Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14316 results about "Sodium silicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium silicate is a generic name for chemical compounds with the formula Na₂ₓSiO₂₊ₓ or (Na₂O)ₓ·SiO₂, such as sodium metasilicate Na₂SiO₃, sodium orthosilicate Na₄SiO₄, and sodium pyrosilicate Na₆Si₂O₇. The anions are often polymeric. These compounds are generally colorless transparent solids or white powders, and soluble in water in various amounts.

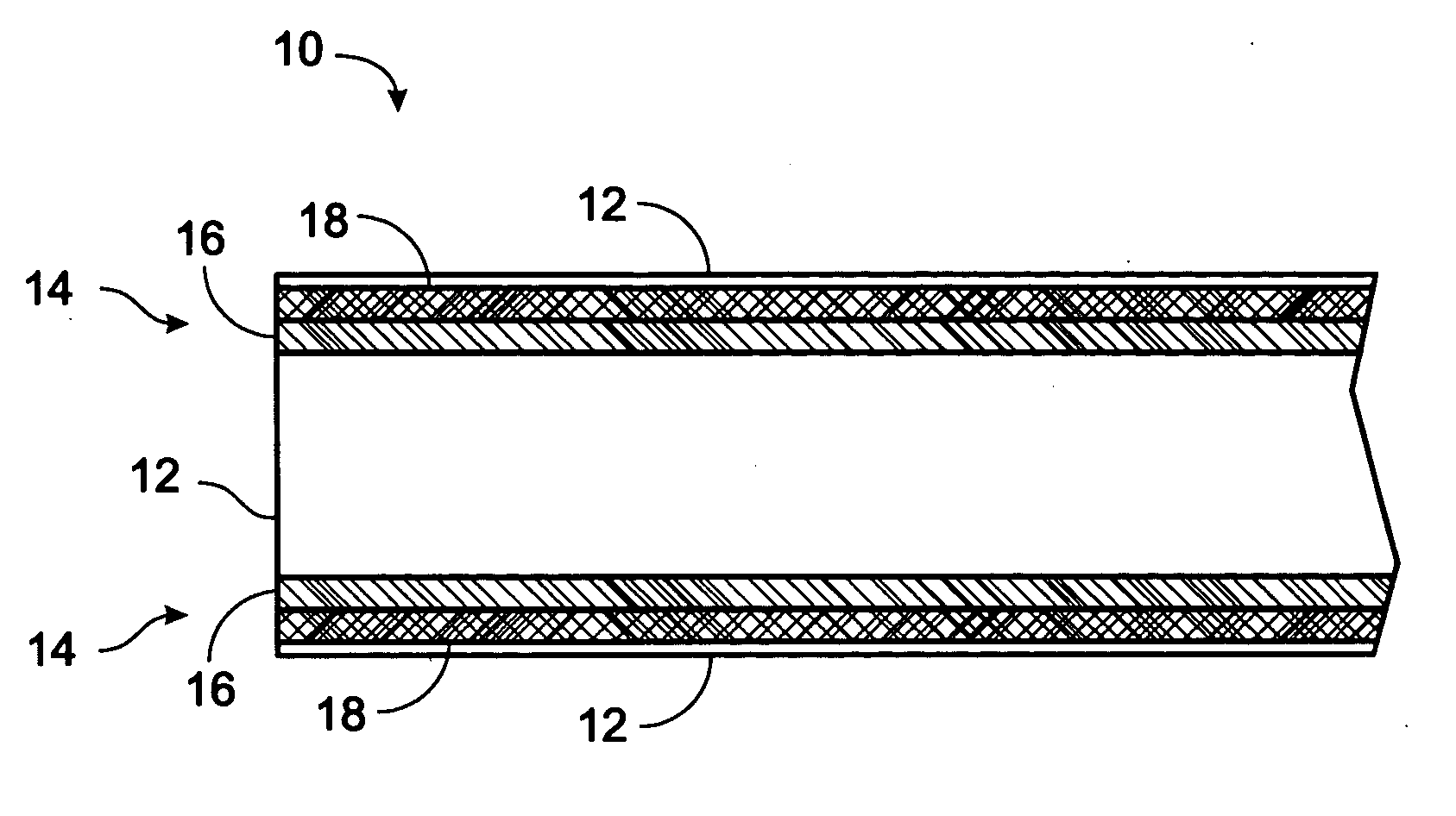

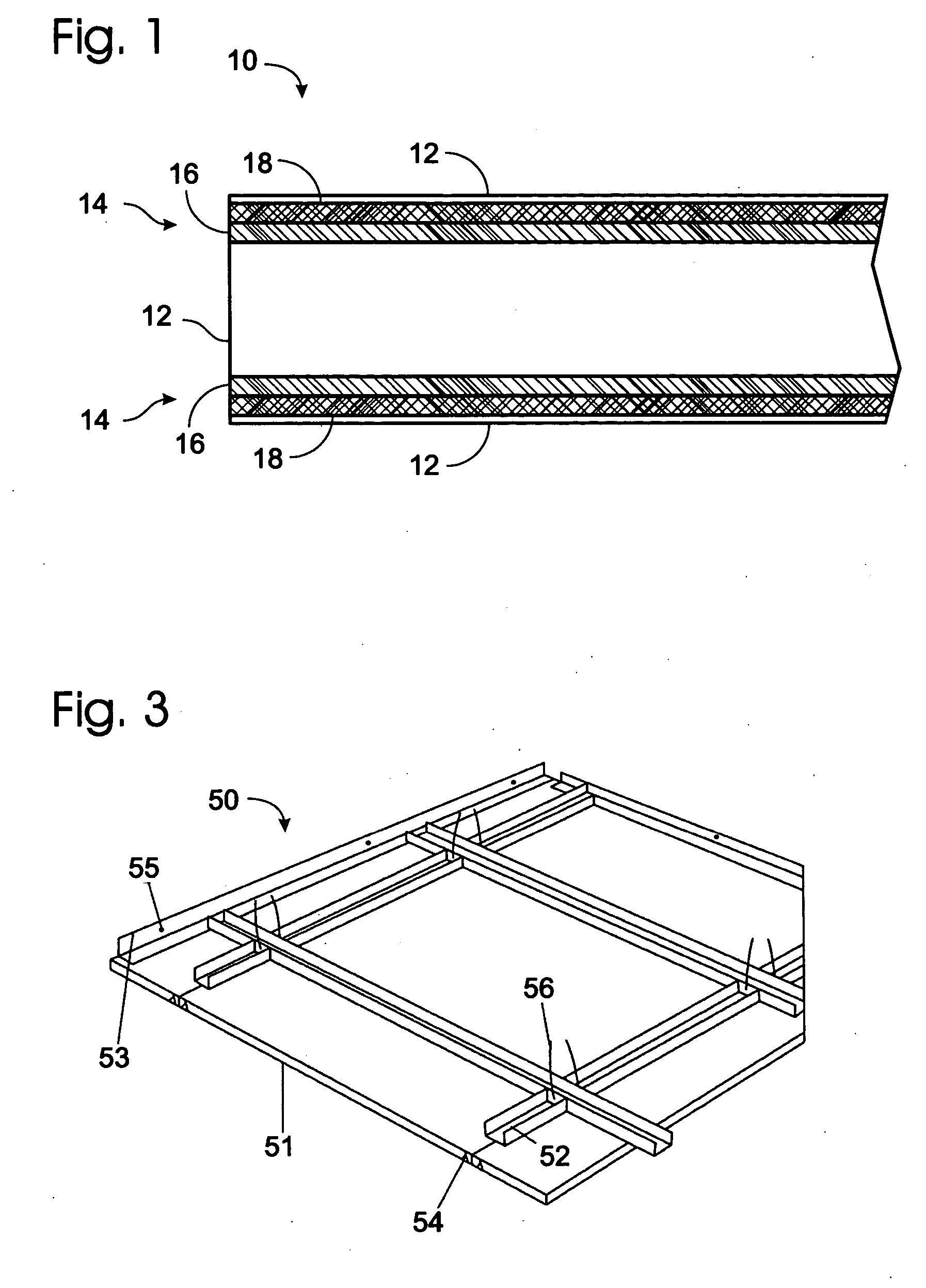

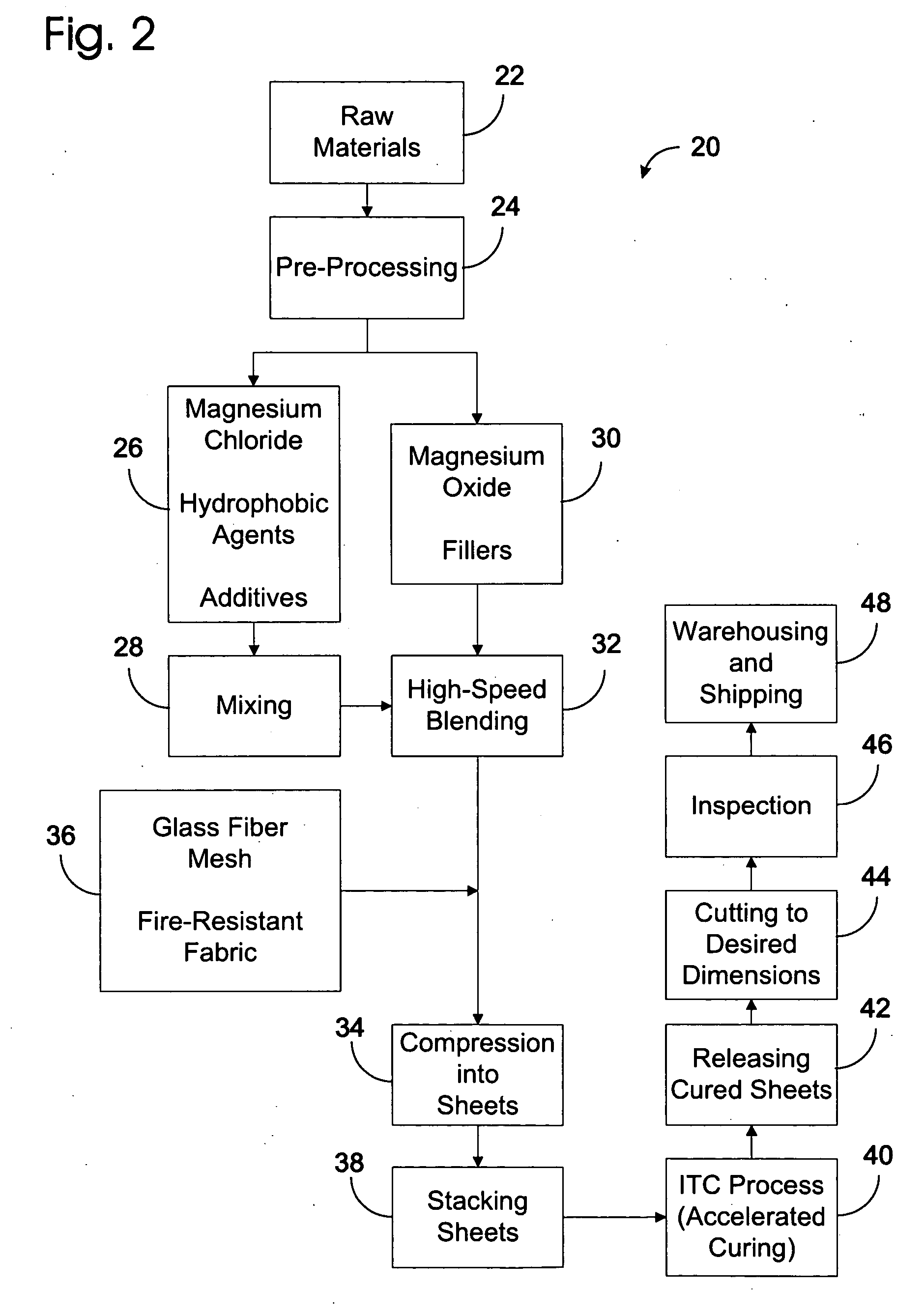

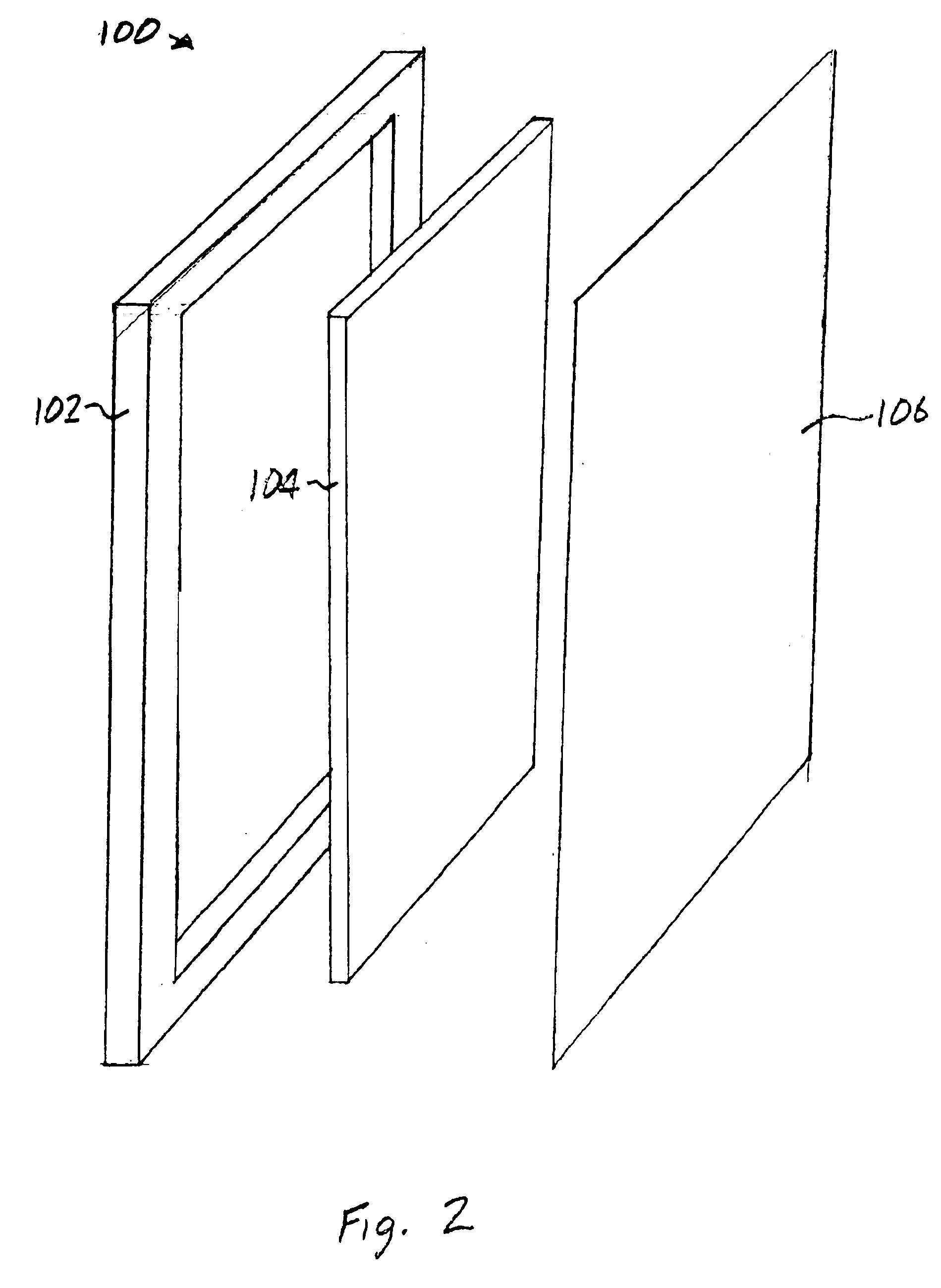

Fire-resistant panel and method of manufacture

A highly fire-resistant and environmentally-friendly panel of 2 mm to 28 mm may be manufactured by a blending of magnesium compounds, sodium silicate, kaolin, fillers, and additives to form the core materials, reinforced by 4 layers of fire-resistant glass fiber meshes and fabrics. Using a proprietary ITC process that accelerates the chemical reactions of the ingredients to generate sufficient heat without external supply of energy, the panels may be completely cured within 24 hours instead of 10 days. The use of waste materials, energy-saving curing system and no gas emission manufacturing process combined to make this panel an eco-friendly product which offers the world's highest-rated fire resistance of 5 hours, high flexural strength, low density, durability and effective water-resistance.

