Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1434results about How to "High pore volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Porous inorganic composite oxide

ActiveUS20120129690A1Improve thermal stabilityHigh pore volumeHeat treatmentsInternal combustion piston enginesPtru catalystCerium

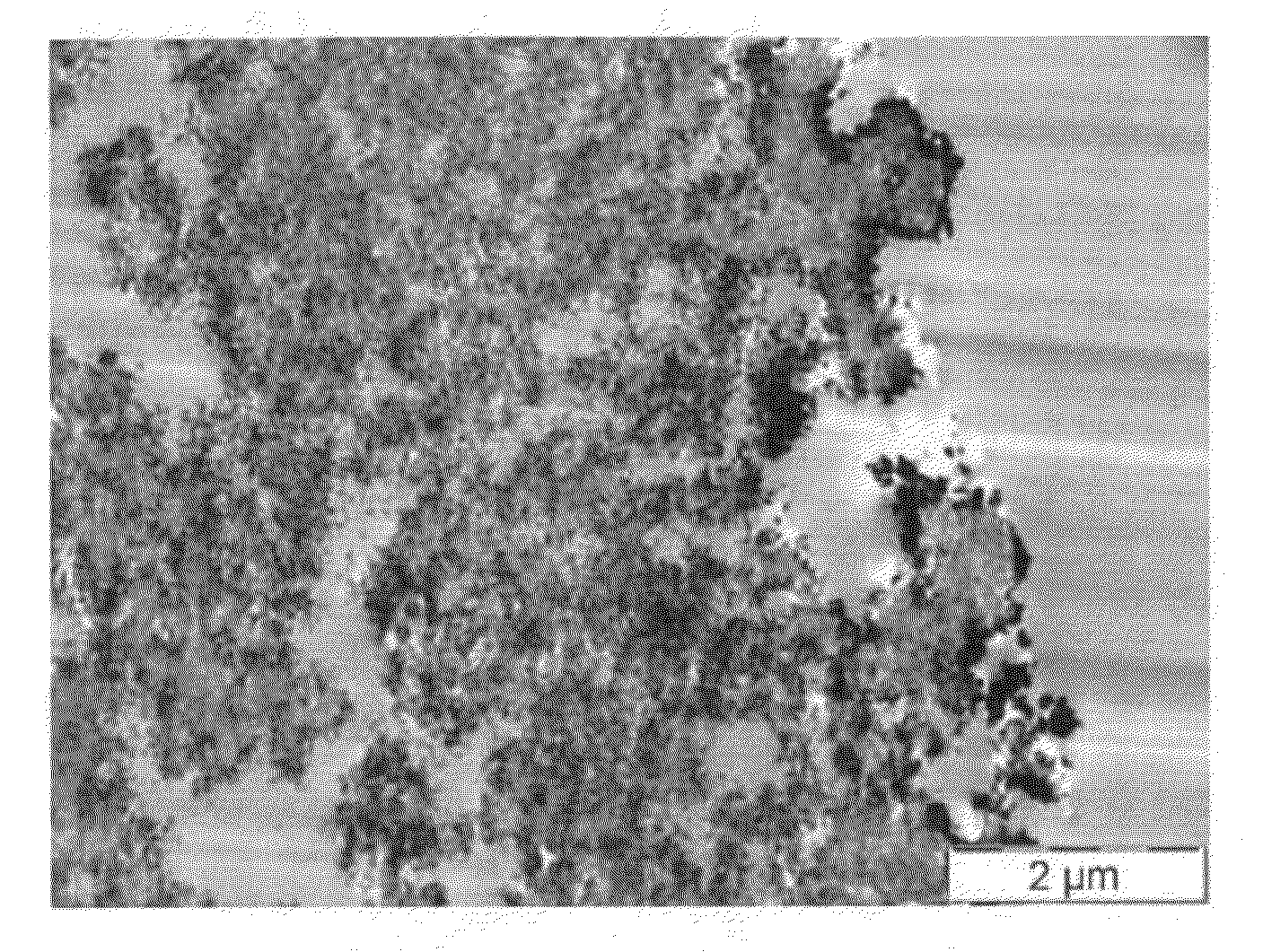

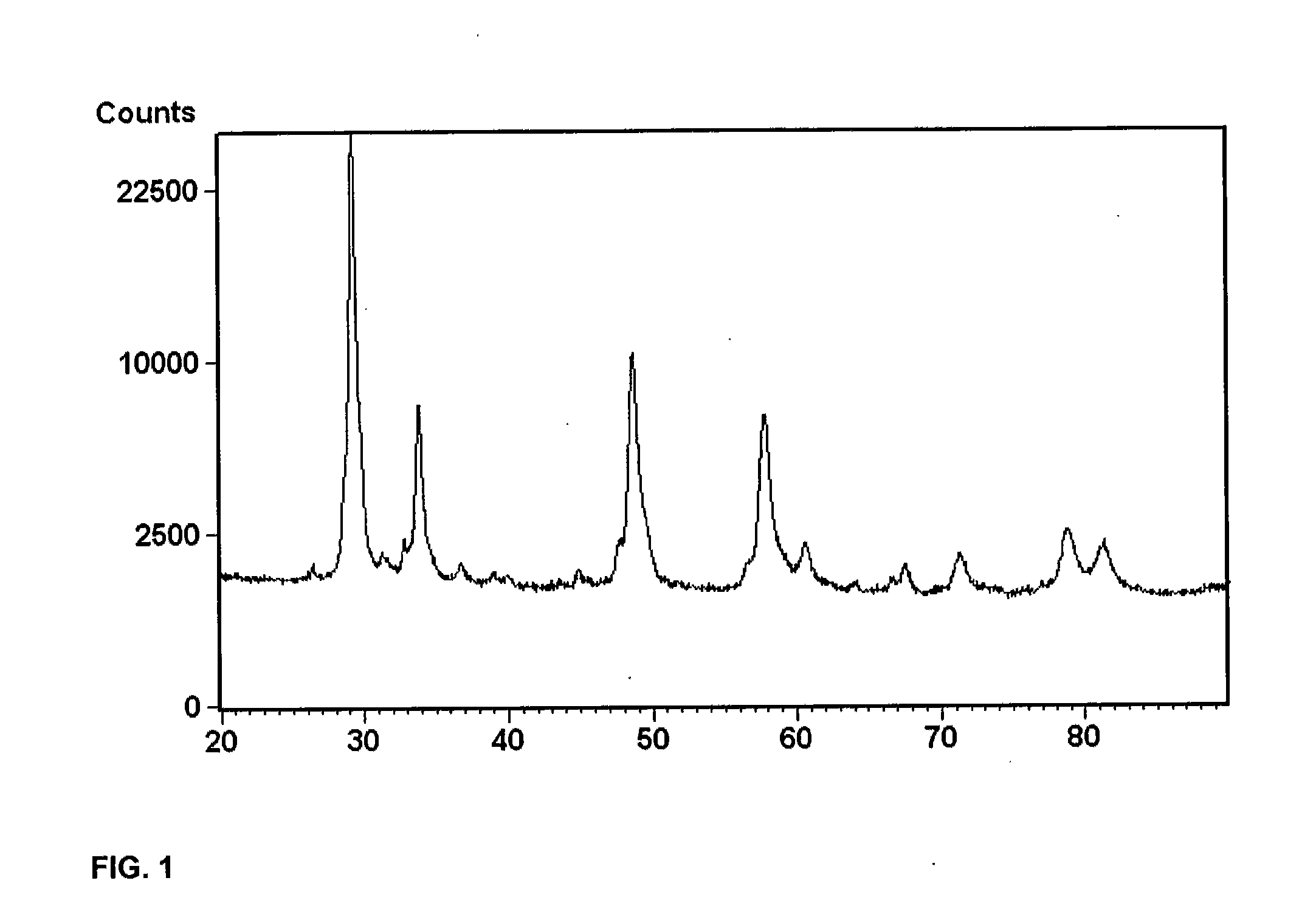

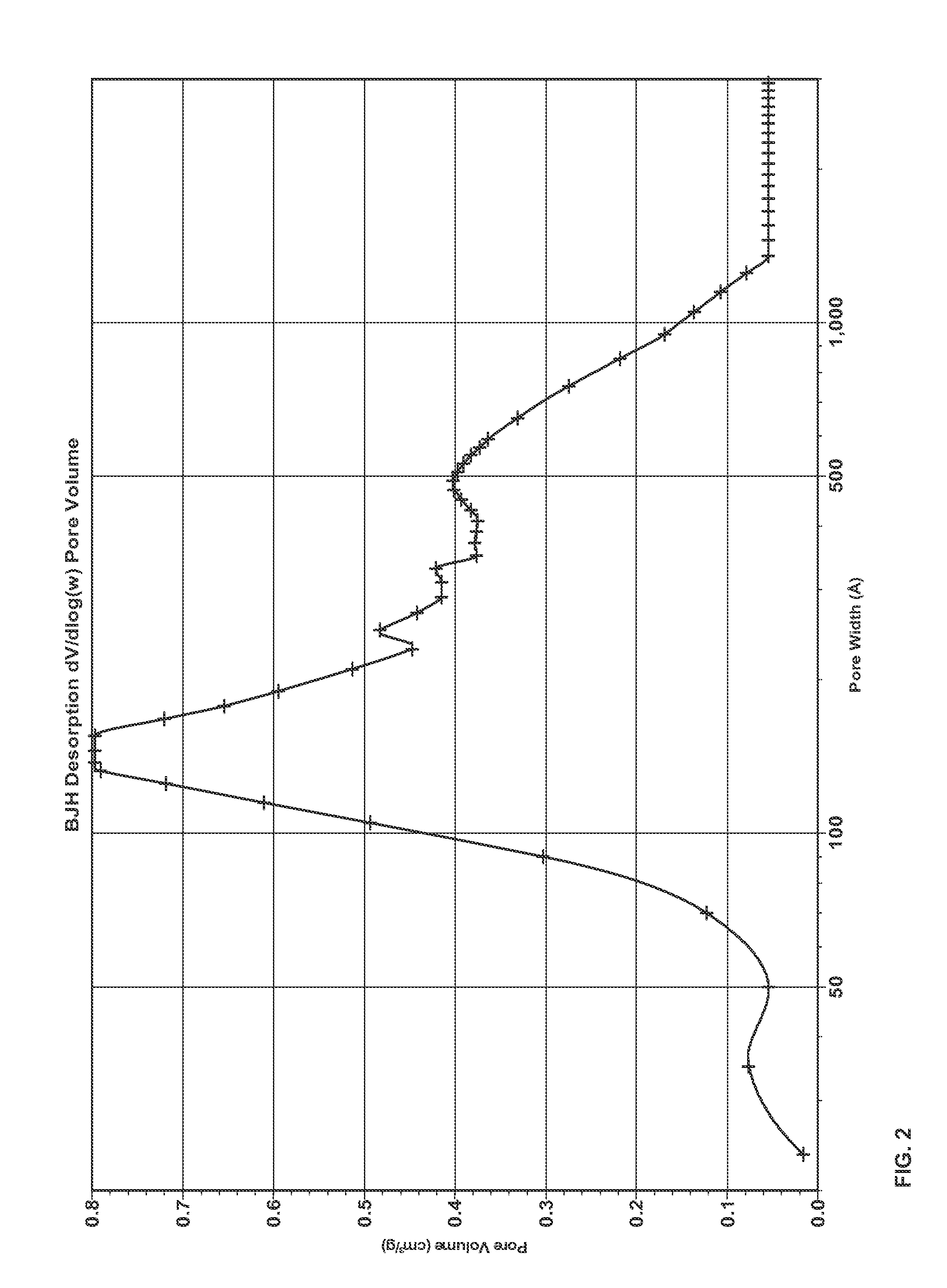

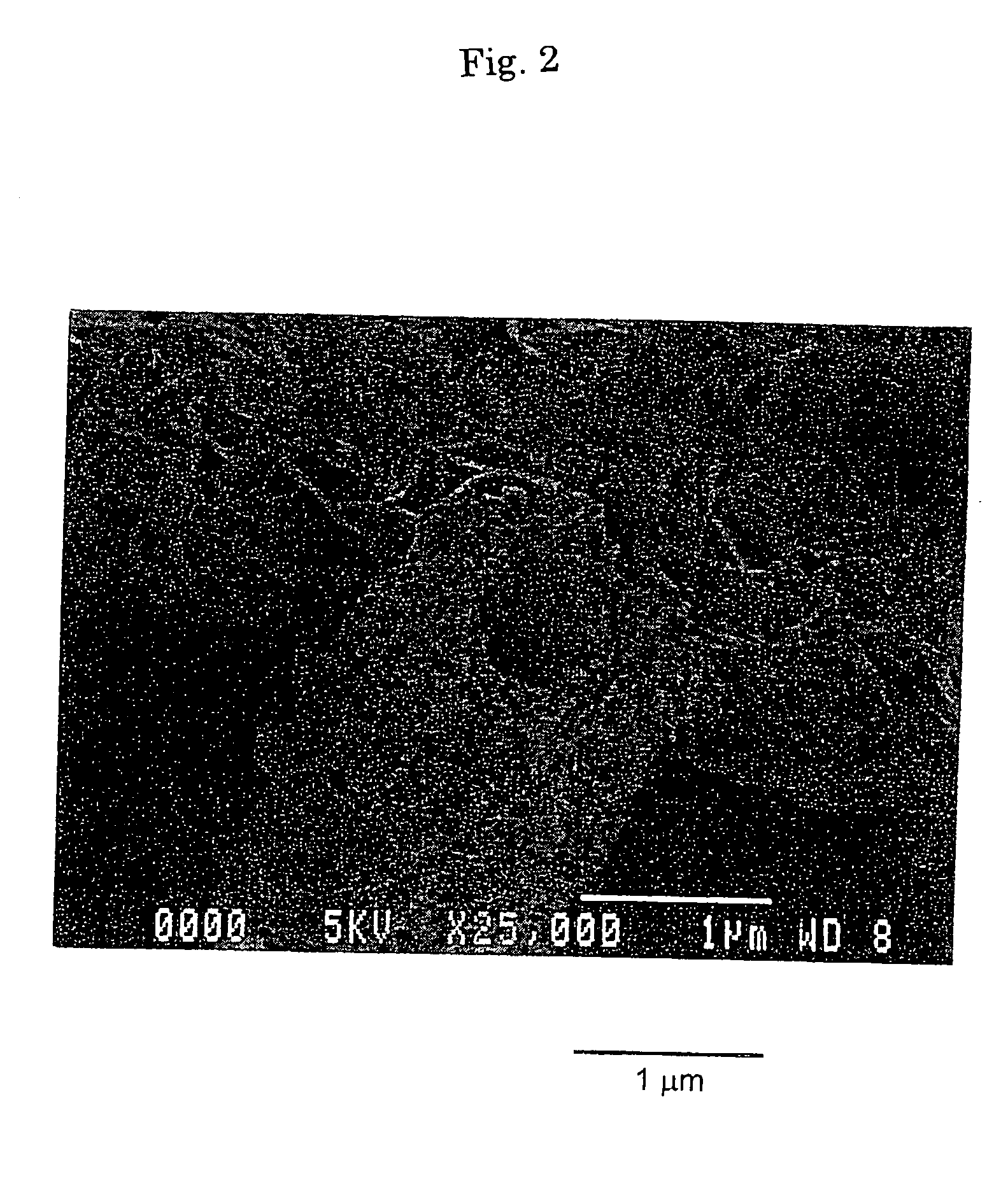

A porous inorganic composite oxide containing oxides of aluminum and of cerium and / or zirconium, and, optionally, oxides of one or more dopants selected from transition metals, rare earths, and mixtures thereof, and having a specific surface area, in m2 / g, after calcining at 1100° C. for 5 hours, of ≧0.8235[Al]+11.157 and a total pore volume, in cm3 / g, after calcining at 900° C. for 2 hours, of ≧0.0097[Al]+0.0647, wherein [Al] is the amount of oxides of aluminum, expressed as pbw Al2O3 per 100 pbw of the composite oxide; a catalyst containing one or more noble metals dispersed on the porous inorganic composite oxide; and a method for making the porous inorganic composite oxide.

Owner:RHODIA OPERATIONS SAS

Large pore volume composite mineral oxide beads, their preparation and their applications for adsorption and chromatography

InactiveUS6613234B2Good chemical stabilityEasy to packIon-exchange process apparatusOther chemical processesPhysical chemistryHafnia

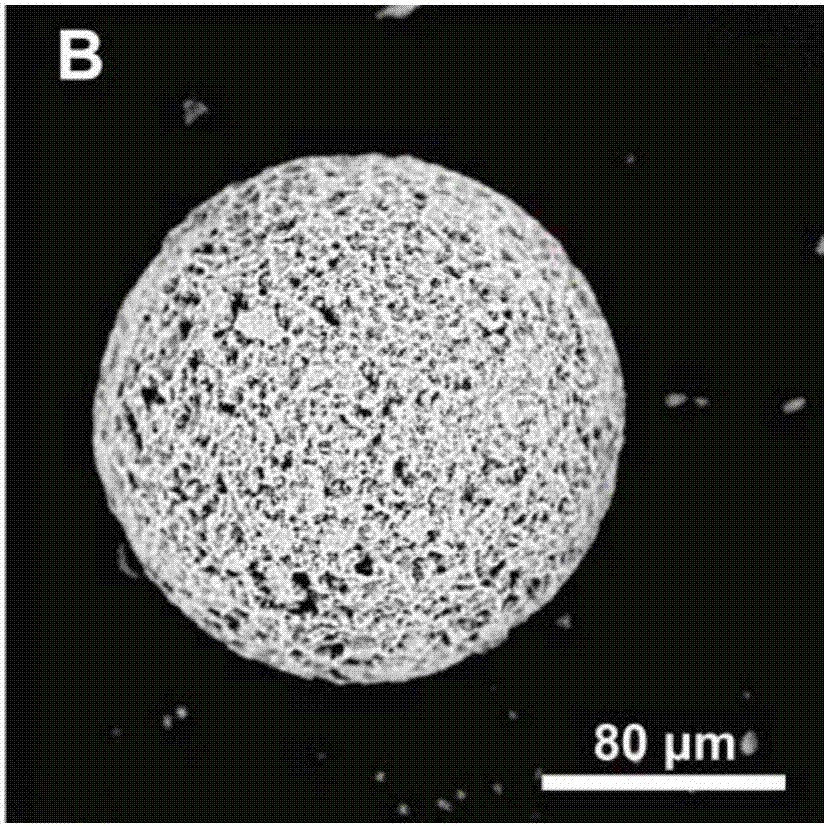

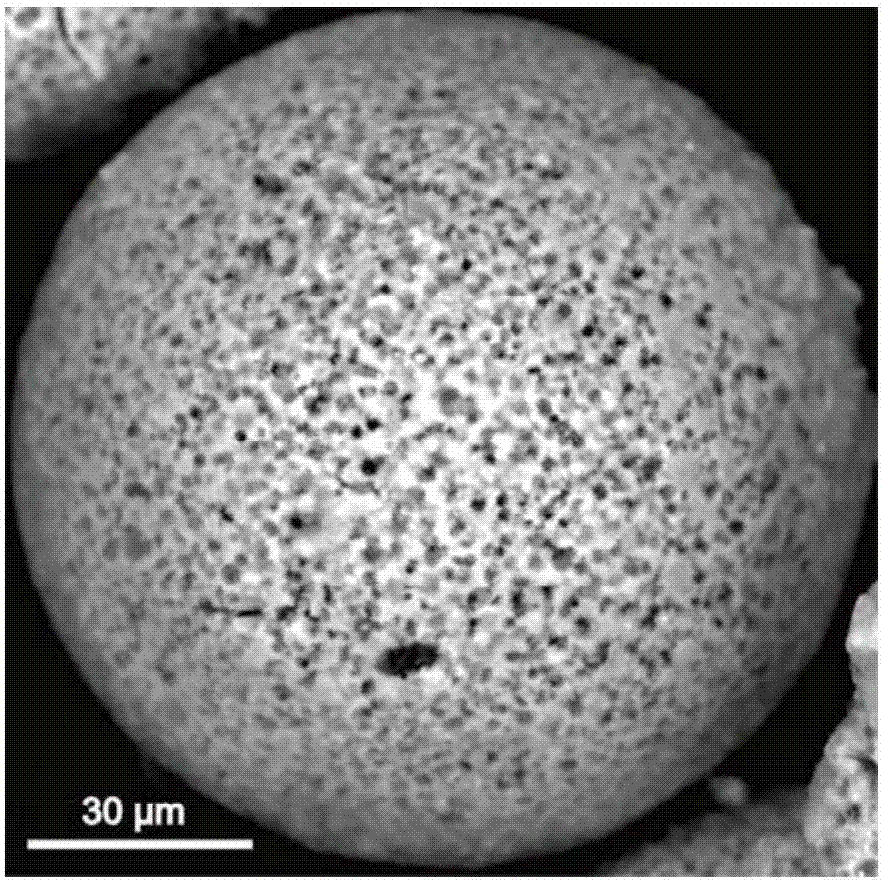

The present invention provides porous mineral oxide beads which have large pore volumes and enhanced stability. The beads are based on a tetravalent metal oxide, such as zirconia, titania or hafnia. These highly porous beads are produced from a mixture of tetravalent mineral oxides, mineral pore inducing agents which are oxides or salts of trivalent metals, and optional binders. The porous mineral beads can be filled with a polymer gel and used for adsorption and chromatography applications.

