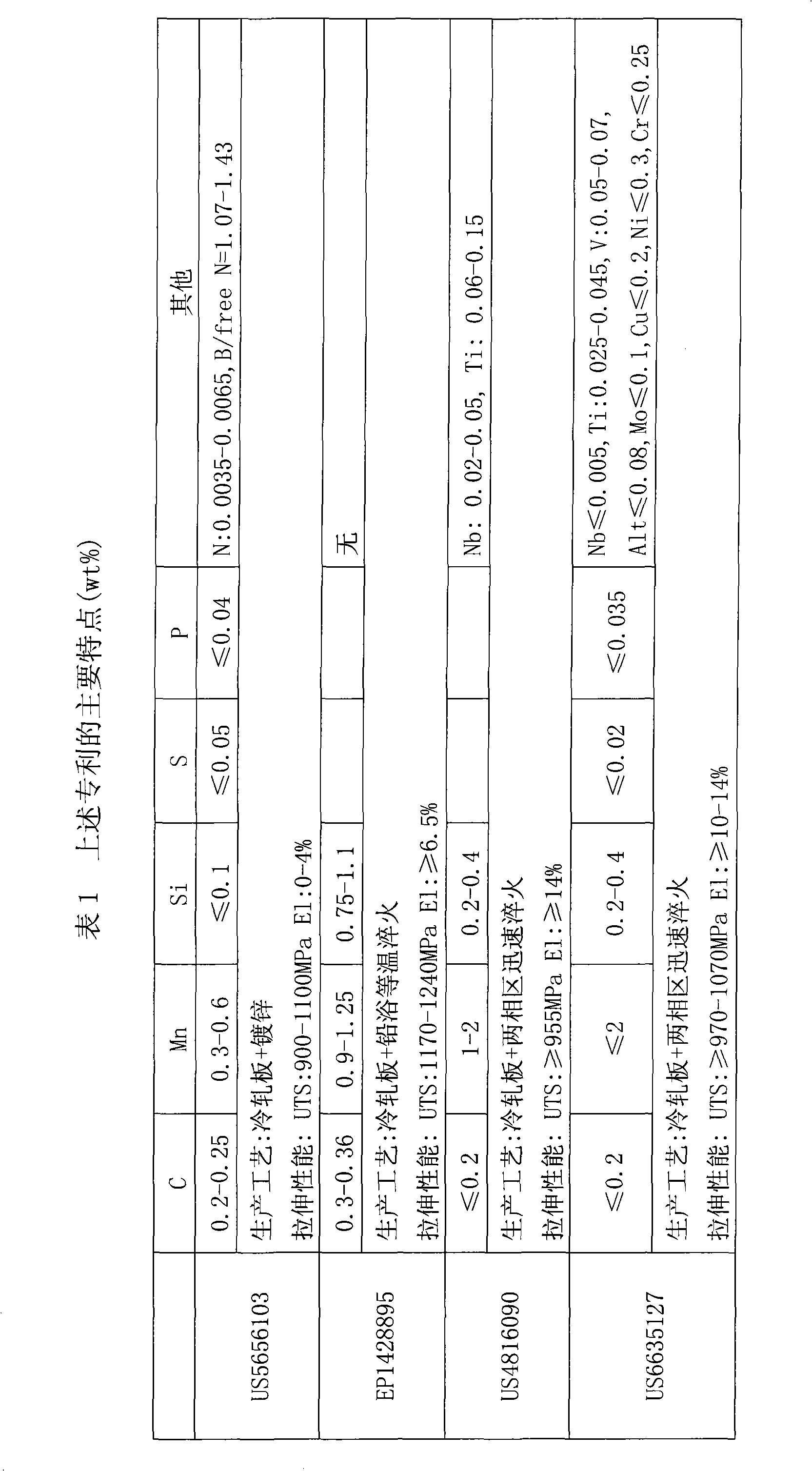

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5655results about How to "Simple ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

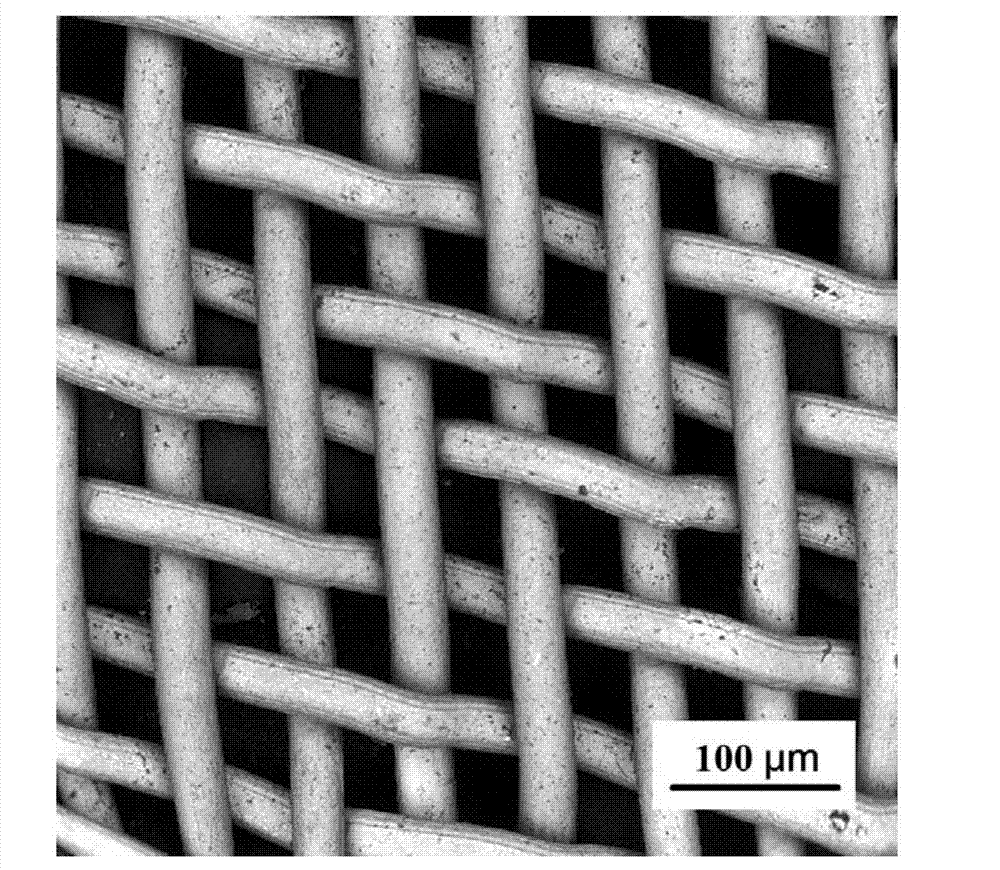

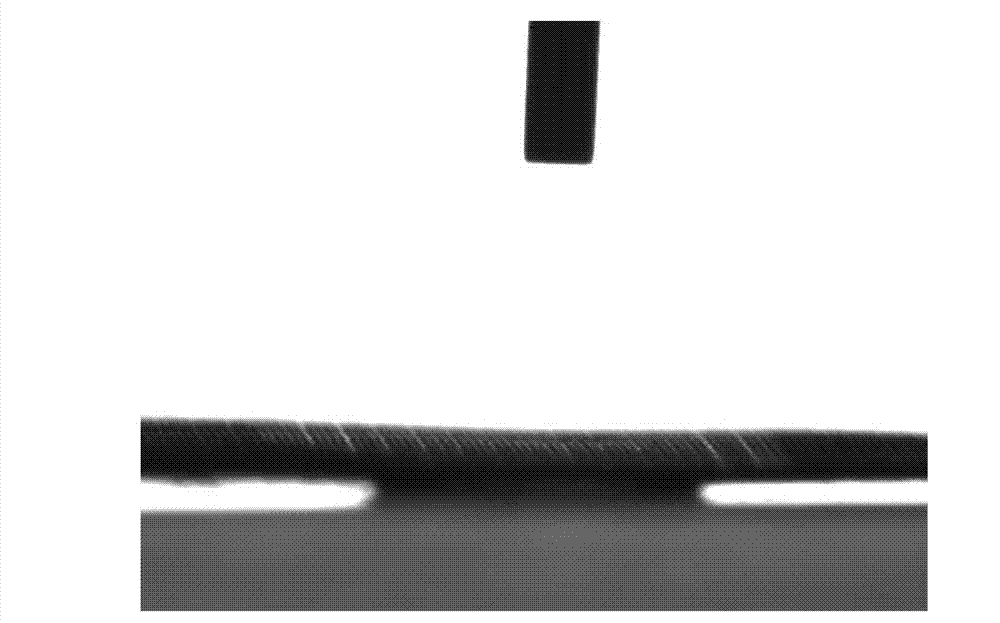

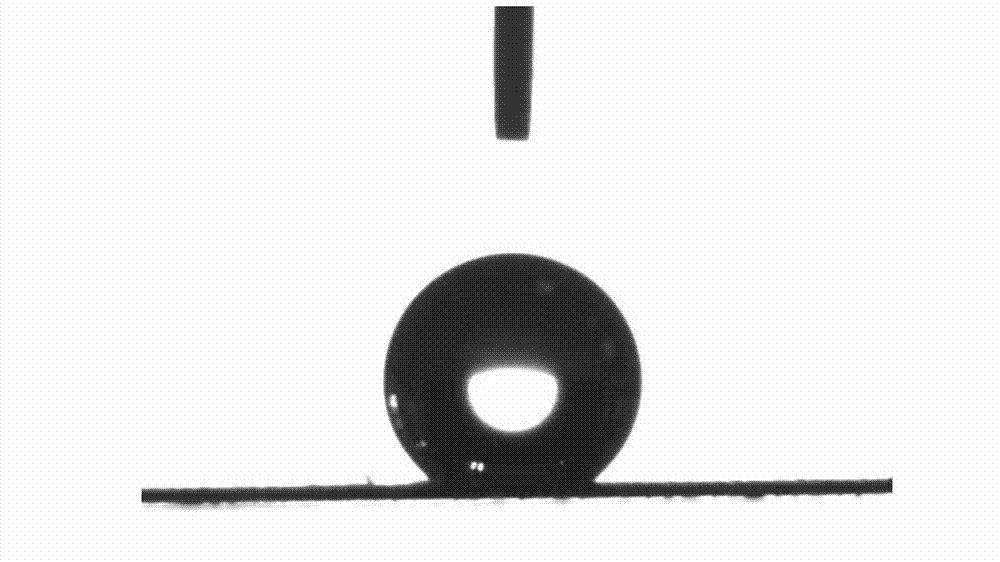

Super-hydrophobic and super-oleophylic oil-water separating mesh membrane and preparation method thereof

The invention discloses a super-hydrophobic and super-oleophylic oil-water separating mesh membrane and a preparation method thereof. The method comprises the following steps of: (1), cleaning a fabric mesh and drying the cleaned fabric mesh; (2), dissolving dopamine hydrochloride and trihytdroxy methyl-aminomethane to water to acquire a mixed solution, wherein the pH value of the mixed solution is 8.0-12.0; (3), soaking the dried fabric mesh in the mixed solution, and then getting out the soaked fabric mesh for drying; (4), dissolving mercaptan compound and sodium hydroxide in water to acquire mixed turbid liquid; (5), soaking the fabric mesh acquired in the step (3) in the mixed turbid liquid, reacting the mixture to acquire the oil-water separating mesh membrane. The oil-water separating mesh membrane disclosed by the invention has high bearing pressure to water so that oil can quickly pass, a separating effect is good, the speed is high, and the separating effect on normal hexane, petroleum ether, benzene, gasoline, diesel oil, animal and vegetable oil, crude oil and the like is good. The oil-water separating mesh membrane is non-toxic and harmless, environment-friendly, easy to clean and keep, can be reusable, and has good stability.

Owner:TSINGHUA UNIV

Dune-fixing vegetative cover restoring material and its production

InactiveCN1854247AImprove water retention and breathabilityImprove desert soilOrganic fertilisersSoil conditioning compositionsFertilizerCellulose

A sort of material used for sand-binding vegetation renewing which consists of plant cellulose, microelements, fertilizer, water-absorbable resin and sand. Rainfall can filter into the sand sufficiently to make sure that seed can germinate and grow while in sunny day sand crusts to prevent water from excess evaporation. It is suitable for migratory dune immobilizing and vegetation renewing. The contradiction between chemical sand-binding and vegetation growth can be settled by this material.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

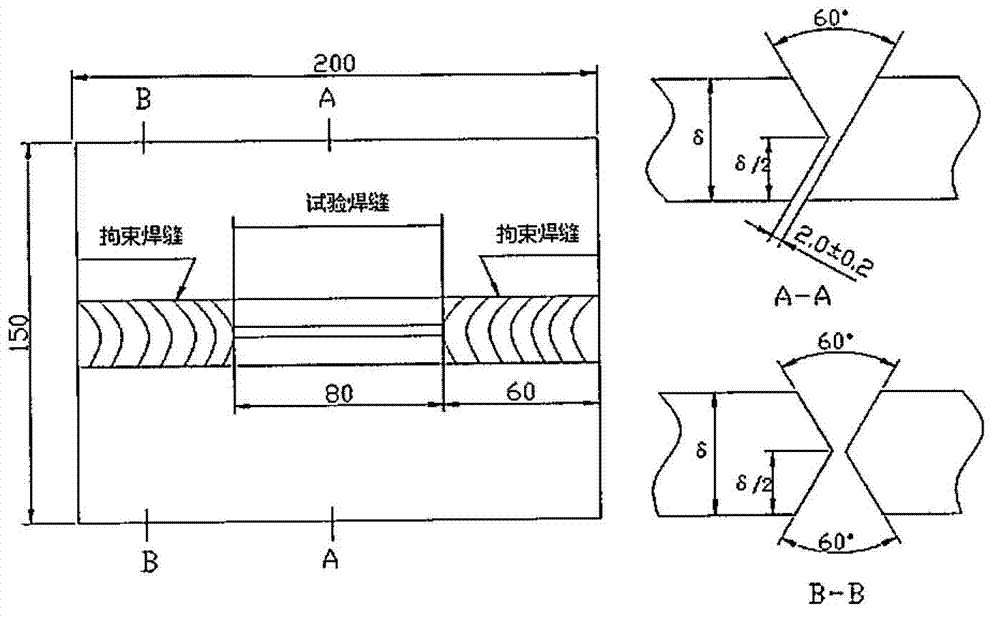

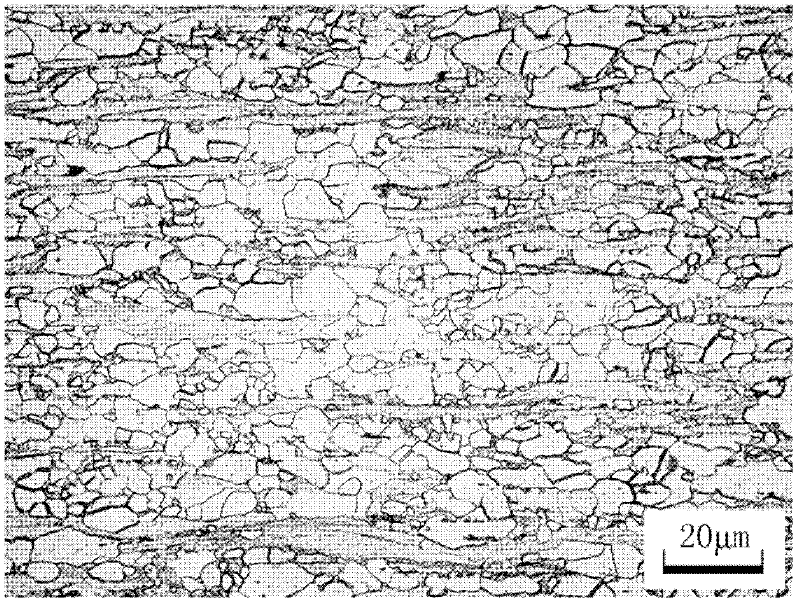

Low alloy steel resisting CO2 and H2S corrosion

The present invention is one kind of low alloy steel capable of being used in oil well pipe to resist CO2 and H2S corrosion. Chemically, its consists of C 0.01-0.30 wt%, Si 0.10-1.0 wt%, Mn 0.10-2.0, Cr 0.50-3.0 wt%, Mo 0.01-1.0 wt%, Ce 0.01-0.25 wt%, V 0.005-0.1 wt%, Cu 0.05-1.0 wt%, Al 0.01-0.10 wt% and small amount of Nb if necessary, except Fe and inevitable impurity, with impurity elements being less than 0.05 wt%. The alloy steel of the present invention after hardening and tempering has mechanical performance reaching the requirement on API 80 and 90 level steel but obviously improved CO2 and H2S corrosion resistance, and is economic oil well pipe steel with moderate cost.

