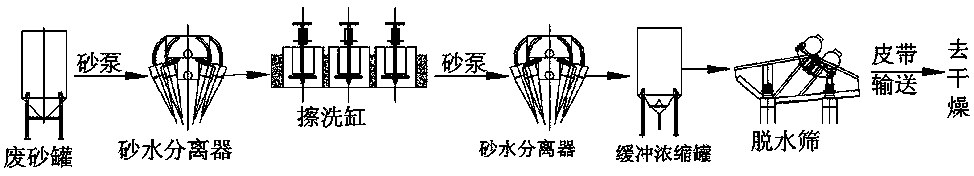

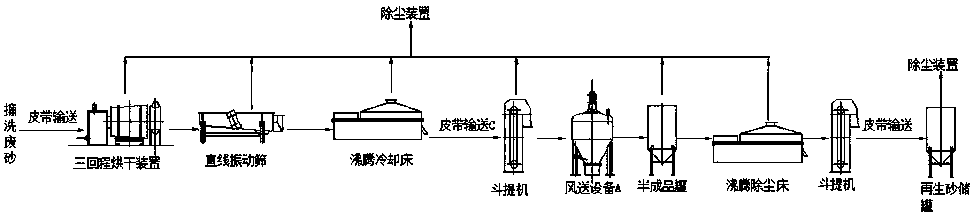

Foundry waste sand regeneration and reuse method and device

ActiveCN103406490ALow impurity contentReduce workloadMould handling/dressing devicesMagnetic separatorIon

A foundry waste sand regeneration and reuse method comprises the following steps: pretreatment of waste sand: the original waste sand is removed with waste garbage through a closed grid unloader, removed with waste iron through a suspension type magnetic separator, removed with large-particle waste sand through a linear vibrating screen, and removed with waste scrap ions through a cut-through magnetic separator, and then enters a waste sand storage tank for storage; cleaning of waste sand: the pretreated waste sand is conveyed to a cleaning area through a sand pump, is introduced to the sand-water separator to remove part of water, then enters a scrubbing-cleaning combined tank for scrubbing and cleaning, enters a buffering concentration tank for sedimentation and concentration, and finally enters a dewatering screen to get rid of part of the water; drying: after the above processing, the waste sand is subjected to low-temperature drying or high-temperature roasting to obtain reclaimed sand, then the reclaimed sand is put into a regeneration sand tank for storage; lamination of regenerated sand: the measured regenerated sand is heated to a certain temperature through a heater, and is put into a precoated sand blender together with adhesive to mix evenly, then the mixture is cooled to room temperature to obtain the precoated sand, and the precoated sand is put into a bucket for storing finished sand.

Owner:广西兰科资源再生利用有限公司

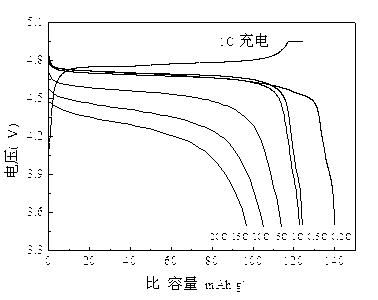

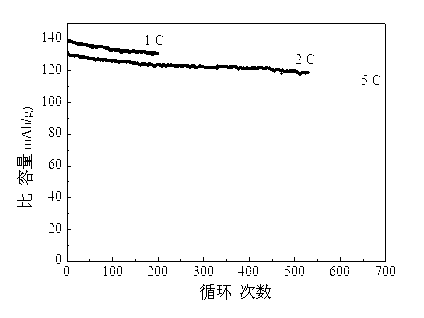

Preparation method of positive pole material (spinel type lithium nickel manganese oxide) of high-voltage lithium ion battery

ActiveCN103227323AAccurately control the ratioReduce concentrationCell electrodesElectrical batteryNickel compounds

The invention relates to a preparation method of a positive pole material (spinel type lithium nickel manganese oxide) of a high-voltage lithium ion battery, which comprises the following steps: simultaneously dissolving a lithium-containing compound, a manganese-containing compound and a nickel-containing compound instead of adding a lithium source afterwards, and ensuring that the lithium compound, the nickel compound and the manganese compound are evenly mixed; and adding precipitant to generate manganese-containing precipitate, wherein the generated manganese-containing precipitate provides crystal nuclei for further precipitation in the hydrothermal process, particles having different sizes can be obtained by controlling hydrothermal conditions, the particle sizes of the products can be increased by decreasing the concentrations of the metal salts, increasing the hydrothermal temperature and prolonging the hydrothermal time, and materials having different shapes can be obtained or porous materials can be prepared by adding different additives. The method omits the steps of filtration and water washing; and the synthesis process is economic and environment-friendly. The lithium nickel manganese oxide material prepared by the invention is in a spinel structure, and is high in crystallinity and excellent in electrochemical performance; and the specific capacity can be up to 130-142mAh / g, 120-135mAh / g and 105-120mAh / g in case of 1C, 2C and 5C rate discharge.

Owner:南京时拓能源科技有限公司

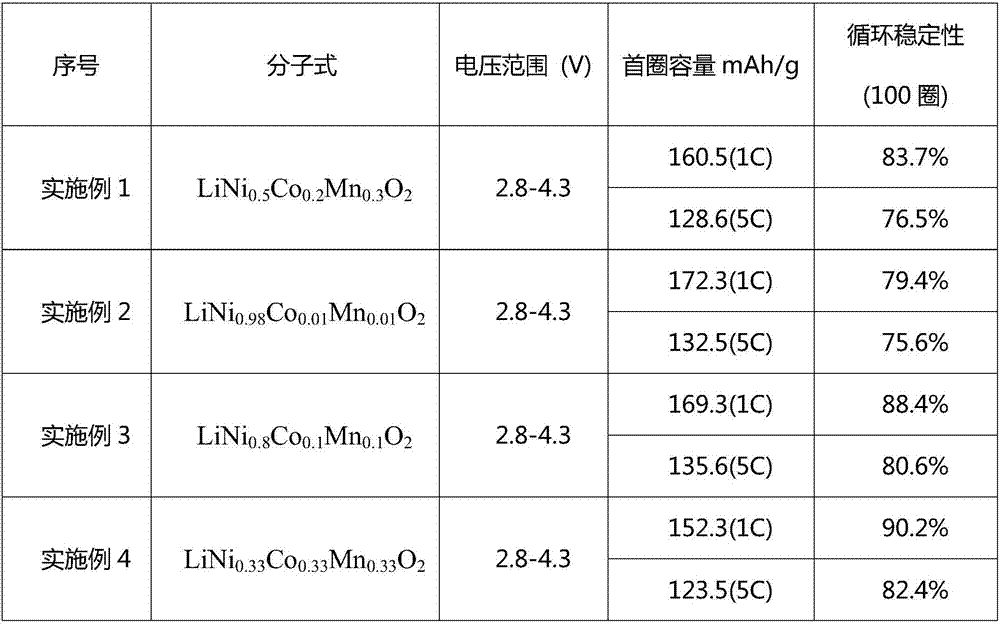

Nickel cobalt lithium manganate composite cathode material and preparation method of nickel cobalt lithium manganate composite cathode material

The invention relates to a nickel cobalt lithium manganate composite cathode material and a preparation method of the nickel cobalt lithium manganate composite cathode material. The nickel cobalt lithium manganate composite cathode material has the chemical formula of Li(NixCoyMn<1-x-y>)O2. The preparation method comprises the steps that after soluble nickel salts, cobalt salts, manganese salts and complexing agents are uniformly mixed, sodium hydroxide precipitating agents are added, the reaction is carried out in a stirring reactor with an ultrasonic device, composite hydroxides of nickel cobalt manganate are obtained, then, the composite hydroxides, water soluble macromolecular compounds and lithium source compounds are placed in the stirring reactor with the ultrasonic device, the spray drying is carried out in the ultrasonic reinforced stirring mixing process, and nickel cobalt lithium manganate precursors are obtained, the precursors are subjected to primary sintering under the certain atmosphere protection, and nickel cobalt lithium manganate products are obtained. When the nickel cobalt lithium manganate composite cathode material and the preparation method are adopted, the prepared product particles are uniform, the morphology is regular, the specific surface area is small, the tap density is high, the electrochemical performance is excellent, the processing performance is good, the cost is low, the environment-friendly effect is realized, and the environment pollution is avoided.

