Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109 results about "Air classifier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

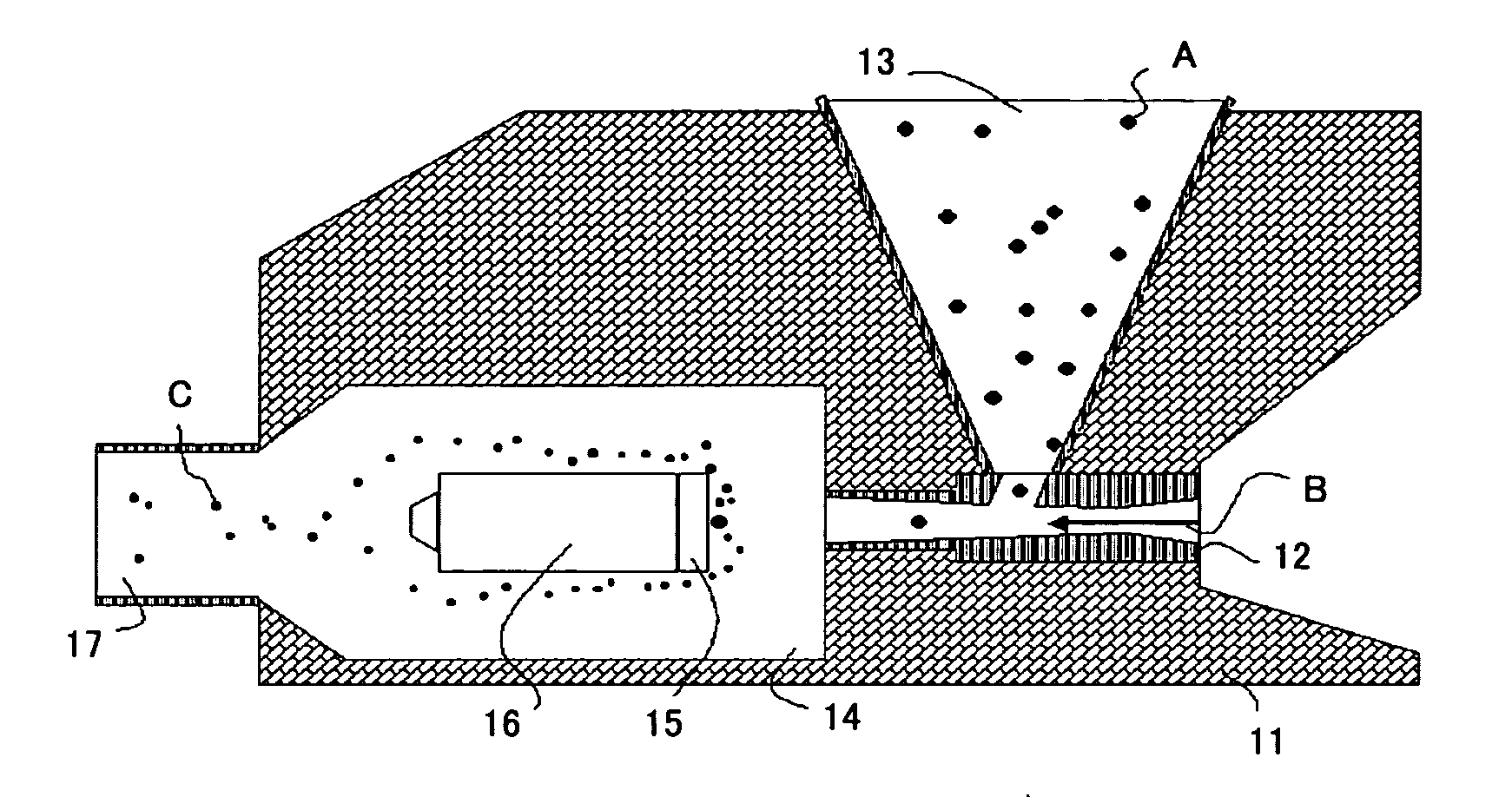

An air classifier is an industrial machine which separates materials by a combination of size, shape, and density. It works by injecting the material stream to be sorted into a chamber which contains a column of rising air. Inside the separation chamber, air drag on the objects supplies an upward force which counteracts the force of gravity and lifts the material to be sorted up into the air. Due to the dependence of air drag on object size and shape, the objects in the moving air column are sorted vertically and can be separated in this manner.

