Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1825 results about "Boehmite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boehmite or böhmite is an aluminium oxide hydroxide (γ-AlO(OH)) mineral, a component of the aluminium ore bauxite. It is dimorphous with diaspore. It crystallizes in the orthorhombic dipyramidal system and is typically massive in habit. It is white with tints of yellow, green, brown or red due to impurities. It has a vitreous to pearly luster, a Mohs hardness of 3 to 3.5 and a specific gravity of 3.00 to 3.07. It is colorless in thin section, optically biaxial positive with refractive indices of nα = 1.644 - 1.648, nβ = 1.654 - 1.657 and nγ = 1.661 - 1.668.

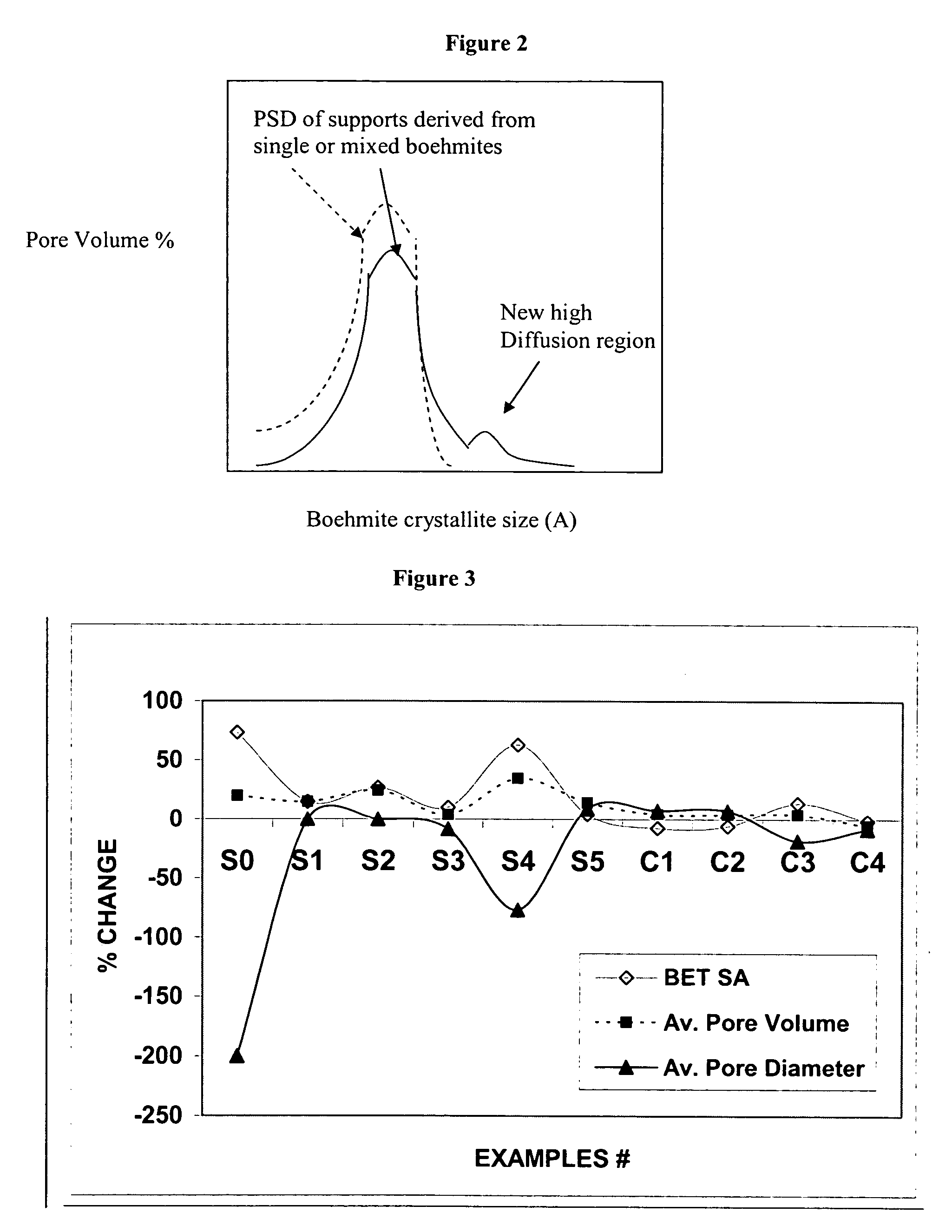

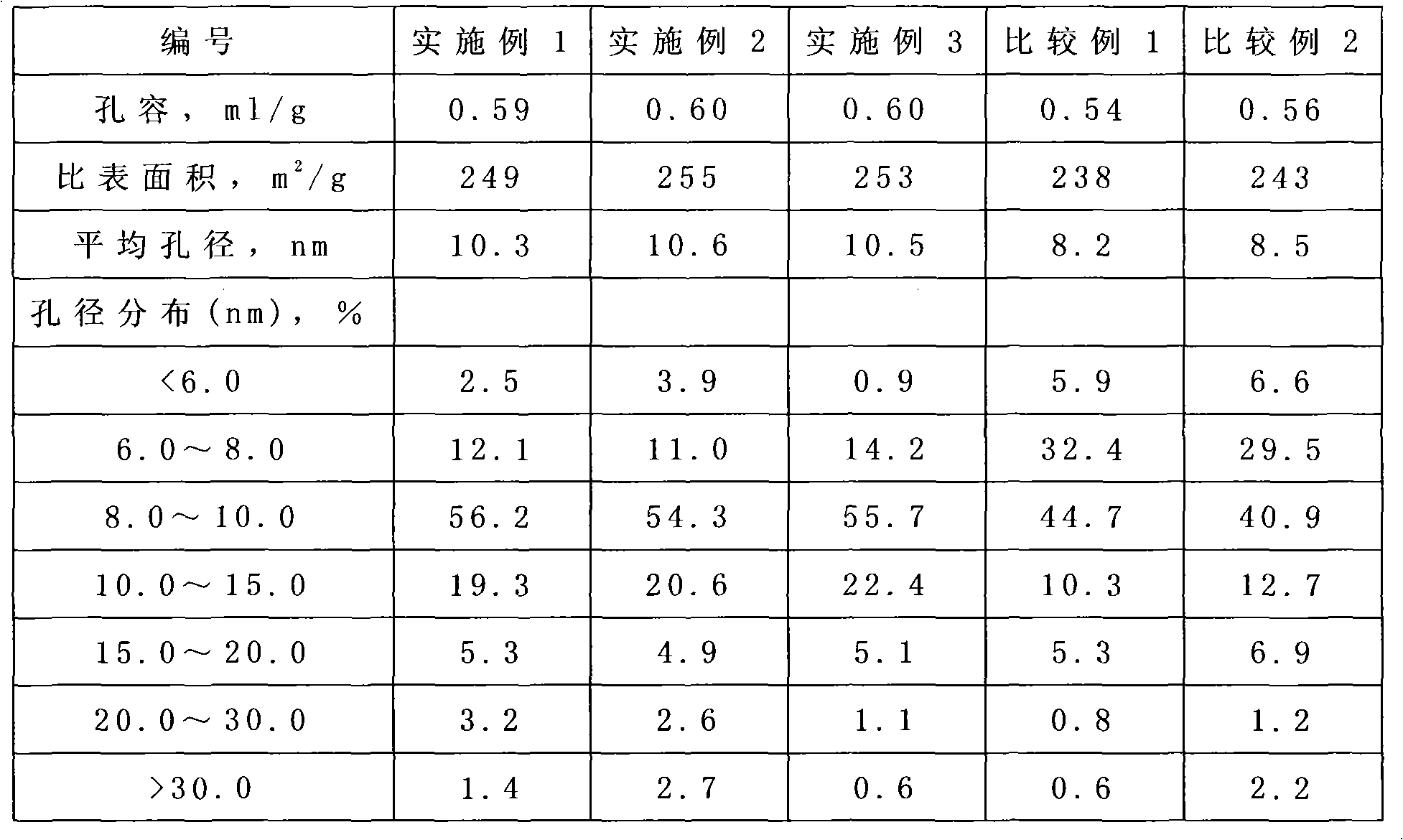

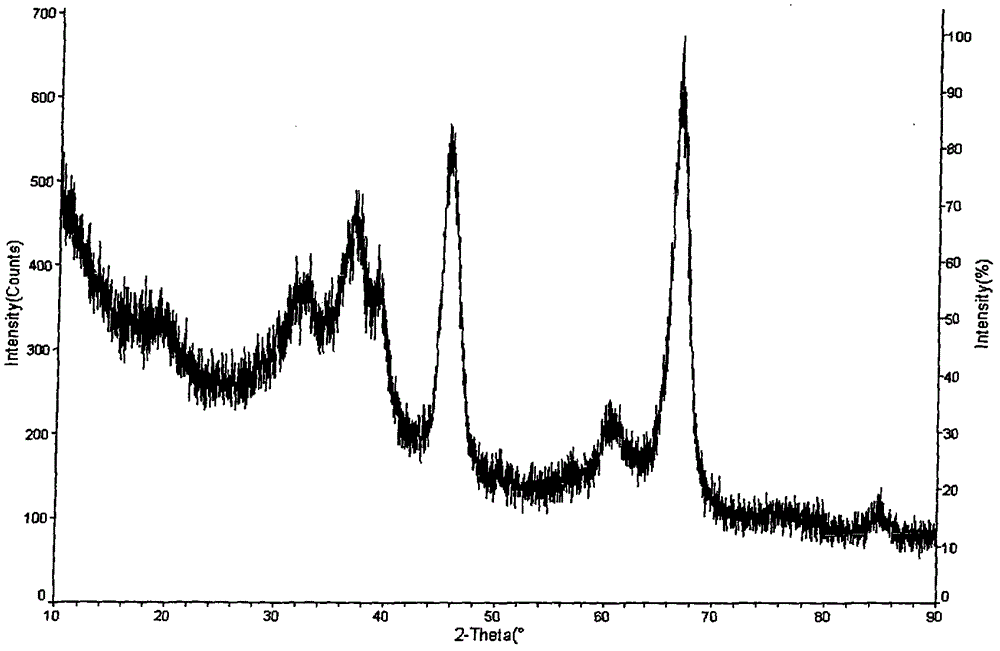

Low-carbon alkane dehydrogenation catalyst and preparation method thereof

ActiveCN101940922AEvenly distributedEnhanced charcoal capacityCatalyst activation/preparationHydrocarbonsAlkaneDehydrogenation

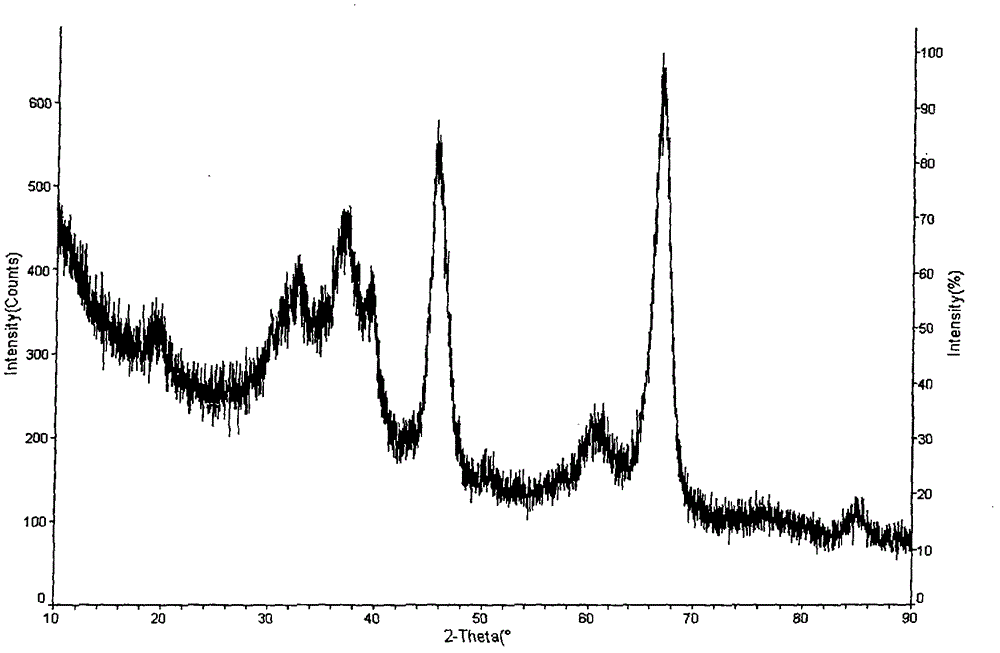

The invention discloses a low-carbon alkane dehydrogenation catalyst and a preparation method thereof. The catalyst is prepared from chromium serving as an active metal ingredient, alkali metal serving as an auxiliary catalytic ingredient and chromium-containing aluminum oxide serving as a carrier, wherein the weight content of the chromium oxide in the carrier is 2.0 to 15.0 percent. In the method, the active metal ingredient, namely chromium, is introduced into the aluminum oxide carrier by partially using a kneading method and partially using an immersion method; pseudo-boehmite mixed with chromium is processed by adopting a three-step roasting method and a hydrothermal method; and thus, the porous structure and the surface character of the carrier can be improved, the content and the distribution of the active metal chromium in the carrier and the mutual effect between the active metal and the aluminum oxide are further modulated, the activity and the stability of the catalyst are improved, the carbon depositing resistance of the catalyst is enhanced, and the service life of the catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