Owner:REP TECH

Inorganic binders employing waste glass

InactiveUS6296699B1Improve processingHighly moldableCovering/liningsAlkali metal silicate coatingsSodium silicateArtificial stone

The present invention relates to a binder composition comprising a glass powder with a particle size of at least less than 0.15 mm and an alkali activator containing at least one alkali metal and at least one silicate. Preferably, a sodium silicate with a SiO2:Na2O weight ratio between about 1.6:1 to about 2.0:1. Mixed with water, the binder composition can be cured at ambient temperature, but rapidly yields a very high strength at an elevated temperature between about 40° C. to about 120° C. Preferably, between about 70° C. to about 90° C. The invention further provides a method of making artificial stone using glass as a sole binder and aggregate.

Owner:JIN WEIHUA

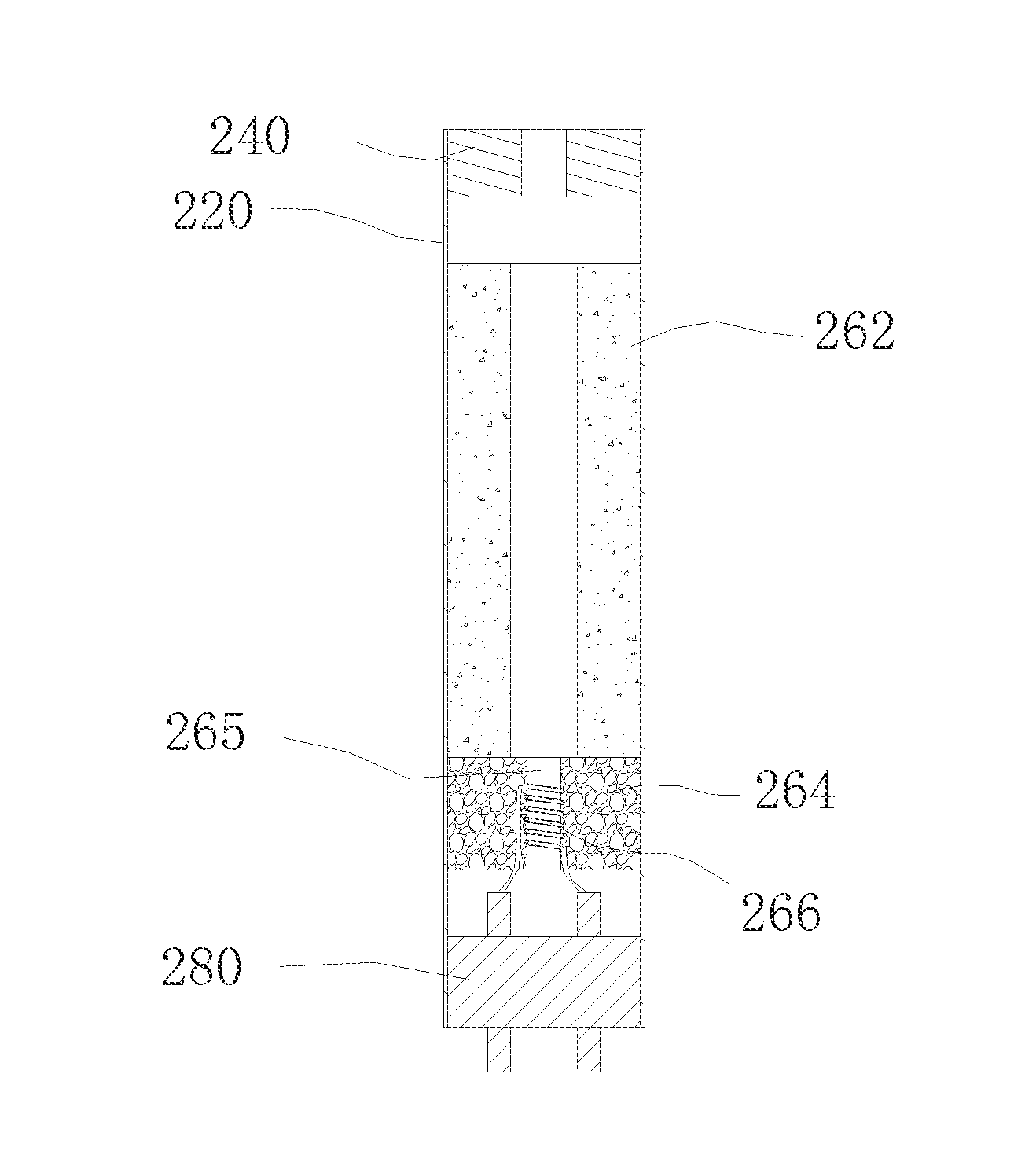

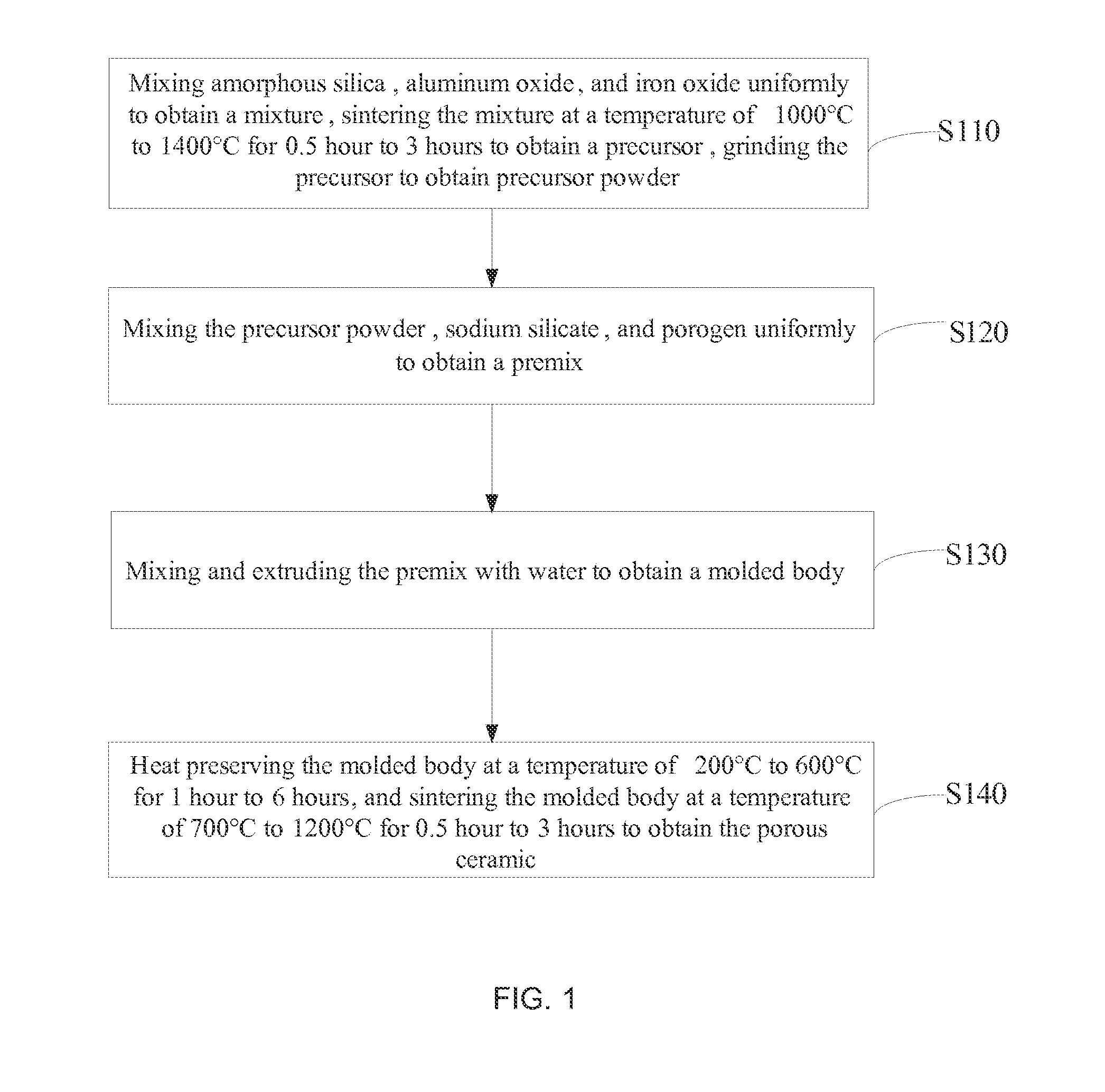

Preparation method of porous ceramic, porous ceramic, and electronic cigarette

ActiveUS20150359262A1Stable structureHigh strengthMedical devicesTobacco pipesElectronic cigaretteSodium silicate

Owner:SHENZHEN SMOORE TECH LTD +1

Acidified attapulgite clay

Owner:XUYI BOTU ATTAPULGITE CLAY HIGH TECH DEV

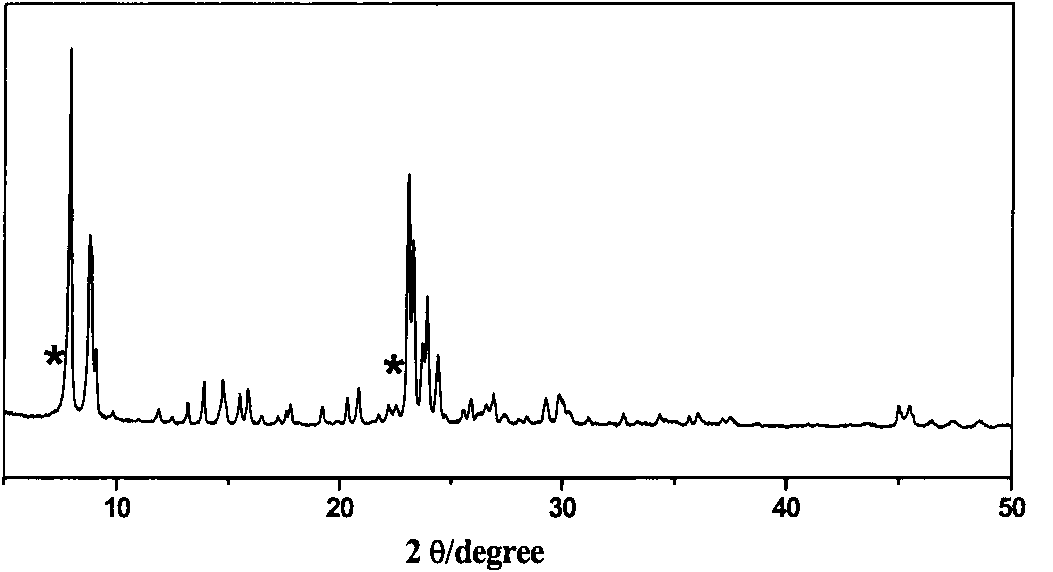

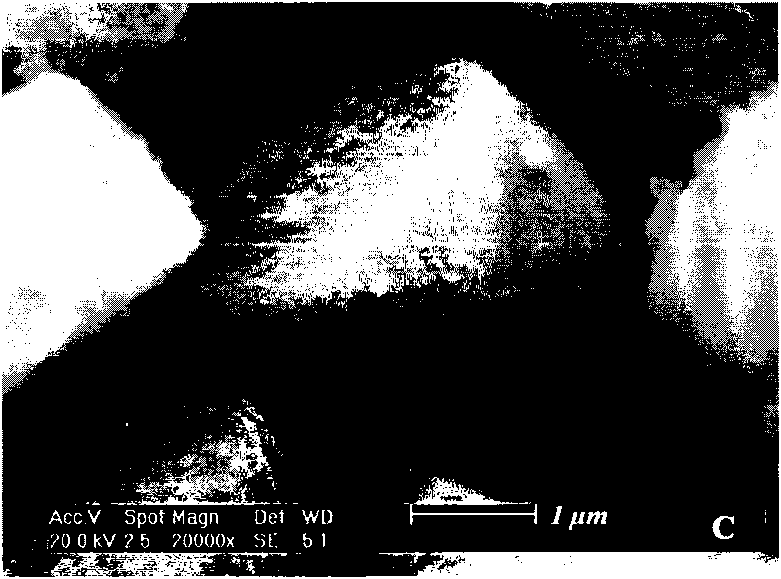

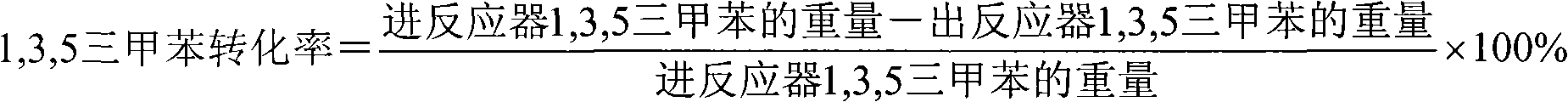

Synthesis method of fine grain ZSM-5 zeolite molecular sieve with high silicon aluminium ratio

InactiveCN1699173AUniform particle sizeHigh ratio of silicon to aluminumPentasil aluminosilicate zeoliteSynthesis methodsSurface-active agents

The invention relates to a synthesis method of fine grain ZSM-5 zeolite molecular sieve with high silicon aluminium ratio, which comprises using a surface active agent, charging it into acidified aluminium salt solution, then slowly dropping alkaline solution formed from sodium silicate, template agent and seed crystal into aluminium saline solution, the overall composition of the obtained reaction mixture being Na2O:Al2O3:SiO2:H2O=1.5-4.0:1:20-280:500-2000 by mol ratio, then subjecting the reaction mixture to thermal crystallization through the conventional method.

Owner:DALIAN LIGONG QIWANGDA CHEM TECH

Small crystal grain molecular sieve preparation method

The invention discloses a method for preparing the NaY molecular screen of high alumina silica ratio and fine grain, firstly synthesizing NaY molecular screen guilding agent according to current technology, then producing gel with sodium silicate, guilding agent, acid aluminium salt and sodium metaaluminate, blooming the gei under the temperature of 50-100 Deg C for 0-70 hours, adding some silicon, then blooming continuously under temperature of 90-120 Deg C for 0.5-50 hours, finally filtering, washing and drying. The NaY molecular screen with the alumina silica ratio being 5.2-7.0, and fine grain being 100-400 nm can be prepared by using the method in this invention.

