Method for preparing electromagnetic shielding light graphite based nanometer magnetic metal composite material

A metal composite material and nano-magnetic technology, applied in the direction of magnetic/electric field shielding, shielding, electrical components, etc., can solve problems such as damage to physical and mental health, difficulty in controlling the content and type of magnetic substances, and leakage of electromagnetic information confidentiality, etc., to achieve good electrical conductivity Sexual and magnetic properties, improved electromagnetic shielding performance, excellent magnetic and electrical conductivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

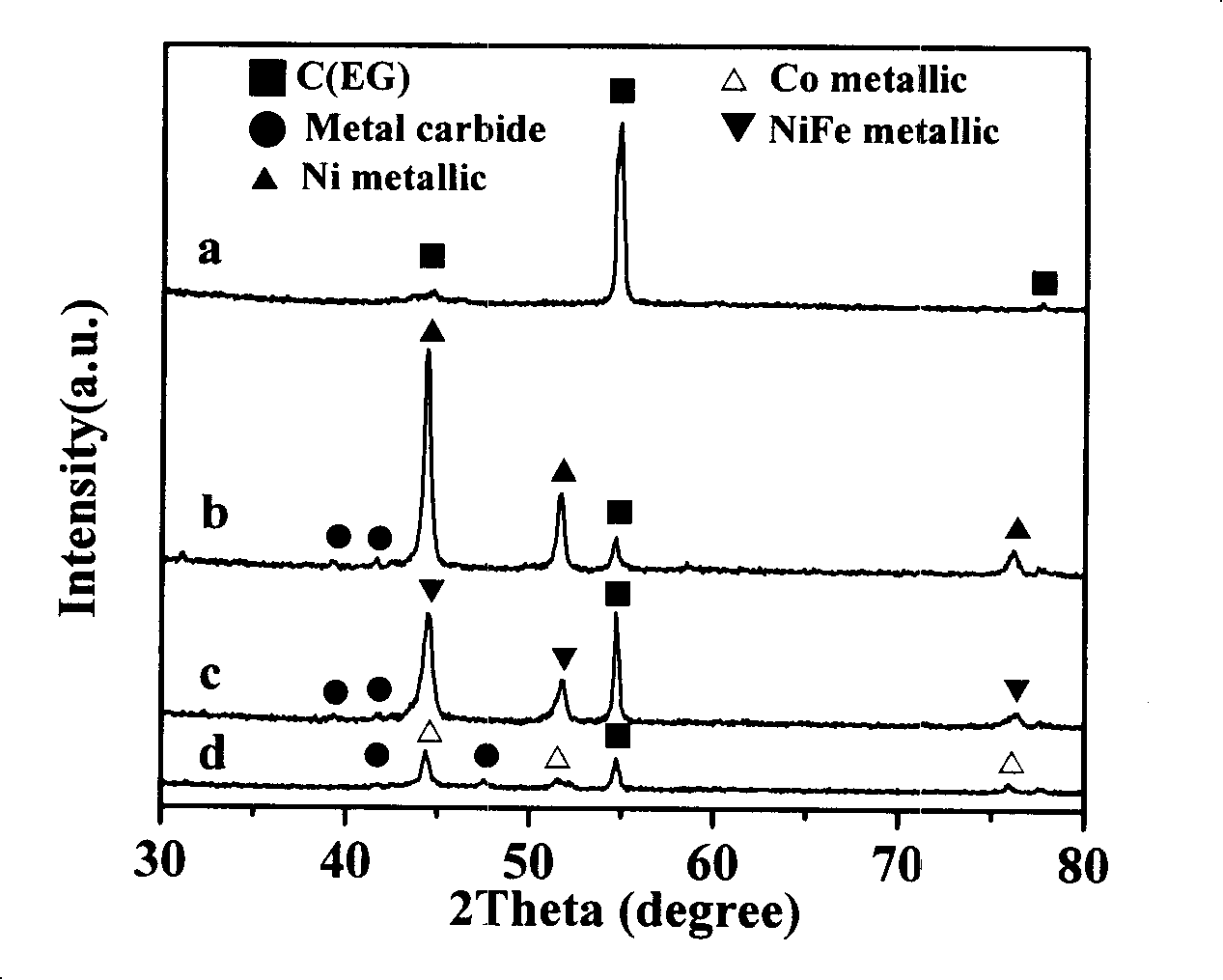

[0030] (1) Dissolve 21.23g of nickel nitrate in 250ml of ethanol, add 10g of expanded graphite, stir evenly, evaporate the solvent in a water bath, and dry the sample.

[0031] (2) The obtained solid mixture is treated in a mixed gas of hydrogen and nitrogen (hydrogen volume fraction 1%) at 300°C for 10 hours, and the sample is passivated with ordinary nitrogen with an oxygen content of 0.1% (volume fraction) and cooled to room temperature. The composite material of graphite and nano metallic nickel is obtained, wherein the mass content of metallic nickel is 30%.

[0032] (3) The composite material can be pressed into various shapes required. In this embodiment, it is pressed into a sheet-like sample with a thickness of 0.5 mm.

Embodiment 2

[0034] (1) Dissolve 10.03g of cobalt chloride in 150ml of acetone, add 10g of expanded graphite, stir evenly, evaporate the solvent in a water bath, and dry the sample.

[0035] (2) The obtained solid mixture was treated in a carbon monoxide atmosphere at 400°C for 6 hours, and the sample was passivated with ordinary nitrogen with an oxygen content of 1% (volume fraction) and cooled to room temperature to obtain a composite material of graphite and nano-metallic nickel. The mass content of metallic nickel is 20%.

[0036] (3) The composite material can be pressed into various shapes required, and is pressed into a sheet in this embodiment.

Embodiment 3

[0038] (1) Dissolve 27.8 g of ferric nitrate in 300 ml of ether, add 10 g of expanded graphite, stir evenly, evaporate the solvent in a water bath, and dry the sample.

[0039] (2) The obtained solid mixture was treated at 600°C for 8 hours in a hydrogen and nitrogen mixed gas (V / V=1 / 1) atmosphere, and the sample was passivated with ordinary nitrogen with an oxygen content of 0.5% (volume fraction) and cooled to At room temperature, a composite material of graphite and nano-metallic iron is obtained, in which the mass content of metallic iron is 40%.

[0040] (3) The composite material can be pressed into various shapes required, and is pressed into a sheet in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com