Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2108 results about "Coarse particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coarse particles are the relatively large airborne particles mainly produced by the mechanical break-up of even larger solid particles.

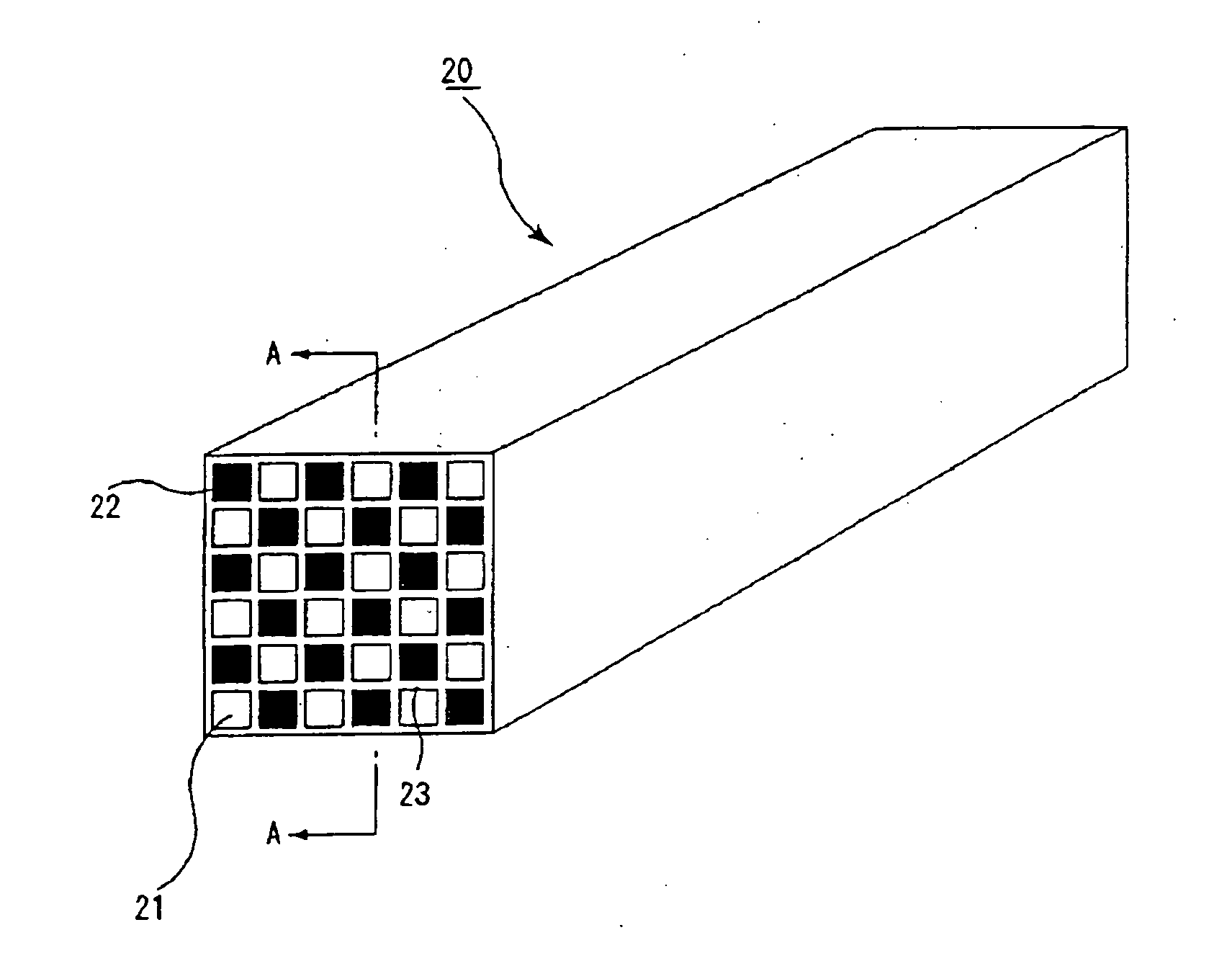

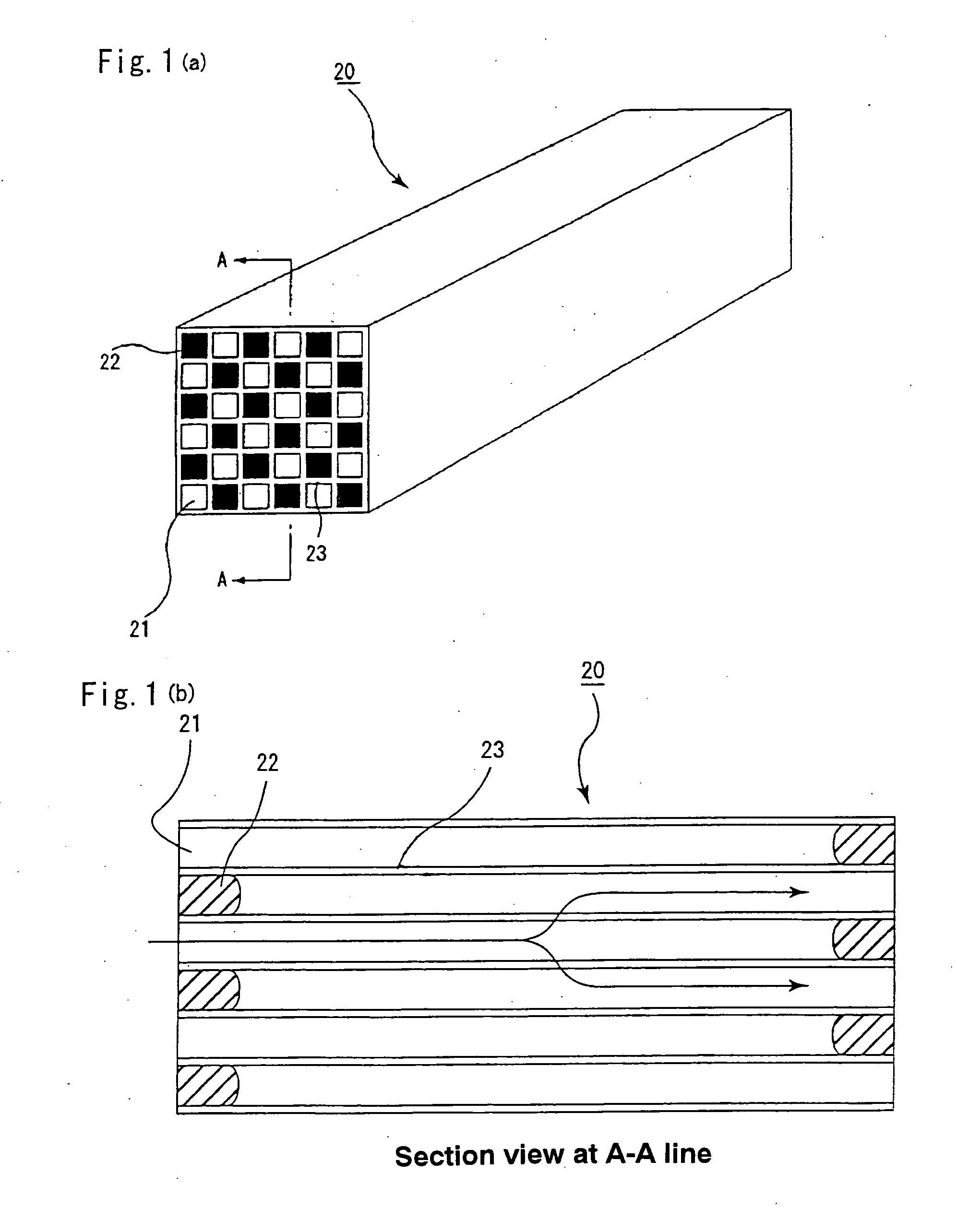

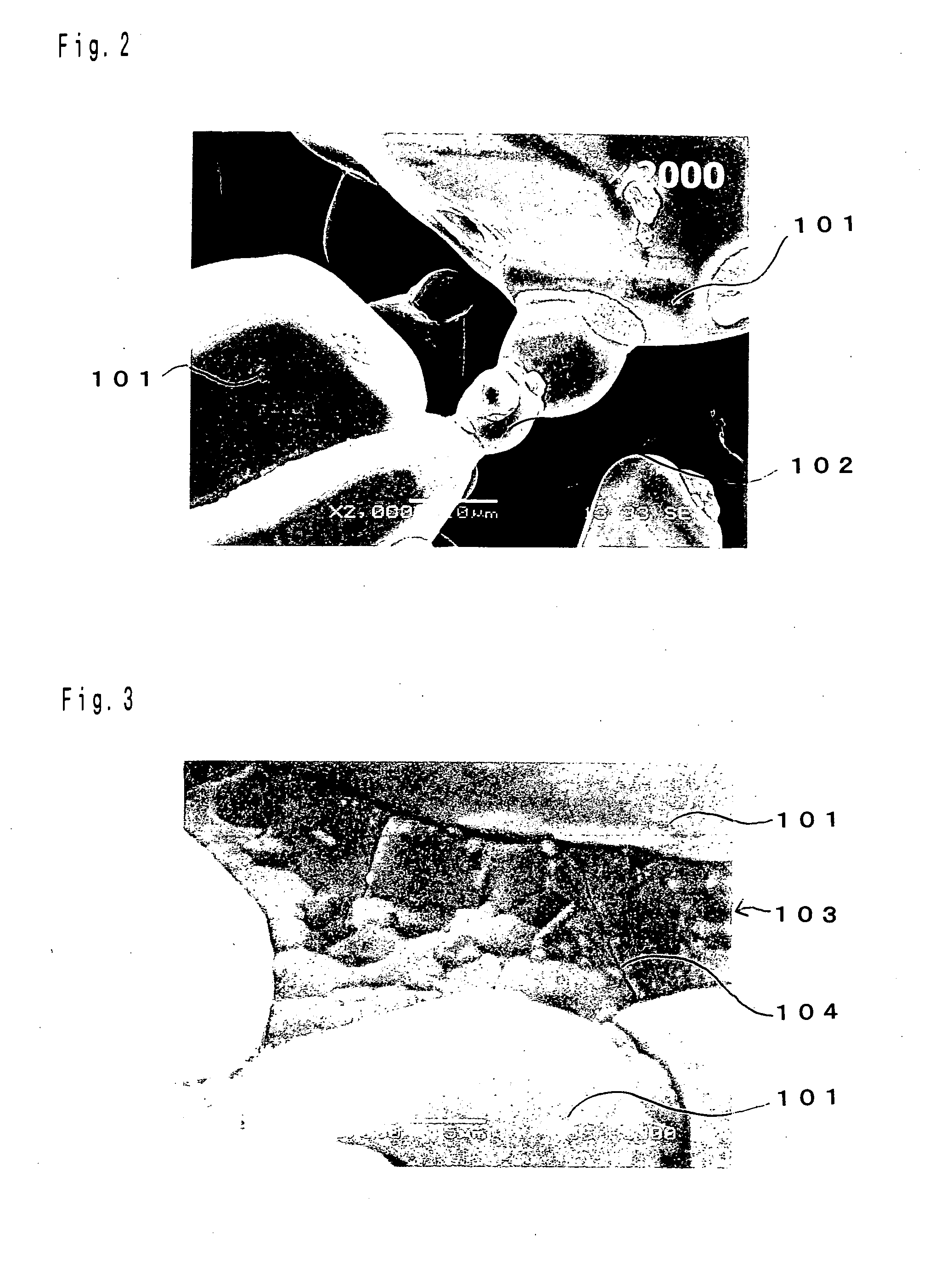

Sintered ceramic compact and ceramic filter

InactiveUS20060051556A1Shock mitigationAvoid micro cracksDispersed particle filtrationExhaust apparatusCeramic sinteringMetallurgy

The present invention provides for a ceramic sintered body and a ceramic filter having a long-term stability which can prevent cracks from occurring due to the breakage of ceramic particles when thermal stress is applied in regeneration process and the like, and can prevent catalyst carried from deteriorating when regeneration treatment is conducted repeatedly. The invention is a ceramic sintered body comprising ceramic coarse particles and porous bonding layers existing between the ceramic coarse particles to connect the particles and comprising ceramic fine particles having an average particle size smaller than that of the ceramic coarse particles and / or the aggregates thereof, and a ceramic filter prepared by using the ceramic sintered body.