Owner:BAOSHAN IRON & STEEL CO LTD

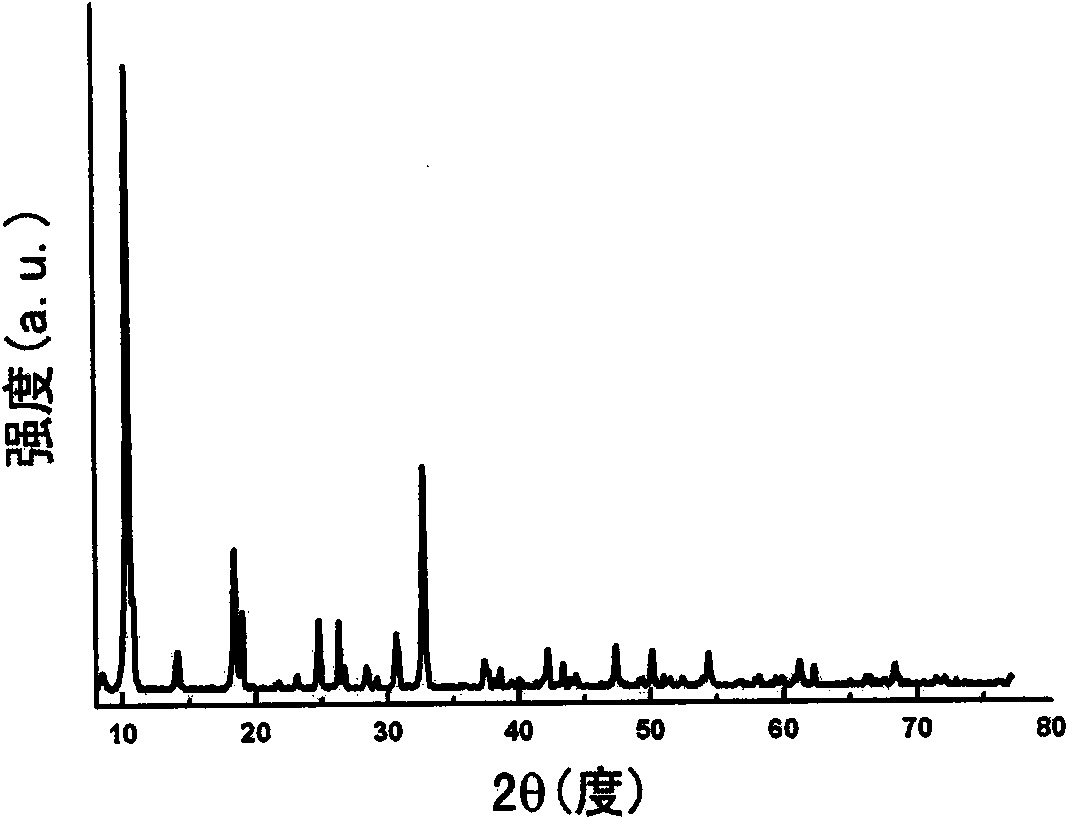

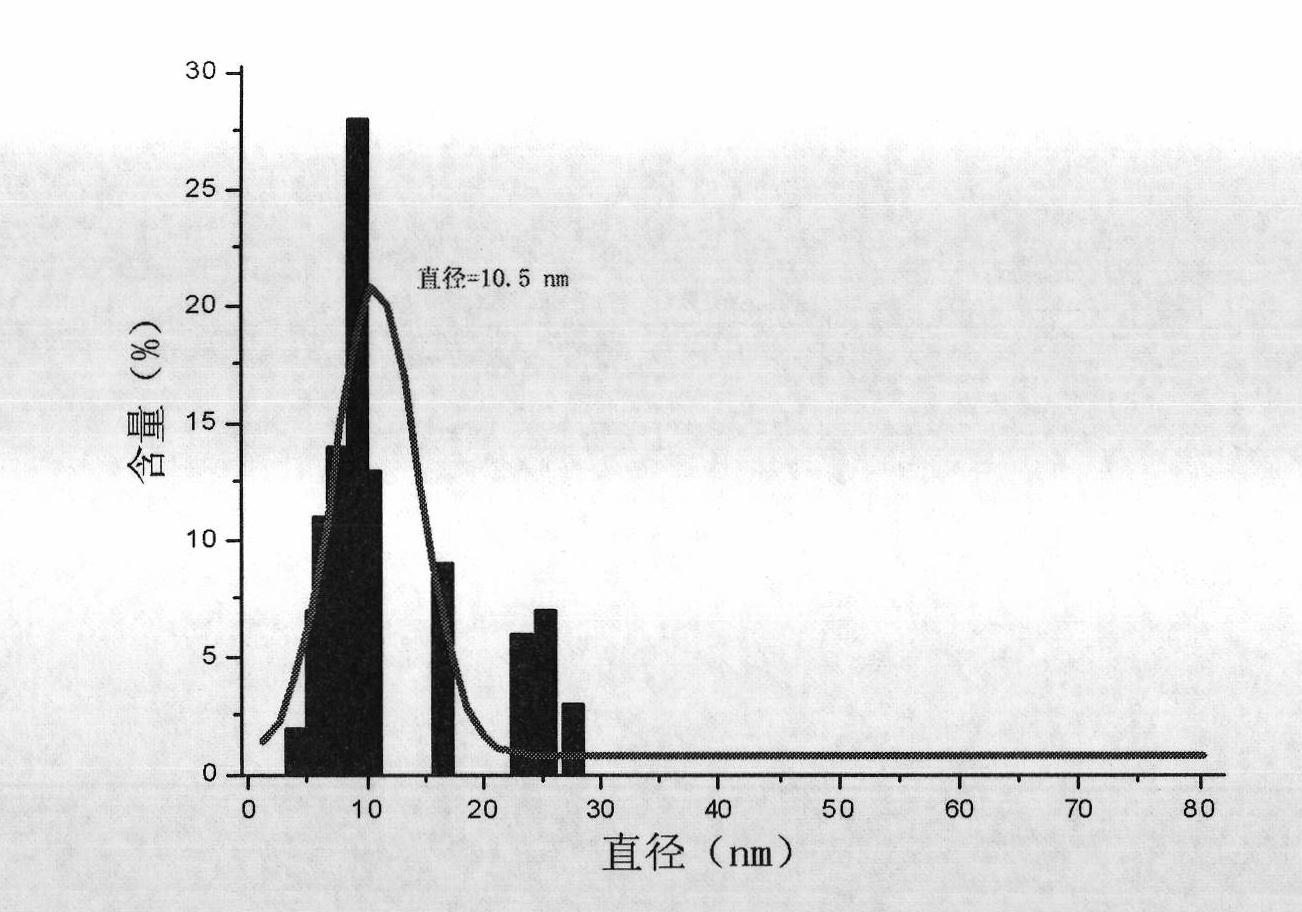

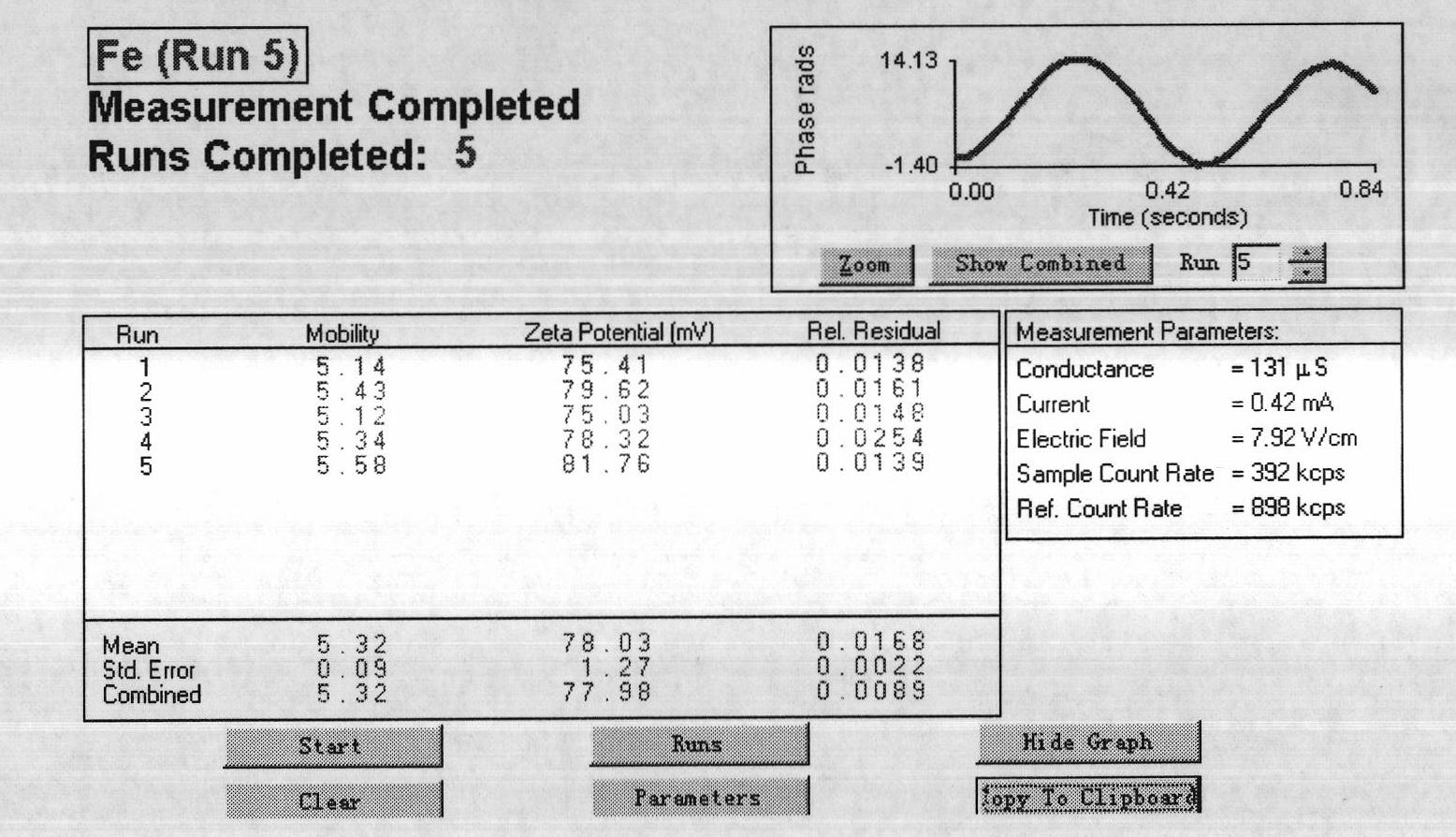

Ultrafine lead oxide prepared by using waste lead plaster and preparation method thereof

InactiveCN103374657AReduce energy consumptionSimple ingredientsReclaiming serviceable partsLead oxidesFiltrationTwo step

The invention discloses an ultrafine lead oxide prepared by using a waste lead plaster and a preparation method thereof. The preparation method comprises the following steps of: carrying out desulphurization process by mixing the waste lead plaster with an aqueous solution containing a composite desulfurizer for reaction; carrying out filtration to remove the desulphurization filtering solution to obtain the desulfurated lead plaster (filter residue); carrying out a leaching and crystal transformation process by adding a citric acid solution and a reducing agent into the desulfurated lead plaster obtained in the process, and carrying out filtration, washing, and drying to obtain the lead citrate after the desulfurated lead plaster reacts with the citric acid solution; carrying out a roasting process by roasting the lead citrate to obtain the ultrafine lead oxide. According to the preparation method disclosed by the invention, the ultrafine lead oxide is prepared from the waste lead storage lead plaster; a two-step leaching process is adopted; the filtering solution is simple in ingredient and can be recycled; a side product is recycled from the desulphurization solution. The preparation method disclosed by the invention is low in energy consumption, simple in equipment, high in lead recycling rate, and high in ultrafine lead product quality, and has the characteristics of good resource recycling effect, environmentally-friendly and pollution-free production process, and capability of clean production.

Owner:湖北金洋冶金股份有限公司 +1

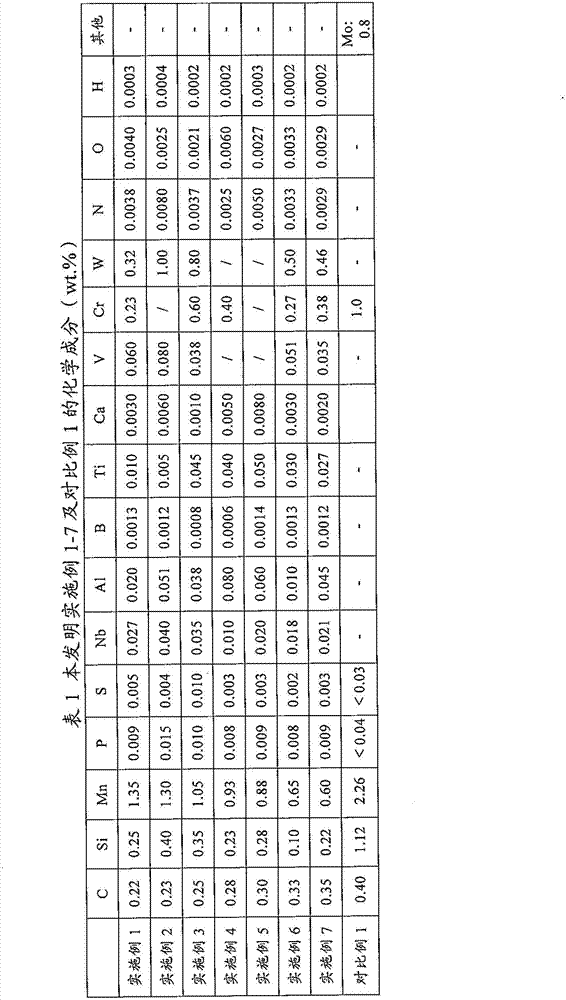

Super-strength high-toughness wear resistant steel plate and production method thereof

ActiveCN102876969AStrong mechanical propertiesGood mechanical propertiesFurnace typesQuenching agentsWear resistantHigh intensity

The invention provides a wear resistant steel plate, comprising the following chemical components (wt%): 0.22-0.35% of C, 0.10-0.40% of Si, 0.60-1.35% of Mn, not more than 0.015% of P, not more than 0.010% of S, 0.010-0.040% of Nb, 0.010-0.080% of Al, 0.0006-0.0014% of B, 0.005-0.050% of Ti, 0.0010-0.0080 wt% of Ca, not more than 0.080% of V, not more than 0.60% of Cr, not more than 1.00 wt% of W, not more than 0.0080% N, not more than 0.0060% of O, not more than 0.0004% of H and the balance of Fe and inevitable impurities, wherein Nb+Ti is not less than 0.025% and not more than 0.080%, and Al+Ti is not less than 0.030% and not more than 0.12%. The production method of the wear resistant steel plate comprises the steps of smelting, casting, rolling and directly cooling after rolling. The wear resistant steel plate obtained through the components and the process has the advantages of high intensity, good low temperature toughness, and excellent mechanical processing performance, and is suitable for easily abrasive devices in engineering and mine machinery, such as a grab bucket, a scraper conveyer and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

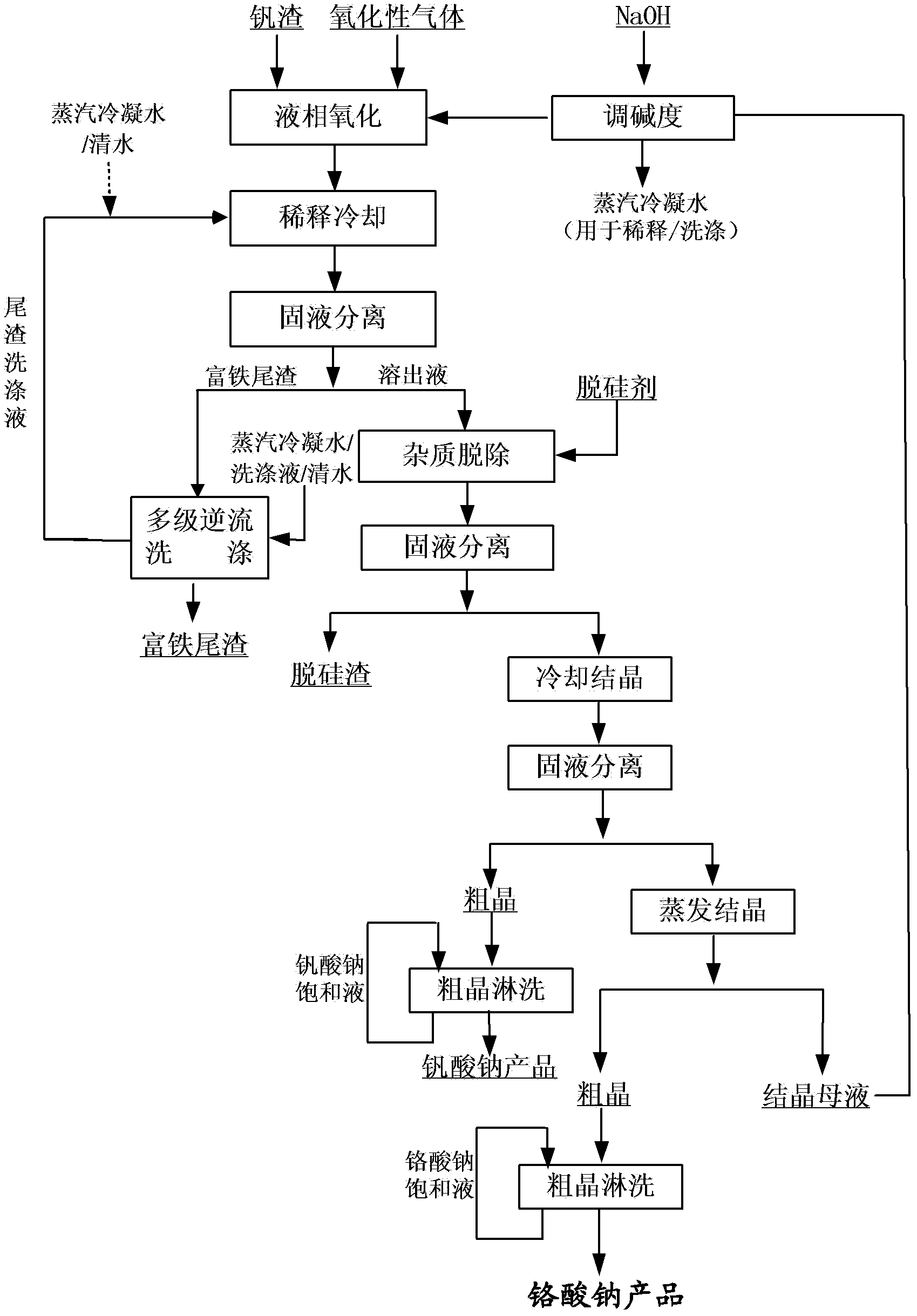

Method for cleaner production of sodium vanadate and sodium chromate by pressure leaching of vanadium slag

ActiveCN102531056ASimple ingredientsAchieve separationChromates/bichromatesVanadium compoundsSlagSlurry

