Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4004 results about "Ceramic particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

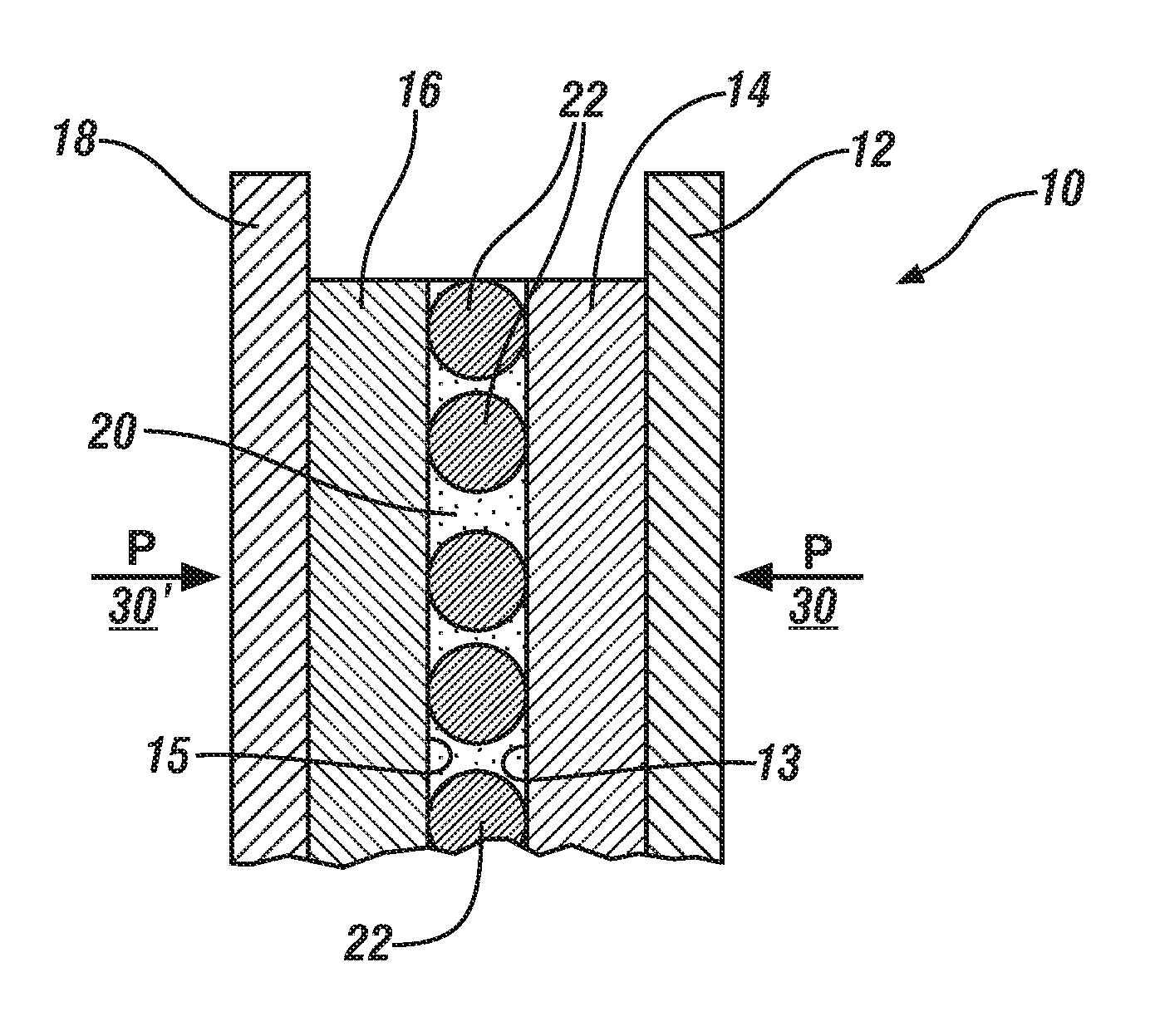

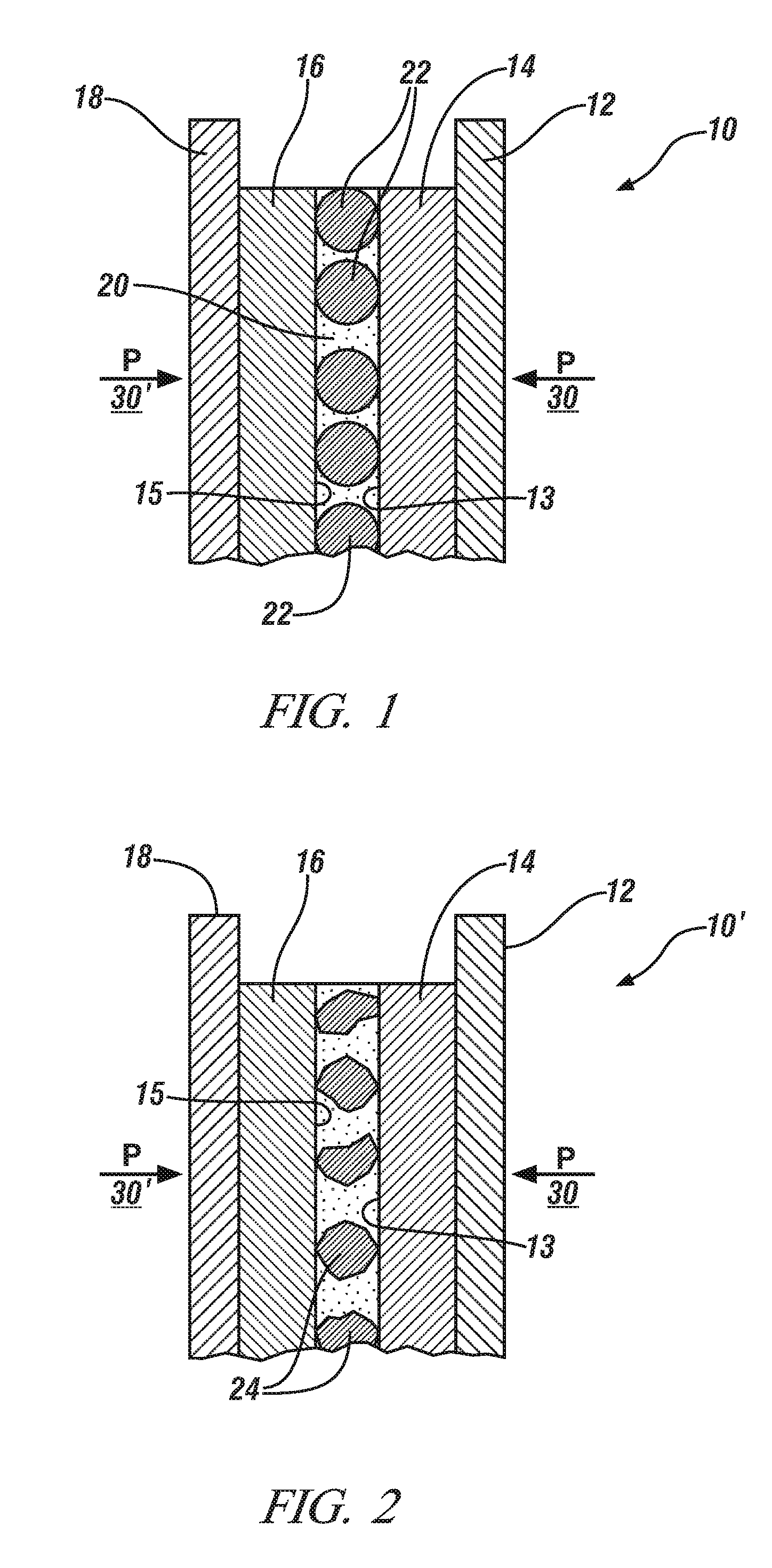

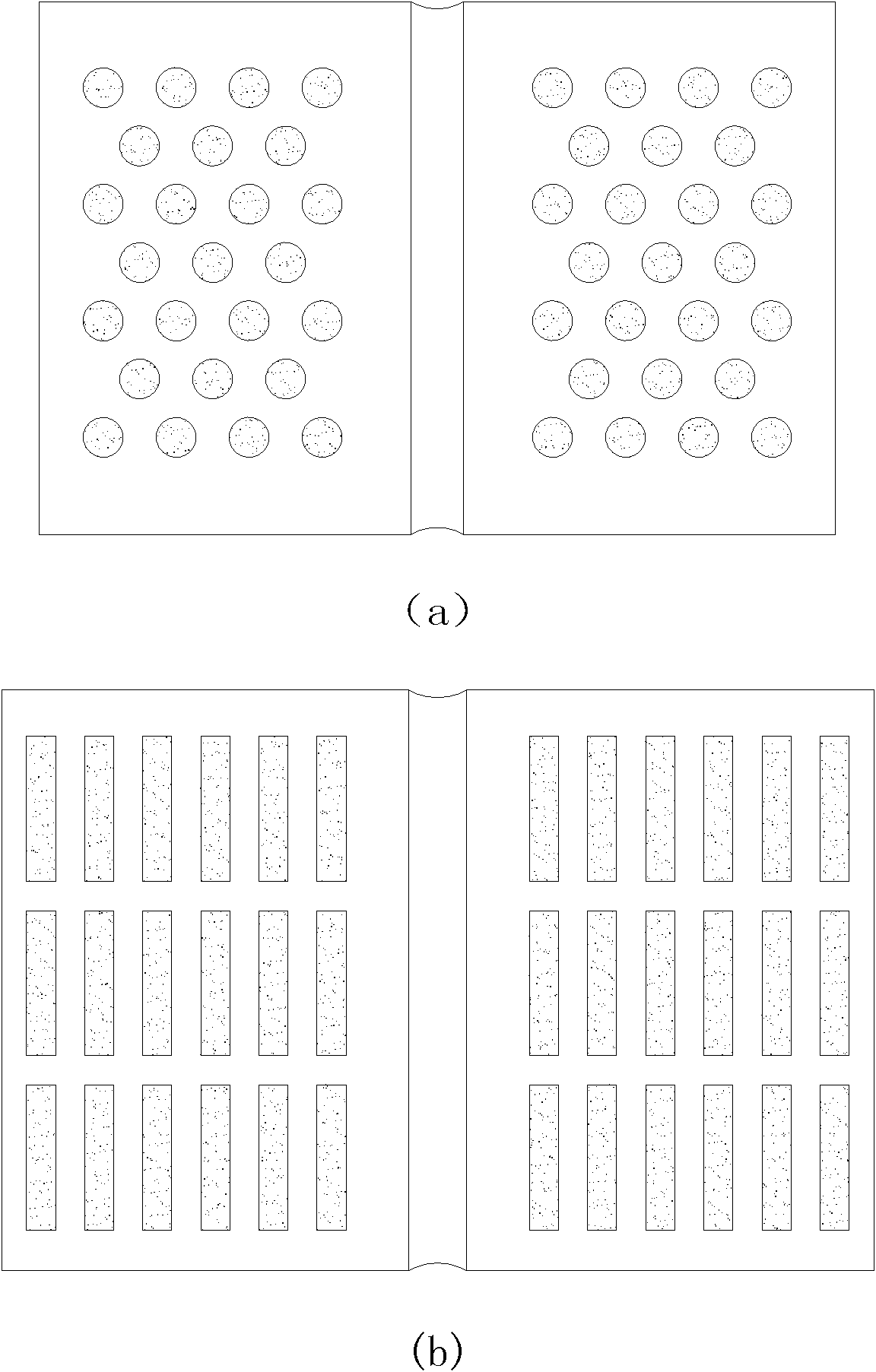

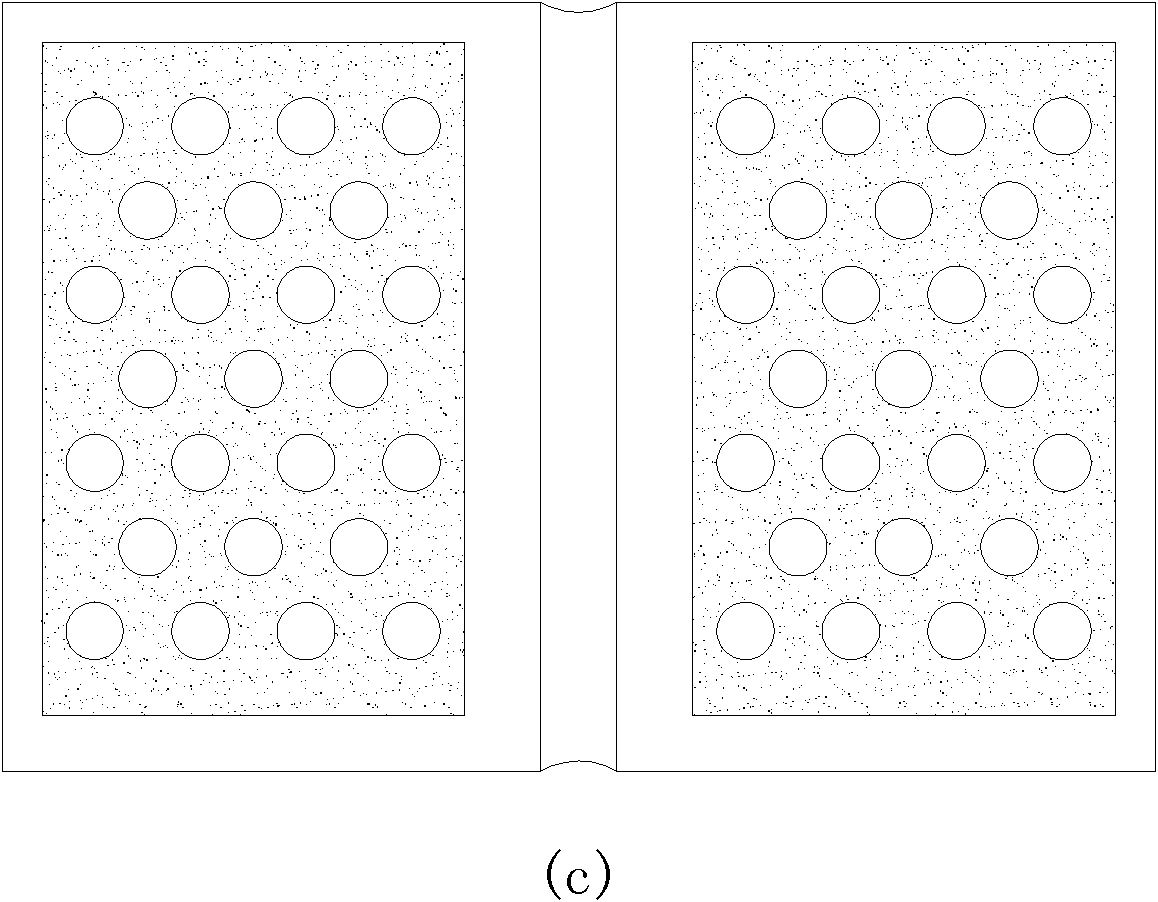

Ceramic Particles With Controlled Pore and/or Microsphere Placement and/or Size and Method Of Making Same

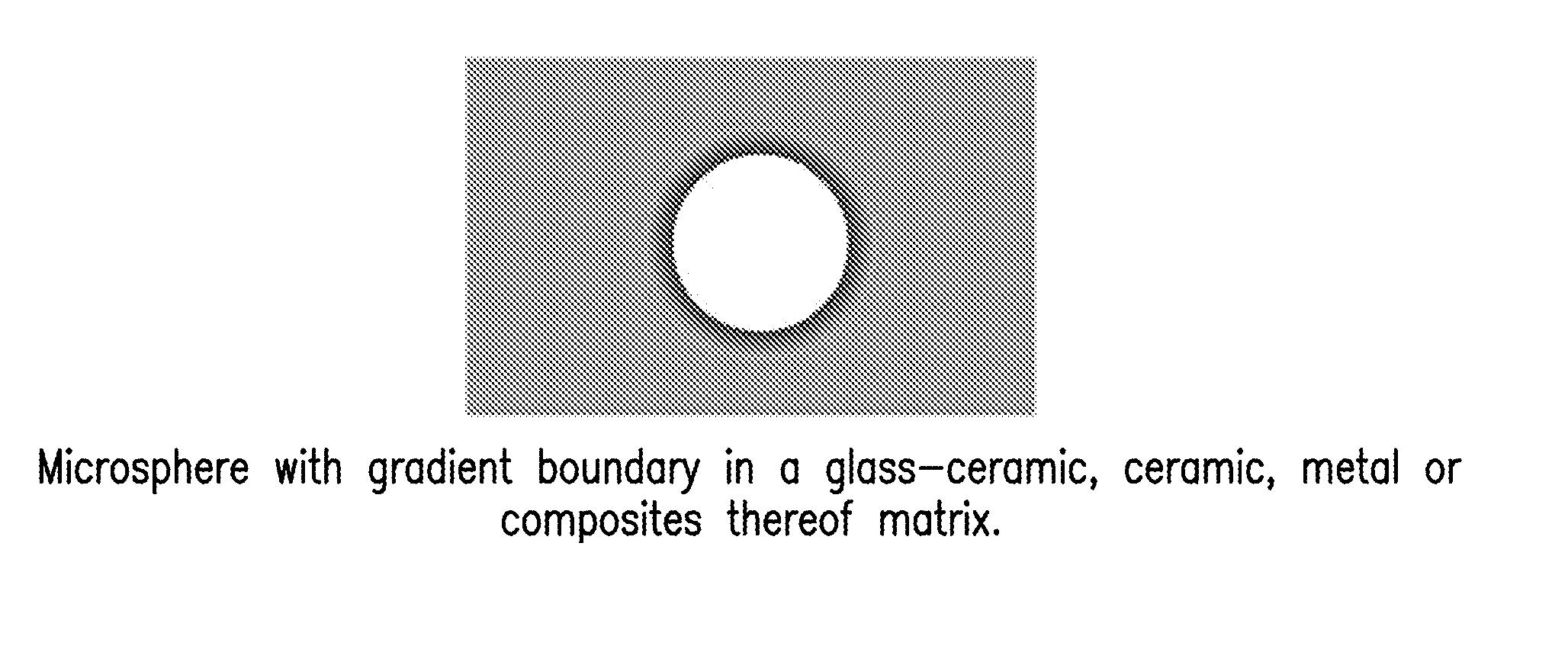

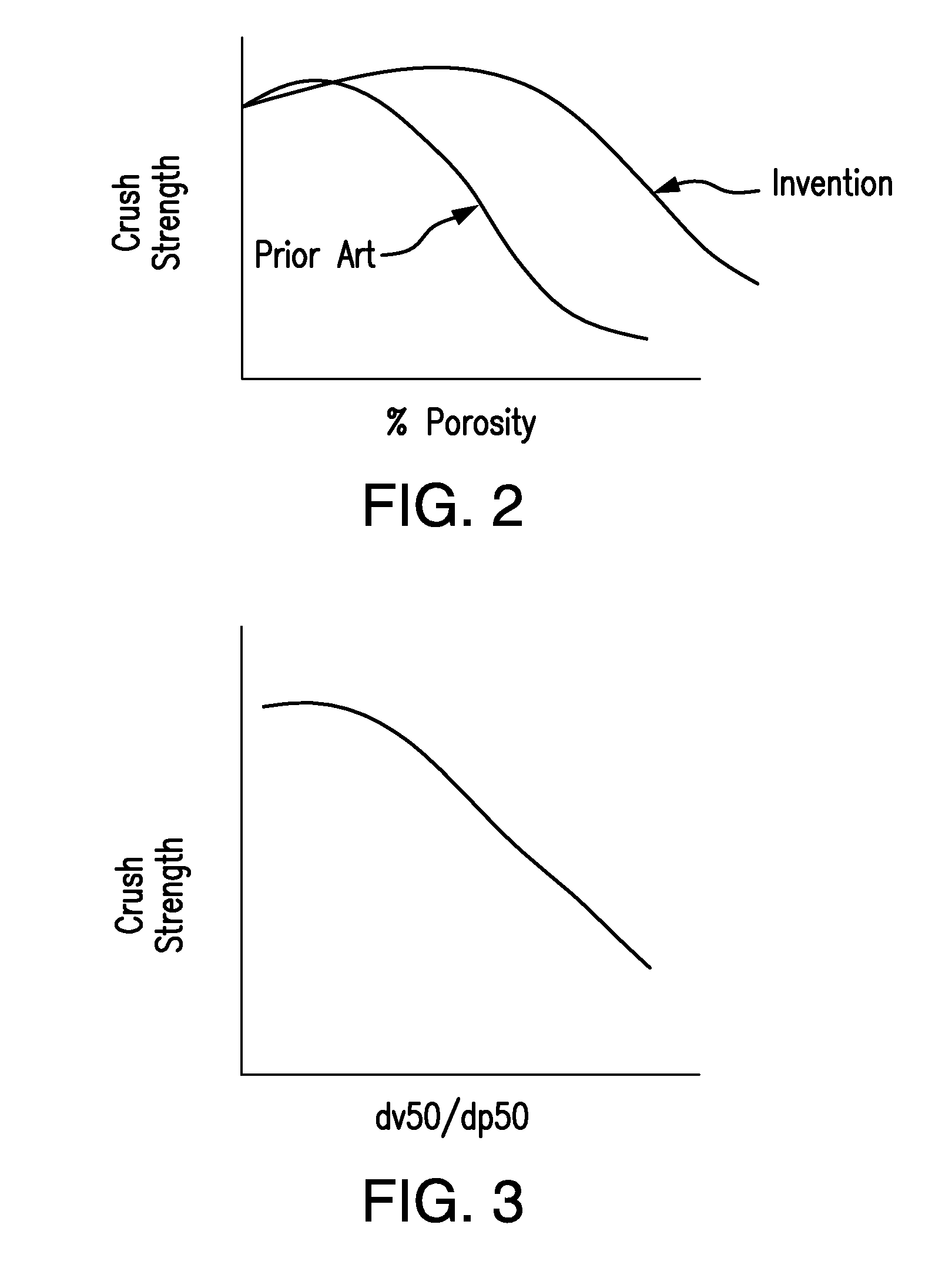

InactiveUS20110160104A1Improve balanceFluid removalCeramic shaping apparatusMicrosphereHigh intensity

The present invention relates to lightweight high strength microsphere containing ceramic particles having controlled microsphere placement and / or size and microsphere morphology, which produces an improved balance of specific gravity and crush strength such that they can be used in applications such as proppants to prop open subterranean formation fractions. Proppant formulations are further disclosed which use one or more microsphere containing ceramic particles of the present invention. Methods to prop open subterranean formation fractions are further disclosed. In addition, other uses for the microsphere containing ceramic particles of the present invention are further disclosed, as well as methods of making the microsphere containing ceramic particles.

Owner:HALLIBURTON ENERGY SERVICES INC

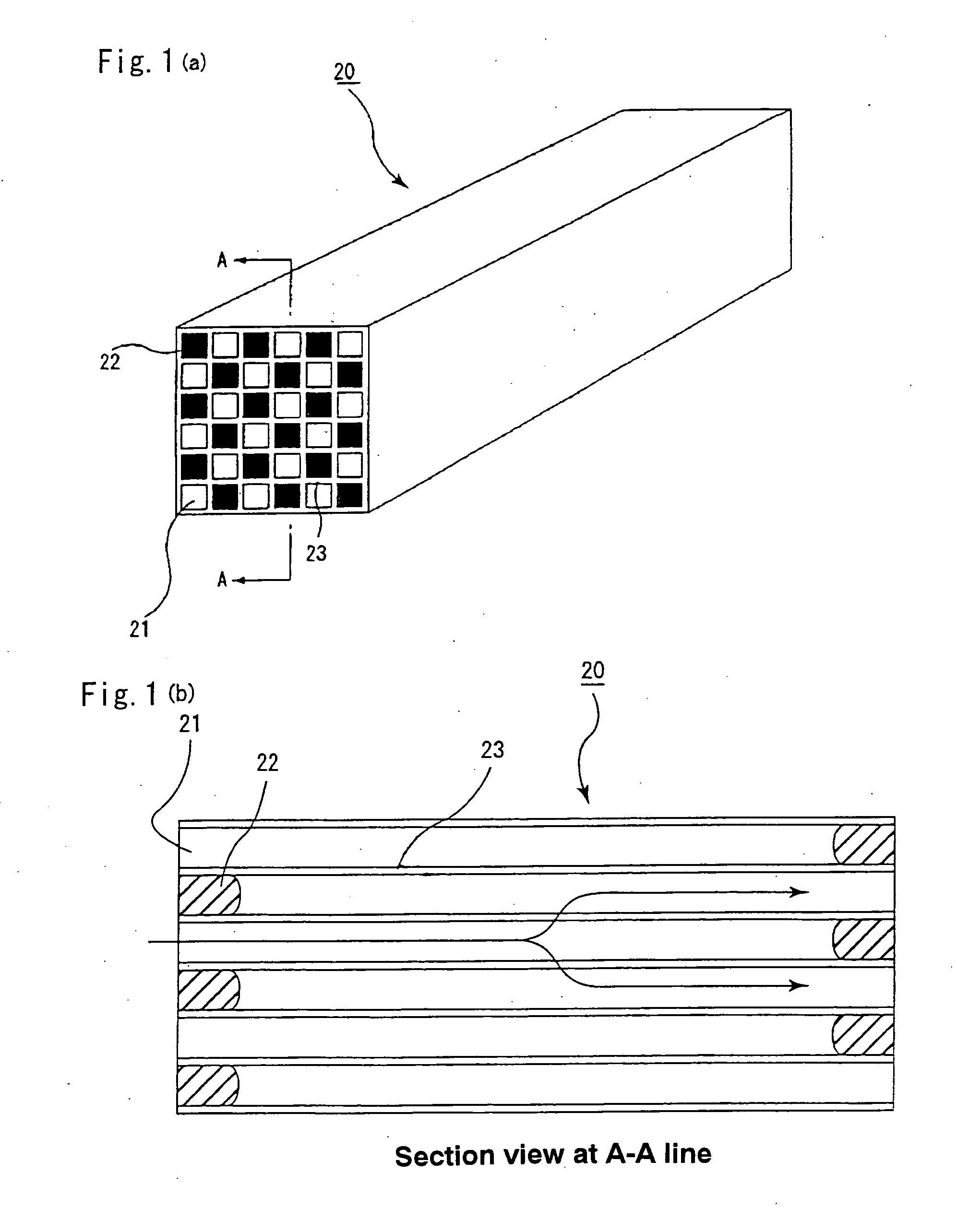

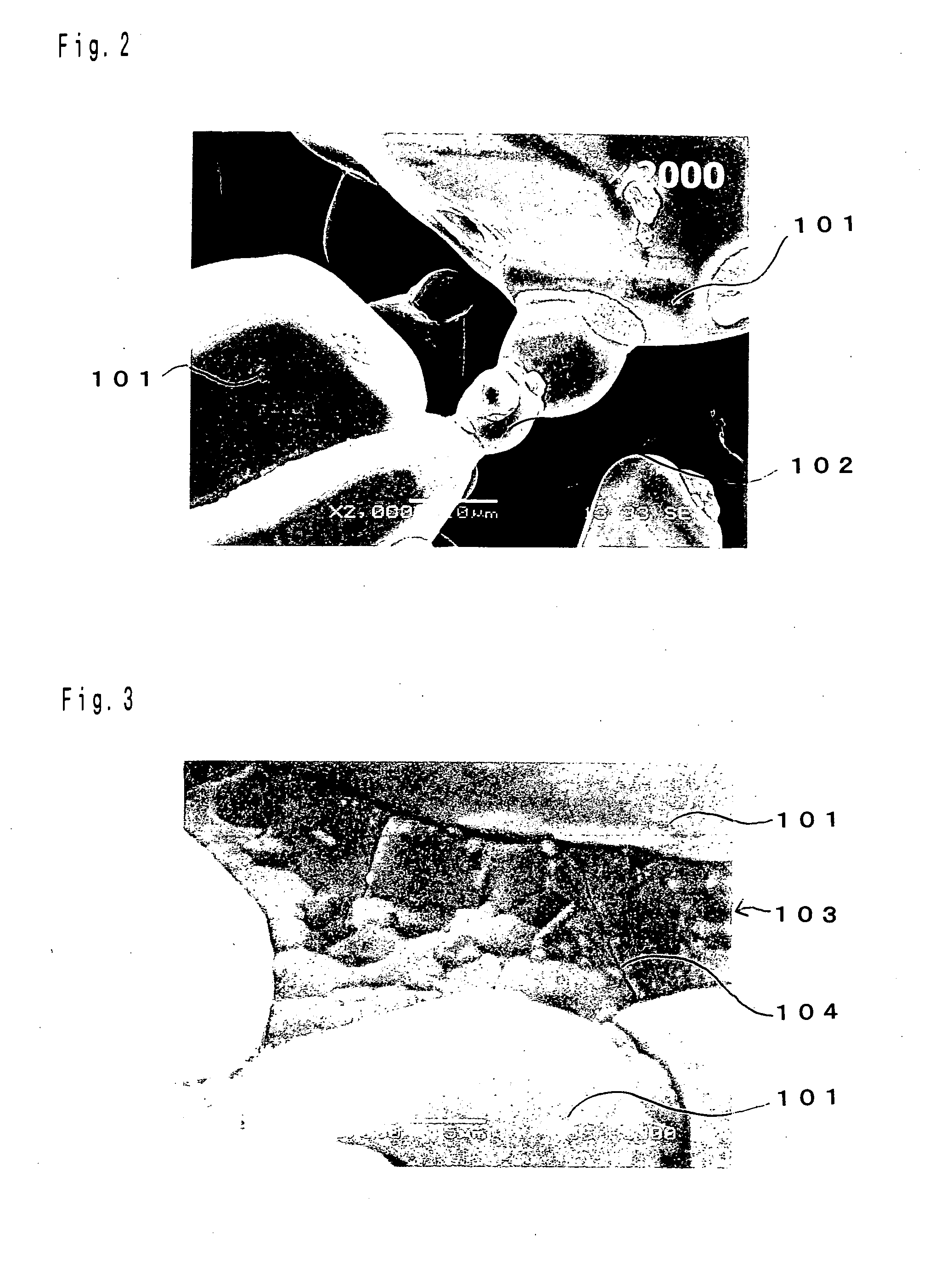

Sintered ceramic compact and ceramic filter

InactiveUS20060051556A1Shock mitigationAvoid micro cracksDispersed particle filtrationExhaust apparatusCeramic sinteringMetallurgy

The present invention provides for a ceramic sintered body and a ceramic filter having a long-term stability which can prevent cracks from occurring due to the breakage of ceramic particles when thermal stress is applied in regeneration process and the like, and can prevent catalyst carried from deteriorating when regeneration treatment is conducted repeatedly. The invention is a ceramic sintered body comprising ceramic coarse particles and porous bonding layers existing between the ceramic coarse particles to connect the particles and comprising ceramic fine particles having an average particle size smaller than that of the ceramic coarse particles and / or the aggregates thereof, and a ceramic filter prepared by using the ceramic sintered body.