Owner:IBIDEN CO LTD

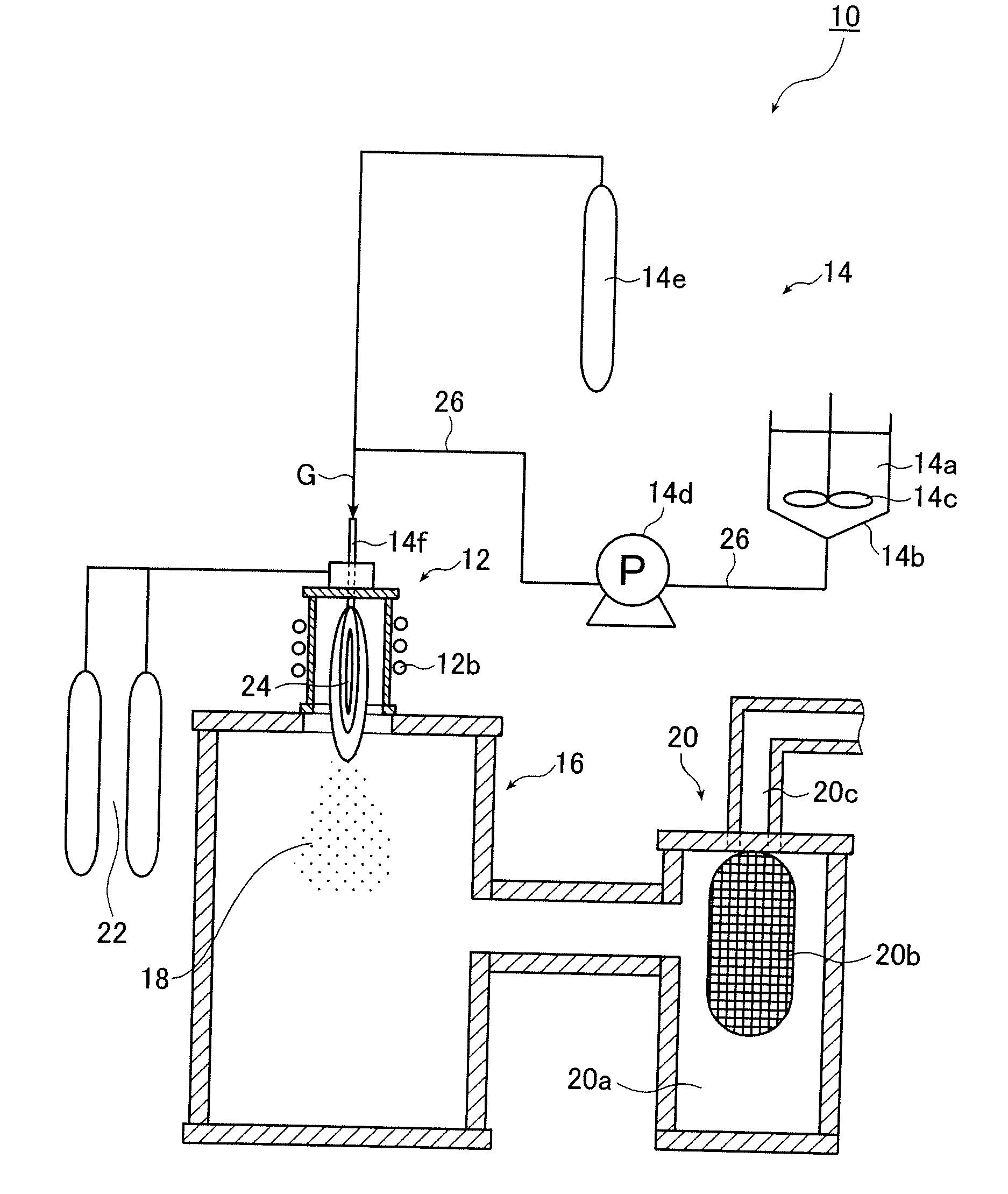

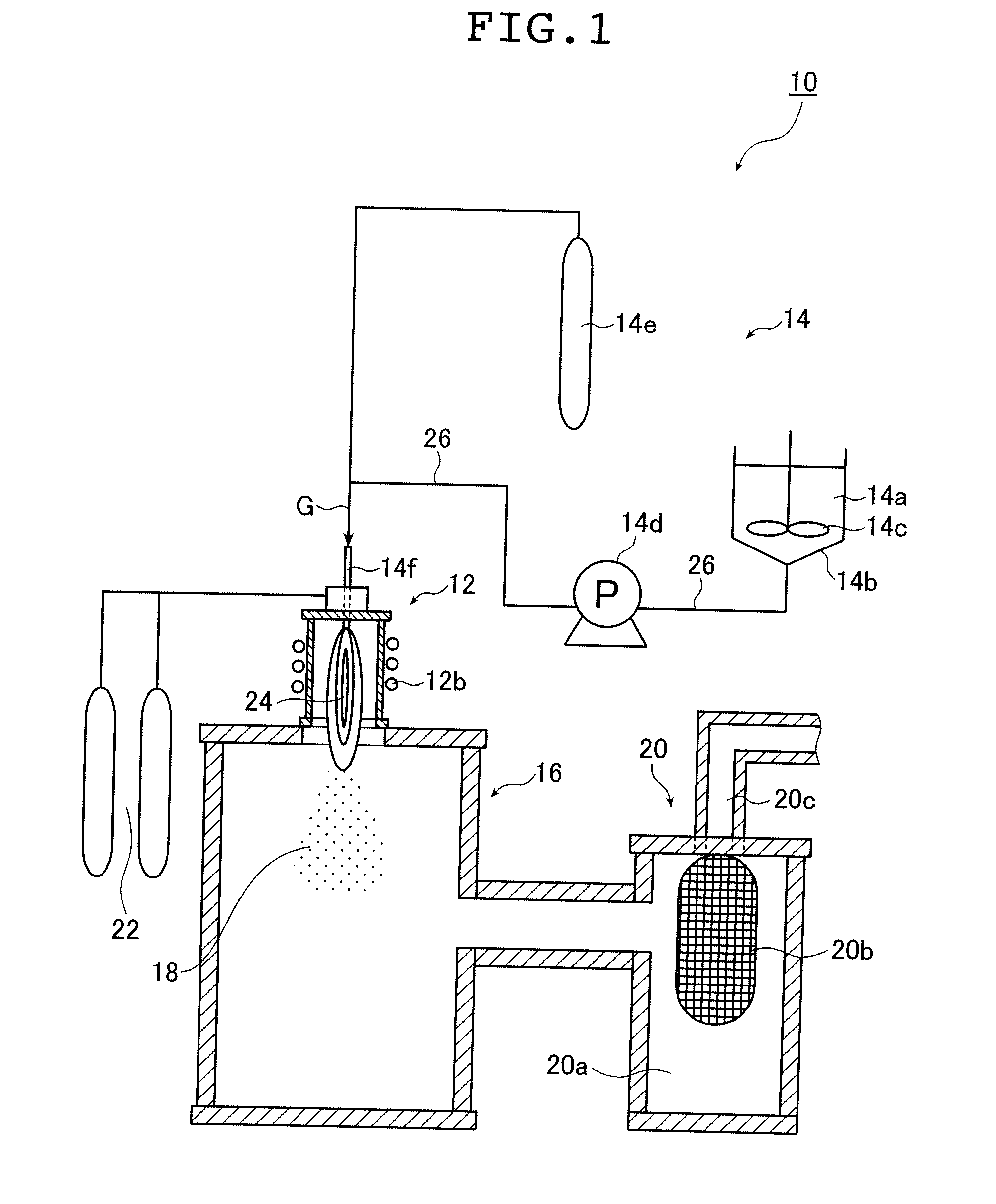

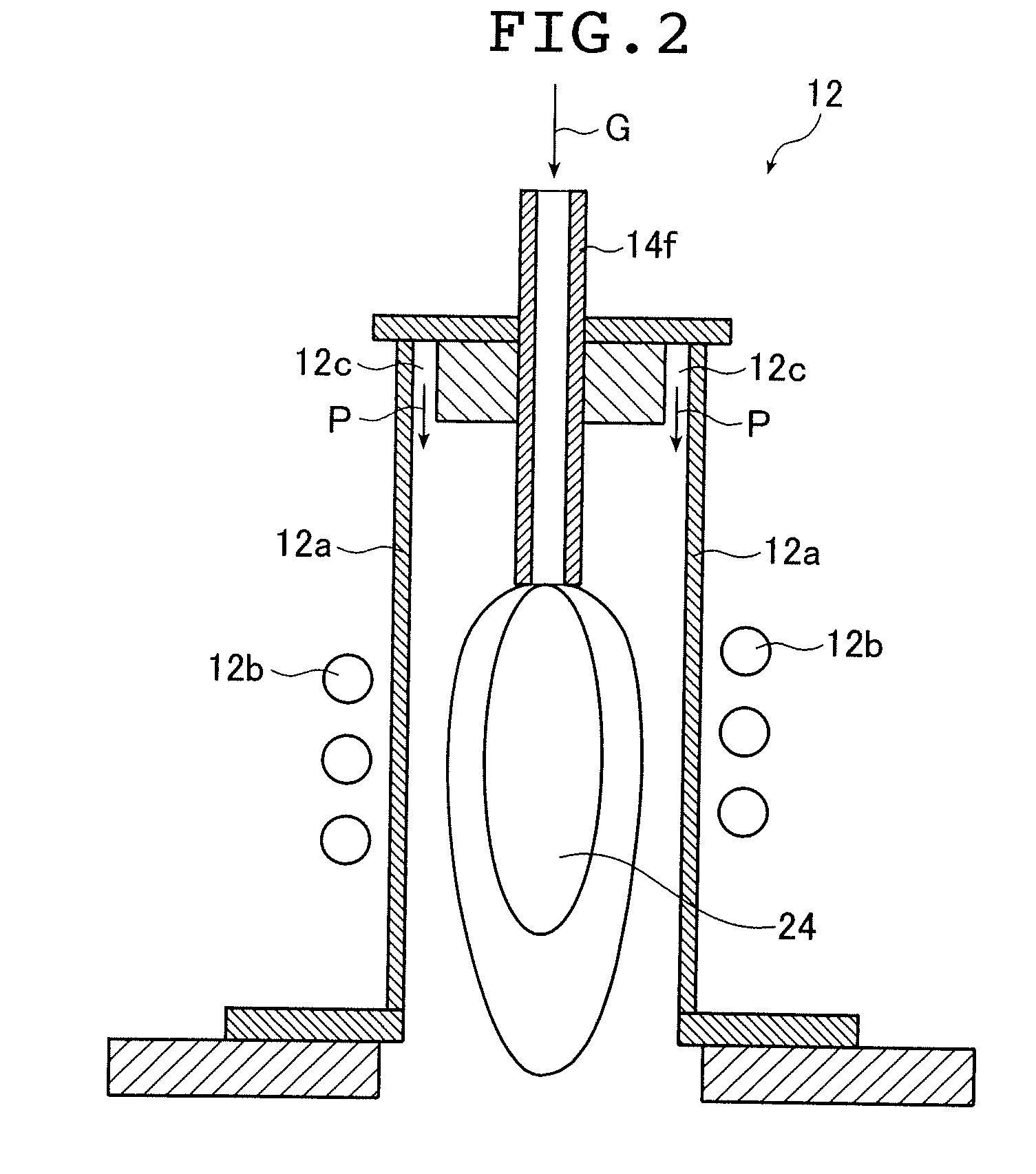

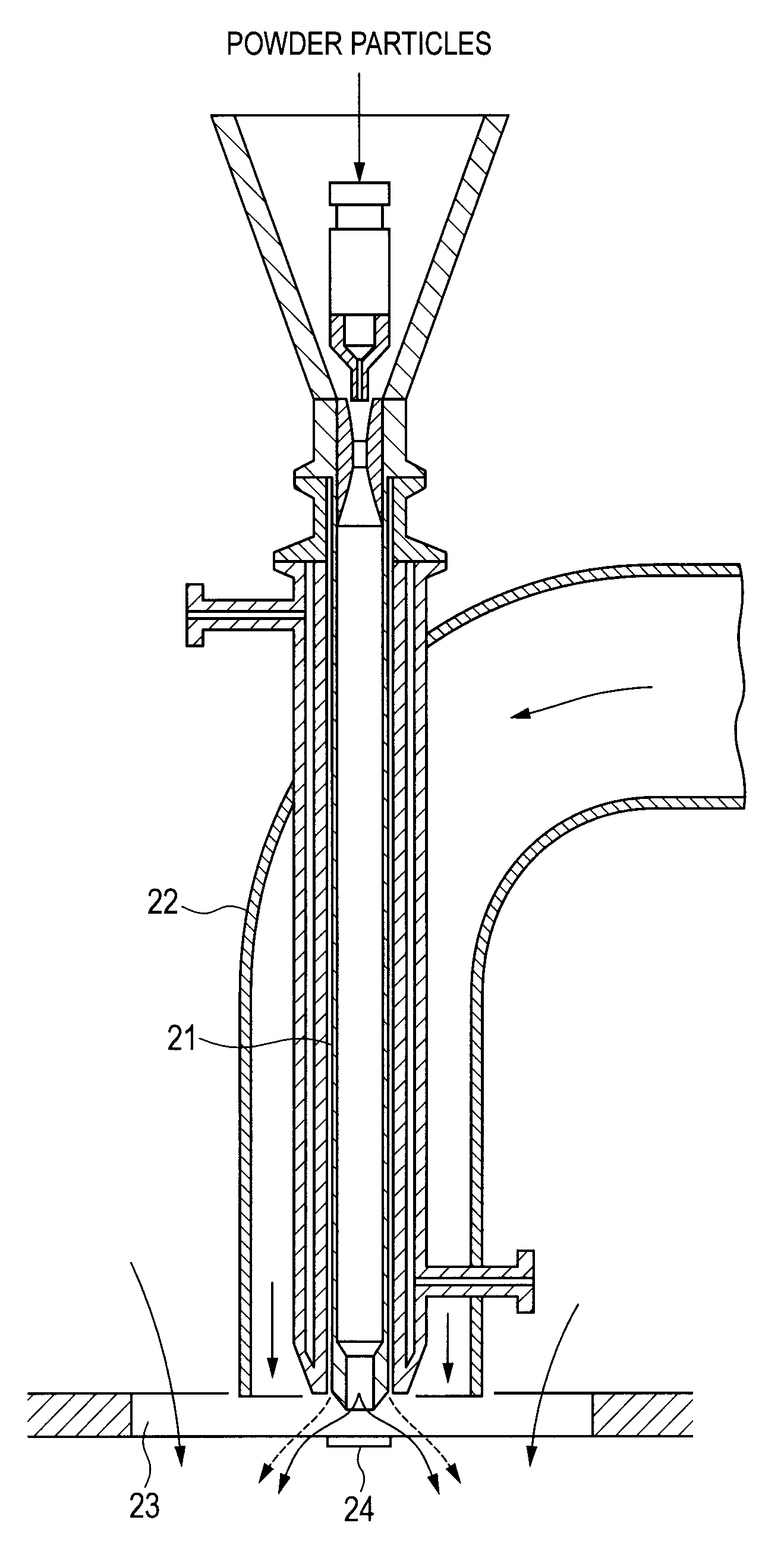

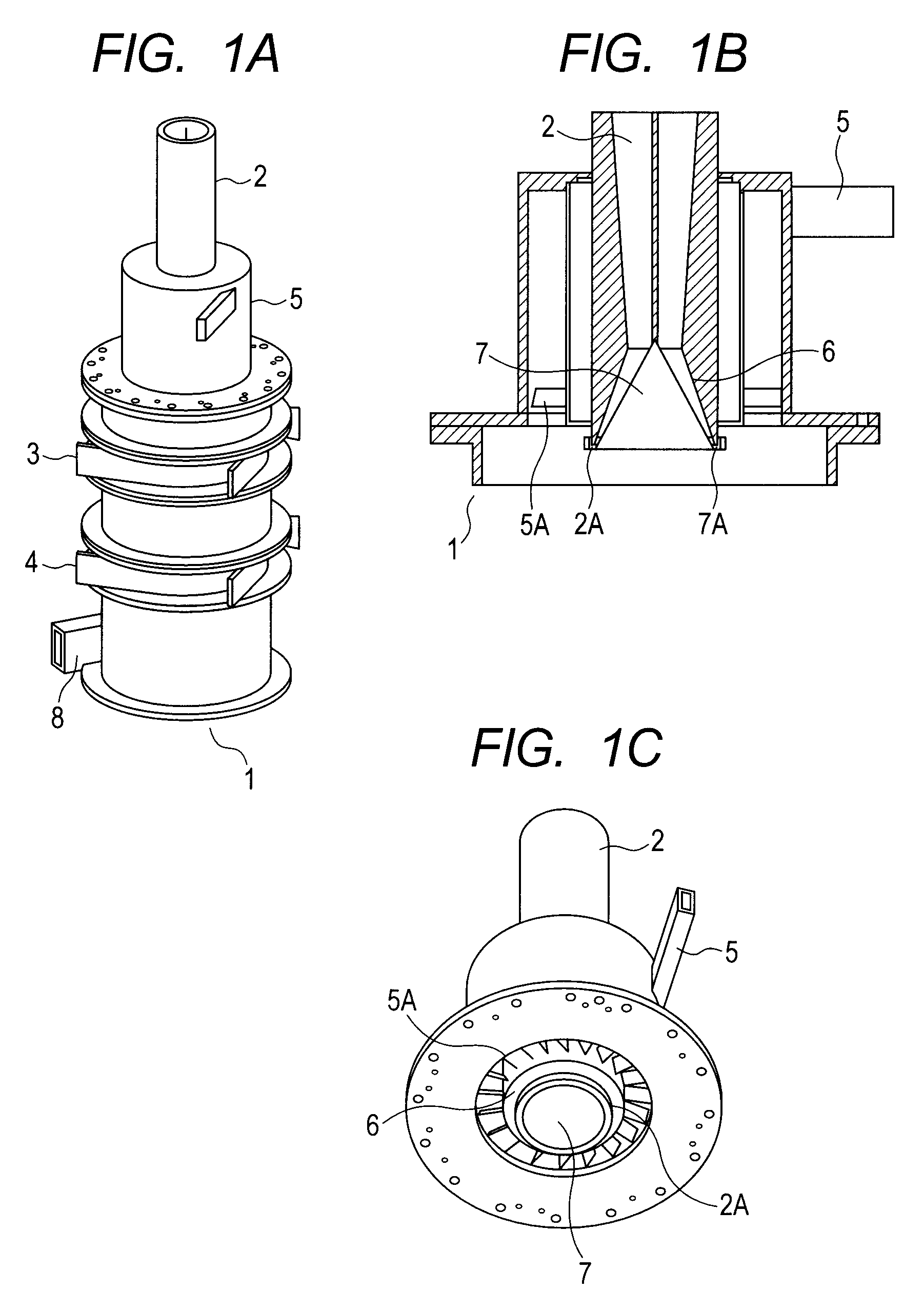

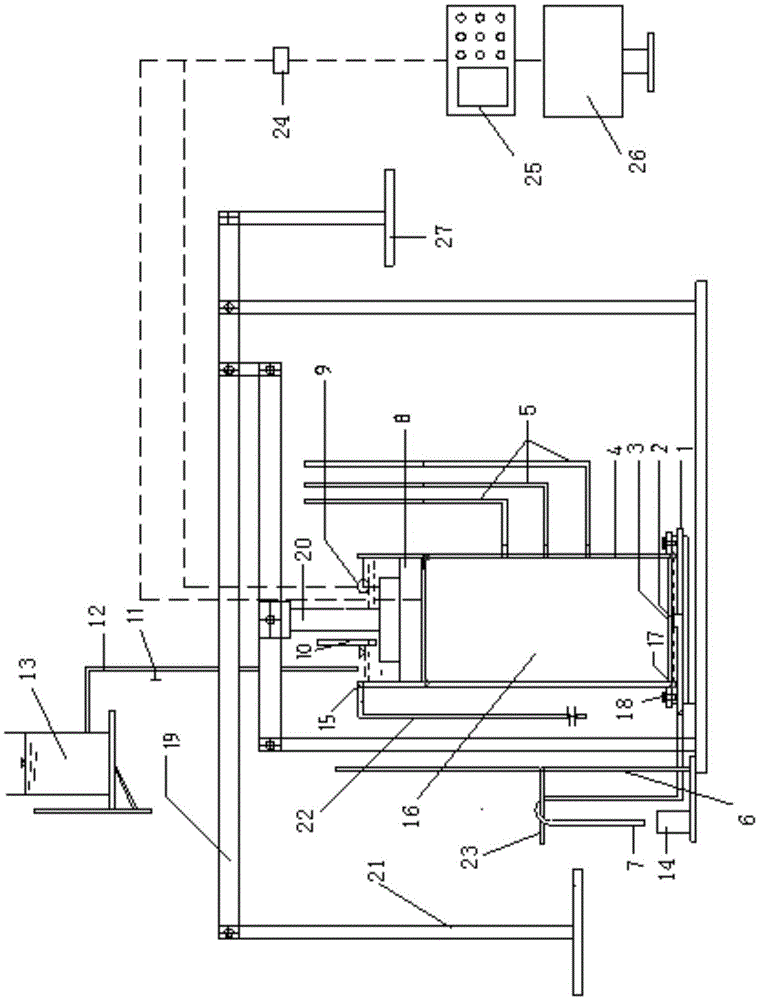

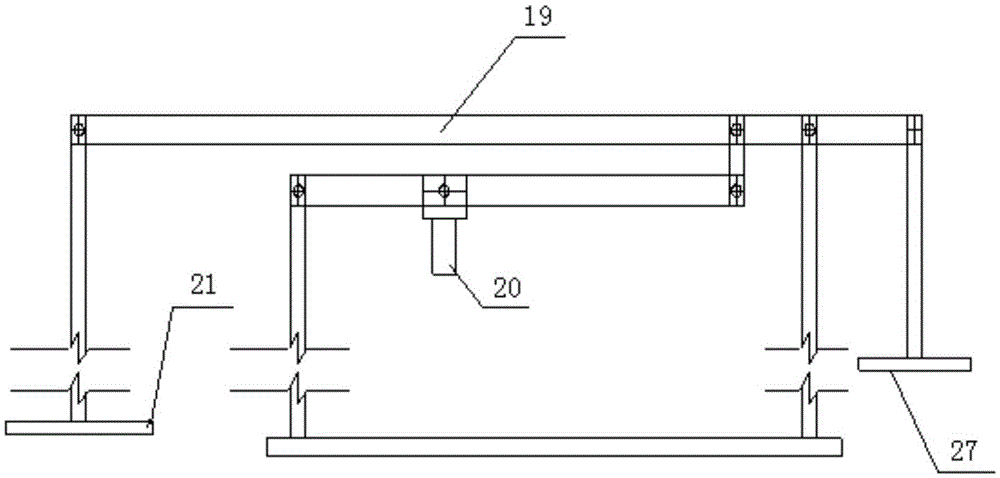

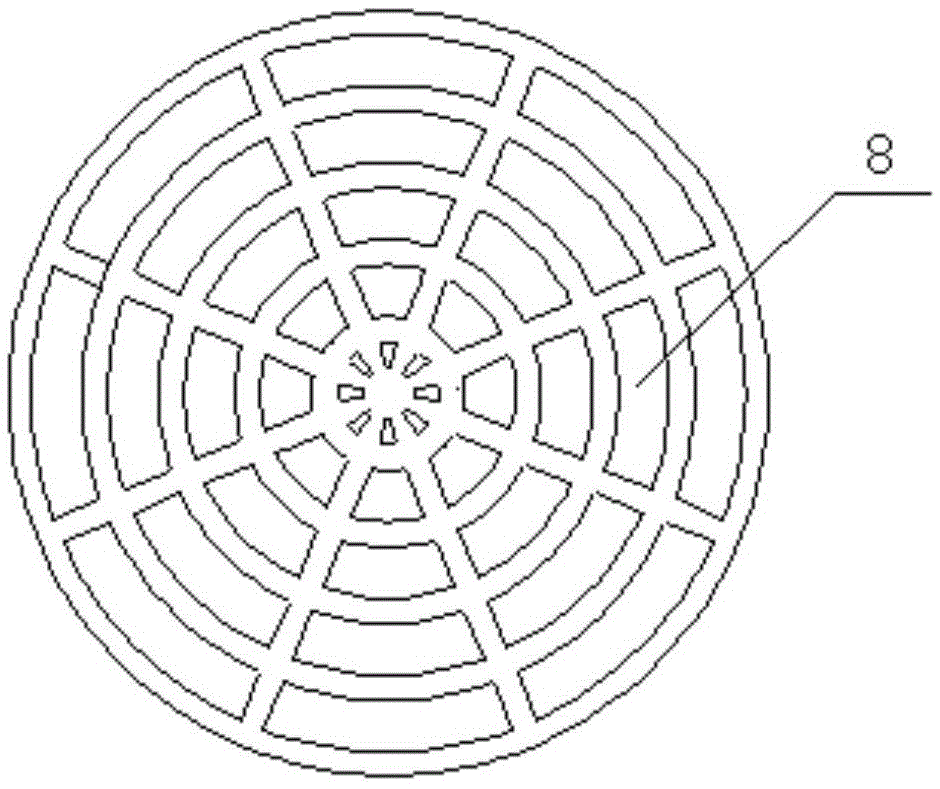

Process and Apparatus for Producing Fine Particles

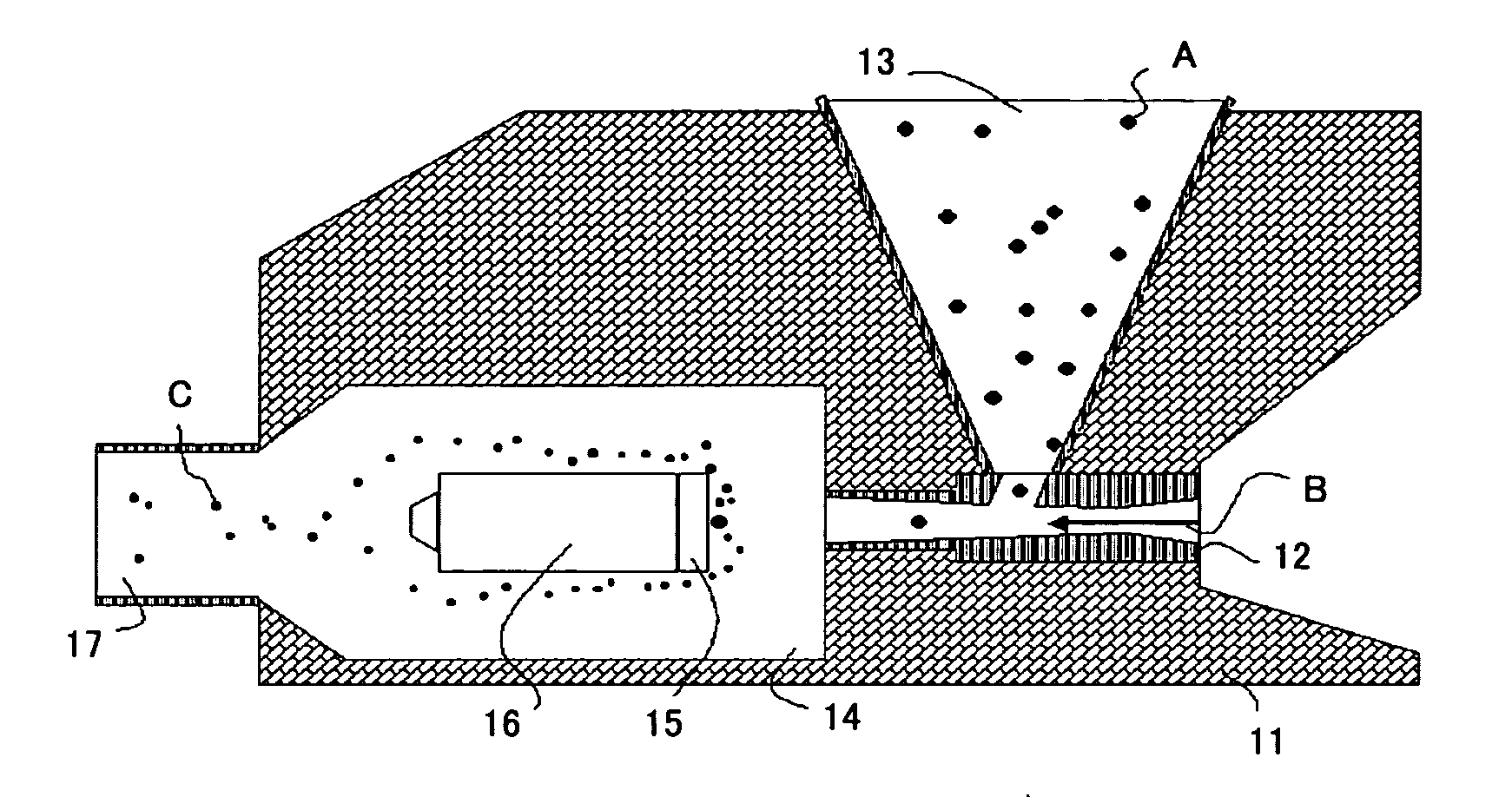

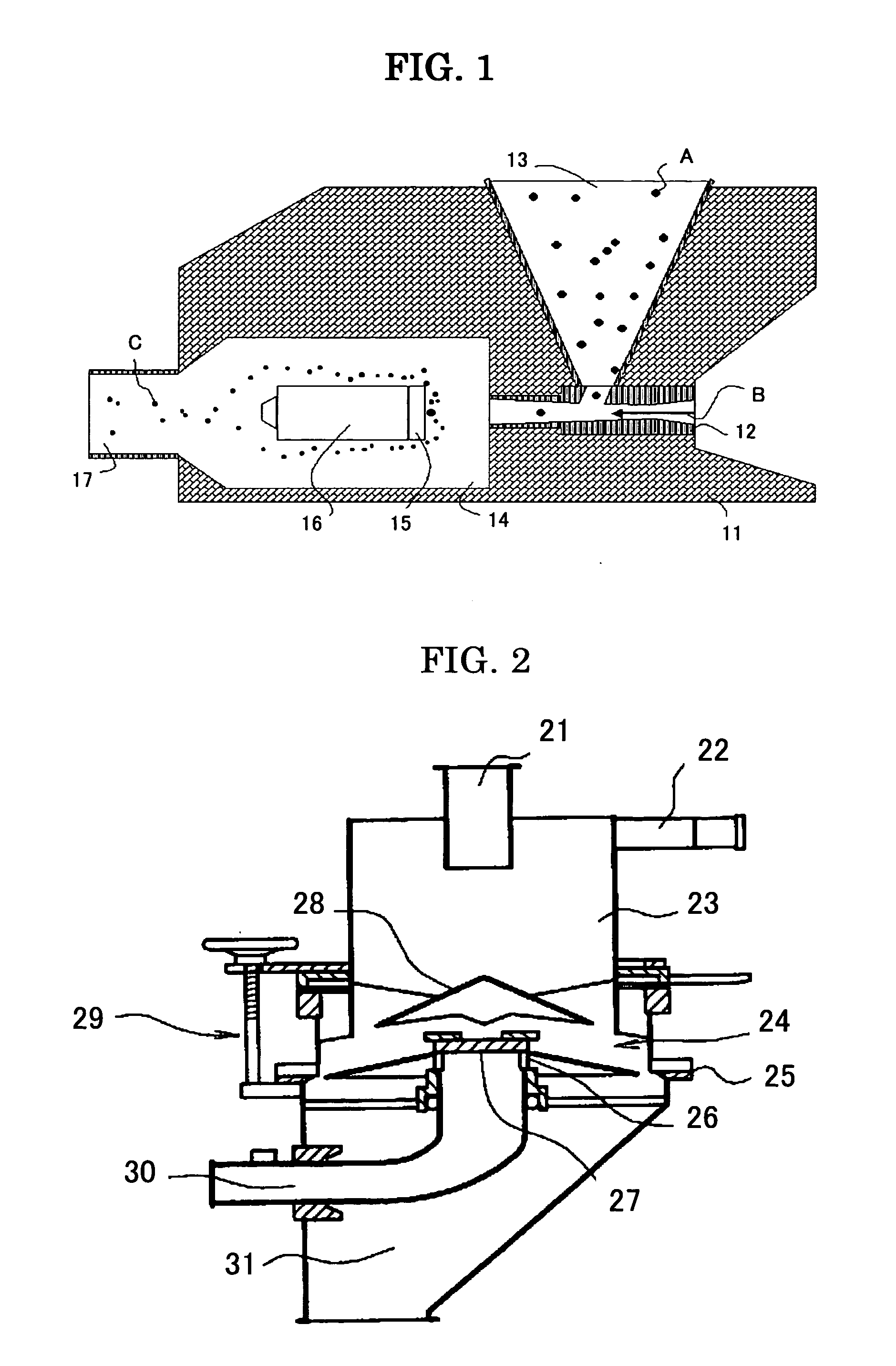

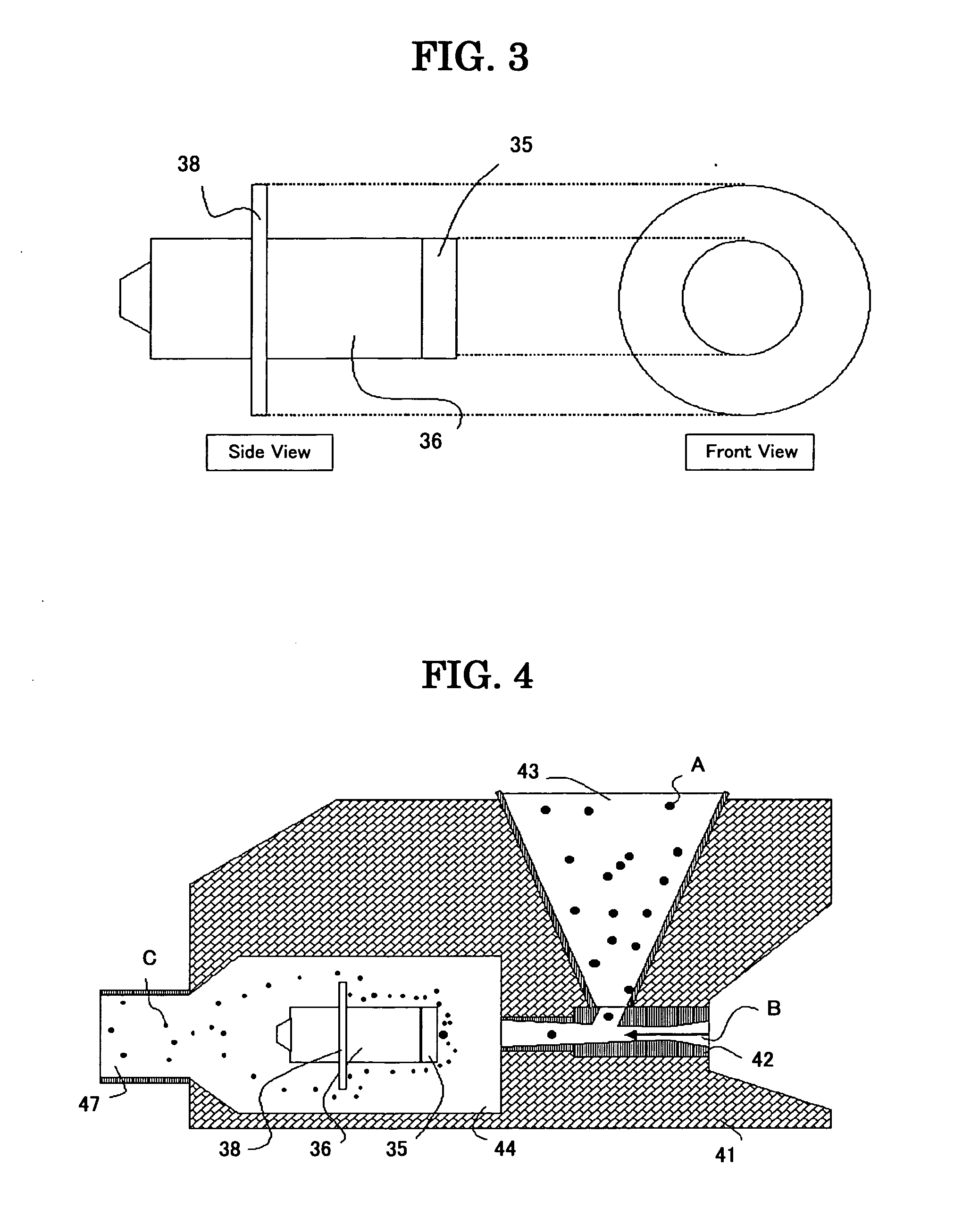

ActiveUS20080006954A1Improve productivityFunction increaseAlkaline earth titanatesMaterial nanotechnologyGas phaseSlurry

A fine particle producing process introduces a material for producing fine particles into a thermal plasma flame to make a vapor-phase mixture and quenches the vapor-phase mixture to form the fine particles. In the process, the material for producing the fine particles is dispersed or dissolved in a dispersion medium or solvent, preferably containing a combustible material to prepare a dispersion such as a slurry, a colloidal solution or a dissolution solution, the dispersion is made into a form of droplets, or the material for producing the fine particles is dispersed with a carrier gas and a combustible material and the dispersion in a droplet form or the dispersed material is introduced into the thermal plasma flame. In the fine particle producing process and apparatus, a gas of an amount sufficient to quench the vapor-phase mixture is supplied toward a tail of the thermal plasma flame. In the process and apparatus, primary fine particles are introduced into a cyclone to be subjected to cooling and classification and secondary fine particles having a particle size of 100 nm or less which are left upon removal of coarse particles are recovered.

Owner:NISSHIN SEIFUN GRP INC +1

Aqueous slurry for the production of thermal and environmental barrier coatings and processes for making and applying the same

ActiveUS20130156958A1Low thermal conductivityConvenient coatingBlade accessoriesPretreated surfacesPorosityMetallurgy

