Preparation method of silica

A silicon dioxide and carbon dioxide technology, applied in the production of silicon dioxide, silicon oxide, bulk chemicals, etc., can solve the problems of complicated process, time-consuming, high temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

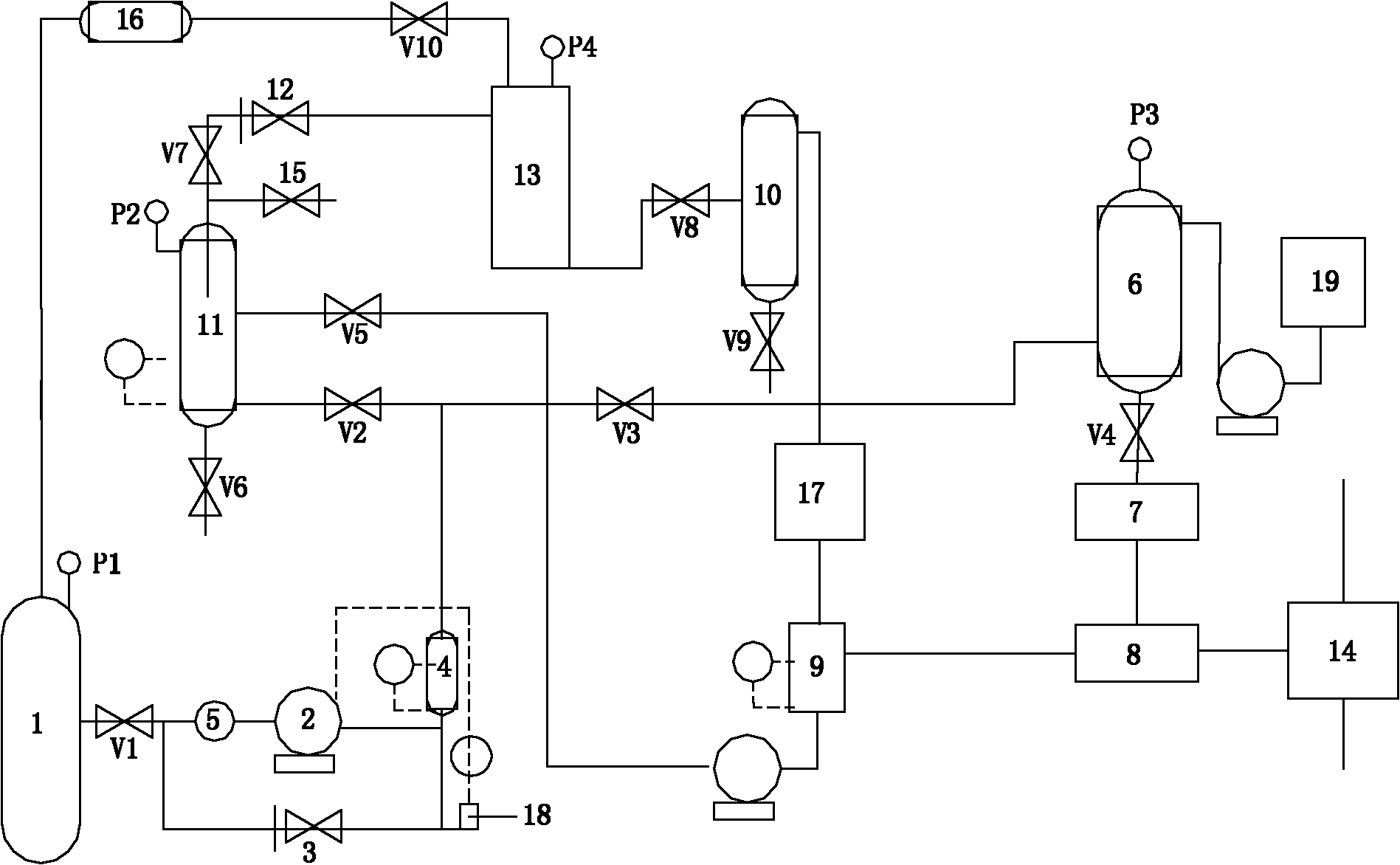

Method used

Image

Examples

Embodiment 1

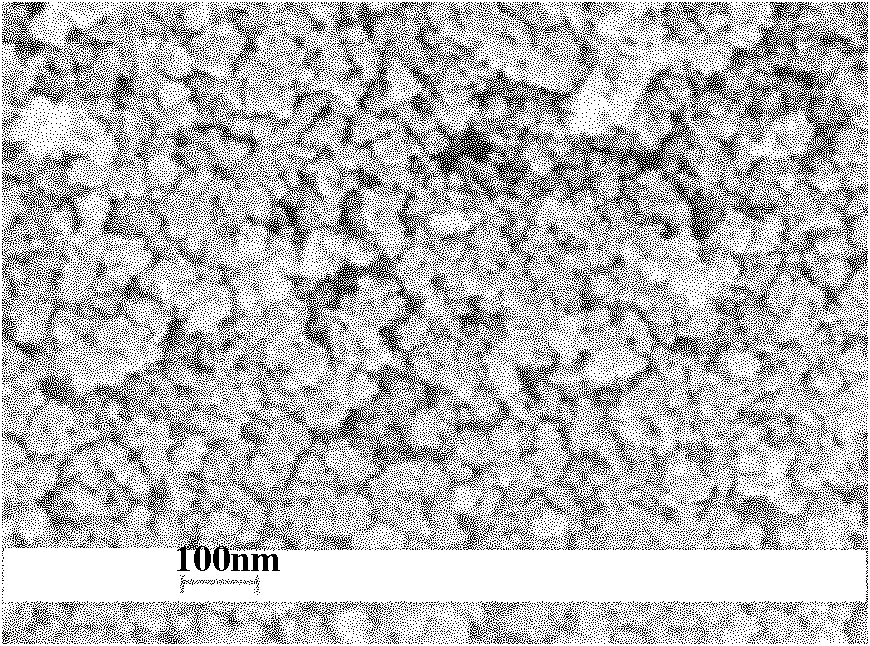

[0030] Example 1: Supercritical carbonization reaction coupled with supercritical drying to prepare high pore volume silica products

[0031] Sodium silicate nonahydrate (Sinopharm Chemical Reagent Co., Ltd., analytical pure), carbon dioxide (Xiamen Tongan Air Separation Special Gas Plant, purity 98%).

[0032] First, load a sodium silicate aqueous solution with a concentration of 1 mol / L in the carbonization reactor, set the stirring speed to 800 rpm, and adjust the water bath temperature control system to the experimental temperature. Then start the supercritical fluid supply system, the supercritical fluid enters the preheater, reaches a certain temperature and pressure (reaction temperature 35℃, reaction pressure 9MPa), through the third valve let high-pressure carbon dioxide into the carbonization reactor for reaction, reaction time 30min . At the end of the reaction, close the third valve, press out the material, wash the material with deionized water 3 times until the by-pr...