Owner:IBIDEN CO LTD

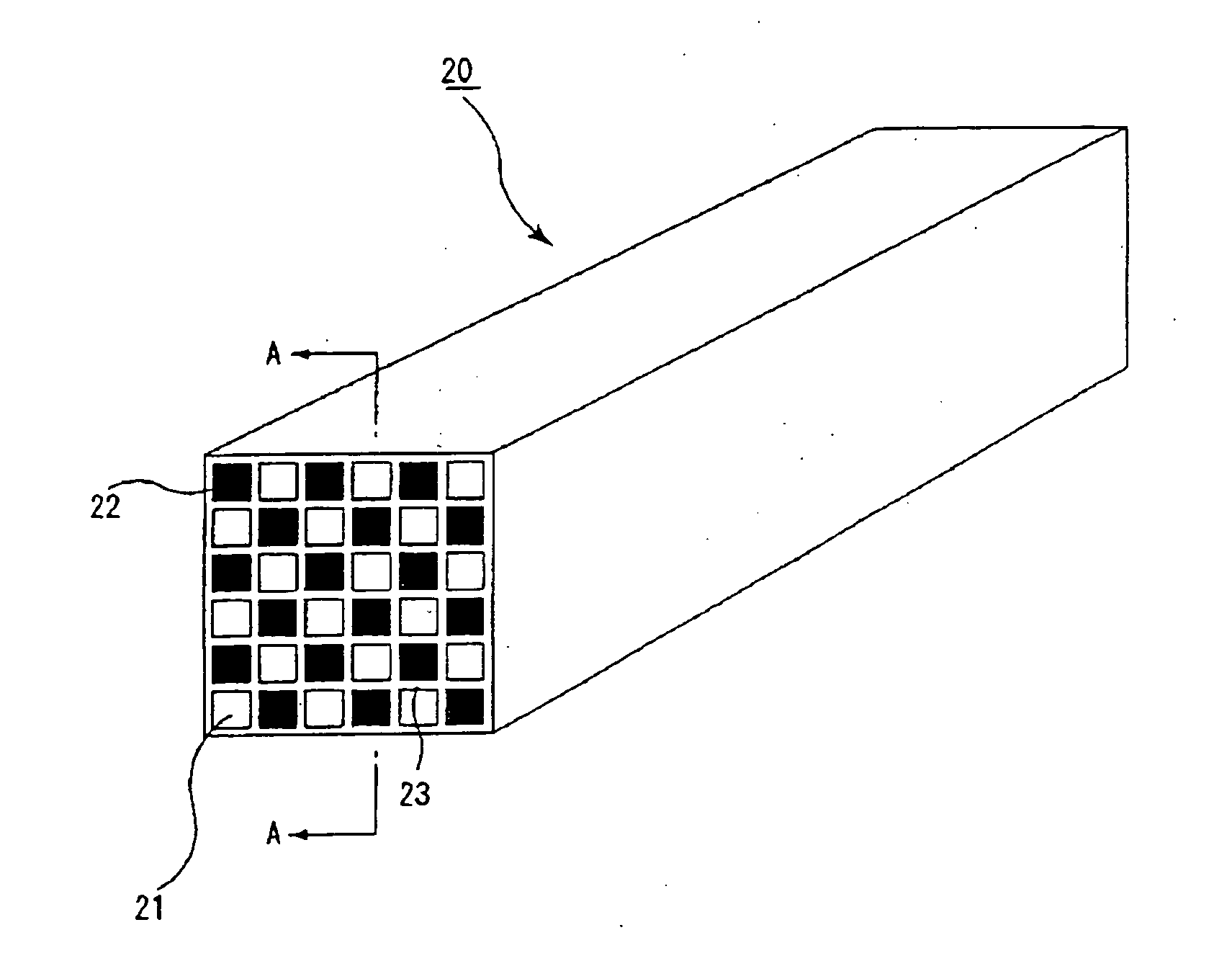

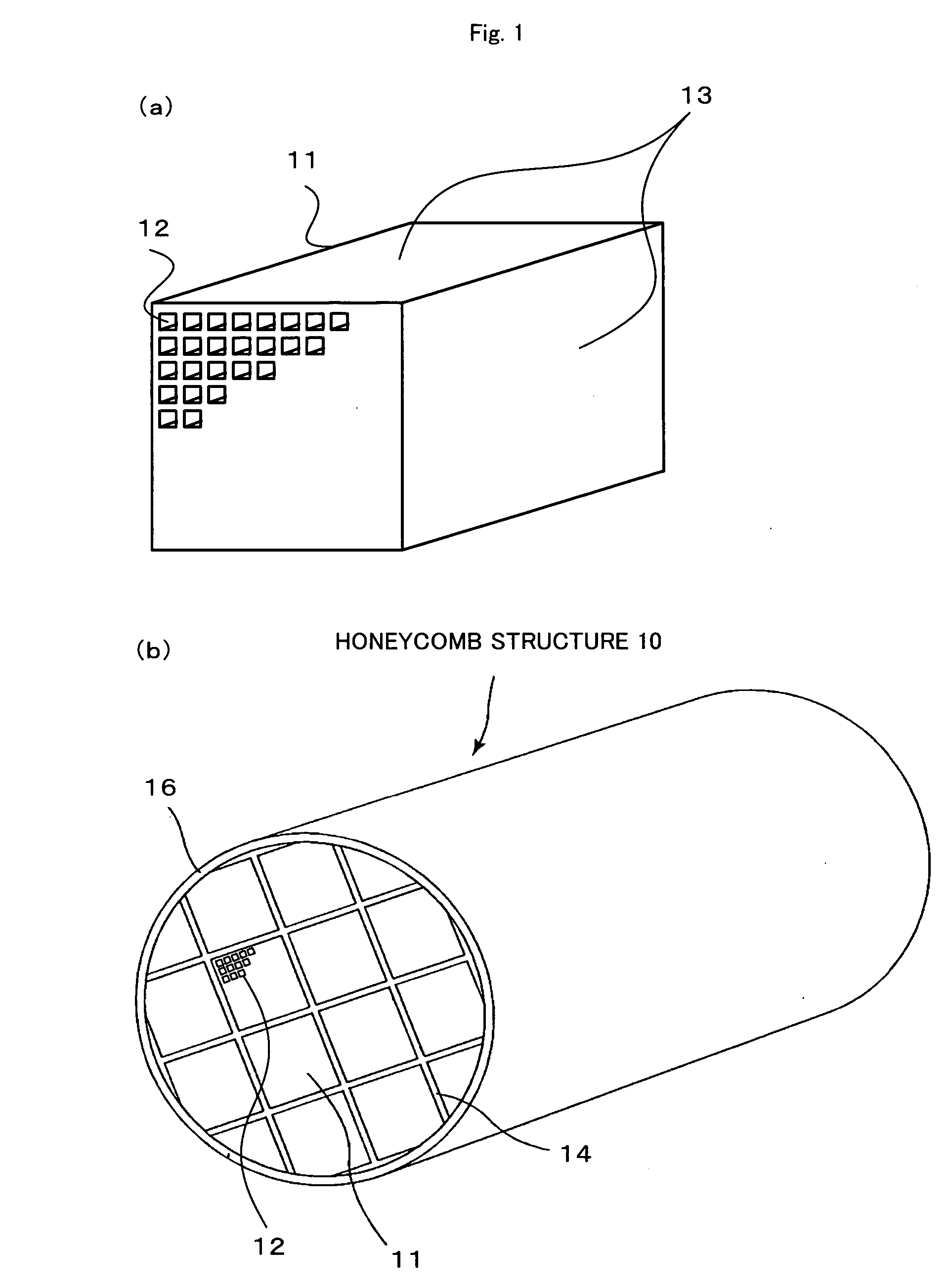

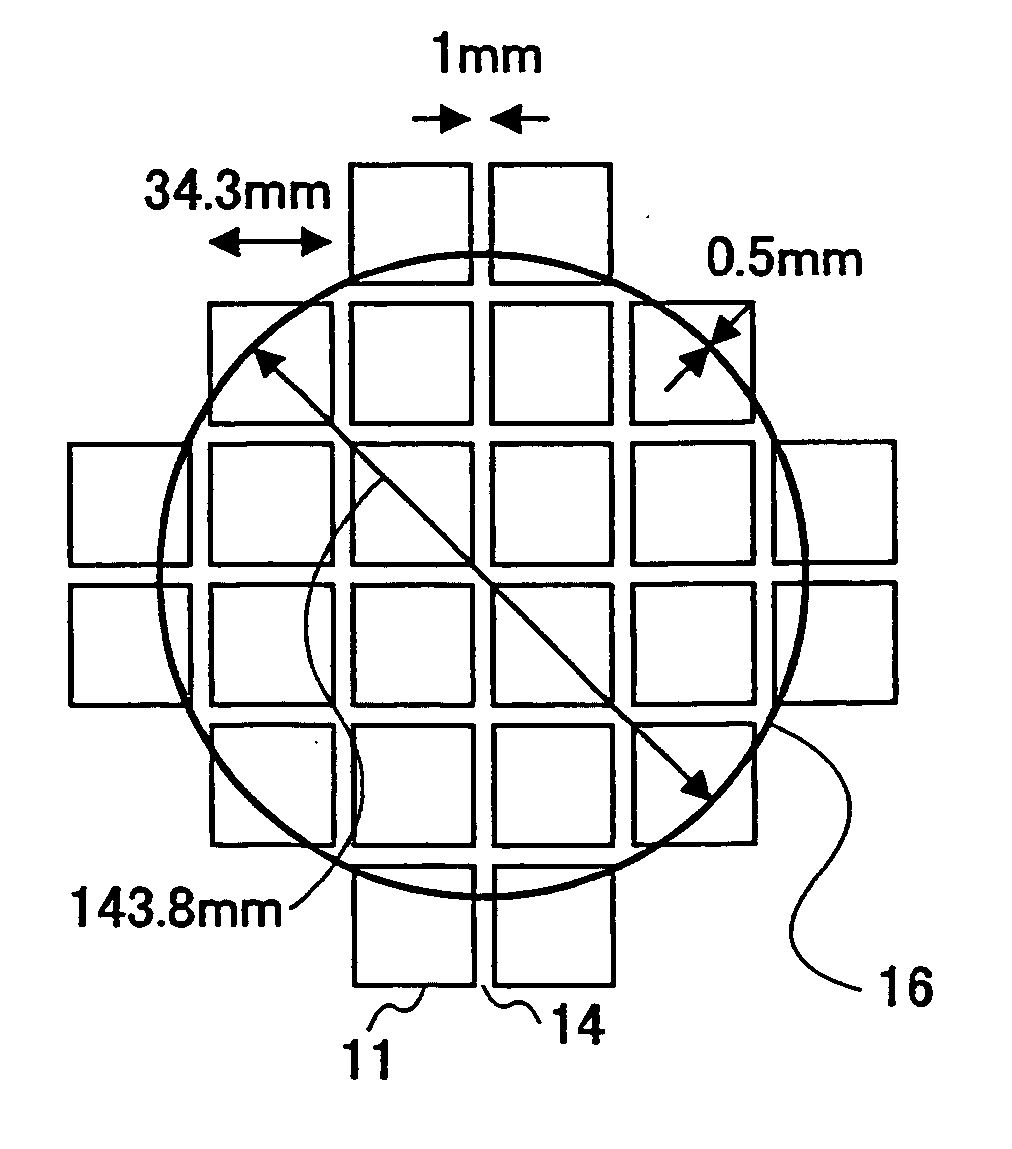

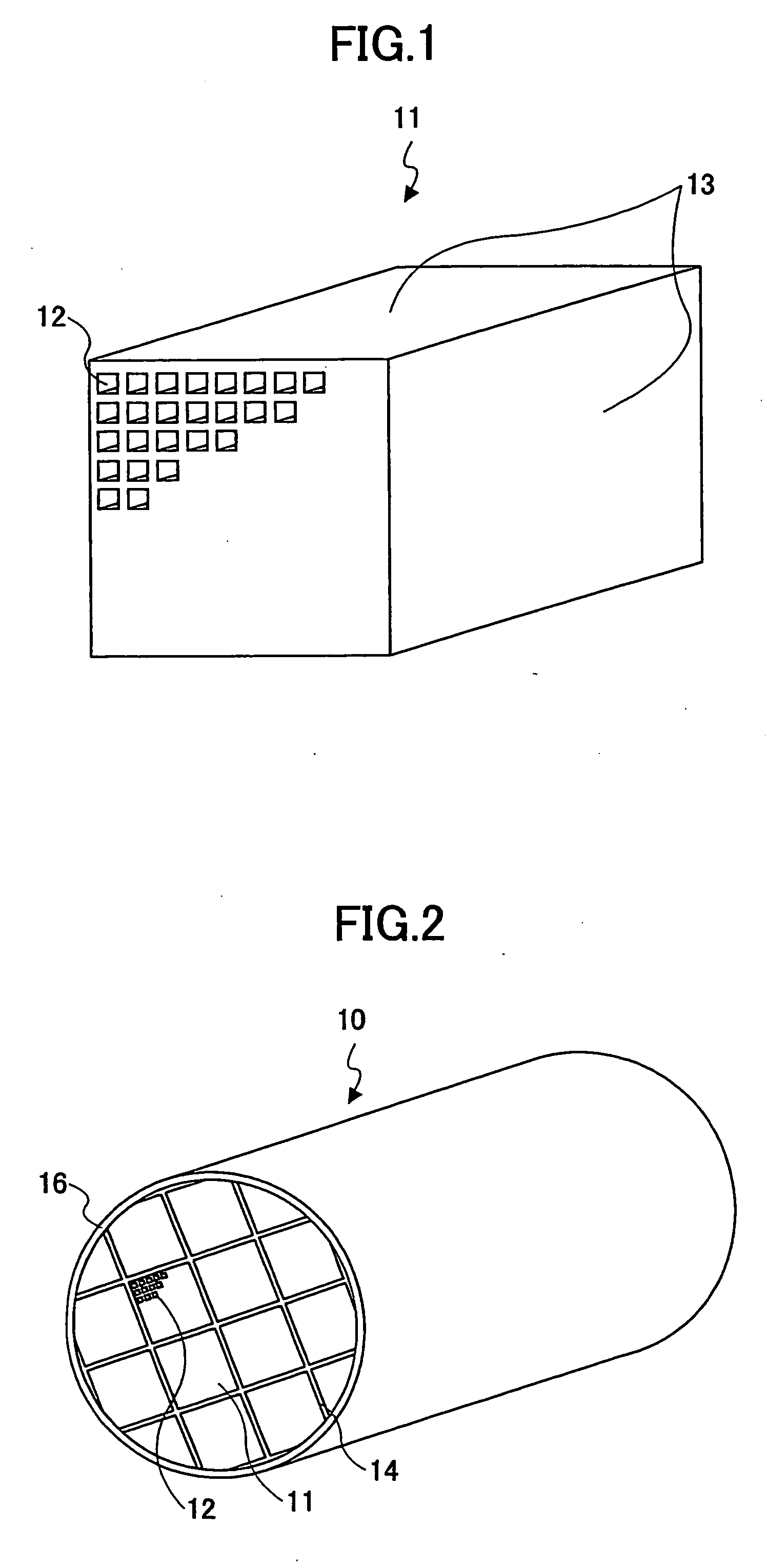

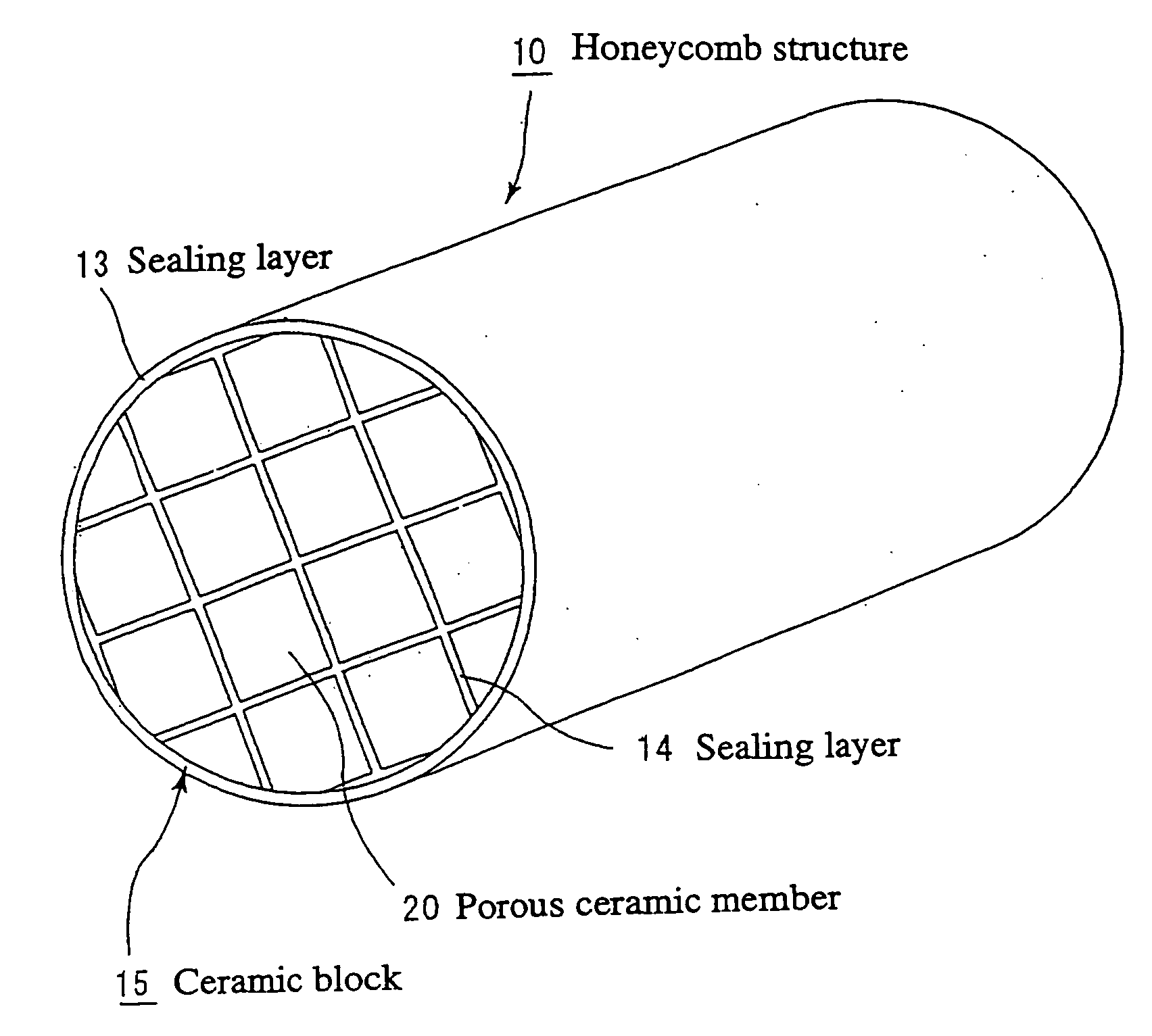

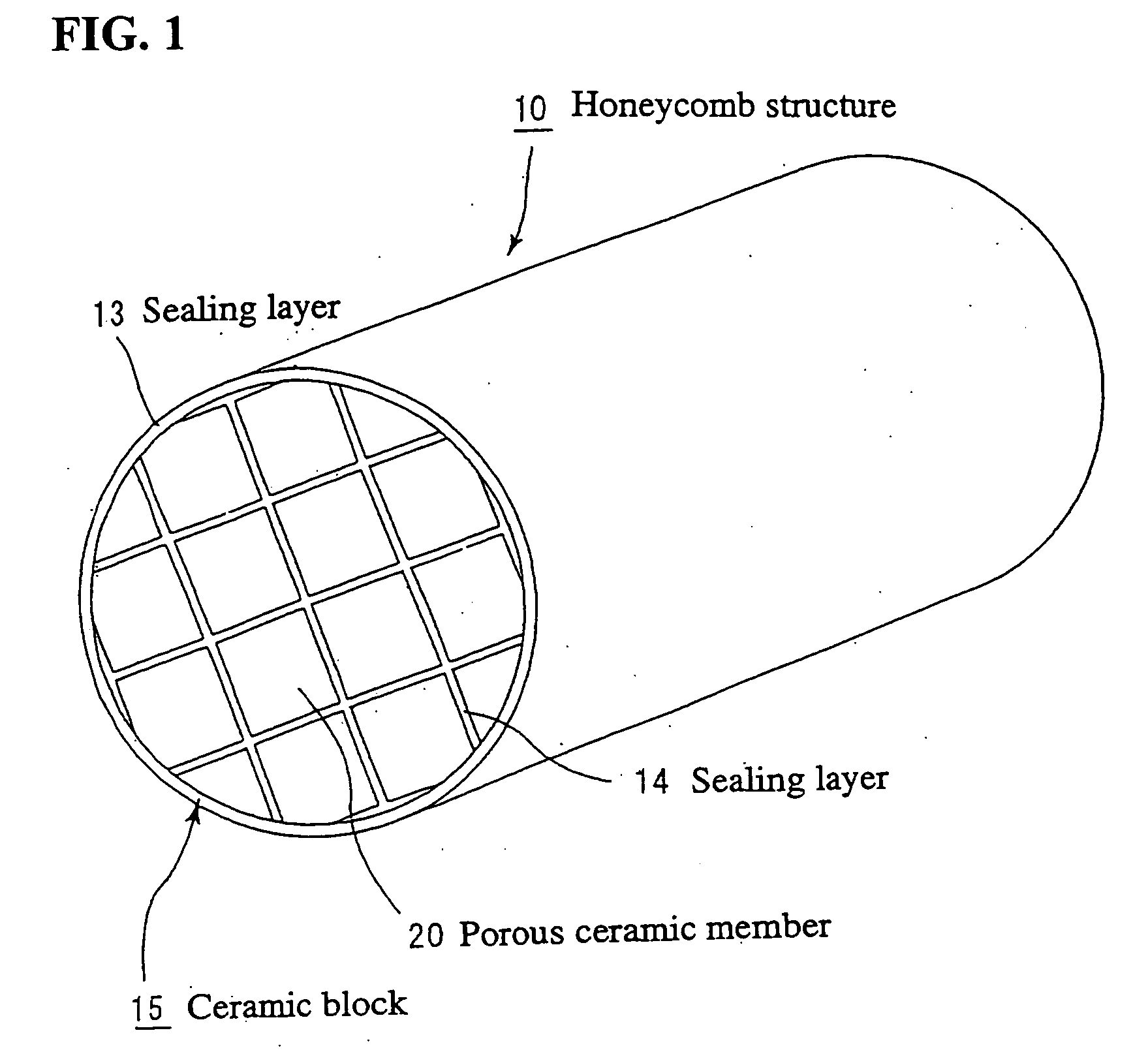

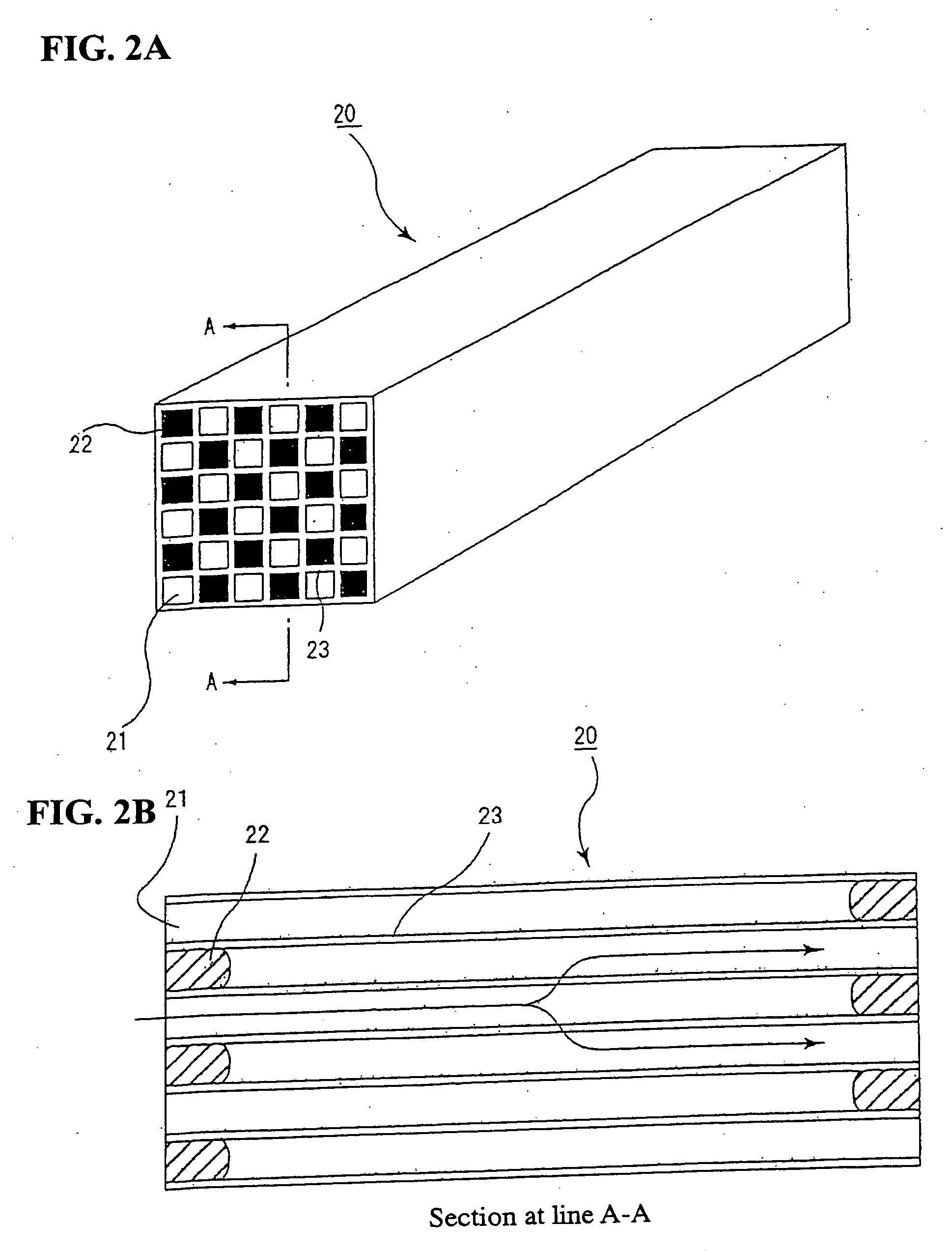

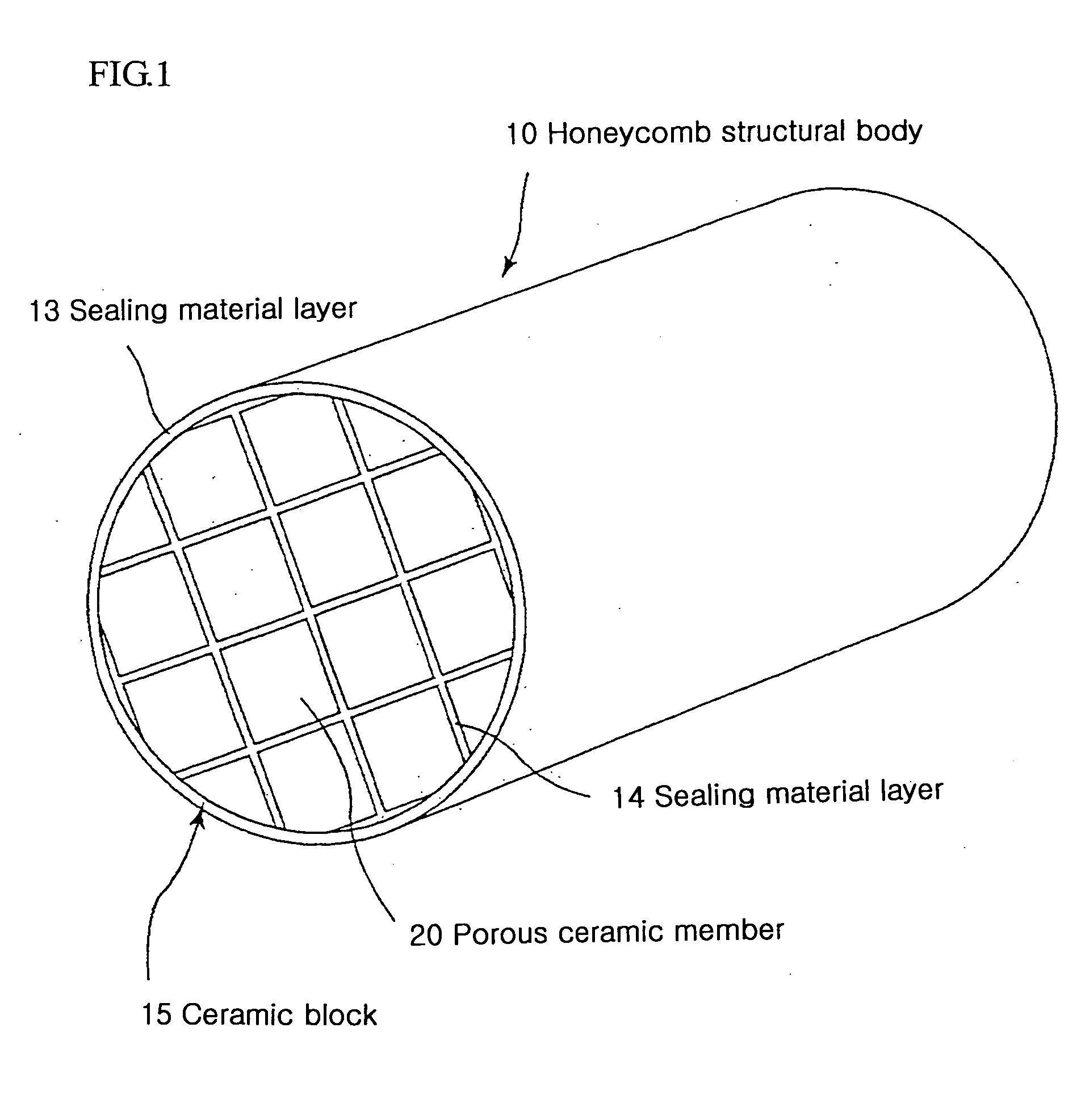

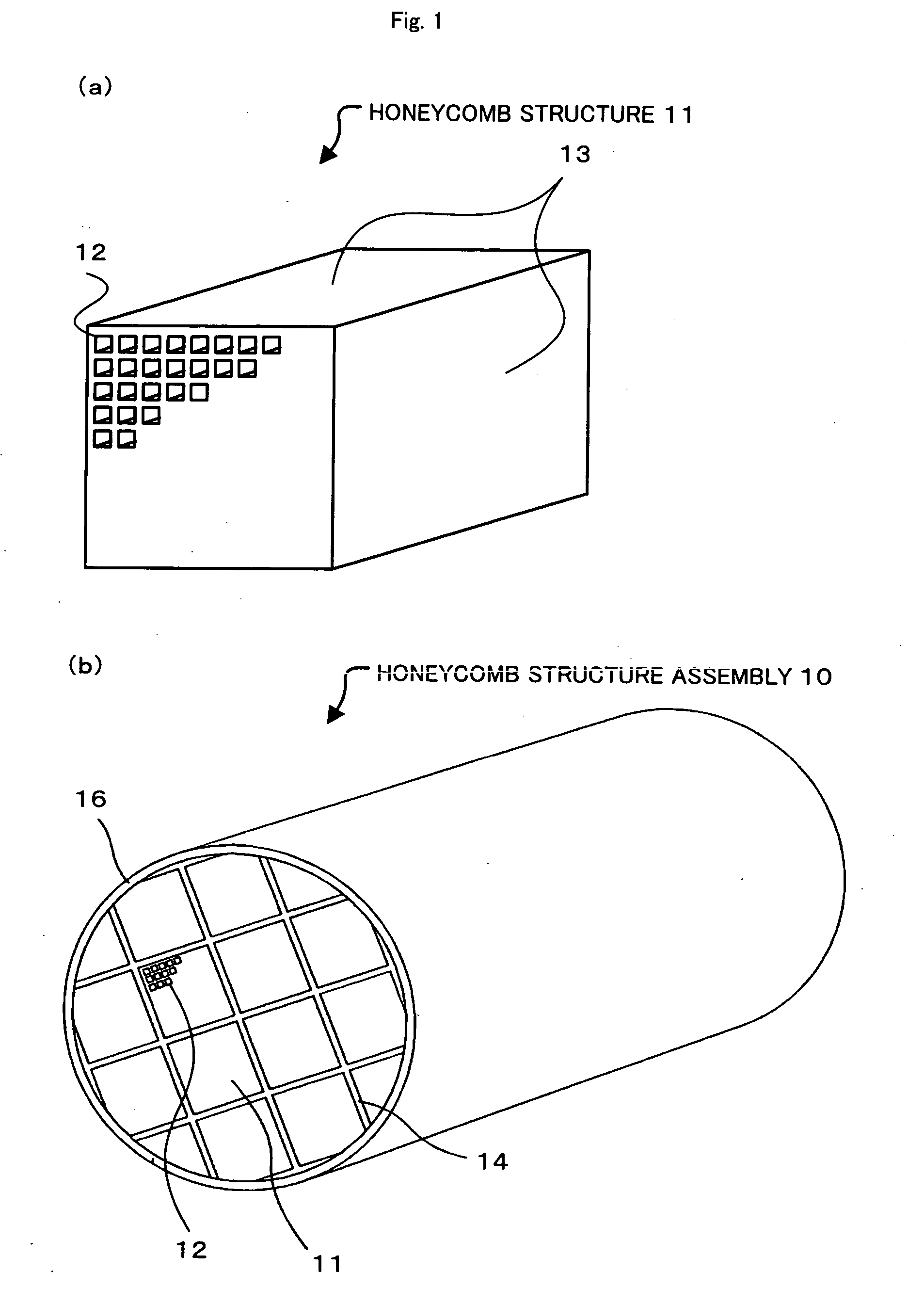

Honeycomb structure

InactiveUS20050266992A1High strengthGood dispersionDispersed particle filtrationExhaust apparatusFiberHoneycomb structure