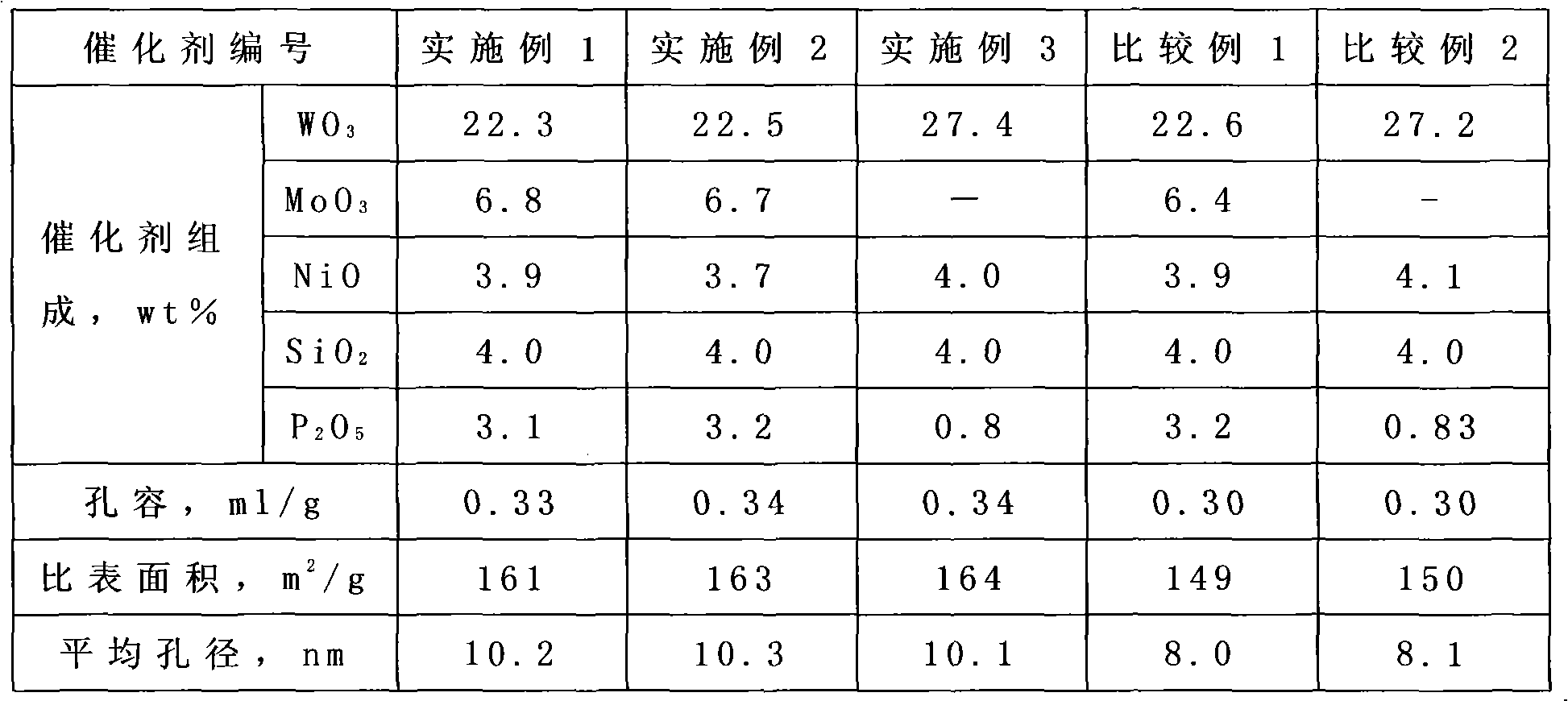

Heavy oil hydrogenation catalyst and preparation method thereof

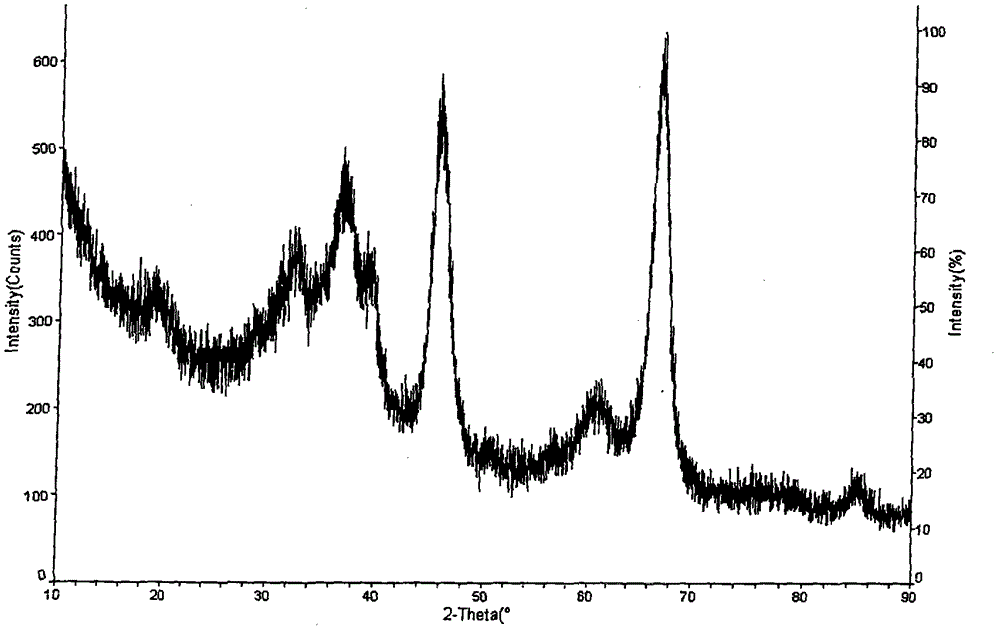

ActiveCN103769118AShorten drying timeAvoid pollutionCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsDry basisBULK ACTIVE INGREDIENT

The invention discloses a heavy oil hydrogenation catalyst and a preparation method thereof. The heavy oil hydrogenation catalyst comprises a carrier and an active ingredient; the carrier is aluminum oxide, and is prepared from pseudo-boehmite with dry basis content below 50% via moulding; the active ingredient are metals selected form family VIII, Co or Ni, and / or family VI B, Mo or W. The preparation method comprises following steps: preparation of pseudo-boehmite, preparation of the carrier, and loading of the active ingredient. The heavy oil hydrogenation catalyst is capable of maintaining high demetalization, desulphurization, and carbon residue removing activities, simplifying drying process of pseudo-boehmite preparation, avoiding dust pollution caused by moulding process, increasing production efficiency, reducing production energy consumption, and reducing catalyst cost further.

Owner:CHINA PETROLEUM & CHEM CORP +1

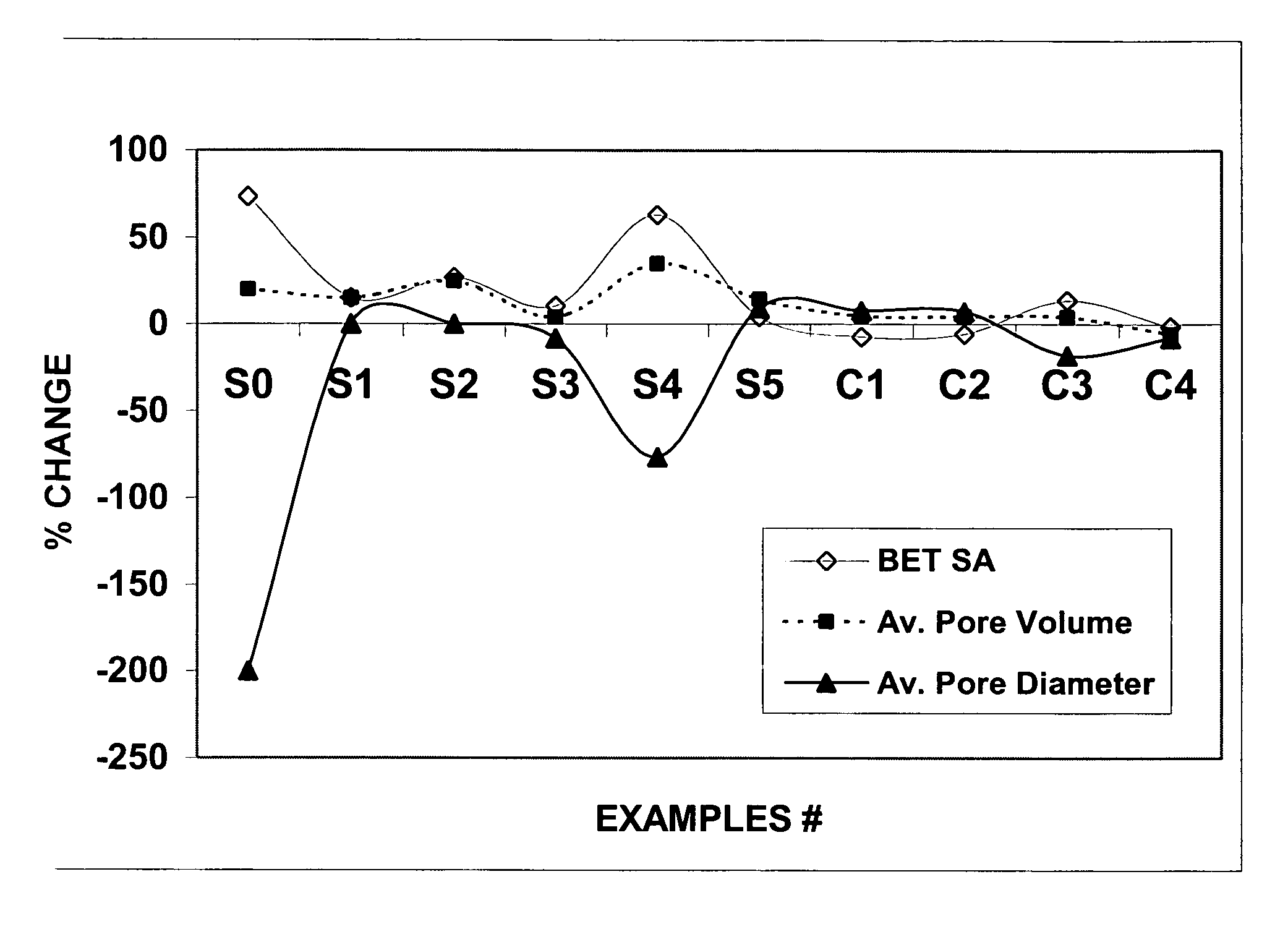

Stabilized boehmite-derived catalyst supports, catalysts, methods of making and using

ActiveUS20050234137A1Good hydrothermal stabilityImprove stabilityMaterial nanotechnologyCatalyst carriersPorosityAluminium hydroxide

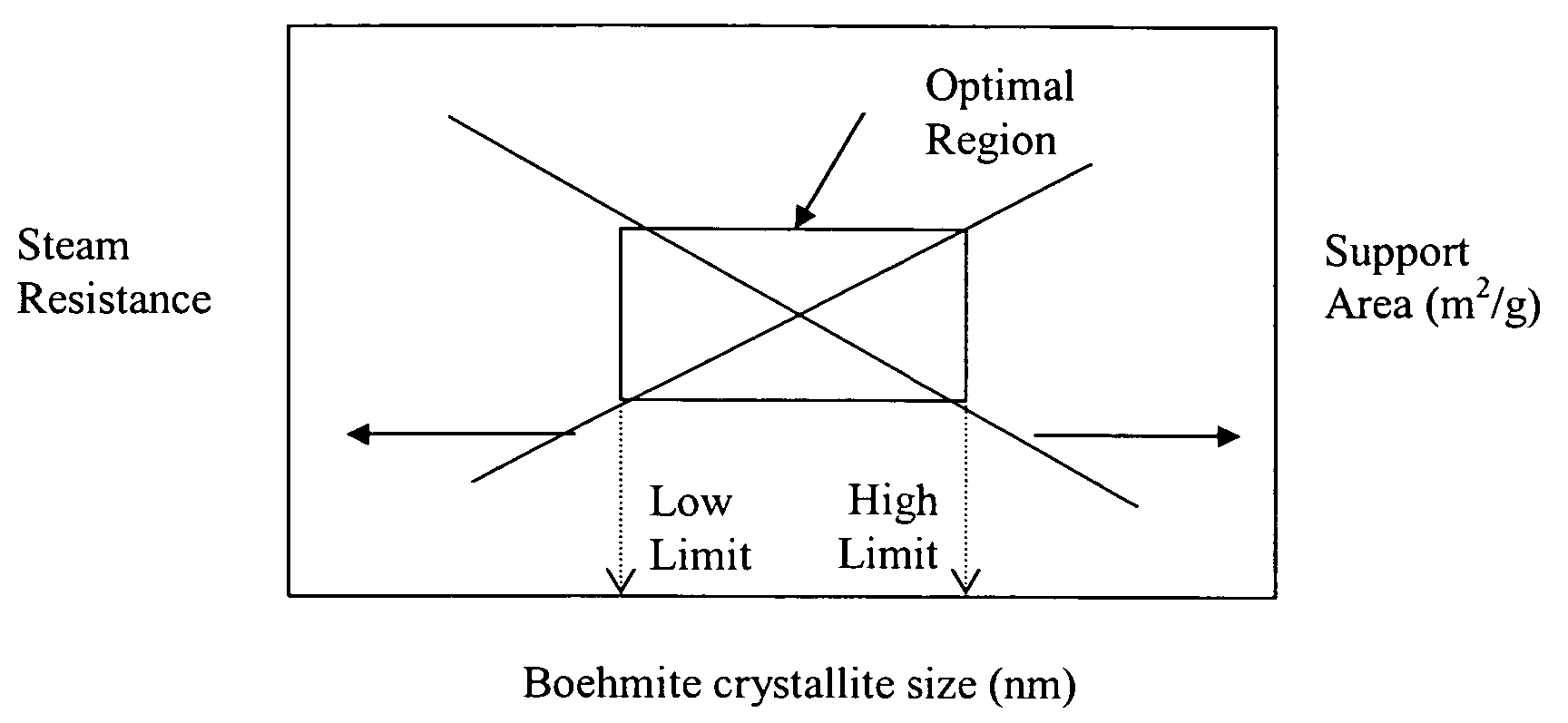

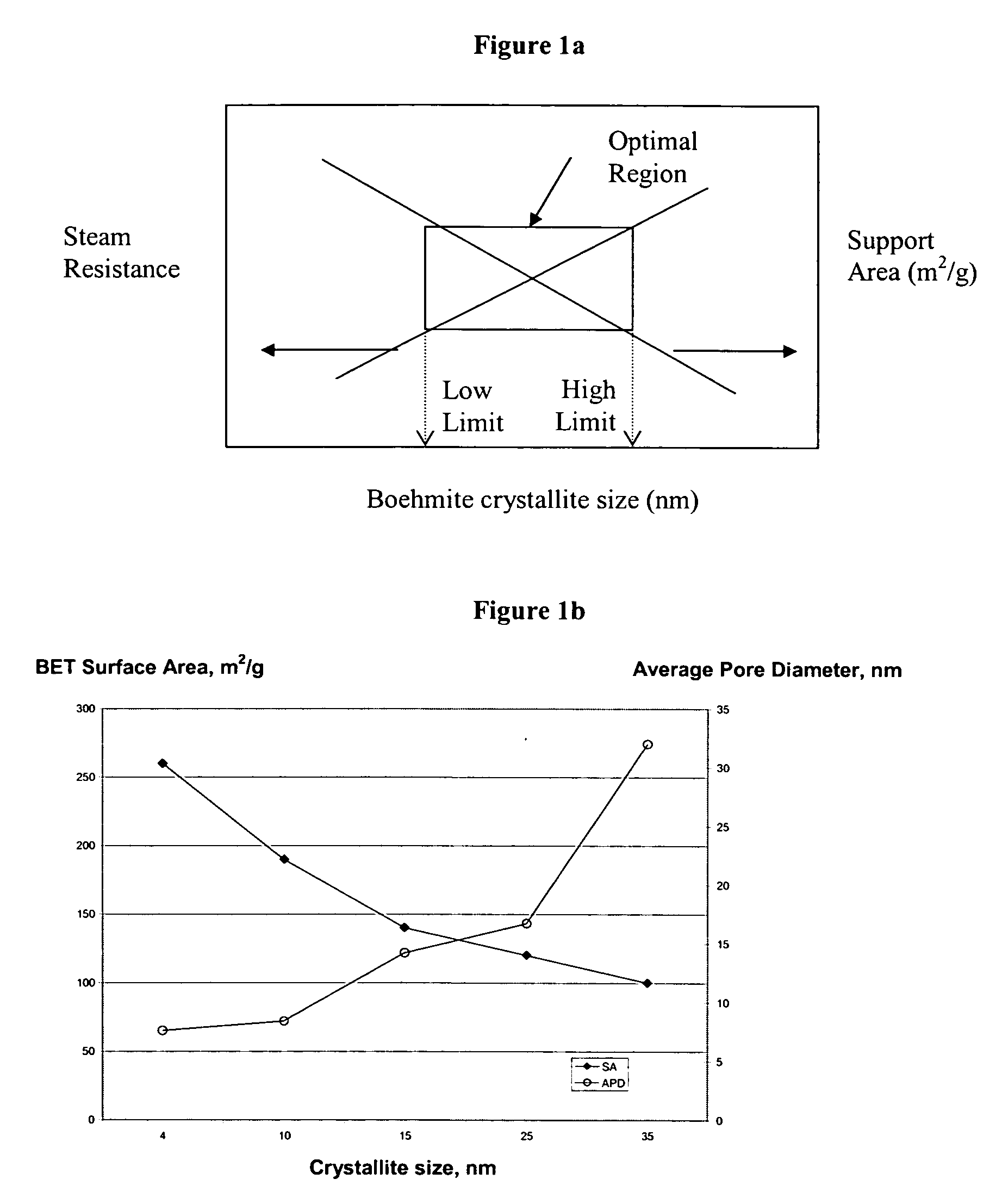

A stabilized catalyst support having improved hydrothermal stability, catalyst made therefrom, and method for producing hydrocarbons from synthesis gas using said catalyst. The stabilized support is made by a method comprising treating a crystalline hydrous alumina precursor in contact with at least one structural stabilizer or compound thereof. The crystalline hydrous alumina precursor preferably includes an average crystallite size selected from an optimum range delimited by desired hydrothermal resistance and desired porosity. The crystalline hydrous alumina precursor preferably includes an alumina hydroxide, such as crystalline boehmite, crystalline bayerite, or a plurality thereof differing in average crystallite sizes by at least about 1 nm. The crystalline hydrous alumina precursor may be shaped before or after contact with the structural stabilizer or compound thereof. The treating includes calcining at 450° C. or more. Preferred structural stabilizers can include cobalt, magnesium, manganese, manganese, zirconium, boron, aluminum, barium, silicon, lanthanum, oxides thereof, or combinations thereof.

