Metal-based powder metallurgy brake lining material and preparation methods thereof

A powder metallurgy and brake pad technology, applied in friction linings, mechanical equipment, etc., can solve the problems of limiting the selection range of ceramic particles, increasing and reducing production costs, and achieving environmental protection, improved service life, and strength. high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] 1. The content of each component of the brake pad material according to the present invention is: Cu powder: 54%, Sn powder: 6%, graphite: 21%, Fe powder: 3%, Ti powder: 8%, al 2 o 3 Powder: 6%, Ni powder: 1% and Cr powder: 1%.

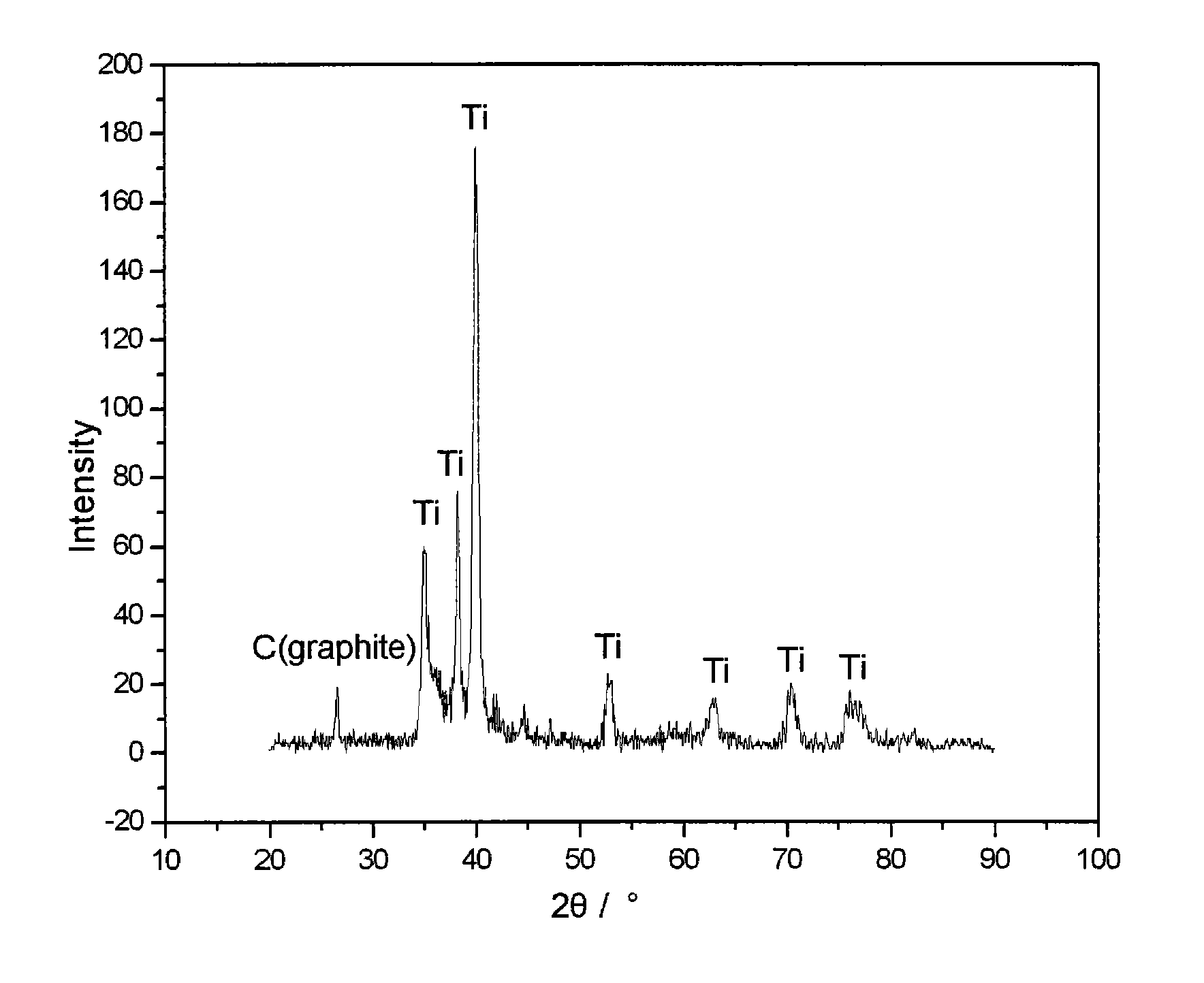

[0069] 2. See figure 1 , mechanically activate Ti powder and graphite with a weight ratio of 4:1, that is, 8% Ti powder and 2% graphite, in a horizontal planetary ball mill at a speed of 500 rpm and an activation time of 10 hours. Ti-C mechanical activation powder: 10%. Shown in the figure is the typical X-ray diffraction pattern of the Ti-C mechanically activated powder.