Owner:PALL CORP

Basic magnesium carbonate, production method and use of the same

ActiveUS20050129606A1Large specific surface areaImprove featuresCalcium/strontium/barium carbonatesBiocideCarbonateMagnesium carbonate hydroxide

Owner:NITTETABU MINING CORP

Large pore volume composite mineral oxide beads, their preparation and their applications for adsorption and chromatography

InactiveUS20020005383A1Good chemical stabilityHigh porosityIon-exchange process apparatusOther chemical processesPhysical chemistryHafnia

The present invention provides porous mineral oxide beads which have large pore volumes and enhanced stability. The beads are based on a tetravalent metal oxide, such as zirconia, titania or hafnia. These highly porous beads are produced from a mixture of tetravalent mineral oxides, mineral pore inducing agents which are oxides or salts of trivalent metals, and optional binders. The porous mineral beads can be filled with a polymer gel and used for adsorption and chromatography applications.

Owner:PALL CORP

Sponge-like pad comprising paper layers and method of manufacture

InactiveUS7799968B2Significant valueHigh fluid capacityCarpet cleanersFloor cleanersFiberPulp and paper industry

A sponge-like pad used for cleaning and other wiping and polishing applications is disclosed. The sponge-like pad is made from a plurality of textured paper webs attached together at selected locations. The paper web can be, for instance, a highly textured throughdried paper web containing high-yield fibers and a wet strength agent. In one embodiment, the stacked plies can be contained within a cover material that is liquid pervious. The sponge-like product of the present invention can be used alone or it can be incorporated into a cleaning tool, such as a mop.

Owner:KIMBERLY-CLARK WORLDWIDE INC

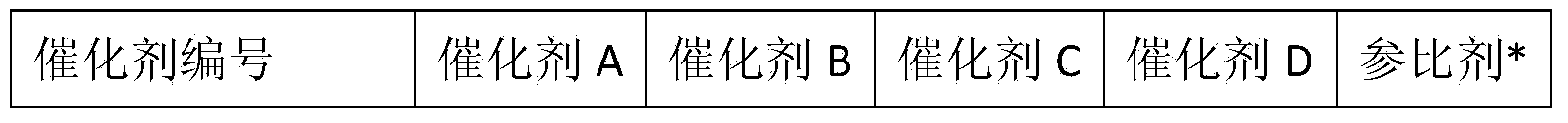

Diesel hydrodesulfurization and denitrification catalyst and preparation method thereof

InactiveCN103551162AGood dispersionIncrease profitMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationOxide composite

The invention discloses a diesel hydrodesulfurization and denitrification catalyst. The catalyst comprises the following compositions: a carrier, an additive, and an active metal, wherein the carrier is an Al2O3-ZrO2-TiO2-SiO2 multibasic oxide composite carrier; the additive is phosphorus; nickel, cobalt, molybdenum and tungsten are taken as active components; through taking the catalyst as a benchmark, in terms of oxides, the catalyst comprises the following components in percentage by weight, 1-6wt% of cobalt oxide, 1-15wt% of nickel oxide, 2-12wt% of molybdenum oxide, 12-35wt% of tungsten oxide and 1.5-5wt% of an additive phosphorus pentoxide; and the pore volume of the catalyst is not less than 0.2 mL / g, the specific surface area of the catalyst is not less than 140 m<2> / g, and the mechanical strength of the catalyst is not less than 15N / mm; and the composite carrier comprises the following components in percentage by weight: 2-15wt% of titanium oxide, 2-20wt% of silicon oxide, 5-15wt% of zirconium oxide, and the balance of aluminum oxide.

Owner:CHINA NAT OFFSHORE OIL CORP +2

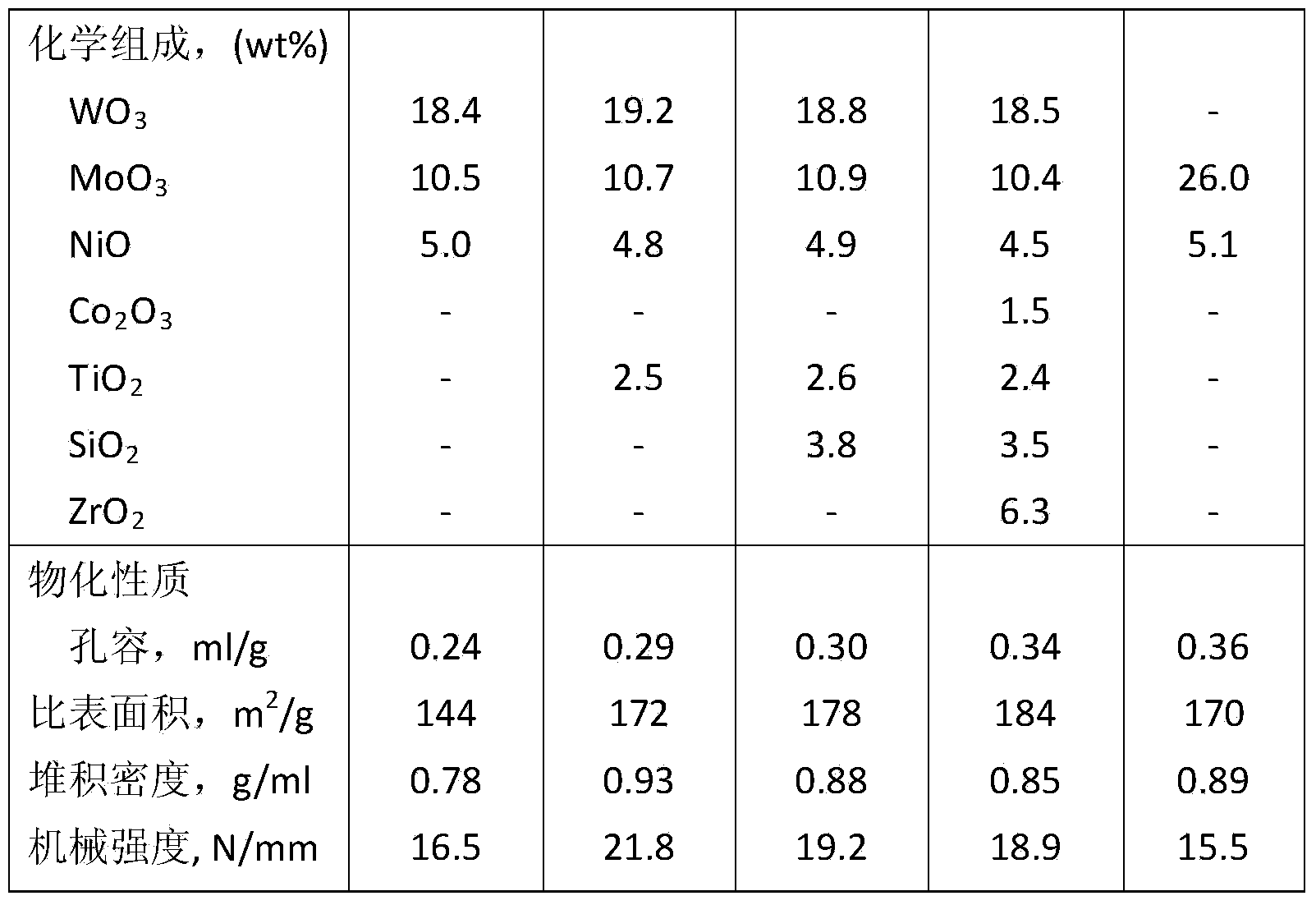

Catalyst with meso pore characteristics and application thereof

InactiveCN102240570AGood dispersionHigh catalytic activityMolecular sieve catalystsDispersed particle separationAdditive ingredientMulti pollutant

The invention discloses a catalyst with meso pore characteristics and an application thereof. The catalyst with meso pore characteristics is produced by loading ingredients with catalytic activity onto the inner tunnel surface of a meso pore molecular sieve carrier, wherein the meso pore molecular sieve carrier contains one or more elements selected from the group consisting of MCM-41, MCM-48, SBA-15, SBA-16, KIT-5 and KIT-6 with the aperture being from 2nm to 50nm; and the active ingredients contain one or more elements selected from the group consisting of Co, Fe, Ni, Mn, Cr, Ti, Cu, Mg, Nb, Ta, Mo, W, Zn, Zr, Ru, Ag, Au, Ru, Rh, Pt, Re, Al, W, Ga, Ge, Sn, Sb and metal oxide thereof. The catalyst with meso pore characteristics can be applied to the catalytic purification of tail gases containing nitrogen oxide. The catalyst provided by the invention has high catalytic activity and is suitable for a plurality of pollutants; in addition, the active ingredients of the catalyst are fixed so as to avoid loss, volatilization and high-temperature sintering.

Owner:BEIJING UNIV OF CHEM TECH

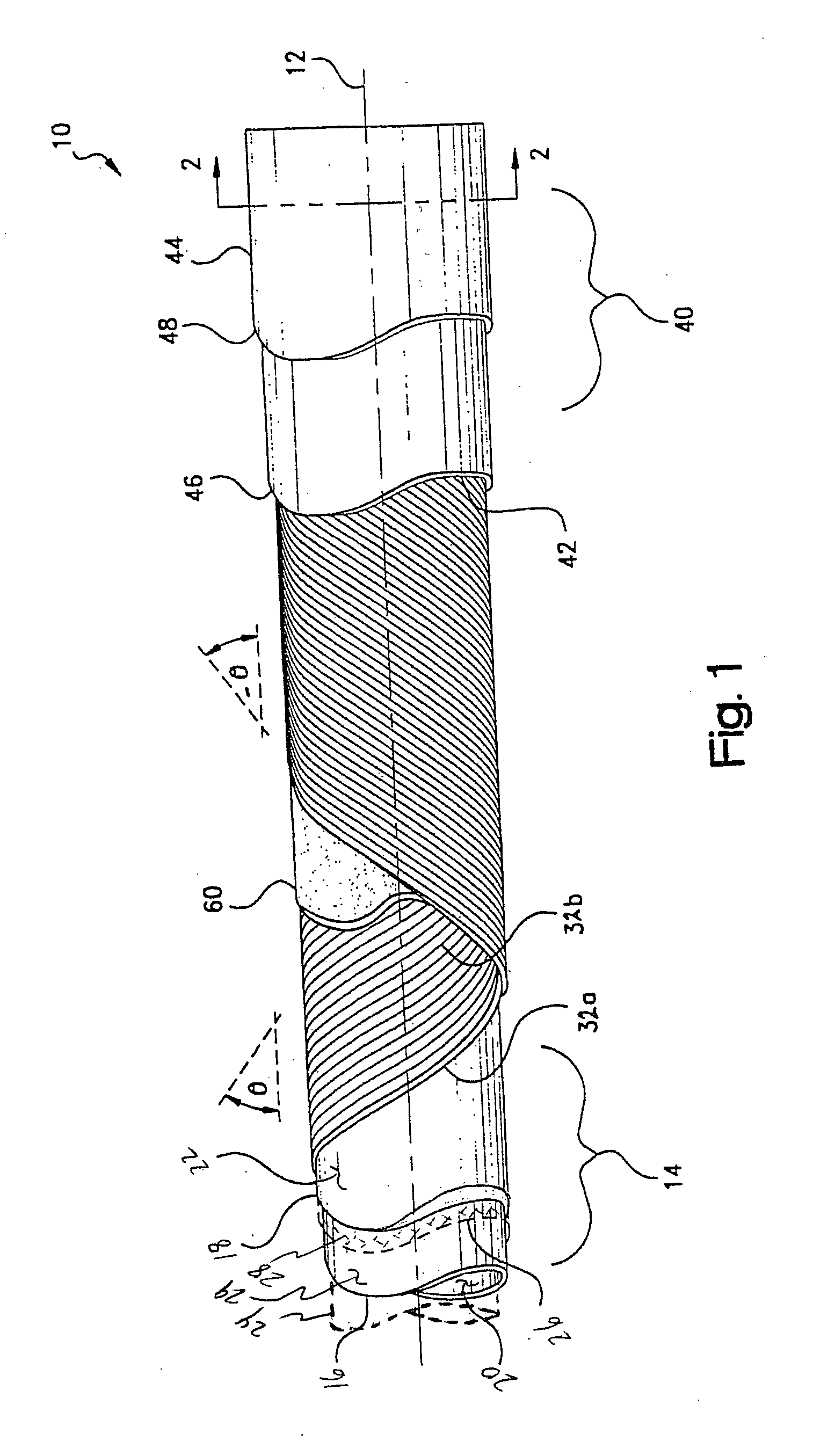

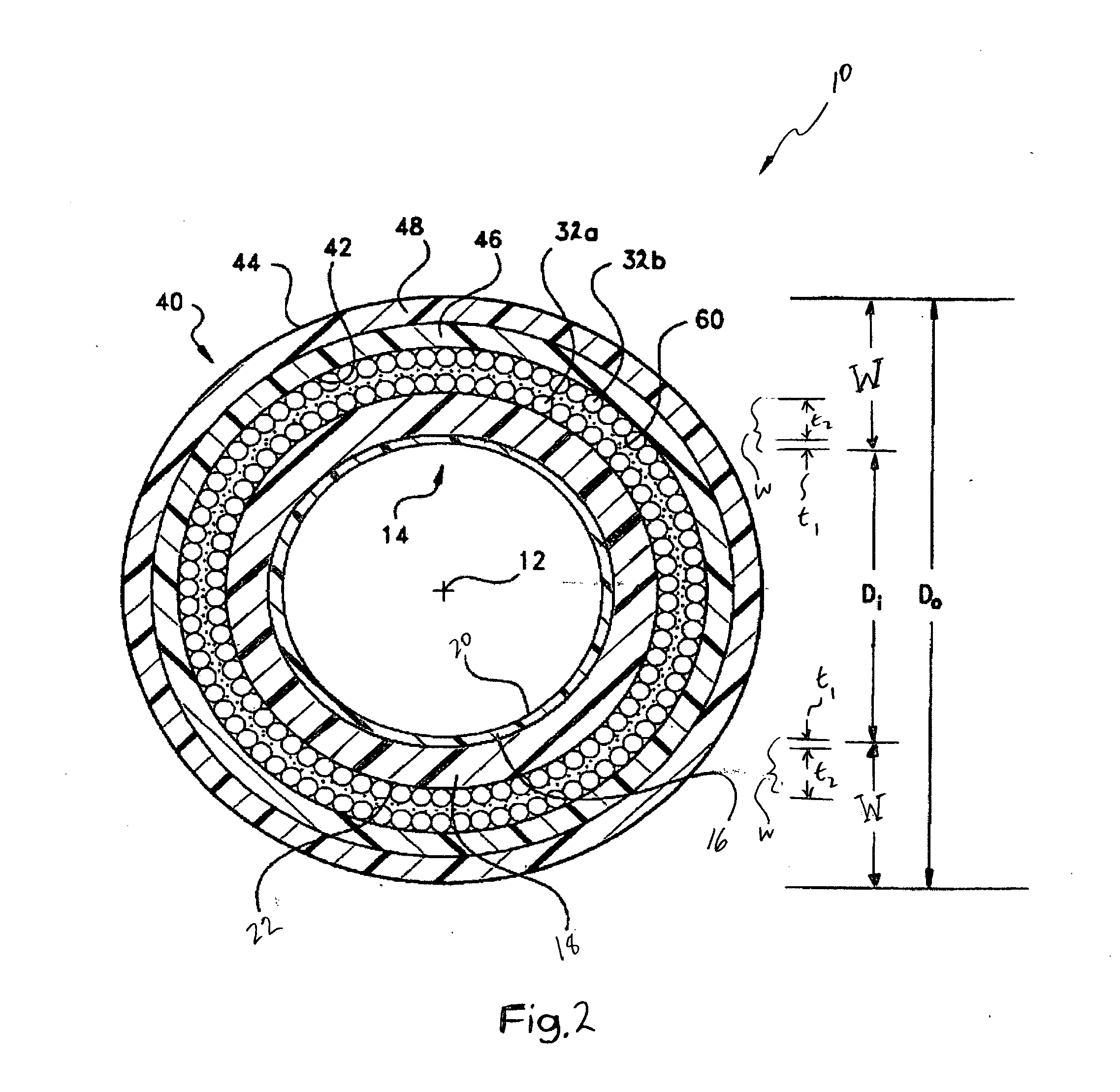

Electrically-conductive hose

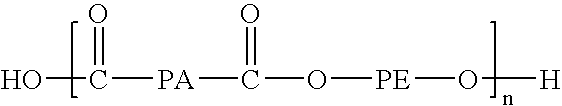

InactiveUS20060127620A1Affect strengthAffect flexibilitySynthetic resin layered productsFlexible pipesPolyesterParticulates

Tubular polymeric composite for articles such as tubing and hoses. The composite is formed of a tubular first layer of a thermoplastic block polyether amide resin (PEBA) filled with a more structured carbon black particulate filler to render it electrically-conductive, and a tubular second layer of a thermoplastic polyamide, polyester, polyolefins, or other thermoplastic resin compatible with the PEBA resin of the first material, and which second material optionally may be filled with a less structured carbon black particulate filler to render it electrically-conductive.