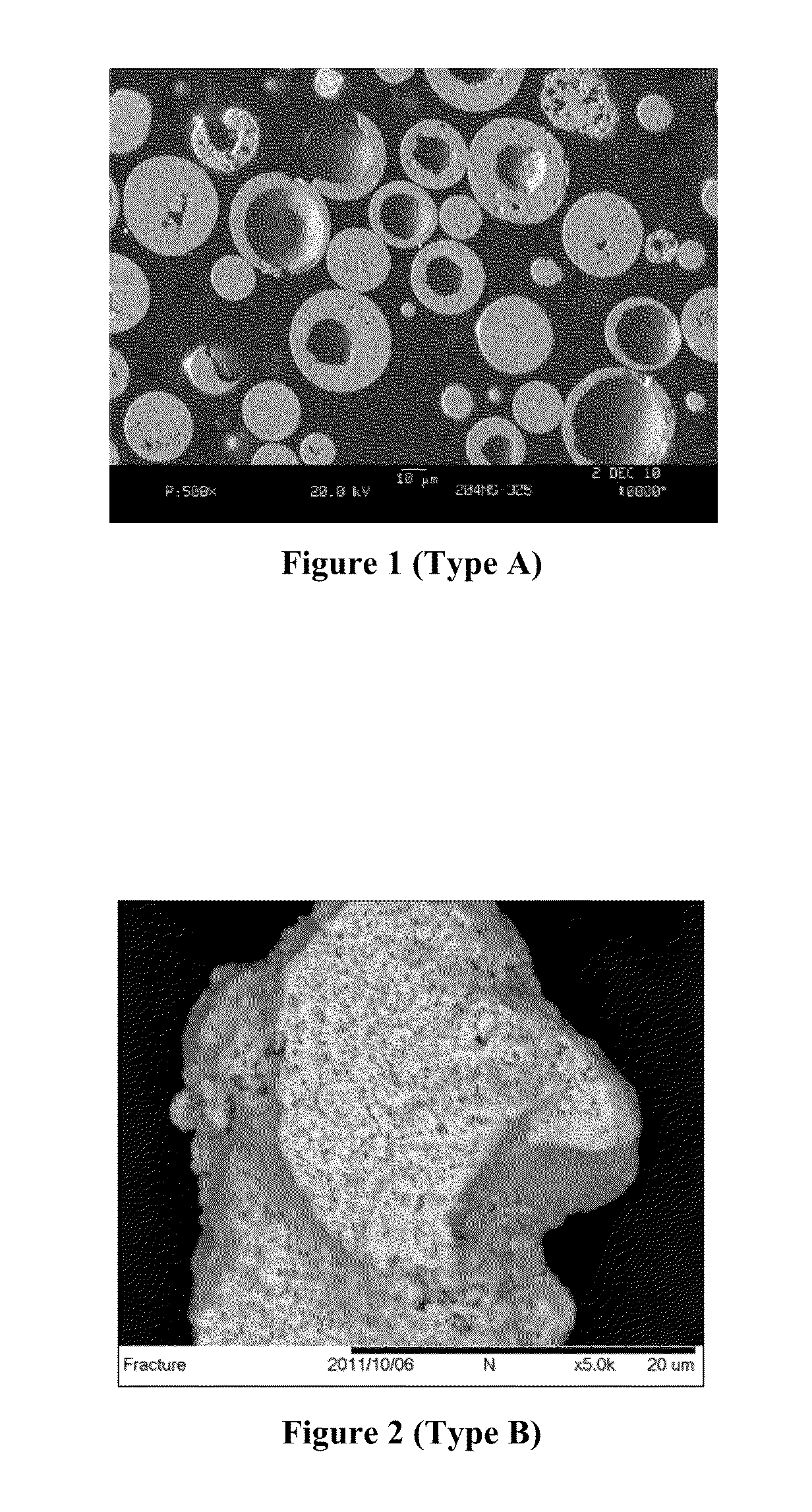

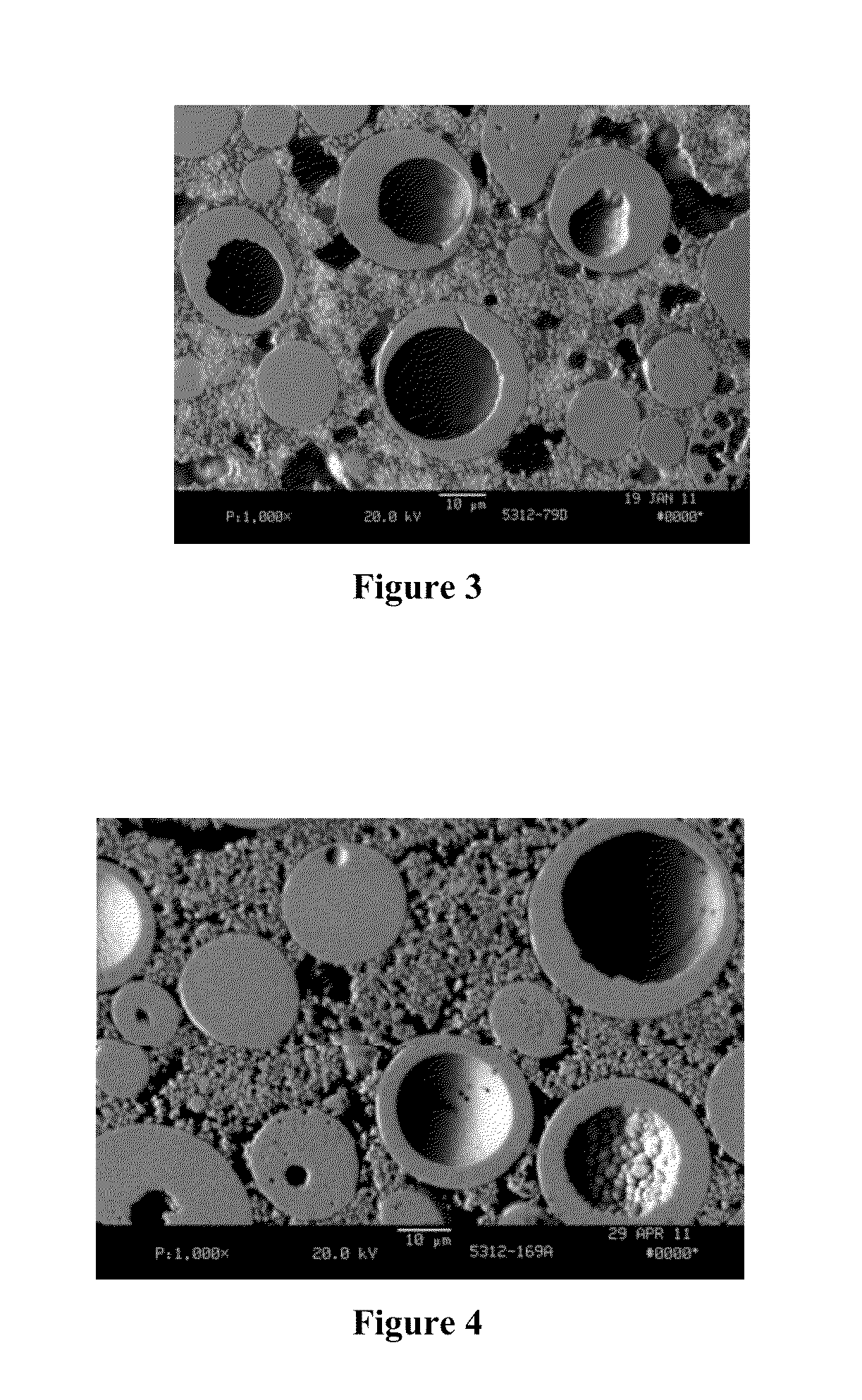

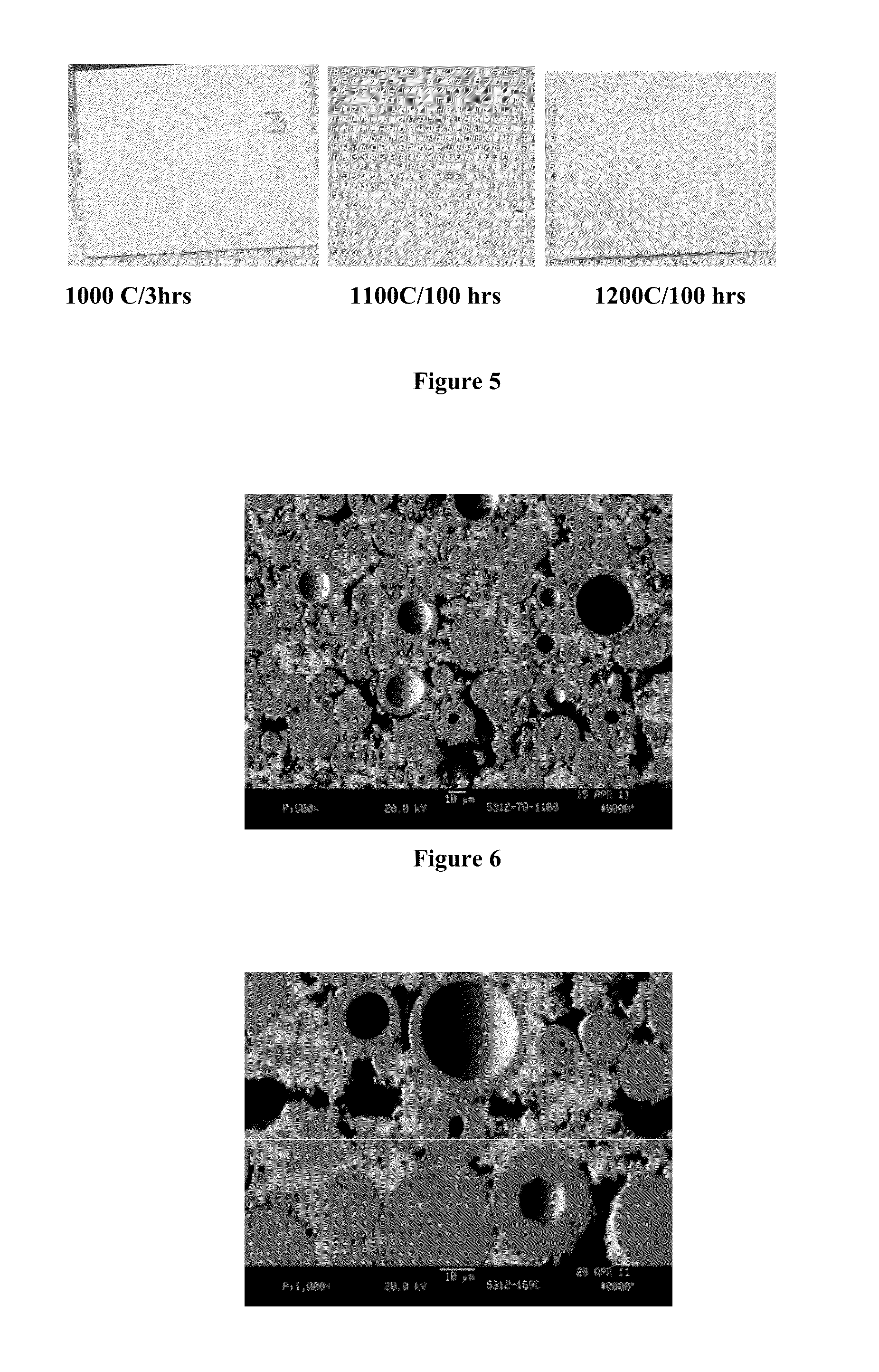

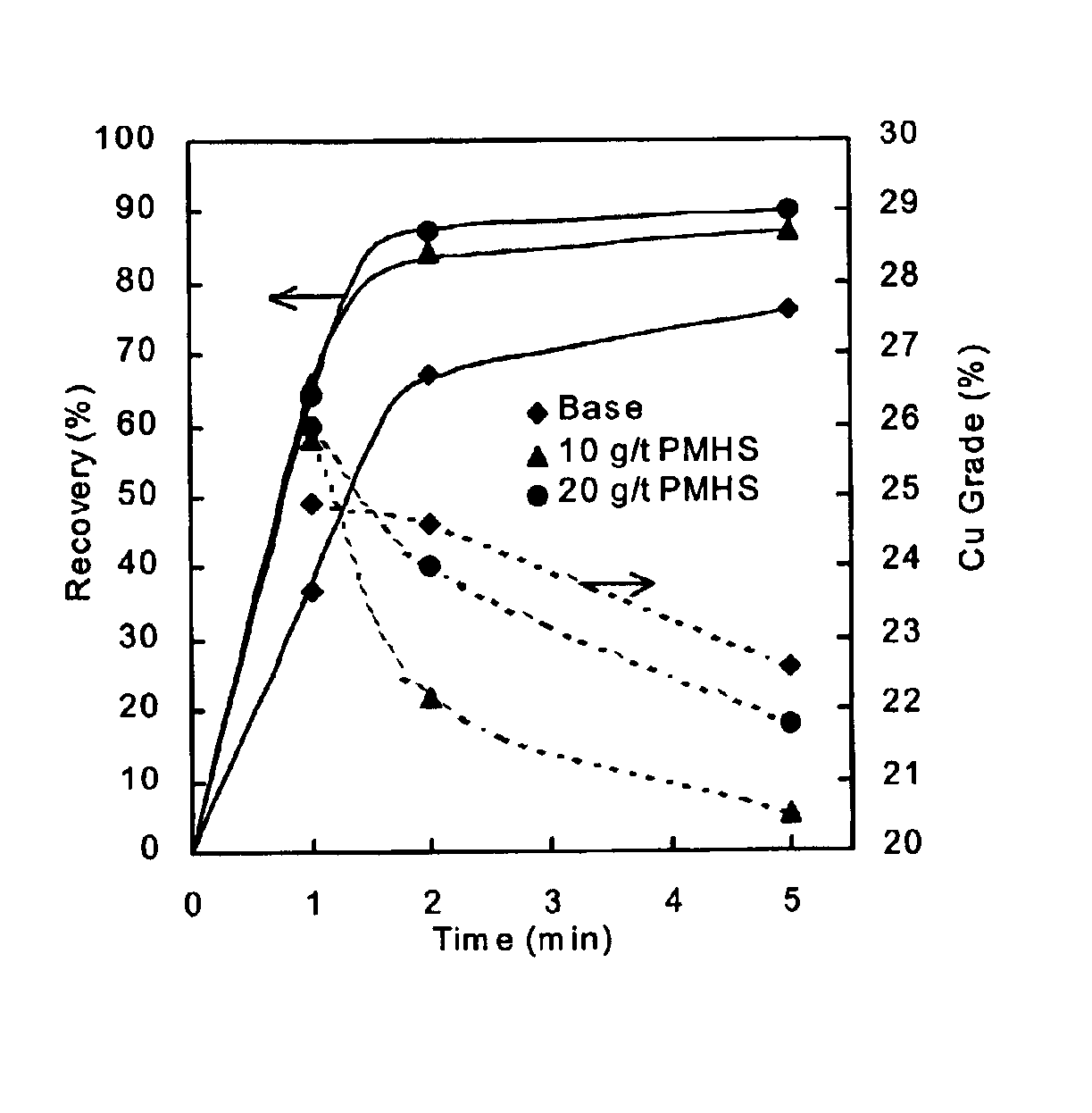

An improved slurry formulation for the production of a thermal and environmental barrier coatings are provided which can withstand high temperature applications. The slurry includes a combination of a coarse ceramic powder fraction having close porosity particles and a fine ceramic powder fraction. The combination of the two powders produces a bimodal particle size distribution having a controlled amount of closed porosity that imparts desirable properties to the coating produced. The finer solid particles are interdispersed within an aqueous binder to produce a ceramic matrix with sufficient mechanical strength. The closed porosity containing coarse particles are embedded within the resultant ceramic matrix and do not disintegrate under high temperature conditions to impart a temperature resistant, non-collapsing closed porosity to the coating which can also act as an environmental barrier.

Owner:PRAXAIR ST TECH INC

Methods of increasing flotation rate

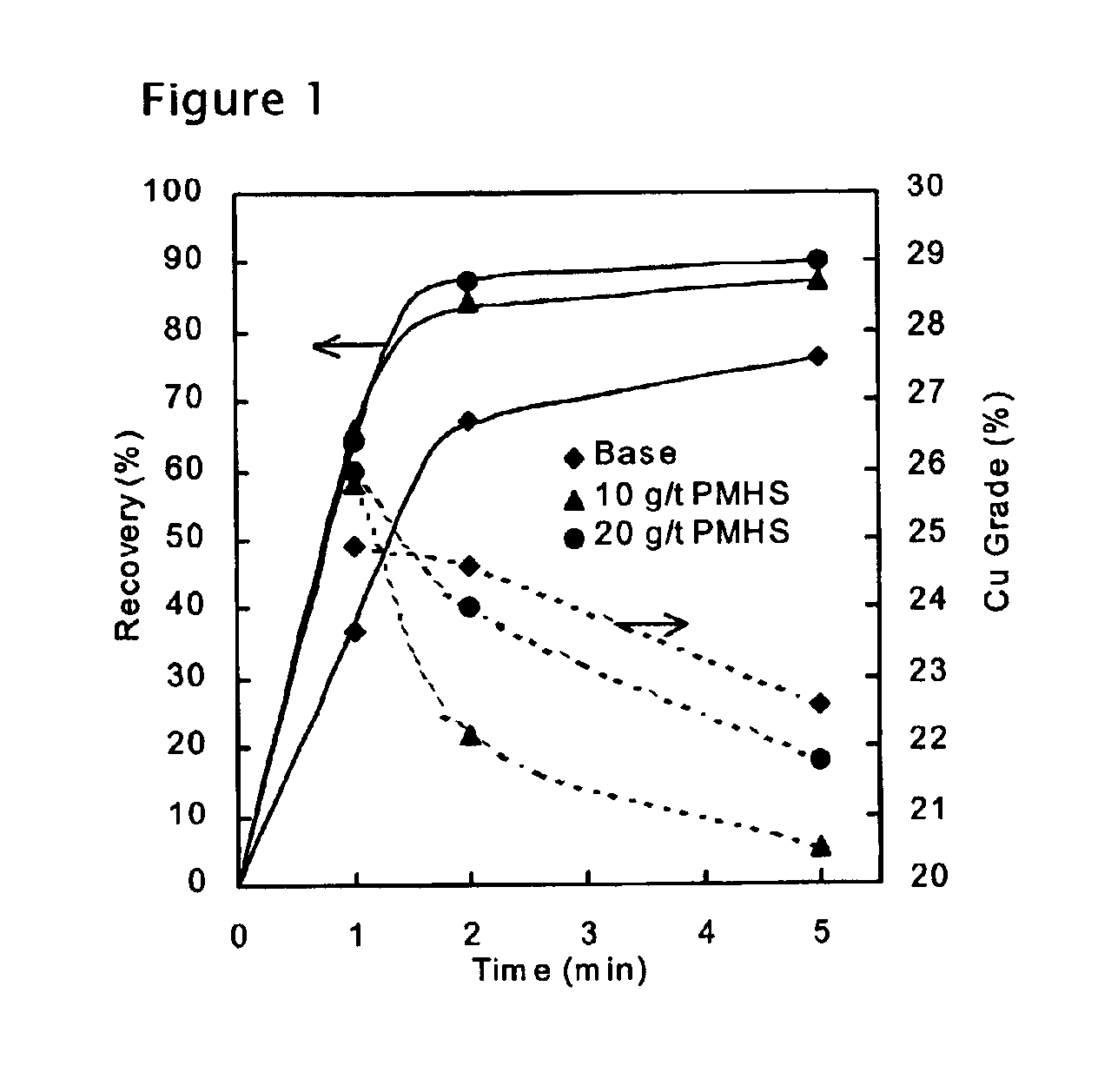

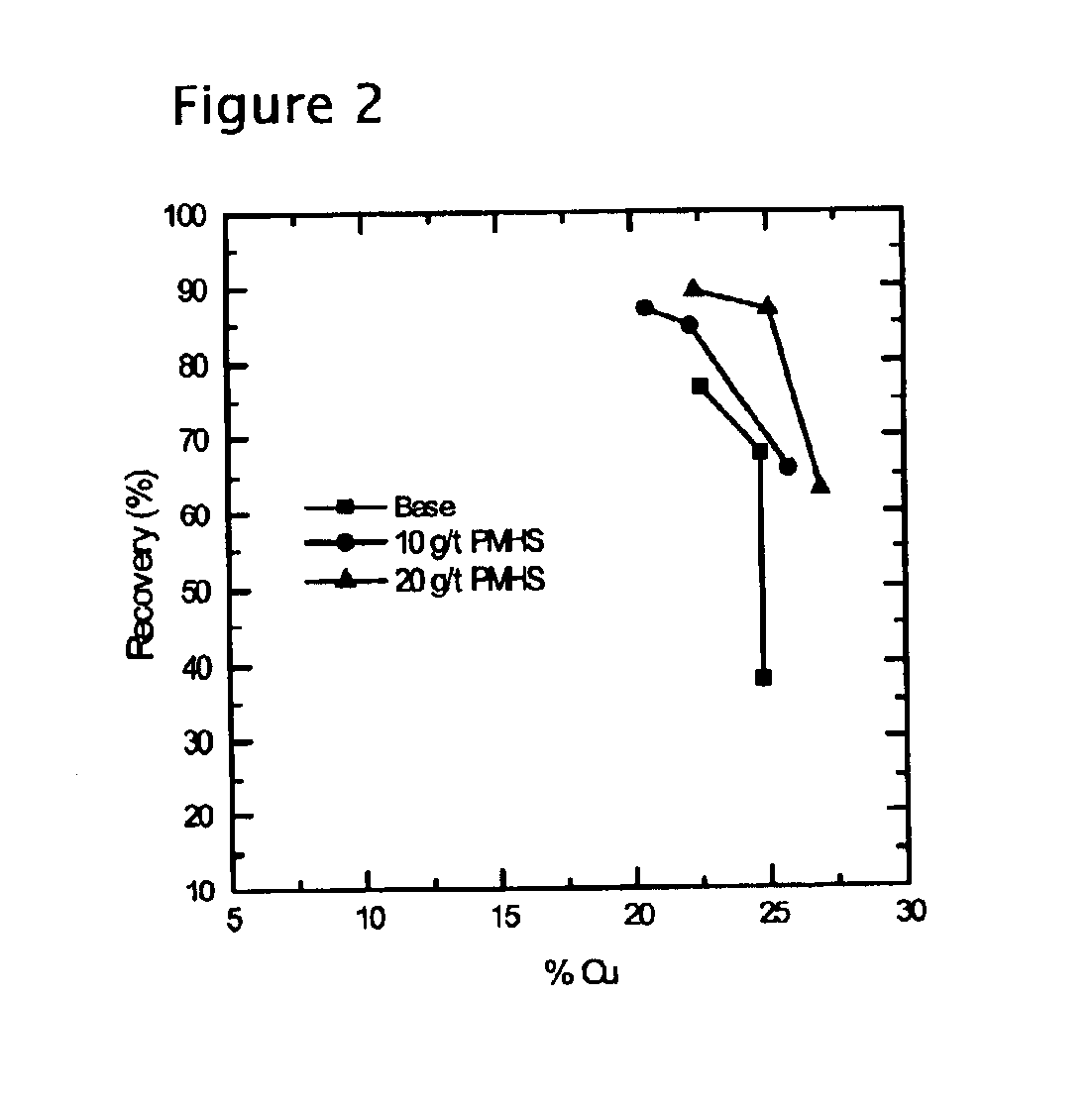

Methods of increasing the rate of separating hydrophobic and hydrophilic particles by flotation have been developed. They are based on using appropriate reagents to enhance the hydrophobicity of the particles to be floated, so that they can be more readily collected by the air bubbles used in flotation. The hydrophobicity-enhancing reagents include low HLB surfactants, naturally occurring lipids, modified lipids, and hydrophobic polymers. These methods can greatly increase the rate of flotation for the particles that are usually difficult to float, such as ultrafine particles, coarse particles, middlings, and the particles that do not readily float in the water containing large amounts of ions derived from the particles. In addition, new collectors for the flotation of phosphate minerals are disclosed.

Owner:MINERAL & COAL TECH

A continuous data protection system and its realization method

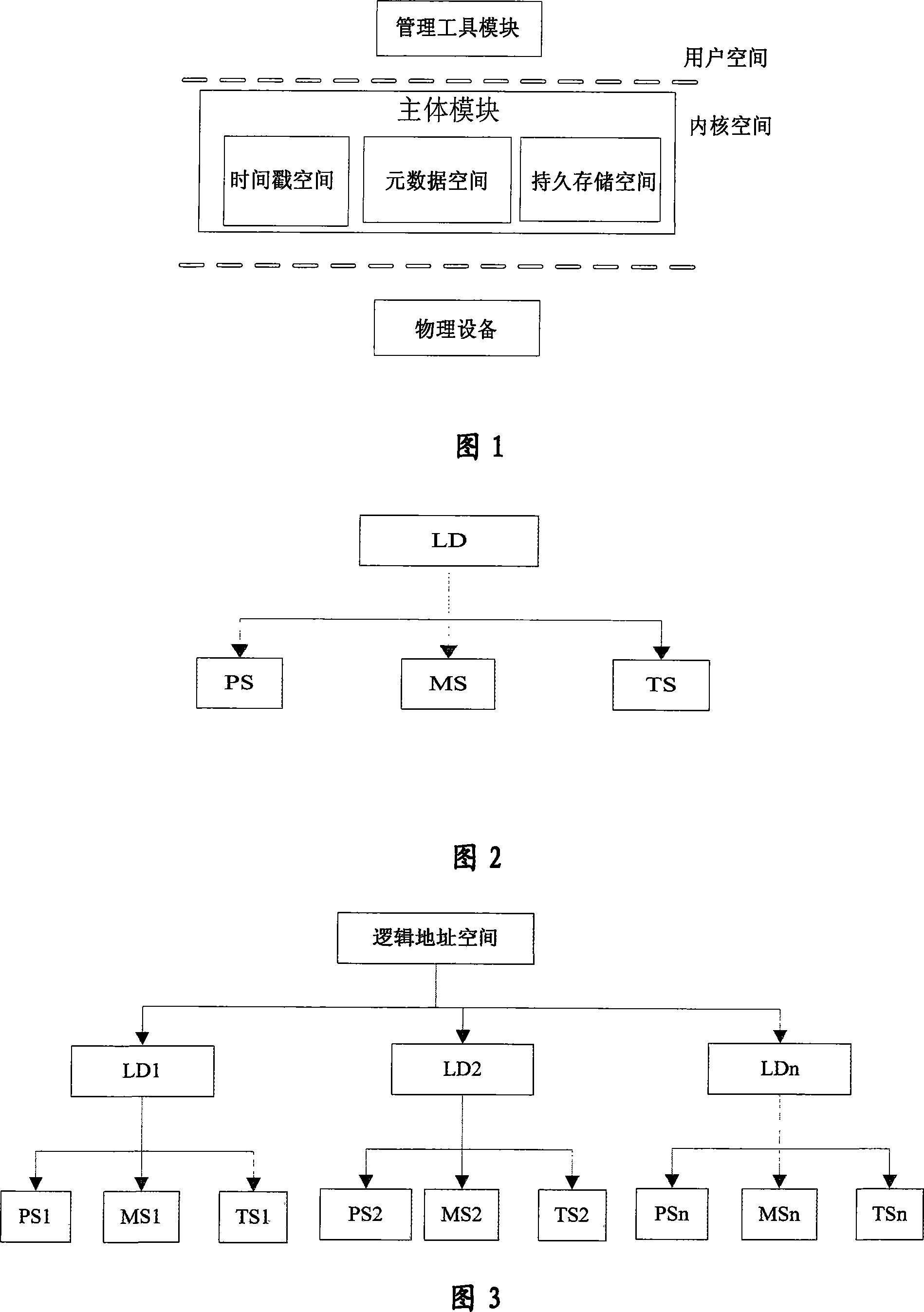

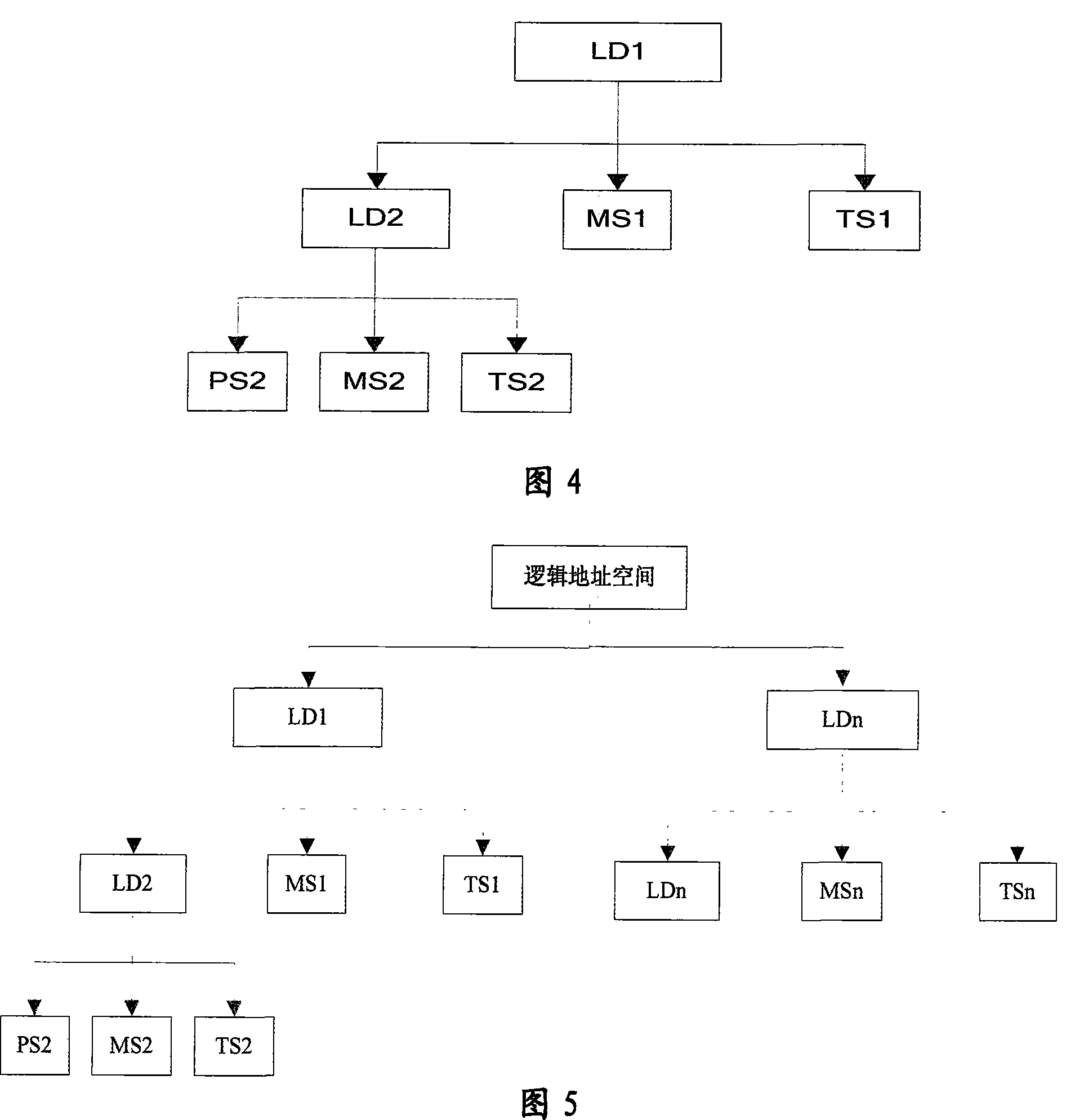

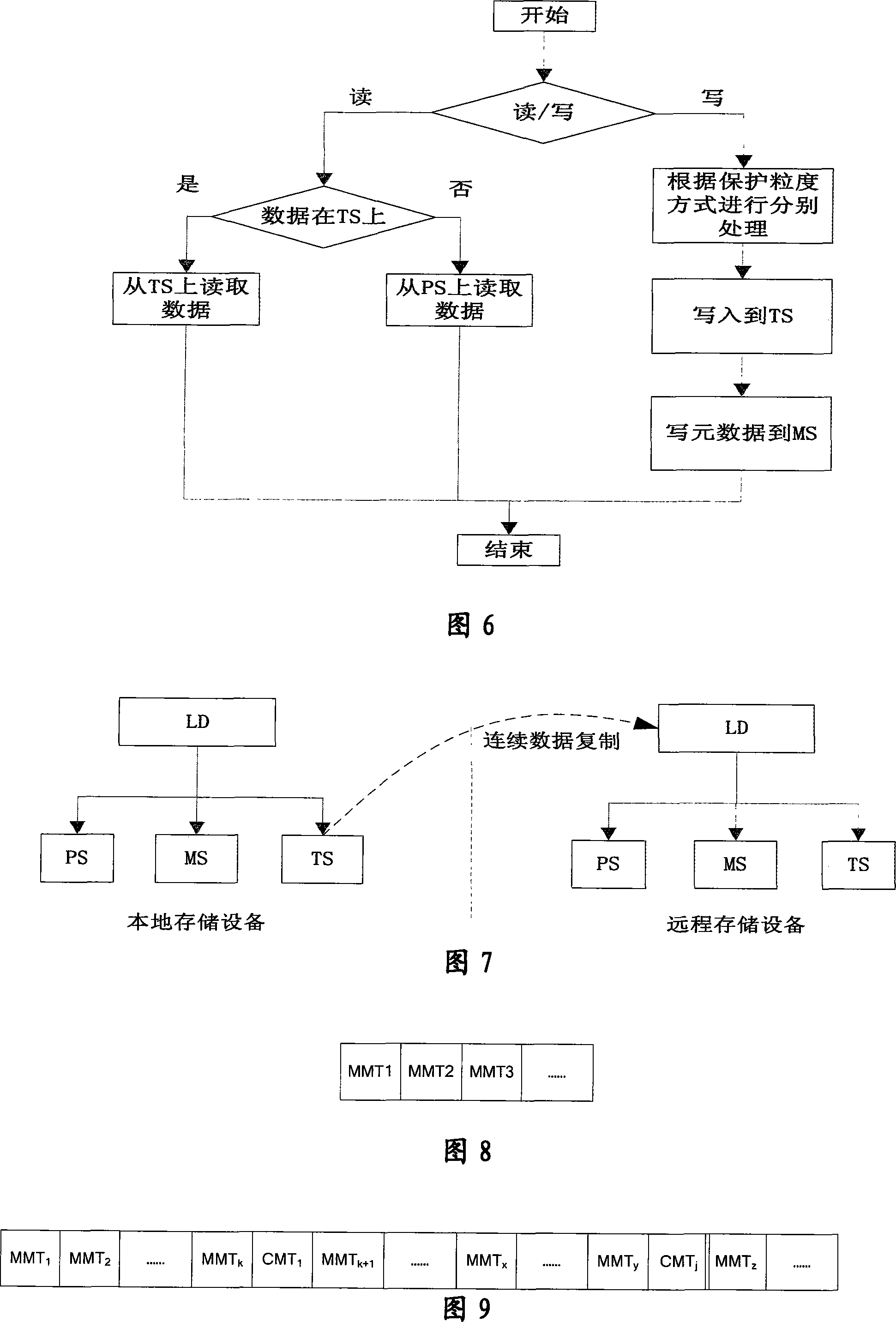

ActiveCN101187948AReliability is not reducedRedundant operation error correctionSpecial data processing applicationsManagement toolGranularity

The invention provides a Continuous Data Protection CDP system and the realizing method thereof. The system comprises a management tool module, a main body module and physical equipment. The system can perform flexible stack. The management tool module is used for building the main body module with a temporal point, and performing the operations of reading, writing and storing to the main body module, according to the difference of the data access frequency and the data level, the important data which is accessed recently adopts a CDP technique with a fine grit, the non-important data which is not accessed often adopts a back-up protection technique with a coarse particle size, thereby the invention can support continuous data protection of different protection granularities, through the flexible stack structure, the requirement of the data memory capacity is reduced, while the reliability for the data continuous protection is not reduced.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

Pharmaceutical formulations for dry powder inhalers

InactiveUS7541022B2Powder deliveryOrganic active ingredientsBULK ACTIVE INGREDIENTPharmaceutical formulation

A powder for use in a dry powder inhaler comprises: i) a fraction n of fine particle size constituted by a mixture of physiologically acceptable excipient and an additive; ii) a fraction of coarse particles; and iii) at least one active ingredient. The powder is suitable for efficacious delivery of active ingredients into the low respiratory tract of patients suffering from pulmonary diseases such as asthma. In particular, the invention provides a formulation to be administered as dry powder for inhalation which is freely flowable, can be produced in a simple way, is physically and chemically stable and capable of delivering accurate doses and / or high fine particle fraction of low strength active ingredients by using a high- or medium resistance device.

