Nickel cobalt lithium manganate composite cathode material and preparation method of nickel cobalt lithium manganate composite cathode material

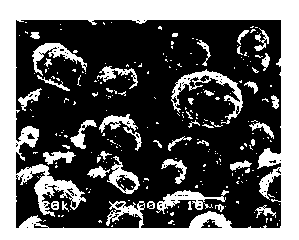

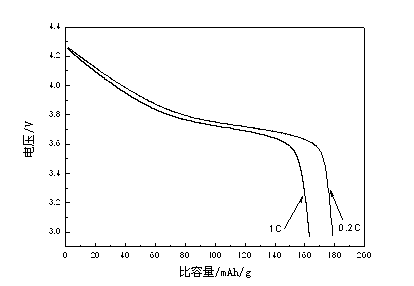

A composite cathode material, lithium nickel cobalt manganate technology, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as environmental pollution, and achieve the effects of no environmental pollution, small specific surface area, and high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

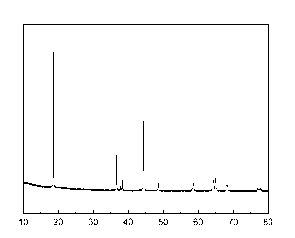

[0031] The nickel-cobalt lithium manganate composite cathode material of the present embodiment has a chemical formula of LiNi 0.5 co 0.3 mn 0.2 o 2 .

[0032] Its preparation method comprises the following steps:

[0033] (1) Weigh 262.86 g of nickel sulfate hexahydrate, 168.69 g of cobalt sulfate heptahydrate, 67.6 g of manganese sulfate dihydrate, and 11.69 g of ethylenediaminetetraacetic acid, dissolve them in 1L of deionized water, stir to mix evenly; weigh 161.64 g of sodium hydroxide, dissolved in 1L of deionized water; then the mixed solution of nickel-cobalt-manganese salt and sodium hydroxide solution were added to the stirred reactor with an ultrasonic device at a rate of 600 mL / h, and the stirrer was turned on Stir with an ultrasonic instrument, control the reaction temperature to 45 ° C, the ultrasonic frequency to 20KHz, and react for 3 h under the condition of a stirring speed of 1000 r / min, to obtain a gray-brown suspension of nickel-cobalt-manganese compos...

Embodiment 2

[0039] The nickel-cobalt lithium manganate composite cathode material of the present embodiment has a chemical formula of LiNi 0.5 co 0.3 mn 0.2 o 2 .

[0040] Its preparation method comprises the following steps:

[0041] (1) Weigh 262.86 g of nickel sulfate hexahydrate, 168.69 g of cobalt sulfate heptahydrate, 67.6 g of manganese sulfate dihydrate, and 7.69 g of citric acid, dissolve them in 1L of deionized water, stir to mix evenly; weigh 161.64 g of hydroxide Sodium, dissolved in 1L deionized water; then the mixed solution of nickel-cobalt-manganese salt and sodium hydroxide solution were added to the stirred reactor with ultrasonic device at a rate of 600 mL / h, and the stirrer and ultrasonic device were turned on Stirring is carried out, the reaction temperature is controlled to be 45°C, the ultrasonic frequency is 30KHz, and the stirring speed is 600 r / min, and the reaction is carried out for 3 h to obtain a gray-brown suspension of nickel-cobalt-manganese composite ...

Embodiment 3

[0047] The nickel-cobalt lithium manganate composite cathode material of the present embodiment has a chemical formula of LiNi 0.5 co 0.3 mn 0.2 o 2 .

[0048] Its preparation method comprises the following steps:

[0049] (1) Weigh 237.69 g of nickel chloride hexahydrate, 142.76 g of cobalt chloride hexahydrate, 50.36 g of manganese chloride, and 11.69 g of ethylenediaminetetraacetic acid, dissolve them in 1L of deionized water, and stir to mix them evenly; weigh 160.84 g of sodium hydroxide was dissolved in 1L of deionized water; then the mixed solution of nickel-cobalt-manganese salt and sodium hydroxide solution were added to the stirred reactor with an ultrasonic device at a rate of 600 mL / h, and the stirring was started Stir with an ultrasonic instrument and an ultrasonic instrument, control the reaction temperature to 40°C, and the ultrasonic frequency to 40KHz. Under the condition of a stirring speed of 1000 r / min, react for 2 h to obtain a gray-brown suspension of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com