Owner:CENT SOUTH UNIV

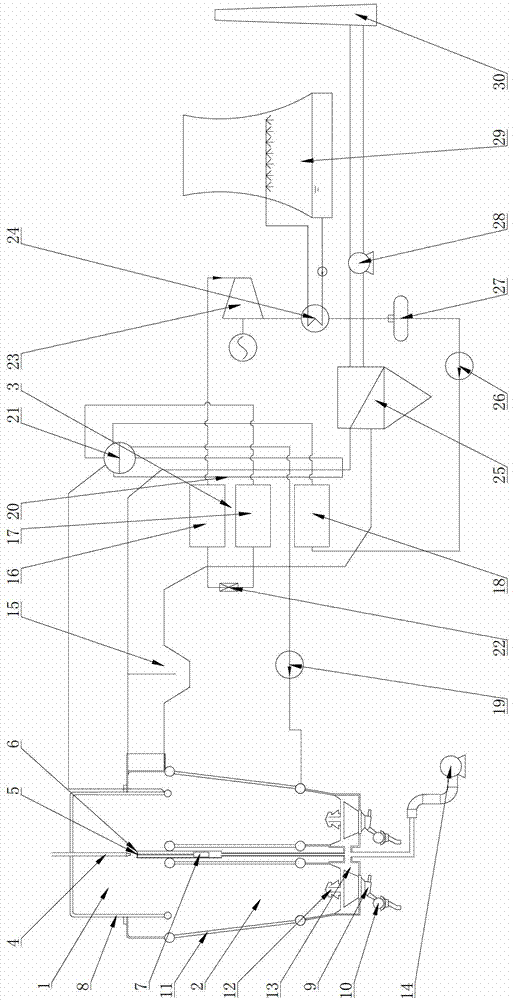

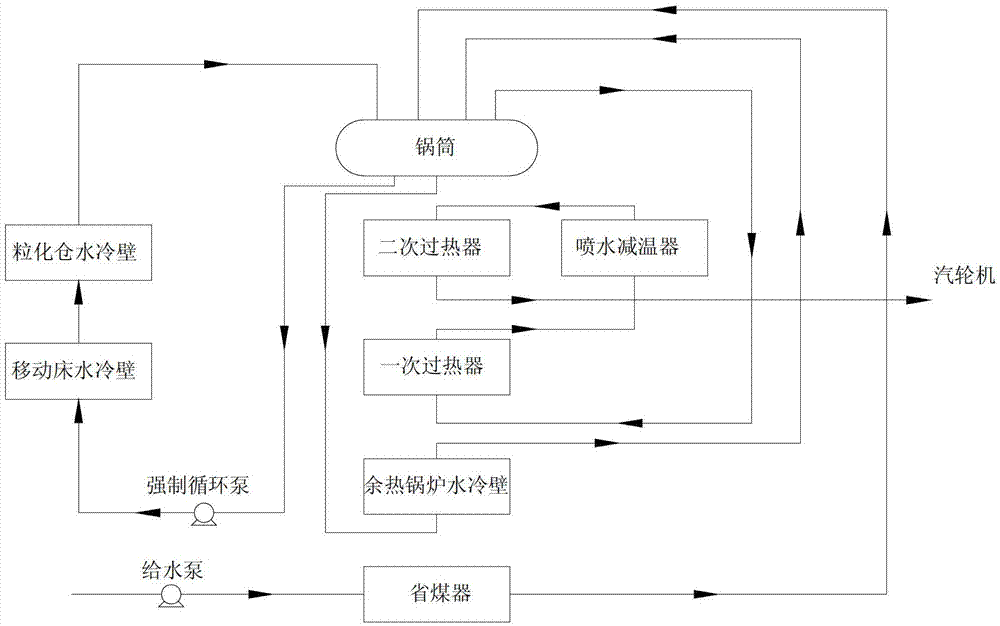

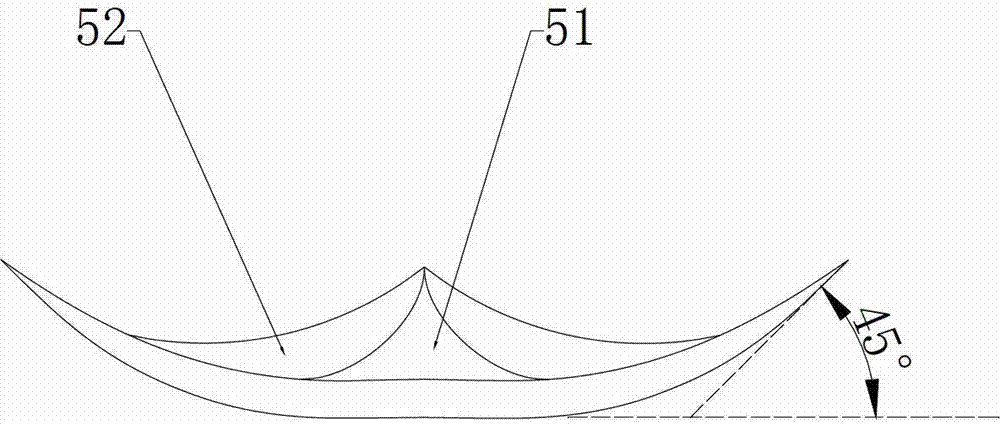

Afterheat recovery system and method of dry granulating liquid slag

ActiveCN102827969AEasy to diluteImprove granulation effectIncreasing energy efficiencyRecycling and recovery technologiesRecovery methodLiquid slag

The invention discloses an afterheat recovery system and an afterheat recovery method of dry granulating liquid slag. The system comprises a granulating cabin, a moving bed and an afterheat recovery system, the inner surface of the granulating cabin is provided with a granulating cabin water cooling wall, the center of the top of the granulating cabin is provided with a slag pipe, the slag pipe extends into the granulating cabin, the lower part of the tail end of the slag pipe is provided with a centrifugal granulator, the centrifugal granulator is connected with a motor arranged at the lower part of the centrifugal granulator, the lateral side of the centrifugal granulator is provided with an air supply pipeline, an annular air opening is formed between the centrifugal granulator and the air supply pipeline, the lower part of the granulating cabin is provided with the moving bed, the inner surface of the moving bed is provided with a moving bed water cooling wall, the top of the moving bed is provided with an air outlet, the bottom of the moving bed is provided with a slag discharge device, an air inlet device is arranged above the slag discharge device, the afterheat recovery system comprises a primary dust remover, an afterheat boiler, a secondary dust remover, an exhaust fan and a chimney which are connected in sequence, and the primary dust remover is connected with the air outlet arranged at the top of the moving bed. The system and the method effectively solve the problems of heat recovery and furnace slag granulation of equipment such as a blast furnace.

Owner:XI AN JIAOTONG UNIV +1

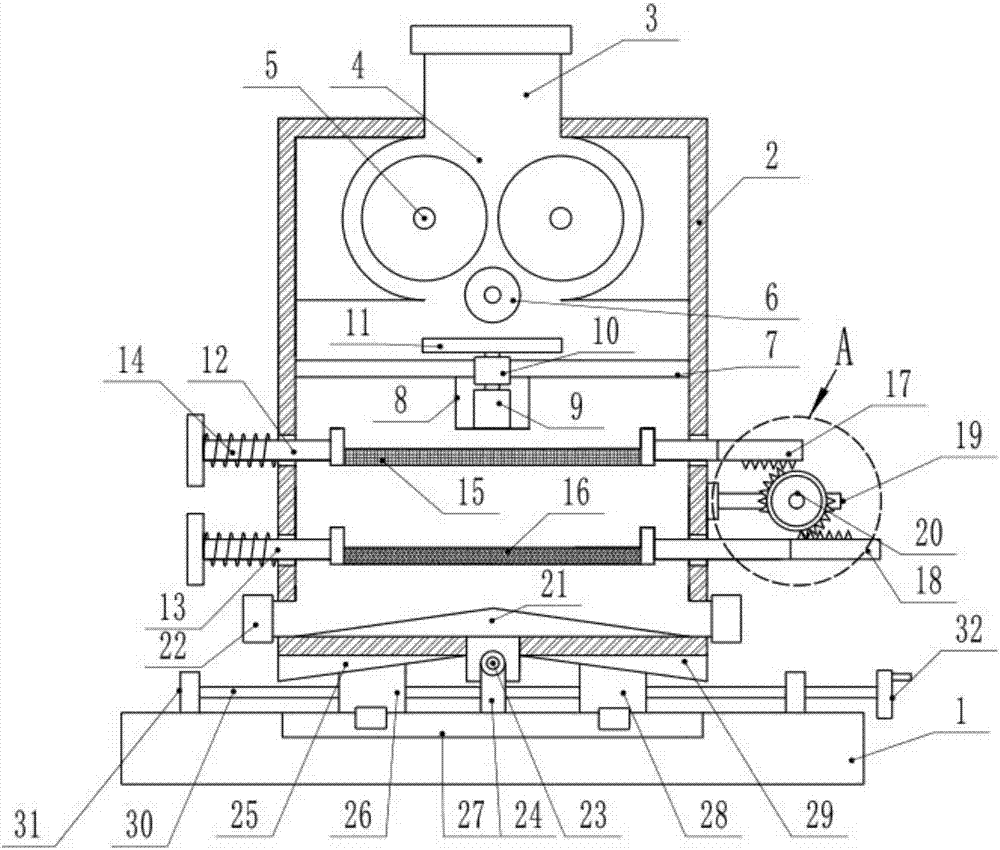

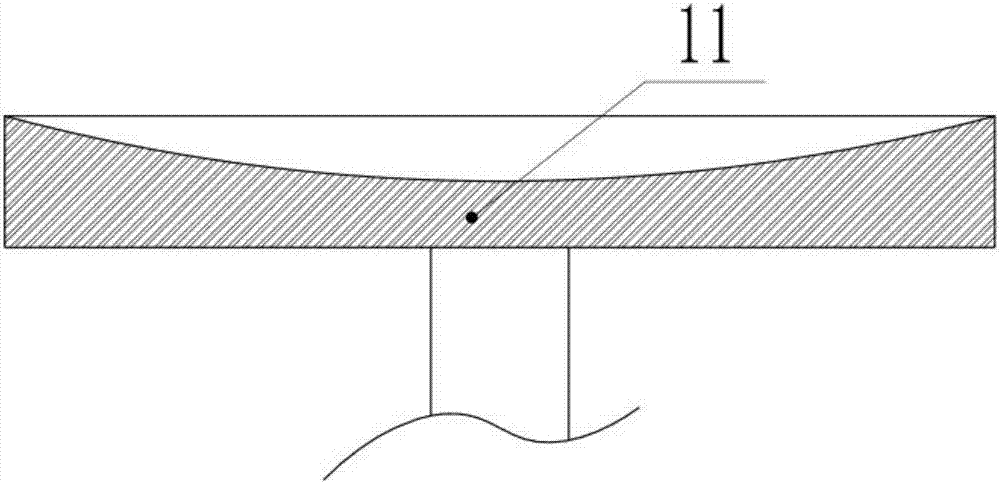

Smashing and screening device for compound fertilizer production

InactiveCN107537621AUniform particlesEvenly distributedSievingScreeningPrimary screeningAgricultural engineering