Owner:PARKER HANNIFIN CORP

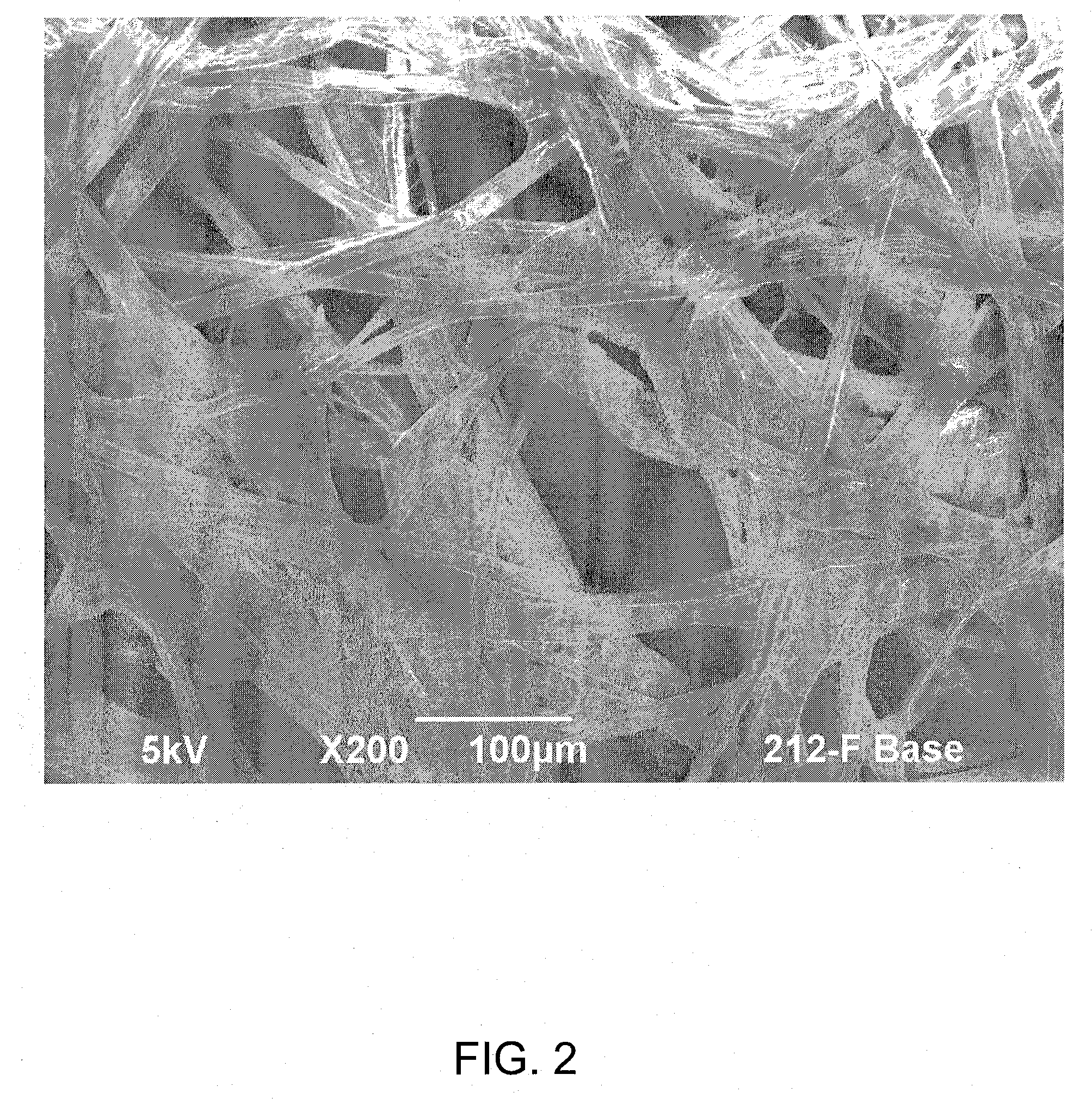

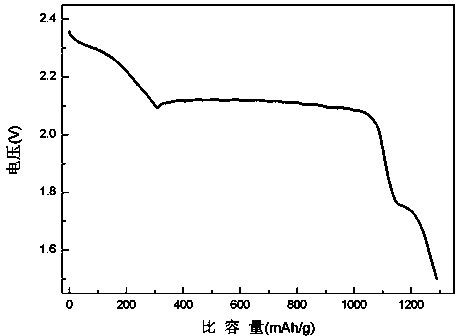

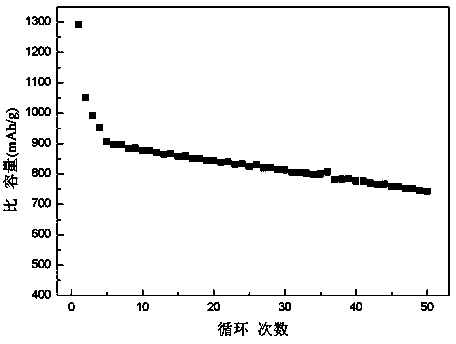

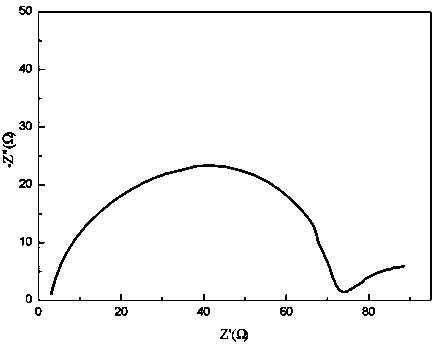

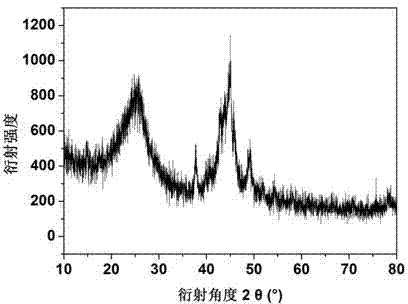

Preparation method of nitrogen-rich multimode beehive carbon-sulfur composite anode material

ActiveCN103746098ALarge specific surface areaHigh nitrogen contentPositive electrodesLi-accumulatorsArgon atmosphereOxide composite

The invention relates to a preparation method of a lithium sulphur battery composite anode material. The preparation method is as follows: preparing a mixed solution of carbon tetrachloride, a nitrogen source and carbonate, heating and flowing back to obtain a nitrogen-rich polymerization / carbonic acid salt compound; high temperature pyrolyzing in a nitrogen or argon atmosphere after drying the compound, so as to form the nitrogen-rich carbon / oxide compound; adding dilute acid to remove vestigial oxide, so as to form the nitrogen-rich multimode beehive carbon material of a multilevel porthole structure; uniformly mixing the nitrogen-rich multimode beehive carbon and sublimed sulfur, heat preserving under vacuum condition, injecting sulfur gas to the nitrogen-rich multimode beehive carbon material, so that the lithium sulphur battery composite positive material can be obtained. The composite anode material provided by the invention is alveolate, and has the advantages that portholes are abundant, sulfur content is high, sulfur particle can be distributed uniformly in the nitrogen-rich multimode beehive carbon material of the multilevel porthole structure, and the carbon sulfur particles can be combined more tightly, the material mechanical stability is high, discharge specific capacity is high, cycle performance is excellent, and technological process is simple, pollution is avoided, cost is low, and the method is liable to large scale production and application.

Owner:CENT SOUTH UNIV

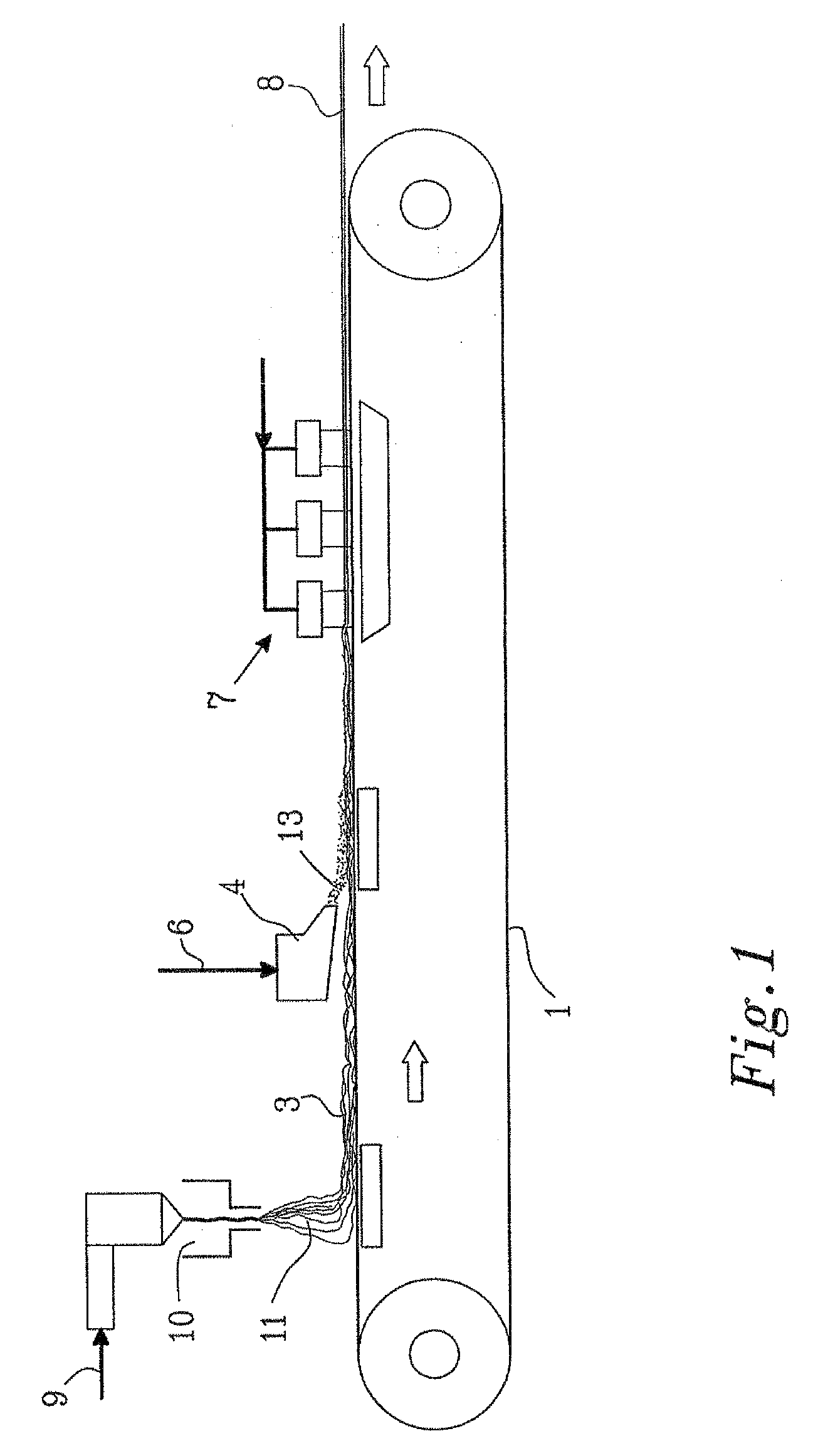

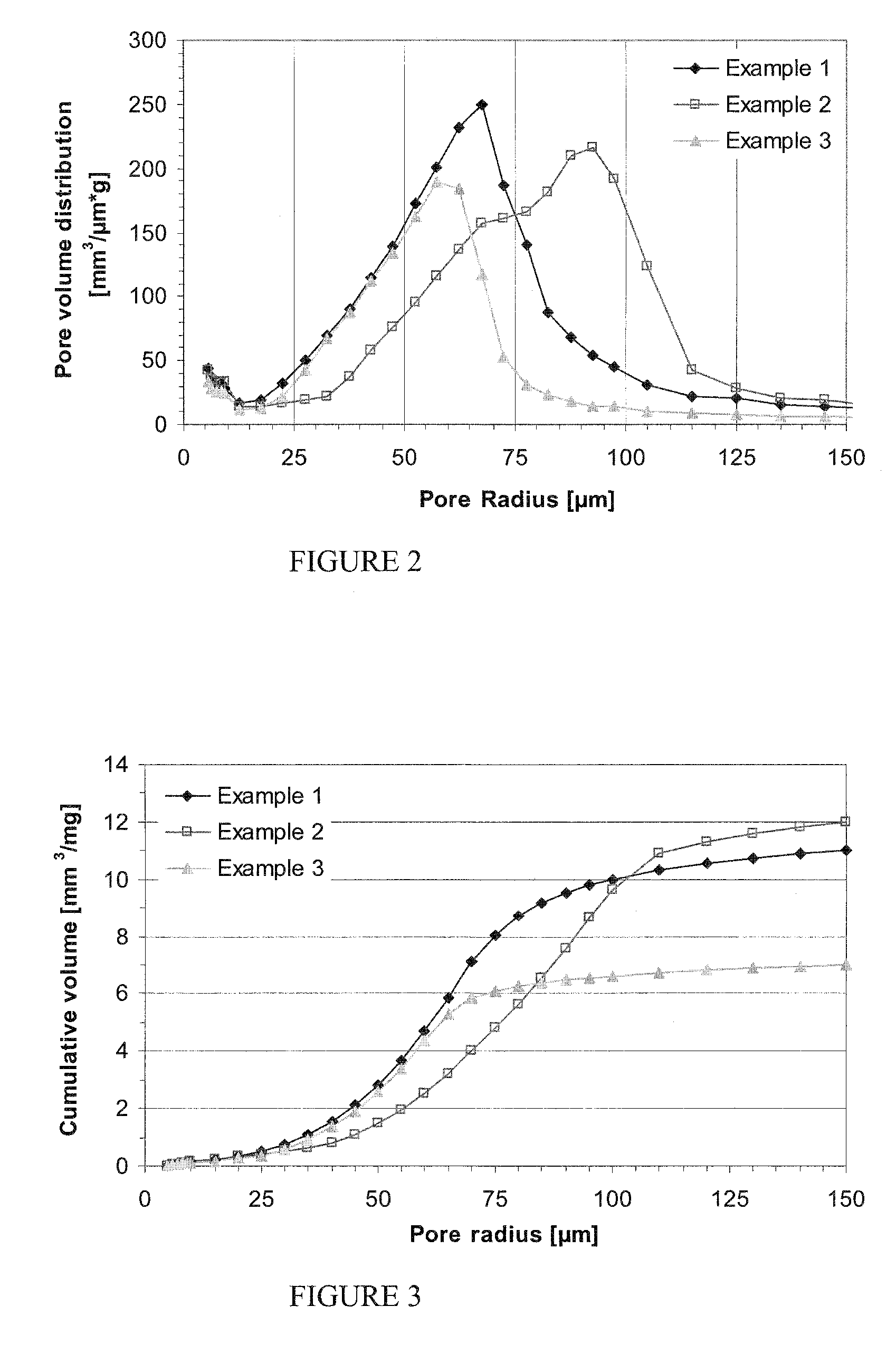

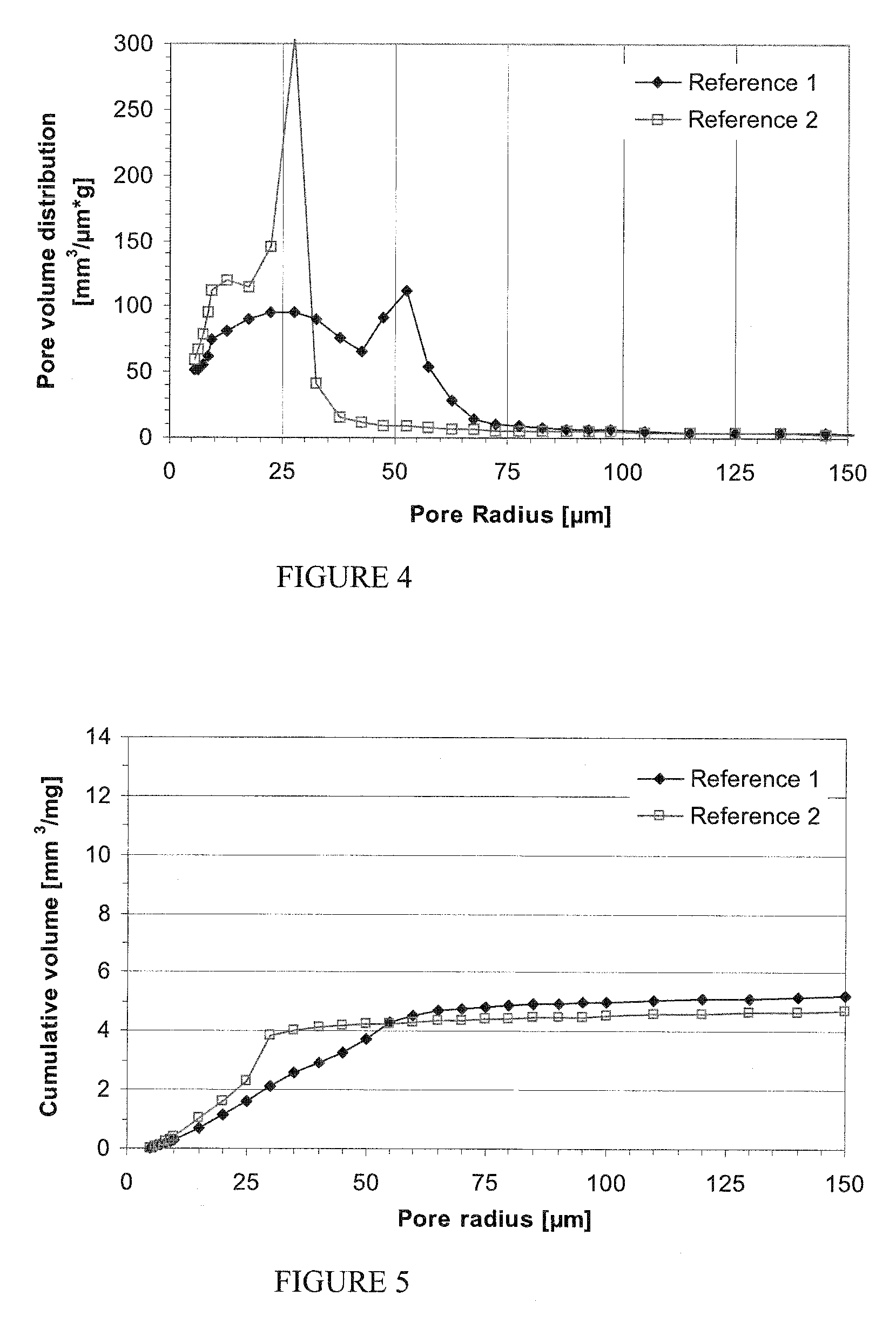

Hydroentangled integrated composite nonwoven material

InactiveUS20080050996A1Facilitated releaseLarge hole volumePattern makingLayered productsPolyesterPolymer science

An hydroentangled integrated composite nonwoven material, includes a mixture of randomized continuous filaments, and synthetic staple fibers, where there are no thermal bonding points between the continuous filaments. The nonwoven material exhibits a cumulative pore volume, measured by PVD in n-hexadecane, in the pore radius range 5-150 μm, where at least 70% of the cumulative pore volume is in the pores with a pore radius above 45 μm. The nonwoven material also exhibits a cumulative pore volume, which when the synthetic staple fibers are chosen from the group of polyethylene, polypropylene, polyester, polyamide, and polylactide staple fibers is at least 9 mm3 / mg, and when the synthetic staple fibers are lyocell staple fibers is at least 6 mm3 / mg.

Owner:SCA HYGIENE PROD AB

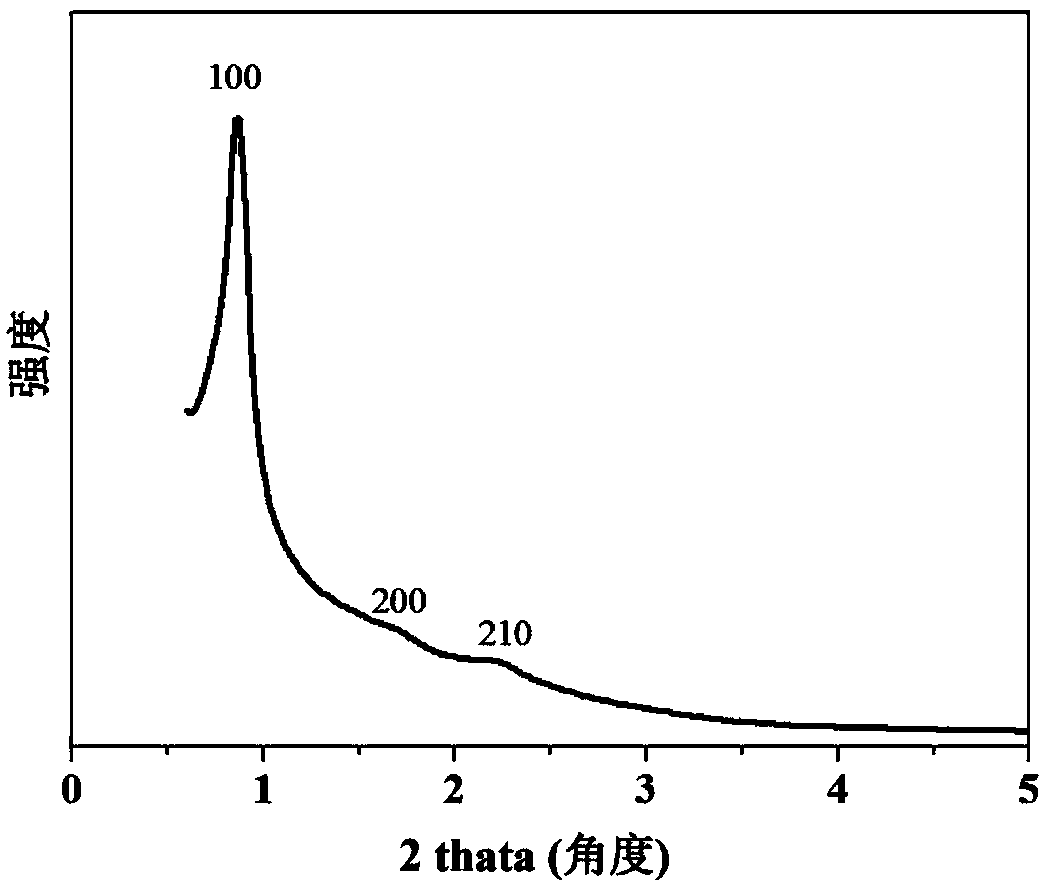

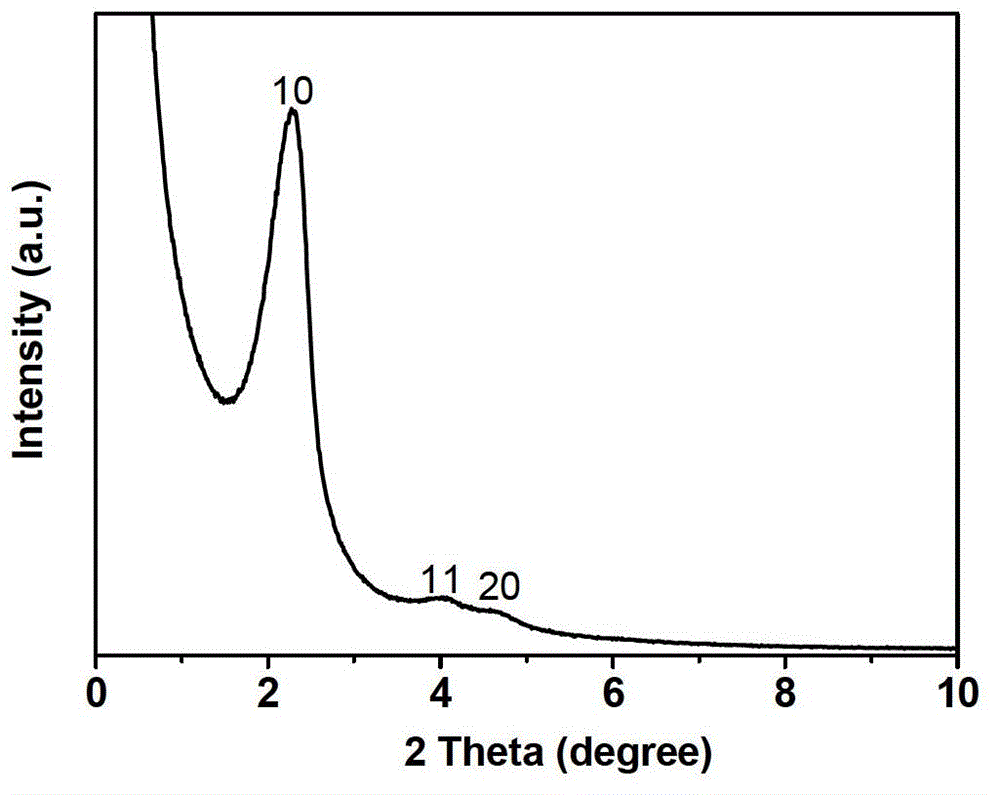

Solid-phase synthetic method of highly ordered mesoporous carbon material

InactiveCN103964414AIncrease the areaHigh pore volumeCarbon preparation/purificationPore diameterSelf-assembly