Owner:CLARIANT INT LTD

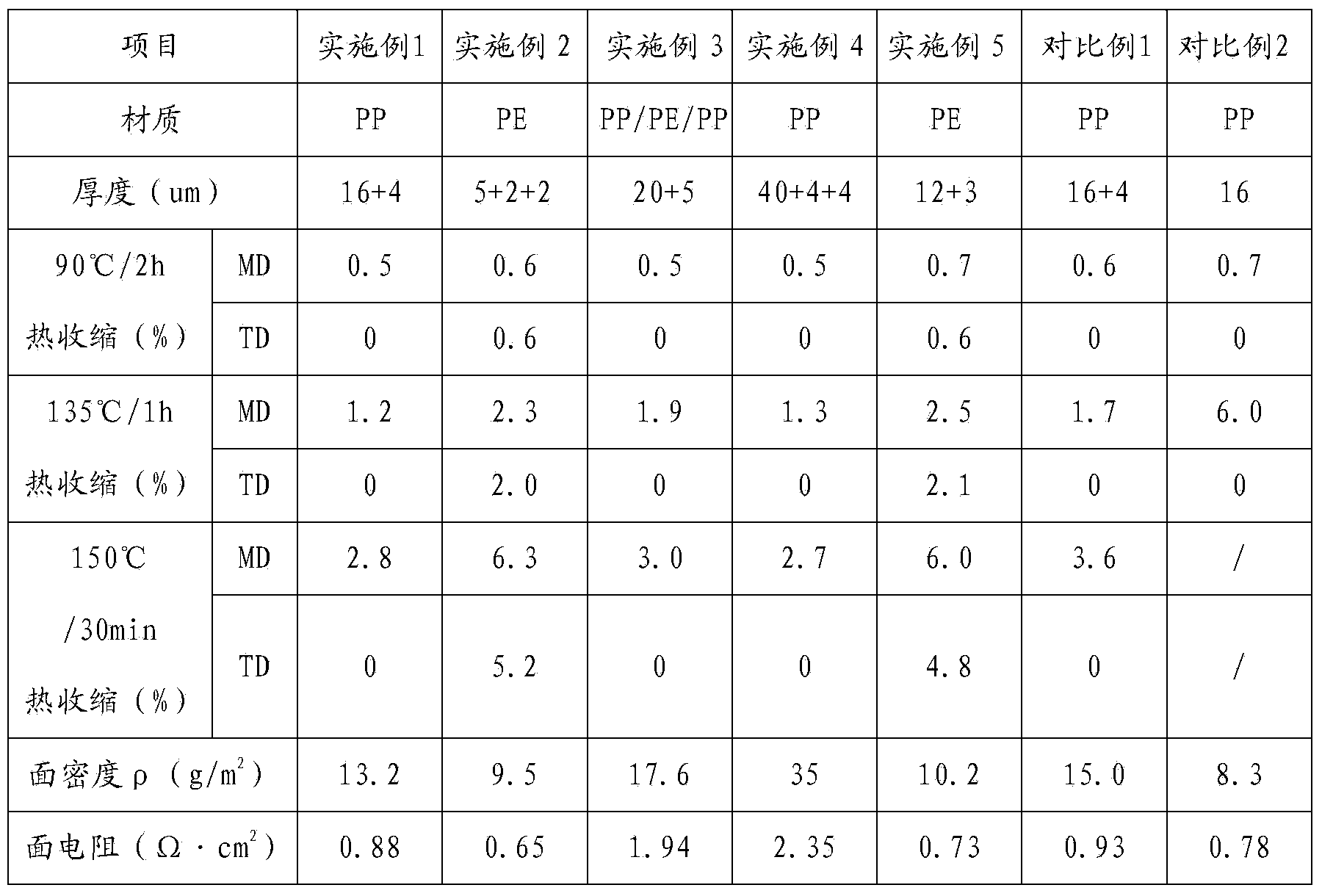

Separator for electrochemical device, electrode for electrochemical device, and electrochemical device

ActiveUS20100015530A1Improve reliabilityImprove load characteristicsHybrid capacitor separatorsHybrid capacitor electrodesPhysical chemistryPolyresin

A separator for an electrochemical device of the present invention includes a porous film including: a filler; an organic binder; and at least one resin selected from resin A that has a melting point of 80 to 140° C. and resin B that absorbs a non-aqueous electrolyte and swells upon heating and whose swelling degree increases with increasing temperature, and the filler contains boehmite having a secondary particle structure in which primary particles are connected.

Owner:MAXELL HLDG LTD

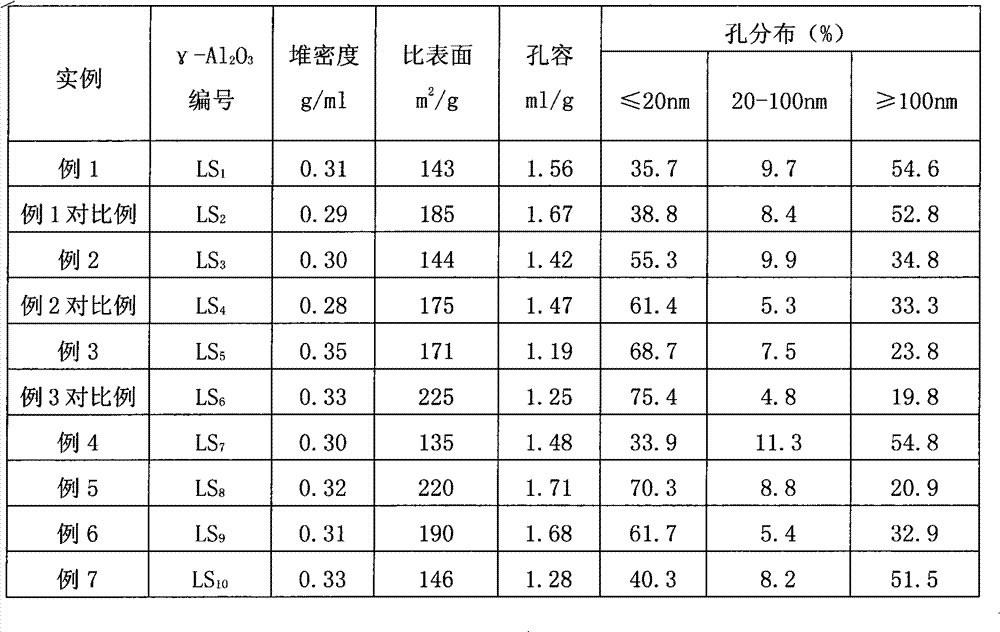

Preparation method of double-hole-structure alumina supporter

ActiveCN102861617ALarge hole volumeNo overheating phenomenonCatalyst carriersMaterials scienceAmmonium bicarbonate

The invention discloses a preparation method of a double-hole-structure alumina supporter. The preparation method comprises the steps of weighing a certain quantity of pseudo-boehmite dry glue powders, evenly mixing the pseudo-boehmite dry glue powder with a certain quantity of peptizing agent and extrusion-auxiliary agent, then adding a certain quantity of ammonium bicarbonate aqueous solution in materials, mixing and nipping obtained materials into a plasticizer, squeezing into stripes and molding, placing molded materials in a sealing container, and roasting to prepare the alumina supporter after hydro-thermal treatment. The temperature of the hydro-thermal treatment is 70-120 DEG C, and the treatment time is 5-10 hours. Roasting is carried out at the temperature of 600-750 DEG C for 2-4 hours. The mass concentration of an ammonium bicarbonate solution is 40%-80%, the adding quantity of the ammonium bicarbonate solution is calculated according to NH<4+> and Al<3+>, and a molar ratio of the NH<4+> to Al<3+> is (0.5-1):1. According to the preparation method, the preparation procedure is simple, the prepared alumina supporter is in double-hole distribution and has good mechanical strength, and the preparation method is suitable to the field of preparation of heavy oil and residual oil hydrodemetallization catalysts and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