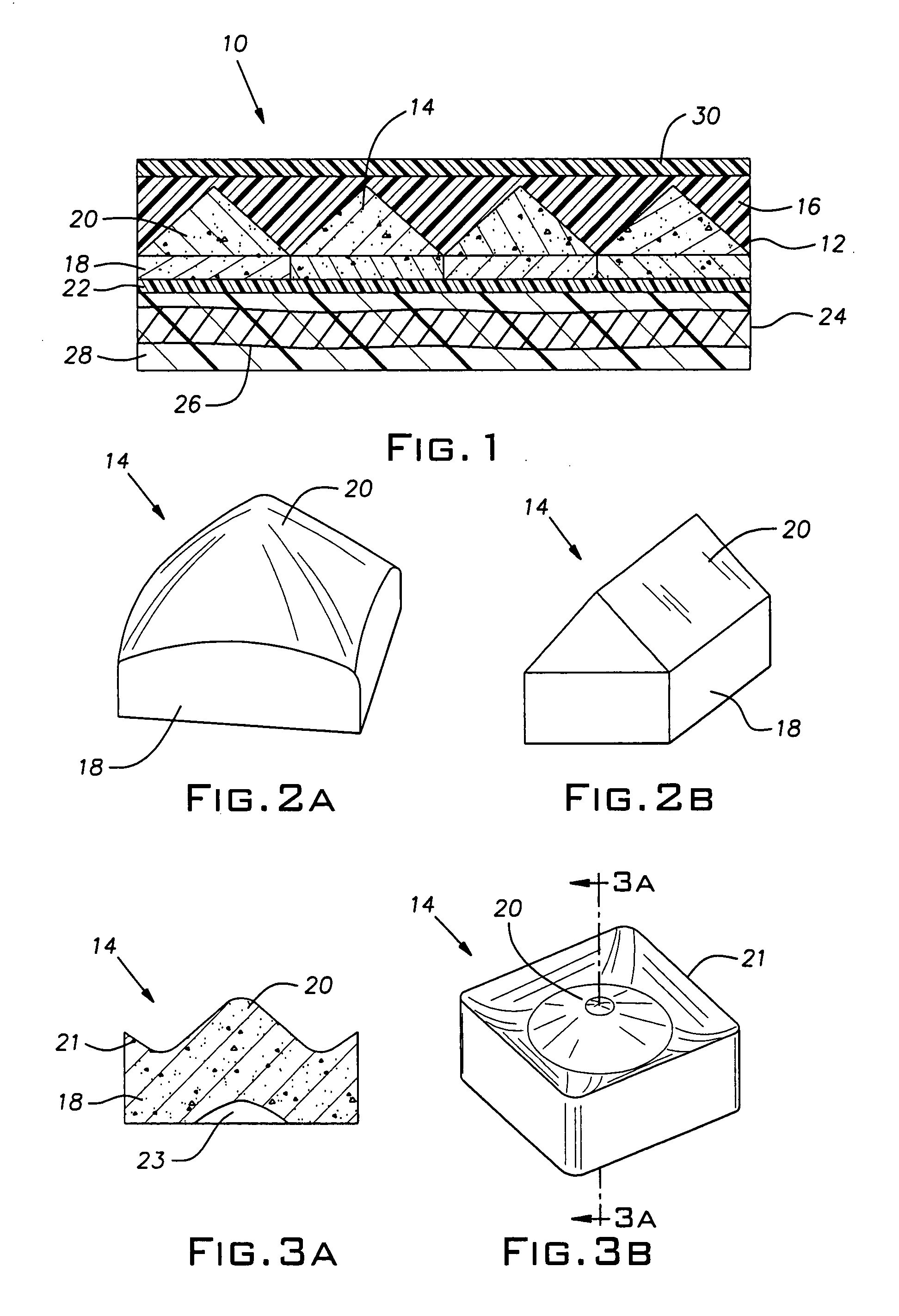

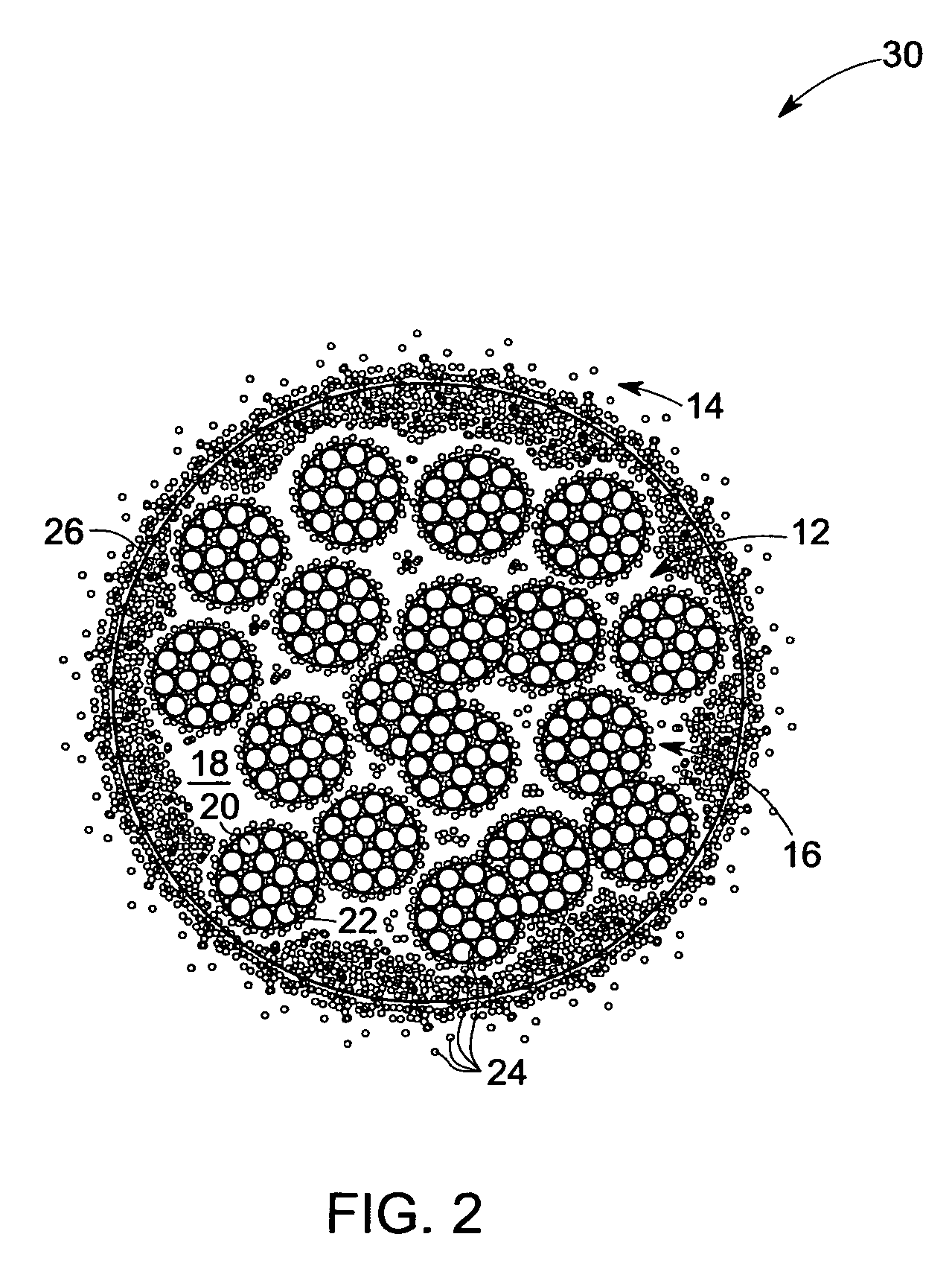

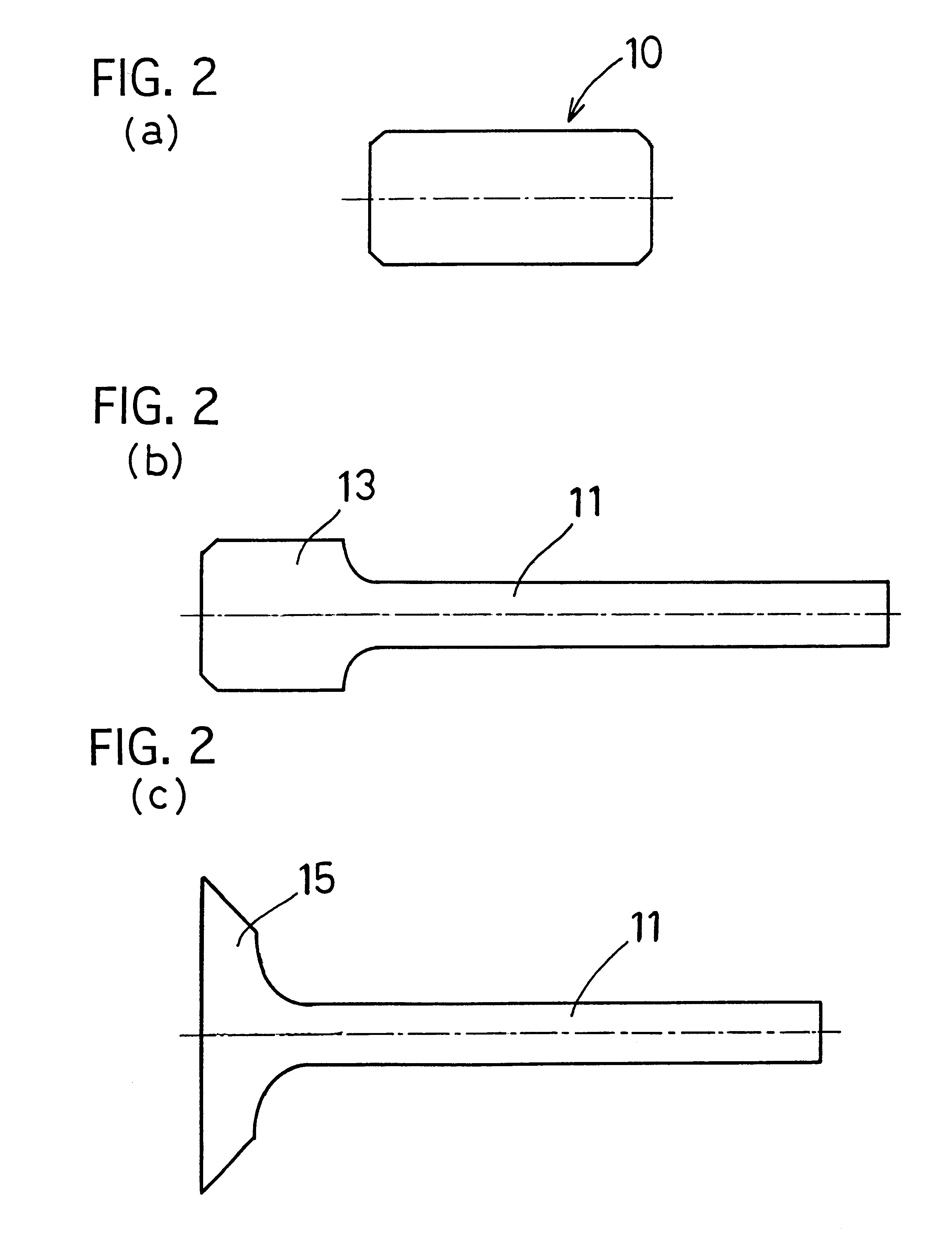

A honeycomb structure 10 of the present invention comprises: porous honeycomb units 11 having multiple through-holes, including the first form of an inorganic material (for example, ceramic particles), the second form of an inorganic material (for example, inorganic fibers or ceramic particles having large particle sizes), and an inorganic binder; and sealing material layers 14 jointing the porous honeycomb units 11 at outer surfaces 13 where the through-holes are not open. The cross-sectional area perpendicular to the through-holes is about 5 to about 50 cm2. The ratio of the total cross-sectional area of the porous honeycomb units 11 to the cross-sectional area of the honeycomb structure 10 is not less than about 85%. The honeycomb structure 10 reduces thermal stress or vibration applied to each porous honeycomb unit 11, by the sealing material layers 14, and allows for amore effective use of surface on which catalyst components are dispersed.

Owner:IBIDEN CO LTD

Prosthetic bone filler and process for the production of the same

InactiveUS6203574B1Preventing good bio-compatibilityPromote resultsIon-exchange process apparatusImpression capsCeramic particleLiving body

A prosthetic bone filler including ceramic granules for use in a living body, the ceramic granules being bonded to each other with a polymeric substance, and having ventilation pores produced as a result of the presence of gaps between the adjacent granules. The prosthetic bone filler is produced by adding the polymeric substance in two portions to the ceramic granules. In addition to good flexibility, the prosthetic bone filler exhibits excellent bio-compatibility.

Owner:ASAHI KOGAKU KOGYO KK

Coated powder particles for producing three-dimensional bodies by means of a layer constituting method

InactiveUS20060251535A1Good storage stabilityHigh distinctnessAdditive manufacturing apparatusTransportation and packagingOrganic solventLaser light

The invention relates a powder material consisting of coated particles for a powder-based rapid generative prototyping methods, in particular by compressing a 3D binder. Said powder material consists of individual plastic, metal and / or ceramic particles and / or granules. A coating essentially consists of an adhesive agent which can be activated by a liquid binder, light or laser light, and of sinterable or glass-forming fine-grained material. Said invention also relates to a method for compressing 3D binder with the aid of an organic solvent having a water content less than 45% and to sintered bodies, in particular for moulding or precision mechanical engineering, which are fixed to each other by sintering or glass formation from a fine grained material.

Owner:PFEIFER ROLF +2

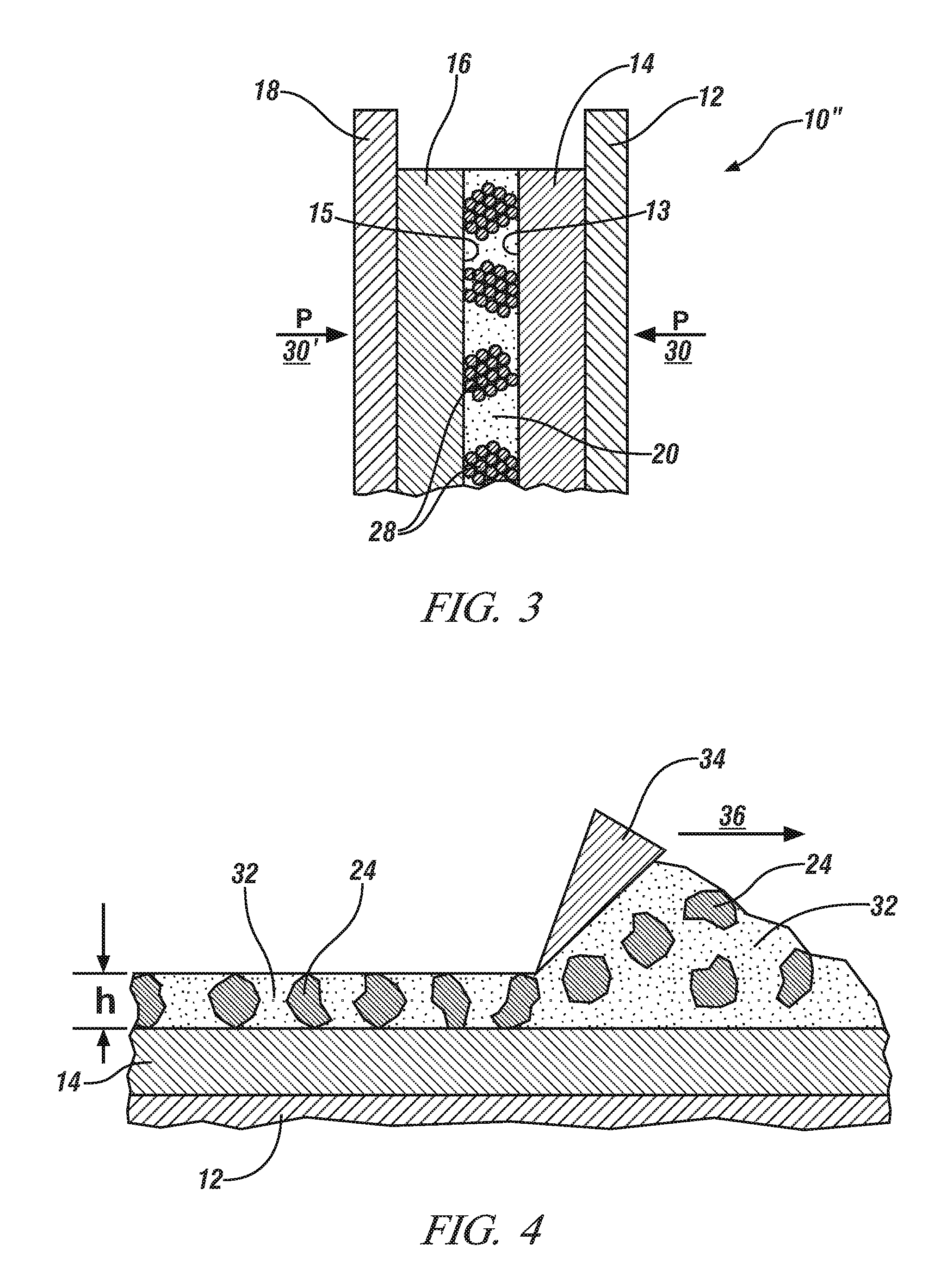

Encapsulated ceramic composite armor

A composite armor including a disrupting layer and a backing layer provides protection against blast and ballistic threats. The disrupting layer includes ceramic particles or tiles that disrupt the incoming projectile, while the backing layer prevents penetration past the armor by the disrupted projectile. The disrupting layer may include a layer of polygonal ceramic tiles with a deflecting front surface, encased by a retaining polymer, and may also include fire-retarding particles.

Owner:INTPROP HLDG

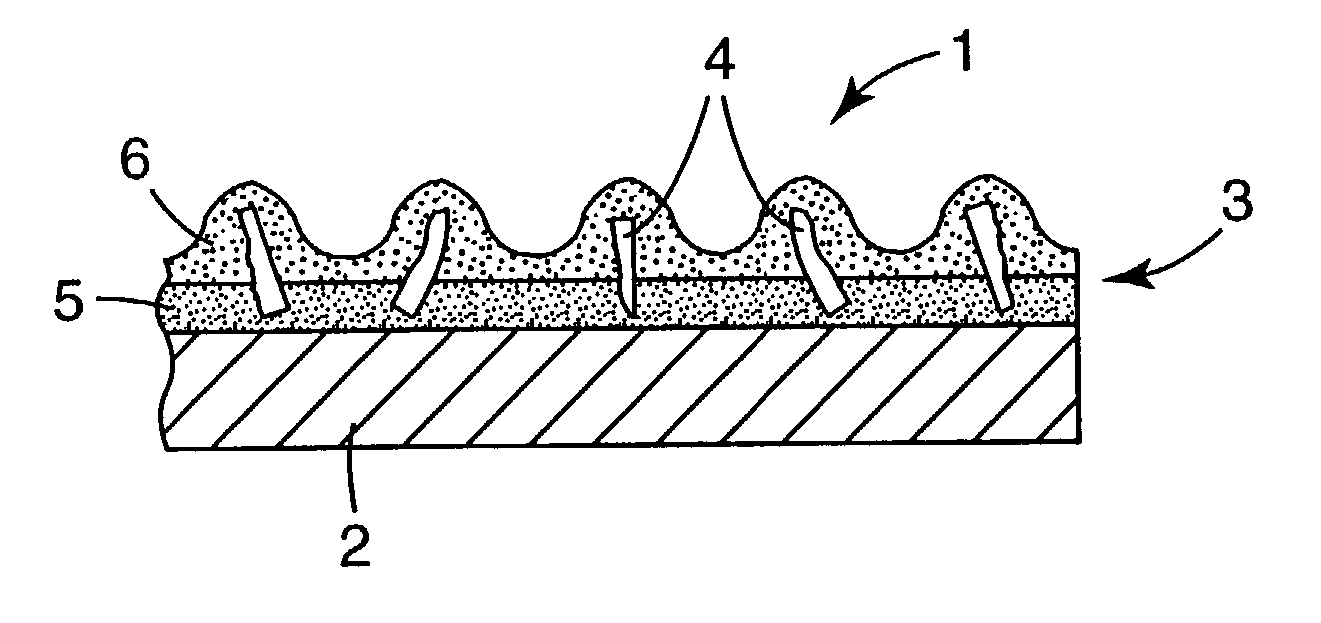

Adsorbent sheet material for parallel passage contactors

ActiveUS7077891B2Maximize capacityImprove efficiencyMaterial nanotechnologyOther chemical processesParticulatesSorbent

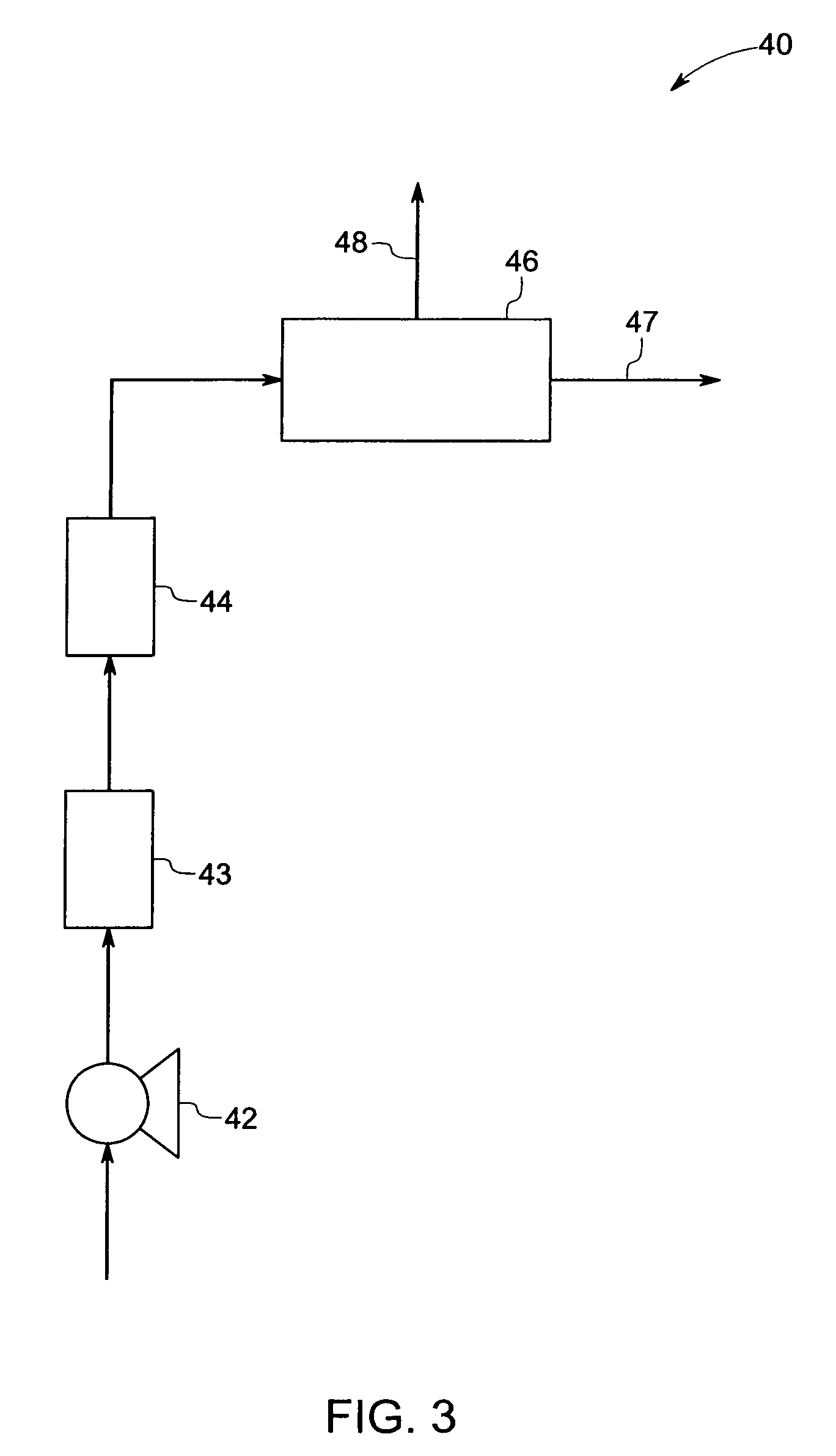

An adsorbent material fabricated into a reinforcement-free, self-supported coherent thin sheet and configured for use as a parallel passage contactor element in adsorption / separation applications with gases and liquids is disclosed. The adsorbent sheet material is obtained by enmeshing fine adsorbent particulates in a polymer binder. Particulates include but are not limited to carbon particles, inorganic oxides particles, or ceramic particles, or synthetic polymer resin particles. The adsorbent sheet advantageously contains a large volume percentage of active adsorbent particles. The parallel passage contactor device fabricated from the adsorbent sheet material is characterized by minimal mass transfer resistance and better separation efficiency expressed as height equivalent to a theoretical plate, while it maintains most of the adsorptive properties of the starting particulates, and can be used in gas separation applications with short adsorption cycles, such as rapid pressure swing adsorption, rotary concentrators, rapid electric swing adsorption.

Owner:AIR PROD & CHEM INC

Nanocomposite ceramics and process for making the same

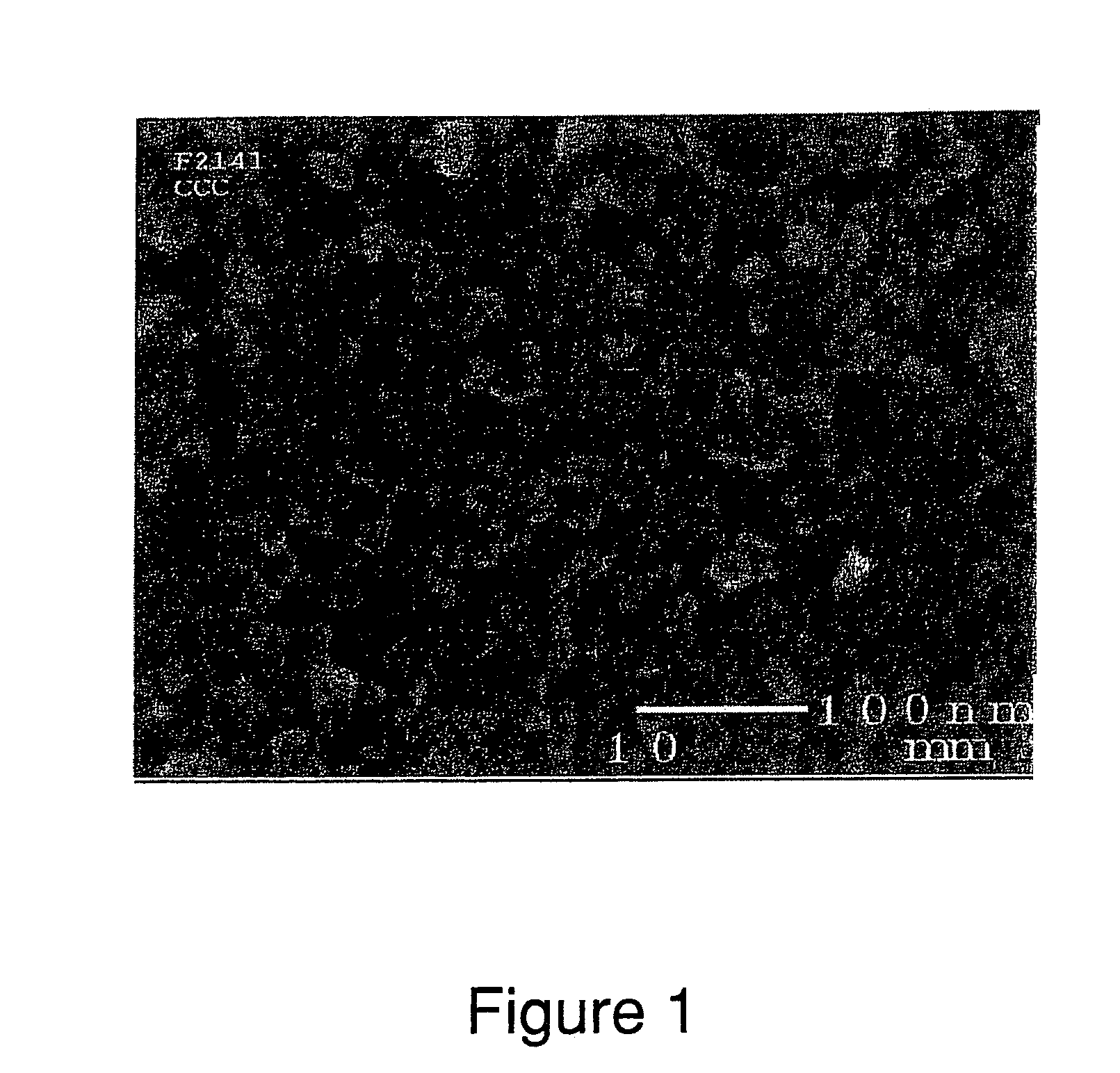

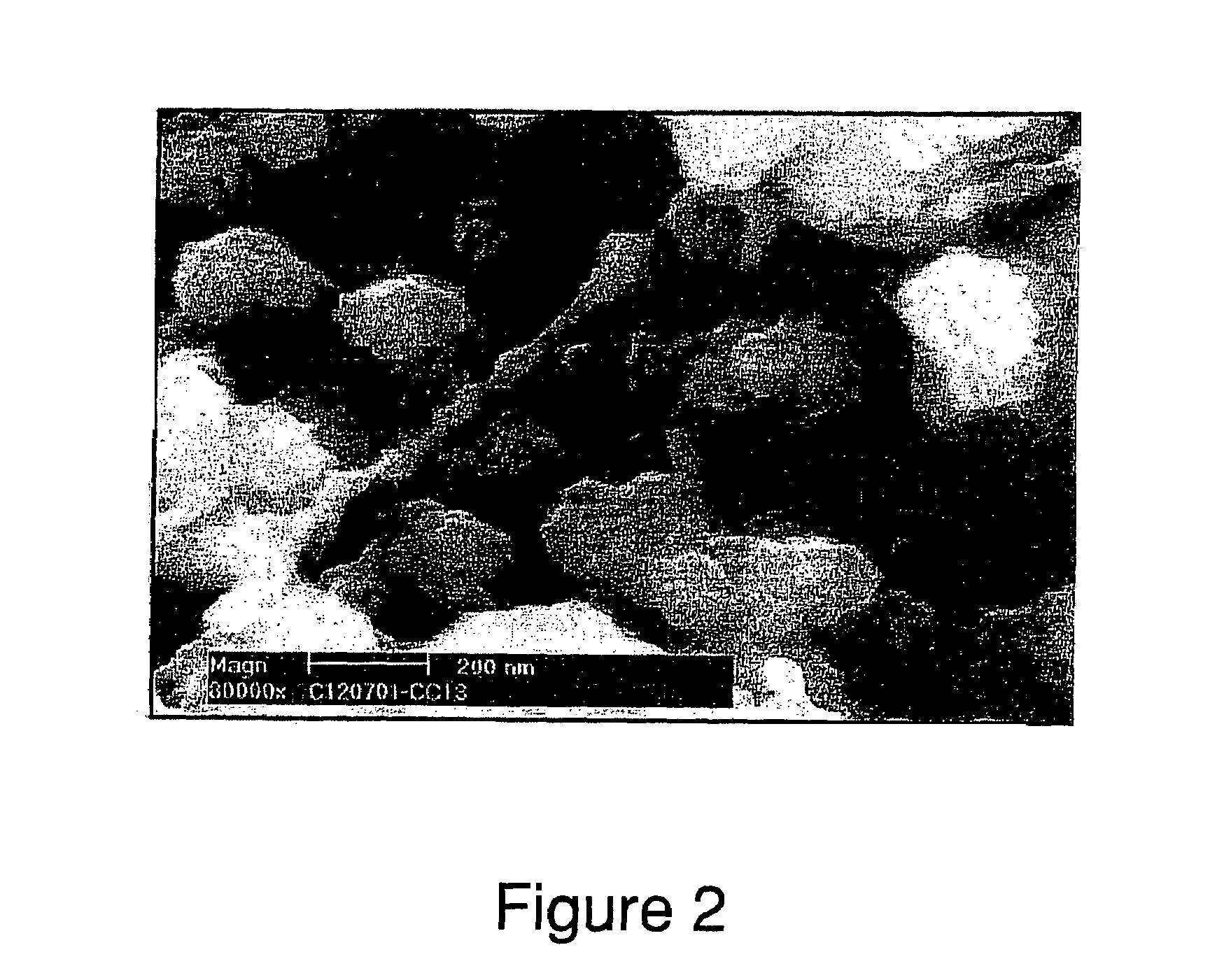

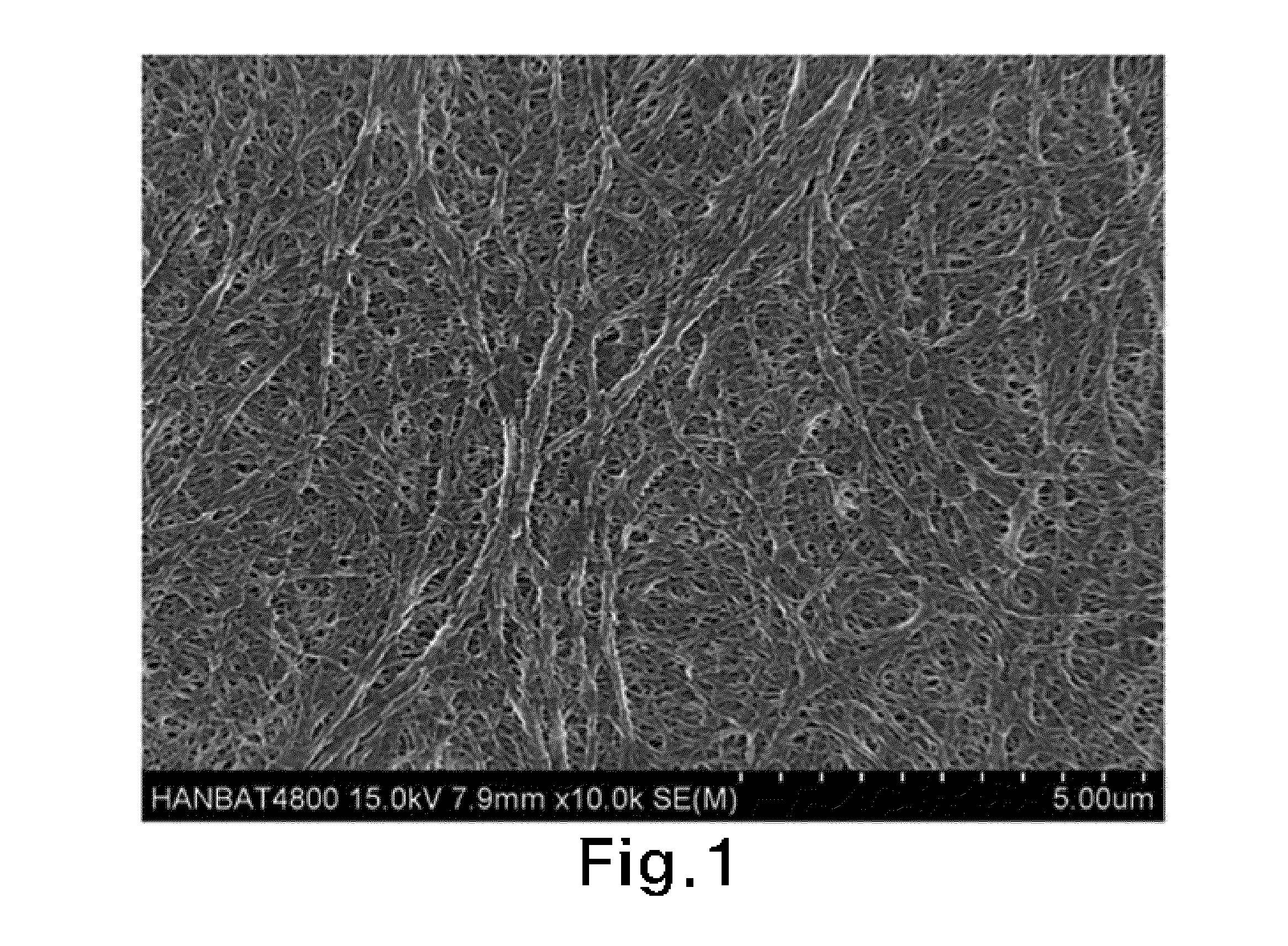

InactiveUS20070049484A1High hardnessImprove fracture toughnessMaterial nanotechnologyNanometreMaterials science

A nanocomposite ceramic composition and method for making the same, the composition comprising a uniform dispersion of nanosize ceramic particles composed of at least one ceramic phase, interspersed and bound throughout a tough zirconia matrix phase.