The invention relates to a method for cleaner production of sodium vanadate and sodium chromate by pressure leaching of vanadium slag. The method comprises the following steps of: (1) mixing materials, namely mixing the vanadium slag and a solution of NaOH to obtain a reaction material; (2) reacting, namely performing oxidization reaction on the vanadium slag and oxidizing gas in the solution of NaOH under high pressure to obtain solid-liquid mixed slurry of a solution containing NaOH, Na3VO4, Na2CrO4 and water-soluble impurity components, and iron-rich tailings; (3) performing solid-liquid separation; (4) removing impurities; (5) crystallizing sodium vanadate; and (6) crystallizing sodium chromate. The method is easy to operate and is high in safety; and the operating temperature is greatly lower than the temperature of the traditional vanadium extraction process, energy consumption is low, the high-efficiency co-extraction of vanadium and chromium is realized, and the extraction rate of vanadium and chromium is over 95 percent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Aluminum alloy and aluminum alloy extruded profile machining method

The invention discloses aluminum alloy and an aluminum alloy extruded profile machining method. The aluminum alloy comprises, by weight, 0.6-1.4% of Si, 0.7-1.3% of Mg, 0.1-1% of Cu, 0.1-1% of Mn, 0.01-0.15% of Ti, 0-0.2% of Zr, 0-0.5% of Cr, 0-0.4% of Fe, 0-0.25% of Zn and the balance Al. The aluminum alloy also meets the requirements that the weight percentage range of Mg+Si+Cu is 1.4-3.7%, themole ratio of Mg to Si is 0.7-1.5, and the weight percentage range of Mn+Cr+Zr is 0.1-1.5%. The machining method comprises the steps that (1) a cast ingot of the alloy is subjected to homogenization treatment; (2) the cast ingot is extruded into aluminum profile; (3) extrusion production is conducted; (4) on-line quenching is conducted; (5) tension leveling is conducted; and (6) artificial aging is adopted. According to the aluminum alloy and the aluminum alloy extruded profile machining method, the technology is simple, and the production cost is low.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

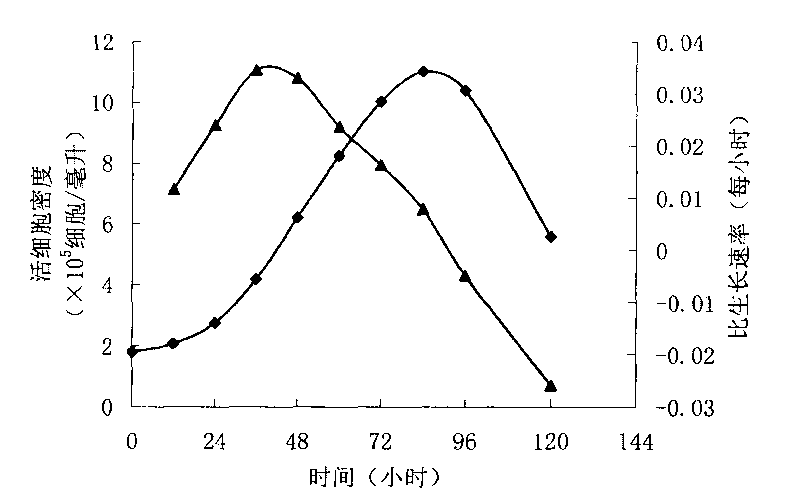

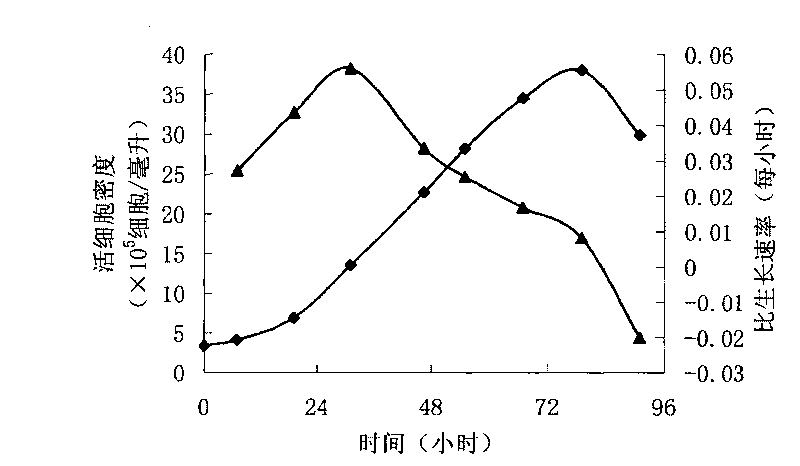

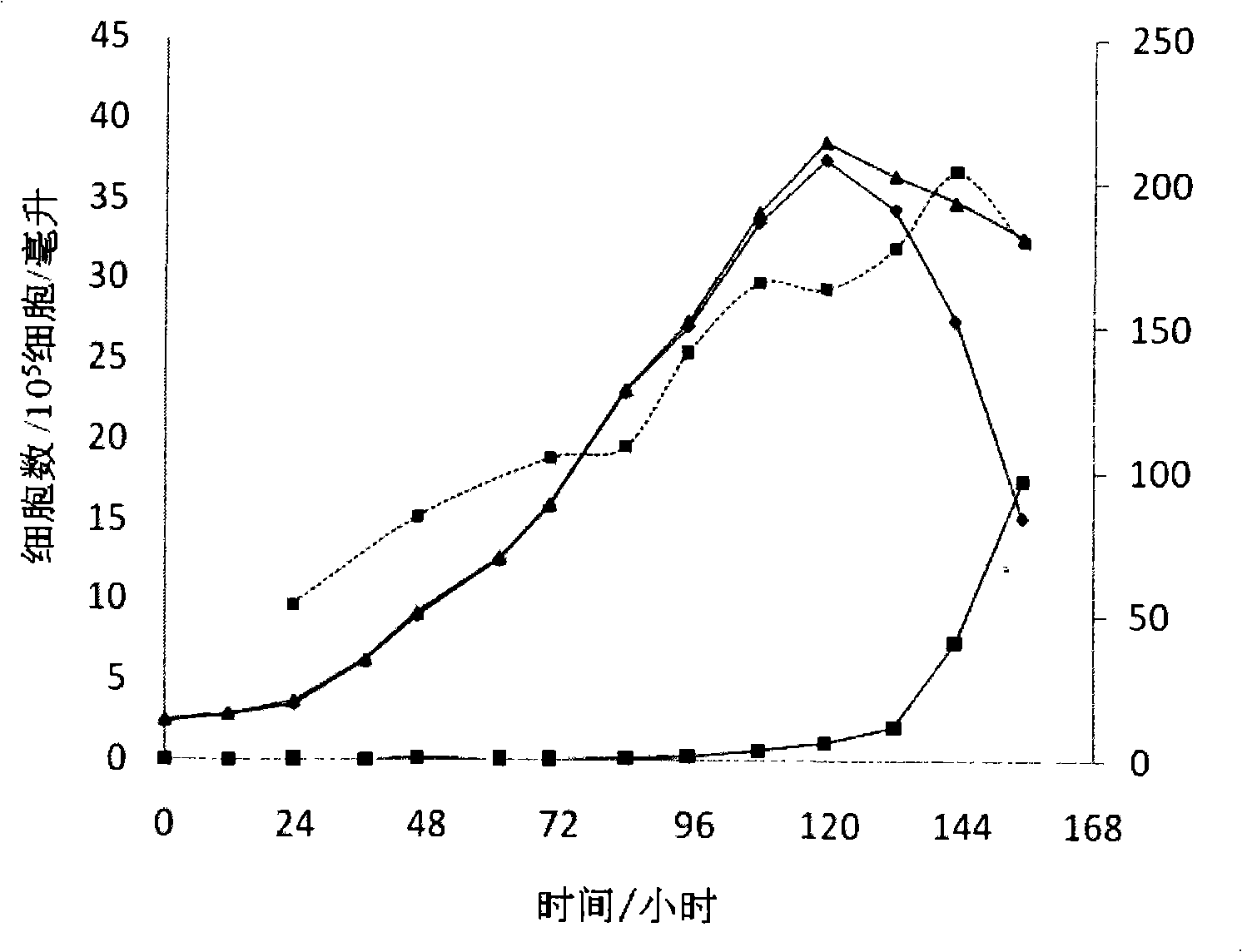

Serum-free medium for MDCK cell large-scale adherent culture and single-cell suspension culture

ActiveCN101760442ASupports adherent growthReduce the burden of separation and purification in the later stageVertebrate cellsArtificial cell constructsLipid formationSerum free media

The invention relates to the culture medium research and development technical field of modern biological technology and provides a serum-free medium for MDCK cell large-scale adherent culture and single-cell suspension culture, which comprises 21 amino acids, 6 vitamins, 8 salts, 8 lipids, 4 trace elements, 2 buffers, 1 protein hydrolysate, 1 acid-base indicator and 6 other additives. The serum-free medium can be prepared by the conventional preparation method, and an application method thereof is the conventional method. The serum-free medium has the beneficial effects that: the serum-free medium does not contain serum, has clear components, is beneficial for separating and purifying the product and improves the product quality; the serum-free medium supports long-term subculture of MDCK cells and does not require long-term and complex adaptation process; and the serum-free medium can well support the adherent growth and single-cell suspension growth of the MDCK cells, has clear components and easy preparation and utilization, and is suitable for mass production of biological products.

Owner:EAST CHINA UNIV OF SCI & TECH

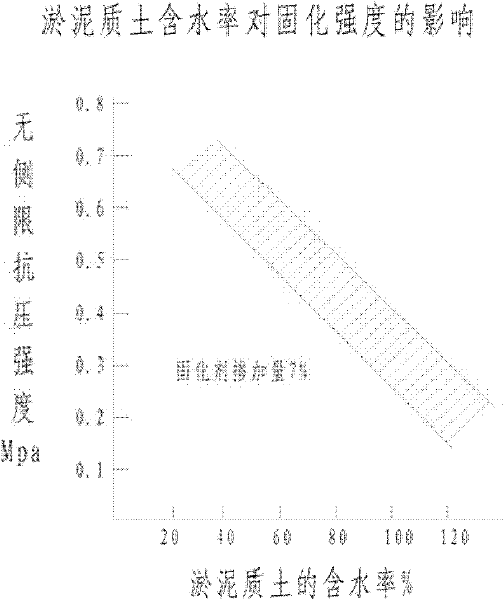

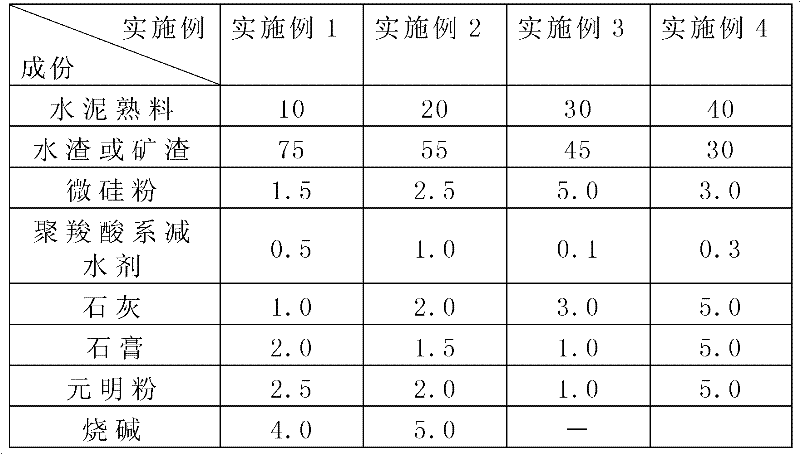

Curing agent for curing marine poor subsoil

ActiveCN102344813ASimple ingredientsCompatibility is reasonableBuilding constructionsOrganic fertilisersSlagSodium silicate

The invention relates to a curing agent for curing marine poor subsoil, which belongs to the technical field of poor subsoil curing. The curing agent for curing the marine poor subsoil is composed by the components of cement clinker, granulating slag or slag, silica fume, polycarboxylic acid type water-reducer, lime, plaster, anhydrous sodium sulphate, caustic soda, sodium silicate and sodium fluosilicate. The adulteration amount of the poor subsoil curing agent is 5%-12% in application, good curing functions can be realized, and the curing agent for curing the marine poor subsoil can be applied in the poor soil curing of building sites, road embankments, roadbeds and ground base layers. The invention has the advantages that: the components of the curing agent are simple, the compatibility is reasonable, the doping amount is less, and the curing effect is good; and during the application process, the construction period is short, the construction cost is low, the induration bearing capacity is high, the induration compression modulus is strong, and the induration permeable resistance is strong.

Owner:徐辰楚 +1

Waste rubber powder modified asphalt composition for increasing storage stability and preparation method thereof

ActiveCN101143968AImproved dispersion and storage stabilitySimple ingredientsBuilding insulationsAsphaltWaste rubber

The invention provides a rubber modified asphalt composition for improving storage stability and a method for preparing the same. Firstly, one or more liquid additives are used to spray the rubber powders, and then the treated waste rubber powders are added into basic asphalt. At appropriate temperature, the rubber powder modified asphalt of the invention can be obtained after treated by high shearing or colloid grinding equipments for a while. The method provided by the invention not only has a simple technology and obviously improves the stability of the rubber powder modified asphalt, and the prepared modified asphalt has good high-and-low temperature performance.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

Nucleocapsid energizing agent for propelling agent and method for preparing same

InactiveCN101549289ASimple ingredientsLow priceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsActive agentVacuum drying

The present invention discloses a nucleocapsid energizing agent for propelling agent and a method for preparing same, the energizing agent is a nucleocapsid structure energizing agent that carbon is encapsulated on a metallic oxide surfaced. The preparing method includes steps as follows: selecting one or some raw materials: address sugar, diose or soluble polysaccharide to mix according with random weight rate for confecting water solution 50-1500g / L, adding the surfactant or dispersant into the water solution, then adding the metallic oxide powder, the metallic oxide weight is 1-60% of the raw material total weight, the surfactants or dispersants weight is 0-4.5% of the metallic oxide weight, ultrasounding or stirring to distribute evenly, heating in 100-260 DEG C during 1-72 hours; reducing the product temperature to a room temperature, washing, centrifuging, removing the water-soluble impurity again and again, then vacuum drying for obtaining the nucleocapsid energizing agent. The nucleocapsid energizing agent has better compatibility with other component of the propelling agent, and has simple preparing technique, low cost, green process and is easy to mass production.