The invention discloses a solid-phase synthetic method of a highly ordered mesoporous carbon material. The solid-phase synthetic method comprises the following steps: 1) mixing a structure-directing agent with a high molecular monomer used as a carbon source, and grinding for 5-180 min at 10-100 DEG C; 2), heating for 0.5-120 h at 40-380 DEG C; 3) under the protection of inert gases, rising the temperature to 500-2,100 DEG C at the temperature rising speed of 1-40 DEG C / min, and roasting for 2-10 h at high temperature. The functionalization mesoporous carbon material is synthetized through the organic-organic self-assembly between the high molecular monomer and the structure-directing agent and between the low polymer of the high molecular monomer and the structure-directing agent, and the mechanical grinding. The solid-phase synthetic method is simple to operate, efficient, and low in cost, and the prepared mesoporous carbon material has a highly ordered mesoporous channel, high specific surface area (500-2,500 m<2> / g and large pore volume (pore diameter of 2.5-20 nm and pore volume of 0.1-2.5 cm <3> / g).

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

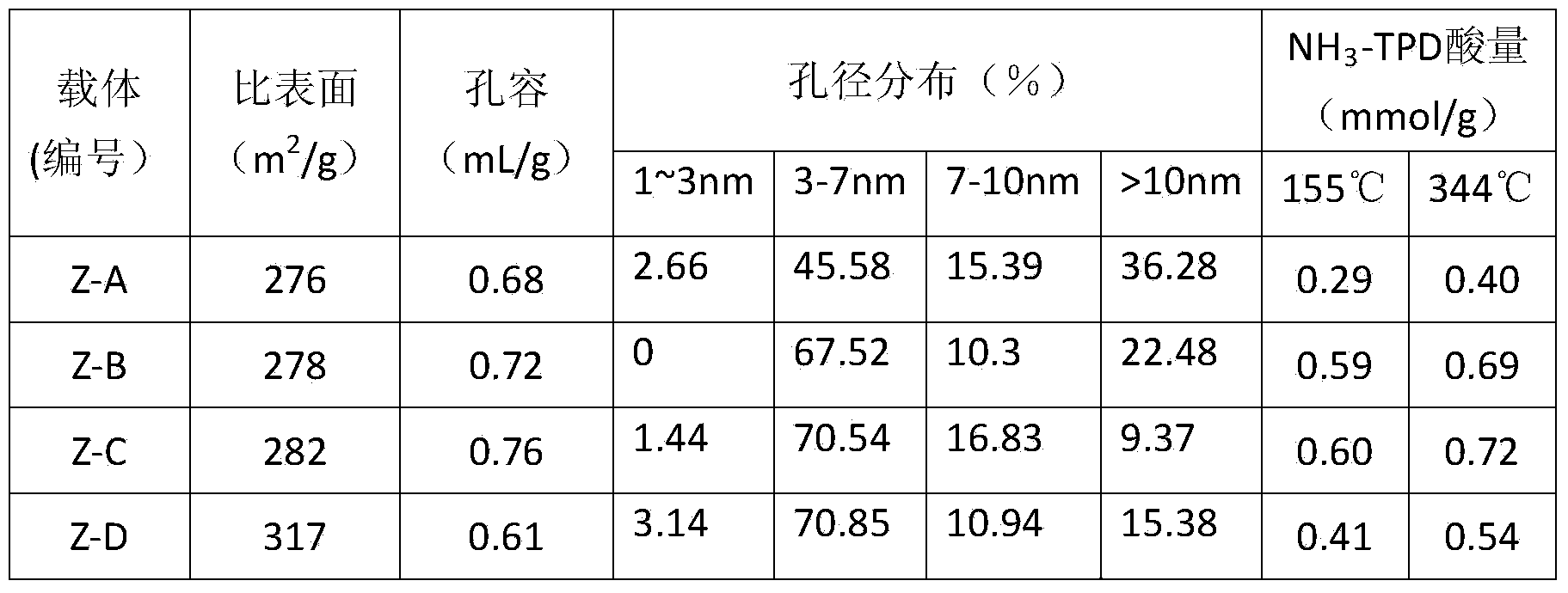

Alumina support containing silicon and titanium and preparation method thereof

ActiveCN1768945AImprove pore structureLarge specific surface areaCatalyst carriersPore distributionAluminium hydroxide

The invention discloses property-transformation alumina carrier which contains titanium and silica agent and its relative preparing method. Said silica agent is added in the sol process of aluminum hydroxide to improve the specific surface, pore diameter and pore capacity of alumina; after the sol process, individually using acid agent and alkali agent to adjust the pH value of mixed paste solution for several times to make the attained alumina with more centralized pore distribution; the titanium agent is added after the sol process and before the aging process, to improve the surface acid property, surface acid amount and B acid amount of carrier. In addition, the surface of alumina is modified by titanium to decrease the interactive condition between active metal and carrier, which can apply the diffusion of active metal components in the catalyst. The property transformation of said invention can be used as catalysis material when processing oil, especially as the catalyst carrier of hydrogenation treatment and hydrogenation transformation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Dechlorinating agent used for removing HCl from gas by dry method and preparation method thereof

InactiveCN101773768AImprove dechlorination activityHigh activityOther chemical processesAluminium silicatesPorosityCross-link

The invention relates to a dechlorinating agent used for removing HCl from a gas by using a dry method and a preparation method thereof. The dechlorinating agent is prepared from Na2CO3, CaCO3, CaO and MaO as active constituents, crosslinked bentonite as a porous auxiliary agent, and methyl cellulose as a foaming agent and an auxiliary extrusion agent through extrusion forming, drying and roasting. The cross-linked bentonite is prepared by exchanging large-size poly aluminum cation with small-size simple cation, so that the crosslinked bentonite has great porosity factor and large specific surface. The specific surface and the pore volume of the crosslinked bentonite are larger than those of non-crosslinked bentonite. By using the crosslinked bentonite as the porous auxiliary agent, the specific surface of the dechlorinating agent is enlarged, and the dechlorinating activity and the chlorosity of the dechlorinating agent are increased. The dechlorinating agent prepared by using the crosslinked bentonite has a pore volume of 0.3-0.4 mL / g, a specific surface of 70-90 m<2> / g and a crushing strength of 60-80 N / cm, not only has lower price than pseudo-boehmite and a molecular sieve, but also has simple preparation process, high dechlorinating activity and great low-temperature penetration chlorosity.

Owner:长春惠工净化工业有限公司

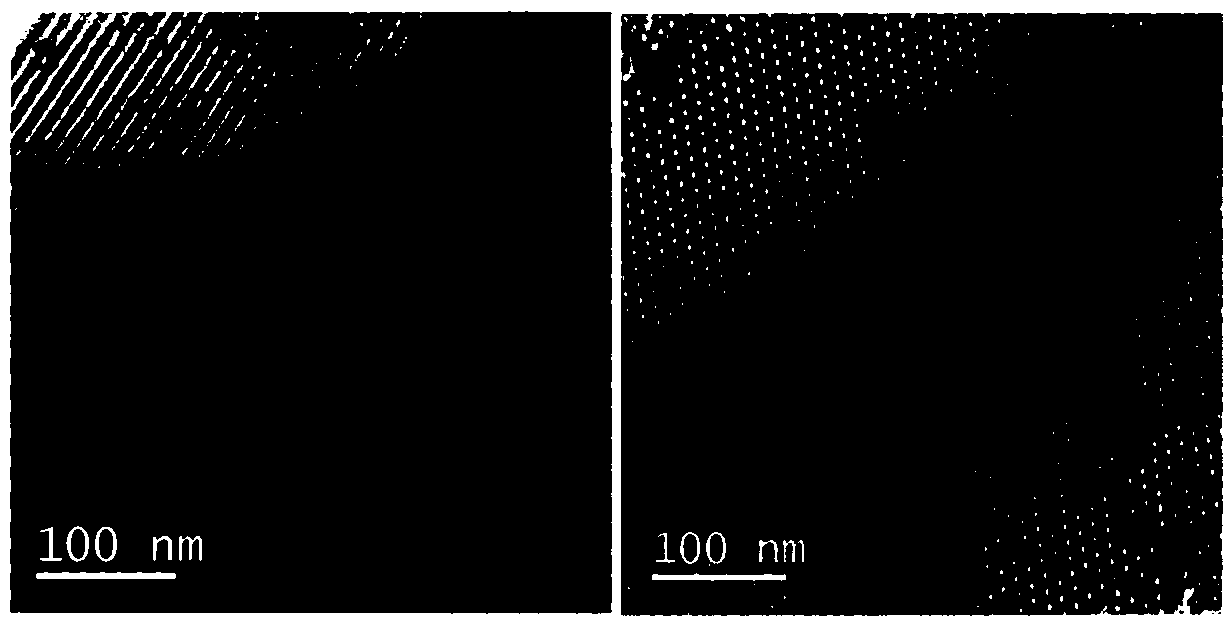

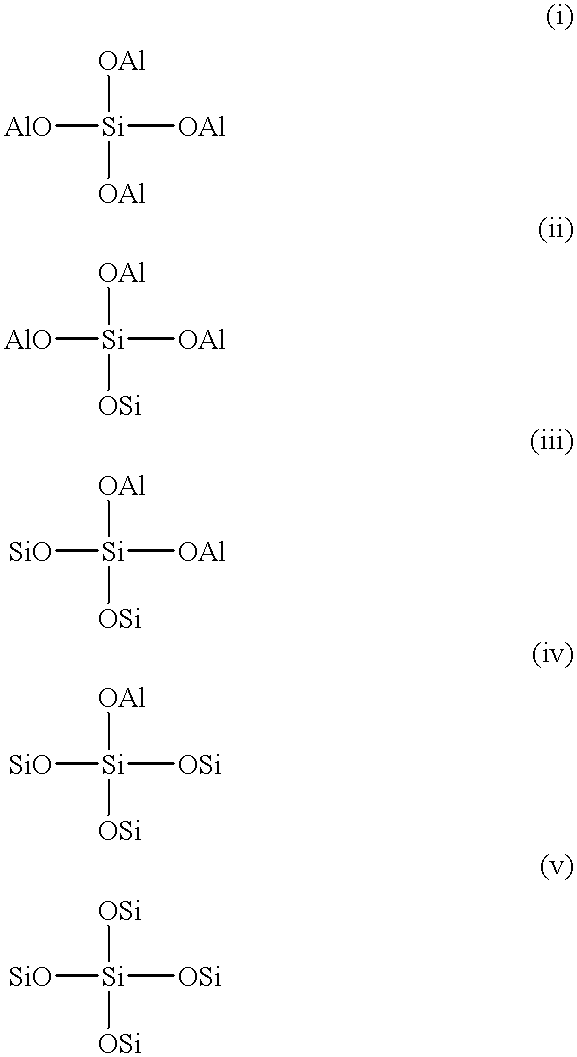

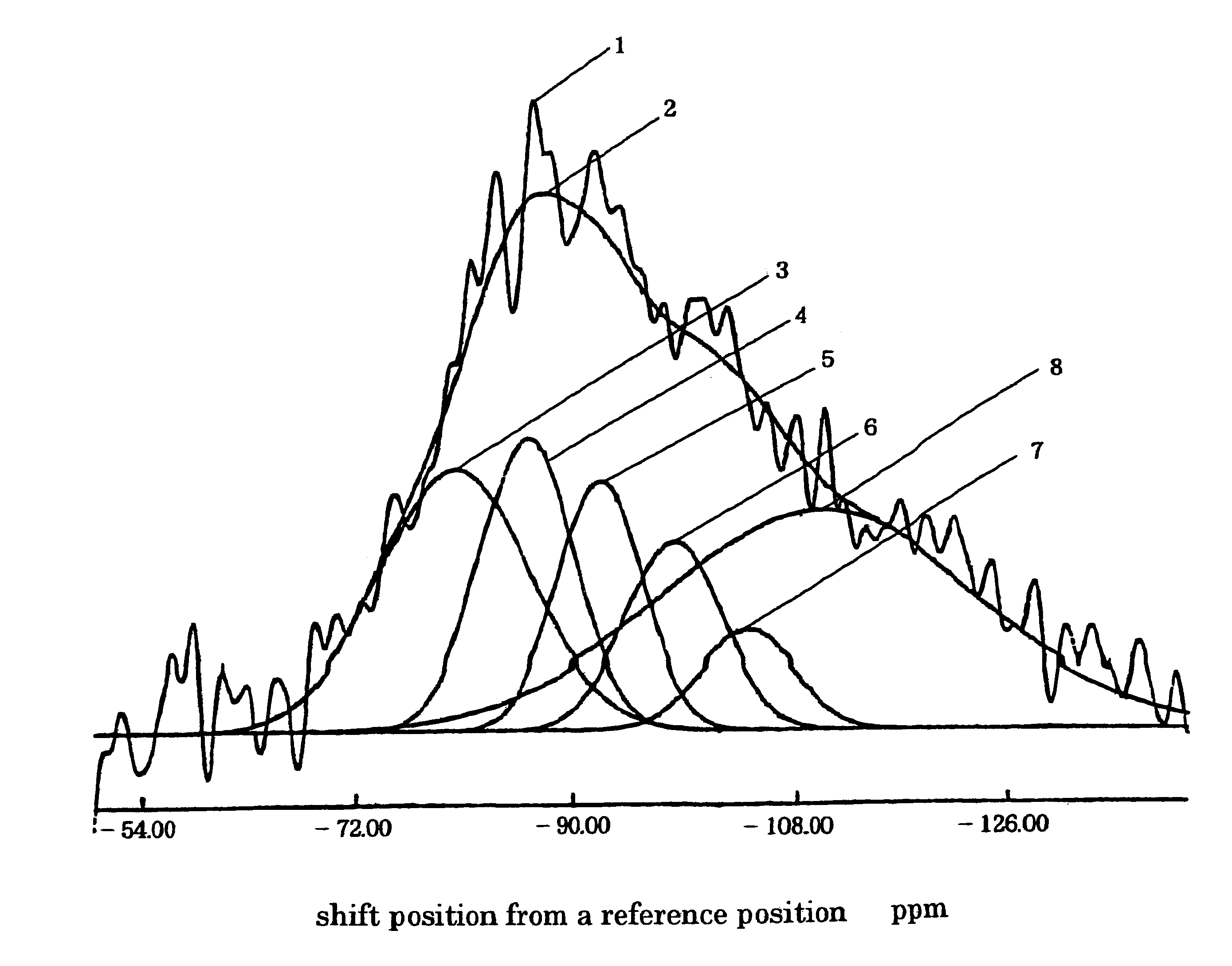

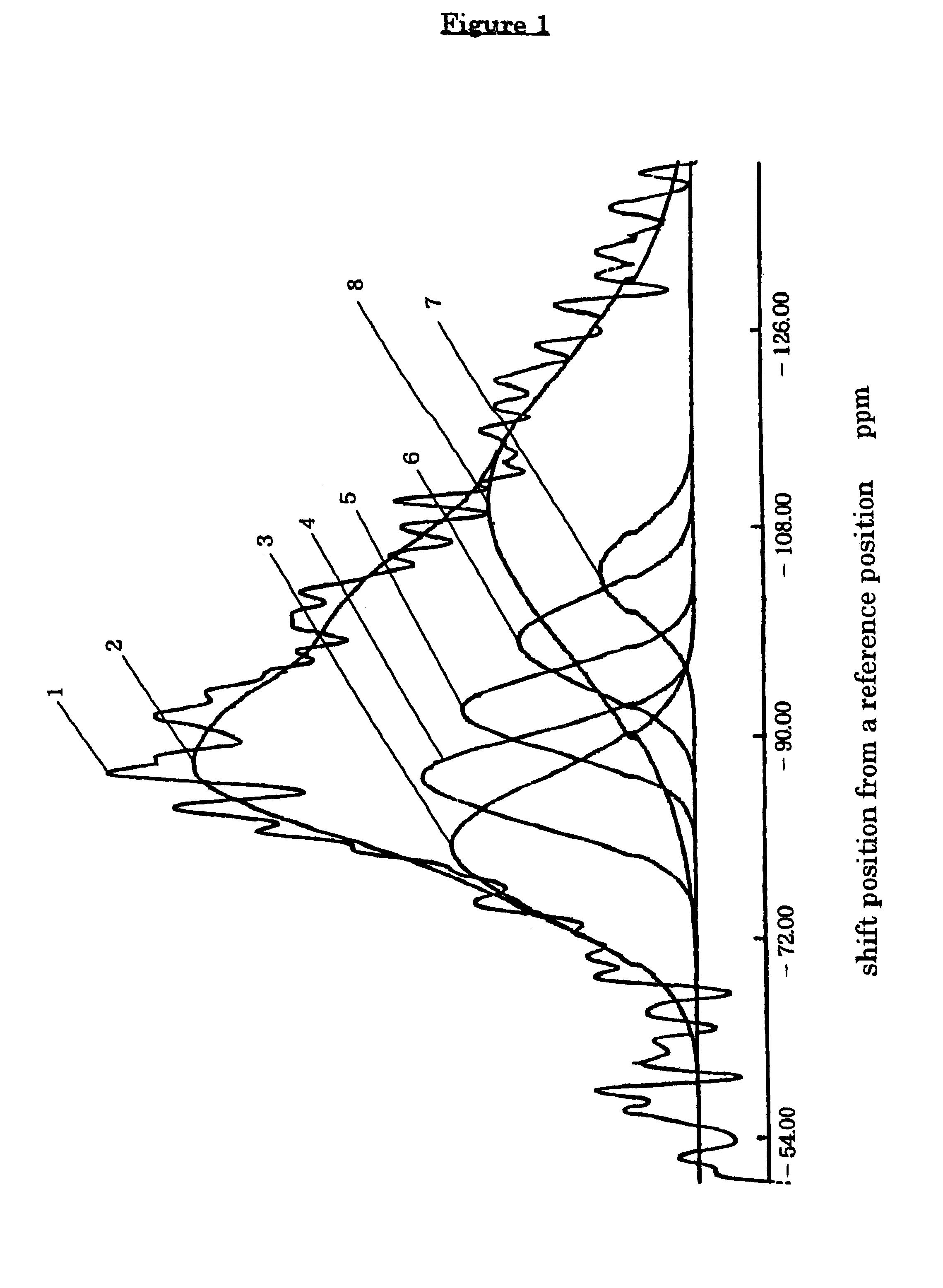

Catalyst for hydrogenation treatment and method for hydrogenation treatment of hydrocarbon oil

InactiveUS6306289B1High desulfurization activityHigh activityCatalyst activation/preparationTreatment with hydrotreatment processesComponent LoadNMR - Nuclear magnetic resonance

A hydrotreating catalyst having both a high desulfurization activity and a denitrogenation activity and a method of hydrotreating a hydrocarbon oil using the same is provided.A hydrotreatment catalyst comprising a silica-alumina carrier loaded with at least one hydrogenation-active component; wherein (1) the silica content is in the range of 2 to 40% by weight based on the total weight of the carrier; and (2) in the spectrum obtained by nuclear magnetic resonance analysis (29Si-NMR), (i) the area of the peak at -80 ppm is 10% or more of the combined area of all the peaks; and (ii) the combined area of peaks at -80 ppm, -86 ppm and -92 ppm is 20% or more of the combined area of all peaks; a hydrotreating catalyst comprising a silica-alumina carrier containing a specific amount of a third component loaded with at lest one hydrogenation-active metal component and having a specific pore structure; and a method of hydrotreating a hydrocarbon oil comprising contacting a hydrocarbon oil with hydrogen in the presence of said hydrotreating catalyst.