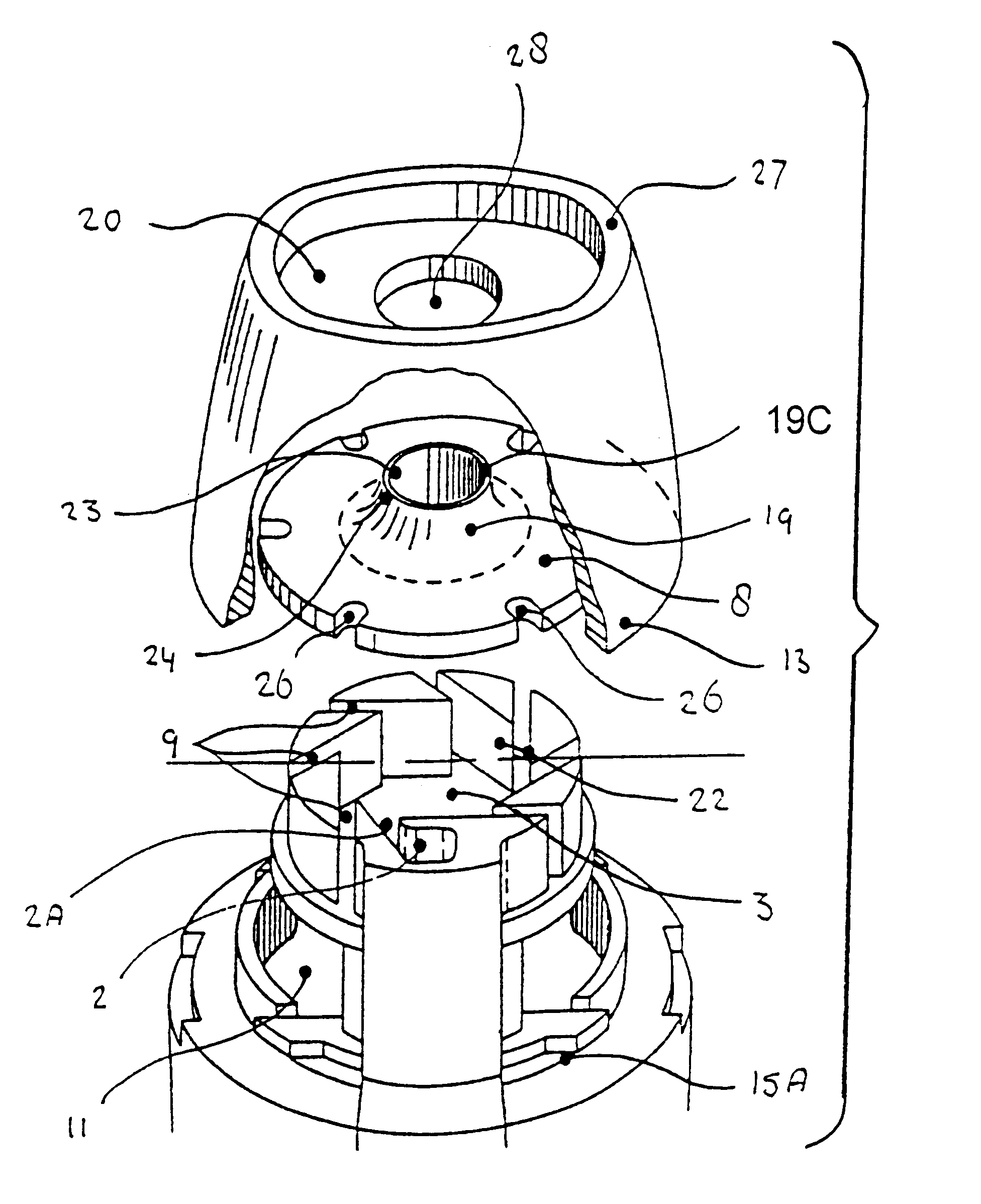

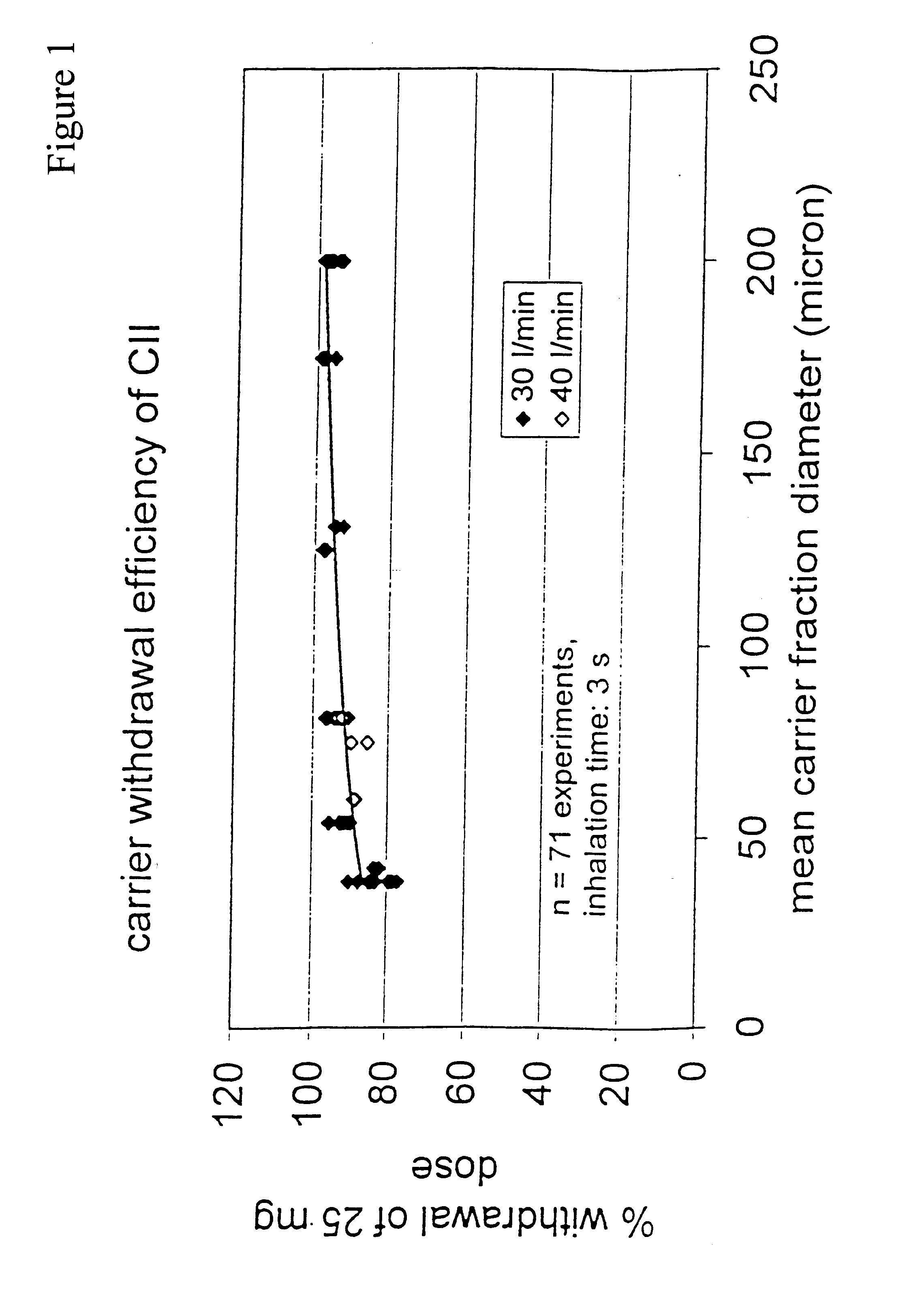

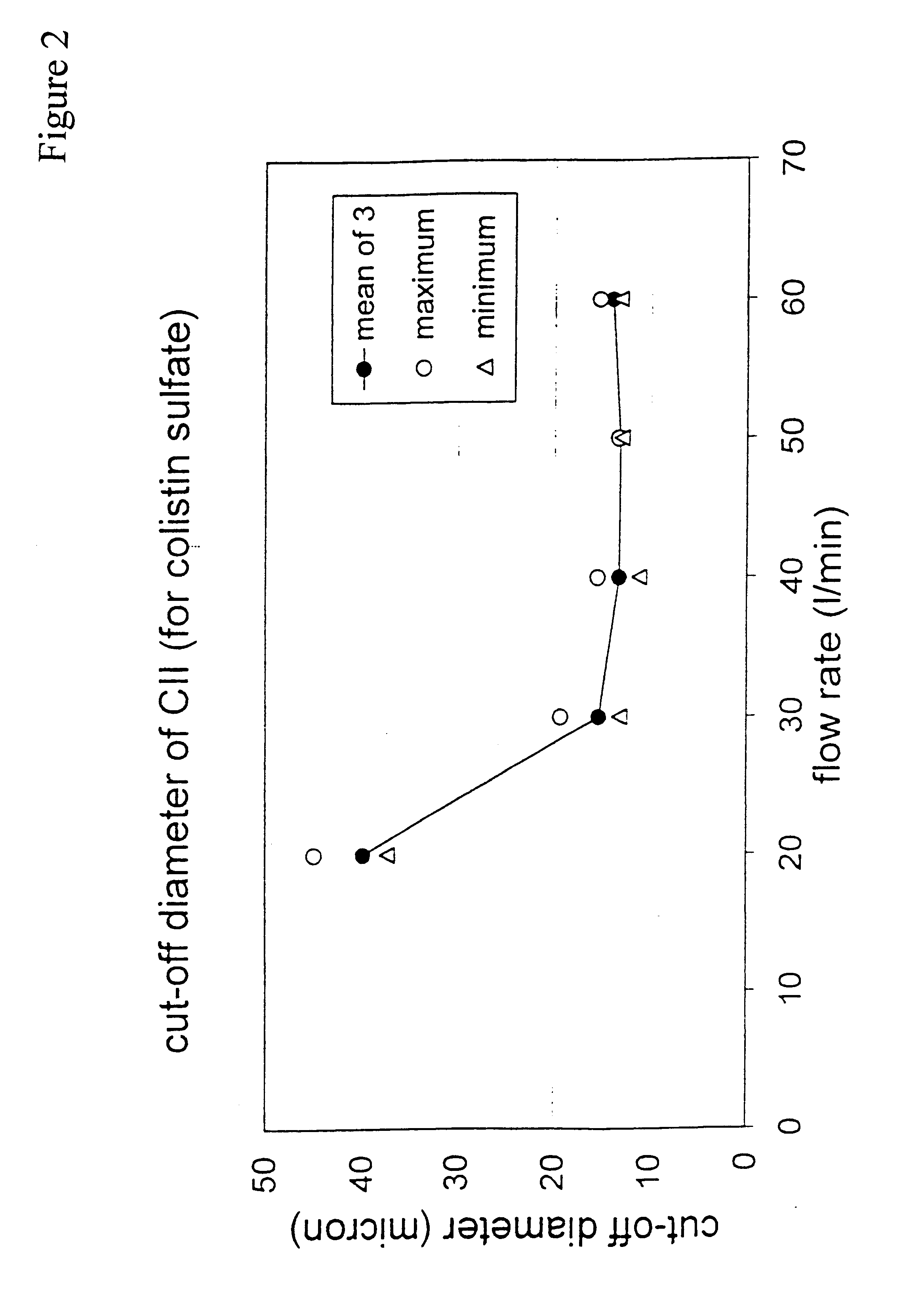

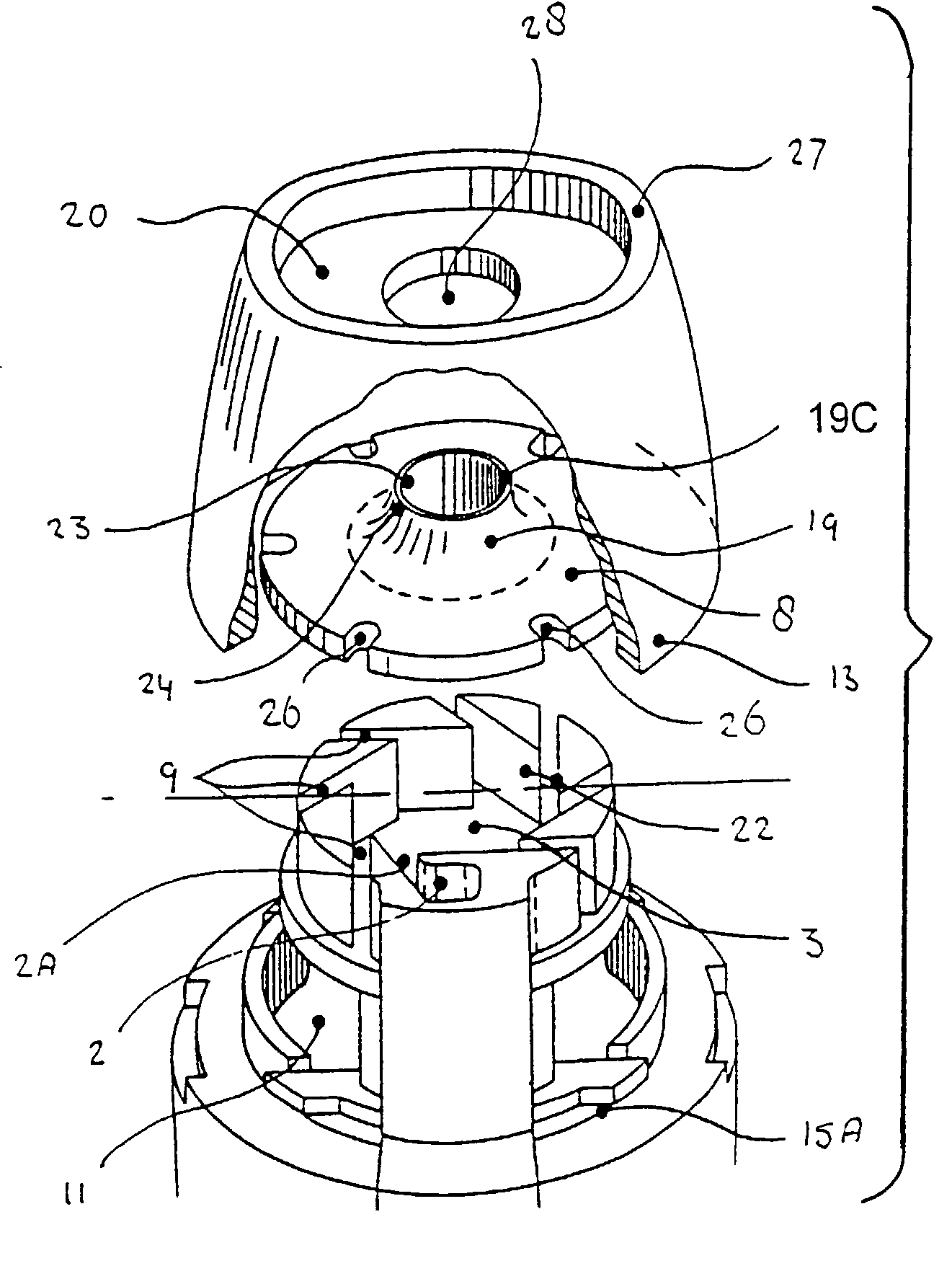

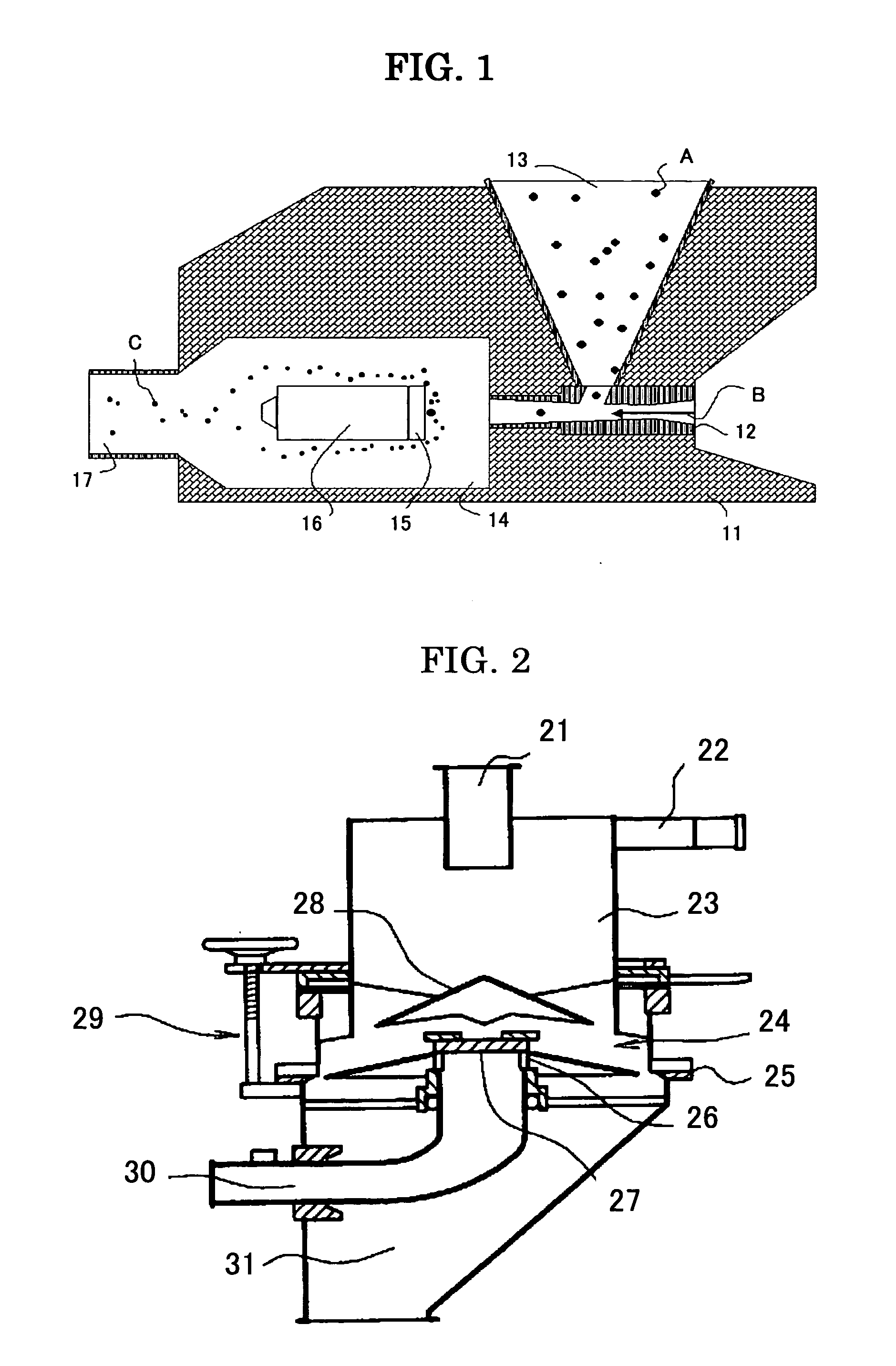

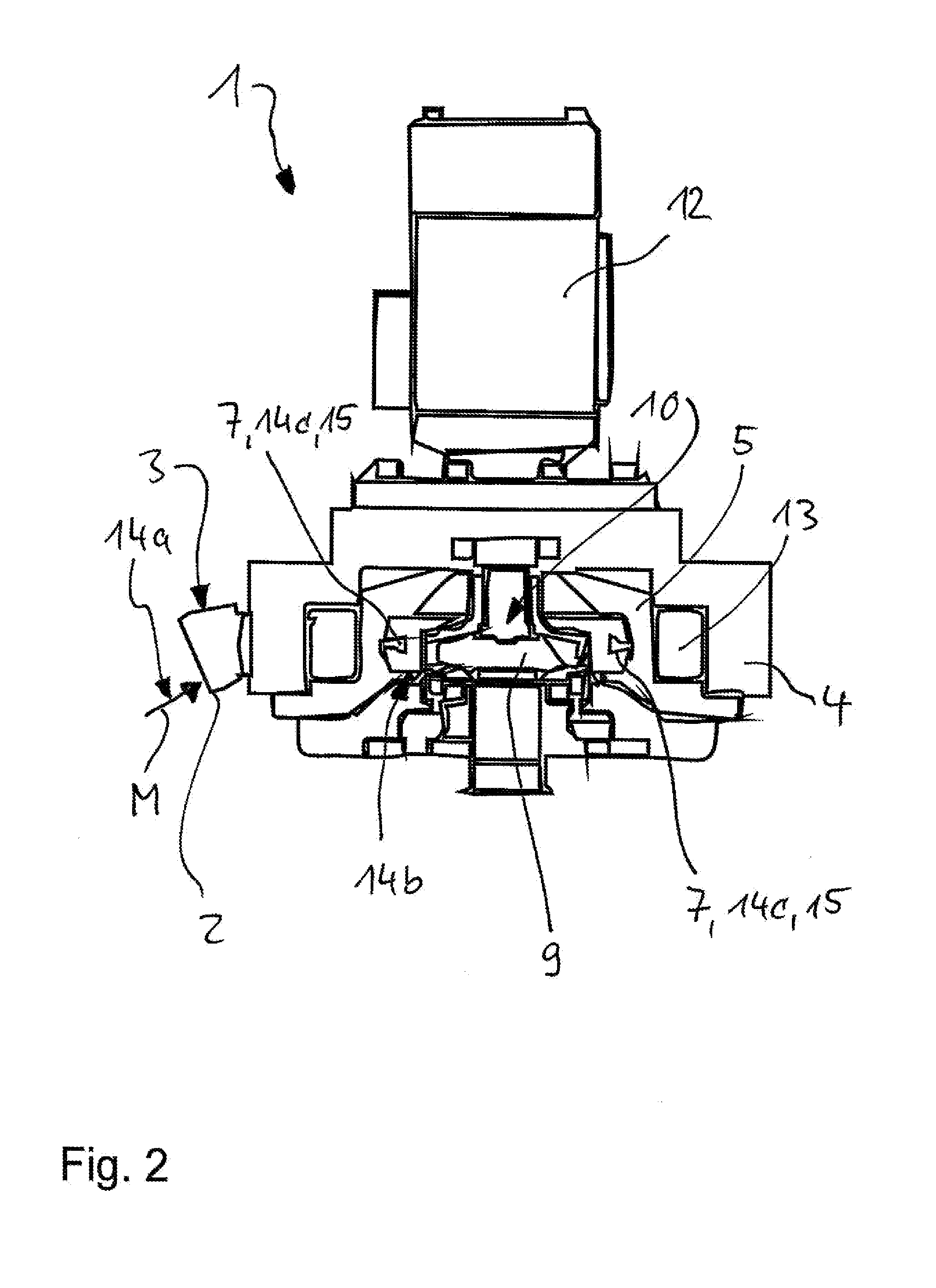

Powder formulation disintegrating system and method for dry powder inhalers

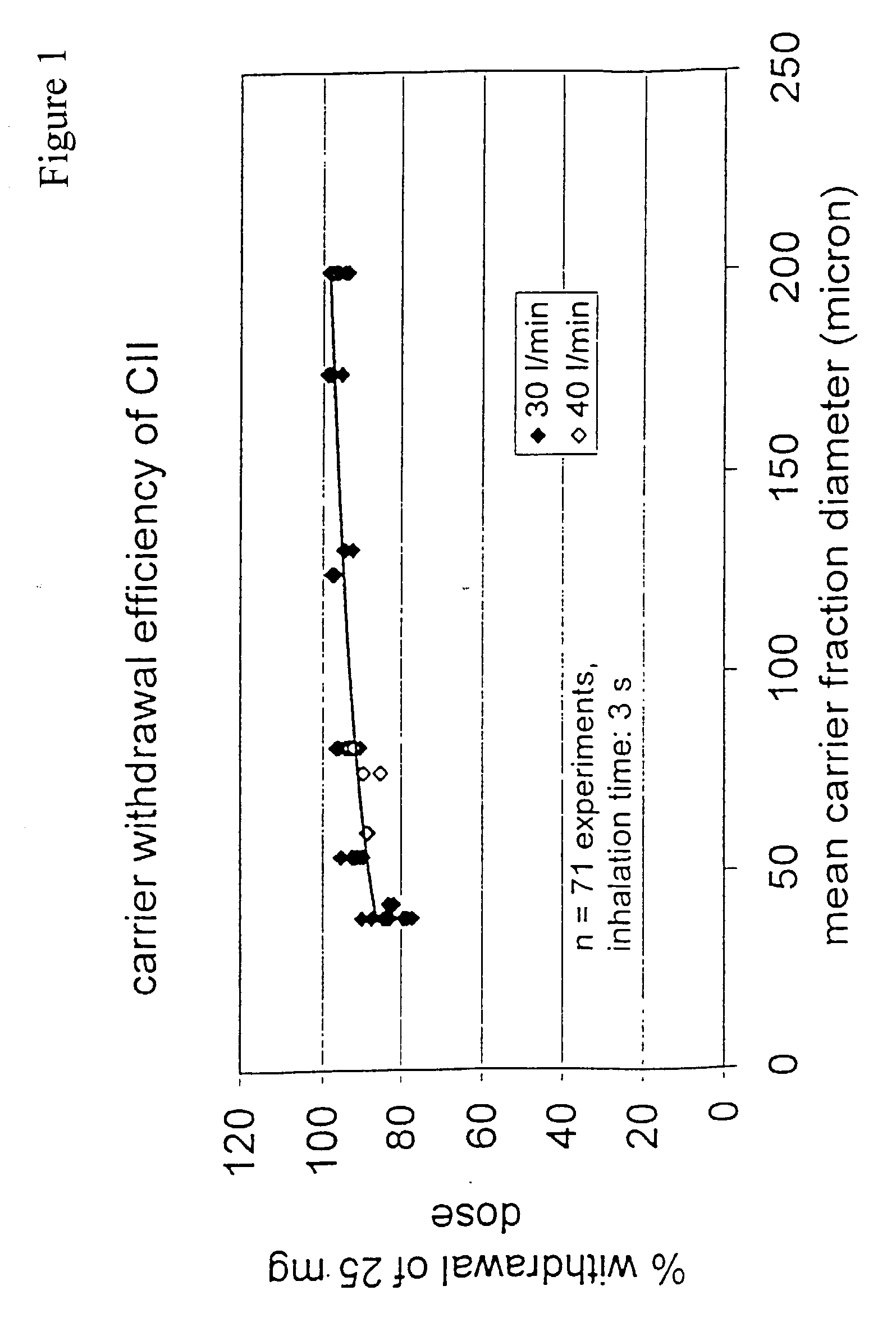

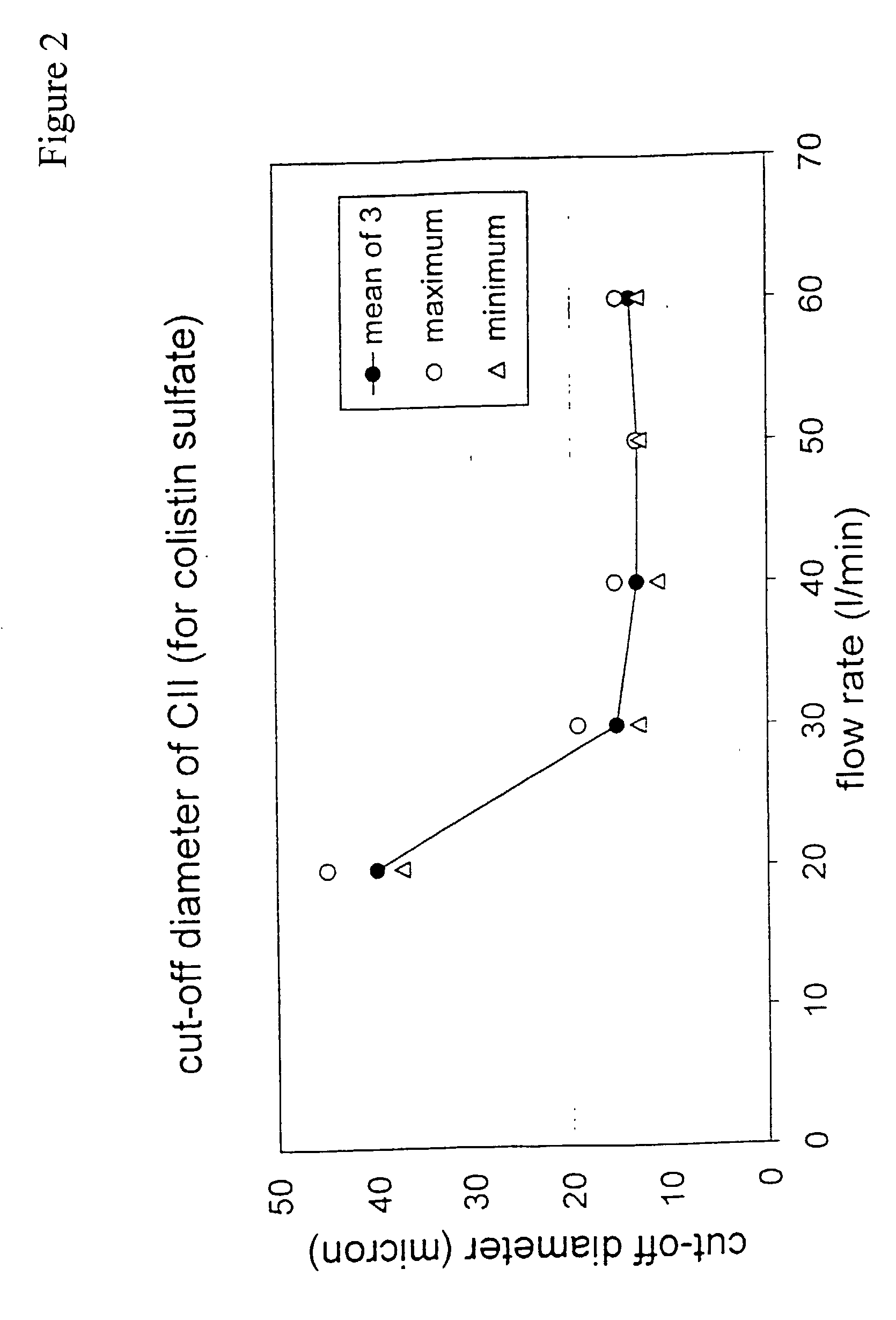

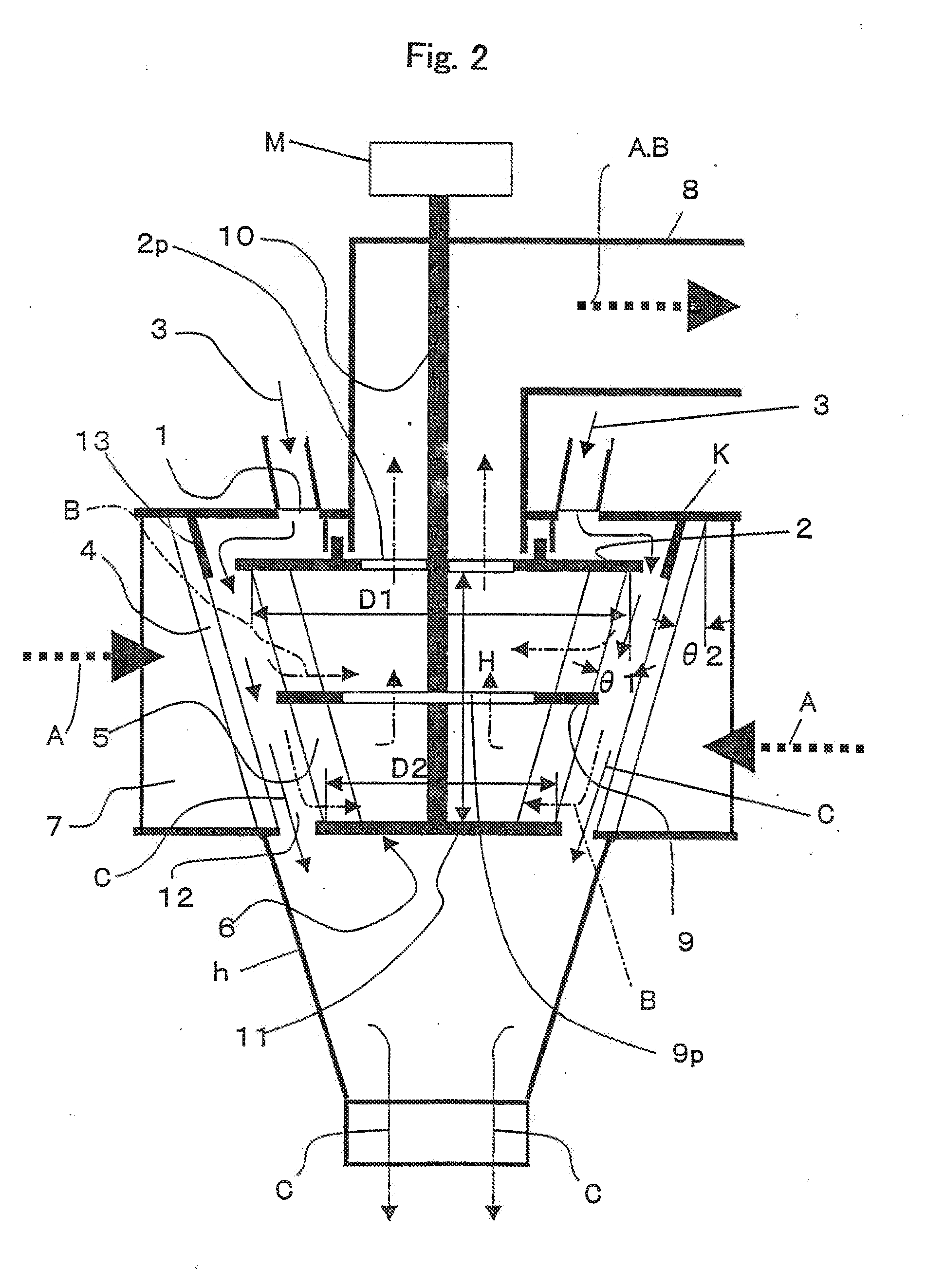

A disperser for dry powders which can be used with different dose systems, dose weights ranging from 2 to 25 mg and different types of powder formulation. In one embodiment, the disperser acts both as a de-agglomeration (disintegration; aerosolization) means and as an air classifier for especially adhesive mixtures. Only fine drug particles are emitted whereas the larger agglomerates and carrier crystals are retained by the disperser. Another embodiment enables time controlled release of carrier crystals in these mixtures. Yet another embodiment has optimized performance with spherical pellets, containing no carrier crystals. Other possible embodiments of the invention make it possible to control the total inhaler resistance and the powder deposition in the upper respiratory tract by means of the addition of a so-called sheath flow of clean air. Modifications also enable carrier retainment in the mouthpiece and elimination of the tangential flow component of the discharge cloud.

Owner:ASTRAZENECA AB

Powder formulation disintegrating system and method for dry powder inhalers

A disperser for dry powders which can be used with different dose systems, dose weights ranging from 2 to 25 mg and different types of powder formulation. In one embodiment, the disperser acts both as a de-agglomeration (disintegration; aerosolization) means and as an air classifier for especially adhesive mixtures. Only fine drug particles are emitted whereas the larger agglomerates and carrier crystals are retained by the disperser. Another embodiment enables time controlled release of carrier crystals in these mixtures. Yet another embodiment has optimized performance with spherical pellets, containing no carrier crystals. Other possible embodiments of the invention make it possible to control the total inhaler resistance and the powder deposition in the upper respiratory tract by means of the addition of a so-called sheath flow of clean air. Modifications also enable carrier retainment in the mouthpiece and elimination of the tangential flow component of the discharge cloud.