Owner:VECTURA LTD

Pharmaceutical formulations for dry powder inhalers

InactiveUS20030185764A1Powder deliveryOrganic active ingredientsBULK ACTIVE INGREDIENTPharmaceutical formulation

A powder for use in a dry powder inhaler comprises: i) a fraction of fine particle size constituted by a mixture of physiologically acceptable excipient and an additive; ii) a fraction of coarse particles; and iii) at least one active ingredient. The powder is suitable for efficacious delivery of active ingredients into the low respiratory tract of patients suffering from pulmonary diseases such as asthma. In particular, the invention provides a formulation to be administered as dry powder for inhalation which is freely flowable, can be produced in a simple way, is physically and chemically stable and capable of delivering accurate doses and / or high fine particle fraction of low strength active ingredients by using a high- or medium resistance device.

Owner:VECTURA LTD

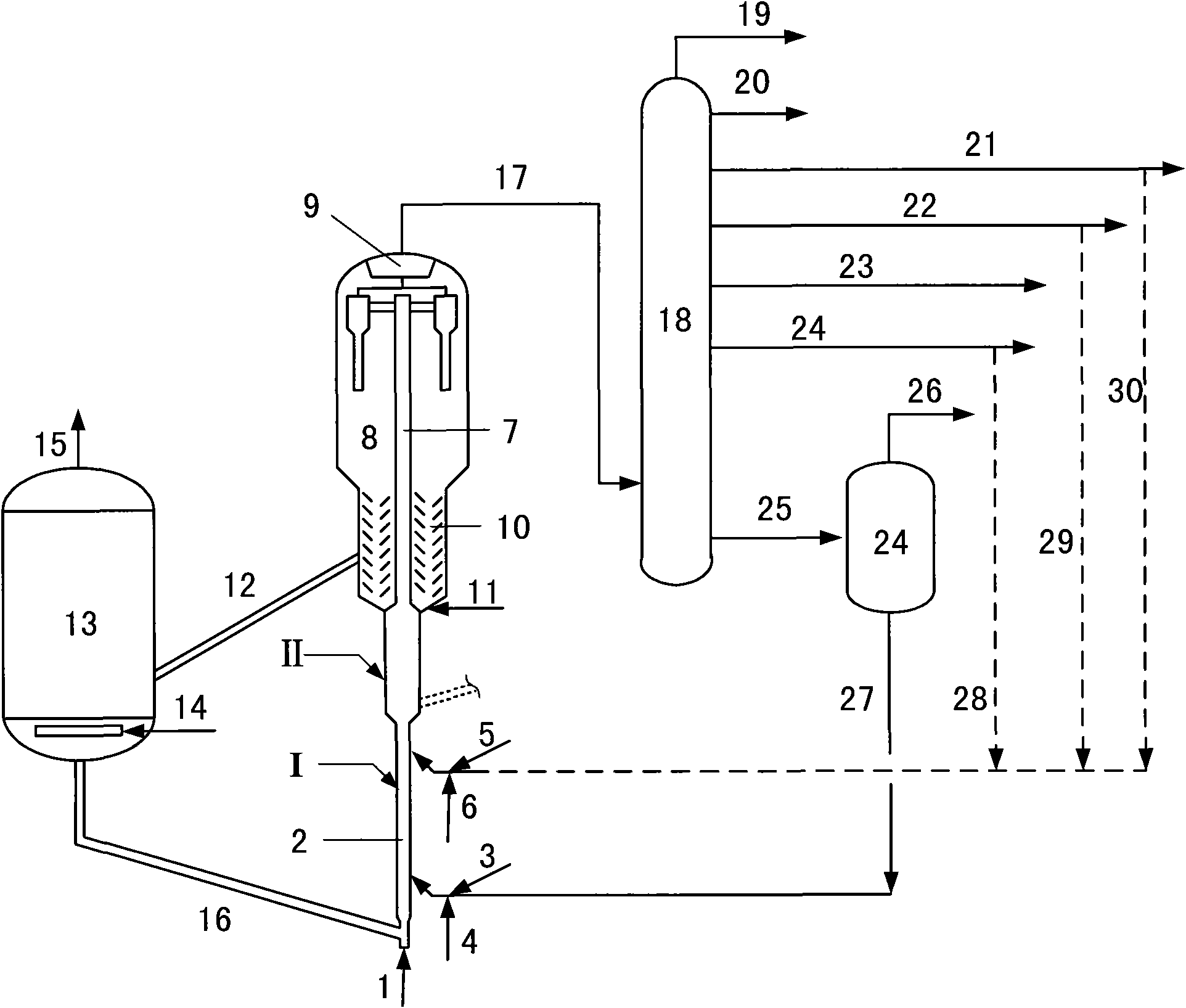

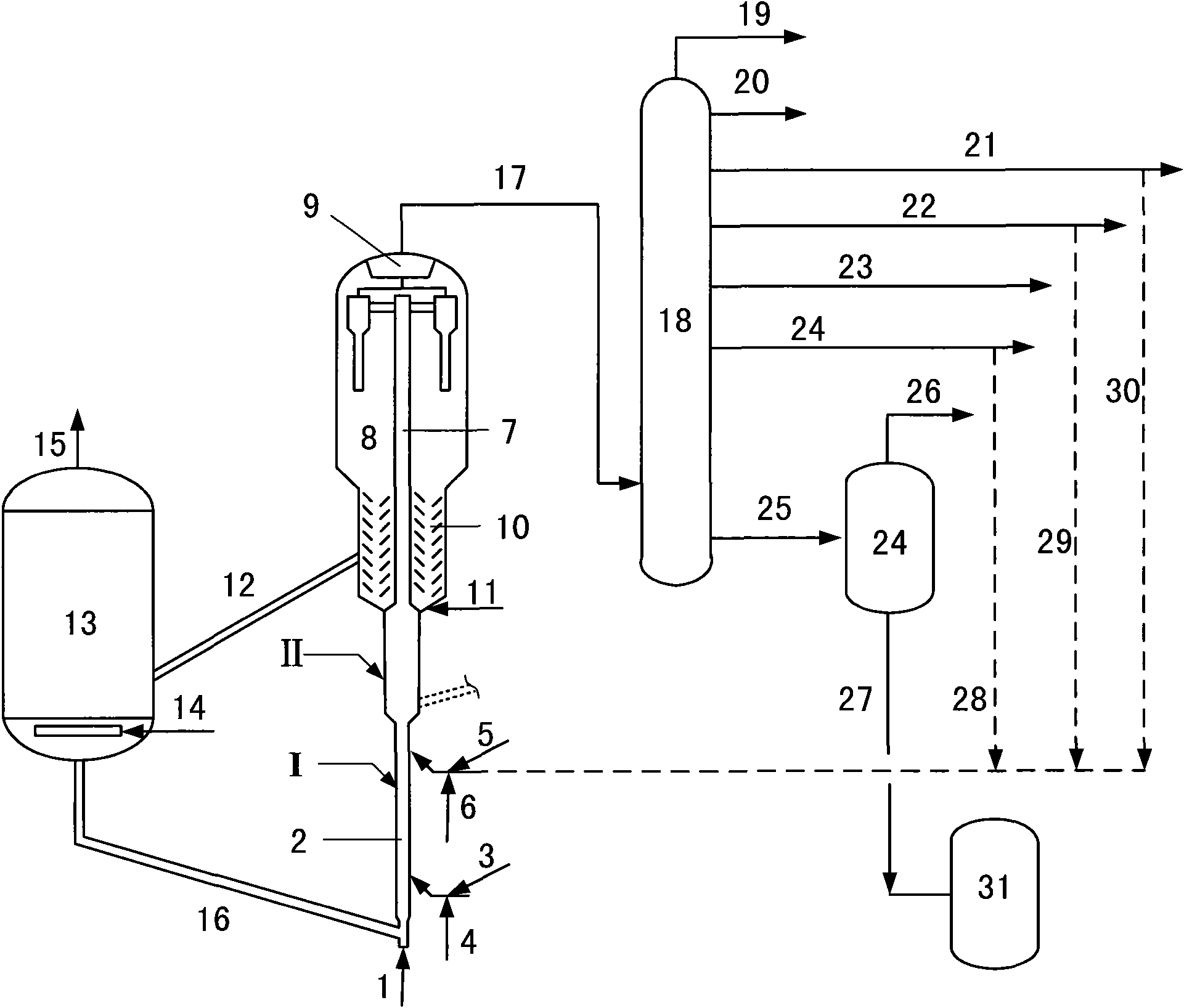

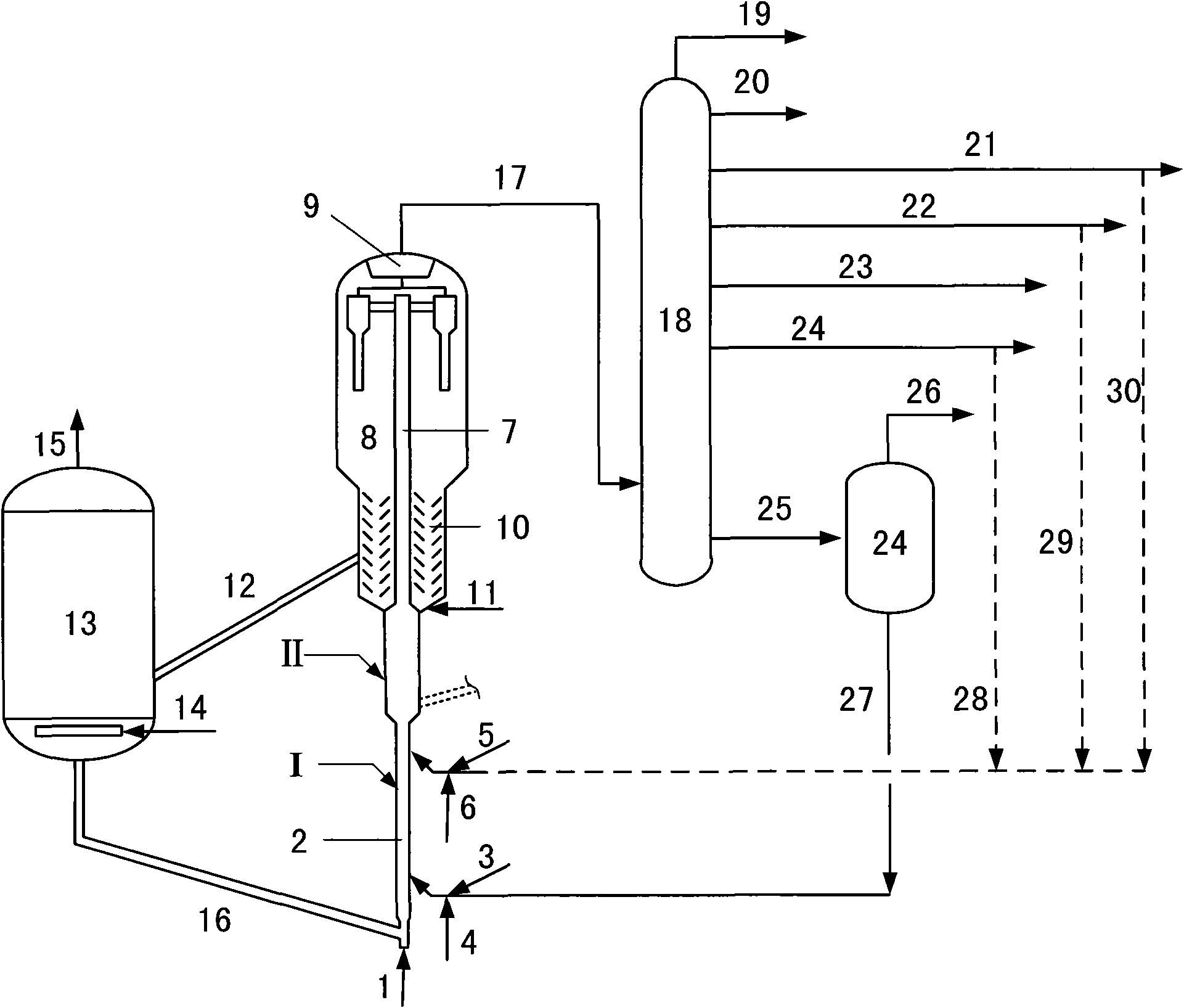

Method for preparing light fuel oil and propylene from inferior raw material oil

ActiveCN101942340AImproved raw material propertiesExtended operating cycleTreatment with plural serial stages onlyTreatment with hydrotreatment processesGas solidWax

The invention discloses a method for preparing light fuel oil and propylene from inferior raw material oil. The inferior raw material oil enters a first reaction area and a second reaction area of a catalytic conversion reactor in turn to contact a catalytic conversion catalyst with coarse particle size distribution so as to perform primary reaction and secondary reaction respectively; after the reaction product and the spent catalyst undergo gas-solid separation, the spent catalyst is subjected to steam stripping and charring in turn and then returned to the reactor for recycling; and the reaction product is separated to obtain propylene, gasoline, catalytic wax oil and other products, wherein the catalytic wax oil enters at least one of hydrotreatment device, an arene extraction device and a hydrocracking device so as to obtain hydrogenated catalytic wax oil, raffinate oil and hydrocracking tail oil. The method improves the yield of the light oil, reduces the yield of oil slurry, realizes efficient utilization of petroleum resources, reduces the consumption of the catalyst, and reduces the catalyst content of the catalytic wax oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

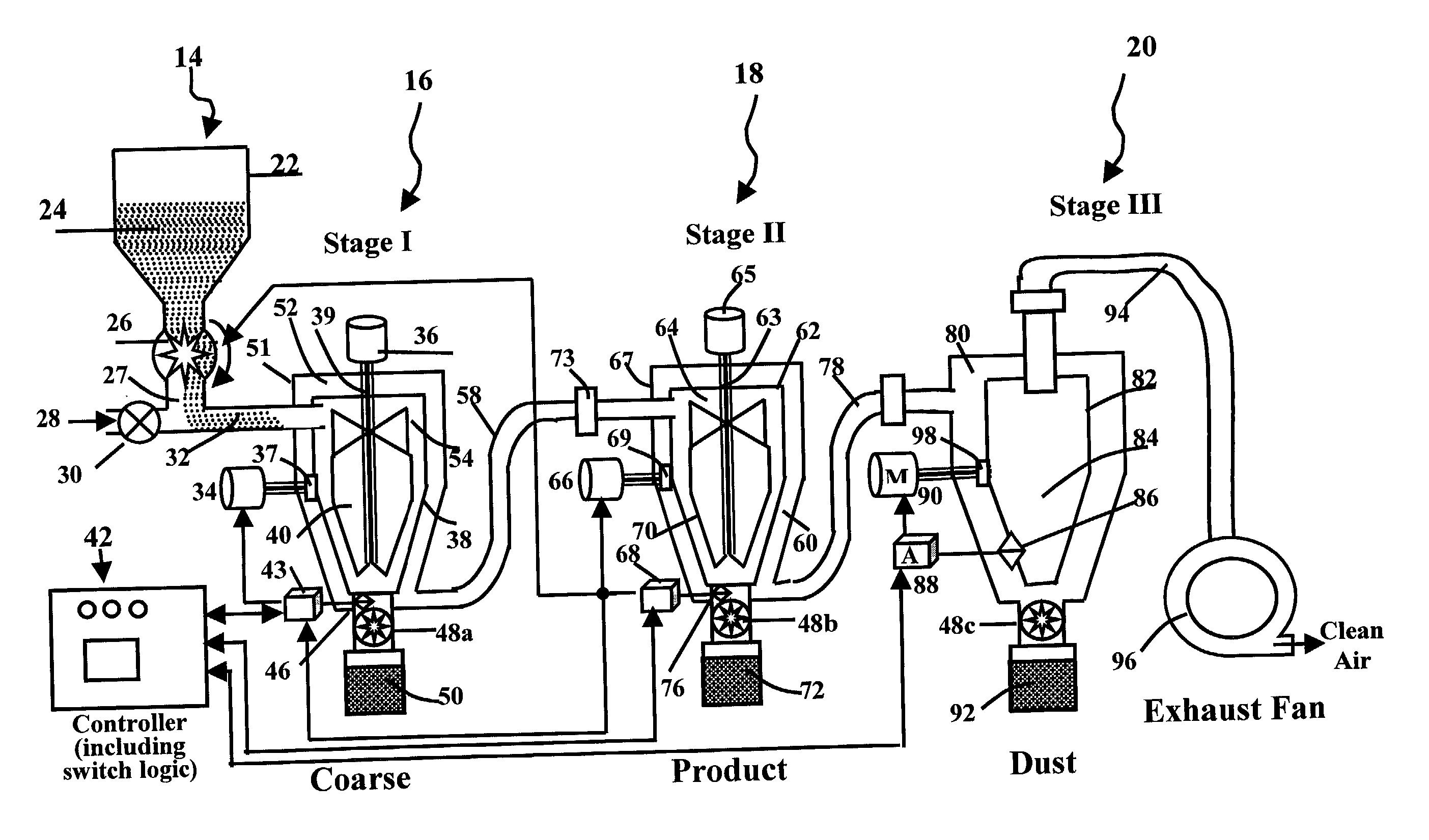

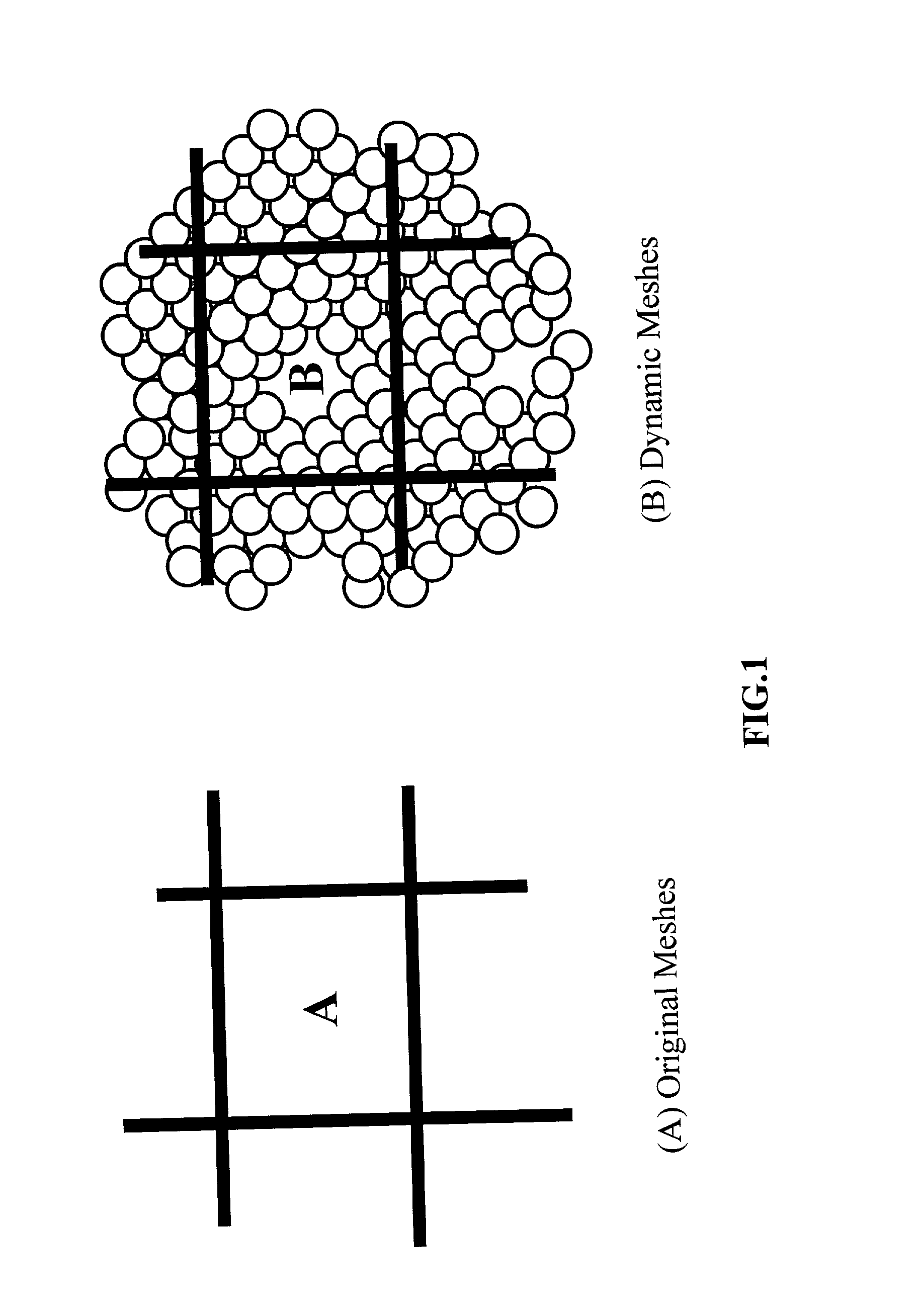

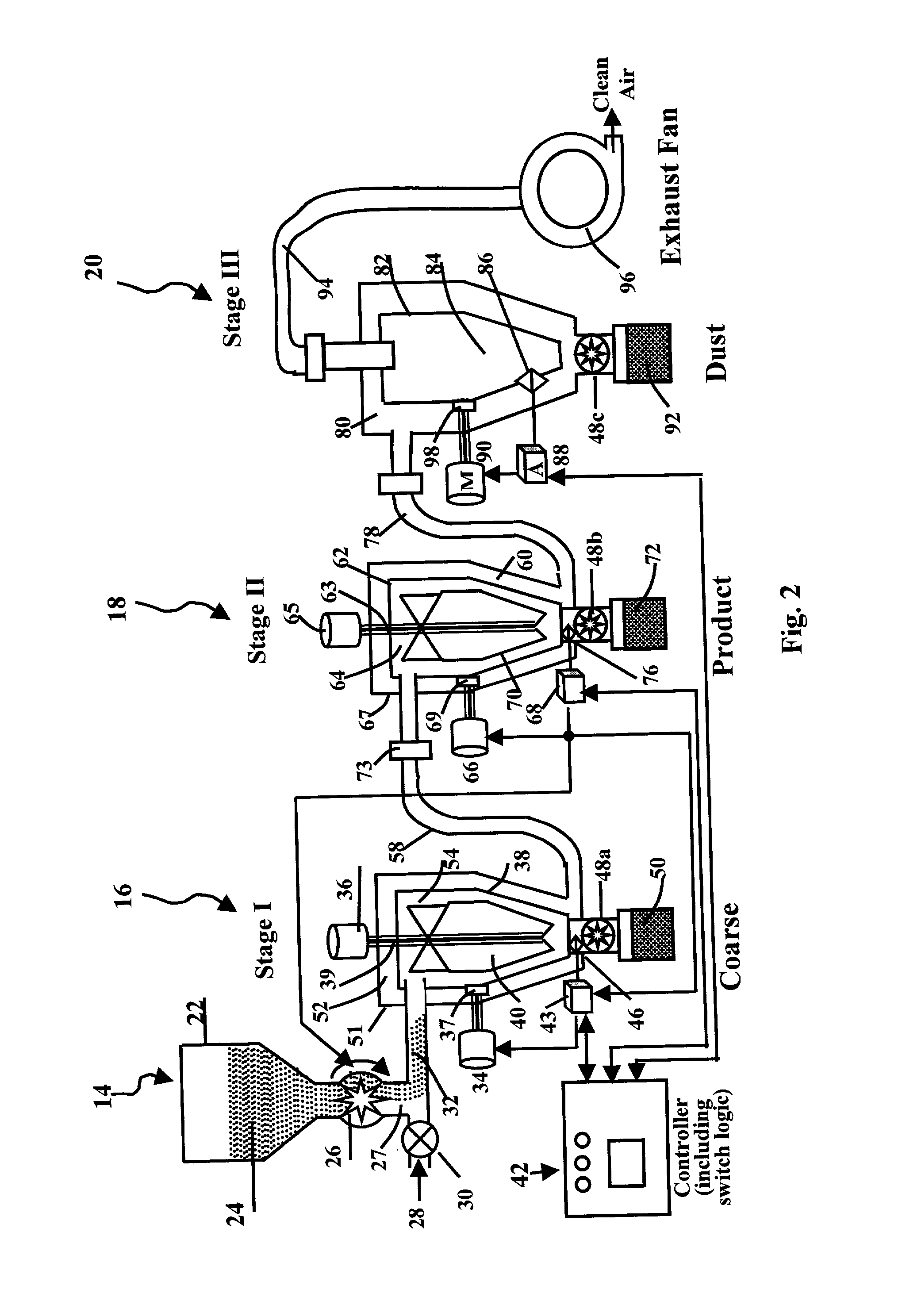

Dynamic filtration method and apparatus for separating nano powders

A method and apparatus for separating nanometer-sized particles of a powder. The method includes (a) feeding the powder particles into a pressurized gas stream which carries the particles into a first stage filter device of a multiple-stage separator system; (b) operating the first stage filter device to remove and collect coarse particles and a filter device in at least another stage to remove and collect finer particles of the powder; the filter device having a dynamic filter which is composed of (b1) a mesh of a multiplicity of openings with the opening size at least two times larger than the average size of the particles, (b2) vibration devices or shakers to shake off the particles that may otherwise clog up the mesh openings, (b3) size sensors to measure the sizes of the particles collected by the filter devices, and (b4) a controller to regulate the operations of the shakers and sensors in order to form desired dynamic mesh holes for the purpose of filtering out the coarse particles in the first stage or the finer particles in another stage; and (c) operating a dust collector to exhaust the residual gas, allowing the finest particles of the powder to be separated and collected.