Owner:WUHAN UNIV

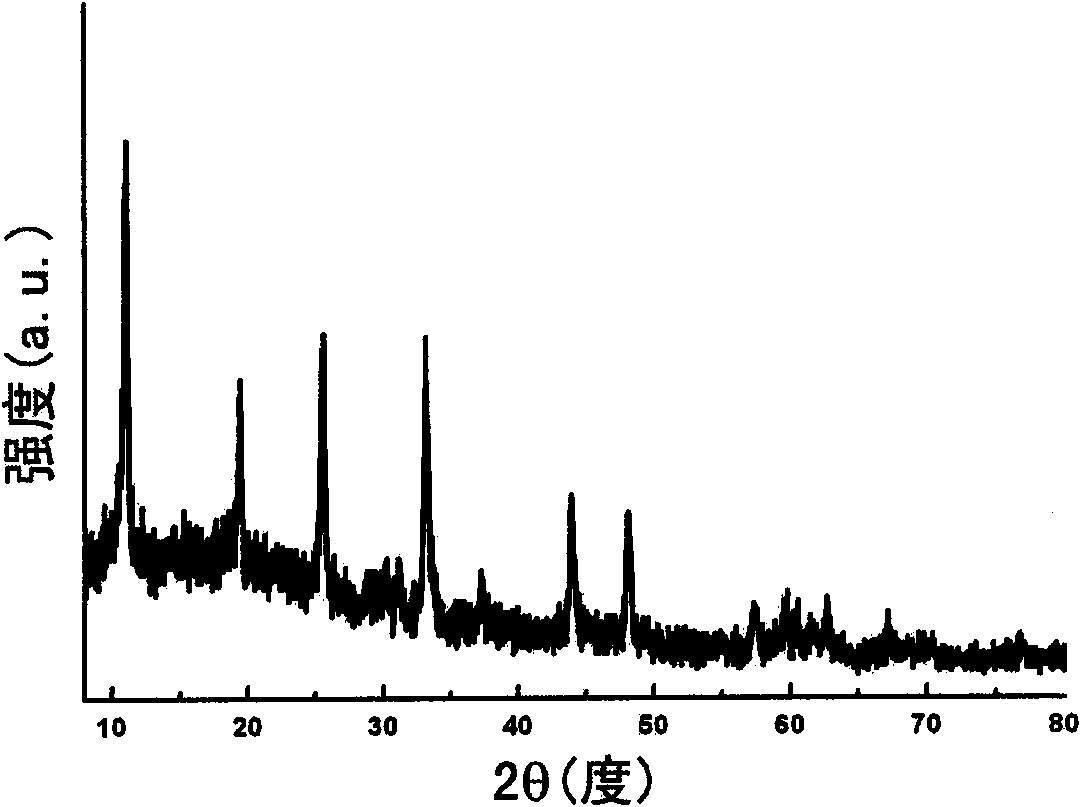

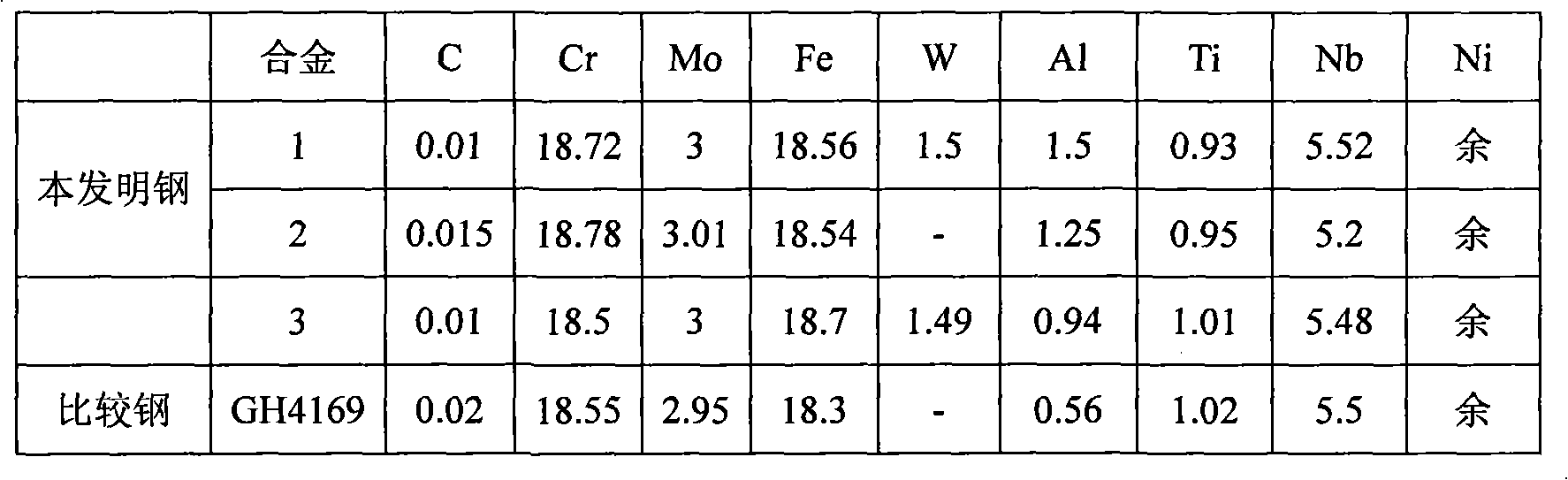

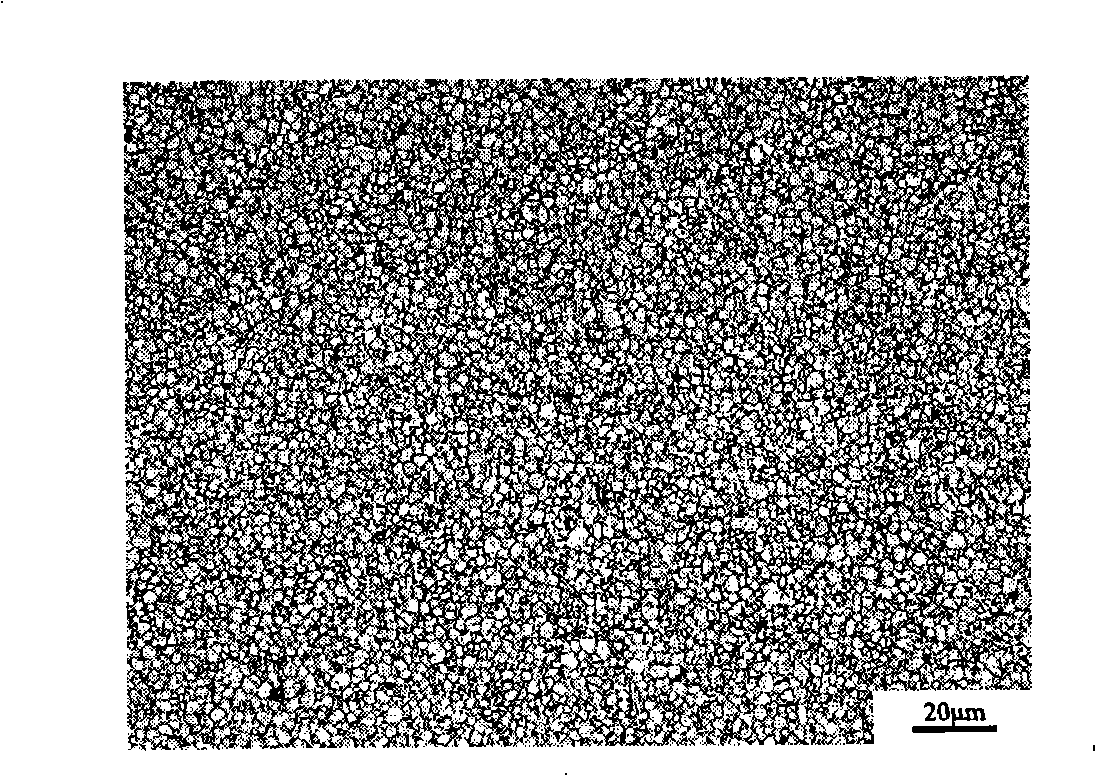

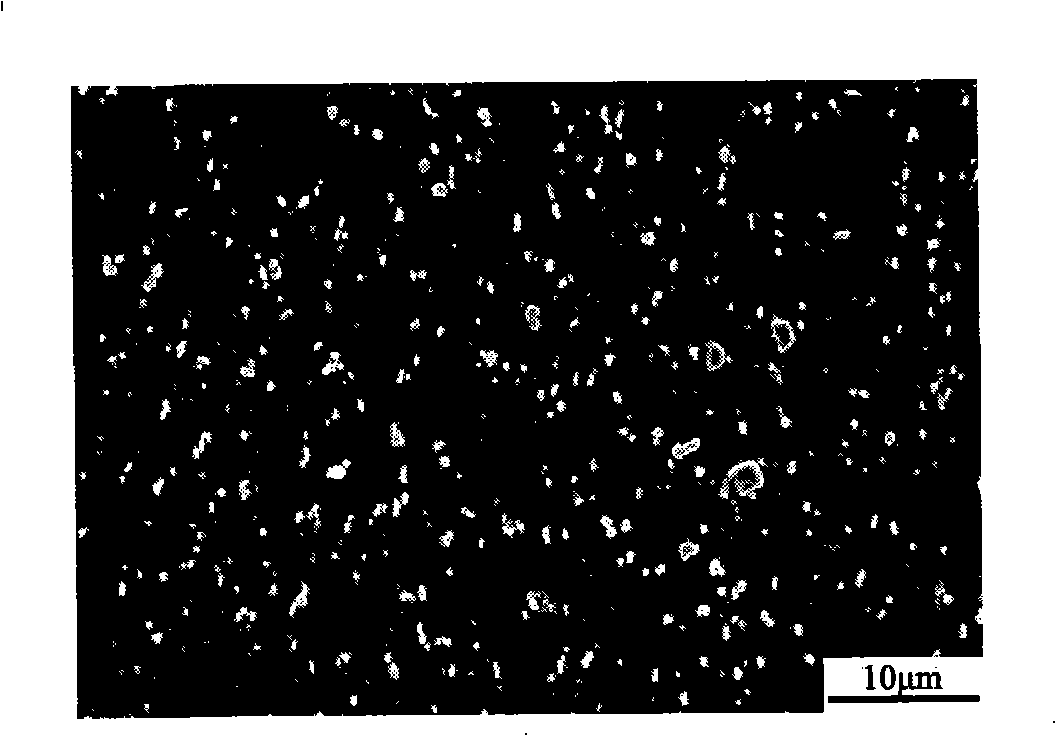

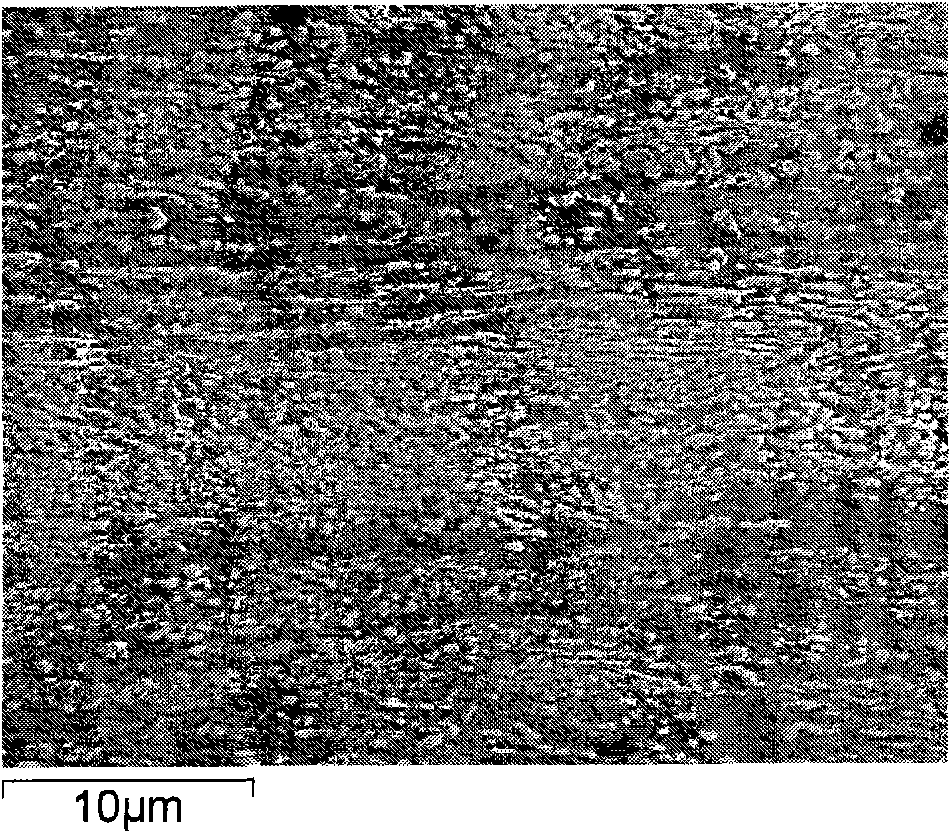

Superfine crystal nickel-based high-temperature alloy and method for preparing same

The invention provides an ultra-fine crystalline nickel base high-temperature alloy and a method for preparing the same, belonging to the high-temperature alloy steel field. The ultra-fine crystalline nickel base high-temperature alloy is particularly applicable to a high-temperature structural component which has high requirement to high-temperature strength and fatigue property, requires superplastic forming and has a complicated structure. The chemical compositions by weight percent of the ultra-fine crystalline nickel base high-temperature alloy are: 17 to 19 percent of Fe, 17 to 20 percent of Cr, 2.8 to 3.3 percent of Mo, 0 to 1.5 percent of W, 0.8 to 1.5 percent of Al, 0.3 to 1.3 percent of Ti, 4.7 to 5.7 percent of Nb, less than or equal to 0.015 percent of C, and the balance being Ni. The preparation method reasonably controls the parameter of a deformation process to allow the deformation temperature to be positioned in a grain boundary precipitated phase region and an austenite phase region which have higher solution temperatures, and uses powerful pinning action of a precipitated phase to the grain boundary to produce the ultra-fine crystalline alloy with a grade of grain fineness of between ASTM12 and ASTM13 grade. Compared with the prior art, the ultra-fine crystalline nickel base high-temperature alloy has simple alloy compositions, greatly reduces the resistance to deformation during forming, has small loss to forging and rolling equipment, and prevents crystal grains from growing when the ultra-fine crystalline nickel base high-temperature alloy is heated for a long time at a high temperature.

Owner:UNIV OF SCI & TECH BEIJING

Solid propping agent for oil-gas well fractrue

InactiveCN1508390ALess types of raw materialsSimple ingredientsFluid removalCeramic particleAluminium

The invention is about to improve the solid ceramic particle proppant of deep oil and gas well fracturing technique, the solid proppant composed of crude bauxitic clay fine powder and 6-10wt% manganese dioxide mineral fine powder. The manganese dioxide reacts with the bauxitic clay main material more completely under high temperature, largely reducing glass phase, and beneficial to raise the compactness of the resultant at the same time, able to largely heighten the guide-flow ability. The solid proppant: bulking density 1.65-1.8g / cu cm, apparent density 3.0-3.15g / cu cm, and breaking resistance (SY / T5108-1997) 86MPa not greater than 10%, the maximum able to reach 100MPa not greater than 10%.