Owner:CHINA PETROLEUM & CHEM CORP +1

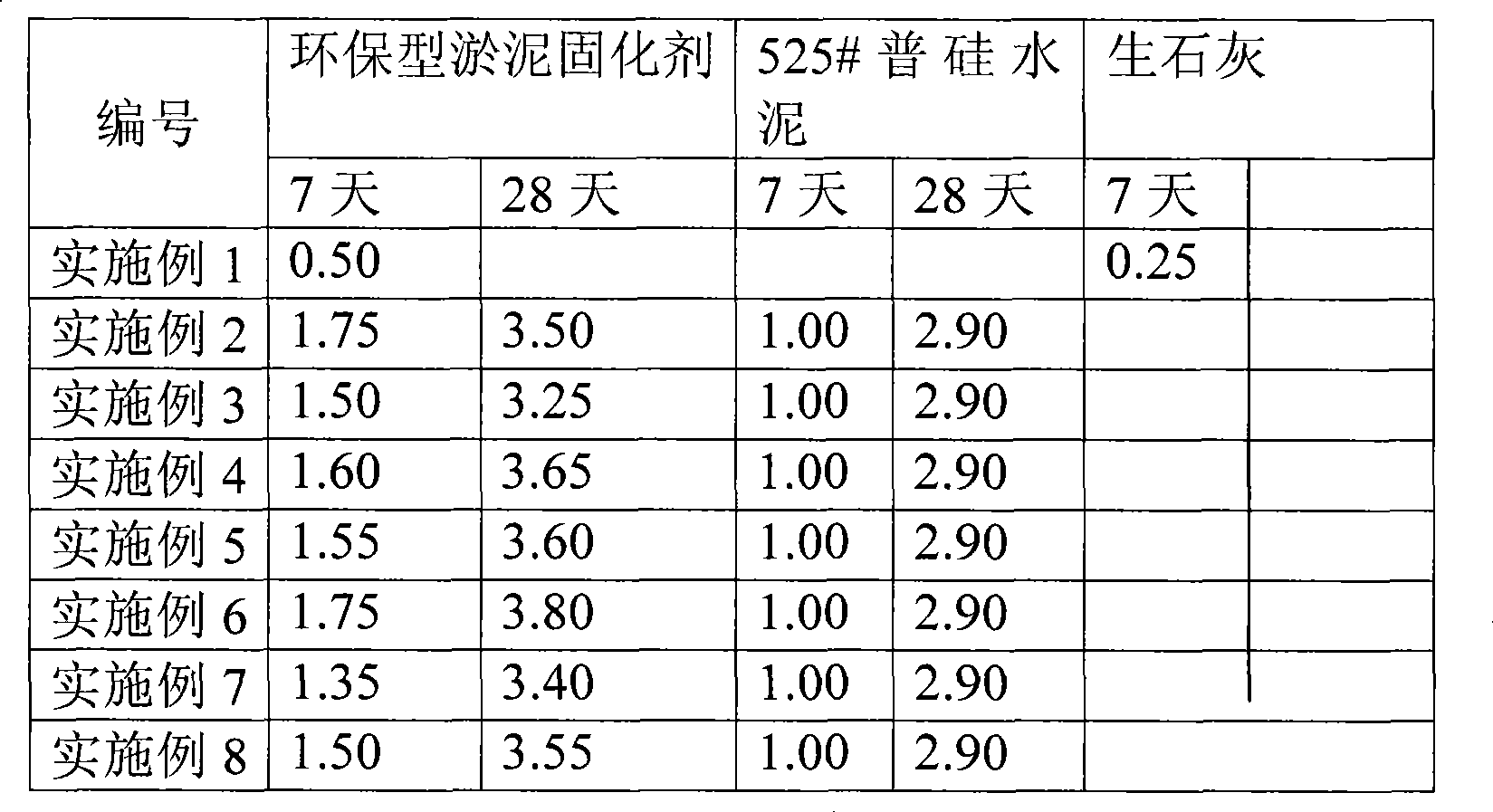

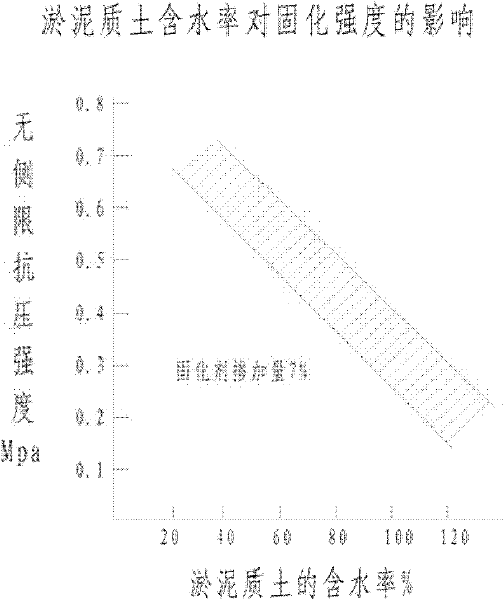

Environment-friendly type sludge firming agent

InactiveCN101381194AImprove curing abilityImprove curing effectSludge treatment by de-watering/drying/thickeningRoad engineeringSlag

The invention provides an environment-friendly silt curing agent, which is manufactured through the following steps: one or two among fly ash, calcium sulfate, sodium sulfate, sodium carbonate and potassium carbonate, one or two among slag, slag combination, potassium hydroxide, calcium oxide, sodium silicate or silicon dioxide, one or two among carbide slag, lime or gypsum, as well as one or two among triethanol amine surfactant, calcium lignosulfonate or sodium lignosulfonate form a plurality of optimal compound formulations according to respective attributes, are optimized, compounded, ground till the Brinell specific surface areas are between 300 and 900 m2 / kg respectively and then mixed, wherein particle sizes are between 0.00040 and 0.5 mm. As a large amount of waste is utilized, the curing agent saves raw materials, solves the problems about waste discharge and environmental pollution, controls waste through waste, and has important significance to environmental protection. The invention aims to provide the environment-friendly silt curing agent which has strong adaptability to a plurality of types of silt and soil, is good in curing effect, good in durability after curing and capable of utilizing industrial waste, and can be widely applied to fill engineering, embanking or embankment reinforcement engineering, road engineering and other fields.

Owner:天津渤海环保工程有限公司 +1

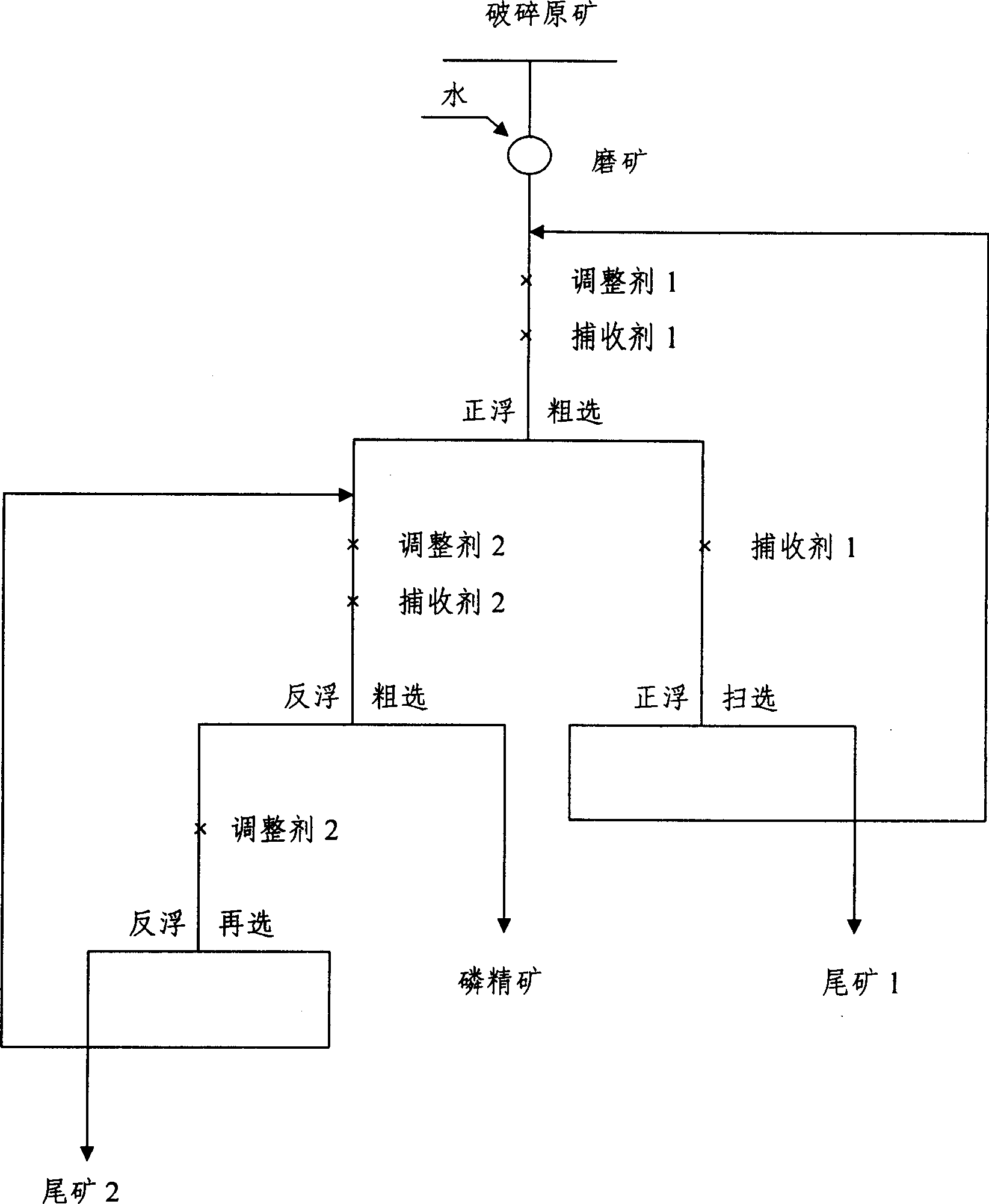

Collophanite direct flotation and reverse flotation technique

The invention relates to a positive-negative floatation technology for cellophane, which comprises the following steps: subjecting siliceous-calcareous collophane ore to breaking and grinding process to dissociate ore monomer; adding water to it get ore pulp with concentration of 20 -50%; Leading the mixture to agitated tank; adding modifying agent sodium silicate and positive collector agent to ore pulp; processing the mixture in positive floating system to get foamed product; adding negative floatation agent inorganic acid and collector agent to the foamed product in negative flotation agitated tank; processing the mixture in negative floating system with carbonate vein mineral negative flotation to get foamed product as negative flotation debris and product in tank as clean ore. The invention can simplify process, deduce cost and recycle the water.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

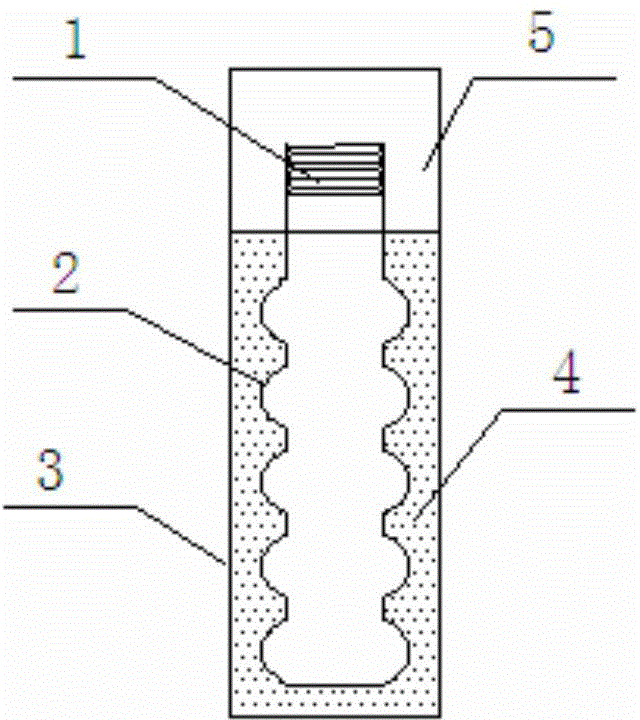

Phase transition temperature adjusting system and phase transition temperature adjusting cup

ActiveCN104887011AHeat absorption and release performance are highly matchedGuaranteed to drink normallyDrinking vesselsCarbon nanotubeSodium Thiosulfate Pentahydrate

Owner:YUTIAN ENERGY CO LTD

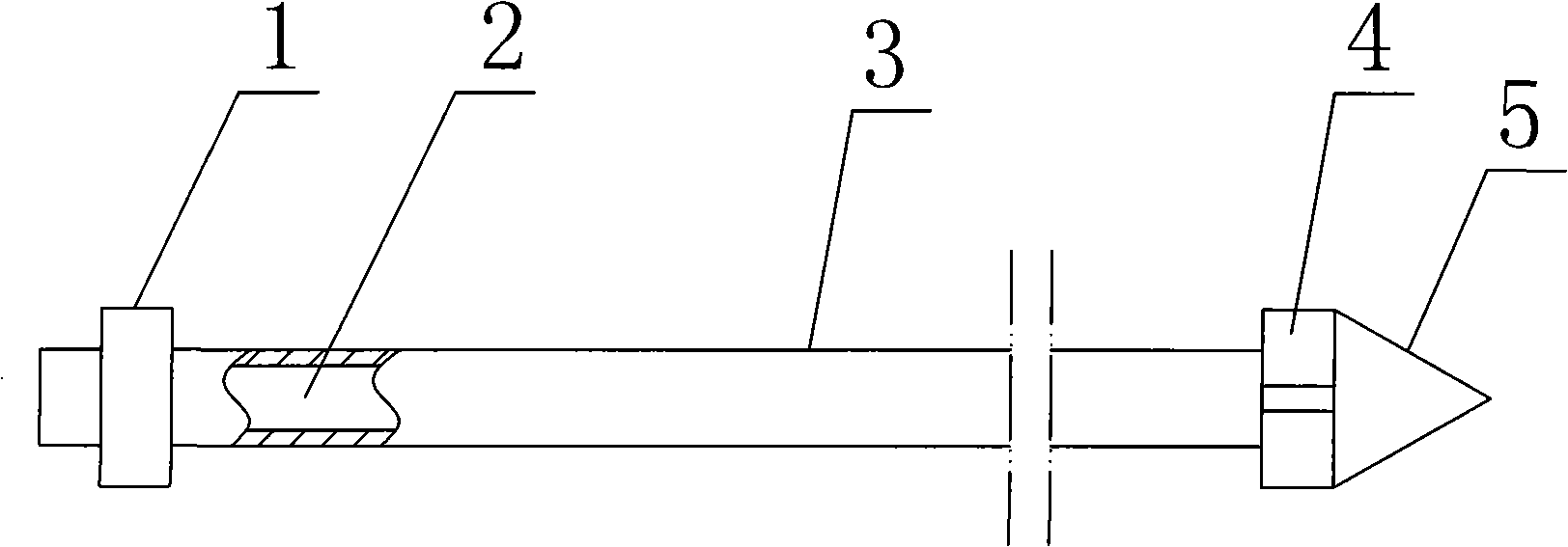

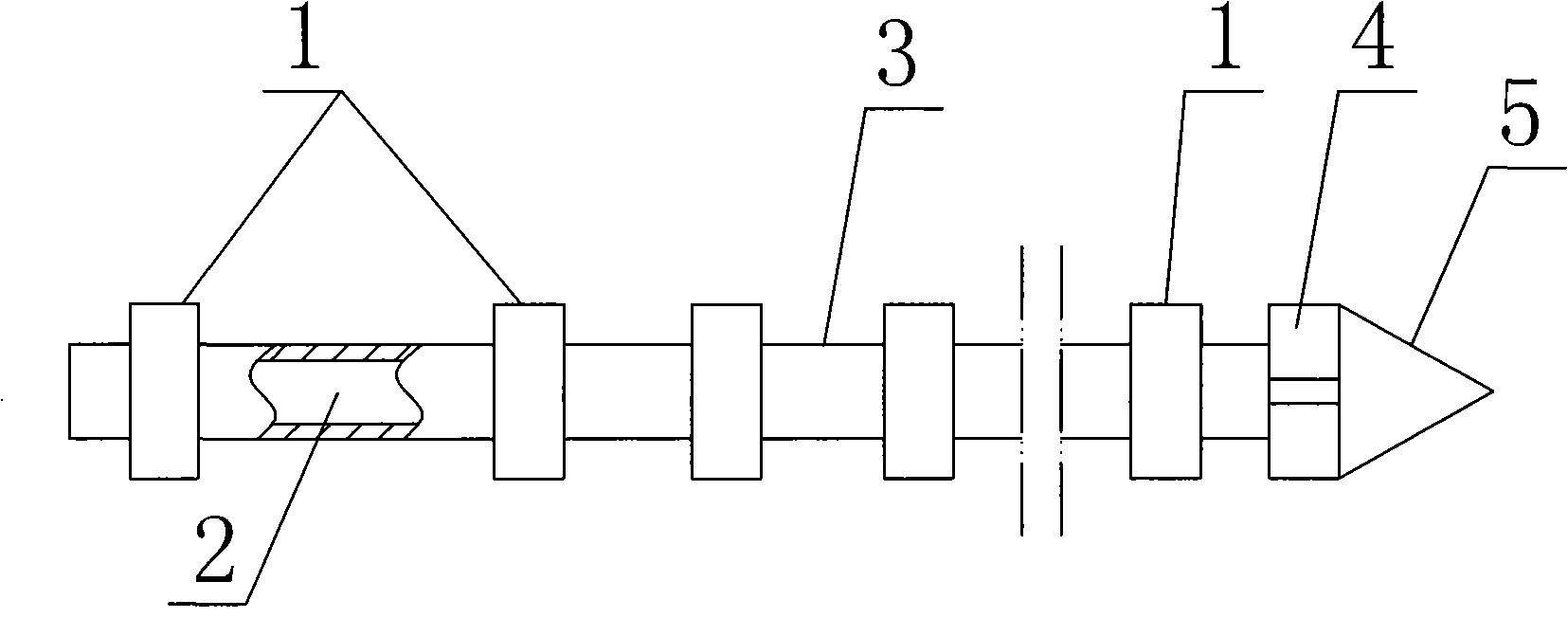

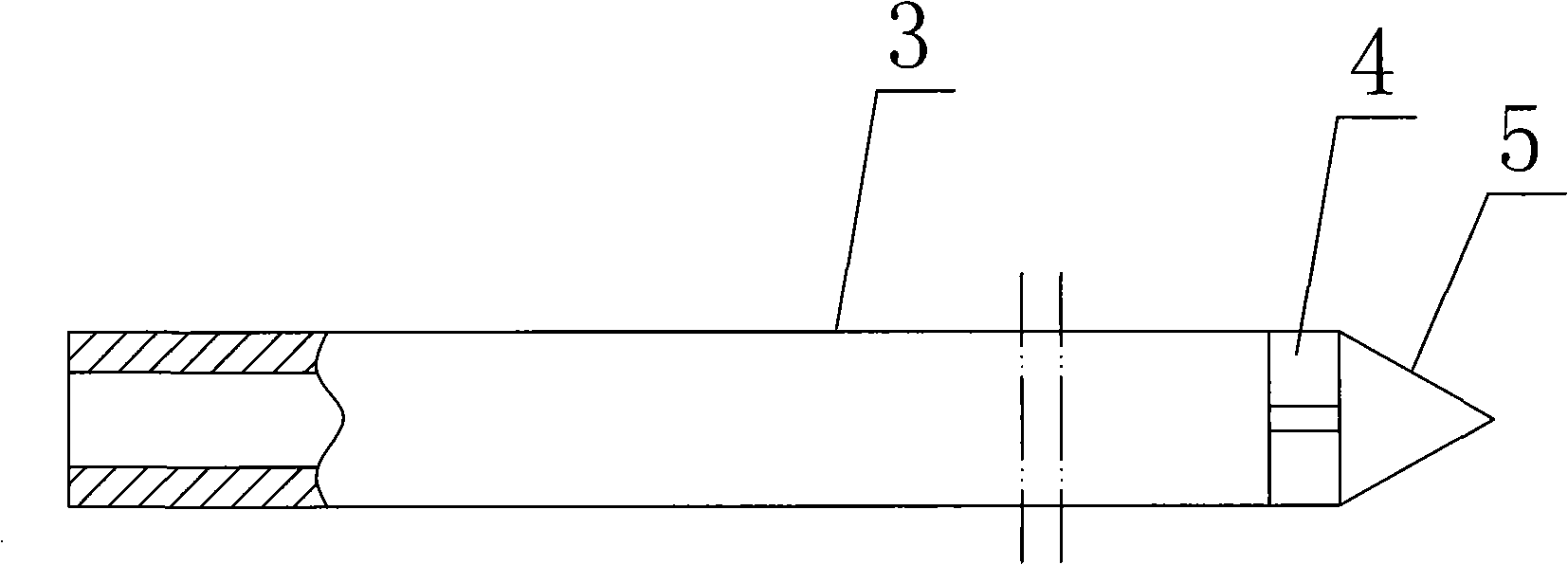

Drifting sand layer and gravel stratum water-moving double-liquid high pressure slip-casting water-blocking construction method