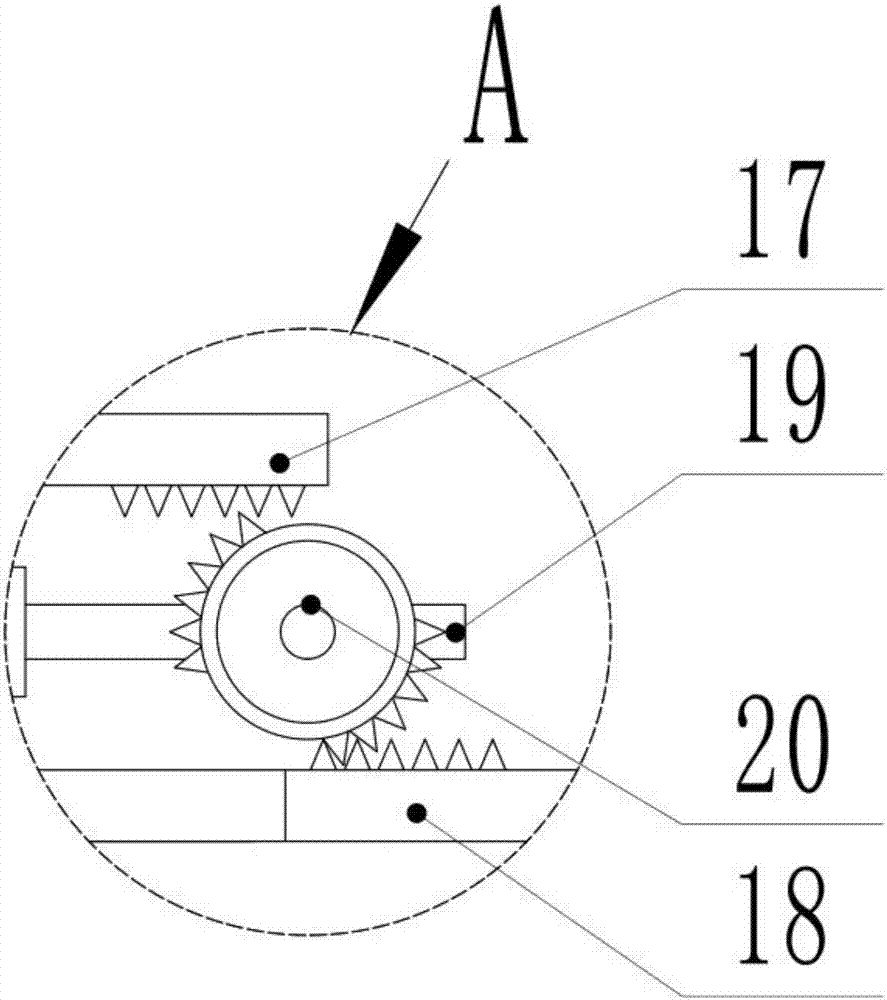

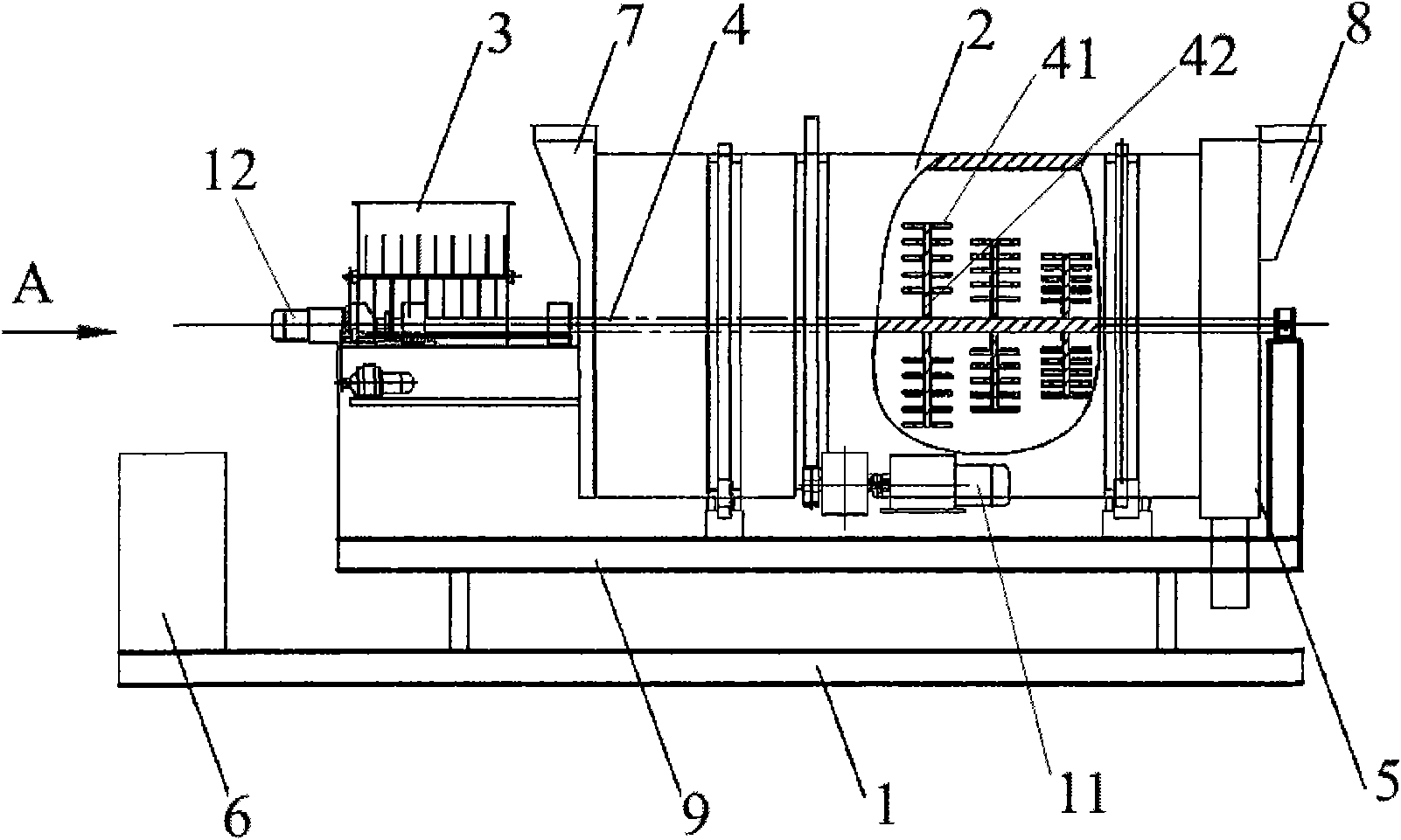

The invention discloses a smashing and screening device for compound fertilizer production. The smashing and screening device for compound fertilizer production comprises a base, a smashing tank, a bearing, a primary screening tank, a secondary screening tank, a second drive motor and a special-shaped gear, wherein the smashing tank is fixedly installed on the base through screws; two sets of mainsmashing rollers are installed in a smashing cavity in a bilateral symmetry mode; auxiliary smashing rollers are further rotationally installed in the smashing cavity; a scattering disc is further fixedly connected to the upper end of an output shaft of a first drive motor; the second drive motor is further fixedly installed on the outer wall of the right side of the smashing tank; and the special-shaped gear is further installed on an output shaft of the second drive motor. According to the smashing and screening device for compound fertilizer production, the structure is novel, and fertilizer particles are more uniform in the smashing process; and through arrangement of the scattering disc, smashed fertilizer is evenly tossed out and then falls into the primary screening tank, so that the fertilizer on the primary screening tank is evenly distributed and prevented from being accumulated on a screen of the primary screening tank.