Owner:NANOTEK INSTR GRP LLC

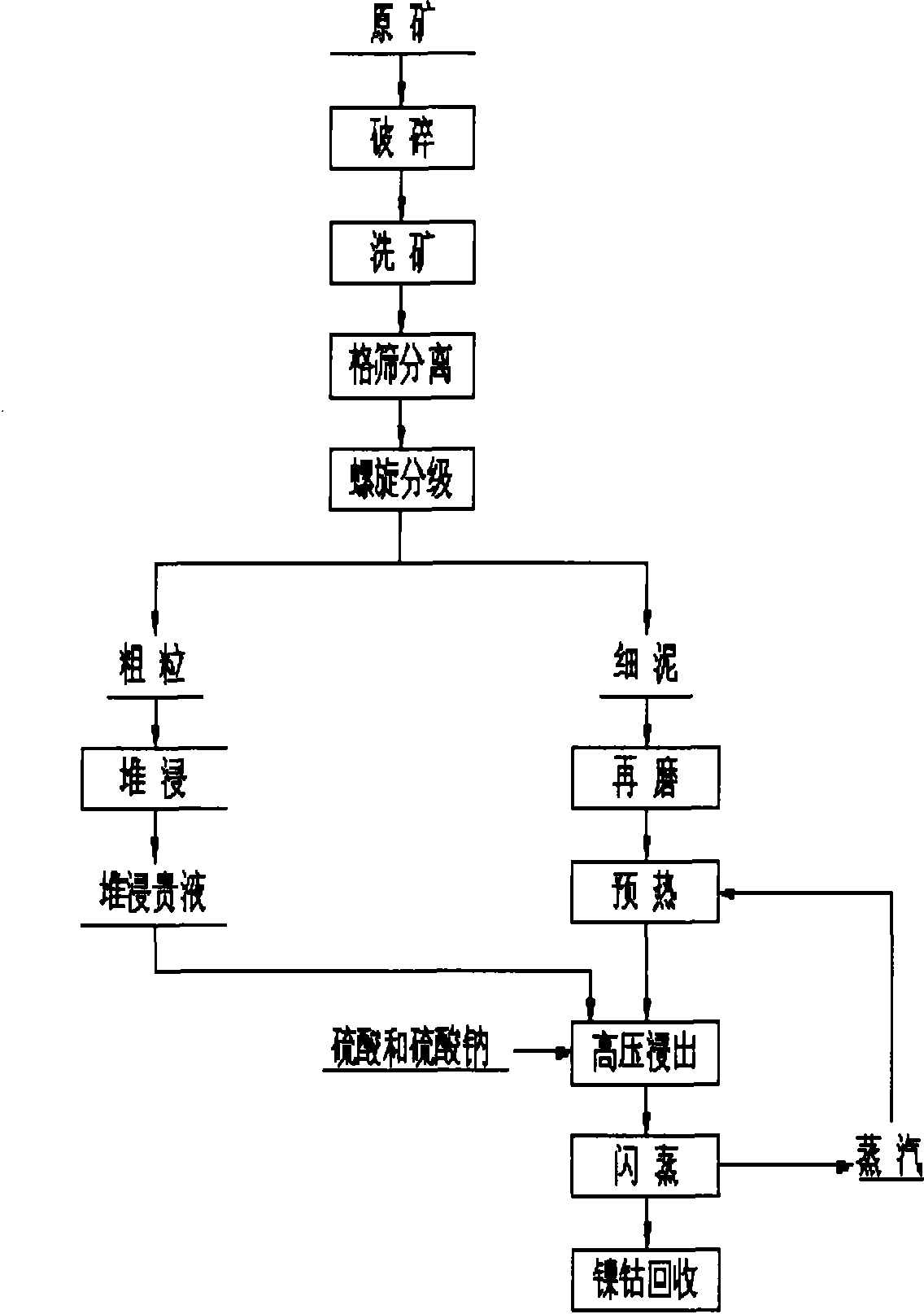

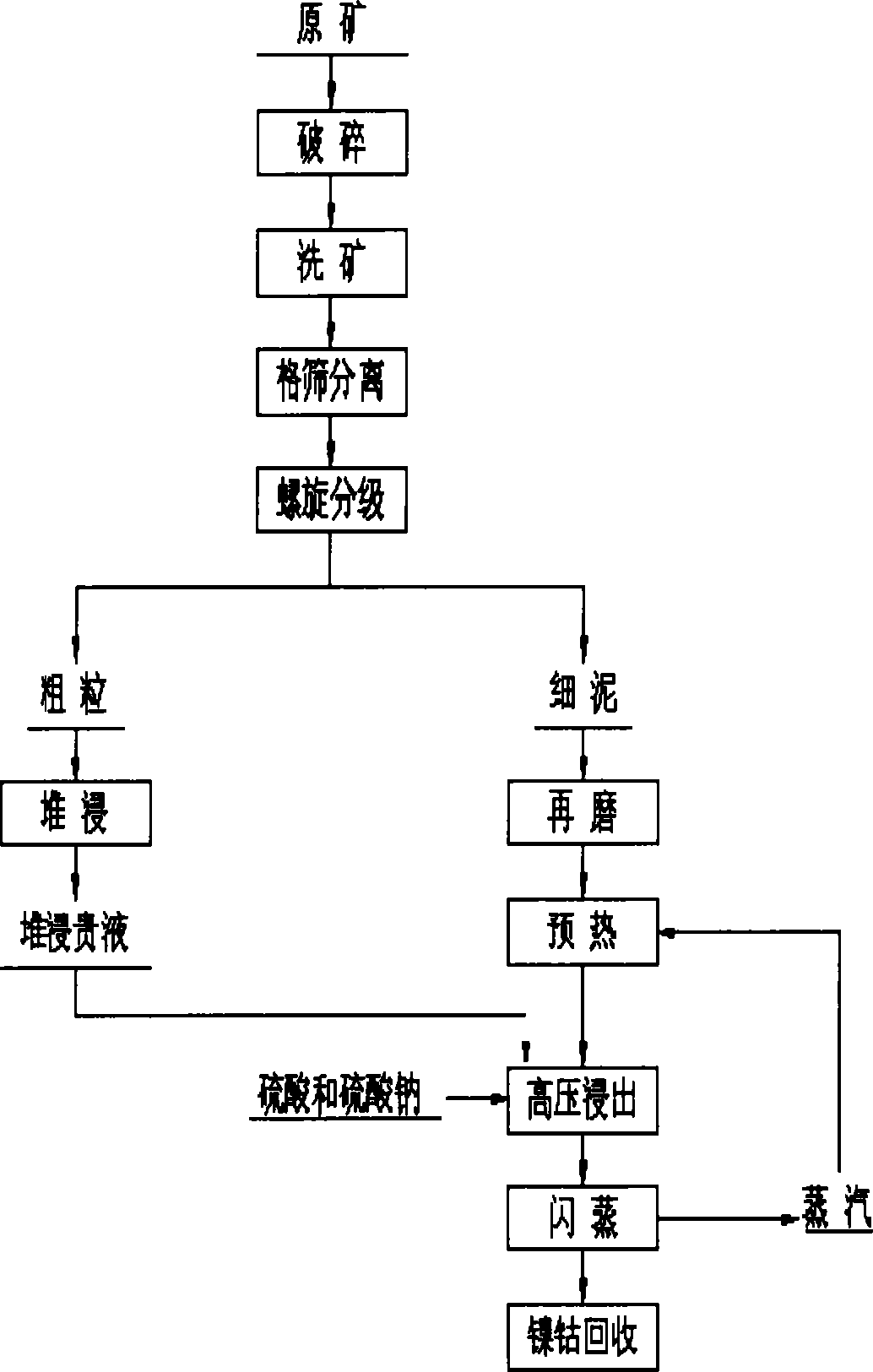

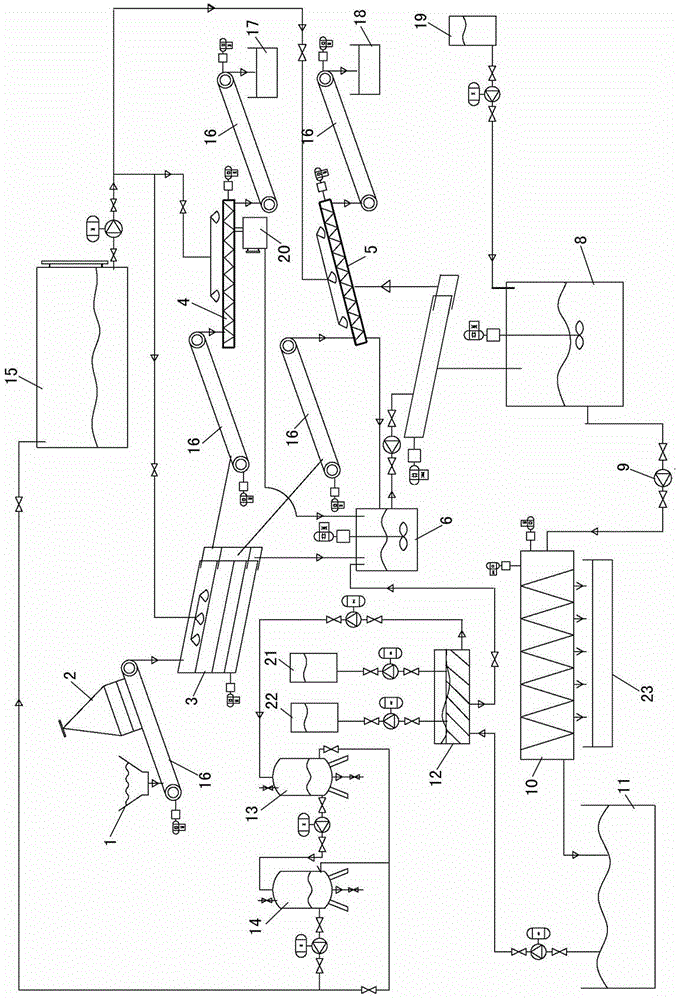

Method for reducing acid consumption during heap leaching and high-pressure leaching of nickel laterite ore

InactiveCN101768665AReduce acid consumptionReduce consumptionProcess efficiency improvementHigh pressureLaterite

The invention discloses a method for reducing acid consumption during heap leaching and high-pressure leaching of nickel laterite ore, which combines the heap leaching technology with the high-pressure leaching technology to reduce acid consumption during the treatment of nickel laterite ore; residual sulfuric acid in coarse particle immersion of limonite heap is sufficiently utilized and sodium sulfate is added during the stage of high-pressure leaching so that sulfuric acid is generated while yellow natrojarosite is formed, thereby further reducing the consumption of sulfuric acid during the stage of high-pressure leaching.

Owner:厦门紫金矿冶技术有限公司

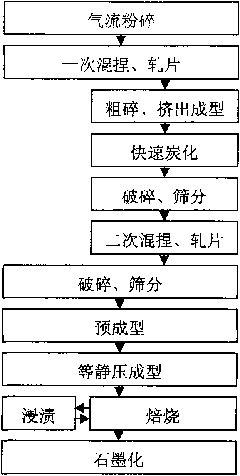

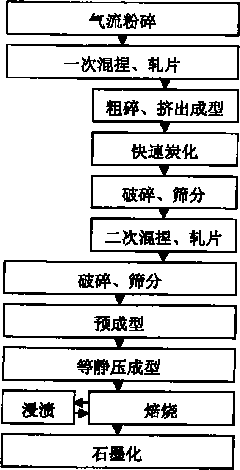

Technical method for producing isostatic pressure graphite

The invention provides a technical method for producing isostatic pressure graphite, which comprises the following steps: using refinery coke or pitch coke as raw materials; crushing raw materials to 5 to 20 mum through airflows; then, carrying out treatment through work procedures such as primary mixing squeezing and sheet milling, extrusion forming, fast carbonization, crushing, sieving, secondary mixing squeezing and sheet milling, crushing, sieving, pre-forming, isostatic pressure forming, calcination, impregnating, graphitization and the like; and obtaining fine particle isostatic pressure isotropical graphite materials. Compared with traditional coarse particle graphite materials, the invention has the characteristics of fine and compact structure, good uniformity, excellent mechanical property, isotropy and the like, and is particularly suitable for the production of large-specification graphite products.

Owner:SICHUAN GUANGHAN SHIDA CARBON +1

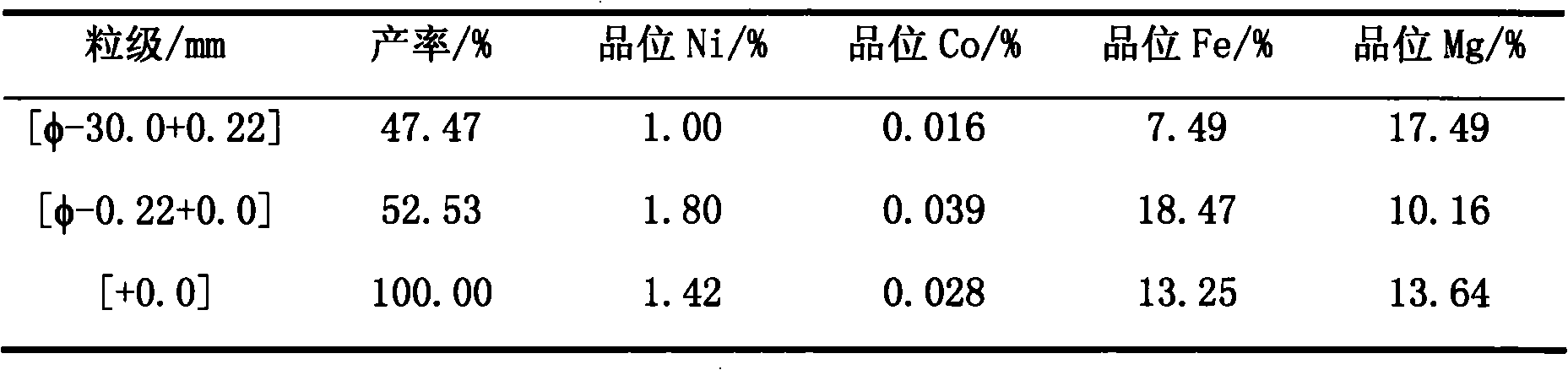

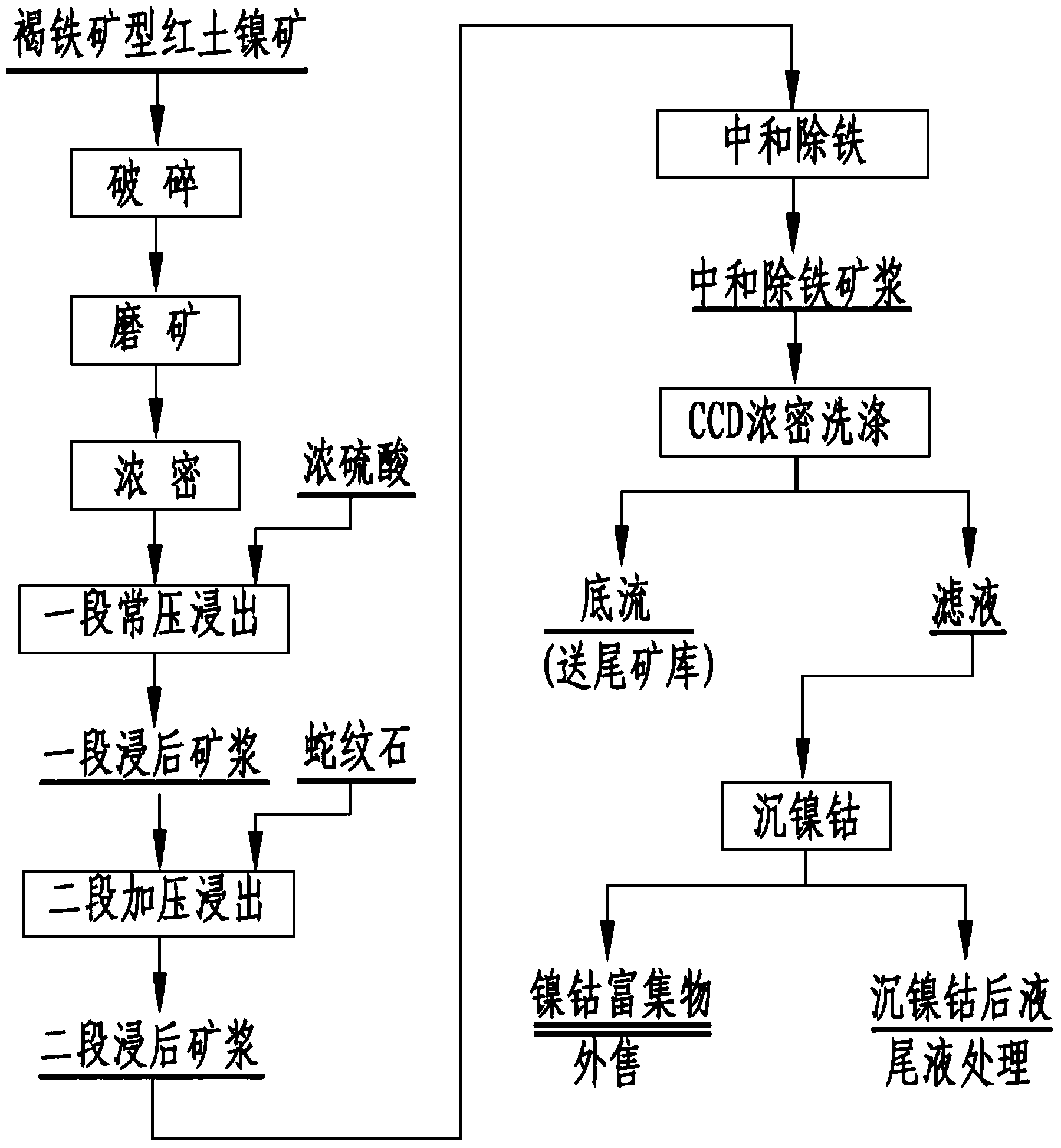

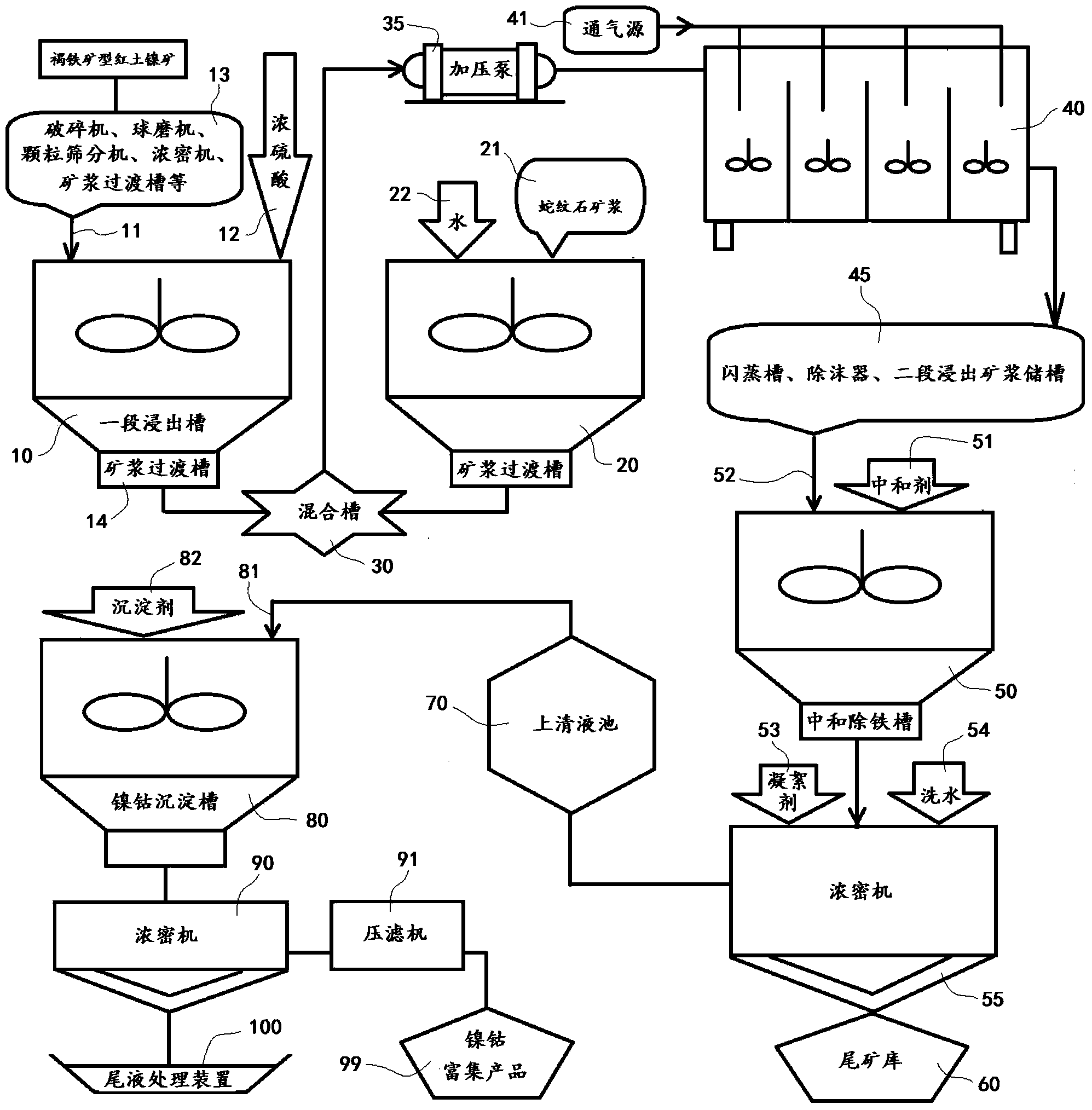

Laterite-nickel ore combination leaching process

InactiveCN103614571AWide adaptabilityImprove leaching rateProcess efficiency improvementMagmaHigh pressure

The invention relates to a laterite-nickel ore combination leaching process, which comprises that: limonite type laterite-nickel ore is subjected to crushing grading, and then is added with concentrated sulfuric acid to carry out primary stage normal pressure stirring self-heating leaching, serpentine type laterite-nickel ore is subjected to crushing grinding, the obtained serpentine type laterite-nickel ore and the primary stage leached ore magma are concurrently conveyed to a pressure kettle, and serpentine is leached by using the primary stage normal pressure leaching residual acid and the acid produced through iron precipitation in the pressure kettle, or mixing type laterite-nickel ore is subjected to grading, the obtained fine particle-grade ore is added with concentrated sulfuric acid to carry out primary stage normal pressure stirring leaching, ore on the sieve is subjected to crushing grinding, the grinded ore and the primary stage leached ore magma are concurrently conveyed to a pressure kettle, and coarse particle-grade ore leaching is performed by using the primary stage normal pressure leaching residual acid and the acid produced through iron precipitation in the pressure kettle. According to the invention, the process has characteristics of no special requirements on ore types and grades, wide raw material adaptability, investment reduction, energy consumption reduction, production cost reduction, and simple process, wherein the Ni recovery rate and the Co recovery rate of the whole process of the present invention are respectively more than 90% and 88%, and are higher than the Ni recovery rate and the Co recovery rate of the treatment method in the existing non-high-pressure acid leaching technology.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Soil washing restoration system based on reduction concentration design concept and method thereof

ActiveCN104475441AShort stayImprove production efficiencyContaminated soil reclamationSoil washingCompound (substance)

The invention discloses a soil washing restoration system based on a reduction concentration design concept and a method thereof. The washing restoration system comprises the following four module units which are sequentially connected with one another: a feeding and screening unit, an ore washing unit, a sludge dewatering unit and a tail-end sewage treatment recycling unit. The pollutants on the surface of coarse particles are eluted, transferred and concentrated into the filter-pressed mud cake by virtue of washing, so that pollutant-containing fine particles in contaminated soil can be effectively separated from crude particles such as gravel and grit. The repaired and discharged clean gravel and grit can be directly recycled to serve as building material. According to the system, purified water serves as a washing solution, so that secondary pollution caused by addition of a chemical washing agent is avoided, and the washing solution is treated by a tail-end sewage treatment system so as to be recycled. The reduction of remediation of contaminated soil is realized, the comprehensive repair cost is greatly reduced, the washed and discharged materials can be recycled, the contaminated soil is repaired, and a novel profit point is created.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

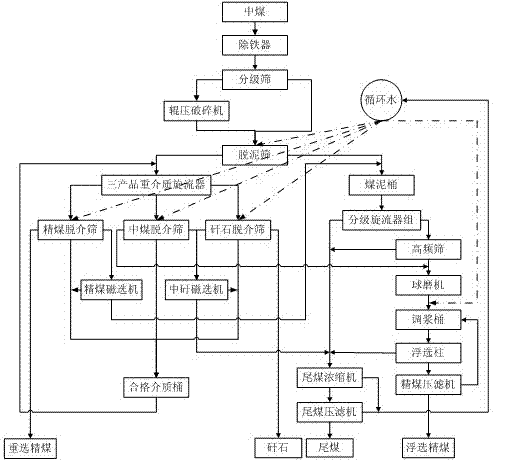

Breaking grinding dissociation and re-flotation two-stage recovery process of coal in scarce coking

A breaking grinding dissociation and re-flotation two-stage recovery process of coal in scarce coking belongs to a coal breaking dissociation flotation process. (1) coal products in a coal preparation plant serve as raw materials, and the coal which is larger than 6mm is rolled and broke into size smaller than 6mm; (2) a desliming screen is used for desliming on middings smaller than 6mm, middings which is 6-0.5mm enters a three-product dense medium cyclone, and dense medium, middings and gangue are obtained after two-stage medium separation is carried out; (3) the middings smaller than 0.5mm is mixed with clean coal magnetic separation gangue, a grading hydrocyclones group is adopted to conduct high frequency screening to obtain high ash fine silt contained slurry water, and coarse particle are mixed with middings on the midding sculping screen to enter a ball mill for wet grinding; and (4) products after grinding enter a flotation column to conduct flotation, foam clean coal and tailing are respectively concentrated, filtered and dewatered to obtain flotation clean coal and tailing products. The breaking grinding dissociation and re-flotation two-stage recovery process has the advantages that the high ash fine silt in fine fraction is pre-selected, pollution of the high ash fine silt is reduced, equipment separation particle size range is reduced, separation accuracy of equipment is improved, and scarce coking coal resources are recovered as far as possible.