Owner:TONENGENERAL SEKIYU

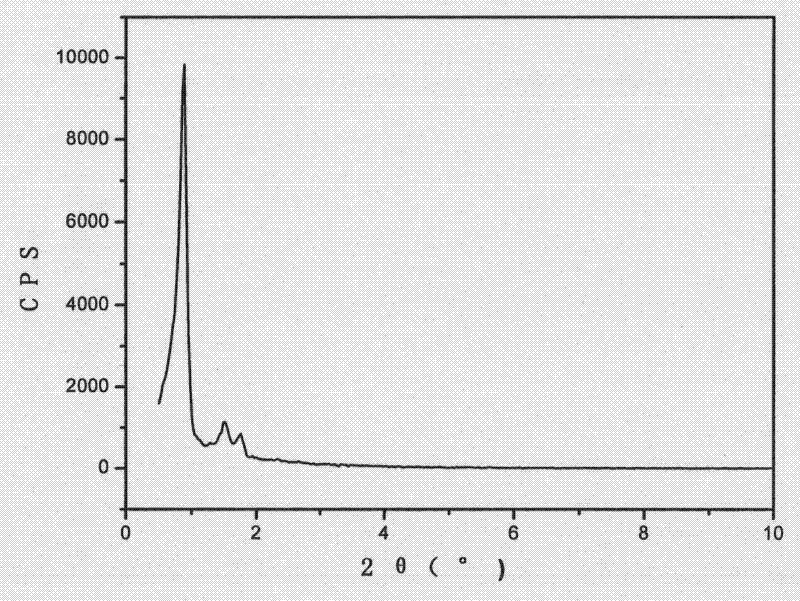

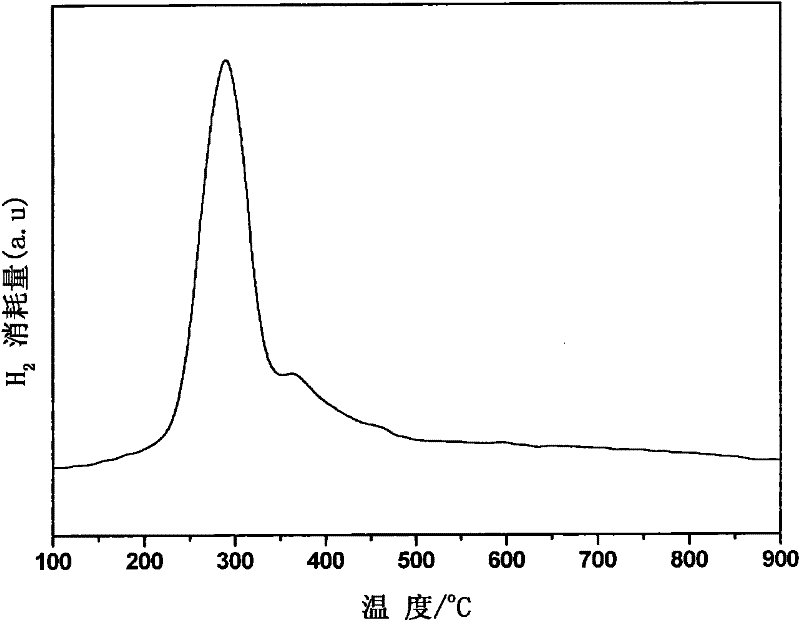

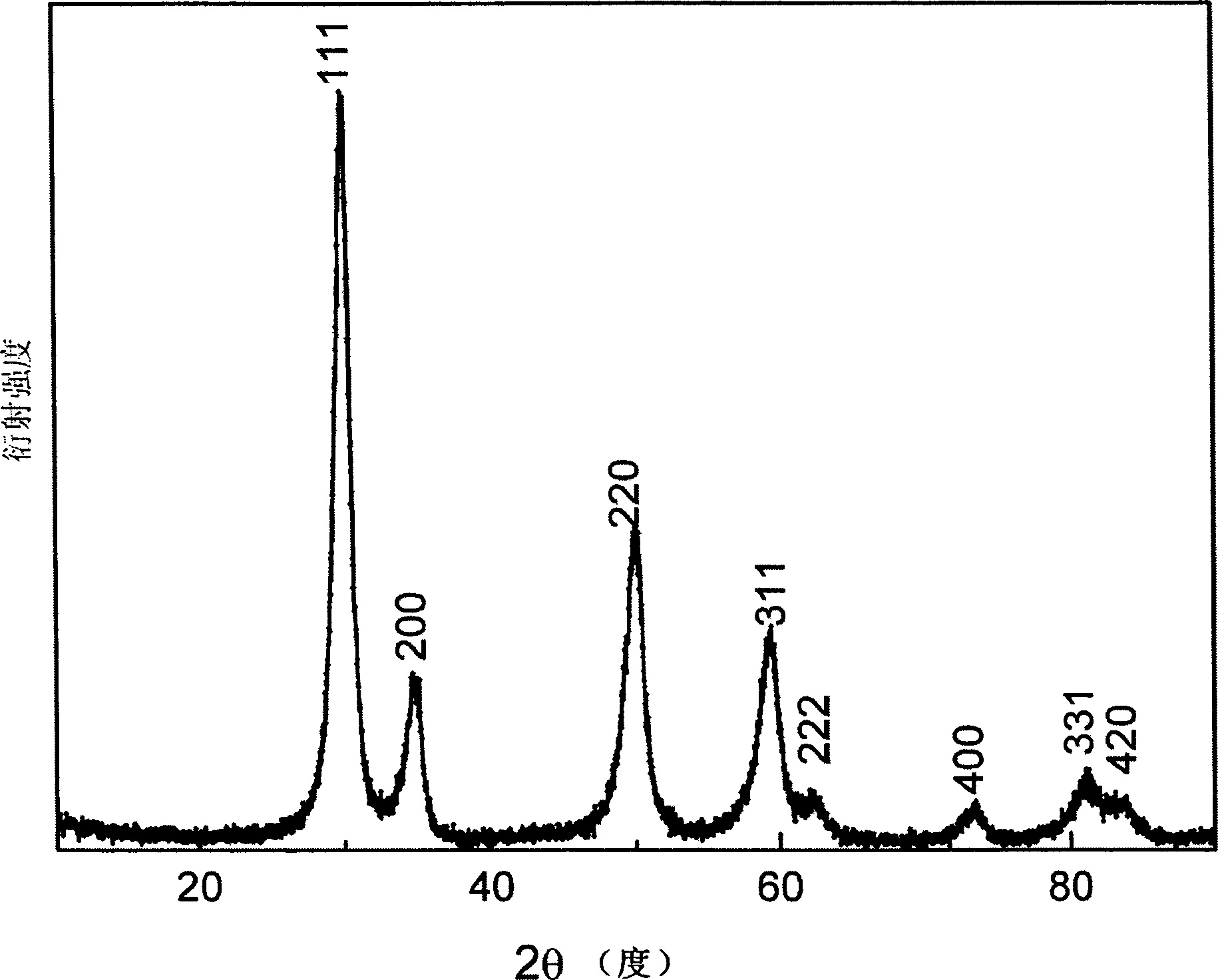

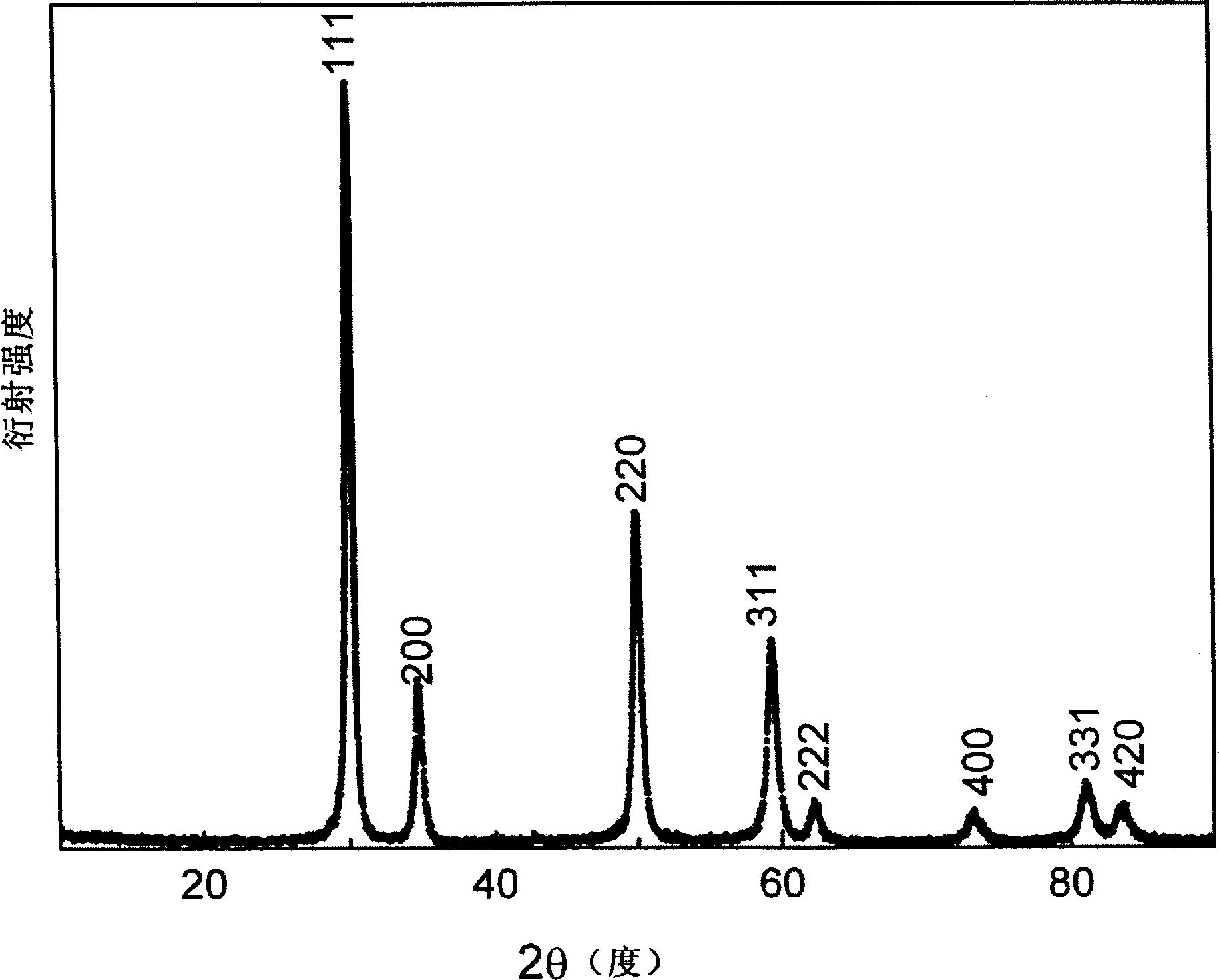

Hydrogen-storing material with low-cerium and production thereof

ActiveCN1817447AHigh oxygen storage performanceIncrease the areaMetal/metal-oxides/metal-hydroxide catalystsHydrogenCerium

An O2-bearing low-Ce RE material with high performance and multiple purposes is a composite oxide consisting of cerium oxide, zirconium oxide and assistant chosen from lanthanum oxide, strontium oxide and yttrium oxide. It is prepared through codeposition and calcining at 500-600 deg.C. It can be used as the carrier and assistant of the catalyst for cleaning the tail gas of car.

Owner:SINOCAT ENVIRONMENTAL TECH

High-silicon amorphous silica aluminum and preparation method thereof

ActiveCN101491774AHigh ratio of silicon to aluminumLarge specific surface area and pore volumeCatalyst carriersLarge poreCoprecipitation

The invention discloses high-silicon amorphous silica alumina and a preparation method thereof. The amorphous silica alumina product has the properties of a specific surface area of 400 to 650m / g, a pore volume of 1.0 to 2.0cm / g, a silicon oxide content of 20 to 80wt percent, a infrared acid content of 0.3 to 0.8 mmol / g and evenly distributed acidic centers. Moreover, the amorphous silica alumina is prepared by a method comprising first coprecipitation of silicon oxide and alumina and then modification of organic silicon. Compared with the prior art, the amorphous silica alumina has larger pore volume and specific surface area, evenly distributed acidic centers and excellent service performance; moreover, the preparation method is simple, free from special environmental protection problem and low in production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

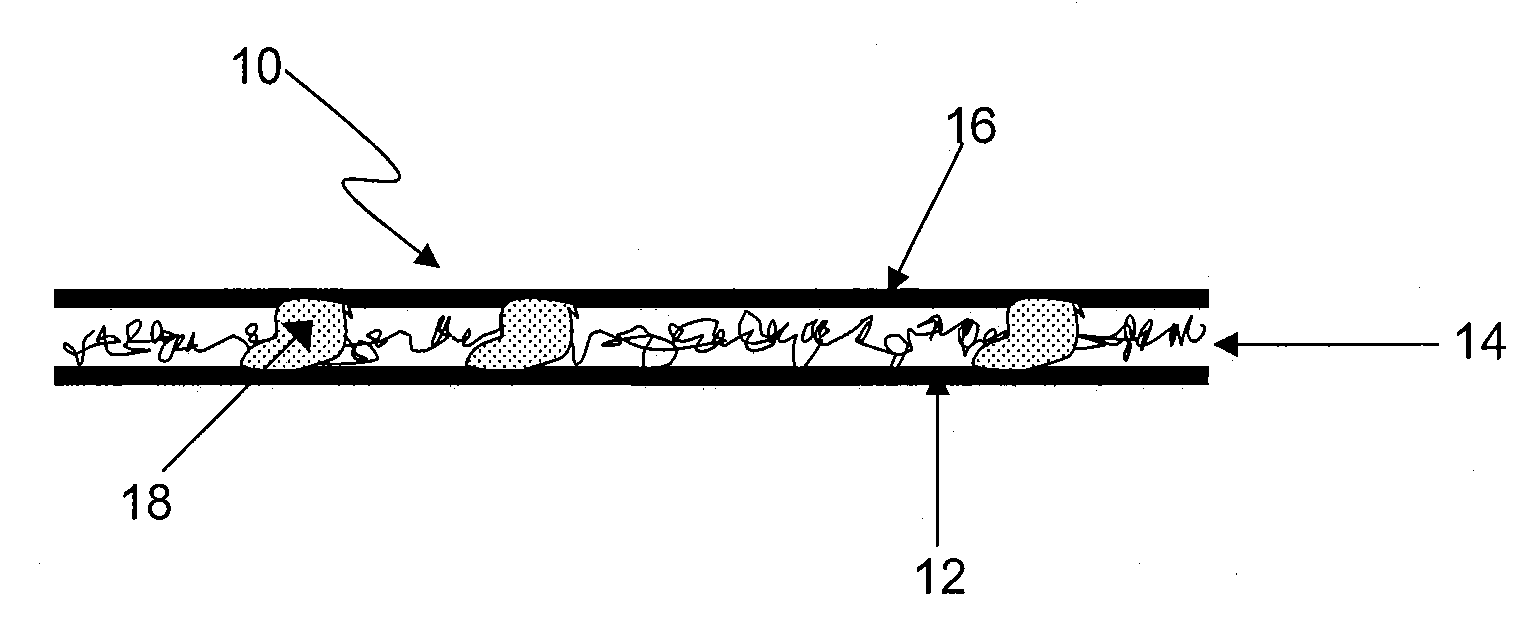

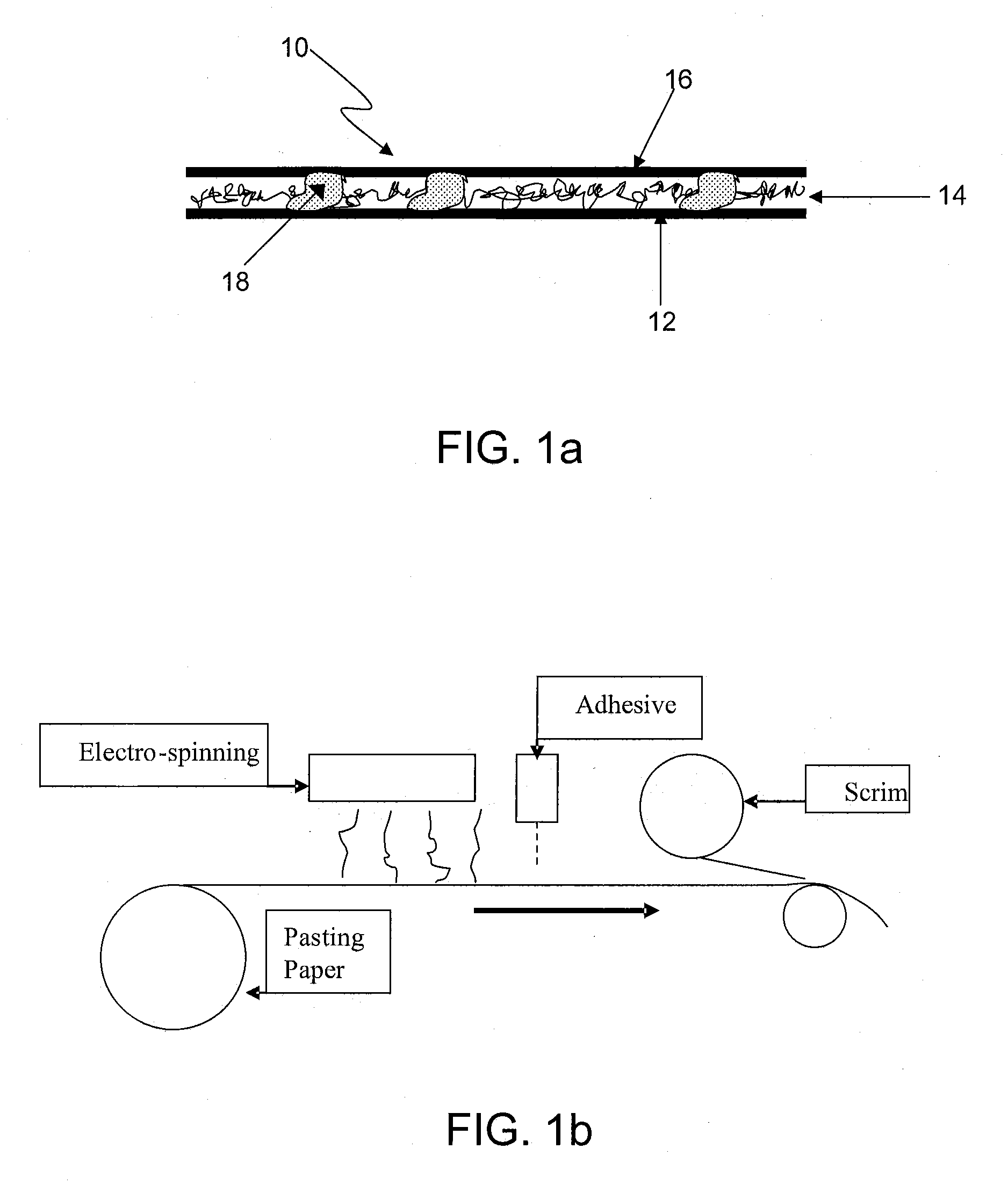

Battery separator structures

InactiveUS20090148760A1Low densityLarge surface area to massMaterial nanotechnologyLead-acid accumulatorsFiberGlass fiber

A multilayer composite sheet for use in a lead-acid battery includesa) a base layer including paper or a glass fiber mat;b) a layer of polymeric nanofibers bonded with discrete adhesive particles to a first surface of the base layer; andc) a scrim layer bonded with discrete adhesive particles to a surface of the layer of nanofibers opposite the base layer.A plate assembly for a lead-acid battery includes one or more multilayer composite sheets located adjacent or partially enclosing a lead plate.