InactiveCN101255698AHigh strengthImprove water stabilitySolid waste managementUnderground chambersWater blockCement slurry

The present invention discloses a running sand layer and sandy gravel layer dynamic-water double-liquid high-pressure slurry-injecting water-shutoff construction method which comprises the following construction steps: drilling a hole, flushing the hole, executing double-liquid high-pressure slurry-injecting operation and sealing the hole. The running sand layer and sandy gravel layer slurry-injecting liquid adopts an ordinary portland cement (P.O.42.5) and 40''Be sodium silicate as material for preparing the slurry, according to the weight proportion of water: cement, namely the cement slurry is prepared with the water cement ratio for 0.5-1.2:1. Then the slurry-injecting liquid is prepared with the volume ratio of cement slurry: sodium silicate for 1:0.08-0.15. The sodium silicate is taken as additive for regulating the initial setting time of the slurry-injecting liquid. The cement slurry can also be doped with fly-ash with cement consumption (weight proportion) for 10%-15%. The invention executes water-insulating construction aiming at the characteristics of large pressure of the underground dynamic water and high flowing velocity in the running sand layer and sandy gravel layer, and can obtain the maximal application sphere and optimum water-shutoff effect.

Owner:HUNAN CONSTR ENG GRP COR

SiO2 aerogel/inorganic cotton compound thermal insulation felt and preparation method thereof

The invention relates to a SiO2 aerogel / inorganic cotton compound thermal insulation felt and a preparation method of the SiO2 aerogel / inorganic cotton compound thermal insulation felt. The method comprises the following steps of: compounding silica sol and inorganic cotton; ageing the silica sol and the inorganic cotton; carrying out modification and solvent replacement processing; and drying at normal pressure to obtain the SiO2 aerogel / inorganic cotton compound thermal insulation felt. The preparation method of the SiO2 aerogel / inorganic cotton compound thermal insulation felt, which is disclosed by the invention, is characterized in that cheap and easily-obtained industrial raw materials, such as industrial sodium silicate, industrial silica sol, glass wool, rock wool and mineral wool are adopted, the production cost can be lowered, and the ordinary pressure drying technology is convenient and easy to realize, is simple to operate and is suitable for large-scale industrial production. Meanwhile, the product is nontoxic and harmless and does not pollute the environment.

Owner:DALIAN POLYTECHNIC UNIVERSITY

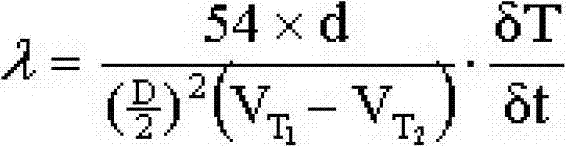

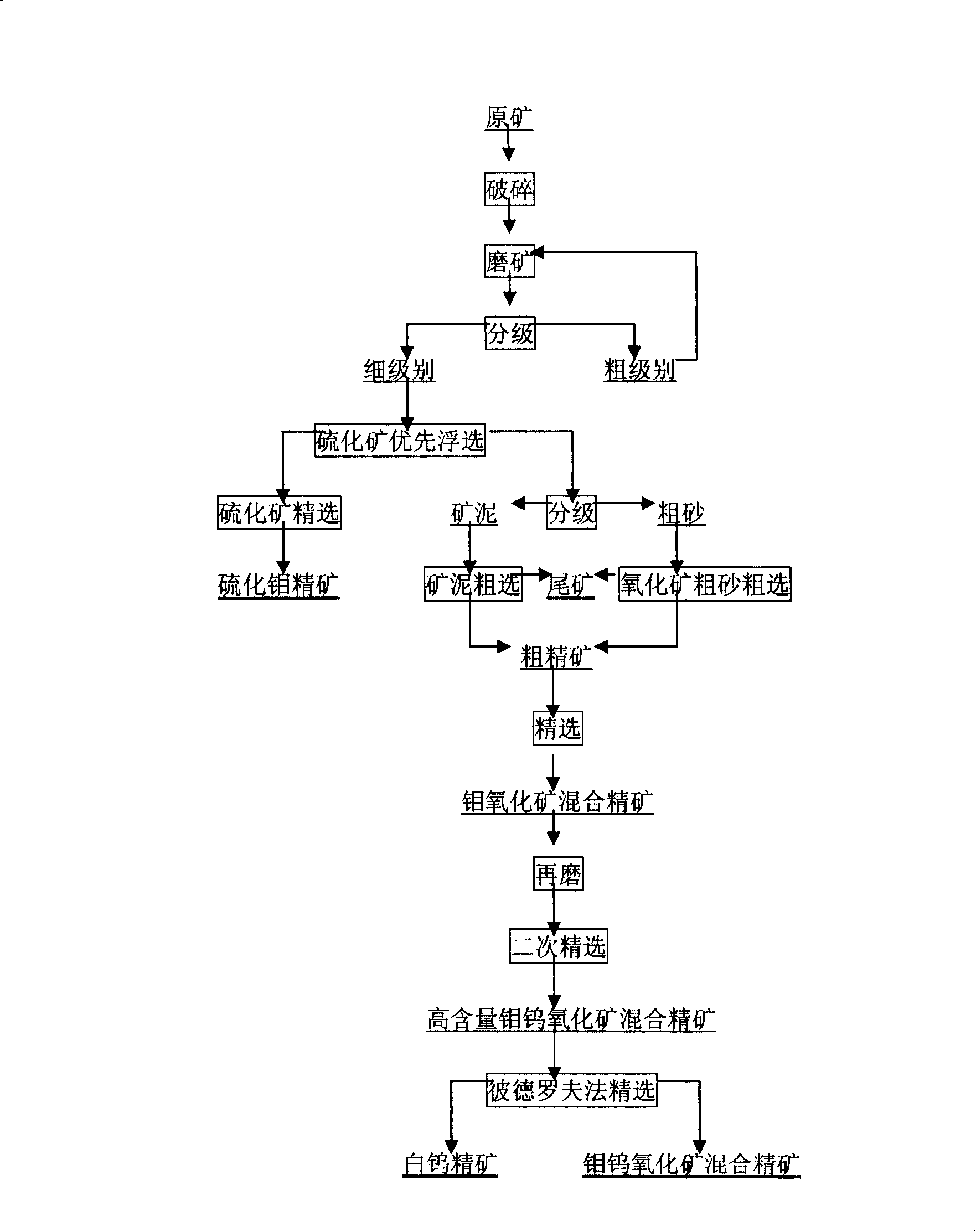

Processing technology for molybdenum and tungsten oxidized ore

InactiveCN101224441AHigh recovery rateResolve recovery rateSievingScreeningLaboratory testFatty acid

The invention discloses a beneficiation process of a molybdenum-tungsten oxide ore. The process of which is that: the liberation degree of ore crushing is higher than or equal to 70%; the flotation of molybdenum sulfide is preferred; the floatation tailing is classified and then a separation of slime and sand is carried out, wherein a slime and sand system takes alkali as the conditioning agent, sodium silicate as the depressant, and emulsified fatty acid as the collecting agent. The rough concentrate obtained from the separation of slime and sand is concentrated after being blended to obtain molybdenum-tungsten oxide ore collective concentrate. The collective concentrate is grounded again and added with the depressant, then a secondary concentrate can be gained through the concentration; the secondary concentrate is concentrated by means of Peter Roph method to obtain scheelite ore and oxidized molybdenum-tungsten beneficiation concentrate. The invention has the advantages that: 1. the invention discloses a beneficiation process flow for treating molybdenum-tungsten oxide ore; 2. the invention solves the difficulty of lowe technical specification of molybdenum - tungsten oxide ore beneficiation; 3. the invention completes laboratory tests and researches and fulfills industrialized implementation for the first time in China.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD +1