Owner:宜兴东方石油支撑剂有限公司

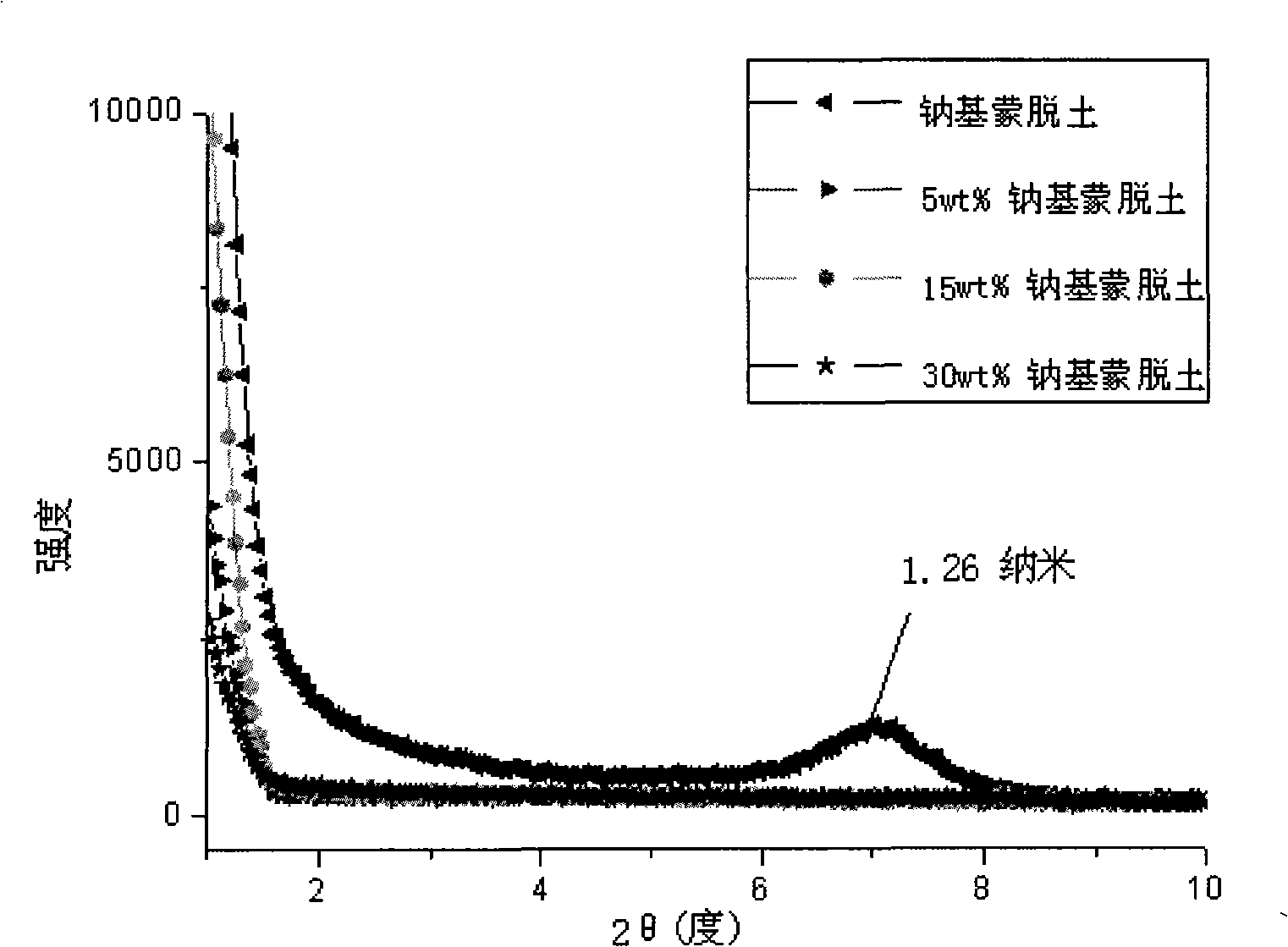

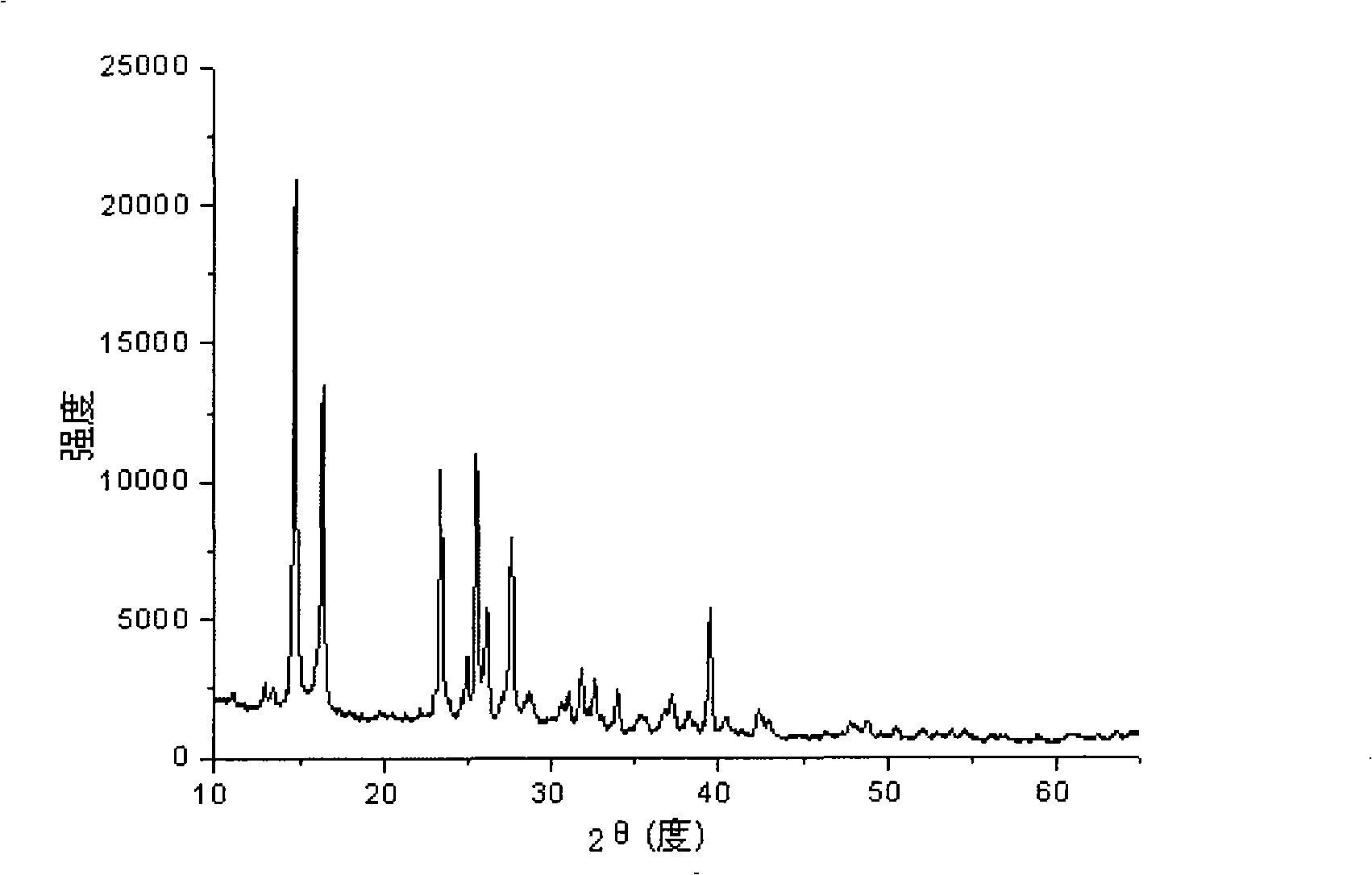

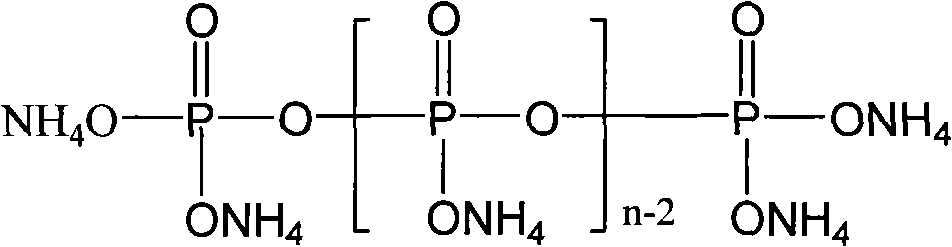

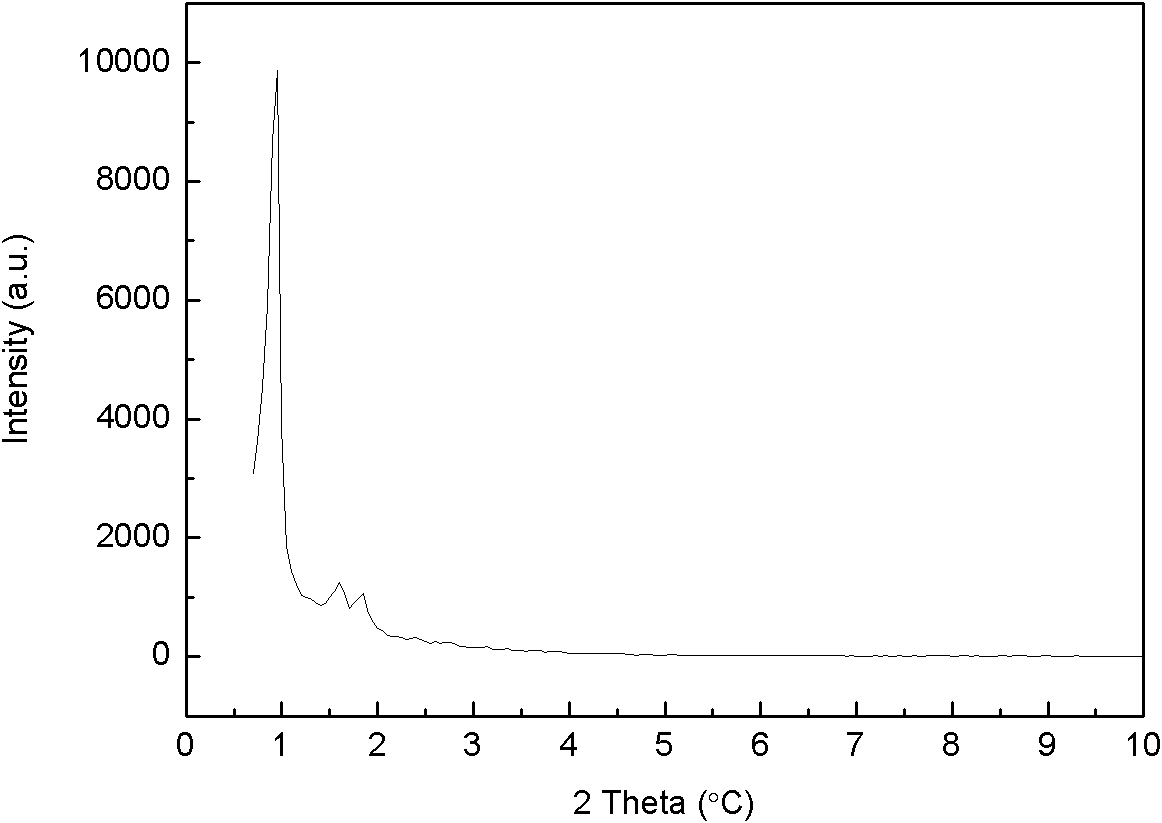

Ammonium polyphosphate, montmorillonite nano complex and preparation thereof

The invention relates to an ammonium polyphosphate and montmorillonite nano compound and a preparation method thereof, which belong to the phosphorous compound preparation, composition, modification and crystalline control field. The method for preparing the nano compound comprises the following steps: montmorillonite is added during the preliminary stage of the process of general preparation of ammonium polyphosphate; ammonia is passed through when the temperature is raised to between 150 and 300 DEG C; heat preservation is performed when the temperature is raised to between 300 and 350 DEG C; and then the ammonium polyphosphate and montmorillonite nano compound are obtained after continuous ammoniation for 30 to 200 minutes. The preparation method controls the purity of an I-type polyphosphoric acid in the product through addition of a specific amount of the montmorillonite; the ammonium polyphosphate completely off a silicate slice of the montmorillonite; and nano-dispersion is formed in the ammonium polyphosphate, and then the ammonium polyphosphate and montmorillonite nano compound is obtained. The nano compound reduces the water solubility of the ammonium polyphosphate, has the function of improving the flame-retardant effect in inflaming retarding of polymer materials, and has the advantages of simple preparation technology and raw materials and low cost.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for producing color-coated plate for structure with yield strength of more than or equal to 550 MPa

InactiveCN102363857APrevent rustNo foamingHot-dipping/immersion processesAcid washingCooling chamber

The invention relates to a method for producing color-coated steel sheet for a structure. The method comprises the following steps of: smelting, namely desulfurizing by molten iron, smelting by a converter, casting continuously to form a blank and performing hot rolling; performing acid washing; performing cold milling; annealing continuously; performing hot dipping on aluminum and zinc; and polishing, straightening, performing color coating and packaging for later use. In the method, the yield strength RP 0.2 (or ReH) is between 550 and 600 MPa; the tensile strength Rm is between 560 and 610MPa; and the percentage elongation after break A80 mm is more than or equal to 6 percent. A neutral salt mist test is performed for 1,200 hours, a coating does not have bubbling and corrosion phenomena. At present, the annealed color-coated plate of which the metallographic structure is ferrite and pearlite or the ferrite and free cementite or the ferrite and the pearlite and less free cementite cannot achieve the effect, and the production cost can be reduced by 10 to 15 percent. By the method, special occasions which have high-yield strength and are used for cooling chambers of automobiles,arch coverings and the like can be met, and a process is simple and easy to implement.

Owner:武钢集团有限公司

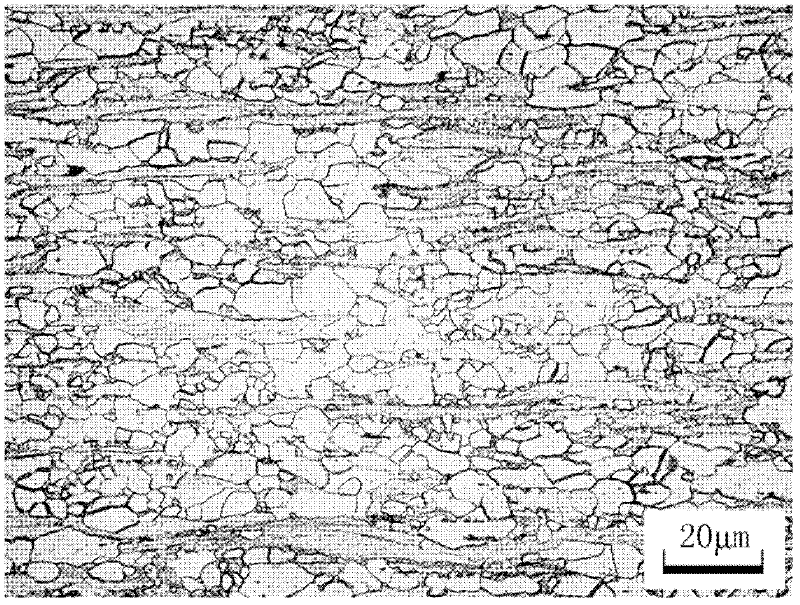

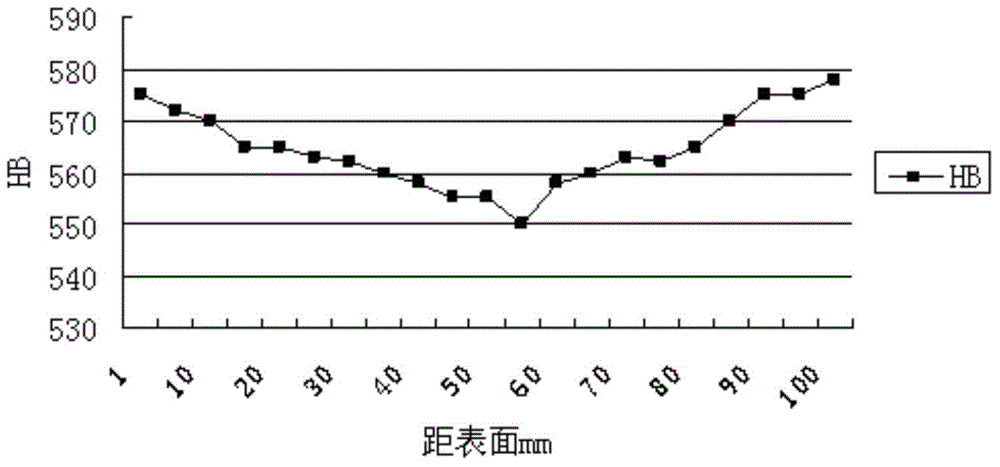

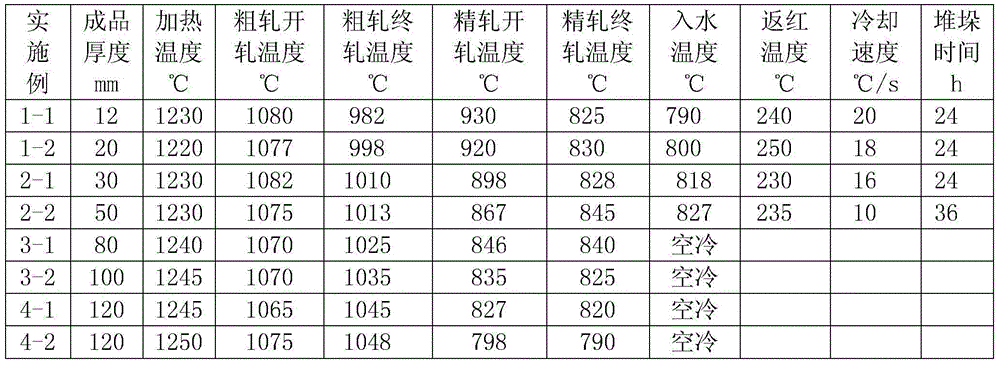

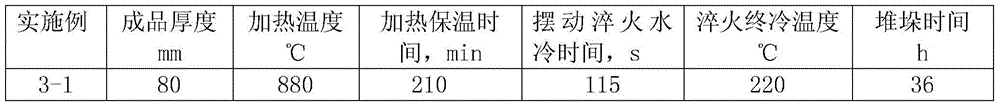

High-strength abrasion-resisting steel plate and production method thereof

The invention provides a high-strength abrasion-resisting steel plate and a production method thereof. The chemical components of the high-strength abrasion-resisting steel plate include, by weight, 0.25-0.30% of C, 0.3-0.5% of Si, 0.40-1.00% of Mn, 0.6-1.2% of Cr, 0.15-0.4% of Mo, 0.01-0.03% of Nb, smaller than or equal to 0.50% of Ni, smaller than or equal to 0.50% of Cu, 0.0005-0.0022% of B, 0.025-0.04% of Ti, 0.020-0.045% of Als, smaller than or equal to 0.015% of P and smaller than or equal to 0.005% of S, wherein Ti / N is greater than or equal to 3.4. During refining, molten steel [N] is controlled to be smaller than or equal to 0.0080%, [O] is controlled to be smaller than or equal to 0.0020%, it is ensured that the effective boron content is 0.0010-0.0020%, and stacking for slow-cooling is performed for 48 hours or more after continuous casting. Two-stage rolling control is adopted, the finish rolling temperature at the first stage is 980-1050 DEG C, out-line quenching is conducted on plate blanks with the thickness greater than 50 mm at the second stage, swinging is performed at the low-pressure section of a quenching machine, on-line quenching is conducted on plate blanks with the thickness smaller than or equal to 50 mm, and residual heat is utilized to perform self tempering. The high-strength abrasion-resisting steel plate has lower carbon and manganese contents and good weldability, the surface hardness is greater than 550 HB, and the toughness at the low temperature of -40 DEG C is greater than 30 J, and the maximum thickness can be up to 120 mm.