Owner:罗娟

Sludge stirring and granulating rotary drying device

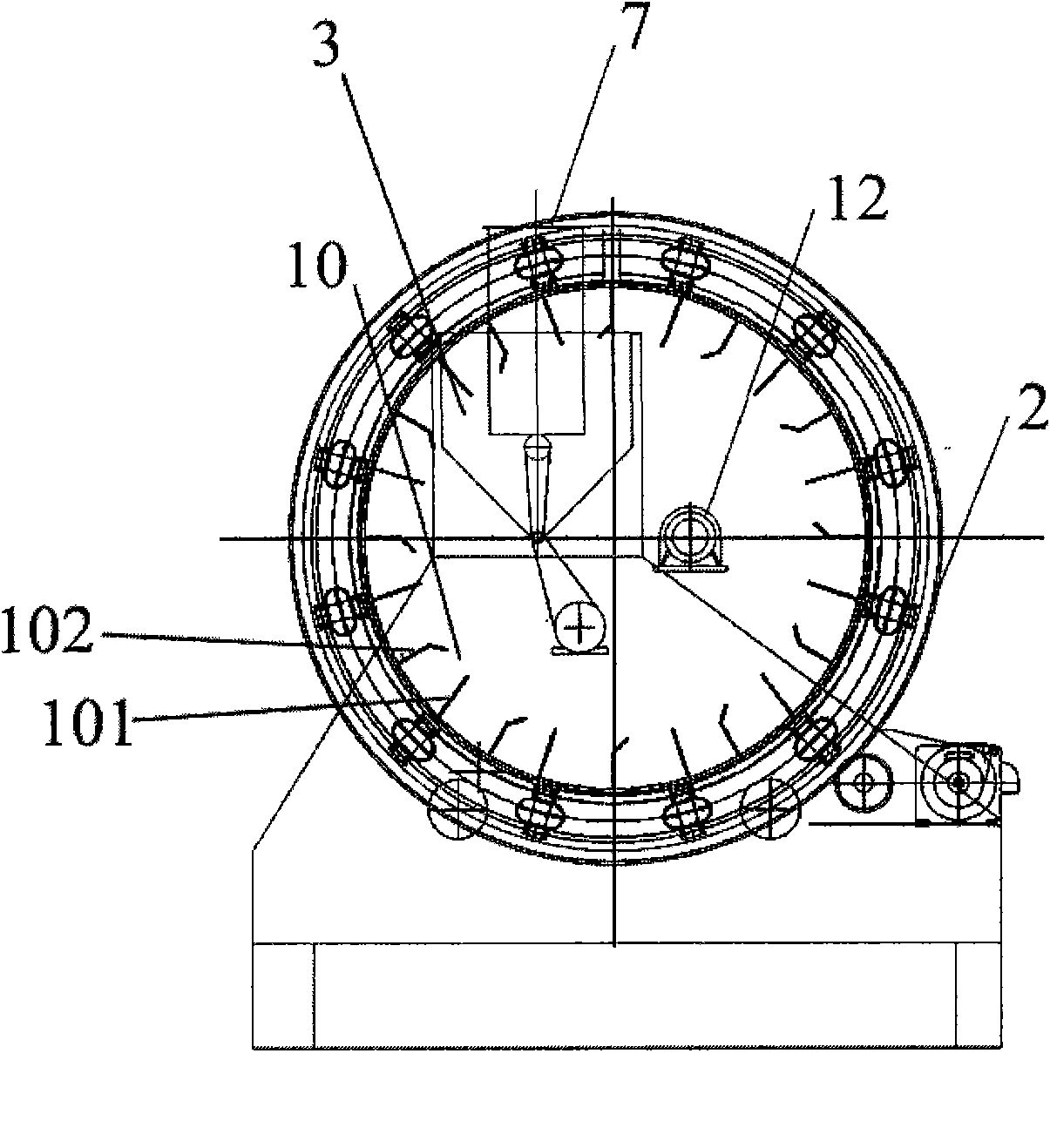

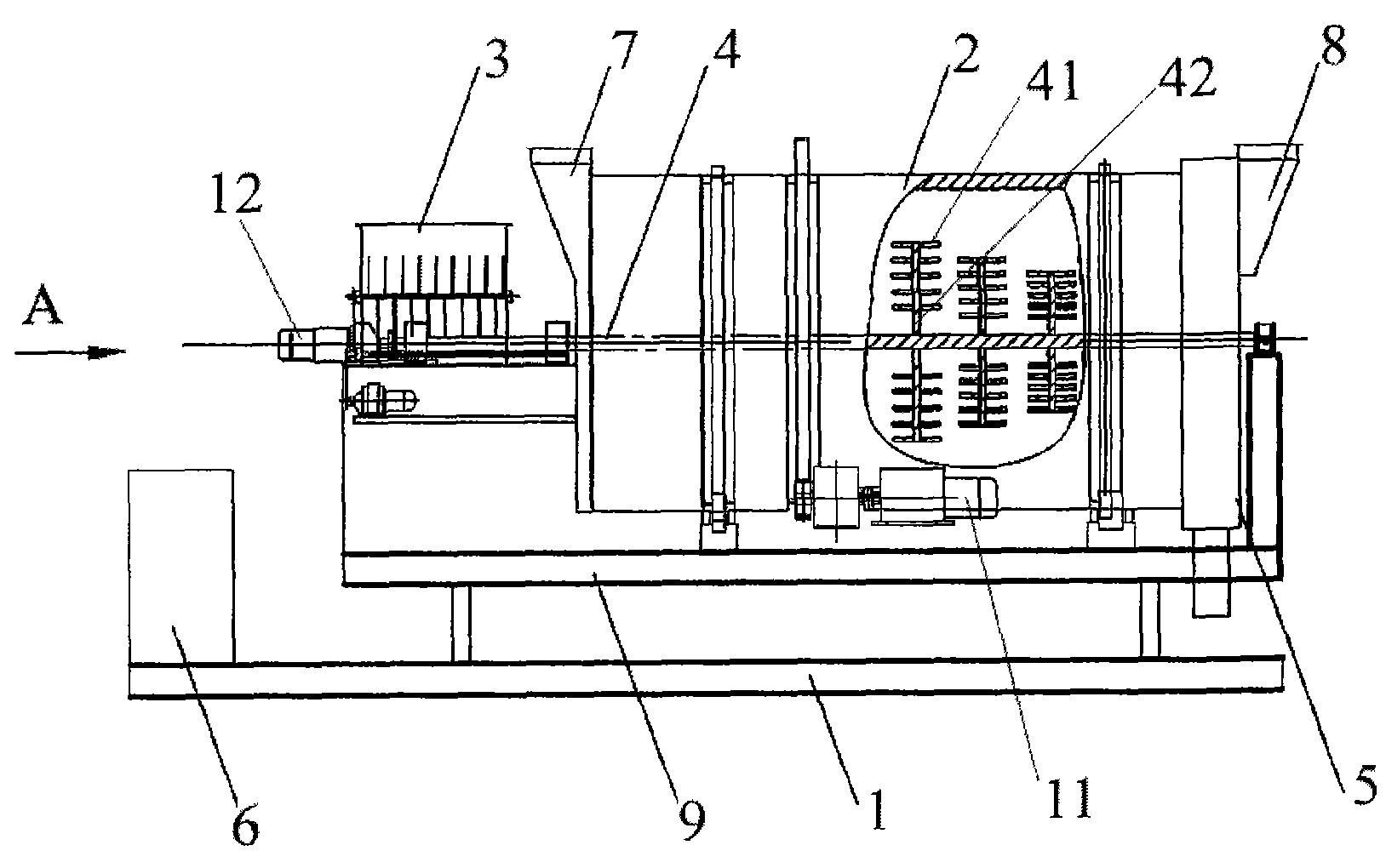

InactiveCN101870548ASolve the problem of clumping and sticking to the wallUniform particlesSludge treatment by de-watering/drying/thickeningDrying solid materials with heatSludgeFlue gas

The invention discloses a sludge stirring and granulating rotary drying device, which consists of a base, a rotary drum, a feeding device, a stirring shaft, a discharging box, a driving device and a control box. The front end in the rotary drum is provided with a guiding screw; two ends of the rotary drum are respectively provided with a flue gas inlet and a flue gas outlet; the base is provided with a lifting bracket on which the rotary drum, the feeding device, the stirring shaft and the discharging box are arranged; the stirring shaft and the rotary drum are eccentrically arranged; a plurality of mixing blades are arranged along the axial direction of the stirring shaft; and the inner wall of the rotary drum is provided with a shovelling plate. The lifting bracket is convenient to adjust the tilt angle of the rotary drum so as to adjust the retention period of materials in the drum and the moisture content of dry sludge; the stirring shaft is provided with the stirring blades to serve as a stirring and granulating device, and the wall of the rotary drum is provided with the shovelling plate, so the problem that the sludge is caked and sticks to the wall in the drying process is solved; and the produced sludge granules are uniform, and are suitable to be burnt and used as building materials and the like.

Owner:上海环保工程成套有限公司

Preparation method of high dispersed white carbon black

ActiveCN102229758AIncreased dispersionReduce forcePigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsDispersityFiltration

The invention discloses a preparation method of high dispersed white carbon black. According to a new method and technology, a synthesis reaction of liquid soluble glass and concentrated sulfuric acid is carried out in two steps by first preparing fine seeds, and then carrying out a synthesis reaction, wherein the synthesis reaction is a precipitation reaction carried out under effects of an organic surfactant SDS and a composite silane coupling agent. The high dispersed precipitated white carbon black specially used in high-performance tyres is obtained through particle surface cladding, modification treatment, press filtration, washing, pulping and pressure drying. The method improves a traditional white carbon black production technology of a precipitation method by optimizing technological parameters and using an optimized auxiliary agent to meet a requirement of enhanced product dispersiveness; besides the method overcomes defects of an ordinary precipitation method, such as crude particles, wide distribution, strong hydrophilism and weak mixing dispersion. A prepared product has characteristics of fine primary particles, low surface hydroxyl content, increased lipophilicity,high bonding force with rubber high molecules and high wettability, and is an ideal reinforcing filling material specially used in high-performance tyres.