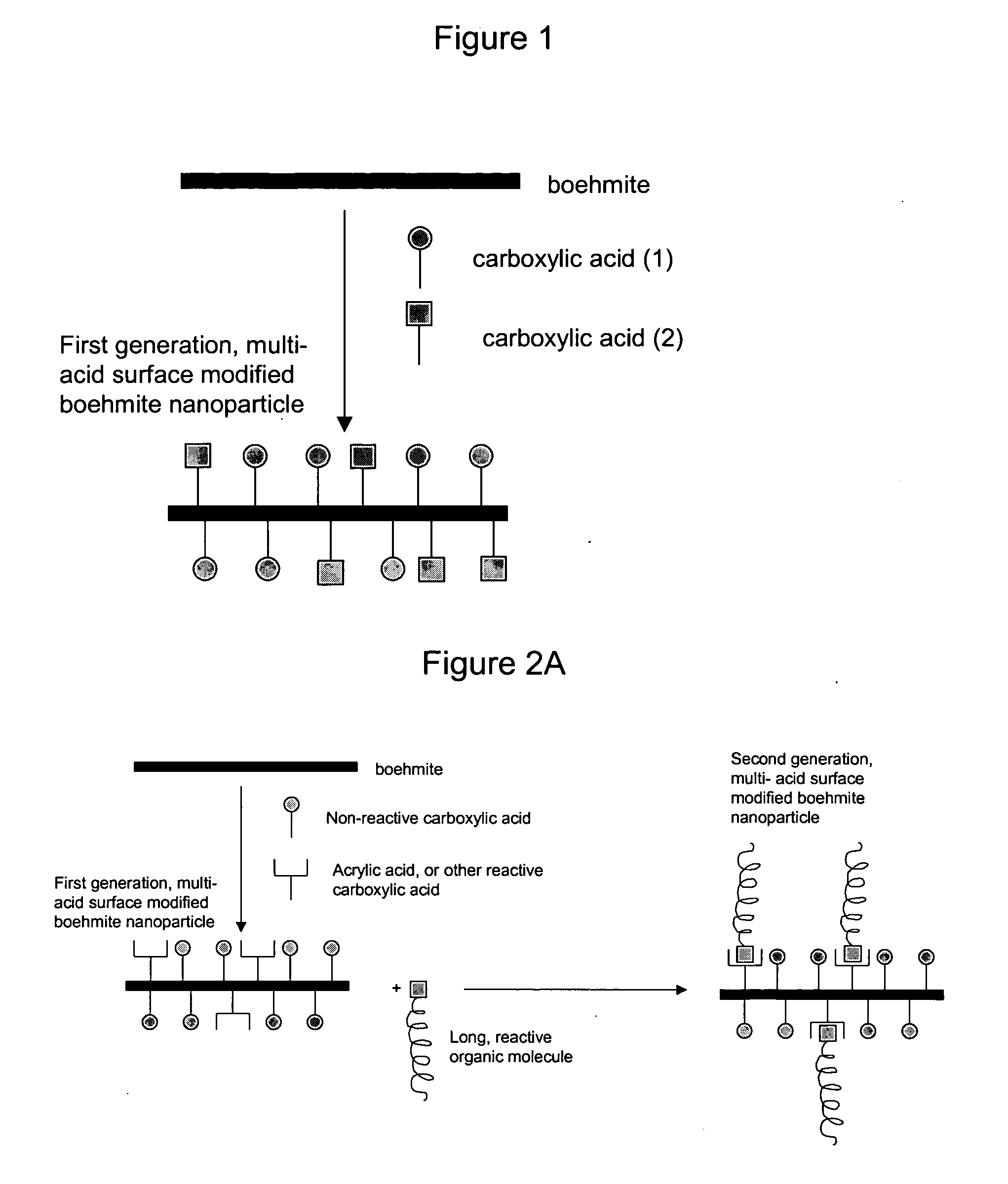

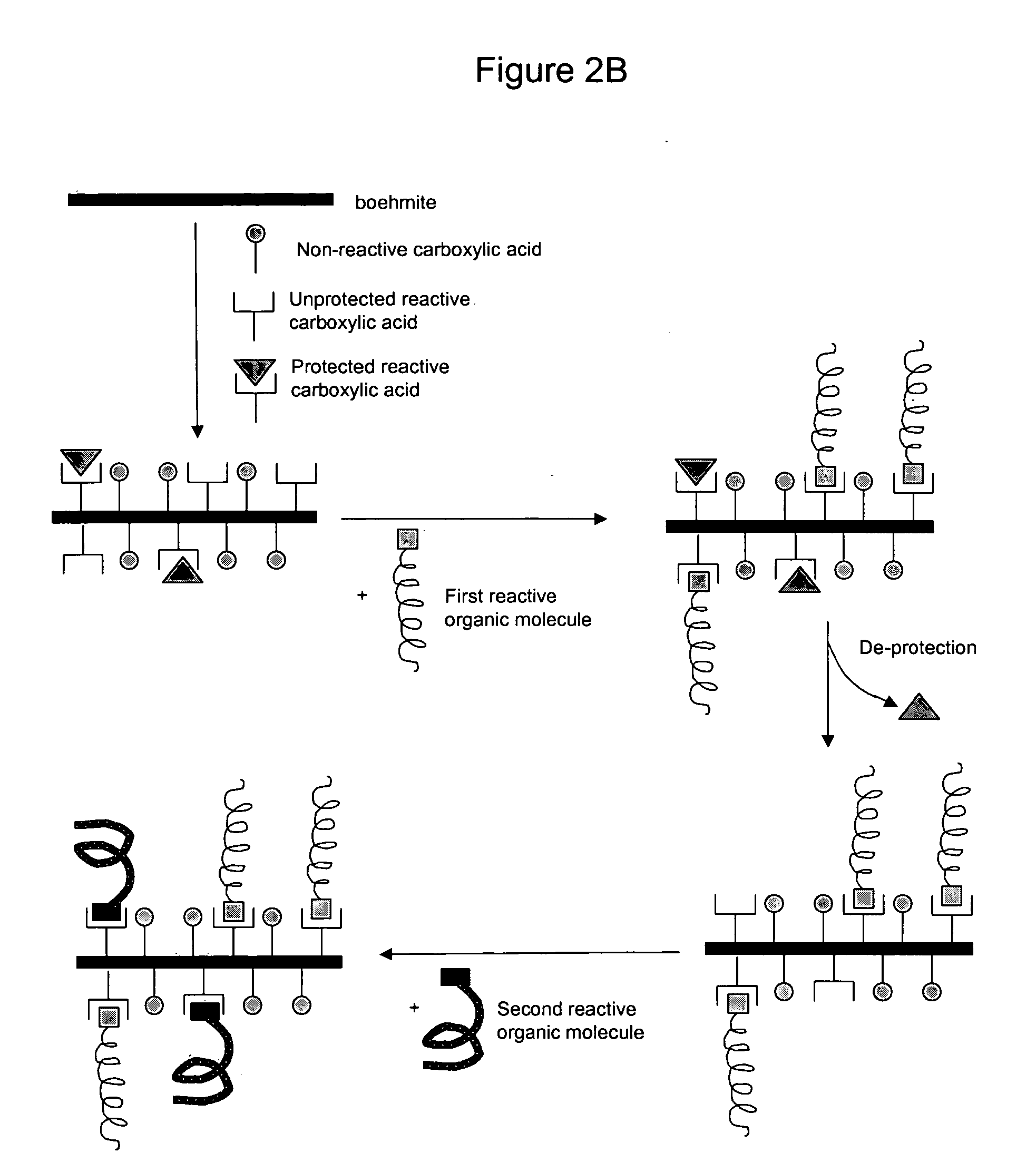

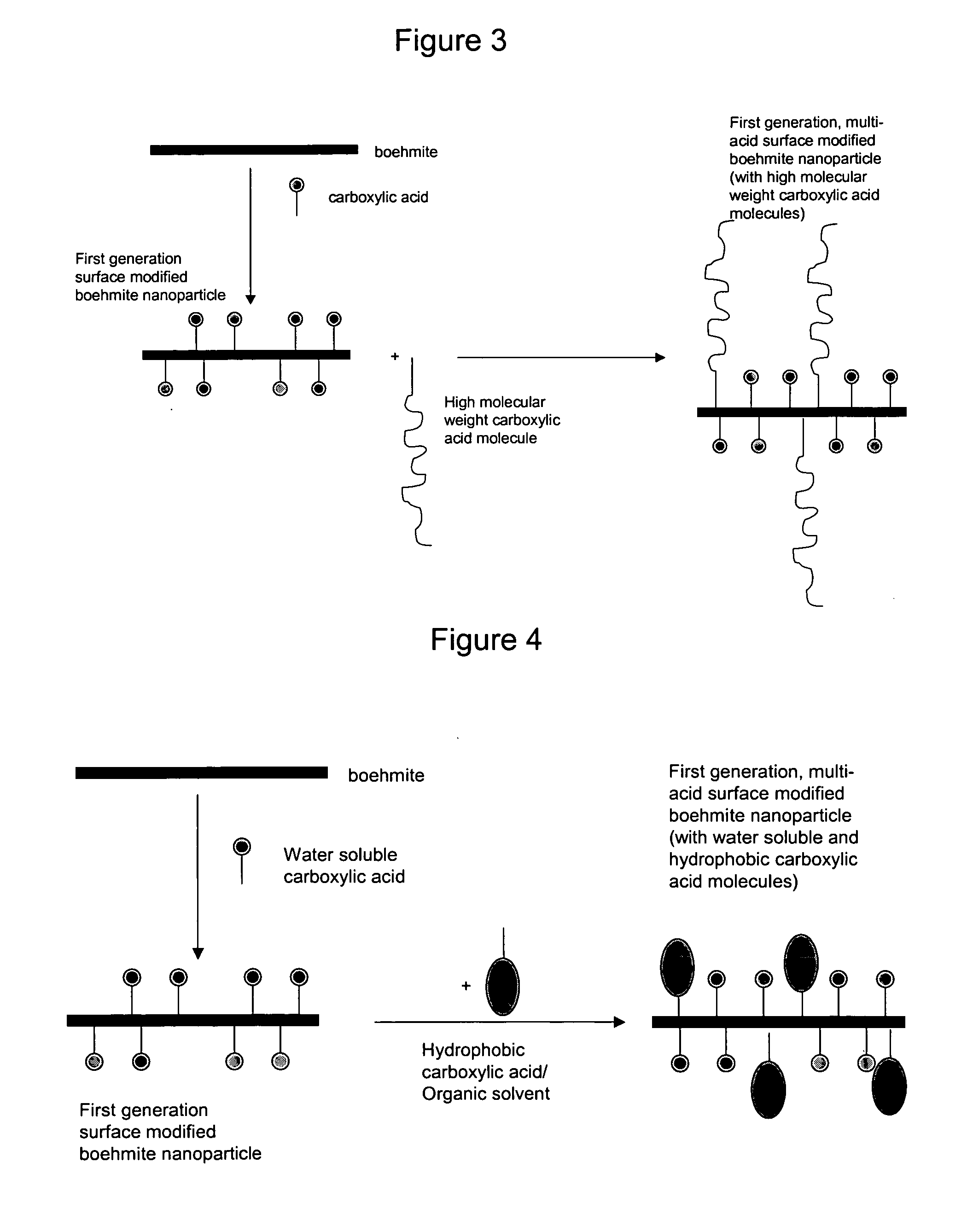

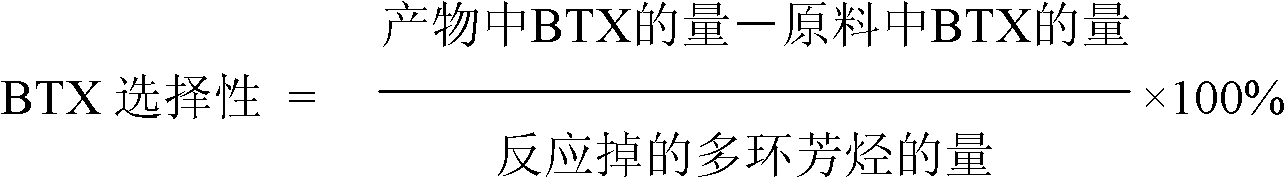

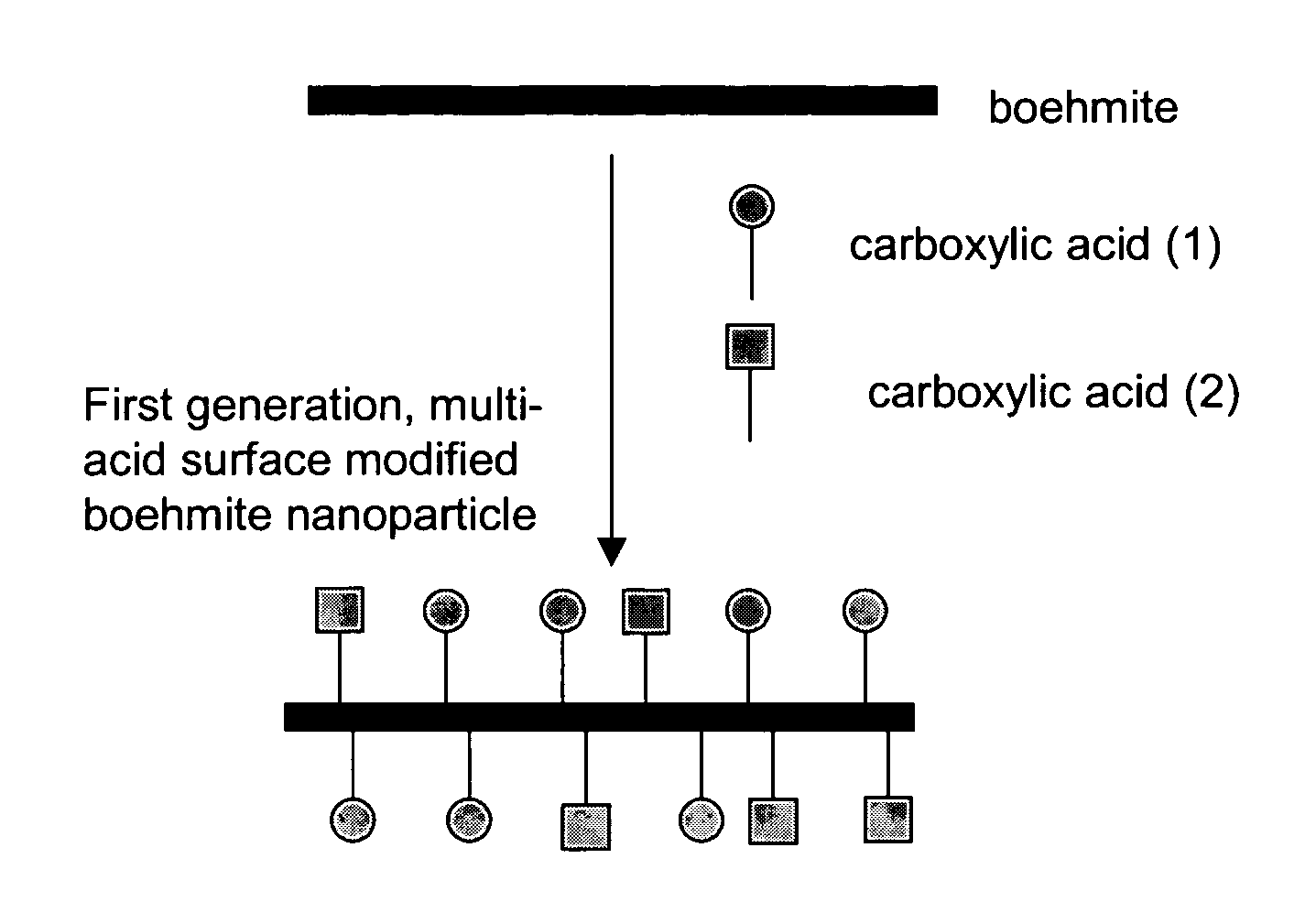

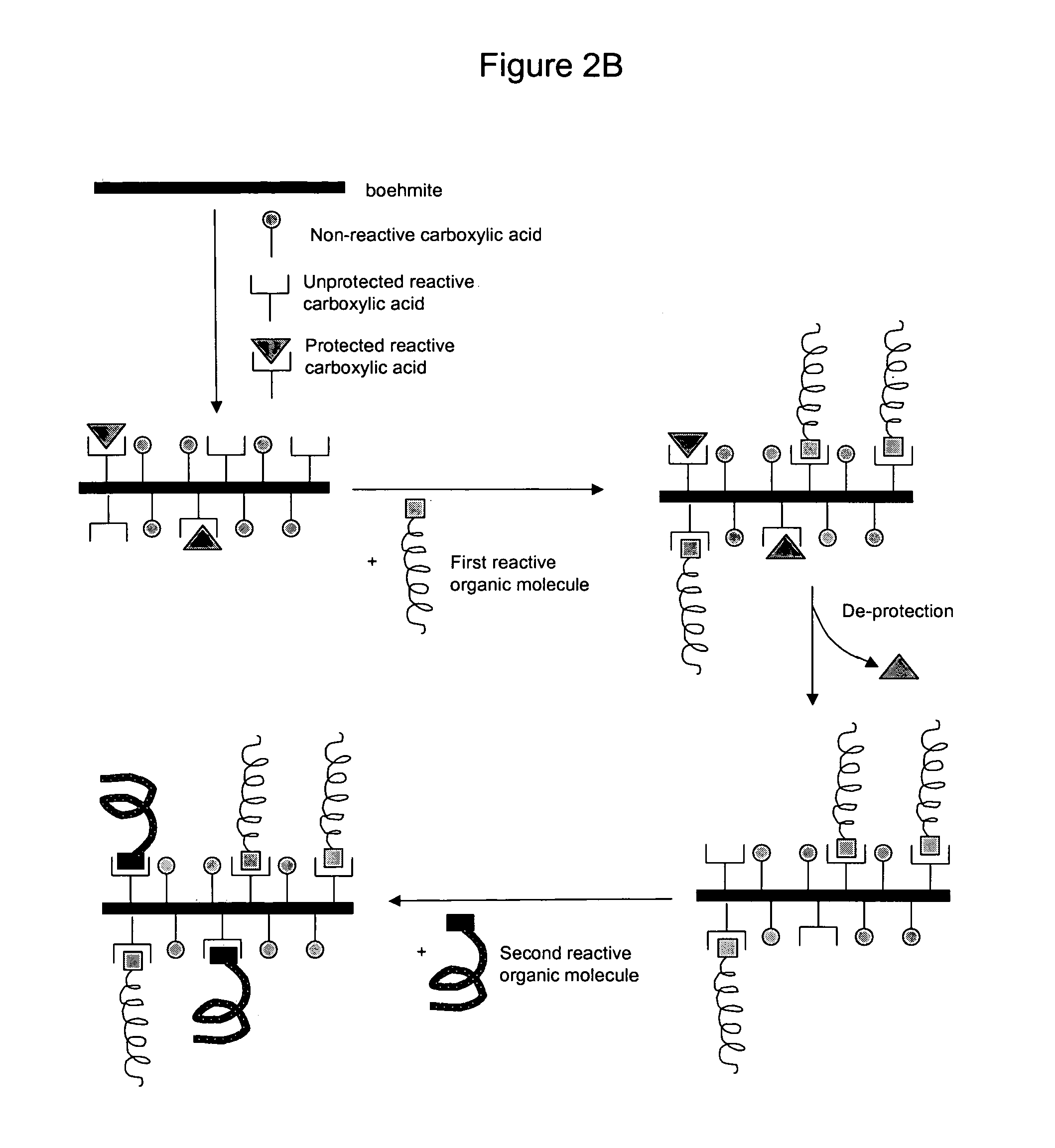

Nanoparticles modified with multiple organic acids

InactiveUS20070098990A1Reduce the amount requiredPigmenting treatmentMaterial nanotechnologySolubilityOrganic acid

Surface-modified nanoparticles of boehmite, and methods for preparing the same. Aluminum oxyhydroxide nanoparticles are surface modified by reaction with selected amounts of organic acids. In particular, the nanoparticle surface is modified by reactions with two or more different carboxylic acids, at least one of which is an organic carboxylic acid. The product is a surface modified boehmite nanoparticle that has an inorganic aluminum oxyhydroxide core, or part aluminum oxyhydroxide core and a surface-bonded organic shell. Organic carboxylic acids of this invention contain at least one carboxylic acid group and one carbon-hydrogen bond. One embodiment of this invention provides boehmite nanoparticles that have been surface modified with two or more acids one of which additional carries at least one reactive functional group. Another embodiment of this invention provides boehmite nanoparticles that have been surface modified with multiple acids one of which has molecular weight or average molecular weight greater than or equal to 500 Daltons. Yet, another embodiment of this invention provides boehmite nanoparticles that are surface modified with two or more acids one of which is hydrophobic in nature and has solubility in water of less than 15 by weight. The products of the methods of this invention have specific useful properties when used in mixture with liquids, as filler in solids, or as stand-alone entities.