Owner:GLATFELTER CORP

Preparation method of S/TiO2 composite material for anode of sodium-sulfur battery

ActiveCN103840143AImprove conductivityIncrease profitElectrode carriers/collectorsLi-accumulatorsSulfur electrodeHYDROSOL

The invention provides a preparation method of an S / TiO2 composite material for an anode of a sodium-sulfur battery. The preparation method comprises the following steps: dissolving butyl titanate, a template agent and a hydrolysis inhibitor into absolute ethyl alcohol; adding a mixed solution of de-ionized water and the absolute ethyl alcohol to form semi-transparent sol; transferring the sol into a high-pressure reaction kettle to react; calcining a solid product in air to remove the template agent to obtain meso-porous titanium dioxide; dispersing the meso-porous titanium dioxide into a sodium thiosulfate solution dissolved with a surfactant; adding hydrochloric acid to react; washing the solid product by a lot of the de-ionized water and drying; and eating under the protection of an inert atmosphere to obtain the S / TiO2 composite material. The meso-porous titanium dioxide prepared by the preparation method is large in specific surface area, high in porosity and strong in adsorption capability; the electrical conductivity of sulfur can be improved and a lot of nano sulfur and polysulfide can be contained; the polysulfide can be effectively prevented from being dissolved and diffused in electrolyte, and the utilization rate of the sulfur is improved; meanwhile, the structure of the meso-porous titanium dioxide is stable and a pore channel cannot be easily damaged, so as to have buffering effects on volume expansion and retraction in a charging / discharging process of a sulfur electrode.

Owner:CENT SOUTH UNIV

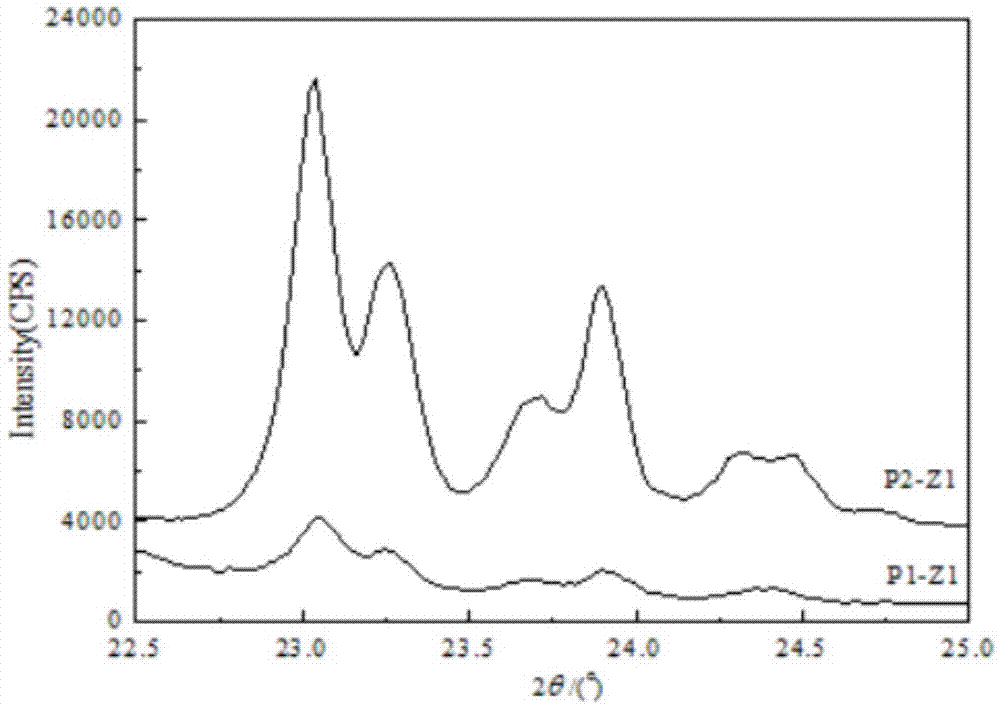

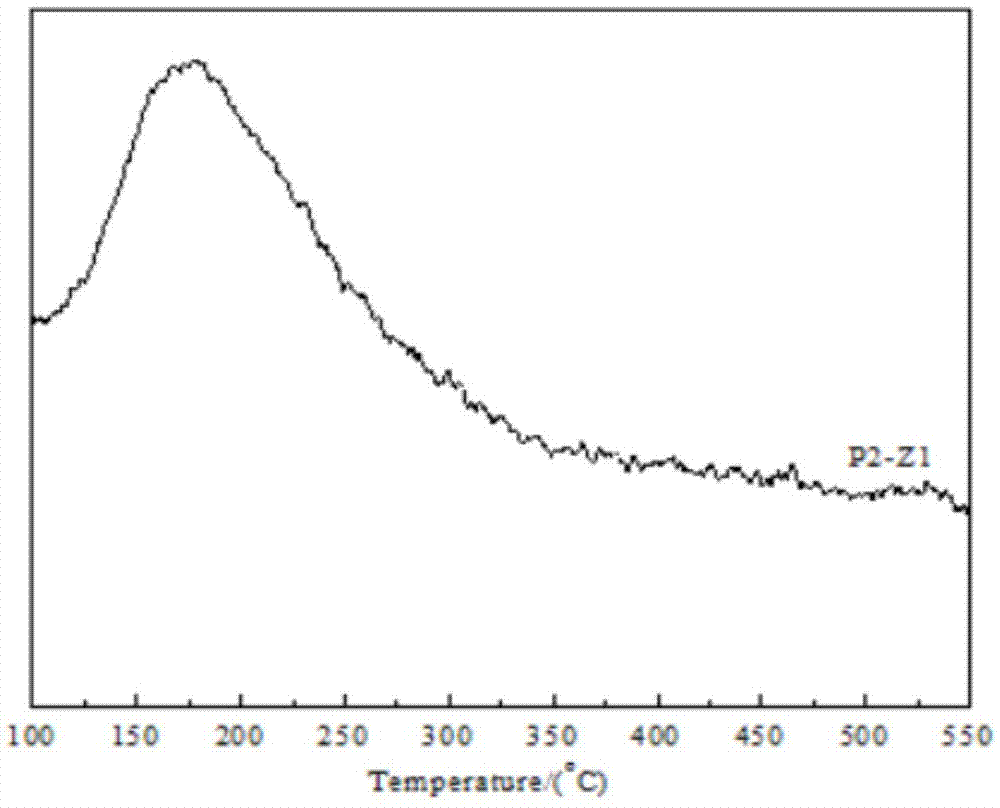

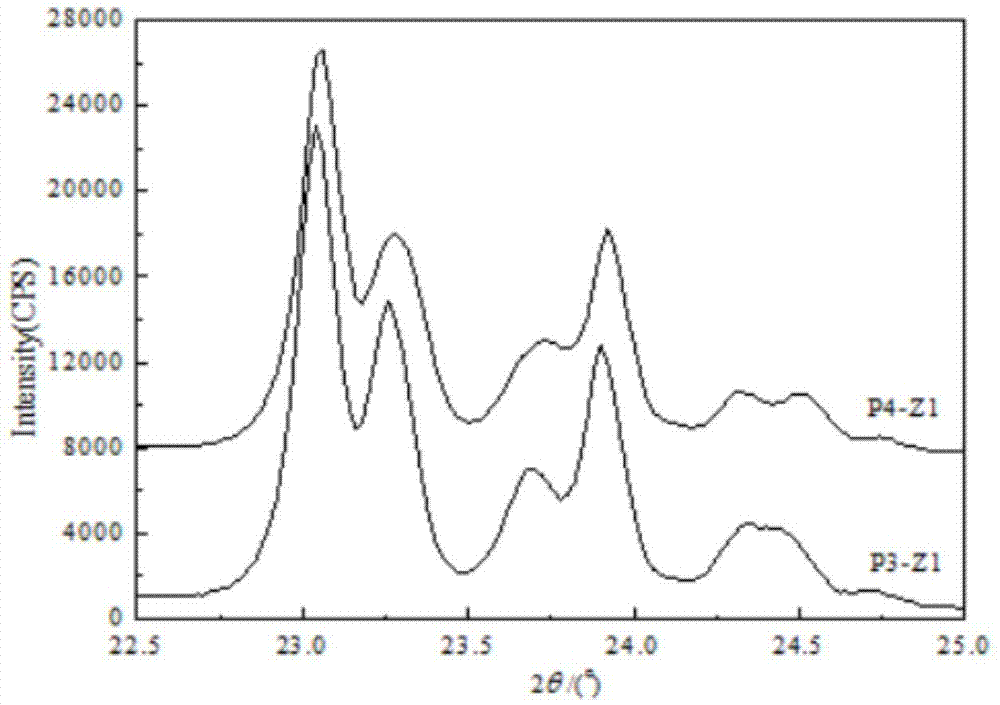

Phosphorus modification method of ZSM-5 molecular sieve

ActiveCN106994364ASuperior Catalytic PerformanceHigh selectivityCatalytic crackingMolecular sieve catalystsIonPhosphoric acid

The invention provides a phosphorus modification method of a high-alkali-metal-ion-content ZSM-5 molecular sieve. The method is characterized by comprising mixing a phosphorus-containing compound selected from one or more of phosphoric acid, diammonium phosphate, ammonium biphosphate and ammonium phosphate with a high-alkali-metal-ion-content ZSM-5 molecular sieve to obtain a mixture with at least 0.1 wt% of phosphorus-loading content, wherein phosphorus is counted in terms of P2O5, drying and calcinating the mixture, carrying out an ammonium exchange process and a washing process to make the alkali metal ion content no more than 0.10 wt%, performing drying, and carrying out hydrothermal aging at the temperature of 400-1000 DEG C in a 100% of vapor condition. The obtained phosphorus-containing ZSM-5 molecular sieve is high in total acid amount, is excellent in cracking conversion rate and propylene selectivity, and is good in hydro-thermal and active stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

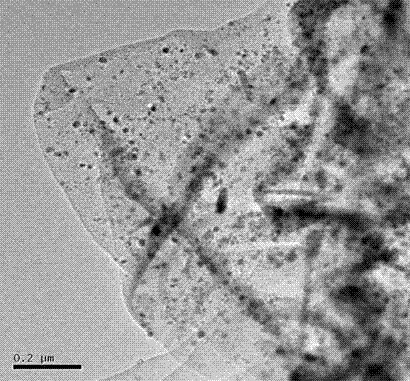

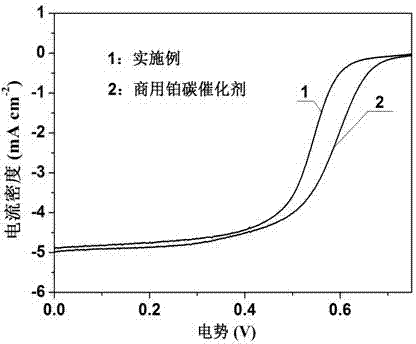

Preparation method and application of nitrogen-doped porous carbon nano sheet composite material

The invention discloses a preparation method of a nitrogen-doped porous carbon nano sheet composite material. The preparation method comprises the steps of performing high-temperature carbonization treatment on a mixture which consists of melamine and adjacent phenanthroline iron and serves as a precursor in a tubular furnace under an inert gas environment, and then removing dissolved iron compounds from an acidic solution to obtain a porous carbon nano sheet layer with carbon-coated iron carbide nano particles. The preparation method has the advantages that the technology is simple, the raw materials are cheap, and operation is easy to implement; in the prepared composite material, iron carbide is uniformly dispersed in the carbon nano sheet layer, so that the composite material is high in specific surface area and pore volume; iron carbide nano particles are completely coated by graphitized carbon, so that oxidization and corrosion are hardly caused; the composite material is stable in acidic electrolyte, and the battery activity can be effectively improved; when used as an electrocatalyst, the composite material is relatively high in electrocatalysis efficiency; the preparation method has an important value and significance in the field of preparation of doped carbon nano composite materials and electrocatalysis of proton membrane fuel batteries.

Owner:NANKAI UNIV

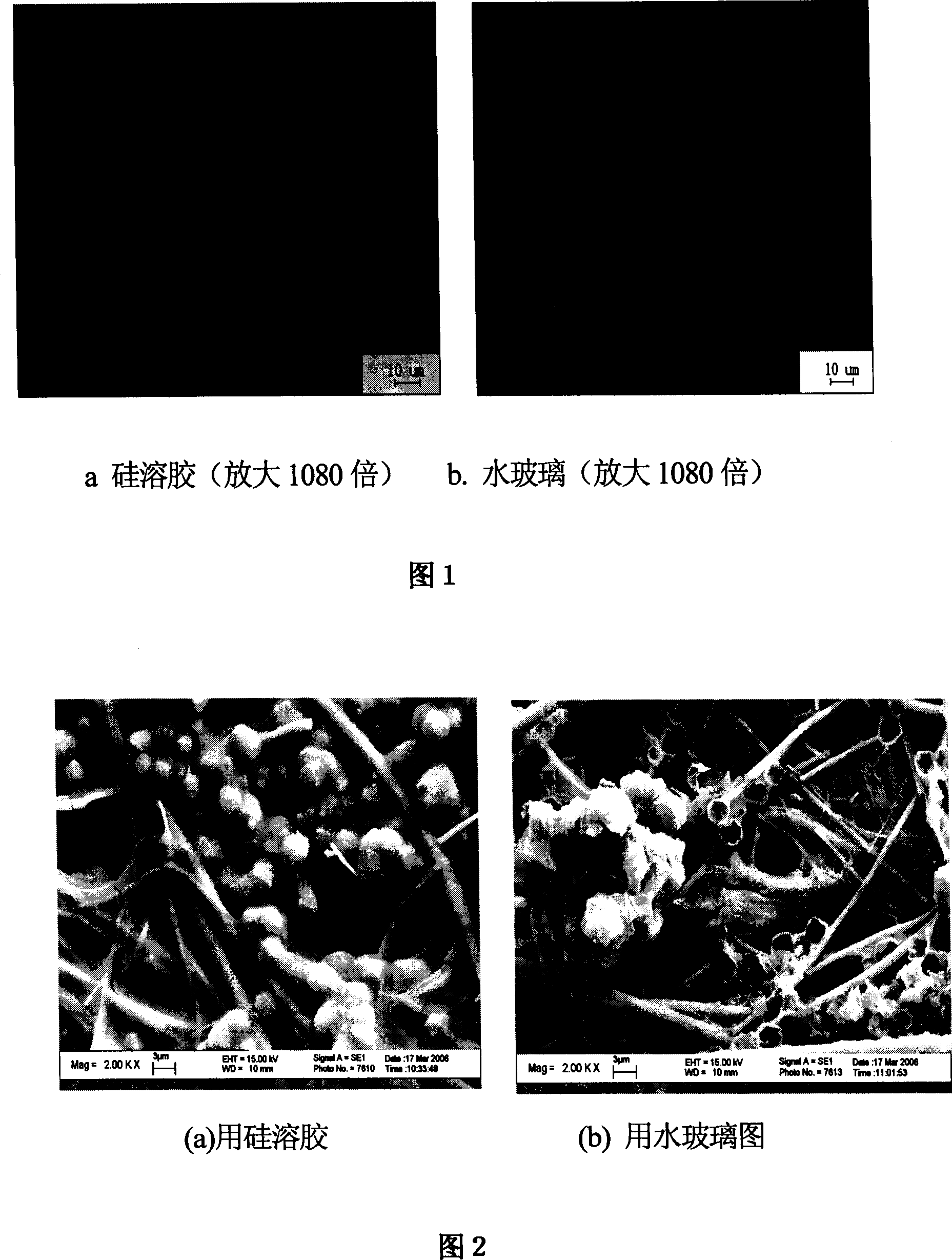

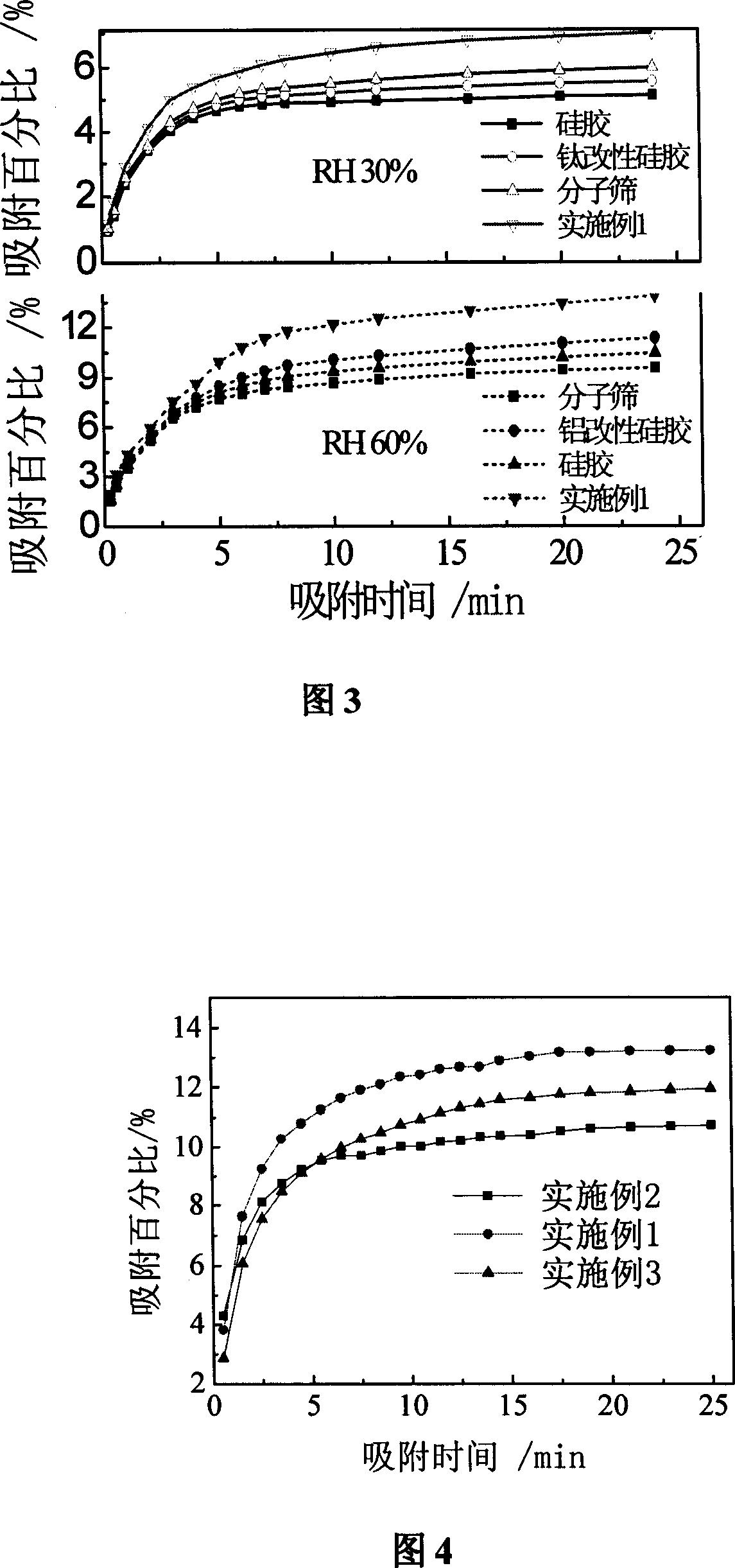

Preparing process of composite block adsorbent of molecular sieve and modified silica gel

InactiveCN1986046AIncrease the areaHigh pore volumeOther chemical processesAlkali metal oxides/hydroxidesFiberSorbent

The preparation process of composite block adsorbent of molecular sieve and modified silica gel includes the following steps: soaking ceramic fiber paper in water glass and hot pressing to form corrugated paper, adhering to flat sheet paper through the soaking at the same condition to form honeycomb block, drying, soaking the block into metal salt solution to react, washing with clear water, soaking the block in mixed liquid comprising silica sol and molecular sieve, taking out, sweeping to eliminate liquid and air drying to obtain the adsorbent. The adsorbent has homogeneous distribution of adsorbent grains on the base material, high adsorption amount, low regeneration temperature and high heat stability, and is suitable for adsorbing dehumidifying and whole heat recovery at different humidity and / or different temperature.

