Curing agent for curing marine poor subsoil

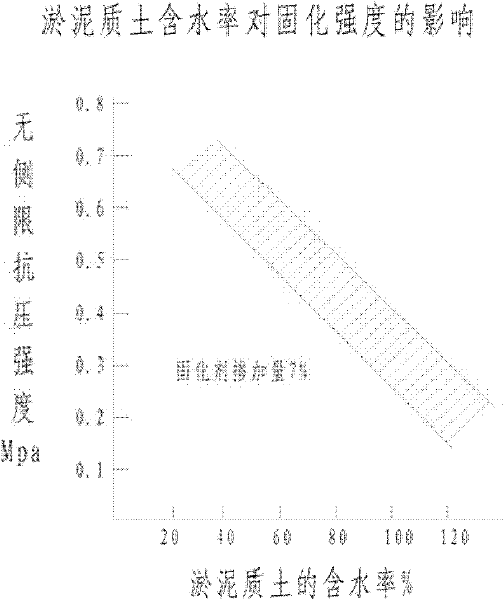

A technology of curing agent and soft soil, which is applied in the field of curing agent and curing agent for curing marine soft soil, and can solve problems such as difficult to popularize and apply in large areas, low compressive strength, and inconvenient source of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

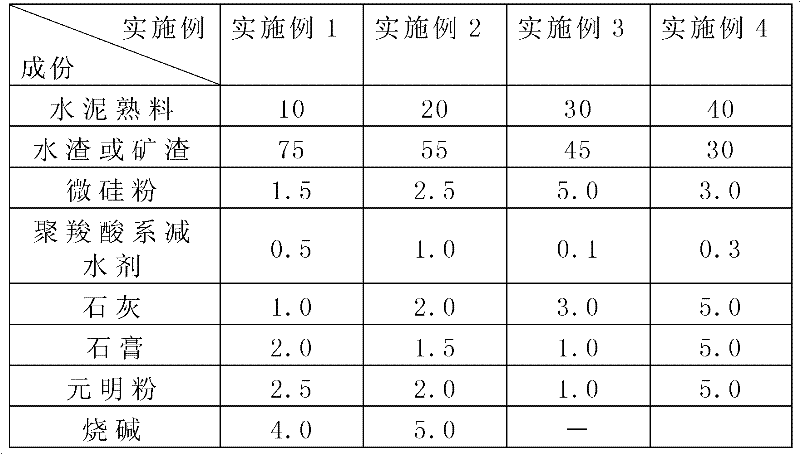

Embodiment 1

[0052] Weigh all the components of the curing agent according to the weight ratio of the components in Example 1 in the above table 1, grind the above components and mix them, grind them into powder, mix them evenly, pass through a 200-mesh sieve, and after sieving, The obtained solidifying agent powder and water are made into a slurry at a water:ash weight ratio of 0.5.

Embodiment 2

[0057] Take the components of the curing agent according to the weight ratio of the components in Example 2 in the above table 1. After mixing the above components, grind them into powder, mix them evenly, and make a slurry with a water-cement ratio of 0.8. .

Embodiment 3

[0062] Take the components of the curing agent according to the weight ratio of the components in Example 3 in the above table 1. After mixing the above components, grind them into powder, mix them evenly, and make a slurry with a water-cement ratio of 1.0. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| bearing capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com