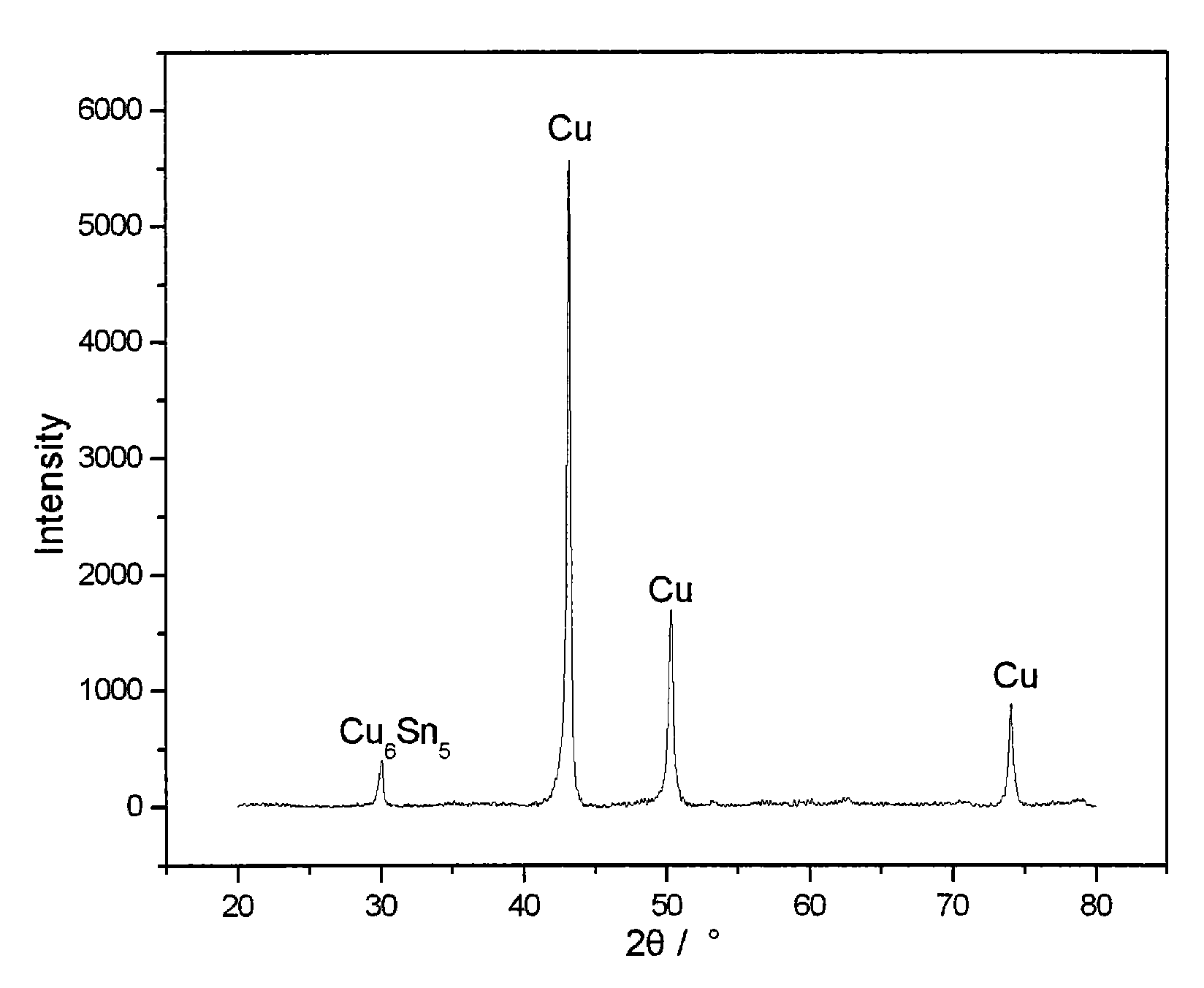

[0070] 3. See figure 2 , mechanical alloying of Cu powder and Sn powder with a weight ratio of 9:1, that is, 54% Cu powder and 6% Sn powder, in a horizontal planetary ball mill with a speed of 500 rpm and an activation time of 10 hours , made of Cu-Sn mechanical alloy powder: 60%. Shown in the figure is the typical X-ray diffraction pattern of the produced Cu-Sn mech...

Embodiment 2

[0077] 1. The content of each component of the brake pad material according to the present invention is: Cu powder: 54%, Sn powder: 6%, graphite: 21%, Fe powder: 3%, Ti powder: 8%, al 2 o 3 Powder: 6%, Ni powder: 1% and Cr powder: 1%.

[0078] 2. Mechanically activate Ti powder and graphite with a weight ratio of 8:1, that is, 8% Ti powder and 1% graphite, in a horizontal planetary ball mill at a speed of 500 rpm and an activation time of 10 hours. Form Ti-C mechanical activation powder: 9%.

[0079] 3. Carry out mechanical alloying in a horizontal planetary ball mill with Cu powder and Sn powder with a weight ratio of 9:1, that is, 54% Cu powder and 6% Sn powder, the speed is 500 rpm, and the activation time is 10 Hours, made Cu-Sn mechanical alloy powder: 60%.

[0080] After making 9% Ti-C mechanical activation powder and 60% Cu-Sn mechanical alloy powder, the content of each component of the brake pad material according to the present invention becomes: Cu-Sn mechanical...

Embodiment 3

[0086] 1. The content of each component of the brake pad material according to the present invention is: Cu powder: 54%, Sn powder: 6%, graphite: 21%, Fe powder: 3%, Ti powder: 8%, Al 2 o 3 Powder: 6%, Ni powder: 1% and Cr powder: 1%.

[0087] 2. Carry out mechanical activation in a horizontal planetary ball mill with Ti powder and graphite that are 8% Ti powder and 1.33% graphite in a weight ratio of 6:1, the speed is 500 rpm, and the activation time is 10 hours. Form Ti-C mechanical activation powder: 9.33%.

[0088] 3. Carry out mechanical alloying in a horizontal planetary ball mill with Cu powder and Sn powder with a weight ratio of 9:1, that is, 54% Cu powder and 6% Sn powder, the speed is 500 rpm, and the activation time is 10 hours, made Cu-Sn mechanical alloy powder: 60%.

[0089] After making 9.33% Ti-C mechanical activation powder and 60% Cu-Sn mechanical alloy powder, the brake pad material according to the present invention has the content of each component by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Average wear | aaaaa | aaaaa |

| Average wear | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com