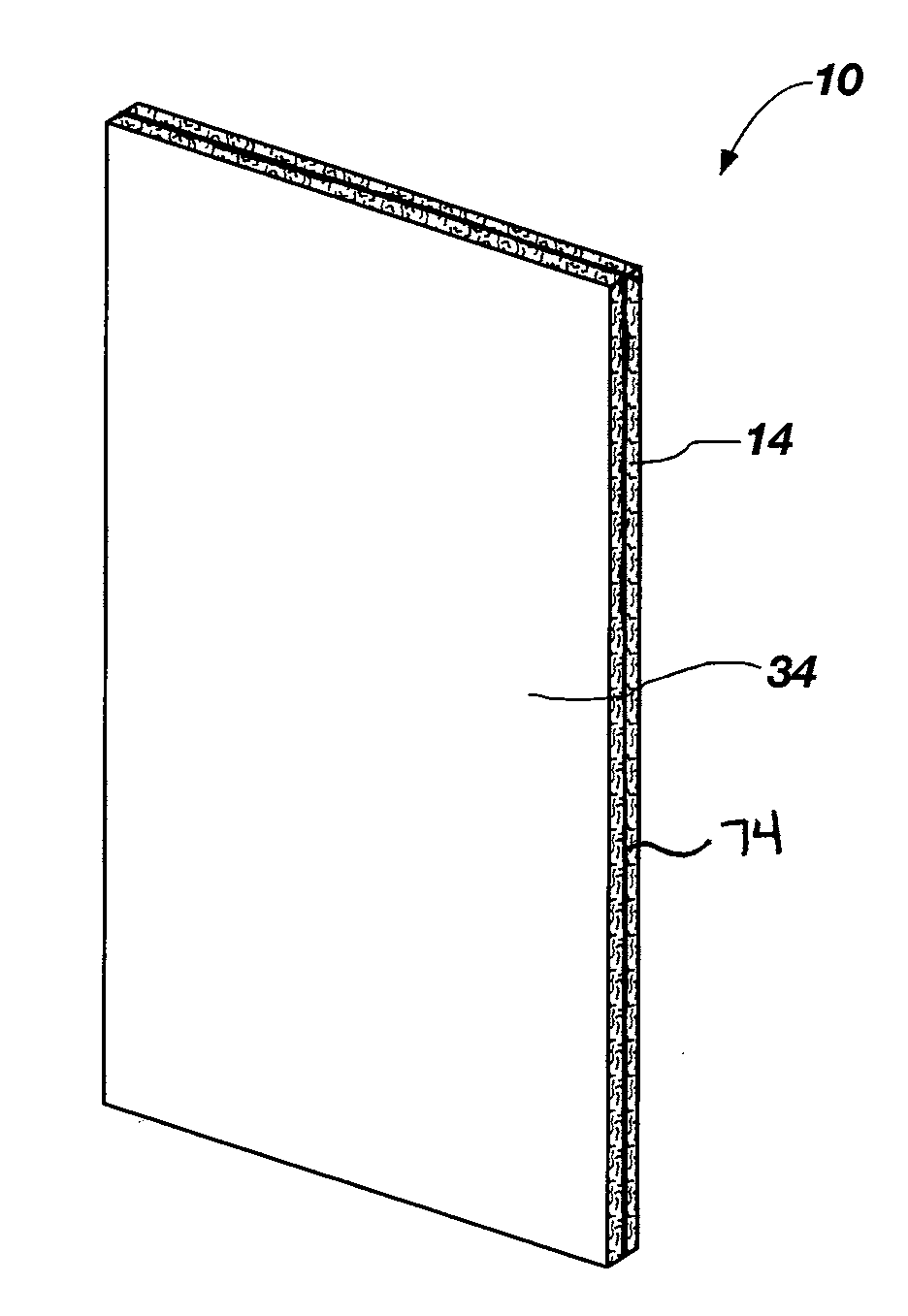

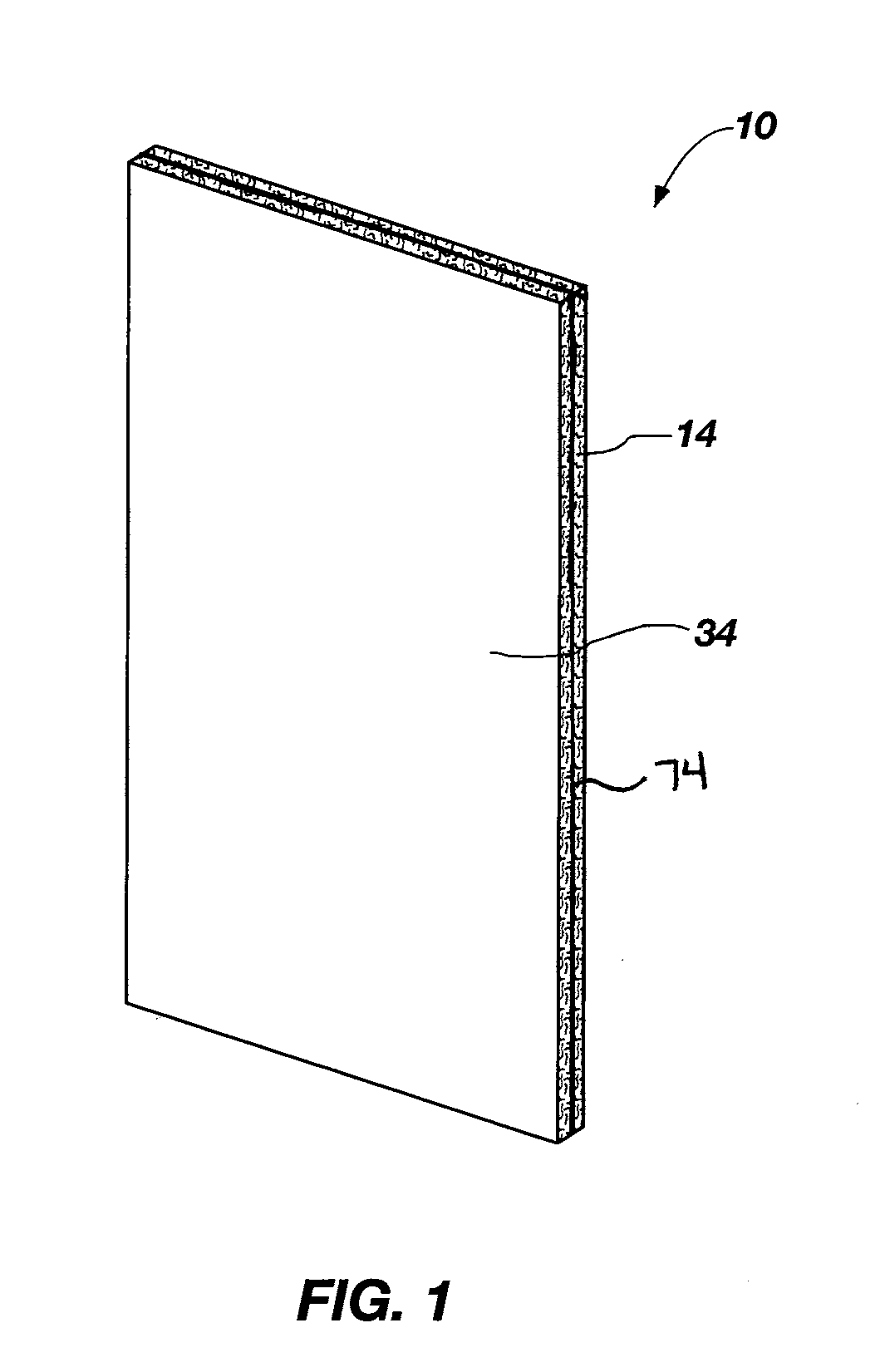

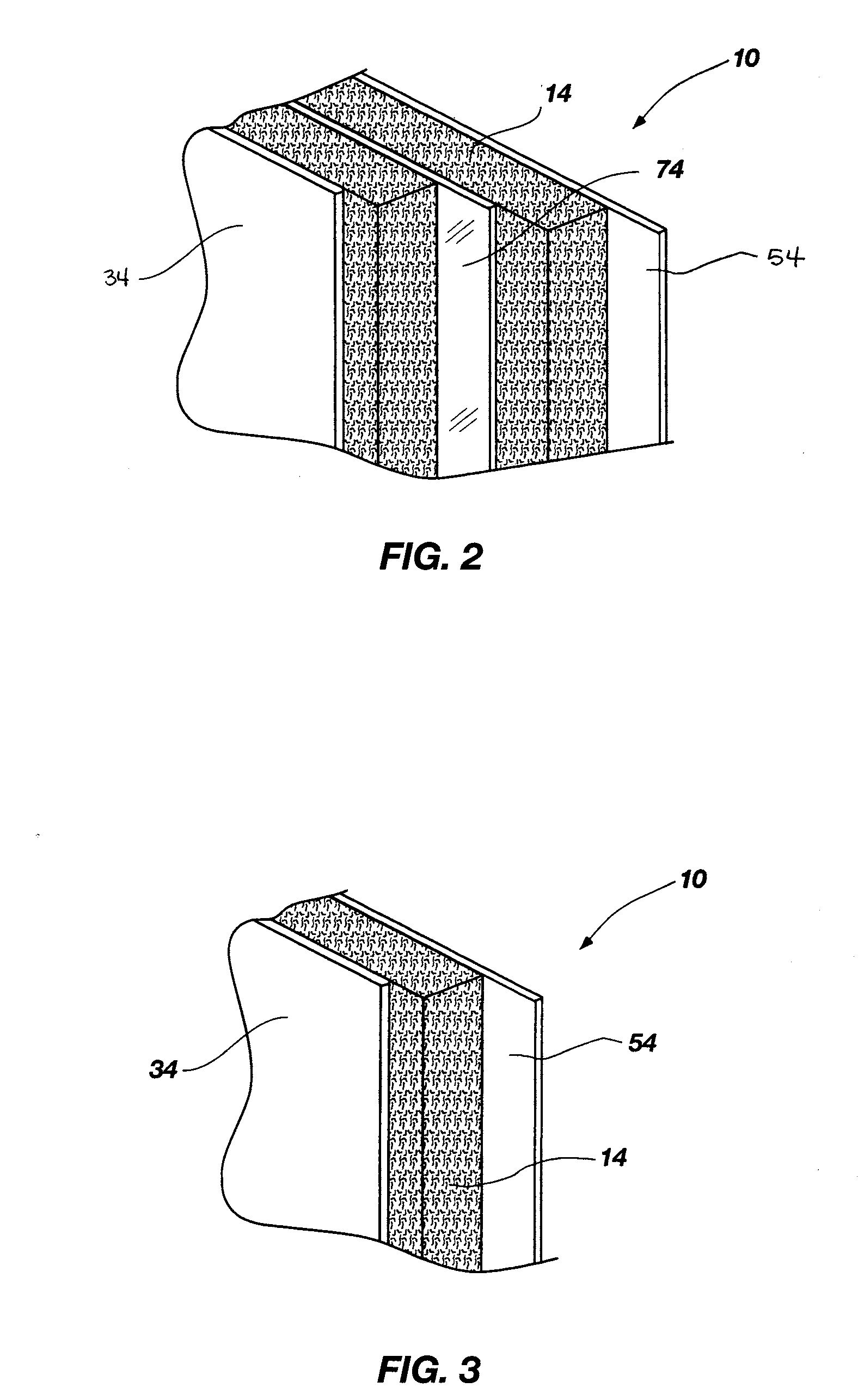

Sound Attenuation Building Material And System

A shear panel building material that includes a first facing membrane, a core matrix disposed on a face of the first facing membrane, and a semi-rigid or rigid material attached to the core matrix. The core matrix can include microspheres having a size of about 200 microns to about 800 microns, sodium silicate, and ethylene vinyl acetate. In one aspect, the shear panel is substantially free from glue and cement.

Owner:ASHTECH IND LLC

Plant nutrient liquid fertilizer

InactiveCN102701861AImprove stress resistanceSolve the problem of lack of nutrientsFertilizer mixturesSucrosePhosphate

The invention relates to a plant nutrient liquid fertilizer. In order to solve the problem of over fertilization, the plant nutrient liquid fertilizer is prepared from the following raw materials in proportion by weight: aqua brassin 12-36, gibberellin 1-4, indoleacetic acid 30-80, abscisic acid 10-20, naphthaleneacetic acid 50-90, salicylic acid 80-180, vitamin C 1-3, cane sugar 40-100, chitin 20-80, 0.05-0.2 percent triacontanol 400-1,000, hydrolyzed protein 2-5, potassium dihydrogen phosphate 300-400, thiourea 40-120, cobalt chloride 5-12, borax 50-100, sodium silicate 30-55, urea 300-500, ammonium molybdate 50-80, copper sulfate 30-65, zinc sulfate 120-200, magnesium sulfate 100-150, calcium chloride 50-120, manganese sulfate 40-80 and water in the amount of 3-8 times the total amount of all the raw materials or water in the amount capable of dissolving all the raw materials, wherein the water is de-ionized water or micro cluster water; and the preparation method is that all the materials are prepared into aqueous solution. The plant nutrient liquid fertilizer has the advantages of favorably solving the problems of over fertilization and shortage of nutrient elements in soil, obviously improving the plant adverse resistance, improving the photosynthesis and the accumulation efficiency of nutritive materials and improving the yield and the quality.

Owner:魏玉芳

Method for preparing vanadium pentoxide

InactiveCN1843938AMeet the needs of domestic chemical productionVanadium oxidesCalcium hydroxideSodium aluminate

The invention relates to a method for preparing vanadic anhydride. It comprises following steps: employing ammonium vanadate, vanadic anhydride of technical grade or waste catalyst discharged in sulfuric acid preparation process; treating with ammonium hydroxide, sulfuric acid and ammonium chloride, washing with water; getting fine active vanadic anhydride; removing foreign matter with ammonium hydroxide, calcium hydroxide, sodium aluminate, sodium silicate, sulfuric acid and ammonium chloride; washing with water again; drying; calcing at 670 Deg. C and getting high-purity vanadic anhydride. The invention is characterized in that it makes use of current material to prepare chemical materials urgently needed by industrial production, and saves a large amount of foreigh exchange.

Owner:宿素满

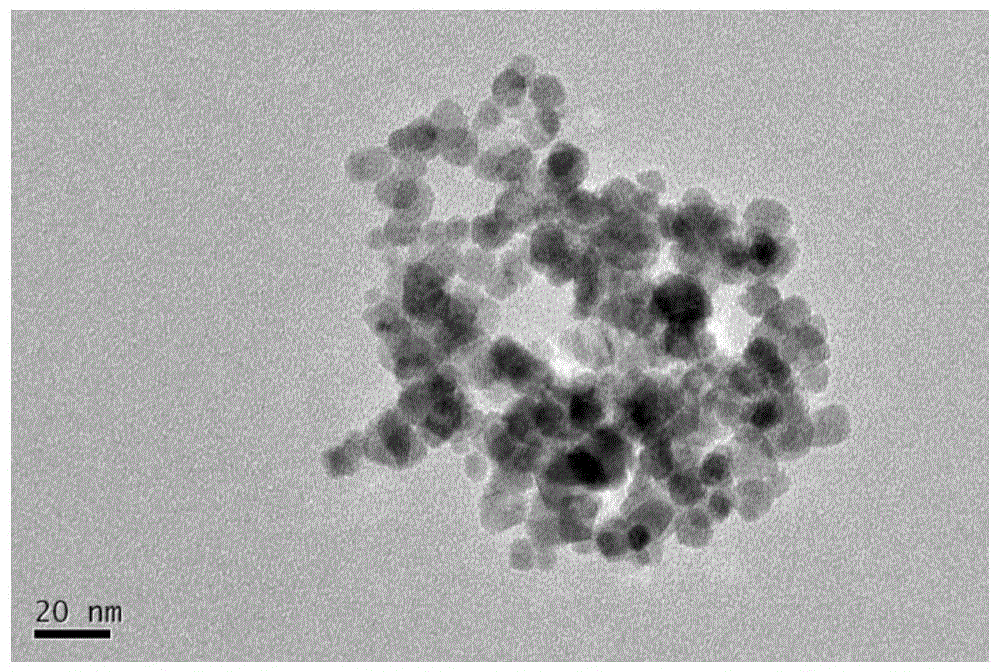

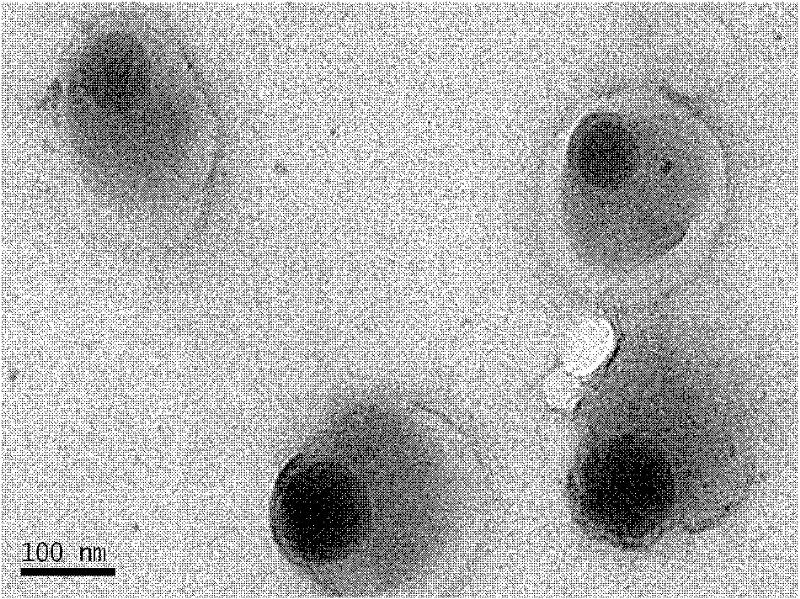

Acid-resistant magnetic chitosan microspheres as well as preparation method and application thereof

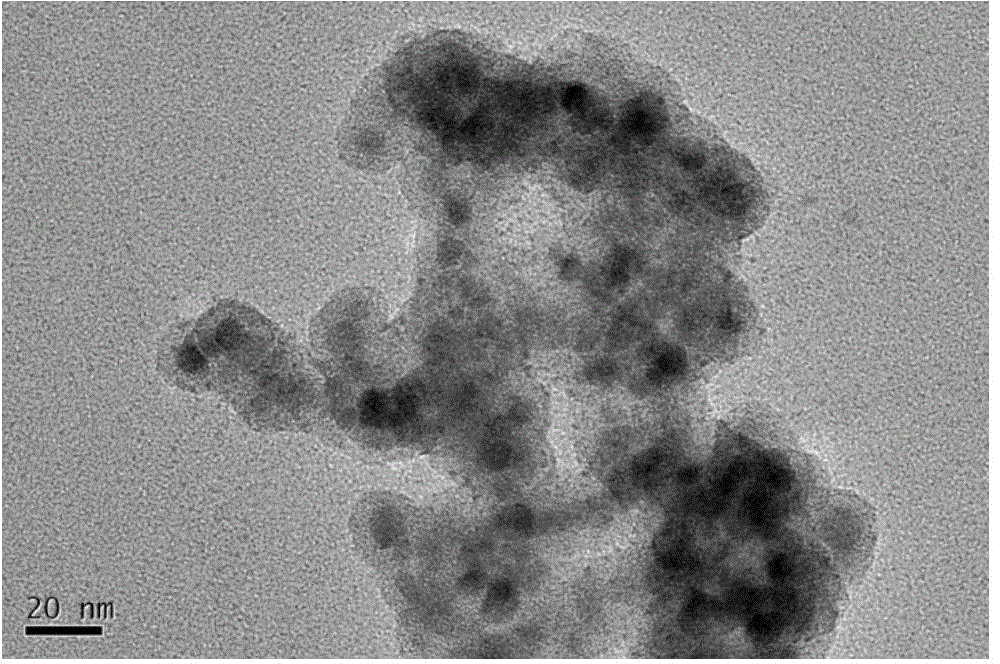

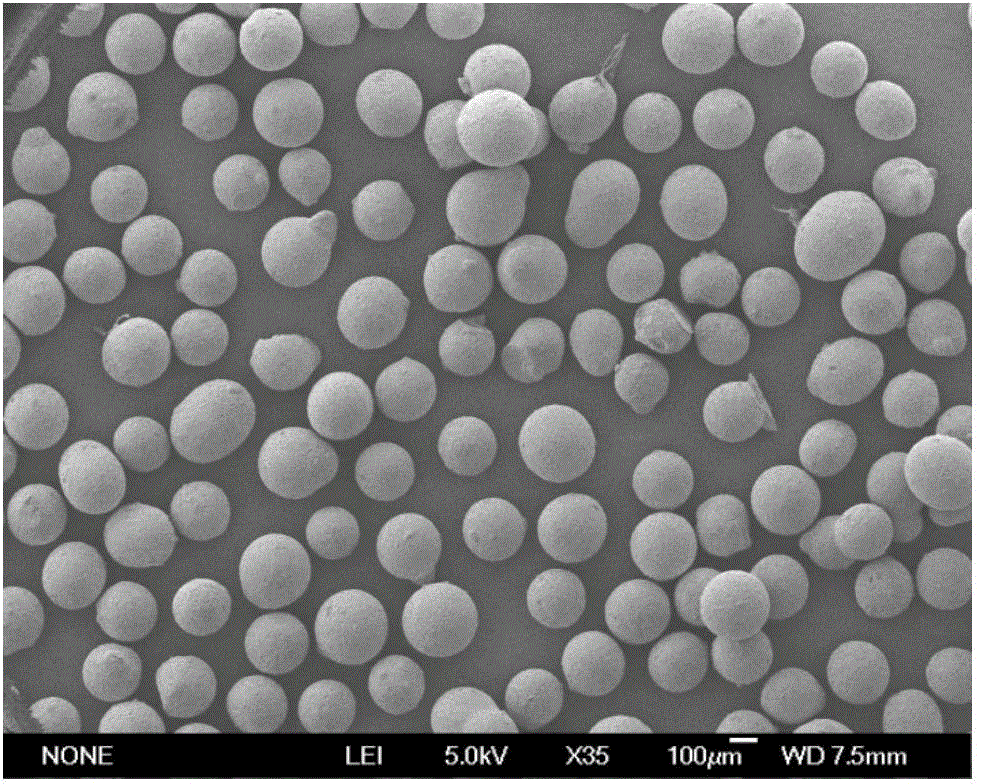

InactiveCN104437395AImprove acid resistanceHigh amino contentOther chemical processesWater contaminantsMicrosphereHydrolysis