Owner:FUJIAN ZHENGSHENG INORGANIC MATERIAL

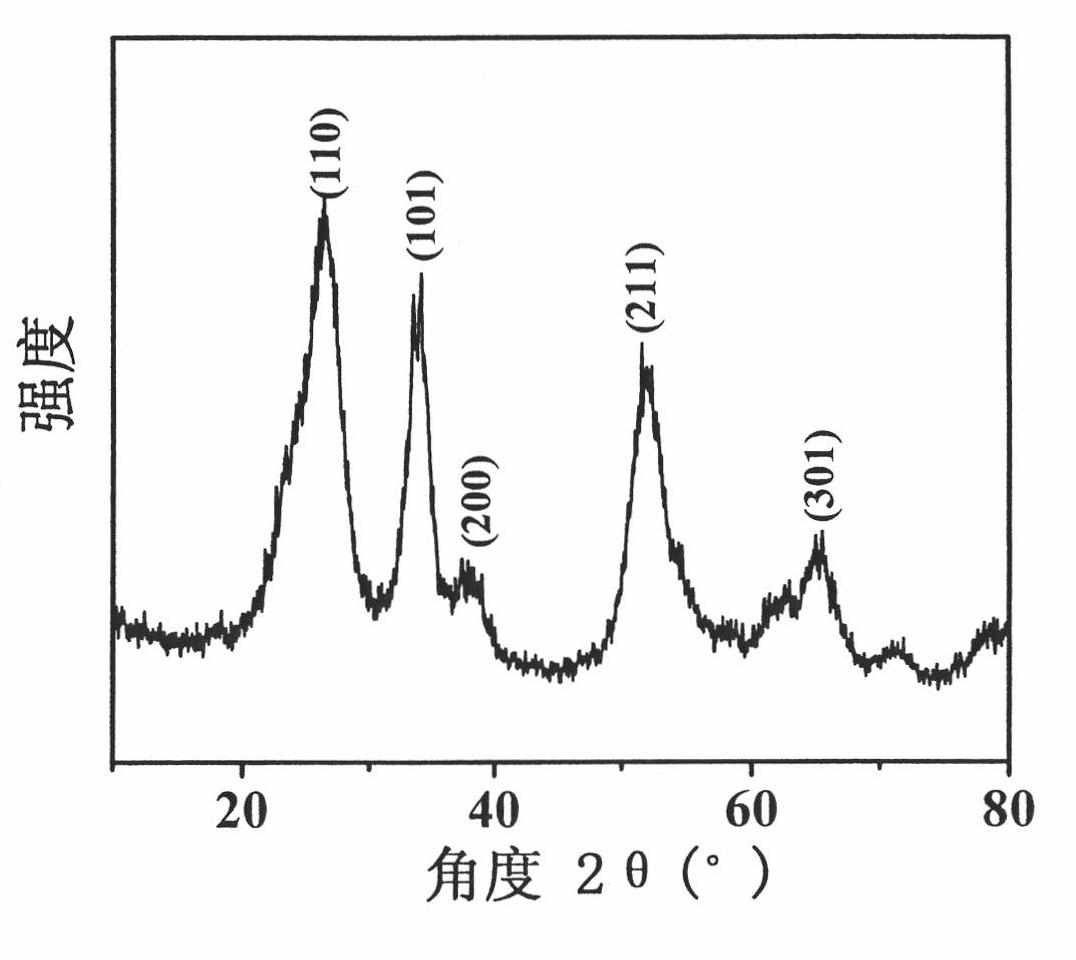

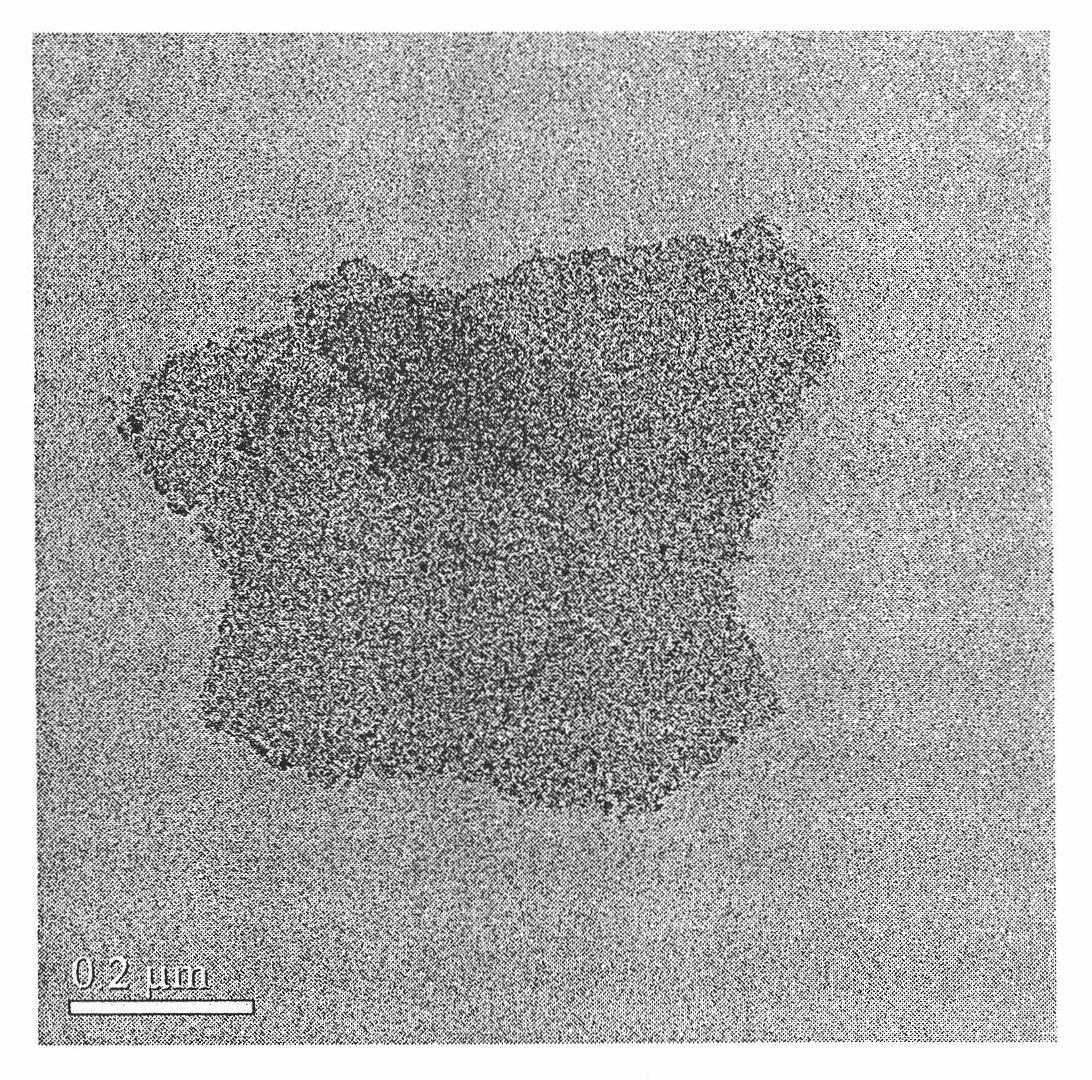

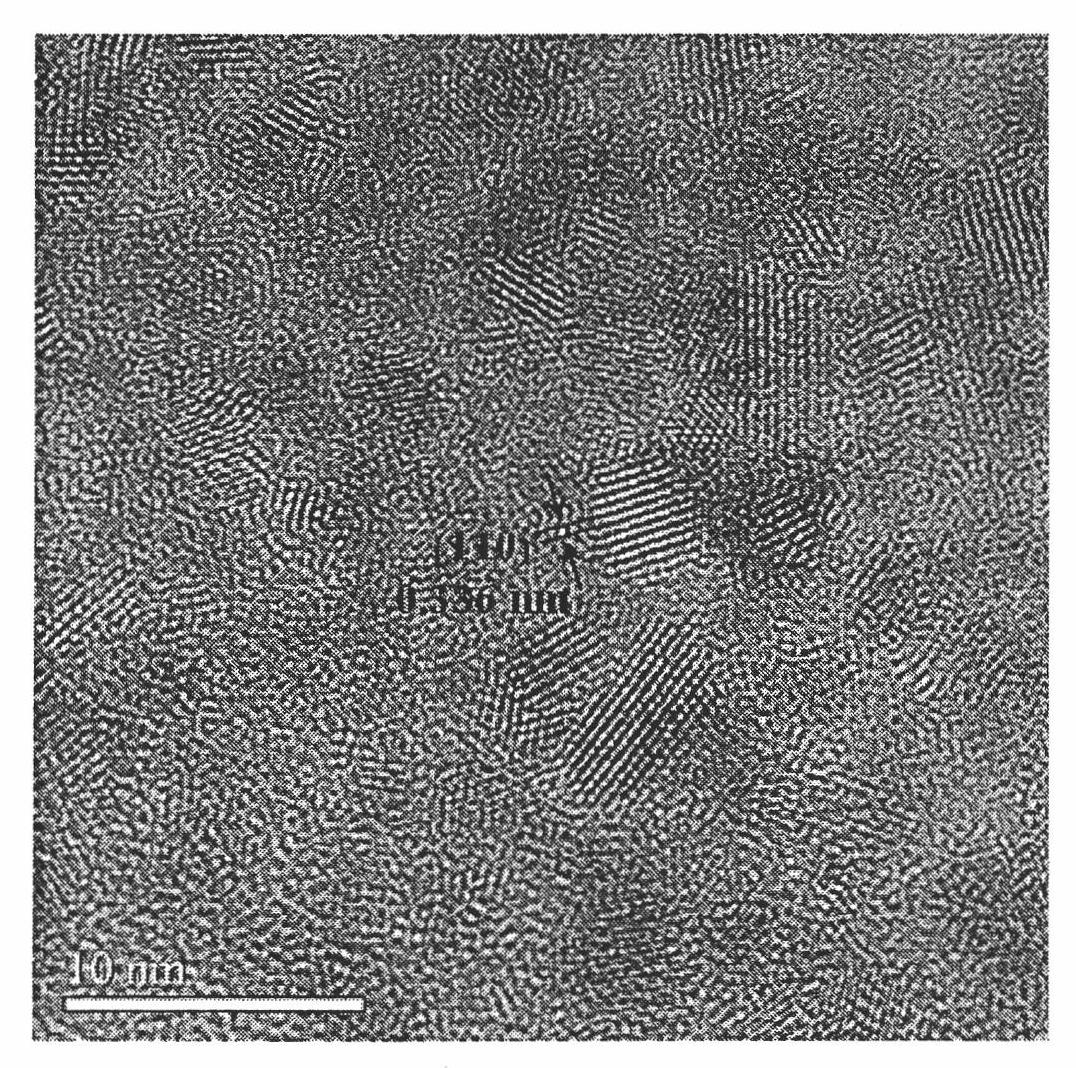

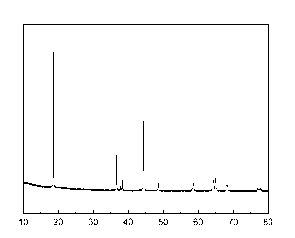

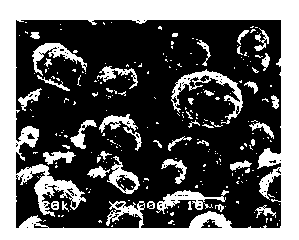

Method for preparing nano-crystal lithium-titanium composite oxide

InactiveCN101058438ARich reservesReserves are cheapNanostructure manufactureCell electrodesCapacitanceWater baths

The invention discloses a making method of nanometer crystal Li-Ti composite oxide, which comprises the following steps: adopting titanium powder or titanium compound as raw material; blending the materials with 30% hydrogen peroxidate under low temperature; adding certain quantity of lithium salt solution and moulder; stirring evenly; reacting under water bath condition at 50-100 deg. c completely; drying the composite system directly to produce predecessor; proceeding heat disposal for the predecessor at 200-400 deg. c for 2-6h; heating to 600-1000 deg. c; sintering 8-36h; cooling; grinding; obtaining the nanometer crystal Li-Ti composite oxide with spinel structure and the content of Li4Ti5O12 over 90%; controlling the even grain size of the product between 15nm and 100nm and specific surface area between 10 and 100m2 / g due to different aperture shape of moulds, sintering time and temperatures; making the reversible specific capacity of the product over 160mAh / g under 0. 1C charging and discharging condition; keeping the capacity maintaining rate between 50% and 70% under discharging condition at 100deg. c as ideal negative electrode material of lithium ion dynamic battery and lithium ion super-capacitance.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