Owner:TDA RES

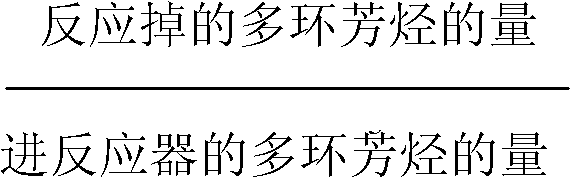

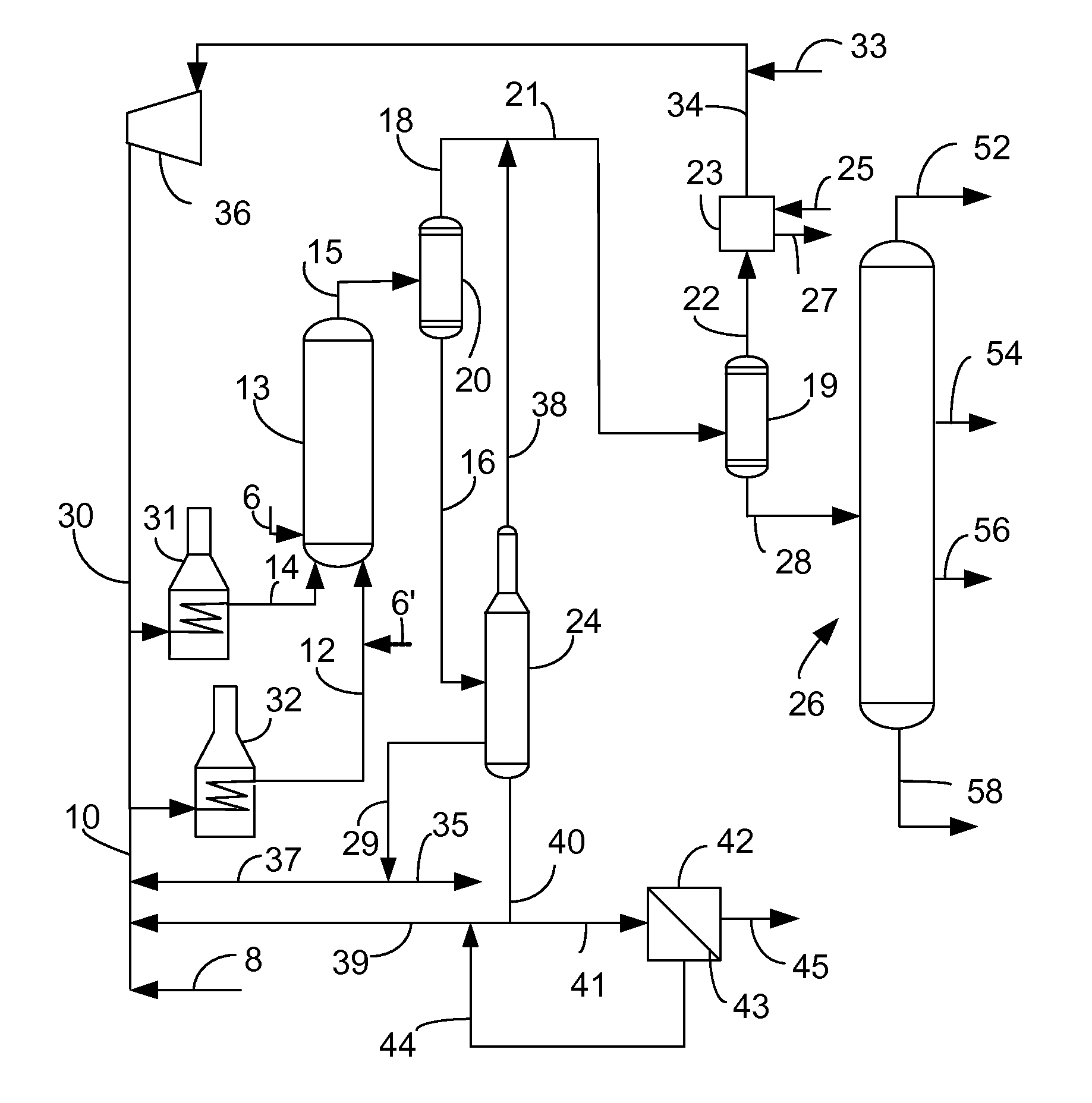

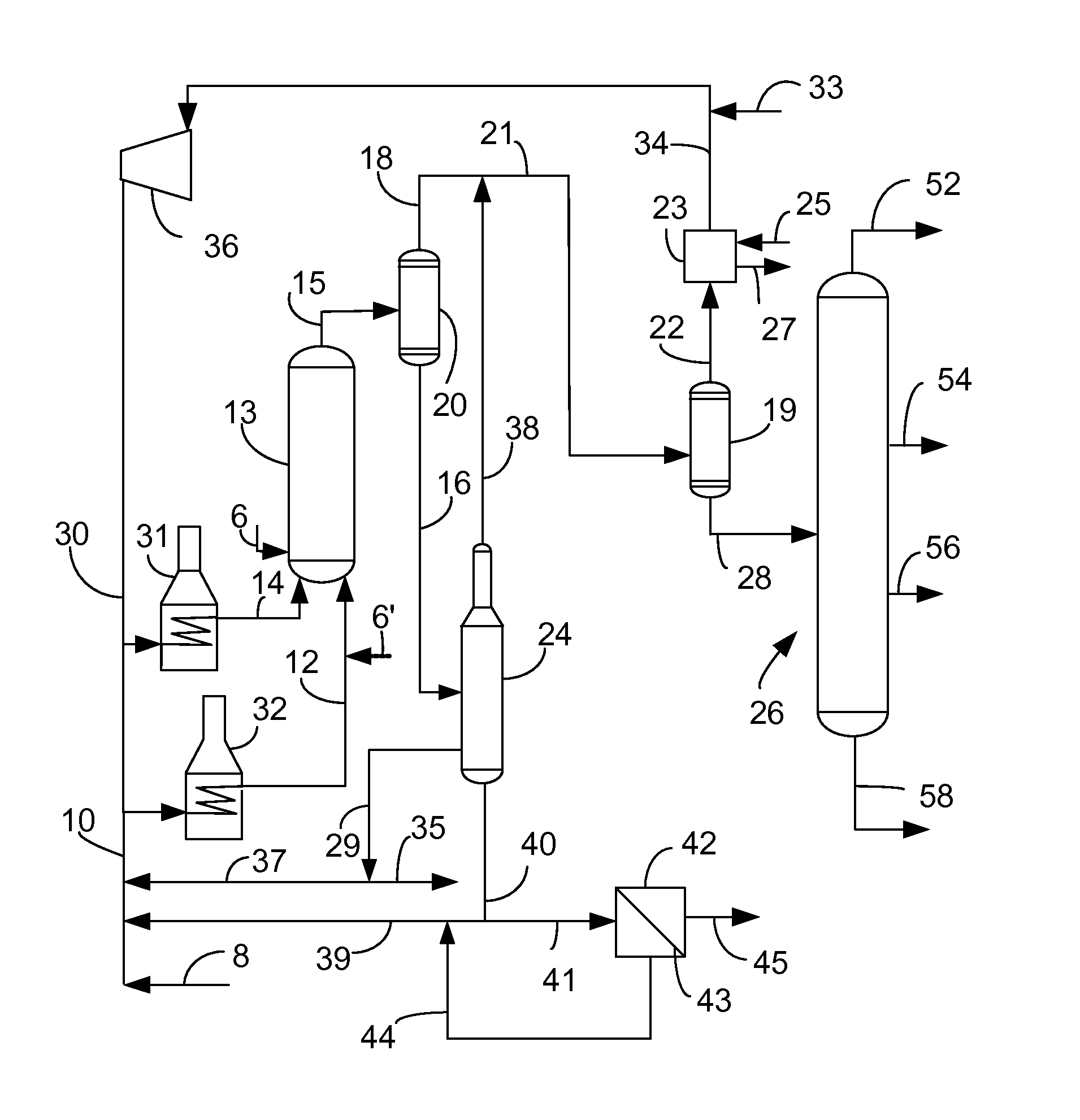

Fischer-Tropsch processes and catalysts using stabilized supports

ActiveUS7071239B2Good hydrothermal stabilityImprove stabilityCatalyst carriersOrganic compound preparationSlurryHYDROSOL

A catalyst and method for producing hydrocarbons using a catalyst support having an improved hydrothermal stability, such as under Fischer-Tropsch synthesis conditions. The stabilized support is made by a method comprising treating a boehmite material in contact with at least one structural stabilizer. Contacting the boehmite with at least one structural stabilizer can include forming a mixture comprising the boehmite material and at the least one structural stabilizer. The mixture can be a sol or a slurry. The treating preferably includes drying or spray drying the mixture, and calcining in an oxidizing atmosphere to obtain the stabilized support. Preferred structural stabilizers can include an element, such as cobalt, magnesium, zirconium, boron, aluminum, barium, silicon, lanthanum, oxides thereof, or combinations thereof; or can include precipitated oxides, such as a co-precipitated silica-alumina.

Owner:CLARIANT INT LTD

Method for preparing petroleum wax hydrofining catalyst

ActiveCN102039148AIncreased dispersionPore Structure ModulationCatalyst carriersPetroleum wax refiningCooking & bakingWax

The invention relates to a method for preparing a petroleum wax hydrofining catalyst. The method comprises the following steps of: weighing boehmite, adding a silicon-containing compound in an amount which is 6 to 17 percent based on the weight of the boehmite and phosphorus-containing organic compound solution in an amount which is 2 to 20 percent based on the weight of the boehmite, and extruding and forming on an extruder; drying at the temperature of between 100 and 120 DEG C; baking at the temperature of between 500 and 700 DEG C to obtain a gamma-Al2O3 carrier containing silicon and phosphorus, wherein the silicon-containing compound is silica solution of which SiO2 accounts for 30 percent based on the weight of the silica solution, or nano-silica; the active ingredients are one or two of NiO and Moo3, and WO3; NiO accounts for 2 to 7 percent based on the total mass of the catalyst, and MoO3 and / or WO3 account for 28 to 32 percent based on the total mass of the catalyst; the prepared catalyst has intensively distributed pores and appropriate surface acidity and still has high hydrogenation activity at a low reaction temperature and under a low reaction pressure.

Owner:PETROCHINA CO LTD

Heavy oil hydrogenating treatment catalyst and preparation method thereof

ActiveCN101433848AIncrease the areaLarge hole volumeMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationPore diameter

The invention discloses a heavy oil hydrotreating catalyst and a preparation method thereof. The method for preparing the catalyst adopts a complete mixed kneading method; a carrier material comprises pseudo-boehmite glue powder and alumina powder; and an active metallic solution contains nonionic surfactant. The catalyst prepared by the method has the characteristics of large pore volume and pore diameter, proper specific surface area, even active metal dispersion and the like, and can be used in the processes of heavy oil hydrodemetalization, hydrodesulfurization and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Methods of preparing separators for electrochemical cells

InactiveUS20070189959A1High porosityHigh strengthCell component detailsSpecial surfacesCarbonateOrganic polymer

Provided are methods of preparing a separator for an electrochemical cell comprising the steps of (a) coating onto a substrate a liquid mixture comprising an inorganic oxide, an organic polymer, a divinyl ether of an ethylene glycol, and / or an organic carbonate; (b) drying the coating; and (c) delaminating the coating from the substrate to form the separator comprising an inorganic oxide and the organic polymer, wherein the inorganic oxide of step (c) comprises a reaction product of the divinyl ether and / or the organic carbonate with the inorganic oxide of step (a). Preferably, the inorganic oxide of step (c) comprises a hydrated aluminum oxide of the formula Al2O3.H2O, wherein x is less than 1.0, and wherein the hydrated aluminum oxide comprises a reaction product of the divinyl ether and / or organic carbonate with the inorganic oxide of step (a), such as pseudo-boehmite.

Owner:CARLSON STEVEN ALLEN +1

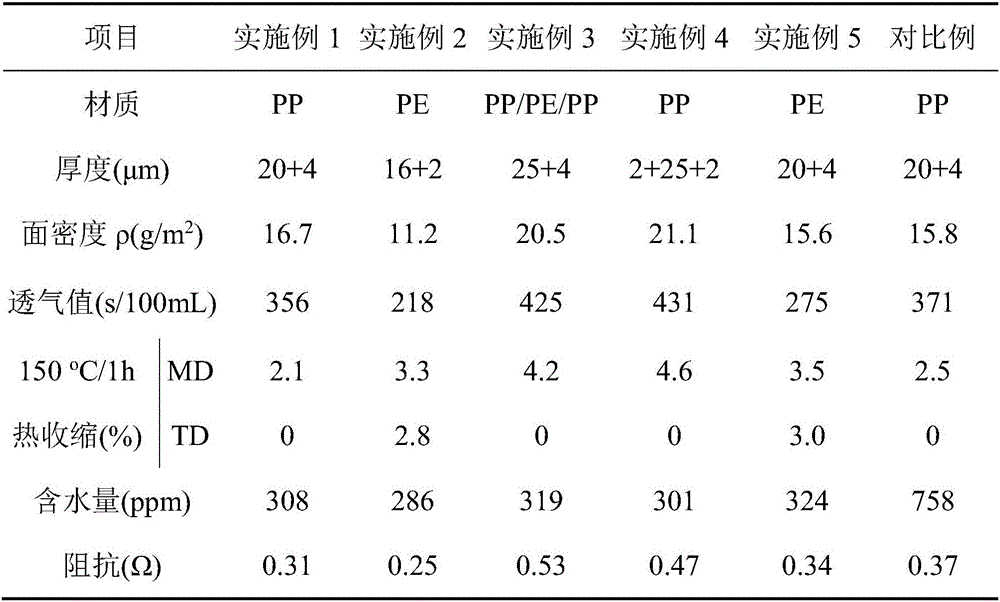

Water-based ceramic coating lithium ion battery diaphragm and processing method thereof

The invention discloses a water-based ceramic coating lithium ion battery diaphragm. The water-based ceramic coating lithium ion battery diaphragm comprises a polyolefin porous membrane and a coating which coats one or both sides of the polyolefin porous membrane, wherein the coating is 2-8 microns in thickness, and consists of 20-60 percent by weight of base material and 40-80 percent of water; the base material comprises 0.1-5 parts by weight of a water-soluble high polymer thickener, 0.1-5 parts of a water-based dispenser, 0.1-10 parts of a water-based adhesive and 80-99.7 parts of boehmite particles. The invention further discloses a processing method of the ceramic coating lithium ion battery diaphragm. The processing method has the advantages of slight wear to mechanical equipment, uniform and consistent coating thickness and contribution to continuous and stable large-scale production.