Owner:CHINA UNIV OF MINING & TECH

Method for sizing of water-absorbent resin

ActiveUS7347330B2Large dispersionInhibit productionOther chemical processesEmulsion paintsCross-linkPolyresin

A method for sizing a surface cross-linked water-absorbent resin removed coarse particles and fine powder is provided. Sized resin particles are obtained by classifying water-absorbent resin particles to remove an aggregates and fine powder in the particles, disintegrating the obtained aggregates and classifying the products of the disintegration to remove coarse particles and fine powder contained in the products.

Owner:NIPPON SHOKUBAI CO LTD

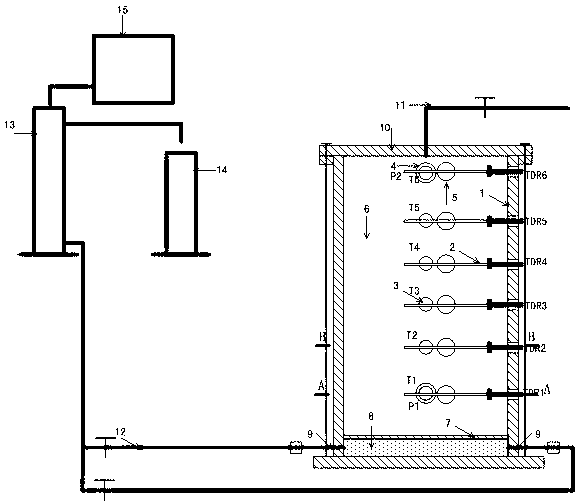

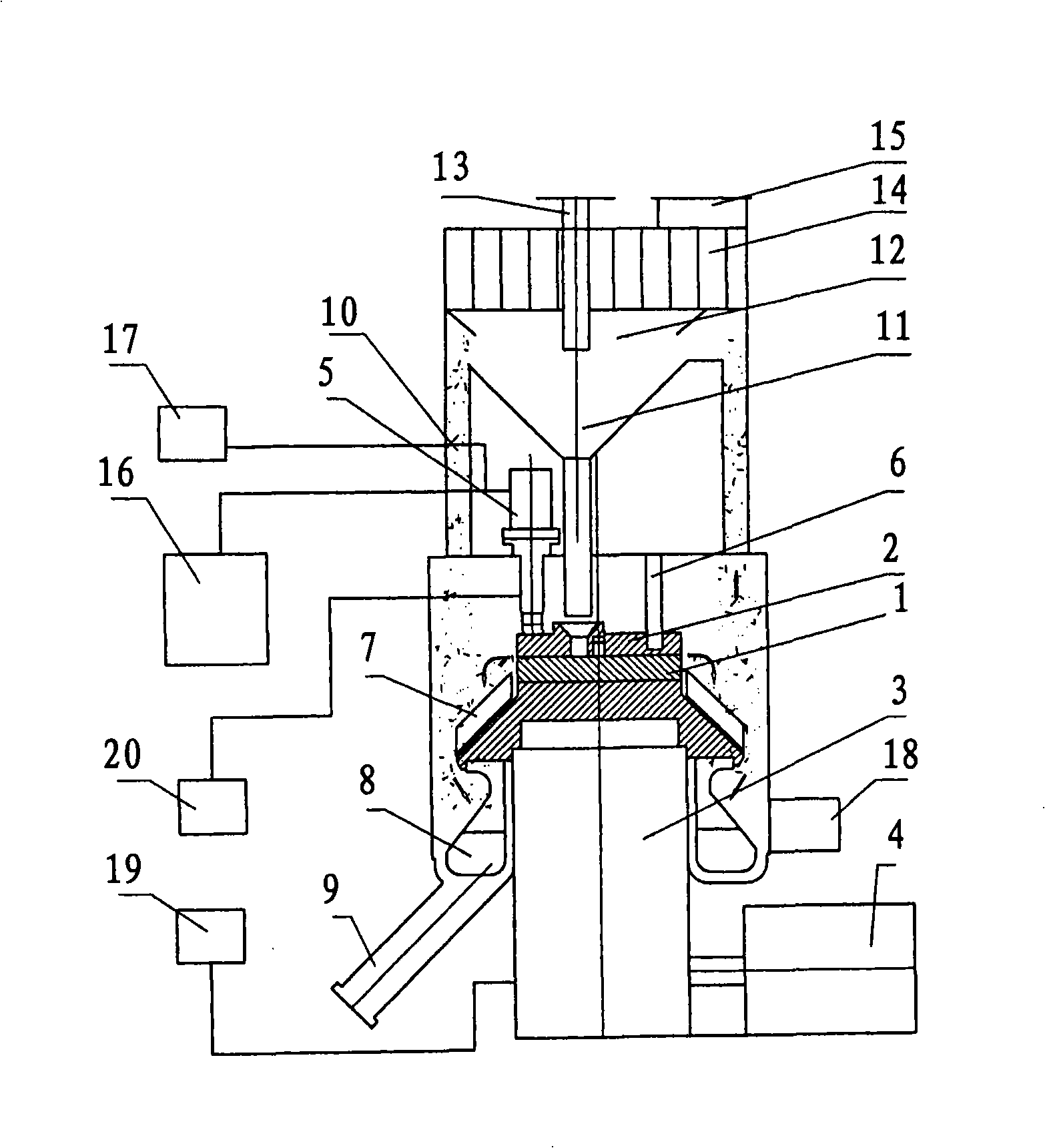

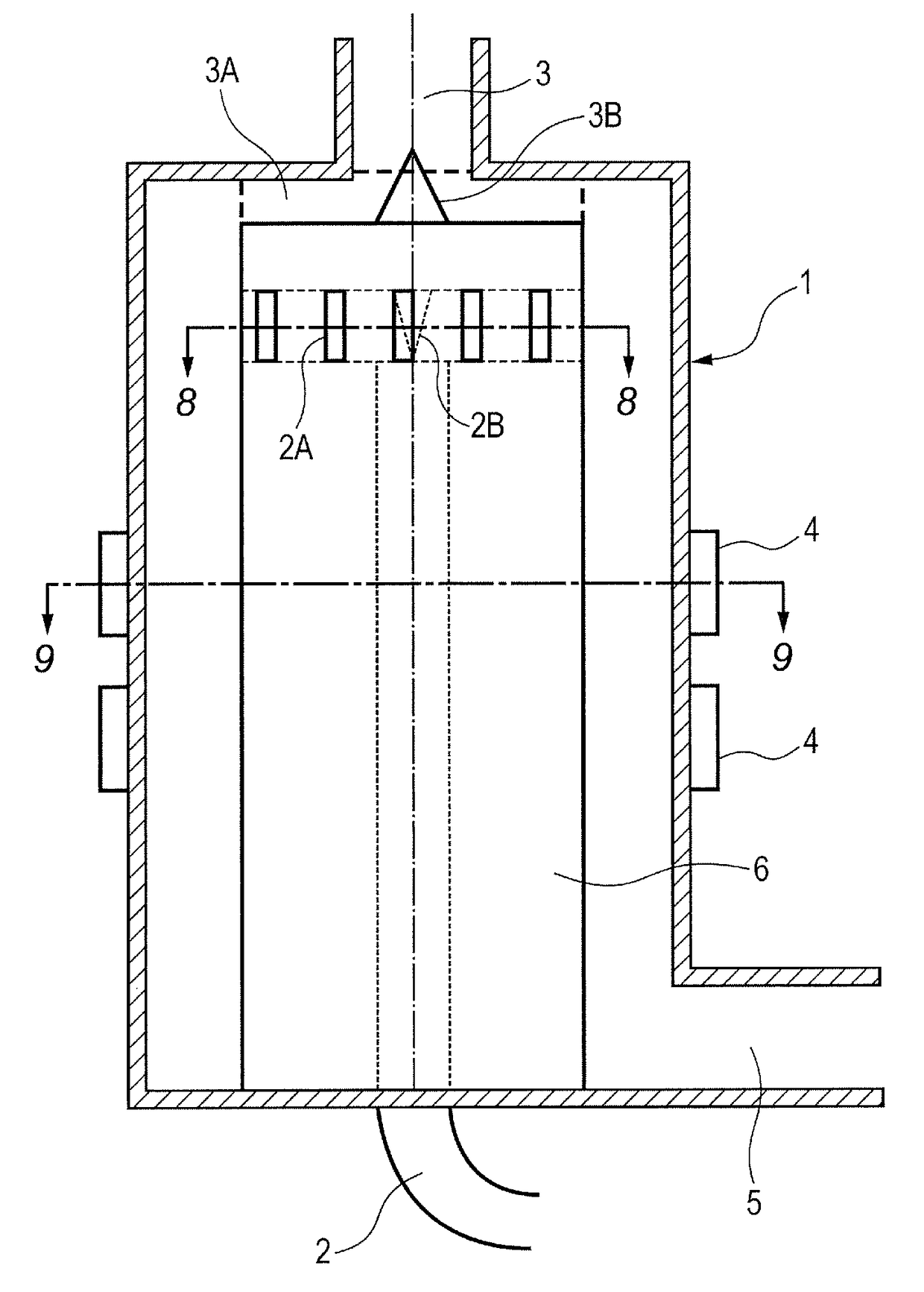

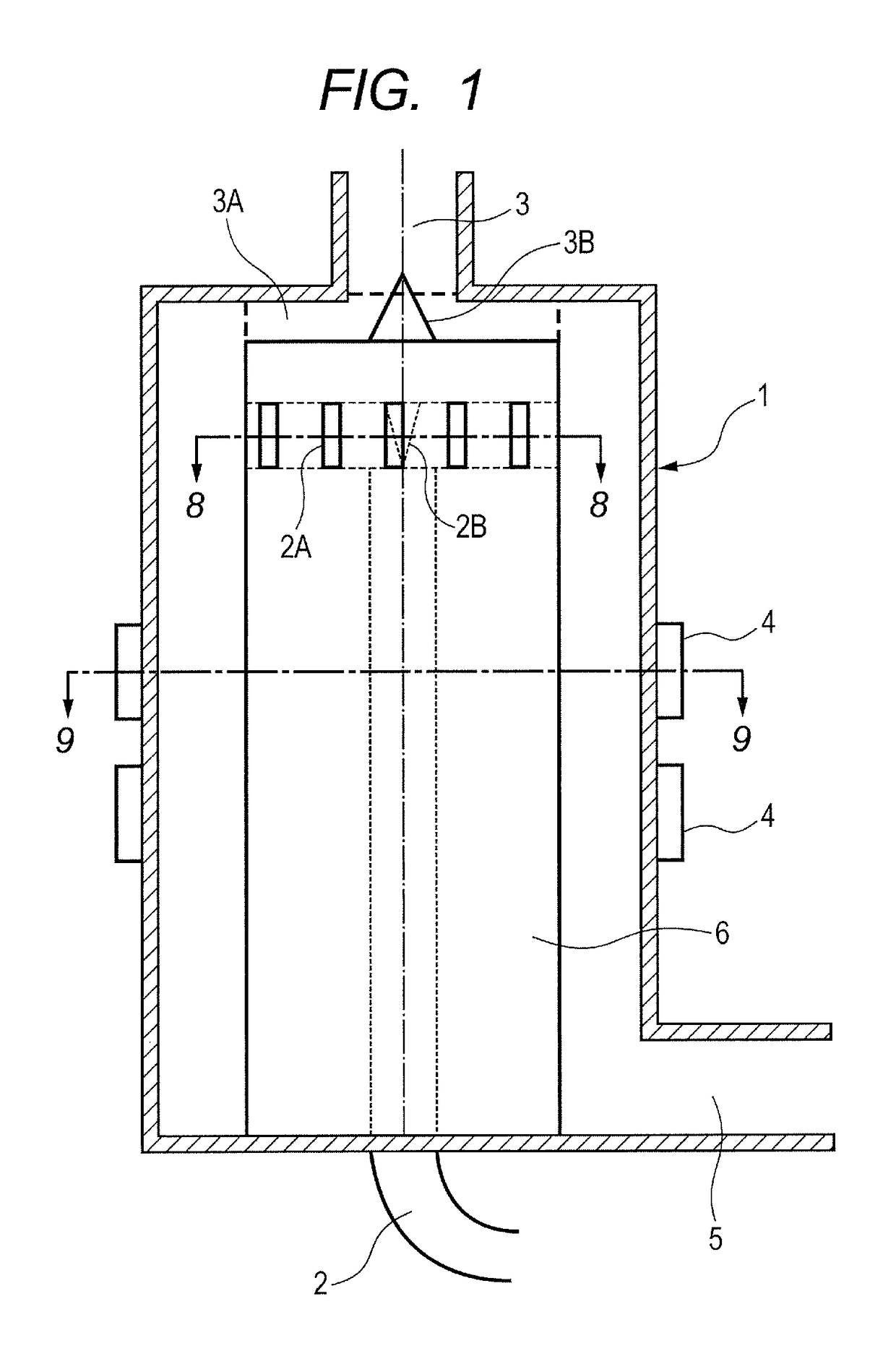

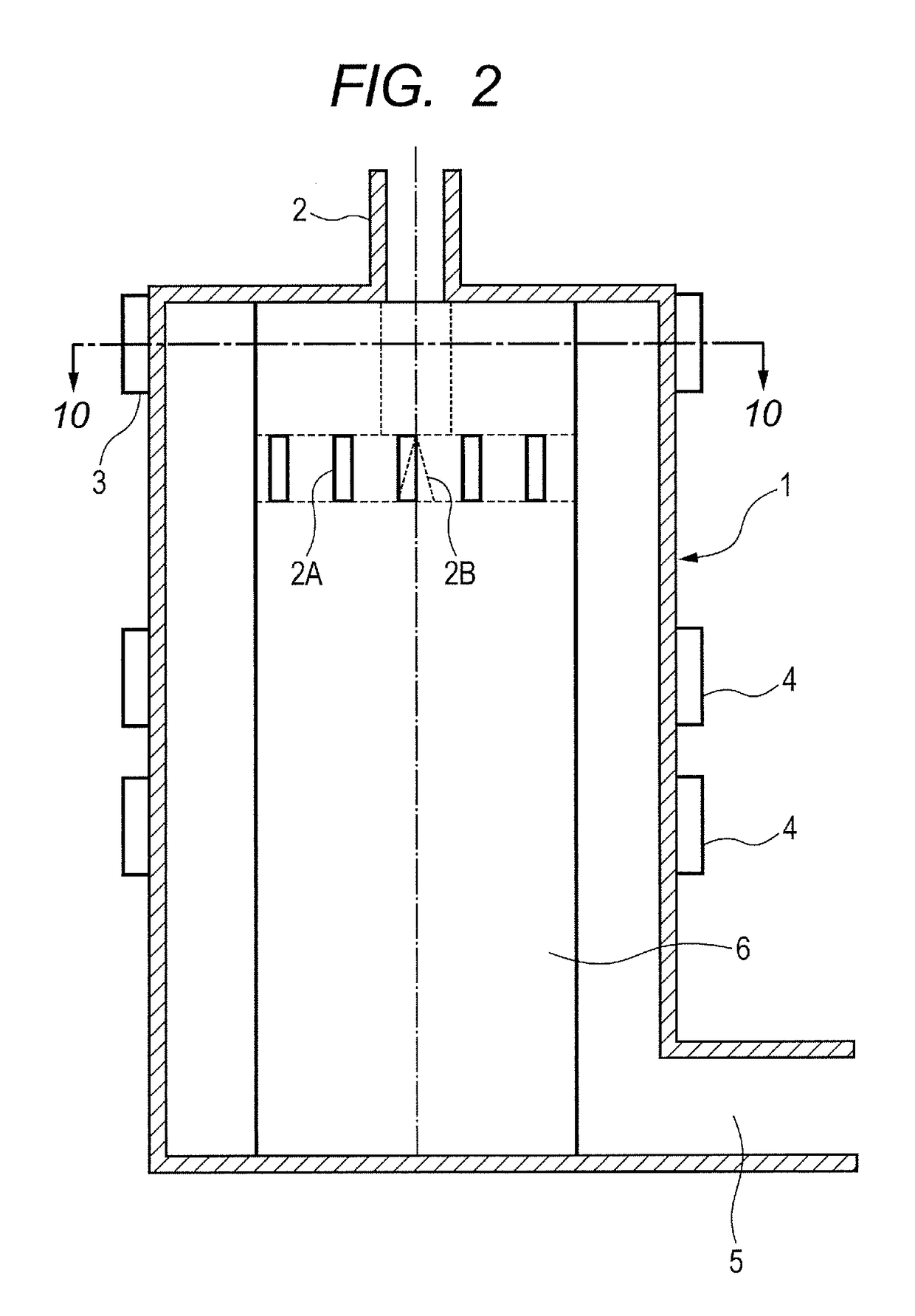

Device for testing characteristic curves and permeability coefficients of unsaturated coarse particle soil and water

InactiveCN103308435AEarth material testingPermeability/surface area analysisWater storageSoil science

The invention discloses a device for testing characteristic curves and permeability coefficients of unsaturated coarse particle soil and water. A reversed filter is arranged at the bottom of a cylindrical rigid permeation column; six layers of compacted soil samples are arranged at the upper part of the reversed filter; a TDR (test data report) sensor, a tensiometer or a humidometer are buried at the same height on the same layer; pore pressure gauges are buried in the first layer and the sixth layer; the TDR sensor, and the tensiometer or the humidometer form 90 degrees; each pore pressure gauges and the tensiometer or the humidometer form 90 degrees; a waterhead stabilizer is externally connected with a water storage container and a water tank for providing a reference liquid level; the waterhead stabilizer is accessed into the reversed filter via a drainage valve; a top plate of the cylindrical rigid permeation column is connected with the drainage valve. Saturated ermeability coefficients of coarse particles can be obtained through the pore pressure gauges and the waterhead stabilizer after the sample is saturated; the change processes of of matric suctions and moisture contents of a soil body in each layer at different moments along with the time can be obtained through the corresponding tensiometer or the corresponding humidometer and the corresponding TDR sensor at the saturation, drainage and evaporation stages at the same time. Thus, mechanical parameters of the unsaturated coarse particle soil and water are obtained.

Owner:ZHEJIANG UNIV

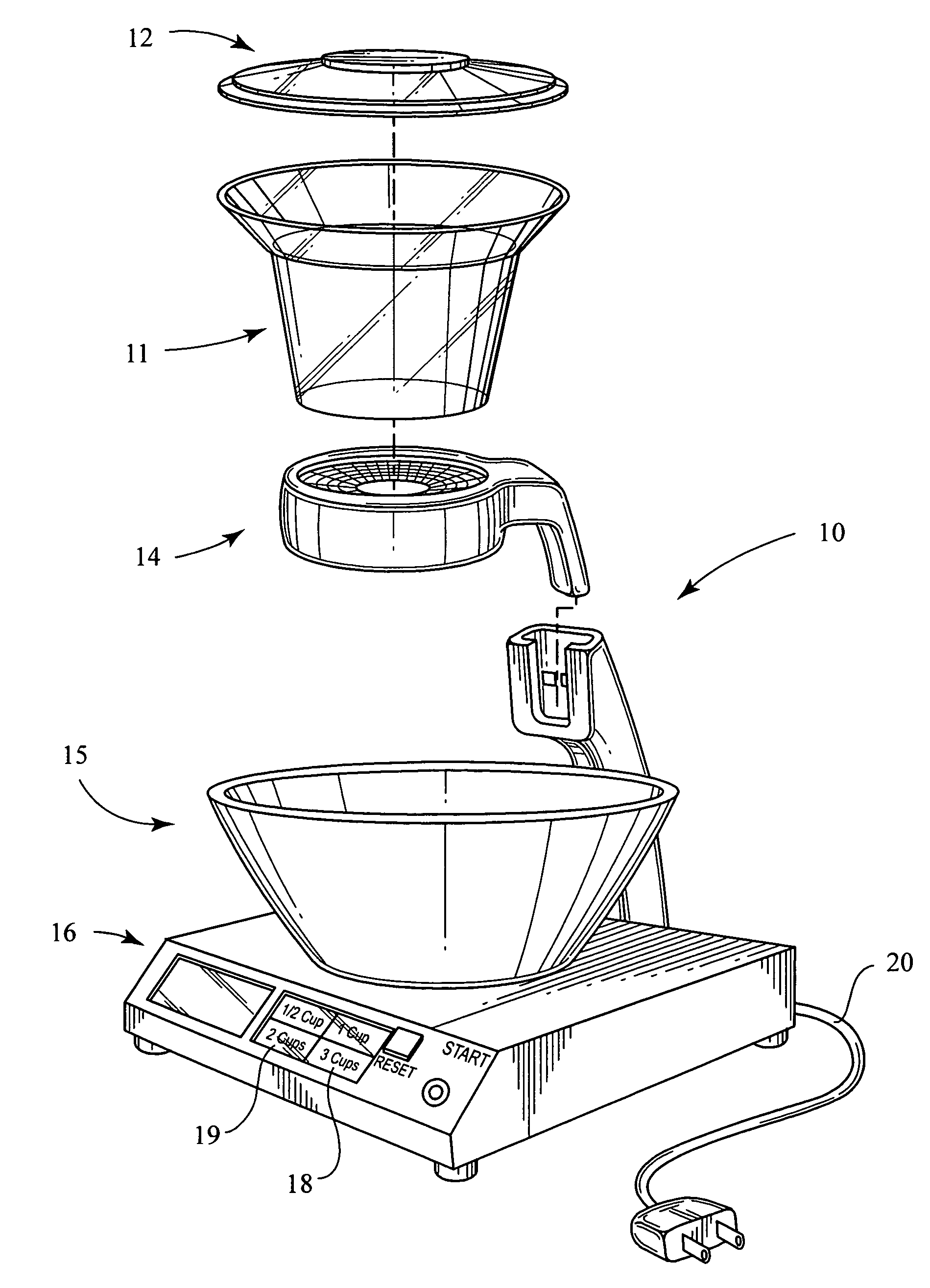

System and method for separation of food particles

A system and method for separating food particles is disclosed here. The system may include means for receiving food particles to be separated, means for screening the food particles into fine and coarse particles, means for controlling the amount of output fine particles, and means for delivering the output for further processing. The method may include receiving food particles to be separated, mechanically screening the food particles into fine and coarse particles, controlling the amount of the fine particles output, and delivering the fine output for further processing.

Owner:FREEMAN RHONDA

Composite materials having a low shrinkage force

ActiveUS7601767B2Reduce riskReducing the maximum force of the shrinkage stressCosmetic preparationsImpression capsTO-18UDMA

For composite materials having a total filler content of 80 to 95% by weight, containingA) 0.5 to 10% by weight of non-agglomerated nanofillers having particle sizes of 1 to 50 nm in the filler component,B) at least 60% by weight of a filler mixture of 50 to 90% coarse-particle and 10 to 50% fine-particle dental glass in the filler component, having a size ratio, relative to the average particle size (d50 value), of coarse to fine particles of >1:4 to 1:30,C) as monomer component, a monomer mixture ofi. 60 to 80% bis-GMA or TCD-di-HEMA or TCD-di-HEA,ii. 10 to 18% UDMA,iii. Residual TEDMA and / or multifunctional crosslinkers,D) up to 1% photoinitiator(s); andE) optionally, at least one additional dental glass in the filler component having a different particle size than the coarse- and fine-particle dental glass,the polymerization shrinkage may be reduced to <1.6% by volume (measured according to the bonded disk method; Dental Materials (2004) 20, 88-95), andthe shrinkage force (measured according to the photoelastic method; Dental Materials (2004) 20, 313-321) may be reduced to <3.5 MPa (measured 24 hours after polymerization).