The invention relates to an acid-resistant magnetic chitosan microsphere adsorbent as well as a preparation method and the application thereof, and in particular relates to acid-resistant magnetic chitosan microspheres which have the excellent absorption performance and recycling performance for acid waste water containing hexavalent chromium, a preparation method of the acid-resistant magnetic chitosan microspheres and the application of the acid-resistant magnetic chitosan microspheres. The preparation method of the acid-resistant magnetic chitosan microspheres comprises the following steps: (1) preparing Fe3O4 nano-particles modified by citric acid by using a coprecipitation method; (2) preparing single-coated magnetic SiO2 nano-particles by using a sodium silicate hydrolysis method or a sol-gel method; and (3) preparing the chitosan microspheres coated with magnetic SiO2 by taking chitosan powder as a raw material by adopting an emulsion crosslinking method. Furthermore, in order to further improve the adsorbing capacity of the microspheres, in the method, dendritic polyethylene imine is taken as a functional group for modifying the adsorbent, so that the modified chitosan microspheres can be obtained. The magnetic chitosan microspheres prepared by adopting the method not only have the excellent acid resistance, but also have the good absorption performance on Cr (VI) ions.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

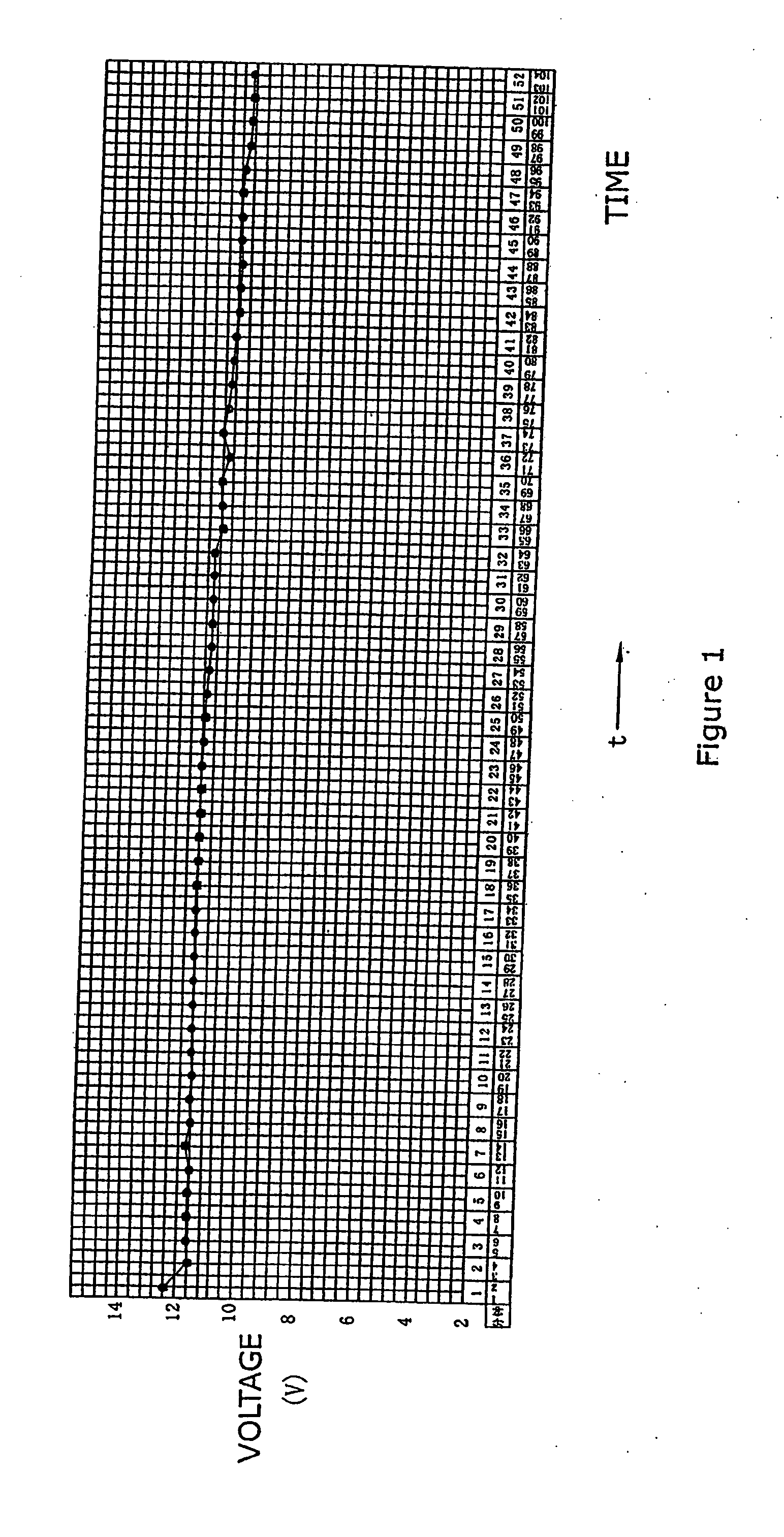

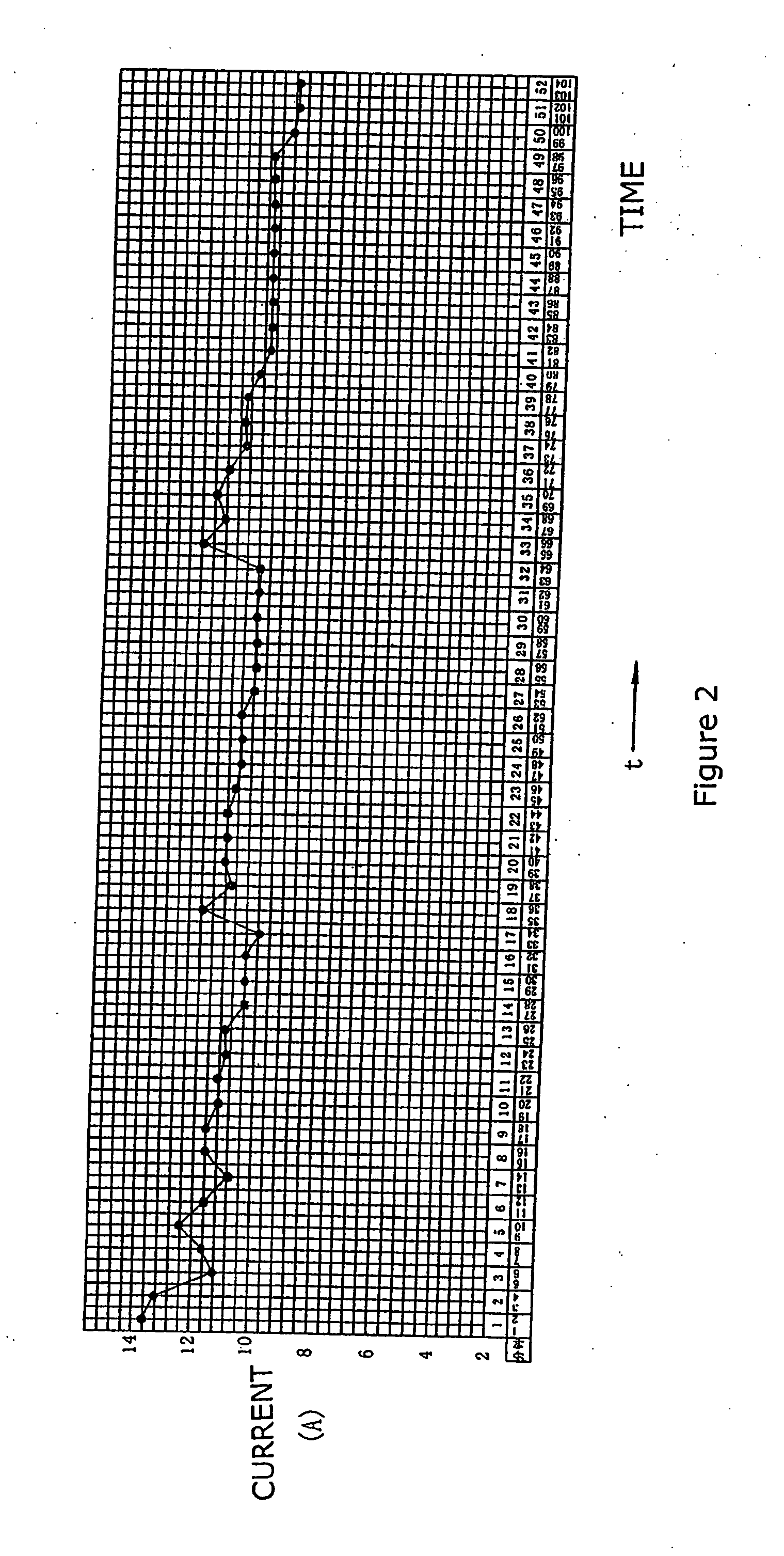

Liquid low-sodium silicate electrolyte used for a storage battery and manufactured by magnetization process, and the usage thereof

InactiveUS20080044726A1Improve liquidityHigh viscosityOther chemical processesMagnetic paintsMagnetizationBiological activation

A liquid low concentration sodium-containing silicate solution as electrolyte for lead-acid storage batteries and its applications, is prepared by mixing a silica gel containing 40˜60 wt % SiO2, the weight units of such a silica gel are 5˜15; add 15-25 weight units water and stir until the concentration of the mixture is 0.65˜0.85 0Be′ measured by a Baum densimeter, adjusting the pH value of this mixture to 1-4 using inorganic acid and magnetizing the mixture under 1000-6000 Gauss magnetic field for 5-10 minutes, stir the magnetized mixture until the viscosity of the mixture is less than 0.02 poise and finally obtain a liquid low concentration sodium-containing silicate solution. The electrolyte can be used as electrolyte or activation solution for common or special lead-acid storage batteries.

Owner:LIDU WANG

Method for producing fluorine series compounds and white carbon black

The invention relates to a method utilizing waste gas containing fluoride in fertilizer production or fluorine-containing gas or sodium fluorosilicate in fluorine chemical production as raw materials to product series compounds of fluorine and white carbon black. The ammonium fluoride and / or ammonia are / is introduced into an absorption system to get a (NH4) 2SiF6 solution with the absorbing solution concentration of 25 to 37 percent or the ammonium fluoride and the sodium fluorosilicate react to get a reaction product of sodium fluoride crystallization, fluosilicic acid solution and septenary-fluorine compound NH4F.(NH4)2SiF6 crystallization. The absorption liquid or the reaction product is aminated to get precipitated silica (white carbon black) with the specific surface of 100-180m<2> / g, and the latter can get a sodium fluoride product and an NH4F solution with the concentration of 30 to 45 percent. The solution used as a starting point can nearly prepare all inorganic fluoride chemical products, and ammonium fluoride, sodium fluoride, potassium fluoride, ammonium bifluoride, cryolite, aluminum fluoride, sodium hydrogen diffluoride and hydrofluoric acid production, etc. are main. The method has simplicity, effectiveness and higher economic benefit, and simultaneously, fluorine and silicon in the waste gas containing fluoride of phosphate fertilizer for the pollution of environment can be basically eliminated, and basically no waste water, waste gas and waste residue are discharged.

Owner:夏克立

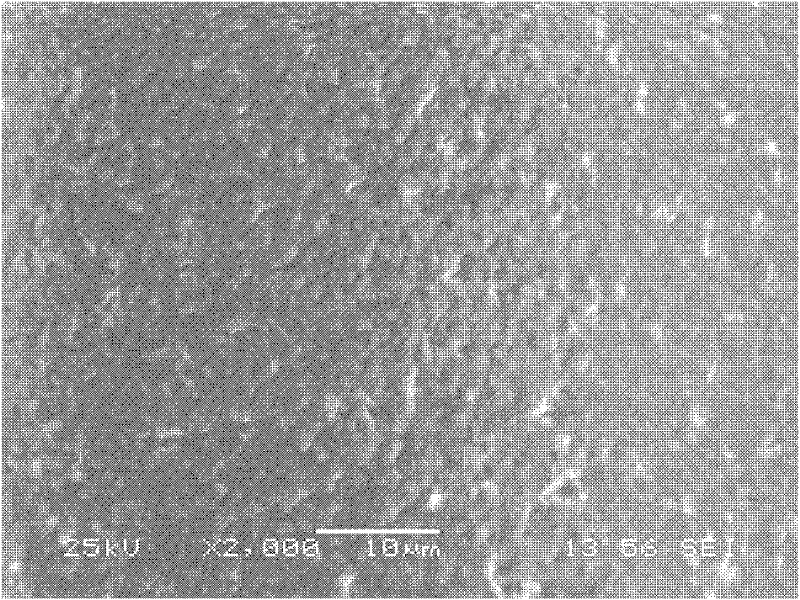

Surface treating method for magnesium lithium alloy

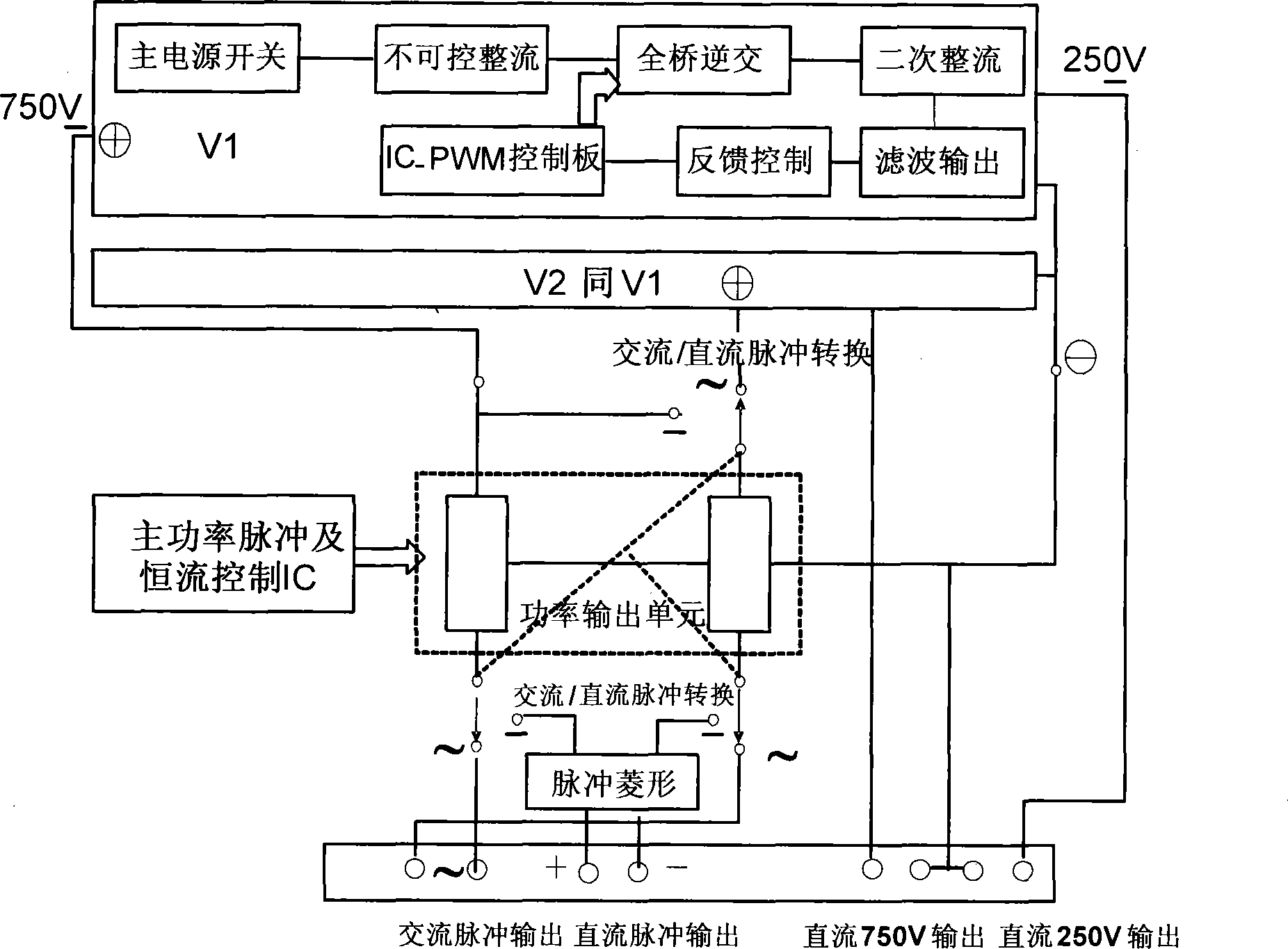

InactiveCN101245485AGood effectImprove corrosion resistanceAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention provides a method for processing the surface of magnesium-lithium alloy. The technique of micro-arc oxidation is successfully applied to processing the surface of the magnesium-lithium alloy. Direct current / DC pulse / alternating current pulse multiplex power supply is used and the magnesium-lithium alloy with different lithium contents in a compound electrolyte system of sodium polyphosphate, sodium silicate, calgon and sodium hydroxide is carried out by micro-arc oxidation for 2-120min. A ceramic oxide film of 10-100Mum with a rigidity higher than 200Hv is formed in situ on the surface of the magnesium-lithium alloy, thus remarkably improving corrosion resistant property compared with an alloy matrix, solving the problem known at home and abroad concerning processing the surface of the magnesium-lithium alloy and broadening the application in the fields of aviation, aerospace, car, electronic, etc.