Owner:RUTGERS THE STATE UNIV

Al2O3-Y2O3-ZrO2/HfO2 materials, and methods of making and using the same

InactiveUS7507268B2Facilitates formation and homogeneityEliminates and minimizes heat transferPigmenting treatmentGlass drawing apparatusFiberThermal insulation

Al2O3—Y2O3—ZrO2 / HfO2 ceramics (including glasses, crystalline ceramics, and glass-ceramics) and methods of making the same. Ceramics according to the present invention can be made, formed as, or converted into glass beads, articles (e.g., plates), fibers, particles, and thin coatings. The particles and fibers are useful, for example, as thermal insulation, filler, or reinforcing material in composites (e.g., ceramic, metal, or polymeric matrix composites). The thin coatings can be useful, for example, as protective coatings in applications involving wear, as well as for thermal management. Certain ceramic particles according to the present invention can be are particularly useful as abrasive particles.

Owner:3M INNOVATIVE PROPERTIES CO

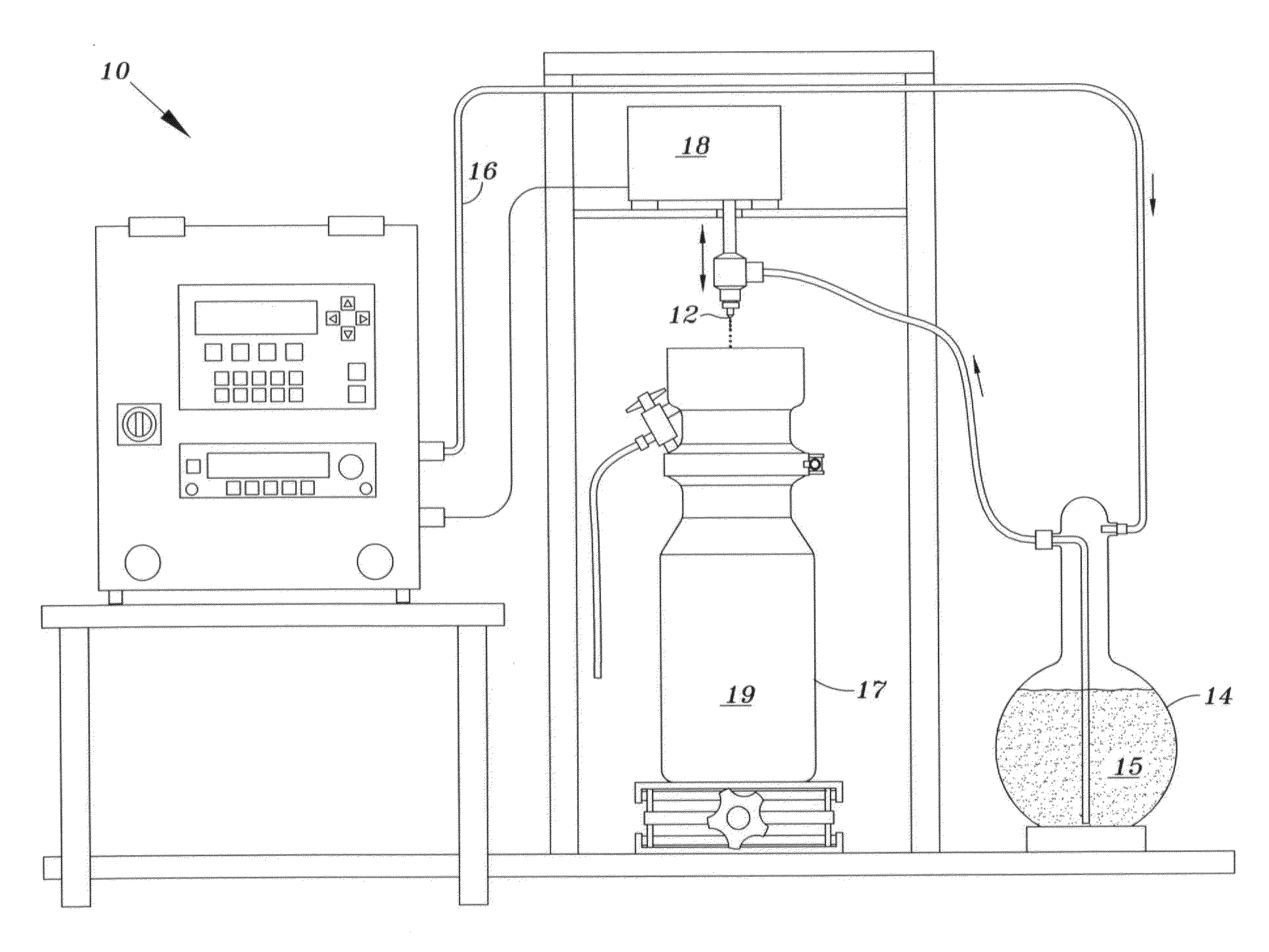

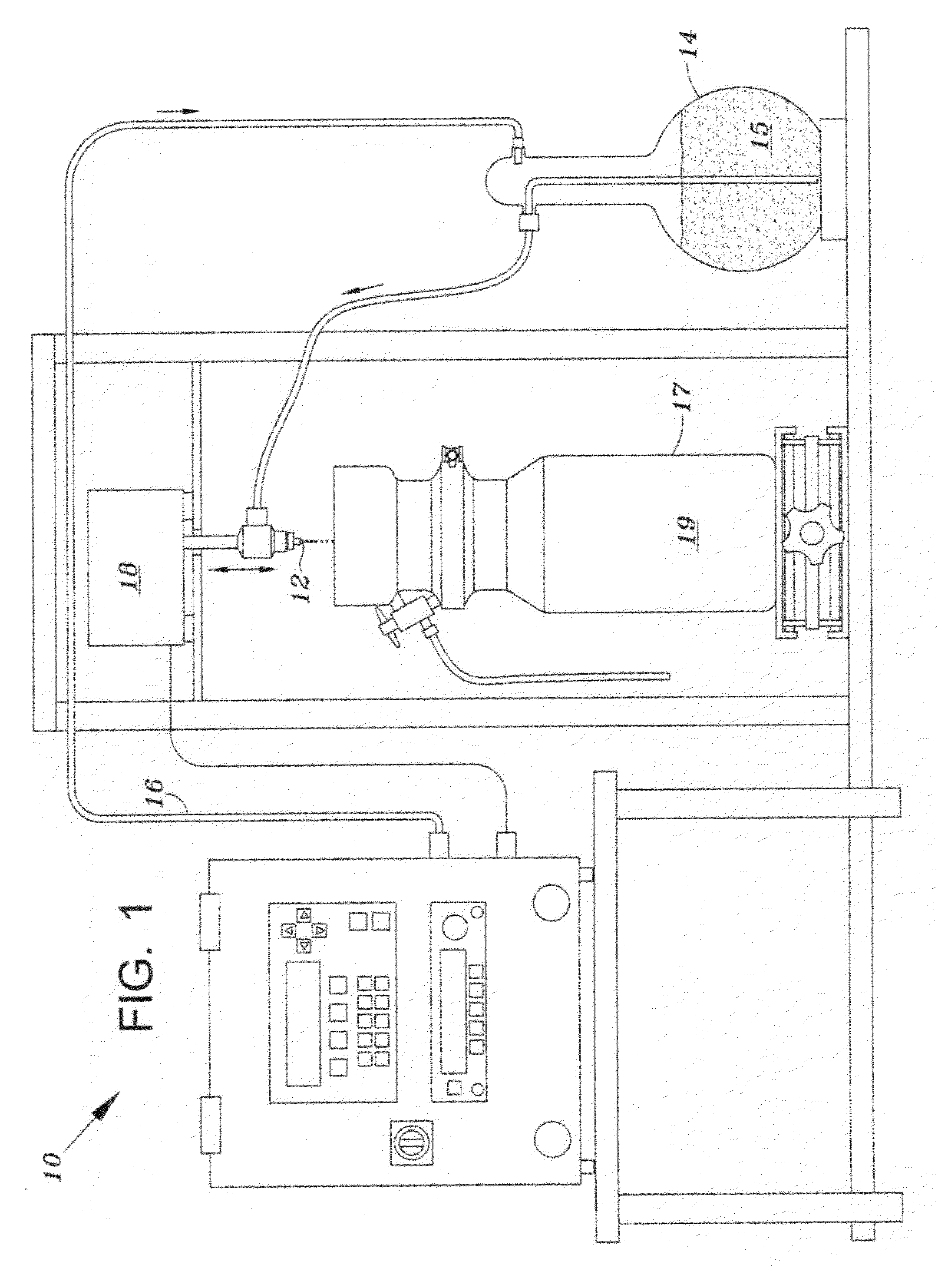

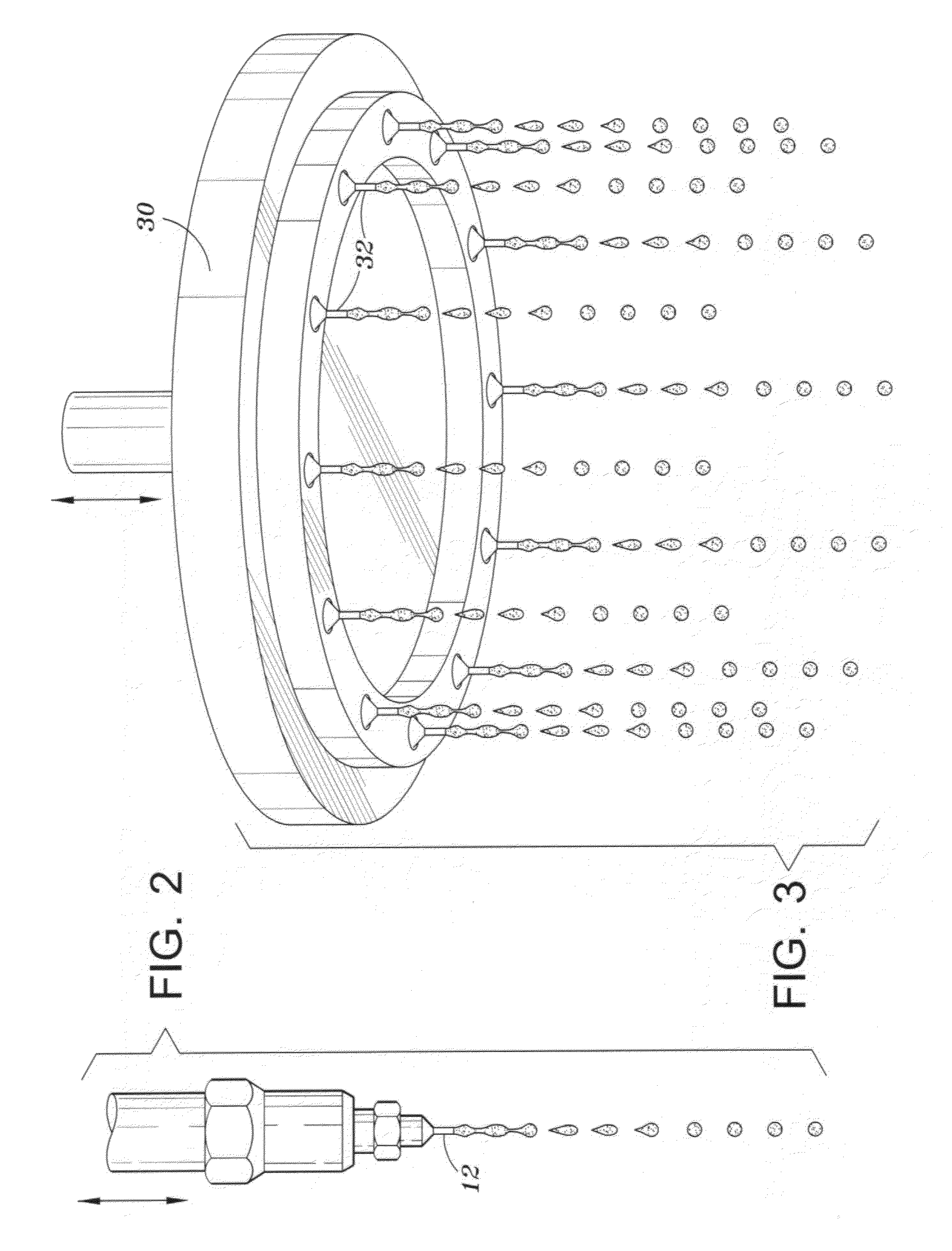

Proppant Particles Formed From Slurry Droplets and Method of Use

Proppant material for hydraulic fracturing is provided. The particles of the proppant are formed by drip casting. A slurry of finely divided ceramic particles is flowed through nozzles and formed into droplets under the influence of vibration. Uniform sized, smooth surface, spherical green particles are formed. The green particles are dried and sintered to form the proppant. The proppant is used in the process of hydraulic fracturing of wells.

Owner:CARBO CERAMICS

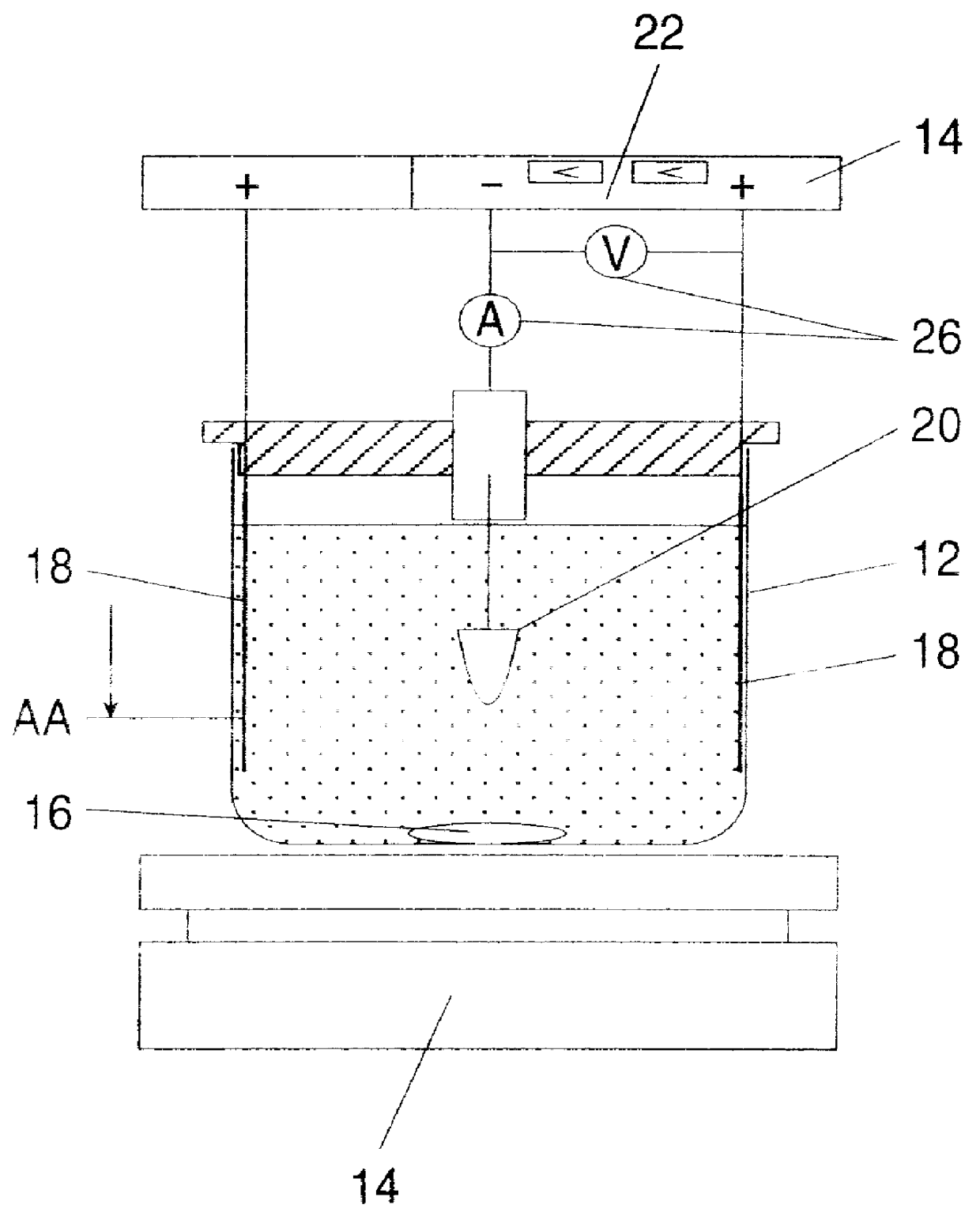

Method of electrophoretic deposition of ceramic bodies for use in manufacturing dental appliances

InactiveUS6059949AHigh strengthImprove toughnessElectrolysis componentsTeeth fillingMetallurgyElectrophoresis

A method for electrophoretic deposition of ceramic particles as a green body shaped as a dental appliance, the method comprising the steps of (a) forming a suspension of the ceramic particles in a first polar solvent, the ceramic particles constituting at least about 5% of the first suspension by weight; (b) passing a direct electrical current through the first suspension, using a deposition electrode shaped as the dental appliance to form a green body; (c) coating the green body with glass particles; and (d) sintering the resultant coated body for obtaining a glass coated all-ceramic dental appliance.

Owner:CEREL CERAMIC TECH

Encapsulated ceramic composite armor

A composite armor including a disrupting layer and a backing layer provides protection against blast and ballistic threats. The disrupting layer includes ceramic particles or tiles that disrupt the incoming projectile, while the backing layer prevents penetration past the armor by the disrupted projectile. The disrupting layer may include a layer of polygonal ceramic tiles with a deflecting front surface, encased by a retaining polymer, and may also include fire-retarding particles.