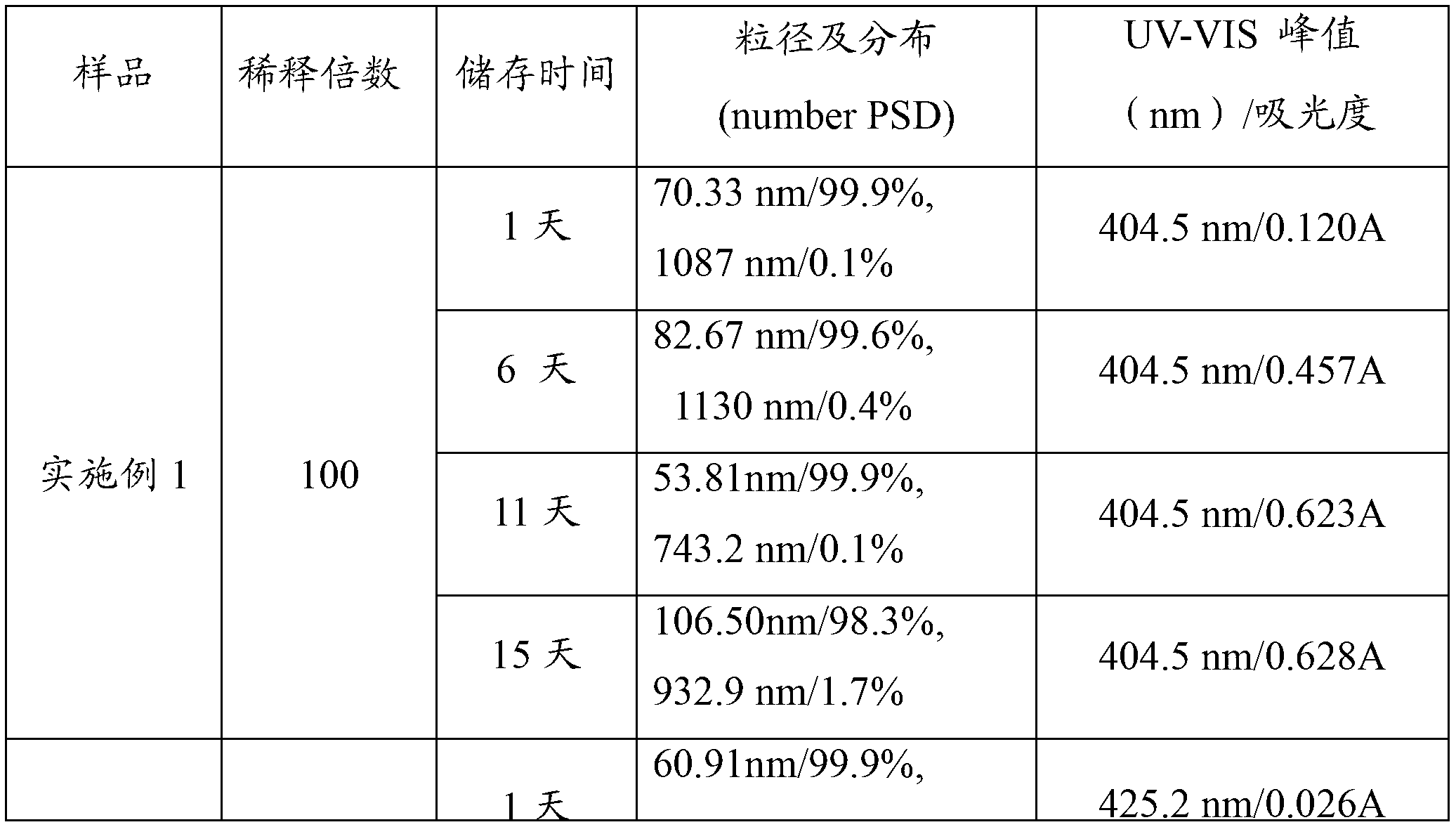

Nano-silver dispersion liquid and preparation method of nano-silver dispersion liquid as well as preparation method of nano-silver antibacterial coating

ActiveCN103212720AControl particle sizeControl shapeLiquid/solution decomposition chemical coatingChemical LinkageRoom temperature

The embodiment of the invention discloses a preparation method of nano-silver dispersion liquid. The preparation method comprises the following steps that thickening agents and dispersing agents are added into pure water or deionized water, then, soluble silver salt is dissolved in solution, and the silver salt solution is obtained; and under the stirring effect, silver complexing agents are firstly added into the silver salt solution, then, reducing agents are added, or silver complexing reduction agents are directly added, the reaction is carried out for at least 12 hours under the condition of room temperature to 90 DEG C, silver ions in the silver salt solution are reduced into metal silver, the nano-silver dispersion liquid is obtained, the silver complexing agents and the silver complexing reduction agents can form the chemical bonding with the nano-silver particle surface, and in addition, functional groups with the cross linking effect are reserved. The invention correspondingly provides the nano-silver dispersion liquid prepared by the method. The process of the preparation method is simple, the stability of the prepared nano-silver dispersion liquid is good, nano-silver particles are uniform, the application is convenient, and the bonding force of the nano-silver and substrates is high. In addition, the invention also provides a preparation method of a nano-silver antibacterial coating.

Owner:ENVIROCHEM TECH

Cobalt-free lithium-rich manganese-based cathode material as well as preparation method and application thereof

ActiveCN103943844AUniform particlesComplete crystal structureCell electrodesSecondary cellsSolid phasesSolvent

The invention discloses a cobalt-free lithium-rich manganese-based cathode material as well as a preparation method and application thereof. The cathode material has a chemical formula Li[1+x]Ni[y]Mn[0.8-y]O2 (x is more than 0 and less than 1 / 3 and y is more than 0 and less than 0.8). The preparation method comprises the following steps: preparing a precursor in an ethanol or de-ionized water solvent by adopting a sol-gel method, pre-sintering at the low temperature, performing ball-milling, and performing high-temperature solid-phase sintering to obtain the cathode material. The cathode material prepared by adopting the method is applied to lithium ion batteries, is high in specific discharge capacity (278mAh / g) and energy density, is expected to replace commercialized mainstream products-LiCoO2 cathode materials and lithium iron phosphate power batteries, and becomes a novel material of high-specific-capacity cathode materials for electric vehicles at present.

Owner:湘乡绿锂新材料科技有限公司

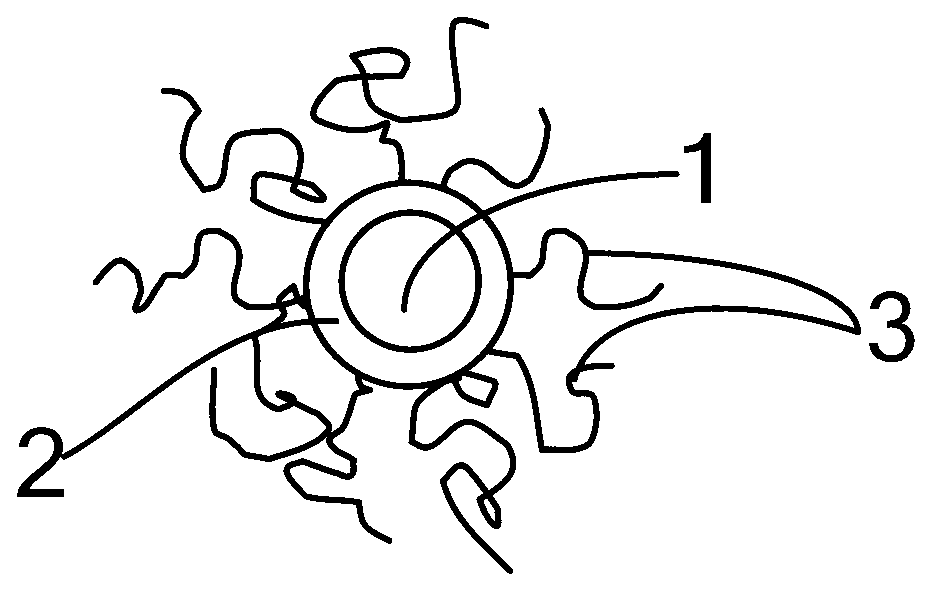

Nanometer ferrous silicate lithium material and preparation method thereof

ActiveCN101546828AHigh purityHigh charge and discharge capacityElectrode manufacturing processesPhosphorus compoundsCarbon nanotubeReaction temperature

The invention relates to a nano ferrous silicate lithium material and a preparation method thereof. The preparation method comprises the following steps: a lithium source, an iron source, a silicate source and a doping element compound are dissolved into a water solution which contains a complexing agent according to a certain stoichiometric ratio, a high-conductivity carbon nano tube dispersed by an auxiliary agent is added into the water solution and used as a wrapping material, an obtained solution is heated under the temperature of 100-200 DEG C for 1-3 hours to obtain gelatin, the obtained gelatin is sintered in an inert atmosphere furnace, the reaction temperature is 600-900 DEG C, and the reaction time is 3-16 hours. The invention effectively controls the chemical composition, the phase composition and the grain diameter of ferrous silicate lithium, and the obtained ferrous silicate lithium is nano ferrous silicate lithium wrapped by the carbon nano tube and has small and uniform grains with high purity quotient, higher charge-discharge capacity and good multiplying power property and circulation property, thus the ferrous silicate lithium is an ideal material for producing lithium ion batteries.