Owner:ASTRAZENECA AB

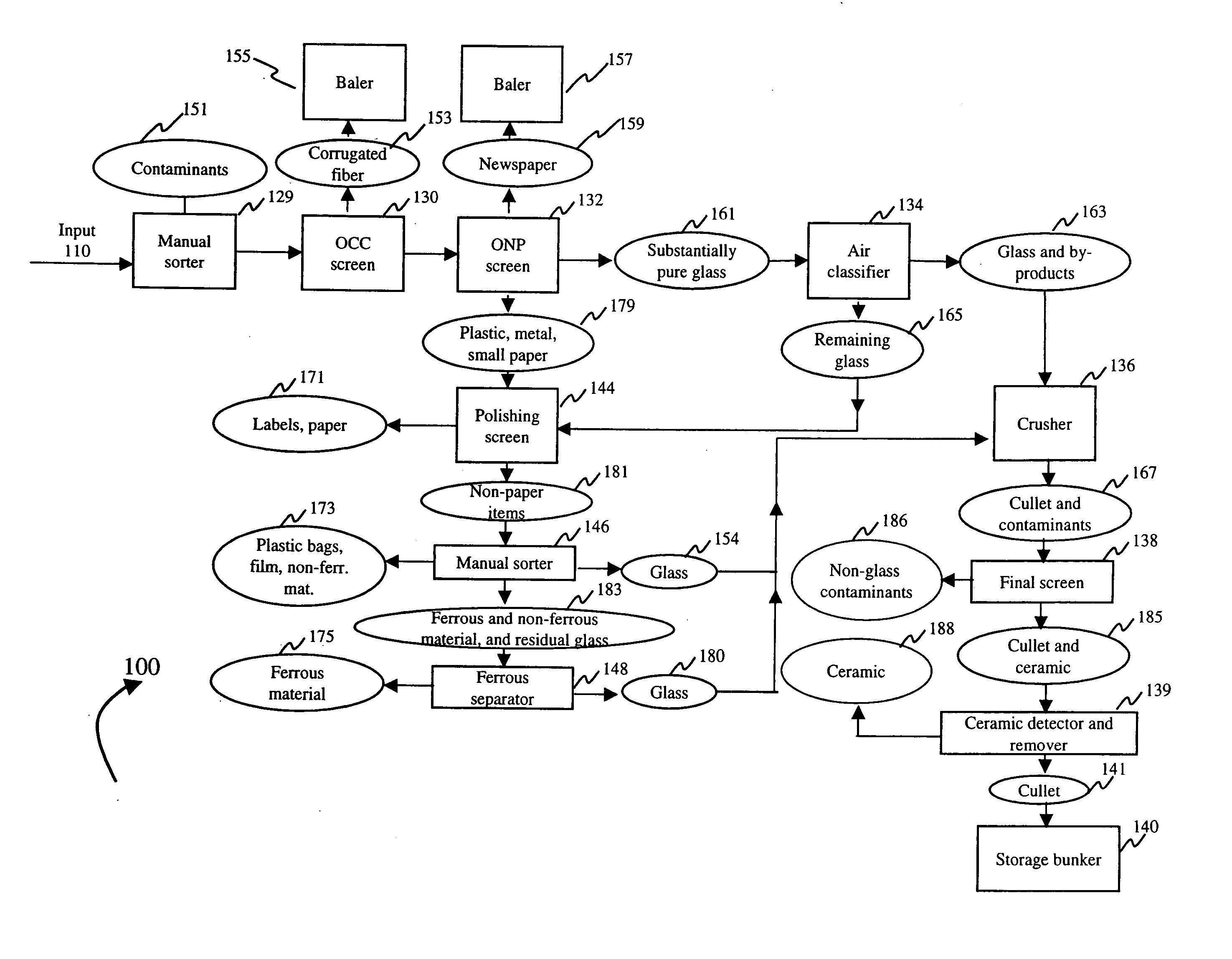

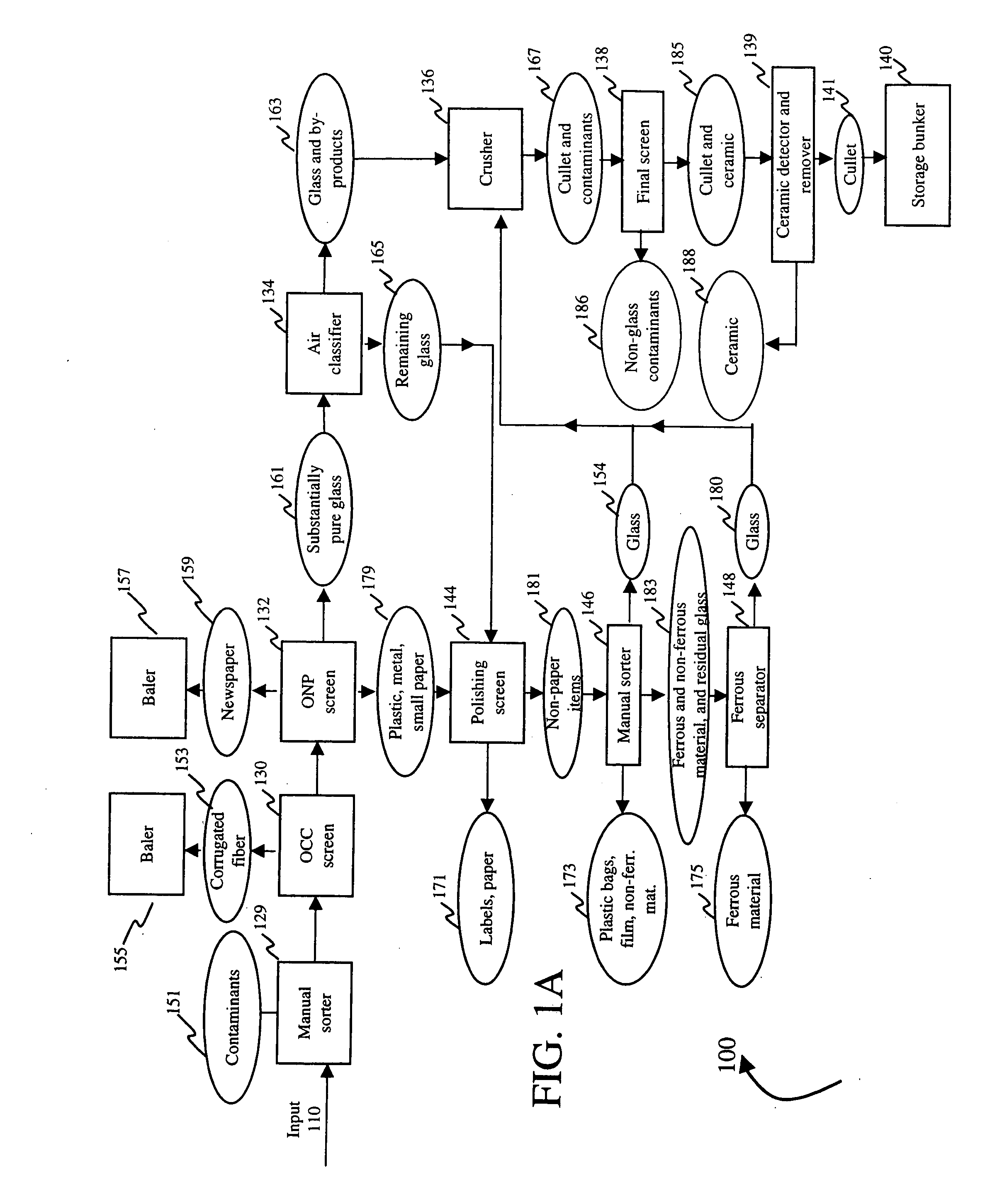

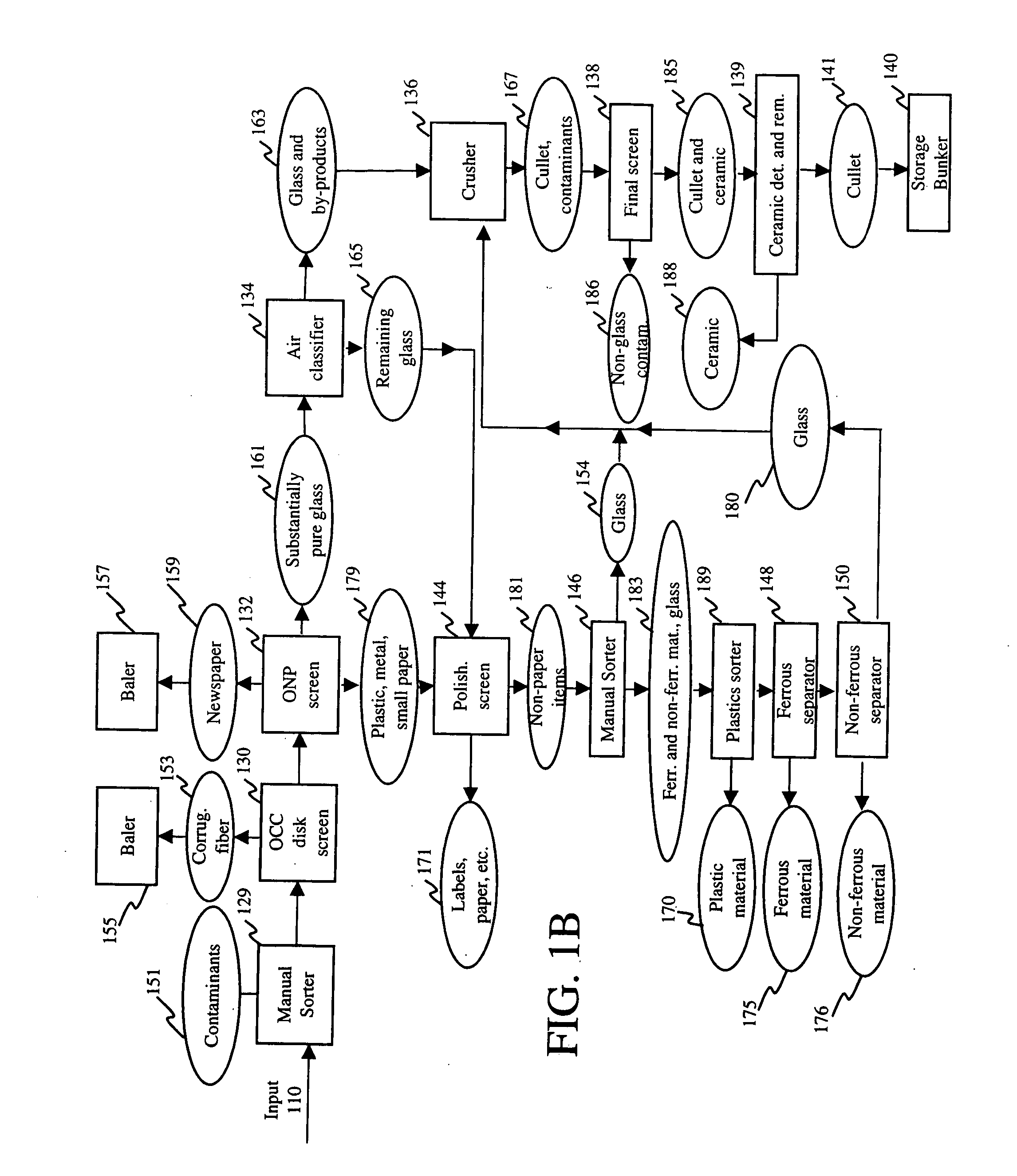

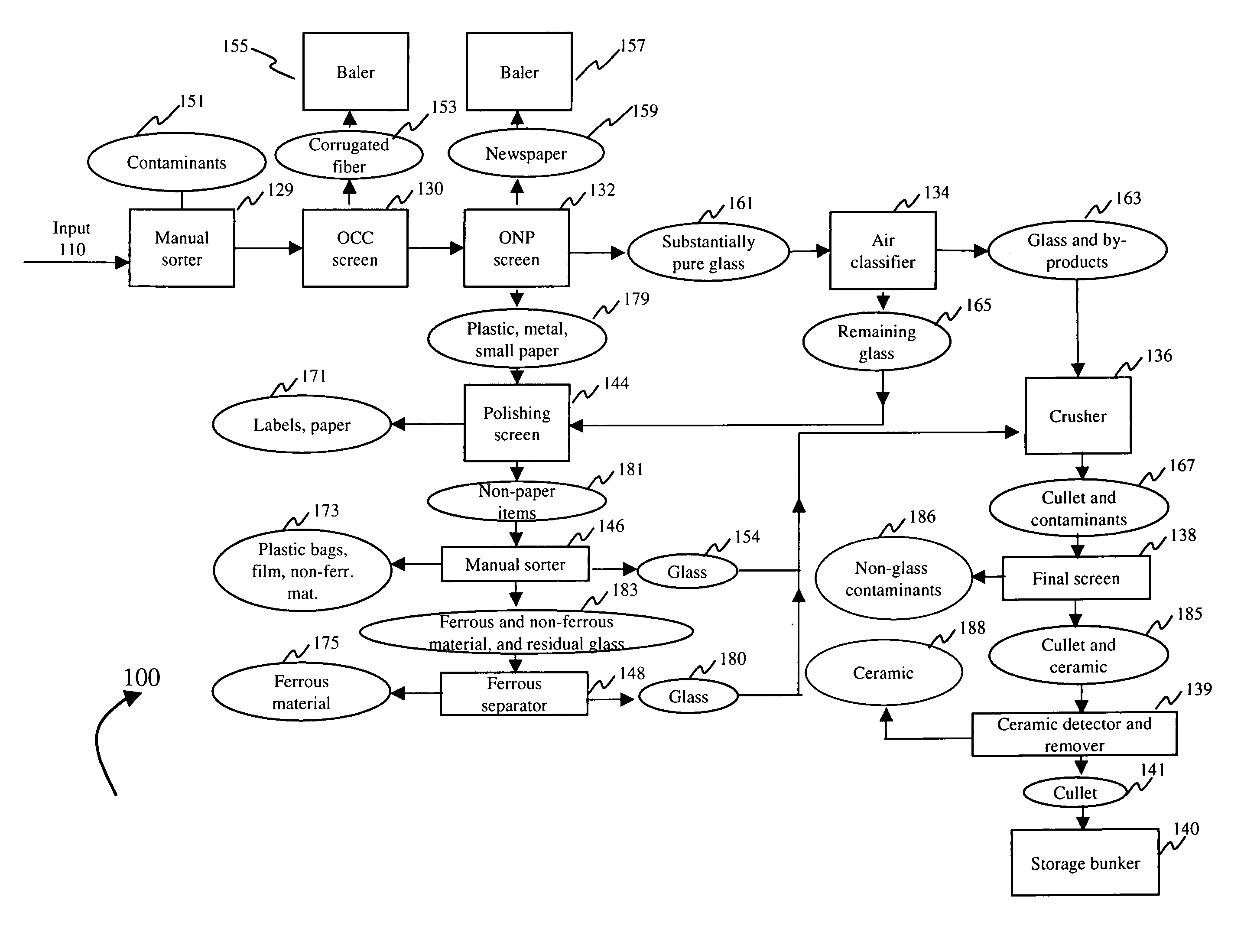

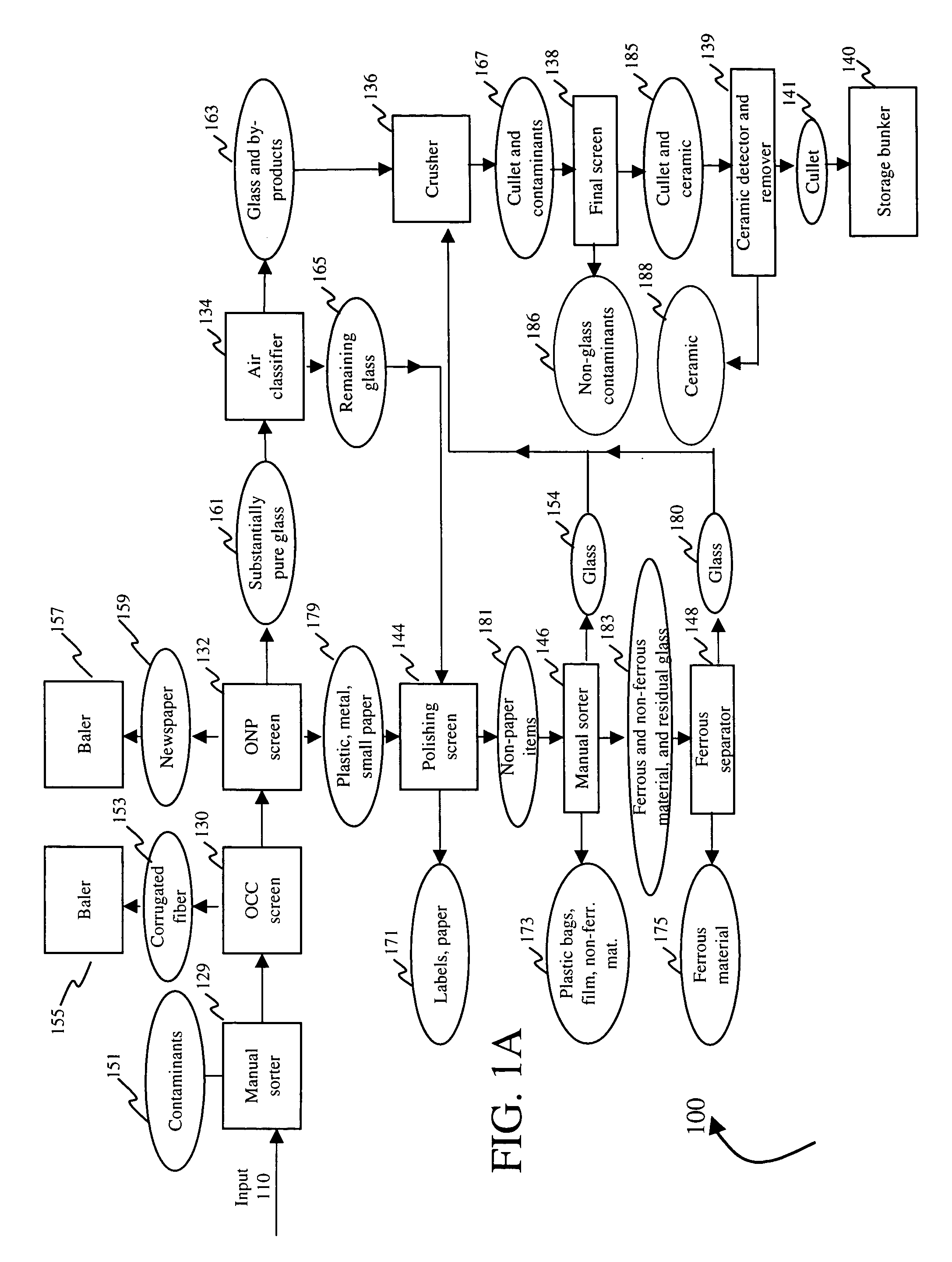

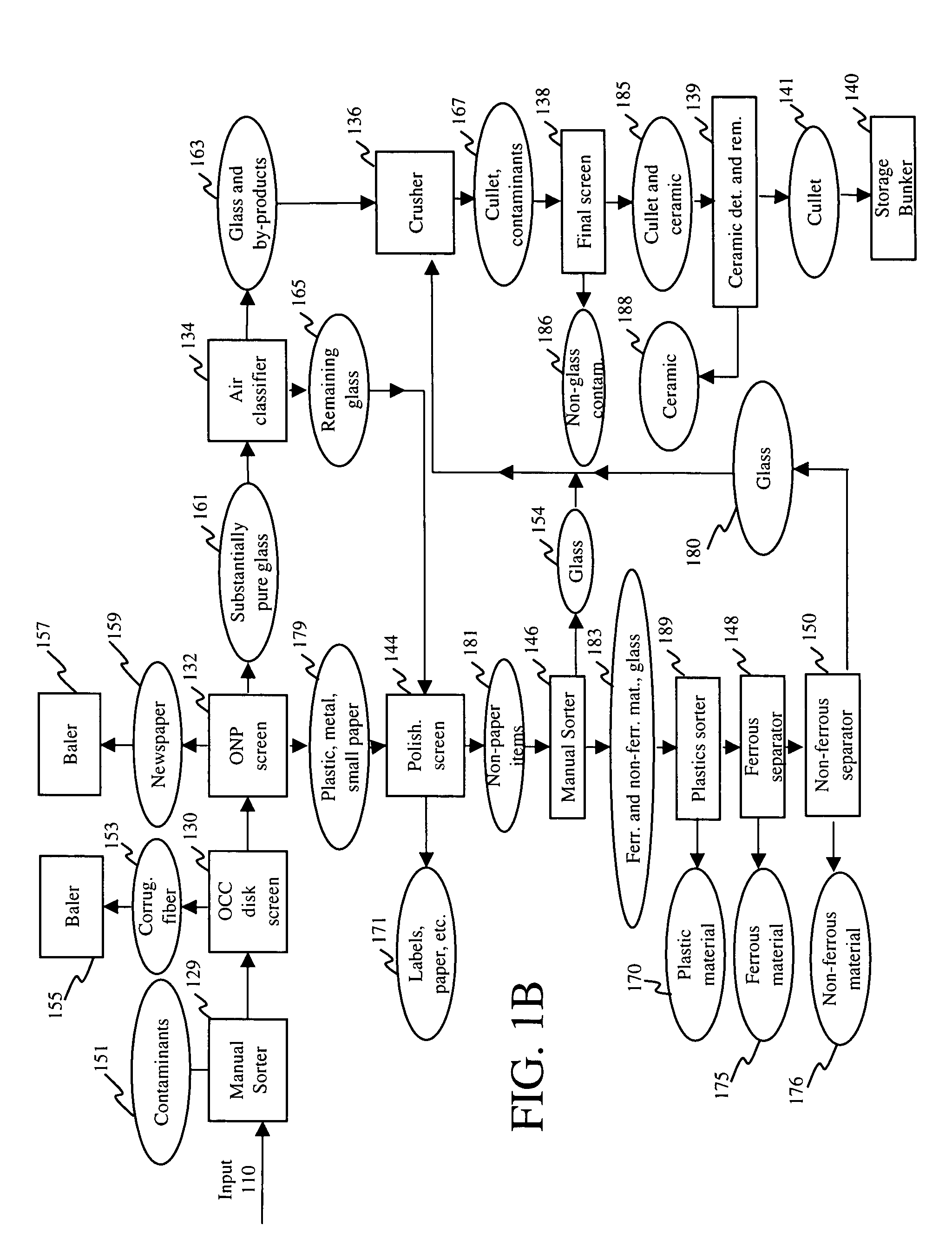

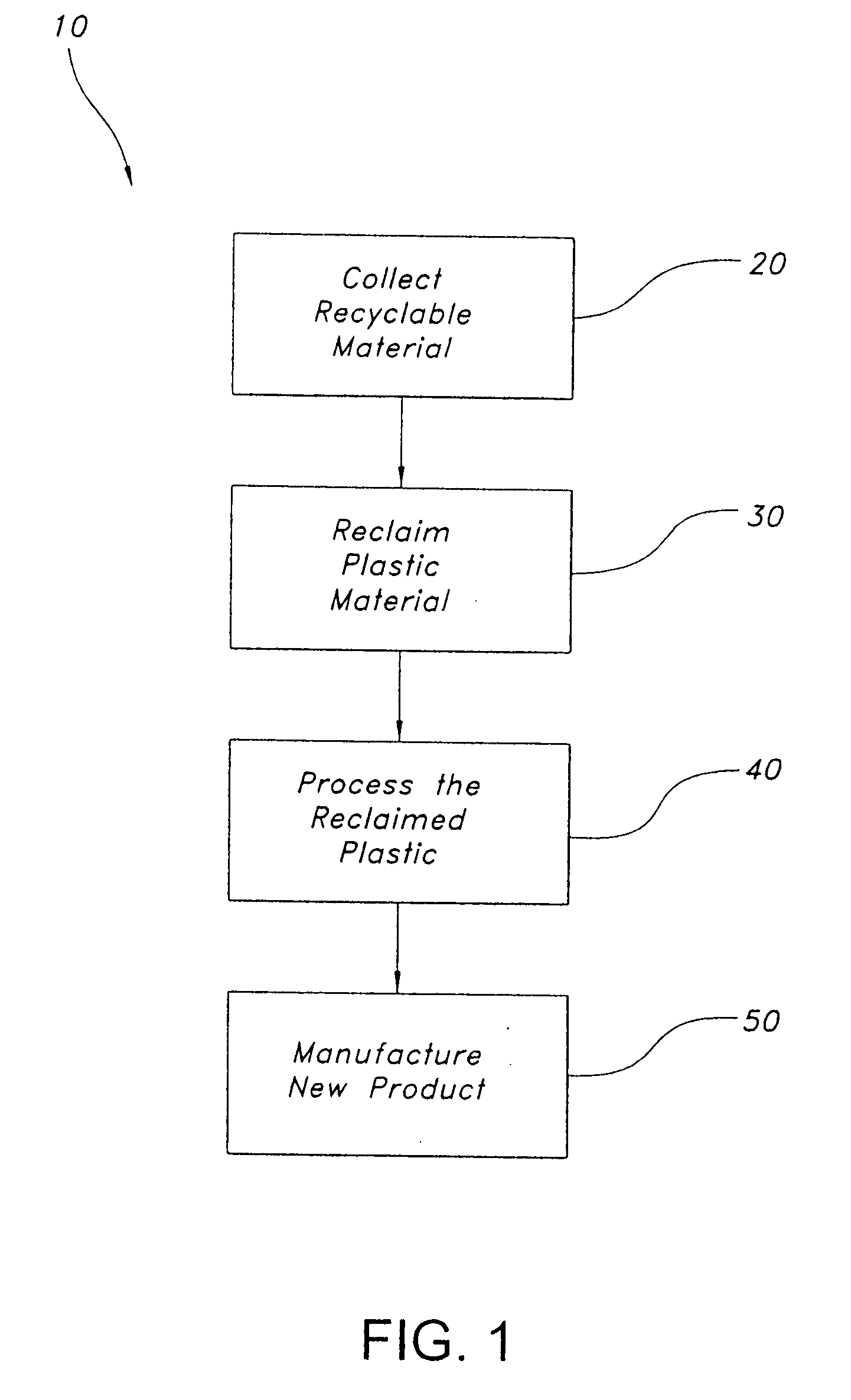

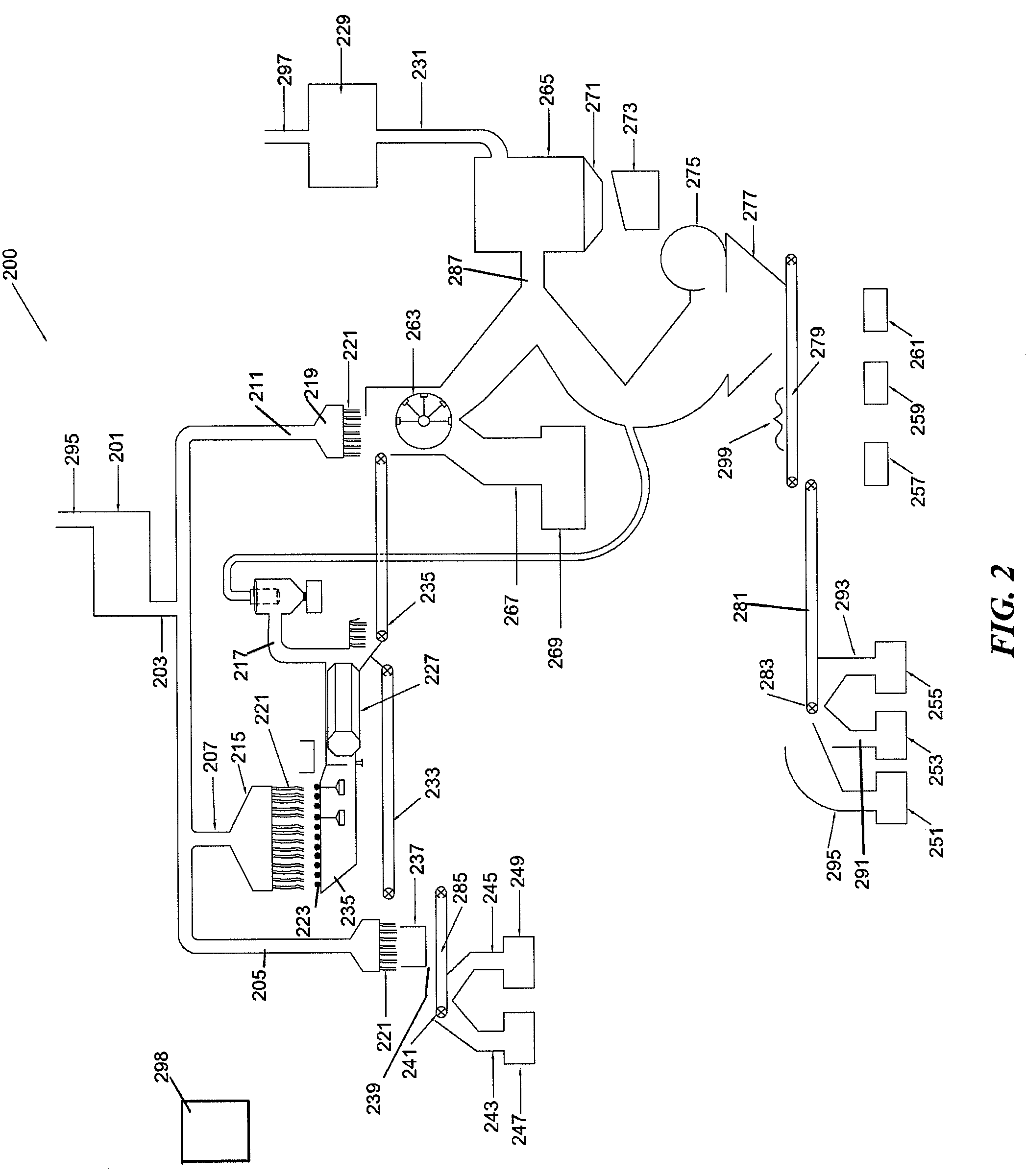

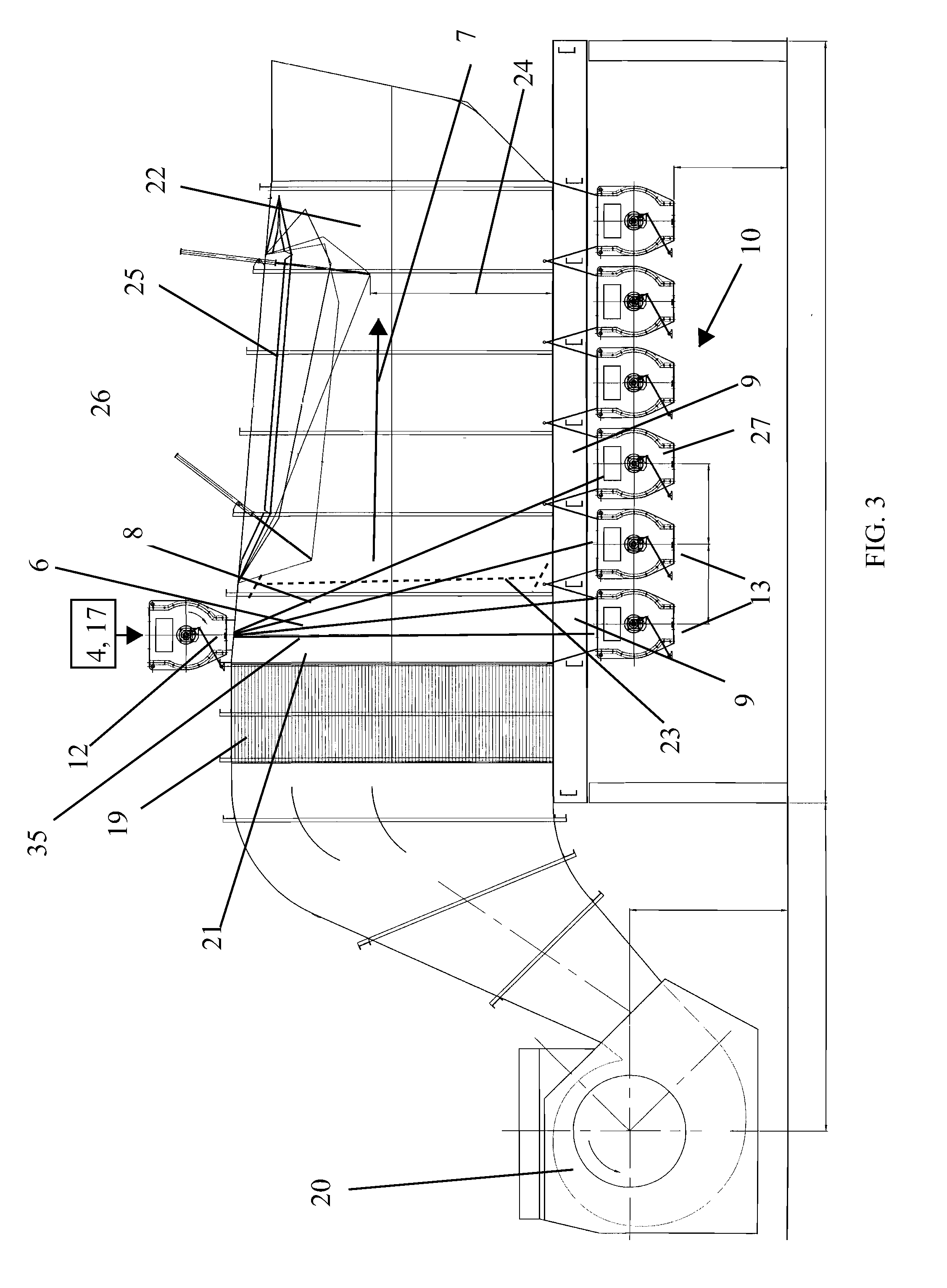

Systems and methods for sorting recyclables at a material recovery facility

InactiveUS20060254957A1Glass recyclingDigital data processing detailsProcess engineeringAir classifier

Owner:RE COMMUNITY HLDG II INC

Systems and methods for sorting recyclables at a material recovery facility

Systems and methods for providing a quantity of cullet having at least two colors of glass from an input stream of recyclable material and non-recyclable material. In an embodiment, the system includes a sortation station, a screening apparatus, an air classifier, and a crushing apparatus to provide as output substantially pure cullet having at least two colors.

Owner:RE COMMUNITY HLDG II INC

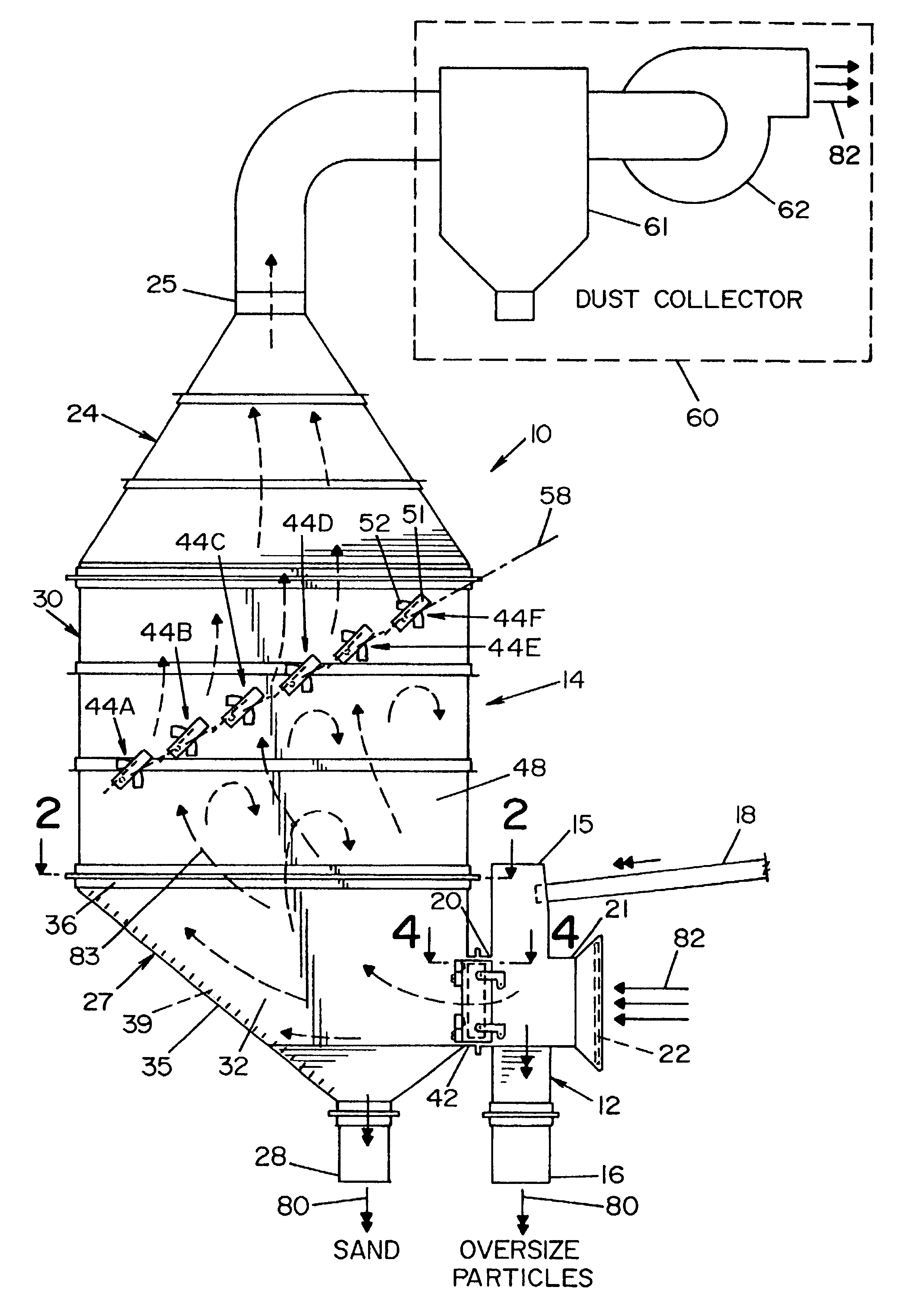

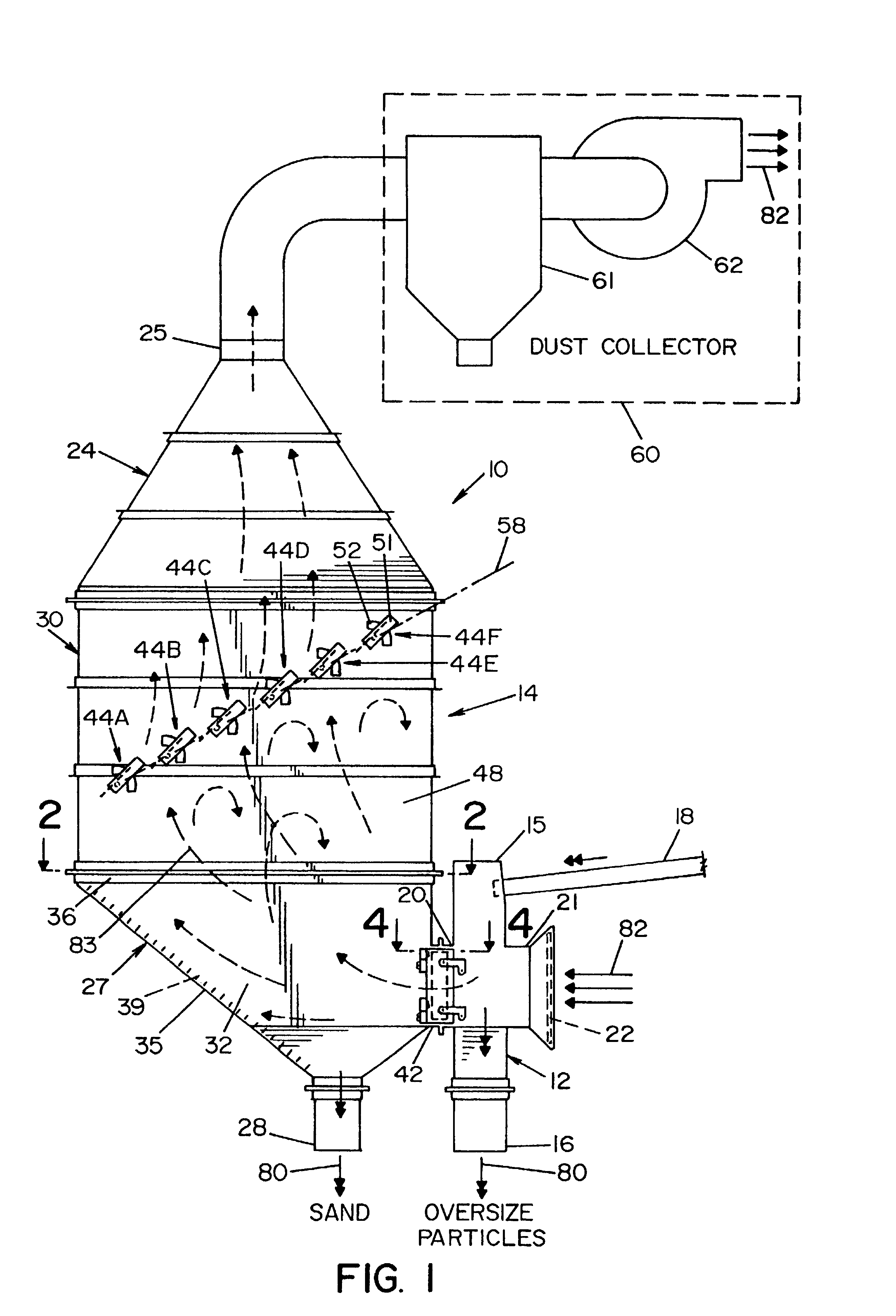

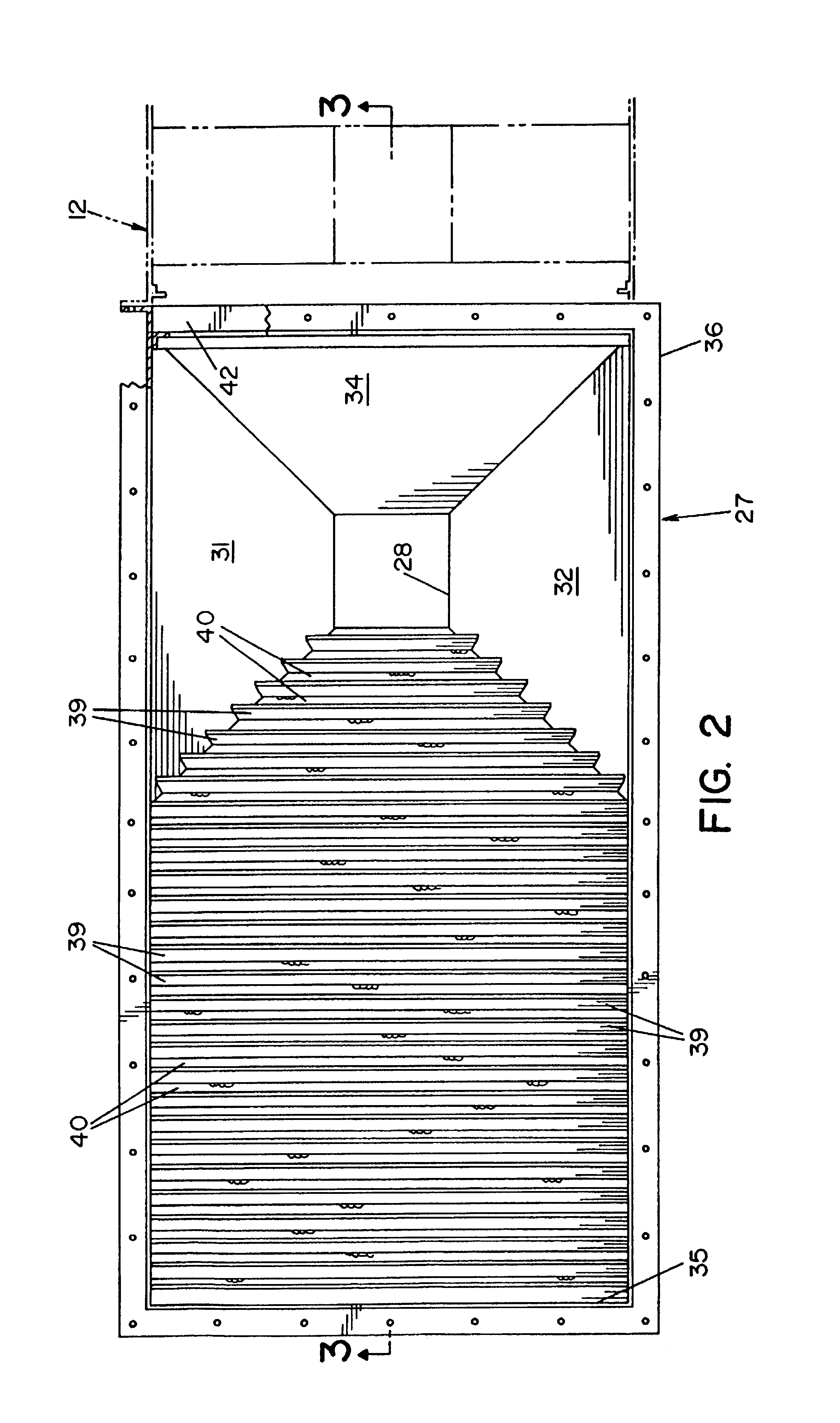

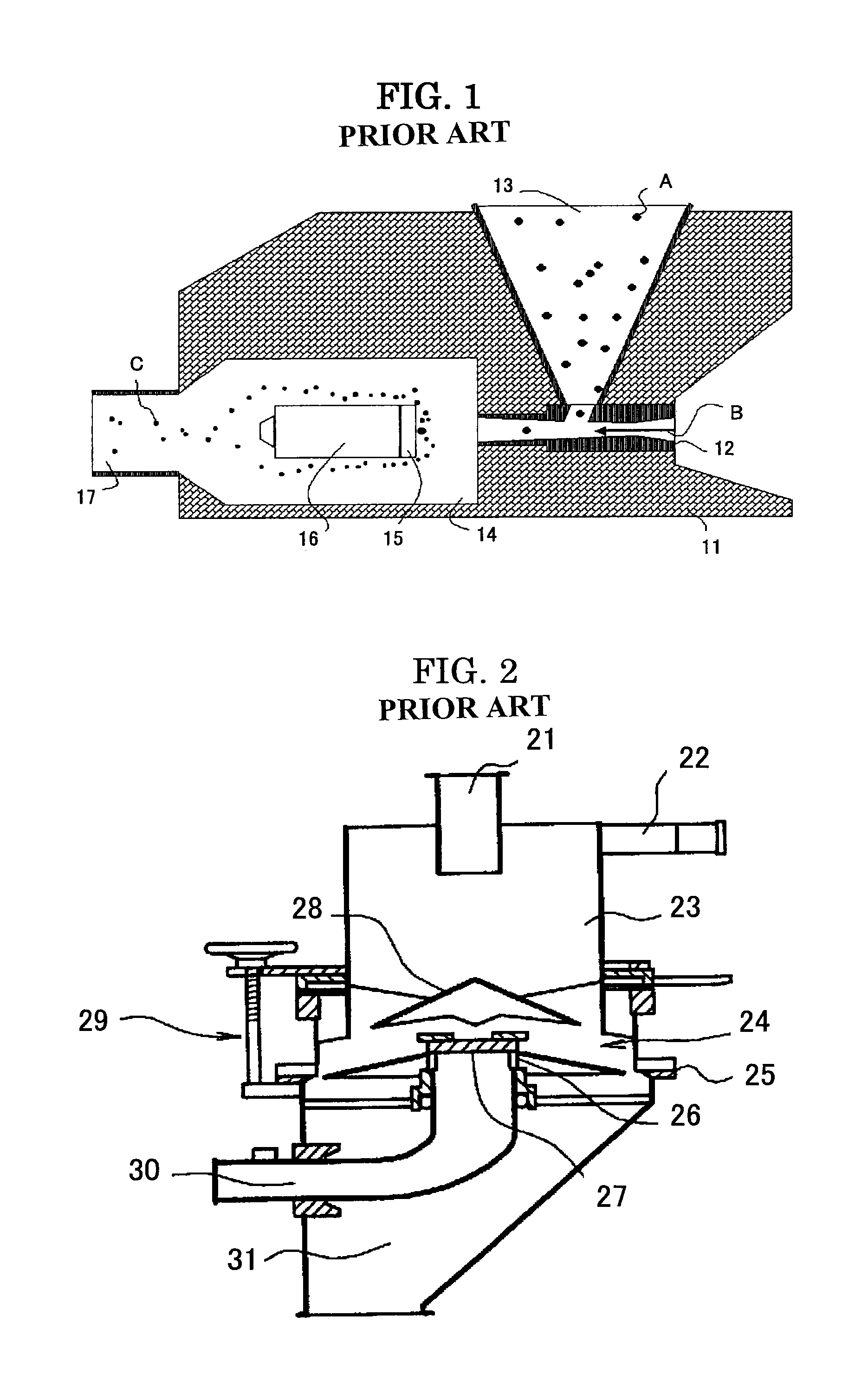

Static two stage air classifier

InactiveUS7104403B1Stable and consistent in operationGas current separationThreshersAir classifierLouver

A two-stage static air classifier has a feed duct through which particles of a granular mixture fall. A classifying louver plate having fins forming upwardly inclined classifying channels is fitted into a side opening in the feed duct. Particles of a set size are drawn by air suction through the classifying channels in the first stage. A separator box having an inlet connected to the outlet of the classifying channels collects the separated particles in a second stage as the entrained particles fall by gravity to the bottom of the separator box while the air streams drawing the particles through the classifying channels pass out the top end of the box. Adjustable baffle plates transversely extending through the box permit control of the quantity of fines collected with the particles at the separator box bottom. Size of the collected particles is determined by the speed of a fan at the top outlet of the separator box.

Owner:COVIA HLDG CORP

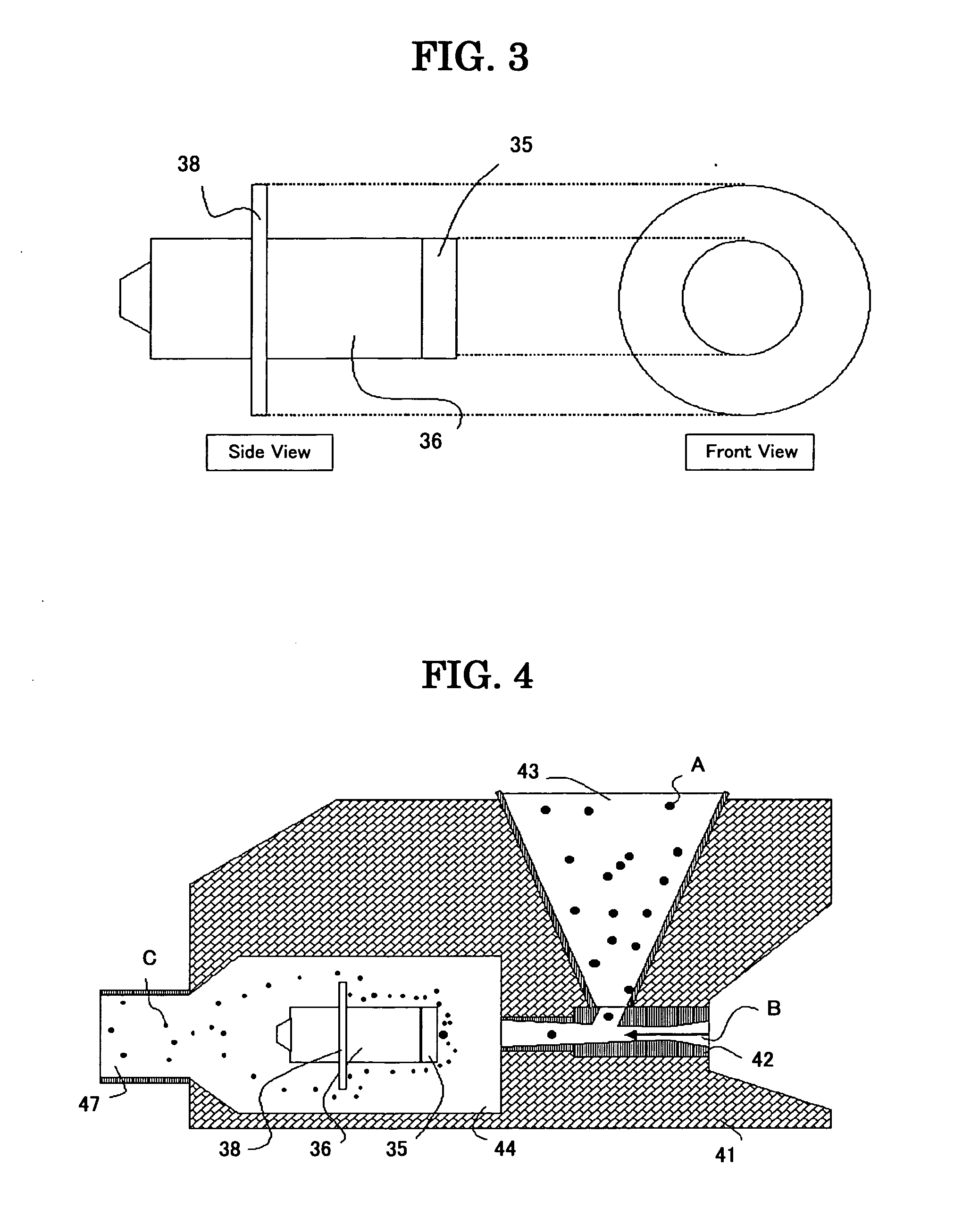

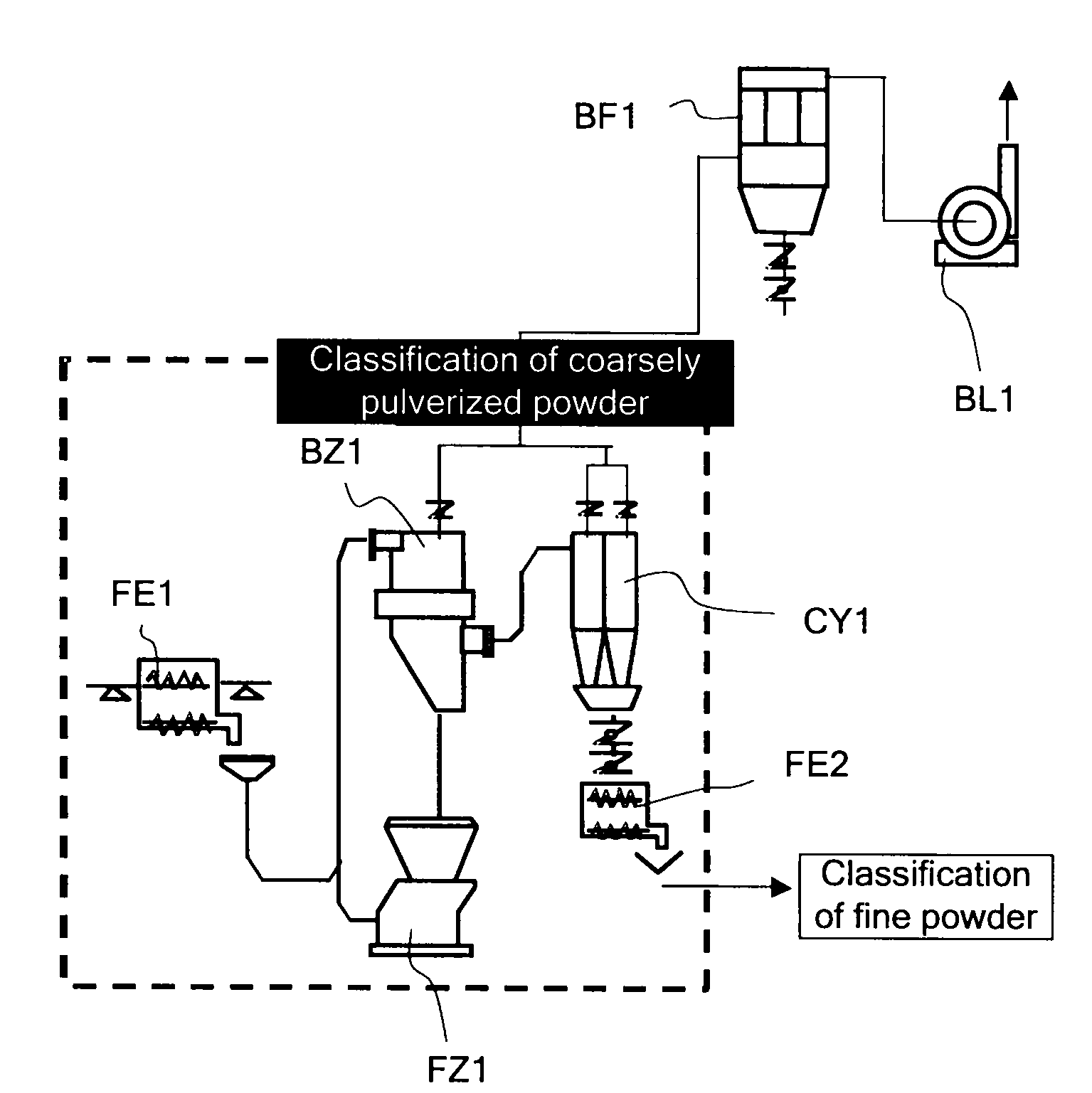

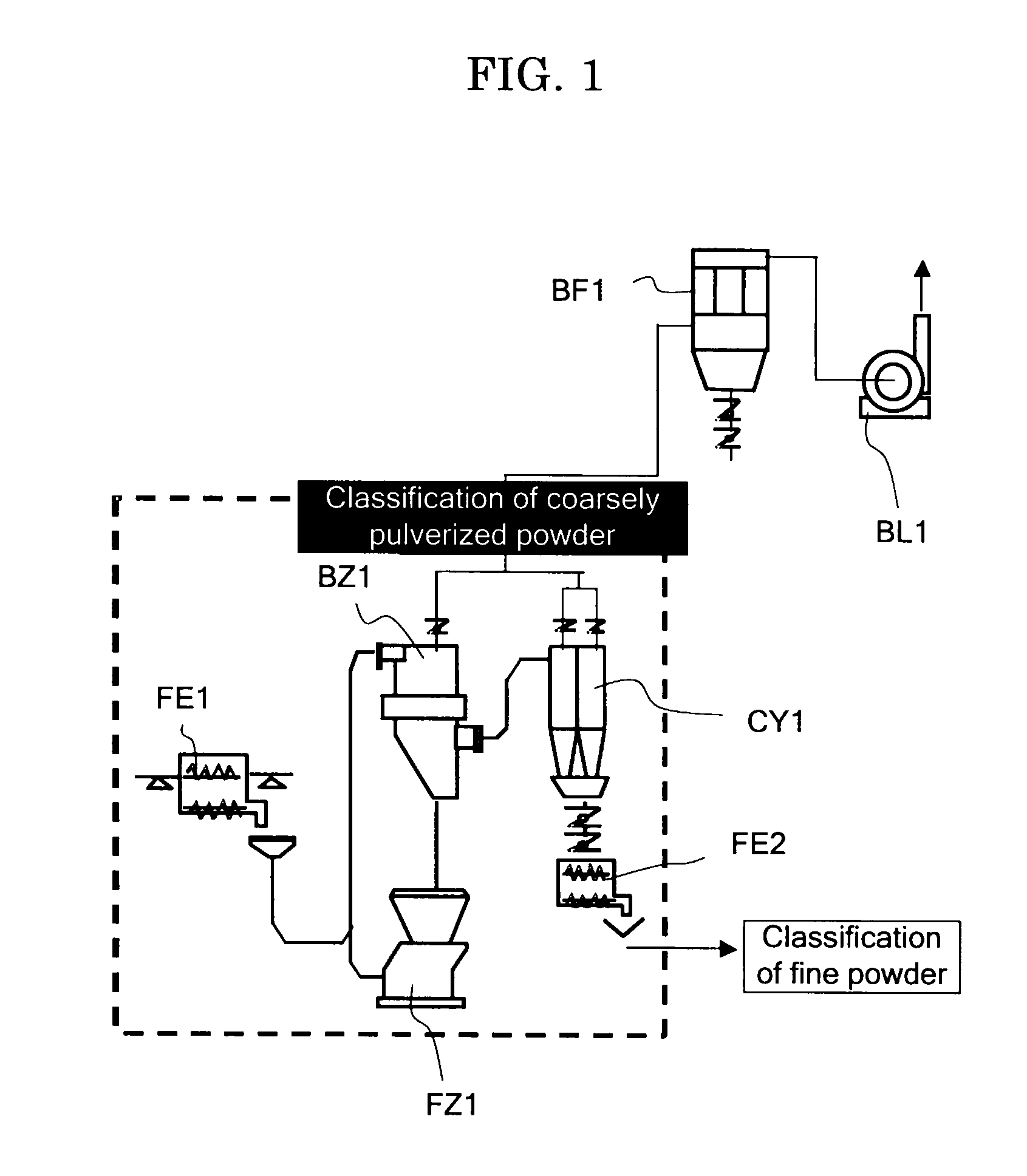

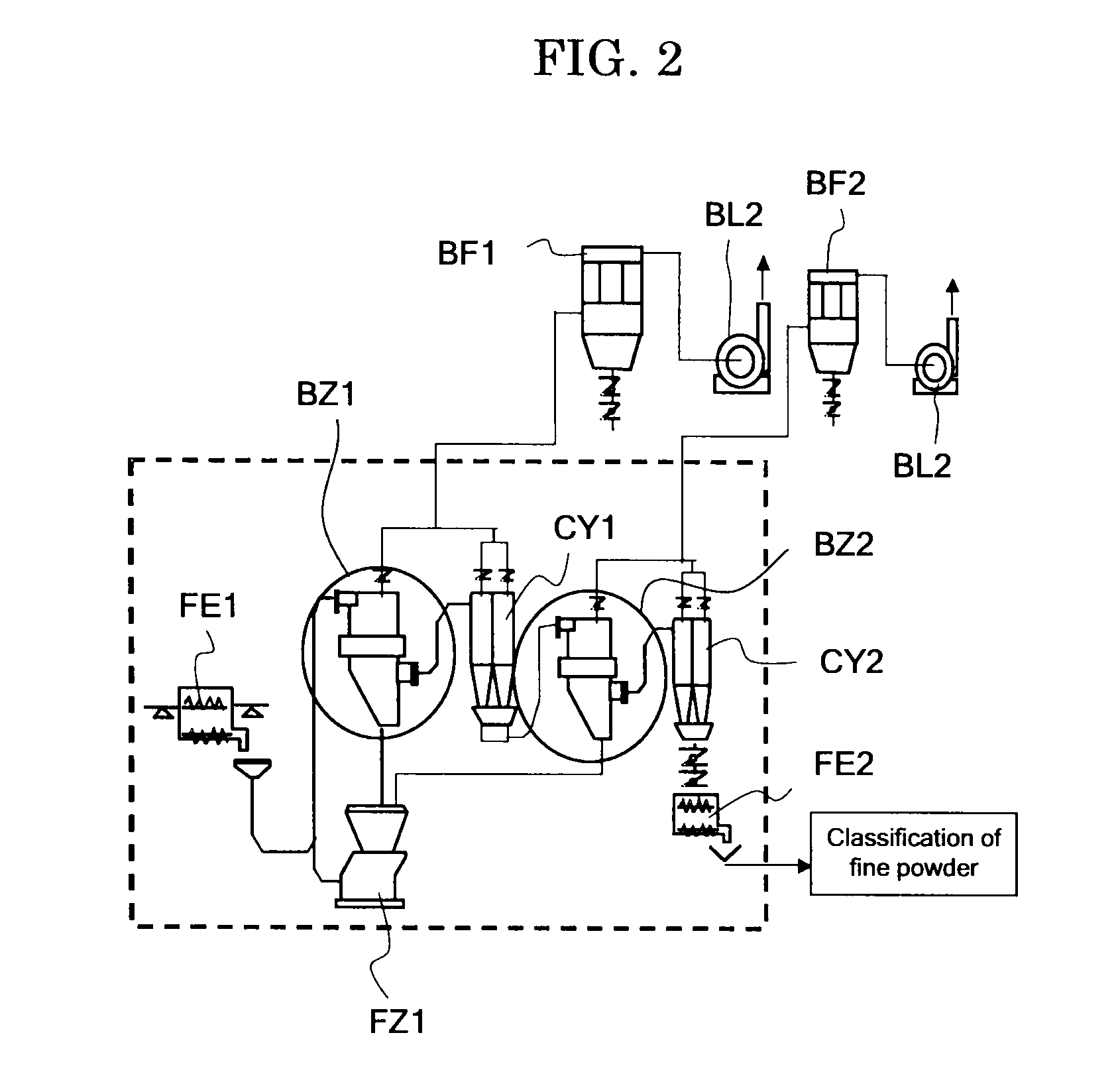

Milling and classifying apparatus, collision mill, air classifier, toner, and method for producing toner

ActiveUS20060032952A1Improve image qualitySmall particle sizeGas current separationDevelopersEngineeringAir classifier

Disclosed is a milling and classifying apparatus, adapted to produce toner fine particles, comprising a collision mill, and an air classifier, wherein the collision mill comprises a jet nozzle room, a path, a collision plate, and a collision member mounted to a support of the collision plate at downstream of the collision plate, the air classifier comprises a dispersion room and a classification room, the classification room is disposed below the dispersion room, and a flow stabilizer is arranged at a central suction of the separator core to control swirl stream generated within the classification room so as to centrifuge the powder into coarse particles and fine particles by action of the swirl stream.