Owner:SHENZHEN SENIOR TECH MATERIAL

Inkjet recording medium

InactiveUS20080241436A1High glossMaintaining film propertyDuplicating/marking methodsCross-linkAlumina hydrate

An inkjet recording medium including a water-resistant support, and on the water-resistant support, two or more ink receiving layers including an upper ink receiving layer and a lower ink receiving layer, each of the two or more ink receiving layers containing a pseudo boehmite alumina hydrate, wherein the upper ink receiving layer further contains a polyvinyl alcohol having a saponification degree of 90% or higher and at least one crosslinking agent selected from the group consisting of boric acid and boric acid salts, and the lower ink receiving layer further contains a polyvinyl alcohol having a saponification degree of less than 90% and at least one cross-linking agent selected from the group consisting of boric acid and boric acid salts.

Owner:FUJIFILM CORP

Preparation process for large pore volume and light bulk density activated alumina

InactiveCN102730724AChange the stacking methodFine grainAluminium oxides/hydroxidesWater vaporSodium aluminate

The invention relates to a preparation process for large pore volume and light bulk density activated alumina, and belongs to the technical field of activated alumina preparation. According to the process, an aluminum sulfate solution and a sodium aluminate solution form a glue in a stainless steel neutralization kettle through a continuous co-current flow method; then an aging treatment is performed for a certain time in a stainless steel aging washing tank; the resulting material is pressed to a plate and frame filter press with a material pressing pump to carry out continuous washing to prepare primary pseudo-boehmite particles with large grains; the removed filter cake is acidified, and proper amounts of a pore expanding agent and a surfactant are added during the acidification process to carry out forming; the formed wet balls are placed in a drying box to carry out drying; and the dried small balls are loaded into a calcination activation furnace to carry out high temperature calcination and pore expanding. The process of the present invention has characteristics of low cost and low equipment corrosion, can performs continuous washing cycle, and has advantages of low wastewater discharging, less pollution, and the like. With the process of the present invention, the production cycle can be reduced, the labor intensity can be reduced, and various performance indicators of the prepared gamma-Al2O3 can meet the international advanced level after pore expanding by water vapor.

Owner:JIANGSU JINGJING NEW MATERIALS

Method for improving solid content of catalytic cracking catalyst slurry

ActiveCN101134906ASimple structureHigh solid contentCatalytic crackingCatalyst activation/preparationMolecular sieveColloid

The present invention is method of raising solid content in catalytic cracking catalyst slurry. The method includes mixing clay, molecular sieve slurry, aluminum-containing binder, pseudo boehmite and inorganic acid to form catalyst slurry and the subsequent spray drying. It features that the addition of inorganic acid before adding pseudo boehmite and the molecular sieve, and the addition of inorganic acid after adding kaolin and aluminum-containing binder or into the aluminum-containing binder. The present invention can raise the solid content in catalyst slurry to over 40 % to short the colloid forming time greatly, raise the catalyst producing efficiency and lower catalyst producing cost while ensuring the wear strength of catalyst. At the same time, the catalyst has great pore volume, high micro reaction activity and improved comprehensive reaction performance.

Owner:PETROCHINA CO LTD

Fischer-Tropsch processes and catalysts made from a material comprising boehmite

ActiveUS7012104B2Improve performanceOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPseudoboehmiteCatalytic metal

A hydrothermally-stable catalyst, method for making the same, and process for producing hydrocarbon, wherein the catalyst is used in synthesis gas conversion to hydrocarbons. In one embodiment, the method comprises depositing a compound of a catalytic metal selected from Groups 8, 9, and 10 of the Periodic Table on a support material comprising boehmite to form a composite material; and calcining the composite material to form the catalyst. In other embodiments, the support material comprises synthetic boehmite, natural boehmite, pseudo-boehmite, or combinations thereof.

Owner:CLARIANT INT LTD

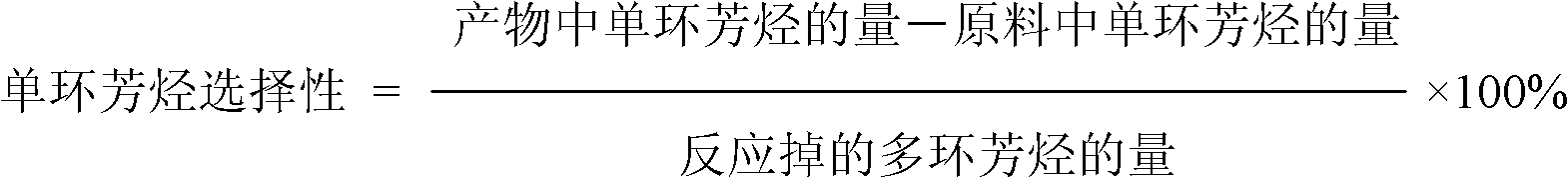

Catalyst for converting polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons and preparation method thereof

ActiveCN103120955AReduced inactivation rateIncrease unsaturationMolecular sieve catalystsHydrocarbonsMolecular sievePolycyclic aromatic hydrocarbon

The invention relates to a catalyst for converting polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons and a preparation method thereof, mainly solving the problems in the prior art that the conversion level of polycyclic aromatic hydrocarbons is low, the monocyclic aromatic hydrocarbon yield and selectivity are low and the catalyst deactivation rate is high. The problems are better solved by adopting the catalyst and the preparation method thereof. The catalyst comprises 34.5-60wt% of mixture of FAU type zeolite and at least one molecular sieve from MOR, BEA, MFI and MCM-22, 39.5-65wt% of at least one of gamma-alumina, eta-alumina and pseudo-boehmite as a binder and 0.05-0.9wt% of at least one metal from Pt, Pd and Ir. The catalyst can be used in the industrial production of converting heavy polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

Titania-alumina mixed oxide hydrodesulfurization catalyst and preparing process thereof

ActiveCN101199935AGuaranteed qualityAssurance controlMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAluminium chlorideHydrodesulfurization

The utility model relates to a synthesis of a titania-alumina mixed oxide material and a catalyst carrier of a supported deep hydrodesulfurization catalyst by taking the compound as the carrier. 1)take the tetrabutyl titanate and the aluminum chloride or the pseudo-boehmite as the raw material, prepare the mesoporous mixed oxide material of TiO2-Al2O3 with the sol-gel method, and use the material as the carrier of the diesel oil deep hydrodesulfurization catalyst; 2)use the dipping method by modifying the active metal variety and the dipping method to get highly dispersed supported mesoporous hydrodesulfurization catalyst of TiO2-Al2O3 compound material after baking; in the diesel oil hydrogenation deep desulfurization reaction, the desulfurization capability is good, and the desulfurization rate can reach 99 percent; if the reaction can be operated under a relative relaxative condition, the sulfur in the diesel oil can be desorbed from 1300ppm to below 15 ppm, or from the 430ppm to below 1ppm; the sulfur content in the product can meet the standard of Europe IV.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Nanoparticles modified with multiple organic acids

InactiveUS7244498B2Reduce the amount requiredPigmenting treatmentMaterial nanotechnologyOrganic acidSolubility

Surface-modified nanoparticles of boehmite, and methods for preparing the same. Aluminum oxyhydroxide nanoparticles are surface modified by reaction with selected amounts of organic acids. In particular, the nanoparticle surface is modified by reactions with two or more different carboxylic acids, at least one of which is an organic carboxylic acid. The product is a surface modified boehmite nanoparticle that has an inorganic aluminum oxyhydroxide core, or part aluminum oxyhydroxide core and a surface-bonded organic shell. Organic carboxylic acids of this invention contain at least one carboxylic acid group and one carbon-hydrogen bond. One embodiment of this invention provides boehmite nanoparticles that have been surface modified with two or more acids one of which additional carries at least one reactive functional group. Another embodiment of this invention provides boehmite nanoparticles that have been surface modified with multiple acids one of which has molecular weight or average molecular weight greater than or equal to 500 Daltons. Yet, another embodiment of this invention provides boehmite nanoparticles that are surface modified with two or more acids one of which is hydrophobic in nature and has solubility in water of less than 15 by weight. The products of the methods of this invention have specific useful properties when used in mixture with liquids, as filler in solids, or as stand-alone entities.

Owner:TDA RES

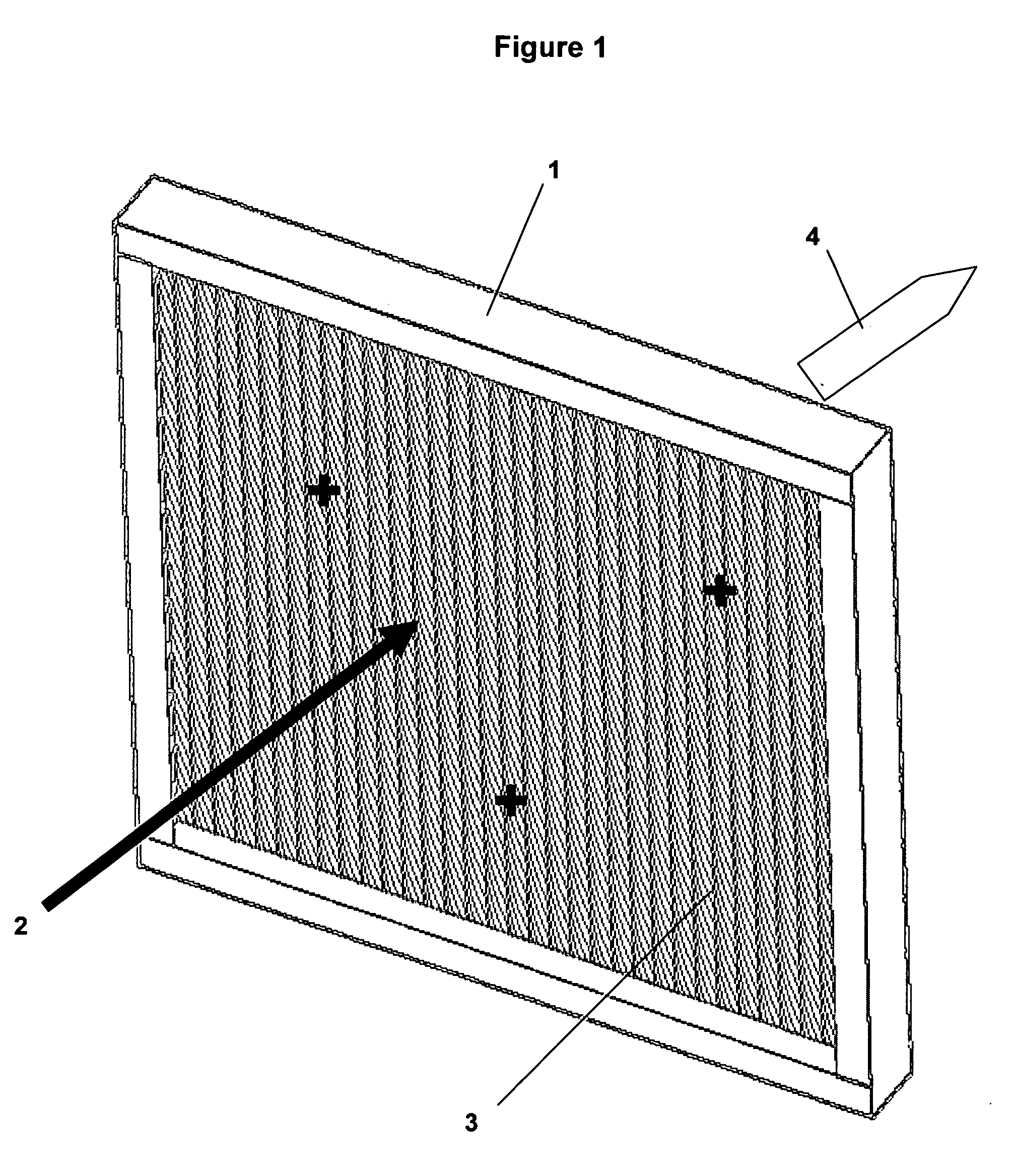

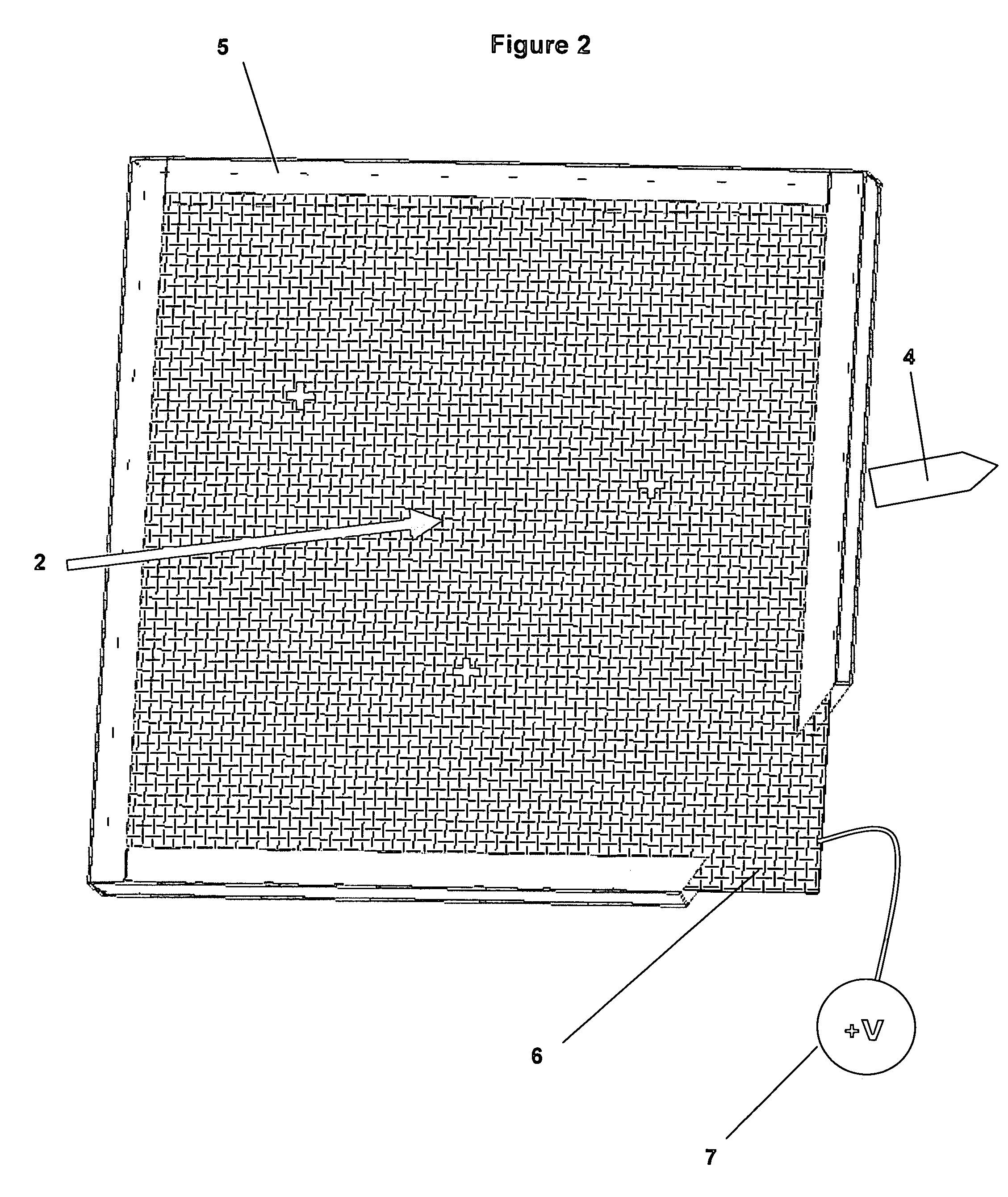

Disinfecting air filter

InactiveUS20100282083A1Improve breathable airEasy constructionCombination devicesDispersed particle filtrationFiberAmmonium compounds

Disclosed is an air purification filter with novel active media that attracts, migrates, binds, and destroys pathogens, including sub-micron pathogens, that are suspended in the air passing through the filter. These properties are incorporated in the micro-fibers comprising the active filter media by several novel methods. One embodiment uses polymers or solgel bound monomers of quaternary ammonium compounds as a biocide with both chemotactic and pathogen membrane lysing properties. Another embodiment uses biocide chemicals blended into the melt before filter fibers are extruded and electret dipole charged. The attracting-binding properties of the embodiments may be enhanced by including electropositive Boehmite nano-fiber strands in the active media, by coating a reversible voltage charged electro-conductive polymer, by the use of supplemental fusing and lysing chemicals, and by optional ion field charging of incoming pathogens.