Owner:HERAEUS KULZER GMBH

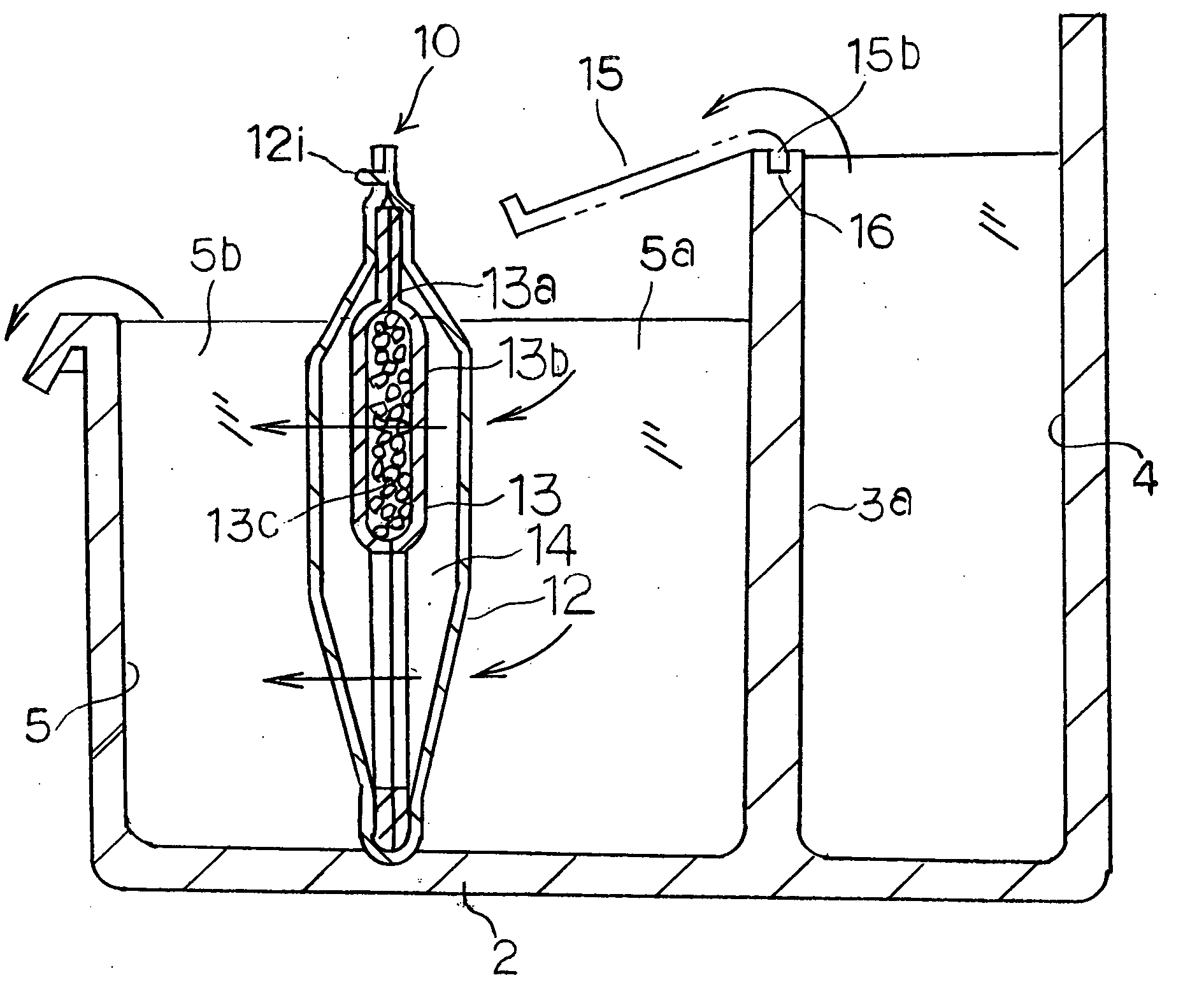

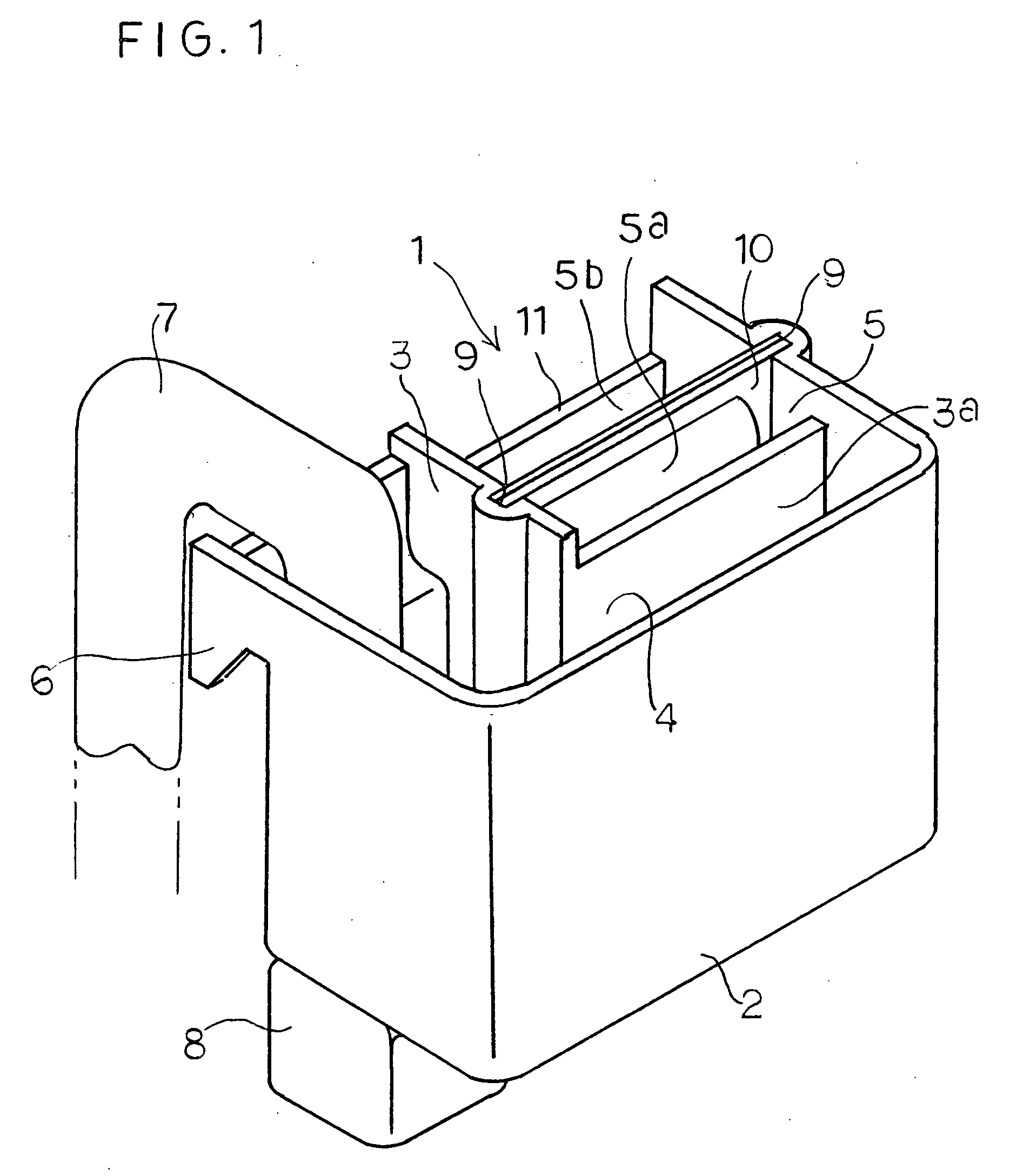

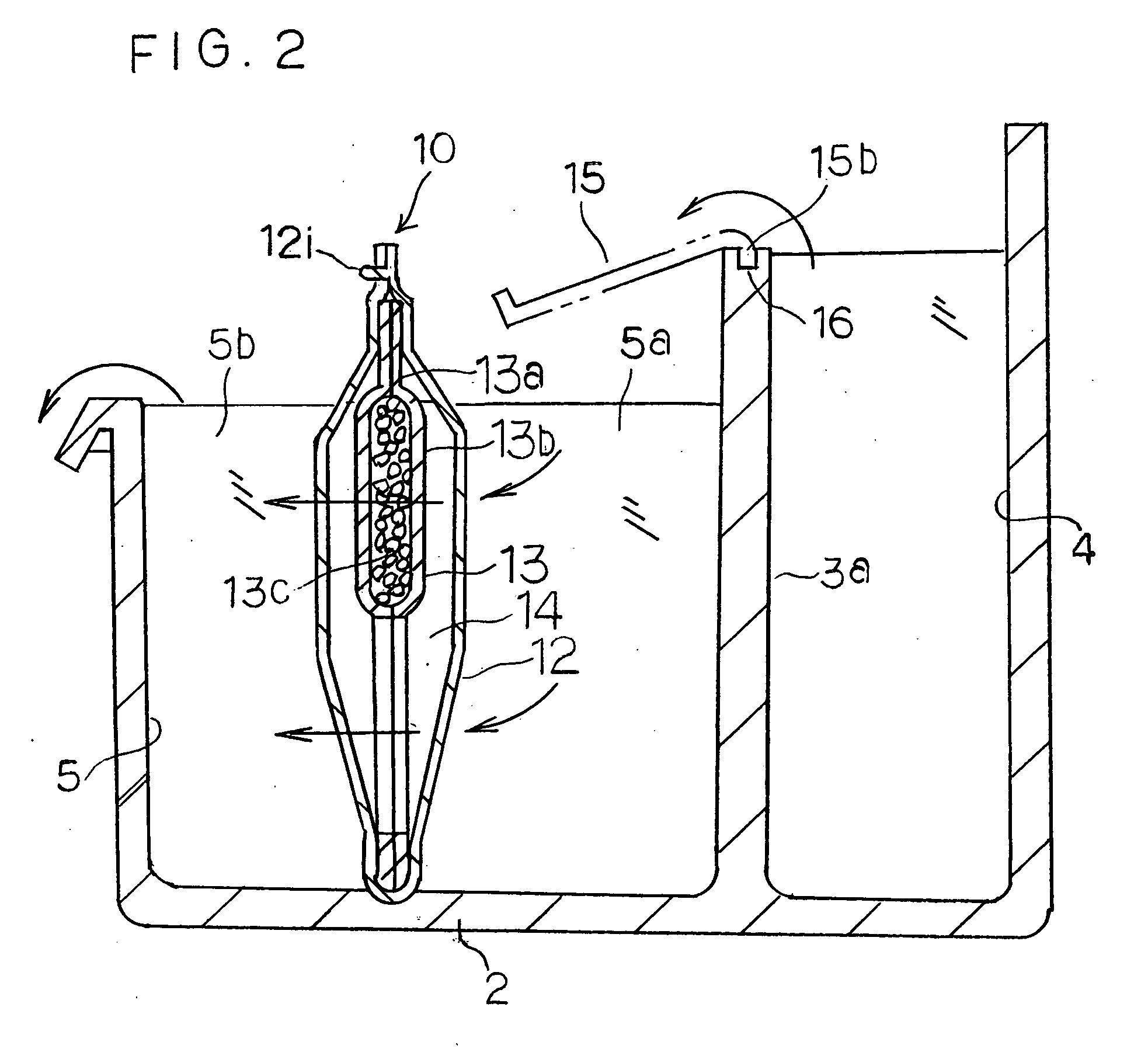

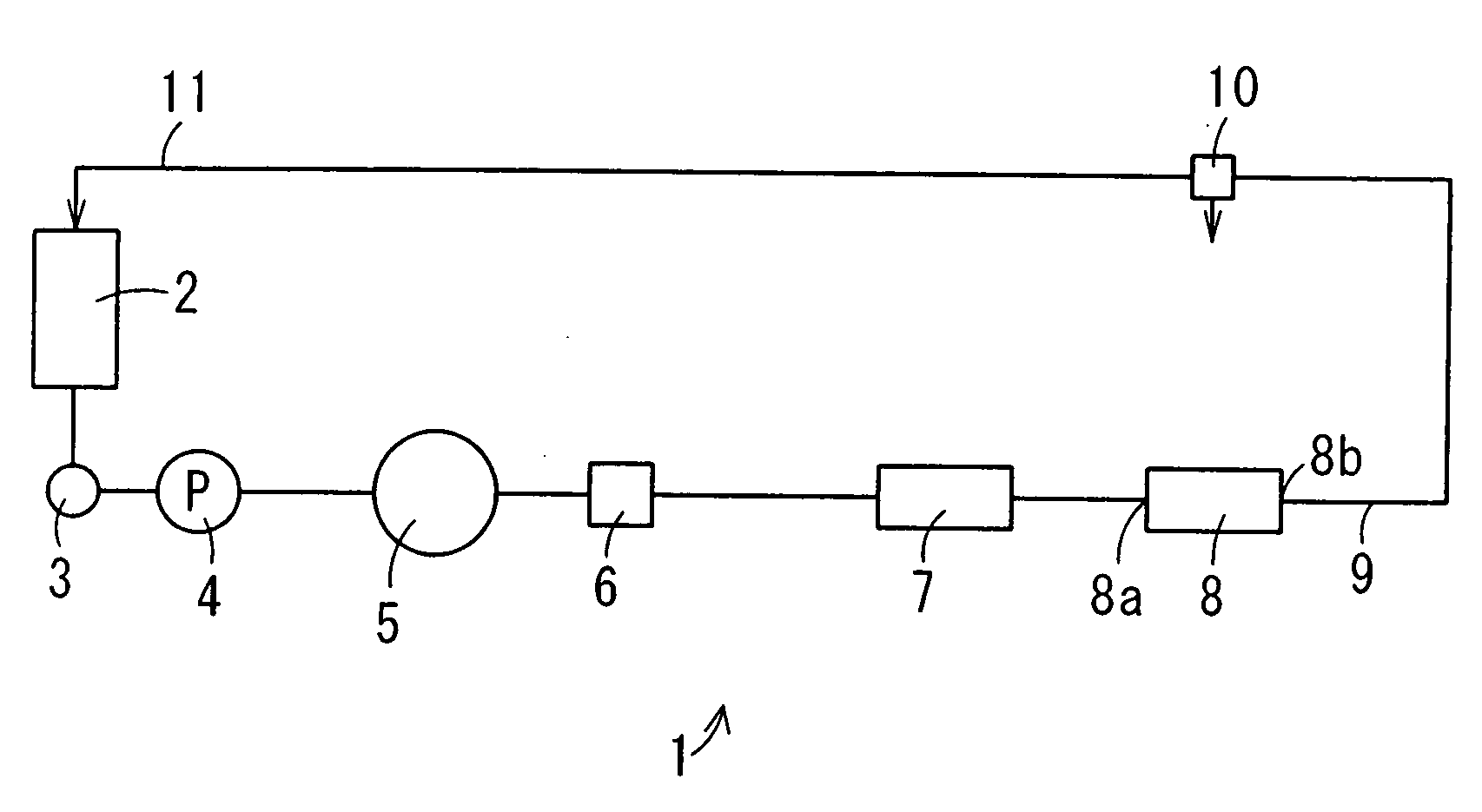

Water tank filter and purifier

InactiveUS20040222137A1Removed satisfactorilyEasy to floatPisciculture and aquariaLoose filtering material filtersInterior spaceEngineering

A water tank filter having a double structure including an inner filter having a small pore size for trapping fine particles of filth from tank water and situated within a hollow outer filter having a large pore size for trapping coarse particles of filth. The inner filter is situated in roughly the upper half of the internal space of the outer filter. Disclosed also is a water tank purifier including the water tank filter. The water tank filter and purifier can effectively remove both coarse and fine particles of filth from a water tank. The filter does not quickly get clogged, and is easy to handle.

Owner:YUGEN KAISHA HOUSEKI NO ANGEL

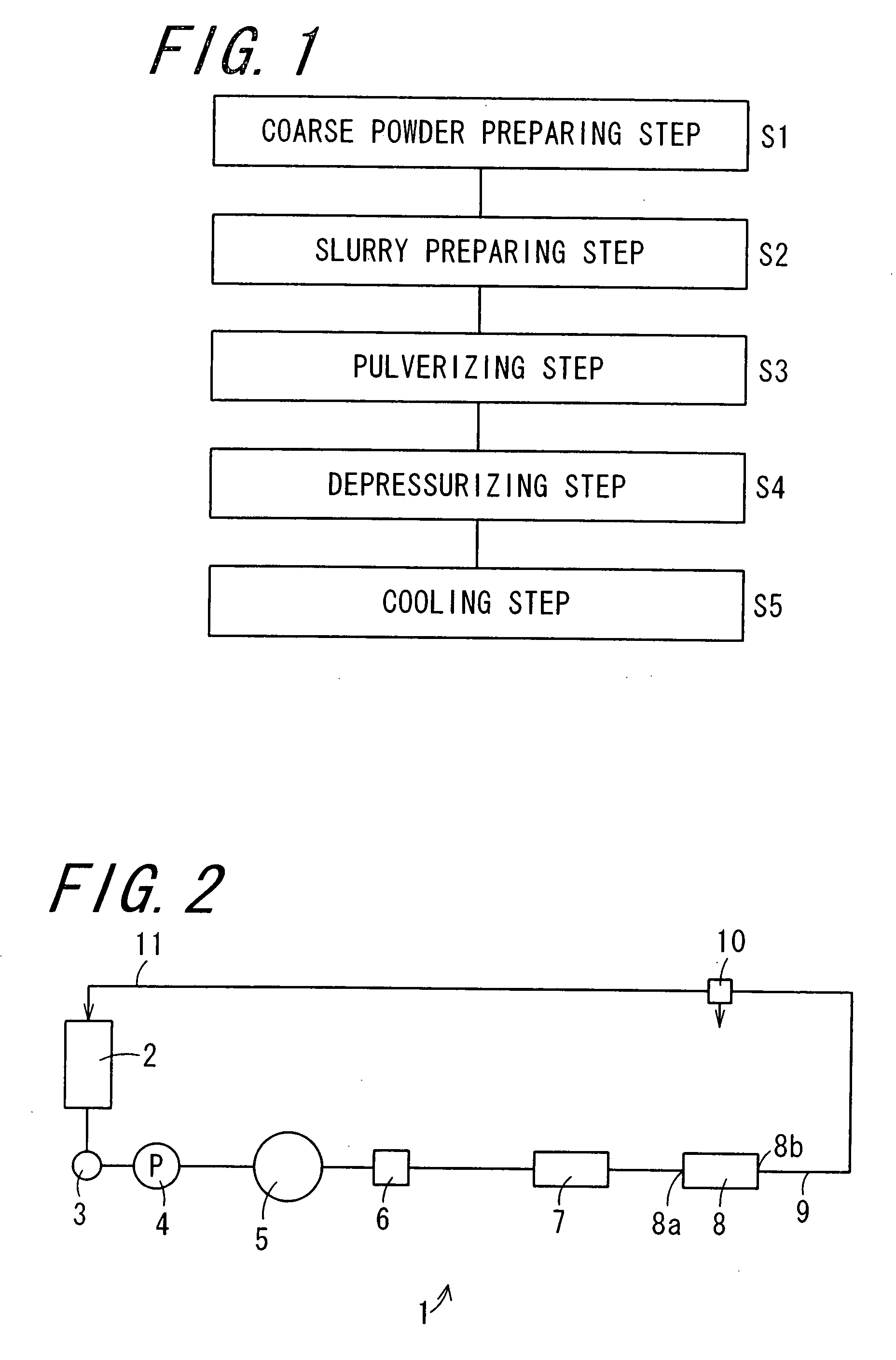

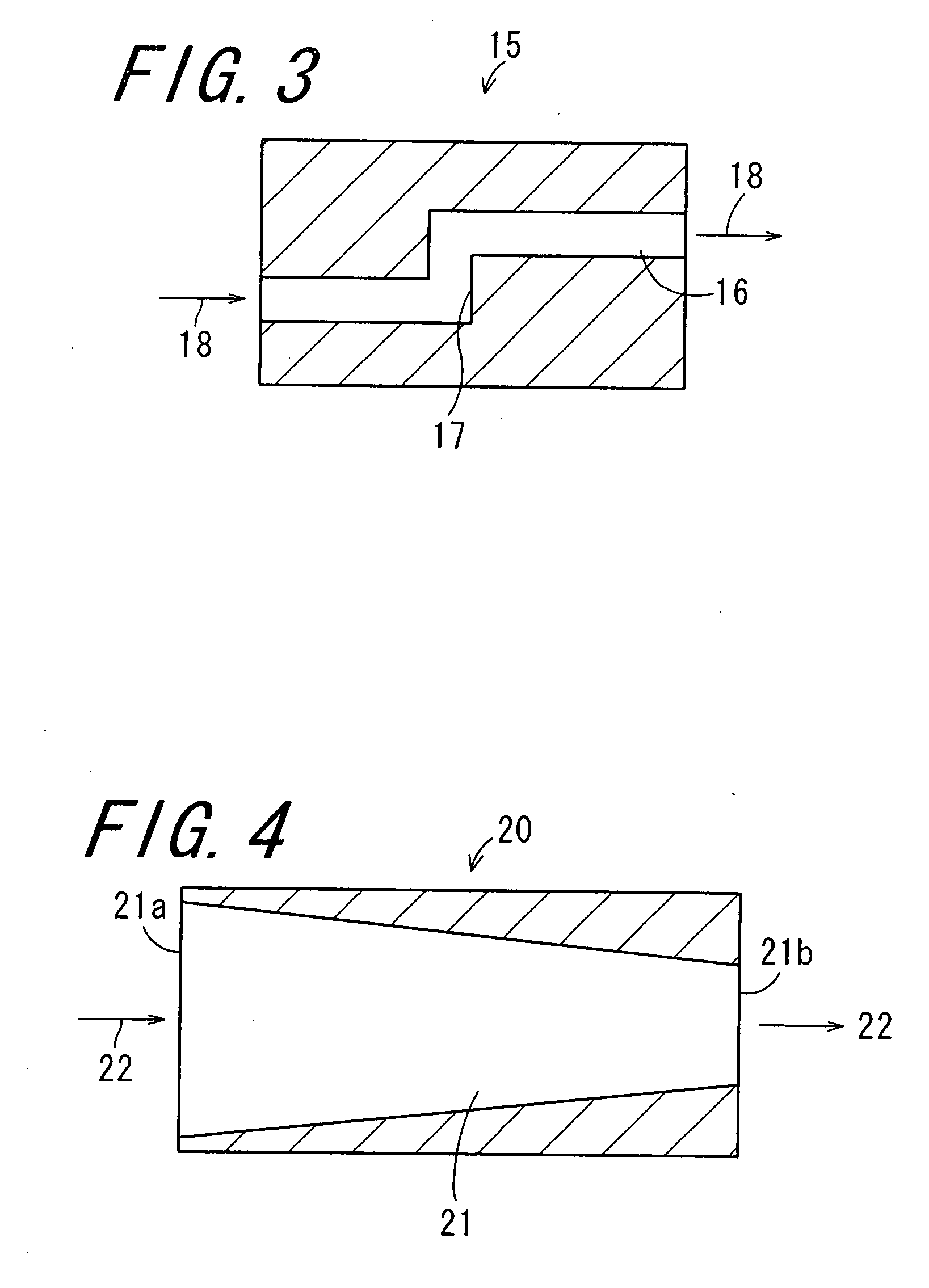

Functional particle and manufacturing method thereof

A functional particle is manufactured by a method including an aggregating step, a depressurizing step, and a cooling step. In the aggregating step, the functional particle is obtained by flowing a mixed slurry containing a core particle and a shell particle through a coiled pipeline while heating the mixed slurry to a glass transition temperature or higher of the core particle, to deposit the shell particles on the surface of the core particle. In the depressurizing step, the grain size of the functional particle is controlled and the coarse particle is pulverized to make the grain size of the functional particles uniform. In the cooling step, re-aggregation of the functional particles with unified grain size is prevented.

Owner:SHARP KK

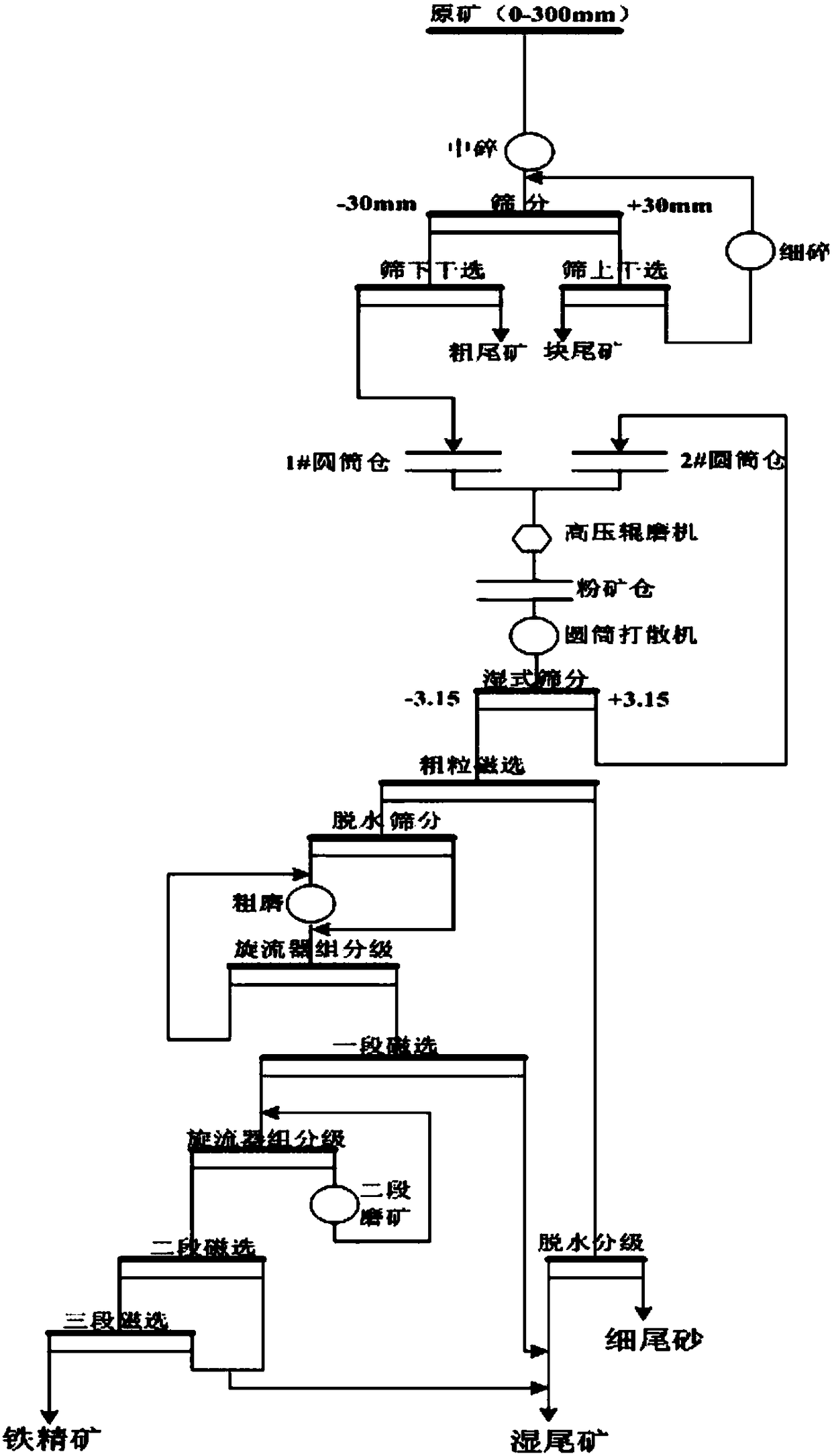

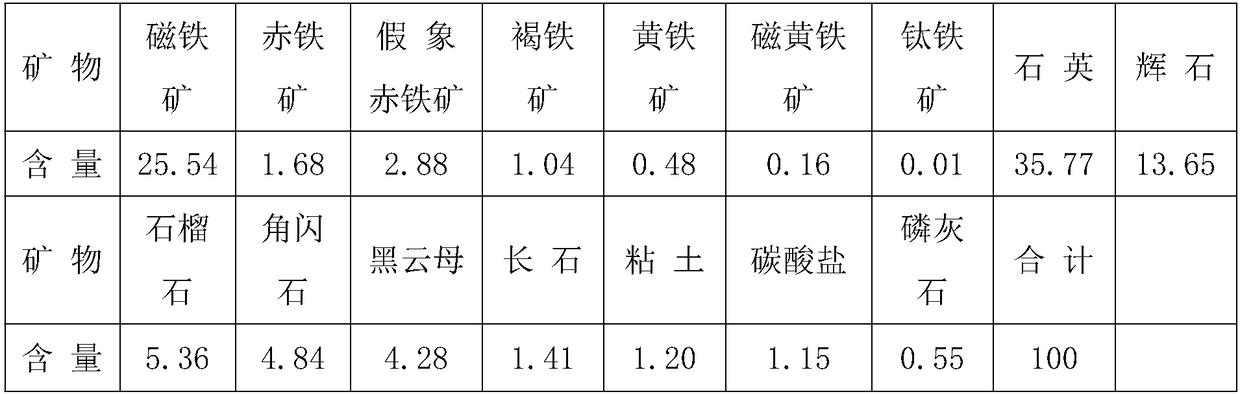

Iron improvement and silicon reduction beneficiation method of high ferrosilite and lean magnet iron ore

ActiveCN108246490AEasy to transportReasonable layoutMagnetic separationWet separationHigh pressureMaterials science

The invention discloses an iron improvement and silicon reduction beneficiation method of high ferrosilite and lean magnet iron ore, the method comprises the following processes of crushing-screening,fine crushing, dry-type preconcentration tailings discardinghigh-pressure roller milling, coarse particle magnetic separation, and coarse particle magnetic separation concentrate rough grinding-low intensity magnetic separation, wherein coarse crushing is arranged underground, medium and fine crushing are arranged on the ground, the placement is reasonable and orderly, reducing of occupied spaceis facilitated, and transporting and lifting of ore from the downhole is convenient. The dry-type preconcentration tailings discarding is carried out on sieve residue and through product after intermediate crushing and fine crushing, mixed barren rock is thrown out, throwing out is carried out and rough gangue and block gangue used as building products are recovered in advance, the iron grade of follow-up separating operations is recovered and improved, the ore content given to the follow-up operations is greatly reduced, " receiving early and losing early" is realized. The feeding grain sizeof high-pressure roller milling is up to 30mm, a precedent is broken, characteristics of low energy consumption and high processing capacity of a high-pressure roller milling machine is fully played,a product stock heap is not arranged in design, and occupied space and dust pollution are reduced.

