Preparation method for macro-porous aluminum oxide carrier

A macroporous alumina carrier technology, applied in catalyst carrier, chemical instrument and method, metal/metal oxide/metal hydroxide catalyst, etc., can solve problems such as collapse, pore volume and macropore content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

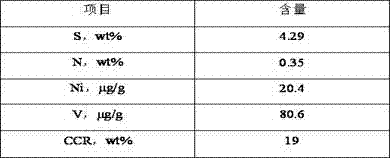

Embodiment 1

[0022] Weigh 100g of pseudoboehmite dry rubber powder (produced by Wenzhou Jingjing Alumina Co., Ltd.) and place it in a round-bottomed flask, add 300 grams of deionized water to the flask for beating, and add an appropriate amount of nitric acid to the above slurry with a molar concentration of 3mol / L, the mixed acid solution whose molar concentration of acetic acid is 1mol / L, the pH value of the slurry is controlled to be 3 and heated to reflux at 40°C for 3 hours. The above slurry was transferred into an autoclave, 10 g of urea was added to the mixed material, and the autoclave was sealed and heat treated at 140° C. for 6 hours. After cooling to room temperature, the mixed slurry was filtered, washed, and dried at 120° C. for 8 hours to obtain pseudo-boehmite.

[0023] Weigh 100 g of the above-mentioned pseudo-boehmite and place it in a beaker, add 200 mL of xylitol aqueous solution with a mass concentration of 25% to the beaker and soak for 4 hours. The impregnated mater...

Embodiment 2

[0025]With embodiment 1, only the add-on of deionized water is 700 grams. The mixed acid is a mixed acid dissolved with 4 mol of sulfuric acid and 1 mol of oxalic acid, the pH value of the slurry is controlled to be 2, and the temperature of heating and refluxing is 30°C for 5 hours. The addition amount of urea is 15 grams, and hydrothermal treatment temperature is 120 ℃, and hydrothermal treatment is 8 hours. The pseudo-boehmite was impregnated with a mixed aqueous solution of sorbitol and mannitol with a mass concentration of 40% and a mass ratio of 1:1 for 3 hours. The carbonization treatment temperature is 130°C, and the treatment time is 14 hours. Alumina carrier A2 was prepared, and the properties of the carrier are shown in Table 1.

Embodiment 3

[0027] With embodiment 1, only the add-on of deionized water is 1000 grams. The mixed acid is a mixed acid dissolved with 6mol / L sulfuric acid and 1mol / L citric acid, the pH value of the slurry is controlled to be 5, the heating reflux temperature is 60°C, and the reflux time is 1 hour. The amount of urea added was 20 grams, the hydrothermal treatment temperature was 160° C., and the hydrothermal treatment time was 4 hours. The pseudo-boehmite was impregnated with a mixed aqueous solution of glucose and ribose with a mass ratio of 1:1 at a mass concentration of 30% for 5 hours. The carbonization treatment temperature is 120° C., and the carbonization treatment time is 16 hours. Alumina carrier A3 was prepared, and the properties of the carrier are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com