Owner:RICOH KK

Method and apparatus for processing municipal waste

InactiveUS6945484B1Lower the volumeSpeed up the extraction processBio-organic fraction processingProductsThermal energySteam pressure

A method for processing municipal waste substantially reduces the volume of material to be disposed into a landfill by increasing the volume of materials of value collected from the municipal waste and by composting the remaining materials to create a salable product. The process includes the removal of materials of value by magnetic devices to extract ferrous materials, by an air classifier to extract light plastic materials, by an eddy current mechanism to extract aluminum materials, and by a plastic sort mechanism to extract large plastic materials. Composting can be accomplished with a composting vessel that is located in the process either before the materials of value are removed or afterward. A grinding of the materials before a final screening allows the commercial grade compost to be separated from the materials that are to be sent to the landfill for final disposal. An alternative embodiment of the process utilizes a steam pressure vessel to disintegrate the waste material and to destroy any pathogens before materials of value are removed and the small and fine materials are composted. Large materials can be gasified to create heat energy for use in the steam pressure vessel.

Owner:TERZINI ROBERT +1

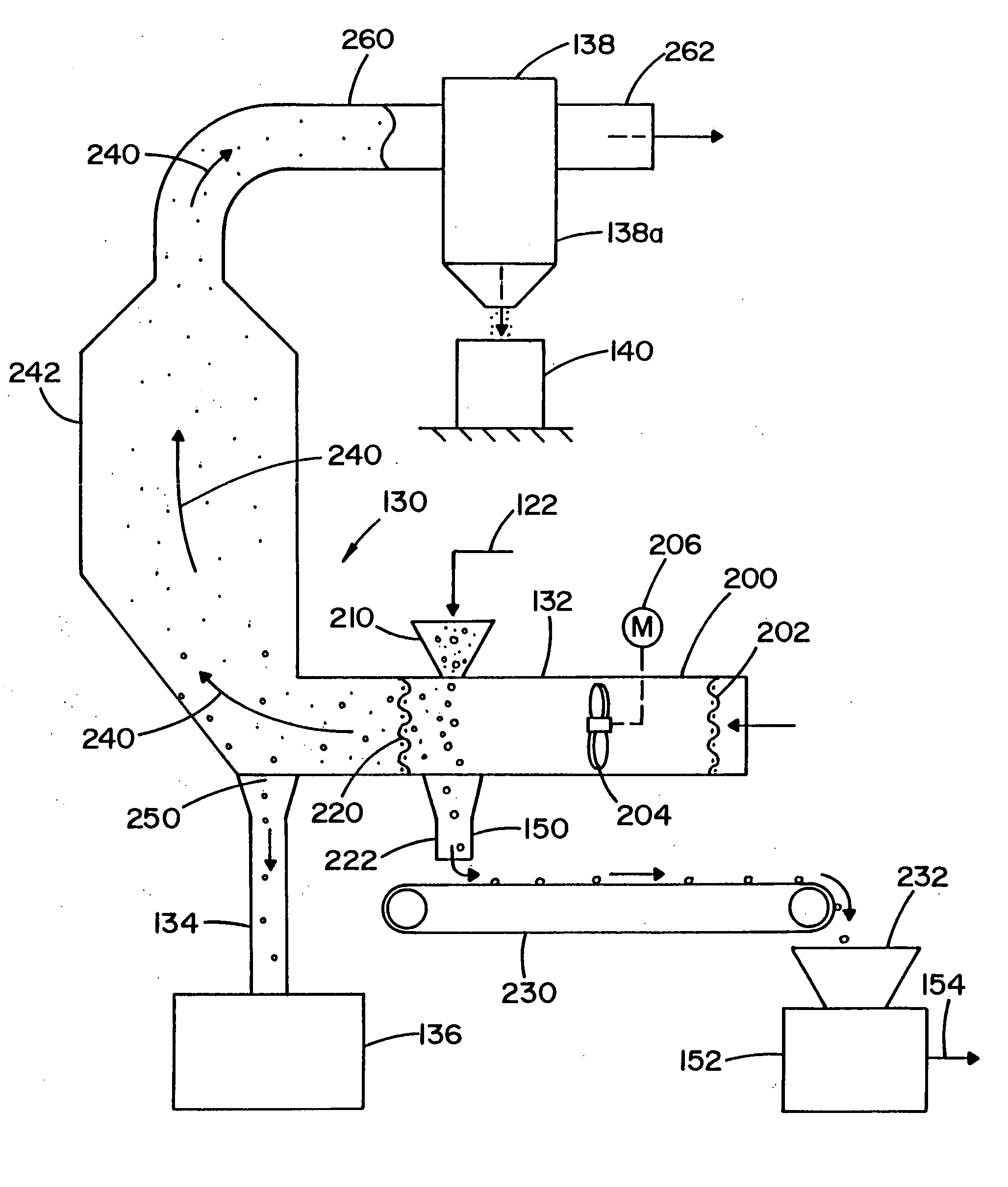

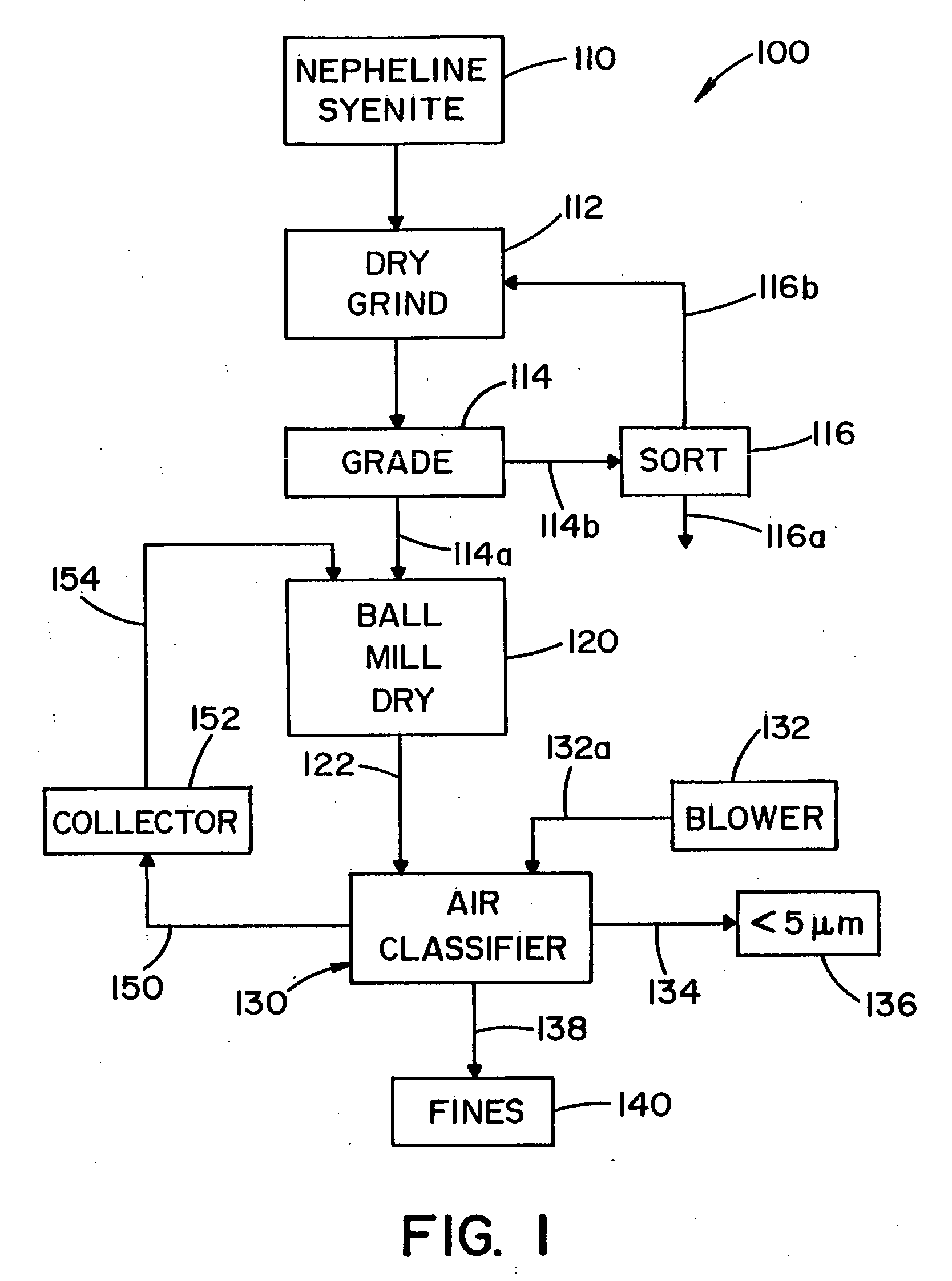

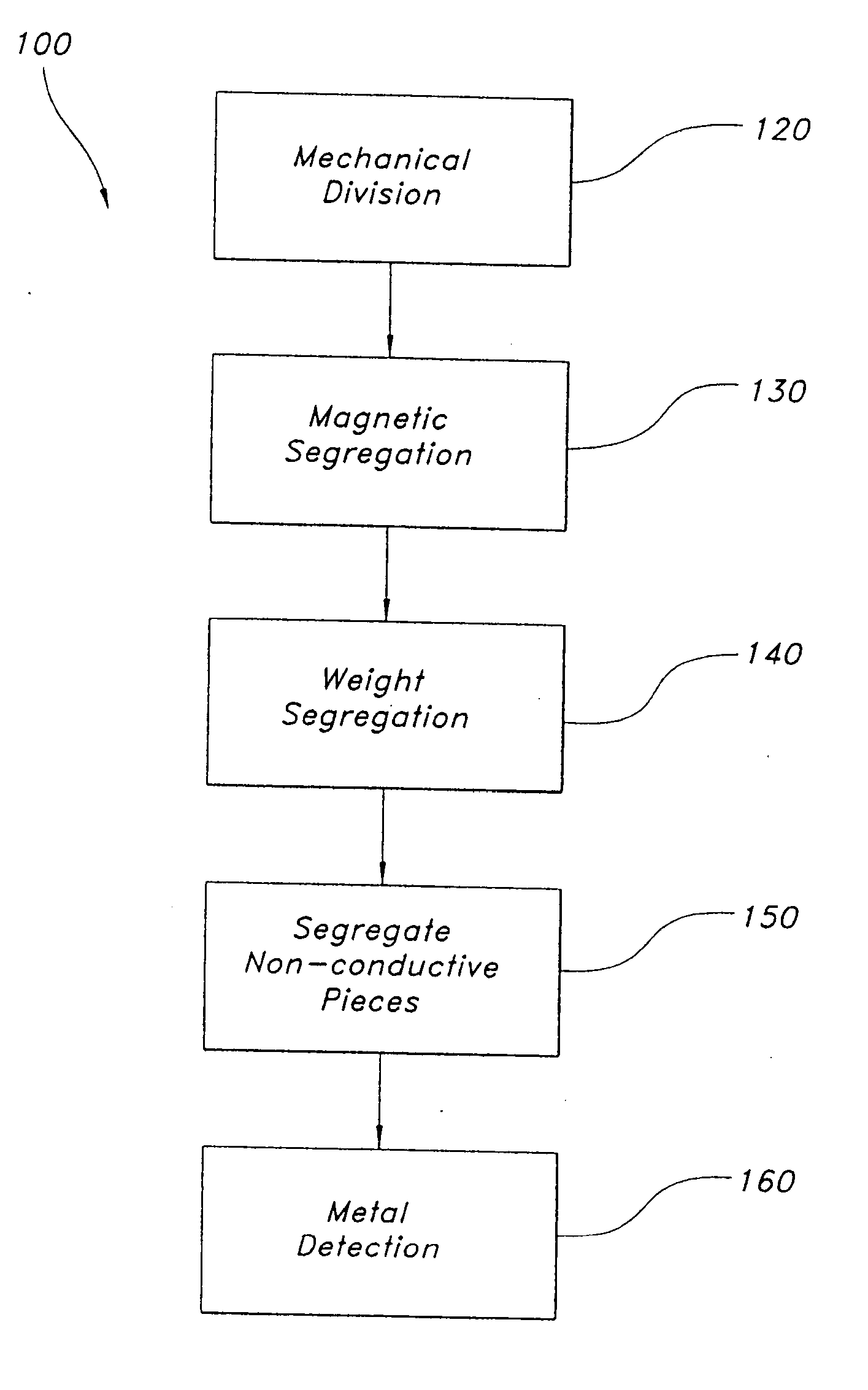

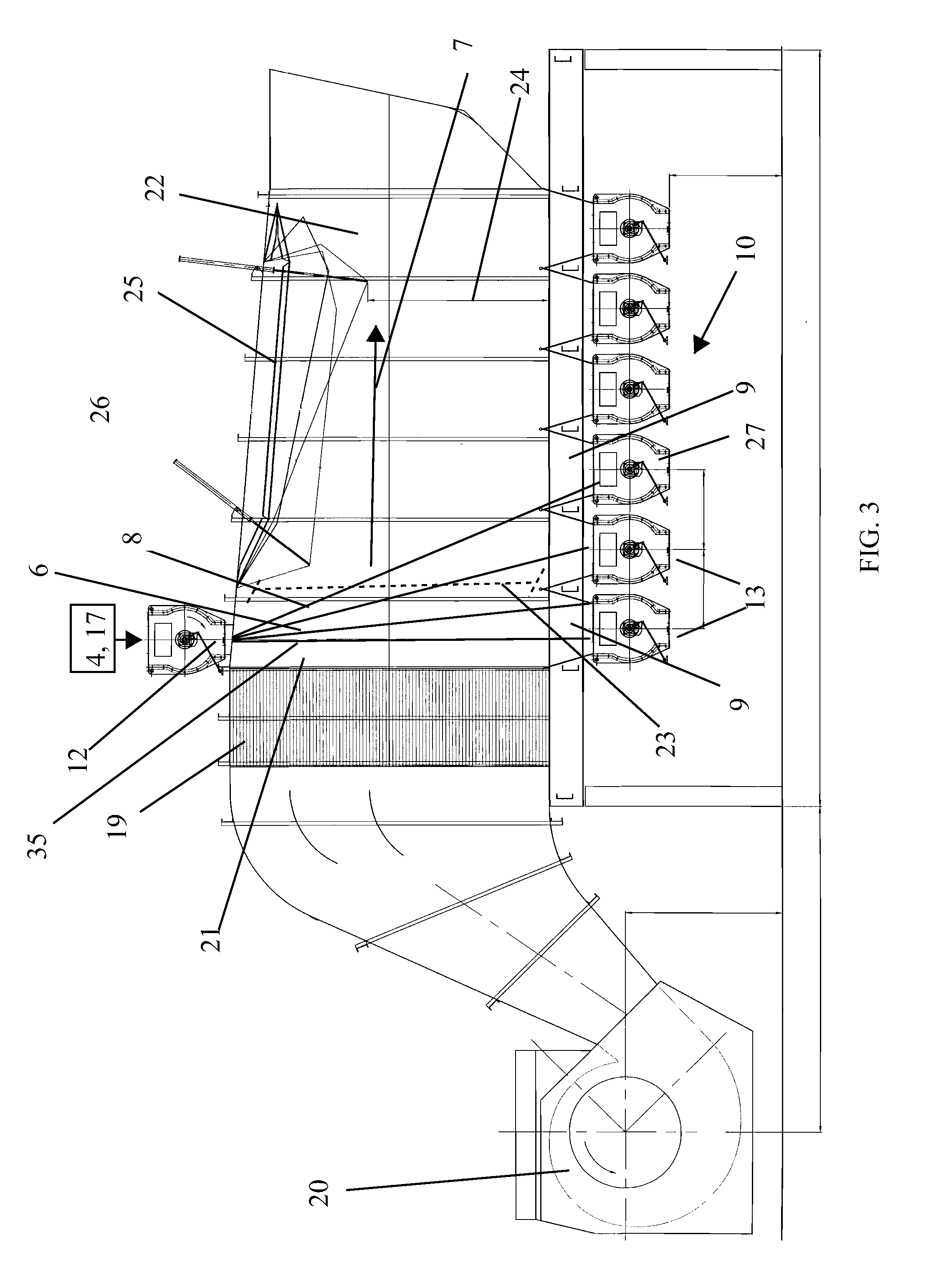

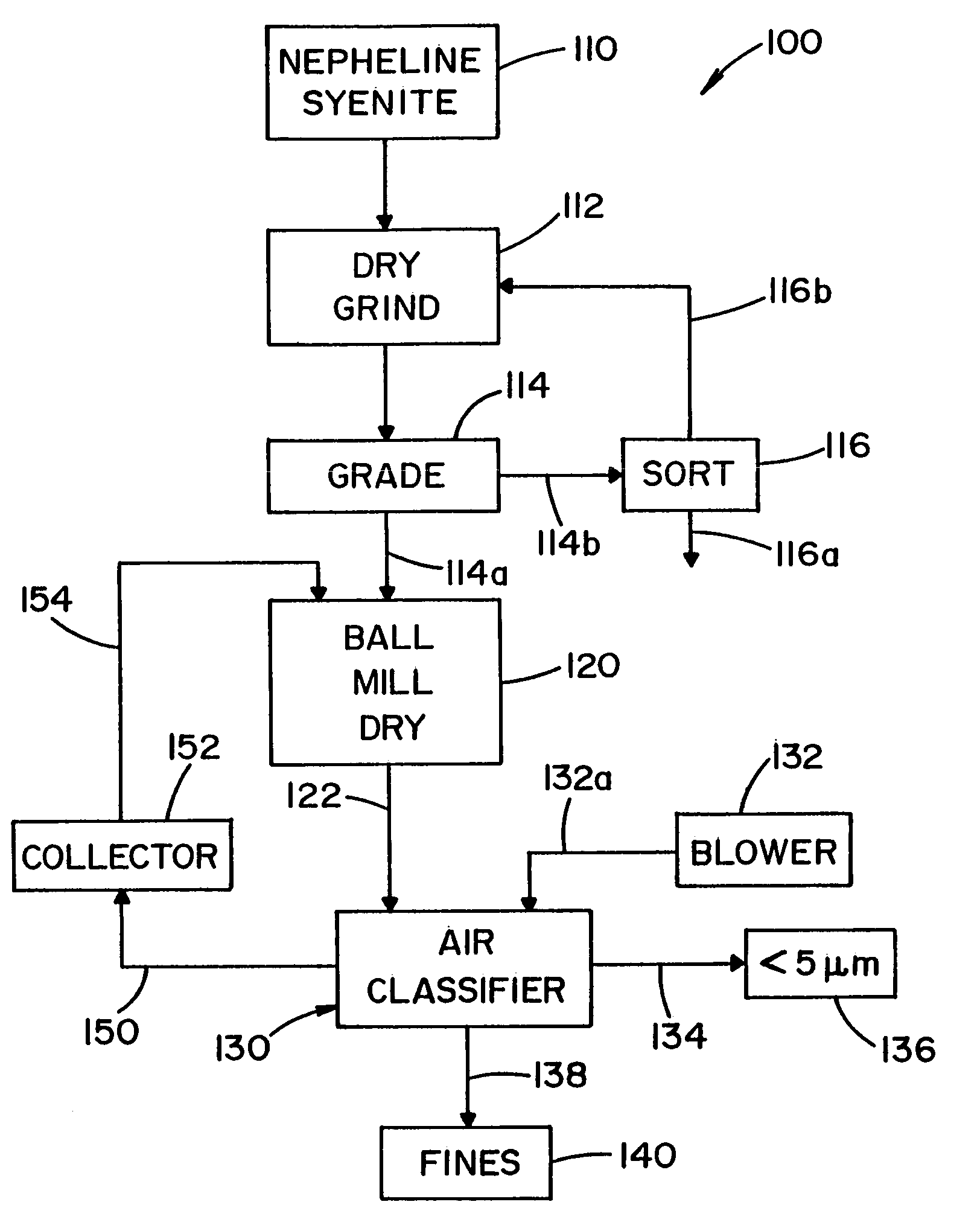

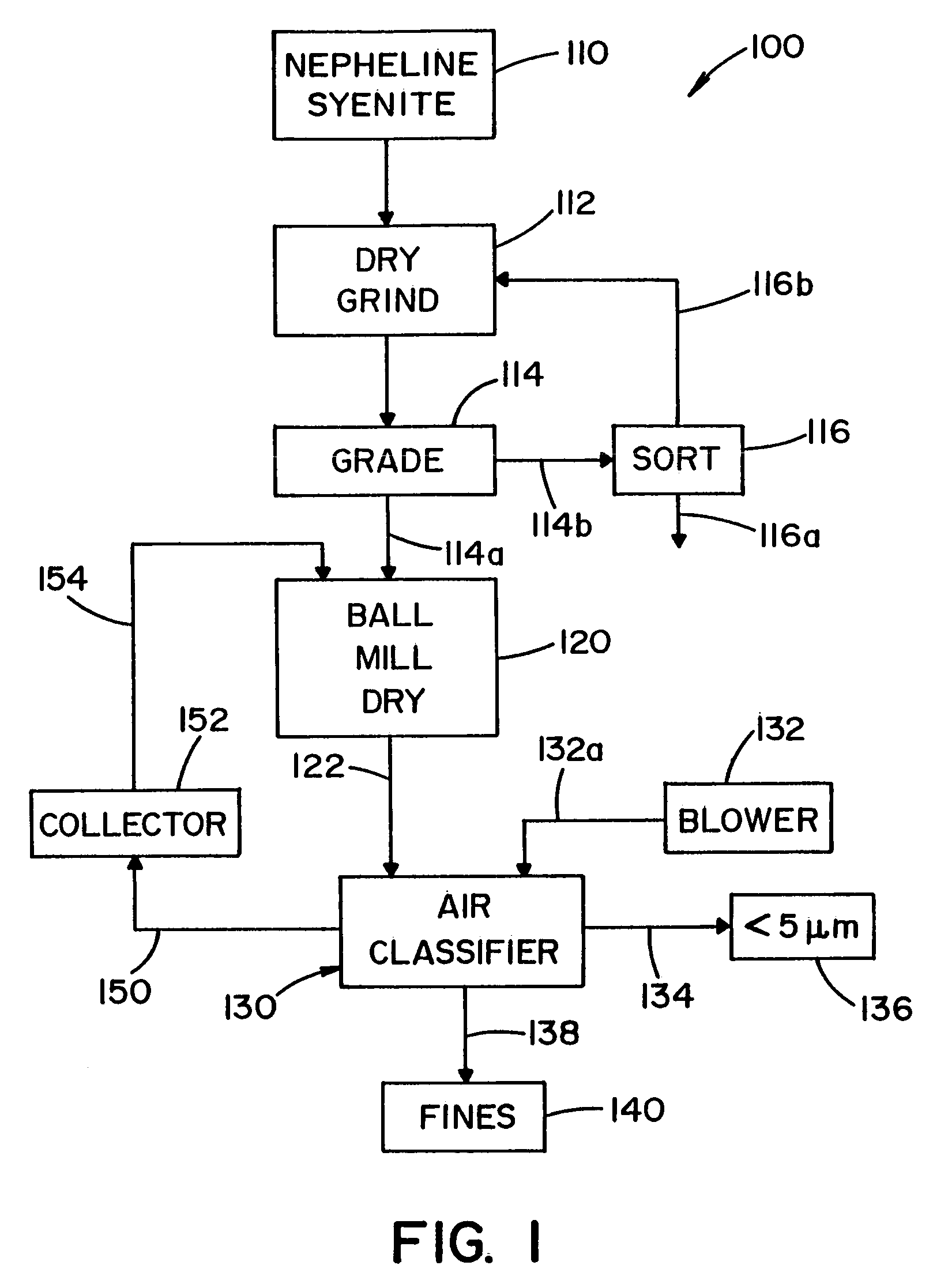

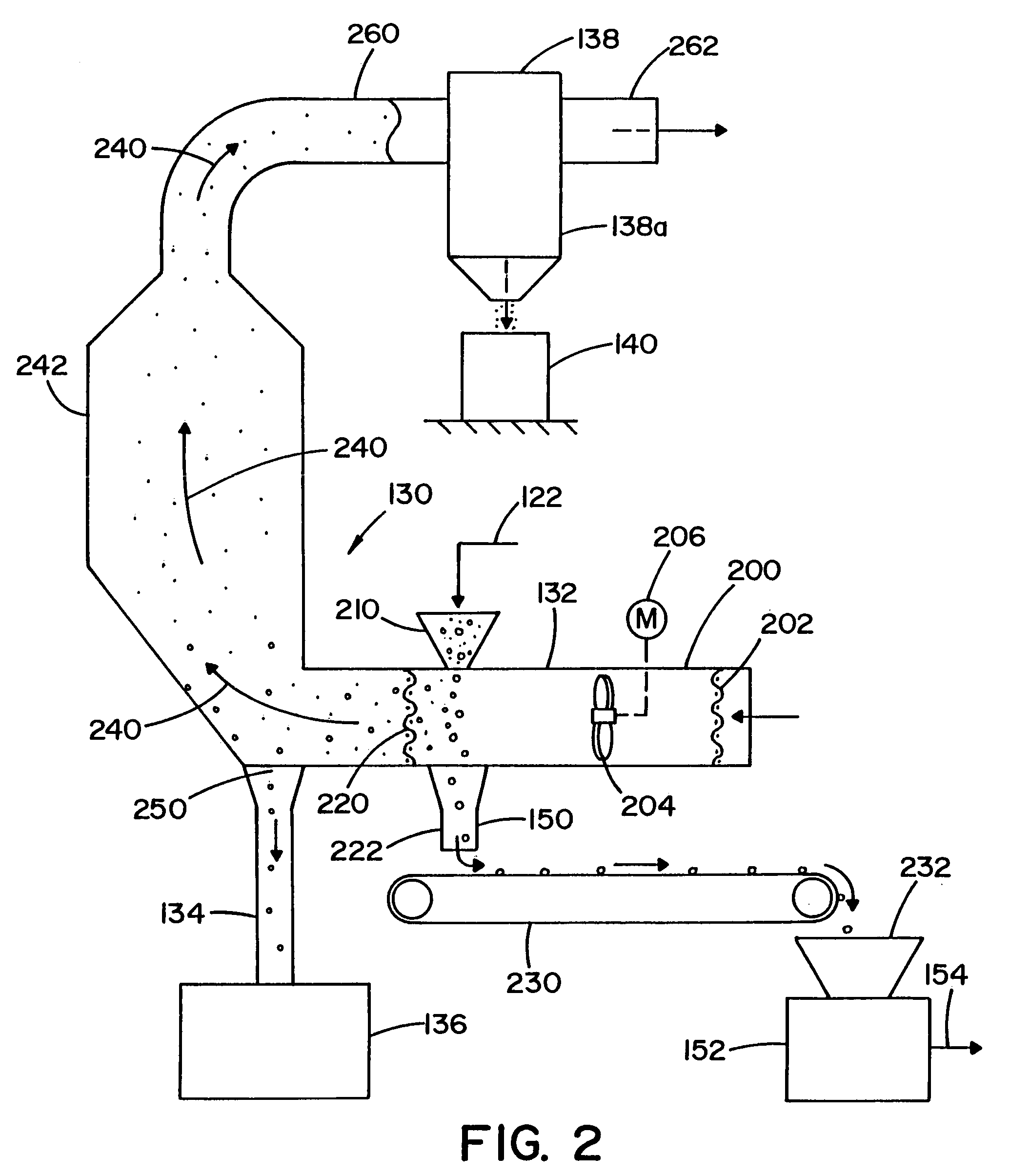

Method of processing nepheline syenite powder to produce an ultra-fine grain size product

The method of converting nepheline syenite particulate feedstock with a grain size profile to an ultra-fine grain finish product for subsequent commercial use, the ultra-fine grain final product has a maximum grain size of less than about 6 microns. The method comprising: providing a dry feedstock with a controlled maximum particle size greater than about 20 microns; grinding the feedstock in a dry state by passing the feedstock vertically downward through a continuous, high-speed stirred ball mill whereby the feedstock is ground into an intermediate powder having a drastically reduced grain size profile than the grain size profile of the feedstock; and passing the intermediate powder from the mill through an air classifier using a rapidly moving high speed air stream moving along a given path to convey the ultra-fine grain product along the path and from the classifier and to allow coarse particulate material including particles larger than the ultra-fine product to be separated and then expelled from the classifier.