Owner:SHENZHEN DYNANONIC

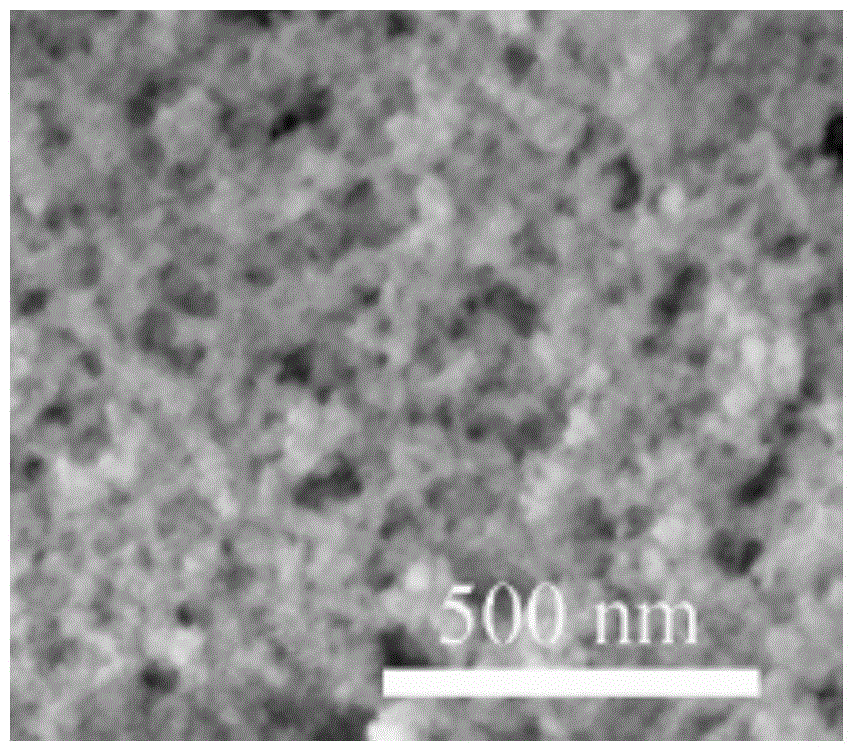

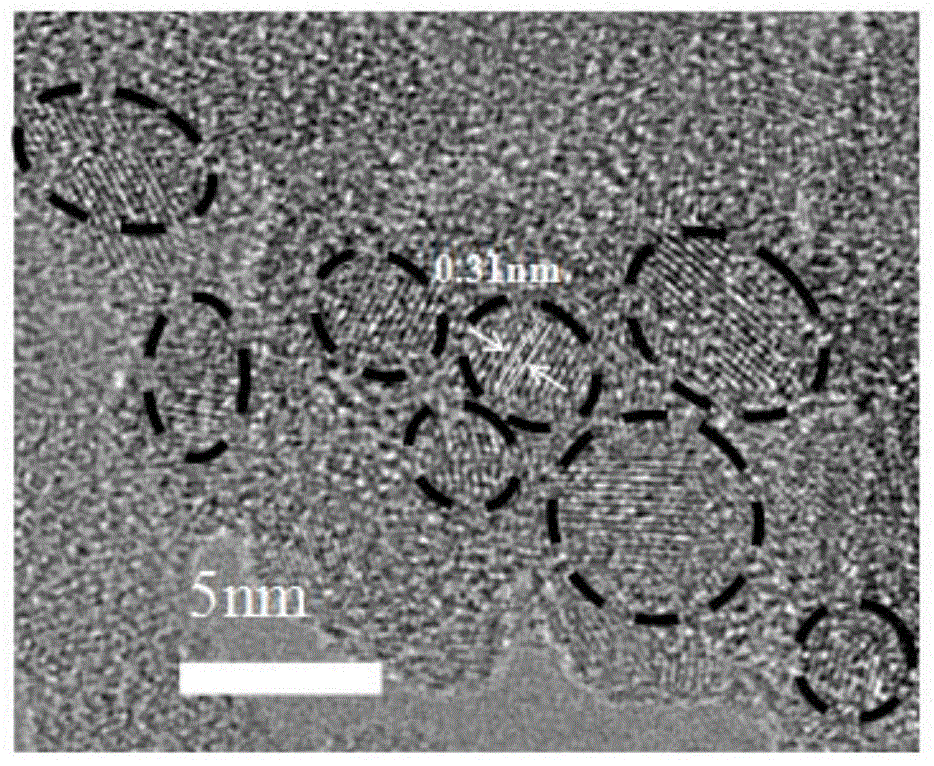

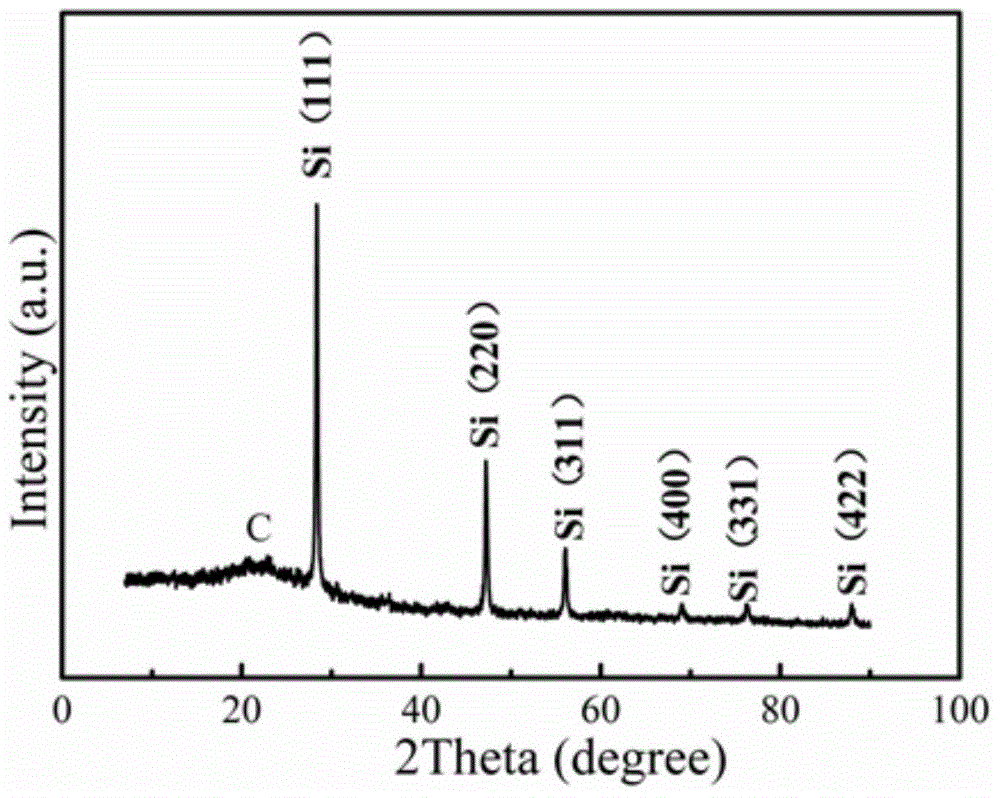

Method for preparing superfine nano-silicon by taking silicon-containing biomass as raw material as well as prepared superfine nano-silicon and application thereof

InactiveCN104671247AWide variety of sourcesNot easy to reuniteMaterial nanotechnologyCell electrodesSemiconductor materialsReaction temperature

The invention discloses a method for preparing superfine nano-silicon by taking a silicon-containing biomass as the raw material. The method comprises the following steps: eliminating an inorganic salt ion impurity by performing acid boiling on the silicon-containing biomass, grinding and smashing the white powders processed by air annealing to obtain a nano-silicon dioxide granule, uniformly mixing the white product, the magnesium powder and the fused salt, putting into a tube furnace, reacting under an inert atmosphere to obtain the silicon and the magnesium oxide, and removing the magnesium oxide by performing acid dipping on the reaction product to obtain the superfine nano-silicon granule. The reaction step is simple and practicable, the sources of the raw materials are extensive, most importantly the reaction temperature is controlled by adding the fused salt to melt and absorb heat, the reactant is hard to agglomerate, the specific surface area of the prepared nano-silicon is 302.13m<2> / g, the purity is greater than 98%, the granules are uniform with mesopores and the nano-silicon can be used in the fields such as the lithium ion battery, the semiconducting material and the medicine.

Owner:WUHAN UNIV OF SCI & TECH

Positive electrode material of lithium ion battery and preparing method thereof

ActiveCN103151521AReduce the effect of tap densityImprove cycle performanceCell electrodesSodium-ion batteryIron phosphate

The invention relates to a lithium titanate-carbon co-cladded lithium manganese iron phosphate positive electrode material. According to the invention, the characteristic of zero stress of a lithium titanate material is utilized for inhibition of deformation of a positive electrode during charging and discharging so as to improve cycle performance and resistance to over-charge and over-discharge of the positive electrode material, and conductivity and electrochemical properties of the positive electrode material are improved through co-cladding of the lithium titanate material and carbon; meanwhile, tap density of lithium titanate is as high as 1.68 g / cm<3>, which enables influence of carbon cladding on the tap density of the positive electrode material to be reduced. A preparation method for the positive electrode material provided by the invention is simple, is easy to operate and can easily realize industrial application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of eurotium cristatum spore suspension

The invention discloses a preparation method of eurotium cristatum spore suspension. The preparation method is characterized by comprising the following steps of: 1) culturing eurotium cristatum; 2) preparing a liquid culture medium of the eurotium cristatum; 3) culturing eurotium cristatum spores; 4) dispersing the eurotium cristatum spores; 5) filtering the eurotium cristatum spores; 6) determining the concentration of the eurotium cristatum spores; and 7) storing the eurotium cristatum spores. The eurotium cristatum spore suspension has high concentration, the eurotium cristatum spores have uniform and hypertrophic size and bright color, and the eurotium cristatum spore suspension can be prepared within a short period of 10 days and can full meet the requirement of eurotium cristatum inoculation of Fuzhuan tea, and has stable and reliable quality.

Owner:HUNAN CITY UNIV

Preparation of pseudo thinolite

ActiveCN1583568AUniform particlesConcentrated pore size distributionAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium oxides/hydroxidesSlurryCarbonation

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

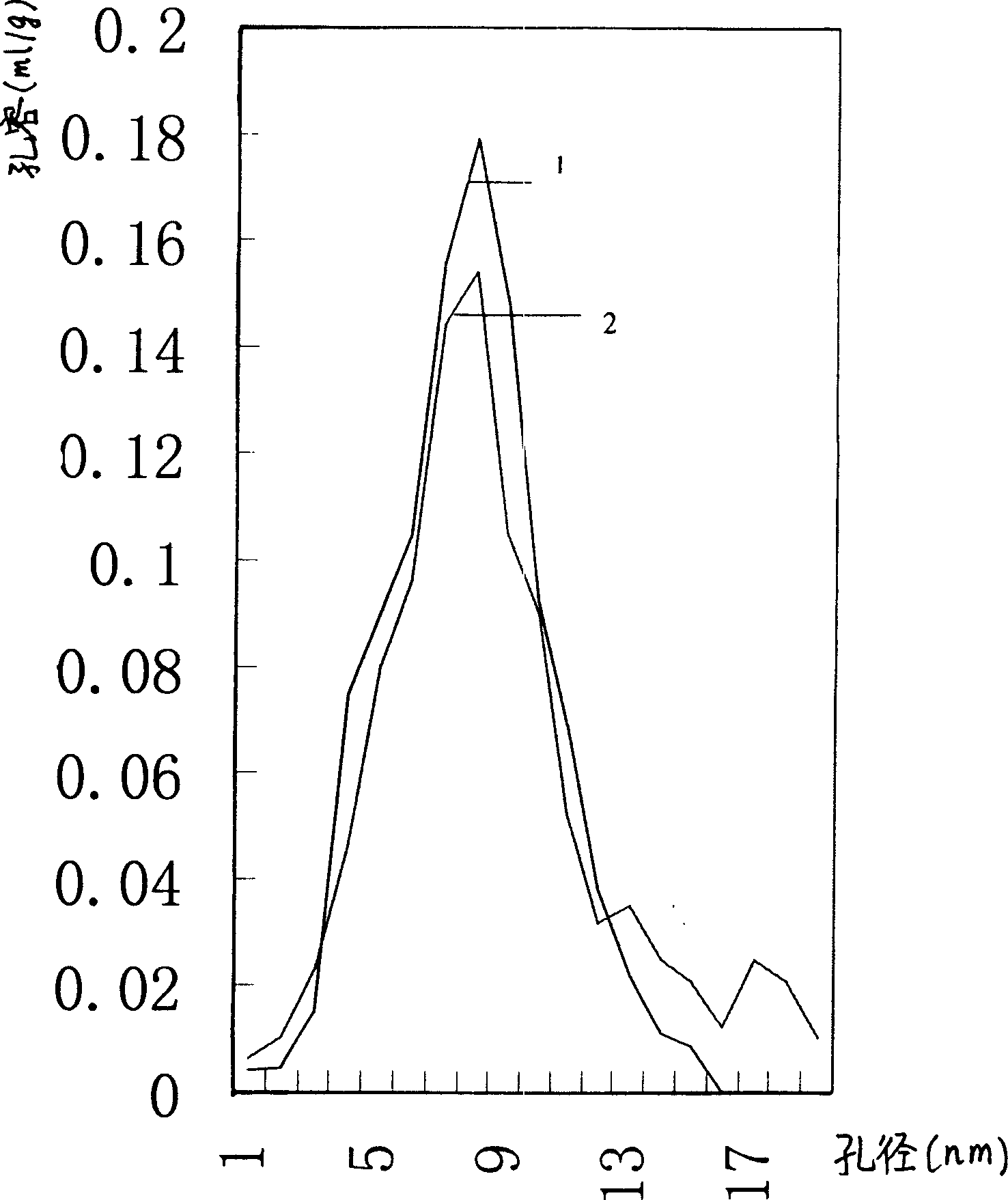

Ternary positive-electrode material prepared by solvothermal method and preparation method thereof

InactiveCN107959022ARegulatory TopographySmall sizeCell electrodesSecondary cellsFiltrationManganese

The invention discloses a ternary positive-electrode material prepared by a solvothermal method and a preparation method thereof. The preparation method includes: dissolving nickel cobalt manganese salt in a solvent, adding a surfactant and hydrolysis auxiliaries, sufficiently stirring, transferring into a reaction kettle, performing solvothermal reaction under certain temperature for 2-24 hours,cooling to room temperature, using a suction filtration method to separate out a nickel cobalt manganese ternary product, washing, drying, and pre-calcining in air to obtain a precursor; grinding andmixing the precursor and a lithium compound, and calcining to obtain the ternary positive-electrode material. The ternary positive-electrode material and the preparation method thereof have the advantages that the ternary oxide precursor prepared by the solvothermal method is small in particle size, uniform in particle distribution and controllable in morphology as compared with a ternary precursor prepared by a conventional precipitation method, so that the finally prepared ternary material is small in granularity, uniform in particle size distribution and controllable in morphology and has excellent electrochemical performance, and the capacity and stability of the prepared ternary material are better than those of a ternary positive-electrode material prepared by the precipitation method.