Owner:ANGANG STEEL CO LTD

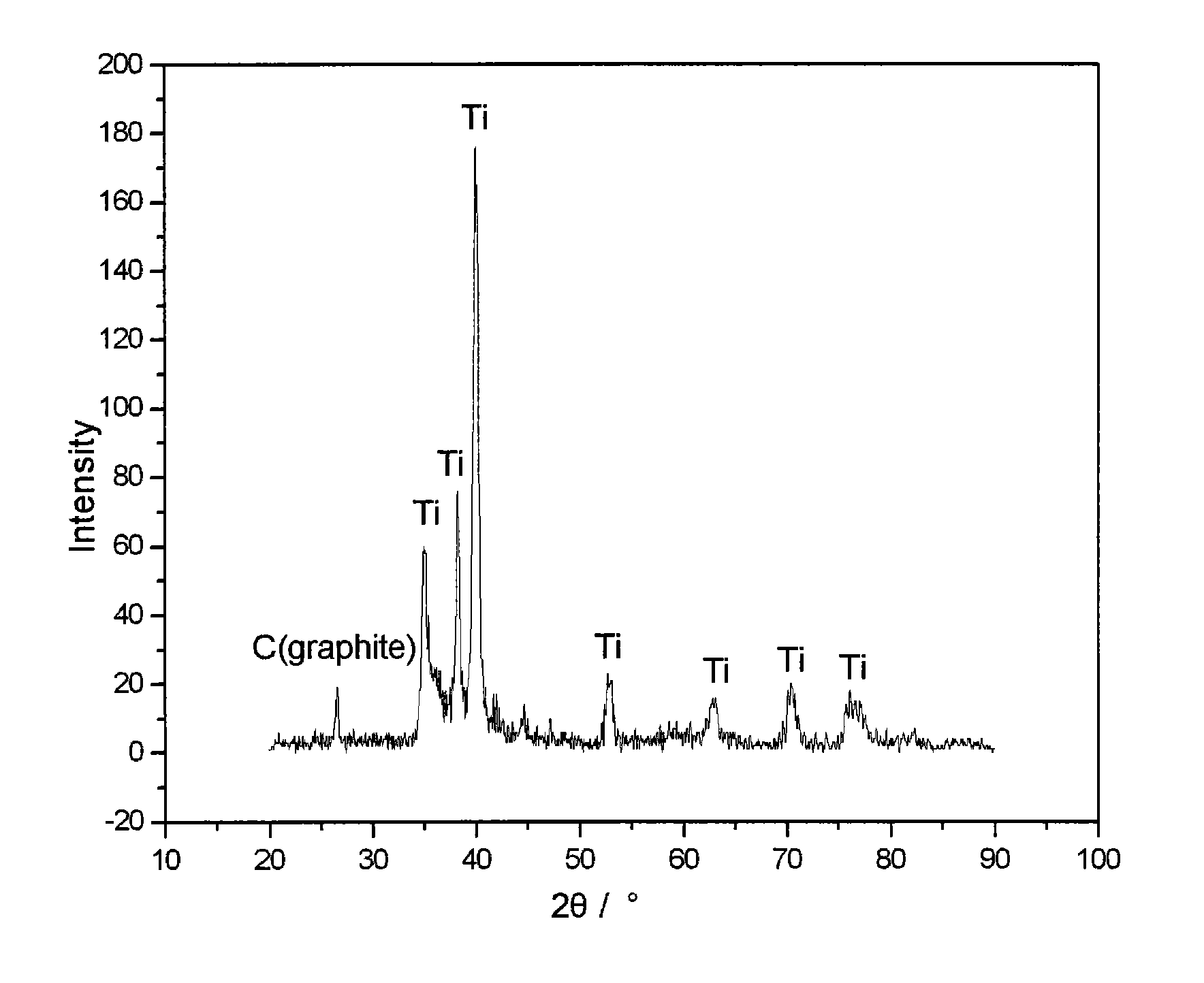

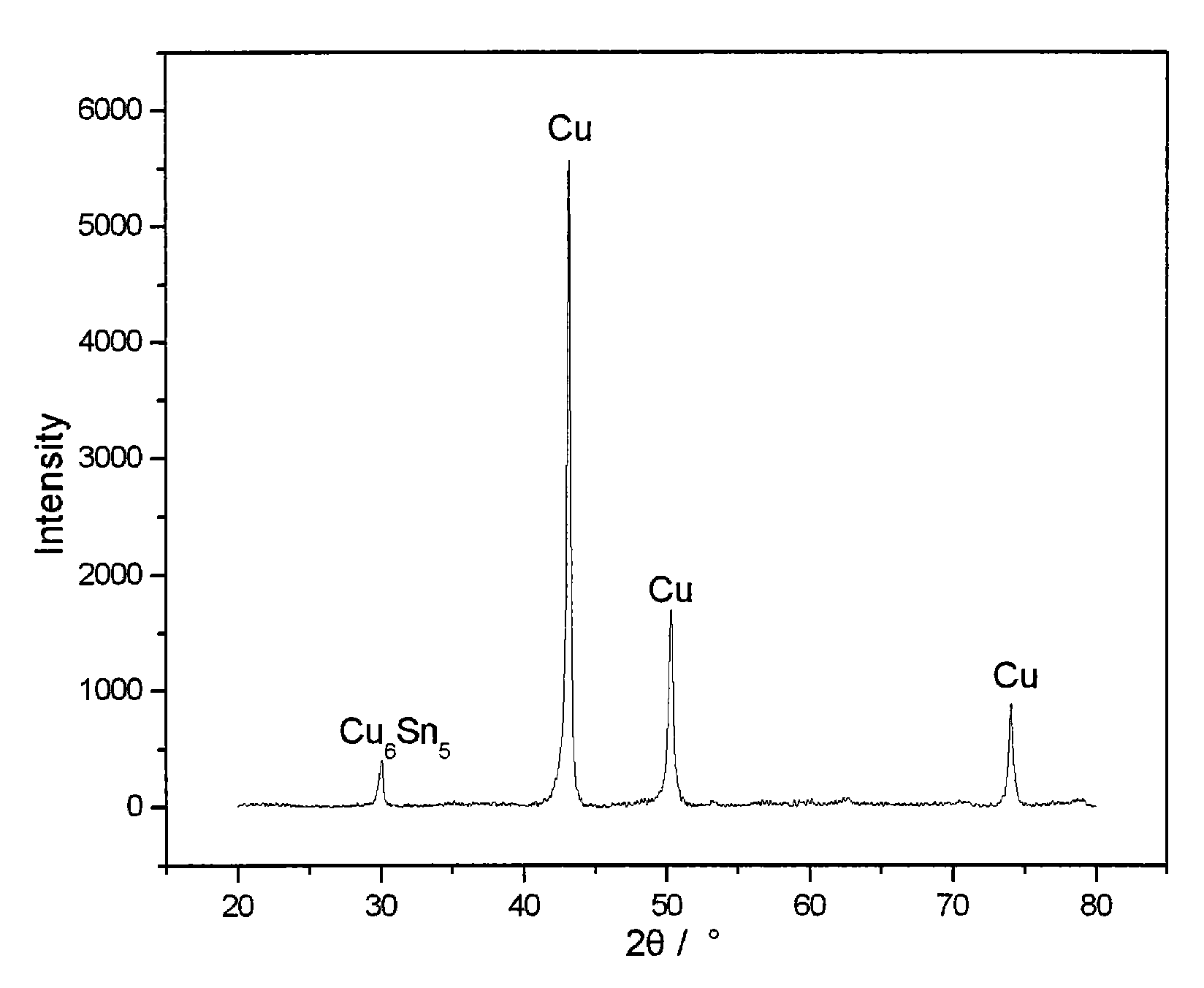

Metal-based powder metallurgy brake lining material and preparation methods thereof

InactiveCN101602105AExcellent material performanceSimple material compositionFriction liningPowder metallurgyCeramic particle

The invention discloses a metal-based powder metallurgy brake lining material and preparation methods thereof. The invention aims to solve the problems that the strength of a material is reduced along with the adding of ceramic particles when the powder metallurgy brake lining material is produced by the prior art and the like. The material comprises the following components in percentage by weight: 10 to 80 percent of Cu-Sn mechanical alloy powder, 1.25 to 15 percent of Ti-C mechanical activated powder, 2 to 65 percent of Fe powder, 0 to 10 percent of Ni powder, 0 to 12 percent of Cr powder, 2 to 8 percent of Al2O3 powder, and 7.75 to 23 percent of graphite, wherein the Cu-Sn mechanical alloy powder is prepared from Sn powder and Cu powder which contains 6 to 10 percent of Sn powder by mechanical alloying beforehand; and the Ti-C mechanical activated powder is prepared from Ti powder and C powder according to the ratio of 2:1-8:1 through mechanical activation beforehand, and forms TiC during the sintering. The invention also provides two preparation methods which combine the mechanical activation and the mechanical alloying with the prior powder metallurgy or discharge plasma sintering method.

Owner:JILIN UNIV

Animal origin-free low-protein culture medium suitable for animal cell product production

ActiveCN101603026AEasy to separate and purifySuitable for productionTissue cultureFermentationLipid formationAntioxidant

The invention relates to an animal origin-free low-protein culture medium suitable for animal cell product production, comprising 24 basic metabolism nutrients, 11 vitamins, 3 transferrin substitute compounds, 5 lipid compounds, 2 nucleic acid compounds, 4 hormones and growth factors, 3 antioxidants, 1 shear-resistant protective agent, 1 pH indicator, 2 pH buffers, 9 other inorganic salts, soy hydrolysates adopted to substitute animal origin component, and composition of ferrous sulfate, ferric nitrate and EDTA-2Na adopted to substitute transferrin. The culture medium can be made by dissolving the aforementioned components in triply distilled water. The positive effects of the culture medium are as follows: the culture medium contains no animal origin component, the total protein content is lower than 10mg / L, which helps separate and purify products and is suitable for production of recombinant protein medicaments; the culture medium supports normal growth and long-term subculturing of animal cells; the culture medium can be used without adaptation, is easily prepared and is suitable for massive production of animal cell products.

Owner:EAST CHINA UNIV OF SCI & TECH

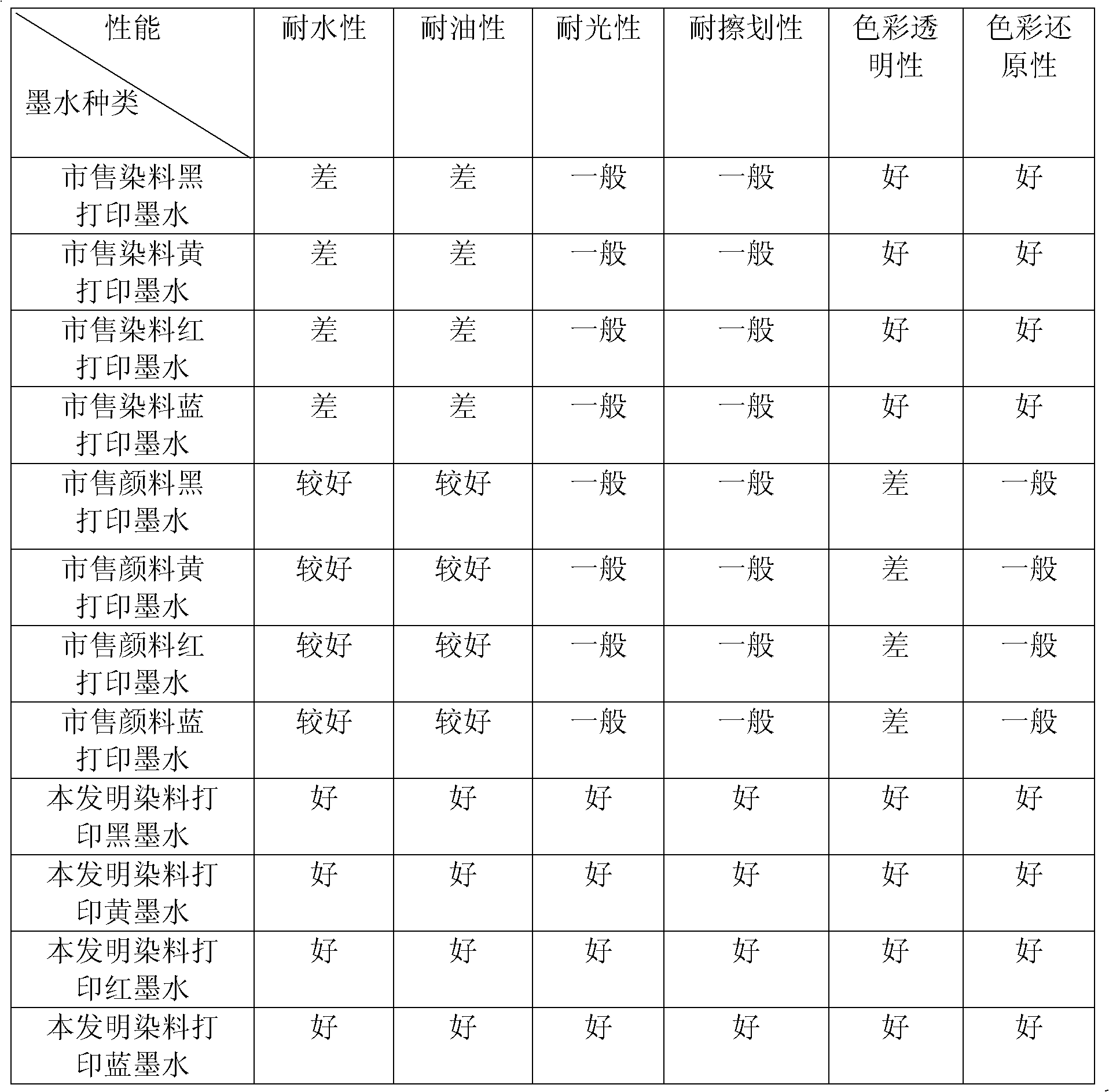

Water-based dye ink and application thereof

InactiveCN101805542AOvercome LightfastnessOvercome fading under lightInksDyeing processTextile printerWater based

The invention discloses a water-based dye ink and an application thereof. The water-based dye ink comprises the following components in percent by weight: 0.2 to 12 percent of water-soluble dye, 55 to 80 percent of modified acrylic resin emulsion, 0.01 to 1 percent of ultraviolet absorbent and balance of water, and different additives can be added. The dye ink can be applicable to the fields such as jet ink, cipher paint ink, textile printing ink, water-type printing ink, fountain pen ink and water ball pen ink, and has the advantages of water resistance, oil resistance, scratch resistance, illumination resistance, high temperature resistance, low temperature resistance, good color reducibility, duration and the like.