Owner:COVIA HLDG CORP

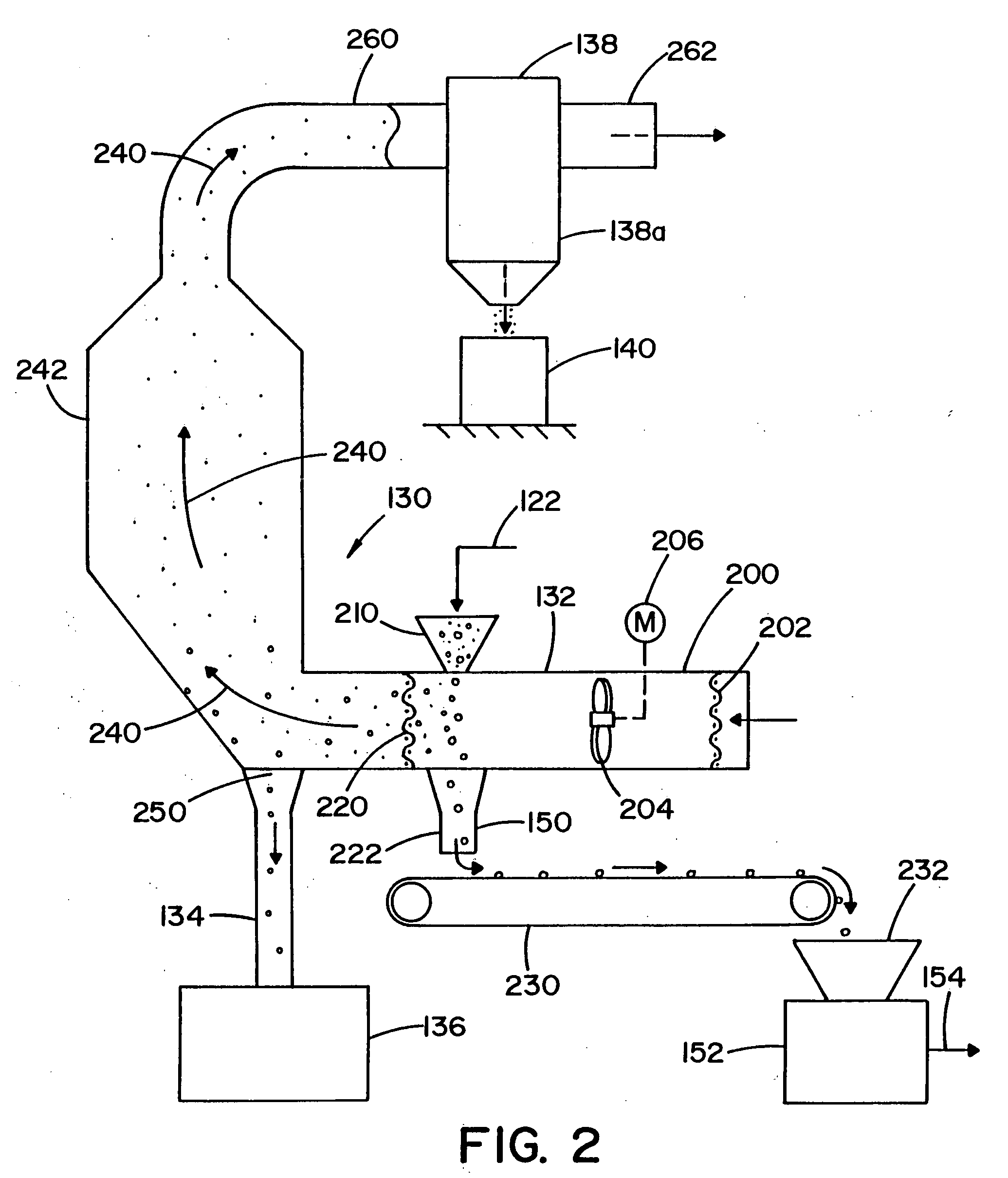

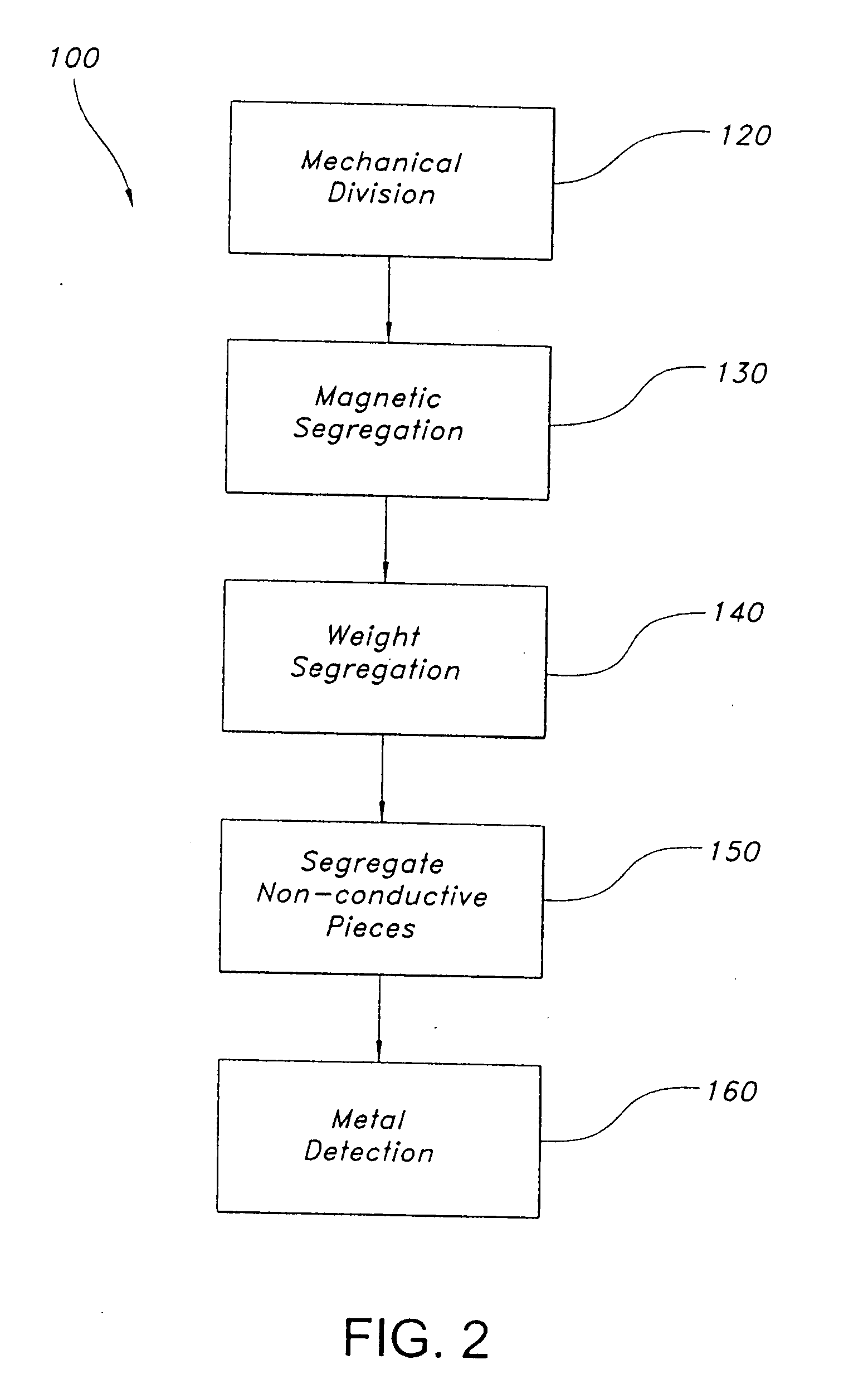

System and process for reclaiming and recycling plastic

A process for reclaiming and recycling plastic from discarded articles includes dividing discarded materials into a plurality of pieces by mechanical force, removing relatively non-magnetic pieces from the plurality of pieces, separating out relatively heavy pieces from the non-magnetic pieces, segregating relatively non-conductive pieces from the relatively heavy pieces, and reclaiming plastic pieces from the relatively non-conductive pieces. The plastic pieces are processed in an injection molding machine to mold plastic product. A system for reclaiming plastic from discarded materials includes a crusher for dividing the discarded materials into a plurality of pieces, a magnetic separator for removing relatively non-magnetic pieces from the plurality of pieces, an air classifier for separating out relatively heavy pieces from the non-magnetic pieces, an electrostatic separator for segregating relatively non-conductive pieces from the relatively heavy pieces, and a metal detector for separating out plastic pieces from the relatively non-conductive pieces.

Owner:TYCO HEALTHCARE GRP LP

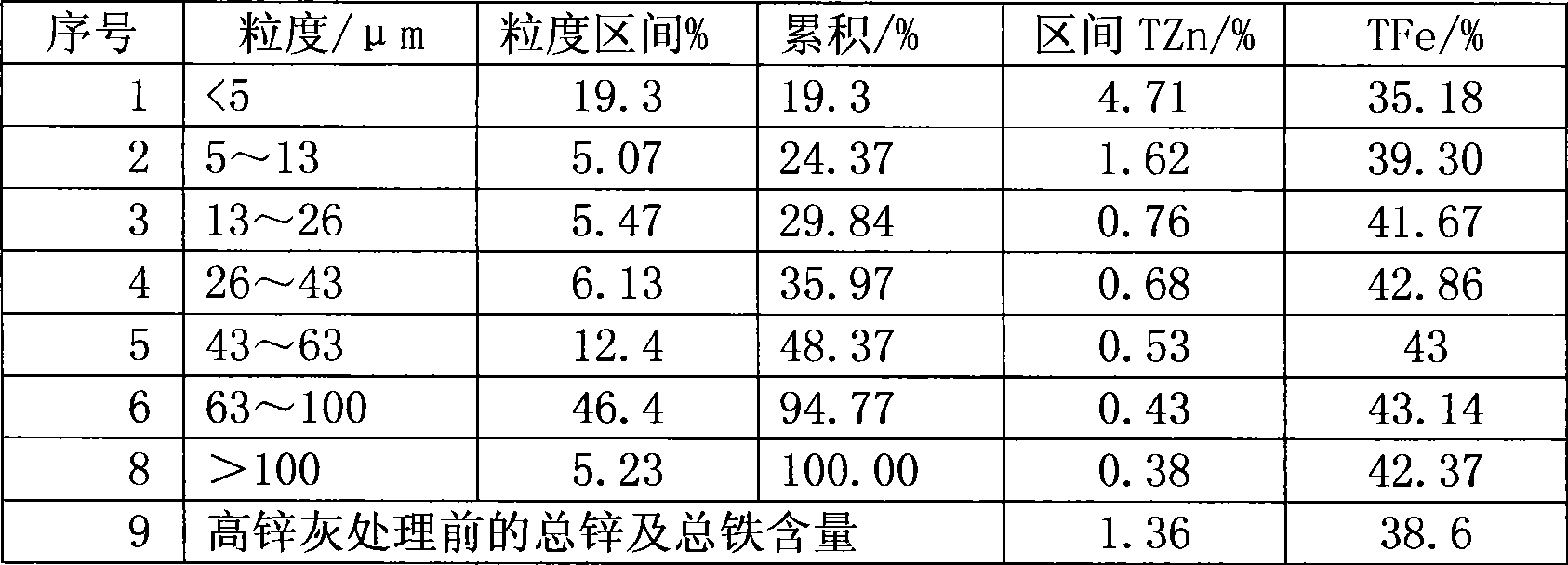

Method for separating zinc-containing substance of blast furnace dry method dust separation ash

ActiveCN101428278AImprove matchNovel and flexible methodCombination devicesGas current separationAir volumeAir classifier

The invention discloses a method for separating zinc contained material from blast furnace gas dry precipitator dust, and the pretreatment for the blast furnace gas dry precipitator dust achieves the purpose of reducing dezincing load at the terminal of the blast furnace gas dry precipitator dust. The key points are that the blast furnace gas dry precipitator dust is absorbed into the main machine of an air classifier through negative pressure with a vacuum degree of 0.4 to 0.6 kgf / cm<2> which is produced by a Roots blower. Self shunt can be realized in a gravity field, most of thick grains deposit on the bottom part of the classifier, the rotating speed of the classified wheel of the classifier main machine can be adjusted within a scope of 2000 rpm to 9000 rpm, the supply air volume is also adjusted, a secondary assorted cut is performed on the fine grained precipitator dust, and a high zinc contained precipitator dust accounting for 10 to 30 percent of the inlet amount can be cut out, and the high zinc contained precipitator dust can be packed by a packaging machine for other treatment after being collected. The invention can be used for recycling low zinc ash of which low zinc ash is no less than 75 percent and the total content of zinc is less than 1 percent, and is applicable to pretreatment for dezincification of the blast furnace gas dry precipitator dust, and zinc accumulation during the reusing process of high zinc contained precipitator dust is reduced.

Owner:SHOUGANG CORPORATION

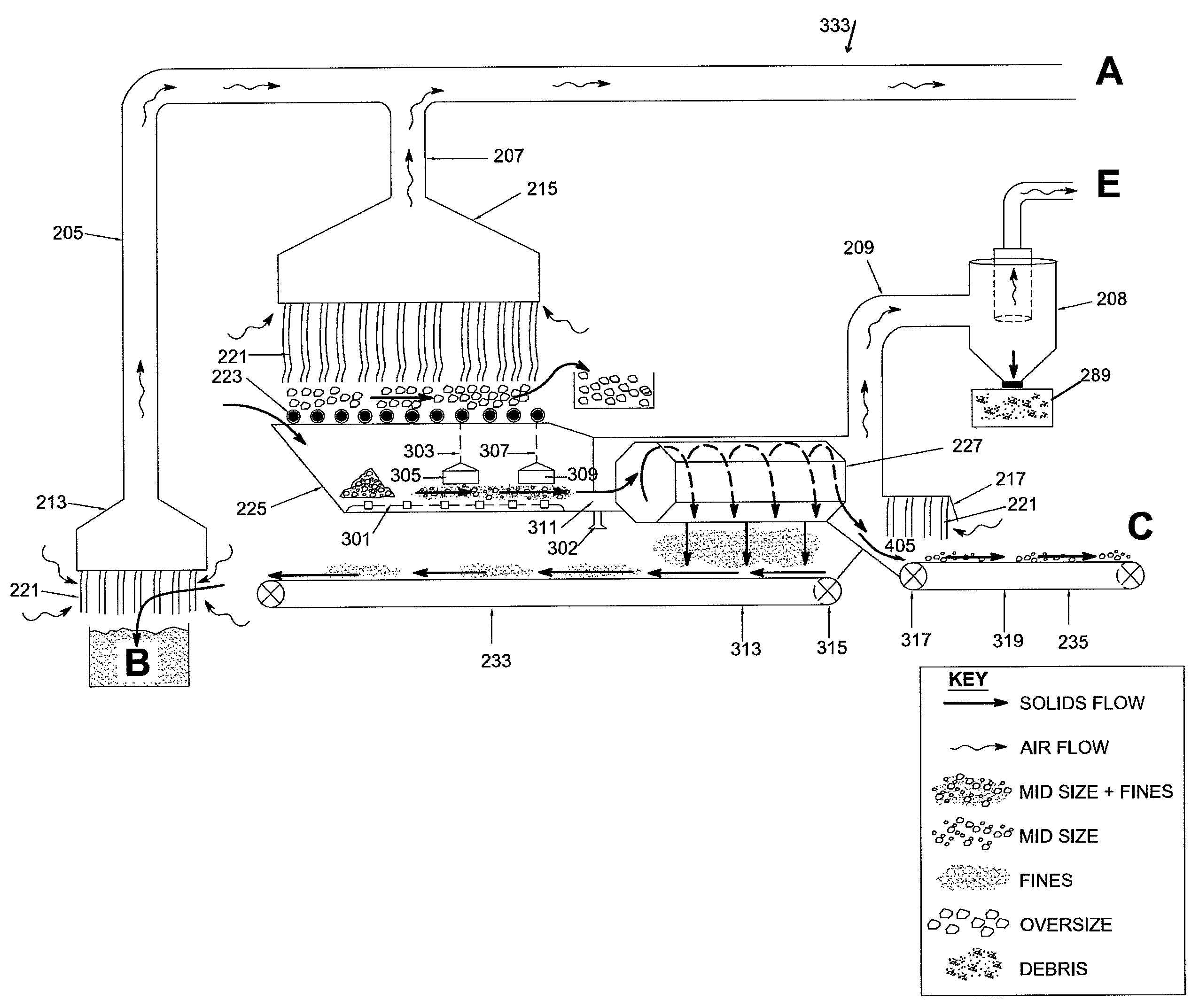

Isotropic Quantization Sorting Systems of Automobile Shredder Residue to Enhance Recovery of Recyclable Materials

ActiveUS20130092609A1Easy to sortReduce wasteGas current separationPlastic recyclingNonferrous metalMicroparticle

Systems and methods for increasing recyclable material recovery from automobile shredder residue (4). Embodiments include separation of automobile shredder residue with a sorting system (5) such as an air sorting system, a non-ferrous automobile shredder residue air sorter, an air-locked automobile shredder residue sorting system, a non-magnetic magnetic sorter, a substantially isotropic quantization sorting system, an air-locked Z-box air classifier, low susceptance microparticle separator, a magnetic fuzz separator, a wind tunnel system, or the like perhaps with substantially horizontal laminar air flow (7) and can be used with or without out other traditional automobile shredder residue sorting systems (16) or (15) perhaps creating additional recyclable quantities and even better separated results such as with zorba and zurik and the like.

Owner:IQASR

Method for recovering waste slurry of multiline cut silicon chips

InactiveCN101513753AReduce clumpingIncrease added valueWorking accessoriesFine working devicesRecovery methodSorbent

The invention discloses a method for recovering waste slurry of multiline cut silicon chips. The method comprises the following steps: recovered waste slurry is diluted by a cutting fluid to 20 to 25 percent of solid mass; particles of a silicon carbide blade material thicker than 6 microns are separated by a continuous centrifugal separation method; residue containing silicon carbide micro powder thinner than 6 microns and cutting fluid slurry of silicon micro powder are pressed into a filter mass by a presser; the filter mass is dried by microwave; the filter mass is subjected to a stage treatment of the silicon carbide micro powder and the silicon micro power by an air classifier; after the pressed cutting fluid and steam of the cutting fluid are filtered by a filter, residual impurities in the fluid is subjected to adsorption and impurity removal by floridin sorbent, and is filled and recovered through dehydration and decolorization. The method has the advantages that in the treatment on the waste slurry, the whole production process does not have any pollution, does not consume water, saves energy consumption over 70 percent, and has product recovery ratio over 98 percent.

Owner:平顶山市中奥磨料有限公司

Method of processing nepheline syenite powder to produce an ultra-fine grain size product

The method of converting nepheline syenite particulate feedstock with a grain size profile to an ultra-fine grain finish product for subsequent commercial use, the ultra-fine grain final product has a maximum grain size of less than about 6 microns. The method comprising: providing a dry feedstock with a controlled maximum particle size greater than about 20 microns; grinding the feedstock in a dry state by passing the feedstock vertically downward through a continuous, high-speed stirred ball mill whereby the feedstock is ground into an intermediate powder having a drastically reduced grain size profile than the grain size profile of the feedstock; and passing the intermediate powder from the mill through an air classifier using a rapidly moving high speed air stream moving along a given path to convey the ultra-fine grain product along the path and from the classifier and to allow coarse particulate material including particles larger than the ultra-fine product to be separated and then expelled from the classifier.

Owner:COVIA HLDG CORP

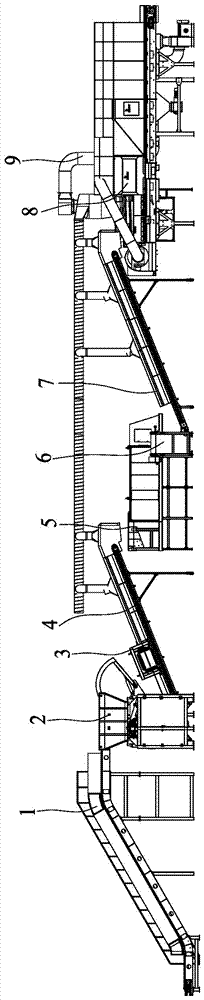

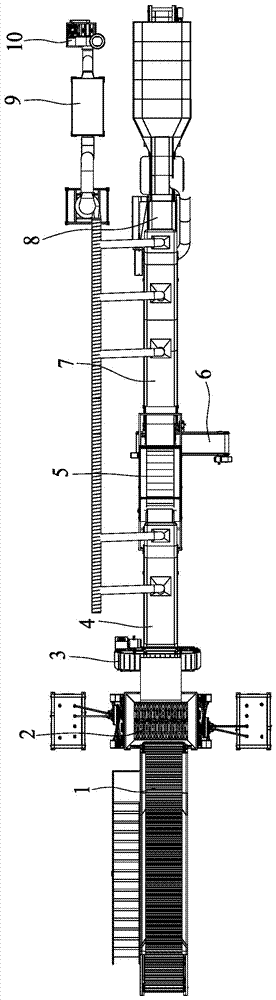

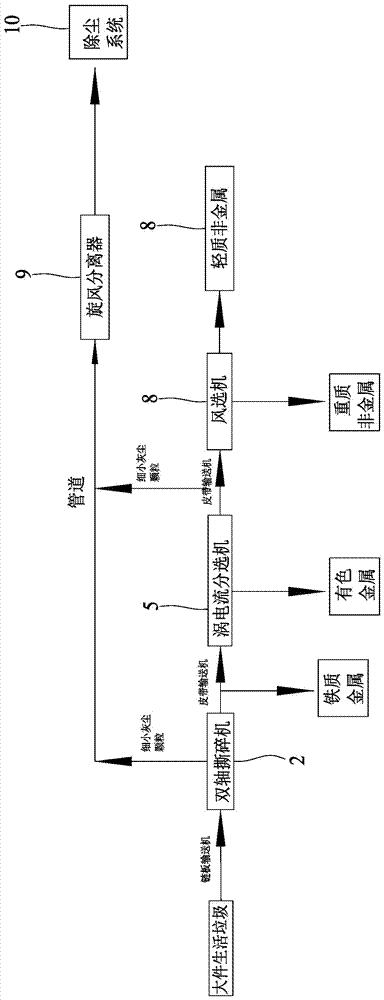

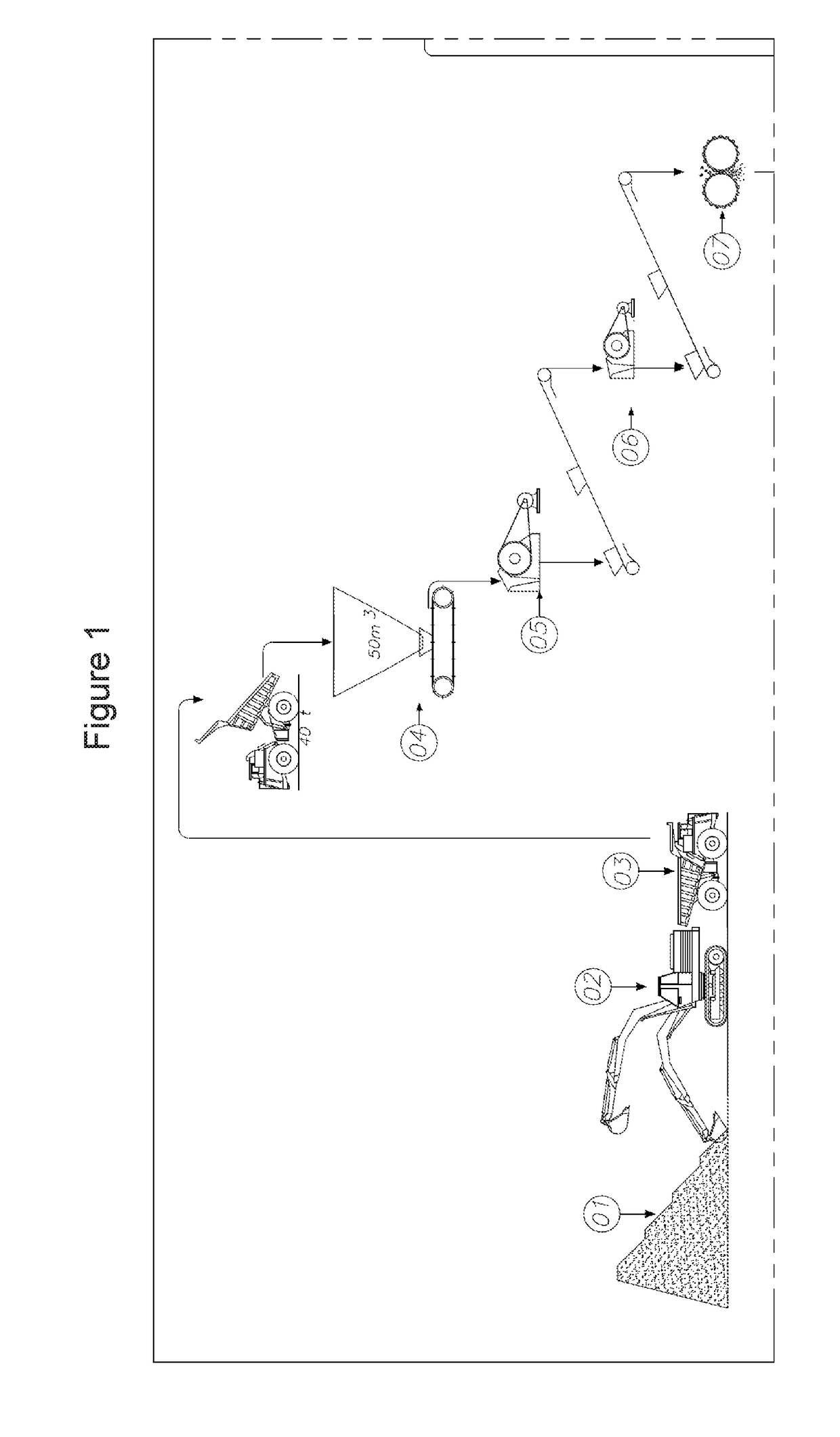

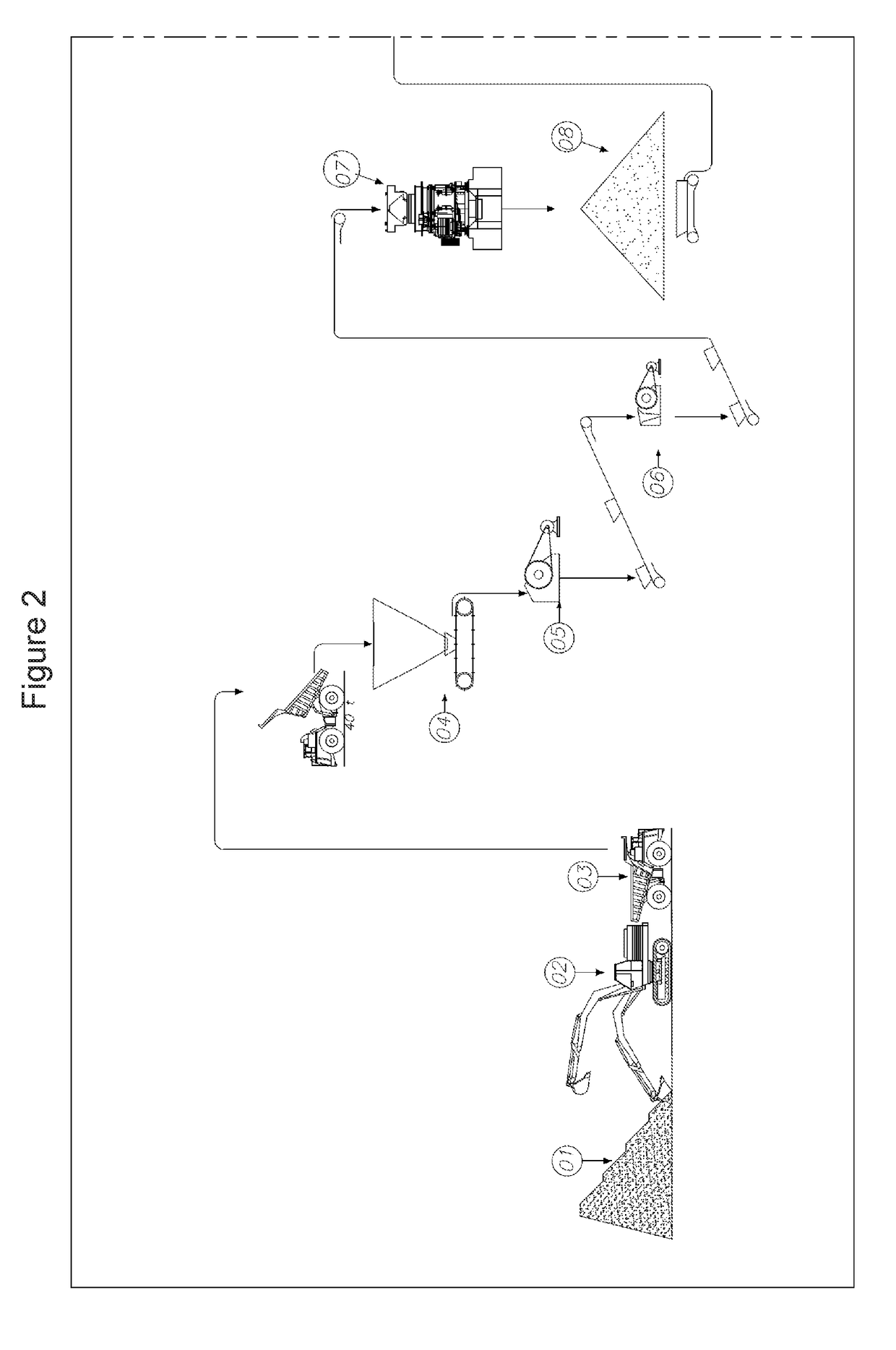

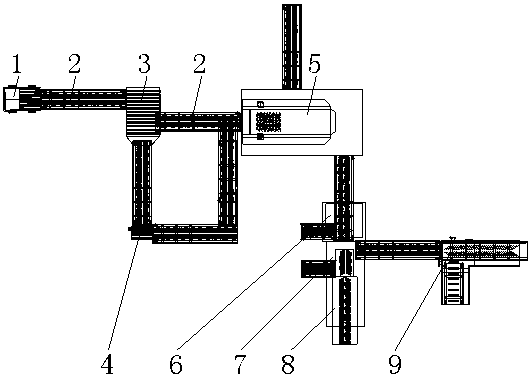

Large-sized garbage crushing and separating equipment and process

PendingCN106903138ASmall sizeRealize automatic sortingTransportation and packagingSolid waste disposalEddy current separatorAir classifier

The invention discloses large-sized garbage crushing and separating equipment and process. The large-sized garbage crushing and separating equipment comprises a chain scraper conveyor, a double-shaft shredder, a first belt conveyor, a magnetic separator, an eddy current separator, a discharged material belt conveyor, a second belt conveyor, an air classifier, a cyclone separator and a dust collector. The chain scraper conveyor, the double-shaft shredder, the first belt conveyor, the eddy current separator, the second belt conveyor and the air classifier are sequentially connected; the magnetic separator is mounted above the first belt conveyor; and the feeding end of the discharged material belt conveyor is connected with non-ferrous metal discharged by the eddy current separator. Large-sized household garbage can be treated by the chain scraper conveyor and the double-shaft shredder, crushed materials can be automatically separated by the magnetic separator and the eddy current separator, and dust produced in the crushing process can be efficiently treated by the cyclone separator and the dust collector, so that no secondary pollution is caused.

