Preparation process for large pore volume and light bulk density activated alumina

A preparation process, alumina technology, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of large differences in the performance of alumina carriers, large ratio of micropores to mesopores, unreasonable pore distribution, etc., to save washing water , low cost, optimized hole distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] NaAlO 2 Solution preparation: under mechanical stirring, add 160g of caustic soda into 800ml of deionized water, then raise the temperature to boiling, slowly add 200g of aluminum hydroxide, after all dissolve, keep warm at 105-110°C for 4 hours, then cool down to room temperature naturally, add water Dubbed 1200ml100g / L solution calculated by alumina.

[0026] Al 2 (SO 4 ) 3 Solution preparation: under mechanical stirring, heat 1200ml deionized water to 60-70℃, then add 396gAl 2 (SO 4 ) 3 1·8H 2 O, after all dissolved, lower to room temperature, add water to make 1800ml33.3g / L solution calculated by alumina.

[0027]First add 1000ml of deionized water into a 5000ml stainless steel reaction kettle, heat it to 85°C under mechanical stirring, and then co-flow to form a gel. Stabilized NaAlO 2 Solution flow rate 3~25ml / min, adjust Al 2 (SO 4 ) 3 The flow rate of the solution is until the pH value of the solution is 8, and overflow begins after 30 minutes to kee...

Embodiment 2

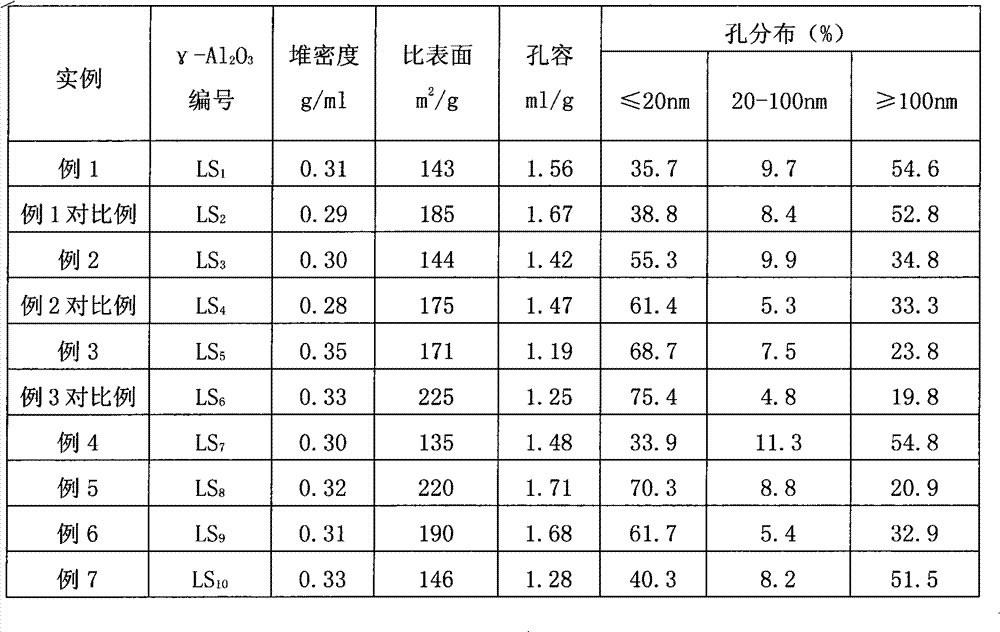

[0031] NaAlO with a concentration of 150g / L as alumina 2 1200ml of solution and Al with a concentration of 50g / L in terms of alumina 2 (SO 4 ) 3 The 1800ml solution is continuously co-flowed into a gel in the neutralization tank to stabilize NaAlO 2 Solution flow rate 3~25ml / min, adjust Al 2 (SO 4 ) 3 Solution flow rate until the pH value of the solution is 9, and the temperature is stable at 75°C. After 30 minutes, overflow begins to keep the liquid level of the neutralization tank stable. After neutralization, it is aged for 30 minutes. Other conditions are the same as in Example 1 to obtain γ-Al 2 o 3 LS 3 . LS is given in Table 1 3 physical properties.

[0032] Example 2 comparative example:

[0033] According to the method of Example 2, the difference is that the dried pellets are not loaded into the activation furnace for steam treatment, but are directly calcined in the muffle furnace to obtain γ-Al 2 o 3 LS 4 . LS is given in Table 1 4 physical properti...

Embodiment 3

[0035] NaAlO with a concentration of 200g / L as alumina 2 1200ml of solution and Al with a concentration of 67.7g / L in terms of alumina 2 (SO 4 ) 3 The 1800ml solution is continuously co-flowed into a gel in the neutralization tank to stabilize NaAlO 2 Solution flow rate 3~25ml / min, adjust Al 2 (SO 4 ) 3 Solution flow rate until the pH value of the solution is 7, and the temperature is stable at 65 ° C. After 30 minutes, it begins to overflow, and the liquid level of the neutralization tank is kept stable. After the neutralization is completed, it is aged for 90 minutes. Other conditions are the same as in Example 1 to obtain γ-Al 2 o 3 LS 5 . LS is given in Table 1 5 physical properties.

[0036] Example 3 comparative example:

[0037] According to the method of Example 3, the difference is that the dried pellets are not loaded into the activation furnace for steam treatment, but are directly calcined in the muffle furnace to obtain γ-Al 2 o 3 LS 6 . LS is given...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com