Preparation of pseudo thinolite

A technology of pseudo-boehmite and sodium meta-aluminate, applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, alumina/aluminum hydroxide, etc., can solve the difference in particle performance, pseudo-boehmite The pore size distribution of stone products is not very concentrated, which achieves the effect of short gel formation time, easy operation and promotion and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Get the sodium metaaluminate solution in the sintering method alumina production, the concentration of this solution is Al 2 o 3 The content is 110g / l, the caustic ratio is 1.45, filtered, cooled and set aside.

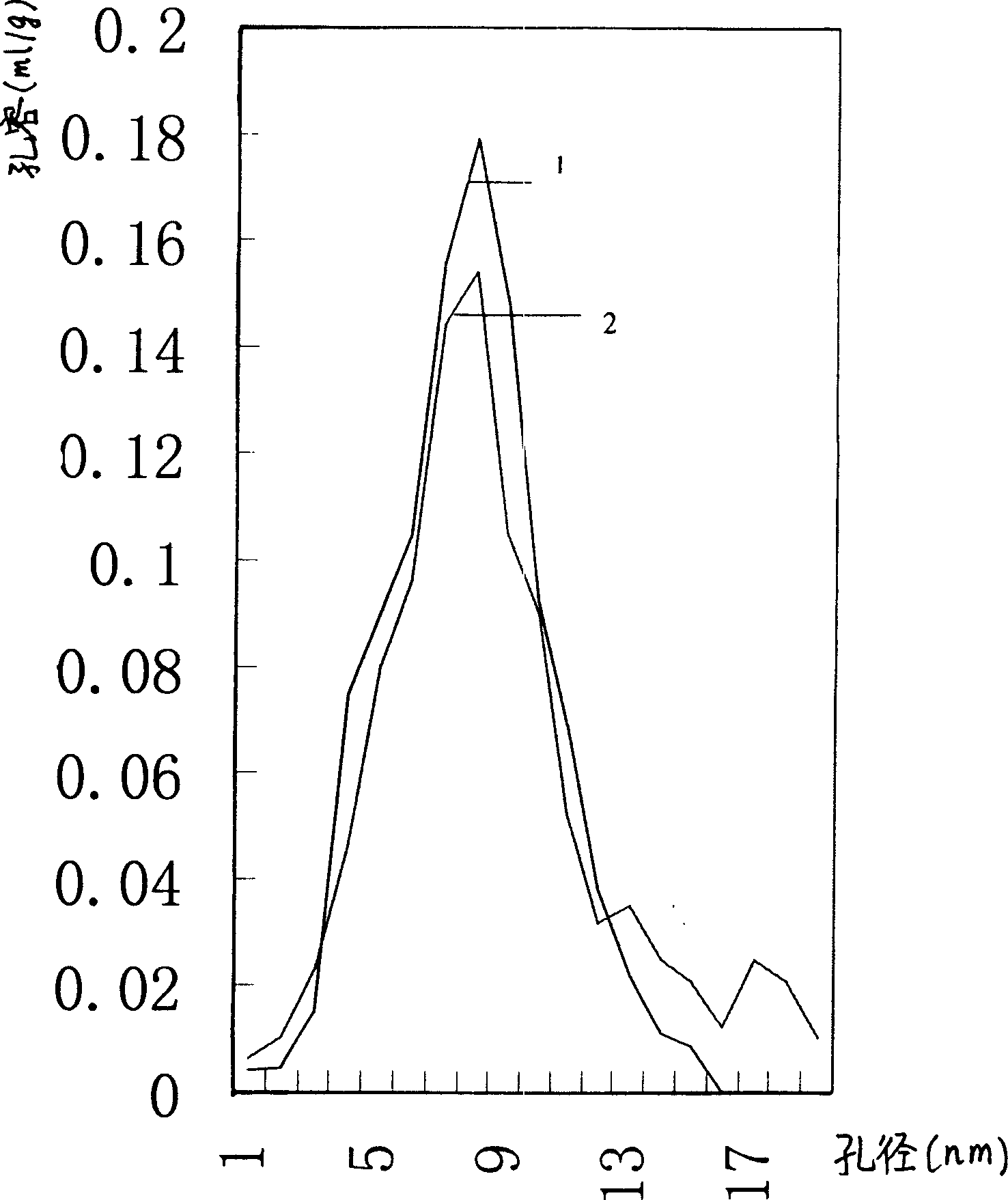

[0028] Add 2L of deionized water with a temperature of 15°C and a pH value of 7 into a 5L reactor, pass through the bottom of the reactor with carbon dioxide with a volume concentration of 50%, and immediately add 400ml of the above-mentioned metaaluminic acid at a temperature of 23°C to the reactor Add the sodium solution in 4.5 minutes. At this time, the pH value of the reaction system is 11.0. Rapidly increase the air flow, so that the reaction drops to a pH value of 9.5 within 6 minutes. Separate, wash with 80°C deionized water three times, and dry at 110°C Dry to obtain pseudo-boehmite. Product pore volume 1.106ml / g, specific surface area 406.4m 2 / g, 92.5% of the pores between 40 and 150 angstroms.

Embodiment 2

[0030] According to the method of embodiment 1, the difference is that the sodium metaaluminate solution of 500ml starts to be added after feeding carbon dioxide, and the addition is completed in 6 minutes. At this time, the pH value of the reaction system is 11.4. Within minutes, the pH value is reduced to 9.8 to obtain pseudo-boehmite. Product pore volume 1.080ml / g, specific surface area 396.0m 2 / g, 91.4% of the pores between 40 and 150 angstroms.

Embodiment 3

[0032] According to the method of embodiment 1, the difference is that the sodium metaaluminate solution of 800ml starts to be added after feeding carbon dioxide, and the addition is completed in 7.5 minutes. At this time, the pH value of the reaction system is 12.0. Within minutes, the pH value is reduced to 10.2 to obtain pseudo-boehmite. Product pore volume 0.995ml / g, specific surface area 385.6m 2 / g, 88.9% of the pores between 40 and 150 angstroms.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com