Owner:INTPROP HLDG

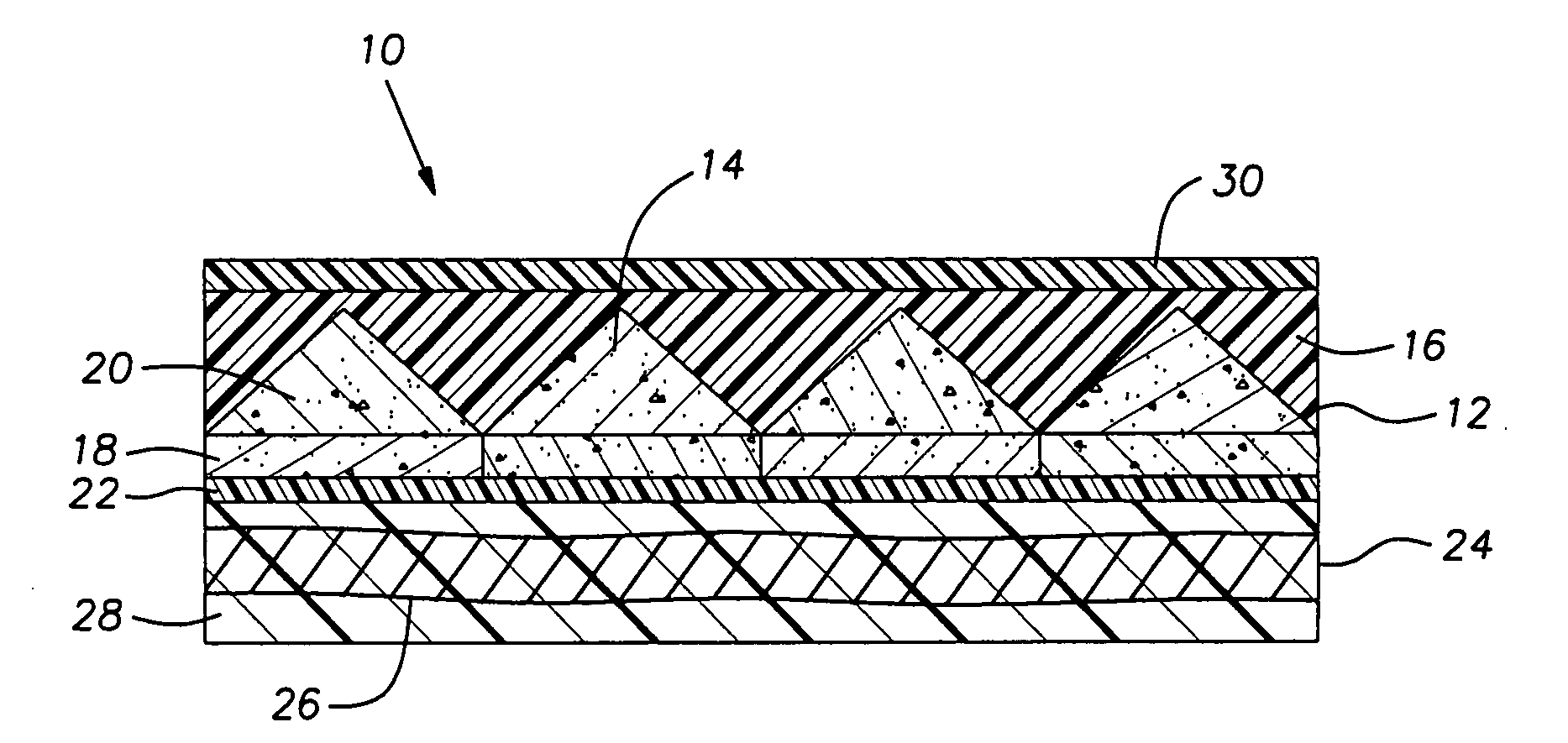

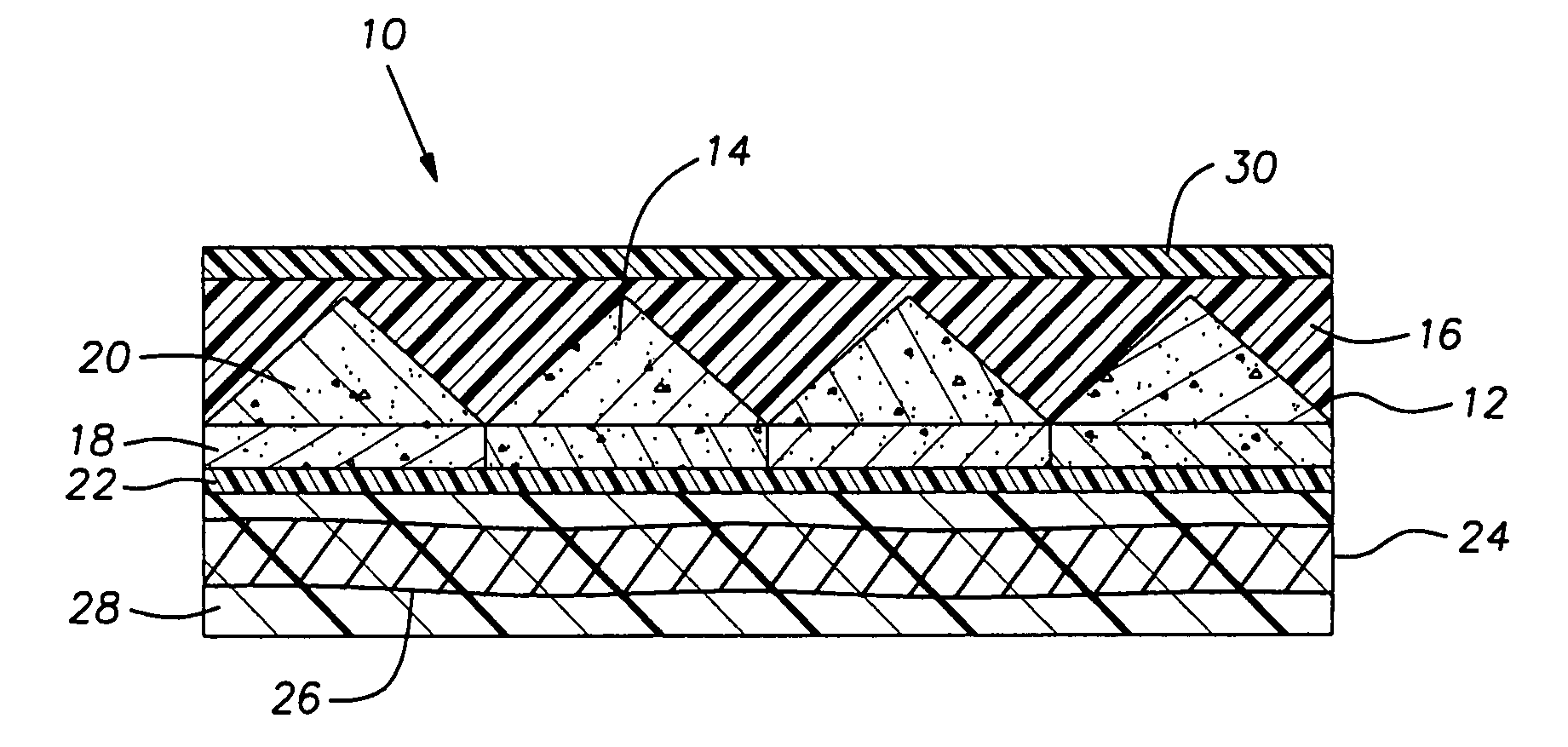

Honeycomb structure thermal barrier coating

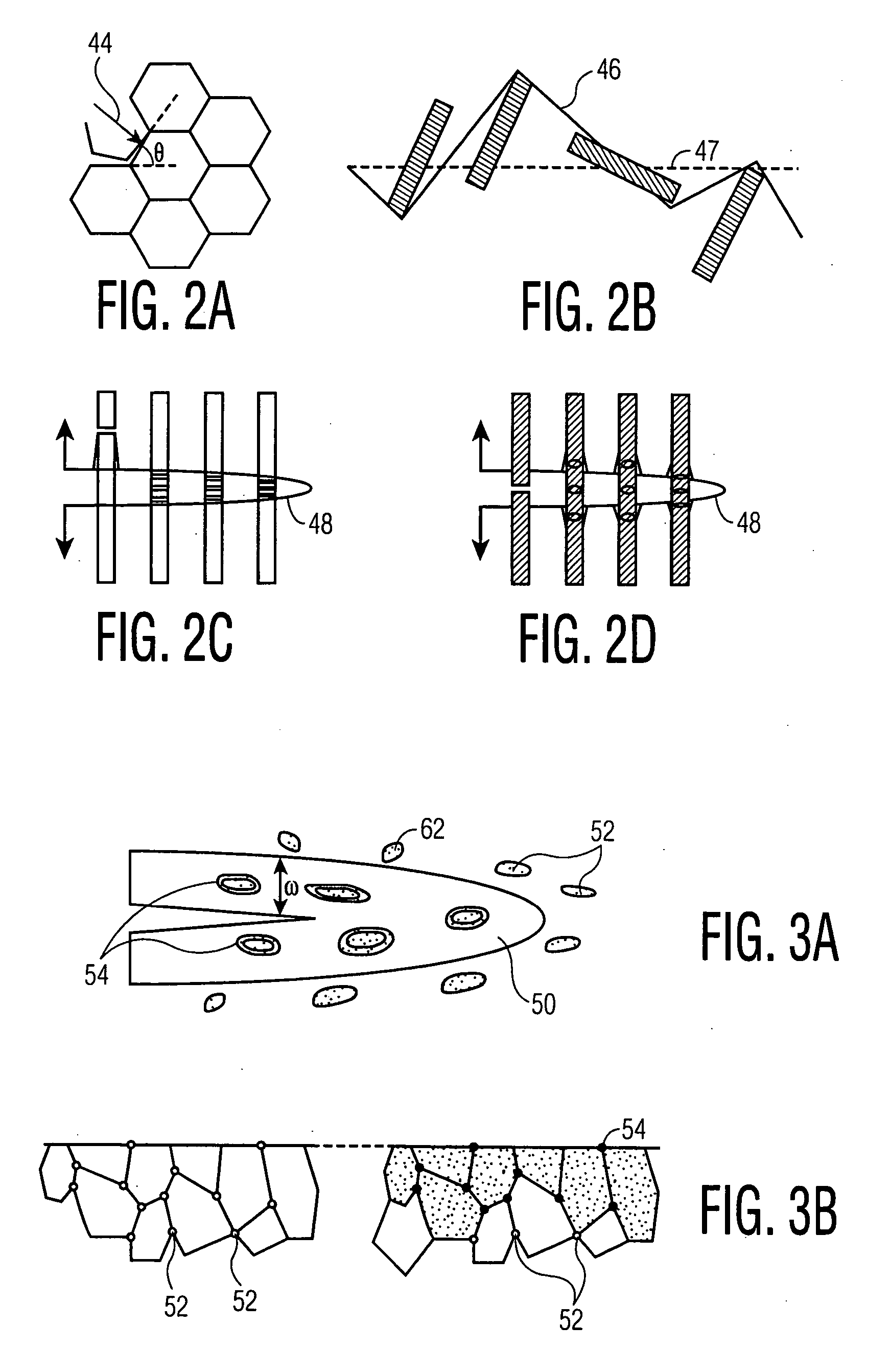

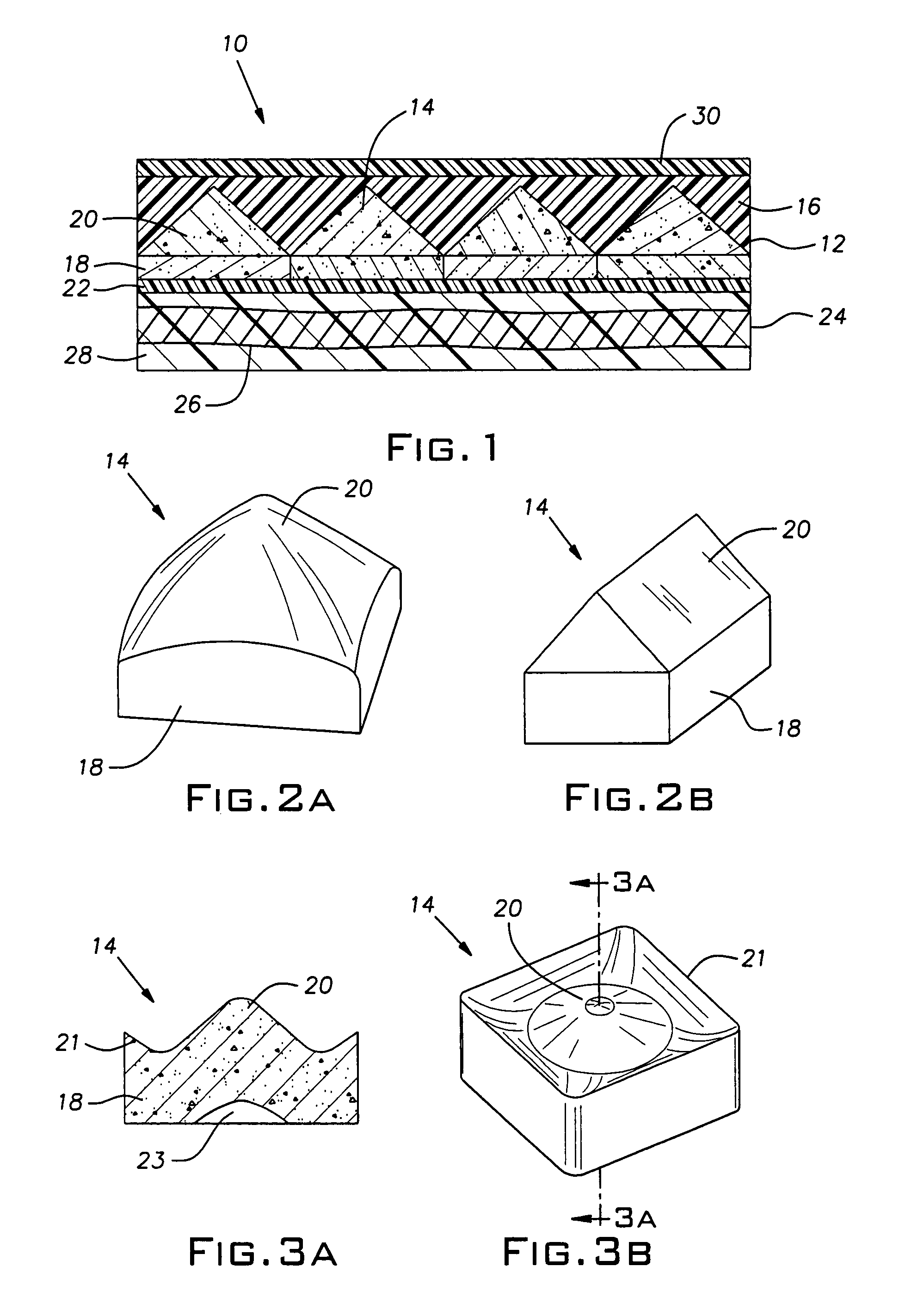

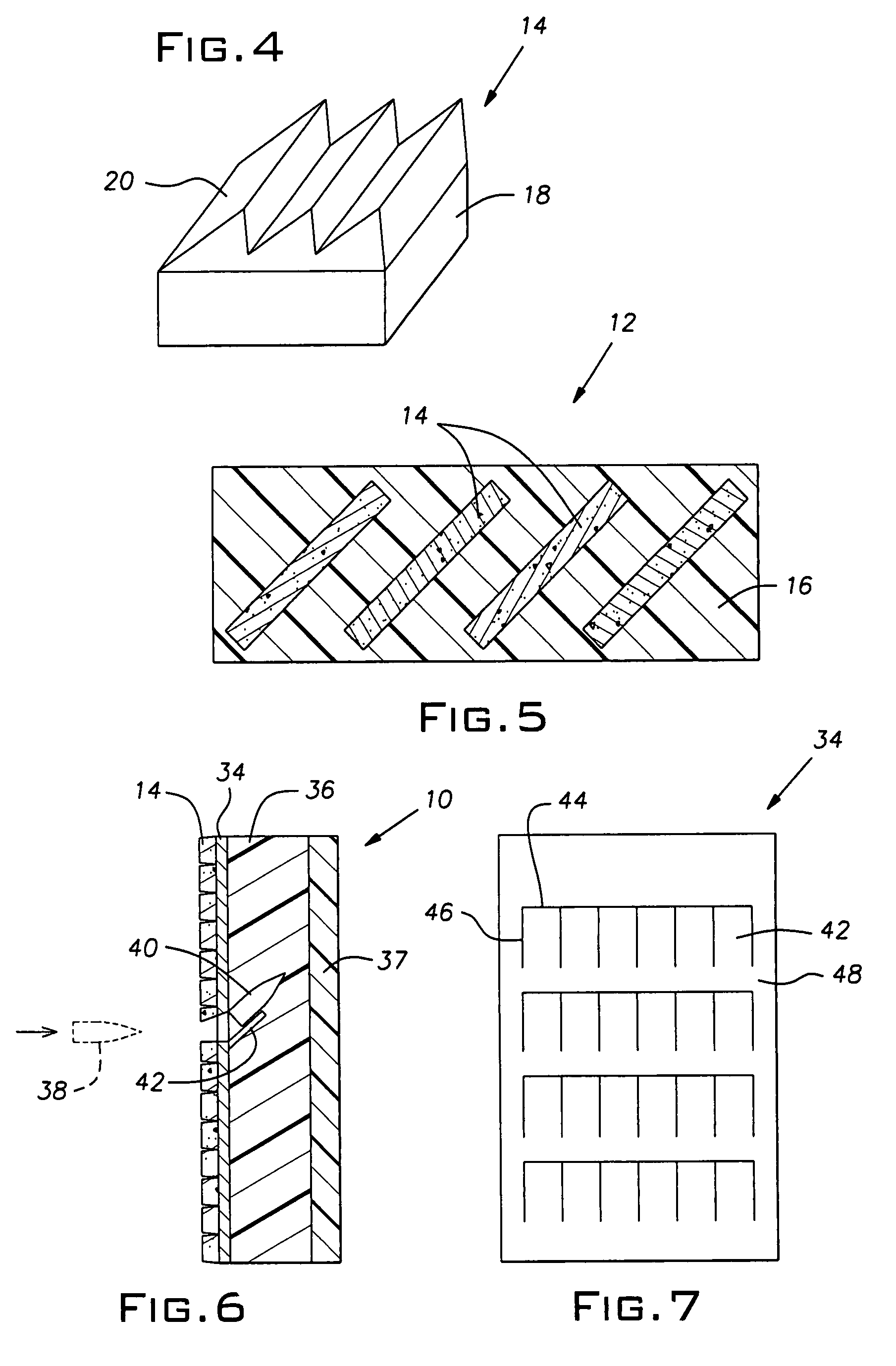

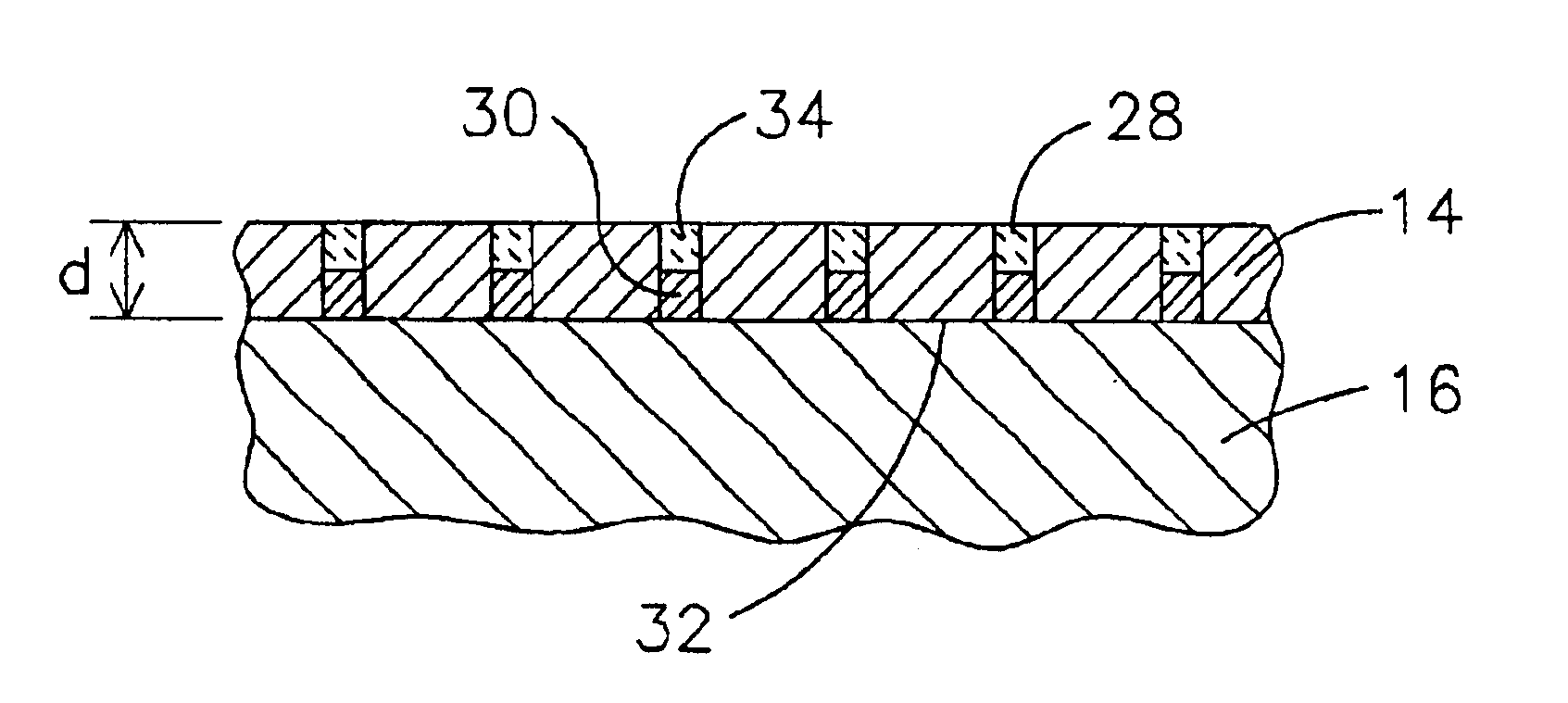

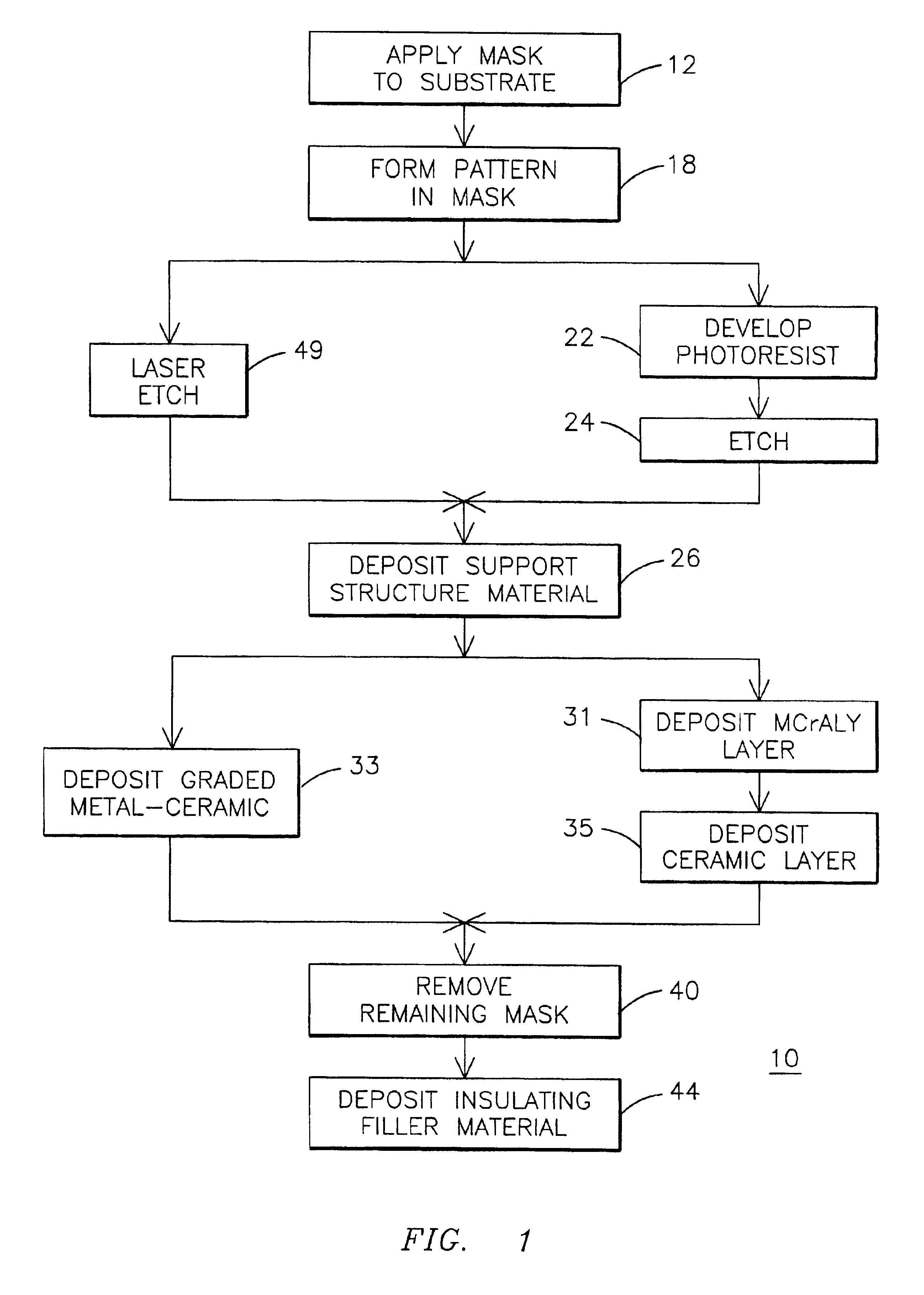

InactiveUS6846574B2Minimize heat transfer rateConvenient coatingMolten spray coatingRecord information storageForeign matterLaser etching

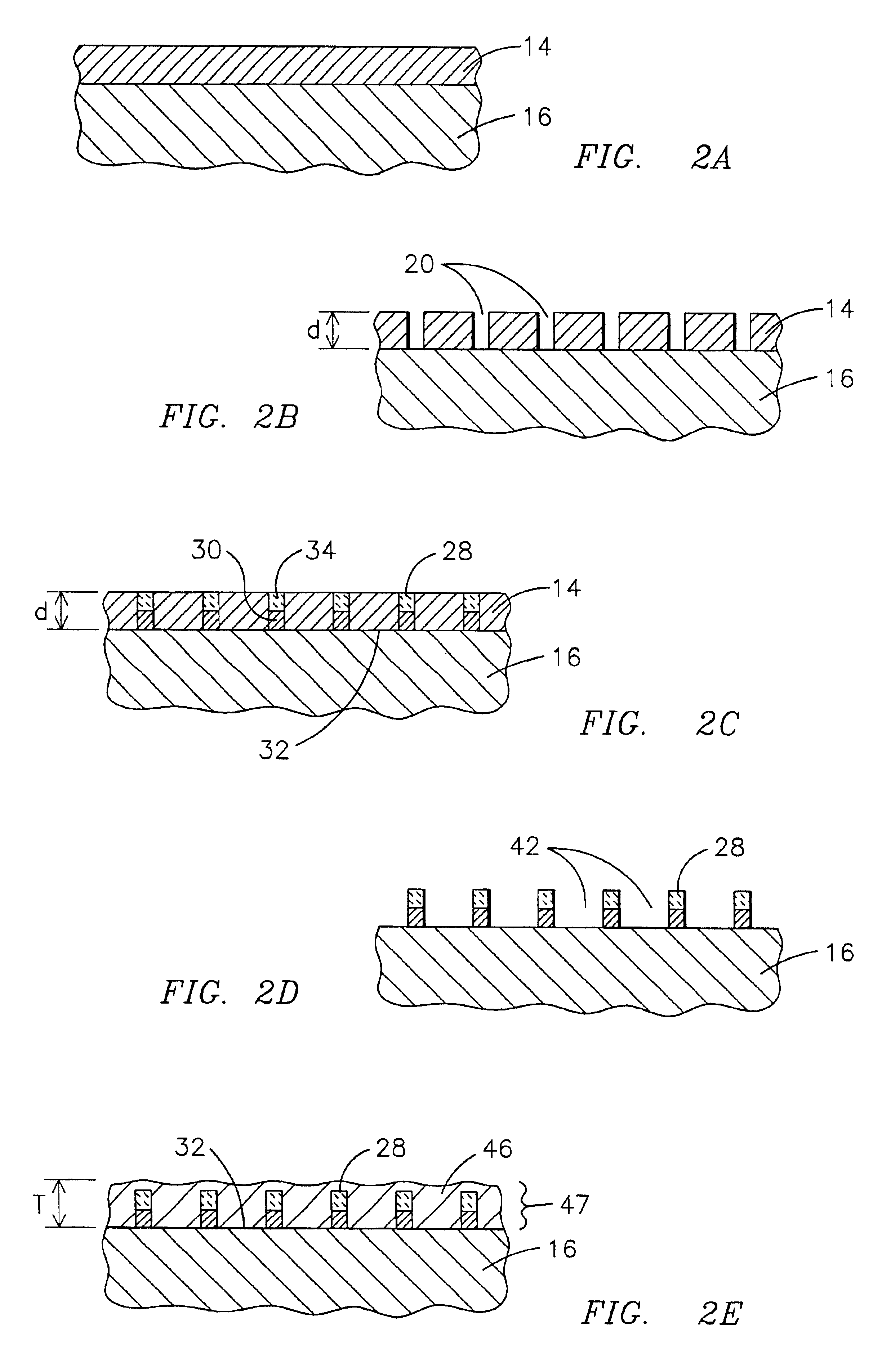

A device having an improved thermal barrier coating (46) and a process for manufacturing the same. A support structure (28) for retaining a ceramic insulating material (46) on a substrate (16) is formed by the deposition of a support structure material through a patterned masking material (14). The support structure can define cells into which the ceramic insulating material is deposited following removal of the masking material. The masking material may be patterned by known photolithographic techniques (22,24) or by laser etching (48). The support structure (28) may be a composite metal-ceramic material having either discreet layers (30,34) or a graded composition and may be deposited by an electro-desposition process followed by a heat treatment to form a solid state diffusion bond with the substrate. The ceramic filler material may be deposited (44) by the electrophoretic deposition of ceramic particles coated with a bonding material that is subsequently heated to oxidize and to bond the particles together. The support structure may be provided with included walls in order to improve its resistance to foreign object impact damage.

Owner:SIEMENS ENERGY INC

Core-shell ceramic particulate and method of making

InactiveUS7670679B2High-temperature mechanical and structural stabilityLiquid surface applicatorsCell electrodesParticulatesCore shell

Owner:BHA ALTAIR

Method for preparing cross-linked ceramic-coated separator containing ionic polymer, ceramic-coated separator prepared by the method, and lithium secondary battery using the same

ActiveUS20110027658A1High bonding strengthImprove battery performanceLi-accumulatorsCell component detailsCross-linkHigh rate

The present invention provides method for preparing a cross-linked ceramic-coated separator containing an ionic polymer, a ceramic-coated separator prepared by the method, and a lithium secondary battery using the same. According to preferred methods for preparing a cross-linked ceramic-coated separator, a coating material containing ceramic particles for improving thermal and mechanical characteristics, a functional inorganic compound for improving cycle characteristics and high rate characteristics of a battery, and an ionic polymer for bonding the ceramic particles and the functional inorganic compound on a porous membrane substrate is coated on the porous membrane substrate and subjected to chemical cross-linking.

Owner:HYUNDAI MOTOR CO LTD +1

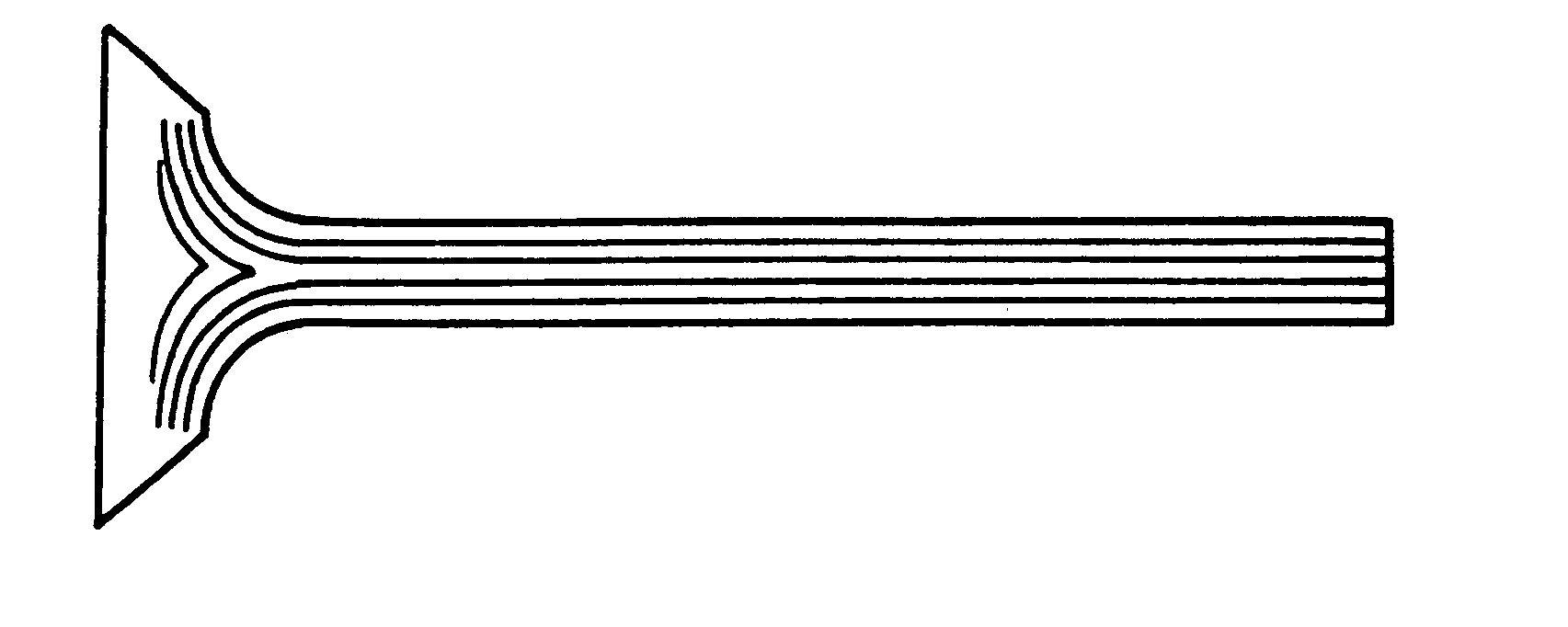

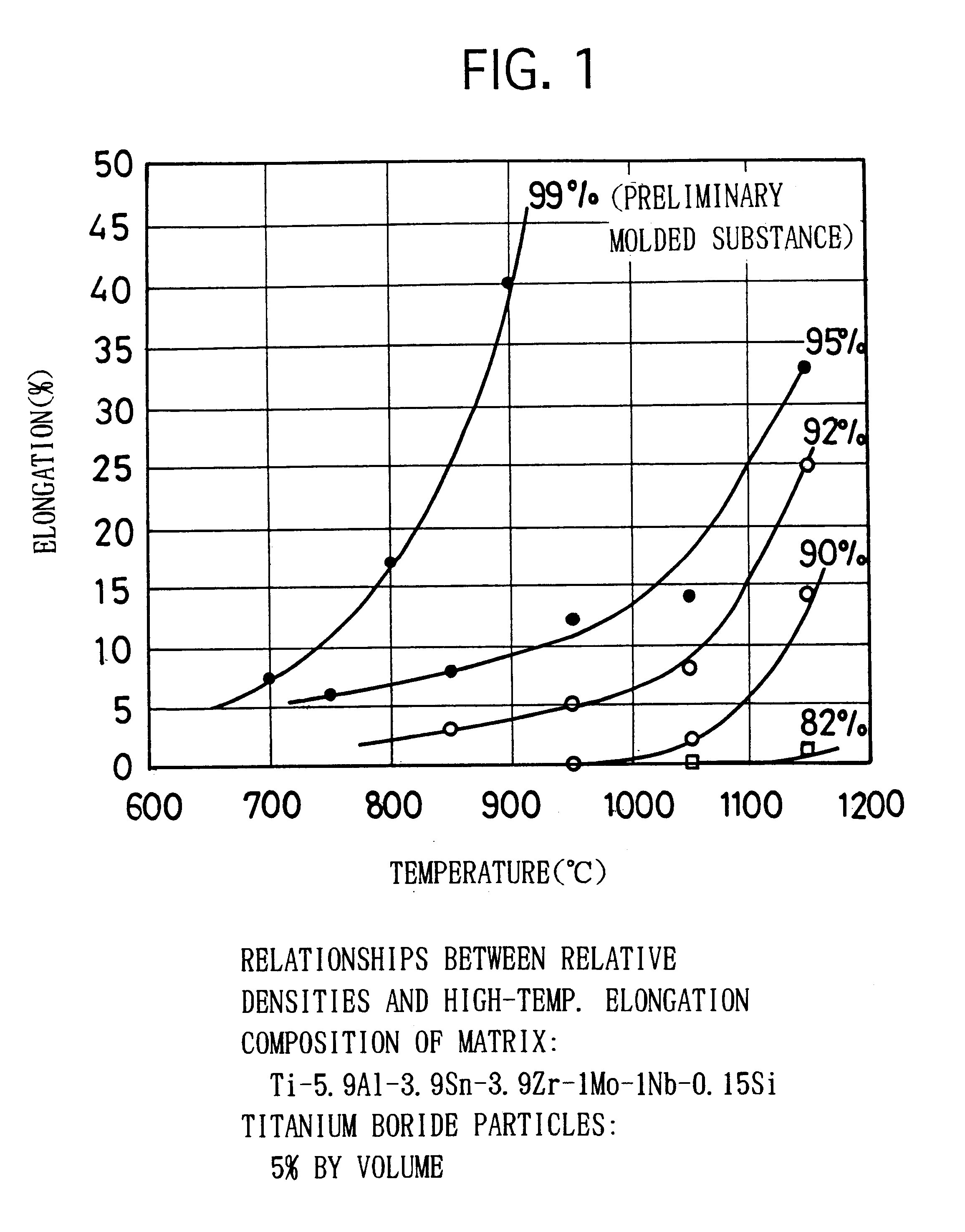

Process for forging titanium-based material, process for producing engine valve, and engine valve

InactiveUS6599467B1Degradation can be suppressedReduced strengthMetal-working apparatusMachines/enginesTitaniumEngine valve

The invention provides a process for forging a titanium-based material comprises the steps of: preparing a titanium-based sintered workpiece including at least one of ceramics particles and pores in a total amount of 1% or more by volume, the ceramics particles being thermodynamically stable in a titanium alloy; and heating the workpiece to a forging temperature and forging the same. In the production process, the pores or the ceramics particles inhibit the grain growth during forging. Accordingly, it is possible to carry out the forging at a relatively high temperature at which the titanium-based material exhibits a small resistance to deformation. Moreover, the titanium-based material can maintain an appropriate microstructure even after the forging. Consequently, the impact value and the fatigue strength are inhibited from decreasing.

Owner:TOYOTA JIDOSHA KK +1

Al2O3-Y2O3-ZrO2/HfO2 materials, and methods of making and using the same

InactiveUS20030110708A1Facilitates formation and homogeneityOxide formationPigmenting treatmentGlass drawing apparatusFiberThermal insulation

Al2O3-Y2O3-ZrO2 / HfO2 ceramics (including glasses, crystalline ceramics, and glass-ceramics) and methods of making the same. Ceramics according to the present invention can be made, formed as, or converted into glass beads, articles (e.g., plates), fibers, particles, and thin coatings. The particles and fibers are useful, for example, as thermal insulation, filler, or reinforcing material in composites (e.g., ceramic, metal, or polymeric matrix composites). The thin coatings can be useful, for example, as protective coatings in applications involving wear, as well as for thermal management. Certain ceramic particles according to the present invention can be are particularly useful as abrasive particles.