Owner:鲁继烈

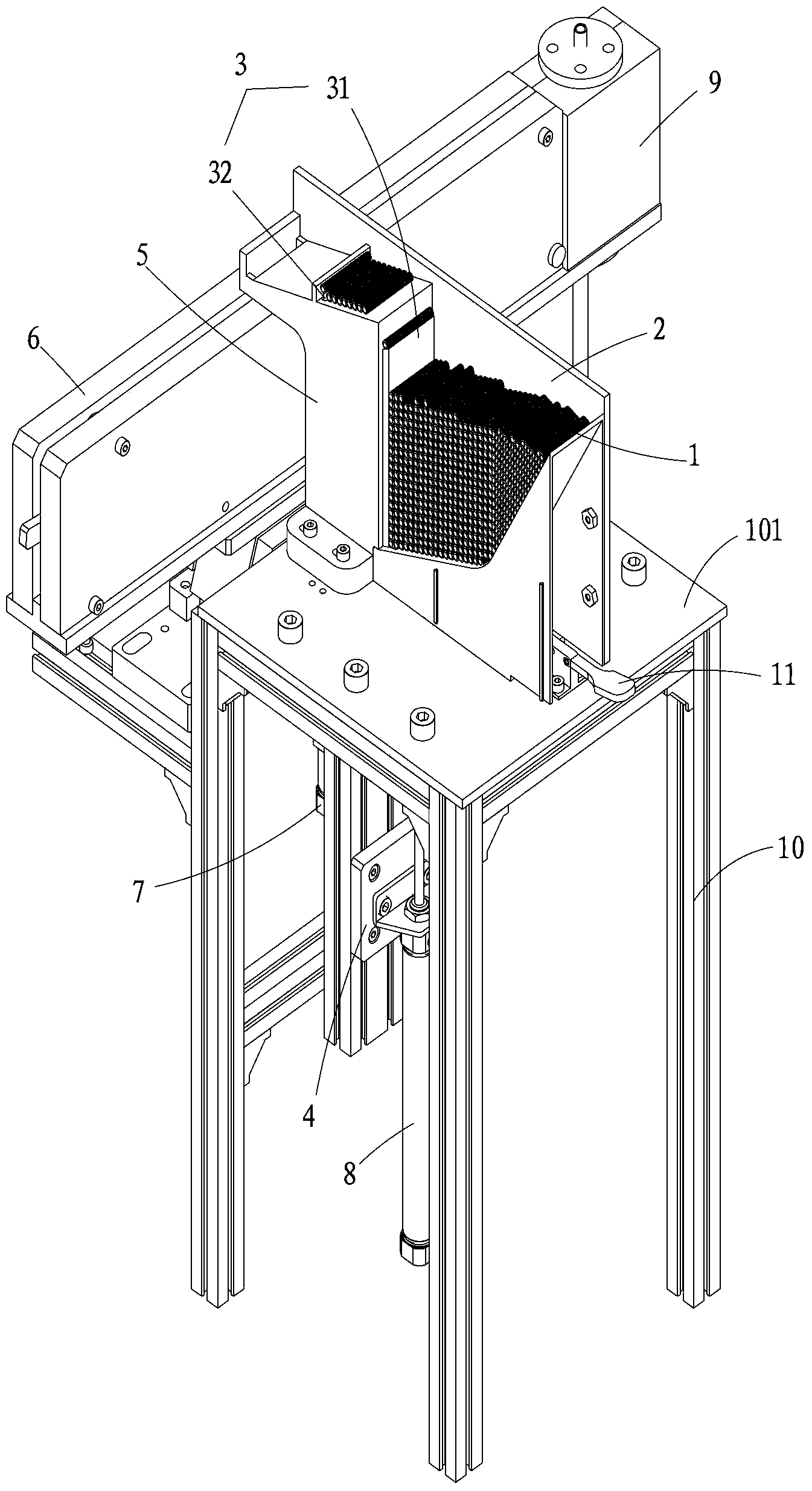

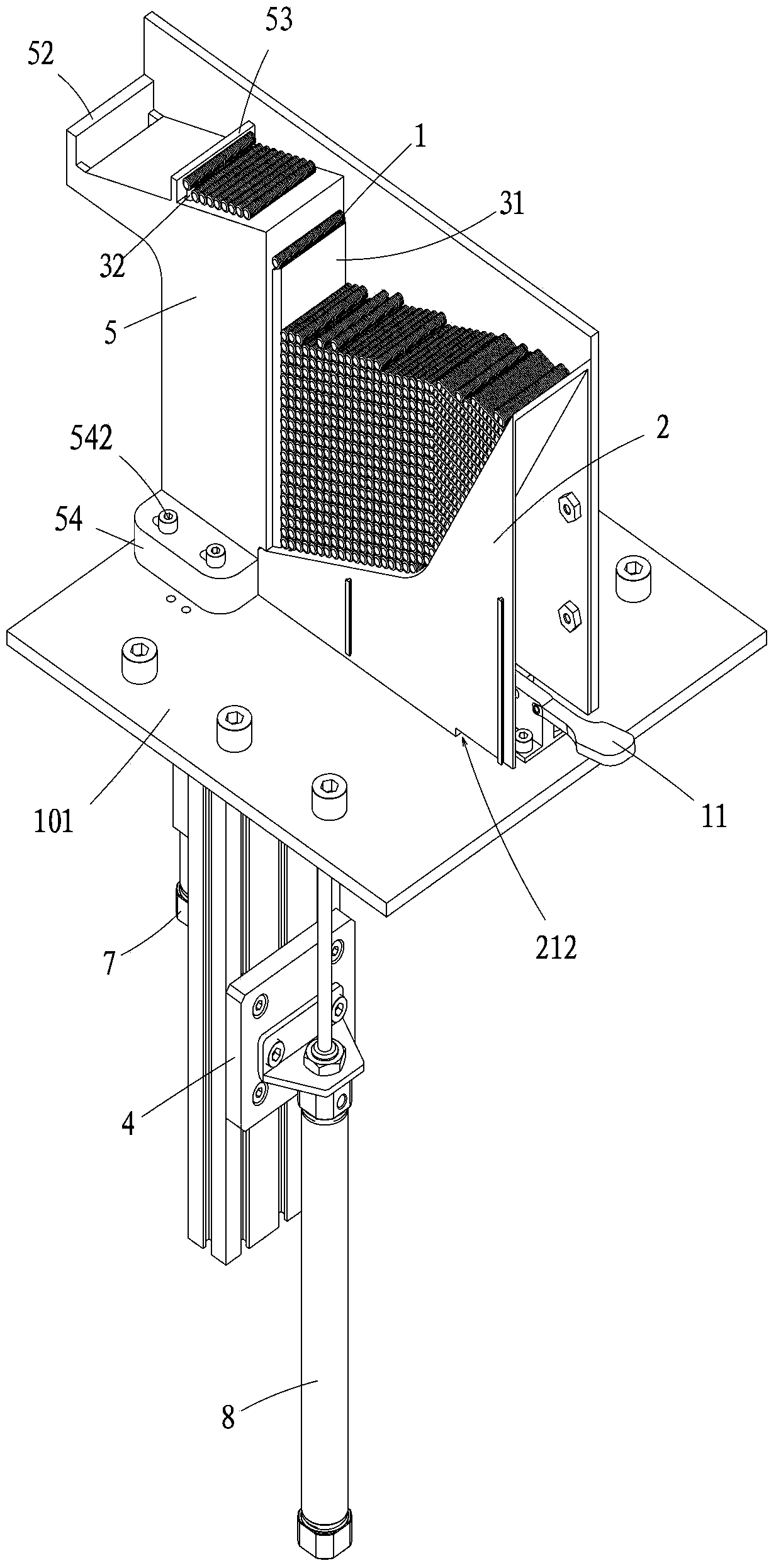

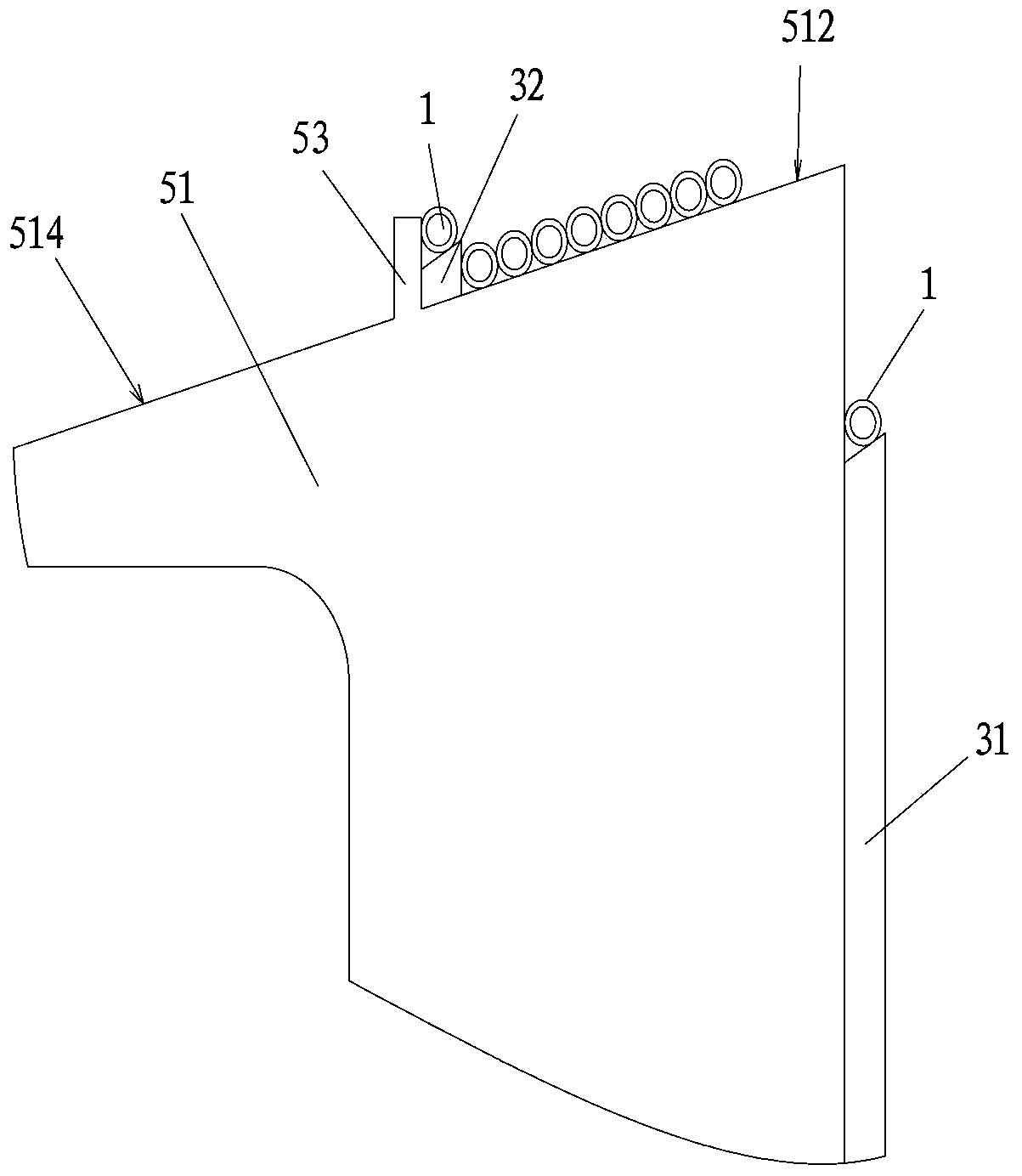

Automatic screw rod feeding device

ActiveCN103523515ASimple ingredientsAccurate and reliable distributionConveyor partsWedge angleButt joint

The invention provides an automatic screw rod feeding device which comprises a machine frame with a worktable, a quick-replaced material box, a feeding part and a material pushing part. The quick-replaced material box is arranged on the worktable of the machine frame and used for carrying screw rods to be conveyed; the feeding part is disposed on the worktable of the machine frame, is in butt joint with the quick-replaced material body and comprises a temporary material storing area and a sliding table of a sliding area, a first blocking element is arranged between the temporary material storing area and the sliding area in a convex mode, a material pushing through groove is formed in the tail end of the temporary material storing area and located in the first blocking element position, a discharging opening is formed in the tail end of the sliding area, and a second blocking element is disposed on the discharging opening; the material pushing part comprises a first-stage wedge angle push plate and a second-stage wedge angle push plate, the two push plates can be driven by a drive mechanism to move vertically, the first-stage wedge angle push plate is vertically arranged on the butt joint portion of the material box and the sliding table, and the second-stage wedge angle push plate is vertically inserted into the material pushing through groove. The automatic screw rod feeding device overcomes the defects that in the prior art, directional feeding of screw rods with special head characteristics is difficult, conveying efficiency is low, and the successful rate of directional feeding is low.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Preparation method and use of poly(lactic-co-glycolic acid) (PLGA) microspheres as nucleic acid vaccine vectors

InactiveCN102485274AGood monodispersityImprove stabilityAntibacterial agentsGenetic material ingredientsMicrosphereGluconic acid

The invention discloses a preparation method and a use of poly(lactic-co-glycolic acid) (PLGA) microspheres as nucleic acid vaccine vectors. A result of an animal immunization experiment shows that the PLGA microspheres can be utilized as gene vaccine vectors. Principles of the PLGA microspheres comprise that 1, the PLGA microspheres have core-shell structures; surface polymers comprise polymine, PLGA, glucose, chitosan, polylysine, FeCl3 and FeCl2; and through static electricity, dewatering interaction and hydrogen bond-nucleic acid vaccine interaction, a nucleic acid vaccine is concentrated to form a compact nucleic acid vaccine so that nucleic acid vaccine degradation is reduced in vivo; 2, the PLGA microspheres have magnetism and thus after immunization injection, in a strong magnetic field, the distribution of the PLGA microspheres in muscular tissue is improved and the defect of limited contact between the PLGA microspheres and target cells is overcome; and 3, through long-term strong magnetic field induction, a magnetic PLGA microsphere / nucleic acid vaccine complex can enter into the skin; and because of rich antigen presenting cells in the skin, a strong and fast immune response can be induced.

Owner:JILIN UNIV

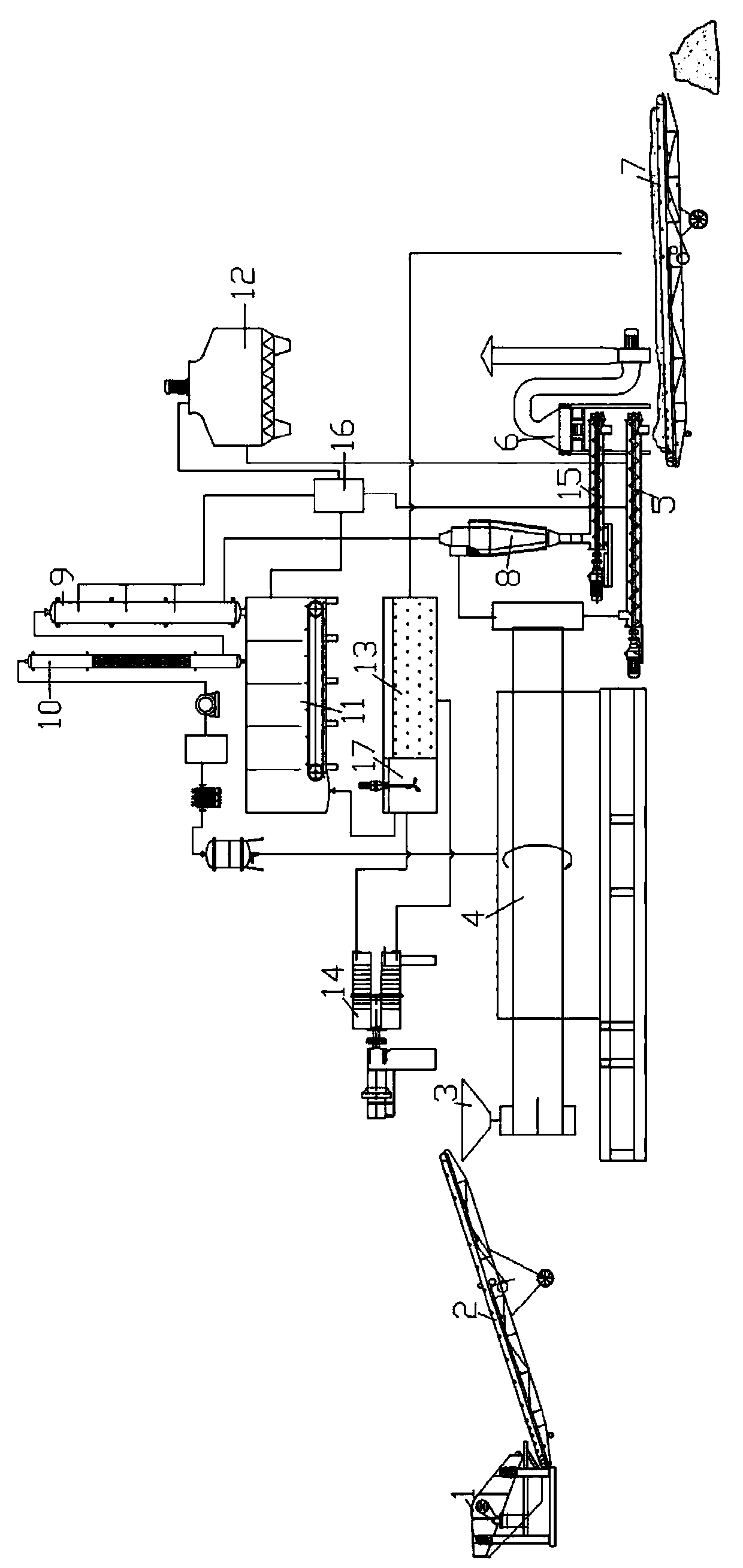

Device and method for indirect thermal desorption disposal of persistent organic pollutant contaminated soil

ActiveCN104226681ASimple ingredientsReduce the risk of secondary pollutionCombination devicesContaminated soil reclamationAutomatic controlCvd risk

The invention discloses a device and a method for indirect thermal desorption disposal of persistent organic pollutant contaminated soil. The device comprises a contaminated soil pretreatment system, a feeding system, a thermal desorption system, a discharging system, a tail gas purification system and an automatic control system, wherein the contaminated soil pretreatment system is connected with a feed opening of the thermal desorption system through the feeding system, a solid discharge opening of the thermal desorption system is connected with the discharging system, and a gas discharge opening of the thermal desorption system is connected with an inlet of the tail gas purification system. According to the method, after pretreatment, contaminated soil is conveyed to the thermal desorption system for desorption for 10-40 min at the temperature of 400-600 DEG C, and desorption exhaust gas adopts a technology including procedures of cyclone dust removal, two stages of spraying, drying and activated carbon adsorption / gliding arc degradation. The device and the method adopt indirect heating, so that risks of generation of poisonous materials such as dioxine and the like are avoided effectively; and a double-layer cylinder rotary kiln type furnace body, the furnace body axis and the ground form a 0-degree angle, and accordingly, the operation and maintenance costs are reduced.

Owner:中节能大地(杭州)环境修复有限公司

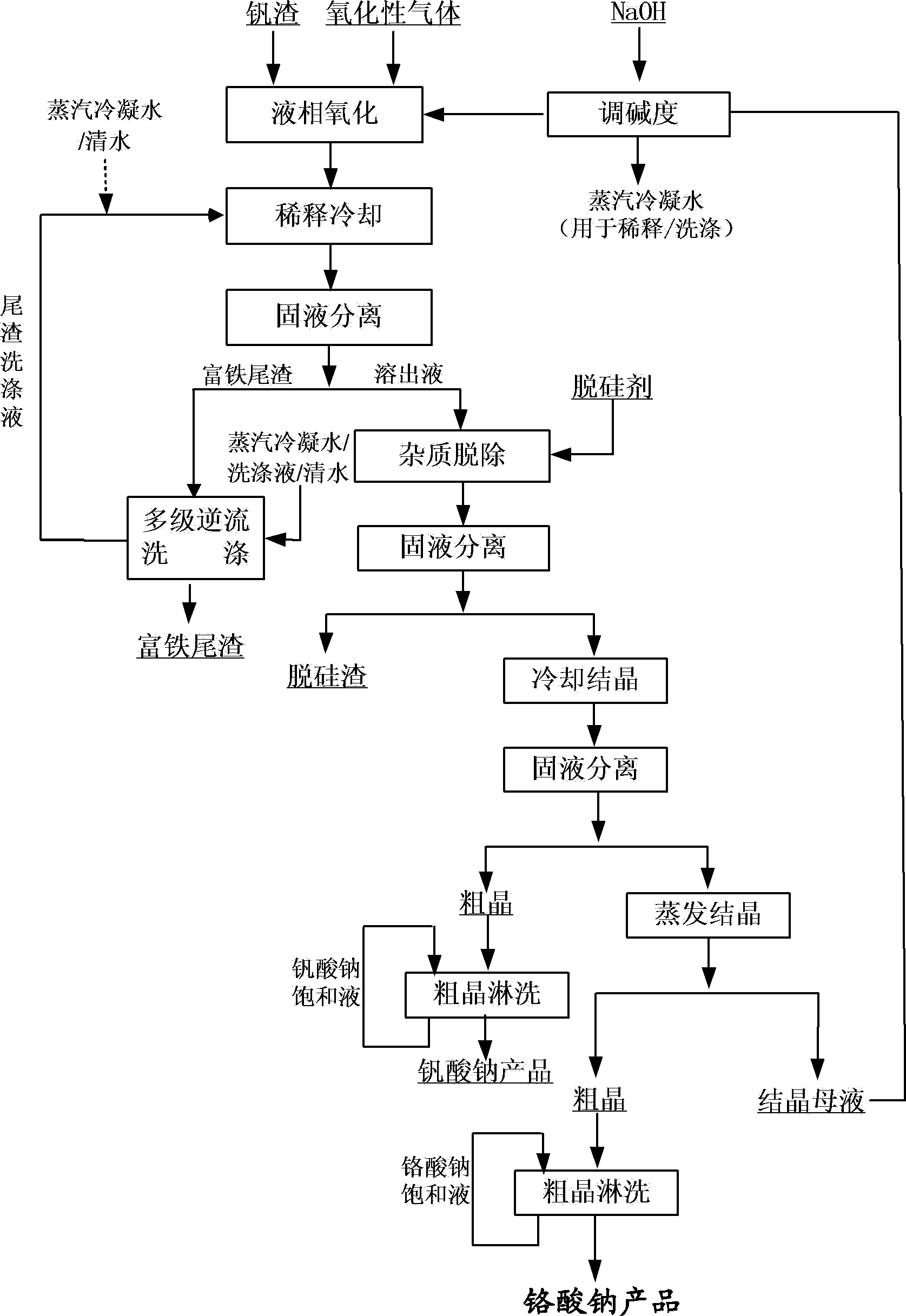

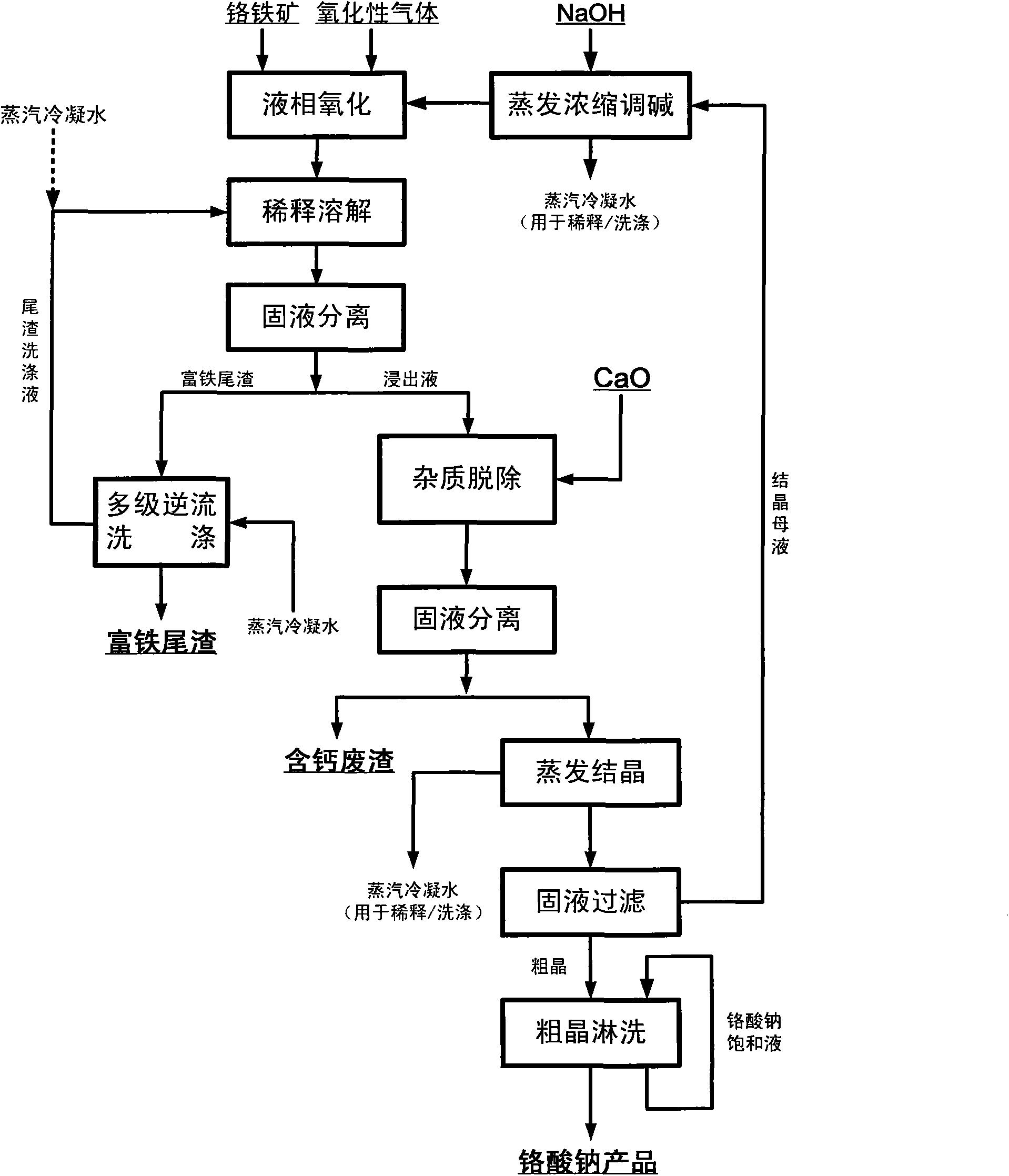

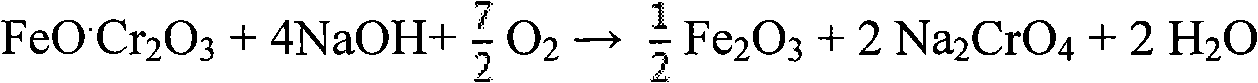

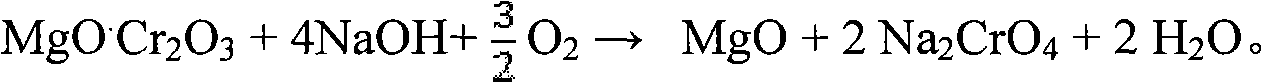

Method for pollution-free production of sodium chromate by pressure leaching of chromite

ActiveCN101817561AObvious superioritySimple ingredientsChromates/bichromatesReaction temperatureHydrometallurgy

The invention belongs to the field of chromite hydrometallurgy and chromium chemical industry, and in particular relates to a method for the pollution-free production of sodium chromate by pressure leaching of chromite. The method comprises the following steps of: 1) reacting the chromite with oxidizing gas in solution of NaOH; 2) diluting the product obtained by the step 1) and making subcrystalline sodium chromate to fully enter a liquid phase; 3) performing solid-liquid separation on the solid-liquid mixed slurry obtained by the step 2); 4) adding calcium oxide into the obtained diluent for removing impurities; and 5) evaporating and crystallizing the obtained solution without the impurities to obtain a sodium chromate crystal and crystallization mother solution; after the solid-liquid separation, rinsing the sodium chromate crystal by using saturated solution of sodium chromate; and drying to obtain a qualified sodium chromate product. The method has the advantages of simple reaction system component, no difficultly separated phase introduced in the system, contribution to high-efficiency separation of the sodium chromate, great reduction in reaction temperature, low energy consumption, effective reduction in production cost of the sodium chromate, and high chromium leaching yield.