Owner:安徽马钢张庄矿业有限责任公司

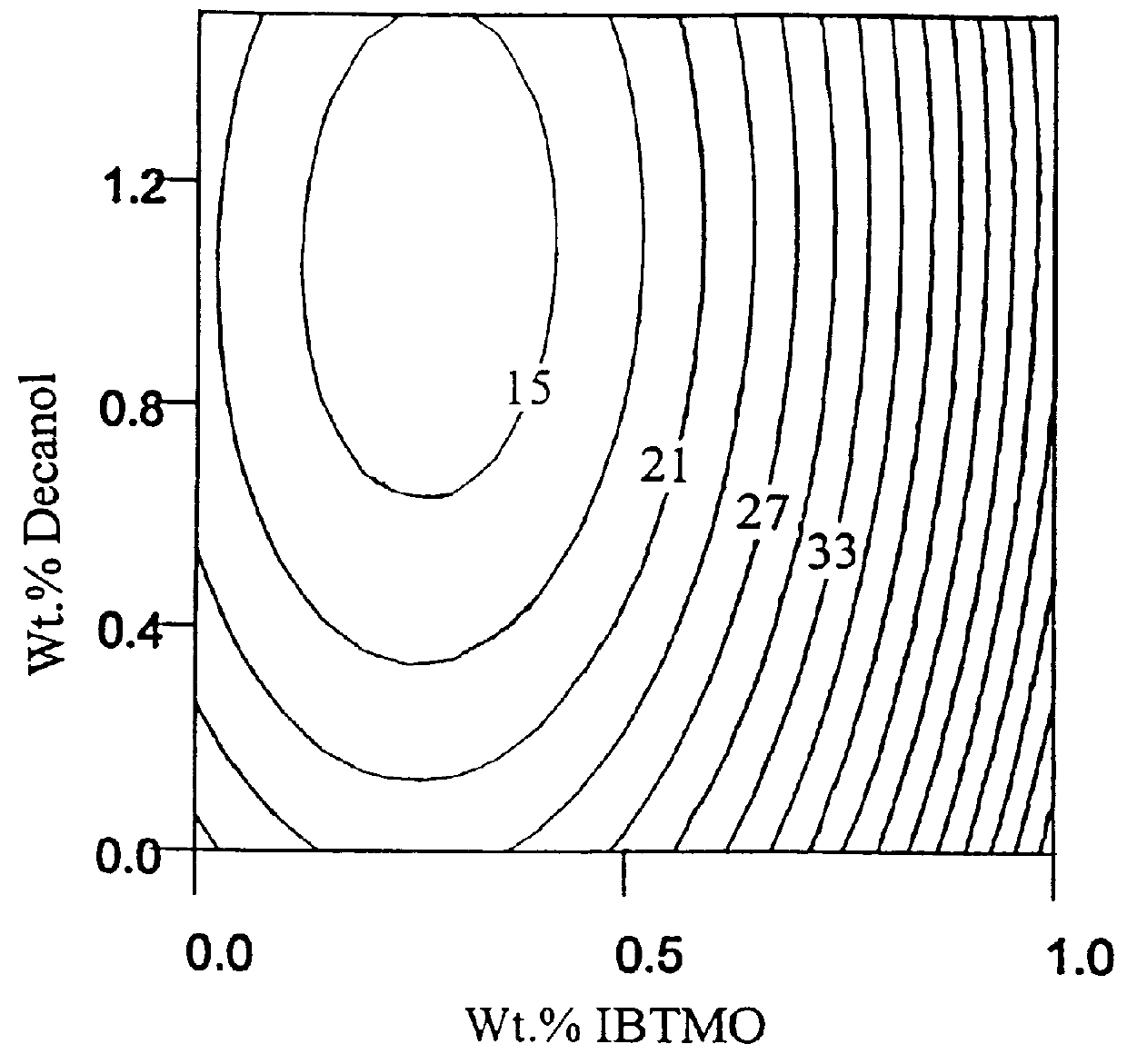

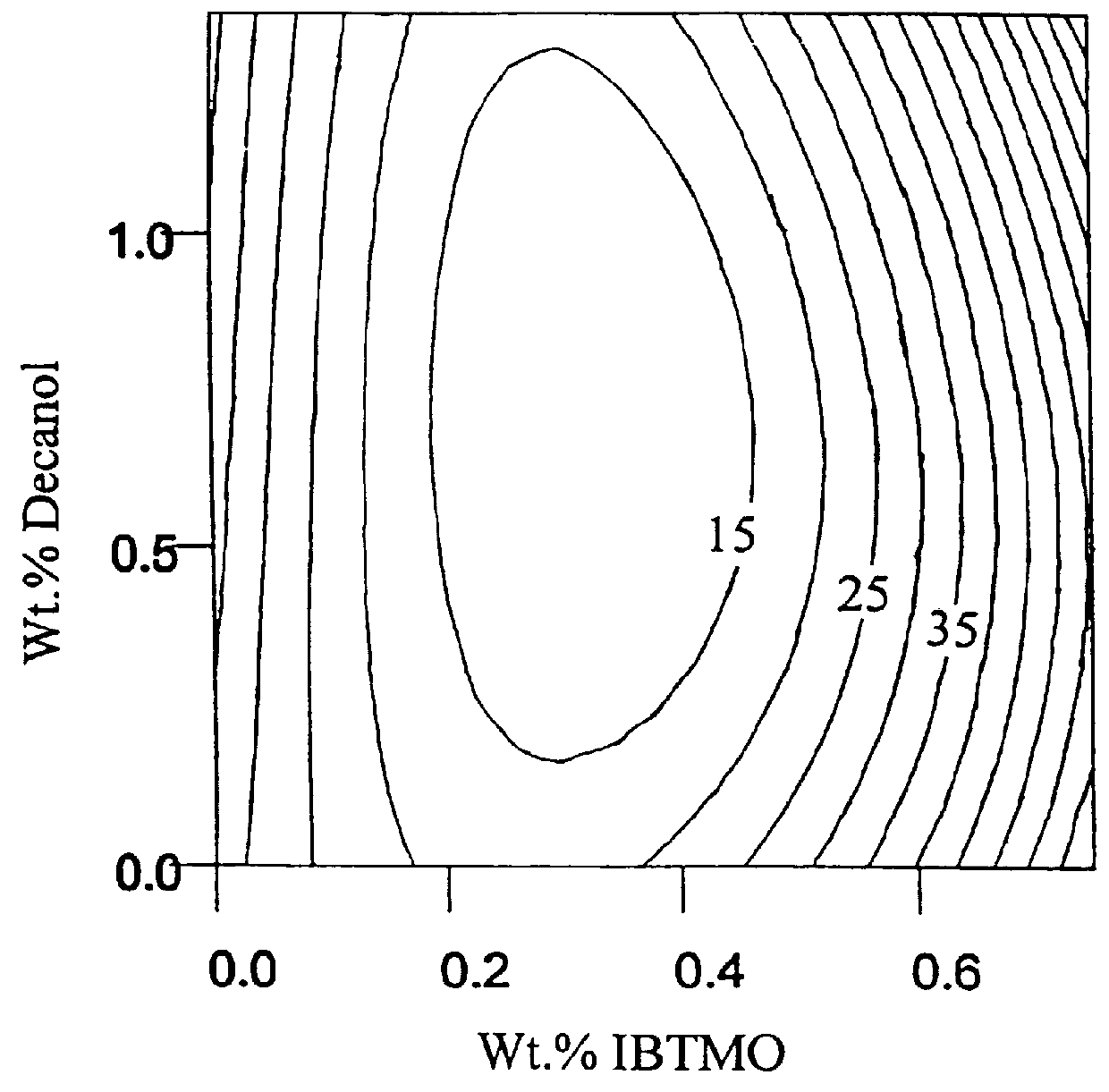

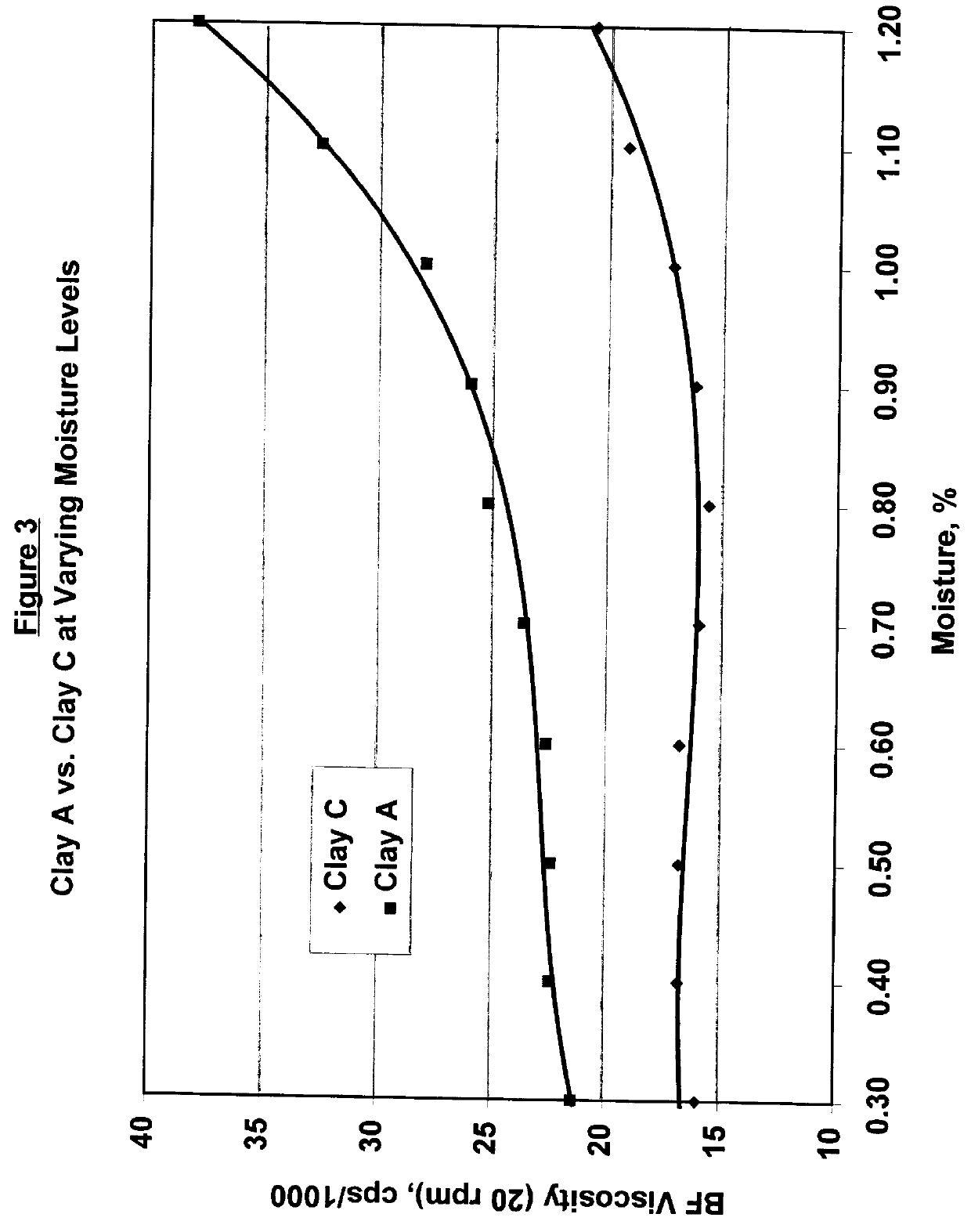

Modified mineral filler for thermosets

InactiveUS6011087APaste viscosityReduction in paste viscosityOther chemical processesMicaSilanesKaolin clay

Modified mineral fillers, derived from either a coarse particle kaolin clay or a coarse particle ATH, having excellent utility in thermoset polymers as low paste viscosity fillers are disclosed. The method of treatment involves the use of specific weight ratio combinations of a silane and a long chain aliphatic alcohol. The treatment of clay can also involve the auxiliary use of a surfactant in small amounts, which is utilized to emulsify the silane and aliphatic alcohol treatment components in water either individually or as a co-emulsion blend prior to their addition to the clay. The surfactant, which is preferably a nonionic surfactant having a HLB value of 12-18, aides in uniformly treating all the clay particle surfaces with the silane / alcohol treatment combination. Coarse particle clays having general utility in the invention are those having an average Stokes equivalent particle diameter of at least 3.0 microns, while the coarse particle ATH fillers having general utility in the invention are those having a BET surface area value less than 5.0 m2 / g. Clays or ATH so treated with the inventive silane / alcohol treatment provide unique viscosity reduction benefits in thermoset polymers unattainable by using either treatment additive alone in any amount. This low viscosity characteristic allows the treated mineral products to be used at high loadings in various thermoset compounds, as fillers or extenders, which is advantageous in terms of reducing cost and / or gaining certain performance properties, such as physical reinforcement, composite surface smoothness or flame retardancy.

Owner:J M HUBER CORP

Ultrasonic remediating method for heavy metal polluted soil/slurry

InactiveCN101811133AAchieve enrichmentAvoid processing powerContaminated soil reclamationSoil aggregateSlurry

The invention discloses an ultrasonic remediating method for heavy metal polluted soil / slurry, which comprises the following steps of: performing ultrasonic cavatition on the slurry so as to scatter soil aggregates and resolve heavy metals combined with soil particles into pore water; after ultrasonic effect is stopped, adsorbing nearly all the heavy metals on the fine particles according to the characteristic that the competitive adsorption capacity of the fine particles is stronger than that of coarse particles; and separating the coarse and fine particles with a vibration sieve so as to obtain clean coarse particles and heavy metal-enriched fine particles, wherein the coarse particles after being simply dehydrated can be used as soil materials; and the fine particles after being subjected to slurry-water separation treatment and then solidification / stabilization treatment can be safely used and sanitarily landfilled. The method is high in treatment efficiency, can treat the soil / slurry by adopting a continuous operation way, and is low in treatment cost. The obtained coarse particle material has good engineering properties; and the obtained a few of fine particle materials containing a large amount of heavy metals can be effectively treated and controlled in pollution by adopting a solidification method.

Owner:HOHAI UNIV

Production method of polycrystalline ceramic body

InactiveUS20060091588A1Improve relationshipHigh porosityPiezoelectric/electrostrictive device manufacture/assemblyCeramic shaping apparatusVolumetric Mass DensityCoarse particle

To provide a production method of a polycrystalline ceramic body with excellent density, a preparation step, a mixing step, a forming step and a heat-treating step are performed. In the preparation step, a coarse particle ceramic powder, and a fine particle powder having an average particle diameter of ⅓ or less of the average particle diameter of the coarse particle ceramic powder are prepared. In the mixing step, the coarse particle ceramic powder and the fine particle powder are mixed to produce a raw material mixture. In the forming step, the raw material mixture is formed to a shaped body. In the heat-treating step, the shaped body is heated and thereby sintered to produce a polycrystalline ceramic body. In the heat-treating step, a temperature elevating process and a first holding process are performed and at the same time, a second holding process and / or a cooling process are performed. In the temperature elevating process, heating is started to elevate the temperature and in the first holding process, the shaped body is held at a temperature T1° C. In the second holding process, the shaped body is held at a temperature T2° C. lower than the temperature T1° C. In the cooling process, the shaped body is cooled at a temperature dropping rate of 60° C. / h or less from the temperature T1° C.

Owner:DENSO CORP

Milling and classifying apparatus, collision mill, air classifier, toner, and method for producing toner

ActiveUS20060032952A1Improve image qualitySmall particle sizeGas current separationDevelopersEngineeringAir classifier

Disclosed is a milling and classifying apparatus, adapted to produce toner fine particles, comprising a collision mill, and an air classifier, wherein the collision mill comprises a jet nozzle room, a path, a collision plate, and a collision member mounted to a support of the collision plate at downstream of the collision plate, the air classifier comprises a dispersion room and a classification room, the classification room is disposed below the dispersion room, and a flow stabilizer is arranged at a central suction of the separator core to control swirl stream generated within the classification room so as to centrifuge the powder into coarse particles and fine particles by action of the swirl stream.

Owner:RICOH KK

High-voltage panel type grinding equipment and its processing method

InactiveCN101342504AEasy to set upAdjustable grinding pressureCocoaGrain treatmentsSmall footprintHigh pressure

The invention relates to a high-pressure disc milling device integrated with the functions of milling, drying and flour screening, and a processing method thereof. An upper mill disc and a lower mill disc of the main machine are overlapped and arranged horizontally; an adjustable pressing force can be applied downward onto the fixed mill disc through a plurality of oil cylinders and accumulators; the milling areas with point contact, linear contact and face-contact between the two mill discs produce multiple crushing and milling effects. After forced separation of the milled materials, the finished products enters into the recovery device following the air flow through the upper outlet; the coarse particles move downward and are expelled from the discharge opening and are fed into the mill for re-milling by a recycling system arranged outside of the mill. All the lubrications of the mill are provided by a centralized concentrated thin-oil lubricating station and a lubricating grease station. A pressure-adjustable hydraulic station supplies hydraulic oil to the operating cylinders and accumulators, as a result, the milling force is adjusted; the device has strong adaptability to various materials and varied water contents, and has ultra-strong pressing, shearing and milling function, and has the advantages of small land occupation, low power consumption and high efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Heat treatment apparatus and method for manufacturing toner

InactiveUS9075328B2Suppress coarseningLess fine powderDrying solid materials with heatDrying gas arrangementsCoarse particleHeat treated

Owner:CANON KK

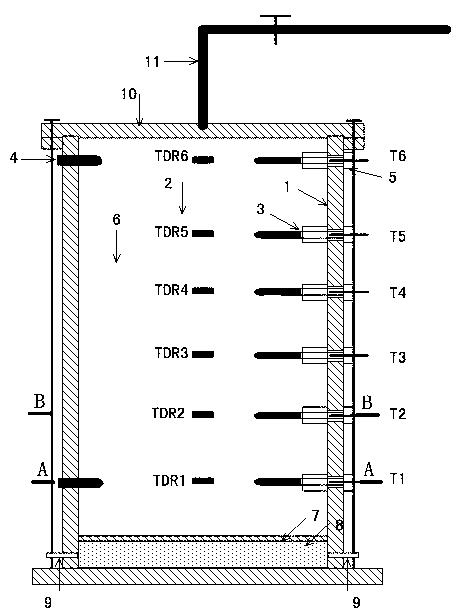

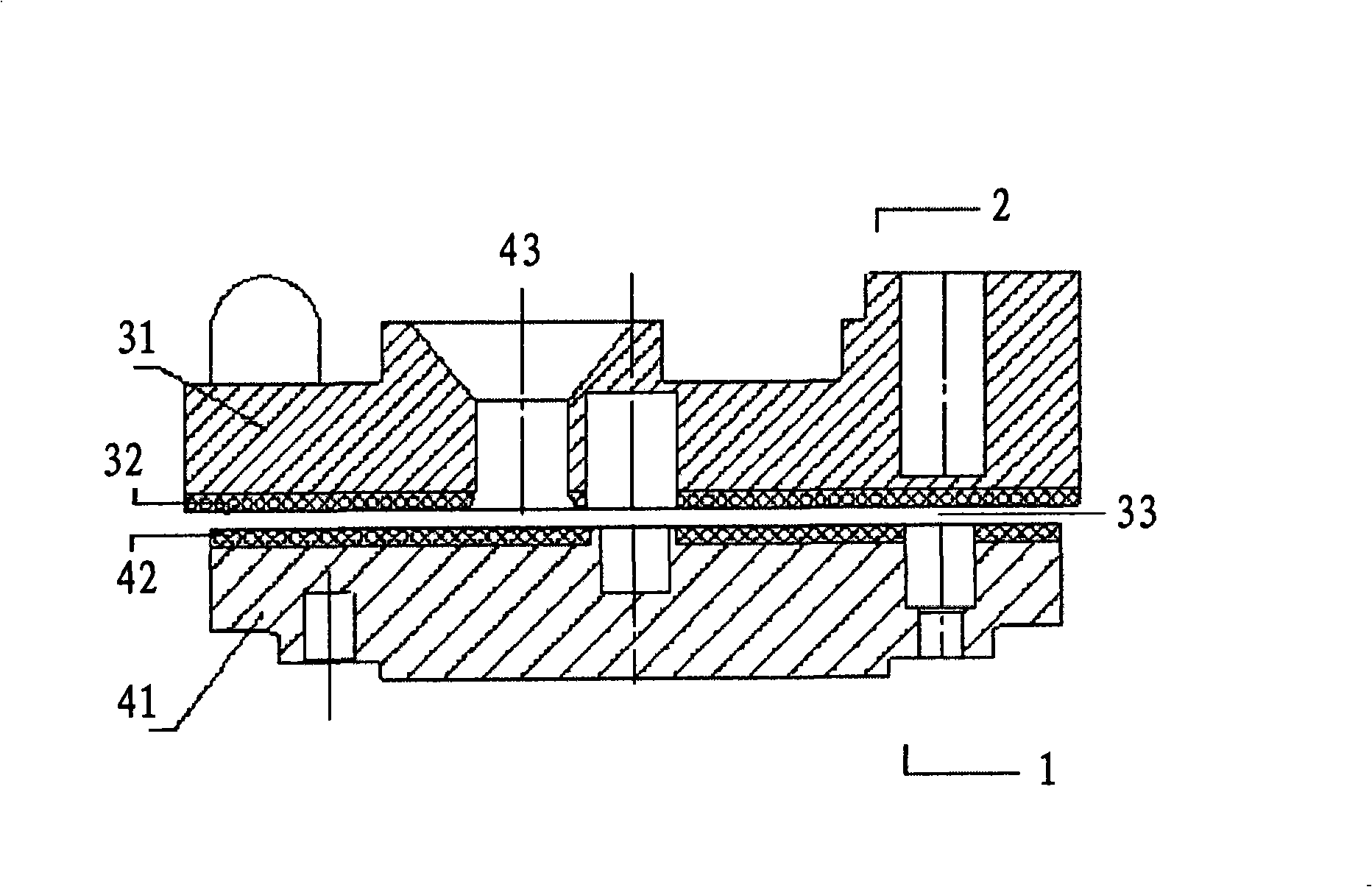

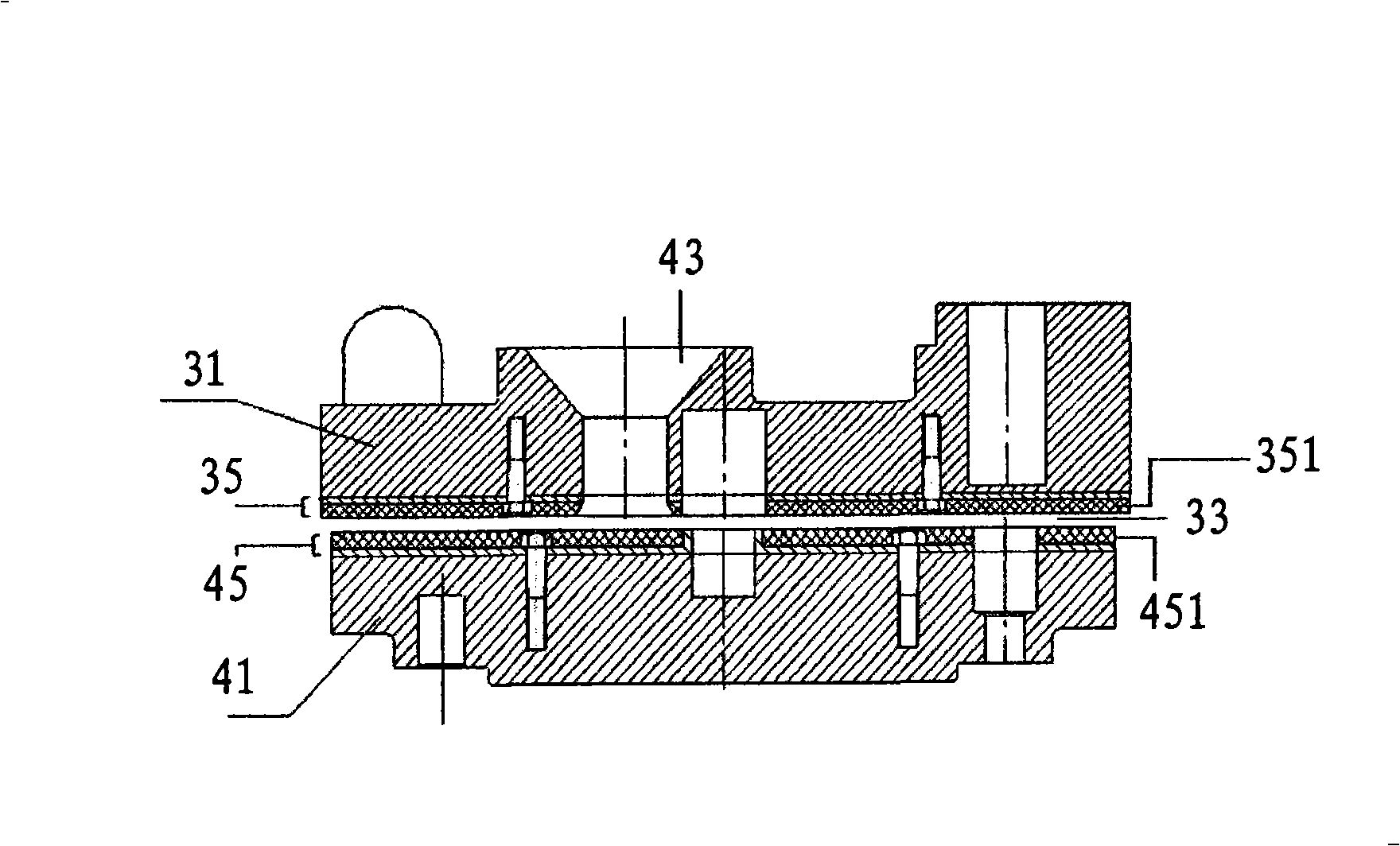

Solidification and permeation combined experimental device

ActiveCN105486840ASimulation is accurateEarth material testingPermeability/surface area analysisCombined testWater discharge

The invention relates to a solidification and permeation combined experimental device. The solidification and permeation combined experimental device comprises a base, a pressure chamber, a pressurizing assembly, a permeation assembly and a numerical value acquisition system, wherein the pressure chamber is fixed on the base; a pressurizing upper cover is arranged at the top of the pressure chamber in a sliding manner; the pressurizing assembly is connected with the pressurizing upper cover and can be used for applying pre-set pressure to the pressurizing upper cover; the permeation assembly comprises a water overflowing pipe, an adjusting pipe and a plurality of pressure detection pipes; a water overflowing hole is formed in the upper end of the pressure chamber; the water overflowing pipe is connected with the water overflowing hole; the adjusting pipe is connected with a water discharging hole; a plurality of pressure detection holes are formed in the pressure chamber along the vertical direction; the plurality of pressure detection pipes are connected with the plurality of pressure detection holes respectively; the numerical value acquisition system comprises a pressure transmitter, a displacement sensor and a control unit; and the control unit is connected with the pressure transmitter and the displacement sensor and is used for receiving pressure information and displacement information. The solidification and permeation combined experimental device can be used for performing a solidification and permeation combined test of coarse-particle soil under different solidification degrees, and a real stress state of large-particle oil with different burying depths is accurately simulated in a laboratory.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Novel flotation column serial connection test system for improving flotation granularity upper limit

The invention relates to a novel flotation column serial connection test system for improving the flotation granularity upper limit. The equipment of the system comprises a fed material stirring barrel, a feeding pump, a feeding pressure meter, a froth generator, a primary-section foam enriching chamber, a lower catheter, a spray type flotation column chamber, a primary-section tailing box, a secondary-section foam enriching chamber, a column flotation chamber, a rotary flow sorting chamber, a circulation ore pulp pump, a circulation pressure meter, a froth generator, a secondary-section tailing box and an FCMC cyclo-microfroth flotation column, wherein a spray type flotation column and the FCMC cyclo-microfroth flotation column are connected in series by the system, and the primary-section tailing is used as secondary-section fed materials. The system is favorable for the static fast flotation of preference flotation of coal with good flotation performance and the strong power efficient recovery of difficult-to-sort coal, in addition, the problem of high-concentration coal slime flotation can be perfectly solved, the recovery rate of coarse particle coal slime can be improved, and the problem of coarse particle running of coarse particle flotation can be solved.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com