Owner:3M INNOVATIVE PROPERTIES CO

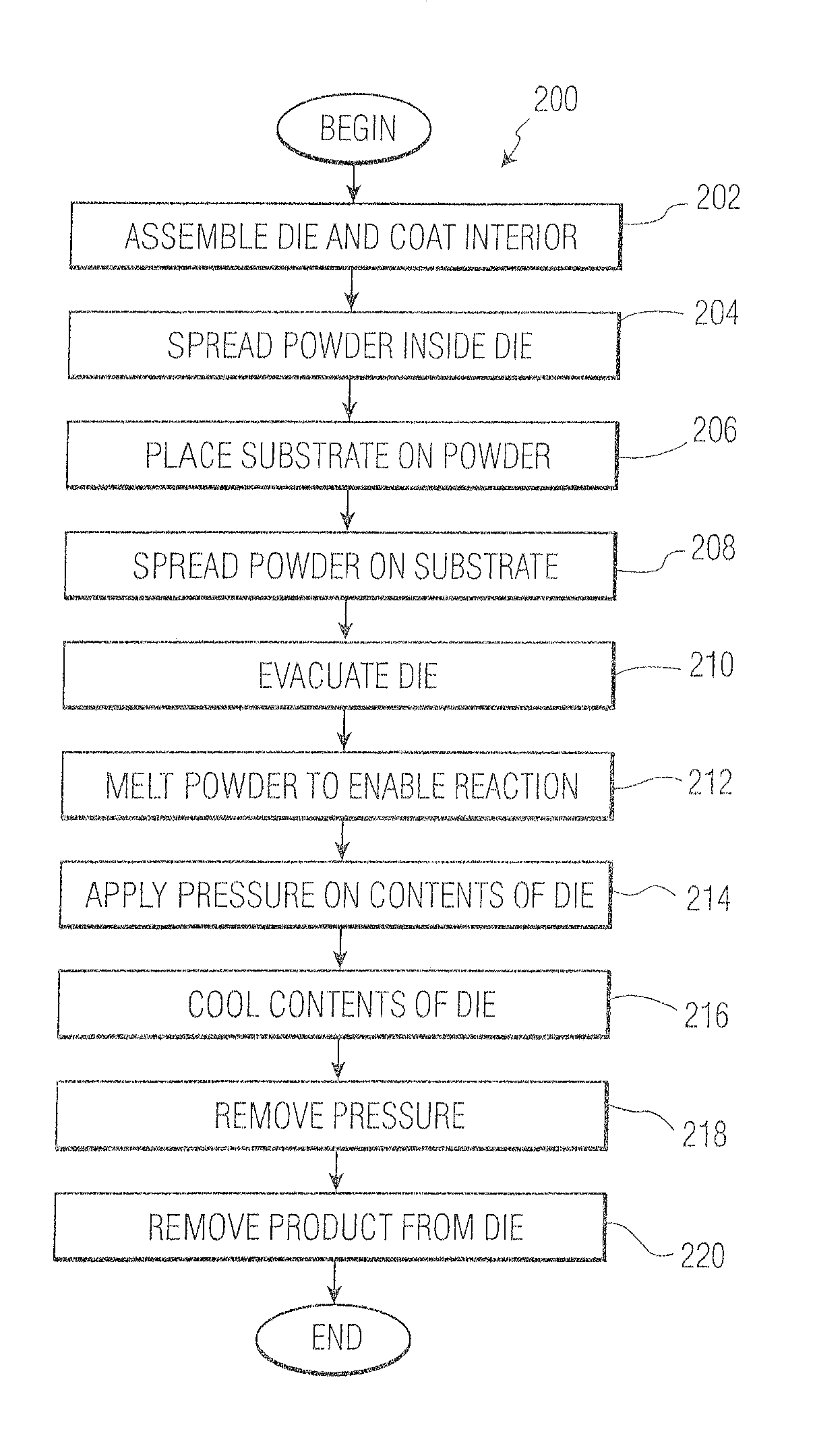

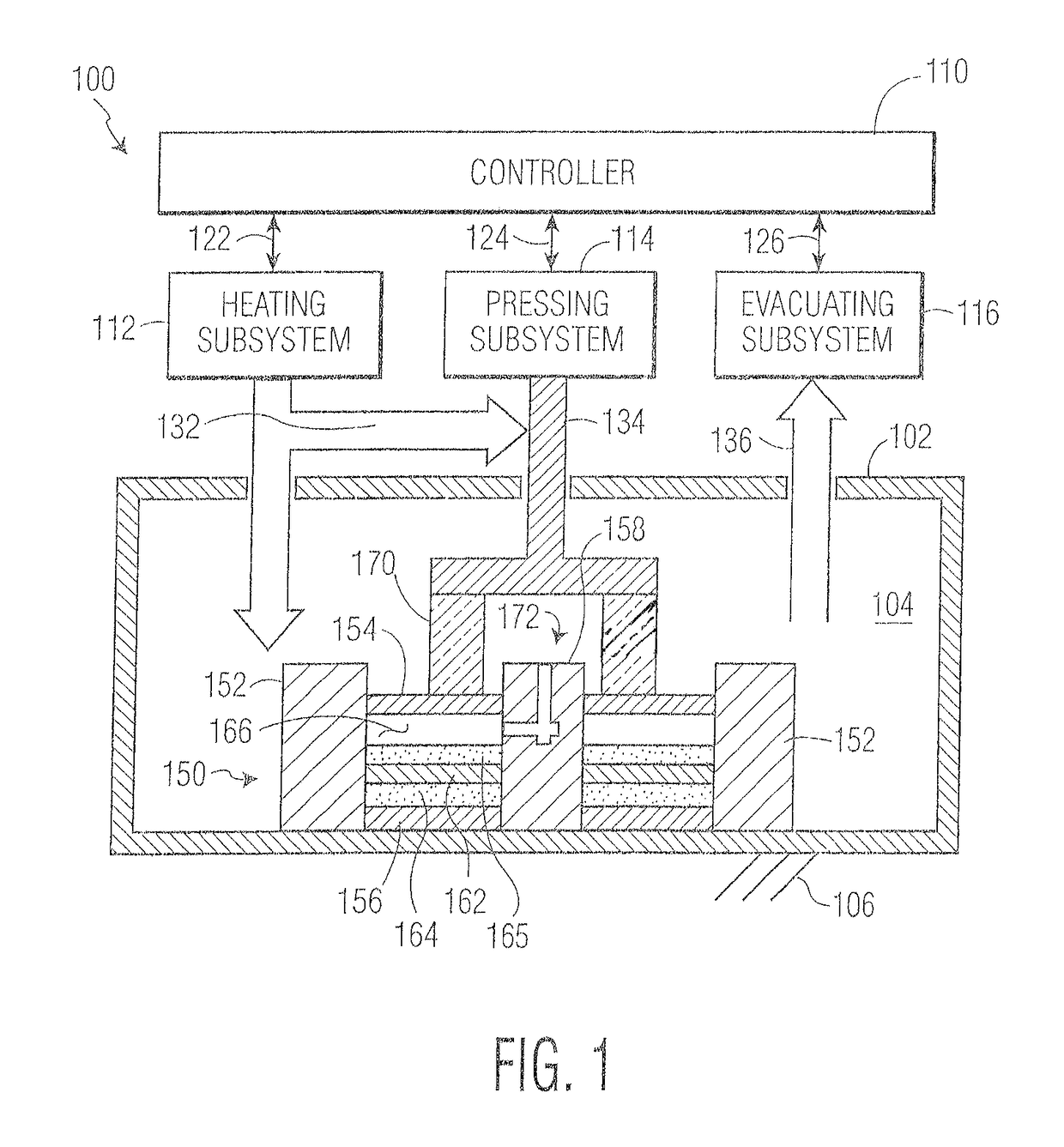

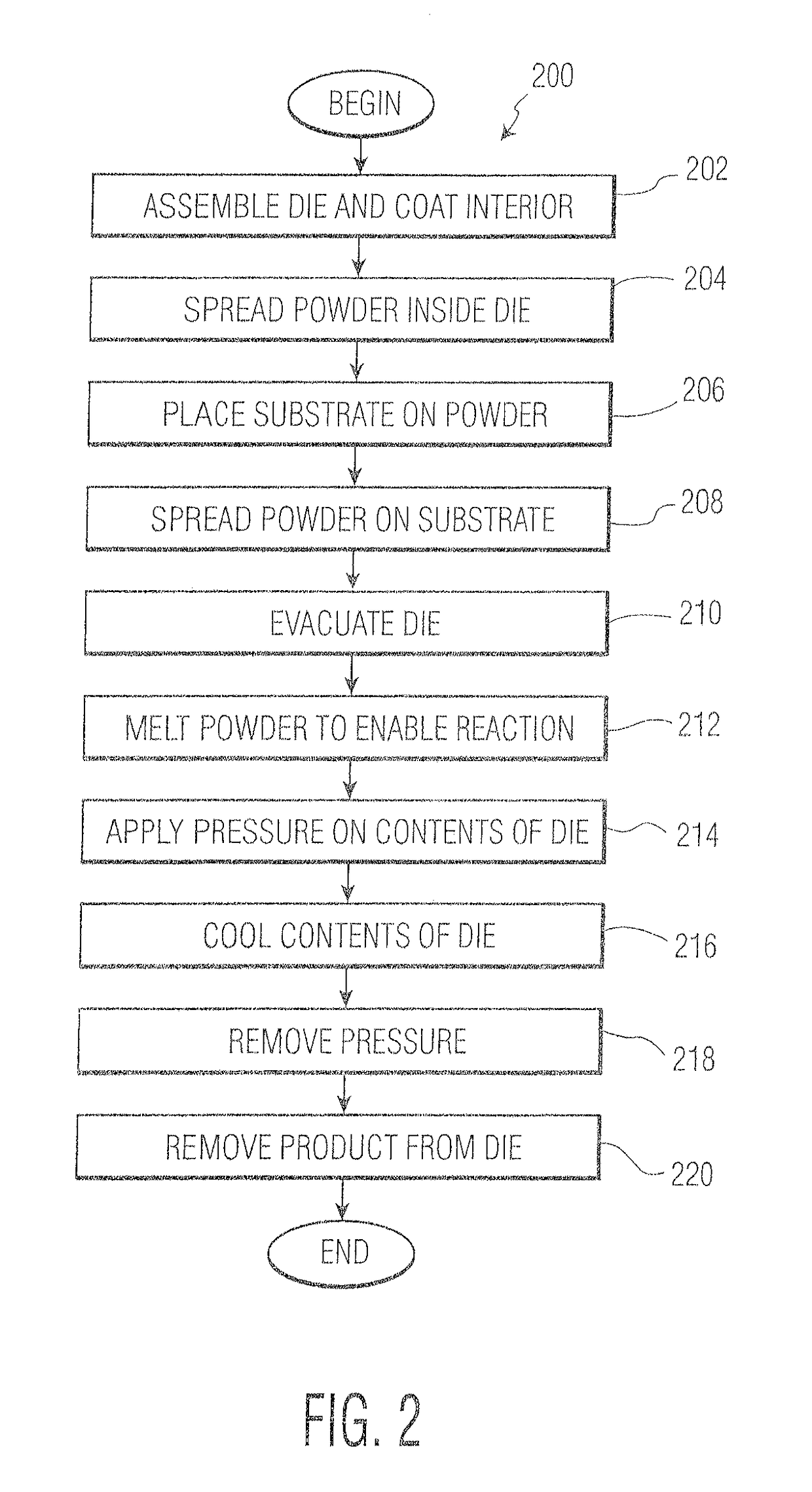

Systems and methods for forming a layer onto a surface of a solid substrate and products formed thereby

InactiveUS9933031B2Increase capacityImprove the overall coefficientBlade accessoriesBraking discsMetal matrix compositeSolid substrate

A method for forming a vehicular brake rotor involving loading a shaped metal substrate with a mixture of metal alloying components and ceramic particles in a dieheating the contents of the die while applying pressure to melt at least one of the metal components of the alloying mixture whereby to densify the contents of the die and form a ceramic particle-containing metal matrix composite coating on the metallic substrate; and cooling the resulting coated product.

Owner:ATS MER LLC

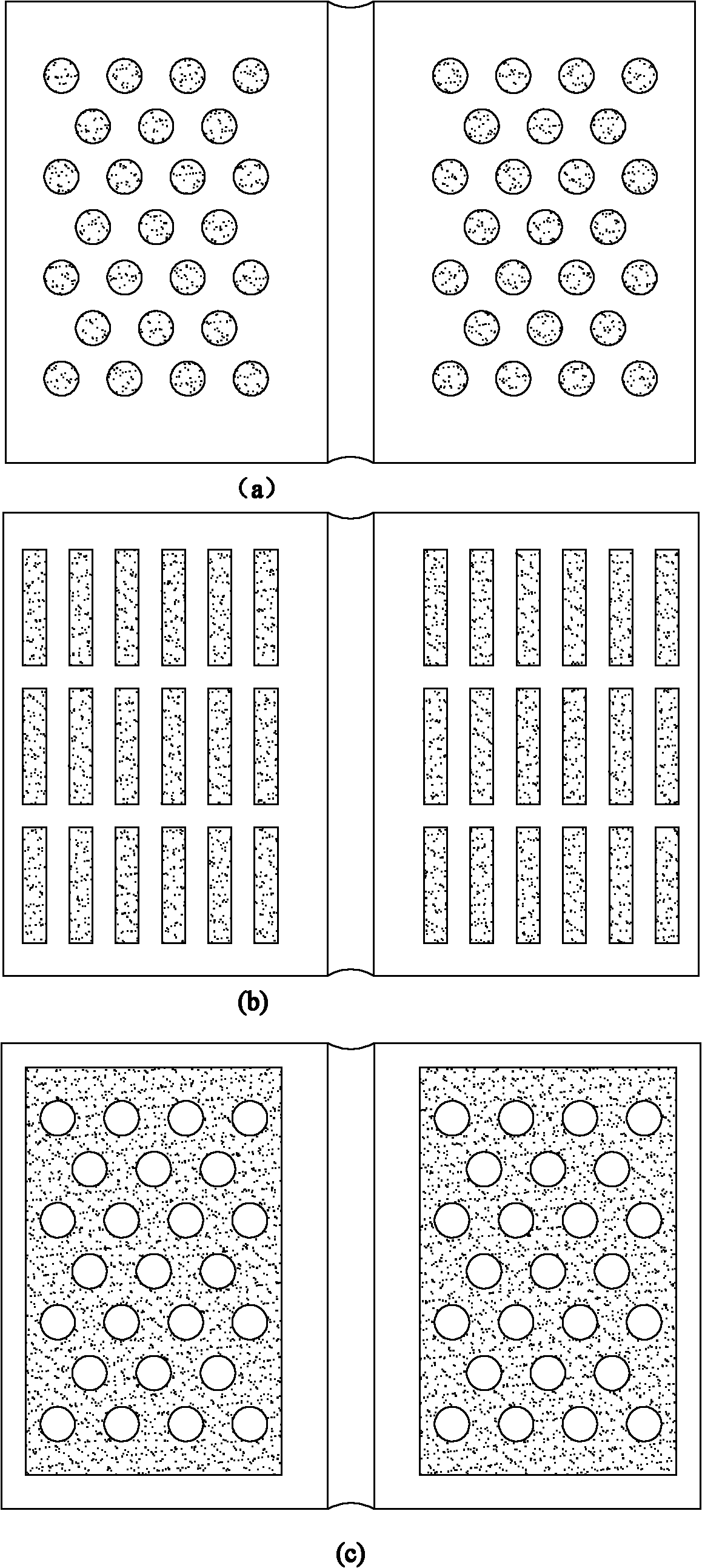

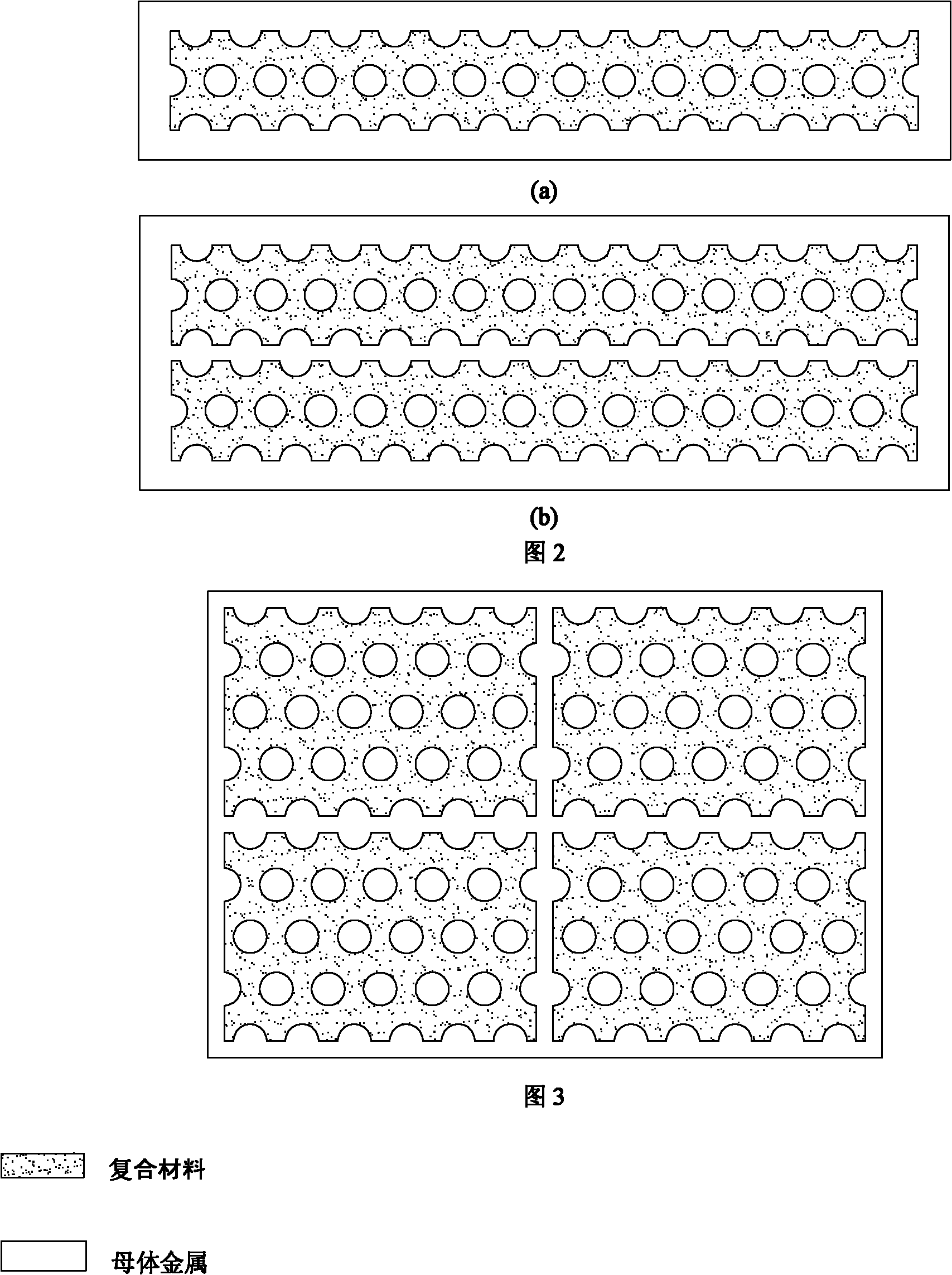

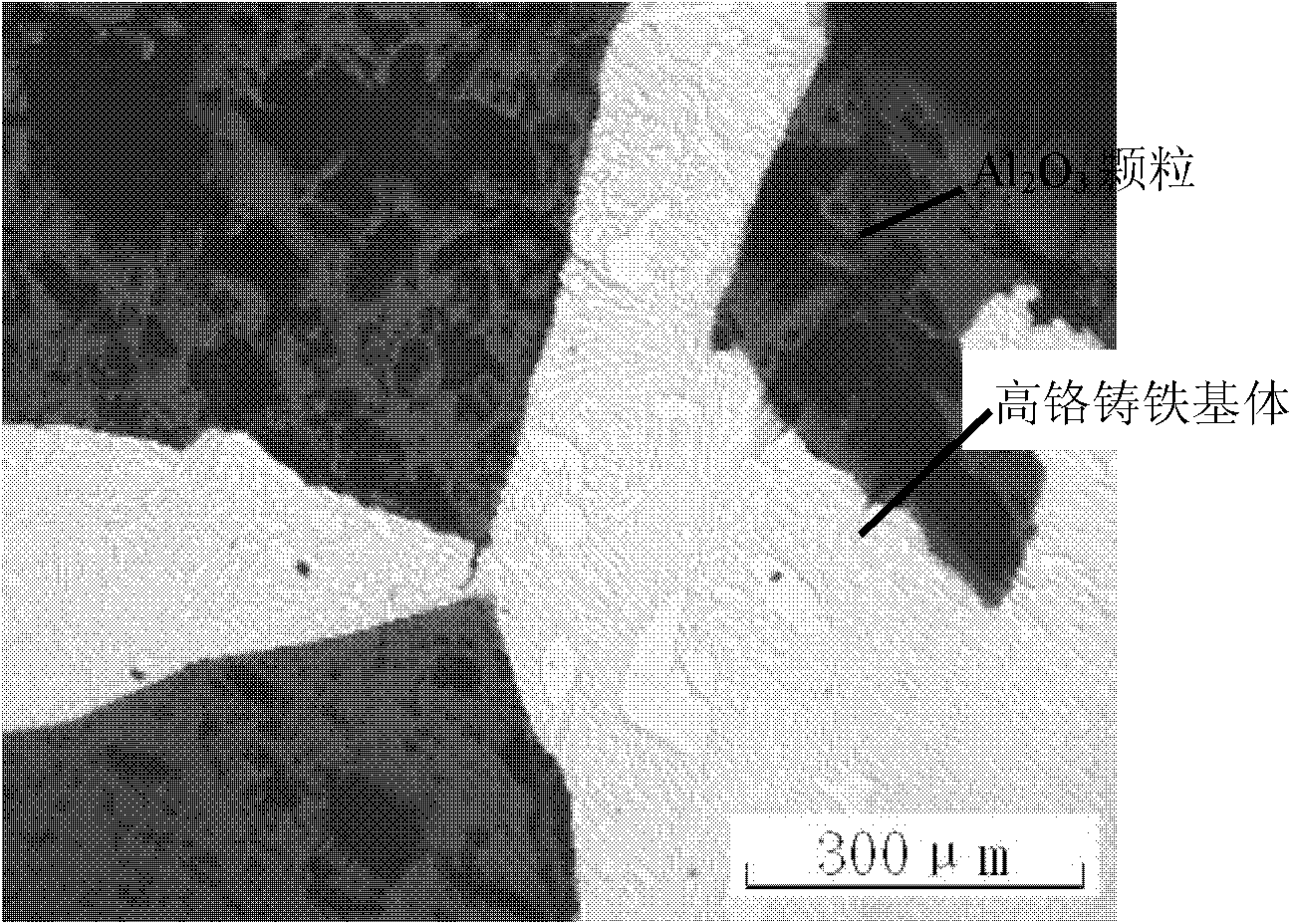

Prefabricated part of composite abrasion-resistant part and method for manufacturing abrasion-resistant part with same

The invention relates to a prefabricated part of a composite abrasion-resistant part and a method for manufacturing the abrasion-resistant part with the same. The prefabricated part is formed by mixing metal powder with carbide ceramic particles or particles by crushing a hard alloy and sintering the mixture at a high temperature and can be made into special shapes of columns, strips, blocks, honeycombs, and the like. The method comprises the following steps of: regularly arranging prefabricated parts on the end surface of a cast form; casting liquid metal by adopting a common or negative pressure cast method; impregnating the liquid metal into the prefabricated parts to form an abrasion-resistant part of a composite material, wherein the surface layer of the abrasion-resistant part comprises a matrix metal and a composite material. The abrasion-resistant part of the composite material, which is made by using the method, ensures the wear-resistant performance of the abrasion-resistant part and has high anti-impact capability.

Owner:XI AN JIAOTONG UNIV +1

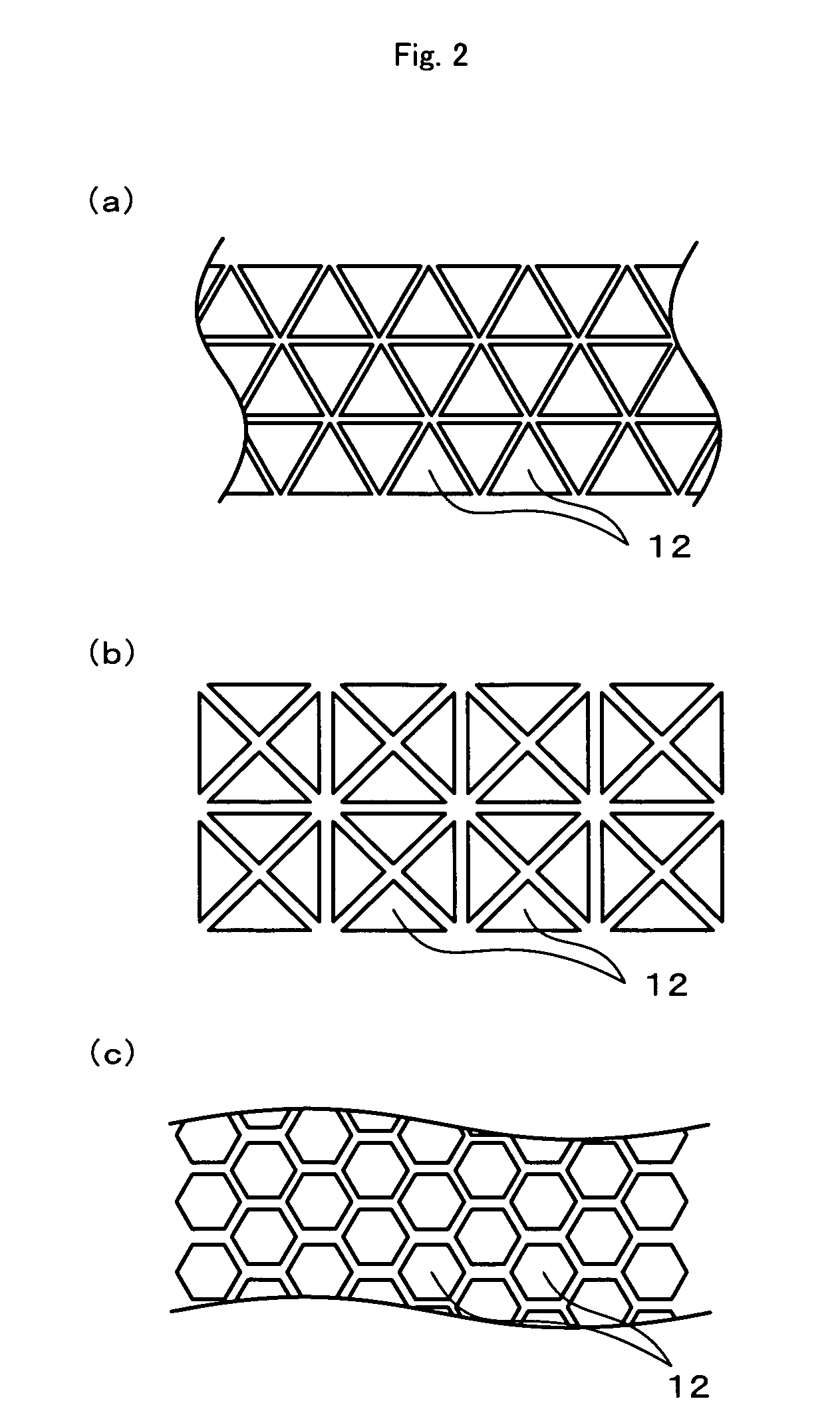

Honeycomb structure

InactiveUS20060292339A1Good dispersionIncrease resistanceLayered productsFiltration separationFiberSurface roughness

A honeycomb structure is disclosed that includes plural honeycomb units bonded together by using a sealing material layer, each of the honeycomb units including plural through-holes separated by plural partition walls and provided in parallel along a longitudinal direction of the honeycomb units, wherein a surface roughness Ra of an outer surface of the honeycomb structure is greater than or equal to about 1 μm and less than or equal to about 50 μm, each of the honeycomb units includes at least ceramic particles, and inorganic fibers and / or whisker, and an area of a cross section of one of the honeycomb units perpendicular to the longitudinal direction of the one of the honeycomb units is greater than or equal to about 5 cm2 and less than or equal to about 50 cm2.

Owner:IBIDEN CO LTD

Anti-abrasion metal-ceramic composite product and preparation method thereof

The invention provides an anti-abrasion metal-ceramic composite product and a preparation method thereof. The structural performance of the product is improved through at least one type of metallic oxides, metal nitrides or metal borides and intermetallic compounds. Metal-ceramic particle prefabricated parts made of ceramic particles and metal powder, or metal-ceramic particle prefabricated parts made of metal powder and mixtures which are obtained through uniform mixing of ceramic particles and metal powder with auxiliaries are subjected to high-temperature sintering thermal treatment to obtain the product. According to the anti-abrasion metal-ceramic composite product and the preparation method thereof, abrasion resistance of ceramic particles and mechanical performances of metal materials are perfectly combined, so that the hardness and the abrasion resistance of traditional metal materials are greatly improved. Compared with traditional anti-abrasion parts, the service life of metal grinding balls is increased by 1 time to 1.9 times, and the service life of liner plates and hammers is increased by more than 2.5 times, accordingly, a large number of metal materials are saved, and the production efficiency is improved.