Owner:SOUTH CHINA UNIV OF TECH

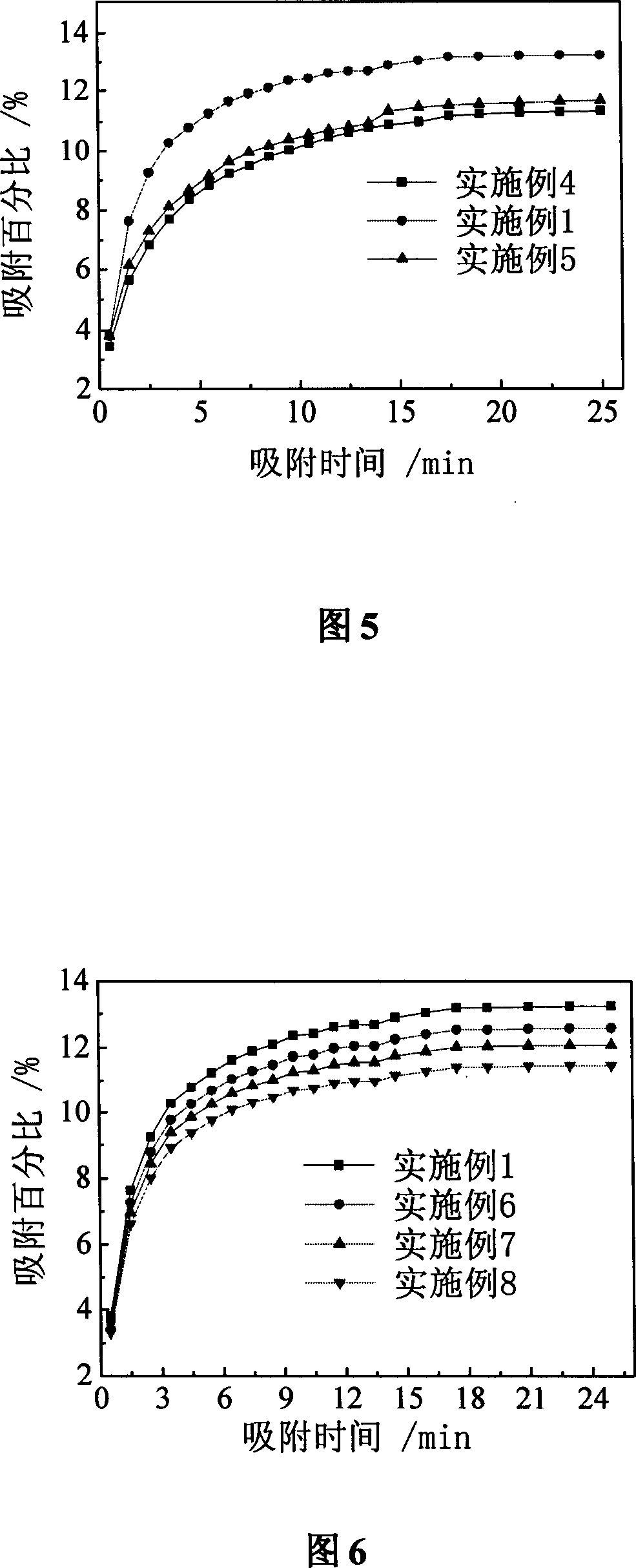

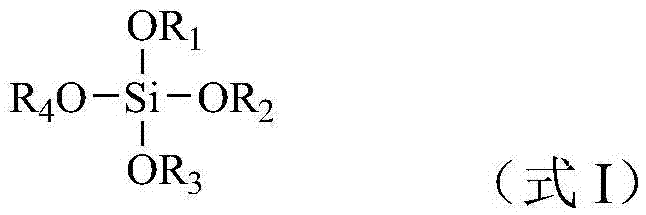

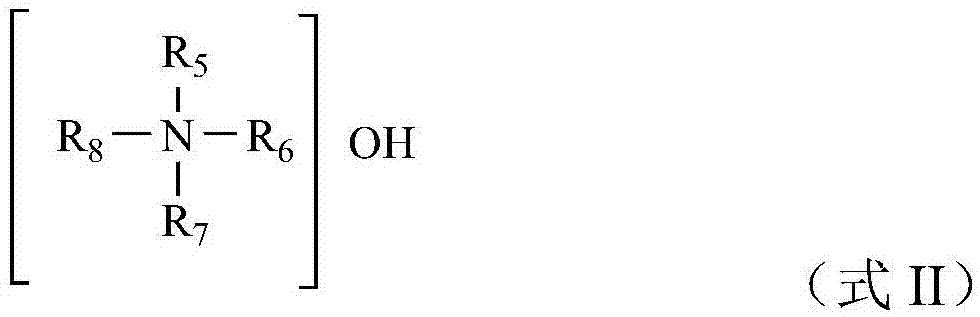

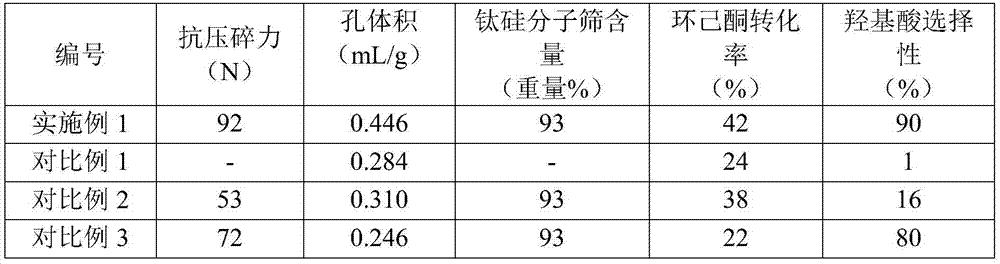

Titanium-silicon molecular sieve molding, molding catalyst, applications of molding catalyst, and cyclohexanone oxidation method

ActiveCN106964400AEfficient use ofOvercoming complexityMolecular sieve catalystsOrganic compound preparationCyclohexanoneSlurry

The present invention relates to the field of catalyst molding, and particularly provides a titanium-silicon molecular sieve molding method, which comprises: mixing a titanium-silicon molecular sieve and a water-containing mixture, carrying out hydrothermal treatment under a sealed condition, molding the slurry obtained from the hydrothermal treatment to obtain a molding body, and calcining the molding body, wherein the water-containing mixture contains a silicon element, a titanium element and a nitrogen element, and is at least partially derived from the crystallization mother liquor of the titanium silicon molecular sieve. The present invention provides a molding catalyst prepared according to the preparation method, and applications thereof. The invention further provides a cyclohexanone oxidation method. According to the present invention, with the titanium-silicon molecular sieve molding method, the industrial waste liquid is effectively utilized, and the problems of complex process, corrosion on equipment, harmful emission and the like of the traditional process are overcome; and the molding catalyst has characteristics of high titanium-silicon molecular sieve content, high pore volume, high crushing resistance, and high selectivity to the target product.

Owner:CHINA PETROLEUM & CHEM CORP +1

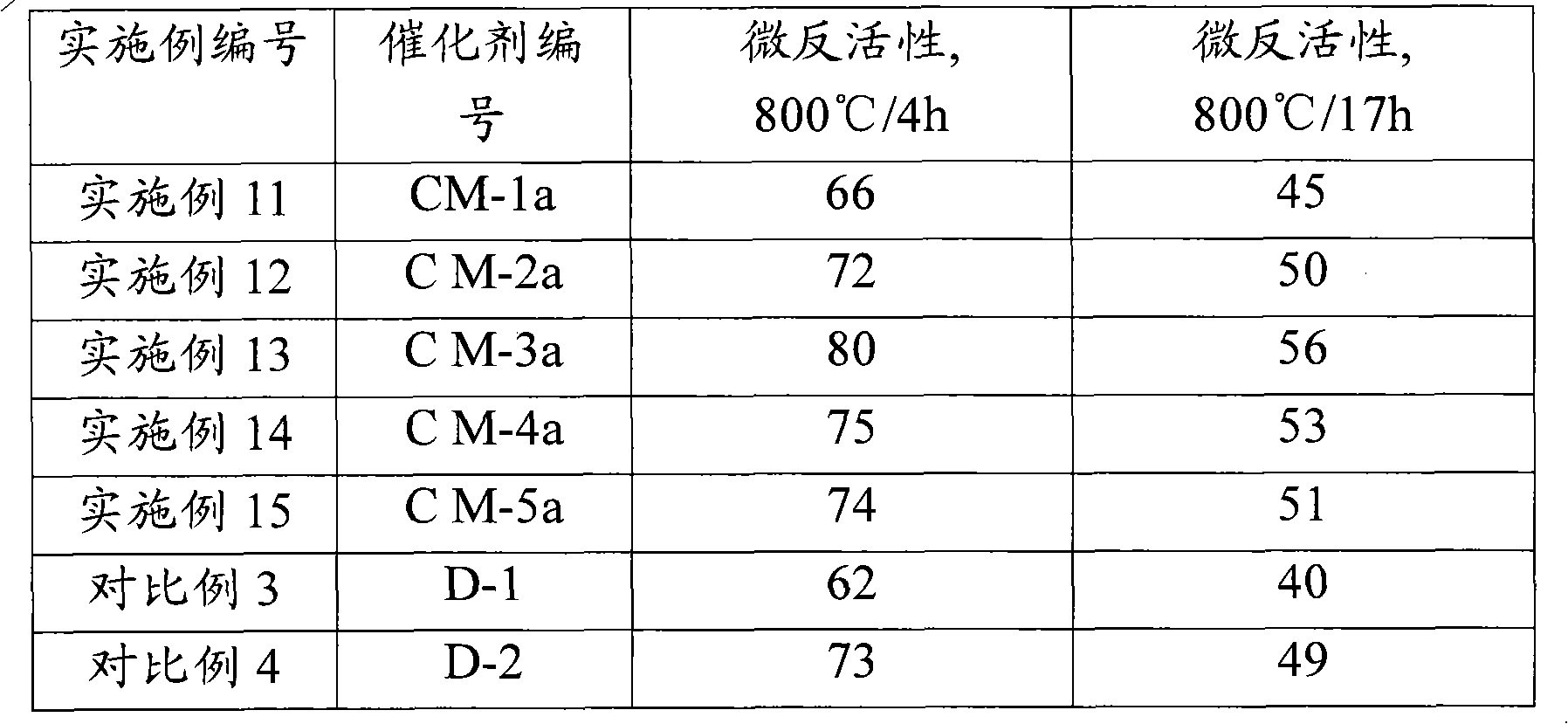

Enhanced FCC catalysts for gas oil and resid applications

ActiveUS6942783B2Sufficient macroporosityHigh pore volumeCatalytic crackingMolecular sieve catalystsMetakaolinFluid catalytic cracking

A fluid catalytic cracking catalyst is provided with a high porosity by in-situ crystallizing an aluminosilicate zeolite from a reactive microsphere comprising metakaolin and hydrous kaolin. Any calcination of the reactive microsphere before reaction with a zeolite-forming solution is done at low temperatures so as to ensure the hydrous kaolin is not converted to metakaolin.

Owner:ENGELHARD CORP

Negative electrode material for lithium ion secondary battery

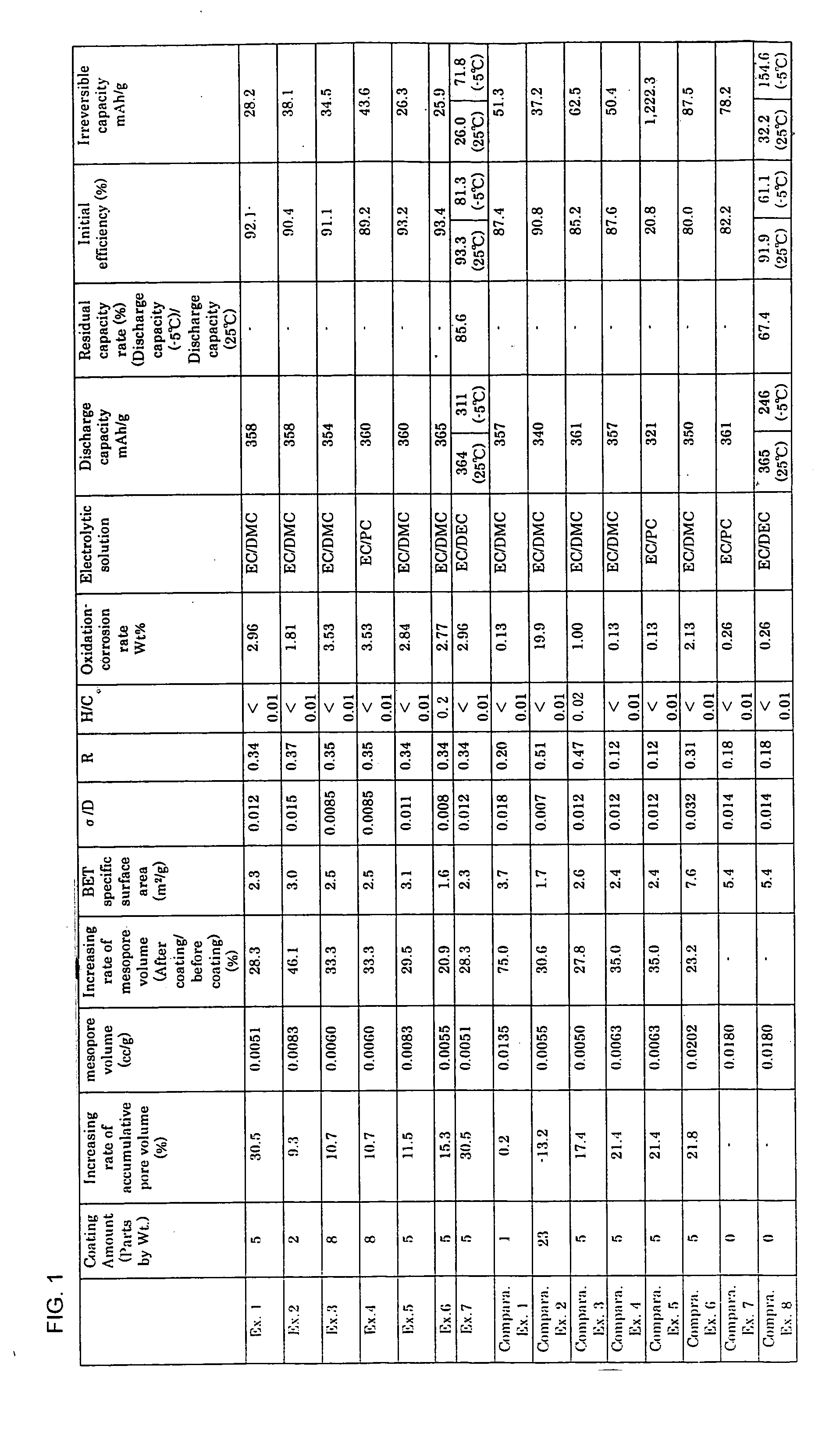

InactiveUS20050158550A1Good effectTrimming is irreversibleSynthetic resin layered productsCellulosic plastic layered productsLaser scatteringLithium

The invention provides an anode material for lithium ion secondary battery using a coated graphite powder as a raw material. The coated graphite powder is coated with carbonized material of thermoplastic resin of a carbonization yield of not more than 20 wt % in a proportion of not more than 10 parts by weight the carbonized material per 100 parts by weight graphite powder. The graphite powder as coated with thermoplastic resin increases 5% or more in accumulative pore volume of the graphite powder having a pore size of 0.012 μm to 40 μm as measured by a mercury porosimeter method, as compared with the graphite powder before coated with the thermoplastic resin. The coated graphite powder has a mesopore volume defined by IUPAC of 0.01 cc / g or less as calculated with the BJH method as viewed from desorption isotherm, which is also equal to 60% or less of the pore volume of the graphite powder before coated with the thermoplastic resin, an average particle size ranging from 10 μm to 50 μm, as measured by a laser-scattering-particle-size-distribution measuring device, and a ratio of standard deviation to the average particle size (σ / D) of 0.02 or less.

Owner:TOYO TANSO KK

Process for preparing hydrophobic silicon dioxide aerogel using rice husk ash as raw material

A process for preparing the hydrophobic SiO2 aero-gel from rice husk ash includes such steps as burning rice husk to obtain its ash, extracting its hydro-gel in inorganic strong-alkaline aqueous solution, neutralizing by inorganic strong acid, laying aside to generate SiO2 hydro-gel, filter, acid treating, ageing, water washing, displacing the water from the hydro-gel by organic solvent, supercritical drying and modifying surface. Its advantages are high specific surface area and pore volume, and low apparent density.