Owner:HARBIN ENG UNIV

Multifunctional concrete structure endurance protective agent, preparation and application method thereof

The invention discloses a multifunctional concrete structure endurance protective agent as well as the preparation and application method thereof. The protective agent provided by the invention contains the following ingredients of: an organic / inorganic composite fluorosilicone-acrylate copolymer, lithium silicate, sodium silicate, lithium molybdate, sodium tetraborate, sal glauberi, 1,2-aminoazophenylene, nanometer titanium dioxide, anhydrous ethanol and water. The protective agent can penetrate inside concrete, wherein a densification ingredient can minimize internal holes and cracks to raise the compactness of concrete, and a rust-resistant ingredient can penetrate into concrete and be adsorbed on the surface of steel bar so as to passivate and protect the steel bar; the low-surface energy silicon fluoride ingredient can be solidified to form a cured film on the surface of concrete so as to endow the protective agent with the hydrophobic performance; a nanometer ingredient can endow the cured film layer with properties of resisting ultraviolet and ageing and improving the organic polymer performance as well as the self-cleaning performance. In addition, hydroxy generated from the hydrolysis of siloxane group can perform a condensation reaction with hydroxy on the surface of concrete to produce chemical bond, so as to raise the anchoring strength between the film and concrete and improve the interface combination. The protective agent provided by the invention can be widely applied in various concrete structure engineering protections to raise the service life of concrete.

Owner:CENT SOUTH UNIV +1

High and low-temperature resistant porcelain glaze for enamel

InactiveCN103274764AImprove smoothnessGood high and low temperature resistanceTemperature resistanceLead sulfate

The invention relates to porcelain glaze and in particular relates to high and low-temperature resistant porcelain glaze for enamel. According to the technical scheme, the highnd low-temperature resistant porcelain glaze for enamel is prepared from the following raw materials in parts by weight: 22-38 parts of sodium silicate with the modulus of 2-3.8, 11-19 parts of aluminum oxide, 10-20 parts of manganese dioxide, 6-9 parts of palladium oxide, 6-9 parts of high-boron calcium borate, 23-29 parts of lead sulfate, 2-4 parts of talc, 7-13 parts of calcium carbonate, 8-12 parts of barium sulfate, 12-19 parts of zinc sulfate and 2-9 parts of titanium oxide. The high and low-temperature resistant porcelain glaze has excellent ultralow-temperature resistance and high-temperature resistance.

Owner:XIANGFENG ZHEJIANG METAL PROD

Heat-preservation and heat-insulation crack-resisting brick made from modified vitrified micro beads

ActiveCN101725208ASolve the weakness of high water absorptionNo pollution in the processSolid waste managementBuilding componentsSocial benefitsBrick

The invention relates to a heat-preservation and heat-insulation crack-resisting brick made from modified vitrified micro beads and effectively resolves the problems of large contractibility rate, poor stability, easy cracking and high cost of masonry walls. According to parts by weight, the brick is composed of the following raw materials: 100 parts of cement, 5-20 parts of coal ash, 0.005-0.015 part of polypropylene fiber, 10-50 parts of modified vitrified micro beads, 10-30 parts of activating agent, 1-5 parts of sodium silicate, 10-50 parts of sand, 10-200 parts of fine stone and 110-330 parts of water. The method for preparing the brick comprises the following steps: evenly stirring and mixing the modified vitrified micro beads, 50 parts of the cement and the activating agent to form material A, then evenly stirring and mixing the fine stone, the sand, the coal ash, the polypropylene fiber and the remaining 50 parts of cement to form material B; adding water to stirring the material A and material B into uniform brick material; pressing the brick material into block-shaped bricks by a die and curing the block-shaped bricks at 10-40 DEG C for 7-30 days, thus obtaining the final product. The brick of the invention features scientific and reasonable components, simple process, stable quality, low contractibility rate, low coefficient of heat conductivity, good heat-preservation and heat-insulation property, low cost, environmental friendliness, economy and tremendous economic and social benefits.

Owner:BEIJING TIANJI NEW MATERIALS

Synthesis method of ZSM-5/beta nuclear shell-shaped molecular sieve

ActiveCN101885493AReduce usageLower synthesis costMolecular sieve catalystsCrystalline aluminosilicate zeolitesSynthesis methodsNanocrystal

The invention relates to a synthesis method of a ZSM-5 / beta nuclear shell-shaped zeolite molecular sieve, mainly solving the problems of expensive raw materials used by the ZSM-5 / beta nuclear shell-shaped molecular sieve, low shell coverage of the product and the like existing in the prior art. The synthesis method comprises the following steps of carrying out surface pretreatment and beta nano crystal adsorption to ZSM-5 nuclear-phase molecular sieve as a seed crystal and then adopting at least one of water glass, silica sol, sodium silicate, white carbon black or activated clay as a silicon source to prepare the ZSM-5 / beta nuclear shell-shaped zeolite molecular sieve with high shell coverage. The invention adopting the technical scheme solves the problems well and can be used for industrially preparing the ZSM-5 / beta nuclear shell-shaped zeolite molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

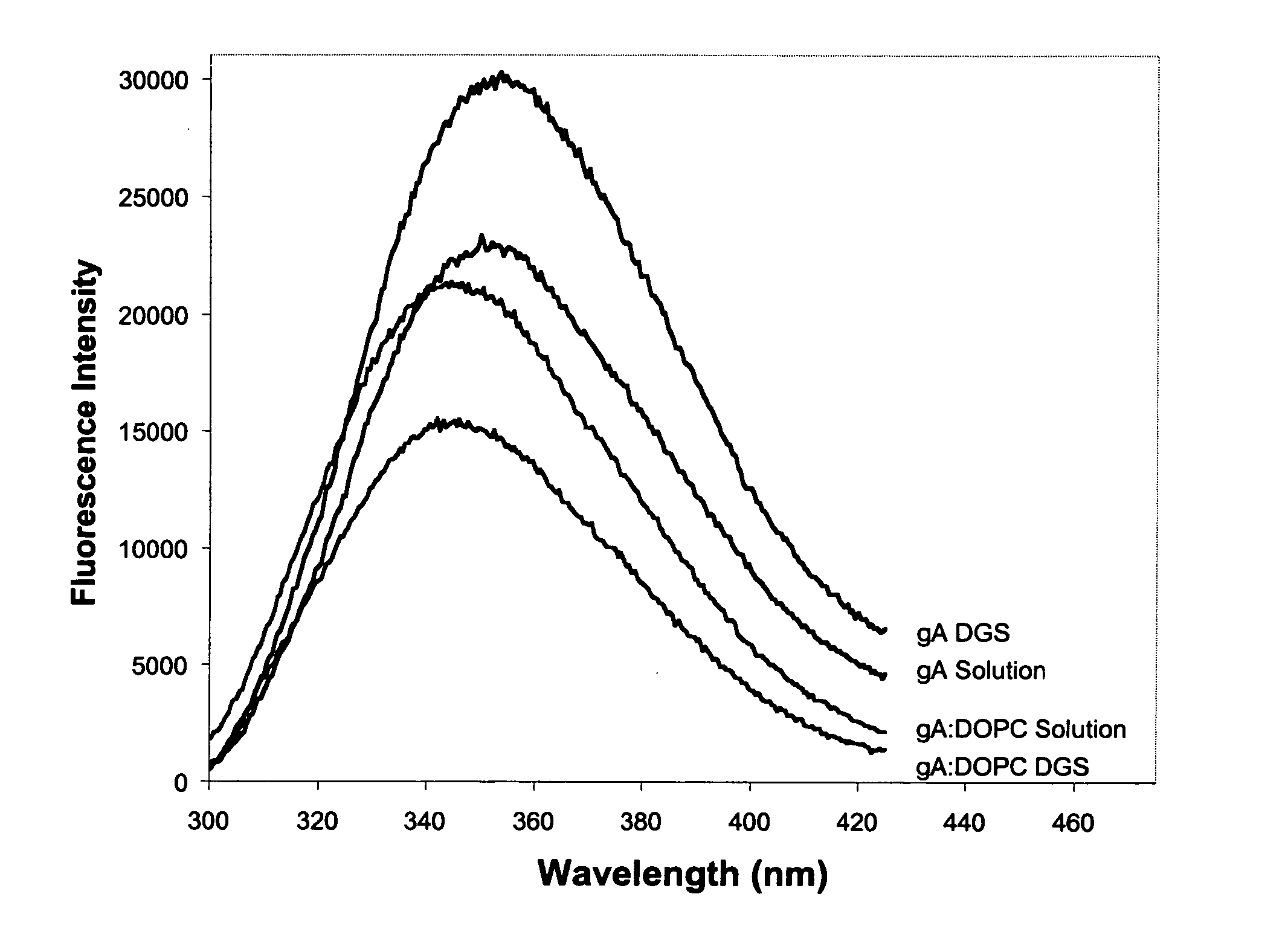

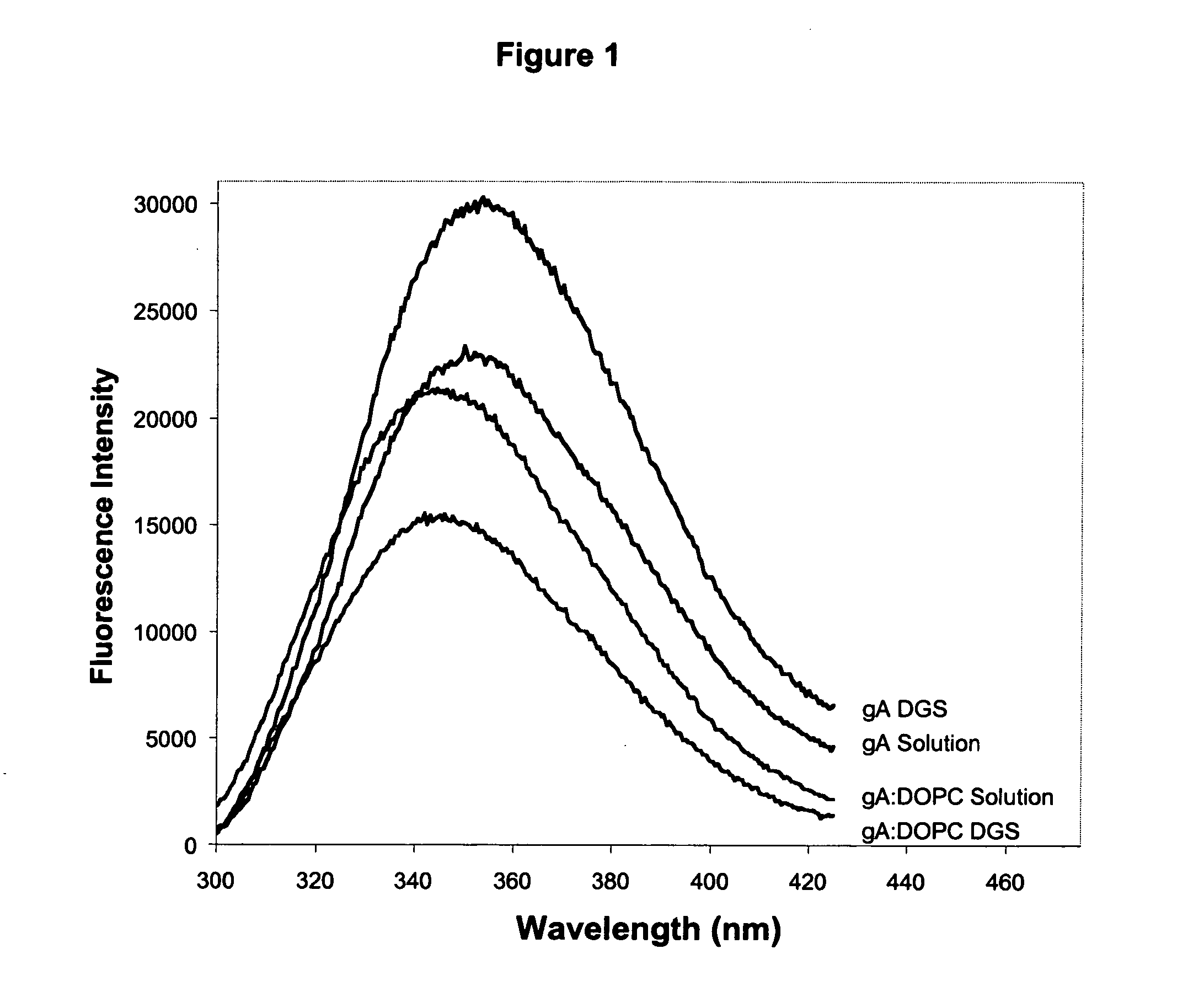

Method of immobilizing membrane-associated molecules

InactiveUS20050032246A1Improve throughputPreparing sample for investigationBiological material analysisSilanesLiposome

The present invention relates to methods of immobilizing membrane-associated molecules within a sol-gel matrix. The membrane-associated molecule is embedded in the bilayer of a liposome. The molecule-liposome assembly remains functionally intact when it is immobilized within a protein and membrane-compatible sol-gel derived from polyol silane precursors or sodium silicate. The activity and stability of the entrapped membrane-associated molecule was significantly improved in macroporous silica.

Owner:MCMASTER UNIV

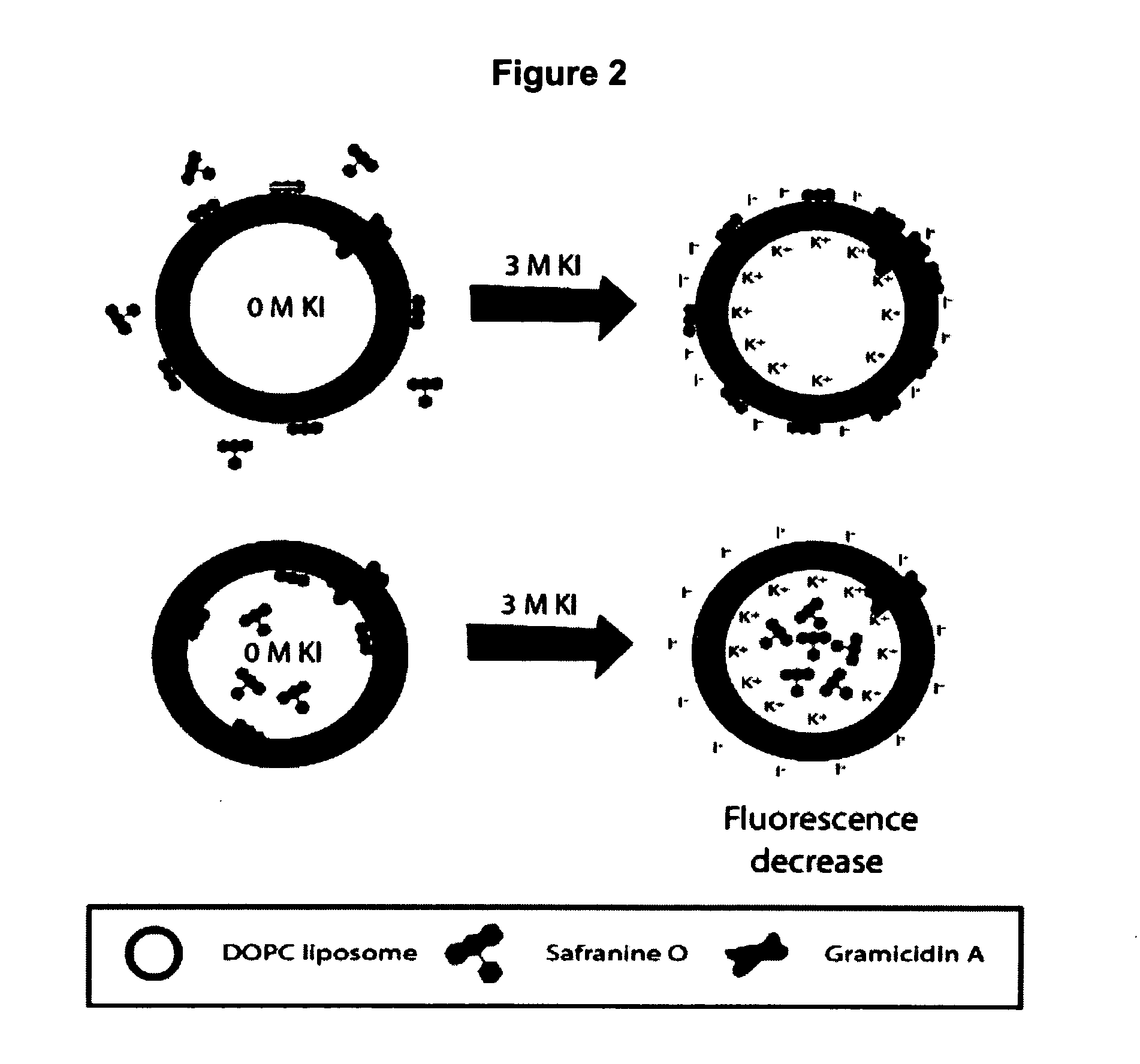

Fire-resistant material and method of manufacture

InactiveUS6886306B2Improve fire resistanceImprove the level ofConstruction materialClimate change adaptationCelluloseZinc borate

The present invention provides a building material derived from straw, such as rice straw, that has significantly improved fire-resistance properties over traditional cellulose-based materials. In one embodiment, the invention provides a method of fabricating a board from milled rice straw. The milled rice straw is blended with a binder to form a mixture. The mixture is then formed into a mat with sufficient size to achieve a predetermined board thickness and density. The mat is then pressed into the board. In another embodiment, the present invention provides a fire resistant board that includes milled rice straw, a resin binder, and a fire retardant material such as an organic phosphate, zinc borate, aluminum trihydrate, sodium silicate, or even rice hulls.