Owner:湖北秦鸿新材料有限公司

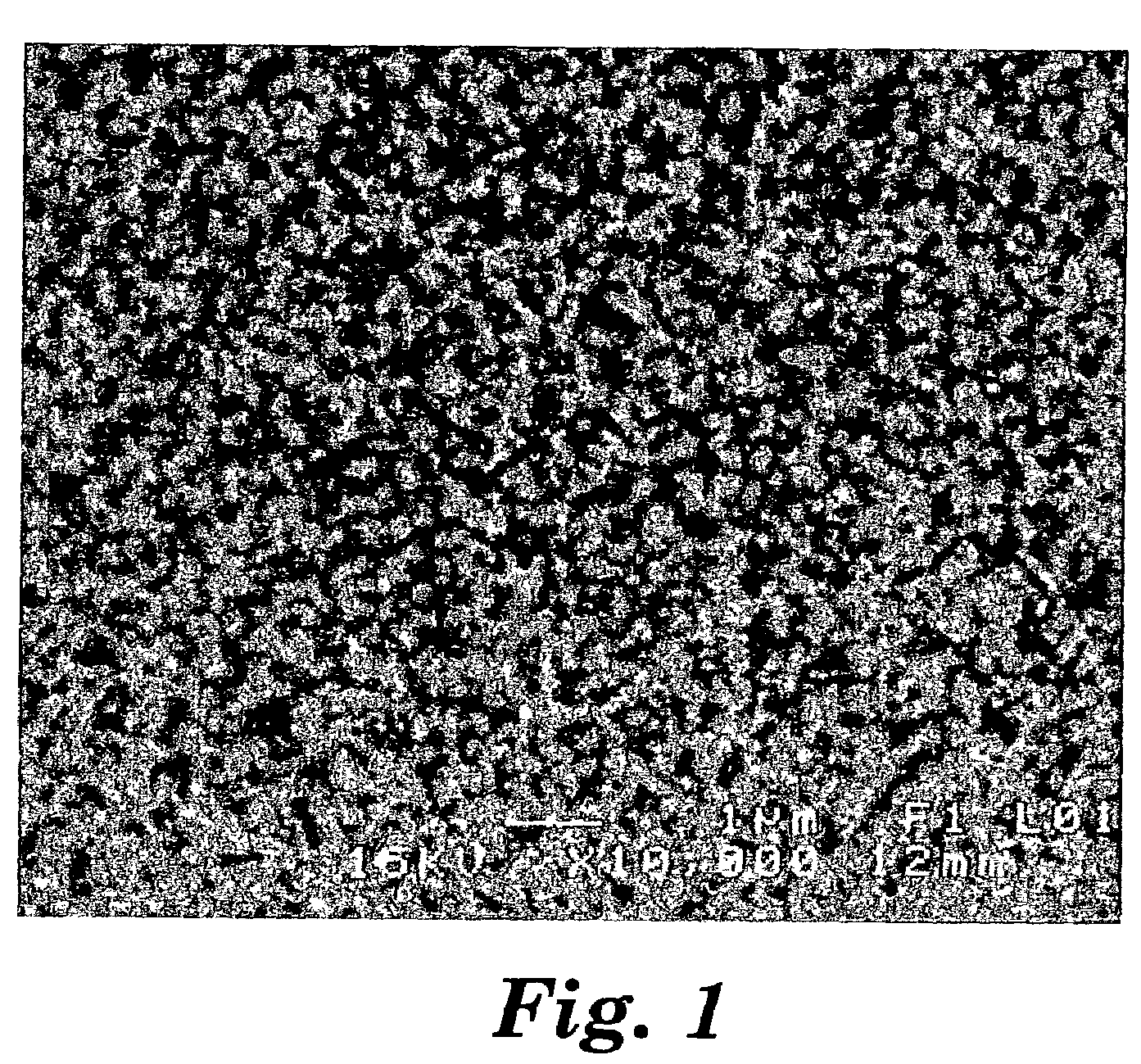

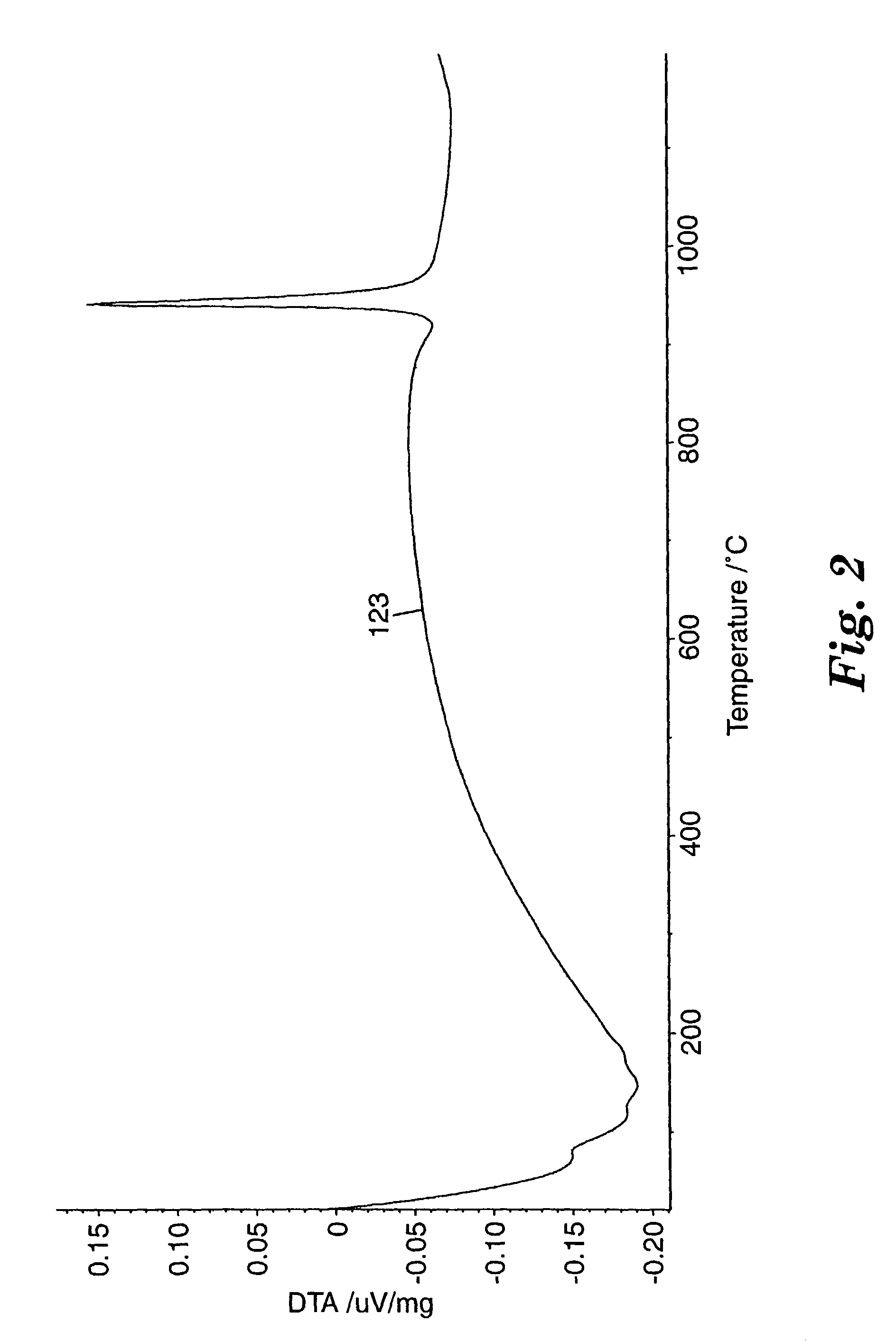

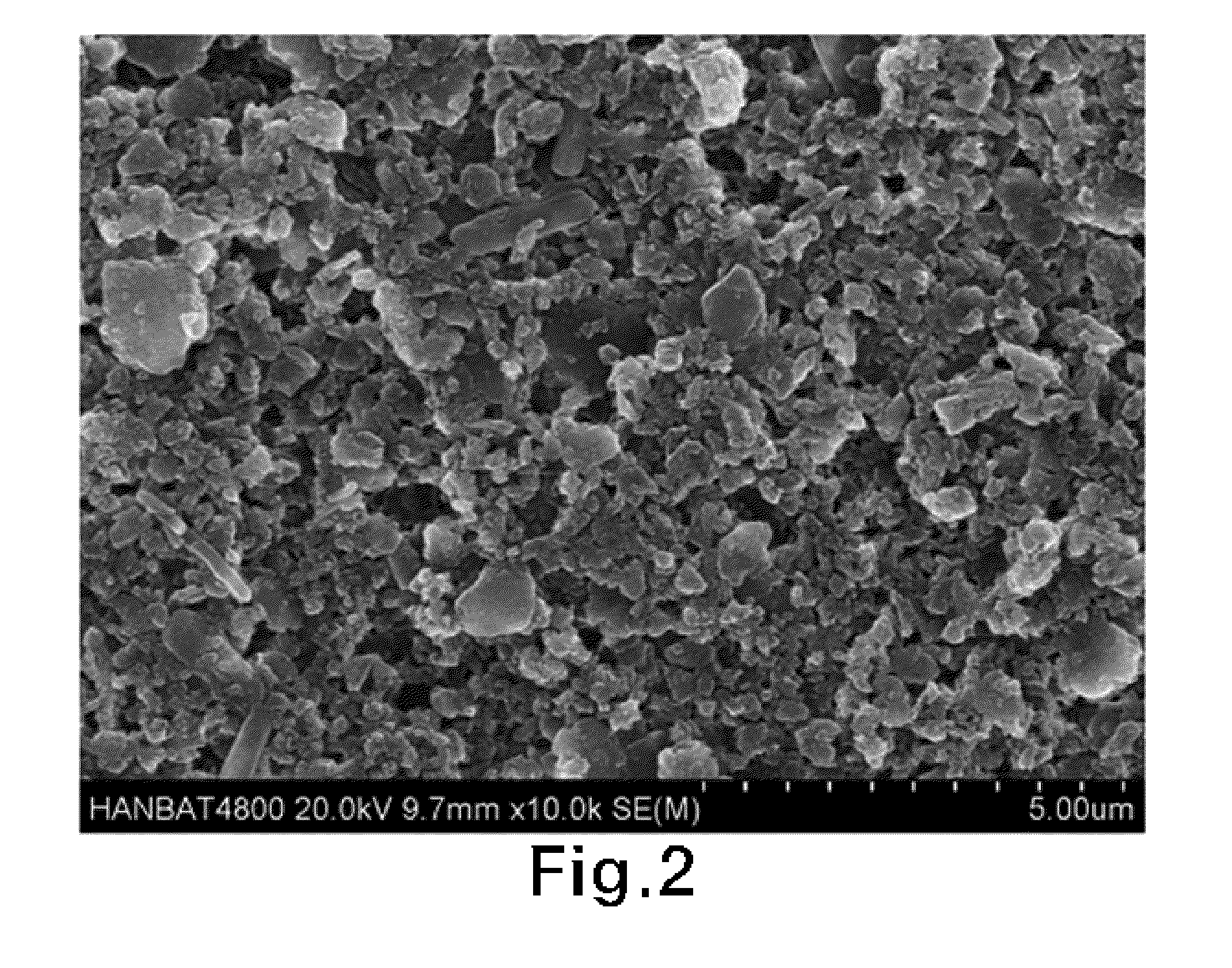

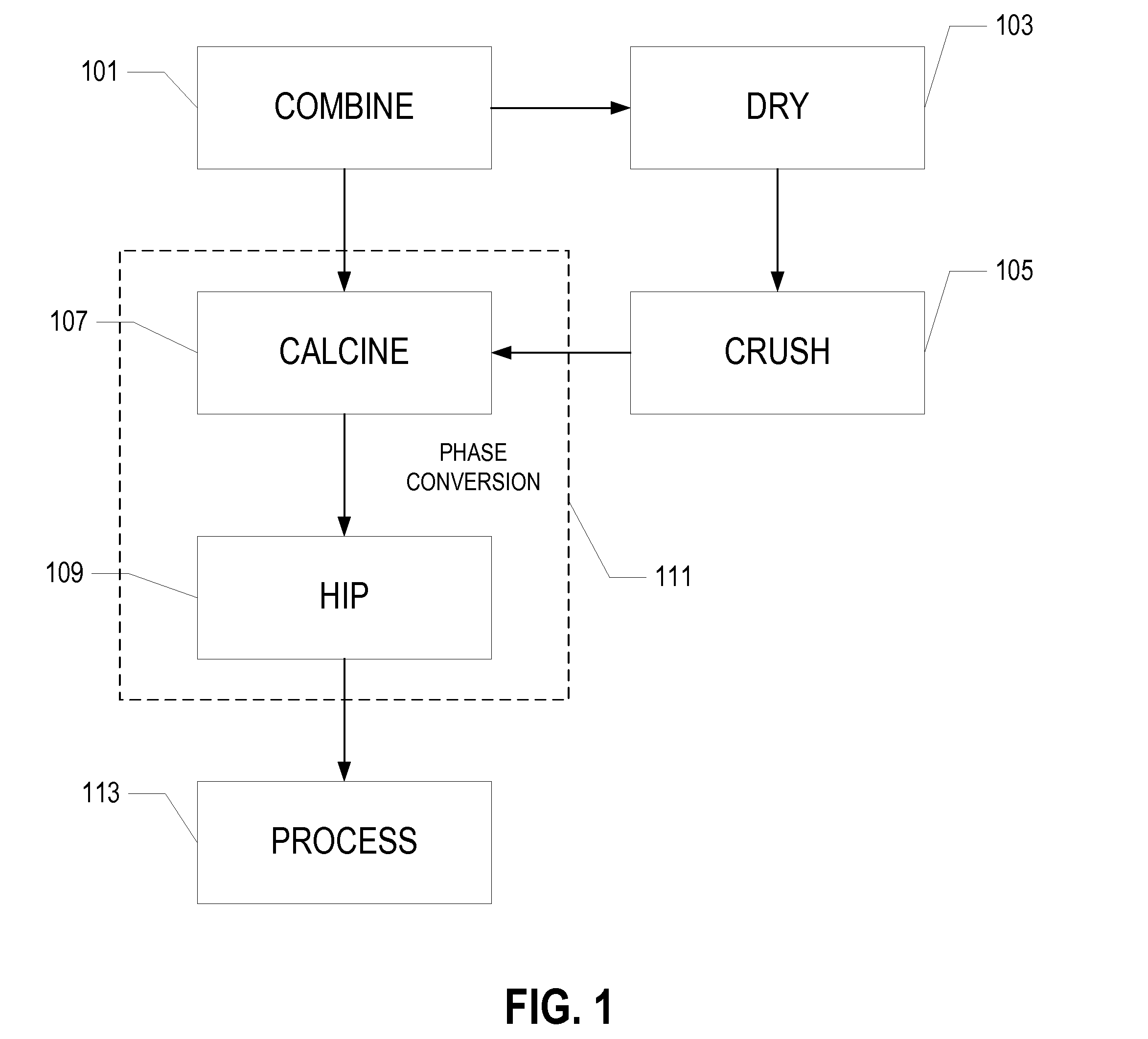

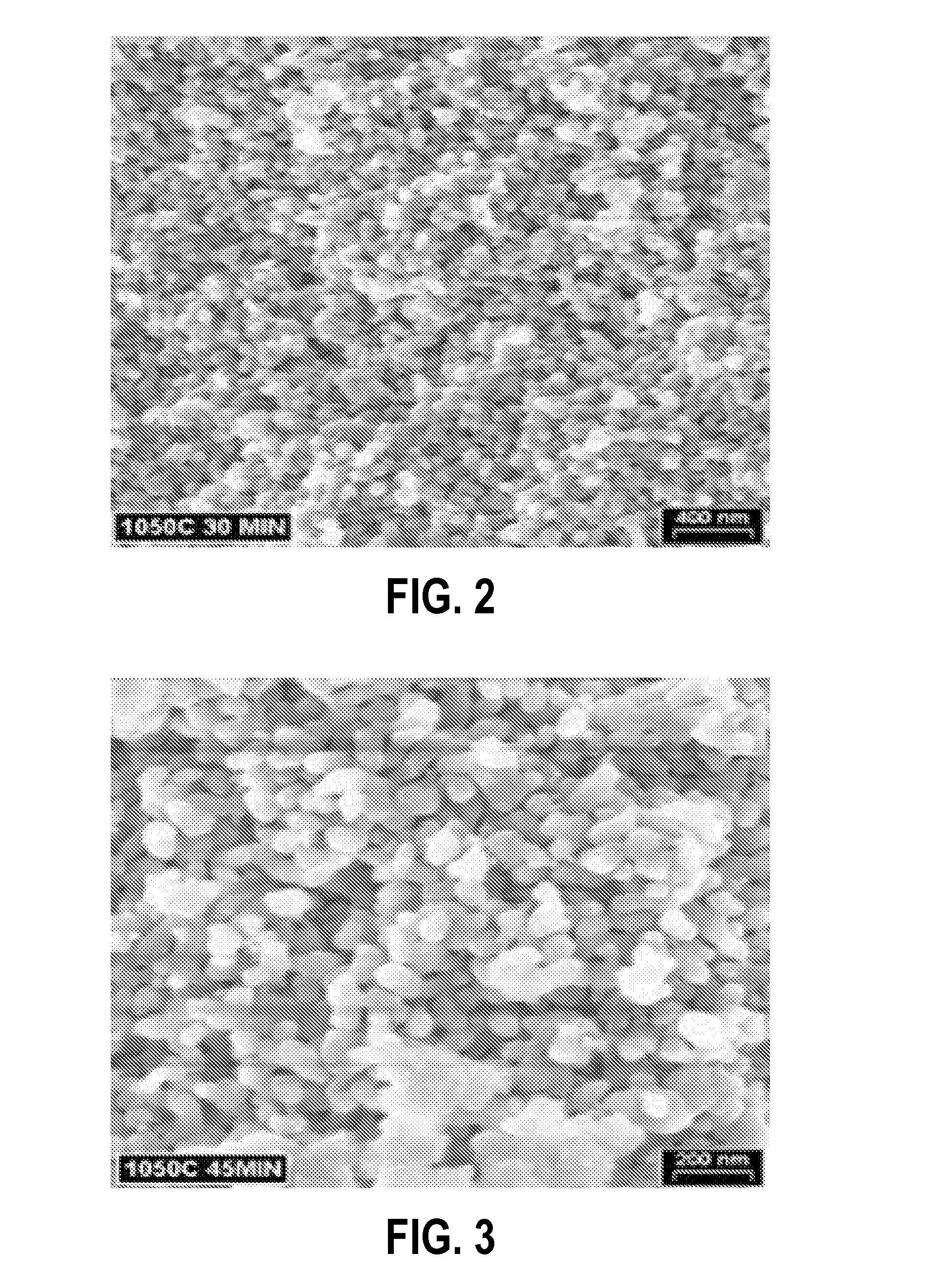

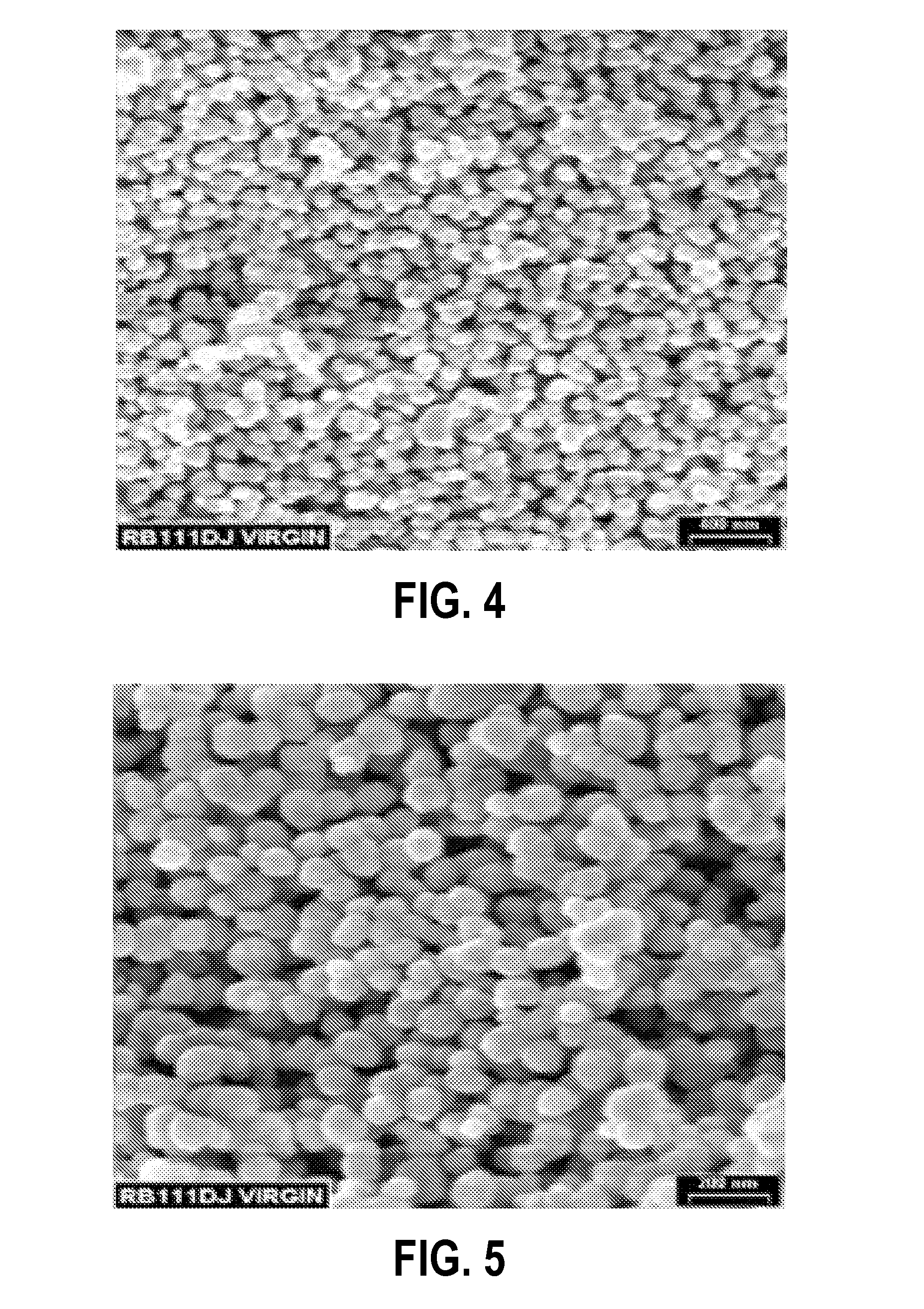

Ceramic particulate material and processes for forming same

InactiveUS20080176075A1Material nanotechnologyCeramic shaping apparatusImaging analysisMaterials science

Ceramic particulate material includes alumina particles, the particles having a specific surface area (SSA) not less than 15 m2 / g and not greater than 75 m2 / g and a sphericity quantified by at least one of (i) a mean roundness not less than 0.710 as measured by Roundness Correlation Image Analysis, and (ii) a concavity less than 20%, wherein concavity is the percent of alumina particles based on a sample of at least 100 particles, which have a concave outer peripheral portion that extends along a distance not less than 10% of d50 by TEM inspection, the concave outer peripheral portion having a negative radius of curvature as viewed from an interior of the particle

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

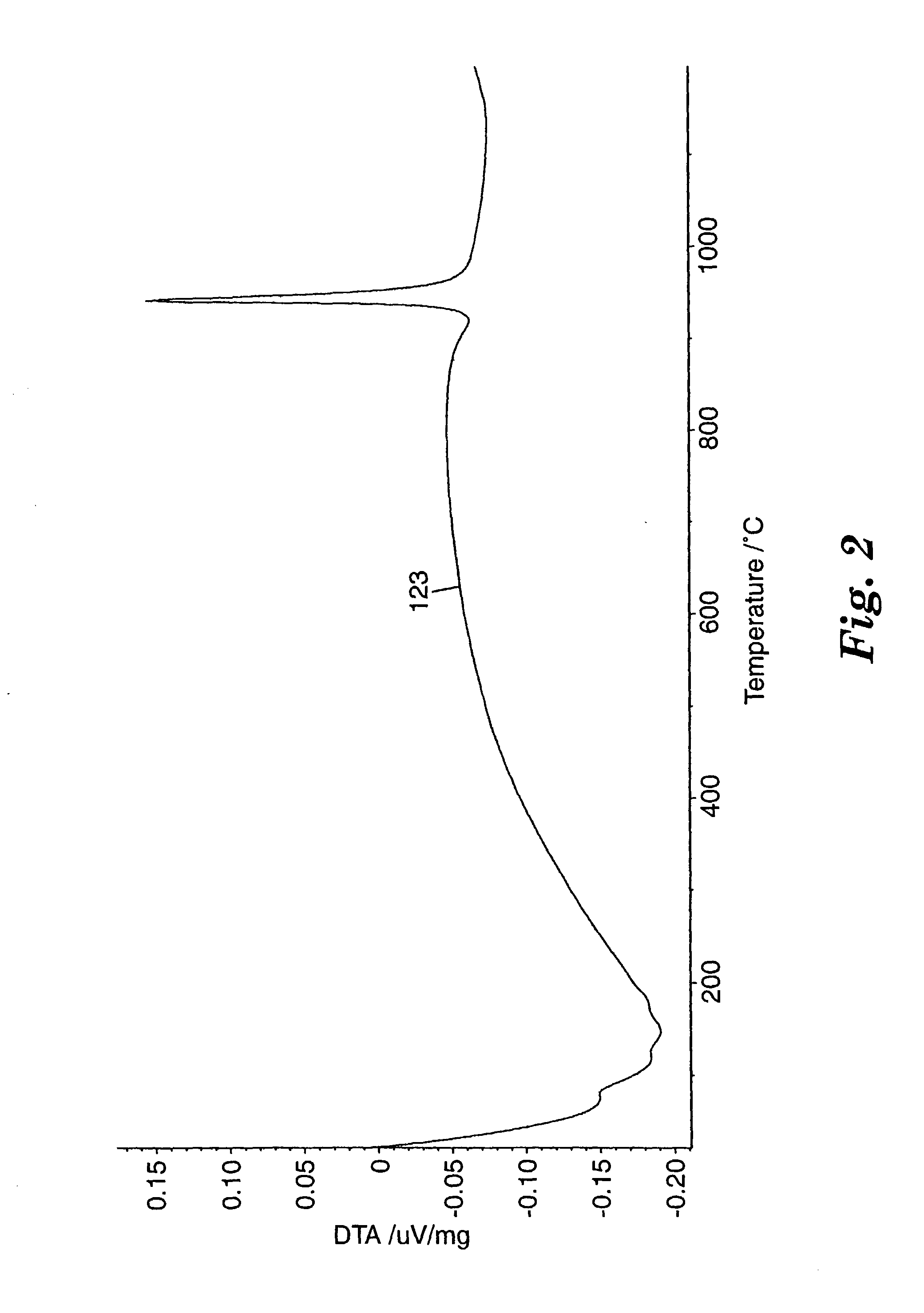

Exhaust gas purifying apparatus and method of regenerating the same

InactiveUS20060059877A1Absorb evenlySmooth releasePhysical/chemical process catalystsNon-fuel substance addition to fuelParticulatesPtru catalyst

An exhaust gas purifying apparatus is provided which includes a honeycomb structure used as a filter to capture particulates in exhaust gas from an internal combustion engine such as diesel engine and as a carrier of a catalyst to convert the exhaust gas. The honeycomb structure is formed from a composite material comprising ceramic particles and crystalline silicon. The particulates captured by the honeycomb structure are removed by combustion at a temperature of 250 to 800° C., thereby, even if a relatively low temperature is distributed or a heat cycle has been repeated from a long term, thermal stress is prevented from being stored, cracking is prevented and thermal shock resistance is thus improved.

Owner:IBIDEN CO LTD

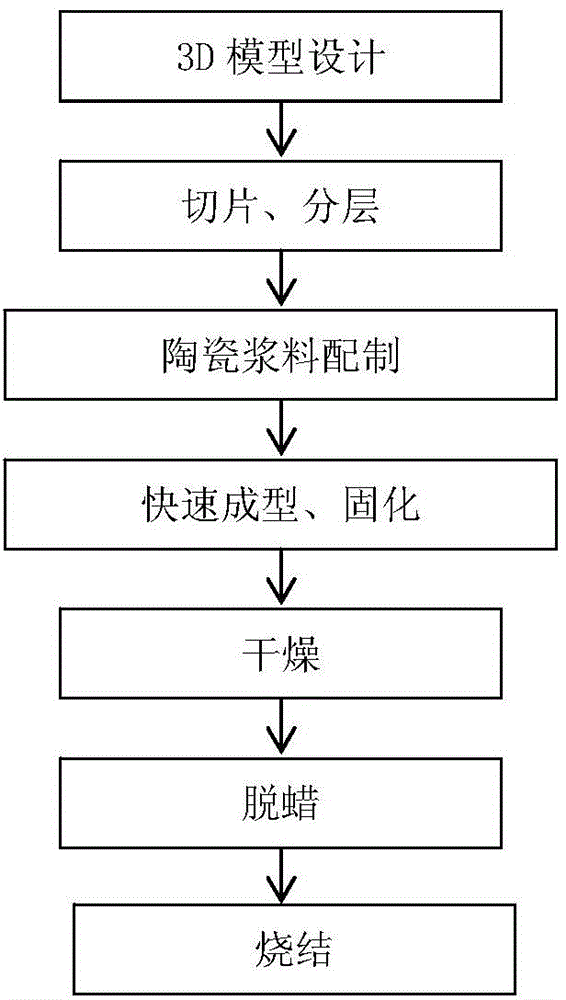

Method for 3D ceramic printing forming

ActiveCN104526838ARapid Dieless ManufacturingShorten the development cycleCeramic shaping apparatusSlurry3d printer

The invention discloses a method for 3D ceramic printing forming. The method comprises the following steps that (1) a 3D model of a target part is established; (2) layering processing is performed, and layered data are imported into a manufacturing program; (3) ceramic slurry is prepared; (4) the prepared ceramic slurry is added into a 3D printer to be made into a ceramic green body quickly formed; (5) the green body is cured at curing temperature for 10 min-60 min and then is placed in a drying oven for drying; (6) the dried green body is dewaxed and sintered to be made into the target part. The method is simple in technology and low in equipment cost; the distance between powder particles in the ceramic slurry can be reduced in the extrusion process, and therefore density is high; besides, the method is not limited by the type of ceramic particles and the shape of the part and is suitable for manufacturing ceramic products made of various ceramic materials and in various complex shapes.

Owner:NINGBO VULCAN TECH CO LTD

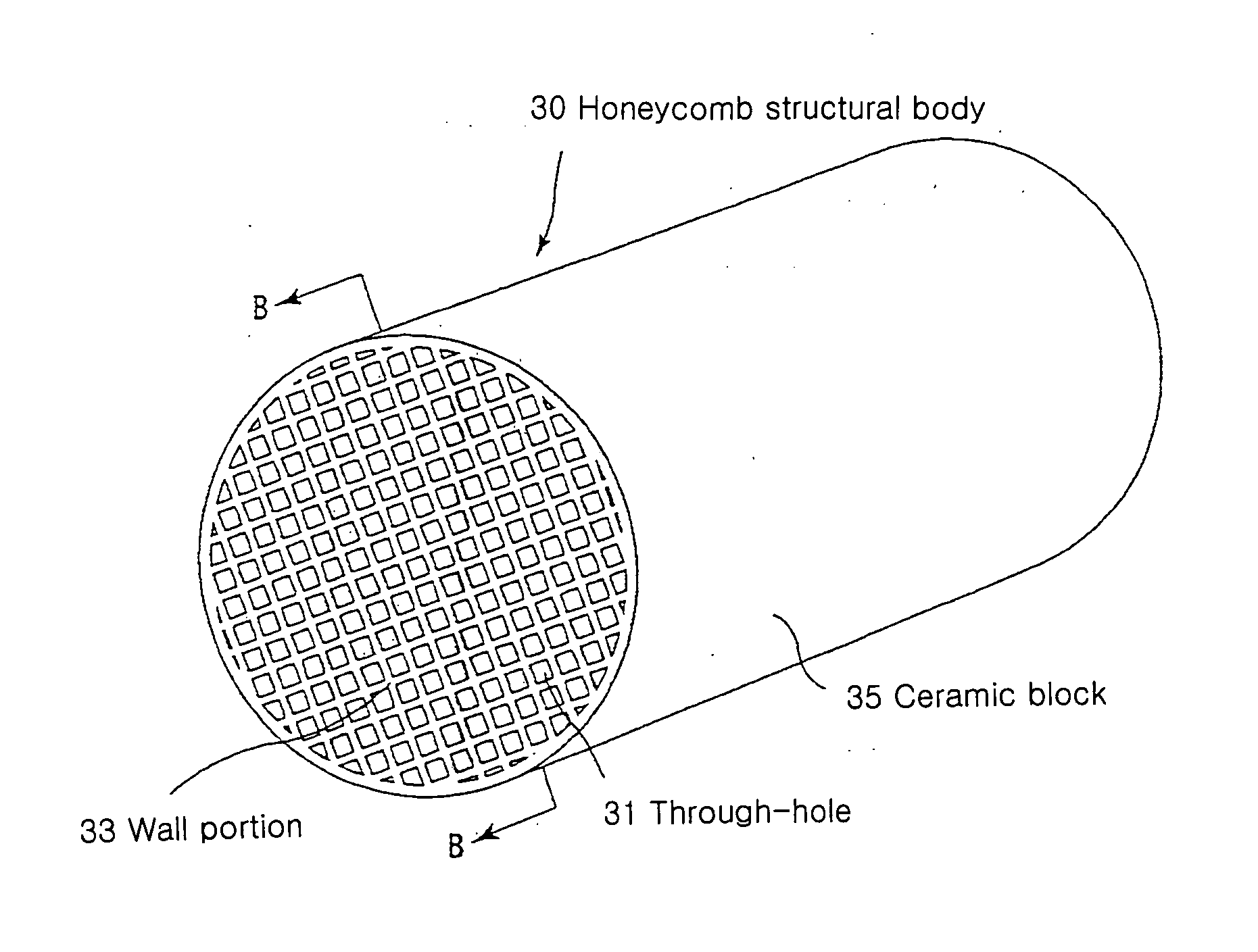

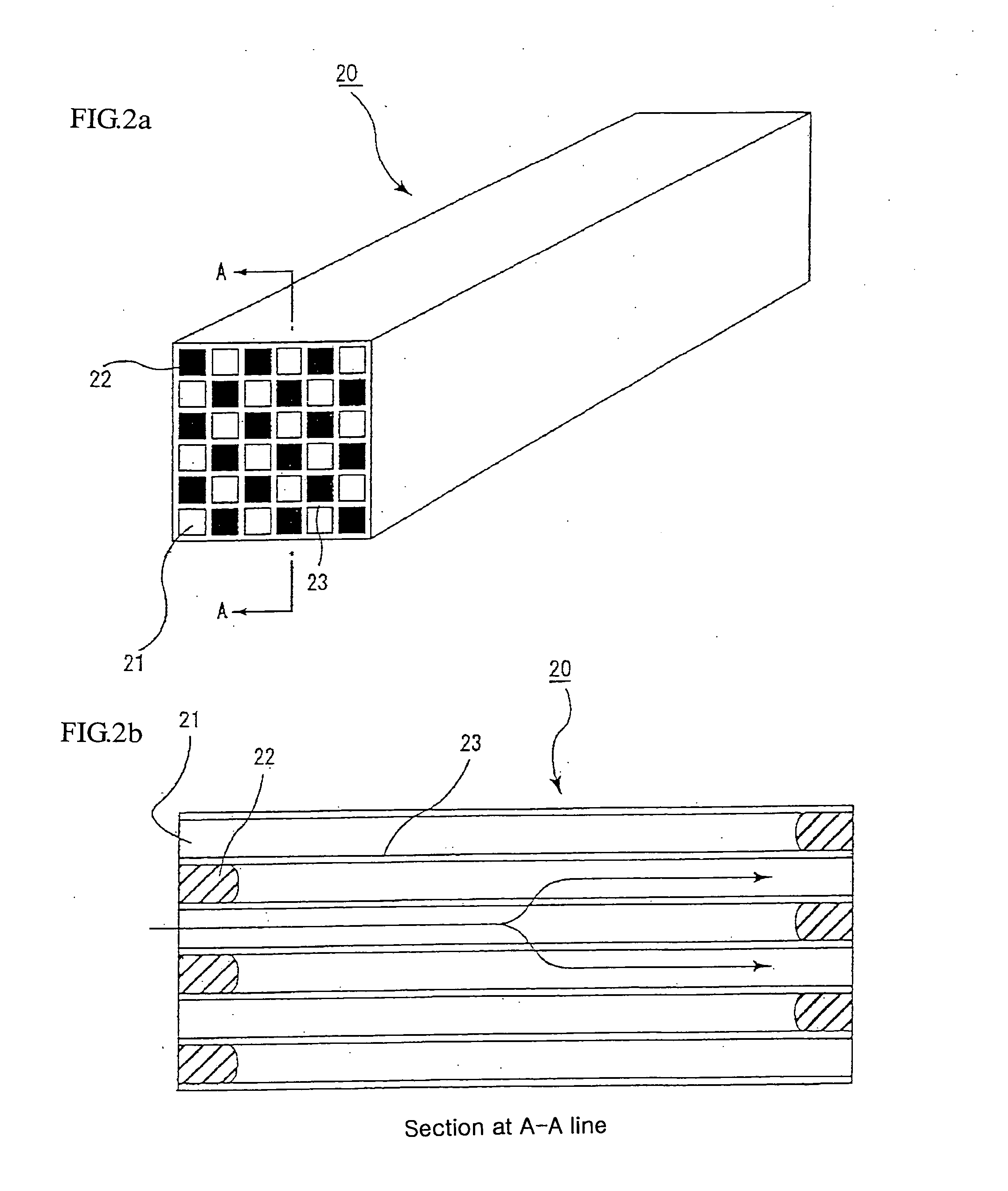

Honeycomb structural body

InactiveUS20050214504A1Certain viscosityStrength of the resulting honeycomb structural bodyCombination devicesAuxillary pretreatmentPorosityMetallurgy

A honeycomb structural body is constituted with a ceramic block made by arranging a plurality of through-holes side by side in the longitudinal direction through partition walls and sealing either one end portions of these through-holes. The ceramic block of this honeycomb structural body is made of a composite member consisting of ceramic particles and amorphous silicon, so that the honeycomb structural body has an excellent compression strength even if its porosity is increased, and is less in the lowering of mechanical strength even if it is heated to a high temperature, and is excellent in the durability.