Owner:TSINGHUA UNIV

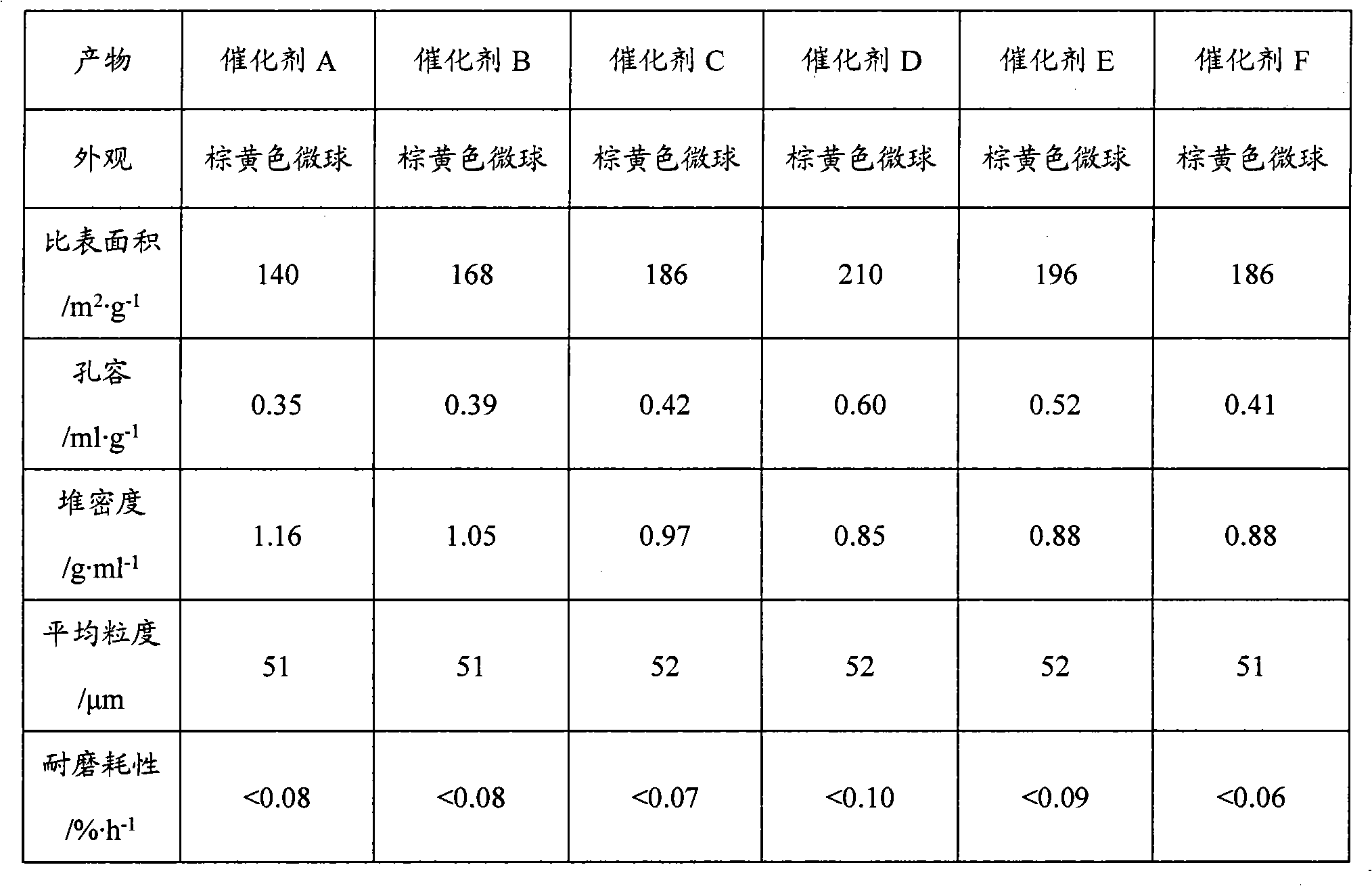

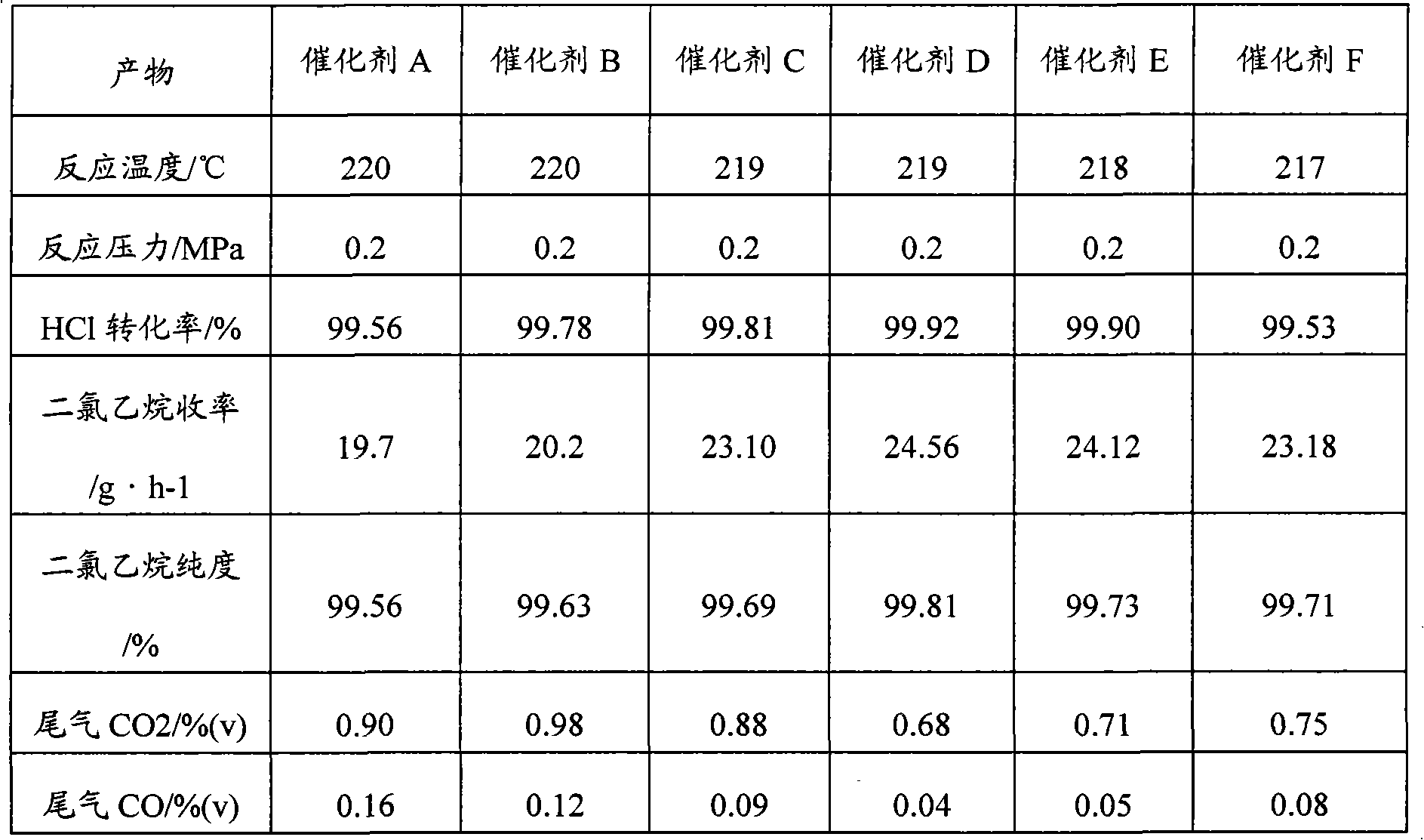

Microspherical ethylene oxychlorination catalyst preparation method

ActiveCN102049314AMaintain catalytic activityProblems Affecting Catalytic PerformanceCatalyst activation/preparationHalogenated hydrocarbon preparationTime extensionMicrosphere

The invention discloses a microspherical ethylene oxychlorination catalyst preparation method, which comprises the following six steps: solution preparation; precipitation and reaction; peptization; active component and assistant component homogenization; spray forming; and post-treatment. Solution of an active component and solution of an assistant component are dissolved in peptized pulp; a proper amount of dispersant and pore-expanding agent are added into the pulped sol solution to ensure the active component and the assistant component are uniformly distributed in the sol solution; the dispersant can prevent active and assistant component deposition caused by the prolongation of spray time; and the added proper amount of pore expanding agent can expand formed pore passage with a microspherical structure in a spraying process of the sol solution so as to improve the volume of the pore passage of a catalyst carrier and improve the pore volume and specific area of the catalyst.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Preparation method and application of porous geological polymer microspheres

ActiveCN107973559AHigh Microsphere EfficiencyParticle size adjustableOther chemical processesRadioactive contaminantsMicrosphereSorbent

The invention discloses a preparation method of porous geological polymer microspheres. The porous geological polymer microspheres are prepared by a dispersion suspension solidification method. Compared with the prior art, low-temperature curing and one-shot molding granulation are realized without requirements of high-temperature calcination and curing and addition of other auxiliaries; and at the same time, large-scale use of solid wastes is realized, and raw materials are widely available, cost is low, process is simple, and the whole process is non-toxic and pollution-free; in addition, the preparation efficiency is high with a ball-forming degree exceeding 90%; the size of the particles can be adjusted, and the pore size distribution is uniform; the pore volume is large, and can be regulated, and a specific surface area of the microspheres reaches 110m2 / g, thus, the porous geological polymer microspheres can be directly used for packed columns for column separation. Experiments show that the porous geological polymer microspheres have a good adsorption effect on heavy metals, and can be used as adsorbents for heavy metals, and have a broad application prospect in the aspect ofremoving heavy metals and radioactive elements in water.

Owner:GUANGXI UNIV

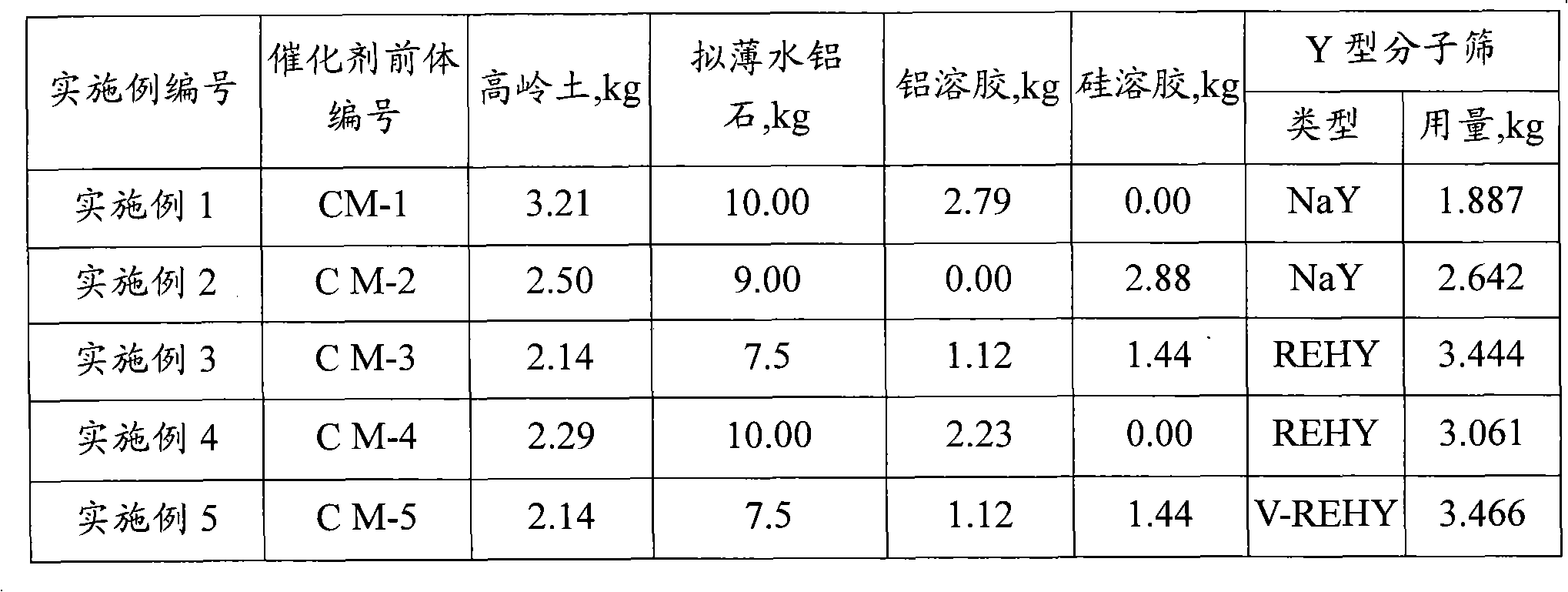

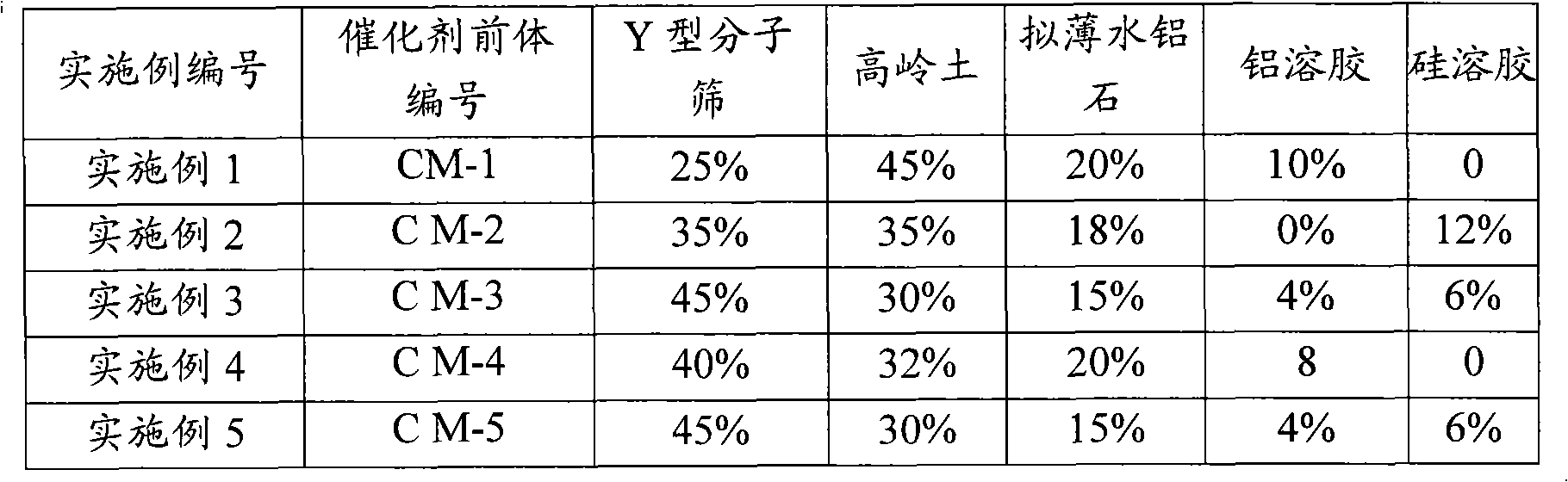

Cracking catalyst and preparation method thereof

ActiveCN102029177AHigh ratio of silicon to aluminumHigh crystallinityCatalytic crackingMolecular sieve catalystsMolecular sieveSulfur

The invention relates to a preparation method of a cracking catalyst, which comprises: raw materials and water are mixed to prepare a slurry solution by utilizing the catalyst containing a Y type molecular sieve and a silicon vector; the slurry solution is dried to obtain a catalyst precursor; the catalyst precursor is baked; and a contact reaction is carried out on the catalyst precursor and an acidic ammonium salt solution. The preparation method of the cracking catalyst can enhance the crystallization retaining degree of the Y type molecular sieve in the catalyst and the stability of the catalyst. The catalyst prepared by utilizing the method is used for the catalytic cracking of heavy oil and has the advantages of strong conversion capability of the heavy oil, high yield of gasoline, and low sulphur content in the gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

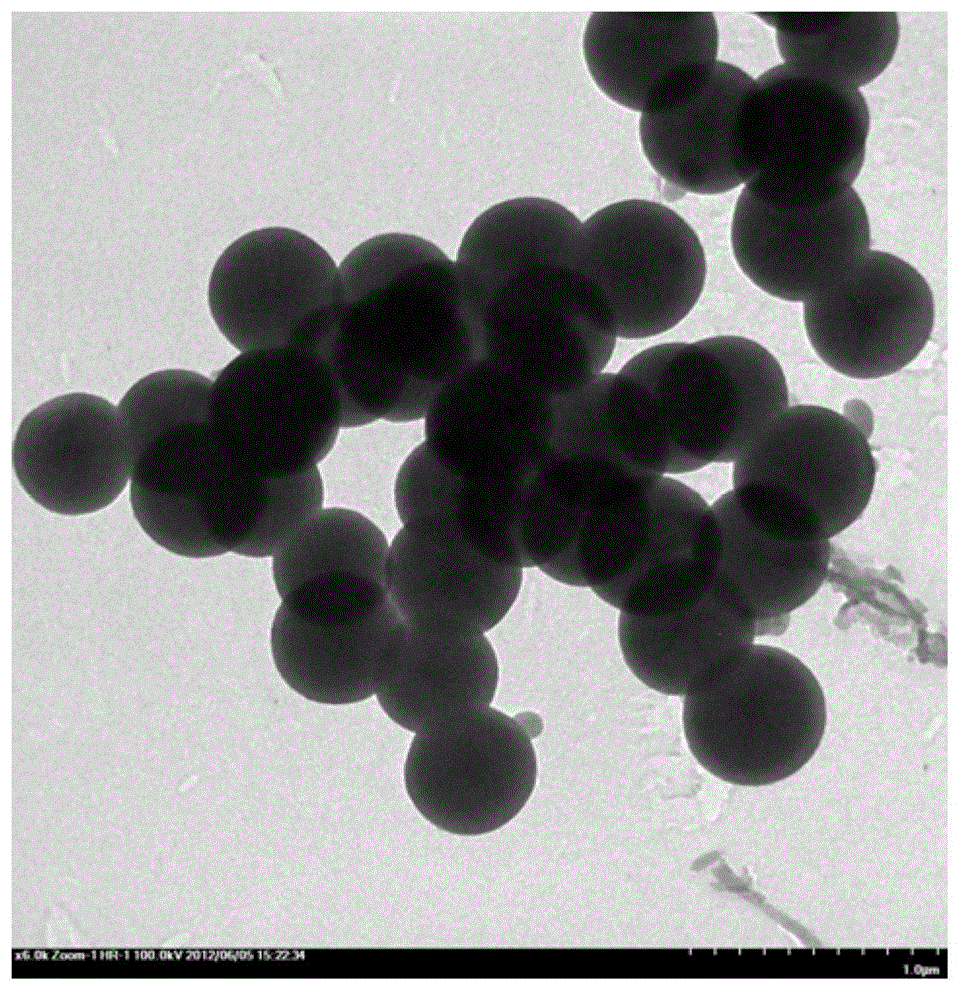

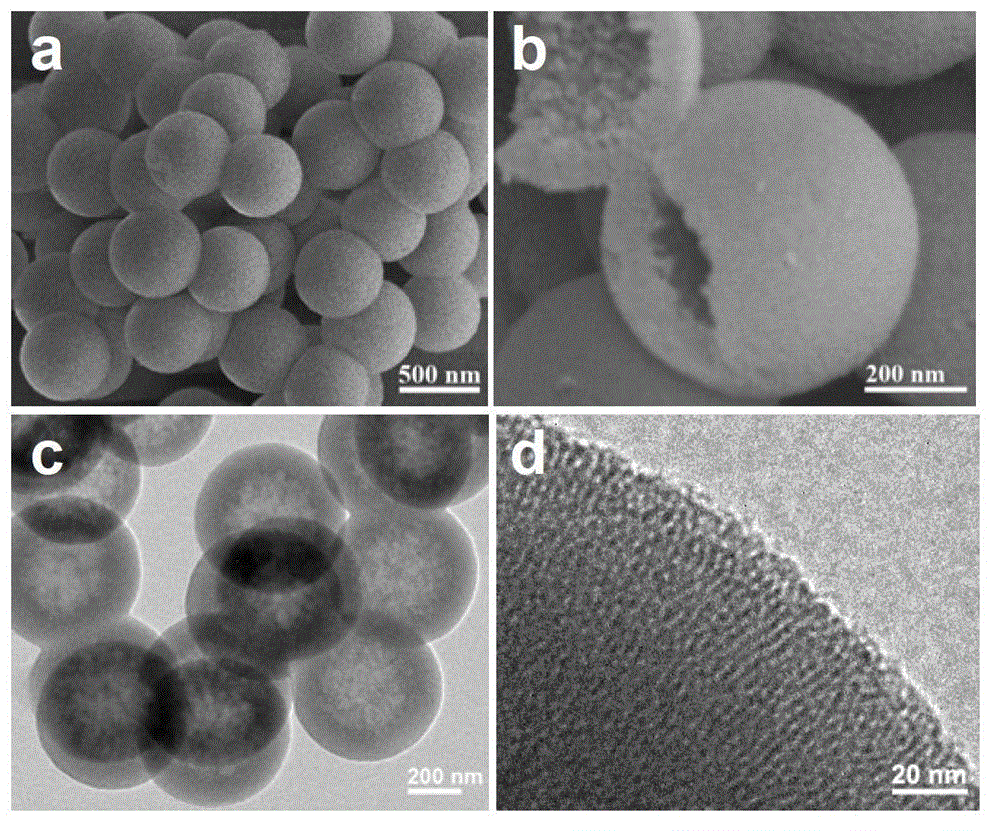

Preparation method of ordered mesoporous silica microspheres with hollow structures

InactiveCN102718225ALow equipment requirementsLow costMaterial nanotechnologySilicaMicrosphereMesoporous silica

The invention discloses a preparation method of ordered mesoporous silica microspheres with hollow structures. The preparation method comprises the following steps: firstly, dissolving a cationic surface active agent in mixed solution of ethanol and water, sequentially adding ammonia water and a silicon source in the mixed solution under the conditions of heating and mixing, and reacting for a period of time to obtain solid silica microspheres; washing the obtained silica, transferring the silica into water for etching, and reacting for a period of time to obtain hollow silica microspheres; and finally, collecting the hollow silica, and obtaining products of ordered mesoporous silica microspheres with hollow structures by drying and roasting. In the preparation method, a sacrificial hard template or an emulsion template does not need to be prepared in advance. The preparation method has the characteristics of simple technological process, mild reaction conditions, low cost, and environmental friendliness; and the prepared hollow mesoporous silica microspheres have great application potential in ultrasonic imaging, drug delivery and other biomedical fields.

Owner:NANJING GENERAL HOSPITAL NANJING MILLITARY COMMAND P L A

Preparation method of silica

ActiveCN102020284AHigh pore volumeGood dispersionSilicaBulk chemical productionSupercritical dryingCarbonization

The invention provides a preparation method of silica, relating to a preparation method of silica materials. In the preparation method, sodium silicate aqueous solution is pumped into a carbonization agitated reactor, supercritical carbon dioxide or subcritical carbon dioxide is added into the carbonization agitated reactor for reaction, so that a reaction product silicide is obtained; after washing and filtering, filtrate enters an evaporator, and carbonate is recycled; a filter cake is pulped by solvent and then forms supercritical fluid which enters a supercritical drying kettle; and after drying, the solvent and the supercritical fluid are separated under reduced pressure in a separation tank, the pressure of the supercritical drying kettle is released, and the product of silica is obtained.

Owner:XIAMEN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com