Owner:EDWARDS JOHN

Composition of supported molybdenum catalyst for slurry hydrocracking

InactiveUS20110306490A1Catalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPseudoboehmiteSlurry

A composition is disclosed for converting heavy hydrocarbon feed into lighter hydrocarbon products. The heavy hydrocarbon feed is slurried with a catalyst comprising molybdenum supported on a base, such as boehmite or pseudo-boehmite alumina. Iron oxide may also be in the base. The base is preferably bauxite. The heavy hydrocarbon slurry is hydrocracked in the presence of the catalyst to produce lighter hydrocarbons.

Owner:UOP LLC

Preparation method for self-complement sub-micron crystal alumina ceramic

The invention relates to a preparation method of a low-cost self-reinforced submicron grain alumina ceramic, which belongs to the fine ceramic field. The method comprises the steps of: adopting industrial aluminum hydroxide or boehmite as a raw material, adding fine grain Alpha-alumina and water for ball milling so as to obtain an even slurry; adding water for mixing at a temperature between 70 and 90 DEG C, and adding acid to control the pH value at 2 to 5, so as to form an emulsion; and adding an additive which is a mixture selected from one or more than two of zinc oxide, magnesium oxide, calcium oxide, yttrium oxide, lanthanum oxide, zirconium oxide, boric oxide, ferric oxide, vanadium oxide, silicon oxide or titanium oxide for forming a gel after water is evaporated, and drying the gel and then sintering the gel under high temperature for preparing the self-reinforced submicron grain alumina ceramic containing alumina elongated grains. The ceramic is characterized in that crystal grains have diameters of less than 0.5mu m, and a microstructure contains elongated alumina grains have length-diameter ratios of larger than 5, and has the advantages of high hardness, high toughness and good wear resistance, and can be widely used in ceramic grinding media and the abrasives industry.

Owner:SUZHOU CHUANGYUAN INVESTMENT DEV

Waterborne ceramic coated membrane for lithium ion battery and preparation method thereof

InactiveCN105789539AHigh porosityImprove thermal stabilityCell component detailsCoatingsCoated membraneAdhesive

The invention discloses a waterborne ceramic coated membrane for a lithium ion battery and a preparation method thereof. The waterborne ceramic coated membrane comprises a microporous membrane and a ceramic coating, the ceramic coating is arranged on one side or two sides of the microporous membrane and prepared from, by weight, 40-70 wt% of water and 30-60 wt% of base materials, and the base materials include, by weight, 65-98 parts of boehmite powder, 1-15 parts of waterborne wetting agent, 1-15 parts of waterborne adhesive and 1-5 parts of waterborne dispersant. The waterborne ceramic coated membrane is good in conduction effect and high in thermostability and safety.

Owner:CANGZHOU MINGZHU SEPARATOR TECH CO LTD

Dechlorinating agent used for removing HCl from gas by dry method and preparation method thereof

InactiveCN101773768AImprove dechlorination activityHigh activityOther chemical processesAluminium silicatesPorosityCross-link

The invention relates to a dechlorinating agent used for removing HCl from a gas by using a dry method and a preparation method thereof. The dechlorinating agent is prepared from Na2CO3, CaCO3, CaO and MaO as active constituents, crosslinked bentonite as a porous auxiliary agent, and methyl cellulose as a foaming agent and an auxiliary extrusion agent through extrusion forming, drying and roasting. The cross-linked bentonite is prepared by exchanging large-size poly aluminum cation with small-size simple cation, so that the crosslinked bentonite has great porosity factor and large specific surface. The specific surface and the pore volume of the crosslinked bentonite are larger than those of non-crosslinked bentonite. By using the crosslinked bentonite as the porous auxiliary agent, the specific surface of the dechlorinating agent is enlarged, and the dechlorinating activity and the chlorosity of the dechlorinating agent are increased. The dechlorinating agent prepared by using the crosslinked bentonite has a pore volume of 0.3-0.4 mL / g, a specific surface of 70-90 m<2> / g and a crushing strength of 60-80 N / cm, not only has lower price than pseudo-boehmite and a molecular sieve, but also has simple preparation process, high dechlorinating activity and great low-temperature penetration chlorosity.

Owner:长春惠工净化工业有限公司

High temperature-resistant activated alumina material and preparation method thereof

ActiveCN102745729AEase of mass productionSimple processAluminium oxide/hydroxide preparationRoom temperaturePeptization

The present invention provides a high temperature-resistant activated alumina material and a preparation method thereof. The alumina material is prepared by the following steps: mixing macroporous pseudo-boehmite, high viscosity pseudo-boehmite and an additive by using water; uniformly stirring at a rotation speed of 100-1000 r / min; adding dilute nitric acid with a concentration of 30% to carry out a reaction until the pH value is 2.0-5.5 and the solution is at the peptization state, and then aging for 3-6 hours at a temperature of 80-100 DEG C while stirring; adding a pore-forming agent at a room temperature, and carrying out uniform stirring, pulping, spraying and drying; and carrying out calcination at a temperature of 900 DEG C to prepare the alumina. The alumina material of the present invention has advantages of convenient mass production, high specific surface, and the like, wherein the specific surface of the alumina material of the present invention can be maintained more than 110 m<2> / g for a long time at a temperature of 1000-1100 DEG C. In addition, the preparation method of the alumina material has characteristics of simple process and low cost.

Owner:浙江欧信环保科技有限公司

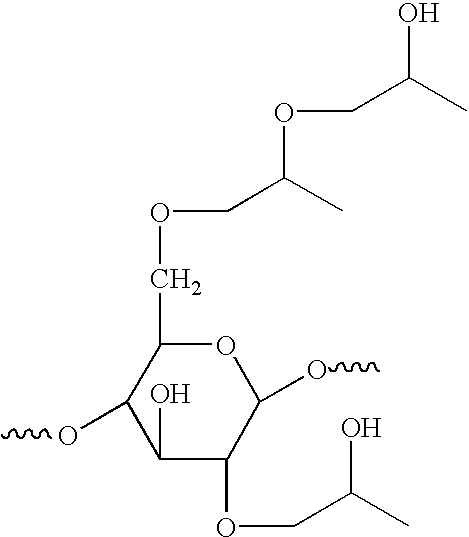

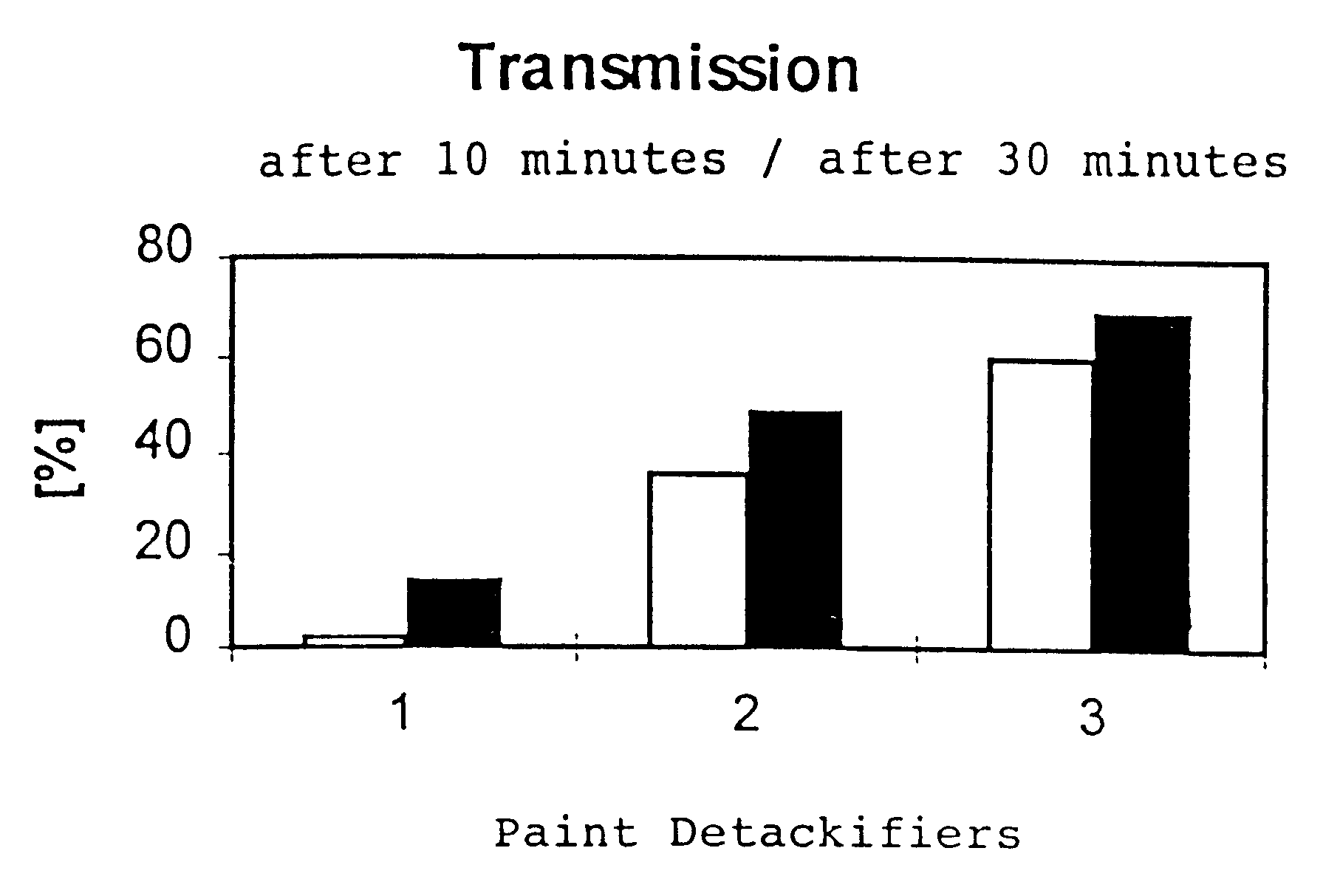

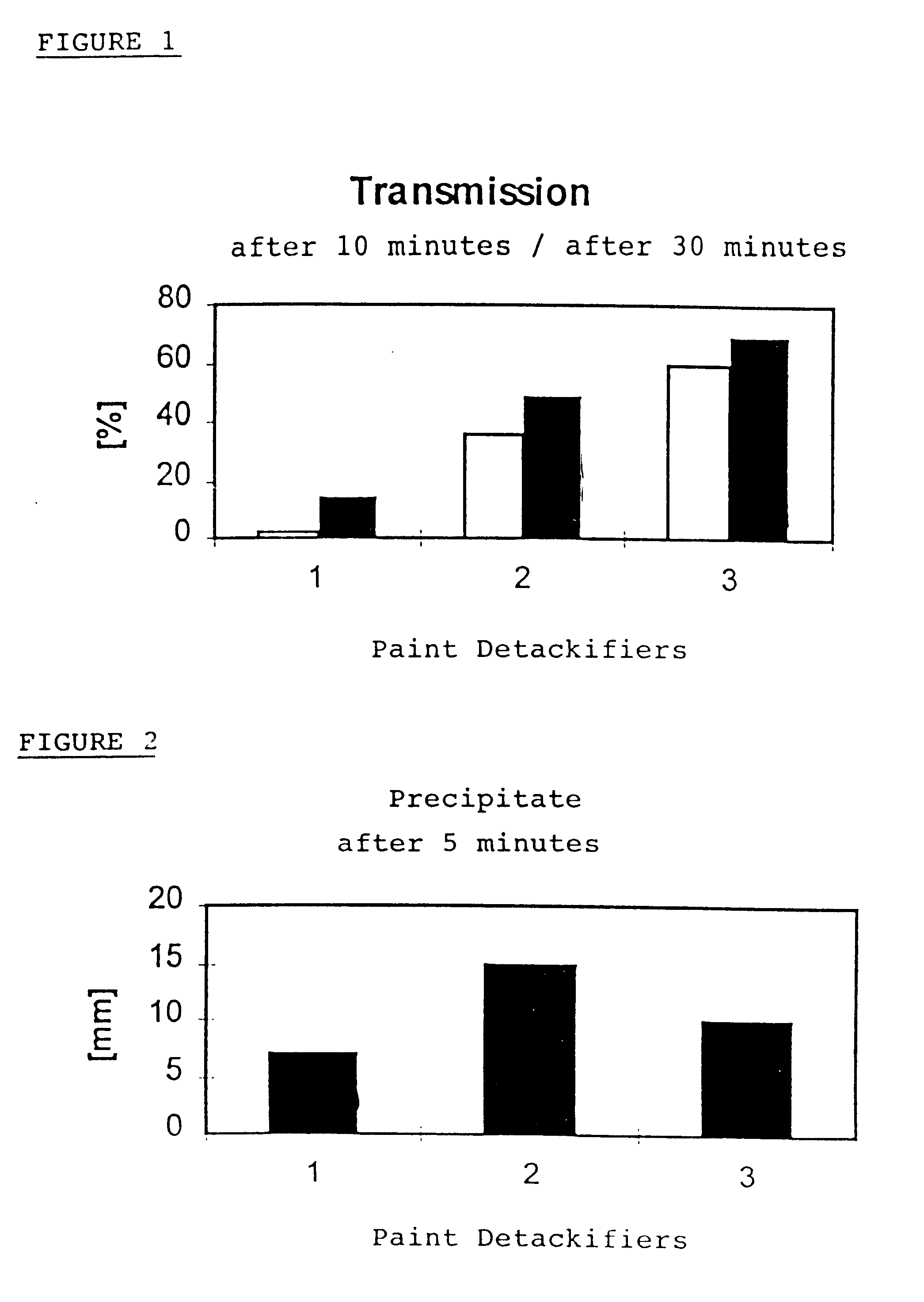

Agents for unsticking paint, and sedimentation agents

Paint detackifiers and / or sedimentation agents are provided which contain amorphous alumina and / or alumina in pseudoboehmite or boehmite form having an average crystallite size of from 0.1 to 15 nm and / or the hydrates and hydroxyalkylpolysaccharides thereof.