Owner:HUBEI ZHENHUA CHEMICAL CO LTD

Preparation method by using Chinese medicine residue as cultivation material of edible mushroom pleurotus ostreatus

The invention relates to a preparation method by using Chinese medicine residue as a cultivation material of edible mushroom pleurotus ostreatus, which uses the Chinese medicine residue, banana peels, bran, sawdust and lime as raw materials, and is prepared by crushing, insolating, proportioning the materials and sterilizing; specific steps are as follows: respectively crushing the banana peels, the bran and the sawdust into granules; placing the bran, the sawdust and the Chinese medicine residue outdoors to expose to the sun for sterilizing and dewatering; mixing the insolated bran, sawdust and Chinese medicine residue with the crushed banana peels, and then adding water and mixing with the lime sufficiently and uniformly, sterilizing at high temperature to obtain the cultivation material. The preparation method has advantages as follows: the waste Chinese medicine residue from medicine factories and the banana peels are used for culturing high-quality edible mushrooms, the waste is changed into things of value, the production cost is saved, the cultivation period is shortened, the yield is increased, the mushroom contamination rate is reduced with no poison or harm, the eating is safe, the waste treatment difficulty is resolved without causing pollution, both the environmental purpose and the economic purpose are achieved, the operation is simple, and the industrial production is easy to achieve.

Owner:AOWEI TIANJIN ENVIRONMENTAL PROTECTION TECH

Economical high-strength binding strip steel with tensile strength more than or equal to 1,000 MPa, and manufacturing method thereof

The invention discloses economical high-strength binding strip steel with tensile strength more than or equal to 1,000 MPa, and a manufacturing method thereof. The steel comprises the following components in percentage by weight: 0.25 to 0.42 percent of C, 1.0 to 2.0 percent of Mn, less than or equal to 0.45 percent of Si, less than or equal to 0.04 percent of S, less than or equal to 0.04 percent of P, less than or equal to 0.08 percent of Al, and the balance of Fe and inevitable impurities. The manufacturing method comprises a steelmaking process for clean steel smelting controlled in inclusion forms, a hot rolling process, a cold rolling process and a bluing-annealing process. The manufacturing method can realize the clean production of high-strength binding strip steel, reduces production processes, improves the production efficiency, and can obtain the economical high-strength binding strip steel with well matched strength and plasticity and the tensile strength more than or equal to 1,000 MPa while significantly reducing production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

Refining agent for aluminum and aluminum alloy

ActiveCN101967565AAffect the service lifeWill not corrodeProcess efficiency improvementSlagPotassium

The invention relates to a refining agent for aluminum and aluminum alloy. The refining agent is characterized by mainly comprising the following components in percentage by mass: 30 to 85 percent of NaCl, 5 to 40 percent of Na2SiF6, 5 to 40 percent of Na2SO4, 2 to 20 percent of CaF2 and 0.5 to 5 percent of C6C16; and the refining agent also can comprise one or more of CaMg(CO3)2, Na3AlF6, Na2S2O3 and NaF. The potassium-free refining agent provided by the invention has good slag forming performance, strong gas and impurity removing capability and low cost; and the aluminum ash produced by refining the aluminum and the aluminum alloy through the refining agent can realize recycle.

Owner:江西广恒铝业有限公司

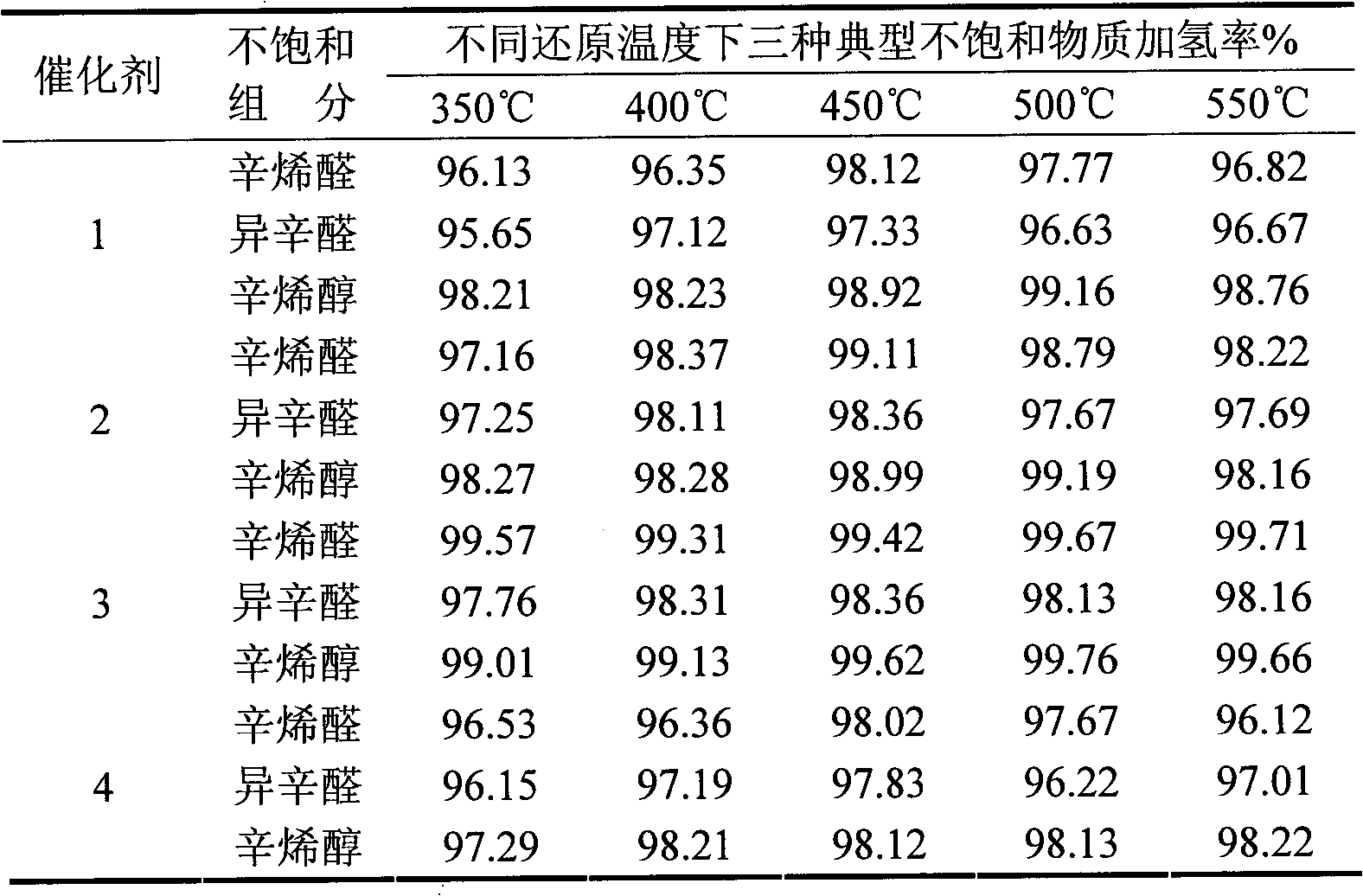

Lanthanum-modified nickel-copper octanol hydrorefining catalyst, preparation and application thereof

ActiveCN102059121AReduce generationReduce coalescenceOrganic compound preparationHydroxy compound preparationReaction temperatureOctanol

The invention relates to a lanthanum-modified nickel-copper octanol hydrorefining catalyst, preparation and application thereof. The catalyst is prepared by taking Gamma-Al2O3 as a carrier, taking lanthanum as an auxiliary agent, taking nickel-copper as a active component and adopting an immersion method; and the aluminum oxide accounts for 40-90%in the terms of 100% by mass, the content of nickel is 1-40% in the terms of NiO, the content of copper is 1-30% in the terms of CuO, and the lanthanum as the auxiliary agent is 0.1-10% in the terms of La2O3; and a hydrogenation evaluation result indicates that the catalyst is reduced at a temperature of 350-550 DEG C, and under the conditions that the reaction temperature is 120 DEG C, the reaction pressure is 2.5MPa, the volume ratio of hydrogen to liquid is 8:1 and the volume air speed is 3.0h<-1>, the hydrogenation rates of unsaturated substances such as octylene aldehyde, isooctyl aldehyde and octylene alcohol are all more than 95%.

Owner:PETROCHINA CO LTD +1

High-dispersity acidic copper plating additive as well as preparation method and application thereof

InactiveCN105734623AImprove ductilityImprove current efficiencyPrinted element electric connection formationDispersityCopper plating

The invention relates to the field of highly dispersive all-bright acidic copper plating of printed circuit boards, in particular to a highly dispersive acidic copper plating additive and its preparation method and application. A highly dispersed acidic copper plating additive: at least one divalent sulfide main brightener, at least one polyethylene glycol or polypropylene glycol or both block copolymer polymer inhibitors, at least one alkyl quaternary ammonium salt Type cationic surfactant, 5‑50ml / L sulfuric acid, 0.1‑4ml / L formaldehyde. Its preparation method is to slowly add a specified amount of concentrated sulfuric acid into water, stir evenly and cool to room temperature, then sequentially add the inhibitor, surfactant, main brightener and formaldehyde into the sulfuric acid aqueous solution, stir until completely dissolved Concentrate to the final volume to obtain the highly dispersed acidic copper plating additive of the present invention. The high-dispersion acidic copper plating additive of the invention is especially suitable for electroplating through-holes with high thickness-to-diameter ratio of printed circuit boards, and can obviously improve the dispersion ability of the plating solution.

Owner:GUANGDONG LEAR ELECTROCHEM LTD

Method for removing cyanogens-containing waste gas

InactiveCN102734812AHigh catalytic activity and selectivitySimple ingredientsMolecular sieve catalystsIncinerator apparatusChemistryNitrogen gas

The invention relates to a method for removing cyanogen-containing waste gas. A catalytic removal reaction is carried out on cyanogen-containing waste gas by using a transition metal supported mesoporous molecular sieve catalyst, wherein a mesoporous molecular sieve carrier is MCM-41, MCM-48, SBA-15, SBA-16, KIT-5 or KIT-6; a transition metal active component is one or more of Cu, Co, Cr, Mn, Ag or V; and the mass ratio of the carrier to the transition metal component is 1;(0.02-0.07). The method comprises the following steps: placing the molecular sieve catalyst in a fixed bed quartz reactor; introducing a mixed gas of the cyanogens-containing waste gas, oxygen and nitrogen into a reaction furnace at the space speed of 17000-24000h<-1> at normal pressure under the condition that the temperature of the reaction furnace is raised to 350-650 DEG; and removing the waste gas through catalytic combustion. The prepared catalyst is used for inspecting the selective catalytic combustion of the cyanogens-containing waste gas, has the characteristics of low combustion starting temperature and high N2 selectivity, and is suitable for efficient purification of the cyanogen-containing waste gas.

Owner:BEIJING UNIV OF CHEM TECH

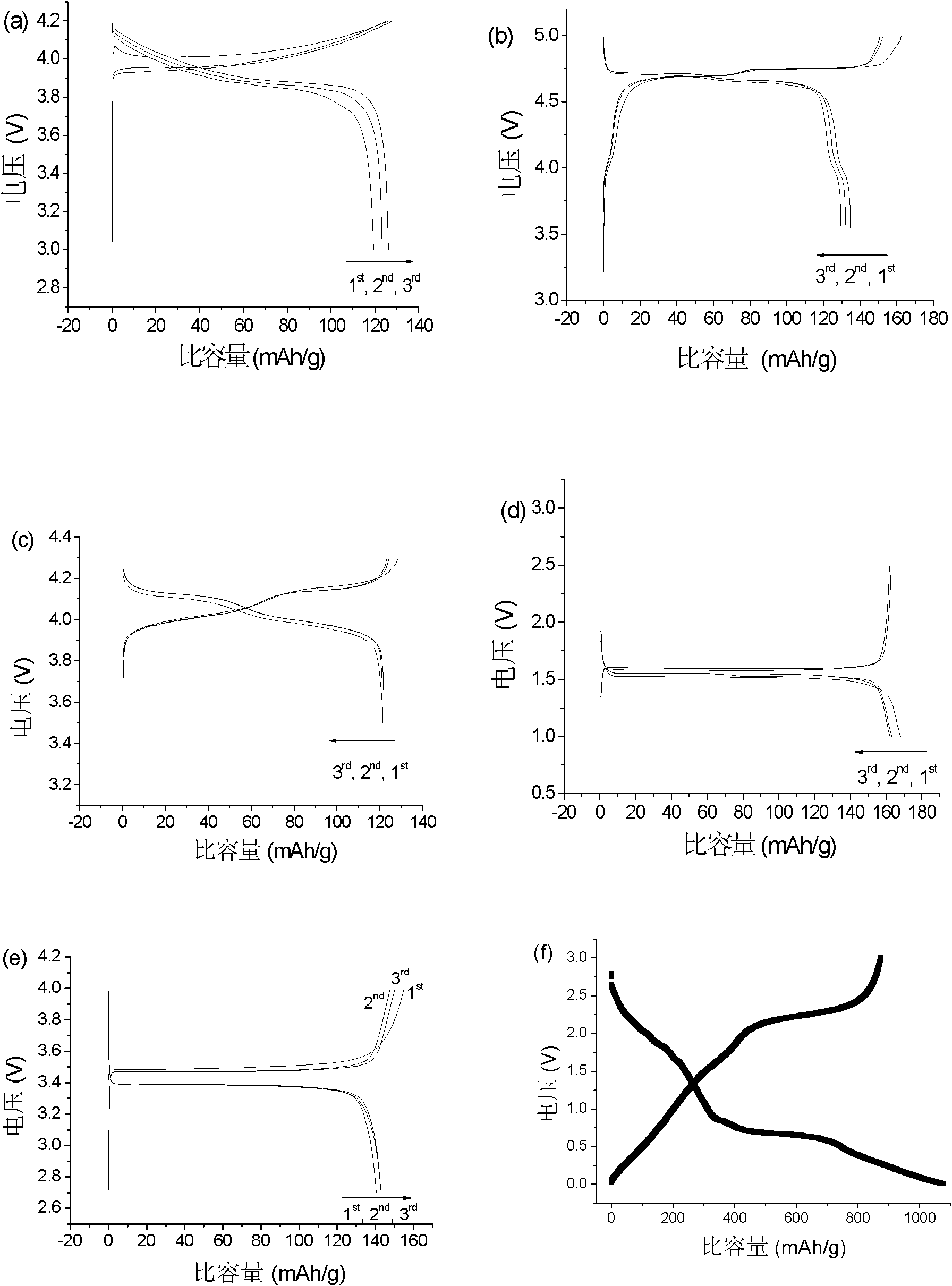

Conducting-polymer dipped and coated lithium-ion battery composite-electrode material and preparation method thereof

InactiveCN102522563ADon't need protectionReduce energy consumptionHybrid capacitor electrodesLi-accumulatorsDischarge efficiencyConductive polymer

The invention provides a conducting-polymer dipped and coated lithium-ion battery composite-electrode material and a preparation method thereof. A high-polymer conducting polymer is coated on the lithium-ion battery electrode material of the composite electrode material, the conducting polymer is the conducting polymer which is easily dispersed into an aqueous solution, and the aqueous solution of dispersants, such as polystyrolsulfon acid and the like is used as a dispersing medium. The composite electrode material is prepared through the following steps of: dipping a lithium-ion anode material or cathode material into the aqueous solution of the high-polymer conducting polymer, and obtaining the surface-coated lithium-ion battery composite-electrode material through dipping and coating processing. The composite electrode material has cheap preparation raw materials, the surface of the novel composite electrode material is uniformly coated, and the composite electrode material has the advantages of high specific capacity, high charging and discharging efficiency and long cycling life. Compared with the prior art, the preparation method of the composite electrode material has the advantages of simple process, low cost, good effect and green and environment-friendly production process, is easy for industrial popularization and is convenient for large-scale industrialized production.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com