Owner:HUANCHUANG XIAMEN TECH

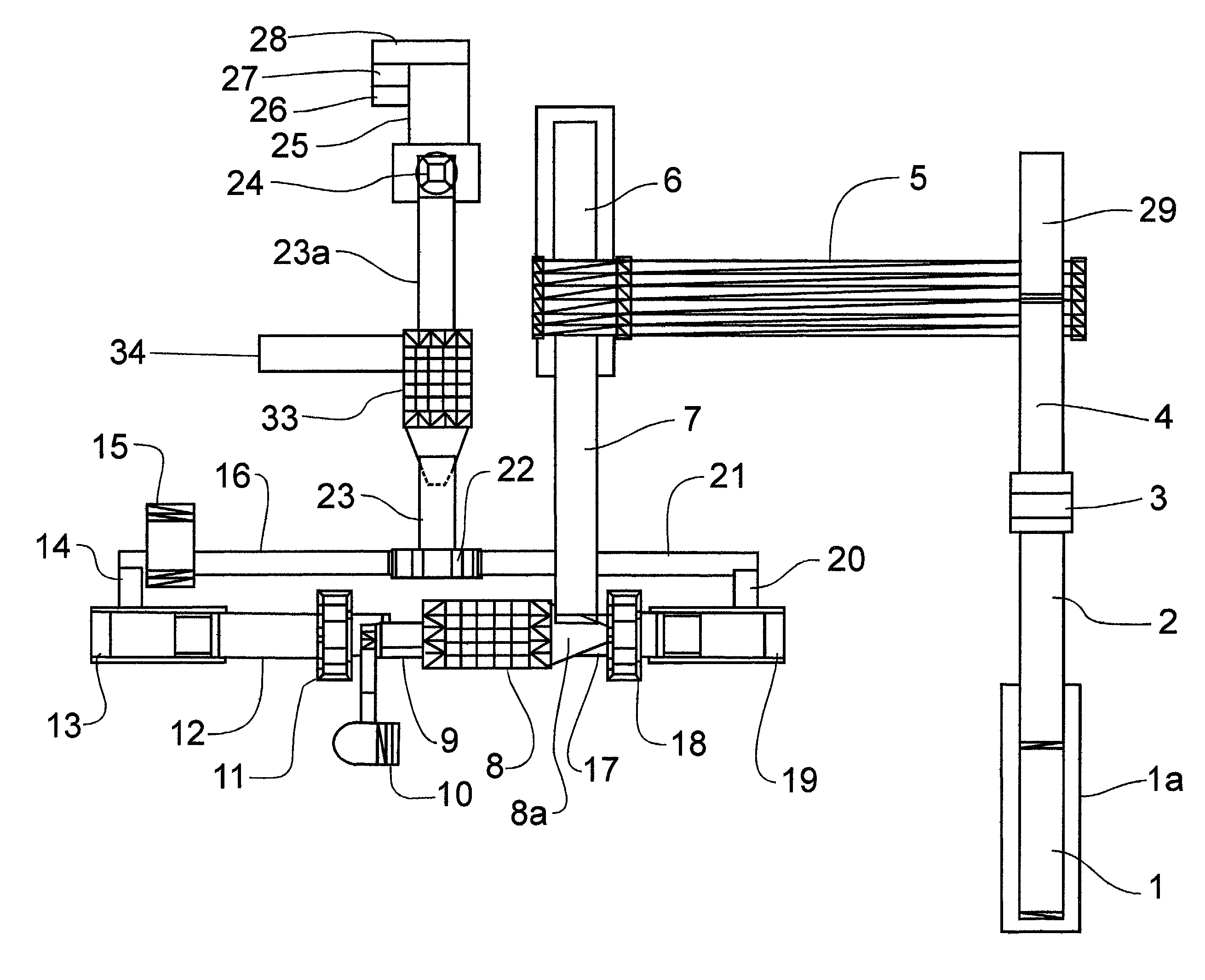

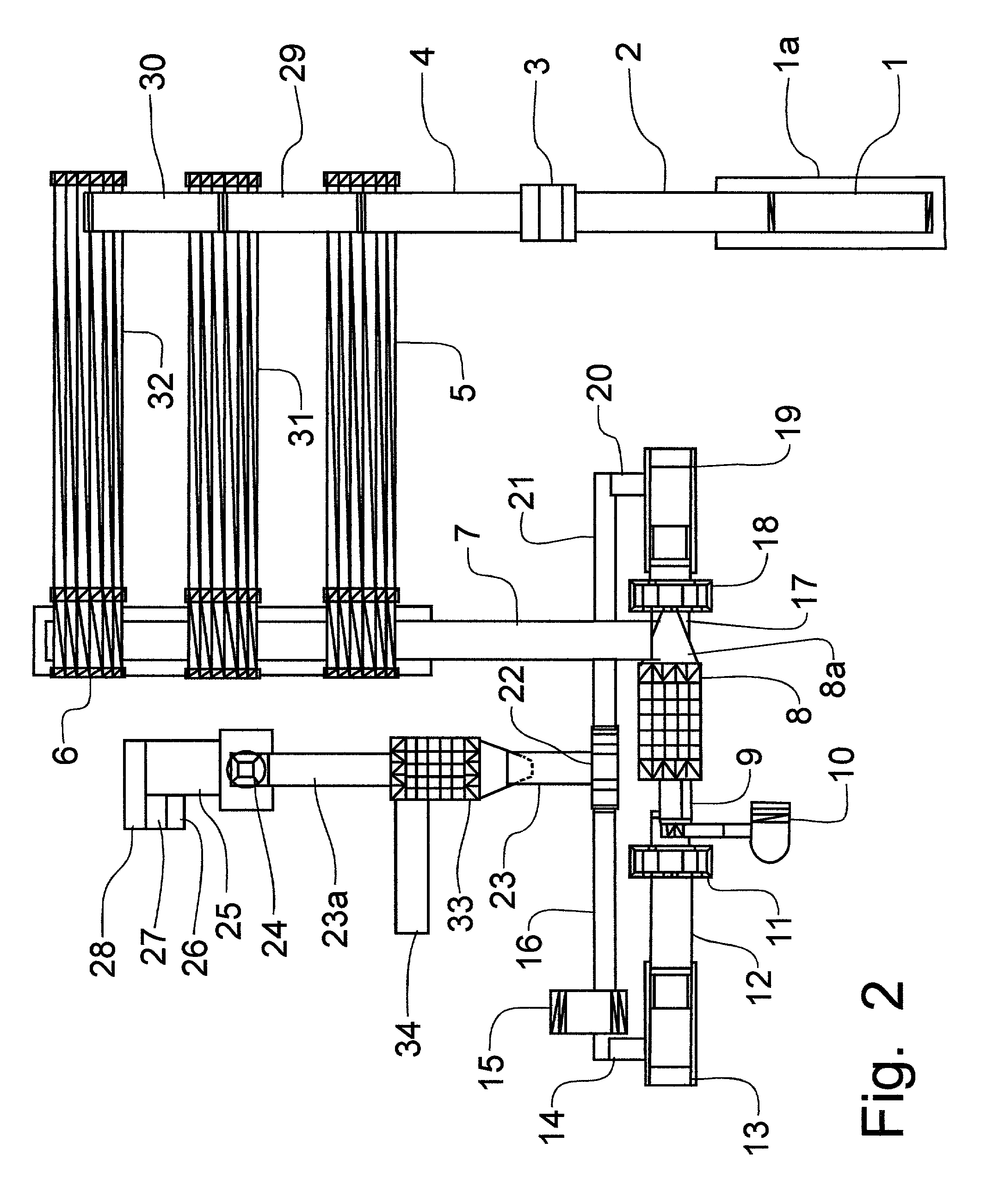

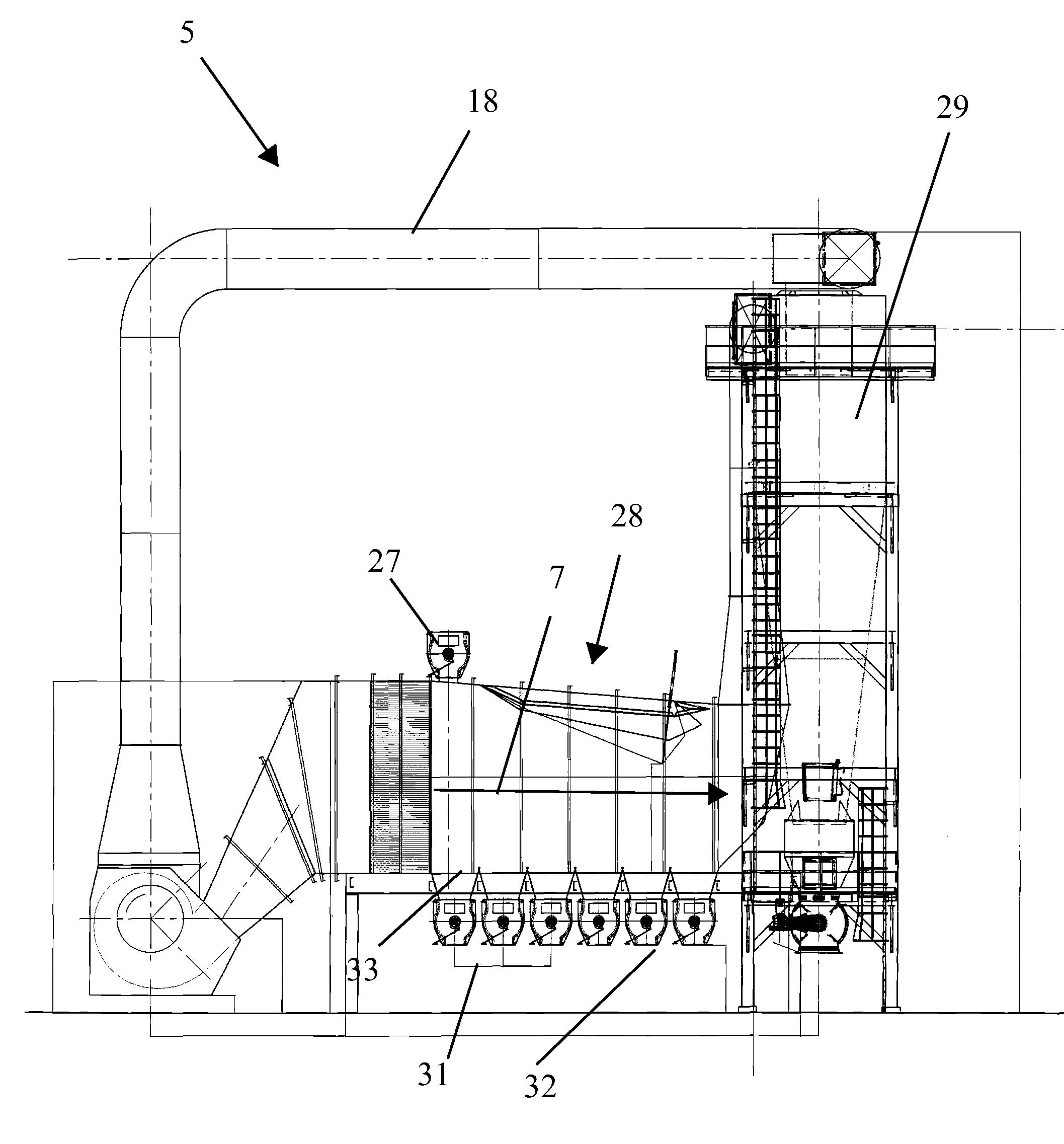

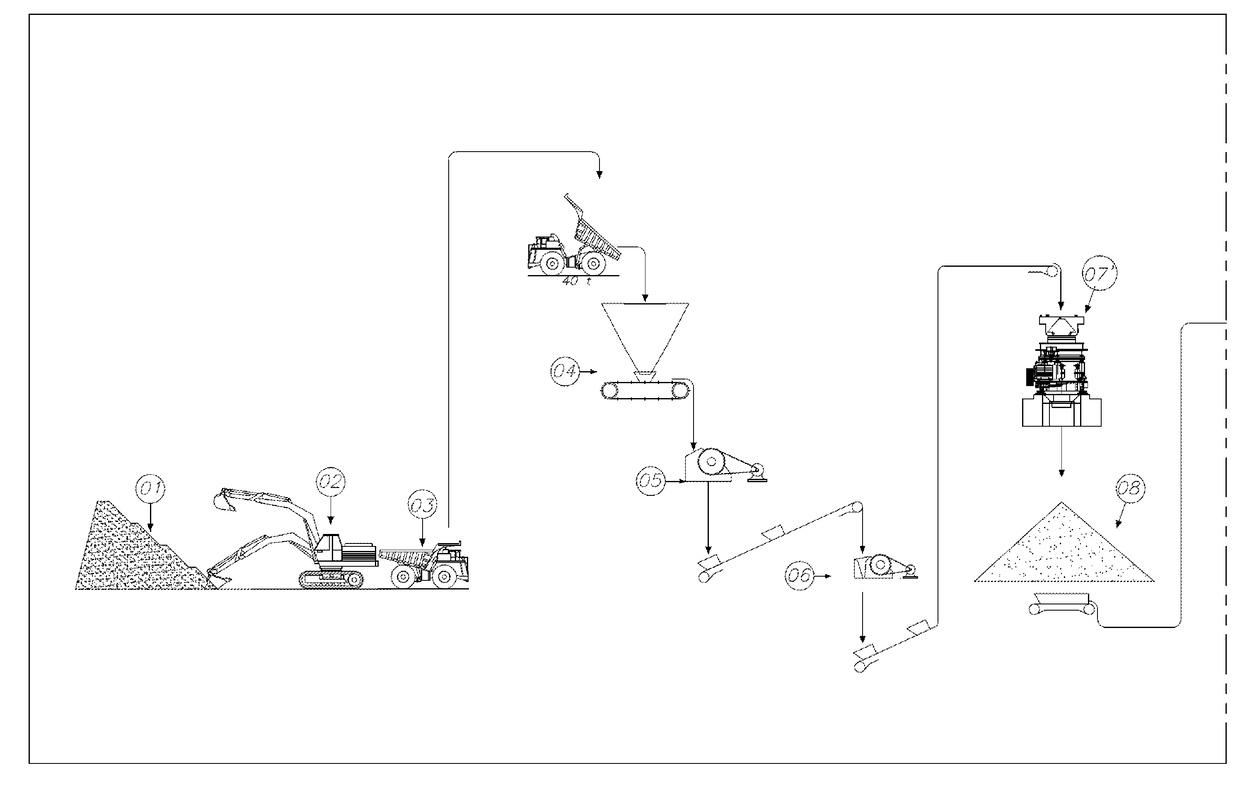

System and process for dry recovery of iron oxide fines from iron bearing compacted and semicompacted rocks

ActiveUS20180036803A1Gas current separationHigh gradient magnetic separatorsAir classifierUltimate tensile strength

The present invention relates to a system and a process for dry recovery of iron oxide fines from iron bearing compact and semicompact rocks that comprise primary (5), secondary (6) and tertiary (7, 7′) crushing means for preliminarily reducing the granulometry of ores containing the iron oxide fines in compact and semicompact rocks; means for finely grinding (10, 10′, 21) iron oxide minerals reduced through primary (5), secondary (6) and tertiary (7, 7′) crushing, provided with a dynamic air classifier (3.5, 4.6, 5.4); means of static air classification (11, 12, 13) arranged in series for intermediate granulometric cuts and bag filters (14) for retaining fine fraction; and means of magnetic separation (15, 16, 17), through magnetic rolls (71, 72, 73) arranged in cascade at a variable leaning angle, and formed by high and / or low magnetic intensity magnets,

Owner:VALE LIMITED

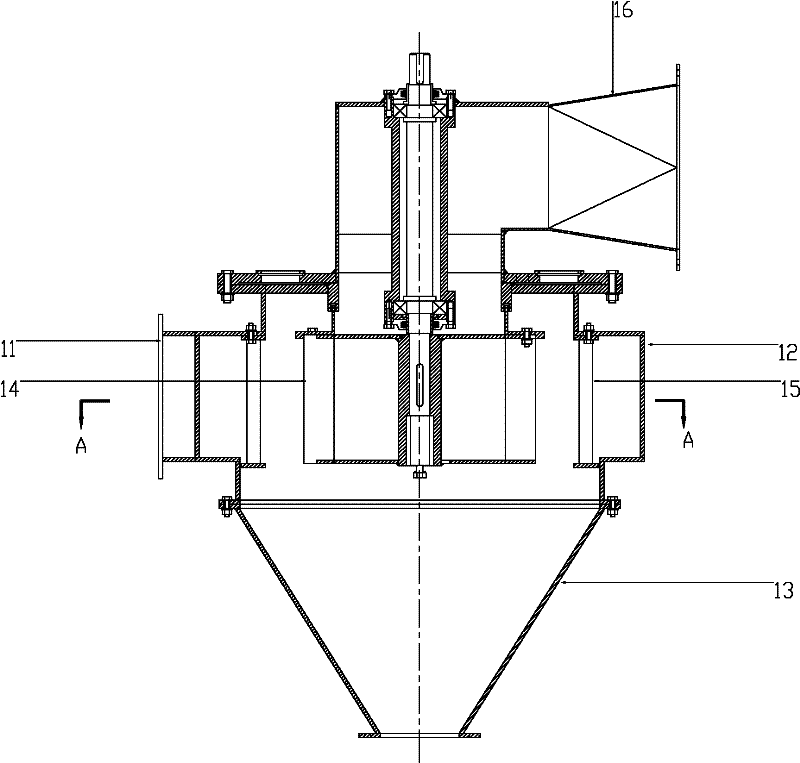

Centrifugal air classifier

ActiveUS20090065403A1Reduce flow rateSufficient of in in classificationGas current separationCentrifugesRotational axisEngineering

A centrifugal air classifier, in which a relation between an area S1 of a side surface of a cylinder or a truncated cone circumscribed about the rotor blades, an axis of the cylinder or a truncated cone being the rotor rotational shaft, and a calculation average value D of a diameter of a circle orthogonal to the rotor rotational shaft and circumscribed about the rotor blades is S1 / D2=0.9 to 1.6, and with the S1, a relation between a cross sectional area S2 of inflow of the air for classification and the D is S2 / D2=0.8 to 1.4.

Owner:TAIHEIYO CEMENT CORP

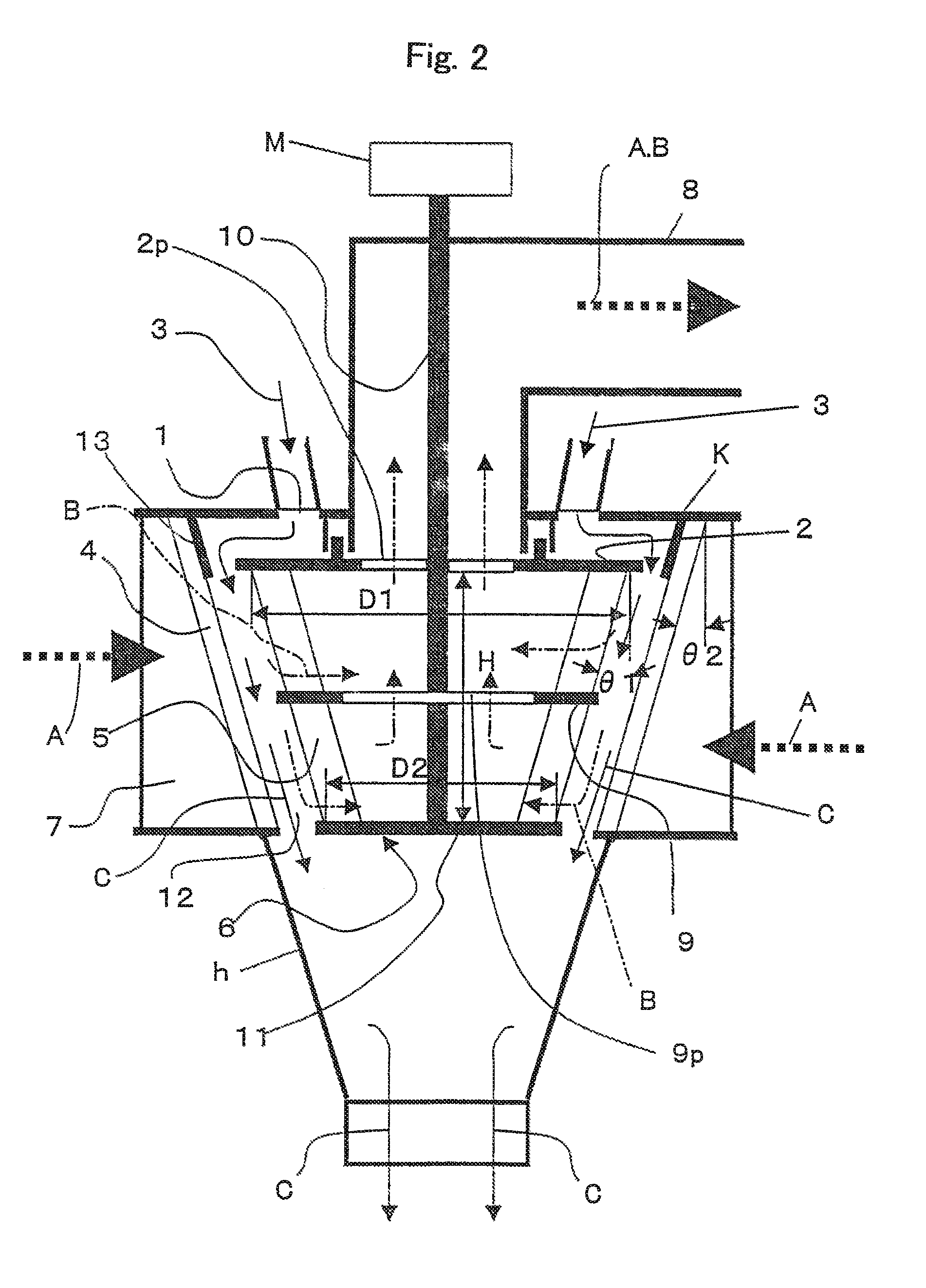

Narrow-sized level multi-stage vortex air classifier classification system

The invention provides a narrow-sized level multi-stage vortex air classifier classification system, belonging to the field of ultrafine powder preparation. The system comprises a motor, a feeder, an optional scatter device, a primary rotoclone collector, a flap valve, a primary vortex air classifier, a secondary rotoclone collector, two stages of vortex air classifiers, a bag type dust collectorand a centrifugal fan, wherein the two stages of vortex air classifiers are connected in series to realize multi-stage classification; the primary rotoclone collector and the first stage of vortex air classifier are separated through the flap valve to realize gas and solid separation and continuous and stable material feeding; the secondary rotoclone collector and the second stage of the vortex air classifier are separated through the flap valve with the same mode; a long and short blade alternate assembly mode or equal-length assembly mode is adopted on rotating cages in the two stages of vortex air classifiers; and air ducting blades are of stream line form or straight plate form. By the classification system, the materials are classified in two stages, so that the granularity range of classified fine powder products is remarkably narrowed, and the granularity of the classified fine powder products is reduced.

Owner:BEIJING UNIV OF CHEM TECH

Air classifier to separate solids while eliminating emissions

ActiveUS7051880B1Eliminate leaksEliminate needReversed direction vortexGas current separationForced-airAir classifier

An air classifier to separate solids by air classification while eliminating emissions. The air classifier includes an in-feed delivery mechanism, such as a continuous conveyer belt in order to deliver solids to an input chamber. A hanging curtain is movable in response to solids entering the input chamber. A balanced gate moves in response to solids exiting from the input chamber. An air fan delivers forced air to an air classifier chamber which is in communication with the input chamber. A heavy fraction discharge is in communication with the air classifier chamber to receive a portion of the solids heavier than the force of air delivered to the air classifier chamber. A light fraction discharge in communication with the air classifier chamber removes light solids. A return air duct in communication with the light fraction discharge returns air from the light fraction discharge to the fan. A bleed-off duct delivers a portion of forced air from the fan back into the input chamber.

Owner:HAMMERMILLS INT

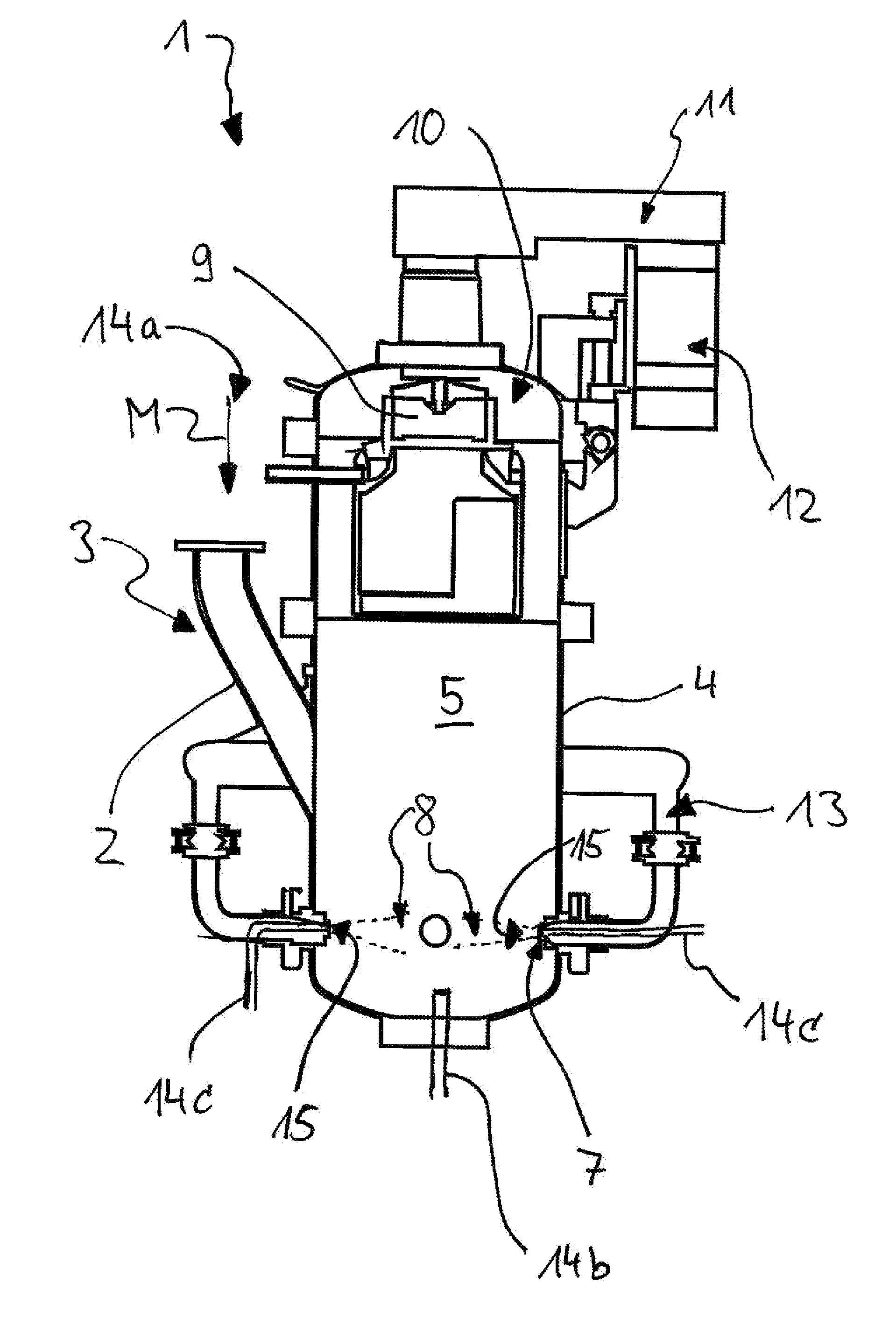

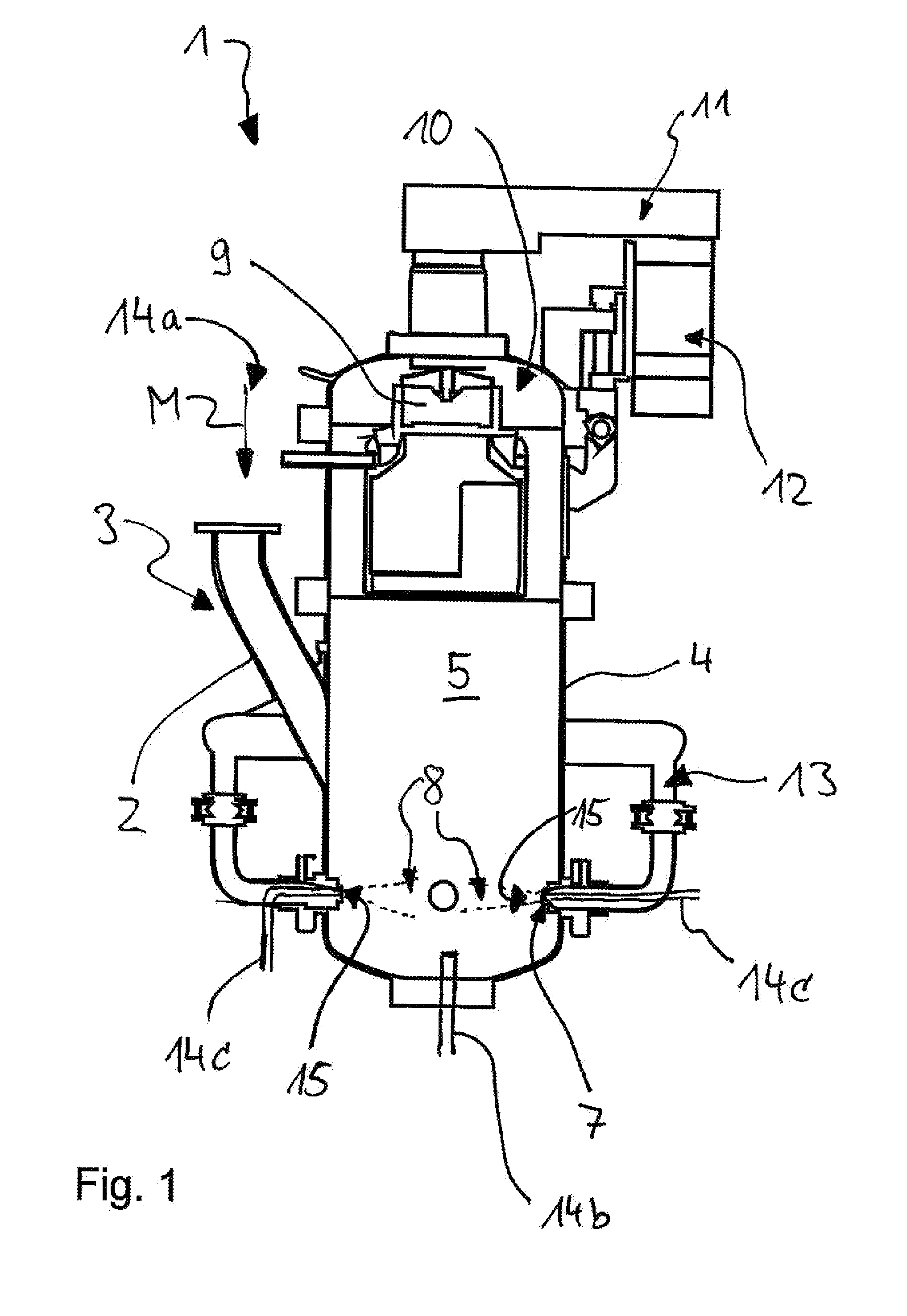

Jet mill and method for operation of a jet mill

ActiveUS20120298782A1Efficient designEasy to operateGas current separationGrain millingUltra fineAir classifier

A method for the operation of a jet mill with an integrated dynamic air classifier, wherein particles are fed as grinding stock into a grinding chamber of the jet mill and are ground there into ultra-fine particles by grinding, in that superheated steam or technical gases is / are used as working stock, wherein at least one surface-active additive is fed to the grinding stock for stabilization of the generated ultra-fine particles. A jet mill for performing this method, having an integrated dynamic air classifier, and a grinding chamber into which superheated steam or technical gases are provided as working stock via working stock feed devices as grinding stock and in which the grinding stock is ground into ultra-fine particles by grinding, and wherein feeding devices for at least one surface-active additive for stabilization of the generated ultra-fine particles are provided.