Owner:IBIDEN CO LTD

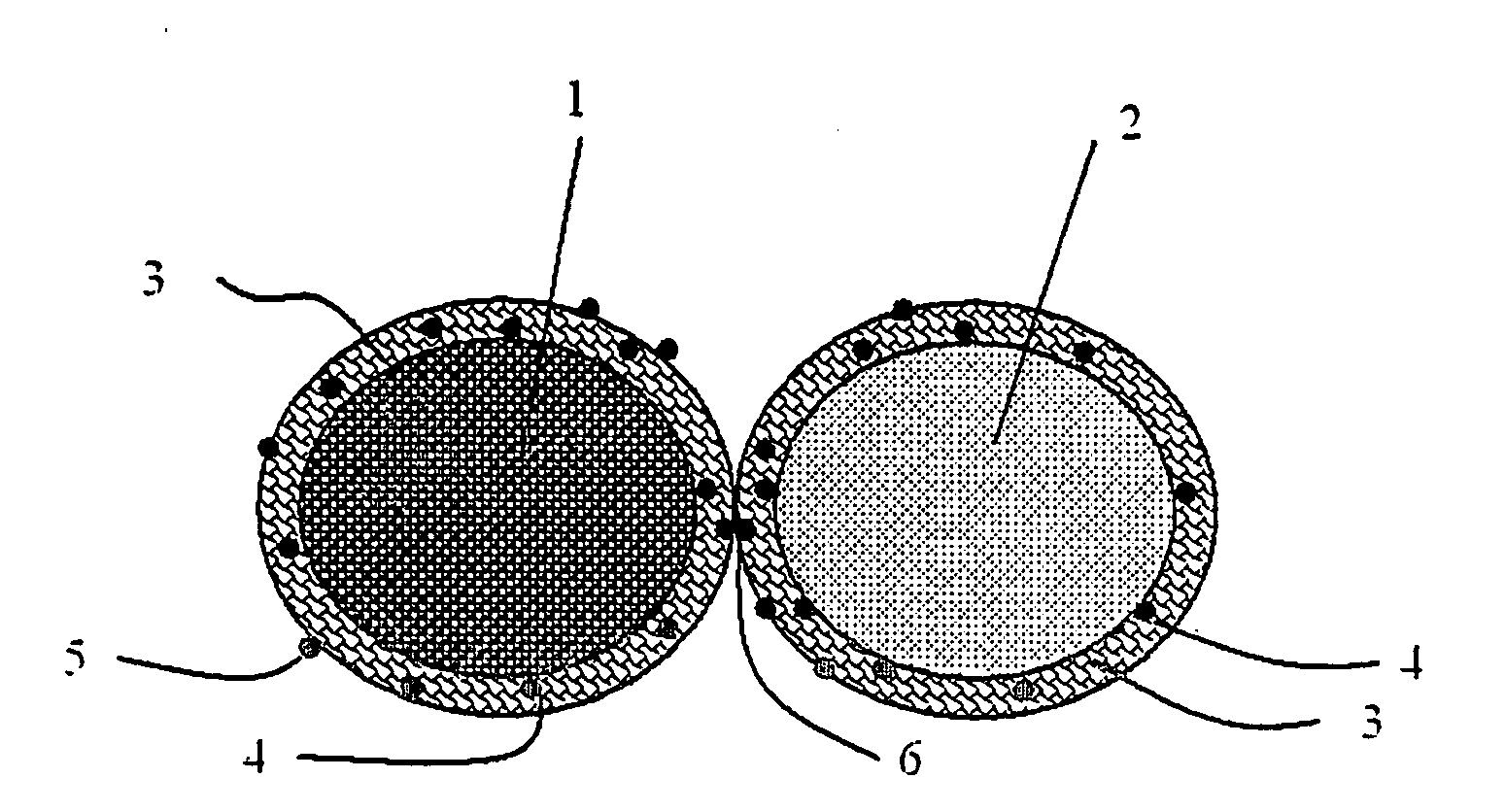

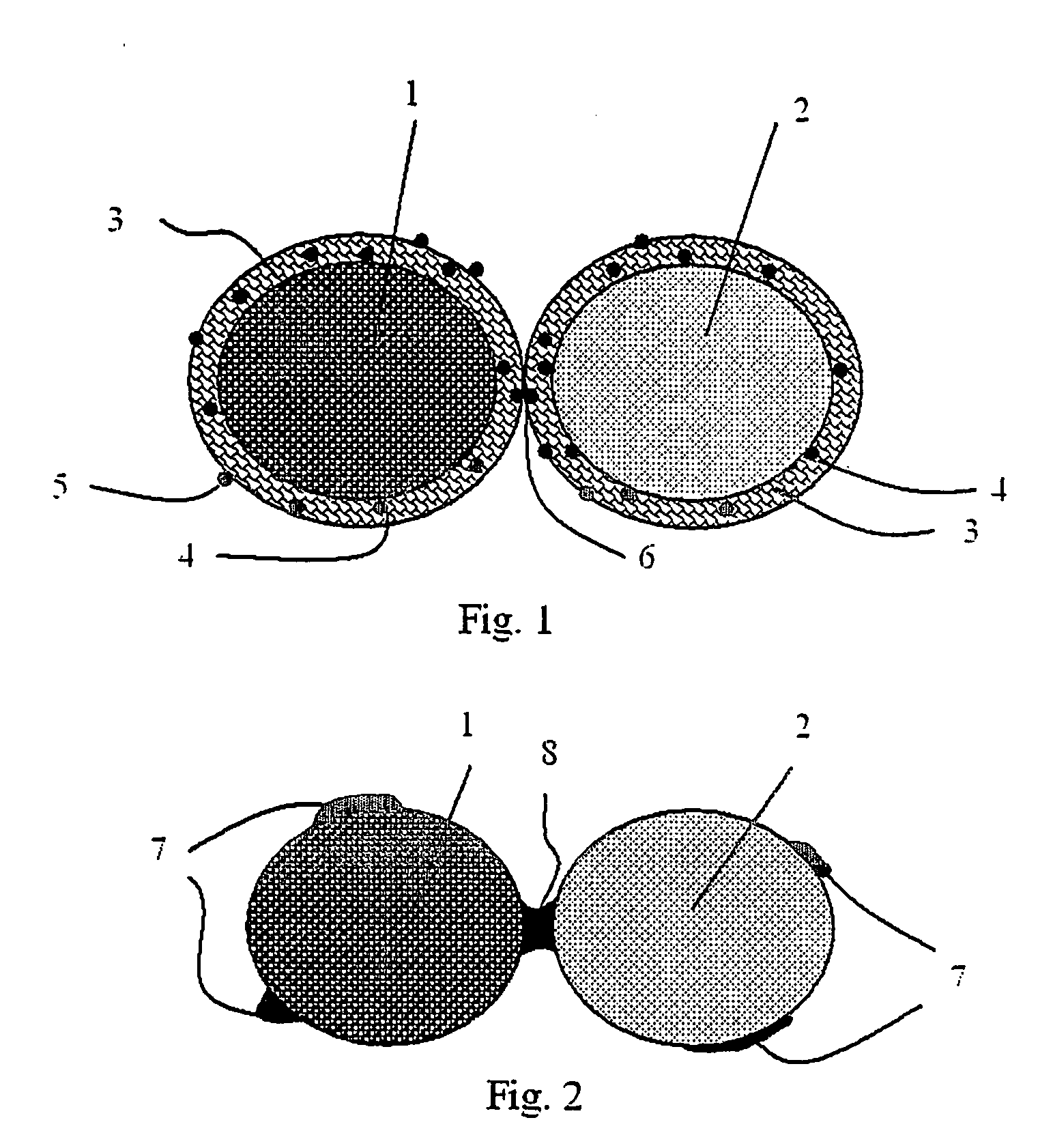

Lithium ion battery with electrolyte-embedded separator particles

InactiveUS20130052509A1Efficient use ofSuitable ionic conductivityFinal product manufacturePrimary cellsLithium-ion batteryViscosity

A lithium ion battery in which electrically-non conducting ceramic particles are interposed between the anode and cathode to enforce separation between them and prevent short circuits is described. The particles, preferably equiaxed or monodisperse, may be generally uniformly dispersed in a non-aqueous gelled or high viscosity electrolyte. The electrolyte may be applied to one or both of the anode and cathode in suitable thickness to deposit the particles with the electrolyte and form a layered composite with substantially uniformly spaced particles suitable for holding the opposing anode and cathode faces in spaced-apart relation. The thickness of the applied electrolyte layer will be selected to enable deposition of the particles substantially as a fractional monolayer, a monolayer, or a multilayer as required for the application.

Owner:GM GLOBAL TECH OPERATIONS LLC

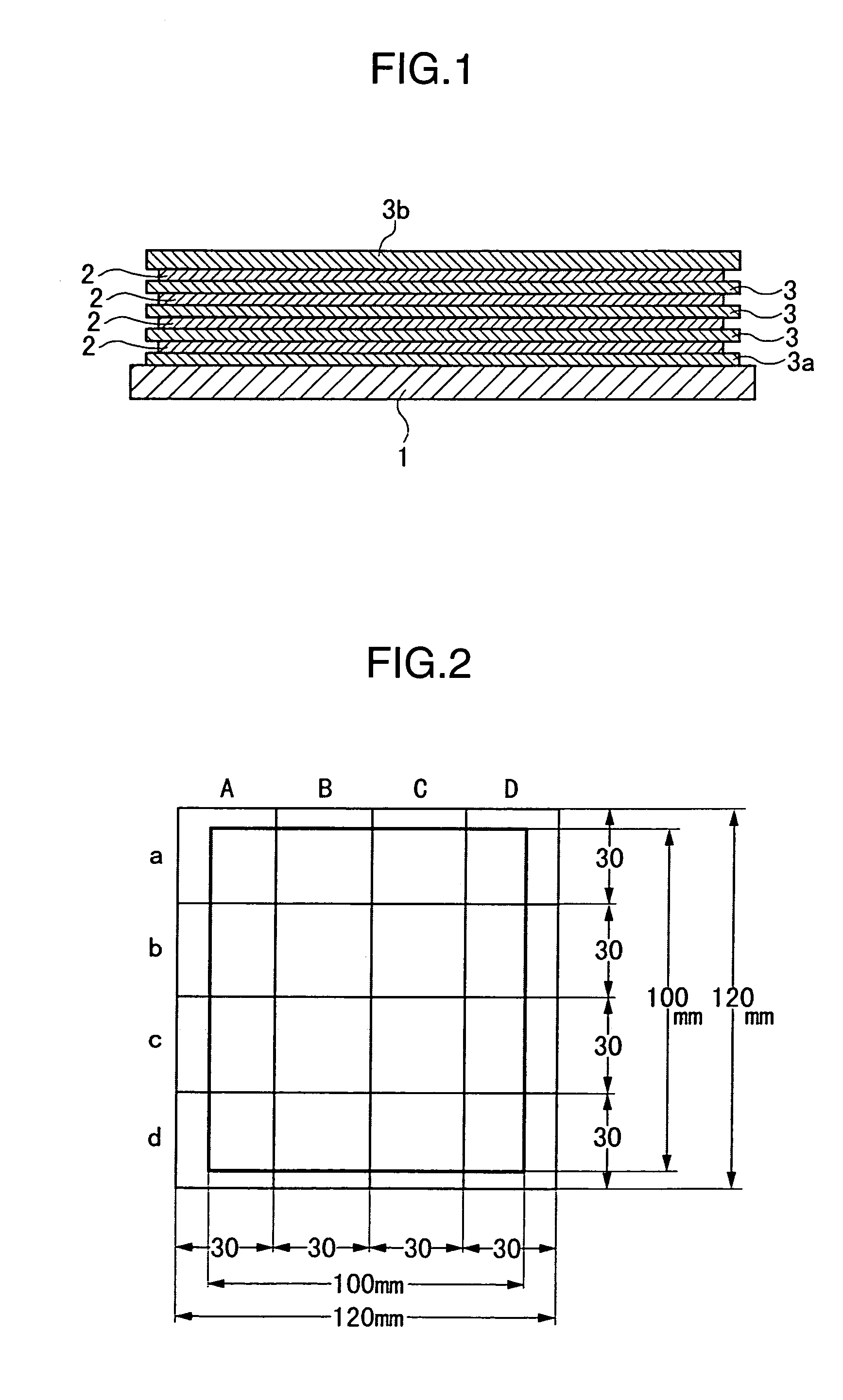

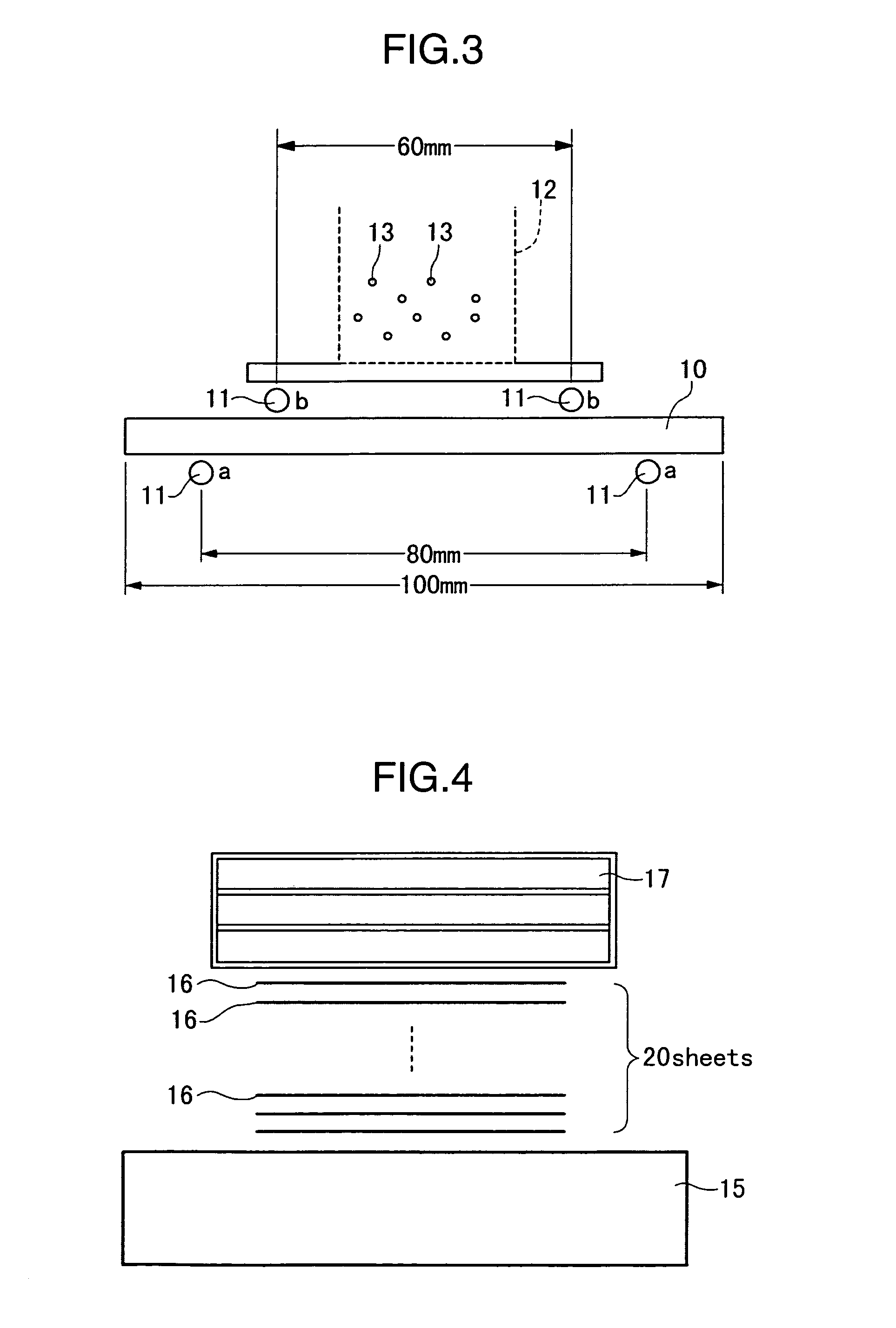

Ceramic sheet and method of producing ceramic sheet

InactiveUS7108827B1Suppress blemishesReduce frictional resistanceSynthetic resin layered productsRecord information storageForeign matterMetallurgy

The present invention relates to a ceramic sheet having uniform quality over its entire surface with a decreased number of defects such as foreign matters and flaws. When the ceramic sheet was divided into sections of 30 mm square or smaller, each divided section has 5 or less defects detected based on an image obtained with a charge coupled device (CCD) camera. The present invention also relates to a method of producing the ceramic sheet. In this method, a green sheet or a calcined sheet mainly including spherical ceramic particles having an average particle diameter of 0.1 to less than 5 μm was used as a spacer. By using this spacer, the green sheet for ceramic sheet slides smoothly on the spacer surface when it shrinks in baking, and the friction resistance between the green sheet for ceramic sheet and the spacer is lowered. In this manner, the method of the present invention can mass-produce the above-described high quality ceramic sheets.

Owner:NIPPON SHOKUBAI CO LTD

Ceramic particle reinforced composite wear-resistant part and preparation method thereof

InactiveCN101898238ASolve the problem of difficult penetrationImprove wear resistanceCeramic particleWear resistant

The invention relates to a ceramic particle reinforced composite wear-resistant part and a preparation method thereof. The method comprises the following steps: ceramic particles and metal powder are mixed evenly to fill in a special mould; then the mixture along with the mould is placed in a vacuum sintering furnace to sinter, wherein metal powder and ceramic particles are bound together to form a perform; after cooled, the mould is opened to take the perform out and place the perform on the side of the end face of a casting mold cavity; parent metal material is smelted by a medium-frequency induction furnace to form molten metal; during the casting, the molten metal is poured, metal powder in the perform is molten to form a cast-penetration path under the heat of molten metal, thus the molten metal can easily penetrate ceramic particles to form particle reinforced composite material in situ; and the surface layer of the obtained wear-resistant part consists of parent metal and composite material. The wear resistance of the composite material prepared by the method of the invention is ensured and the composite material has high impact resistance.

Owner:XI AN JIAOTONG UNIV +1

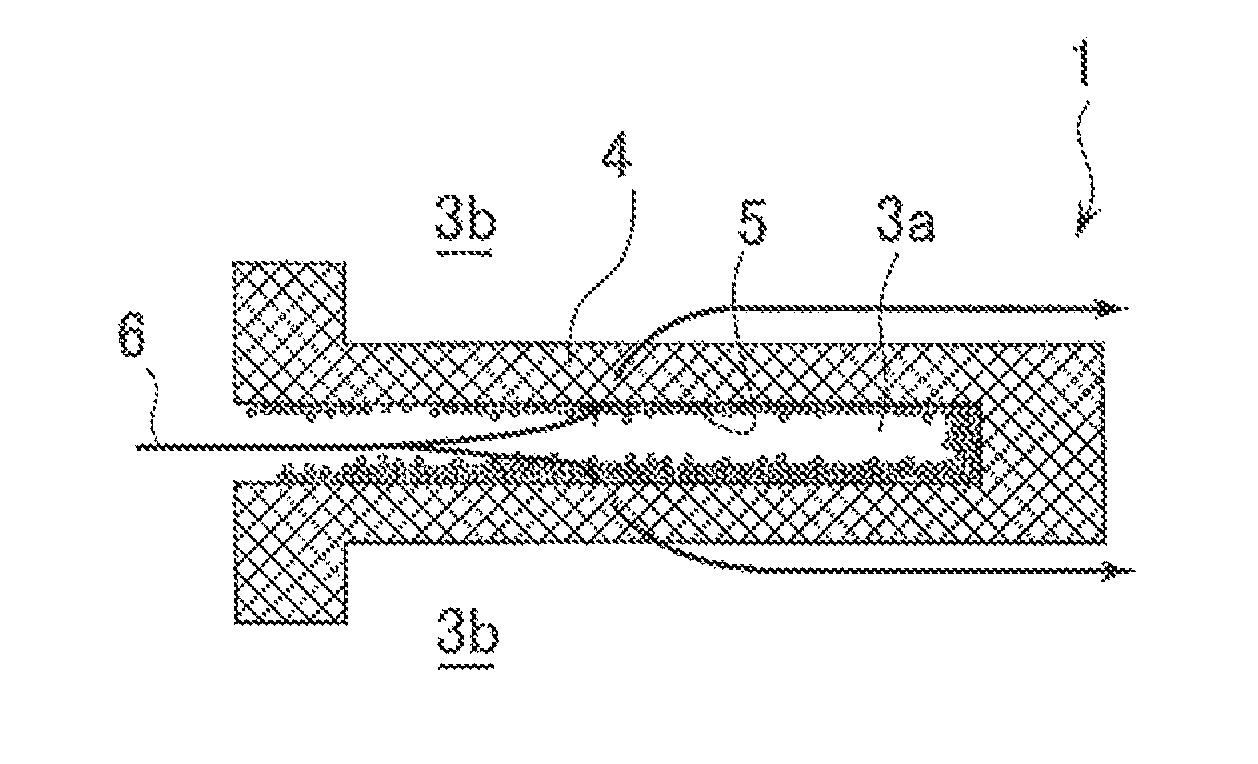

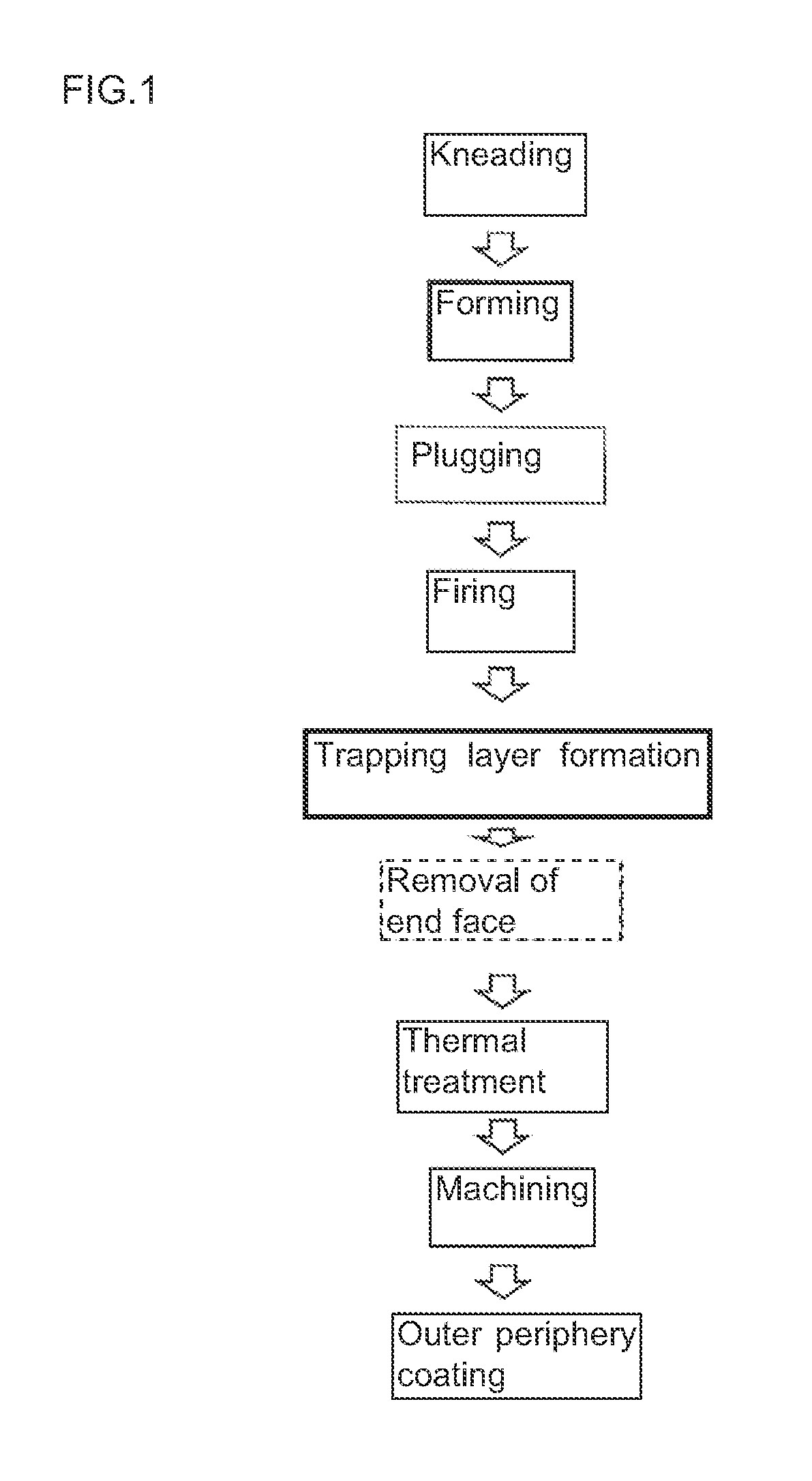

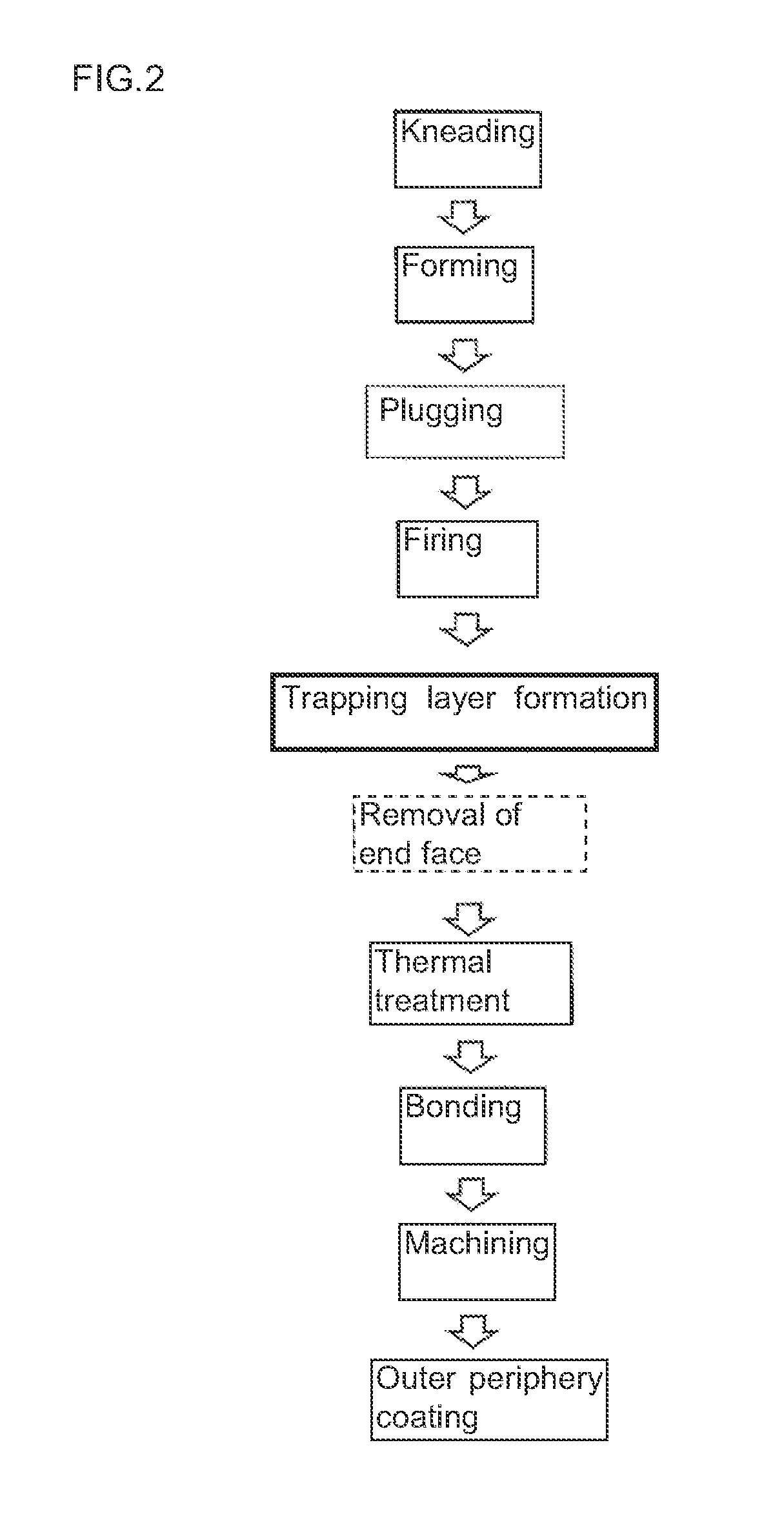

Method for manufacturing plugged honeycomb structure

ActiveUS8277880B2Suppress scatterIncrease production costCatalyst carriersPretreated surfacesHoneycomb structureMaterials science

A method for manufacturing a plugged honeycomb structure including a step of mixing ceramic particles with a gas on one end face side of the plugged honeycomb structure, and a step of sucking the gas containing the ceramic particles from the other end face side of the plugged honeycomb structure to send the ceramic particles mixed in the gas into cells of the plugged honeycomb structure to allow the ceramic particles to adhere to surfaces in the cells of the plugged honeycomb structure.

Owner:NGK INSULATORS LTD

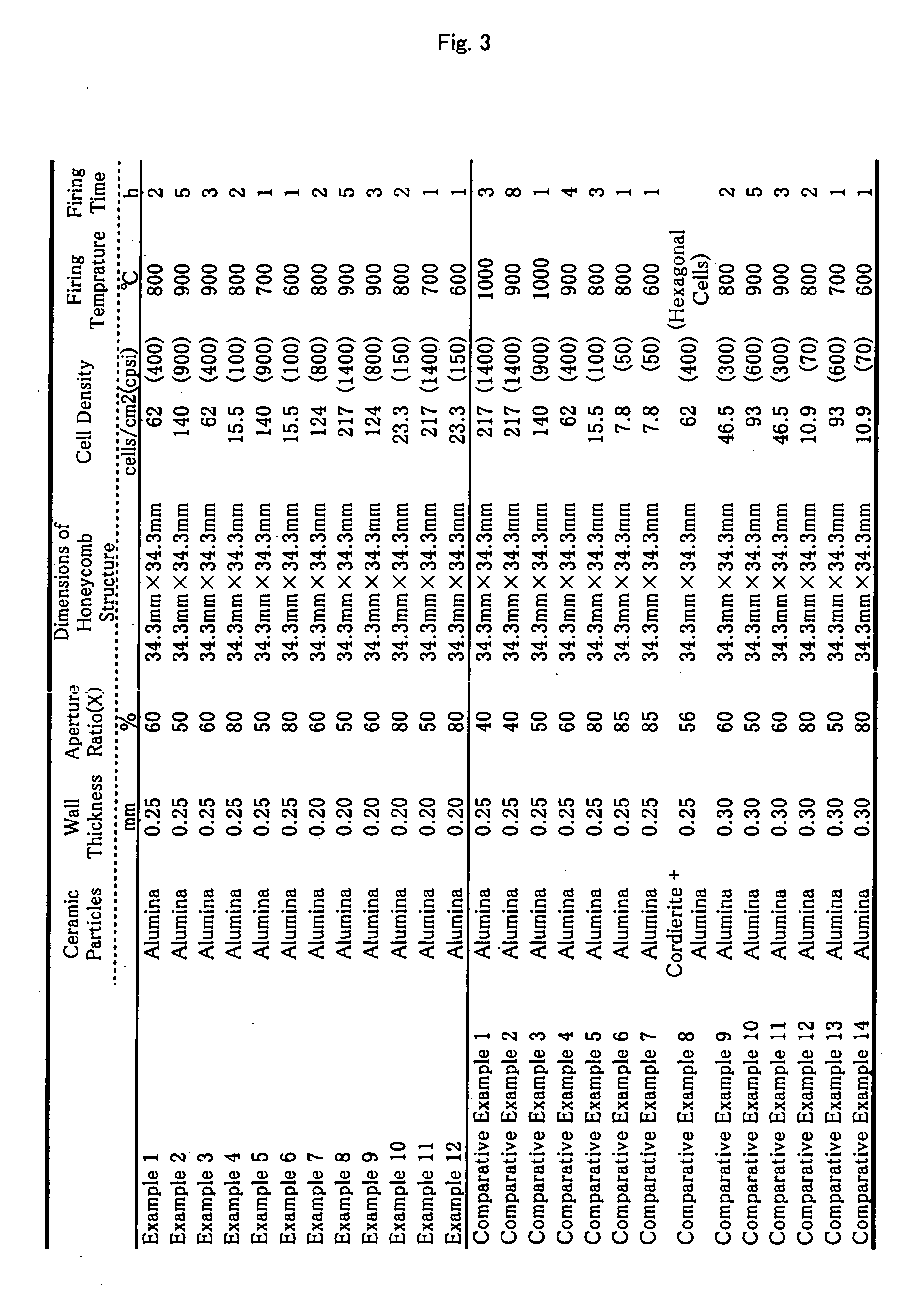

Honeycomb structure, honeycomb structure assembly, and honeycomb catalyst

InactiveUS20050227869A1Valid conversionCombination devicesCatalyst carriersHoneycomb structureAperture ratio

A honeycomb structure having multiple through holes includes at least ceramic particles and an inorganic binder. A wall thickness of each wall between adjoining through holes, on which a catalyst component is carried, is designed to be not greater than about 0.25 mm. The honeycomb structure satisfies a relation of Y≧250×X+22500 (50≦X≦80), where X denotes an aperture ratio (%) of a honeycombed face of the honeycomb structure perpendicular to the multiple through holes and Y denotes a specific surface area per unit volume (m2 / L) of the honeycomb structure.

Owner:IBIDEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com