Embodiment 2

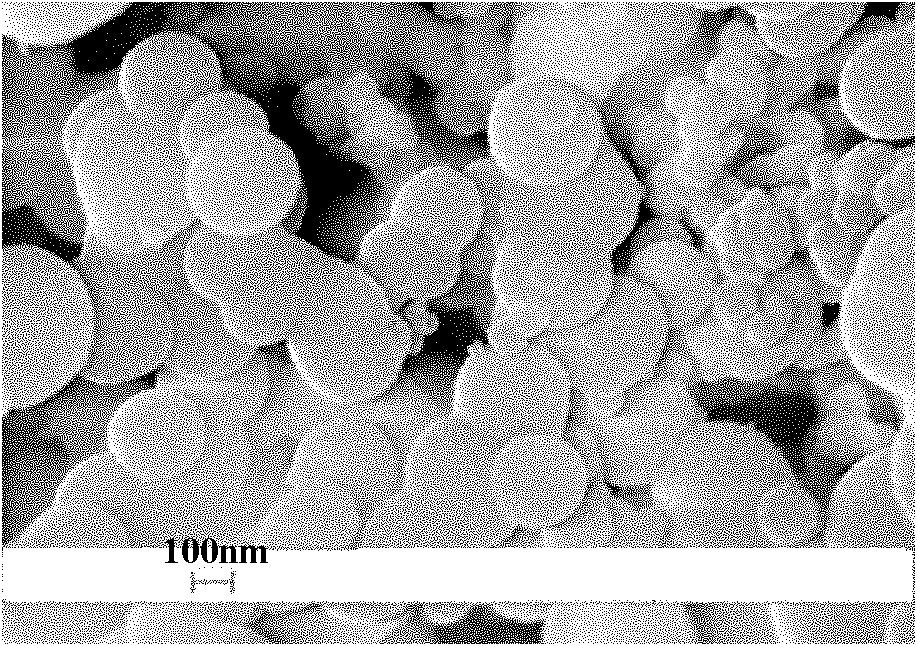

[0037] Example 2: Supercritical carbonization reaction coupled with supercritical drying to prepare highly dispersed silica products

[0038] Sodium silicate nonahydrate (Sinopharm Chemical Reagent Co., Ltd., analytical grade), carbon dioxide (Xiamen Tongan Air Separation Special Gas Plant, purity 98%), ethanol (Sinopharm Group Chemical Reagent Co., Ltd., analytical grade)

[0039] First, load a sodium silicate aqueous solution with a concentration of 1mol / L in the carbonization reactor, add ethanol as an additive (the volume ratio of sodium silicate aqueous solution to ethanol is 4:1), set the stirring speed (800rpm), and adjust the water bath temperature control system to the experiment temperature. Then start the supercritical fluid supply system, the supercritical fluid enters the preheater, reaches a certain temperature and pressure (reaction temperature 35℃, reaction pressure 9MPa), through the third valve let high-pressure carbon dioxide into the carbonization reactor for re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Oil absorption value | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com