Owner:GREENCOR COMPOSITES

Water shutoff agent applicable to high-temperature high-salt oil reservoir water shutoff profile control

The invention relates to a water shutoff agent applicable to high-temperature high-salt oil reservoir water shutoff profile control. The water shutoff agent consists of a main agent, a cross-linking agent, a stabilizing agent and water, wherein the main agent is sulfonated tannin or sodium humate; the cross-linking agent is the combination of an aldehyde cross-linking agent and a phenolic cross-linking agent; and the stabilizing agent is sodium silicate and non-ionic polyacrylamide. The water shutoff agent applicable to the high-temperature high-salt oil reservoir water shutoff profile control provided by the invention is applicable to the oil reservoir water shutoff profile control at the temperature of 90 to 150 DEG C and with the mineralization degree of greater than 2.0*10<5> mg / L; the gelation time is between 5 to 28 hours; and the strength of the formed gel is 0.060 to 0.085 MPa. The water shutoff agent has high integrity; and the plugging ratio to a rock core can be over 92 percent.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Cementitious capillary crystalline waterproofing agent

InactiveCN101759414AImprove impermeabilityPromotes self-healingSolid waste managementSelf-healingSodium Bentonite

The invention discloses a cementitious capillary crystalline waterproofing agent, which contains the following raw materials in parts by weight: 50 parts of Portland cement; 25 parts of quartz sand; 9 parts of siliceous dust; 3 parts of calcium hydroxide; 2 parts of sodium bentonite; 1 part of kieselguhr; 3.9 parts of instant sodium silicate; 2.5 parts of aluminum potassium sulfate; 0.3 parts of zinc fluosilicate; 0.20 parts of sodium polyacrylate; 0.2 parts of hydroxypropyl methyl cellulose; 2 parts of zinc stearate; 0.5 parts of naphthalene water reducer; 0.2 parts of sugar lime; 0.1 parts of citric acid; and 0.1 parts of antifoaming agent. After the raw materials are weighed according to the proportions, the raw materials are ground into particles with grain size more than or equal to 200-mesh sieve in a ball mill to obtain the finished product. The invention has the advantages that the cost is low, the anti-permeability is good, the self-healing performance is good, the bonding power is strong, the steel bar corrosion is prevented, no toxicity and no harmfulness are caused and the construction is easy.

Owner:河南奥思达新材料有限公司

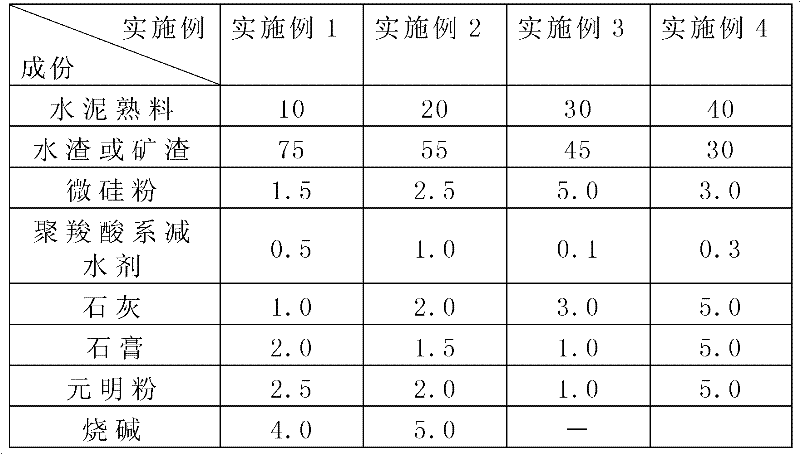

Curing agent for curing marine poor subsoil

ActiveCN102344813ASimple ingredientsCompatibility is reasonableBuilding constructionsOrganic fertilisersSlagSodium silicate

The invention relates to a curing agent for curing marine poor subsoil, which belongs to the technical field of poor subsoil curing. The curing agent for curing the marine poor subsoil is composed by the components of cement clinker, granulating slag or slag, silica fume, polycarboxylic acid type water-reducer, lime, plaster, anhydrous sodium sulphate, caustic soda, sodium silicate and sodium fluosilicate. The adulteration amount of the poor subsoil curing agent is 5%-12% in application, good curing functions can be realized, and the curing agent for curing the marine poor subsoil can be applied in the poor soil curing of building sites, road embankments, roadbeds and ground base layers. The invention has the advantages that: the components of the curing agent are simple, the compatibility is reasonable, the doping amount is less, and the curing effect is good; and during the application process, the construction period is short, the construction cost is low, the induration bearing capacity is high, the induration compression modulus is strong, and the induration permeable resistance is strong.

Owner:徐辰楚 +1

Method for preparing environment-friendly micro-arc oxidation black ceramic film on aluminum alloy surface

ActiveCN102154673AUniform colorImprove corrosion resistanceAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a method for preparing an environment-friendly micro-arc oxidation black ceramic film on an aluminum alloy surface, and the method comprises the following steps: firstly, pouring deionized water into an oxidation tank, weighing 1-10g / L of sodium hexametaphosphate, 1-3g / L of sodium silicate, 0.5-2g / L of potassium hydroxide, 0.2-2g / L of sodium fluoride and 0.5-20g / L of ferric ammonium oxalate in terms of the volume of the added deionized water, and uniformly stirring and mixing the sodium hexametaphosphate, the sodium silicate, the potassium hydroxide and the sodium fluoride to obtain a micro-arc oxidation base electrolyte; adding the weighed ferric ammonium oxalate into the base electrolyte, and stirring and mixing uniformly to obtain an aluminum alloy micro-arc oxidant solution; and then, sequentially carrying out surface deoiling and cleaning, water washing, aluminum alloy micro-arc oxidation, sealing and drying on the aluminum alloy to prepare the environment-friendly micro-arc oxidation black ceramic film on the aluminum alloy surface. By means of the preparation method disclosed by the invention, the problems of single color, limited application range, and environment pollution caused by a vanadate electrolyte, of the existing aluminum alloy ceramic film layer, are solved.

Owner:CSIC NO 12 RES INST

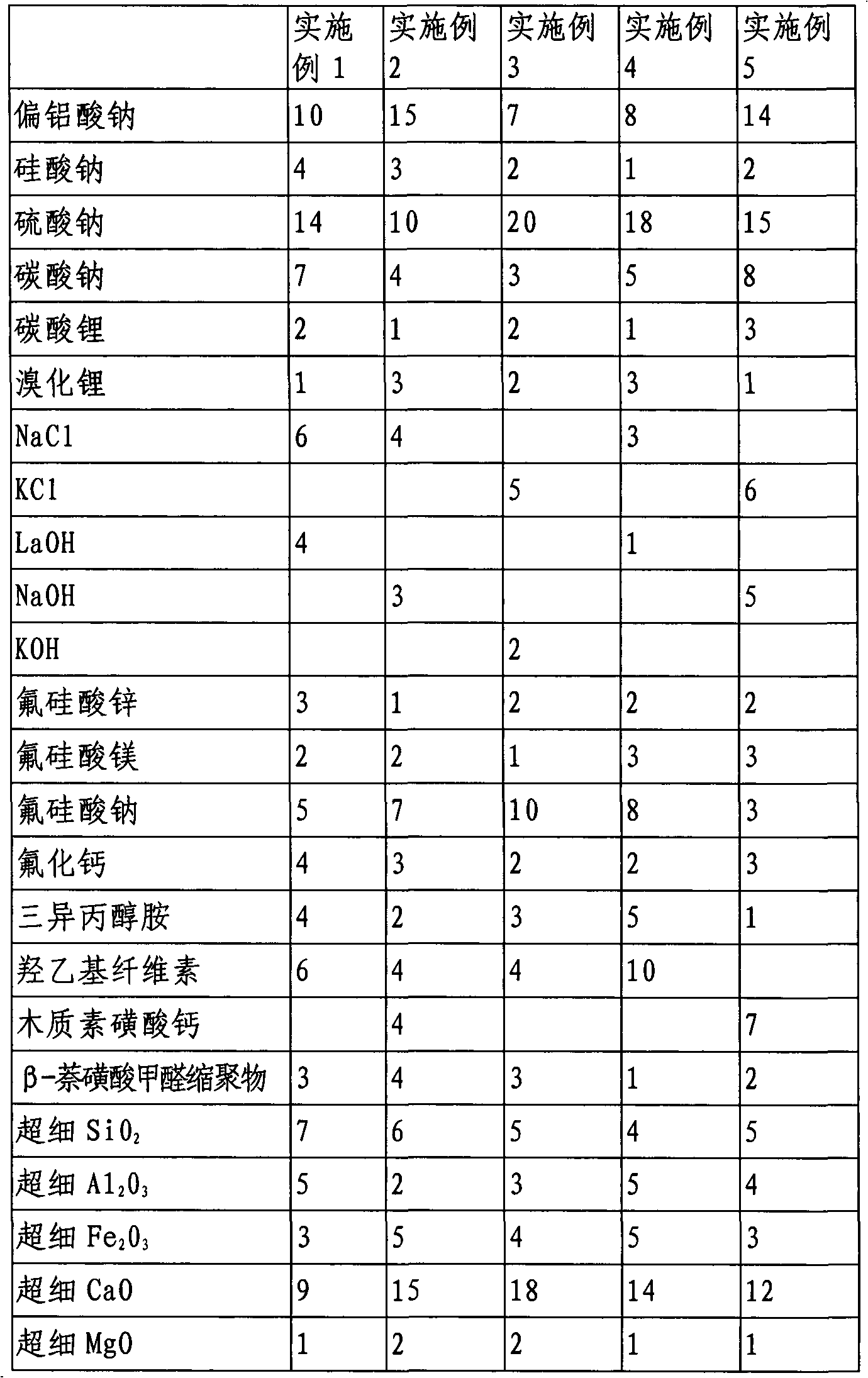

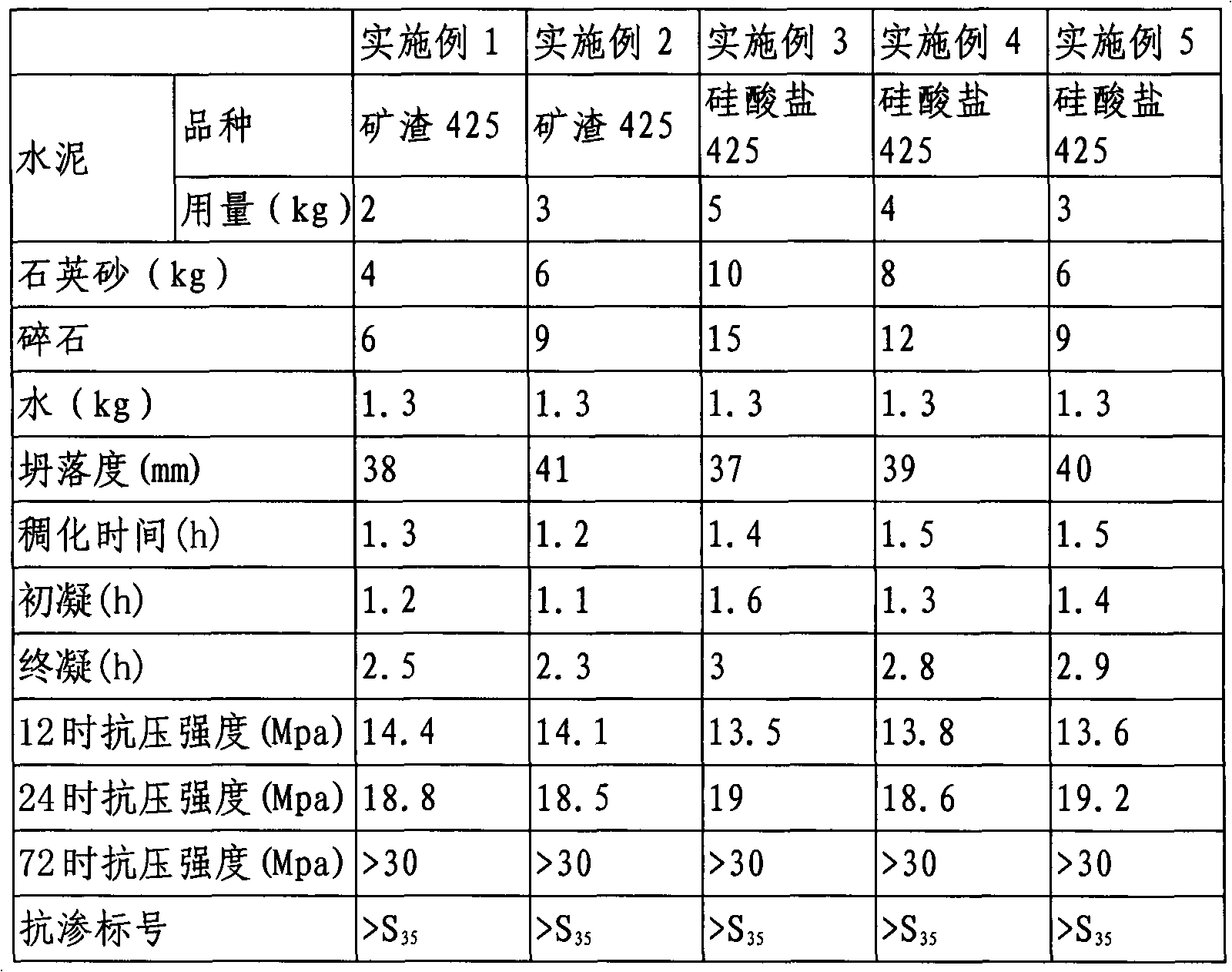

Low-temperature concrete early strength agent

The invention relates to a low-temperature concrete early strength agent, which belongs to cement additives. The early strength agent consists of sodium metaaluminate, sodium silicate, sodium sulfate, sodium carbonate, lithium carbonate, lithium bromide, alkali metal chlorides, alkali metal hydroxides, zinc fluosilicate, magnesium fluosilicate, sodium fluosilicate, calcium fluoride, triisopropanolamine, a filtrate reducer, beta-naphthalene formaldehyde sulfonate polycondensate, ultrafine powder SiO2, ultrafine powder Al2O3, ultrafine powder Fe2O3, ultrafine powder CaO and ultrafine powder MgO. The early strength agent is mainly applied to winter concrete construction or low-temperature environmental emergency projects; when the early strength agent is used, the composition mixture is added into concrete according to 2 to 5 percent of the total weight of cement, water is added and then stirring is performed; and a cement block with the strength of 13.5MPa can be formed in a low-temperature environment at the ambient temperature of approximately 4 DEG C within 12 hours, a cement block with the strength of 18.5MPa can be formed within 24 hours and a cement block with the high strength of 30MPa can be formed within three days.

Owner:陈子川

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com