Owner:SASOL GERMANY GMBH

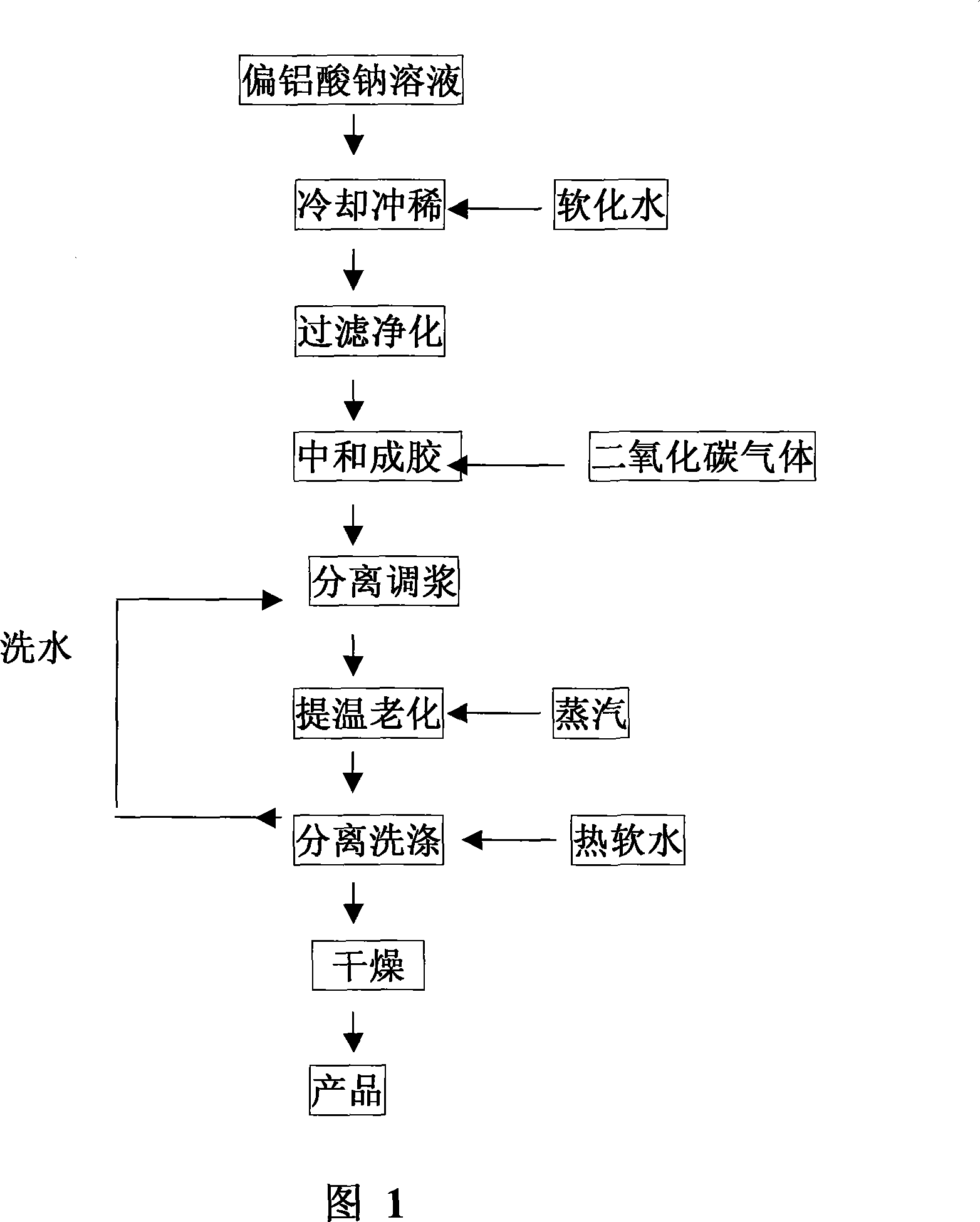

Method of producing pseudo boehmite

ActiveCN101172631AGood effectAchieving low alkali agingAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium oxides/hydroxidesSlurryCarbonation

The invention relates to a preparative method of pseudo-boehmite, belonging to the field of the preparative technology of alumina exclusive of metallurgical usage. The method comprises the steps as follows: sodium metaaluminate solution is carbonated into mucus, aging, separating, washing and drying. The invention is characterized in that after the sodium metaaluminate solution becomes mucus, pulp-liquid separation is carried out primarily; filter cake is added; heating and aging are performed after water washing and mixed pulping. The invention has the advantages of low washing water consumption, low production cost, easy control of product quality and good practicality.

Owner:中铝山东新材料有限公司

Method for preparing hydrogenation purification catalyst

InactiveUS6919294B2High mechanical strengthEasy to implementOther chemical processesManganese carbonylsPseudoboehmitePore diameter

A method for producing a hydrorefining catalyst is used to produce the hydrorefining catalyst which contains an inorganic oxide carrier and a hydrogenation-active metal and which has such a bimodal pore characteristic that pores having pore diameters of not more than 50 nm have a pore volume of not less than 0.4 cm3 / g, pores having pore diameters of not less than 50 nm have a pore volume of not less than 0.2 cm3 / g, and pores having pore diameters of not less than 1000 nm have a pore volume of not more than 0.1 cm3 / g. The method comprises the steps of mixing and forming a pseudo-boehmite powder having a dispersibility index of 0.13 to 0.28, and calcinating the formed pseudo-boehmite under a condition in which the pseudo-boehmite is converted into γ-alumina. The hydrorefining catalyst, which has the bimodal pore characteristic, can be produced easily at low cost.

Owner:JAPAN ENERGY CORP

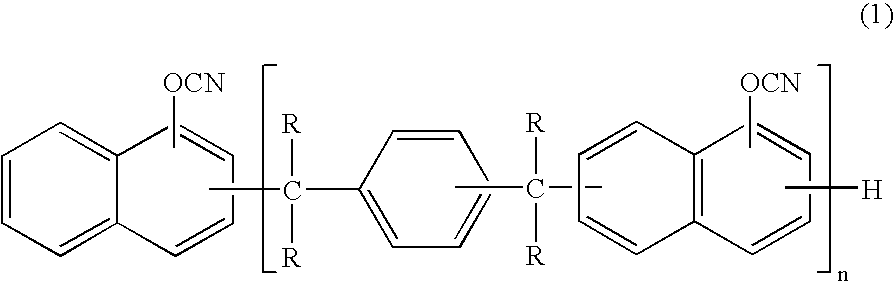

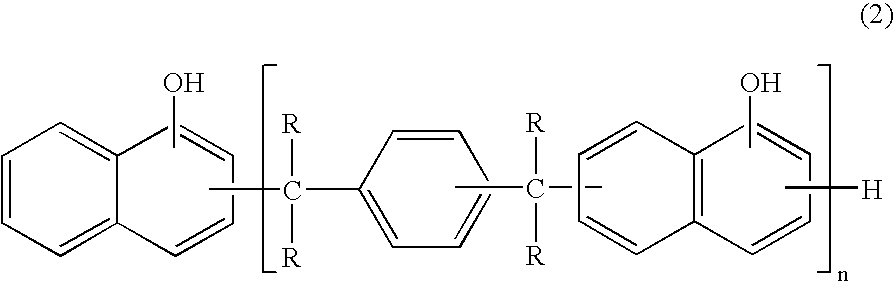

Prepreg and laminate

ActiveUS20080187763A1Improve the immunityImprove flame retardant performanceOther chemical processesSynthetic resin layered productsHalogenMetal foil

A prepreg, for printed wiring boards, comprising a flame resistant resin composition containing a specific cyanate ester resin, a nonhalogen epoxy resin, boehmite which is hardly soluble in acids or alkalis and a silicone powder which is a flame retardant assistant, and a base material, which prepreg retains high-degree flame resistance without a halogen compound and has excellent resistance to chemical, high glass transition temperature, excellent soldering heat resistance and excellent heat resistance after moisture absorption, and a laminate or metal-foil-clad laminate obtained by curing the above prepreg.

Owner:MITSUBISHI GAS CHEM CO INC

Cracking catalyst containing mesoporous silica-alumina materials

ActiveCN102078821AIncrease productivityHigh solid contentCatalytic crackingMolecular sieve catalystsAdhesiveActive component

The invention discloses a cracking catalyst containing mesoporous silica-alumina material, wherein the cracking catalyst is composed of cracking active components: clay, adhesive and mesoporous silica-alumina material. The mesoporous silica-alumina material is of a pseudo-boehmite crystal phase structure. In case of the weight of oxide, the anhydrous chemical expression formula is: (0-0.3) Na2O (40-90) Al2O3 (10-60) SiO2, the specific surface area is 200-400m<2> / g, pore volume is 0.5-2.0ml / g, the average pore size is 8-20nm, and the most probable pore size is 5-15nm. The adhesive is selected from one or two mixtures of silica sol or aluminum sol. Compared with the conventional catalyst with pseudo-boehmite, the cracking catalyst has the advantages of low production cost and better crude oil conversion capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

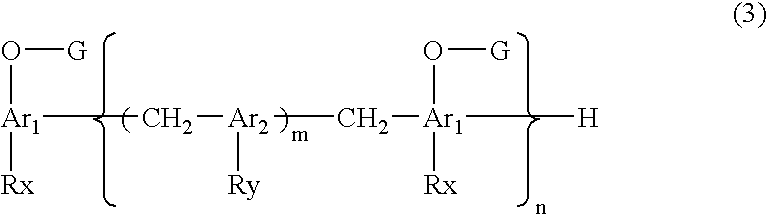

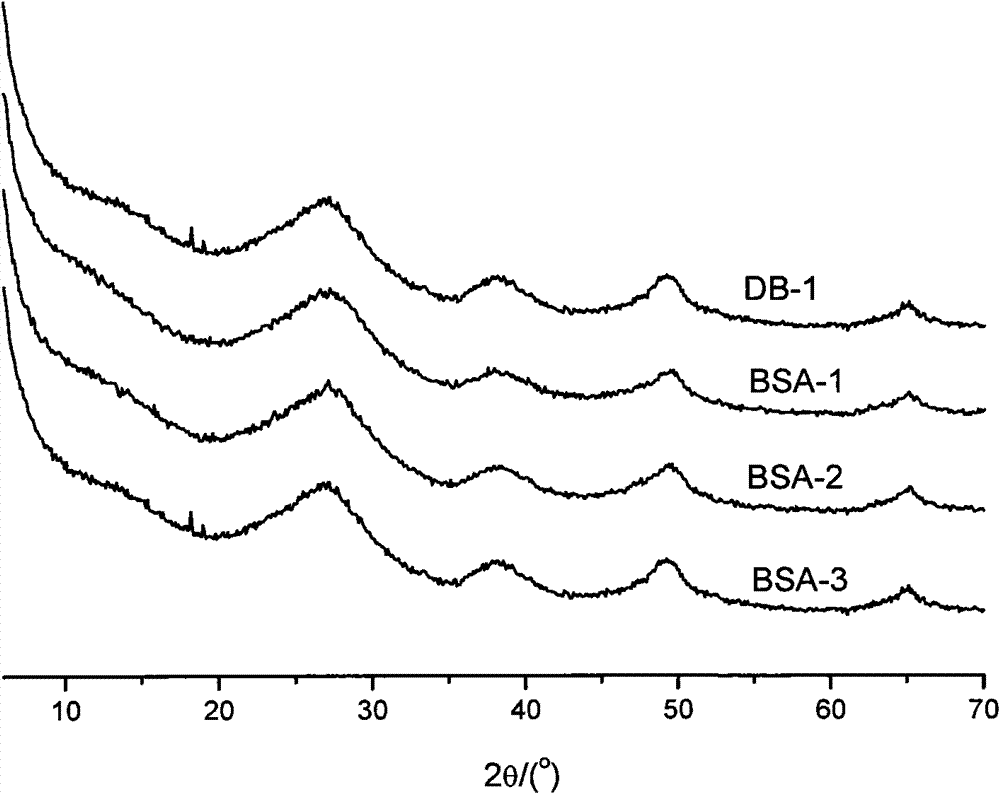

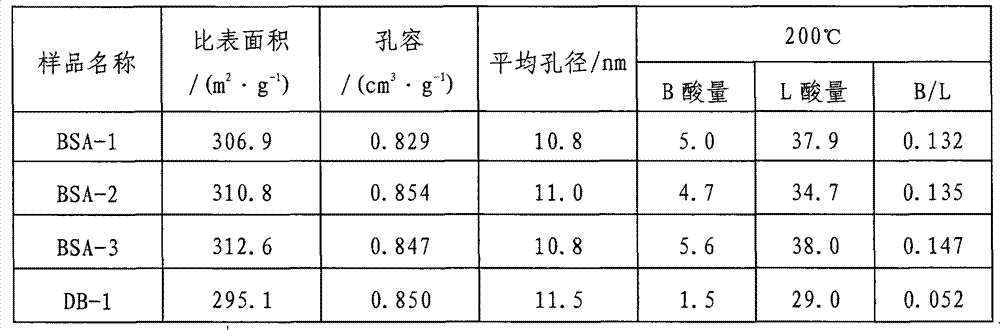

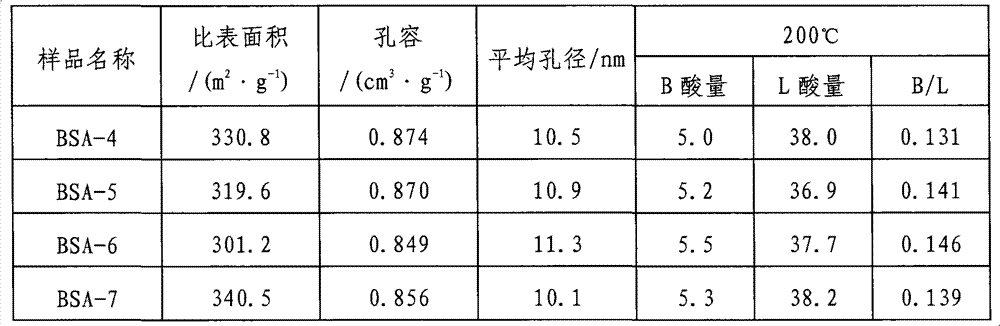

Acidic silicon-aluminium catalytic material

ActiveCN102949987APore characteristics are obviousHigh crystallinityCatalytic crackingHydrocarbon oil crackingCrystal structureCrystallinity

The invention provides an acidic silicon-aluminium catalytic material with a pseudo-boehmite crystal structure. By oxide weight, the anhydrous chemical formula of the catalytic material is (0-0.2)Na2O.(44-46)SiO2.(54-56)Al2O3, the specific surface area is 200-400m<2> / g, the pore volume is 0.5-1.0ml / g, and the mean pore size is 8-15nm. The catalytic material is characterized in that the ratio of pyridine infrared B acid to L acid, measured at 200 DEG C, in the catalytic material is 0.130-0.150. The silicon-aluminium catalytic material has the beneficial effects that the mesopore characteristic of the acidic silicon-aluminium catalytic material is obvious, the pores are distributed in a concentrated manner, meanwhile, the silicon-aluminium catalytic material contains B acid and L acid centers, the ratio of B acid to L acid is obviously increased and the material has better light oil micro-activity. Besides, the acidic silicon-aluminium catalytic material provided by the invention has higher degree of crystallinity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com