Owner:SOUTH CHINA UNIV OF TECH

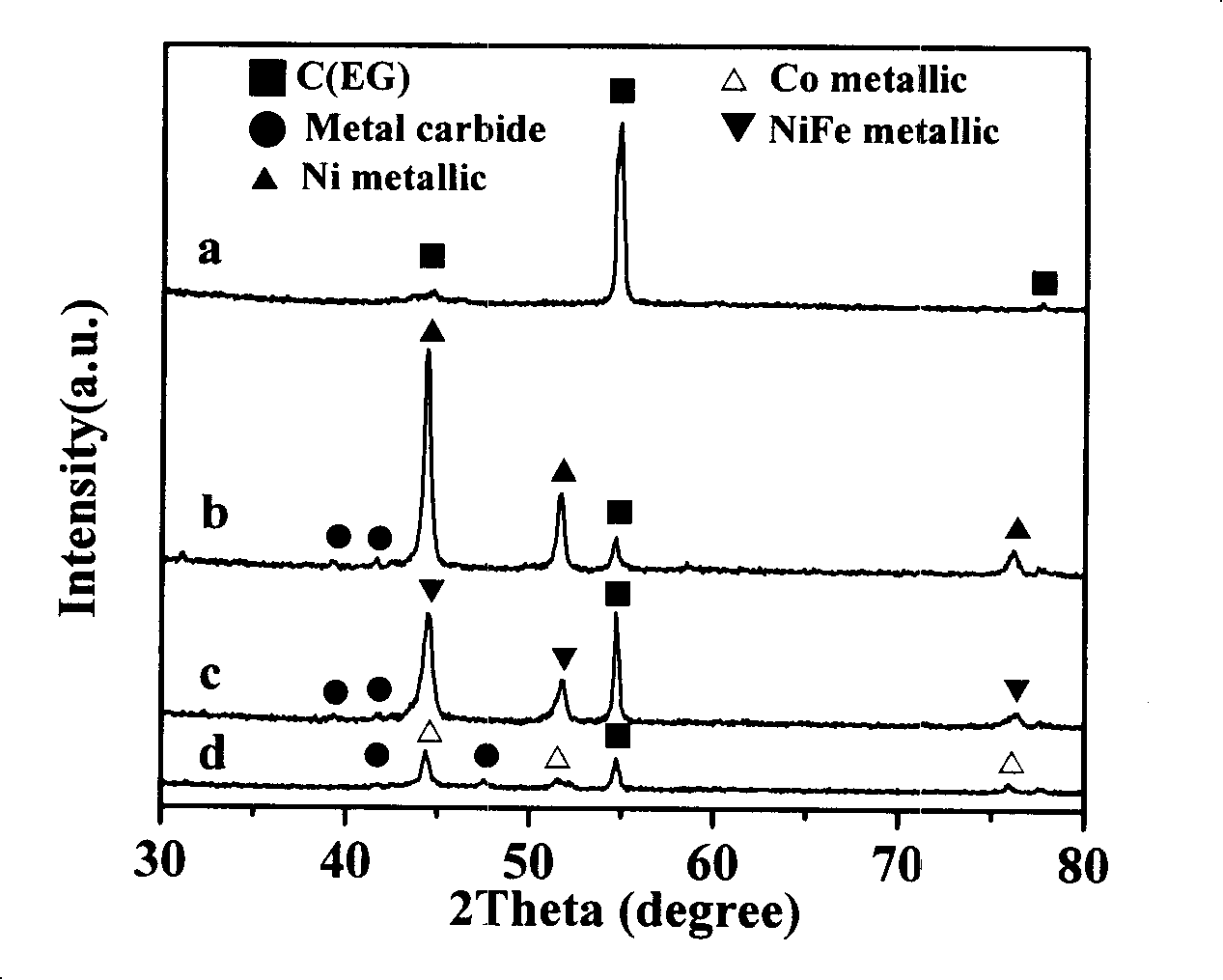

Method for preparing electromagnetic shielding light graphite based nanometer magnetic metal composite material

InactiveCN101179921AStir and disperse evenlyEnable mass manufacturingMagnetic/electric field screeningScreening apparatusLow frequency bandElectromagnetic shielding

The invention relates to a preparation method of a lightweight graphite-based nano-magnetic metal composite material used for electromagnetic shielding, which belongs to the related field of electromagnetic shielding materials; the precursor solution of expanded graphite and magnetic metal is mixed and stirred evenly, and dried after evaporating the solvent. The obtained mixture is treated in a reducing atmosphere at 300°C-1000°C, passivated with ordinary nitrogen and cooled to room temperature to obtain a composite material of expanded graphite and magnetic nanometer metal, and the relative content of the two can be adjusted. The composite material is light in texture, has excellent electromagnetic properties, and can be pressed into various shapes required. The material has excellent electromagnetic shielding performance in the range of 300kHz-1.5GHz, reaching 70-105dB, and the addition of magnetic metal improves the electromagnetic shielding performance of the expanded graphite in the low-frequency band. The method is simple and efficient, suitable for mass preparation, and the obtained product is expected to be applied in aerospace, military, electronic and electrical products.

Owner:NANJING UNIV

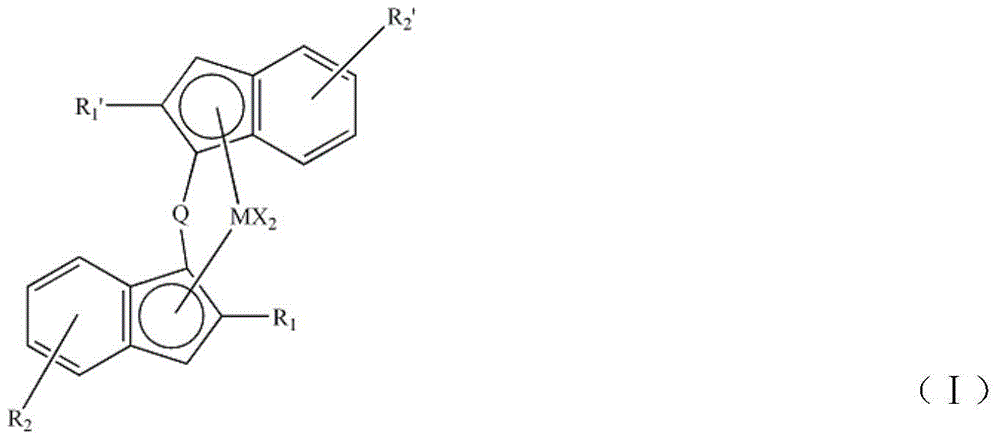

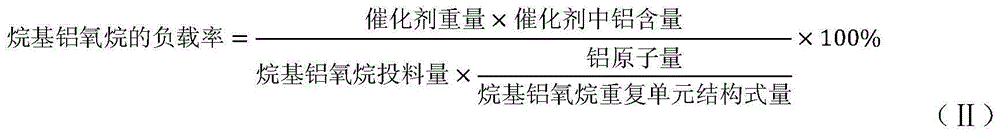

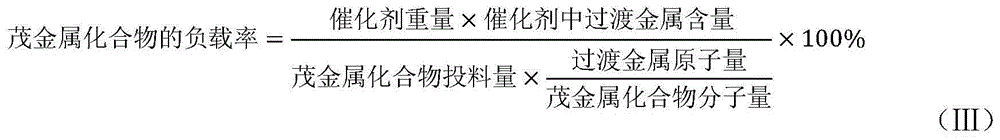

Preparation method of polypropylene wax

The invention relates to a preparation method of polypropylene wax. The method is characterized in that a liquid phase bulk polymerization technology is used, a supported metallocene catalyst is used, hydrogen is adopted as a molecular weight regulator, and a granular polypropylene wax product is directly obtained through catalyzing liquid propylene polymerization. The propylene polymerization reaction activity is not lower than 1000 times / h. The method has the characteristics of simple operation and high polymerization reaction activity, and the molecular weight of the polypropylene wax product obtained in the invention is adjustable and has narrow distribution.

Owner:CHINA PETROLEUM & CHEM CORP +1

Technological process of producing high-quality organic fertilizer with domestic garbage

InactiveCN1337381AUniform particlesUniform Compost VolumeBio-organic fraction processingClimate change adaptationCelluloseSludge

The technological process for producing high-quality organic fertilizer by using house refuse includes the following steps: separating useful organic material and sewage sludge, making the mixture ofexcrement and urine, pulverized plant straw, nitrogen and phosphorus elements implement anaerobic fermentation to produce impure methane, mixing residual dregs and liquor and making aerobic compost fermentation. The product made up by using said invented method possesses brown colour and loose and uniform granules, and is smellless. The examination shows that total quantity of measured carbon, cellulose and fats is reduced, the colibacillus and ascarid ova are obviously reduced or eliminated, and its fertilizer efficiency is high, and includes organic matter is greater than 40%, total nitrogen 10-12%, total phosphorus 5-7%, total potassium 3-5%, rapidly available nitrogen 223.4 ppM and rapidly available phosphorus 215.8 PPM.

Owner:郭高友

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com