Owner:NETZSCH TROCKENMAHLTECHN

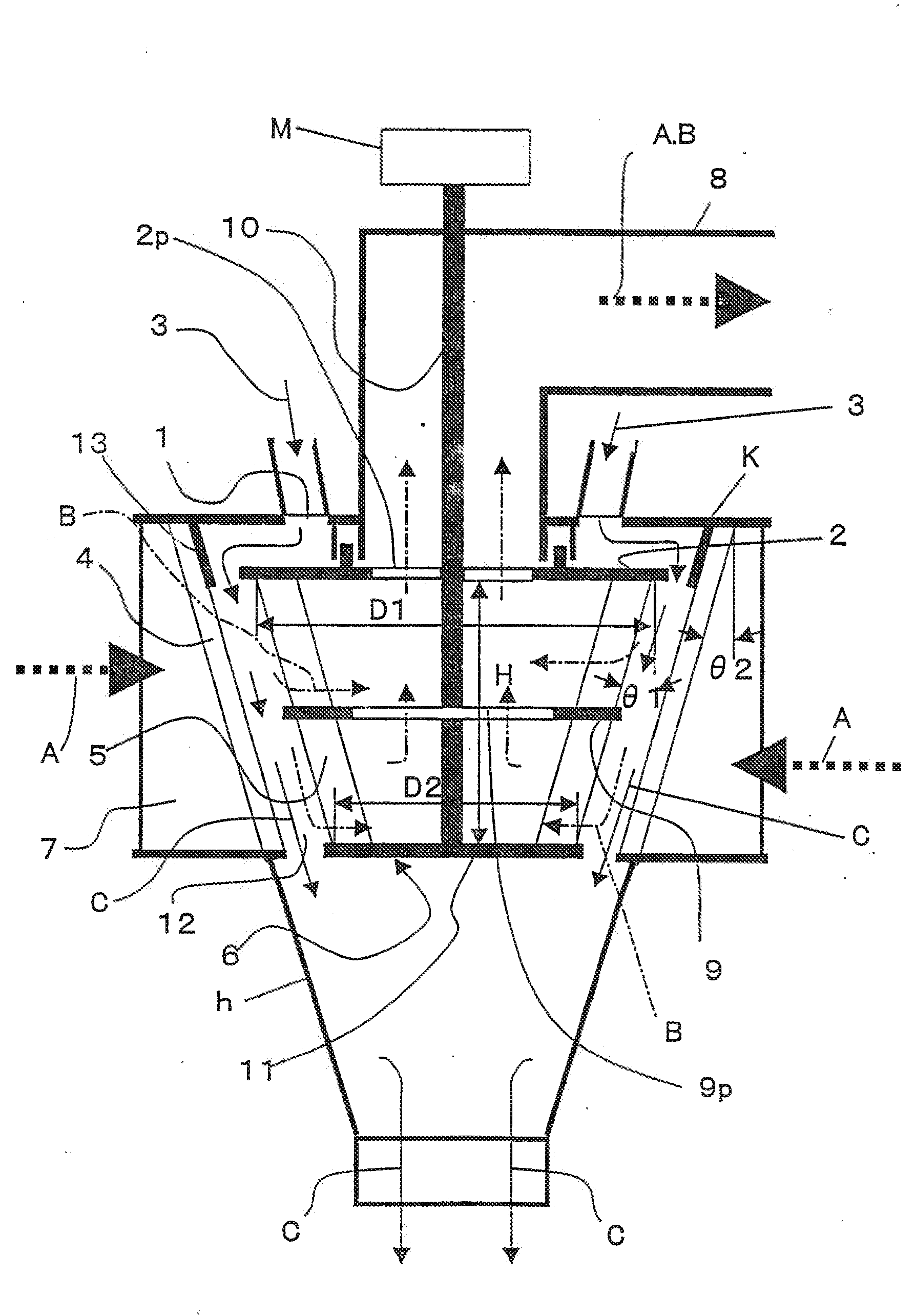

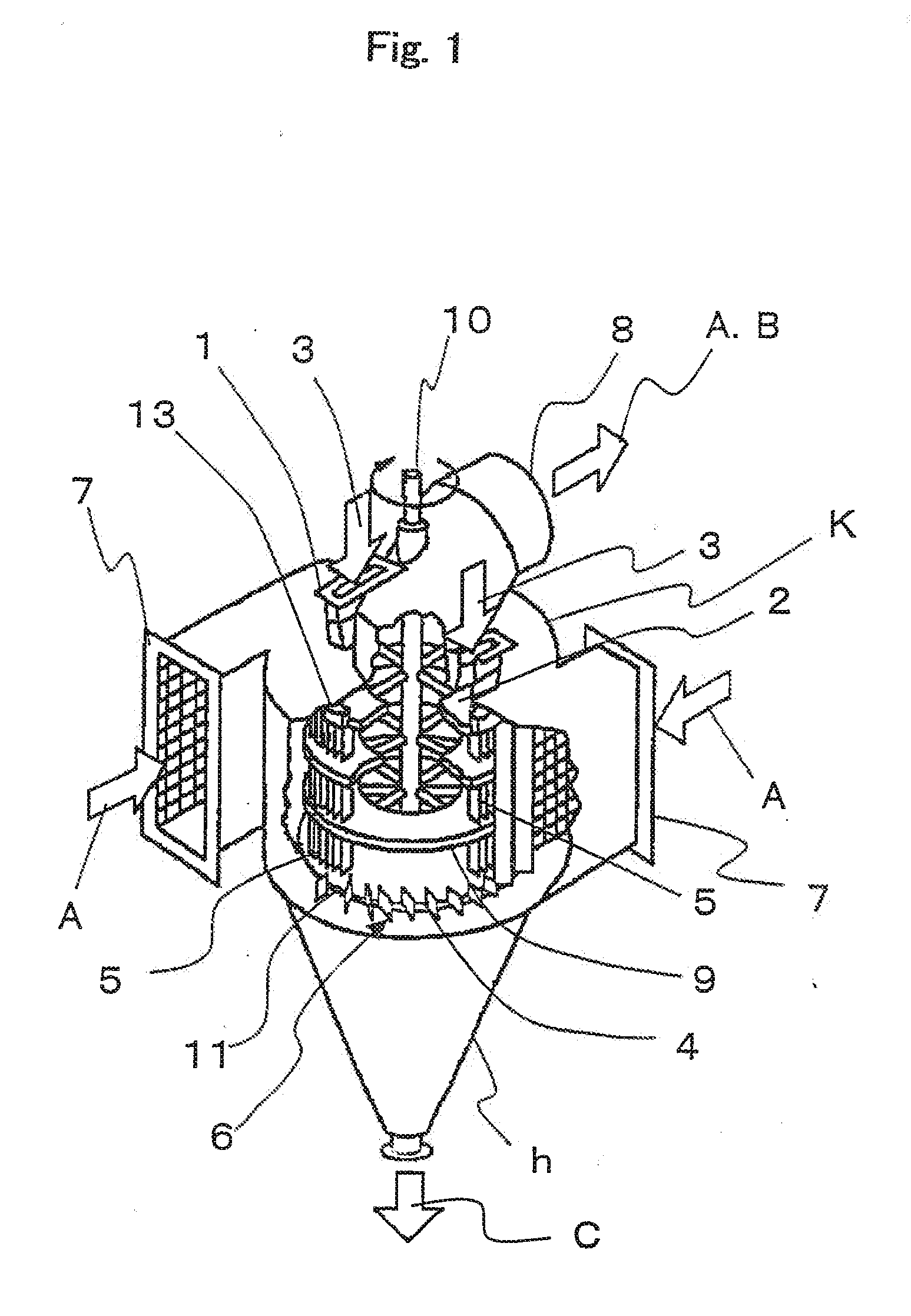

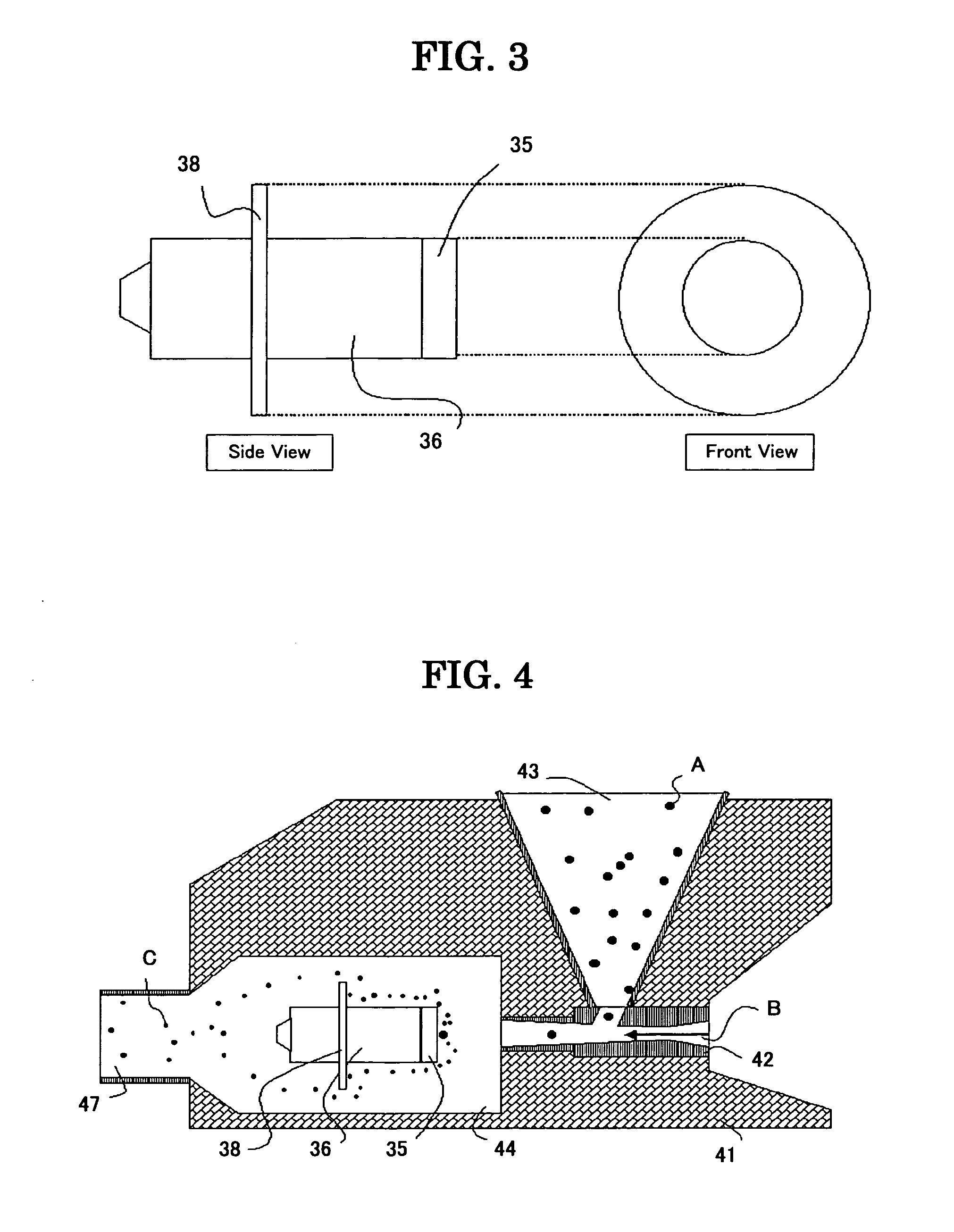

Air classifier

ActiveUS20090206008A1Efficient recyclingEasy to disperseSievingGas current separationCentrifugationEngineering

An air classifier contains a cylindrical casing provided with at an upper part thereof a feed port to feed high pressure air and a powder material, an umbrella-shaped center core in the casing, and an umbrella-shaped separator core arranged downstream of the center core in the casing and including an opening at center thereof. The air classifier has a configuration containing a dispersion chamber to disperse the powder material, being surrounded by an inner wall of the upper part casing and the center core, and a classification chamber to classify the powder material into fine and coarse powders by centrifugation, being surrounded by the center core, separator core and inner wall of the casing. In the dispersion chamber provided are a louver ring containing guide slats circularly arranged at regular intervals, and a space encircling the louver ring and serving as flow passage of the air and powder material.

Owner:RICOH KK

Centrifugal air classifier

ActiveUS8353408B2Reduce flow rateSufficient of in in classificationGas current separationCentrifugesEngineeringAir classifier

A centrifugal air classifier, in which a relation between an area S1 of a side surface of a cylinder or a truncated cone circumscribed about the rotor blades, an axis of the cylinder or a truncated cone being the rotor rotational shaft, and a calculation average value D of a diameter of a circle orthogonal to the rotor rotational shaft and circumscribed about the rotor blades is S1 / D2=0.9 to 1.6, and with the S1, a relation between a cross sectional area S2 of inflow of the air for classification and the D is S2 / D2=0.8 to 1.4.

Owner:TAIHEIYO CEMENT CORP

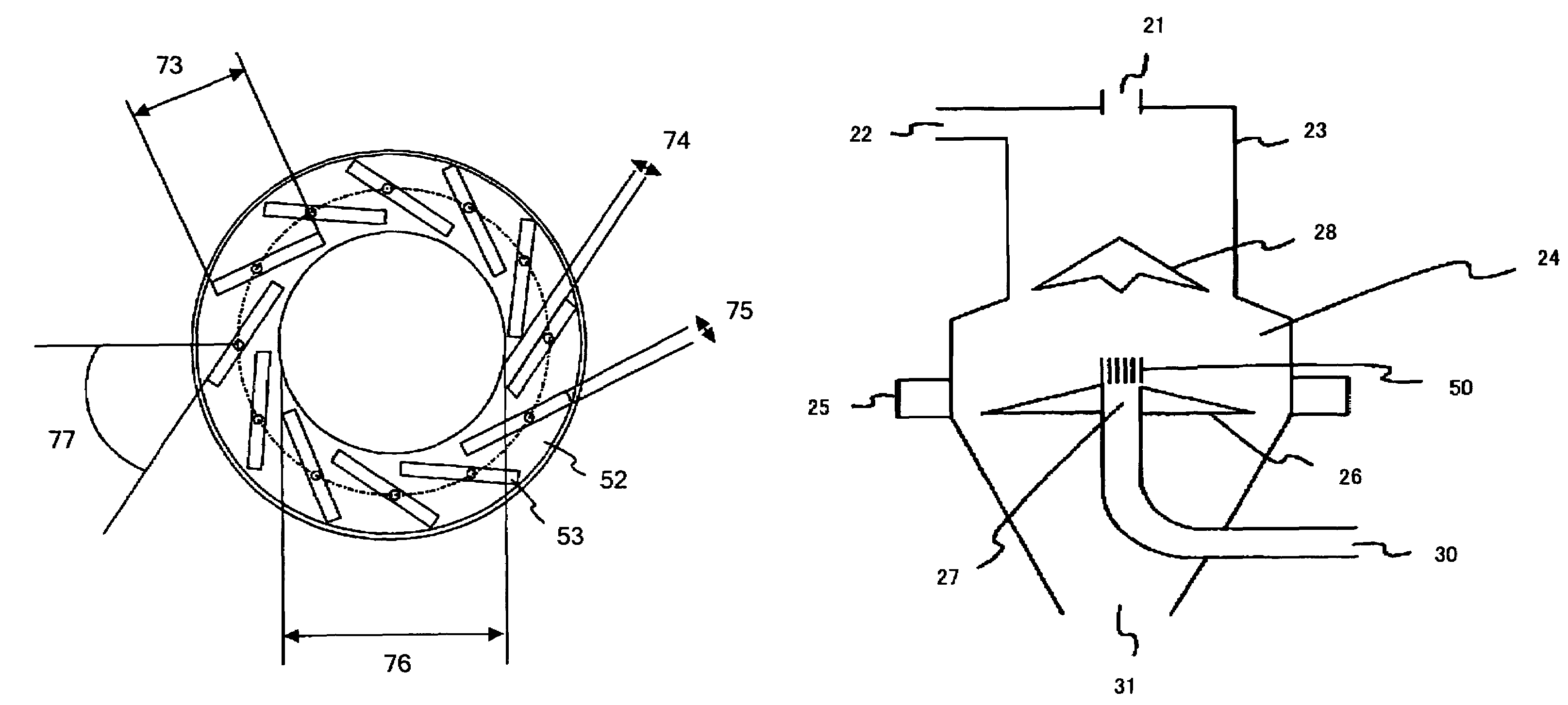

Milling and classifying apparatus, collision mill, air classifier, toner, and method for producing toner

ActiveUS7438245B2Improve image qualitySmall particle sizeGas current separationDevelopersEngineeringAir classifier

Disclosed is a milling and classifying apparatus, adapted to produce toner fine particles, comprising a collision mill, and an air classifier, wherein the collision mill comprises a jet nozzle room, a path, a collision plate, and a collision member mounted to a support of the collision plate at downstream of the collision plate, the air classifier comprises a dispersion room and a classification room, the classification room is disposed below the dispersion room, and a flow stabilizer is arranged at a central suction of the separator core to control swirl stream generated within the classification room so as to centrifuge the powder into coarse particles and fine particles by action of the swirl stream.

Owner:RICOH KK

Dry fractionation for plant based protein extraction

ActiveUS10264805B2Reducing attendant moistureEasy to operateGrain huskingGrain polishingFractionationAir classifier

Owner:TATE & LYLE SOLUTIONS USA LLC

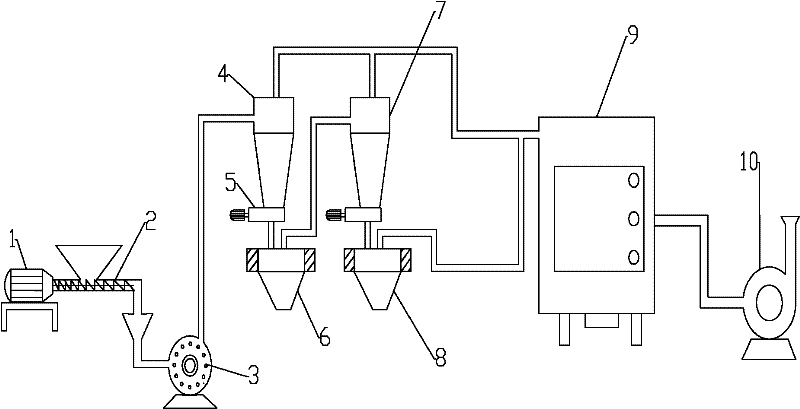

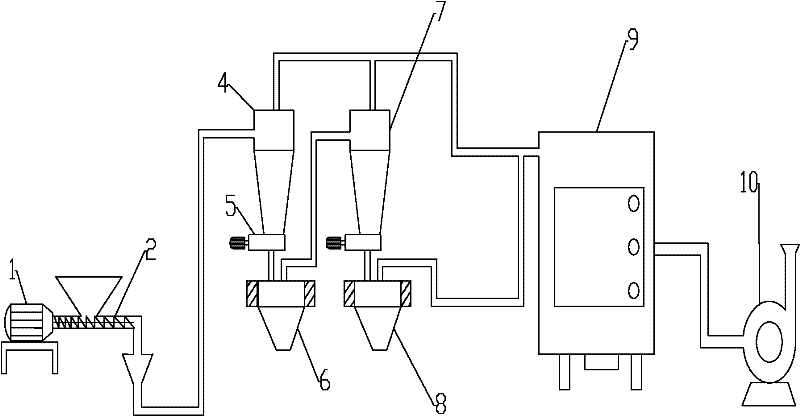

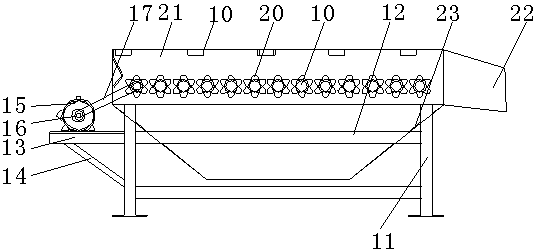

Continuous dry ball milling device

ActiveCN102814222AReduce labor intensityImprove product qualityGrain treatmentsEngineeringAir classifier

The invention relates to a continuous dry ball milling device. The continuous dry ball milling device comprises a ball mill, an air classifier, a cyclone collector and a dust collector. The ball mill comprises a frame and a barrel body. Two ends of the barrel body are fixedly and respectively connected to a feeding pipe and a discharge pipe by end covers. A front part of the barrel body is provided with a hopper. The hopper is connected to the feeding pipe by an automatic delivery pipe. The discharge pipe of the barrel body is connected to a storage bin. A fine material outlet of the storage bin is connected to a raw material inlet of the air classifier by a pipe. A fine powder outlet of the air classifier is connected to a powder inlet of the cyclone collector by a pipe. A dust outlet of the cyclone collector is connected to a dust inlet of the dust collector by a pipe. The continuous dry ball milling device has the advantages that continuous production is realized; products are obtained by one-step feeding; product quality is stable; production efficiency is high; a production cost is low; product granularity is controllable; particle size distribution is reasonable; large particles and superfine particles are avoided; automatic production is realized; and labor intensity is reduced.

Owner:DONGHAI JINGSHENGYUAN SILICA

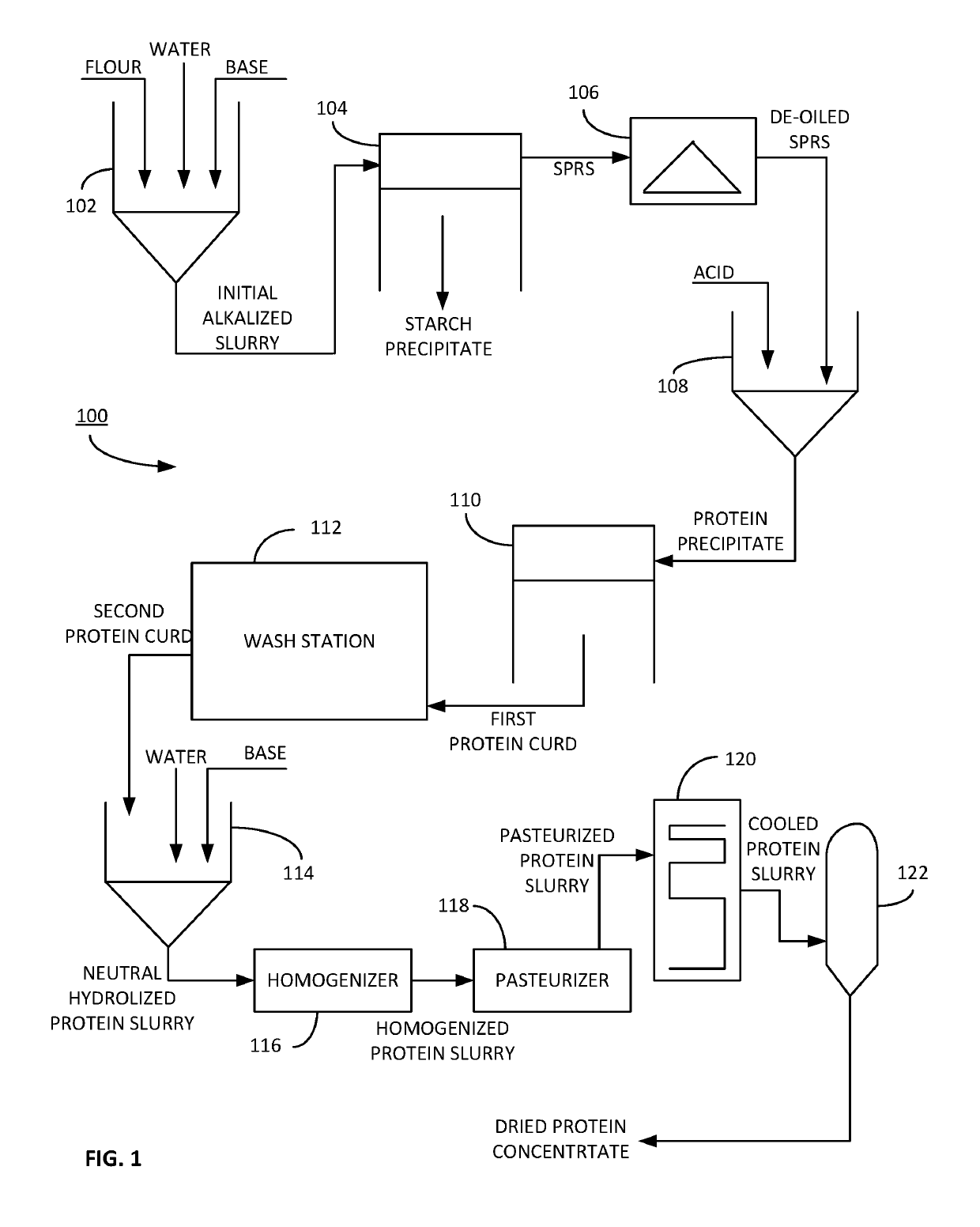

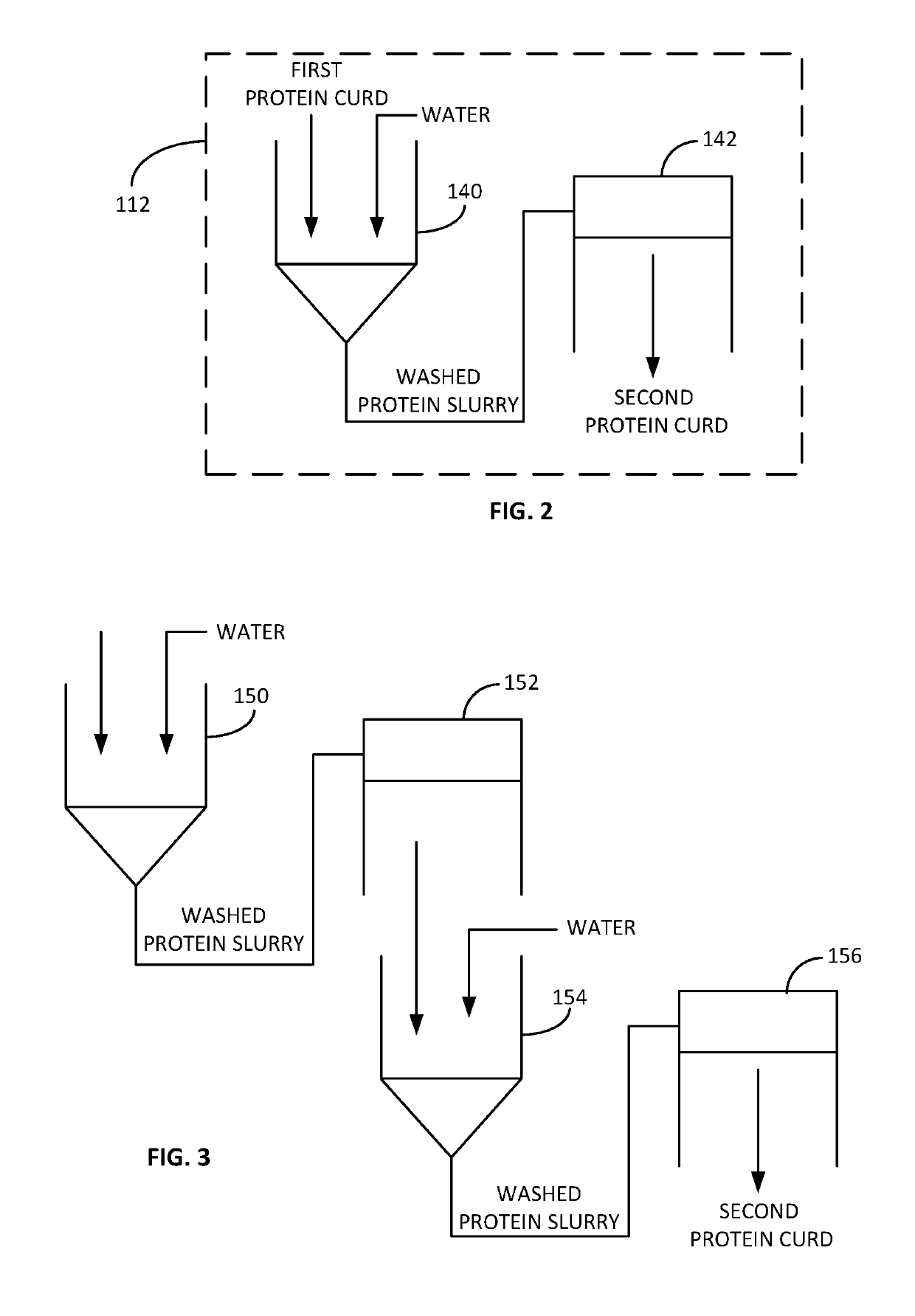

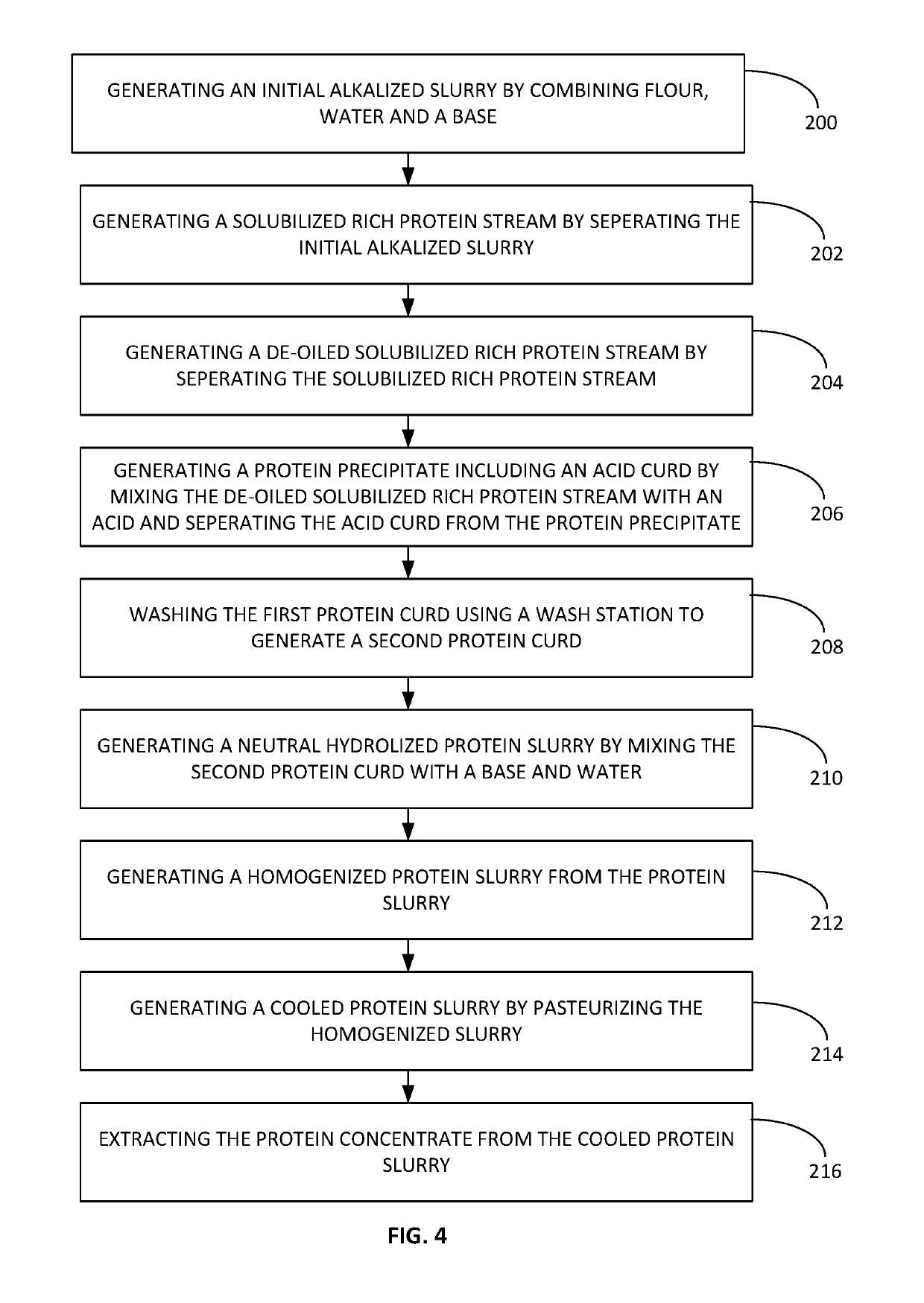

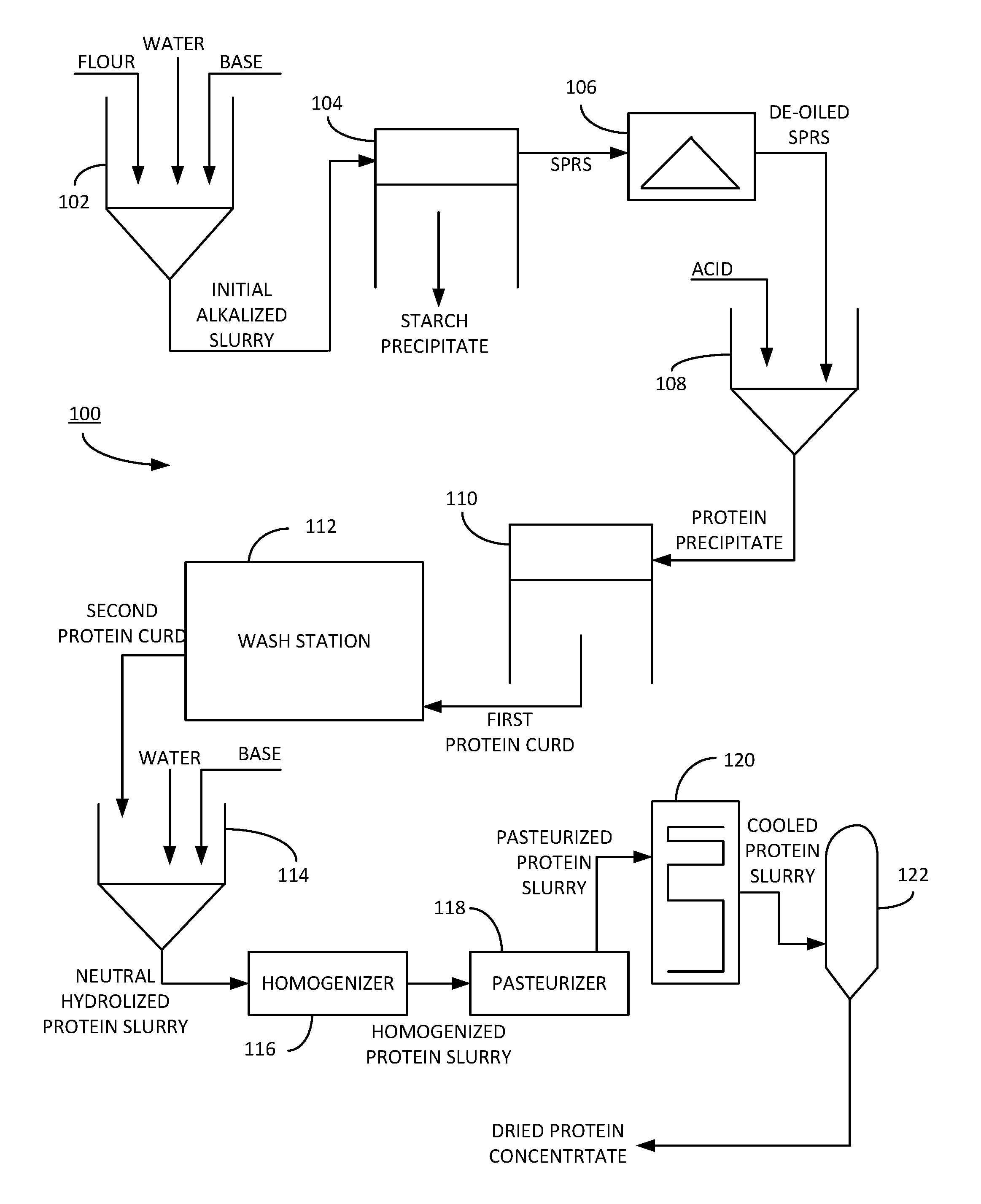

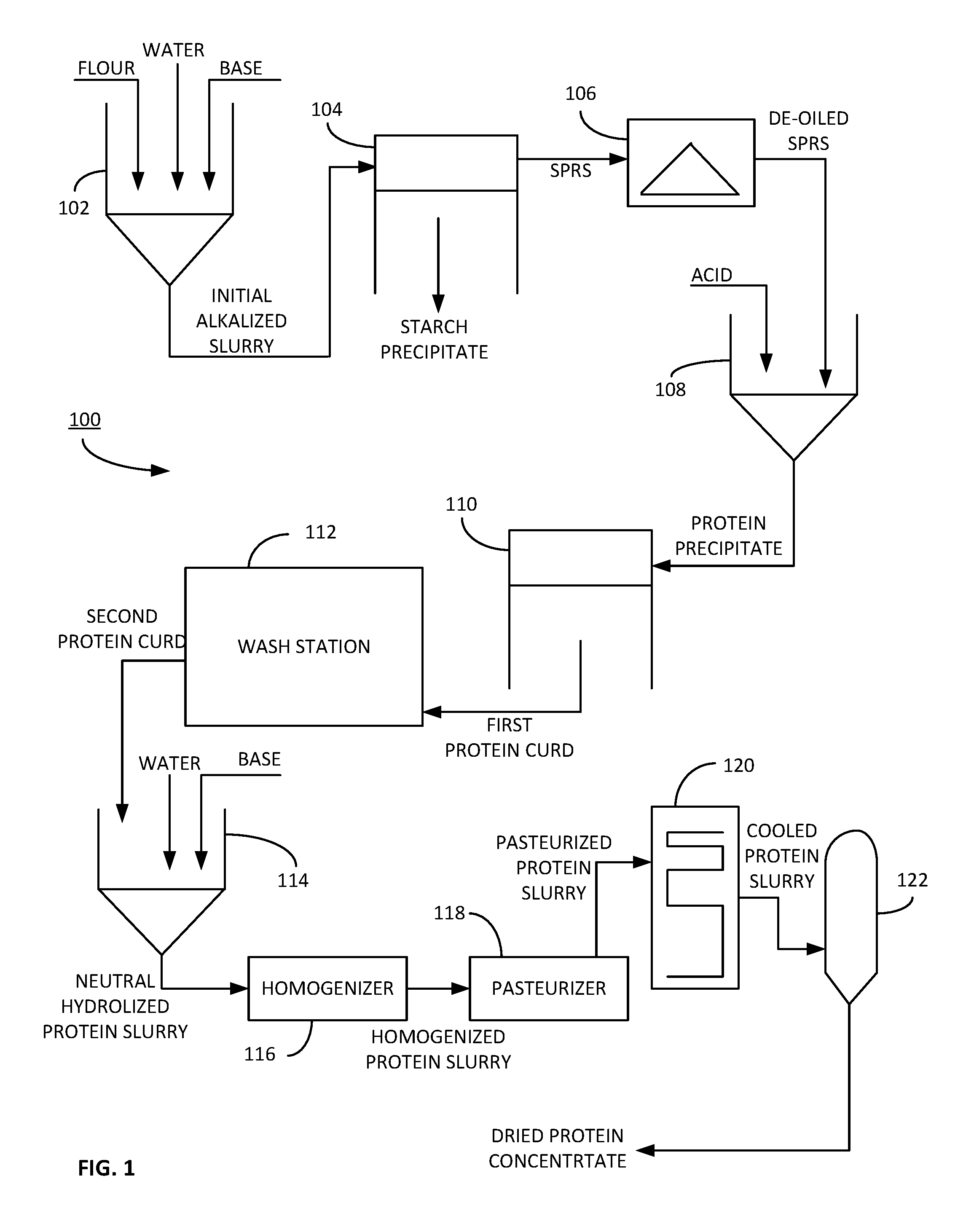

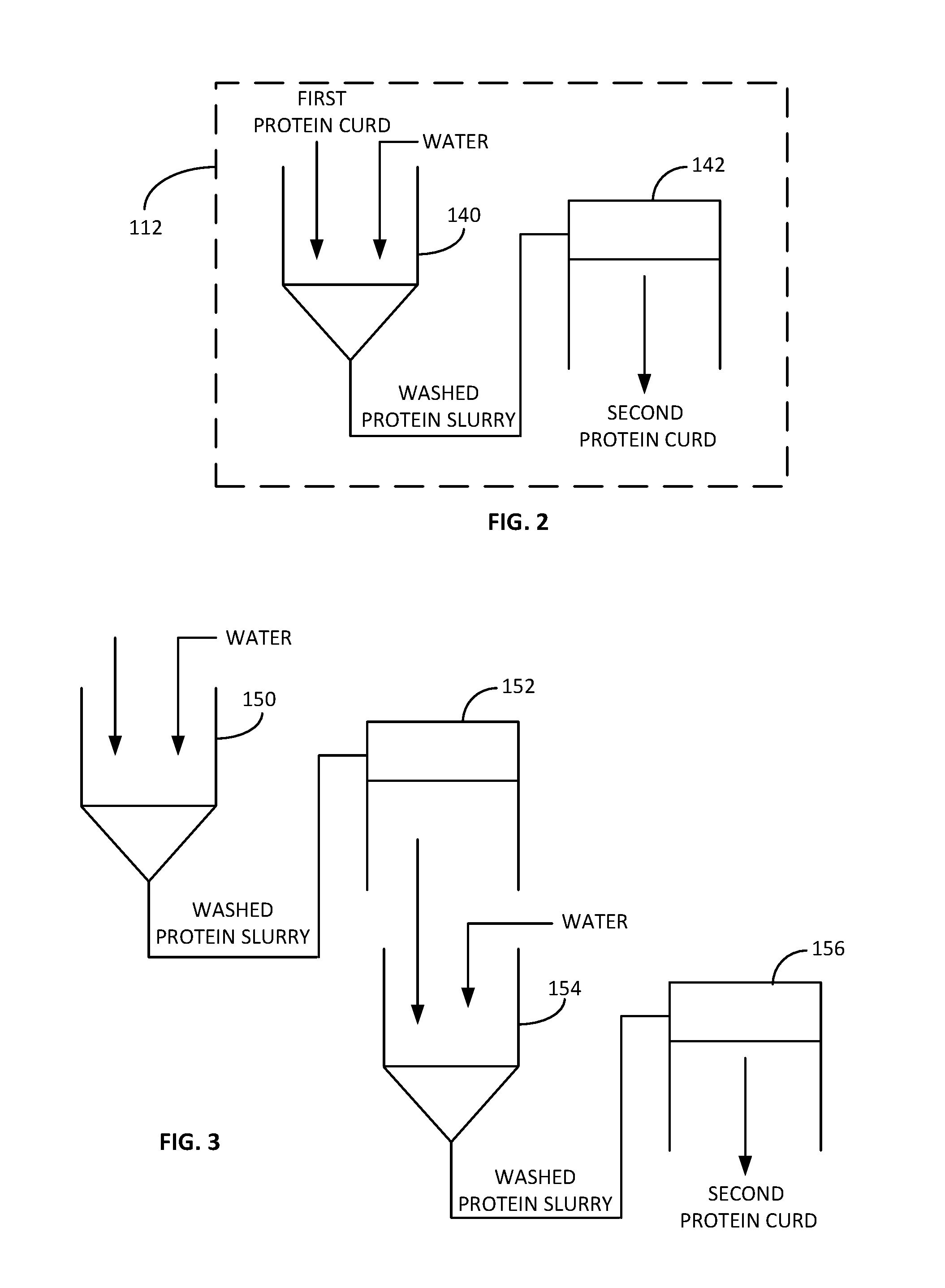

Dry fractionation for plant based protein extraction

ActiveUS20160309744A1Operation efficiency can be improvedReducing attendant moistureGrain huskingGrain polishingFractionationSlurry

A dry fractionation method and system provides for generating a protein concentrate product therefrom. The method and system includes milling a plant-based flour to generate milled flour and generating a first protein concentrate from the milled flour using an air classifier. The method and system includes processing the first protein concentrate to generate a protein rich curd and generating a neutral hydrolyzed protein slurry by mixing the protein curd with a base, water and enzymatic cocktail. The method and system includes generating a homogenized protein slurry from the protein slurry and generating a cooled protein slurry by pasteurizing the homogenized protein slurry. Therein, the method and system provides for extracting the protein concentrate product from the cooled protein slurry.

Owner:TATE & LYLE SOLUTIONS USA LLC

Systems and methods for recovering materials from soil

Owner:GRAHAM BARRY D

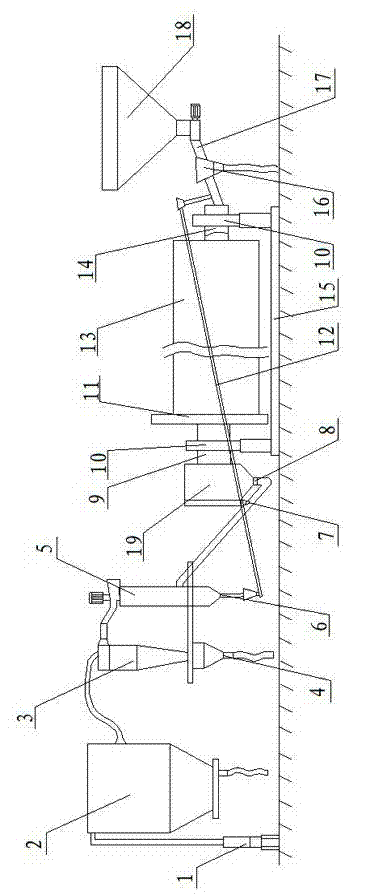

Multi-stage household waste disposal apparatus and method

ActiveCN108480365APlay a role in separationEasy to handleSievingGas current separationAir classifierProcess efficiency

A multi-stage household waste disposal apparatus and method, the apparatus includes a feeder, environmental belts, a multi-axis butterfly-shaped large particle separator, an environment-friendly smartseparator, an air classifier, a non-ferrous separator, and an iron removing machine., The feeder is connected to the multi-axis butterfly-shaped large particle separator through the environmental belt, the multi-axis butterfly-shaped large particle separator is connected to an environment-friendly shredder and the environment-friendly smart separator via the environmental belt respectively, the environment-friendly smart separator is connected to the air classifier via the environmental belt, the air classfier is connected to a light and heavy material separator by the environmental belt, thenon-ferrous separator and the iron removing machine are mounted on the environmental belt between the air classifier and the light and heavy material separator. The present invention solves the problems of low process efficiency and poor process effect by the feeder, environmental belts, multi-axis butterfly-shaped large particle separator, environment-friendly smart separator, air classifier, non-ferrous separator, and iron removing machine.

Owner:XINXIANG ZHEN YING MACHINERY EQUIP CO LTD

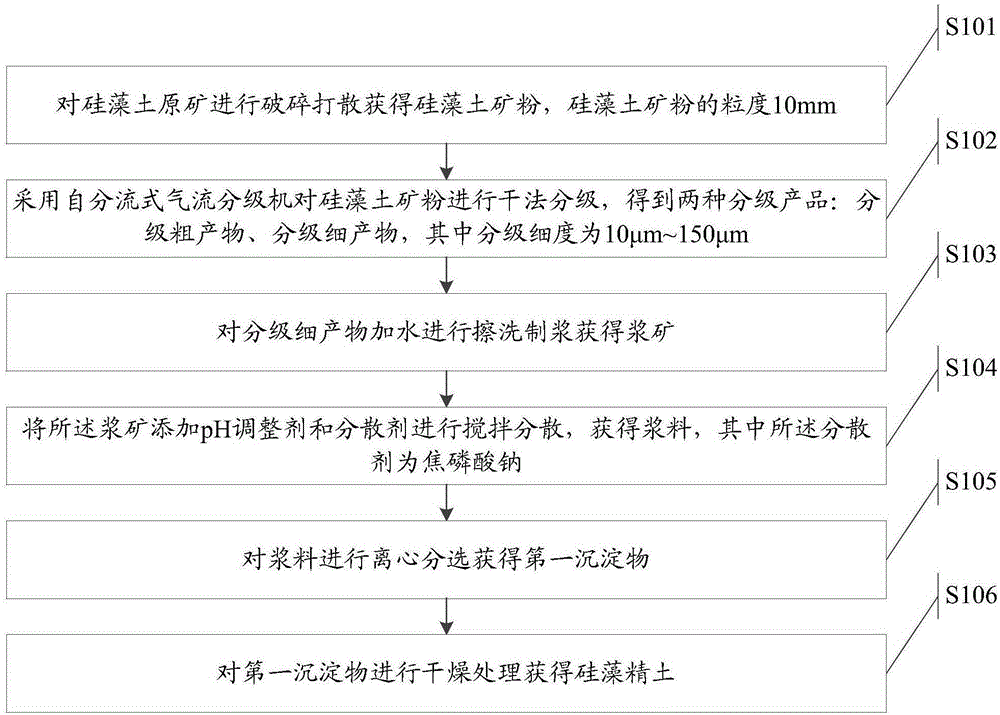

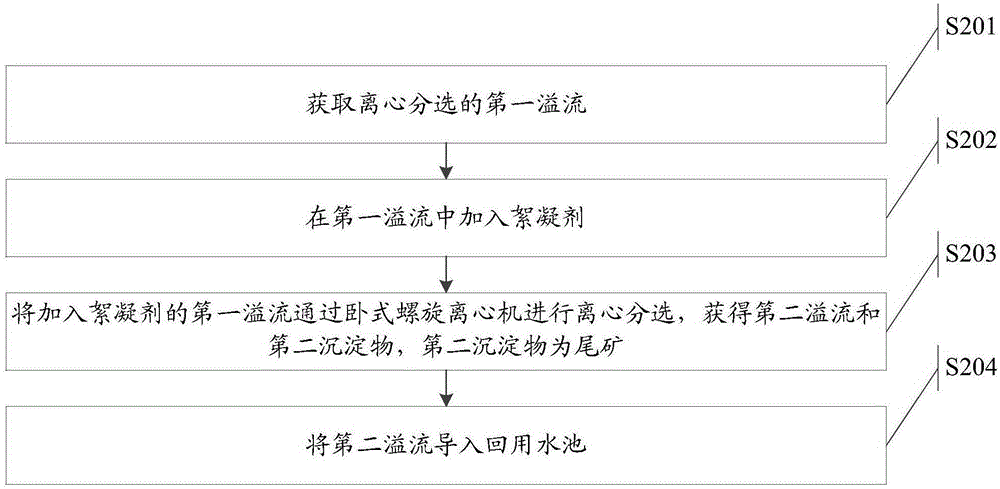

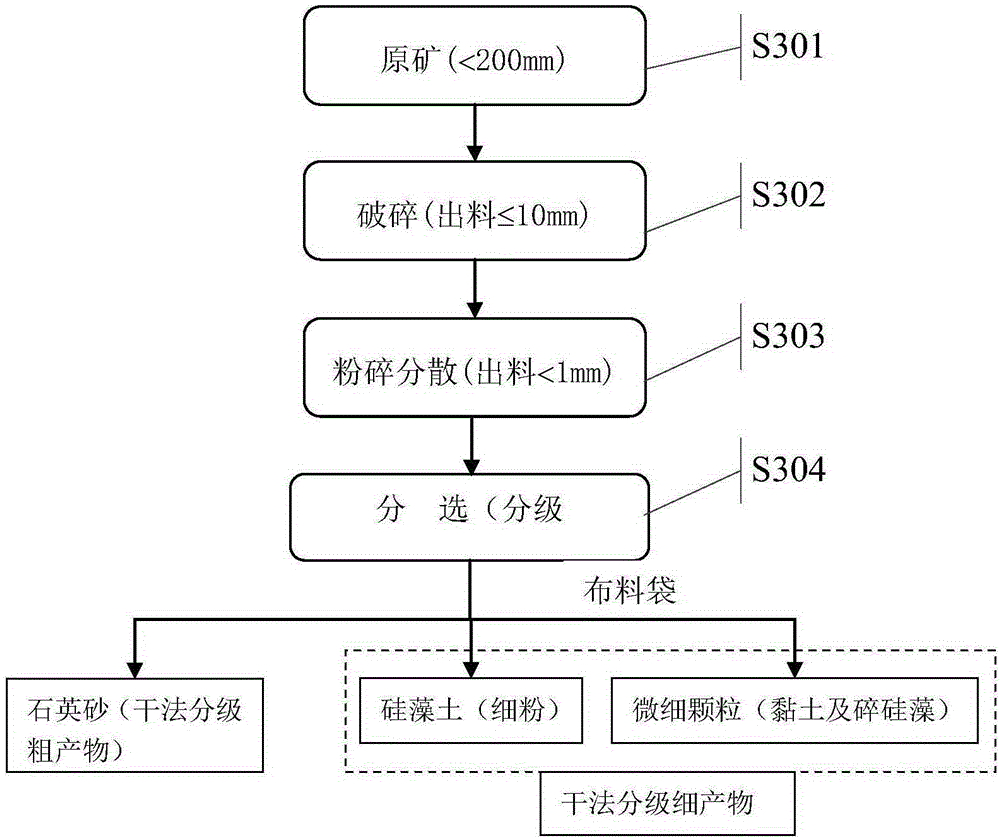

Dry-wet-method mineral separation method used for African sandy diatomite ore

InactiveCN105149084AHigh recovery rateThe fine soil quality is good and stableWet separationPyrophosphateSeparation scheme

The invention relates to the field of mineral processing, and discloses a dry-wet-method mineral separation method used for African sandy diatomite ore. The technical problem that in the prior art, a mineral separation scheme is difficultly suitable for mineral separation and purification of ultralow-grade sandy diatomite ore can be solved through the method. The method comprises the steps that raw diatomite ore is crushed and scattered to obtain diatomite ore powder, and the granularity of the diatomite ore powder is smaller than 10 mm; a self-flow-dividing type air classifier is used for carrying out dry-method classification on the diatomite ore powder to obtain two classified products, namely a classified course product and a classified fine product, and the classification fineness is 10-150 micrometers; water is added to the classified fine product for scrubbing pulping to obtain ore pulp; pH regulators and a dispersing agent, namely sodium pyrophosphate, are added and stirred to be scattered, so that pulp is obtained; the pulp is subjected to centrifugal separation to obtain first precipitate; and the first precipitate is dried to obtain purified diatomite. The technical effects of mineral separation and purification on the ultralow-grade sandy diatomite ore are achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

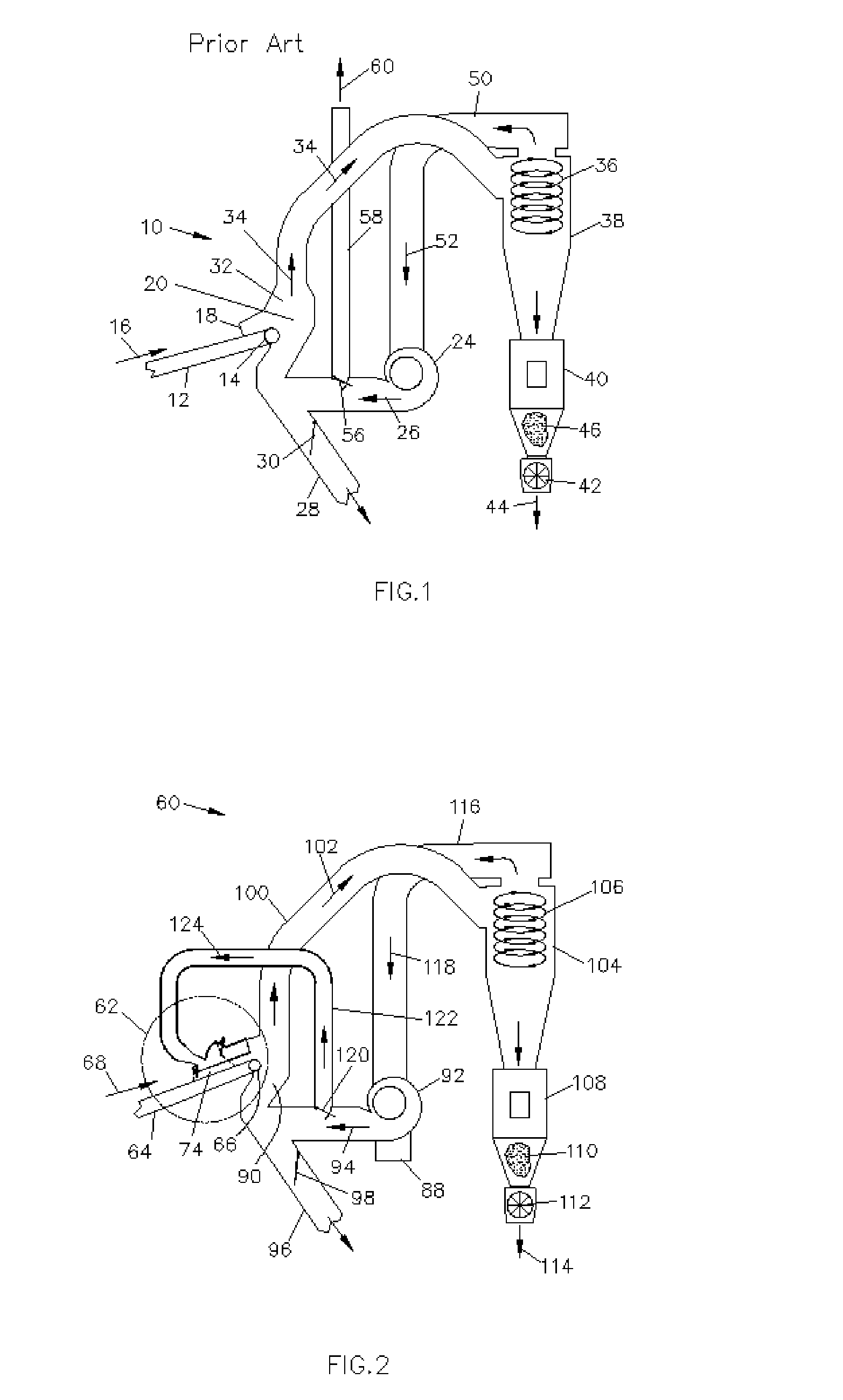

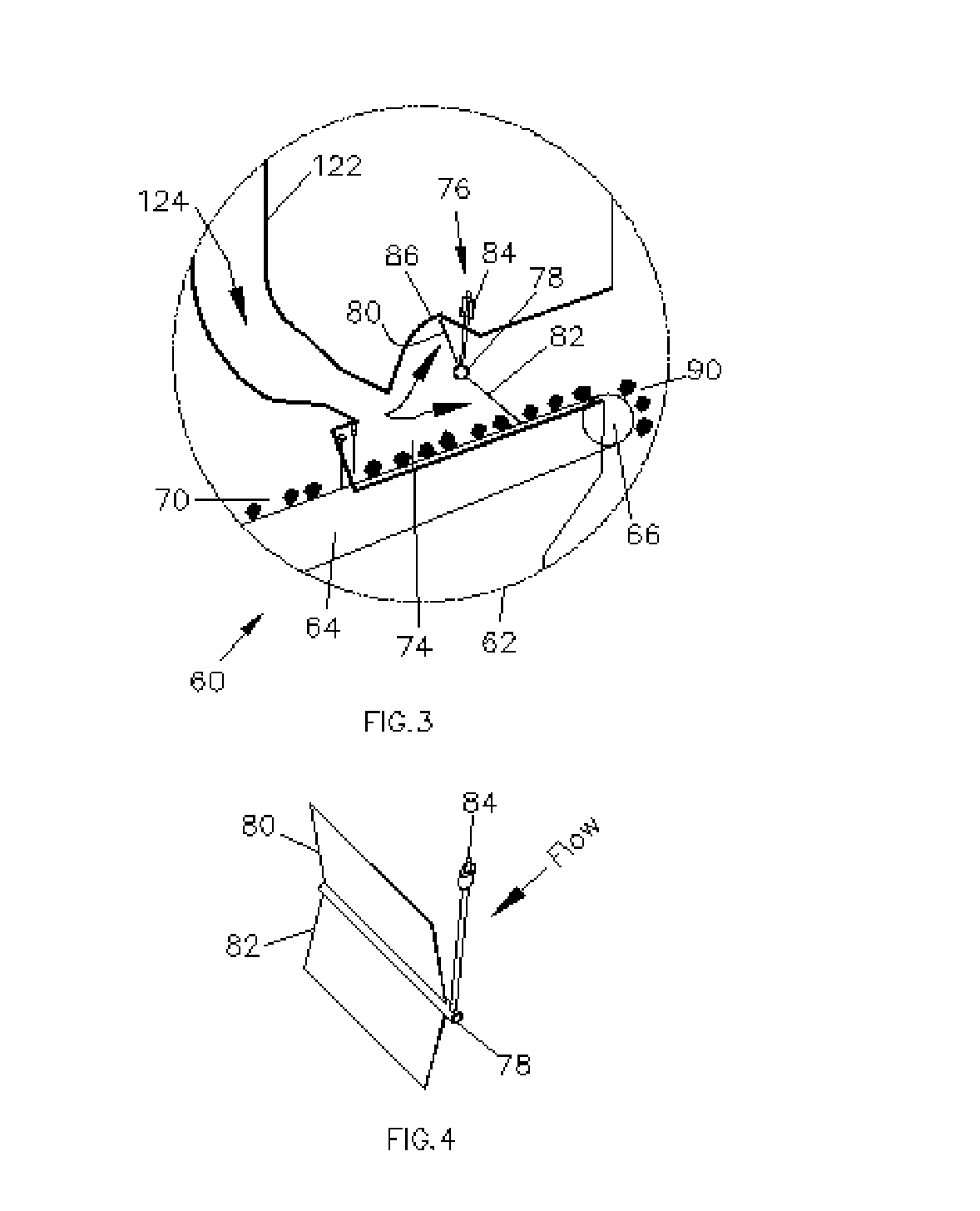

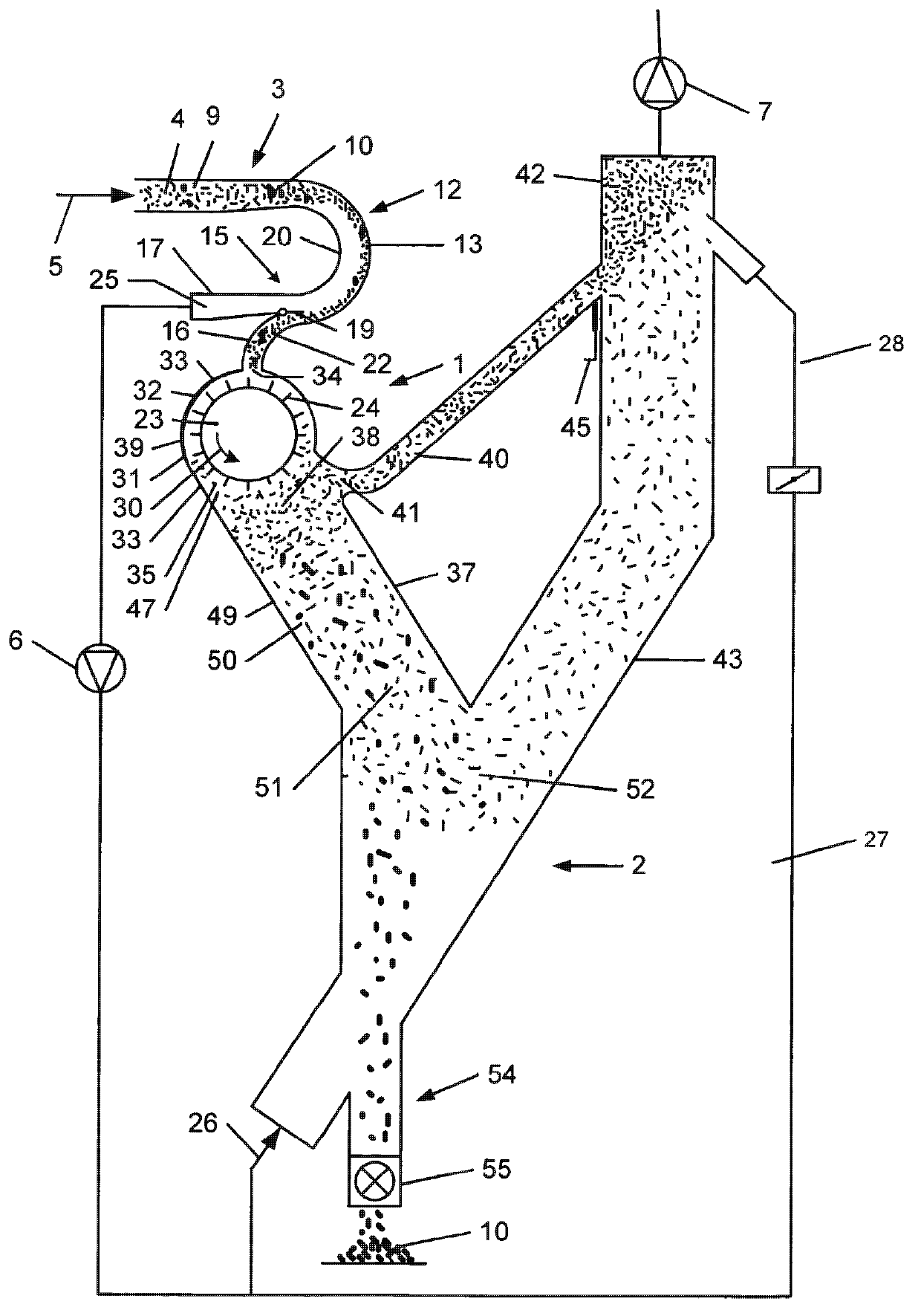

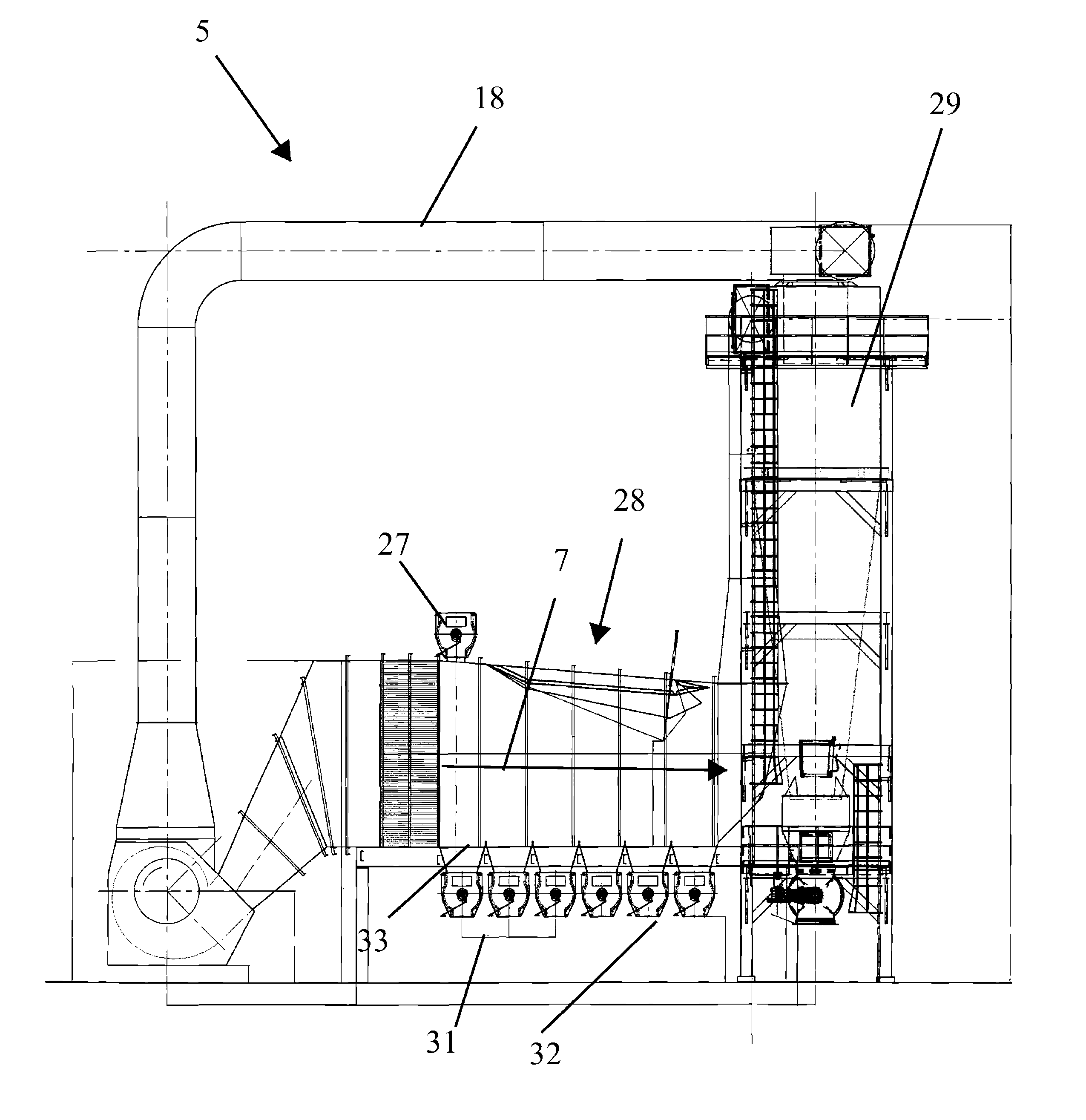

Method and device for separating out contaminants from a pneumatic fibre stream

InactiveCN103313802AEasy to controlEfficient suctionGas current separationWood working apparatusFiberAir classifier

The invention relates to a method and a device for separating out contaminants in the form of coarse material (10) from a pneumatic fibre stream (4) intended for producing fibre boards, wherein the fibre stream is divided into a separating air stream (25), which merely contains air and normal material (9) consisting of fibres, and a main fibre stream (22), containing the coarse material (10) and normal material (9), by using centrifugal force, in that the fibre stream (4) undergoes a curvature (12), wherein the main fibre stream is conducted in an outer region (13) of the curvature and the separating air stream is sucked away in an inner region (20) of the curvature, wherein the main fibre stream is fed to a separating roller (23), which has a multiplicity of pins (24); on its surface and rotates in such a way that the impinging coarse material and normal material is deflected and conducted along a shaft portion (33) and the normal material is accelerated to approaching the circumferential speed of the roller in such a way that some of the normal material leaves the effective range of the roller with a horizontal movement component, wherein some of the normal material is sucked away through a suction removal line (40) and some of the normal material and the coarse material enter a drop shaft (37) and from the latter enter an air classifier unit (2), wherein at least some of the separating air stream is fed to the air classifier unit in such a way that it acts on the normal material and coarse material arriving from the drop shaft (37) and deflects the normal material into a normal-material suction removal shaft (43), while the coarse material enters a coarse material discharge (54). The method and the device can be integrated in an existing transporting line.

Owner:DIEFFENBACHER GMBH & CO KG

Isotropic quantization sorting systems of automobile shredder residue to enhance recovery of recyclable materials

ActiveUS9132432B2Easy to sortReduce wasteGas current separationPlastic recyclingNonferrous metalMicroparticle

Systems and methods for increasing recyclable material recovery from automobile shredder residue (4). Embodiments include separation of automobile shredder residue with a sorting system (5) such as an air sorting system, a non-ferrous automobile shredder residue air sorter, an air-locked automobile shredder residue sorting system, a non-magnetic magnetic sorter, a substantially isotropic quantization sorting system, an air-locked Z-box air classifier, low susceptance microparticle separator, a magnetic fuzz separator, a wind tunnel system, or the like perhaps with substantially horizontal laminar air flow (7) and can be used with or without out other traditional automobile shredder residue sorting systems (16) or (15) perhaps creating additional recyclable quantities and even better separated results such as with zorba and zurik and the like.

Owner:IQASR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com